Patents

Literature

63results about How to "For subsequent cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

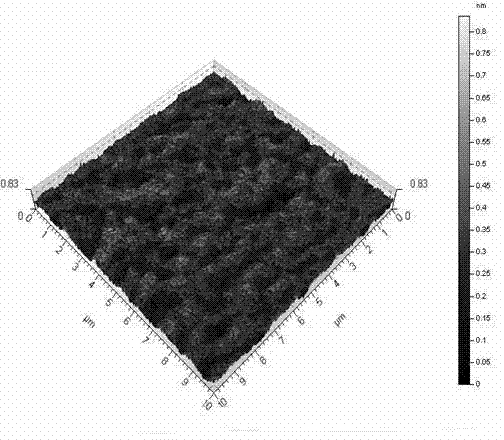

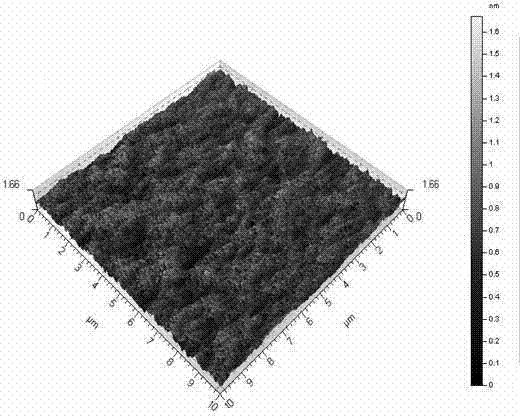

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for alkaline sapphire substrate and preparation method thereof

ActiveCN103571333ASolve pollutionSolve many disadvantages such as easy gelPolishing compositions with abrasivesNano sio2SURFACTANT BLEND

The invention relates to a CMP (Chemical-Mechanical Polishing) polishing liquid with mixed grinding materials for an alkaline sapphire substrate and a preparation method thereof. The CMP polishing liquid consists of the following components in percentage by weight: 0.5-35% of a main grinding material, 0.015-0.09% of an auxiliary grinding material, 0.005-0.05% of a chelating agent, 0.005-0.05% of a surfactant, 0.01-0.5% of a pH adjustor, and the balance of deionized water, wherein the main grinding material is a nano SiO2 sol and the auxiliary grinding material is an Al2O3 sol. The auxiliary grinding material, the chelating agent, the surfactant and the alkaline pH adjustor are sequentially added into a nanosilicon sol suspension. In the polishing liquid, as the content of the main grinding material SiO2 sol is reduced, the phenomenon that the polishing liquid residue on the surface of the substrate after CMP is relatively severe is reduced to facilitate subsequent cleaning. A less amount of the auxiliary grinding material Al2O3 is added, so that the polishing speed is remarkably increased, and the roughness of the substrate after CMP is reduced.

Owner:江西伟嘉创展企业管理有限公司

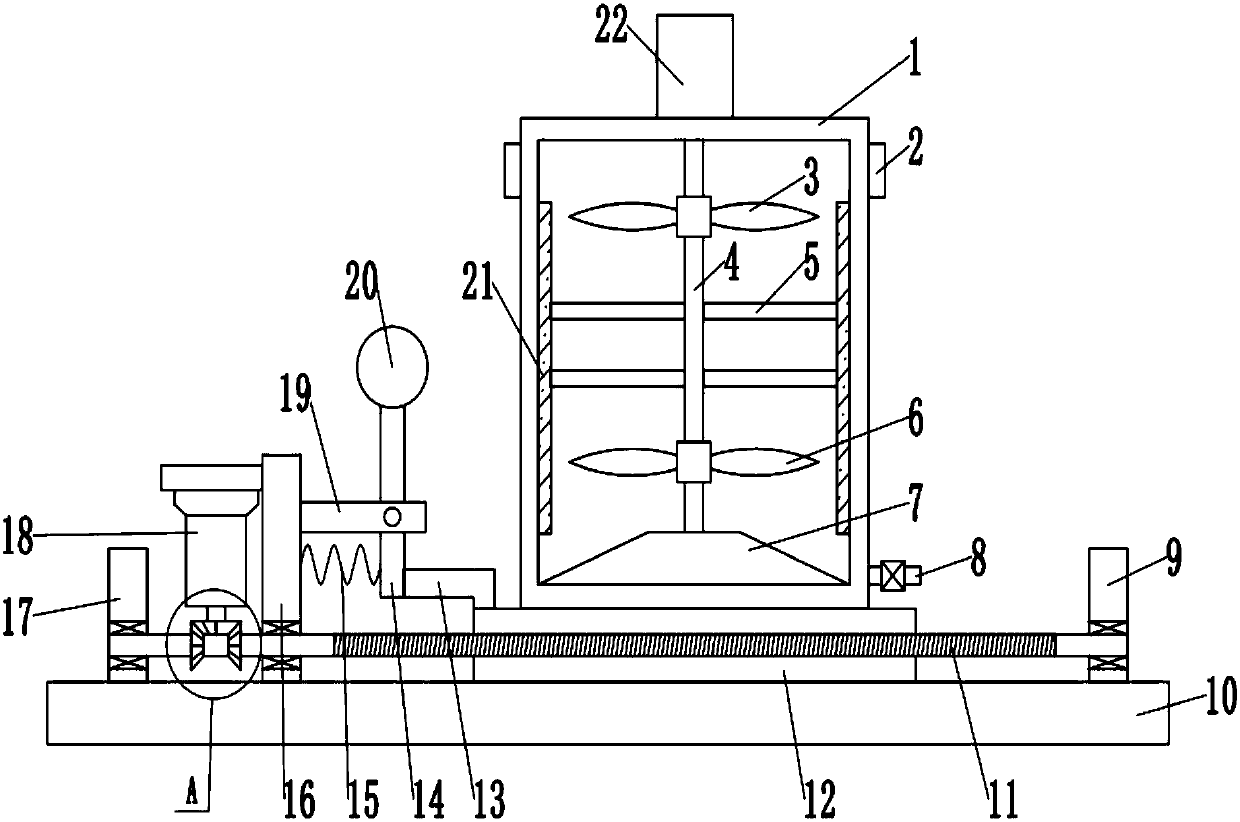

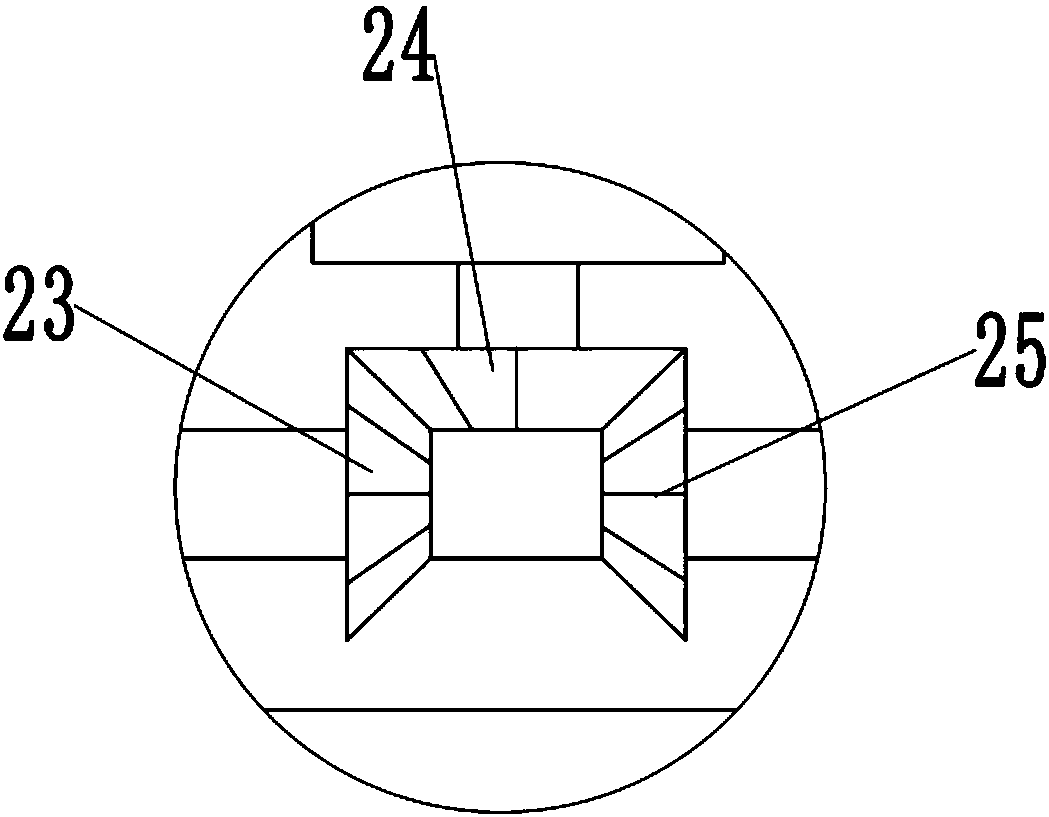

Left-right-movement efficient mixing device for building coating

InactiveCN108031321AAvoid stickingSpeed up the mixingTransportation and packagingRotary stirring mixersArchitectural engineeringMixing effect

The invention discloses a left-right-movement efficient mixing device for a building coating. The left-right-movement efficient mixing device comprises a mixing barrel and a base, wherein the bottom of the mixing barrel is arranged on the upper surface of the base by a sliding block in a sliding manner; a rotating shaft is rotationally arranged inside the mixing barrel; first screw blades are fixedly arranged at the upper part of the rotating shaft; second screw blades are fixedly arranged at the lower part of the rotating shaft; stirring rods are fixedly arranged at the middle position of therotating shaft; a support is fixedly arranged on the left side of the base; the lower side of the support is rotationally connected with a screw; a rotating motor is fixedly arranged on the upper-left side of the support; a driving bevel gear is fixedly connected to the output end of the rotating motor and is of a semi-bevel gear structure; a first bevel gear and a second bevel gear are also symmetrically arranged on the screw. According to the left-right-movement efficient mixing device disclosed by the invention, by arranging the mixing barrel which can move leftwards and rightwards, the first screw blade, the second screw blade and the stirring rod, the coating in the barrel is quickly mixed, the mixing speed is increased and the mixing effect is improved.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

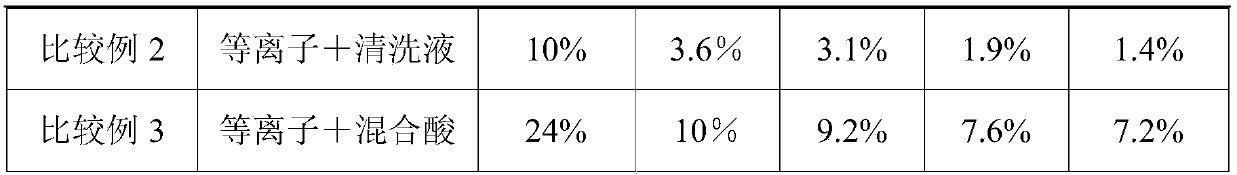

Cleaning equipment for automobile parts

InactiveCN111804635AFor subsequent cleaningReasonable structural designDrying gas arrangementsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses cleaning equipment for automobile parts. The cleaning equipment comprises two supports, wherein a cleaning box is fixedly connected to the upper ends of the supports, a rotating assembly is connected to the right ends of first rotating shafts, a linkage assembly is connected to the rotating assembly, sweeping rollers are arranged on the two first rotating shafts, a discharging assembly is arranged in the middle of an inner cavity of the cleaning box, a lifting assembly is arranged in a supporting table, an overturning assembly is arranged in an outer cylinder, and a vibration assembly is arranged at the lower end of a filter plate; and parts are swept and brushed through sweeping brushes, a large amount of sweeps and dirt adhering to the parts can be brushed away, the parts, cleaning liquid and water in an inner barrel are driven by the overturning assembly to be overturned and cleaned, the cleaning efficiency is high, solid-liquid separation of the parts and waste liquid is achieved through the filter plate, the vibration assembly drives the filter plate to vibrate up and down in a reciprocating mode, the solid-liquid separation efficiency can be improved,parts on the filter plate are dried through a drying assembly, follow-up part treatment and use are facilitated, the cost is reduced, and the machining efficiency is improved.

Owner:杭州巾成科技有限公司

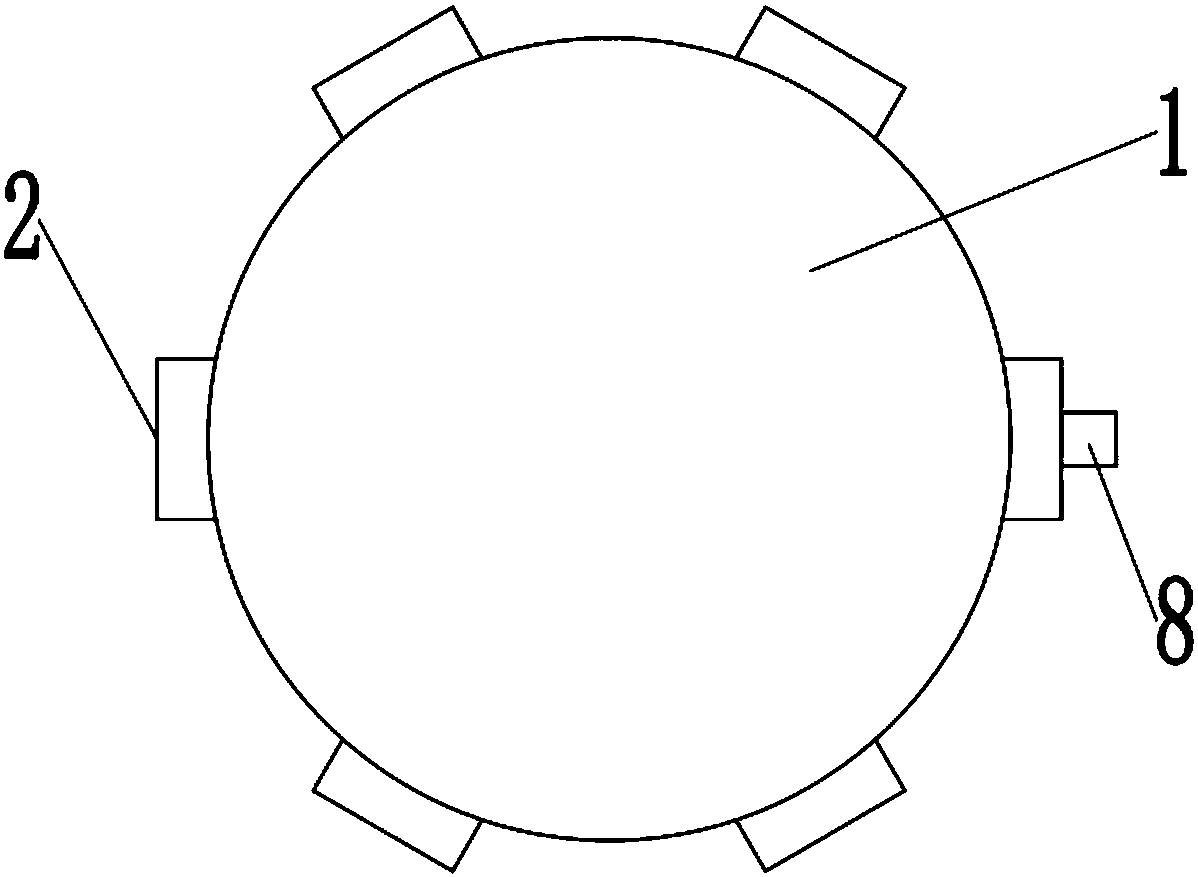

Glass test tube cleaning device for hematology department

PendingCN112337924AFor subsequent cleaningAchieve cleaning effectHollow article cleaningTest tubeElectric machinery

The invention relates to a glass test tube cleaning device, in particular to a glass test tube cleaning device for the hematology department. The glass test tube cleaning device for the hematology department can automatically clean test tubes, dry the test tubes and automatically take down the dried test tubes. The glass test tube cleaning device for the hematology department comprises a base, a rotating shaft, a mounting plate, a clamping mechanism and a washing mechanism, wherein the rotating shaft is arranged on the base in a rotating mode; the mounting plate is arranged on the rotating shaft; the clamping mechanism is arranged at the lower part of the mounting plate; and the washing mechanism is arranged on the base. By arranging the clamping mechanism, a clamping block in the clampingmechanism achieves the effect of replacing manual test tube holding for cleaning; and by arranging the washing mechanism, a motor in the washing mechanism drives a brush to rotate to wash test tubesup and down, and the situation that a person holds a washing tool to wash the test tubes is replaced.

Owner:雷红军

Washable stamping and drawing oil

ActiveCN106635344AMeet the needs of useEasy to cleanLubricant compositionPhosphateChlorinated paraffins

The invention discloses washable stamping and drawing oil. The washable stamping and drawing oil is prepared from the following components in percentage by weight: 10 to 15 percent of base oil 150SN, 5 to 10 percent of high-viscosity self-emulsified ester, 3 to 5 percent of vulcanized aliphatic acid ester, 1 to 3 percent of sulfurized olefin, 30 to 40 percent of chlorinated paraffin, 1 to 5 percent of phosphate, 1 to 5 percent of calcium petroleum sulfonate, 5 to 15 percent of sodium petroleum sulfonate, 1 to 5 percent of tall oil fatty acid, 1 to 5 percent of iso-tridecanol polyoxyethylene ether, 1 to 5 percent of organic alcohol ether, 1 to 5 percent of pH buffering agent and 1 percent of corrosion inhibitor. The performance of the washable stamping and drawing oil disclosed by the invention can completely meet the service demand of a stamping and drawing process; the washable stamping and drawing oil can successfully replace the current pure oil type stamping and drawing oil and is easy to clean.

