Patents

Literature

185results about How to "Suppress splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Handpiece and horn for ultrasonic surgical instrument

Owner:STRYKER CORP

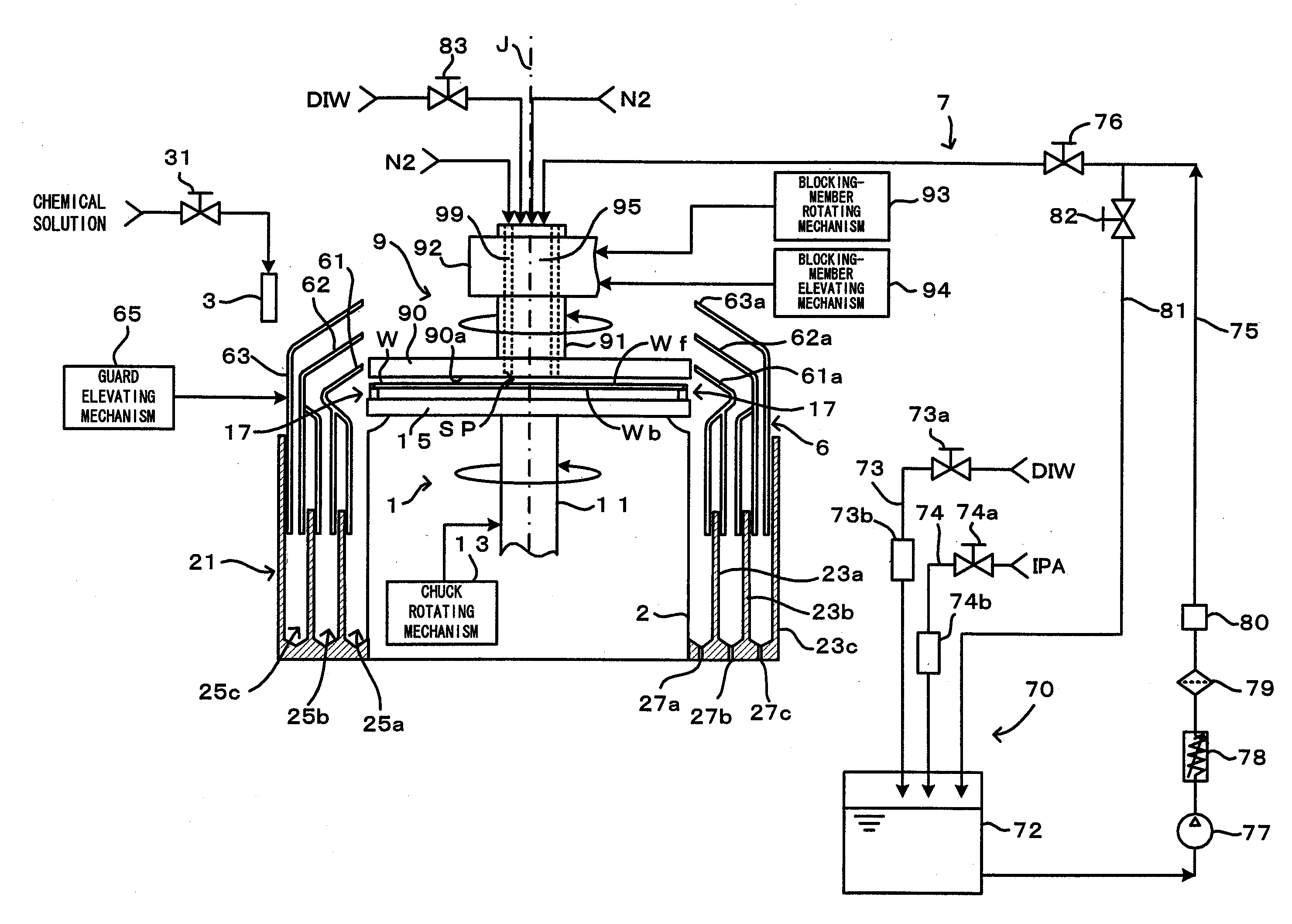

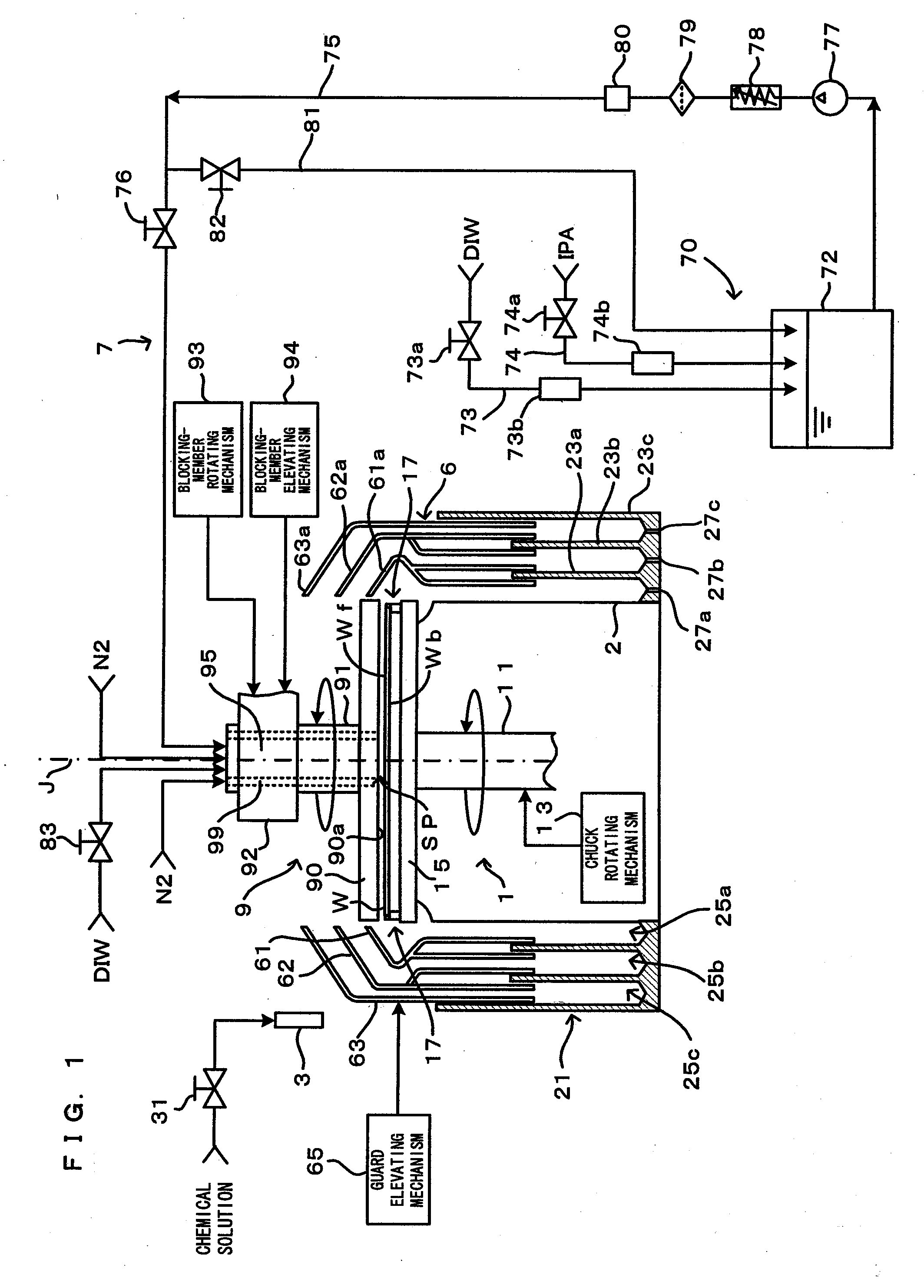

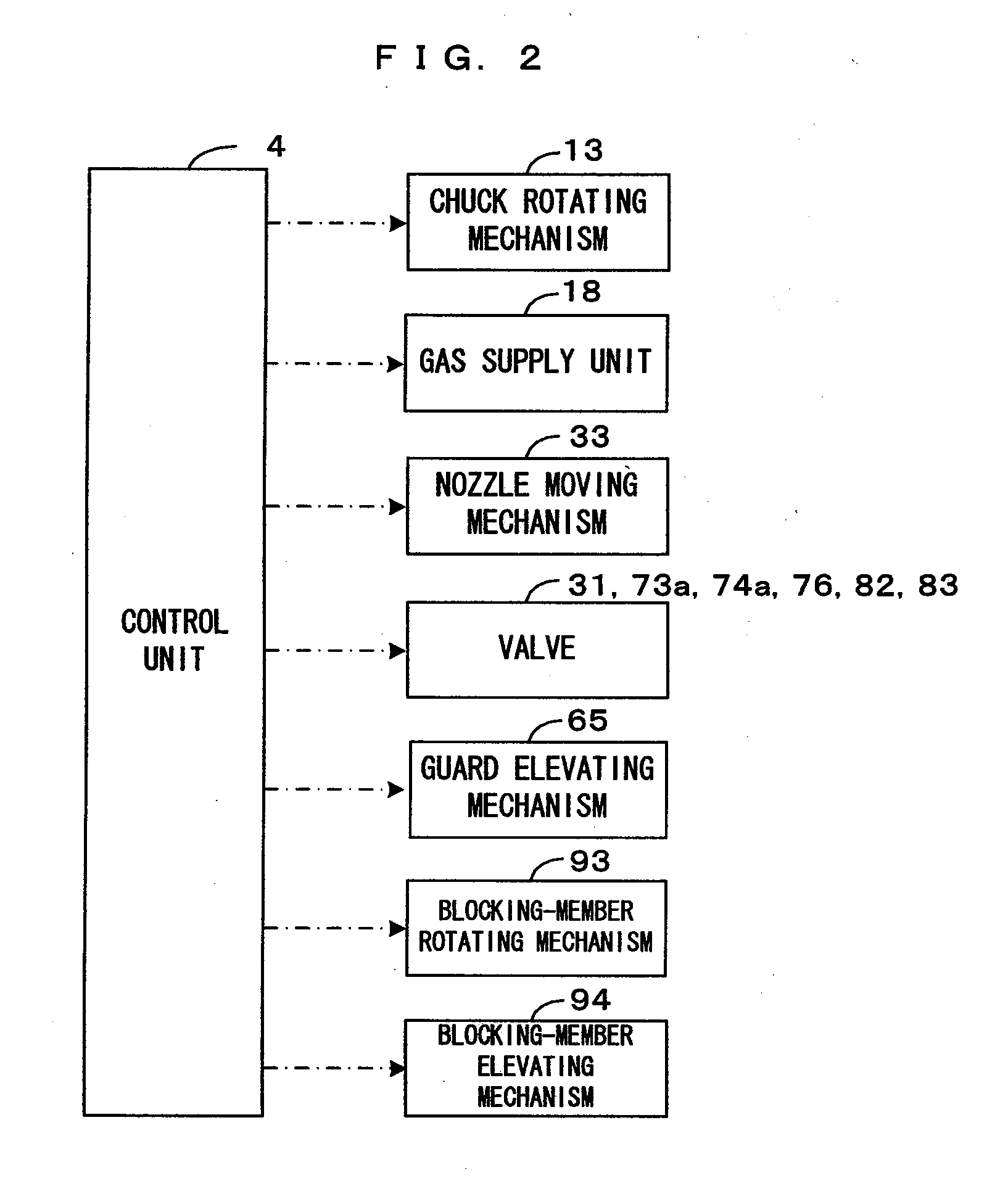

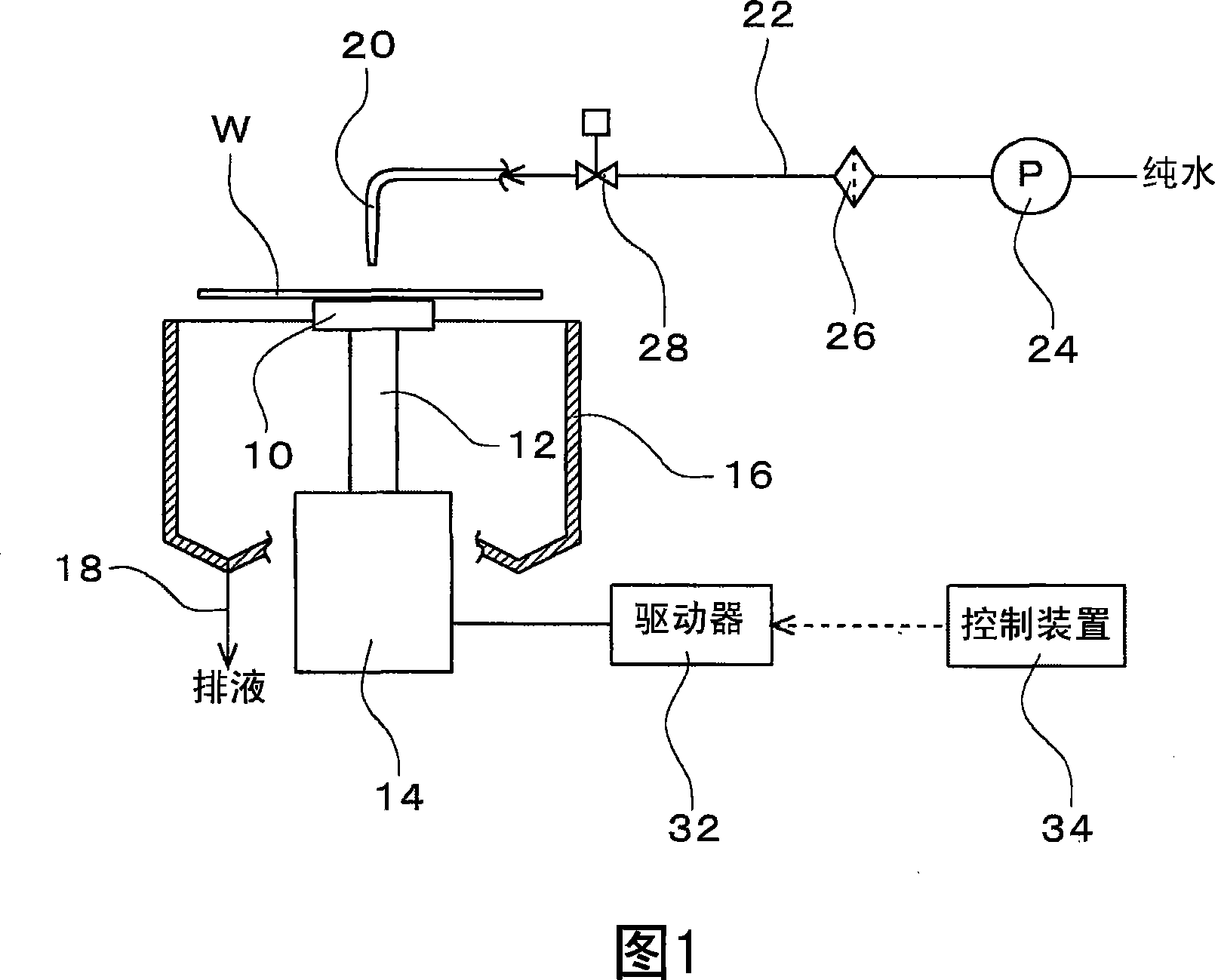

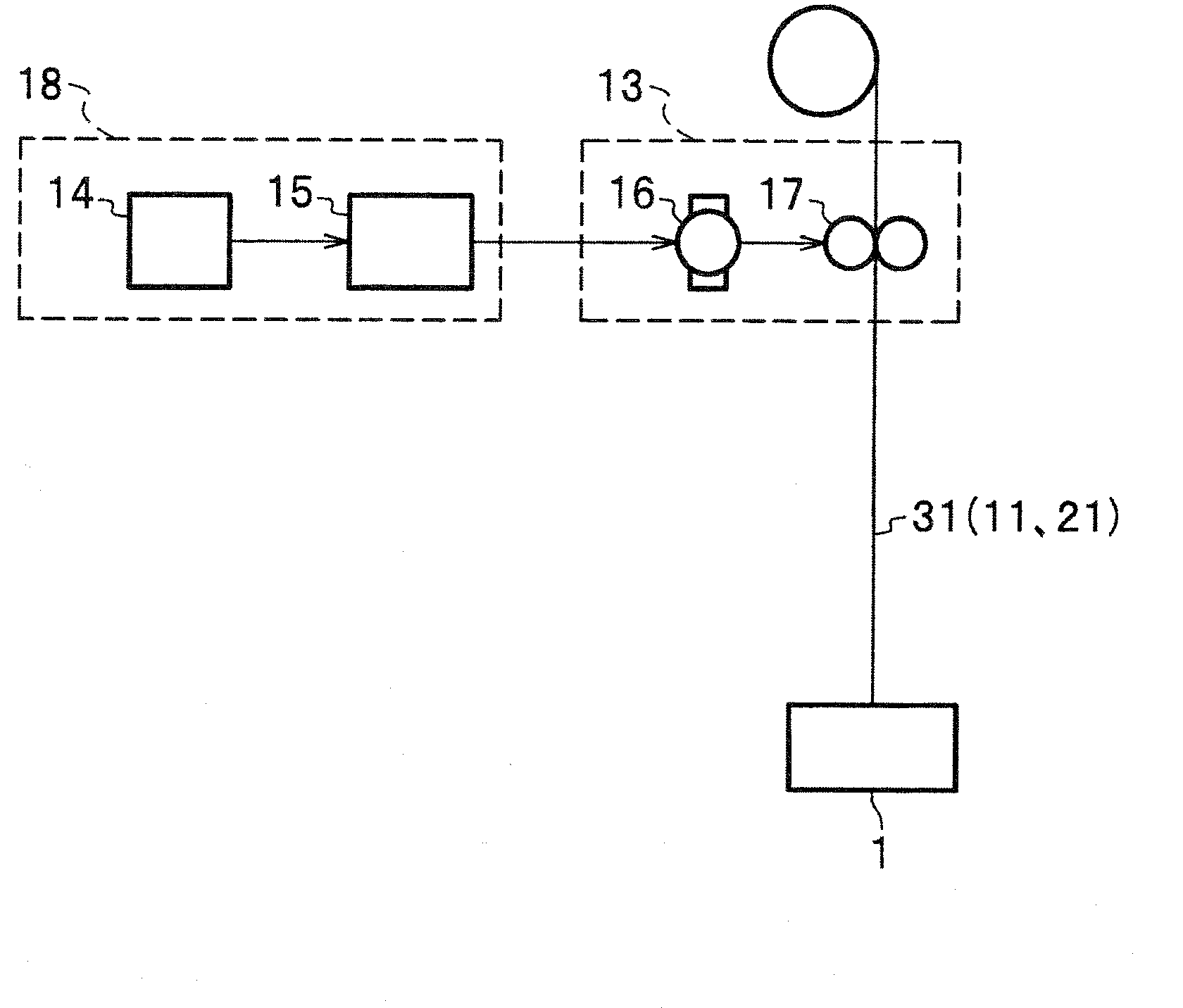

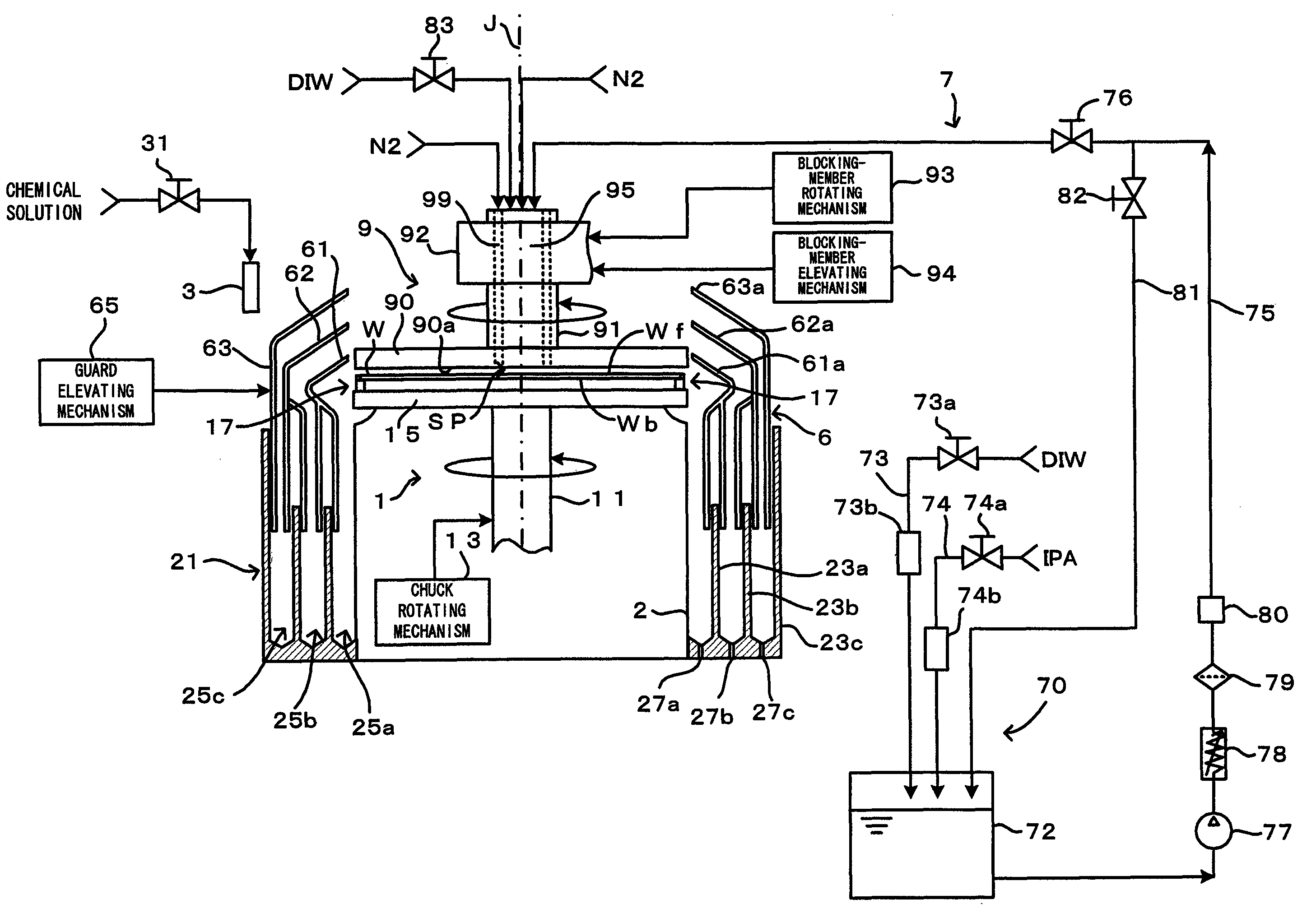

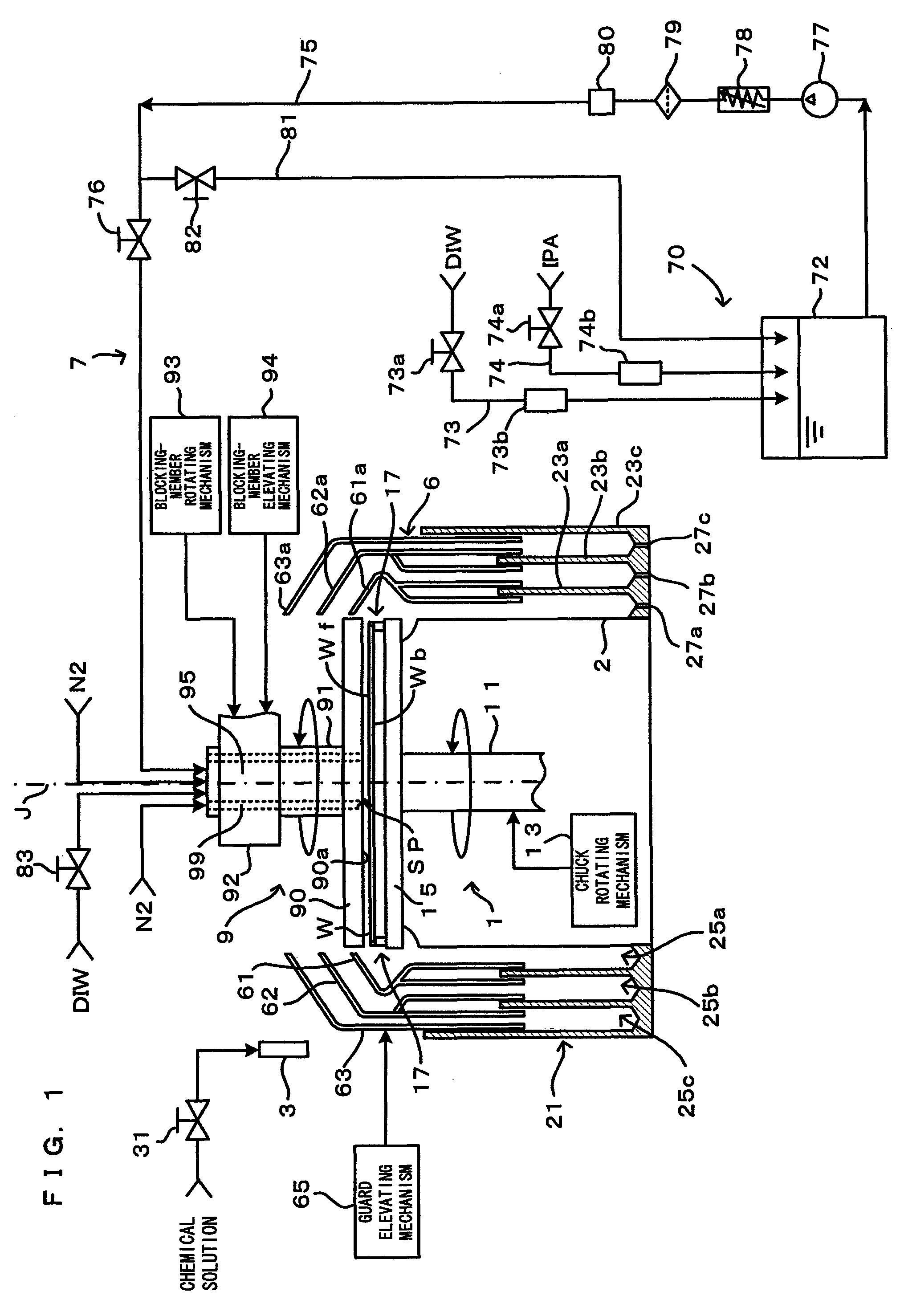

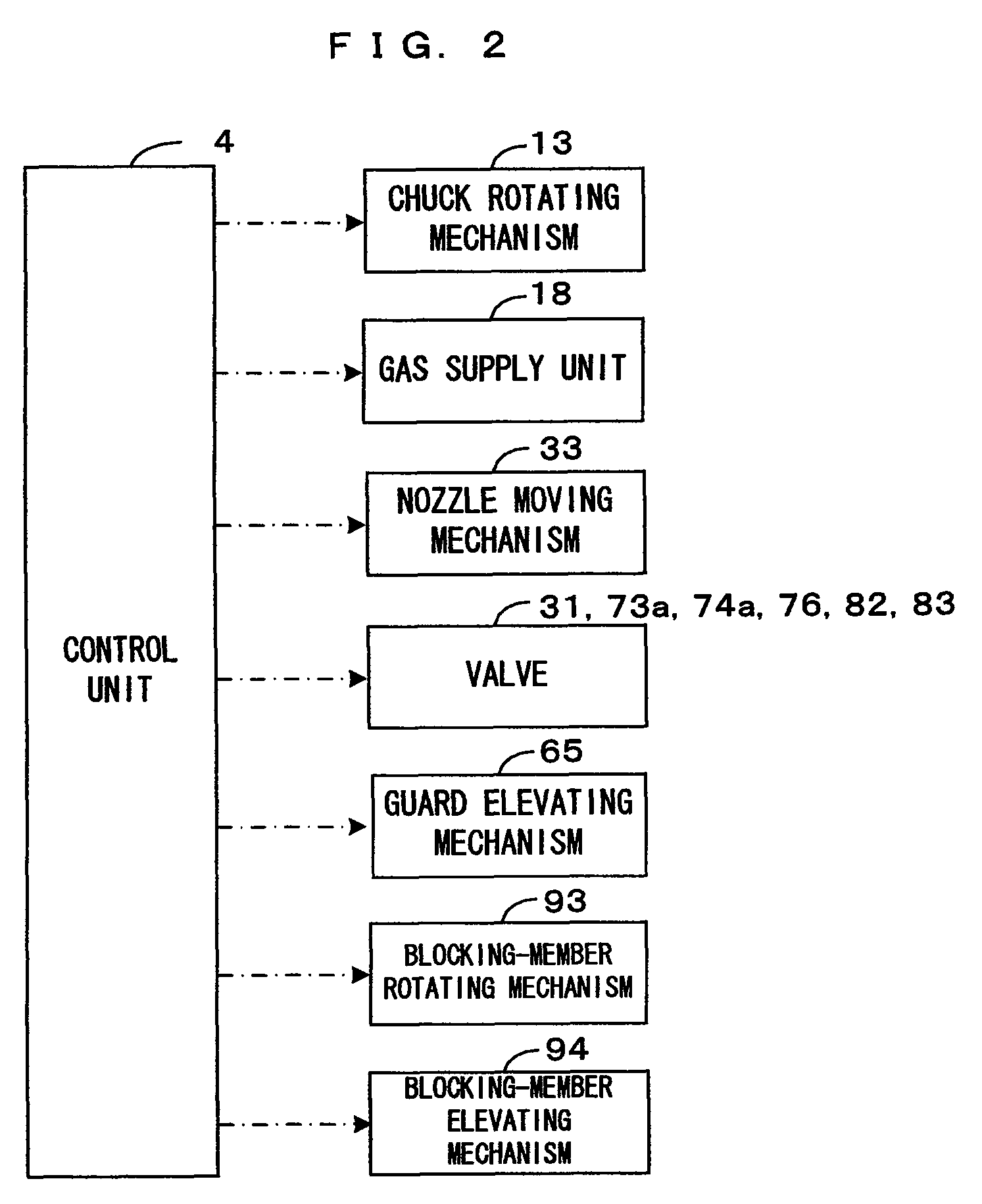

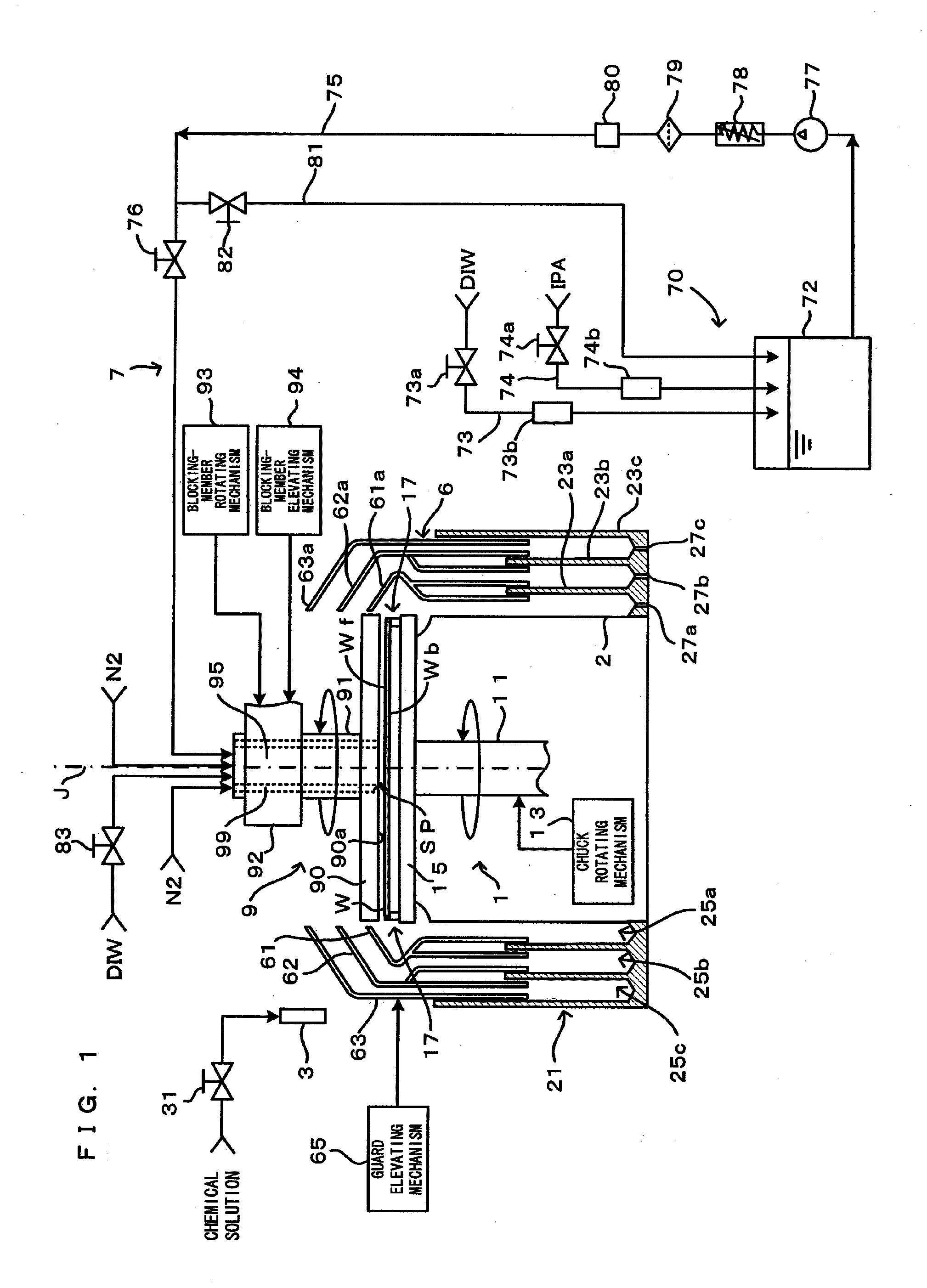

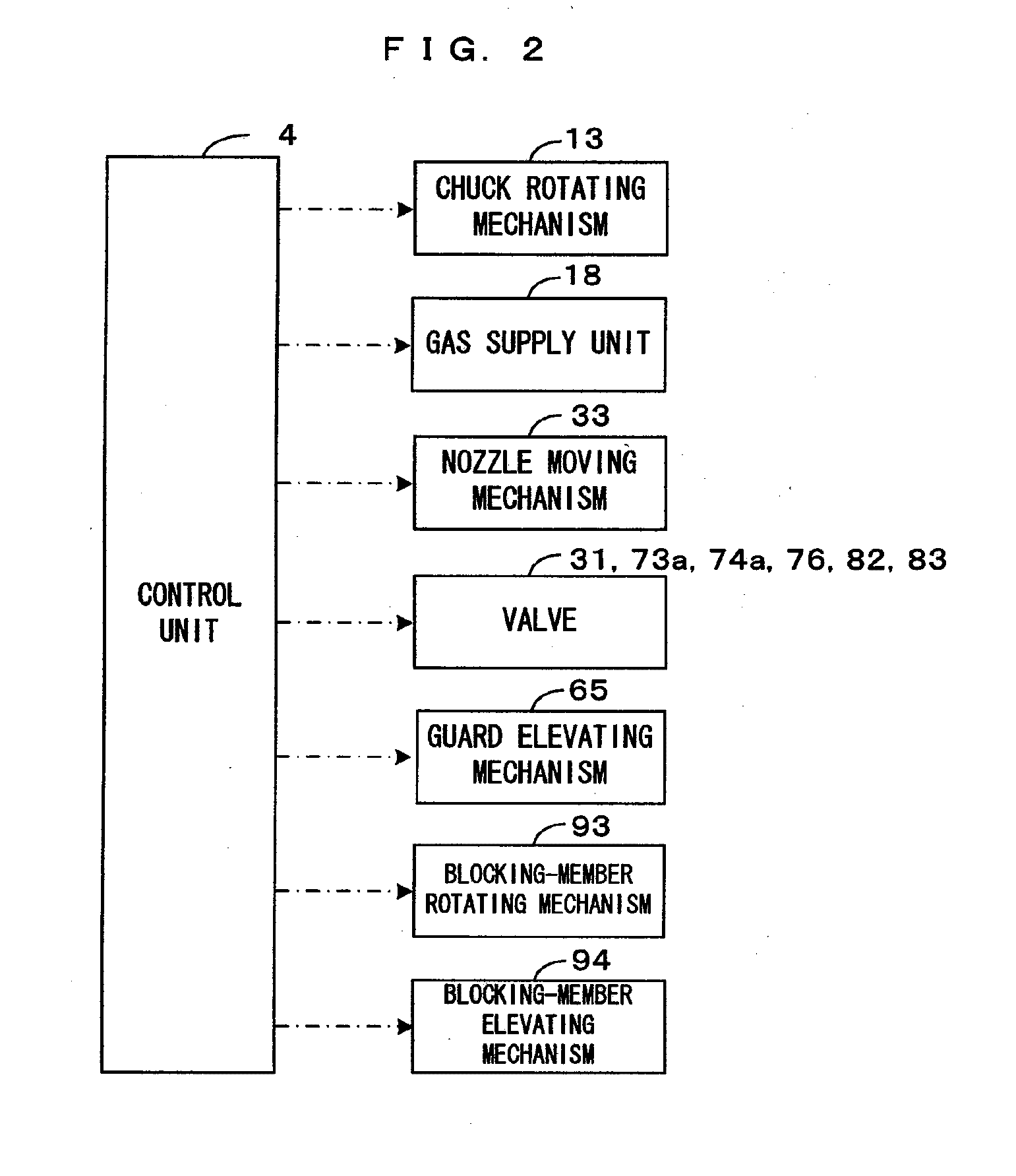

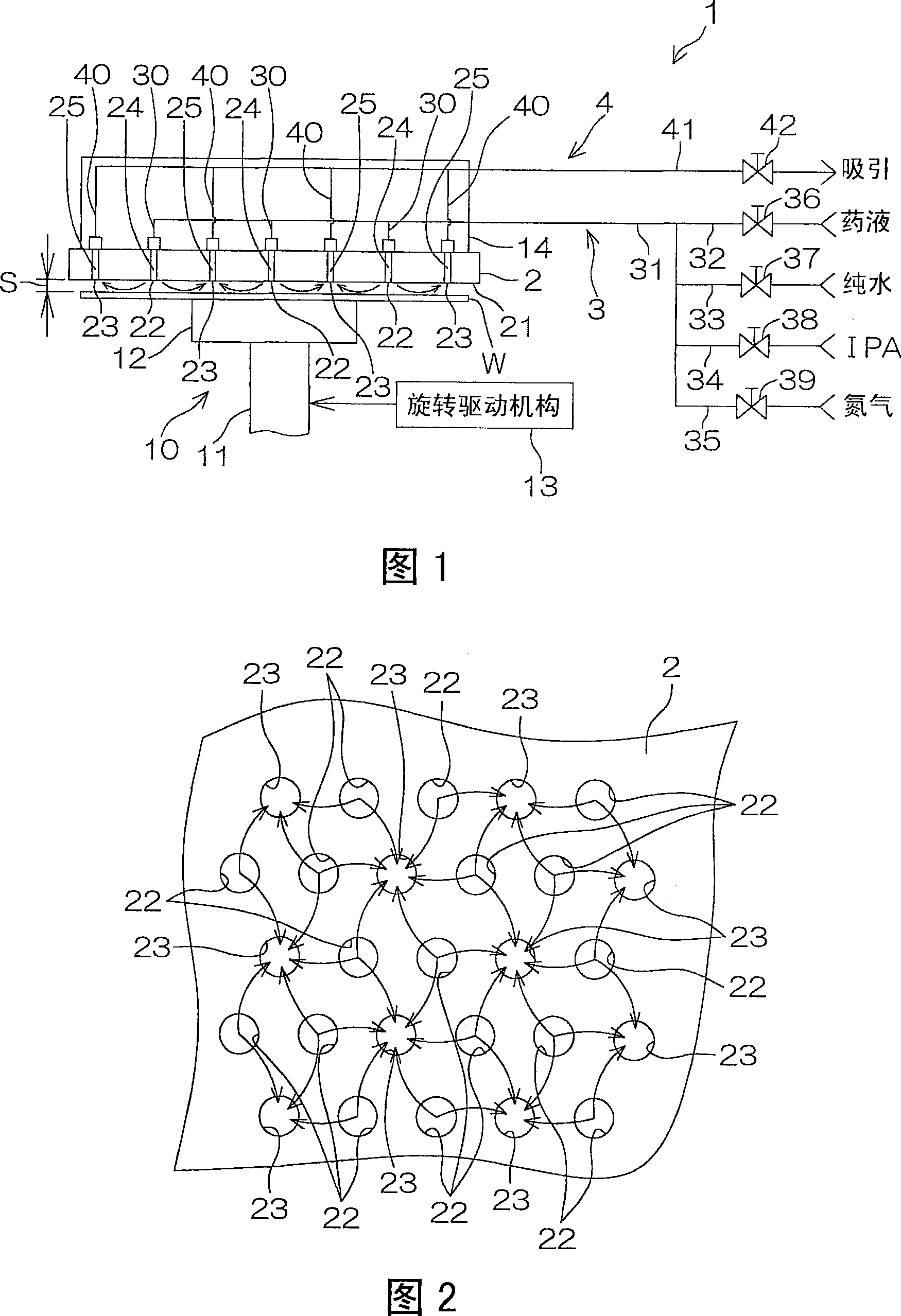

Substrate processing apparatus and substrate processing method

ActiveUS20080078426A1Facilitate agitationReduce surface tensionSemiconductor/solid-state device manufacturingCleaning using liquidsNitrogen gasOxygen

A rinsing liquid (DIW) is discharged from a rinsing liquid discharge port formed in a blocking member to perform rinsing processing to a substrate surface while a nitrogen gas is supplied into a clearance space, and a liquid mixture (IPA+DIW) is discharged from