Patents

Literature

37results about How to "Without increasing number of component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

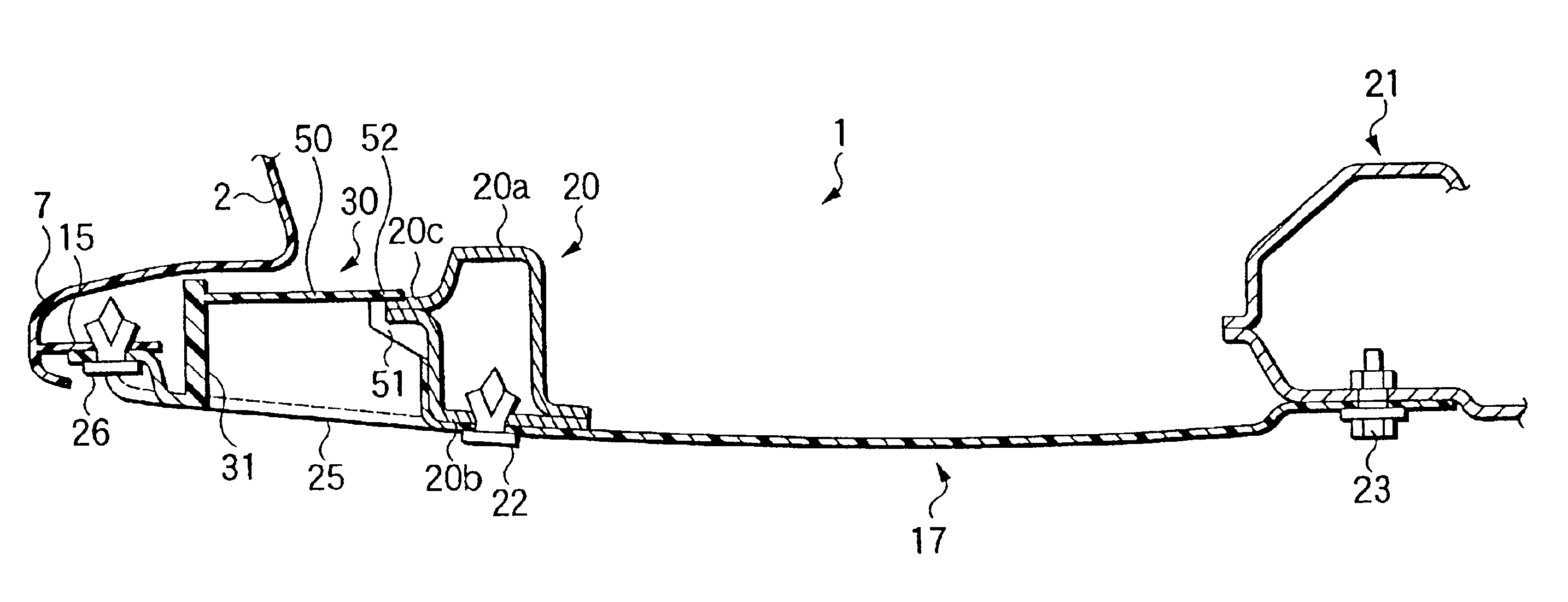

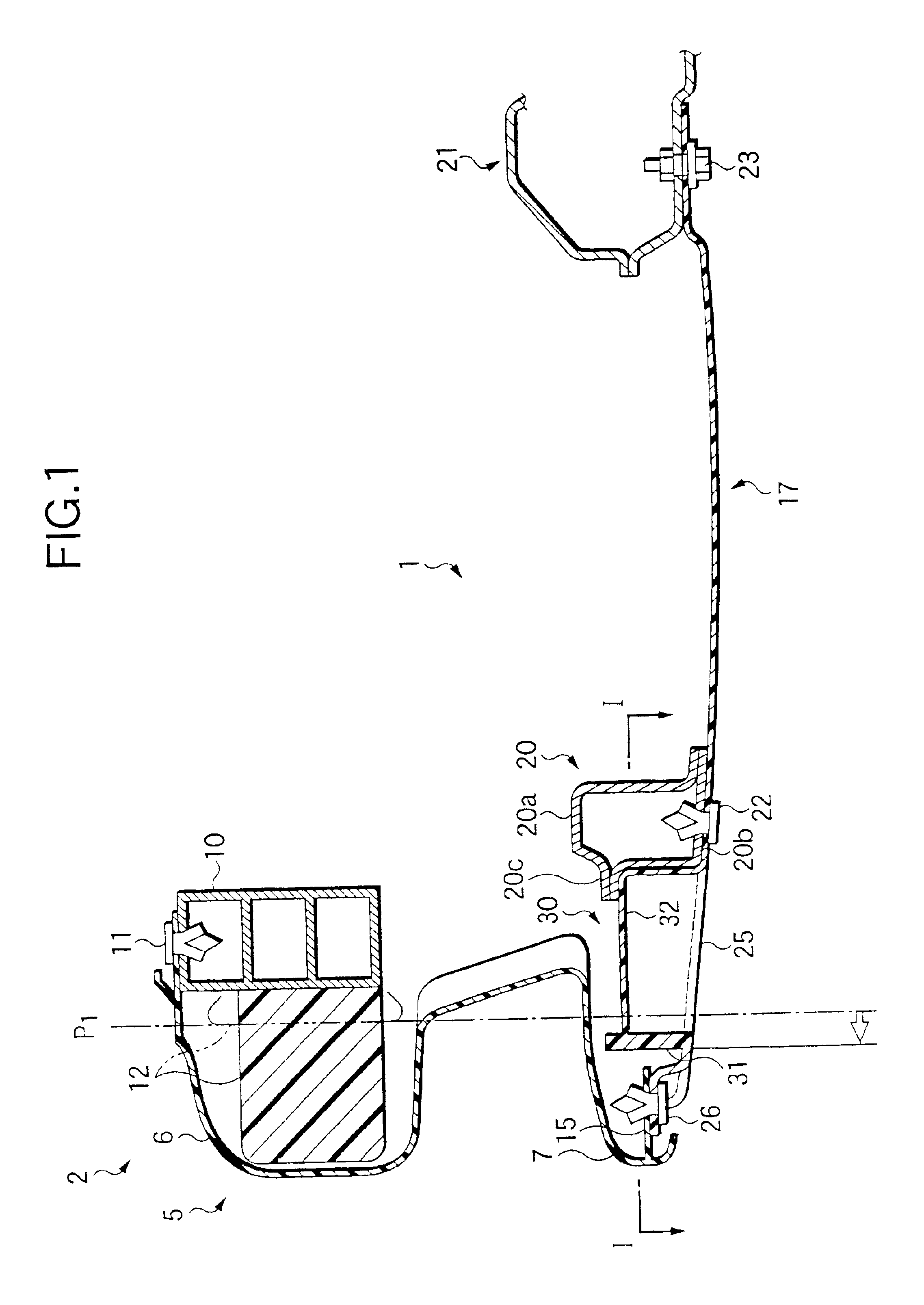

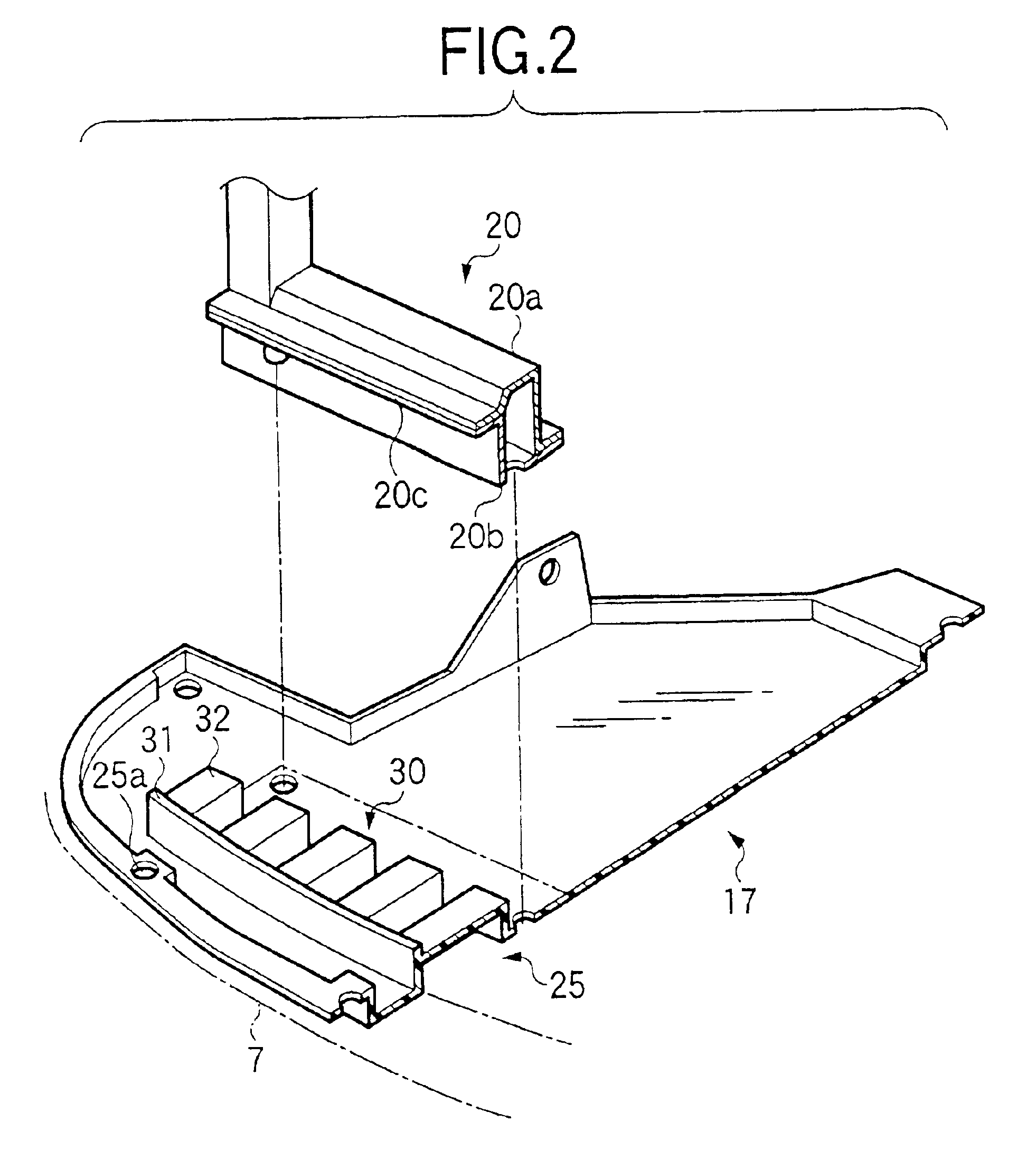

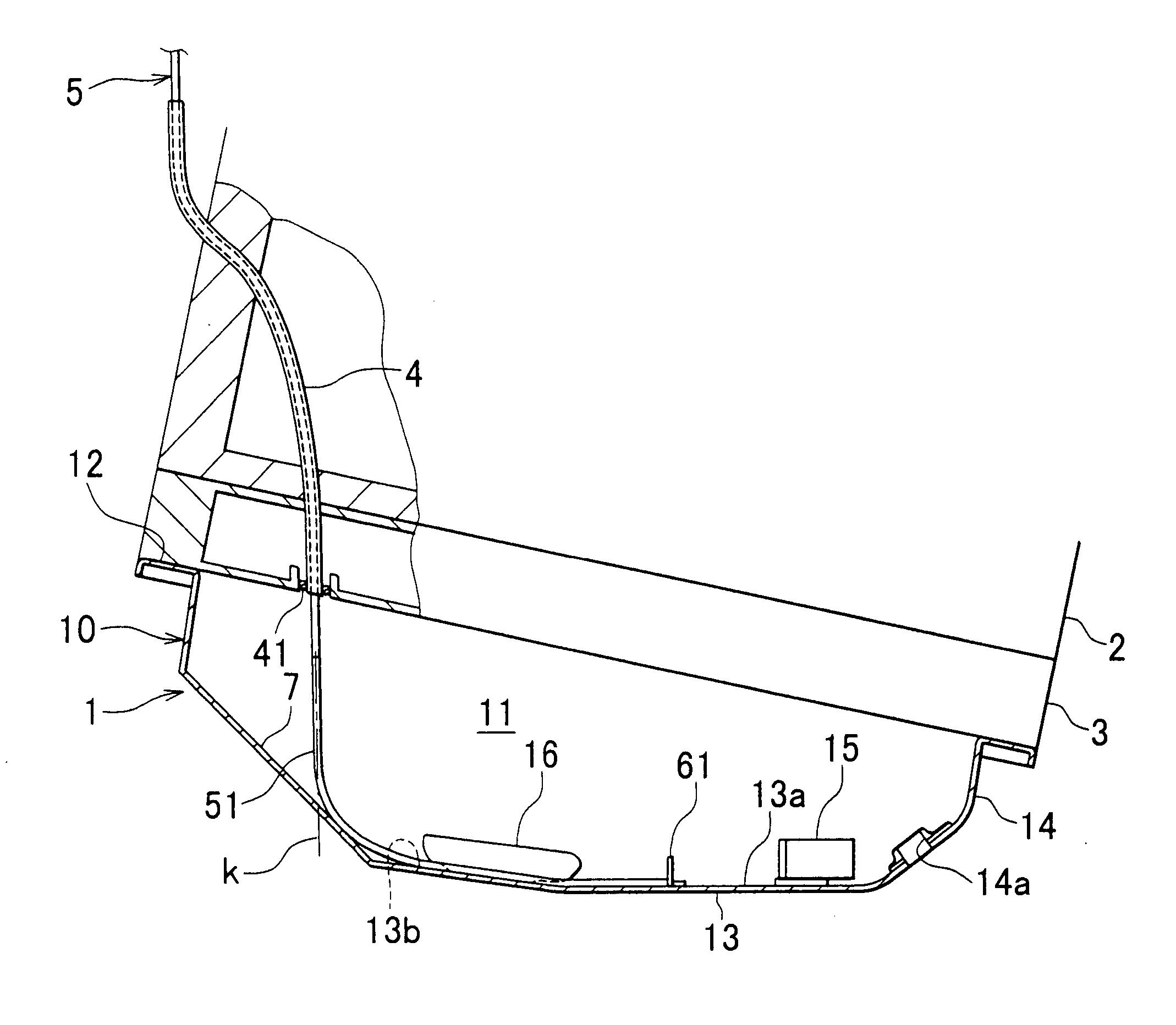

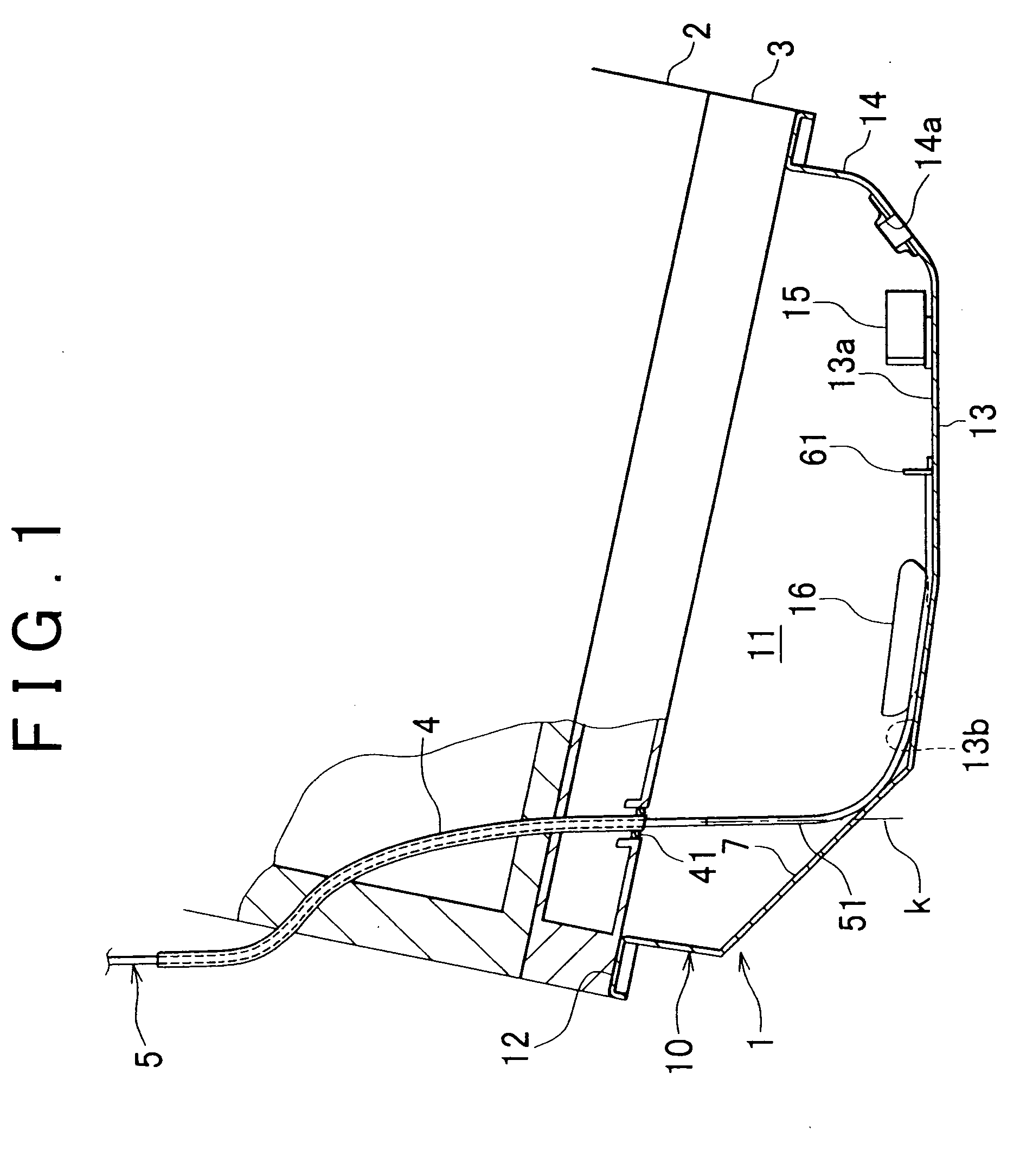

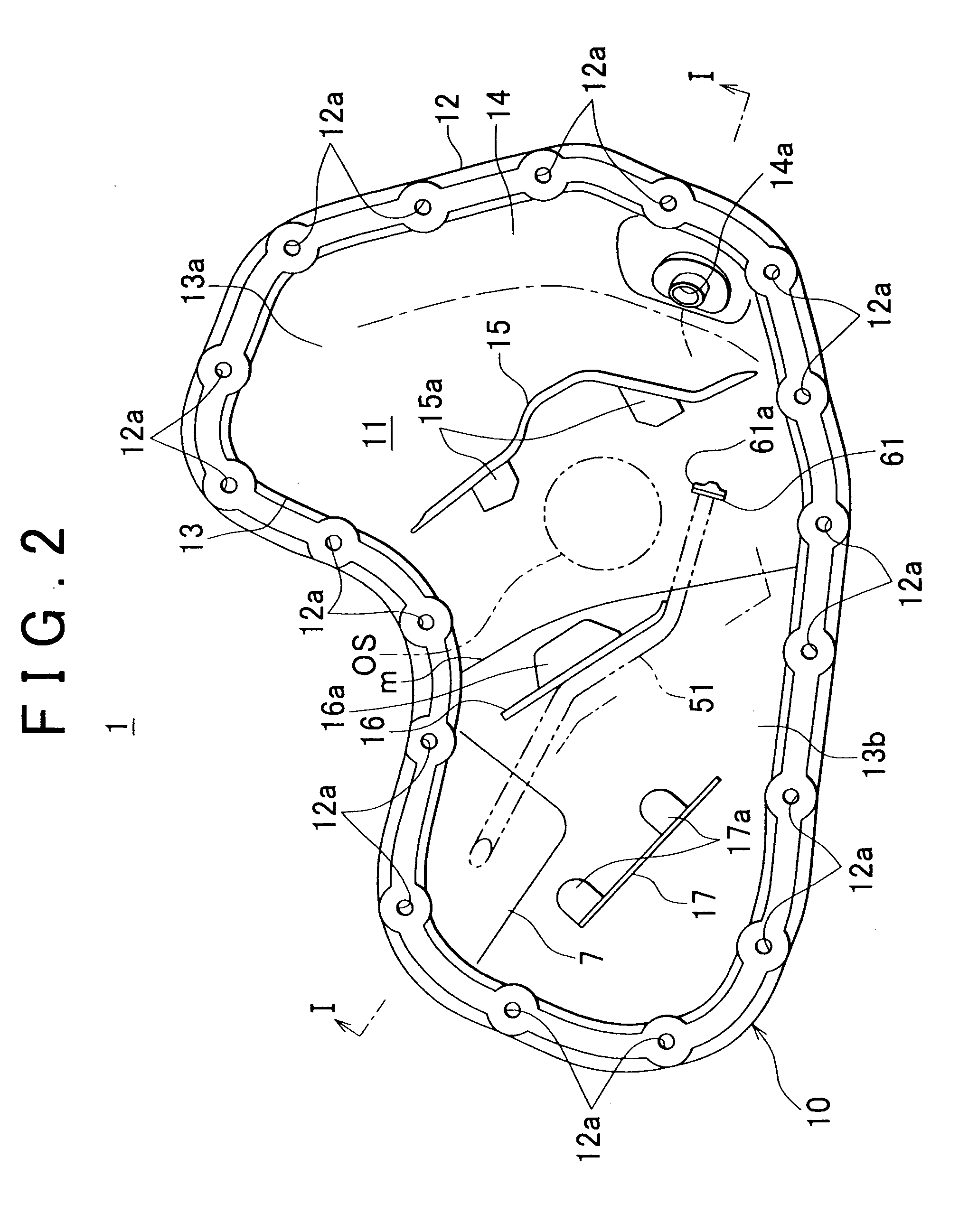

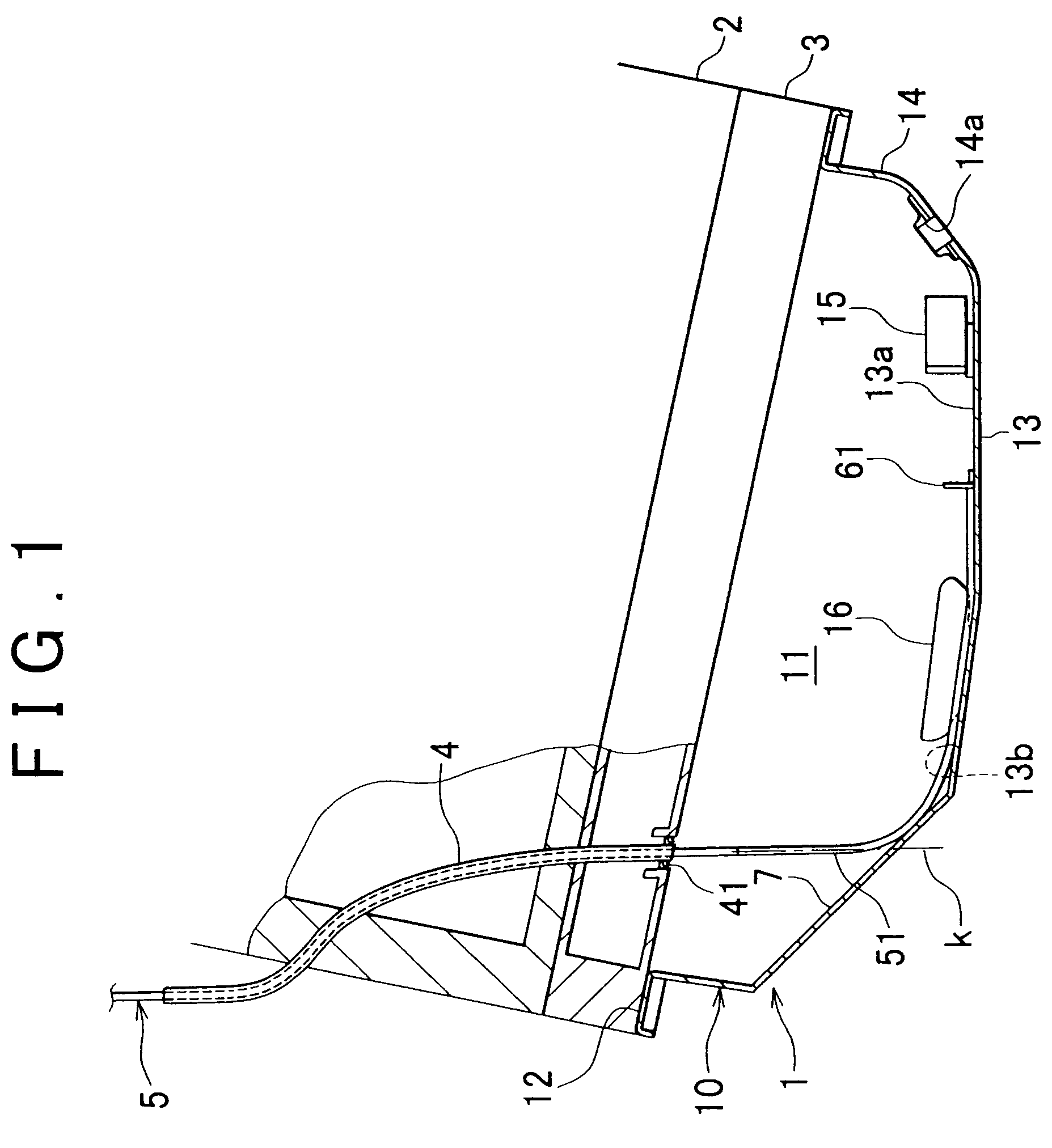

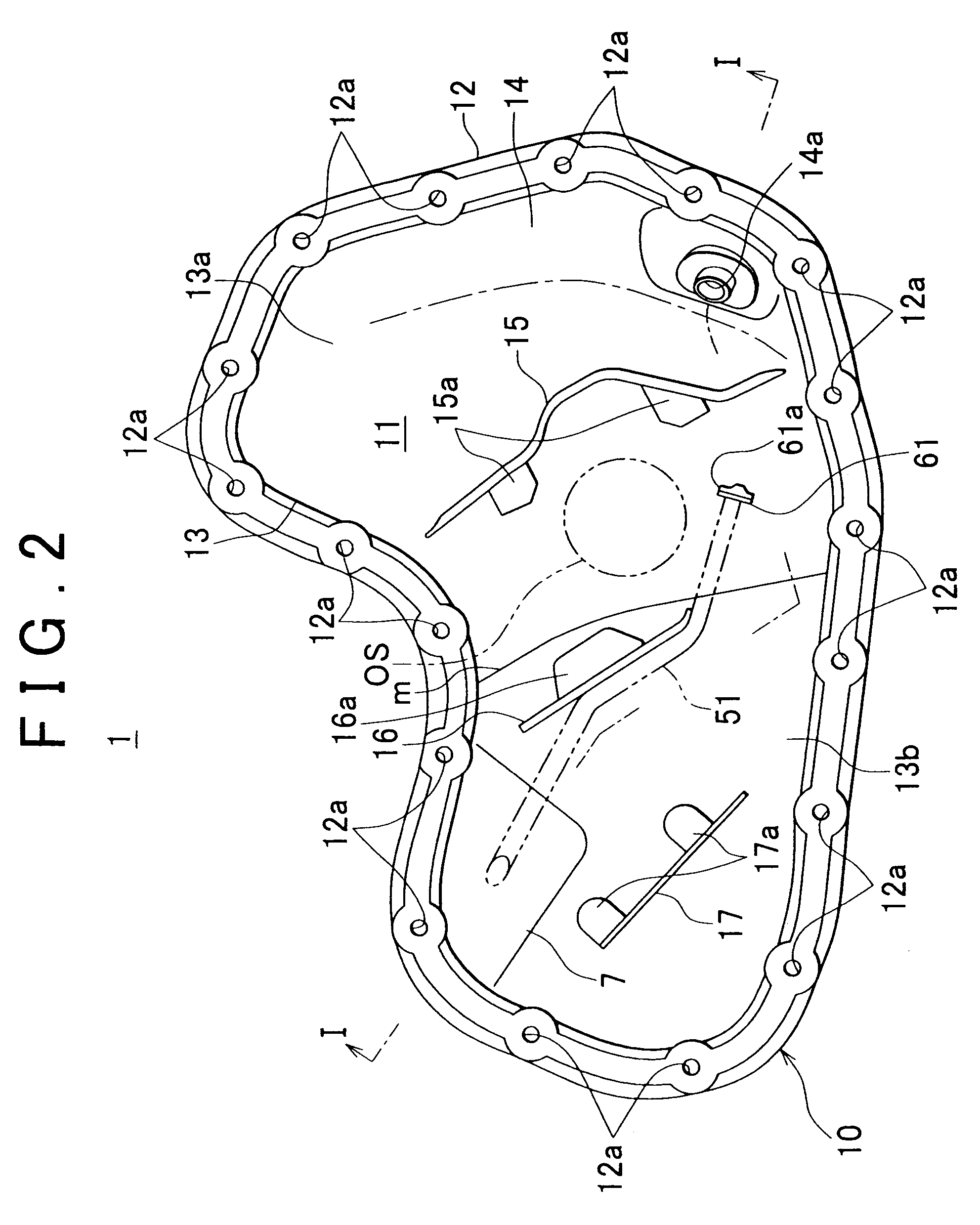

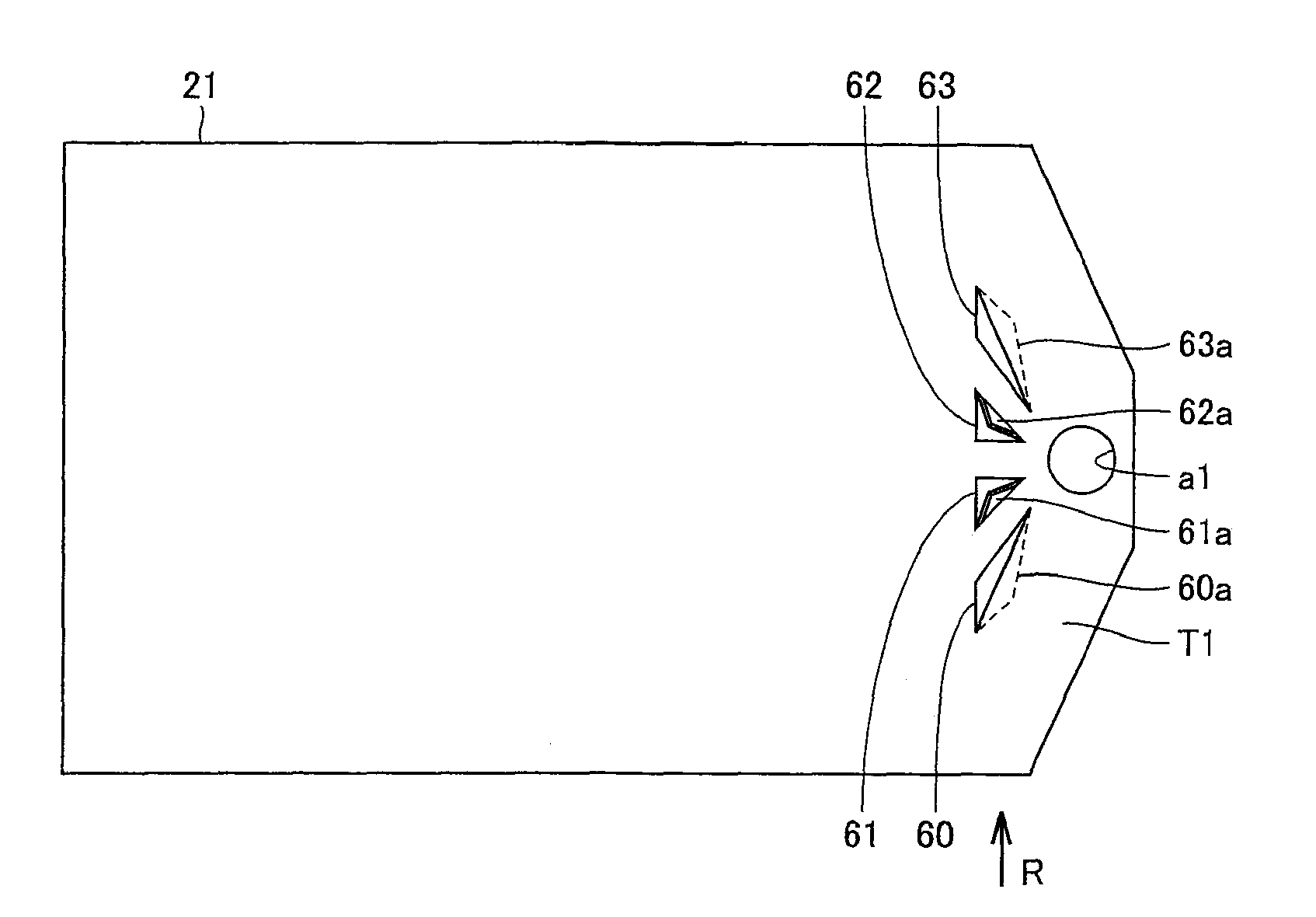

Bumper structure

InactiveUS6893064B2Without increasing number of componentSimple structureVehicle seatsPedestrian/occupant safety arrangementEngineeringMechanical engineering

A front portion of an under cover fastened to a cross member extends to the front, so that the extension is formed as a mounting bracket for a bumper face. A lower impact absorbing member is integrally formed on the bracket which lower impact absorbing member has a rib provided to erect from the bracket in such a manner as to be opposed to an inner vertical surface of a lower protruding portion of the bumper face and a plurality of beads disposed behind the rib for transmitting an impact from the rib to the cross member, to thereby provide a bumper structure with appropriate impact absorbing function at a lower portion thereof, with a simple structure and without increasing the number of components.