Owner:上海森帝润滑技术有限公司

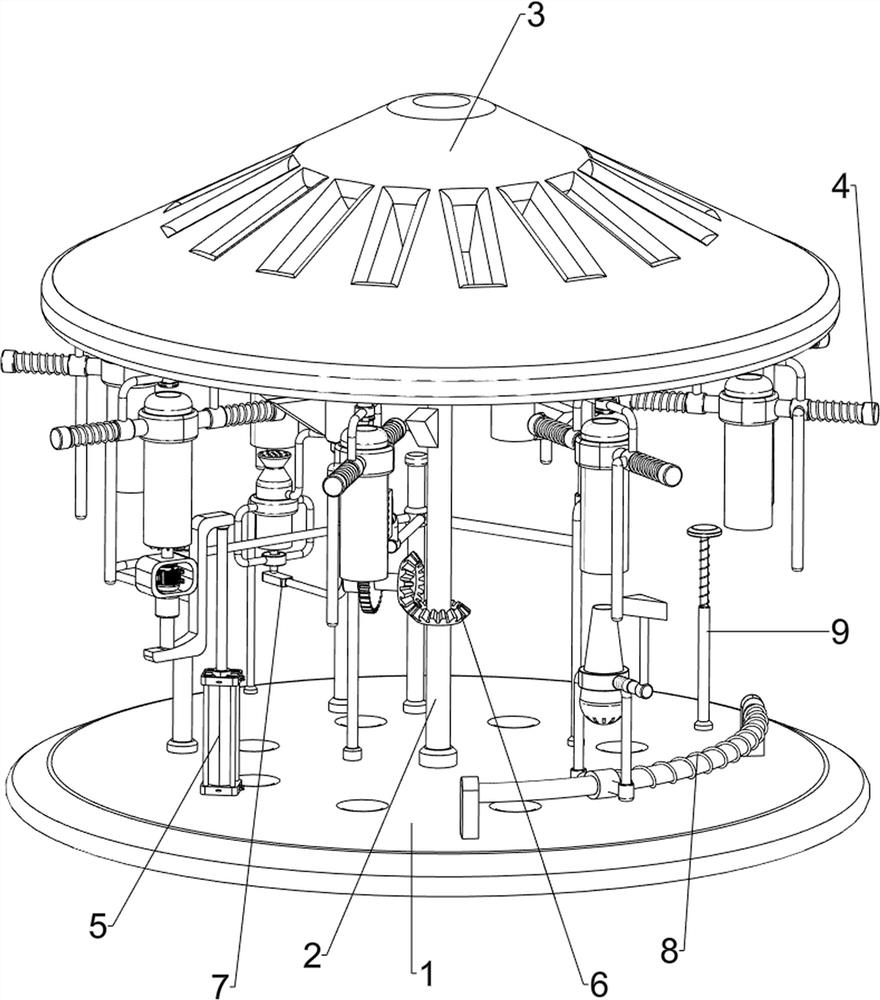

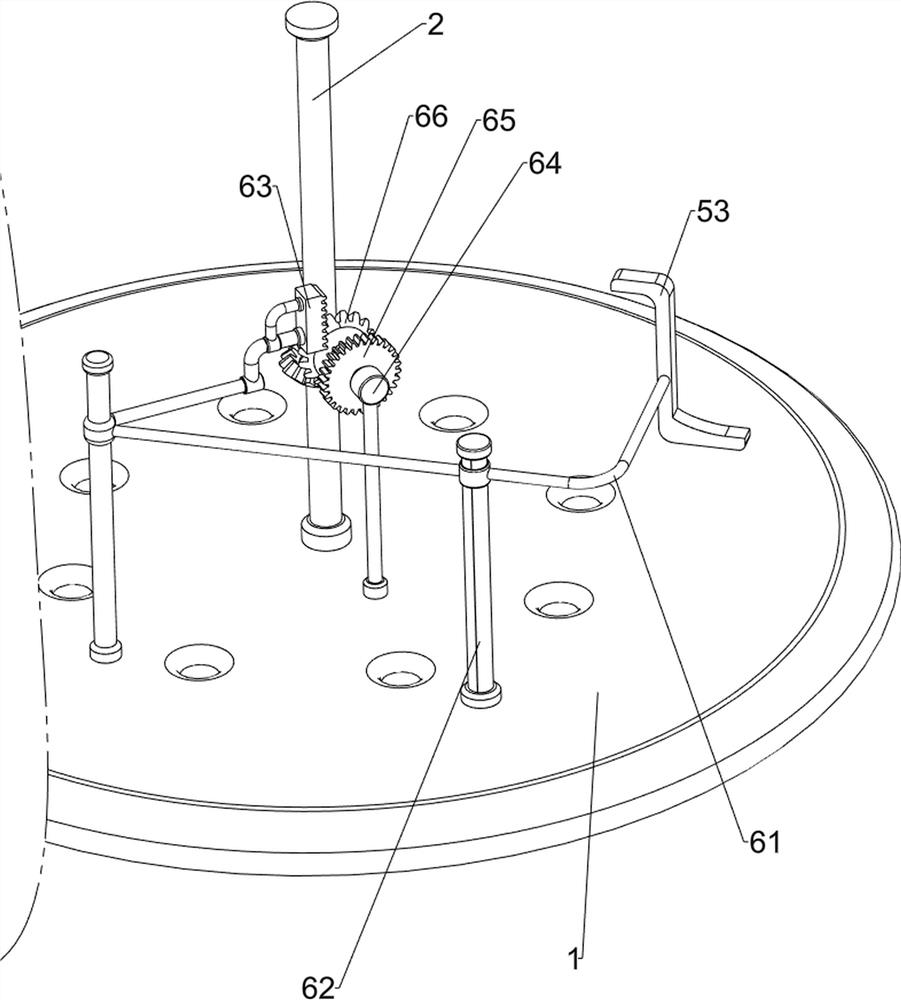

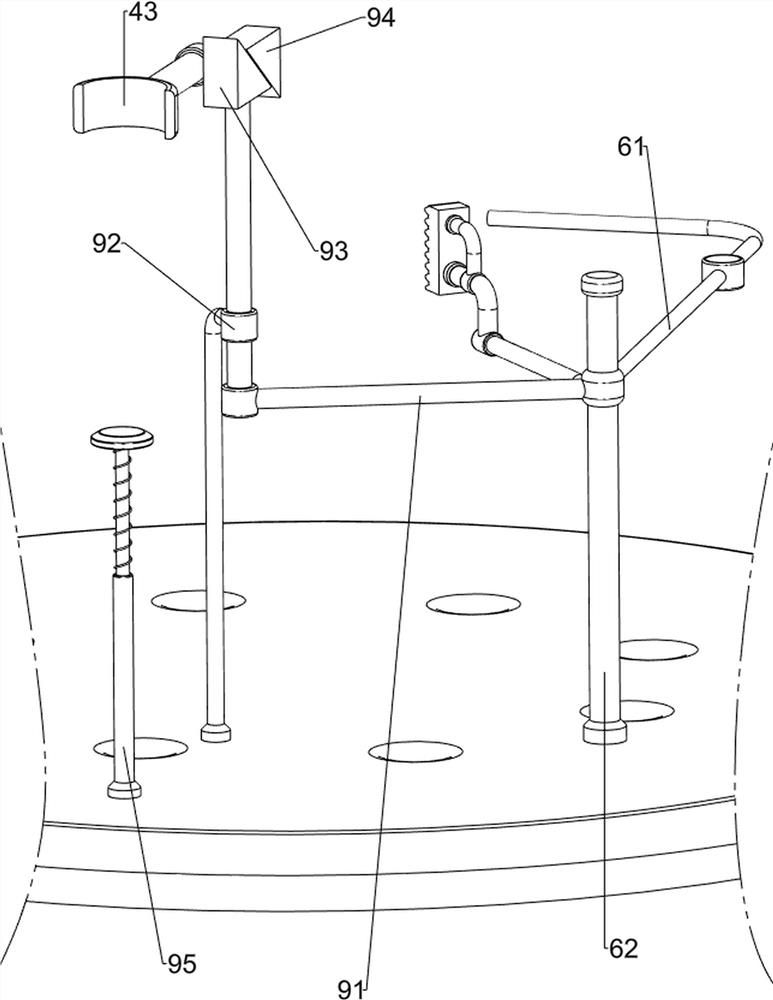

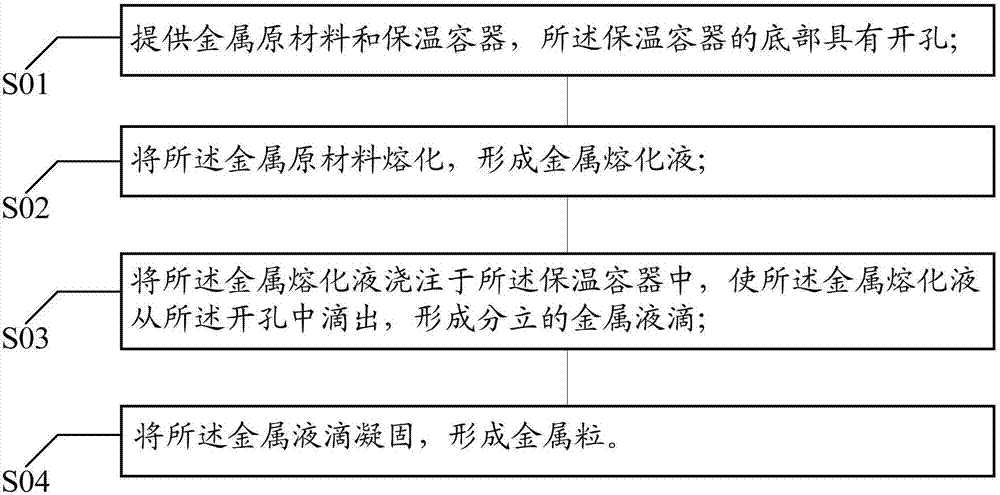

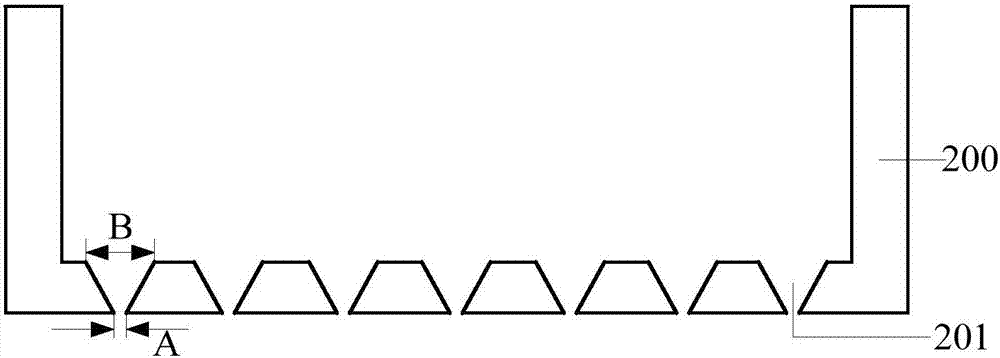

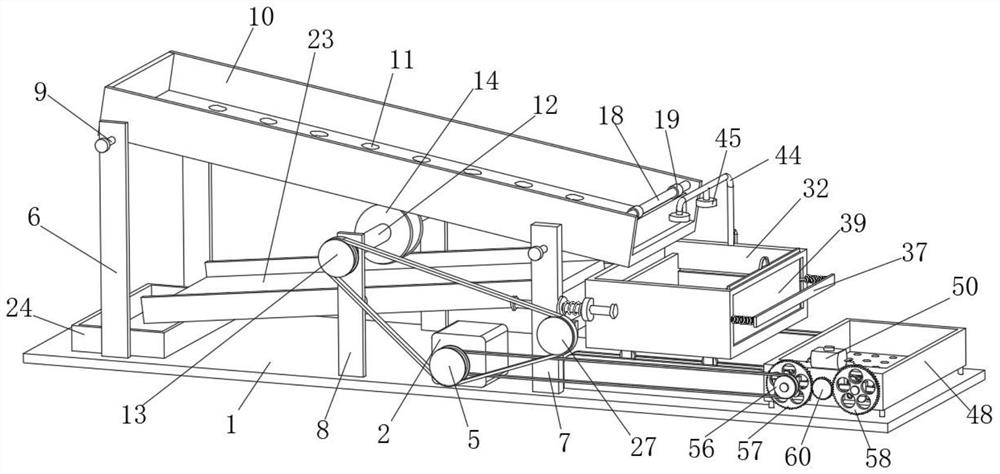

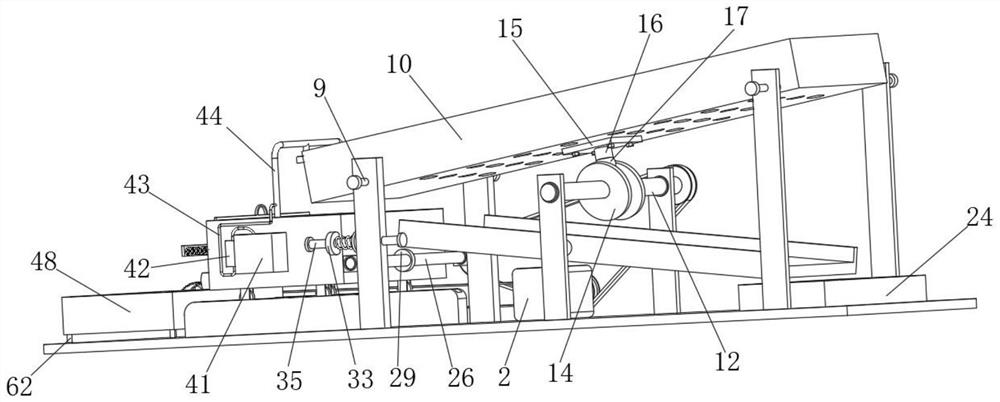

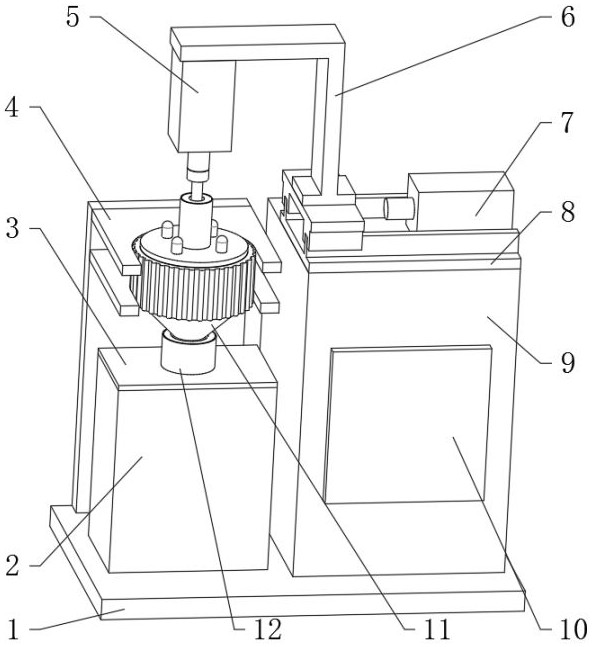

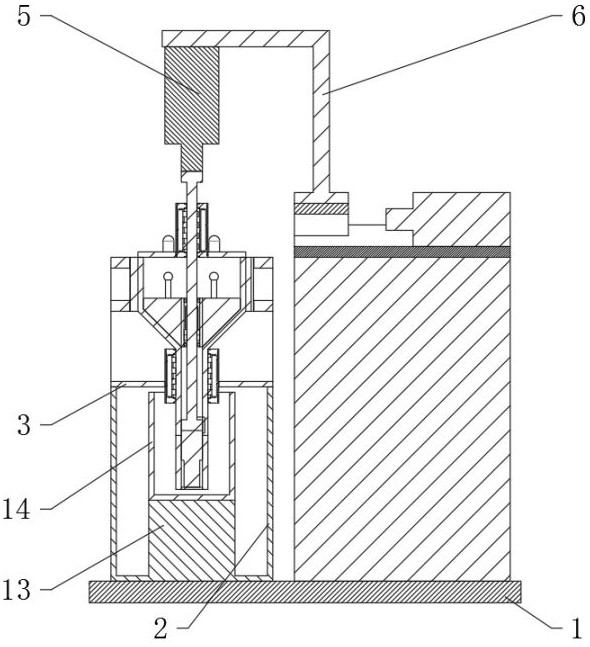

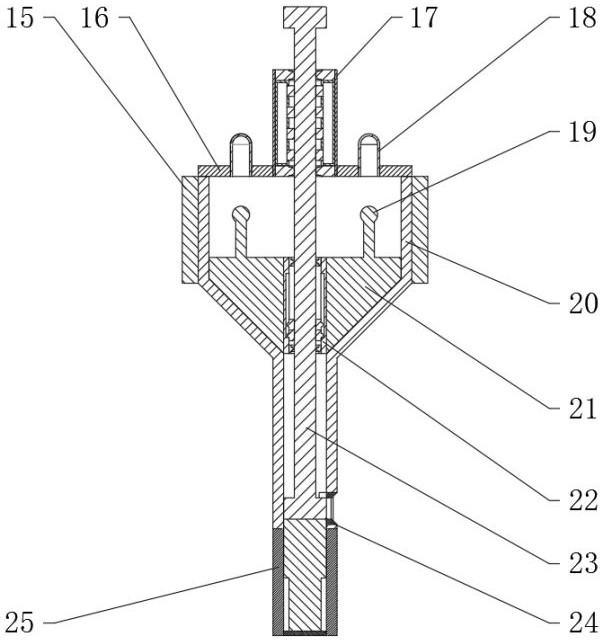

Metal particle forming method and metal particle preparing device

The invention provides a metal particle forming method and a metal particle preparing device. The metal particle forming method comprises the steps that a metal raw material and a heat preservation container are provided, and the bottom of the heat preservation container is provided with holes; the metal raw material is melted, and metal molten liquid is formed; the metal molten liquid is poured into the heat preservation container and dripped out of the holes, and independent metal liquid drops are formed; and the metal liquid drops are solidified, and metal particles are formed. According to the metal particle forming method, the purity of the metal particles can be guaranteed, and the technology efficiency is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

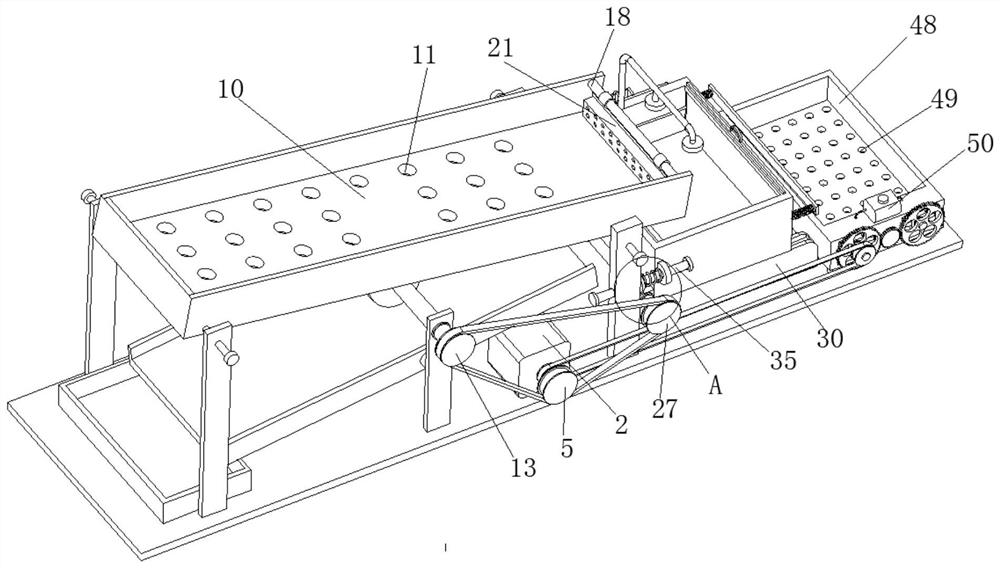

Potato cleaning device and potato chip processing method

ActiveCN112715994AFlexible layoutLow costClimate change adaptationFood treatmentChipped potatoesReciprocating motion

The invention relates to the technical field of potato cleaning devices, and discloses a potato cleaning device, which comprises a bottom plate, one end of a first rotating shaft is fixedly connected with a soil removing belt wheel, the first rotating shaft is fixedly sleeved with an inclined wheel, and the position of the inclined wheel corresponds to that of a swing ball; a second belt wheel drives the soil removing belt wheel and an extrusion belt wheel to rotate through a first transmission belt, the soil removing belt wheel rotates to enable the first rotating shaft to rotate in a rotating hole, the first rotating shaft drives the inclined wheel to rotate, and due to the fact that the inclined wheel is arranged in an inclined mode, a swing ball swings leftwards and rightwards rapidly, the swing ball reciprocates, a soil removing frame is driven to move left and right in the direction of the two horizontal guide rods, so that potatoes on the soil removing frame shake left and right, soil falling off due to shaking falls out of the leakage holes, subsequent cleaning of the potatoes is facilitated, and the cleaning speed is increased.

