Patents

Literature

130results about How to "Improve injection accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

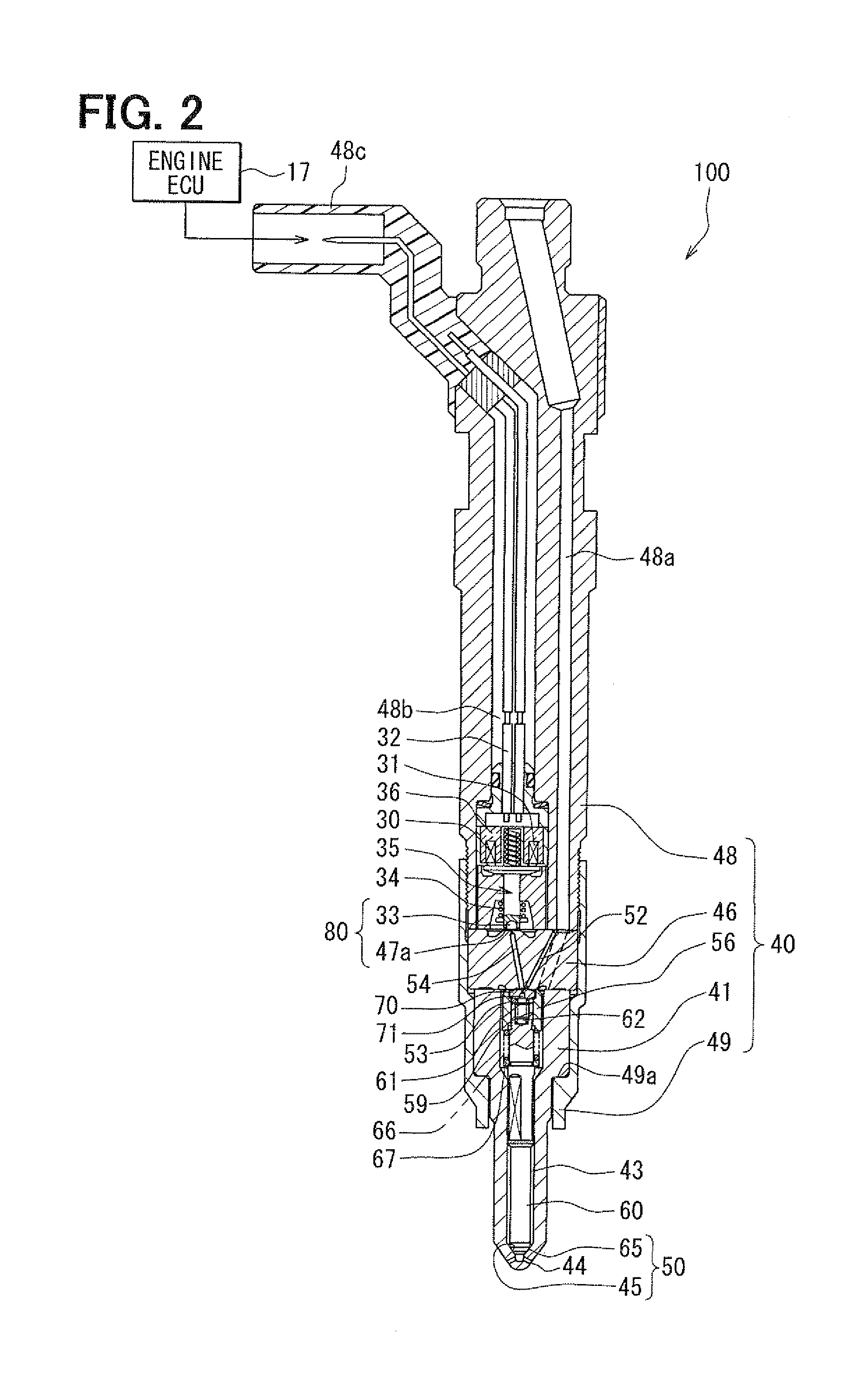

Fuel injection valve

ActiveUS20090289131A1DistanceCurb reboundSpray nozzlesMachines/enginesBiomedical engineeringFuel injection

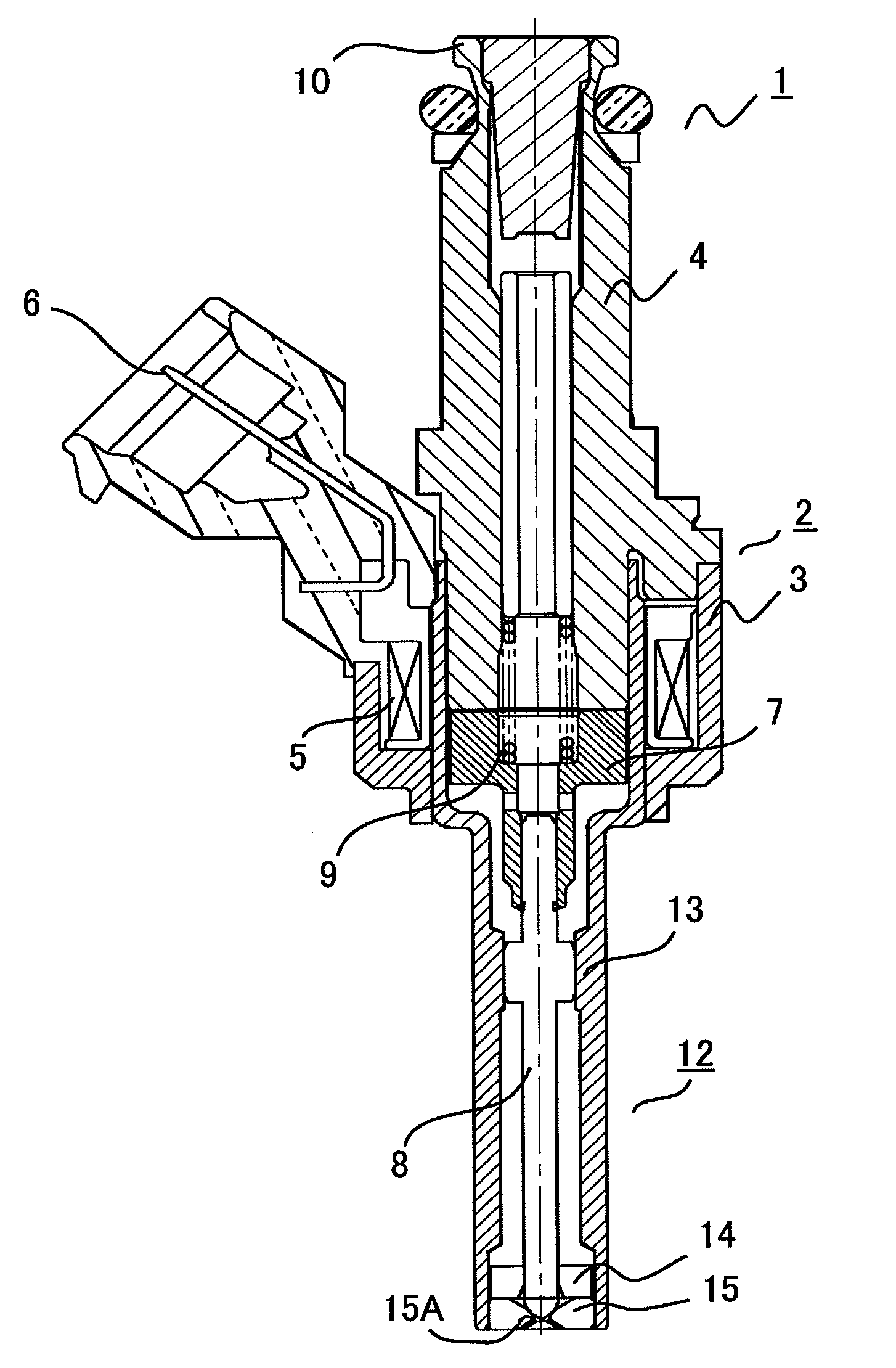

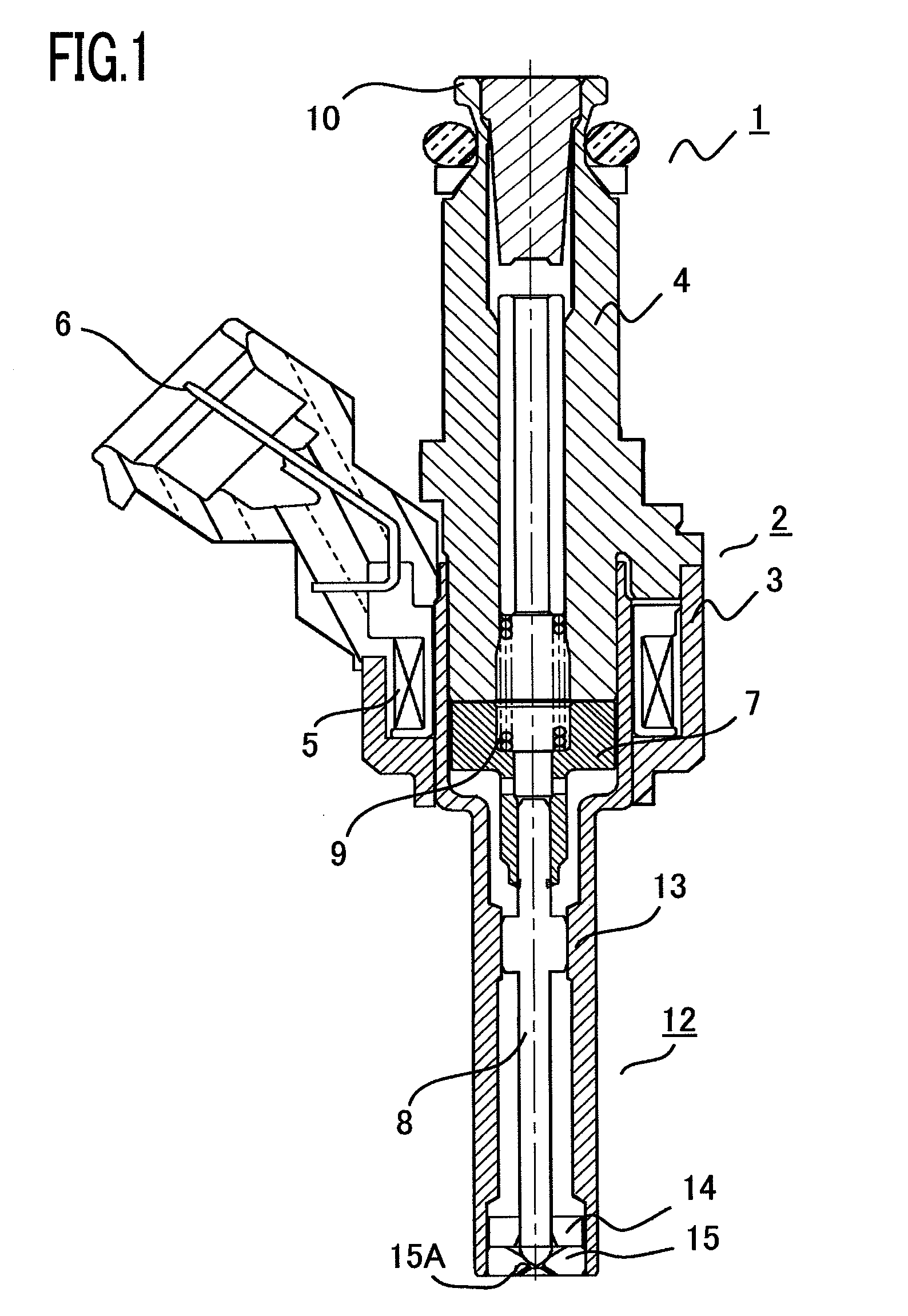

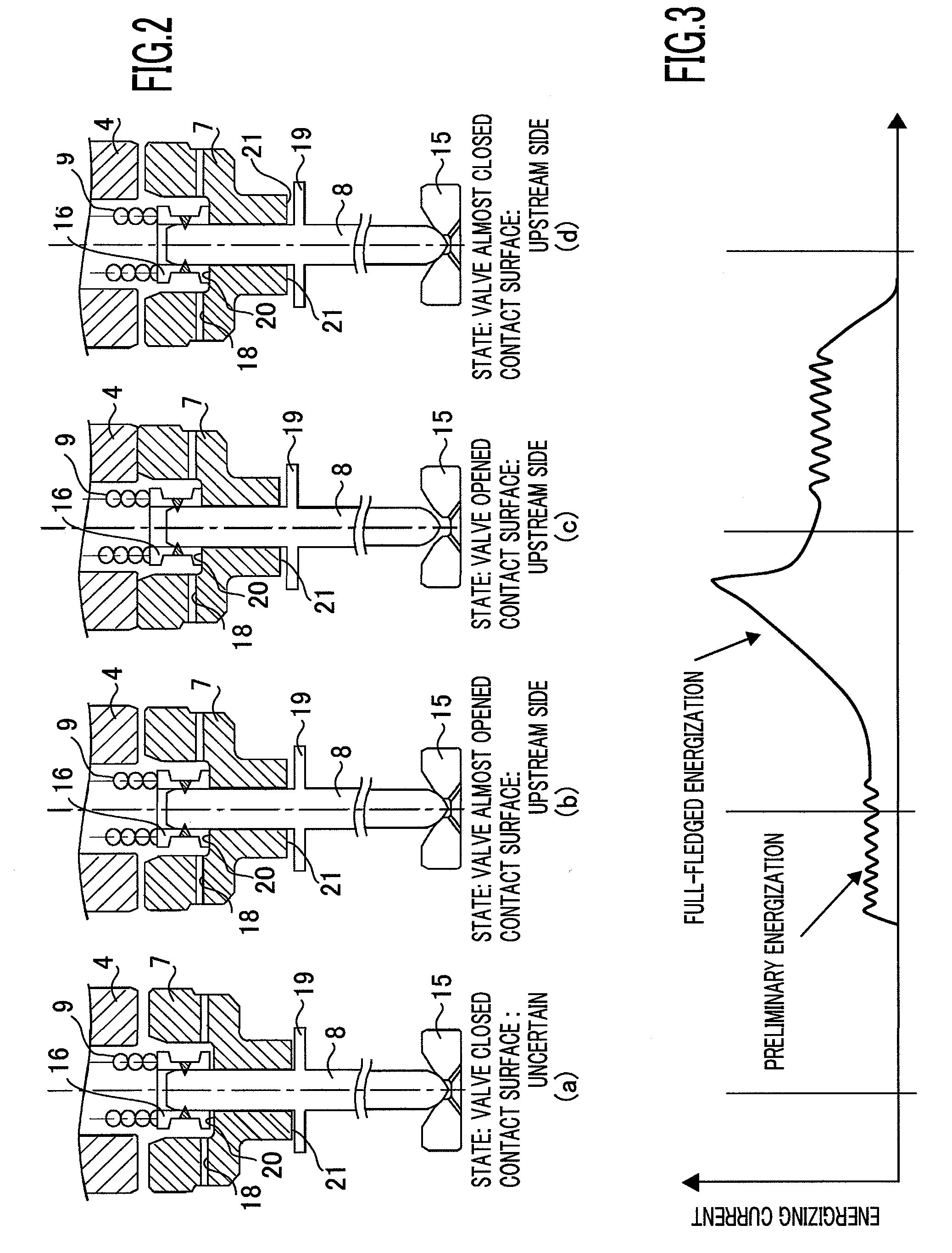

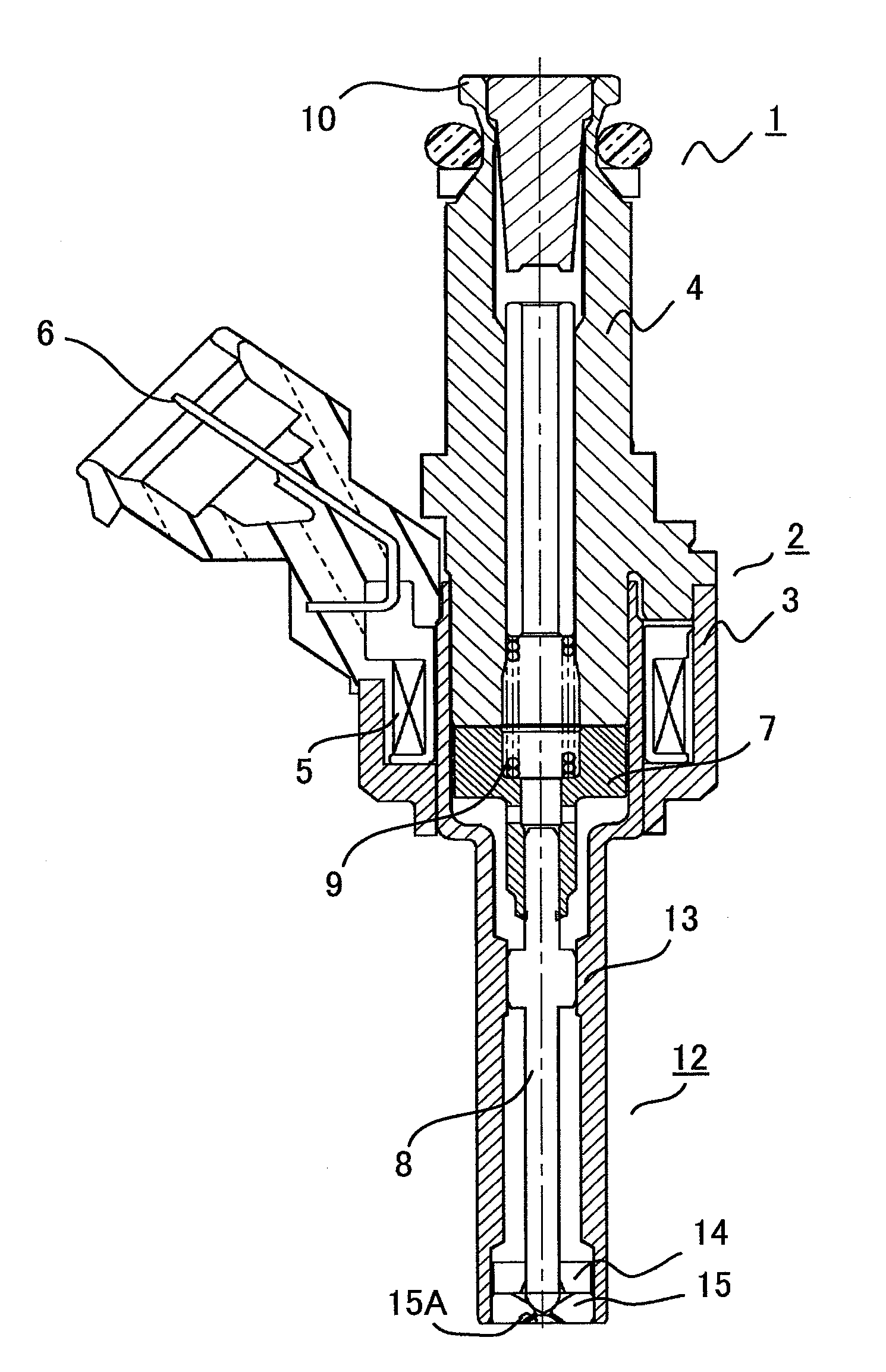

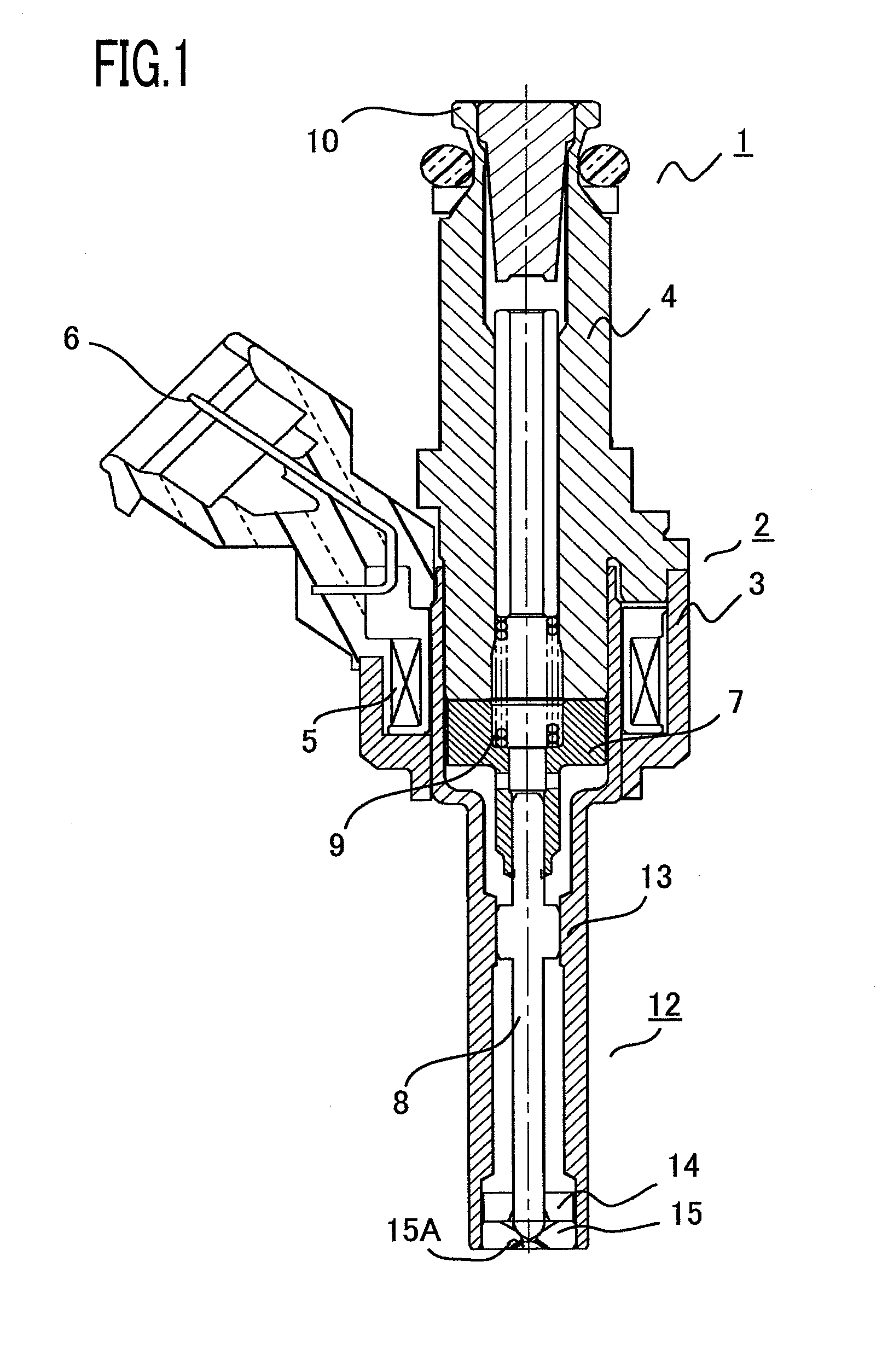

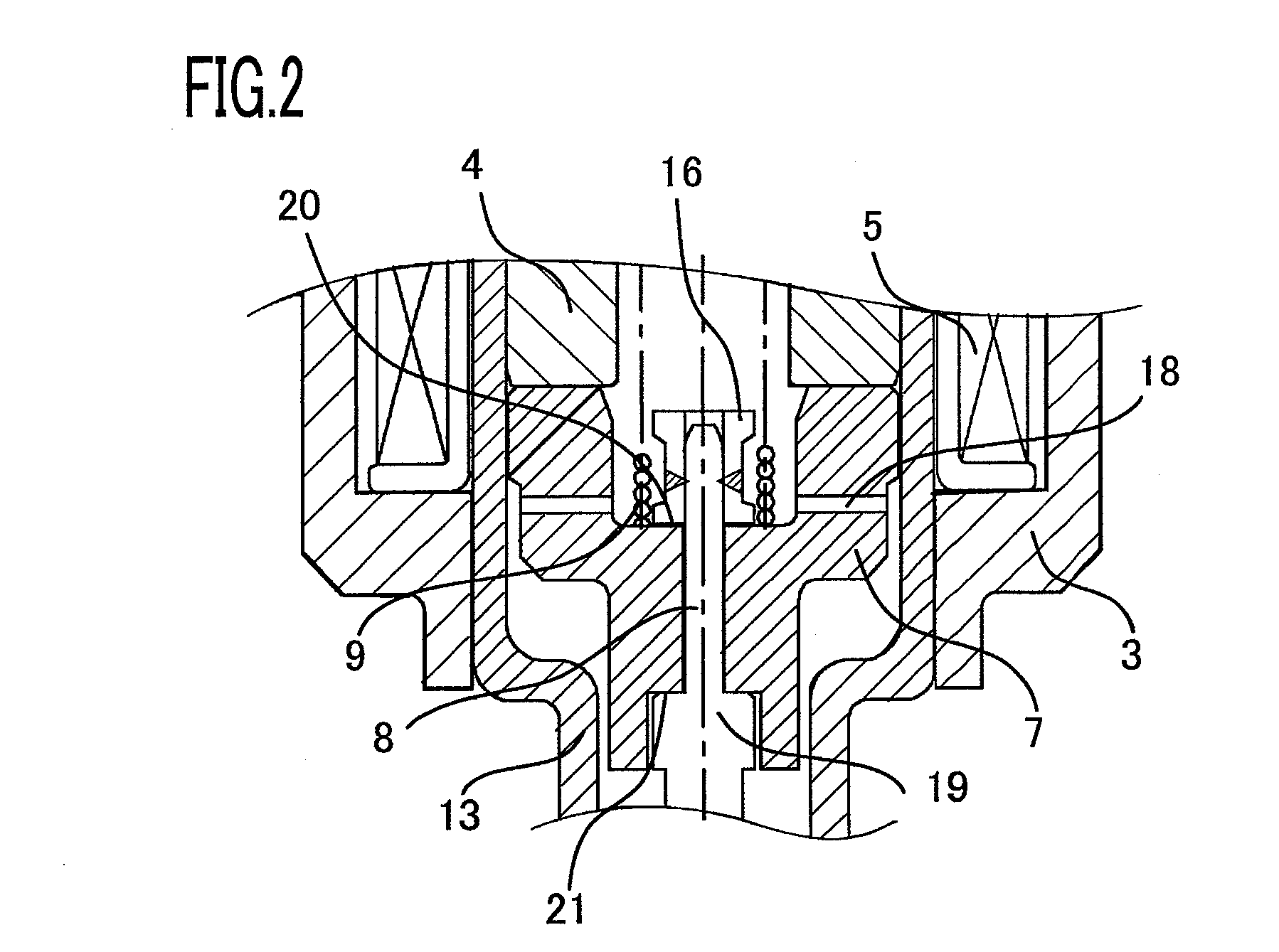

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil; a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature; and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle, and the coil is preliminarily energized while the fuel injection valve is closed by the needle.

