A honey shaker and honey production line

A technology of a honey shaker and a honey room, which is applied in the fields of honey collection, beekeeping, animal husbandry, etc., can solve the problems of reducing the working efficiency of honey shaking, reducing the efficiency of honey production, and easily hindering the flow of honey, so as to promote the flow of honey as soon as possible. The effect of preventing honey hoarding and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

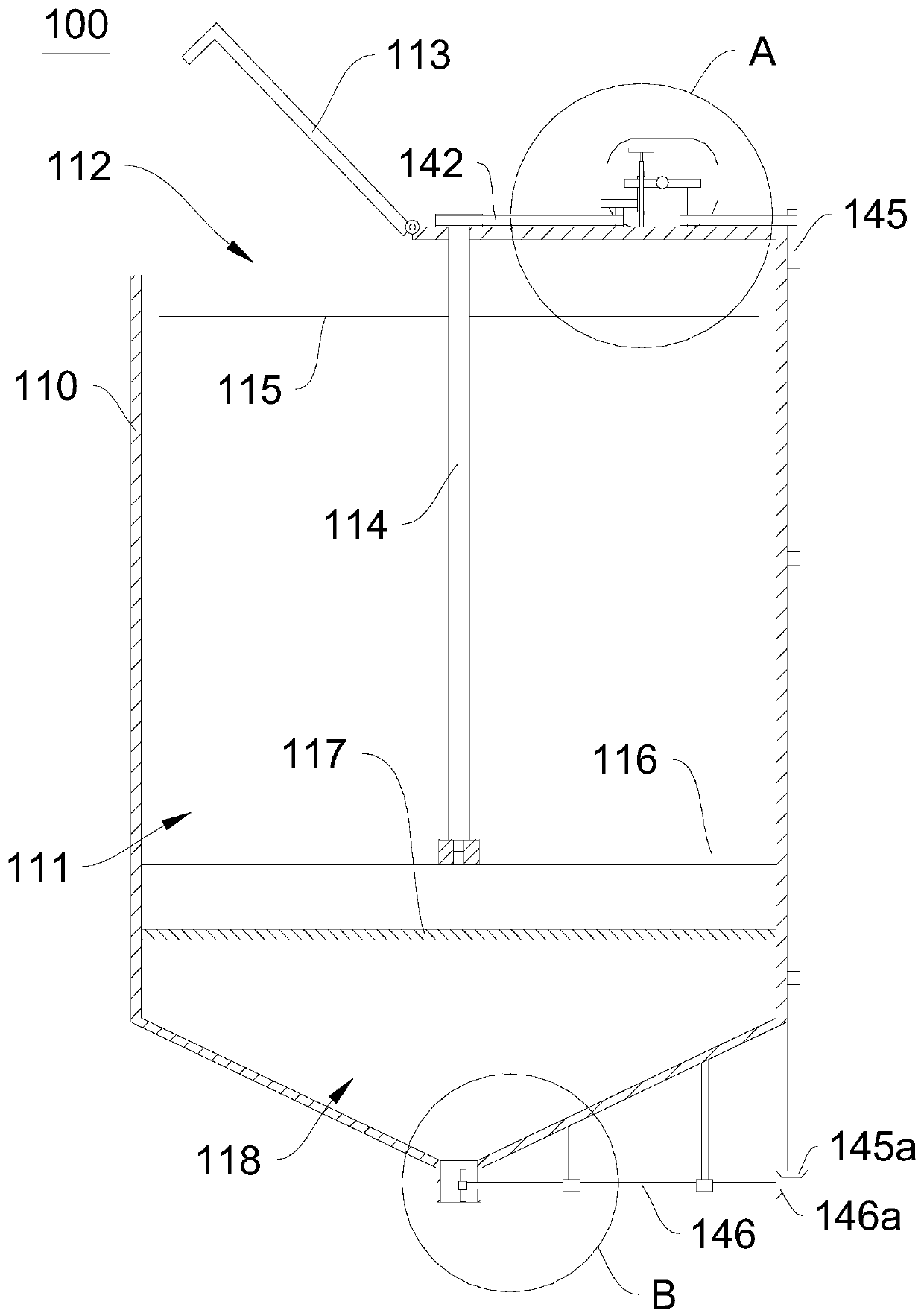

