Patents

Literature

30results about How to "Increase outflow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

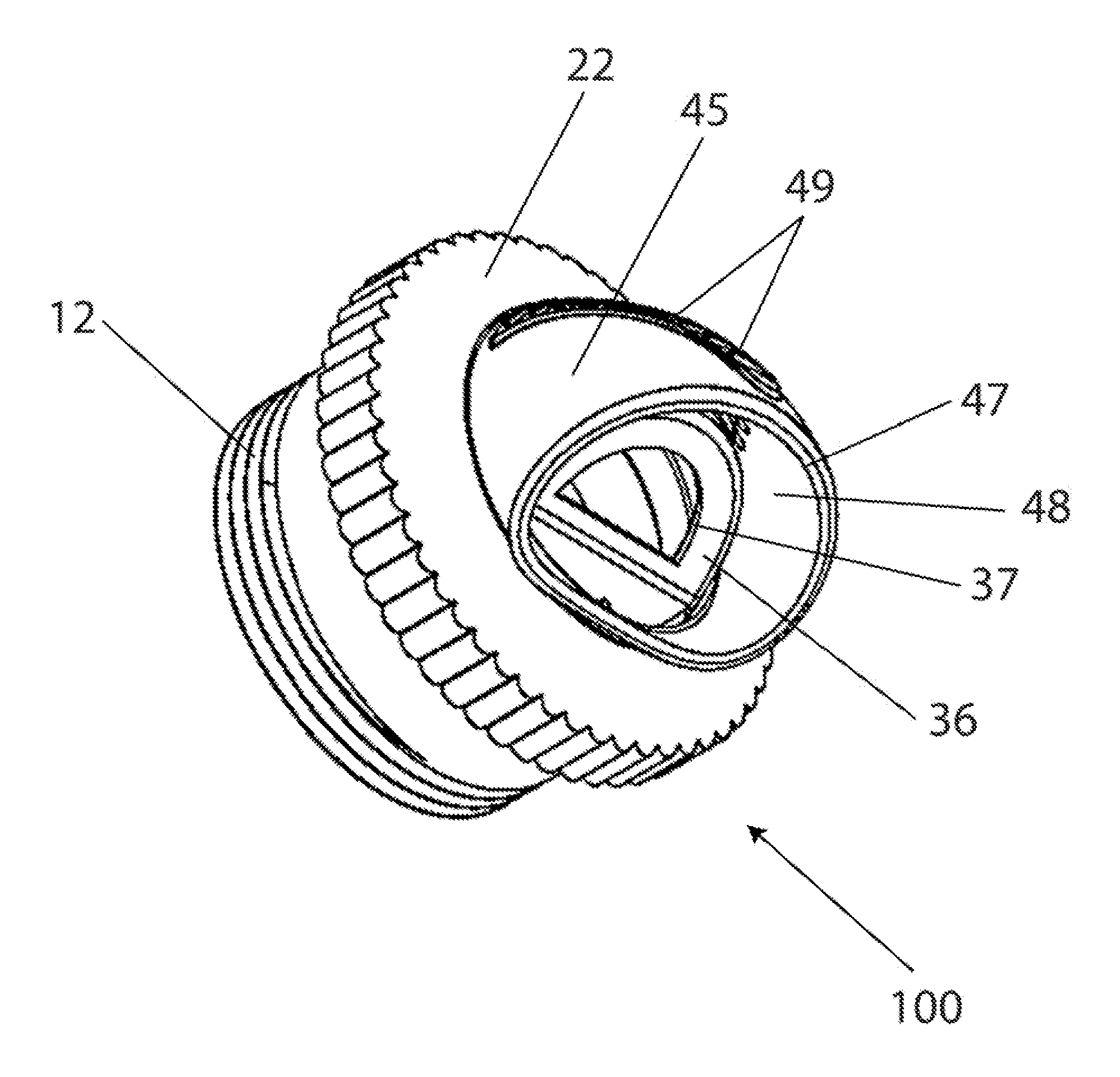

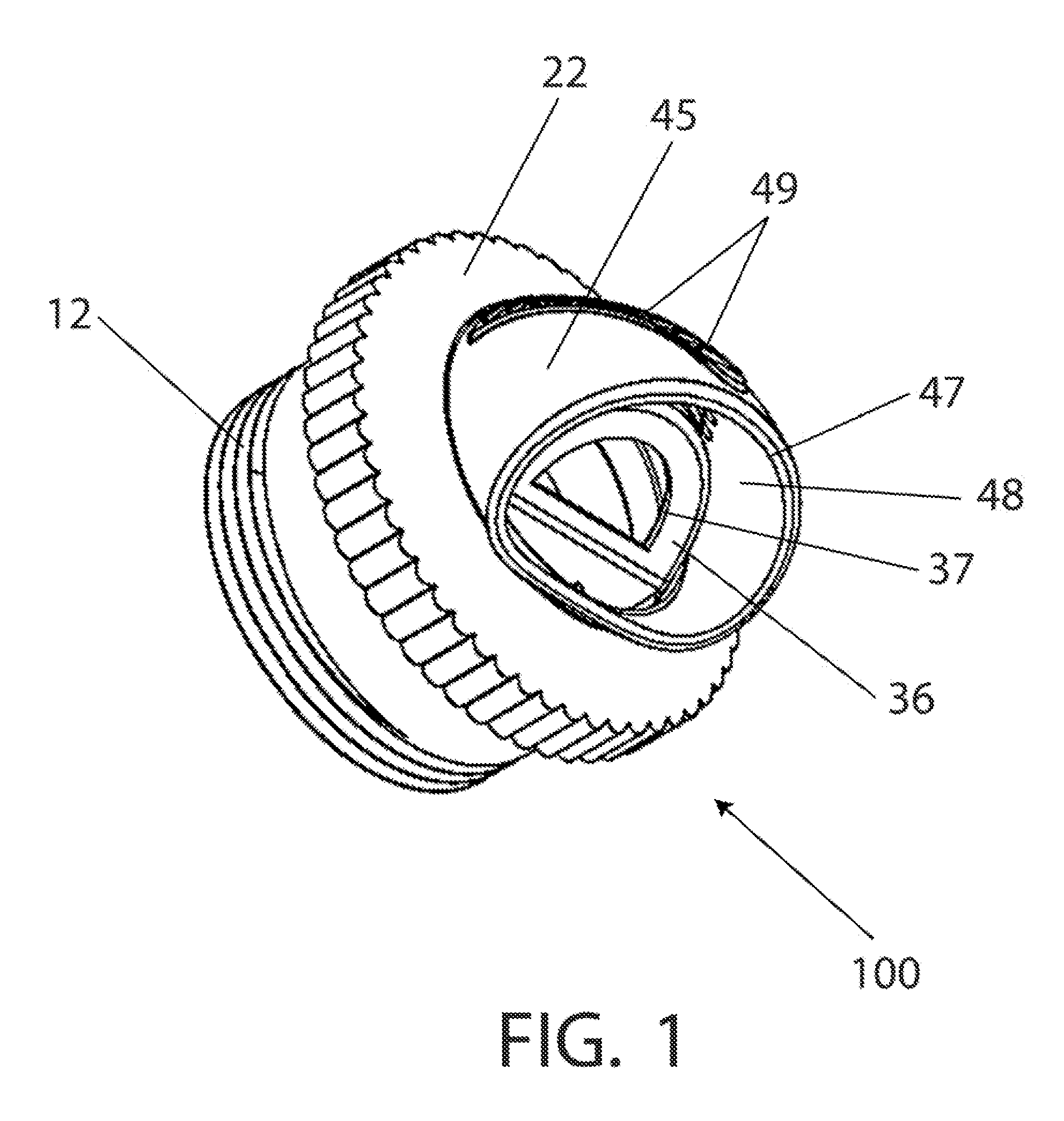

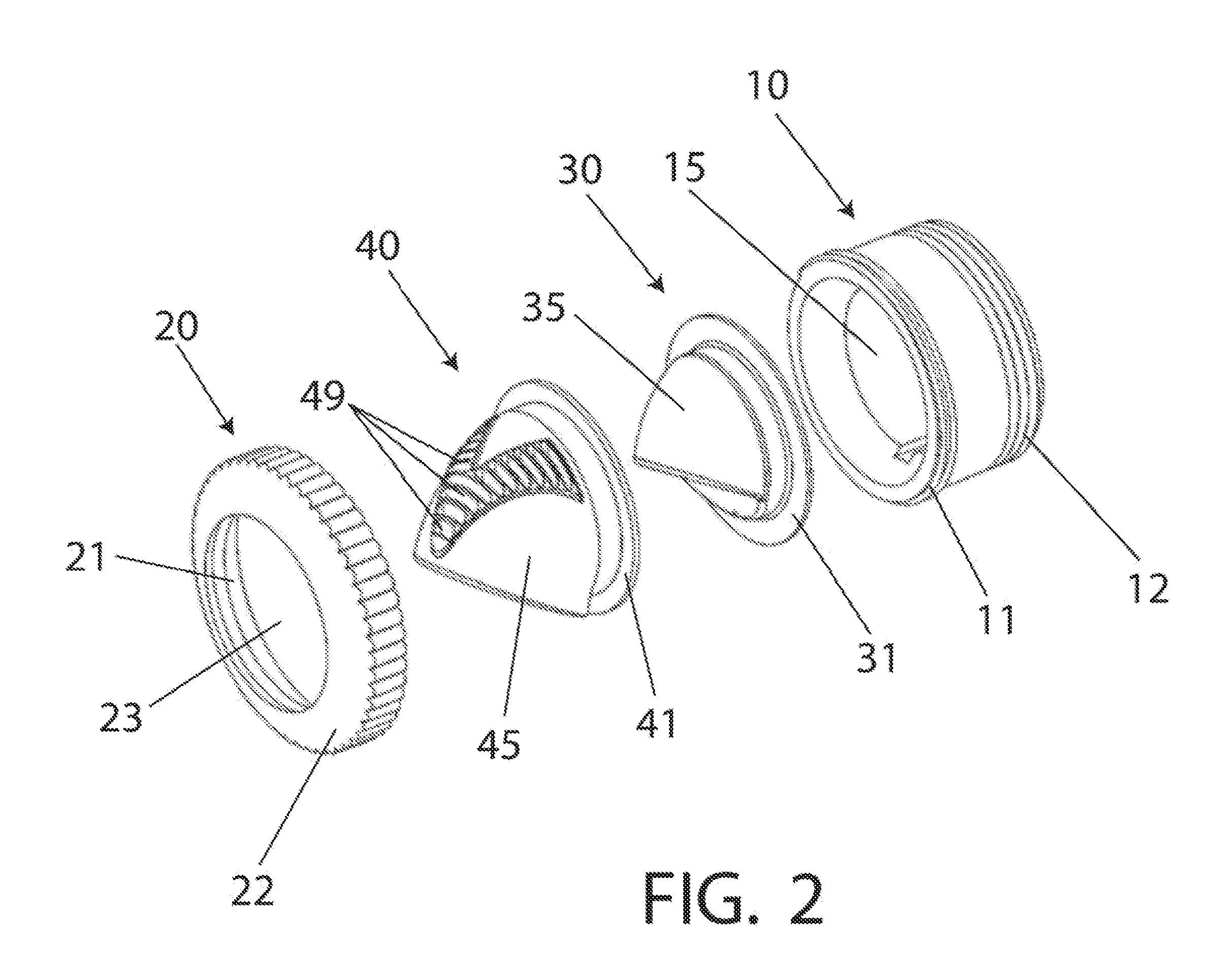

High flow water return fitting for swimming pools and spas

ActiveUS20130061383A1Increase outflowIncrease outflow rateFlow mixersTransportation and packagingStream flowWater flow