Owner:SUBARU CORP

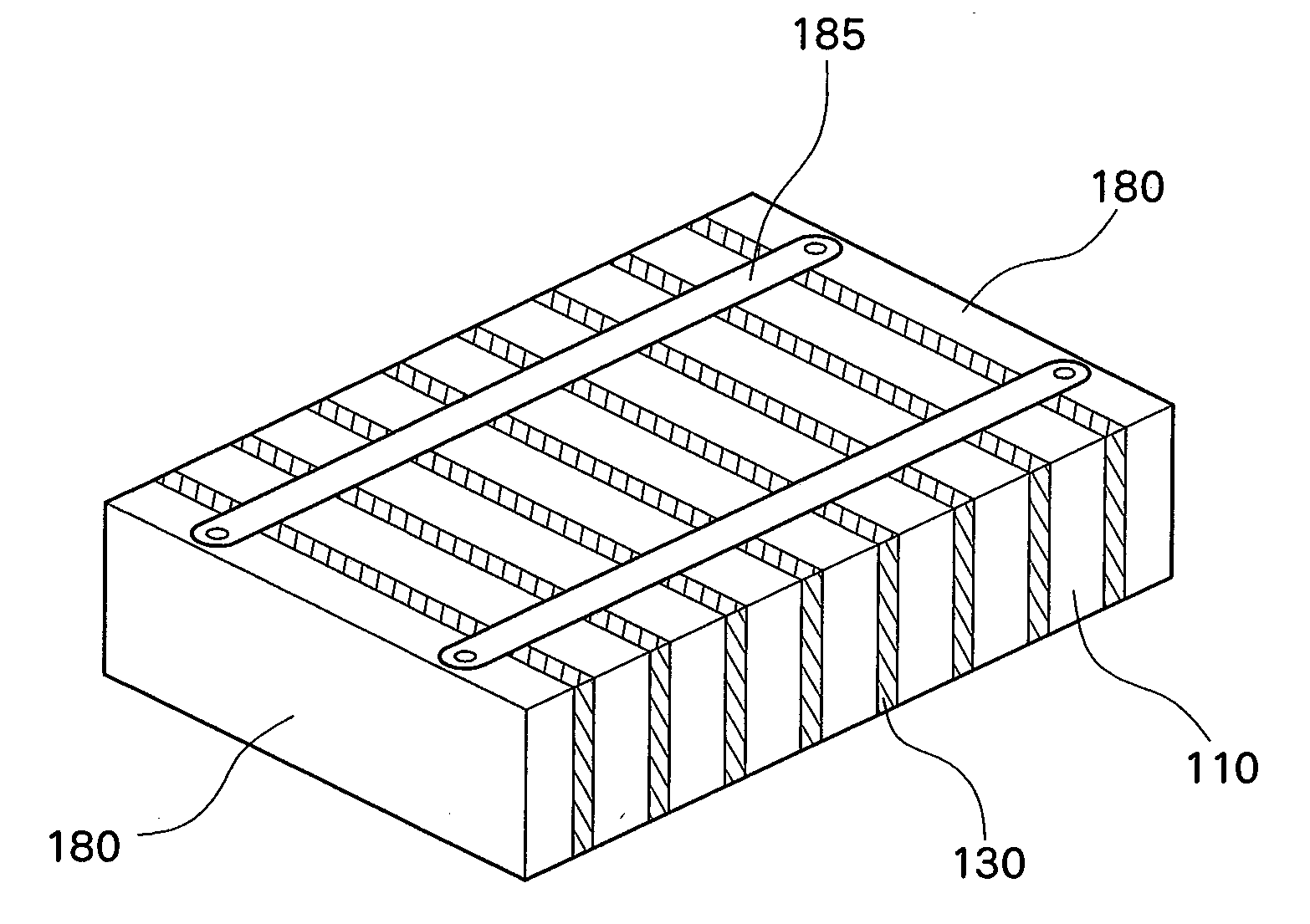

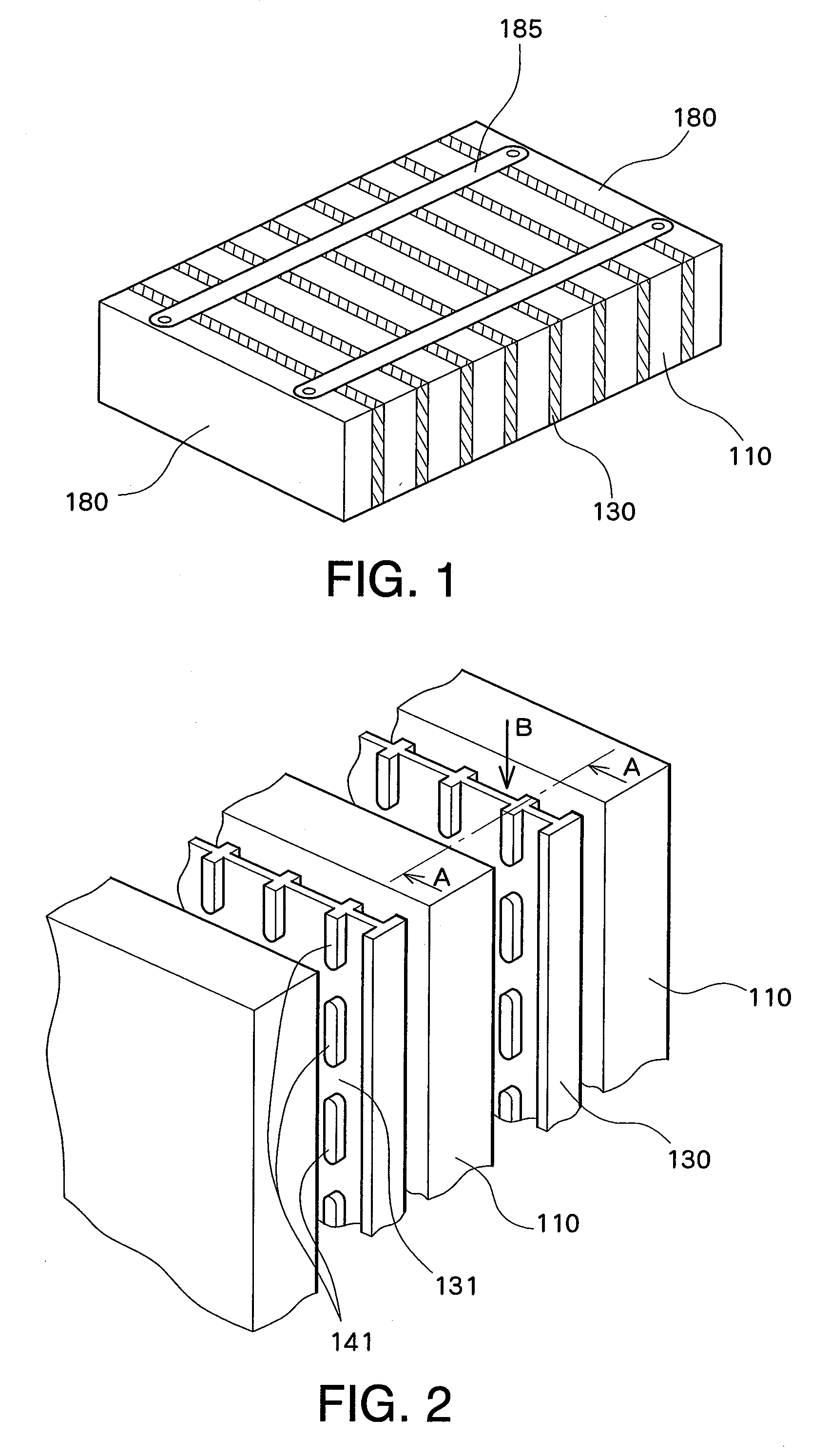

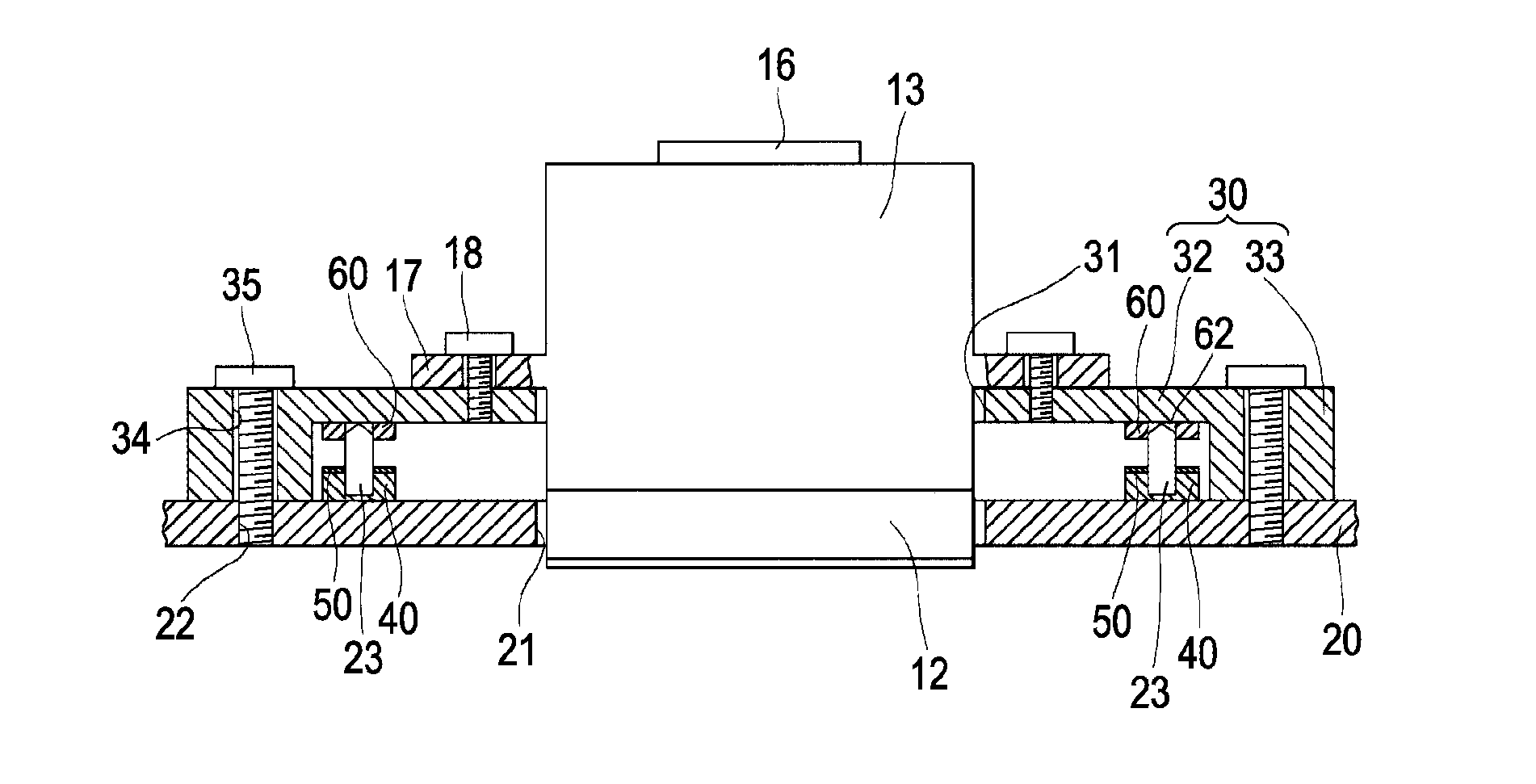

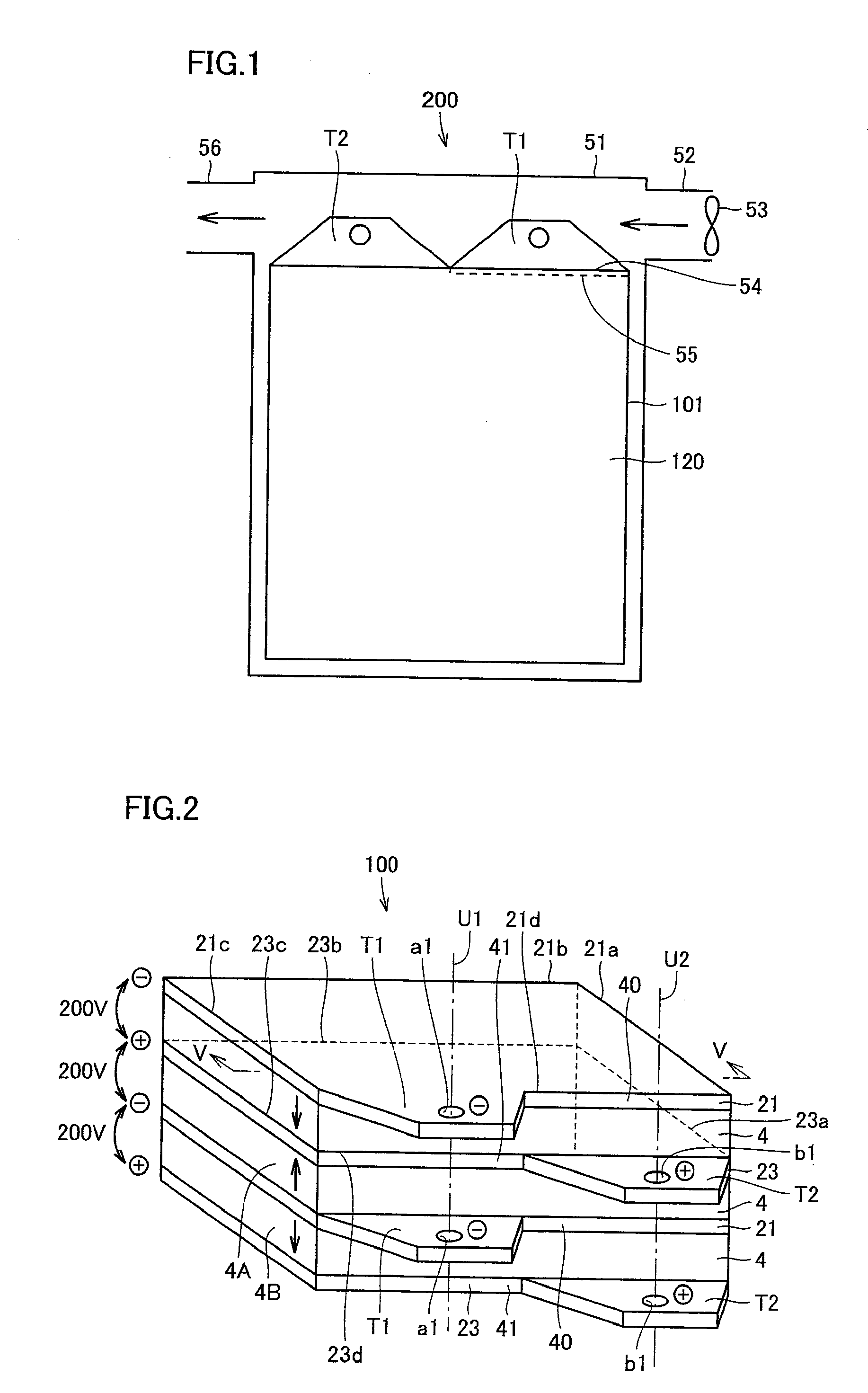

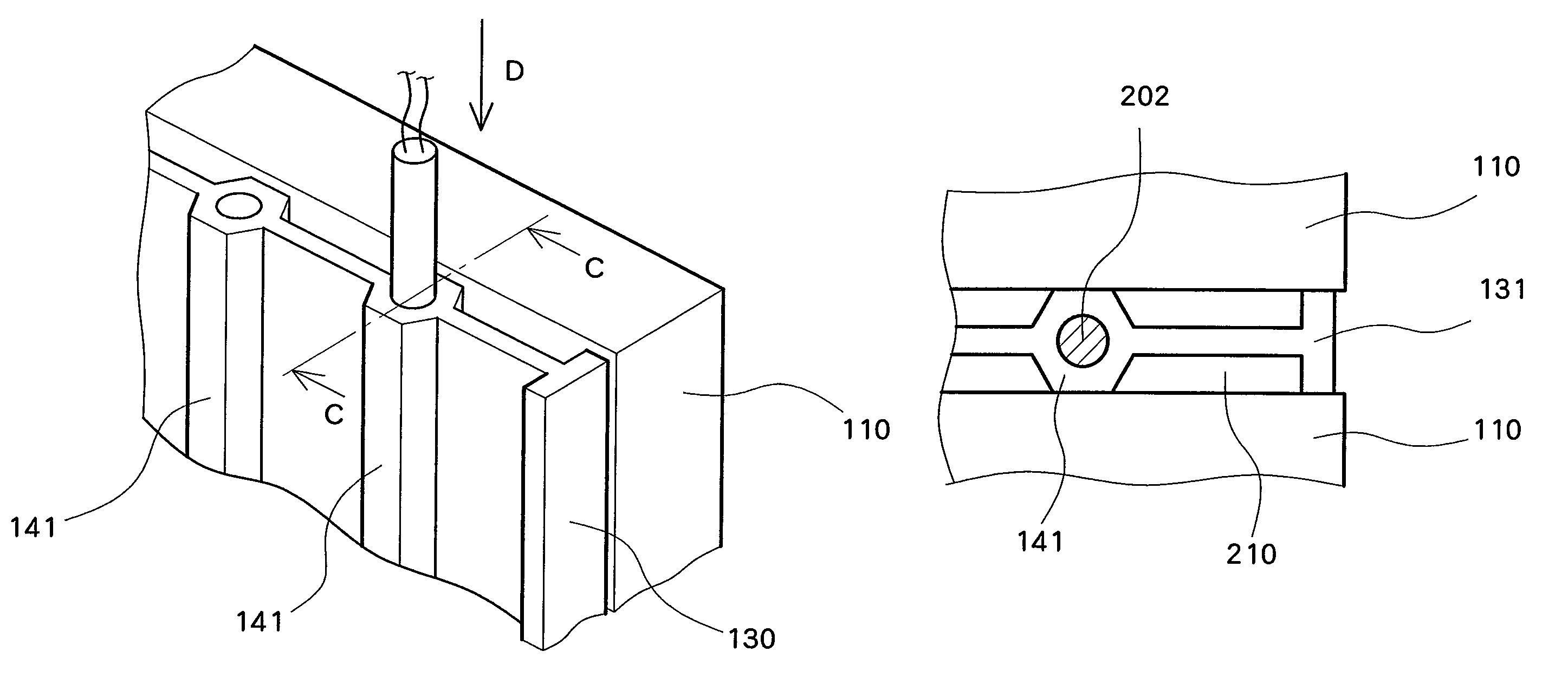

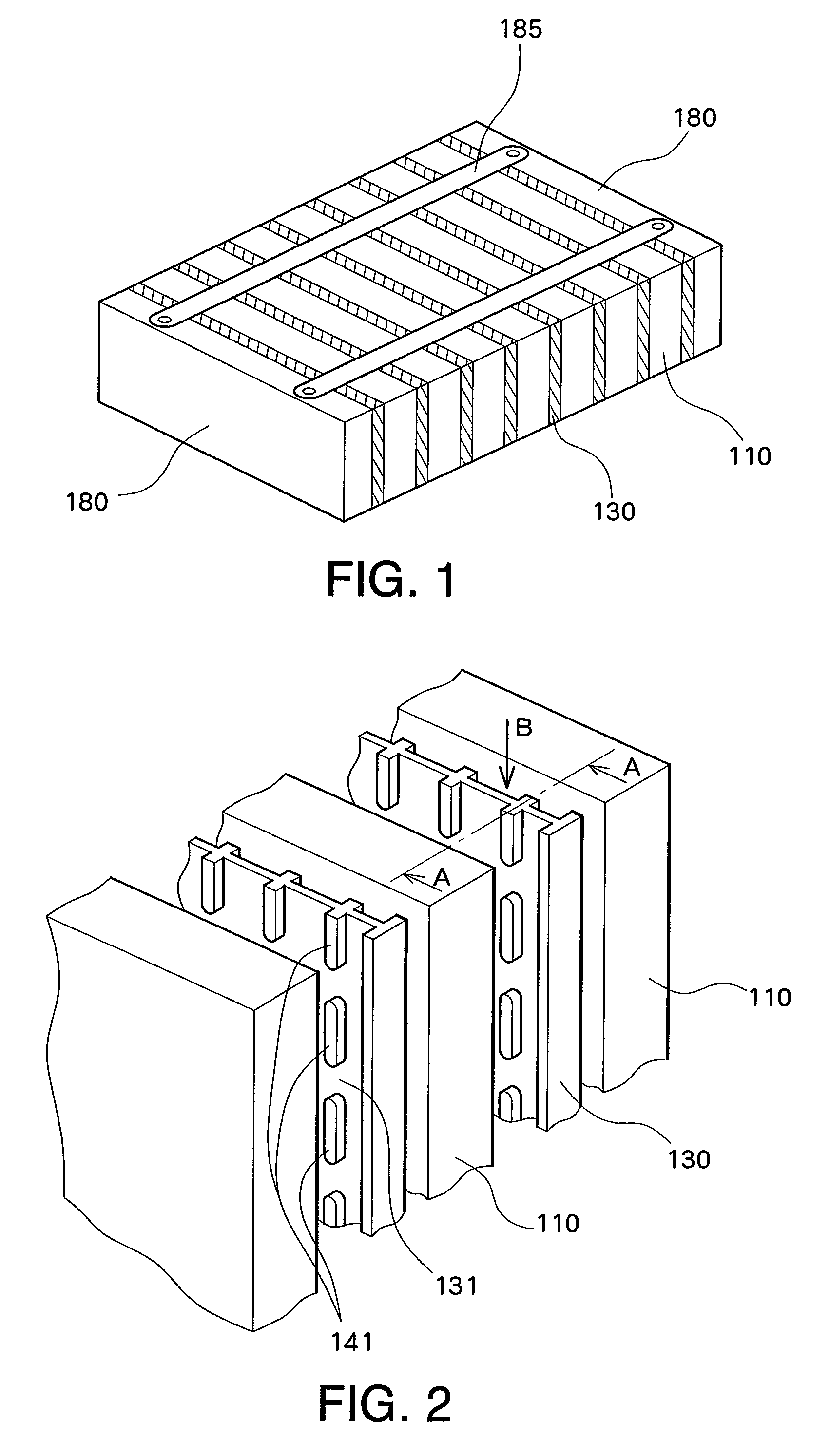

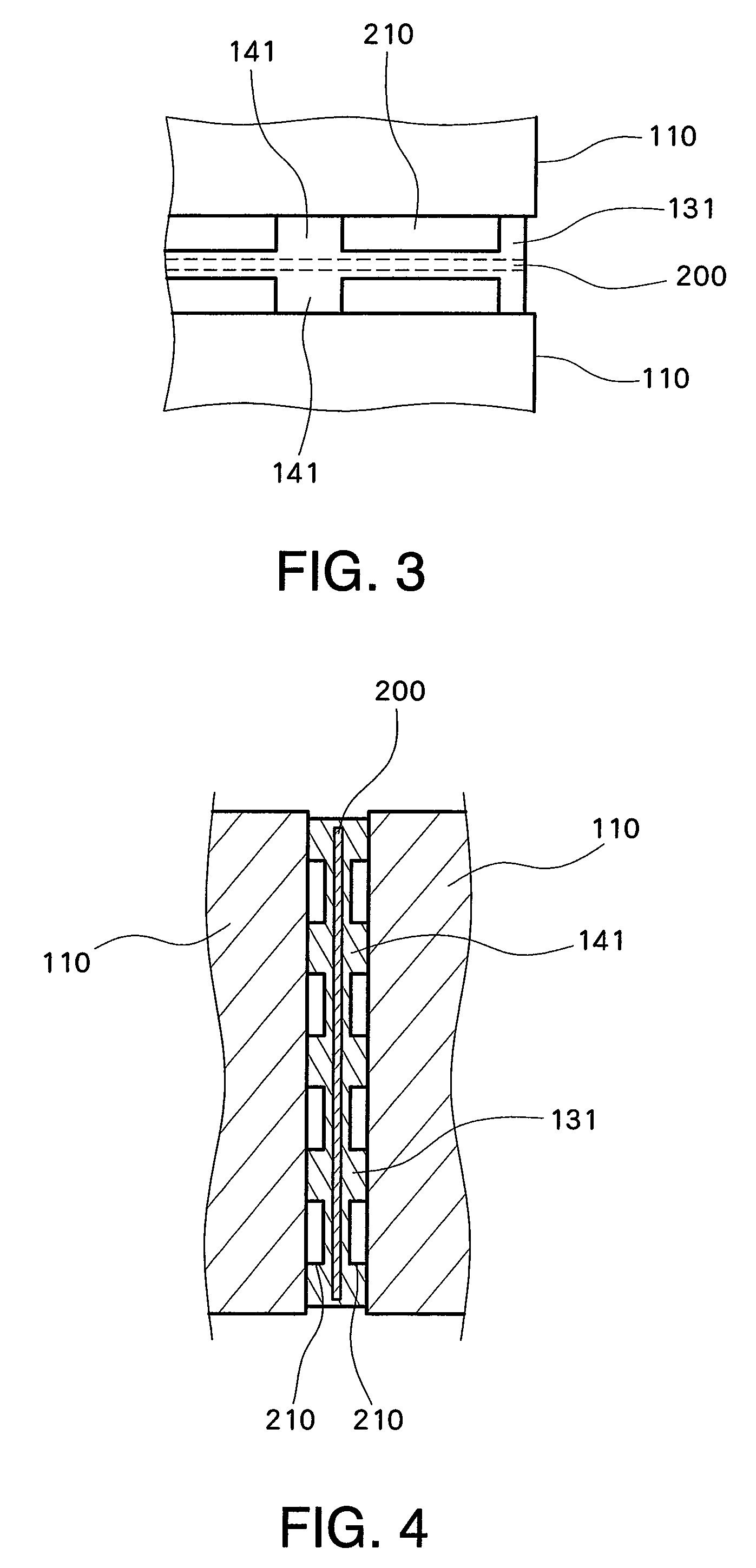

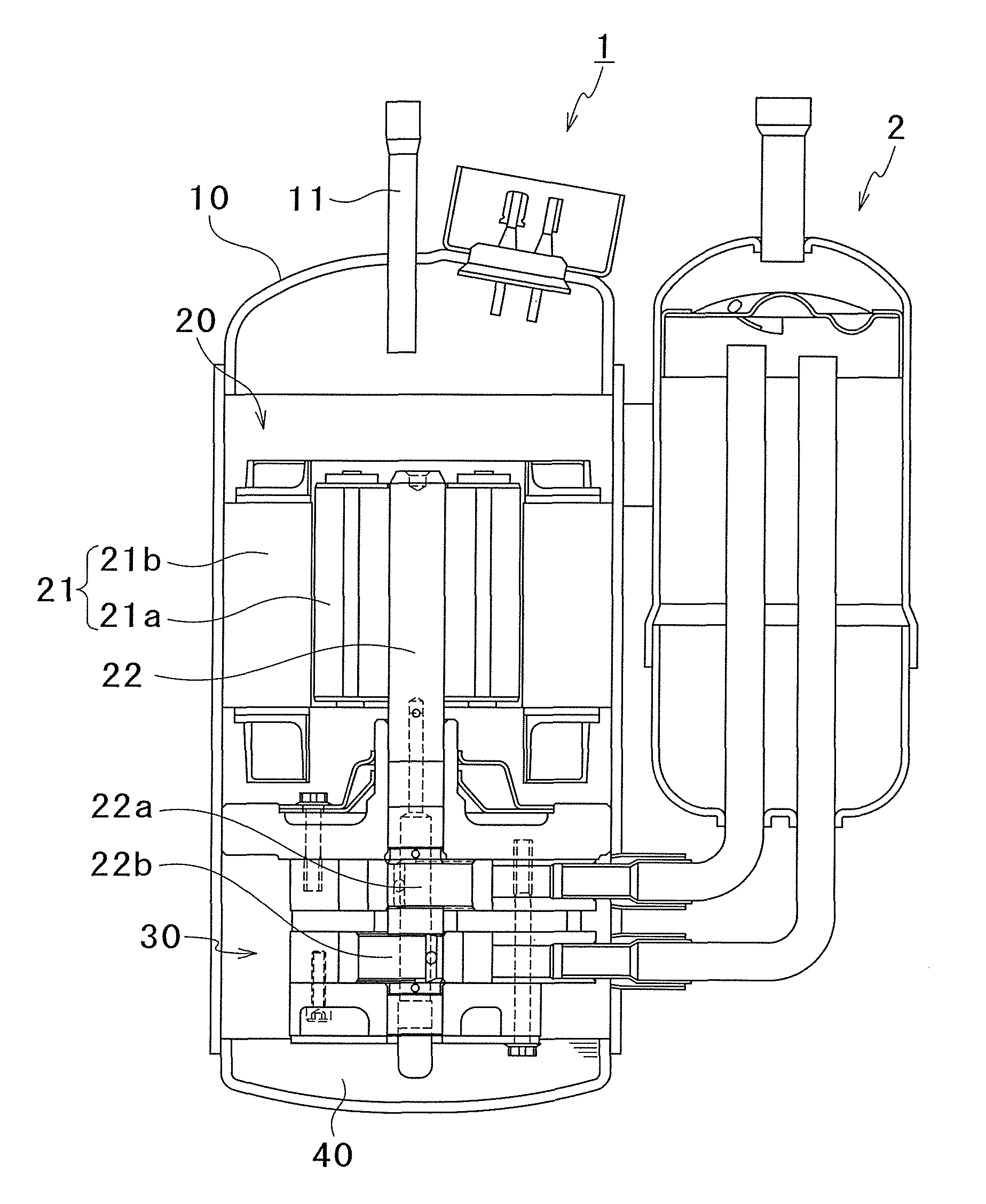

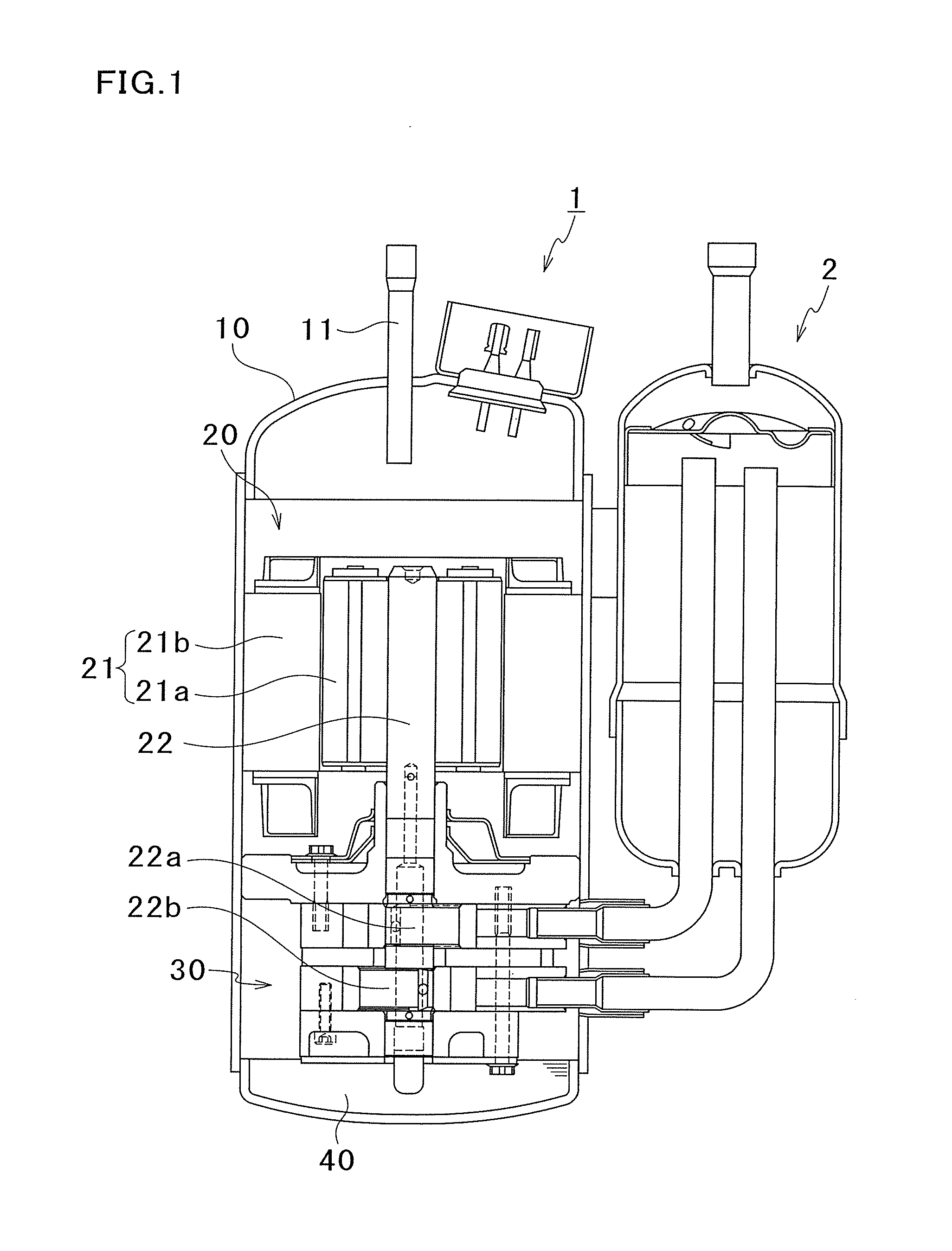

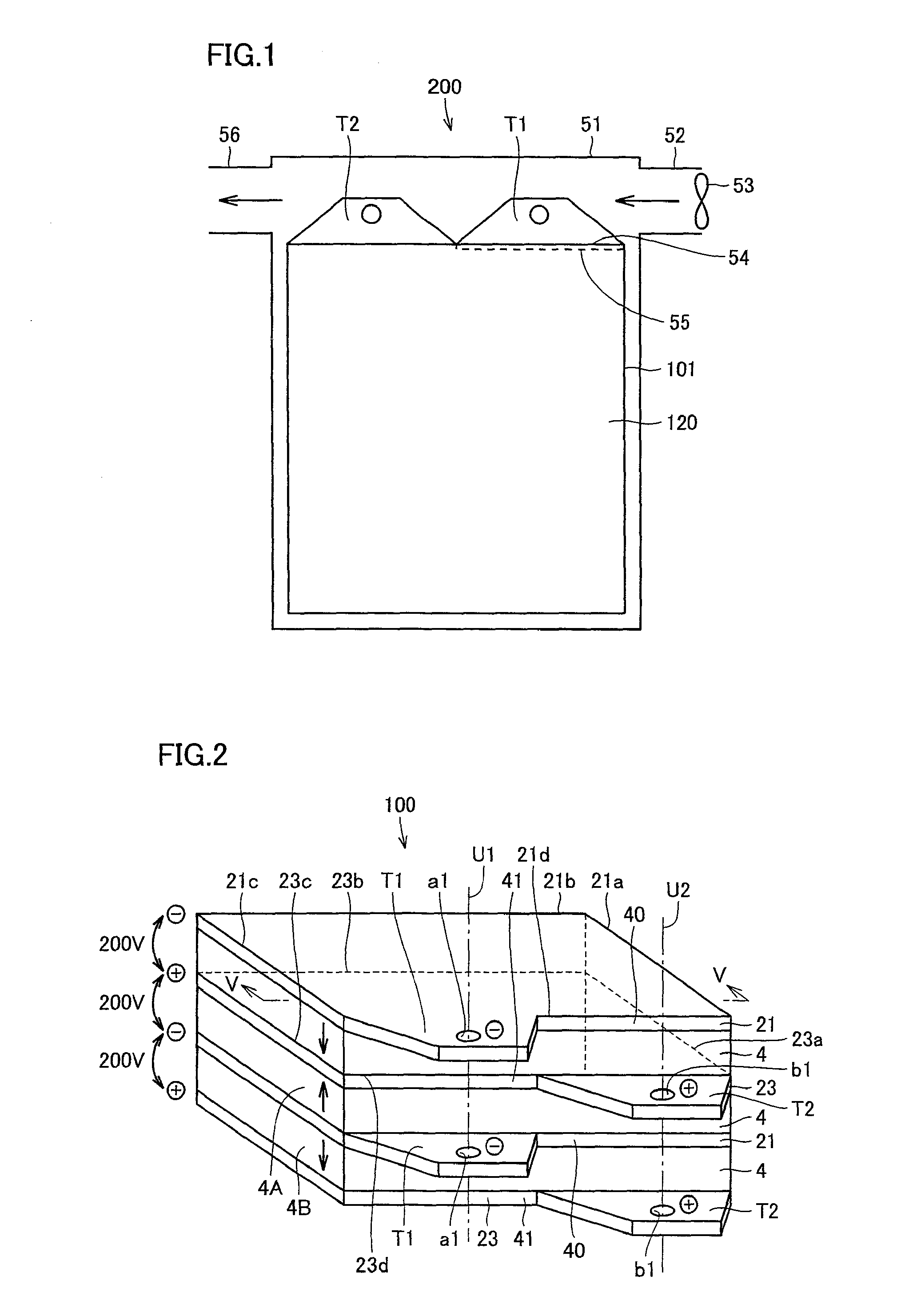

Battery pack

ActiveUS20100151309A1Without increase numberReliably heatCell temperature controlCell component detailsElectricityCold climate

A battery pack comprises a plurality of battery modules and a holding spacer which holds the battery module. A plurality of projections are provided on the holding spacer. The projections contact the battery module to hold the battery module and form a flow path for a coolant. A heat generating structure is embedded in the holding spacer or inserted into a hollow section of the holding spacer. In a cold climate, electricity is applied to the heat generating structure, to heat the battery module.