Owner:杭州麦爽食品有限公司

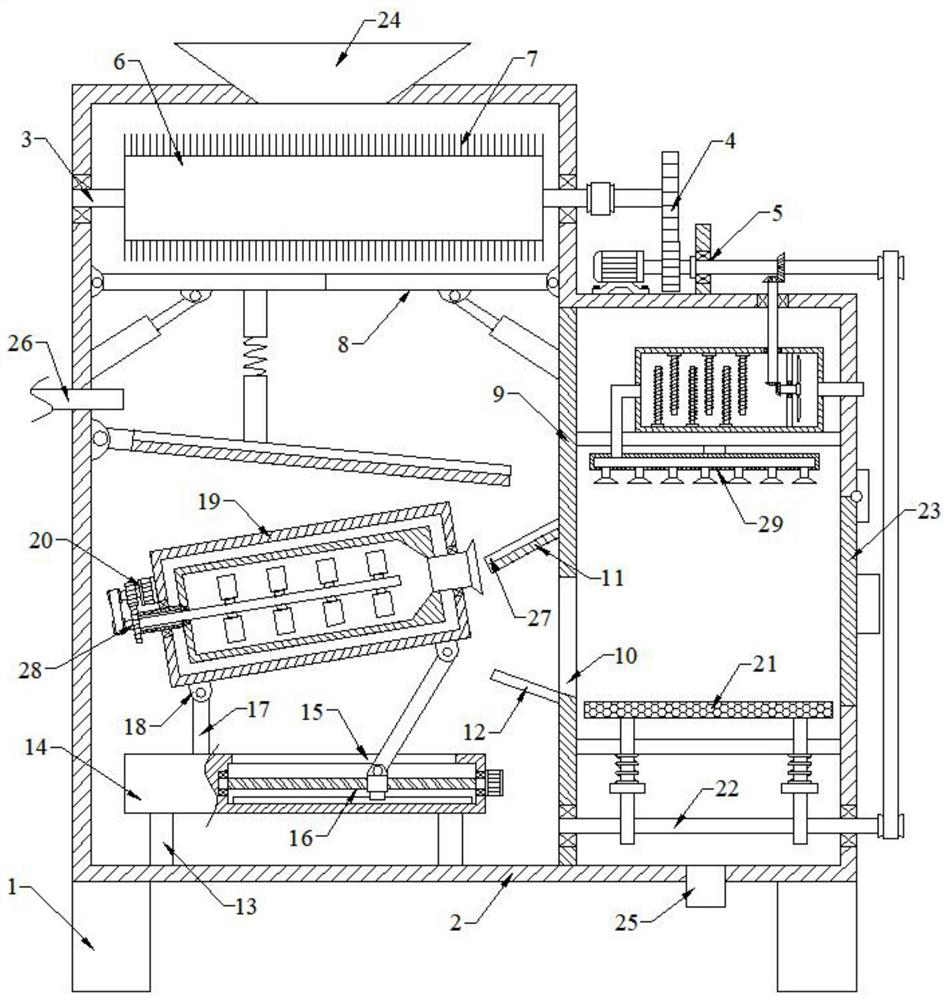

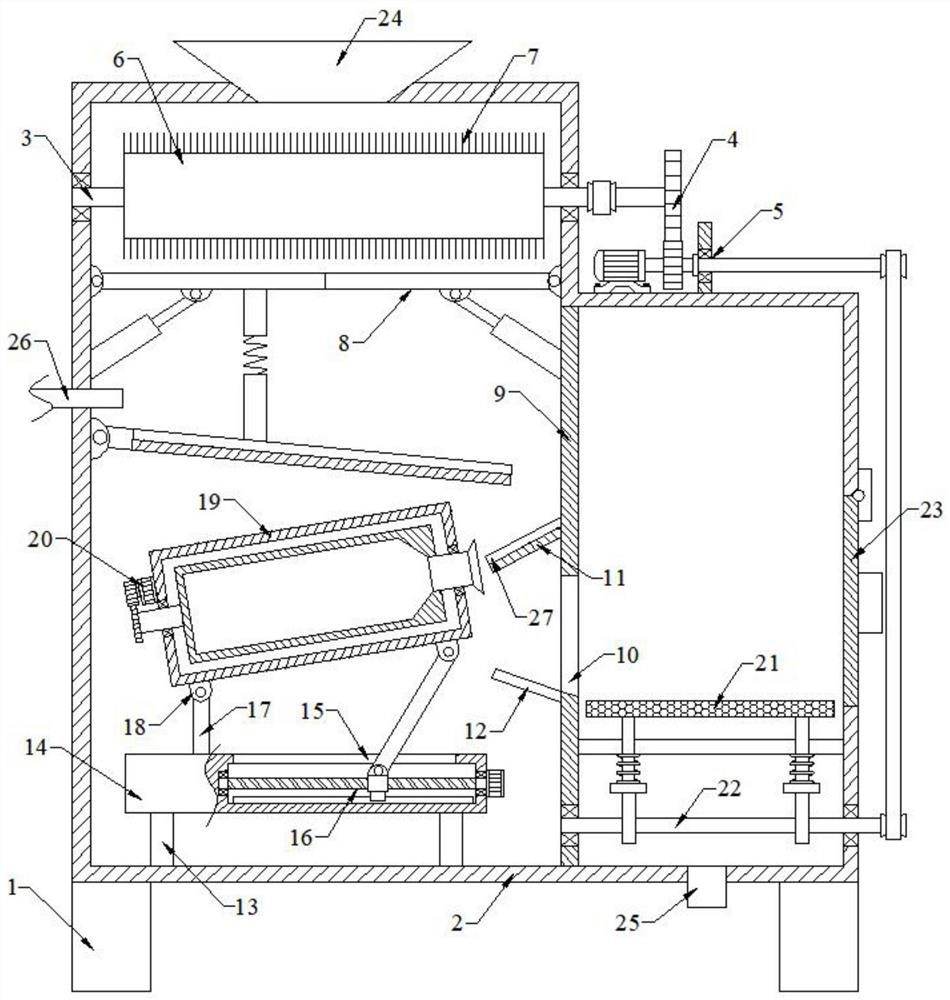

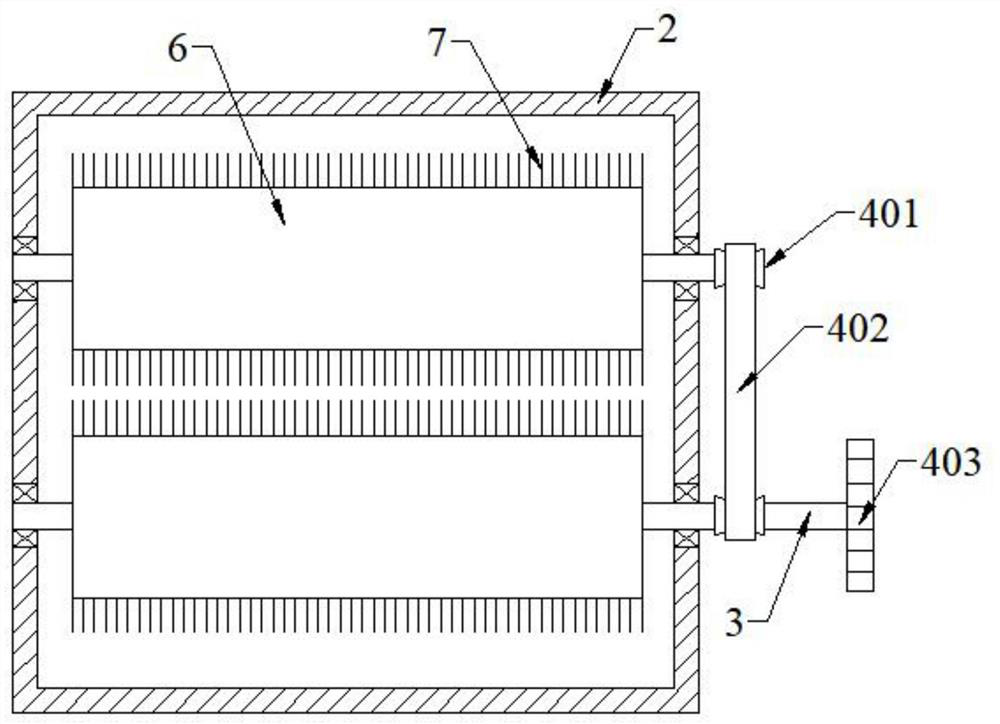

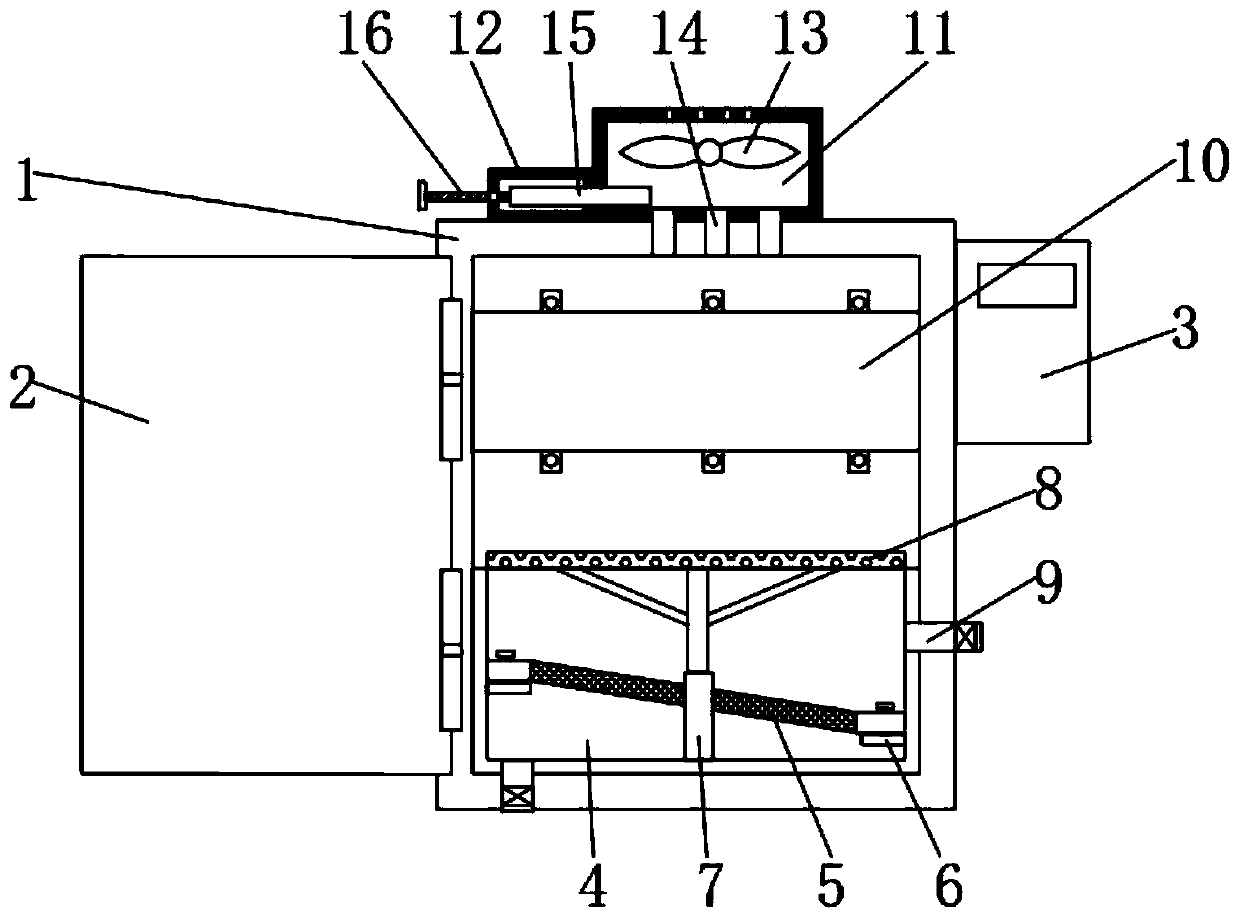

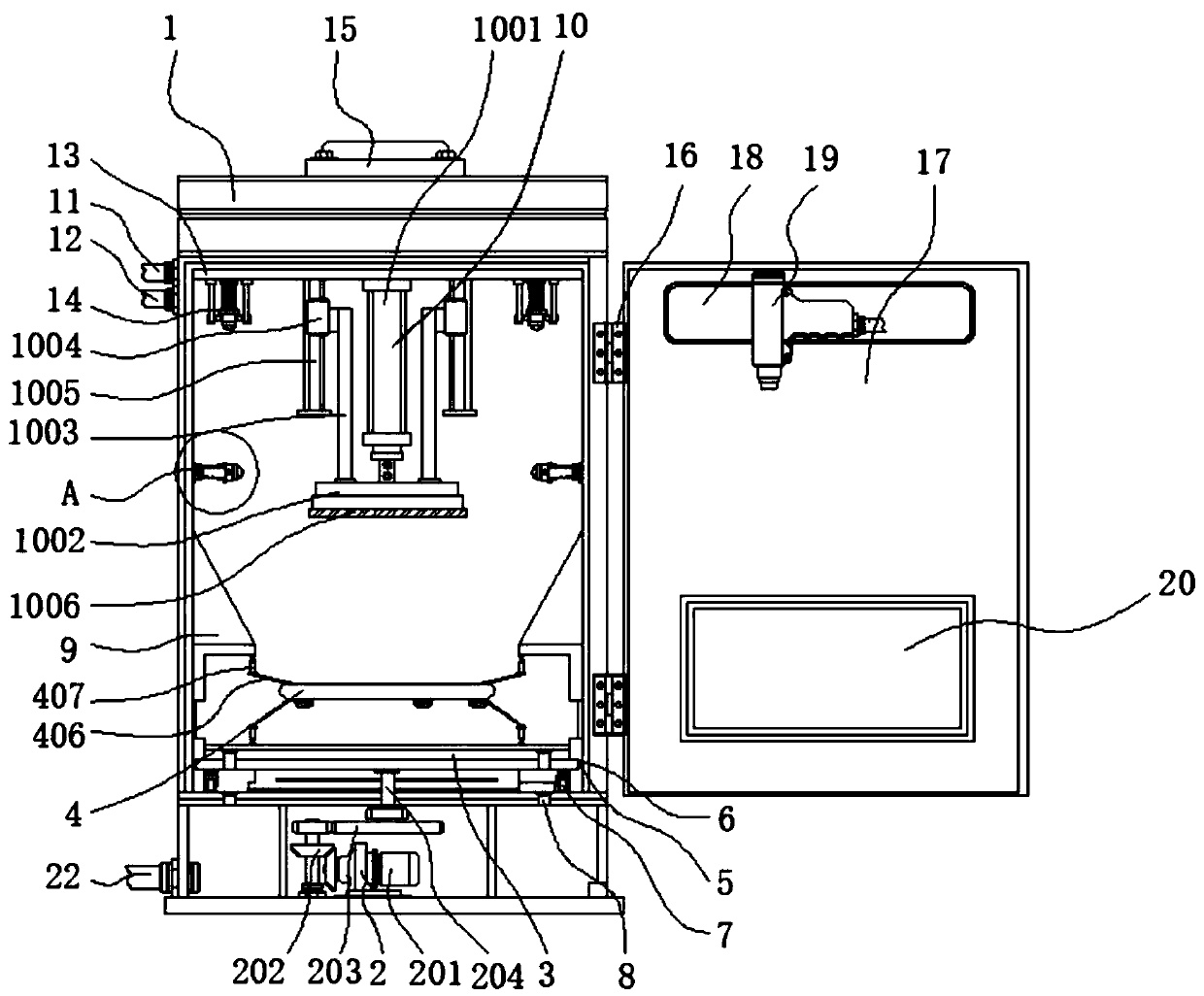

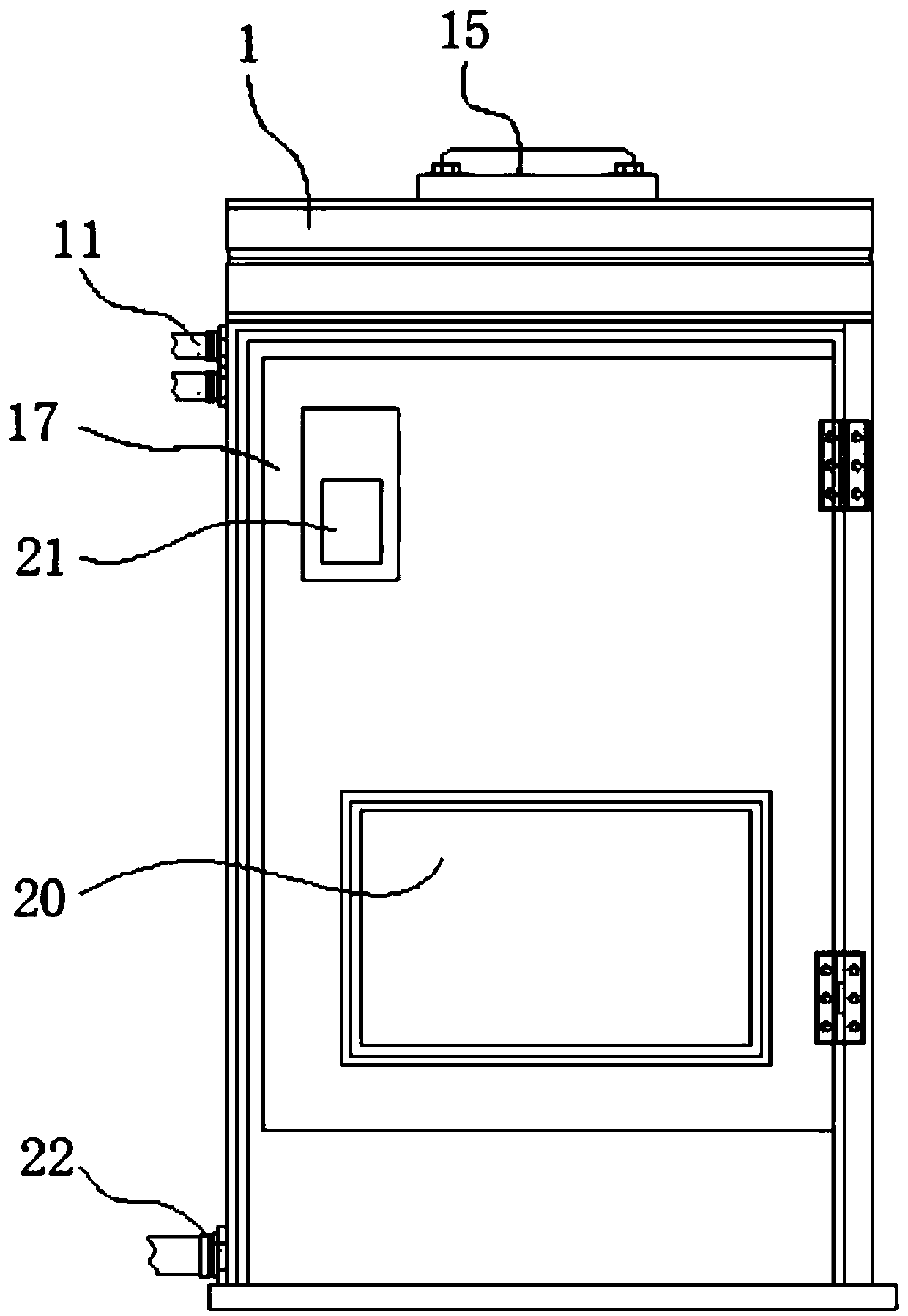

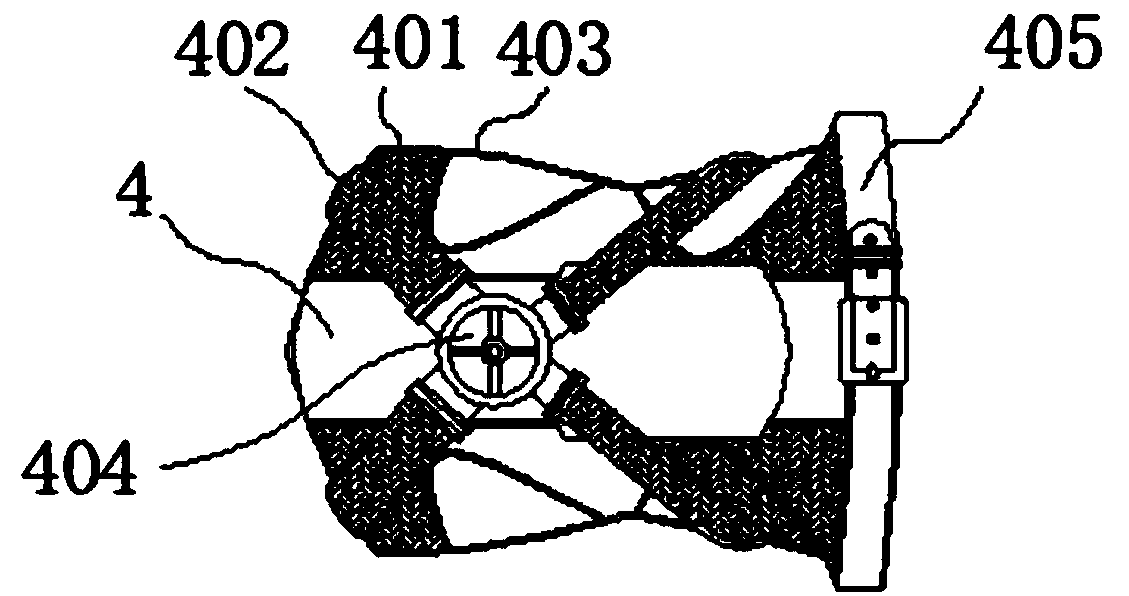

Temperature-controllable box type quenching furnace

InactiveCN110964887AEasy to control temperatureQuick releaseFurnace typesHeat treatment furnacesEngineeringControl switch

The invention discloses a temperature-controllable box type quenching furnace, and belongs to the technical field of quenching furnaces. The temperature-controllable box type quenching furnace comprises a quenching box main body. A filter plate assembly is obliquely arranged in the quenching liquid box. an electric telescopic rod is arranged in the center of the inner wall of the bottom of the quenching liquid box; the top of the electric telescopic rod penetrates through the filter plate assembly and is provided with a working partition plate; a heating device is arranged in the inner cavityof the quenching box main body; an exhaust fan is arranged at the top of the inner cavity of the first shell; ventilation channels are uniformly arranged in the top of the quenching box main body; andan adjusting screw rod is inserted in the left side of the shell II. According to the quenching furnace, a heating device is adopted and is matched with two branch pipes, and the heating wires in thebranch pipes can be controlled to conduct heating through the control switch; meanwhile, the exhaust fan is arranged to be matched with the ventilation channels, when the internal temperature is excessively high, the exhaust fan is started to extract and dissipate heat in the quenching furnace, the adjusting screw rod is arranged to be matched with the sealing baffle, the heat dissipation amountis controlled and the controllable internal temperature of the quenching furnace is realized.