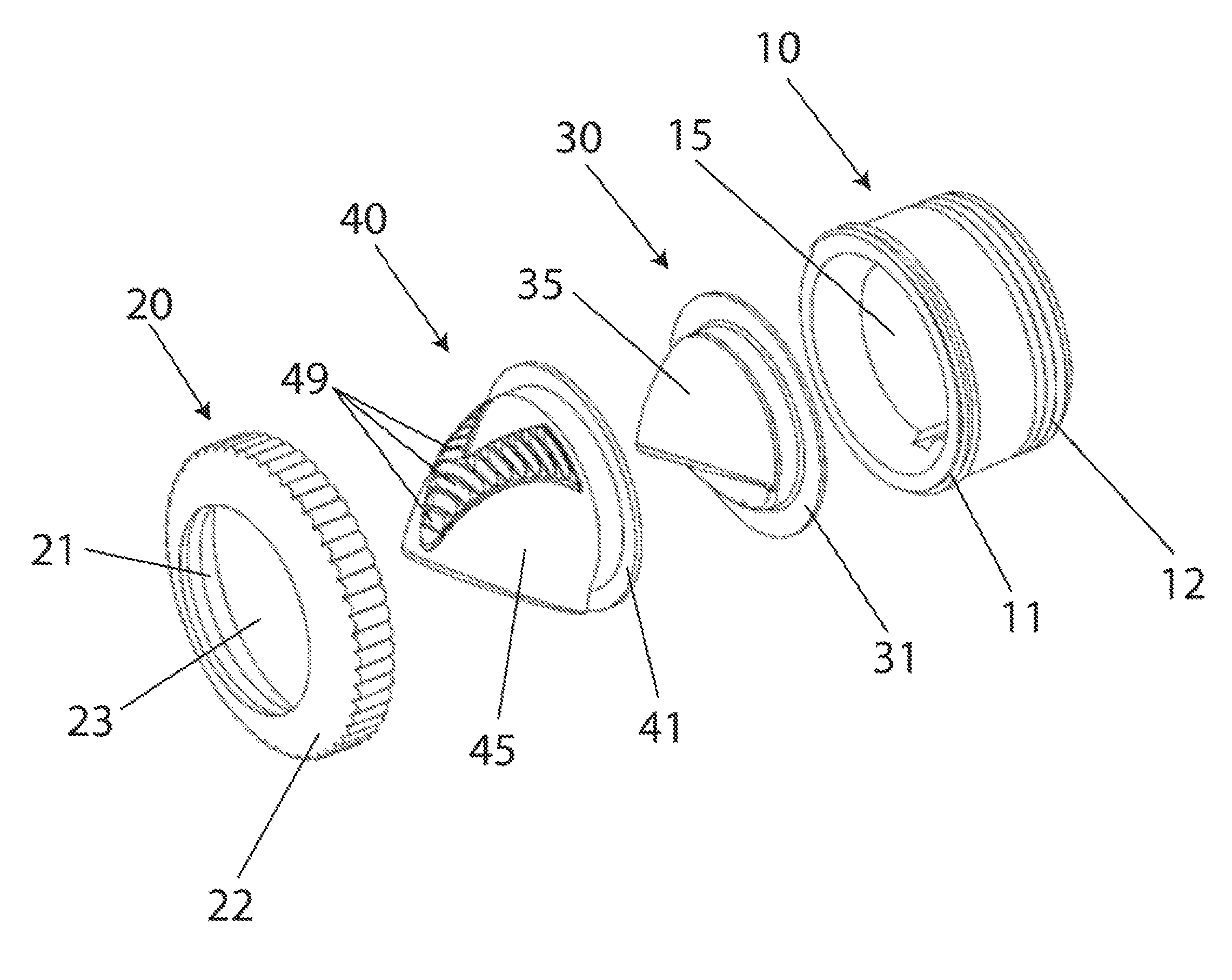

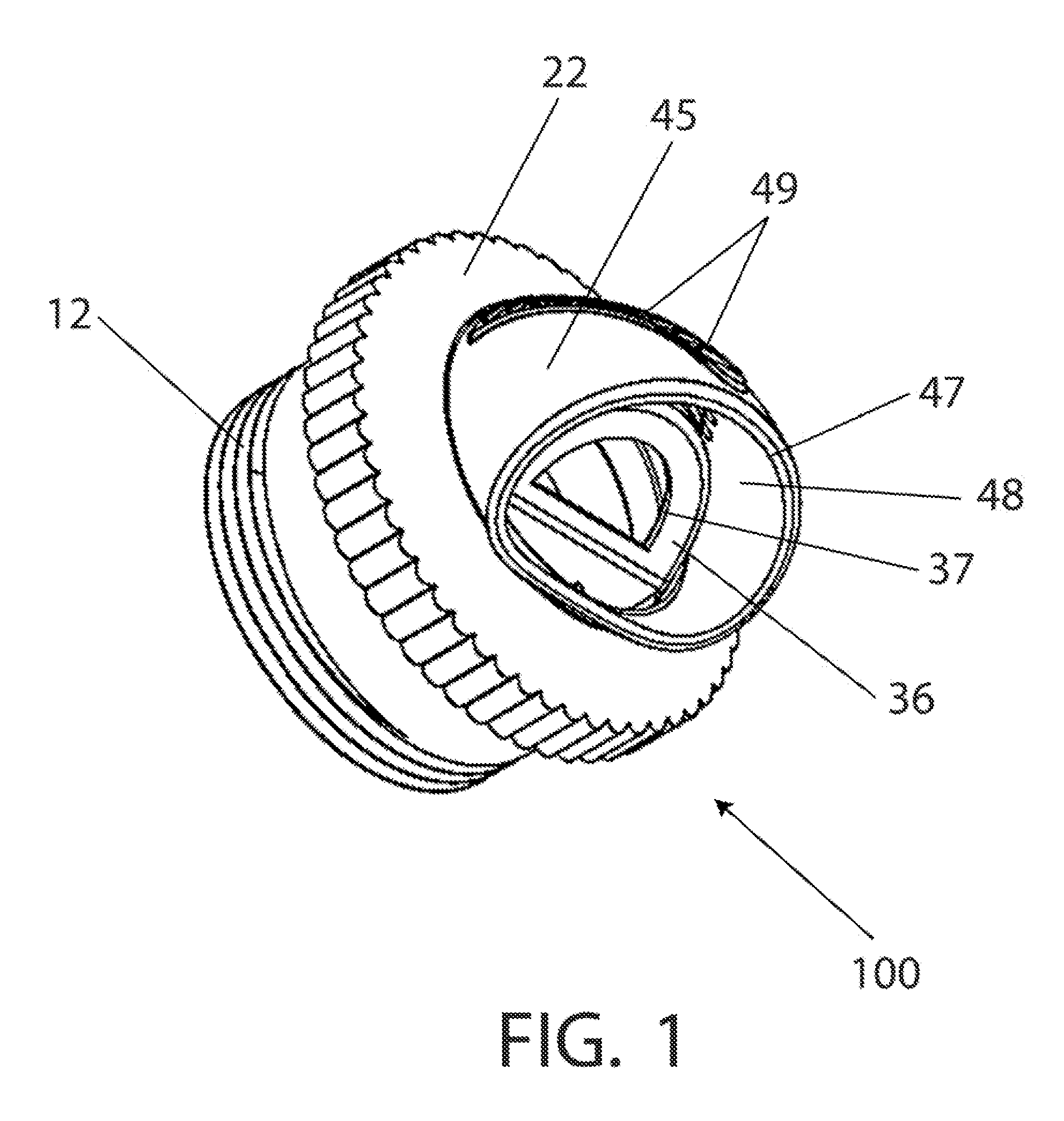

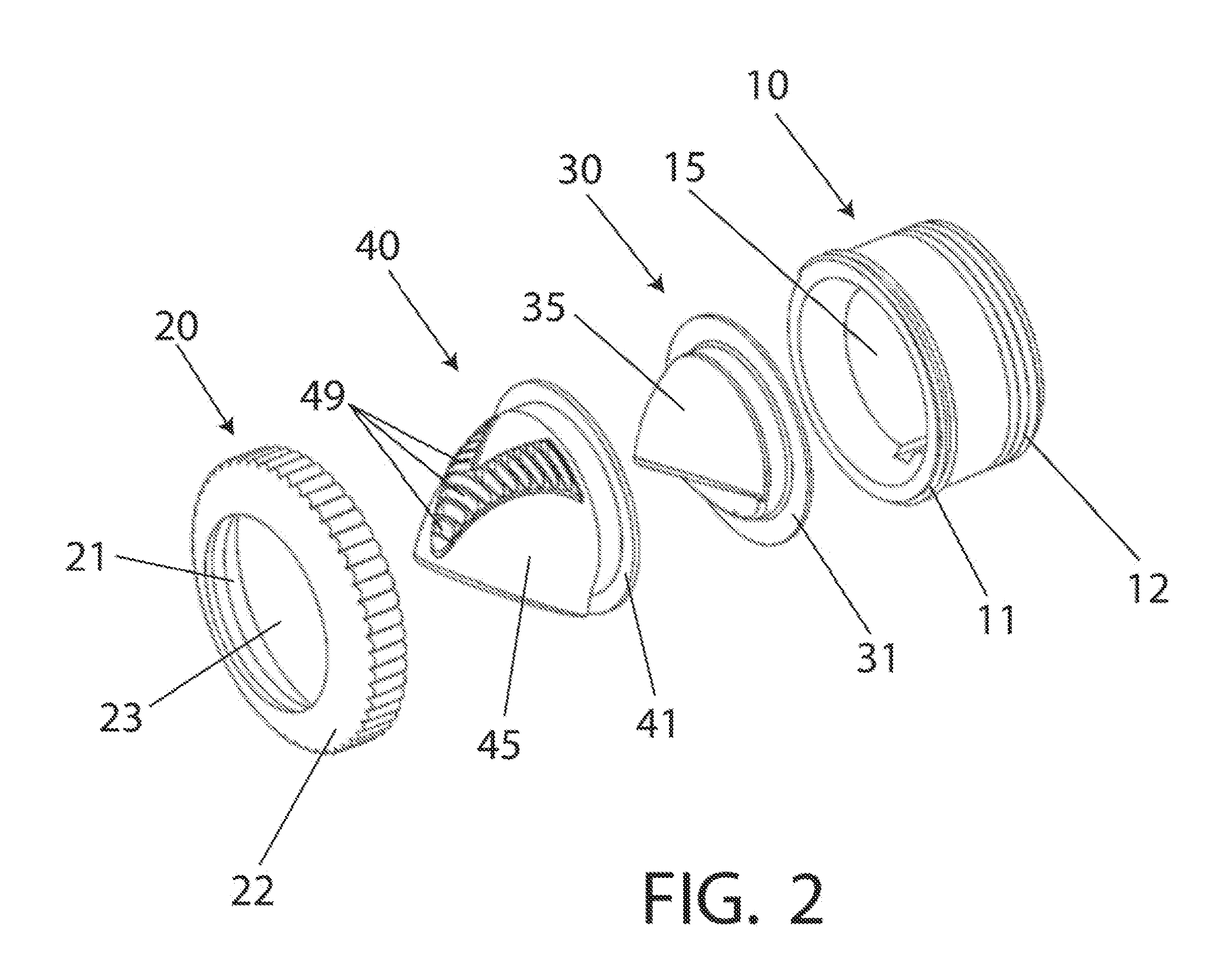

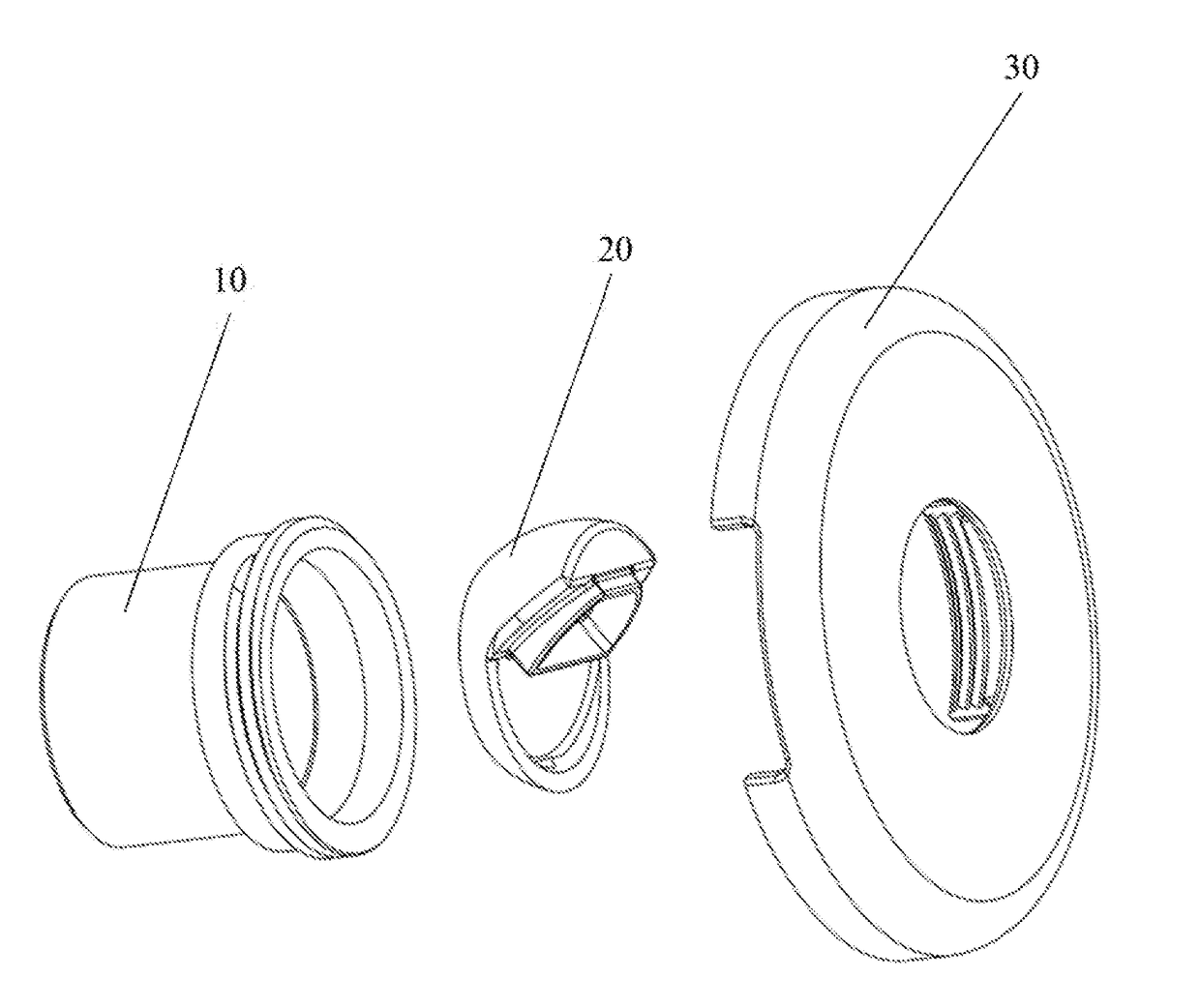

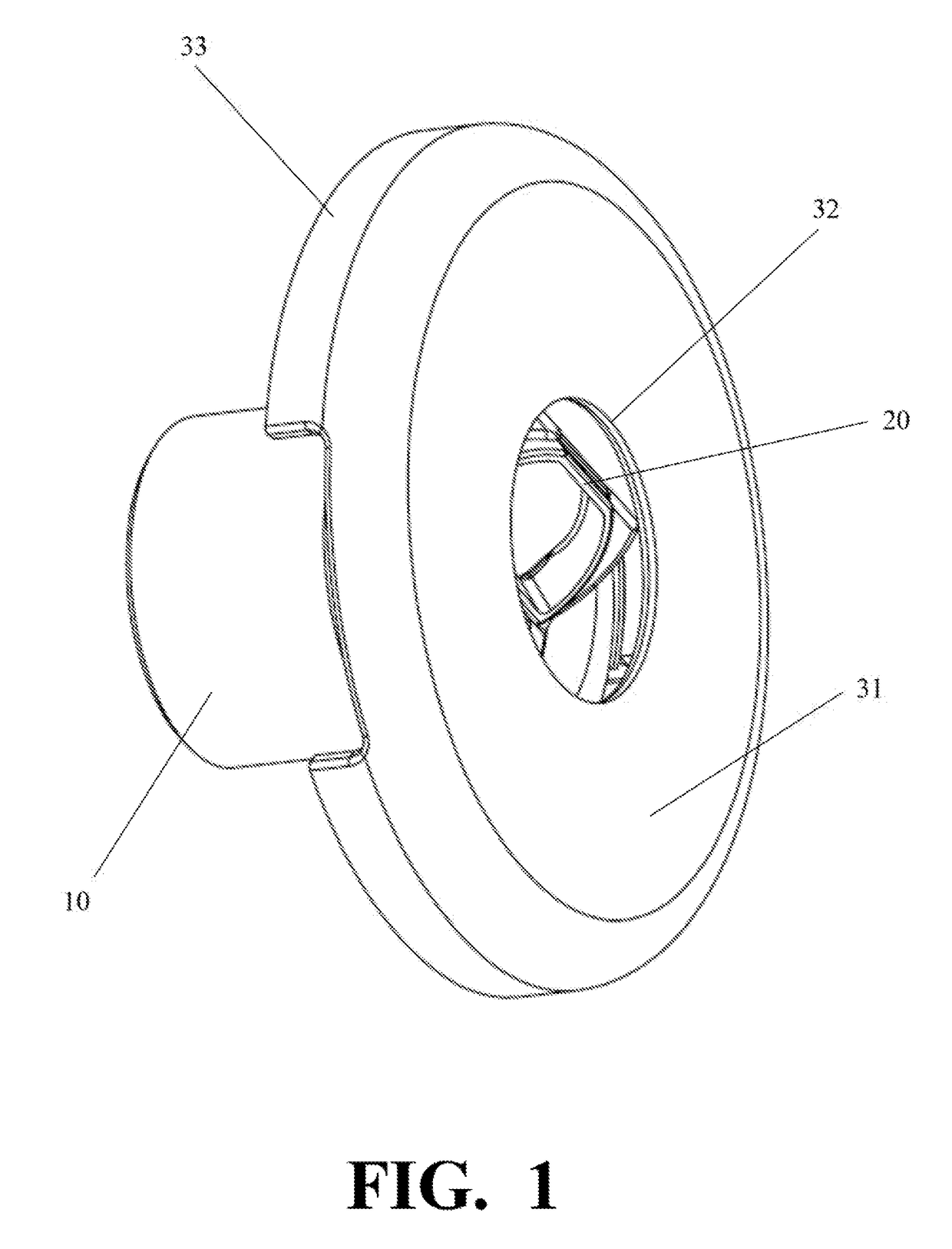

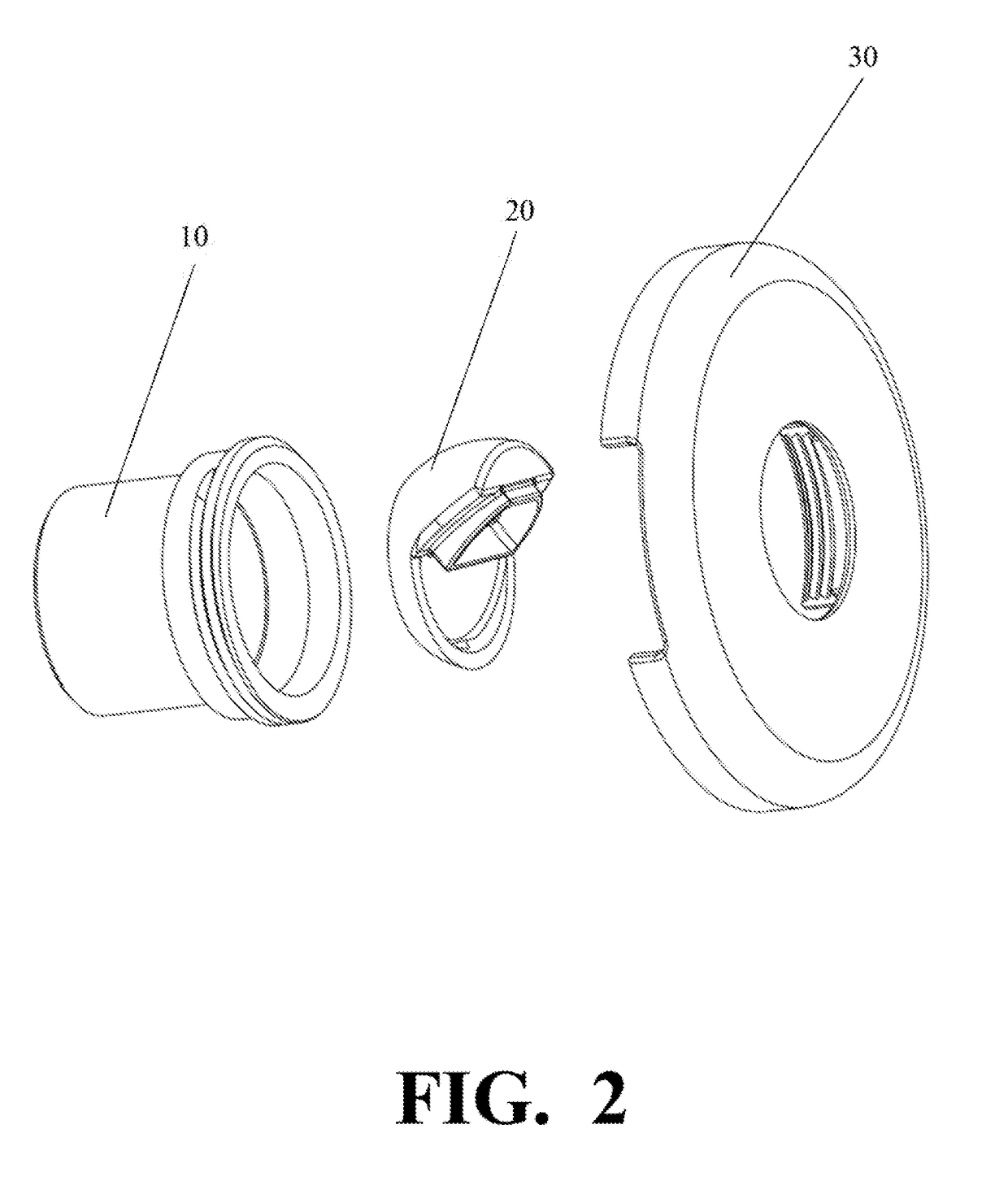

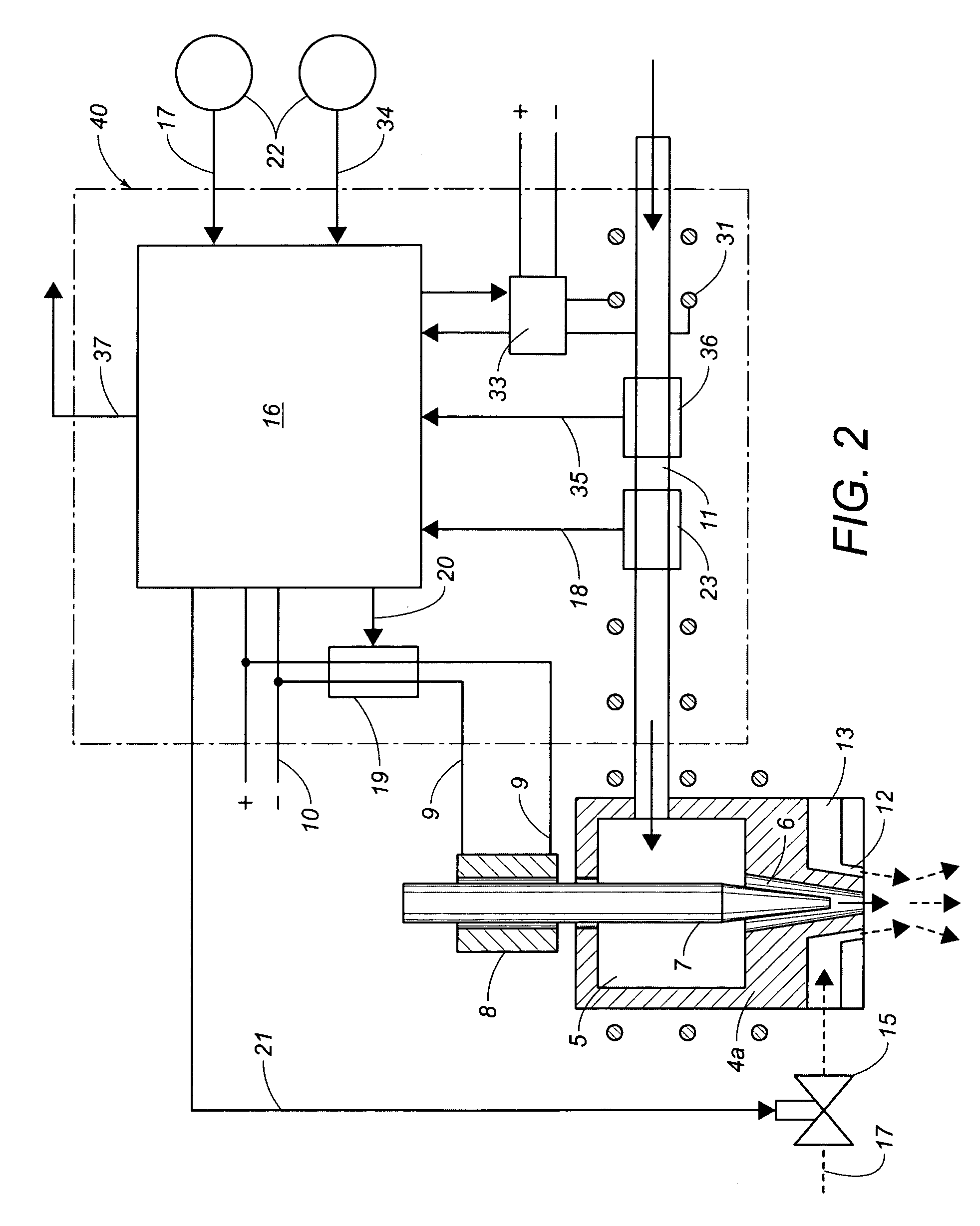

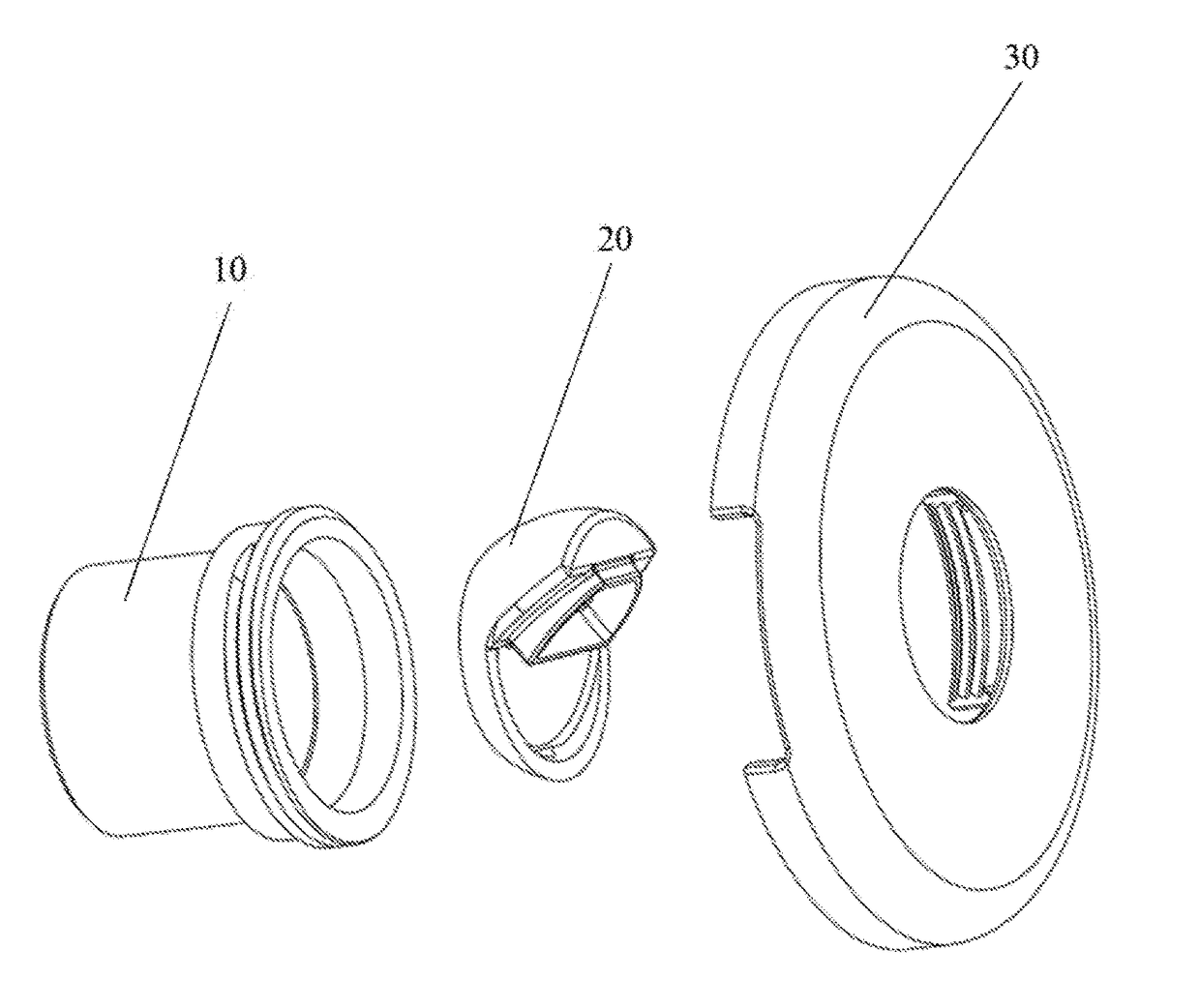

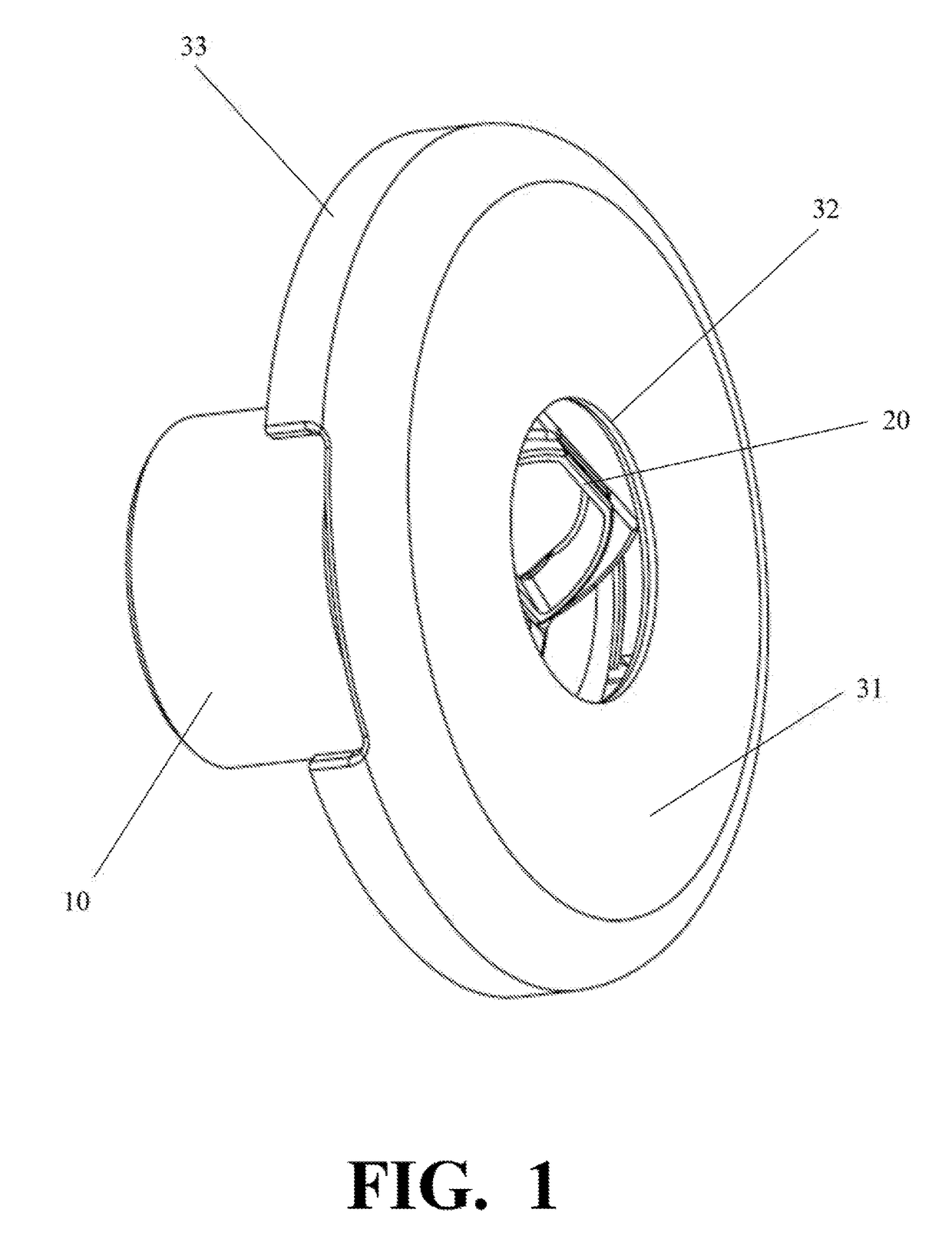

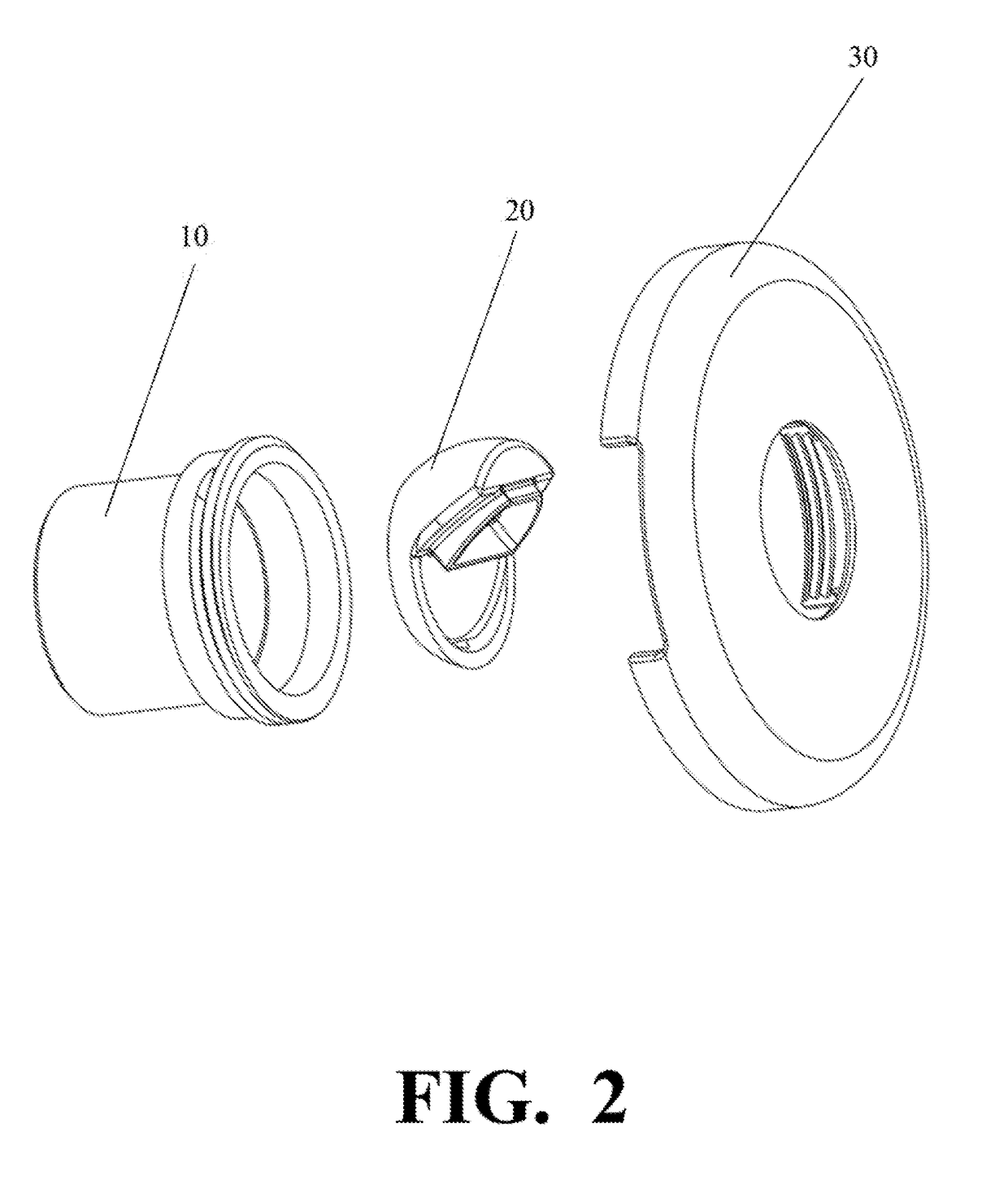

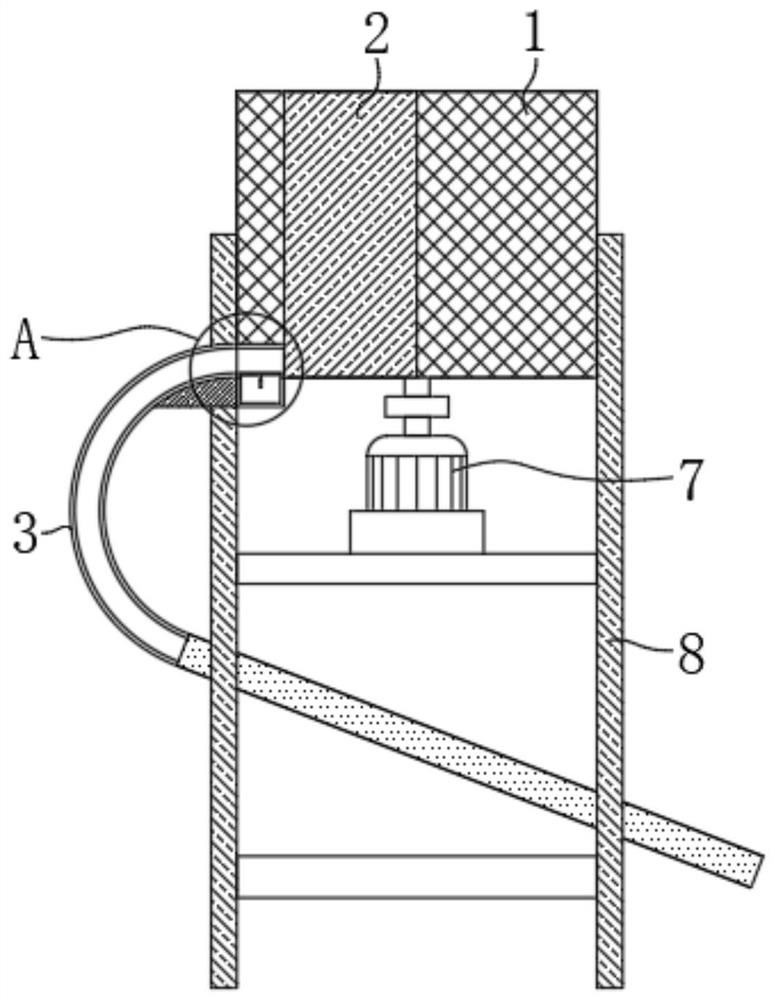

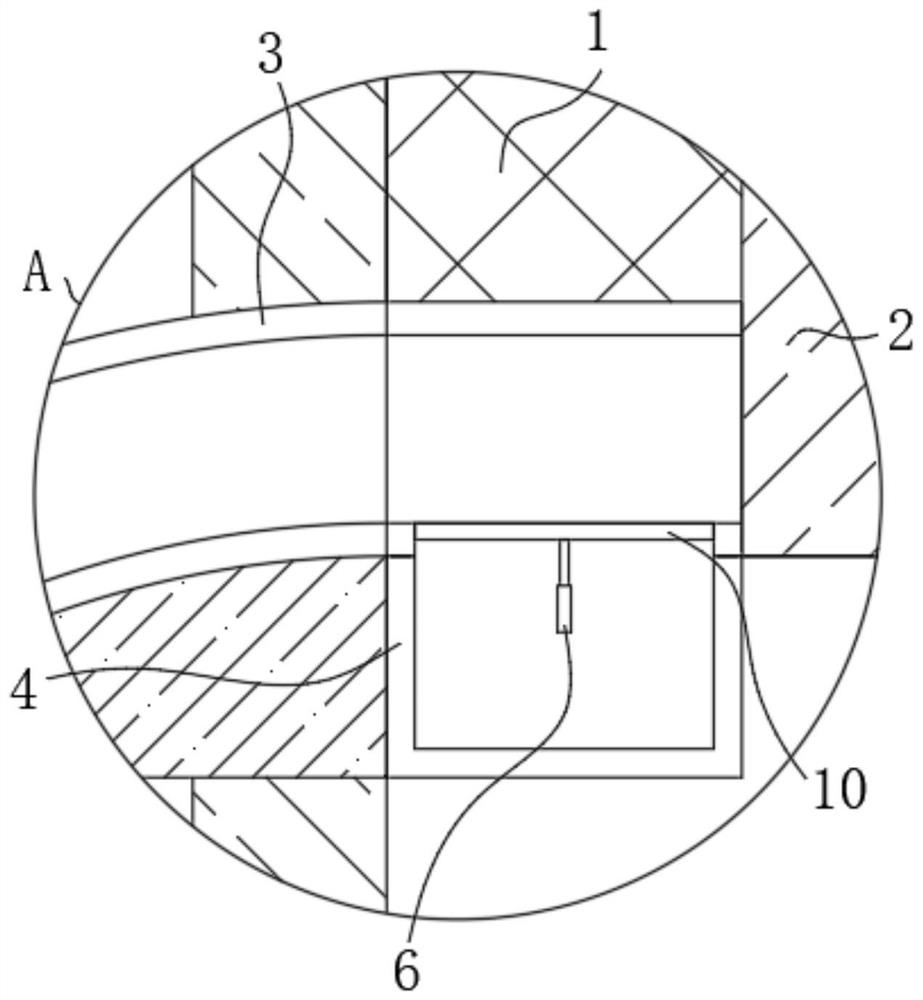

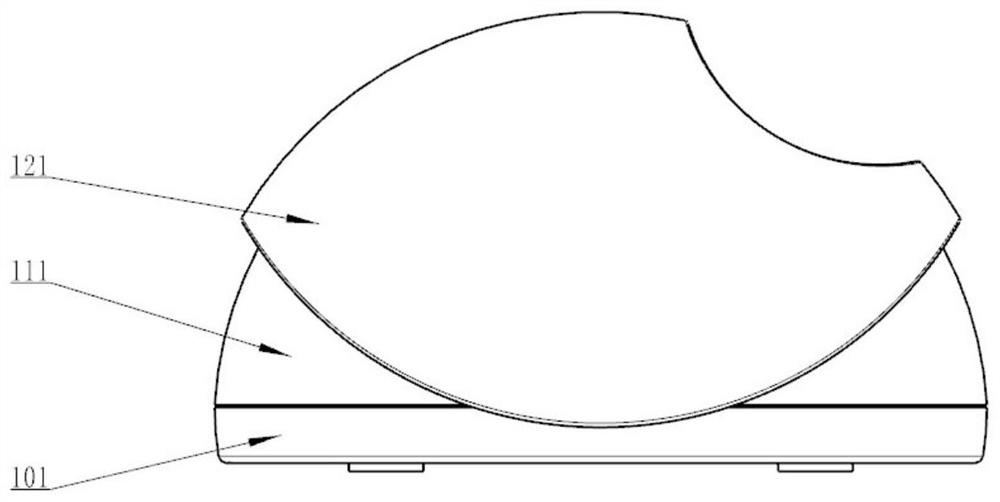

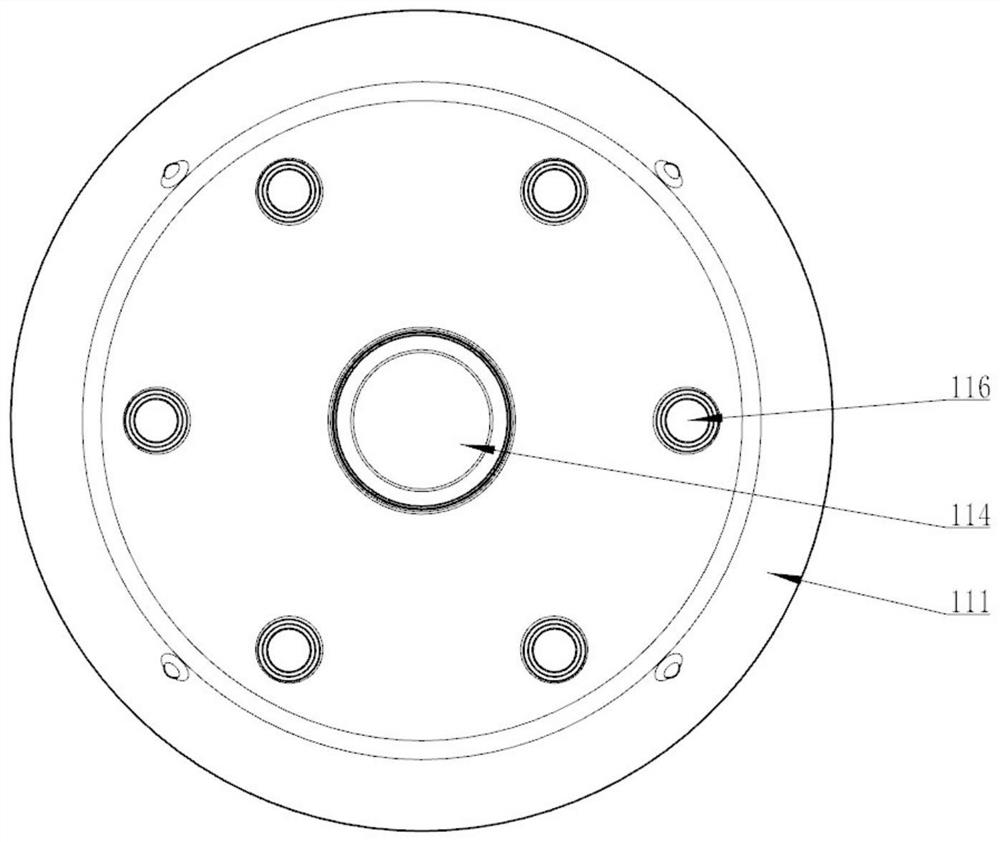

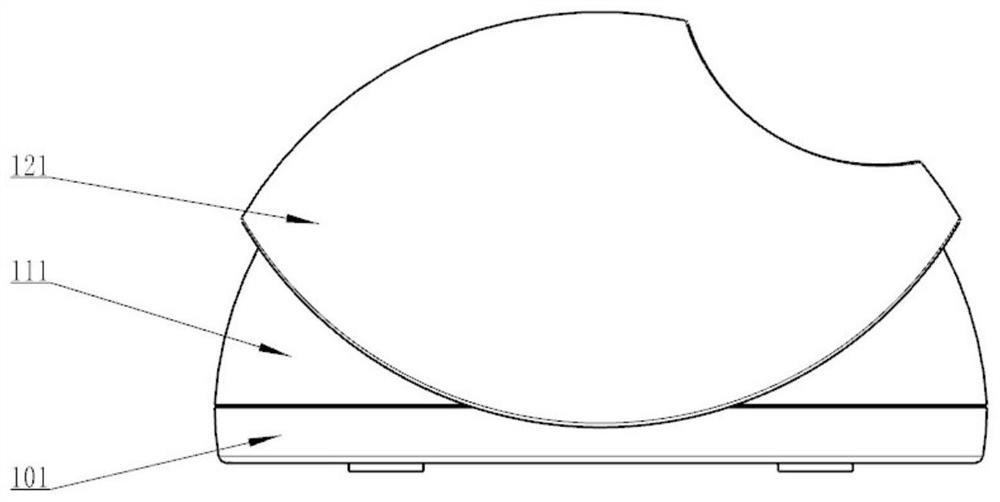

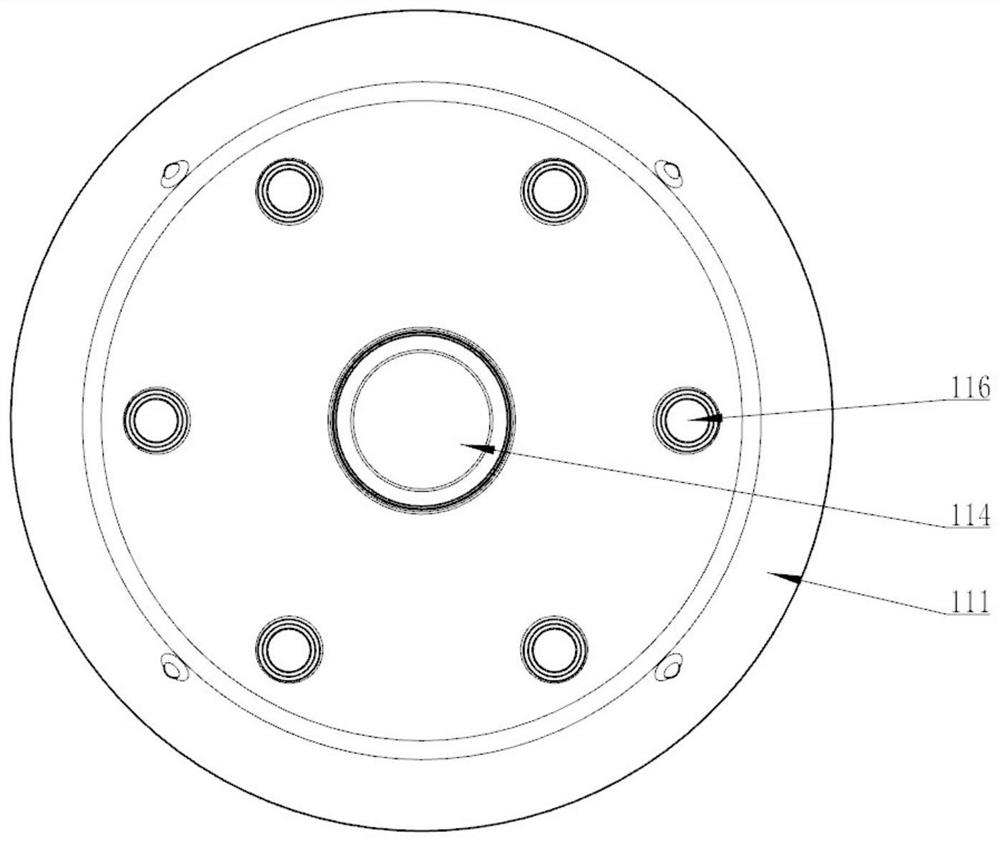

The high flow water return fitting of the present invention is designed to connect directly to the end of a water return pipe in a swimming pool, spa, or the like. Water return fittings have been available for many years and have the primary purpose of returning filtered water back into a swimming pool, spa, or the like. However, the water return fitting of the present invention does not only return water into the swimming pool, it also substantially increases the water outflow so that a greater area of water in the pool can be circulated or agitated. The present invention has a uniquely curved nozzle with a flat flange. Both the curvature of the nozzle and the flat flange promote the accumulation of water within the nozzle so as to build up pressure that then pushes the water out a small outlet hole at a greater rate than does a conventional water return fitting. The outflow from the nozzle then creates a low pressure condition within a mixing chamber. Thus, the low pressure condition draws water in from the swimming pool through various louvers into the mixing chamber where it is mixed with the outflow of water from the nozzle to increase the total amount of water flowing out of the water return fitting of the present invention.

