Patents

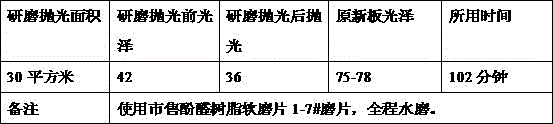

Literature

175results about How to "Increase grinding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

Granulation type pouncing paper, preparation method and application thereof

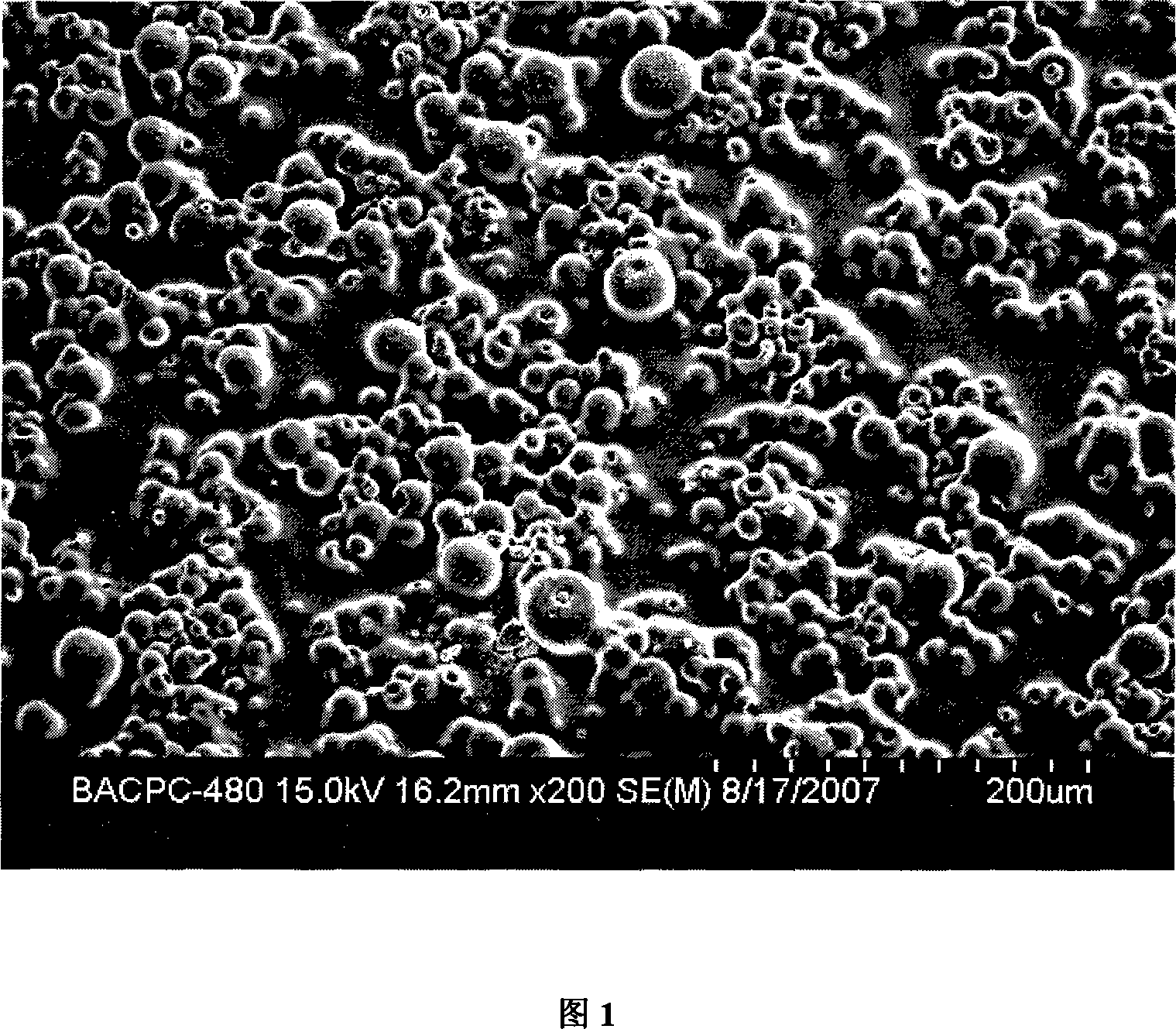

ActiveCN101219530AEvenly dispersedGrinding force does not decreaseAbrasion apparatusFiberMetal alloy

The invention provides a pelleting emery paper which can sharpen self and has durable grinding property and a preparation method and applications thereof. The invention comprises compound grinding grains which are coated to the surface of a substrate through adhesive and show aggregate ball shape. The grinding powders in the compound grinding grains are dispersed in one or more metal oxide sol which is mixed with organic adhesives or inorganic adhesives. The grain diameter of the grinding powder is not more than 10 micron meters and the diameter of the compound grinding grain is 5-50 micron meters. The emery paper is applicable in the grinding and polishing of most work pieces including metal, metal alloy, ceramic, optical element, fiber connecter, hard disc and semiconductor, etc.

Owner:BEIJING GRISH HITECH

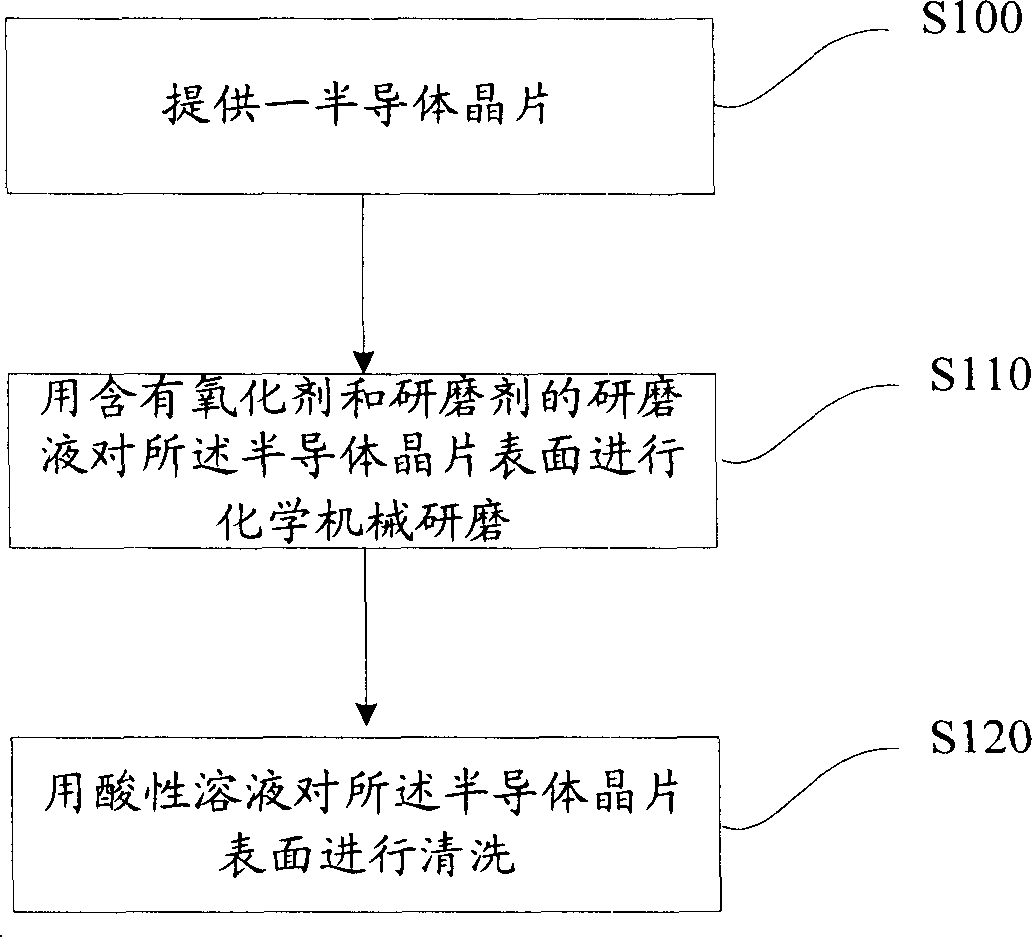

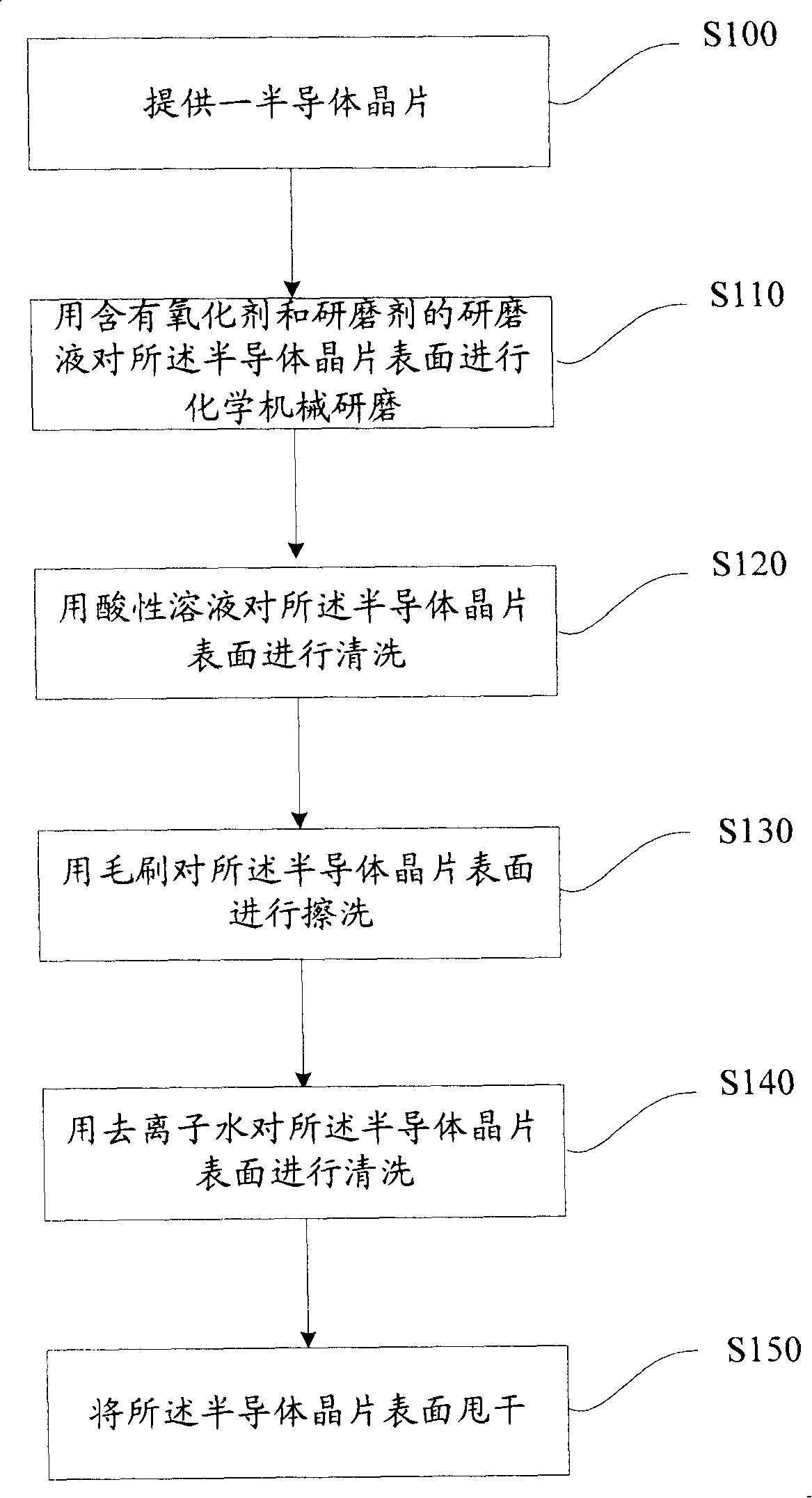

Method for eliminating leftover after chemical mechanical grinding

InactiveCN101197268AReduce or eliminate corrosionImprove reliabilitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesElectrical conductorCompound (substance)

The invention relates to a removing method for residue after chemical and mechanical grinding, which comprises the following steps of: providing a semi-conductor wafer; performing chemical and mechanical grinding for the surface of the semi-conductor wafer by using a grinding solution containing oxidizer and grinding agent; and cleaning the surface of the semi-conductor by acidity solution. The method can remove the grinded pollutant residue.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

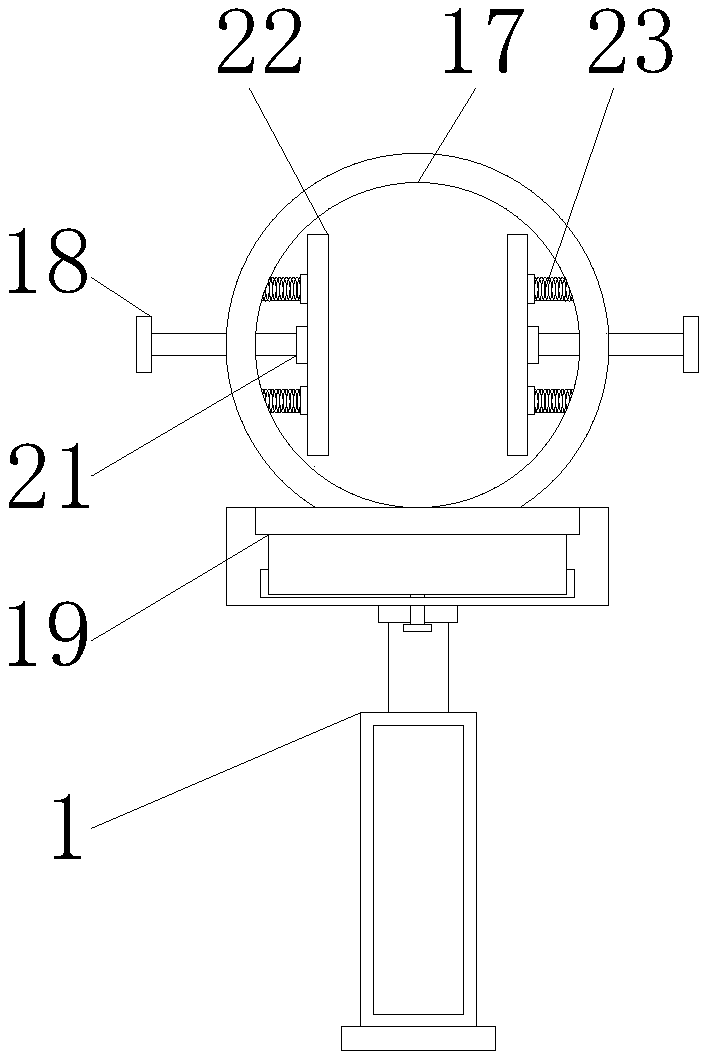

Polishing equipment suitable for steel pipes of different pipe diameters

ActiveCN109702634ASpeed up the flowImprove sanding qualityEdge grinding machinesPolishing machinesSteel tubeEngineering

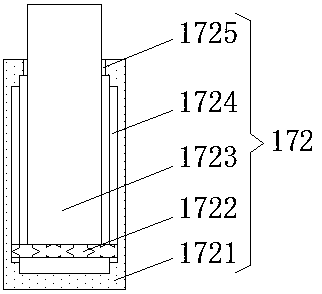

The invention belongs to the technical field of steel pipe polishing equipment, and particularly relates to polishing equipment suitable for steel pipes of different pipe diameters. The polishing equipment comprises a rack, an outer cylinder, an inner cylinder and a pipe body, wherein the inner side of the rack is fixedly connected to the outer cylinder; through holes are formed in the top and bottom of the rack; the top end of the outer cylinder is fixedly connected to the inner cylinder; the outer cylinder is used for storing gravels; a polishing module is arranged at the bottom of the outercylinder and comprises a polishing ring No. 1, a polishing ring No. 2, a polishing ring No. 3, a polishing ring No. 4, a curved gear No. 1 and a curved gear No. 2; the polishing ring No. 1, the polishing ring No. 2, the polishing ring No. 3 and the polishing ring No. 4 are arranged from top to bottom in sequence; the inner diameters of a through hole No. 1, a through hole No. 2, a through hole No. 3 and a through hole No. 4 are decreased in sequence; and the through hole No. 1, the through hole No. 2, the through hole No. 3 and the through hole No. 4 are used cooperatively for the fine polishing of pipe bodies of different pipe diameters. The polishing equipment can effectively improve the polishing quality of the pipe body and reduces the clearing workload of the later period.

Owner:张家港市银坤泰金属制品有限公司

Polishing device for machining of stainless steel pipe

InactiveCN109605147AEasy to replaceIncrease grinding rateGrinding wheel securing apparatusGrinding carriagesArchitectural engineeringMachining

The invention discloses a polishing device for machining of a stainless steel pipe. The polishing device comprises a hydraulic telescopic cylinder, a motor, a fixed installing sleeve and a pipe body.The bottom of the hydraulic telescopic cylinder is fixed to an extending bottom plate. One end of the extending bottom plate is connected in a support seat. A side edge ball is fixed to the outer sideof an installing disc. The fixed installing sleeve is fixed to the left side face of the installing disc. The pipe body and the outer sides of first polishing rollers are attached to each other. A fixed table is fixedly welded to the top of the hydraulic telescopic cylinder. An extending table is connected to the right side of the fixed table. A second threaded rod penetrates through the fixed table to be connected with a bearing. The left side face of the installing disc is provided with a sliding groove. Side edge blocks are welded to the outer side of a movable installing sleeve symmetrically. According to the polishing device for machining of the stainless steel pipe, three parallel polishing rollers are arranged, the first polishing rollers are symmetrically installed at the upper and lower ends of the second polishing roller, and thus the inner and outer sides of the pipe body can be polished simultaneously.

Owner:沈勤娟

Grinding liquid used for grinding back surface of storage hard disk magnetic head

InactiveCN1651544AEvenly distributedImprove dispersion stabilityOther chemical processesAntistatic agentPreservative

An abrasing liquid for abrasing the back of magnetic head for hard disc contains proportionally mineral oil containing C11-C13 alkane, oiling agent, superfine monocrystal diamond powder, antioxidizing anticorrosion agent, non-ionic surfactant, defoaming agent, and antistatic agent.

Owner:TSINGHUA UNIV +1

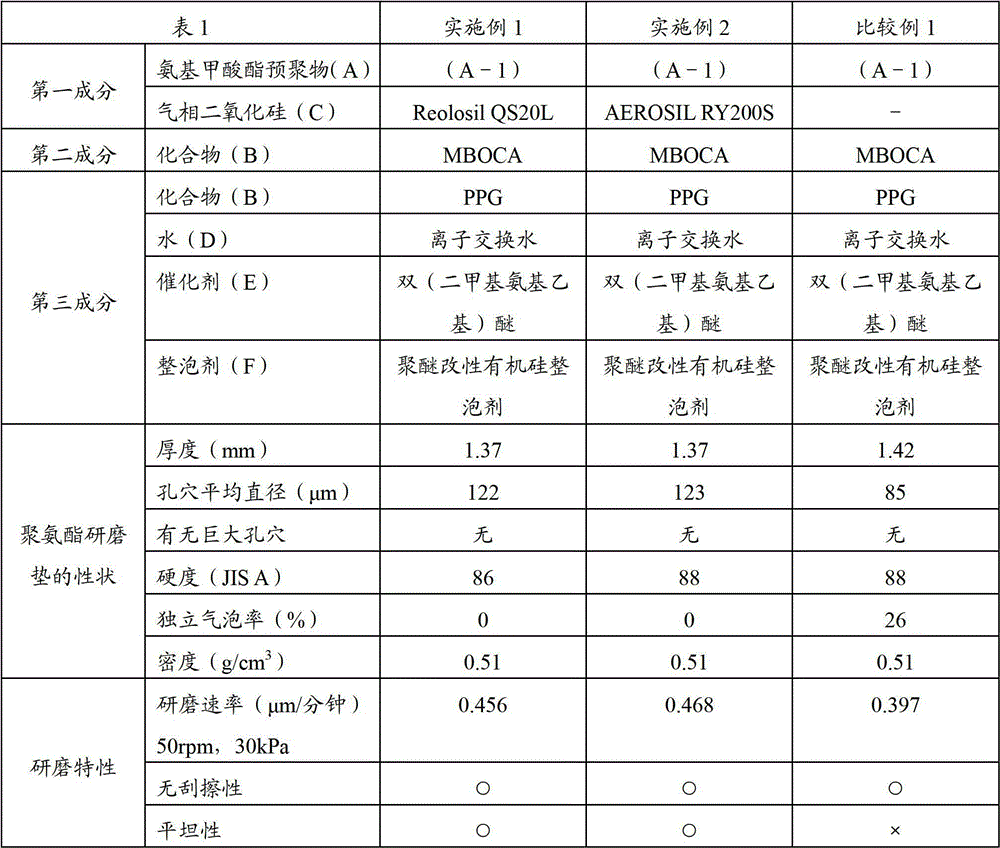

Carbamate resin composition for polishing pad and polyurethane polishing pad

ActiveCN103059551AIncrease grinding rateNon-scratchSemiconductor/solid-state device manufacturingLapping toolsCarbamateFumed silica

The invention aims at providing a CMP method polishing pad having excellent polishing characteristics (high polishing rate, non-scraping, and flatness). The invention relates to a carbamate resin composition for the polishing pad which comprises a base resin of isocyanate group-containing carbamate prepolymer (A) and a curing agent (B) of a functional group which reacts with isocyanate group and also fumed silica (C). In addition, a polyurethane polishing pad obtained by using the composition is also provided.