Owner:徐州中治新能源科技有限公司

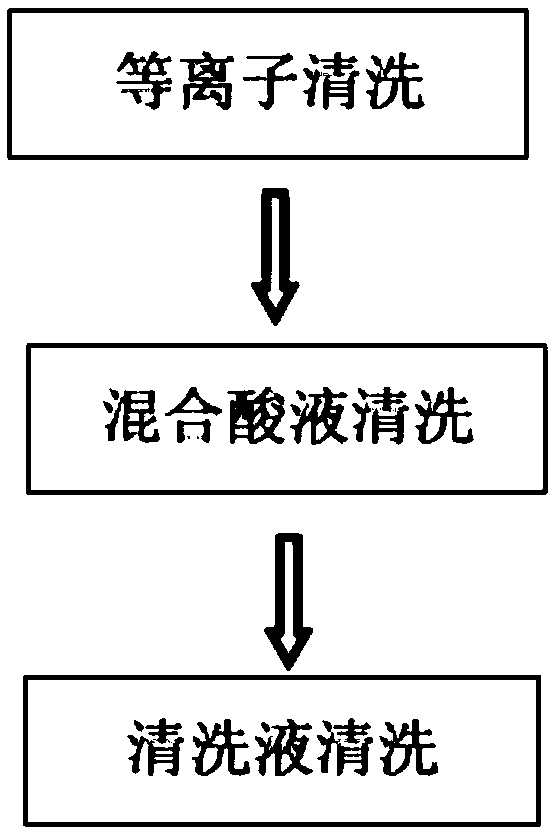

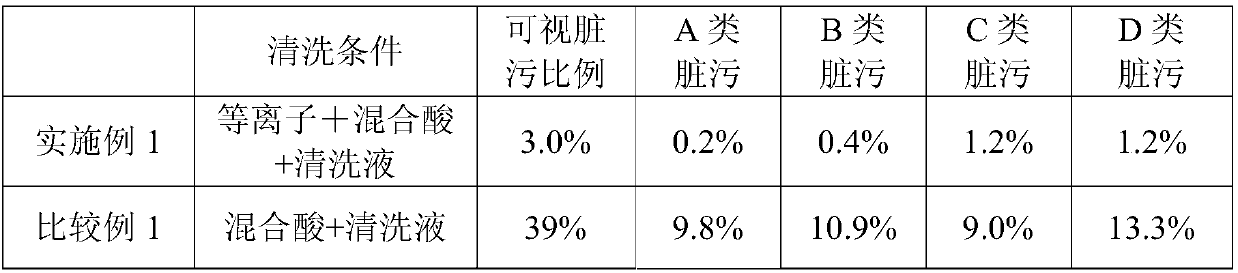

Sapphire lens cleaning method

InactiveCN110449397AReduce usageSimple processInorganic/elemental detergent compounding agentsLens cleaning compositionsSodium metasilicateStrong acids

The invention discloses a sapphire lens cleaning method. The sapphire lens cleaning method comprises the following steps of plasma cleaning, mixed acid solution cleaning and cleaning fluid cleaning. According to the sapphire lens cleaning method, the cleaning modes such as plasma cleaning is introduced to bear the cleaning task of most impurities and dirt of a sapphire lens, and the surface of sapphire is prevented from adsorbing the impurities and dirt again; then, cleaning is carried out in a mixed liquid acid solution of hydrogen peroxide and concentrated sulfuric acid, and then deionized water cleaning is carried out so as to further remove the dirty and impurities; and then cleaning and drying the sapphire lens in an ultrasonic container filled with cleaning liquid so as to thoroughlyremove the residual impurities and dirt, wherein the cleaning fluid comprises the components of a nonionic surfactant, carboxymethyl cellulose, sodium metasilicate, sodium hydroxide, a perfluoropolyether-based surfactant and deionized water. According to the cleaning method, a cleaning agent is reasonably selected, and the cleaning steps are reasonably designed, so that the use of strong acid anda strong oxidant is reduced; and the method is simple in technological process, efficient and environment-friendly, the operation method is easy to master, the production is safe, and the automationimplementation of a production line is facilitated.

Owner:LENS TECH

Potato cleaning machine

InactiveCN110214961AEfficient removalFor subsequent cleaningFood treatmentEngineeringReciprocating motion

The invention discloses a potato cleaning machine which comprises a mud removing box. A bearing net disc is nested in the mud removing box, and pushing plates distributed circumferentially abut against the bearing net disc; a feeding pipe is communicated with the upper end of the mud removing box, a discharging pipe is nested on the bearing net disc, and the discharging pipe and the feeding pipe are staggered; a scrubbing disc is arranged above the bearing net disc. By arranging the scrubbing disc communicated with a water inlet pipe, the bearing net disc and the pushing plates, efficient removing of the sludge on the surfaces of potatoes is realized, and follow-up cleaning is facilitated; a conveying roller which is obliquely arranged and is fixedly connected with a rotating plates and abrush plate which is provided with a water leaking groove and can move back and forth are arranged, so that the potatoes continuously turn downwards and roll on the conveying roller, the brush plate and the surfaces of the potatoes are subjected to contact brushing, and the brushing effect is improved.

Owner:田锦

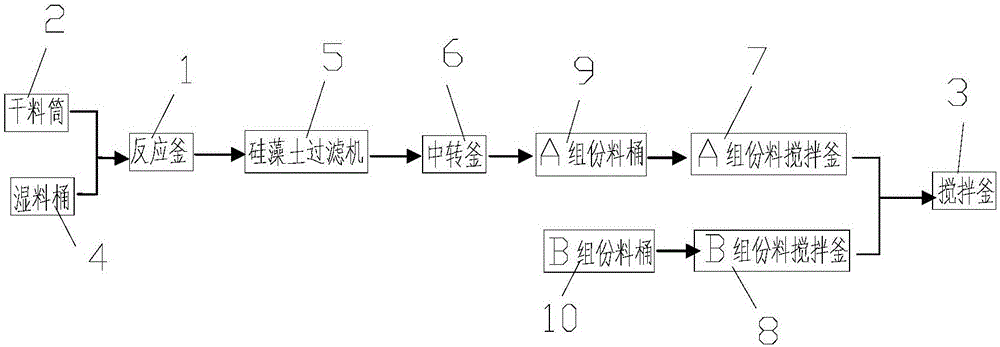

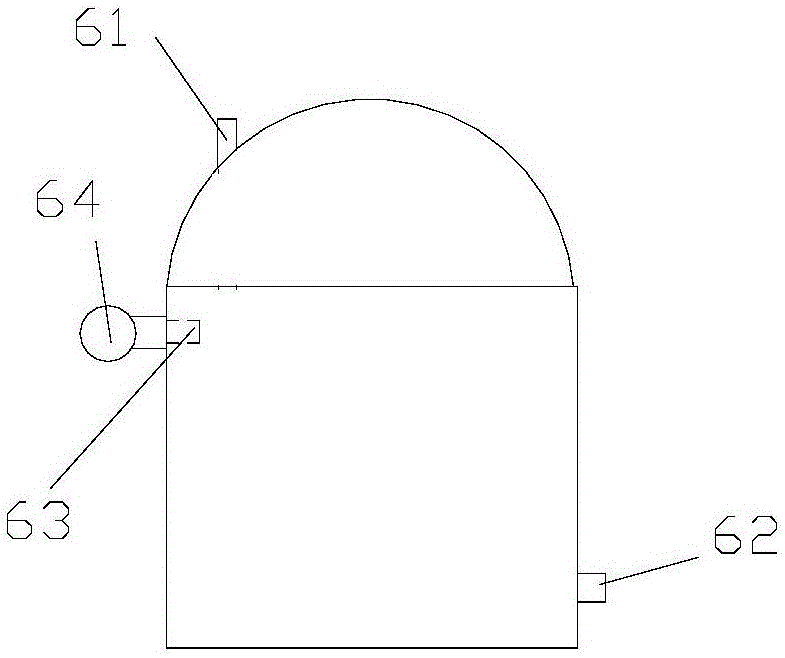

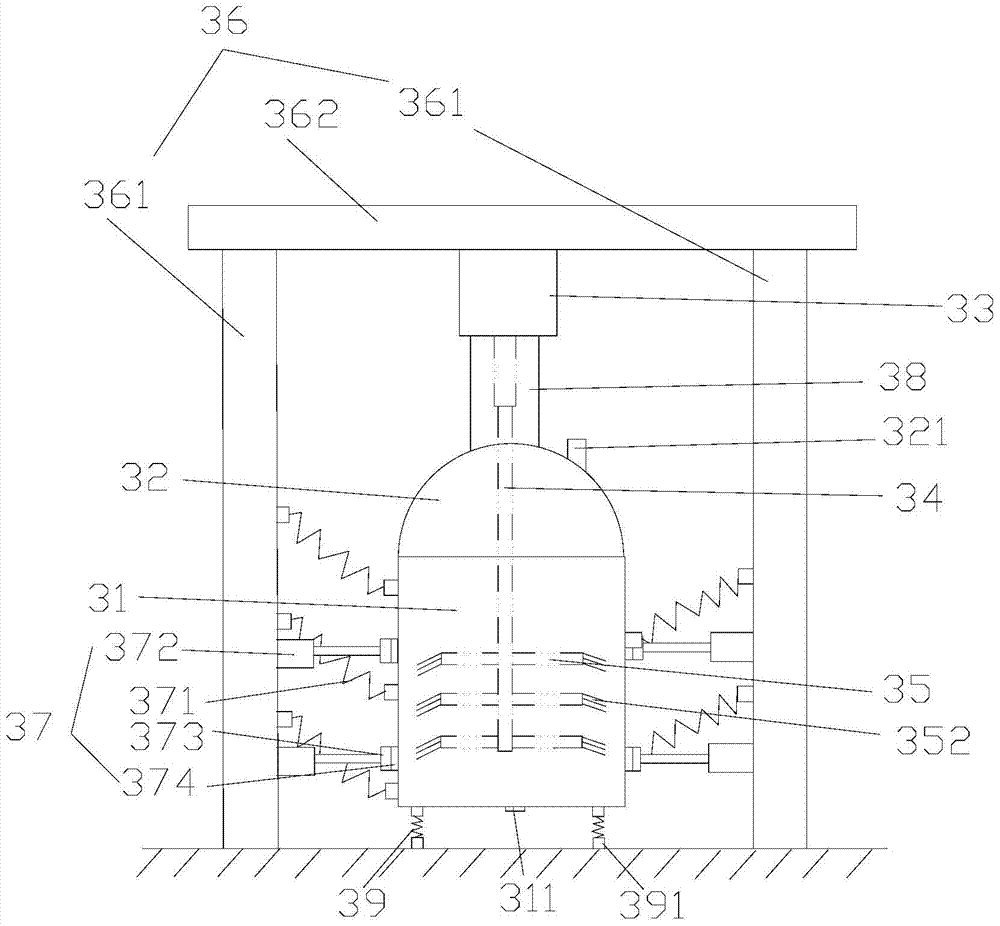

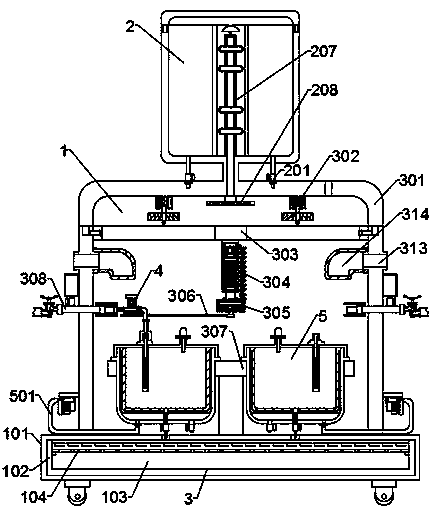

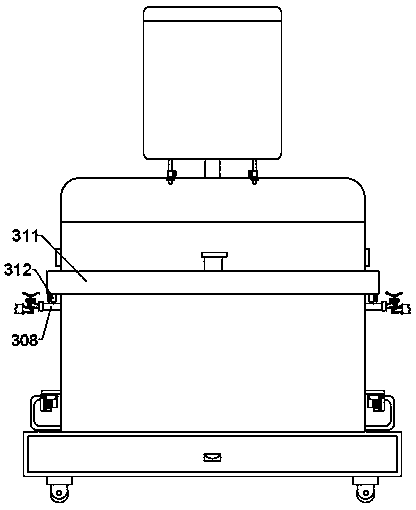

Production device and production method for double-component polyurethane adhesive

ActiveCN105153988AReduce heat transferGuaranteed temperature uniformityPolyureas/polyurethane adhesivesChemical/physical/physico-chemical stationary reactorsPolyurethane adhesiveChemistry

The invention discloses a production device for a double-component polyurethane adhesive. The production device comprises a reaction kettle, a dry material barrel, a wet material barrel, a diatomite filter, a transfer kettle, a component A stirring kettle, a component B stirring kettle, a stirring kettle, a component A barrel and a component B barrel. The invention further discloses a method for producing the double-component polyurethane adhesive with the production device of the double-component polyurethane adhesive. The production device and the production method have the advantages that the stability, the adhesiveness and the stirring uniformity are good, follow-up clearing is facilitated, and the discharge amount is increased.

Owner:安徽省思维新型建材有限公司

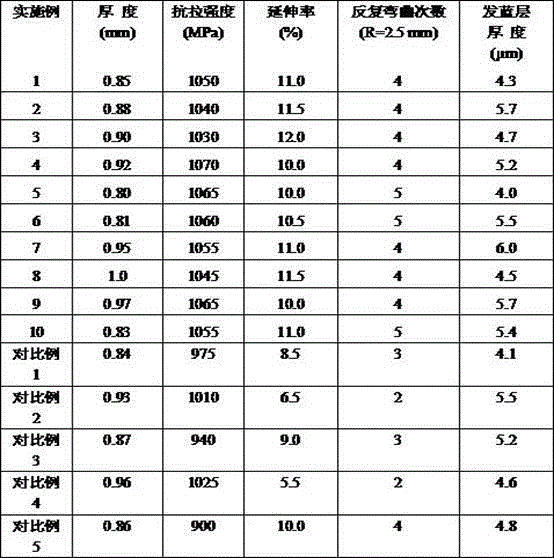

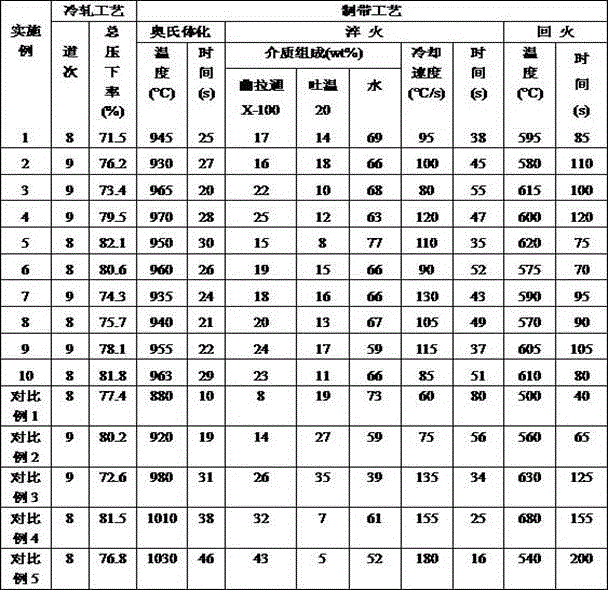

Production method of binding strap with tensile strength more than or equal to 1000MPa

ActiveCN104878178AReduce internal stressReduce cooling rateFurnace typesQuenching agentsRoom temperatureHot Temperature

The invention discloses a production method of a binding strap with tensile strength more than or equal to 1000MPa. The method comprises the following steps: cold-rolling a pickled 30Mn2 hot-rolled coil; uncoiling, stripping and removing burrs, and then carrying out high temperature austenitizing; quenching the coil in a mixed solution consisting of triton X-100, Tween 20 and water; washing with water as conventional means and tempering the coil; naturally air-cooling to room temperature; and coiling. A finished product of the invention is 0.8-1.0mm thick, 1030-1070MPa in tensile strength, 10-12% in elongation rate and no less than 4 times in repeated bending time, and a blue layer which is uniform and dense, strong in adhesive force and 4-6microns thick is generated on the surface. The performances of the finished product completely meet the demands of binding and packaging heavy-coil hot-rolled steel coils.

Owner:宝武轻材(武汉)有限公司

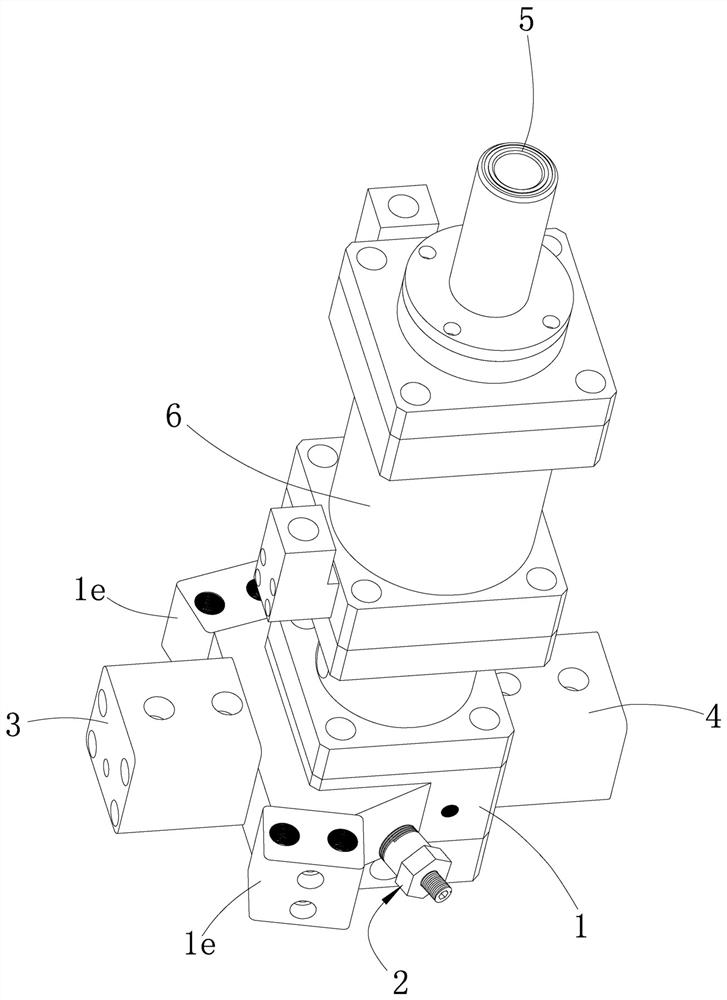

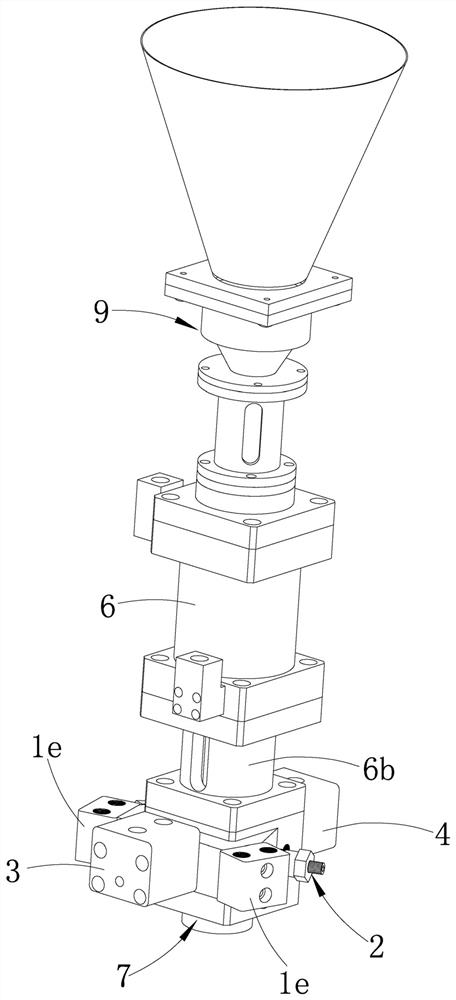

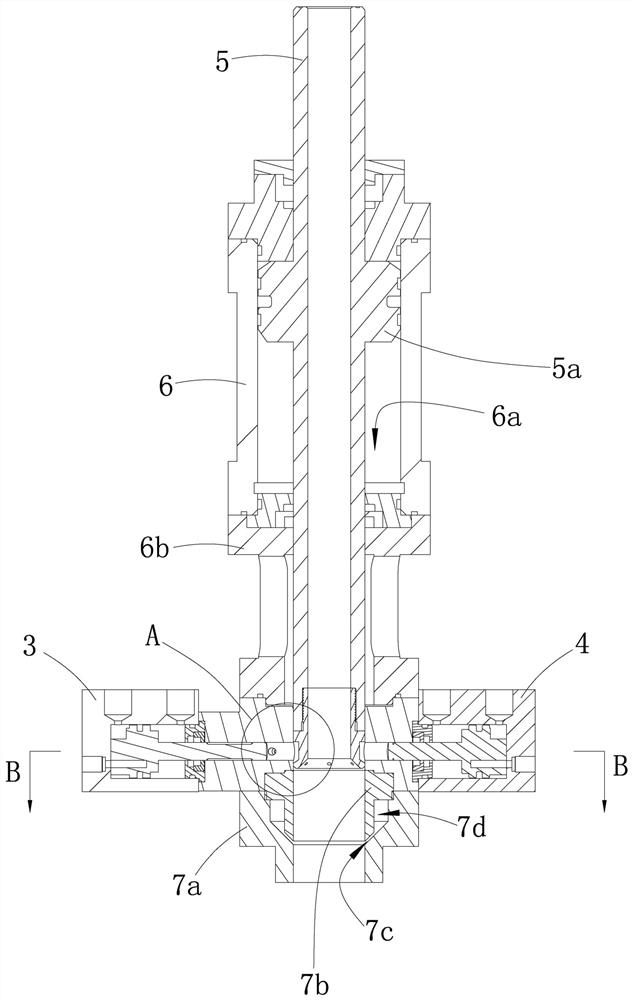

Polyurethane multifunctional high-pressure mixing head device

PendingCN112643957AGuaranteed genuine rateControl atomization injection volumeInjection airPiston rod

The invention provides a polyurethane multifunctional high-pressure mixing head device. According to the device, a main feeding through hole is formed in the side wall of a main mixing seat, a feeding hole and a discharging hole are further formed in the main mixing seat, a cavity is formed in a valve shell of a material pressure adjusting valve, a valve element and a pressure spring are installed in the valve shell, an atomizing nozzle is formed between the valve element and a valve body outlet of the valve shell, a material spraying control piston rod of a material spraying control assembly extends into the main feeding through hole, a main air inlet through hole is formed in the side wall of the main mixing seat, an air inlet hole is further formed in the main mixing seat, an air injection control piston rod of a cleaning control assembly extends into the main air inlet through hole, the tail end of a material conveying pipe extends into an inner hole of the main mixing seat; an auxiliary mixing seat is fixedly connected to the lower side of the main mixing seat, a buffer cavity is further formed in the auxiliary mixing seat, an inlet is formed in the auxiliary mixing seat, and a mixing opening is formed in the inner wall of the auxiliary mixing seat. Through cooperation of the material pressure adjusting valve and the material spraying control assembly, accurate control over the polyurethane raw material spraying amount is achieved, and the device is suitable for mixing polyurethane and solid materials and suitable for industrial application.

