Patents

Literature

356results about How to "Precision grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

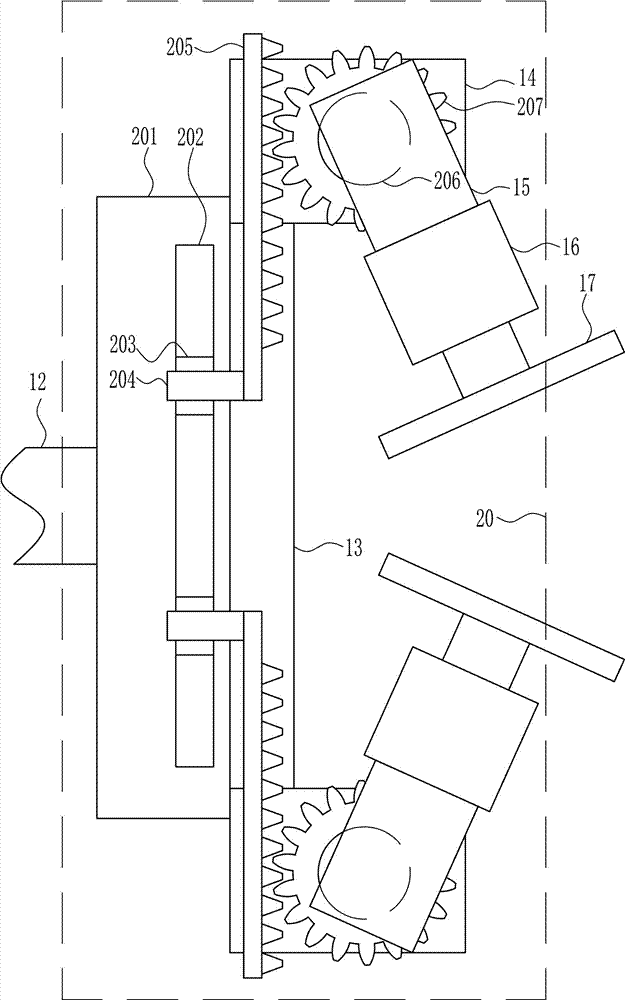

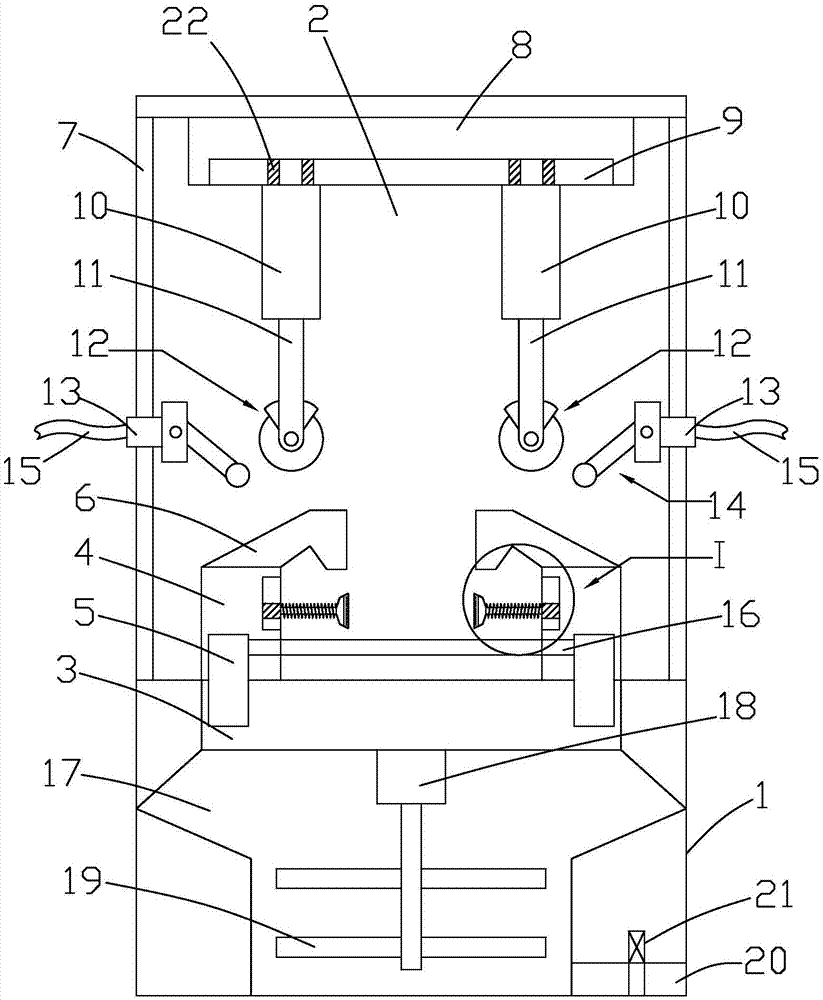

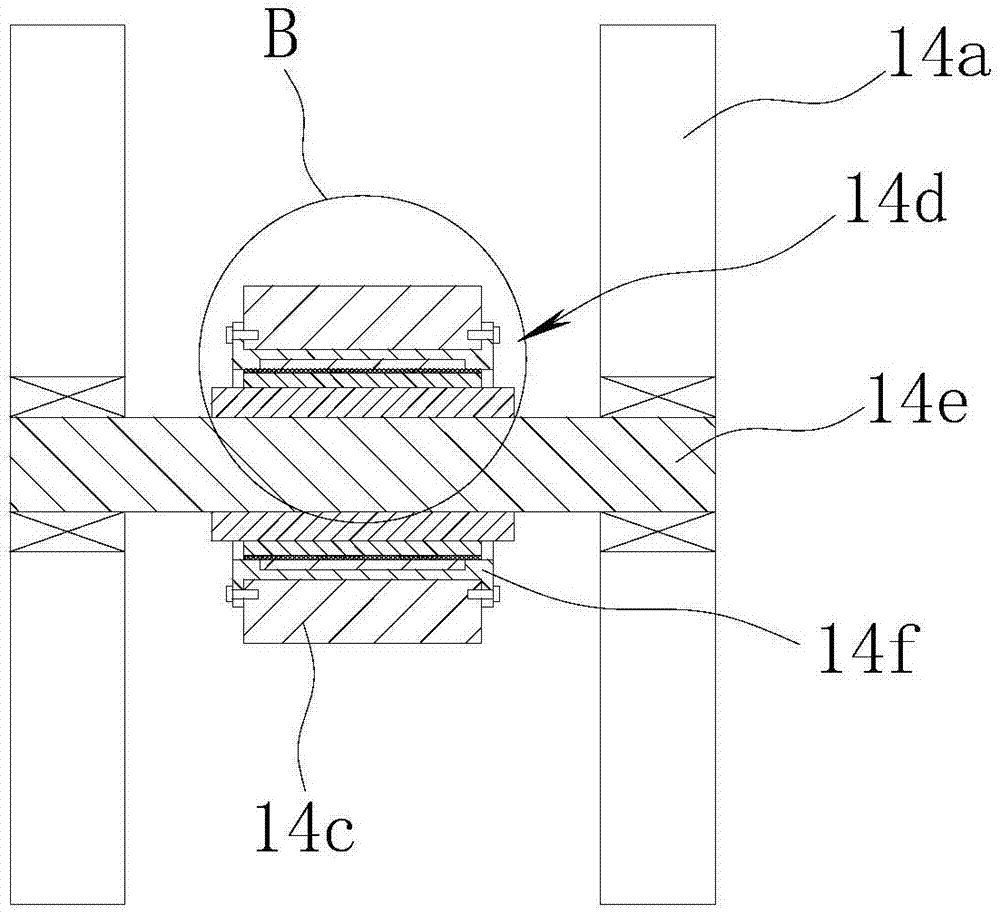

Rapid glass side edge grinding device applied to glass factory

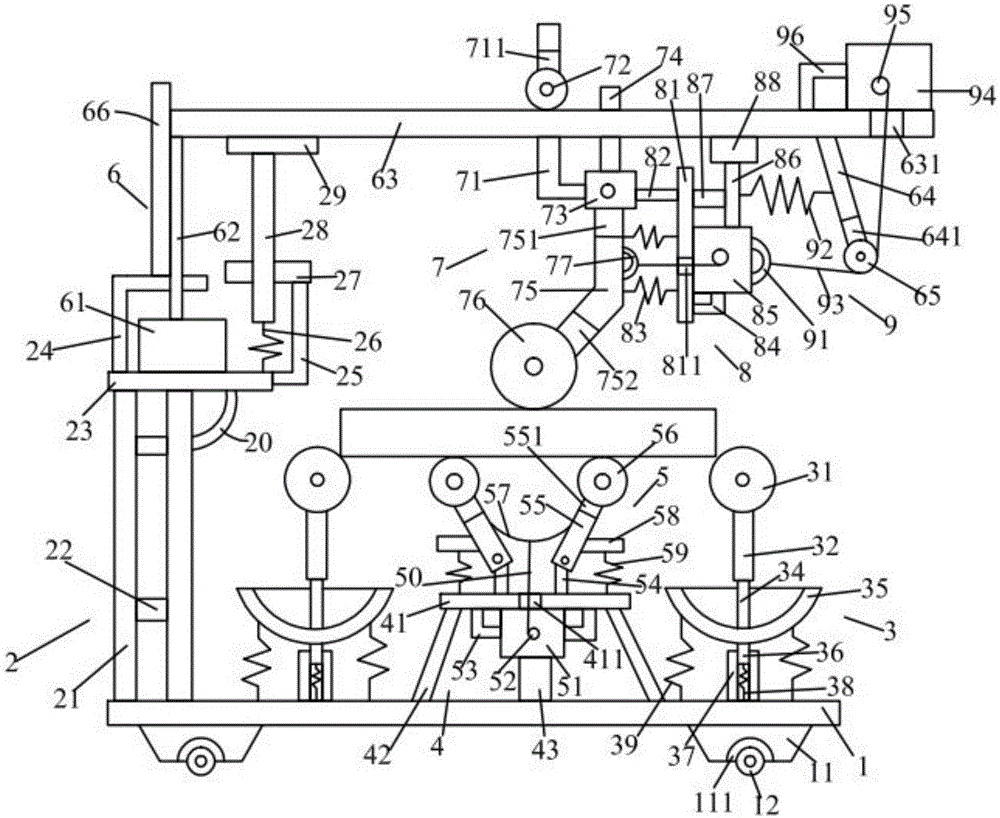

ActiveCN106956181AChange angleImprove sanding qualityEdge grinding machinesGrinding carriagesEngineeringBolt connection

The invention relates to and particularly relates to a rapid glass side edge grinding device applied to a glass factory and aims to provide the rapid glass side edge grinding device which is relatively high in grinding quality, capable of saving time and effort in a grinding process and applied to the glass factory. The rapid glass side edge grinding device applied to the glass factory, provided by the invention, comprises a base plate, a first sliding rail, a first slider, a first motor, a first gear, an arranging table, a first gear rack, a baffle, a first fixing plate, a second sliding rail, a second slider and the like; the first sliding rail is installed at the right side inside the base plate in a bolt connection way; and the first slider is slidably connected within the first sliding rail. The rapid glass side edge grinding device provided by the invention realizes the effects of relatively high grinding quality and time-saved and effort-saved grinding process, and realizes grinding by adopting four tap position slots which form an angle of 90 degrees with one another to precisely move a glass side edge to make sure the glass side edge is parallel to the first sliding rail.

Owner:广东朗博玻璃实业有限公司

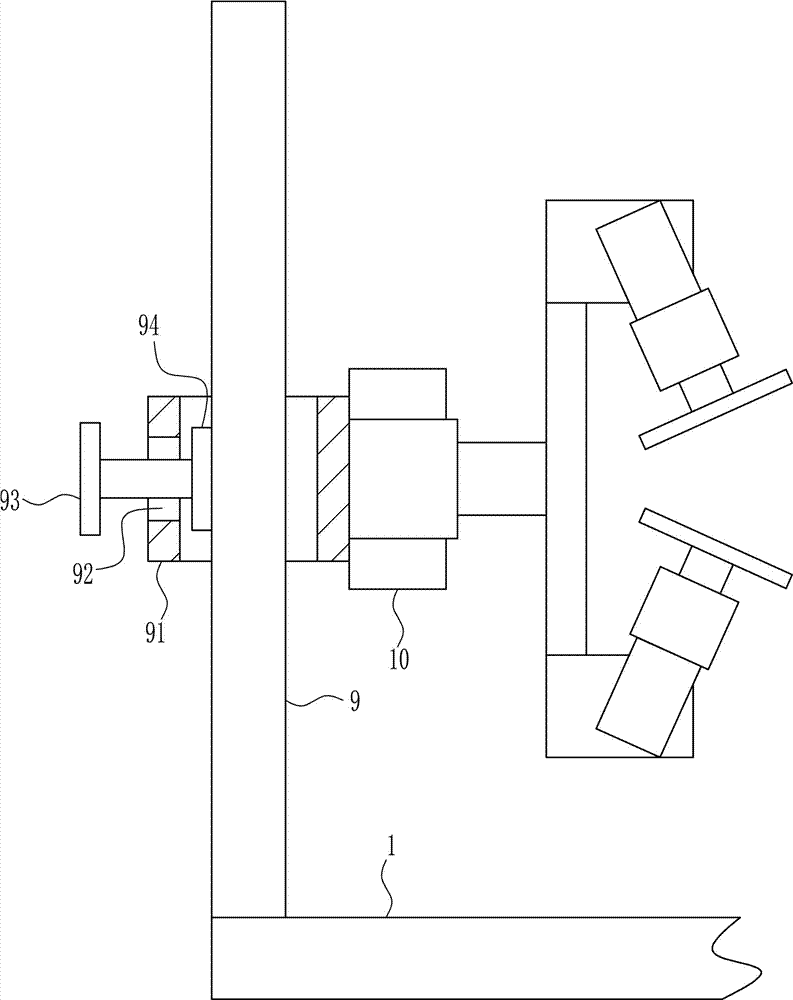

Five-freedom shoemaking automatically grinding glue-spraying processing device

InactiveCN101214098APrecision grindingPrecise gluingSolesShoe gluingThree phase asynchronous motorEngineering

The invention discloses a shoemaking automatic buffing and gel spraying processing device with five degrees of freedom, which is realized mainly through a mobile mechanism and a rotation mechanism. The mobile mechanism can control the movement of a work piece at three space orthogonal positions. A buffing head mechanism or a gel spraying mechanism is respectively connected with an arm swinging binding part. The rotation of a swing arm and a buffing head box or a spray gun is respectively driven through an AC servo motor, which leads to that the buffing plate or the spray gun can swing along two orthogonal directions to realize the posture regulation of the buffing plate or the spray gun. A three-phase asynchronous motor drives the buffing plate to rotate at a high speed through a flexible shaft to realize the buffing work. The automatic buffing and the gel spraying work can be respectively realized through different connections of the buffing head mechanism or the gel spraying mechanism with the arm swinging combining part.

Owner:ZHEJIANG SCI-TECH UNIV

Grinding device for production of machine part

InactiveCN105437035AReduce the temperatureStable deliveryGrinding carriagesGrinding drivesHydraulic cylinderMachine parts

The invention discloses a grinding device for production of a machine part. The device comprises a device body and a grinding chamber, wherein vertical guide rails on which a cooling device is mounted are arranged at two sides of the grinding chamber; the cooling device is movably connected to the vertical guide rails through first slide blocks; a cross beam is arranged on the top surface of the grinding chamber; hydraulic cylinders, which are connected to grinding mechanisms through telescopic rods, are movably connected to the bottom part of the cross beam; a liquid collecting box in which stirring mechanisms are mounted is arranged in the device body; a supporting platform above which grinding tables are mounted is arranged on the top surface of the liquid collecting box; the grinding tables are fixedly connected to the supporting platform through positioning racks; lifting mechanisms are arranged on the positioning racks. The grinding device is simple in structure and high in practicability; the movable cooling device and the grinding mechanisms are designed, so that the cooling liquid spraying area and volume can be improved; in addition, the surface of a complex machine part can be grind, and meanwhile, the operations of clamping, positioning and conveying of the machine part are integrated.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

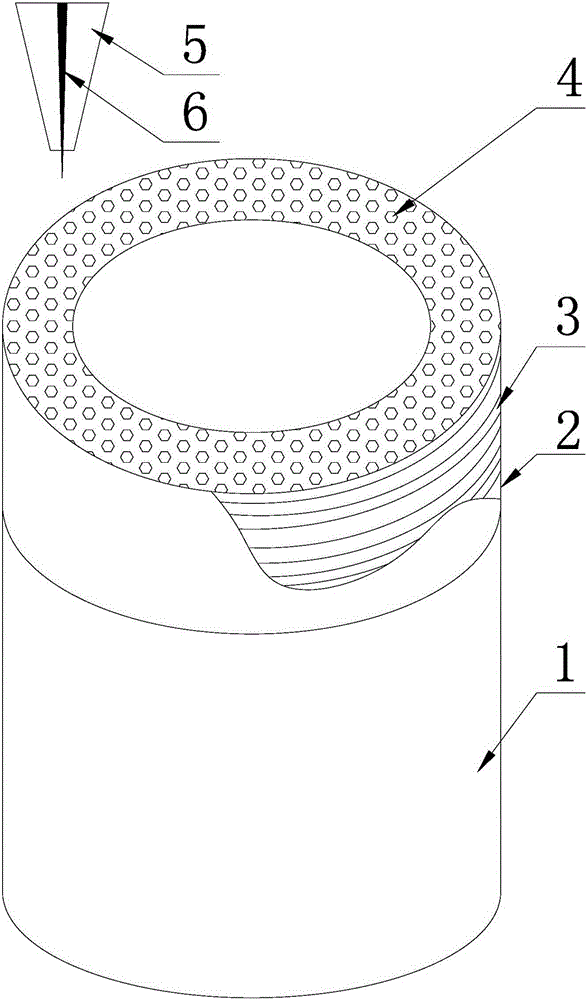

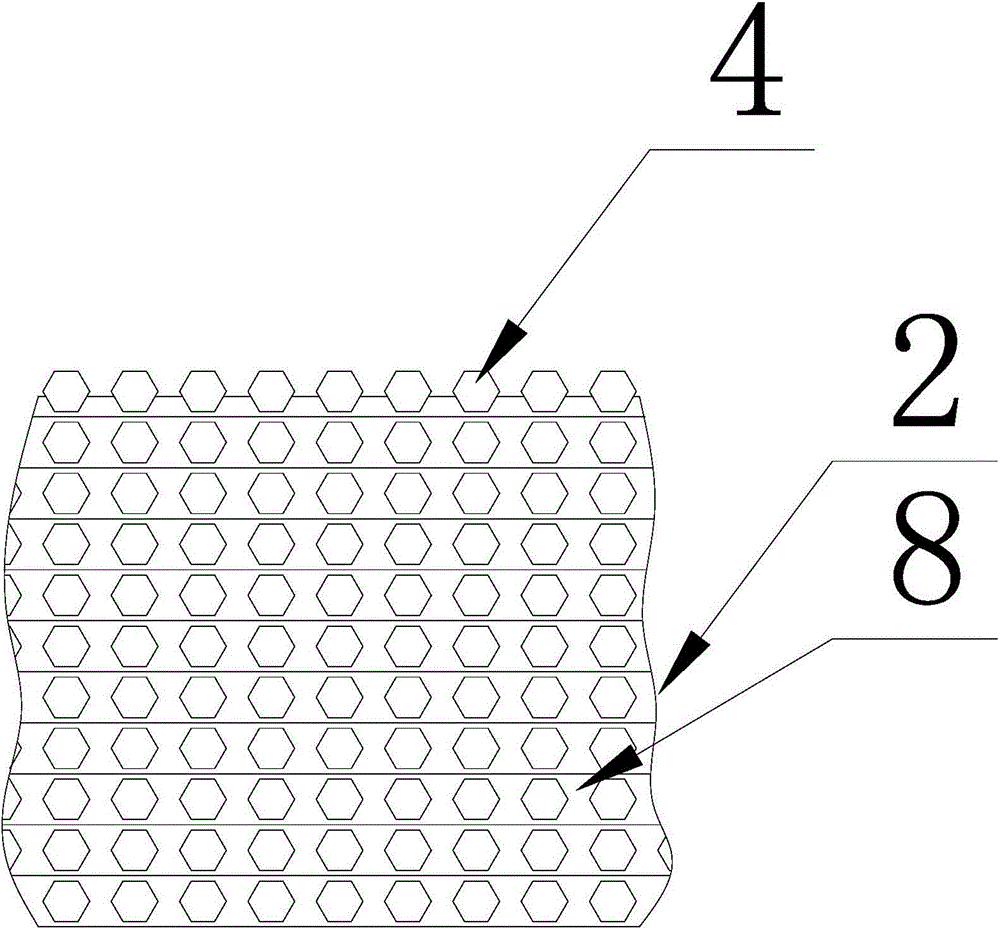

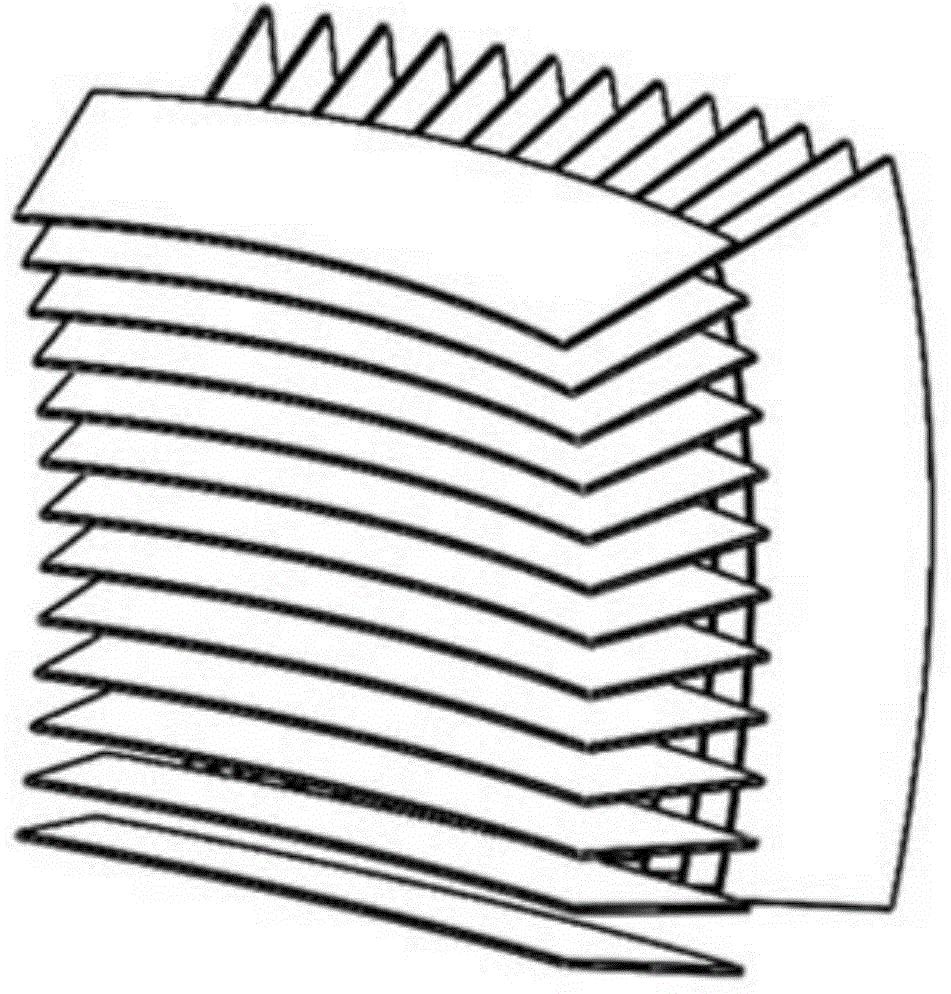

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

Dust-free environment-friendly architectural decorative stone polishing device

InactiveCN107088799AAutomatically control the left and right movement of the grinding workImprove grinding accuracyGrinding carriagesGrinding drivesAutomatic controlEngineering

The invention discloses a dust-free environment-friendly architectural decorative stone polishing device. The dust-free environment-friendly architectural decorative stone polishing device comprises a shell, a polishing cavity is formed in the shell, a first sliding groove is formed in the left side of the top wall in the polishing cavity, a second sliding groove arranged in a longitudinal extension manner is formed in the inner wall of the right side of the polishing cavity, and an opening with the left side end communicated with the polishing cavity is formed in the position, below the second sliding groove, of the right side wall of the shell in a penetrating manner; a fixed connection assembly and a sinking groove are arranged on the left and right sides of the bottom wall in the polishing cavity correspondingly, a first threaded rod extending left and right is arranged in the first sliding groove, and a movement block with the bottom extending into the polishing cavity is connected to the first threaded rod in a threaded fit manner; and a first sliding cavity is formed in the movement block, a lifting sliding block is connected into the first sliding cavity in a slide fit manner, and protruding sliding blocks connected with the inner walls of the two sides of the first sliding cavity in a slide fit manner are arranged at the edges of the tops of the two sides of the lifting sliding block. The dust-free environment-friendly architectural decorative stone polishing device is simple in structure, convenient to operate and high in safety, opening and closing of a separating plate can be automatically controlled, the dust suction effect is good, the polishing is accurate, and the stability is high.