Owner:PANASONIC EV ENERGY CO LTD

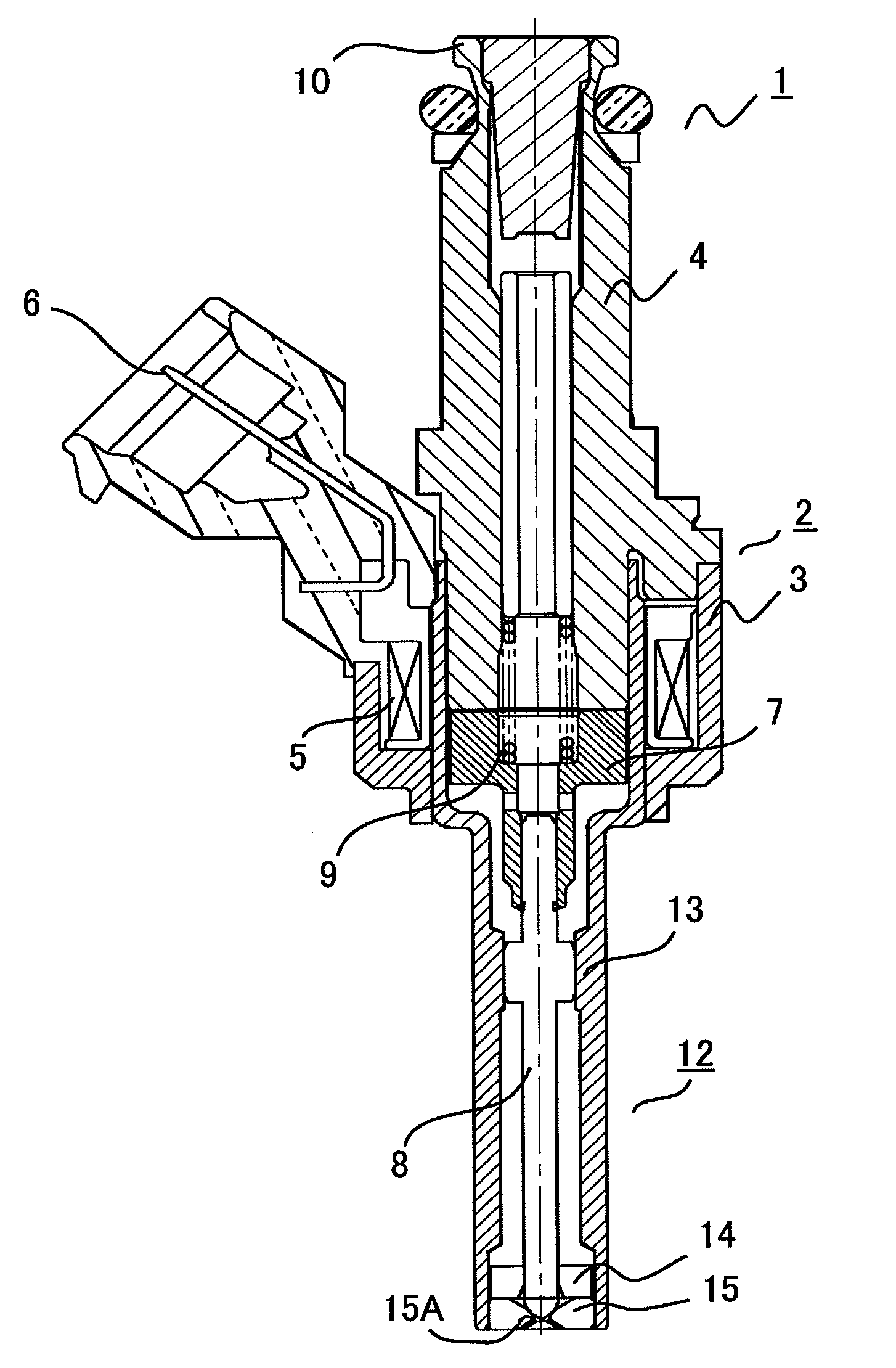

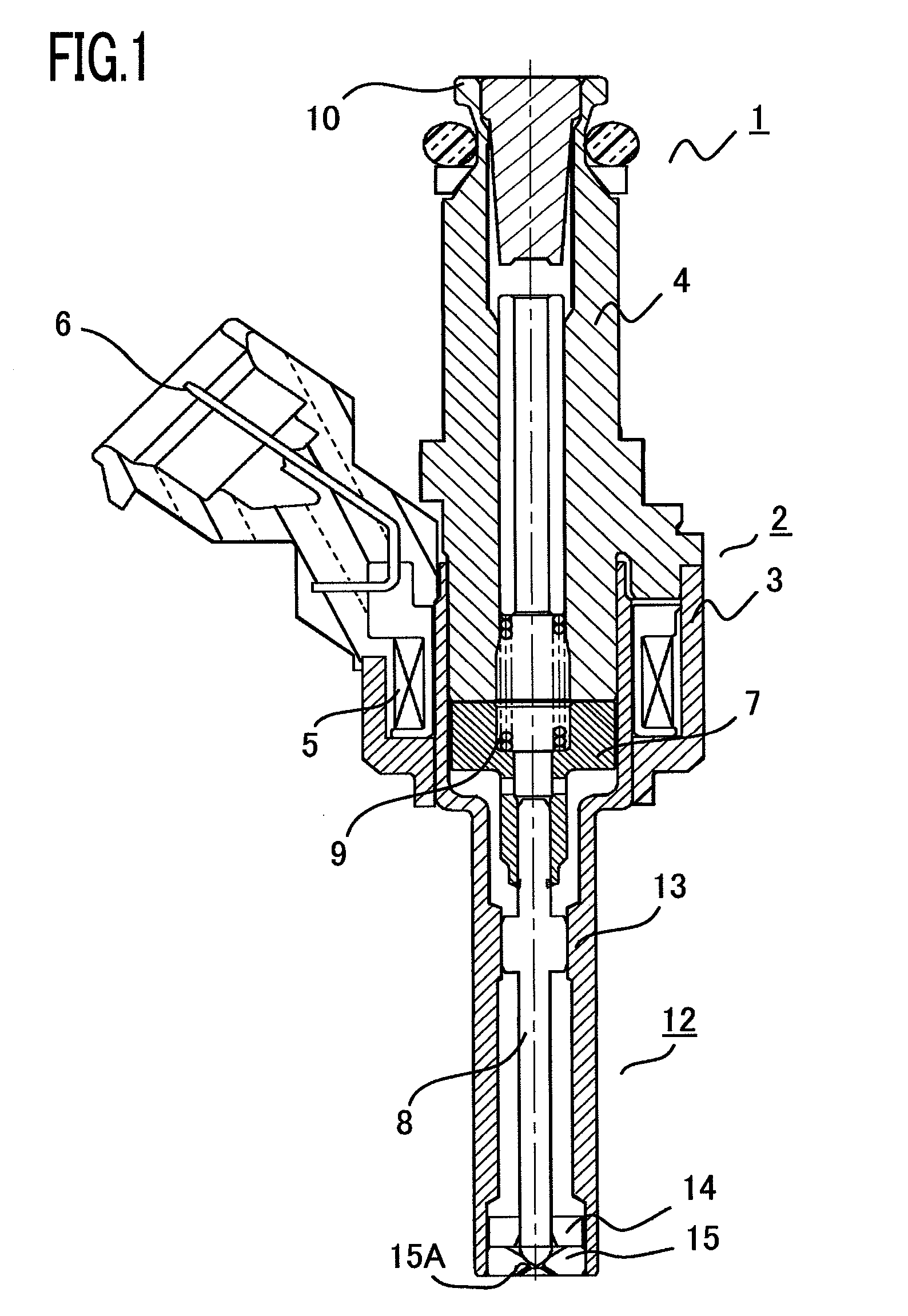

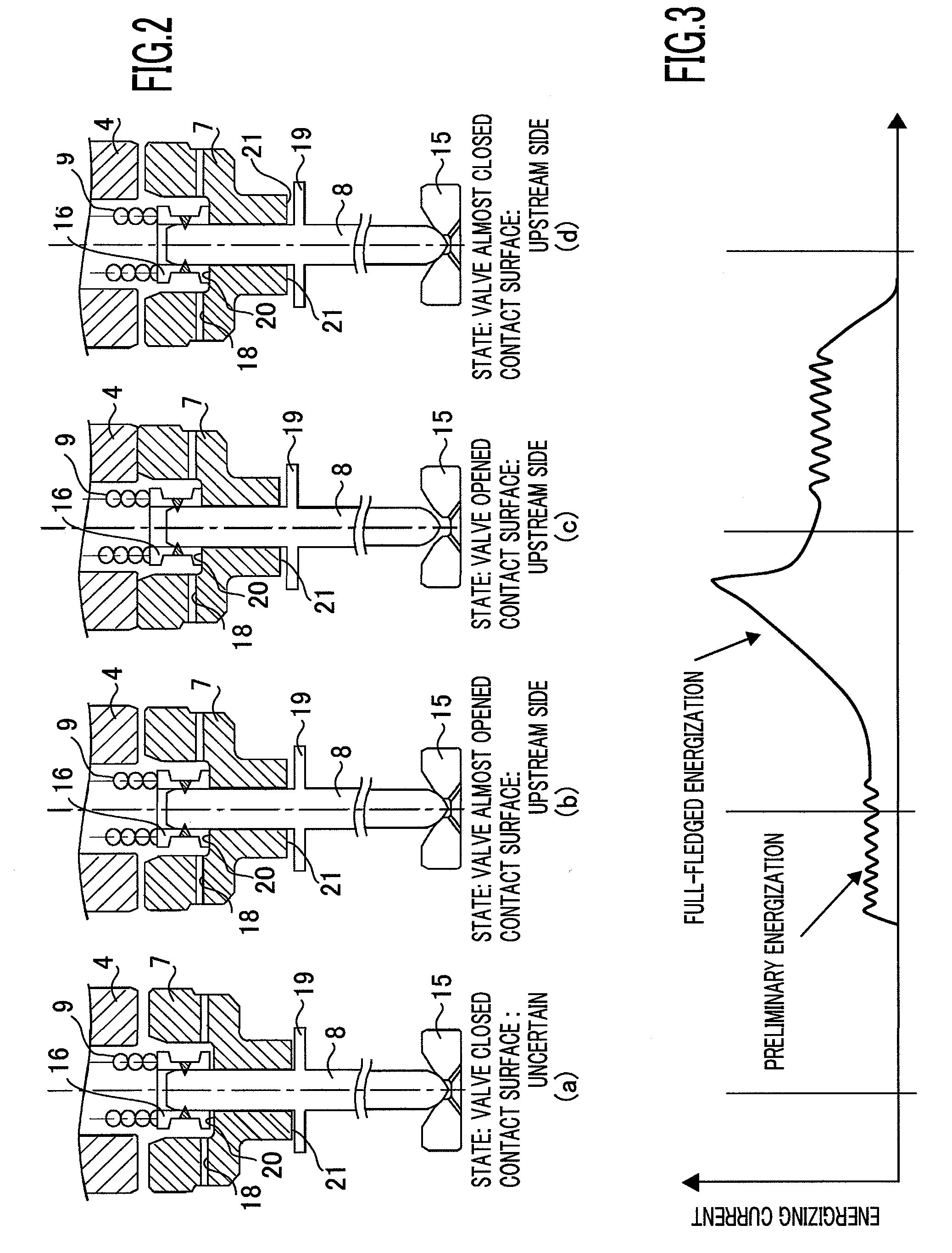

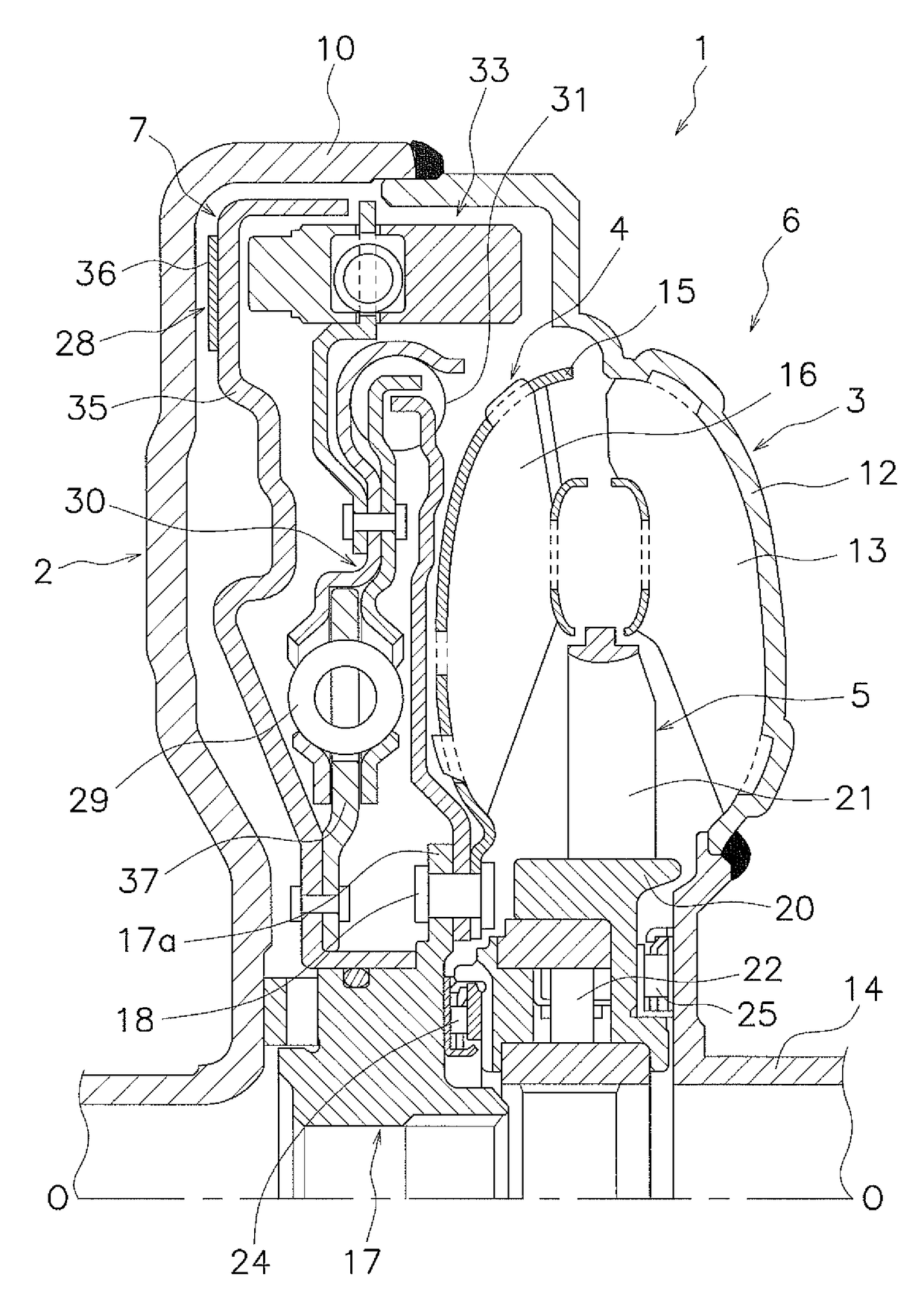

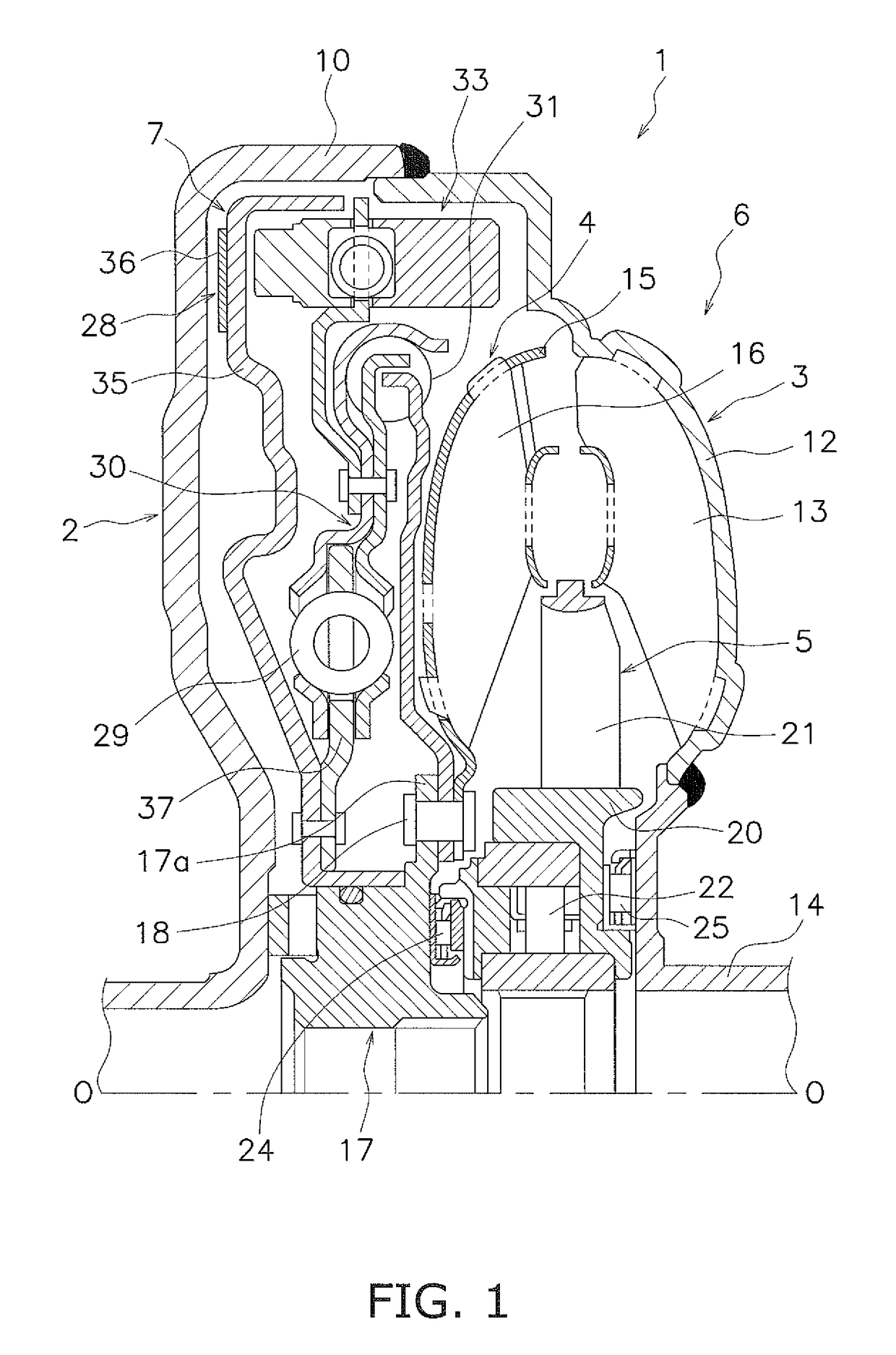

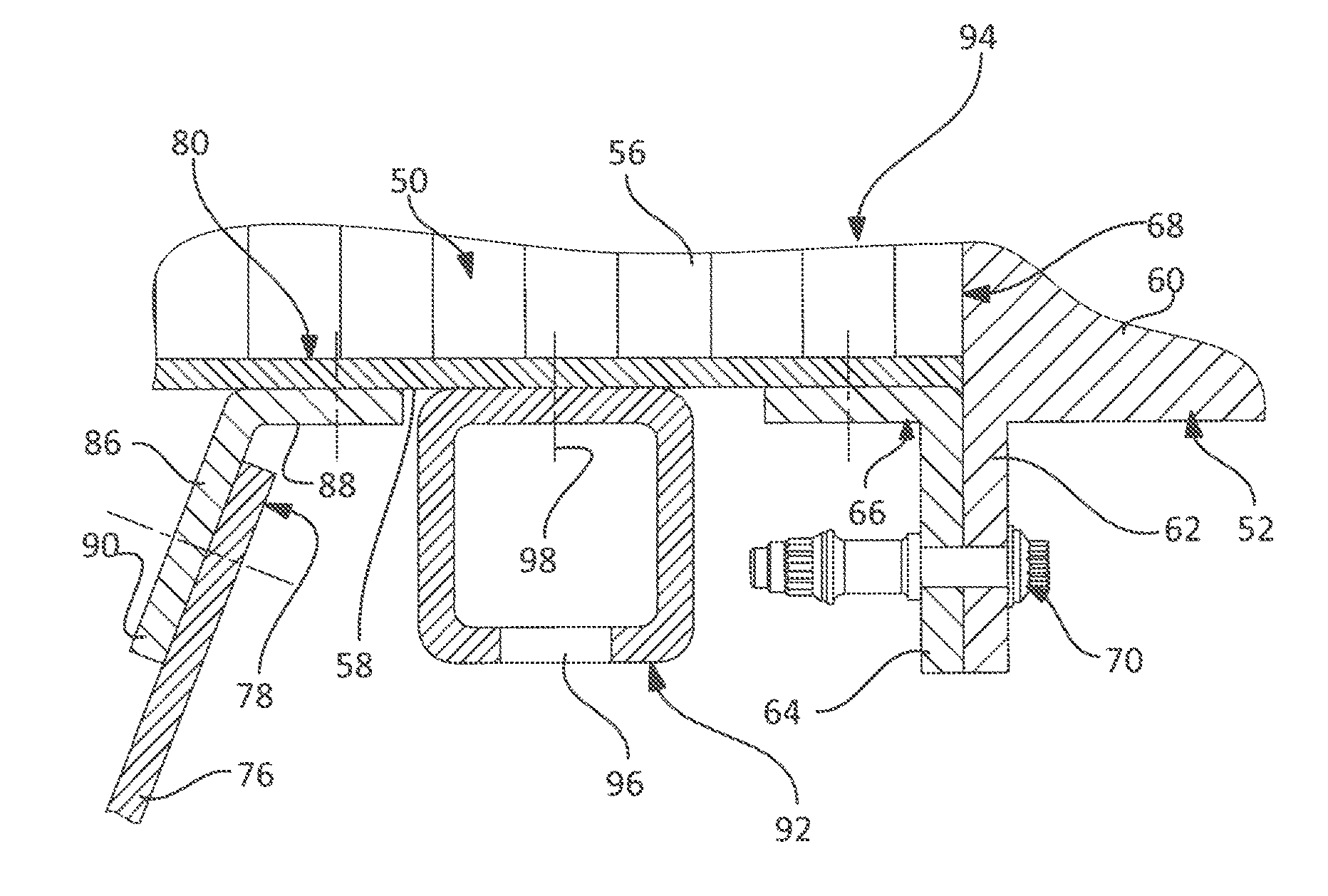

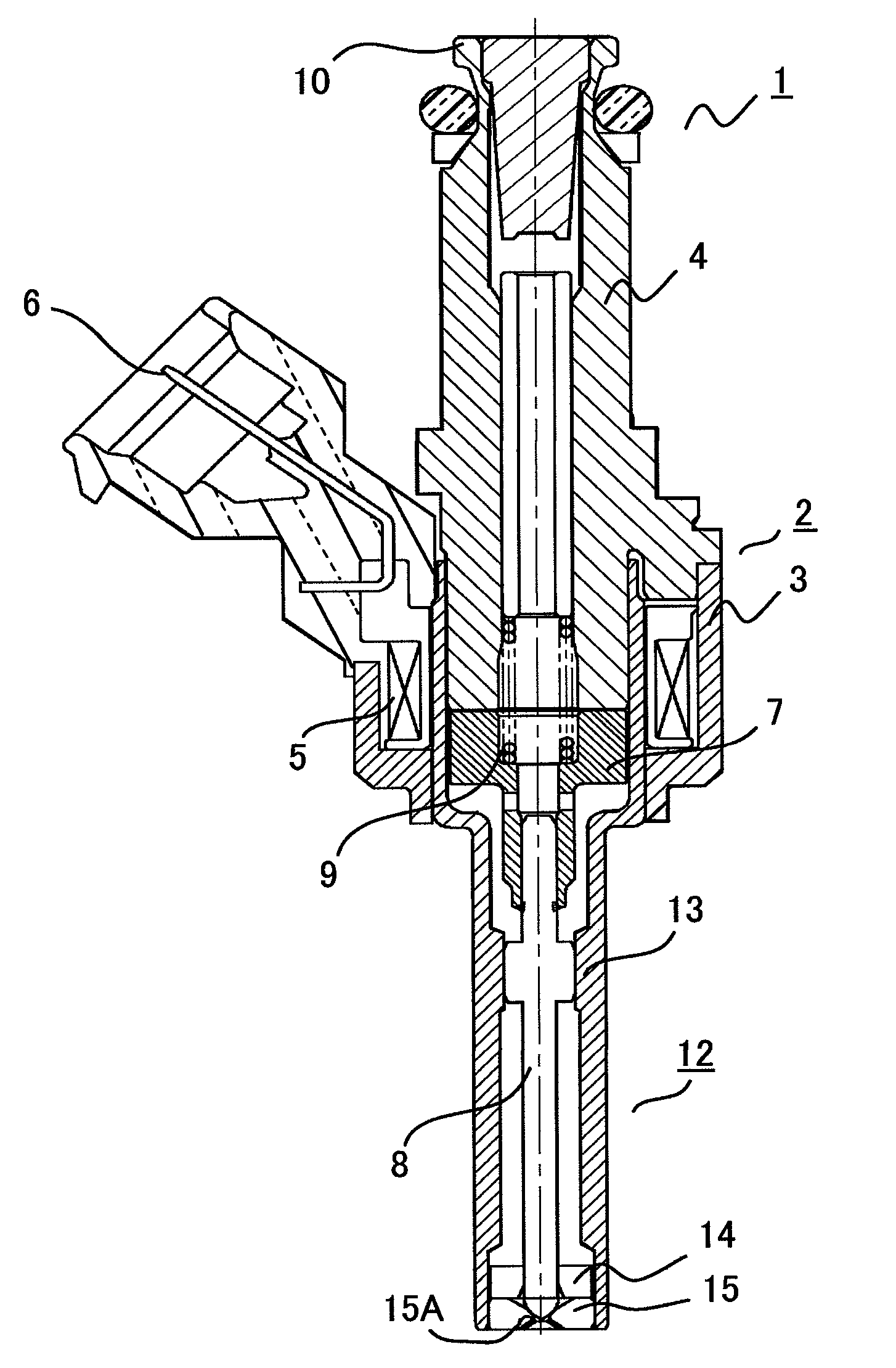

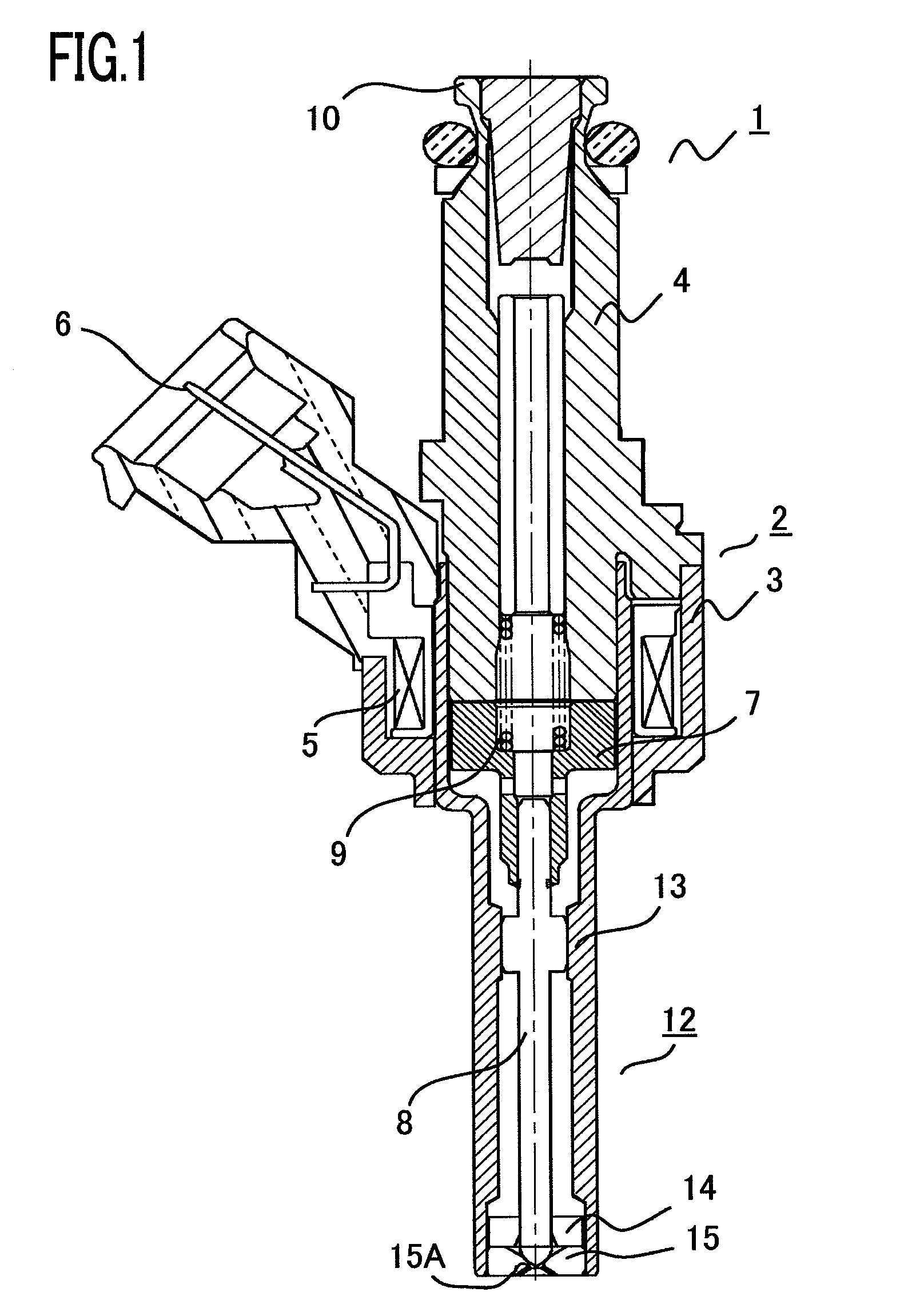

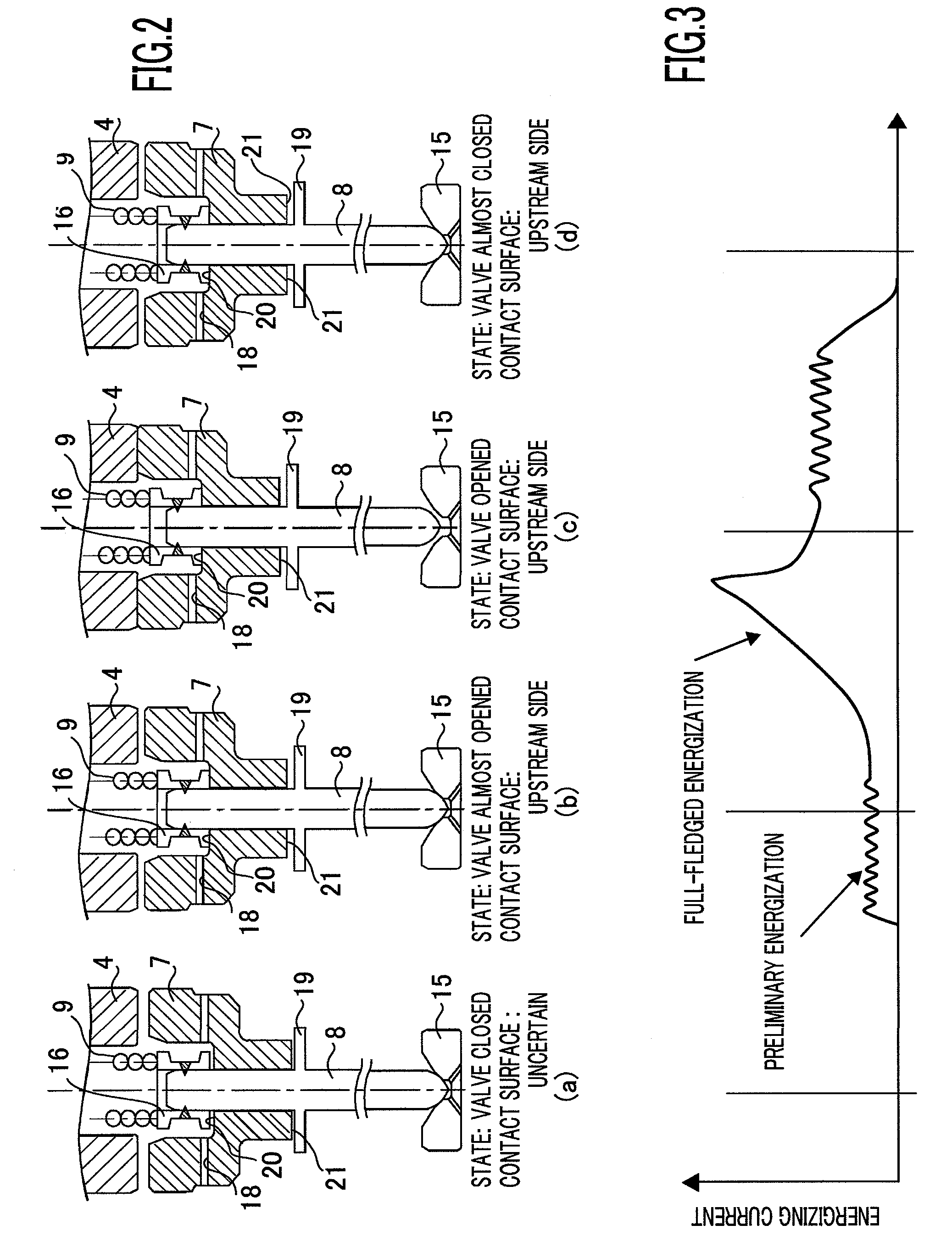

Fuel injection valve

ActiveUS20090289131A1DistanceCurb reboundSpray nozzlesMachines/enginesBiomedical engineeringFuel injection

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil; a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature; and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle, and the coil is preliminarily energized while the fuel injection valve is closed by the needle.