Owner:INFUSION POOL PROD

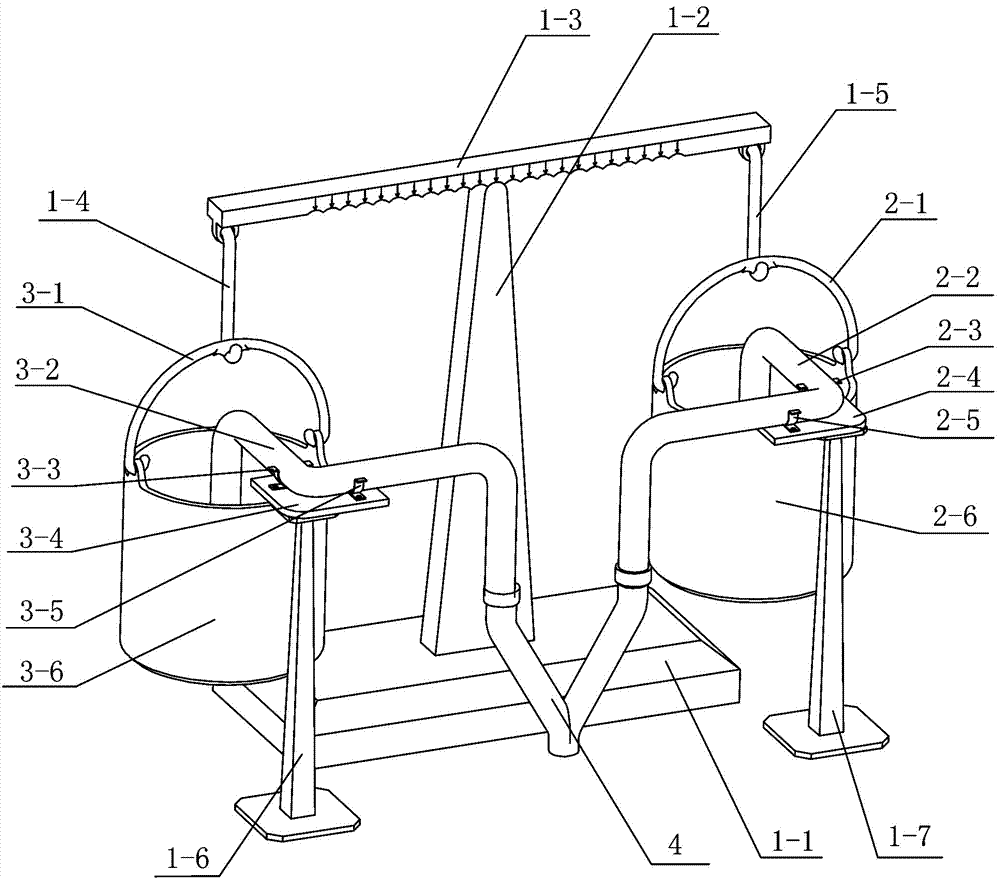

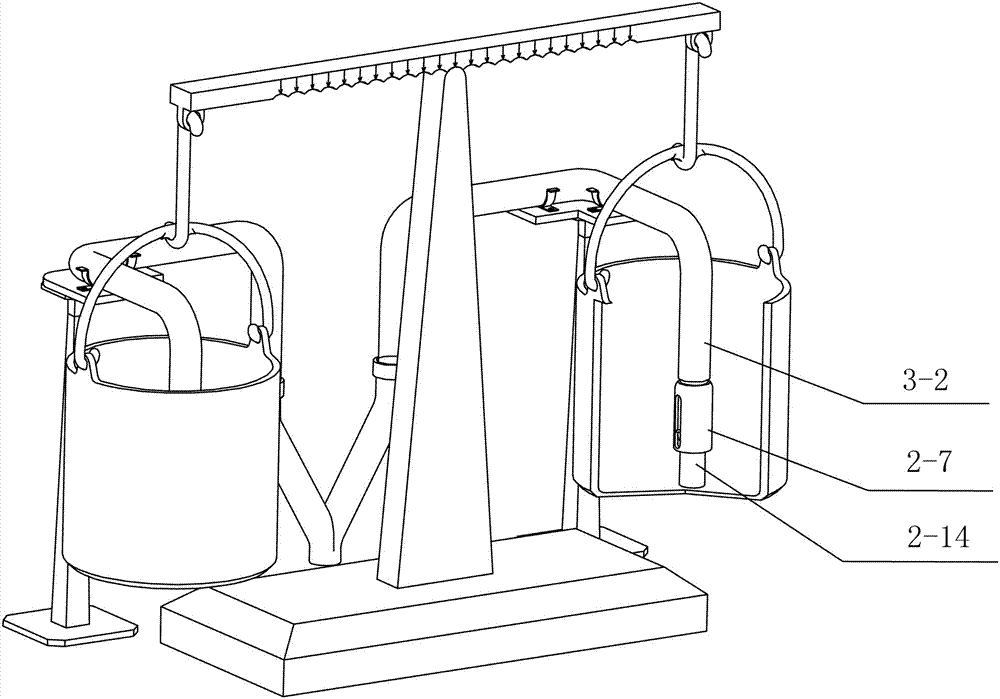

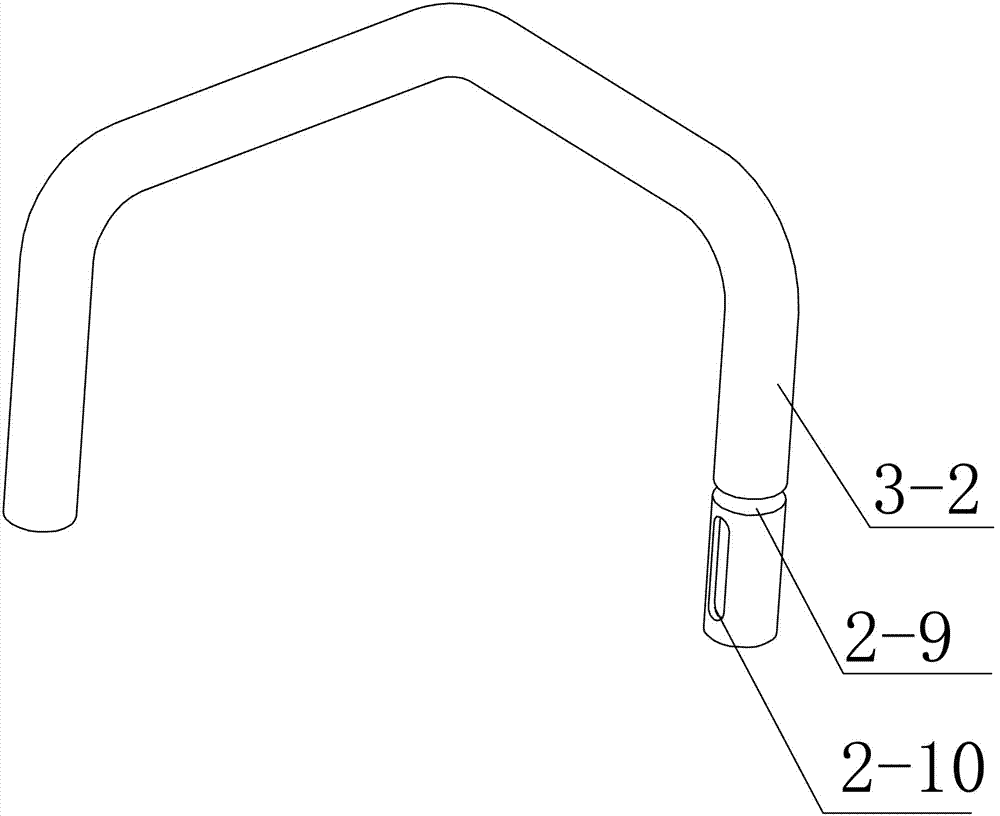

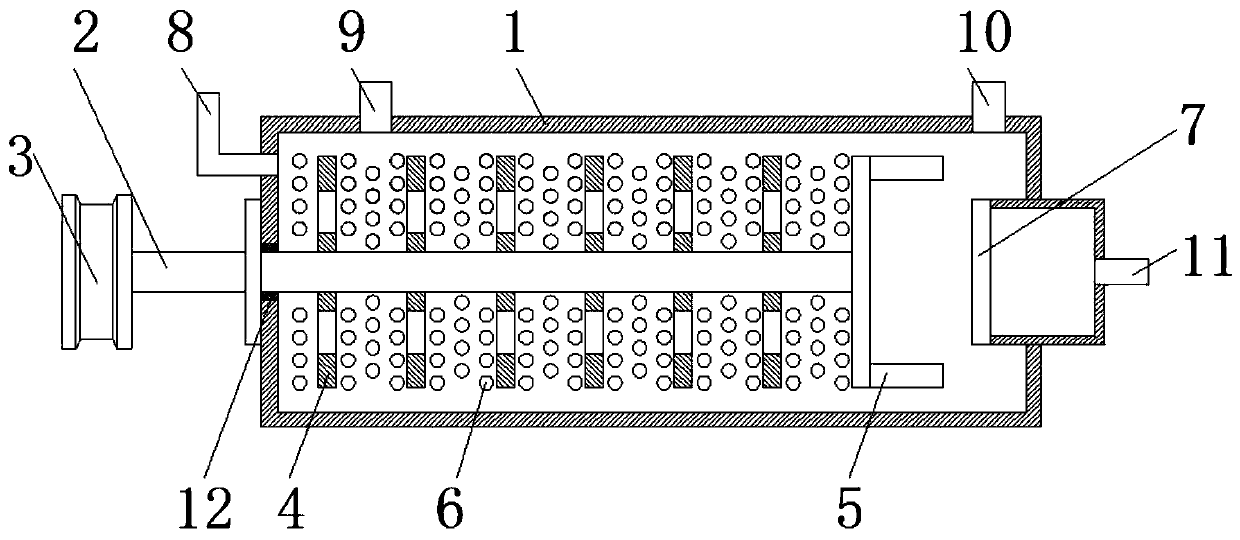

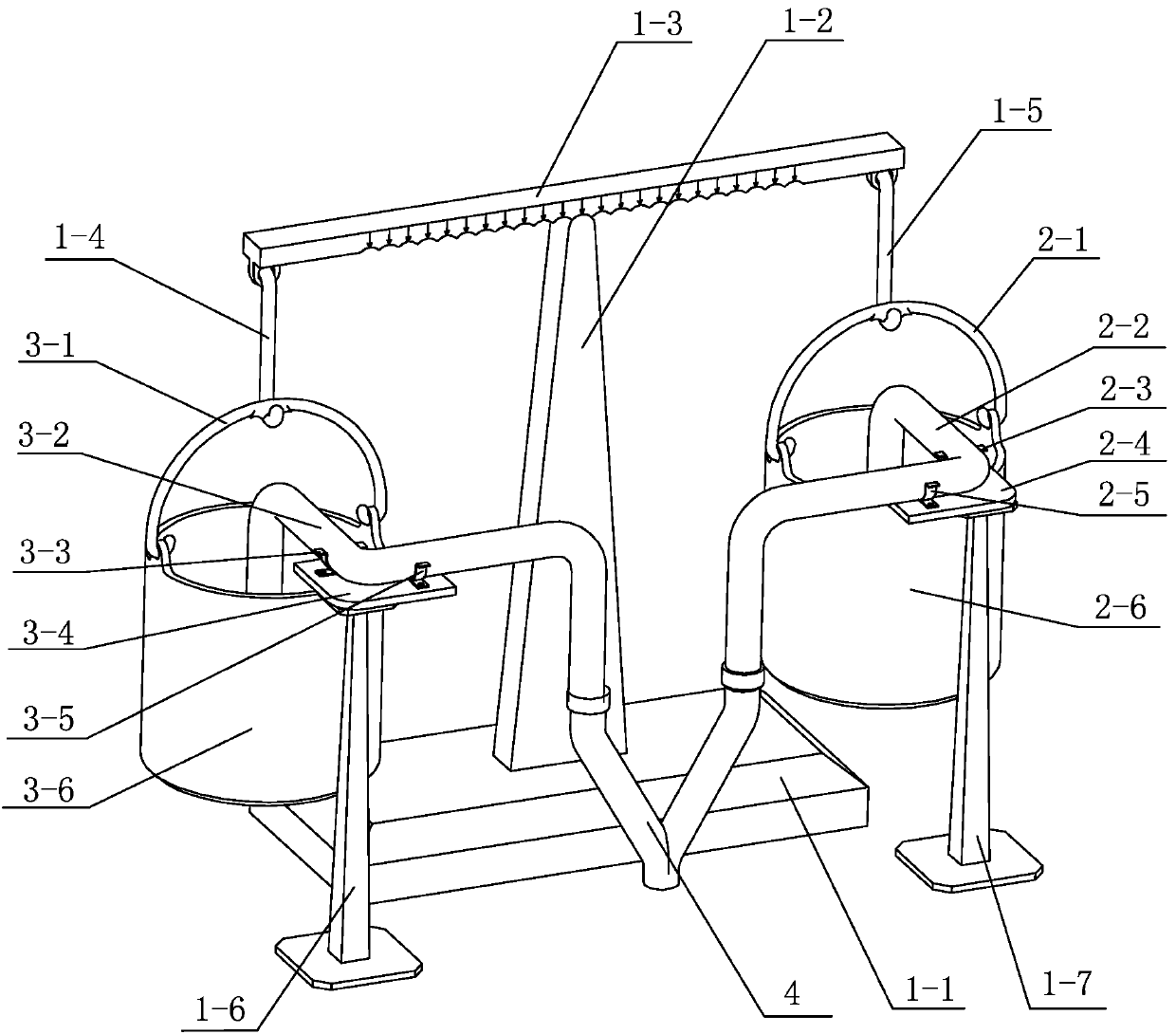

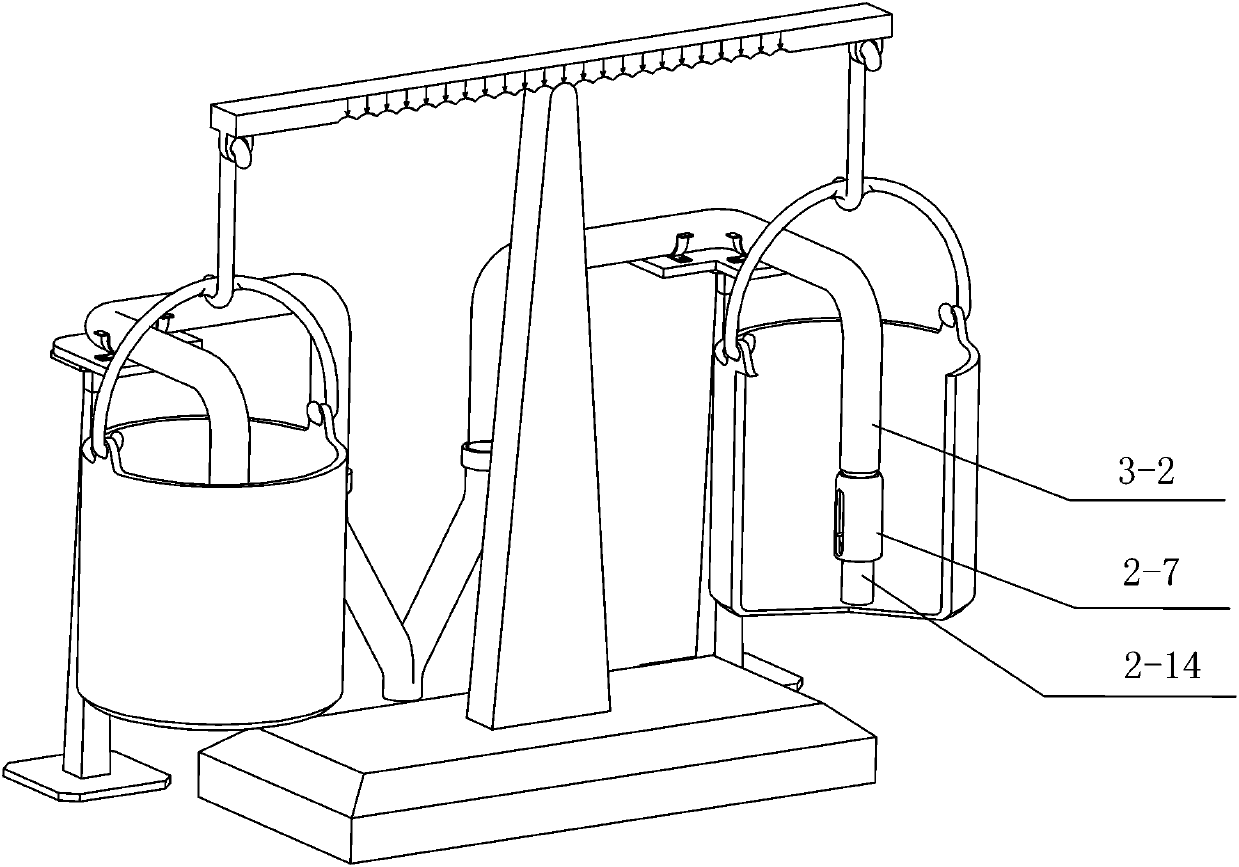

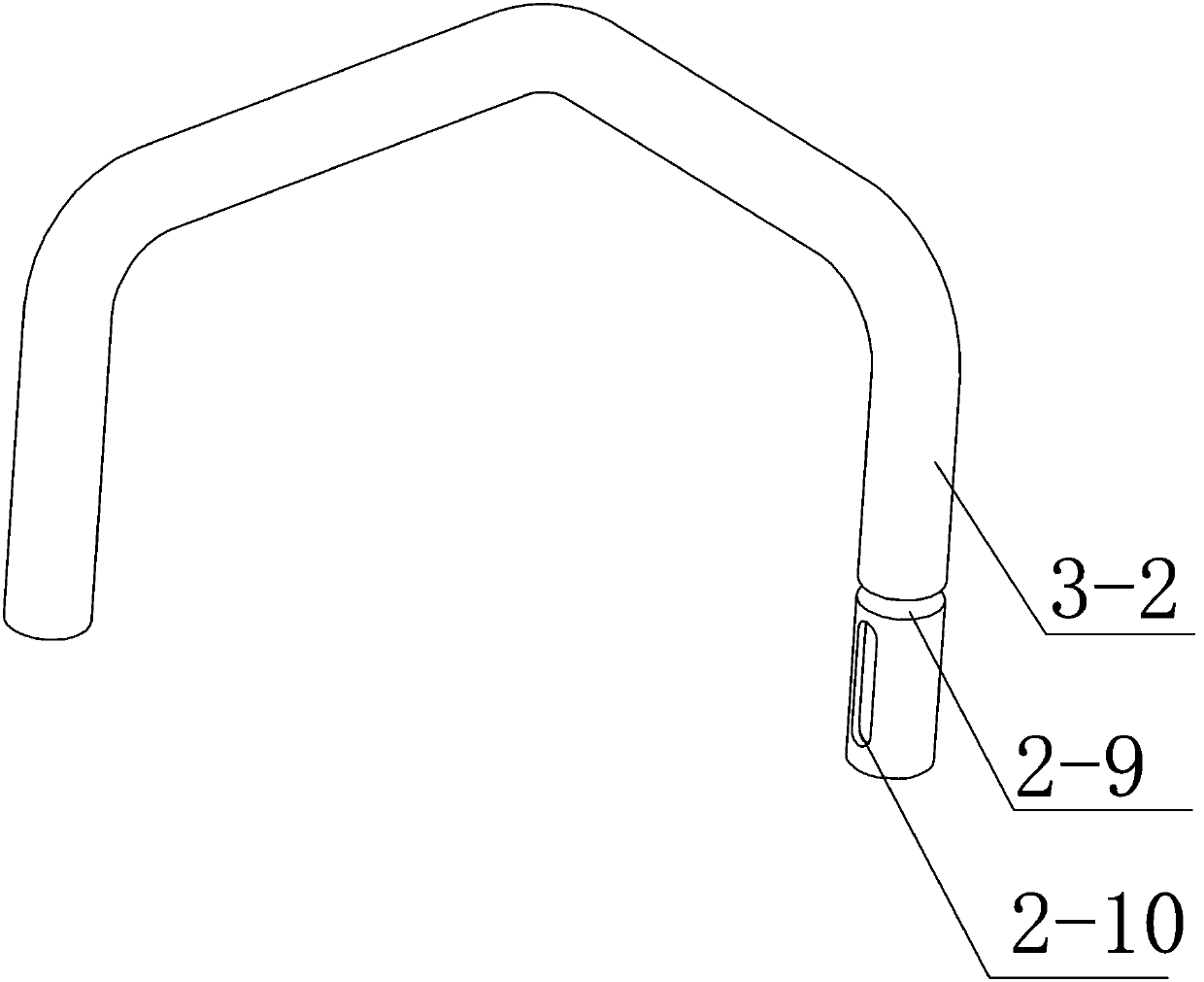

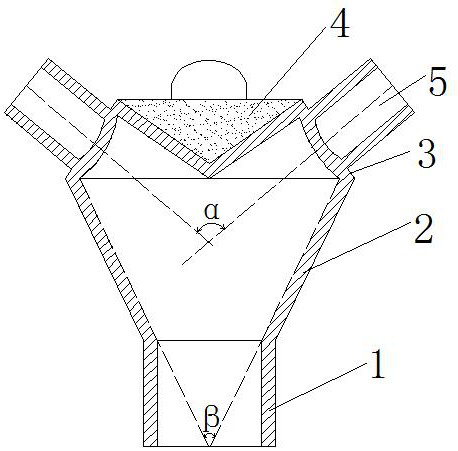

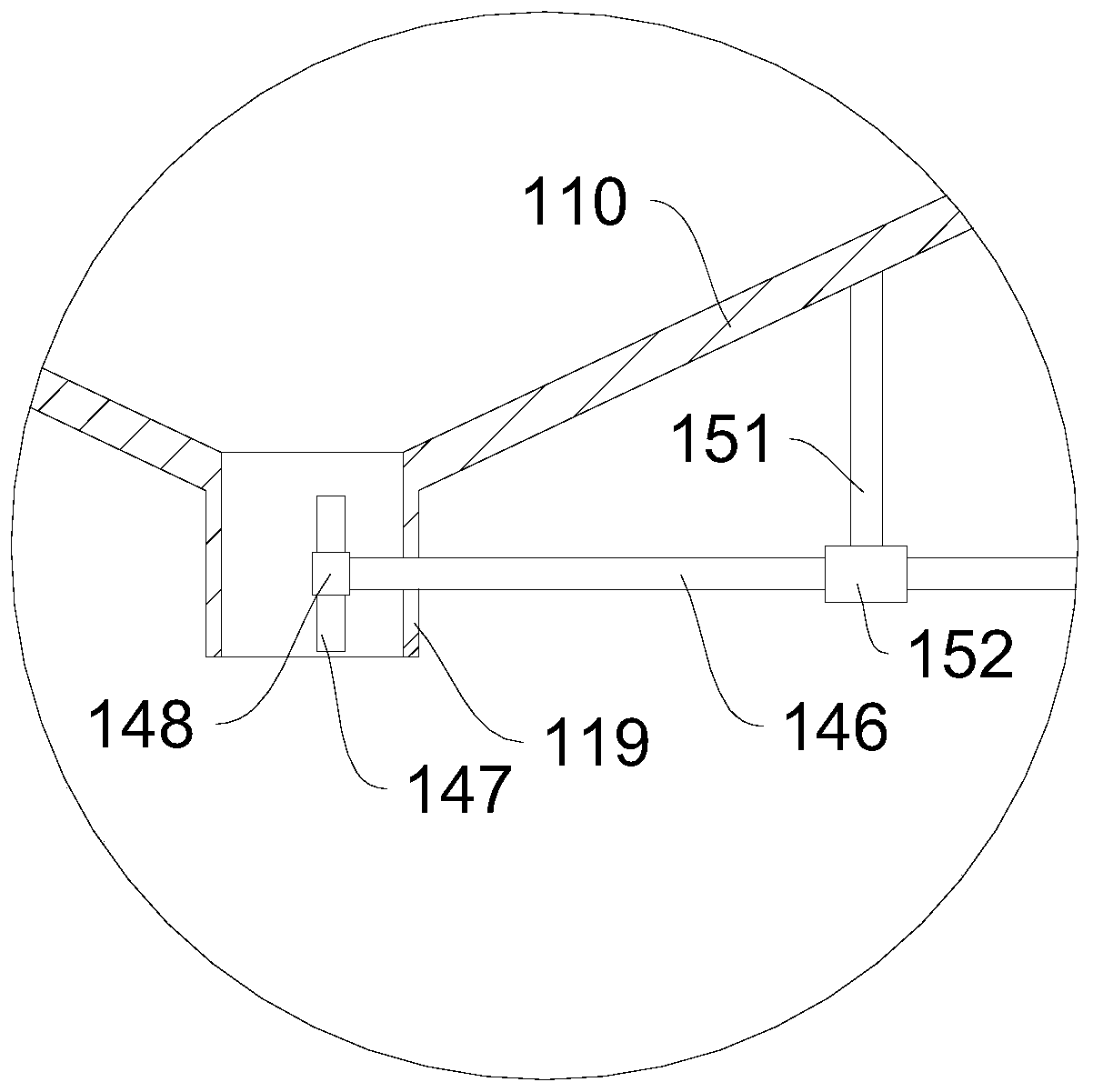

Balance type apparatus for mixing two liquids according to arbitrary ratio, and operating method thereof

ActiveCN106853345ASmall outflow rateIncrease outflow rateFlow mixersTransportation and packagingBucket HandleEngineering