Owner:徐州惠泉新型建材有限公司

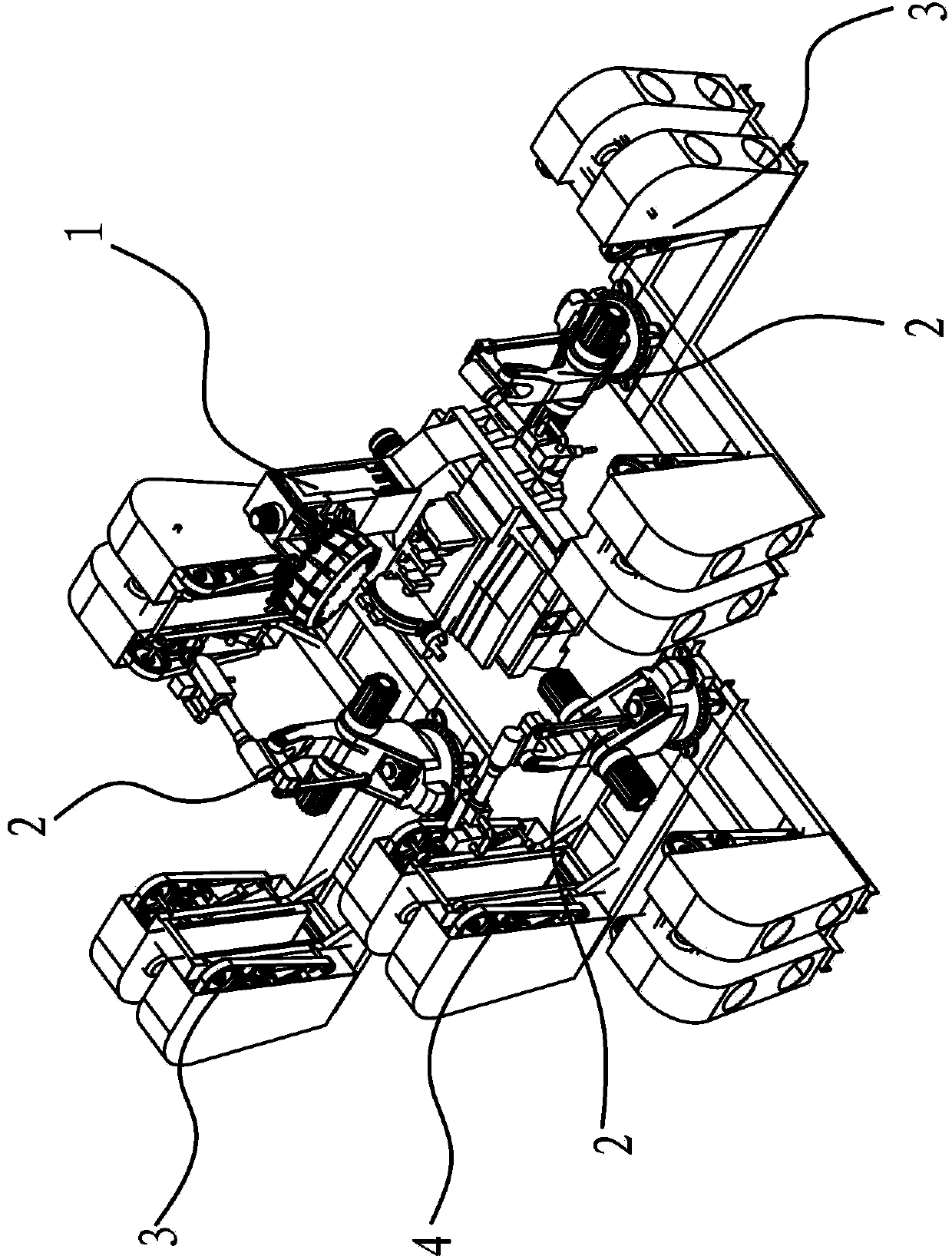

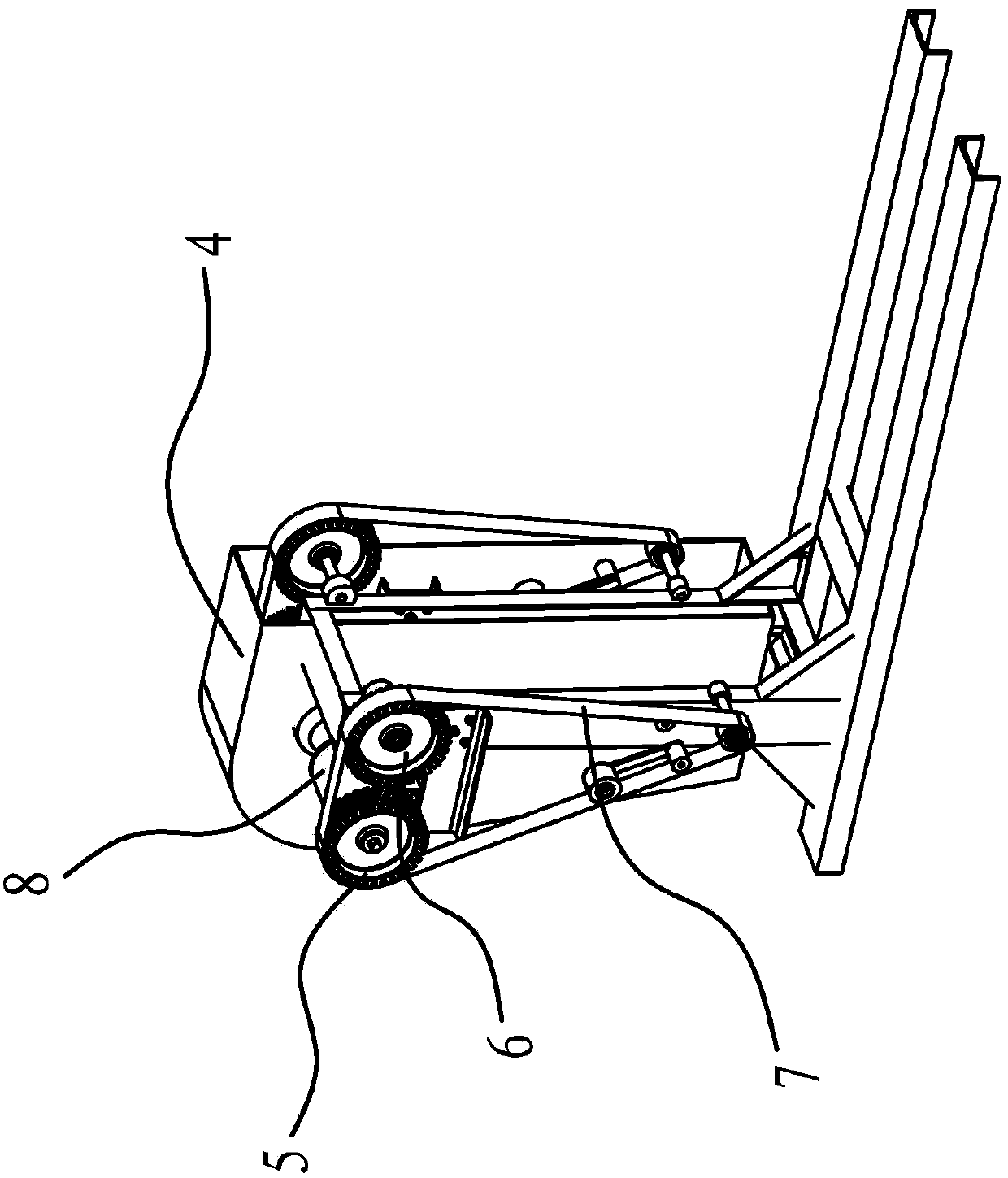

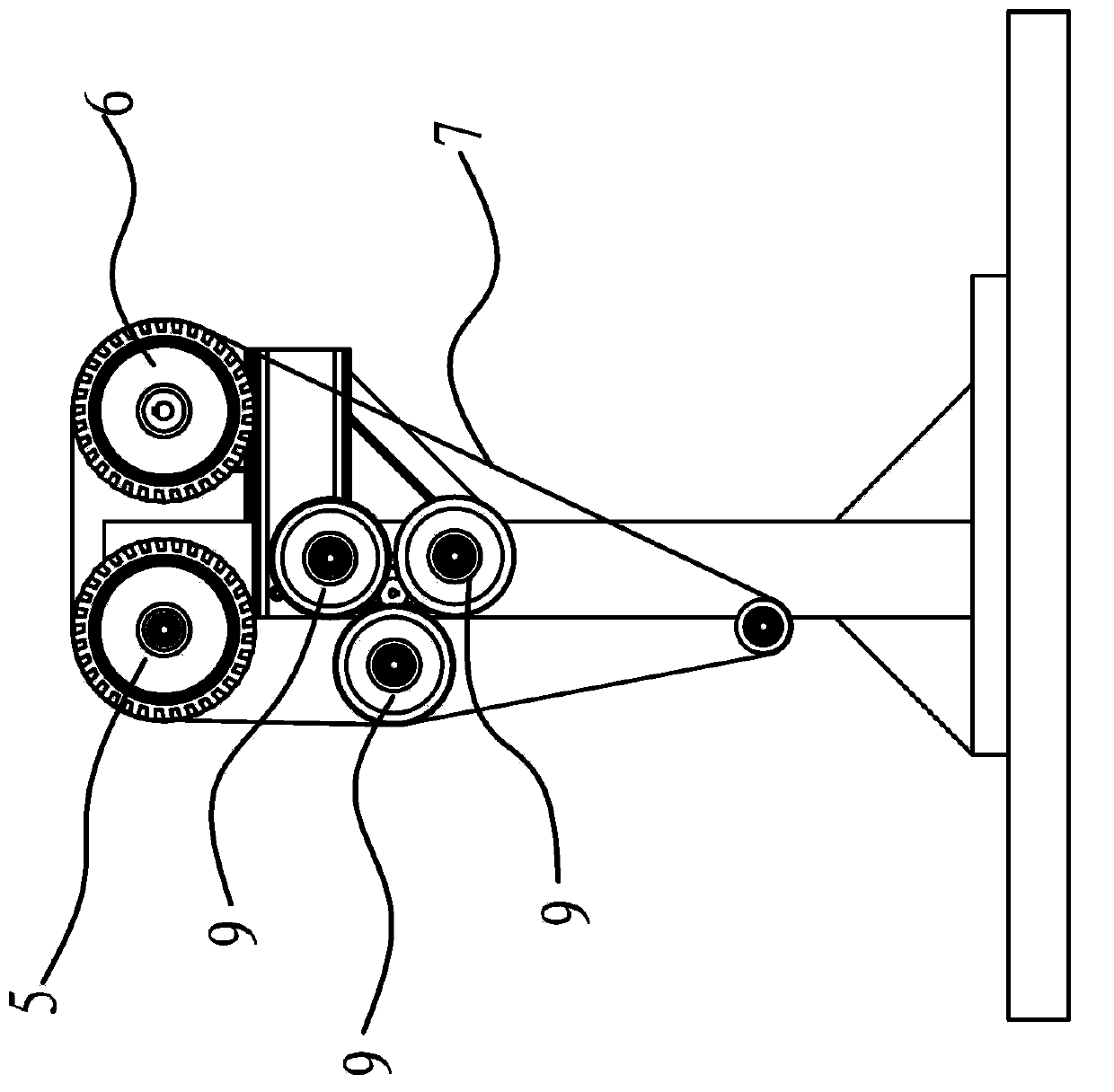

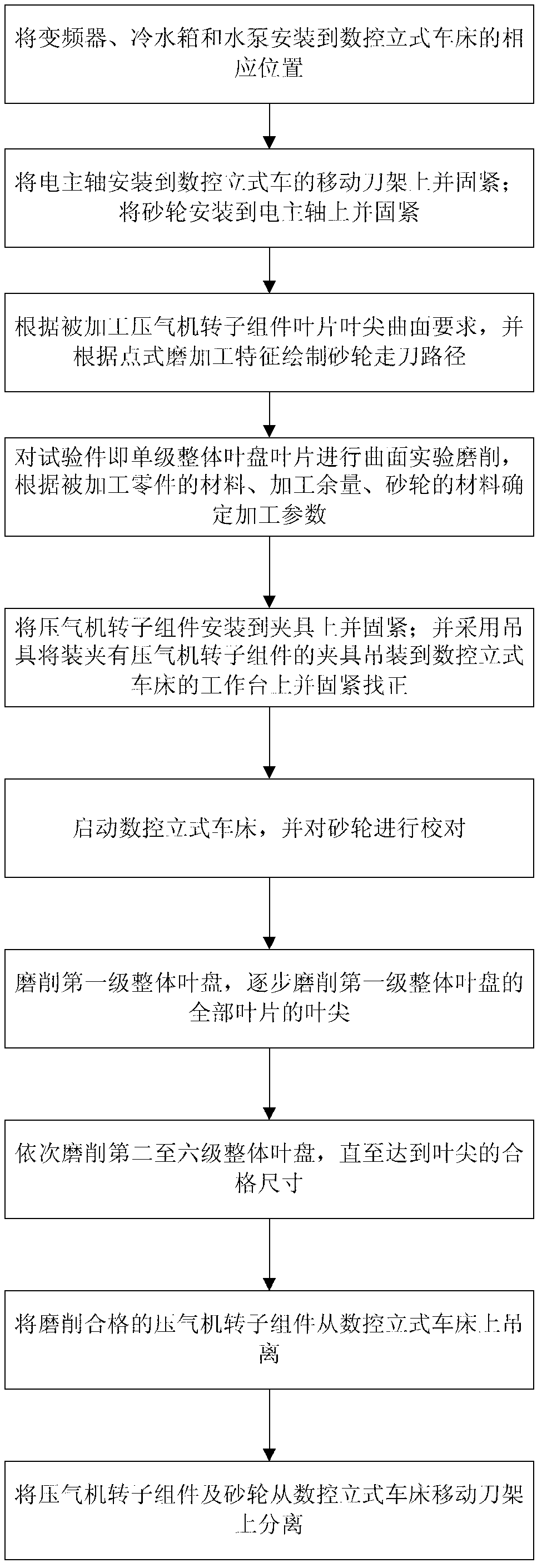

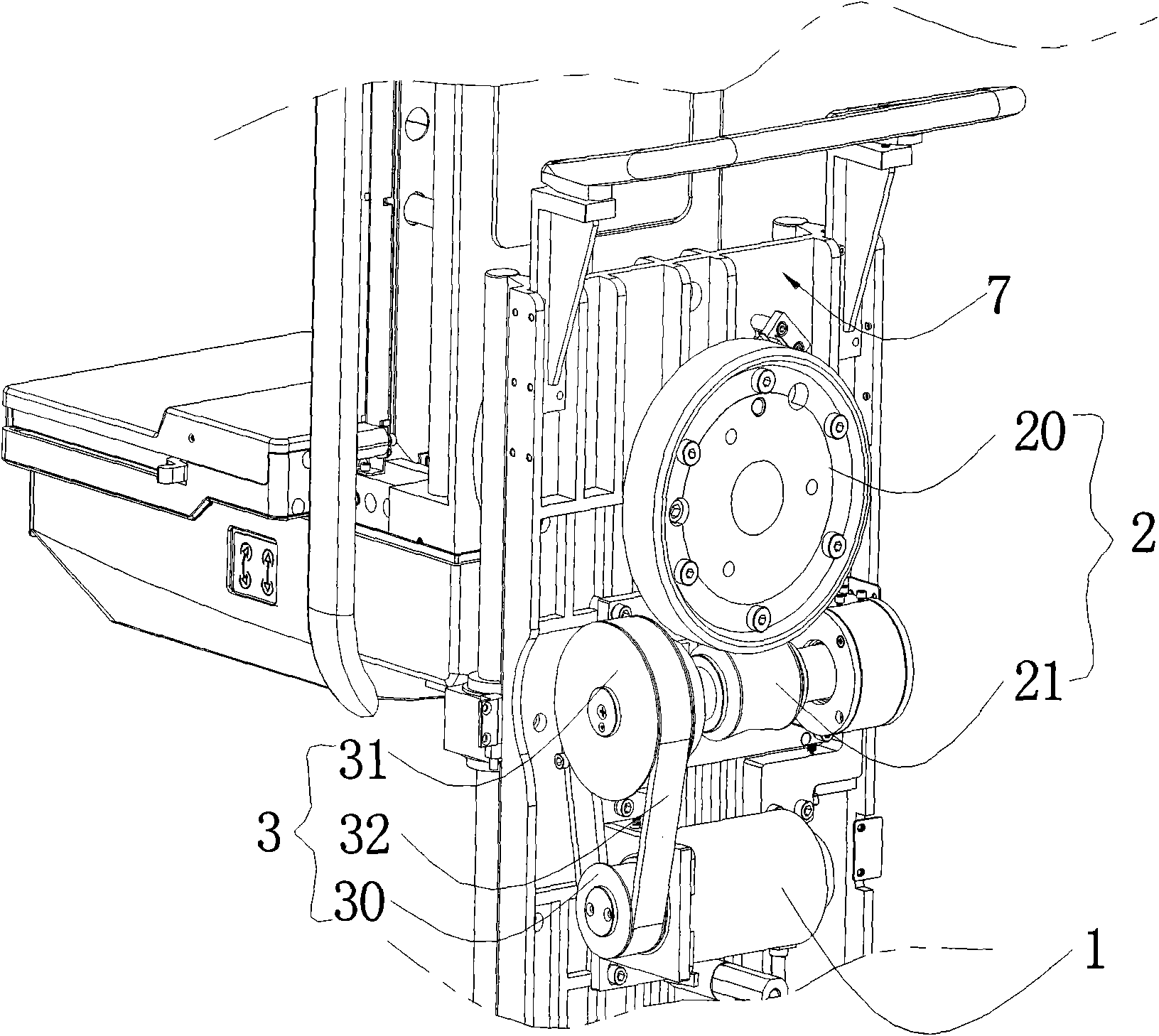

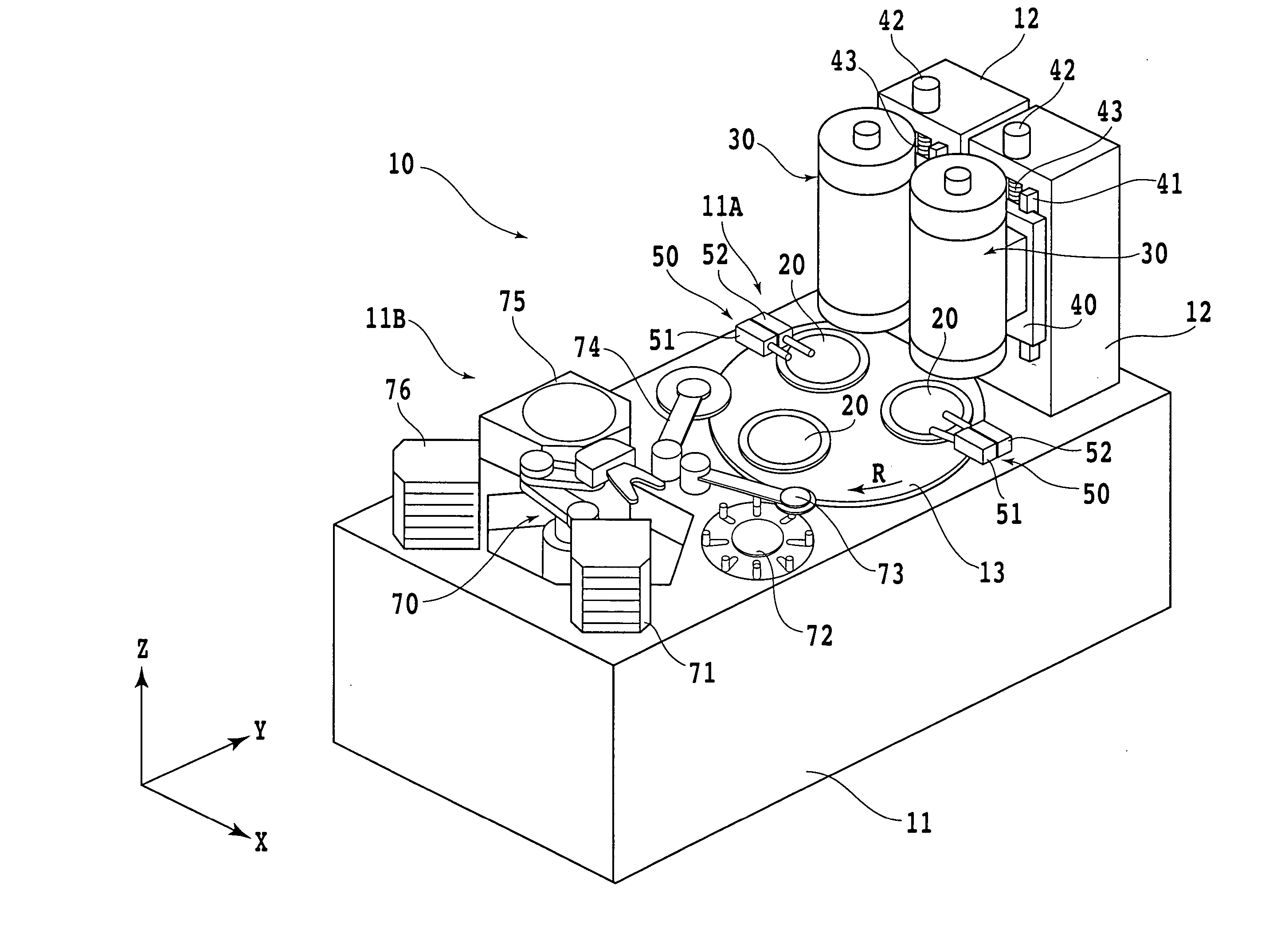

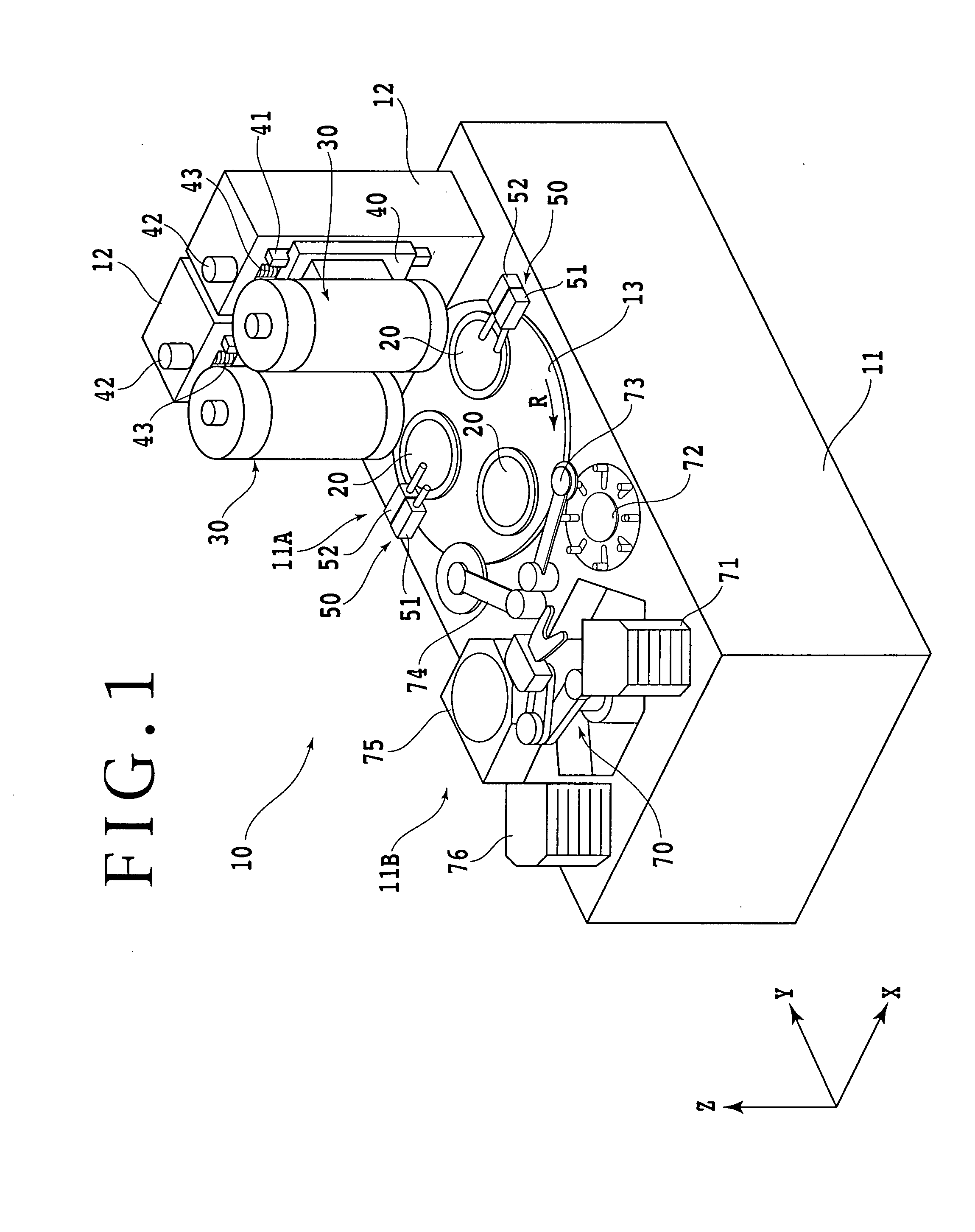

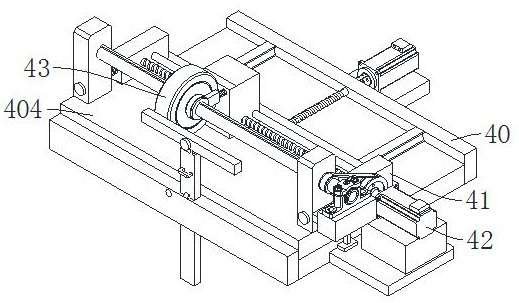

Workpiece automatic machining system and grinding method of surface of workpiece

ActiveCN103419111AHigh precisionImprove integrityBelt grinding machinesMechanical engineeringEngineering

The invention provides a workpiece automatic machining system and a grinding method of the surface of a workpiece, and belongs to the technical field of machines. The problems that an existing grinding polishing machine is not unified in machining precision and not uniform in workpiece forming are solved. The workpiece automatic machining system comprises a machining center which conducts machining work on the workpiece, and further comprises a grinding unit which is adjacent to the machining center. The grinding unit is provided with a mechanical arm and a plurality of grinding machines, and the mechanical arm can clamp and convey the workpiece which has been machined at the machining center to the grinding machines to be ground. The workpiece automatic machining system and the grinding method of the surface of the workpiece have the advantages of being high in automatic degree, good in uniformity of workpiece forming, high in grinding precision and the like.

Owner:WUHU HUIYING AUTOMATIC EQUIP CO LTD

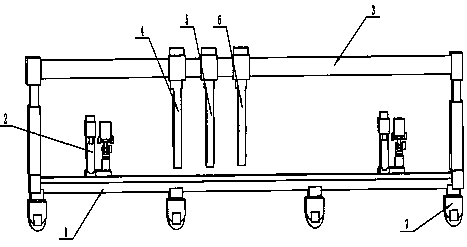

Grinding equipment for cathode roller

ActiveCN107009207AAvoid excessive wearGuaranteed grinding effectGrinding carriagesRevolution surface grinding machinesEngineeringCathode

The invention discloses grinding equipment for a cathode roller and belongs to the technical field of grinding equipment. According to the technical key point, the grinding equipment comprises a support arranged on the side edge of the roller surface of the cathode roller; guide rails are arranged on the support; an axial sliding seat is arranged on the guide rails and connected with a driving screw rod in a threaded mode; the driving screw rod is connected with a first driving motor, and the driving screw rod and the guide rails are arranged parallelly; supporting seats matched with the driving screw rod are arranged at the two ends in the length direction of the support correspondingly; the driving screw rod is connected with a displacement detecting mechanism; a radial sliding seat is movably arranged on the axial sliding seat and connected with a radial driving mechanism; an installing table is arranged on the radial sliding seat; a second driving motor is installed on the installing table in the axial direction of the cathode roller; and a power output shaft of the second driving motor is connected with a grinding wheel. The grinding equipment for the cathode roller is reasonable in structure, high in using safety, convenient to use and used for grinding the cathode roller.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