Owner:MITSUBISHI ELECTRIC CORP

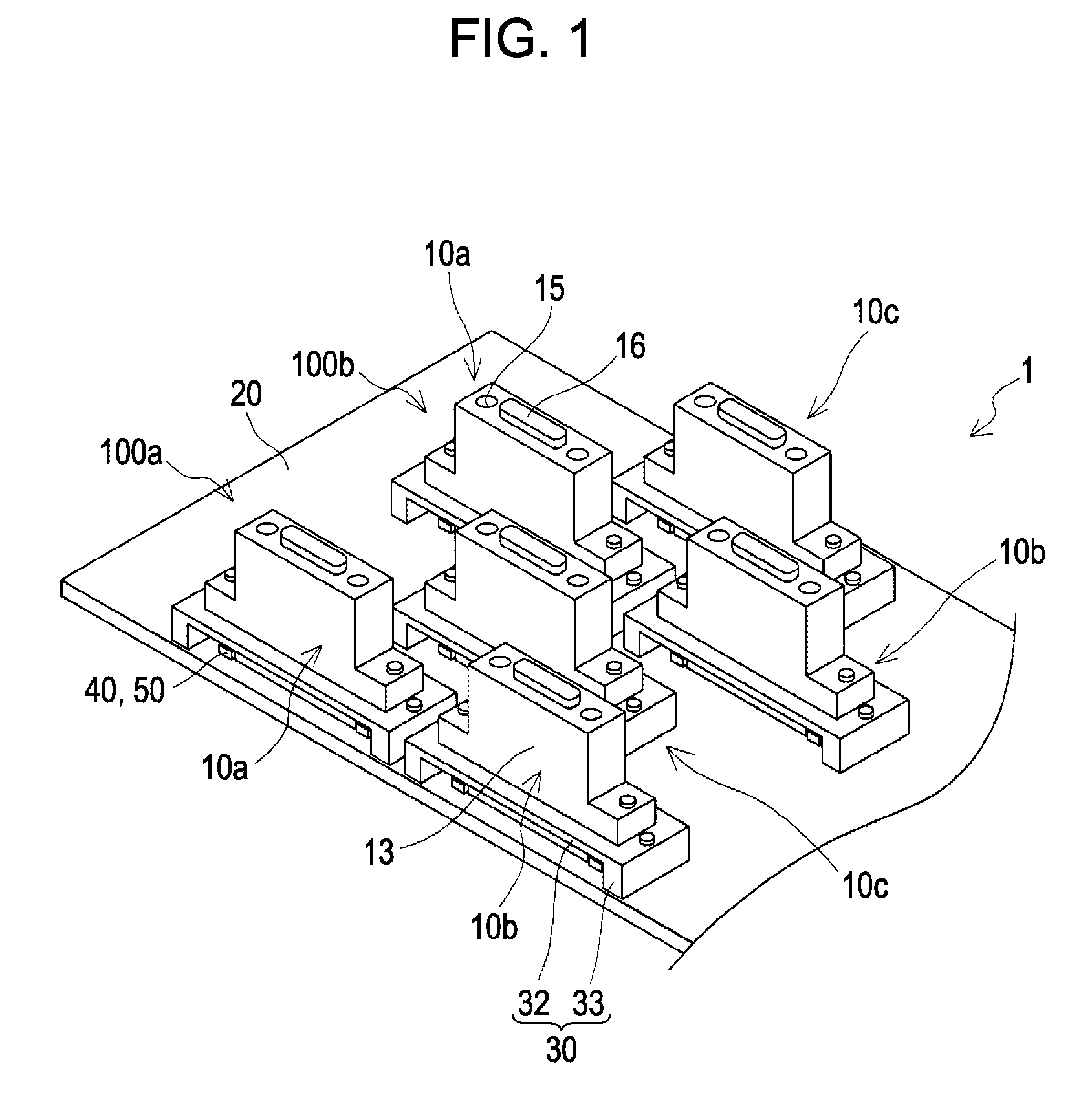

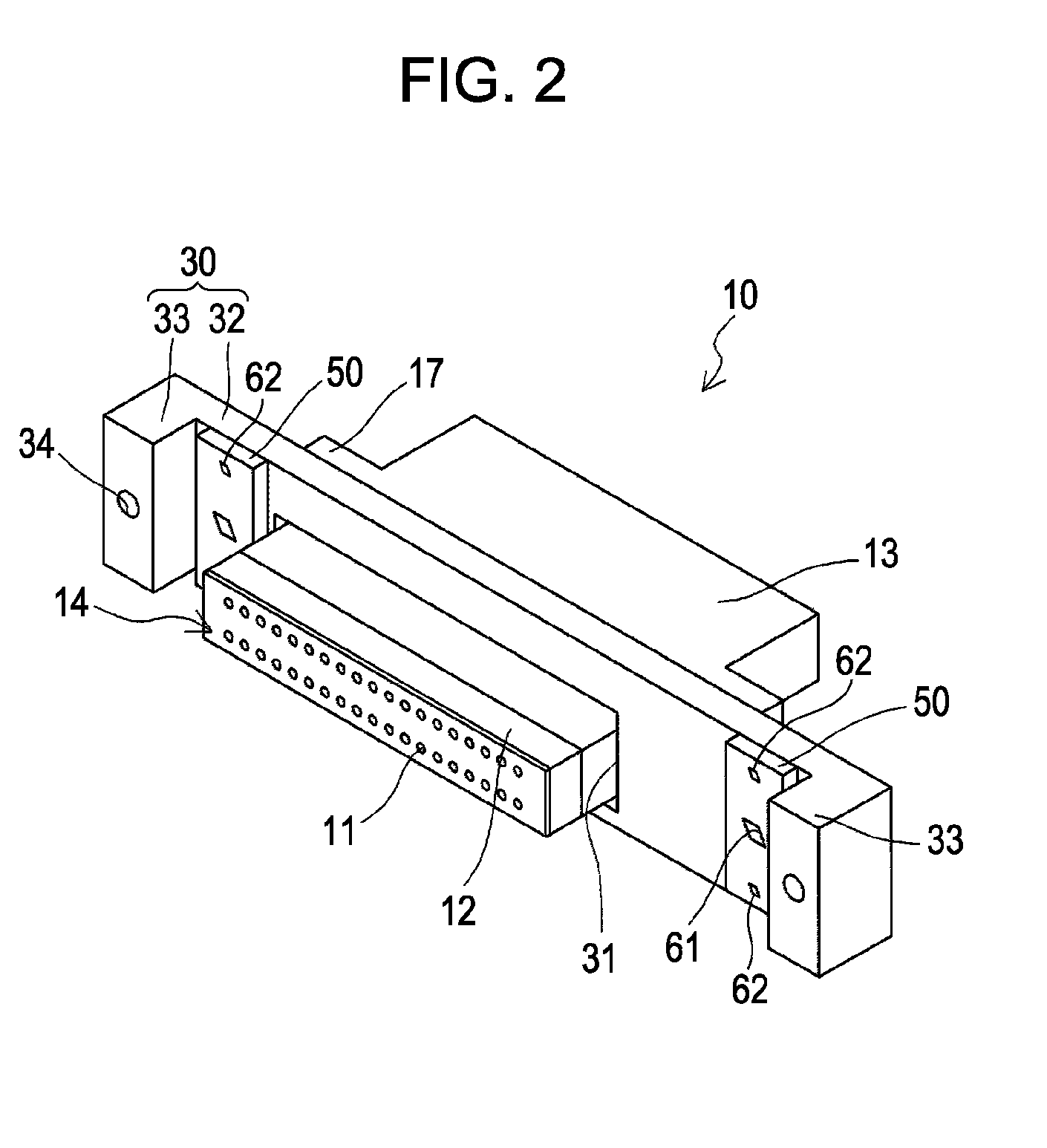

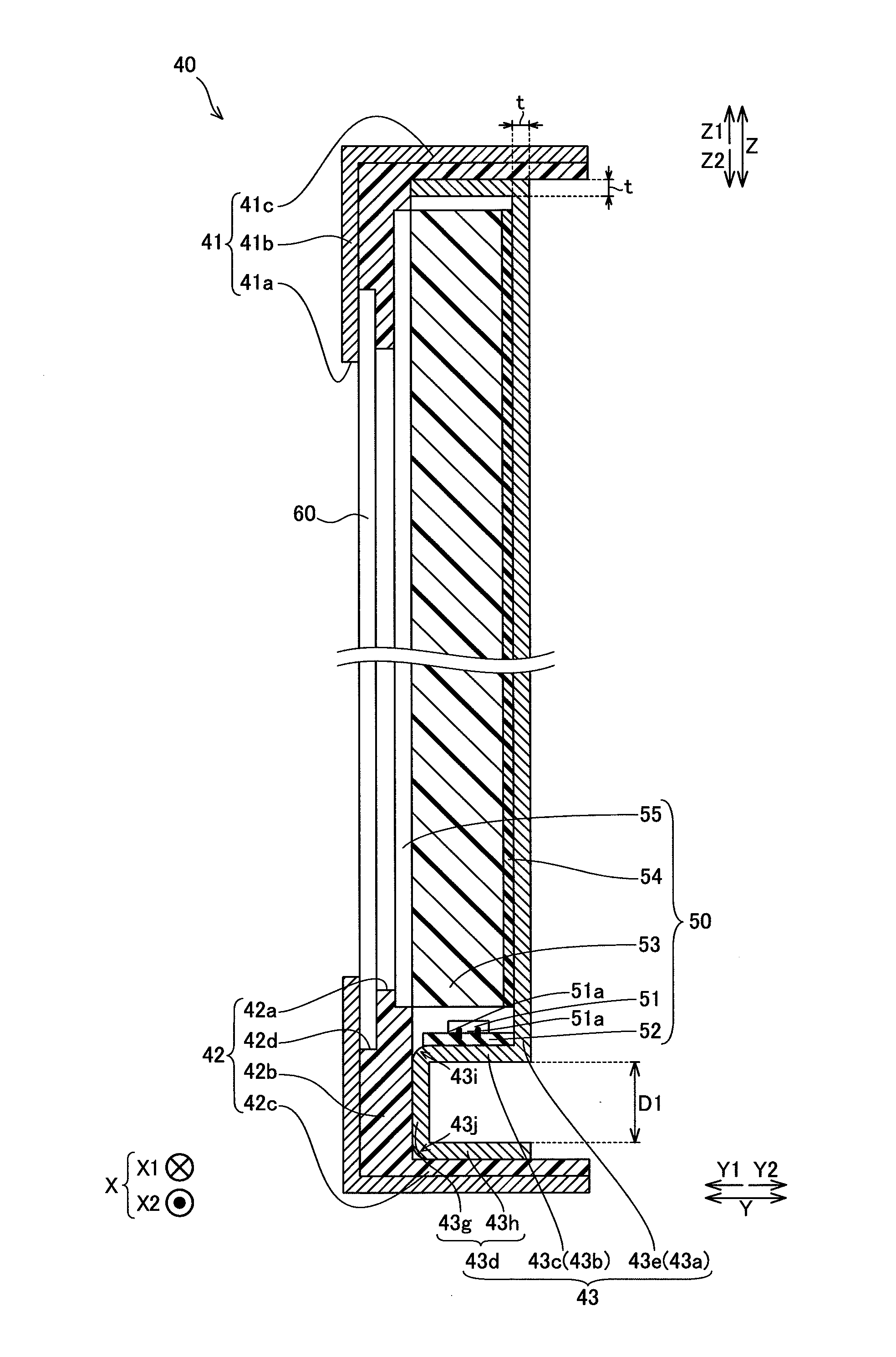

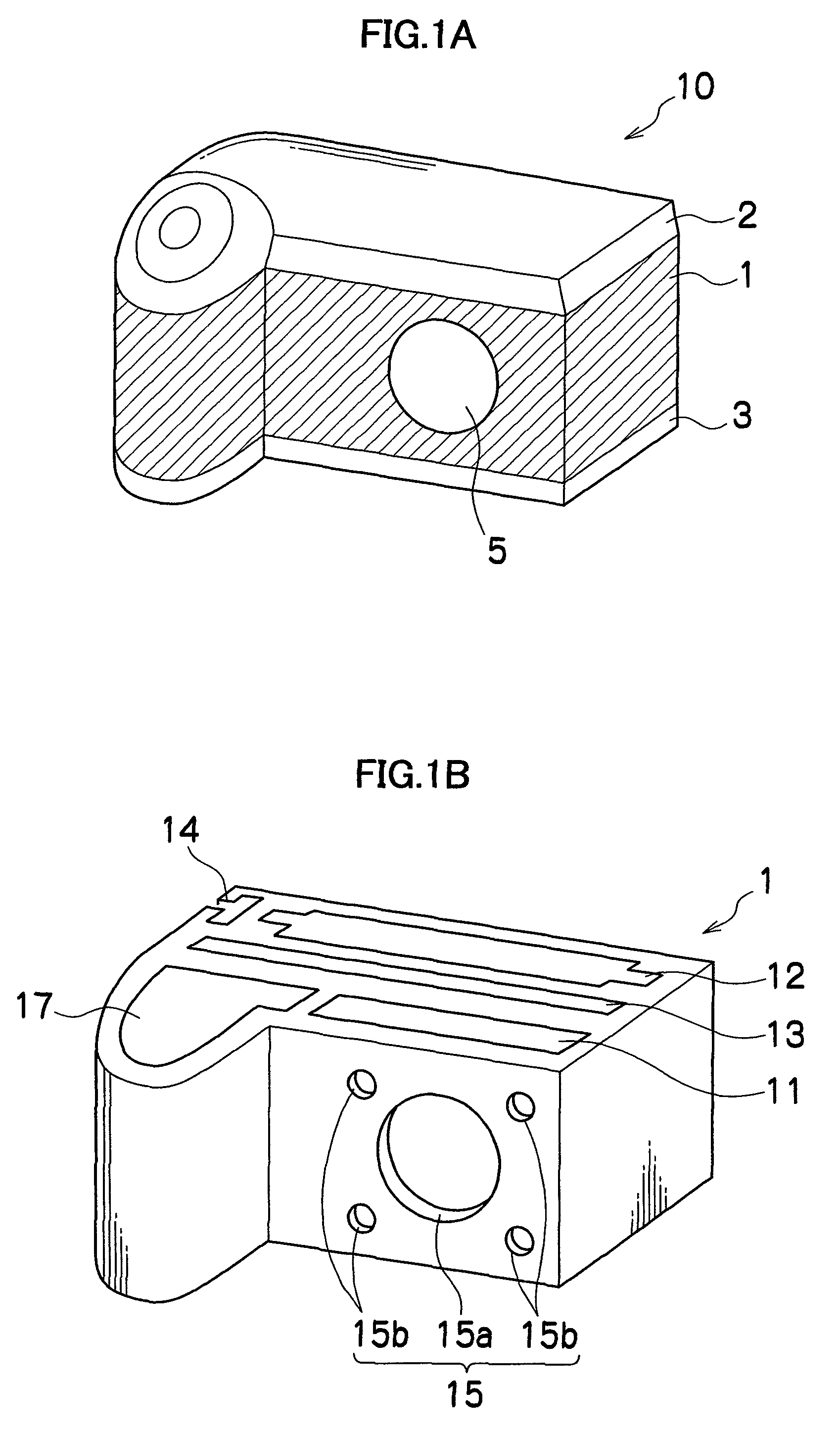

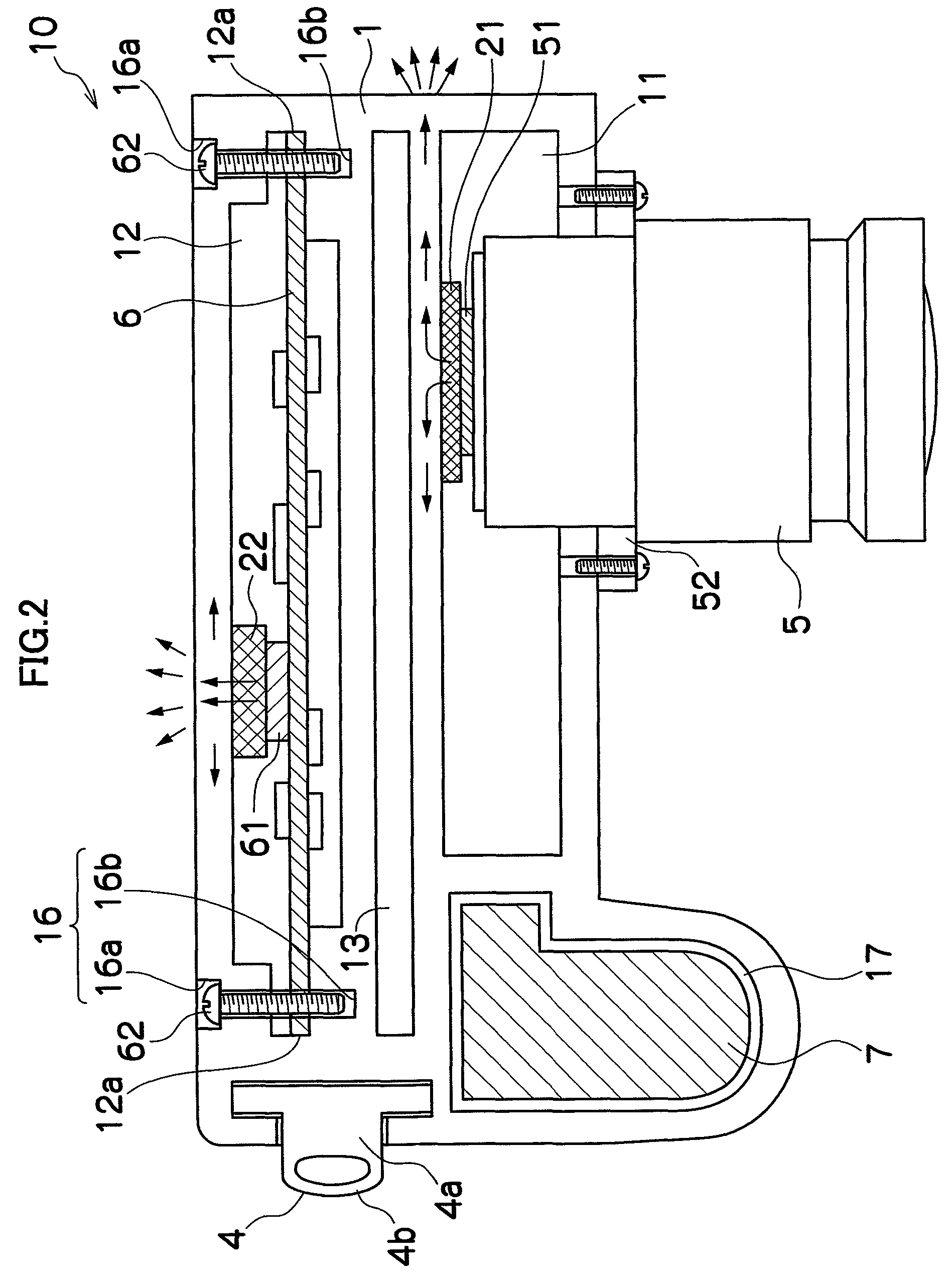

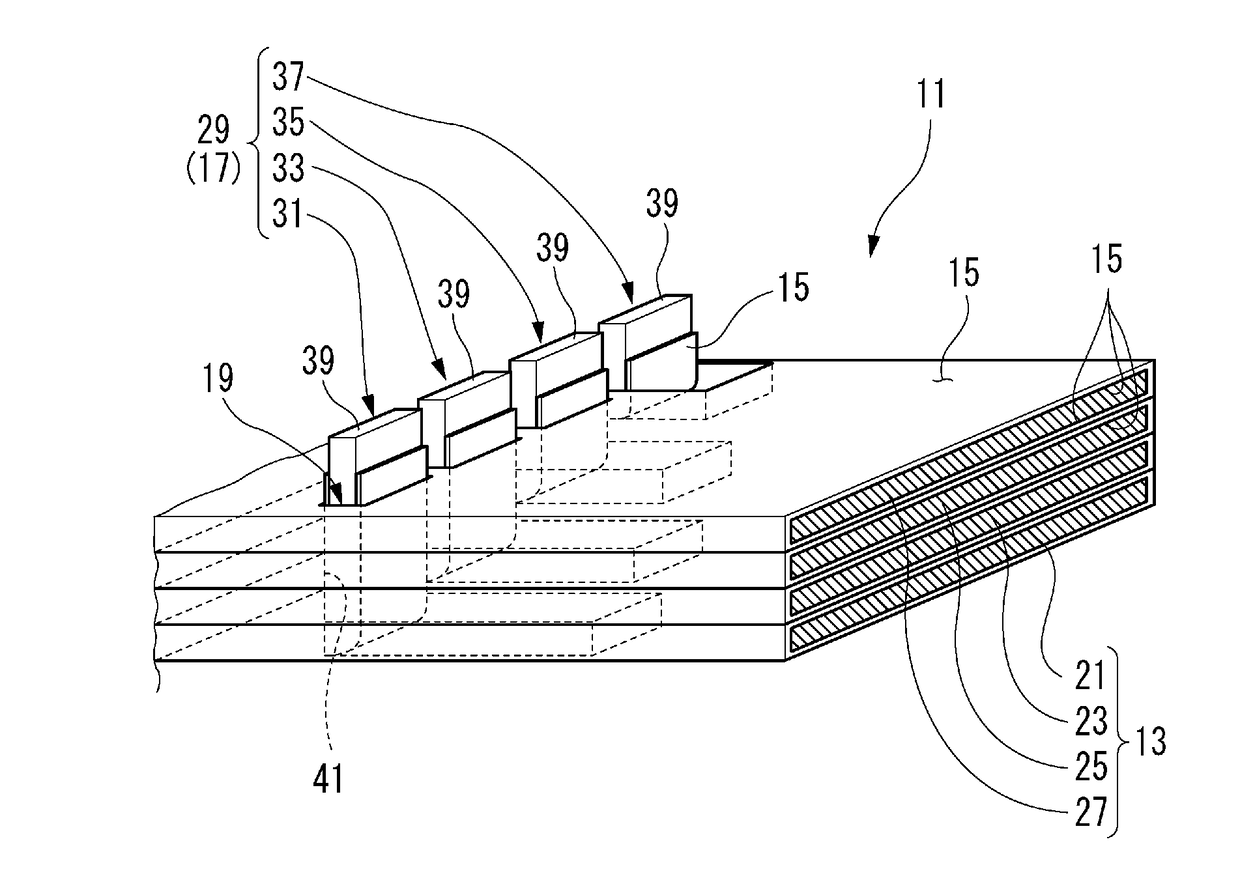

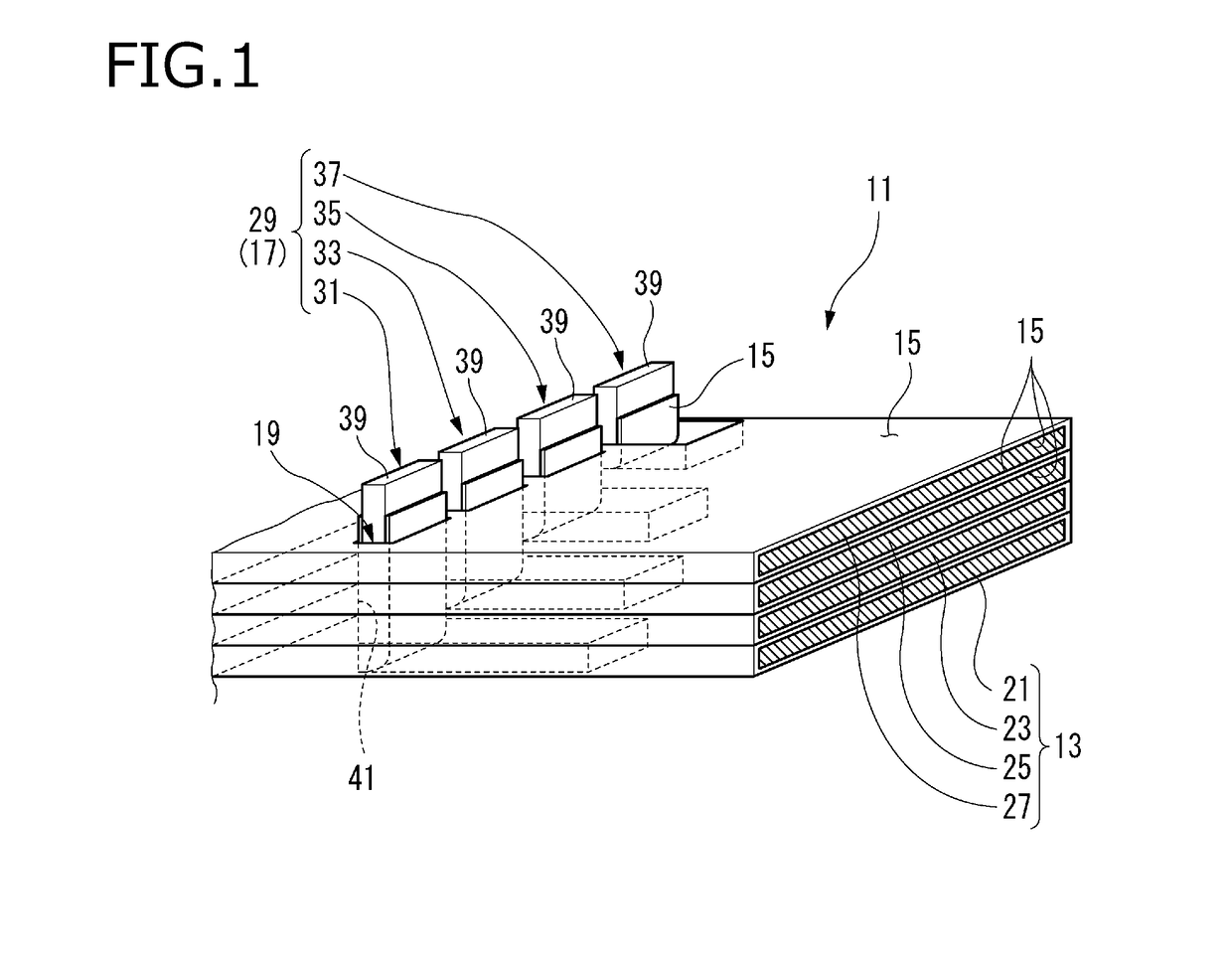

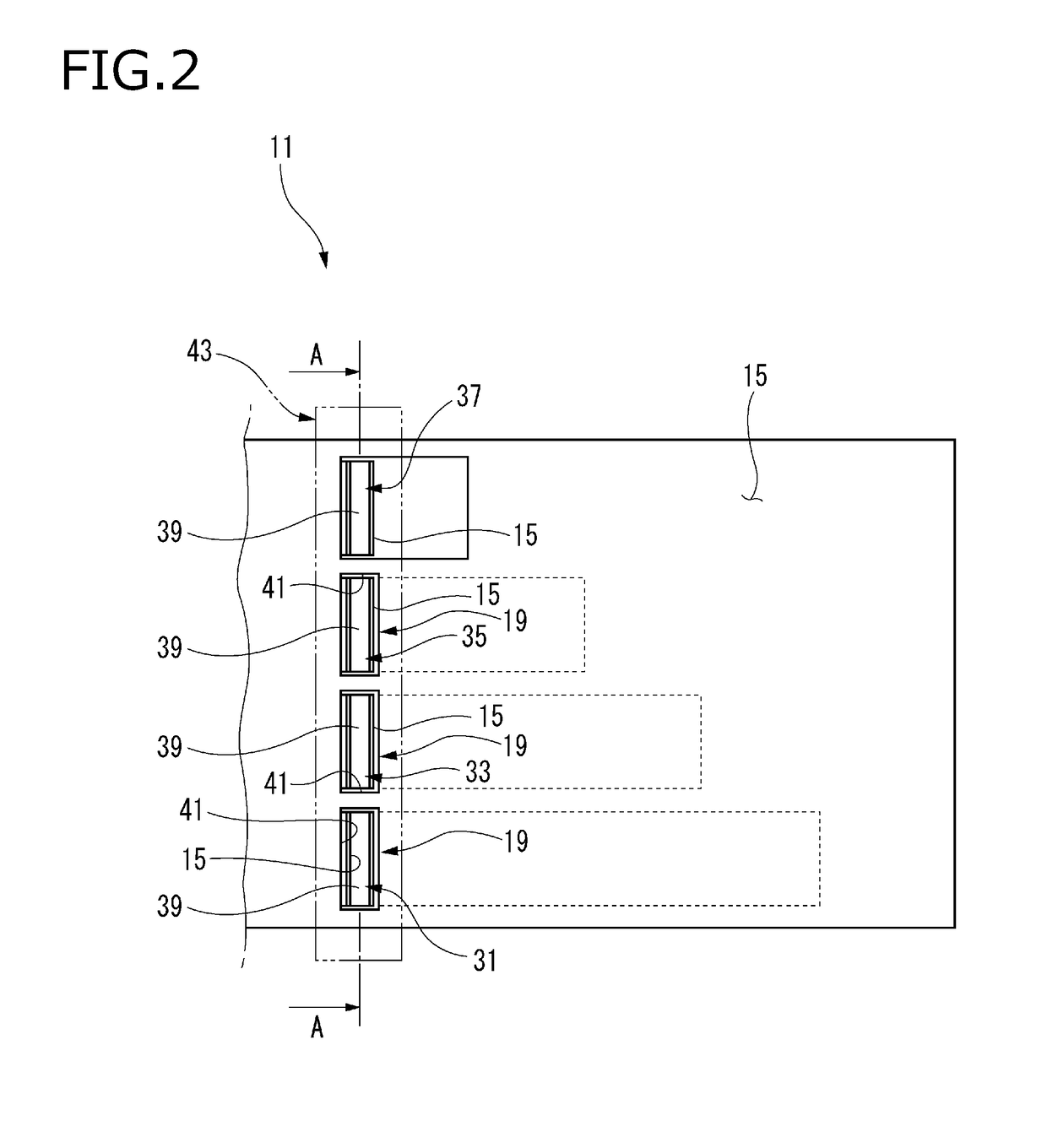

Manufacturing method for liquid ejecting head unit, and liquid ejecting apparatus

ActiveUS20100289854A1Without increasing number of componentHigh positioning accuracyInking apparatusWriting implementsImage resolutionEngineering

