Patents

Literature

240results about How to "Realize automatic production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

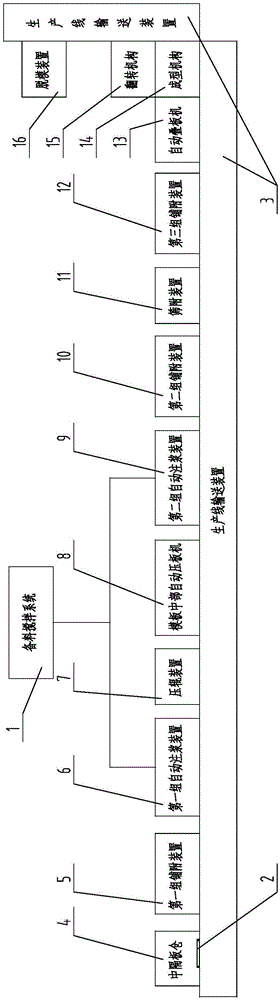

Composite heat insulation light wall board production process and production device

ActiveCN104070600AEasy to produceShorten molding timeDischarging arrangementCeramic shaping plantsMaterials preparationProduction line

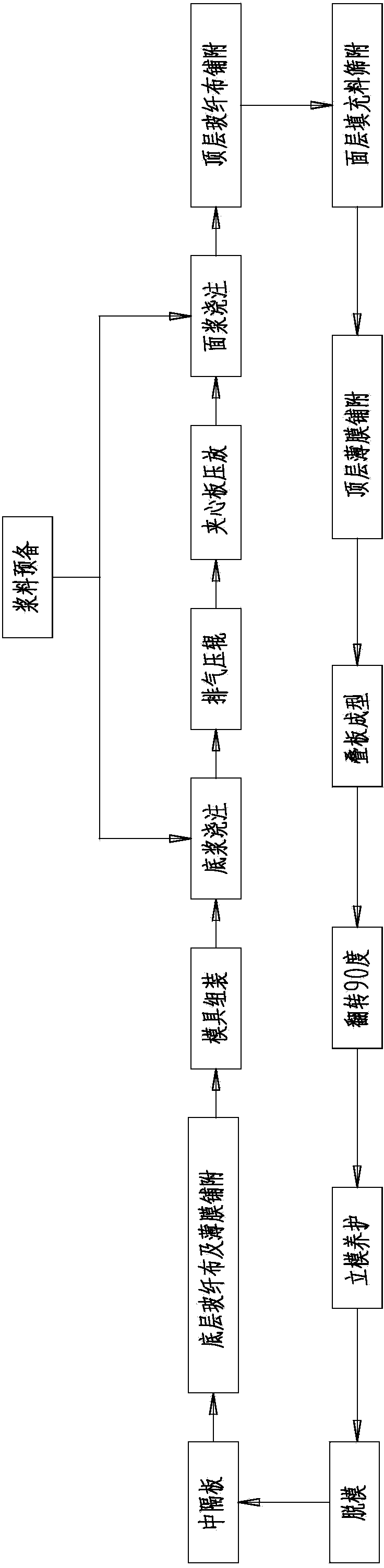

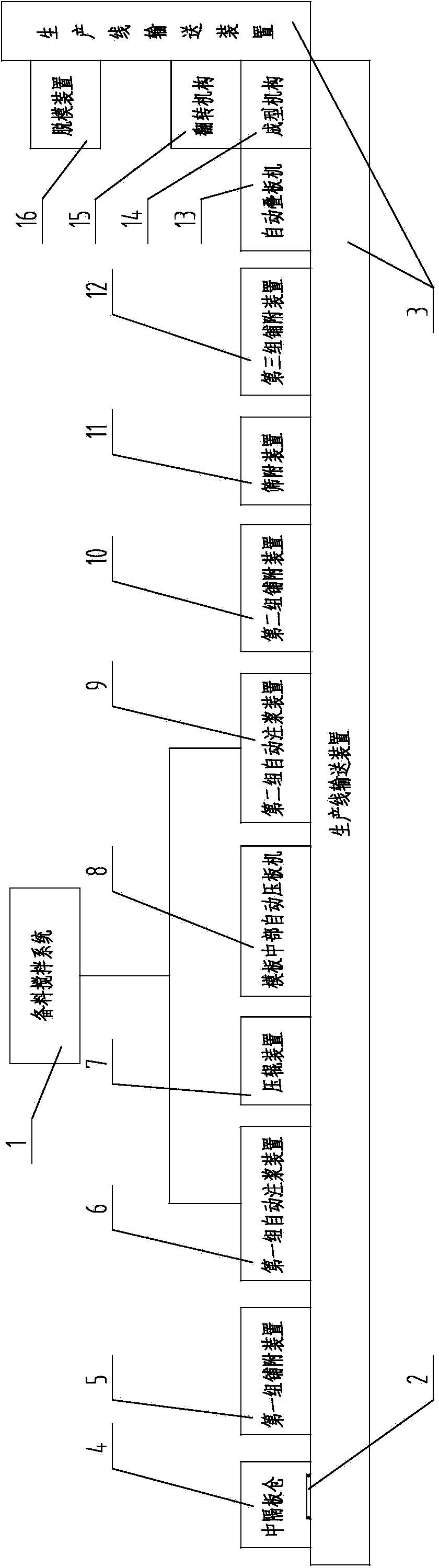

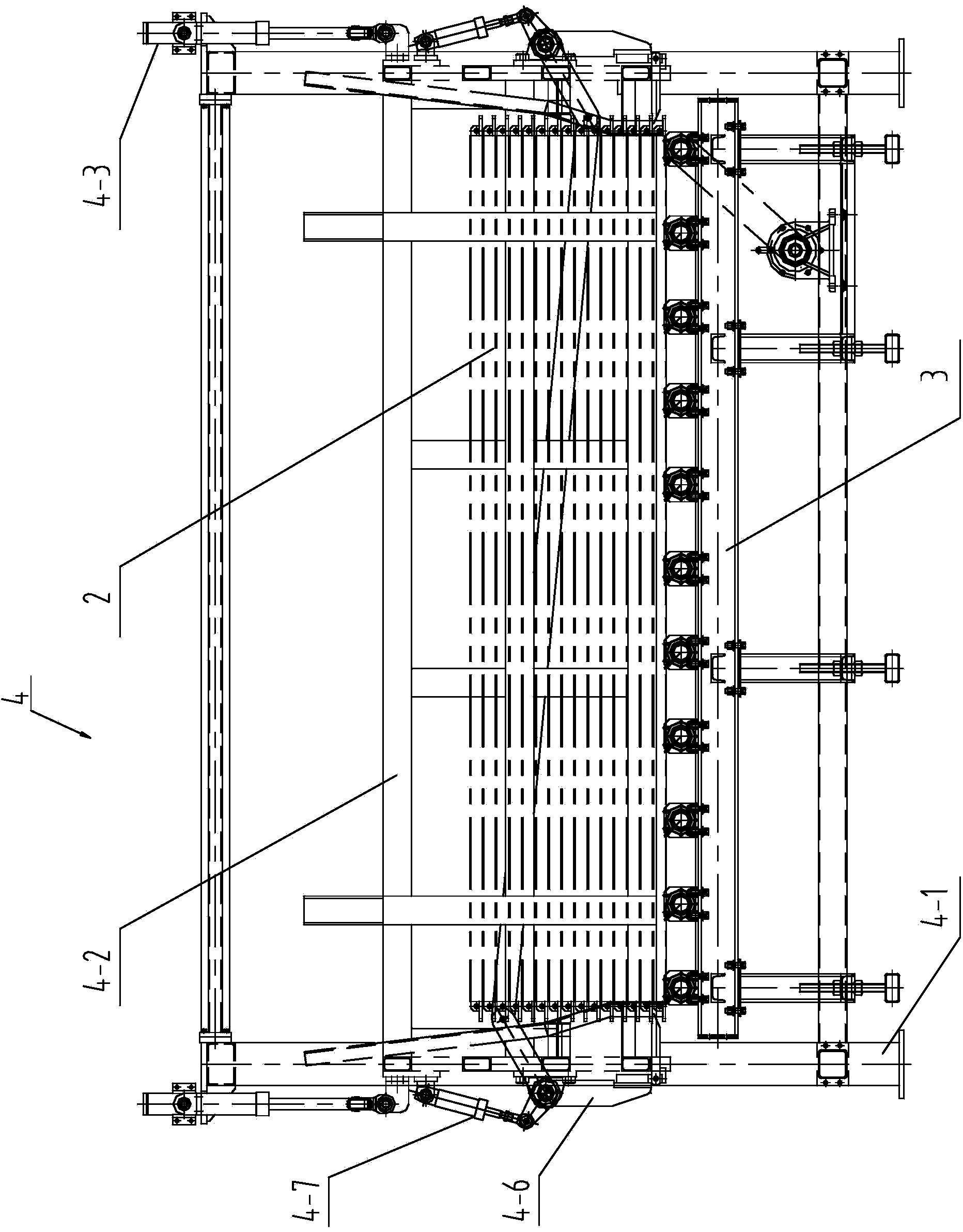

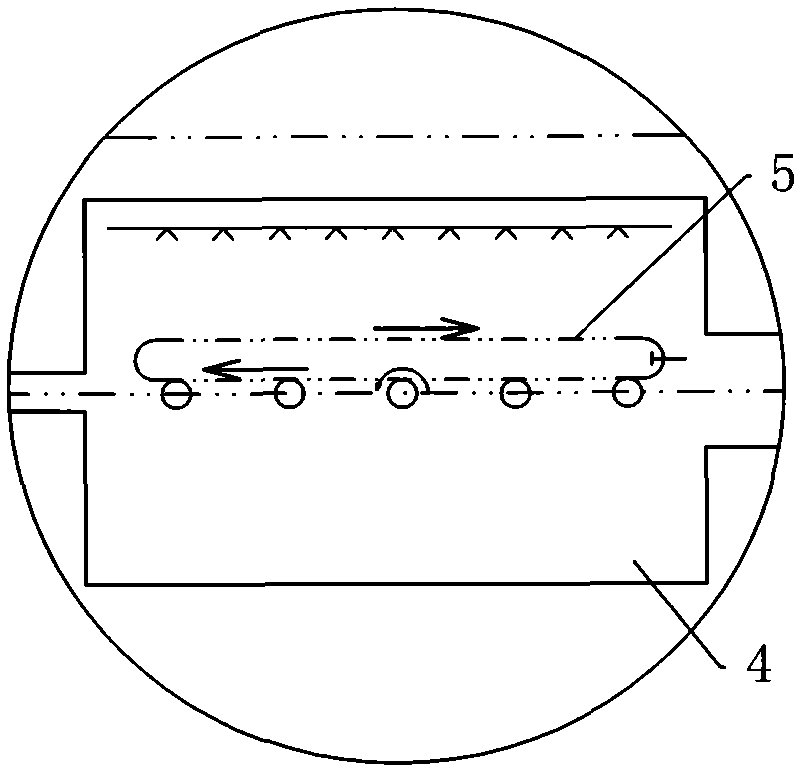

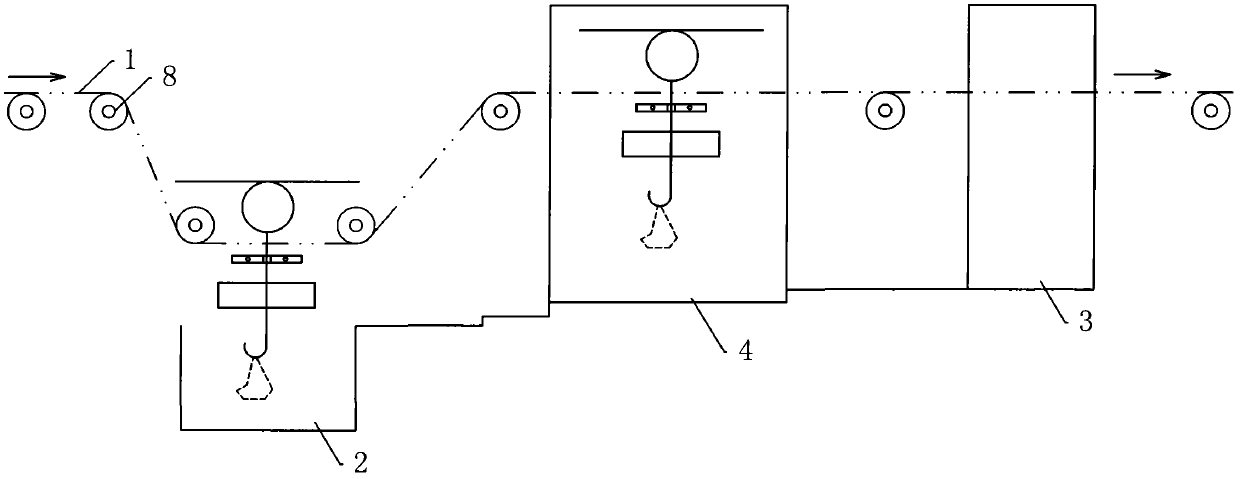

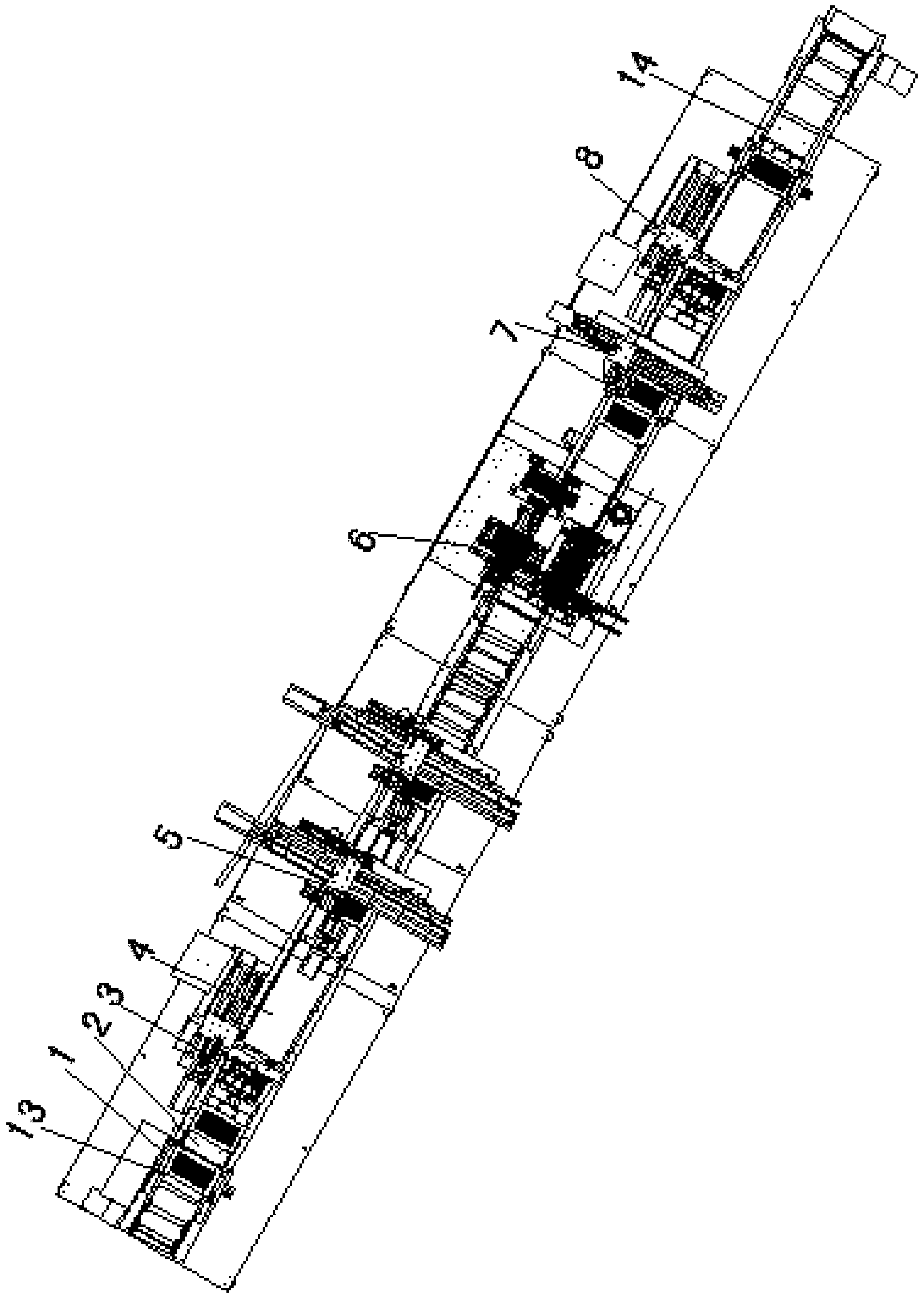

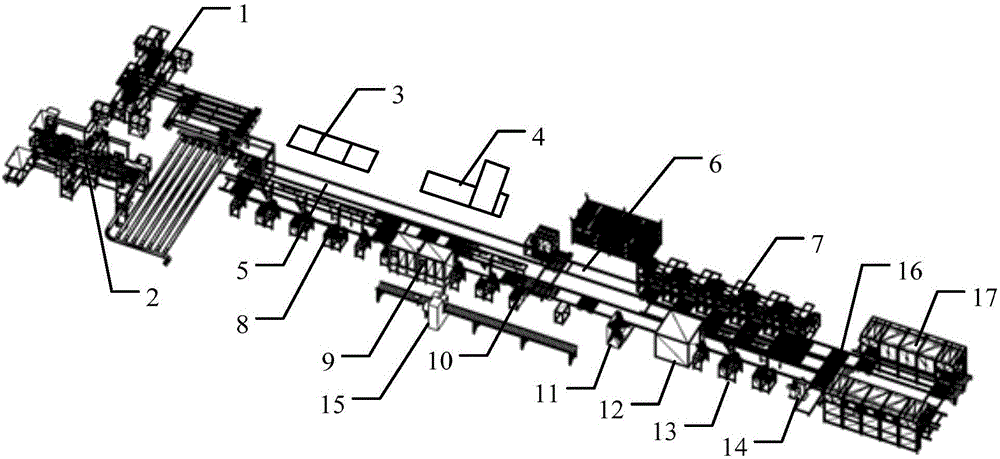

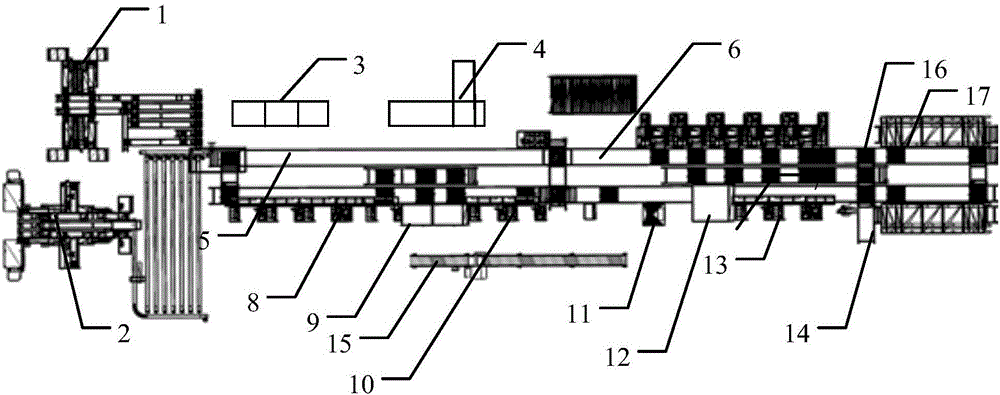

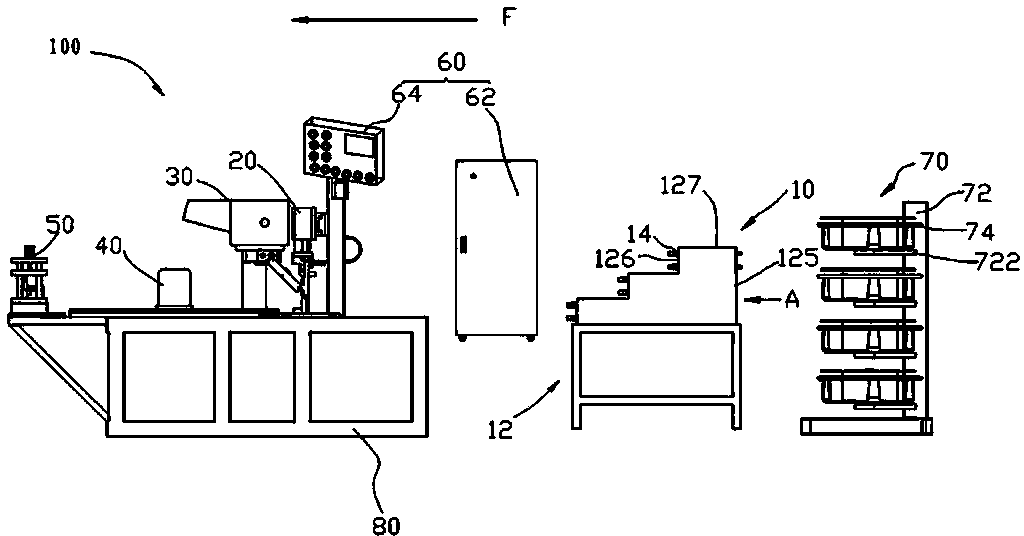

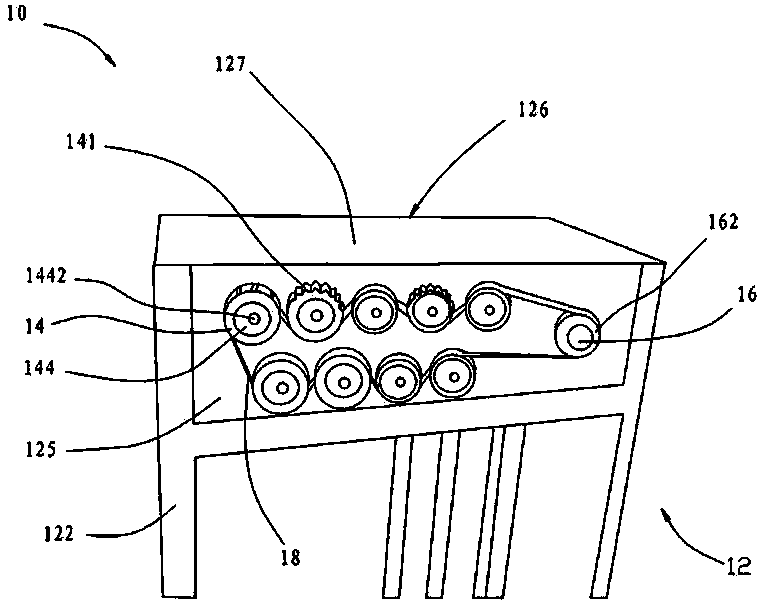

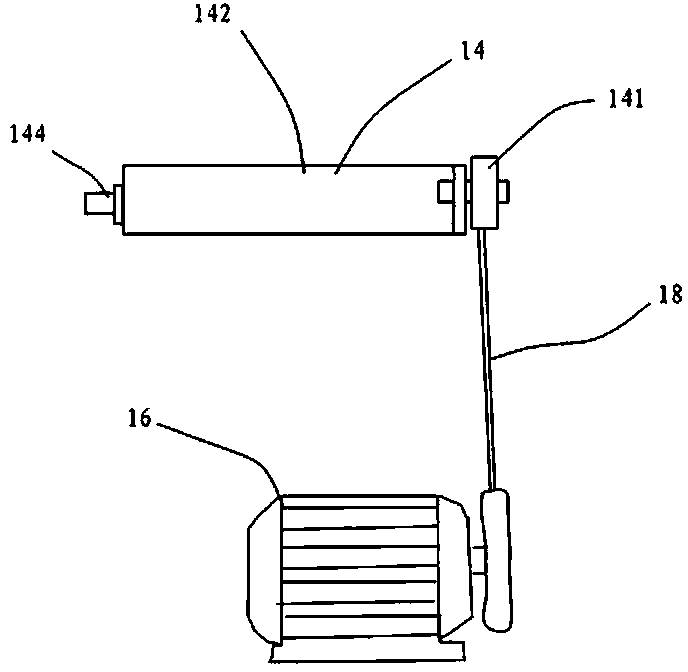

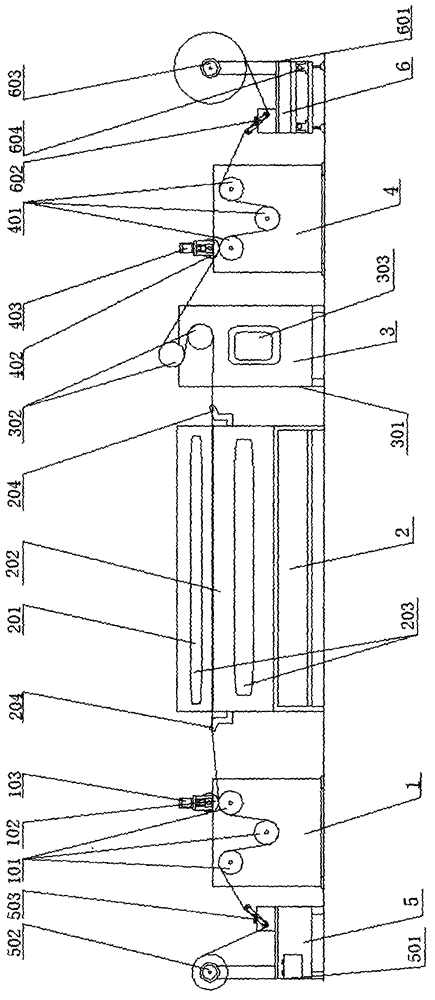

The invention relates to a composite heat insulation light wall board production process and a production device for achieving the process. The process includes the procedures of paste preparation, flat mould grouting, vertical mould curing and demoulding which are conducted sequentially. The production device comprises a material preparation stirring system, a production line conveying device and a middle partition plate bin, a first group of paving devices, a first group of automatic grouting devices, a compression roller device, a mould plate middle automatic plate pressing machine, a second group of automatic grouting devices, a second group of paving devices, a screening device, a third group of paving devices, an automatic plate stacking machine, a molding mechanism, an overturning mechanism and a demoulding device which are sequentially arranged in the conveying direction of the production line conveying device. Flat mould grouting and vertical mould curing are adopted by the process, double-layer or multi-layer structure arrangement can be achieved, and diversified products can be produced conveniently. The production device adopts a flat mould automatic production line. By means of the production device, the molding time of a composite heat insulation light wall board is greatly reduced, the labor intensity is reduced, and the quality of the produced products is stable.