a liquid mixture discharge port formed in the blocking member to replace the rinsing liquid adhering to the substrate surface with the liquid mixture while the nitrogen gas is supplied into the clearance space. Thus, an increase of the dissolved oxygen concentration of the liquid mixture can be suppressed upon replacing the rinsing liquid adhering to the substrate surface with the liquid mixture, which makes it possible to securely prevent from forming an oxide film or generating watermarks on the substrate surface.

Owner:DAINIPPON SCREEN MTG CO LTD

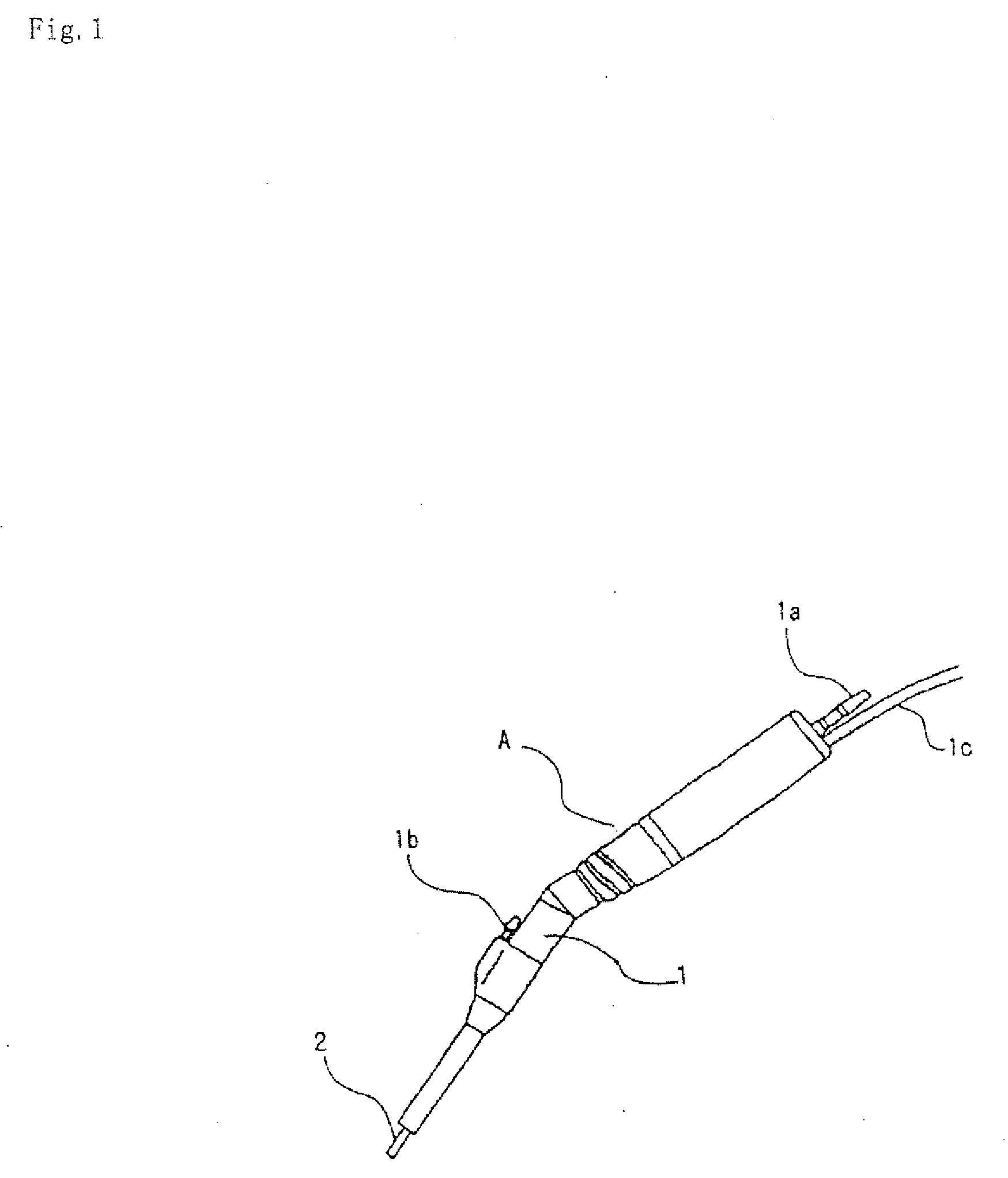

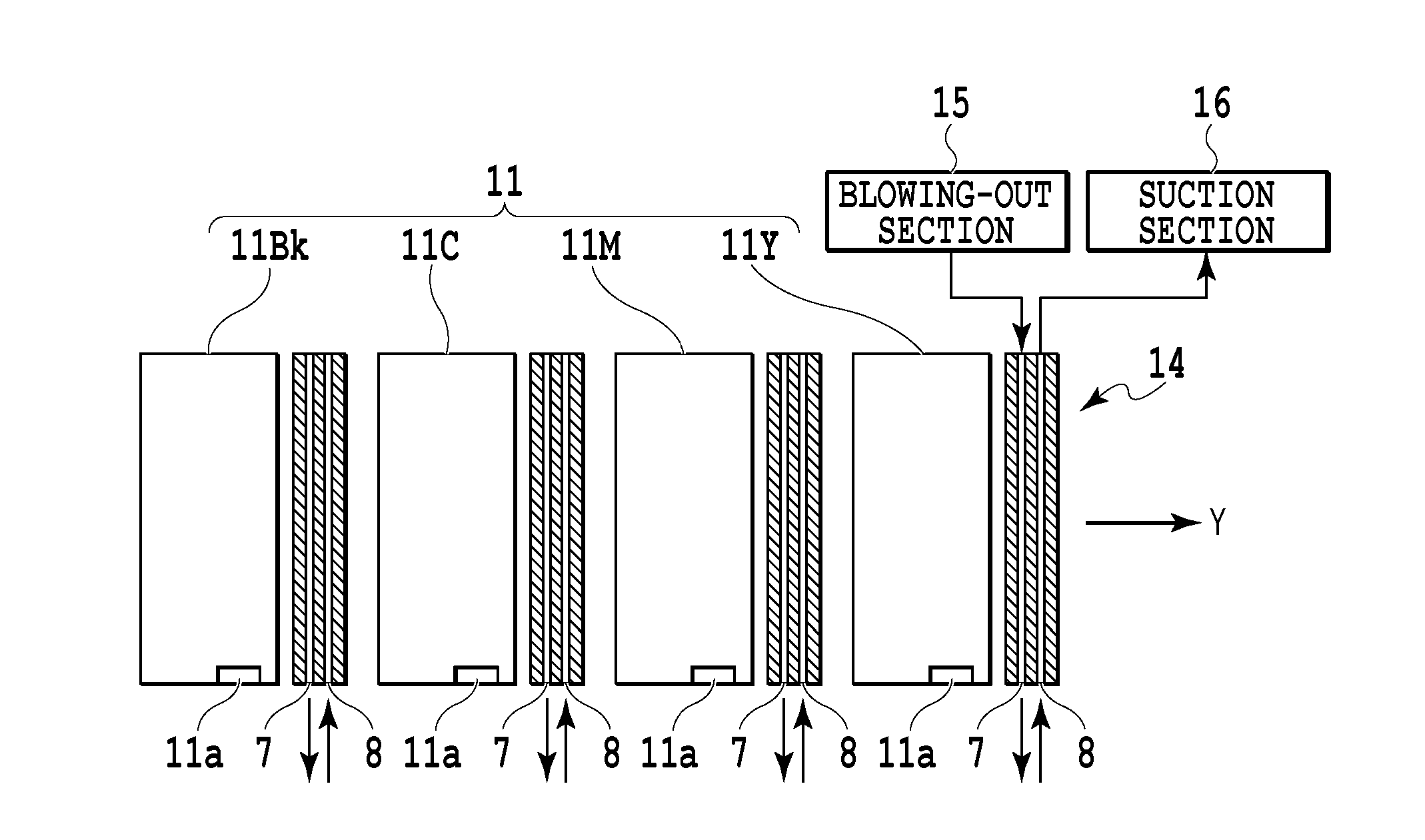

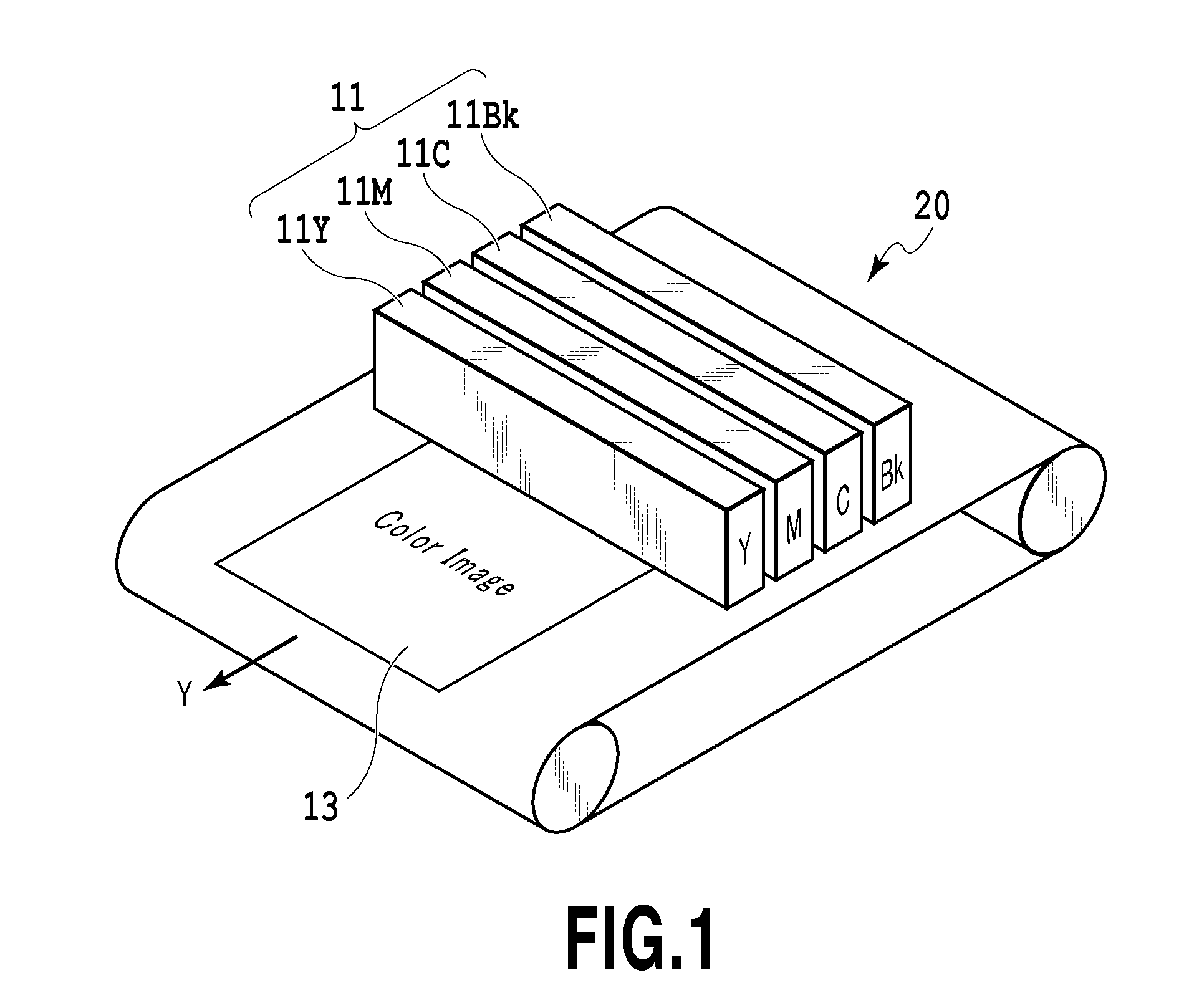

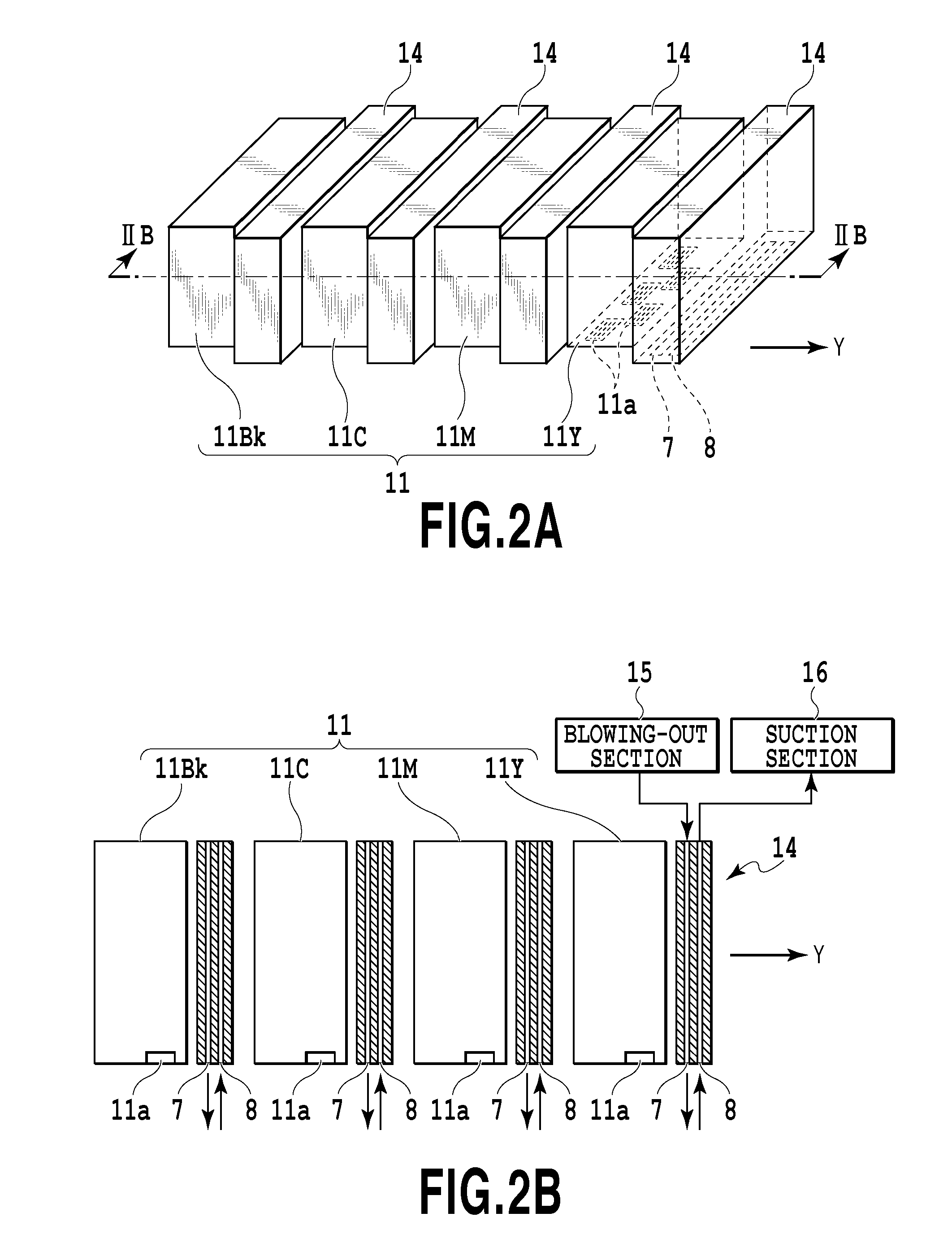

Liquid ejection apparatus and liquid ejection method

Owner:CANON KK

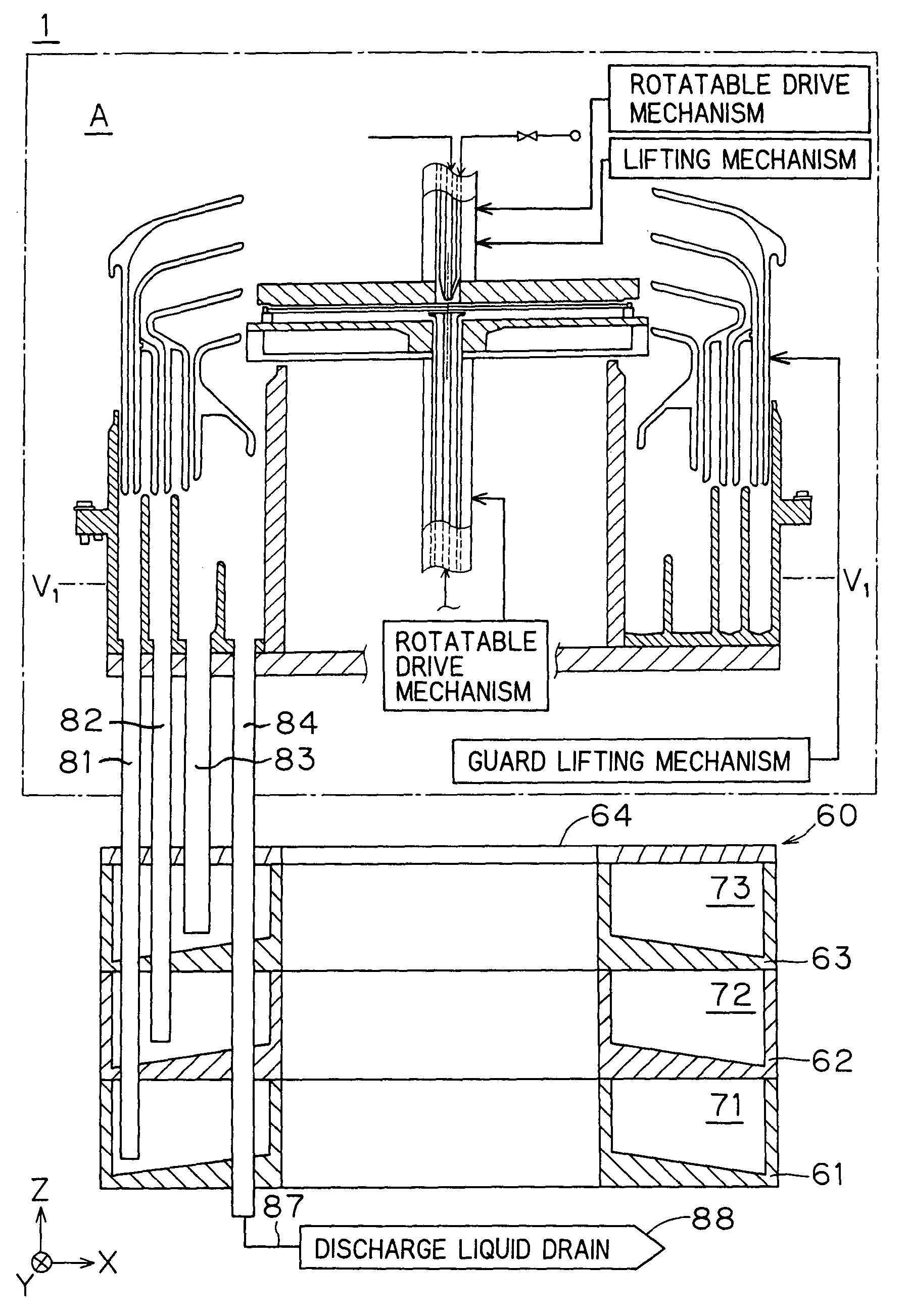

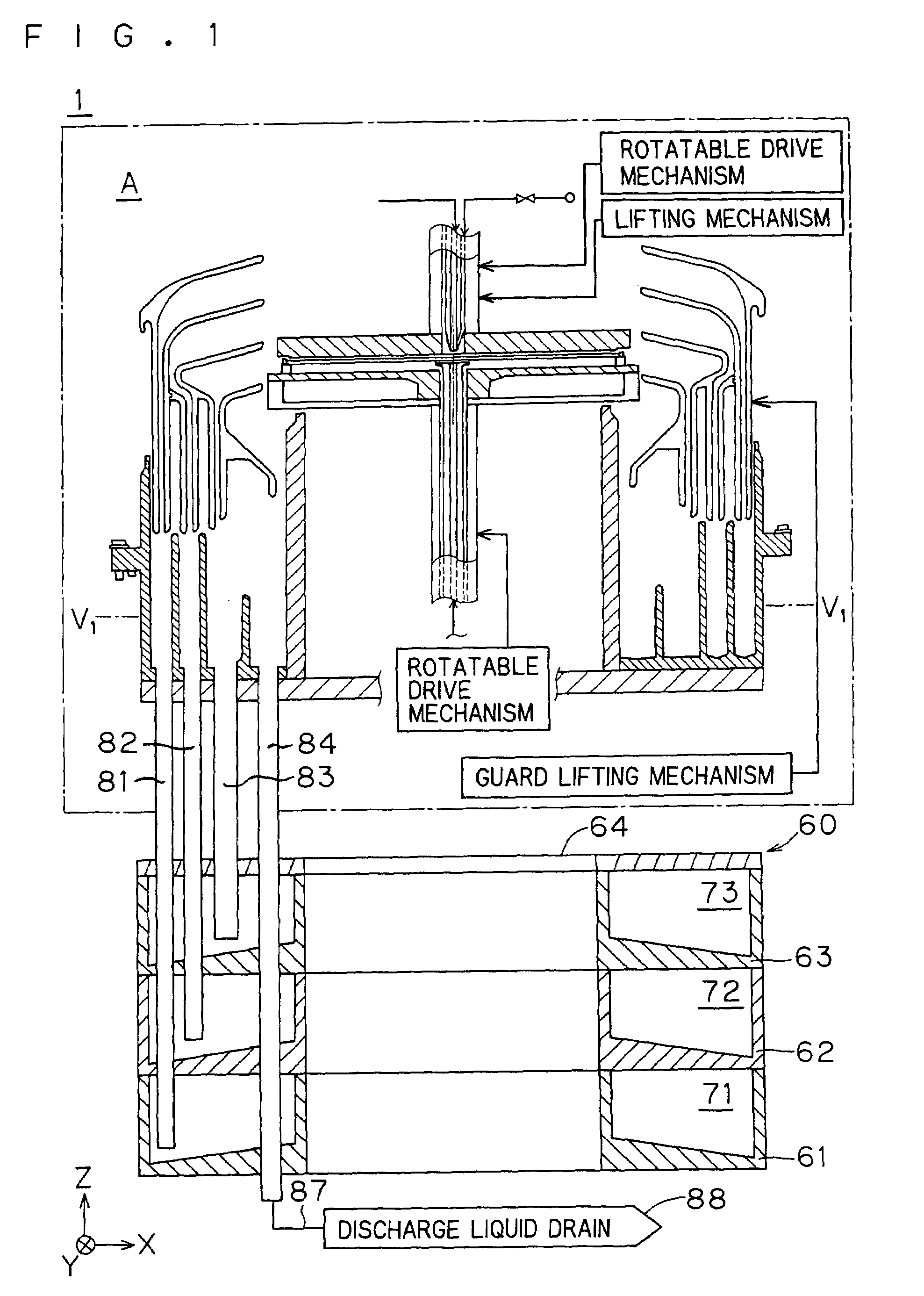

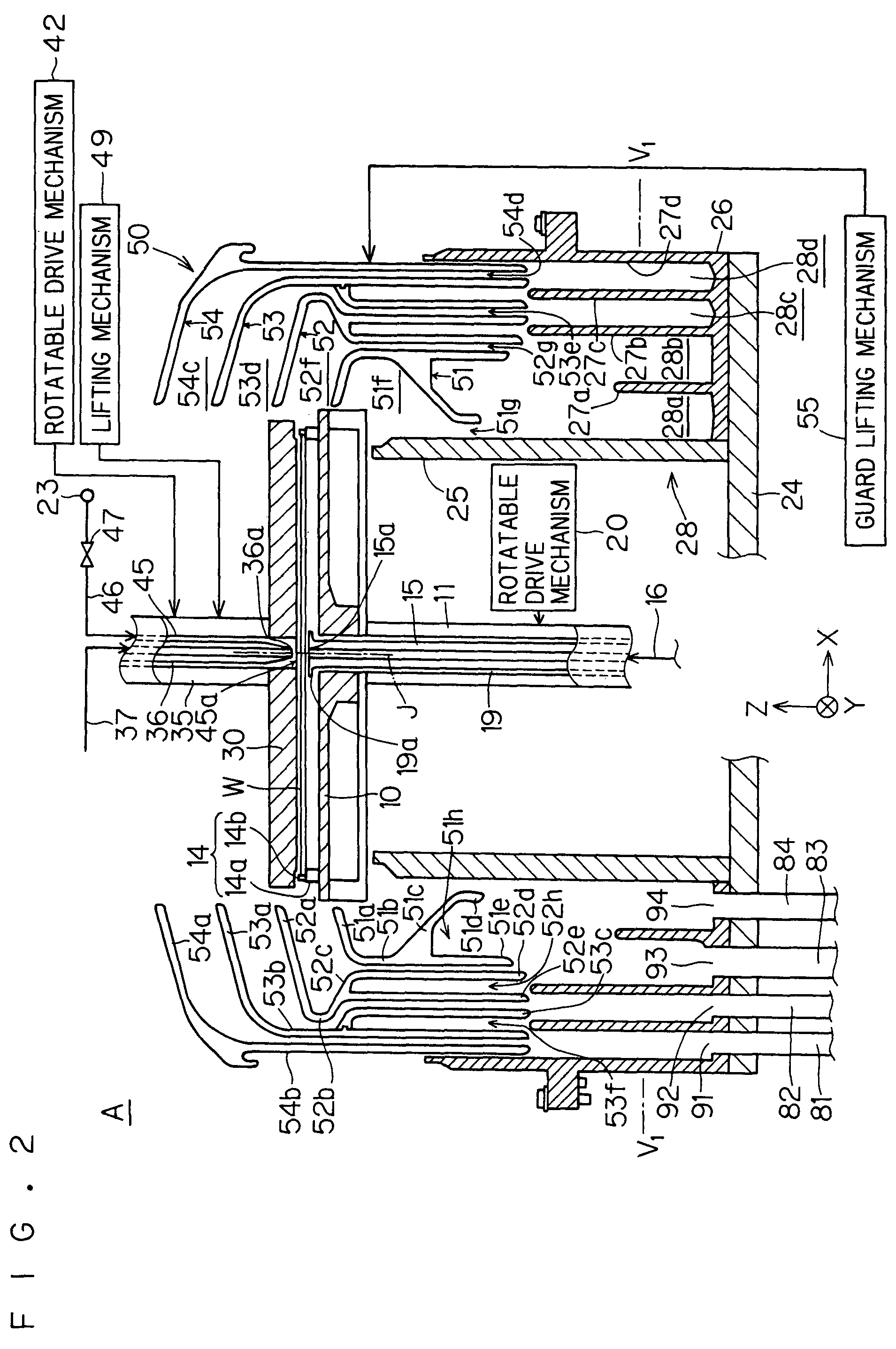

Substrate processing apparatus

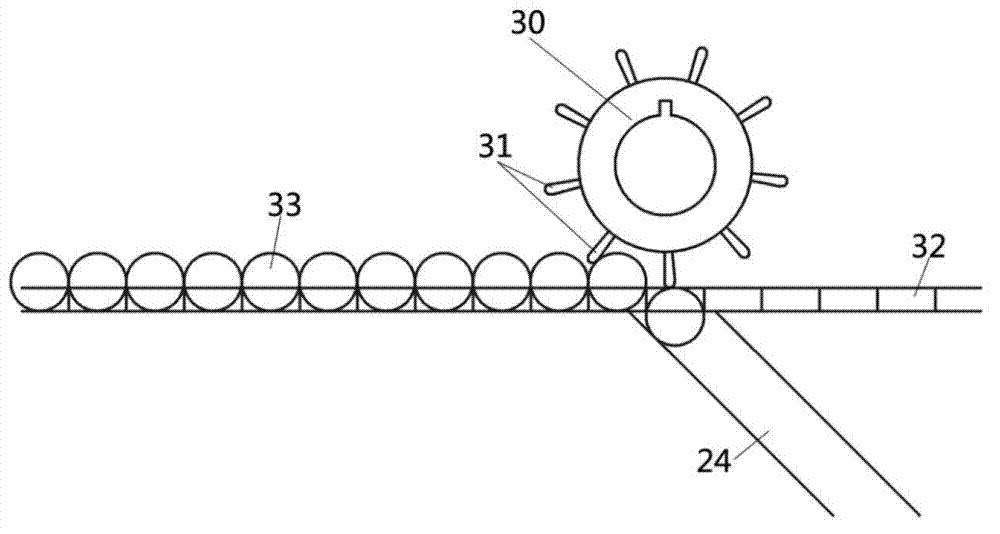

ActiveUS7584760B2Curb reboundShorten the timeFouling preventionSemiconductor/solid-state device manufacturingEngineeringNozzle

