Patents

Literature

114results about How to "Curb rebound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seat Structure

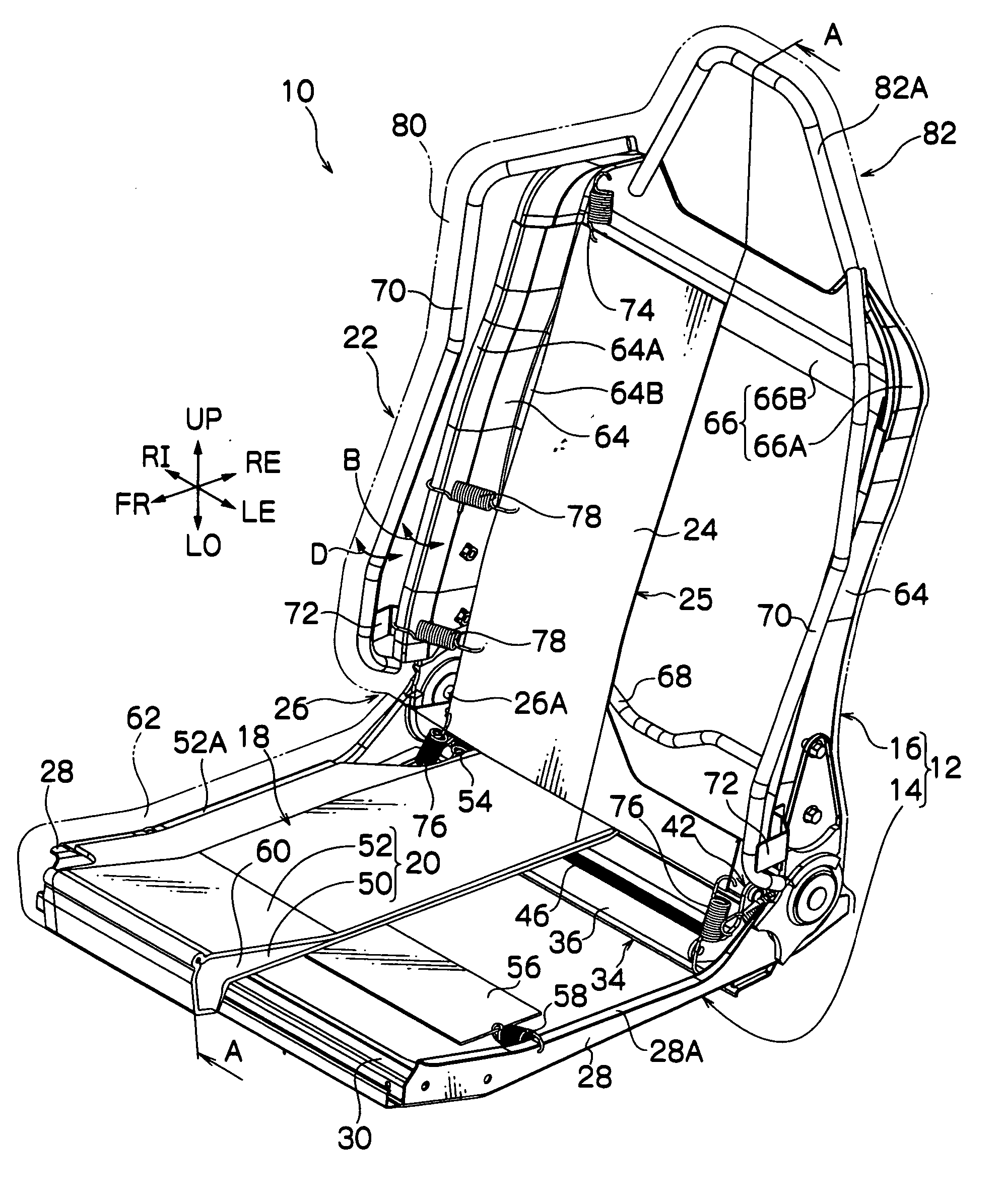

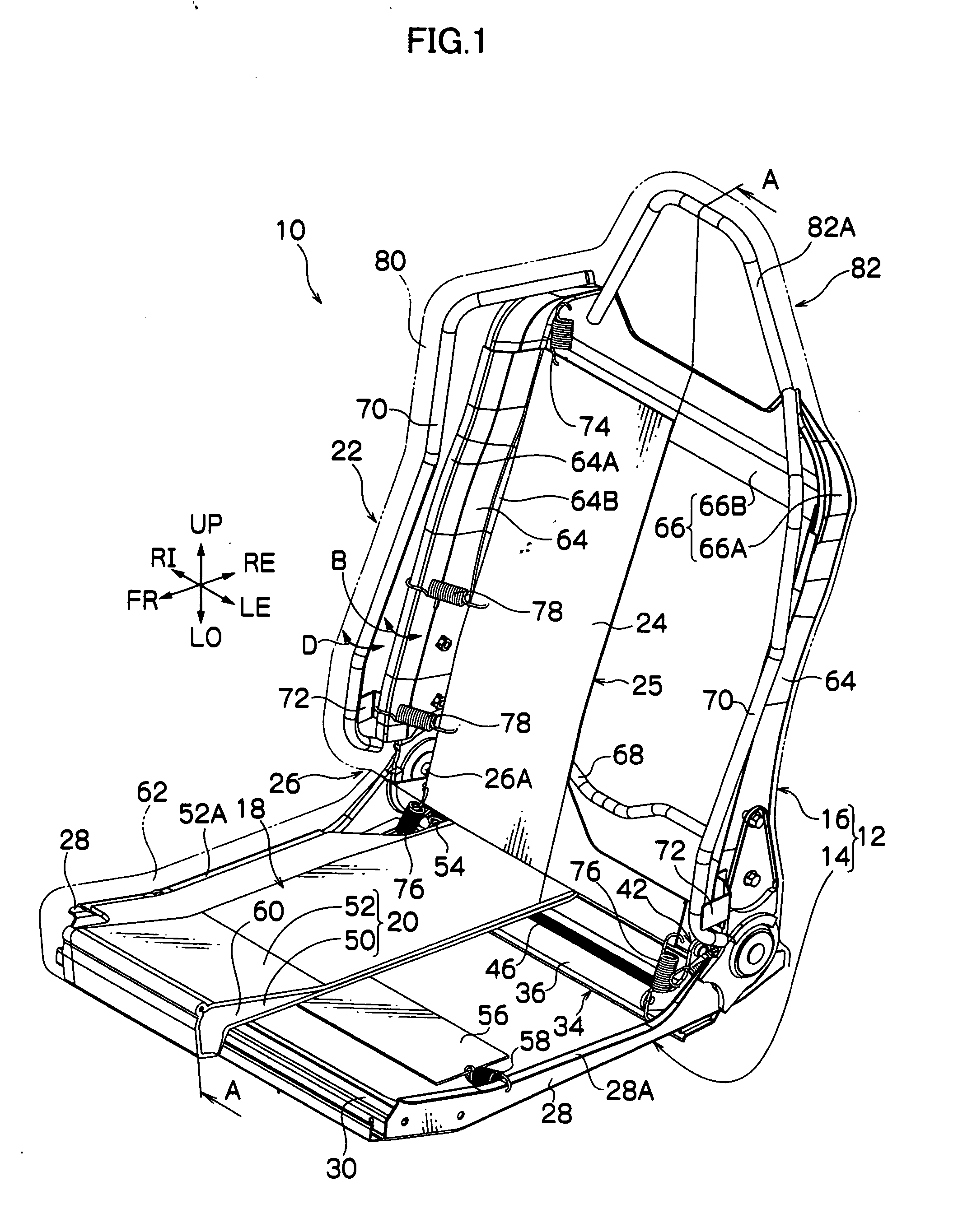

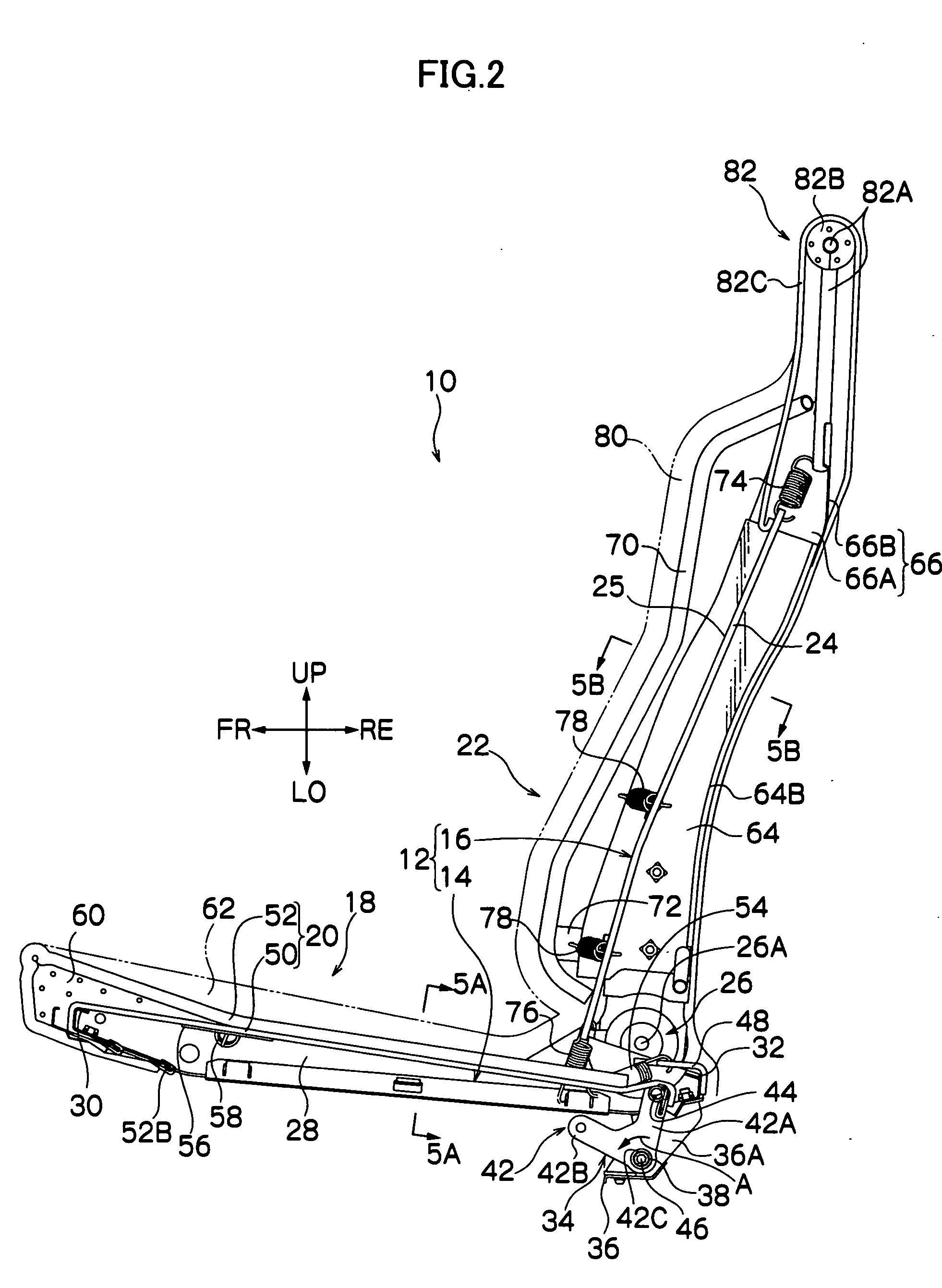

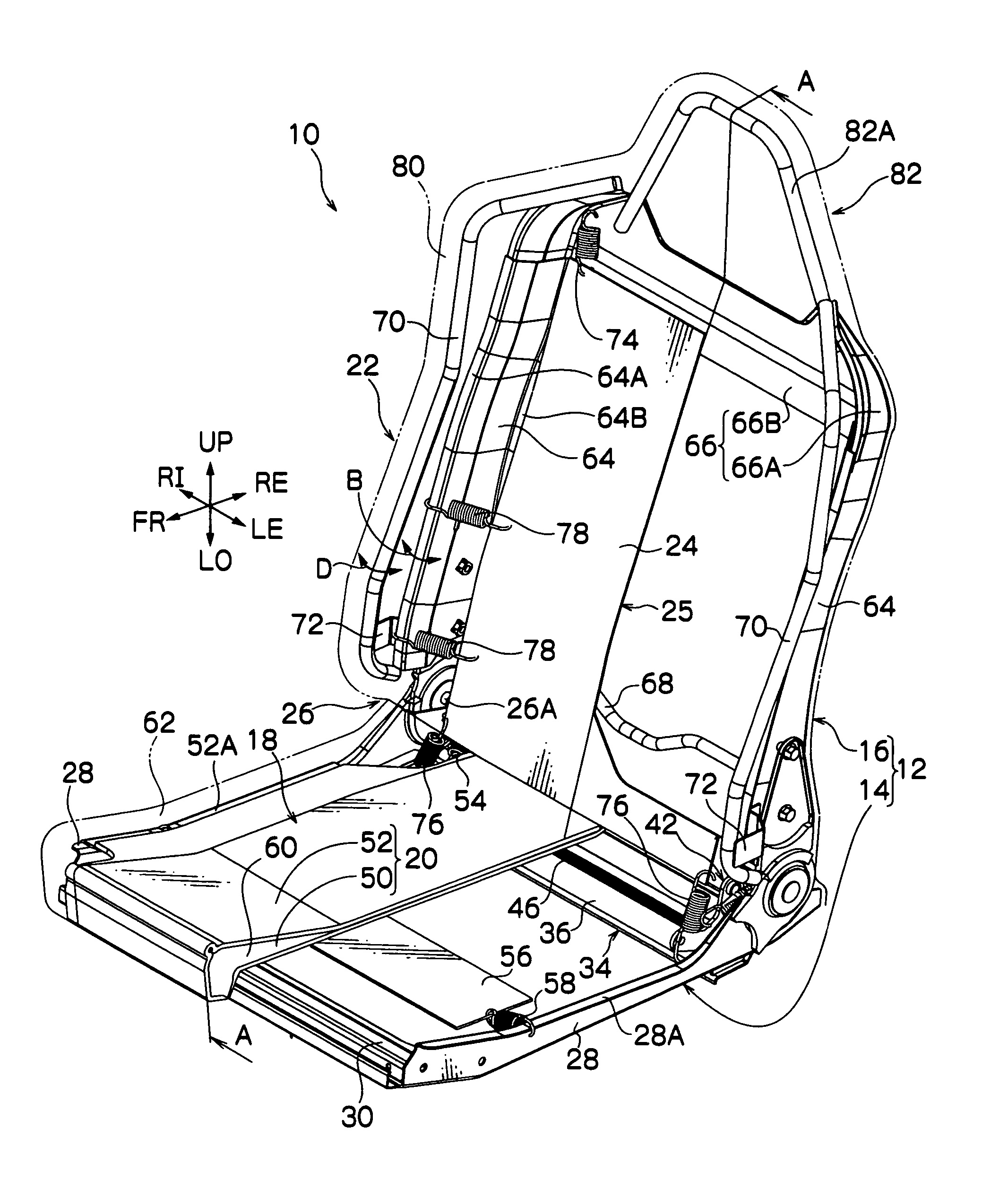

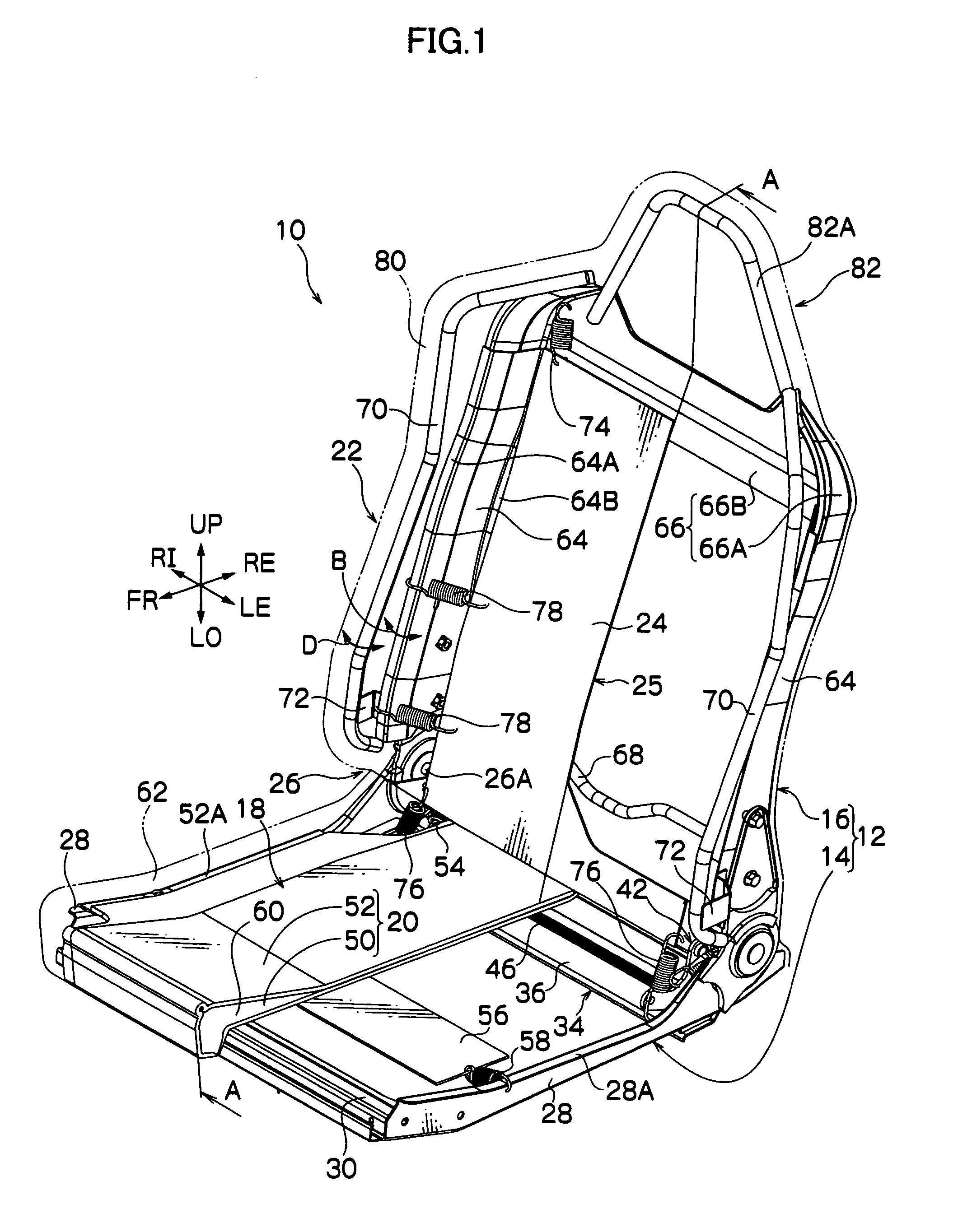

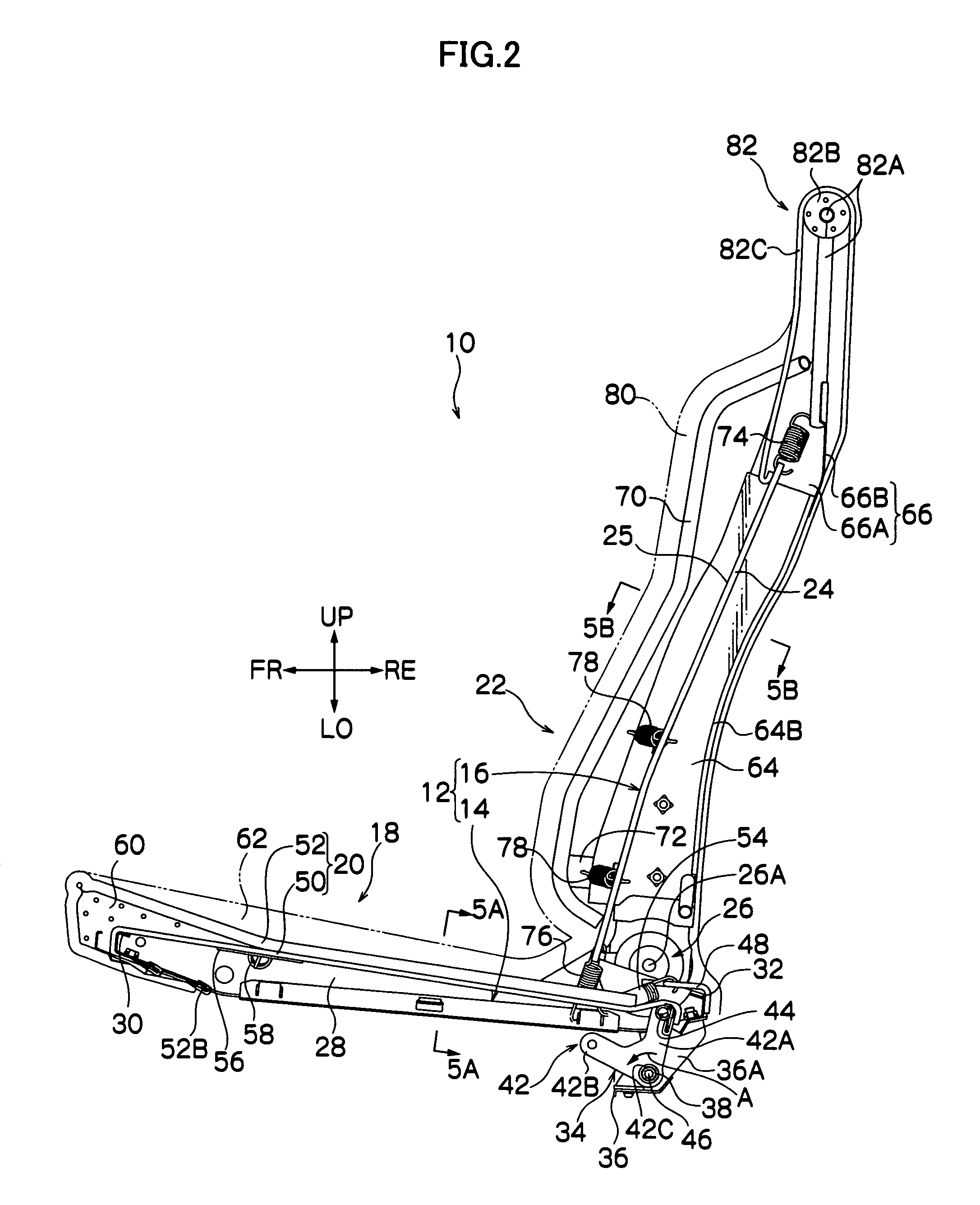

InactiveUS20070236071A1Good effectHindering the biological rhythms of a sitterVehicle seatsStoolsSpinal columnResonance

A seat structure which can ameliorate fatigue of a sitting person in accordance with a long period of sitting is provided. In a vehicle seat 10, a back edge side of a lower layer sheet 50 of a cushion material 20, of which a front edge side is fixed to a front edge side of a sitting portion frame 14, is resiliently connected to a back edge side of the sitting portion frame 14 via a movable frame 34 and a torsion bar 46, which is a resilient member. The cushion material 20 has a spring zero characteristic in which a spring constant of a portion that supports a protrusion portion of the sitting person is smaller than a spring constant of other portions. This vehicle seat 10 makes smaller the energy of vibrations which are transmitted to a spinal column portion of the sitting person through the sitting portion frame 14, and peripheral portions thereof convert vibrations corresponding to fluctuations in the body and transmit these through the sitting portion frame 14. α waves of 10 Hz to 12 Hz, which occur in a relaxed waking state, are caused in the brain of the sitting person. Vibrations in a resonance frequency region are attenuated in amplitude and transmitted to the sitting person.

Owner:DELTA TOOLING CO LTD

Seat structure

InactiveUS7971939B2Good effectHindering the biological rhythms of a sitterStoolsSeat suspension devicesSpinal columnResonance

A seat structure which can ameliorate fatigue of a sitting person in accordance with a long period of sitting is provided.In a vehicle seat 10, a back edge side of a lower layer sheet 50 of a cushion material 20, of which a front edge side is fixed to a front edge side of a sitting portion frame 14, is resiliently connected to a back edge side of the sitting portion frame 14 via a movable frame 34 and a torsion bar 46, which is a resilient member. The cushion material 20 has a spring zero characteristic in which a spring constant of a portion that supports a protrusion portion of the sitting person is smaller than a spring constant of other portions. This vehicle seat 10 makes smaller the energy of vibrations which are transmitted to a spinal column portion of the sitting person through the sitting portion frame 14, and peripheral portions thereof convert vibrations corresponding to fluctuations in the body and transmit these through the sitting portion frame 14. α waves of 10 Hz to 12 Hz, which occur in a relaxed waking state, are caused in the brain of the sitting person. Vibrations in a resonance frequency region are attenuated in amplitude and transmitted to the sitting person.