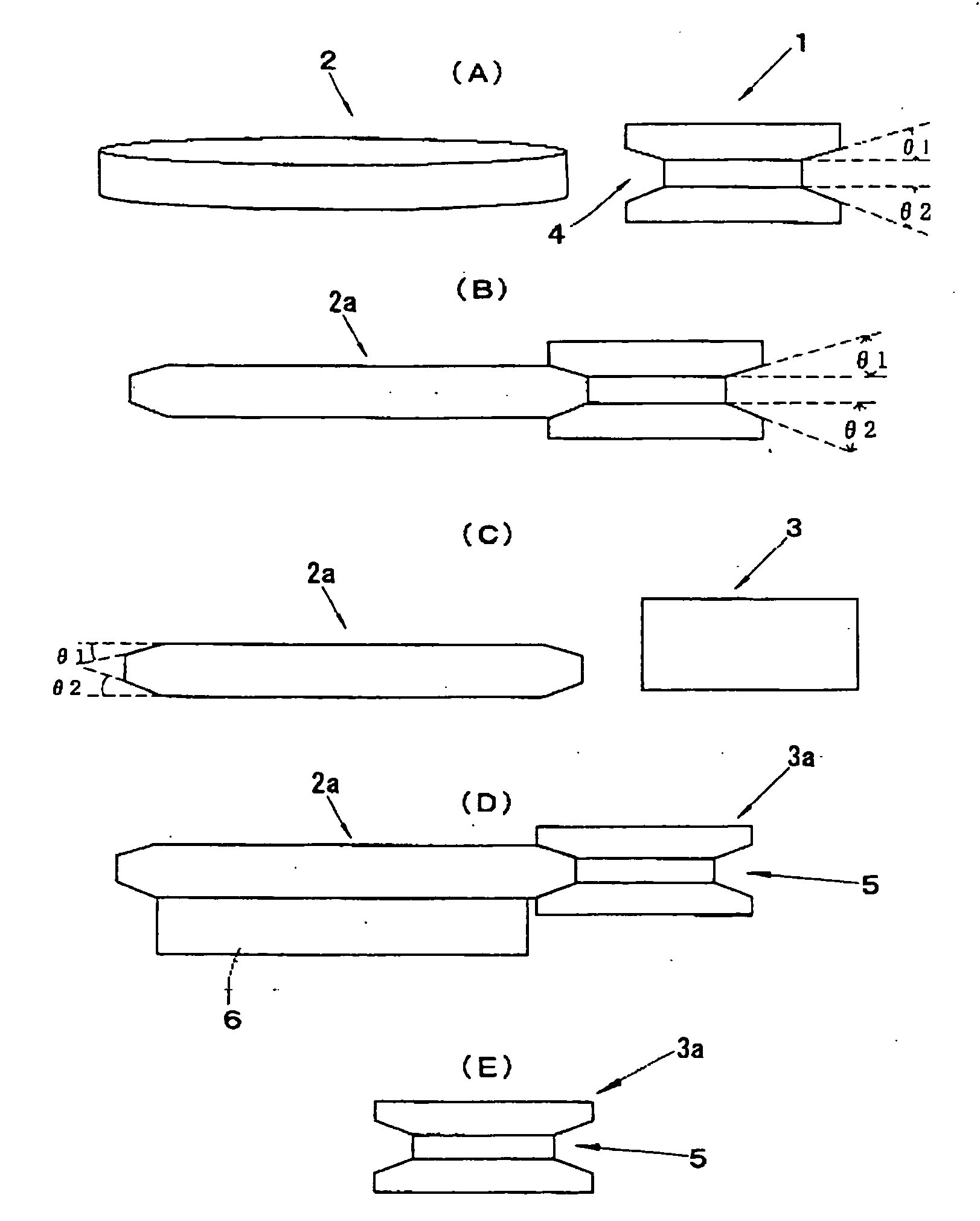

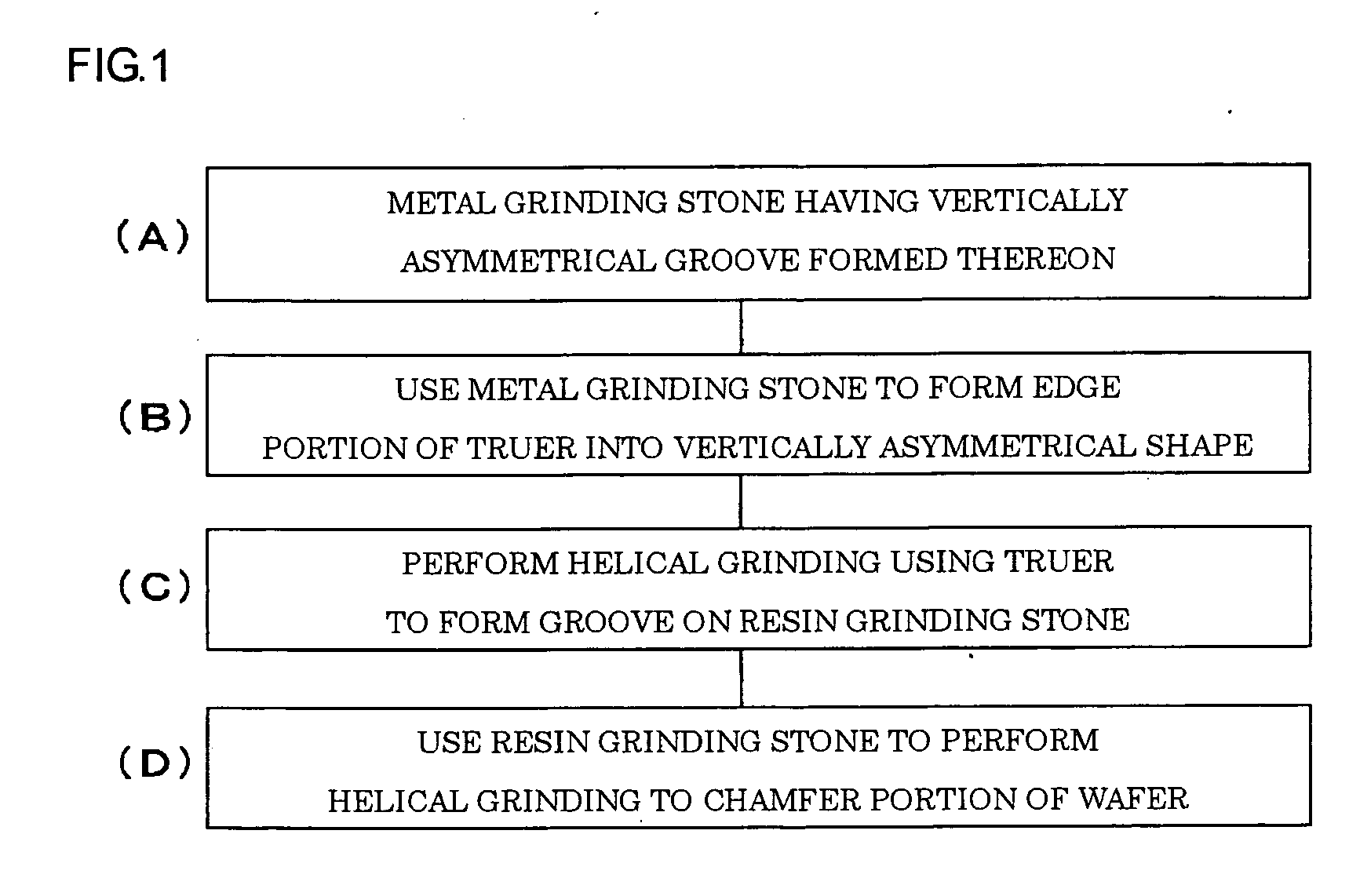

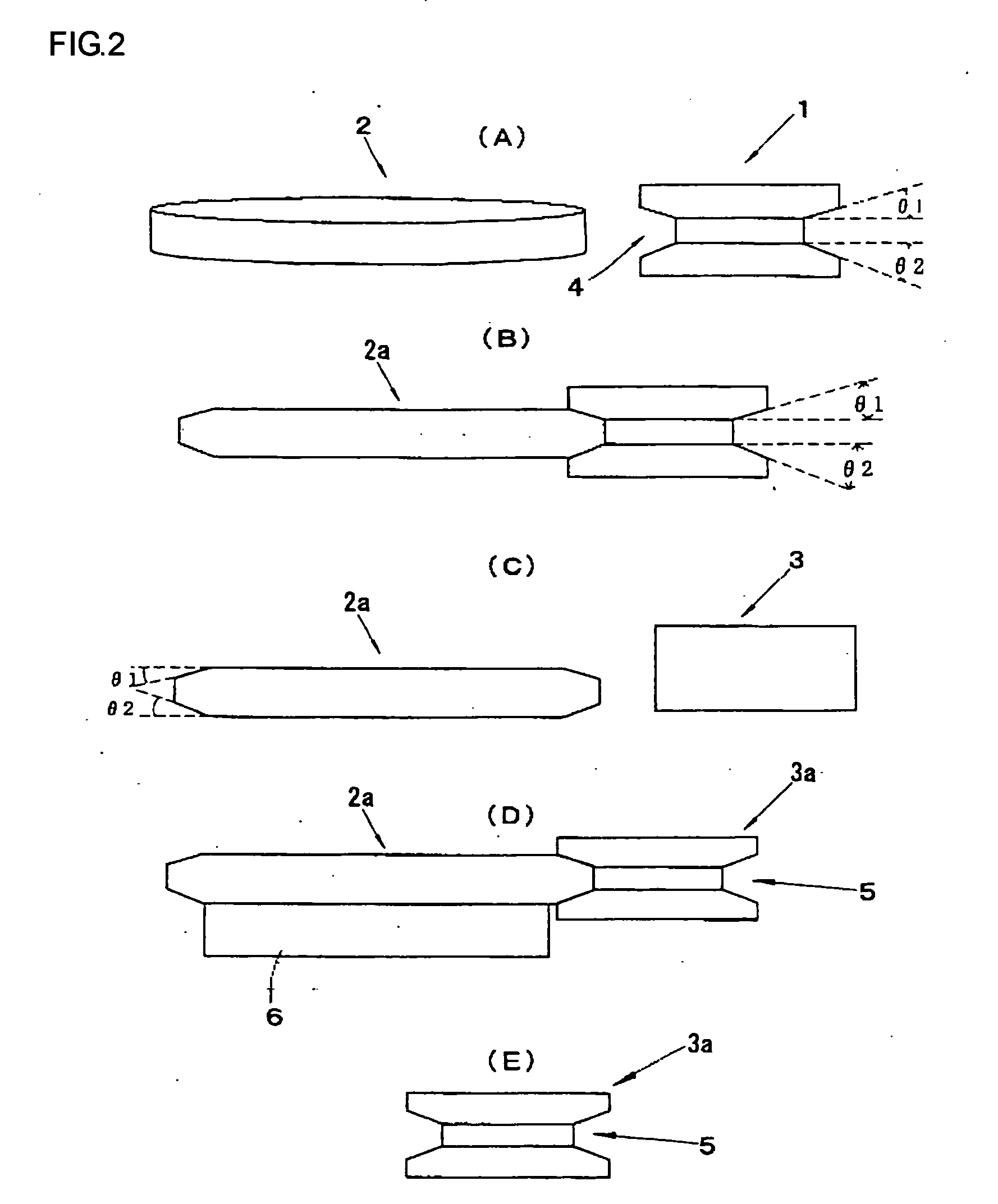

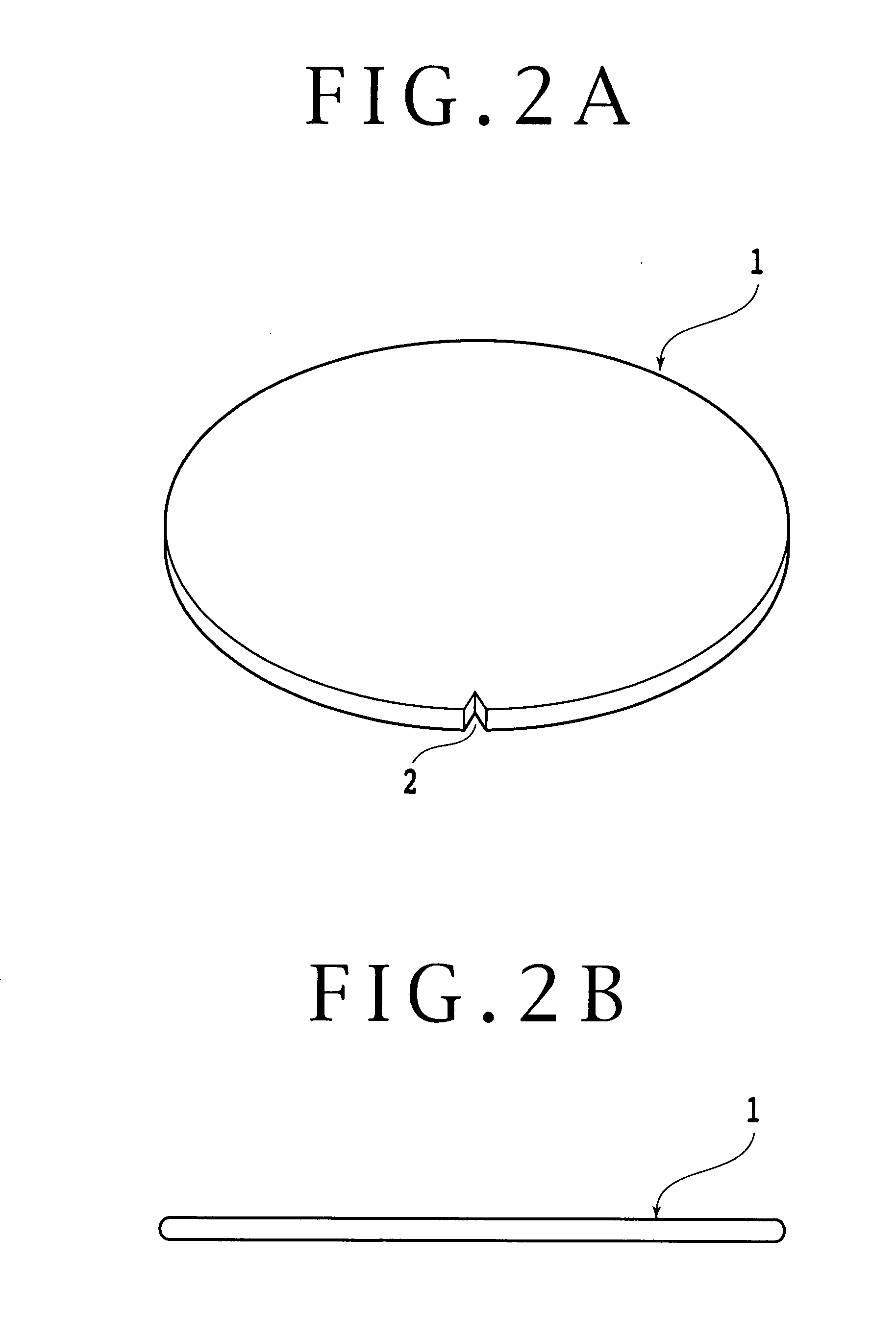

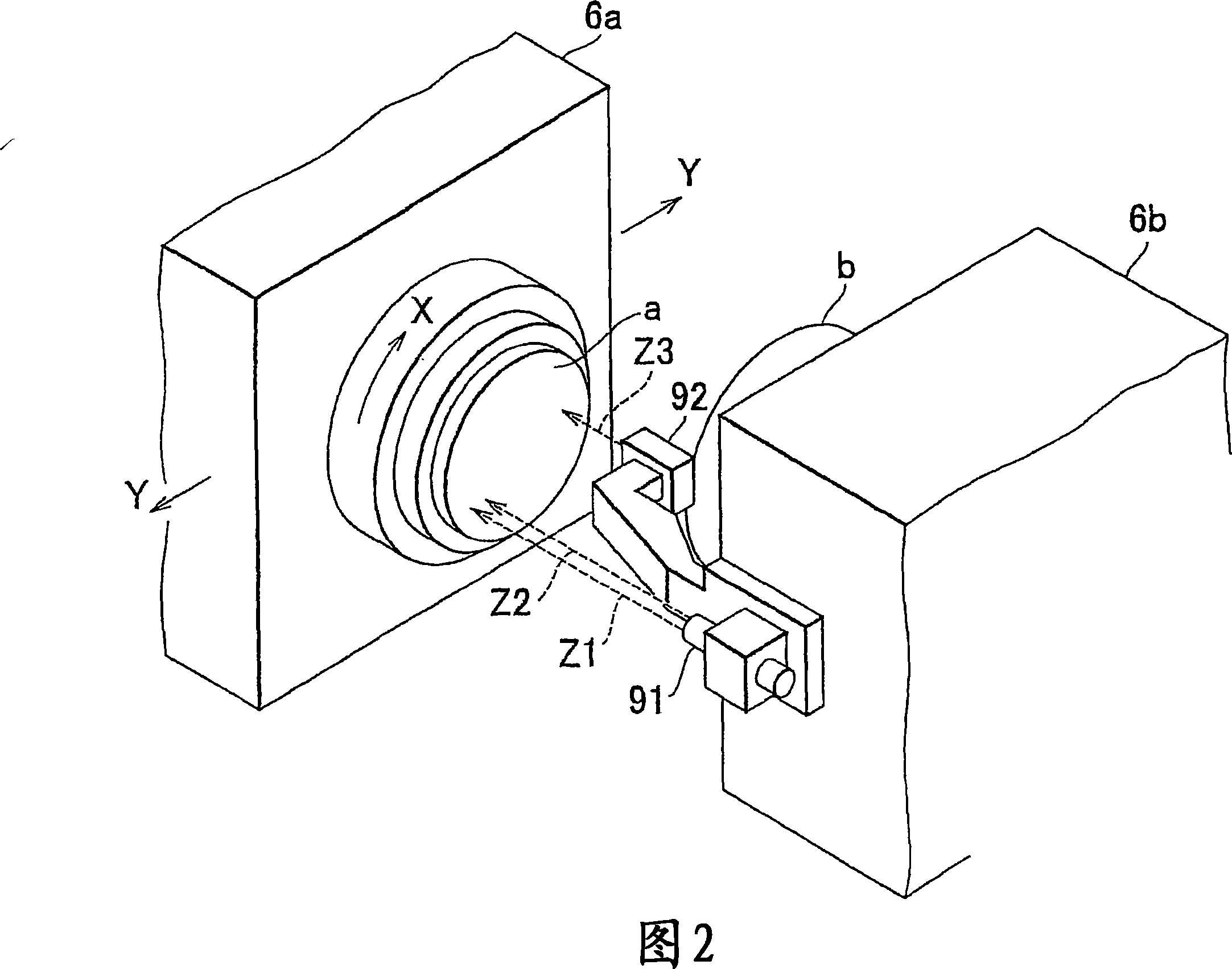

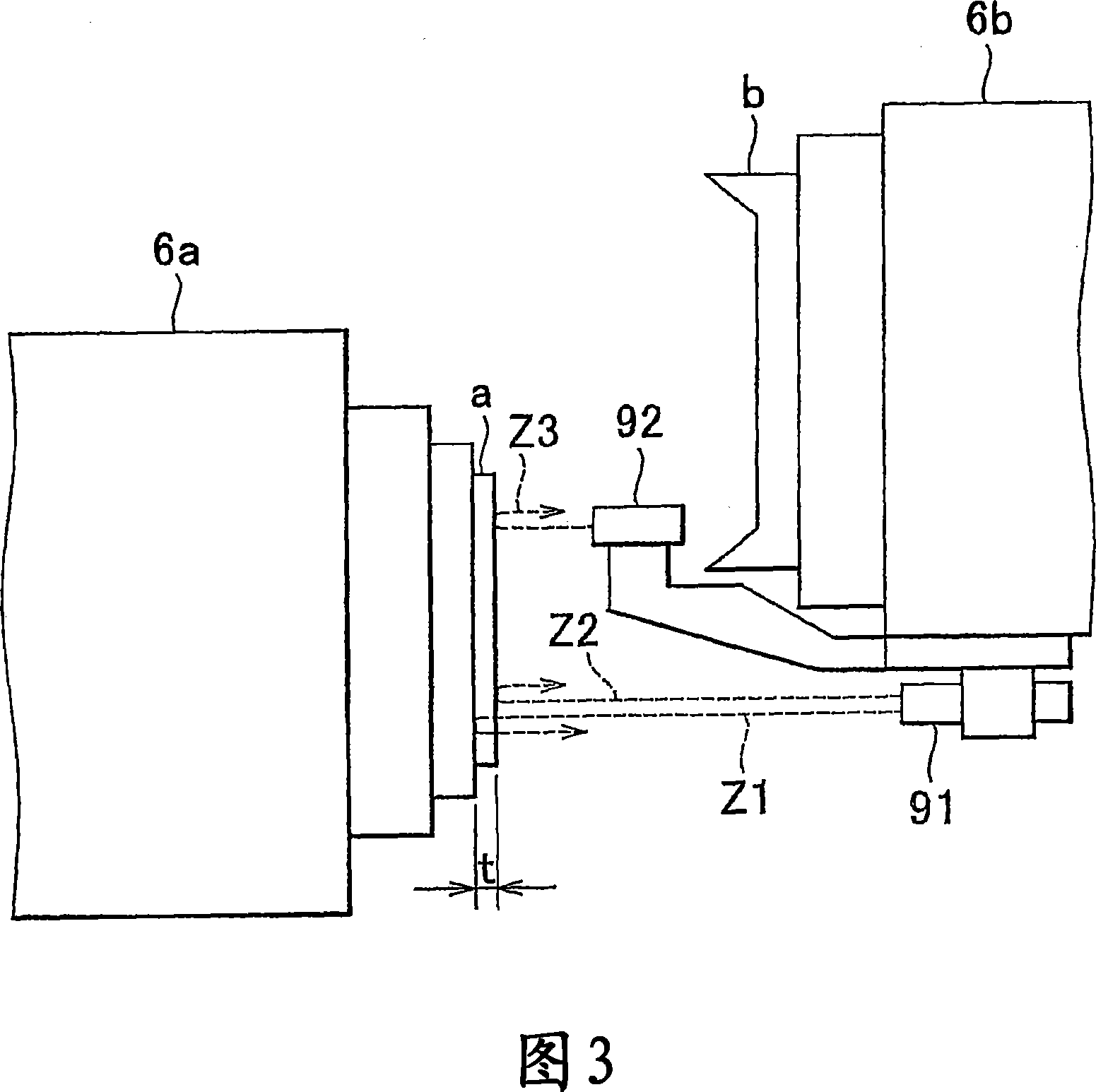

Method for Machining Chamfer Portion of Semiconductor Wafer and Method for Correcting Groove Shape of Grinding Stone

ActiveUS20090163119A1Precision grindingEdge grinding machinesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

According to the present invention, in a method for subjecting a roughly ground chamfer portion of a semiconductor wafer to helical grinding by relatively inclining the wafer and a second grinding stone to perform precise grinding, an edge portion of a discoid truer is formed into a vertically asymmetrical groove shape of a first grinding stone by using the first grinding stone having a vertically asymmetrical groove formed on a periphery thereof to grind the edge portion of the truer by the groove of the first grinding stone without being relatively inclined, a groove is formed on a periphery of the second grinding stone by relatively inclining the truer and the second grinding stone to subject the second grinding stone to helical grinding, and the chamfer portion of the wafer is precisely ground based on helical grinding by relatively inclining the semiconductor wafer with respect to a direction of the groove formed on the periphery of the second grinding stone. As a result, there is provided the method for machining a chamfer portion of the semiconductor wafer, which can machine the chamfer portion of the wafer into a vertically symmetrical shape when subjecting the chamfer portion of the semiconductor wafer to helical grinding, e.g. a resin grinding stone and the like.