Owner:DIC CORP

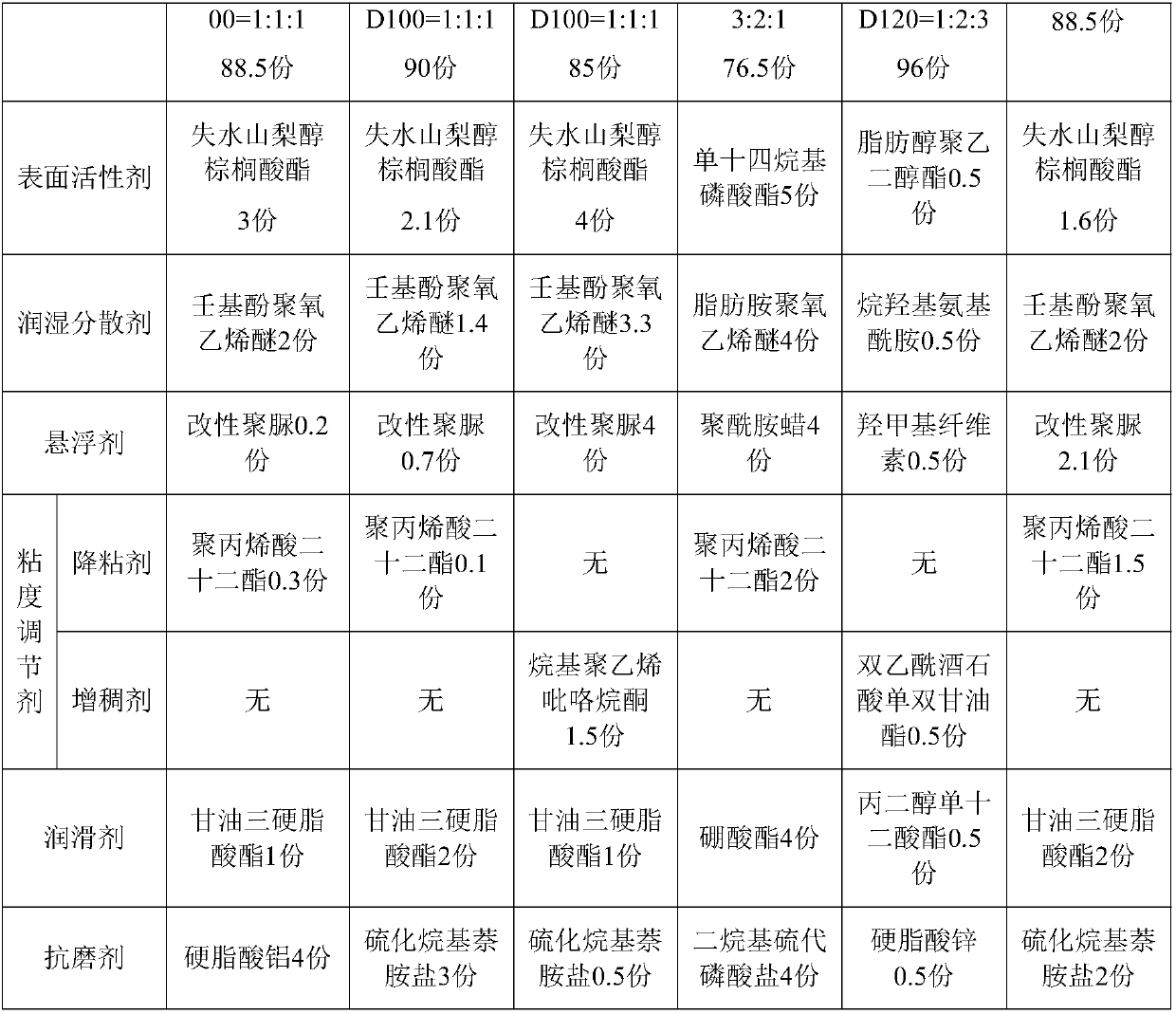

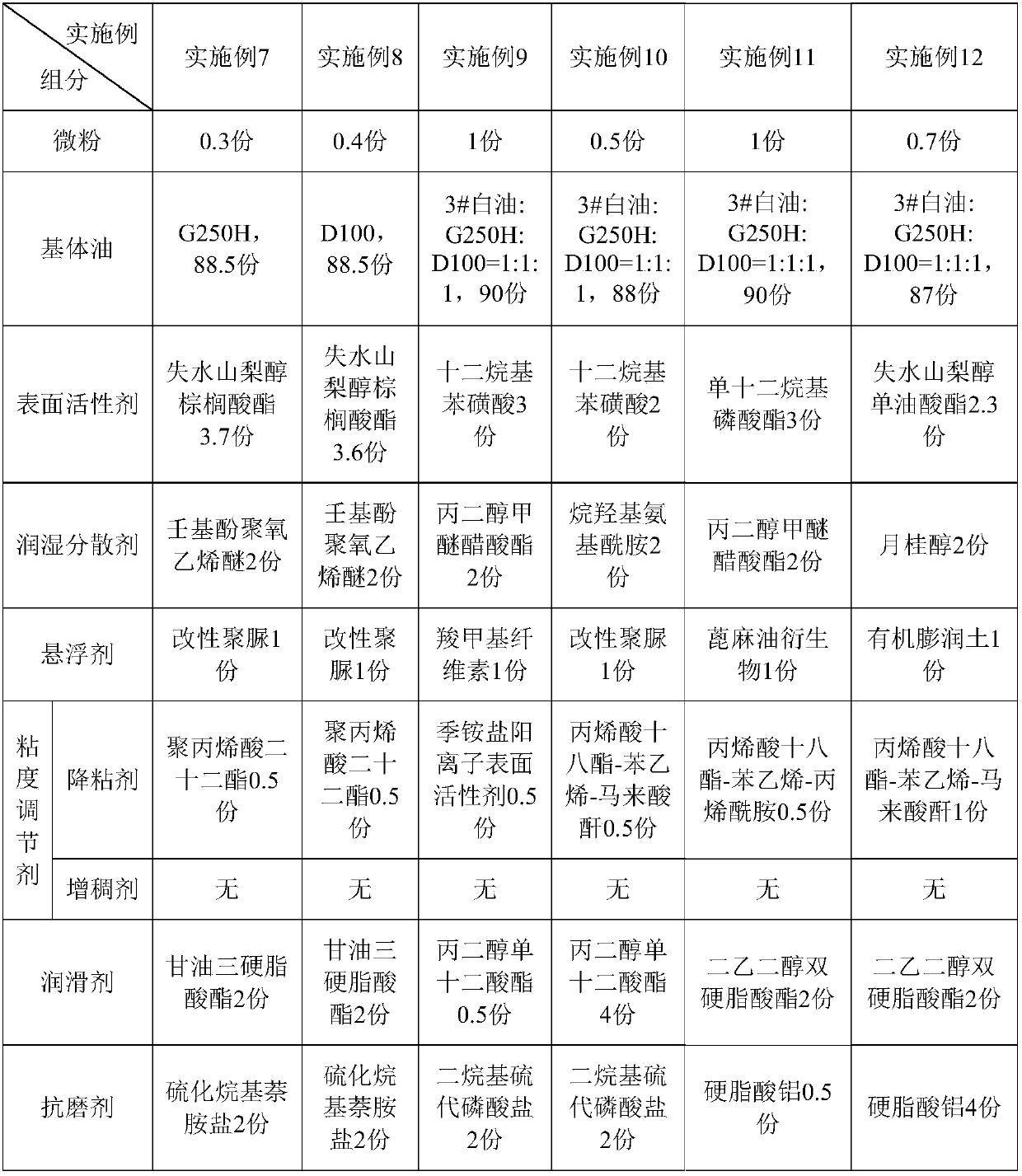

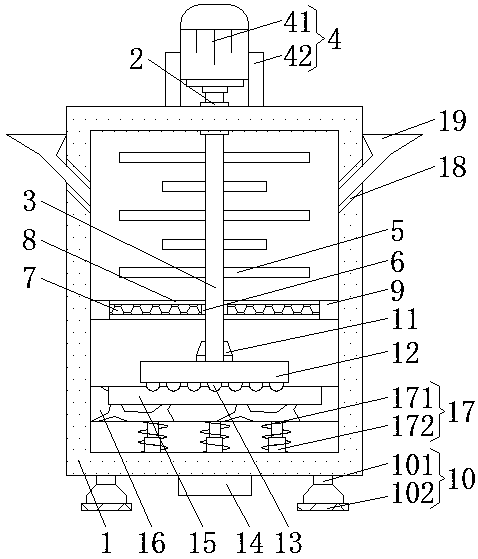

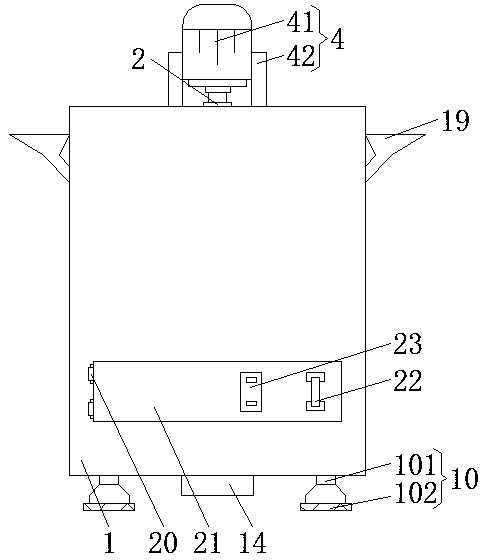

Oily grinding liquid and preparation method thereof

ActiveCN107699140AImprove processing efficiencyPlate temperature controllableOther chemical processesPolishing compositions with abrasivesPolymer scienceReducer

The invention provides oily grinding liquid and a preparation method thereof. The oilness grinding liquid is mainly prepared from the following components: diamond micropowder, matrix oil, a surfactant, a wetting dispersant, a suspension concentrate, a lubricant, an antiwear additive and a viscosity modifier. The preparation method comprises the following steps: after performing ultrasonic stirring on the diamond micropowder, the surfactant and the matrix oil for 5-10min, adding the wetting dispersant and the suspension concentrate, and performing ultrasonic stirring for 5-10min; and then adding the lubricant and the antiwear additive, performing ultrasonic stirring for 5-10min, determining viscosity, and stirring for a period of time after adding a viscosity reducer or a thickener according to the actual viscosity to obtain the oily grinding liquid. When being applied to sapphire substrate precision machining, the oily grinding liquid provided by the invention has the outstanding features of high grinding rate, controllable grinding disc temperature and small TTV, can improve the grinding processing efficiency, lowers the processing cost, is small in smell and liable to clean andis green and environmentally friendly.

Owner:BEIJING GRISH HITECH

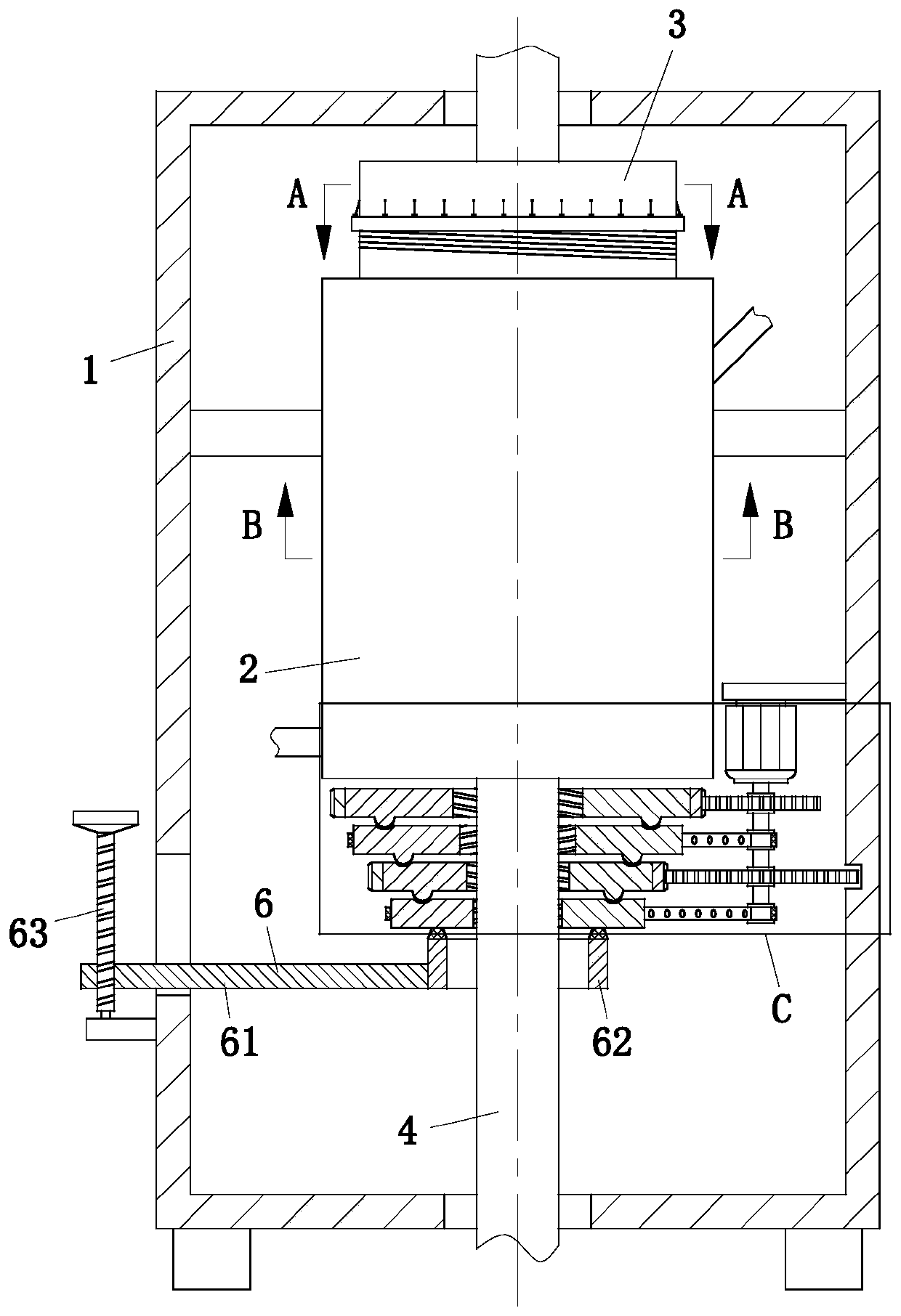

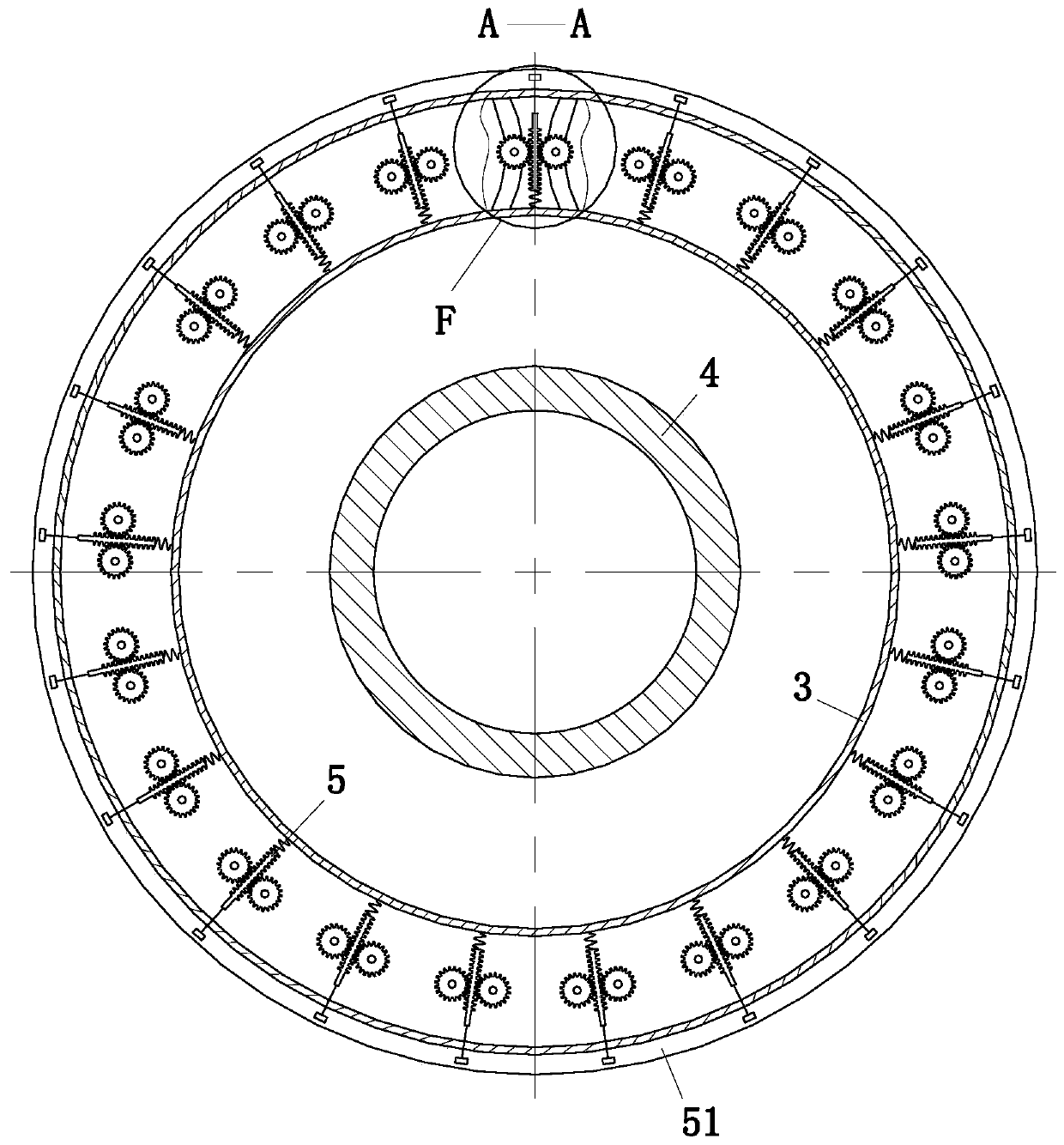

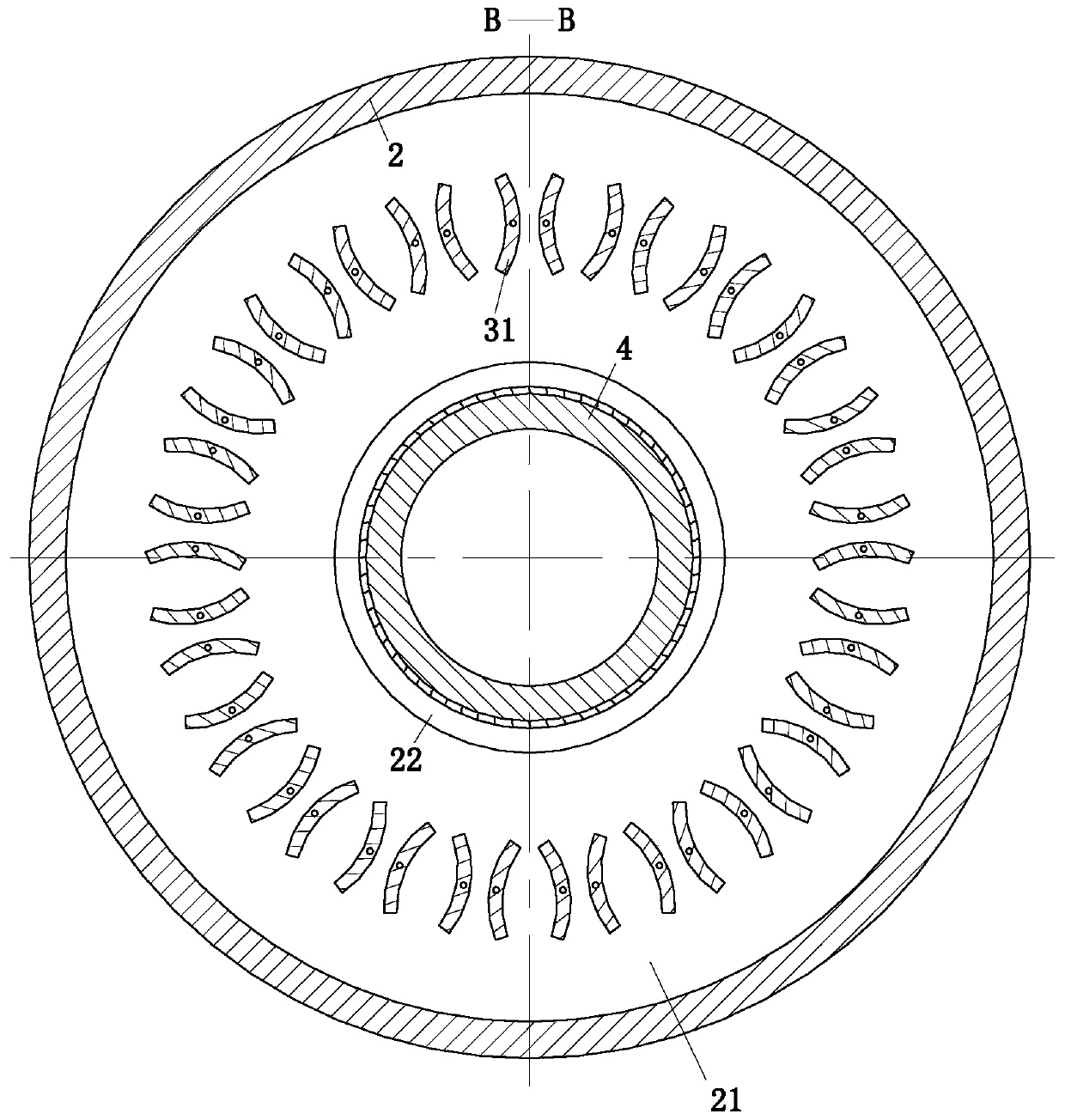

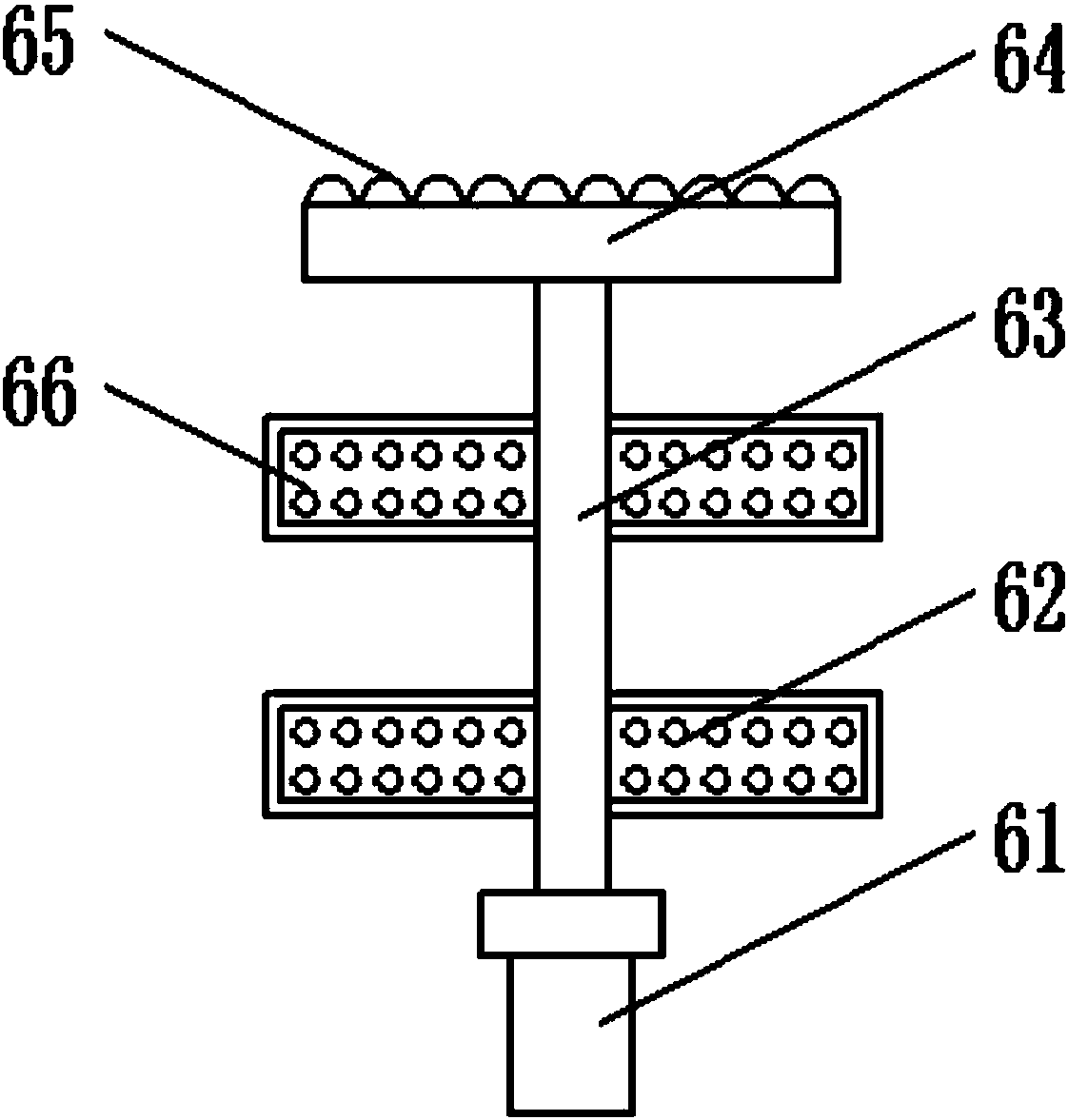

Grinding device for finish machining of ores

InactiveCN108993682AImprove work efficiencyIncrease grinding rateCocoaGrain treatmentsEngineeringMachining

The invention discloses a grinding device for finish machining of ores. The grinding device for finish machining of the ores comprises a grinding box body; a bearing is clamped in the middle part of the upper surface of the grinding box body; a rotating shaft is sleeved with the bearing; the top of the rotating shaft is fixedly connected with an output shaft of a driving device; the lower surfaceof the driving device is fixedly connected to the upper surface of the grinding box body; a plurality of crushing blades are fixedly connected to the left and right side surfaces of the rotating shaft; and the crushing blades are positioned in the grinding box body. The grinding device for finish machining of the ores, disclosed by the invention, has the advantages that ore raw materials penetratethrough small holes in a screening plate to fall into a grinding groove by arranging the driving device when the ore raw materials are small to a certain degree; a grinding disc can also be driven torotate at a high speed in the rotating process of the rotating shaft so that the ore raw materials in the grinding groove can be ground and machined; the ore raw materials entering the grinding box body are crushed and ground in sequence so that the grinding effect and the grinding efficiency of the grinding disc can be both guaranteed.

