Automatic production process for automobile seat frame sideboards

An automobile seat and automatic production technology, applied in the field of automobile parts manufacturing, can solve the problems of large manpower, low precision of parts, low production efficiency, etc., and achieve the effects of high production efficiency, improved product quality, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0020]

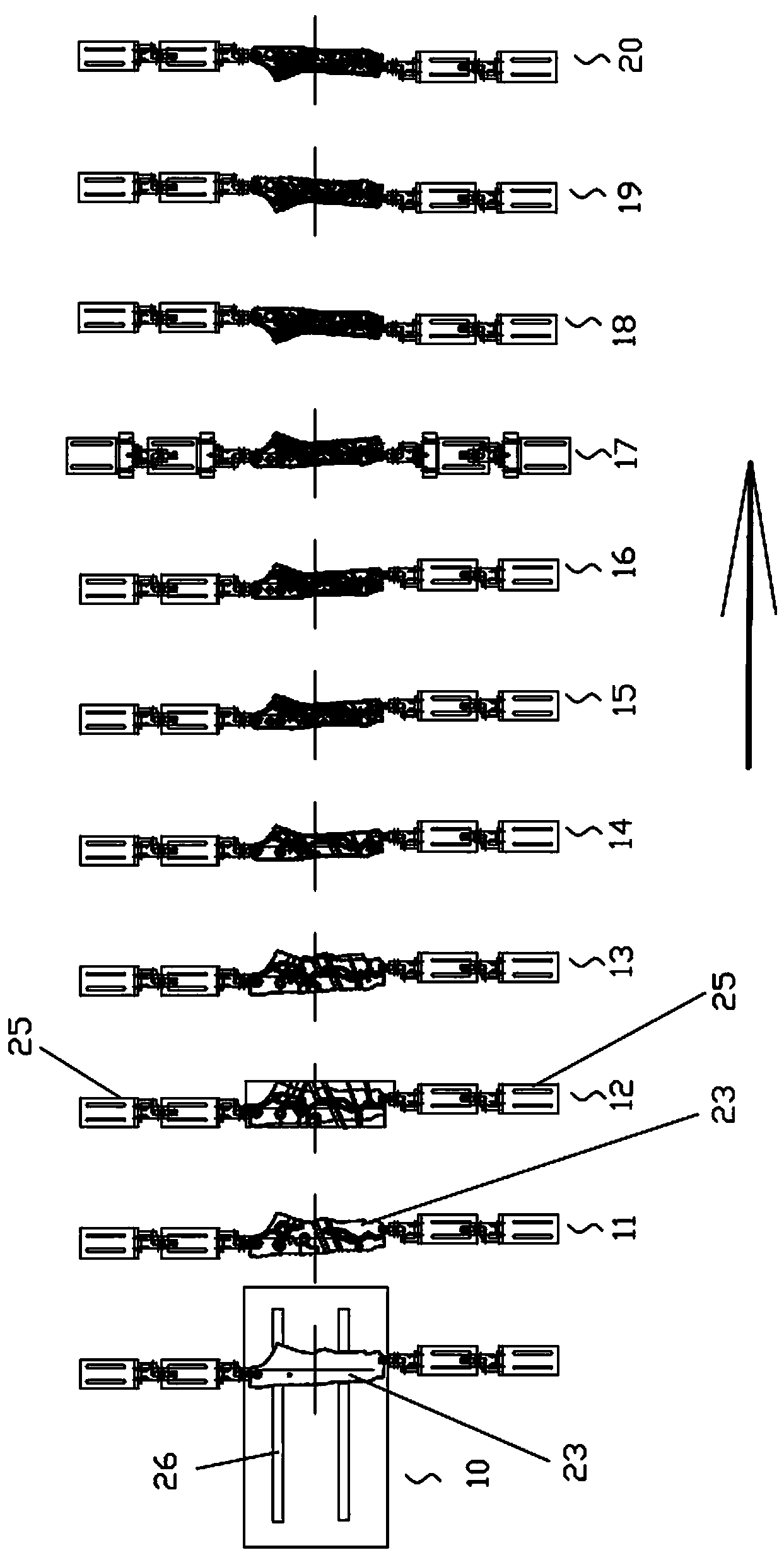

[0021] Figure 5 The car seat frame side panel 100 produced by the automatic production process of the present invention.