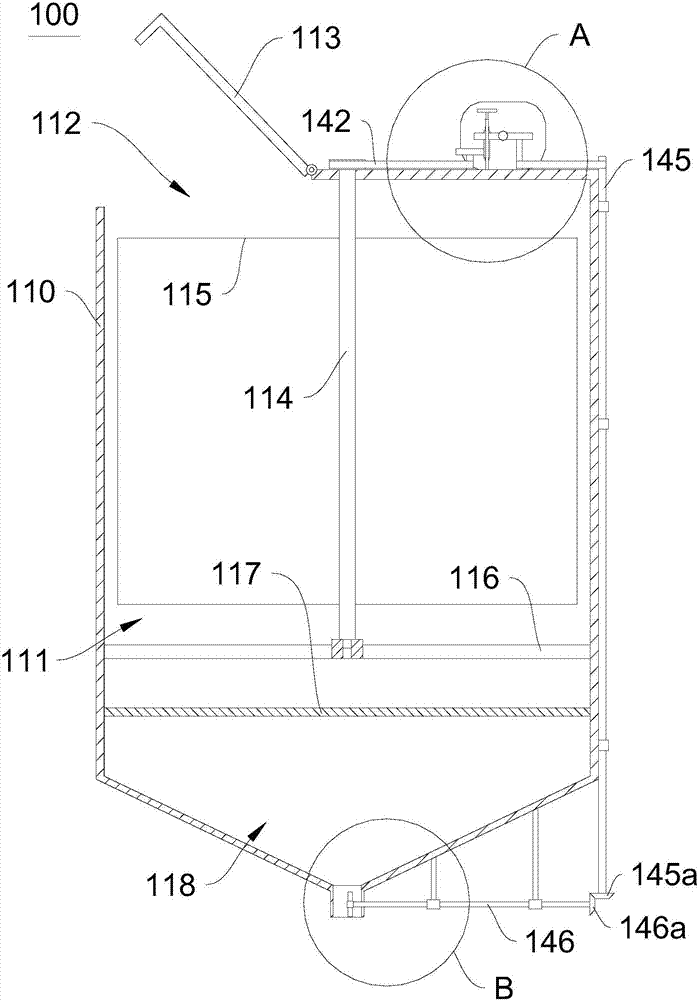

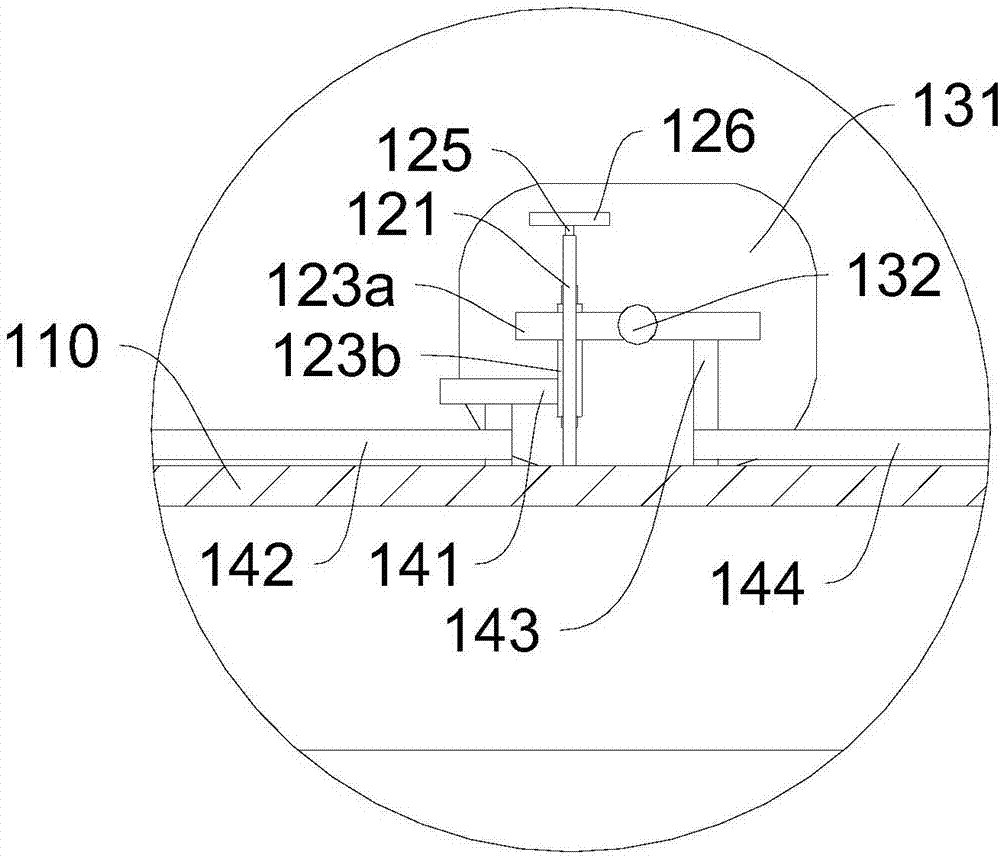

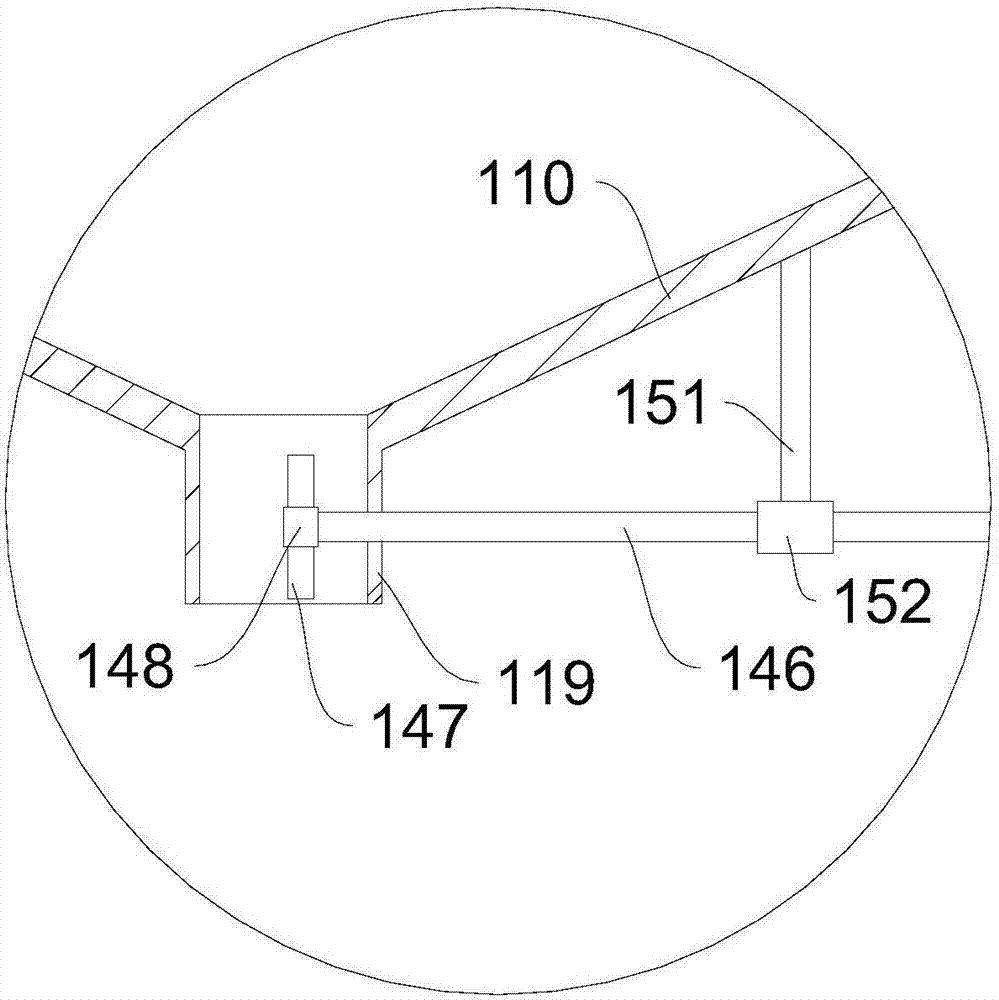

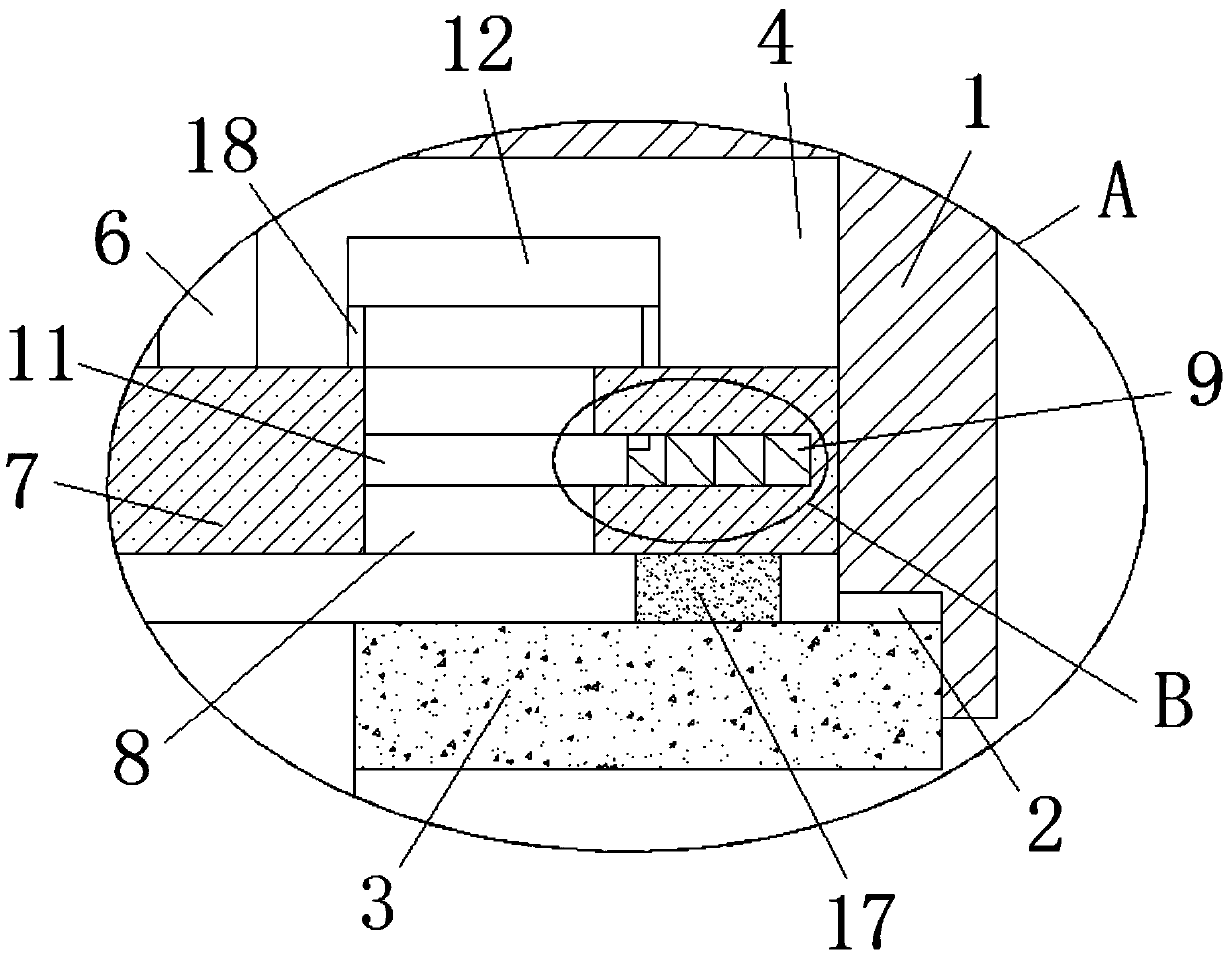

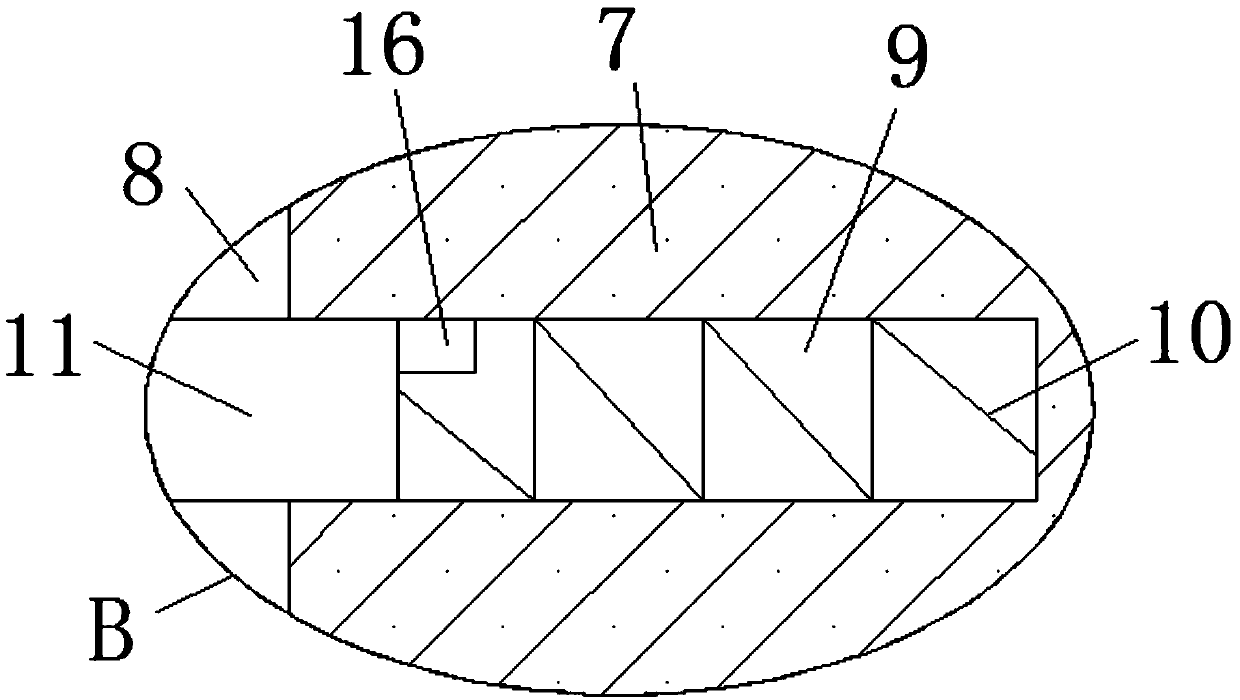

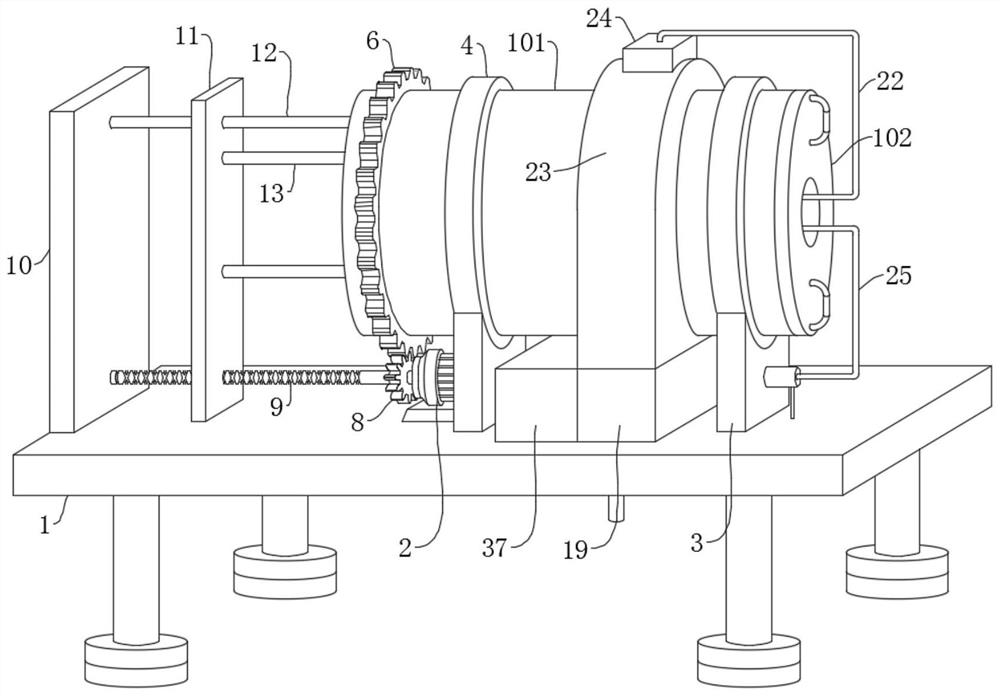

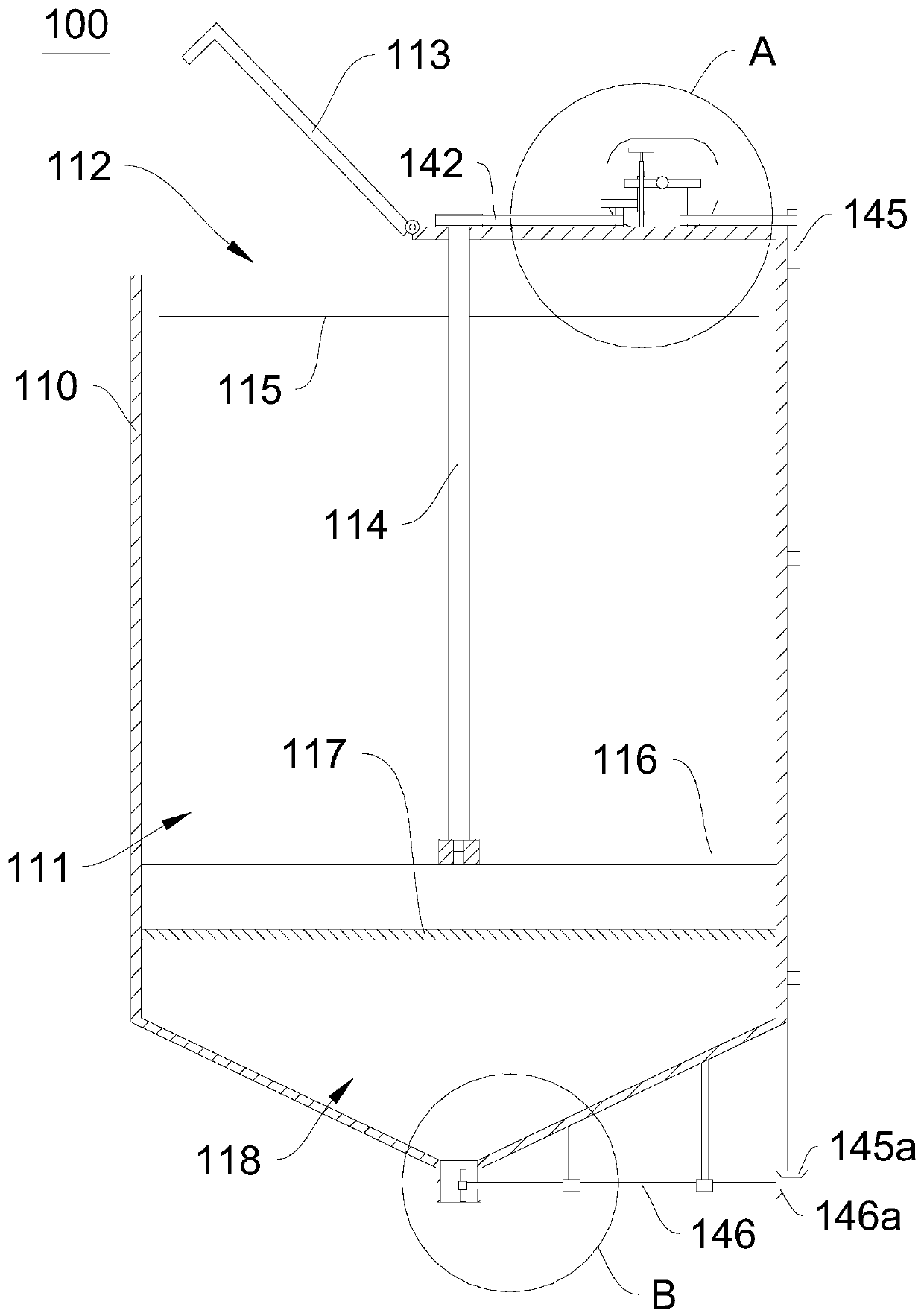

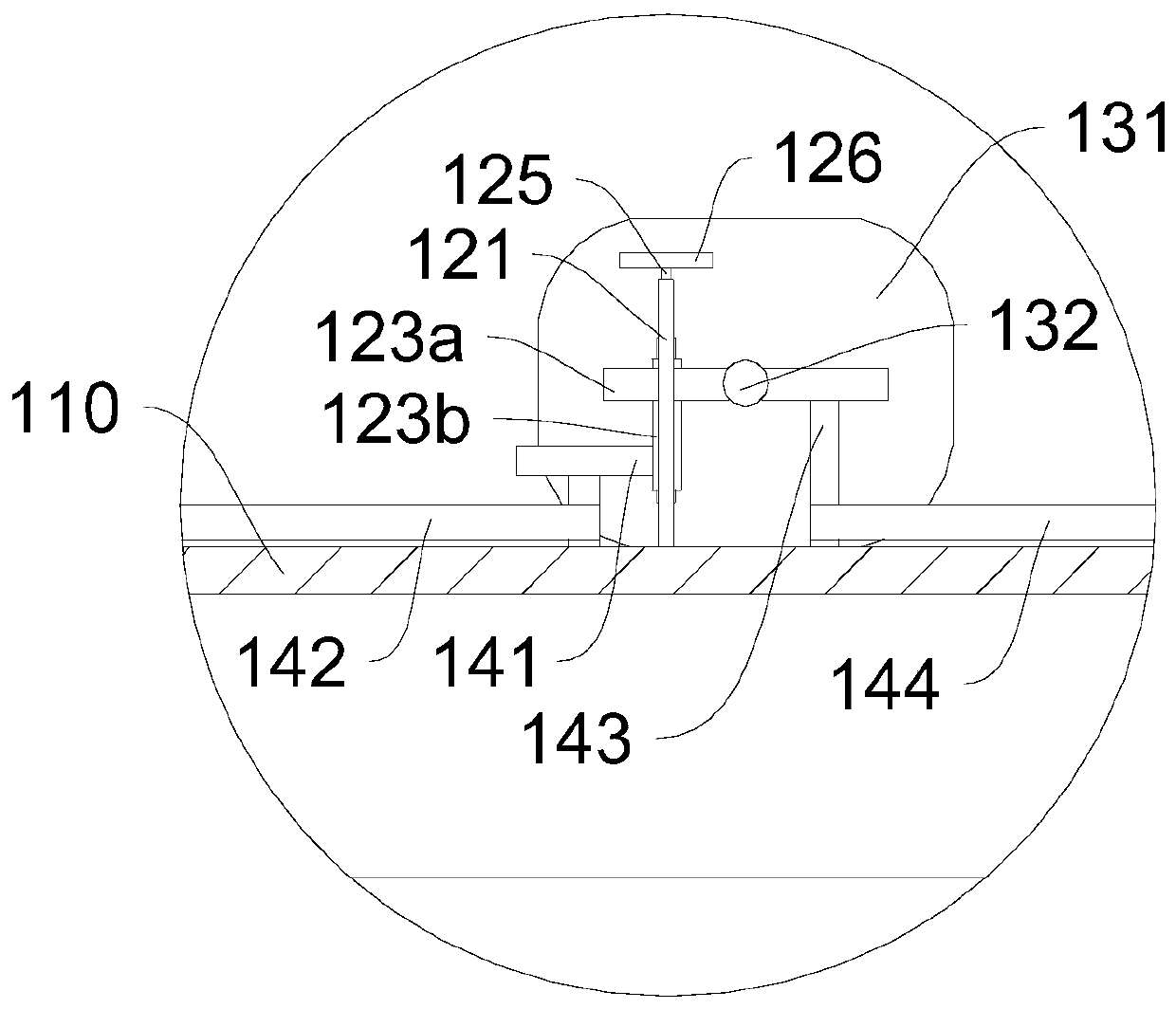

The invention relates to a balance type apparatus for mixing two liquids according to an arbitrary ratio, and an operating method thereof. The apparatus comprises a pedestal, a support is fixed at the top of the pedestal, a crossbeam is supported on the top of the support, a first hook and a second hook are respectively hinged to two ends of the crossbeam, a first liquid storage cylinder hangs on the first hook through a first bucket handle, a second liquid storage cylinder hangs on the second hook through a second bucket handle, an A liquid guiding tube is arranged in the first liquid storage cylinder, a B liquid guiding tube is arranged in the second liquid storage cylinder, and the A liquid guiding tube and the B liquid guiding tube are connected with two liquid outlets of a three-way piece. When the flow-out proportions of the two liquids are imbalanced, a balance tips and drive solid slide blocks in a two-flow regulator at the bottom of the guiding tubes to change the sizes of the liquid outlets in order to afresh reach balance. The apparatus has a simple structure, is convenient for a worker to operate, allows liquids to stably flow out in proportion in real time, and realizes mixing of the liquids according to an arbitrary ratio.

Owner:CHINA THREE GORGES UNIV

High flow water return fitting for swimming pools and spas

ActiveUS8905625B2Increase outflowIncrease outflow rateFlow mixersTransportation and packagingWater flowEngineering

Owner:INFUSION POOL PROD

High flow water return fitting for swimming pools and spas

The high flow water return filling of the present invention is designed to connect directly to the end of a water return pipe in a swimming pool, spa, or the like. Water return fittings have been available for many years and have the primary purpose of returning filtered water back into a swimming pool, spa, or the like. However, the water return fitting of the present invention does not only return water into the swimming pool, it also substantially increases the water outflow so that a greater area of water in the pool can be circulated or agitated. In addition, the present invention has a uniquely curved nozzle that does not extend past the face plate, thus, the nozzle does not extend more than one inch from the swimming pool wall. The outflow from the nozzle creates a low pressure condition within the face plate. Thus, the low pressure condition draws water in from the swimming pool through various gaps into the face plate where it is mixed with the outflow of water from the nozzle to increase the total amount of water flowing out of the water return fitting of the present invention.

Owner:INFUSION POOL PROD LLC

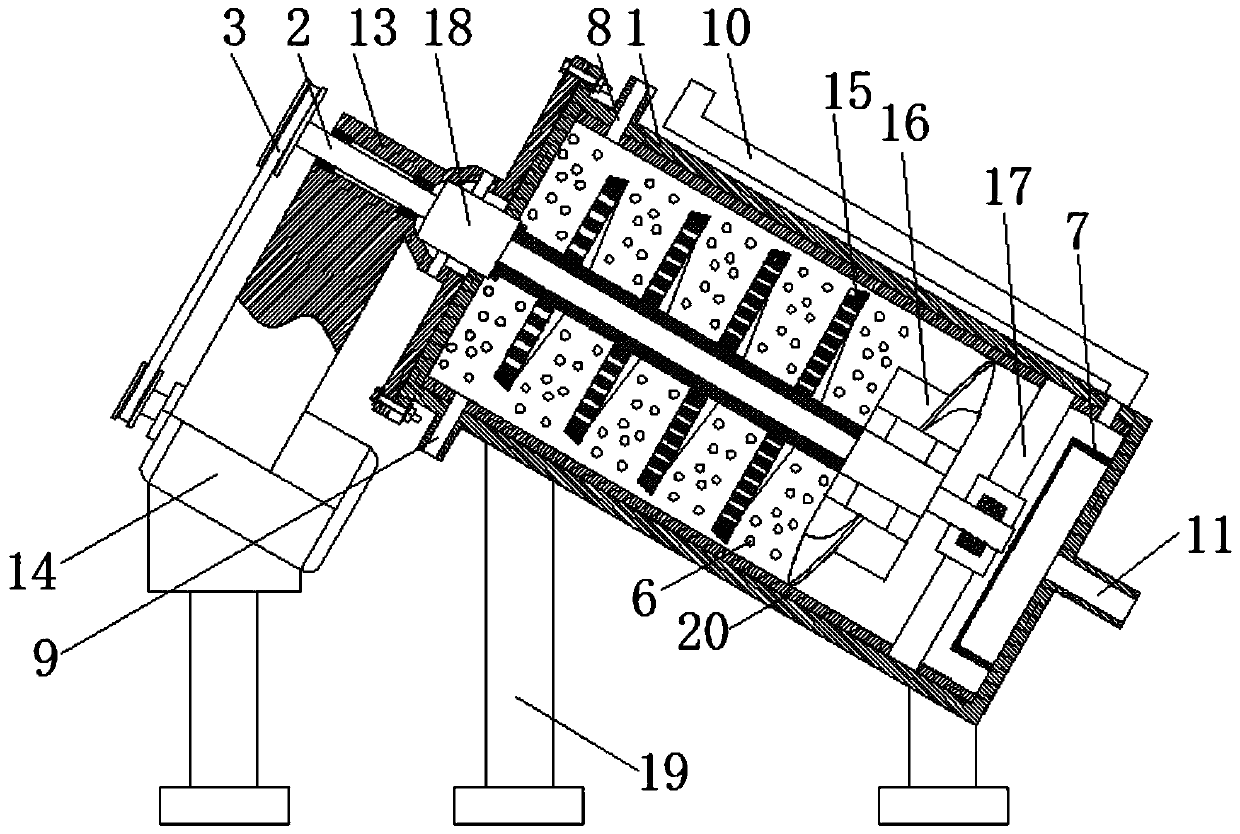

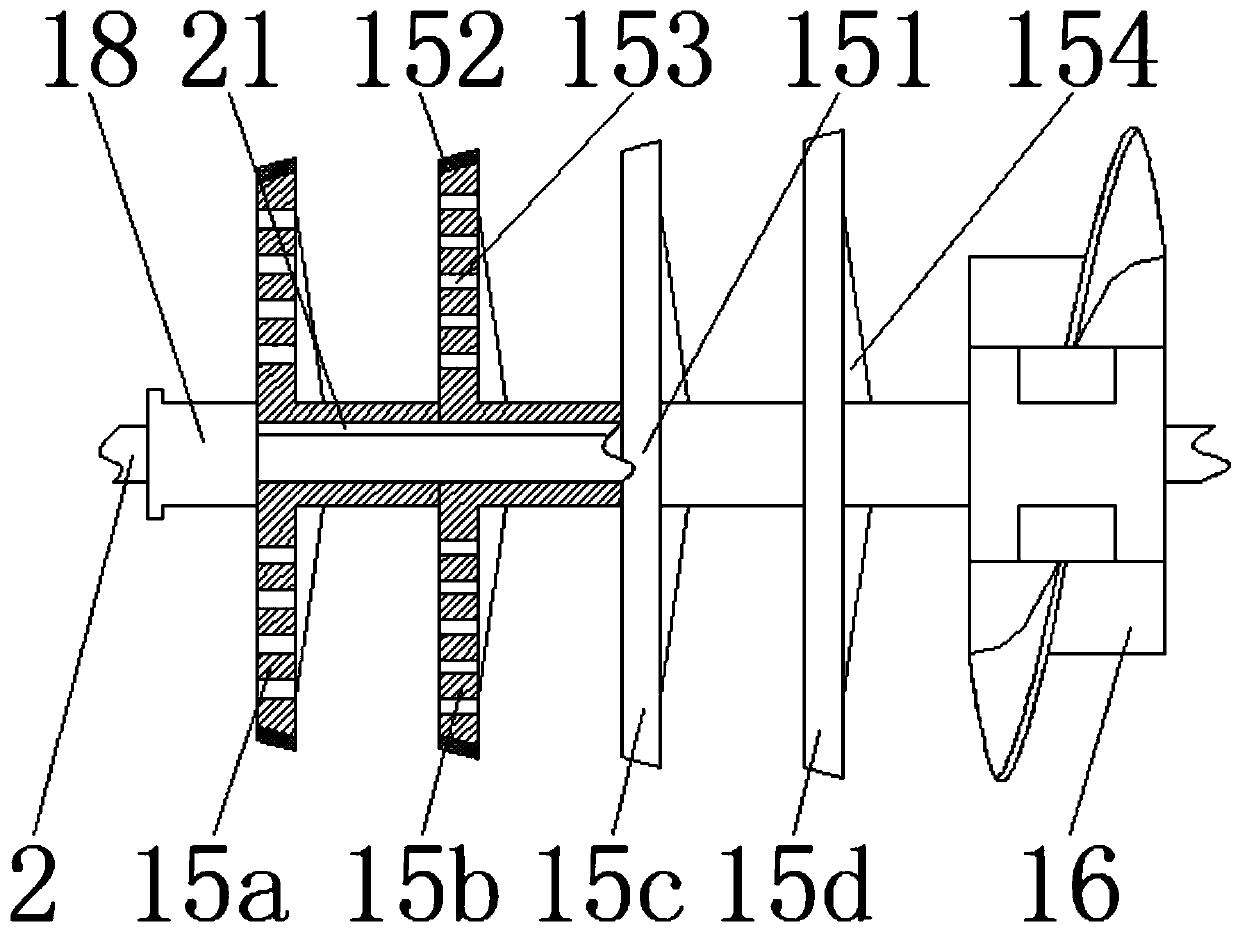

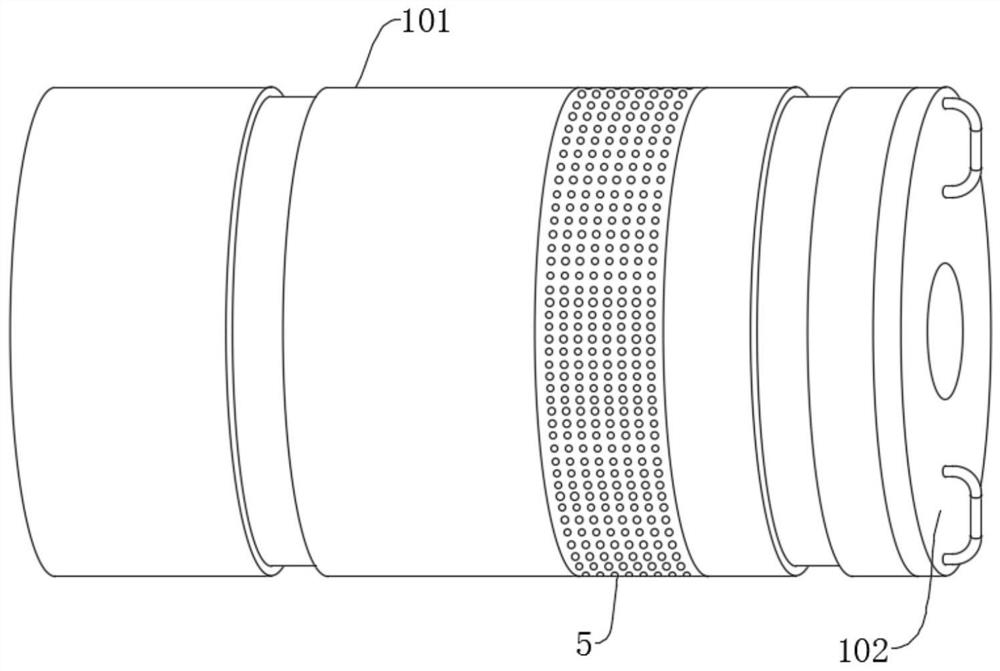

Efficient inclined horizontal grinding machine

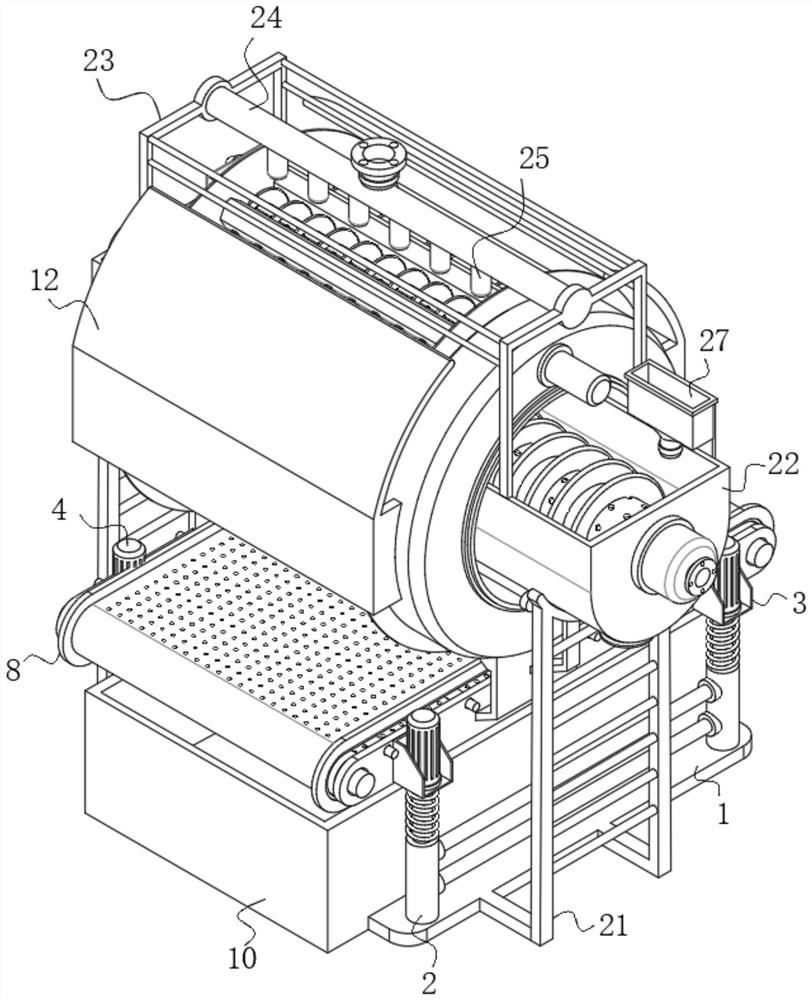

The invention relates to the technical field of grinding equipment, and discloses an efficient inclined horizontal grinding machine. The grinding machine comprises a barrel, a rotation shaft, a belt driving device, a grinding medium, an outlet filter screen, a feeding port, a cooling water inlet, a cooling water outlet pipe and a discharging port. Compared with the prior art, the grinding machinehas the advantages that the barrel is inclined for 30 degrees, and a grinding device is matched with a grinding body to grade the material grinding, so that the materials are ground in sequence and enter the next spaces after entering the barrel, and when finally passing through a fourth grinding disk d, the materials are sufficiently ground, so that the material transfer speed is enhanced and thematerial grinding fineness is improved; meanwhile, through the grinding between a grinding ring and the grinding body and the collision grinding between the grinding medium and the materials, the material grinding rate is improved; and through the setting of a rib plate, the force transfer between the grinding device and the grinding medium is increased, so that the effective movement rate of thegrinding medium is improved and then the material grinding speed is further improved.