Owner:QUANZHOU S L MACHINERY MFG

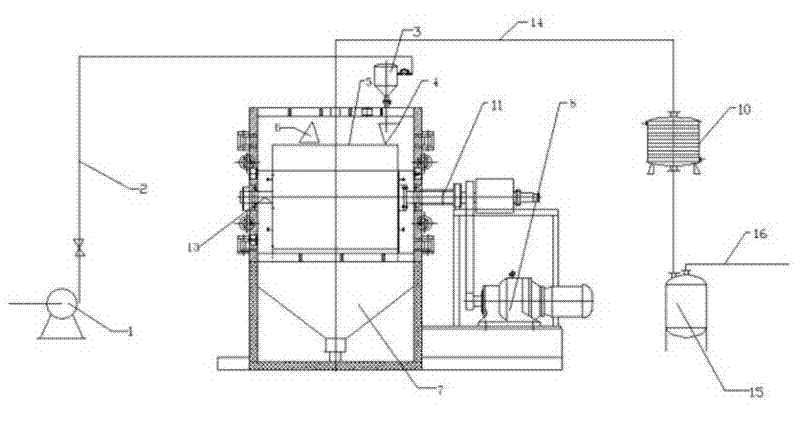

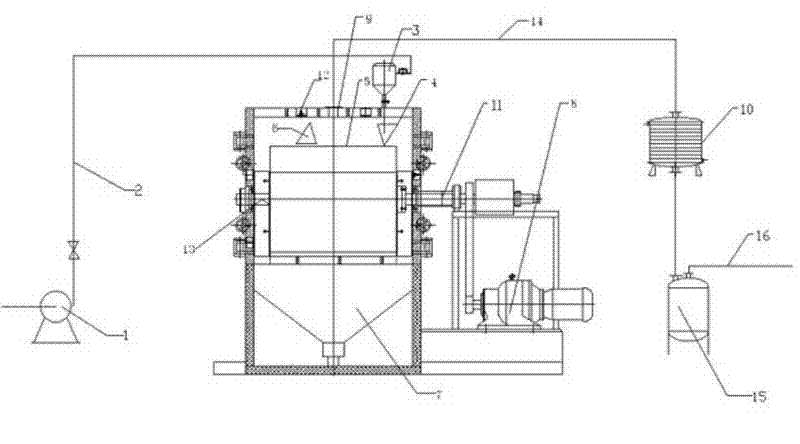

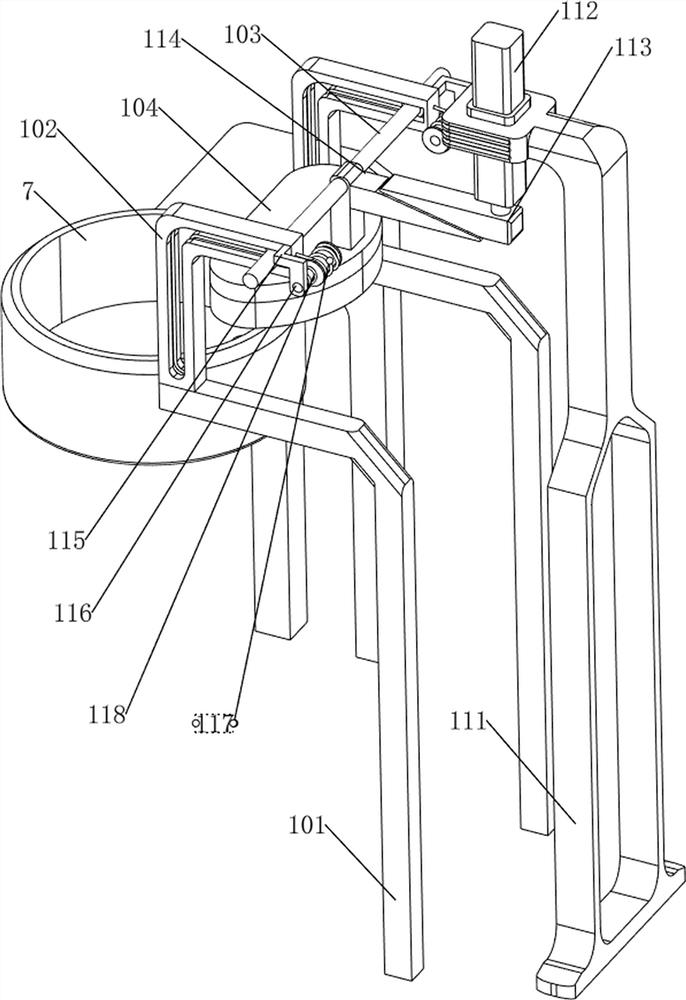

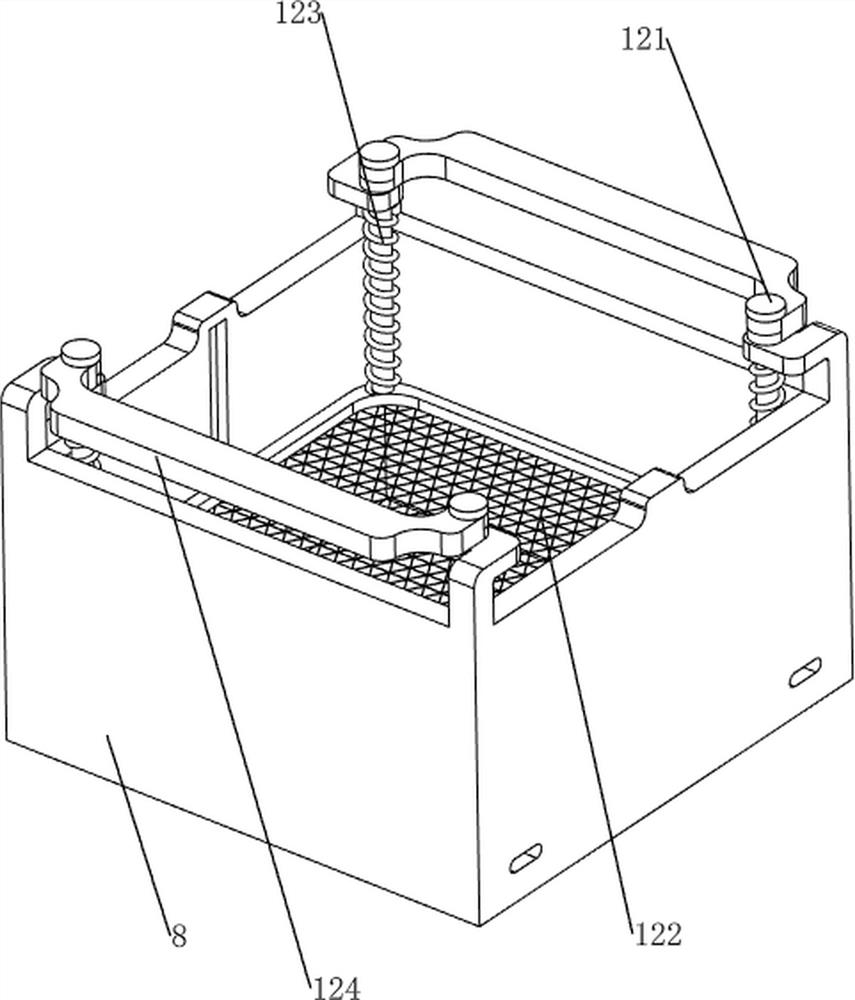

Automatic painting production line capable of recycling excess paint

InactiveCN101992175ANo human intervention requiredRealize automatic productionPretreated surfacesCoatingsLacquerEngineering

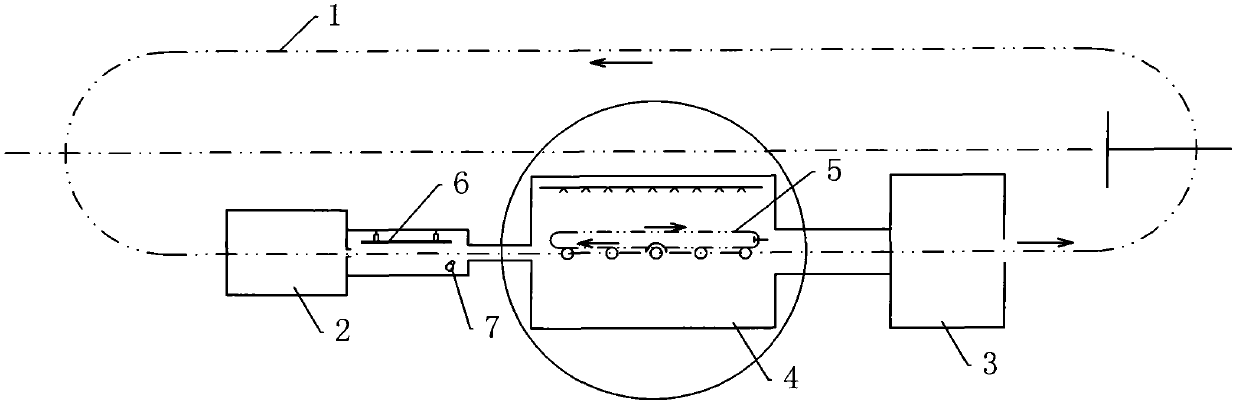

The invention discloses an automatic painting production line capable of recycling an excess paint. The production line comprises a closed annular main conveying chain, wherein the main conveying chain is dynamically connected with a main chain driving device; a rotatable workpiece hanging and holding device is arranged on the main conveying chain; and a paint dipping device, an excess paint recycling device and a drying chamber are arranged along the running direction of the main conveying chain in turn. When a workpiece is hung on the rotatable workpiece hanging and holding device, the workpiece passes through the paint dipping device, the excess paint recycling device and the drying chamber in turn along with the movement of the main conveying chain, wherein the workpiece is automatically dipped into a paint in the paint dipping device; the paint on the workpiece is automatically thrown off and the excess paint is automatically recycled in the excess paint recycling device; and finally, the workpiece is dried in the drying chamber. The whole process is automatically completed without an operator; and the recycled excess paint flows back into the paint dipping device for recycling.

Owner:王钧祥

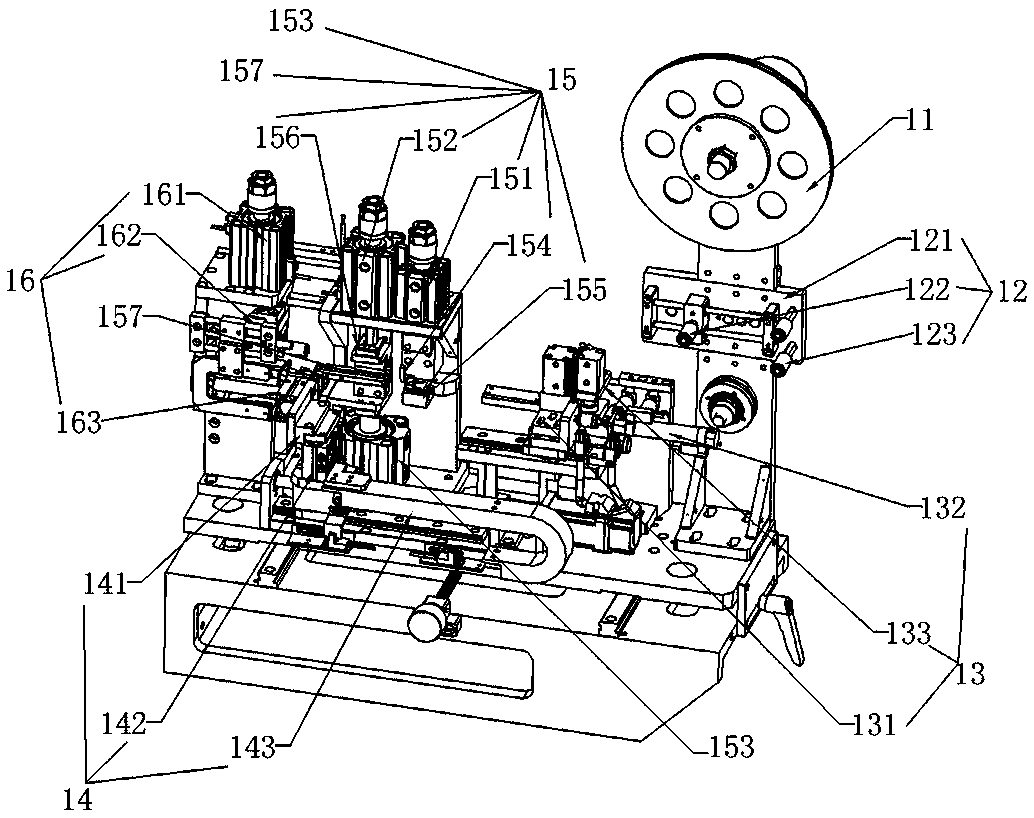

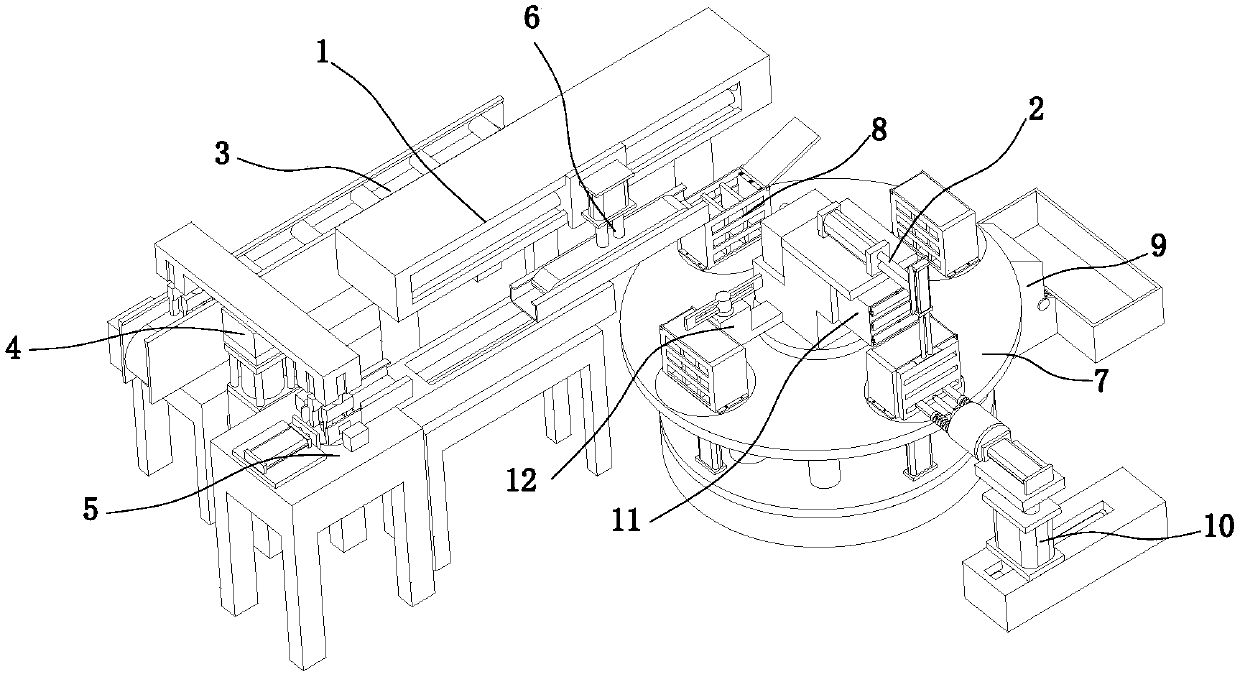

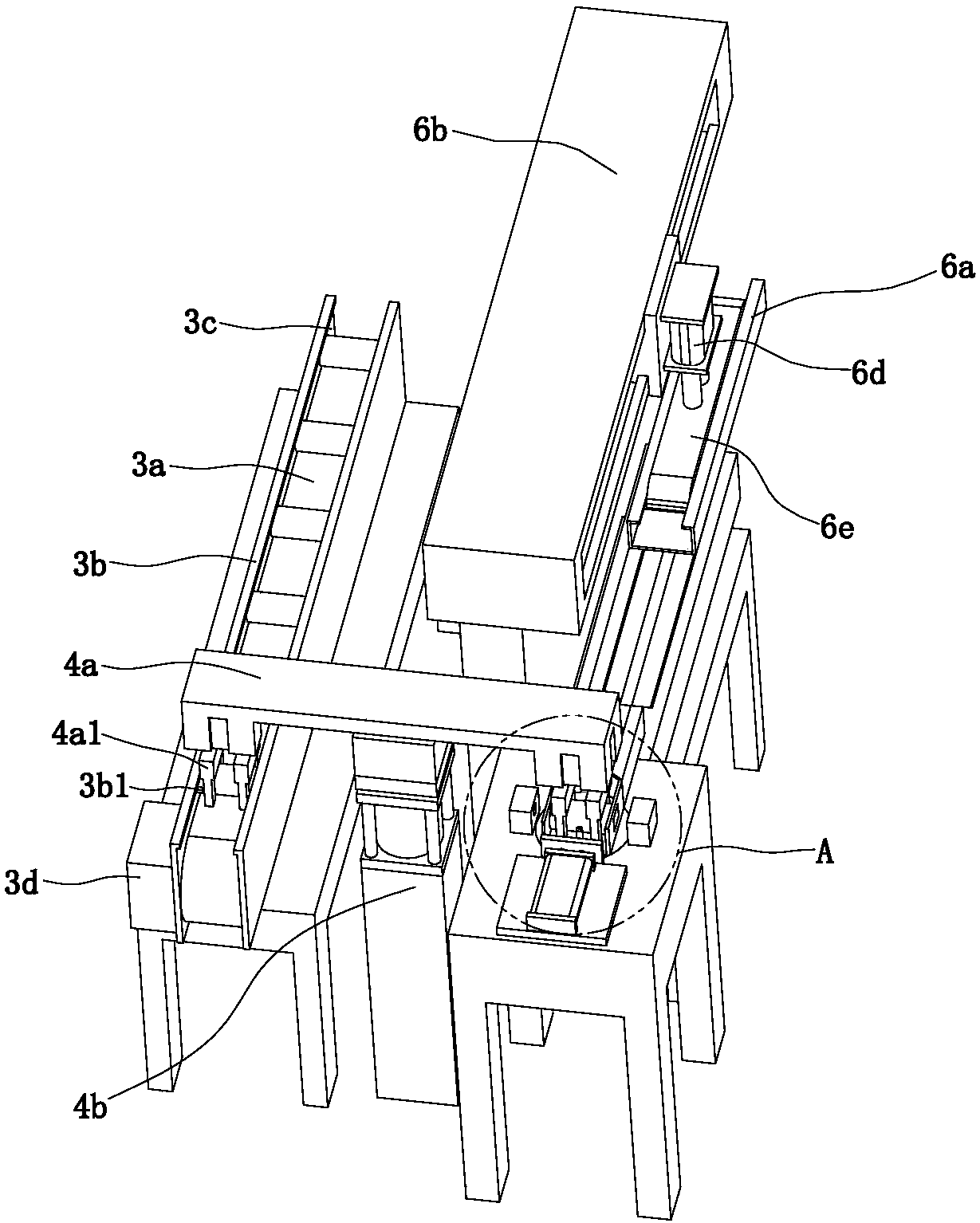

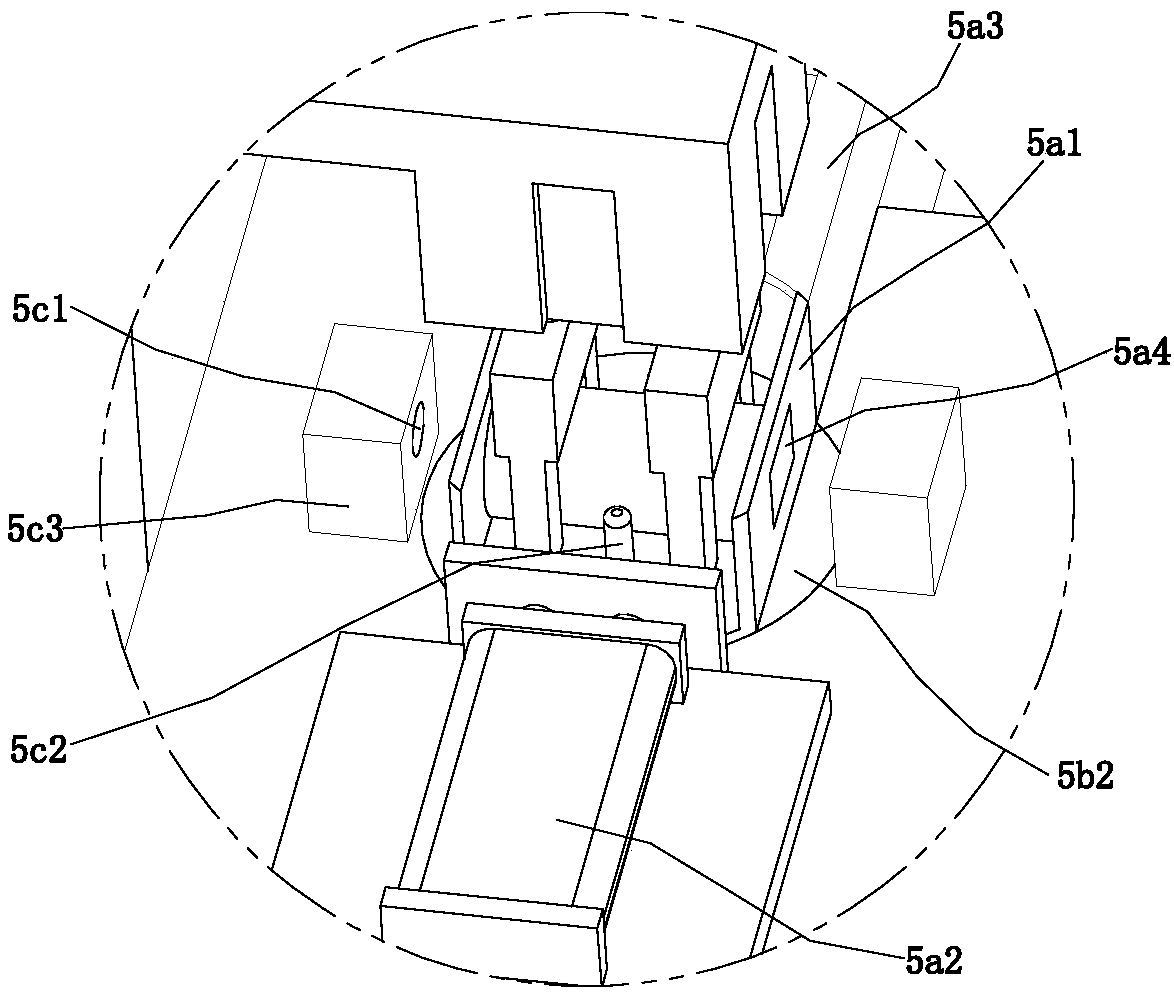

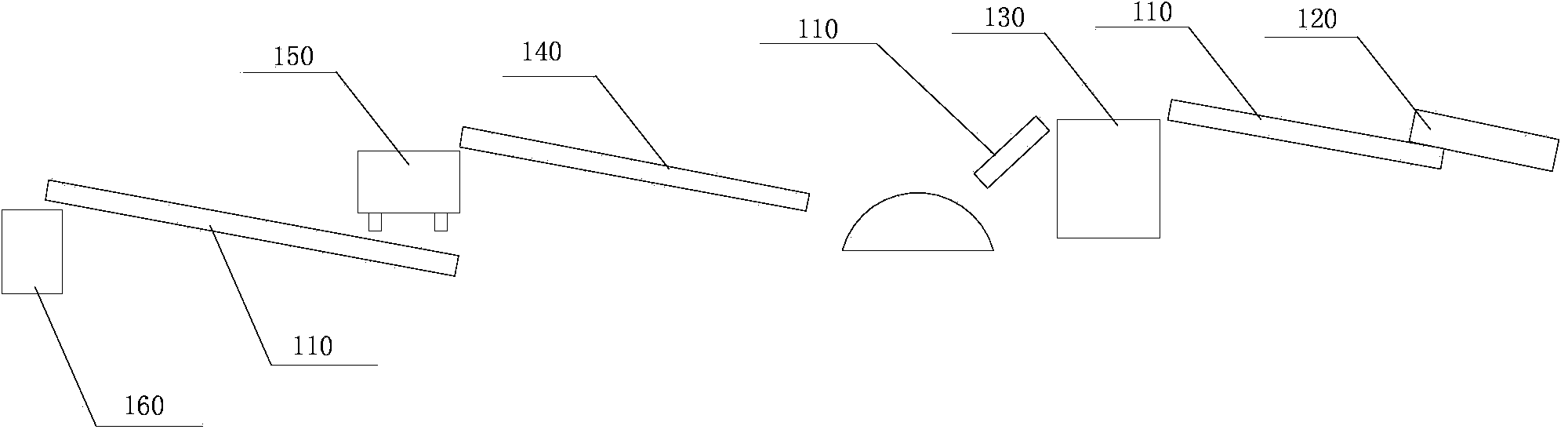

Automatic stator production line

ActiveCN103532318ARealize automatic productionRealize automatic assembly productionManufacturing stator/rotor bodiesProgrammable logic controllerMagnet

The invention discloses an automatic production line for producing a spare part, namely a stator, of a vibration motor of a mobile phone. The automatic production line comprises a PLC (Programmable Logic Controller) system and a jig circulation device, wherein the jig circulation device comprises a circulation disc and a conveyer for driving the circulation disc to move; and an automatic stator housing arrangement unit, an automatic catalyst dripping unit, a stator housing direction screening unit, an automatic magnetic steel mounting unit, an automatic magnetic steel pressing unit, an automatic glue dispensing unit, a drying unit, an automatic air blowing unit, an automatic magnet charging unit and a qualified product inspection unit are sequentially arranged along the conveyer. According to the production line, all procedures for producing the stator are accomplished on a single assembly line; a circulation jig is only required to be replaced once; the automatic assembly of the stator can be realized; the manpower can be saved; the circulation time is shortened; and the production efficiency is improved.