Owner:蚌埠中正聚氨酯发泡设备有限公司

Vomit sampling device for digestive department detection

InactiveCN112629942AShorten the transportation distanceFor subsequent cleaningWithdrawing sample devicesHollow article cleaningVomit sampleStraight tube

The invention discloses a vomit sampling device for digestive department detection, which relates to the field of medical instruments. The problem that an existing device is prone to being polluted by vomit is solved. The equipment specifically comprises a bottom plate, a placement box is fixedly connected to the outer wall of the top of the bottom plate, and a cover plate is fixedly connected to the outer wall of the top of the placement box. By arranging a containing assembly, the sliding shaft moves to drive the circular truncated cone to slide along the inner wall of the straight pipe, and when the top of the circular truncated cone slides to the bottom of the plug frame, due to the fact that the straight pipe is located in the vomit environment, materials enter the inner wall of the straight pipe through the plug frame, then the sliding shaft ascends, and the circular truncated cone drives the materials to ascend to continuously convey the materials into the funnel barrel; when the circular truncated cone returns to the original position due to the action of the elastic telescopic column, the movable block already seals the space of the inner wall of the straight pipe at the bottom of the funnel barrel, surface materials are separated out, the vomit transportation distance is fundamentally shortened, and meanwhile the containing assembly can be separated from the device, and subsequent cleaning is facilitated.

Owner:班海鑫

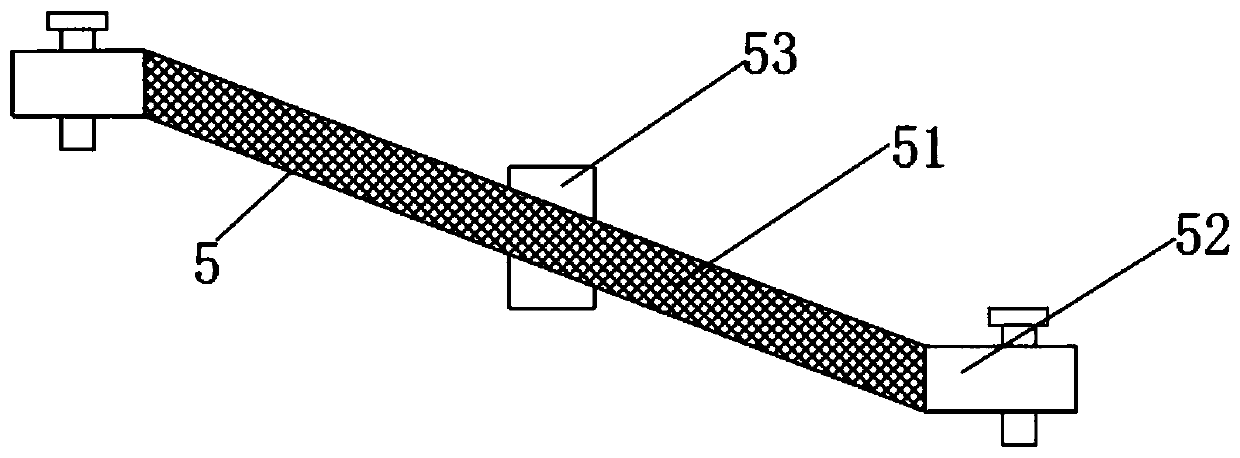

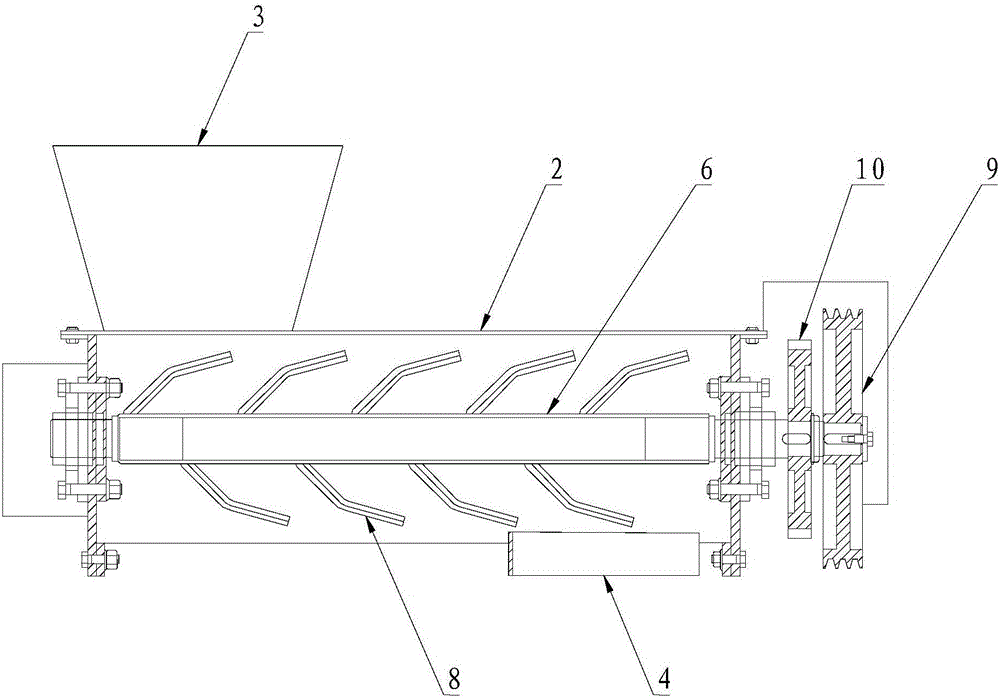

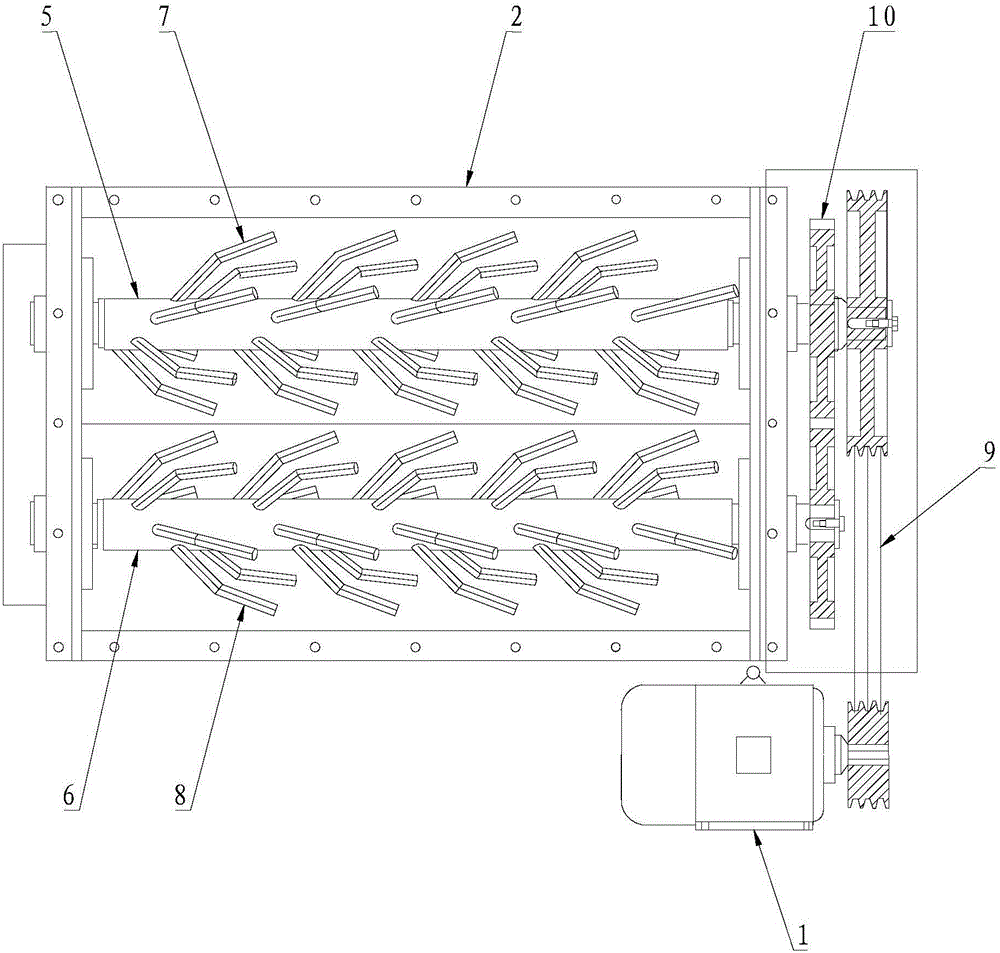

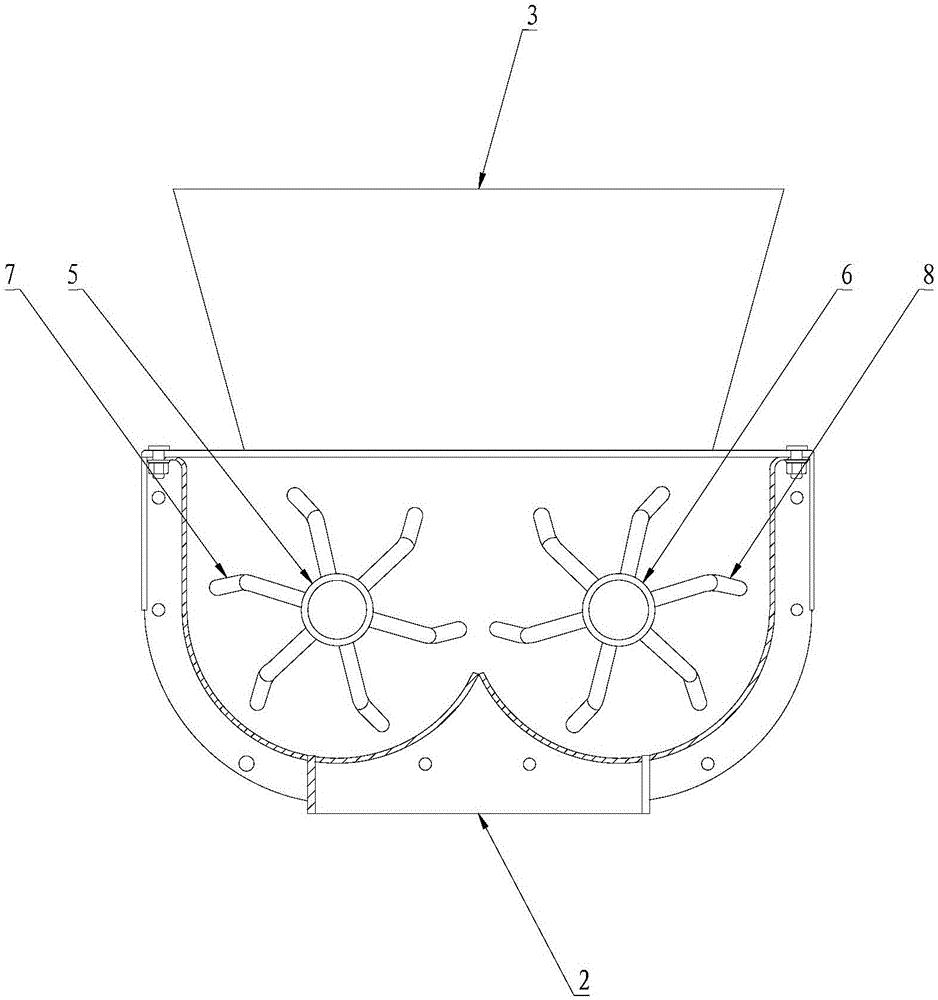

Chicken's gizzard-membrane preparation equipment

ActiveCN105994575ARealize automatic productionFor subsequent cleaningPoultry eviscerating devicesGizzardEngineering

The invention relates to chicken's gizzard-membrane preparation equipment. The equipment comprises a rack and a drive motor, wherein a feed cylinder is horizontally arranged on the rack, a driving roller and a driven roller are arranged in the feed cylinder and rotate synchronously in opposite directions, first stirring rod groups which are in a claw shape and have claw openings facing the other end of the feed cylinder are axially distributed on the outer peripheral surface of a roller body of the driving roller at intervals, and second stirring rod groups which are in a claw shape and have claw openings facing the other end of the feed cylinder are axially distributed on the outer peripheral surface of a roller body of the driven roller at intervals. The chicken's gizzard-membrane preparation equipment can automatically peel off the inner wall of the gizzard of a chicken and output the inner wall through a discharge port under the stirring, peeling and feeding action of the first stirring rod groups and second stirring rod groups, follow-up cleaning, drying and other treatment are facilitated, a chicken's gizzard-membrane is automatically prepared, the production efficiency is greatly improved, and the labor cost is reduced.