Owner:DELTA TOOLING CO LTD

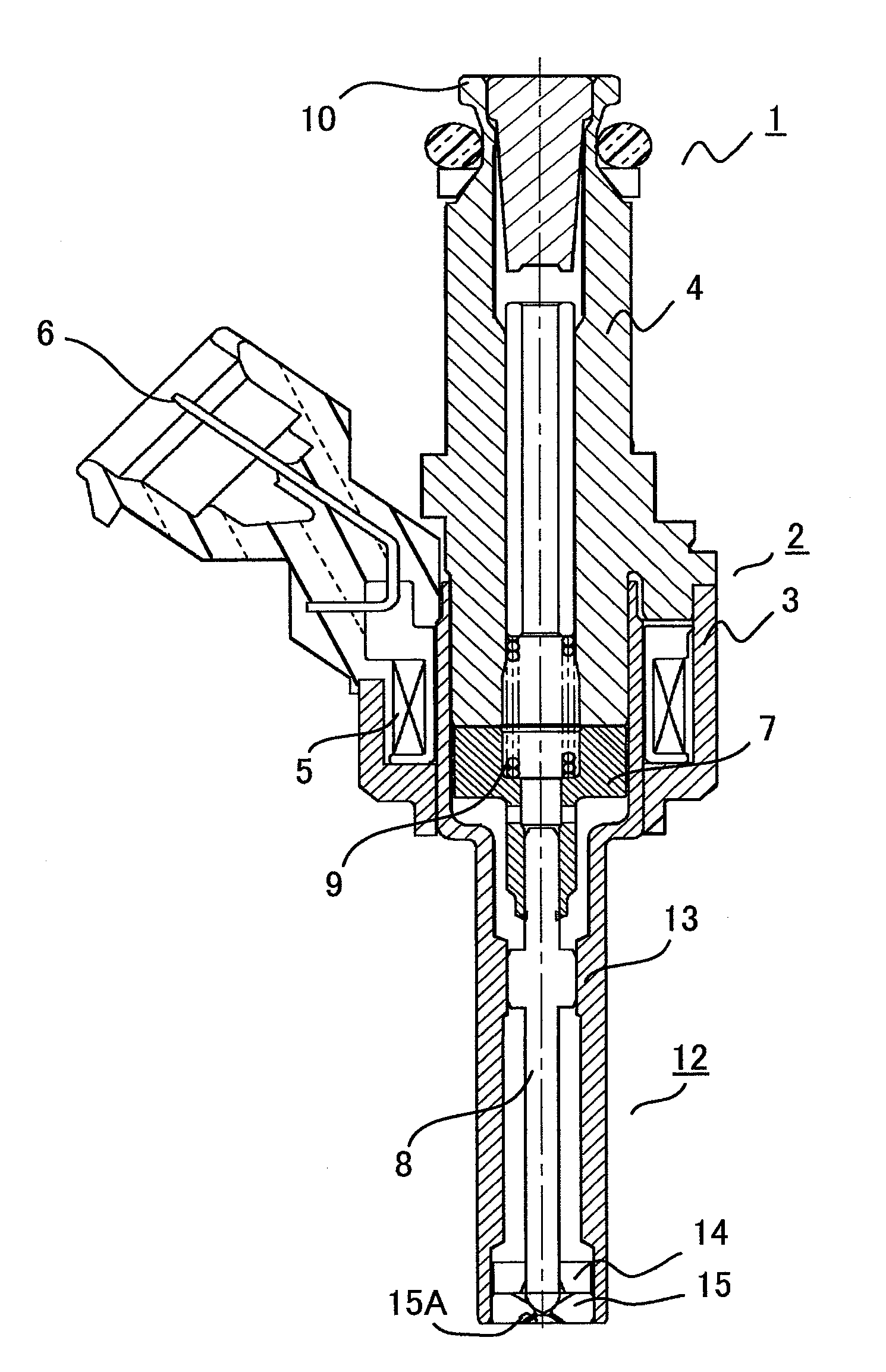

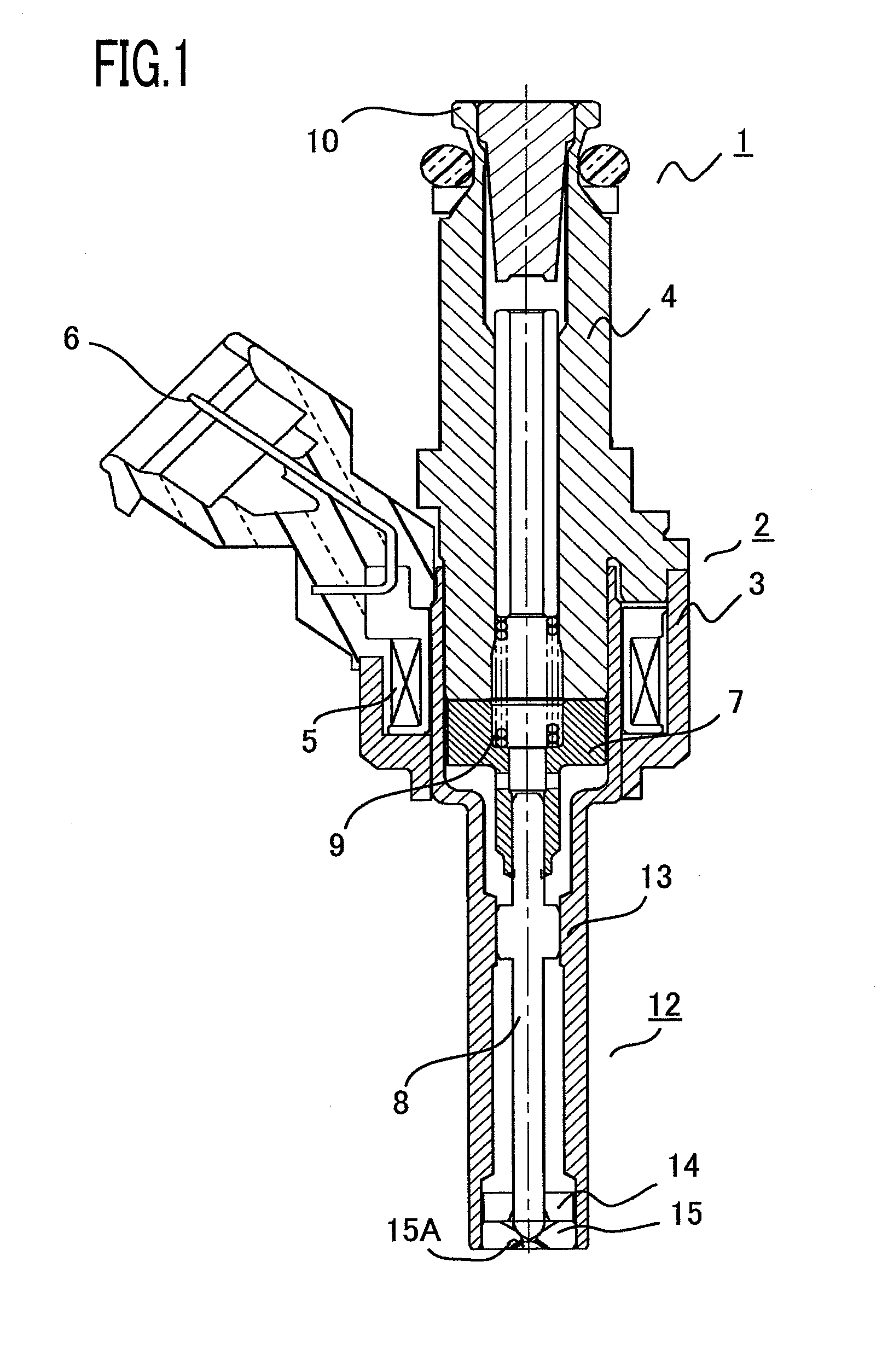

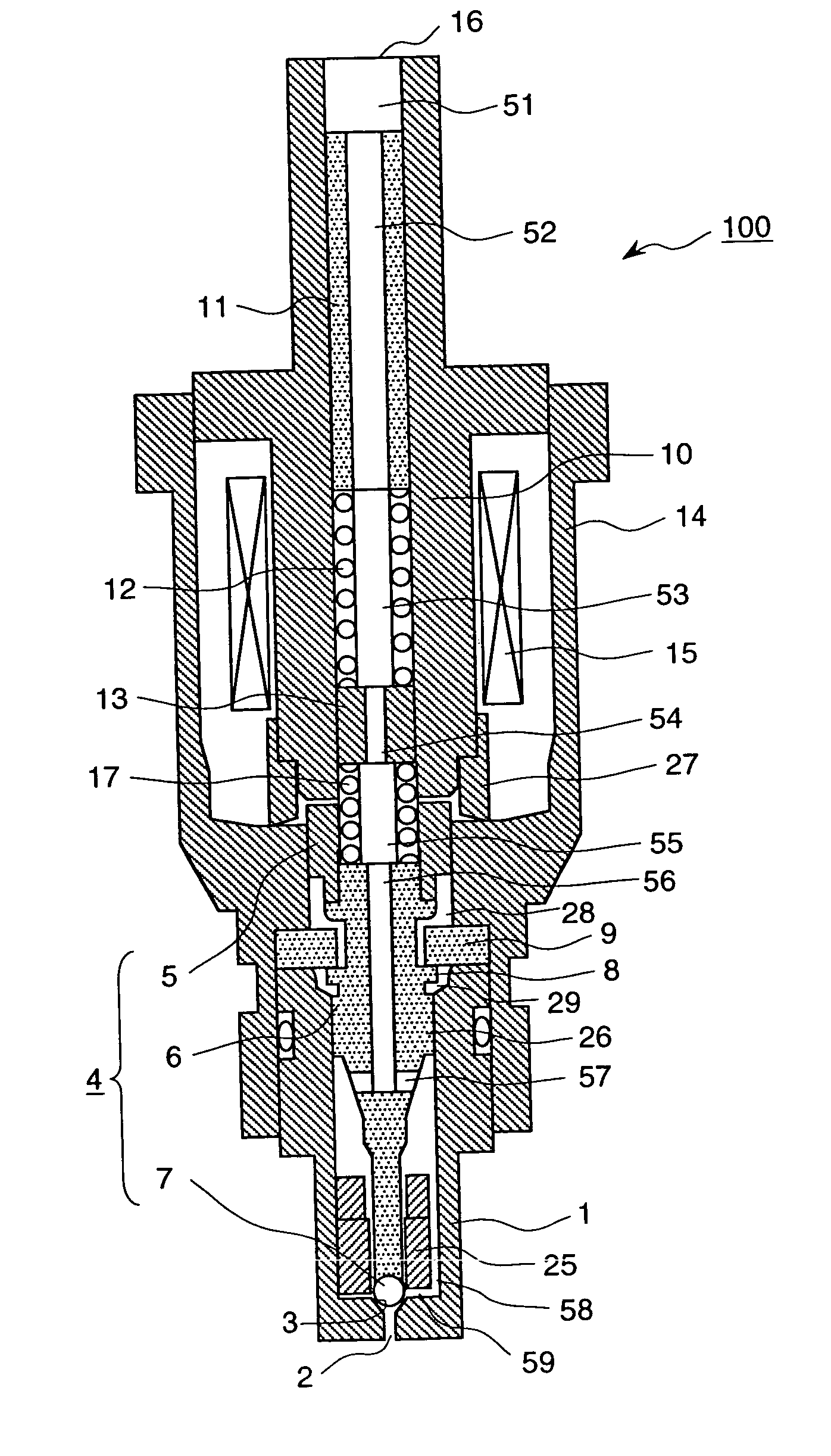

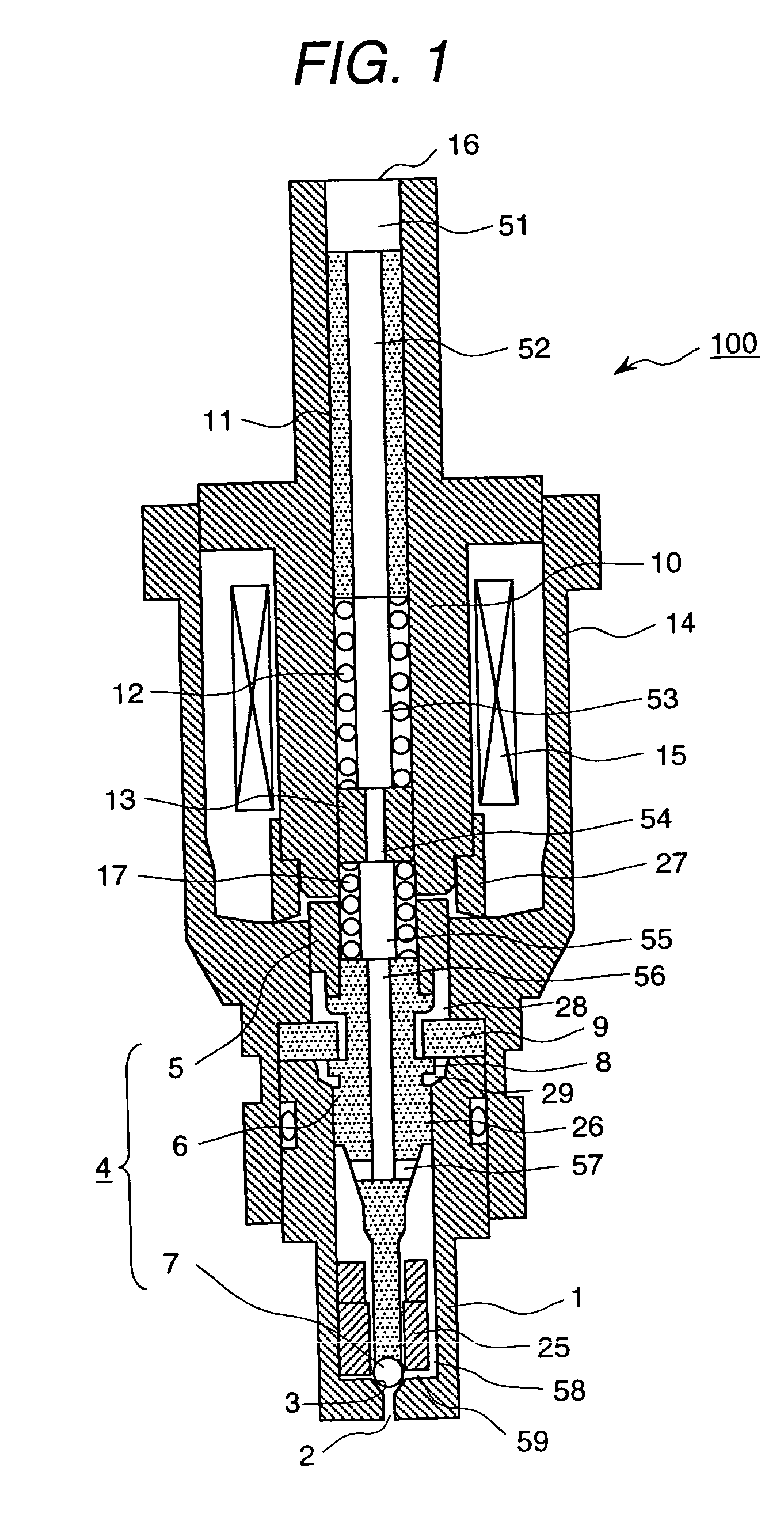

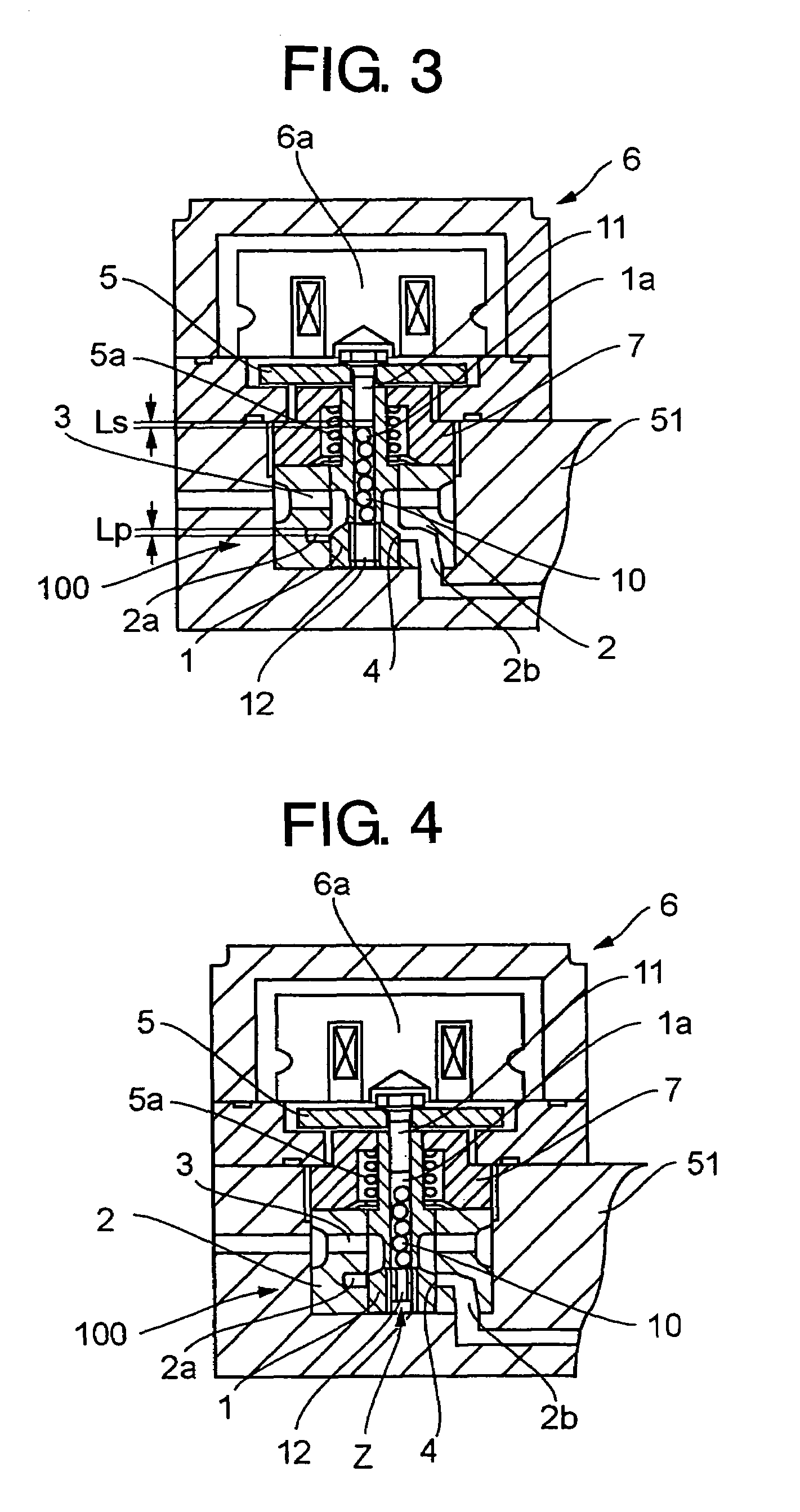

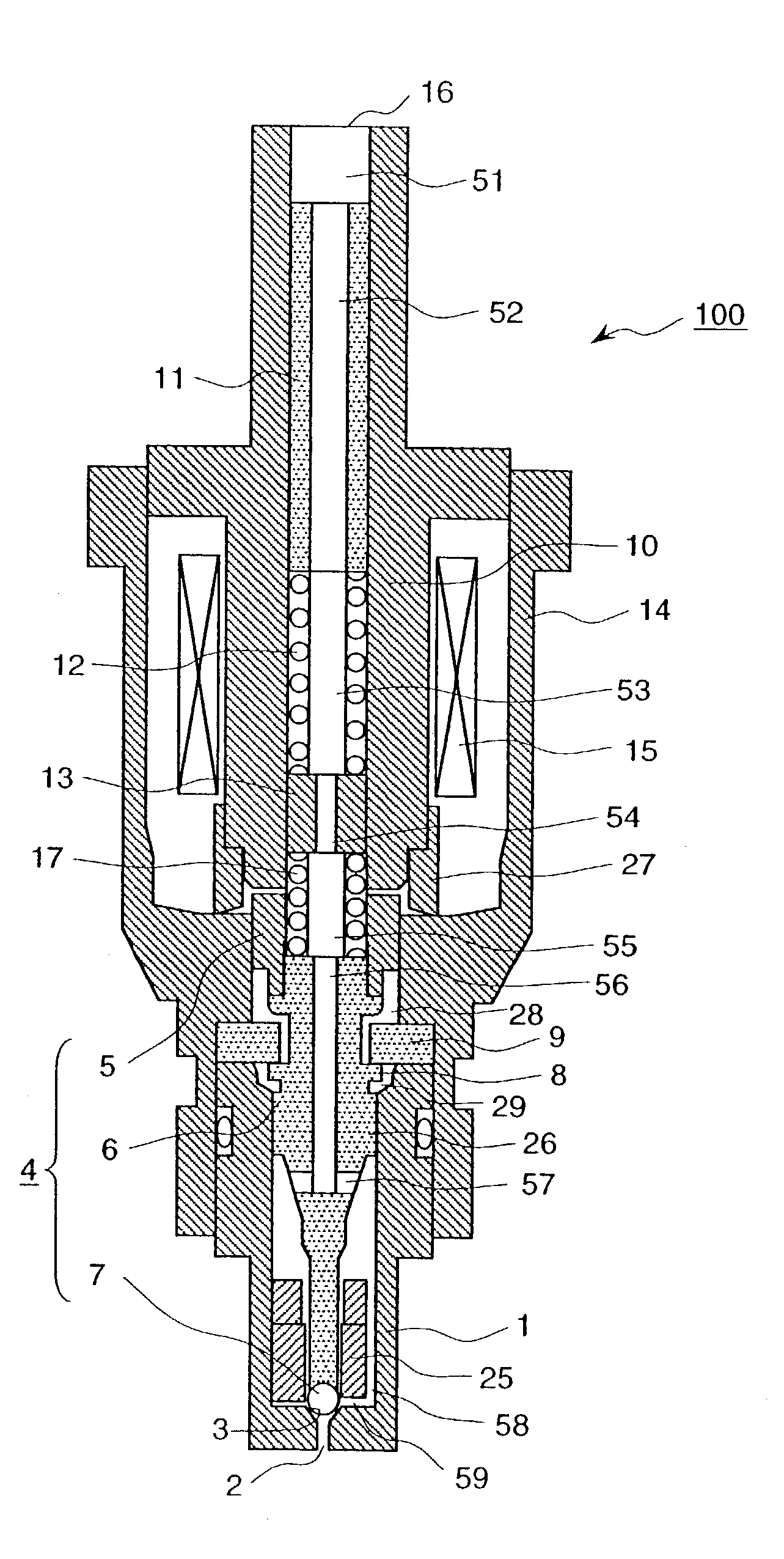

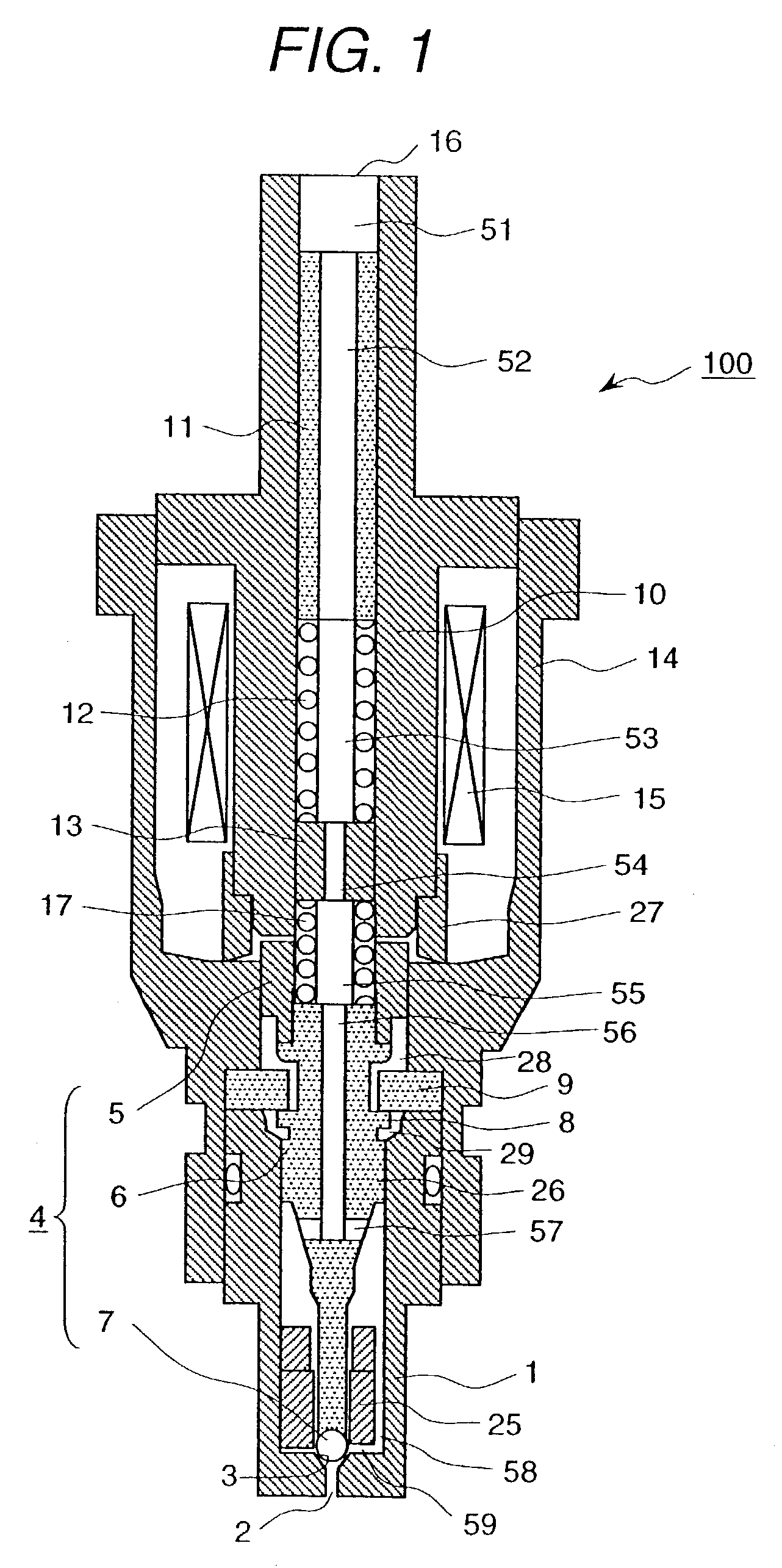

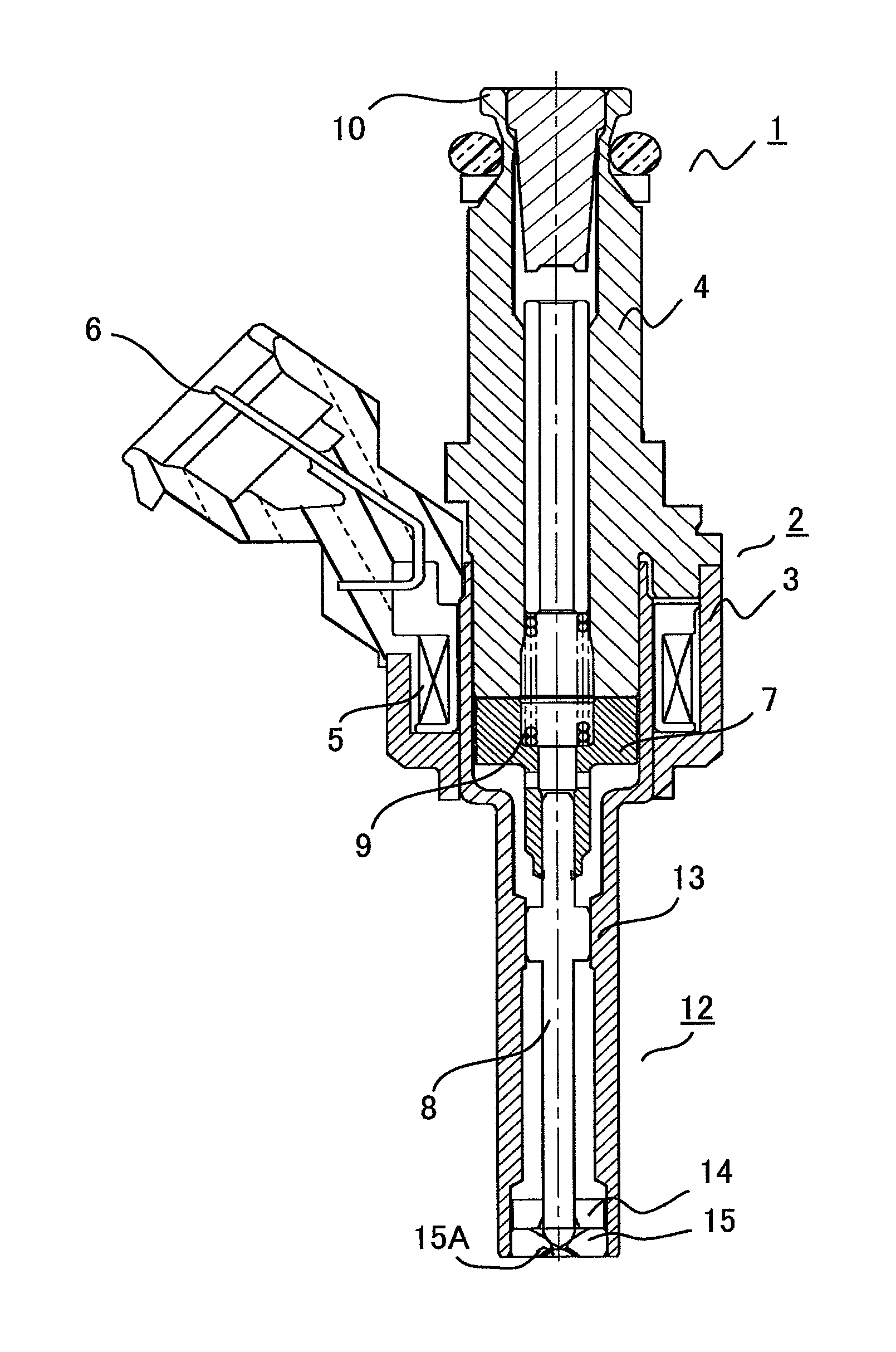

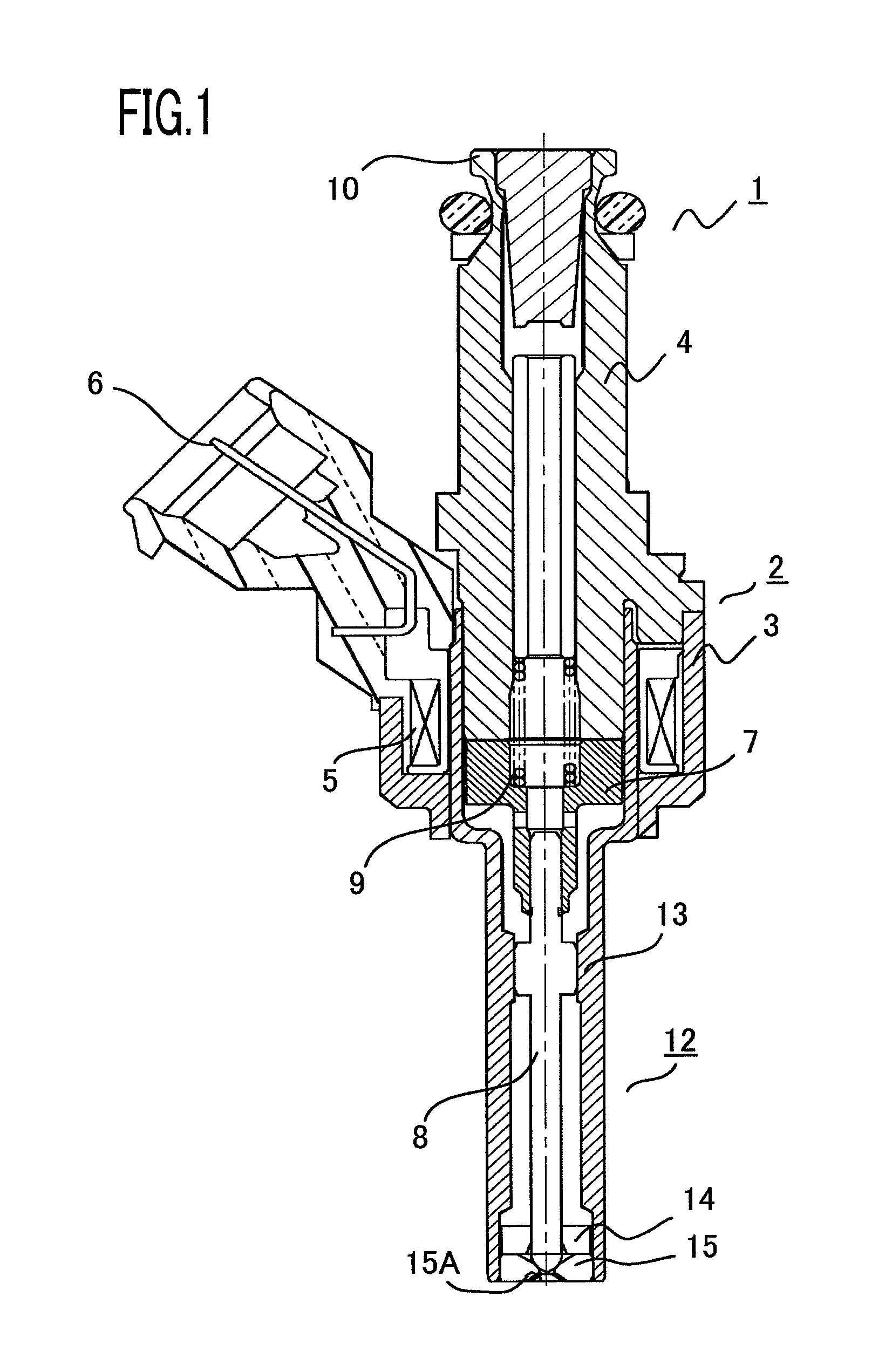

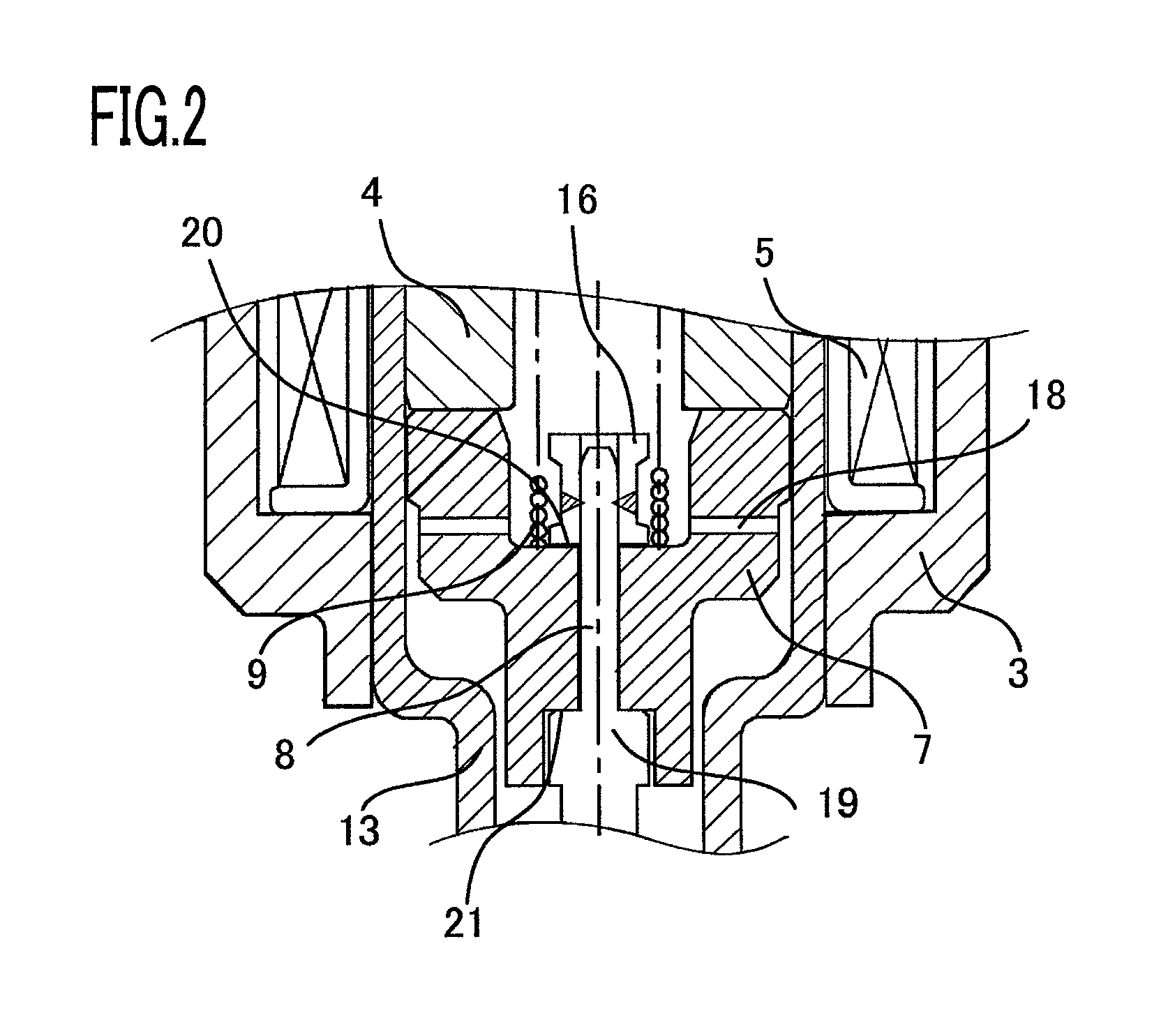

Fuel injection valve

InactiveUS20090288640A1Improve injection accuracyCurb reboundSpray nozzlesFuel injection apparatusBiomedical engineeringVALVE PORT

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil, a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature, and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the valve-closing spring is disposed on the armature, and the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle.

Owner:MITSUBISHI ELECTRIC CORP

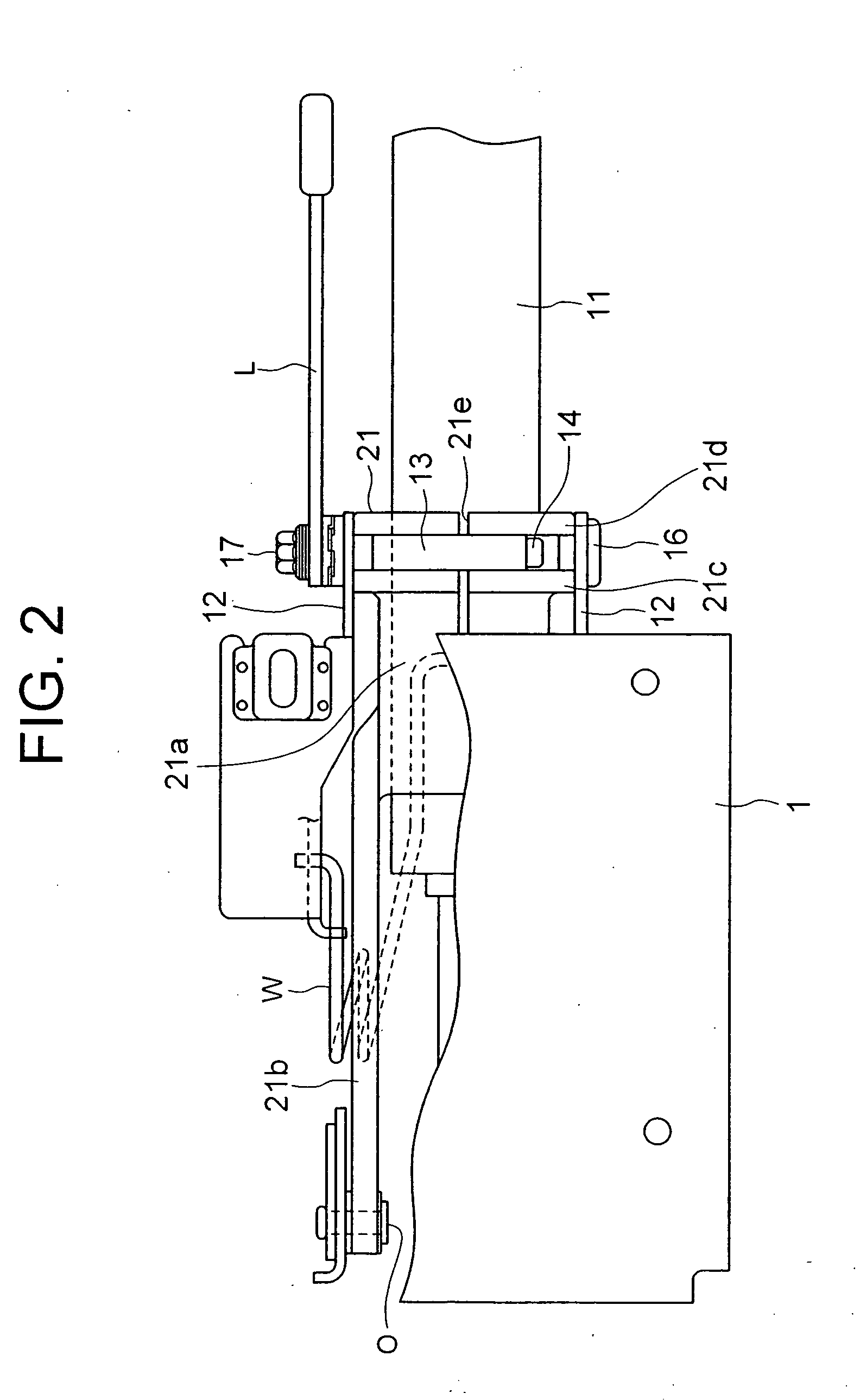

Substrate processing apparatus

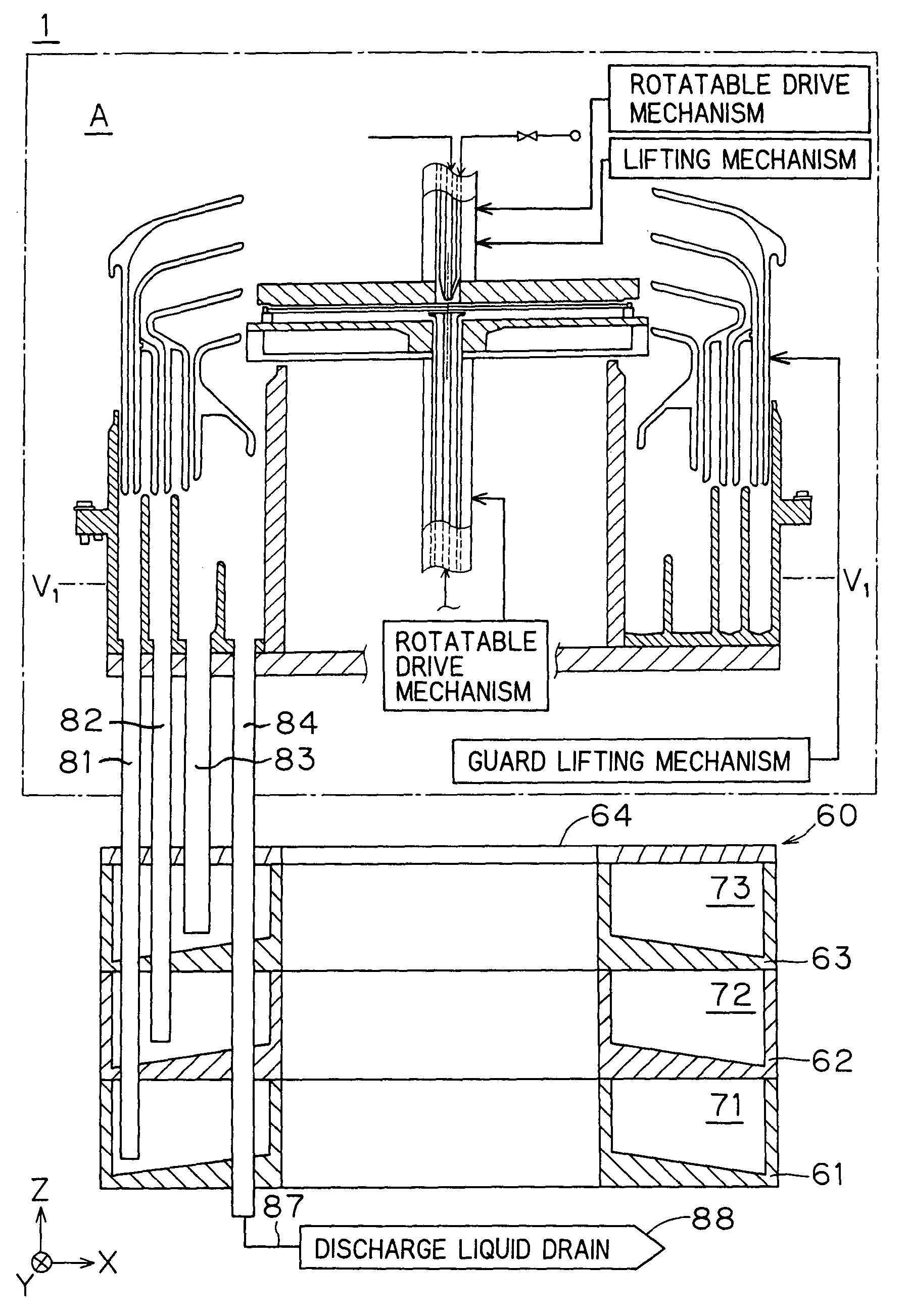

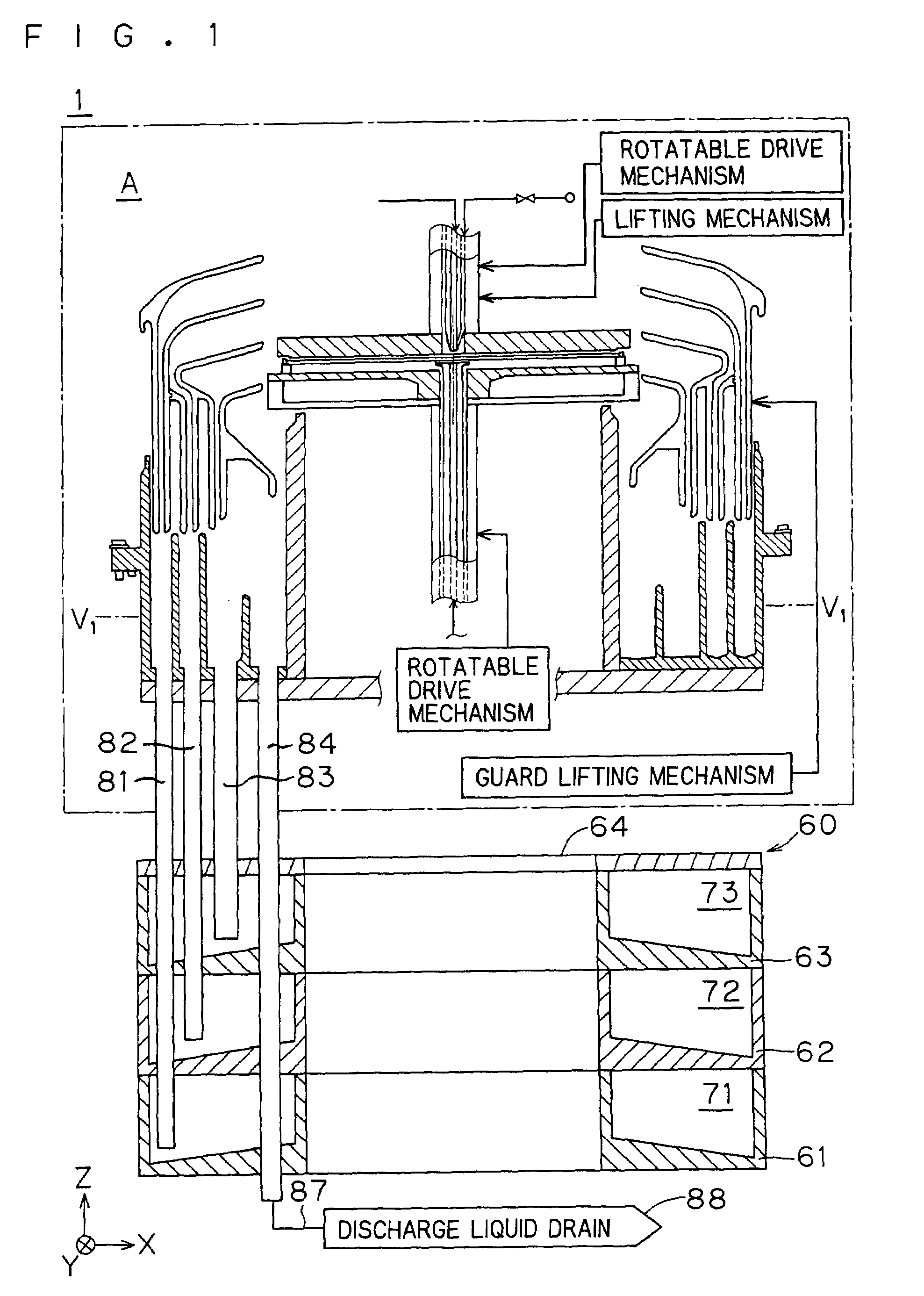

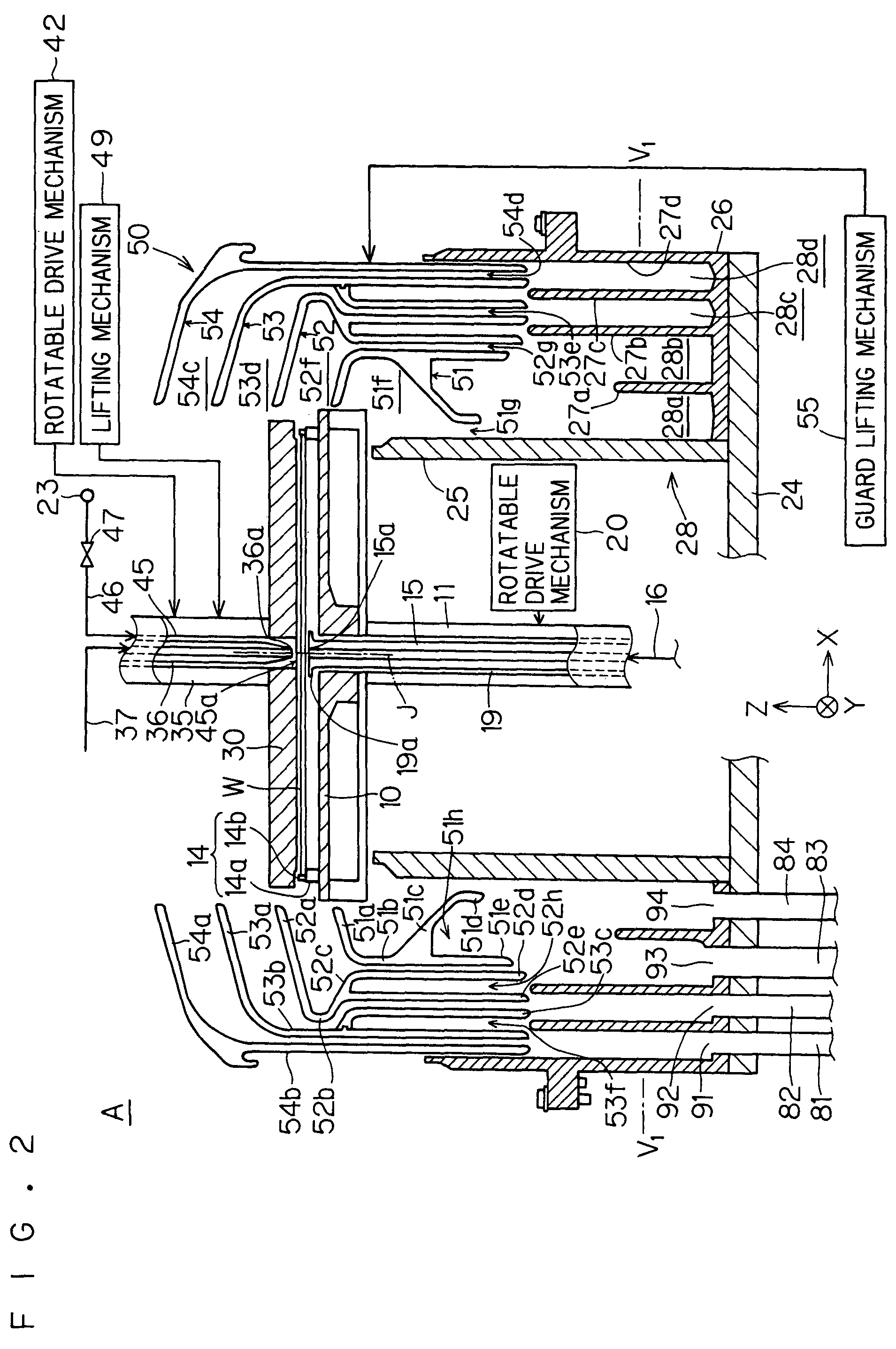

ActiveUS7584760B2Curb reboundShorten the timeFouling preventionSemiconductor/solid-state device manufacturingEngineeringNozzle

A substrate (W) is held and rotated in its horizontal position on a spin base (10). A processing liquid can be supplied from a processing liquid lower nozzle 15 to the lower surface of the substrate (W). The upper surface of the substrate (W) is covered with an atmosphere blocking plate (30). A splash guard (50) is disposed so as to circumscribe the substrate (W). A guard (52) is curved such that the vertical cross section of a recovery port (52f) of the splash guard (50) is of substantially U-shape opening to the center of the splash guard (50), so that the maximum internal diameter part of the recovery port (52f) is brought near a guard (53). The space between the internal wall surface of the recovery port (52f) and the substrate (W) is increased to thereby suppress the bounce of the processing liquid flying spattering from the substrate (W) in rotation.