Owner:周佩龙

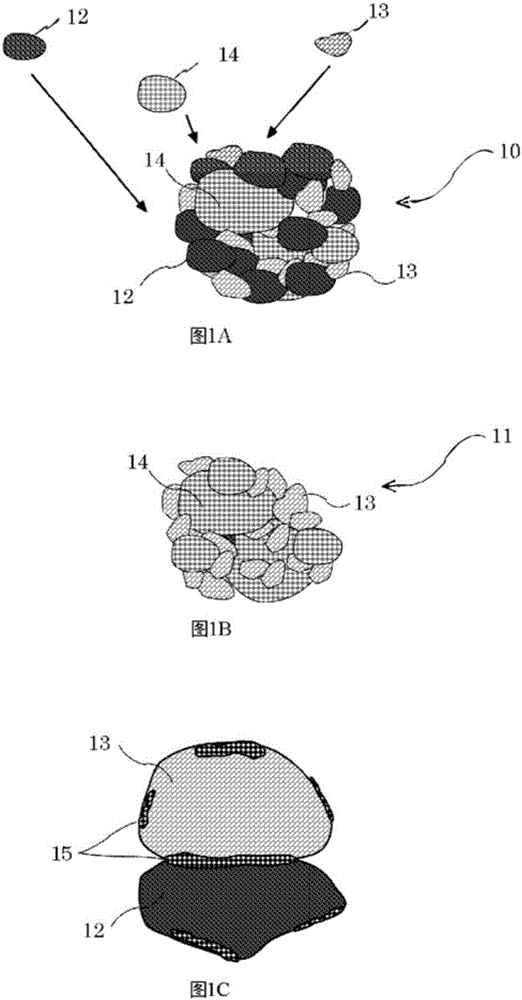

Polishing abrasive particle, production method therefor, polishing method, polishing device, and slurry

ActiveCN105940076AChemical abrasive action promotesFacilitates chemical abrasive actionOther chemical processesSemiconductor/solid-state device manufacturingLiquid wasteSlurry

[Problem] To polish the surface of an object material at a high removal rate and into a high-quality surface. [Solution] The object material is polished by wet polishing. A slurry comprises polishing abrasive particles dispersed in pure water. Each of the polishing abrasive particles comprises a component that exerts a mechanochemical action, a component that reacts to a frictional heat generated when polishing the object material, and the like, integrated into a particle as a whole. The components are bonded directly to one another by mechanical alloying while each retains the inherent properties of the substances in the individual component. Using this slurry in a lapping process for sapphire, silicon carbide, gallium nitride, and the like, allows the polishing time to be much shorter than conventionally, and allows the processing costs to be reduced significantly. The quality of the polished surface is high. The polishing abrasive particle can be used repeatedly for polishing. As the pH of the slurry is on the order of 3 to 9, there is no impact on the environment of the polishing work area, and processing of liquid waste is simple.

Owner:ASAHI CHEM IND CO LTD

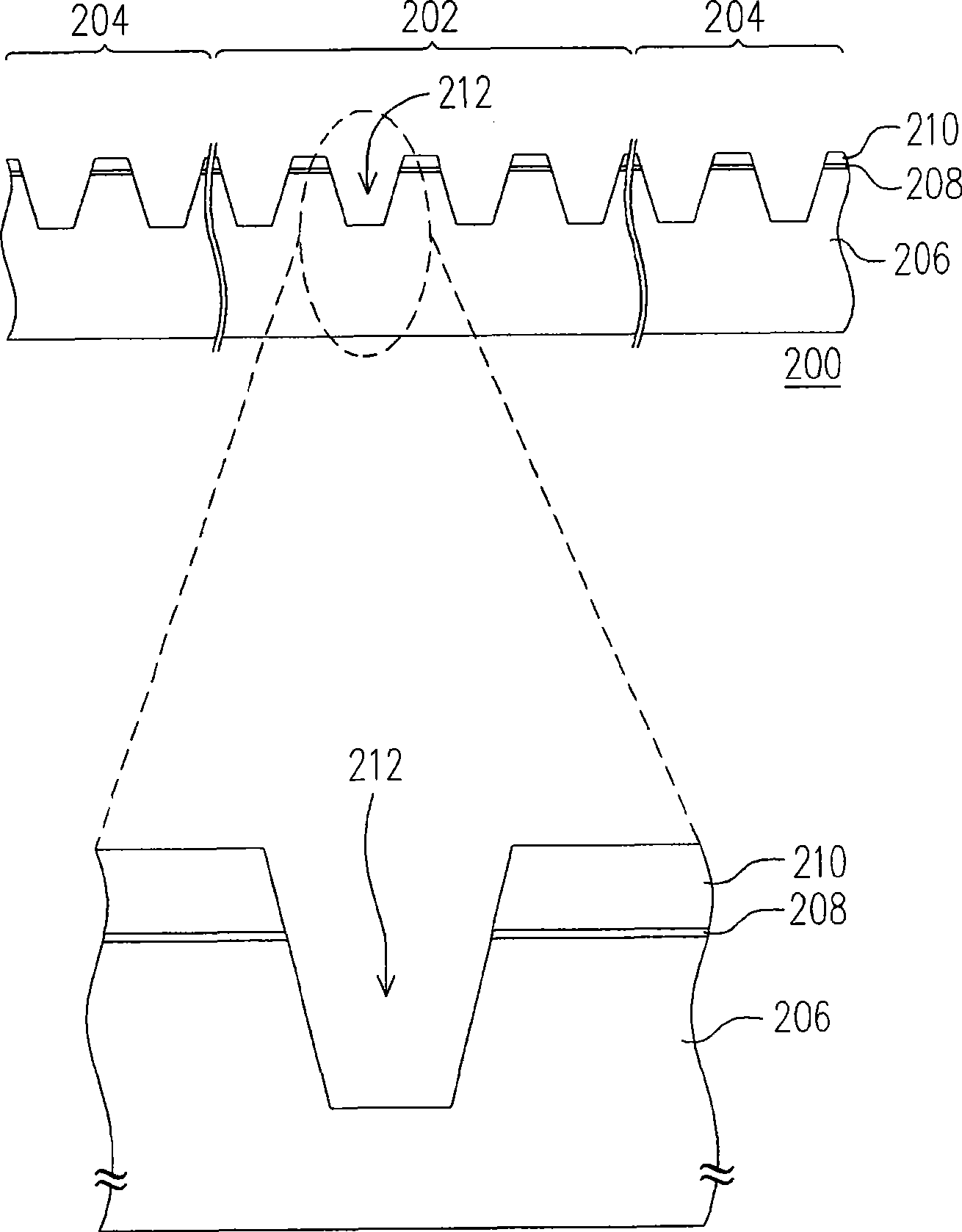

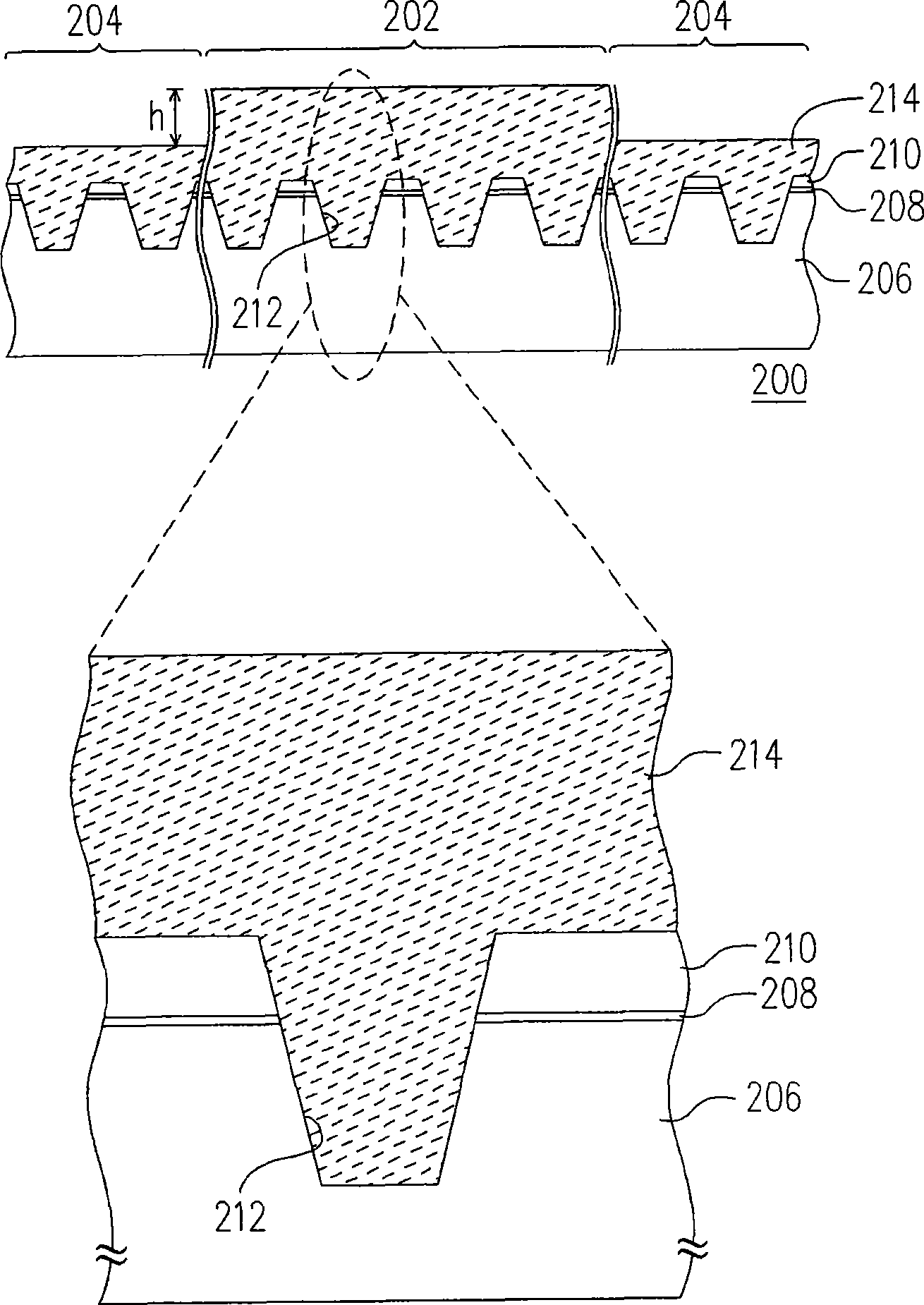

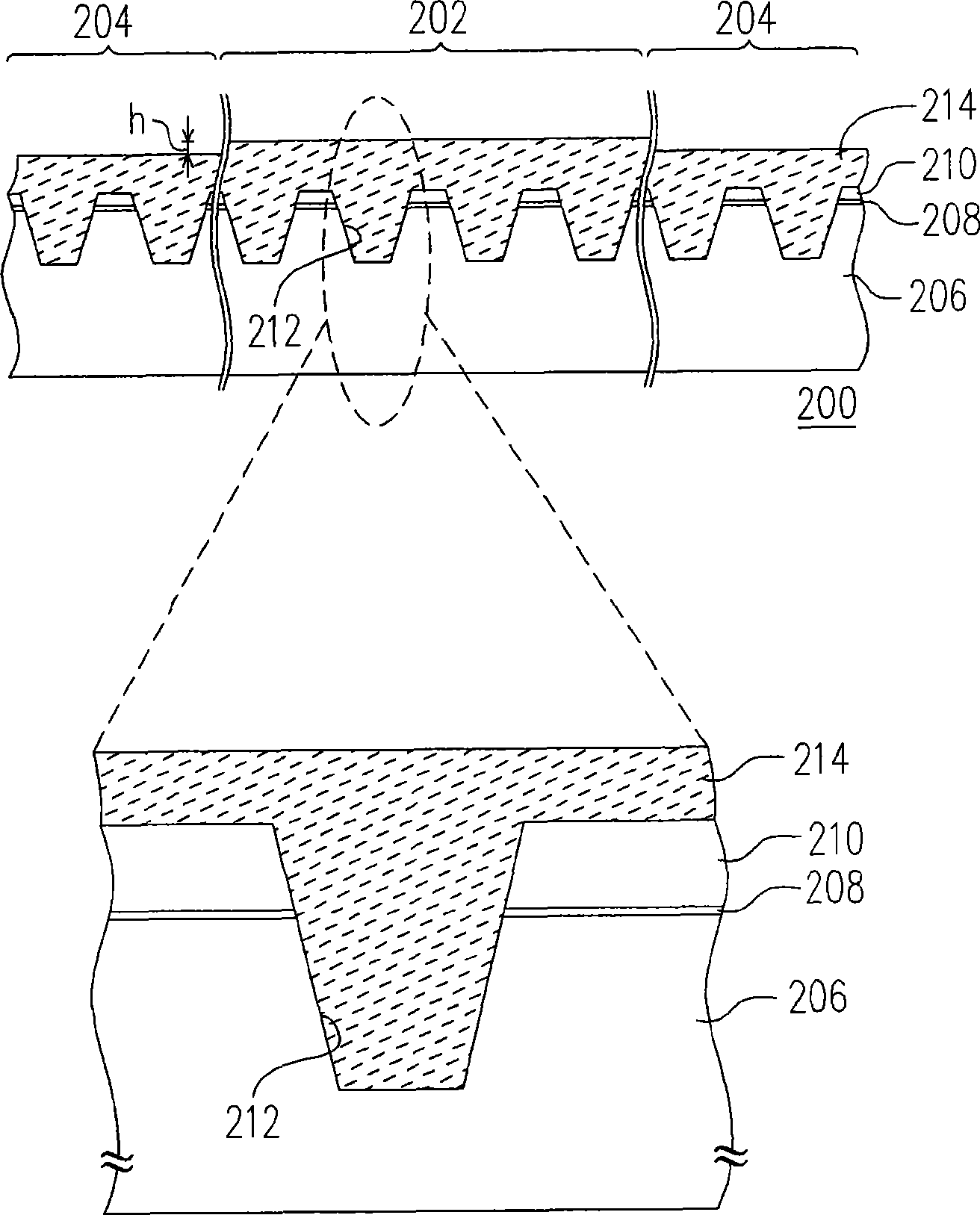

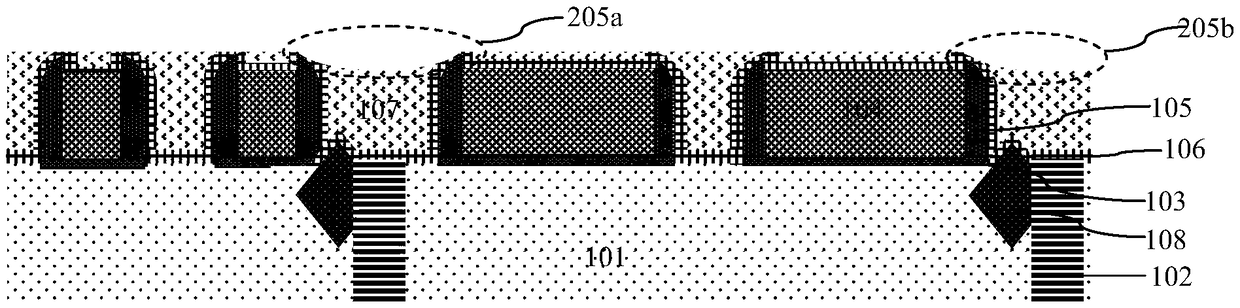

Forming method of shallow groove isolation and grinding method of semiconductor structure

InactiveCN101425477AImprove thickness uniformityReduce height differenceSemiconductor/solid-state device manufacturingSemiconductor structureCompound (substance)

The invention discloses a formation method of a shallow groove insulating structure and a grinding method of a semiconductor structure. The formation method of the shallow groove insulating structure comprises the following steps: forming a mask layer on the substrate of a wafer and removing the partial substrate which is not covered with the mask layer, so as to form a plurality of shallow grooves in the substrate; successively, forming a dielectric layer on the substrate and filling the dielectric layer into the shallow groove; then, carrying out first chemical-mechanical polishing process to remove the partial dielectric layer; and finally carrying out second chemical-mechanical polishing process to remove the partial dielectric layer and the mask layer, so that the surface of the dielectric layer is lower than that of the mask layer. The grinding velocity of the second chemical-mechanical polishing process is lower than that of the first chemical-mechanical polishing process; and the grinding selection ratio between the dielectric layer and the mask layer of the second chemical-mechanical polishing process is higher than that of the first chemical-mechanical polishing process. At last, the mask layer is removed.

Owner:UNITED MICROELECTRONICS CORP

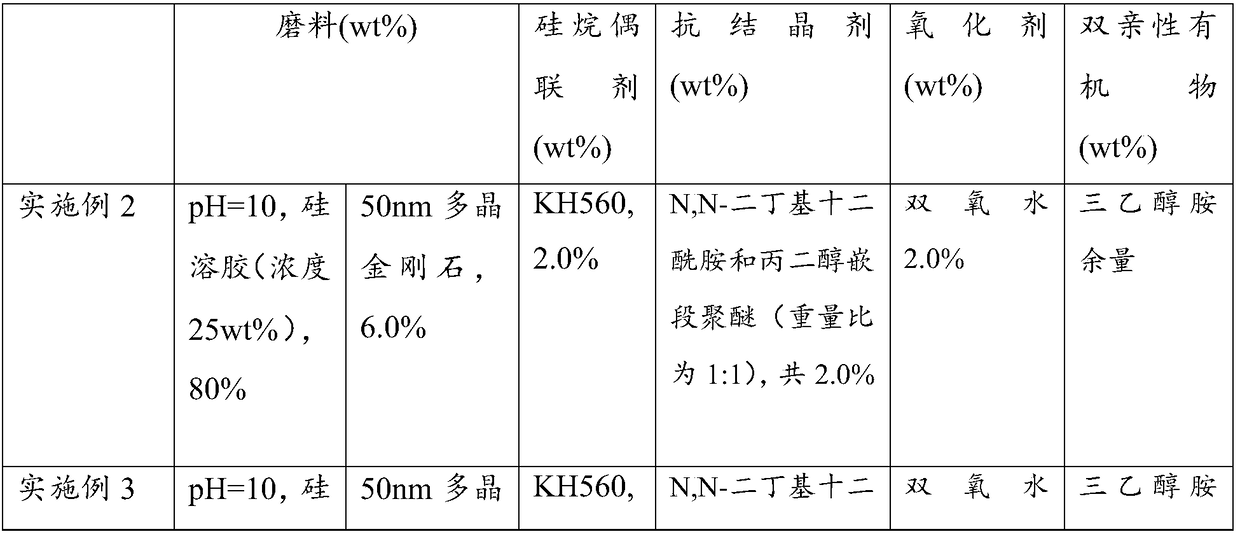

Polishing solution and polishing method of silicon carbide crystals

ActiveCN108949036ASmall scratchSmall roughnessPolishing compositions with abrasivesSoft layerOrganic matter

The invention relates to a polishing solution and a polishing method of silicon carbide crystals. The polishing solution comprises the following components in percentage by weight: 6-10% of nanoscalepolycrystalline diamond, 75-87% of alkaline silica sol, 1-2% of a silane coupling agent, 1-3% of an anti-crystallization agent, 1-2% of an oxidant, and the balance of amphiphilic organic matter. The polishing solution of the invention has the advantages of good wet spreading performance, high soft layer removal rate, being not prone to crystallization, and the like, and therefore polishing for silicon carbide solves the problems of low polishing rate and poor polishing effect. In addition, as the polishing solution is used in combination with a coarse grinding fluid and a fine grinding fluid,a high-speed, high-flatness, high-gloss, low-roughness polishing effect can be achieved.