Owner:CHONGQING LINGLONG AUTOMATION EQUIP CO LTD

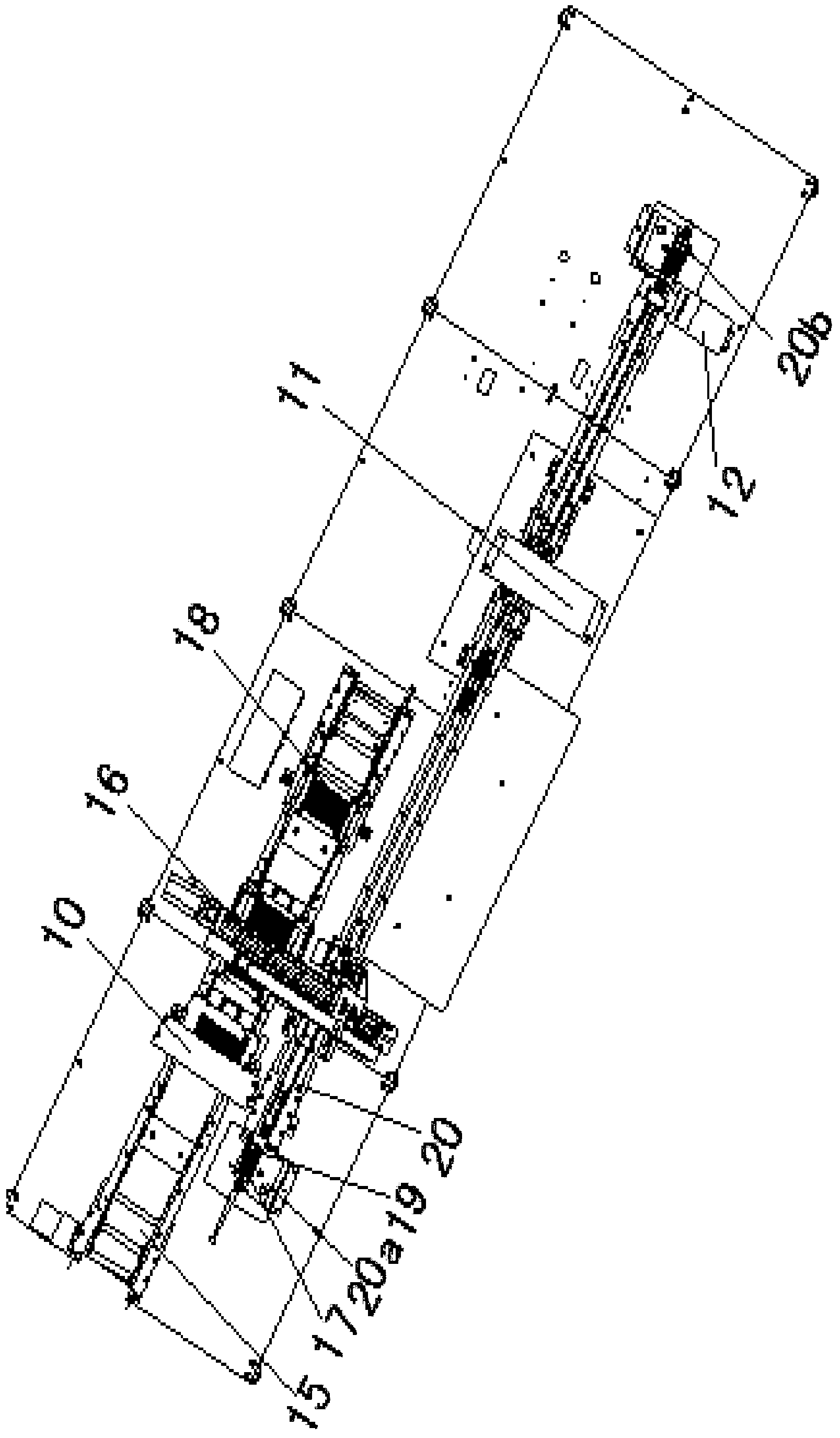

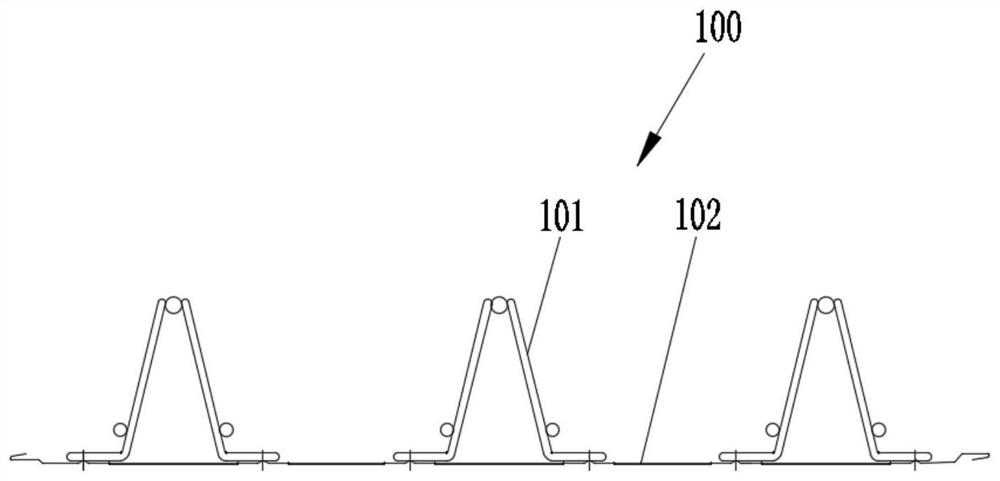

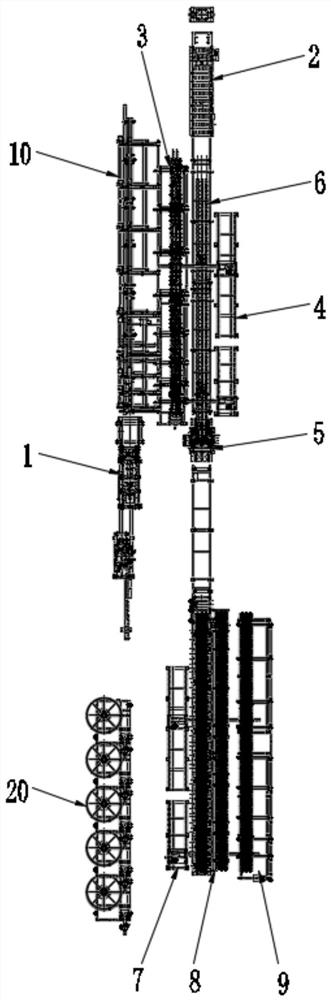

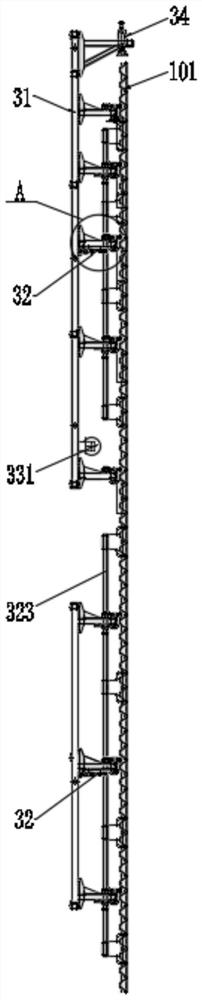

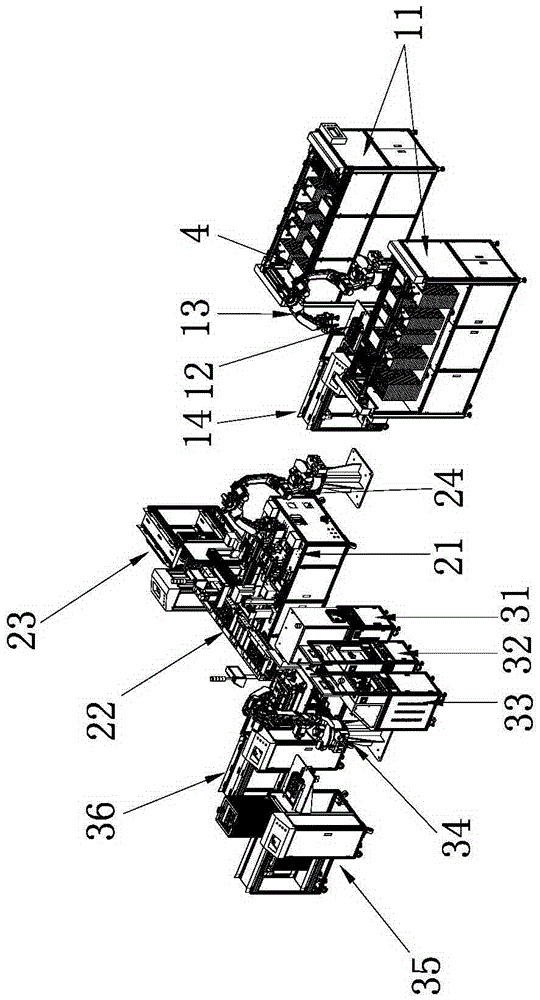

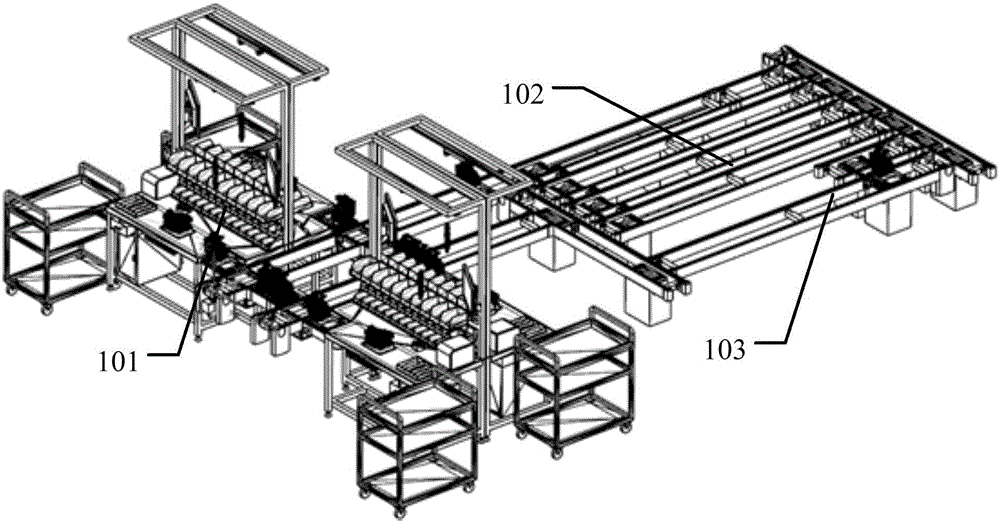

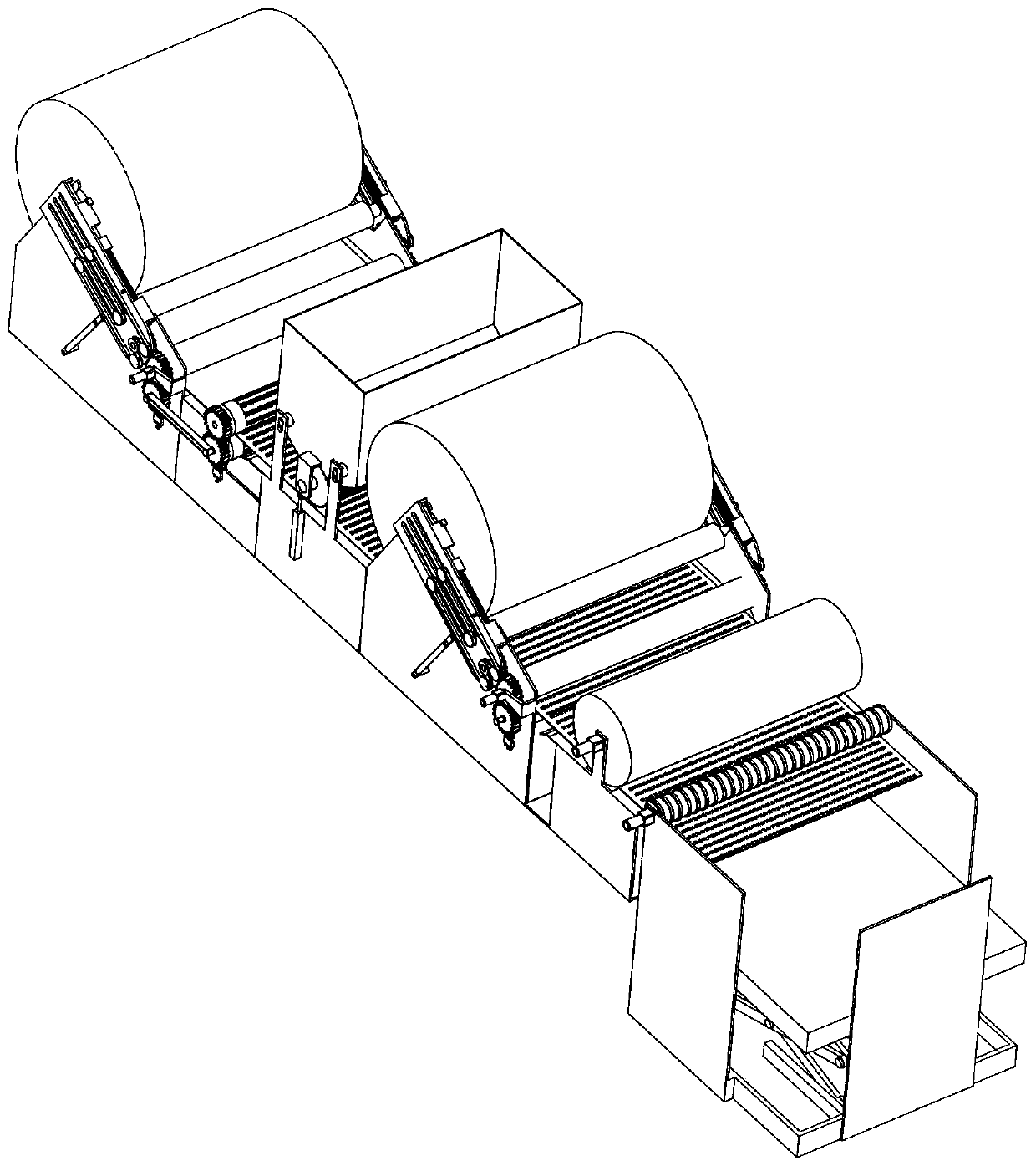

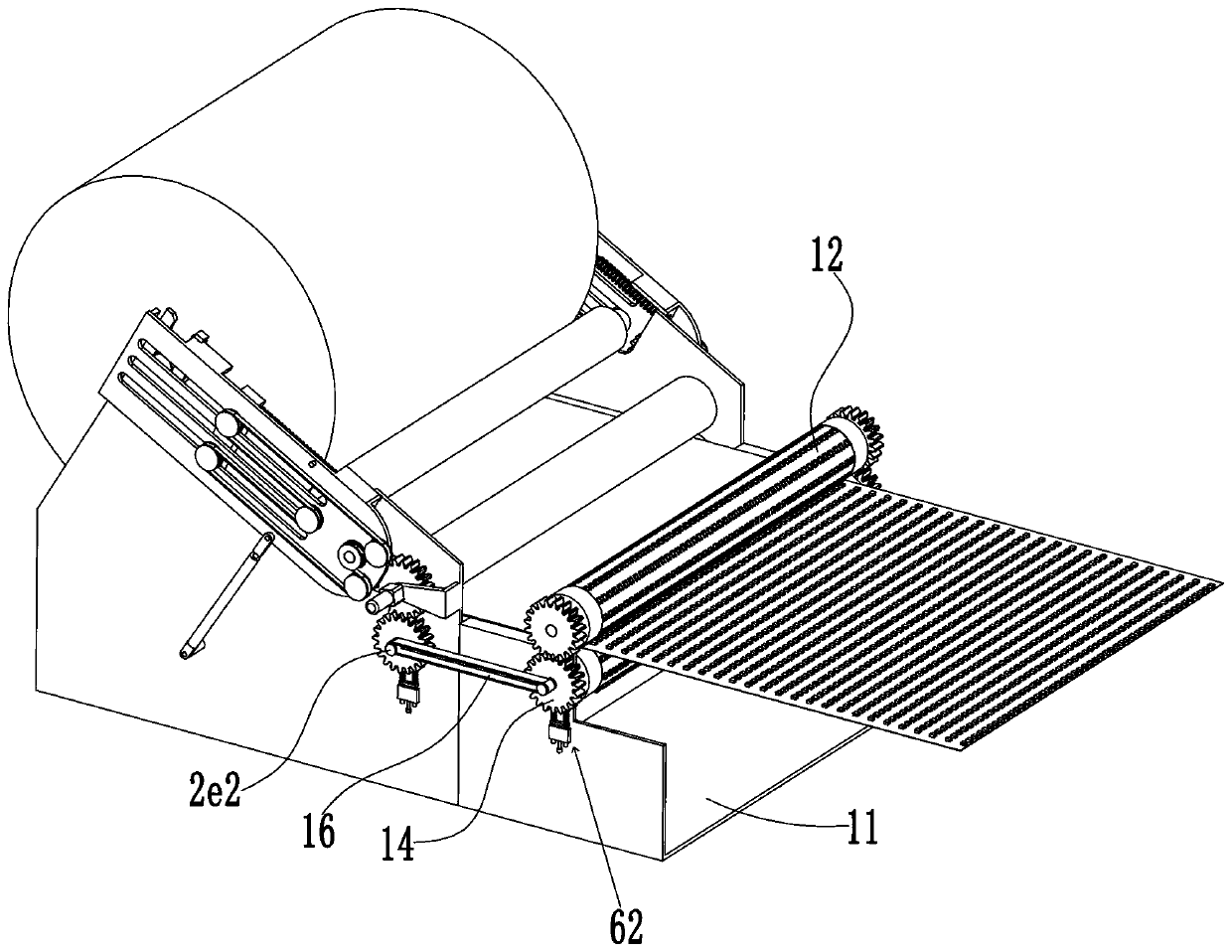

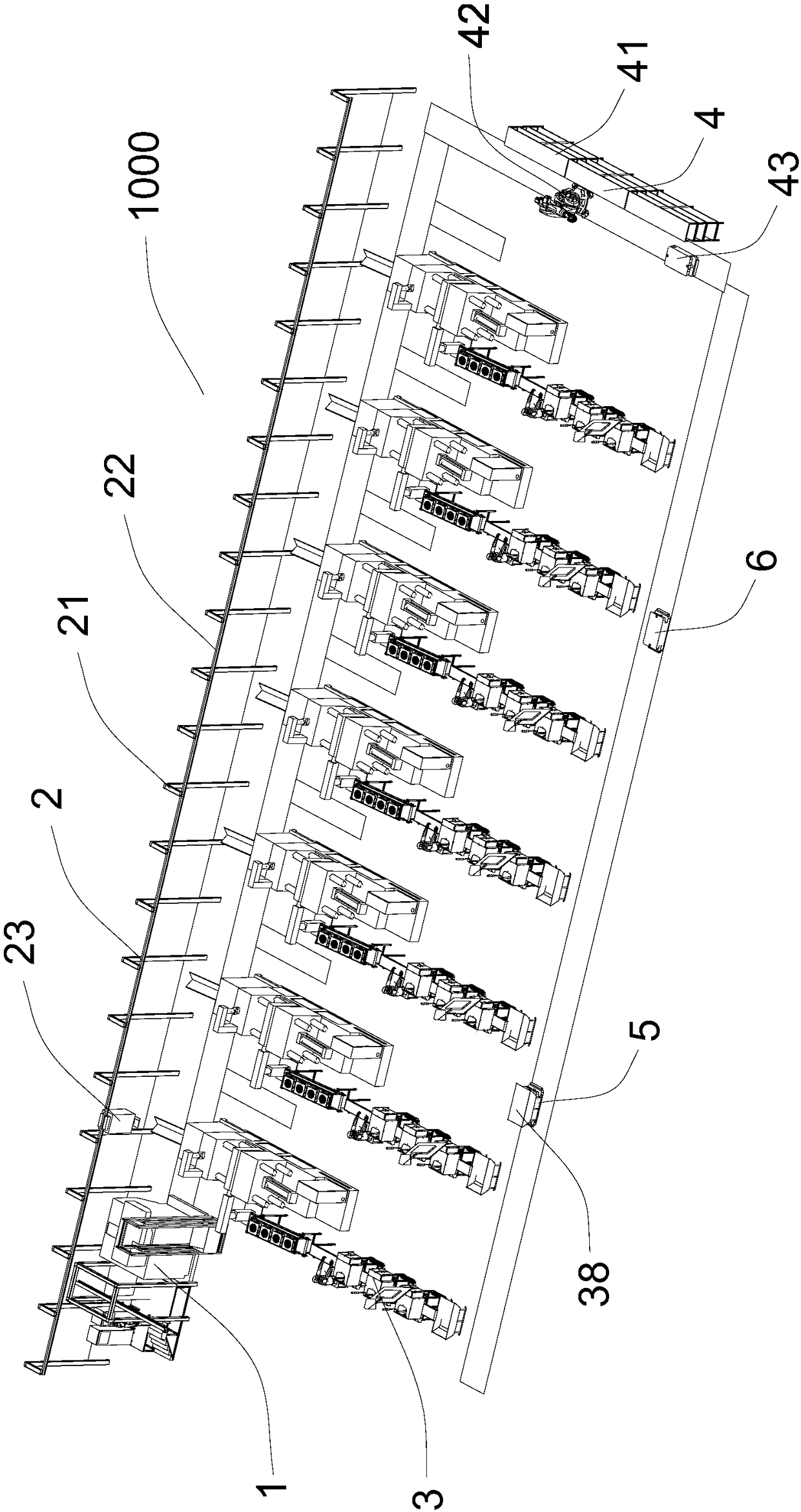

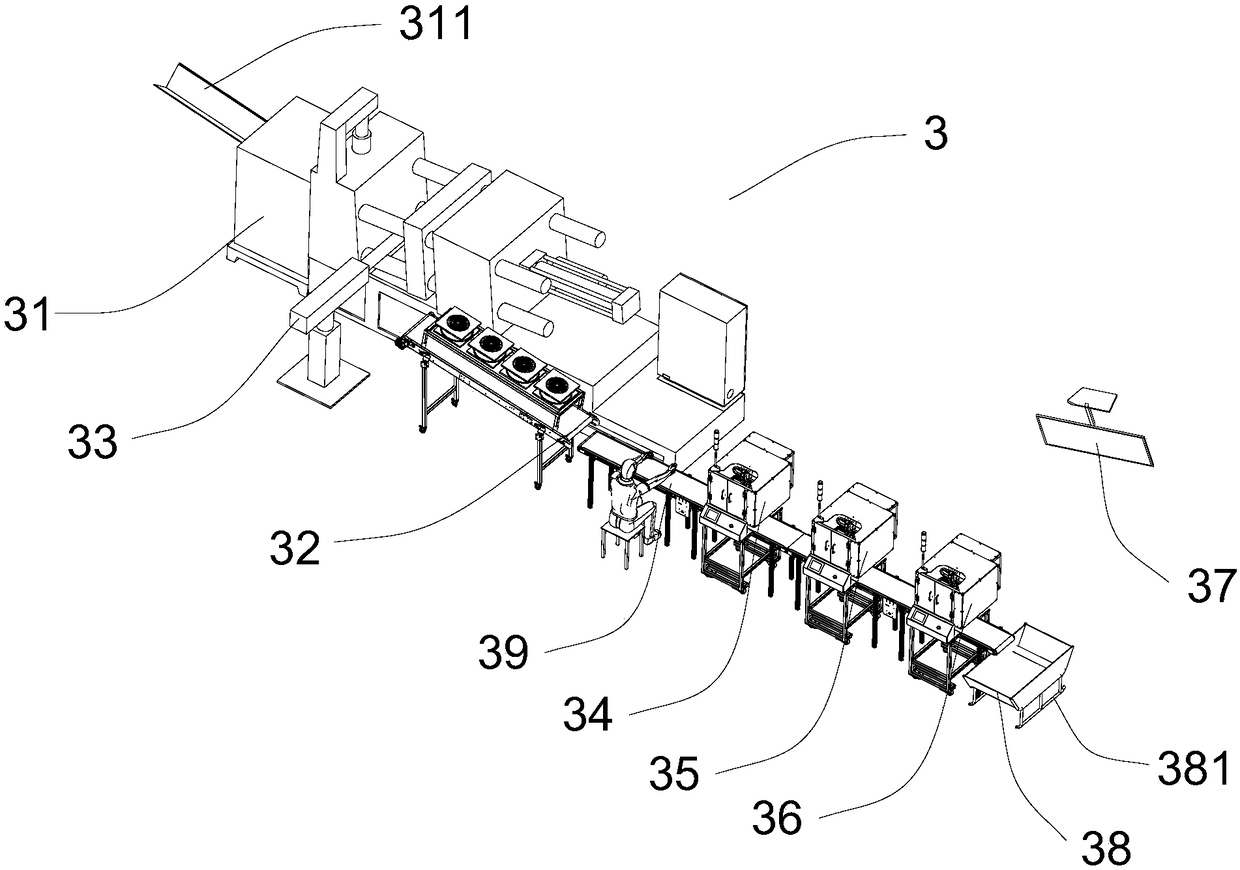

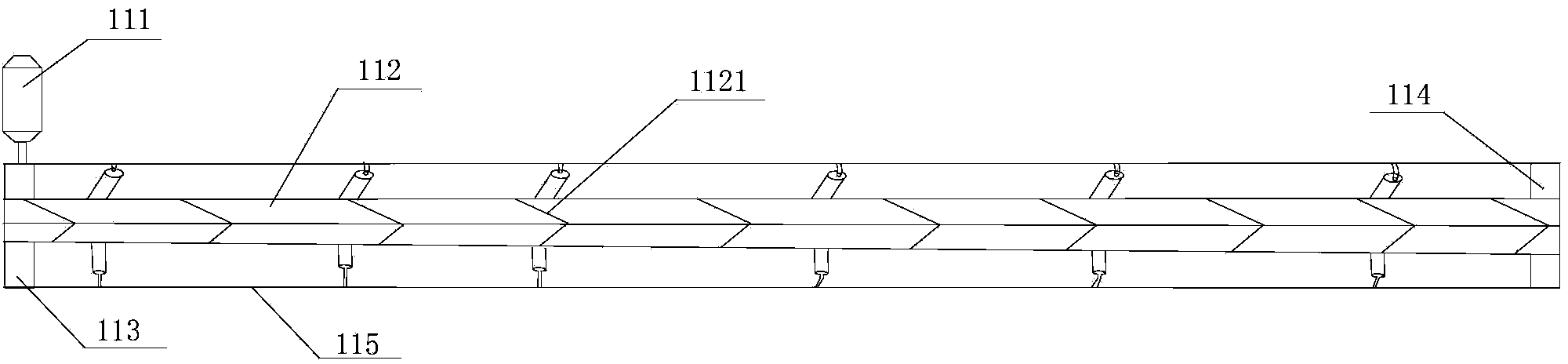

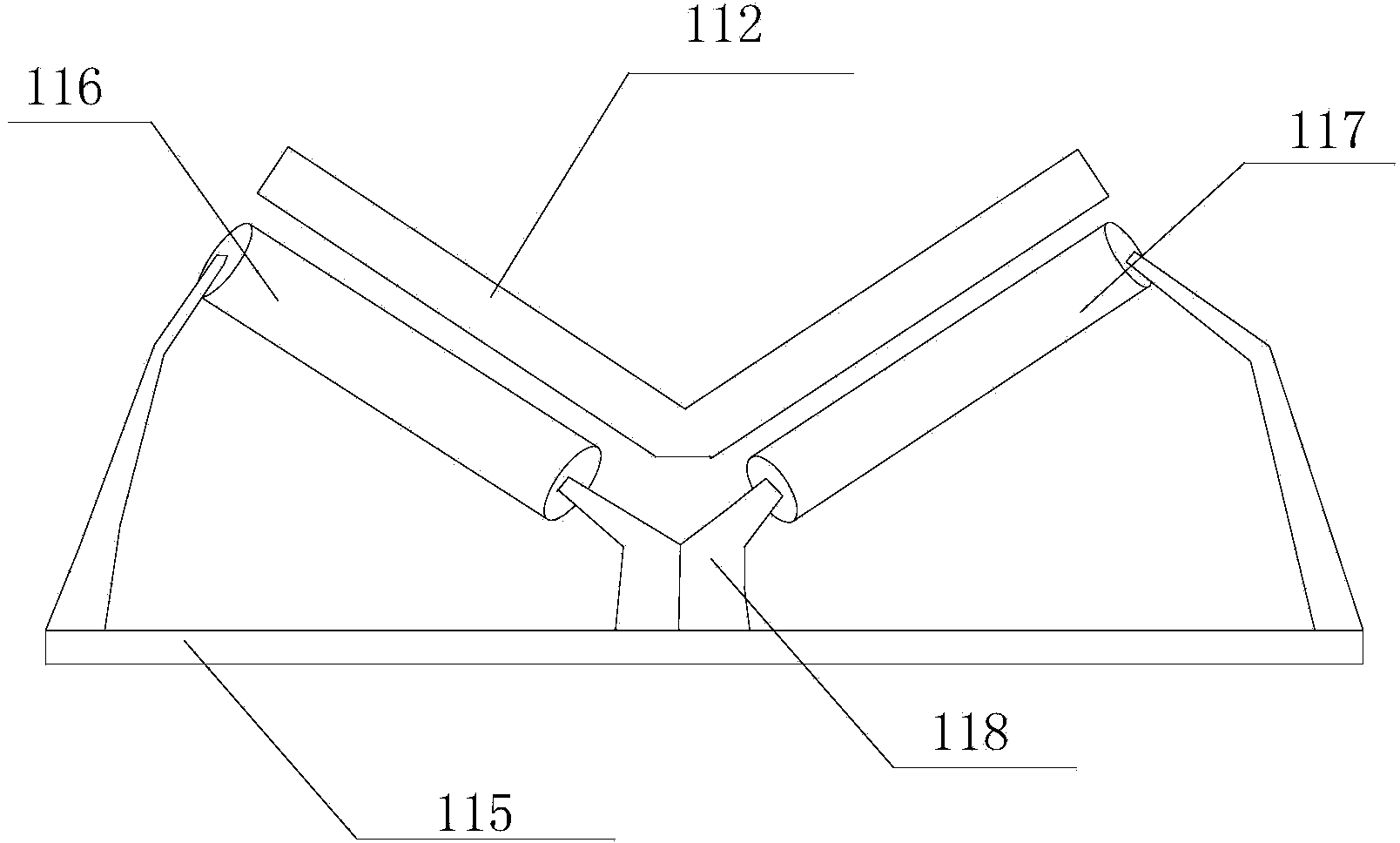

Steel bar truss floor support plate production line

PendingCN112192223ARealize automatic productionReduce manpowerOther manufacturing equipments/toolsRebarManufacturing line