Owner:DAINIPPON SCREEN MTG CO LTD

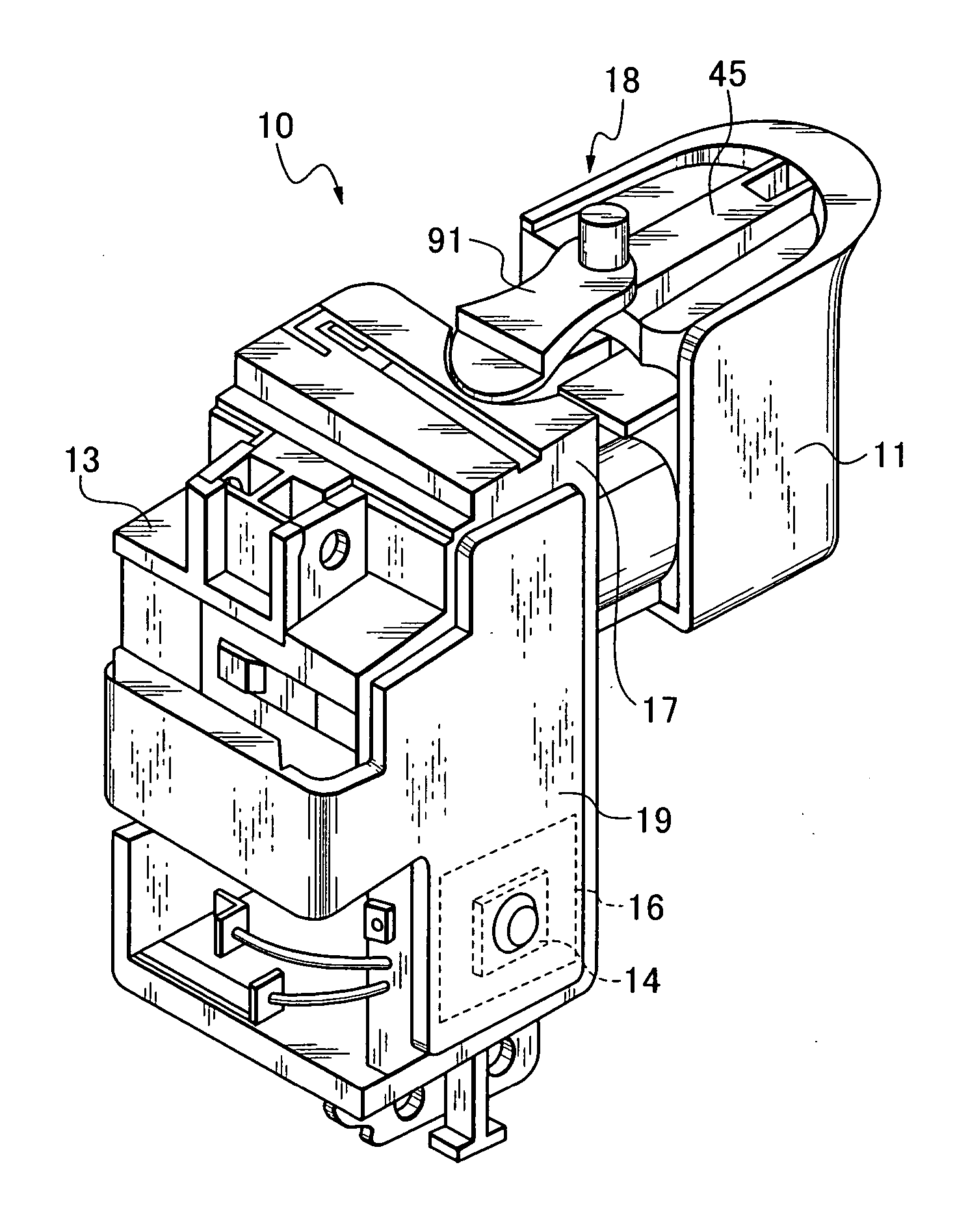

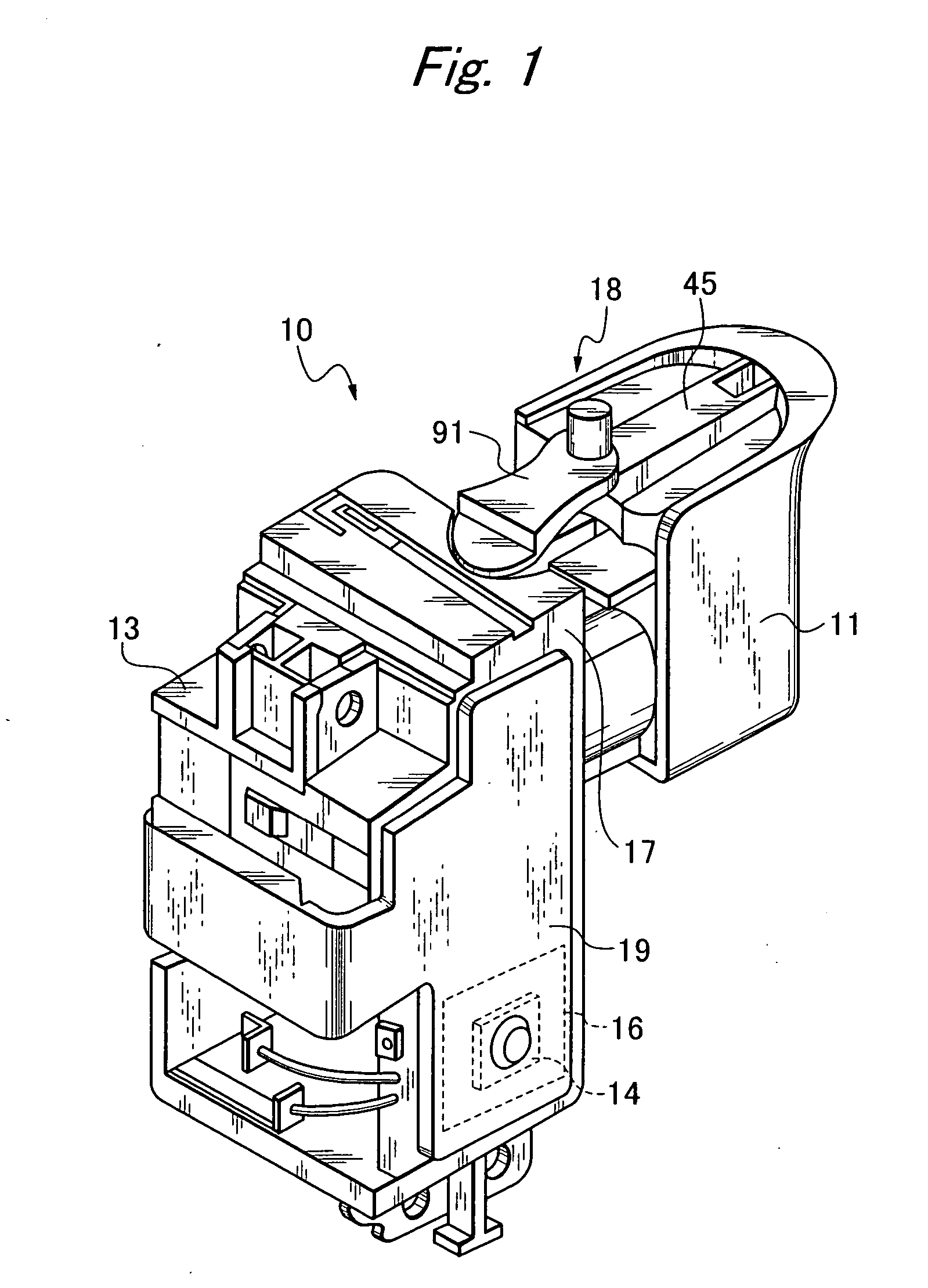

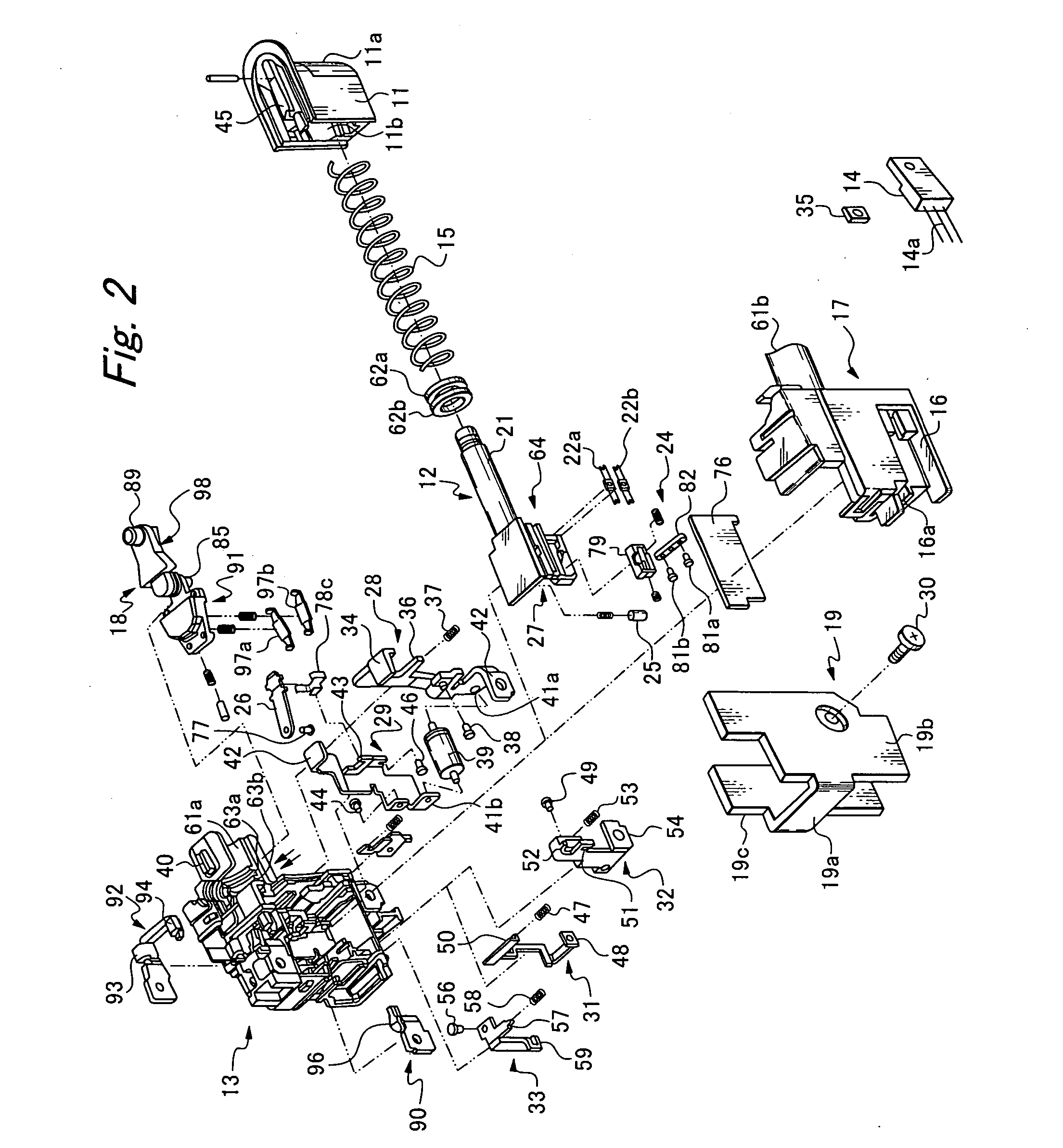

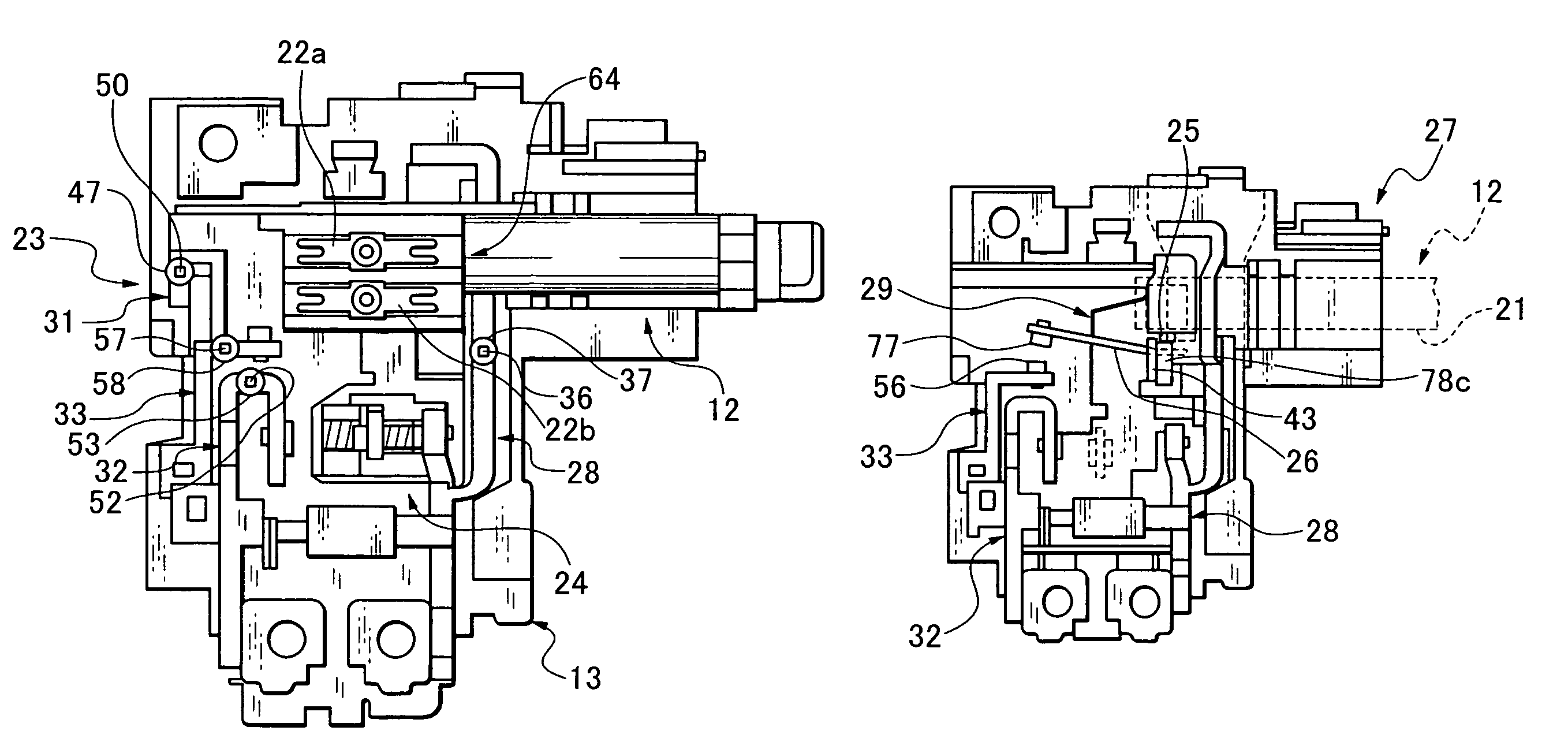

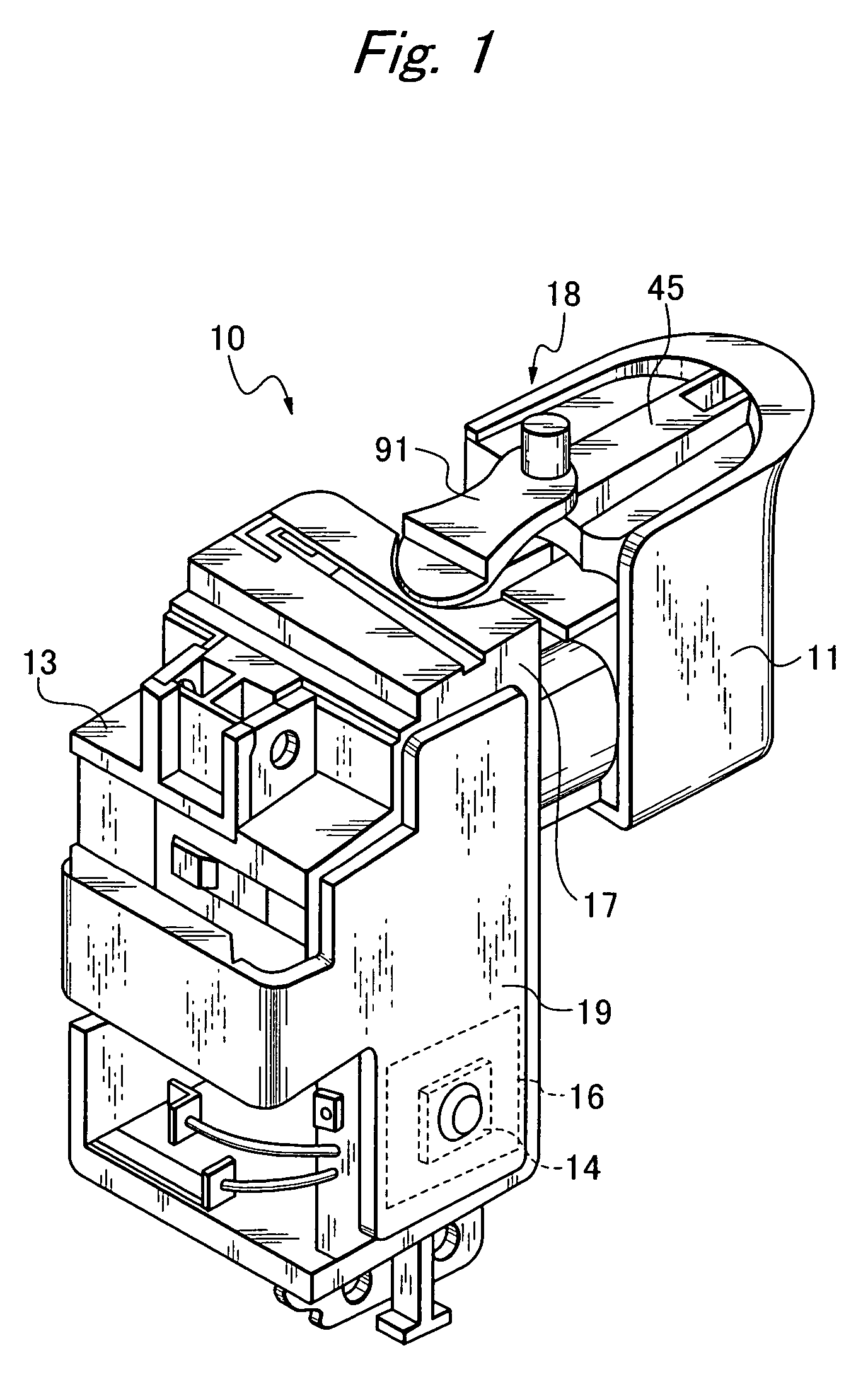

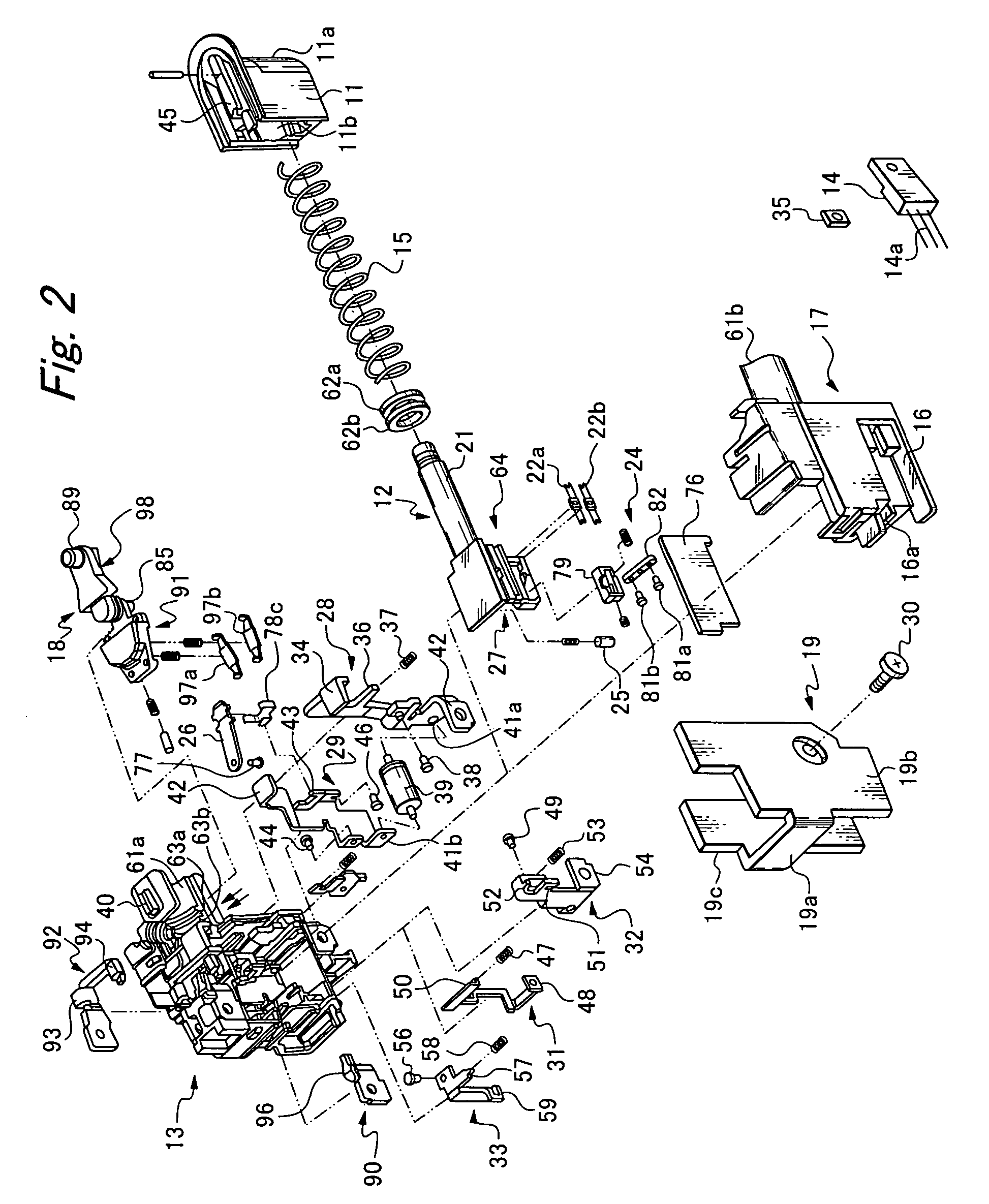

Trigger switch

ActiveUS20060186102A1Simple structureCurb reboundArc welding apparatusElectric switchesSliding contactControl unit

To provide a trigger switch having a simple structure that is capable of reducing bouncing when the contacts are switched ON / OFF, the trigger switch includes a switch mechanism integrated in a single assembly a power control unit that turns a plurality of switches provided on the switch mechanism ON / OFF depending on a degree of retraction of the control unit by moving a pressing member over a top of a seesaw-shaped switching bar, a motor brake and control element short-circuit unit that drives a movable armature having two short-circuit contacts and is sandwiched and held between two springs, and a speed control unit that slides a plurality of moving contacts disposed in parallel over sliding contacts disposed on a sliding circuit substrate so as to control both the supply of power and a control element, and thus control the rotation speed of a motor.

Owner:SATORI ELECTRIC

Trigger switch

To provide a trigger switch having a simple structure that is capable of reducing bouncing when the contacts are switched ON / OFF, the trigger switch includes a switch mechanism integrated in a single assembly a power control unit that turns a plurality of switches provided on the switch mechanism ON / OFF depending on a degree of retraction of the control unit by moving a pressing member over a top of a seesaw-shaped switching bar, a motor brake and control element short-circuit unit that drives a movable armature having two short-circuit contacts and is sandwiched and held between two springs, and a speed control unit that slides a plurality of moving contacts disposed in parallel over sliding contacts disposed on a sliding circuit substrate so as to control both the supply of power and a control element, and thus control the rotation speed of a motor.

Owner:SATORI ELECTRIC

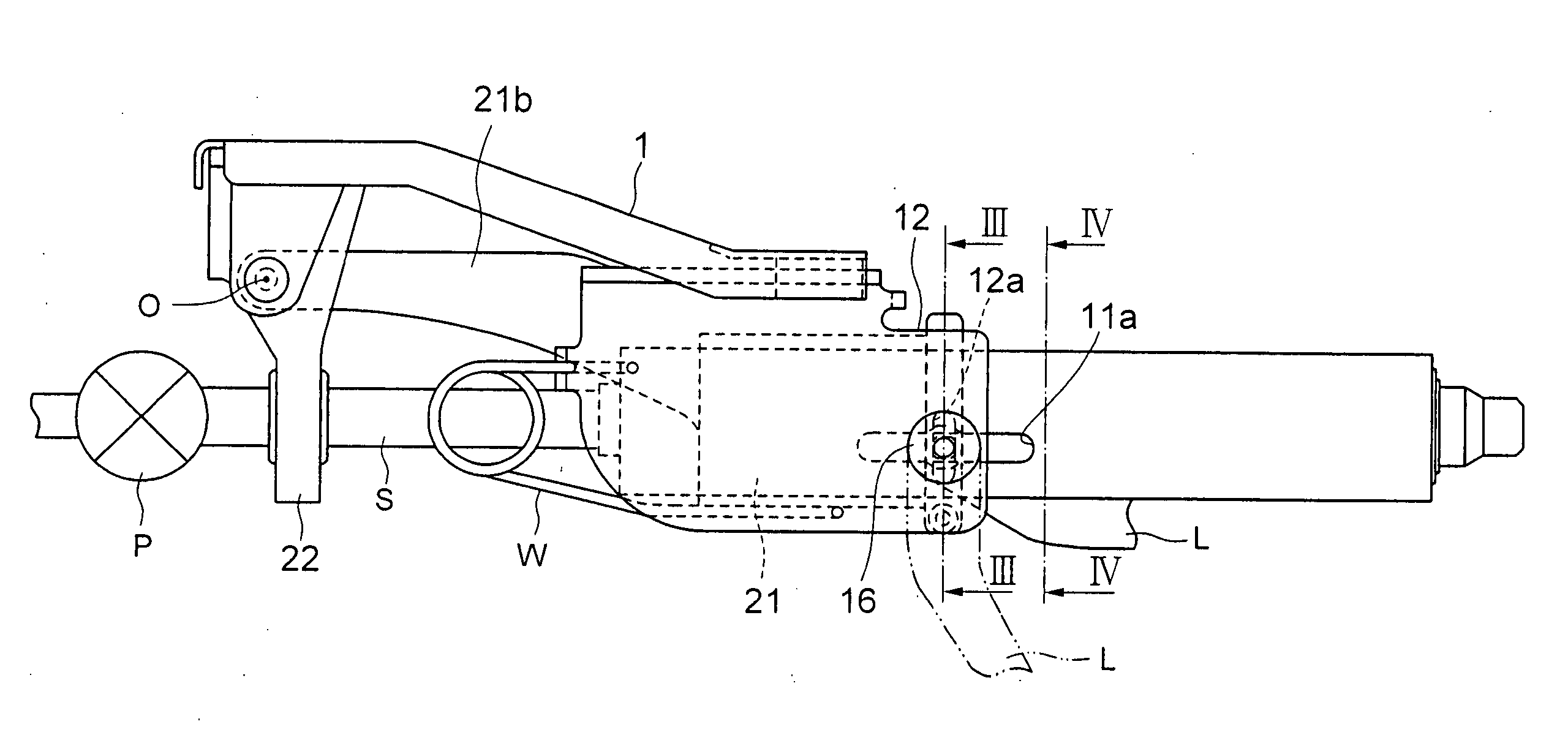

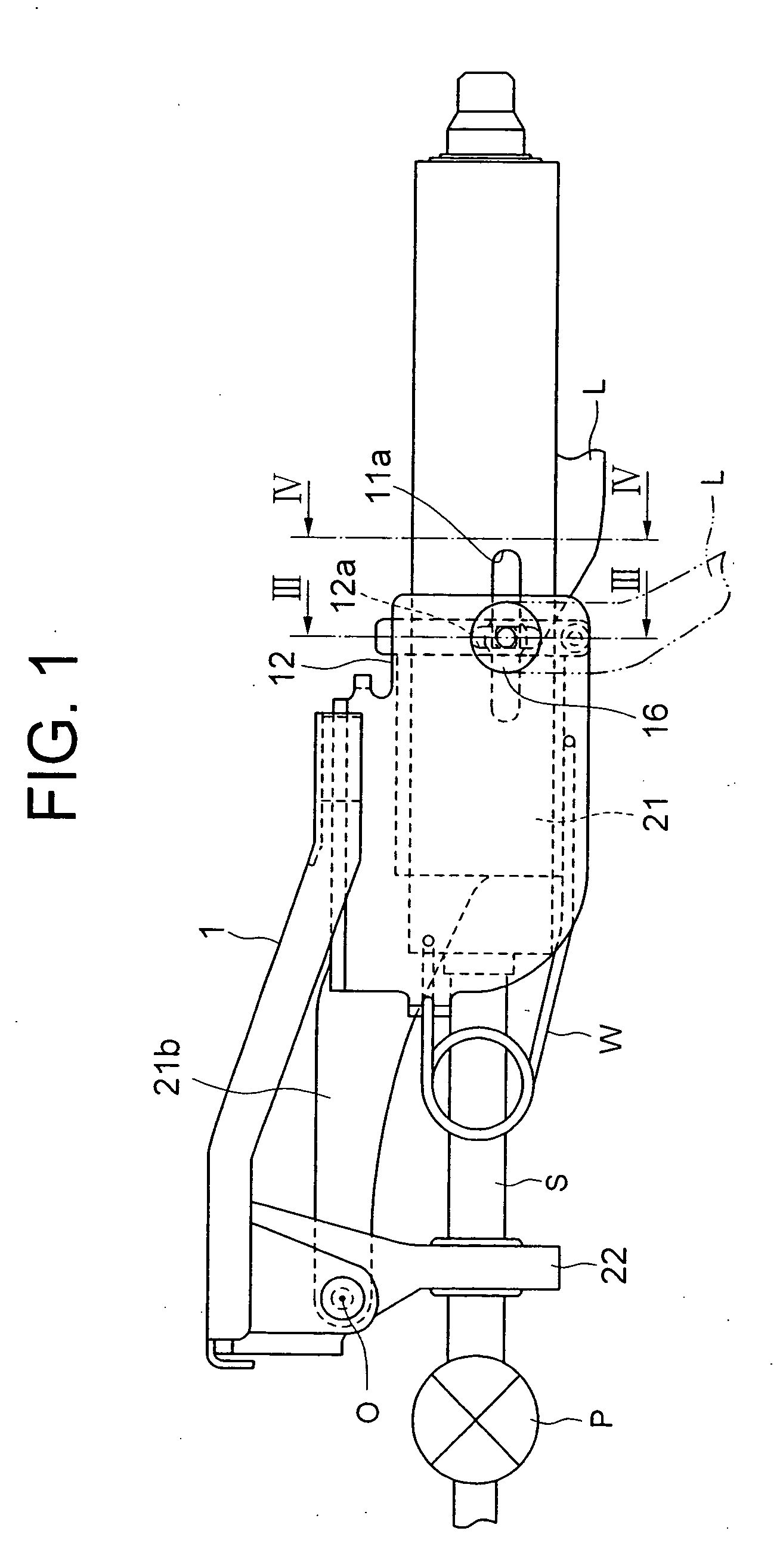

Steering device

Owner:NSK LTD

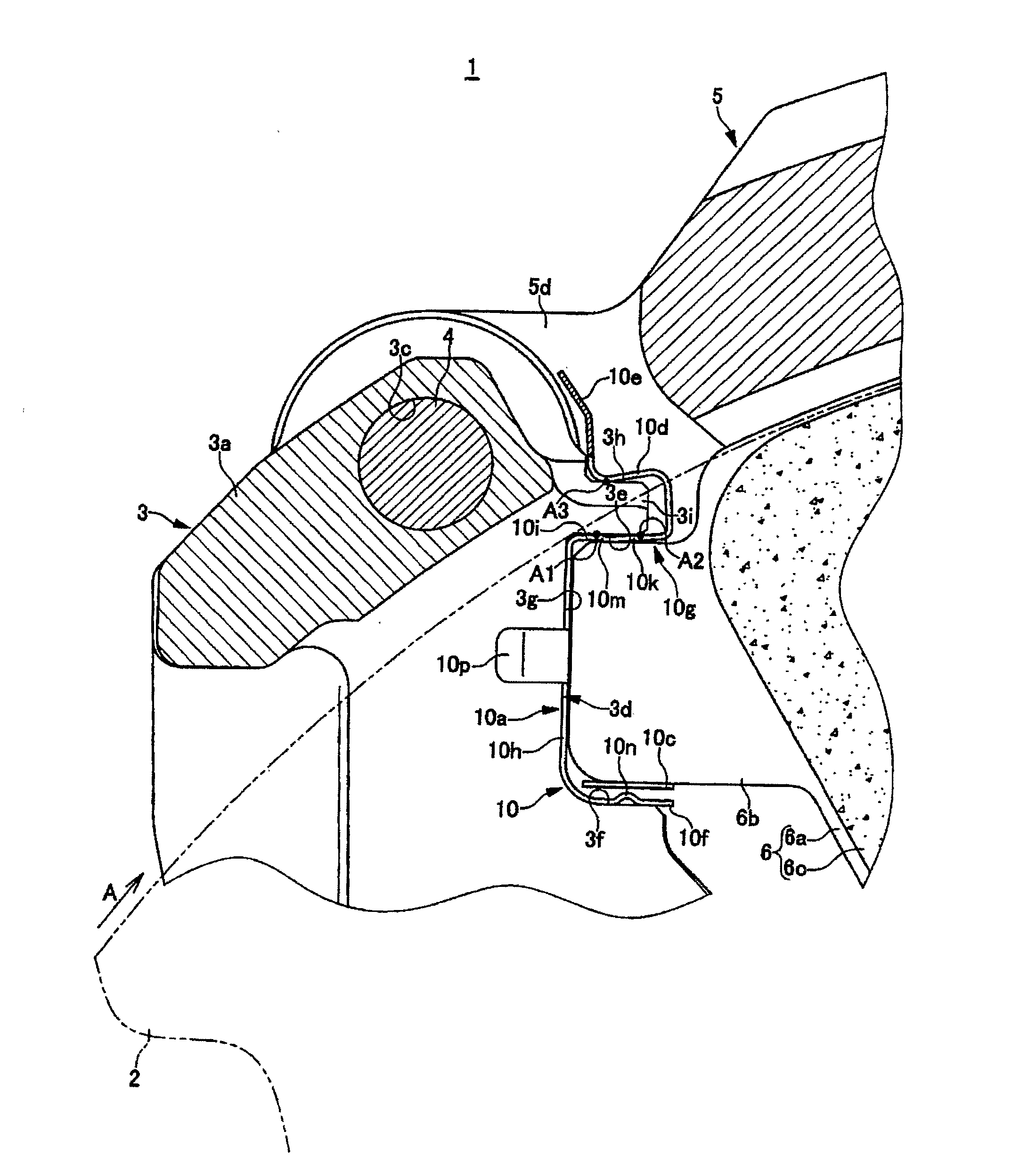

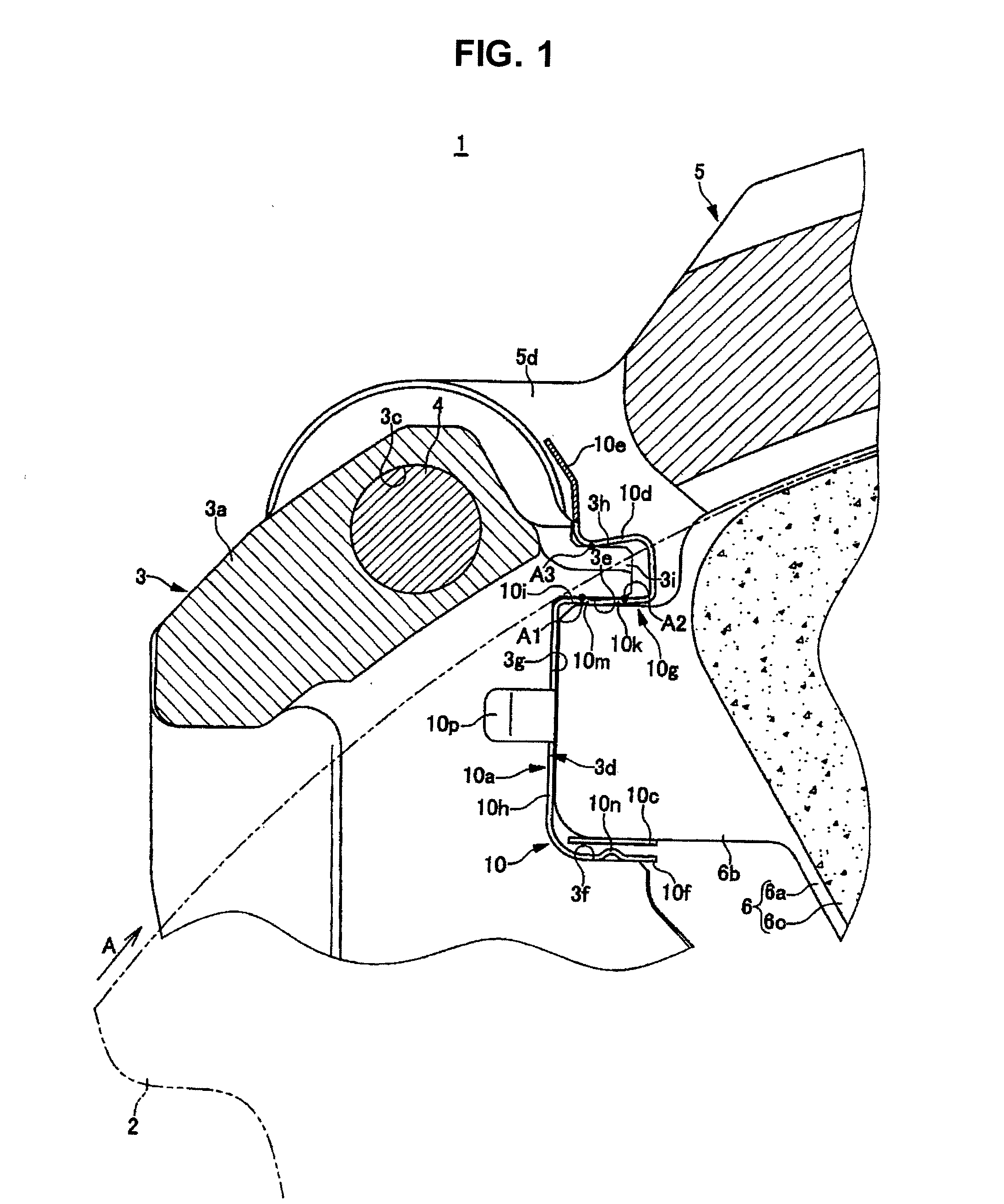

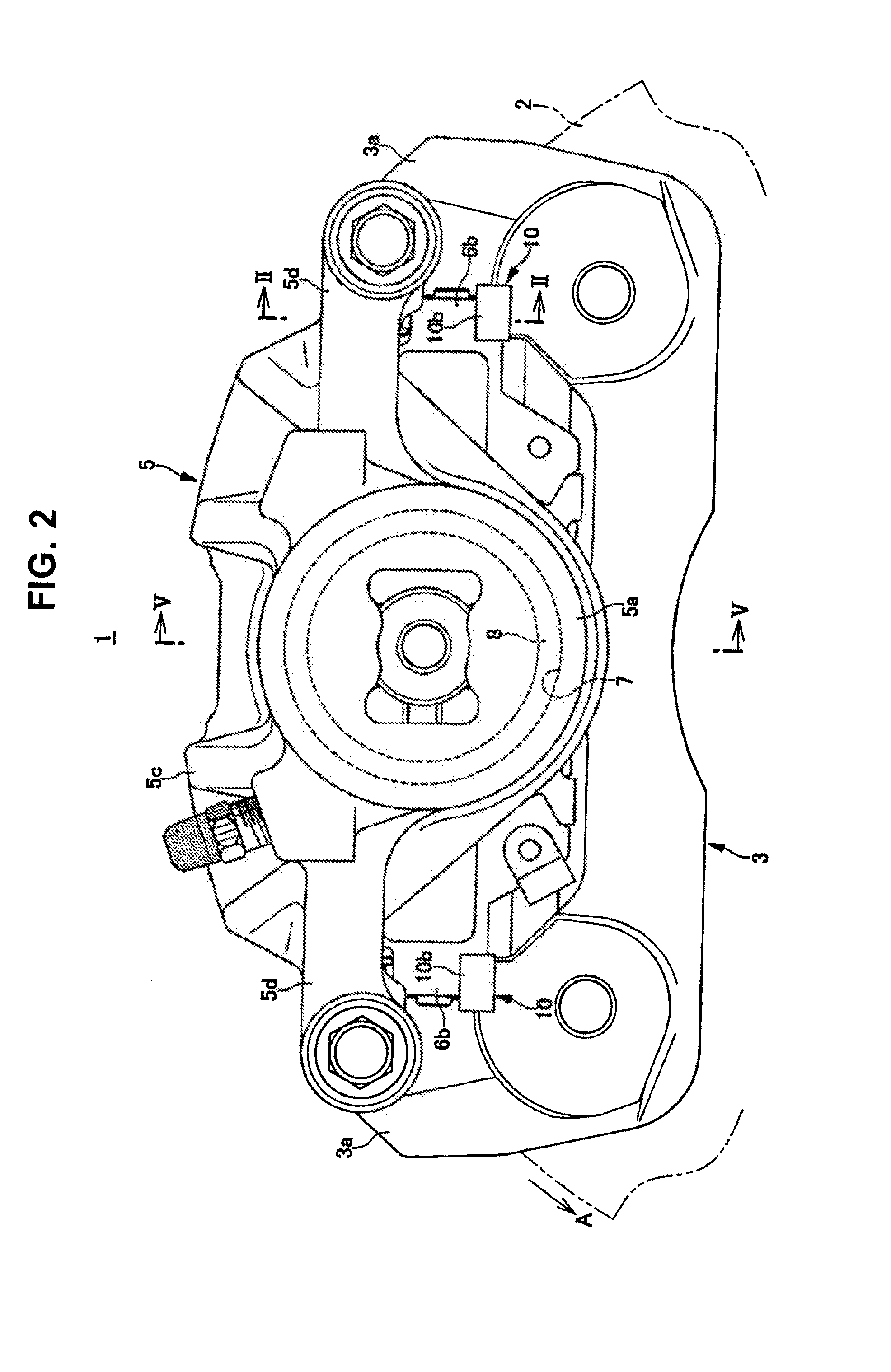

Disk brake for vehicle

ActiveUS20100243389A1Suppress collisionAvoid it happening againBrake actuating mechanismsSlack adjustersEngineeringCalipers

A disk brake for a vehicle includes: a caliper bracket; a pair of caliper support arms; pad guide grooves that have outer side surfaces, inner side surfaces and opposed surfaces; and lug pieces that protrude on both side parts of back plates of friction pads supported by the pad guide grooves through a pad retainer, the pad retainer including a pair of retainer parts, a connecting piece and pad resilient parts, wherein: the retainer parts include inner side pieces arranged along the inner side surfaces of the pad guide grooves, outer side pieces arranged along the outer side surfaces of the pad guide grooves and interior pieces that connect the outer side pieces to the inner side pieces; and the outer side pieces include impact suppressing parts that restrain the lug pieces from colliding with the outer side surfaces through the outer side pieces.

Owner:HITACHI ASTEMO LTD

Disk brake for vehicle

ActiveUS8020674B2Curb reboundAvoid it happening againBraking membersSlack adjustersEngineeringCalipers

A disk brake for a vehicle includes: a caliper bracket; a pair of caliper support arms; pad guide grooves that have outer side surfaces, inner side surfaces and opposed surfaces; and lug pieces that protrude on both side parts of back plates of friction pads supported by the pad guide grooves through a pad retainer, the pad retainer including a pair of retainer parts, a connecting piece and pad resilient parts, wherein: the retainer parts include inner side pieces arranged along the inner side surfaces of the pad guide grooves, outer side pieces arranged along the outer side surfaces of the pad guide grooves and interior pieces that connect the outer side pieces to the inner side pieces; and the outer side pieces include impact suppressing parts that restrain the lug pieces from colliding with the outer side surfaces through the outer side pieces.

