Cleaning equipment for automobile parts

A technology for cleaning equipment and spare parts, applied to lighting and heating equipment, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as unfavorable use of accessories, poor cleaning quality, and a large amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

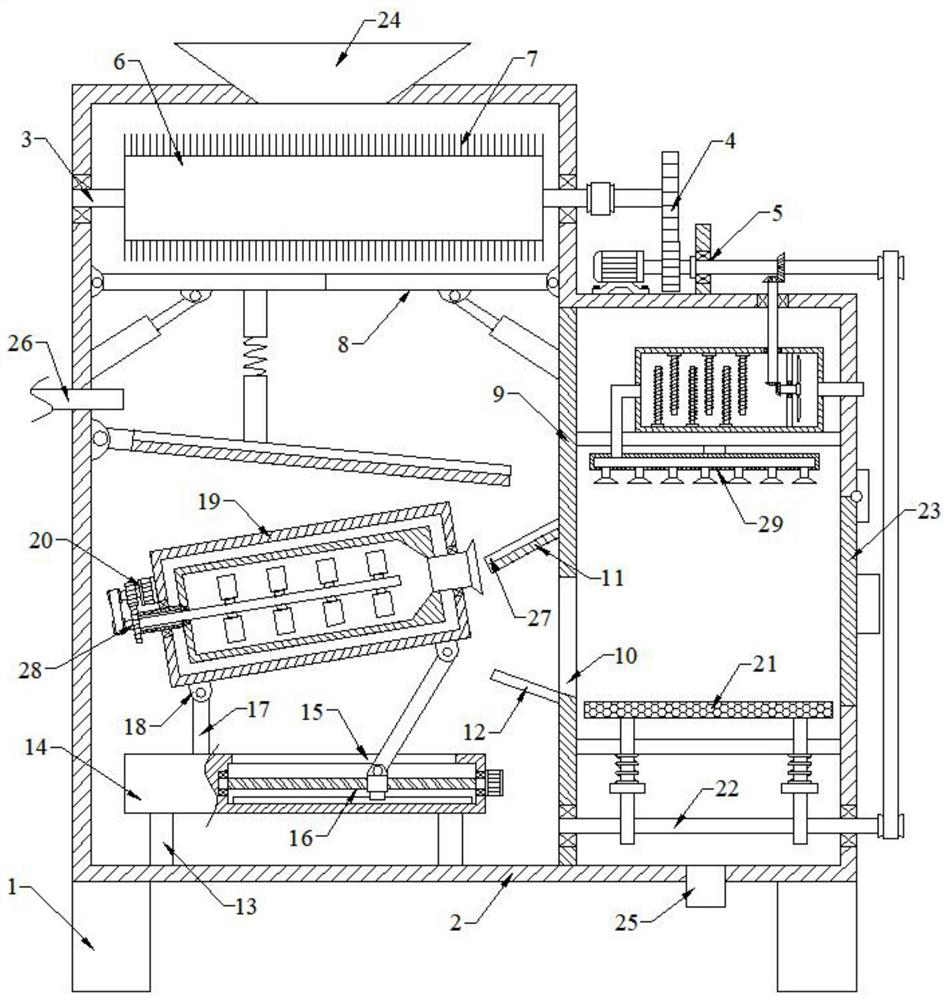

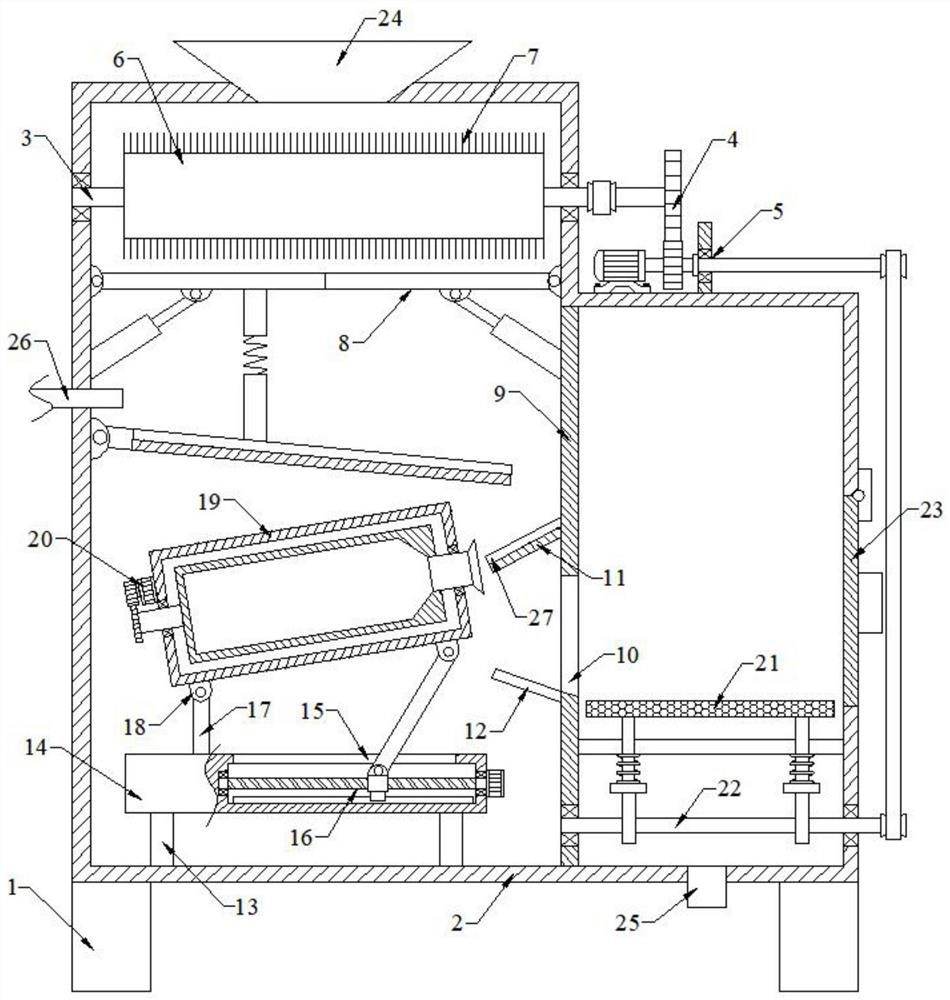

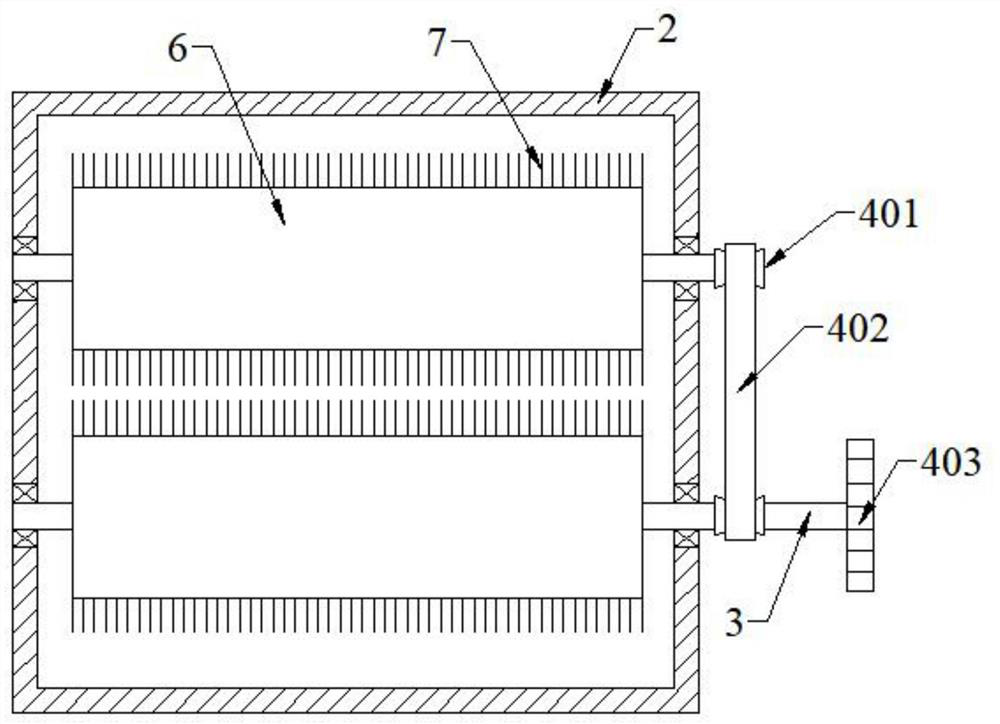

[0048] Please refer to the accompanying drawings, the present embodiment is a kind of cleaning equipment for auto parts, including two sets of supports 1, the upper end of the support 1 is fixed with a cleaning box 2, and the left and right side walls of the inner cavity of the cleaning box 2 are rotatably connected with two A first rotating shaft 3, the right end of the first rotating shaft 3 is connected with a rotating assembly 4, the rotating assembly 4 is connected with a linkage assembly 5, both first rotating shafts 3 are provided with cleaning rollers 6, and the side walls of the cleaning rollers 6 are evenly provided with cleaning brushes 7. A blanking assembly 8 is installed in the middle of the inner cavity of the cleaning box 2. A partition 9 is fixedly connected between the upper and lower walls of the inner cavity of the cleaning box 2. The middle part of the partition 9 is provided with a feeding trough 10. The left end of the partition 9 is fixed with a lower Th...

Embodiment 2

[0067] Please refer to the accompanying drawings, on the basis of Embodiment 1, it also includes a stirring assembly 28, the stirring assembly 28 includes a stirring shaft 2801, the stirring shaft 2801 is rotatably connected to the left wall of the inner cylinder 2002, and the upper and lower side walls