Grinding device for production of machine part

A technology for mechanical parts and cooling devices, which is used in grinding drive devices, grinding/polishing safety devices, grinding machine parts, etc. quality and other issues, to achieve the effect of simple structure, lower temperature and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

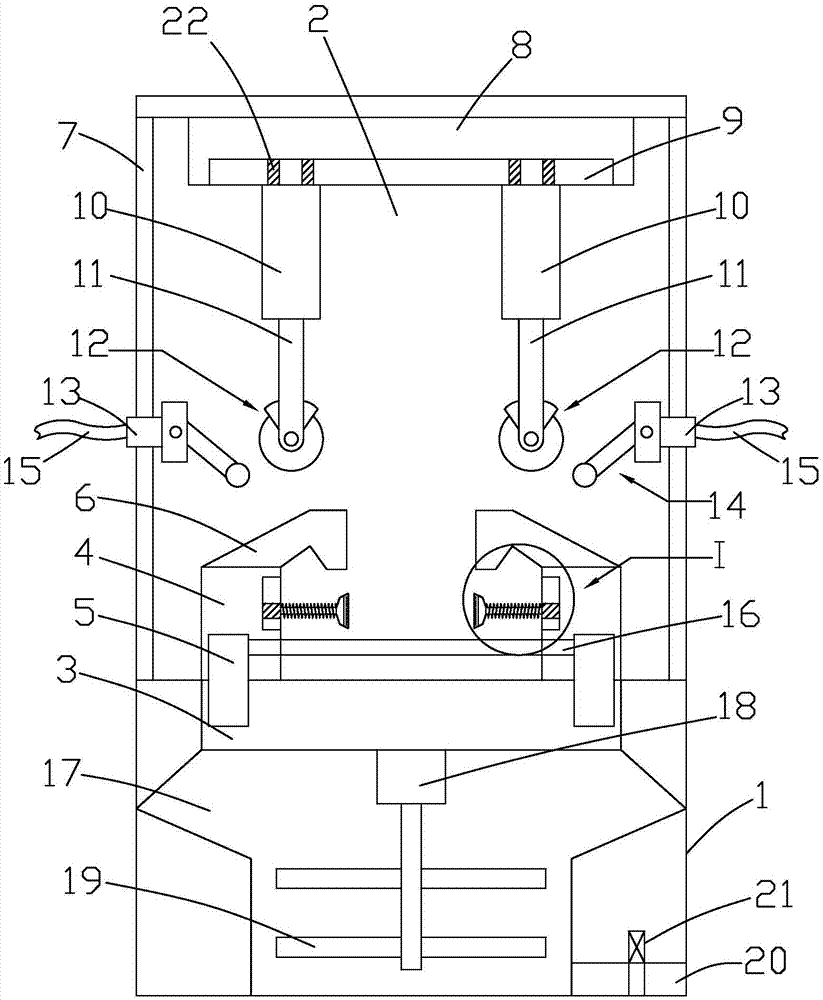

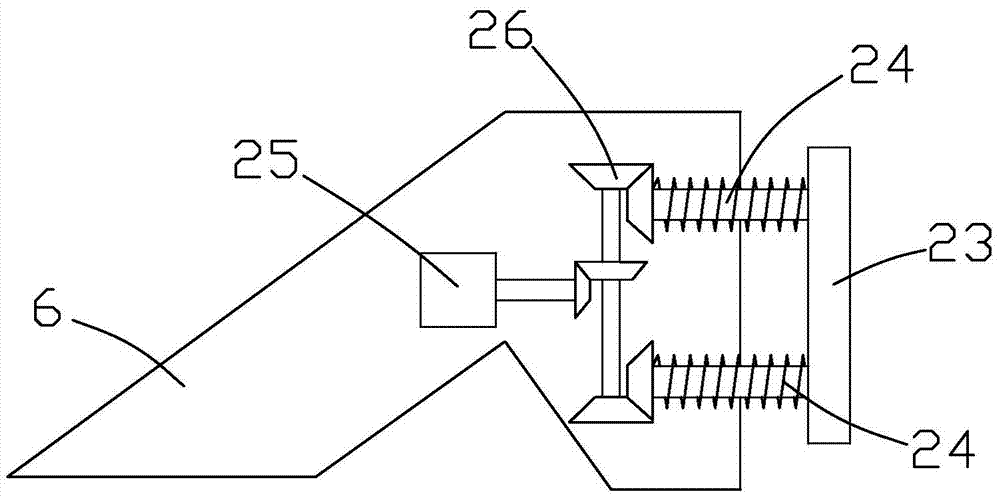

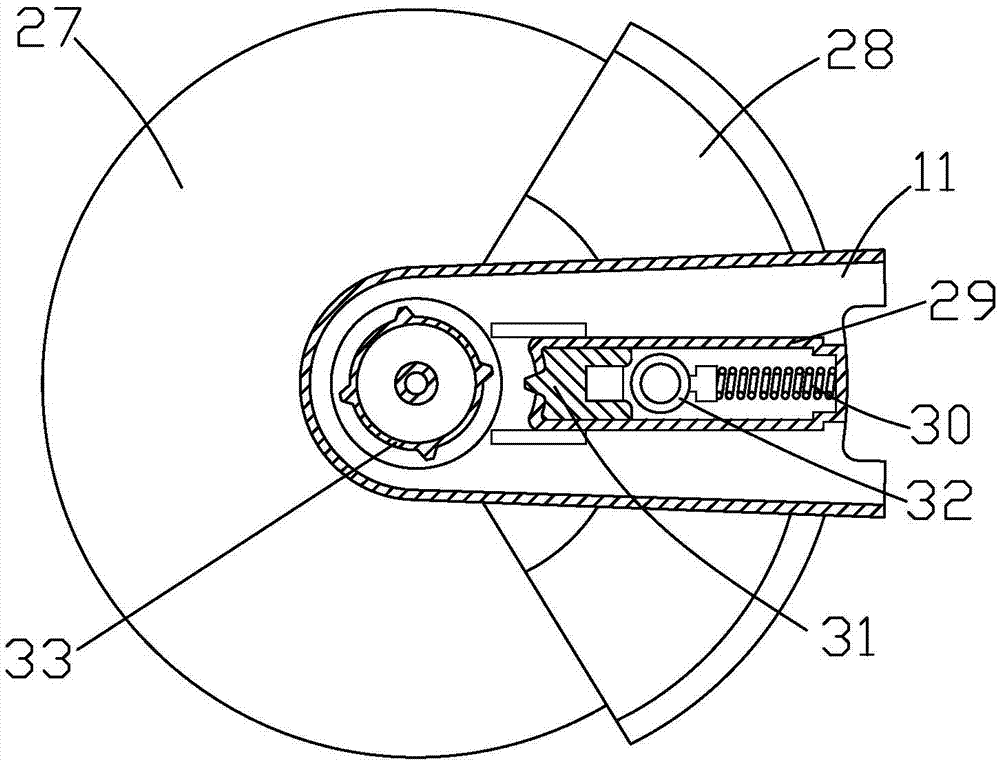

[0027] Such as Figure 1 to Figure 5 As shown, it is a grinding device for the production of mechanical parts of the present invention, including a body 1 and a grinding chamber 2, the grinding chamber 2 is located above the body 1, and vertical guide rails 7 are arranged on both sides of the grinding chamber 2, and on the vertical guide rail 7 A cooling device 14 is provided, and the cooling device 14 includes a positioning pinch plate 34, a rotating arm 35 and a spray head 36. The positioning pinch plate 34 is fixedly connected to the first slider 13, and the spray head 36 is rotatably connected to the positioning pinch plate 34 through the rotating arm 35. , spray holes 37 are evenly arranged on the spray head 36, and the spray head 36 can rotate around the positioning buckle plate 34 through the rotating arm 35 according to the needs of actual operation, so as to ensure that the grinding part is sprayed with cooling liquid in real time, so as to reduce the surface of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com