Owner:HITACHI ASTEMO LTD

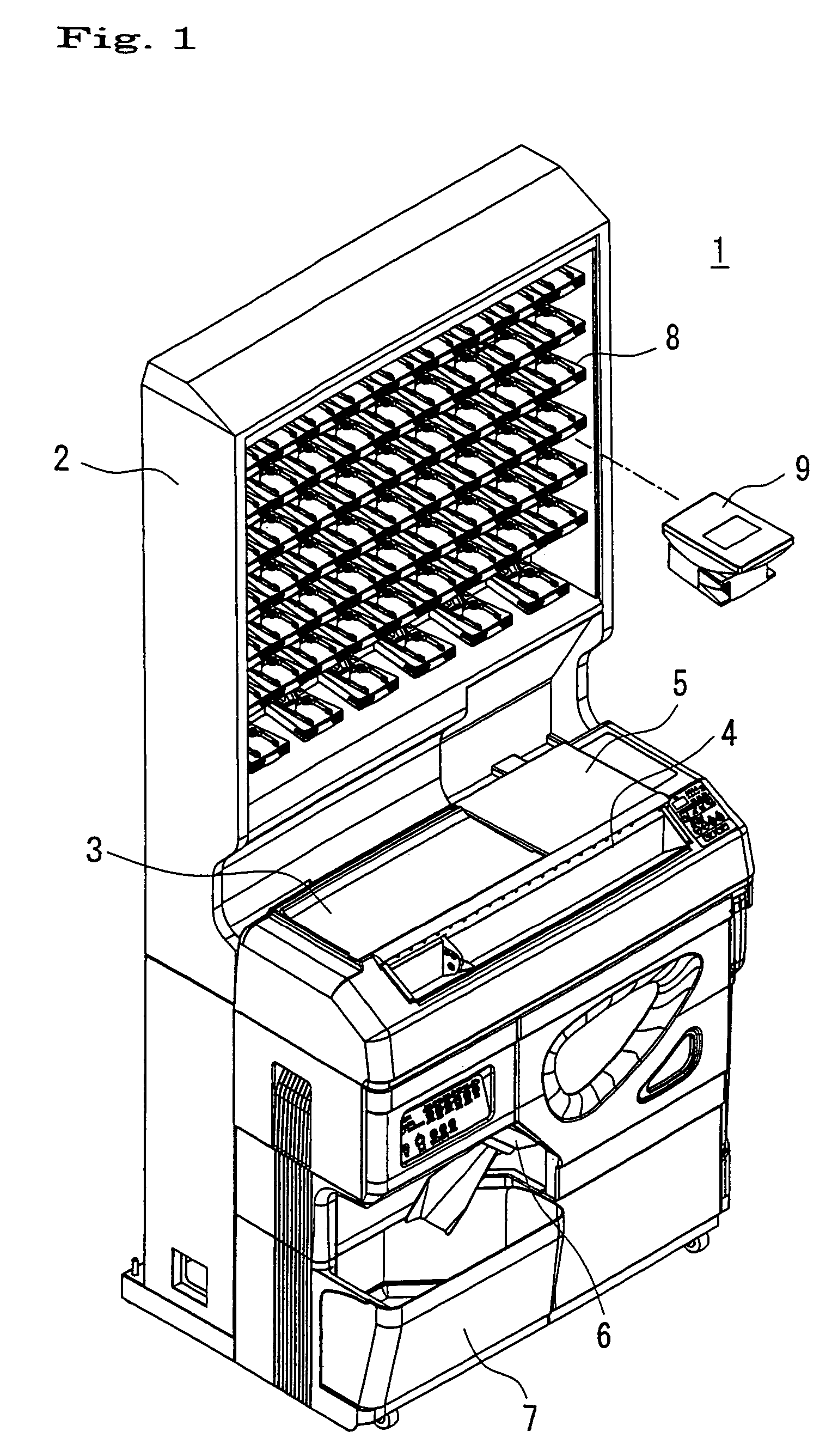

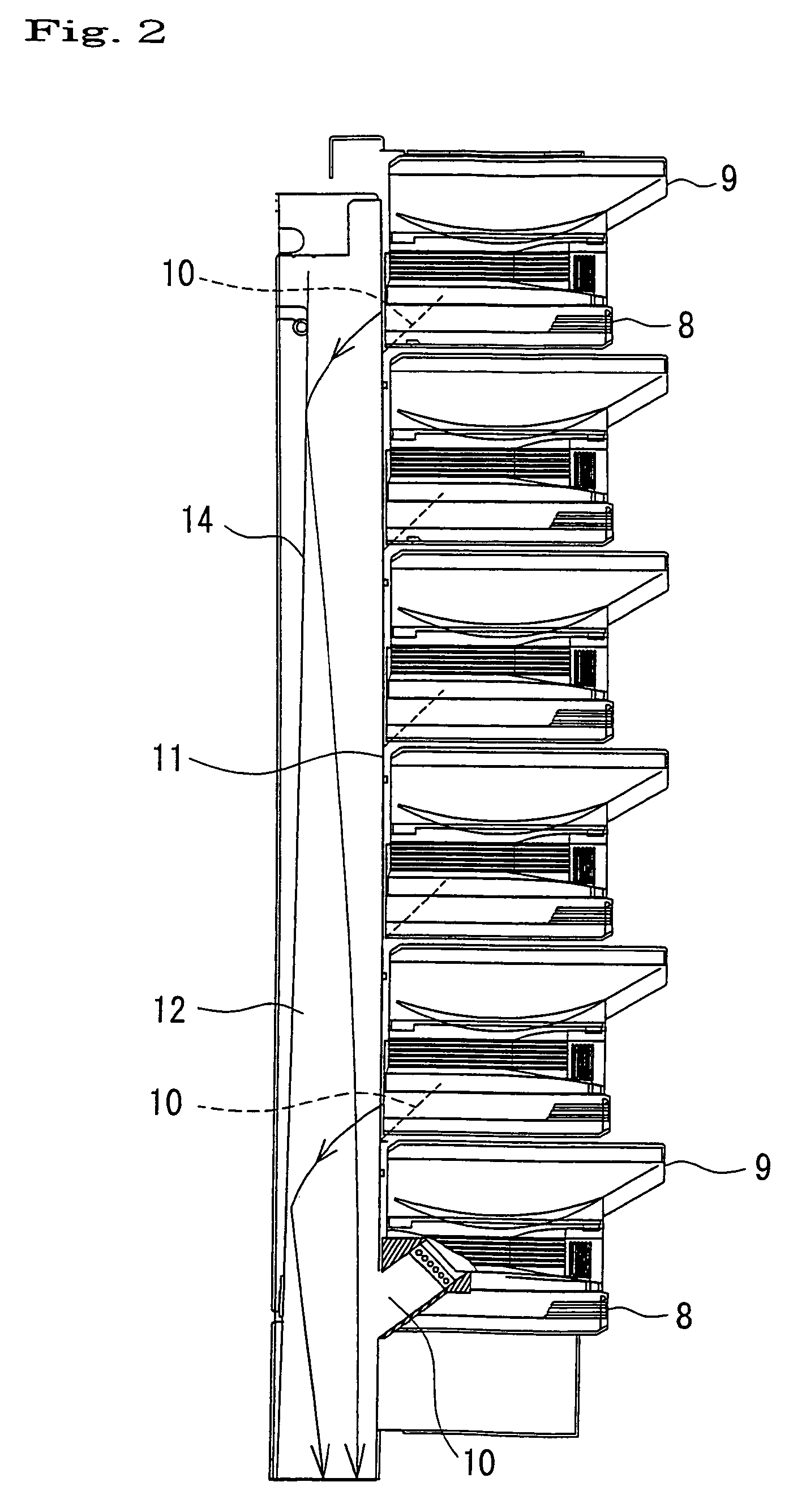

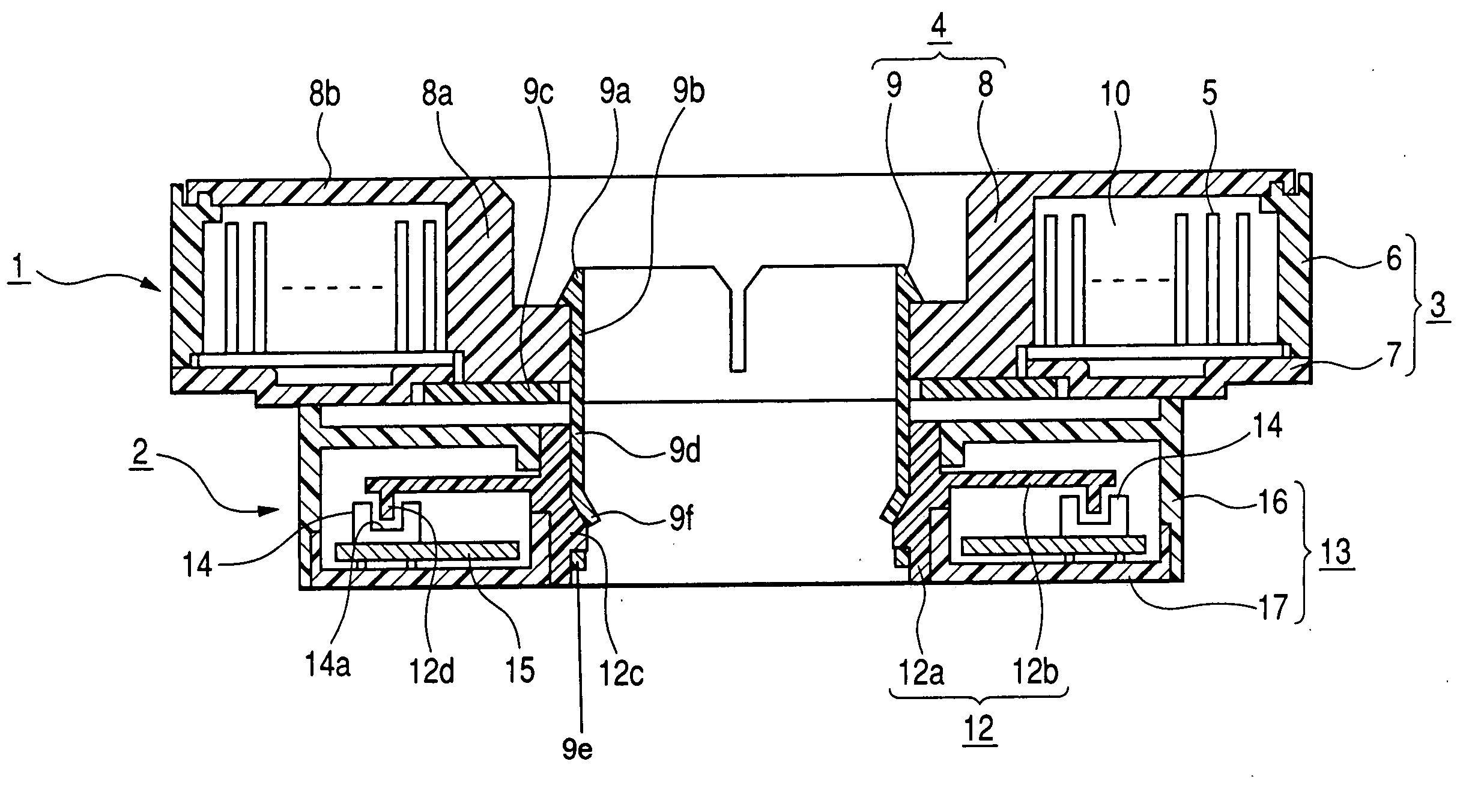

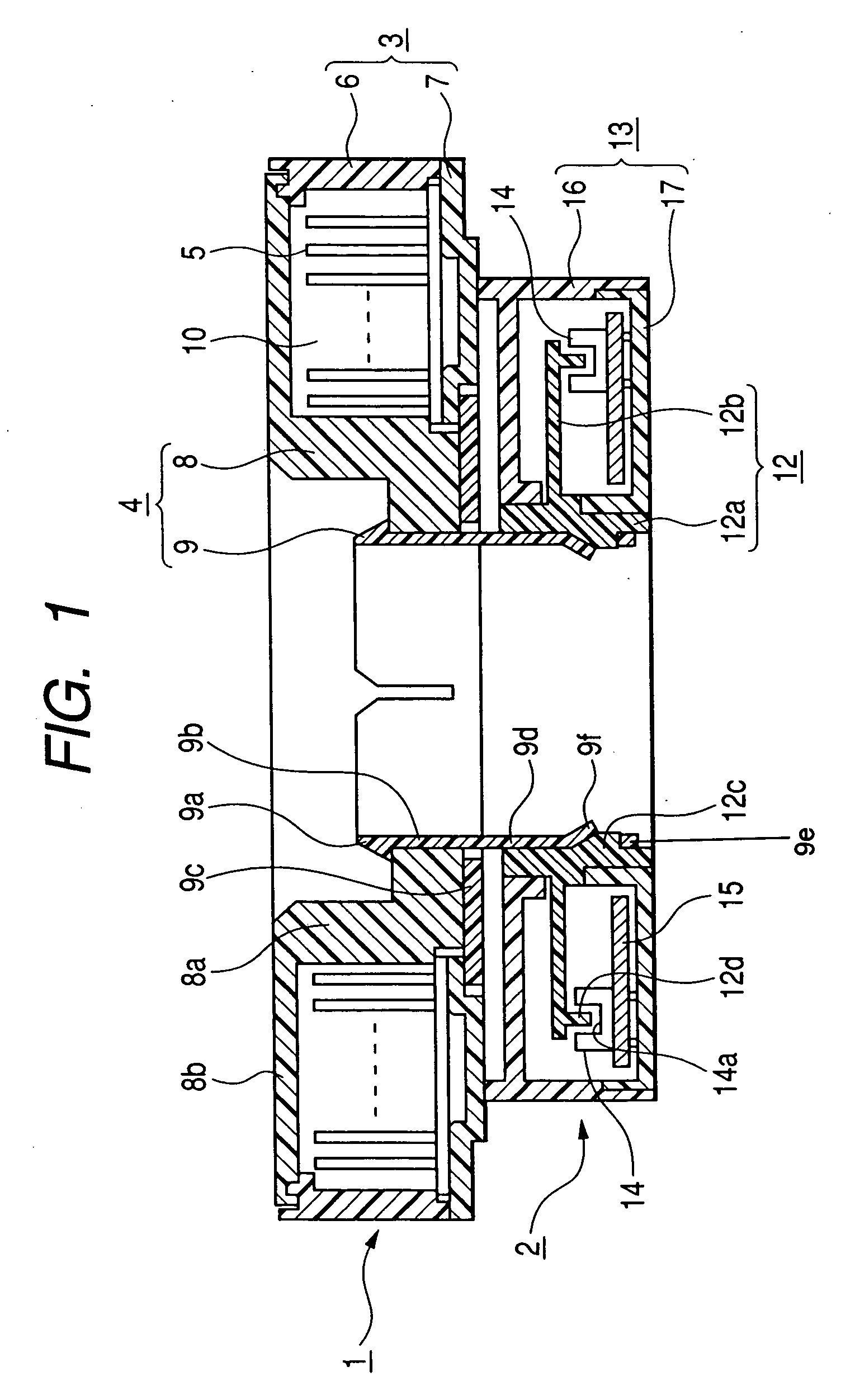

Tablet packaging device

InactiveUS7455163B2Bounce angle of the tablet is suppressedReduce drip timeCoin-freed apparatus detailsPharmaceutical containersEngineering

Owner:YUYAMA MFG CO LTD

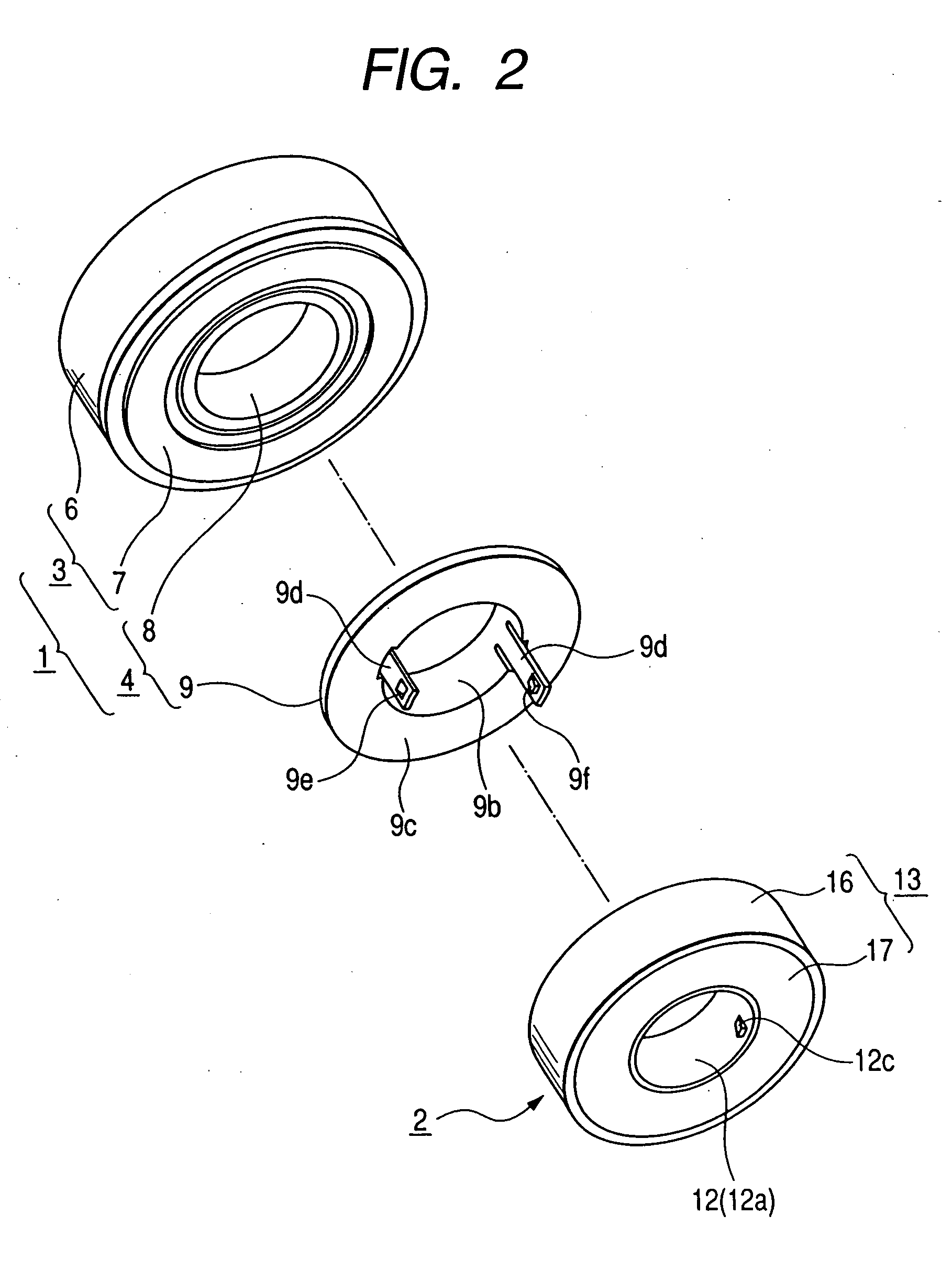

Connecting structure of rotary connector and steering angle sensor

InactiveUS20060272430A1Reduce noiseCurb reboundWork measurementSteering partsSteering angleMechanical engineering

Ae connecting structure of a first rotor member (rotor housing) of a rotary connector and a second rotor member (rotary member) of a steering angle sensor is provided. A plurality of elastic pieces are formed on the inner peripheral portion of the first rotor member and extend downward. An engaging protrusion is provided in the inner peripheral portion of the second rotor member so as to be inserted in an engaging hole of the elastic piece, and the elastic piece is combined with the engaging protrusion in a snap-in relationship.