Owner:MITSUBISHI ELECTRIC CORP

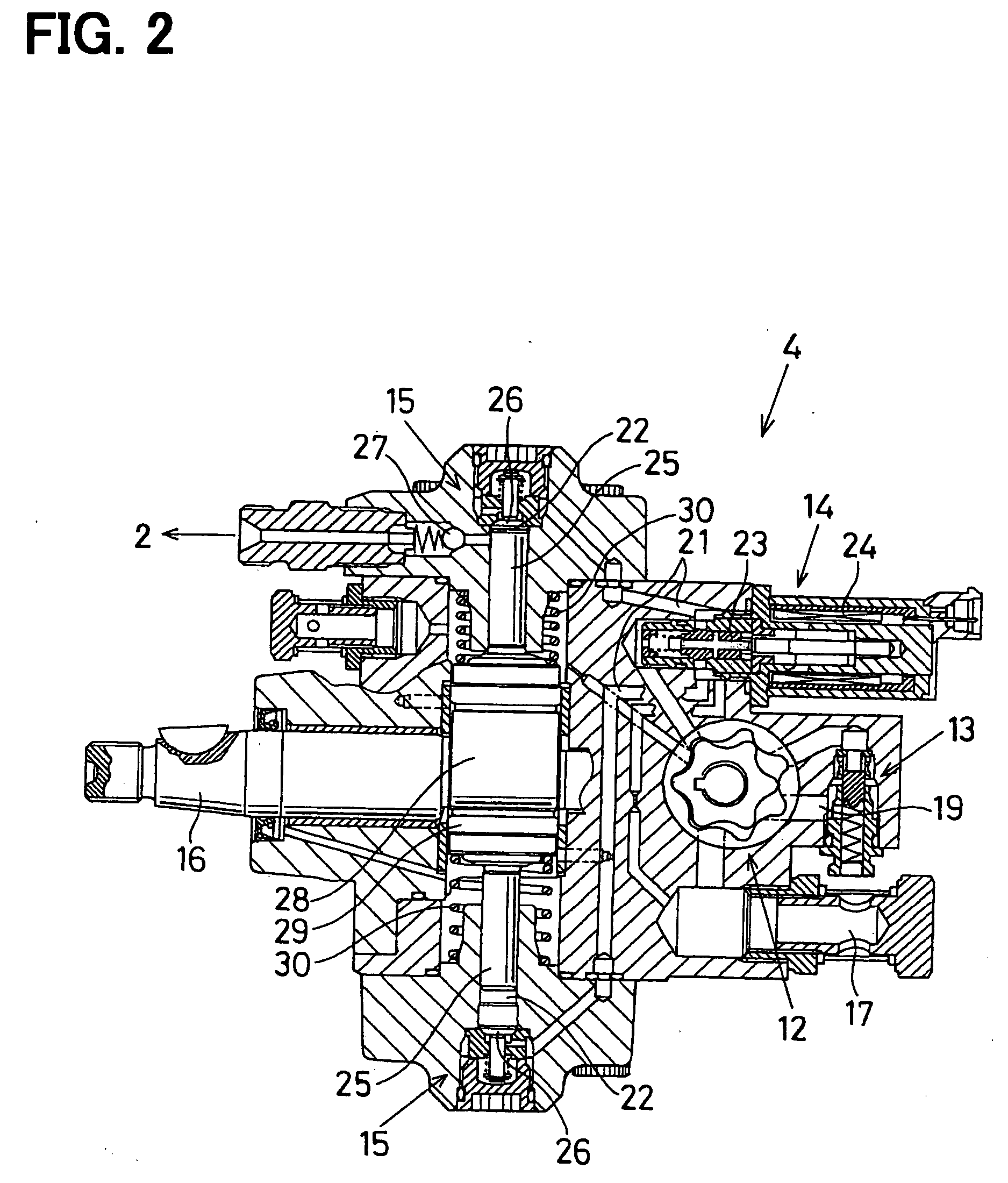

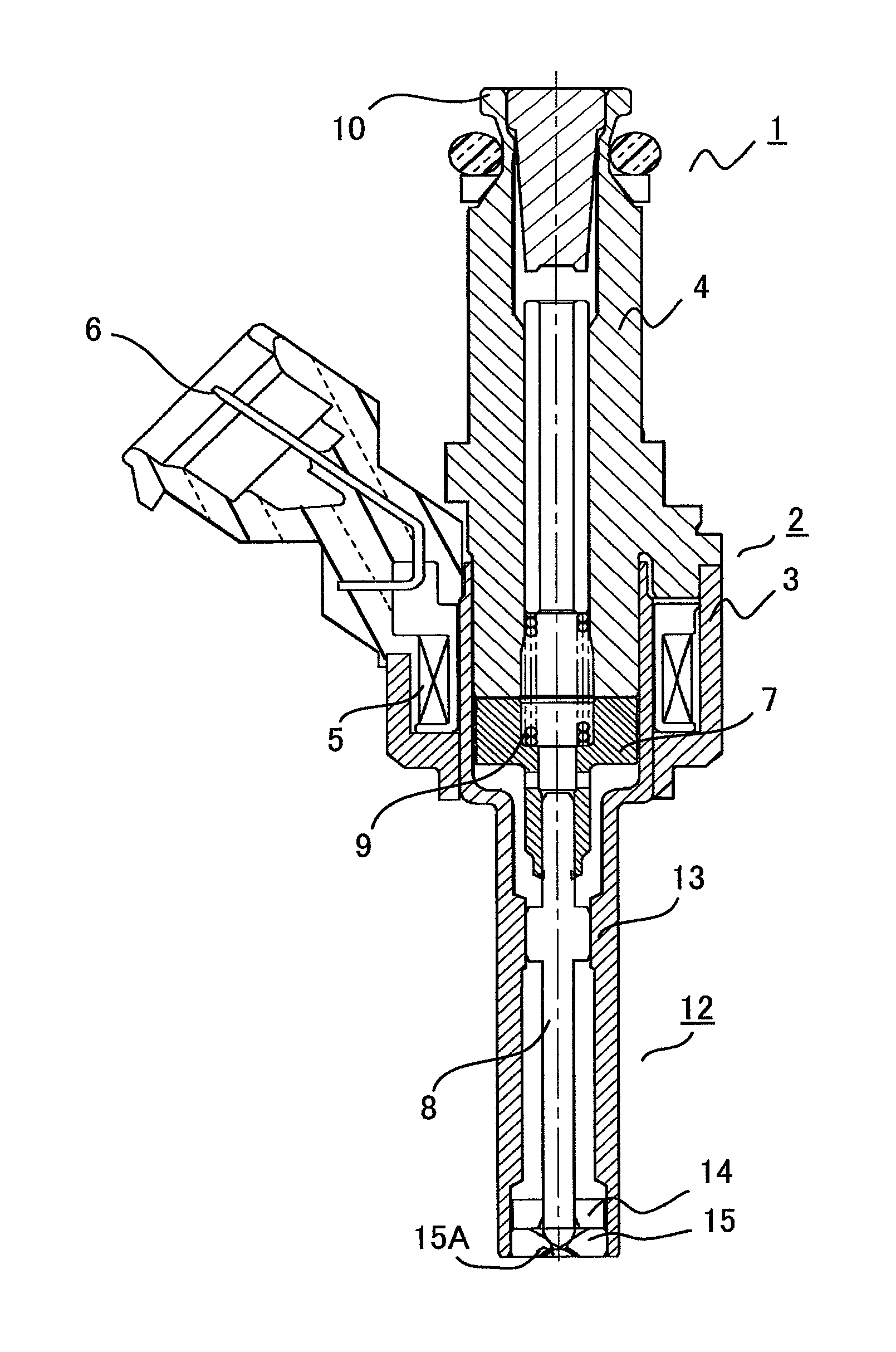

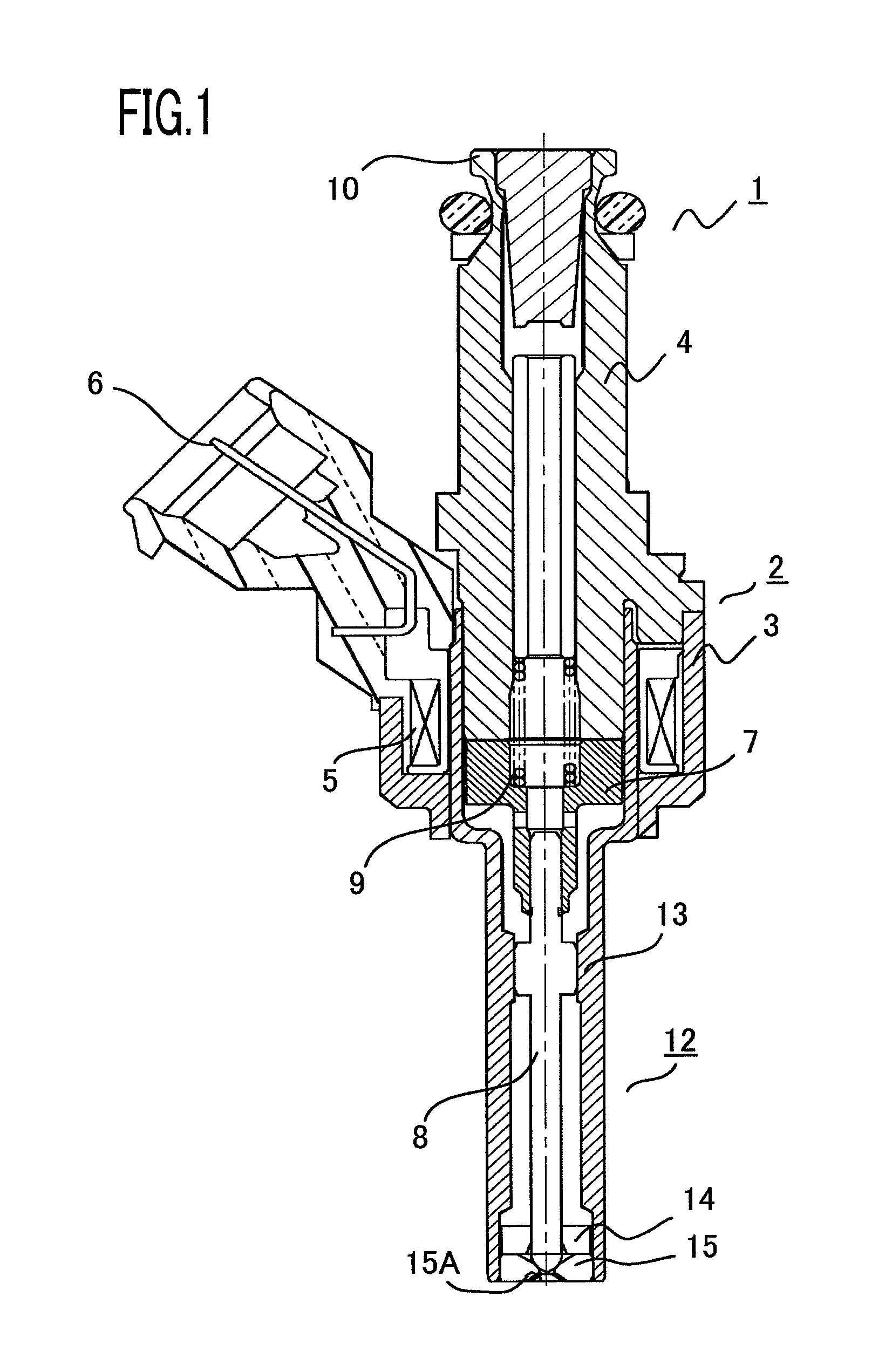

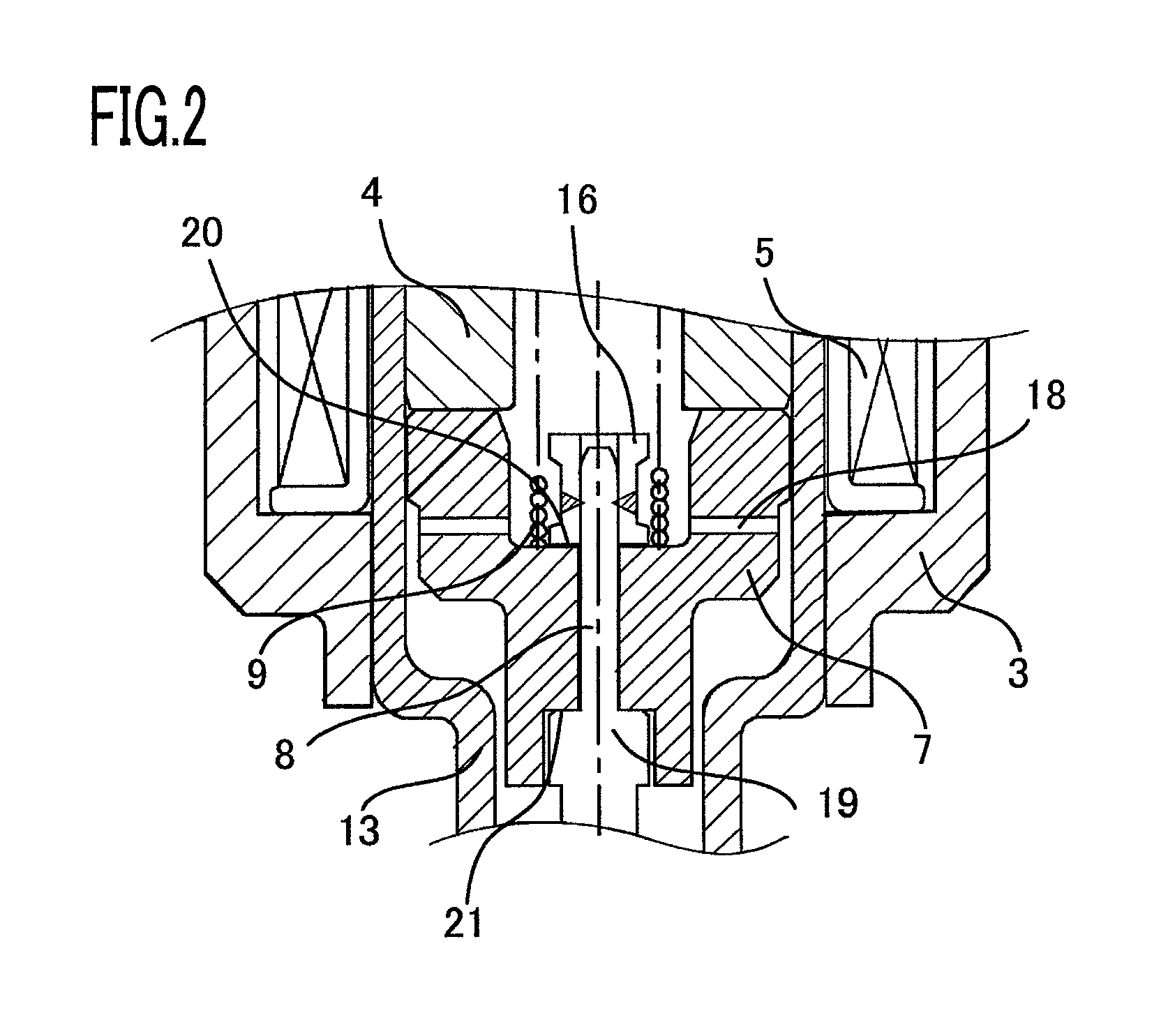

Fuel injection valve

InactiveUS20090288640A1Improve injection accuracyCurb reboundSpray nozzlesFuel injection apparatusBiomedical engineeringVALVE PORT

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil, a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature, and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the valve-closing spring is disposed on the armature, and the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle.

Owner:MITSUBISHI ELECTRIC CORP

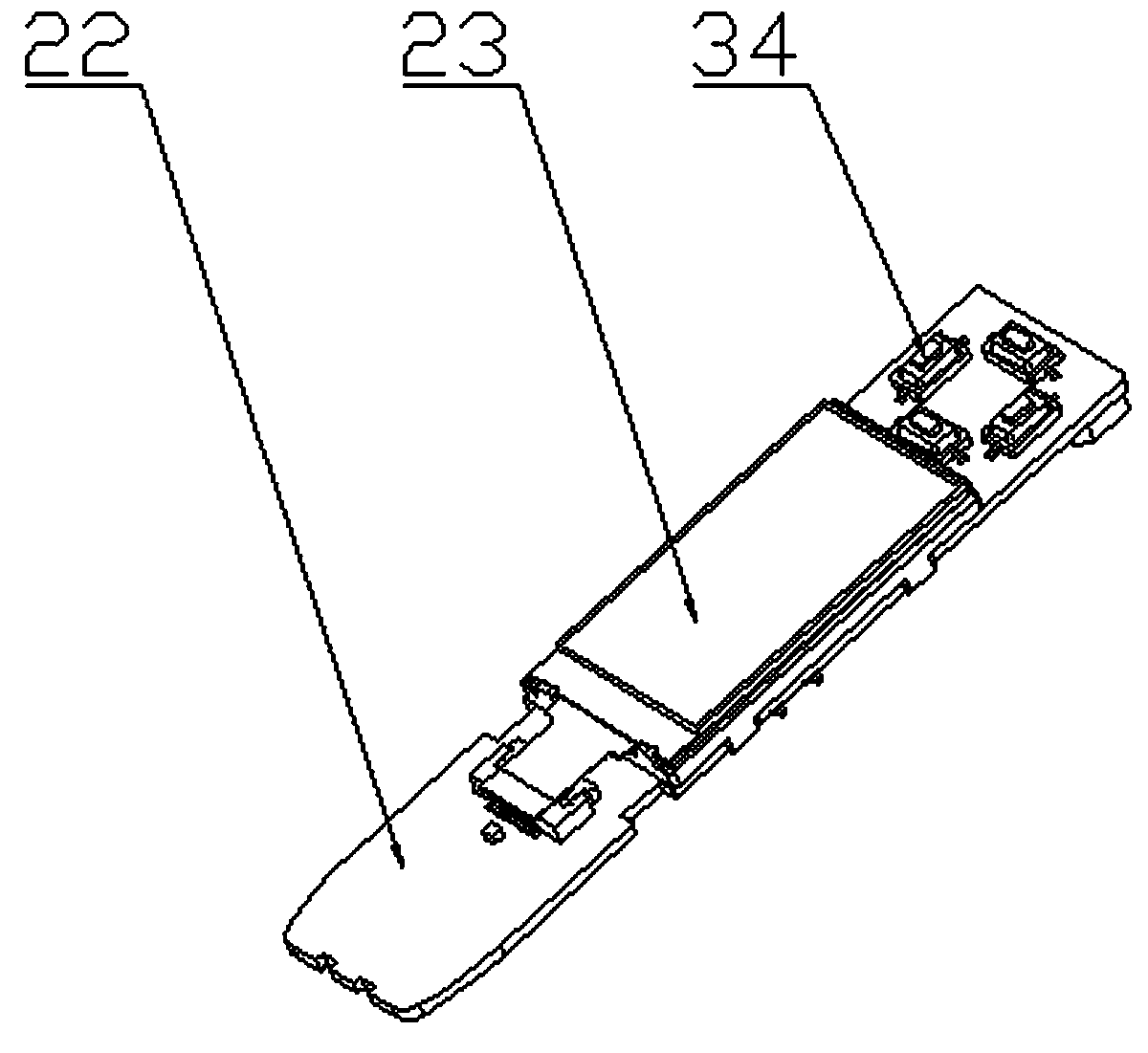

Injection device

InactiveCN101574550ASimple structureImprove injection accuracyAutomatic syringesElectricityPiezoelectric actuators

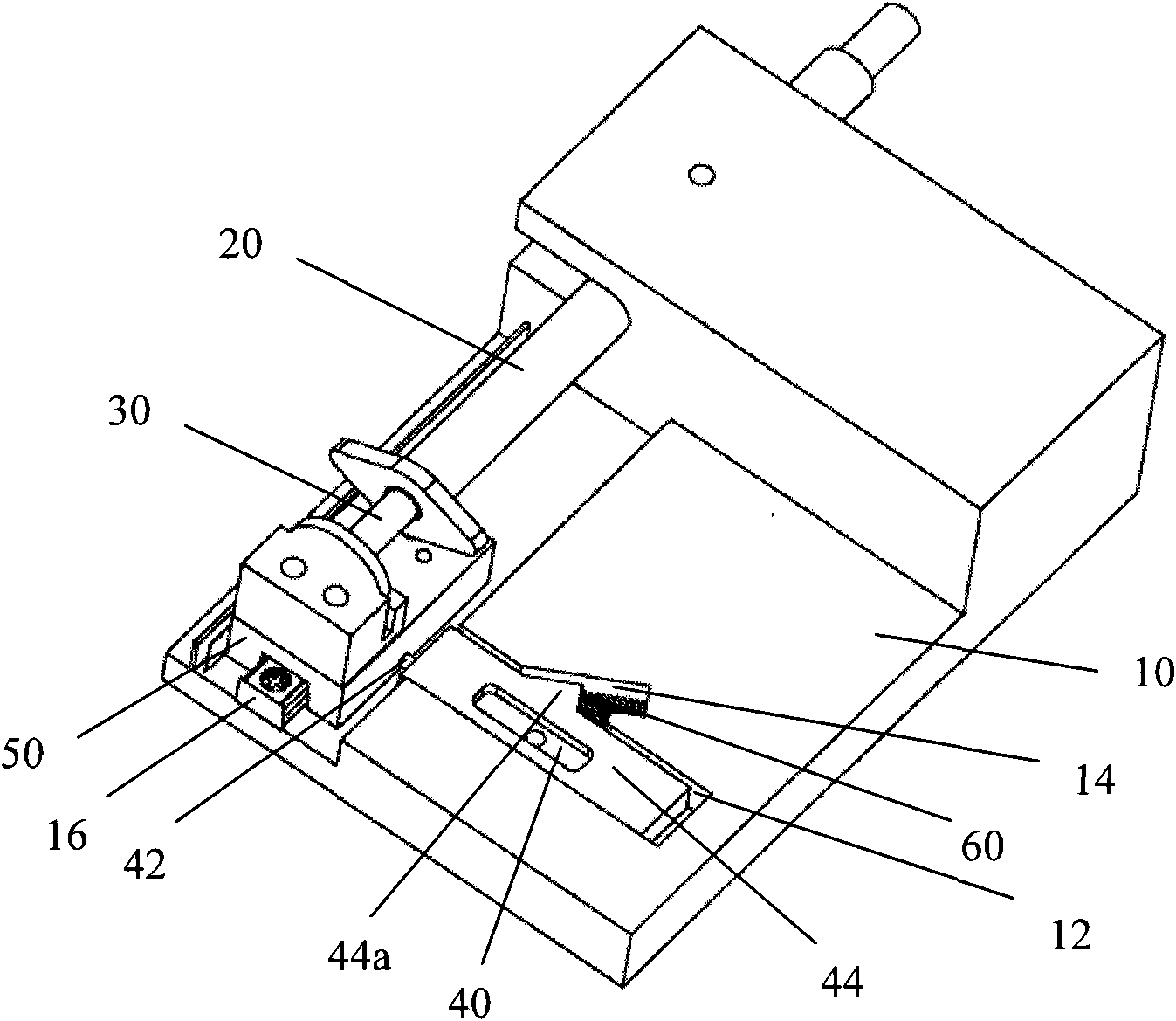

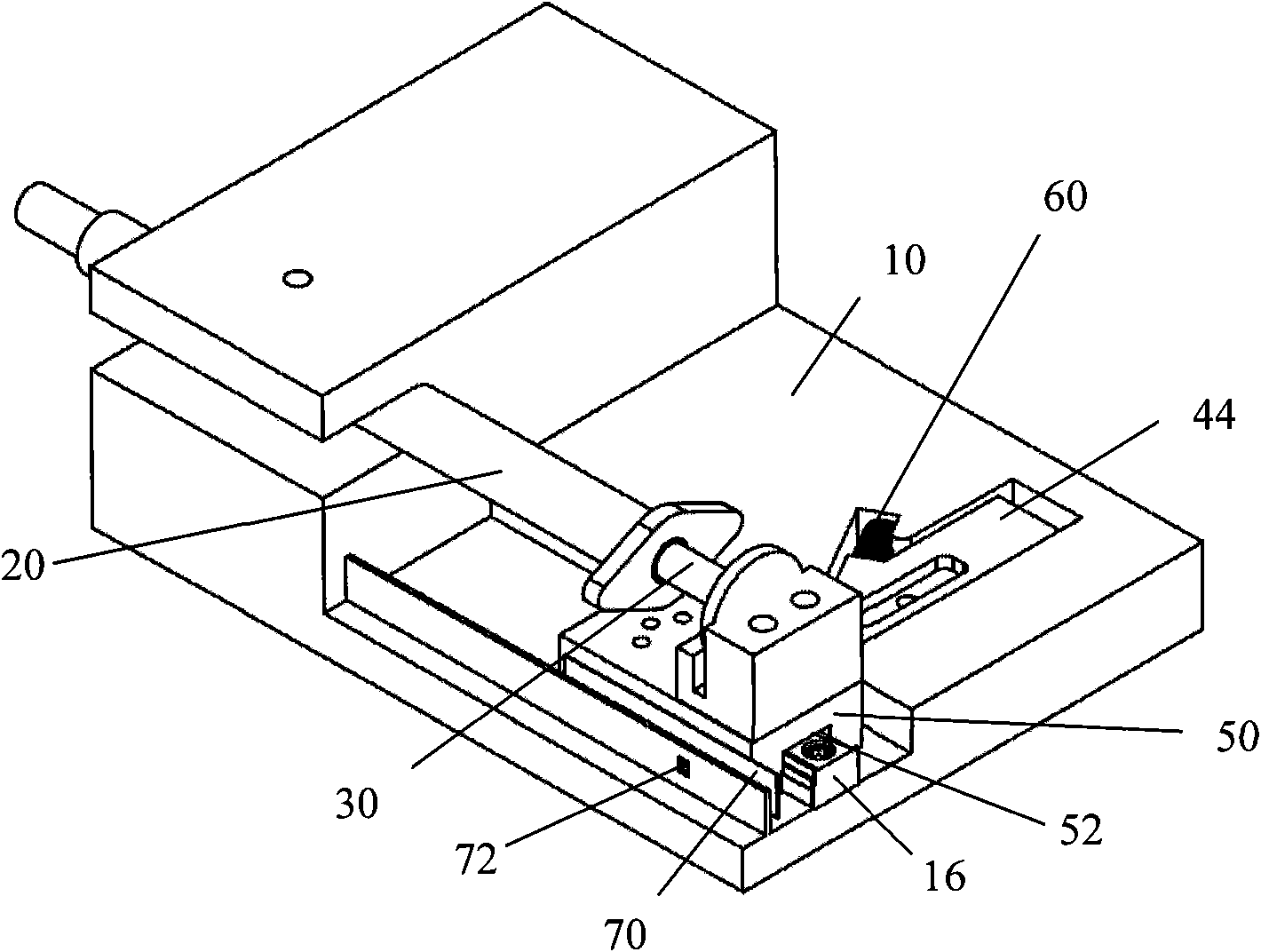

The invention provides an injection device which comprises a base, an injector kit, a piezoelectric motor and a driving mechanism, wherein the injector kit comprises a syringe arranged on the base anda push rod capable of being movably inserted into one end of the syringe; the piezoelectric motor is arranged on the base and provided with a motor head; the driving mechanism is connected between the motor head of the piezoelectric motor and the push rod; and when the piezoelectric motor is excited, the motor head selectively drives the driving mechanism along one of two opposite directions so as to selectively push the push rod to advance or retreat. The injection device has simple structure. Because the displacement of the piezoelectric motor under the action of a serial drive pulse is ofa nanometer level, higher injection precision can be guaranteed. Because electromagnetic force is not utilized to drive, the injection device is more suitable for some special occasions such as strongmagnetic fields or electromagnetic sensitivity, and the like.

Owner:JOHNSON ELECTRIC SHENZHEN

Positioning device for endocrine clinical injection

ActiveCN109224204AEasy to usePrevent injection deviationPneumatic massageInfusion syringesEngineeringMedical device

The invention relates to the technical field of medical devices, and especially relates to a positioning device for endocrine clinical injection. The device includes a base, an external power supply,an upper fixture, an upper position cylinder and a positioning frame, A fix groove is arranged in that middle of the base, the upper fixing bracket comprises two, At that top end of the third height adjust lever, a first support frame is fixedly connected; at the top end of the fourth height adjusting lever, a second support frame is fixedly connected; at the front and rear sides of the upper positioning cylinder, a sliding cylinder is fixedly connected; the sliding cylinder is sleeved on the adjusting cross bar; the positioning frame is cross-shaped and is clamped in the positioning groove ofthe four corners of the upper positioning cylinder; and a laser positioning lamp is fixedly connected at the center of the positioning frame. So that that structure design of the invention is reasonable, The fixing groove and the upper fixing bracket can fix and clamp the arm of the patient, and the height, the longitudinal position and the transverse position of the positioning device can be adjusted by irradiating the lower arm of the patient with the laser positioning lamp as a reference, and the syringe can carry out precise injection by relying on the centralizing action of the lower positioning barrel, so that the injection precision is greatly improved.

