Special drying device for organic silicon-resin production

A drying device and silicone technology, applied in heating devices, drying, dryers, etc., can solve the problems of yellowing and deterioration of materials, low drying efficiency, and difficulty in obtaining qualified products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

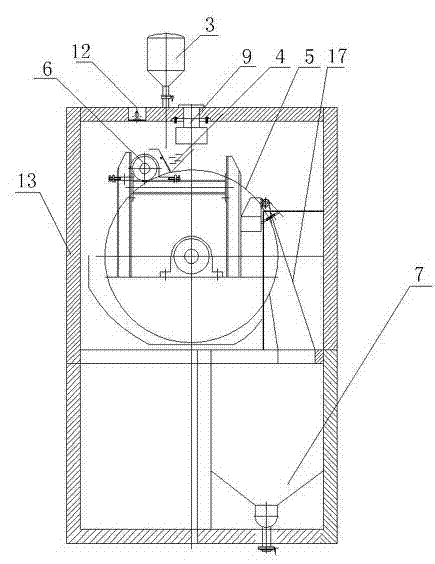

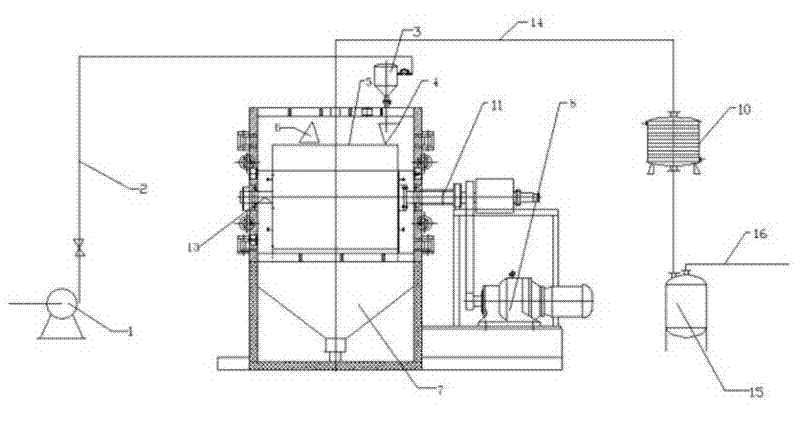

[0013] Embodiment 1, a special drying equipment for the production of silicone resin, refer to figure 1 , the feeding pump 1 communicates with the high-level storage tank 3 installed on the top of the closed casing 13 through the feed pipe 2, the high-level storage tank 3 communicates with the homogenizer 4 at the top of the housing 13, and the homogenizer 4 is arranged below There is a drying drum 5 shaft mounted on the shell 13, the scraper 6 is close to the outer wall of the drying drum 5, a silo 7 is arranged under the drying drum 5, a transmission pump 8 is connected to drive the drying drum 5, and the heater is connected to the drying drum 5 through a heat transfer oil delivery pipe 11. The inner cavity of the drum 5, the solvent recovery pipeline 14 extending into the housing 13 at one end communicates with the cooler 10, the cooler 10 communicates with the solvent recovery storage tank 15, and the solvent recovery storage tank 15 is connected to the vacuum pump through ...

Embodiment 2

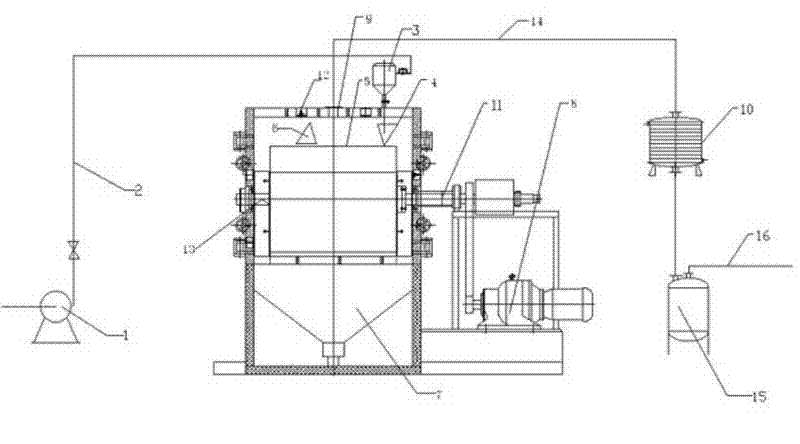

[0014] Embodiment 2, a special drying equipment for the production of silicone resin, refer to figure 2 , image 3 , on the basis of Embodiment 1, a baffle 17 is provided under the side of the drying drum 5, and an observation port 12 and a moisture discharge port 9 are provided on the upper part of the housing 13, and the others are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com