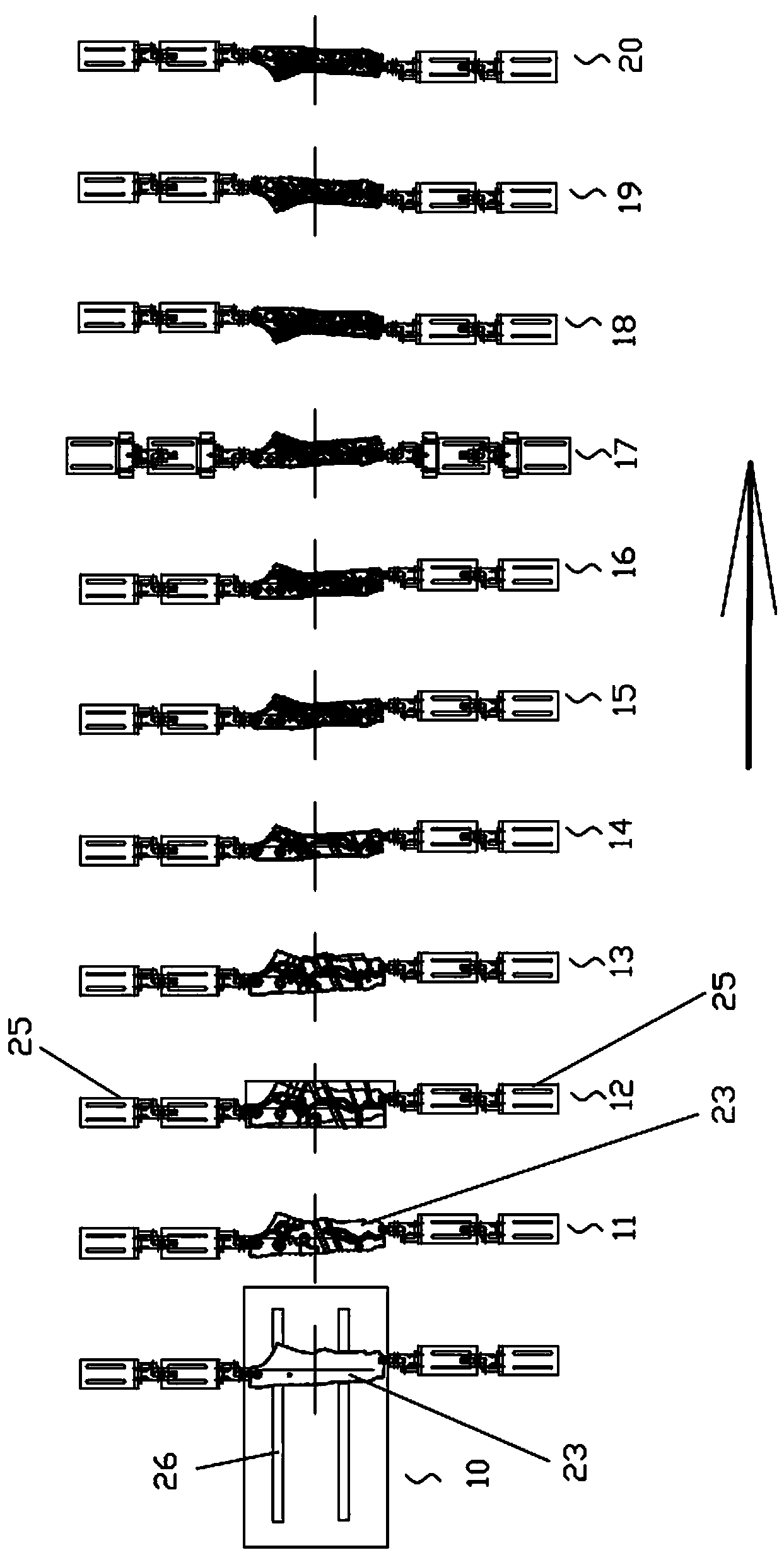

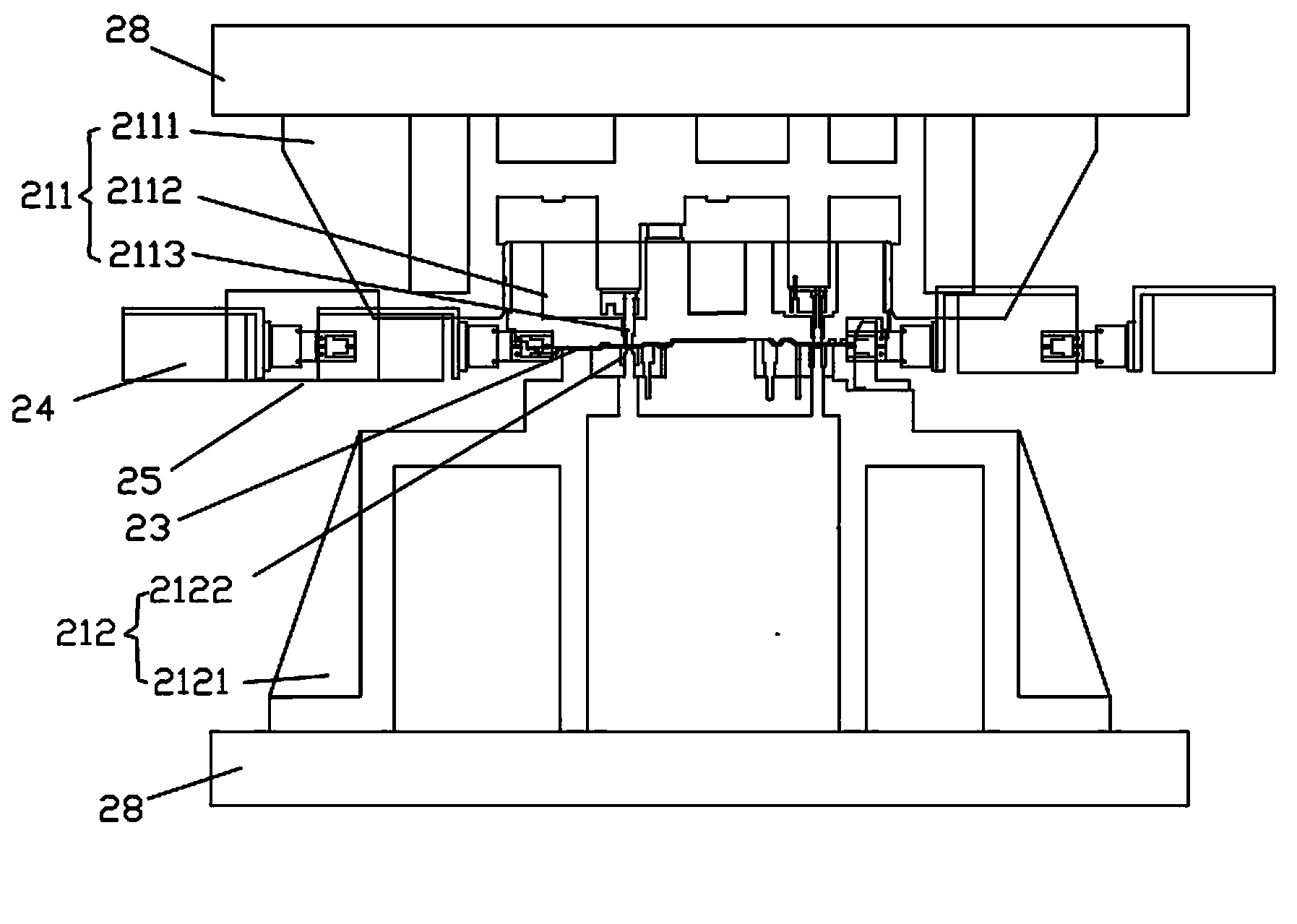

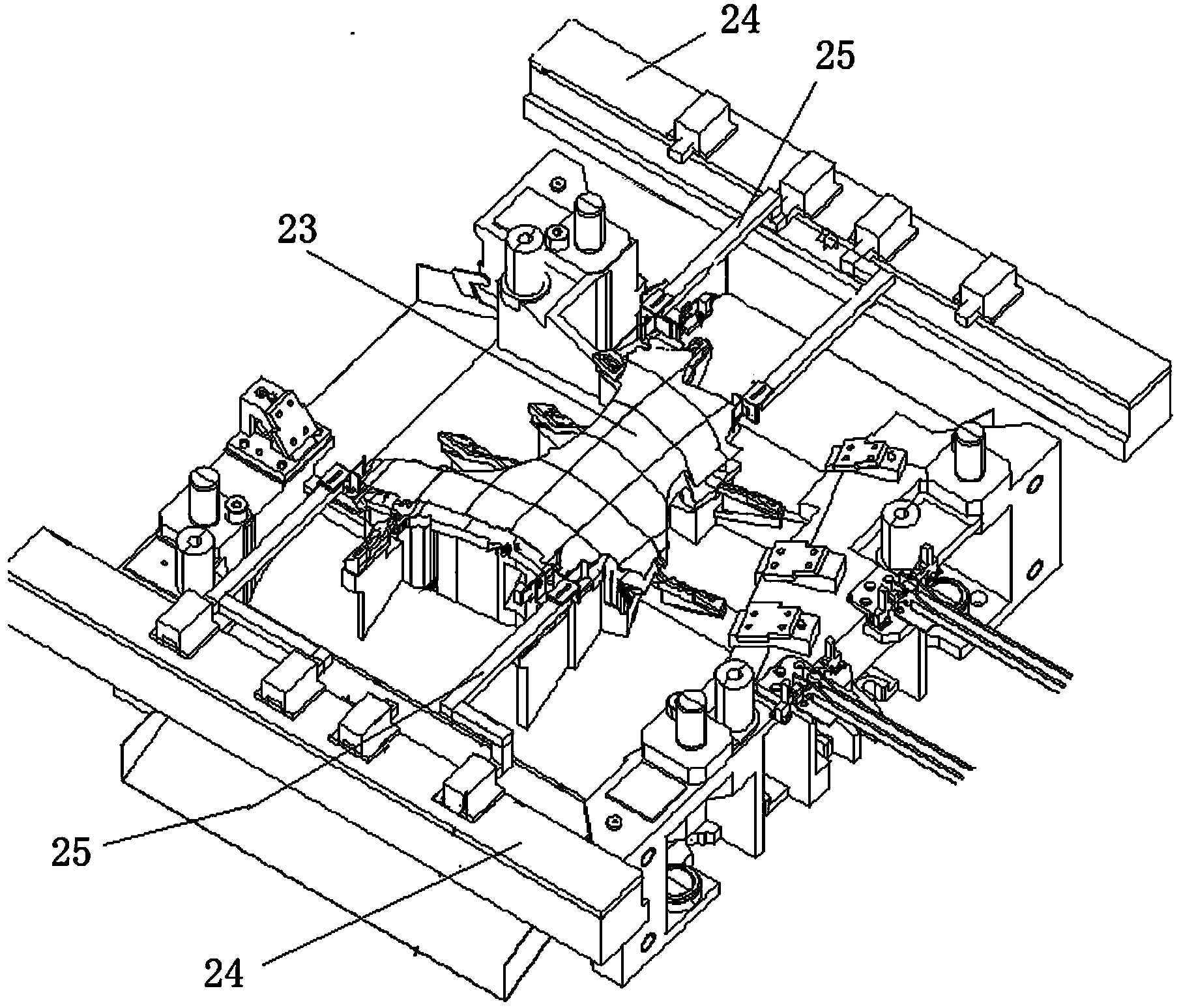

The invention belongs to the technical field of steel bar truss floor support plate production, and discloses a steel bar truss floor support plate production line which comprises a truss machine usedfor producing steel bar trusses, a plate pressing machine used for producing bottom plates, a truss positioning mechanism used for receiving and positioning the steel bar trusses, a truss carrying mechanism used for carrying the steel bar trusses positioned by the truss positioning mechanism to a welding mechanism a bottom plate conveying mechanism used for conveying the bottom plates to the welding mechanism, the welding mechanism used for welding the steel bar trusses and the bottom plates to form steel bar truss floor support plates, and a truss floor support plate carrying mechanism usedfor carrying and stacking the steel bar truss floor support plates. By means of the steel bar truss floor support plate production line, automatic production, carrying and stacking of the steel bar truss floor support plates can be achieved, manpower is reduced, labor intensity and potential safety hazards are reduced, and machining efficiency and the automation degree are improved.

Owner:TJK MACHINERY TIANJIN

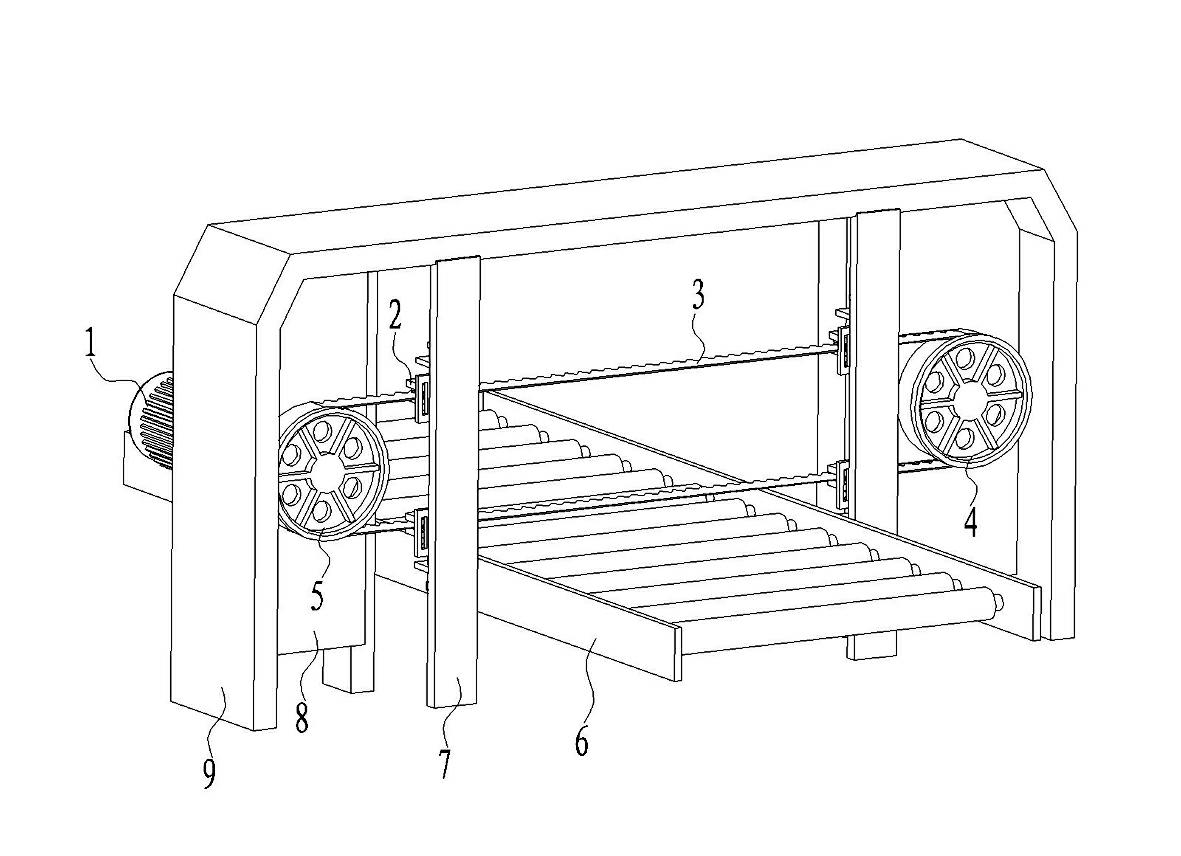

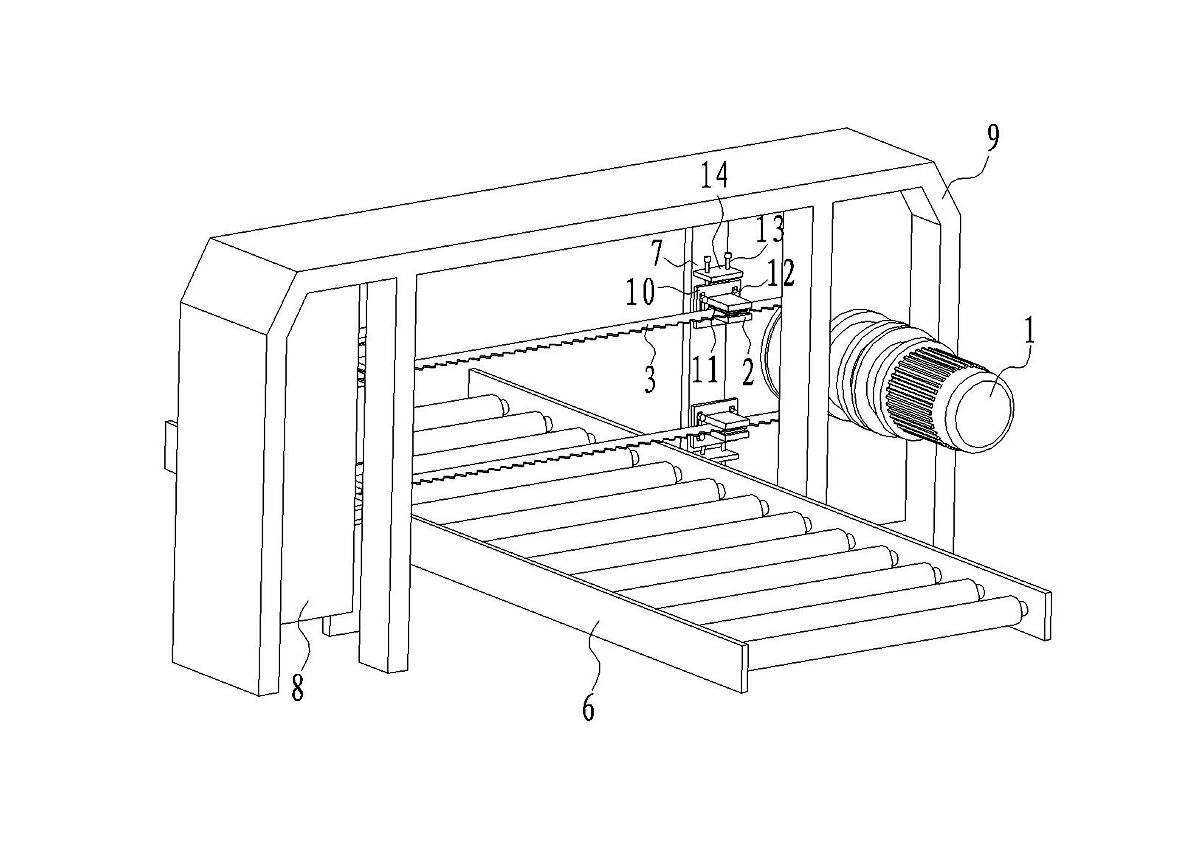

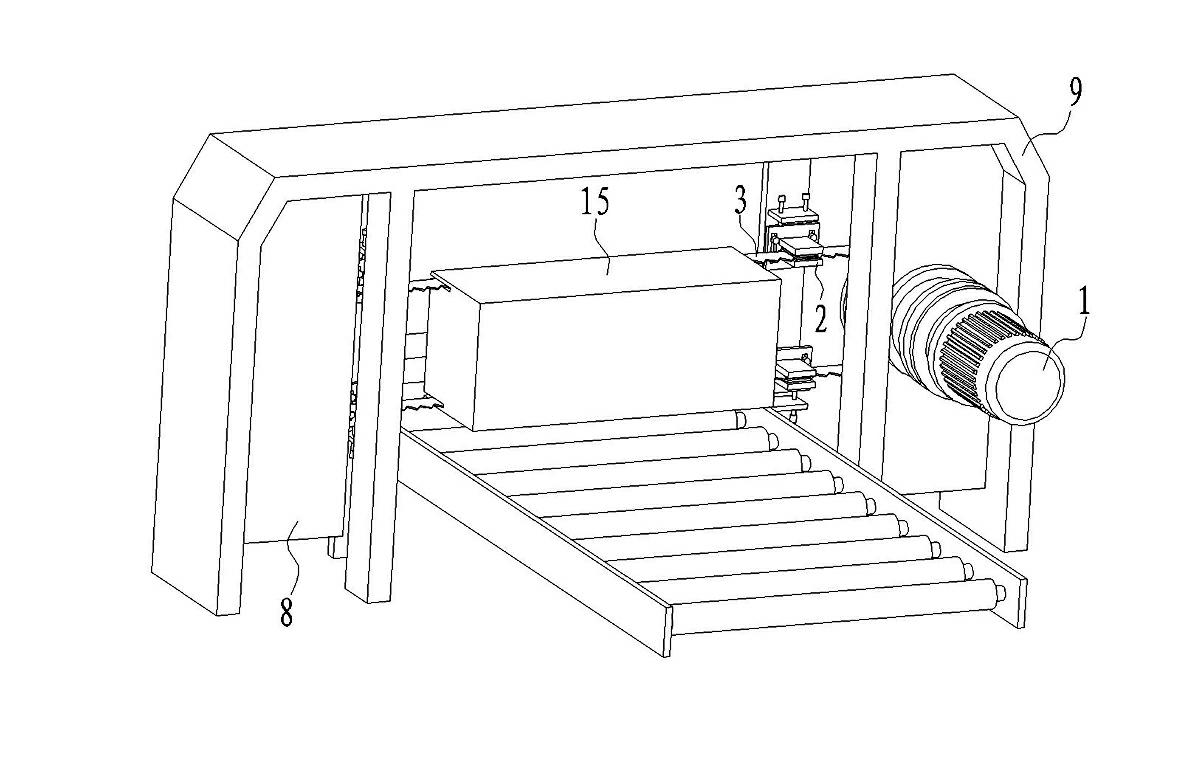

Insulation board horizontal cutting device

InactiveCN102431096ARealize automatic productionIncrease productivityStone-like material working toolsProduction lineEngineering

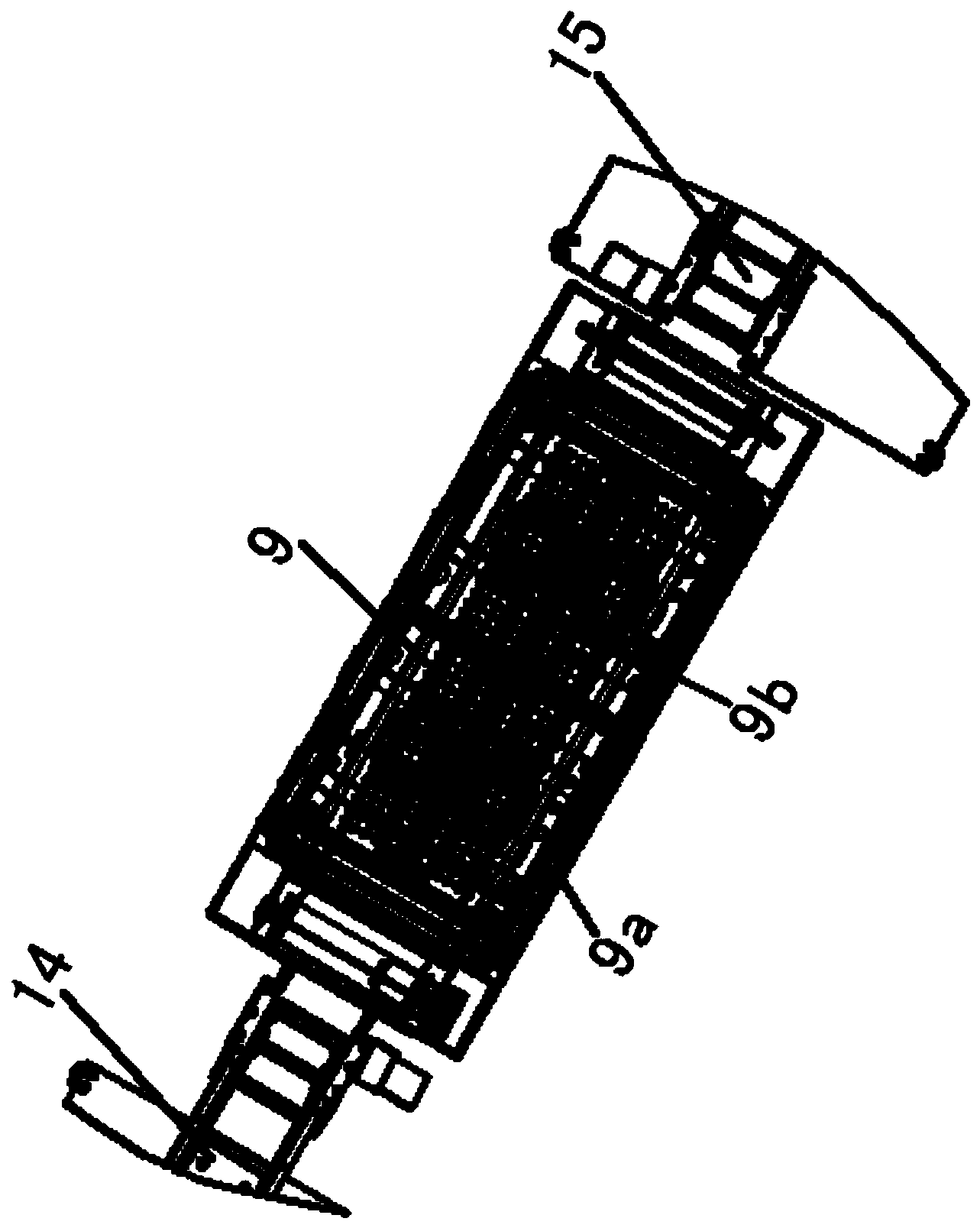

The invention relates to an insulation board horizontal cutting device comprising a horizontal conveyor device (6) for conveying the insulation board. It is characterized in that left and right sides of the horizontal conveyor device (6) are provided with a stand (9) on which a driving belt wheel (5) and a driven belt wheel (4) are provided which are connected by a flexible cutting tool. The stand (9) is further installed with a motor (1) connected with the driving belt wheel (5). The beneficial effect of the invention lies in that the device can horizontally cut upper and lower surfaces of the insulation board, does not need to turn the building block for cutting, improves the production efficiency, can realize automatic production of external wall insulation board and double-face cutting to form finished board.

Owner:JIANGSU HETIAN BUILDING ENERGY SAVING TECH DEV

Automatic smart watch production line

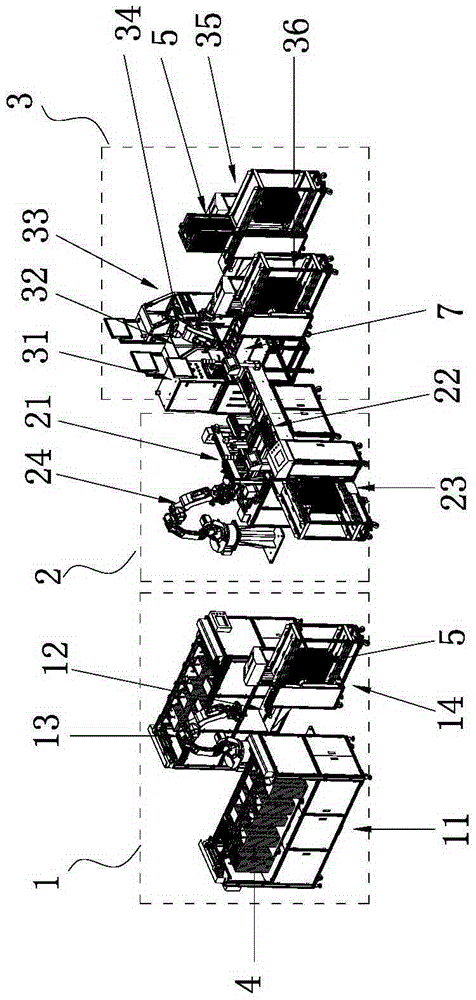

ActiveCN105382551ARealize automatic productionReduce manual operationsOther manufacturing equipments/toolsManipulatorManufacturing engineering

The invention provides an automatic smart watch production line. The automatic smart watch production line comprises an automatic part sorting area, an automatic assembly area and an automatic detection area; the automatic part sorting area comprises an automatic loading device, a receiving worktable, and a first manipulator moving back and forth between the automatic loading device and the receiving worktable; the automatic assembly area comprises an automatic assembling machine, and a roller conveyor; a second manipulator for transferring parts in a material disc into an assembly jig is arranged beside the automatic assembling machine; the automatic detection area comprises a finished product function detector and a third robot for grabbing and settling finished products for detection; a third material conveyor for discharging finished products passing detection is arranged beside the third robot. Sorting and conveying of parts and assembly and detection of products are carried out through the automatic part sorting area, the automatic assembly area and the automatic detection area, such that the production of smart watches is realized through completely mechanical operations and automatic production of smart watches is realized; further, the quality of products is good and stable and the production efficiency is high.