Owner:鄂东医疗集团市中心医院

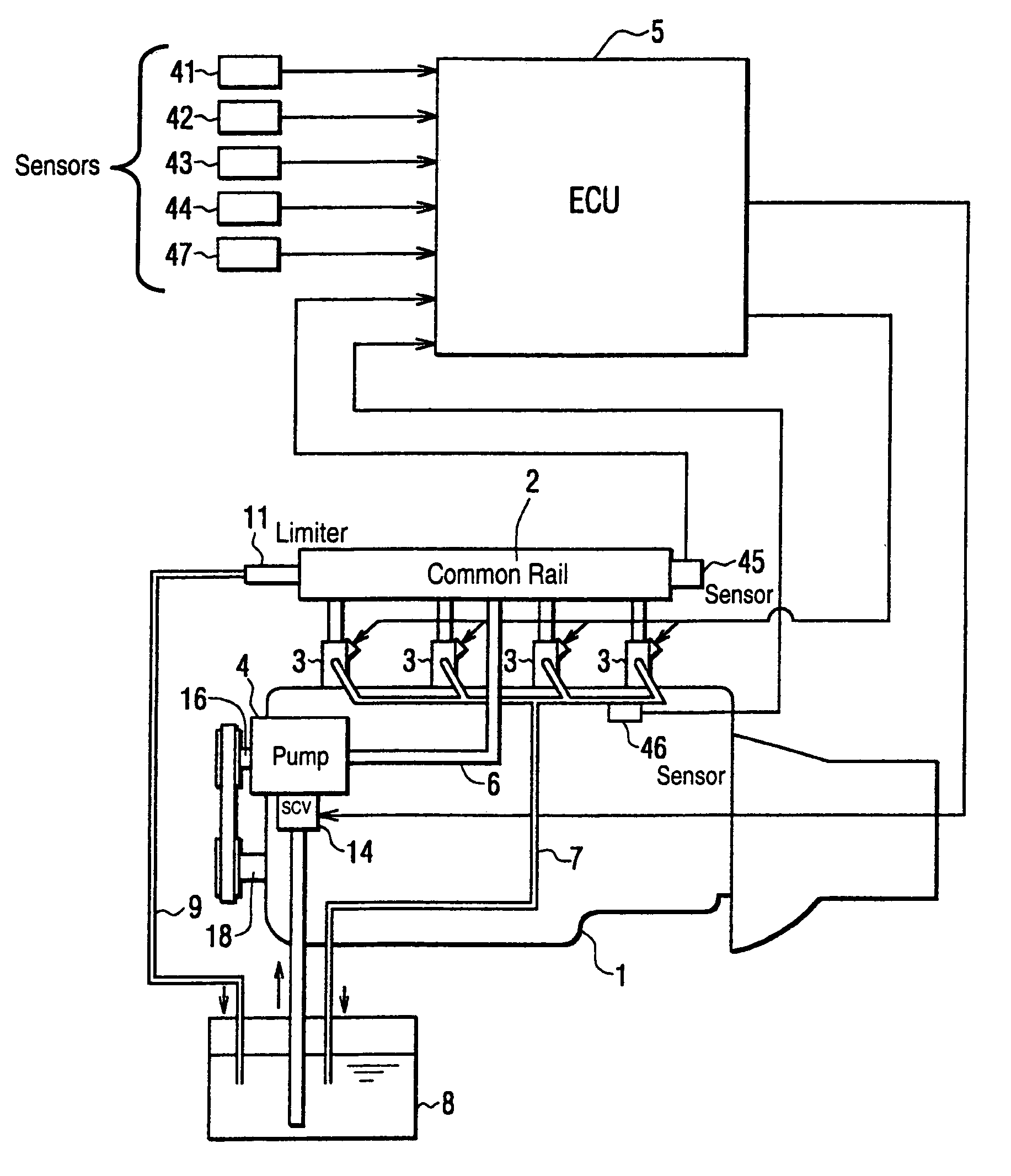

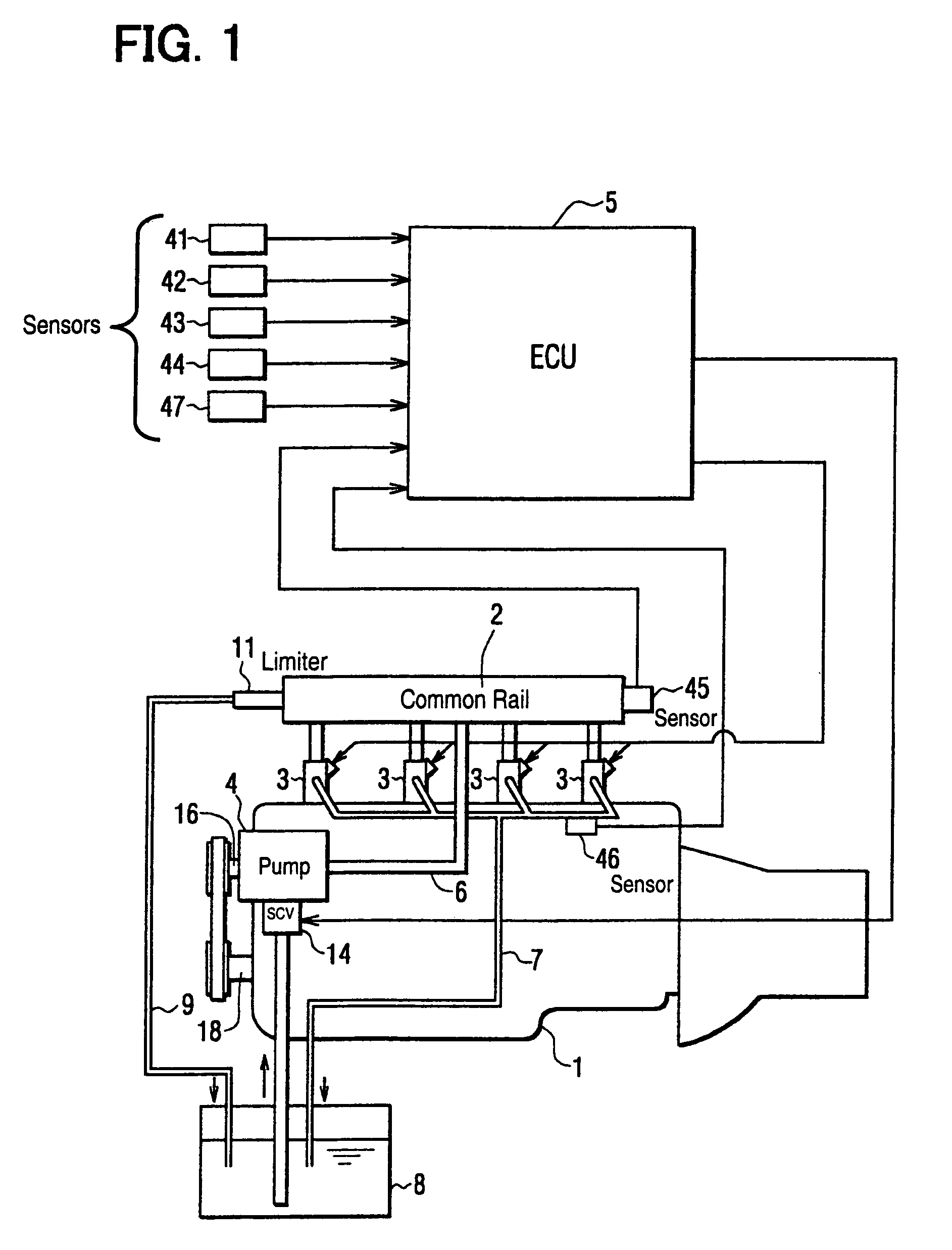

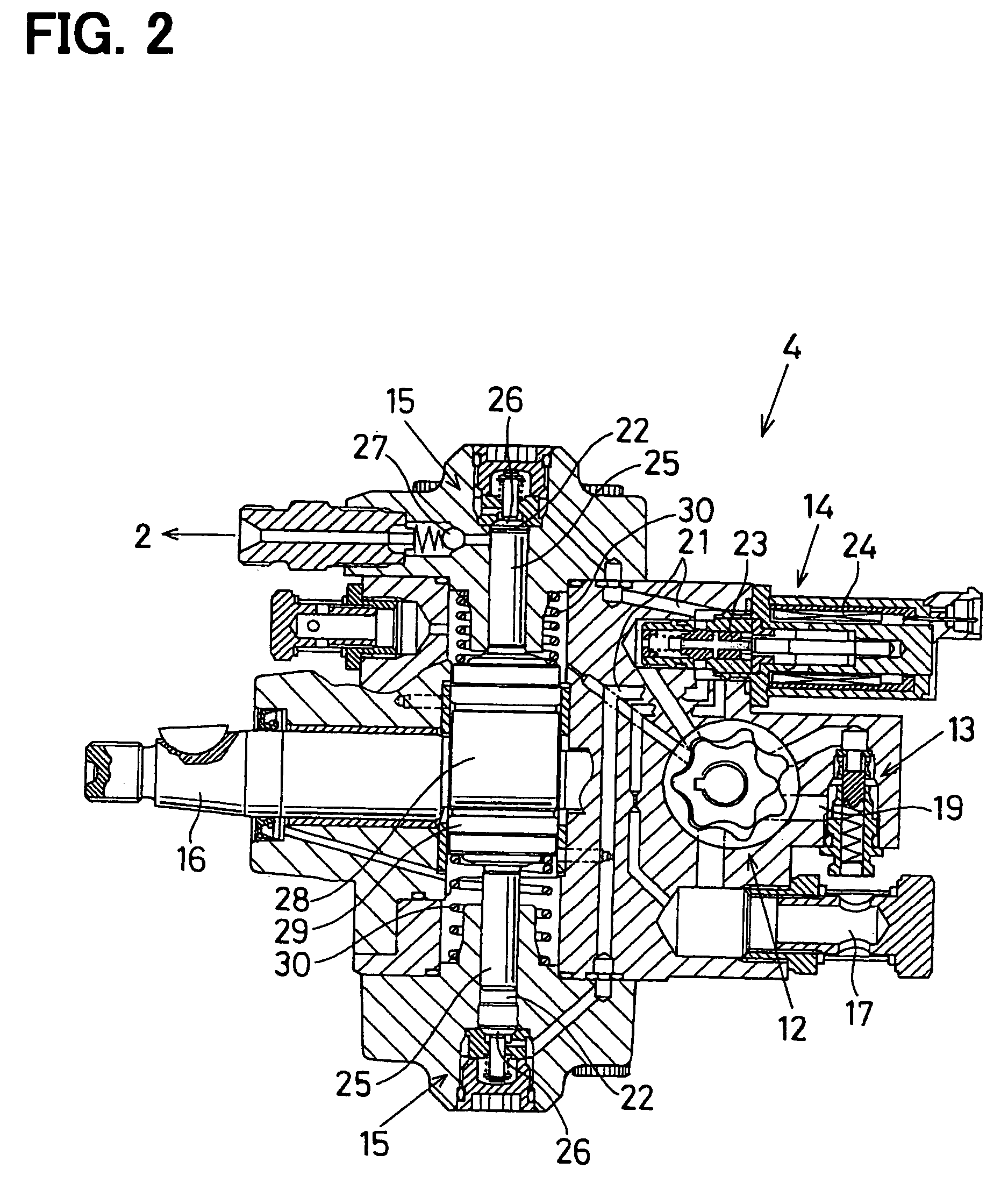

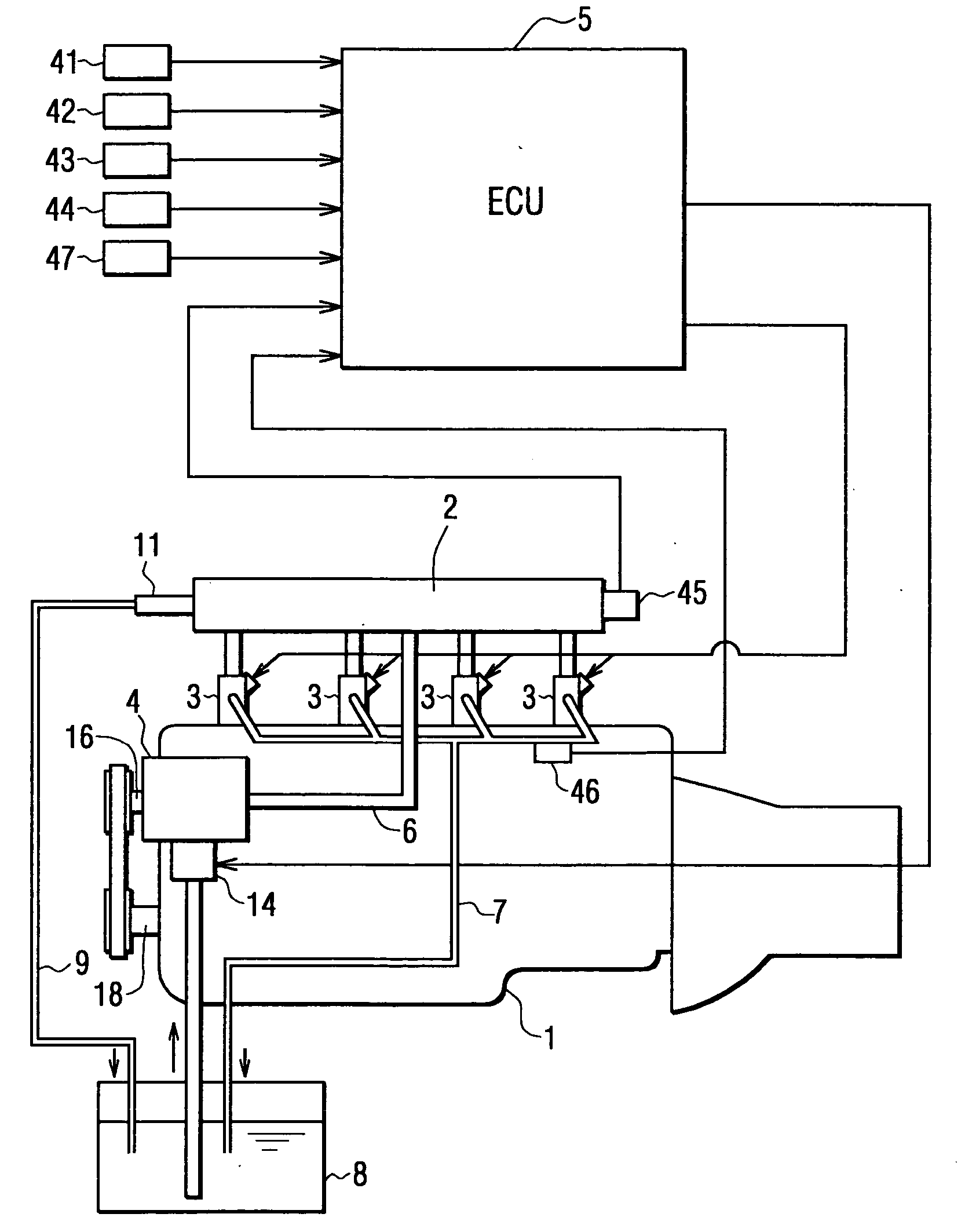

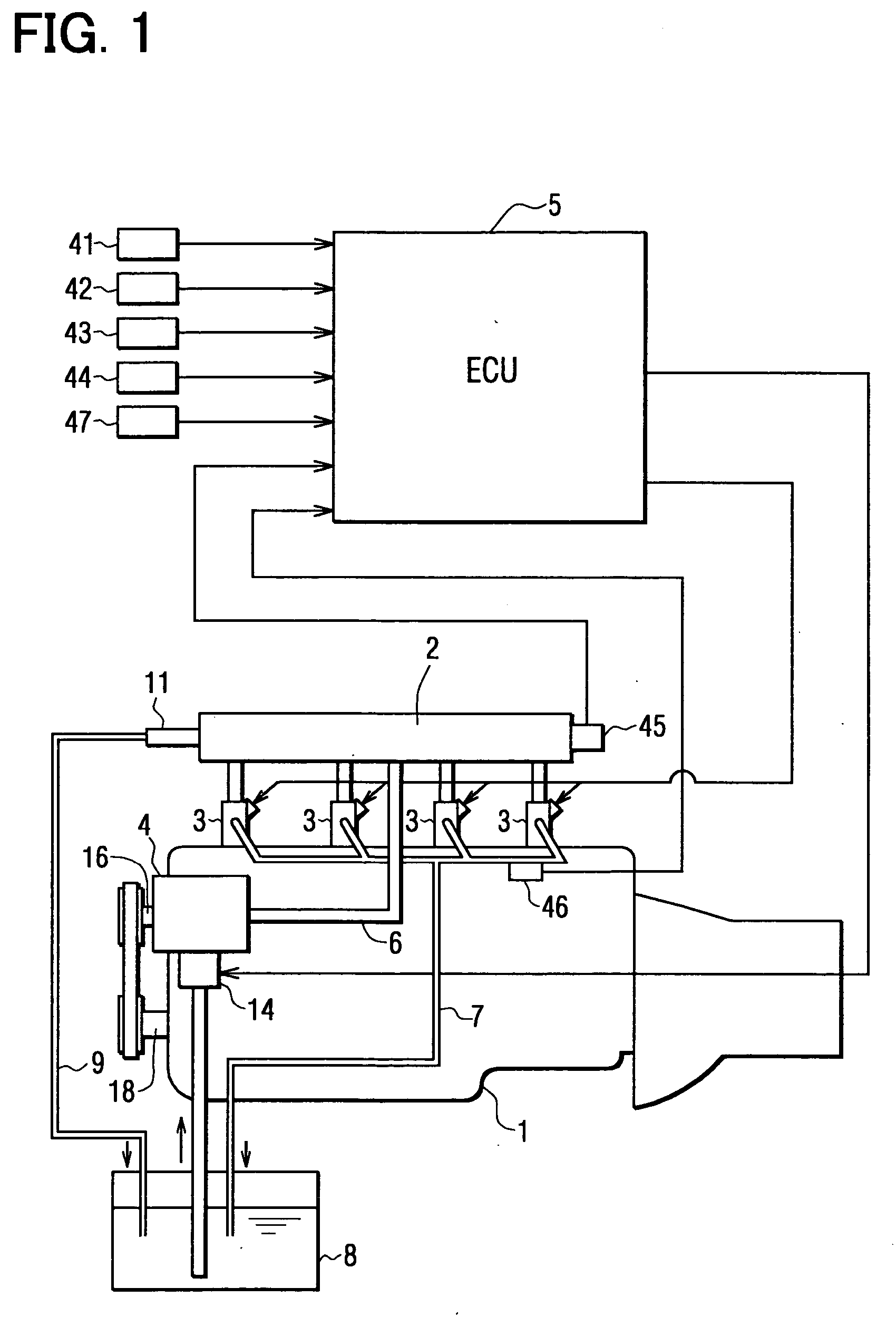

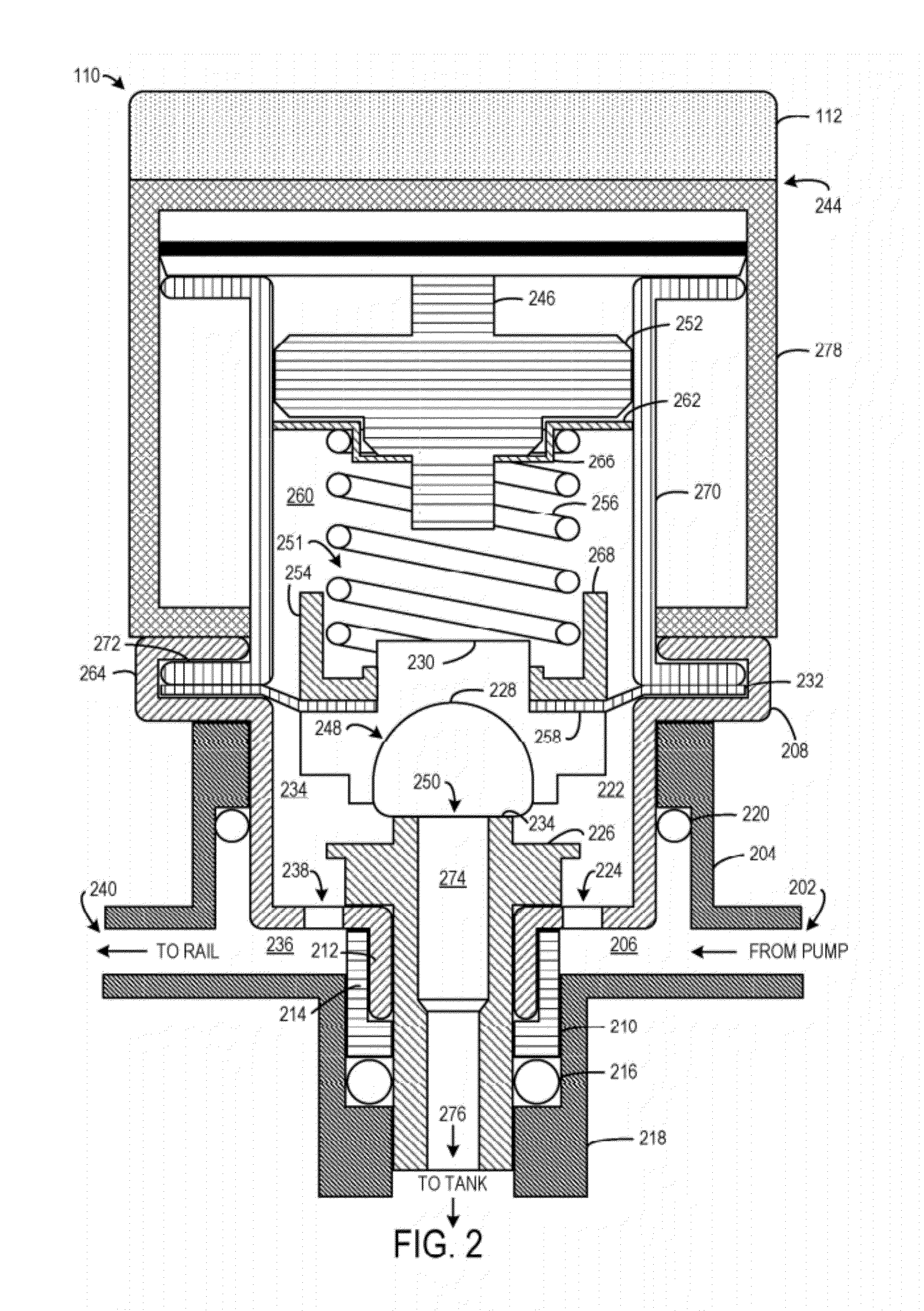

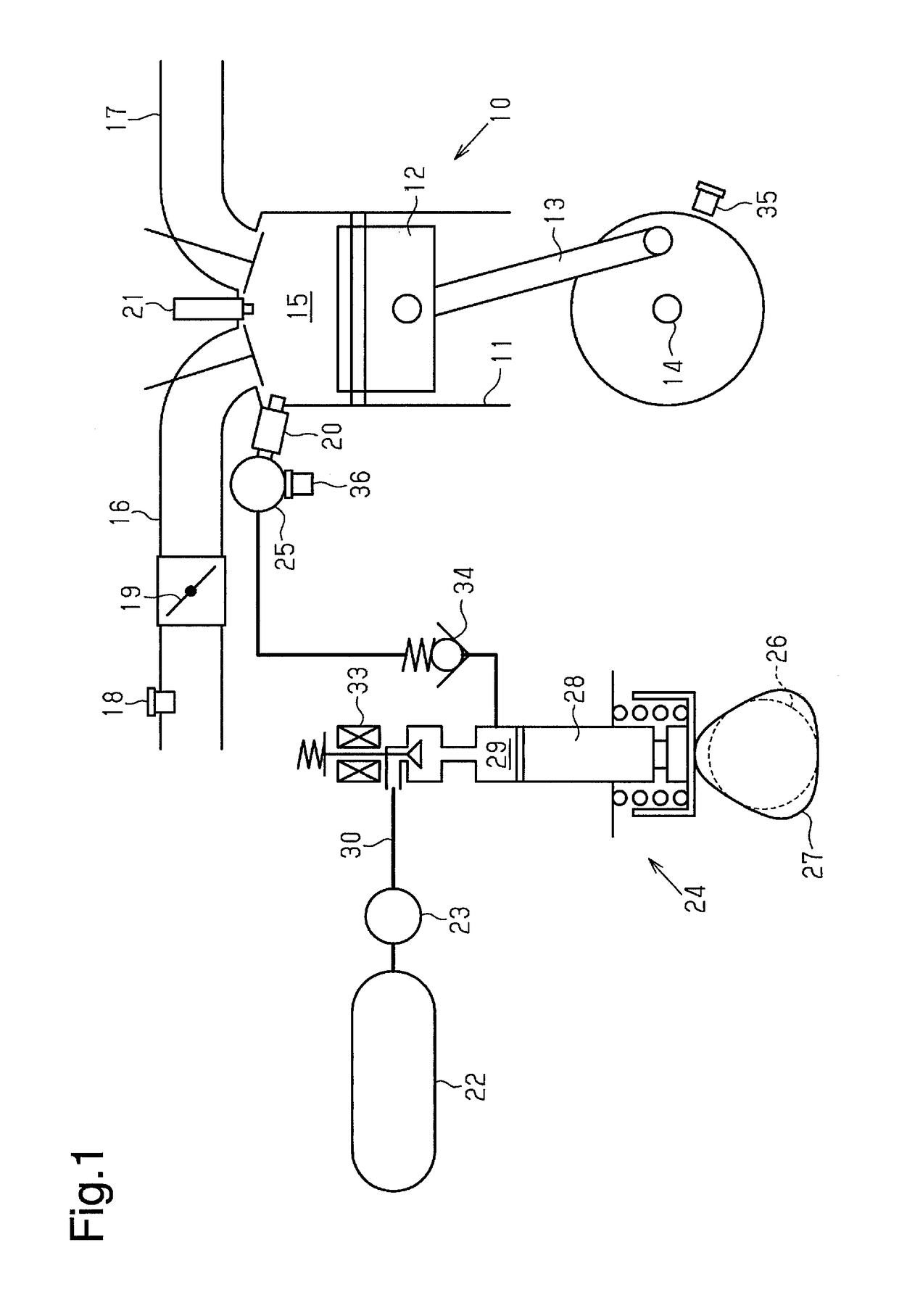

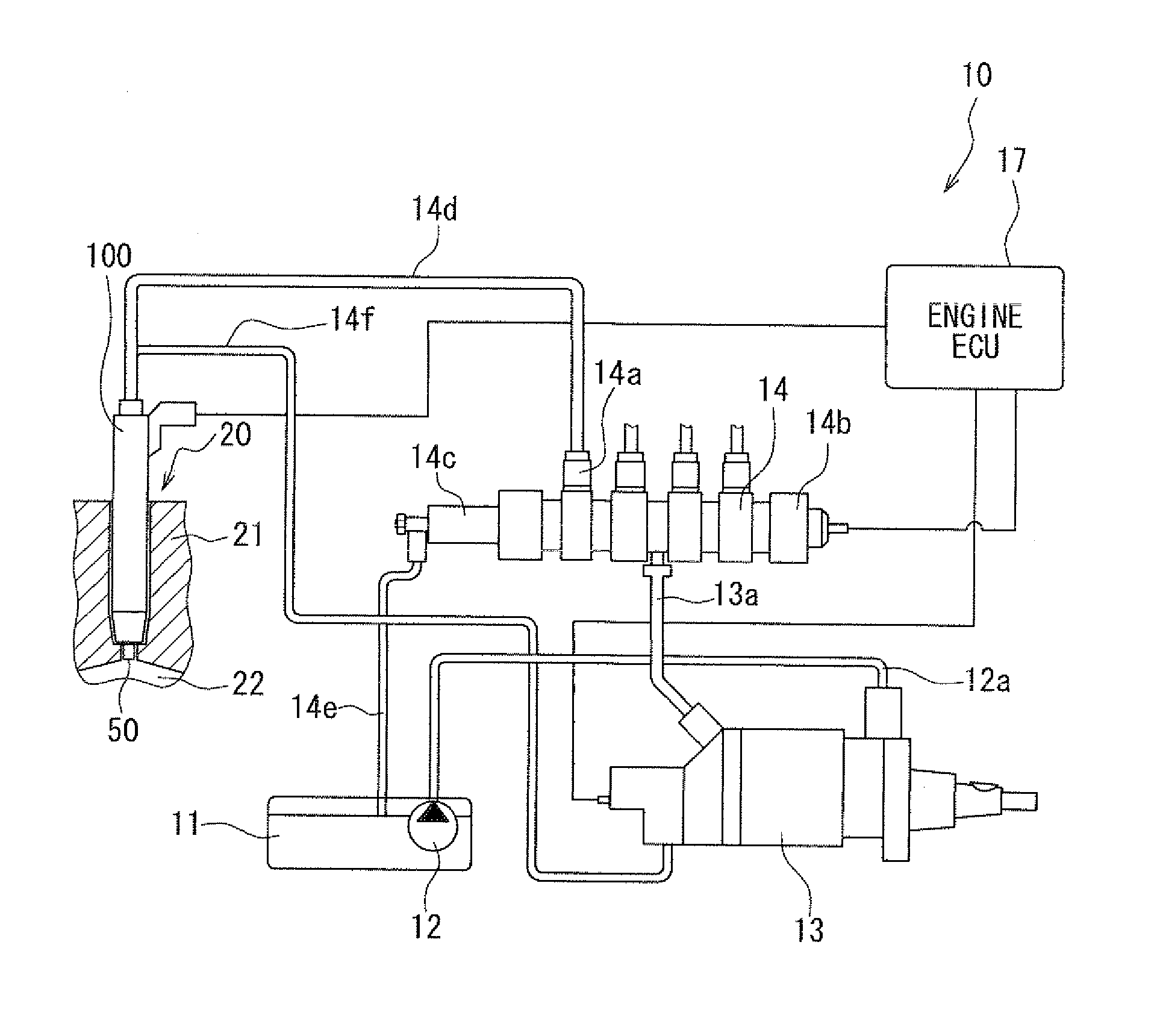

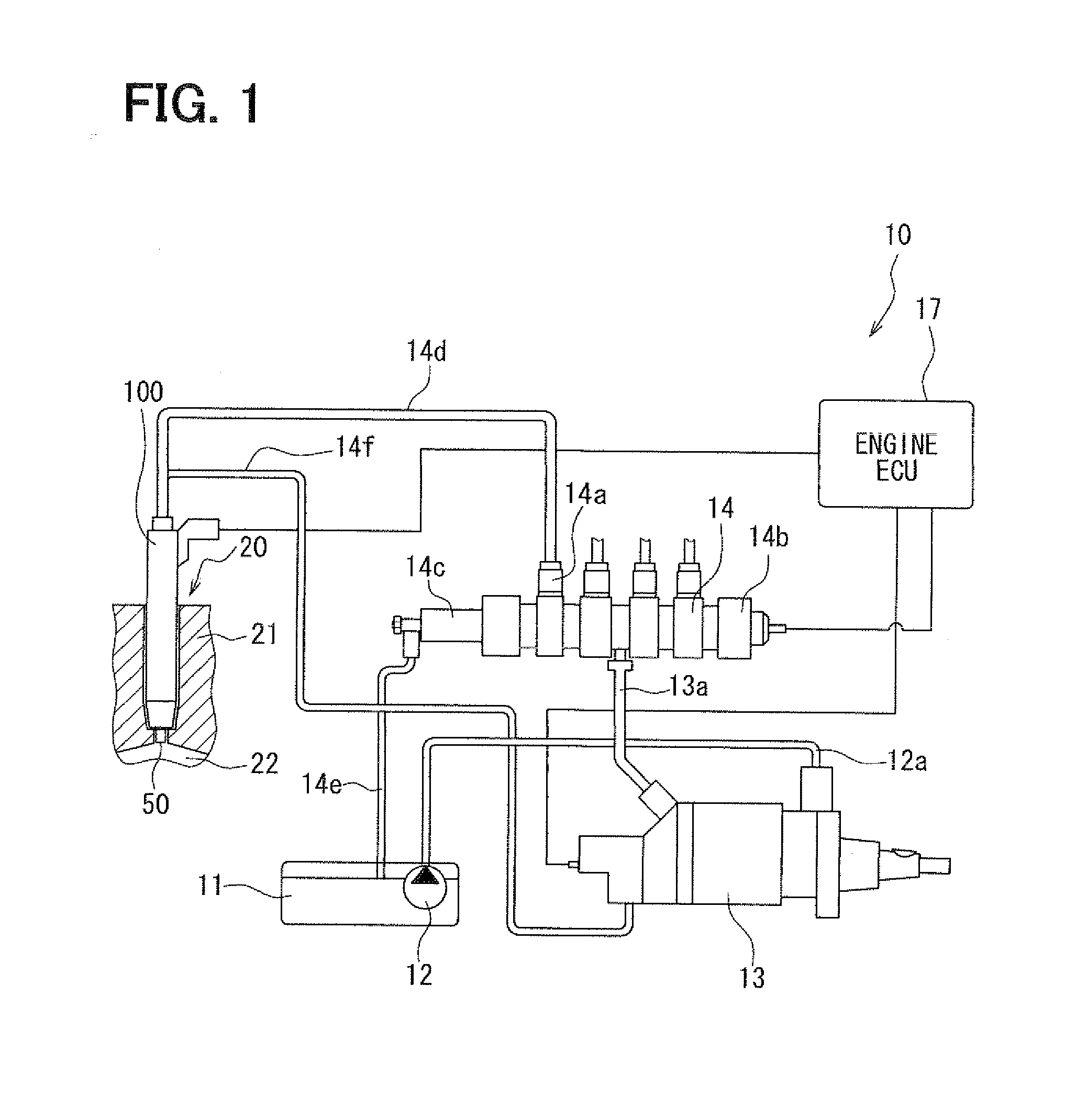

Common rail type fuel injection system

InactiveUS6971370B2Suppress mutationImprove accuracyElectrical controlFuel injection apparatusStart timeCommon rail

When a pressure-feeding period of a supply pump and an injection period of an injector overlap and an actual injection quantity is affected by a pump pressure-feeding quantity of fuel supplied by the supply pump, an engine control unit (ECU) calculates the pump pressure-feeding quantity supplied during the injection period and calculates a correction value in accordance with the pump pressure-feeding quantity. The ECU corrects a command injection quantity with the correction value. Thus, even if injection start timing changes in accordance with a change in an operating state and if the pump pressure-feeding quantity supplied during the injection period changes because of the change in the injection start timing, variation in the actual injection quantity can be inhibited. As a result, the injector can inject an optimum quantity of the fuel.

Owner:DENSO CORP

Common rail type fuel injection system

InactiveUS20050081825A1Suppress mutationImprove accuracyElectrical controlFuel injection apparatusStart timeCommon rail

When a pressure-feeding period of a supply pump and an injection period of an injector overlap and an actual injection quantity is affected by a pump pressure-feeding quantity of fuel supplied by the supply pump, an engine control unit (ECU) calculates the pump pressure-feeding quantity supplied during the injection period and calculates a correction value in accordance with the pump pressure-feeding quantity. The ECU corrects a command injection quantity with the correction value. Thus, even if injection start timing changes in accordance with a change in an operating state and if the pump pressure-feeding quantity supplied during the injection period changes because of the change in the injection start timing, variation in the actual injection quantity can be inhibited. As a result, the injector can inject an optimum quantity of the fuel.

Owner:DENSO CORP

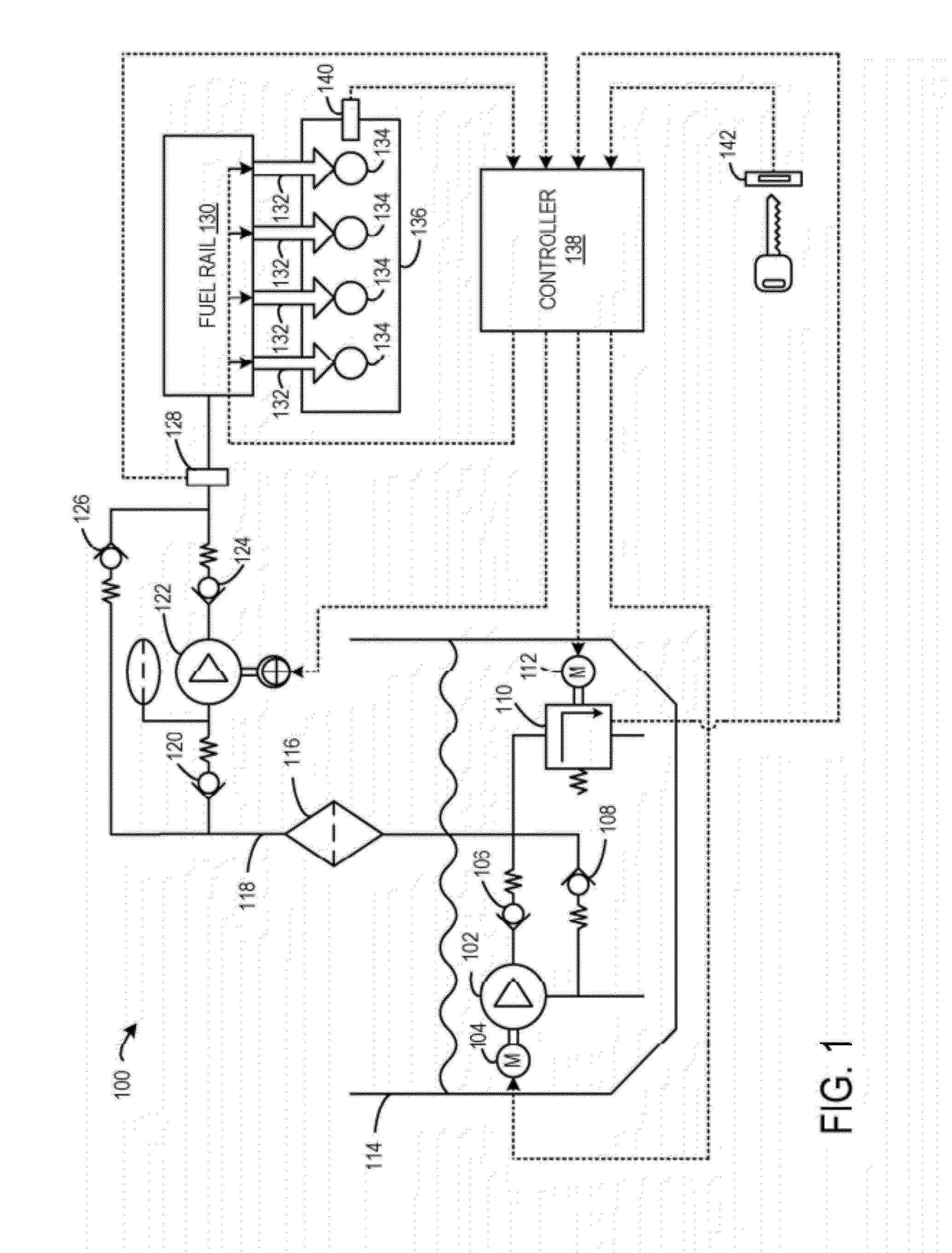

Fuel system with electrically-controllable mechanical pressure regulator

InactiveUS8210156B2Improve efficiencyIncrease rangeElectrical controlExhaust apparatusEngineeringMechanical pressure

A method for operating an engine direct injection fuel system is provided. The direct injection fuel system includes a mechanical fuel pressure regulator that has a spring actuatable by an electric motor. The method includes adjusting a preload of the spring by operating the electric motor to adjust a set-point fuel pressure from a first set-point fuel pressure to a second set-point fuel pressure in response to an operating condition, and maintaining the preload of the spring mechanically when the electric motor is not operating.

