X-ray lobster-eye object lens assembling apparatus and application thereof

A lobster eye and X-ray technology, which is applied in the field of X-ray imaging system installation and adjustment, can solve the problems of few, difficult and high-energy X-ray imaging, and lack of reliable installation and adjustment technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

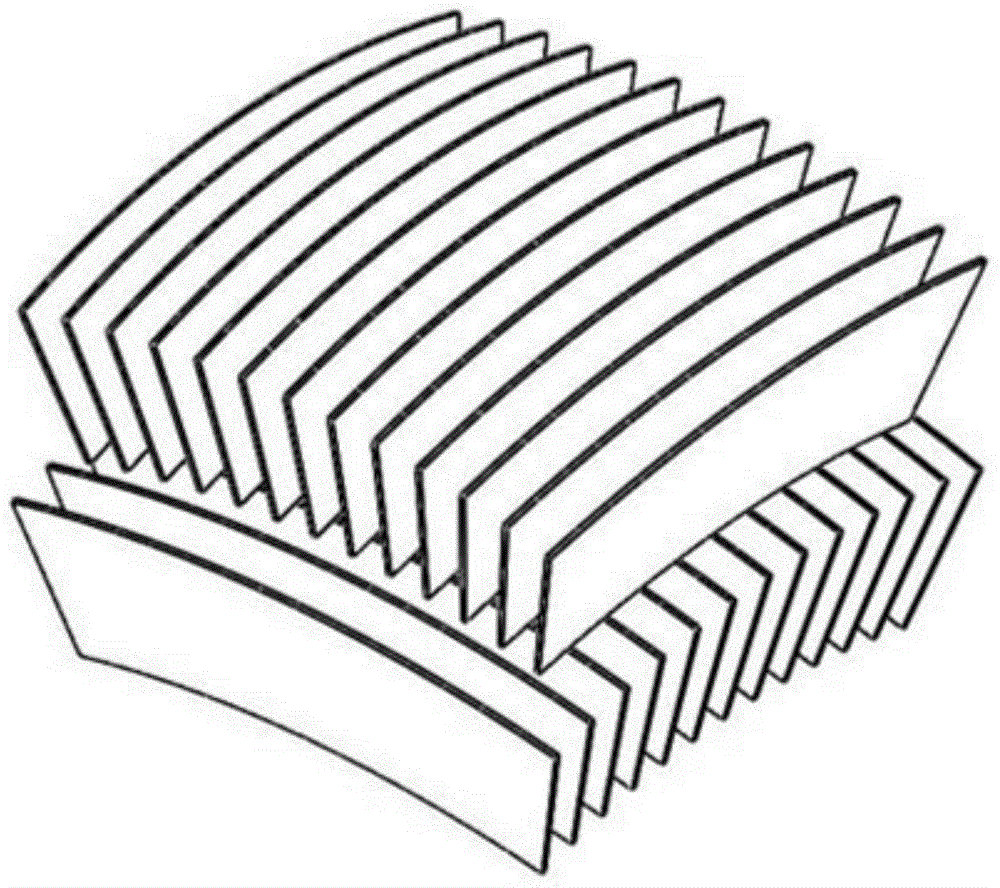

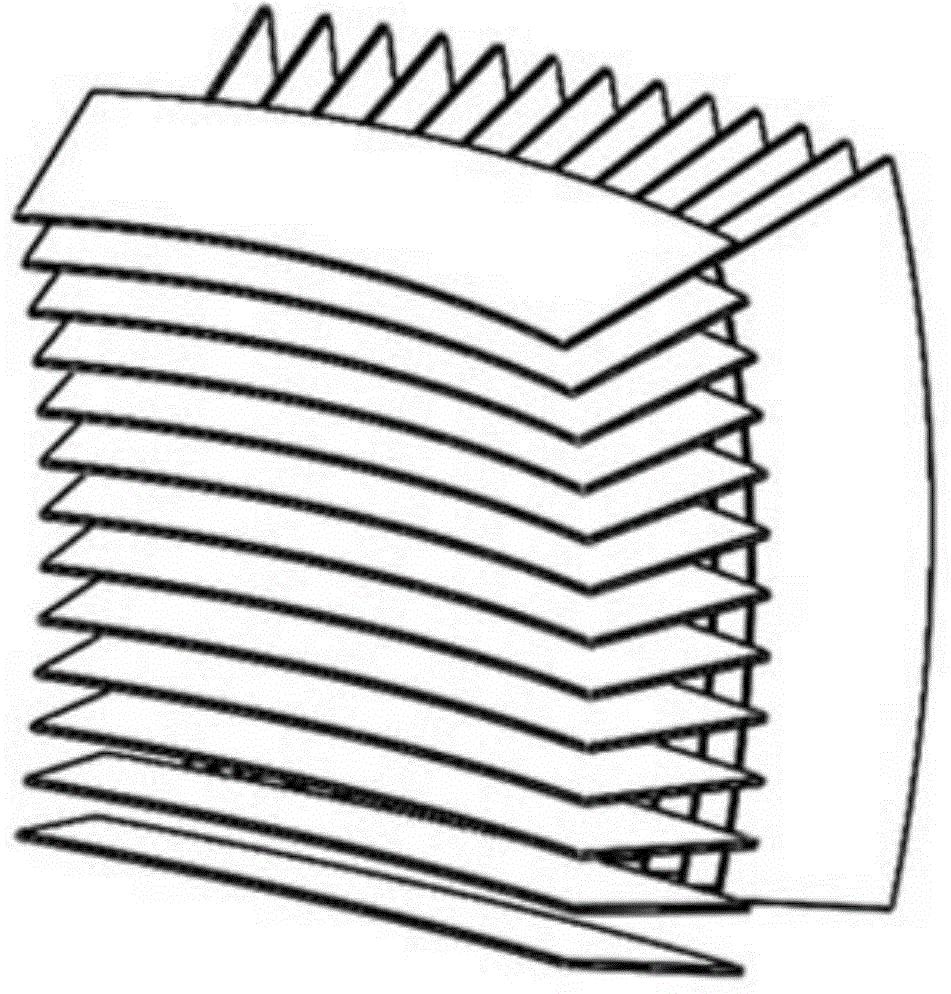

[0050] This embodiment is used to complete the assembly of the objective lens of the X-ray lobster eye whose parameters are shown in Table 1.

[0051] Table 1

[0052] lens material

D263 (SiO 2 )

Number of layers of objective lens

2x30

lens length

100mm

Lens width

24mm

0.21mm

Lens spacing