Owner:SHIN-ETSU HANDOTAI CO LTD

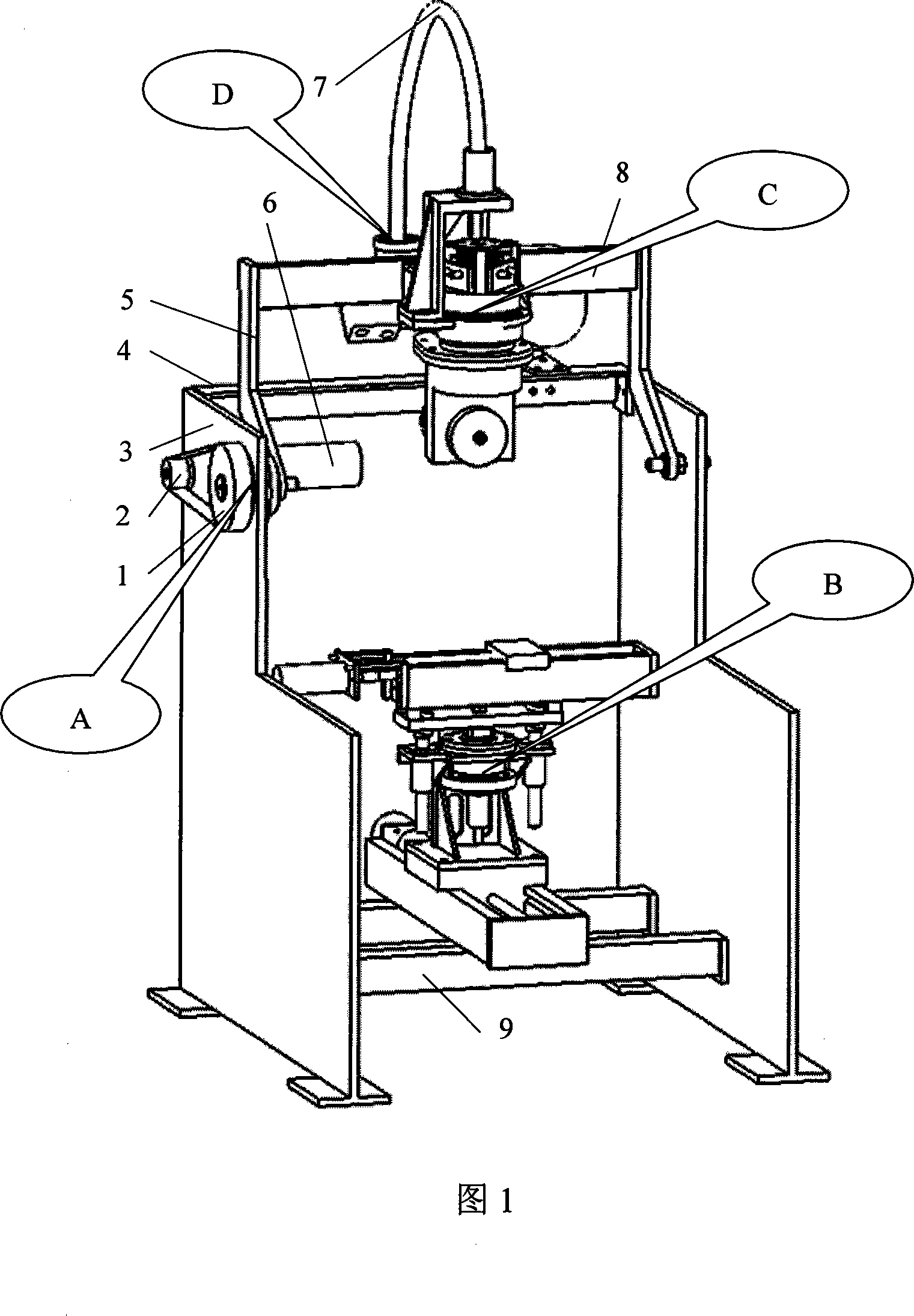

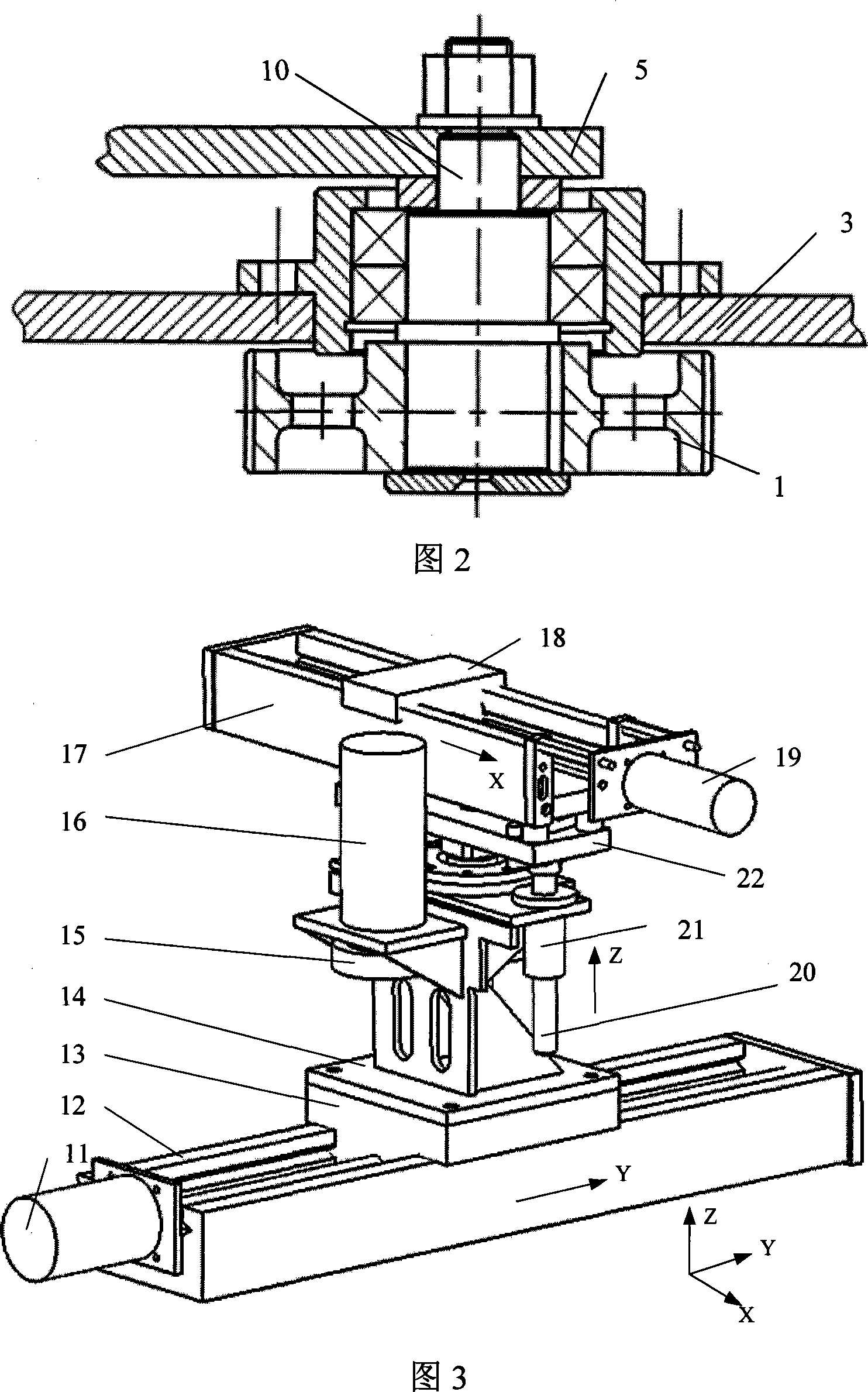

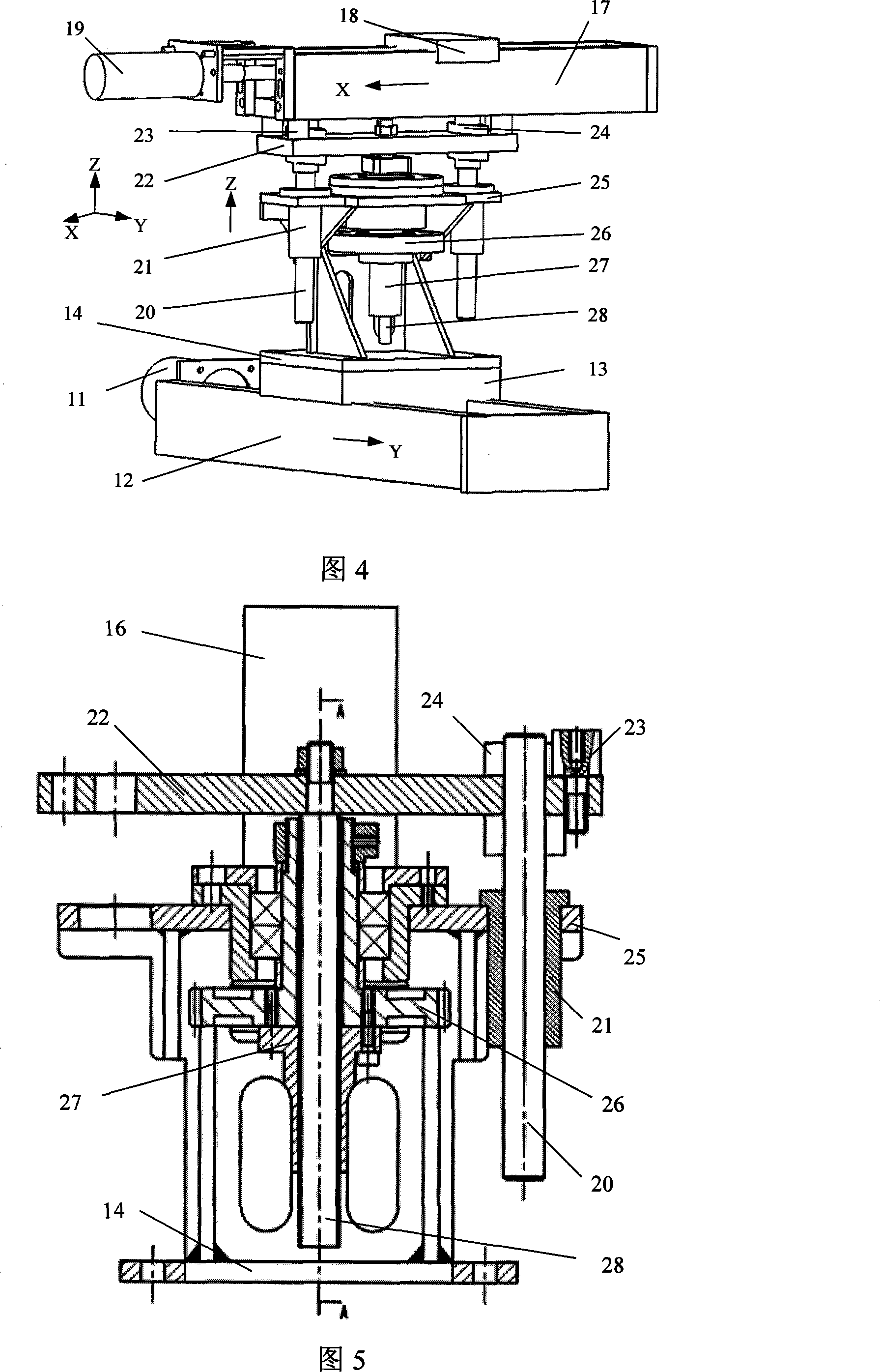

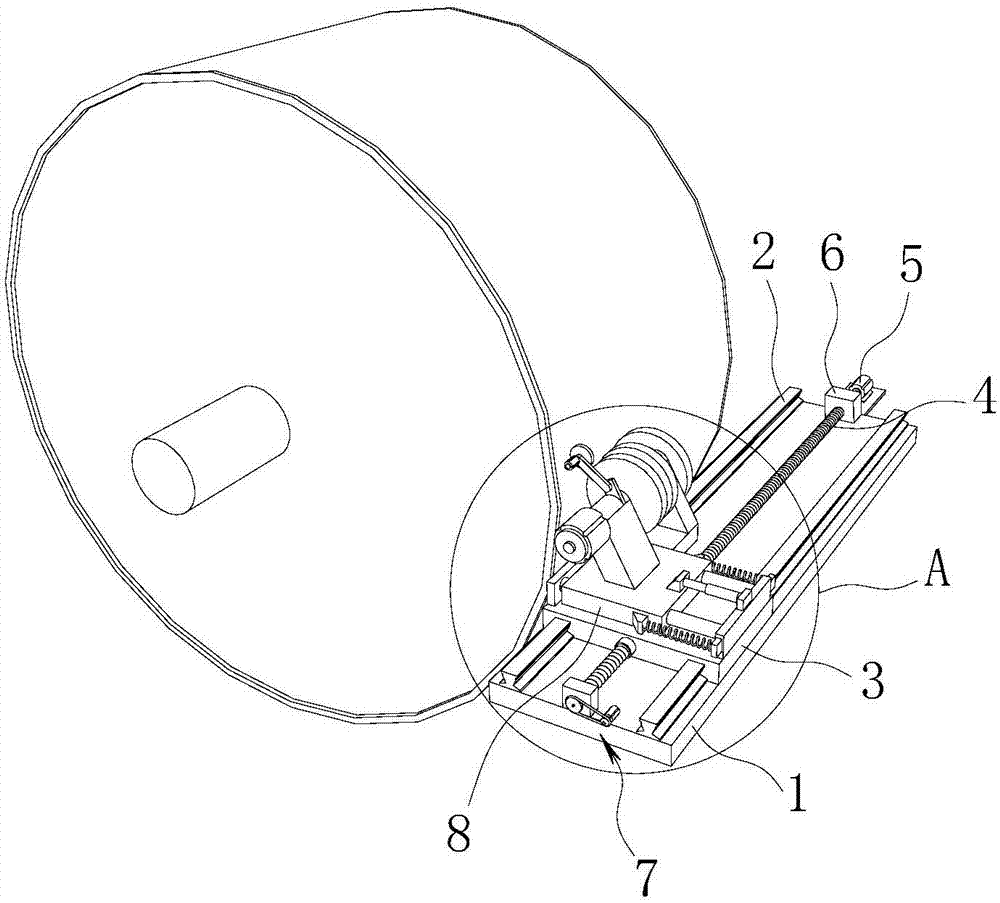

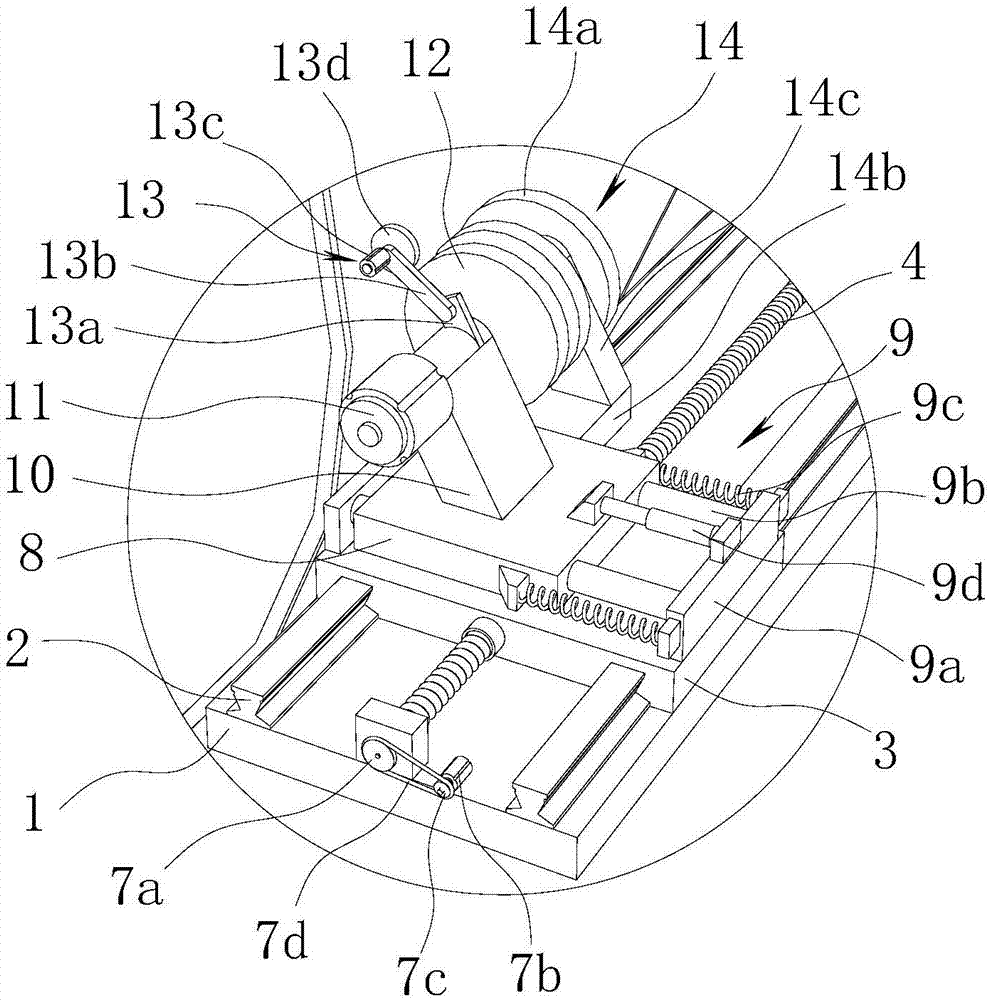

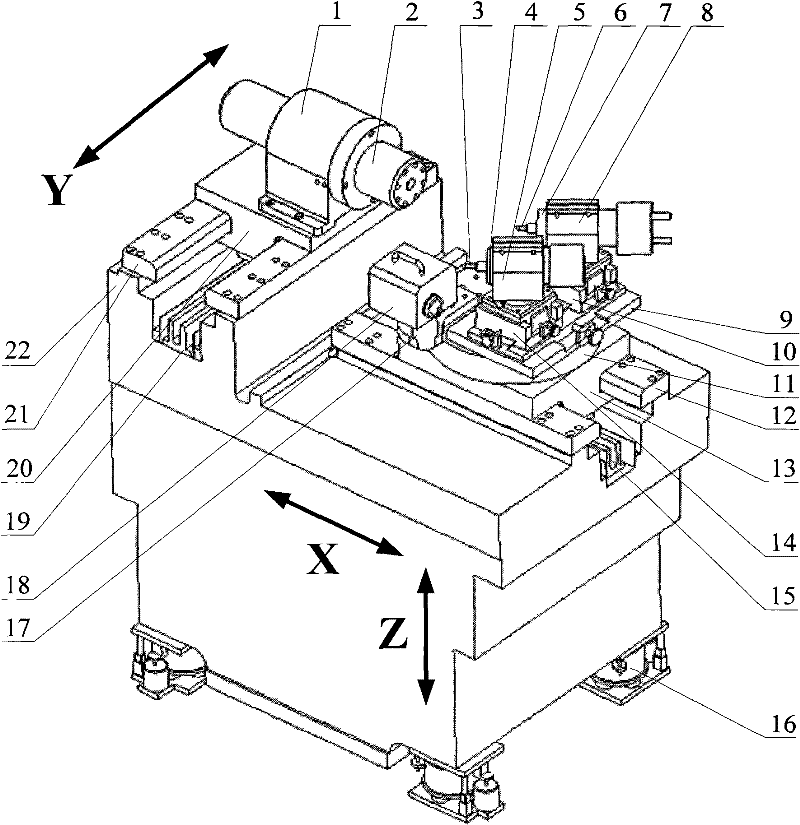

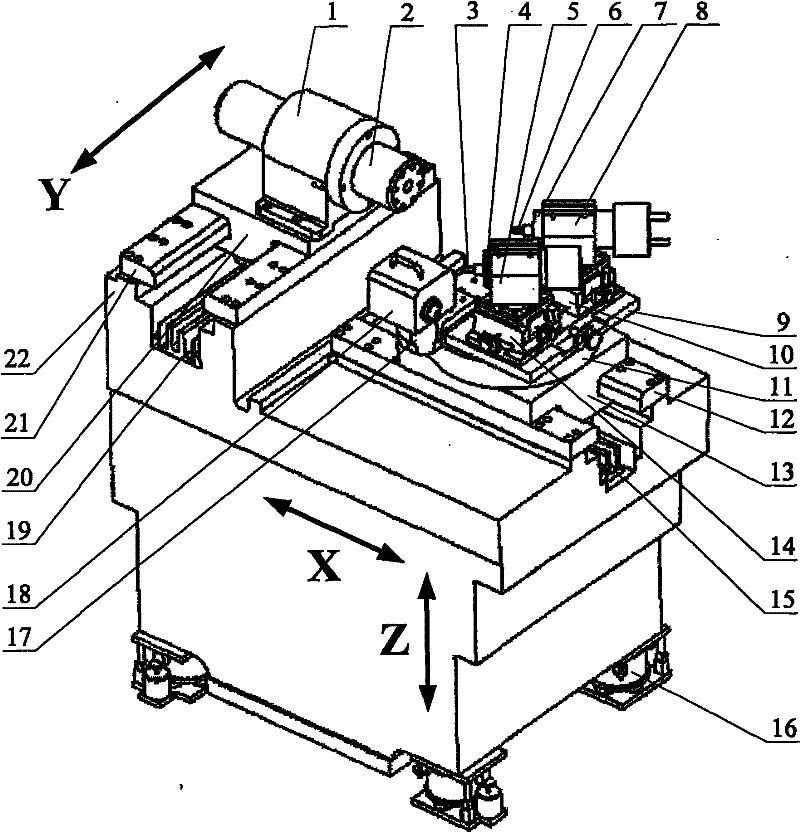

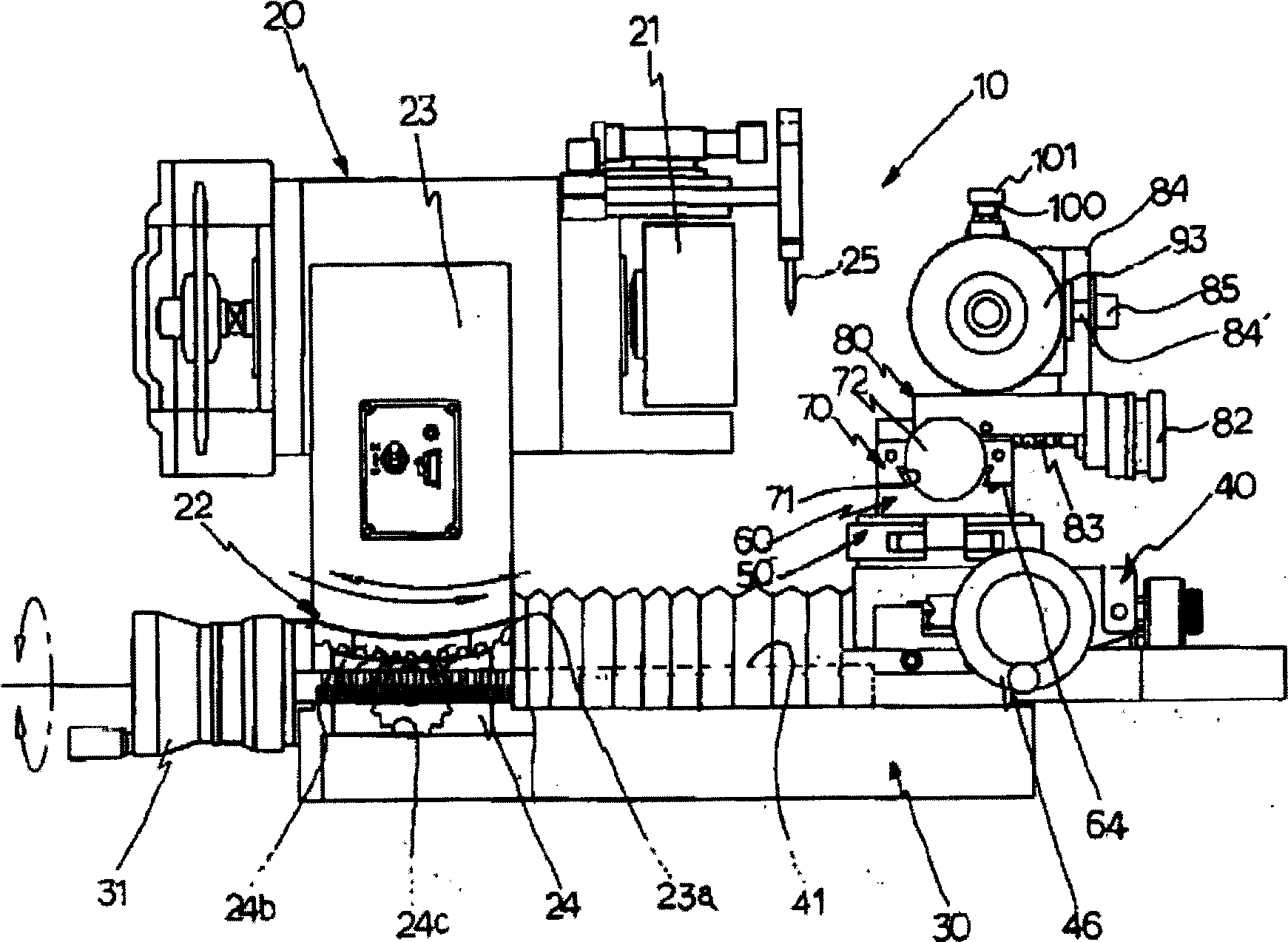

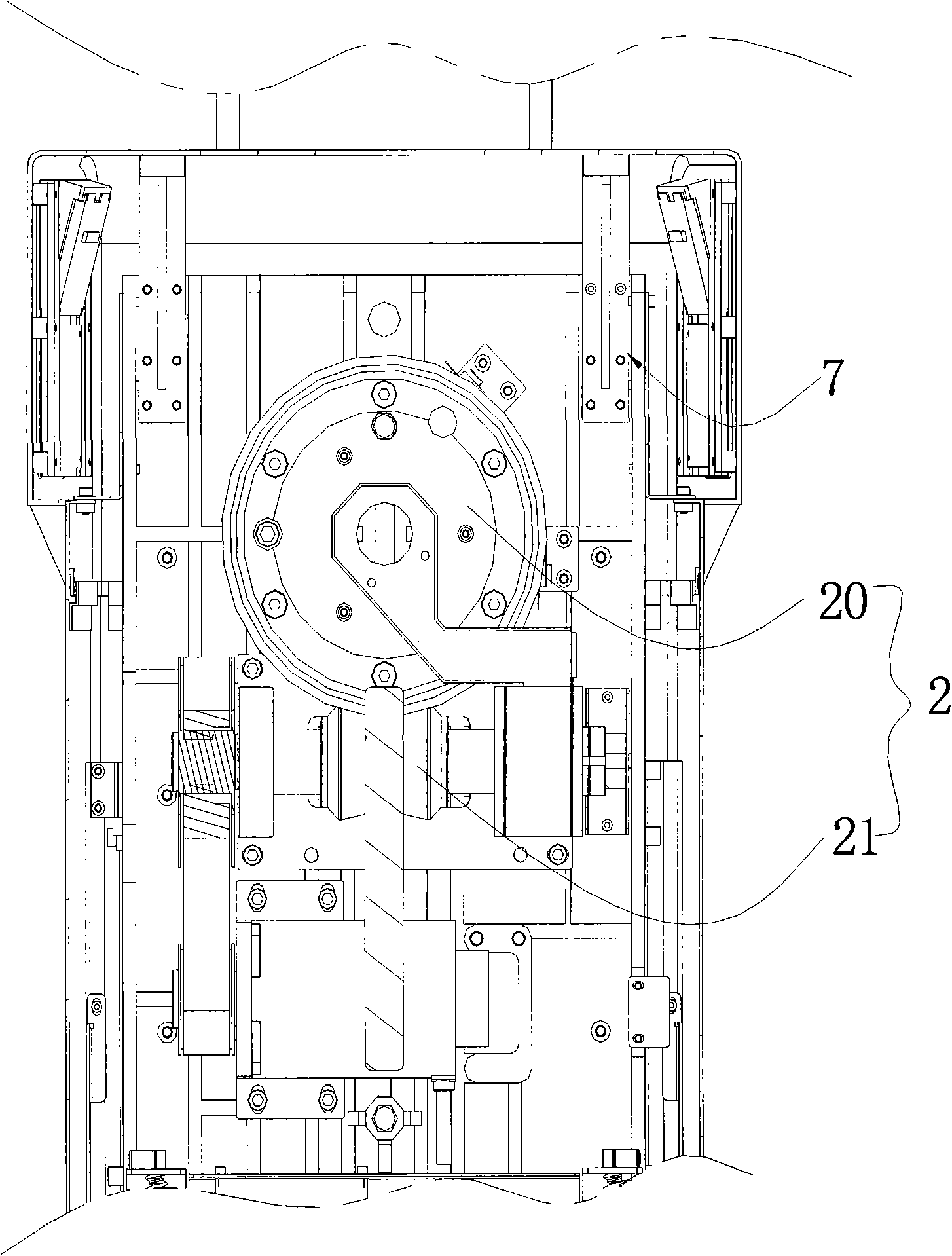

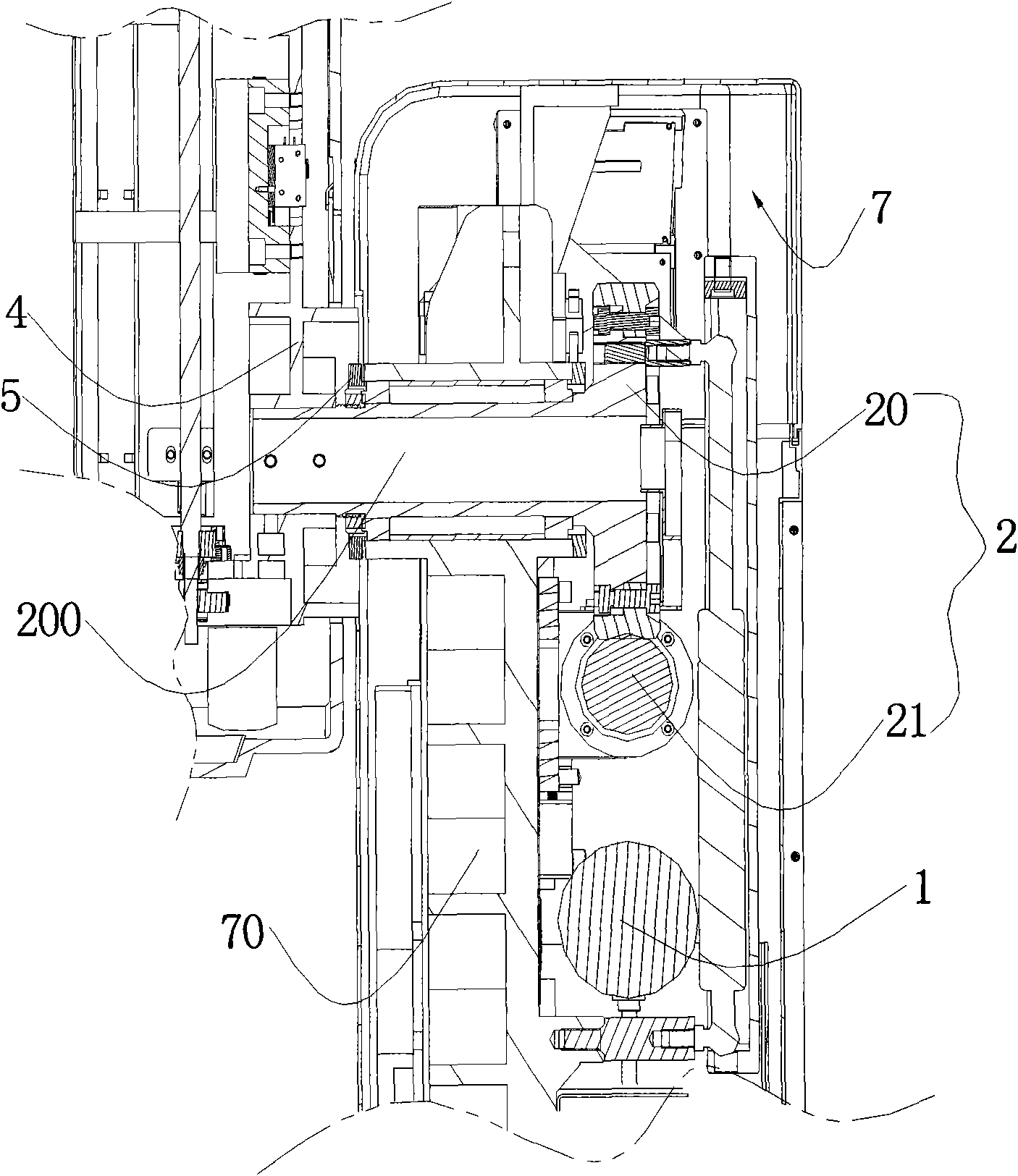

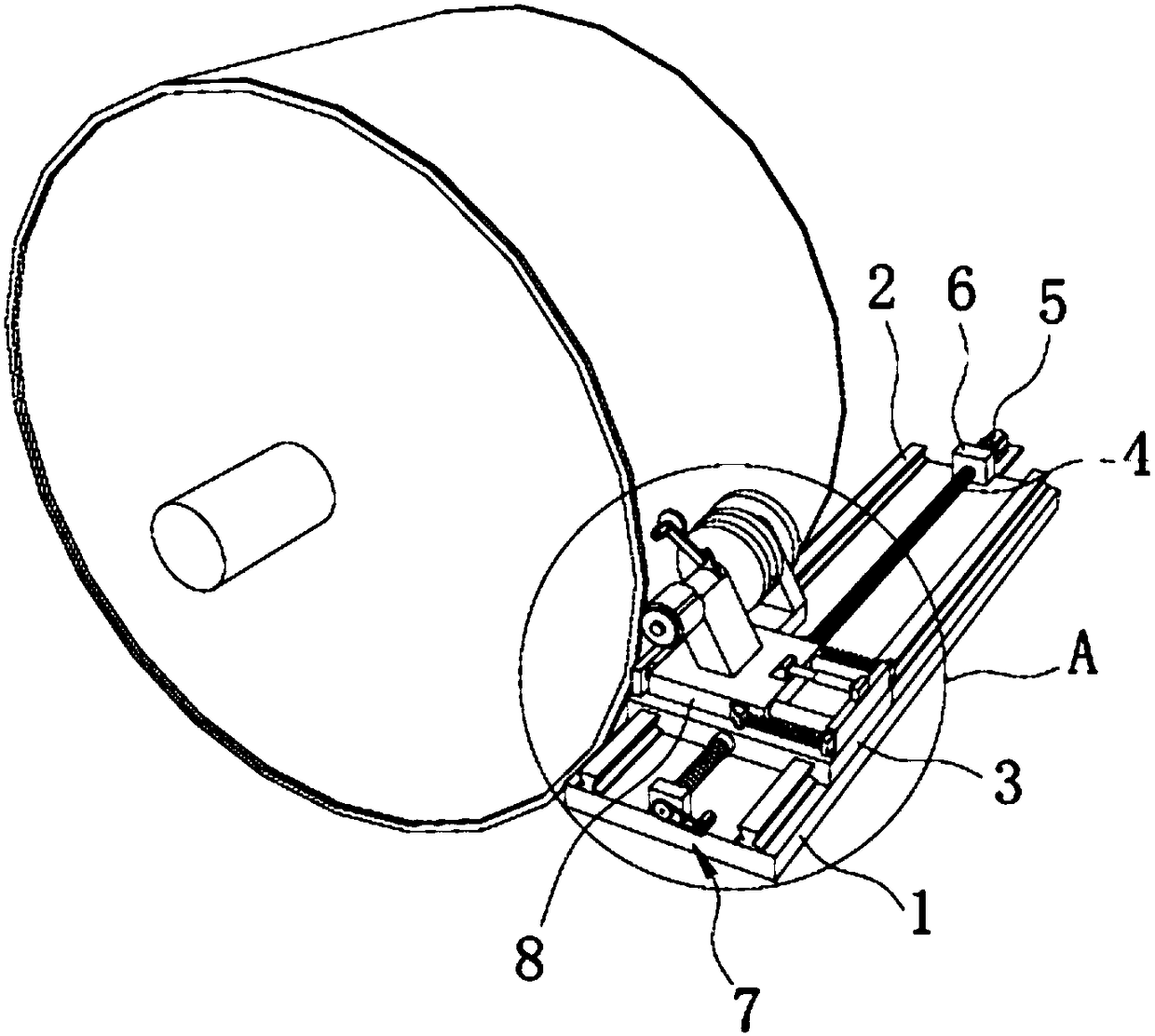

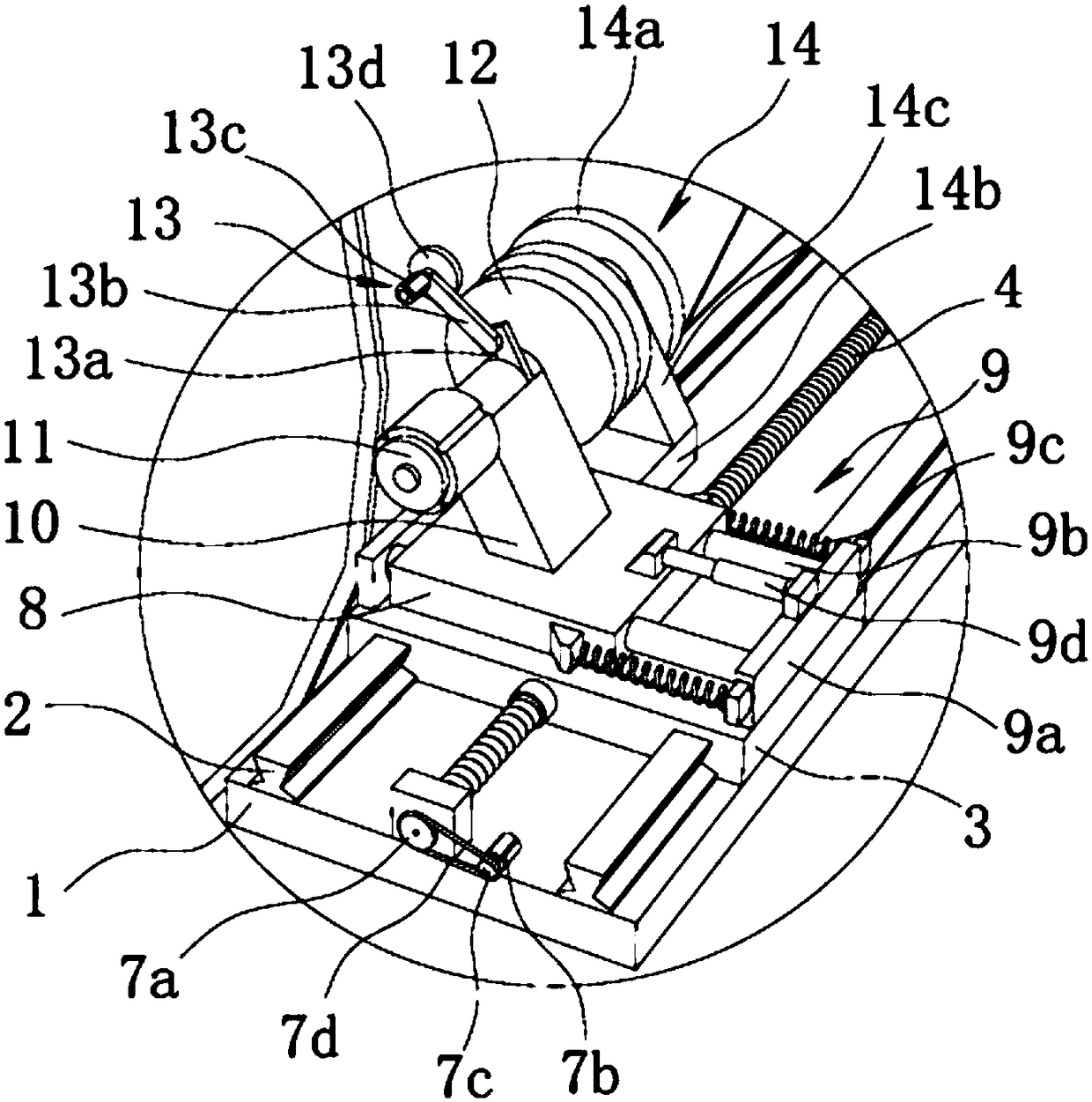

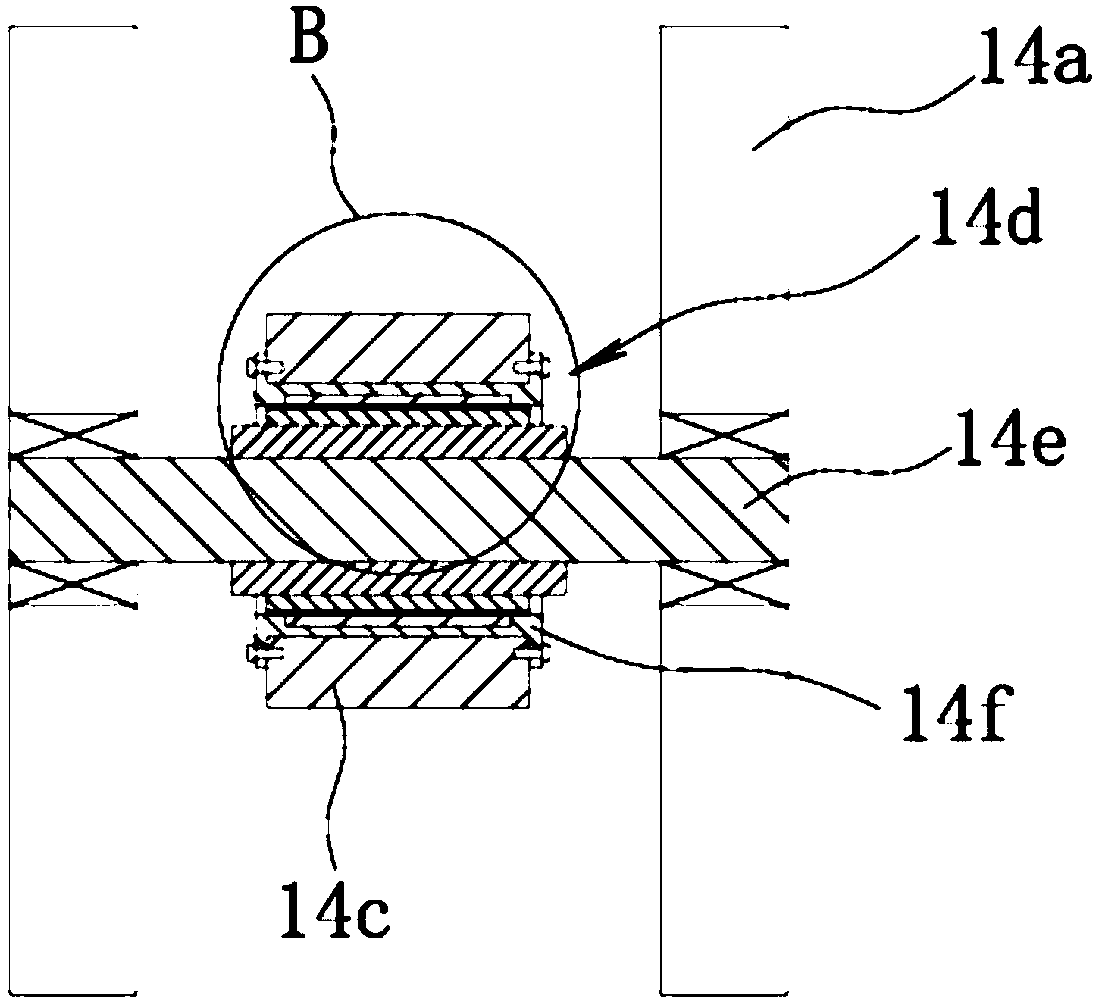

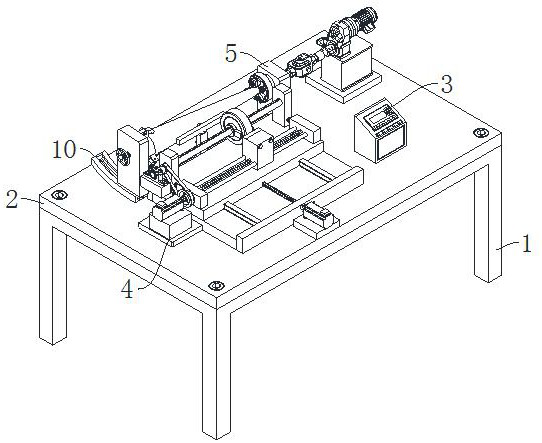

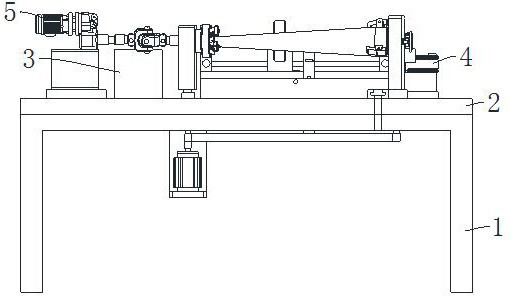

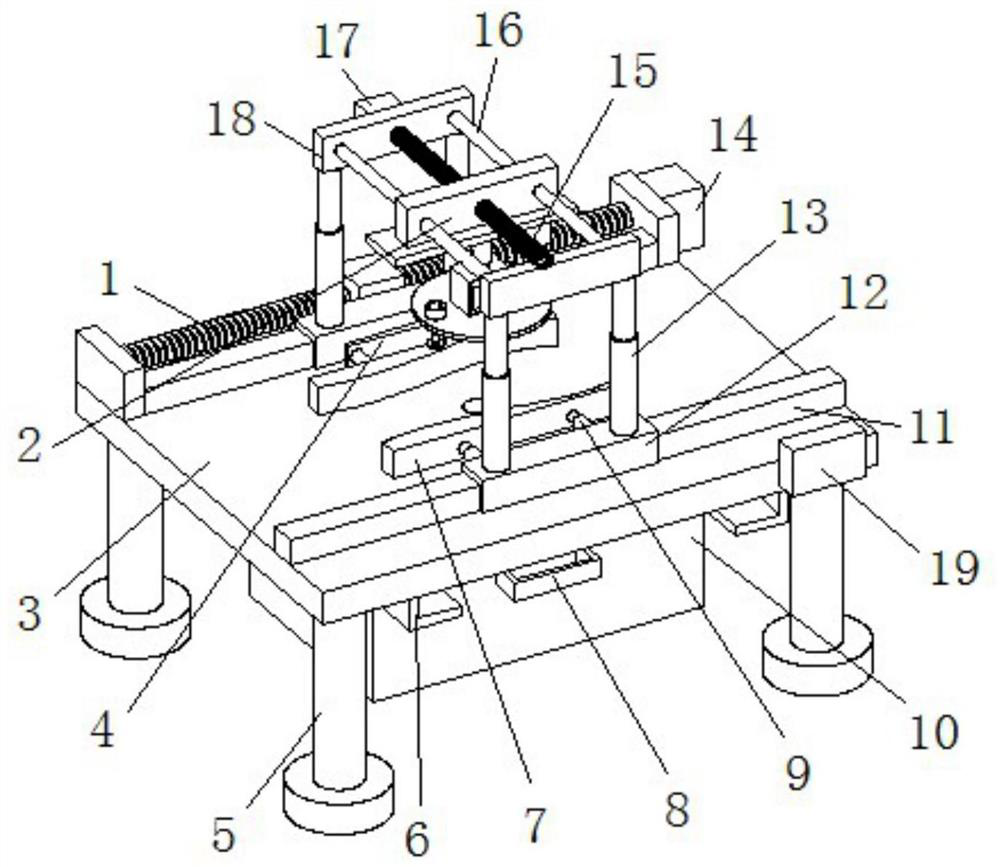

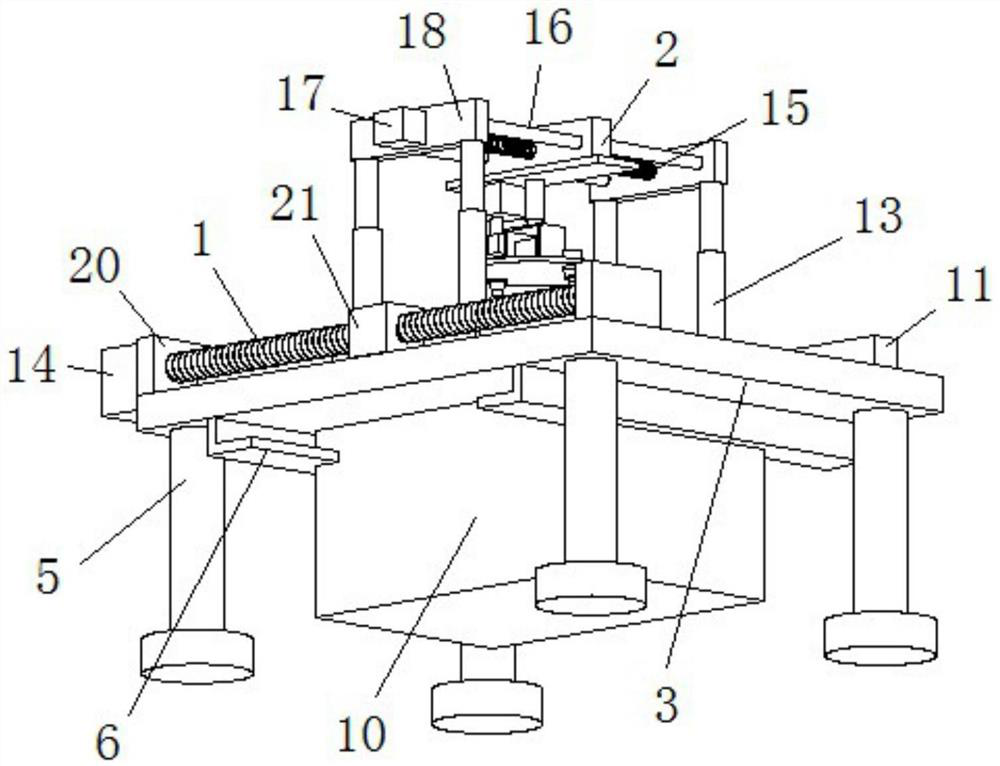

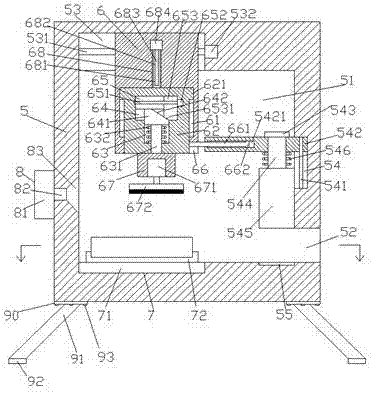

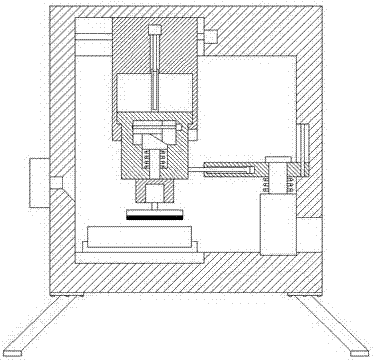

Small-caliber aspherical composite precise processing machine tool

InactiveCN102161168AReduce installation errorsReduce tool setting errorsControllabilitySmall caliber

The invention relates to a small-caliber aspherical composite precise processing machine tool, comprising a tool body (22) with a shock absorber (16), wherein the tool body (22) is provided with a first sliding table (20) which is provided with a spindle bracket (1); a second sliding table (13) is arranged correspondingly to the first sliding table (20) and is provided with a rotating bracket (17) and a supporting plate (9); the rotating bracket (17) is provided with a detecting device (18); and an inclined axis mirror grinding device (10) with a triaxial fine-tuning frame and an inclined axis magnetorheological grinding and polishing device (14) are arranged in parallel on the supporting plate (9). In the small-caliber aspherical composite precise processing machine tool, the precise inclined axis mirror grinding device and the inclined axis magnetorheological grinding and polishing device are integrated on a single tool body; through the combination of the two techniques of the precise inclined axis mirror grinding and the inclined axis magnetorheological grinding and polishing, the good controllability of the processing path is achieved, and the phenomenon of the interference is effectively prevented; and by in-place measurement of the shape of a workpiece, the error compensation processing of the workpiece is realized, and the accuracy of the shape of the workpiece is improved.

Owner:HUNAN UNIV

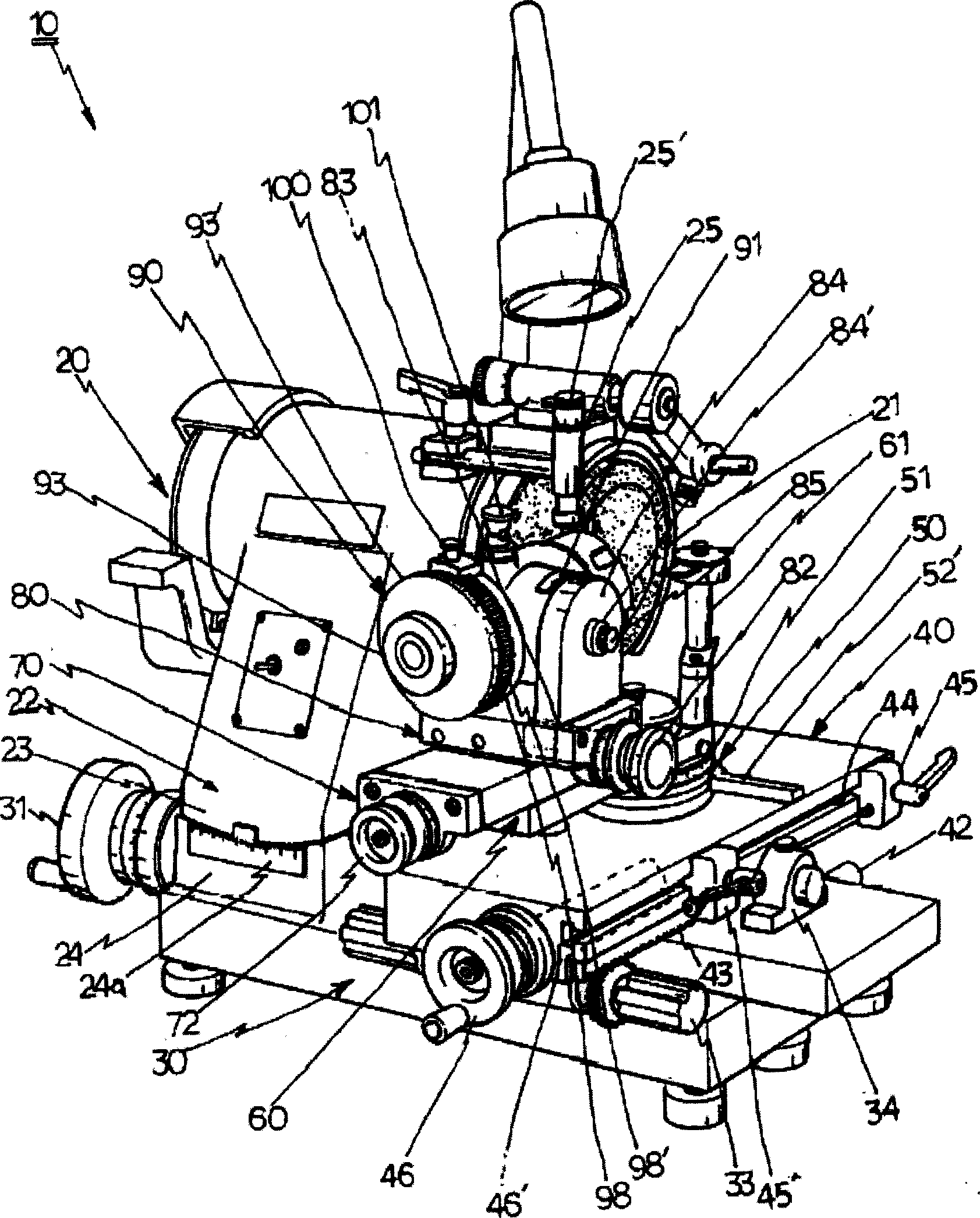

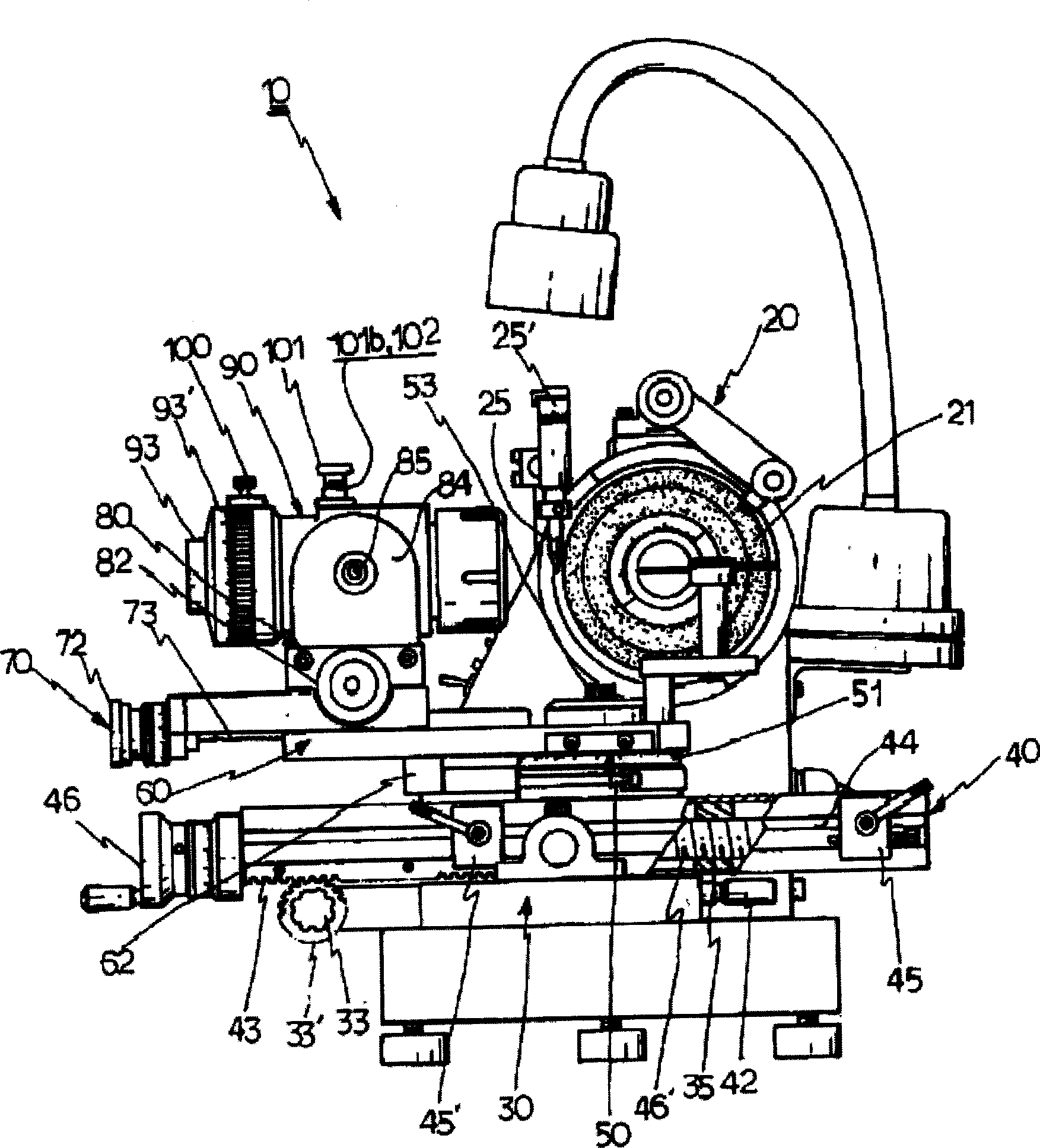

Tool grinding machine

The present invention relates to a tool grinding machine. That is, the present invention is characterized in that a hinge is formed at the center of a body of a chuck holder and a slope scale plate is attached to a top of the hinge such that an angle of a under blade of a tool such as an end mill is accurately ground, the first and second angles of the peripheral cutting blade of the tool are simultaneously ground using an angle adjustment lever in an end of the chuck holder, in an angle scale plate at a rotation portion a fixed block gauge is again adhered to a sin value of a desired angle using the fixed block gauge as a reference, thereby accurately grinding the under blade of the tool and the first and second angles of the peripheral cutting blade, a body of the grinding portion is divided into upper and lower portions so that the upper body is rotated in a desired angle and at the same time, and an angle scale plate is formed so that a worker checks up the angle in the rotation state, thereby forming a spherical angle of the tool.