Owner:BEIJING POLYSTAR HITECH CO LTD

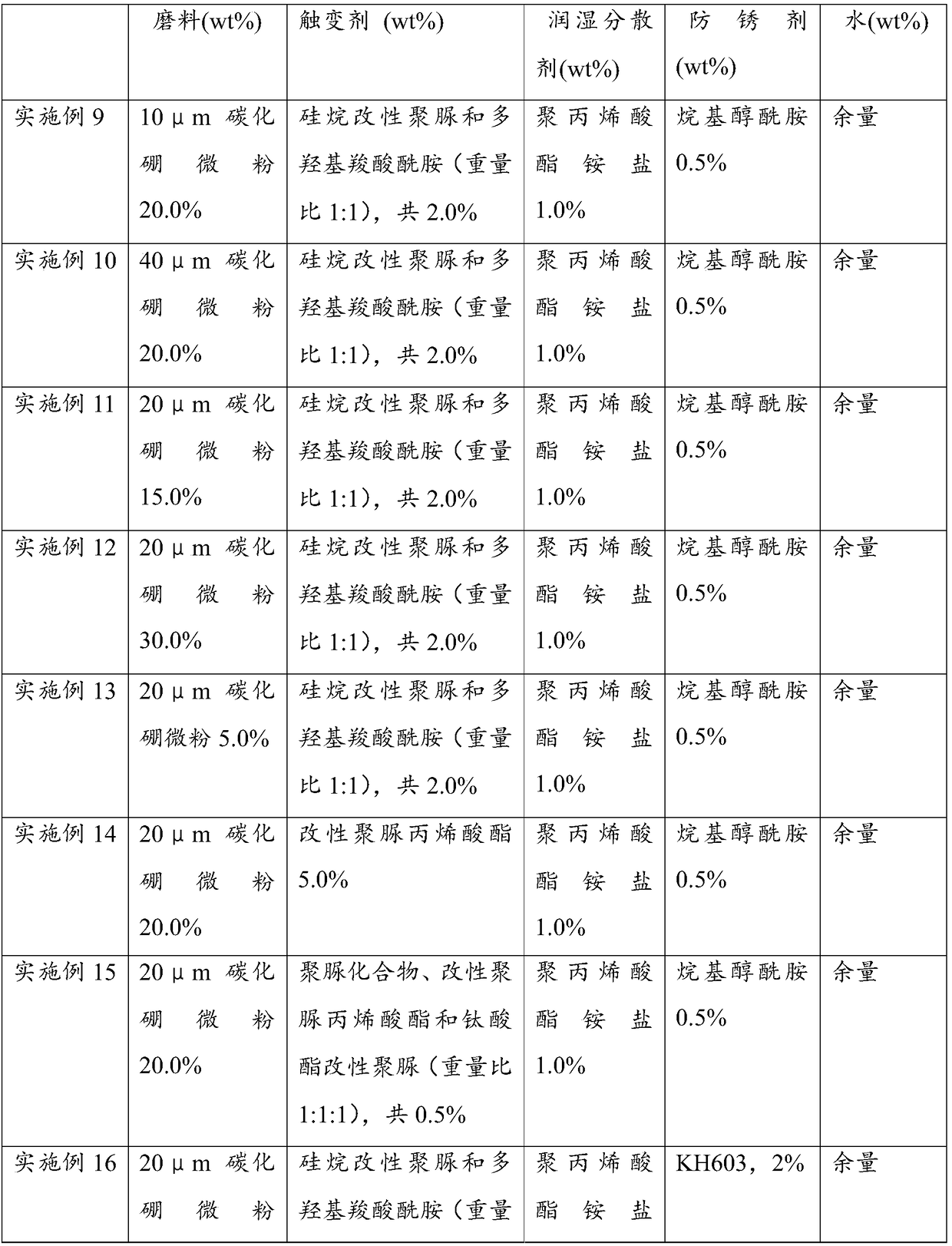

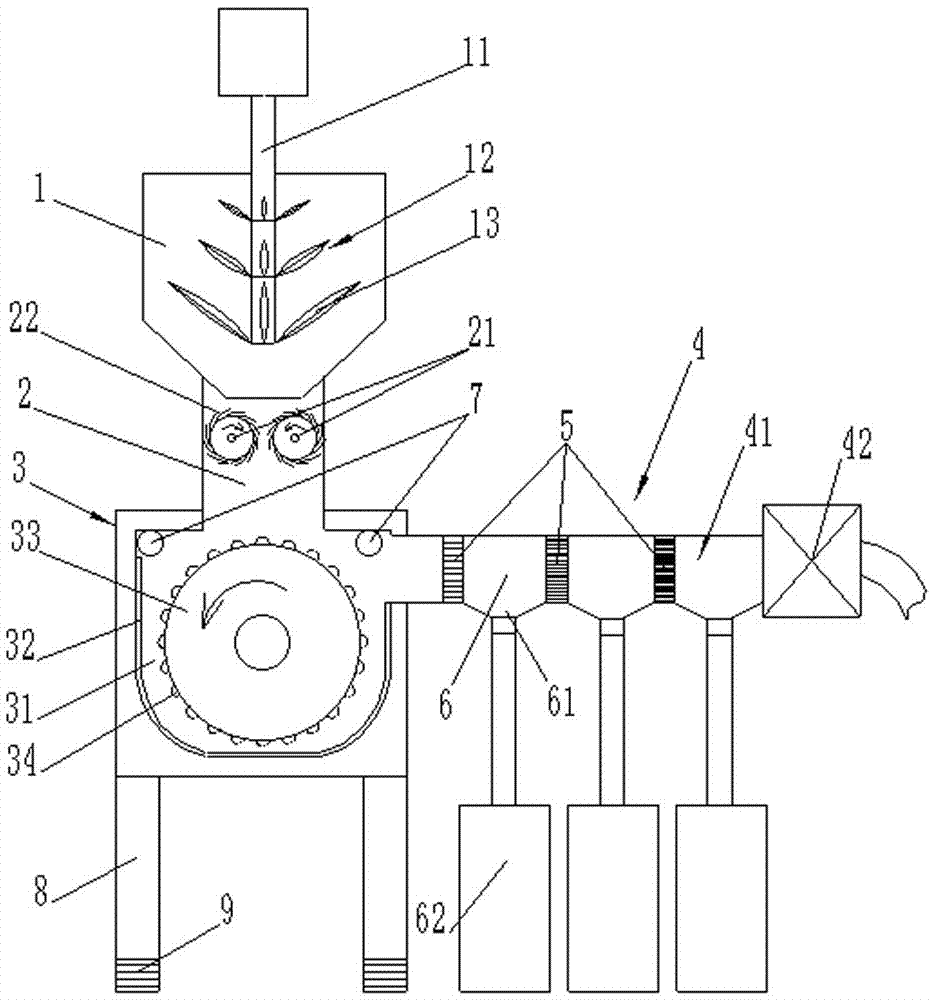

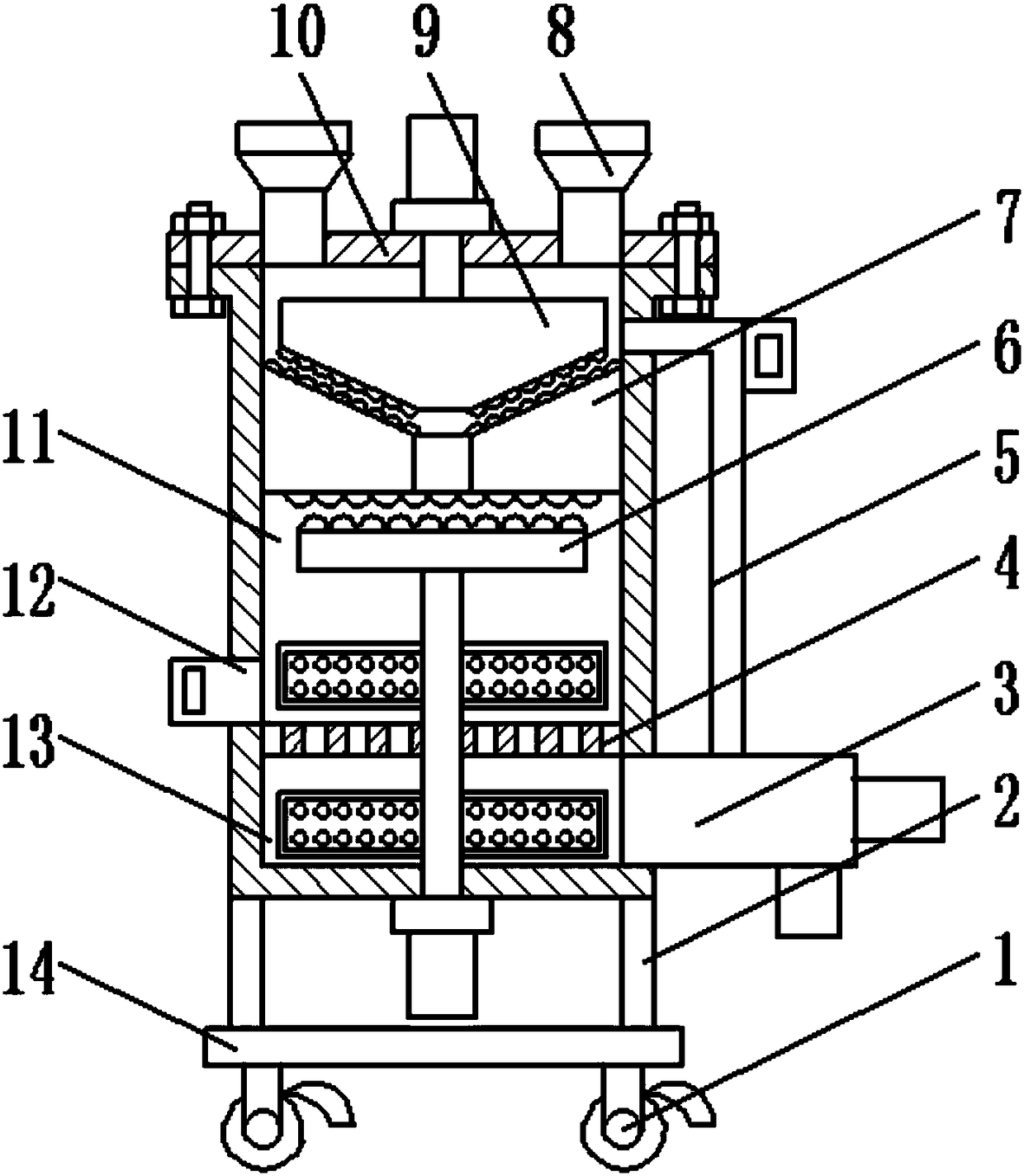

Food material milling processing device

InactiveCN106984405AIncrease grinding rateImprove grinding effectGrain treatmentsEngineeringFood material

The invention relates to a material grinding processing equipment, comprising a discharge mechanism, a crushing hopper, a material cutting channel and a grinding box arranged sequentially from top to bottom; an abrasive cavity is arranged in the grinding box; the upper end of the cutting channel is connected to a stirring The lower end of the crushing hopper and the lower end of the cutting channel are connected to the abrasive chamber; the middle part of the crushing hopper is provided with a vertically placed stirring shaft, and the stirring shaft is provided with a crushing knife group; the inner wall of the abrasive chamber is provided with a grinding layer, and the abrasive chamber is provided with a horizontal The placed grinding roller has densely arranged abrasive grains on the outer surface of the grinding roller; the discharge mechanism includes a ventilation pipe, one end of the ventilation pipe is connected to the air outlet of an exhaust fan, and the other end is connected to the upper part of the abrasive chamber; the inside of the ventilation pipe is sequentially There are multi-layer filter plates with successively smaller diameters of filter holes; a discharge space is formed between adjacent filter plates and the inner wall of the ventilation pipe, and a funnel-shaped discharge port is provided at the lower end of the discharge space.

Owner:熊磊

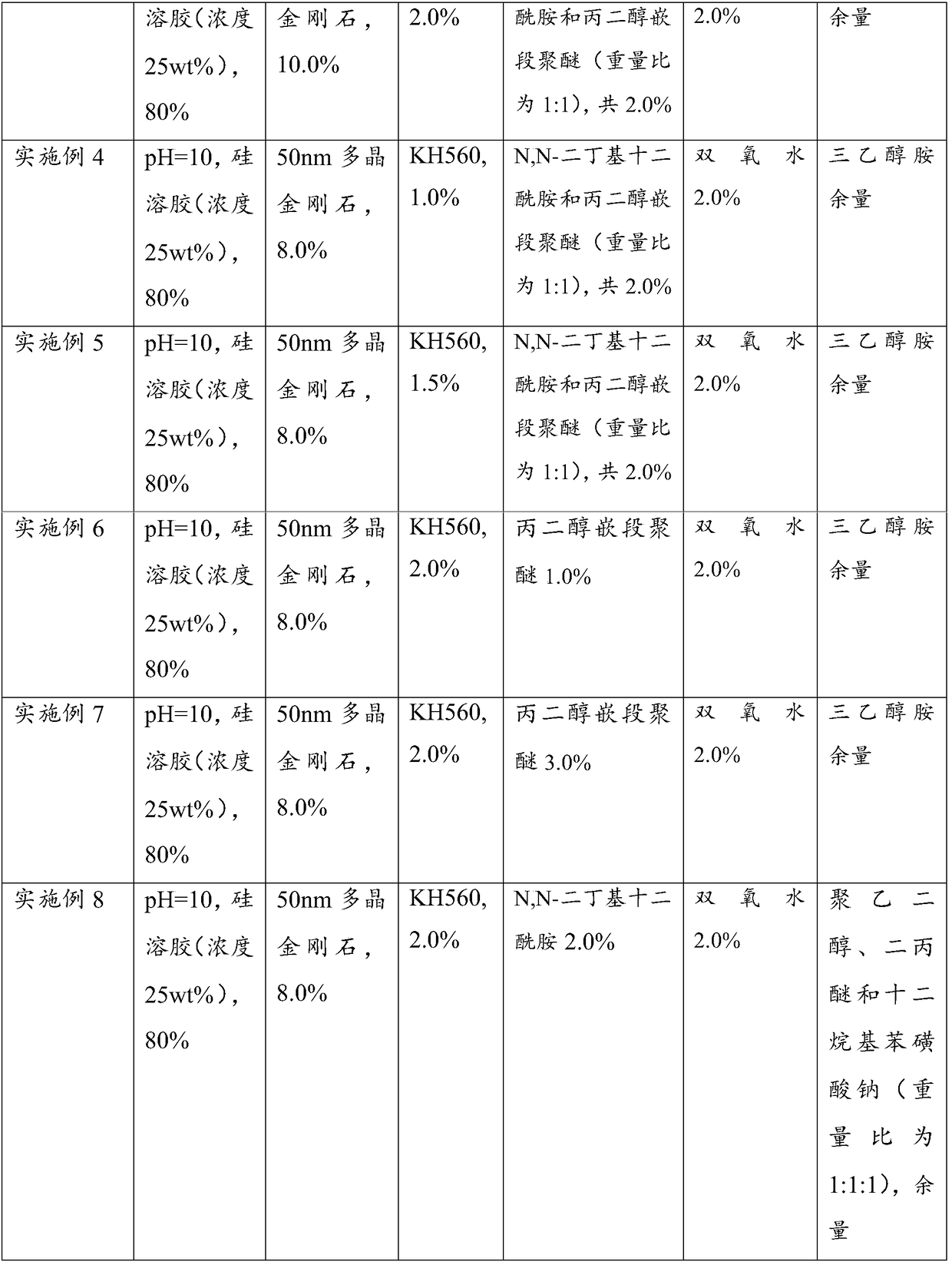

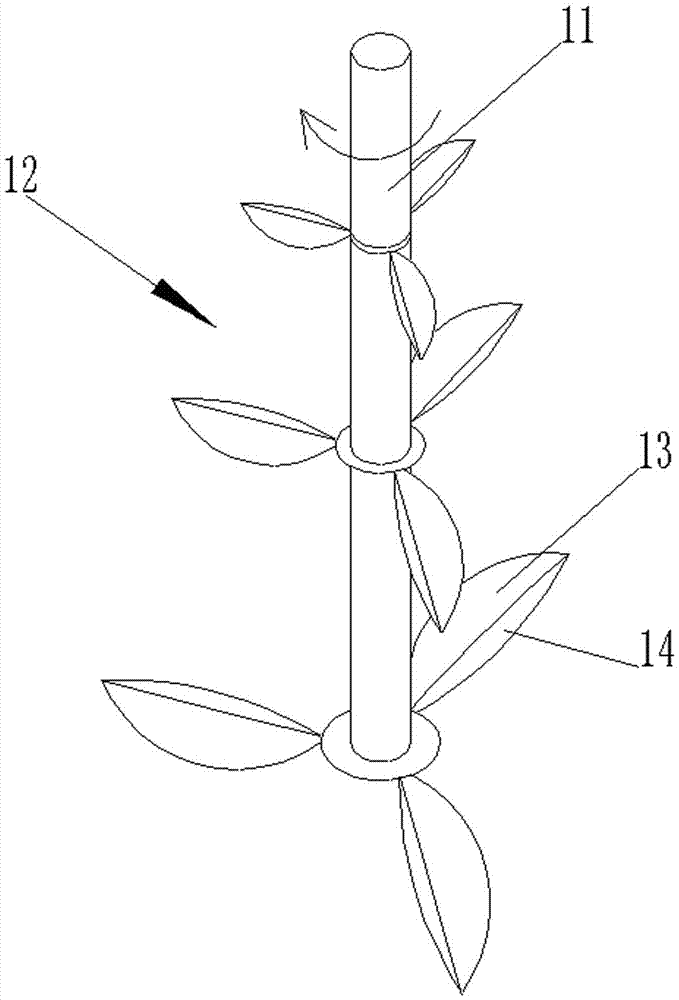

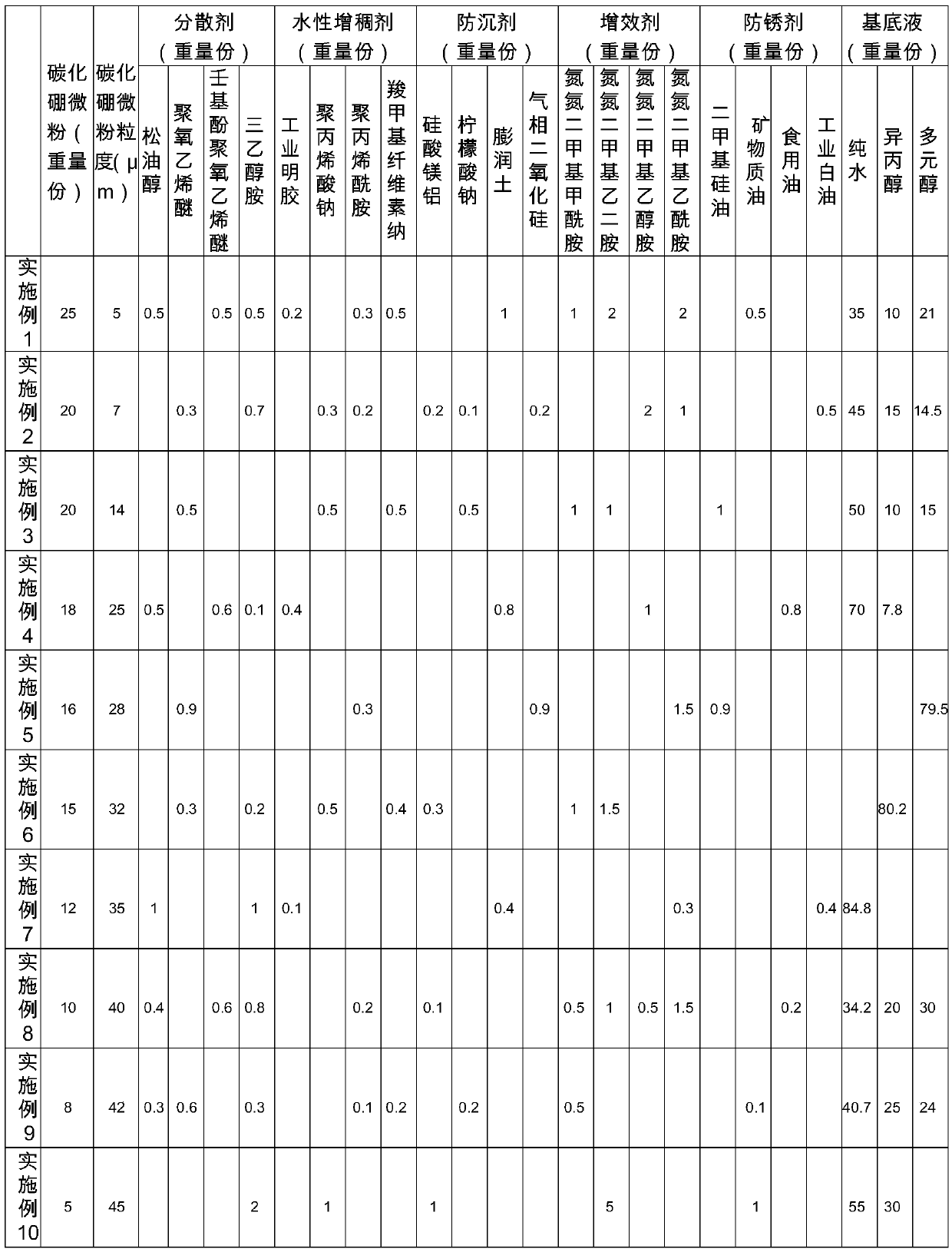

Efficient boron carbide grinding fluid and method for preparing same

InactiveCN105505231AImprove flatnessQuick grindingOther chemical processesPolishing compositions with abrasivesWater basedAlcohol

The invention discloses efficient boron carbide grinding fluid and a method for preparing the same, and relates to the field of technologies for grinding sapphire. The efficient boron carbide grinding fluid comprises, by weight, 5-25 parts of boron carbide micro-powder, 1-2 parts of dispersing agents, 0.5-1 part of water-based thickeners, 0.5-1 part of anti-settling agents, 0.5-5 parts of synergists, 0.5-1 part of antirust agents and 65-92 parts of substrate fluid. The substrate fluid can be one of pure water, isopropyl alcohol and polyhydric alcohol or a mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol, and various components of the substrate fluid have equal weight parts or other proportions when the substrate fluid comprises the mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol. The efficient boron carbide grinding fluid and the method have the advantages that the efficient boron carbide grinding fluid is long in service life, good in stability and applicable to rough grinding for processing sapphire wafers, the A-direction and M-direction sapphire grinding rates can be increased, processed products are good in surface flatness, and the like.