Owner:FORD GLOBAL TECH LLC

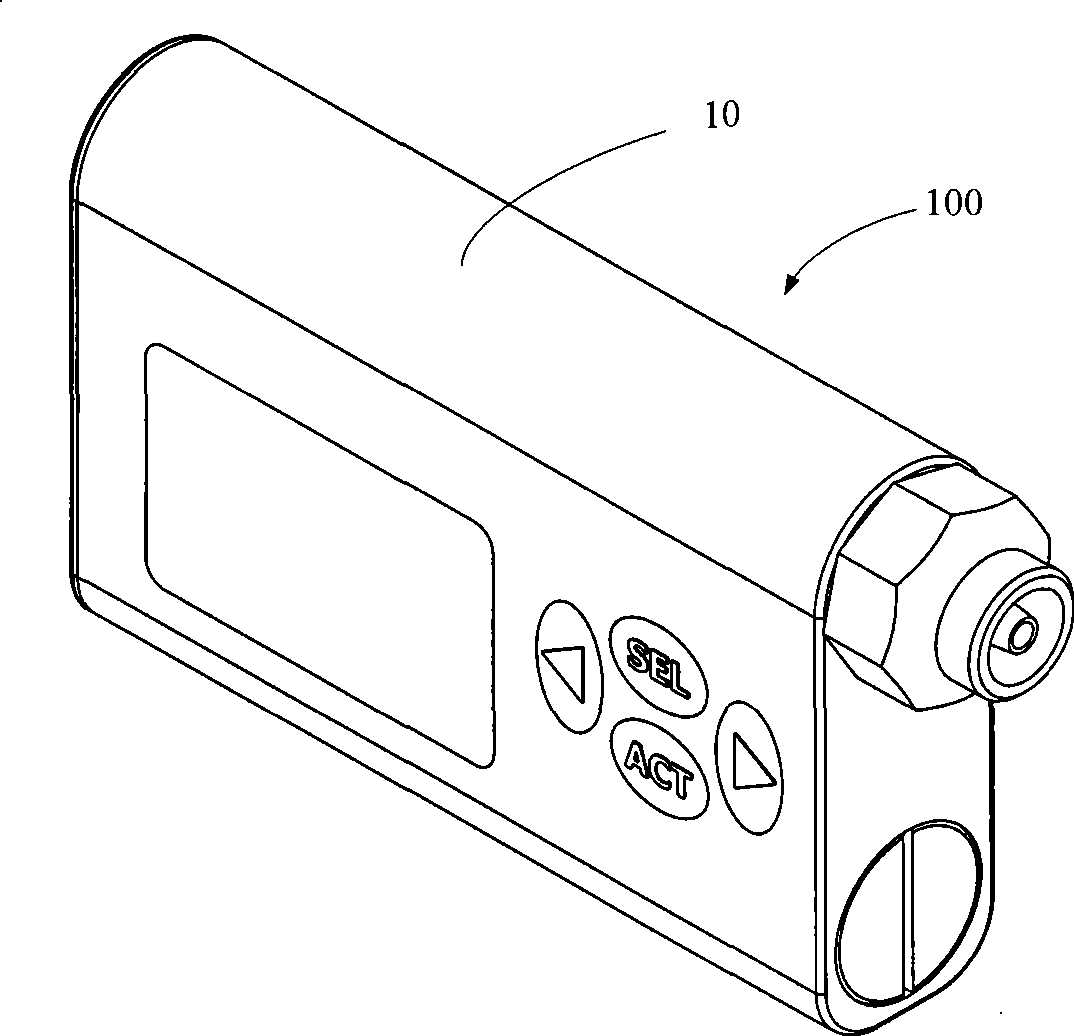

Dose-adjustable reusable injection pen

The invention discloses a dose-adjustable reusable injection pen, comprising an external button, a button shaft sleeve, a bidirectional ratchet wheel, a knob, a graduated disc, an internal thread sleeve, a rotational pawl, a rotating shaft rod, a ratchet disc, an upper shell, a pen hook, a thread connector, an engaging-disengaging connector, an engaging-disengaging ratchet wheel, a screw, an engaging-disengaging spring, a refill support and a lower shell. One end of the external button encases the manually rotated knob and drives the rotational pawl to rotate, the rotational pawl is fully mated in the internal thread sleeve through three positional points different in specification, the rotational pawl can rotationally rise only according to a spiral of the internal thread sleeve when rotating, the graduated disc also rotational rises at the same time, graduation changes can be observed through the transparent window, and the knob is rotated continuously until a graduation mark corresponding to a pointer indicates an injection dose to be applied. The dose-adjustable reusable injection pen has the advantages such as low product cost, adjustable injection dosage, high injection precision, transmission mechanism simplicity, small size, portability and reusability, and a simple, convenient, precisely dosed and low-cost injection mode is provided for patients.

Owner:JIANGSU DELFU MEDICAL DEVICES CO LTD

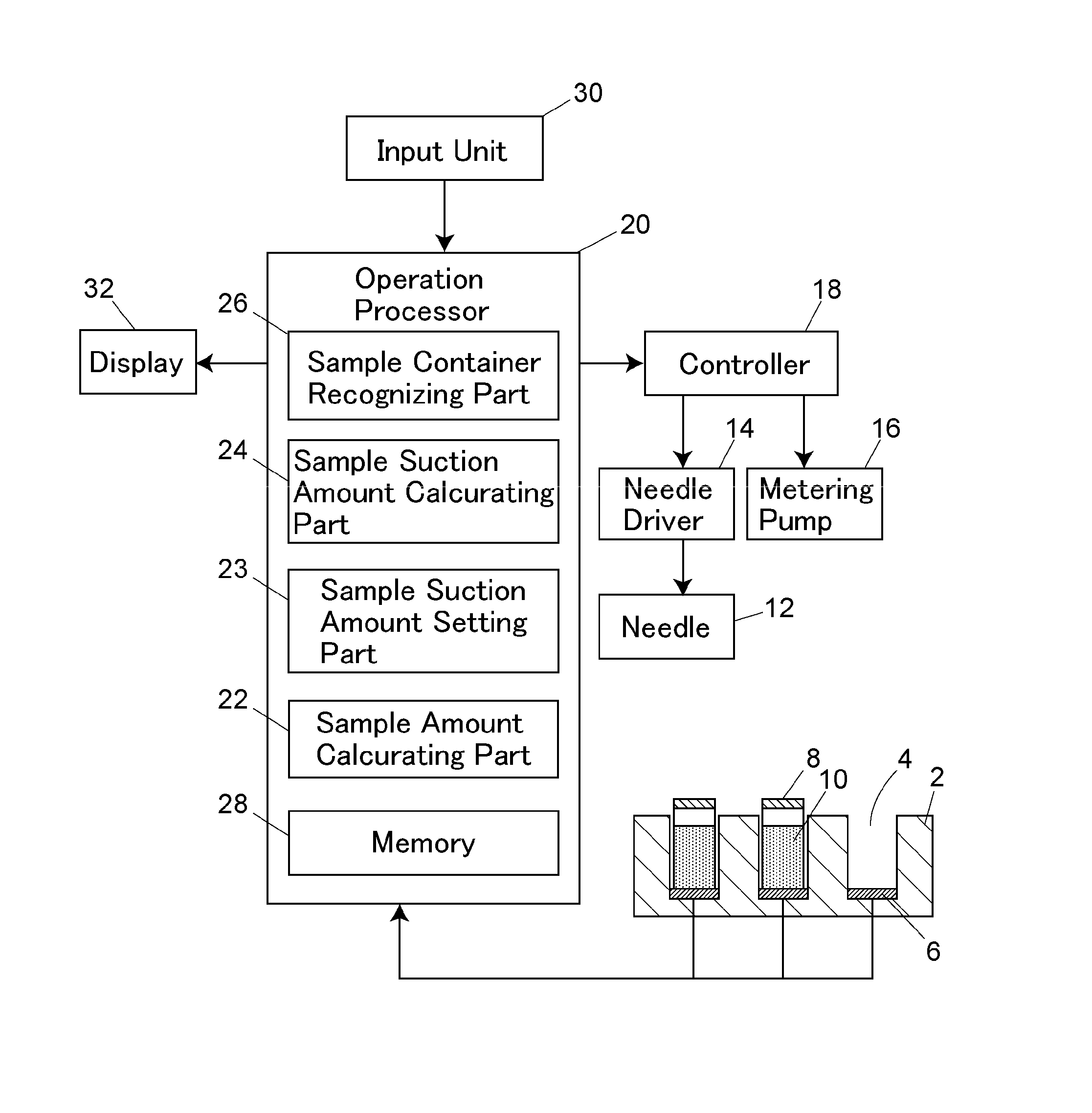

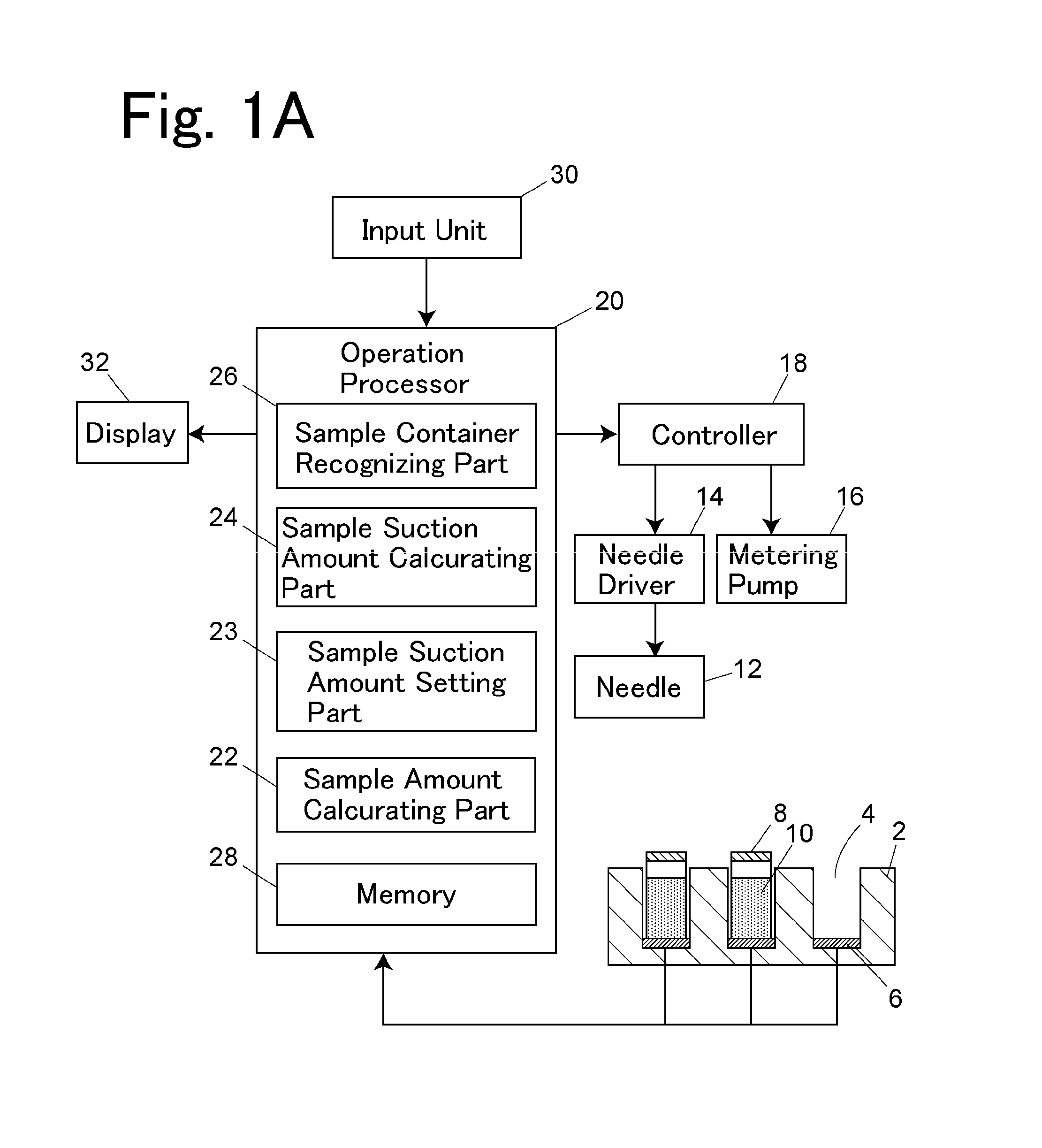

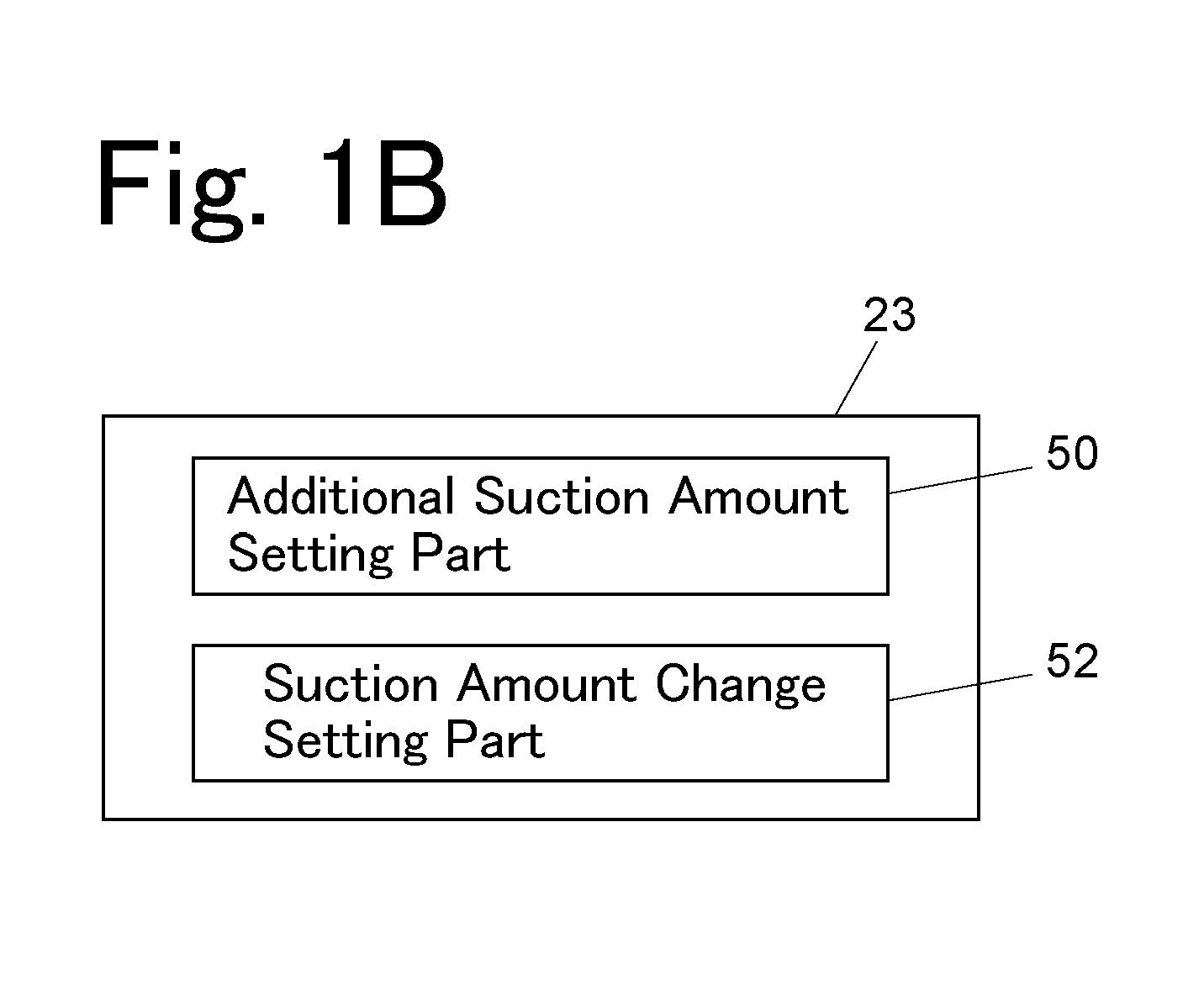

Automatic sampler

ActiveUS20140182396A1Facilitate verificationEasy to confirmWithdrawing sample devicesPhysicsAutosampler

Owner:SHIMADZU CORP

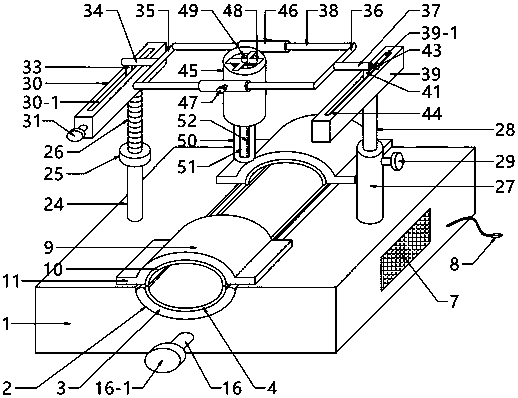

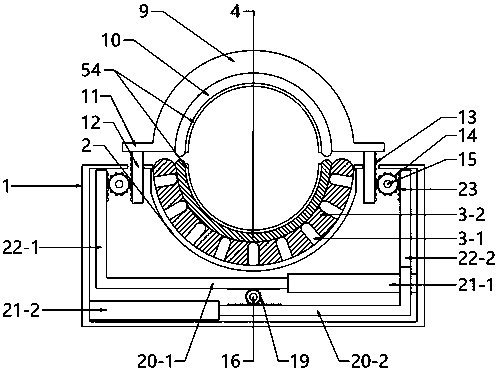

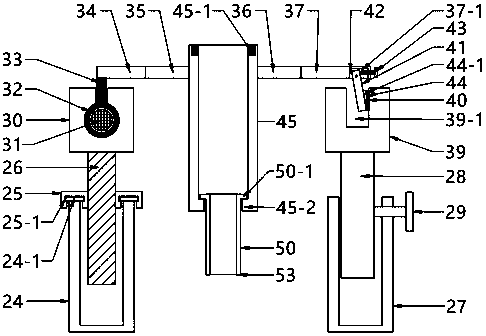

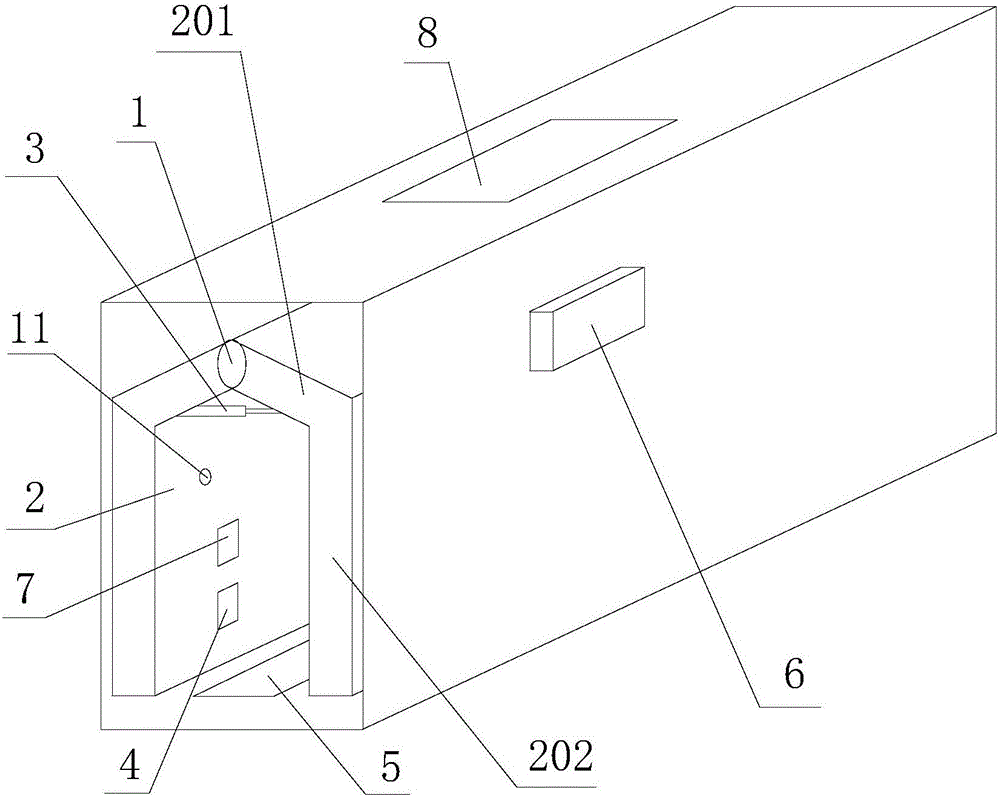

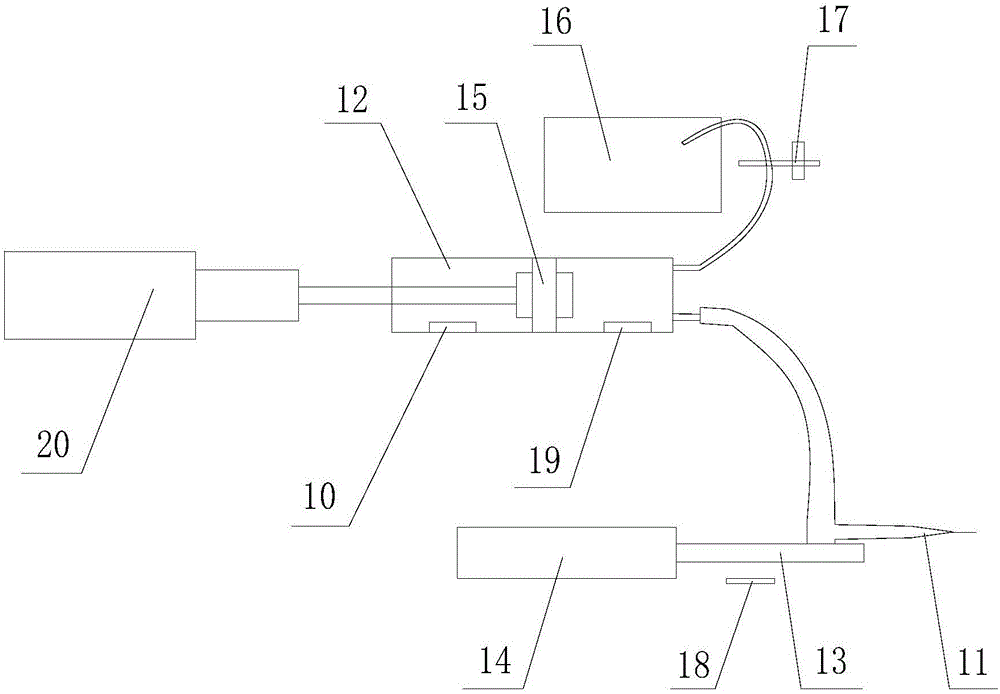

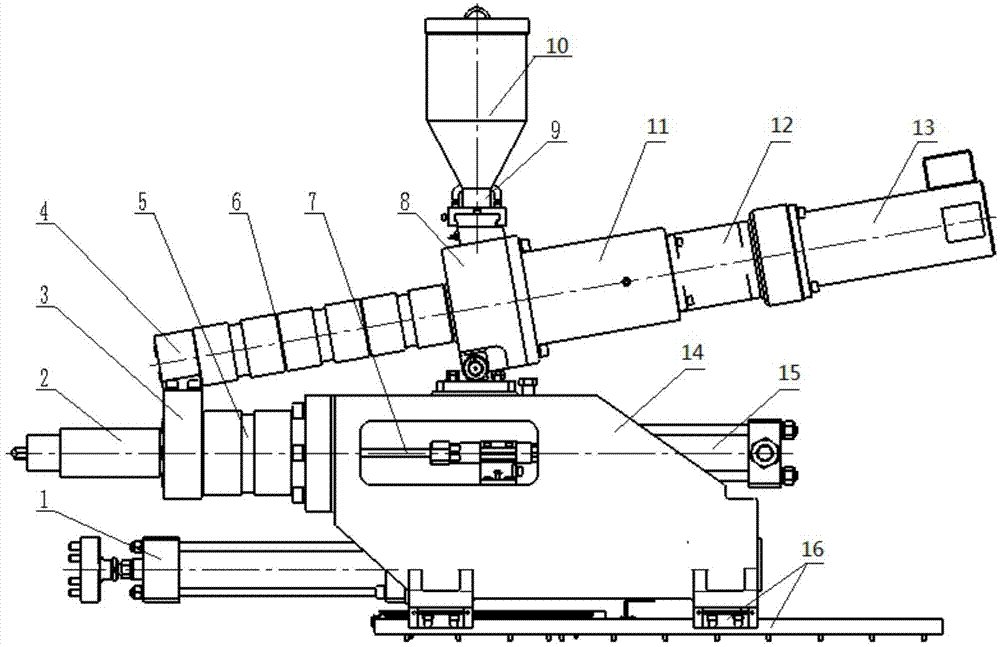

Automatic fed livestock and poultry injection device

ActiveCN106618788AAutomatic injectionImprove injection efficiencyWeighing apparatus for materials with special property/formVeterinary instrumentsReciprocating motionInsertion stent

The invention discloses an automatic fed livestock and poultry injection device. A spindle is arranged in a channel, two clamping plates are located on two sides of the spindle, and an extensible device is connected between the two clamping plates. A pressure sensor and a livestock and poultry sensing device is arranged on the surface, facing the other clamping plate of one clamping plate. A weighing sensor is arranged on the bottom surface of the channel. The automatic fed livestock and poultry injection device further comprises an injection mechanism. The injection mechanism comprises a syringe needle, the syringe needle is connected to a needle cylinder and is fixed to a syringe needle support, and the syringe needle support is fixed to a first linear reciprocating motion mechanism. The needle cylinder comprises a piston core rod, and the end, located outside of the needle cylinder, of the piston core rod is fixedly connected with a second linear reciprocating motion mechanism. The automatic fed livestock and poultry injection device further comprises a medicine storage tank, wherein the medicine storage tank is connected to the needle cylinder through a medicine delivery tube. The syringe needle points to the inside of the channel. The automatic fed livestock and poultry injection device is used for solving the problem that weighing and medicine injection are inconvenient during livestock and poultry breeding in the prior art, and the purposes of conveniently capturing and weighing livestock and poultry, meanwhile improving the livestock and poultry injection efficiency and reducing the labor and time costs are achieved.