Owner:DONGGUAN LONGLY MACHINERY +1

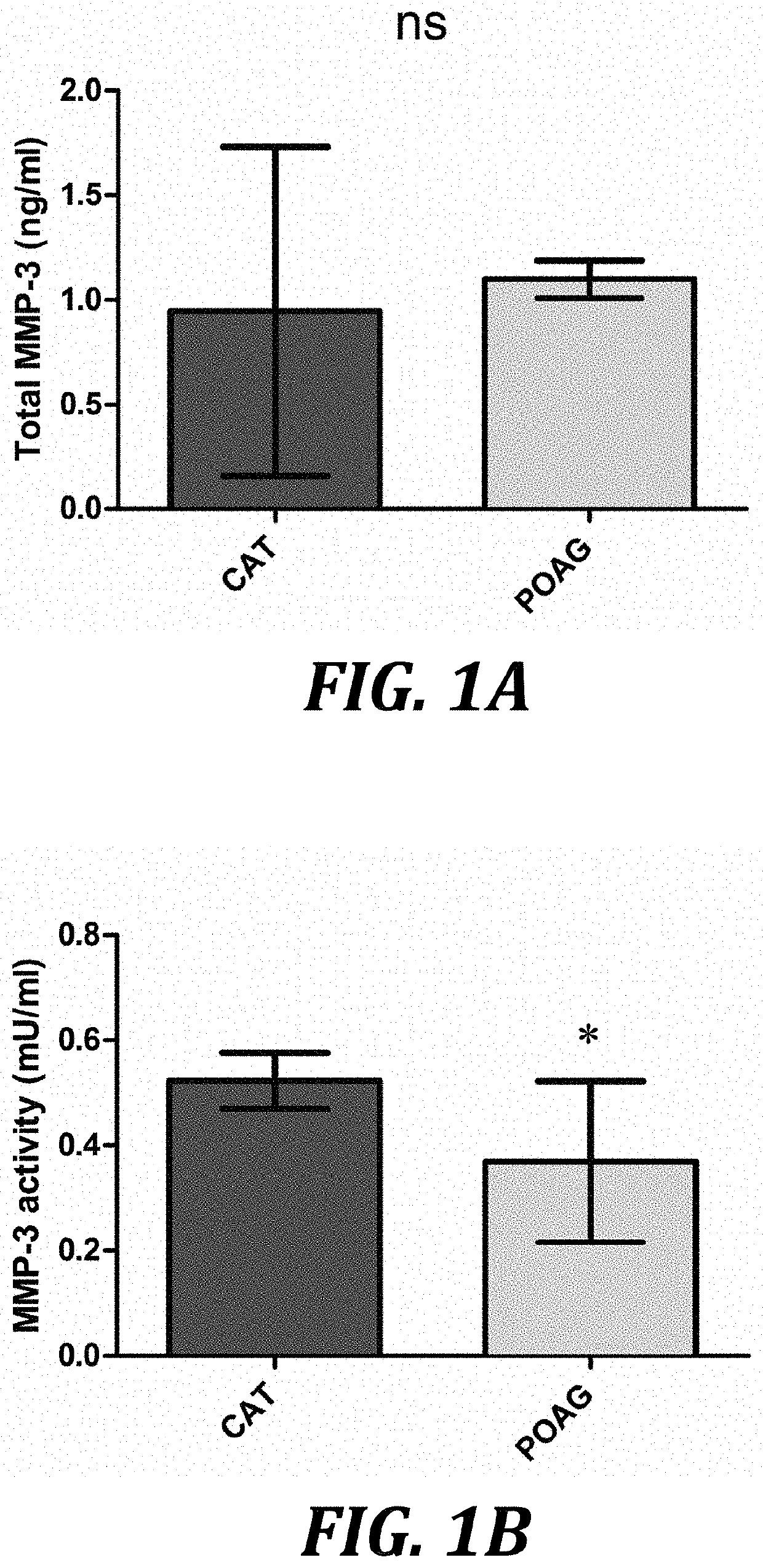

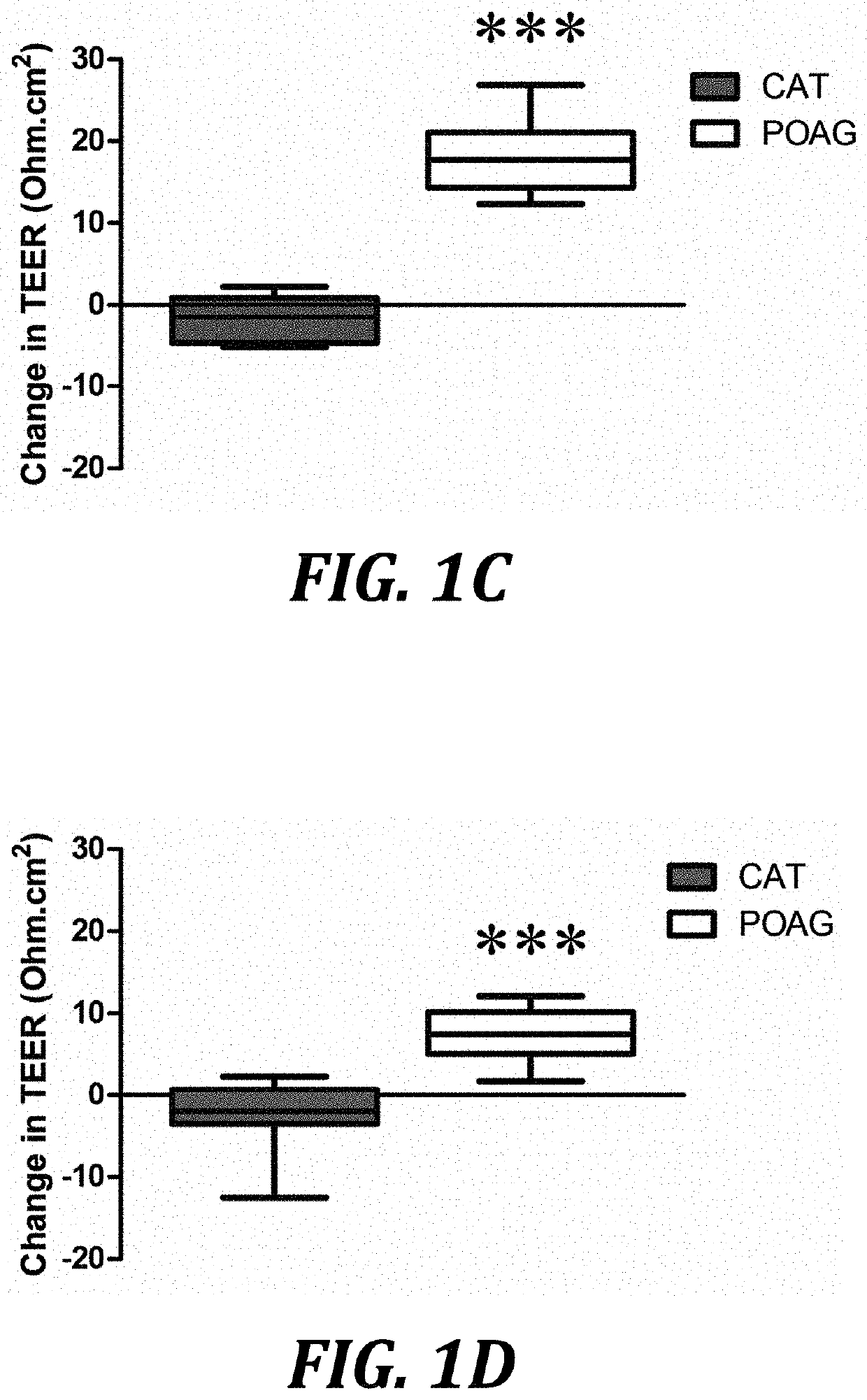

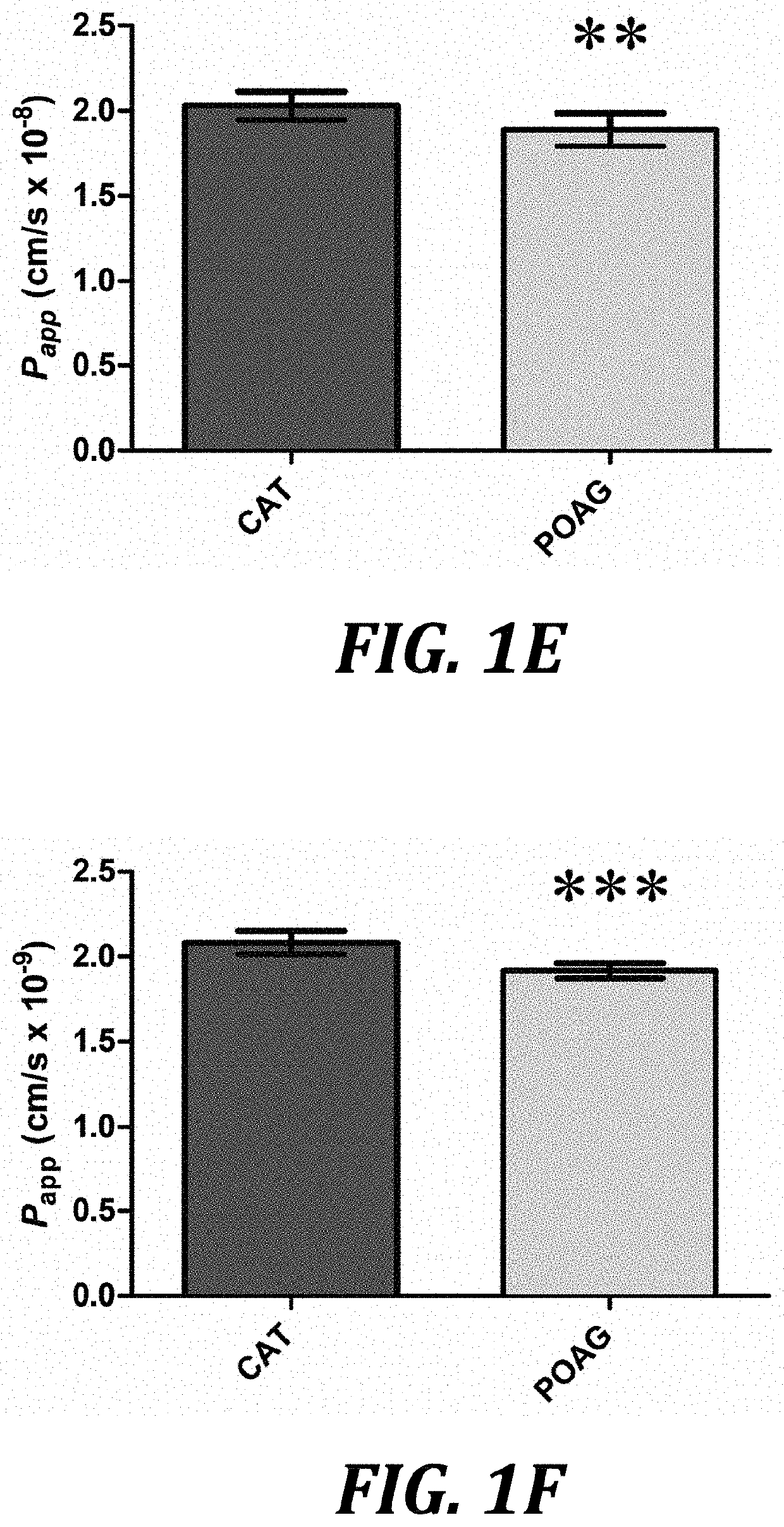

Aav-based gene therapy for glaucoma

PendingUS20190358305A1Increase ratingsReduce resistanceSenses disorderPeptide/protein ingredientsCell-Extracellular MatrixTherapeutic protein

The disclosure provides compositions and methods useful for treating glaucoma. In particular, the invention provides an adeno-associated viral (AAV)-mediated gene therapy for glaucoma in which transduced cells of the eye secrete a therapeutic protein (for example, a matrix metalloproteinase) resulting in remodeling of the extracellular matrix of the trabecular meshwork of said eye.

Owner:TRINITY COLLEGE DUBLIN

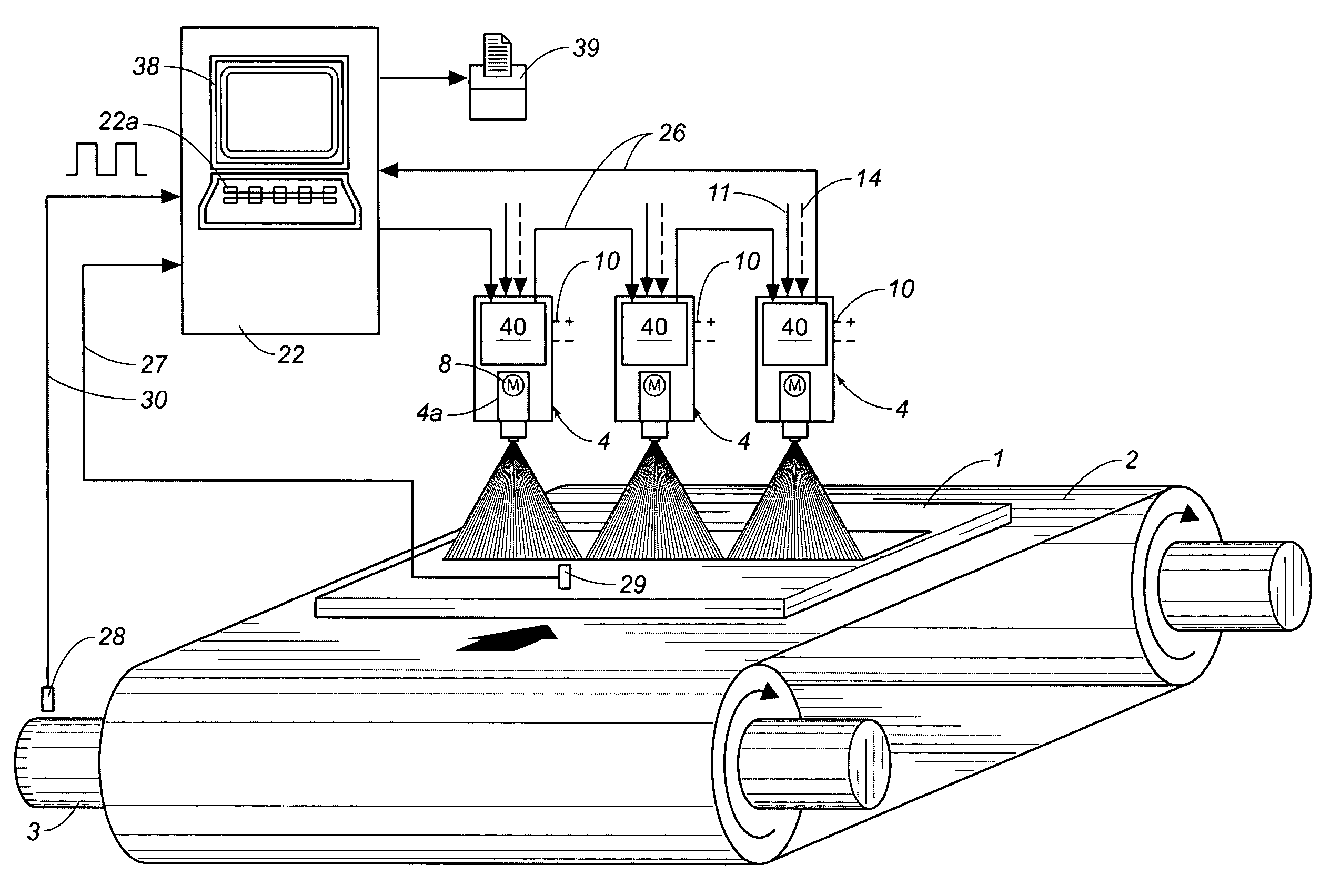

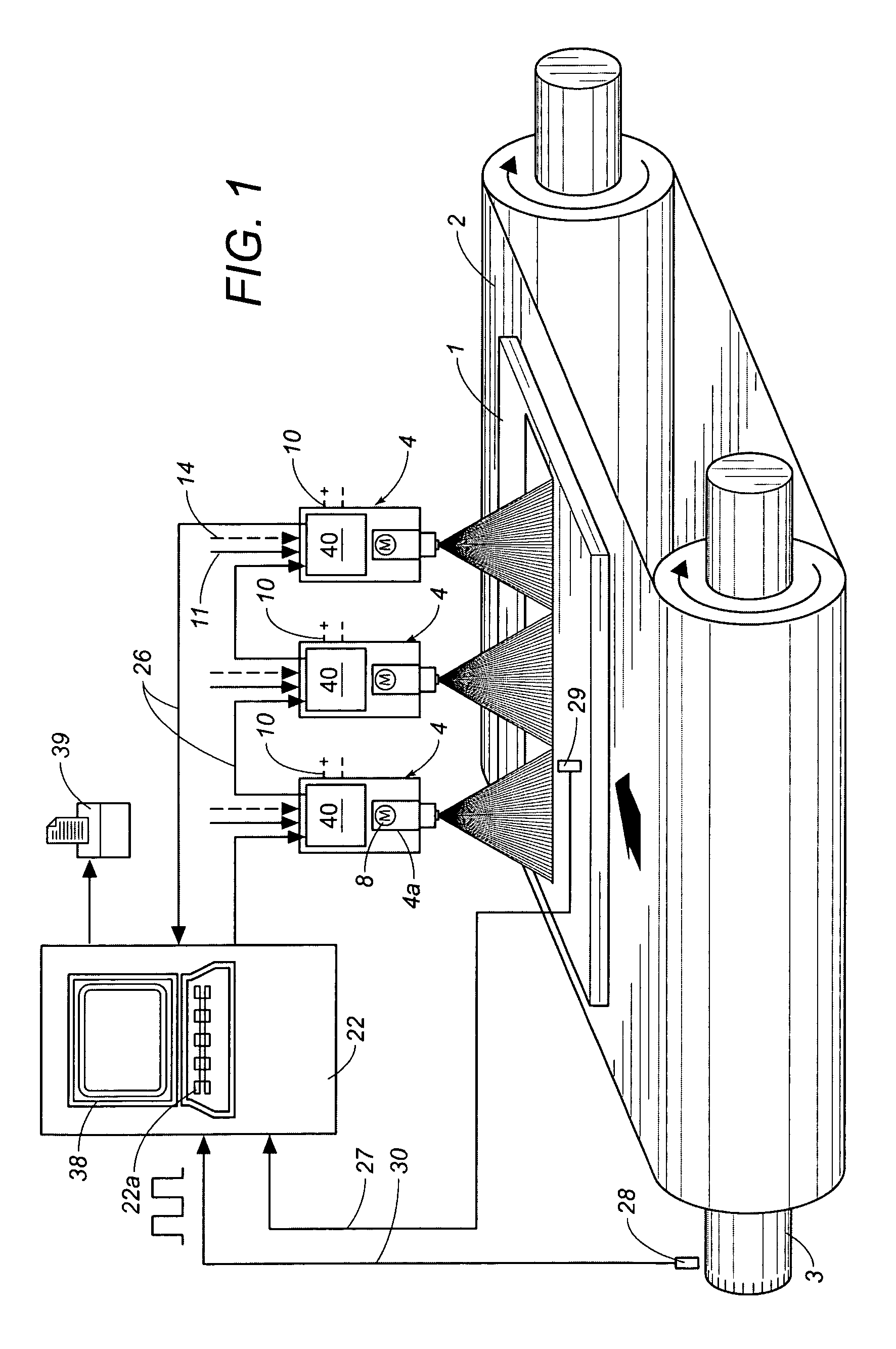

Device for applying a coating agent

InactiveUS7018476B2High precisionIncrease outflow rateLiquid surface applicatorsSpray nozzlesLine tubingStreamflow

A device for applying a coating medium onto a substrate, includes at least one spray valve that has a nozzle opening that can be adjusted with regard to its effective outlet area using a closing mechanism, whereby the substrate can be moved past the spray valve, which can be supplied with the coating medium under pressure via a supply line, whereby the positioning device is assigned a regulator that has at least one target value input for the instantaneously required outflow rate of the coating medium from the spray valve and at least one actual value input for the mass flow rate through a supply section arranged in front of the nozzle opening, and from the deviation between these values, the regulator forms an adjustment signal that moves the positioning device in the direction to offset the deviation.

Owner:AMTEC KISTLER

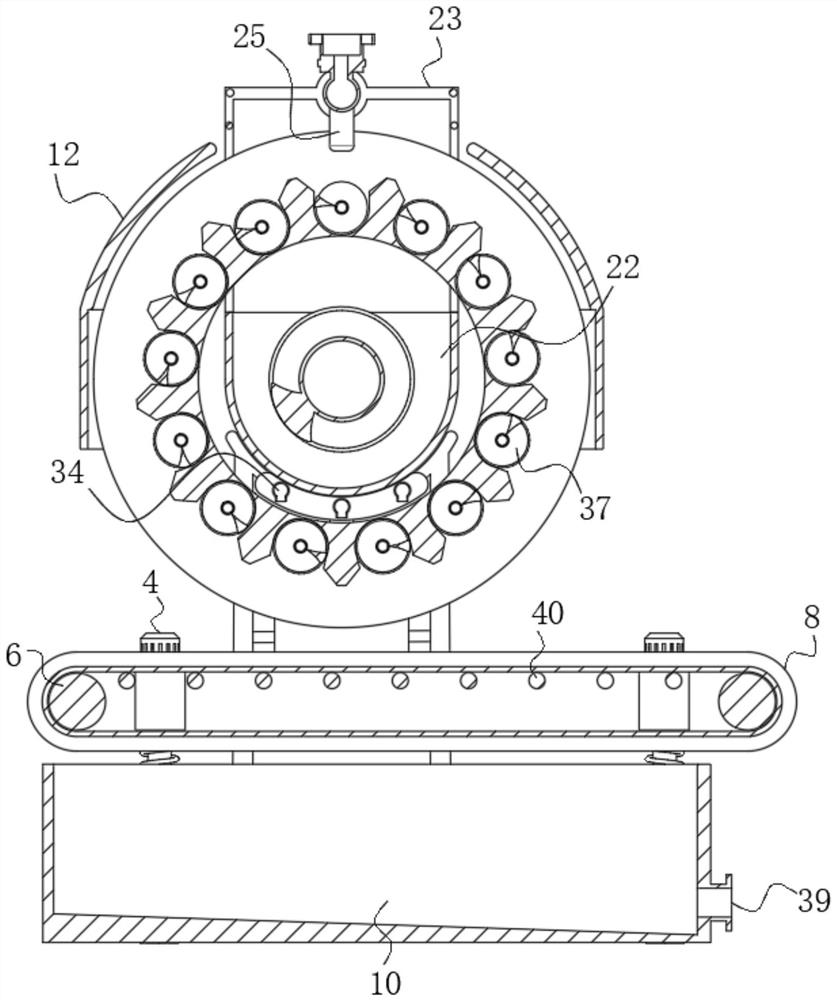

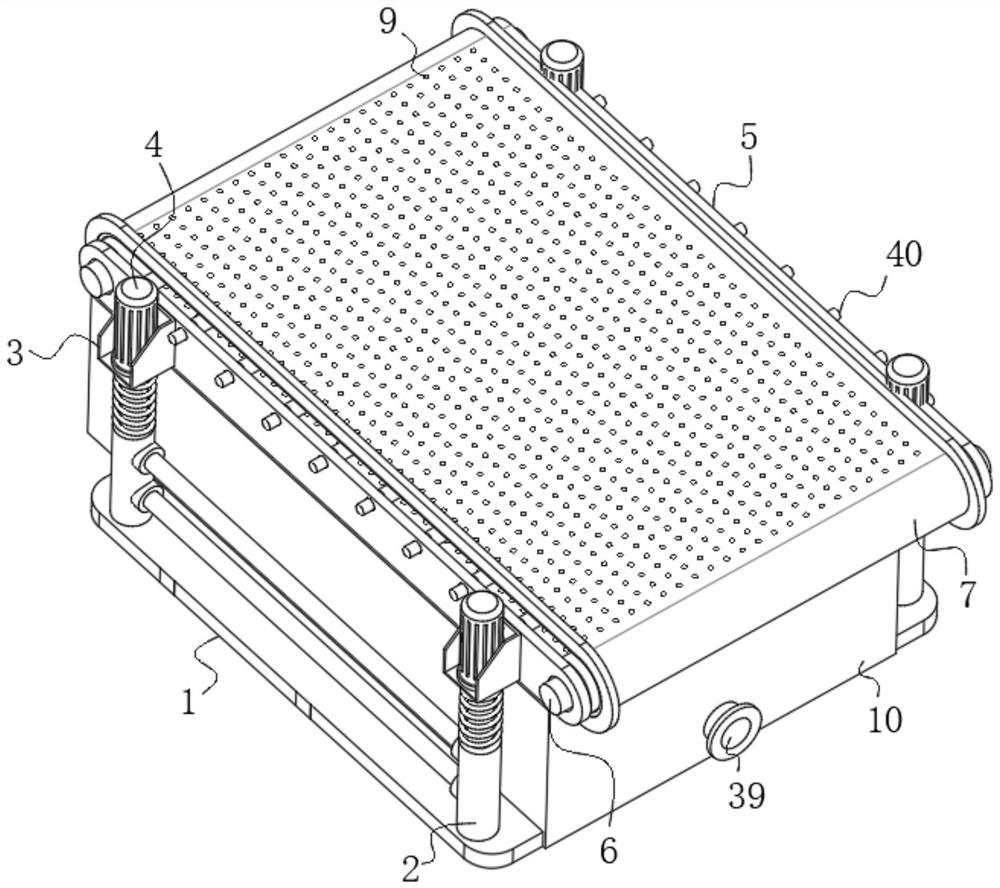

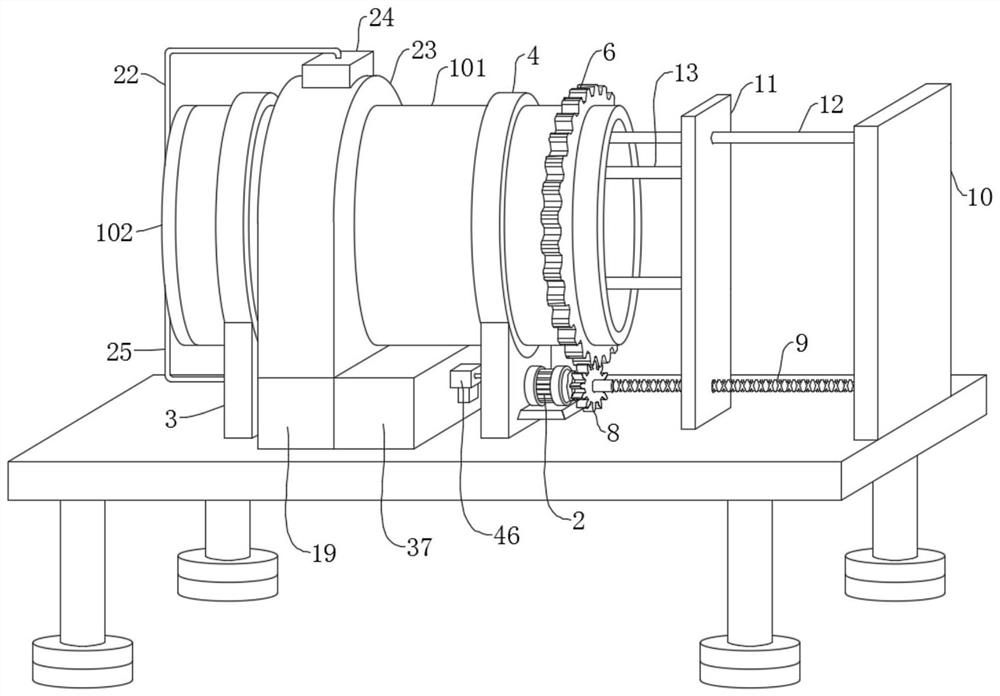

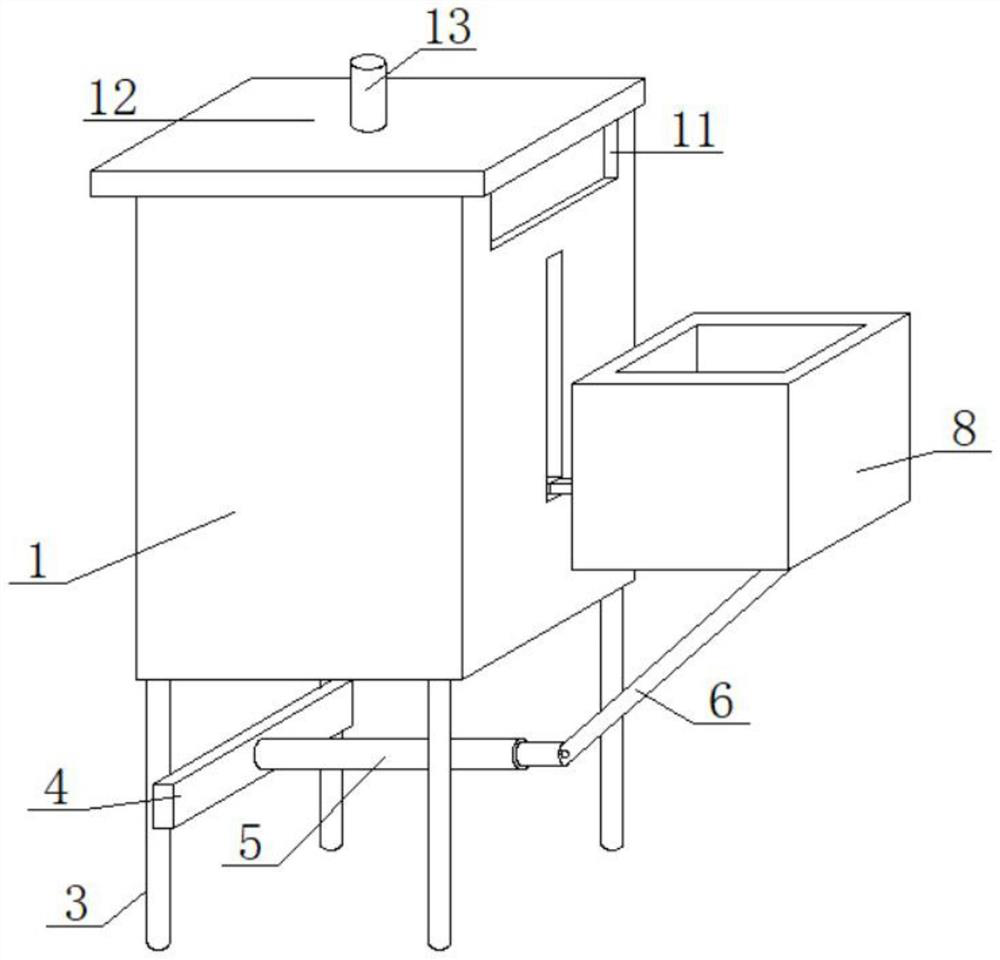

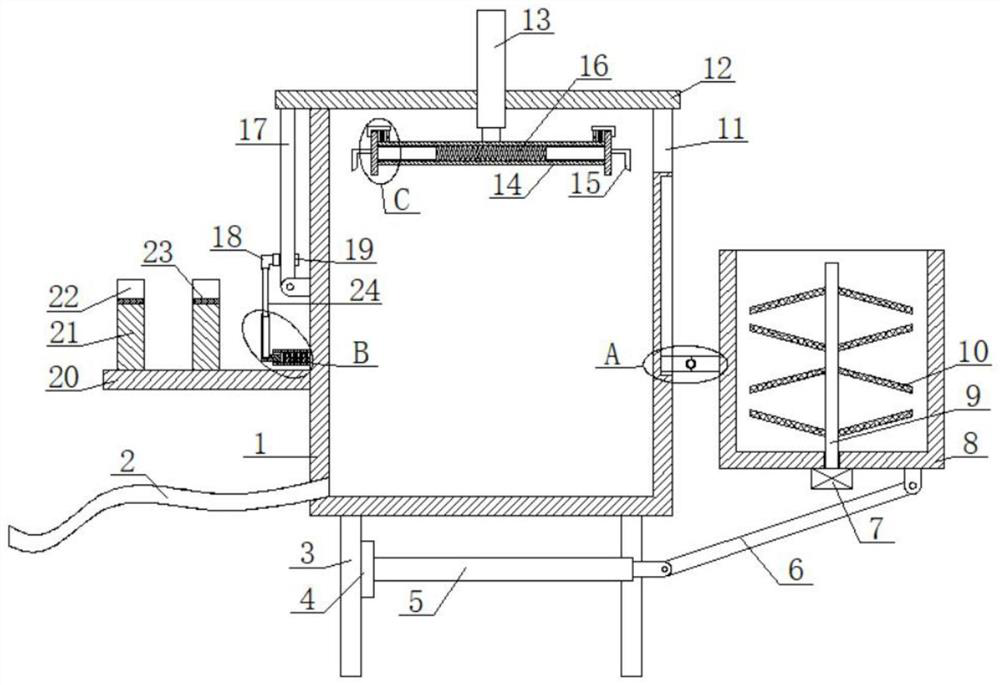

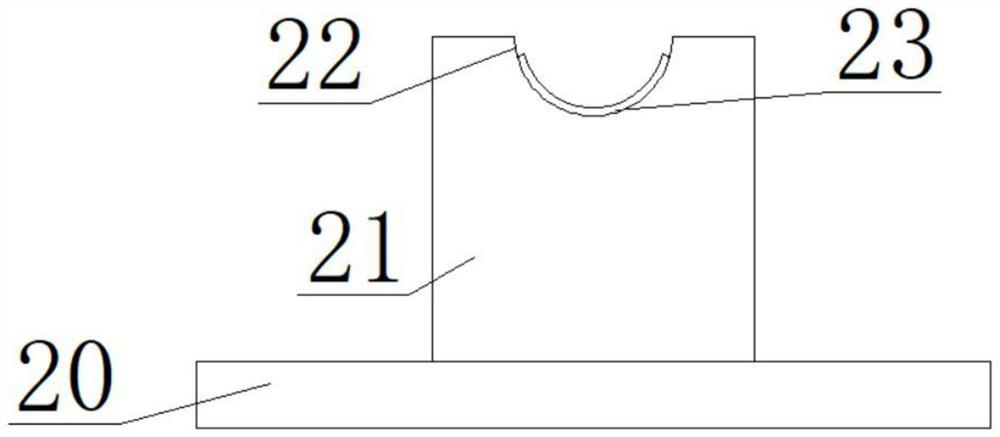

Honey extractor and honey production line

InactiveCN107094665ANo cloggingIncrease outflow rateHoney collectionFood scienceGear wheelEngineering

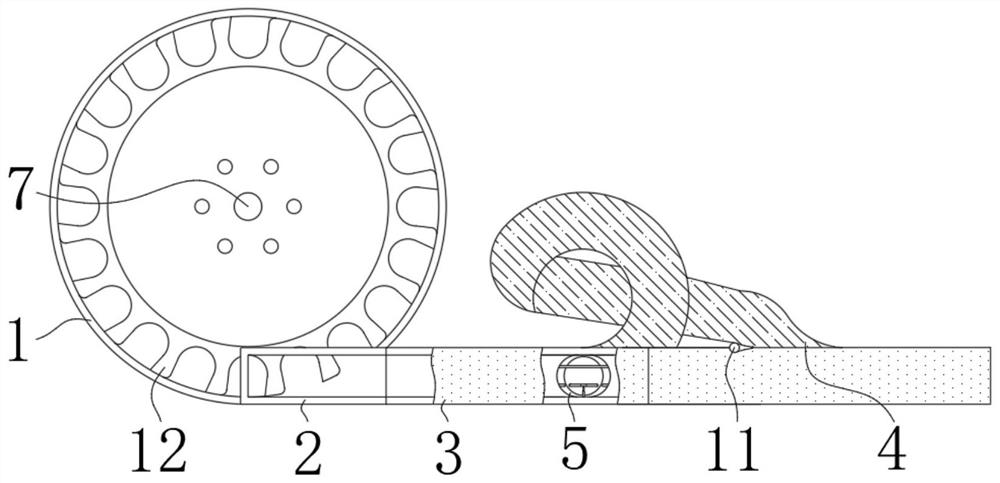

The invention provides a honey extractor and a honey production line, and relates to the technical field of honey production. The honey extractor comprises a power device, a first transmission assembly, a stirring blade, a first gear, a second gear and a gear adjusting part, wherein the output shaft of the power device is provided with a worm; the gear adjusting part comprises a gear frame, a limit rod, an adjusting screw and a slide rail; the first gear is arranged on the gear frame which is slidably arranged on the slide rail; the limit rod is connected with the slide rail; the adjusting screw rotatably penetrates through the limit rod and is rotatably riveted with the gear frame; the adjusting screw is provided with a hand wheel; the second gear is in transmission connection with the main rotating shaft of the honey extractor; the stirring blade is arranged on a honey outlet pipe; the rotating shaft of the stirring blade penetrates through the honey outlet pipe and is in transmission connection with a power output shaft; the gear frame is positioned at a first slide stop point; a first gear ring is in transmission fit with the worm; the gear frame is located at a second slide stop point; and the first gear ring is separated from the worm. The honey production line comprises the above-mentioned honey extractor. The honey production line and the honey extractor can accelerate the outflow of honey, improve the extraction efficiency of the honey, and do not need closing the power device during replacement of a honey comb.