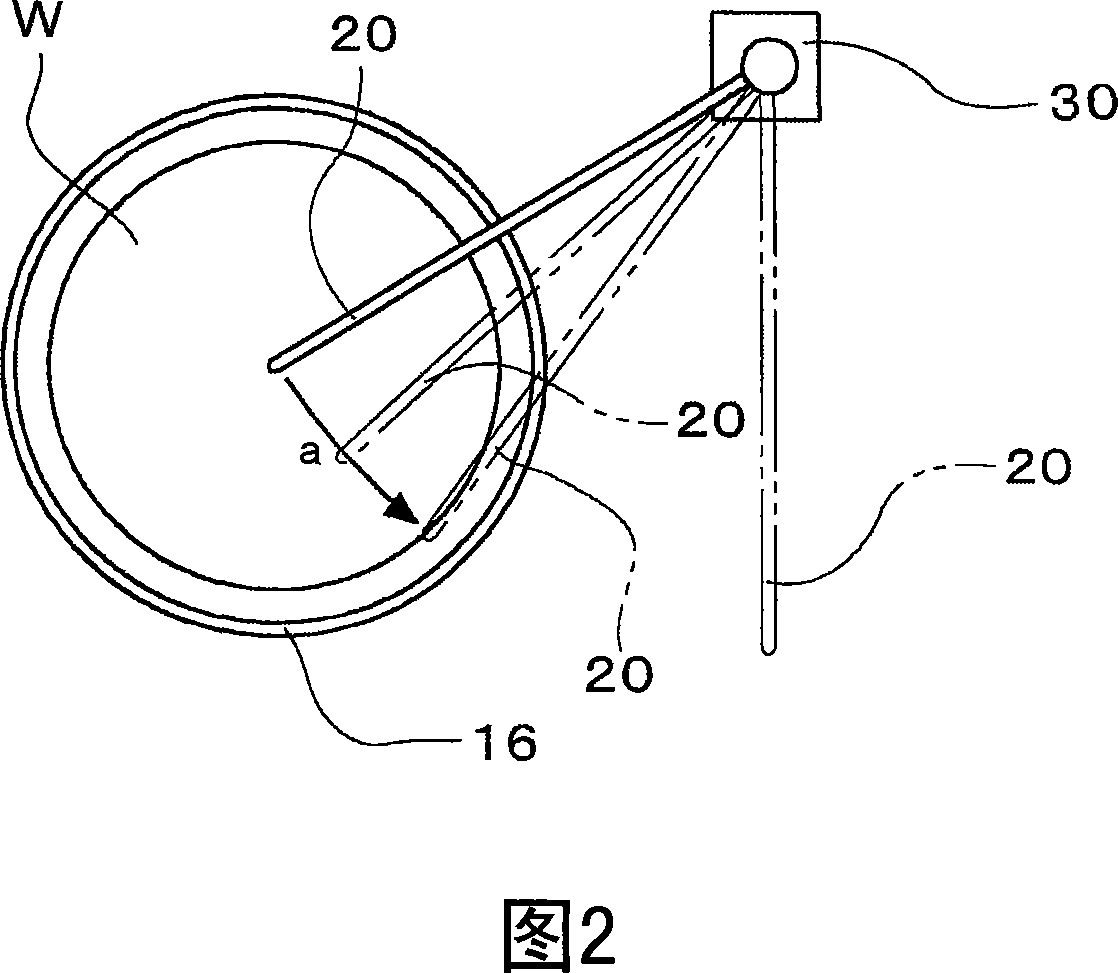

A substrate (W) is held and rotated in its horizontal position on a spin base (10). A processing liquid can be supplied from a processing liquid lower nozzle 15 to the lower surface of the substrate (W). The upper surface of the substrate (W) is covered with an atmosphere blocking plate (30). A splash guard (50) is disposed so as to circumscribe the substrate (W). A guard (52) is curved such that the vertical cross section of a recovery port (52f) of the splash guard (50) is of substantially U-shape opening to the center of the splash guard (50), so that the maximum internal diameter part of the recovery port (52f) is brought near a guard (53). The space between the internal wall surface of the recovery port (52f) and the substrate (W) is increased to thereby suppress the bounce of the processing liquid flying spattering from the substrate (W) in rotation.

Owner:DAINIPPON SCREEN MTG CO LTD

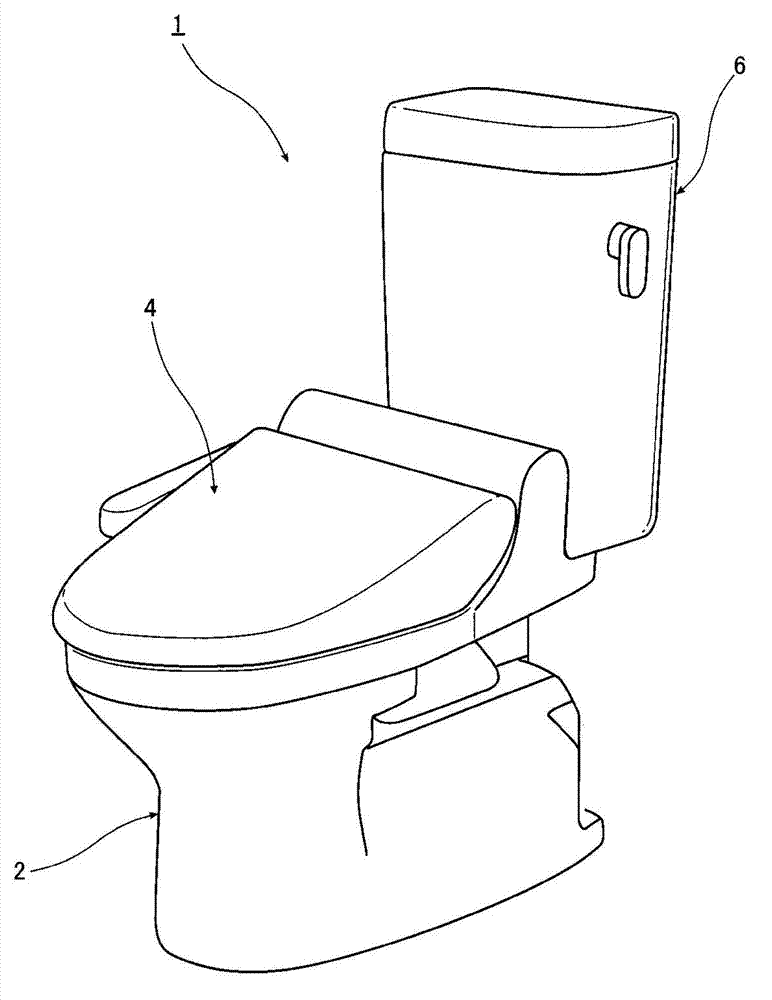

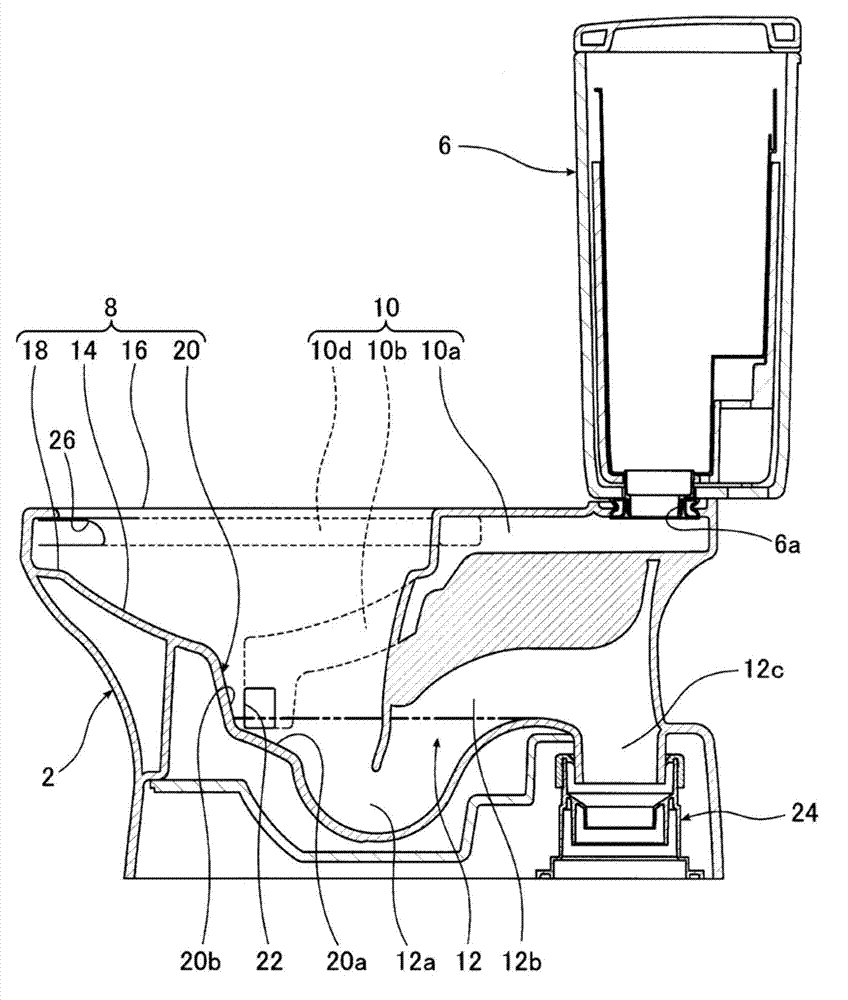

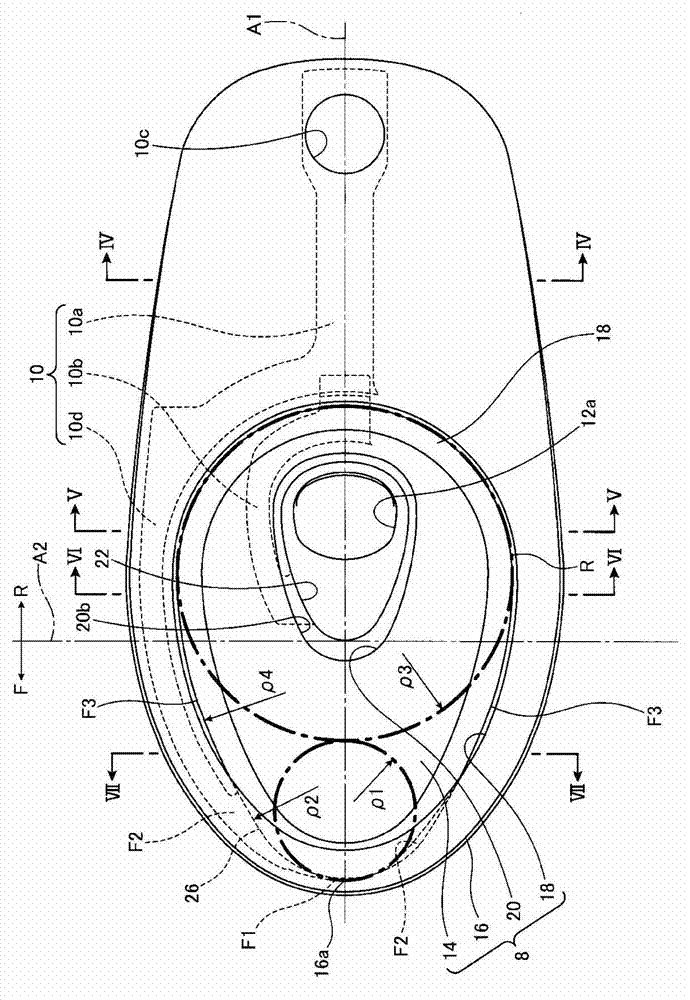

Flush toilet

The invention provides a flush toilet which can suppress the splash-up produced when the second circulation swirl flow collides with the first circulation swirl flow spouted from the water spouting portion. The flush toilet (1) of the invention includes a bowl portion (8) having a bowl-shaped waste receiving surface (14), a rim portion (16) formed on the top edge portion thereof, and a shelf portion (18) formed between the rim portion and the waste receiving surface; a water discharge path (12) for discharging waste, the path including an inlet (12a) which is connected at the bottom of the bowl portion; a water spouting portion (26) for spouting flush water onto the shelf portion of the bowl portion to form a swirl flow; and a water conduit (10d) for supplying flush water to the spouting portion. The water spouting portion is formed on the rim portion, and a first swirl trajectory (T1) of a first circulation and a second swirl trajectory (T2) of a second circulation are mutually different when flush water spouted from the water spouting portion swirls along the rim portion.

Owner:TOTO LTD

Substrate processing method and substrate processing apparatus

ActiveCN101075553ASuppress splashReduce speedSemiconductor/solid-state device manufacturingPhotosensitive material processingEngineeringVertical axis

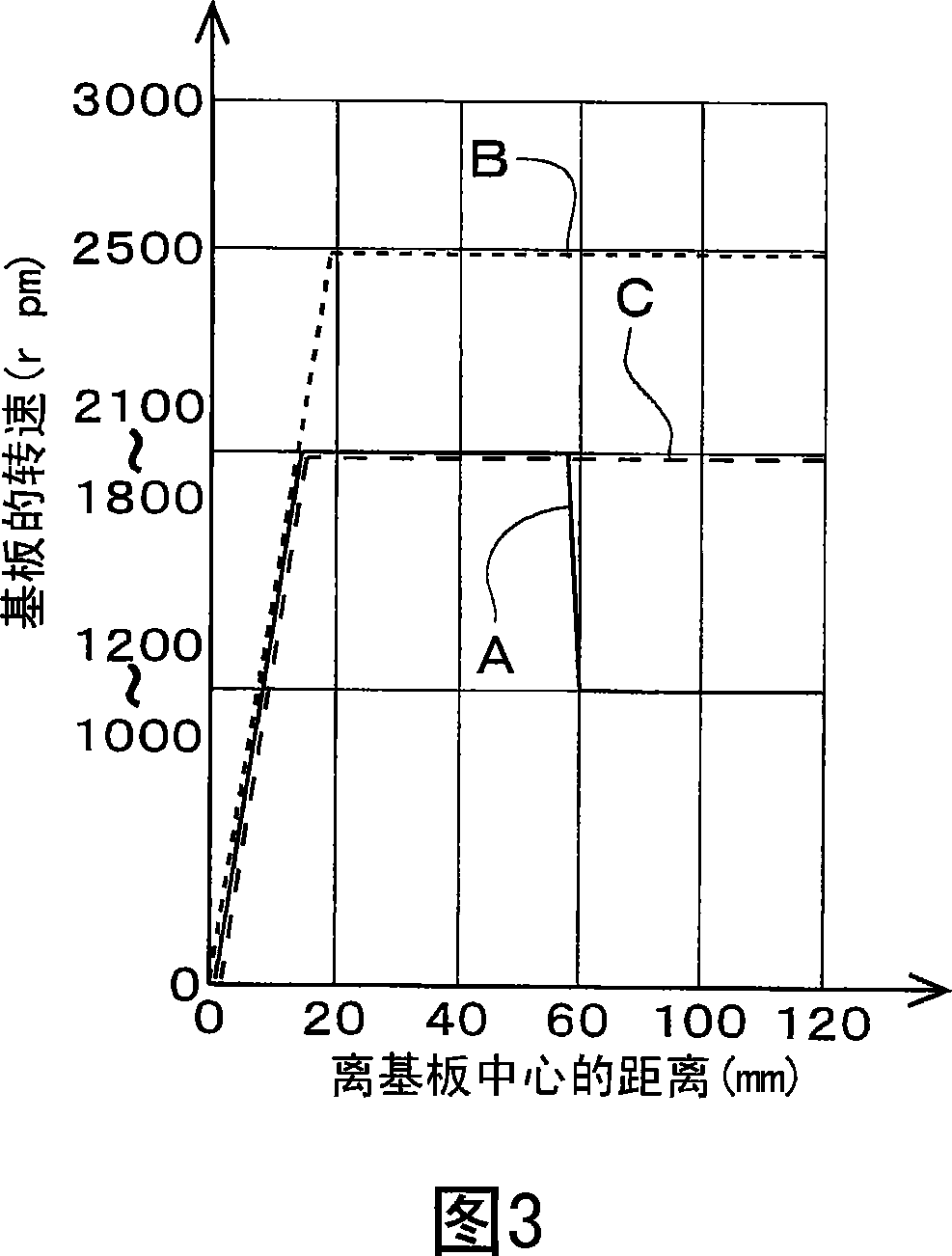

The invention provides a method capable of suppressing liquid splash at the circumferential edge of a substrate, and preventing liquid droplets due to liquid splash from adhering to the substrate again when moving a discharge nozzle for scanning while discharging a cleaning solution from the discharge nozzle to the surface of the substrate to make spin drying of the substrate. When a substrate W is held in a horizontal posture by a spin chuck 10 and rotated about a vertical axis with a rotation motor 14, while discharging the cleaning solution onto the surface of the substrate from an outlet of a de-ionized water discharge nozzle 20, the rotation speed of the substrate is decreased in a process that the outlet of the discharge nozzle is traveled from a position opposed to a center of the substrate to a position opposed to the circumferential edge of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

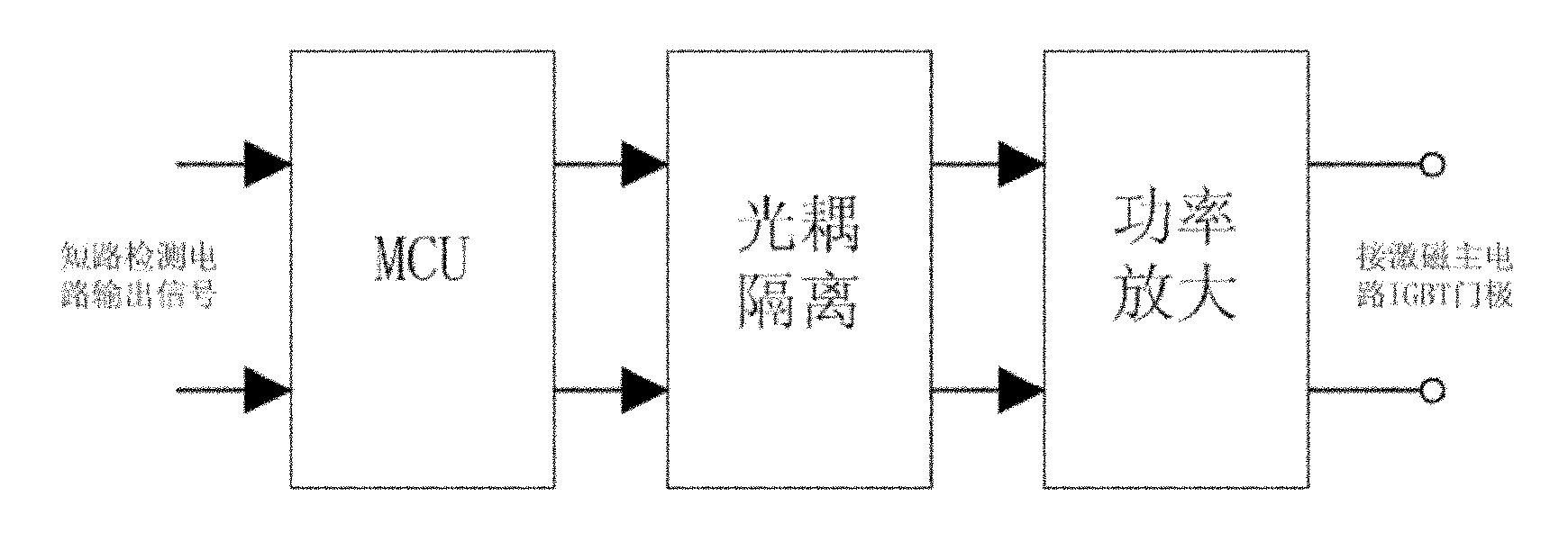

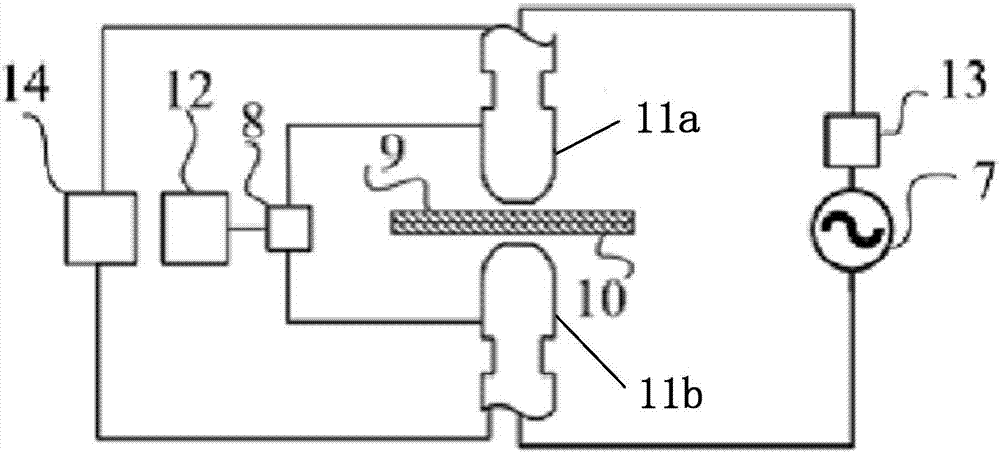

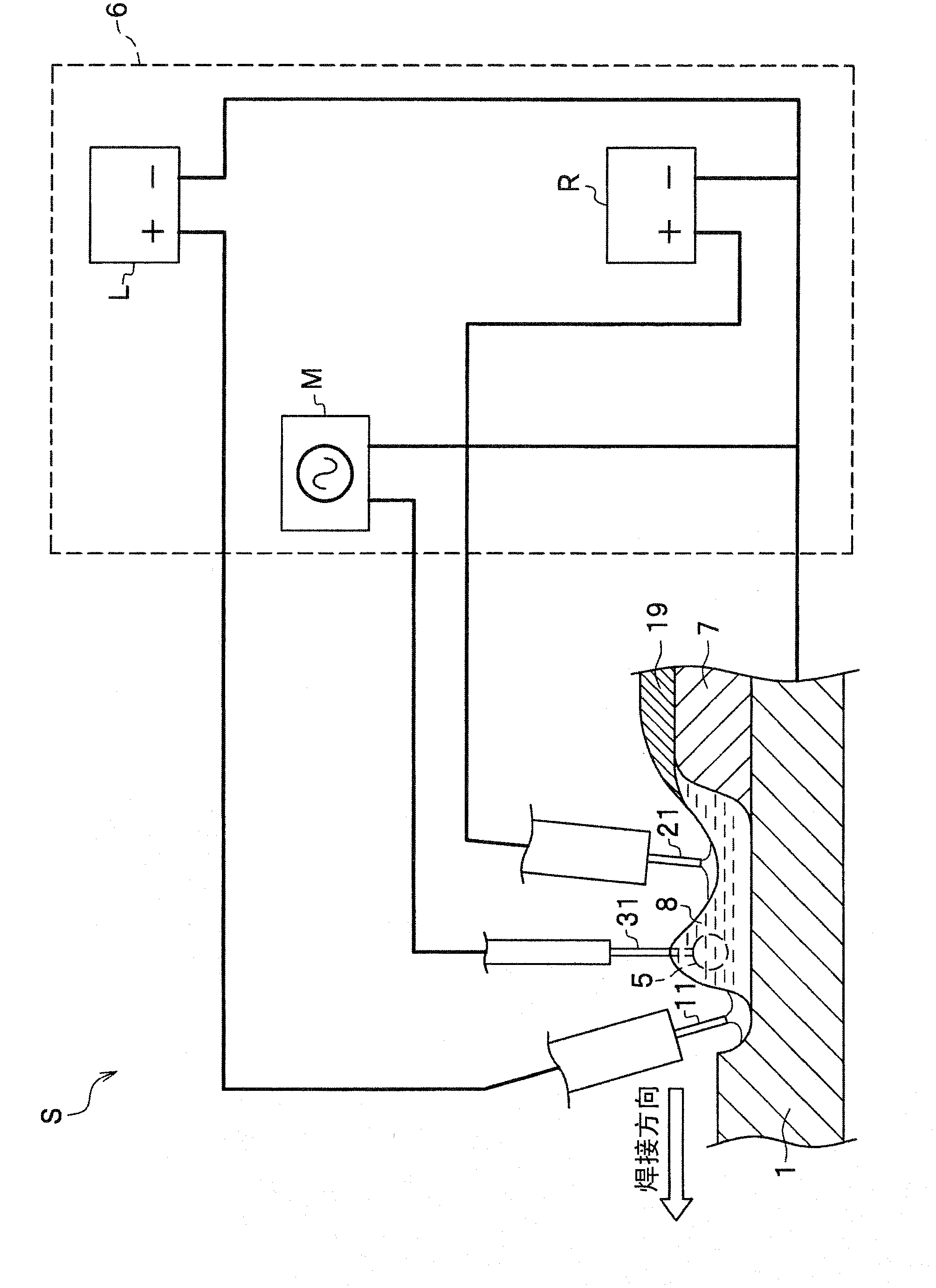

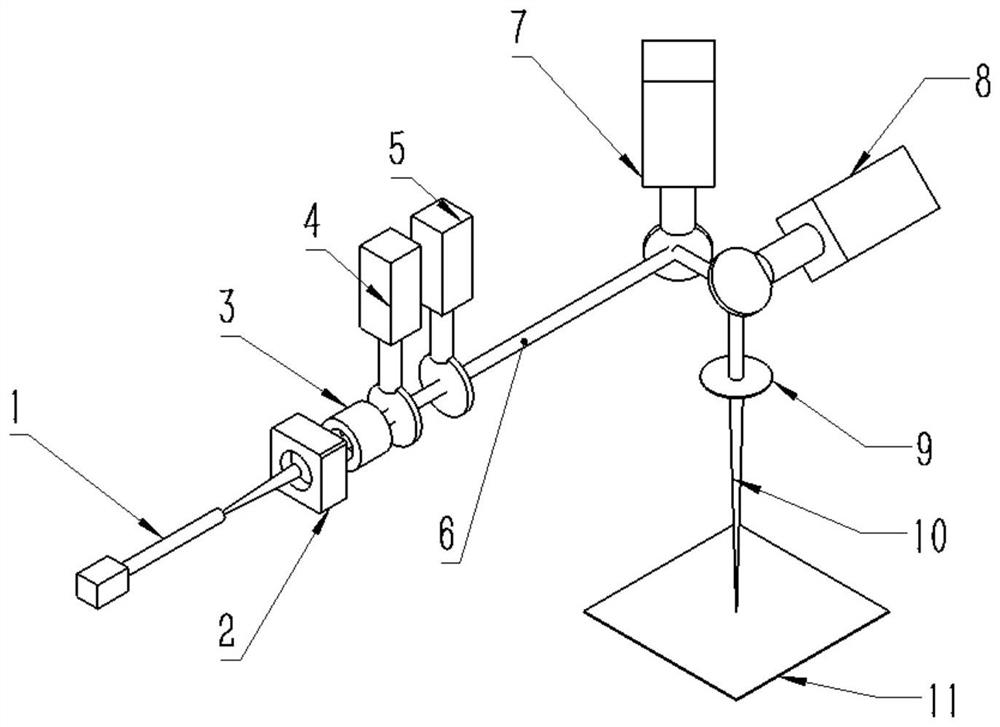

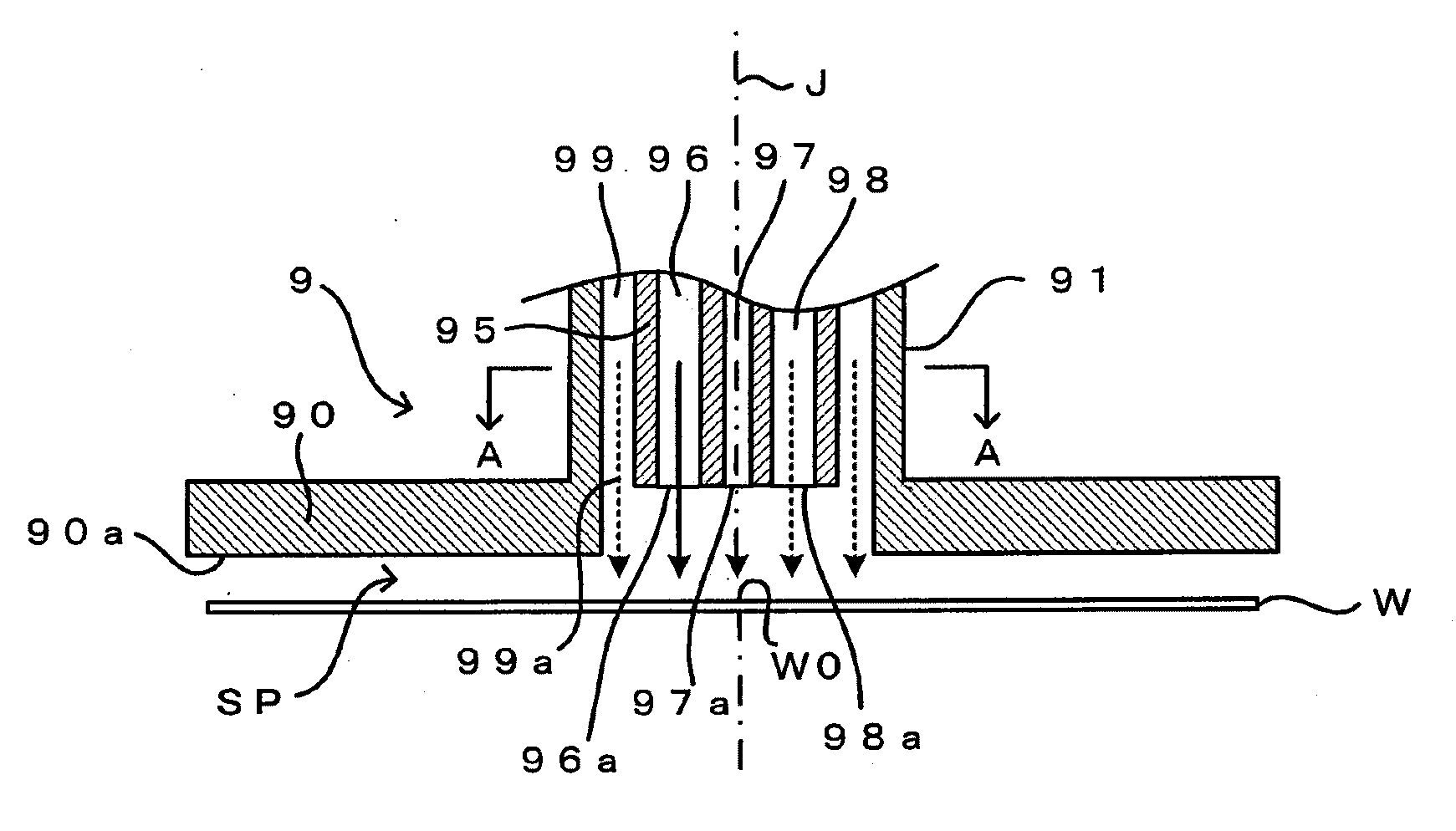

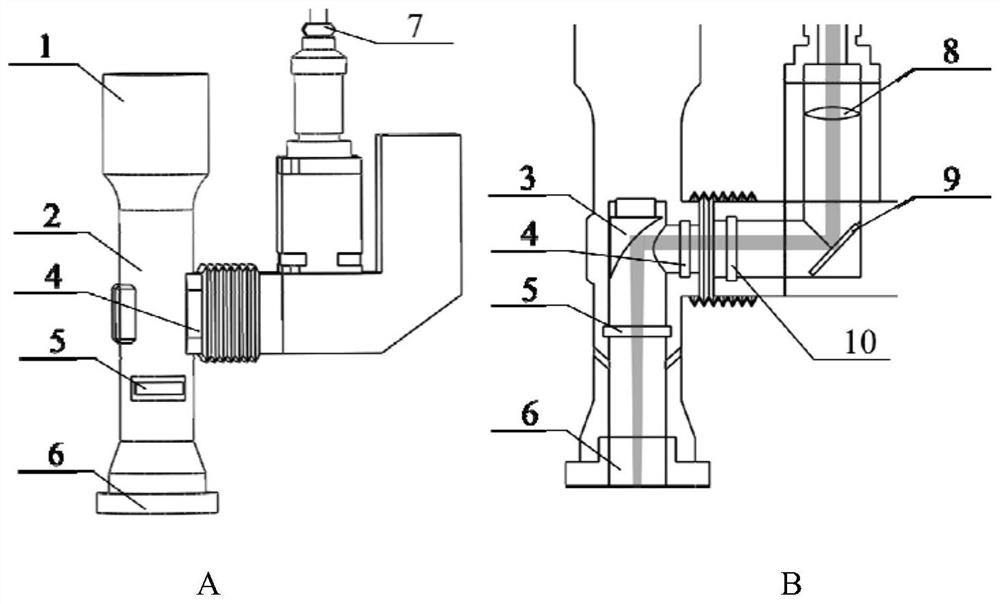

Device and method for assisting gas metal arc welding by using externally applied magnetic fields