Owner:HUNAN HAOZHI TECH

Polishing composition and polishing method for its use

InactiveCN1340583AImprove polishing effectBest chemical polishingOther chemical processesSemiconductor/solid-state device manufacturingPhysical chemistryCopper

A polishing composition comprising: (a) an abrasive, (b) a compound to form a chelate with copper ions (c) a compound to provide a protective layer-forming function to a copper layer, (d) hydrogen peroxide, and (e) water, wherein the abrasive of component (a) has a primary particle size within a range of from 50 to 120 nm. This is used for polishing a semiconductor device having at least a layer of copper and a layer of a tantalum-containing compound formed on a substrate.

Owner:FUJIMI INCORPORATED

Aluminum alloy metal part grinding and polishing device

ActiveCN112775777AEffectively fixedEasy to polishGrinding carriagesGrinding drivesStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining equipment, and discloses an aluminum alloy metal part grinding and polishing device which comprises a grinding table and an aluminum alloy plate. Two symmetrically-distributed fixing assemblies are arranged at the top of the grinding table. Each fixing assembly comprises a first hydraulic rod, wherein the mounting end of the first hydraulic rod is arranged at the top of the grinding table, a fixing plate is arranged at the output end of the first hydraulic rod, a first electric telescopic rod is arranged on one side of the fixing plate, a first moving plate is arranged at the output end of the first electric telescopic rod, second electric telescopic rods are arranged on the end face of the periphery of the first moving plate, second moving plates are arranged at the other ends of the second electric telescopic rods, first air guide pipes are arranged at one ends of the second moving plates, and suckers are arranged at the other ends of the first air guide pipes. According to the aluminum alloy plate polishing device, through the arrangement of a polishing assembly, the fixing assemblies and a containing plate, the two side faces of an aluminum alloy plate can be ground at a time, the aluminum alloy plate can be ground and pre-cleaned, and the grinding precision is controlled.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