Owner:福建承天农林科技发展有限公司

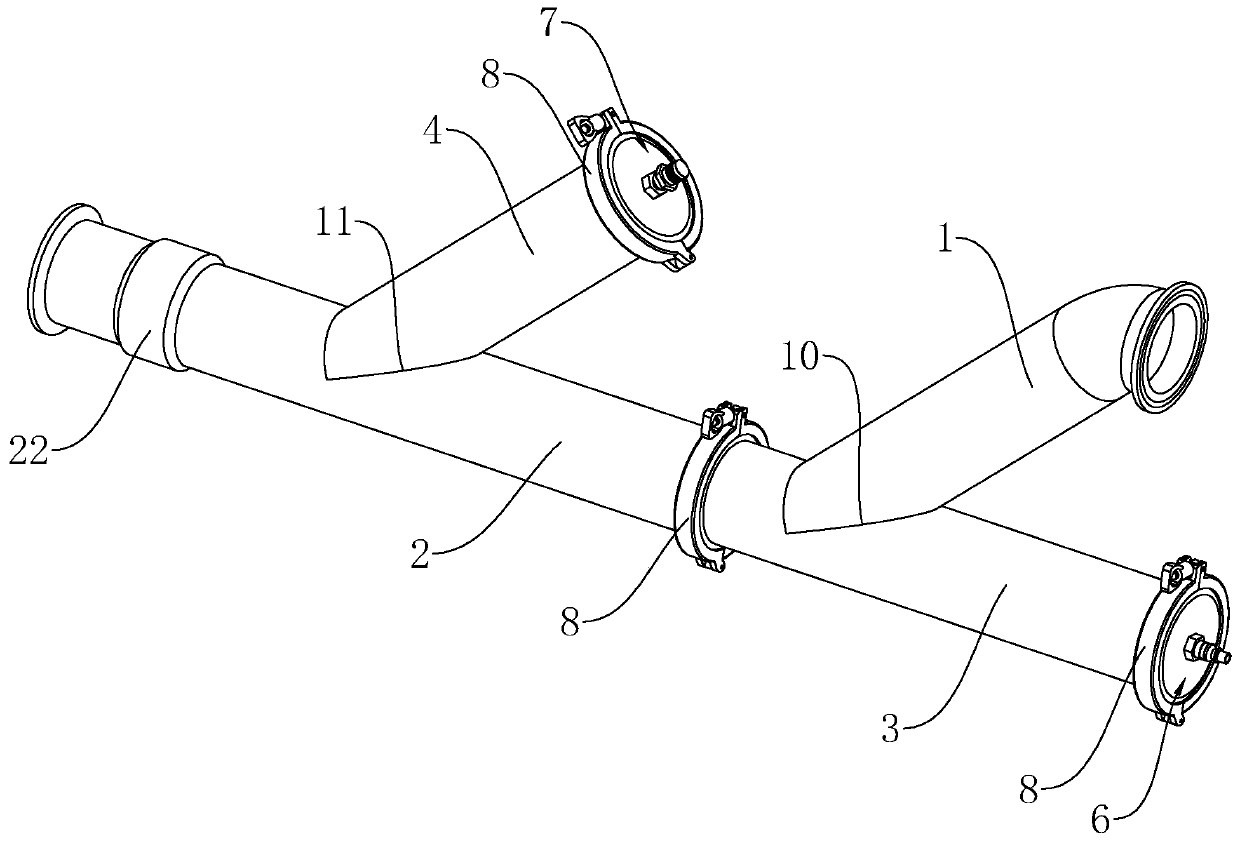

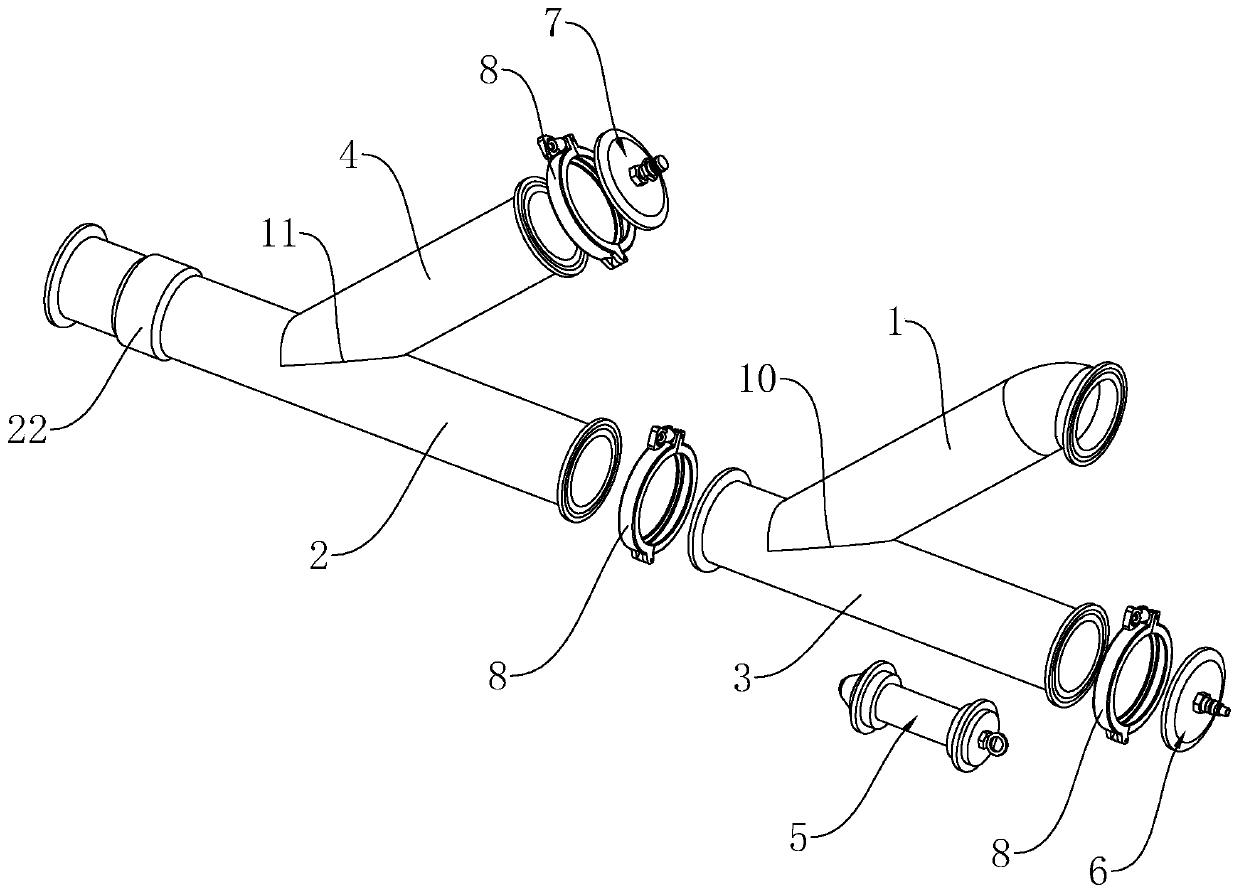

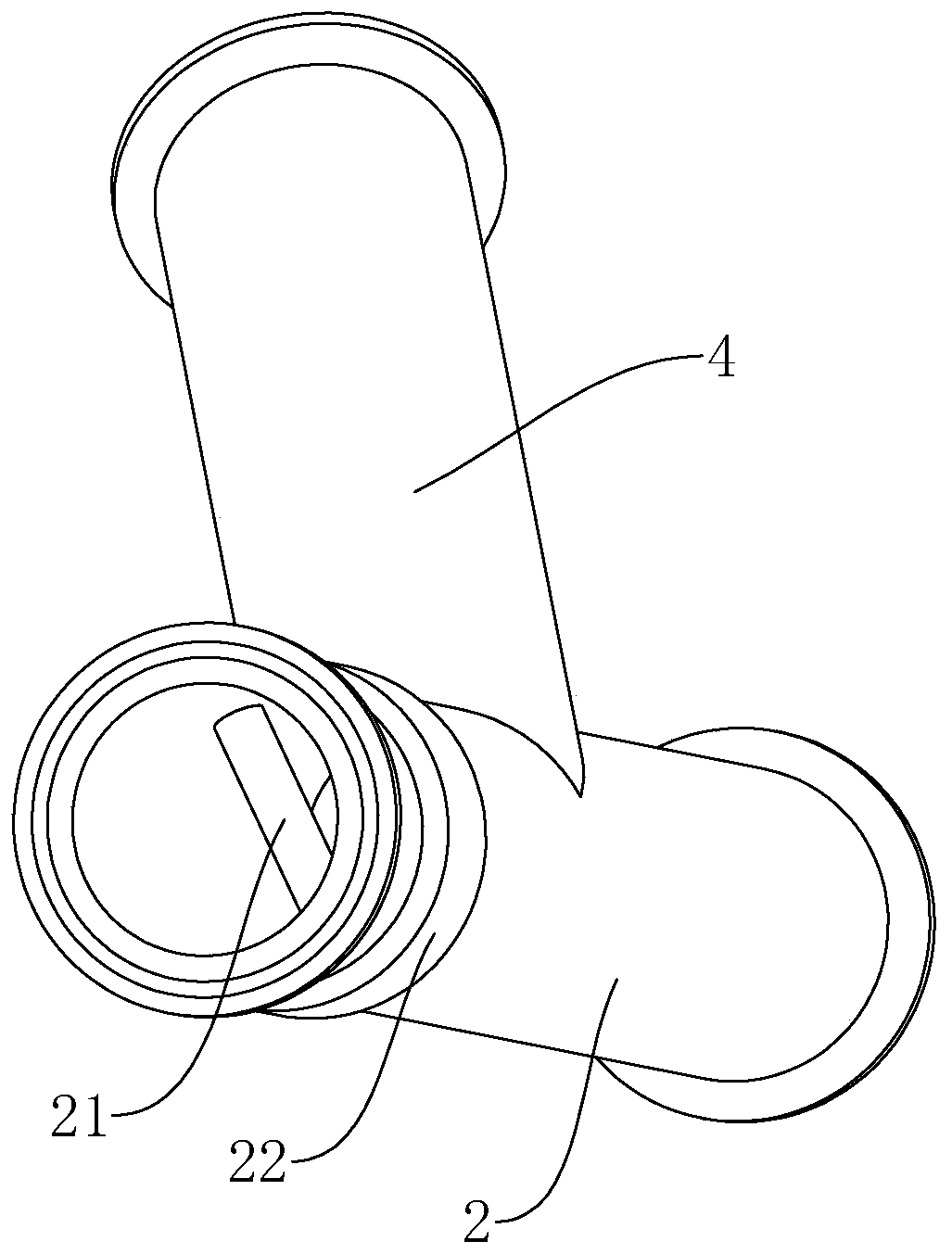

Material recycling system

PendingCN110332461AImprove recycling efficiencySimple structureHollow article cleaningPipeline systemsPetroleum engineeringMaterial recycling

The invention discloses a material recycling system, and relates to the field of pipeline conveying. According to the technical scheme, the material recycling system comprises a feeding pipeline and adischarging pipeline, and further comprises an emission pipeline, a cleaner, an air inlet device, a pressure relief pipeline and a pressure relief device, and the emission pipeline and the discharging pipeline are directly connected through a hoop or are connected through at least one middle pipeline through hoops; the feeding pipeline is connected to one side of the emission pipeline, the connecting position between the feeding pipeline and the emission pipeline is a feeding position, the air inlet device is arranged at the end, away from the discharging pipeline, of the emission pipeline, and the cleaner is arranged between the feeding position and the air inlet device and is tightly attached to the inner wall of the emission pipeline; and the pressure relief pipeline is connected to one side of the discharging pipeline, the connecting position the pressure relief pipeline and the discharging pipeline is the pressure relief position, the pressure relief device is arranged at the end, away from the discharging pipeline, of the pressure relief pipeline, and a stop rod used for blocking the cleaner is connected to the inner wall of the end, away from the emission pipeline, of the discharging pipeline. The system is simple in overall structure, convenient to install and high in material recovery efficiency.

Owner:齐力控股集团有限公司

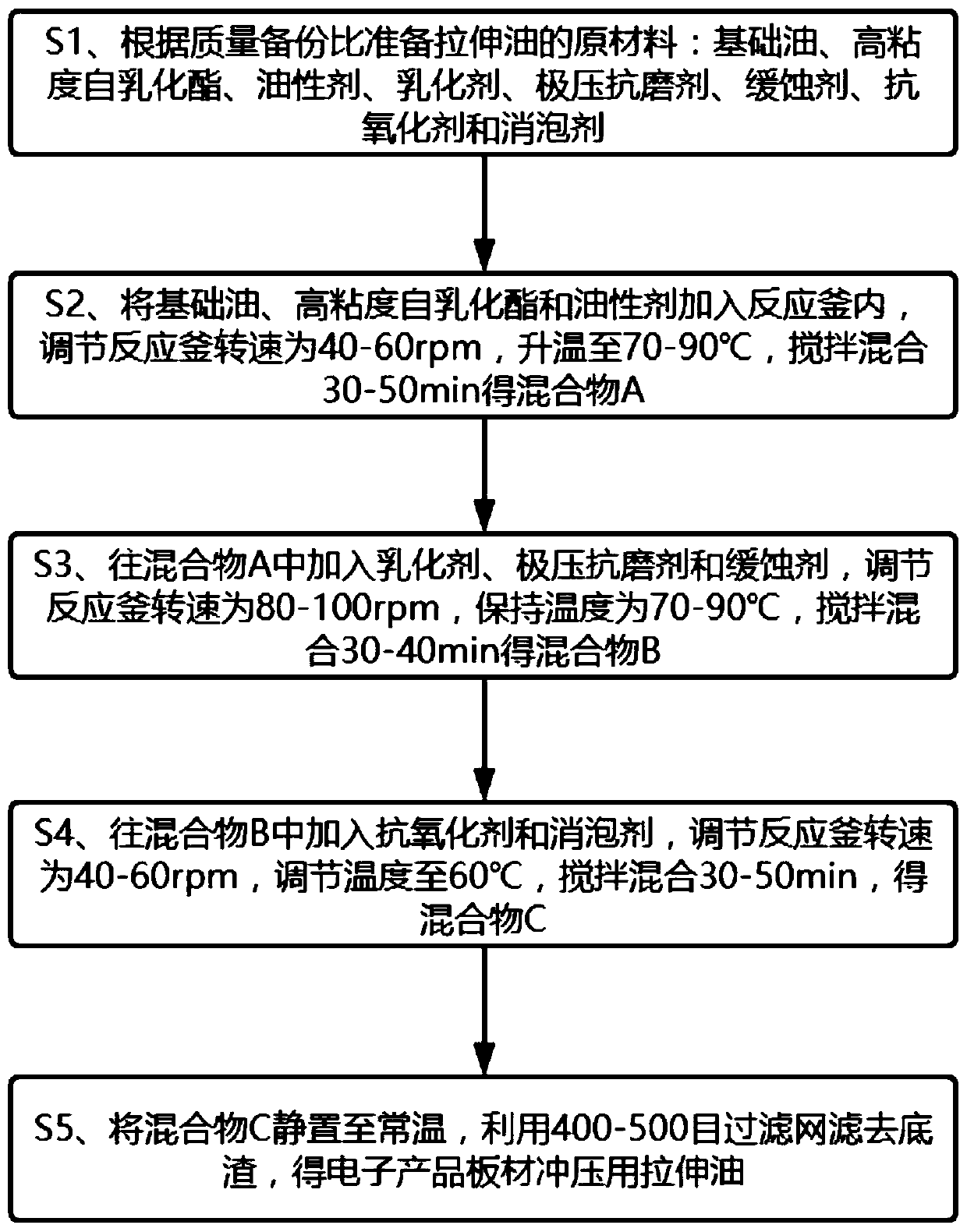

Drawing oil for stamping electronic product plates, and preparation method thereof

InactiveCN111560284AImprove carrying capacityImprove anti-friction and anti-wear propertiesLubricant compositionDefoaming AgentsProcess engineering

The invention discloses drawing oil for stamping electronic product plates, and a preparation method thereof, and belongs to the technical field of electronic product processing. The drawing oil for stamping electronic product plates comprises, by mass, 10-15% of high-viscosity self-emulsifying ester, 3-9% of an oiliness agent, 3-6% of an emulsifier, 1-3% of an extreme-pressure anti-wear agent, 0.1-0.5% of a corrosion inhibitor, 0.05-0.1% of an antioxidant, 0.05-0.1% of defoaming agent, and the balance of base oil. The drawing oil for stamping electronic product plates is used for stamping plates of electronic products. Through the combined action of the base oil, the oiliness agent, the emulsifier, the extreme-pressure anti-wear agent and other preparation raw materials, the bearing capacity and antifriction and anti-wear properties of the drawing oil can be improved, and the drawing oil has the advantages of excellent lubricating property, excellent cooling property, excellent extreme pressure anti-wear property, high efficiency, no chlorine, extreme pressure resistance, low odor, environmental friendliness and suitability for large-scale popularization, and meets the modern market requirements.

Owner:昆山久茂电子科技有限公司

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718BGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySurface roughness

Owner:AMER TECH CO LTD

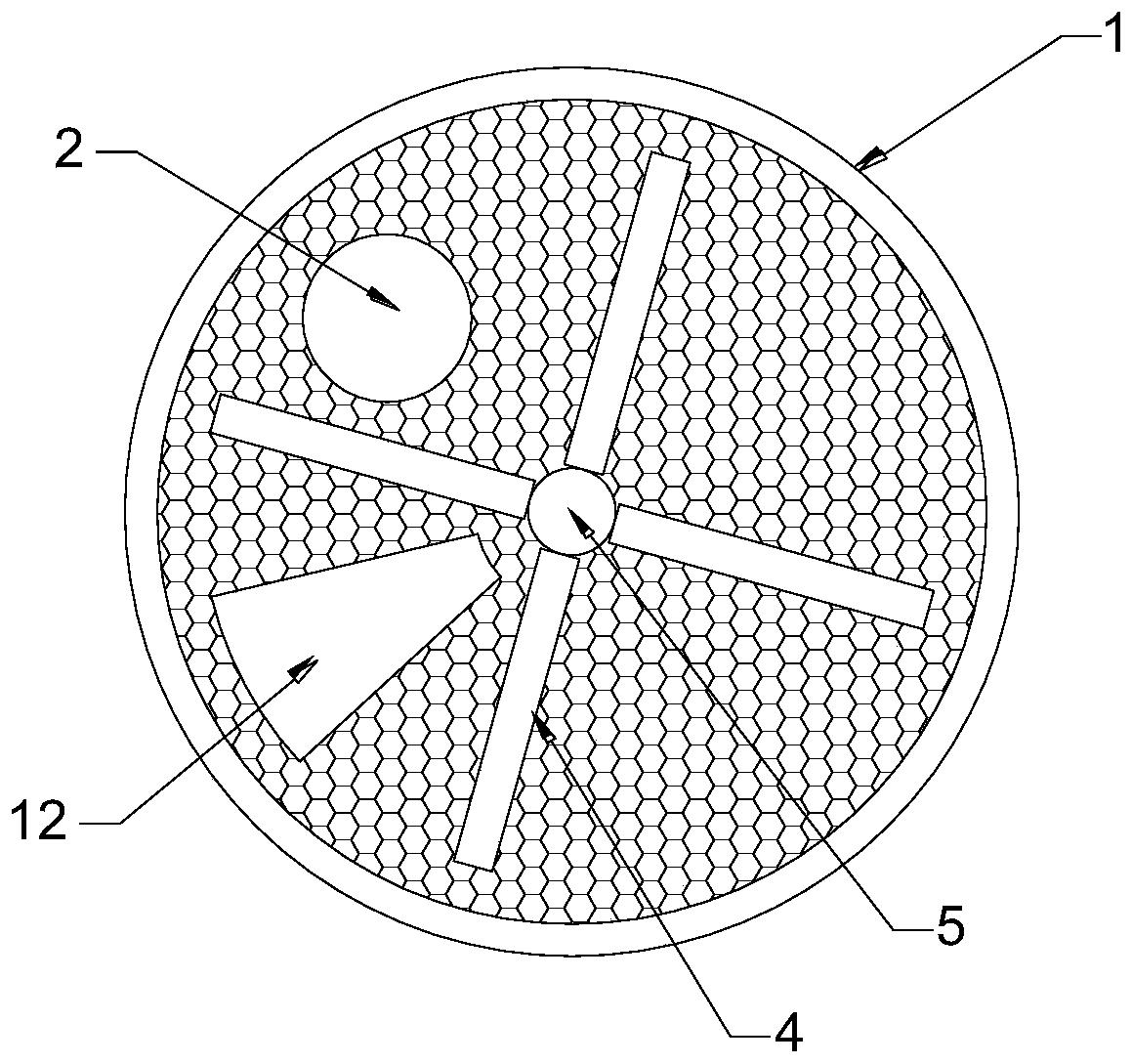

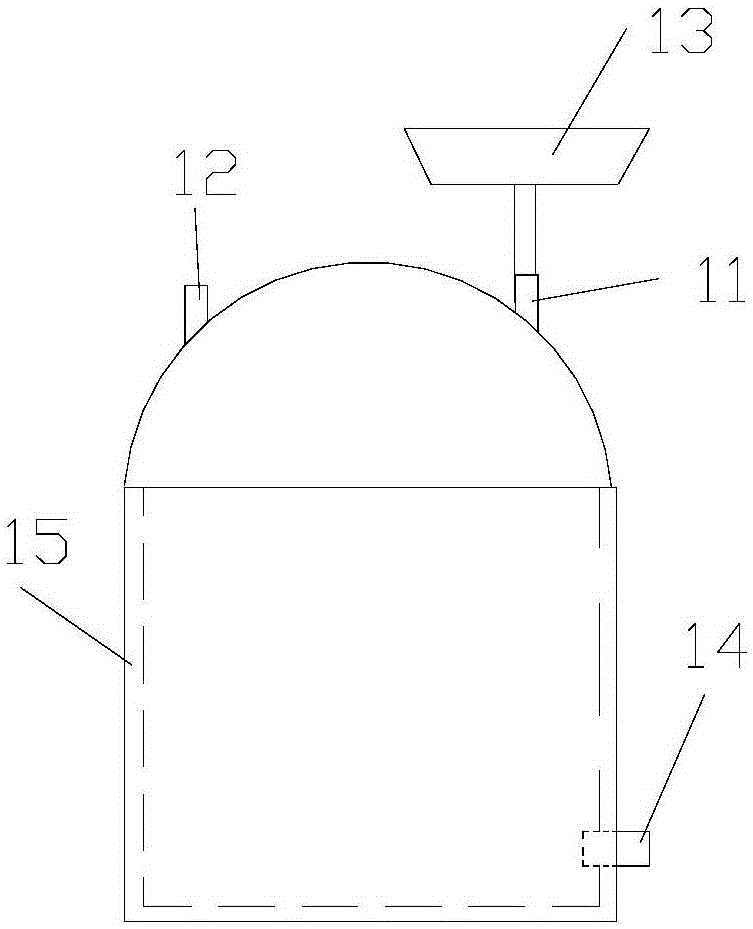

A paint mixing tank

The invention discloses a paint stirring kettle, which comprises a kettle body, a kettle cover, a motor, a rotating shaft, a stirring paddle, a frame, a swing mechanism and a rubber sleeve. The lid of the kettle is closed on the body of the kettle, the lid of the kettle is provided with a feed port, the bottom of the body of the kettle is provided with a discharge port, and the frame includes two brackets and beams. The swing mechanism includes a first spring part and a telescopic device, and a plurality of first spring parts are distributed on both sides of the kettle body; one end of the first spring part is connected with the corresponding bracket, and the other end of the first spring part is connected with the kettle body; The fixed end of the device is arranged on the bracket, and the telescopic end of the telescopic device extends toward the position direction of the still body. The rubber sleeve is sleeved on the part of the rotating shaft protruding from the kettle cover and the output shaft of the motor, and the bottom of the rubber sleeve is sealed and connected to the kettle cover. The invention has the advantages of good stirring uniformity, high stirring effect, convenient follow-up cleaning and increased output.

Owner:安徽省思维新型建材有限公司

Circulating dredging type industrial wastewater treatment device and using method thereof

InactiveCN110697926AImprove filtering effectImprove purityTreatment involving filtrationMultistage water/sewage treatmentIndustrial waste waterThreaded rod

The invention provides a circulating dredging type industrial wastewater treatment device and a using method thereof. The device comprises a movable base, a waste residue box and filter cotton, a fixed block is fixed to the middle of the lower portion of the movable base, a threaded rod penetrates through the inner side of the fixed block, the waste residue box is located on the left side of the upper portion of the movable base, fixed columns are fixed to the two sides of the waste residue box, and a filter screen is installed below the fixed columns. Through the circulating dredging type industrial wastewater treatment device and the using method thereof, blockages can be crushed and treated, the blockages are more thoroughly crushed, and crushed blockage waste residues can be synchronously scraped out; thus, the waste residues are discharged in time, so that the device can be circularly dredged, the waste residues and wastewater can be filtered out, the waste residues are treated ina centralized mode, the device is convenient to clean subsequently, the wastewater can be filtered for three times, the filtering effect of the device on industrial wastewater is better, and the purity of the wastewater can be improved.