Owner:DONGGUAN TIANFU LIDE IND CO LTD

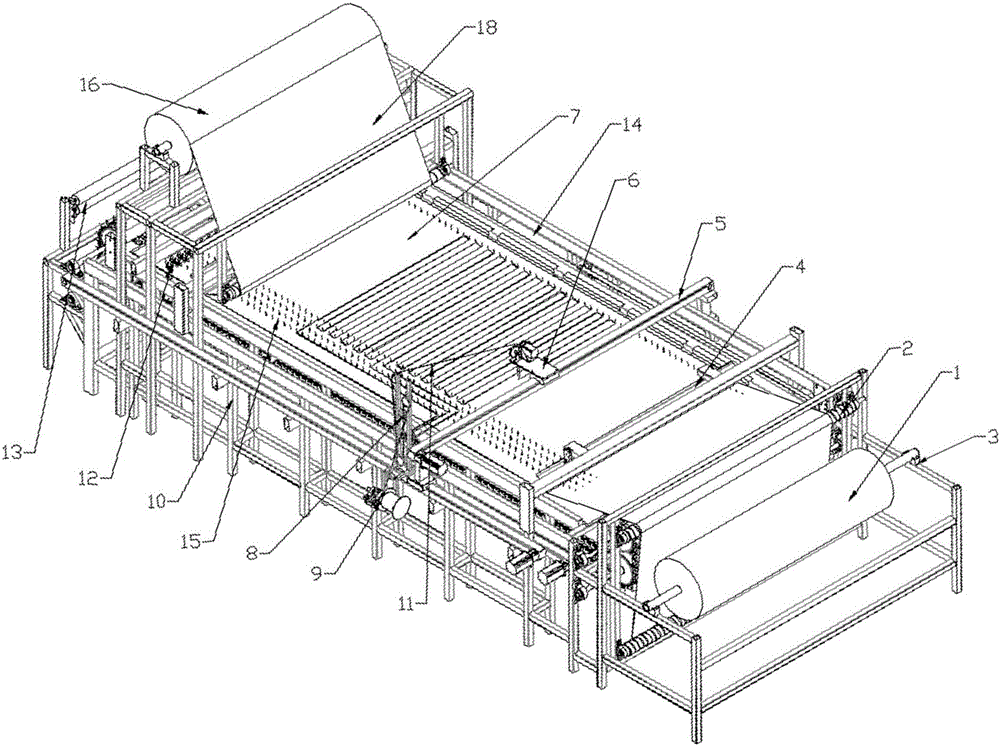

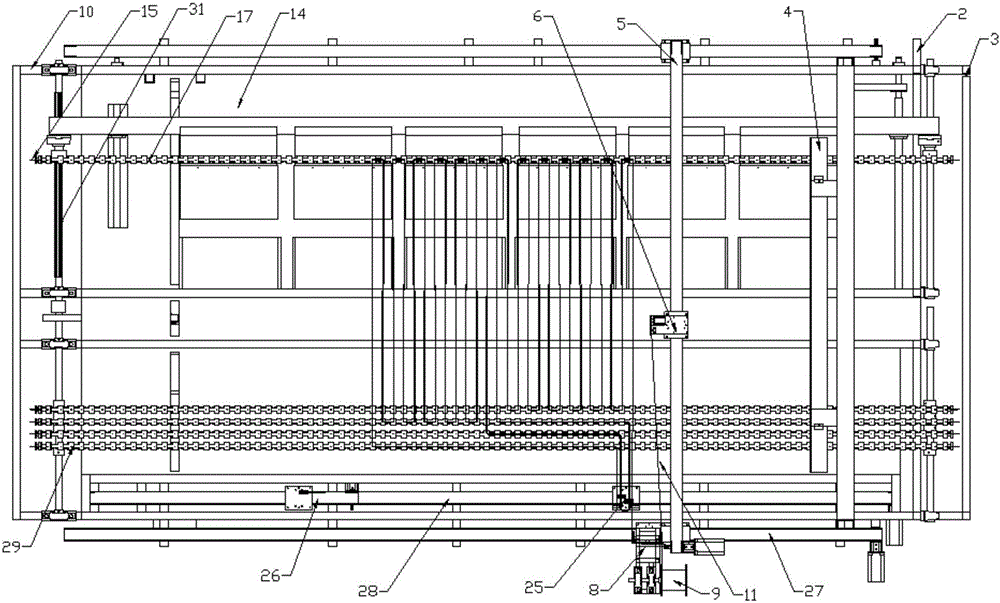

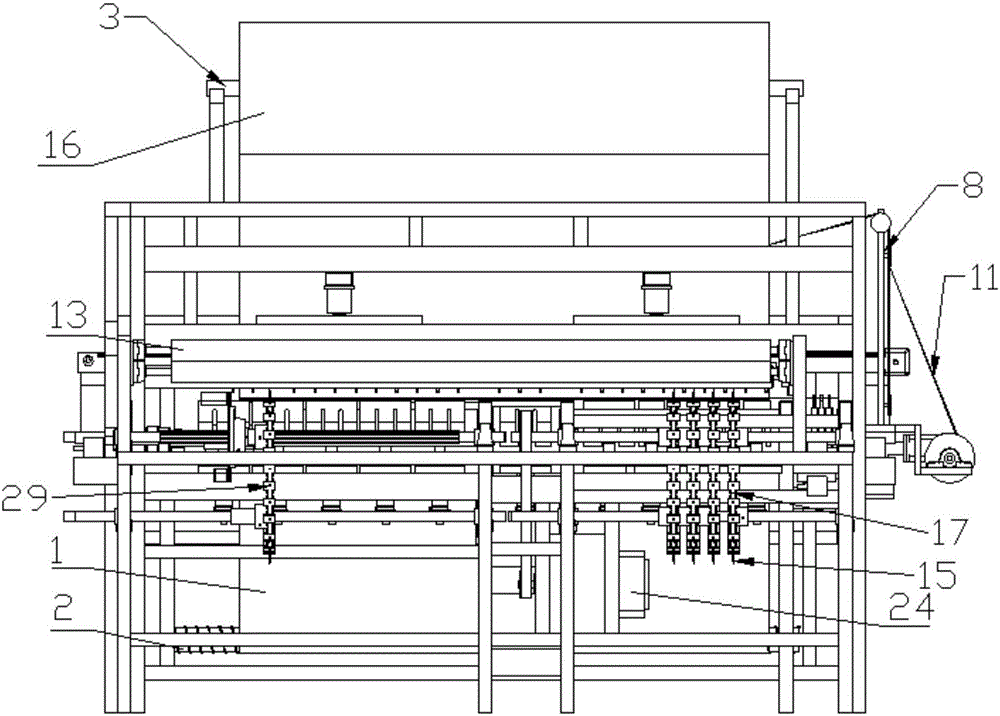

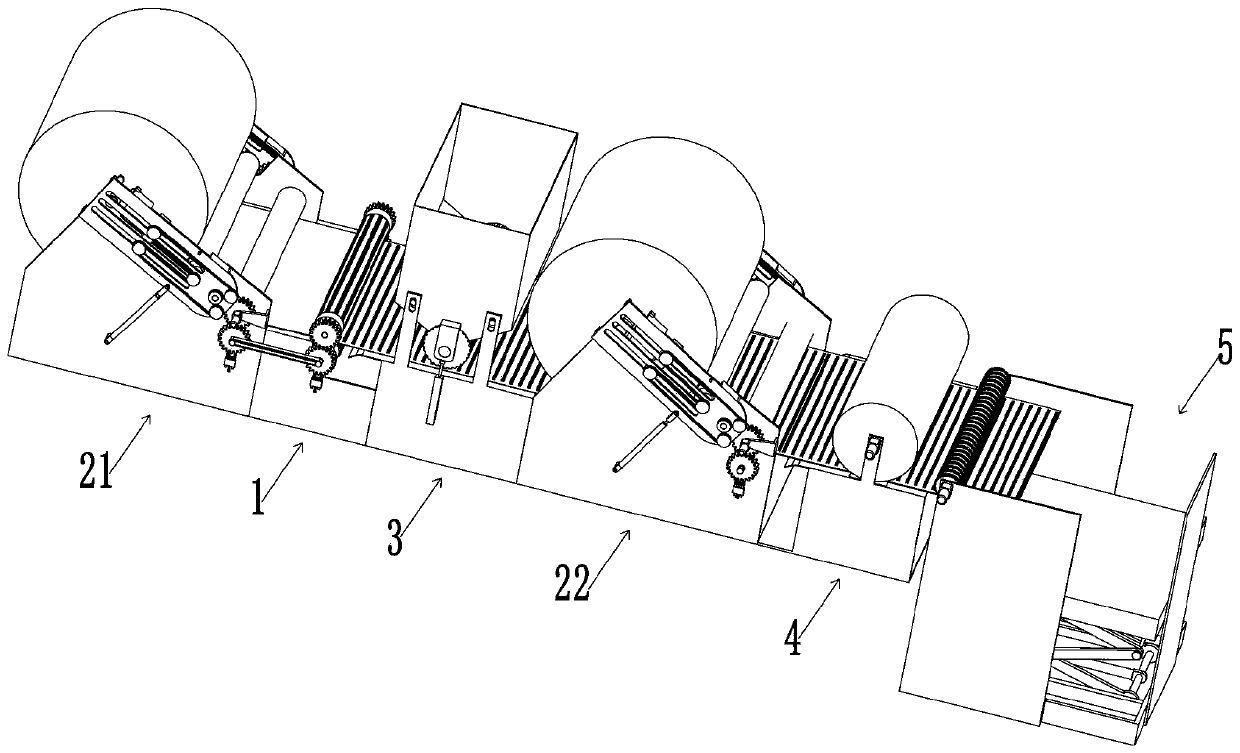

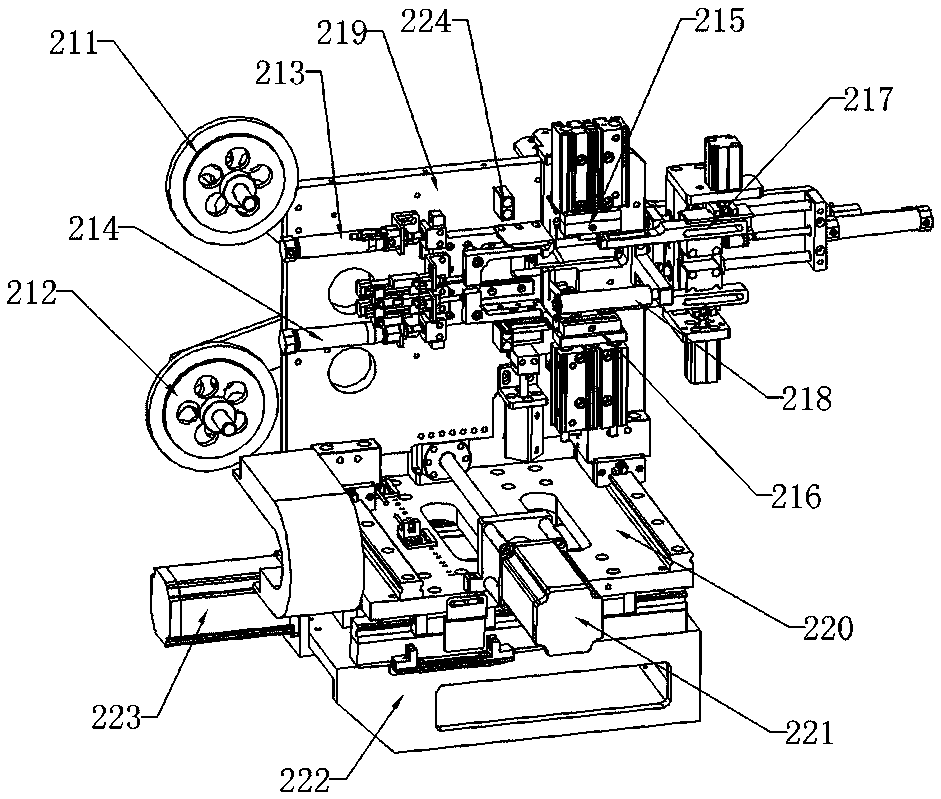

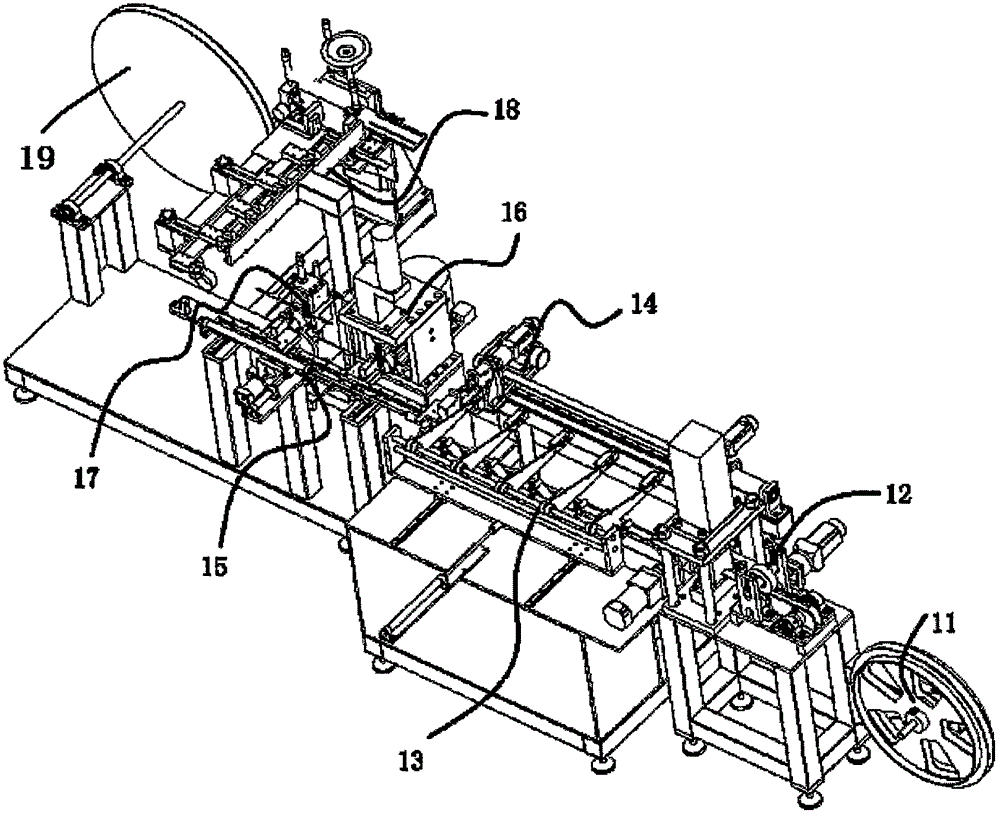

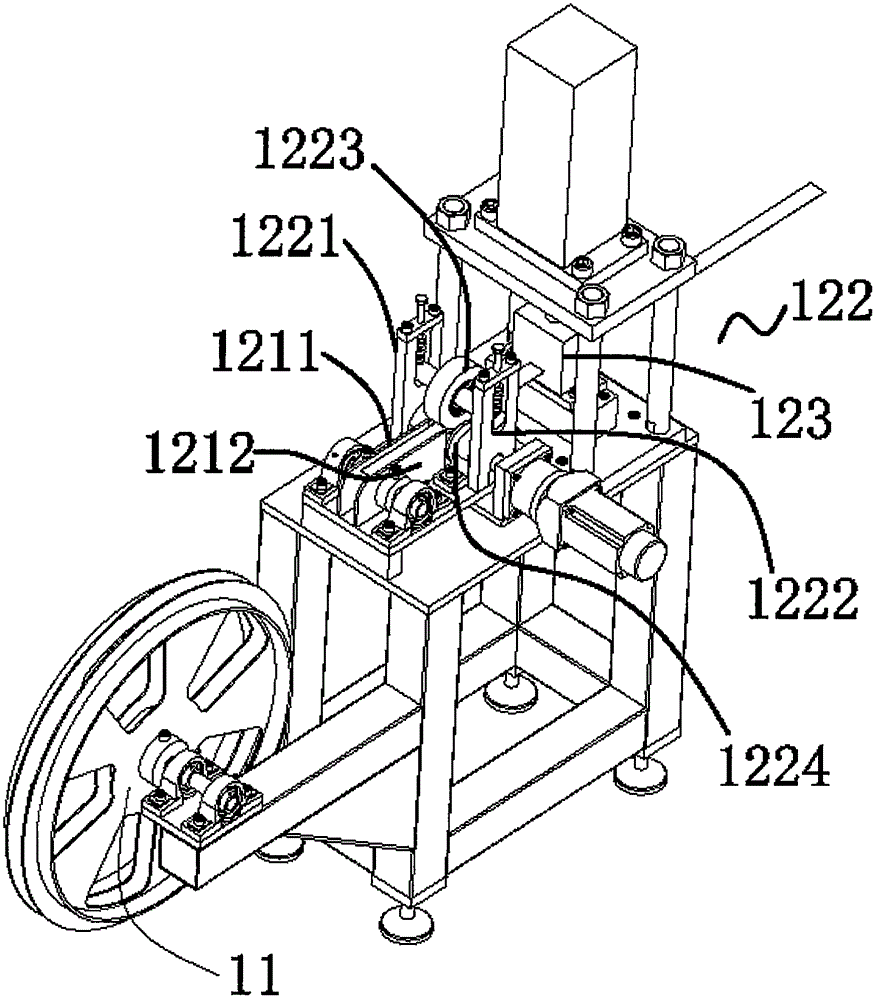

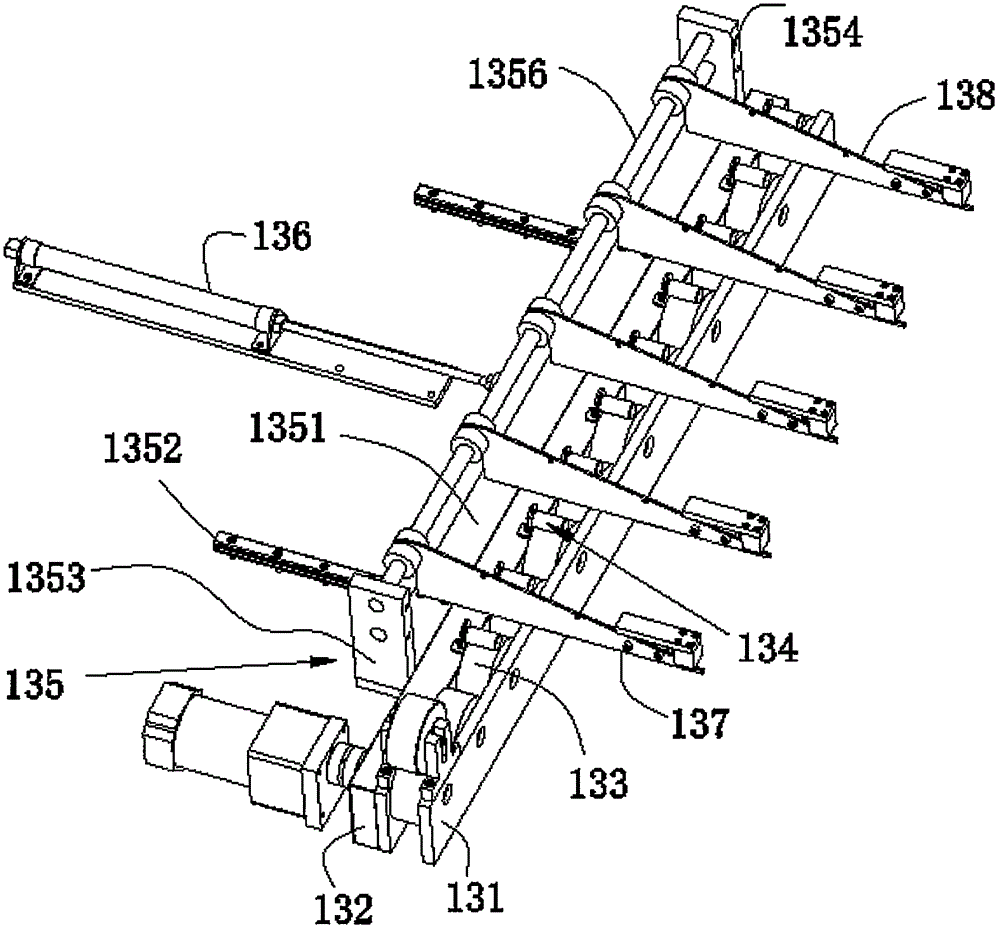

Automatic production device for electric blanket

The invention relates to an automatic production device for an electric blanket. The automatic production device comprises a frame, a cloth conveying unit, a paying-off and breaking unit, a wiring unit, a seaming unit and an electric blanket output unit. The paying-off and breaking unit cooperates with the wiring unit; the cloth conveying unit is installed at the front end of the frame; the paying-off and breaking unit is arranged on the frame horizontally; the wiring unit is arranged above the frame; the seaming unit is arranged at the rear end of the frame; and the electric blanket output unit is installed at the rear of the seaming unit. A device capable of driving a piece of cloth to move from the front end to the rear end of the frame is installed on the frame. While, automatic work of cloth feeding, paying off and breaking, wiring and cloth seaming can be carried out, the equipment structure is simplified, the equipment cost is lowered, and the device is also suitable for production of electric blankets with different specifications. And waiting time of all parts in equipment can be shortened to the greatest extent; and the production efficiency is improved substantially.

Owner:WUHAN TEXTILE UNIV

Automatic breaker production line and work method thereof

InactiveCN106252165ARealize automatic productionRealize resource coordinationEmergency protective device manufactureCombined testAgricultural engineering

The invention discloses an automatic breaker production line and a work method thereof. According to the method, an operation mechanism, a terminal box assembling mechanism, a BCB stock mechanism, an energy storage spring assembling mechanism, a BCB burdening mechanism, an accessory burdening mechanism, an accessory assembling mechanism, a BCB assembling mechanism, a running-in mechanism, an arc extinguishing cover mounting mechanism, a full-detection mechanism, a visual detection mechanism, a panel assembling mechanism, a laser marking machine, a package line, a visual inspection station mechanism and an integrated test stand are integrated and are controlled in a same mode, and automatic production of breakers can be realized. The automatic breaker production line comprises the operation mechanism, the terminal box assembling mechanism, the BCB stock mechanism, the energy storage spring assembling mechanism, the BCB burdening mechanism, the accessory burdening mechanism, the accessory assembling mechanism, the BCB assembling mechanism, the running-in mechanism, the arc extinguishing cover mounting mechanism, the full-detection mechanism, the visual detection mechanism, the panel assembling mechanism, the laser marking machine, the package line, the visual inspection station mechanism and the integrated test stand.

Owner:江门市博道工业自动化设备有限公司 +1

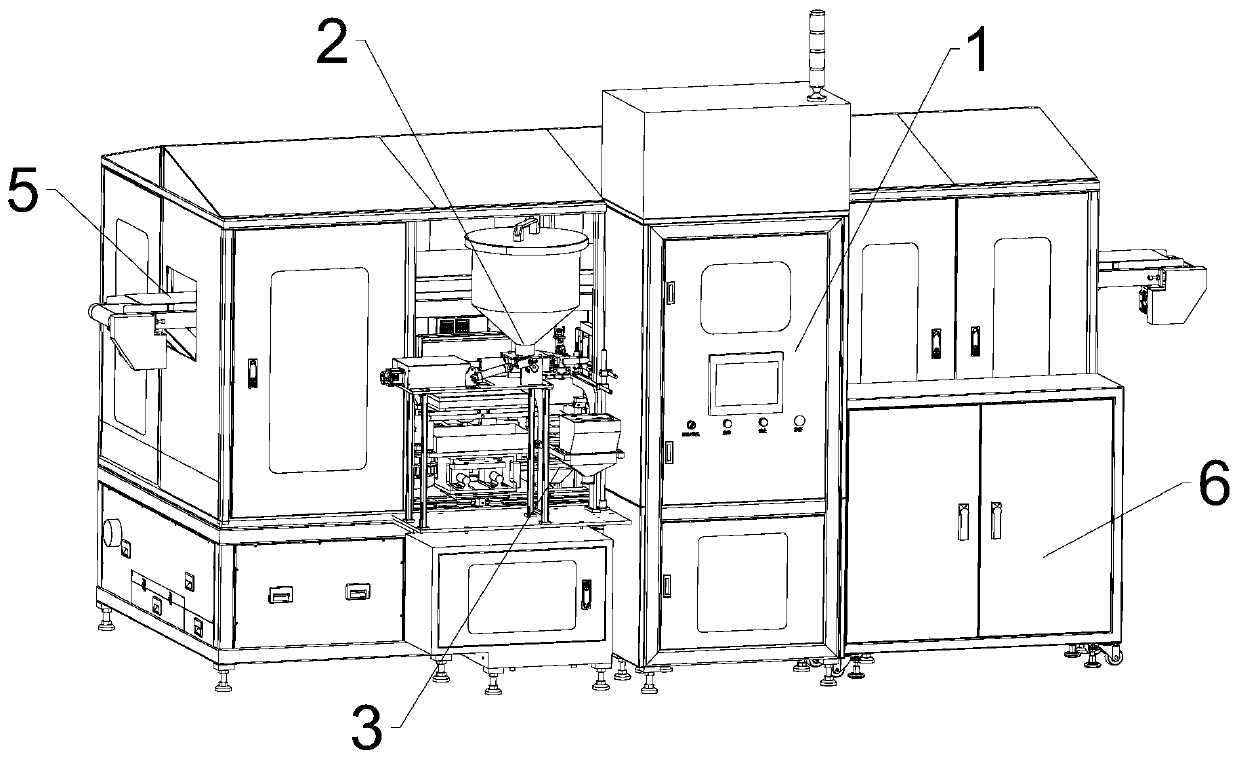

Novel corrugated paper processing device and process

InactiveCN111546704AUniform qualityRealize automatic productionMechanical working/deformationMetal working apparatusPaperboardAdhesive glue

The invention discloses a novel corrugated paper processing device and process. The novel corrugated paper processing device comprises a belling mechanism, and a first raw paper conveying mechanism isarranged at the input end of the belling mechanism. A gluing mechanism is arranged at output end of the belling mechanism, and a second raw paper conveying mechanism is arranged at the output end ofthe gluing mechanism. A slitting mechanism is arranged at the output end of the second raw paper conveying mechanism, and a stacking mechanism is arranged at the output end of the slitting mechanism.The first raw paper conveying mechanism is used for conveying a first paper board to the belling mechanism, and the gluing mechanism is used for smearing pressed protrusions on the first paper board with glue. The second raw paper conveying mechanism is used for conveying a second paper board to the position above the protrusions of the first paper board and compressing the second paper board to form corrugated paper, the slitting mechanism is used for cutting the corrugated paper, and the stacking mechanism is used for stacking the cut corrugated paper. The novel corrugated paper processing device is high in production efficiency, and the quality of the produced novel corrugated paper is uniform.