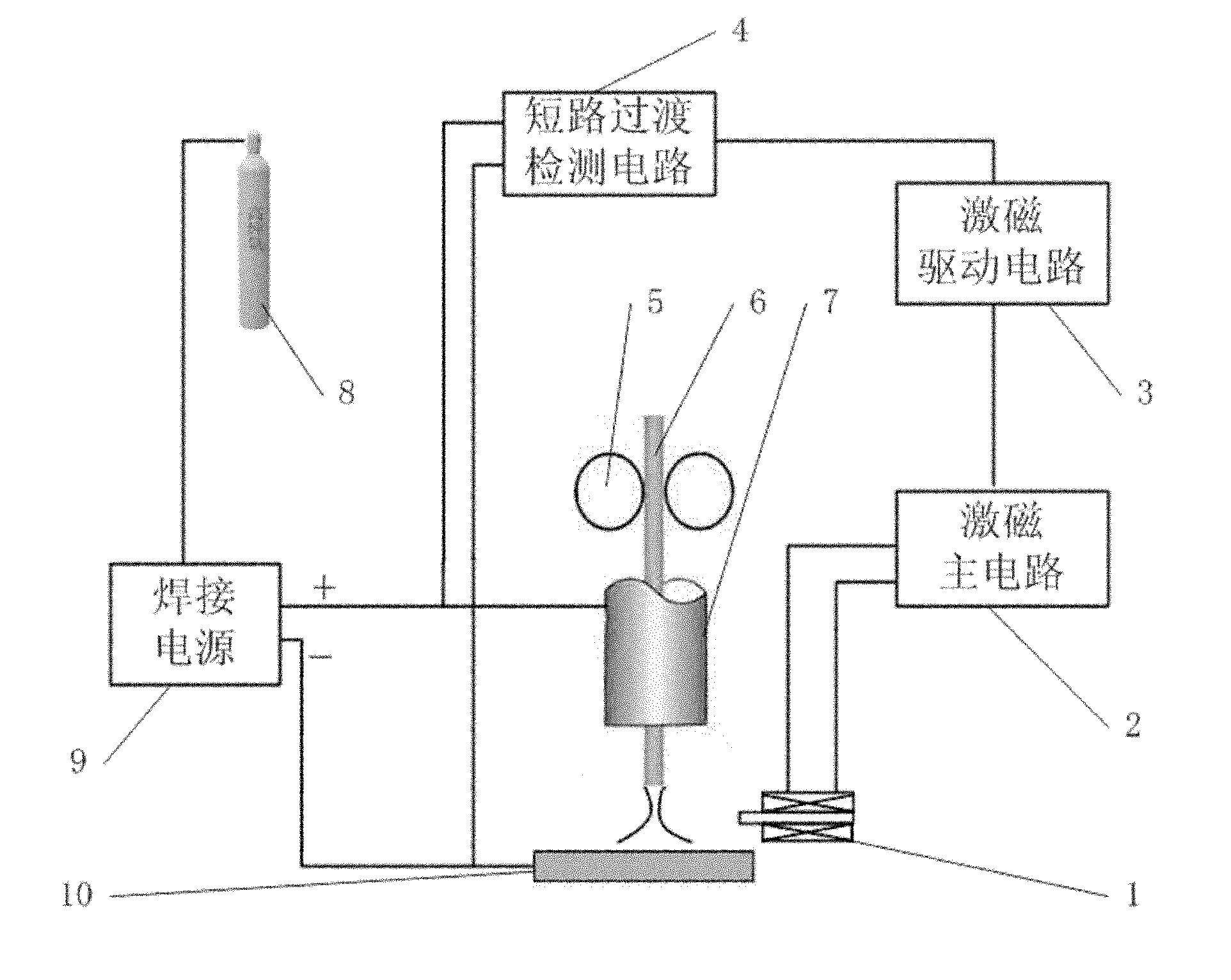

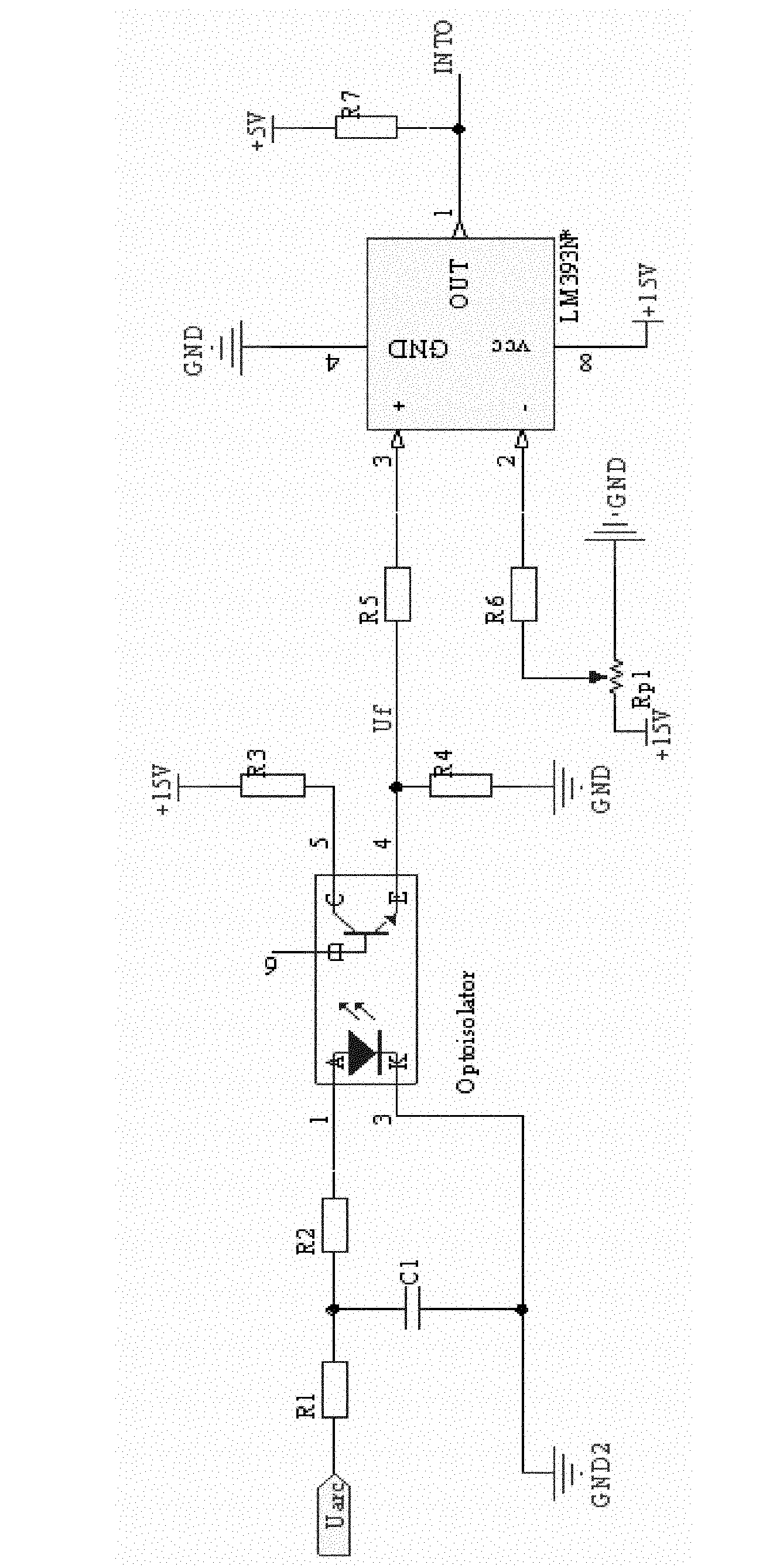

InactiveCN102133679AImproving Short Circuit Transition Welding ProcessReduce peak currentArc welding apparatusElectricityPulsed magnet

The invention discloses a device and a method for assisting gas metal arc welding by using externally applied magnetic fields, belonging to the field of welding techniques under the action of magnetic fields. The device comprises necessary conventional equipment for gas metal arc welding, a short circuiting transfer detection circuit, an exciting drive circuit, a main exciting circuit and a magnetic head device. According to the invention, during droplet short circuit period, a transverse pulsed magnet field which is acted on a short circuit liquid bridge and perpendicular to a welding-wire axis can be generated so as to promote the advanced fracture of the short circuit liquid bridge; and compared with the conventional method, the method provided by the invention has the advantages that the peak current during the short circuit period is reduced, the induced explosion and splash are lowered, and the regularity of a short circuit cycle in the process of short circuiting transfer welding can be improved. The device disclosed by the invention is simple in manufacturing, and the welding process of short circuiting transfer is obviously improved.

Owner:BEIJING UNIV OF TECH

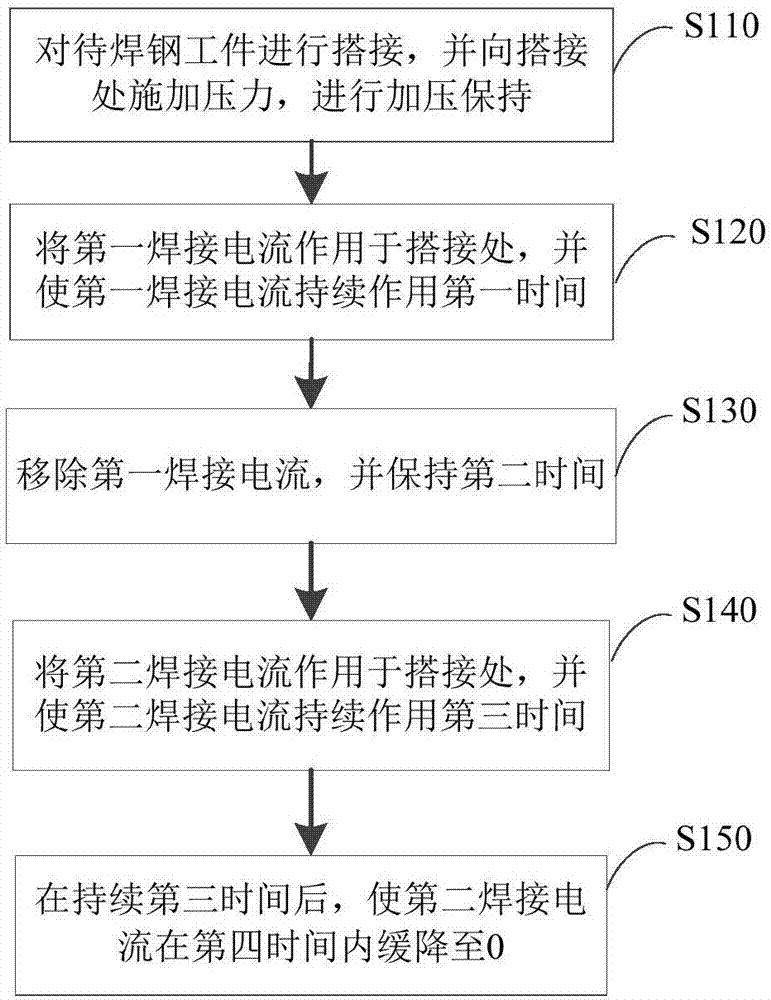

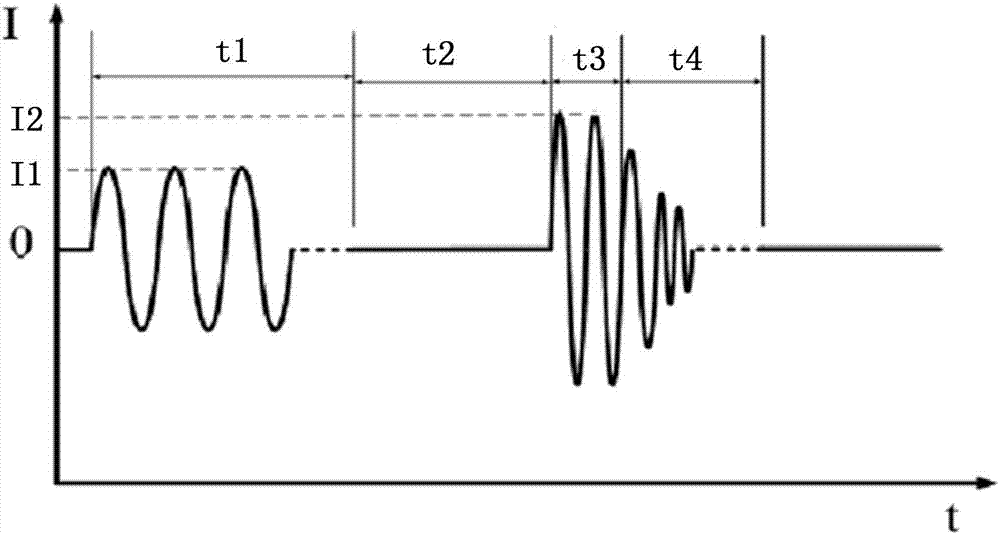

Resistance spot welding technique for steel workpiece with coating layer

ActiveCN107350613AEasy dischargeGuaranteed implementabilityWelding/soldering/cutting articlesResistance welding apparatusPower flowEngineering

The invention discloses a resistance spot welding technique for steel workpiece with a coating layer. According to the technique, the steel workpiece to be welded is connected in a lap joint mode, pressure is applied to the lap joint, and is increased and maintained; a first welding current is applied to the lap joint, and is enabled to continuously act for a first time; then the first welding current is removed and a second time is maintained; after the second time is maintained, a second welding current is applied to the lap joint, and is enabled to continuously act for a third time; after keeping for the third time, the second welding current is gradually reduced to zero within a fourth time; and wherein the second welding current is larger than the first welding current, and the sum of the first time and the second time is larger than or equal to 600 ms. The technique has the advantages that the coating layer is damaged by outputting the first welding current, the second welding current is output to complete heating welding, a longer stopping output timing sequence is arranged between the two, coating material is promoted to be discharged, splashing is inhibited, and a wide process window can be obtained.

Owner:江苏育材堂车身技术有限公司 +1

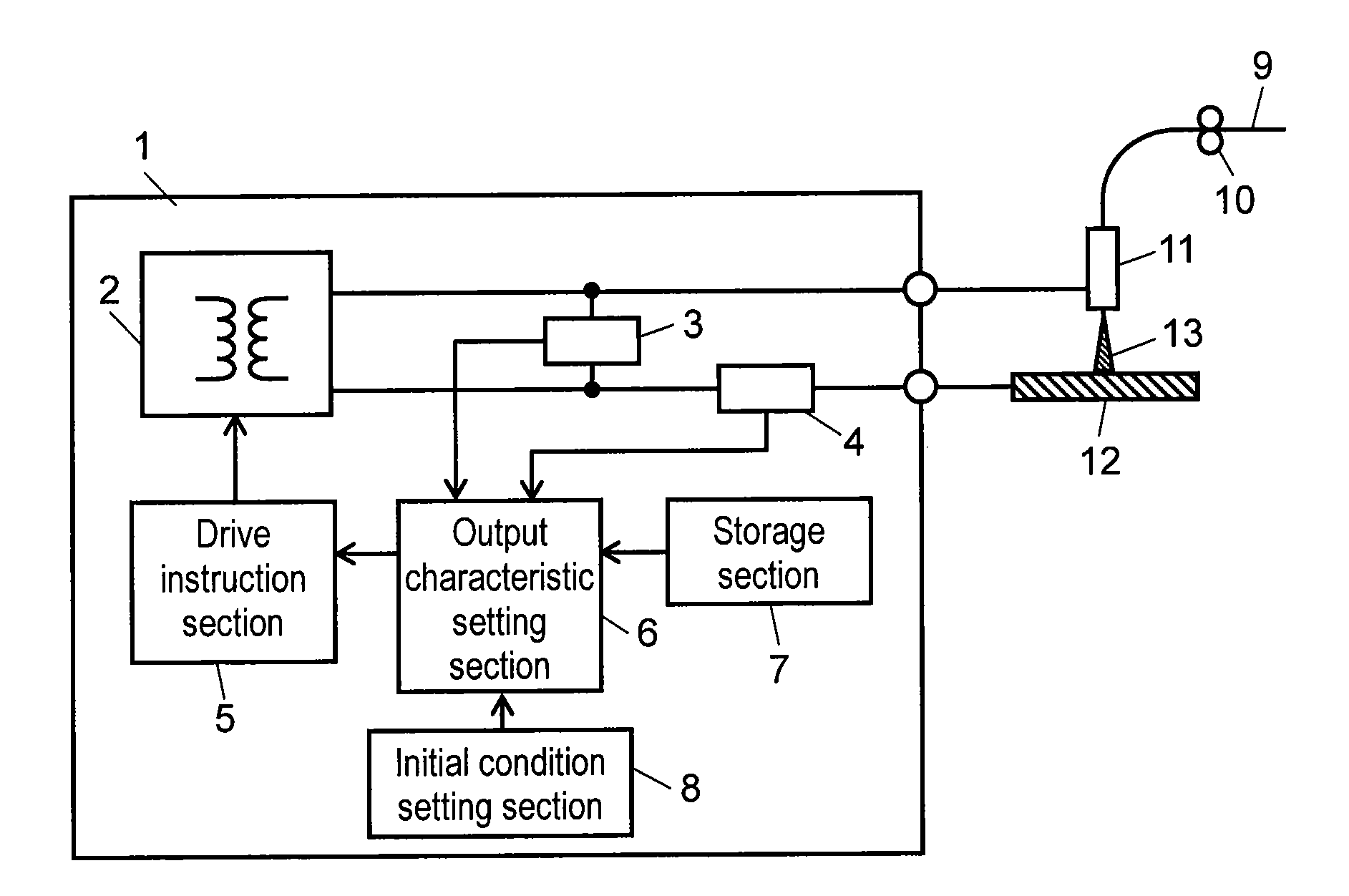

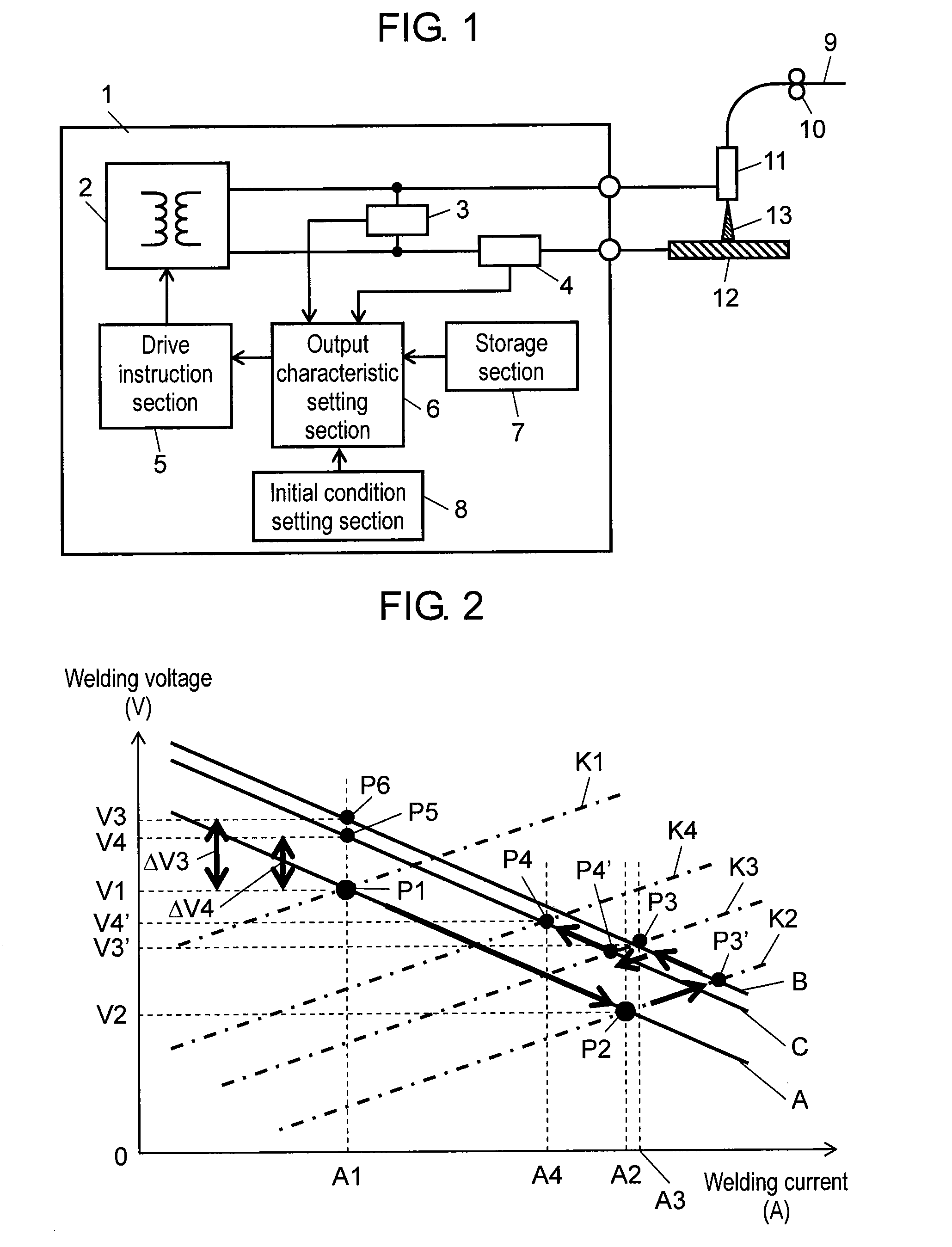

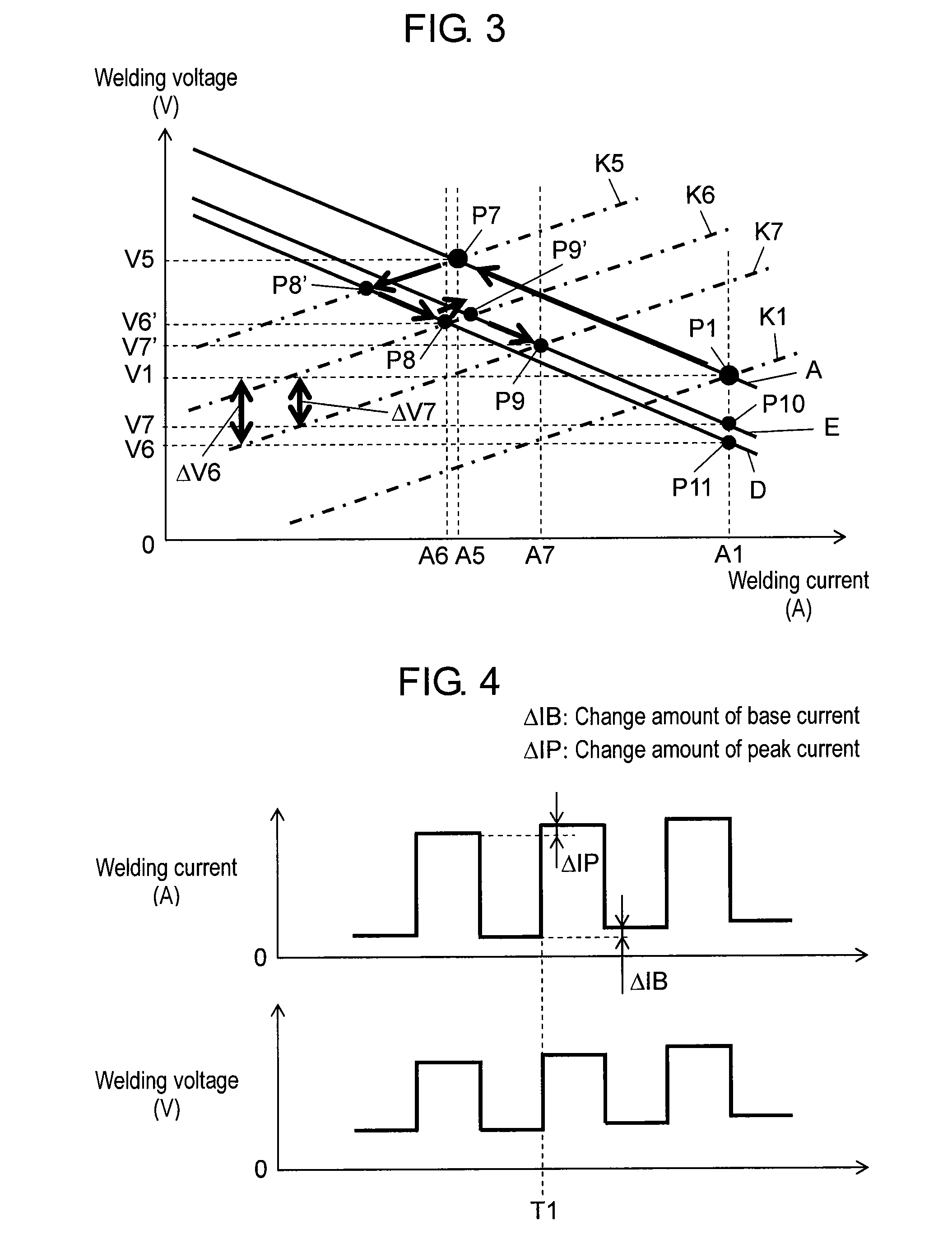

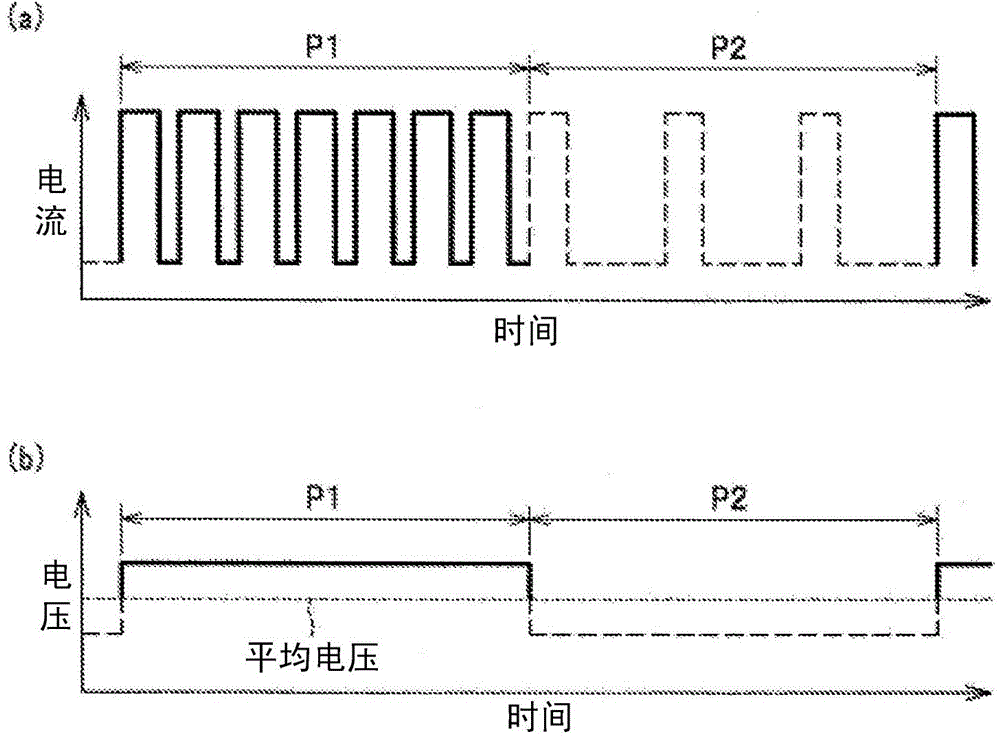

Method of controlling welding

ActiveUS20120000895A1Stable droplet transferInhibitionArc welding apparatusControl theoryVoltage control

A welding control method for a welding device having an output characteristic with a predetermined gradient showing a relation between a welding output voltage and a welding output current. By setting a set target welding voltage that is higher than the set initial welding voltage according to a difference between the set initial welding voltage and the welding output voltage, the welding output voltage is controlled to be the set target welding voltage. Thus, a proper arc length can be achieved early by correcting the change of the arc length due to, for example, motion of the hands of a welding operator.