Owner:SEIKO EPSON CORP

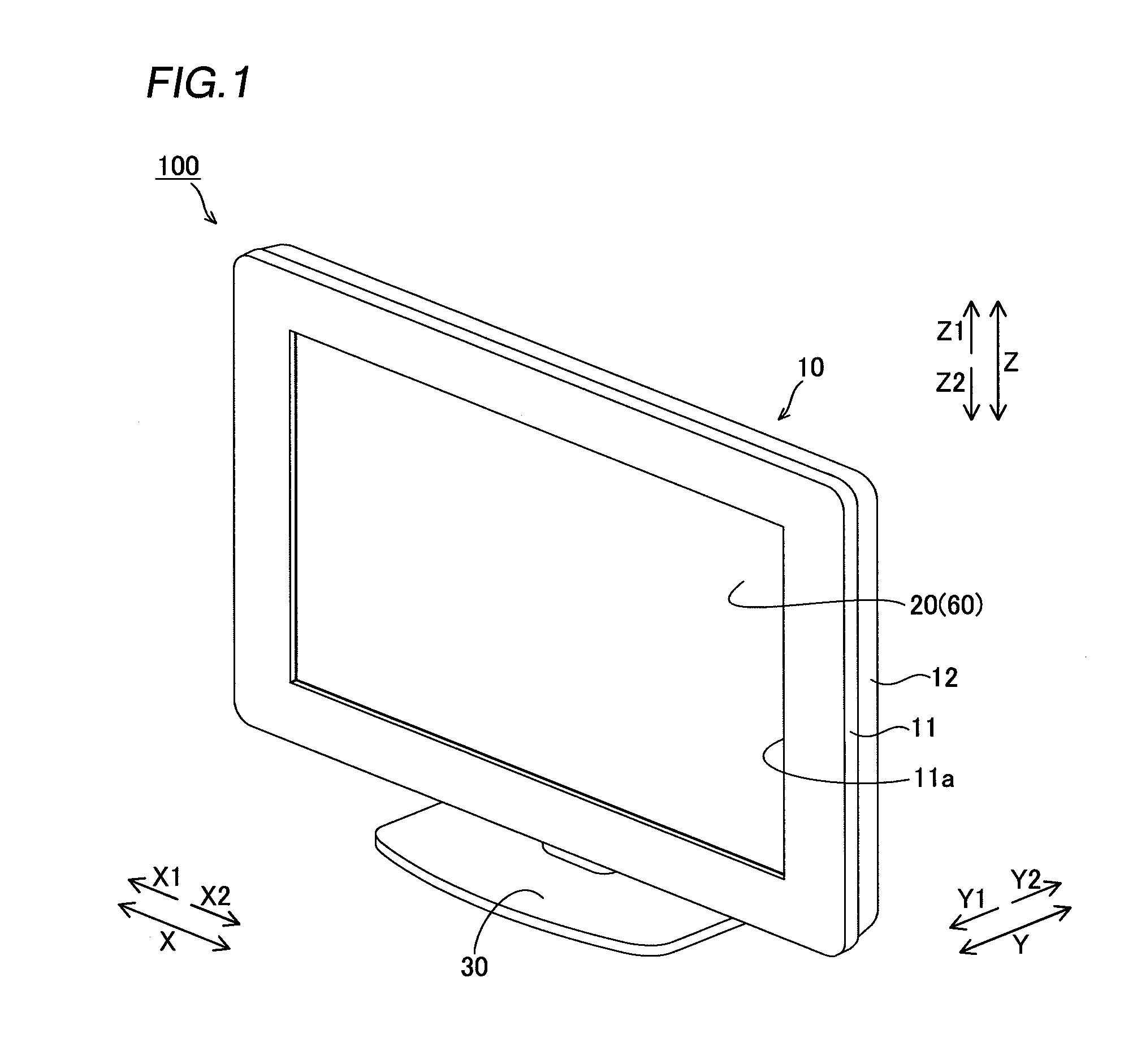

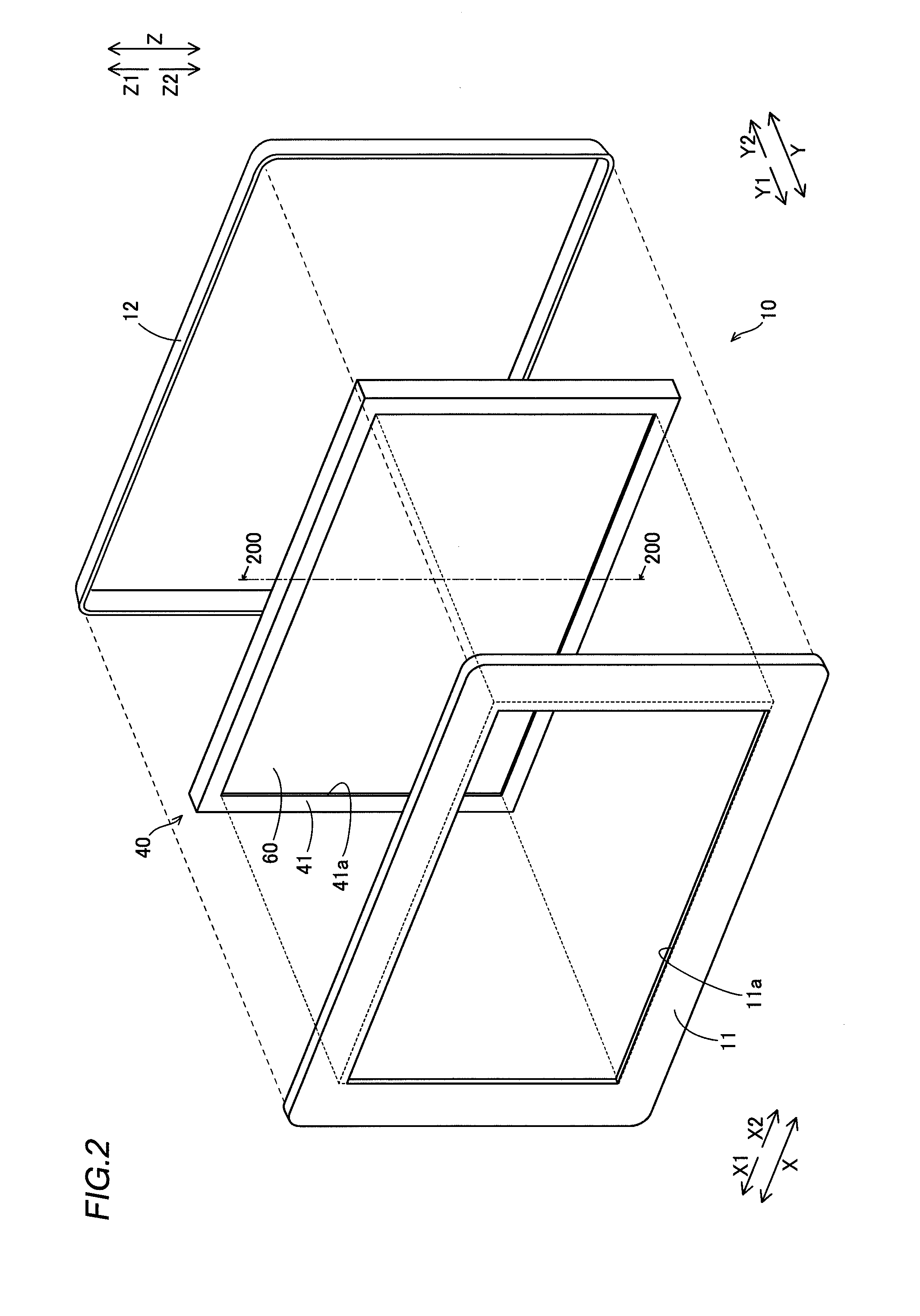

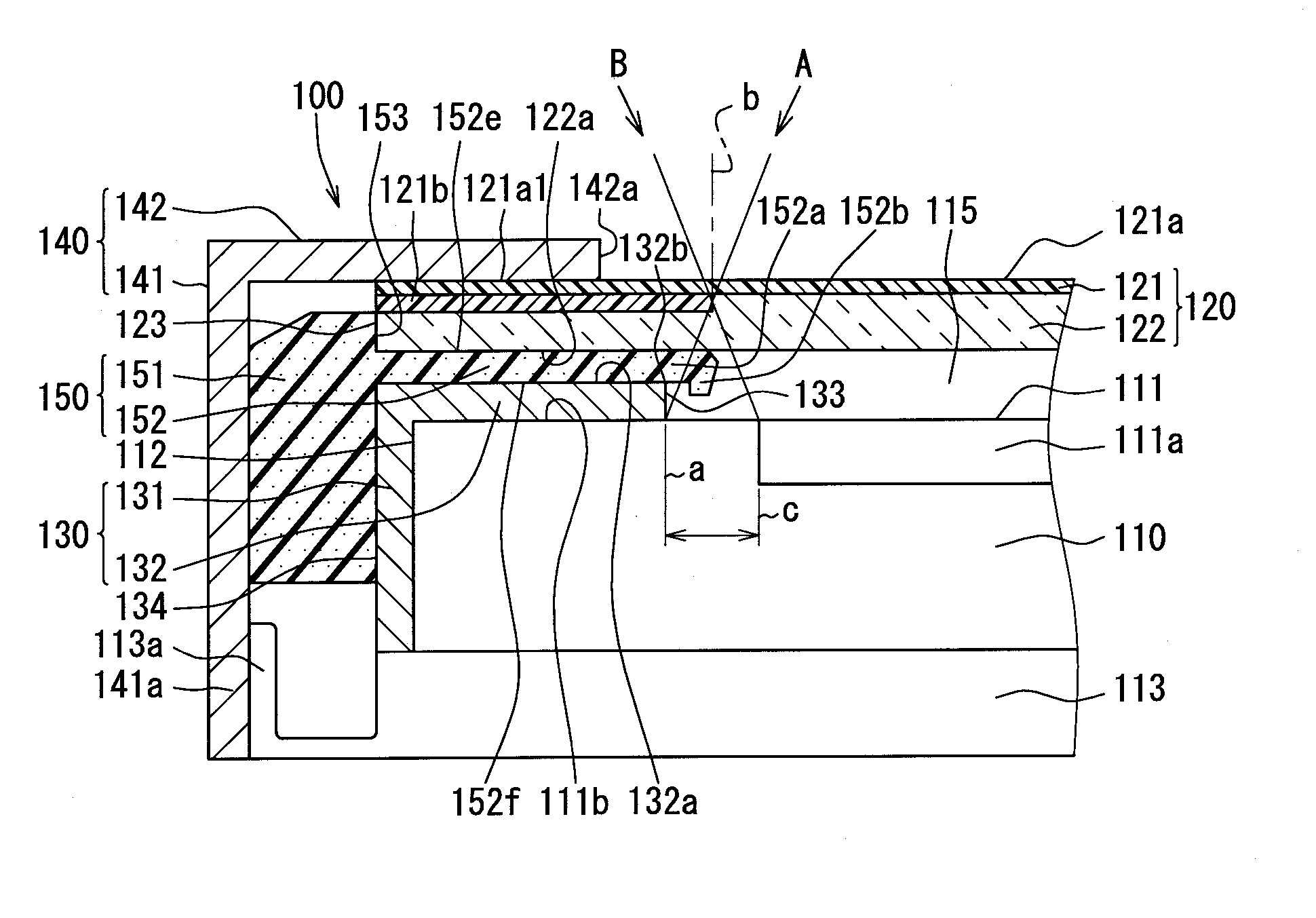

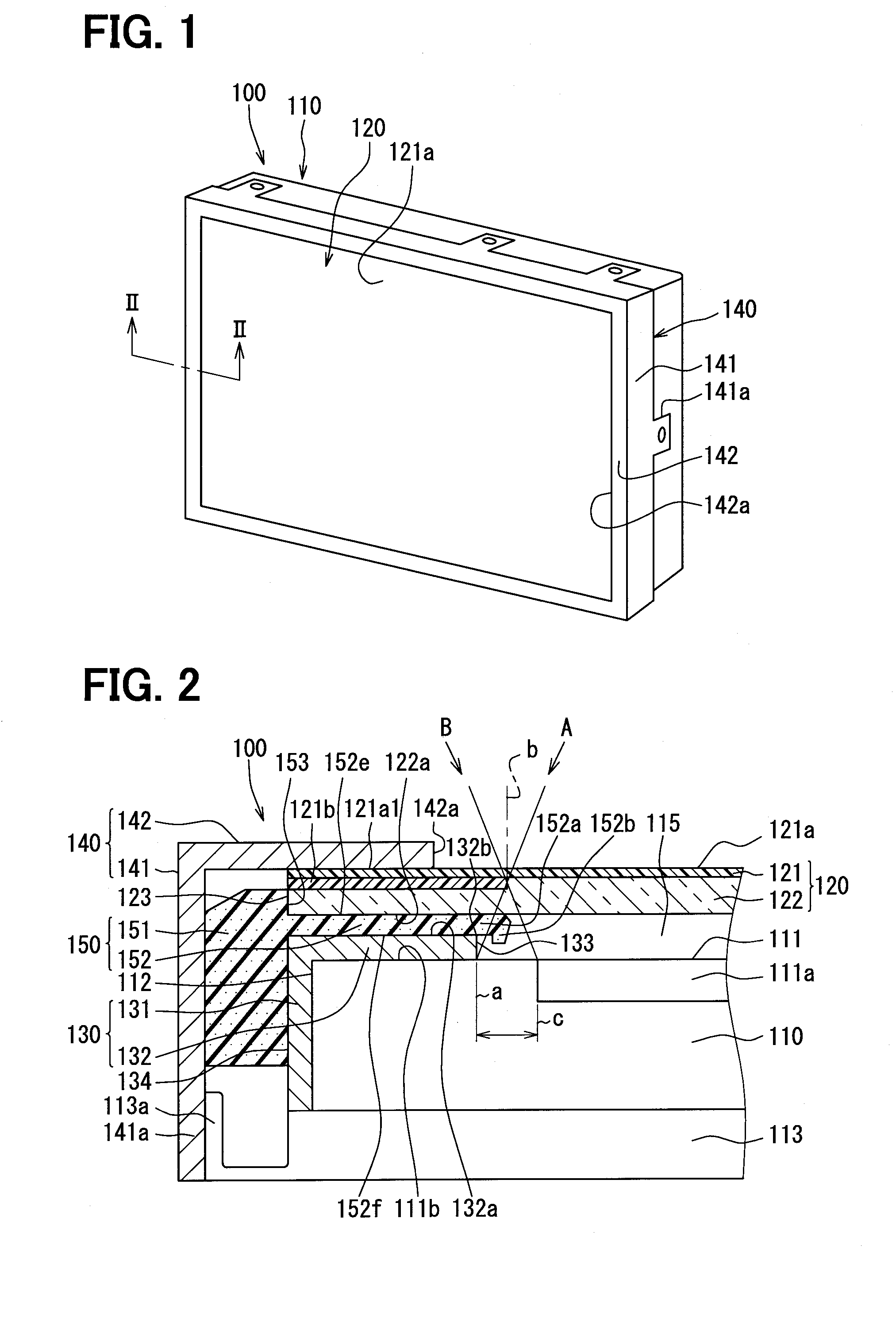

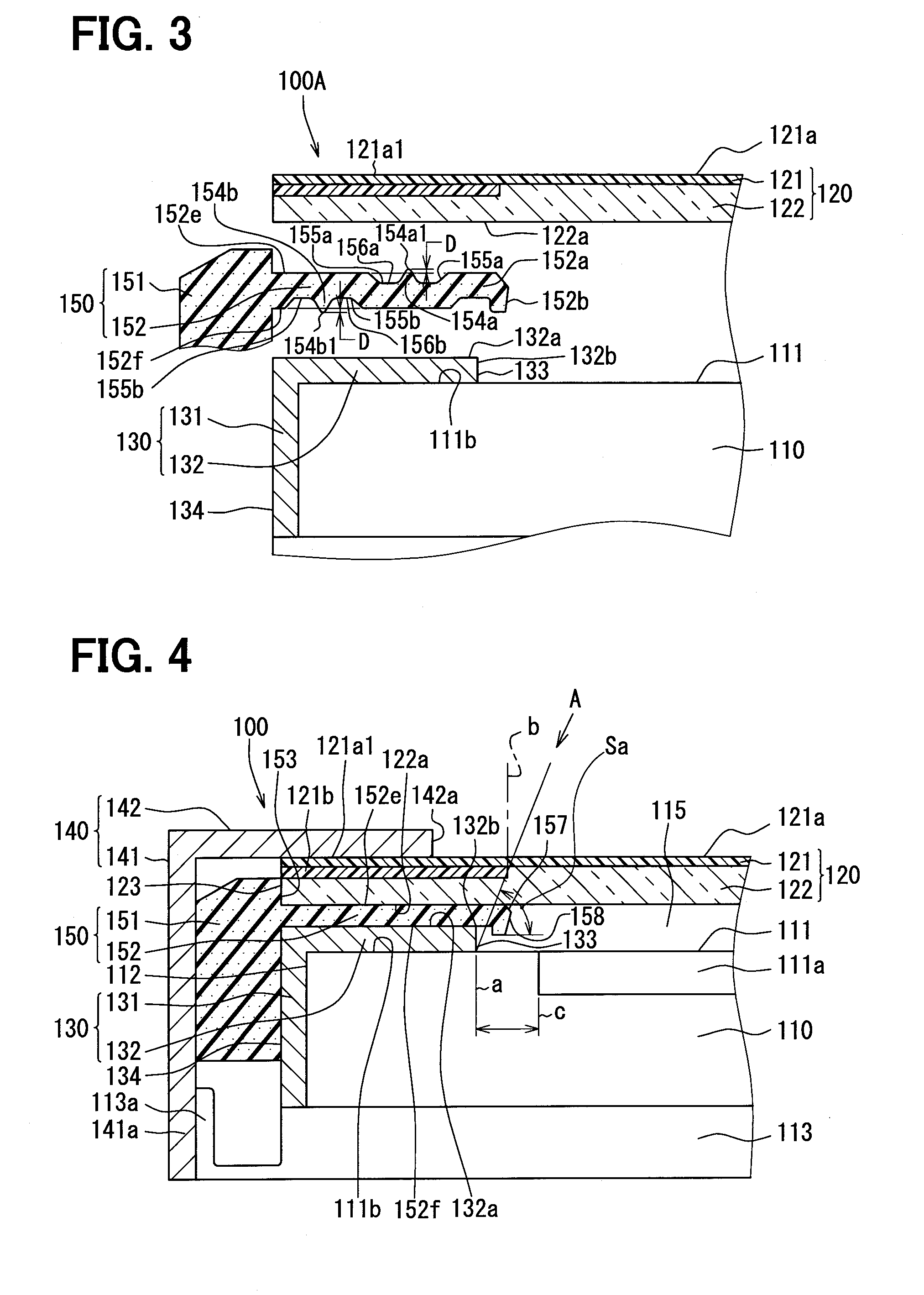

Display and Display Module

InactiveUS20120257136A1Effective coolingWithout increasing number of componentMechanical apparatusLight guides for lighting systemsLight guideDisplay device

This display includes a display module including a substrate mounted with a light source, a light guide guiding light received from the light source and a platelike member of a metal radiating heat generated by the light source. The platelike member integrally includes a substrate mounting portion, a first heat radiation portion extending from a first end portion of the substrate mounting portion oppositely to the light guide and a second heat radiation portion extending from a second end portion of the substrate mounting portion oppositely to the first heat radiation portion.

Owner:FUNAI ELECTRIC CO LTD

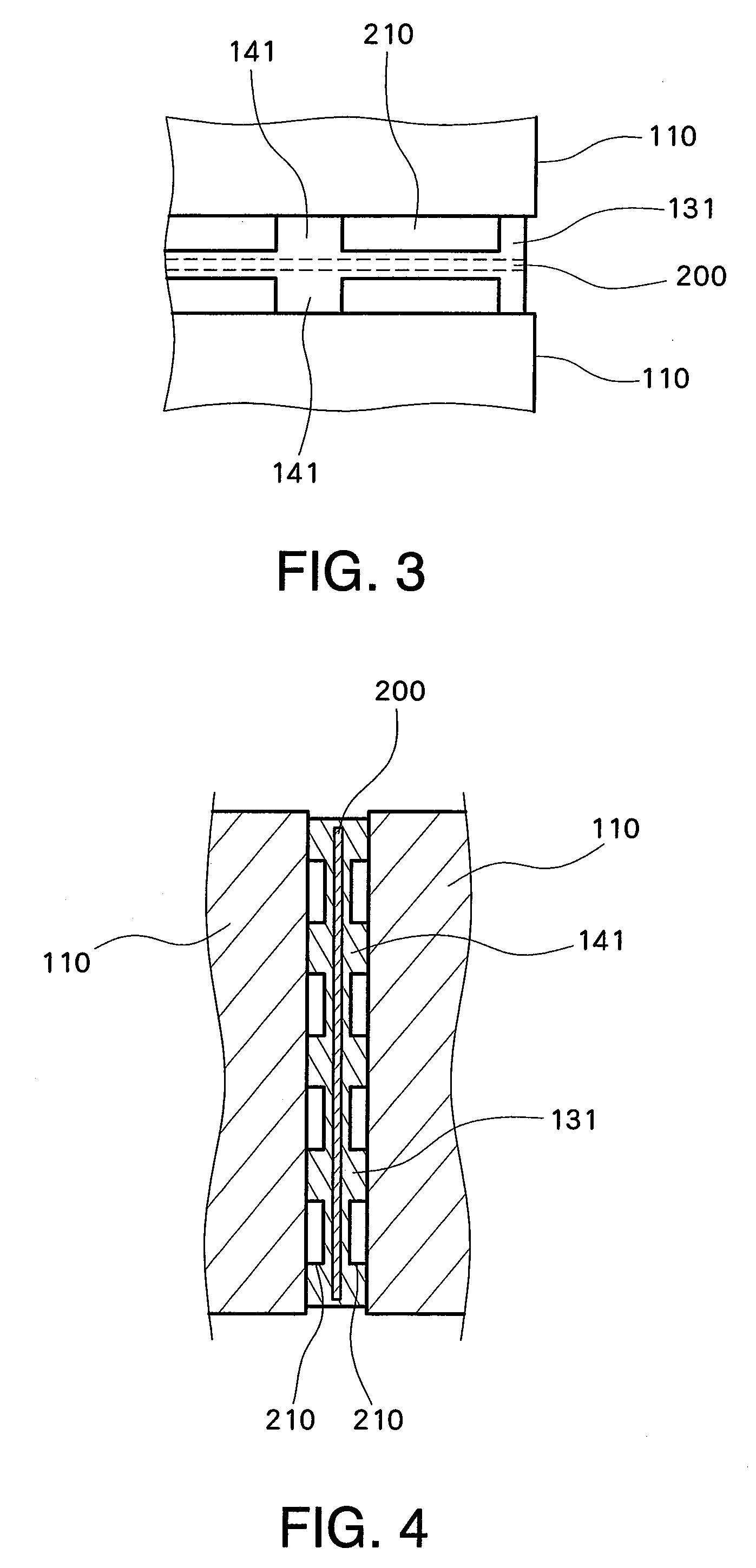

Battery assembly

ActiveUS20090286141A1Increasing number of componentIncreasing of costLarge-sized flat cells/batteriesFinal product manufactureBattery cellCharge and discharge

A battery assembly of the invention includes a secondary battery formed by stacking a plurality of unit battery cells having a cathode and an anode, collector electrodes provided on respective end surfaces of the secondary battery positioned in the stacking direction of the unit battery cells; and terminal portions formed at the collector electrodes, protruded outward from a side surface of the secondary battery, to which conductive members are connected for charging and discharging. A coolant is supplied to the terminal portions to cool the terminal portions.