Owner:上海汉维生物医药科技有限公司

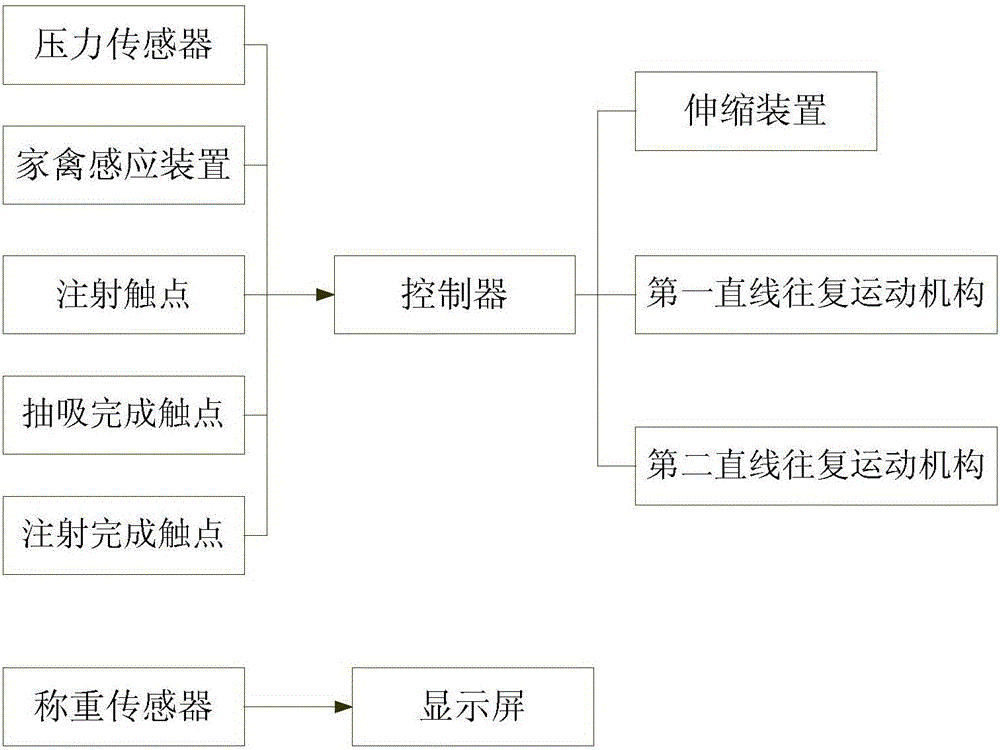

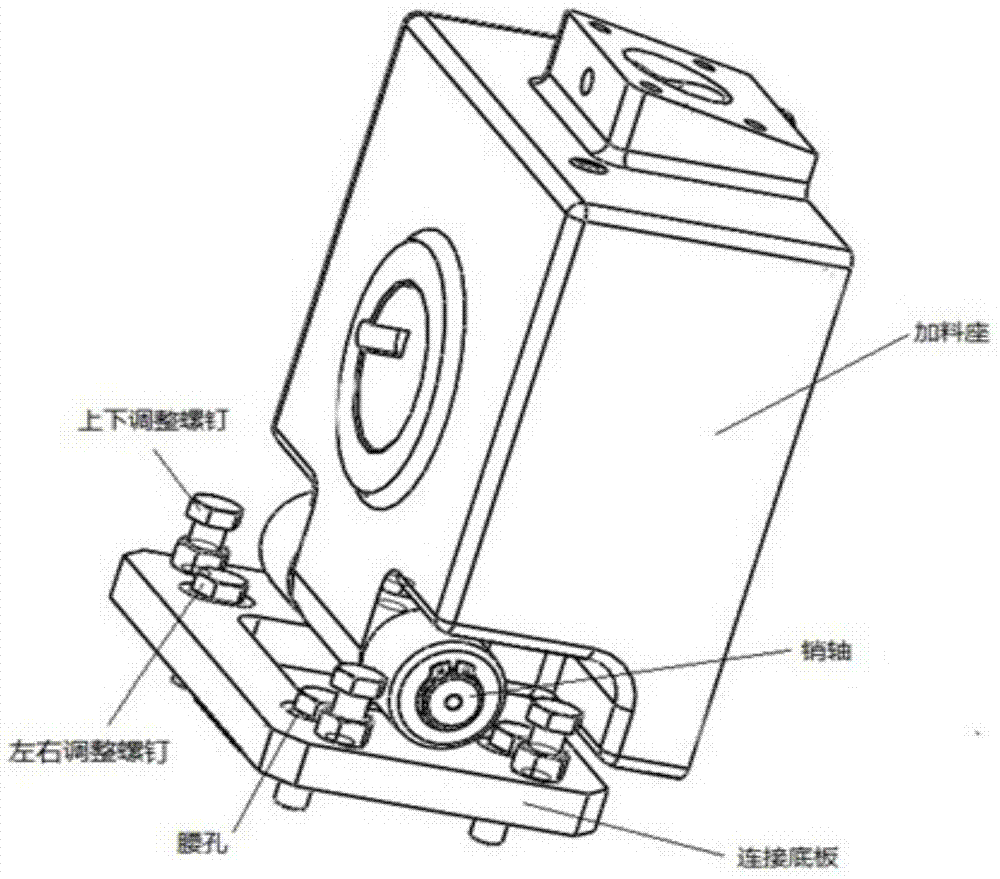

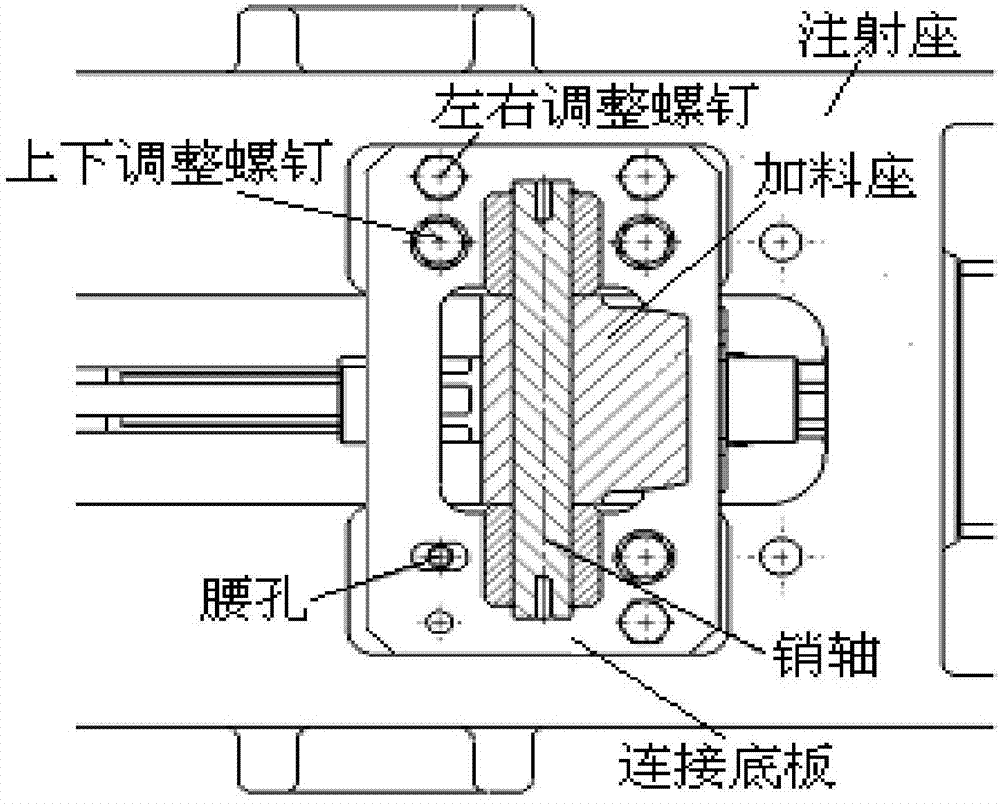

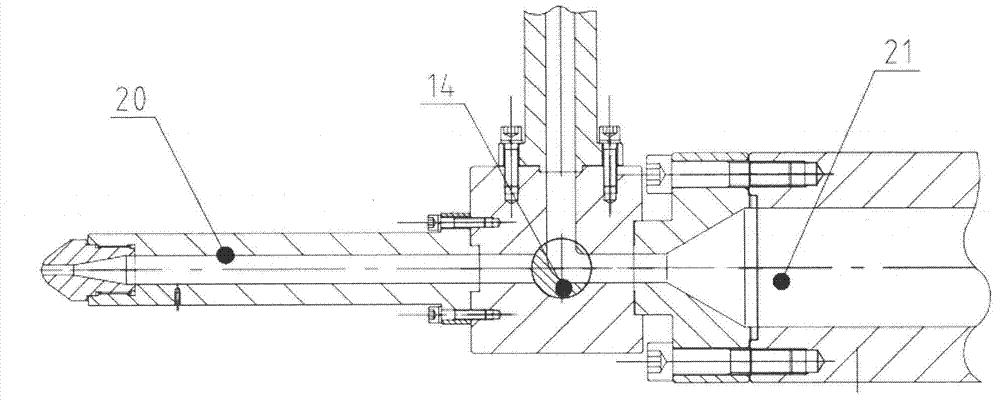

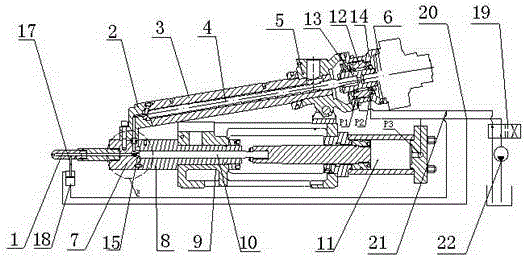

Injection molding machine microinjection device capable of realizing high-speed and high-precision injection

InactiveCN103692625AReduce deformation effectsQuality improvementHydraulic cylinderInjection molding machine

The invention relates to an injection molding machine microinjection device capable of realizing high-speed and high-precision injection. The device can be divided into five parts, namely a plasticization unit, an injection unit, a charging unit, an injection platform moving unit and other units; the plasticization unit adopts screw plasticization and is driven by a servo motor so as to improve the plasticization quality and the plasticization precision; the injection unit adopts plunger injection and is driven by a hydraulic cylinder equipped with an energy storage device so as to improve the injection precision and the injection speed. According to a plasticization and non-return transmission device of an injection device, a connecting passage between a plasticization cavity and an injection cavity can be blocked and opened intermittently, and the existence of a one-way valve is prevented, so that a flow passage between the plasticization cavity and the injection cavity is free of dead angle, and the melt retention can be effectively reduced; meanwhile, the system is provided with a testing device capable of detecting abraded quantity of a screw head, thus providing guarantee for overhaul and normal use of an injection molding machine.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH +1

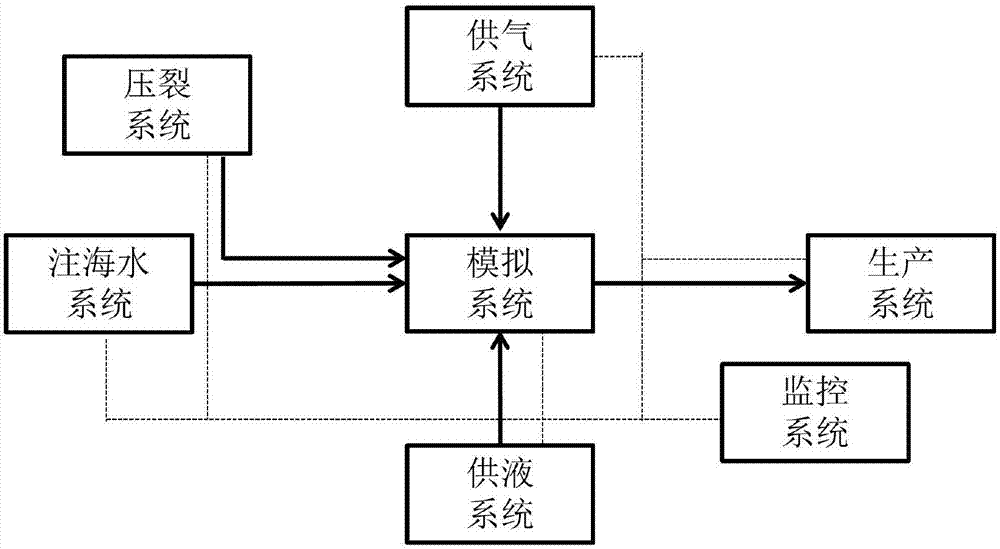

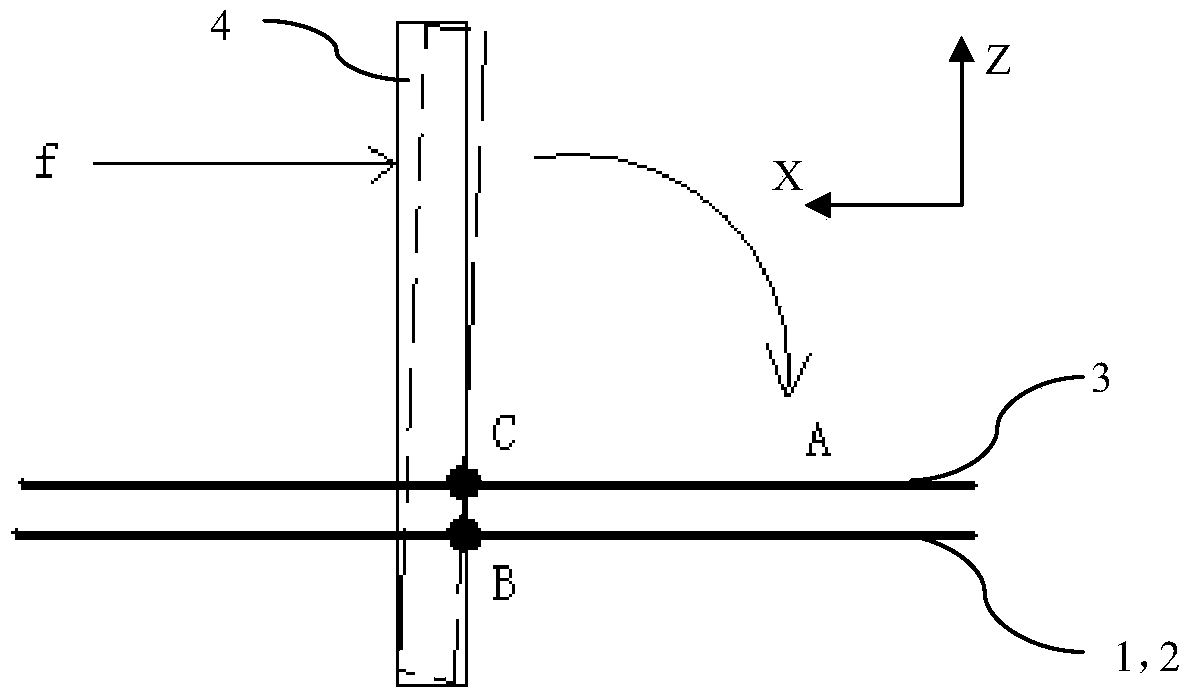

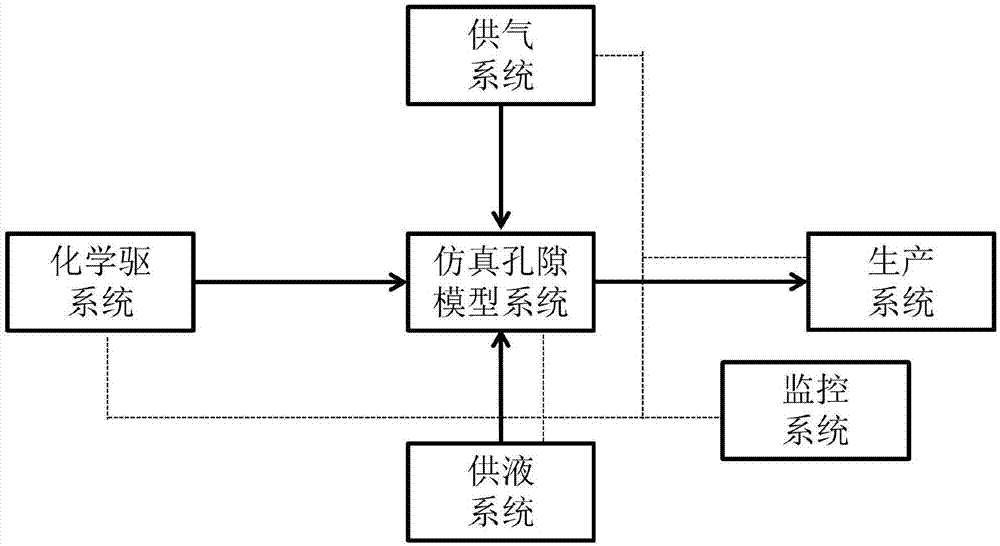

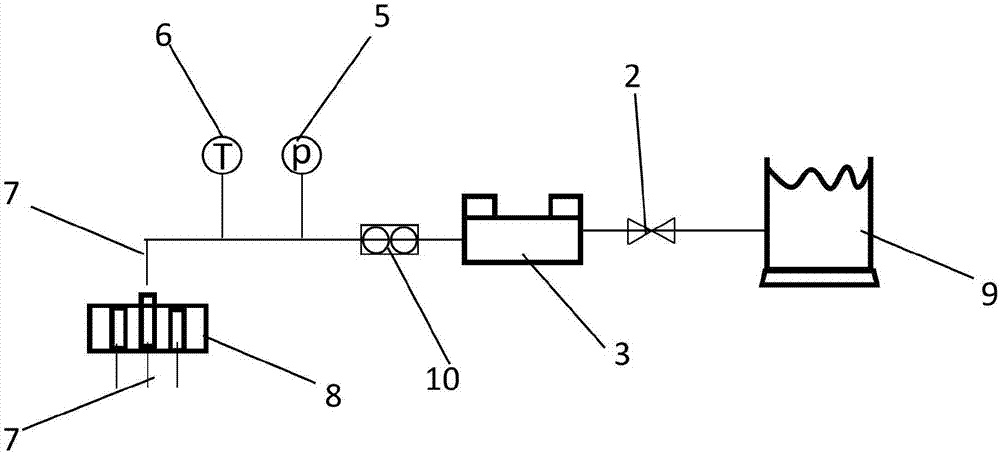

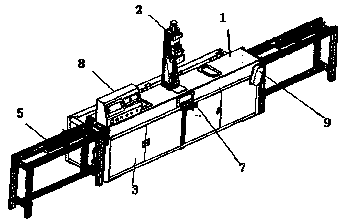

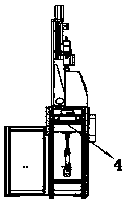

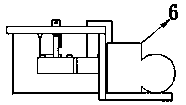

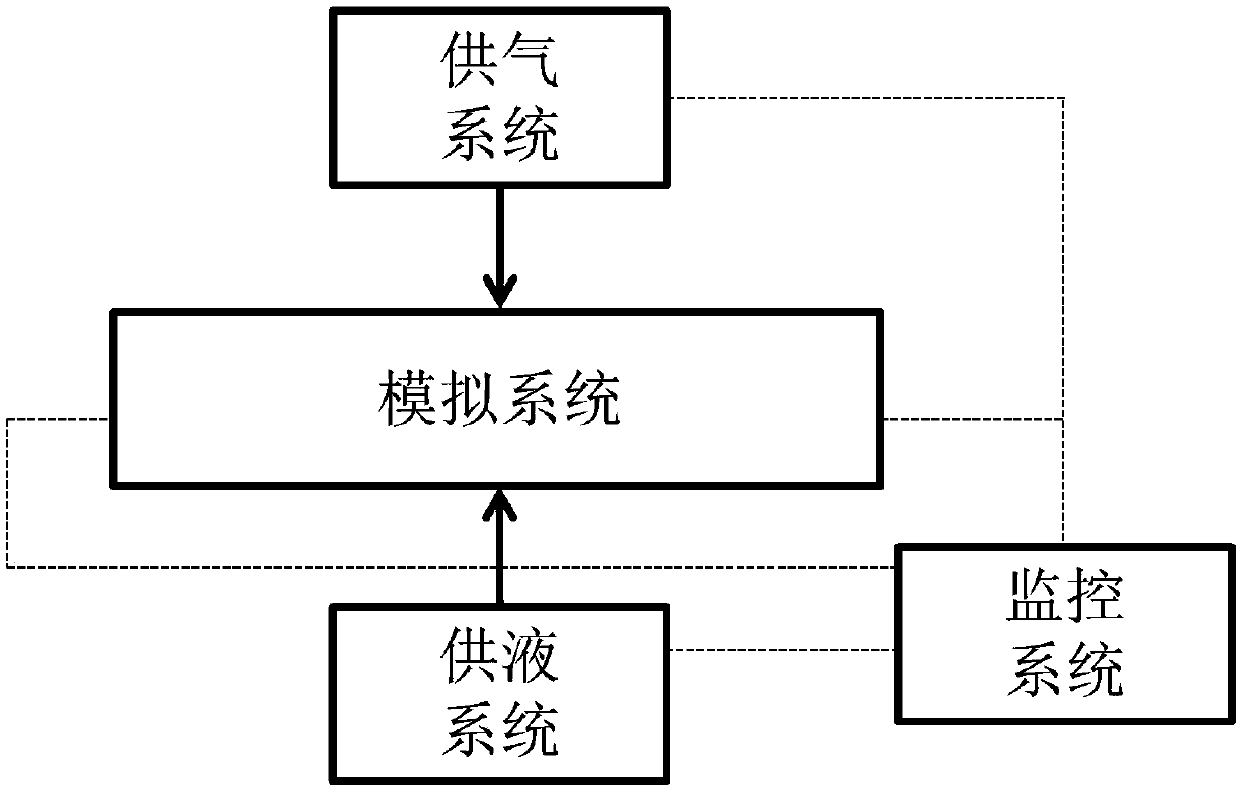

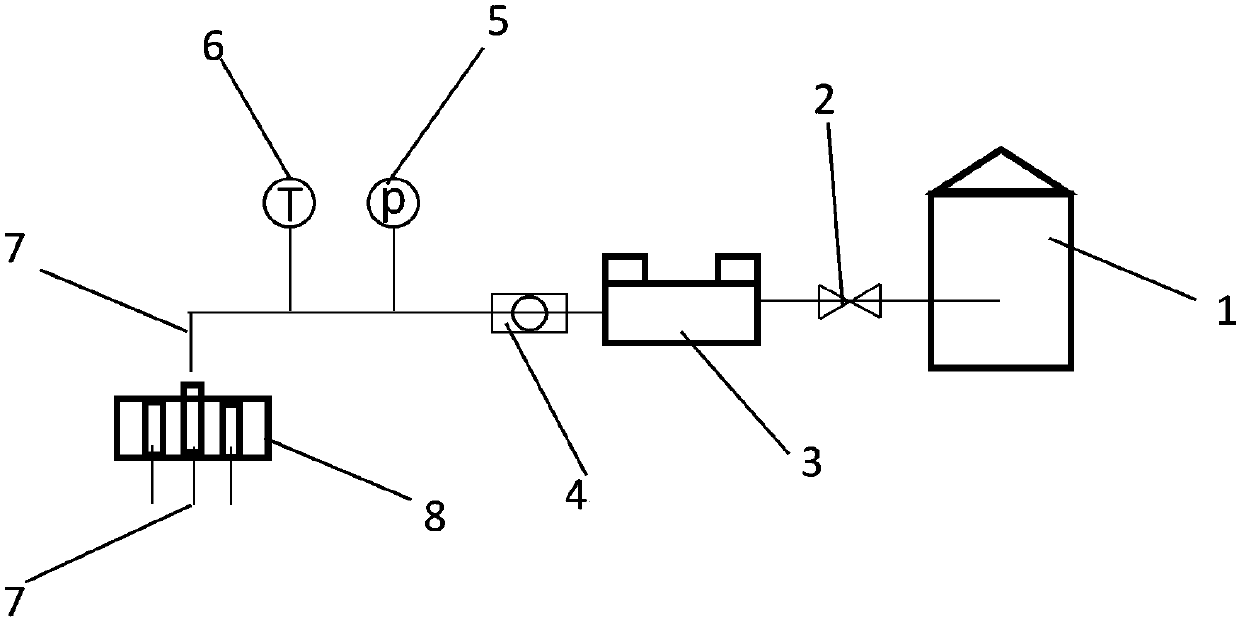

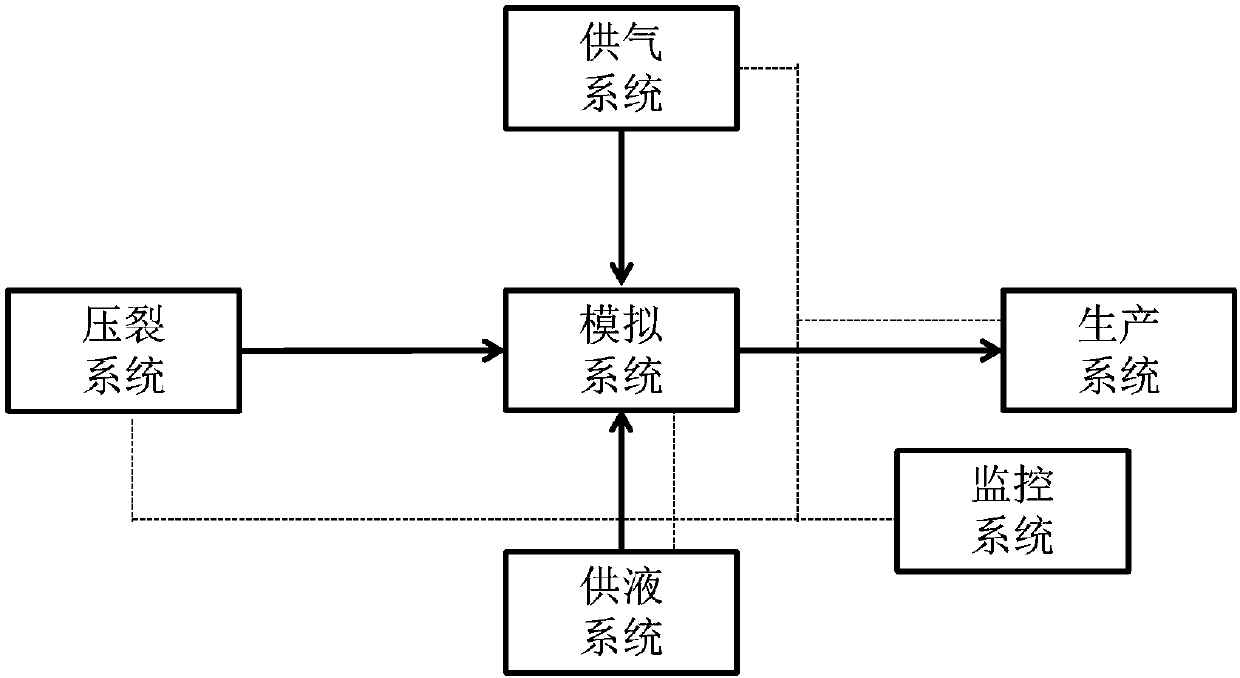

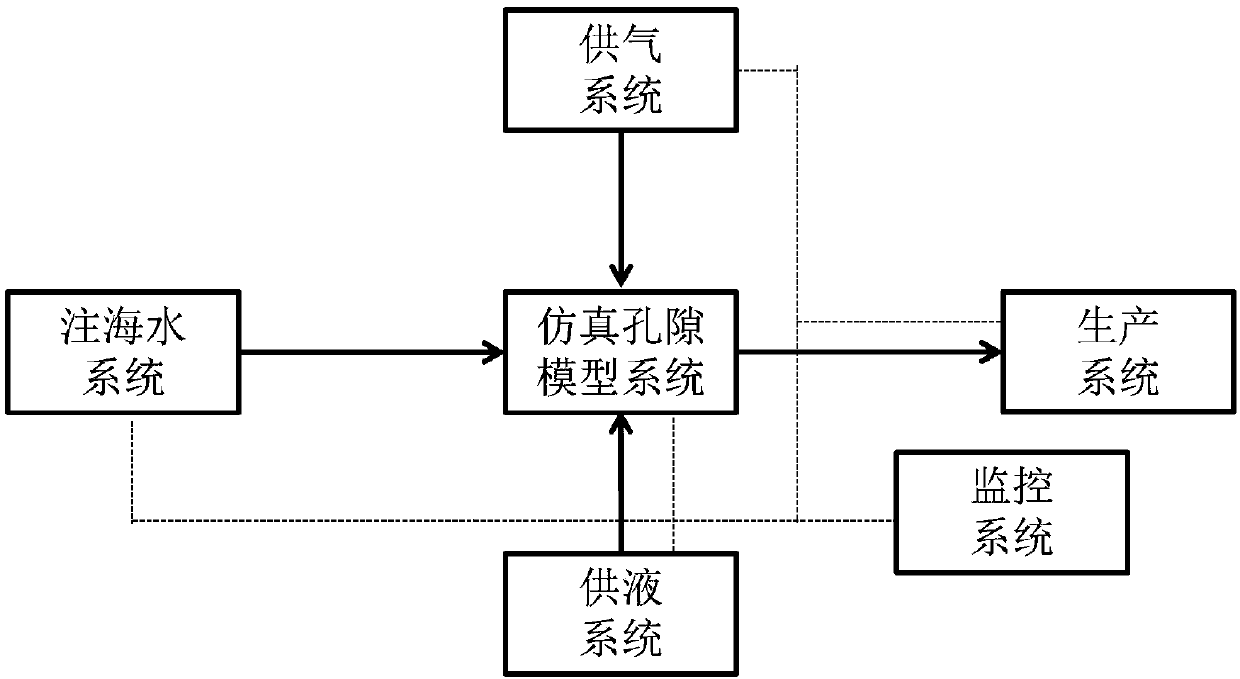

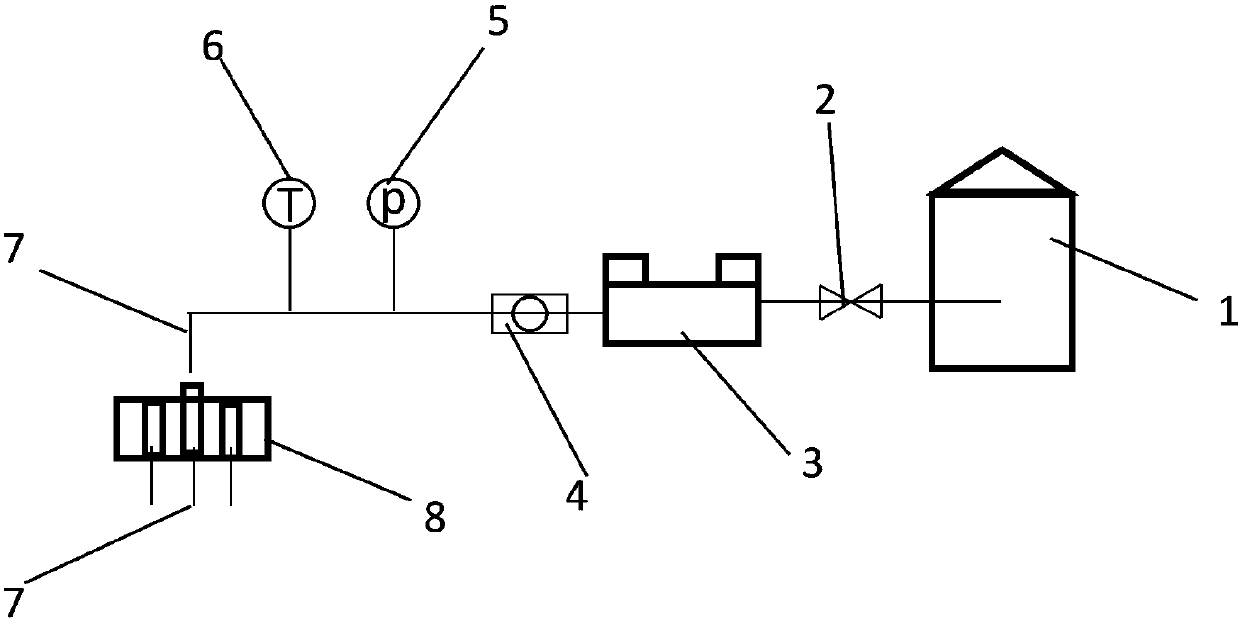

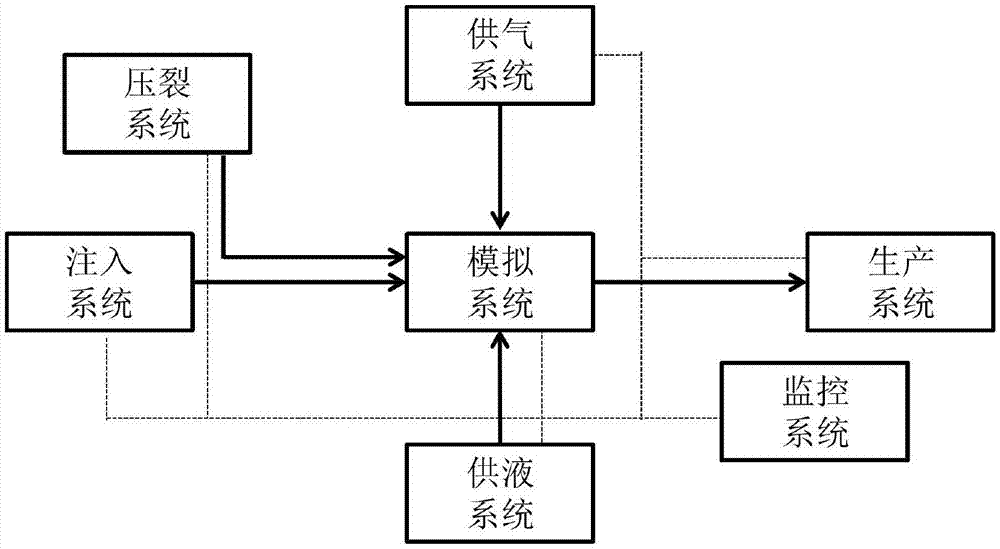

Device for simulating natural gas hydrate row type horizontal well seawater injection mining

InactiveCN107514247AImprove injection accuracySimulation is accurateFluid removalMonitoring systemProcess engineering

The invention discloses a device for simulating natural gas hydrate row type horizontal well seawater injection mining, and relates to the field of natural gas hydrate development. The device comprises an air supply system, a liquid supply system, a simulation system, a fracturing system, a seawater injection system, a production system and a monitoring system, the device adopts a sand filling box to serve as a main body of the simulating system, a row type horizontal well pattern can be simulated, and by means of the air supply system and the liquid supply system, natural gas and water are supplied into the simulation system to form a natural gas hydrate; fracturing operation is implemented through the fracturing system for simulating natural gas hydrate storage, seawater is injected through the seawater injection system to simulate seawater injection mining, associated gas and water are collected through the production system, and the whole experimental process is monitored through the monitoring system. Accordingly, an experimental device adopts a three-dimensional mode, the seawater injection mining natural gas hydrate is simulated, and a certain guiding effect on natural gas hydrate seawater injection mining mechanism study is achieved.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