Owner:PANASONIC CORP

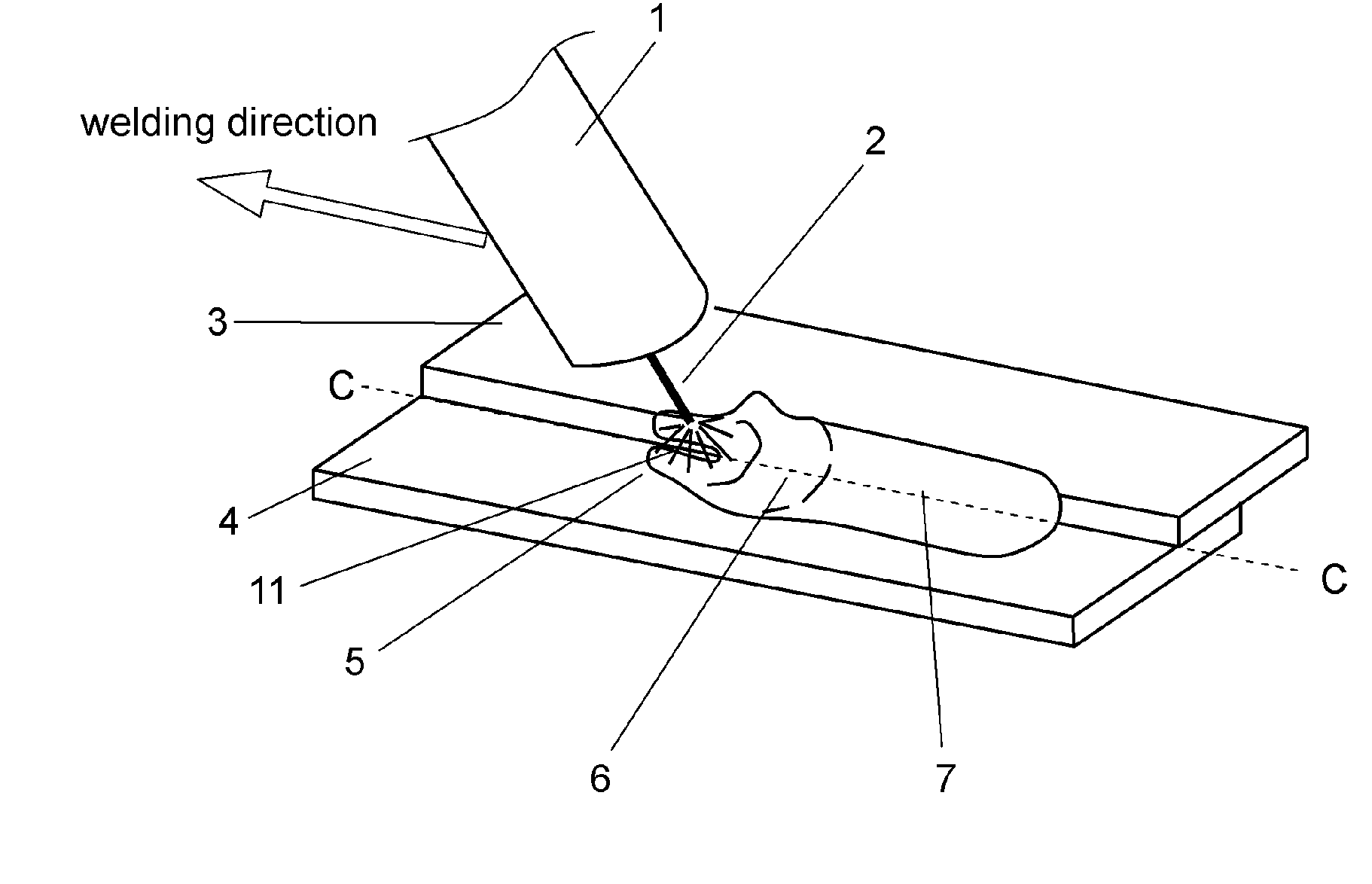

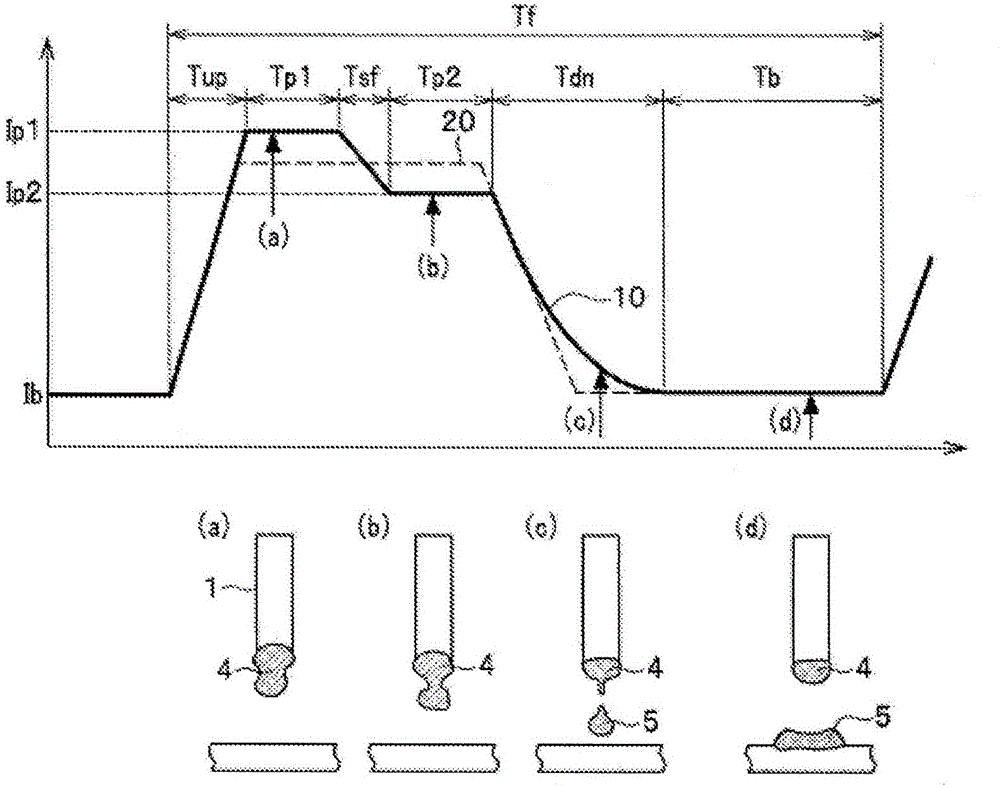

Arc welding control method

ActiveUS20150096965A1Minimize defectSuppress splashArc welding apparatusWelding/soldering/cutting articlesSteel platesElectric arc

As a conventional problem, welding on surface-treated material, such as a zinc-coated steel plate, considerably generates air holes including blowholes and also generates lots of spatters. Present invention provides a method of controlling arc welding performed in a manner that a short-circuit period, in which a short circuit is generated between a welding wire and an object to be welded, and an arc period, in which an arc is generated after release of the short circuit, are repeated alternately. According to the method, welding current is increased from an arc-regeneration-before current to a first welding current at a detection of release of the short circuit such that an increase gradient of the welding current becomes not less than 750 A / msec. This suppresses generation of air holes and spatters in welding work on a surface-treated material, such as a zinc-coated steel plate.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

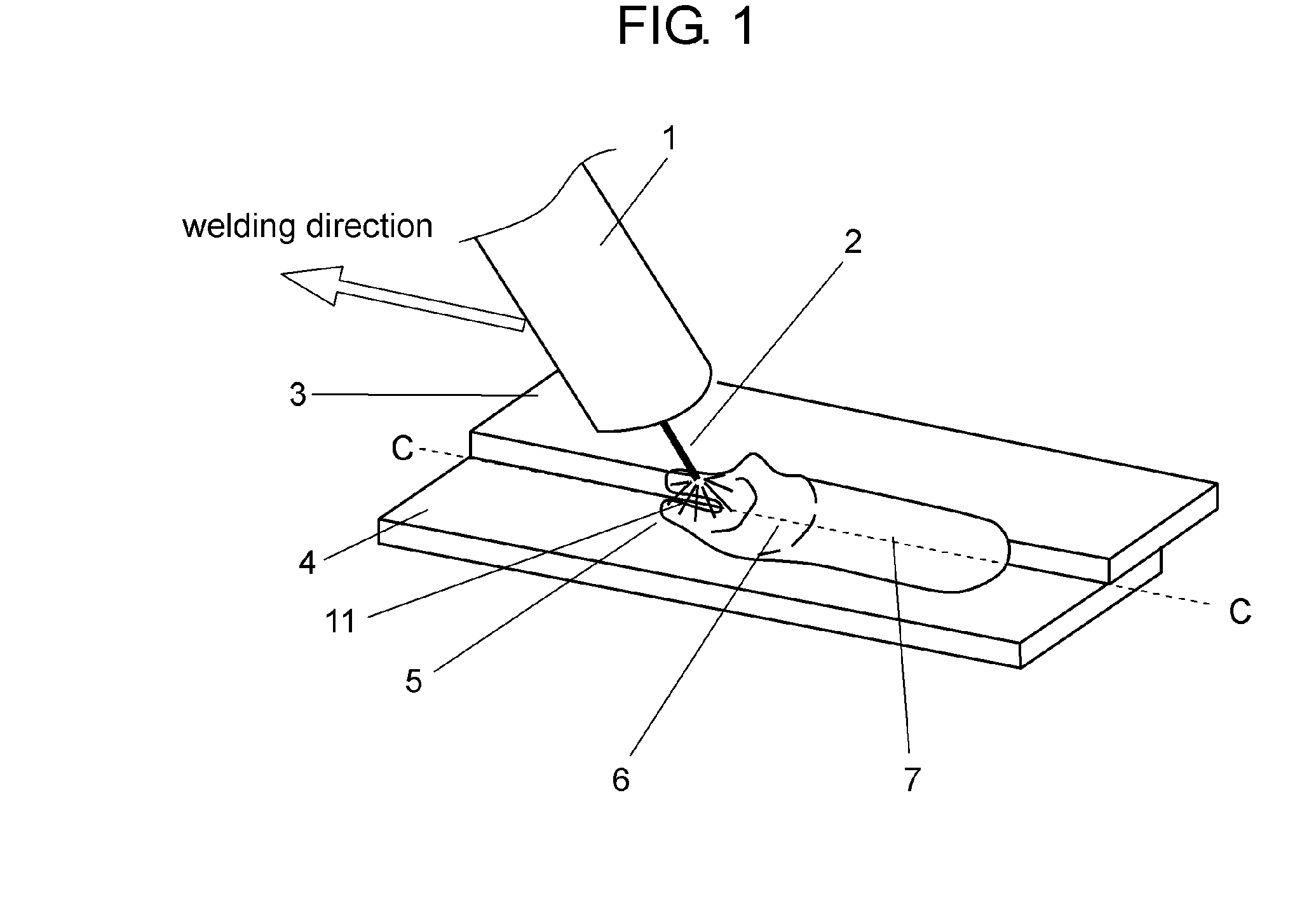

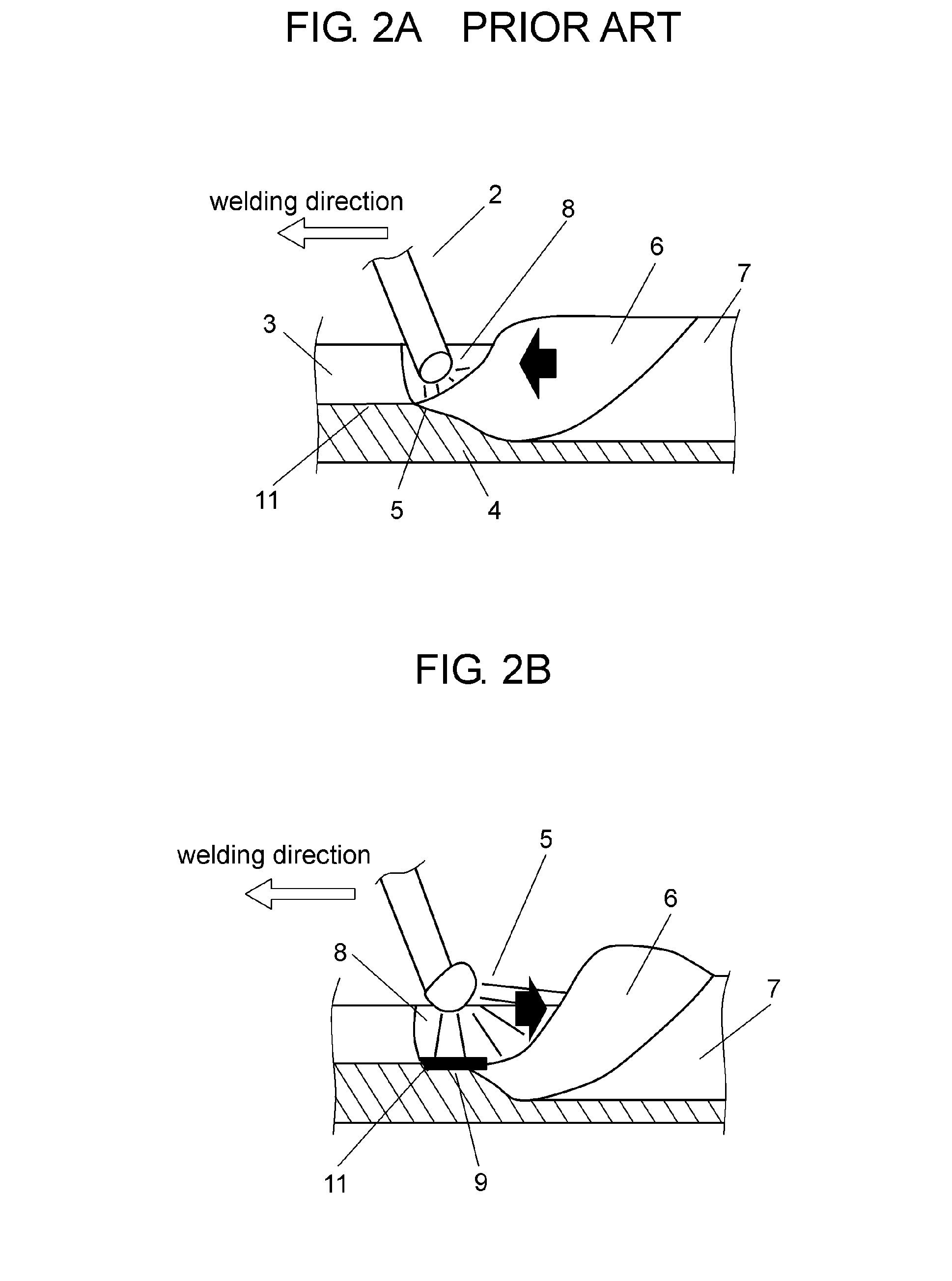

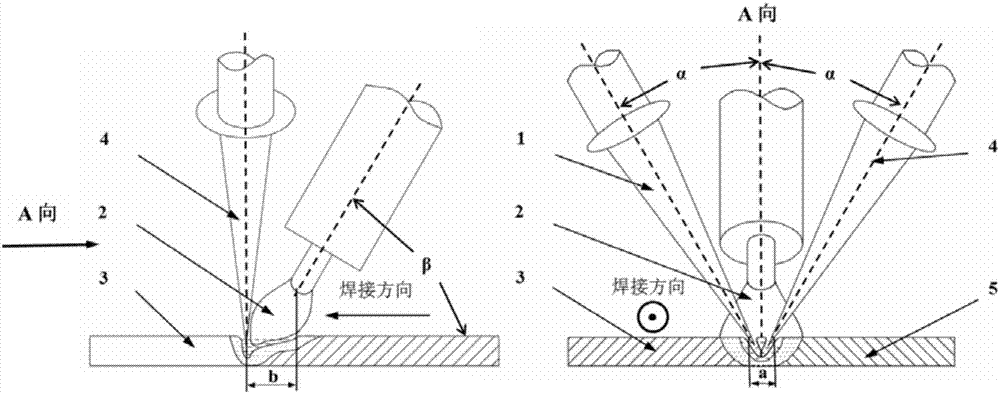

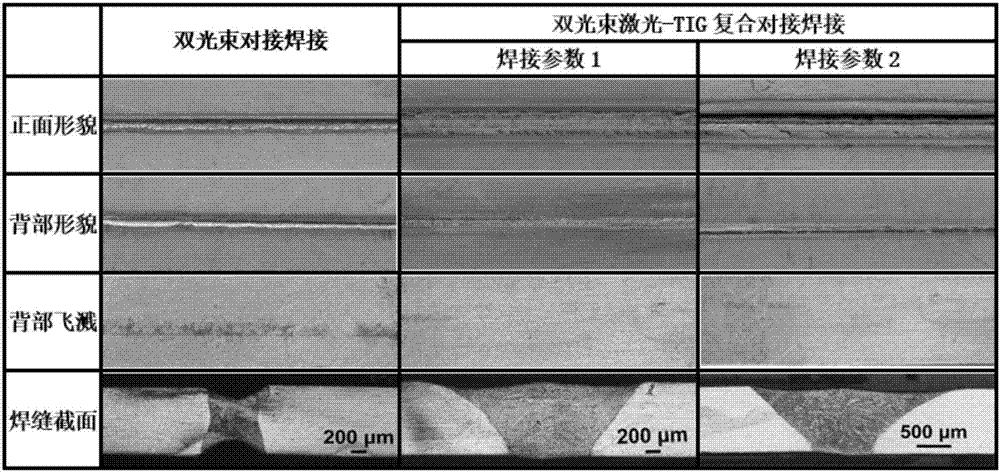

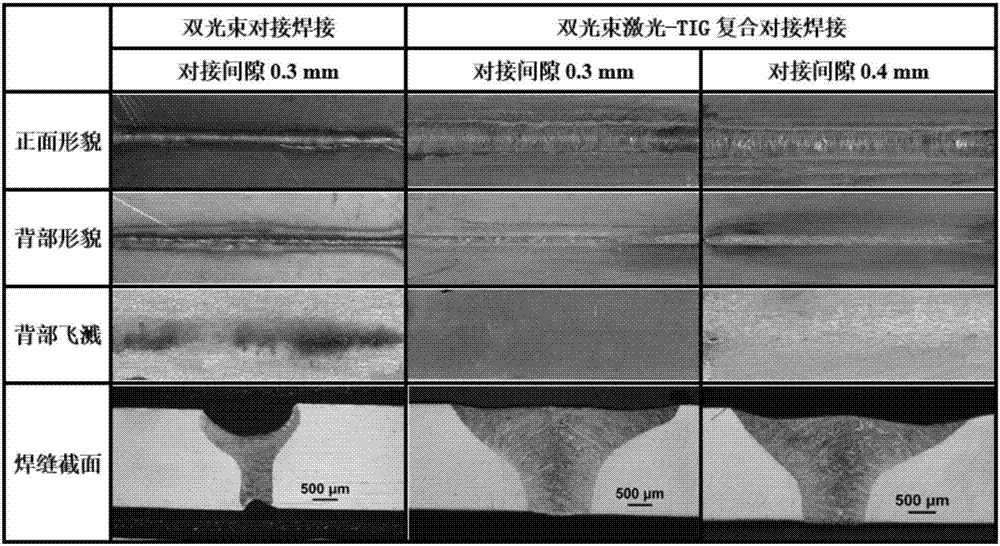

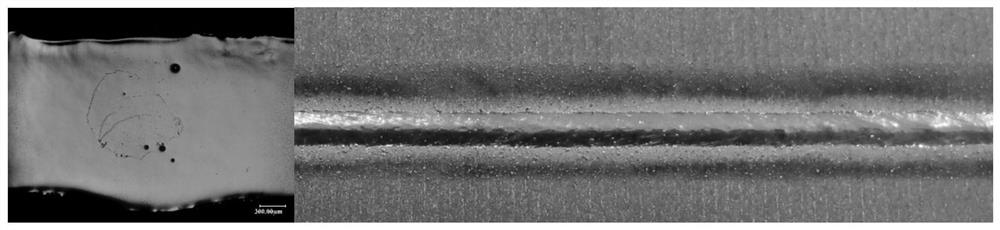

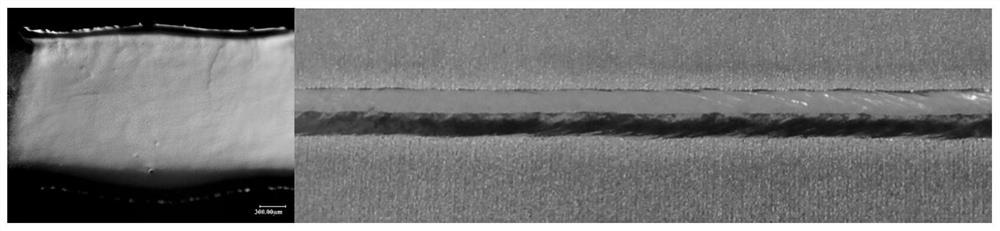

Double-beam laser TIG composite welding process for thin plate butt welding net forming

InactiveCN106944756AImprove bridgingImprove adaptabilityWelding/soldering/cutting articlesMetal working apparatusButt weldingButt joint

The invention discloses a double-beam laser TIG composite welding process for thin plate butt welding net forming, and the double-beam laser TIG composite welding process is suitable for butt welding of a thin plate. A provided welding method is suitable for realizing butt welding net forming of the thin plate under a butt joint clearance condition, and defects such as the sinking, the undercut, the back protrusion and splash which are prone to appear in a butt welding process are overcame. The process is characterized in that a butt welding seam serves as a center, incidence of double laser beams is conducted obliquely, and focuses of the double laser beams are symmetrically distributed on mental base materials at the two sides of the butt clearance; and a centre line of a TIG electric arc is in the same plane as a centre line of the butt welding seam and has a certain angle with a plate face; during the welding, the TIG electric arc is located at the rear side of the perpendicular bisector of the connection line of the focuses of the double laser beams. Compared with the traditional laser butt welding method, the clearance adaptability of the double-beam laser TIG composite welding process for thin plate butt welding net forming is greatly improved in the thin plate butt welding process, the weld width of a welding seam is obviously increased, surface forming and back forming of the welding seam are significantly improved, and the defects of back splash, protrusions and the like are effectively suppressed.

Owner:BEIJING UNIV OF TECH

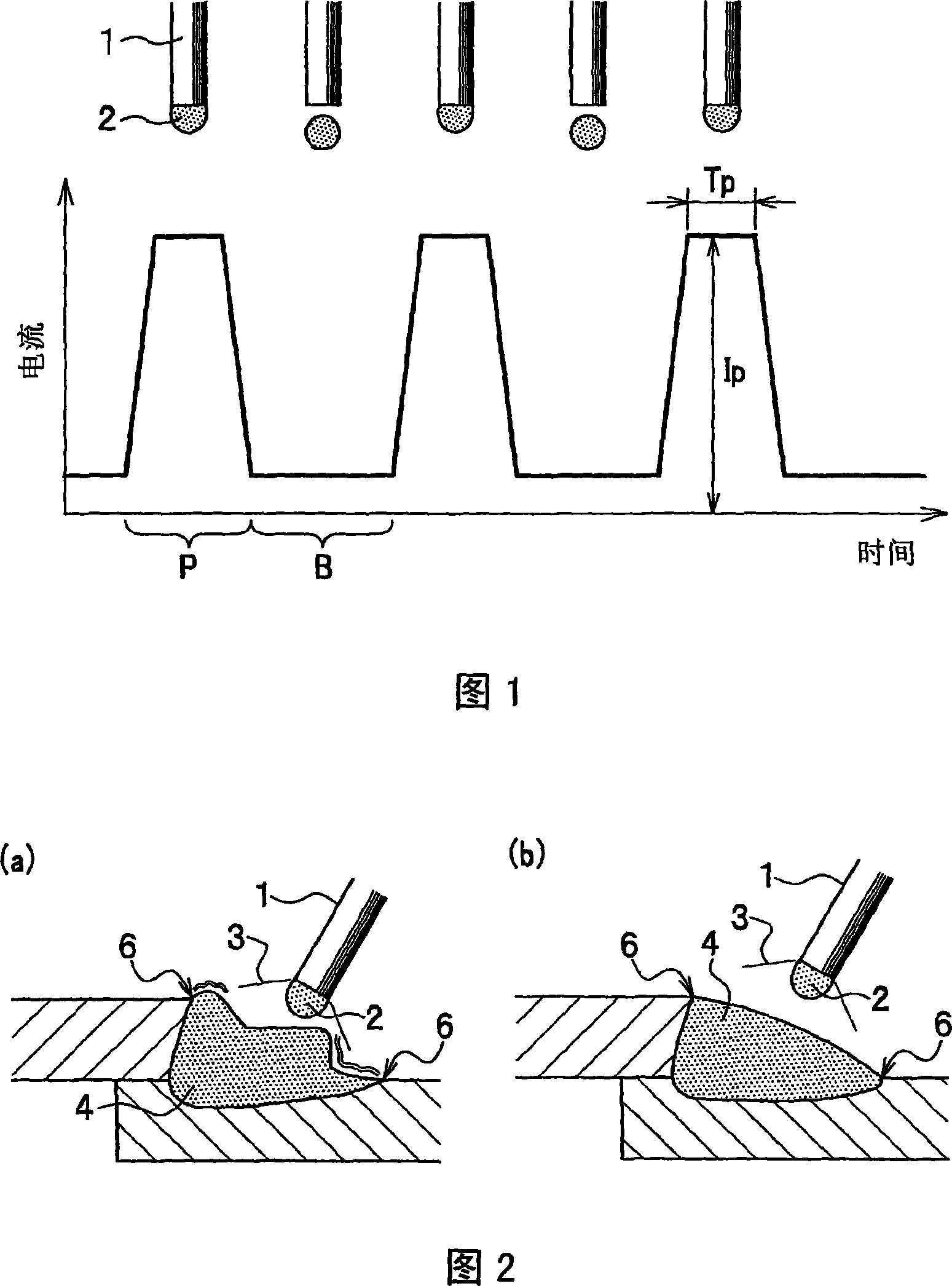

Gas-shielded arc welding method

InactiveCN101200017AImprove orderSuppress splashArc welding apparatusWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A gas-shielded arc welding method uses a shielding gas and a solid wire for pulsation welding. The solid wire contains S, Si, Mn, C and P in predetermined S, Si, Mn, C and P contents, and other elements including Fe and unavoidable elements. A pulsating current used for pulsation welding has a peak current Ip of 350 A or above and a pulse peak duration Tp between 0.5 and 2.0 ms. The shielding gas is a mixed gas containing 75 to 98% by volume Ar and others including at least either of CO2 and O2. The gas-shielded arc welding method can suppress the generation of spatters regardless of welding speed even if the welding speed is high, and can form a wide, flat bead having uniform toes. A weld metal produced by the gas-shielded arc welding method is resistant to cracking and excellent in preventing the formation of blowholes.

Owner:KOBE STEEL LTD

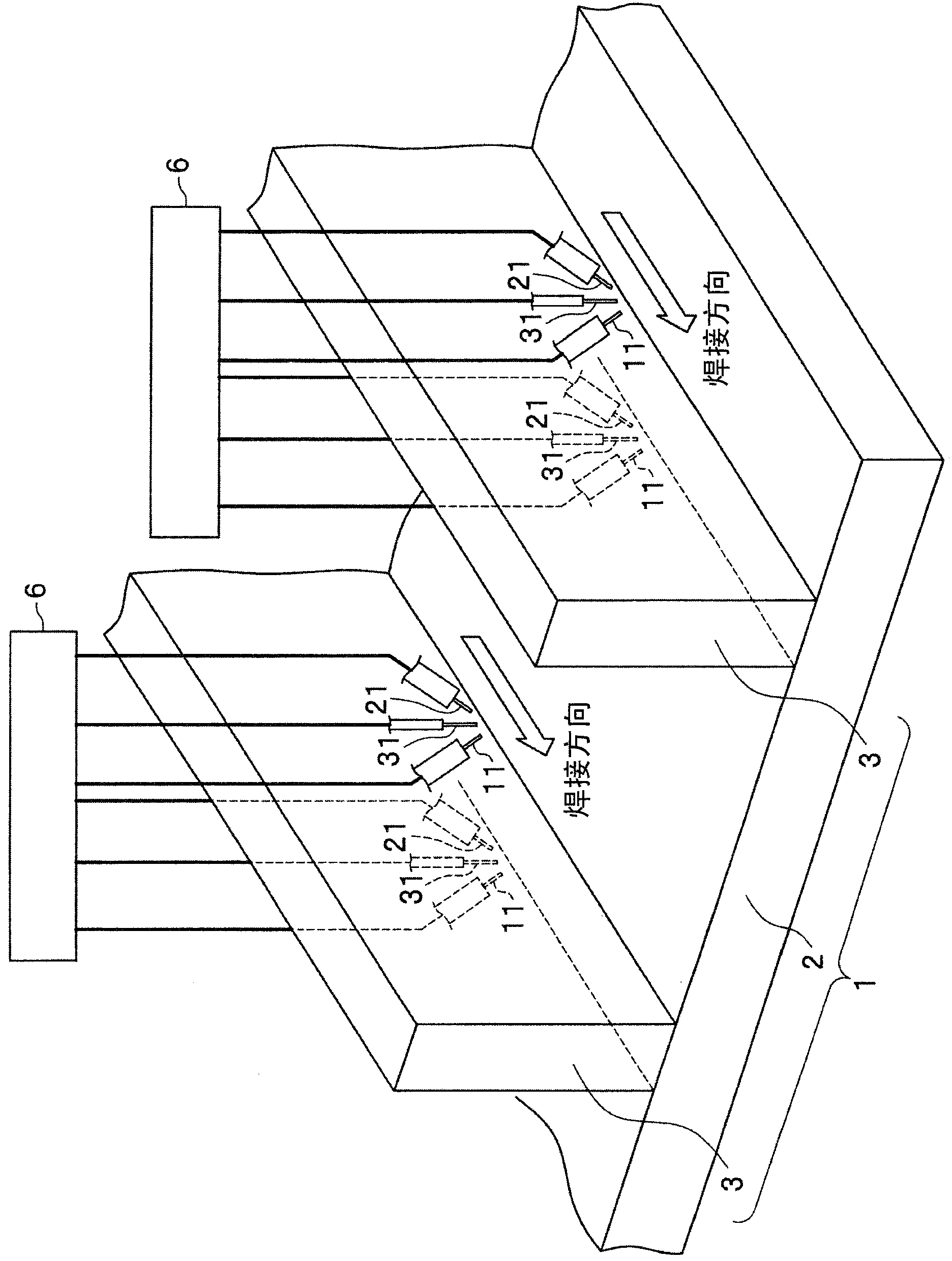

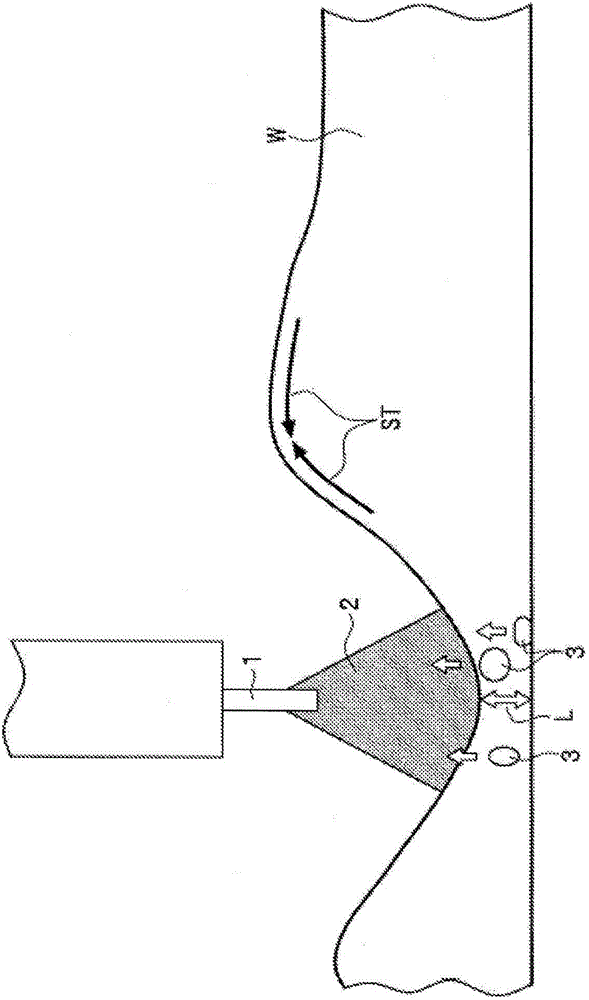

Multielectrode gas-shield arc welding method and device

The invention provides a multielectrode gas-shield arc welding method and a multielectrode gas-shield arc welding device. A welding pass can be good in appearance, the shape of the welding pass is prevented from deforming and the stability of a fusing metal accummulating portion can be achieved even if high-efficiency welding by three electrodes is performed. The multielectrode gas-shield arc welding method is a method using the multielectrode gas-shield arc welding device (S) which comprises a first electrode (11), a follow-up electrode (21) and a central electrode (31) between the first electrode (11) and the follow-up electrode (21). The multielectrode gas-shield arc welding methos is characterized in that the distance between the first electrode (11) and the follow-up electrode (21) is set to be 15mm to 50mm, direct currents with reversed polarities flow across the first electrode (11) and the follow-up electrode (21), and alternate currents with the fixed current characteristics or decreasing characteristics are made to flow across the central electrode (31) for welding.