0.4mm

[0053] A kind of adjusting device for X-ray lobster eye objective lens, such as Figure 7 , Figure 8 As shown, the adjusting device includes a lens assembly unit, a displacement sensing unit and a gasket grinding unit;

[0054] Lens assembly unit; including the objective lens base 5 and the six-dimensional electronically controlled displacement platform 4 for placing the lens to be assembled and adjusted. The six-dimensional electronically controlled displacement platform 4 drives the objective lens base 5 to move up and down, left and right, and forward and backward; It includes 3 sets of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

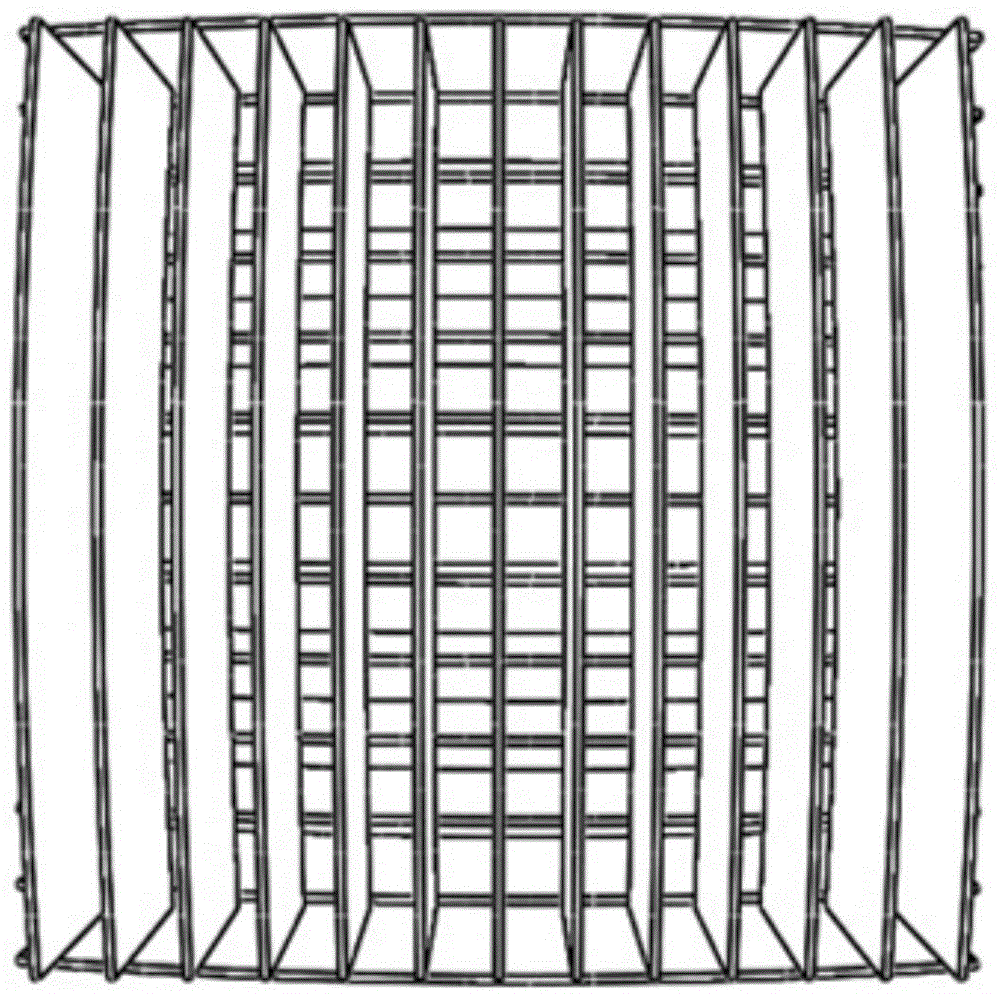

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com