Owner:ALPS ALPINE CO LTD

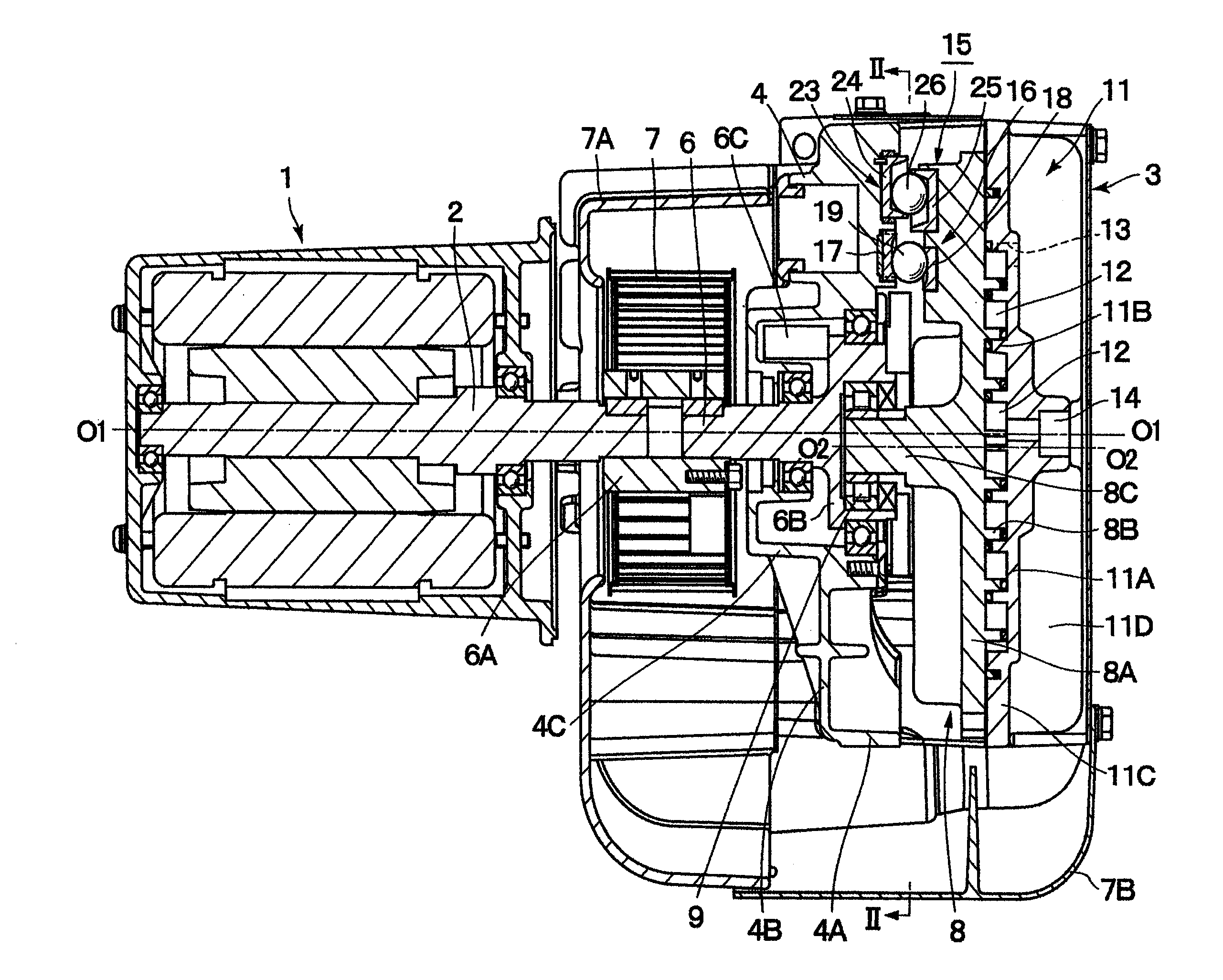

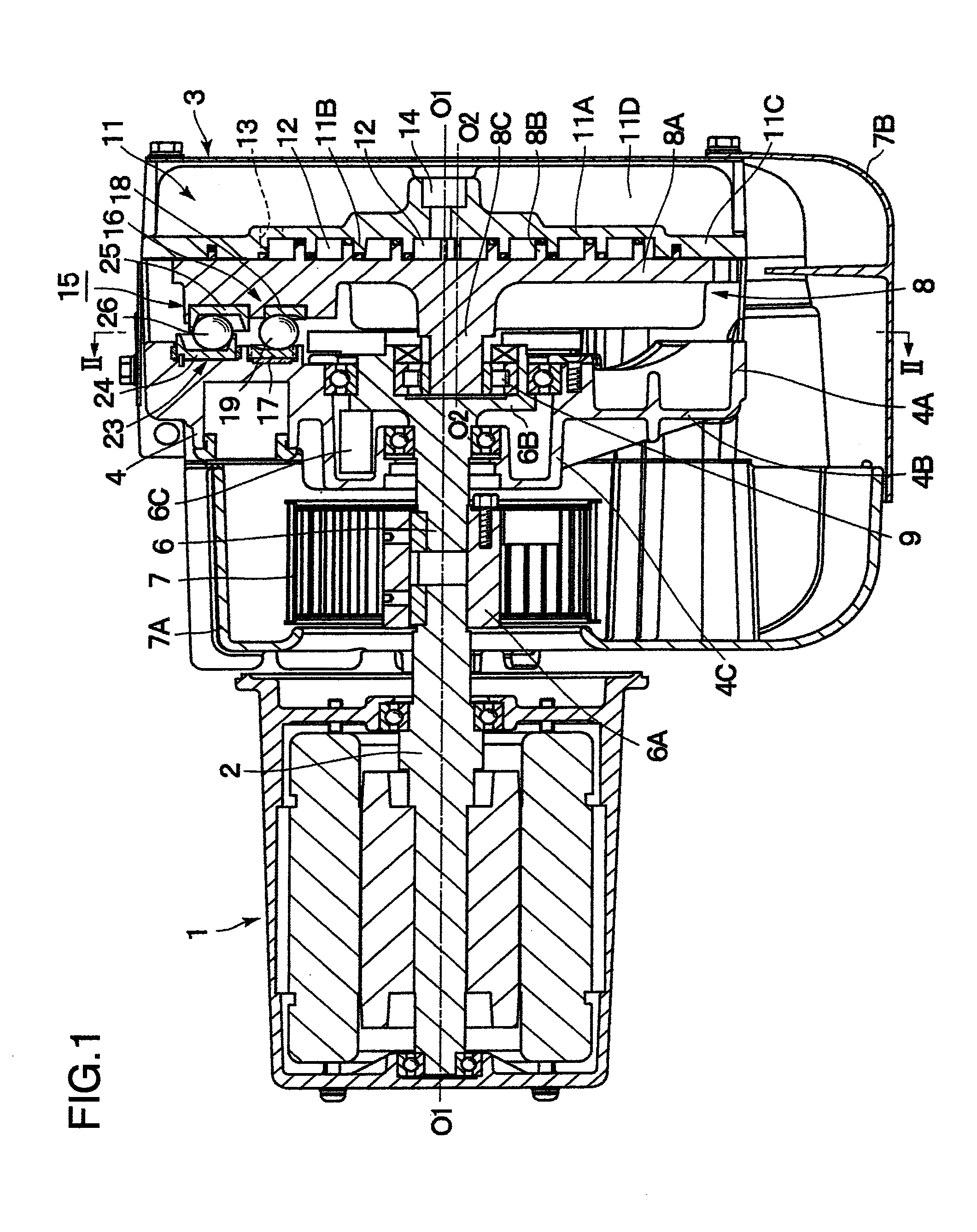

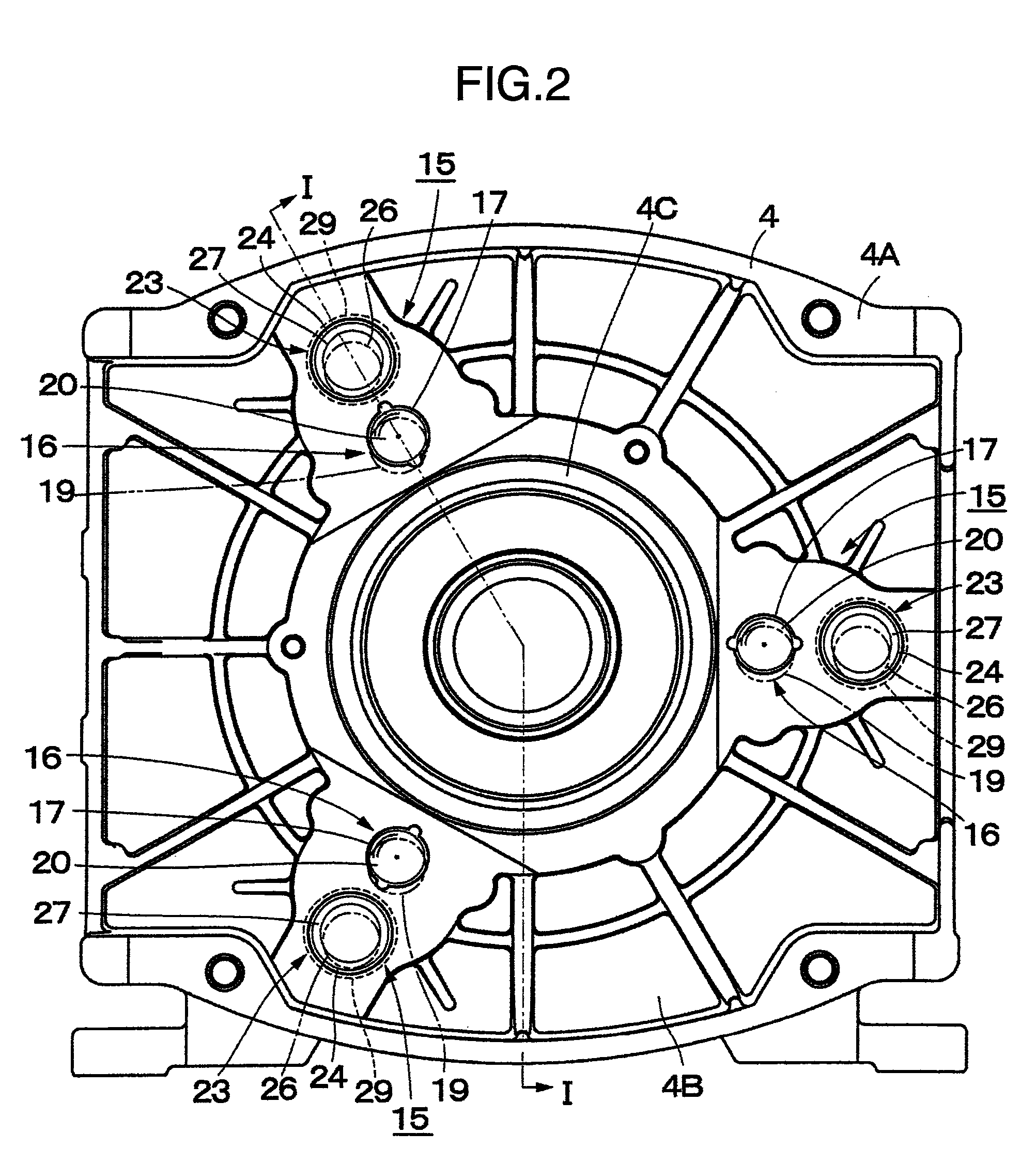

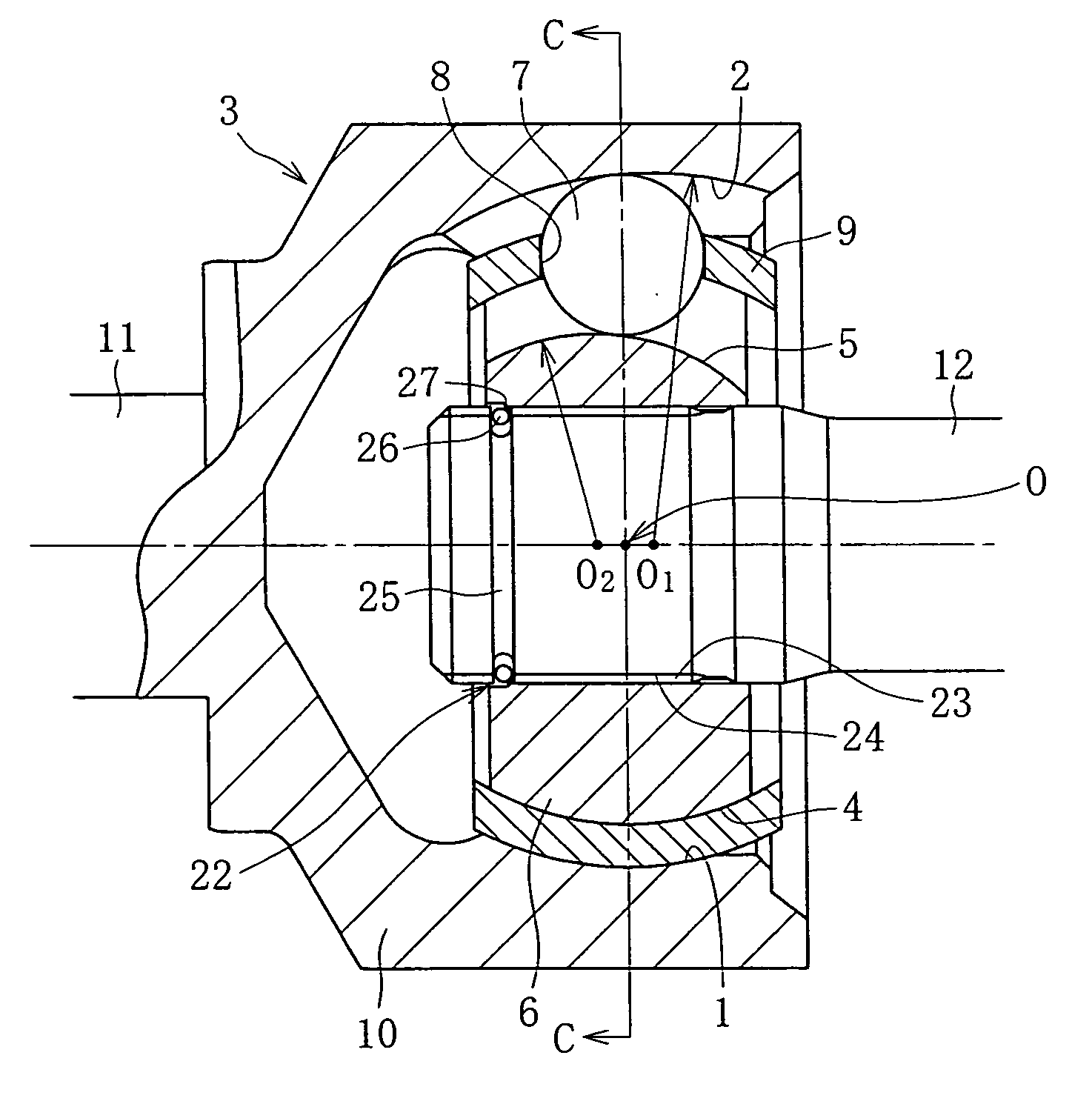

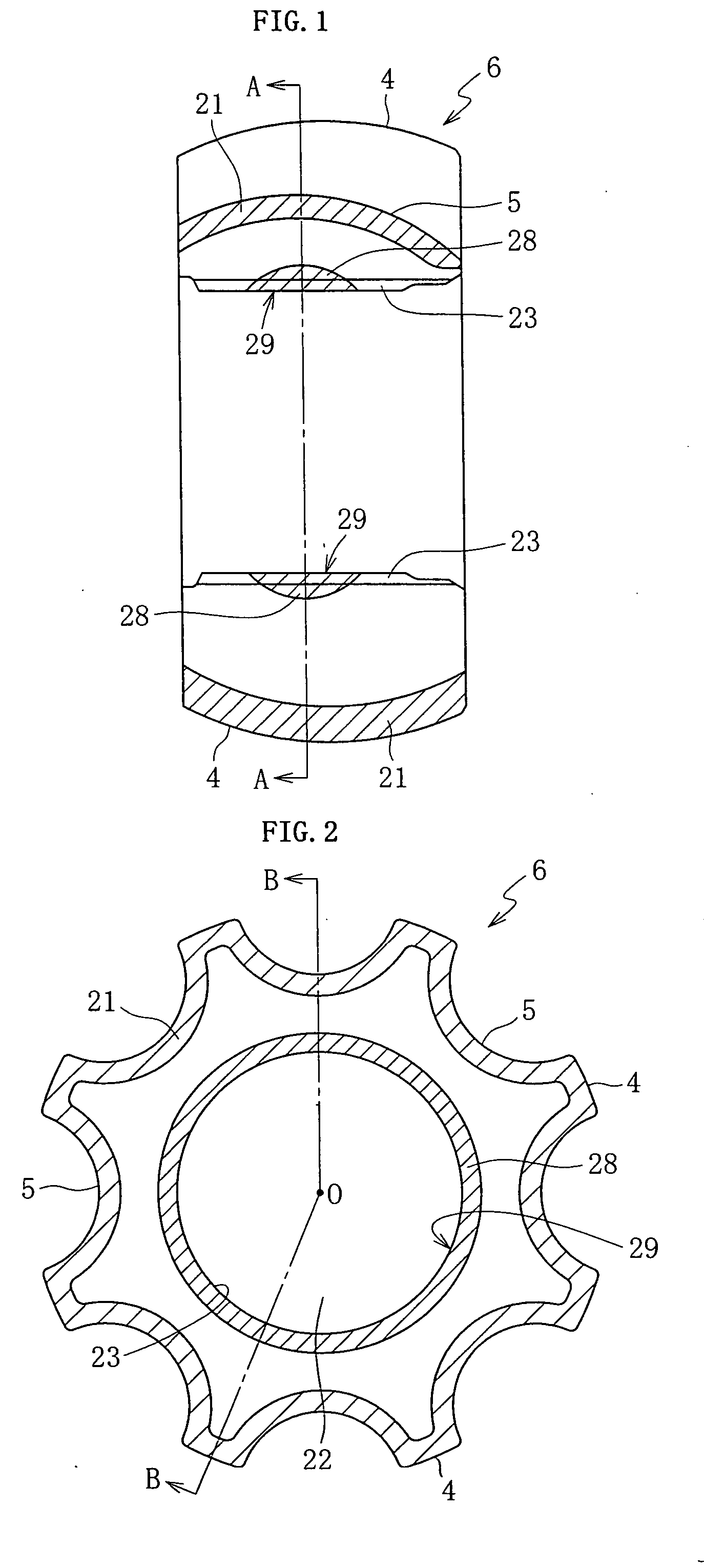

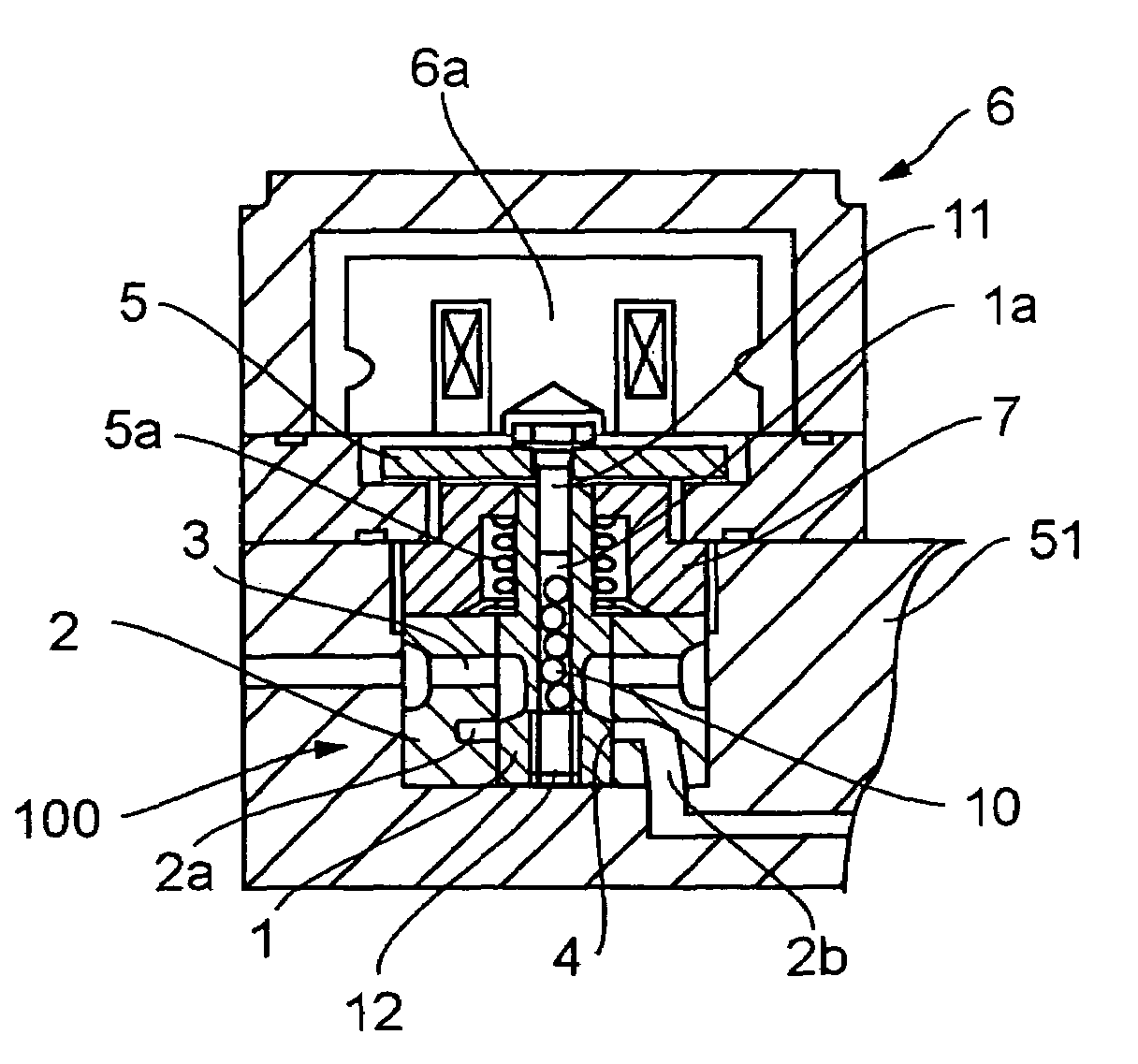

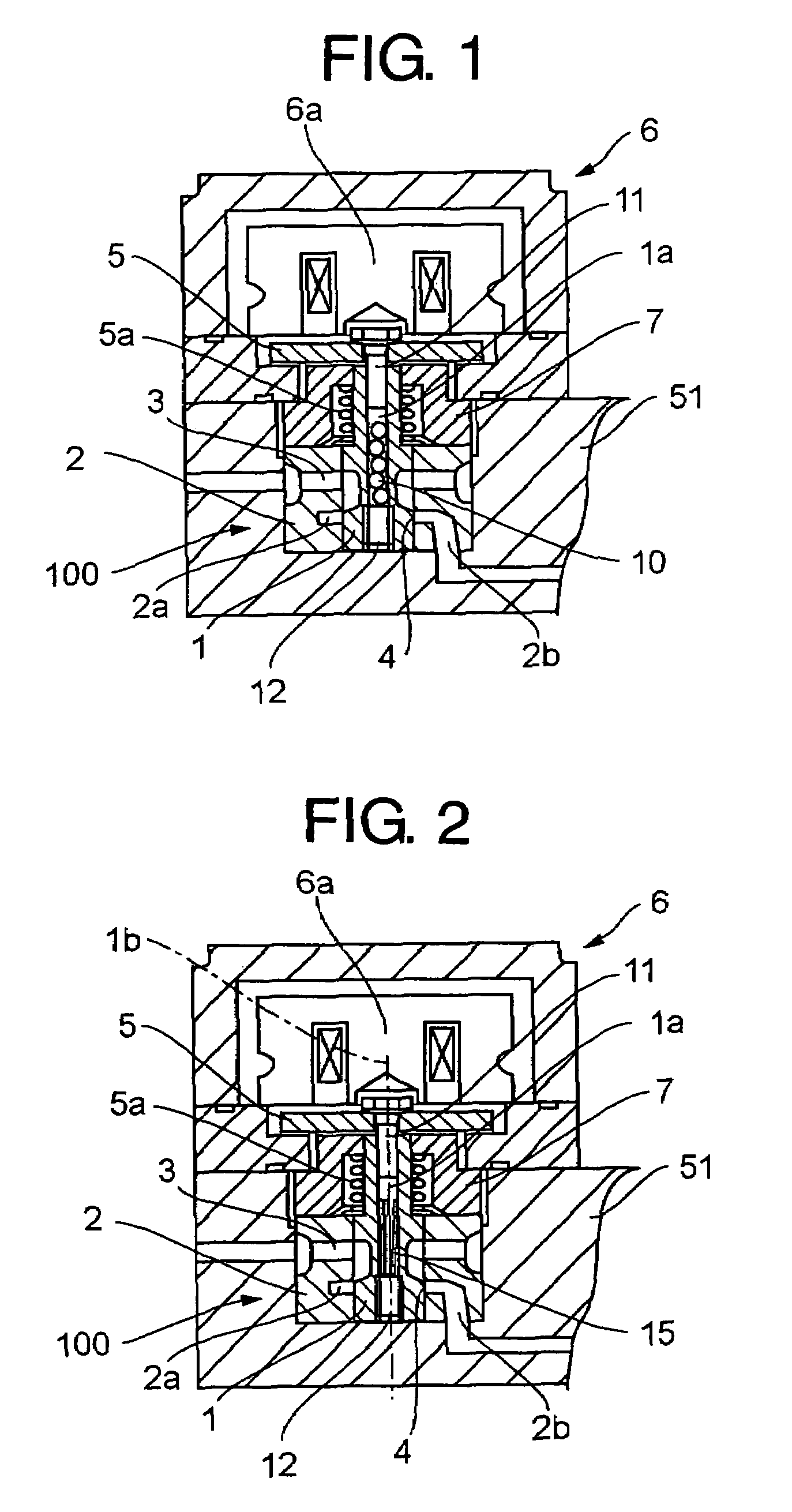

Scroll Fluid Machine

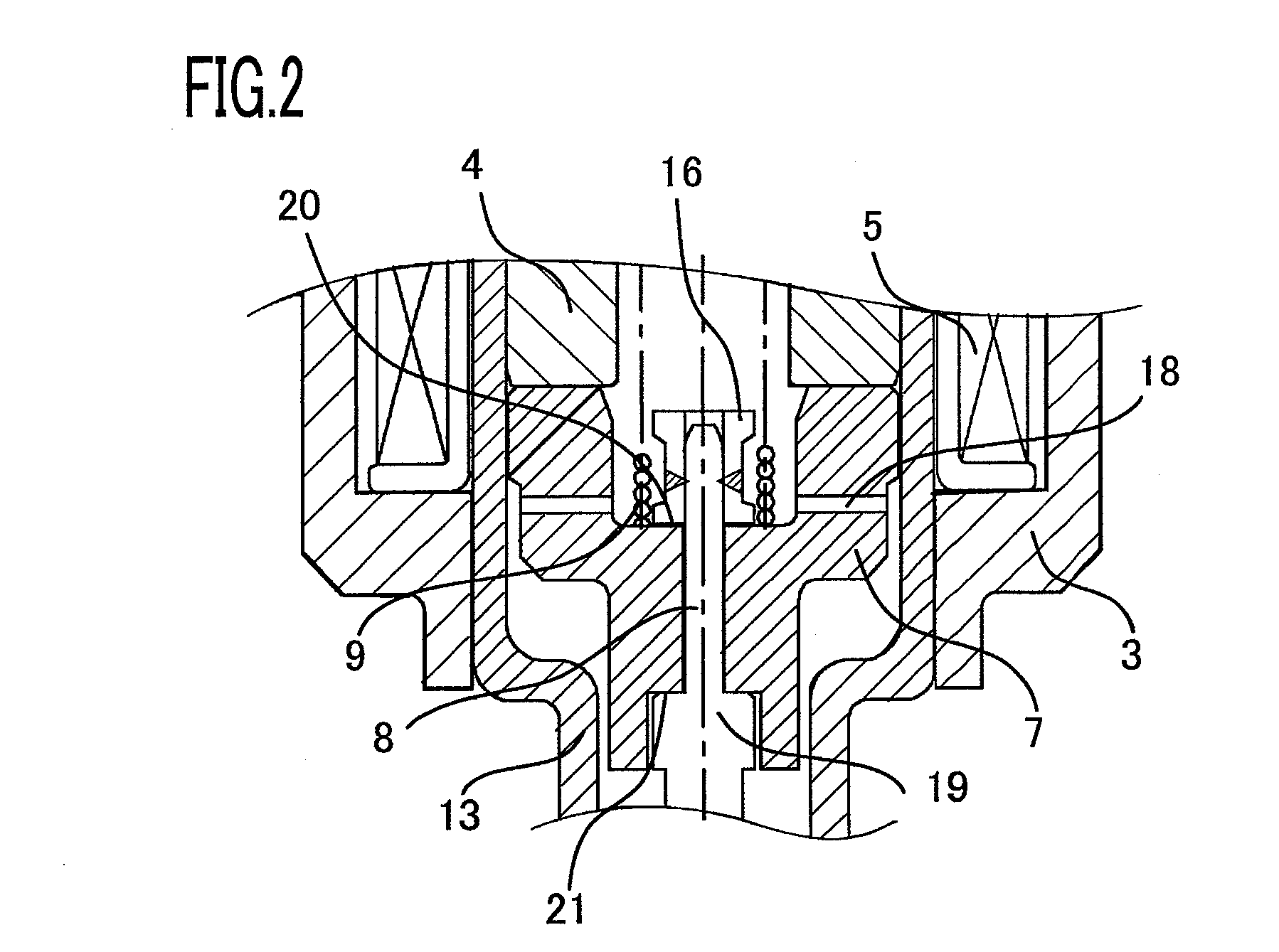

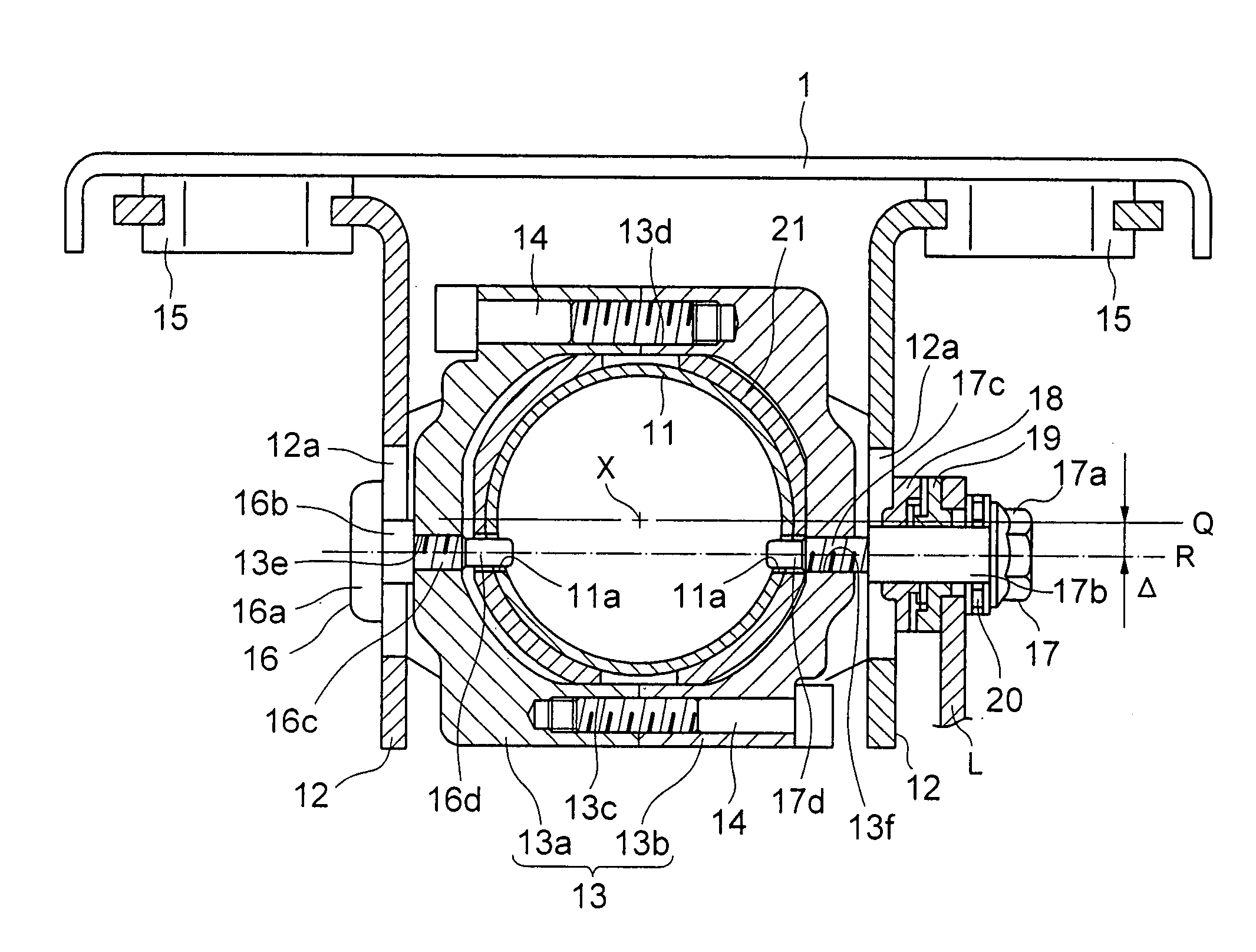

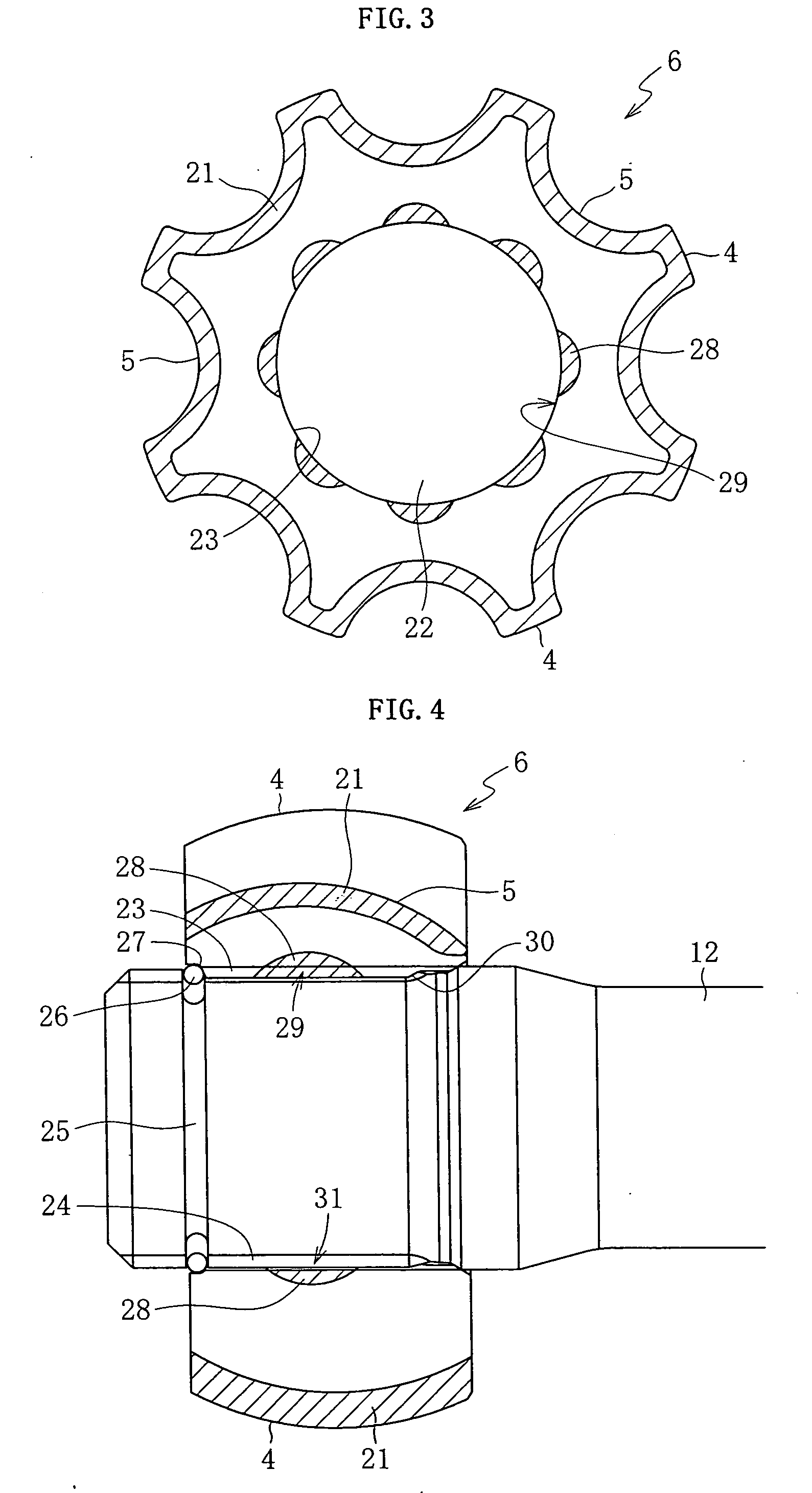

ActiveUS20100028185A1Behavioral stabilityImprove production yieldYielding couplingEngine of arcuate-engagement typeCouplingEngineering

A scroll fluid machine comprises a fixed-side member including a cylindrical casing and a fixed scroll fixed to the casing, and an orbiting scroll and a plurality of ball coupling devices provided between the fixed-side member and the orbiting scroll to prevent self-rotation of the orbiting scroll on its axis and receive a thrust load between the fixed-side member and the orbiting scroll. Each of the ball coupling devices comprises a first ball coupling mechanism for supporting the thrust load generated between the fixed-side member and the orbiting scroll and a second ball coupling mechanism disposed with a space from the first ball coupling mechanism to prevent the self-rotation of the orbiting scroll.

Owner:HITACHI IND EQUIP SYST CO LTD

Steering device

Owner:NSK LTD

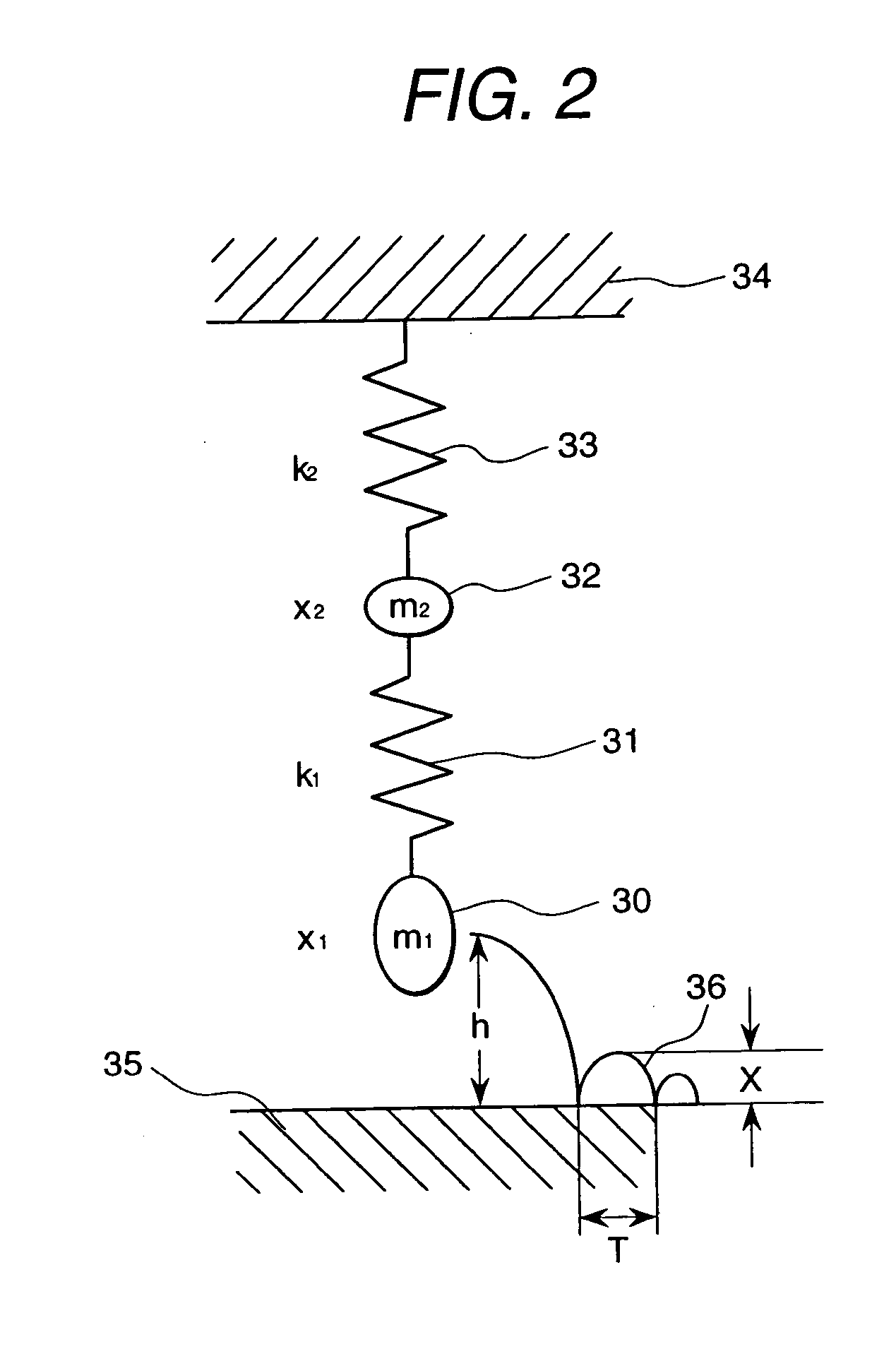

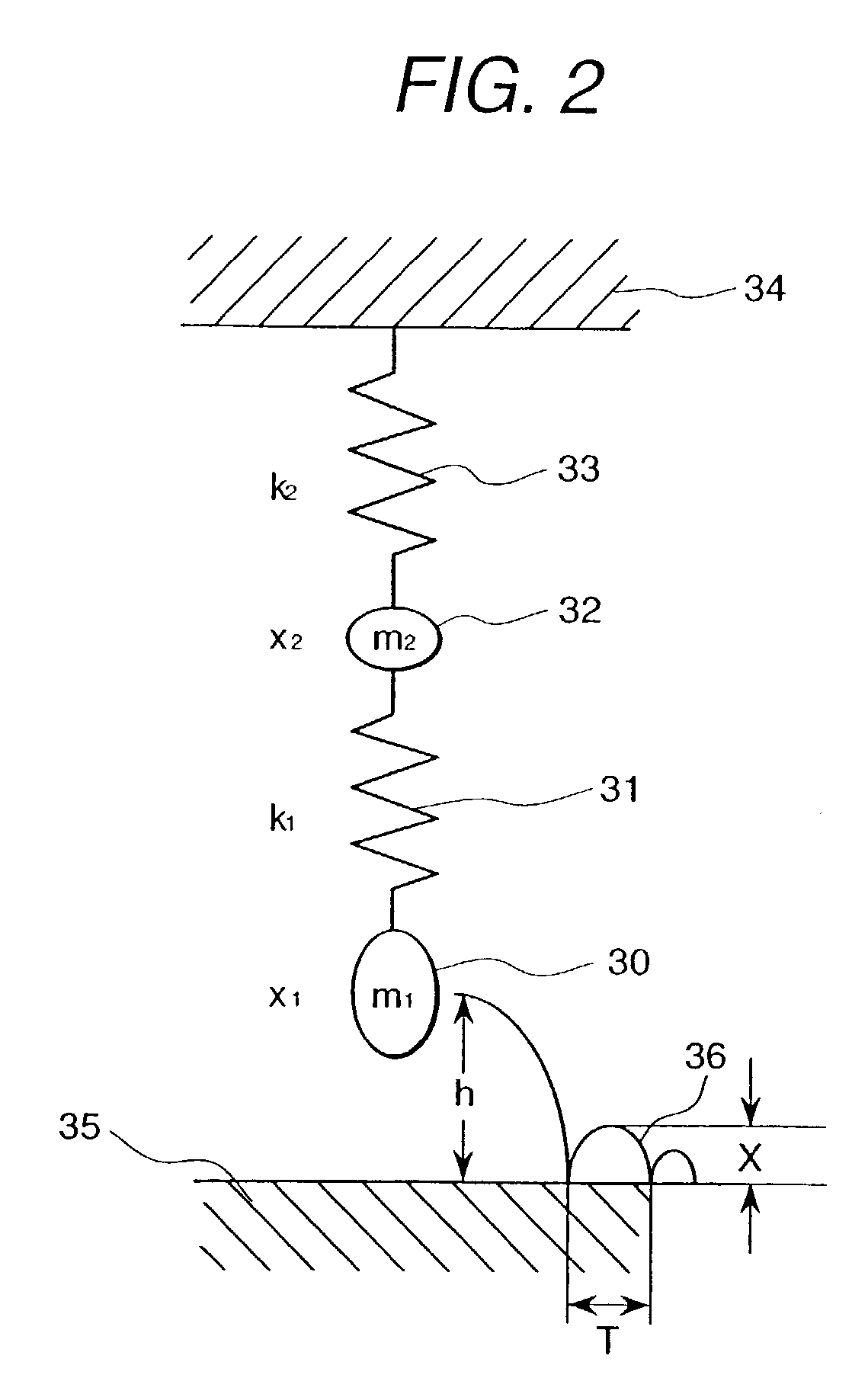

Fuel-injection valve

InactiveUS20070075166A1Easy to controlCurb reboundOperating means/releasing devices for valvesSpray nozzlesEngineeringVALVE PORT

A fuel-injection valve includes a fuel-injection hole, a valve element and a valve seat for opening and closing the fuel-injection hole, a force-applying member for applying force to the valve element in a direction of motion of the valve element, and a drive unit for applying force to the valve element in the direction opposite to that of the force applied by the force-applying member; wherein a secondary oscillation system, which interacts with a primary oscillation system including the valve element and the force-applying member, is added to the primary oscillation system, and the phase angle of force applied to the primary oscillation system by the secondary oscillation system is also staggered from that of force applied to the primary oscillation system, which is other than the force applied to the primary oscillation system by the secondary oscillation system, whereby the bouncing of the valve element during opening and closing of the valve is reduced, which in turn makes it possible to achieve very accurate fuel-injection control.

Owner:TSUCHIYA MASAHIRO +9

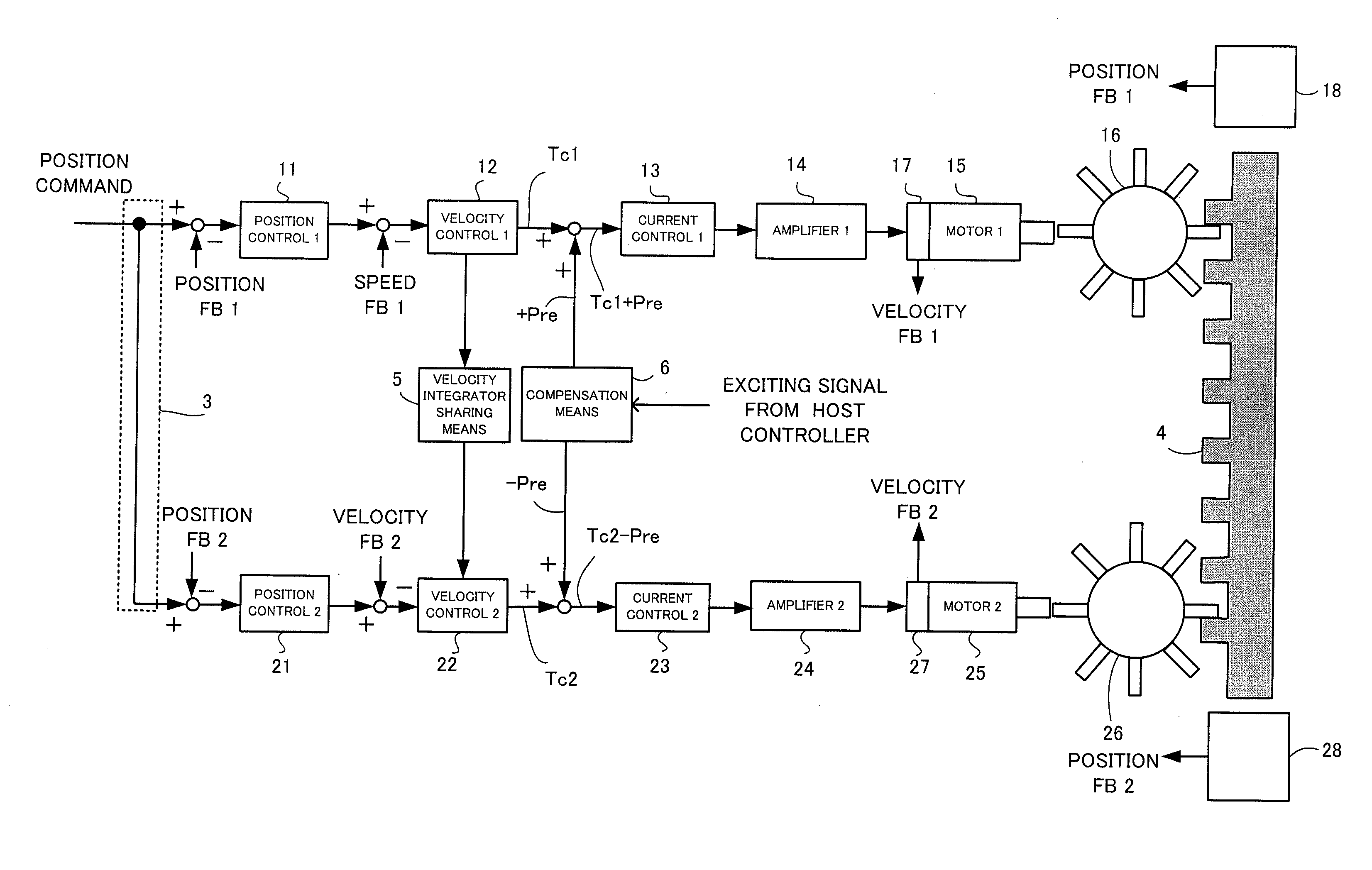

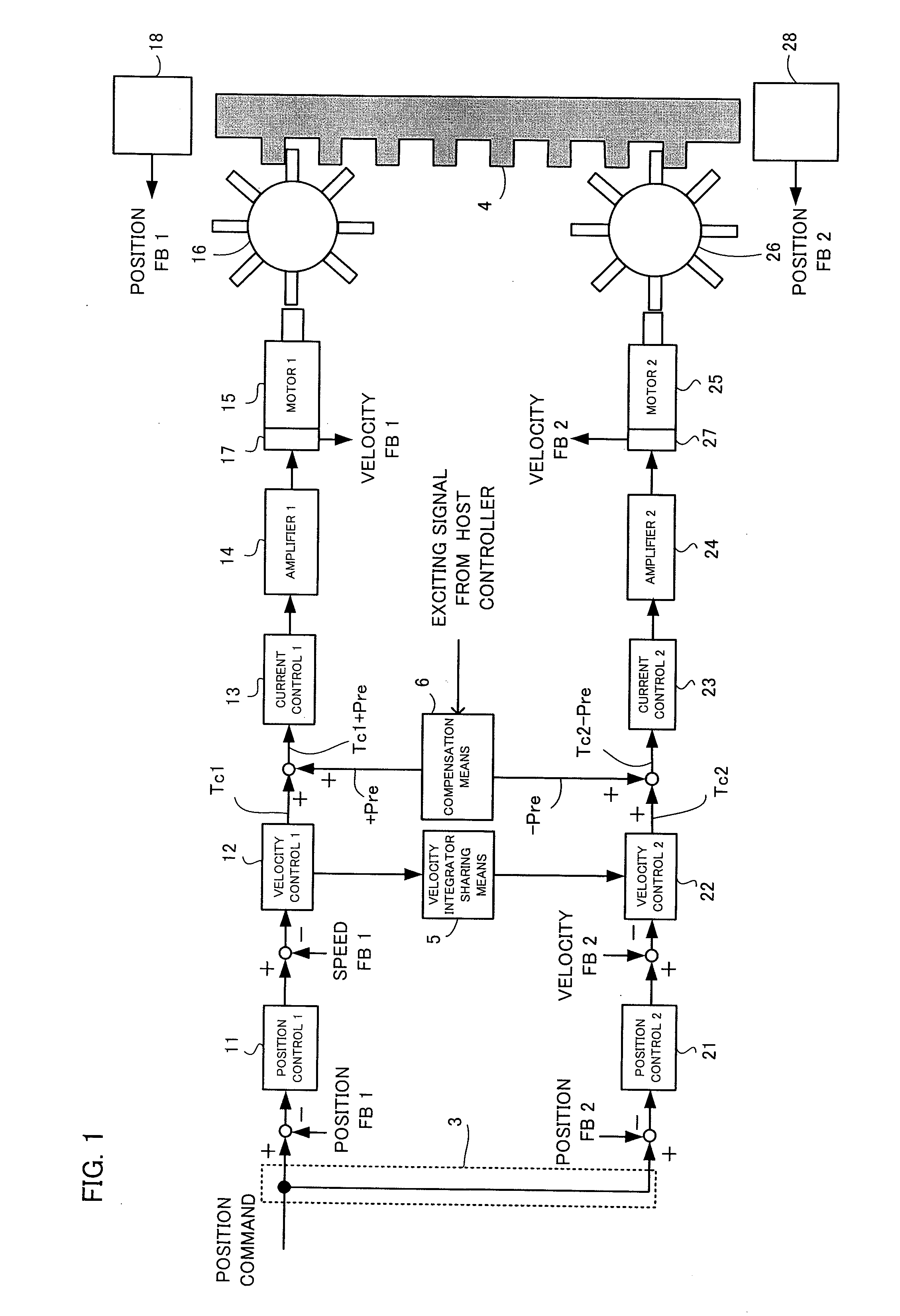

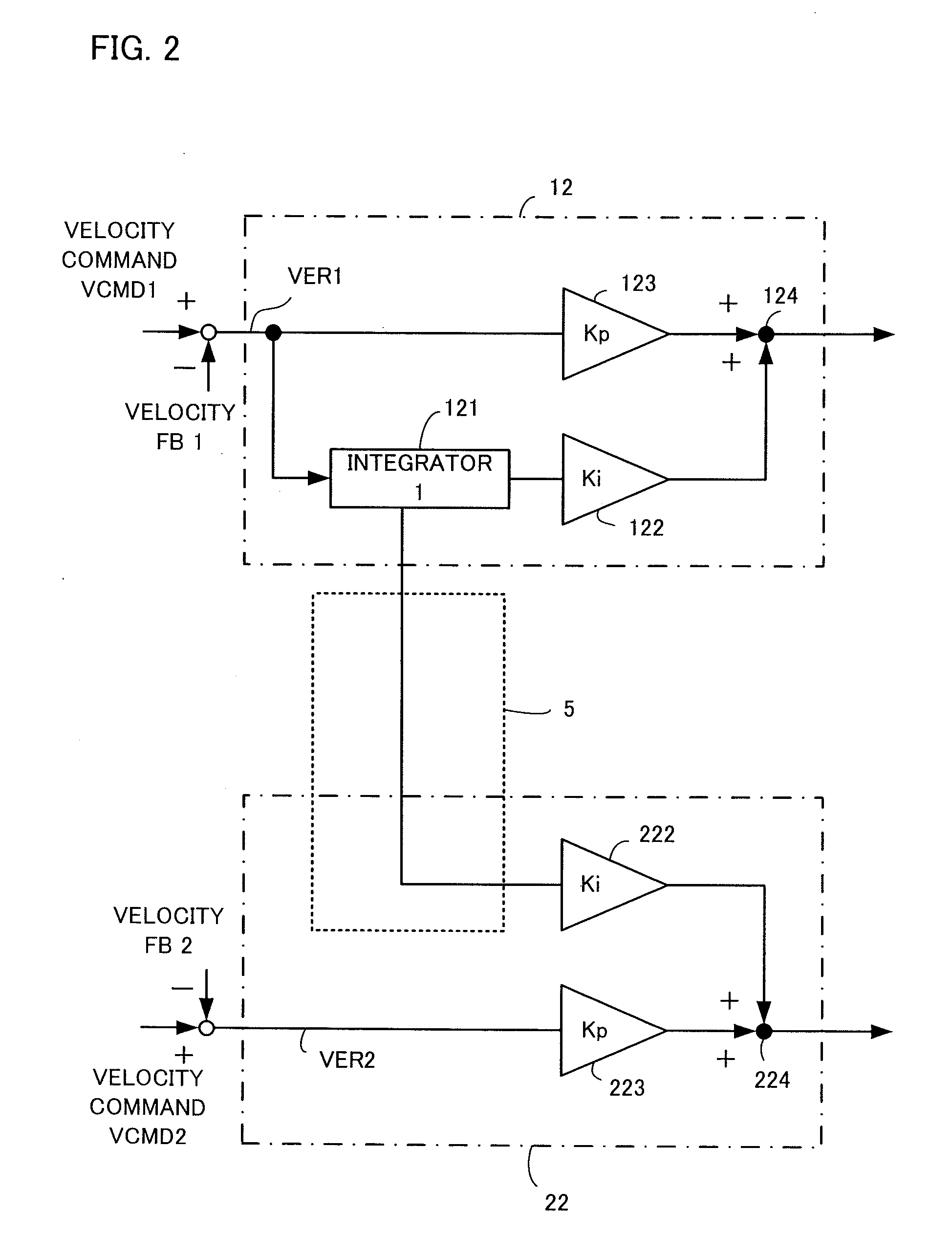

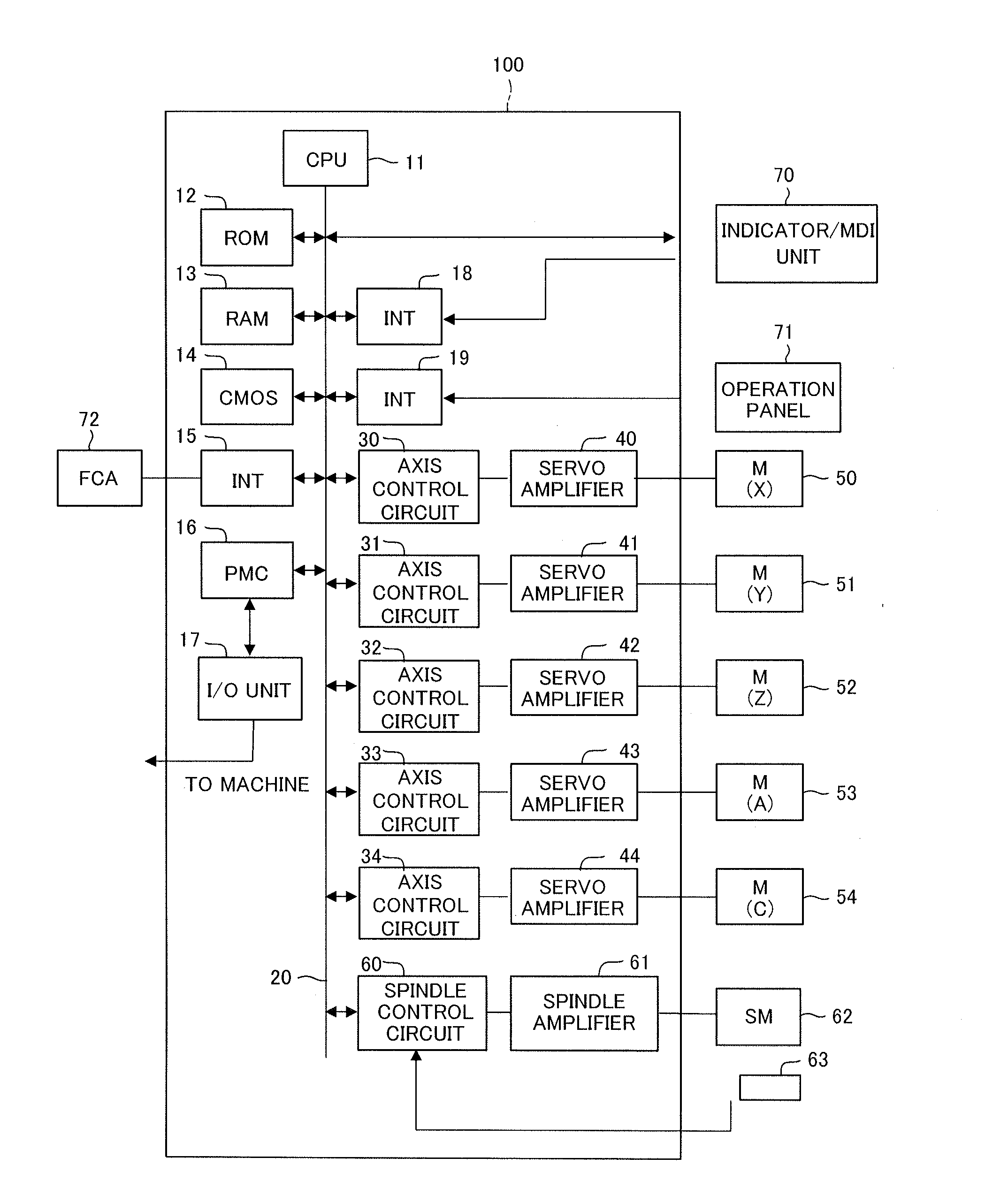

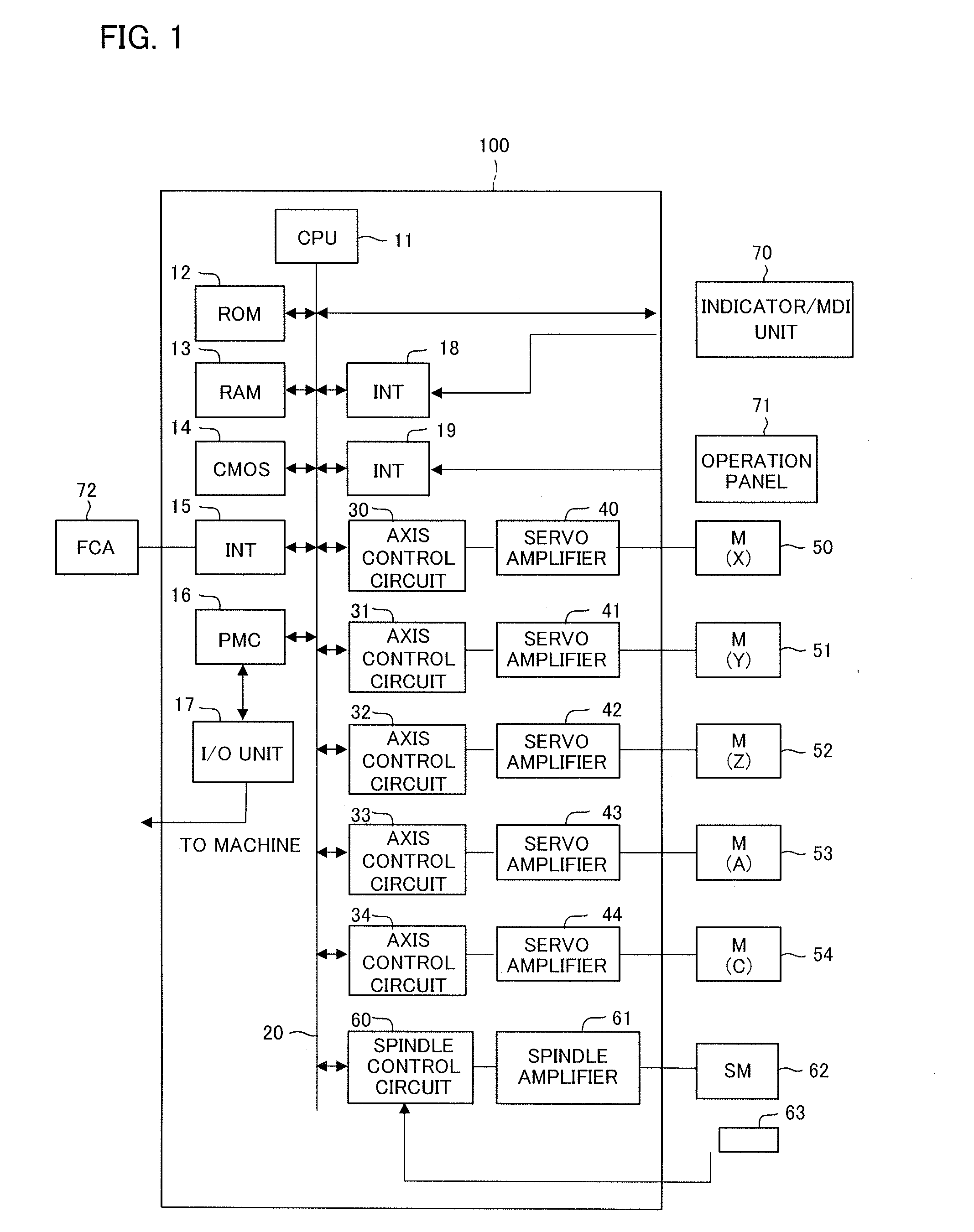

Motor controller for tandem control

ActiveUS20100181955A1Prevent reboundCurb reboundDC motor speed/torque controlComputer controlElectric machineControl system

In position tandem control in which one movable member is driven by two motors, an output of the integral element of the velocity control unit in the control system for one motor is copied to the integral element of the velocity control unit in the control system for the other motor. A preload is added to a torque command output from each of the velocity control units in the motor control systems for two motors so that torques in mutually opposite directions are generated to suppress backlash between gears.