Owner:KOBE STEEL LTD

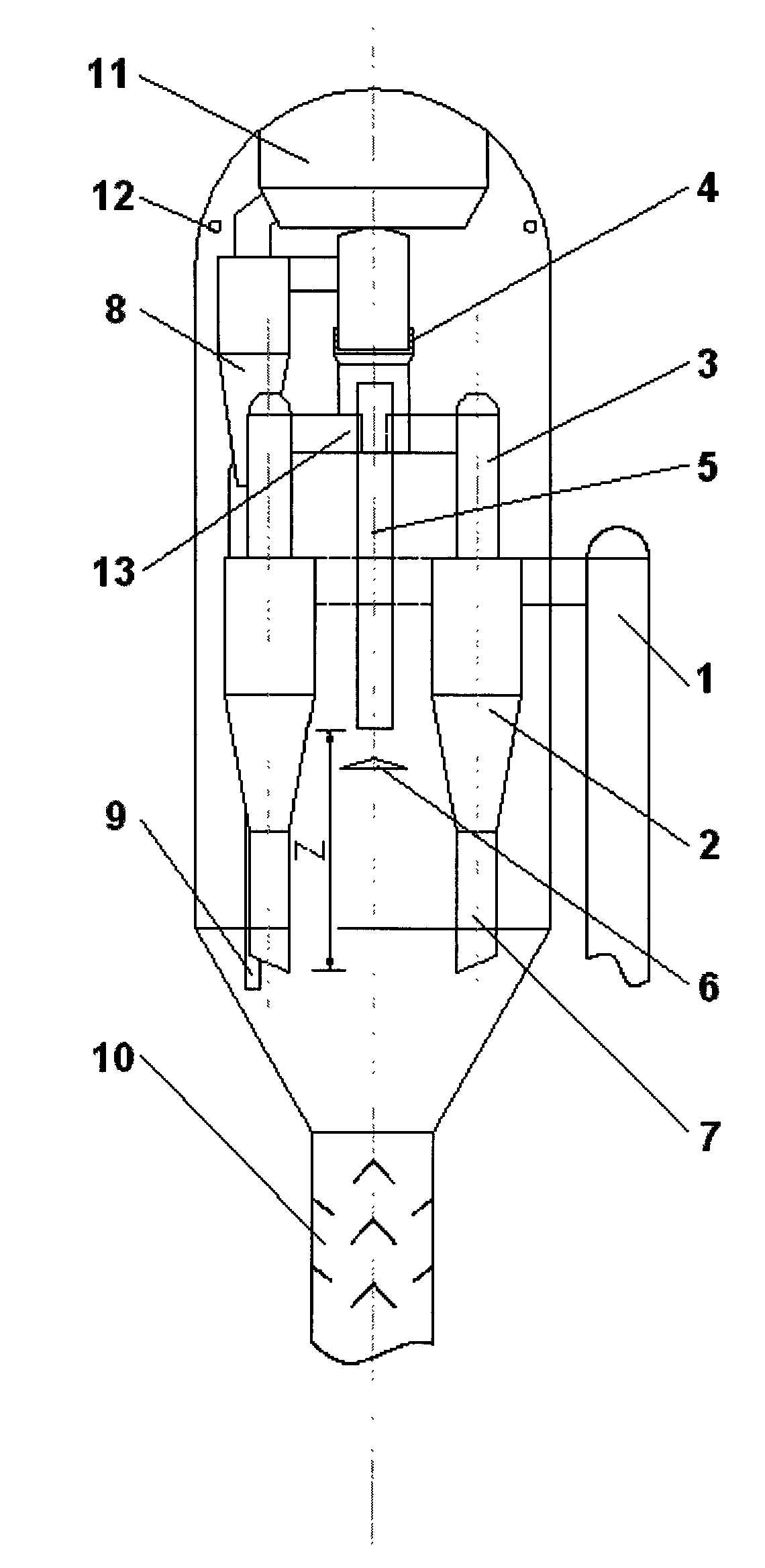

Method and device for inhibiting coking of residue fluid catalytic disengager

ActiveCN102041096AEliminates the possibility of cokingFast drainageCatalytic crackingTreatment apparatus corrosion/fouling inhibitionDrainage tubesPetroleum

The invention provides a method and a device for preventing interior of a disengager from coking by quickly extracting oil gas from the fluidized catalytic cracking disengager of petroleum, wherein the device comprises a primary cyclone separator, a straight connection component which is arranged on the tail end of exit tube of the primary cyclone separator, a top cyclone separator, an oil gas drainage tube, an inertial separation component which is on the lower end of inlet of the drainage tube, a stripping section, an anti-coking steam ring and a disengager. The oil gas and the steam within the disengager are discharged out from the oil gas drainage tube only, the lower end of opening of the oil gas drainage tube is equipped with the inertial separation component so as to reduce the catalyst which is entered into the oil gas drainage tube by splashing while discharging from the dipleg of the primary cyclone separator and the dipleg of the top cyclone separator, the exit tube of the primary cyclone separator is tangentially connected to the oil gas drainage tube by means of the straight connection component, and a rotational flow is formed on the upper section of the oil gas drainage tube, so that a vortex low-pressure region is formed and the drainage draft of the oil gas is increased. The method and the device for inhibiting coking of residue fluid catalytic disengager provided by the invention have the advantages that the structure is simple and compact, the fast and efficient separation between the oil gas and the catalyst is ensured, the oil gas within the space of the disengager is extracted quickly, the retention period of the oil gas within the disengager is reduced greatly, the coking phenomenon within the disengager is inhibited effectively and therefore the operation cycle of the catalytic device is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

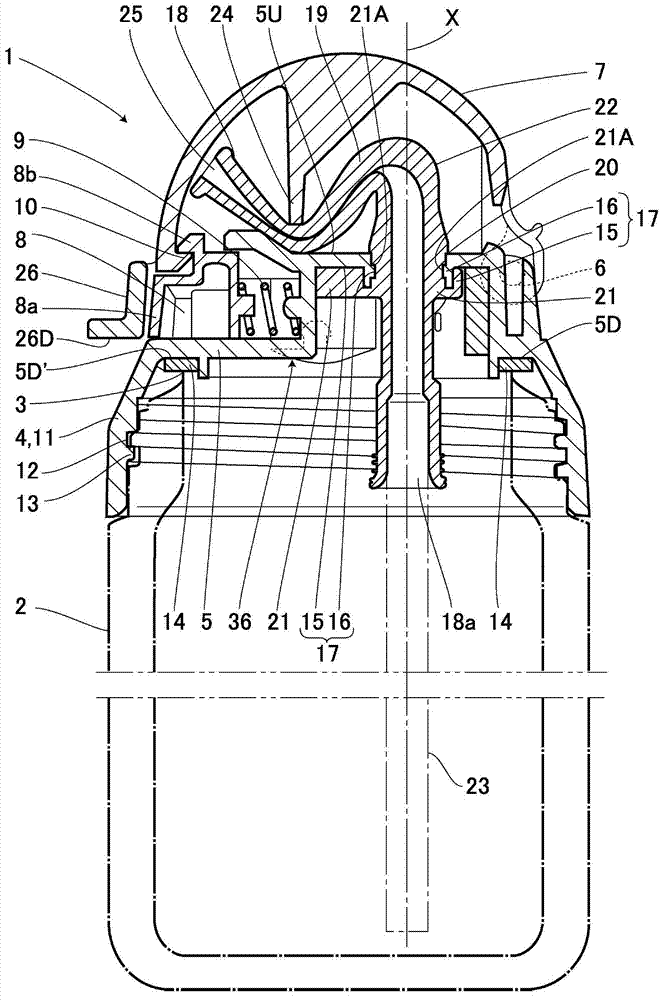

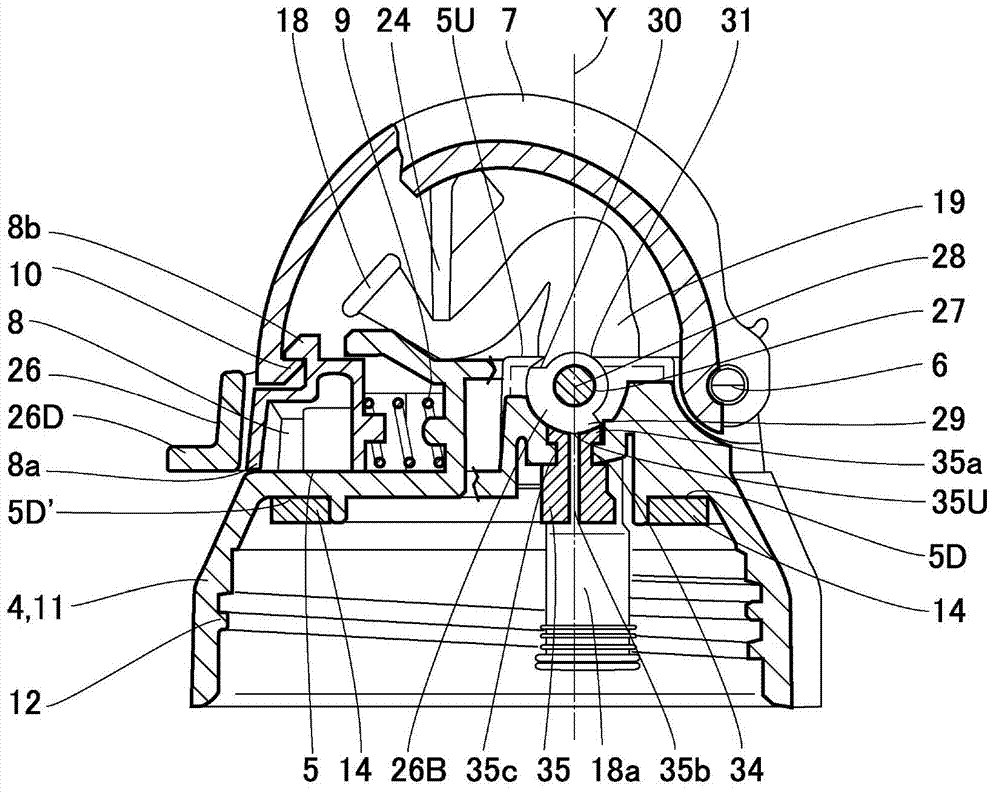

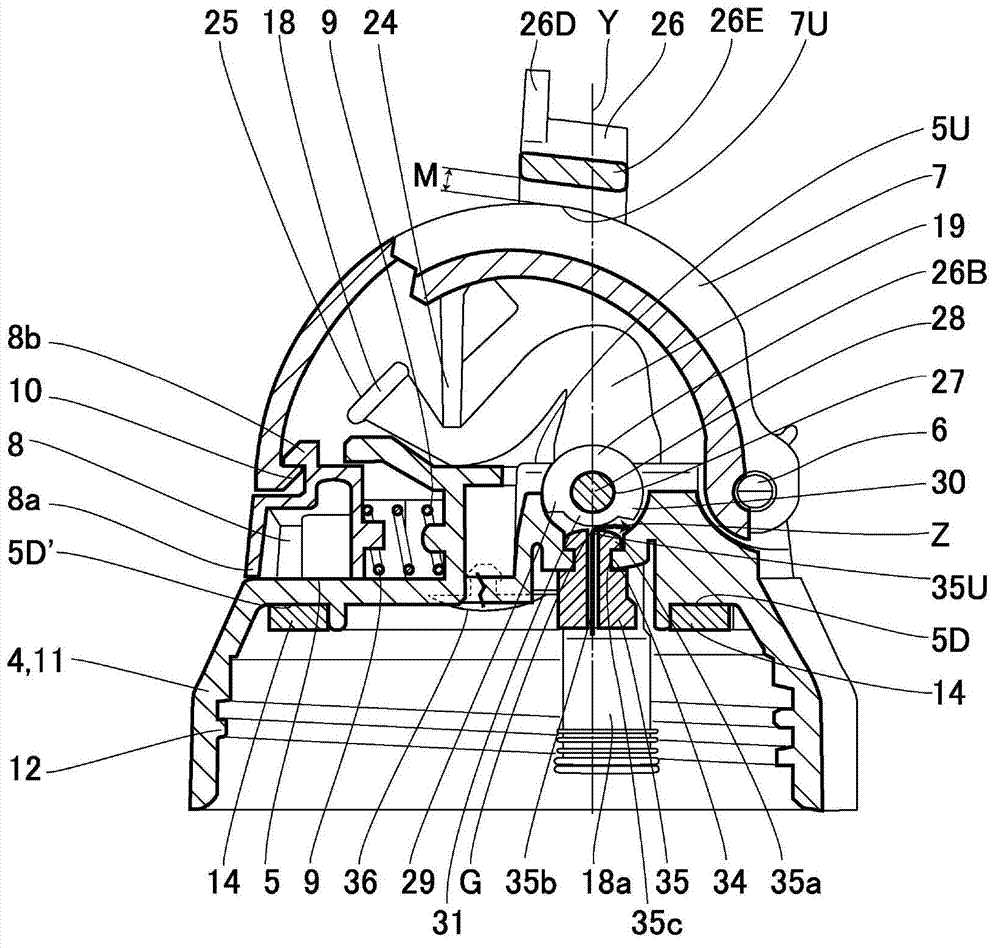

Plug of beverage vessel

The invention provides a plug of a beverage vessel. The plug cannot be easily opened due to misoperations or the like, and the operation and closure states of a locking mechanism are definite so that content liquid is prevented from spraying from the front end of a sucker. The plug comprises a plug main body (11), a shaft supporting cover (7), a clamping part (8), a drinking port member (22), and a blocking member (14). The clamping part (8) is arranged in a manner allowing a cover to be kept in or released from the closure state. The drinking port member (22) is clamped in the plug main body (11). The blocking member (14) is pressed against a vessel opening (3) and blocks a vessel main body. The blocking member (14) is clamped in a hole (34), and a ventilation hole (35b) is formed in the through part of the hole (34). The ventilation hole is in the closure state when the cover is in the closure state and temporarily in the open state when a reversing handle member is in a circumferential reversing process, and the ventilation hole is back to the closure state again by virtue of further reversing the reversing handle member, so that the closure state is enabled to be definite and the closure / open / closure action time of the ventilation hole is delayed accurately.

Owner:THERMOS LLC +1

Substrate processing apparatus and substrate processing method

ActiveUS8109282B2Facilitate agitationReduce surface tensionSemiconductor/solid-state device manufacturingCleaning using liquidsOxygenNitrogen gas

Owner:DAINIPPON SCREEN MTG CO LTD

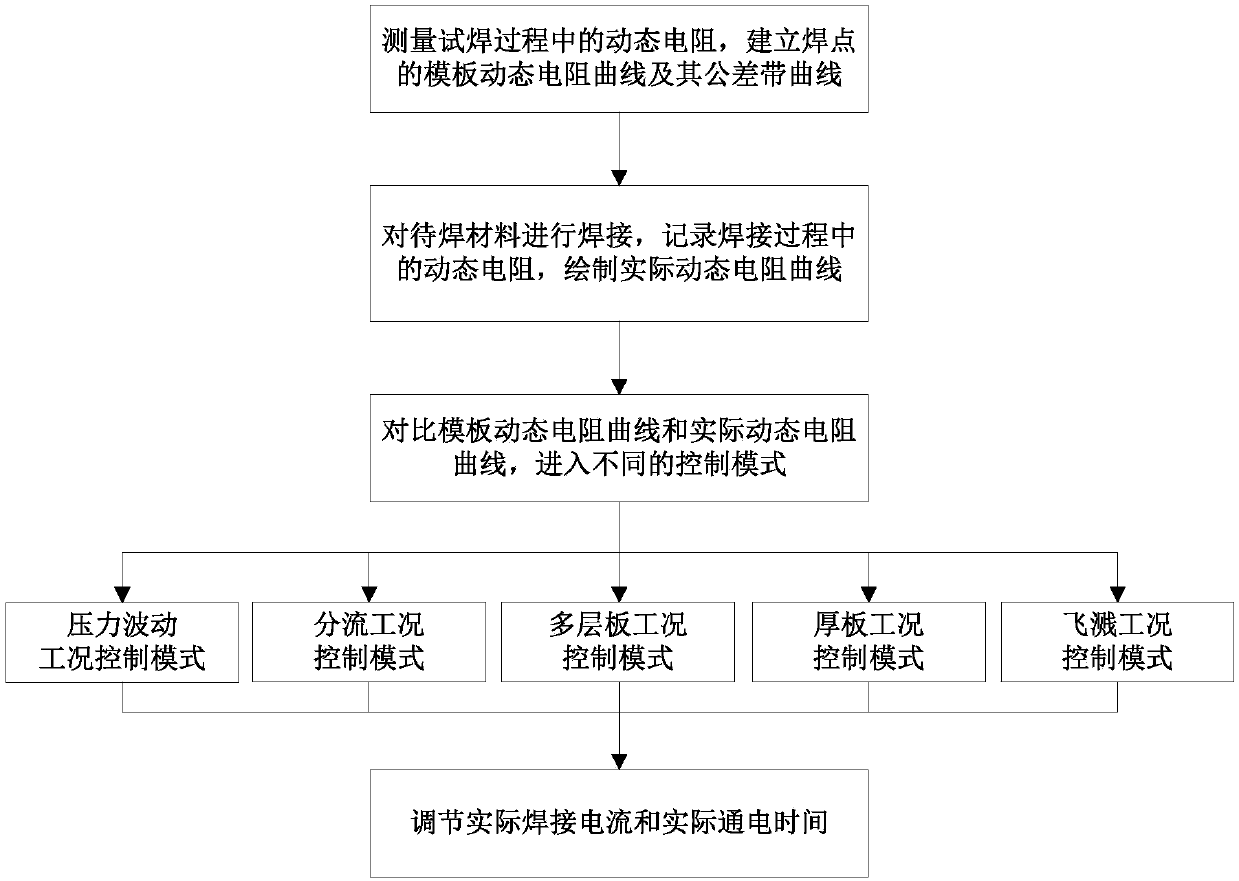

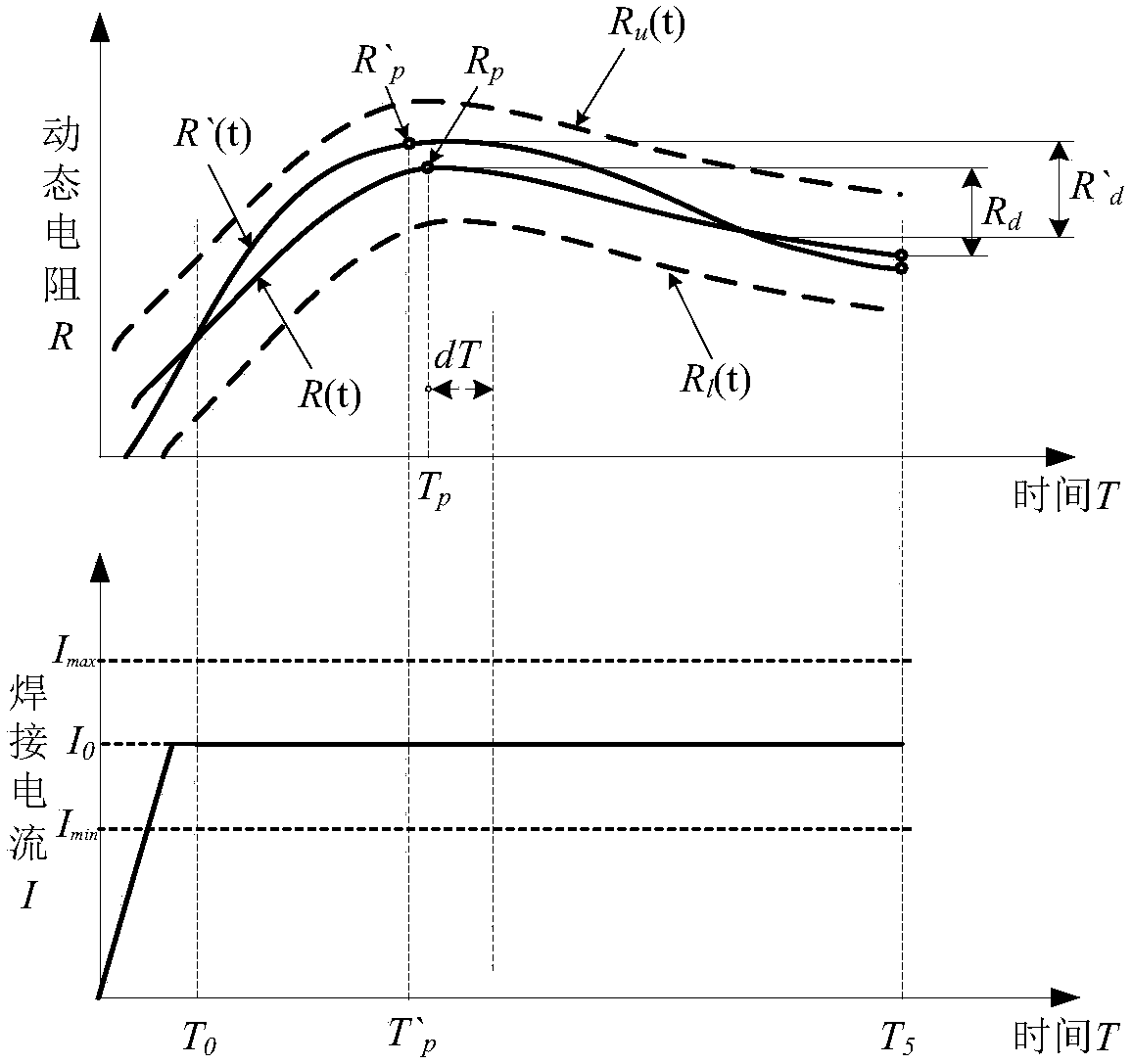

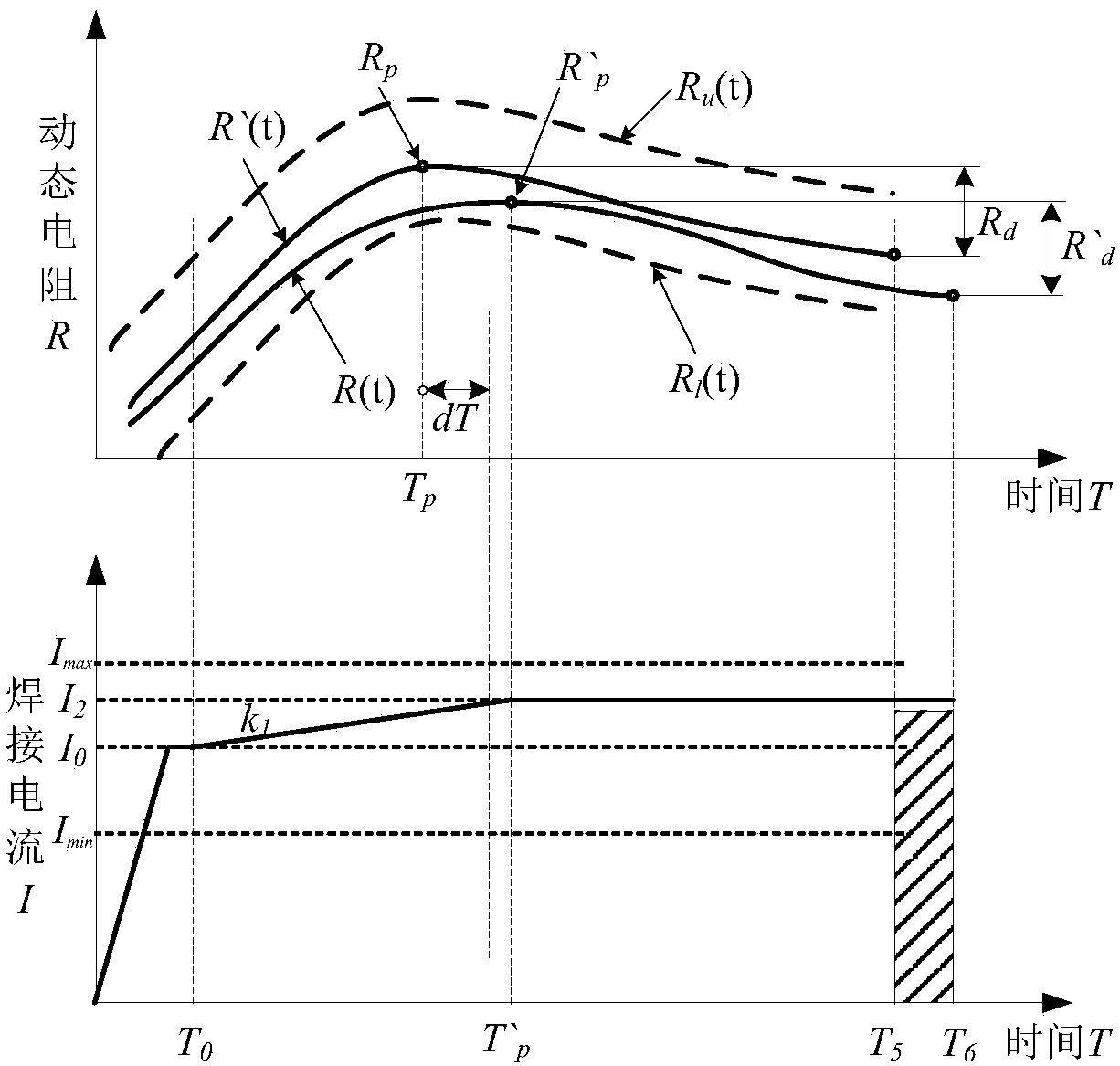

Direct-current resistance spot-welding multi-mode feedback control method

ActiveCN107671406AImprove solder joint qualitySuppress splashWelding monitoring devicesElectrical resistance and conductanceEngineering

The invention relates to a direct-current resistance spot-welding multi-mode feedback control method, which comprises the steps of (1) carrying out test weld under a standard welding condition, wherein a welding current magnitude is I0; and building a template dynamic resistance curve R (t), an upper tolerance zone curve Ru (t) and a lower tolerance zone curve R1 (t) of a welding spot, wherein a peak value of the template dynamic resistance curve is Rp, the moment corresponding to the Rp is Tp, the declining volume of the template dynamic resistance curve after the peak value is Rd, and the maximum conduction time is T5; (2) welding a material to be welded, wherein an initial welding current magnitude is I0; and drawing an actual dynamic resistance curve R' (t), wherein a peak value of theactual dynamic resistance curve is R'p, the moment corresponding to the R'p is T'p, and the declining volume of the actual dynamic resistance curve after the peak value is R'd; and (3) entering different control modes, and dynamically adjusting an actual welding current and actual conduction time. According to the direct-current resistance spot-welding multi-mode feedback control method providedby the invention, the welding spot quality and a welding process are controlled in real time, the welding spot quality of a key station is remarkably improved, the spattering during the welding process is effectively inhibited, the stability of the welding quality is improved, and a lot of technological parameter adjusting time aiming at different working conditions is saved.

Owner:SHANGHAI JIAO TONG UNIV

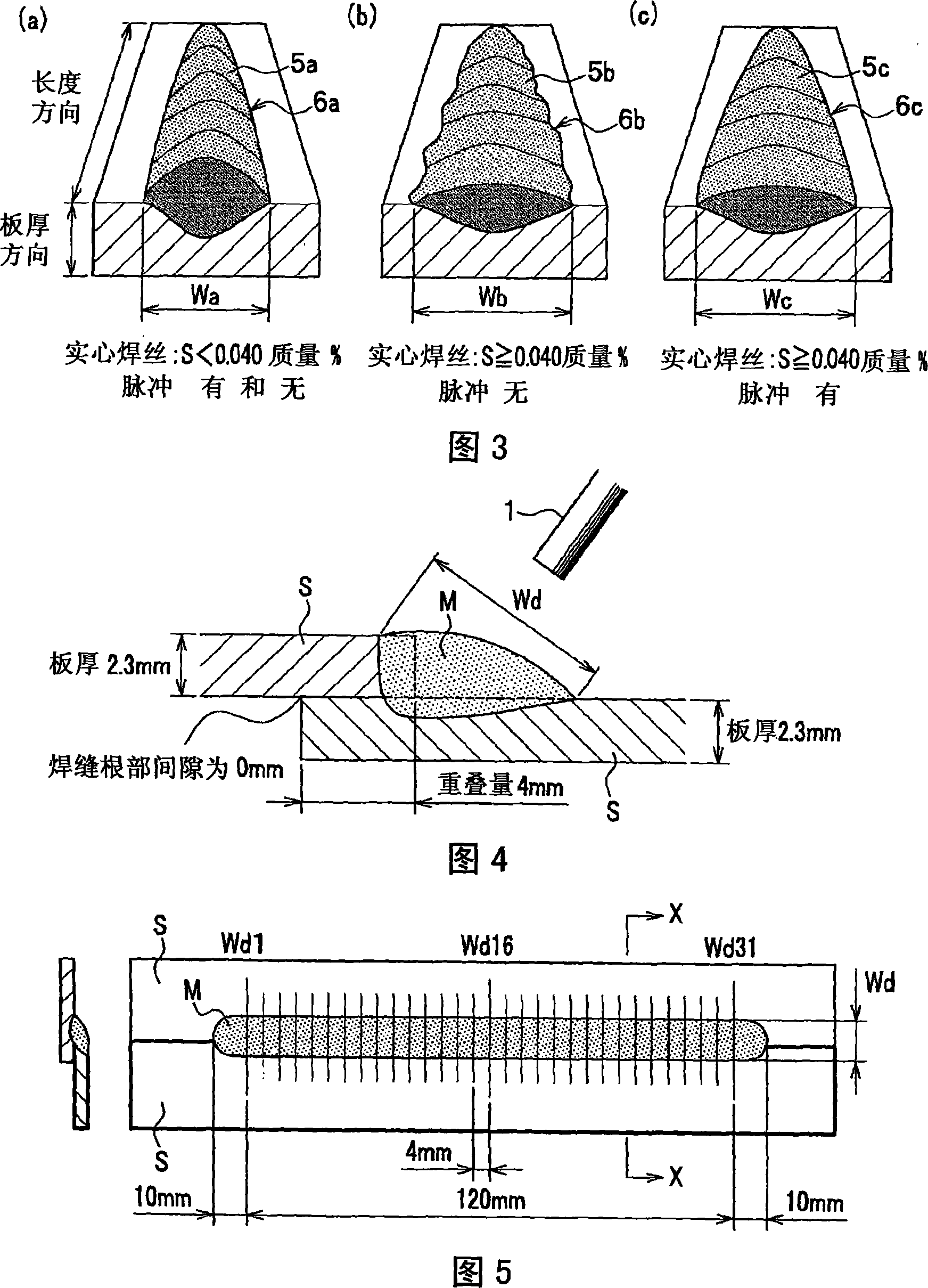

Solid wire, and gas-shielded arc welding method using same

ActiveCN104159700AInhibition defectSuppress splashArc welding apparatusVehicle componentsSheet steelShielding gas

A solid wire which is for use in gas-shielded arc welding that employs a shielding gas and which is for use in welding galvanized steel sheets. The solid wire contains C, Si, Mn, P, S, O, and Cr in respective given amounts relative to the total mass of the solid wire, the remainder comprising Fe and unavoidable impurities. The solid wire satisfies the relationships 1.0<=(Si mass%+Mn mass%) / {100(S mass%+O mass%)}<=4.0 and 0.50<=(Mn mass% / Si mass%)<=2.00. The shielding gas is an argon gas which contains 25-40% CO2 gas. Improvements in spattering inhibition and pore generation inhibition (performance of inhibiting the generation of pore defects such as pits or blow holes) and an excellent bead appearance are rendered possible.

Owner:KOBE STEEL LTD +1

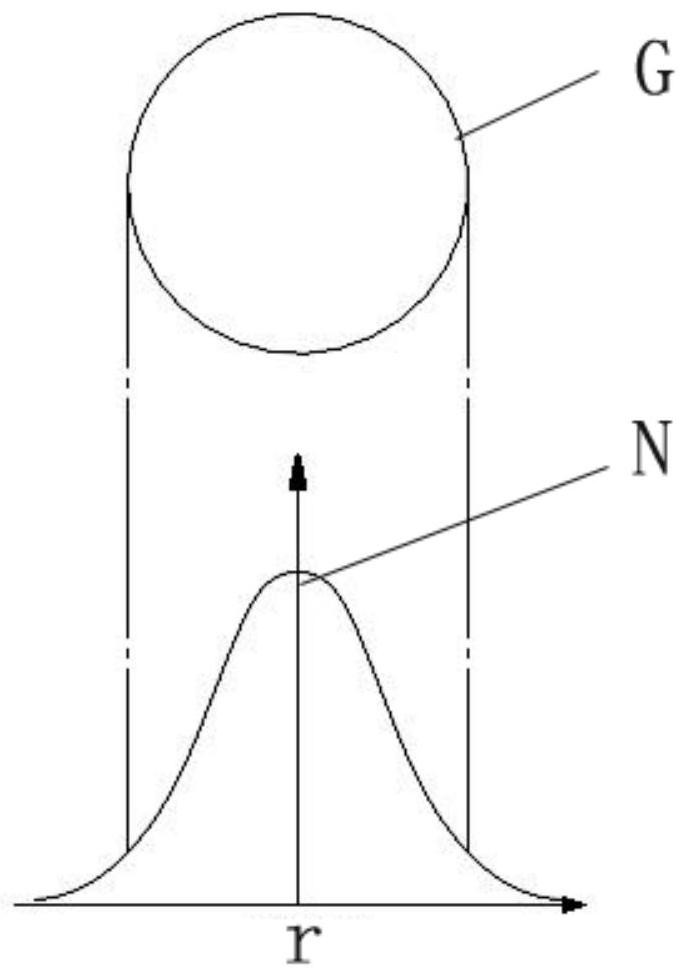

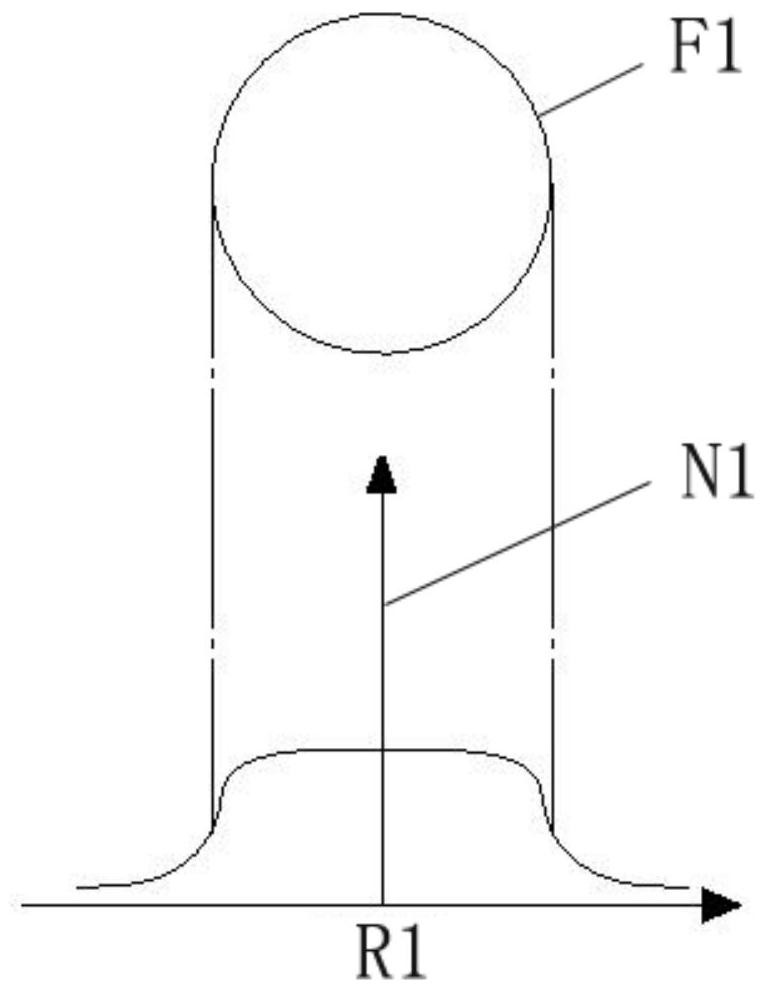

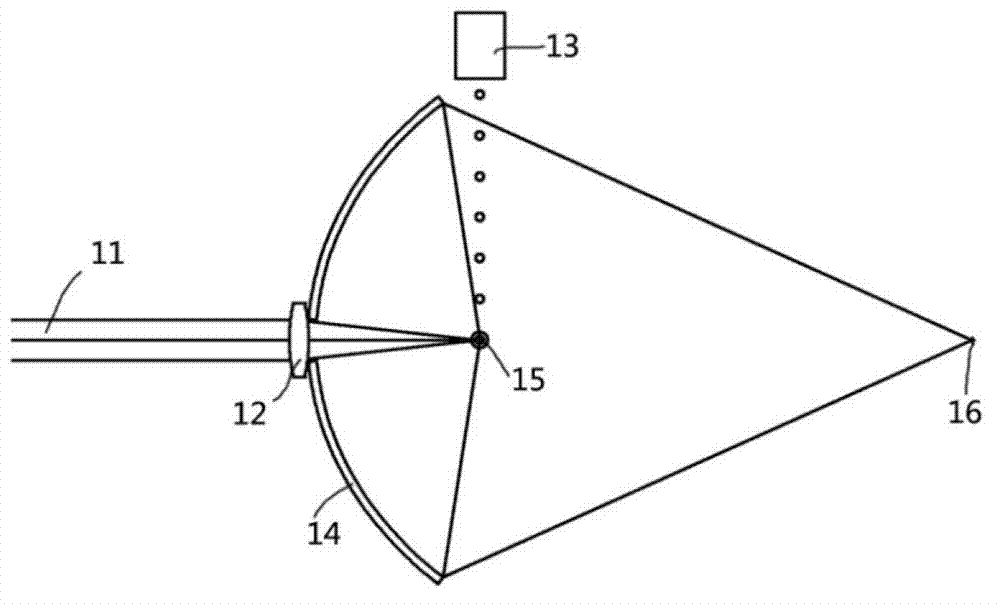

Beam shaping system for metal SLM printing

ActiveCN111796429AAuto switchMeeting Research Application NeedsAdditive manufacturing apparatusIncreasing energy efficiencyLight spotFacula

The invention provides a light beam shaping system for metal SLM printing. The system comprises a laser, and a collimator, a zoom beam expander, a beam shaping mechanism, a galvanometer system and a working platform which are sequentially arranged in the propagation direction of laser beams emitted by the laser. A laser beam emitted by the laser is transmitted through an optical fiber to the collimator with an optical fiber interface for collimation, and the spot size is adjusted through the zoom beam expander to meet the incident spot size requirement of the beam shaping mechanism, the incident spots are shaped through a beam homogenizer or a beam shaper and then converted into flat-topped spots, the flat-topped spots are focused through the galvanometer system to form gathered spots, andthen the gathered spots reach the working surface to machine the metal powder. According to the system, light beam energy is redistributed to obtain circular, rectangular and oval flat-topped light spots or flat-topped light spots of specific shapes are customized according to requirements, metal printing defects can be effectively reduced through shaping of the system, and meanwhile, efficient printing can be conducted by introducing a high-power laser system in cooperation with large-size light spots.