of the stirring shaft 2801 are arranged symmetrically. There are multiple sets of stirring paddles 2802, the left end of the stirring shaft 2801 passes through the hollow shaft 2001 and is fixedly connected with the fourth pulley 2803, the third belt 2804 is installed on the fourth pulley 2803, the output end of the third servo motor 2005 is fixedly connected with the The fifth pulley 2805 and the fifth pulley 2805 are in drive connection with the fourth pulley 2803 through the third belt 2804 .

[0068] Specifically, step S7 is also included: the third servo motor 2005 rotates clockwise and at the same time drives the fifth pulley 2805 to rotate clockwise, and then drives the f...

Embodiment 3

[0070] Please refer to the accompanying drawings, on the basis of Embodiment 1, it also includes a drying assembly 29, the drying assembly 29 includes a support plate 2901, and the support plate 2901 is fixed between the right end of the partition plate 9 and the right wall of the inner cavity of the cleaning box 2 Between them, a heating box 2902 is arranged on the upper end of the support plate 2901, and multiple sets of heating tubes 2903 are installed alternately on the upper and lower walls of the inner cavity of the heating box 2902. Rod 2905, the fan blade 2906 is installed on the right end of the rotating rod 2905, the first bevel gear 2907 is fixedly connected to the left end of the rotating rod 2905, the upper wall of the heating box 2902 and the upper wall of the cleaning box 2 are rotatably connected with a third rotating shaft 2908, and the lower end of the third rotating shaft 2908 A second bevel gear 2909 is fixedly connected, the second bevel gear 2909 is meshed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com