Owner:武汉康思农生物科技有限公司

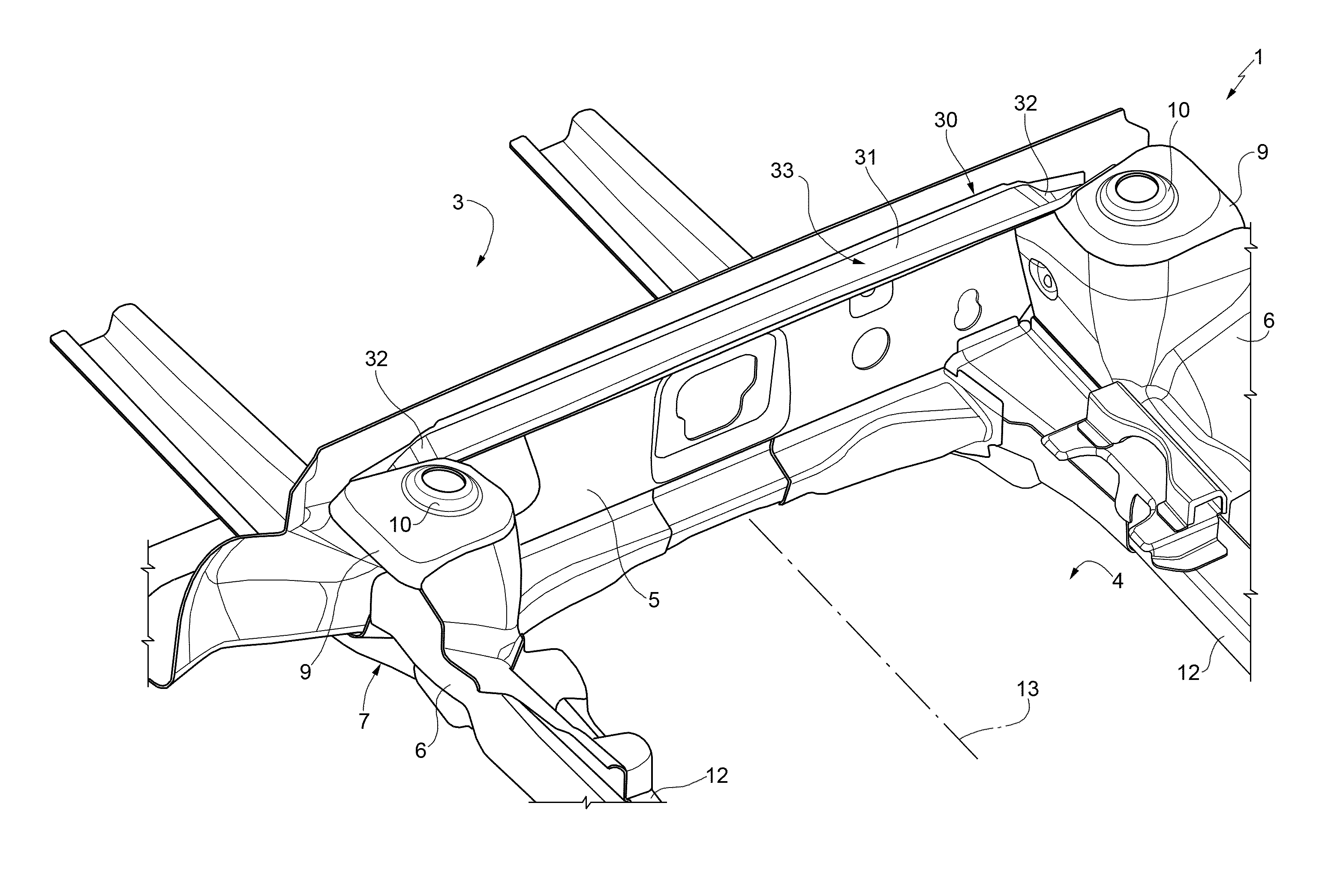

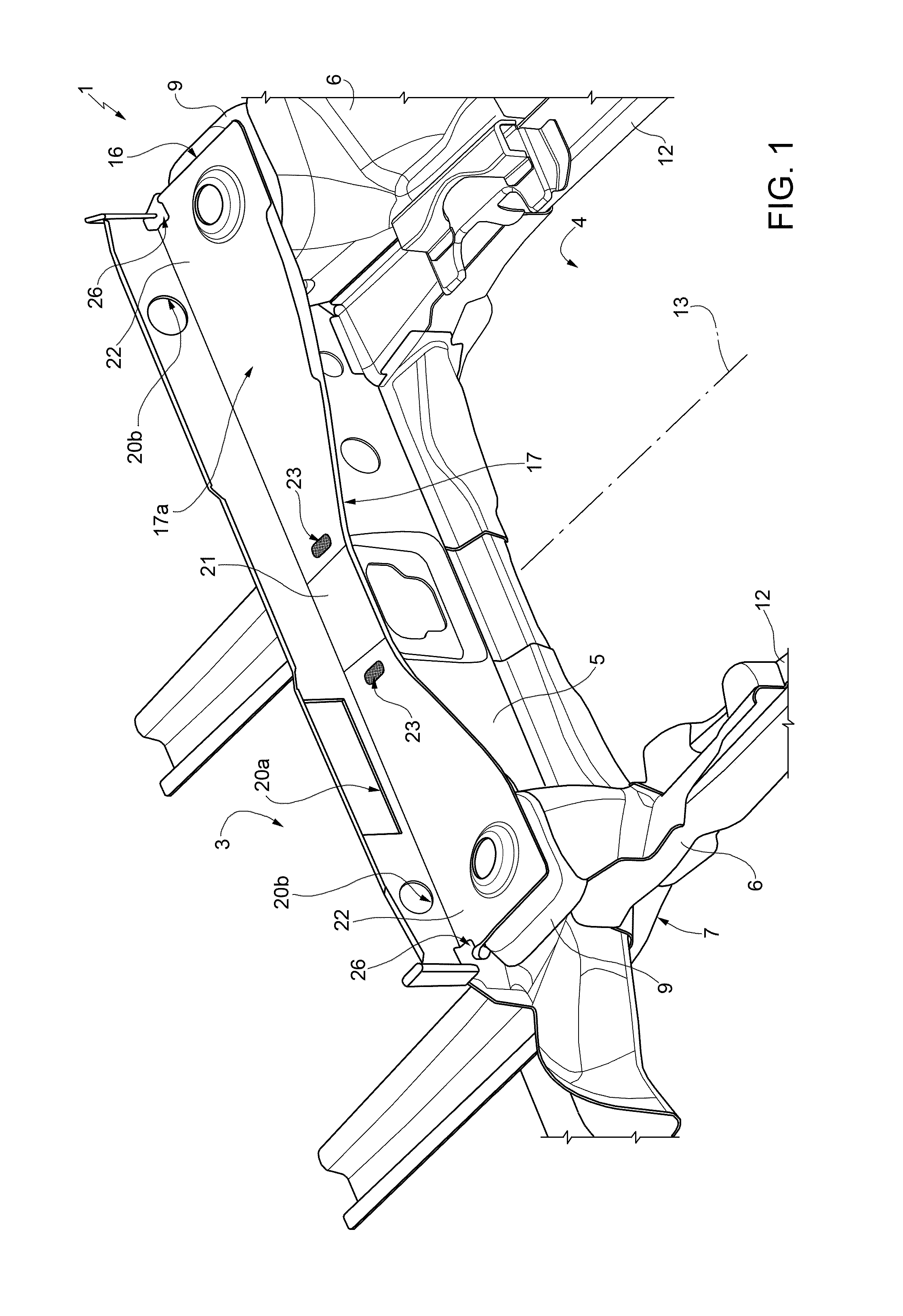

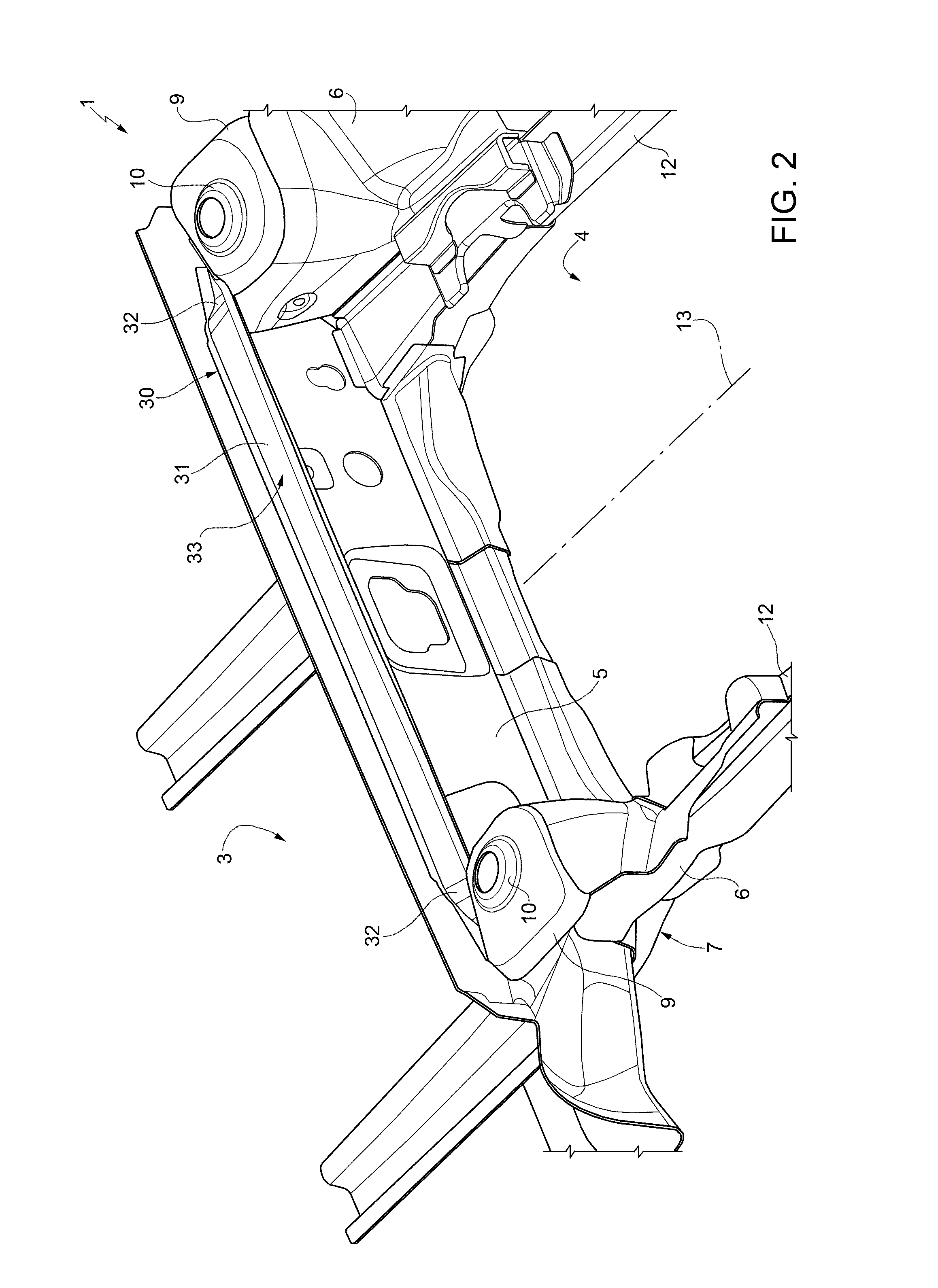

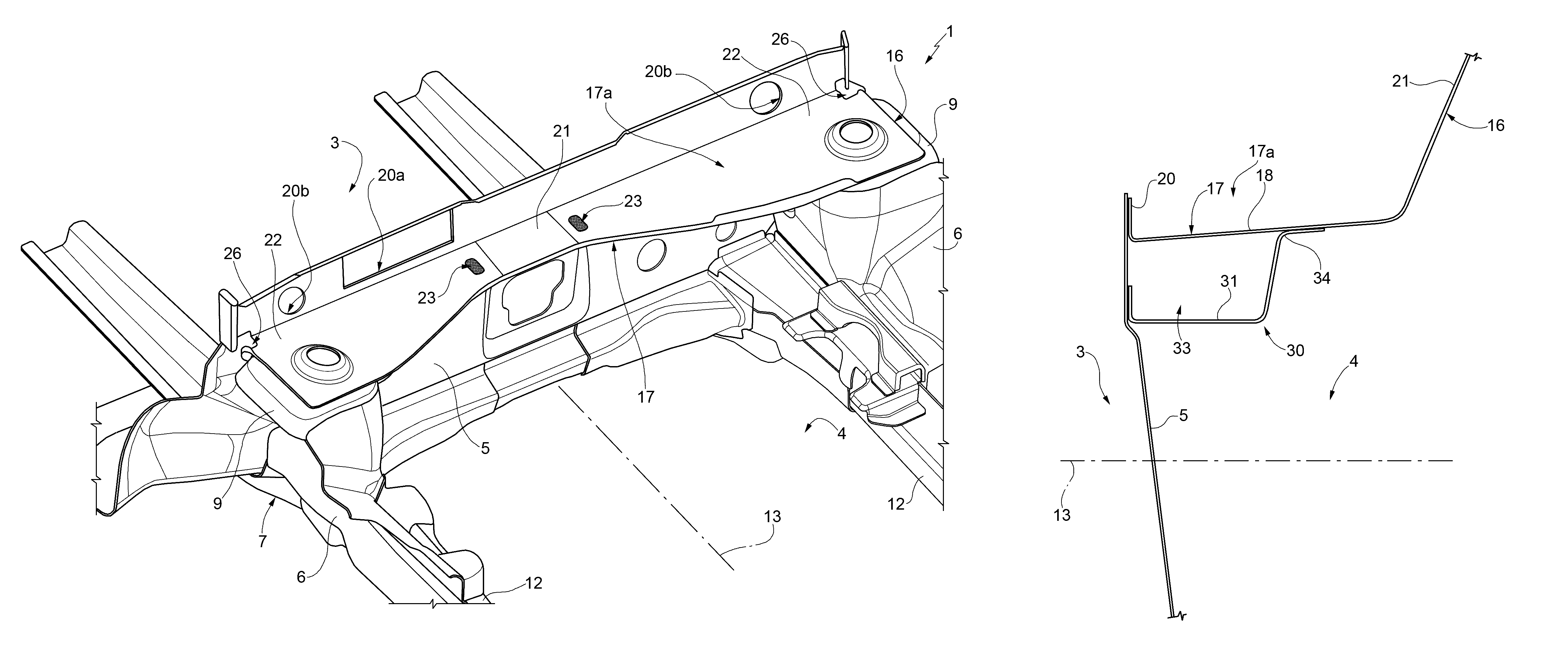

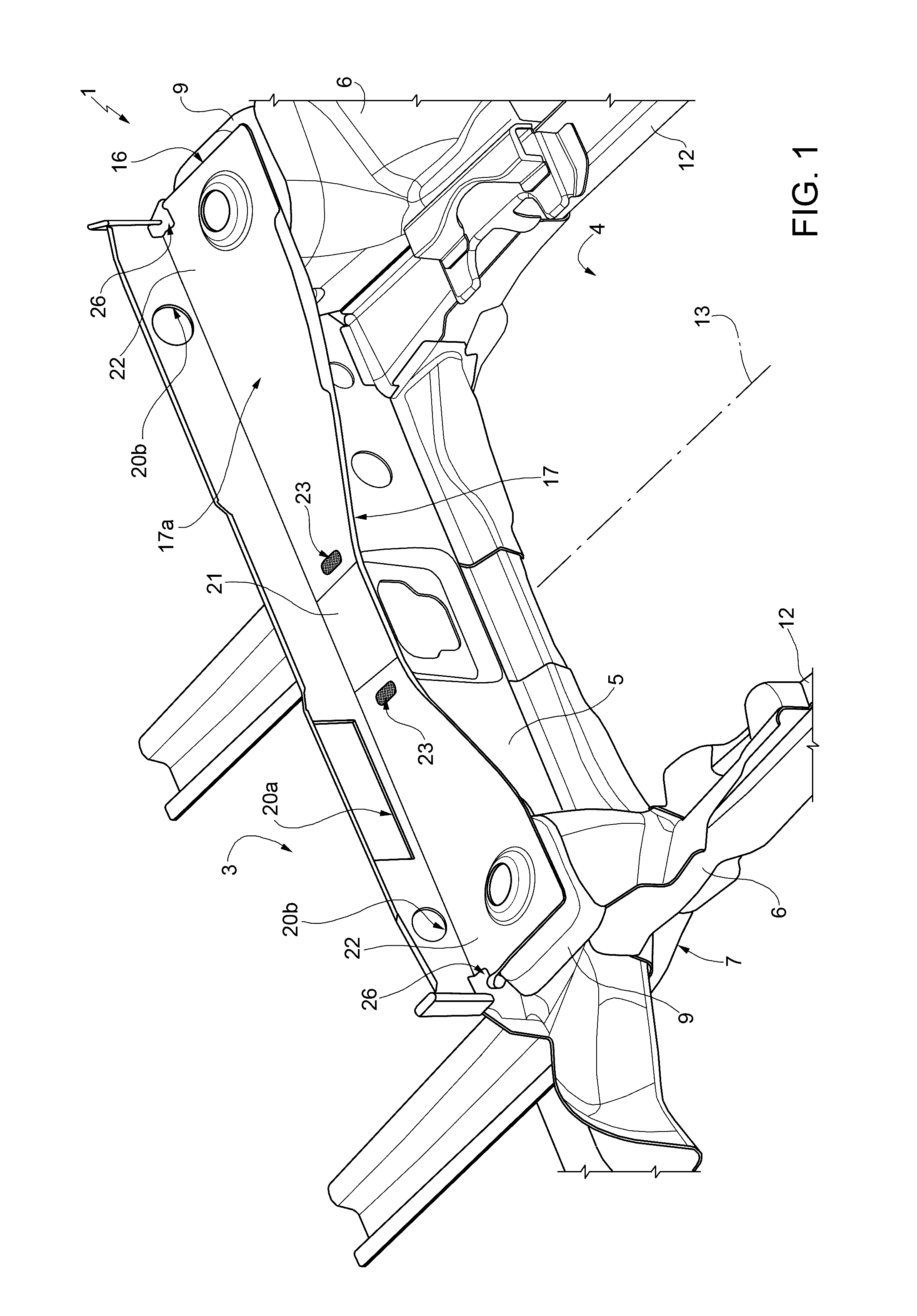

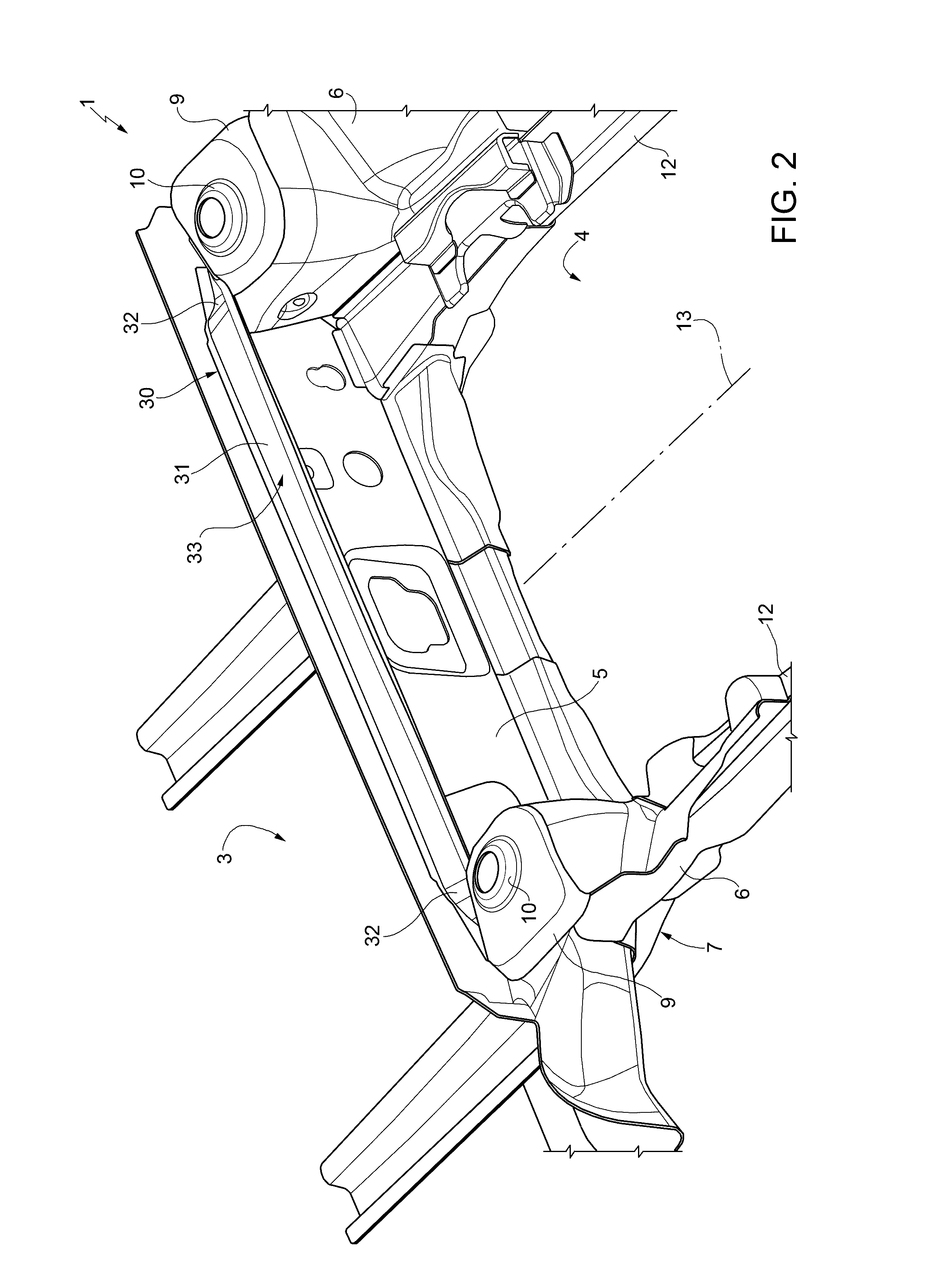

Motor vehicle body provided with a structure for receiving and draining water

ActiveUS20150360732A1Increasing rainwater outflow rateAvoid stagnationVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

A motor vehicle body is provided with a substantially vertical wall, which separates a lower zone of the passenger compartment from the engine compartment, and with a structure for receiving and draining water; such a structure protrudes forward into the engine compartment from an upper end of the substantially vertical wall and has an upper crosspiece shaped so as to define a manifold for receiving water; the upper crosspiece has a perforated intermediate portion and two opposite end portions provided with respective openings for draining water into drain passages; the structure further has a reinforcing crosspiece, which is arranged underneath the perforated intermediate portion for receiving some of the water and is shaped so as to define a channel which is elongated in the transversal direction so as to divert the water sideways and outwards.

Owner:FCA ITAL

High flow water return fitting for swimming pools and spas

The high flow water return filling of the present invention is designed to connect directly to the end of a water return pipe in a swimming pool, spa, or the like. Water return fittings have been available for many years and have the primary purpose of returning filtered water back into a swimming pool, spa, or the like. However, the water return fitting of the present invention does not only return water into the swimming pool, it also substantially increases the water outflow so that a greater area of water in the pool can be circulated or agitated. In addition, the present invention has a uniquely curved nozzle that does not extend past the face plate, thus, the nozzle does not extend more than one inch from the swimming pool wall. The outflow from the nozzle creates a low pressure condition within the face plate. Thus, the low pressure condition draws water in from the swimming pool through various gaps into the face plate where it is mixed with the outflow of water from the nozzle to increase the total amount of water flowing out of the water return fitting of the present invention.

Owner:INFUSION POOL PROD LLC

Fruit sugar refining method

InactiveCN106349297AFully removedQuality assuranceSugar derivativesFermentationDesalinationSugar refining

The invention relates to a fruit sugar refining method which comprises the following steps: (1) fruit quality inspection, (2) fruit cleaning, (3) breaking, (4) enzymolysis, (5) membrane concentration, (6) decoloration, (7) desalination, (8) purification, (9) post-treatment and (10) finished product filling. A fruit sugar concentration in a fruit sugar product produced by the method can reach 90% or higher. The product has high color value stability and no crystallization, and is low in production cost and high in production efficiency.

Owner:HEBEI LVNUO FOOD

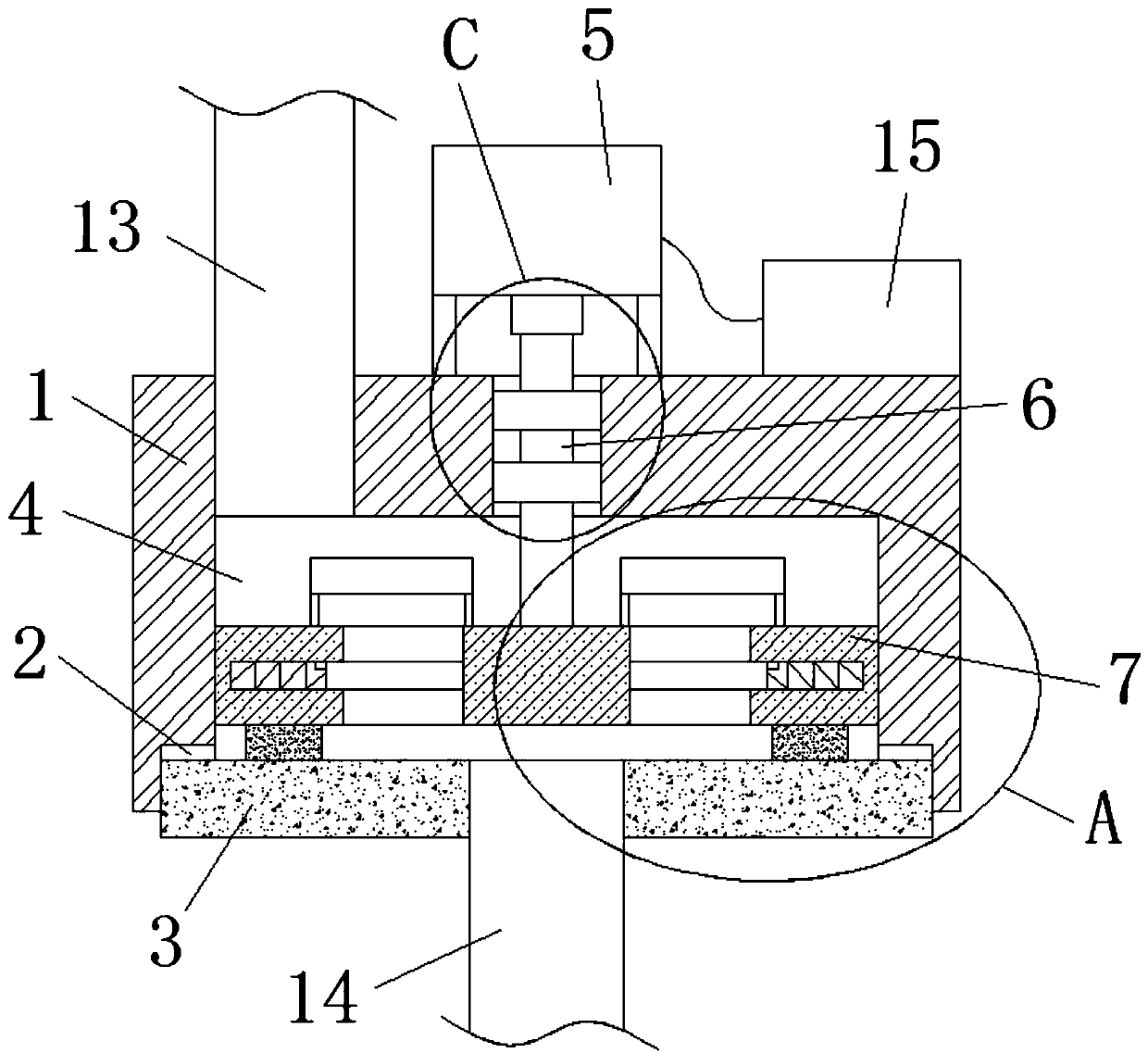

Drum-type sewage filtering device with self-maintenance mechanism

PendingCN112624392AEasy to handleReduce residual rateSpecific water treatment objectivesWater/sewage treatmentFiltrationElectric machine

The invention discloses a drum-type sewage filtering device with a self-maintenance mechanism, and belongs to the technical field of sewage treatment. The device comprises a base, wherein the top surface of the base is fixedly connected with two sets of symmetrically-arranged damping shock absorption pieces; the top ends of the two damping shock absorption pieces are fixedly connected with supporting angle seats; vibrating motors are fixedly connected to the top surfaces of the two sets of supporting corner bases; a conveying frame is fixedly connected between the opposite surfaces of the two sets of supporting corner bases; an annular driving mechanism is fixedly mounted between the inner surfaces of the conveying frame; the surface of the annular driving mechanism is connected with an annular draining conveying belt; and the surface of the annular draining conveying belt is fixedly connected with two symmetrically-arranged annular material blocking barrier strips. Through the design of a coarse filter cartridge, a flocculation box and a fine filter cartridge, the device can automatically and sequentially complete the graded filtration and flocculation treatment process of sewage, and the sewage treatment effect of the device is effectively improved through the automatic implementation of the operation.