Owner:商兆惠

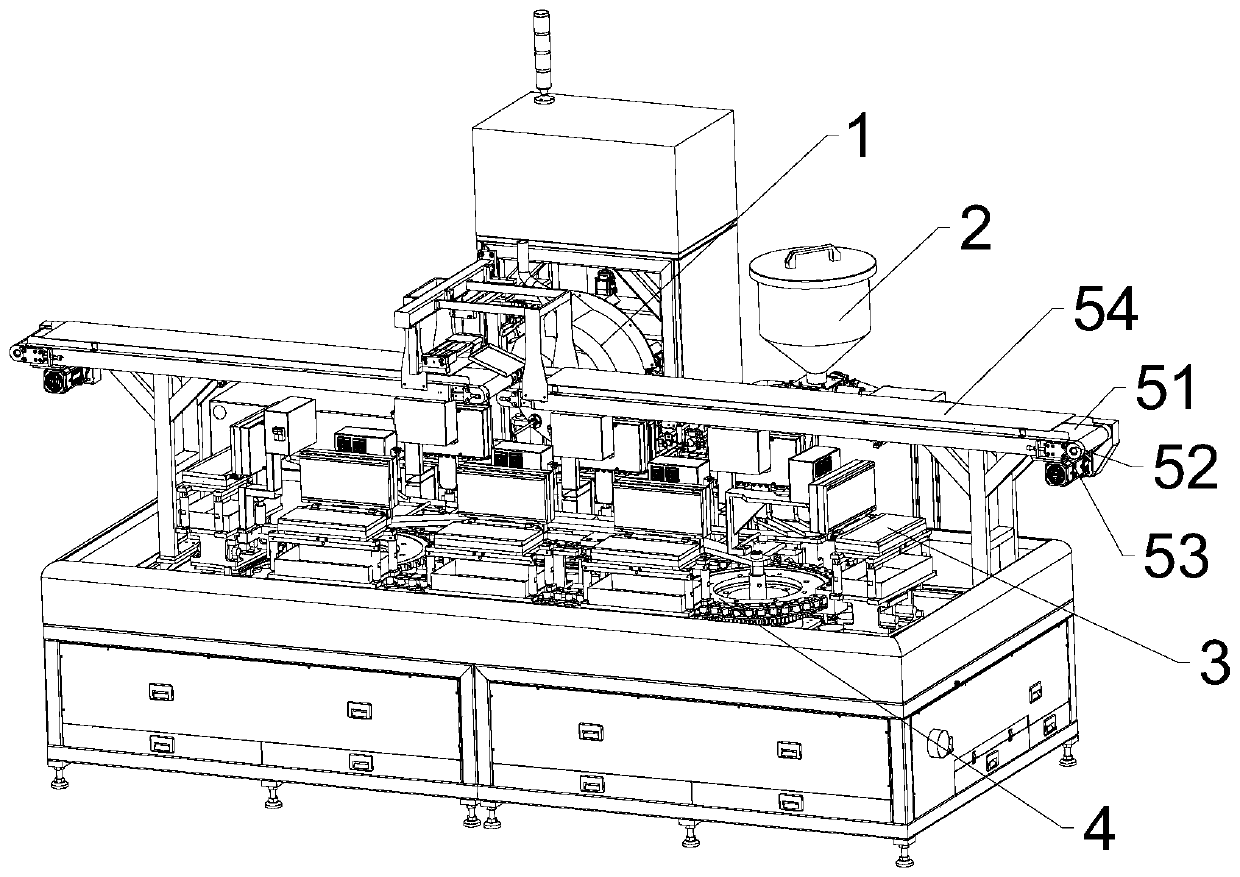

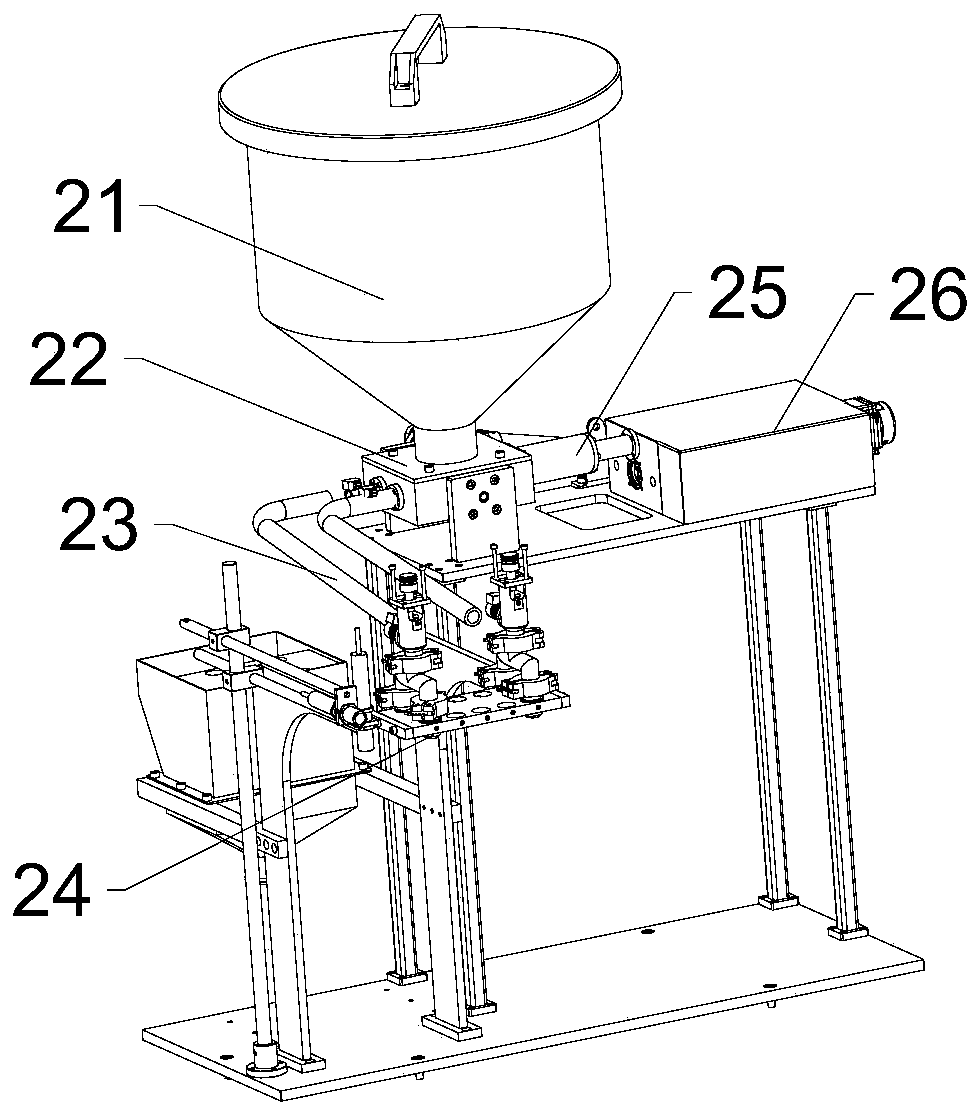

Egg roll processing equipment

PendingCN111150008ARealize automatic productionIncrease productivityOil/fat bakingPancakes bakingBiotechnologyMechanical engineering

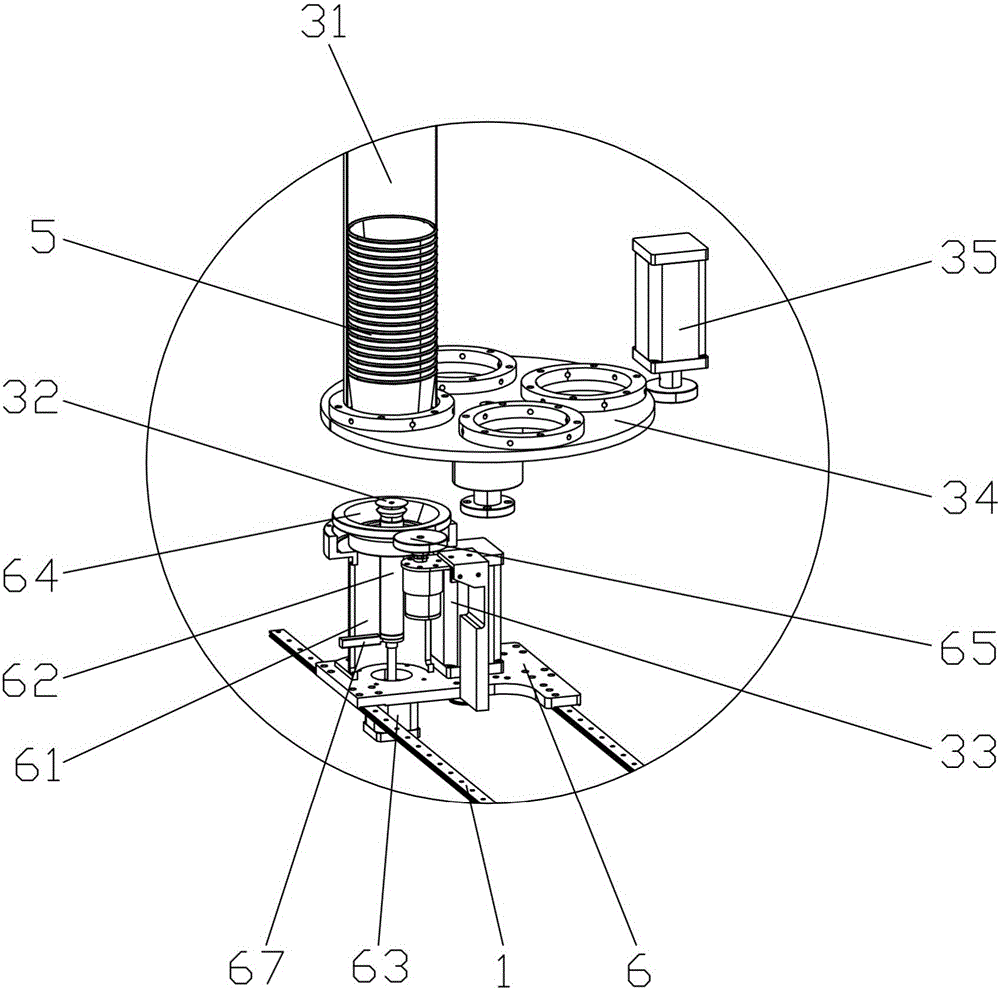

The invention discloses egg roll processing equipment. The egg roll processing equipment comprises a baking plate mechanism, a baking plate circulating mechanism and an egg roll forming mechanism, wherein the baking plate mechanism comprises a plurality of baking plates which are provided with grouting positions and rolling positions and used for making egg roll wrappers from a slurry dripping onto the baking plates by a grouting mechanism; the plurality of the baking plates are fixedly arranged on the baking plate circulating mechanism; the baking plate circulating mechanism drives the bakingplates to circularly rotate and controls the baking plates to be opened and closed; and the egg roll forming mechanism is arranged at the rolling positions and used for rolling egg roll wrapper on the baking plates to form egg rolls. The egg roll processing equipment provided by the invention comprises the grouting mechanism, the baking plate mechanism, the baking plate circulating mechanism, theegg roll forming mechanism and a discharging mechanism; automatic production of egg rolls is achieved; and the production efficiency is greatly improved. The baking plate mechanism is fixedly arranged on the baking plate circulating mechanism; opening and closing of the baking plates are achieved under driving of the baking plate circulating mechanism; the baking plate mechanism is matched with the grouting mechanism to make the egg roll wrappers; and the consistency of the egg roll wrappers is effectively improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

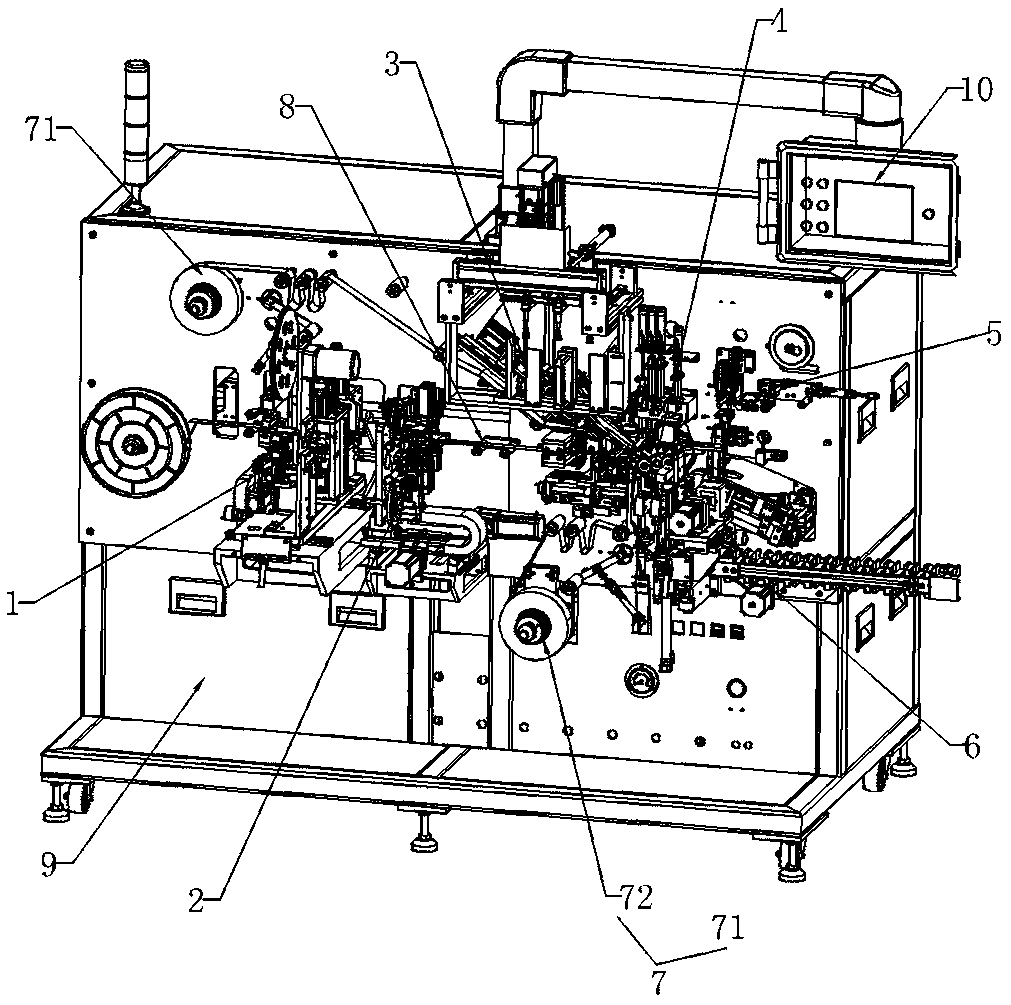

Fully automatic winding machine for lithium manganese cylindrical battery

ActiveCN107845819ARealize automatic productionPromote ProducerOrganic electrolyte cellsWinding machineLithium

The invention discloses a fully automatic winding machine for a lithium manganese cylindrical battery; the fully automatic winding machine includes a negative electrode riveting pole ear mechanism, anegative electrode gluing mechanism, a negative electrode supply mechanism, a positive electrode supply mechanism, a diaphragm supply mechanism, an electric core winding mechanism, a termination adhesive supply mechanism, and a product discharge mechanism; a feeding end of the negative electrode gluing mechanism is connected with the negative electrode riveting pole ear mechanism, and a discharging end of the negative electrode gluing mechanism is connected with the negative electrode supply mechanism; a discharging end of the negative electrode supply mechanism, a discharging end of the positive electrode supply mechanism and a discharging end of the diaphragm supply mechanism are all connected to a feeding end of the electric core winding mechanism; a feeding end of the termination adhesive supply mechanism is connected with a discharging end of the electric core winding mechanism, and a discharging end of the termination adhesive supply mechanism is connected with a feeding end of the product discharge mechanism. Metal lithium sheets are automatically prepared, pole sheet diaphragms are fully automatically wound, the efficiency of sheet preparation and winding is greatly improved, and a complete set of a fully automatic winding machine series for the fully automatic lithium manganese cylindrical battery is formed.

Owner:深圳市鸿德机电科技有限公司

Automatic welding machine

ActiveCN103464655AIncrease productivityRealize automatic productionWire networkAutomatic controlEngineering

The invention provides an automatic welding machine, comprising a straightening mechanism, a welding mechanism, a feeding mechanism, a traction mechanism, a shearing mechanism and an automatic control system; the strengthening mechanism is used for strengthening a to-be-welded metal line in the first direction; the traction mechanism is used for the traction of the metal line in the strengthening mechanism; the feeding mechanism is used for providing the metal line in the second direction for the welding mechanism to enable the metal line in the second direction to be crossed with the metal line in the first direction on the welding mechanism; the welding mechanism is used for forming the crossed metal lines into a metal net; the shearing mechanism is used for shearing the metal net; the automatic control system is used for performing automatic control on action of each mechanism. According to the automatic welding machine, the strengthening mechanism, the welding mechanism, the feeding mechanism, the traction mechanism and the shearing mechanism are continuously controlled by the automatic control system, automatic production of a welding metal net assembly line can be realized, continuous welding can be realized, most part of labor can be replaced, and the production efficiency can be greatly improved.

Owner:广东达洋宠物用品实业有限公司

Method for preparing nanometer high-strength copper flat wire through pulling-up, continuous ECAP, and drawing processes

InactiveCN106098246AReduce energy wasteImprove business efficiencyCable/conductor manufactureCrystalliteSmelting process

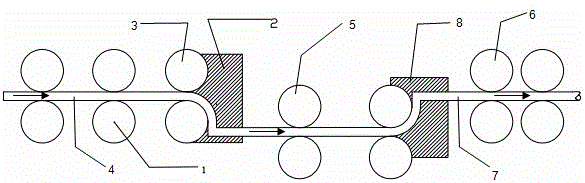

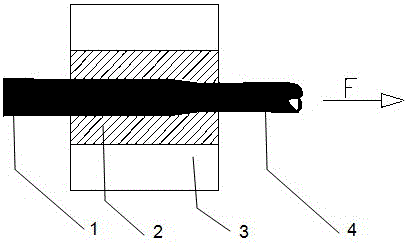

The invention relates to a method for preparing high-strength copper flat wire, which combines smelting with efficient up-drawing continuous casting technology, through a composite process flow of continuous equal-channel angle extrusion technology, and finally obtains high-strength nano-copper through a drawing process flat line. Coarse-grained copper rod blanks prepared by smelting-uplinking are driven by rollers to push the copper rod blanks into the continuous ECAP mold, and the copper rod blanks pass through the cavity of the continuous equal-channel mold driven by the continuous ECAP driving rollers , when the blank passes through the mold cavity, the material undergoes pure shear deformation, without changing the cross-sectional area of the material, the high strengthening and nanonization of the severe plastic deformation of the material are achieved, and it can be achieved by increasing the continuous ECAP cavity The number realizes the accumulation of equivalent strain, and can produce high-strength nano-copper flat wires with nano-equiaxed structures with different degrees of grain refinement.

Owner:SHANDONG JIANZHU UNIV

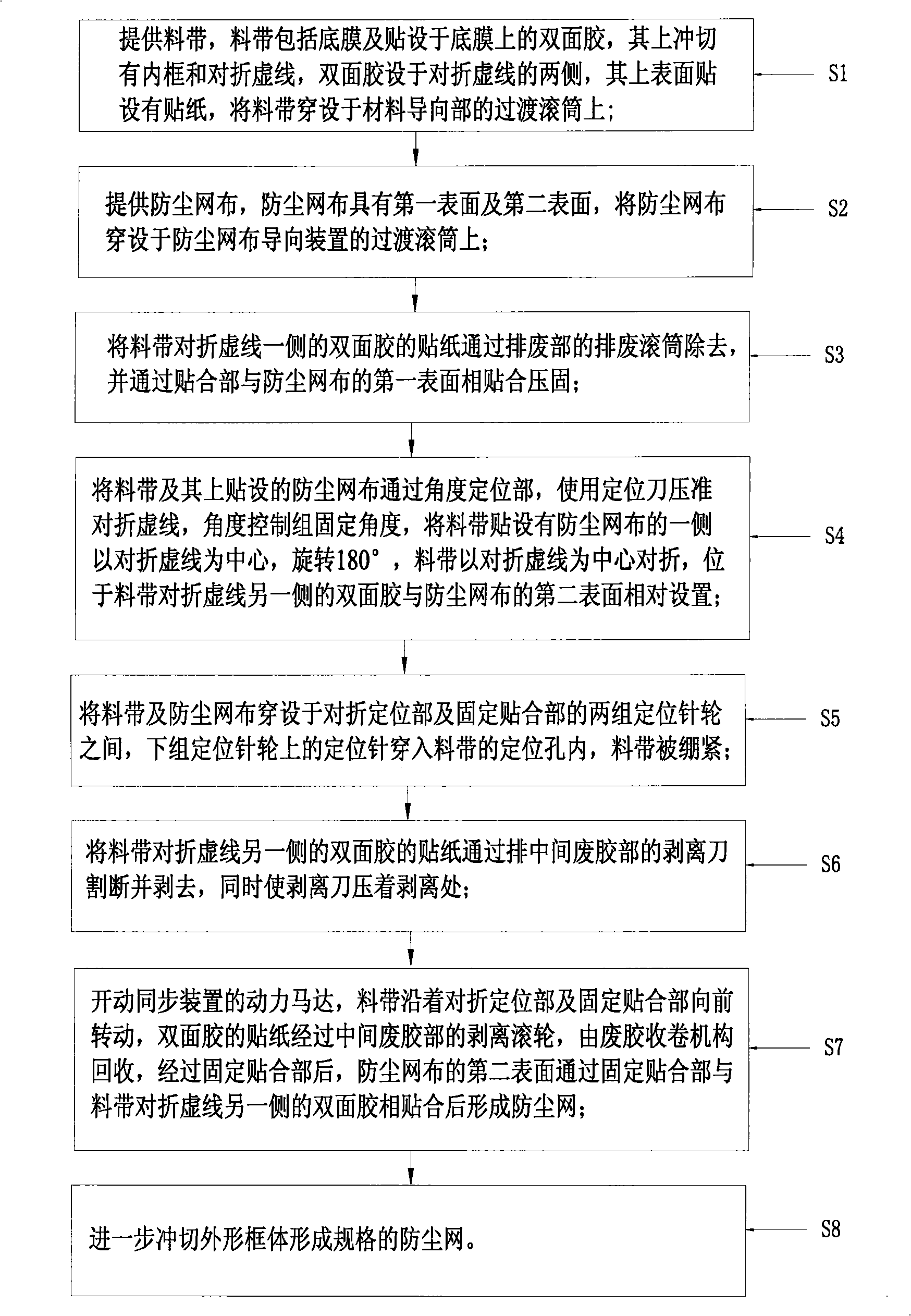

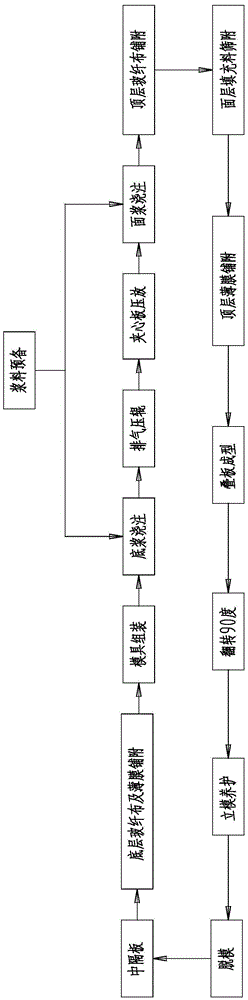

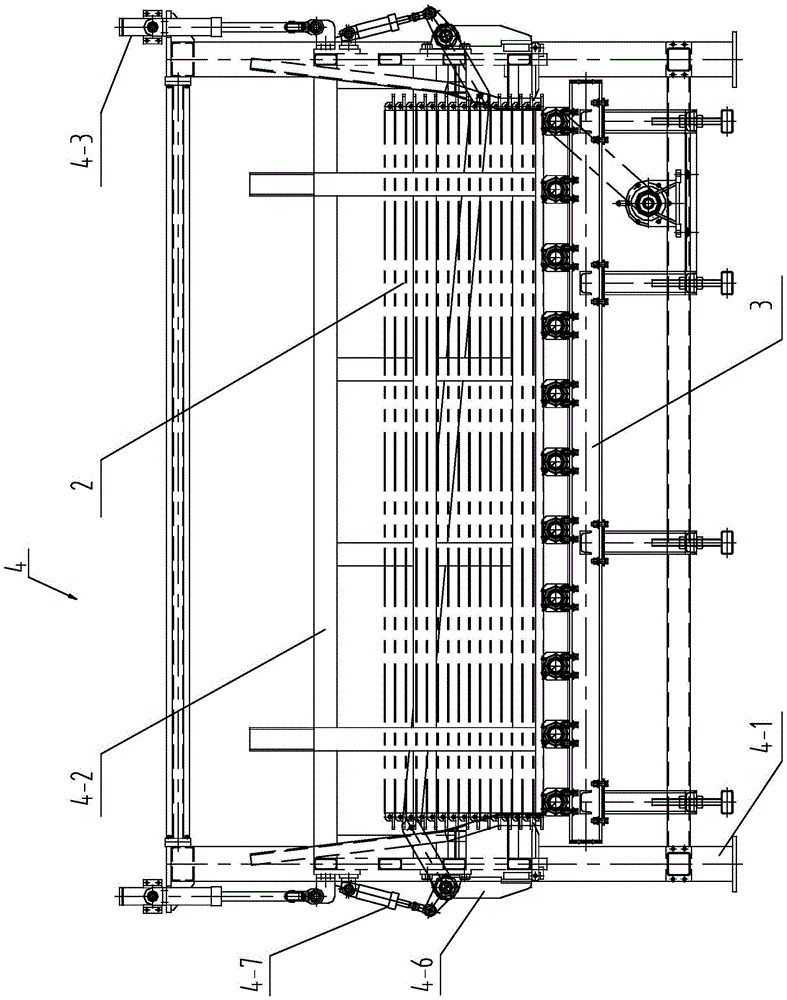

Production equipment and technique for dustproof mesh

InactiveCN101342808ARealize automatic productionIncrease productivityLamination ancillary operationsLaminationElectrical controlWaste management

The invention relates to manufacturing equipment for producing a dust-proof net and a production technology thereof. The manufacturing equipment comprises: a stander, and a material guide part, a waste discharge laminating part, an angle stereotyped part, a doubling and locating part, a middle waste glue discharge part and a fixed laminating part which are sequentially arranged on the stander; wherein, the waste discharge laminating part comprises a waste discharge part and a laminating part; one side of the waste discharge part is provided with a dust-proof net guide device which is arranged corresponding to the material guide part; one side of the angle stereotyped part is provided with an electrical control gear; the doubling and locating part is connected with the fixed laminating part through a synchronization unit which is arranged at one side of the fixed laminating part; the manufacturing equipment is also used for automatically producing dust-proof nets, thus increasing production efficiency of the dust-proof net, saving labor and improving the quality of products; in addition, the manufacturing equipment is simple in structure, convenient for operation, simple in technique, and high in automatization. Therefore, the manufacturing equipment of the invention can be used for producing wide variety of dust-proof nets and can effectively save production cost.