Owner:徐州市国栋生化装备有限公司

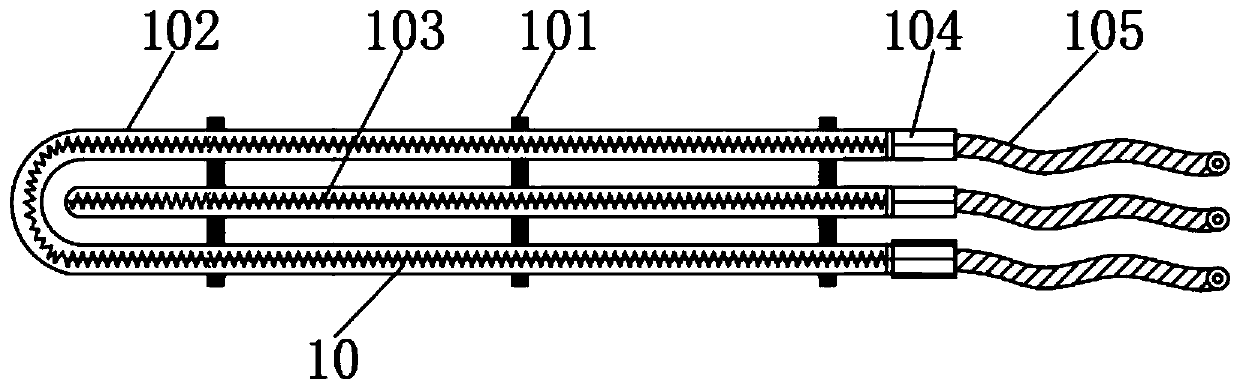

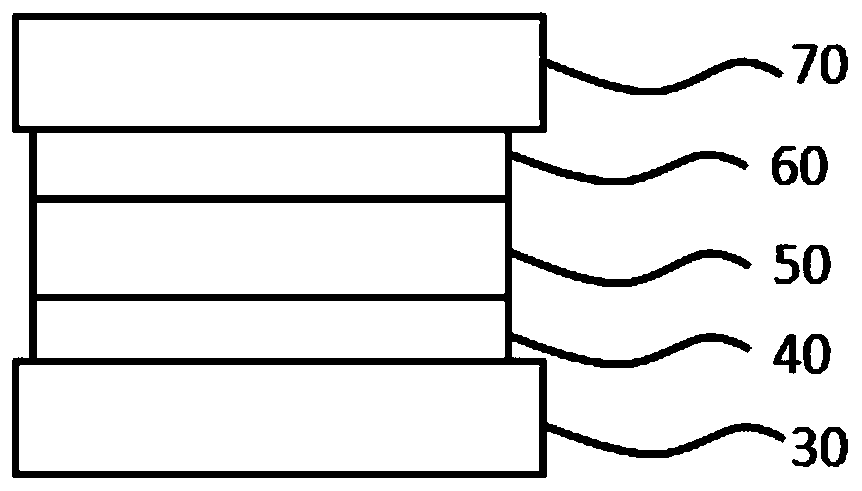

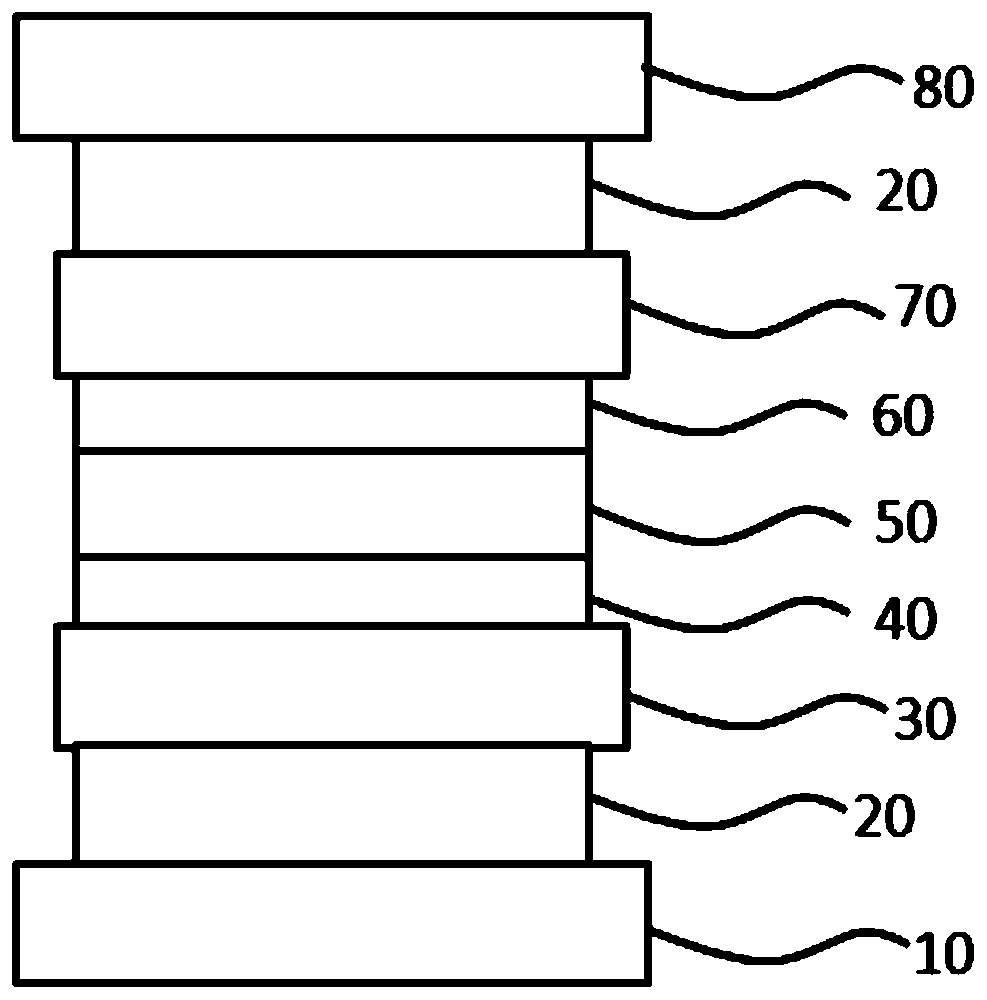

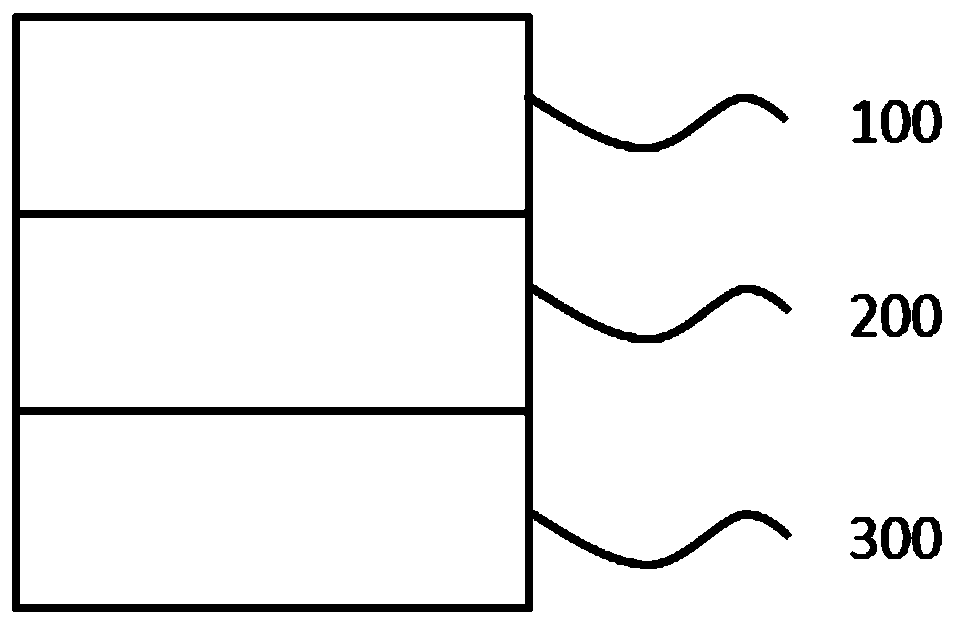

Laminating method of PCB and buffer layer

InactiveCN110366333AGive full play to the buffer capacityGive full play to temperature resistanceMultilayer circuit manufactureCopper foilEngineering

The invention relates to a laminating method of a PCB. The method comprises the following steps: carrying out browning treatment on inner-layer circuit boards; laminating, fusing and fixing the two ormore browned inner-layer circuit boards by utilizing prepregs to obtain a multi-layer core board; sequentially laminating a first copper foil, the multi-layer core plate, a second copper foil and a second steel plate on a first steel plate to obtain a laminated plate; ND placing the laminated plate between a bottom plate and a cover plate of a pressing machine, arranging a first buffer layer between the laminated plate and the bottom plate, arranging a second buffer layer between the laminated plate and the cover plate, and carrying out laminating and disassembling to obtain the PCB, whereinthe first buffer layer and the second buffer layer are first old kraft paper, new kraft paper and second old kraft paper which are sequentially arranged in a stacked mode. By adopting the laminating method for lamination, the generation of sticking substances on the steel plate, the bottom plate and the cover plate of the pressing machine can be reduced.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Washable stamping stretch oil

ActiveCN106635344BMeet the needs of useEasy to cleanLubricant compositionPhosphateChlorinated paraffins

The invention discloses washable stamping and drawing oil. The washable stamping and drawing oil is prepared from the following components in percentage by weight: 10 to 15 percent of base oil 150SN, 5 to 10 percent of high-viscosity self-emulsified ester, 3 to 5 percent of vulcanized aliphatic acid ester, 1 to 3 percent of sulfurized olefin, 30 to 40 percent of chlorinated paraffin, 1 to 5 percent of phosphate, 1 to 5 percent of calcium petroleum sulfonate, 5 to 15 percent of sodium petroleum sulfonate, 1 to 5 percent of tall oil fatty acid, 1 to 5 percent of iso-tridecanol polyoxyethylene ether, 1 to 5 percent of organic alcohol ether, 1 to 5 percent of pH buffering agent and 1 percent of corrosion inhibitor. The performance of the washable stamping and drawing oil disclosed by the invention can completely meet the service demand of a stamping and drawing process; the washable stamping and drawing oil can successfully replace the current pure oil type stamping and drawing oil and is easy to clean.

Owner:上海森帝润滑技术有限公司

Environment-friendly interventional administration device for treating liver cancer

The invention discloses an environment-friendly interventional administration device for treating liver cancer. The environment-friendly interventional administration device comprises a feeding device, a batching device is installed above a sealing top cover of the feeding device, an environment-friendly circulating water using device is installed below the feeding device, and the feeding device comprises a cover body. According to the environment-friendly interventional administration device, a liquid storage rubber diaphragm is arranged in an administration tank, when administration is conducted on a user, gas can be introduced between a transparent shell and the liquid storage rubber diaphragm through a gas pump according to the use requirements, so that a bearing block rises, meanwhile, the actual volume of the administration tank is determined according to a scale line, thus the required dosage can be injected at a time when administration is conducted on the user, multi-time operation does not need to be selected, thus operation is easy and convenient, the time and labor are saved, contact with the outside environment is avoided during operation, the situation of bacterial pollution is avoided, and the environment-friendly interventional administration device is high in safety.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