Owner:陈泽柱

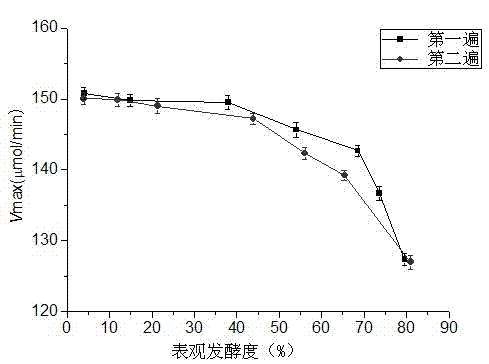

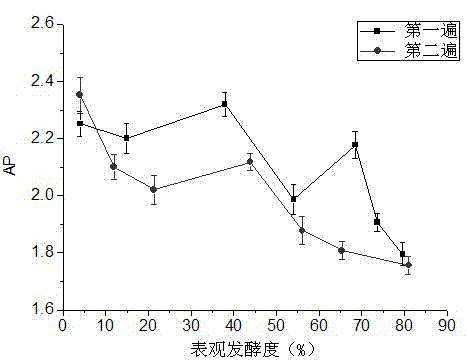

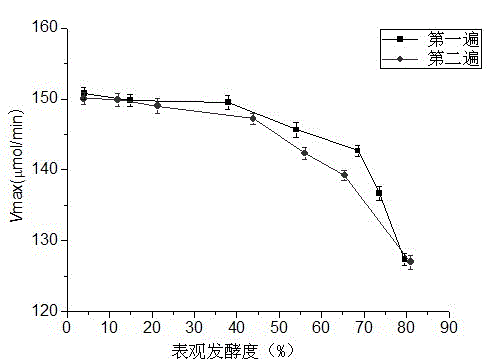

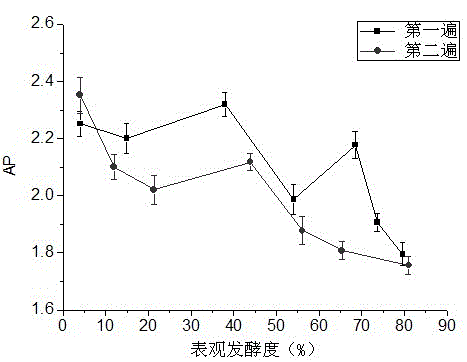

Method for detecting yeast metabolic activity in fermentation process of beer

ActiveCN102212603AReflect metabolic capacityThe result is accurateMicrobiological testing/measurementMicroorganism based processesYeast strainYeast

The invention discloses a method for detecting yeast metabolic activity in the fermentation process of beer. The method comprises the following steps: performing starvation treatment on the yeast collected from fermented liquid, adjusting the induction initial pH value of bacterium suspension, adding glucose to induce yeast H<+> to flow out, and calculating the maximum flowing-out rate to characterize the metabolic activity of yeast. By adopting the method, the activity difference of the yeast strains can be accurately reflected; the method can be used to evaluate the metabolic activity of yeast in the fermentation process; and the method has accurate result and good repeatability. The invention can be used to rapidly analyze the metabolic condition and fermentation performance of yeast in the fermentation process of beer.

Owner:SOUTH CHINA UNIV OF TECH

Motor vehicle body provided with a structure for receiving and draining water

ActiveUS9481397B2Simple and cost-effectiveIncrease outflow rateSuperstructure subunitsEngineeringMechanical engineering

A motor vehicle body is provided with a substantially vertical wall, which separates a lower zone of the passenger compartment from the engine compartment, and with a structure for receiving and draining water; such a structure protrudes forward into the engine compartment from an upper end of the substantially vertical wall and has an upper crosspiece shaped so as to define a manifold for receiving water; the upper crosspiece has a perforated intermediate portion and two opposite end portions provided with respective openings for draining water into drain passages; the structure further has a reinforcing crosspiece, which is arranged underneath the perforated intermediate portion for receiving some of the water and is shaped so as to define a channel which is elongated in the transversal direction so as to divert the water sideways and outwards.

Owner:FCA ITAL

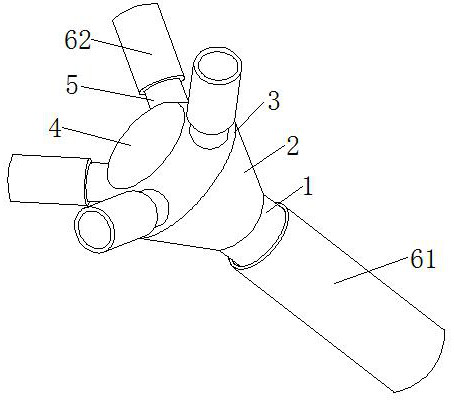

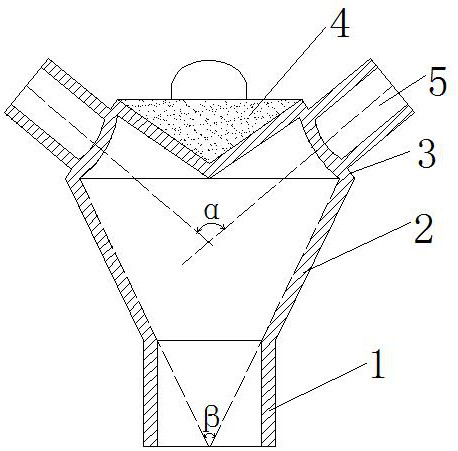

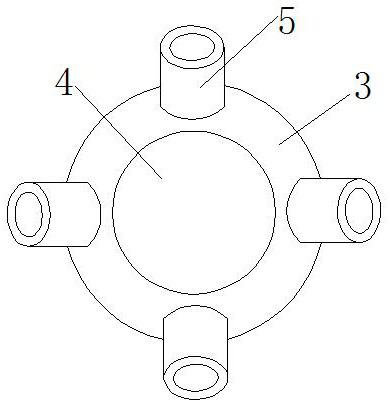

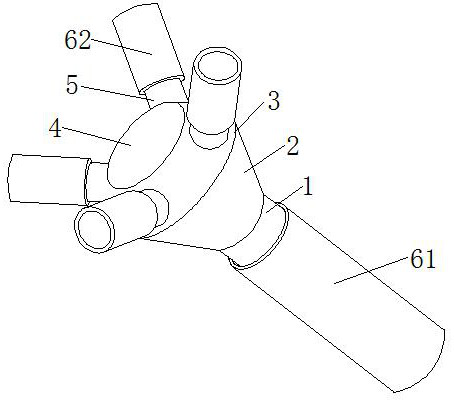

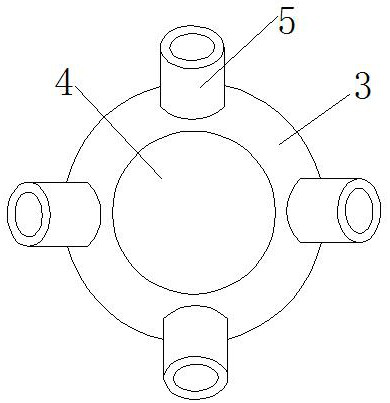

Small seed dual-purpose cone-embedded double-circular-truncated-cone annular air distribution mechanism

ActiveCN112470623AReduce lossesReduced Power RequirementsSeed depositing seeder partsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of agricultural machinery seeding, and particularly relates to a small seed dual-purpose cone-embedded double-circular-truncated-cone annular air distribution mechanism. The small seed dual-purpose cone-embedded double-circular-truncated-cone annular air distribution mechanism comprises an airflow access pipe, an air distribution mechanism shell and a plurality of airflow distribution pipes, the air distribution mechanism shell comprises a high circular truncated cone cylinder, a short circular truncated cone cylinder and an inverted cone, and the multiple airflow distribution pipes communicating with a special-shaped through cylinder body are uniformly distributed on the outer side surface of the short circular truncated cone cylinder in the circumferential direction. Compared with the prior art, the small seed dual-purpose cone-embedded double-circular-truncated-cone annular air distribution mechanism has the following advantages that by reasonably designing the structures of the airflow access pipe, the air distribution mechanism shell and the airflow distribution pipes, airflow is stably transited from a cylindrical section to an annular channel, finally seeds uniformly and stably flow out of the air distribution mechanism along with the airflow, and the multiple airflow distribution pipes achieve equivalent distribution of the airflow in multiple directions, so that the outflow efficiency of small seeds in different shapes along with the airflow is further ensured; and the whole structure is regular, the integrally-formed structure is easy to process, processing cost can be effectively controlled, and application and popularization are facilitated.

Owner:ANHUI AGRICULTURAL UNIVERSITY

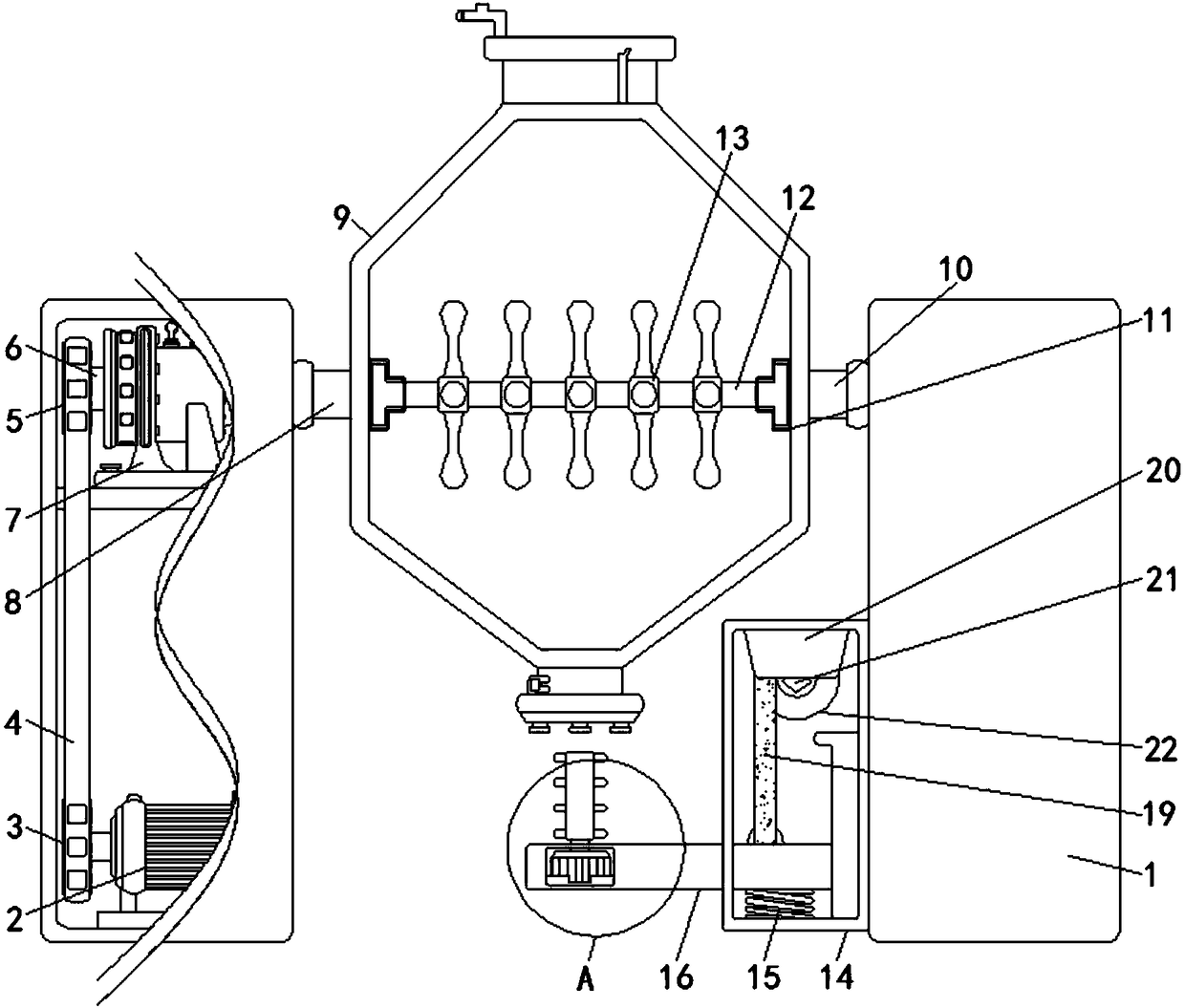

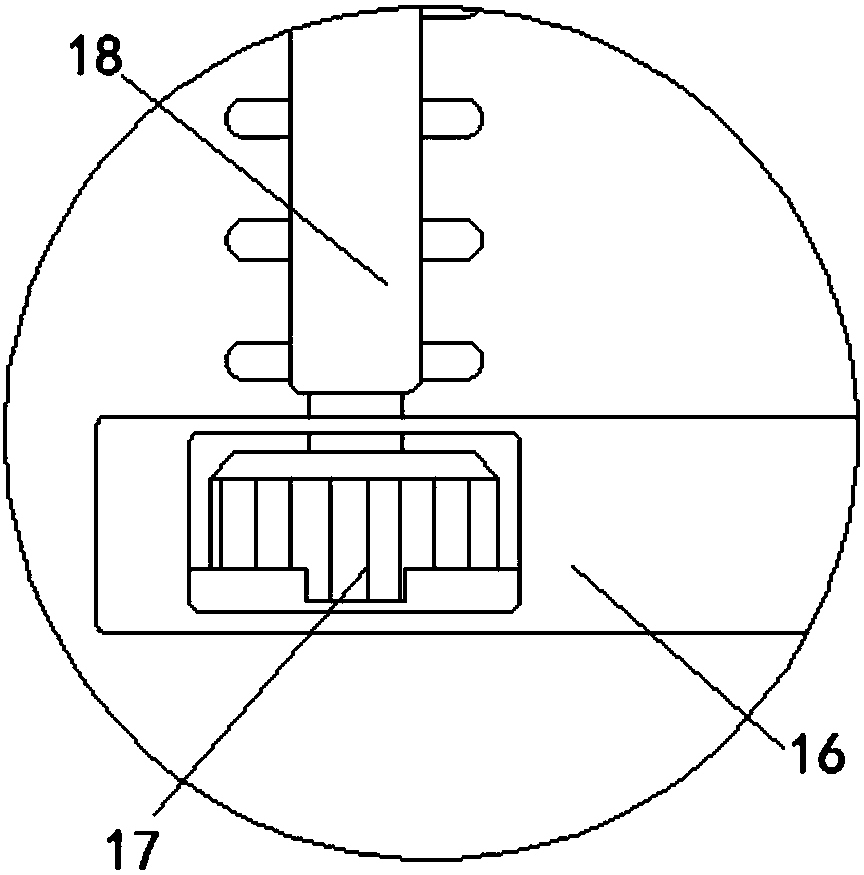

Efficient dual-cone type mixer

InactiveCN108295731AMixed materials effectively deal withWell mixedRotating receptacle mixersTransportation and packagingDrive motorEngineering

The invention relates to the technical field of mixers, and discloses an efficient dual-cone type mixer which comprises two supporting columns. A driving motor is fixedly installed at the bottom of aninner cavity of the supporting column on the left side. An output shaft of the driving motor is fixedly connected with a driving gear. The outer surface of the driving gear is meshed with a conveyingbelt. By means of the efficient dual-cone type mixer, the rotation of the driving gear is driven by the rotation of the driving motor, the rotation of a driven gear and a connecting column is realized through force transmission, the rotation speed, borne by the connecting column, of the driving motor is properly changed through a transmission, the circular rotation of a tank body is realized through force transmission when the transmission is connected with a first rotating shaft, a connecting rod is pushed under the effect of centrifugal force to rotate in a fixing block, the rotation of a mixing plate is realized, the mixing of materials in the tank body is increased, it is effectively avoided that materials prone to heating and caking are attached together and can not be easily scattered, and the mixing effect of the mixer is improved.

Owner:苏州苏丰机械科技有限公司

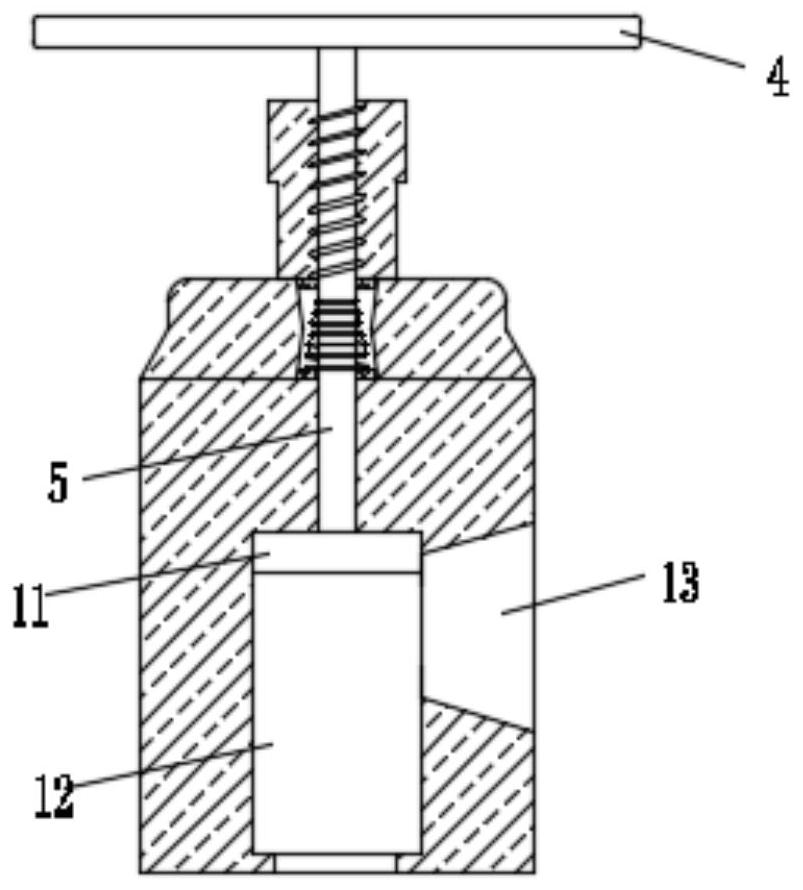

Micro-electronic control switch

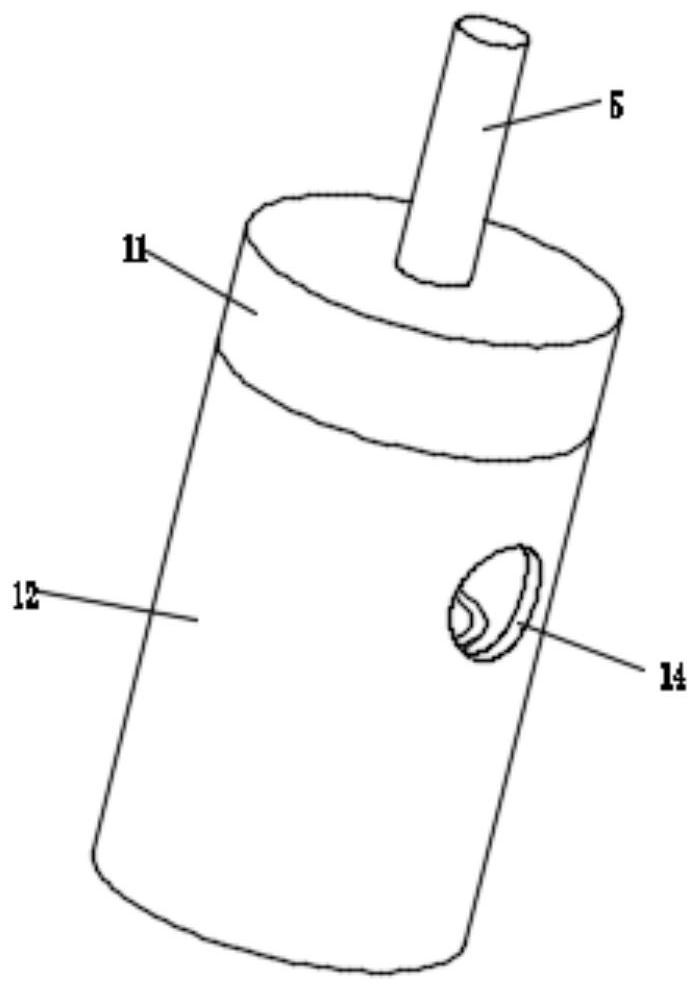

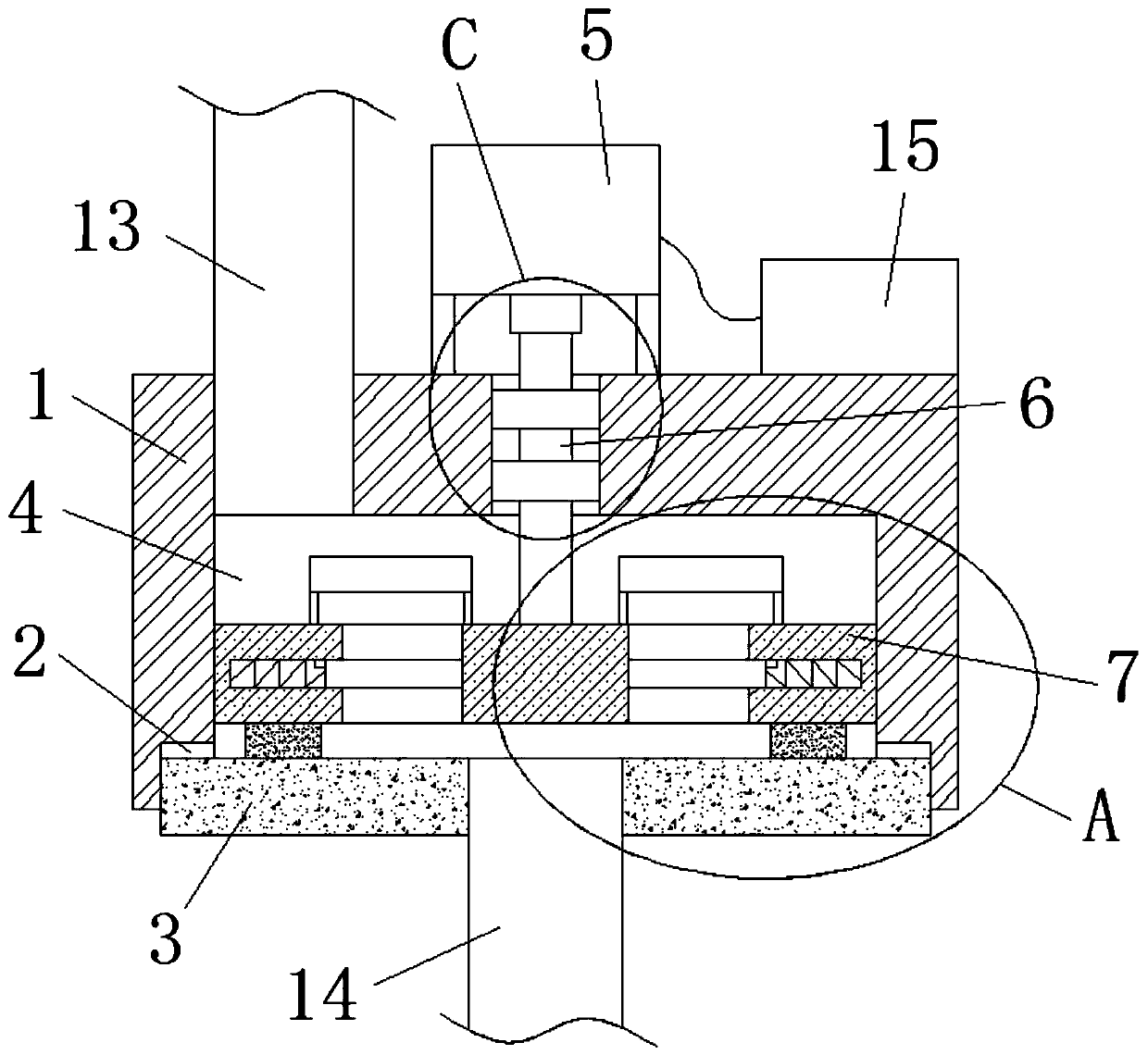

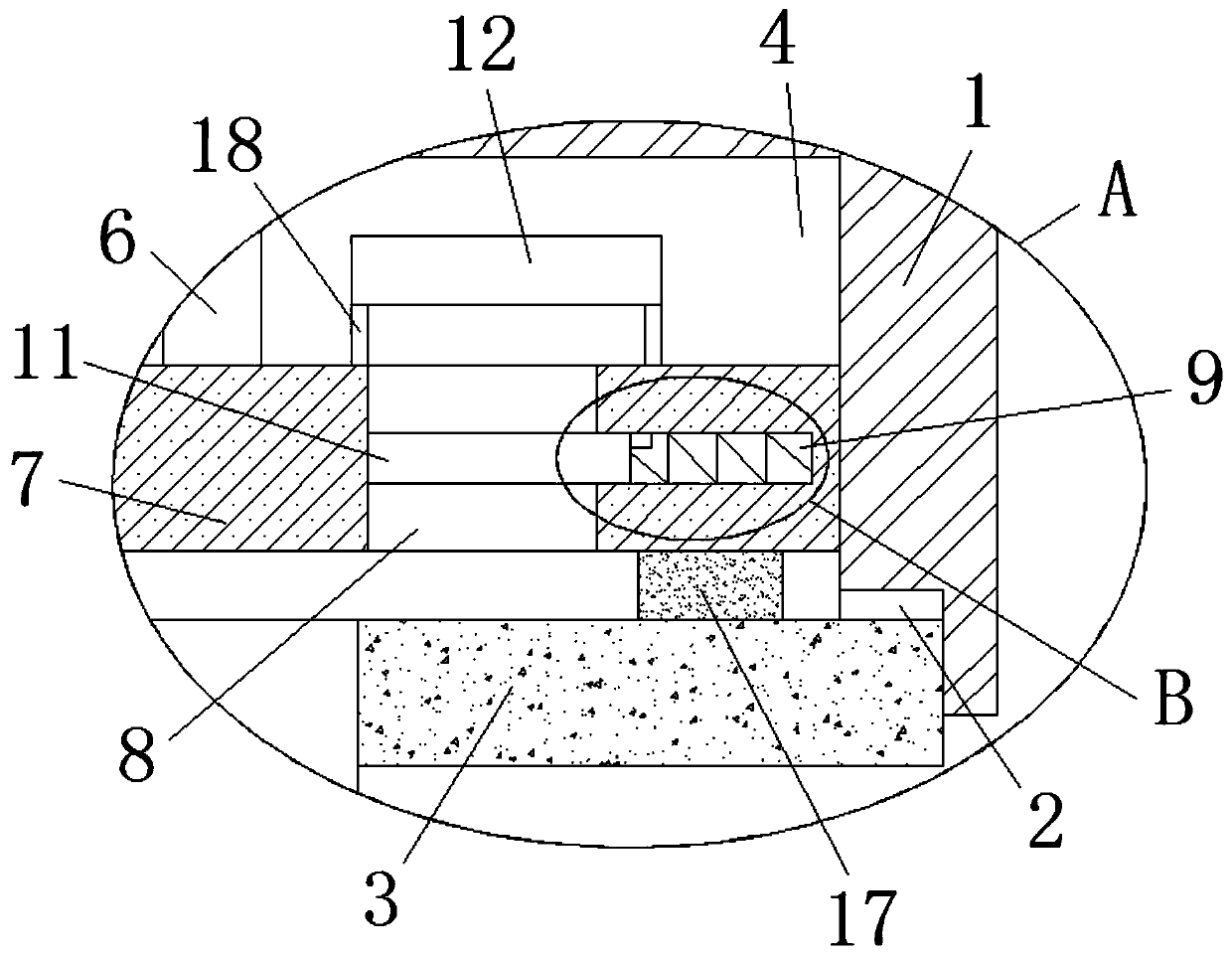

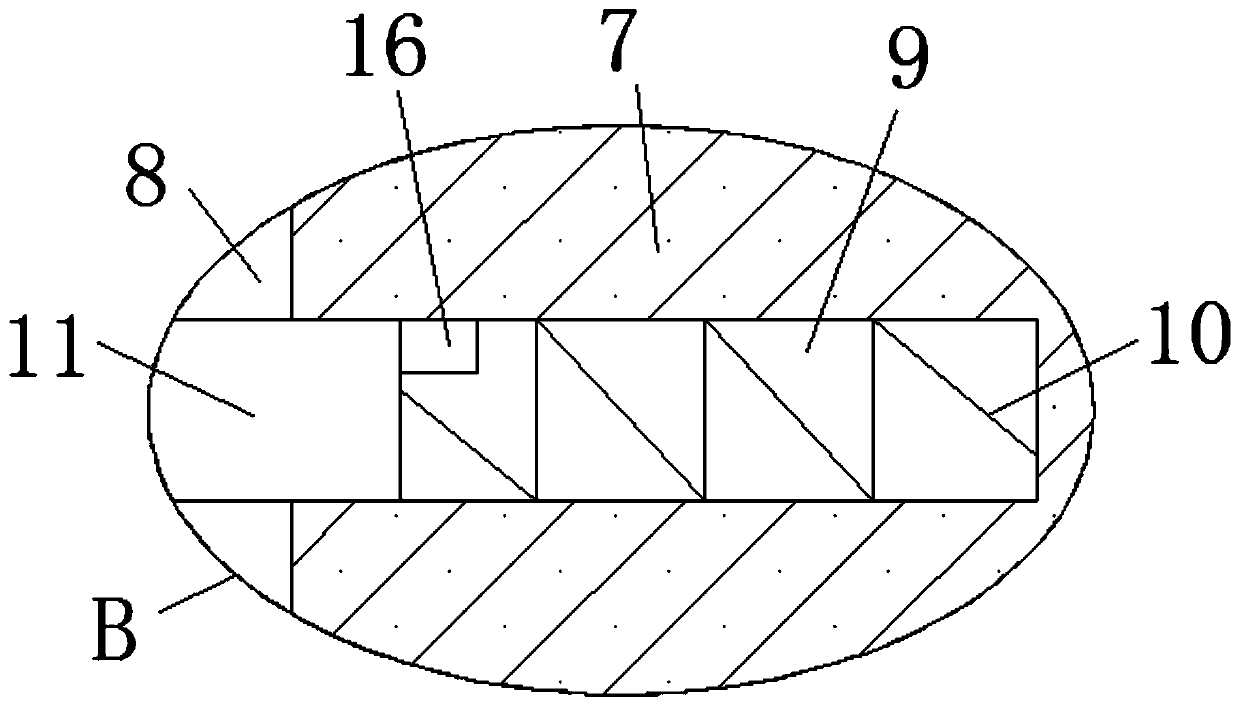

ActiveCN109630708AIncrease outflow rateUnable to flowOperating means/releasing devices for valvesSlide valveTarComputer module

The invention discloses a micro-electronic control switch. The micro-electronic control switch comprises a box body and a motor control module, wherein the motor control module is fixedly connected toone side of the top of the box body; a groove is formed in the bottom of the box body, a threaded groove with bottom open is formed in the side wall of the groove, and an end cover is installed in the threaded groove in a threaded mode; a driving motor is fixedly installed at the top of the box body, an output shaft of the driving motor is fixedly connected with a rotating shaft, the bottom end of the rotating shaft extends into the groove, and a rotating disk is welded to the bottom end of the rotating shaft; and a plurality of discharging holes are formed in the periphery of the bottom of the rotating disk, and containing slots are formed in the inner walls of the sides, away from the rotating shaft, of the discharging holes. According to the micro-electronic control switch, the rotating rate of the driving motor can be adjusted by the motor control module, and then the open range of discharging holes can be adjusted; and tar can be pushed into a discharging pipe by paddle blades, the tar outflow rate is increased, the condition that the tar with high stickiness cannot flow out is avoided, and the tar outflow rate can be regulated and controlled by people conveniently.

Owner:HUIZHOU TONGFABAO MICRO CONTROL TECH CO LTD

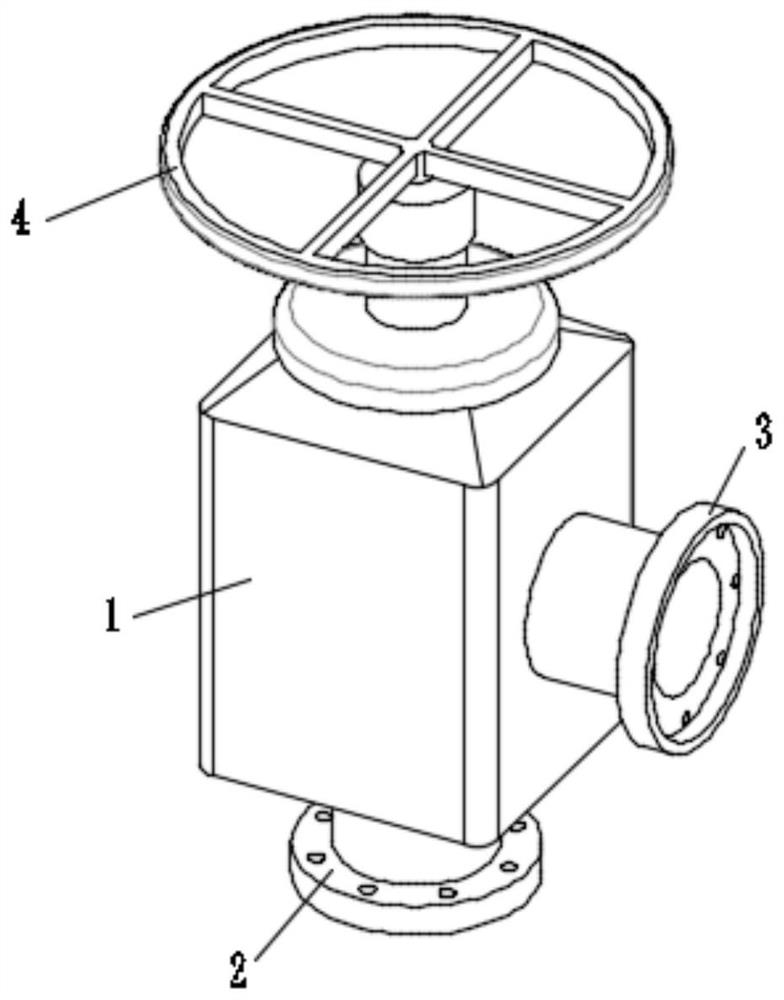

A Subsea Christmas Tree Throttle Valve

ActiveCN113217637BAvoid cloggingAvoid cleaning inconvenienceCombination devicesPipe elementsEngineeringOil production

The invention relates to the technical field of choke valves, and discloses a choke valve for a subsea oil tree. Both the oil outlet pipe and the oil inlet pipe are connected with the valve body, and the top of the valve body is provided with a rotating disk, and the left side of the bottom of the rotating disk is fixedly connected with a valve stem. The present invention can make the oil and gas entering the interior of the fixed sleeve The leak plate falls into the inside of the anti-blocking ring, so that the impurities in the oil and gas can be filtered by the leak holes opened by the trapezoidal block, and the filtered oil and gas are discharged from the oil outlet pipe, avoiding the blockage of the oil outlet pipe by the impurities in the oil and gas, thus avoiding the blockage The problem of inconvenient cleaning occurs. By setting the connecting piece 1, the oil and gas can impact the baffle to make it rotate, and can drive the oil and gas to rotate and discharge inside the connecting piece 1, so that the impurities in the oil and gas can be concentrated when the connecting piece 1 rotates inside, so that the subsequent The filtering effect is better.