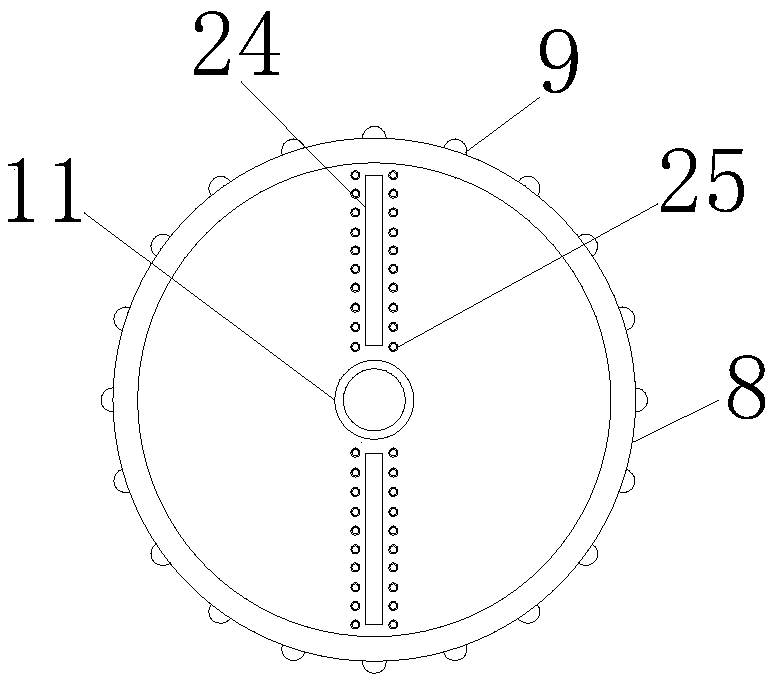

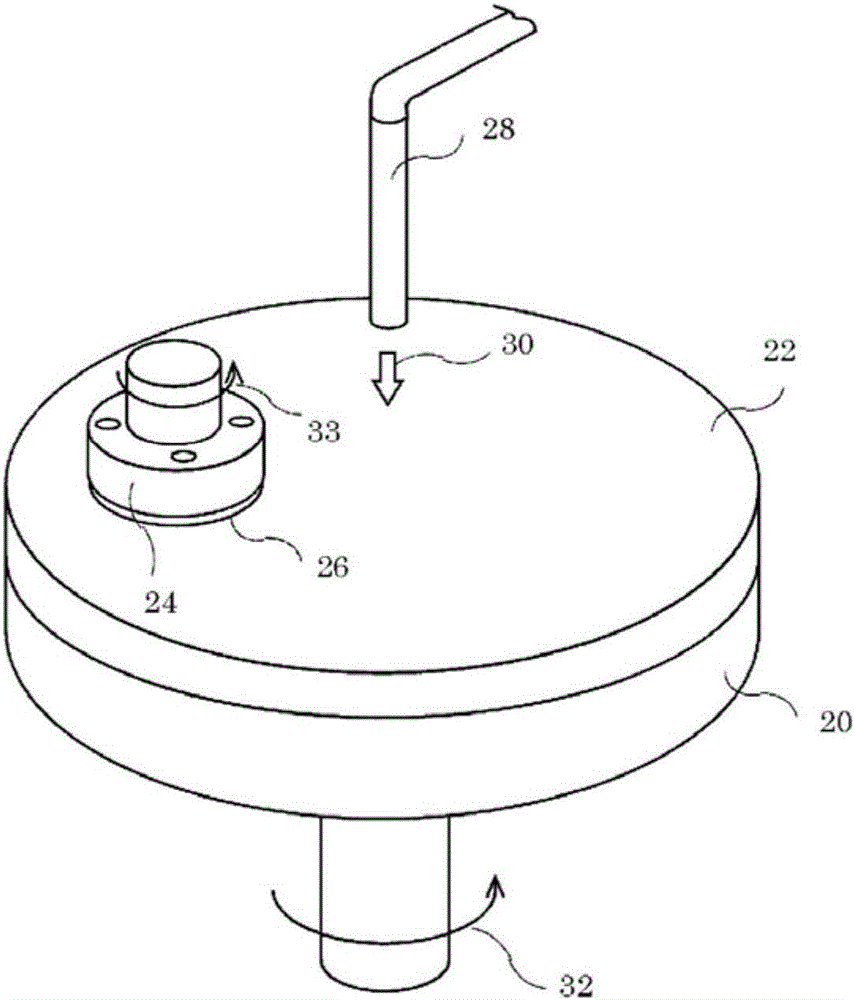

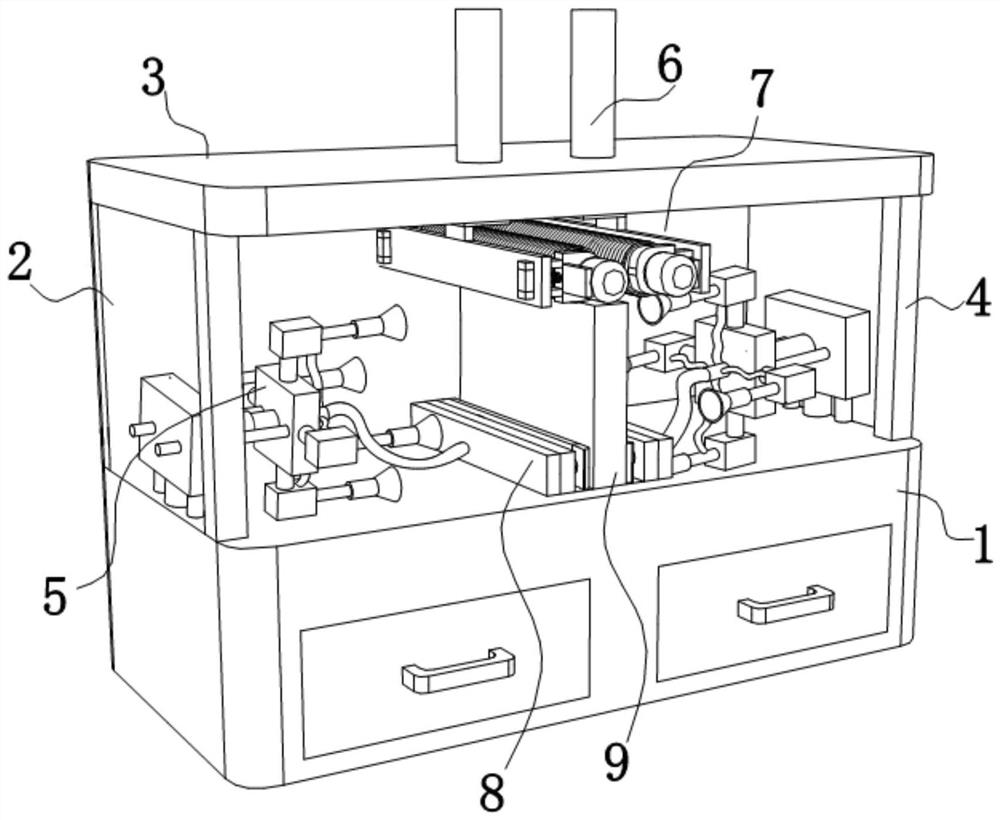

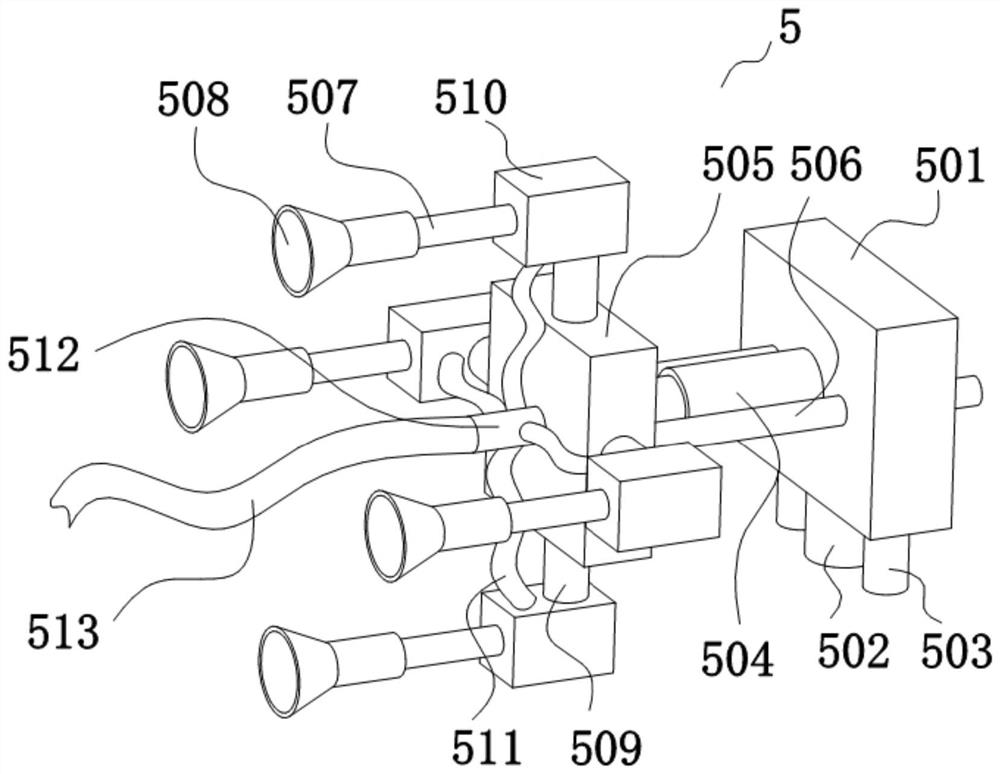

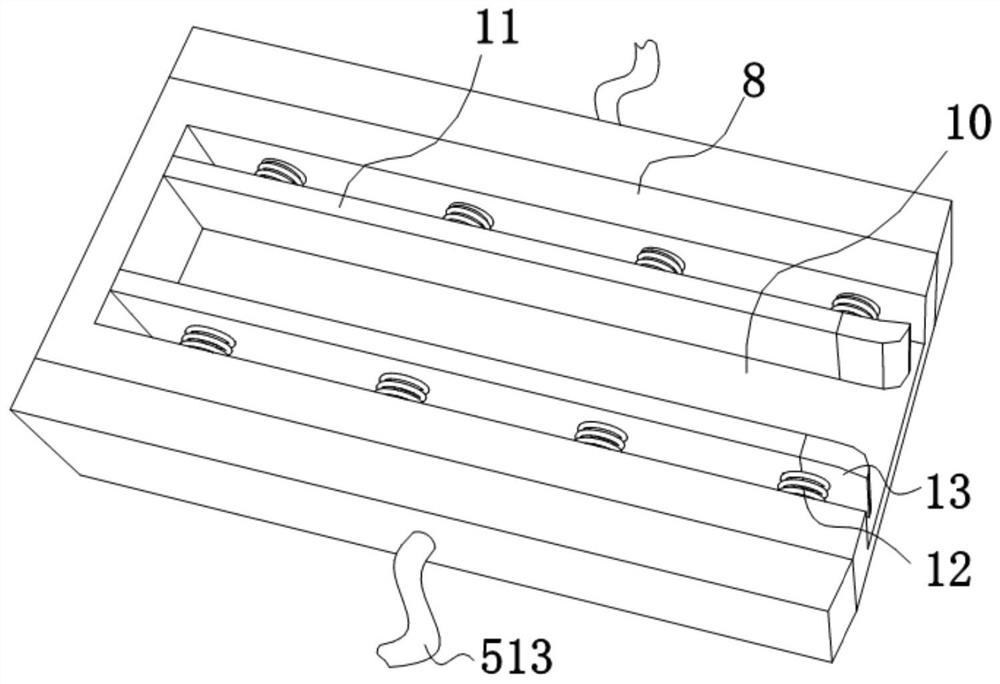

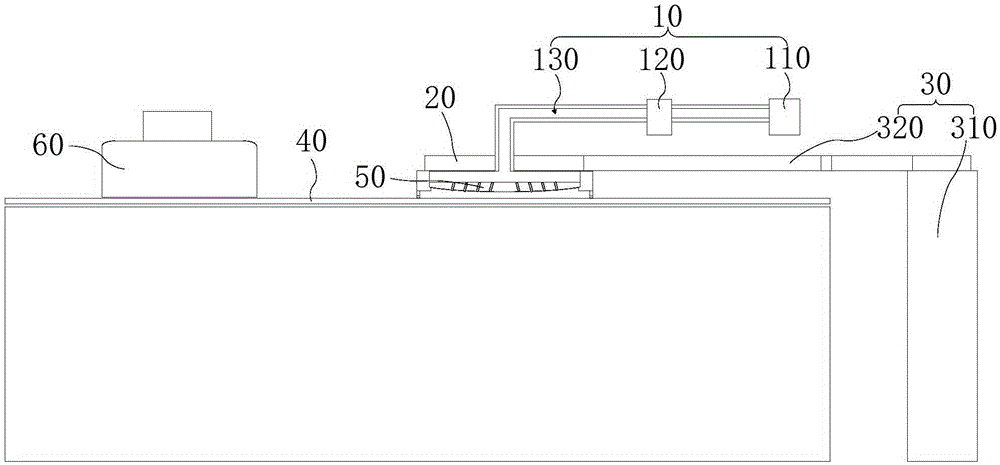

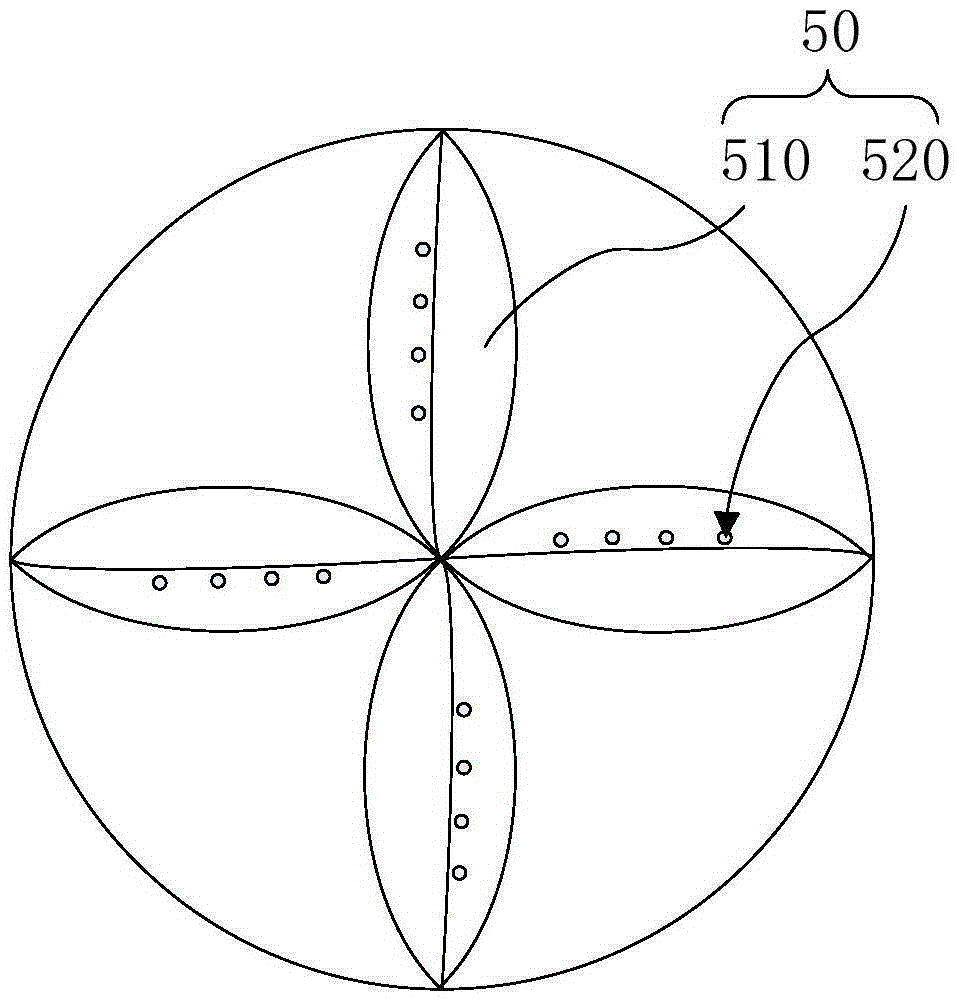

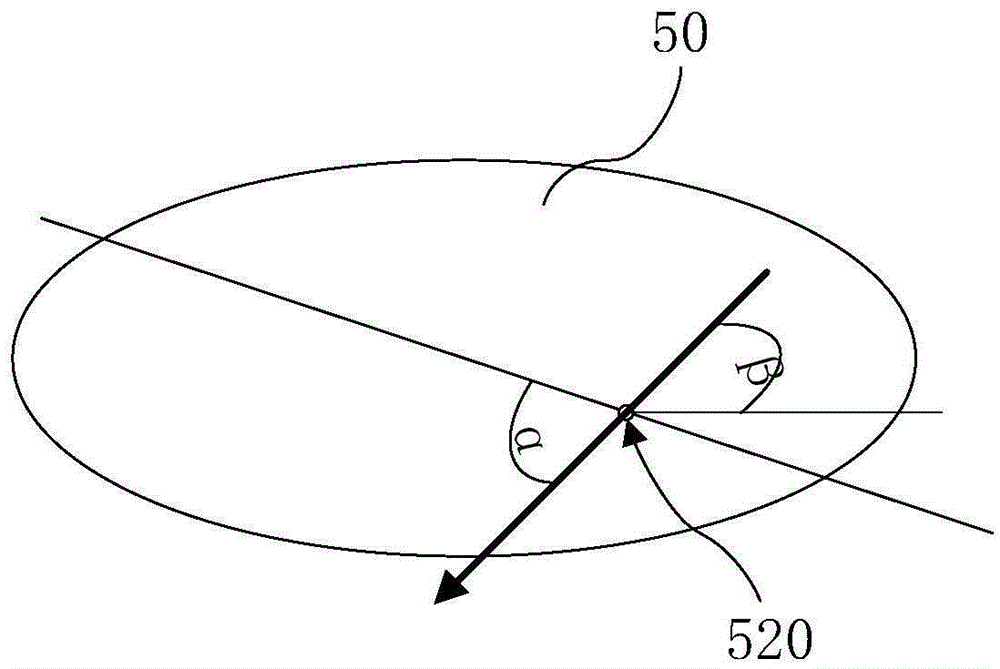

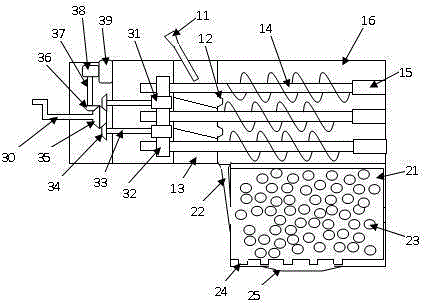

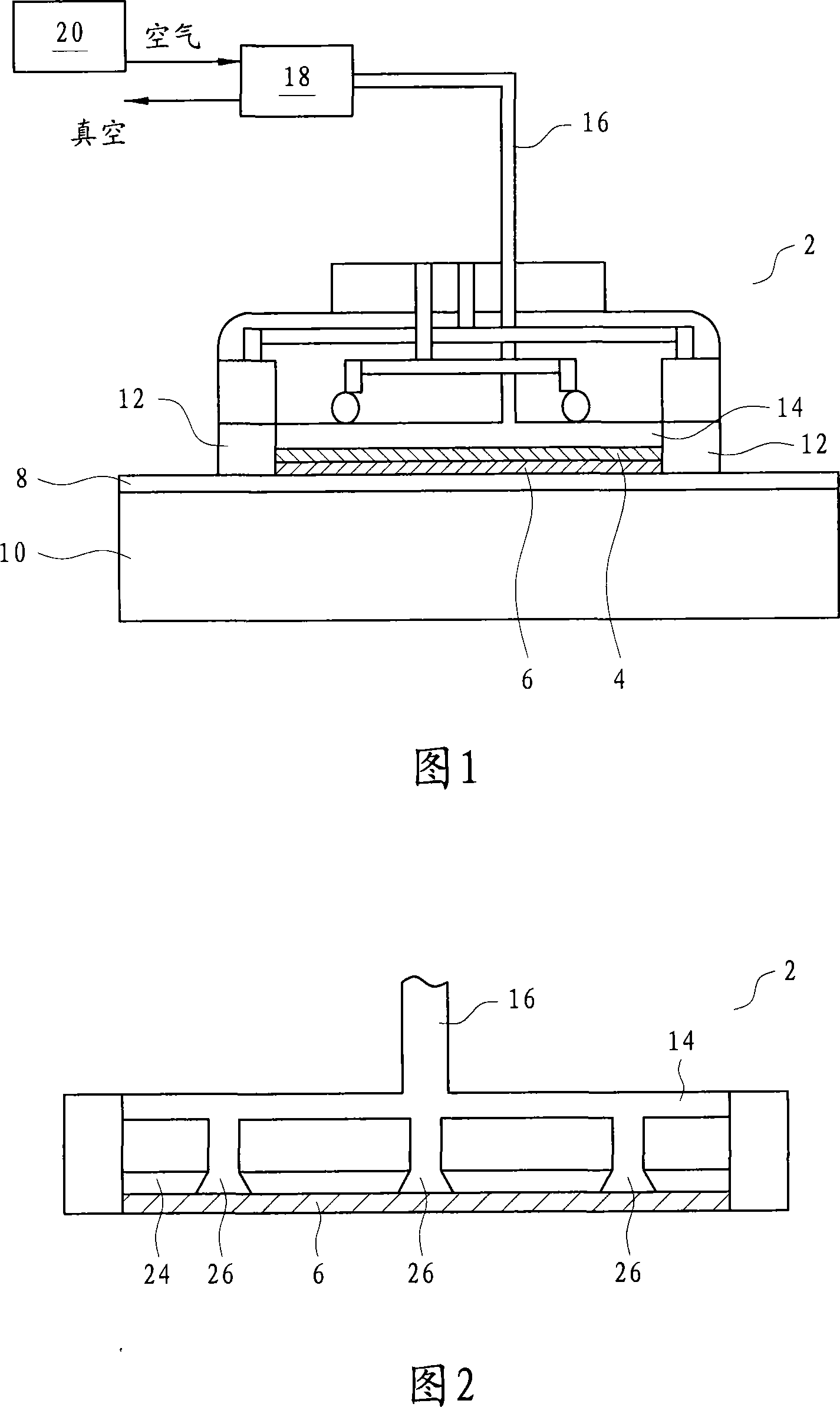

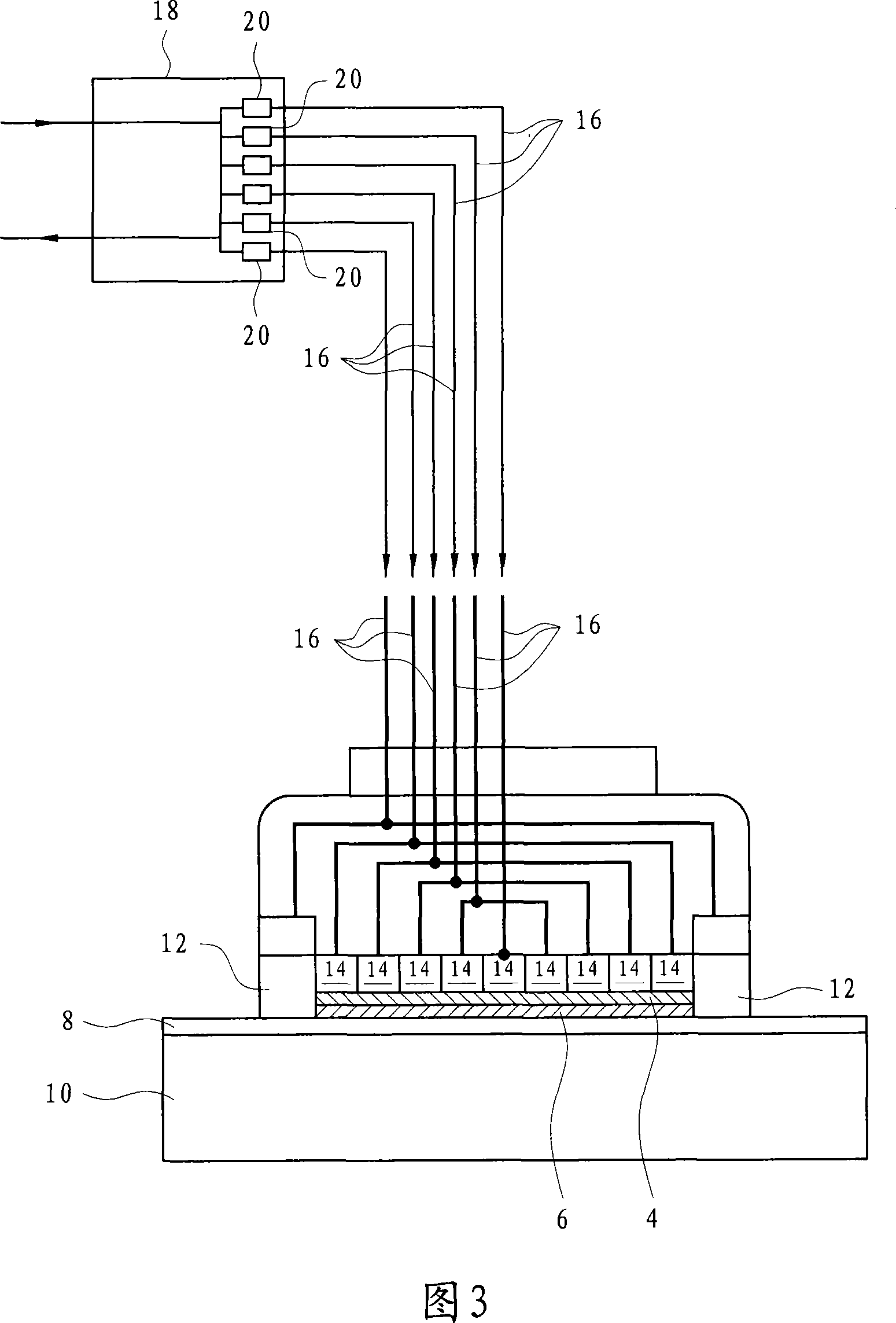

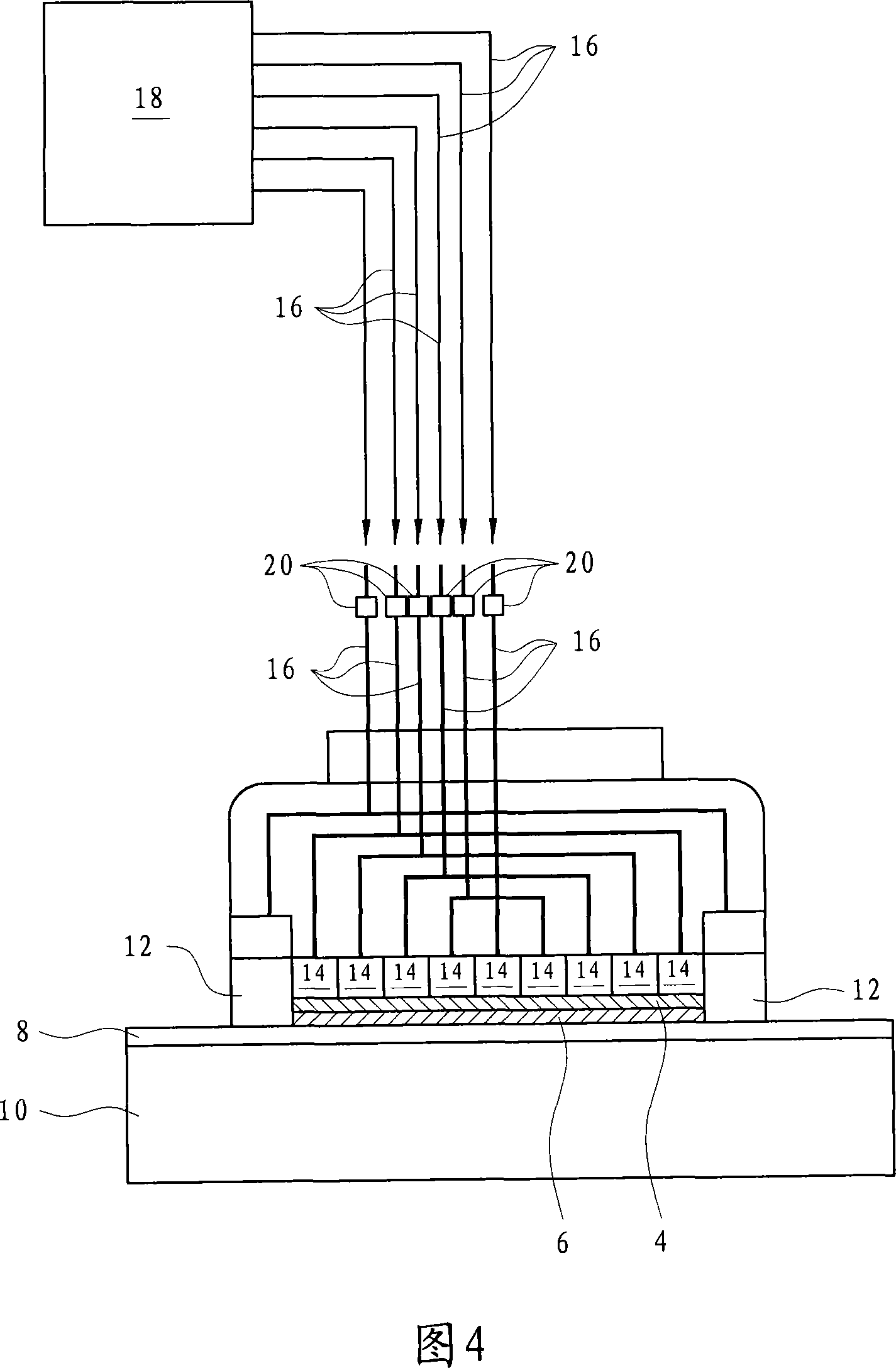

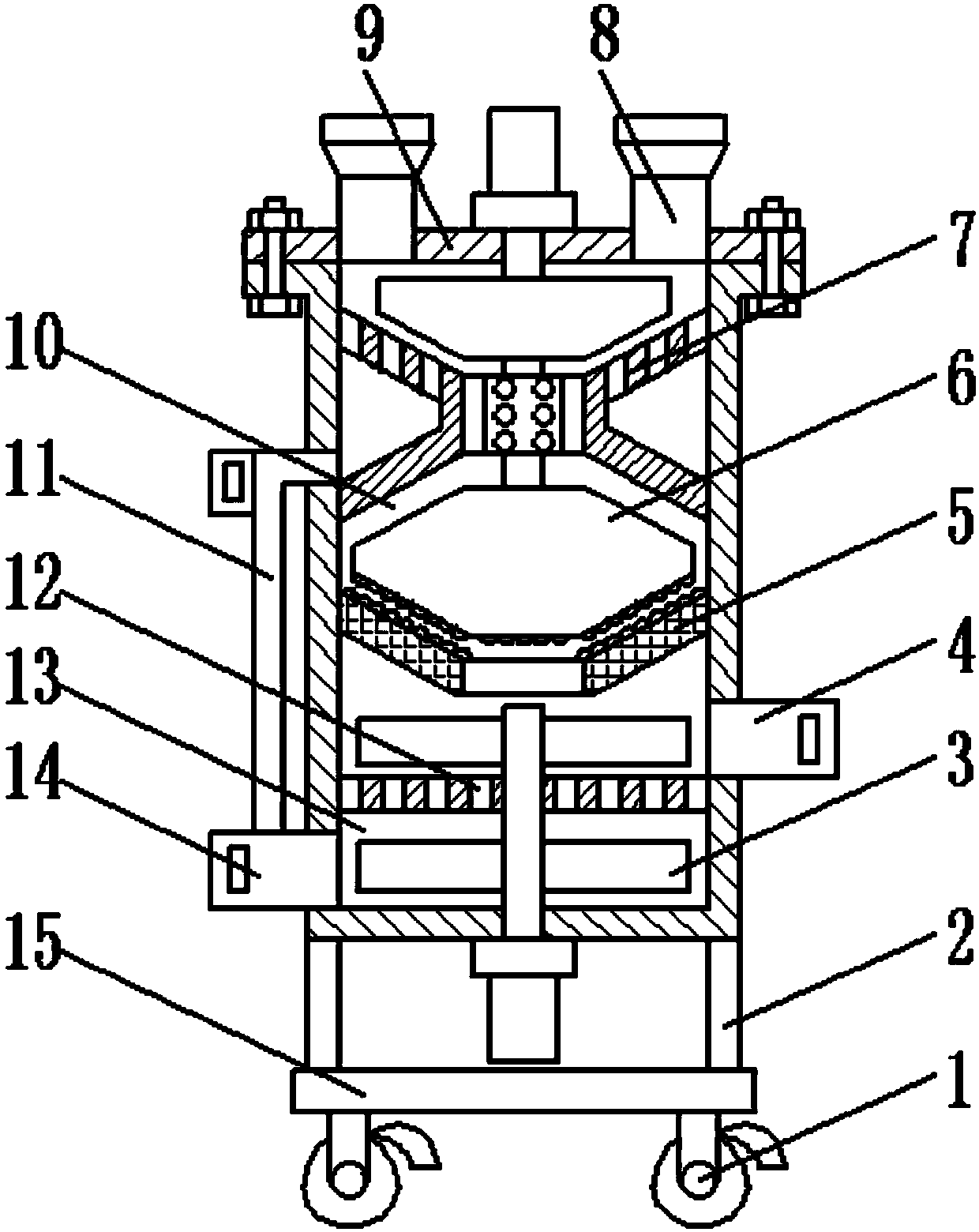

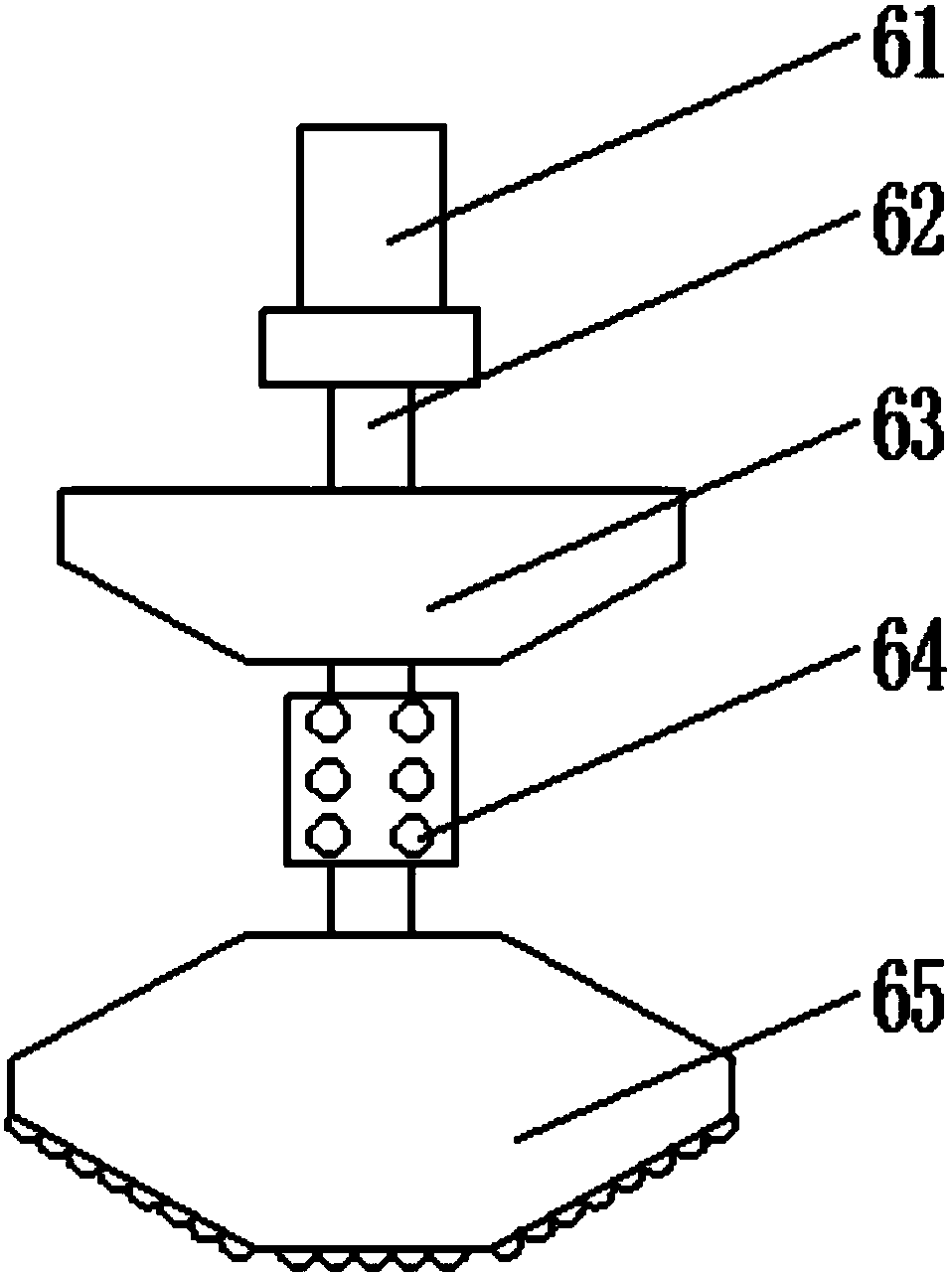

Grinding liquid supply and grinding pad trimming device and grinding drilling crew

ActiveCN105234823AEvenly distributedExtend your lifeLapping machinesAbrasive surface conditioning devicesEngineering

The invention discloses a grinding liquid supply and grinding pad trimming device and a grinding drilling crew. The grinding liquid supply and grinding pad trimming device comprises a grinding liquid supply system, a cavity communicated with the grinding liquid supply system, a drainage plate arranged in the cavity and provided with multiple drainage holes and a drive system for bearing and driving the cavity. The grinding liquid supply system is used for providing boosted grinding liquid. The pressure of the boosted grinding liquid is larger than or equal to 50 MPa. The boosted grinding liquid is sprayed to a grinding pad through the cavity via the drainage holes. According to the grinding liquid supply and grinding pad trimming device and the grinding drilling crew, the grinding pad is scoured through the boosted grinding liquid to be trimmed, meanwhile, the cavity moves on the surface of the grinding pad so that the grinding liquid can be distributed more evenly, the grinding rate of the grinding pad is increased, the service life of the grinding pad trimming device is prolonged greatly, and thus cost is lowered.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