Owner:GUANGXI UNIV

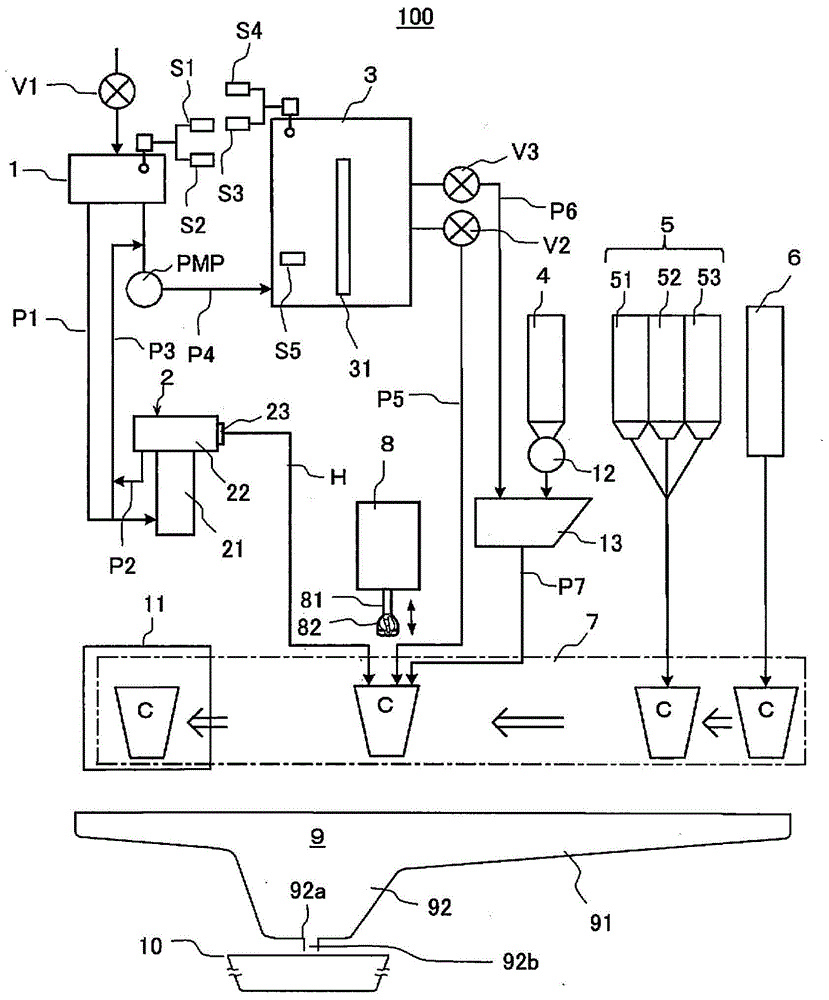

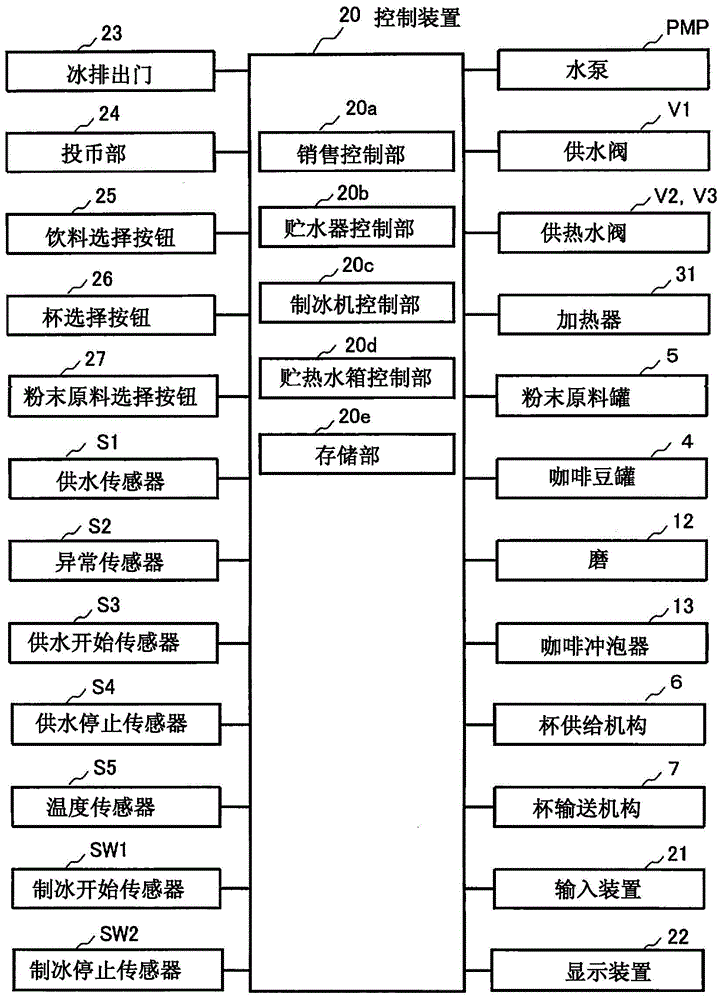

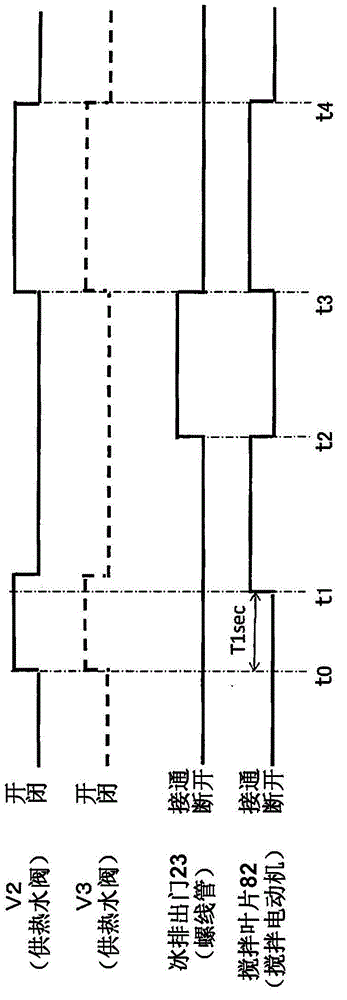

Beverage mixing method inside cup

InactiveCN105321263ACan't avoid splashEliminates splash situationsBeverage vesselsApparatus for dispensing fluids/granular materialsDiluentEngineering

The invention provides a beverage mixing method inside the cup, which prevents the beverage from spilling due to the dropping of the ice without installing a new member. The beverage mixing method is used for mixing the ice beverage by mixing the raw material, the diluents and the ice inside the cup (C). The beverage mixing method comprises steps of pouring into the diluents into the cup (C) which is about the cup volume, mixing with the raw material, dropping ice into the cup, and injecting the diluents inside the cup until the cup is full to make the beverage. Because when the ice is dropped into the cup, the original fluid inside the cup is less than the volume of the cup and the liquid surface of the original fluid is lower than the cup rim (L1), the spilling range of the original liquid can only reach the inner wall of the cup (C) when the ice is dropped into the original liquid and the liquid is not spilled out of the cup (C).

Owner:FUJI ELECTRIC CO LTD

Substrate processing apparatus and substrate processing method

ActiveUS20120090647A1Facilitate agitationReduce surface tensionSemiconductor/solid-state device manufacturingCleaning using liquidsOxygenNitrogen gas

A rinsing liquid (DIW) is discharged from a rinsing liquid discharge port formed in a blocking member to perform rinsing processing to a substrate surface while a nitrogen gas is supplied into a clearance space, and a liquid mixture (IPA+DIW) is discharged from a liquid mixture discharge port formed in the blocking member to replace the rinsing liquid adhering to the substrate surface with the liquid mixture while the nitrogen gas is supplied into the clearance space. Thus, an increase of the dissolved oxygen concentration of the liquid mixture can be suppressed upon replacing the rinsing liquid adhering to the substrate surface with the liquid mixture, which makes it possible to securely prevent from forming an oxide film or generating watermarks on the substrate surface.

Owner:DAINIPPON SCREEN MTG CO LTD

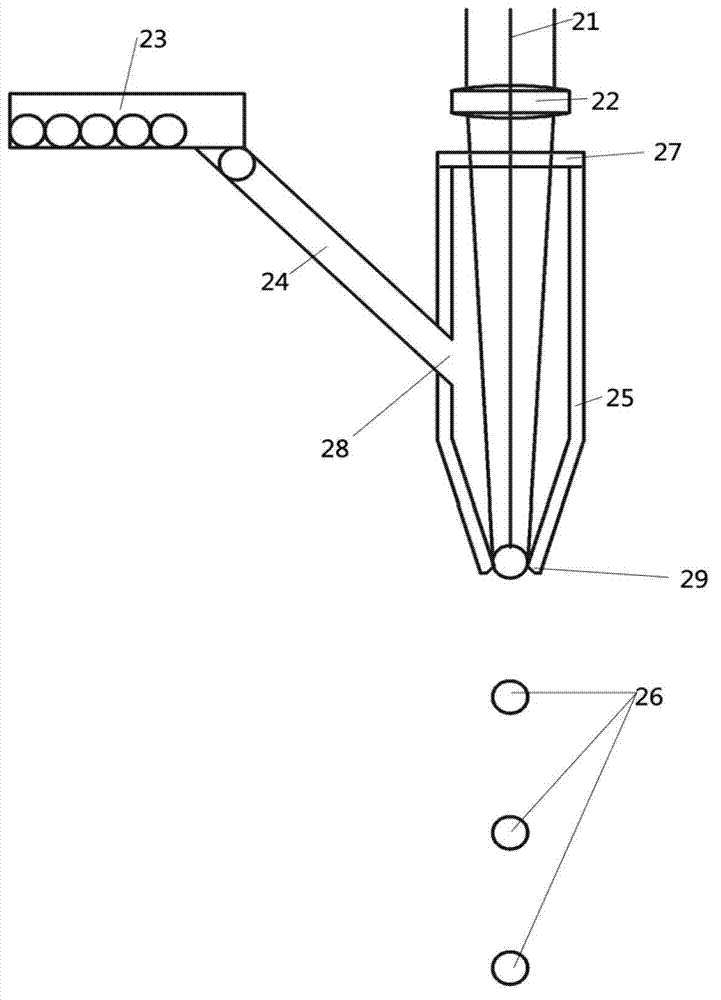

High-melting-point material droplet target generating device for extreme ultraviolet light source

The invention discloses a high-melting-point material droplet target generating device for an extreme ultraviolet light source. The generating device comprises laser, a lens, a particle feeding device, a nozzle and a pipeline, the laser and the nozzle are coaxial, the laser enters the nozzle through the lens in a focusing manner and is used for heating target solid particles entering the nozzle, and the particle feeding device is connected with the nozzle through the pipeline and is used for continuously and uniformly delivering the target solid particles into the nozzle. The target solid particles are heated by the laser and melted into liquid when entering the nozzle, and the liquid is ejected by the nozzle to form uniform droplet targets. The droplet targets generated by the generating device are uniform and stable, the sizes of the droplet targets can be controlled, a method is simple and reliable, a layer of rarefied gas wraps the peripheries of the targets when the targets are ejected, neutral or dotted particle fragments formed after action of the laser and the droplet targets can be suppressed from splashing everywhere by the layer of rarefied gas.

Owner:HUAZHONG UNIV OF SCI & TECH

Bowl type turbulence-inhibiting flow-stabilizing flow distribution device for continuous casting of thin band

The invention relates to a bowl type turbulence-inhibiting flow-stabilizing flow distribution device for the continuous casting of a thin band, comprising a flow distributor and a casting water gap, wherein the flow distributor is arranged above a roller and in a V-shaped cavity structure; the casting water gap extends into a cavity of the flow distributor; the upper part of the flow distributor is provided with an opened rectangular cavity, the lower part of the flow distributor is a long and narrow slot cavity with a V-shaped section, and the bottom of the flow distributor is transited with an arc; the two skew walls of the slot cavity are provided with a plurality of flow distribution holes near the bottom of the slot cavity; a horizontal arranged hole plate positioned in the V-shaped long and narrow slot cavity and above the flow distribution holes covers the V-shaped long and narrow slot cavity; one to three rows of small holes are uniformly distributed on the hole plate along a roll shaft direction; a bowl type turbulence-inhibiting flow-dividing device is arranged in the center of the hole plate. The invention obviously improves the distribution of liquid steel in a molten pool, promotes the liquid steel to stably flow and inhibits the influence of the impact of casting flows so that the flow of the liquid steel is more reasonable and the temperature distribution is more uniform, thereby enhancing the casting quality of the thin band.

Owner:SHANGHAI UNIV

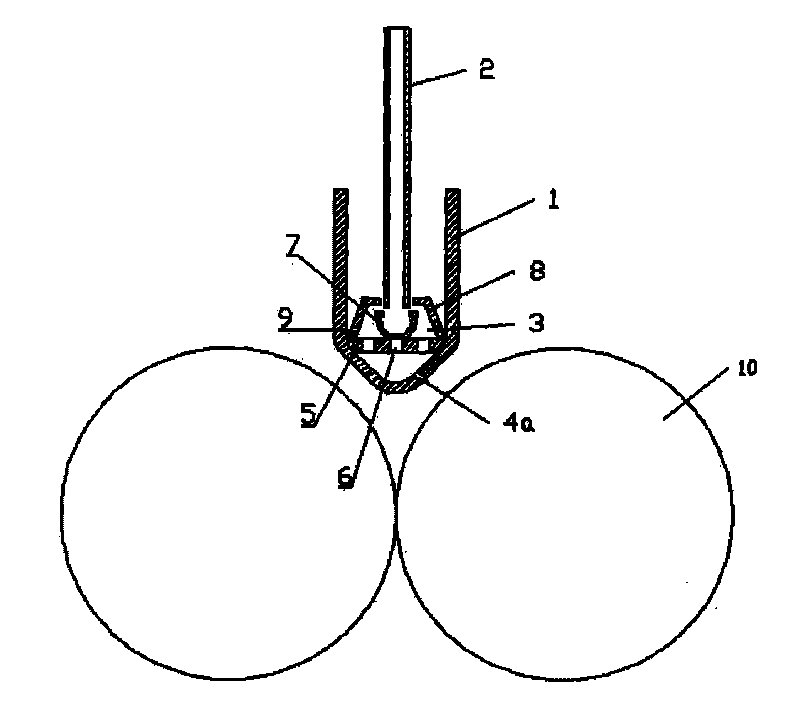

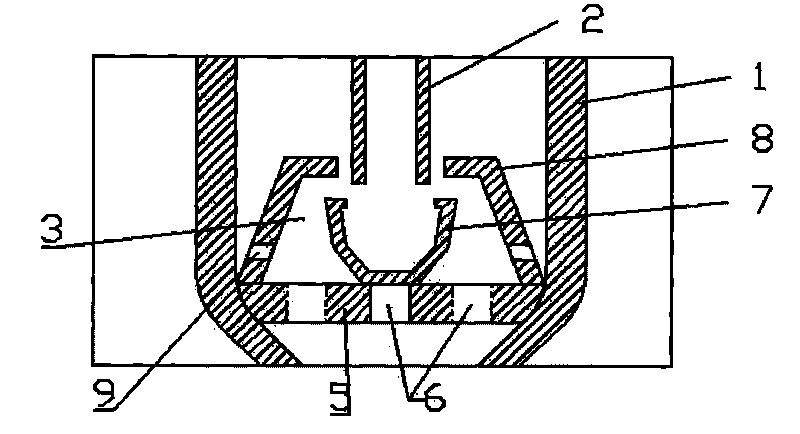

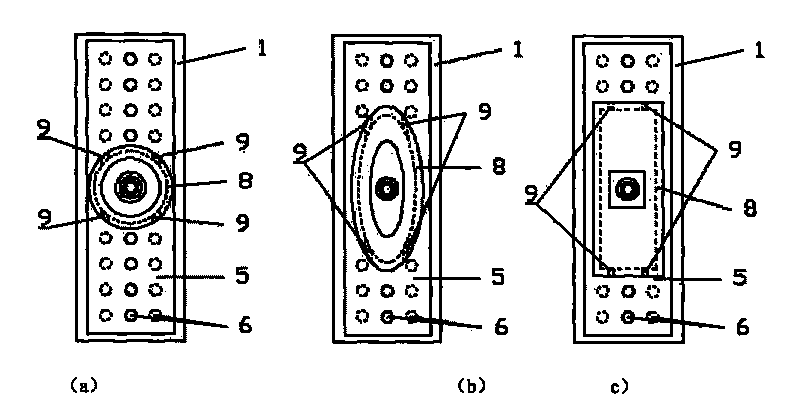

Substrate treatment apparatus and substrate treatment method

InactiveCN101136320AEasy to handleSuppress splashSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentPush pullElectrical and Electronics engineering

A substrate treatment apparatus according to the present invention includes: a substrate holding unit which holds a substrate; a push-pull plate to be positioned in spaced opposed relation to one surface of the substrate held by the substrate holding unit, the push-pull plate having a plurality of outlet ports which discharge a treatment liquid and a plurality of suction ports which suck the treatment liquid discharged from the outlet ports, the outlet ports and the suction ports being provided in a surface of the push-pull plate to be opposed to the one surface of the substrate; and a relative rotation unit which rotates the substrate held by the substrate holding unit and the push-pull plate relative to each other.