Owner:CEPAI GRP CO LTD

A balance-type two-liquid arbitrary proportion mixing device and its operation method

ActiveCN106853345BSmall outflow rateIncrease outflow rateFlow mixersTransportation and packagingEngineeringFlow ratio

The invention relates to a balance-type double-liquid mixing device in any proportion and an operation method thereof, which comprises a base, a bracket is fixed on the top of the base, a beam is supported on the top of the bracket, and first A hook and a second hook, the first hook is hung with a first liquid storage cylinder through the first bucket handle, the second hook is hung with a second liquid storage cylinder through the second bucket handle, and the first liquid storage cylinder is A liquid conduit is arranged inside, and a B liquid conduit is arranged inside the second liquid storage cylinder, and the A liquid conduit and the B liquid conduit are connected to the two liquid outlets of the three-way joint at the same time. When the outflow ratio of the two liquids is out of balance, the balance tilts, driving the solid slider in the double flow adjustment device at the bottom of the conduit to change the size of the opening, so that it can be balanced again. The device has a simple structure, is convenient for workers to operate, and the liquid can flow out in real time and steadily in proportion, and can realize mixing of the liquid in any proportion.

Owner:CHINA THREE GORGES UNIV

Bottled water bottle cap automatic reversing device

PendingCN112320287AGood reversalEffective change of directionConveyorsConveyor partsBottle capBottled water

The invention relates to the technical field of bottle cap automatic reversing devices, and discloses a bottled water bottle cap automatic reversing device which comprises a bottle cap screening box.A supporting frame is arranged at the bottom of the bottle cap screening box, and the left side and the right side of the bottle cap screening box are fixedly connected with the inner side of the topof the supporting frame. According to the bottled water bottle cap automatic reversing device, through cooperation of an arc-shaped pipe, a curved spiral pipe, a through groove and an inclined slidingdevice, when a bottle cap with a downward opening passes through an inclined sliding device in the through groove, and the bottle cap with the downward opening completely slides onto the inclined sliding device, at the moment, the bottle cap with the downward opening completely covers the inclined sliding device and then inclines downwards, the elastic force of an elastic telescopic component ina reverse cap separating device is smaller than the sum of the gravity of the bottle cap with the downward opening and the gravity of the inclined sliding device, the bottle cap with the downward opening is effectively turned, the structure is simple, cost is low. and meanwhile the direction adjusting speed of the reverse bottle cap is increased.

Owner:张曼玲

Plant extraction device for environment-friendly deodorant and extraction method thereof

ActiveCN114771003AReduce crushFully squeeze outPressesStationary filtering element filtersAgricultural engineeringElectric machinery

The invention discloses a plant extraction device for an environment-friendly deodorant and an extraction method thereof, and belongs to the technical field of deodorant production. The invention discloses a plant extraction device for an environment-friendly deodorant. The cylinder body is installed on the base, the cylinder body is composed of a cylinder shell and a cylinder bottom, the front side and the rear side of the cylinder shell are rotationally connected with limiting rings respectively, and the bottoms of the limiting rings are fixedly connected with the base through fixing blocks; the gear ring is fixedly connected to the end, away from the barrel bottom, of the barrel shell; the motor is fixedly connected to the side, close to the gear ring, of the base; according to the plant juice extraction device, plants can be crushed again while being squeezed to extract juice, so that the plants are crushed to be finer, juice of the plants can be squeezed out more sufficiently during squeezing, the plant juice extraction efficiency and the extraction amount of the plant juice extraction device are effectively improved, and the plant juice extraction device is suitable for popularization and use.

Owner:江苏天新环保科技有限公司

Small seed dual-purpose type built-in cone double-circular platform ring-type gas distribution mechanism

ActiveCN112470623BReduce lossesReduced Power RequirementsSeed depositing seeder partsAgricultural engineeringStructural engineering

The invention belongs to the technical field of agricultural machinery sowing, and specifically relates to a small-grain seed dual-purpose embedded cone-shaped double-circle ring-type air distribution mechanism, which includes an air flow access pipe, an air distribution mechanism housing, and an air distribution pipe. The mechanism housing includes three parts: a high round table tube, a short round table tube and an inverted cone. The outer surface of the short round table tube is evenly distributed on the circumference of a plurality of air distribution pipes connected with the special-shaped through-tube body. Compared with the prior art, the present invention has the following advantages: by rationally designing the structure of the airflow access pipe, the housing of the gas distribution mechanism and the airflow distribution pipe, the airflow is smoothly transitioned from the cylindrical section to the annular channel, and finally the seeds flow out evenly and steadily with the airflow The air distribution mechanism and multiple air distribution pipes realize the equal distribution of air flow in multiple directions, thereby ensuring the efficiency of small seeds of different shapes flowing out with the air flow; the overall structure is regular, and the integrated structure is easy to process, which can effectively control the processing cost. for promotional use.

Owner:ANHUI AGRICULTURAL UNIVERSITY

A microelectronic control switch

ActiveCN109630708BSuppress interferenceIncrease outflow rateOperating means/releasing devices for valvesSlide valveElectric machineryDrive motor

Owner:HUIZHOU TONGFABAO MICRO CONTROL TECH CO LTD

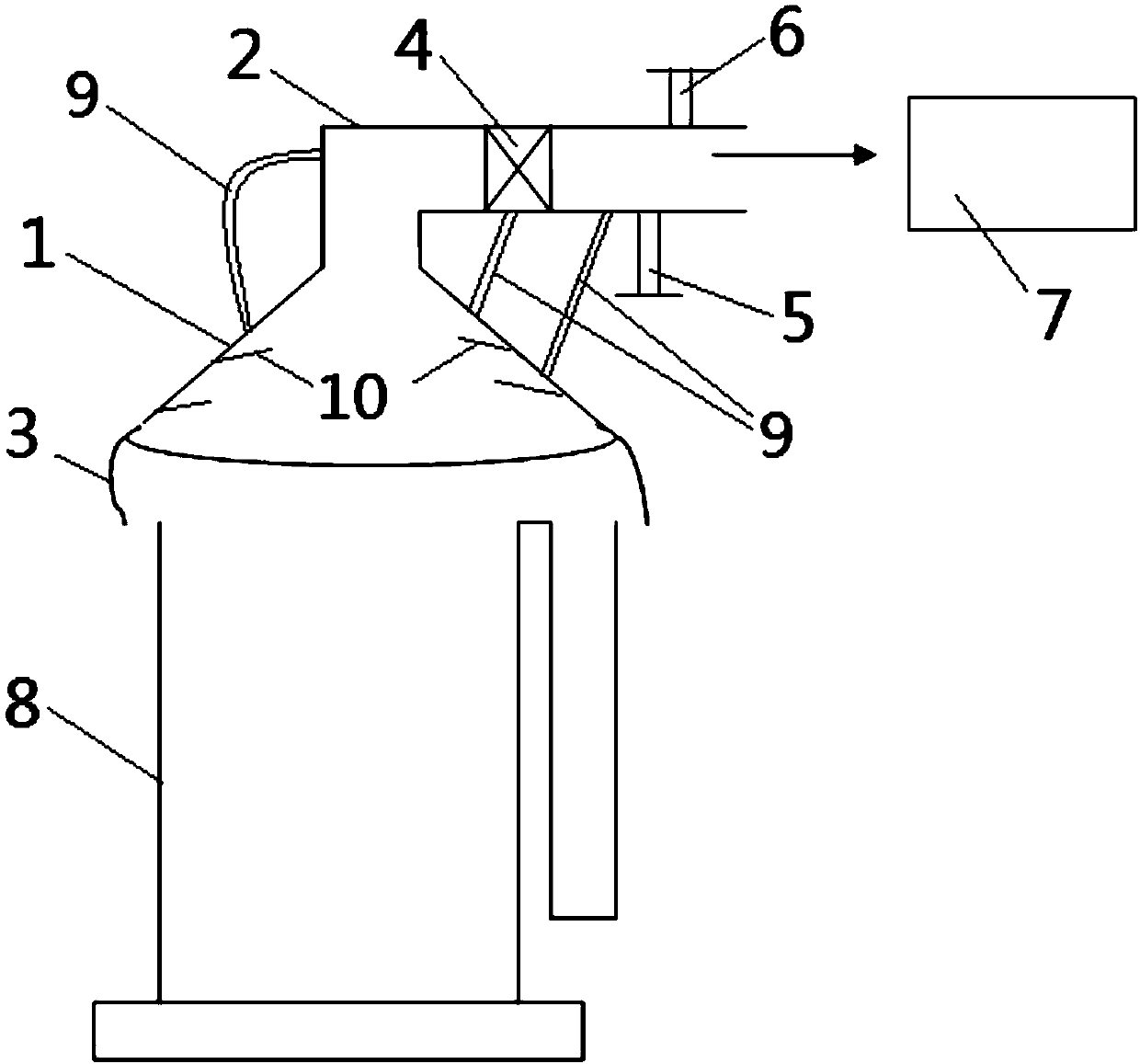

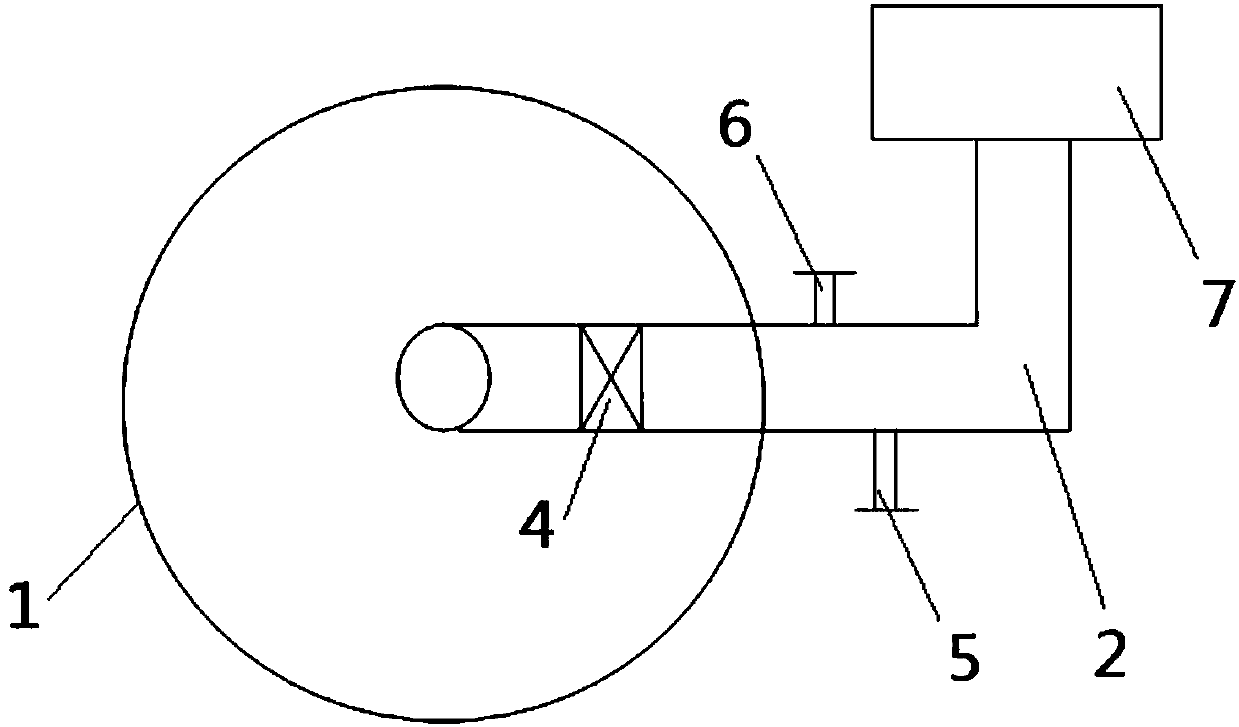

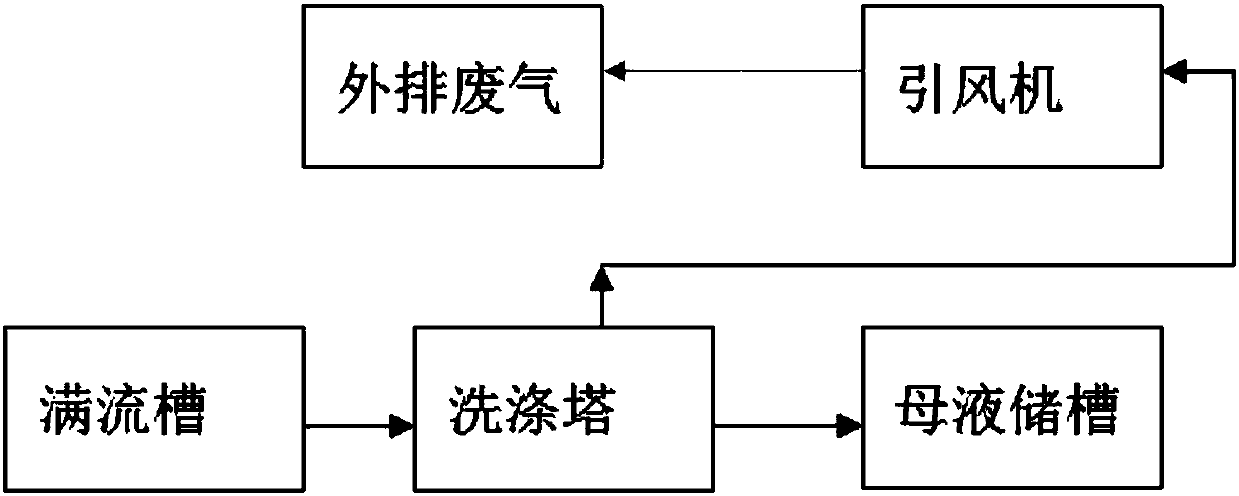

Efficient ammonium sulfate overflow groove tail gas treatment device

PendingCN107715655AIncrease outflow ratePrevent fallingGas treatmentDispersed particle separationPhysical chemistryCapillary Tubing

The invention discloses an efficient ammonium sulfate overflow groove tail gas treatment device. The efficient ammonium sulfate overflow groove tail gas treatment device comprises a cylinder opened atthe two ends and a communicating pipe; the cylinder is arranged at the top of an overflow groove, and the top of the cylinder is communicated with a washing tower through the communicating pipe; multiple capillary pipes are communicated with the part between the communicating pipe and the middle of the cylinder; a multi-layer annular lug plate is arranged on the inner wall of the cylinder and tilts upwards. The efficient ammonium sulfate overflow groove tail gas treatment device has an excellent capability of purifying smoke of the overflow groove.

Owner:WUHU XINXING DUCTILE IRON PIPES

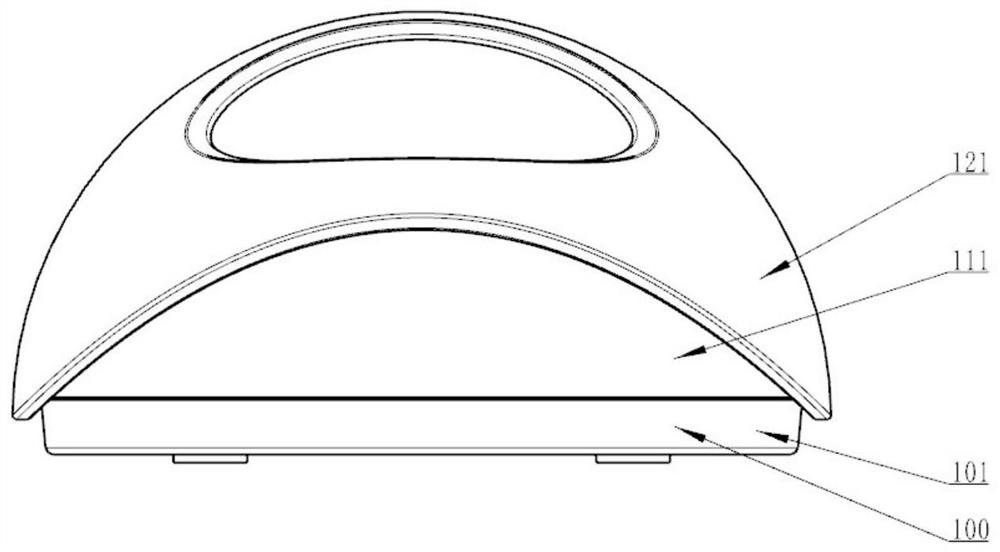

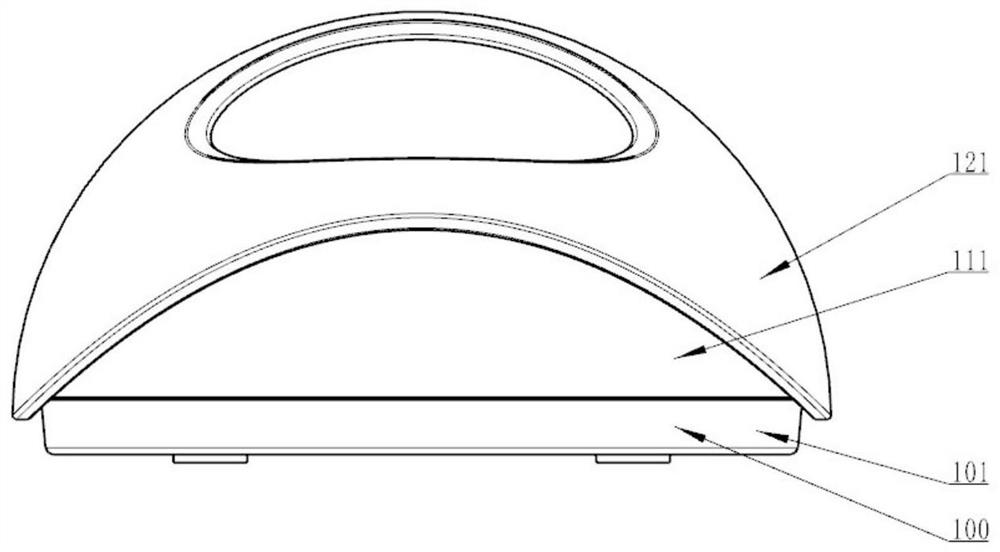

Multi-container liquid or solid vaporization mixed flow device and odor release method

ActiveCN111991599BChange the smellSolve the release problemGaseous substancesMechanical engineeringAirframe

The invention provides a multi-container liquid or solid vaporization mixed flow device and an odor release method, comprising: a main board, a body, a machine cover, a plurality of containers and a plurality of heating modules; the plurality of heating modules are respectively connected with the The main board is electrically connected, and the multiple heating modules and the main board are arranged inside the fuselage, and the multiple containers respectively pass through the outer wall of the fuselage and correspond to the multiple heating modules one by one connected; the cover is connected to the fuselage to cover the plurality of containers, the cover has an opening; there is a gap between the cover and the fuselage to form a first wind road. The heating combination of different fragrances is realized through multiple heating modules, and the released smells are mixed in the machine cover, so as to achieve the purpose of changing the smell and taste. Through the first air duct between the fuselage and the machine cover, the outflow rate of the smell released to the outside is increased, and the problem of releasing the smell after mixing is solved, and the problem of heat dissipation inside the machine cover is also solved.

Owner:无界工场(上海)设计科技有限公司

Method for detecting yeast metabolic activity in fermentation process of beer

ActiveCN102212603BOutflow rate constantIncrease outflow rateMicrobiological testing/measurementMicroorganism based processesBiotechnologyYeast

The invention discloses a method for detecting the metabolic activity of yeast in the beer fermentation process, comprising the following steps: after starving the yeast collected in the fermentation liquid, adjusting the induced initial pH of the bacteria suspension, adding glucose to induce the outflow of yeast H+, and calculating Yeast maximum H+ efflux rate, and it is used to characterize the metabolic activity of yeast. The method of the invention can not only accurately reflect the difference in the activity of yeast strains, but also can be used to evaluate the metabolic activity of yeast in the fermentation process, and the result is accurate and repeatable. The invention can be used to quickly analyze the metabolic status and fermentation performance of yeast in the beer fermentation process.

Owner:SOUTH CHINA UNIV OF TECH

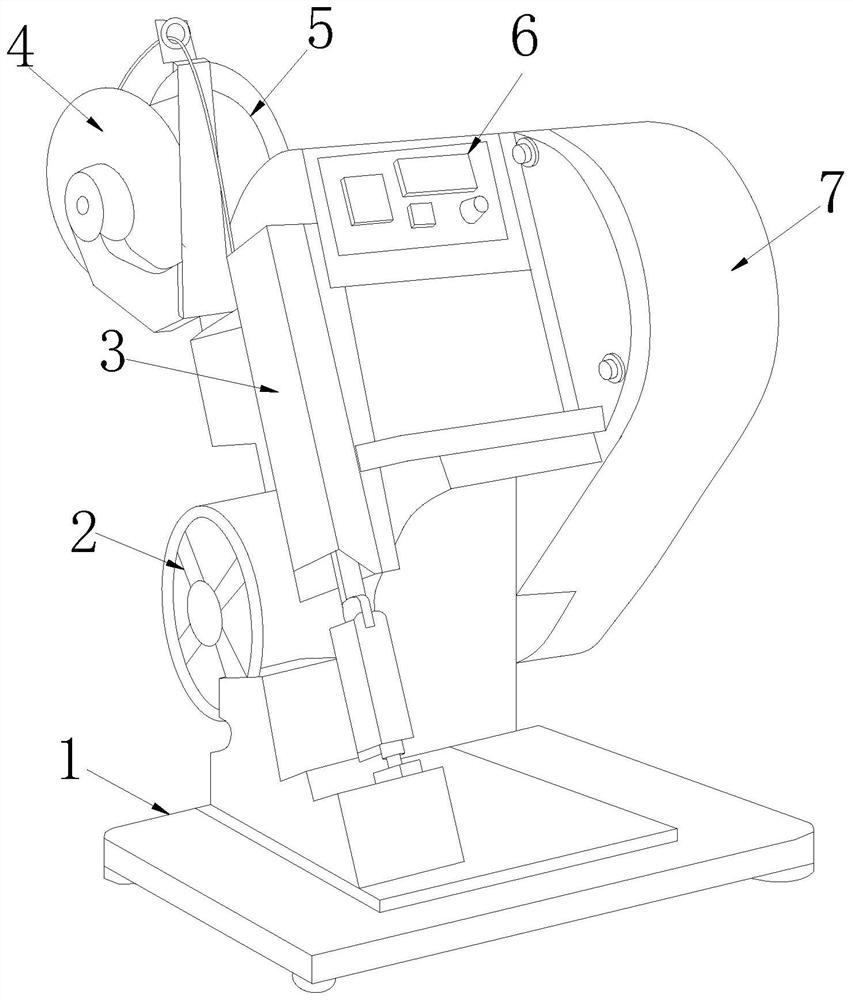

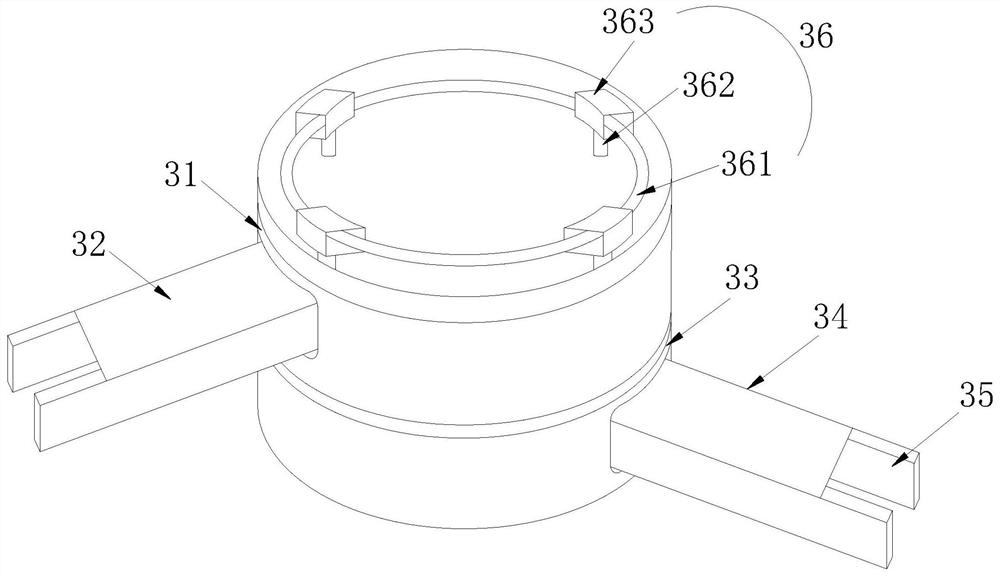

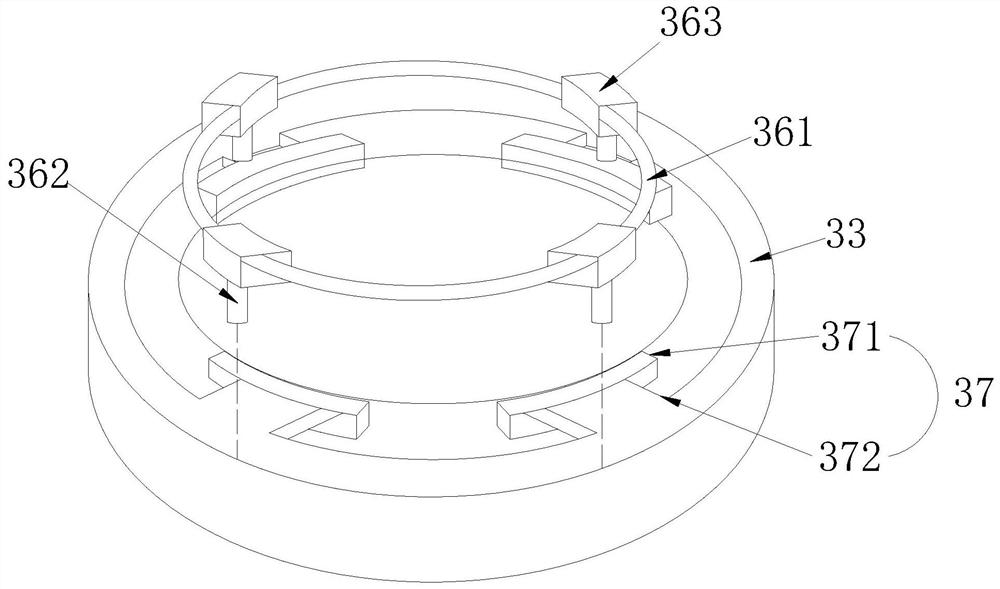

A multifunctional copper belt machine

ActiveCN111390032BAvoid sideways situationsImprove alignment accuracyShaping toolsShaping safety devicesEngineeringMechanical engineering

The invention discloses a multi-functional copper strip machine, the structure of which comprises a base, a traction wheel, a mold base, a feeding wheel, a wire management disc, a control panel, and a main control box. The main control box is installed on the side of the mold base, and the mold base Fixed on the base, the outer surface of the mold base is provided with a control panel, the control panel is electrically connected to the main control box, and the back of the mold base is mechanically connected to the feeding wheel and the cable management disc, and the transmission between the cable management disc and the feeding wheel is coordinated. There are copper strips, and the mold base includes an upper mold, an upper mold shaft, a lower mold, a lower mold shaft, a cutter loading port, a mold base aligner, and an alignment member. The mold base is used for alignment between the upper mold and the lower mold of the present invention. Only when the alignment shaft is completely embedded in the calibration groove, the upper and lower molds are completely aligned to avoid the situation of being squeezed to one side, and effectively prevent the burr at the cut-off from not being able to catch the line and clamping The knife problem.

Owner:安徽金池新材料有限公司

Multi-container liquid or solid vaporization flow mixing device and odor release method

ActiveCN111991599AChange the smellSolve the release problemGaseous substancesThermodynamicsProcess engineering

The invention provides a multi-container liquid or solid vaporization flow mixing device and an odor release method. The device comprises a main board, a machine body, a machine cover, a plurality ofcontainers and a plurality of heating modules; a plurality of the heating modules are electrically connected to the main board respectively, a plurality of the heating modules and the main board are arranged in the machine body, and a plurality of the containers penetrate through the outer wall of the machine body respectively and are connected to a plurality of the heating modules in a one-to-onecorrespondence manner; the machine cover is connected to the machine body, covers a plurality of the containers, and is provided with an opening; and a gap is formed between the machine cover and themachine body to form a first air duct. Heating combination of different spices is achieved through a plurality of the heating modules, released smells are mixed in the machine cover, and therefore the purpose of changing the smells is achieved. Through the first air duct between the machine body and the machine cover, the outflow rate of outward smell release is increased, and the problem of heatdissipation in the machine cover is solved while the problem of smell release after mixing is solved.

Owner:无界工场(上海)设计科技有限公司

A honey shaker and honey production line

InactiveCN107094665BNo cloggingIncrease outflow rateHoney collectionFood scienceGear wheelEngineering

The invention provides a honey extractor and a honey production line, and relates to the technical field of honey production. The honey extractor comprises a power device, a first transmission assembly, a stirring blade, a first gear, a second gear and a gear adjusting part, wherein the output shaft of the power device is provided with a worm; the gear adjusting part comprises a gear frame, a limit rod, an adjusting screw and a slide rail; the first gear is arranged on the gear frame which is slidably arranged on the slide rail; the limit rod is connected with the slide rail; the adjusting screw rotatably penetrates through the limit rod and is rotatably riveted with the gear frame; the adjusting screw is provided with a hand wheel; the second gear is in transmission connection with the main rotating shaft of the honey extractor; the stirring blade is arranged on a honey outlet pipe; the rotating shaft of the stirring blade penetrates through the honey outlet pipe and is in transmission connection with a power output shaft; the gear frame is positioned at a first slide stop point; a first gear ring is in transmission fit with the worm; the gear frame is located at a second slide stop point; and the first gear ring is separated from the worm. The honey production line comprises the above-mentioned honey extractor. The honey production line and the honey extractor can accelerate the outflow of honey, improve the extraction efficiency of the honey, and do not need closing the power device during replacement of a honey comb.

Owner:武汉康思农生物科技有限公司

Crack pouring device for straight seam of assembly type capping beam pier column

PendingCN114703754AWith cleaning functionAccelerate the filling processHollow article cleaningBridge structural detailsClassical mechanicsEngineering

The crack pouring device comprises a shell, the top of the shell is open, supporting rods are fixedly connected to the positions, close to the four corners, of the bottom of the shell, and a feeding mechanism is arranged on the right side of the shell. According to the multifunctional crack pouring machine, the inner wall of the shell is cleaned, raw materials are stirred to manufacture crack pouring slurry, the crack pouring progress is accelerated, and the multifunctional crack pouring machine is diversified in function; according to the crack pouring device, the flowing-out speed of crack pouring slurry through the slurry outlet pipe can be increased, the crack pouring efficiency is further improved, the use effect is good, and through cooperative use of a series of components such as a scraper, a cross rod and a first spring, the inner wall of the shell can be conveniently cleaned after crack pouring operation is completed.

Owner:朱晓东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com