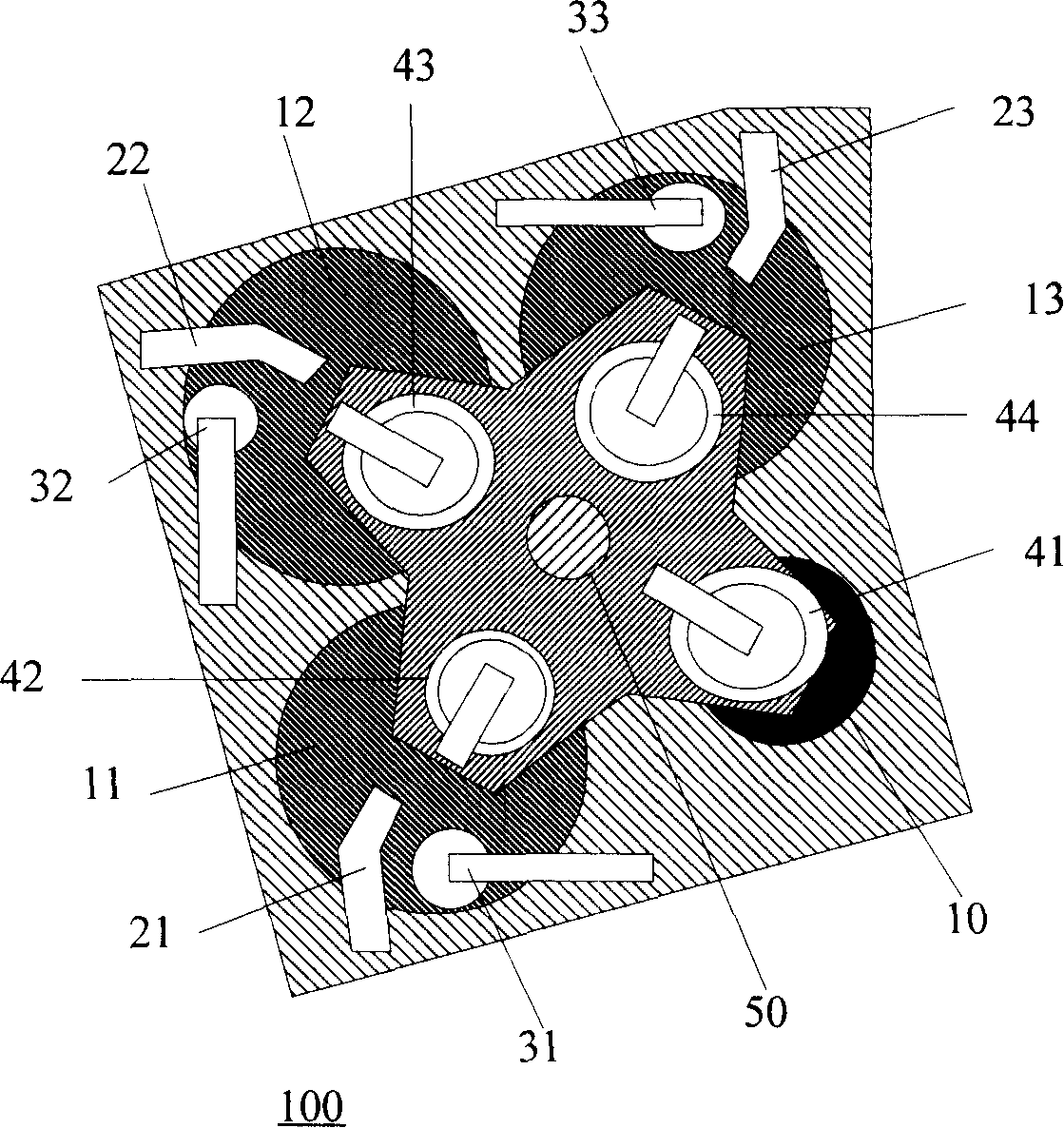

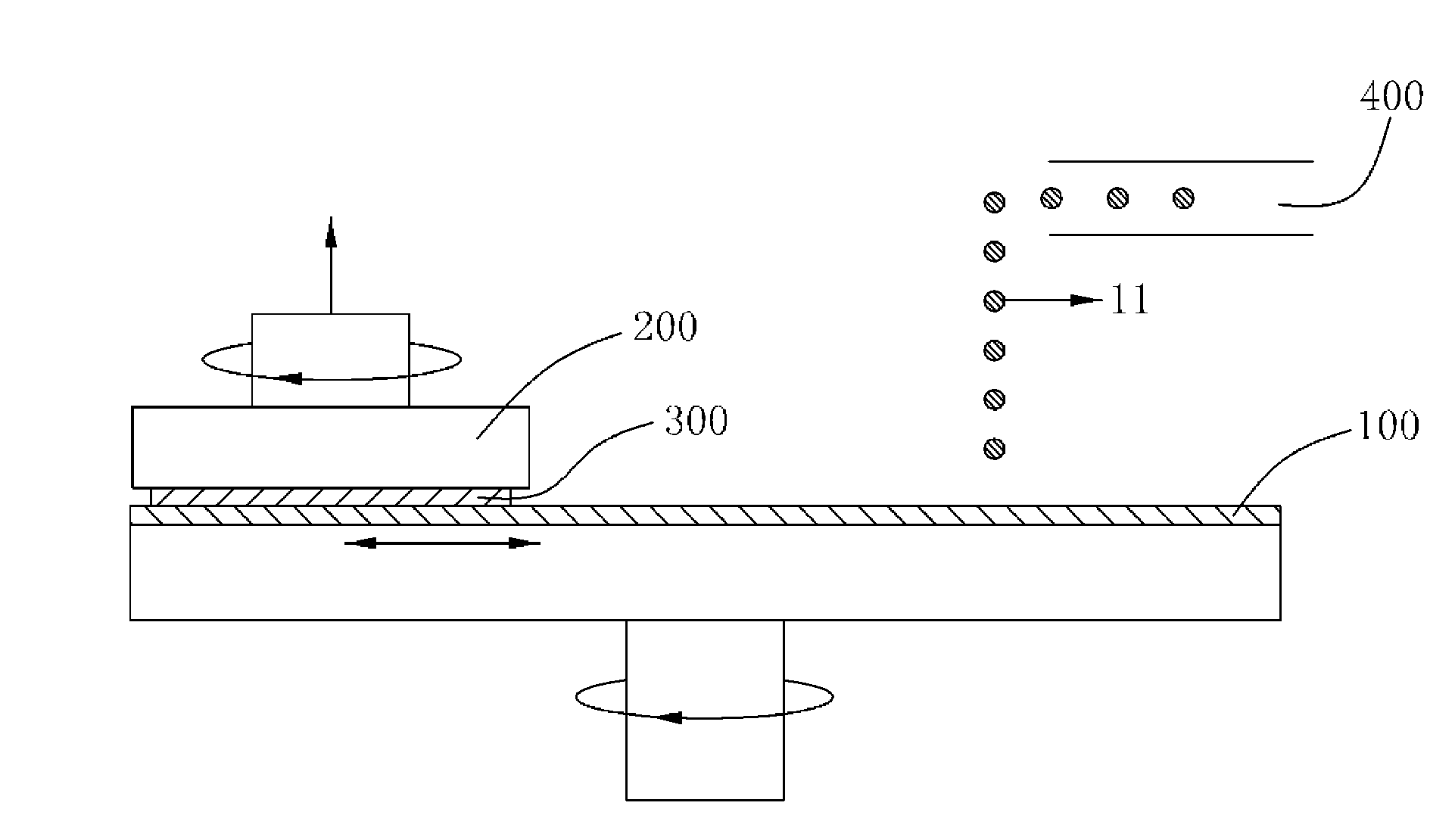

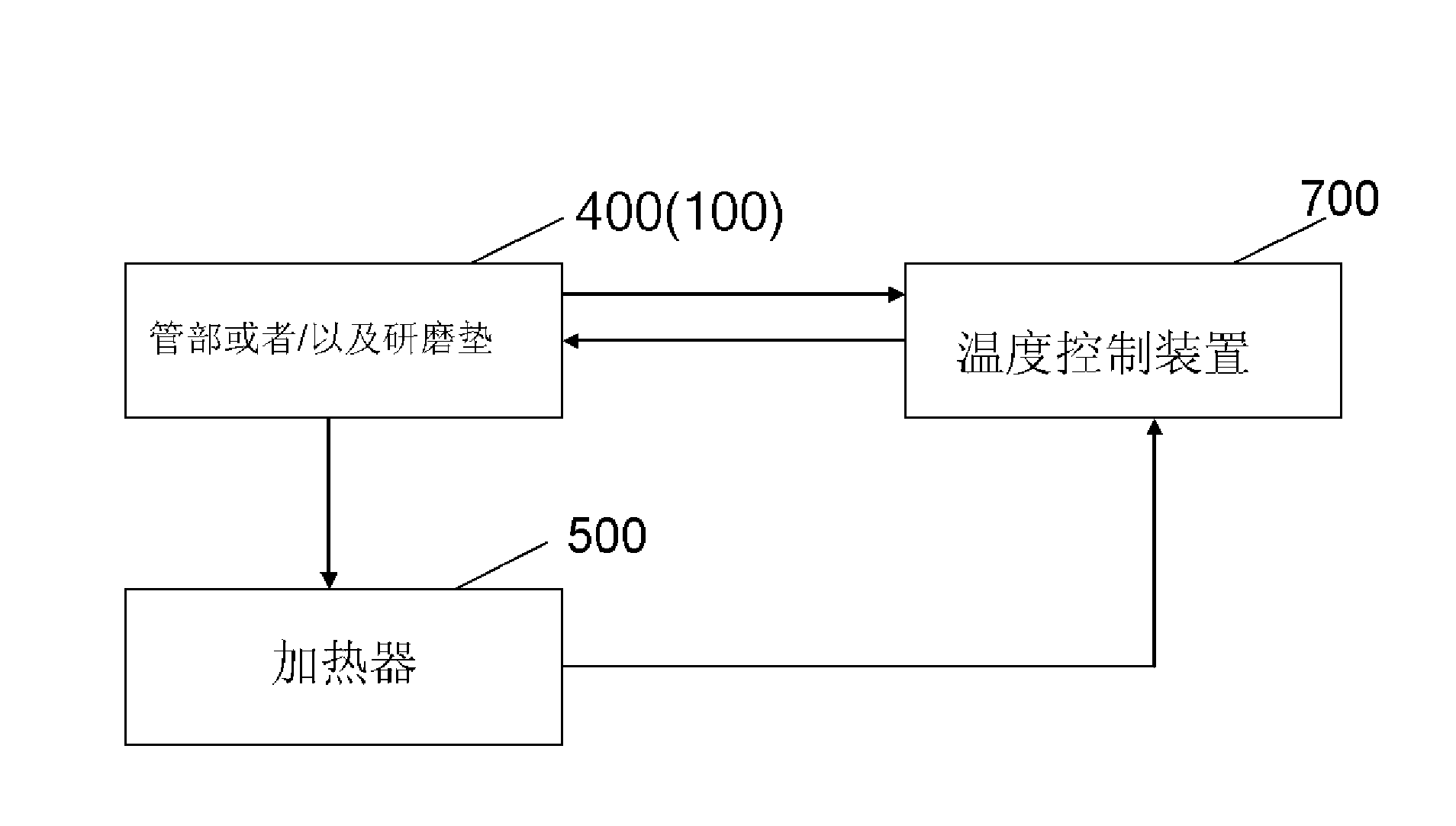

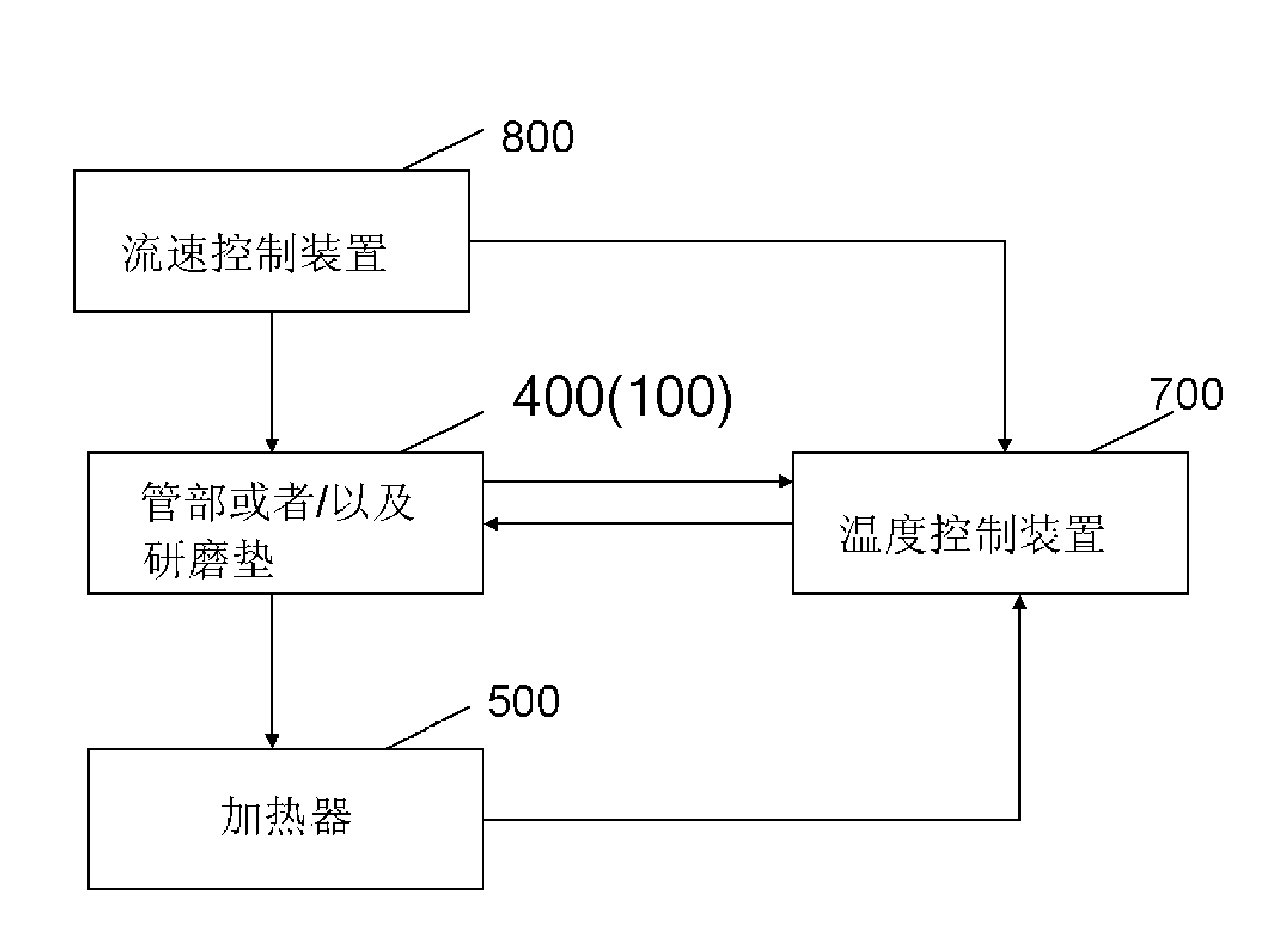

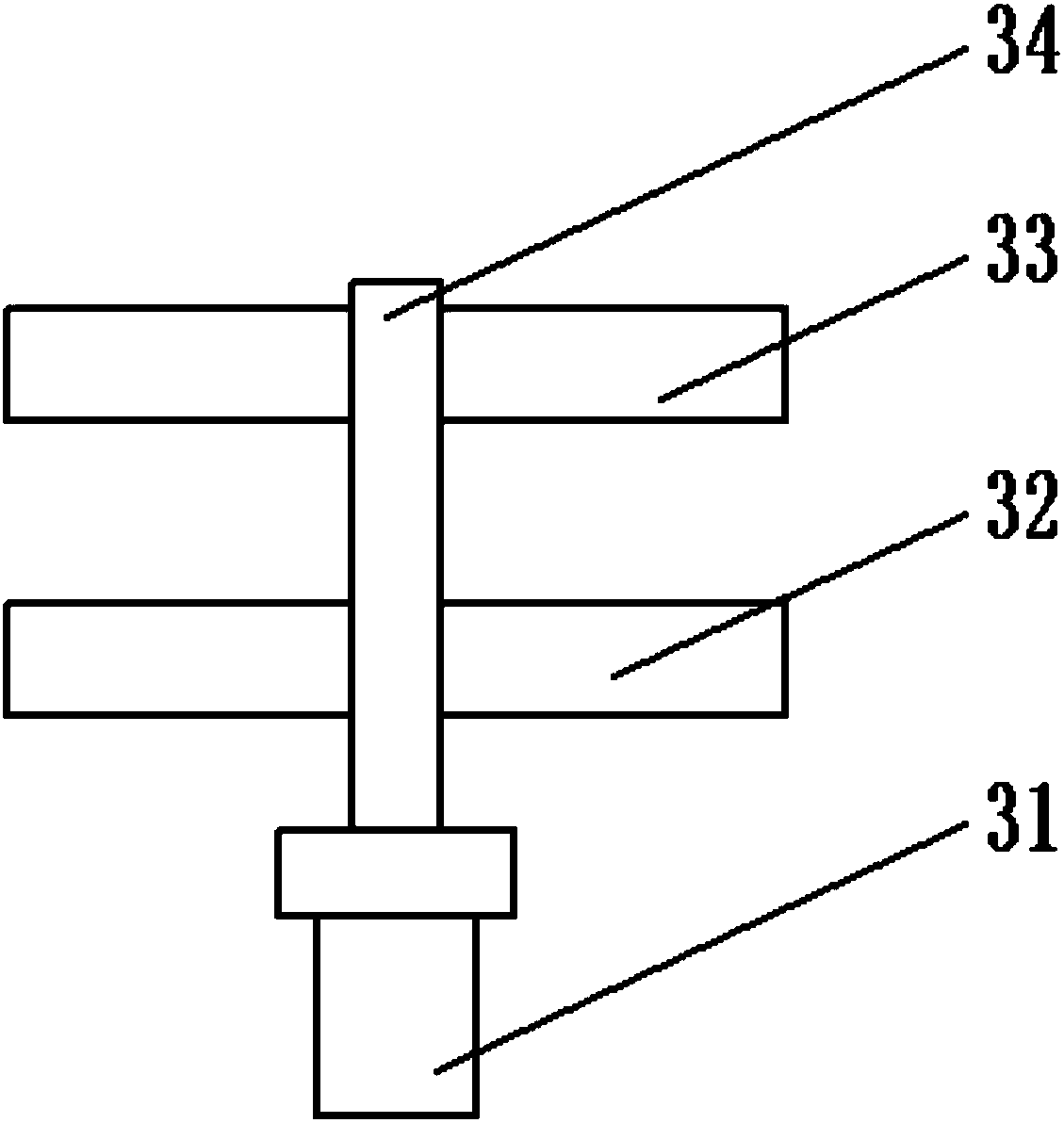

WCMP (wolfram chemical mechanical polishing) grinding device and method for improving WCMP grinding rate

InactiveCN103182674AIncrease grinding rateGrinding rate increases rapidlyLapping machinesAutomatic grinding controlPolymer chemistryChemical-mechanical planarization

The invention relates to a WCMP (wolfram chemical mechanical polishing) grinding device and a method for improving WCMP grinding rate. The grinding device utilizes grinding liquid for grinding a processed object (300), and comprises a grinding pad (100) for containing the grinding liquid, a tray (200) for holding and enabling the processed object (300) to be on the grinding pad (100) to be subjected to WCMP grinding, a tubular part (400) for introducing the grinding liquid, a heater (500) for heating the tubular part (400) and / or the grinding pad (100), and a temperature controller (600) for controlling the heater (500) to keep the temperature of the grinding liquid flowing in the tubular part (400) to be 30-60 DEG C. The WCMP grinding device and the method for improving WCMP grinding rate have the advantages of improving the grinding rate, no influence on the service life of the grinding pad, simple structure and low cost.

Owner:CSMC TECH FAB2 CO LTD

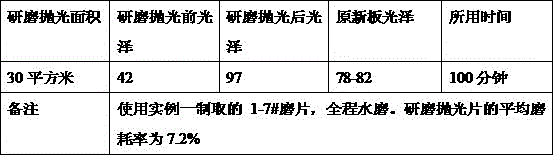

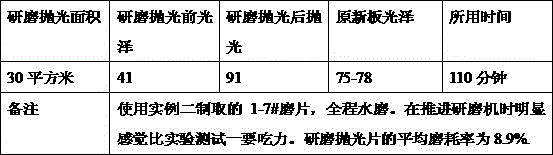

Preparation method of polyurethane matrix stone grinding and polishing disc

ActiveCN106272125AGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideZinc

The invention discloses a preparation method of a polyurethane matrix stone grinding and polishing disc, and relates to a synthesis technology adopting a prepared polyurethane matrix and mixed artificial diamond micro powder, silicon carbide, silicon oxide, aluminium oxide and zinc oxide super fine powder as abrasive components. The novel stone grinding and polishing material can better meet the requirement on high luster during the decorative stone processing process or the later renovation process, the efficiency is higher, and the material has better environmental protection property.

Owner:王建秋

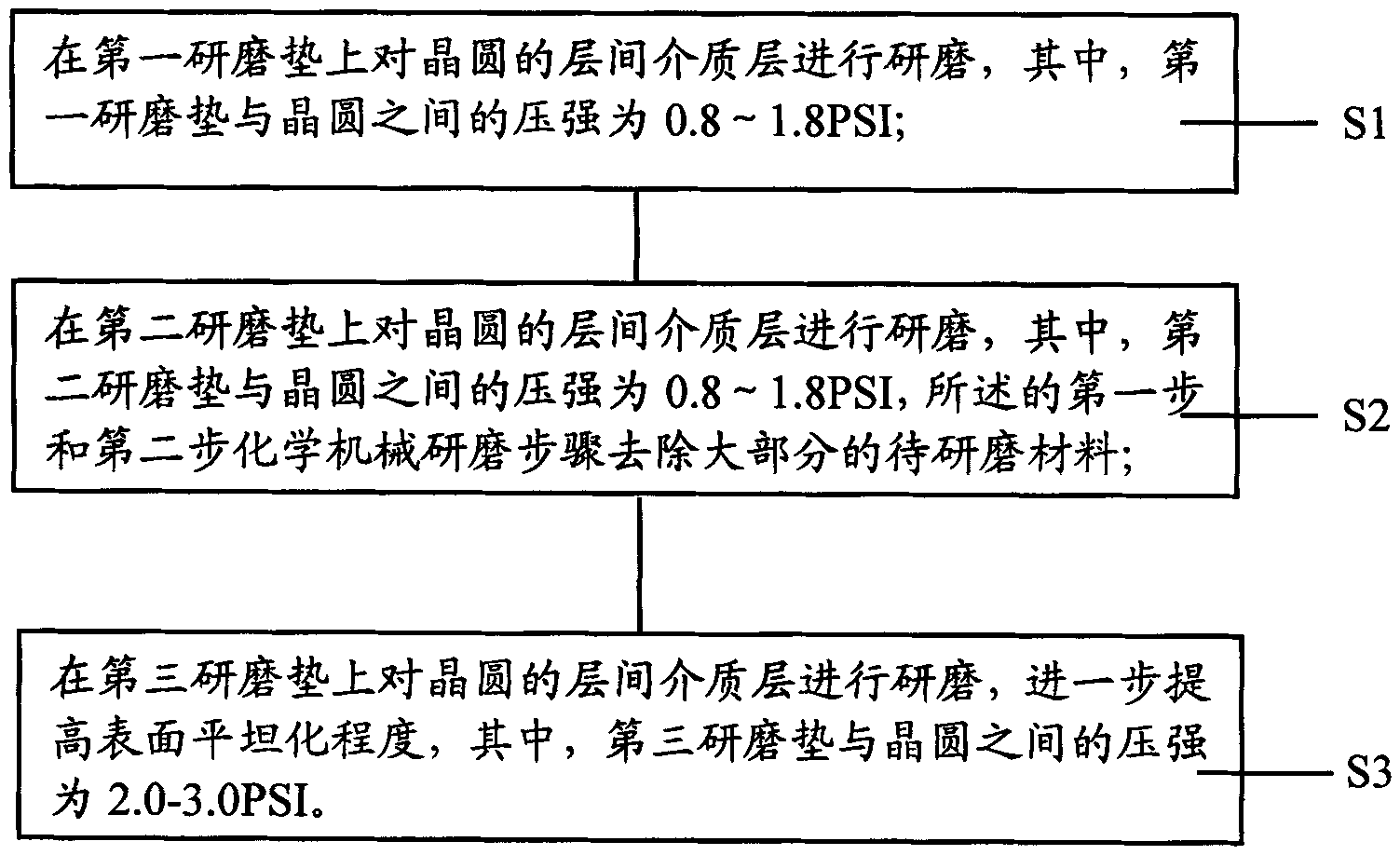

Chemical mechanical grinding method for interlayer dielectric layer

InactiveCN101961852AReduce grinding rateIncrease grinding rateSemiconductor/solid-state device manufacturingLapping machinesPolymer chemistryMaterials science

The invention relates to a chemical mechanical grinding method for an interlayer dielectric layer, which comprises the following steps of: 1. grinding an interlayer dielectric layer of a wafer on a first grinding pad, wherein pressure between the first grinding pad and the wafer is 0.8-1.8PSI; 2. grinding the interlayer dielectric layer of the wafer on a second grinding pad, wherein pressure between the second grinding pad and the wafer is 0.8-1.8PSI, and most materials to be ground are removed in the first and second chemical mechanical grinding steps; and 3. grinding the interlayer dielectric layer of the wafer on a third grinding pad so as to further improve surface flat degree, wherein pressure between the third grinding pad and the wafer is 2.0-3.0PSI. The method can effectively reduce chemical mechanical grinding scratches of the interlayer dielectric layer and improve product yield.