Owner:广东坤轮电子医疗器械科技有限公司

Production technique for composite light heat-insulation wallboards

ActiveCN105538495AEasy to produceShorten molding timeDischarging arrangementCeramic shaping plantsSlurryEngineering

Owner:QUANZHOU S L MACHINERY MFG

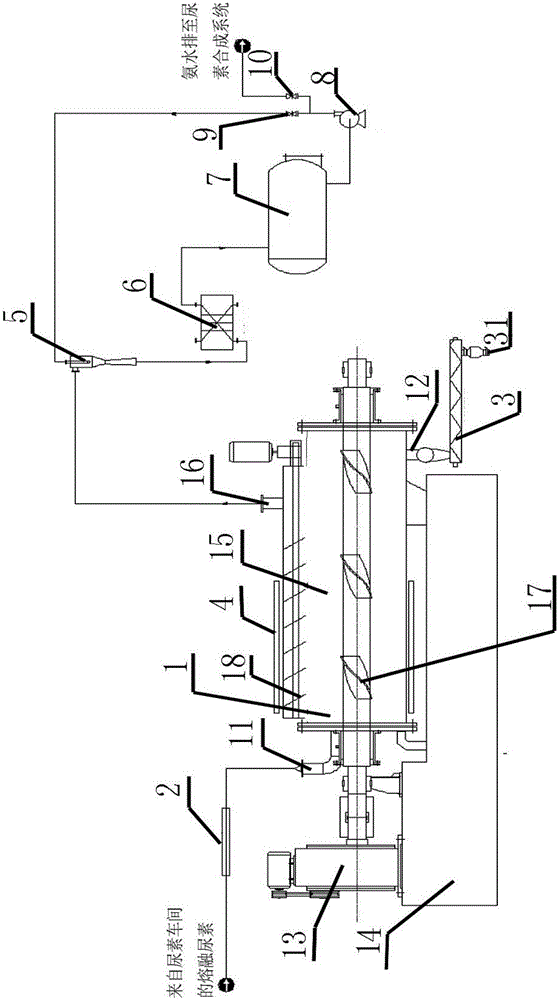

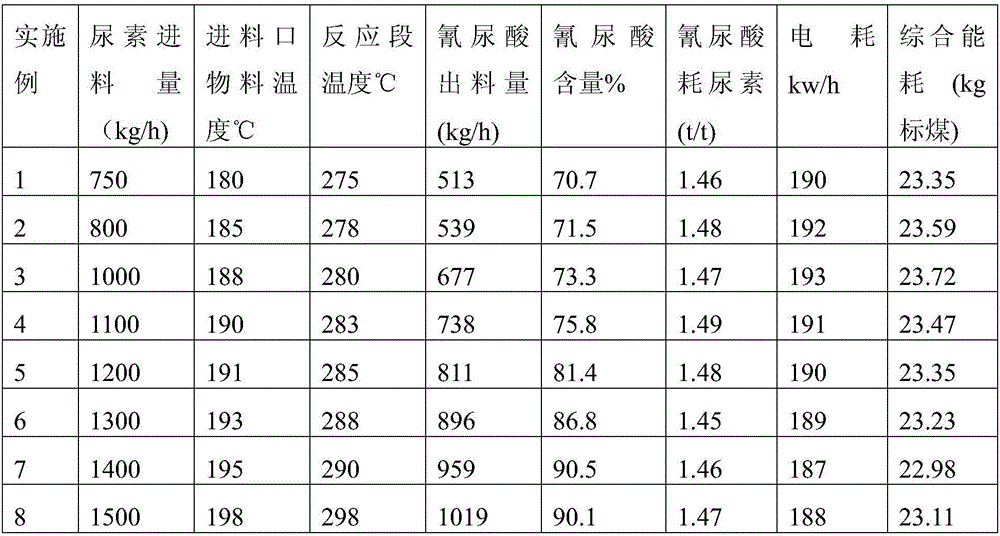

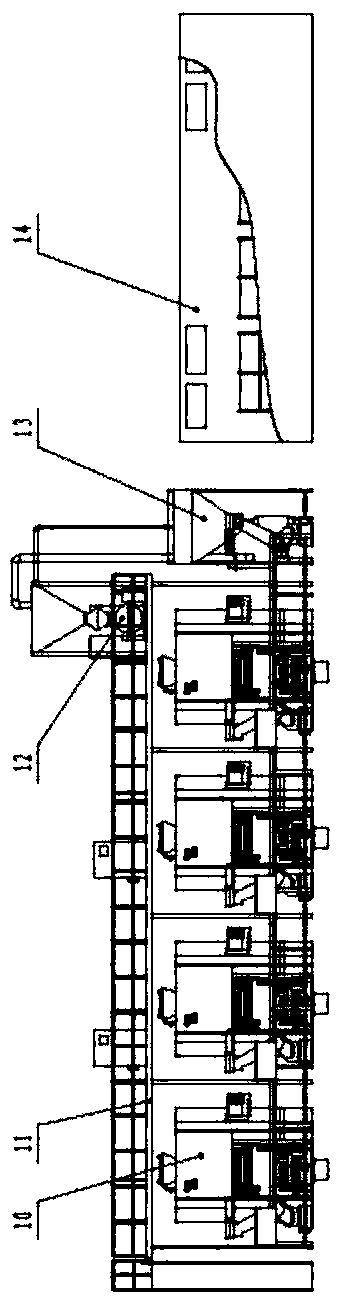

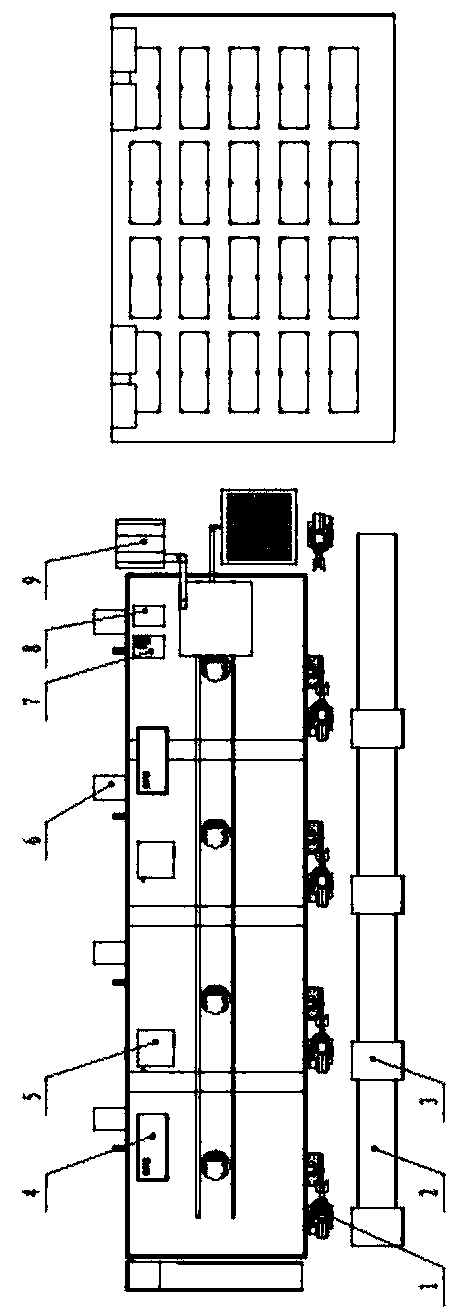

System and method for preparing crude cyanuric acid continuously by using urea

ActiveCN106008383AReduced granulation processReduce the heating and melting process of urea particlesOrganic chemistryTemperature controlWorking environment

The invention discloses a system and method for preparing crude cyanuric acid continuously by using urea. The system comprises: a differential stirring reactor for receiving urea melt and for deaminating it to produce crude cyanuric acid; a heating device disposed outside a reaction barrel of the differential stirring reactor and used for heating the reaction barrel; an ammonia recycling device connected with a gas outlet of the differential stirring reactor and used for recycling ammonia as a material for urea synthesis. The system and method enable continuous feeding, automated temperature control and automated discharging, rarely cause equipment blockage and blocking, reduce operation intensity of workers and improve work environment, optimize an operation process, and provide an organic integrity of human, machinery, material, process and environment.

Owner:河北冀衡集团有限公司

Full-automatic series core-making center of inorganic precoated sand

InactiveCN104325094ARealize automatic productionRealize the intelligent production of core shootingFoundry mouldsMoulding machine componentsHardnessEngineering

The invention discloses a full-automatic series core-making center of inorganic precoated sand, which is suitable for the condition of making a core by using inorganic sand. The full-automatic series core-making center comprises an independent core shooting machine and is characterized in that cooling devices are arranged on a sand storing hopper, a sand shooting cylinder, a sand shooting hopper and a sand shooting plate of the core shooting machine, each cooling device comprises insulating interlayers arranged on the outer walls of the sand storing hopper, the sand shooting cylinder, the sand shooting hopper and the sand shooting plate, a hot gas blowing device used for sending hot air into a mould is arranged on the core shooting machine, and positioned above the mould. The inorganic sand is rapidly hardened under a high-temperature environment, thus the hardness required by a process is rapidly realized, and the efficiency of the whole process is improved.

Owner:CHONGQING HONGQI CYLINDER HEAD MFG

Intelligent coffee machine control system and control method based on user identification

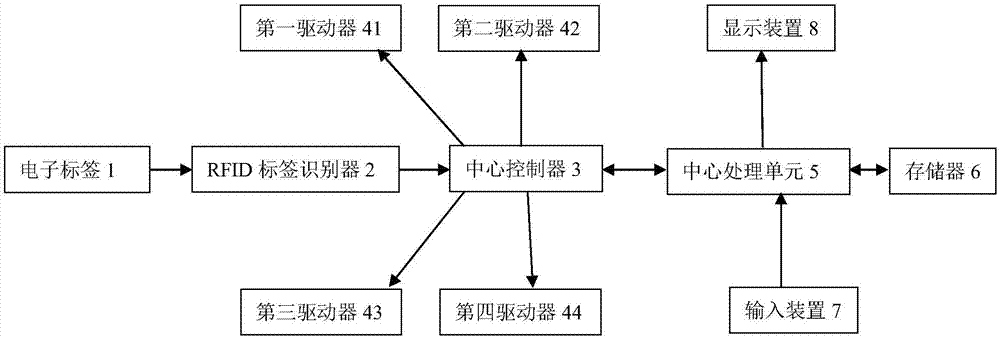

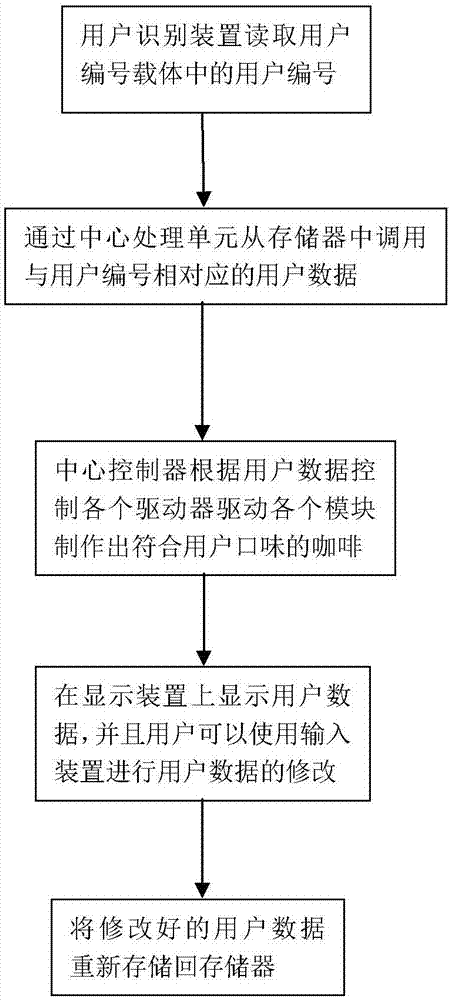

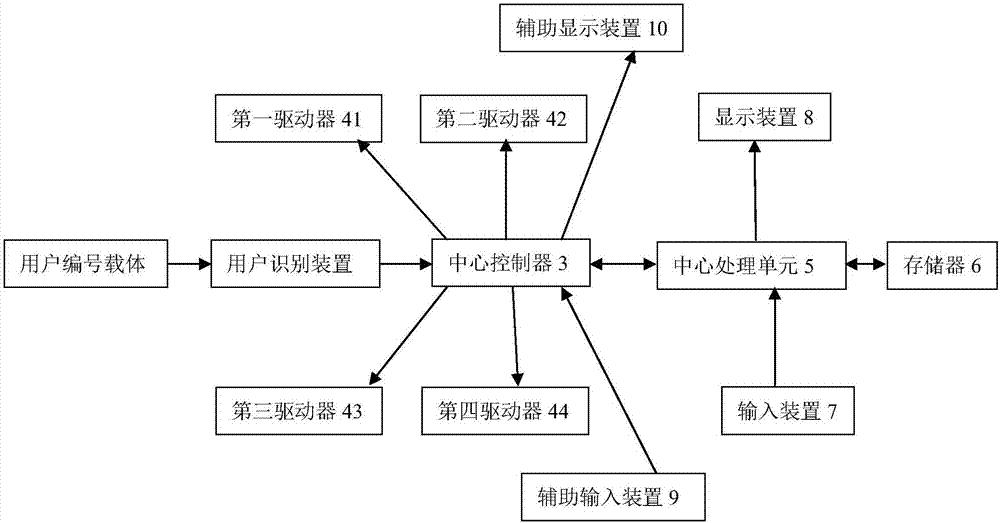

InactiveCN107977235ARealize personalized customizationRealize automatic productionCo-operative working arrangementsBeverage vesselsPersonalizationMachine control

An intelligent coffee machine control system based on user identification is provided. The system comprises a plurality of drivers for controlling coffee tastes, a central controller, a user number carrier, a user identification device, and a central processing unit. The central processing unit is connected with a memory; the central processing unit can store the user data corresponding to the user number in the memory; and the central processing unit can retrieve the user data corresponding to the user number from the memory and transmit the data to the central controller. According to the intelligent coffee machine control system and control method provided by the present invention, cups of users can be automatically identified and corresponding user data can be automatically retrieved,and personalized customization and automatic production of the coffee tastes can be implemented; the data can be adjusted by the users according to the tastes, and convenient experience can be realized; and integration of common social tools, smart wearable devices, Internet of Things devices, and mobile payment functions is realized, and the technical scheme is a breakthrough and innovation in the coffee machine application.

Owner:范天予

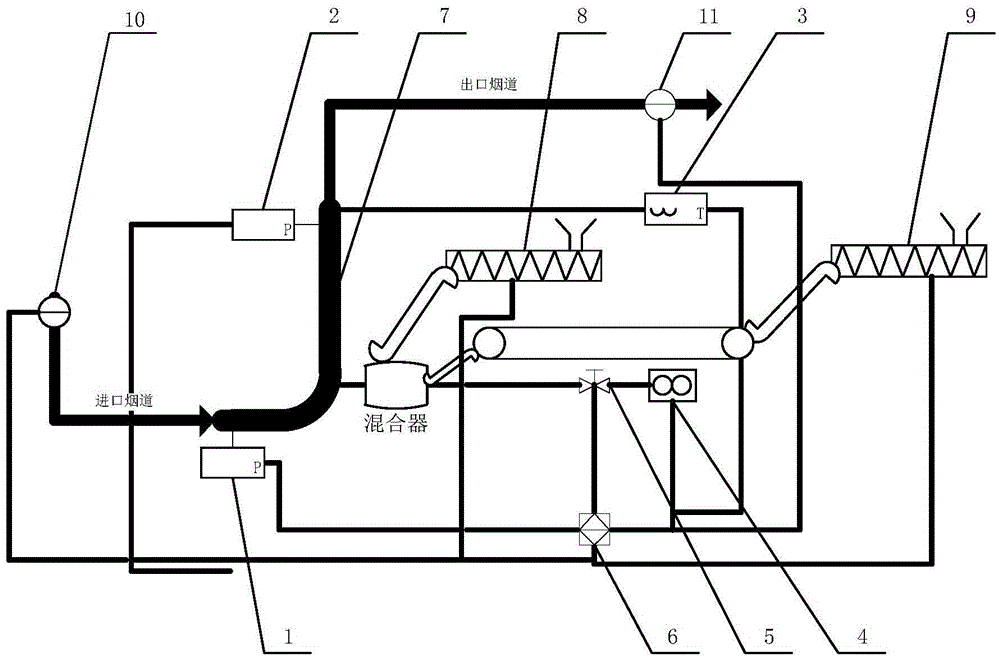

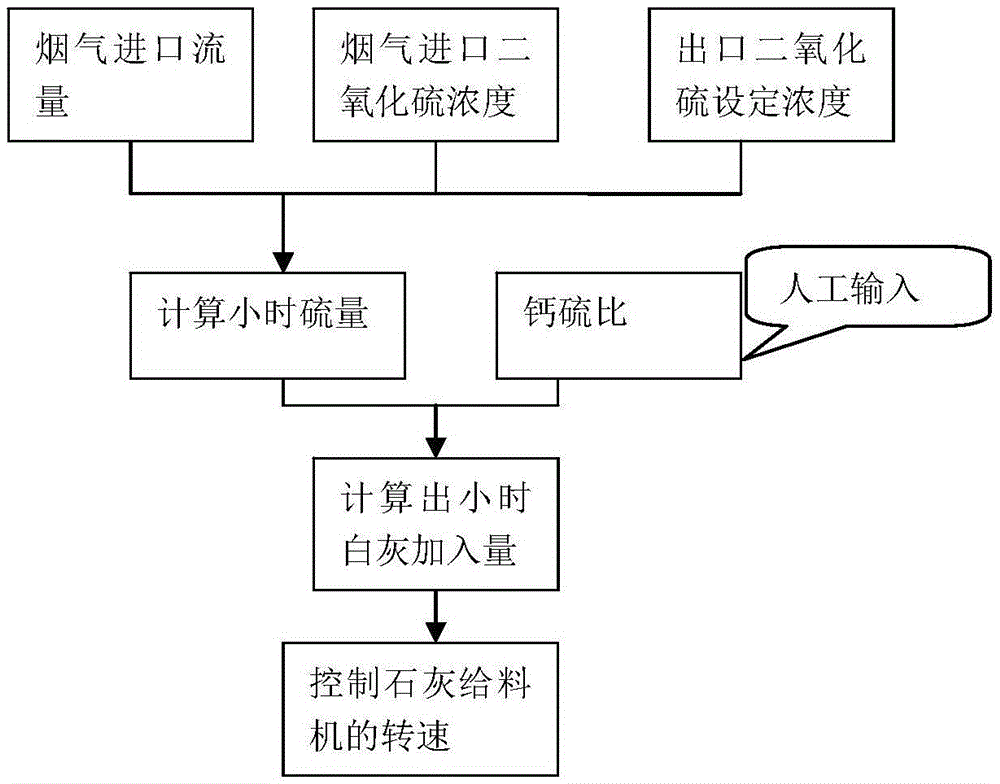

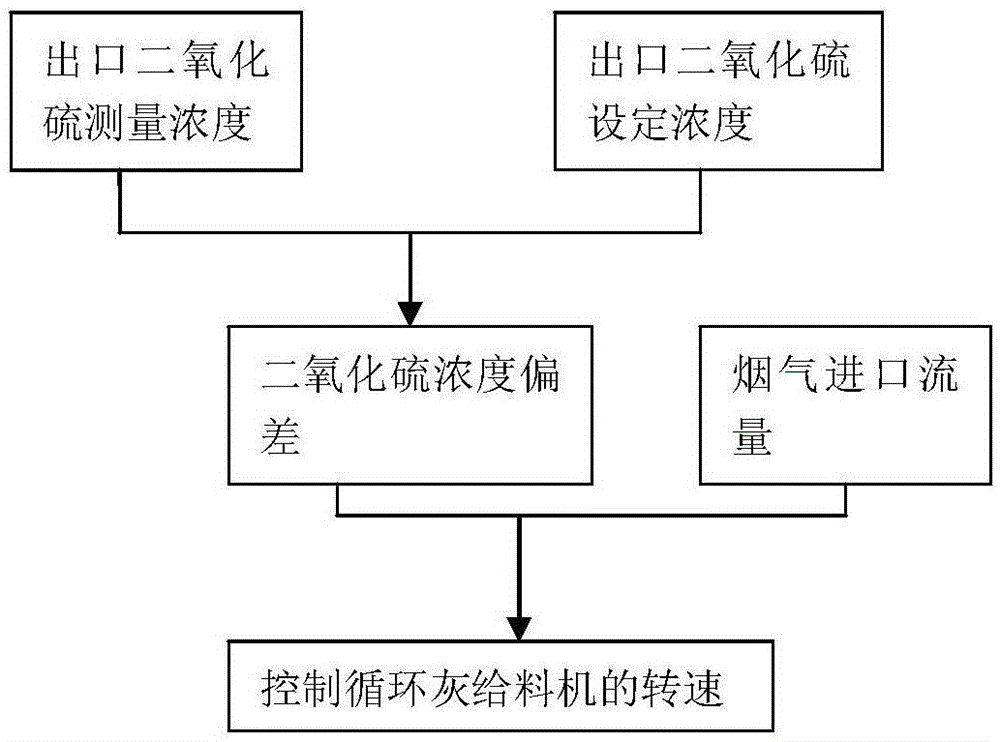

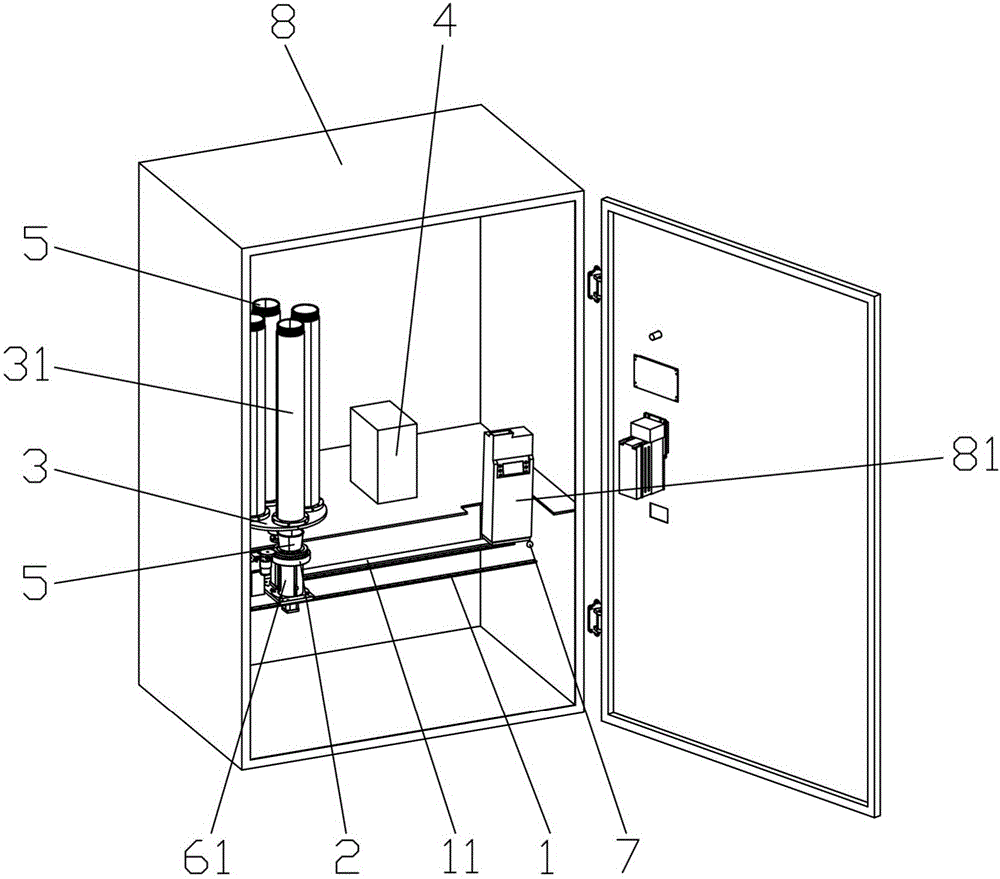

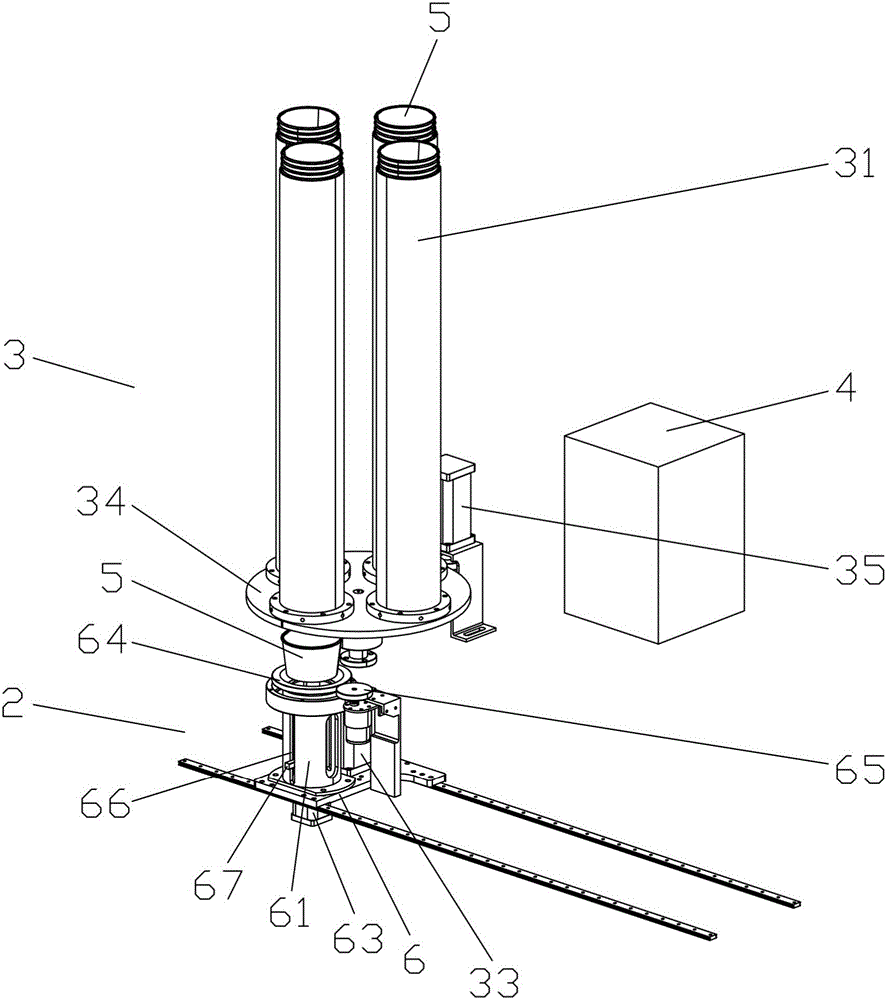

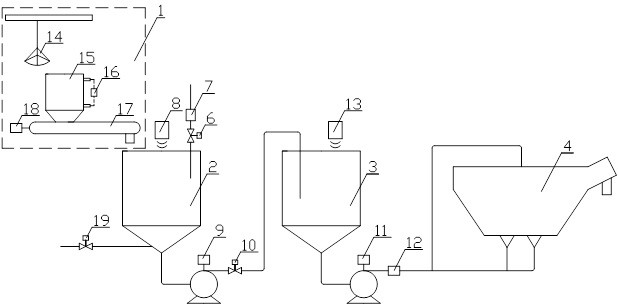

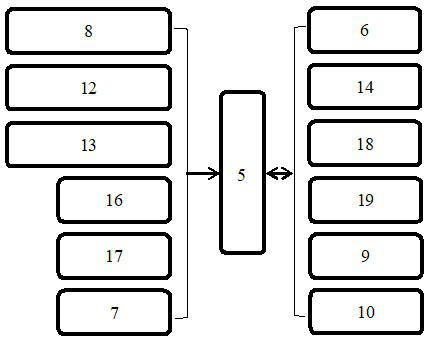

Automatic desulfurization system and method for sintering flue gas

ActiveCN105536490AReduce consumptionAvoid emissionsGas treatmentDispersed particle separationFlue gasSulfur

The invention discloses an automatic desulfurization system and method for sintering flue gas, and belongs to the technical field of desulfurization of sintering flue gas. Automatic ash conveying of a lime feeder is realized by controlling the ash conveying amount according to the concentration of inlet sulfur dioxide, flow of inlet flue gas and the calcium-sulfur ratio. The method comprises the following steps: calculating the bring-in amount of sulfur in the flue gas of an inlet flue each hour according to the flow of the flue gas of the inlet flue and the concentration of the inlet sulfur dioxide; calculating the desulfurization amount of a desulfurization system in total hours according to set concentration of outlet sulfur dioxide; calculating hourly new ash consumption according to a set calcium-sulfur ratio for desulfurization; calculating an hourly feeding amount of each lime feeder according to an average distribution rule of the desulfurization system, and controlling the rotating speed of the lime feeder; calculating the concentration deviation of sulfur dioxide according to the measured concentration of outlet sulfur dioxide and the set concentration of the outlet sulfur dioxide; calculating an hourly sulfur amount deviation according to the inlet flow of flue gas; calculating adjustment hertz of a circulating feeder for adjustment according to a corresponding relation between the sulfur amount deviation and circulating ash.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Full-automatic ice cream machine

PendingCN105707401ARealize automatic productionSelf-serviceFrozen sweetsIce CreamsElectric machinery

The invention discloses a full-automatic ice cream machine.The full-automatic ice cream machine comprises horizontal guide rails and a conveying module located on the horizontal guide rails; a cup feeding module and an ice cream outlet module are arranged above the conveying module; the cup feeding module comprises a cup barrel which is vertically installed; the inner side of the cup barrel is provided with a protruding positioning capable of clamping an ice cream cup; the conveying module comprises a telescopic sucker towards the bottom end of the cup barrel and a mobile motor used for driving the conveying module to horizontally move.By means of reasonable design, especially cooperation of the conveying module, the cup feeding module and the ice cream outlet module, of the ice cream machine, the automatic ice cream making effect is achieved, people can convenient make ice cream on their own, the structure is simple, use is easy, and application and popularization of the technology are facilitated.