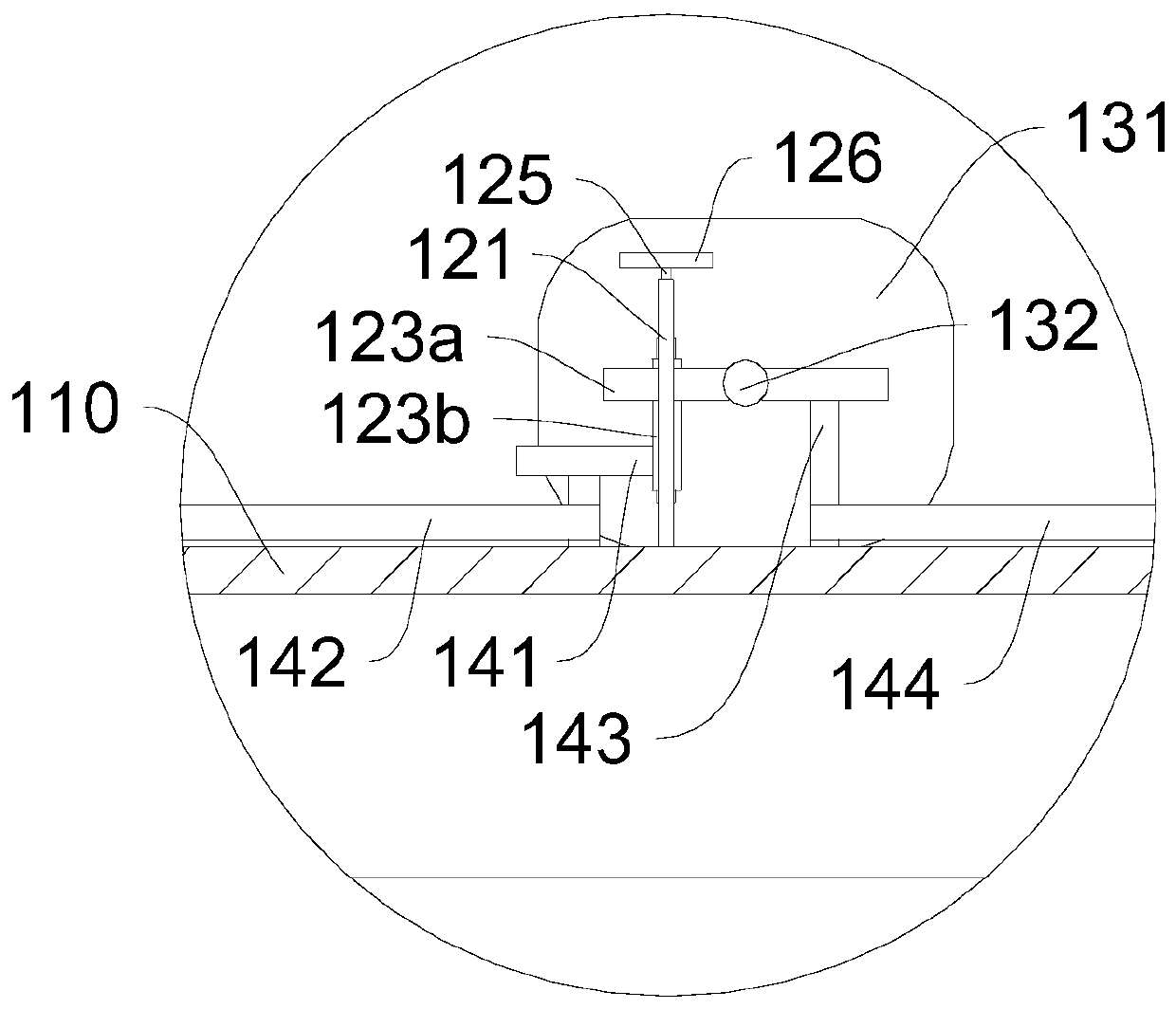

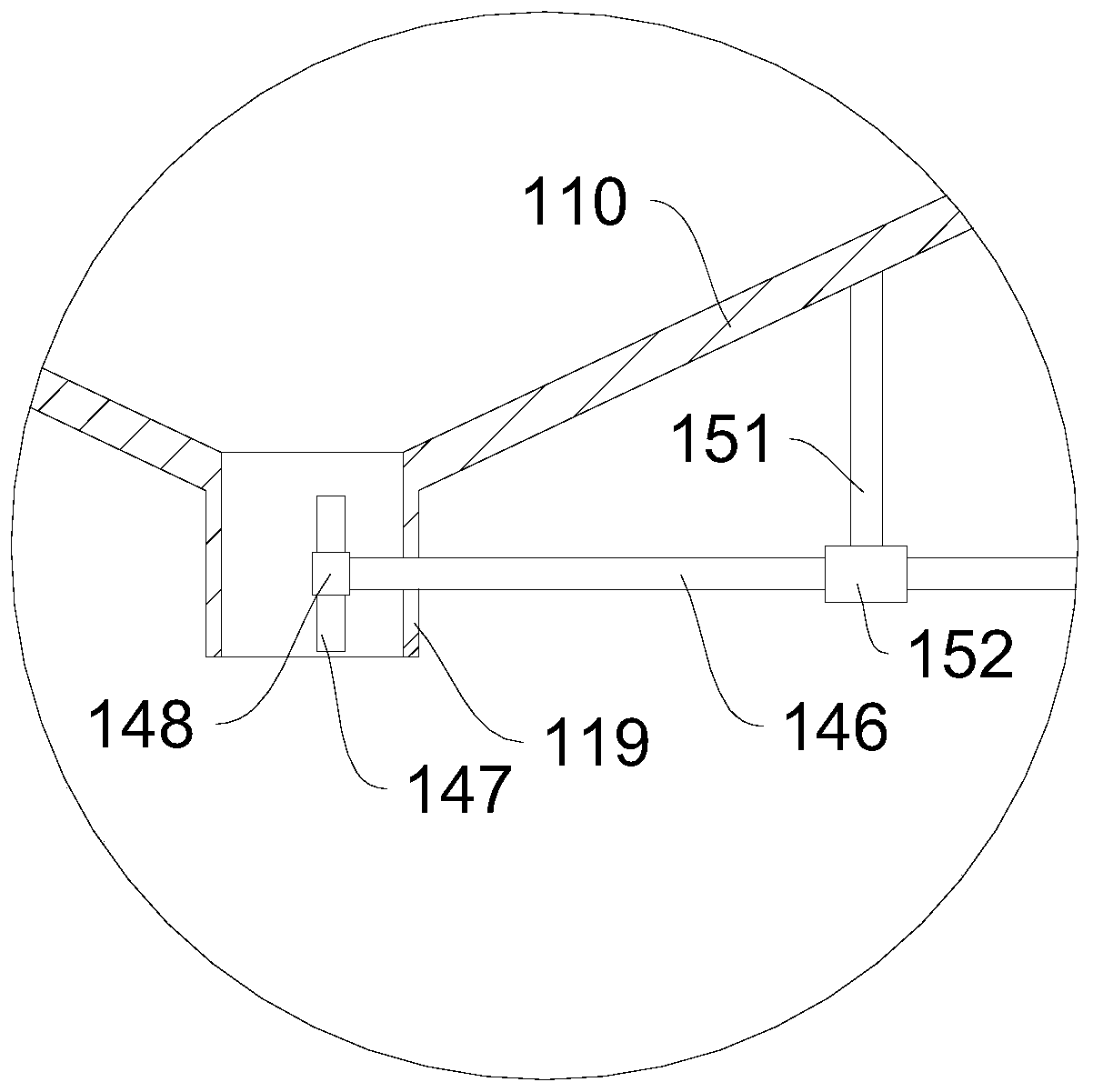

[0035] Please refer to figure 1 , figure 2 with image 3 , the present embodiment provides a honey shaker 100 , the honey shaker 100 includes a power device 131 , a first transmission assembly and a stirring blade 147 . The honey shaker 100 has a honey shaker chamber 111 surrounded by side walls 110, the honey shaker chamber 111 has a feed port 112 for putting honeycombs in and a honey discharge pipe for outputting the shaken honey out of the honey shaker chamber 111 119.

[0036] The power device 131 is arranged on the outside of the side wall 110 of the honey shaker chamber 111 of the honey shaker 100 , and the power output shaft of the power device 131 is coaxially connected with a worm 132 .

[0037] The honey shaker chamber 111 is provided with a main rotating shaft 114, one end of the main rotating shaft 114 runs through the side wall 110 for transmission connection with the power unit 131, and the other end rotatably abuts against the stabilizing frame 116, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com