Owner:FANUC LTD

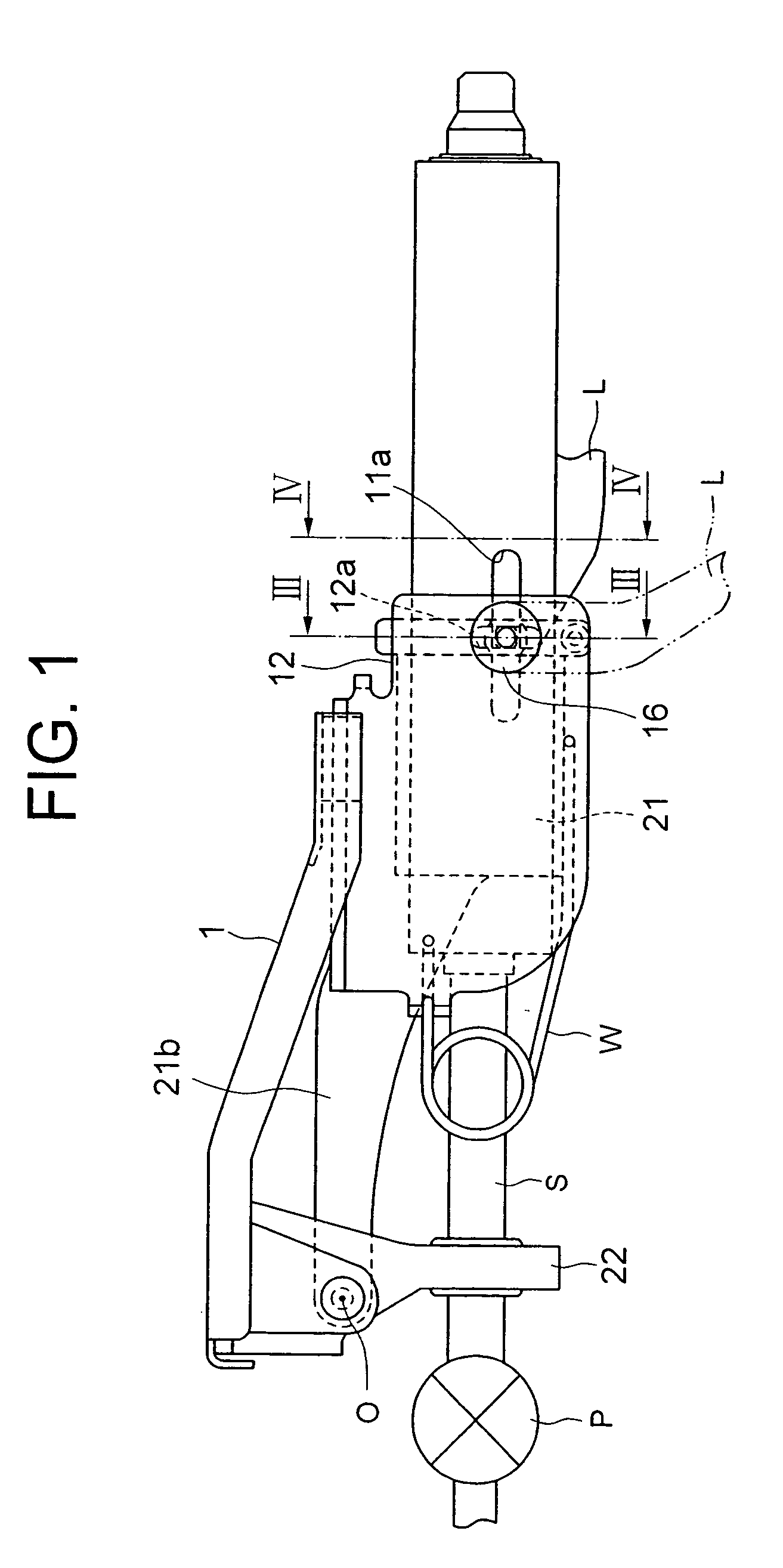

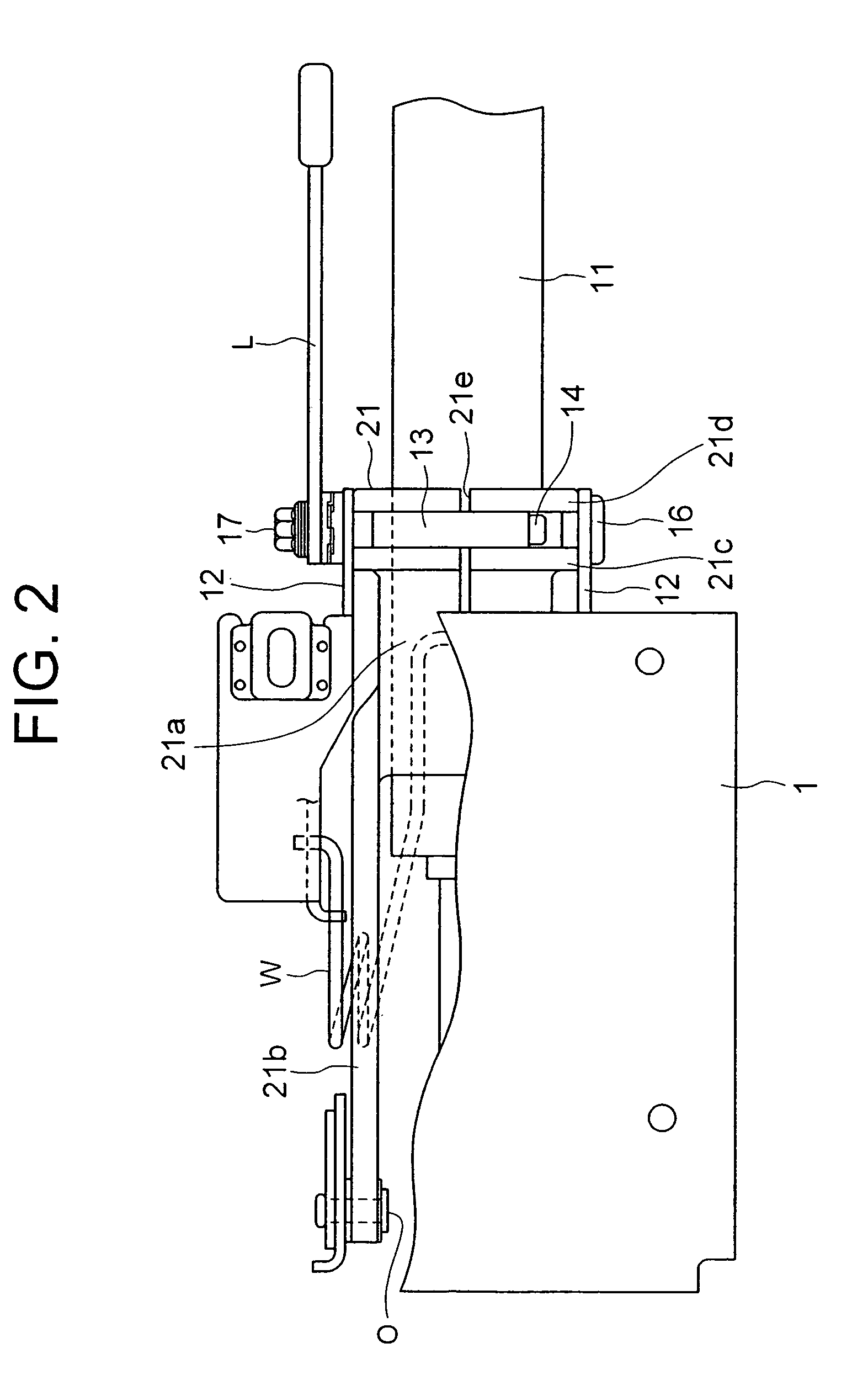

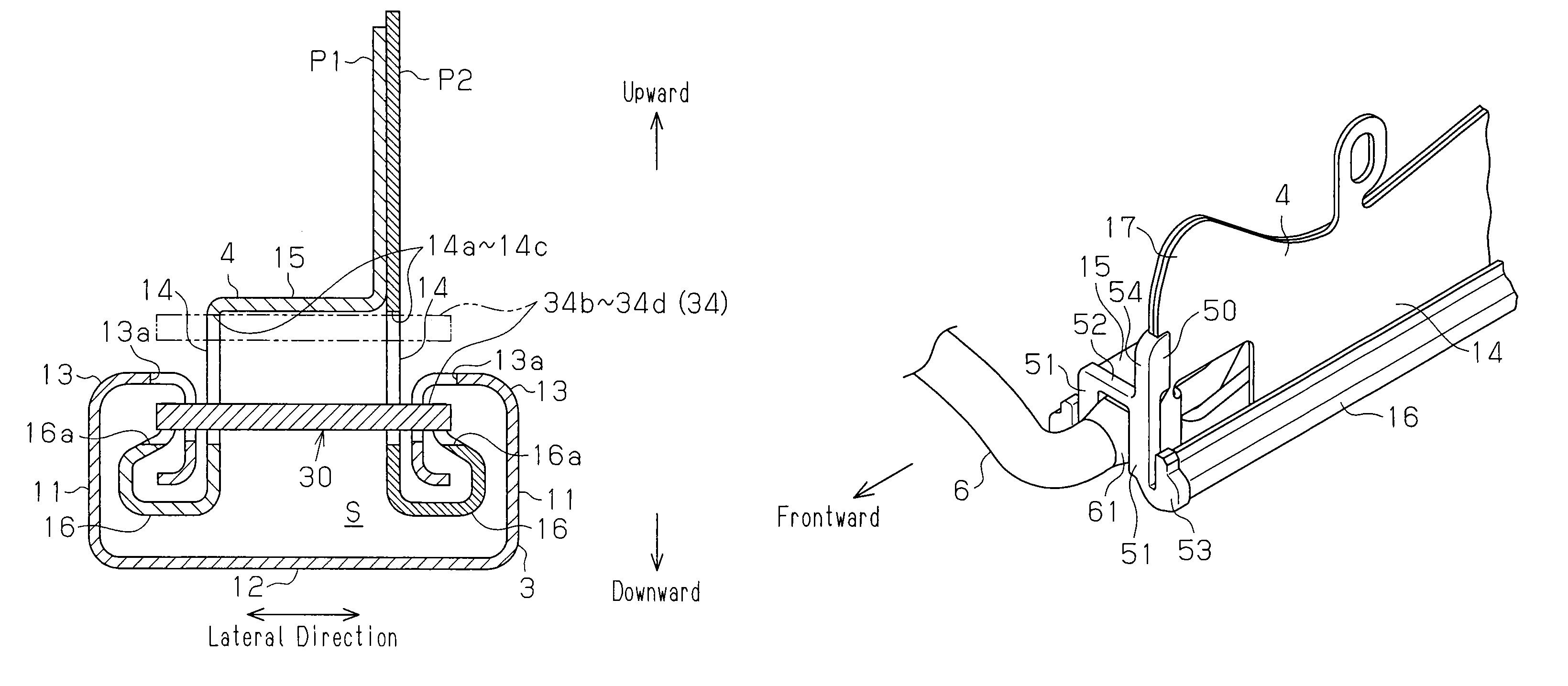

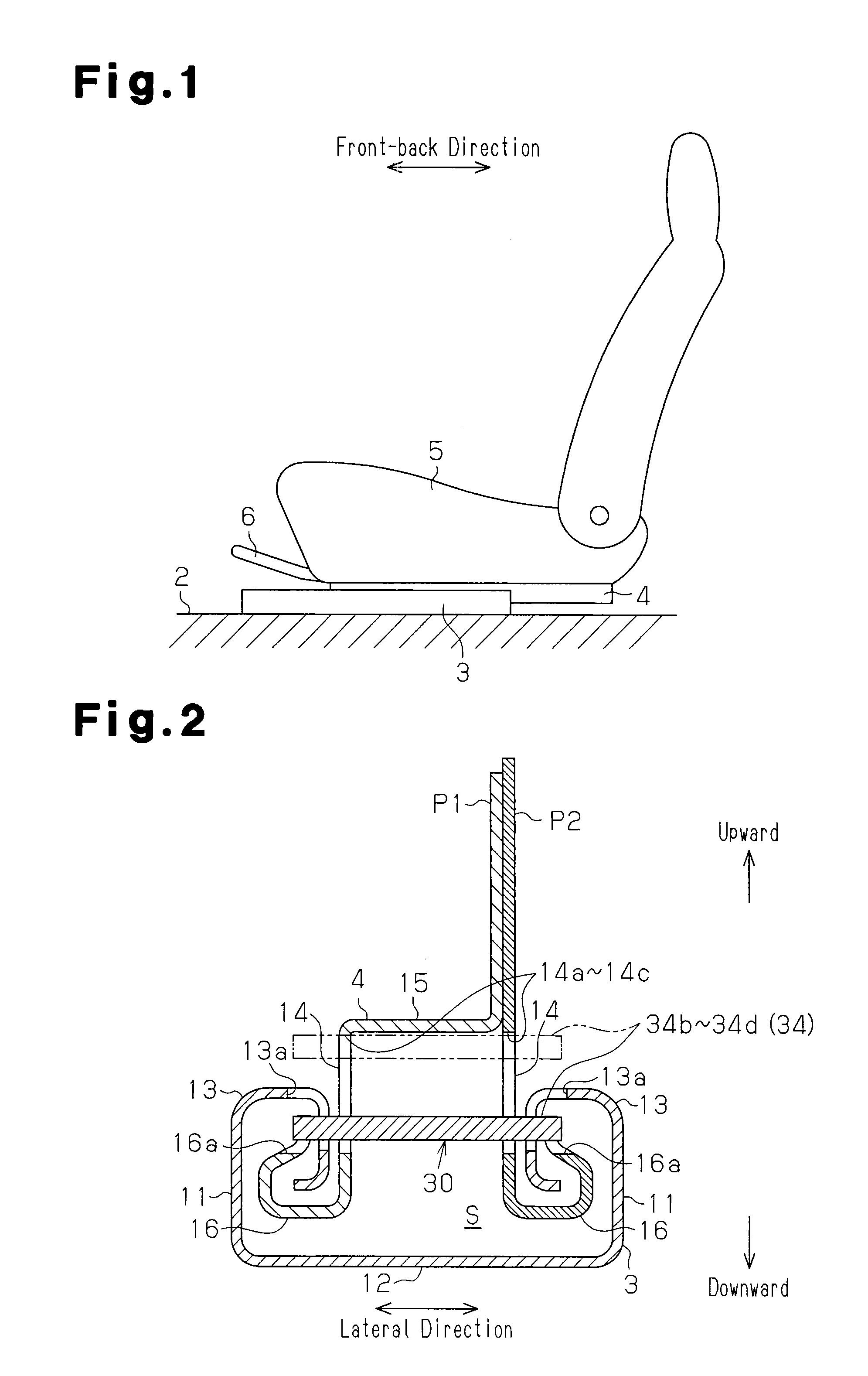

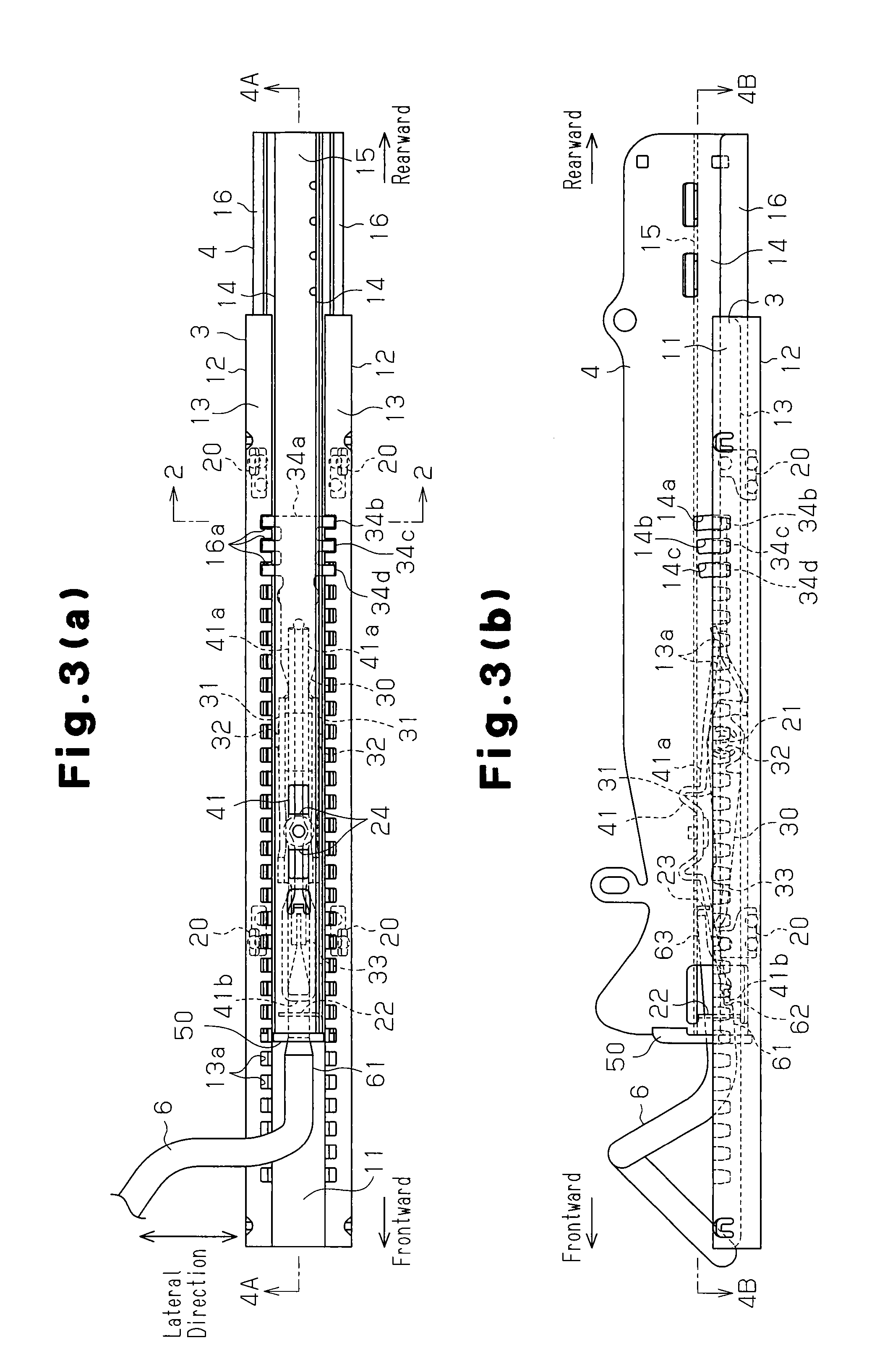

Vehicle seat sliding device

ActiveUS8925889B2Limit backlashIncrease in slide resistanceStands/trestlesKitchen equipmentSupporting wallMechanical engineering

Owner:AISIN SEIKI KK

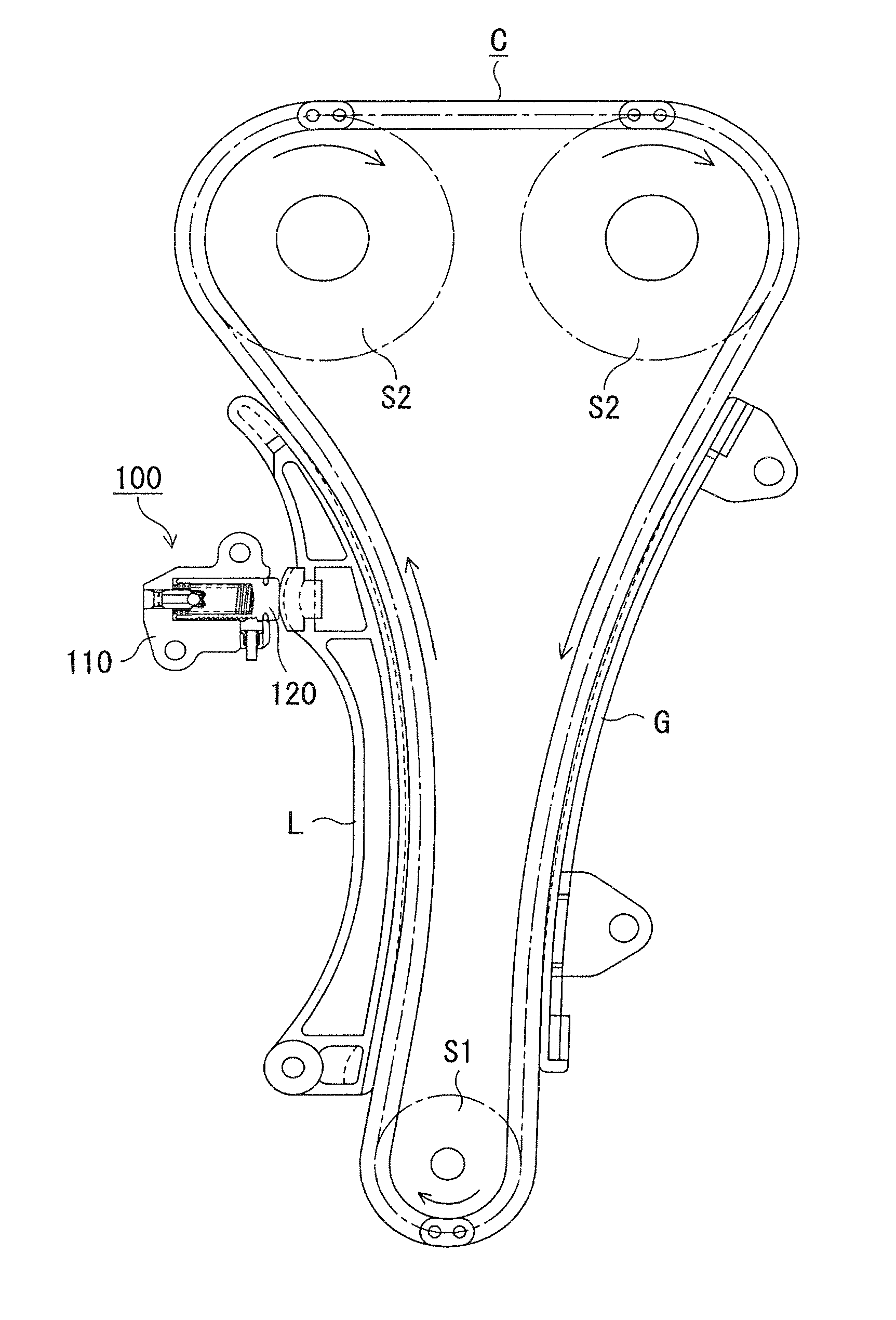

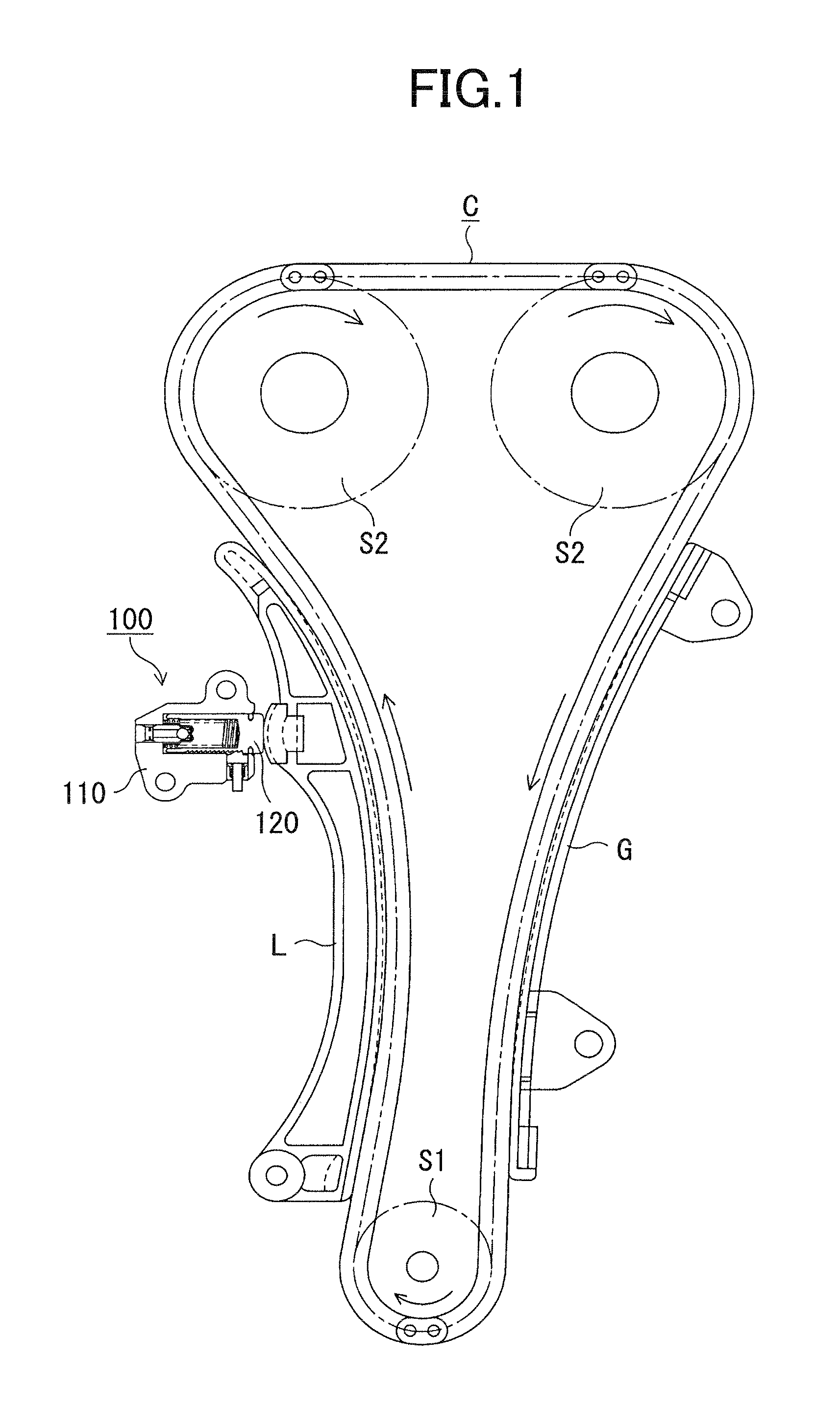

Ratchet-type tensioner

InactiveUS20110183796A1Prevent reboundRestricting retracting movementGearingMechanical engineeringPiston

In a ratchet-type tensioner having a toothed ratchet piston biased toward a rack of teeth formed on a protruding plunger in a direction transverse to the direction of plunger movement, the rack teeth and the ratchet teeth are mutually engageable and inclined at angles such that the biasing force urging the teeth of the ratchet piston into engagement with the rack teeth is sufficient to block retraction of the plunger during engine start-up but can be overcome when chain tension becomes excessive during engine operation following engine start-up.

Owner:TSUBAKIMOTO CHAIN CO

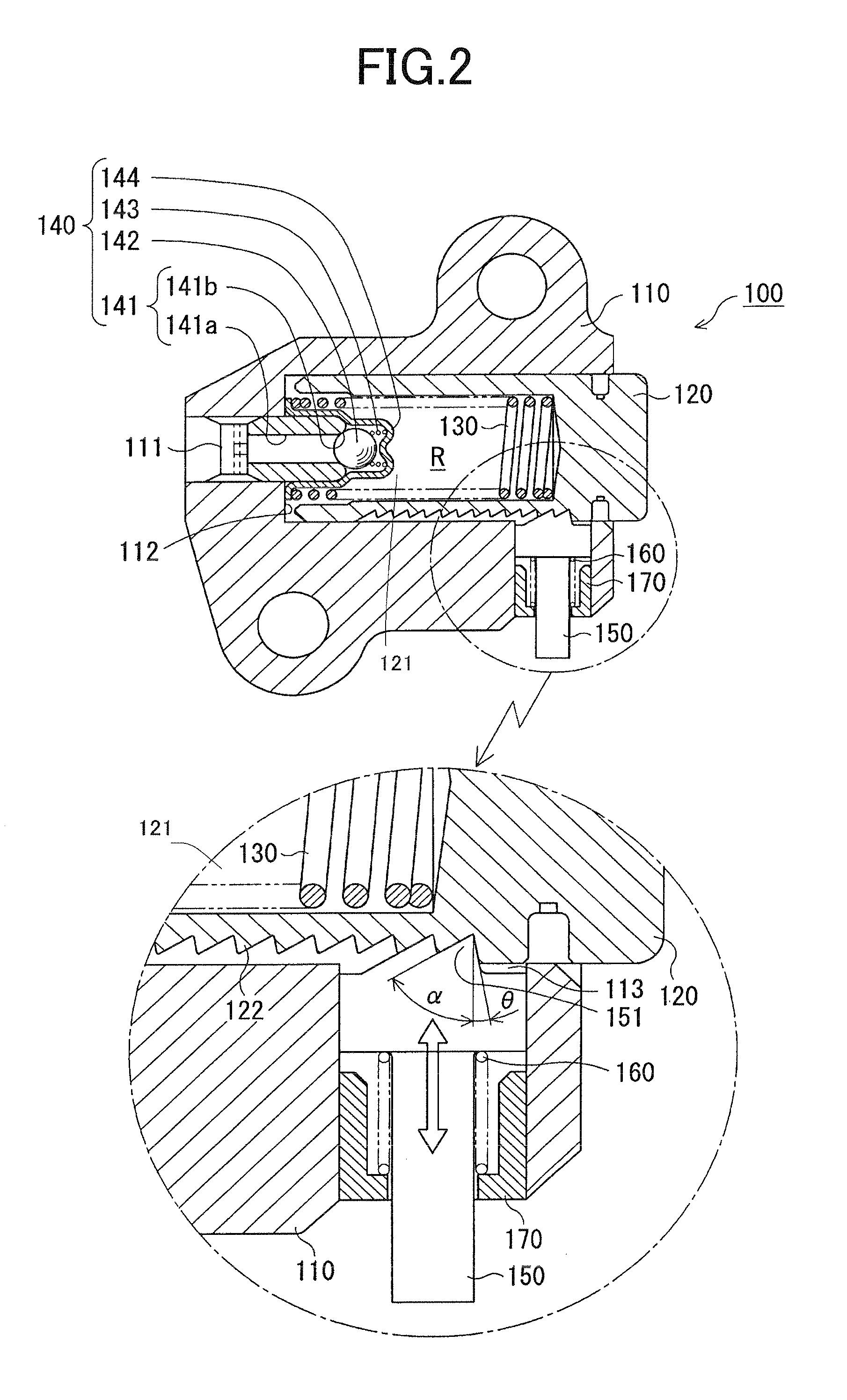

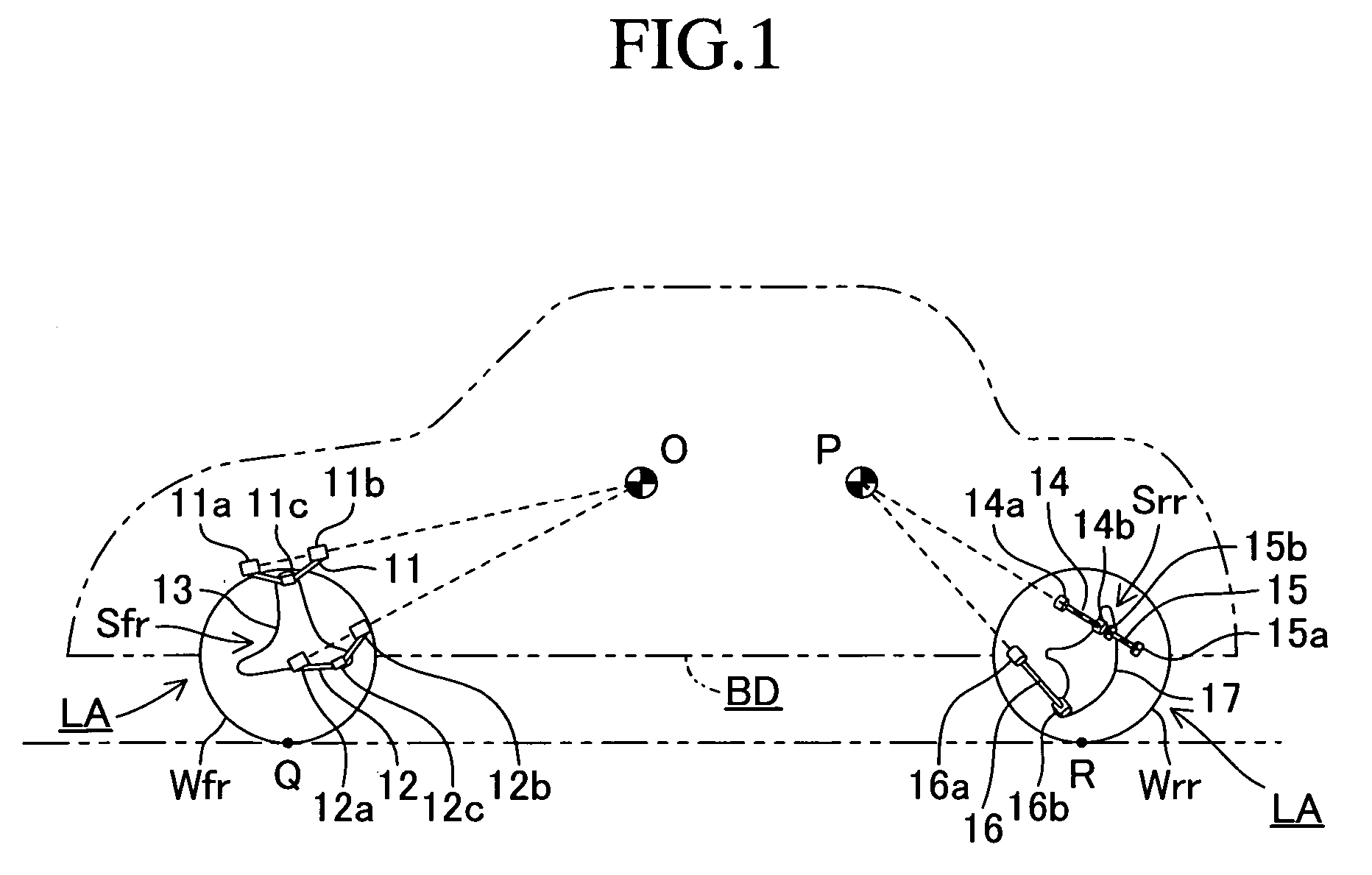

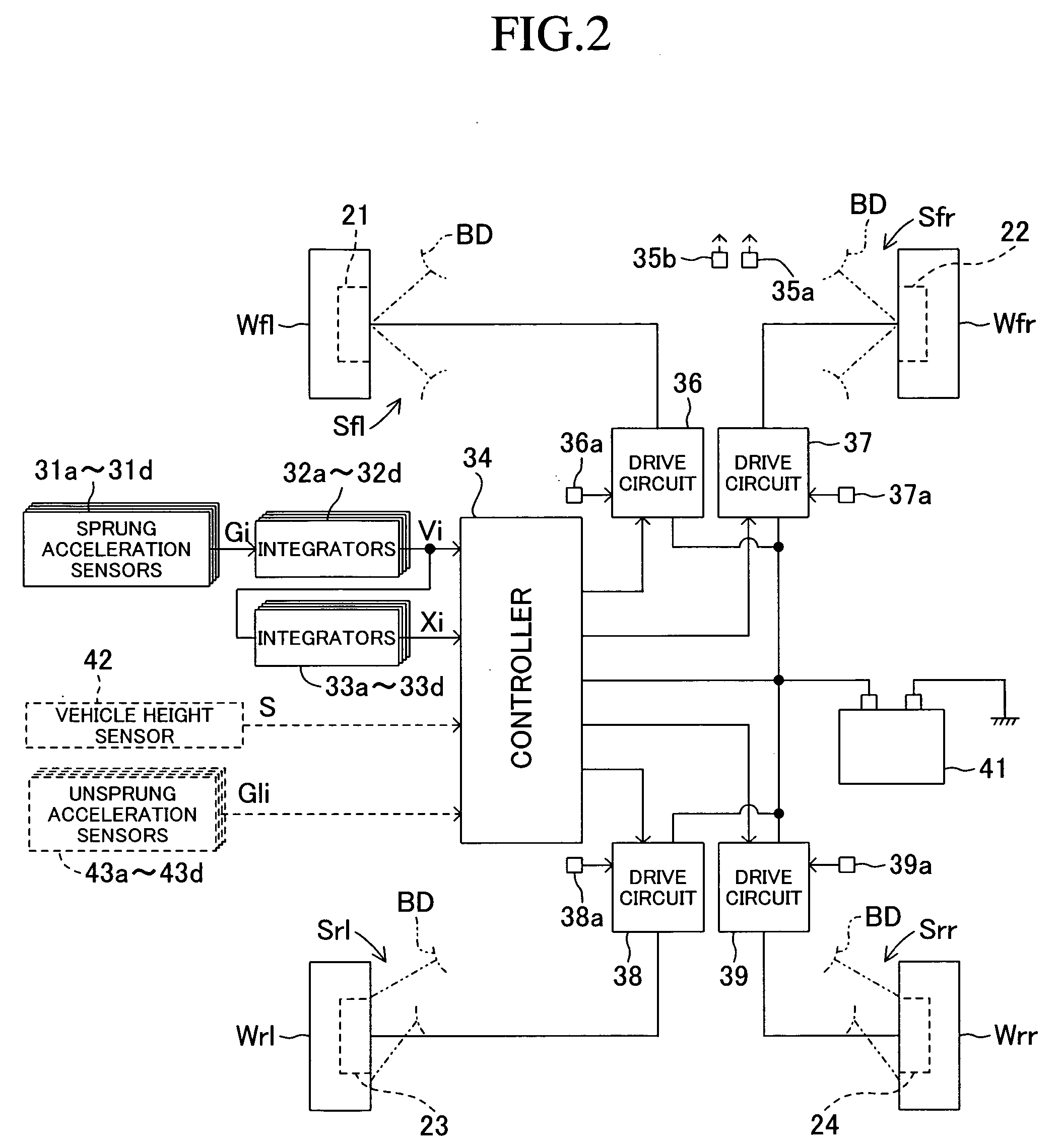

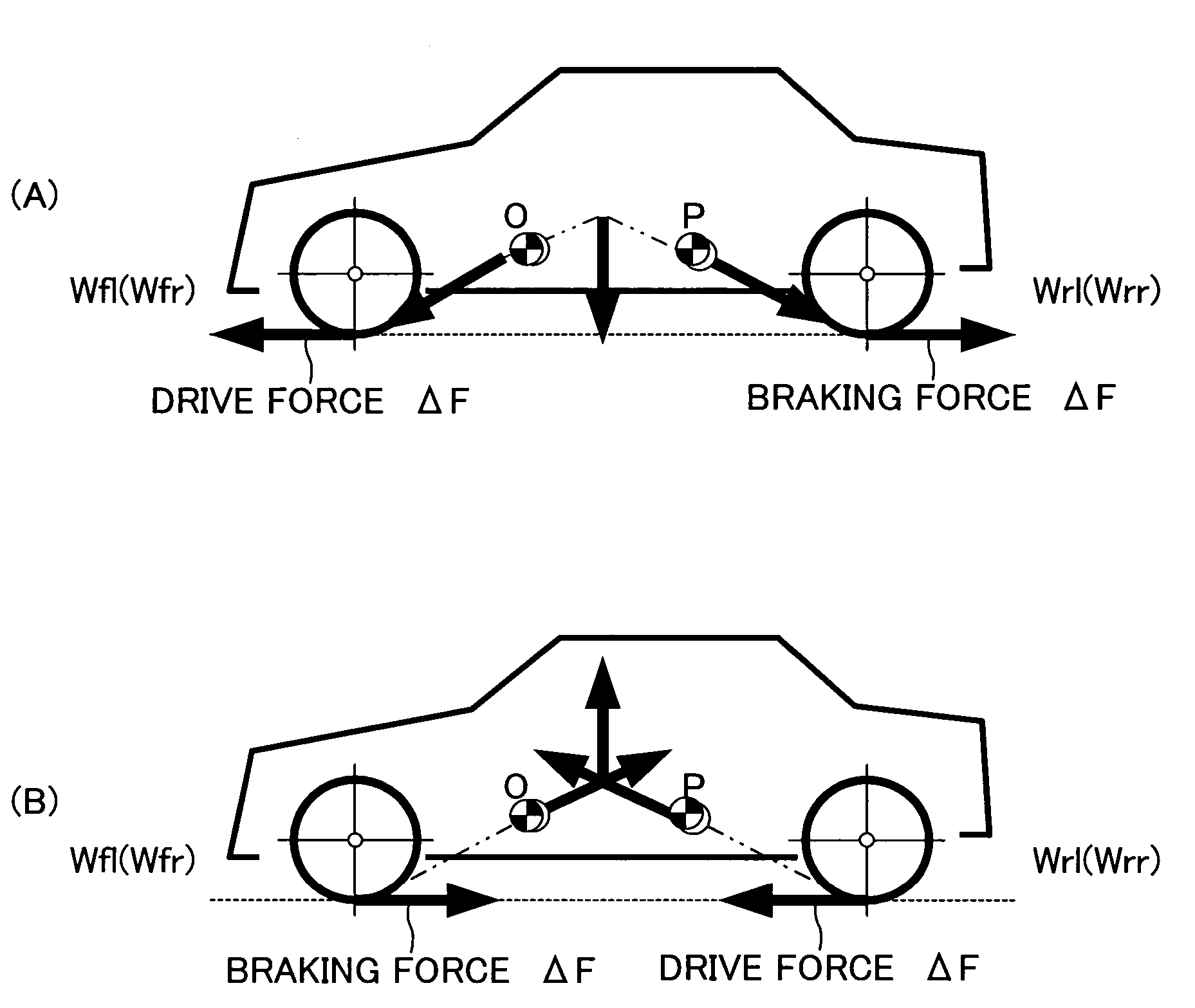

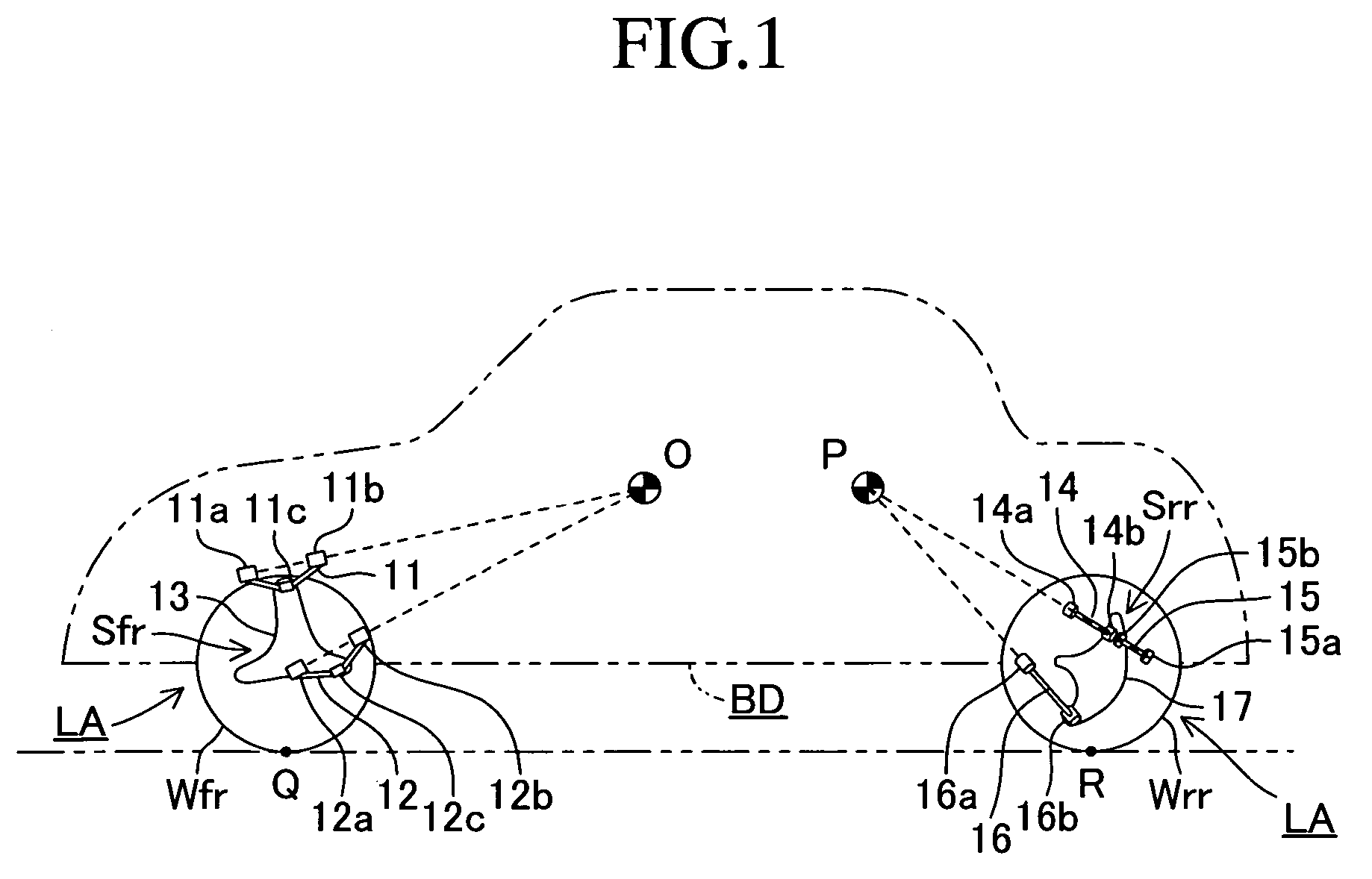

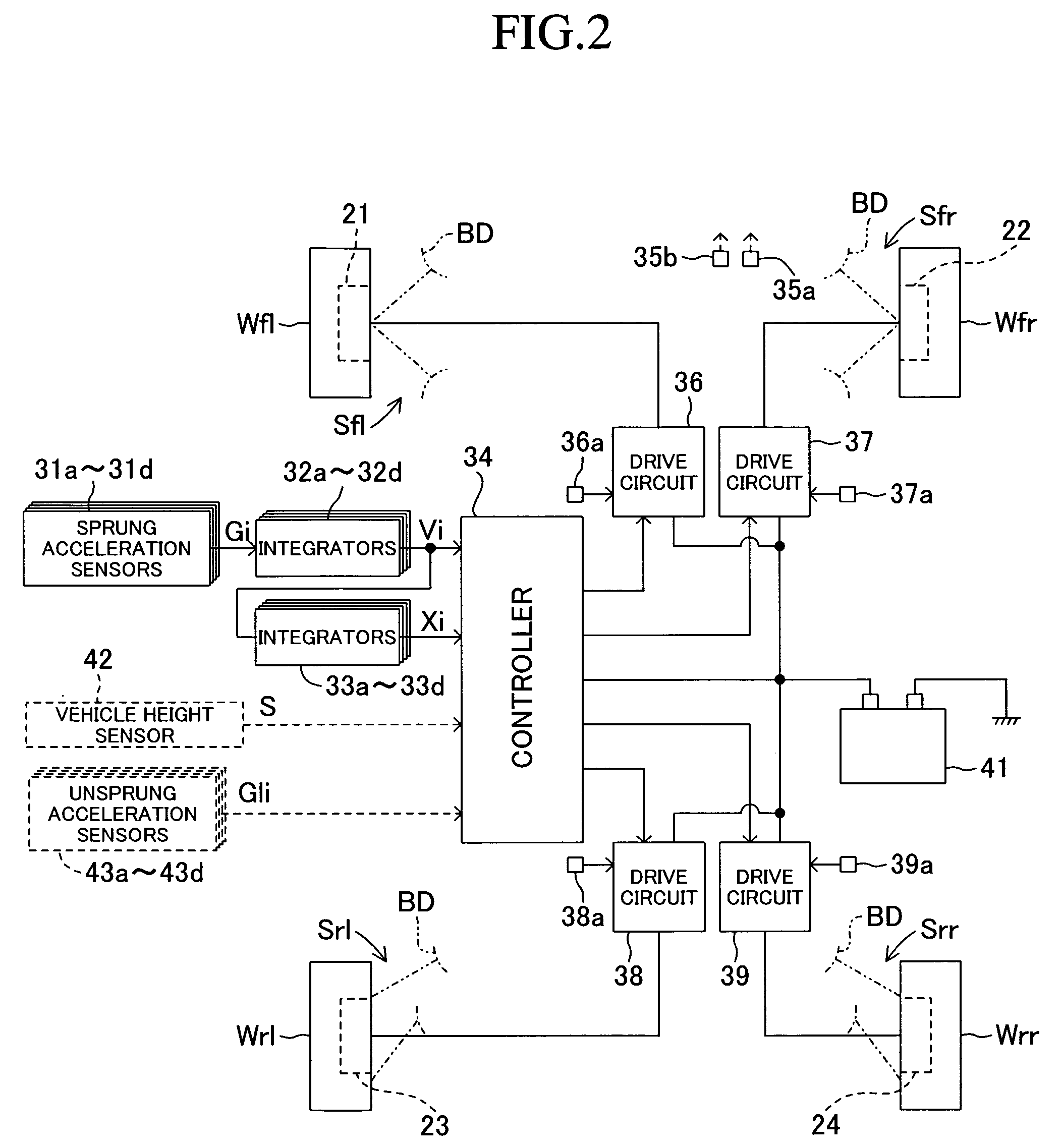

Braking and drive force control apparatus for a vehicle

ActiveUS20060076740A1Suppress bouncing of a vehicle bodySuppress variation in ground contact loadHybrid vehiclesSpeed controllerGround contactEngineering

A braking and drive force control apparatus for a vehicle whose wheels are separately driven by electric motors. A controller calculates a drive force or a braking force to be applied to each wheel in accordance with the average sprung displacement and average sprung velocity of the vehicle body which are calculated based on sensed sprung acceleration. By adding the calculated drive force or braking force to the drive force at the time of running, at the time of bouncing of the vehicle body, a downwards force can be generated in the vehicle body which is rising, and an upwards force can be generated in the vehicle body which is descending. By applying an upwards or downwards force to each wheel so as to permit upwards and downwards vibration of the wheels, variations in the ground contact load can be suppressed.

