Method for manufacturing polycrystalline silicon solar cells with selective emitters

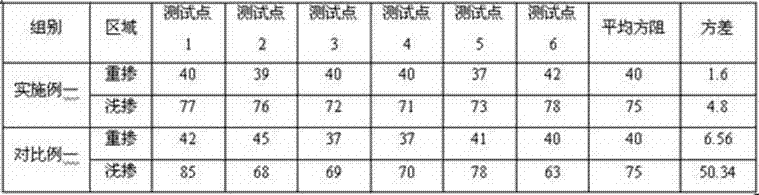

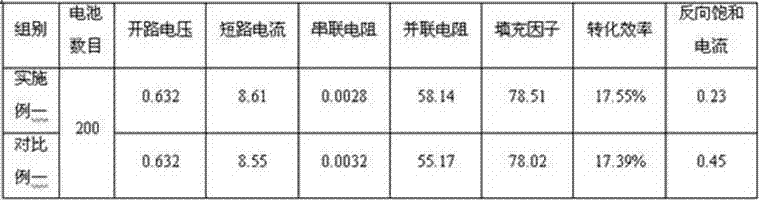

A solar cell and emitter technology, applied in the field of solar energy, can solve the problems of poor square resistance uniformity and poor cell efficiency of ultra-polycrystalline silicon solar cells, and achieve the effects of convenient subsequent cleaning, simple and easy preparation method, and shortened process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a selective emitter polycrystalline silicon solar cell includes the following steps:

[0028] (1) Cleaning and texturing;

[0029] (2) Growing active dopants on silicon wafers;

[0030] (3) Place the silicon wafer in a diffusion furnace, and cool it down to 530°C at a cooling rate of 3~5°C / min, and pass in N 2 , The N 2 The flow rate is 15 slm;

[0031] (4) After the temperature stabilizes, pass in N 2 And O 2 For oxidation, the oxidation time is 40 min; the N 2 Flow rate is 5 slm, O 2 The flow rate is 5000 sccm;

[0032] (5) Raise the temperature to 865°C at a heating rate of 8°C / min. After the temperature stabilizes, pass in the phosphorus source gas for diffusion; the phosphorus source gas is phosphorus oxychloride with a flow rate of 1000 sccm, O 2 The flow rate is 600 sccm, N 2 The flow rate is 20 slm and the diffusion time is 10 min;

[0033] (6) Keep the temperature of the above step (5), stop the phosphorus source, and introduce N 2 And O 2 Carry out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com