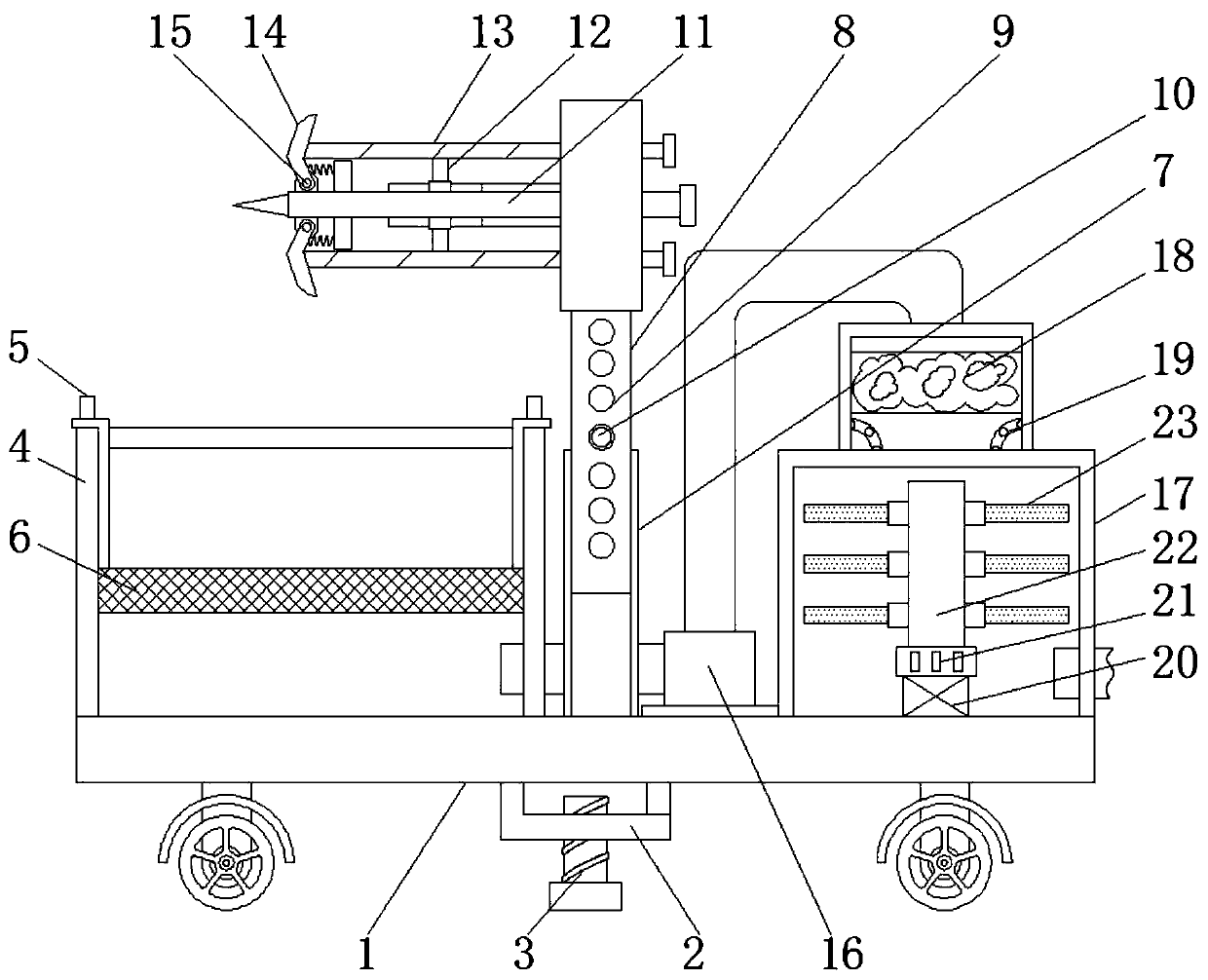

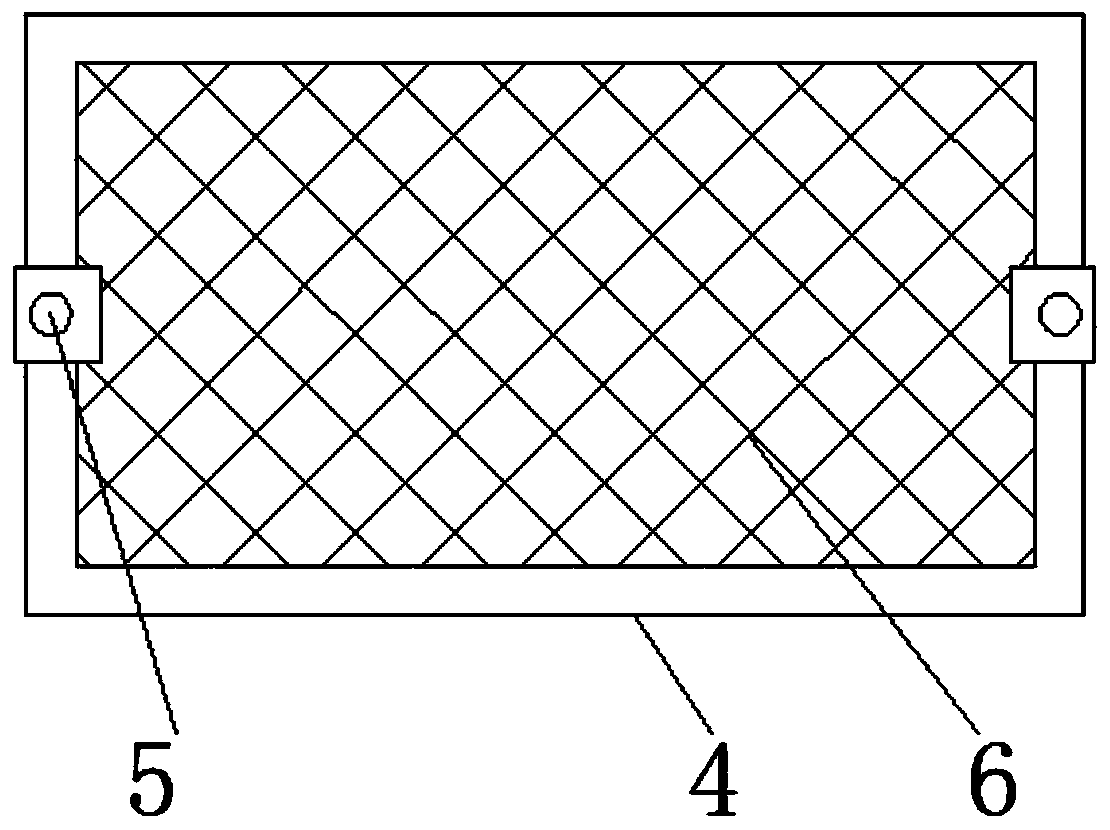

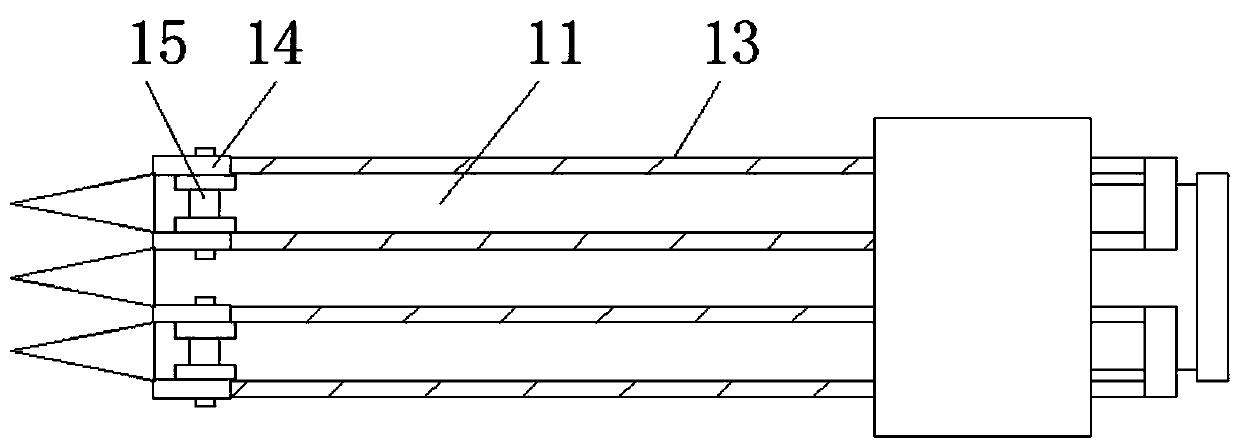

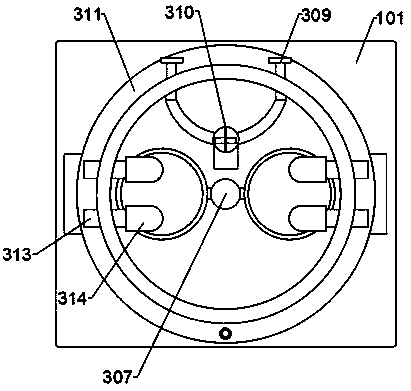

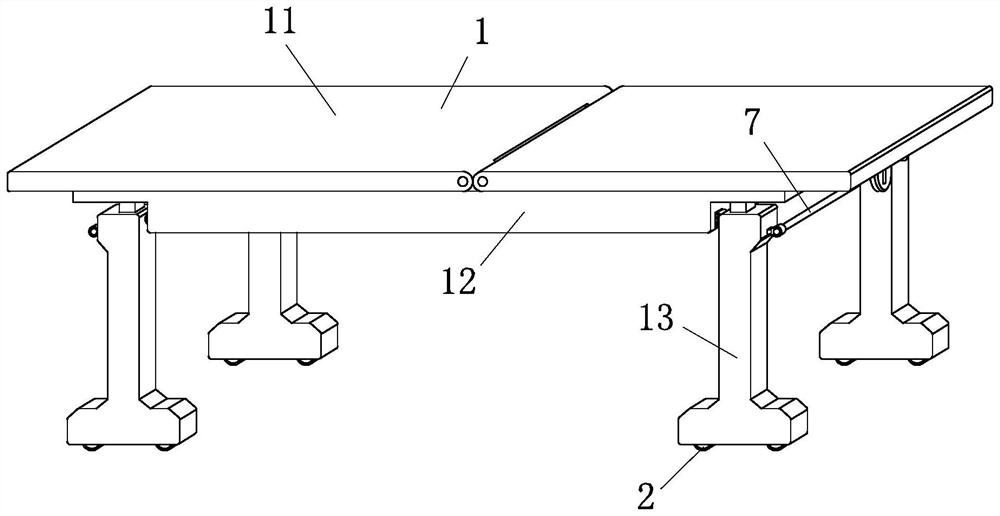

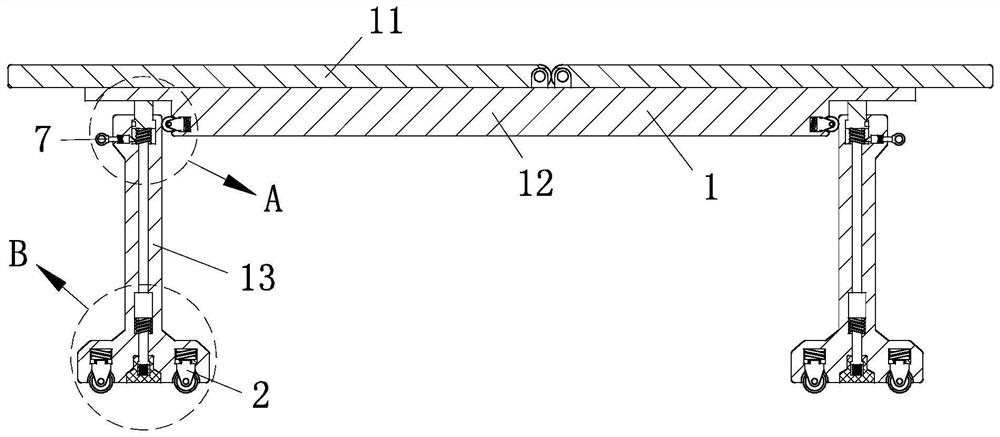

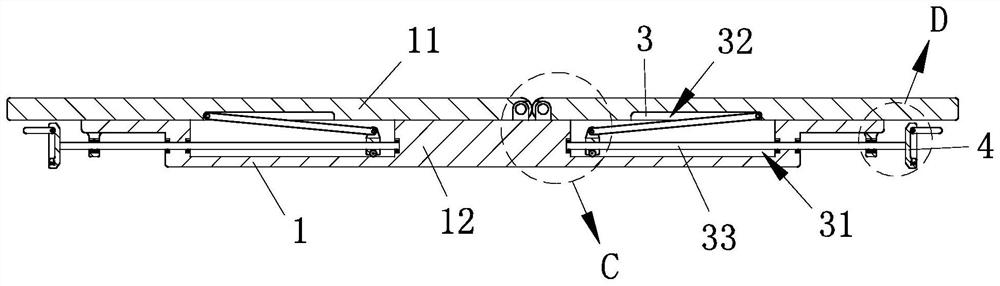

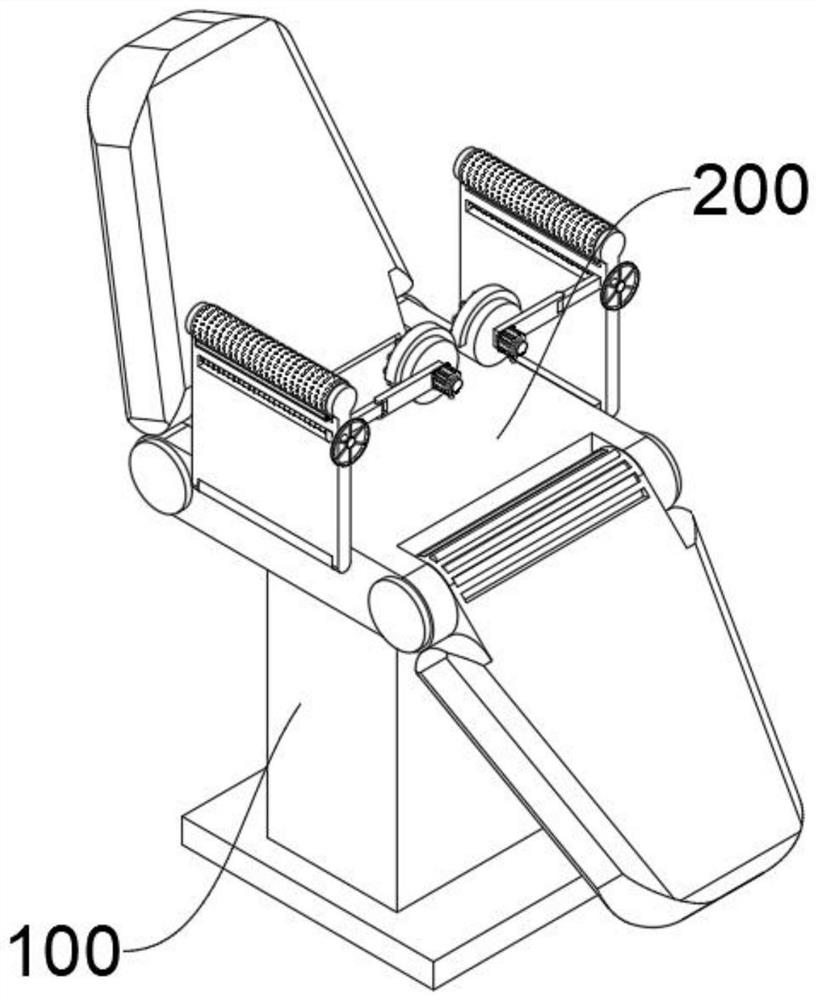

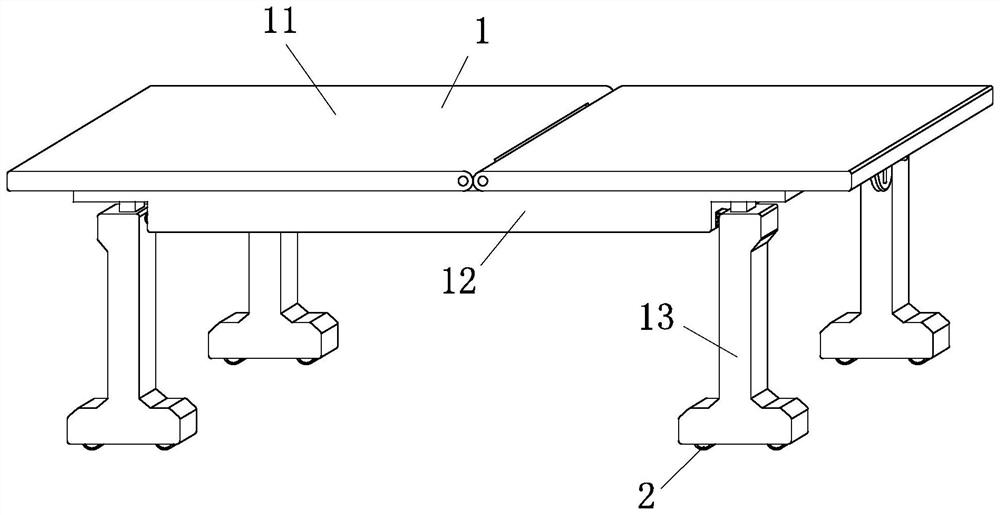

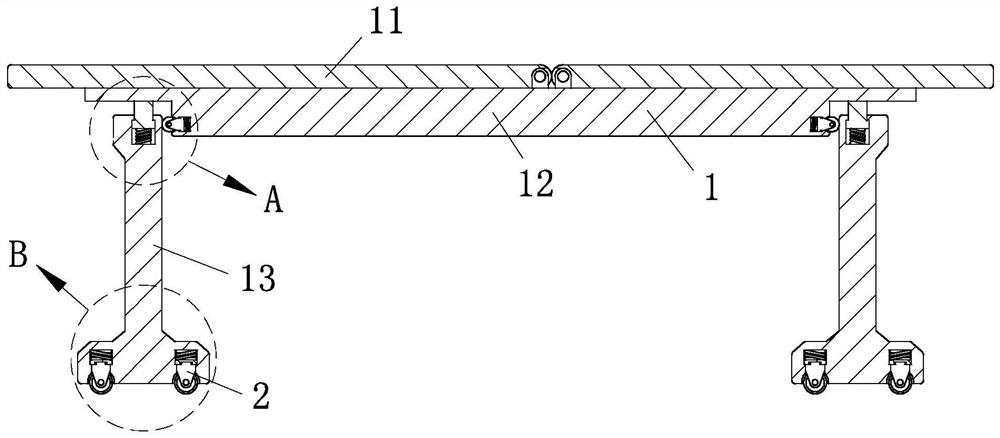

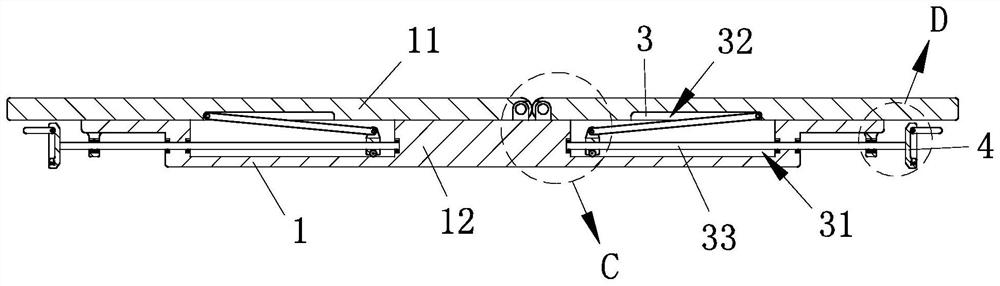

Acupuncture table convenient for adjusting acupuncture angle

InactiveCN114469618AConvenience for recliningEasy to lie downAcupunctureOperating tablesPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of acupuncture table adjustment, in particular to an acupuncture table facilitating acupuncture angle adjustment, which comprises a supporting mechanism, a moving mechanism, an adjusting mechanism, a rotating mechanism, a pressure reducing mechanism, a limiting mechanism and a locking mechanism, under the action of the supporting mechanism, a patient can lie down conveniently, under the action of the pressure reduction mechanism, pressure reduction and pressure resistance can be conducted on the supporting mechanism conveniently, under the action of the adjusting mechanism, rotation adjustment can be conducted on the top side of the supporting mechanism conveniently, and a doctor can conduct acupuncture work conveniently; meanwhile, under the action of a rotating mechanism, a worker can conveniently drive an adjusting mechanism, under the action of a moving mechanism, a supporting mechanism can easily move relative to the ground, a patient can conveniently conduct acupuncture and moxibustion in different areas, through contact between a limiting mechanism and the ground, limiting braking on the supporting mechanism is facilitated, and the acupuncture and moxibustion efficiency is improved. Therefore, the moving mechanism does not drive the supporting mechanism to move, and the limiting mechanism is conveniently controlled under the action of the locking mechanism.

Owner:林明养

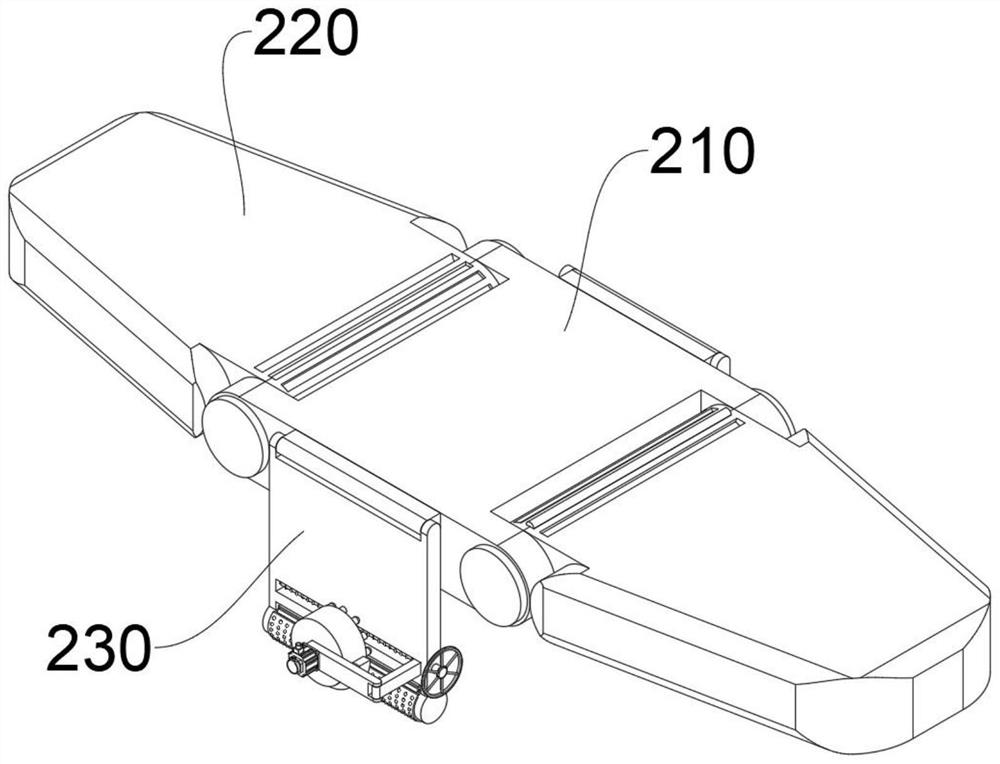

Hinge type seat for digestion nursing

InactiveCN113350059ADigestive Care BenefitsEasy to adjustDevices for heating/cooling reflex pointsWheelchairs/patient conveyanceNursing careEngineering

The invention relates to the technical field of nursing seats, in particular to a hinge type seat for digestion nursing. The hinge type seat comprises a supporting column and a digestion nursing seat on the top of the supporting column, the digestion nursing seat at least comprises a seat plate, the bottom of the seat plate is fixedly connected with the bottom of the supporting column, hinge forks are arranged at the two ends of the seat plate, two symmetrical fixing rods are arranged in the two hinge forks respectively, limiting grooves are formed in the outer walls of the fixing rods, clamping blocks are slidably arranged in the limiting grooves, hing blocks are arranged at the ends of hing plates, the two hing blocks are rotationally arranged in the two hing forks respectively, through holes are formed in the ends of the hing blocks, the inner diameter of the through holes is matched with the outer diameter of the fixing rods, a plurality of clamping grooves are formed in the outer walls of the hing blocks at equal intervals, the interiors of the clamping grooves are communicated with the interiors of the through holes, and the clamping grooves are matched with the clamping blocks in size. According to the hinge type seat, the angle can be conveniently adjusted, the angle can be limited and fixed, a patient can conveniently sit down or lie down to have a rest, and the intestines and the stomach can be massaged and subjected to hot fumigation nursing.

Owner:宿州市易鑫信息科技有限公司

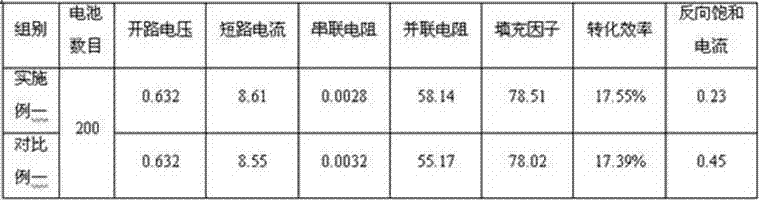

Method for manufacturing polycrystalline silicon solar cells with selective emitters

ActiveCN103178157BReduce manufacturing costShort preparation timeFinal product manufactureSemiconductor devicesScreen printingSolar cell

Owner:CSI CELLS CO LTD

Makeup cosmetic and preparation method thereof

PendingCN112451441AIncreased sweat resistanceFor subsequent cleaningCosmetic preparationsMake-upHorticultureChemistry

The invention belongs to the technical field of cosmetics, and particularly relates to a makeup cosmetic and a preparation method thereof. The makeup cosmetic is mainly prepared from 32.1% of olive oil, 0.8% of vitamin B5, 1.0% of vitamin E, 7% of tea-seed oil, 26% of castor oil, 3.6% of talcum powder, 4% of hyaluronic acid, 2.6% of silicon dioxide, 8.6% of near-color powder, 0.3% of cucumber extracting solution, 3.2% of shea butter, 0.8% of candelilla wax, 2.2% of beeswax, 6% of coconut water and a proper amount of water. By adding a proper amount of talcum powder, silicon dioxide and tea-seed oil, the sweat-proof effect of the makeup cosmetic is effectively improved, the phenomenon that a flower shape appears on a stage performer in a hot environment is effectively avoided, meanwhile, subsequent cleaning is facilitated, the performance effect of the performer is not affected, and application and popularization are facilitated. The near-color powder is added into the makeup cosmetic,the color of a current makeup finished product tends to be marginalized, the phenomenon that colors are similar and are not reasonably matched is avoided, and the makeup looks more coordinated and hasthe aesthetic feeling.

Owner:浙江百姿化妆品股份有限公司

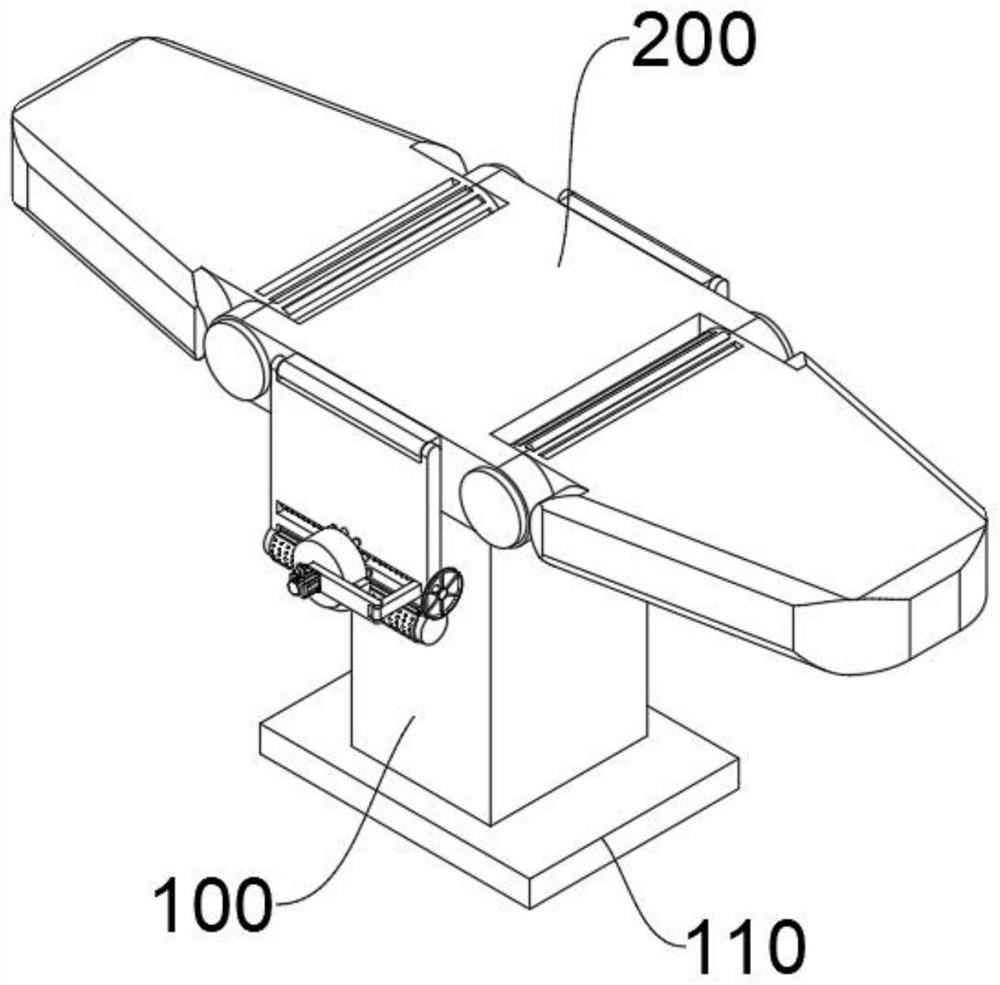

Movable acupuncture and moxibustion table with elevation angle convenient to adjust

InactiveCN114569389AEasy to moveEasy to lie downAcupunctureOperating tablesPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of acupuncture table adjustment, in particular to a movable acupuncture table convenient for elevation angle adjustment, which comprises a supporting mechanism, a moving mechanism, an adjusting mechanism, a rotating mechanism and a pressure reducing mechanism, under the action of the supporting mechanism, a patient can lie down conveniently, a doctor can conduct acupuncture work conveniently, meanwhile, under the action of the pressure reduction mechanism, pressure reduction and pressure resistance are conducted on the supporting mechanism conveniently, the supporting mechanism is more stable, and under the action of the adjusting mechanism, the top side of the supporting mechanism can be rotated and adjusted conveniently; according to the acupuncture and moxibustion device, the angle of lying of a patient is changed, a doctor can conduct acupuncture and moxibustion work conveniently, meanwhile, under the action of a rotating mechanism, a worker can drive an adjusting mechanism conveniently, through installation of a moving mechanism, a supporting mechanism can easily move relative to the ground conveniently, and physical output of carrying of the worker is reduced; and acupuncture and moxibustion can be conveniently carried out on the patient in different areas.

Owner:林明养

Automatic pet bathing machine

InactiveCN109526781AIncrease storage spaceEasy to placeGrooming devicesSoftware engineeringCompanion animal

The invention relates to an automatic pet bathing machine which comprises a machine body, a fixing structure and side baffles, wherein the bottom of the lower end of the machine body is connected witha transmission structure; a placing table is mounted at the top of the transmission structure; the fixing structure is fixed at the top end of the middle of the placing table; first sliding blocks are arranged around the outer wall of the placing table; a first sliding rail penetrates through one side of the outer wall of each first sliding block; and rolling wheels are connected around the lowerend of the placing table. Through the arrangement of the machine body, hinges and a door body, the machine body forms an axial rotating structure with the door body through the hinges, the door bodyserves as sealing equipment of the whole machine, a two-dimensional code payment system is adopted as a unlocking structure of the entire machine (the two-dimensional code payment system adopts an existing shared bicycle system, and an on-time billing function in the system can help an investor to obtain a certain reward), and when a user opens the door body through the two-dimensional code payment system, the user can put a pet into the placing table.

Owner:宁波益佳电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com