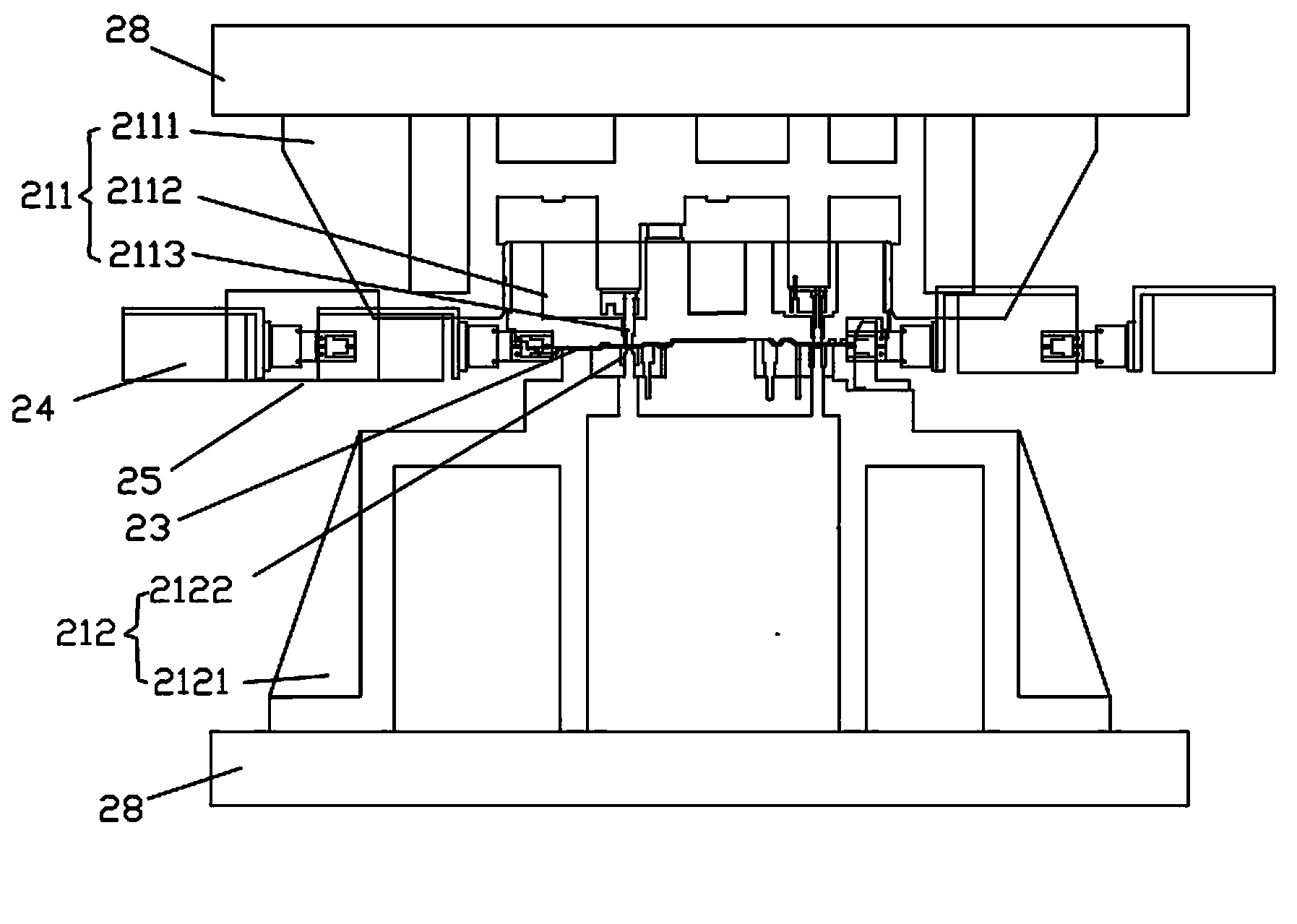

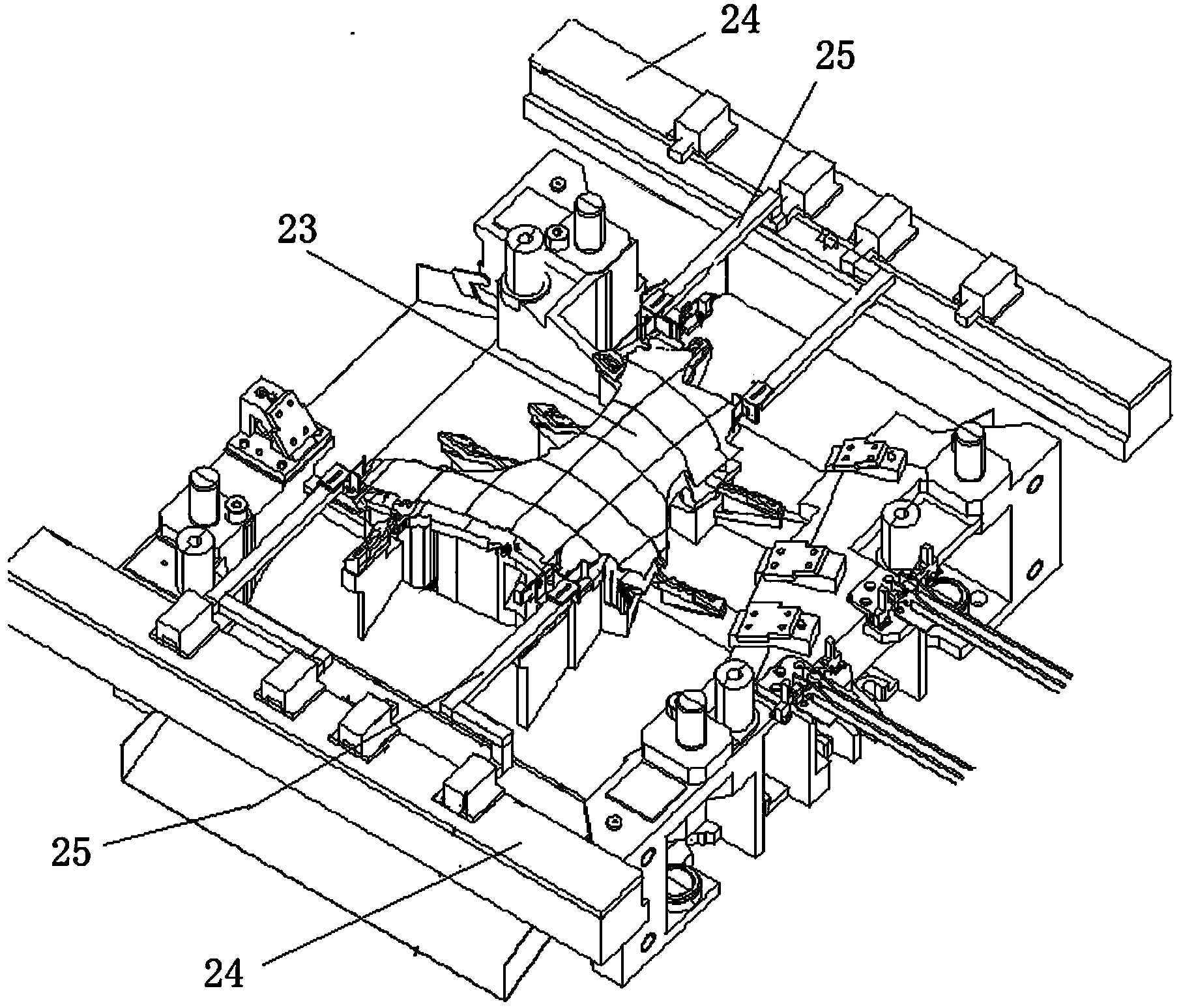

[0022] Such as Figures 1 to 4 As shown, an automatic production process of the seat frame side panel of an automobile seat includes a processed material sheet supply process 10 and a first drawing process 11 of sequentially setting the processed material sheet 23 used for manufacturing the seat frame side panel of the automobile seat , second drawing process 12, trimming and punching process 13, first flanging process 14, first punching process 15, punching plus side punching process 16, second flanging process 17, turning Hole process 18, the second punching process 19 and shaping process 20; the first drawing process 11 forms the processed material sheet 23; the second drawing process 12 makes convex h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com