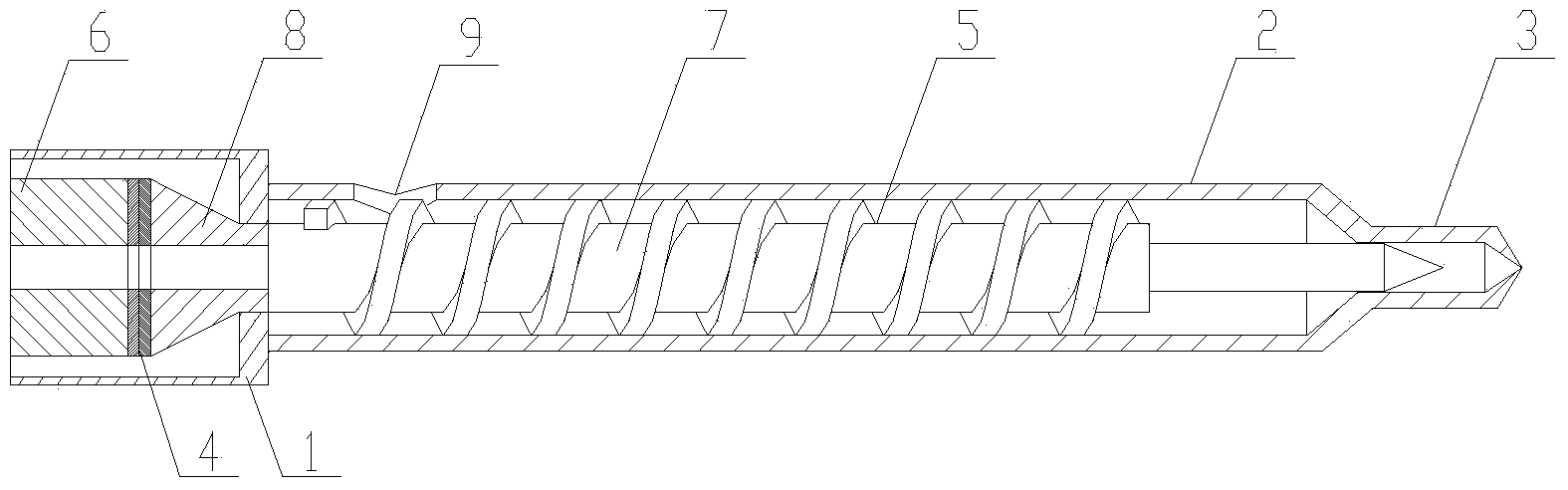

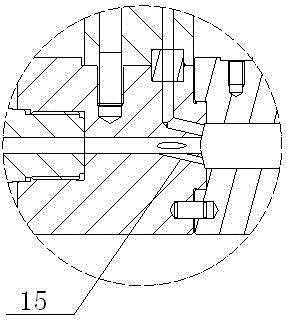

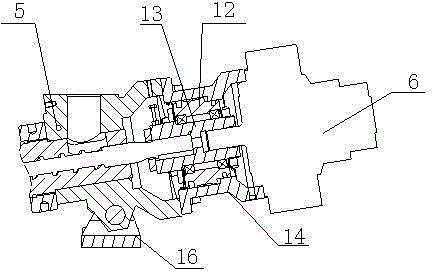

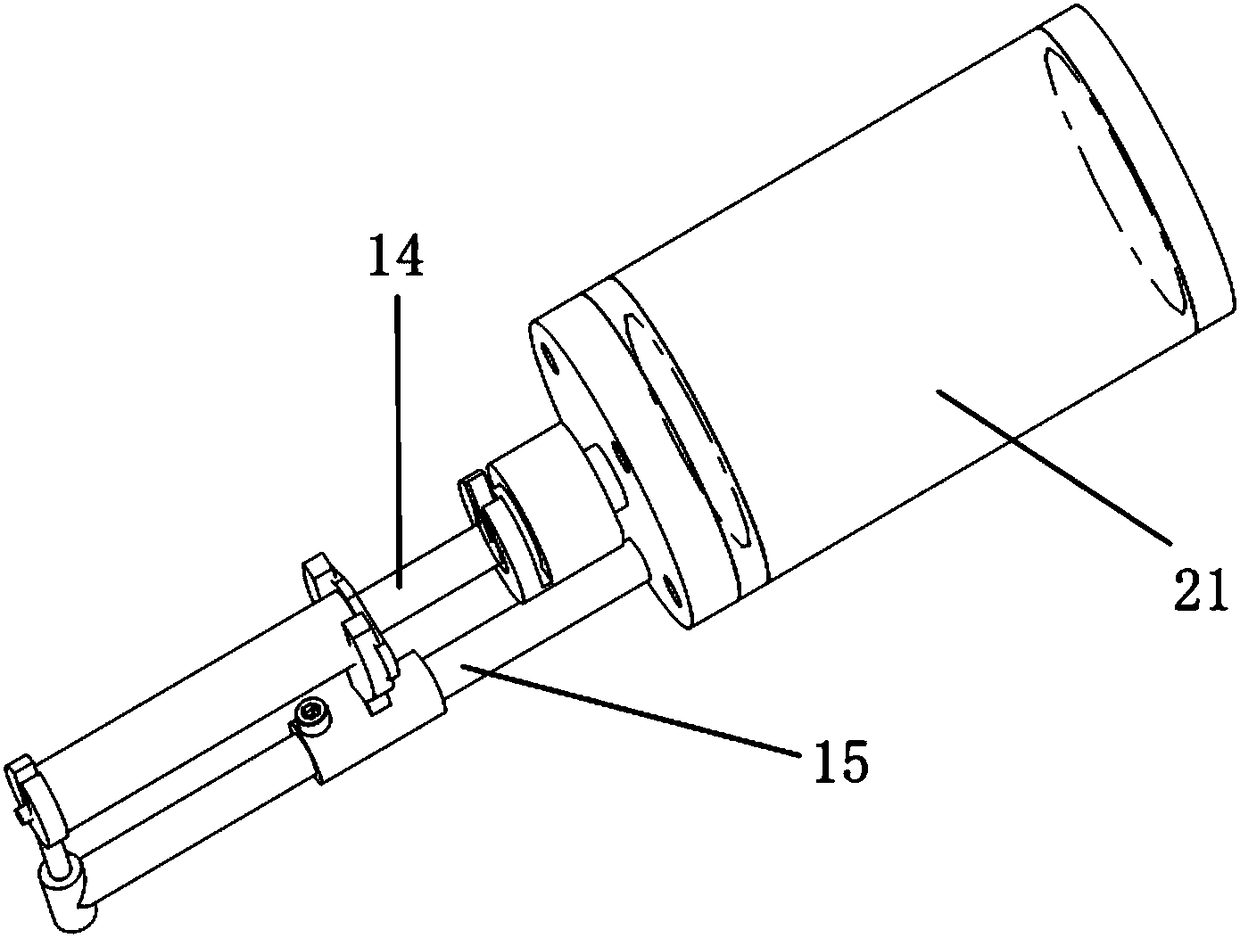

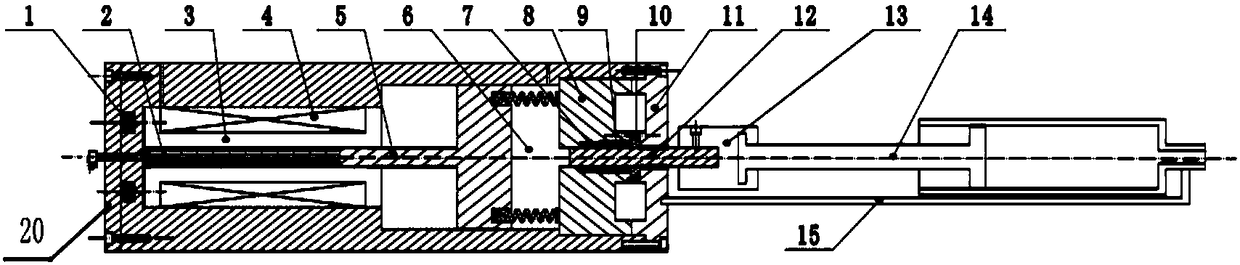

Plastic microinjection structure additionally with longitudinal-torsional ultrasonic vibration

The invention discloses a plastic microinjection structure additionally with longitudinal-torsional ultrasonic vibration. The plastic microinjection structure comprises a housing and an injection sleeve connected with the housing, wherein an injection nozzle is formed in one end part of the injection sleeve; a piezoelectric ceramic piece for energy conversion is arranged in the housing; an injection screw rod is arranged in the injection sleeve and is fixedly connected with the piezoelectric ceramic piece in the housing; the piezoelectric ceramic piece is electrified to enable the injection screw rod to generate the high-frequency longitudinal-torsional ultrasonic vibration. According to the plastic microinjection structure provided by the invention, an axial reciprocating vibration part is decomposed into circumferential high-frequency torsion by virtue of a injection screw rod structure, so that a plastic raw material is further sheared and thinned, the injection operation is smoothly and uniformly performed under the conditions of relatively low pressure and temperature, and the influence of pores and warpage of a plastic product on the precision of the product and the working efficiency of a machine is avoided.

Owner:苏州创聚信电子科技有限公司

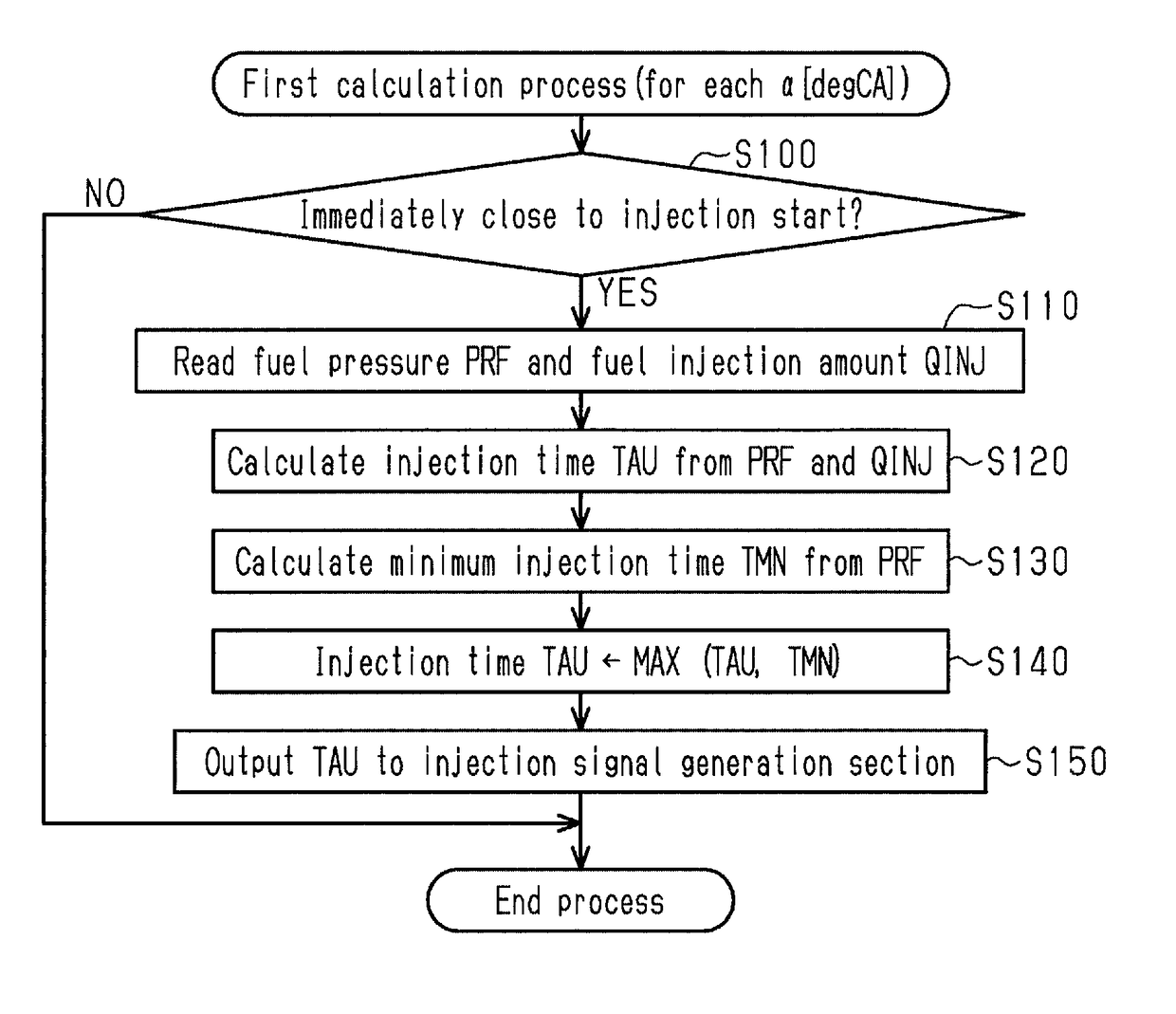

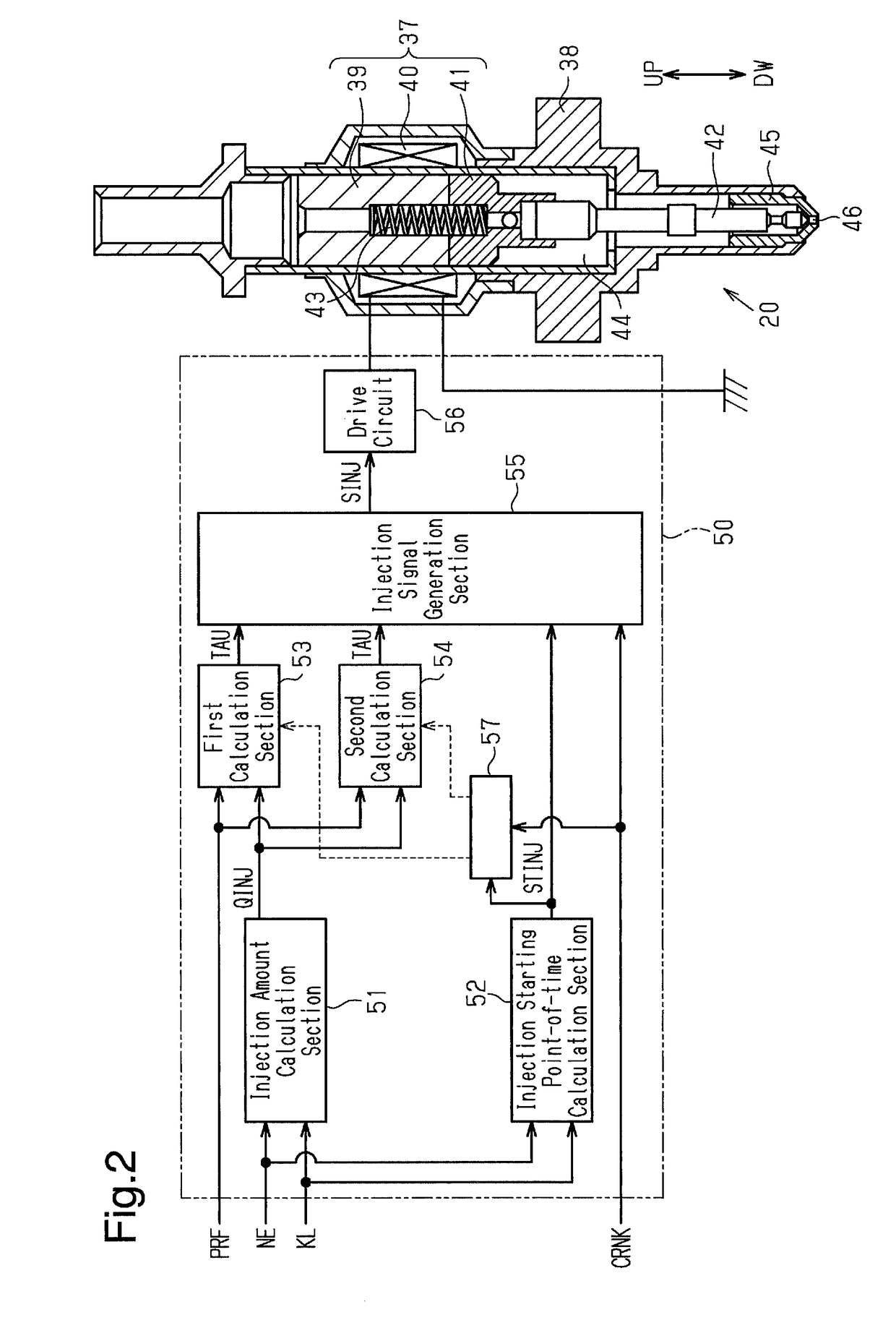

Fuel injection controller and fuel injection control method for internal combustion engine

ActiveUS20180230931A1Error minimizationError in fuel injection amountElectrical controlInternal combustion piston enginesExternal combustion engineSimulation

A fuel injection controller for an internal combustion engine includes first and second calculation sections. The first calculation section acquires a fuel pressure at a predetermined point of time before an injection starting point of time and calculates an injection time using the acquired fuel pressure. The second calculation section acquires a fuel pressure when the injection starting point of time arrives and calculates the injection time by using the acquired fuel pressure. The controller is configured to, before starting the energization to the injector, set a point of time to stop energization to an injector based on a calculation result of the injection time by the first calculation section. The controller is also configured to, after starting the energization to the injector, reset the point of time to stop the energization to the injector based on a calculation result of the injection time by the second calculation section.

Owner:TOYOTA JIDOSHA KK

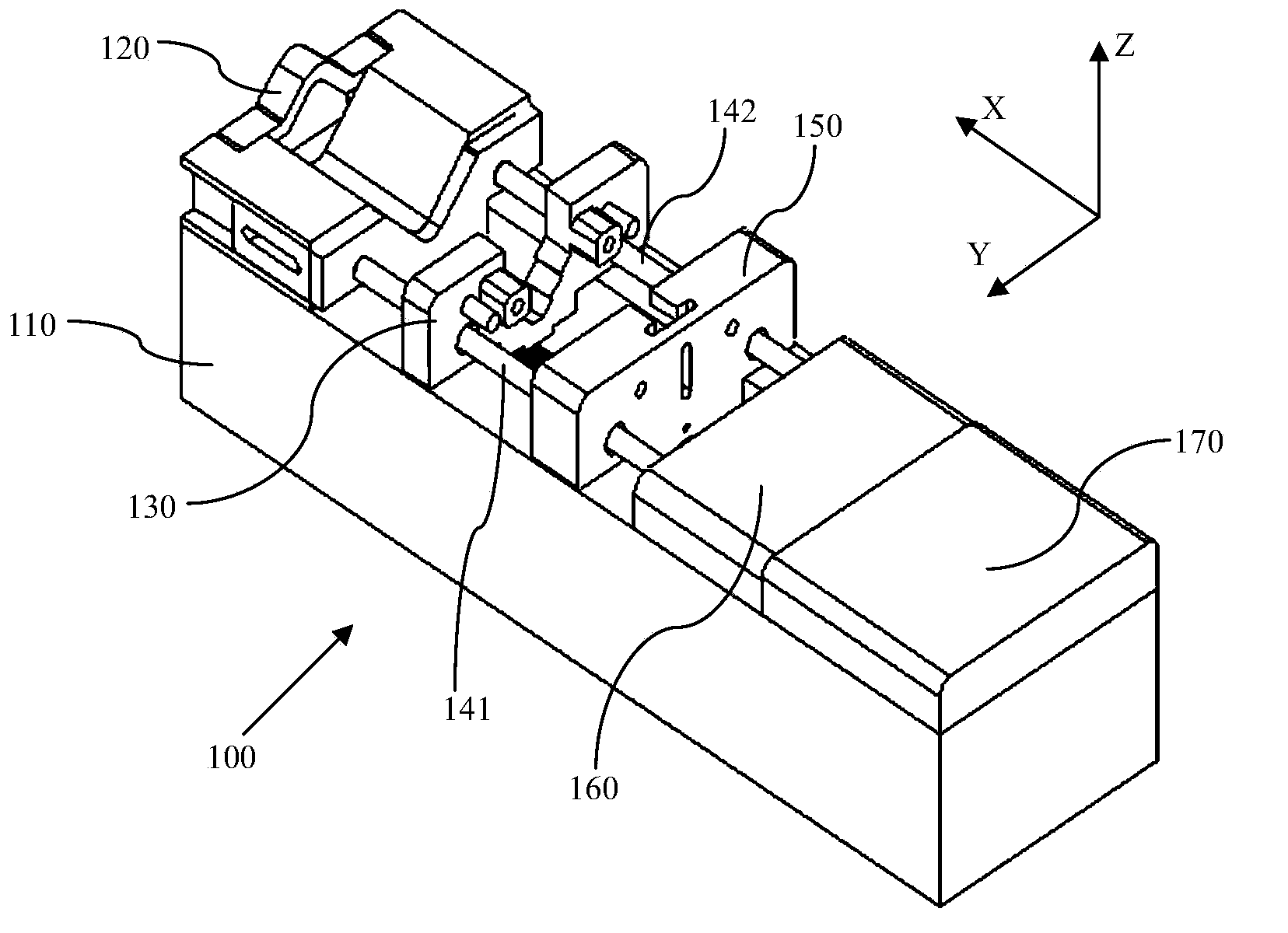

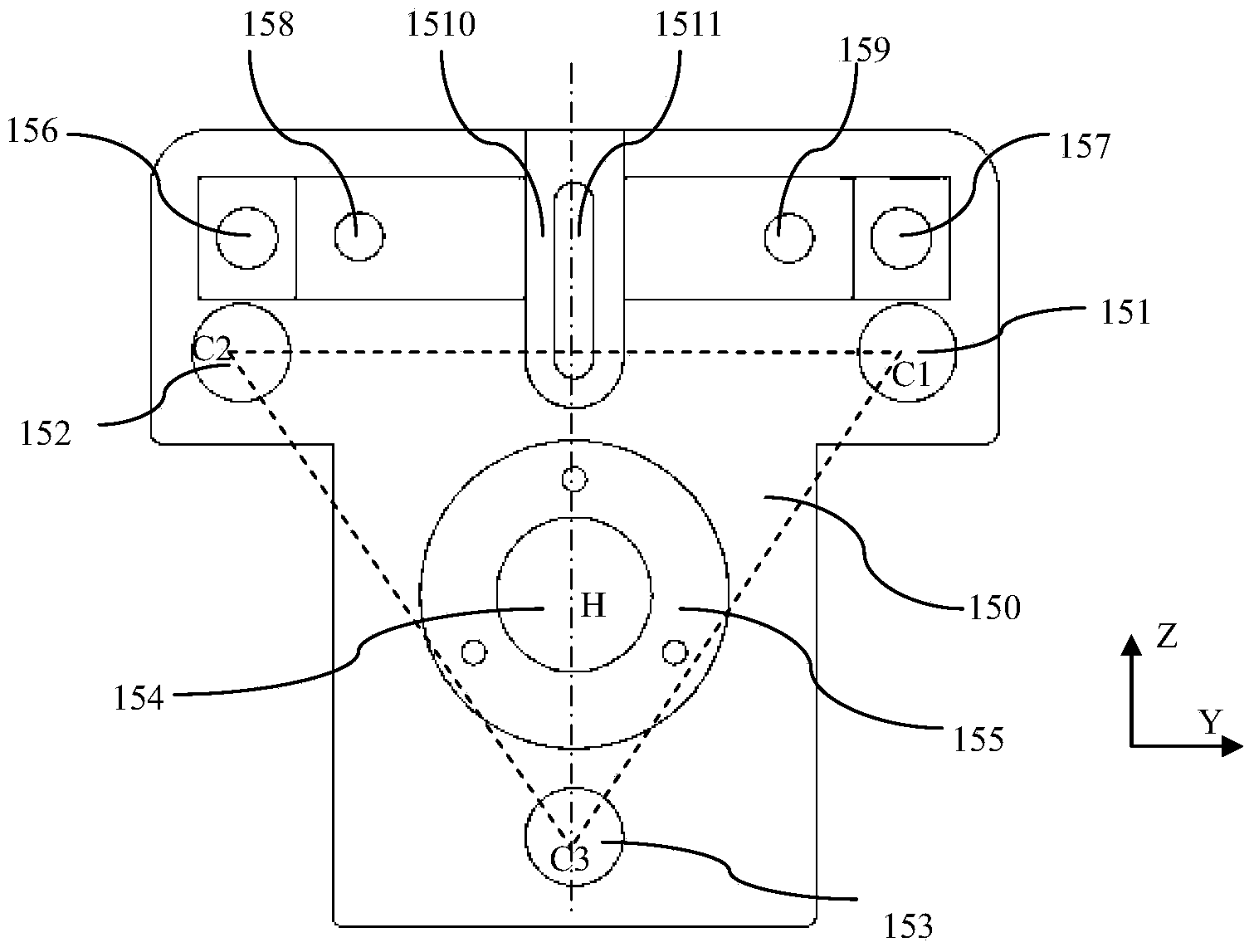

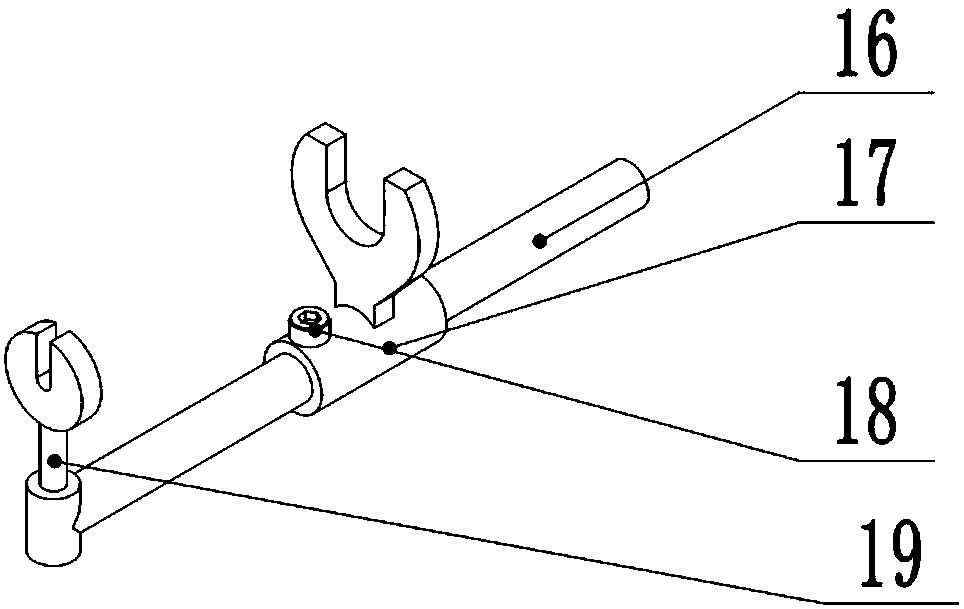

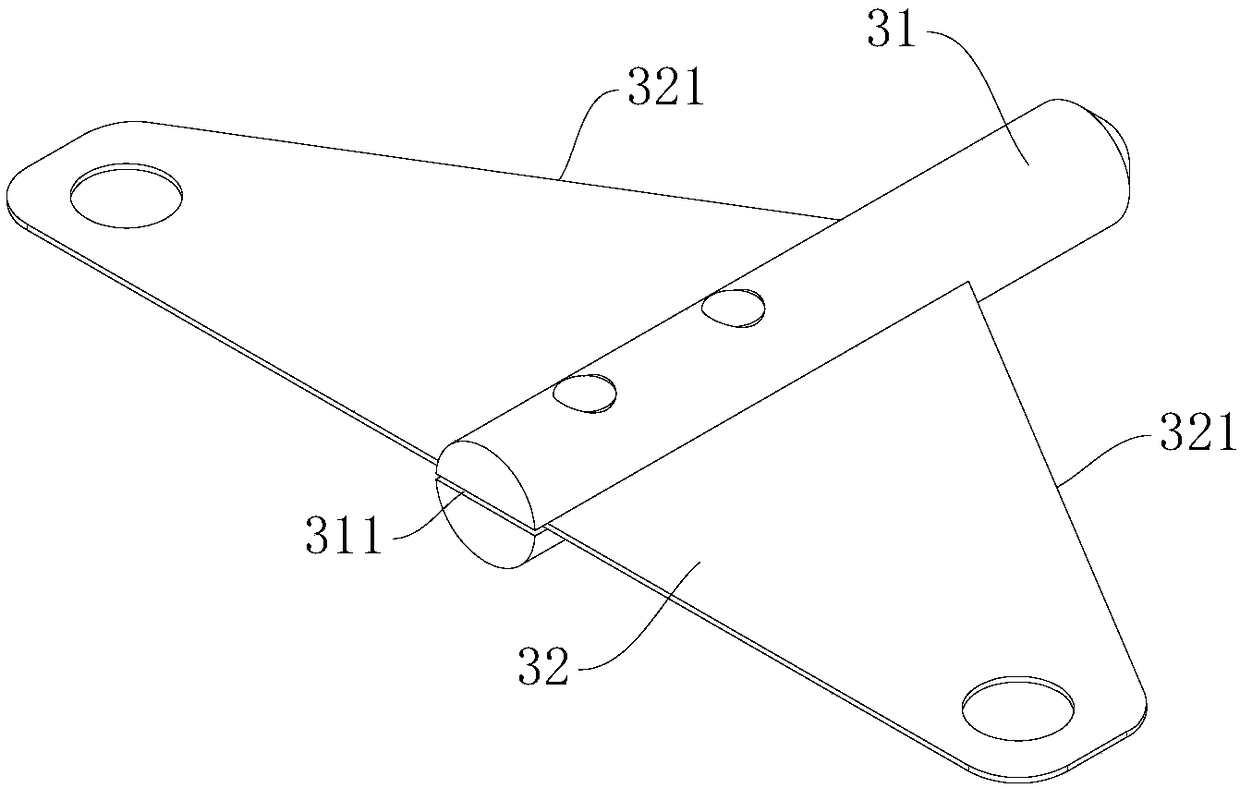

Injection pump, injection system and injection method

ActiveCN103511216AReduce stress concentrationReduce wearPump controlPumpsIsoetes triquetraEngineering

The invention provides an injection pump. The injection pump comprises a base, a motor, an injector tube pressing block, three X-axis parallel guide rods, a lead screw and an injector handle assembling mechanism, wherein the motor, the injector tube pressing block and the three X-axis parallel guide rods are installed on the base, the lead screw is driven by the motor, the injector handle assembling mechanism is provided with three guide holes, an injector handle limiting groove and a drive hole, the lead screw is matched with the drive hole to form a lead screw pair, and the guide rods are matched with the guide holes to form a sliding pair; the centers of the three guide holes are located on three vertexes of an equilateral triangle, the center of the drive hole is located in the center of the equilateral triangle, and the symmetrical axis of the injector handle limiting groove coincides with the Z-axis center line of the equilateral triangle. The invention further provides an injection system and an injection method through which the parallel control can be achieved. The injection pump, the injection system and the injection method have the advantages of being high in injection precision and high in universality.