Owner:TOYOTA JIDOSHA KK

Constant velocity universal joint and inner member thereof

InactiveUS20070037626A1Low inner diameter requirementDimensional accuracy can be ensuredClutchesYielding couplingUniversal jointHeat treated

An inner ring is configured to simultaneously ensure the strength thereof and the dimensional accuracy of a female spline portion of a shaft hole thereof in the case where the female spline portion is subjected to heat treatment. Also it is configured to suppress the backlash of spline fit with a shaft. The inner ring is mounted in a constant velocity universal joint for transmitting torque while the inner ring is allowed to be angularly displaced relative to an outer ring and is spline-fitted to a shaft inserted into a shaft hole formed through the inner ring. The inner ring has a hardened layer by means of heat treatment which is formed only in an axial central portion of the shaft hole, but is not formed in remaining inner diameter surface other than the axial central portion.

Owner:NTN CORP

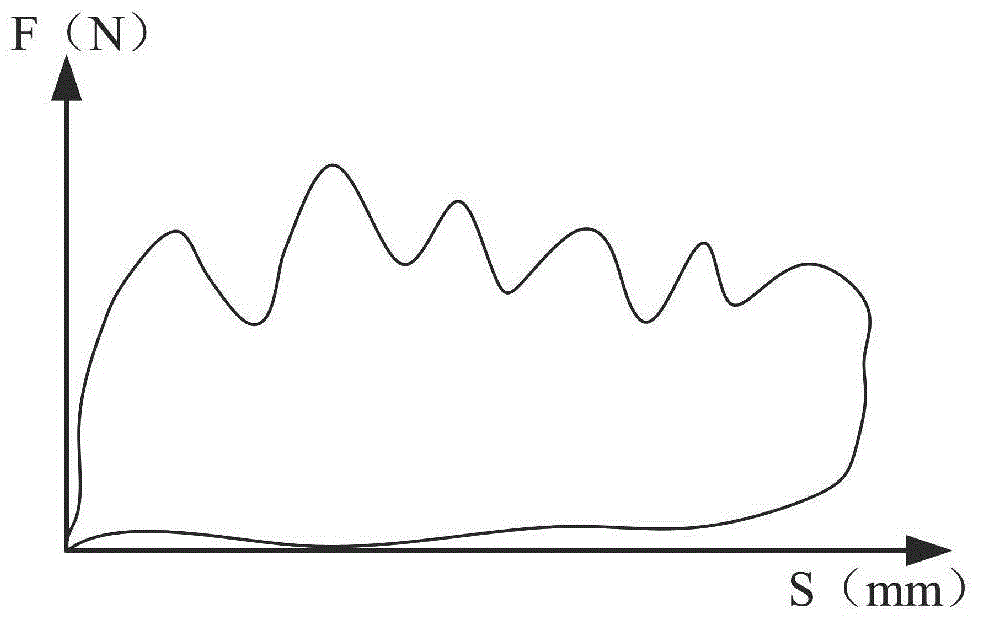

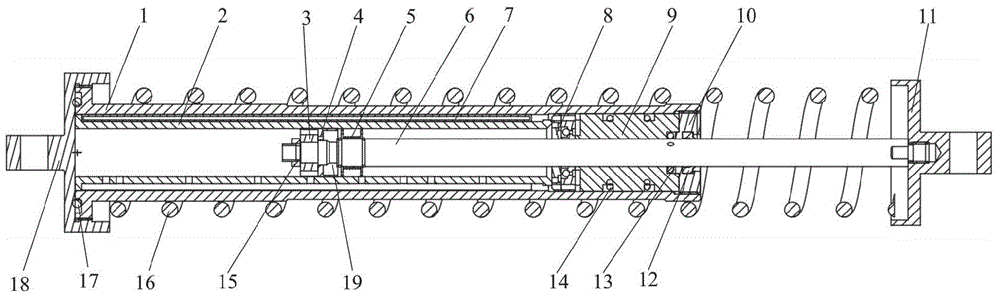

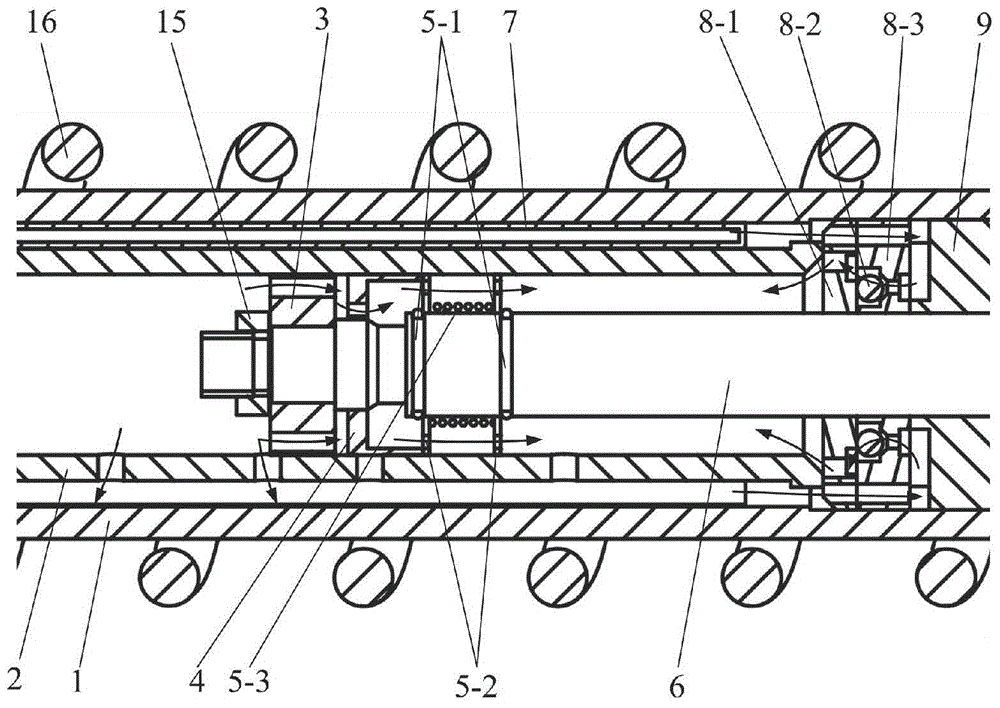

Small unmanned plane undercarriage buffer

InactiveCN104895995AIncrease the damping factorCurb reboundSpringsShock absorbersAviationUpper joint

A small unmanned plane undercarriage buffer relates to the field of aviation aircrafts and solves problems of low buffering efficiency, easy bounce, low reliability of a present flat spring type buffer. The small unmanned plane undercarriage buffer comprises an external cylinder, a first spring on the external cylinder, an internal cylinder having a damping hole, an air sac between the external cylinder and the internal cylinder; an upper joint, a lower joint, a piston rod extending into the internal cylinder, a piston, a damping plate, a pressure-limiting valve, a check valve, a guide sleeve and a locking cover, wherein the piston rod is orderly covered with the piston, the damping plate and the pressure-limiting plate; the piston rod is orderly covered with the check valve, the guide sleeve and the locking cover; the check valve, the guide sleeve and the locking cover are all disposed in the external cylinder; an internal-external cylinder annular oil storage cavity is formed between the internal cylinder and the external cylinder; the damping plate axially moves along the piston rod; the pressure-limiting plate limits maximum damping force to a preset valve during compression stroke; after the locking cover is tightly screwed, the guide sleeve, the check valve and the internal cylinder are axially pressed to the lower joint; the check valve controls communication between the internal-external cylinder annular oil storage cavity and a right cavity of the internal cylinder; and two ends of a first spring are respectively pressed against the upper and lower joints. The small unmanned plane undercarriage buffer possesses high buffering efficiency, uneasy bounce, stable performance and great reliability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Manufacturing method for titanium welded pipe

InactiveCN102989820AMeet high standard finished pipe requirementsConsistent bending forceProduction lineTitanium

The invention discloses a manufacturing method for a titanium welded pipe. The manufacturing method mainly comprises the following steps of: filling a titanium tape coil into an uncoiler, and pulling out a titanium tape which then enters a forming device; rolling and bending the titanium tape through a mold, thus forming the tape into an open pipe blank; welding the pipe blank through an argon arc welding machine to form a closed titanium welded pipe; sending the closed titanium welded pipe into a sizing device, and rolling the titanium welded pipe in the sizing device by a mold to fix the outer diameter of the titanium welded pipe; heating the titanium welded pipe which moves forward to enter an induction annealing device so as to eliminate uneven stress generated in welding; then straightening the pipe in a pull-out straightening device, measuring the diameter of the pipe in a laser diameter measuring device, and detecting the pipe at an eddy current inspection station; and finally cutting the pipe at a sizing cut-off station through a flying sawing machine in a sizing manner, and sending the formed titanium welded pipe into a finishing line. According to the manufacturing method, continuous and stable running can be realized, and the operation efficiency of an overall production line can be improved by more than 20%.

Owner:江苏三得利不锈钢集团有限公司 +2

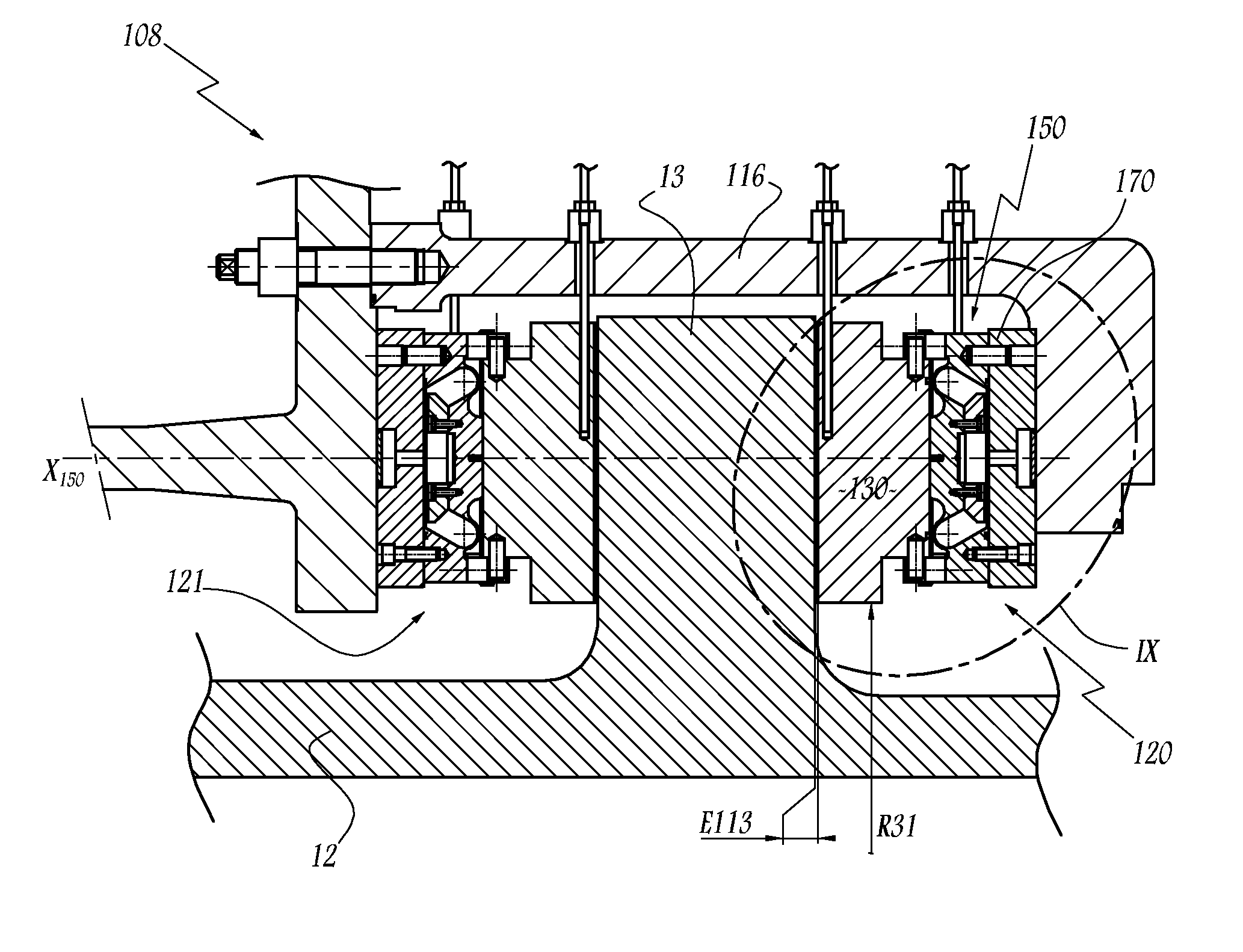

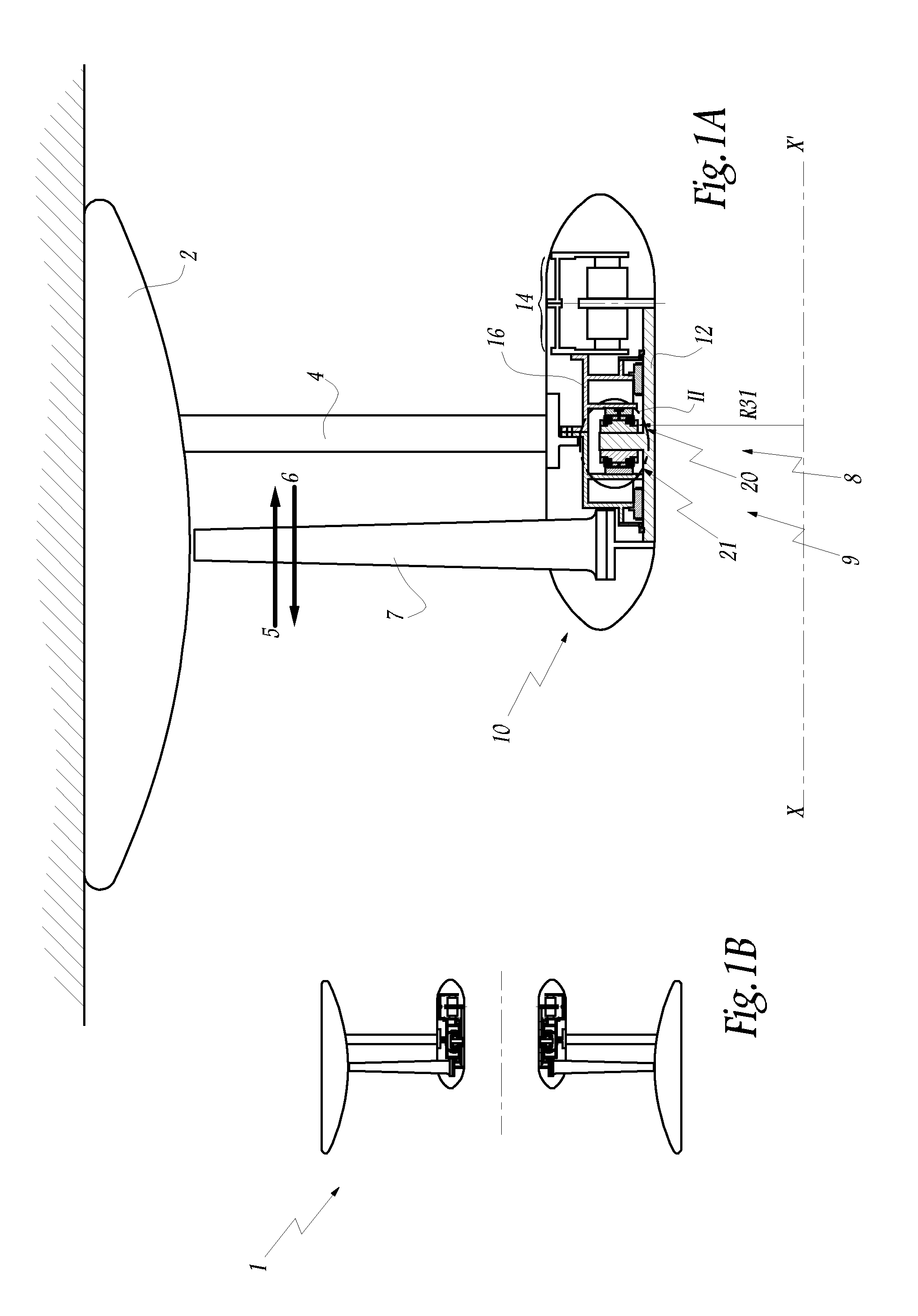

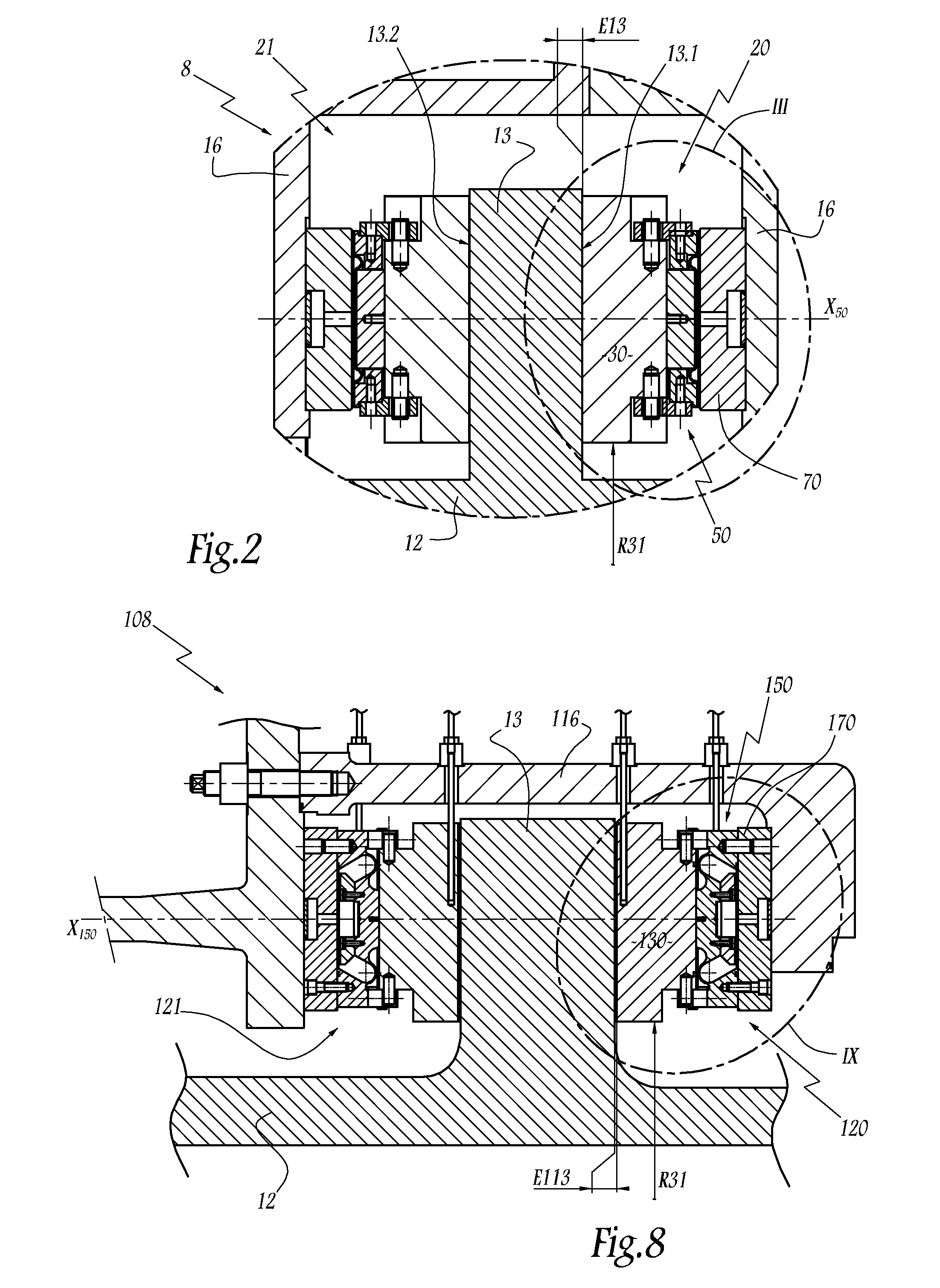

Bearing assembly for a marine turbine shaft, and marine turbine including such a bearing assembly

To recover the axial forces transmitted by a rotating shaft, a bearing assembly includes a plurality of distributed bearing units. Each bearing unit comprises: a stationary base; a resilient member having a stationary portion and a portion that is completely movable in a main direction of the forces to be supported; and a bearing surface that defines, together with the shaft, a water film. The bearing surface is connected to the movable portion. The minimum radius of the bearing surface is between 1 m and 3 m. The resilient member and the base define at least one water chamber. A plurality of ducts are arranged so as to connect the chambers together, thereby defining a closed circuit.

Owner:ALSTOM RENEWABLE TECH

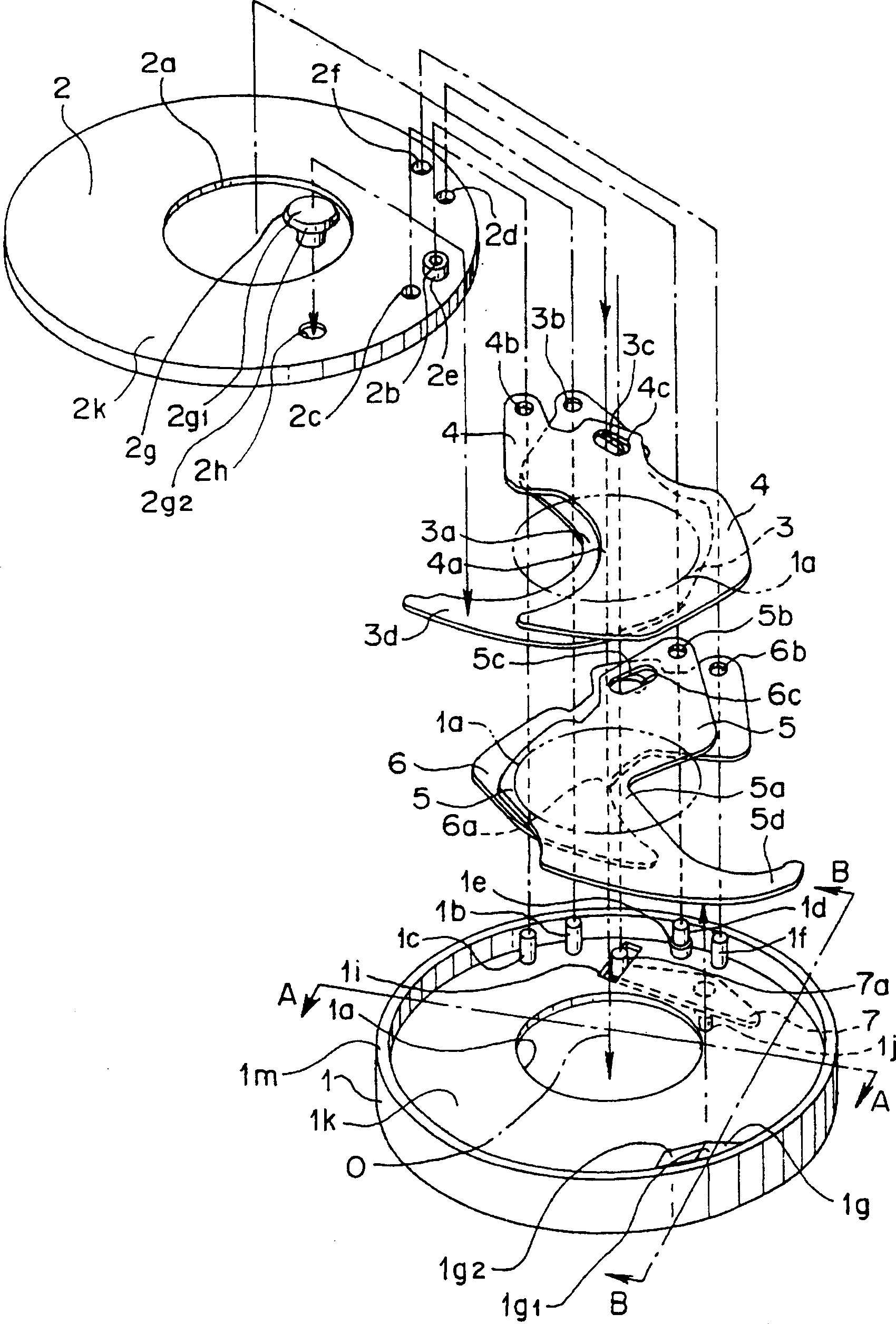

Shutter device

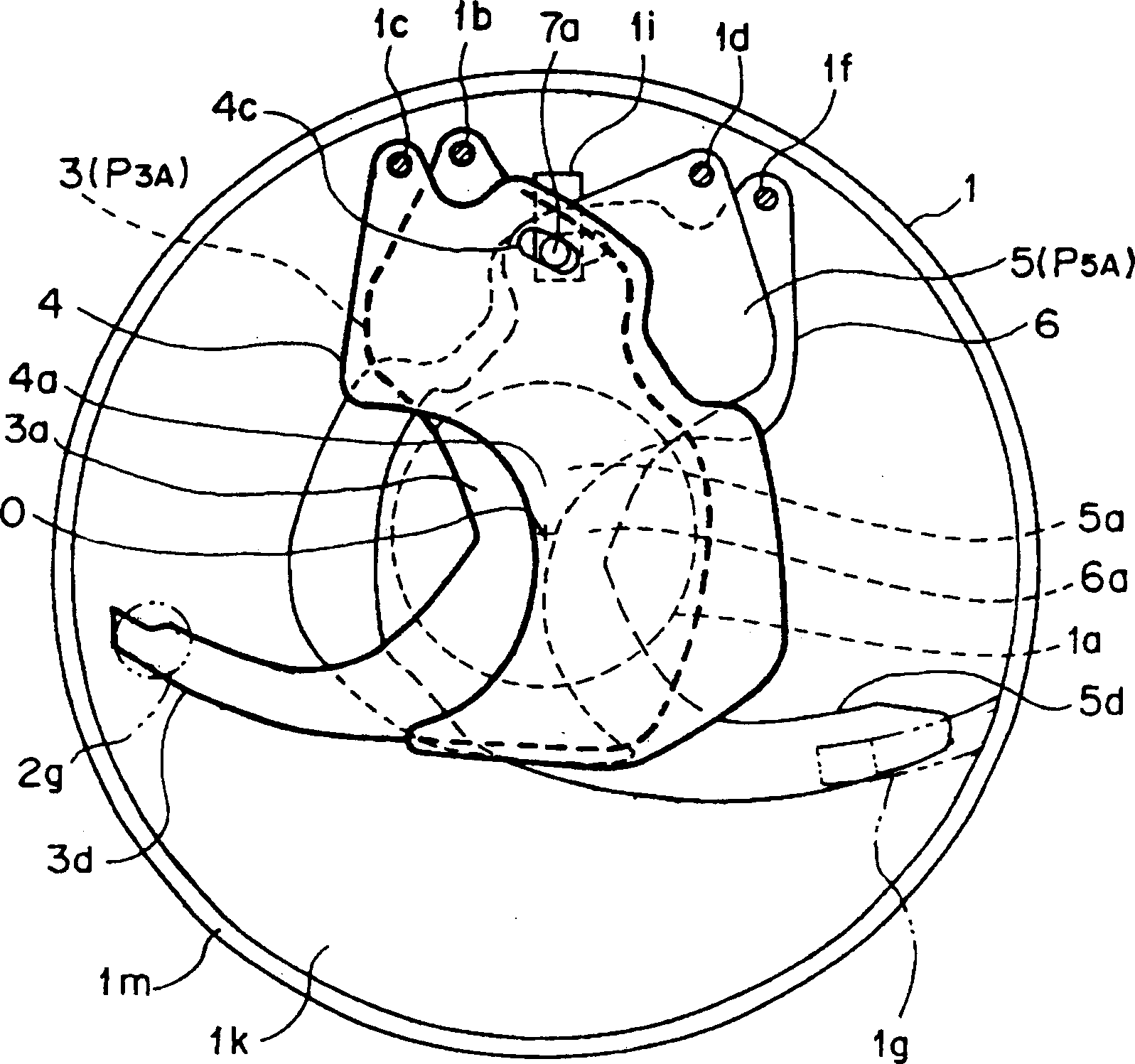

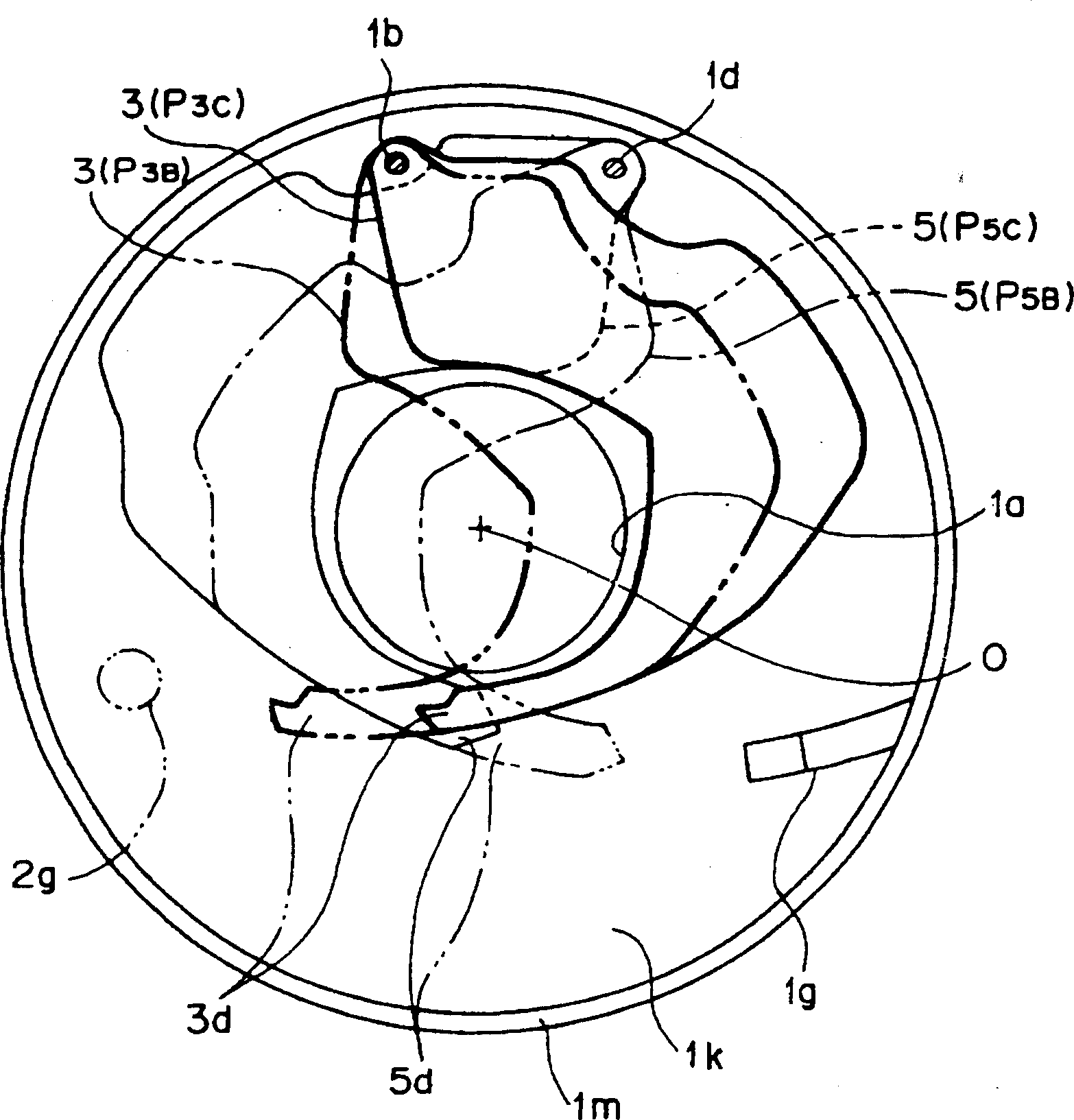

Provided is a shutter unit which performs secure shutter operation while deterring shutter blades from bounding in opening / closing operation and is arranged in a small space. This shutter unit has main blades 3 and 5 and subordinate blades 4 and 6 which can rotate and travel in the space formed of a shutter case 1 and a case lid 2 in opening / closing directions; and the main blades 3 and 5 are provided with extension projection parts 3d and 5d and braking members 2g and 1g made of shock-absorbing raw materials are arranged opposite closure-state termination positions of the extension projection parts 3d and 5d separately from their movement traces across slight gaps. When this shutter unit is driven from the opening state to the closure state, the main blades 3 and 5 suddenly stop at their termination positions and when the extension projection parts 3d and 5d are displaced along the optical axis, they abut against the braking members 2g and 1g to be braked, so that the main blades 3 and 5 and subordinate blades 4 and 6 are deterred from bounding.

