Multi-petal composite material launching box cover and preparation method thereof

A technology of composite materials and launching boxes, which is applied in the direction of launching devices, etc., can solve the problems of large throwing weight of the box cover, achieve good sealing, increase bearing capacity, and increase structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

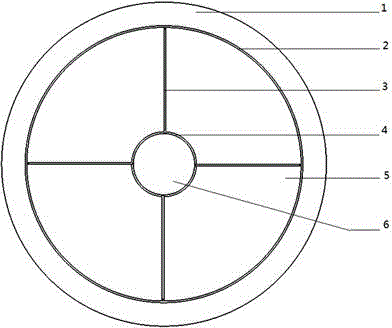

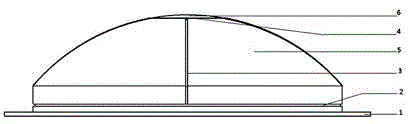

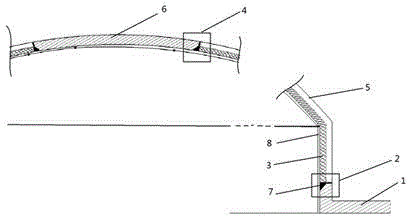

[0028] Such as figure 1 Shown: A multi-lobed composite launching box cover, with high-strength glass fiber cloth and epoxy resin as the main materials, designed and manufactured by step-lamination method. Specifically, a kind of multi-lobe type composite launch case cover of the present invention comprises 1, frame, and described frame 1 is circular; The joint of the side sub-cover unit adopts a 45° V-shaped groove structure, the inside is filled with AB glue, and the outside is pasted with 2 layers of glass fiber cloth strips; 3. The side sub-cover separation area, the side sub-cover separation area 3 is located Between the side sub-cover units, adopt the same structure as the throwing body separation zone 2; 4, the top sub-cover separation zone, the top sub-cover separation zone 4 is located at the junction of the top sub-cover 6 and the side sub-cover unit 5 , adopts the same structure as the projectile separation area 2; 5, the side sub-cover unit, the side sub-cover unit...

Embodiment 2

[0056] Such as Figure 4 Shown: A multi-lobed composite launching box cover, with high-strength glass fiber cloth and epoxy resin as the main materials, designed and manufactured by step-lamination method. Specifically, a multi-lobed composite launch case cover of the present invention includes 1. a frame, and the frame is circular; 2. a throwing body separation area; 3. a side sub-cover separation area; 4. a top sub-cover Cover separation area; 5. Side sub-cover, the side sub-cover unit is formed by cutting the ejector body, with a total of 8 petals; 6. Top sub-cover, the top sub-cover and the side sub-cover unit are made In the same way, a total of 1 petal. This embodiment is adopted when the mass of the launching box cover is too large, and the unit mass of the projectile is alleviated by increasing the quantity of the side sub-cover units. Therefore, the multi-lobed launch box cover can effectively solve the problem of large quantities of objects thrown by the launch box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com