Owner:武汉奇书科技有限公司

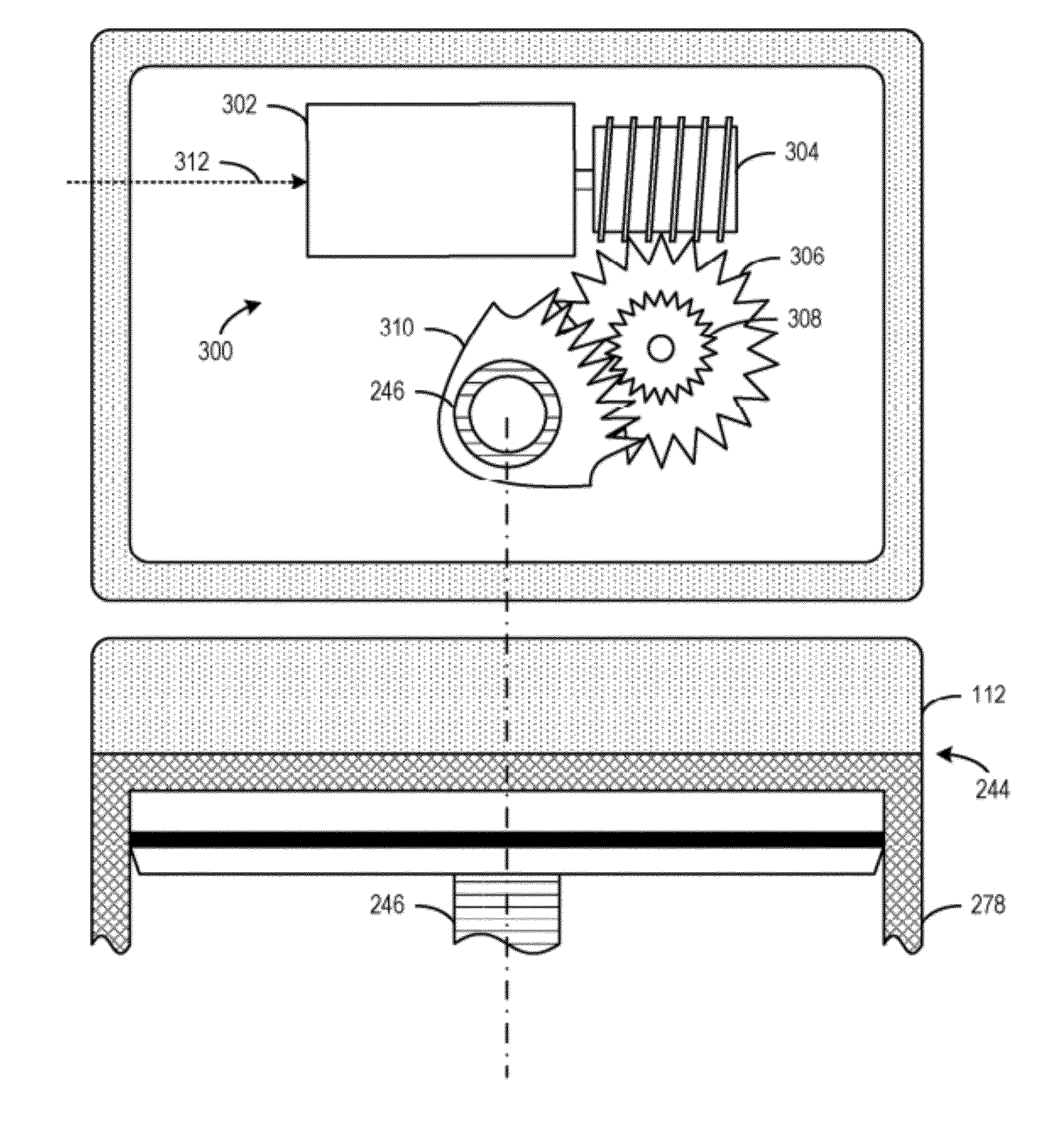

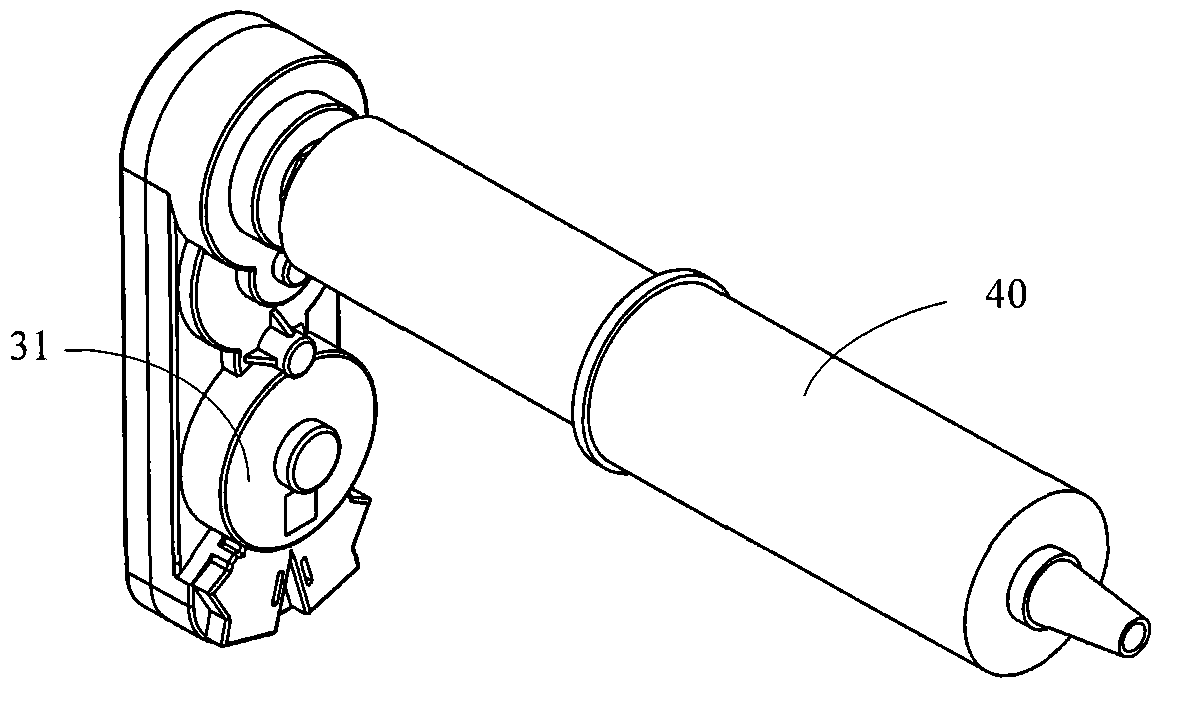

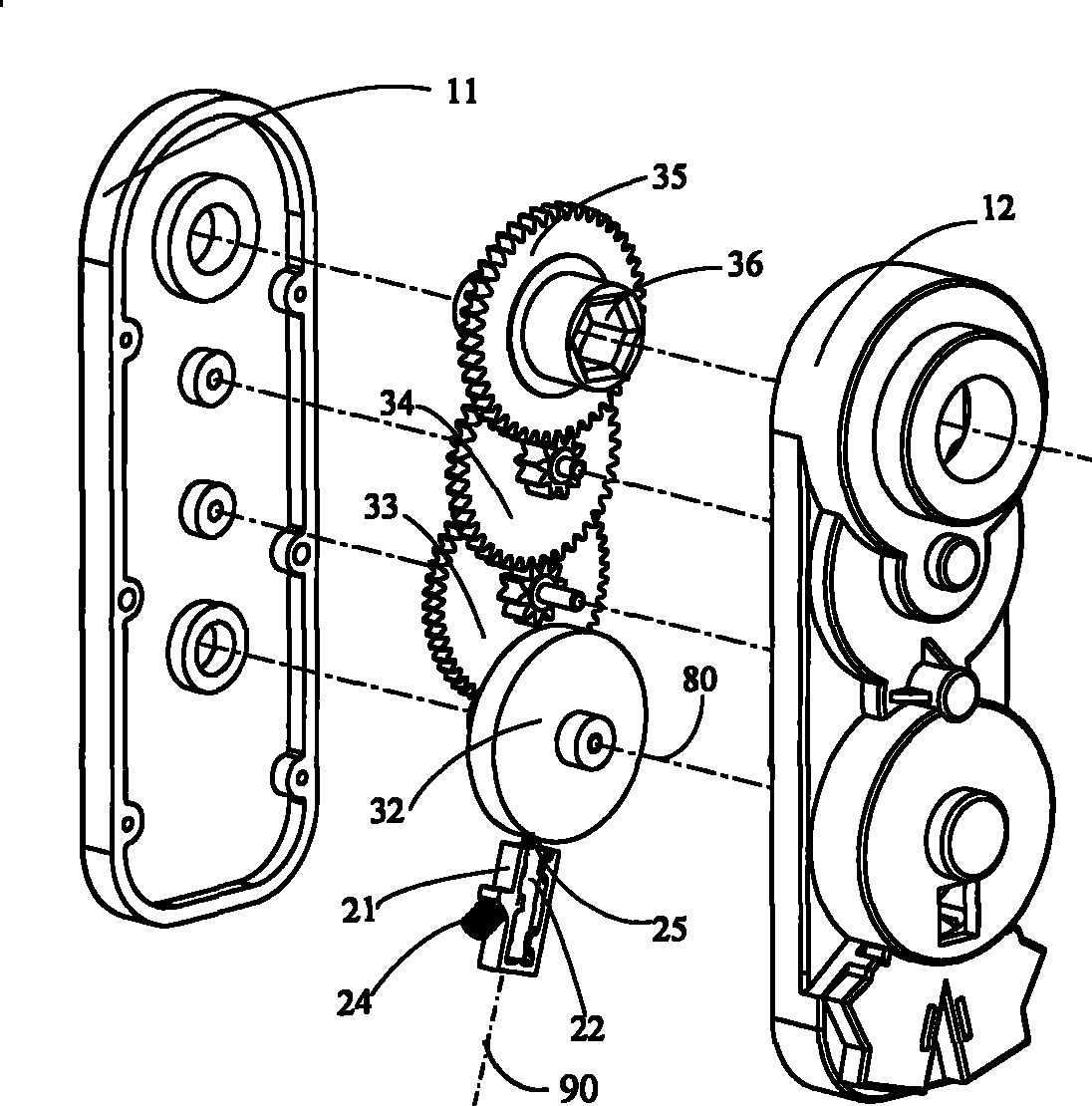

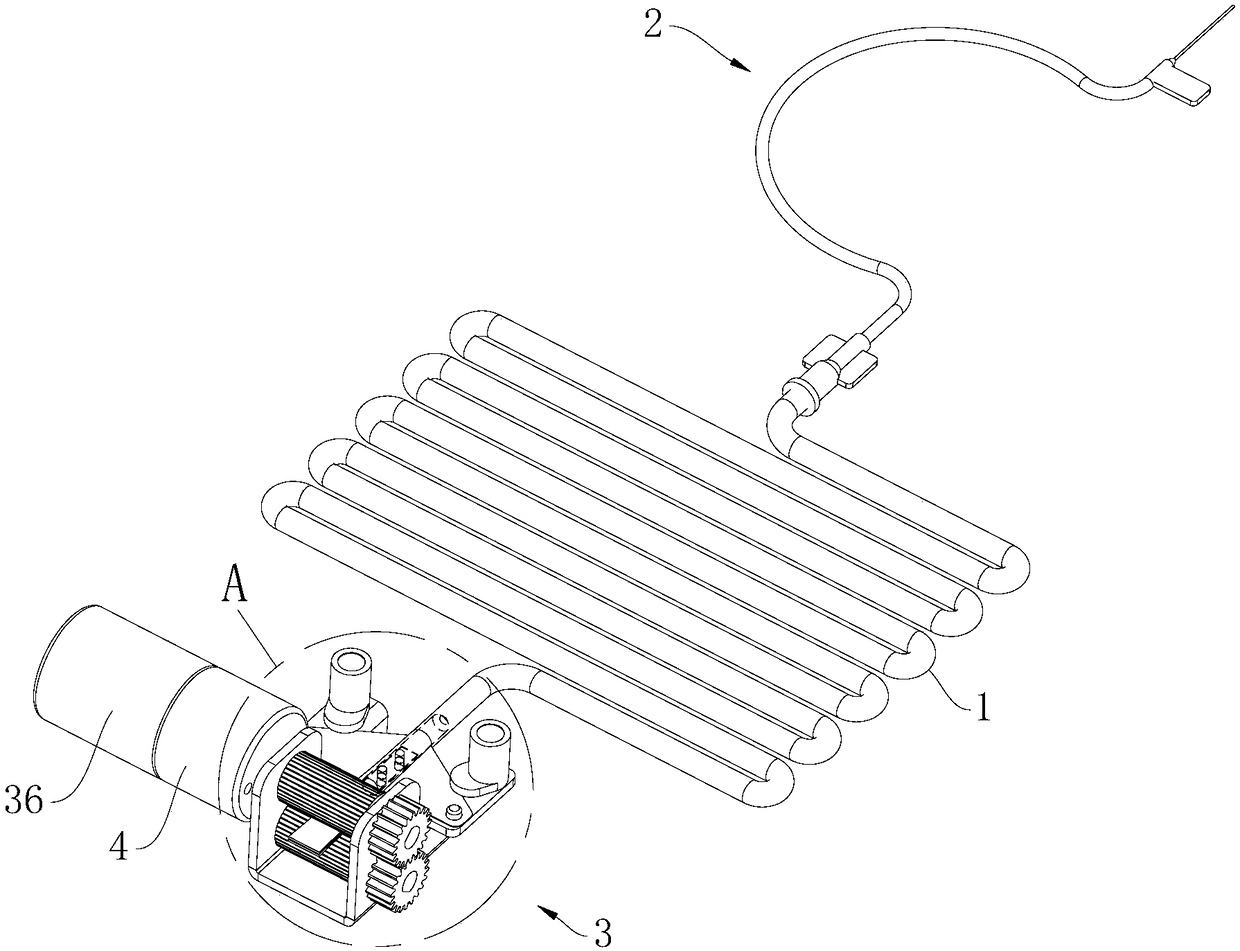

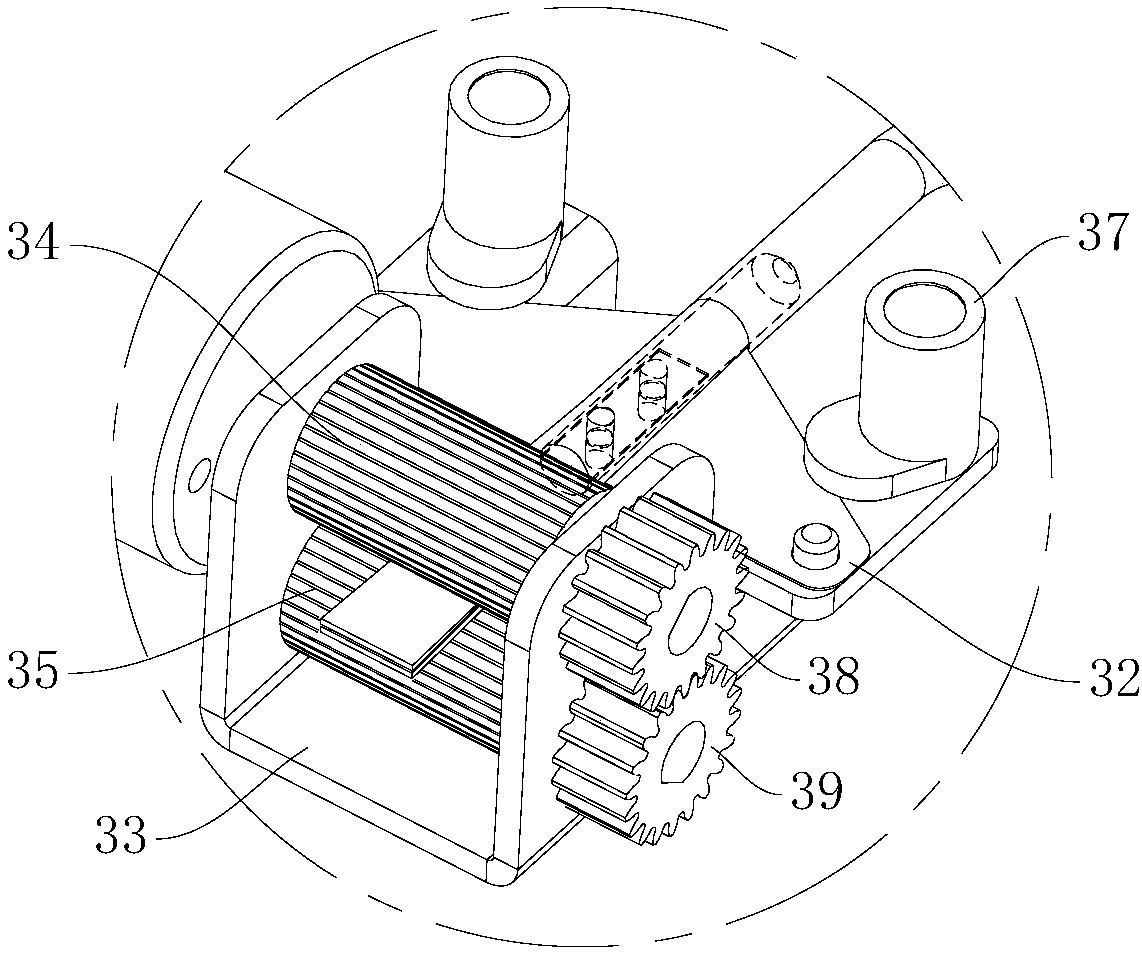

Injection pump

ActiveCN101745163BSmall gear ratioReduce in quantityIntravenous devicesPumpsElectricityPiezoelectric generator

The invention relates to an injection pump, comprising a casing, a motor assembly mounted inside the casing and an advancing mechanism connected with an injector, wherein the injection pump further comprises a gear transmission device connected between the motor assembly and the advancing mechanism, the motor assembly comprises a base and a piezoelectric motor mounted at the base; the piezoelectric motor drives the gear transmission device when being excited, and the gear transmission device then leads the advancing mechanism to rectilinear motion. The injection pump according to the embodiment of the invention has the advantages of simple structure, small volume, higher injection precision, etc.

Owner:JOHNSON ELECTRIC SHENZHEN

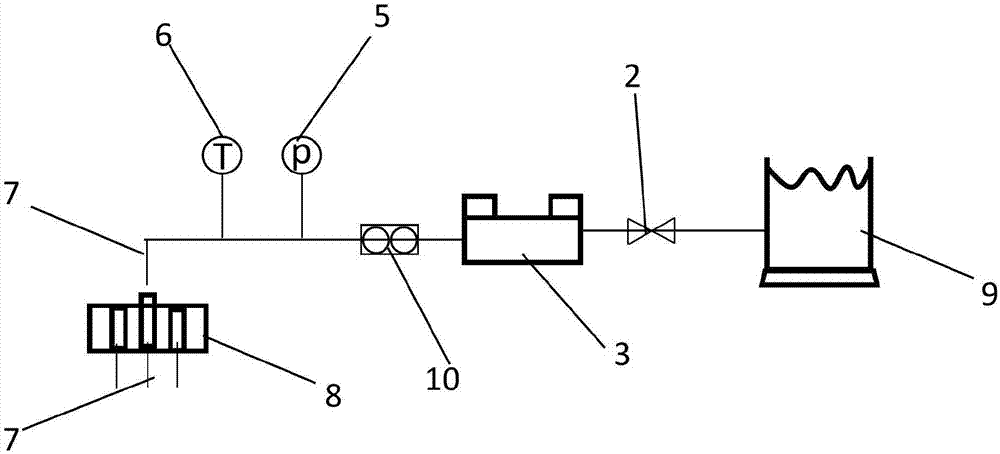

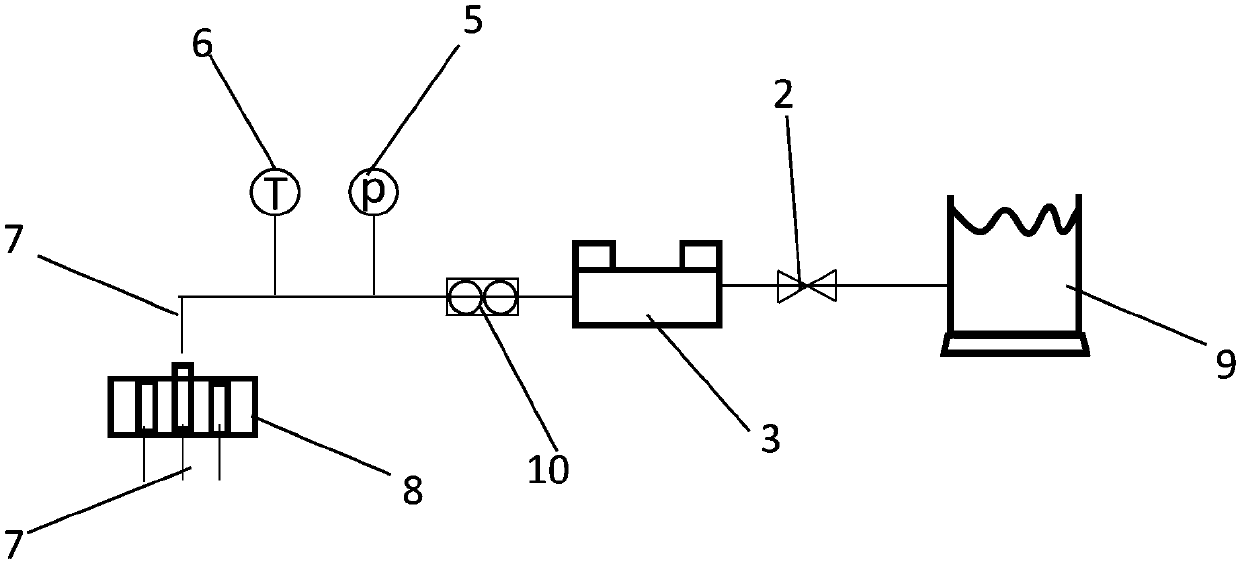

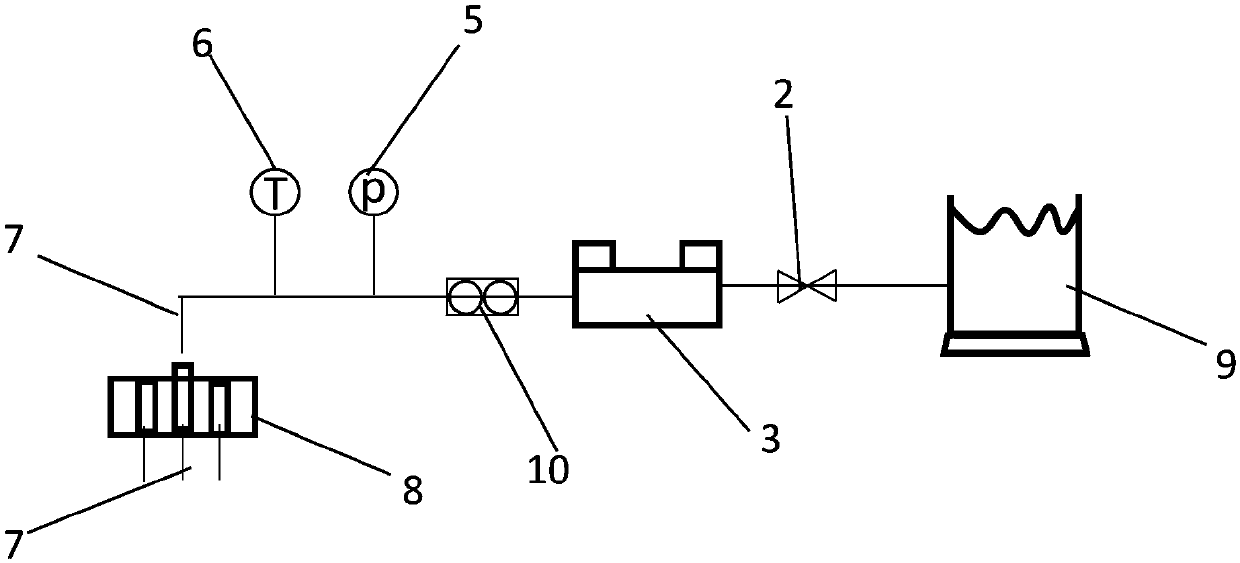

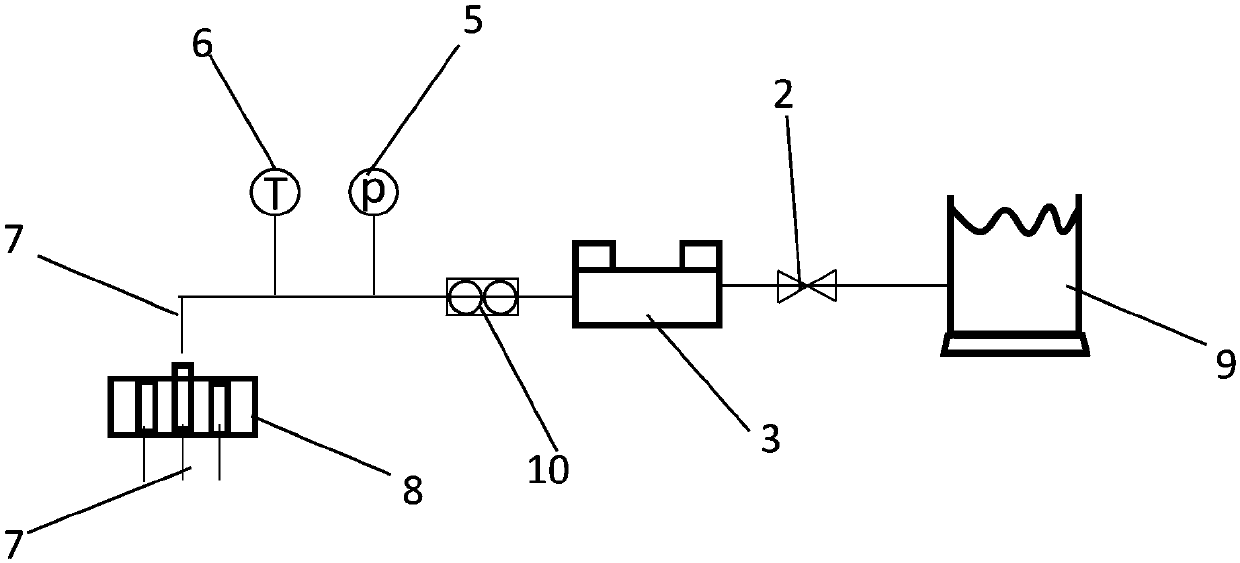

Chemical flooding photoetching glass model microcosmic experiment device for natural gas hydrates

InactiveCN107514249AImprove injection accuracyEfficient collectionFluid removalDecompositionMonitoring system

The invention discloses a chemical flooding photoetching glass model microcosmic experiment device for natural gas hydrates and relates to the field of natural gas hydrate development. The device comprise a gas supply system, a liquid supply system, a simulation pore model system, a chemical flooding system, a production system and a monitoring system. In the device, photoetching glass is adopted to serve as the main body of the simulation pore model system, nature gas and water are injected into the simulation pore model system through the gas supply system and the liquid supply system so as to form the natural gas hydrates, a chemical agent is injected through the chemical flooding system so as to simulate chemical flooding exploitation, the products decomposed by the natural gas hydrates are collected through the production system, and the growth and decomposition parameters of crystals in the natural gas hydrate experiment process are collected through the monitoring system. The photoetching glass used in the device is made in the mode that plain glass is subjected to precise photoetching by using a photochemical etching technology according to the real pores of natural core casting body slices, the precision of the experiments is ensured, and a certain guidance effect on research on the natural gas hydrates is achieved.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

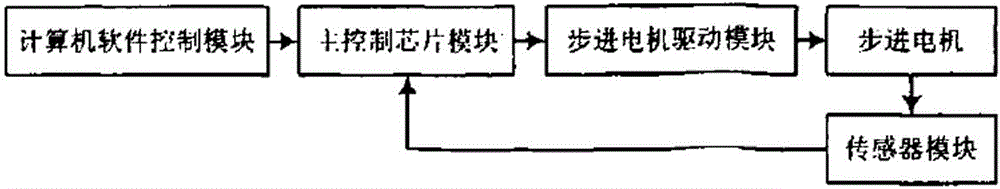

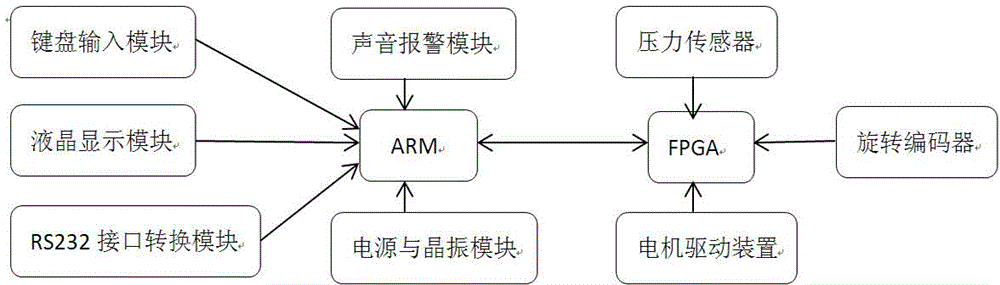

Multi-channel micro-injection pump

InactiveCN104623759AFunction increaseEasy to handlePressure infusionProgramme total factory controlMultiple injectionAutomatic control

The invention relates to the field of modern electronics, in particular to a multi-channel micro-injection pump. The multi-channel micro-injection pump is composed of a computer software control module, a main control chip module, a stepping motor driving module, a stepping motor and a sensor module in a sequence connection mode. The other end of the sensor module is connected with the main control chip module. The multi-channel micro-injection pump has an even deceleration and acceleration injection function, multiple injection pumps can be controlled to work in a linkage mode, and a good man-machine conversion interface and a good data processing function of a computer are used for achieving automatic control. A combination of ARM+FPGA is adopted for hardware, the advantages of an excellent logic time sequence function and good parallel processing performance of an FPGA are brought into full play, high subdivision of stepping motor drivers improves injection precision, multiple sensors are used for detecting the injection state, and intelligent precise injection and protection of an injector are successfully achieved.

Owner:掌蕴东

Fuel injection device

ActiveUS20110198418A1Improve injection accuracyReduce variationSpray nozzlesFluid pressure injection controlEngineeringPressure controlled ventilation

In a fuel injection device, a control body has a pressure control chamber, an inflow port and an outflow port. The inflow port and the outflow port are opened at an abutting surface exposed to the pressure control chamber. In the pressure control chamber is arranged a floating plate for pressing the abutting surface by a pressing surface with the pressure of the fuel to interrupt communication between the inflow port and the pressure control chamber. The abutting surface of the control body is provided with an outer opposite surface portion opposite to an outer edge of the pressing surface in a displacement axis direction of the floating plate, and the outer opposite surface portion has a special depressed portion that is depressed in the displacement axis direction and that extends along the shape of the outer edge of the pressing surface.