Owner:金明珍

Integrated steel pipe cutting, drilling and polishing equipment

InactiveCN109940399AShorten the timeAvoid inaccuraciesOther manufacturing equipments/toolsPunchingGear wheel

The invention discloses integrated steel pipe cutting, drilling and polishing equipment. The equipment comprises a base, a fixing part, a slide rod part, a cutting part, a punching part, a polishing part and a moving part. The equipment is characterized in that the upper end surface of a fourth steering engine of the moving part is fixedly mounted on the lower end surface of a base plate of the base; the equipment is shifted to a specific place through the moving part; a steel pipe is put in a steel pipe fixing clamp of the fixing part for clamping; a second stepper motor of the slide rod partdrives a second gear so as to drive a first slide block and further to drive the cutting part, the punching part and the polishing part to move to a specific position; then, the steel pipe is cut, punched and polished; and through integrated steel pipe cutting, drilling and polishing, the manual operating time is fully shortened, the manual operation inaccuracy is prevented, the human resources are saved, the safety of workers is guaranteed, and the integrated steel pipe cutting, drilling and polishing operation is achieved.

Owner:青岛博捷环保工程有限公司

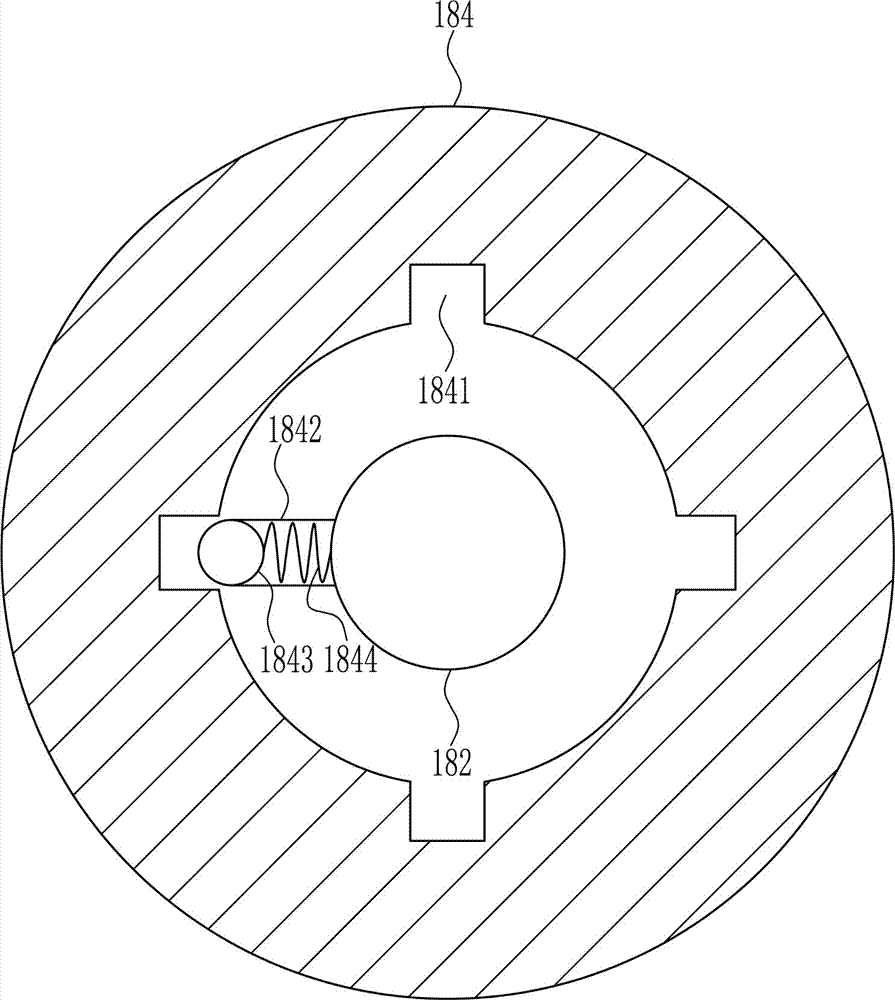

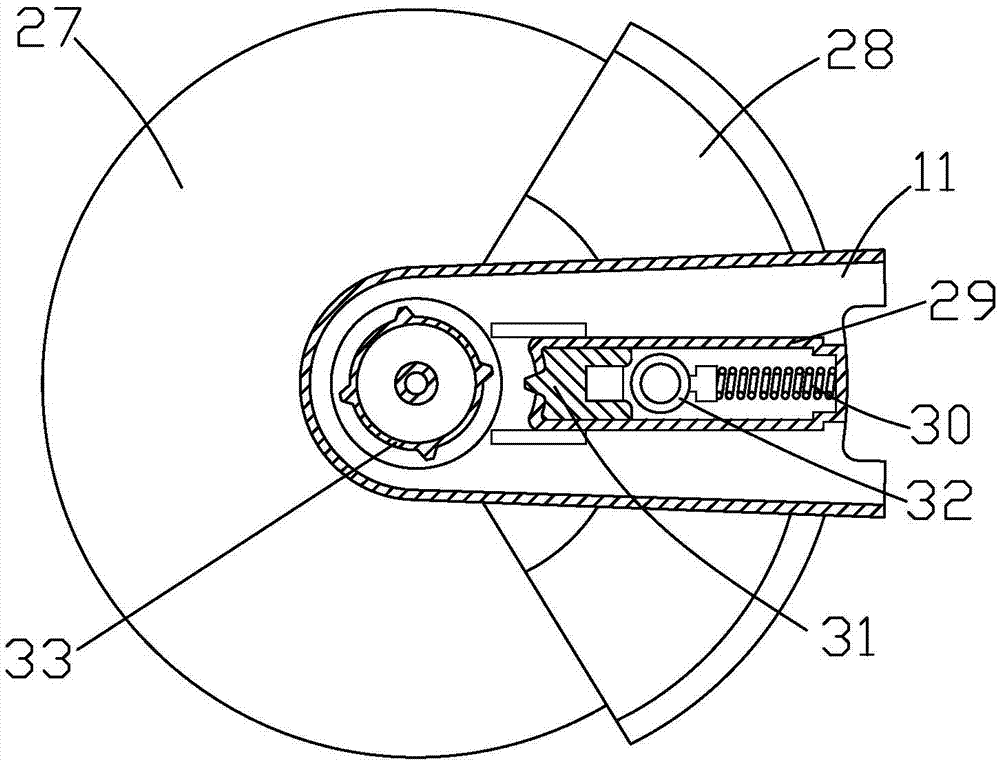

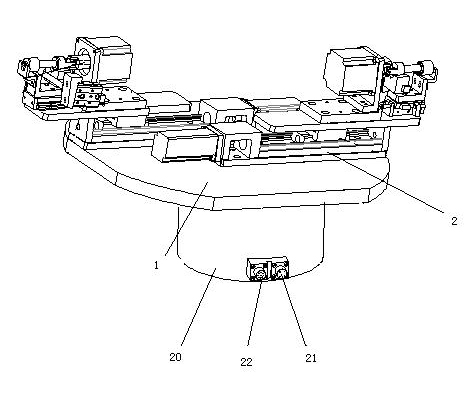

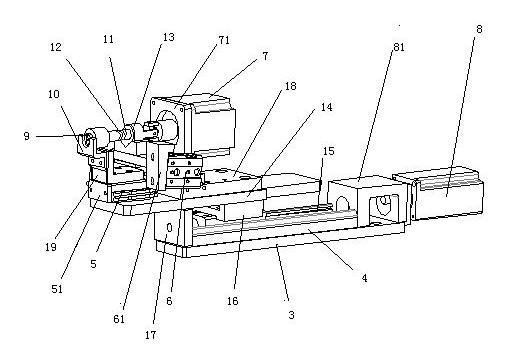

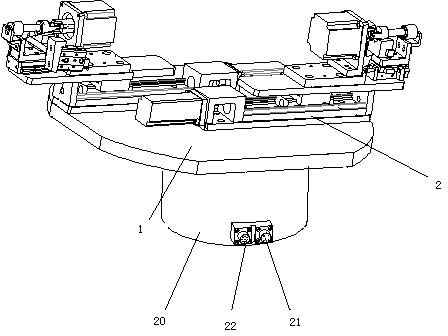

High-precision rotary positioning workbench

The invention relates to a high-precision rotary positioning workbench. The workbench comprises a fixed turn table substrate, two feed workbenches, a direct drive motor and a power port, wherein each feed workbench comprises a linear module mounting plate, a module support seat, two cylinders, two motors, a drill point rotating shaft, a grip elastic clamp, a cushion collar, a spring, a universal joint, a linear module slip-way plate and a roller screw. According to the high-precision rotary positioning workbench, the drill point rotating shaft can be calibrated by controlling the grip tightness of the grip elastic clamp through the two cylinders and adjusting the height of the universal joint, and a micro-drill is ground by controlling the rotation and driving of the rotating shaft through the motors; and after the grinding operation is completed, the direct drive motor drives the fixed turn table substrate to rotate 180 degrees, so that the two feed workbenches perform operation exchange, thus the automatic operation process is realized, and the production efficiency is improved. The structure of the high-precision rotary positioning workbench can be used for not only improving the production efficiency, but also realizing precise grinding of the micro-drill.

