Composite heat insulation light wall board production process and production device

A light-weight wallboard and composite thermal insulation technology, applied in unloading devices, manufacturing tools, transportation and packaging, etc., can solve the problem of inability to realize double-layer or multi-layer structure layout, inconvenient production of diversified products, long molding time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

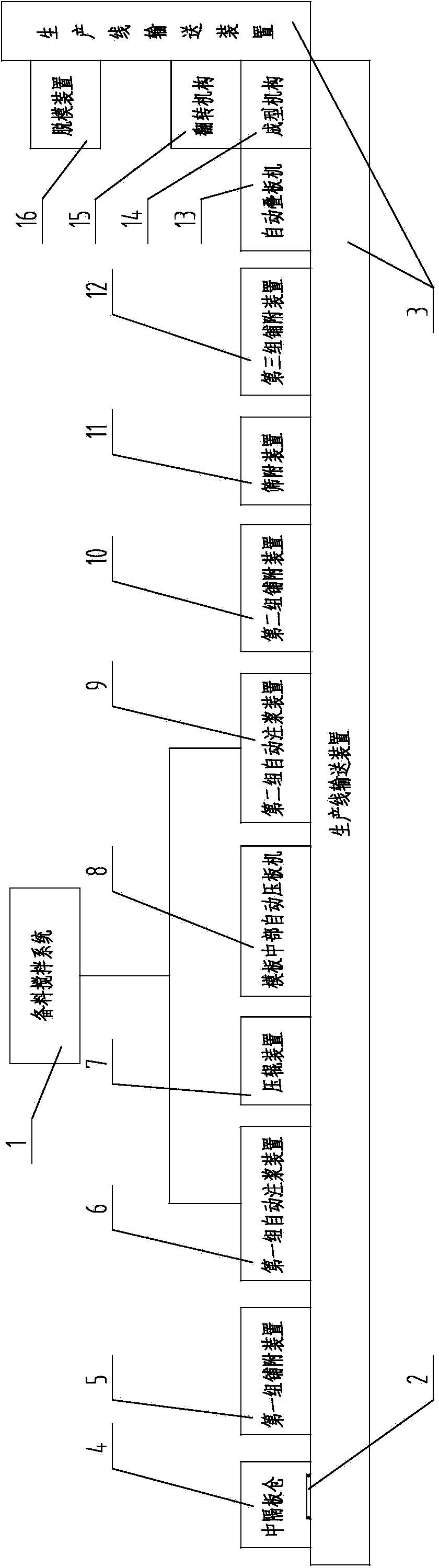

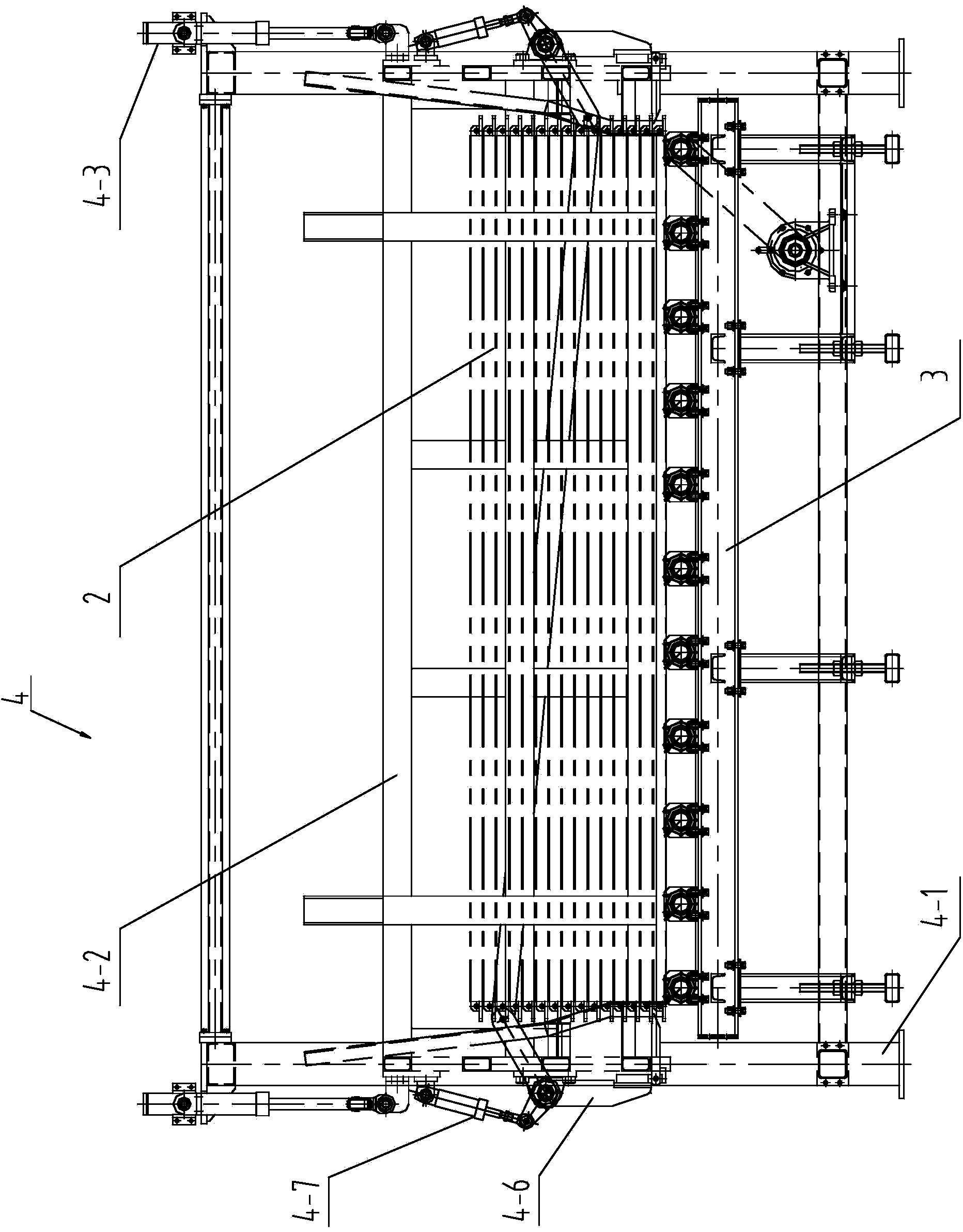

[0104] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

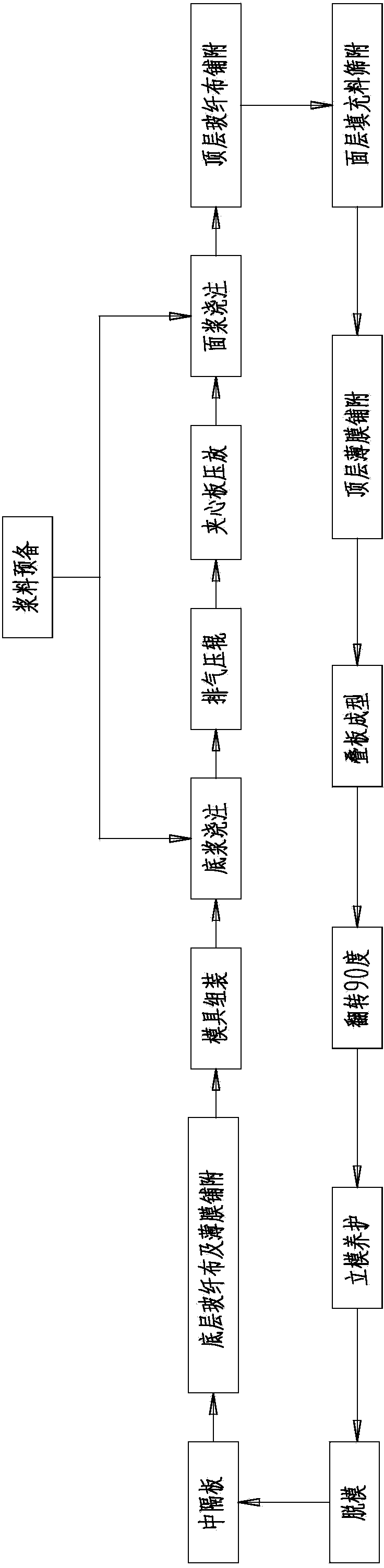

[0105] A production process of a composite thermal insulation lightweight wallboard, the process includes the steps of slurry preparation, flat mold grouting, vertical mold maintenance and demoulding in sequence;

[0106] The slurry preparation process is to mix and stir the prepared materials evenly according to the preset ratio, and set them aside;

[0107] The flat die grouting process comprises the following steps in sequence:

[0108] ①Convey the template to the bottom laying station, and lay the bottom glass fiber cloth and film on the top of the template;

[0109] ②Then transport the template with fiberglass cloth and film to the mold assembly station, assemble the frame around the template, and form a pouring cavity with an open top above the template;

[0110] ③Then transport the template to the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com