Owner:DENSO CORP

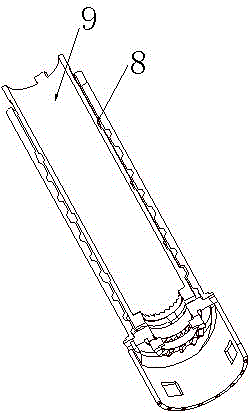

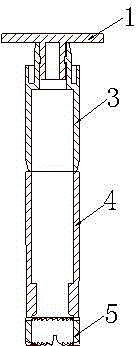

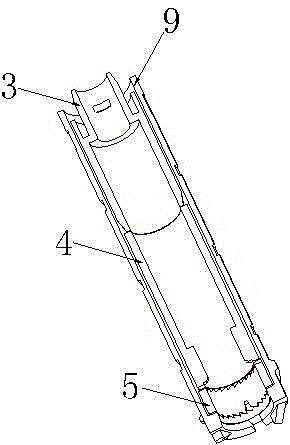

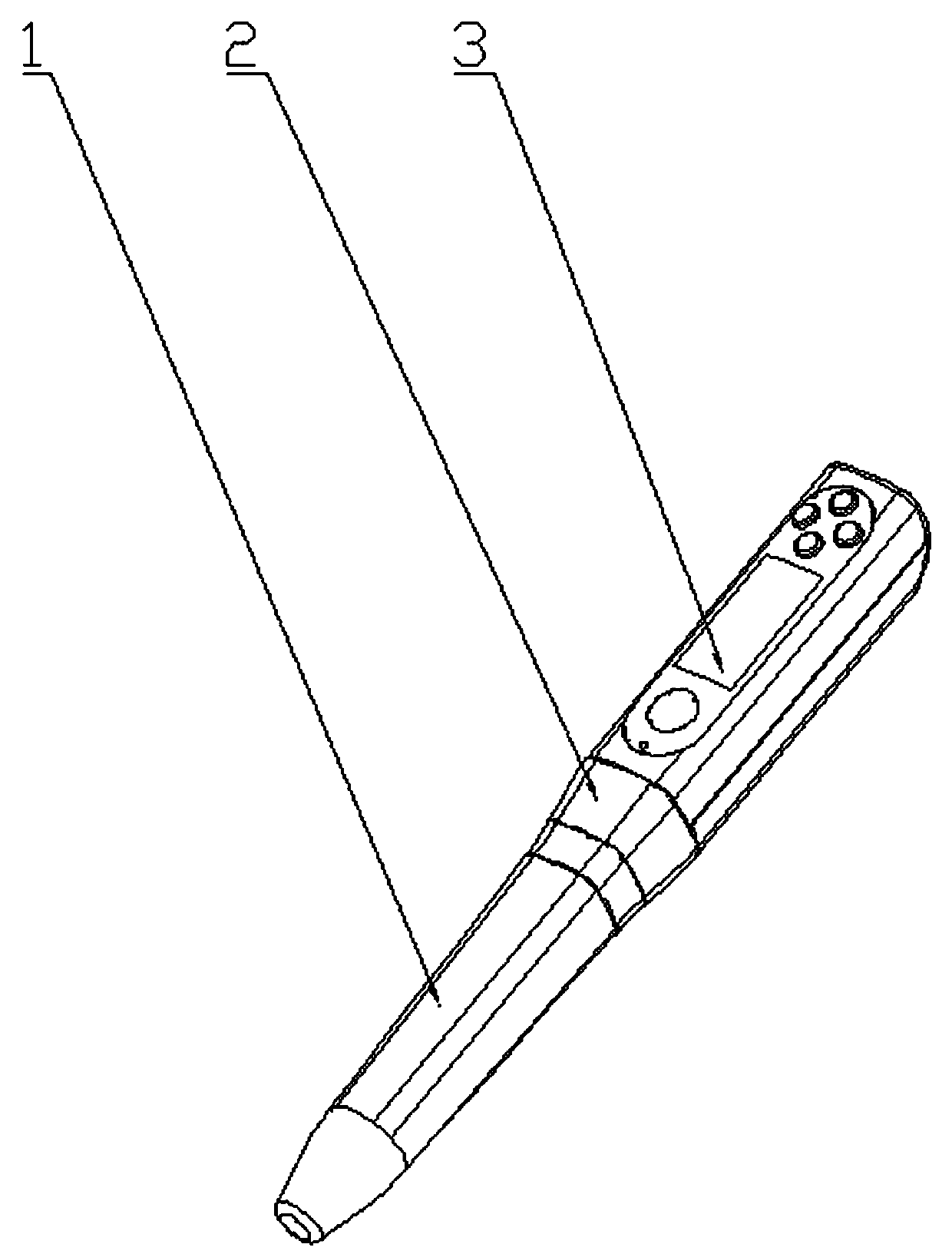

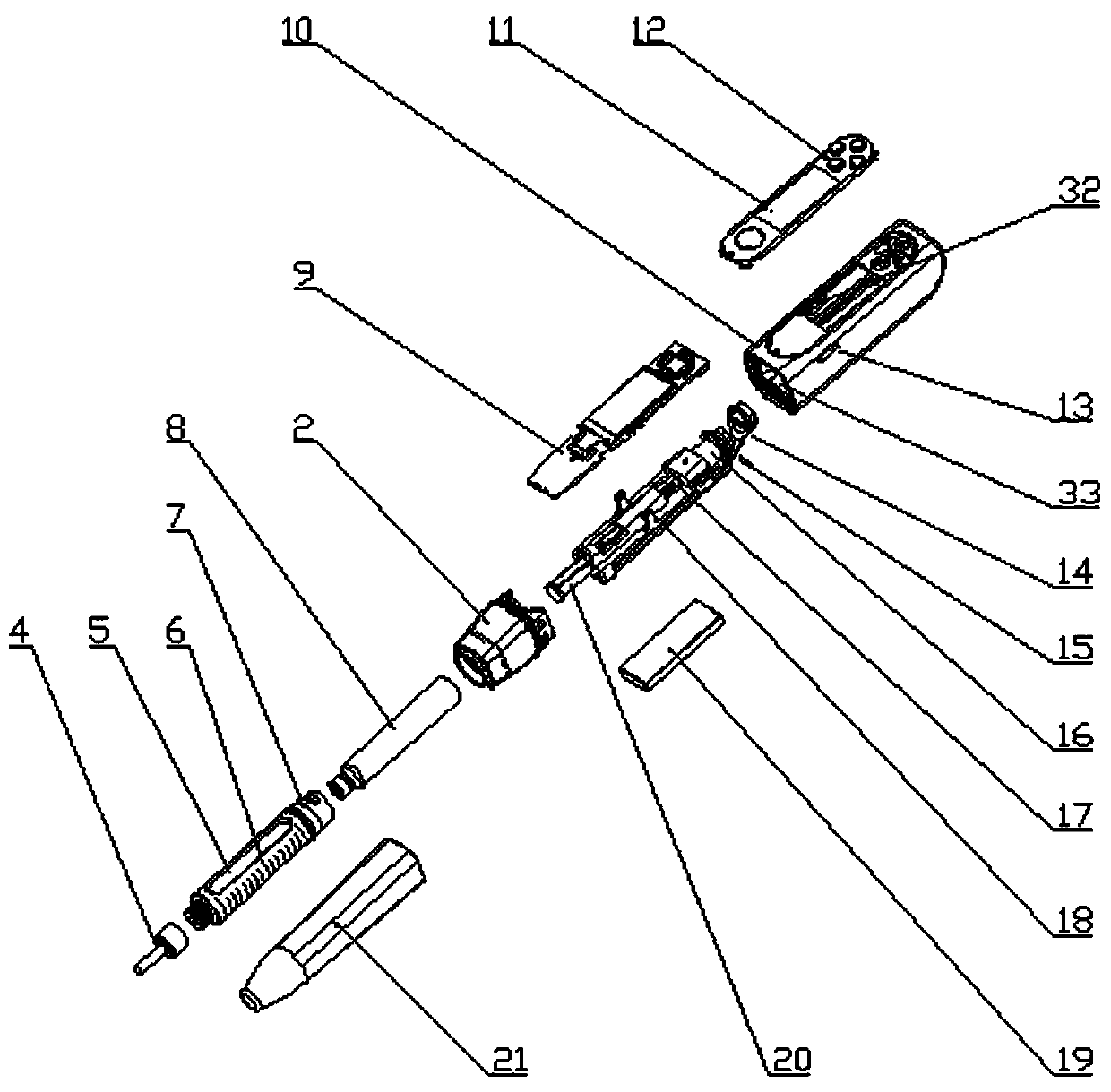

Novel electronic pen syringe

PendingCN110711294AImprove injection accuracySimple structureAutomatic syringesMedical devicesMedication injectionPharmacy medicine

The invention relates to a novel electronic pen syringe, and belongs to the technical field of drug injection. The electronic pen syringe comprises an injection component, an injection driving component and a control component. A front shell is arranged between the injection component and the injection driving component. The injection component mainly includes a medicine cartridge in which a medicine bottle can be placed. The injection driving component mainly includes a bracket, a motor, a driving screw and a push rod. The control component mainly includes a circuit board and a battery. The circuit board is fixed in a clamping groove at the upper part of the bracket, and the battery is fixed in a clamping groove at the lower part of the bracket. The motor is fixed on the rear end of the bracket. The driving screw and the push rod are placed in a cavity of the bracket. The bracket can be put into a casing along a clamping groove of the inner wall of the casing. A buckle is arranged atthe rear end of the front shell for being fastened on the casing. The bracket and components on the bracket are fixed in the casing. The electronic pen syringe has the characteristics of high injection accuracy, safety and reliability, simple structure, small size, convenient carrying and mass production.

Owner:杭州瀚科医疗科技有限公司

Fuel injection valve

InactiveUS8857743B2Improve injection accuracyCurb reboundSpray nozzlesFuel injection apparatusBiomedical engineeringValve seat

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil, a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature, and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the valve-closing spring is disposed on the armature, and the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle.

Owner:MITSUBISHI ELECTRIC CORP

Intelligent vacuum glue filling machine

InactiveCN107626528AImprove injection accuracyImprove insulation performanceLiquid surface applicatorsCoatingsPulp and paper industryAtmospheric pressure

The invention relates to an intelligent vacuum glue filling machine. The intelligent vacuum glue filling machine comprises a base. A vacuum cavity is formed in the base. A vacuum pump is arranged outside the vacuum cavity. A glue filling machine body is connected with the vacuum cavity in an inserted mode. A glue filling port of the glue filling machine body is inserted into the vacuum cavity forglue filling. A front sealing door and a rear sealing door used for maintaining the vacuum degree are arranged at the two ends of the vacuum cavity. The problems that the glue viscidity is too high, bubbles generated inside are not prone to being eliminated, the surfaces of products formed through glue injection are unsmooth, and the insulation performance is poor due to glue injection in the atmospheric pressure environment are solved. Through the intelligent vacuum glue filling machine, glue is injected in the vacuum state, bubbles can be prevented from being generated, the product glue injection precision and benefits are improved, and meanwhile, the appearance and insulation performance of the products are improved.

Owner:YANGZHOU DEFENDI INTELLIGENT EQUIP CO LTD

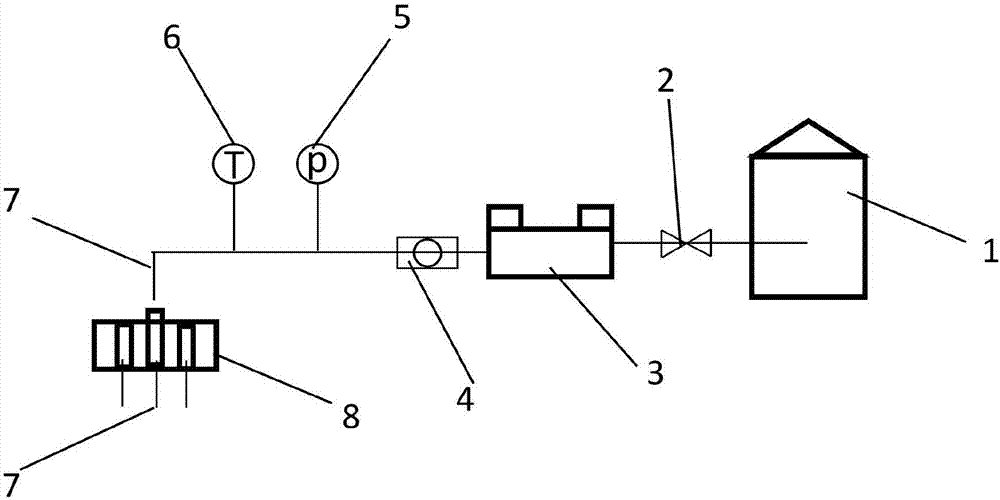

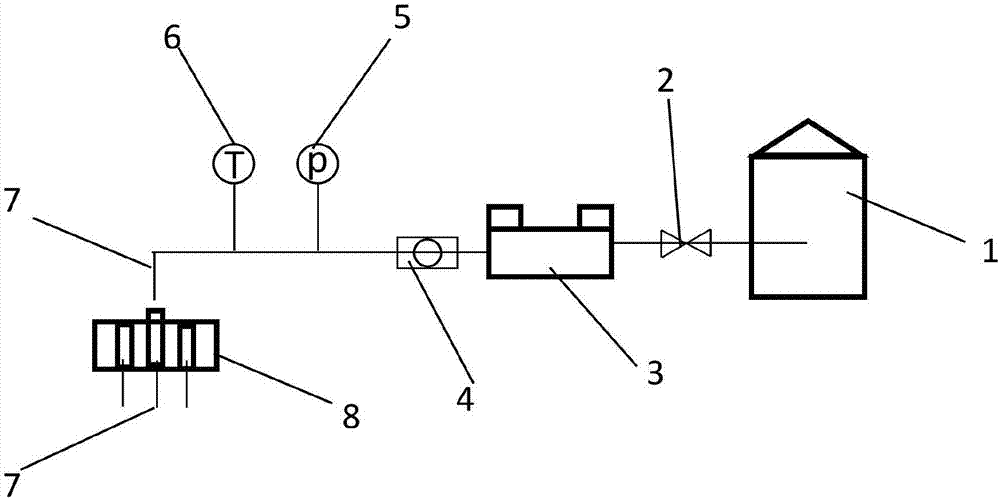

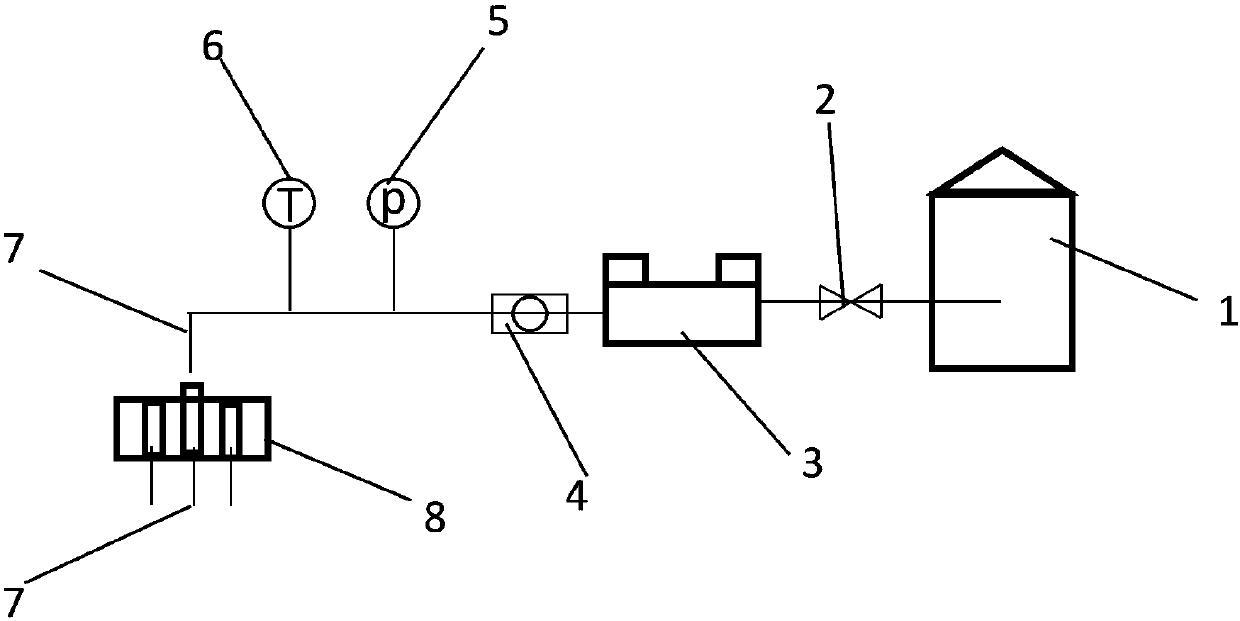

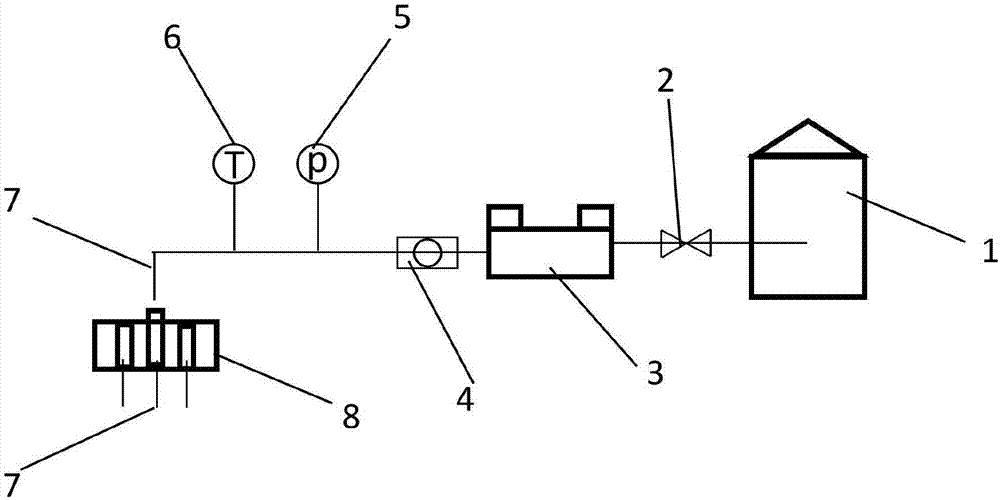

Experiment device for measuring physical property of natural gas hydrate

InactiveCN107764868AHigh precisionImprove injection accuracyMaterial resistanceMaterial analysis by transmitting radiationDecompositionProcess engineering

The invention discloses an experiment device for measuring a physical property of a natural gas hydrate, relating to the development field of natural gas hydrates. Specifically, the experiment deviceis an indoor experiment device for measuring specific parameters in generation and decomposition of the natural gas hydrate. The device comprises a gas supply system, a liquid supply system, an analogsystem and a monitor system. In the device, an insulated, transparent sand filling tube is used as a main body of the analog system, the gas supply system and the liquid supply system feed natural gas and water to the analog system so as to form the natural gas hydrate, and the monitor system collects parameters of temperature, pressure, physical property, resistance and other normal parameters of the natural gas hydrate in the whole generation and decomposition process of the natural gas hydrate. The experiment device stimulates the natural gas hydrate in a three-dimensional manner, and cansimulate the saturation of multiple sands and natural gas hydrates, thereby being capable of guiding the research of the physical property of the natural gas hydrate.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

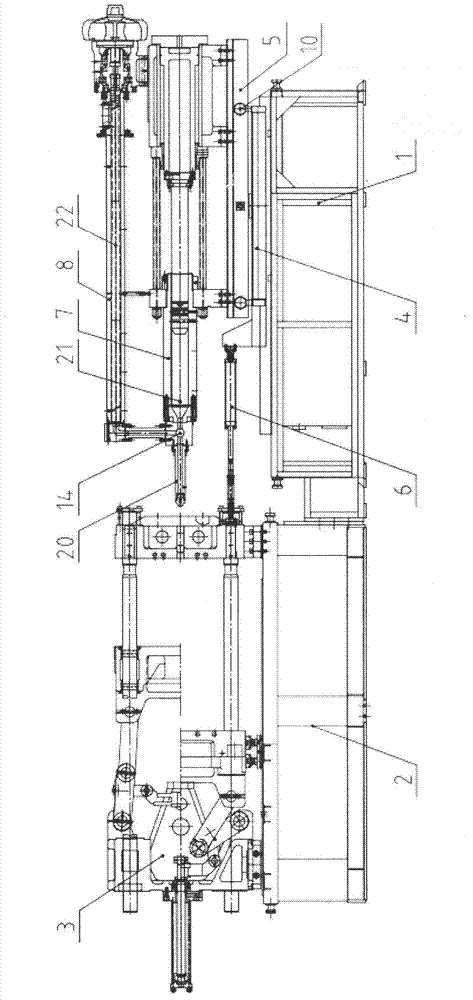

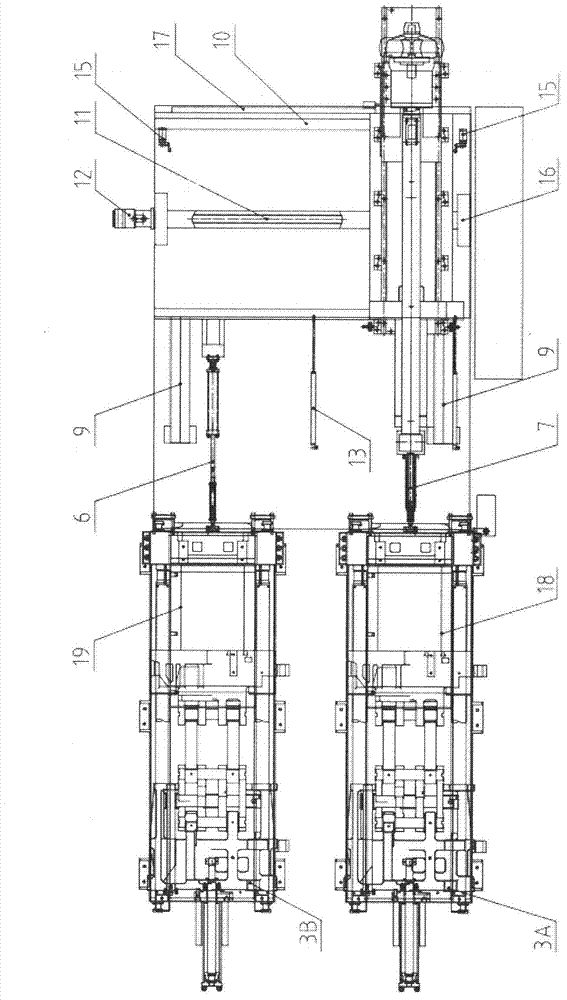

Bi-module-injection plastic extrusion and injecting molding machine

InactiveCN102962943ATake full advantage of cooldownIncrease productivityEngineeringEnergy consumption

The invention discloses a bi-module-injection plastic extrusion and injecting molding machine which comprises an injecting machine body (1), a module assembling machine body (2), an extruding and injecting device and module assembling devices (3), wherein the extruding and injecting device is arranged on the injecting machine body (1), and the module assembling devices (3) are fixed on the module assembling machine body (2). The bi-module-injection plastic extrusion and injecting molding machine is characterized in that the injecting machine body (1) is provided with a dovetail groove guide rail (9); the module assembling devices (3) are two; the extruding and injecting device comprises an integral inlet base (4), a horizontally moving slide seat (5), an integral inlet oil cylinder (6), an injection component (7) and a plasticized component (8); the lower part of the integral inlet base (4) is provided with a dovetail groove (9) which is sleeved on the dovetail groove guide rail (9), and the upper part of the integral inlet base (4) is provided with a horizontal guide post (10); the horizontally moving slide seat (5) is provided with a guide sleeve which is sleeved on the horizontal guide post (10) of the integral inlet base (4); the injection component (7) and the plasticized component (8) are installed on the horizontally moving slide seat (5); and one end of the integral inlet oil cylinder (6) is fixed on the integral inlet base (4), and the other end of the integral inlet oil cylinder (6) is fixed on the module assembling devices (3). According to the invention, a second module is produced by utilizing the cooling time of a first module, the energy consumption is saved, the production efficiency is improved, and the product weights of the two modules can be different.

Owner:TEDERIC MACHINERY

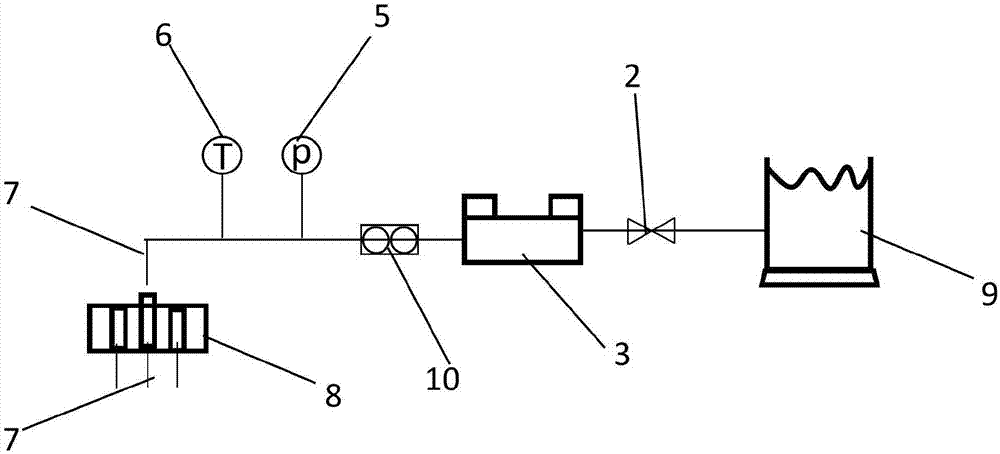

Experimental facility for simulating natural gas hydrate horizontal well fracturing

InactiveCN107701181AImprove injection accuracyEfficient collectionConstructionsFluid removalMonitoring systemX-ray

The invention discloses an experimental facility for simulating natural gas hydrate horizontal well fracturing, and relates to the field of natural gas hydrate exploration. The experimental facility comprises a gas supply system, a liquid supply system, a simulation system, a production system, a fracturing system and a monitoring system. The experimental facility adopts a sand filling box as a main body of the simulation system to simulate a natural gas hydrate reservoir and a horizontal well spacing mode, the natural gas hydrate formed by natural gas and water is supplied to the interior ofthe simulation system through the gas supply system and the liquid supply system, depressurizing production is carried out on the simulated reservoir through the production system, fracturing operation is conducted on the simulated natural gas hydrate reservoir through the fracturing system, and whole-process monitoring is carried out on the experimental process through the monitoring system. Theexperimental facility adopts a three-dimensional visualized mode to execute simulated fracturing to extract the natural gas hydrate, collecting is conducted on fracturing crack parameters through X-ray imaging, and the experimental facility has certain guiding effects on research of the natural gas hydrate fracturing mechanism.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Seawater driven photolithographic glass model microscopic experiment device for NGH (natural gas hydrate)

InactiveCN107632134AImprove injection accuracyEfficient collectionFuel testingSeawaterProcess engineering

The invention discloses a seawater driven photolithographic glass model microscopic experiment device for NGH (natural gas hydrate) and relates to the field of NGH exploitation. The device comprises agas supply system, a liquid supply system, a simulated pore model system, a seawater injection system, a production system and a monitoring system. According to the device, photolithographic glass istaken as a main body of the simulated pore model system, natural gas and water are supplied to the simulated pore model system by the gas supply system and the liquid supply system to form NGH, seawater is injected by the seawater injection system to simulate seawater injection exploitation, NGH decomposed products are collected by the production system, and crystal growing and decomposing parameters in the experiment process of NGH are collected by the monitoring system; the photolithographic glass is prepared with a photochemical etching technology by precisely photolithographing real poresof natural core casting slices onto plain glass, so that precision of the experiment is guaranteed, and the device has certain guidance function for study of NGH physical nature.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Double-step precision injection molding device

InactiveCN104441403ARealize self-locking sealNot prone to material stagnationHydraulic motorThrust bearing

The invention relates to the field of injection molding machines, in particular to a double-step precision injection molding device. The invention discloses the double-step precision injection molding device with the following structure, the device comprises a pre-injection storing mechanism, an injection mechanism, a hydraulic system and a spray nozzle, wherein the pre-injection storing mechanism comprises a front premolding material barrel, a premolding material barrel, a screw rod, a feeding seat and a hydraulic motor, and the hydraulic motor is used for driving the screw rod to rotate; the injection mechanism comprises a front material barrel, a material barrel, an injection seat, a plunger rod and an injection electro-hydraulic system; a double-acting cylinder is arranged between a thrust bearing and a sealed groove, and movements of the pre-injection storing mechanism, the injection mechanism and the spray nozzle are coordinated and controlled by the hydraulic system. The double-step precision injection molding device has the advantages that the flow channel is short, the stagnation of materials is avoided, and the injection precision is high.

Owner:浙江泰瑞重型机械有限公司

Ultra-high precision magnetostrictive injection pump with self-sensing function

InactiveCN108525070AImprove injection accuracyWide speed rangeMedical devicesPressure infusionBobbinControl system

The invention discloses an ultra-high precision magnetostrictive injection pump with a self-sensing function. The pump comprises a pump body, a syringe and a bracket, the pump body comprises a housingand left and right end covers at two ends of the housing, the inner axis of the inside of the housing is provided with a giant magnetostrictive rod, a piston and a transmission shaft from left to right, the transmission shaft is connected to the syringe through the right end cover, a plunger is arranged between the transmission shaft and the housing, a guiding ring is arranged between the plungerand the transmission shaft, a pump chamber filled with liquid is arranged between the plunger and the piston, a spring abutting the plunger is embedded in the right side of the piston, the outer portion of the giant magnetostrictive rod is sleeved with a coil bobbin, the piston is connected with the giant magnetostriction rod through the coil bobbin, a driving coil is arranged on the coil bobbin,a permanent magnet is arranged on the left end cover and is opposite to the driving coil, and the elongation of the giant magnetostrictive rod is adjusted in real time through a control system. The pump has high injection precision, wide speed regulation range and simple operation, is capable of self-sensing control, can effectively avoid errors caused by the manual operation, and is high in injection efficiency.

Owner:SHANGHAI INST OF TECH +1

Self-destructive precision infusion device

PendingCN108273153AImprove injection accuracyReduce the cross-sectional areaInfusion devicesRisk strokeSurgery

The invention discloses a self-destructive precision infusion device. The device comprises an infusion tube filled with medical liquid, an infusion needle arranged at the tail end of the infusion tubeand an injection mechanism arranged at the head end of the infusion tube; the injection mechanism comprises a piston which is inserted at the head end of the infusion tube and used for pushing the medicine liquid for feeding, a blade arranged at the end, away from the medical liquid, of the piston and a driving mechanism used for pulling the infusion tube separated by the blade for feeding; the blade is fastened with the driving mechanism and extends out of the infusion tube. Through the structural design and the arrangement of the infusion tube, the cross-sectional area of the piston can beeffectively reduced, the stroke of the piston can be effectively increased, and the liquid medicine injection precision can be effectively improved; in addition, through the arrangement of the injection mechanism, the product structure is greatly simplified, the injection precision is improved, and meanwhile the production cost of products is greatly reduced.

Owner:深圳中科光电医疗电子有限公司

Device for simulating natural gas hydrate row type horizontal well miscible-phase displacement mining

InactiveCN107514256AImprove injection accuracyEfficient collectionSurveyConstructionsMonitoring systemProcess engineering

The invention discloses a device for simulating natural gas hydrate row type horizontal well miscible-phase displacement mining, and relates to the field of natural gas hydrate development. The device comprises an air supply system, a liquid supply system, a simulation system, a fracturing system, an injection system, a production system and a monitoring system, the device adopts a sand filling box to serve as a main body of the simulating system, a row type horizontal well pattern can be simulated, and by means of the air supply system and the liquid supply system, natural gas and water are supplied into the simulation system to form a natural gas hydrate; fracturing operation is implemented through the fracturing system for simulating natural gas hydrate storage, carbon dioxide and a chemical agent are injected through the injection system to simulate miscible-phase displacement mining, associated gas and water are collected through the production system, and the whole experimental process is monitored through the monitoring system. Accordingly, an experimental device adopts a three-dimensional mode, the miscible-phase displacement mined natural gas hydrate is simulated, and a certain guiding effect on natural gas hydrate miscible-phase displacement mining mechanism study is achieved.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com