Owner:东莞市升力智能科技有限公司

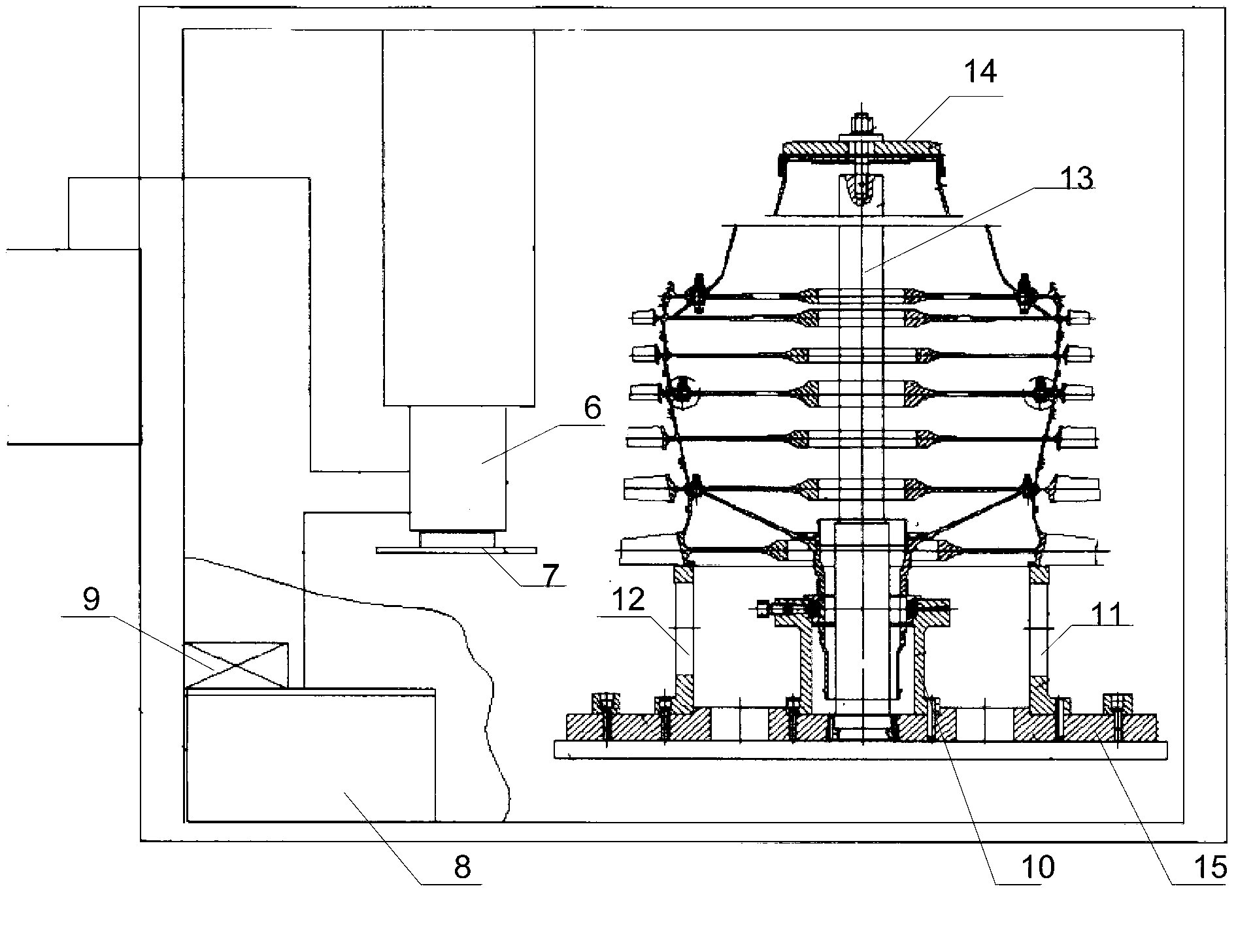

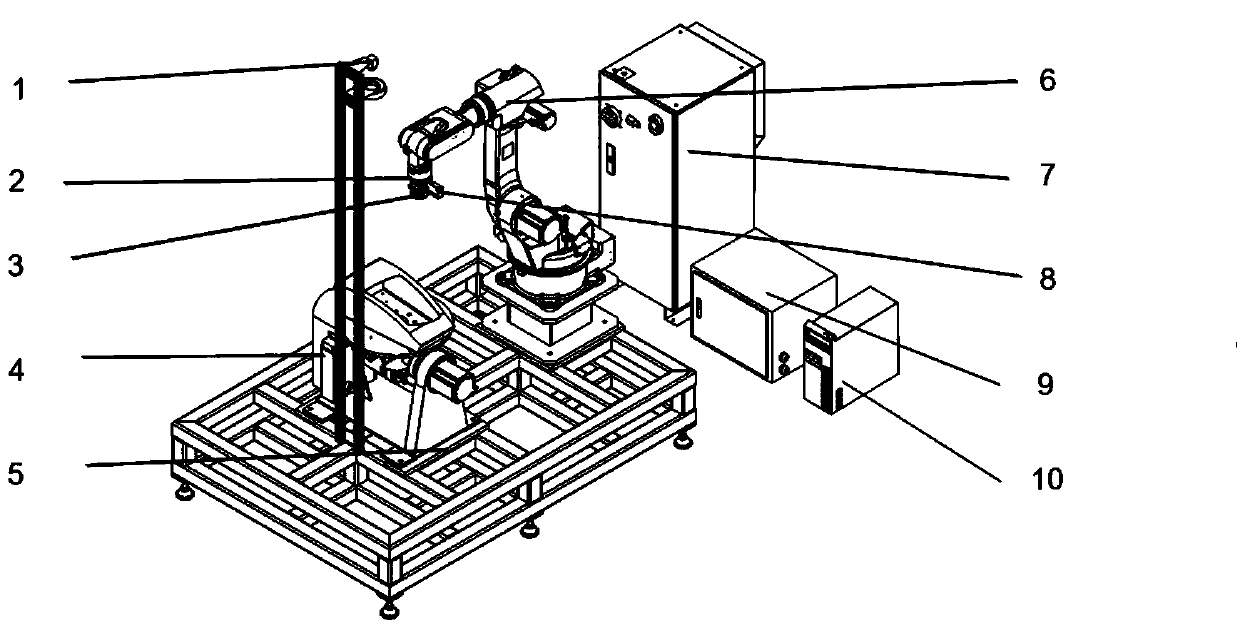

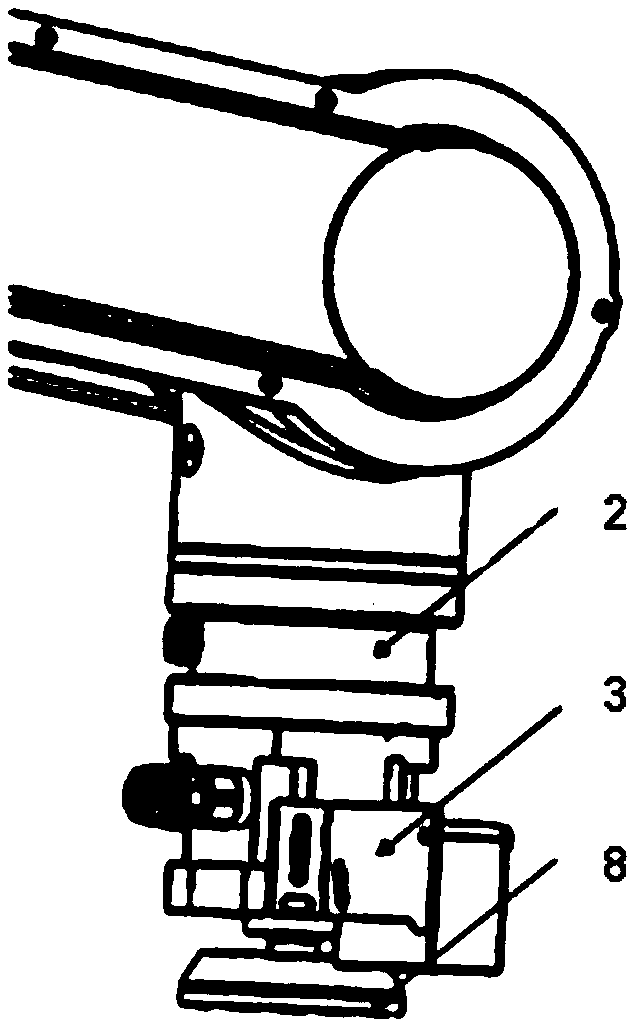

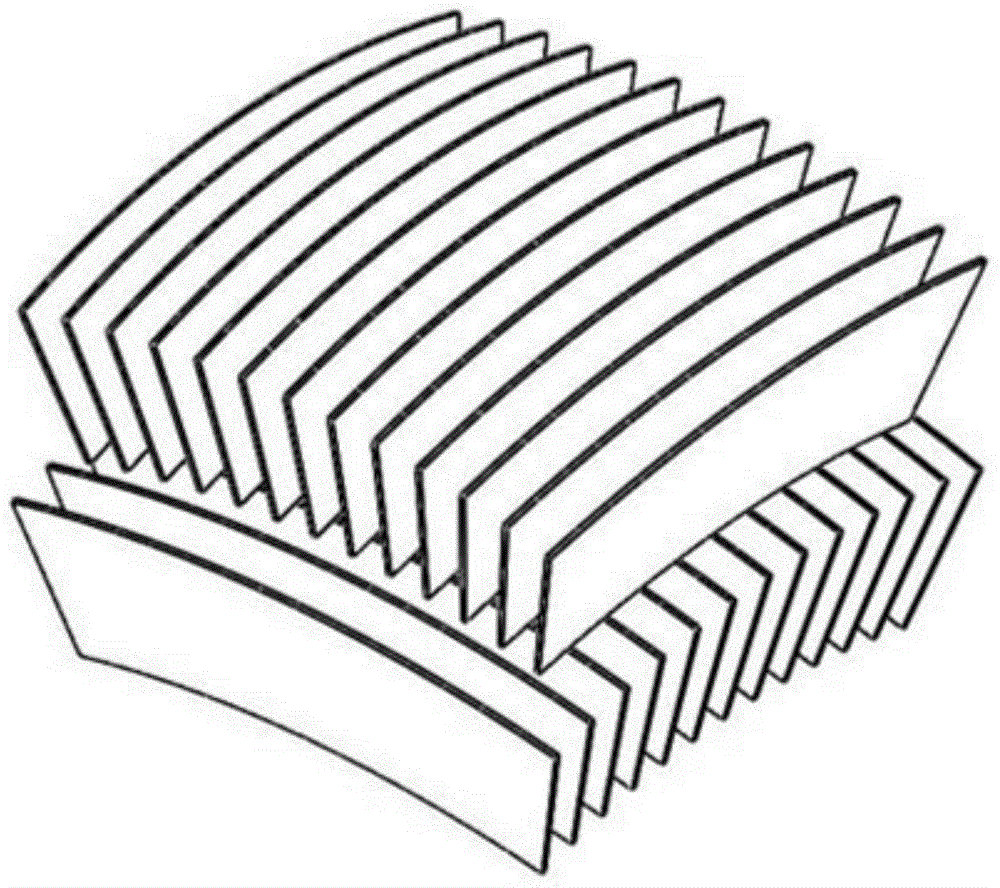

Engine rotor blisk blade-tip curved surface processing device and method

ActiveCN102935610AEffective control of processing temperaturePrecision grindingGrinding machine componentsGrinding machinesFrequency changerNumerical control

The invention discloses an engine rotor blisk blade-tip curved surface processing device and a method and belongs to the technical field of cold processing in aerotechnics. The device comprises a vertical type numerical control lathe, an electrical main shaft grinding head device, a cooling device, a frequency changer and a clamp. On the premise that functions of the vertical type numerical control lathe are not changed, the electrical main shaft grinding head device and the cooling device are increased, and processing temperatures of an electrical main shaft and a grinding wheel are controlled effectively, so that both turning and curved surface grinding of the vertical type numerical control lathe can be achieved, and the cost is saved. According to the device and the method, a point type grinding method is adopted, complex curved surfaces can be ground accurately and reliably, the production cost of the grinding wheel is low, and a modification method is simple and reliable.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

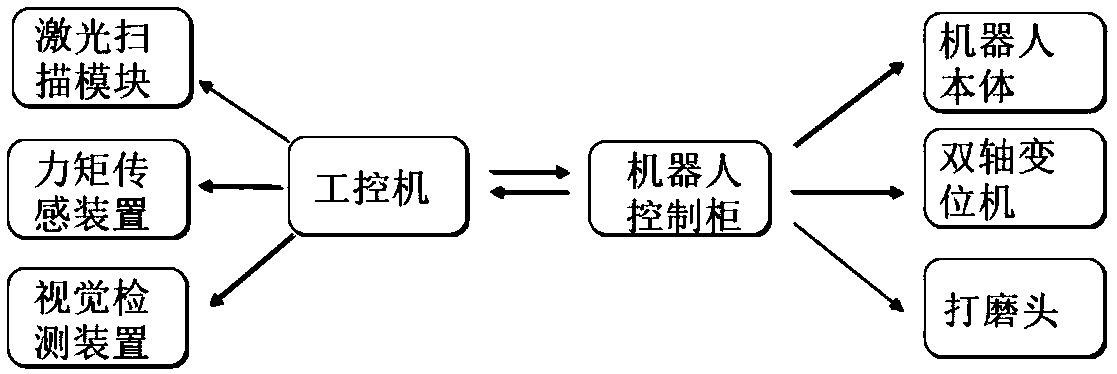

Intelligent grinding system of industrial robot and grinding method

The invention discloses an intelligent grinding system of an industrial robot. The intelligent grinding system comprises an industrial robot performing module, a posture change module, a laser scanning and detecting module, a visual inspection module, a moment of force control module, a grinding module and a data processing module, wherein the visual inspection module is matched with the industrial robot performing module to sample and photograph; the moment of force control module is matched with the grinding module for grinding and processing a workpiece; the laser scanning and detecting module is used for scanning workpiece allowance; and the data processing module and the industrial robot performing module perform data interaction to accomplish a whole set of automatic grinding process. The intelligent grinding system adopts novel various detecting systems, is uniform in grinding, and realizes fully-automatic grinding of curves and curved surfaces.

Owner:NANJING PANDA ELECTRONICS +1

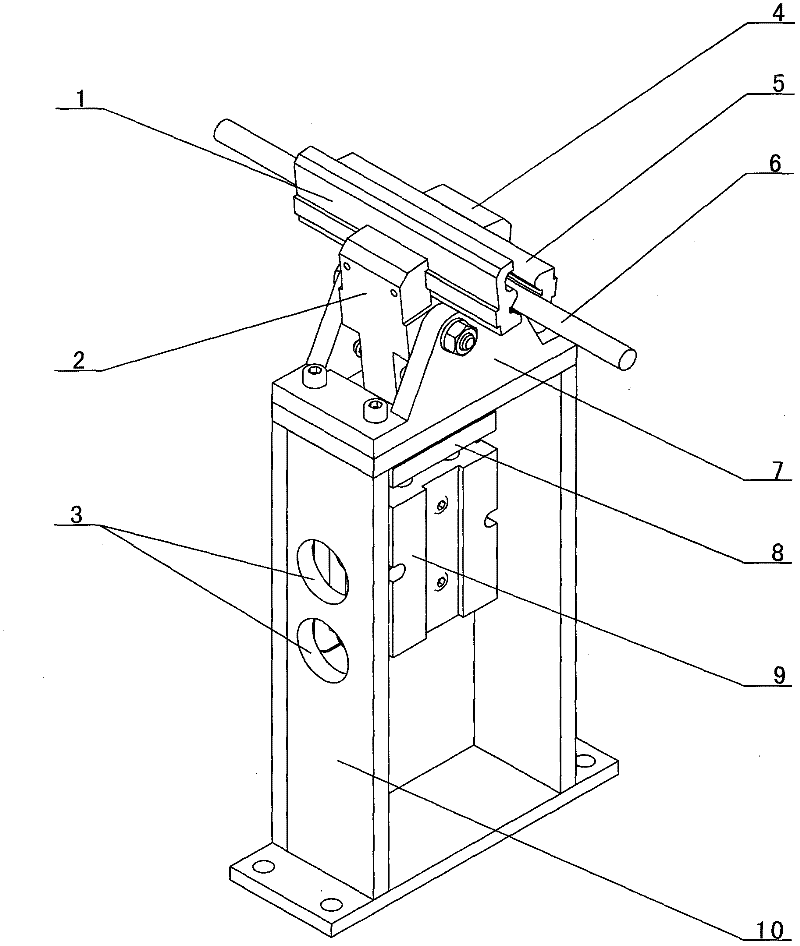

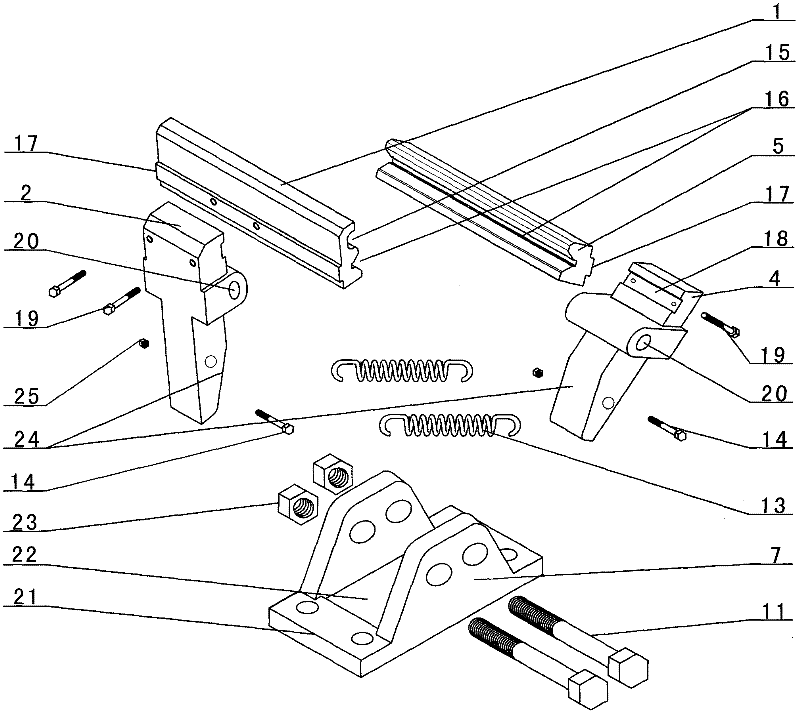

A centering clamping device for crystal material processing

ActiveCN102294761AImprove work efficiencyGrinding evenlyWorking accessoriesGrinding work supportsCrystalline materialsRocker arm

The invention relates to a fixture for a crystal material, in particular to a centering and clamping device used for processing the crystal material. The fixture is characterized in that the opposite faces of the upper parts of a rocker arm (2) at one side and a rocker arm (4) at the other side are respectively fixedly connected with a big clamping piece (1) and a small clamping piece (5), the opposite faces of the big clamping piece and the small clamping piece are respectively provided with slots (16), the lower part at a hinge joint of rocker arm support plates (7) on the bases of the rocker arm at one side and the rocker arm at the other side is respectively connected with the two ends of an elastic body; a corresponding lower part between the rocker arm at one side and the rocker arm at the other side is provided with a wedge-shaped block (8) which is small at the top and big at the bottom, and the lower part of the wedge-shaped block (8) is provided with a power mechanism which moves up and down. In the invention, by virtue of the big clamping block on the rocker arm at one side and the small clamping block on the rocker arm at the other side, stable positioning on a silicon core is realized, and accurate drilling or grooving or grinding on the silicon core is realized; and the defect that a hole or grinding groove on a transverse or vertical silicon core is non-standard due to the traditional manual operation mode is overcome by using the fixture provided by the invention.

Owner:LUOYANG JINNUO MECHANICAL ENG

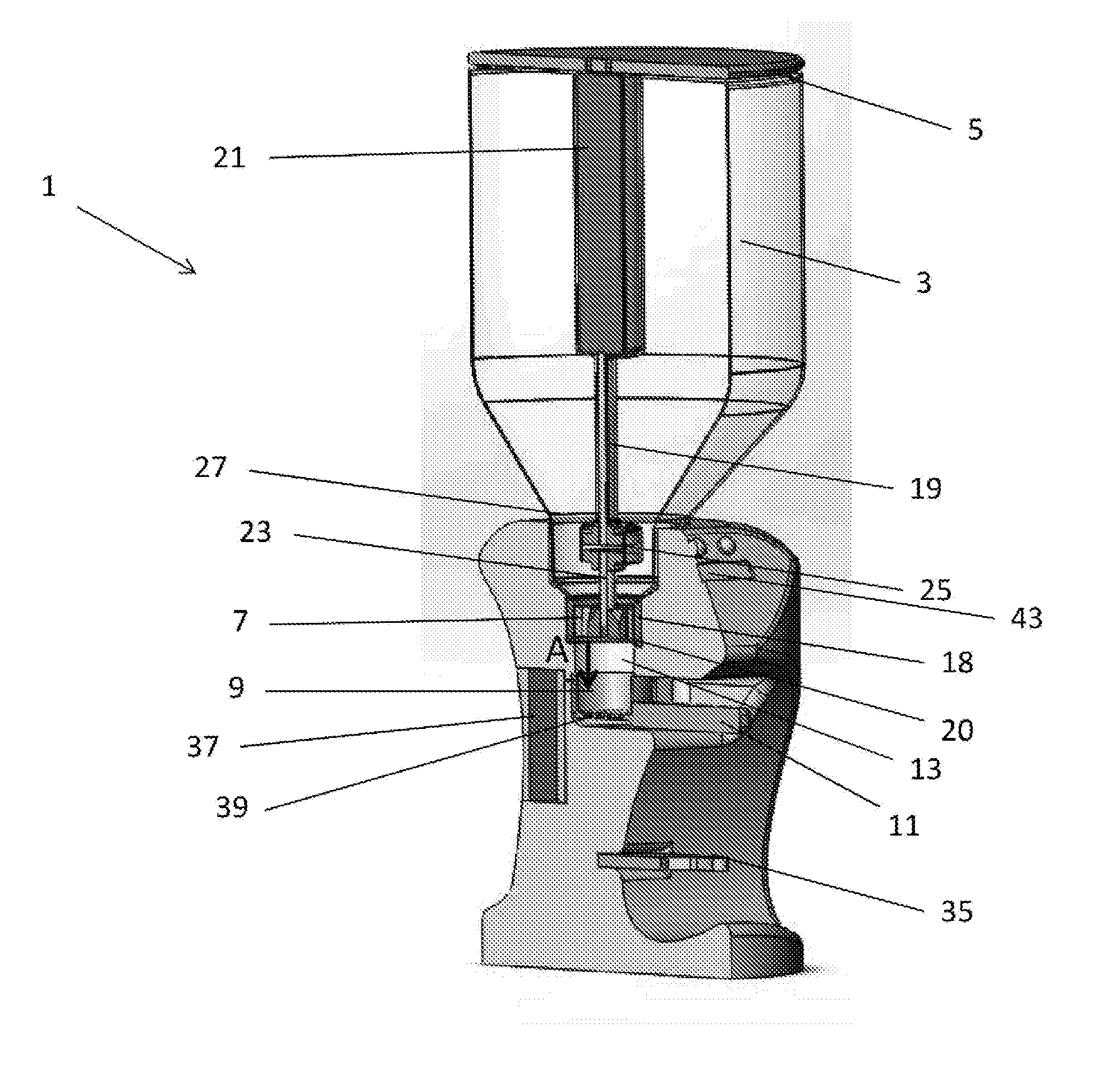

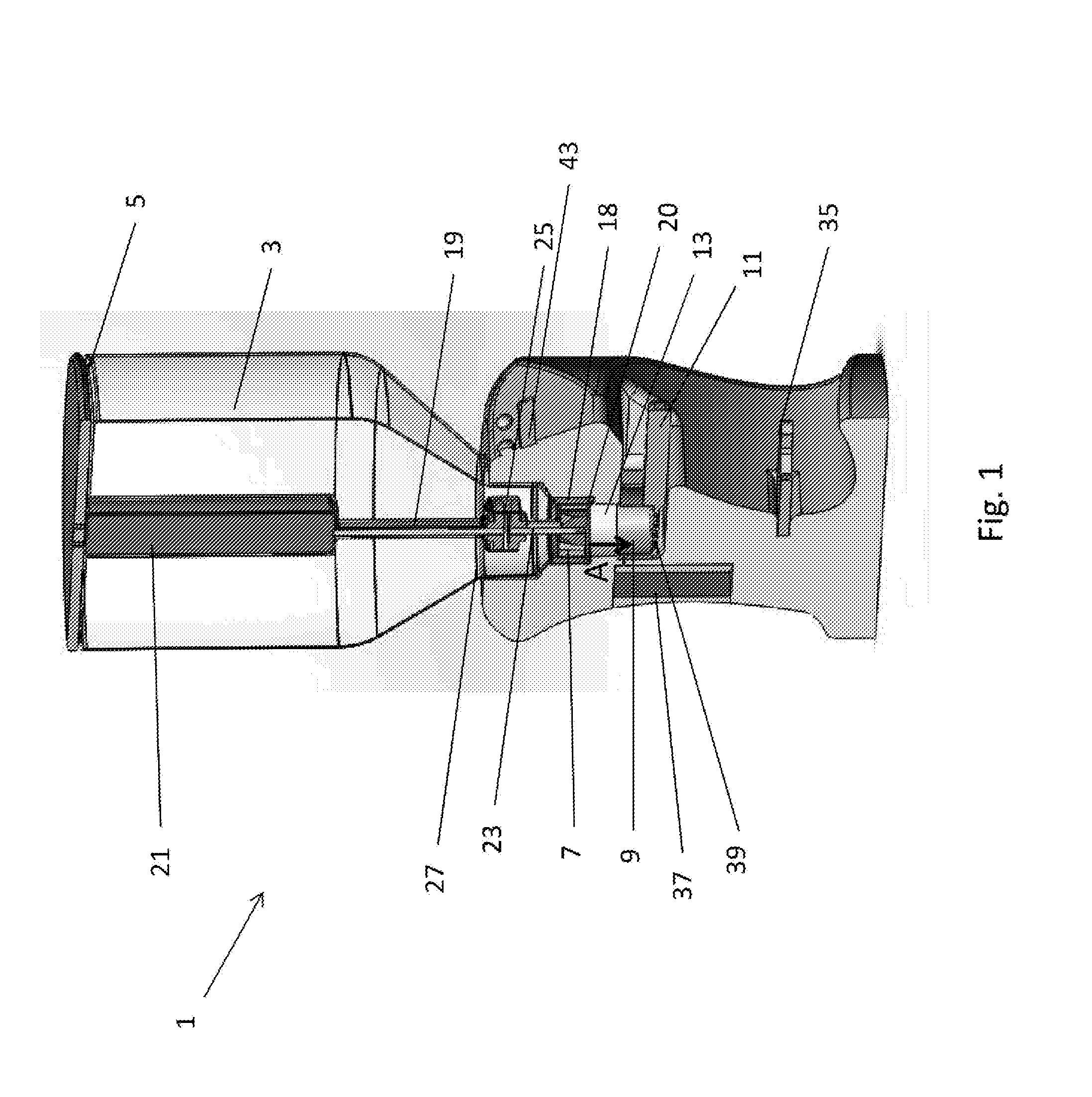

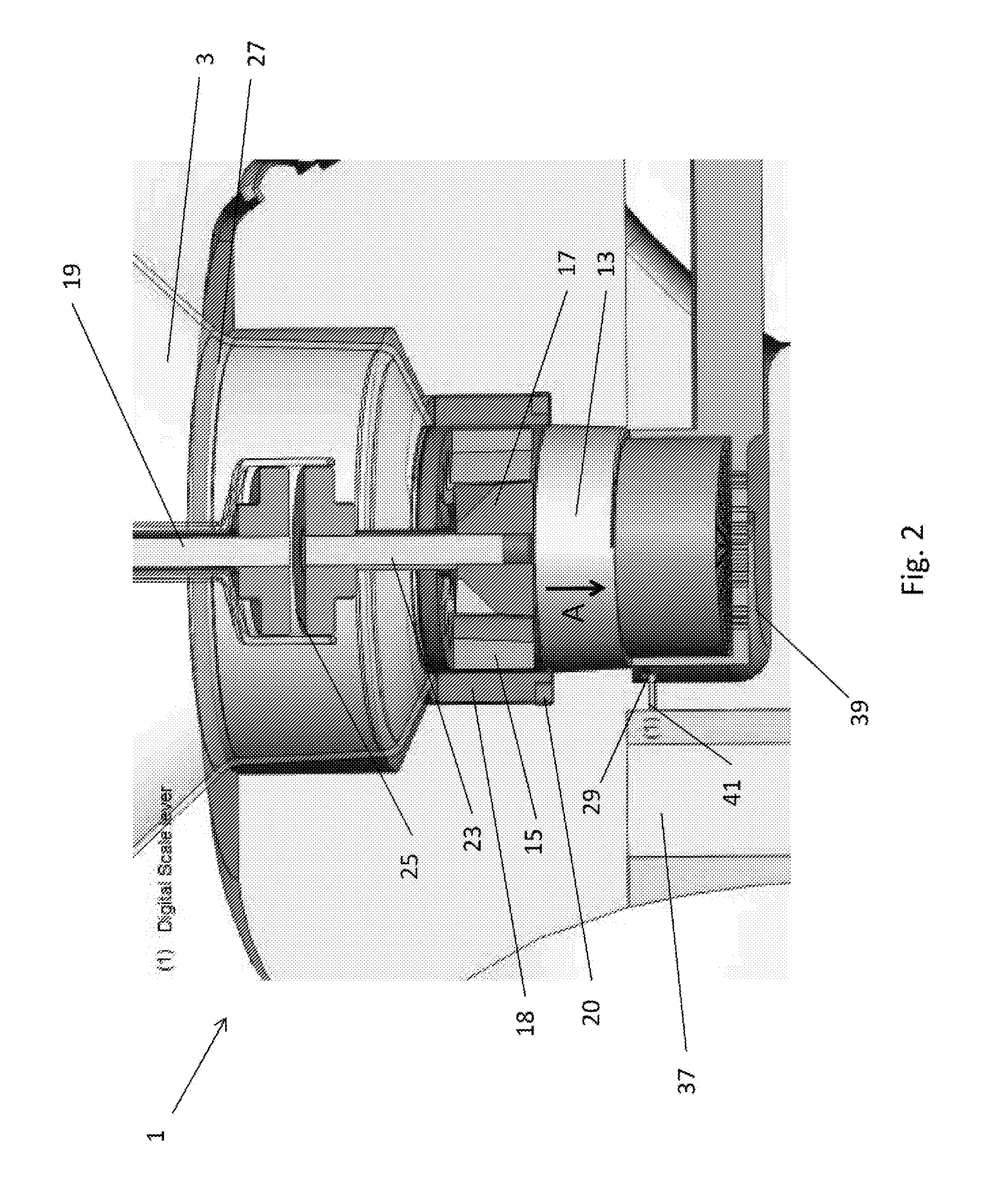

Coffee grinder

This disclosure relates to an apparatus for grinding coffee beans. In one form, the apparatus comprises a hopper arranged to receive and dispense coffee beans. The coffee grinder also includes a conical burr arranged to grind the coffee beans dispensed by the hopper. The apparatus may be employed to grind roasted coffee beans for use in a coffee extraction (conventional coffee machines), for example in a cafe.

Owner:VAN DEUCE

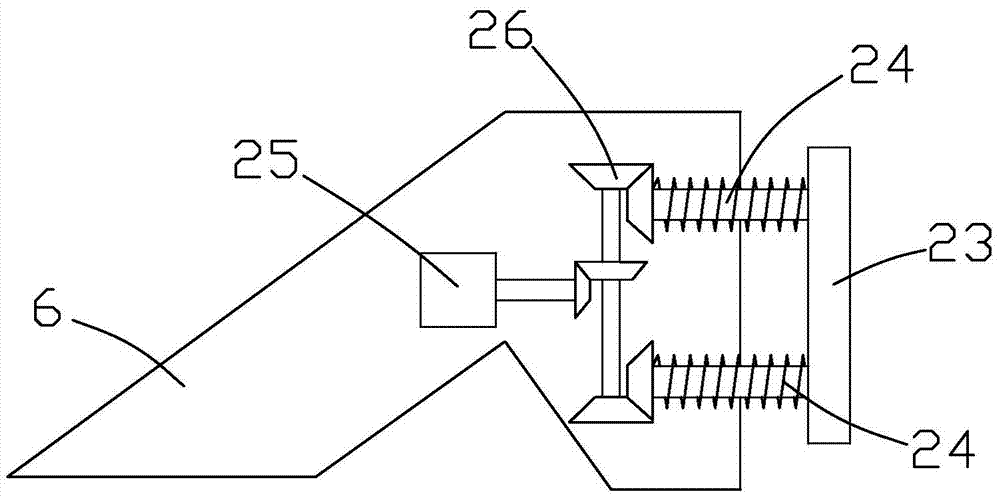

Isocentric rotating system of mammary gland X-ray machine

The invention relates to an isocentric rotating system of a mammary gland X-ray machine, comprising a power element and a transmission assembly, wherein the transmission assembly is connected with thepower element and a C-shaped arm and comprises a ring-surface screw gearing, and the ring-surface screw gearing is connected with the C-shaped arm, drives the C-shaped arm to act and comprises a wormand a worm wheel; the ring-surface screw gearing is used for driving the C-shaped arm to act so that the transmission assembly is in multi-teeth meshing transmission so as to achieve steady transmission, very low noise, a large number of contracted teeth during the transmission, larger contact surfaces of tooth surfaces, instantaneous double-wire contact, long total length of a contact wire, longcomprehensive curvature radius, little contact stress, large meshing lubrication angle, easy dynamic pressure oil film forming during meshing and tooth surface abrasion reduction; an equivalent weight curvature radius is long, thus the transmission efficiency is higher, and the carrying capacity is high; and besides, the ring-surface screw gearing has a self-locking function so as to play safetyand protection roles and realize the accurate positioning of the C-shaped arm at different positions.

