Spray tube electrospinning head

An electrospinning and spinning technology, applied in spinneret assemblies, textiles and papermaking, fiber processing, etc., can solve problems such as elongation and thinning, and achieve higher forming speed, higher polarization, and increased Coulomb static. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

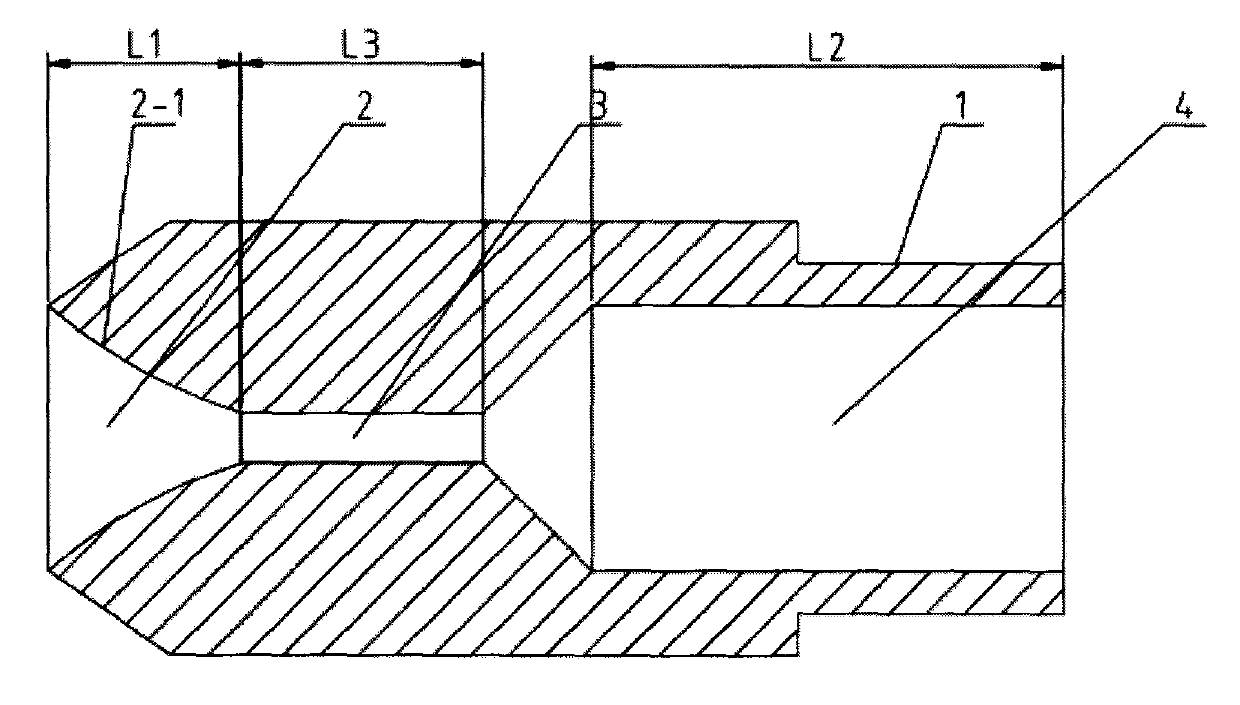

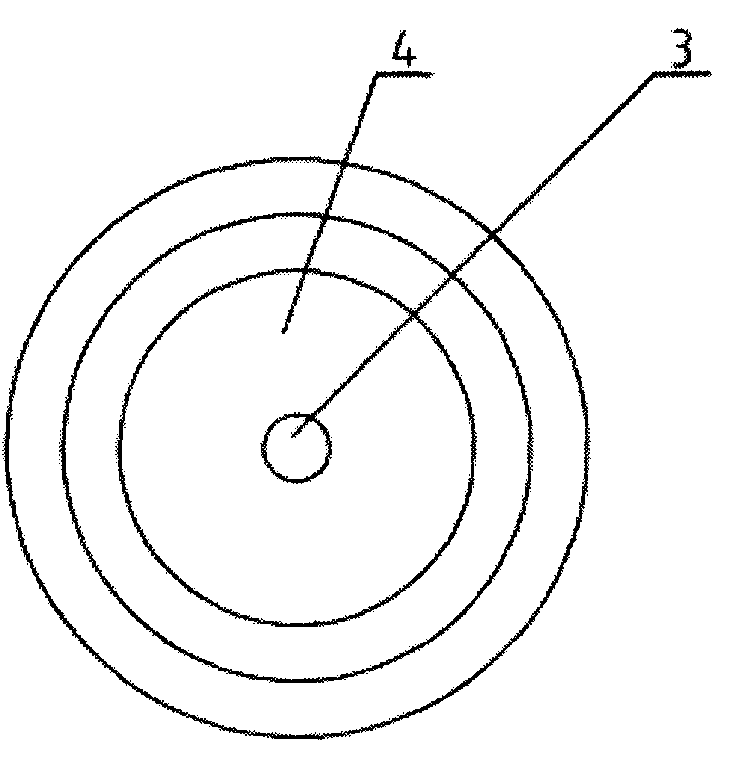

[0019] Such as figure 1 , 2 As shown, a nozzle electrospinning head, which includes an electrospinning head body, the tail of the electrospinning head body is provided with a solution connection part 1, and there are connected trumpet-shaped spinning nozzles in the electrospinning head body from the beginning to the end. 2. The polarization throat hole 3 and the solution cavity hole 4, the diameter of the polarization throat hole 3 is smaller than that of the solution cavity hole 4, and the outer wall of the head of the electrospinning head body is in the shape of a cone whose diameter gradually shrinks outward. Such a structure increases the velocity of the solution passing through the nozzle electrospinning head, increases the degree of polariza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com