Owner:OLYMPUS CORP

Electromagnetic controlled fuel injection apparatus with poppet valve

ActiveUS7350539B2Curb reboundOperating means/releasing devices for valvesMachines/enginesInterior spaceReciprocating motion

An electromagnetic controlled fuel injection apparatus has a poppet valve which controls the beginning and end of fuel injection by reciprocation. Inertia force and friction force arising from the reciprocating motion of the poppet valve are utilized effectively to suppress bounce of the poppet valve. The poppet valve has a sealed inside space, and a plurality of mass objects are received in the inside space so that the mass objects can move axially while contacting with each other in the inside space due to the inertia force generated by the reciprocating motion of the poppet valve.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

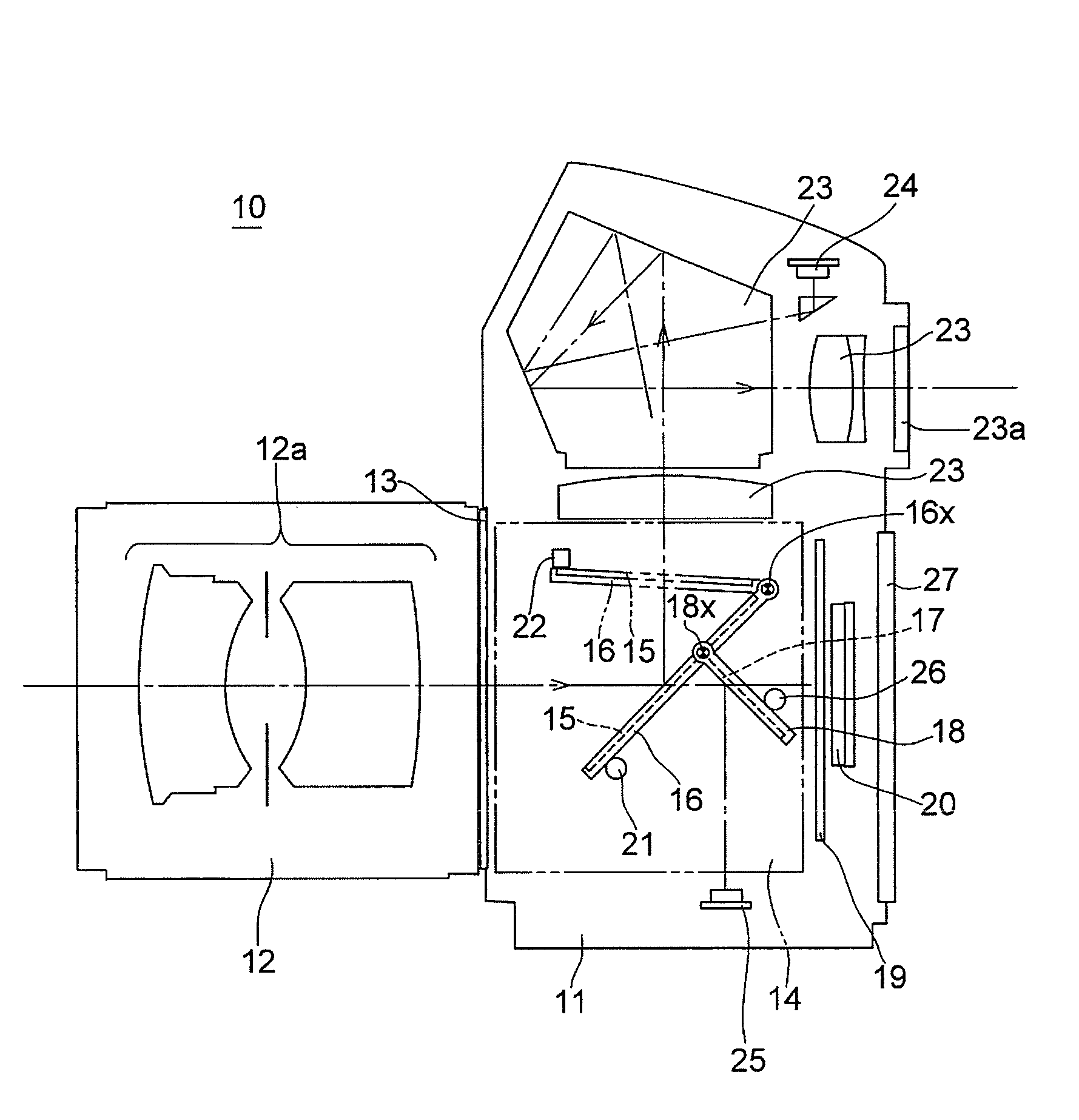

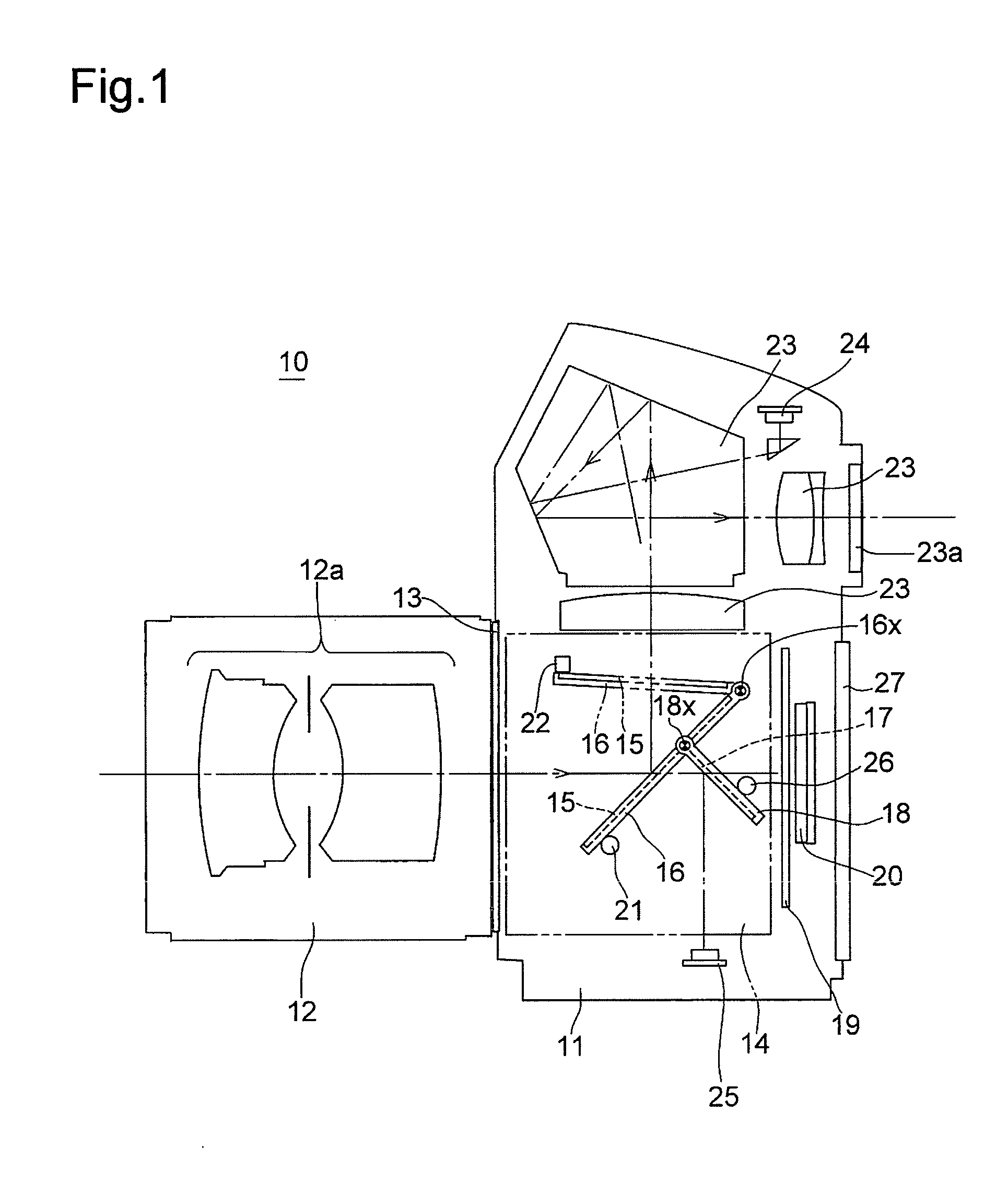

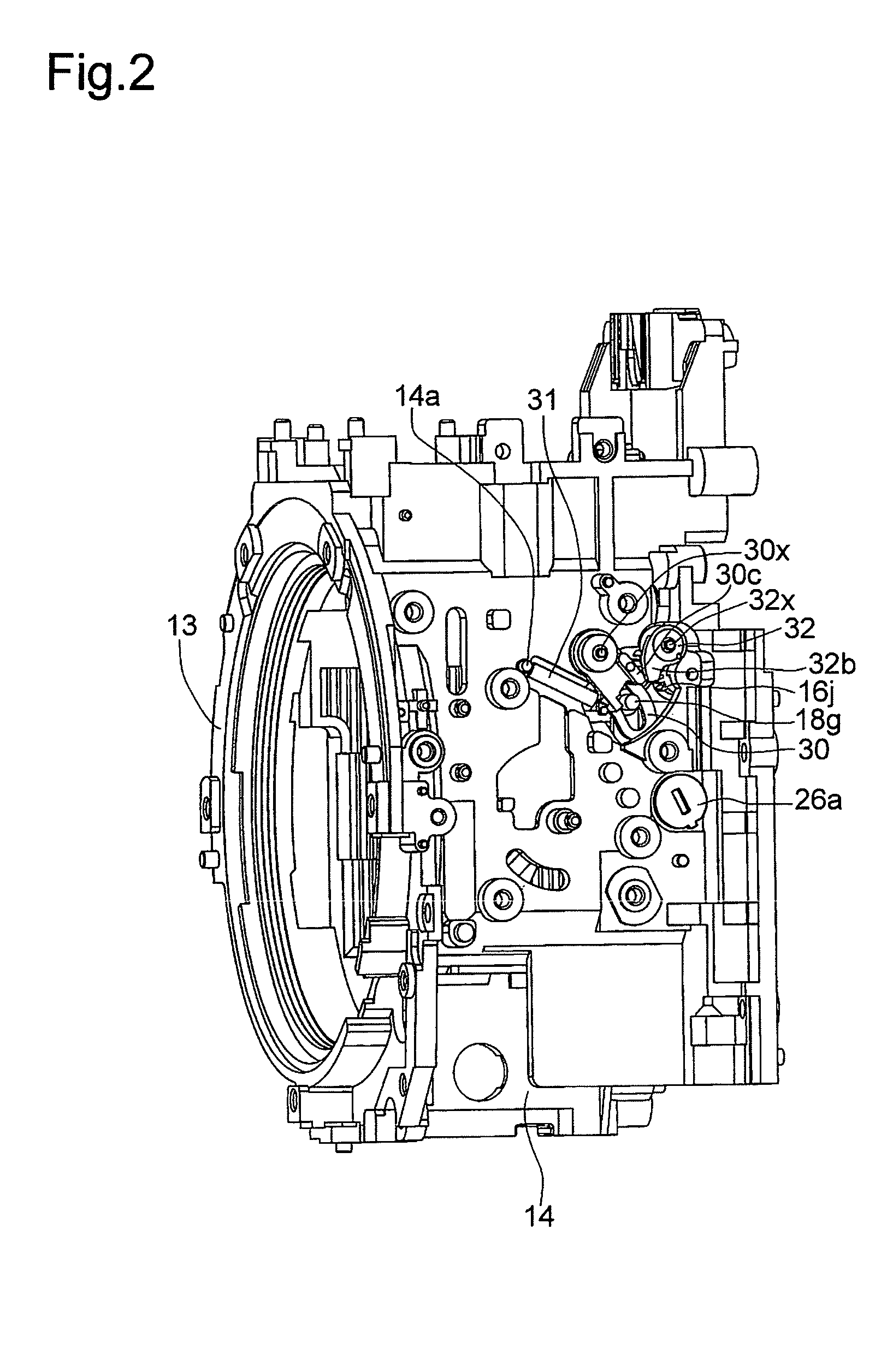

Drive mechanism for movable mirror of camera

ActiveUS20150010297A1Reliably control bouncingSimple structureExposure controlVibration controlLight guide

A movable-mirror drive mechanism of a camera includes a main mirror held by a main-mirror holding frame rotatable between a viewfinder light-guiding position and a retracted position; a sub-mirror held by a sub-mirror holding frame that is rotatably supported by the main-mirror holding frame, wherein the sub-mirror holding frame is positioned in a jutting-out position when the main mirror is in the viewfinder light-guiding position, and the sub-mirror holding frame is retracted with the main mirror when the main mirror is in the retracted position; and a vibration control member which rotates in association with rotation of the main-mirror holding frame and holds the sub-mirror holding frame in the jutting-out position to prevent the sub-mirror holding frame from rotating toward the sub-mirror retracted position when the main mirror rotates to the viewfinder light-guiding position.

Owner:RICOH IMAGING COMPANY

Braking and drive force control apparatus for a vehicle

ActiveUS7788011B2Suppress bouncing of a vehicle bodySuppress variation in ground contact loadHybrid vehiclesDigital data processing detailsGround contactControl theory

A braking and drive force control apparatus for a vehicle whose wheels are separately driven by electric motors. A controller calculates a drive force or a braking force to be applied to each wheel in accordance with the average sprung displacement and average sprung velocity of the vehicle body which are calculated based on sensed sprung acceleration. By adding the calculated drive force or braking force to the drive force at the time of running, at the time of bouncing of the vehicle body, a downwards force can be generated in the vehicle body which is rising, and an upwards force can be generated in the vehicle body which is descending. By applying an upwards or downwards force to each wheel so as to permit upwards and downwards vibration of the wheels, variations in the ground contact load can be suppressed.

Owner:TOYOTA JIDOSHA KK

Fuel-injection valve

InactiveUS7163162B2Easy to controlCurb reboundOperating means/releasing devices for valvesSpray nozzlesEngineeringFuel injection

A fuel-injection valve includes a fuel-injection hole, a valve element and a valve seat for opening and closing the fuel-injection hole, a force-applying member for applying force to the valve element in a direction of motion of the valve element, and a drive unit for applying force to the valve element in the direction opposite to that of the force applied by the force-applying member; wherein a secondary oscillation system, which interacts with a primary oscillation system including the valve element and the force-applying member, is added to the primary oscillation system, and the phase angle of force applied to the primary oscillation system by the secondary oscillation system is also staggered from that of force applied to the primary oscillation system, which is other than the force applied to the primary oscillation system by the secondary oscillation system, whereby the bouncing of the valve element during opening and closing of the valve is reduced, which in turn makes it possible to achieve very accurate fuel-injection control.

Owner:HITACHI LTD

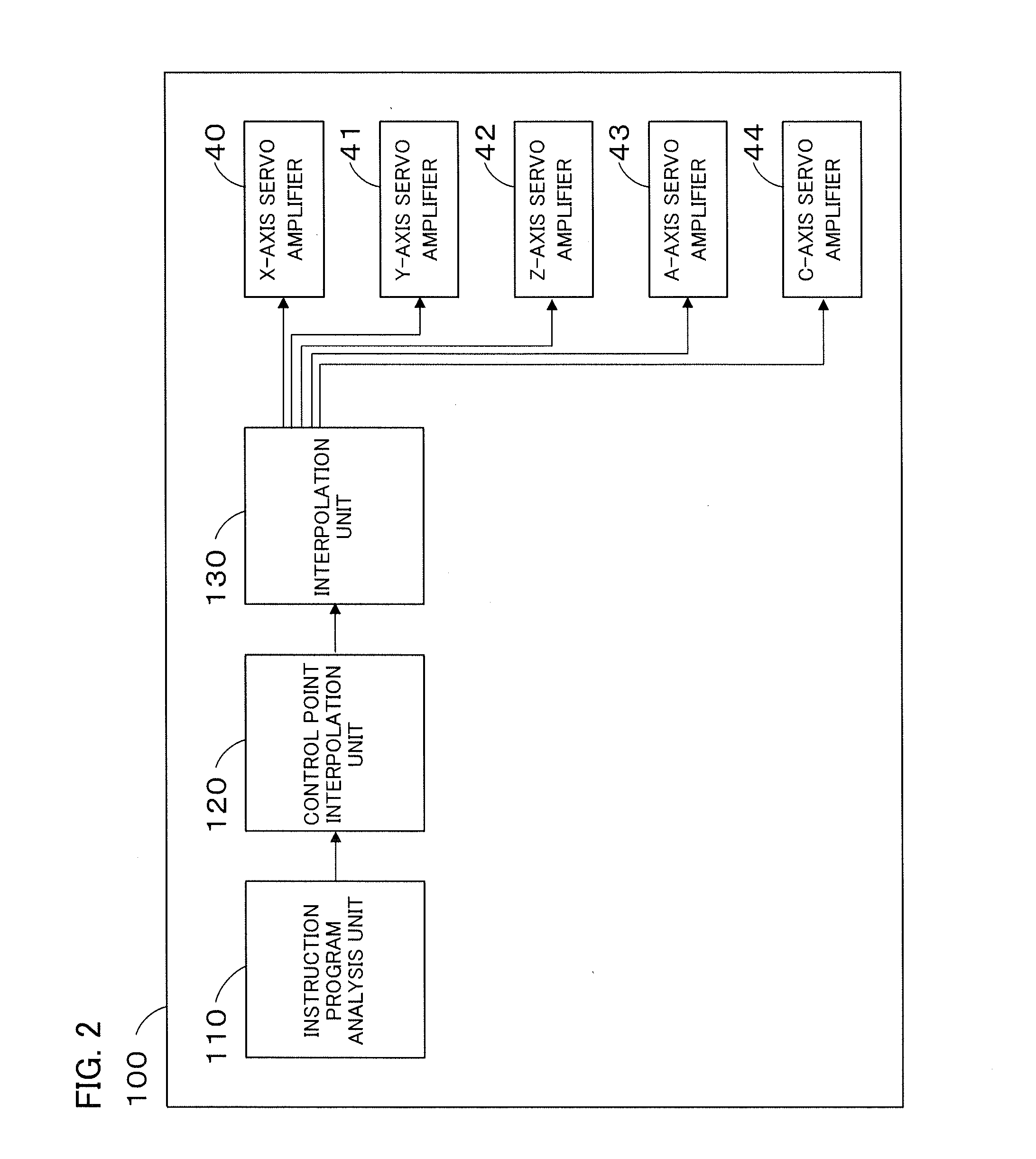

Numerical controller having tool tip point control function

ActiveUS20150378343A1Improve machined surface qualityMinimizing functionSpecial data processing applicationsNumerical controlPath computation elementLinearity

In a numerical controller having a tool tip point control function, a provisional tool tip point movement path calculation unit calculates a fourth movement path of a tip point of a tool on the basis of a third movement path obtained by linearly interpolating a second movement path for moving a control point of the tool along the second movement path, and a post-linear interpolation movement instruction output unit outputs a third movement instruction if it is determined that the difference between a first movement path for moving the tip point of the tool along the first movement path and the fourth movement path is within a predetermined tolerance.

Owner:FANUC LTD

Fuel injection valve

InactiveUS8857743B2Improve injection accuracyCurb reboundSpray nozzlesFuel injection apparatusBiomedical engineeringValve seat

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil, a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature, and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the valve-closing spring is disposed on the armature, and the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle.

Owner:MITSUBISHI ELECTRIC CORP

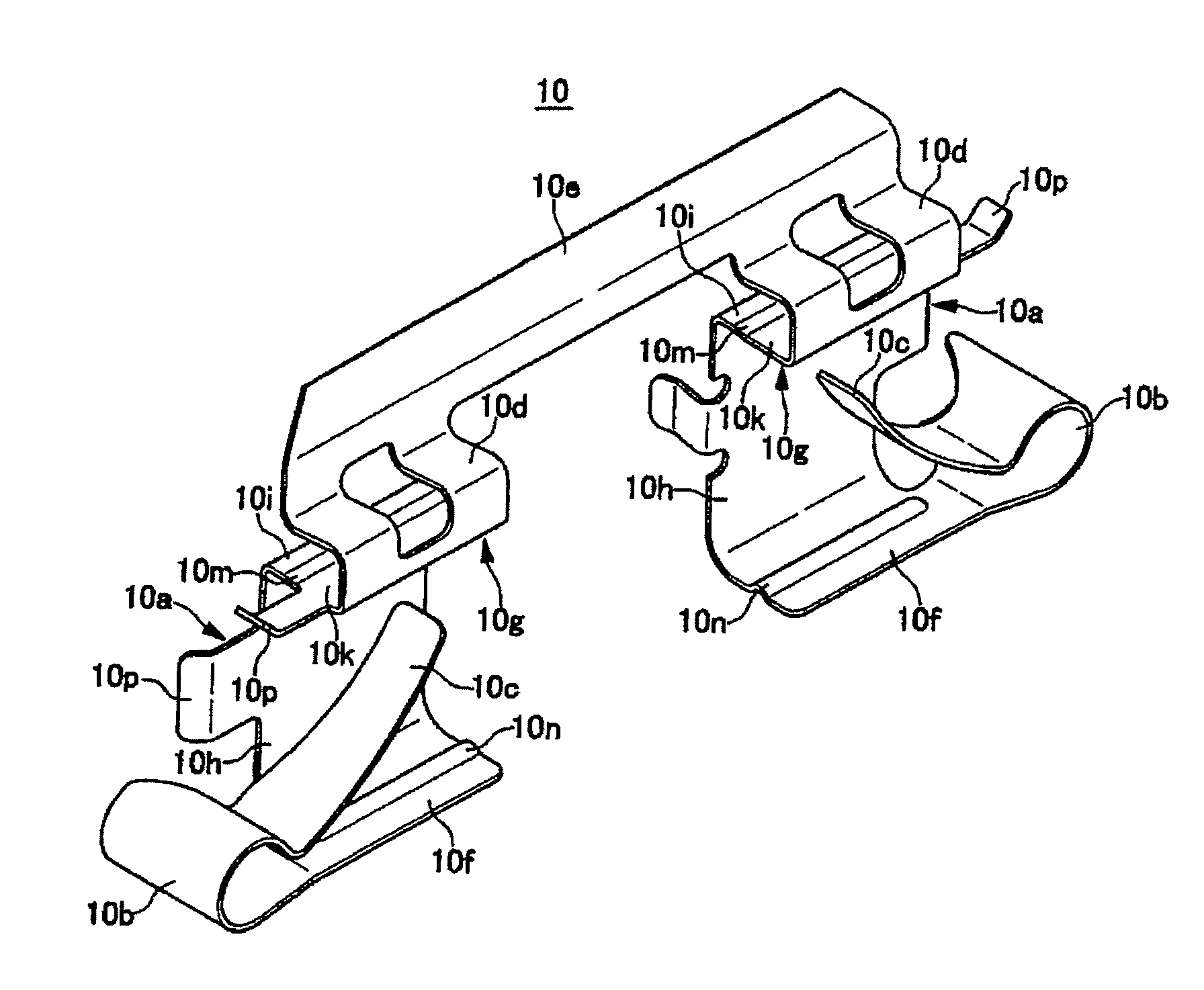

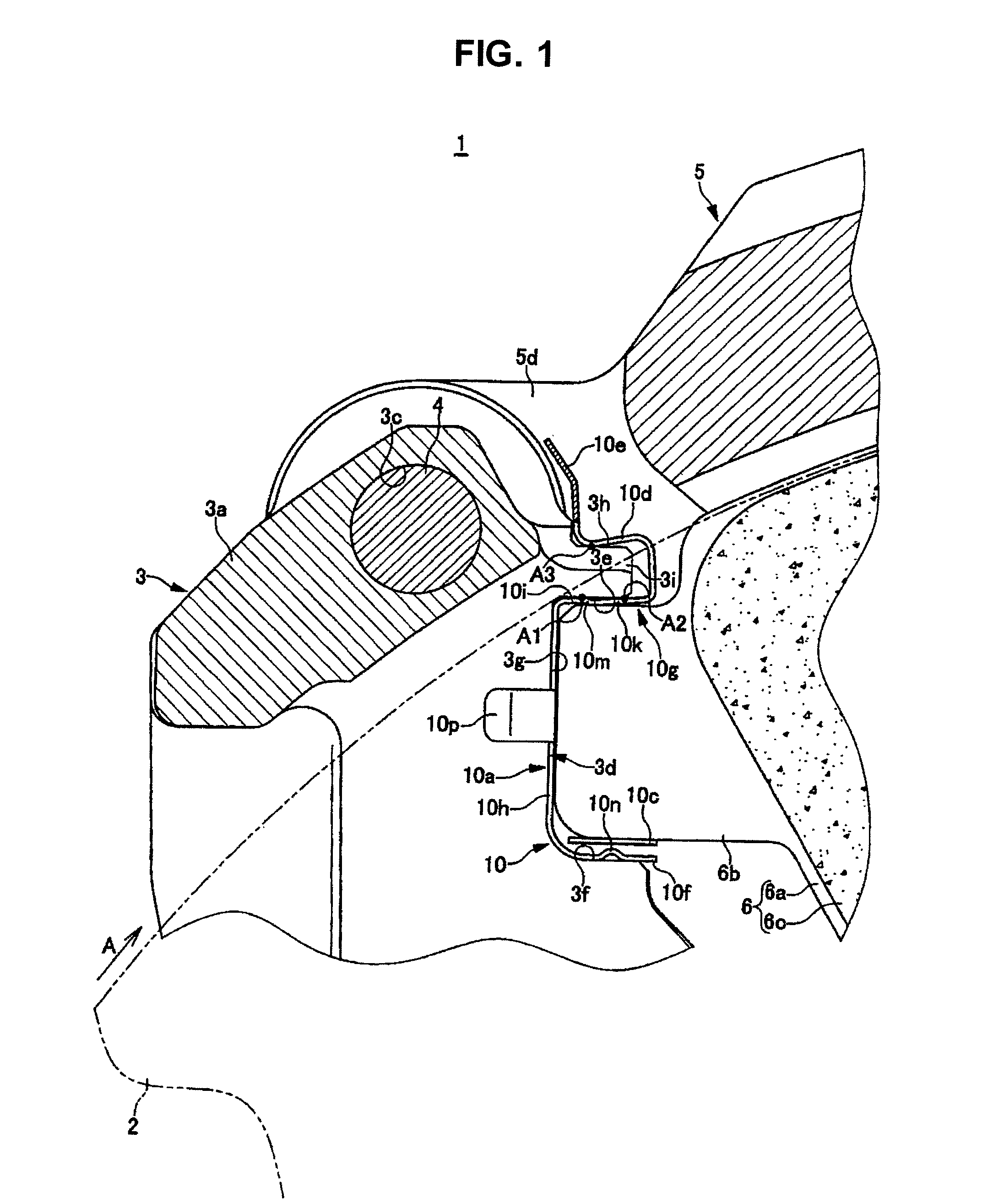

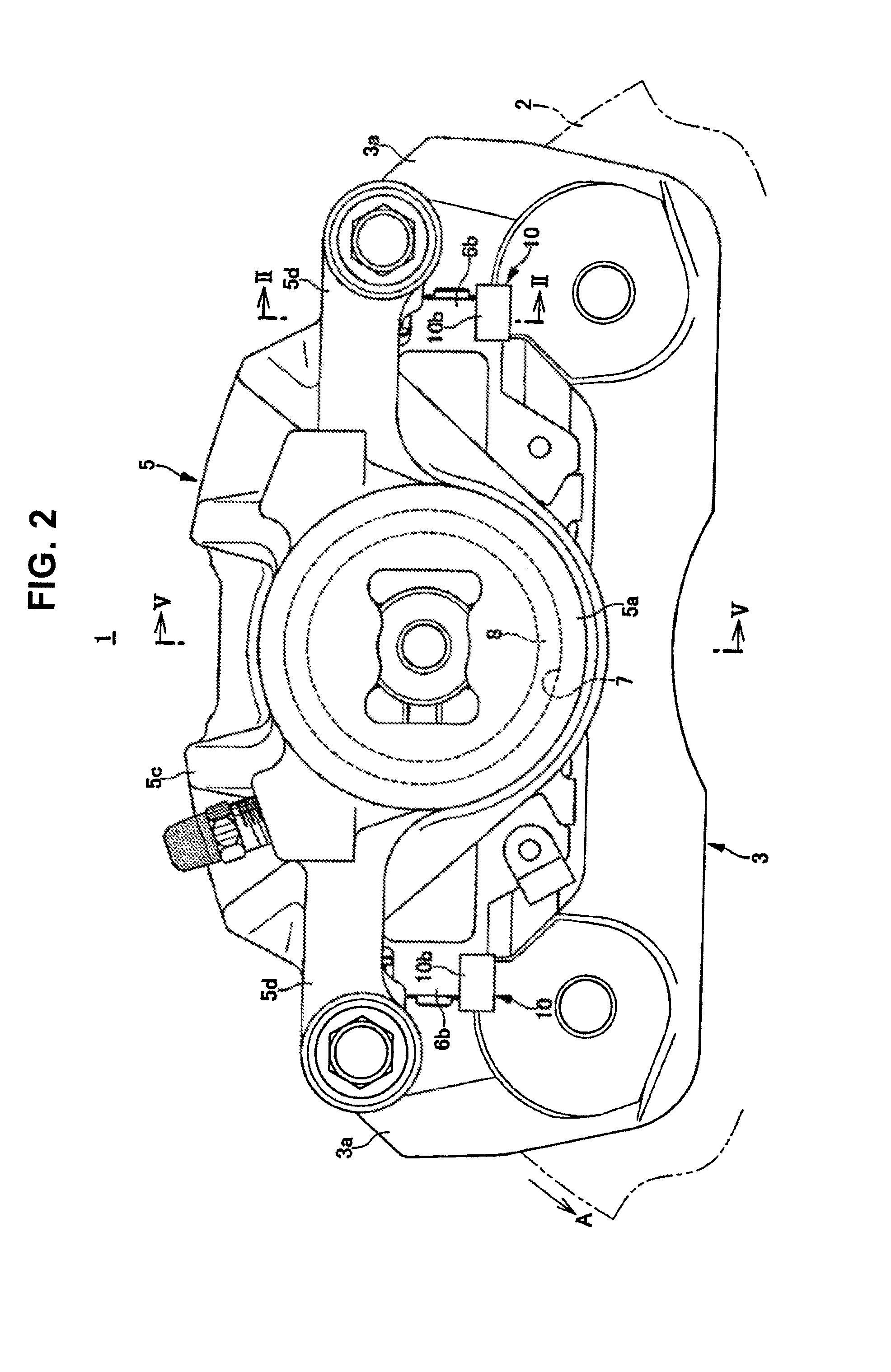

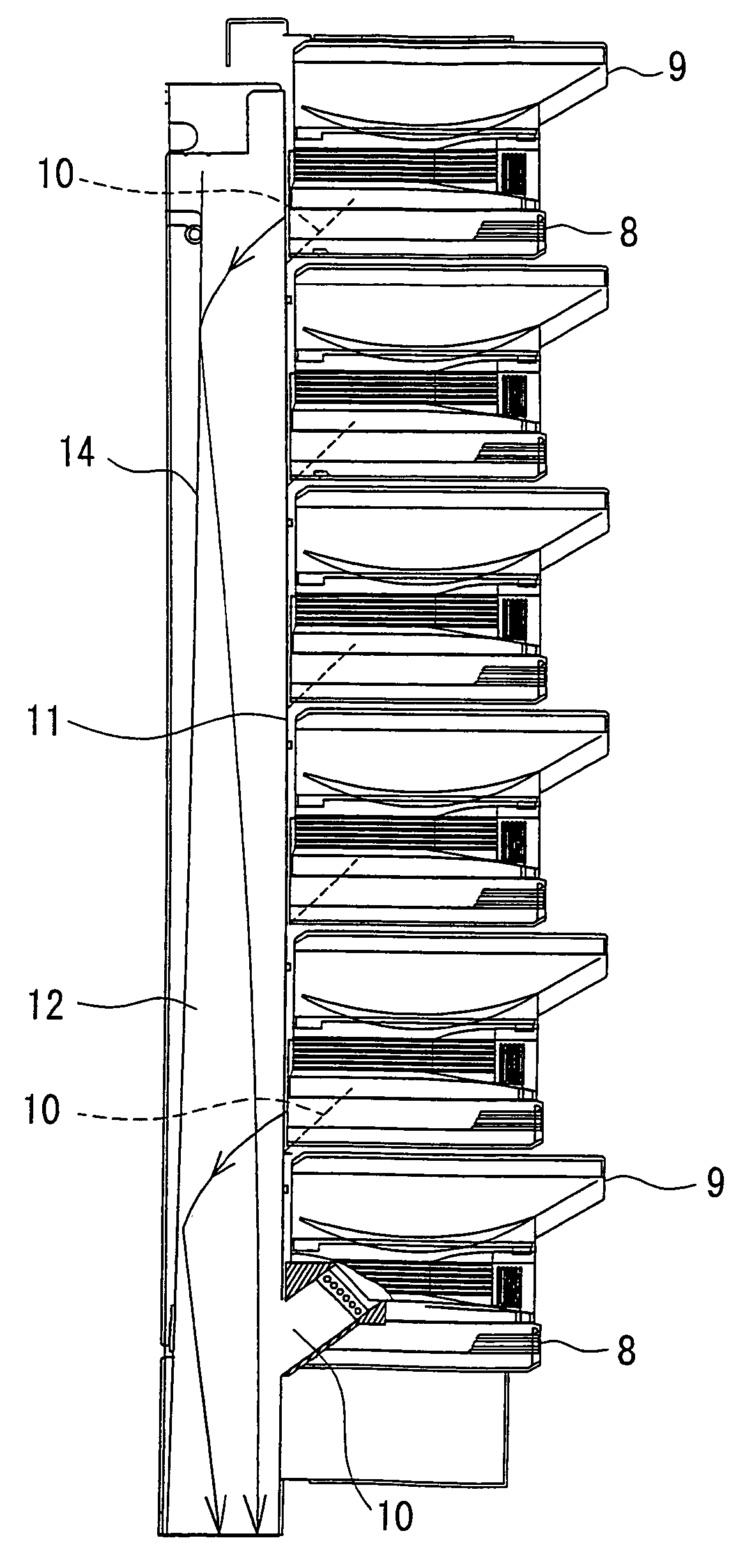

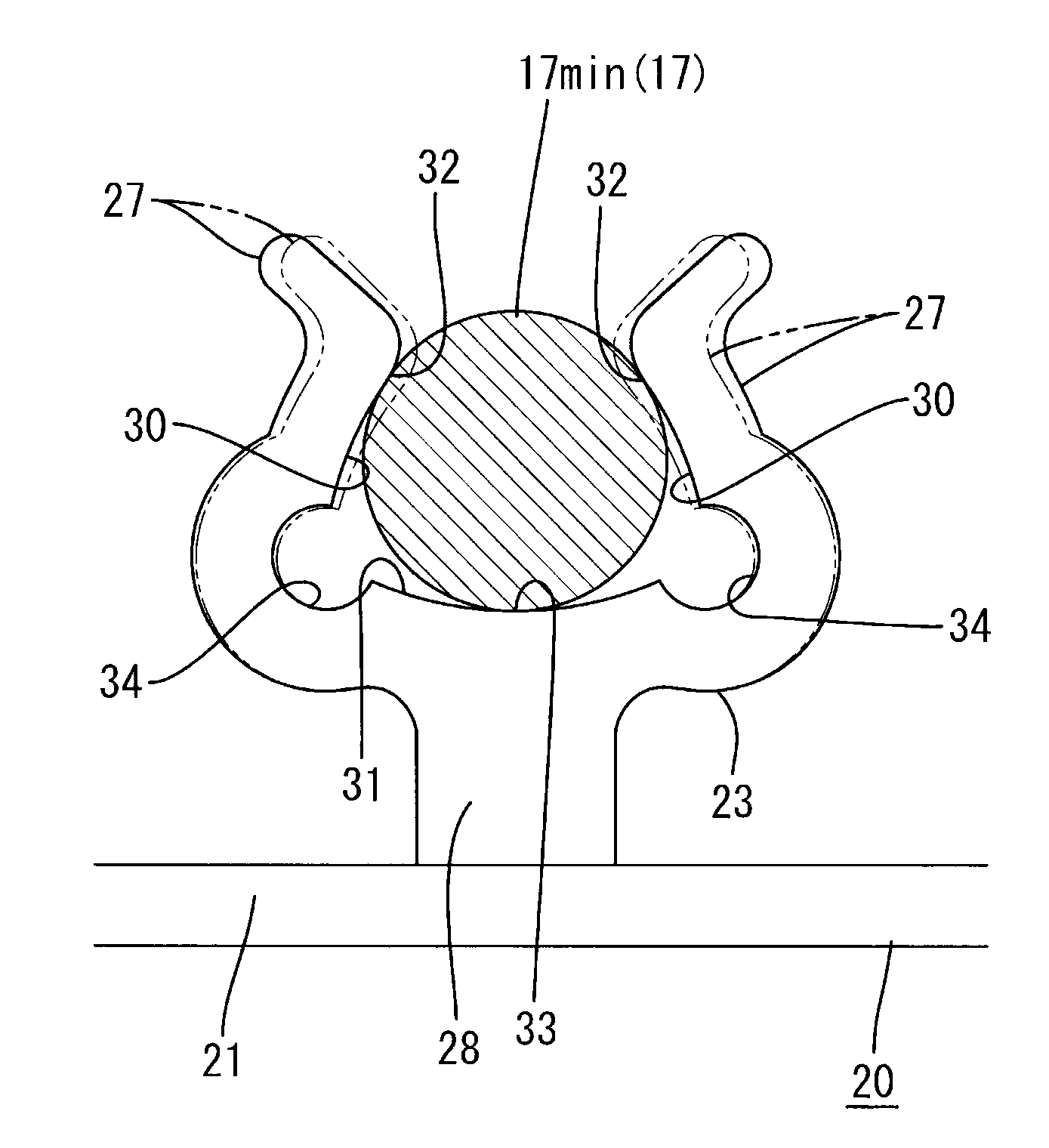

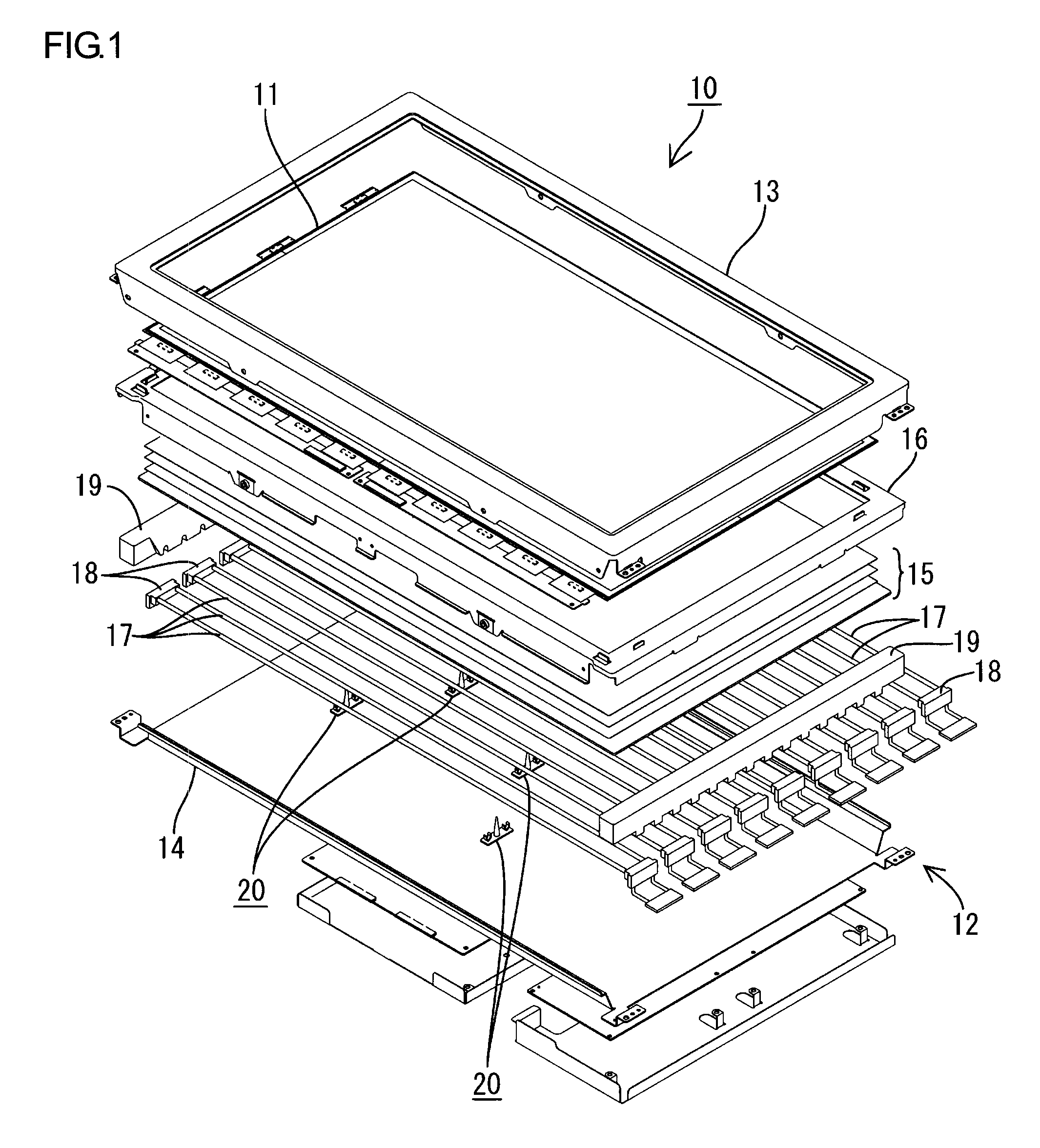

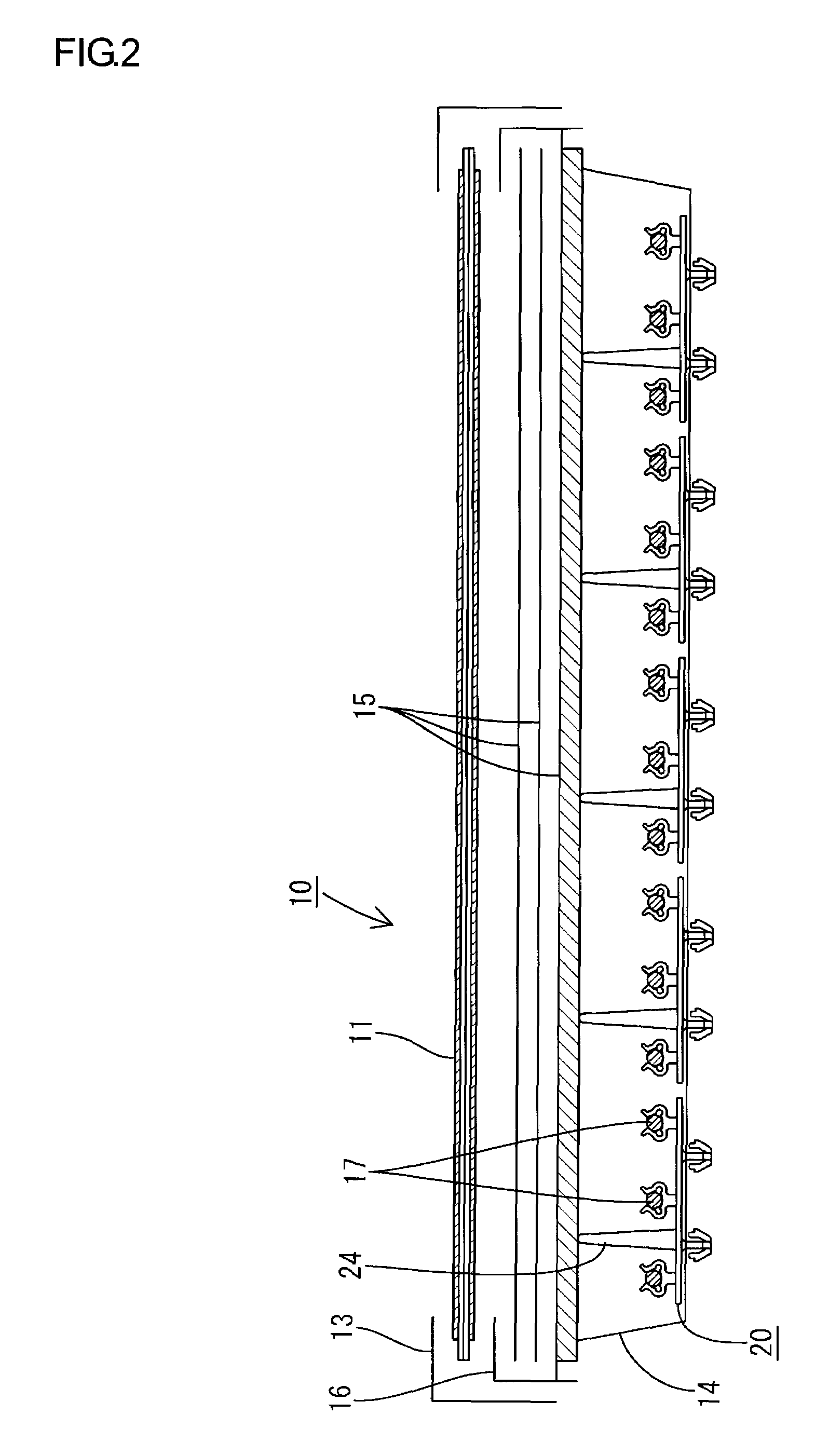

Lamp holder, backlight device using the same, and display using the same

InactiveUS7677757B2Curb reboundEasy to operatePoint-like light sourceLighting support devicesDisplay deviceEngineering

A lamp holder includes a mounting portion, a lamp holding part which is connected to the mounting portion, and includes an end capable of surrounding a peripheral surface of a lamp, and is capable of being elastically opened and deformed with attaching and detaching of the lamp. The present invention also includes a recessed portion positioned at an opposed surface to the lamp in the lamp holding part and in a position between an end portion and a connecting region to a mounting portion, such that the recessed portion allows the lamp holding part to bend so that the end portion displaces in a direction to be away from the peripheral surface of the lamp.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com