Owner:SINO MEDICAL DEVICE TECH

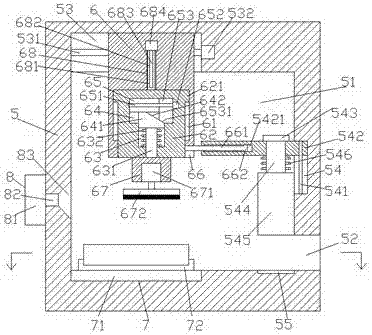

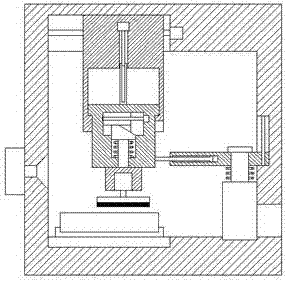

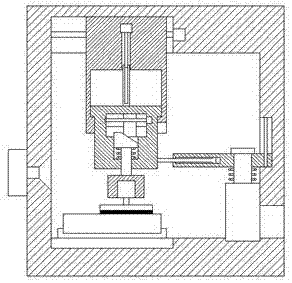

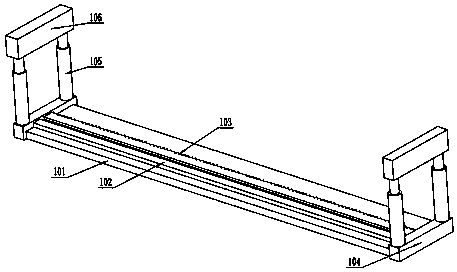

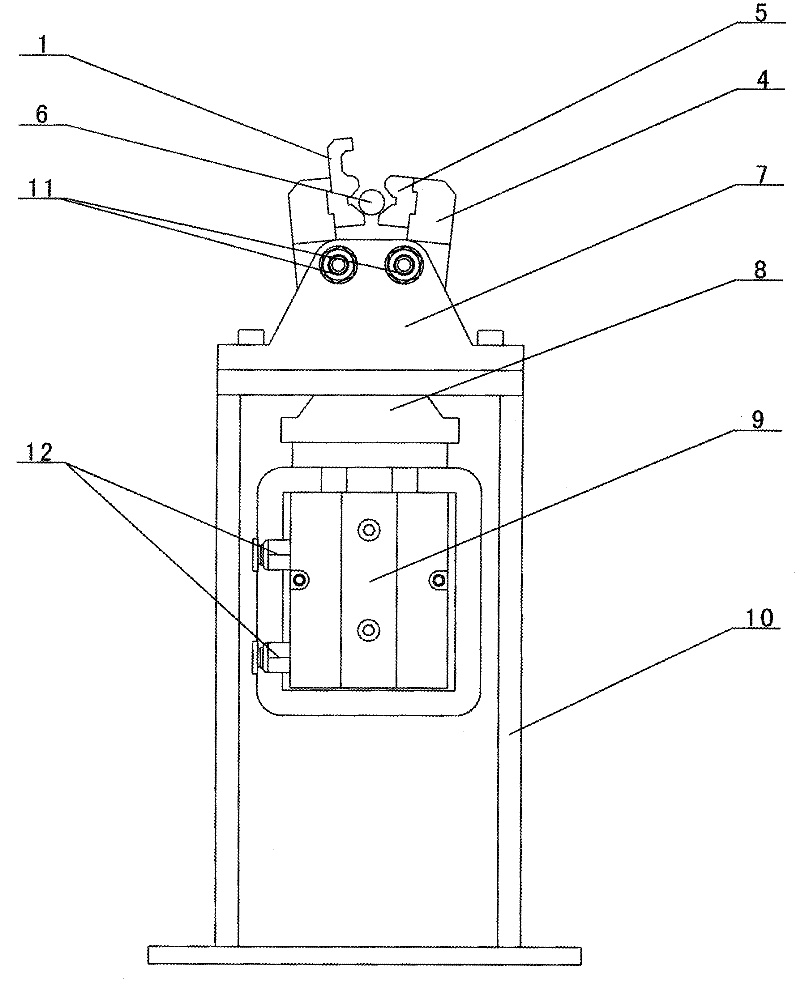

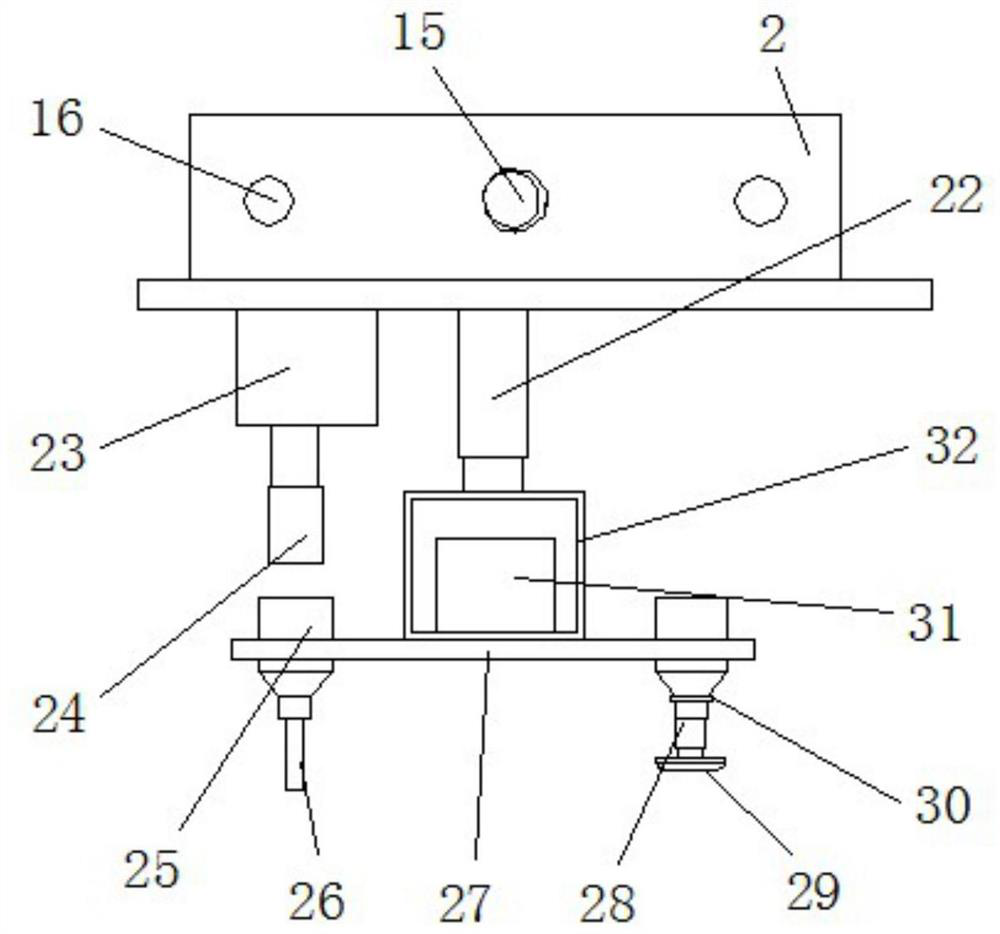

X-ray lobster-eye object lens assembling apparatus and application thereof

InactiveCN104819828AGuaranteed pressureWork face exact matchTesting optical propertiesMaterial analysis by transmitting radiationEngineeringX-ray

The invention relates to an X-ray lobster-eye object lens assembling apparatus and an application thereof. The assembling apparatus is based on dispersion confocal detection and comprises a lens assembling unit, a displacement sensing unit and a pad grinding unit, wherein the lens assembling unit comprises an object lens base for placing a lens to be assembled and a six-dimensional electric control displacement platform driving vertical, left-to-right and front-to-back movement of the object lens base; the displacement sensing unit comprises a one-dimensional adjusting platform, a displacement sensor positioning support connected with the one-dimensional adjusting platform and a dispersion confocal displacement sensor clamped on the displacement sensor positioning support; and the pad grinding unit comprises a U-shaped support, a air floatation shaft arranged on the U-shaped support, and a grinding head connected with the air floatation shaft. Compared to the prior art, through scanning a mirror surface by use of the dispersion confocal displacement sensor, high-precision lens assembling can be realized, an object lens which is already installed can also be calibrated, and the problem of difficult control of the interval of a conventional lobster-eye object lens is overcome.

Owner:TONGJI UNIV

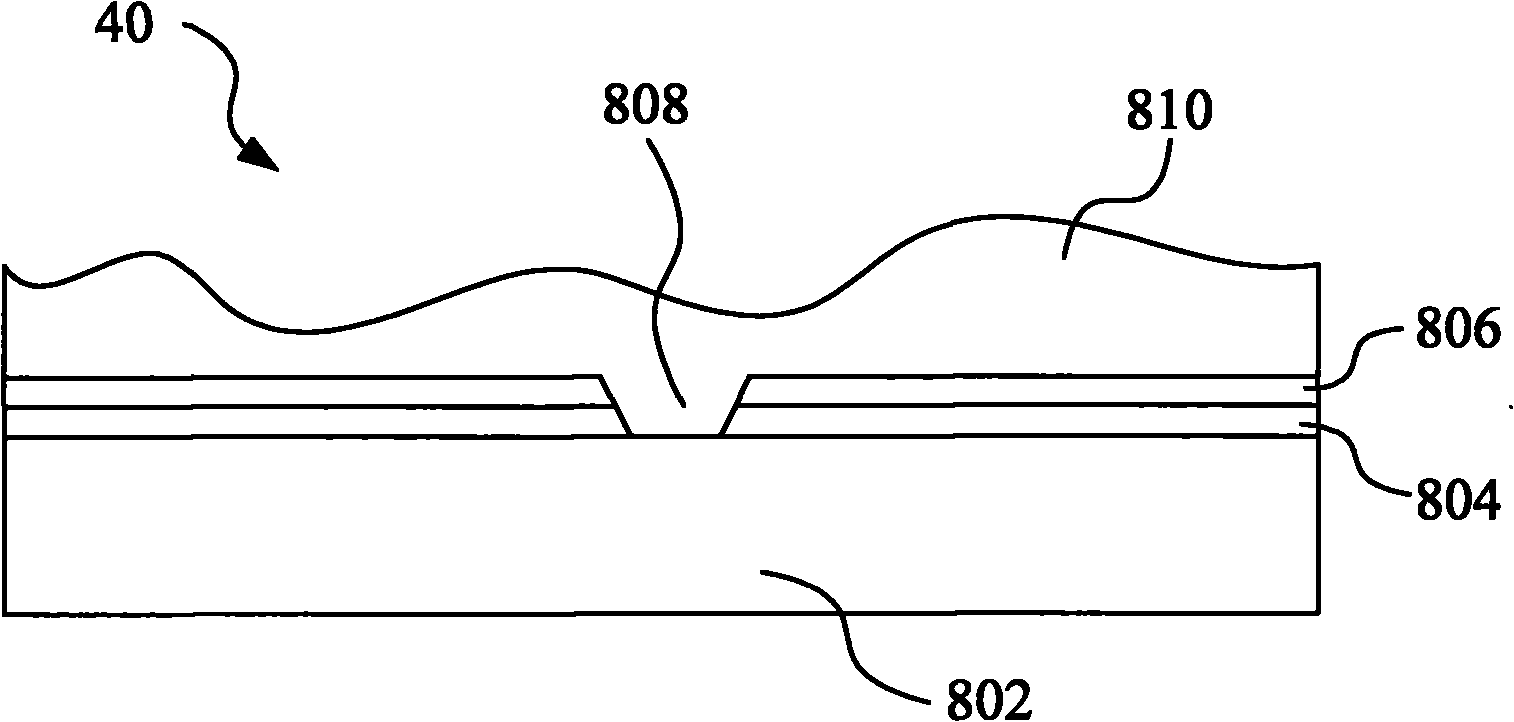

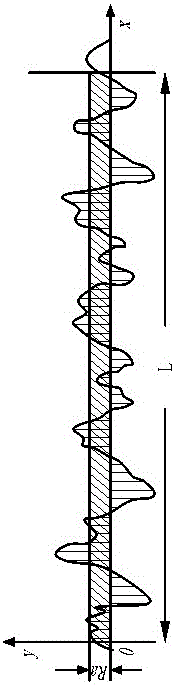

Thickness-measuring method during grinding process

ActiveUS20080070480A1Inhibit wearPrecision grindingPolishing machinesRevolution surface grinding machinesEngineeringGrind

In a thickness-measuring method during a grinding process, which suppresses wear of a probe coming into contact with a chuck table subjected to self-grind and accurately grinds a workpiece, measurement of wafer thickness is performed only at the commencement and termination of grinding, and a reference probe of a reference side height gauge is separated from the upper surface of the chuck table in the practical grinding time between the commencement and termination so as to interrupt the measurement of wafer thickness, thereby significantly reducing a time of the reference probe brought into contact with the upper surface of the chuck table.

Owner:DISCO CORP

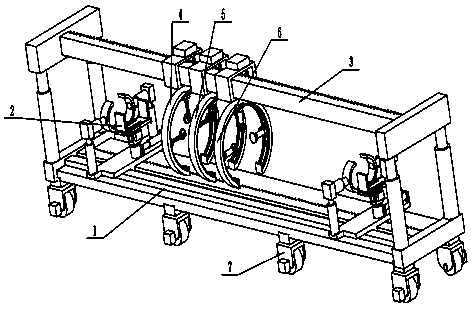

Grinding equipment for cathode roller and using method thereof

ActiveCN108466116AAvoid excessive wearGuaranteed grinding effectGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention discloses grinding equipment for a cathode roller and a using method thereof, and belongs to the technical field of grinding equipment. The grinding equipment is characterized in that asupport seat is arranged on the side edge of the roller surface of the cathode roller, a guide rail is arranged on the support, an axial sliding seat is arranged on the guide rail, the axial sliding seat is in threaded connection with a driving screw rod, the driving screw rod is connected with a first driving motor, the driving screw rod and the guide rail are arranged in parallel, supporting seats matched with the driving screw rod are arranged at the two ends of the support in the length direction, the driving screw rod is connected with a displacement detection mechanism, a radial slidingseat is movably arranged on the axial sliding seat, the radial sliding seat is connected with a radial driving mechanism, a mounting table is arranged on the radial sliding seat, a second driving motor is arranged on the mounting table in the axial direction of the cathode roller, and a power output shaft of the second driving motor is connected with a grinding wheel. The grinding equipment for the cathode roller and the using method thereof are reasonable in structure, high in use safety, and convenient to use; and the grinding equipment is used for grinding the cathode roller.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Grinding device with function of adjusting angle of conical roller and method

ActiveCN112139877AEasy to processAvoid wear and tearRevolution surface grinding machinesGrinding drivesEngineeringGrinding wheel

The invention relates to the technical field of cone roller grinding, and in particular relates to a grinding device with the function of adjusting the angle of a conical roller and a method. The grinding device comprises a workbench and a bottom plate, and further comprises a controller, a grinding mechanism and an adjusting mechanism, wherein the bottom plate is fixedly arranged at the top of the workbench, the controller is fixedly arranged on one side of the top of the bottom plate, a grinding assembly comprises a first-stage sliding assembly, a second-stage sliding assembly, a first-stagedriving assembly and a polishing assembly, and the adjusting mechanism comprises a three-jaw chuck, a second-stage driving assembly, a clamping assembly and a rotating assembly. According to the grinding device and the grinding method, by clamping and fixing the conical roller, the position of the conical roller can be self-adaptively adjusted so that an inclined curved surface at one end of theconical roller becomes a horizontal curved surface; by controlling the controller, the conical roller can be accurately ground by a grinding wheel; and therefore, the grinding device is safe, efficient, accurate and controllable, and the grinding efficiency of the conical roller is greatly improved.

Owner:佛山市科普卓机械制造有限公司

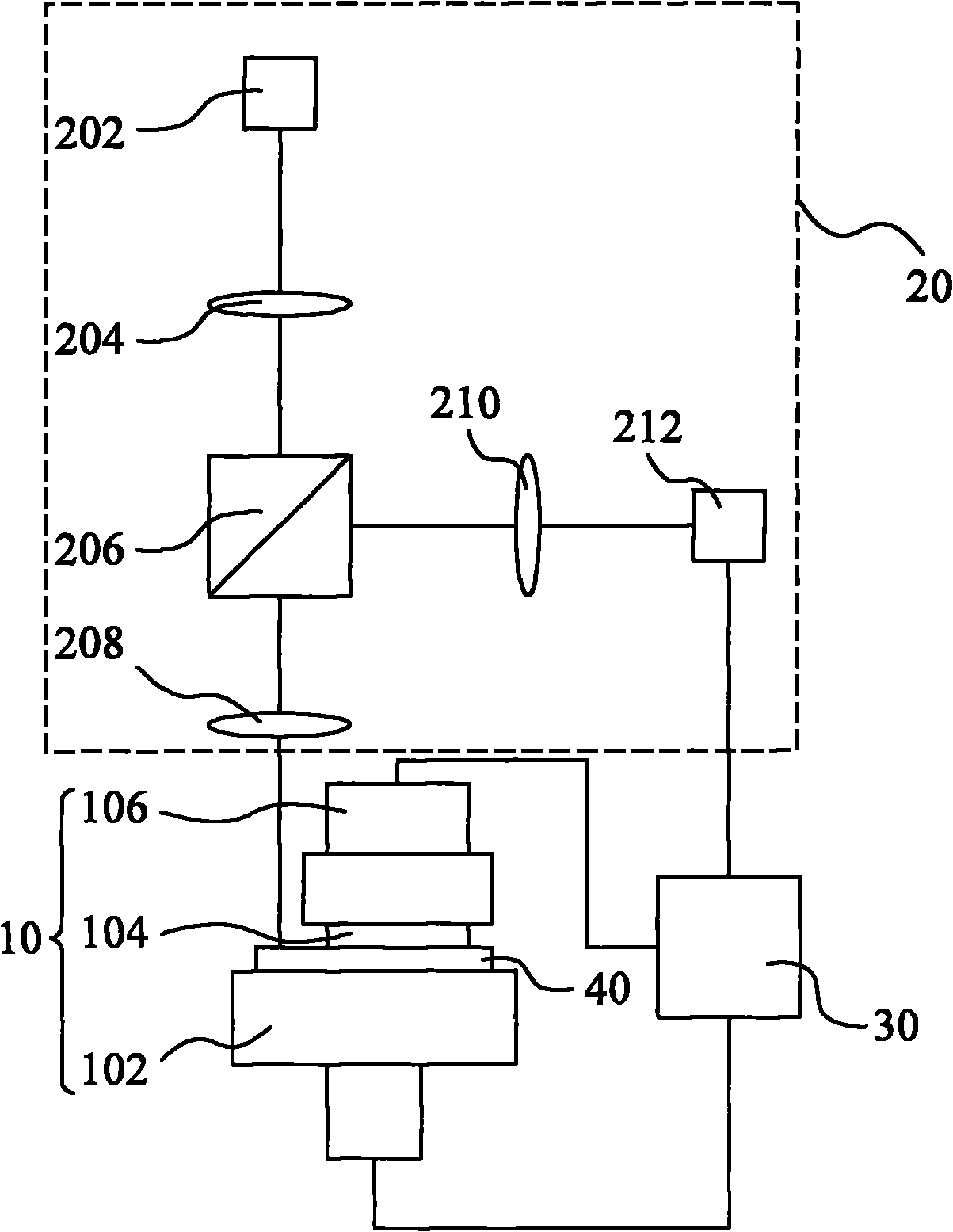

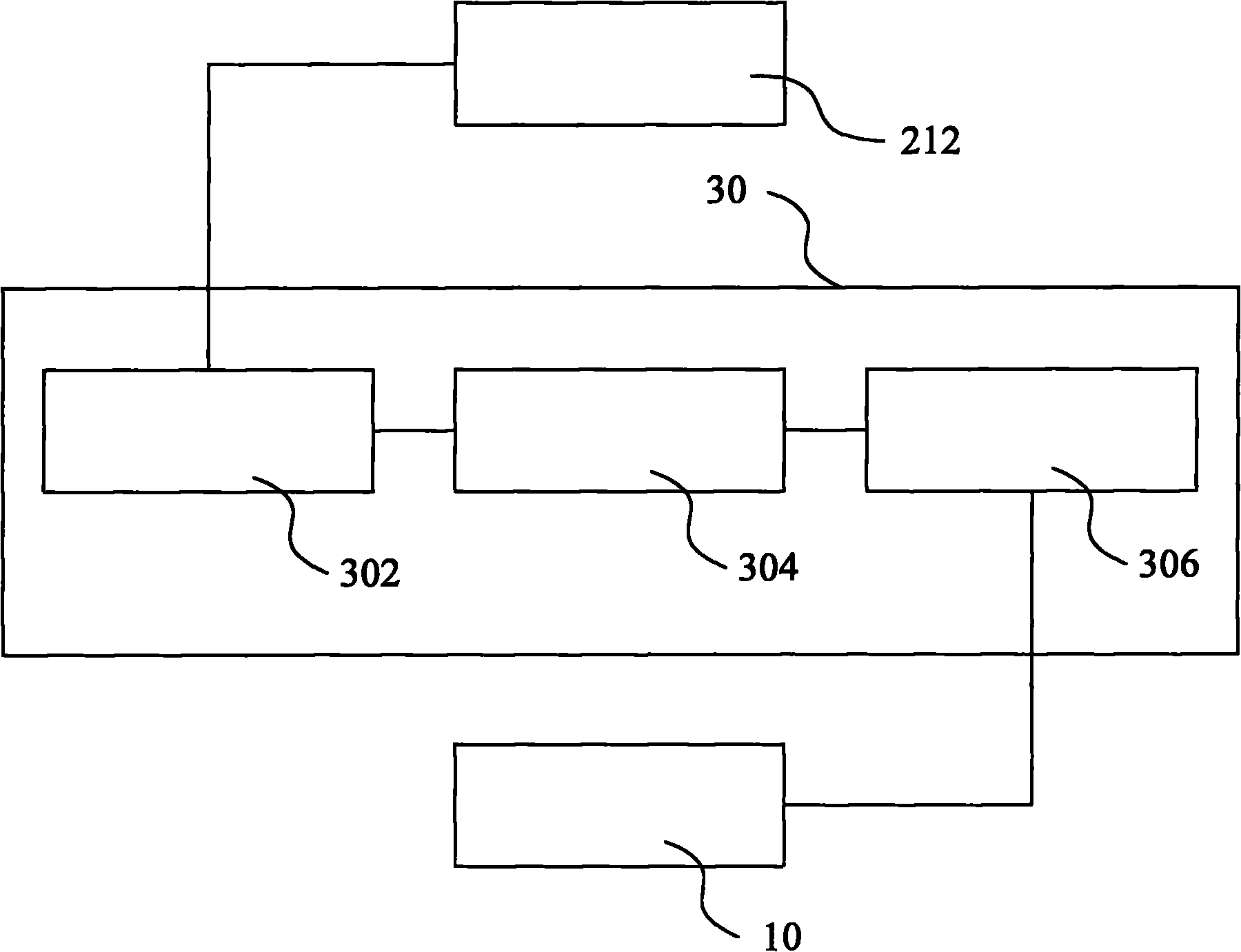

Grinding device of shallow trench isolation structure and method therefor

ActiveCN101927453APrecision grindingGrinding stops accuratelySemiconductor/solid-state device manufacturingLapping machinesSilicon nitrideEngineering

The invention relates to a grinding device of a shallow trench isolation structure, comprising a grinding part, a monitoring part and a control part. The grinding part is used to grind a silicon dioxide layer on a silicon nitride layer. The monitoring part is used to project downgoing monitoring light to a grinding surface and receiving upgoing light reflected by the grinding surface so as to generate induction signals corresponding to the upgoing light. The control part is used to carry out preset comparison according to the induction signals and then determine whether the grinding surface reaches the dividing line between the silicon nitride layer and the silicon dioxide layer, and generate corresponding control signals to control grinding motion of the grinding part. The invention also provides a corresponding grinding method of the shallow trench isolation structure.

Owner:CSMC TECH FAB2 CO LTD

Full-automatic pliers head machining drilling and grinding machining production center

InactiveCN111993081AAdjust front and rear positionsEasy to punchMeasurement/indication equipmentsOther manufacturing equipments/toolsElectric machineryMachining

The invention discloses a full-automatic pliers head machining drilling and grinding machining production center. The full-automatic pliers head machining drilling and grinding machining production center comprises a machining working table. Two sliding rails are arranged on the front side and the rear side of the upper surface of the machining working table. A sliding connection seat in sliding connection is arranged on the sliding rails. Supporting lug plates are welded to the two ends of the rear side of the upper surface of the machining working table. A first threaded rod is connected between the two supporting lug plates in a bearing connection mode. One sides of the supporting lug plates are connected with a first motor through a bolt. An output shaft of the first motor penetrates through one sides of the supporting lug plates, and is connected with one end of the first threaded rod. The full-automatic pliers head machining drilling and grinding machining production center is simple in structure and easy and convenient to operate. A pliers head can be fixed more conveniently and can be drilled and ground, so that much manpower is saved, and convenience is brought to people.

Owner:东阳市俊华电器销售有限公司

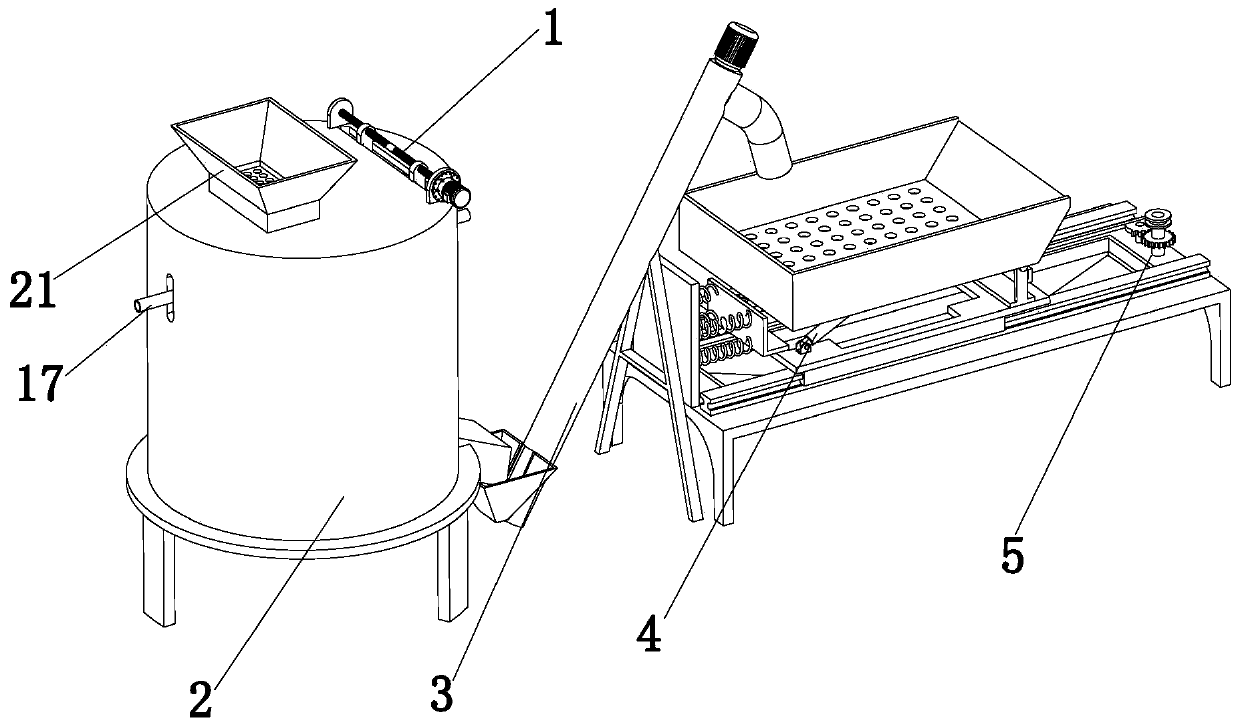

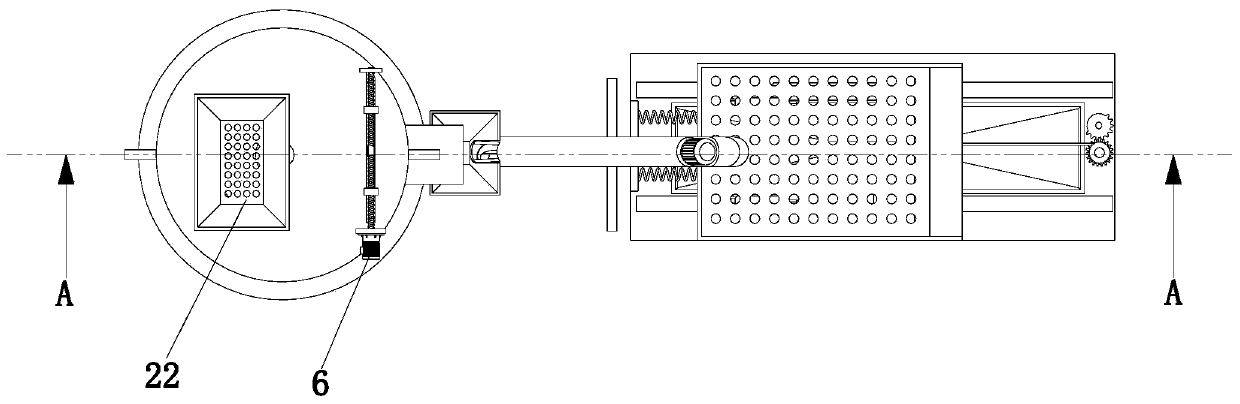

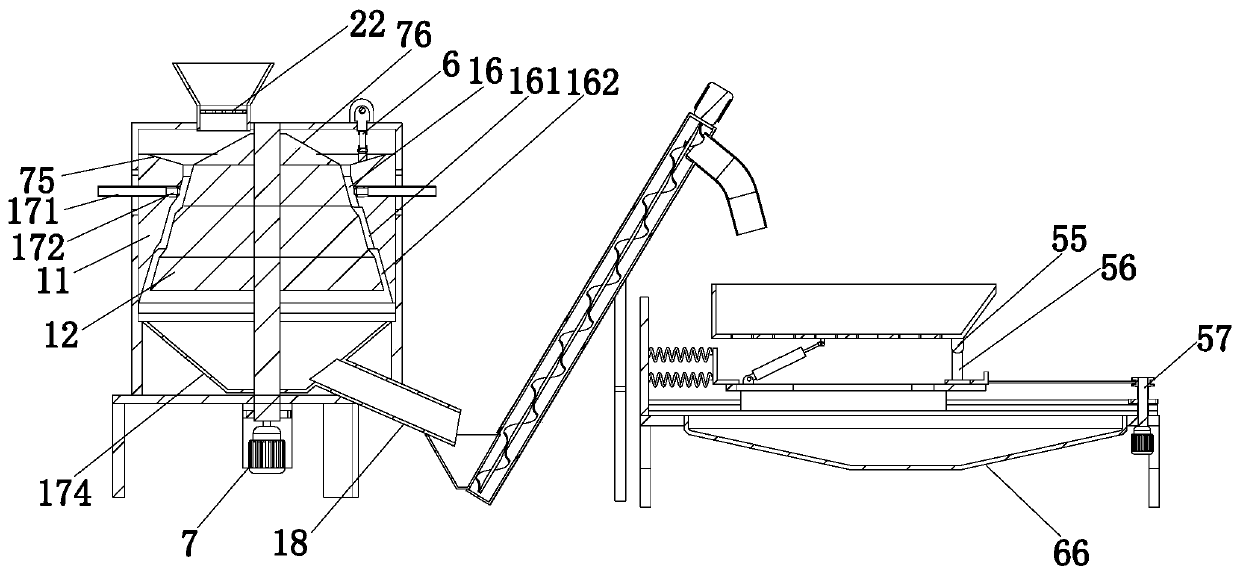

Precise polishing and scrap removing equipment for bearing steel balls

InactiveCN111515842ATimely processingHigh degree of automationSievingPolishing machinesPolishingSteel ball

The invention relates to precision polishing and scrap removing equipment for bearing steel balls, and belongs to the technical field of steel ball production equipment. The precision polishing and scrap removing equipment for the bearing steel balls comprises a multi-stage polishing mechanism, a shell, an auger feeder, an automatic discharging mechanism and a vibration scrap removing mechanism; afeeding hopper is arranged at the top of the shell, and a filtering grid is arranged in the feeding hopper; the multi-stage polishing mechanism comprises a scrap blowing anti-blocking assembly, a polishing shell, a multi-stage polishing block, a rotating assembly and a height adjusting assembly; and a vertically-arranged rotating shaft is arranged in the center of the interior of the shell, a frosted layer is arranged on the inner wall of the polishing shell, and the two ends of the rotating shaft are rotationally connected with the shell. The precision polishing and scrap removing equipmentis high in automation degree, steel balls within a certain range of diameters can be treated in batches under the action of the multi-stage polishing mechanism, and the height of the polishing shell is adjusted at high precision under the action of the height adjusting assembly, so that multi-stage polishing treatment is carried out on steel balls of different specifications, and scraps generatedby steel ball polishing can be treated in time under the action of the vibration scrap removing mechanism.