Owner:DAINIPPON SCREEN MTG CO LTD

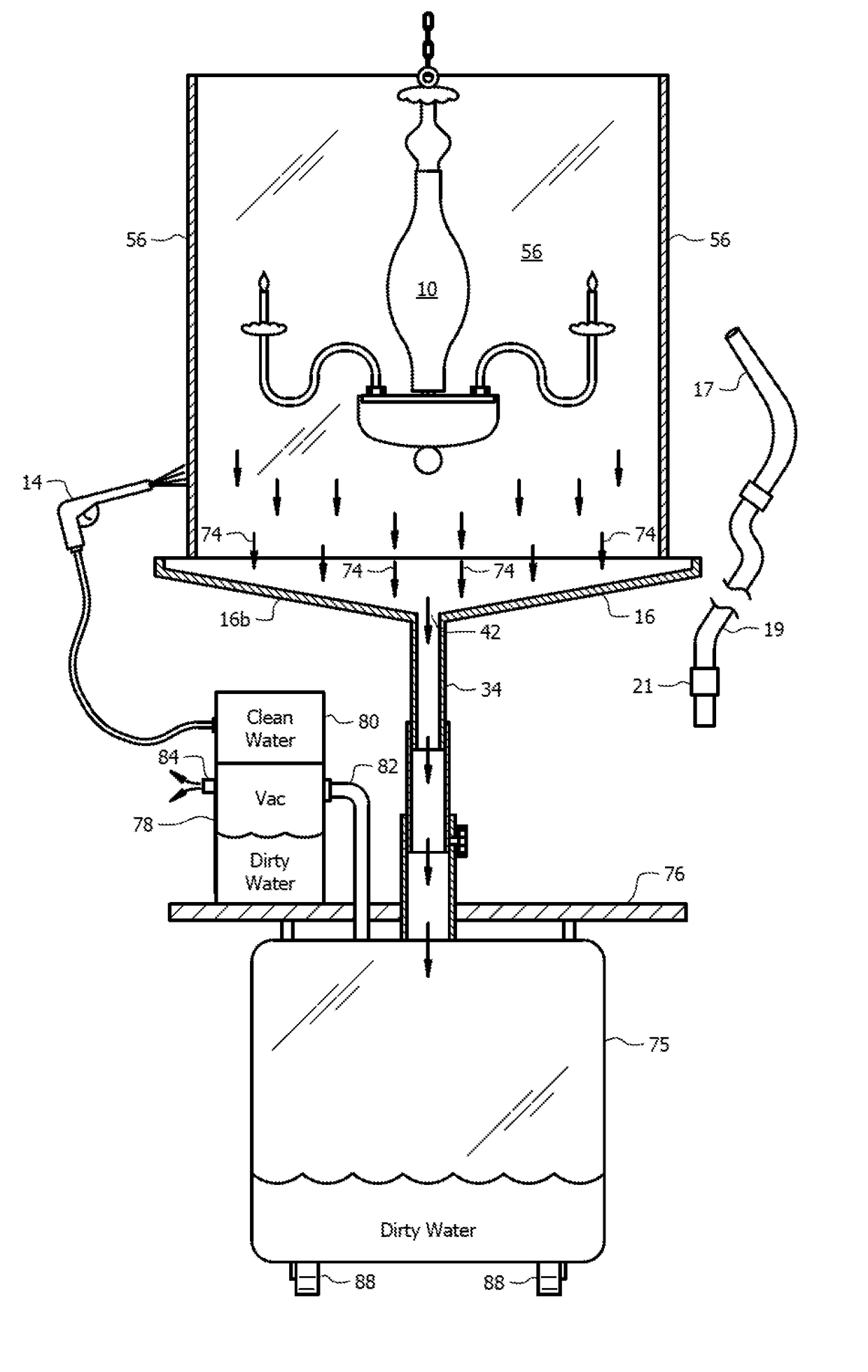

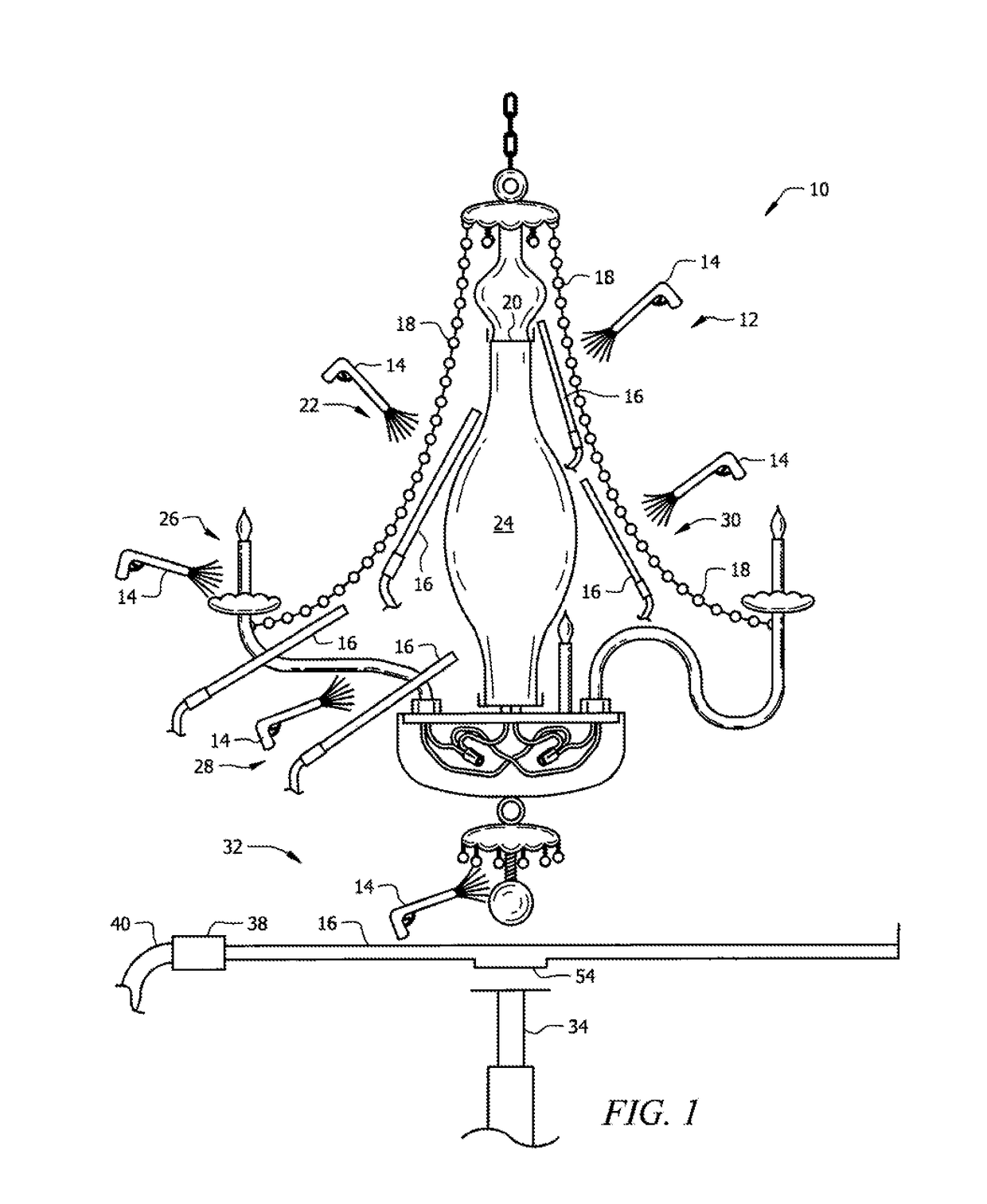

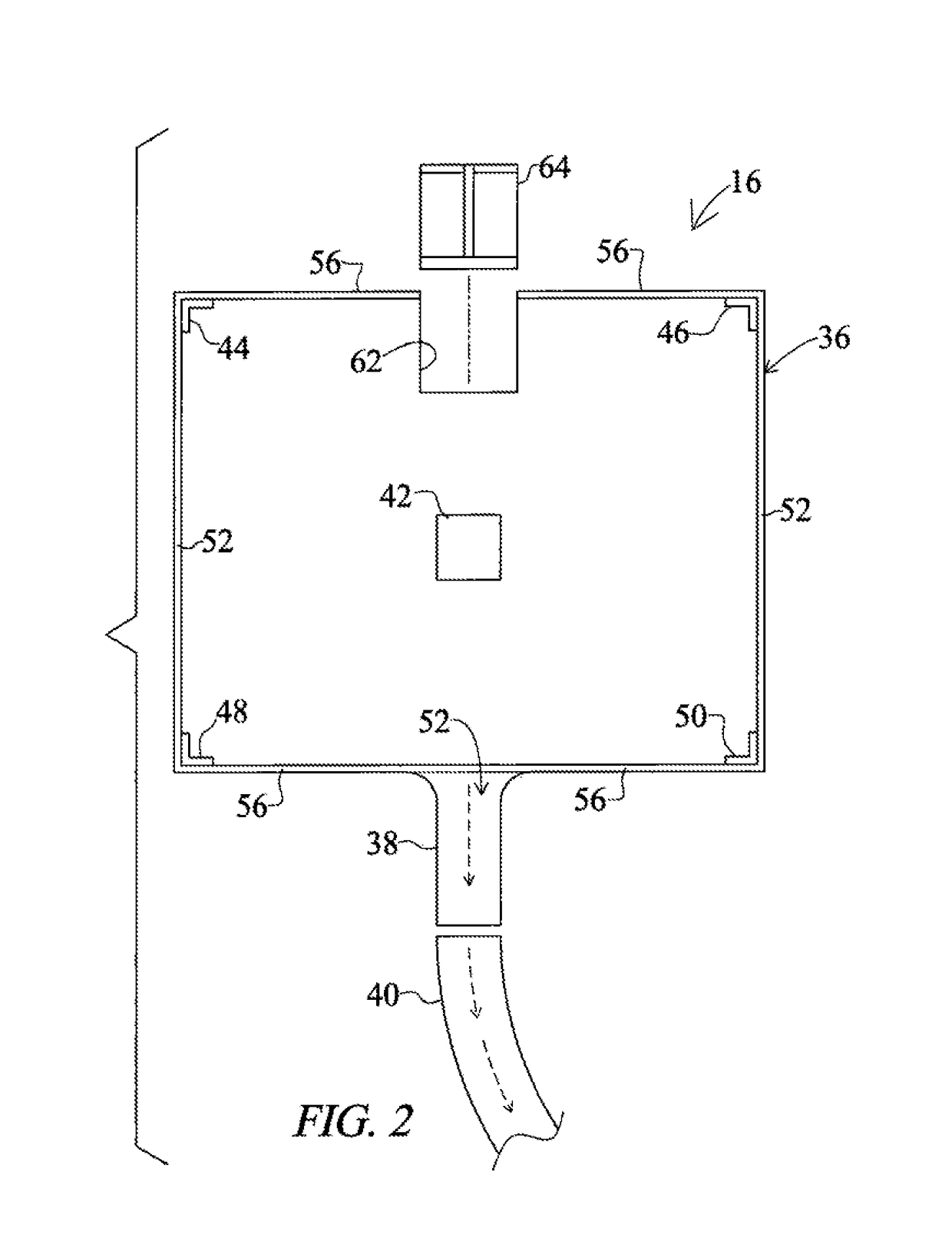

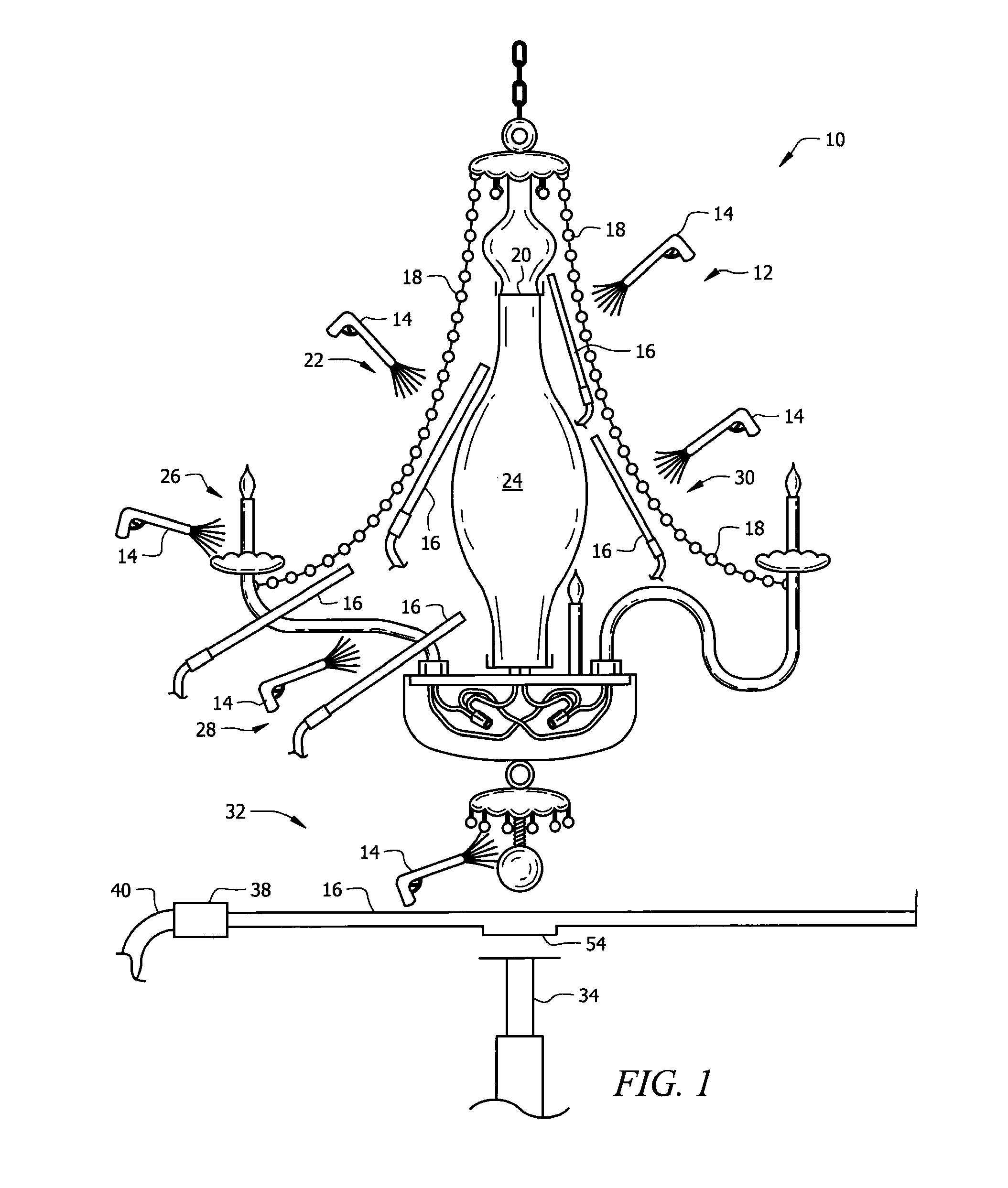

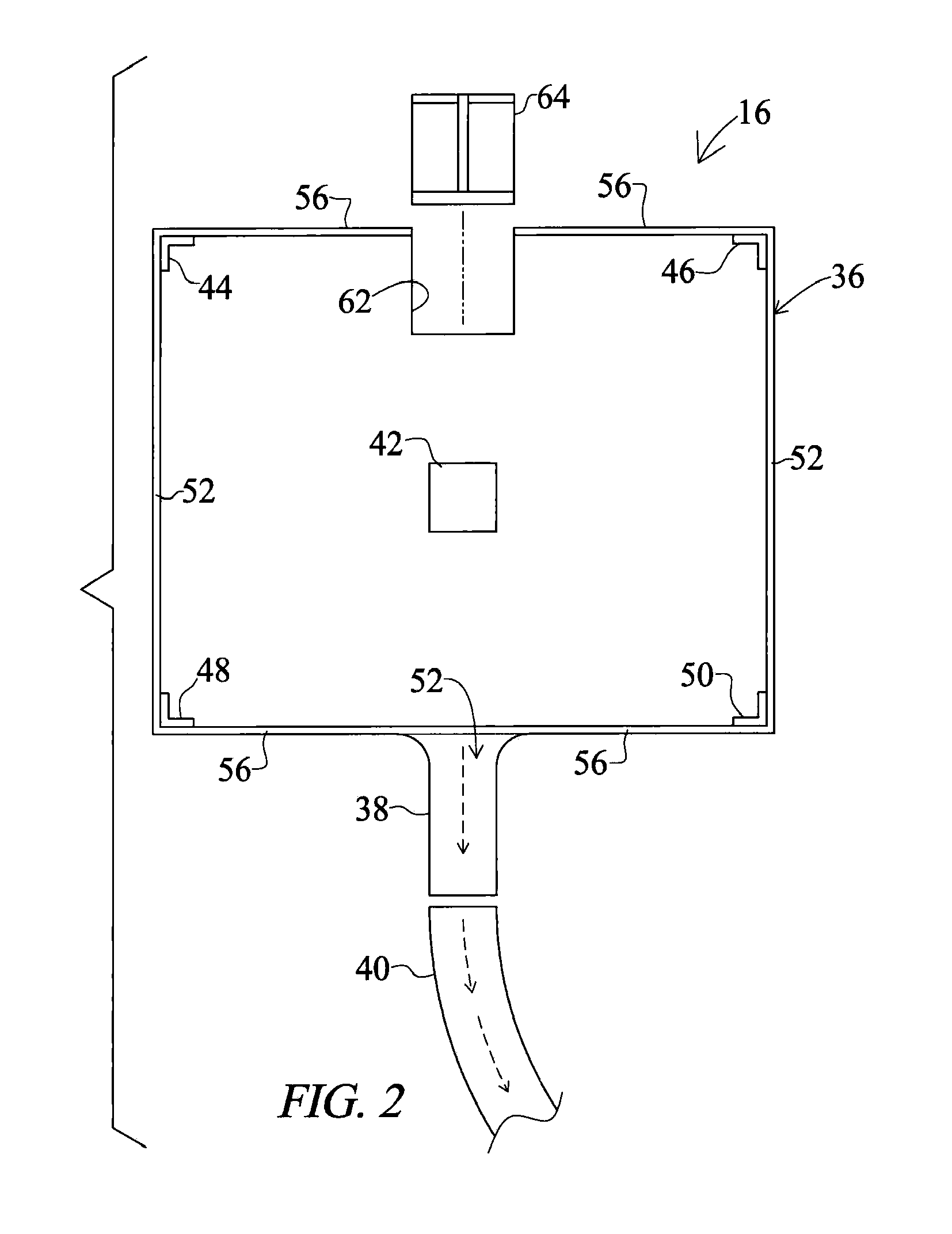

Directional atomizer system for cleaning chandeliers

An apparatus for cleaning chandeliers includes a hand-held fluid source having a proximal end connected to a source of hot water under positive pressure and a distal end having a spray head for discharging hot water under pressure in a spray pattern. A vacuum shield has at least one vacuum inlet connected to a source of negative pressure. Hot water discharged from the spray head is attracted to the vacuum shield when the spray head and the vacuum shield are disposed in relatively close proximity to one another and the vacuum shield is in fluid communication with the source of negative pressure. An object disposed between the spray head and the vacuum shield is cleansed by the action of hot water under positive pressure impinging against it. The vacuum shield protects objects not disposed between the spray head and the vacuum shield.

Owner:INVENTIVE SOLUTIONS

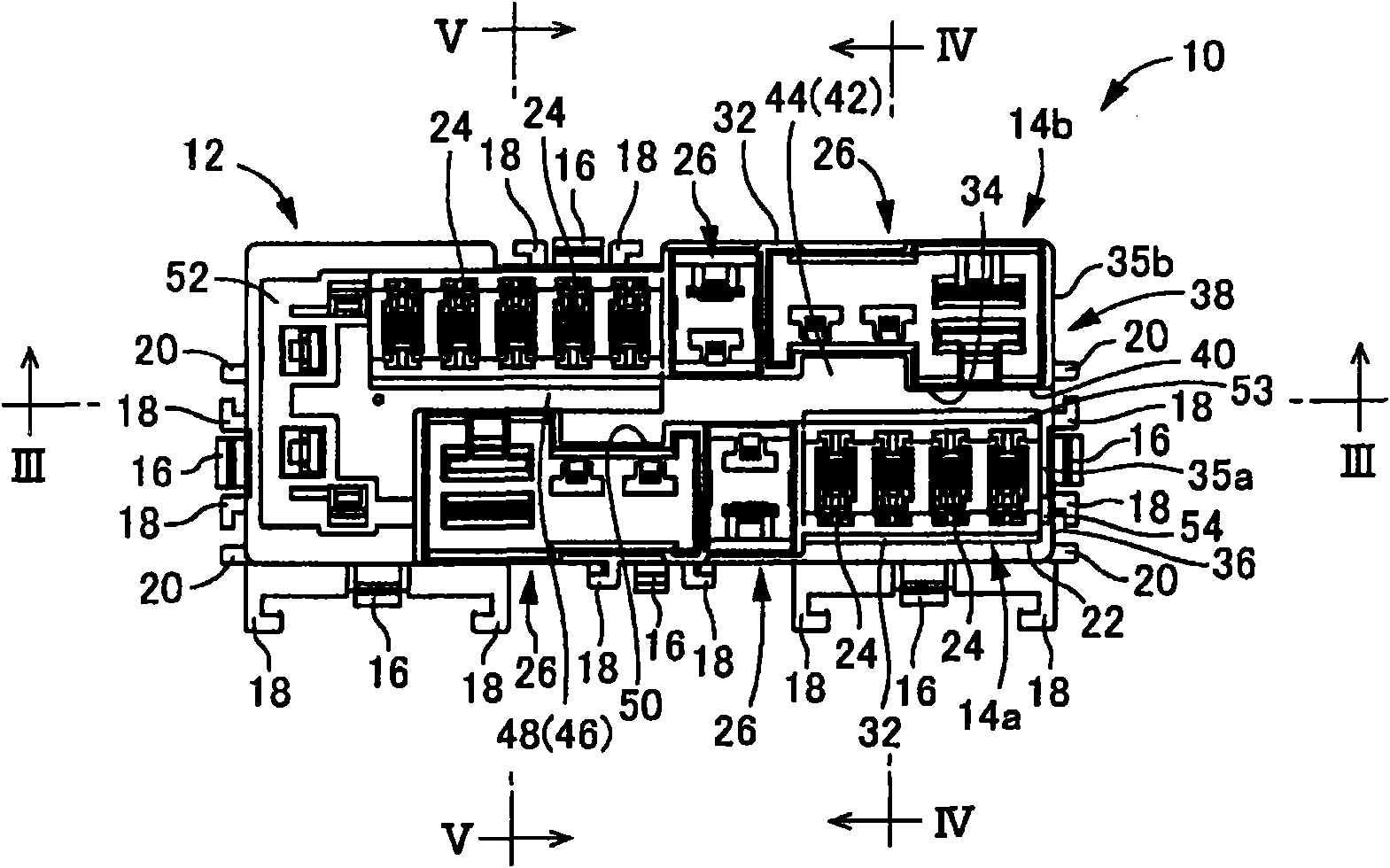

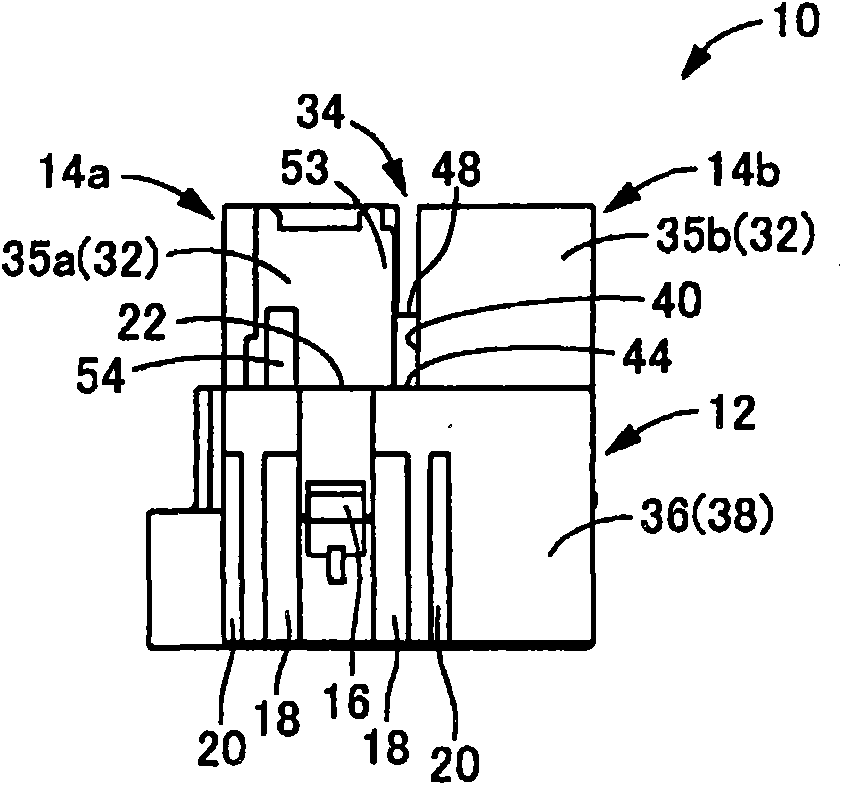

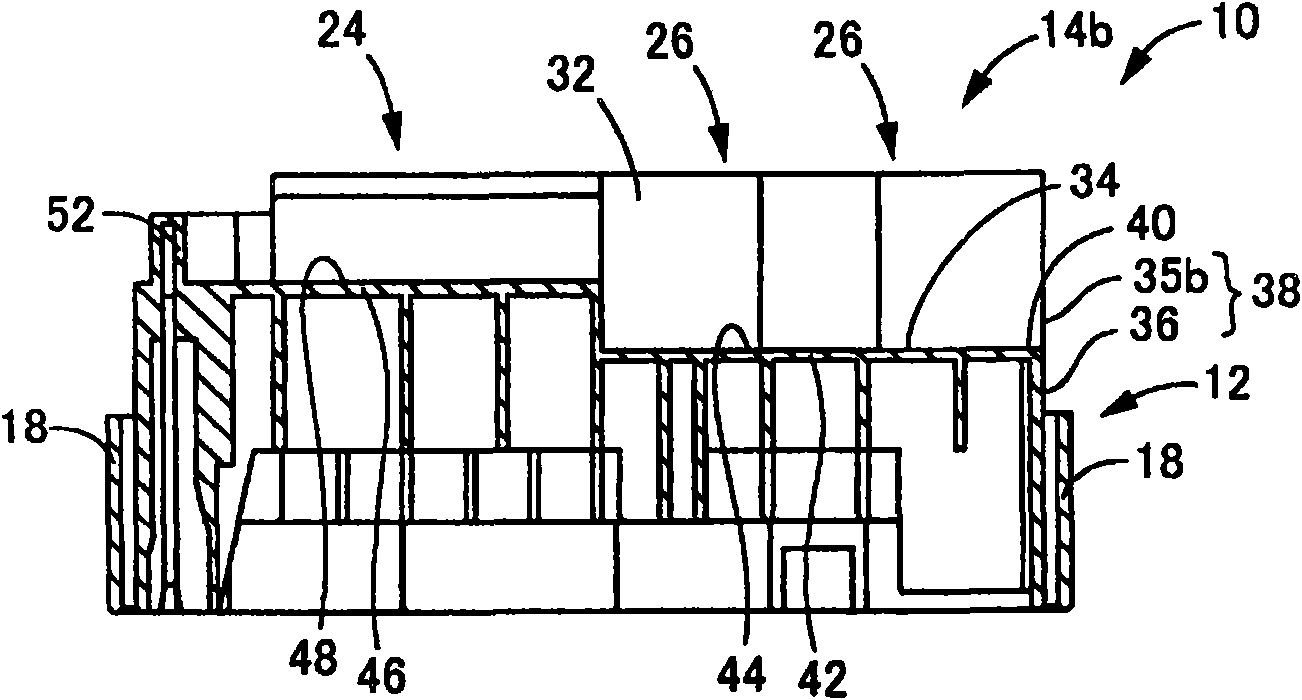

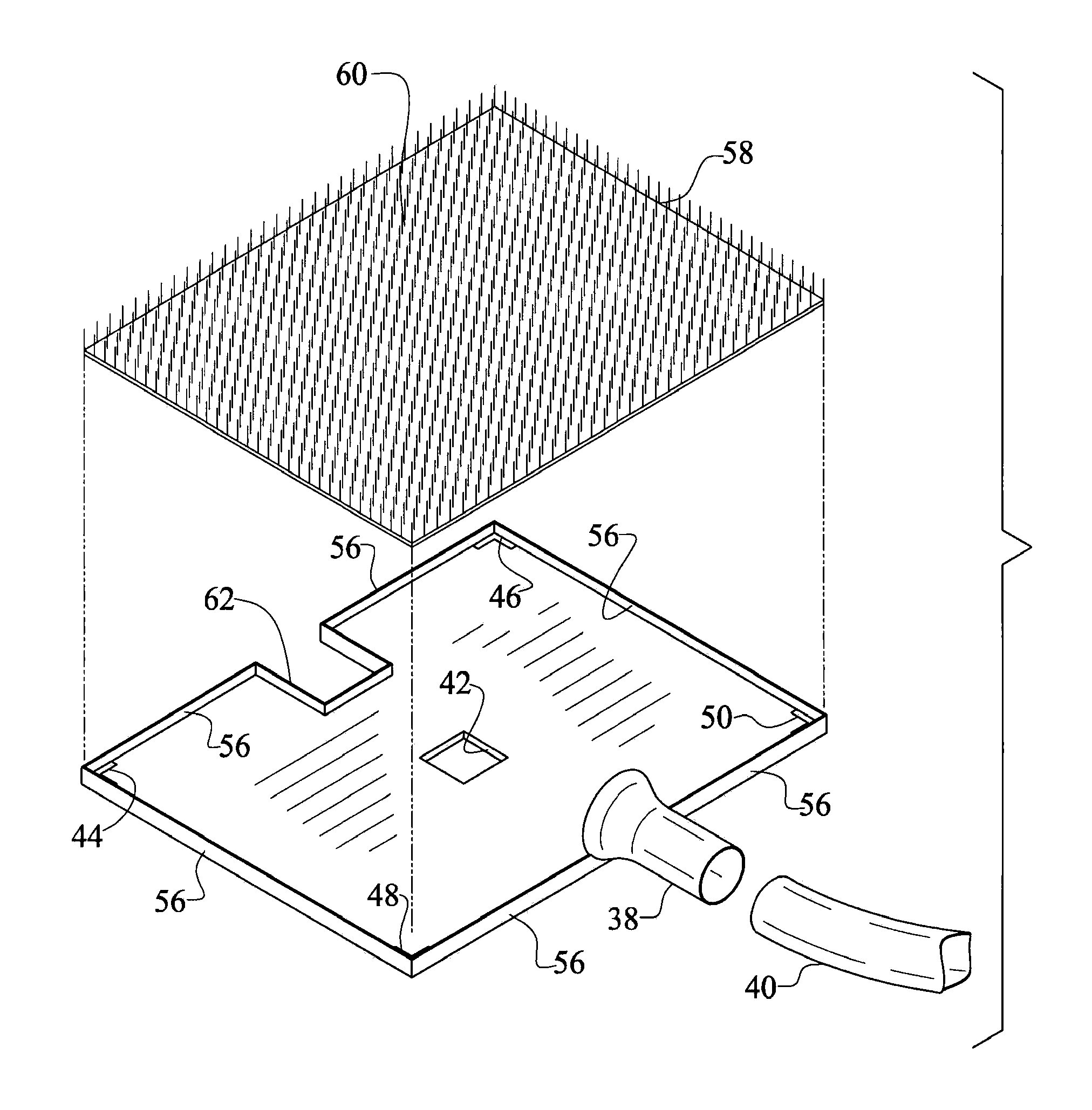

Electrical junction box

InactiveCN101938101AImprove space efficiencyImprove cooling effectCircuit arrangements on support structuresElectric/fluid circuitElectrical junctionElectricity

To provide an electrical junction box having a new structure that includes a plurality of electrical component mounting sections that are open in an upper surface, such that (1) the structure is provided with a drainage groove for preventing accumulation of water without requiring any special space, and (2) the structure can eliminate a problem of heat generation from electrical components. An electrical junction box includes a first and second electrical component mounting section units. A plurality of electrical component mounting sections are arranged in straight lines to from the first and second units, respectively. The first and second electrical component mounting segment units are separated apart from each other by a given distance and are arranged in parallel with each other. A heat radiation drainage groove is provided between opposed portions of peripheral walls that constitute the adjacent first and second units. The heat radiation drainage groove is provided in at least one end with an end opening that extends to ends of the first and second units and is open in an outer peripheral surface.

Owner:SUMITOMO WIRING SYST LTD

Directional atomizer system for cleaning chandeliers

ActiveUS20110308033A1Eliminate the problemSuppress splashFouling preventionSuction cleanersWater dischargePositive pressure

An apparatus for cleaning chandeliers includes a hand-held jet gun having a proximal end connected to a source of hot water under positive pressure and a distal end having a spray head for discharging hot water under pressure in a spray pattern. A hand-held vacuum shield has at least one vacuum inlet connected to a source of negative pressure. Hot water discharged from the spray head is attracted to the hand-held vacuum shield when the spray head and the hand-held vacuum shield are held in relatively close proximity to one another and the hand-held vacuum shield is in fluid communication with the source of negative pressure. An object disposed between the spray head and the hand-held vacuum shield is cleansed by the action of hot water under positive pressure impinging against it. The hand-held vacuum shield protects objects not disposed between the spray head and the hand-held vacuum shield.

Owner:INVENTIVE SOLUTIONS

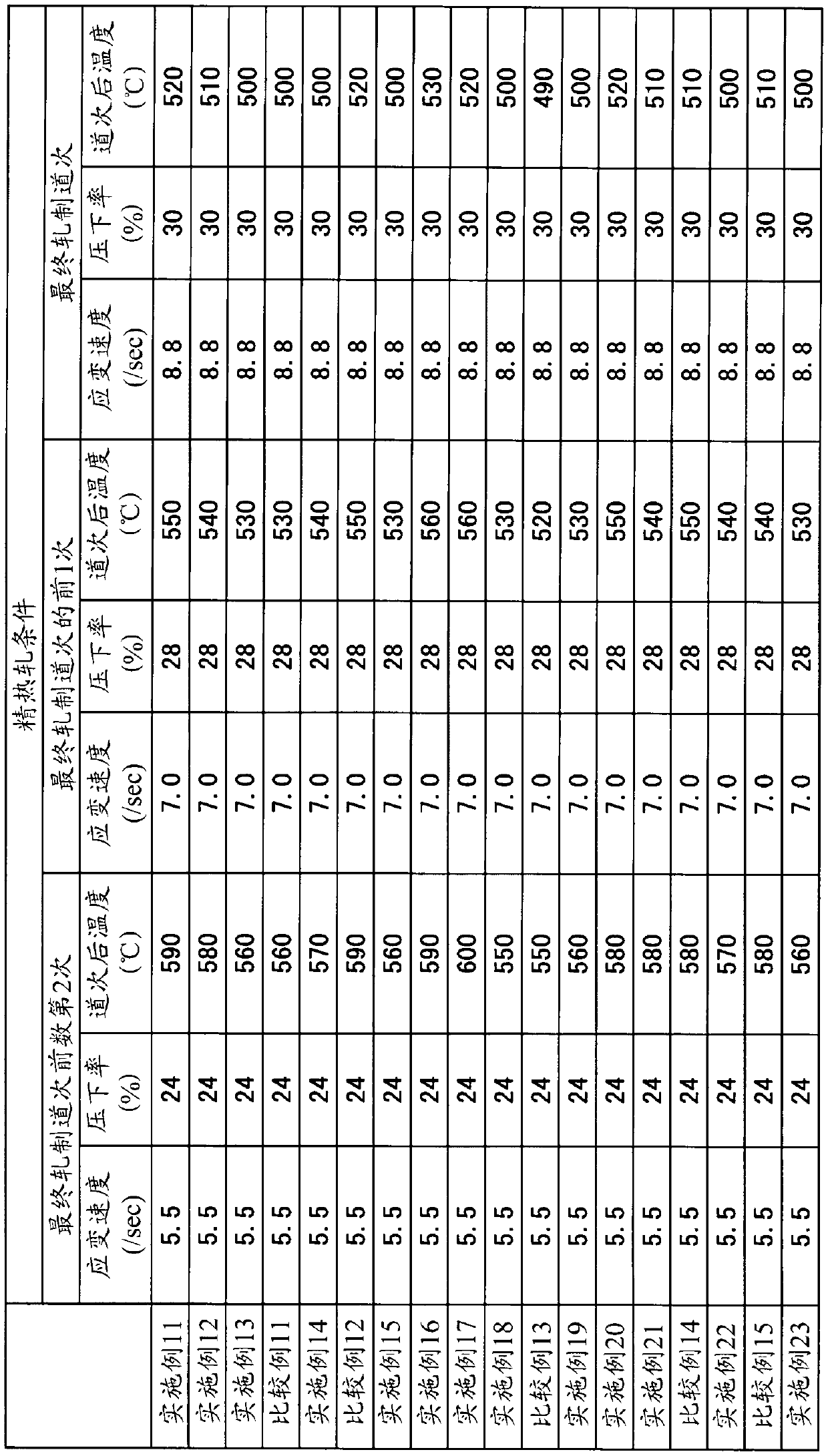

Silver-alloy sputtering target for conductive-film formation, and method for producing same

ActiveCN103298970AArcing suppressionSuppress splashElectroluminescent light sourcesVacuum evaporation coatingIngotMachining

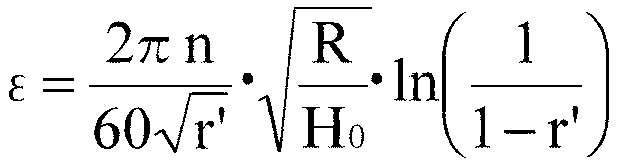

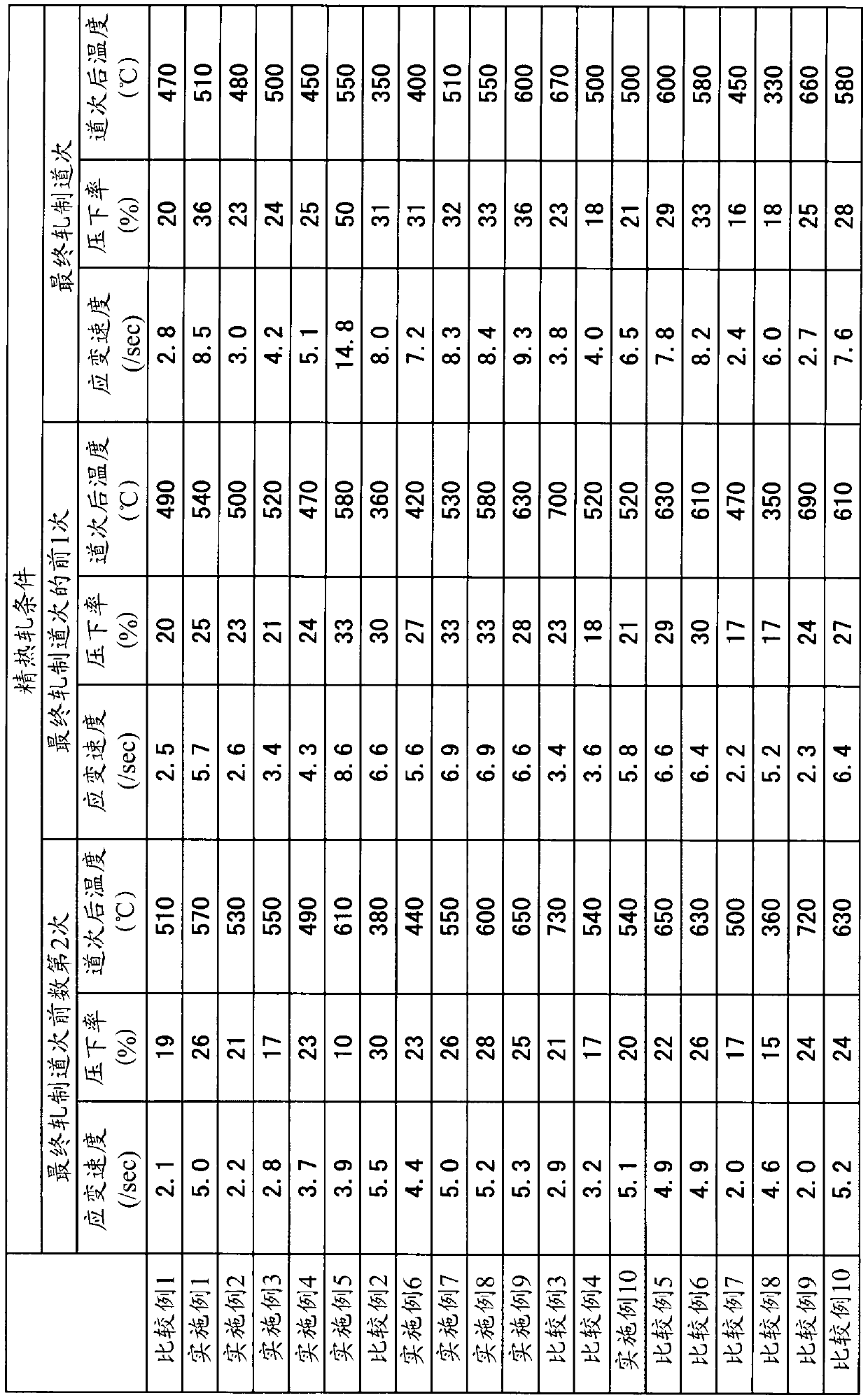

One embodiment of the sputtering target having a component composition containing In in the amount of 0.1-1.5 mass%, with the remainder comprising Ag and inevitable impurities, wherein the average particle diameter of the alloy crystal grains is 30mum or more and less than 150mum, and the variation in the particle diameter of the crystal grains is 20% or less of the average particle diameter. One embodiment of the method for producing the sputtering target in which a melt-cast ingot having the component composition is subjected to a hot-rolling step, a cooling step, and a machining step, in this order, wherein: the hot-rolling step involves one or more passes of finish hot rolling under conditions in which the rolling reduction for each pass is 20-50%, the strain rate is 3-15 / sec, and the temperature after the pass is 400-650 DEG C; and the cooling step involves quickly cooling at a cooling rate of 200-1000 DEG C / min.

Owner:MITSUBISHI MATERIALS CORP

Swinging laser-ultrasonic hybrid welding method

ActiveCN111673272AReduce volumeEasy to implementLaser beam welding apparatusShielding gasUltrasonic vibration

The invention provides a swinging laser-ultrasonic hybrid welding method, and relates to the field of material processing engineering. The swinging laser-ultrasonic hybrid welding method aims to solvethe problems of forming defects and pores in welded parts after swinging laser welding. Ultrasound is used for assisting in changing the melt flow condition, and the undercut defects on two sides areavoided. After the use of ultrasonic wave assistance, crystal grains are further refined, the pores are suppressed, the shape of a keyhole is improved by ultrasound, the plasma and splash eruption are suppressed, and the effective utilization of energy is increased. The use of coaxial shielding gas for welding protection has a better protection effect on a molten pool, and the method is more suitable for welding titanium alloys, aluminum alloys and other easily oxidized materials. Compared with contact ultrasonic wave assistance, non-contact ultrasonic wave vibration can be applied to weldingof various complex structures and tracks, and application obstacles caused by poor contact and space limiting are avoided. The swinging laser-ultrasonic hybrid welding method is applied to the fieldof material processing.

Owner:HARBIN INST OF TECH

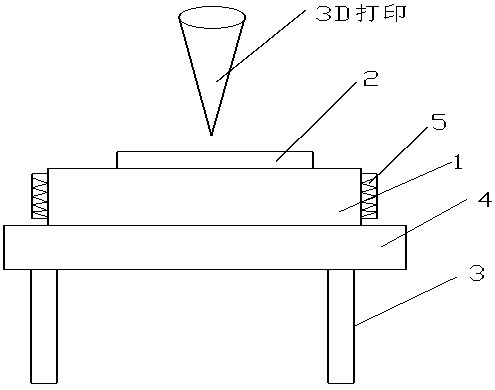

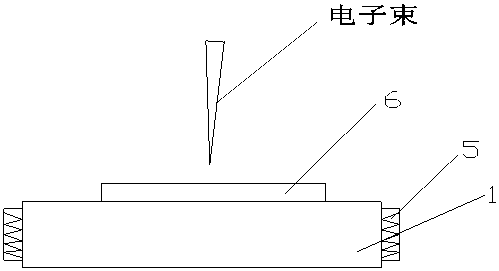

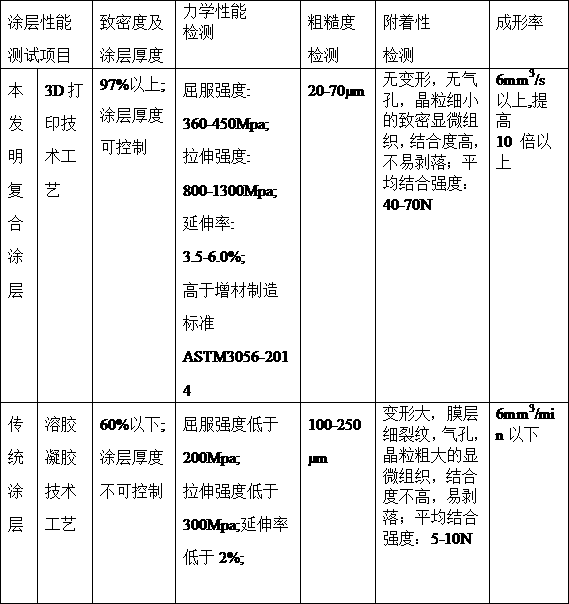

Method for preparing coating by 3D printing overlapping electron beam

InactiveCN110714199AGood molding precisionAvoid low powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyCermetCeramic composite

The invention relates to a method for preparing a coating by 3D printing overlapping an electron beam. Metal or ceramic powder and metal / ceramic powder are printed on the surface of a base material layer by layer through 3D printing, layer-by-layer printing is carried out by a three-dimensional model according to the set layer thickness, and then the metal or ceramic powder and metal / ceramic powder on the surface of the base material are preheated to form a fusion layer. A heating device used for the preheating includes a high-frequency vibrator and an induction heating coil which are placed on a workbench, the high-frequency vibrator acts on the bottoms of the fusion layer and the base material, the induction heating coil is arranged around the base material for preheating, after preheating is carried out, the fusion layer is melted with the electron beam to form a metal / ceramic. composite coating, and finally the metal / ceramic composite coating is subjected to post-heat treatment through the induction heating coil. The product development cycle is greatly shortened, production rate is improved, and the production cost is reduced.

Owner:FUJIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com