Integrated steel pipe cutting, drilling and polishing equipment

A steel pipe and equipment technology, applied in the field of integrated steel pipe cutting, drilling and grinding equipment, can solve the problems of time-consuming and laborious, manual cutting, drilling and grinding accuracy are not high, so as to avoid inaccuracy, save the time of manual operation, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

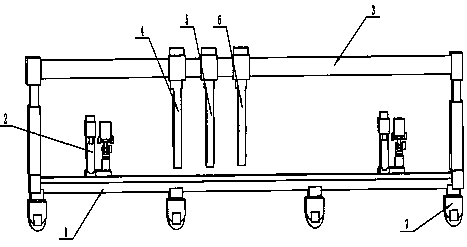

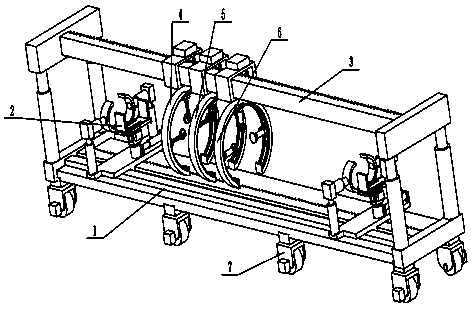

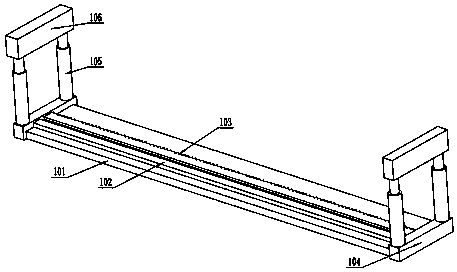

[0027] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, an integrated steel pipe cutting, drilling and grinding equipment includes a base 1, a fixed part 2, a sliding rod part 3, a cutting part 4, a punching part 5, a grinding part 6 and a moving part 7, and is characterized in that: The first slide rail 202 of the fixed part 2 is slidably installed in the first dovetail groove 102 of the base 1, and its first gear 204 is meshed with the first rack 103 of the base 1; The end of the rod 301 is fixedly connected to the side of the sliding rod fixing plate 106 of the base 1; the top end of the first sliding ring 401 of the cutting part 4 is fixedly connected to the lower end surface of the first slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com