Owner:刘波梅

Automatic production process for automobile seat frame sideboards

ActiveCN103722076ARealize automatic productionRealize mass productionShaping toolsMetal-working feeding devicesCar seatManufacturing technology

The invention discloses an automatic production process for automobile seat frame sideboards, and relates to a manufacturing technology for automobile parts. The automatic production process comprises a processed material board feeding process, a first drawing process, a second drawing process, a trimming and punching process, a first flanging process, a first punching process, a punching and side punching process, a second flanging process, a hole flanging process, a second punching process and a shaping process which are set in sequence, wherein processed material boards in the processed material board feeding process are used for manufacturing the automobile seat frame sideboards; the processed material board feeding process is finished by using a processed material board feeding device; the other processes are finished by using corresponding dies arranged on all the process positions; two parallel feeding rods for feeding the processed material boards are arranged between an upper die and a lower die; the feeding rods are provided with manipulators for feeding the processed material boards; each pair of manipulators are used for finishing actions for synchronously grabbing the processed material boards from the former die, lifting, displacing and overturning the processed material boards and putting down the processed material boards by the next die; a control system is also provided in the automatic production process. The automatic production process is used for realizing the automatic production of the automobile seat frame sideboards and is high in production efficiency, low in production cost and high in product quality.

Owner:RAINBOW METAL TECH

Device for spot welding of cells

ActiveCN107745205ARealize automatic productionSave human effortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAnode

The present invention relates to the field of battery spot welding, and especially relates to a device for spot welding of cells. The device comprises a feed mechanism and a spot welding mechanism. The feed mechanism comprises a conveyor device, a transfer device, a detection device and a blanking device. The spot welding mechanism comprises a rotating device, a transporting device, an unloading device, a spot welding device and a metal sheet feed device. Cells are conveyed to the detection device by the conveyor device and the transfer device for detection of anode and cathode directions of the cells, the anode and cathode directions of the cells are adjusted to be consistent, the cells are installed into jigs by the blanking device and successively rotated with 90 degrees by the rotatingdevice, three steps of closing a feed door, spot welding and blanking are implemented side by side, and spot welding processes of the cells are achieved. During the processes, the anode and cathode directions of the cells and automatic spot welding of the spot welding mechanism are automatically detected and adjusted by the feed mechanism, automatic production is achieved, manpower is saved, production efficiency is improved, and production cost is reduced.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

Die-casting workshop

PendingCN108326278ASave manpower and material resourcesIncrease productivityCasting plantsSite managementManufacturing line

The invention provides a die-casting workshop. The die-casting workshop comprises a control system, a central smelting furnace, a conveying device and a plurality of die-casting production lines arranged side by side, wherein the central smelting furnace and the conveying device are electrically connected with the control system. Each die-casting production line comprises a die-casting machine, aconveyor belt and a workpiece taking robot, wherein the part taking part is used for taking out workpieces die-cast by the die-casting machine and transferring the workpieces onto the conveyor belt. The die-casting machines can transmit melt demand signals to the control system. The control system can send a control instruction to drive the conveying device to convey melt of the central smelting furnace to the die-casting machines after receiving the melt demand signals. The die-casting workshop can achieve workshop automation and intelligent production through the control system, reduce the field management cost and improve the production efficiency.

Owner:广东顶固集创家居股份有限公司

Equipment used for producing spring ring

PendingCN106392640ARealize automatic productionIncrease productivityOther manufacturing equipments/toolsEngineeringEquipment use

The invention discloses equipment used for producing a spring ring. According to the basic scheme, the equipment comprises a feeding mechanism, a guide cutting mechanism, a first clamping mechanism, a crimping mechanism, a second clamping mechanism, a riveting mechanism, a gluing mechanism and a cloth feeding mechanism. By means of the technology, automatic production of the spring ring is achieved, intelligentization, automation and the continuity of production are ensured, and the production efficiency of the spring ring is improved.

Owner:东莞市冠霖环保滤材配件有限公司

Film drafting device used for manufacturing PTFE sewing thread

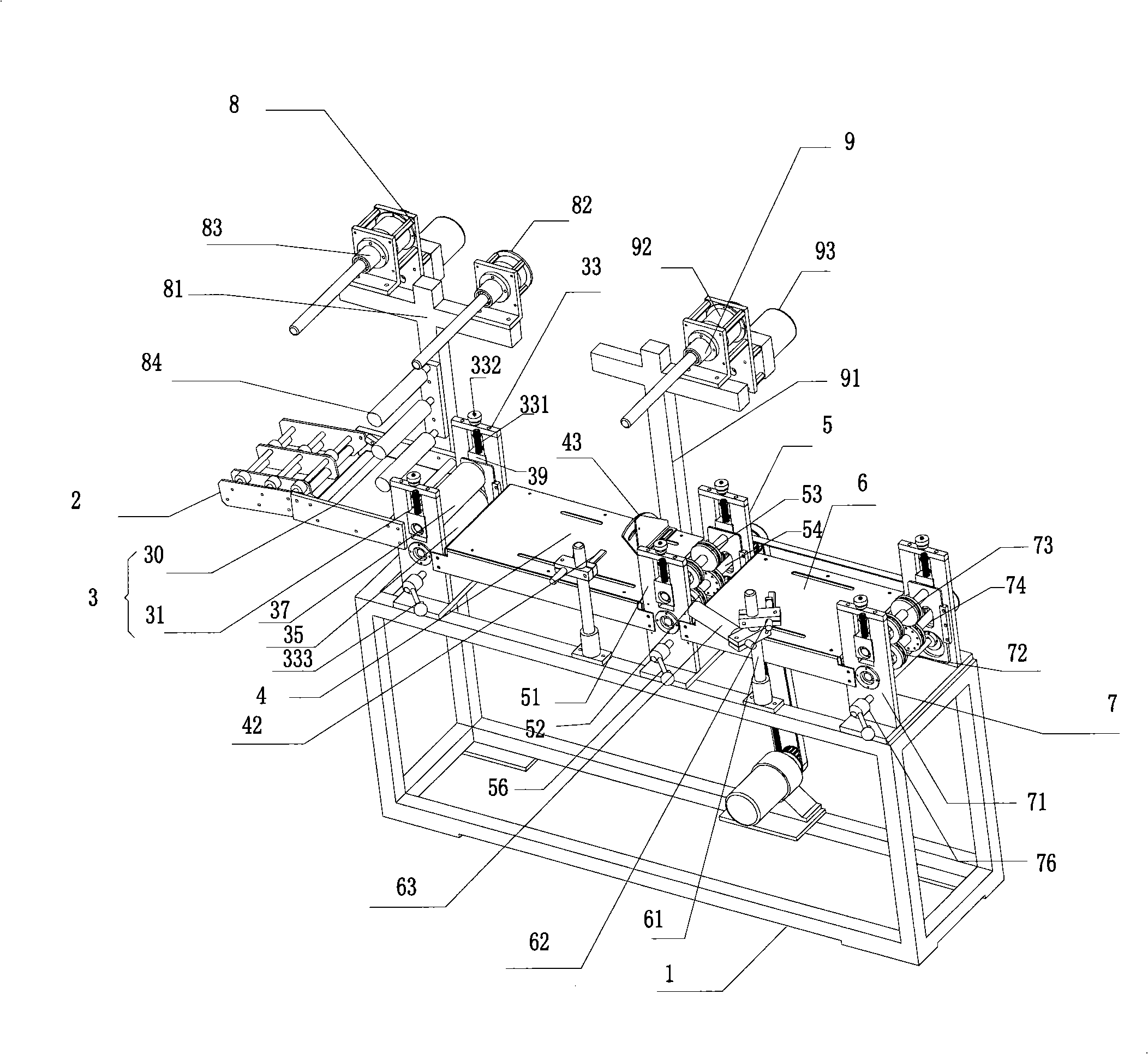

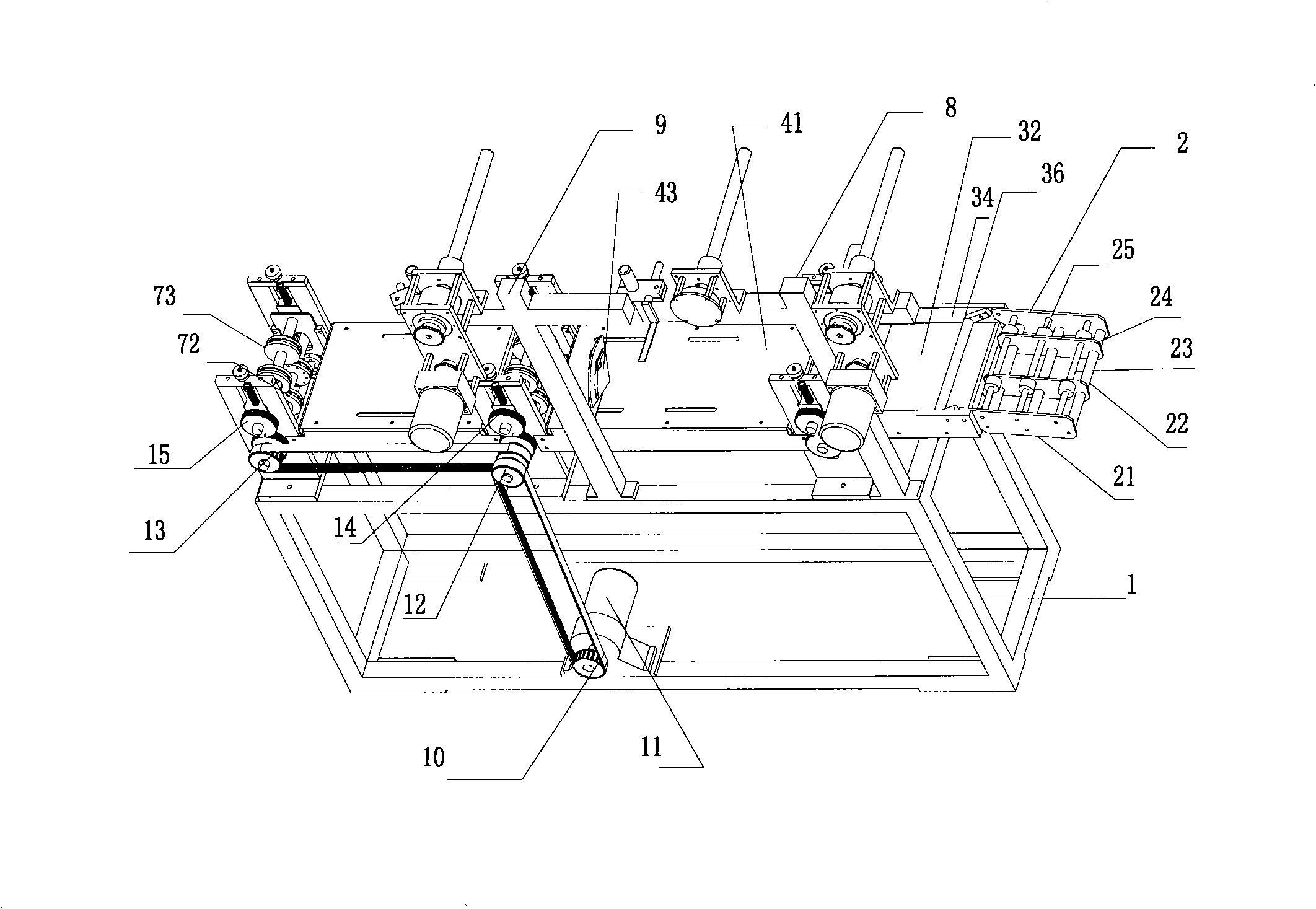

InactiveCN105887222AGuaranteed uniformityGuaranteed StrengthArtificial filament heat treatmentStretch-spinning methodsEngineeringMechanical engineering

The invention discloses a film drafting device used for manufacturing a PTFE sewing thread. The film drafting device comprises a film drafting front pressing roller set, a film drafting drying oven, a film drafting cooling roller set and a film drafting rear pressing roller set which are sequentially arranged from left to right. The film drafting front pressing roller set comprises first guide rollers and a first pressing roller arranged on one first guide roller; the film drafting drying oven comprises an upper drying oven body and a lower drying oven body which are each internally provided with a heating mechanism; the film drafting cooling roller set comprises a cooling box, and cooling rollers and a cooling mechanism are arranged in the cooling box; the film drafting rear pressing roller set comprises second guide rollers and a second pressing roller arranged on one second guide roller. The rotating speed of the first guide rollers is lower than that of the second guide rollers. The film drafting device is simple in structure and easy to manufacture, use and operate, reduces labor intensity and labor input, and improves production efficiency and ensures uniformity, strength and the yield of the PTFE sewing thread, product quality is easy to control, and the drafted film is uniform.

Owner:陈路

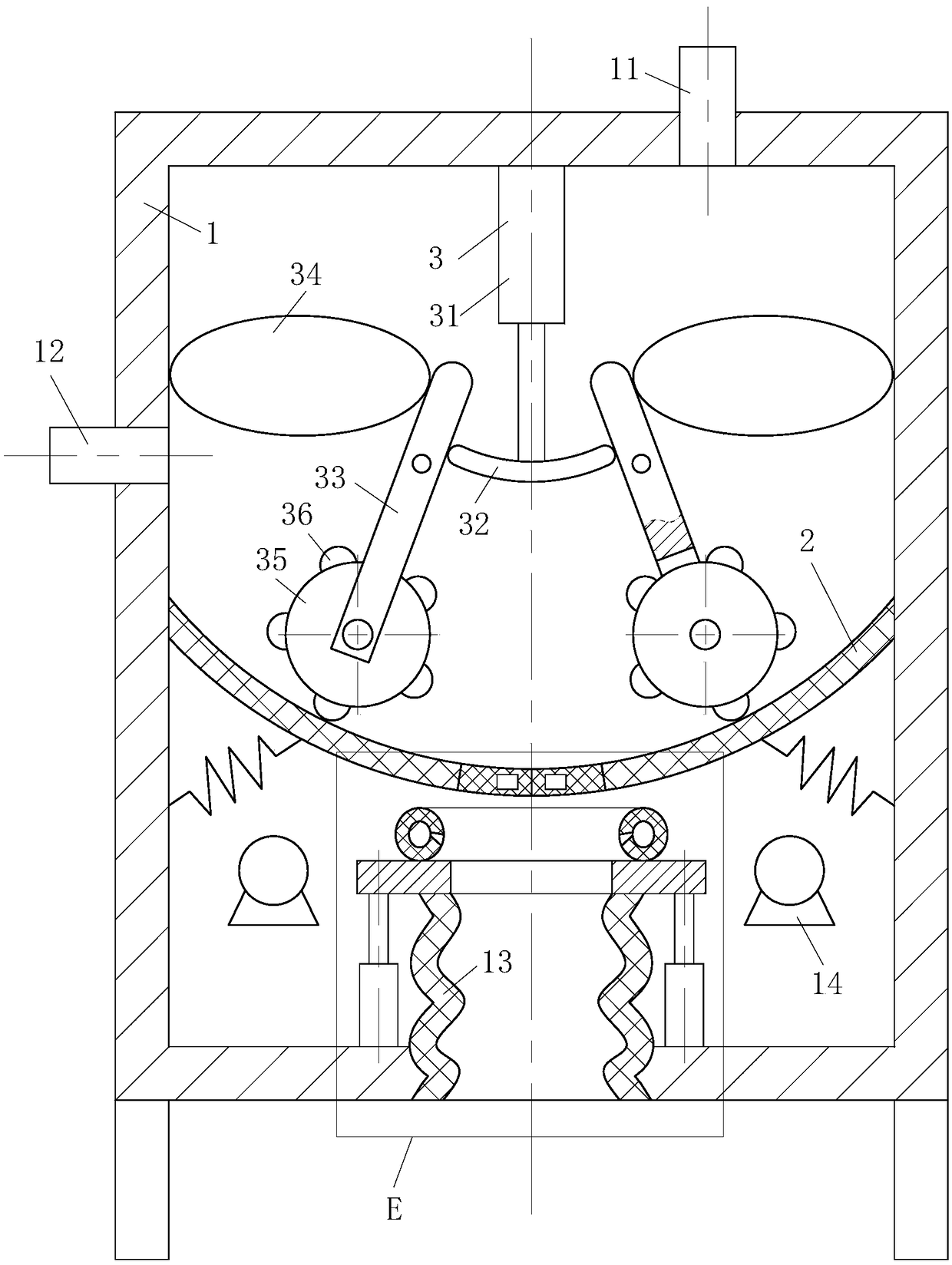

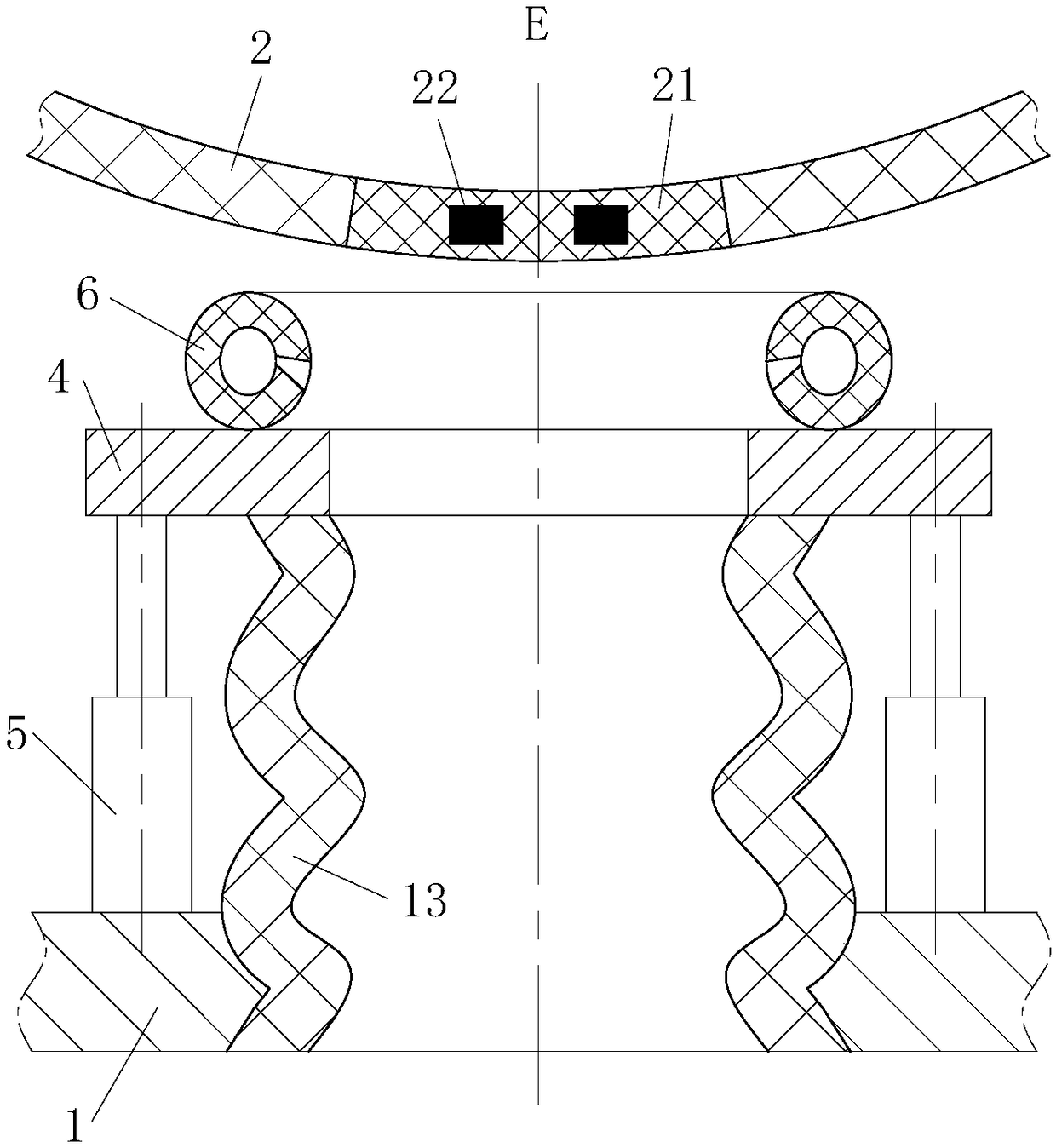

Edible salt production equipment

PendingCN109123583AImprove output efficiencyConvenience for energy savingFood scienceElectric driveEngineering

The invention belongs to the technical field of edible salt production, and particularly provides edible salt production equipment. The edible salt production equipment comprises a box, an air outletpipe, a water inlet pipe, discharge pipes, microwave radiators, an elastic arc-shaped plate and a stirring module, wherein the stirring module comprises an electric drive pusher, a pushing plate, stirring plates, support air bags, stirring rollers and first air bags; the pushing plate performs reciprocating movement up and down to push the stirring plates to oscillate periodically, one stirring roller is rotationally mounted at the lower end of each stirring plate, one group of first air bags are uniformly arranged on the outer ring of each stirring roller, the first air bags are connected with the support air bags through air pipes and are inflated to extrude the elastic arc-shaped plate, and an opening in the center of the bottom of the elastic arc-shaped plate can be opened. The first air bags are inflated through the support air bags, bittern and edible salt crystals are pushed to the middle of the elastic arc-shaped plate, the elastic arc-shaped plate is extruded to enable the opening in the center of the bottom of the elastic arc-shaped plate to open, the bittern and edible salt crystals are discharged from the discharge pipes, and automatic production of edible salt is realized.

Owner:杨兆兰

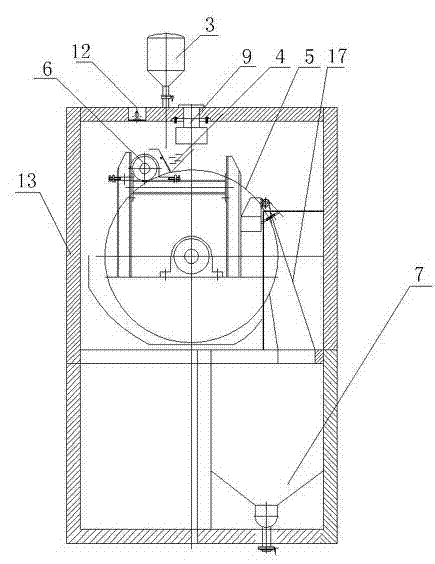

Special drying device for organic silicon-resin production

InactiveCN102374762AAvoid flyingGuaranteed to workHeating arrangementHeat conductingPulp and paper industry

The invention discloses a special drying device for organic silicon-resin production, which comprises a closed shell, a delivery pump and a driving pump, wherein the delivery pump is installed on a high-position storing slot at the upper part of the shell by being communicated with a feeding pipeline, the high-position storing tank is communicated with a material homogenizer at the upper part in the shell, a drying roller which is installed on the shell through a shaft is arranged below the material homogenizer, a scraper clings to the outer wall of the drying roller, a bunker is arranged below the drying roller, the drying roller is connected with and driven by the driving pump, a heater is communicated with an inner cavity of the drying roller through a heat-conducting oil-conveying pipe, a solvent-recovering pipeline, one end of which extends into the shell is communicated with a cooler, the cooler is communicated with a solvent-recovering and storing tank, and the solvent-recovering and storing tank is connected with a vacuum pipe through a vacuum pipeline. The special drying device for the organic silicon-resin production has the characteristics that roller-drying equipment is adopted, the product quality and the production efficiency are improved, the solvent-recovering efficiency is high, environmental pollution is avoided, and the special drying device is safe and reliable.

Owner:山东大易化工有限公司

Meat ball making and forming device for food processing

InactiveCN113575655AAutomatic productionThe effect of automatic shreddingMeat processing devicesEngineeringMechanical engineering

The invention relates to a forming device, in particular to a meat ball making and forming device for food processing. The invention aims to provide the meat ball making and forming device for food processing, which can automatically smash meat stuffing and can automatically make meat balls. The meat ball making and forming device for food processing comprises a supporting plate, a first supporting frame, a first loading frame, a second supporting frame, a motor and a smashing rod, the first supporting frame is arranged on one side of the top of the supporting plate, the first loading frame is arranged on the upper side of the first supporting frame, the second supporting frame is arranged on the top of the first supporting frame, and the motor is arranged on the second supporting frame; a smashing rod is arranged on the lower side of the motor and located in the first loading frame. The device achieves the effects that the meat stuffing can be automatically smashed, and the meat balls can be automatically made; the meat is placed in the first loading frame, and the mincing rod rotates, so that the effect of automatically mincing the meat can be achieved.

Owner:林梦婷

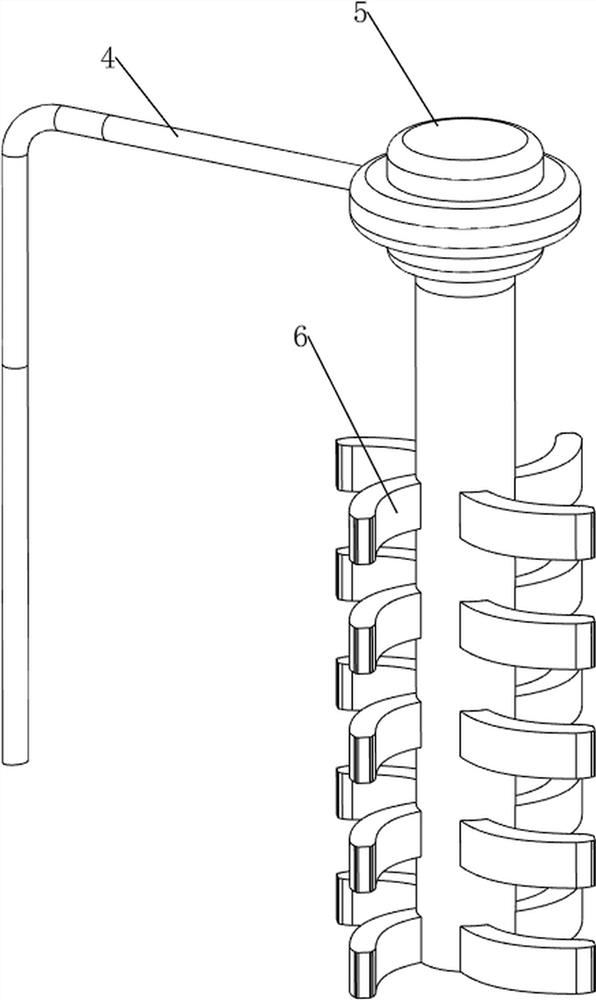

Organic fertilizer production equipment with stirring fermenting device

InactiveCN104355717ASimple processEasy to useBio-organic fraction processingExcrement fertilisersFuel tankProcess engineering

The invention discloses organic fertilizer production equipment with a stirring fermenting device. A stirring motor is arranged at the top of a fermenting tank, a stirring mechanism is arranged in the fermenting tank, the stirring mechanism is driven by the stirring motor, a fermenting inlet is arranged at the top of the fermenting tank, a fermenting outlet is arranged at the bottom of the fermenting tank, a heating mechanism comprises a heat transfer oil return box, an oil-in pipe, an oil return pipe and four heating cavities, the four heating cavities are arranged at the bottom of the fermenting tank, the heat transfer oil return box is arranged at the top of the fermenting tank, heating coiled pipes are respectively arranged in the heating cavities, one end of the oil-in pipe and one end of the oil return pipe are respectively connected in parallel with the four heating cavities, the other end of the oil-in pipe and the other end of the oil return pipe are respectively connected with the heat transfer oil return box, and the oil return pipe in the heat transfer oil return box is higher than the oil-in pipe. The organic fertilizer production equipment is simple in technology and convenient to use and integrates multiple functions of fermenting, heating, sterilizing and stirring, thereby realizing automatic production, reducing labor cost and improving the production efficiency.

Owner:安徽云健生态农业科技有限公司

Automatic medium adding system for dense medium density separation in coal preparation plant, and working method

InactiveCN112264180ARealize automatic identificationAvoid sorting exceptionsWet separationAutomatic controlMedium density

The invention discloses an automatic medium adding system for dense medium density separation in a coal preparation plant, and a working method, and belongs to the technical field of coal washing. Thesystem comprises a feeding device, a dense medium barrel, a qualified medium barrel, a dense medium separation device and a controller, wherein the feeding device, the dense medium barrel, the qualified medium barrel and the dense medium separation device are connected in sequence; and the operation of the device is controlled by the controller. After the system is applied to the coal preparationplant, automatic identification for medium preparation and adding requirements can be realized, abnormal separation caused by insufficient medium mass is avoided, and automatic preparation and addingfor media are realized by automatically controlling medium feeding, mixing and conveying processes, so that the manpower is saved, and the working efficiency is increased.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com