Owner:SEMICON MFG INT (SHANGHAI) CORP

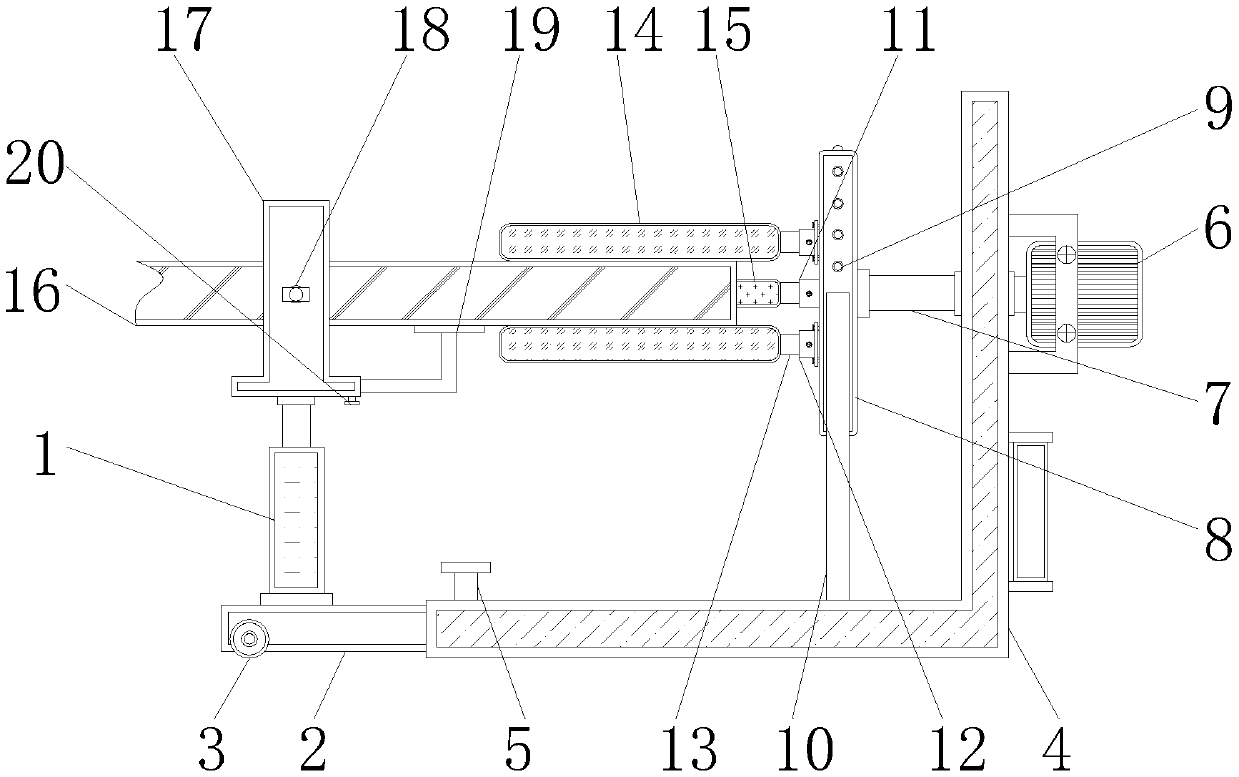

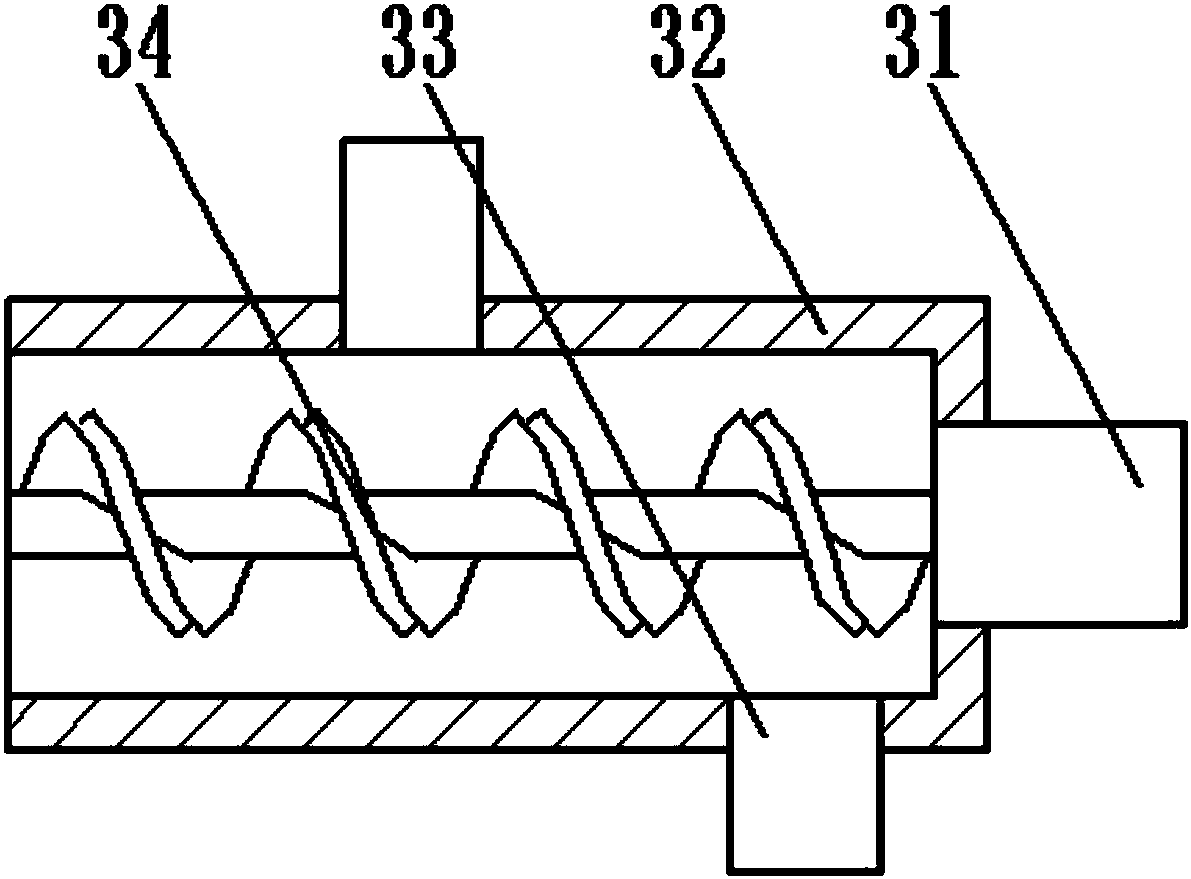

Drug breaking and grinding device

InactiveCN106733109AIncrease grinding rateImprove grinding effectFurnace typesGrain treatmentsDrugTransmission system

The invention relates to a drug breaking and grinding device which comprises a breaking system, a grinding system and a power and transmission system. Through the improvement and reasonable arrangement of the various components, breaking and grinding are separated, so that the working efficiency is improved. In addition, with the creative adoption of the grinding system in which grinding balls are matched with a grinding internal barrel and a grinding external barrel, the grinding efficiency and the product quality are improved.

Owner:王宝林

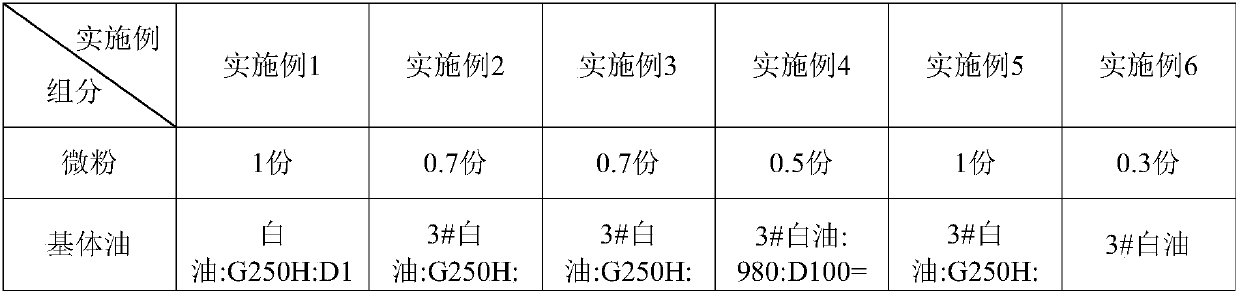

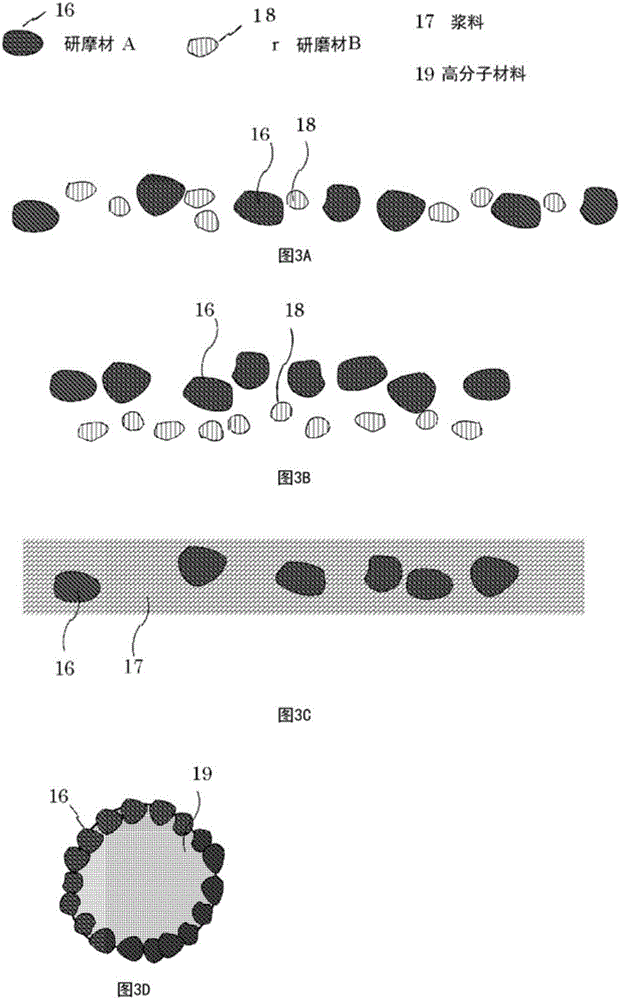

Micro powder prepolymer formula and preparation method thereof

PendingCN107936917AHigh speed grinding characteristicsIncrease grinding rateOther chemical processesPrepolymerHigh-speed grinding

The invention discloses a micro powder prepolymer formula, which is prepared from the following ingredients including 30 to 70 percent of grinding materials, 0.1 to 3.5 percent of auxiliary agents, 8to 45 percent of filling materials and 25 to 65 percent of adhesive water solution. Small-particle micro powder can be combined through bonding agents to become a larger micro powder prepolymer. In the grinding process of the prepolymer, the large-area multi-point contact is realized; the big particle high-speed grinding characteristics are realized; high grinding speed is realized; in addition, the prepolymer can gradually release fine and crushed ground materials in the grinding process; the restoration and polishing effects are achieved; the durable and stable cutting force is realized; meanwhile, the fine grinding surface can also be obtained. In addition, the roasting process can be regulated to obtain a smooth surface and a rough surface; the prepolymers with different combination force can also be obtained; the prepolymer is applied to the preparation of grinding liquid, coating milling tools and concretion milling tools; the high-speed and high-flatness surface processing can be realized.

Owner:河北思瑞恩新材料科技有限公司

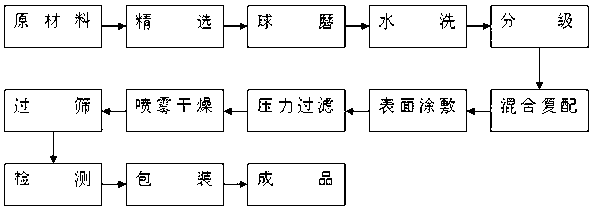

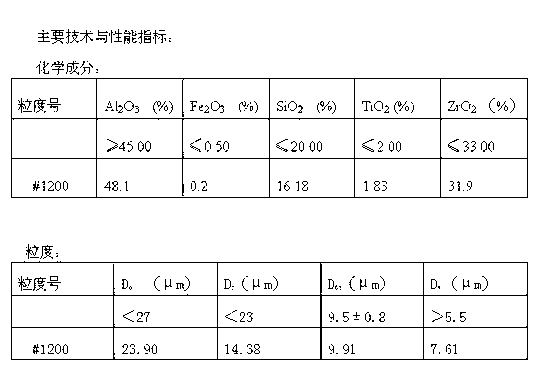

Special zirconium-aluminium composite ground micro-powder for optoelectronic industry and production method for same

ActiveCN103342987AStrong grinding forceImprove grinding efficiencyOther chemical processesManufactured materialSpray dried

The invention discloses special zirconium-aluminium composite ground micro-powder for the optoelectronic industry and a production method for the same. The special zirconium-aluminium composite ground micro-powder for optoelectronic industry is produced from two main raw materials, namely, fused alumina and zirconium silicate, via ball-milling, water-washing, grading, compounding, surface coating, filtering, spray-drying and sieving, wherein the compounding ratios of the contents of the raw materials are as follows: the content of alumina particles is 30-50%, and the content of zirconium silicate particles is 70-50%. The product disclosed by the invention is reasonable in particle shape collocation, wide in particle size distribution, stable in median diameter, high in basic particle size ratio, without large particles and ultrafine particles, excellent in interparticle lubrication property, and especially suitable for grinding and polishing high-tech products in the optoelectronic industry.

Owner:ZIBO JINJIYUAN ABRASIVES

Suspension auxiliary agent applied to grinding of large-size silicon wafer, and preparation method and application thereof

ActiveCN113621346AGood suspensionPrevent coagulationOther chemical processesEmulsionPhysical chemistry

The invention provides a suspension auxiliary agent applied to grinding of a large-size silicon wafer, a preparation method and application thereof. The suspension auxiliary agent comprises the following components in parts by weight: 0.5 to 5 parts of a hydrogen bond thixotropic agent, 0.5 to 5 parts of a suspension synergist, 0.1 to 1 part of a charge neutralizer, 0.5 to 10 parts of a dispersant, 10 to 20 parts of a lubricant, 0.1 to 0.5 part of an antirust agent, and 50 to 85 parts of water. The invention also discloses a preparation method of the suspension auxiliary agent. The preparation method comprises the following steps: sequentially adding the dispersant, the lubricant, the charge neutralizer and the antirust agent into the deionized water; heating to 40 DEG C, adding the hydrogen bond thixotropic agent into the solution, and standing to swell and stabilize the emulsion; and adding the suspension synergist into the solution to prepare the suspension auxiliary agent applied to large-size silicon wafer grinding. The prepared suspension auxiliary agent can effectively improve the suspension performance of the composite abrasive material, has good dispersity on different abrasive materials, and avoids abrasive material agglomeration and abrasive material hard precipitation in circulating grinding.

Owner:ZHEJIANG AUFIRST MATERIAL TECH CO LTD

Efficient battery cathode material graphite smashing device

InactiveCN108187887AImprove concentrationConcentrate on inputCocoaGrain treatmentsDrive motorEngineering

The invention provides an efficient battery cathode material graphite smashing device, and belongs to the technical field of battery production. The device comprises universal wheels, a bottom plate is arranged on the tops of the universal wheels, a supporting rod is arranged on the top of the bottom plate, the bottom of the supporting rod is welded to the top of the bottom plate, and the top of the supporting rod is welded to the bottom of a discharging chamber. The efficient battery cathode material graphite smashing device is simple in structure and reasonable in design, due to arrangementof feeding hoppers, materials can be conveniently concentrated to be input to a smashing chamber, a grinding device is arranged, a drive motor drives a grinding shaft and a grinding block to move, a check block can be subject to primary grinding, the material grinding quality can be greatly improved, a stirring device is arranged, the material can be subject to grinding and smashing again, the material grinding quality is improved, a filter plate is arranged, the ground material can be filtered, the material is screened, filtered qualified materials are discharged from a discharging device, and the material which is ground and disqualified is discharged from an impurity discharging pipe.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Silicon slice grinding rate control method

InactiveCN101367194AIncrease grinding rateGood surface qualityPolishing machinesOther chemical processesSilicon chipSurface-active agents

The invention provides a method for controlling the lapping speed of a silicon chip, which comprises the following steps: the silicon chip to be lapped is clamped to a lapping plate of a lapper, the surface of the silicon chip to be lapped is supplied with lapping liquid, the lapper is subjected to pressure and the lapping plate of the lapper is controlled to rotate, and the surface of the object to be lapped is lapped; the improvement of the method is that the lapping liquid used comprises abrasive filler, osmotic agent, pH regulator, surface active agent and deionized water; and the lapping pressure of the lapper is controlled below 50kPa, the rotating speed of an upper lapping plate is controlled below 200 rounds per minute, and the rotating speed of a lower lapping plate is controlled below 200 rounds per minute. The method can effectively improve the lapping speed for lapping the silicon chip, guarantee that the silicon chip has better surface quality after lapping, improve the production efficiency, and reduce the production cost.

Owner:JIANGSU HAIXUN IND GROUP SHARE

Cmp system with temperature-controlled polishing head

InactiveCN101224561AIncrease grinding rateImprove grinding uniformityPolishing machinesSemiconductor/solid-state device manufacturingTemperature controlEngineering

The invention relates to a chemical mechanical polishing system with a temperature-controlled grinding head for grinding wafers, which includes a grinding head; an inner tube connected to the grinding head, wherein the inner tube is filled with a heat medium; a connected inner tube medium heater; and a pressure controller connected to the inner tube. The chemical mechanical polishing system of the present invention does not create unnecessary complexity on the wafer, and can increase the chemical mechanical polishing rate and improve the chemical mechanical polishing uniformity.

Owner:TAIWAN SEMICON MFG CO LTD

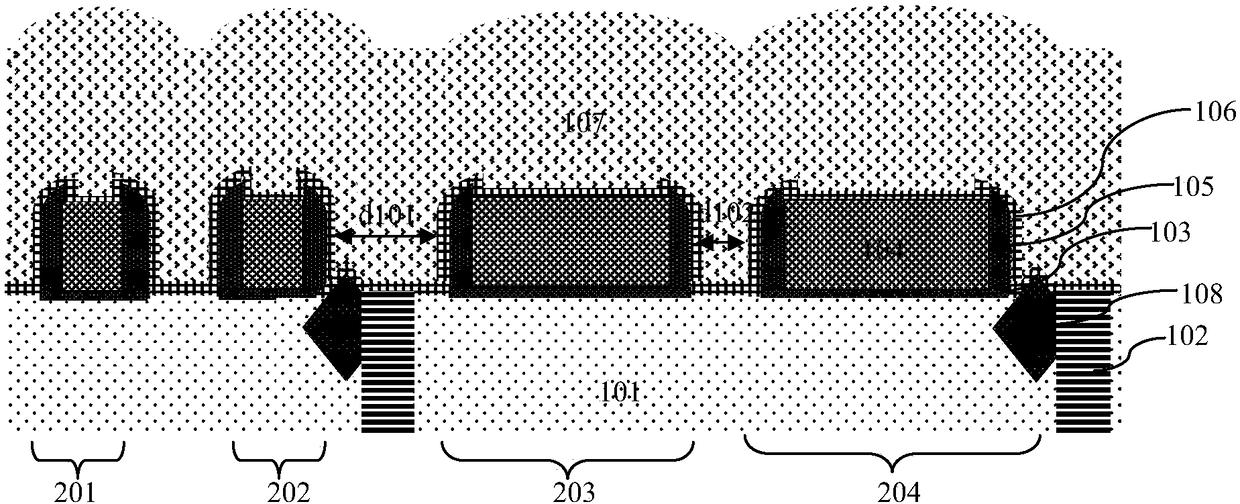

Interlayer film manufacturing method

ActiveCN108878288AEffect on electrical performanceImprove surface flatnessSemiconductor/solid-state device manufacturingPower semiconductor deviceDevice material

The invention discloses an interlayer film manufacturing method. The interlayer film manufacturing method comprises the following steps: step one, providing a semiconductor substrate on which a pattern structure of a semiconductor device is formed; step two, forming a first insulating layer on the bottom surface and side surfaces of the pattern spacer and the surface of the pattern structure outside the pattern spacer; step three, forming a second insulating layer to completely fill the pattern spacer and extend outside the pattern spacer; and step four: performing chemical mechanical polishing on the second insulating layer and the first insulating layer with the pattern structure as a stop layer, and forming the interlayer film formed by stacking the first and second insulating layers filled in the pattern spacer. The interlayer film manufacturing method can reduce or eliminate dishing defects on the interlayer film surface at the top of the pattern spacer, can improve the flatness of the entire interlayer film, and can improve the electrical properties of semiconductor devices.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

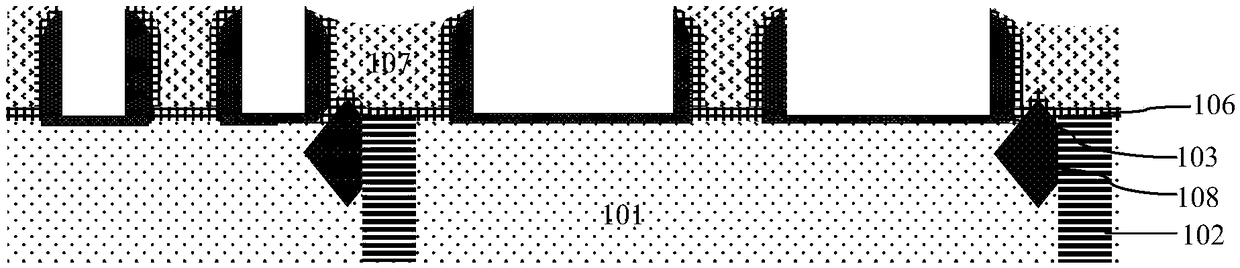

Chemical mechanical polishing method

InactiveCN102737986AImprove grinding efficiencyIncrease grinding rateSemiconductor/solid-state device manufacturingCompound (substance)Engineering

A chemical mechanical polishing (CMP) method is provided. The method is capable of polishing a substrate in a CMP apparatus by using a hydrophobic polishing pad and includes following steps. A first CMP process is performed to the substrate. A first cleaning process is performed to the hydrophobic polishing pad. A second CMP process is performed to the substrate, wherein the first CMP process, the first cleaning process and the second CMP process are performed in sequence. The invention enables the polishing efficiency to be improved effectively when the hydrophobic polishing pad is used.

Owner:NAN YA TECH

Efficient glass waste crushing and screening equipment

InactiveCN110152865AImprove grinding qualityIncrease grinding rateTransportation and packagingRotary stirring mixersPulp and paper industryDrive motor

The invention provides efficient glass waste crushing and screening equipment, and belongs to the technical field of glass waste treatment. The equipment comprises universal wheels; a bottom plate isarranged at the tops of the universal wheels; supporting rods are arranged at the top of the bottom plate; the bottoms of the supporting rods are welded to the top of the bottom plate, and the tops ofthe supporting rods are welded to the bottom of a discharging chamber; a stirring device is arranged inside the discharging chamber; and a discharging pipe is arranged on the left side of the discharging chamber. The equipment is simple in structure, reasonable in design and convenient to use; due to the arrangement of feed hoppers, materials can be collected to be input into a crushing chamber;due to the arrangement of a stop block, the materials can be filtered primarily, and crushed waste glass can be sucked out through a dust collecting pipe and discharged along with the discharging pipe; and due to the arrangement of a grinding device, under the action of a driving motor, a stirring transverse plate is driven to uniformly input the materials from the interior of a connecting pipe tothe position below the stop block, and under the action of an upper grinding block and a lower grinding block, the materials are subjected to grinding treatment, so that the grinding quality of the materials is greatly improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com