Owner:芜湖宏超钢球科技有限公司

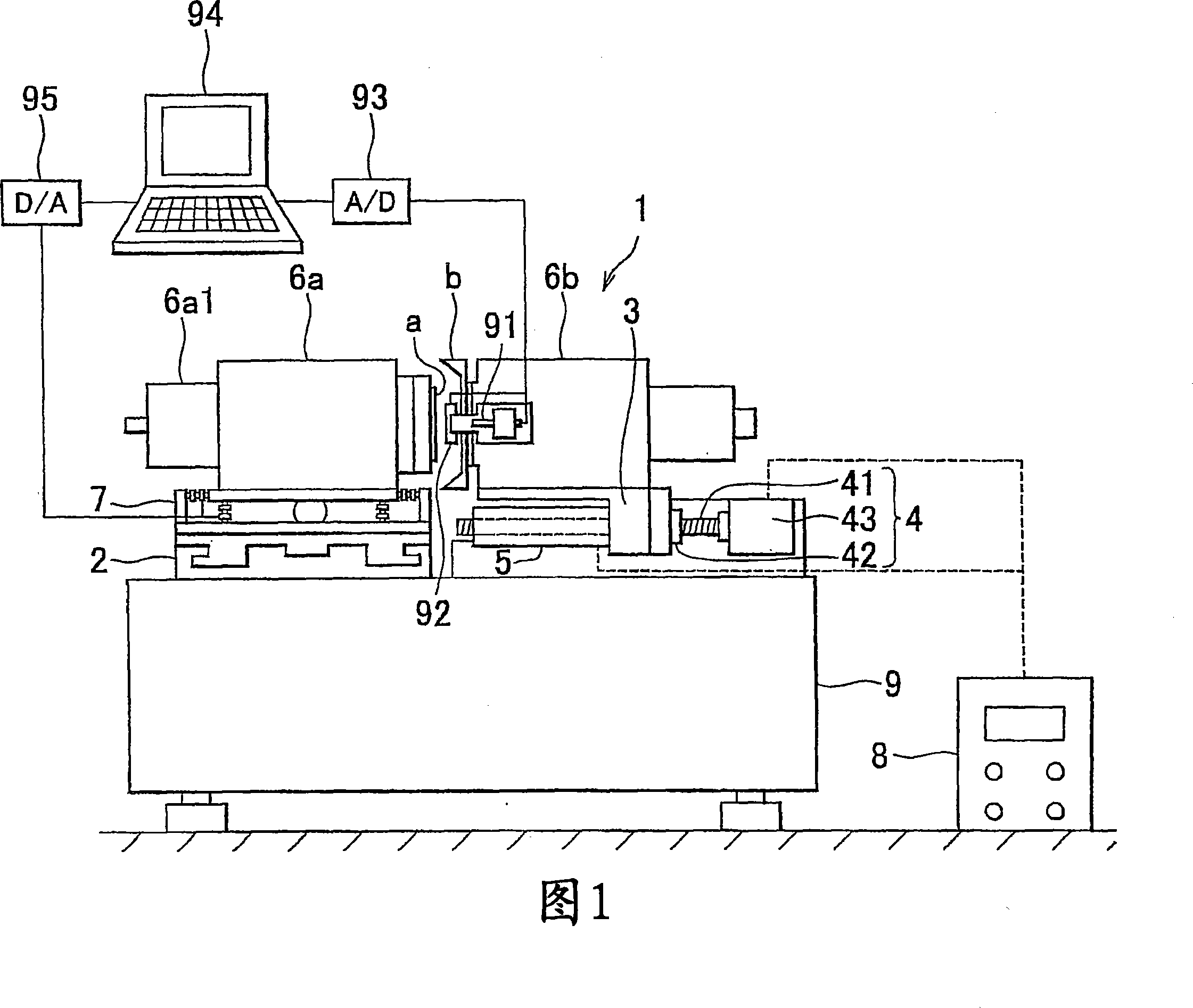

Precision machining apparatus and precision machining method

InactiveCN101237960AAvoid settingQuality improvementAutomatic control devicesGrinding drivesEngineeringActuator

Owner:TOYOTA JIDOSHA KK

Board section fixed grinding equipment applicable to the field of furniture processing

ActiveCN106625078AEffectively fixedFixed grinding is effectiveGrinding carriagesGrinding work supportsElectric machineEngineering

The invention discloses board section fixed grinding equipment applicable to the field of furniture processing. The board section fixed grinding equipment comprises a base plate, a support device, a supporting device, a fixed device, a first grinding device, a lifting device, a second grinding device, a first motor device and a second motor device, a first supporting block and a first idler wheel are arranged on the base plate, the support device comprises a first cross rod, a first supporting rod, a first cross plate, a first locating frame, a first support, a first spring, a second cross rod, a first abutting-leaning rod, a first abutting-leaning plate and a first bent rod, the support device comprises a abutting- wheel, a second abutting- leaning rod, a first vertical rod, a curving plate, a second vertical rod, a first location rod, a second spring, and a third spring, the fixed device comprises a second cross plate, a second supporting rod, and a third supporting rod, and the first grinding device comprises a first motor, a first output shaft, a second support, a fourth supporting rod, a rotating rod, a first grinding wheel and a first bracing wire. According to the board section fixed grinding equipment applicable to the field of furniture processing, effective fixation can be conducted on a panel when the panel is grinded, so that the grinding is more accurate.

Owner:GUANGZHOU LANGU HOUSEHOLD TECH CO LTD

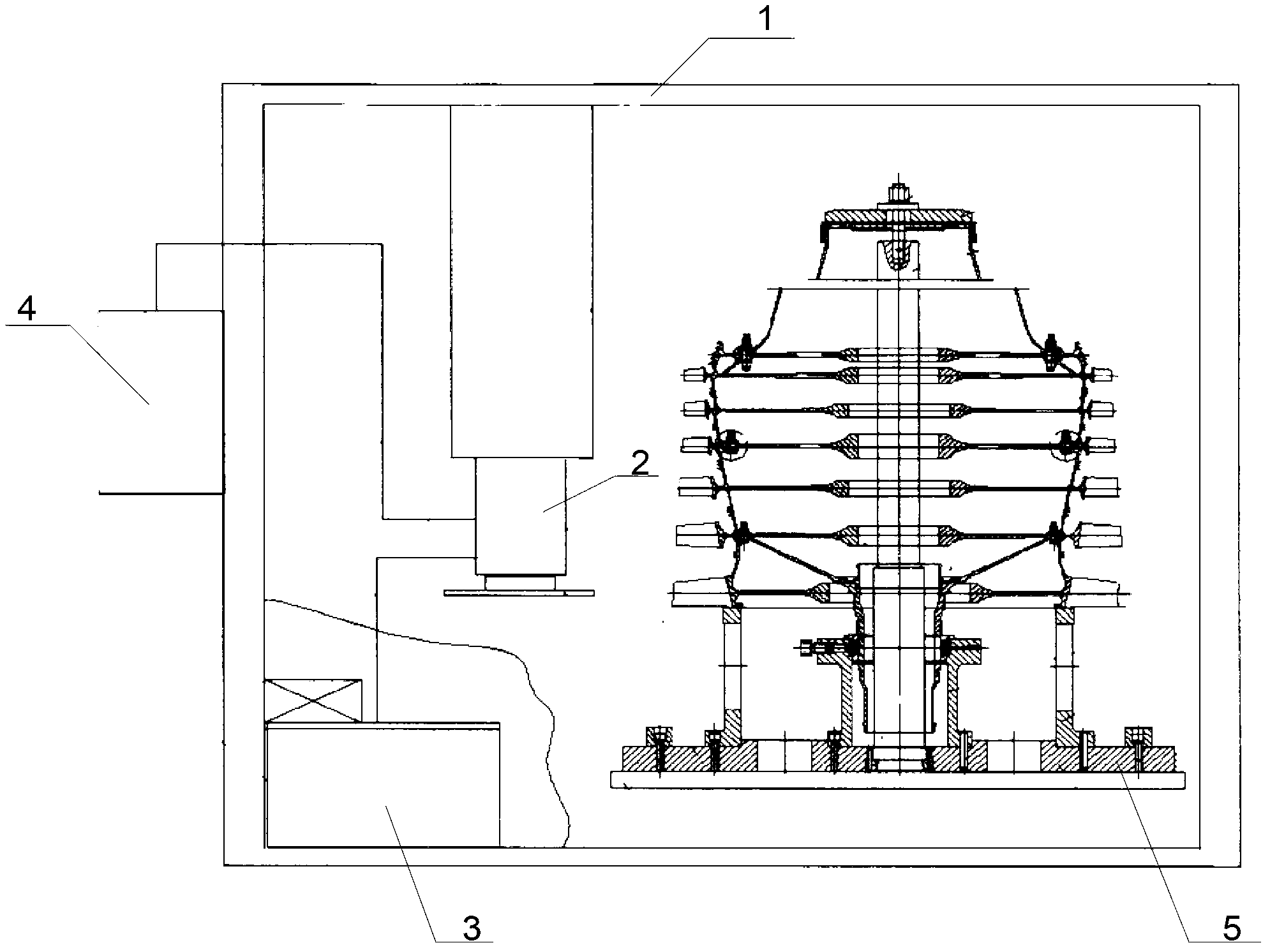

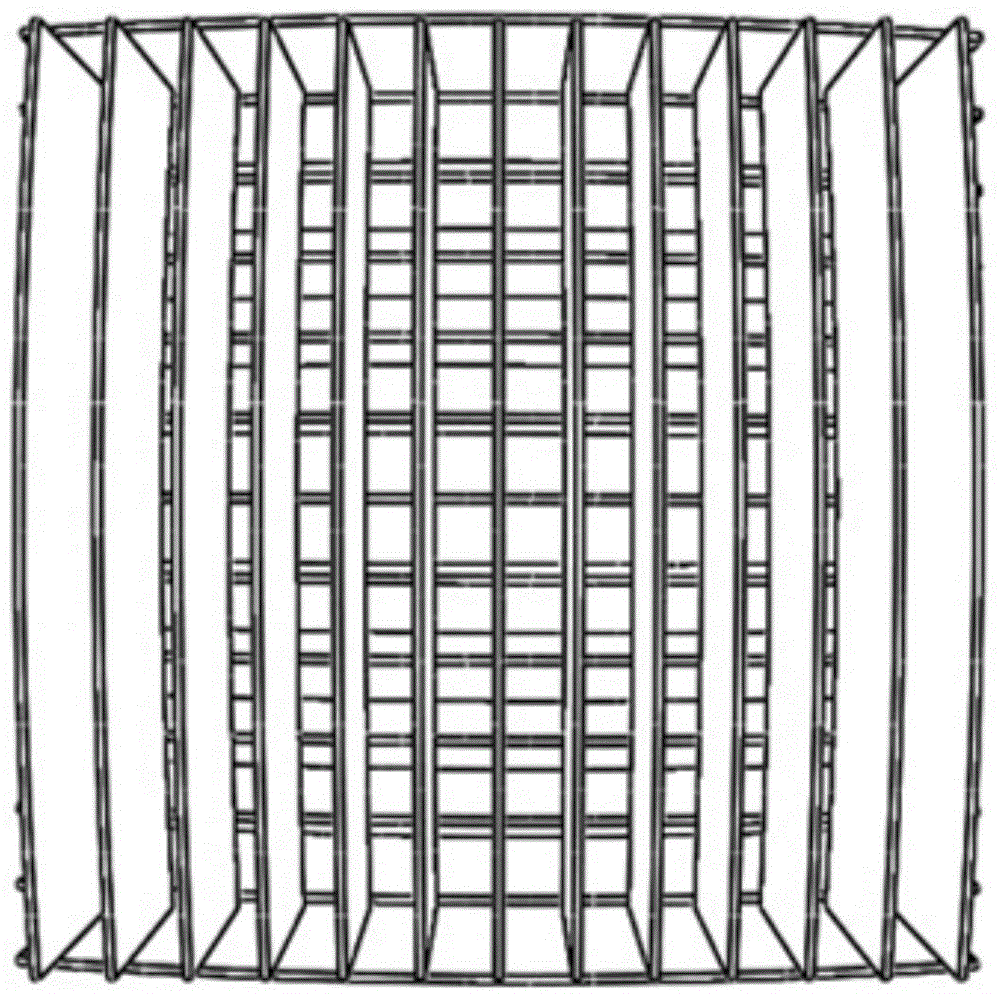

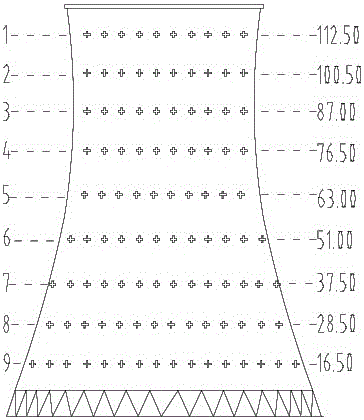

Simulation method for large-scale cooling tower wind tunnel test

InactiveCN106644373APrecision grindingAccurate sanding methodAerodynamic testingCooling towerEngineering

The invention discloses a simulation method for a large-scale cooling tower wind tunnel test, and relates to the technical field of wind tunnel test simulation. The method comprises the following steps: making a cooling tower test model, wherein the reduced scale is 1: 150; selecting different types of wallpaper, respectively testing the roughness of each type of wallpaper, carrying out the throat model test of each type of wallpaper, and measuring the pressure coefficient of the throat part of a cooling tower; enabling the pressure coefficient measured through the test to be compared with the standard, and selecting the optimal roughness; carrying out the full-tower wind tunnel test through employing the wallpaper with the optimal roughness. The uniform wallpaper with the specific roughness is pasted on the surface of the cooling tower, so as to eliminate the impact caused by the inconsistency with the Reynolds number of an actual structure.

Owner:SHIJIAZHUANG TIEDAO UNIV

Environment-friendly architectural ornament stone polishing device

ActiveCN107097112AAutomatically control the left and right movement of the grinding workImprove grinding accuracyGrinding carriagesGrinding drivesAutomatic controlEngineering

The invention discloses an environment-friendly architectural ornament stone polishing device. The device comprises a shell, wherein a polishing cavity is arranged in the shell; a first sliding groove is arranged in the left side of the inner top wall of the polishing cavity; a longitudinally-extending second sliding groove is arranged in the inner wall of the right side of the polishing cavity; an opening penetrating the right side wall of the shell below the second sliding groove is formed; the left end of the opening is communicated with the polishing cavity; a fixed connection module and a settling groove are respectively arranged at left and right sides of the inner bottom wall of the polishing cavity; a first threaded rod extending left and right is arranged in the first sliding groove; a moving block is in threaded connection on the first threaded rod; the bottom of the moving block is stretched into the polishing cavity; a first sliding cavity is arranged in the moving block; a lifting sliding block is in sliding connection in the first sliding cavity; and convex sliding blocks in sliding connection with inner walls of two sides of the first sliding cavity are arranged at top edges of two sides of the lifting sliding blocks. The device disclosed by the invention is simple in structure, convenient to operate, high in safety, good in dust absorbing effect, accurate in polishing and high in stability and is capable of automatically controlling the open / close of a separating plate.

Owner:甘肃丰嘉建筑工程有限公司

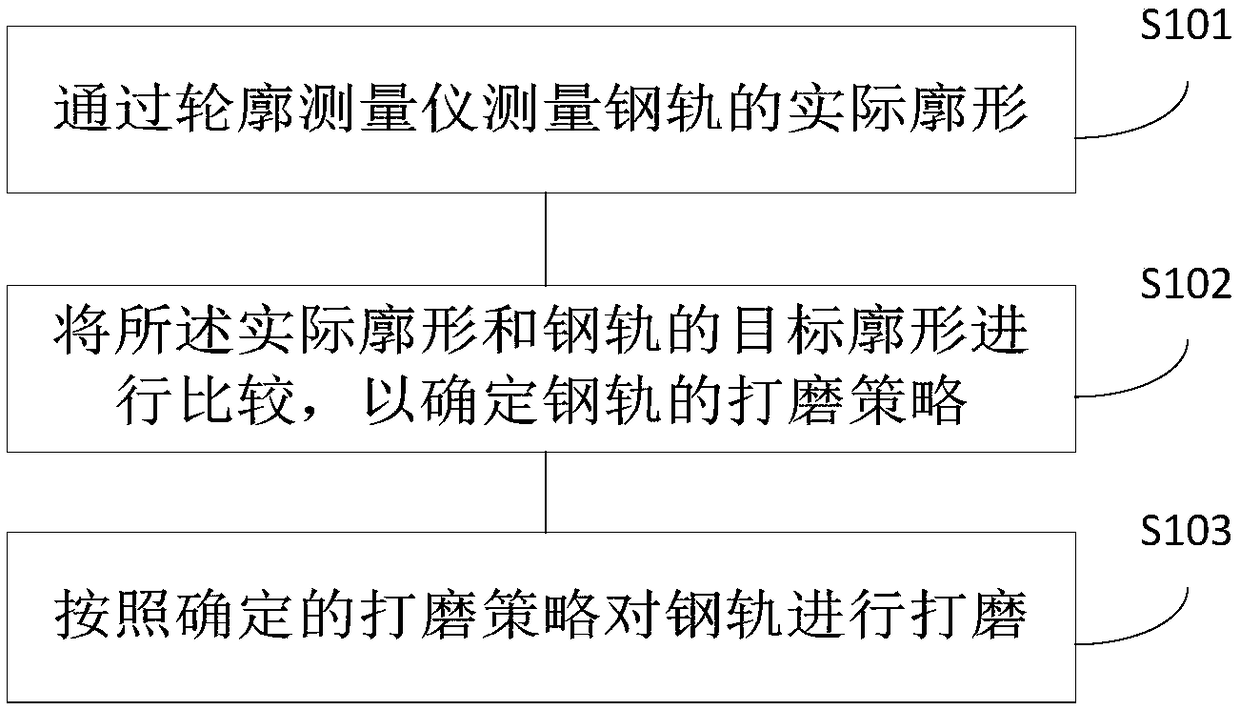

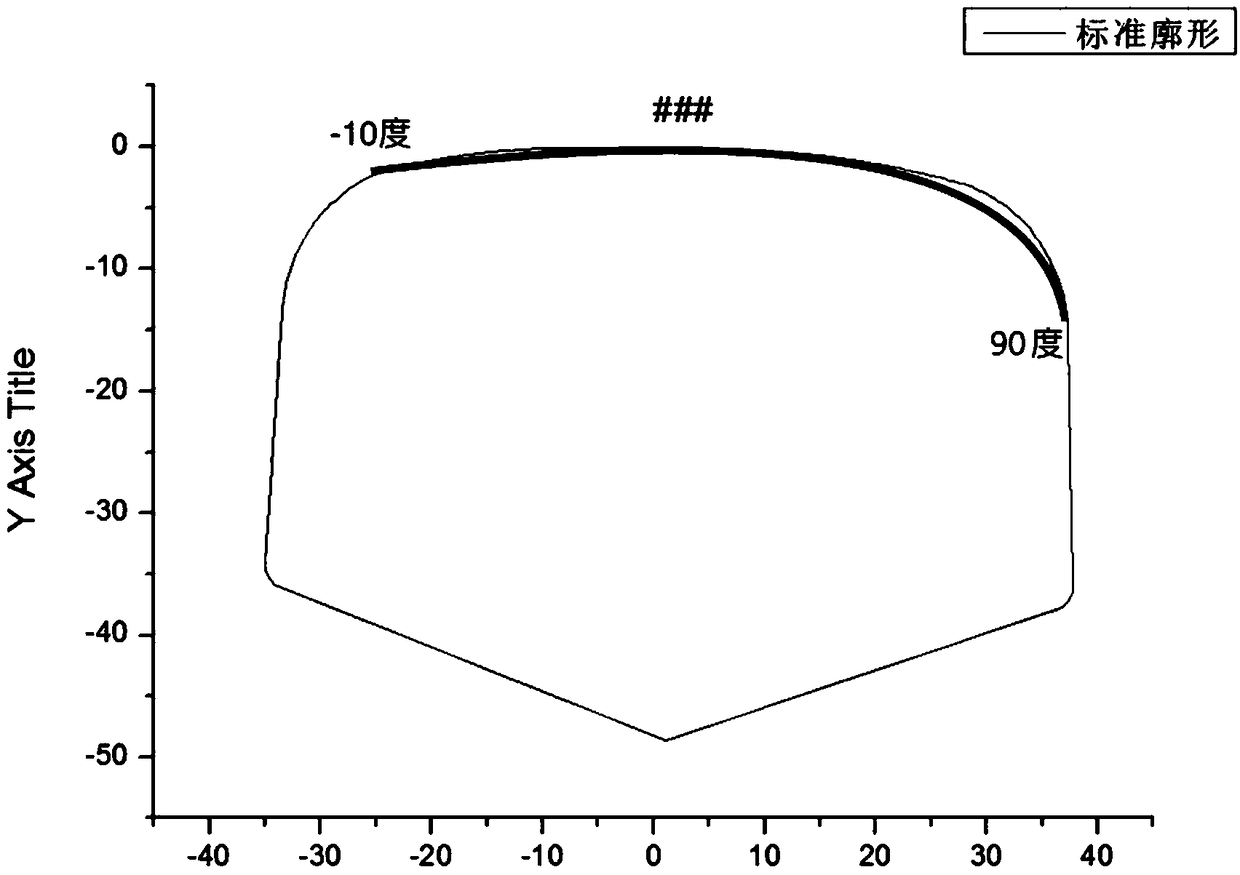

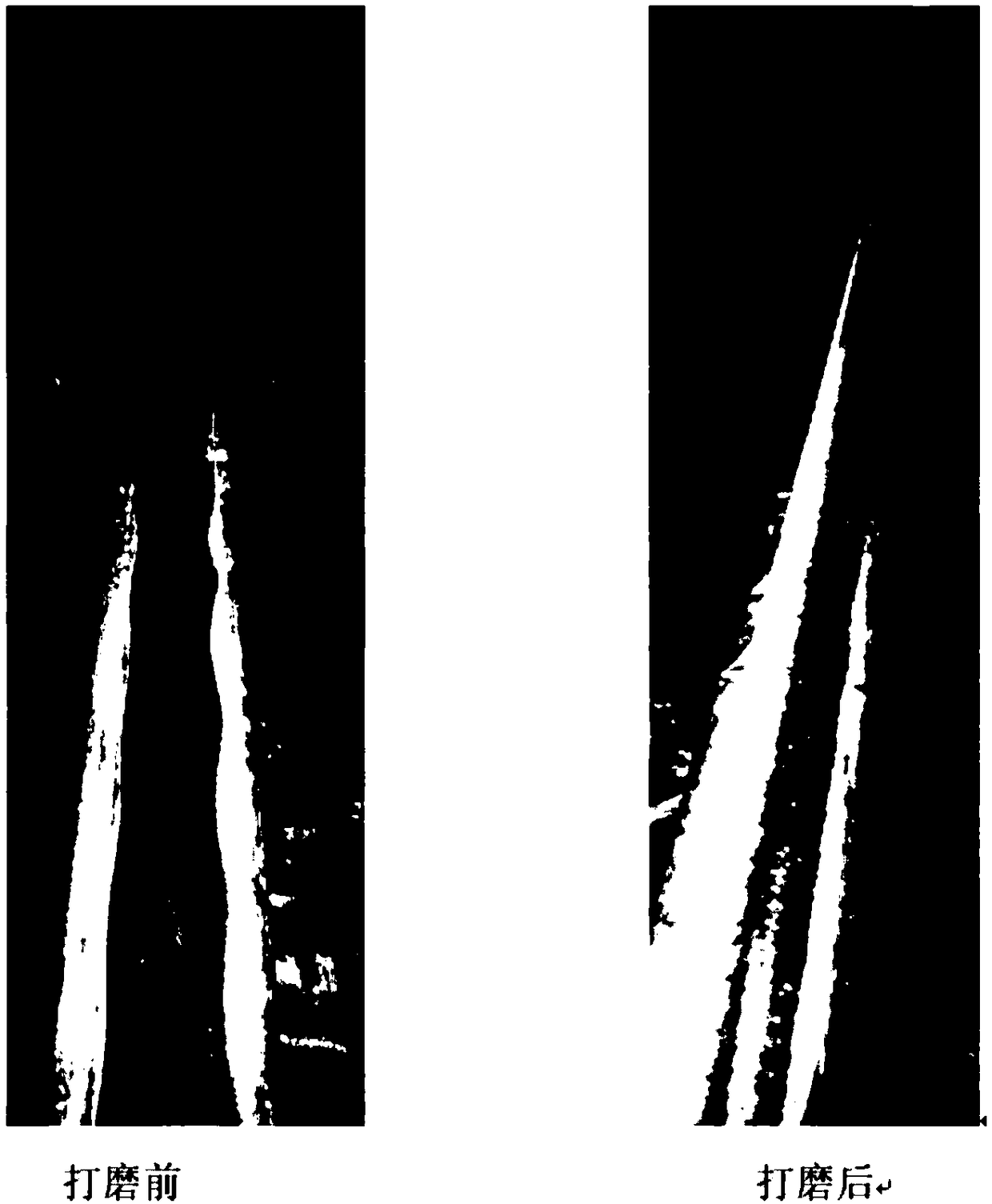

Steel rail maintenance method and device

The invention provides a steel rail maintenance method and device, and relates to the field of steel rail maintenance. The steel rail maintenance method comprises the steps of firstly, measuring an actual profile of a steel rail through a profile measuring instrument, and then comparing the actual profile with a target profile of the steel rail to determine a grinding strategy for the steel rail,wherein the grinding strategy at least comprises the grinding position and the grinding amount; finally, grinding the steel rail according to the determined grinding strategy. According to the methodand device, since the profile measuring instrument is utilized for collection, and the target profile is utilized as a reference, grinding of the steel rail is more precise.

Owner:华夏高铁运营维护有限公司

Coated one-piece golf ball

The present invention provides a coated one-piece golf ball having excellent adhesion of a paint layer to a golf ball body and good appearance. The present invention relates to a coated one-piece golf ball comprising a golf ball body formed by vulcanizing and press-molding rubber composition, and a clear paint layer formed on the golf ball body, wherein the rubber composition comprises not less than 0.5 and less than 2.0 parts by weight of titanium oxide, based on 100 parts by weight of base rubber, and the clear paint comprises 0.1 to 2.0 parts by weight of fluorescent brightener, based on 100 parts by weight of resin solid content.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com