Owner:TOYOTA JIDOSHA KK

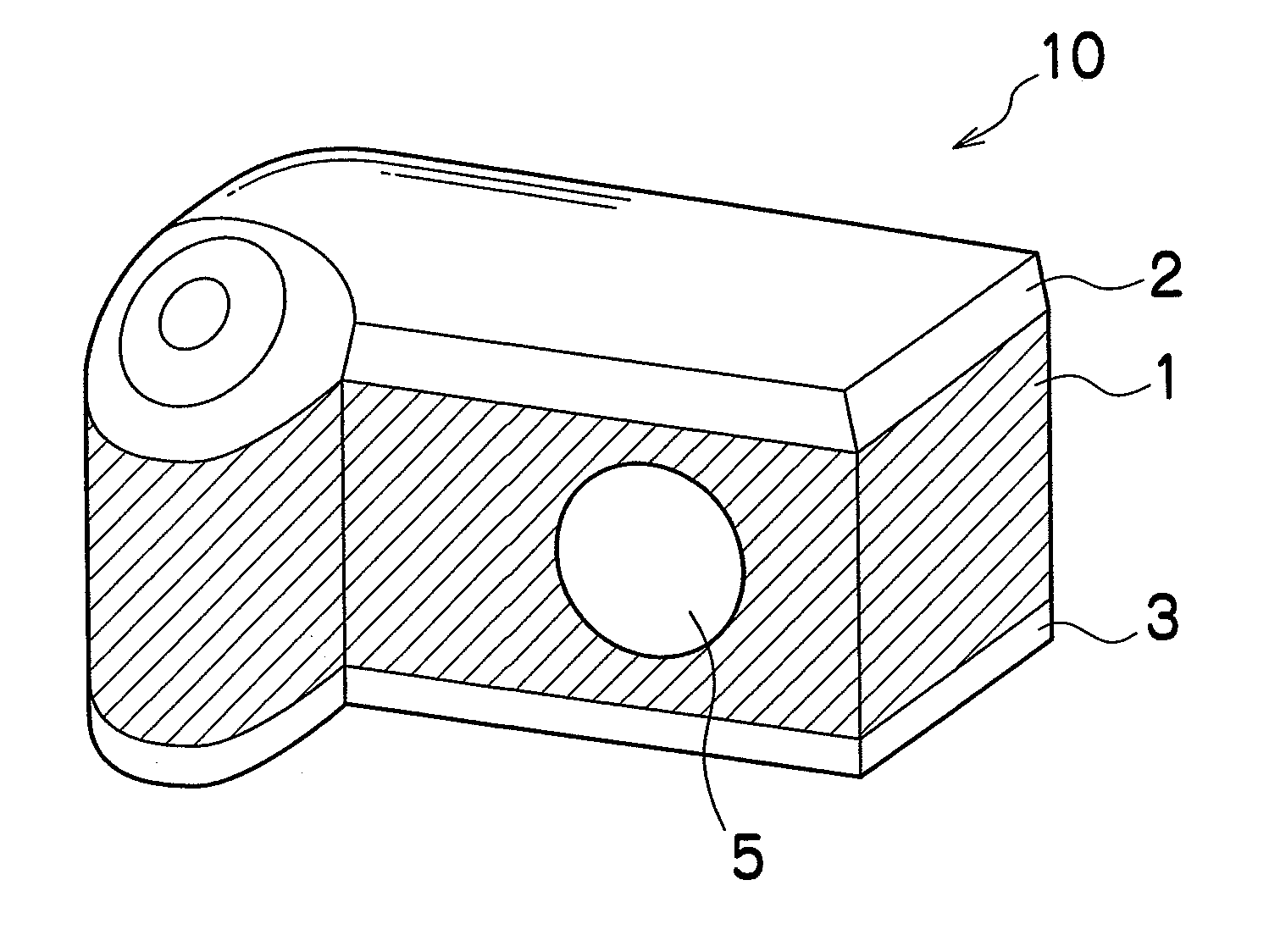

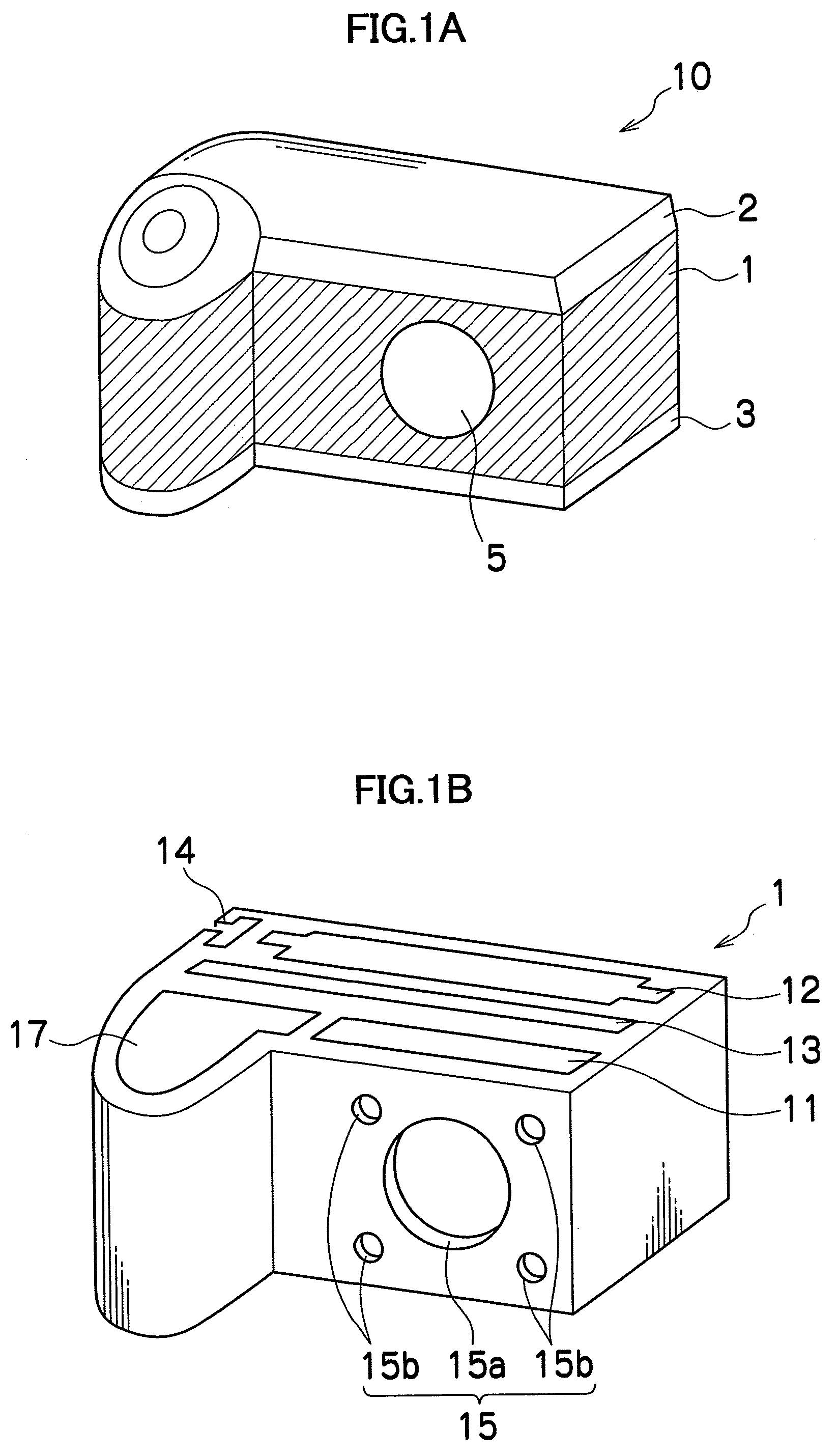

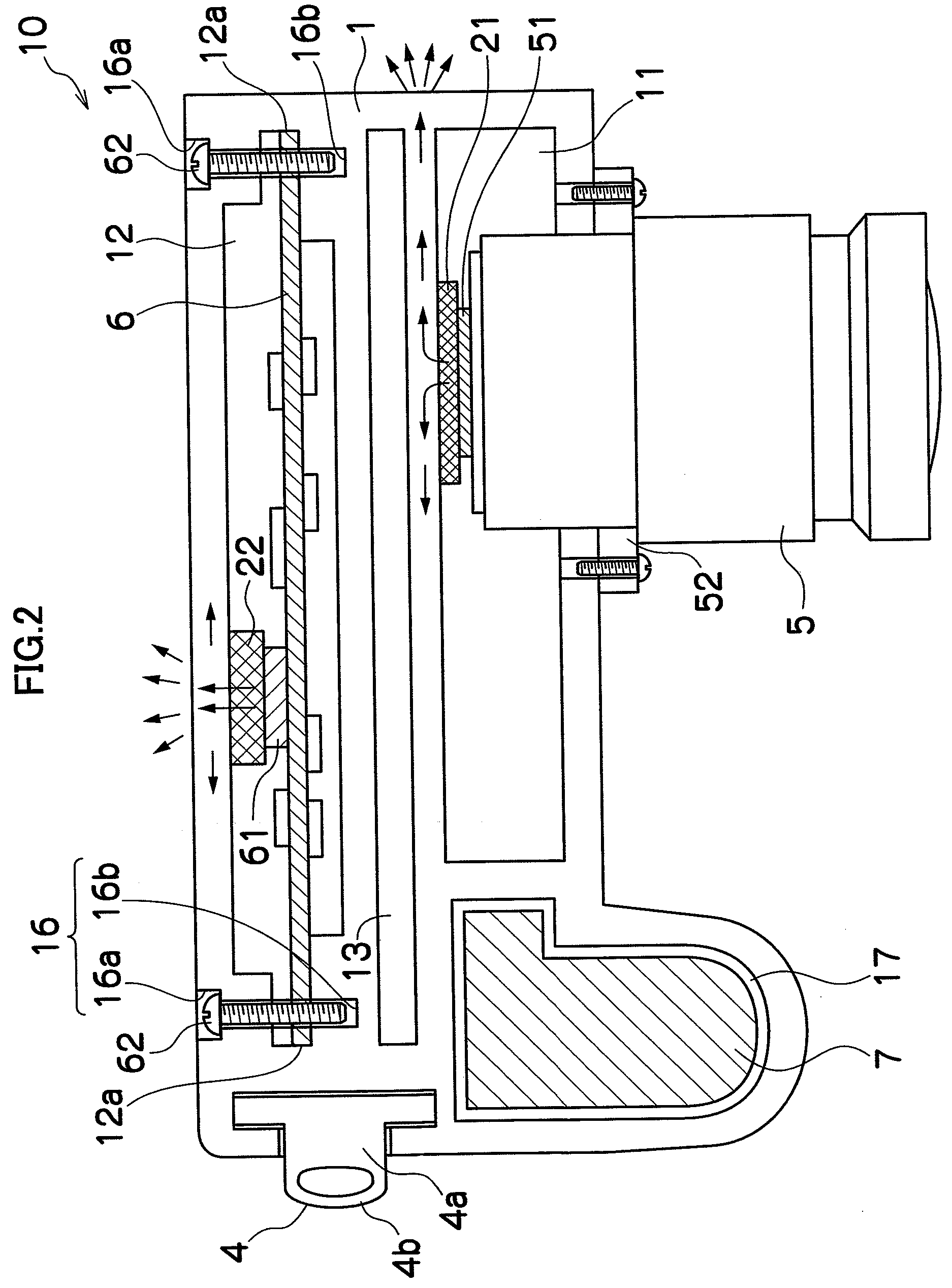

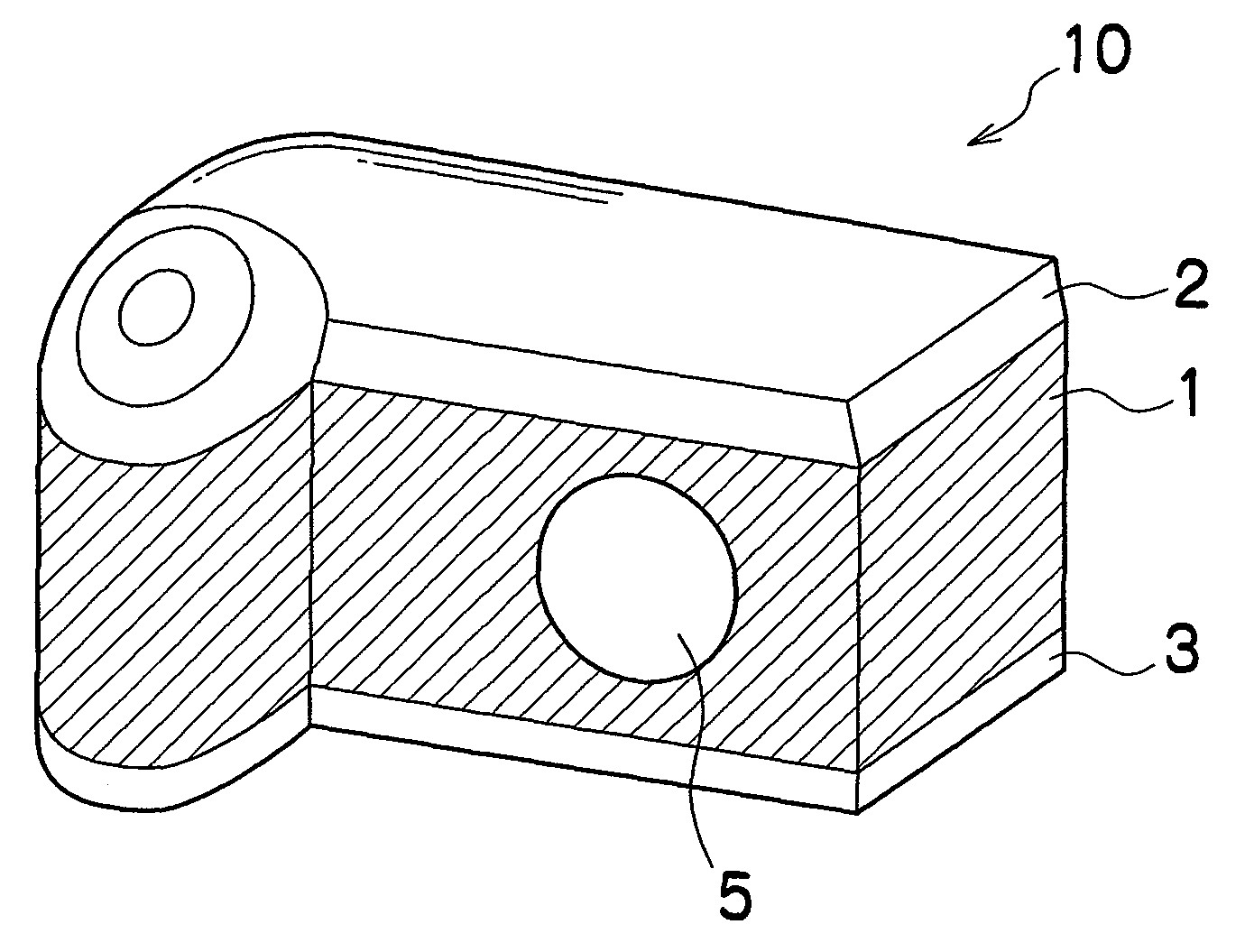

Enclosure for electric equipment and imaging device

InactiveUS20090086417A1Prevent insertionImprove assembly performanceTelevision system detailsSubstation/switching arrangement detailsManufacturing cost reductionElectrical devices

According to an enclosure for electric equipment of an aspect of the present invention, the enclosure having the plurality of accommodation portions accommodating separate contents, respectively, can be formed by one molding without assembling a plurality of components, which can reduce the number of assembling processes. Also, formation by one component eliminates a gap which would be generated by assembling components, which can improve enclosure strength and designability and reduce manufacturing costs.

Owner:FUJIFILM CORP

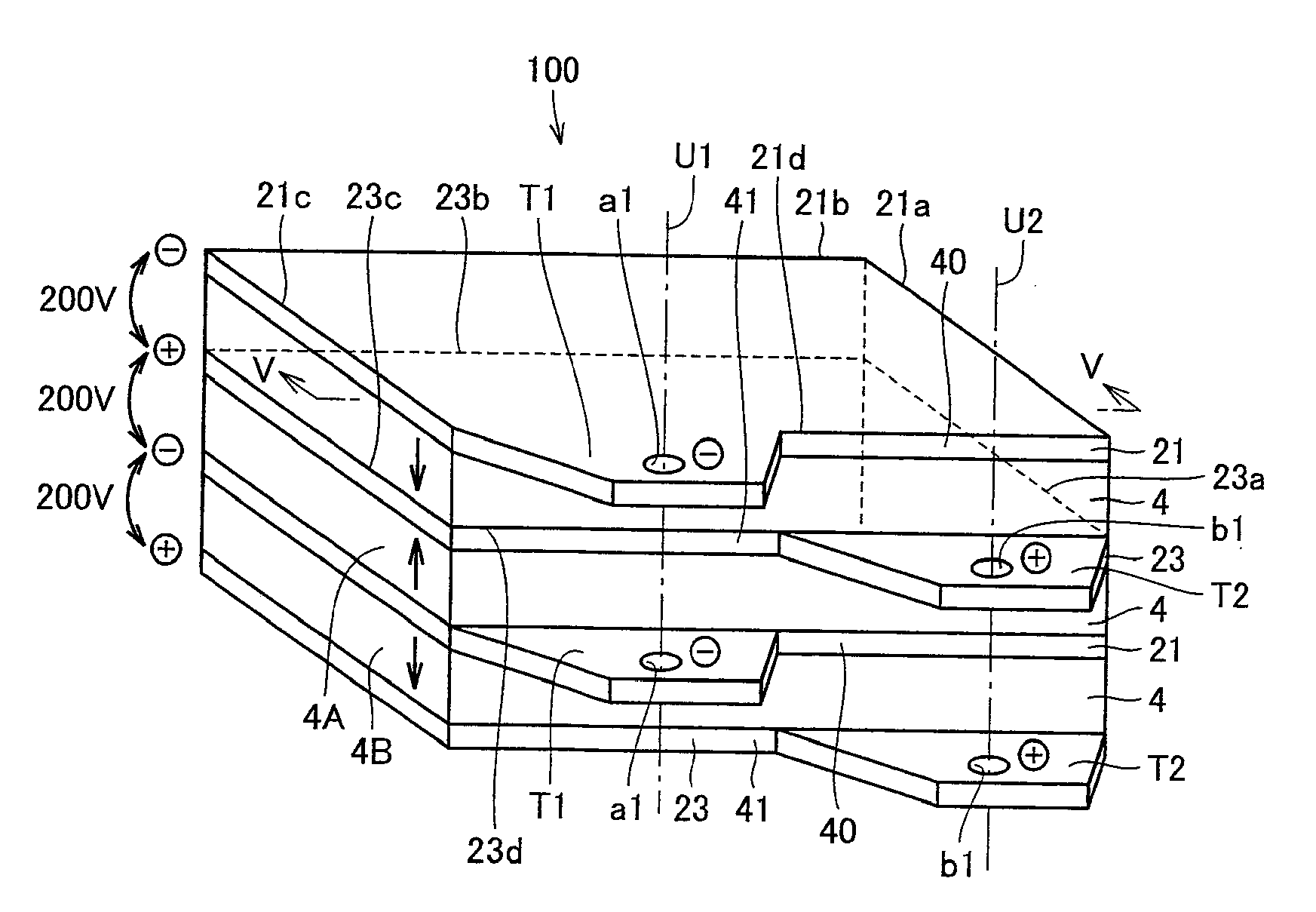

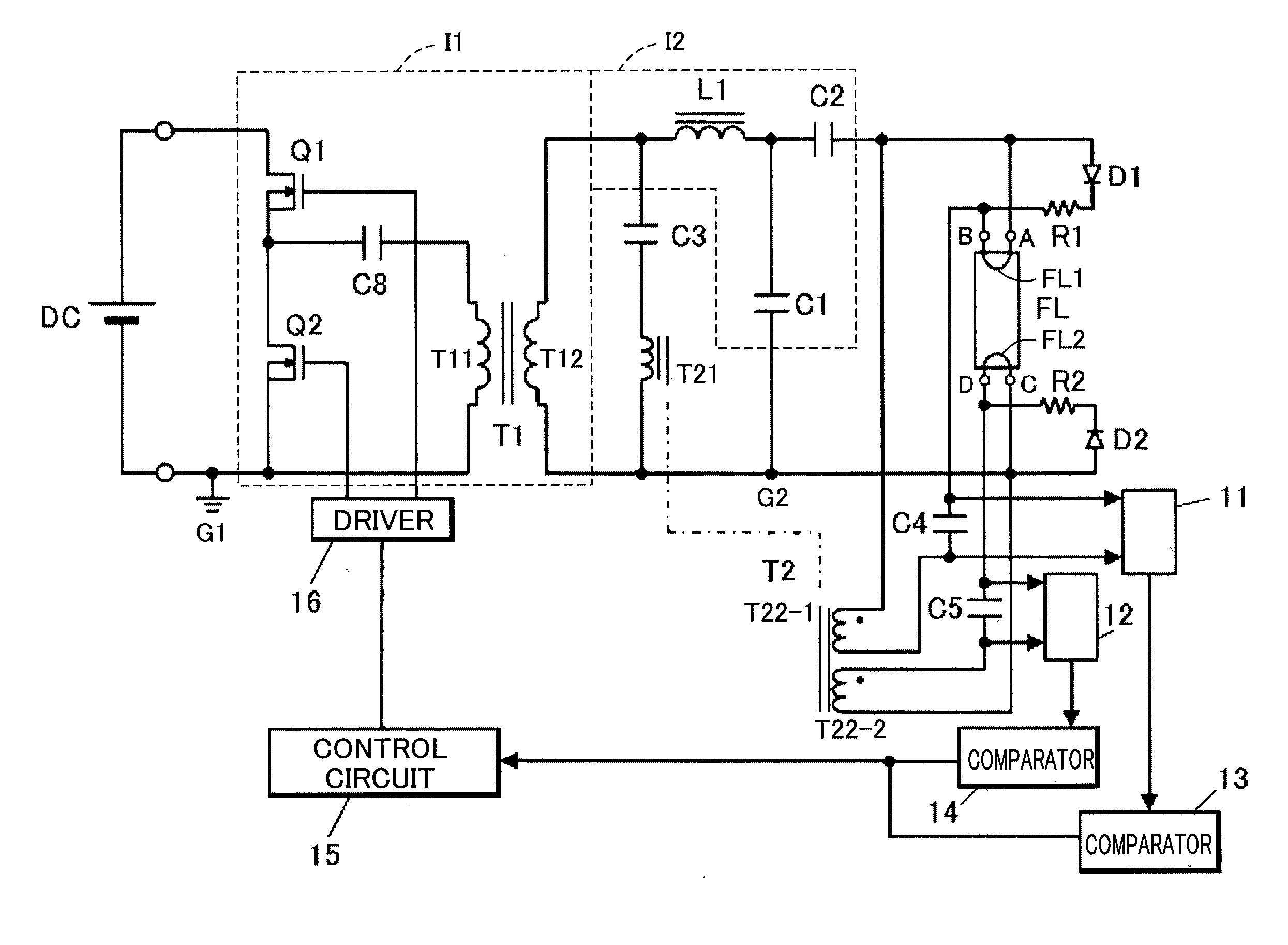

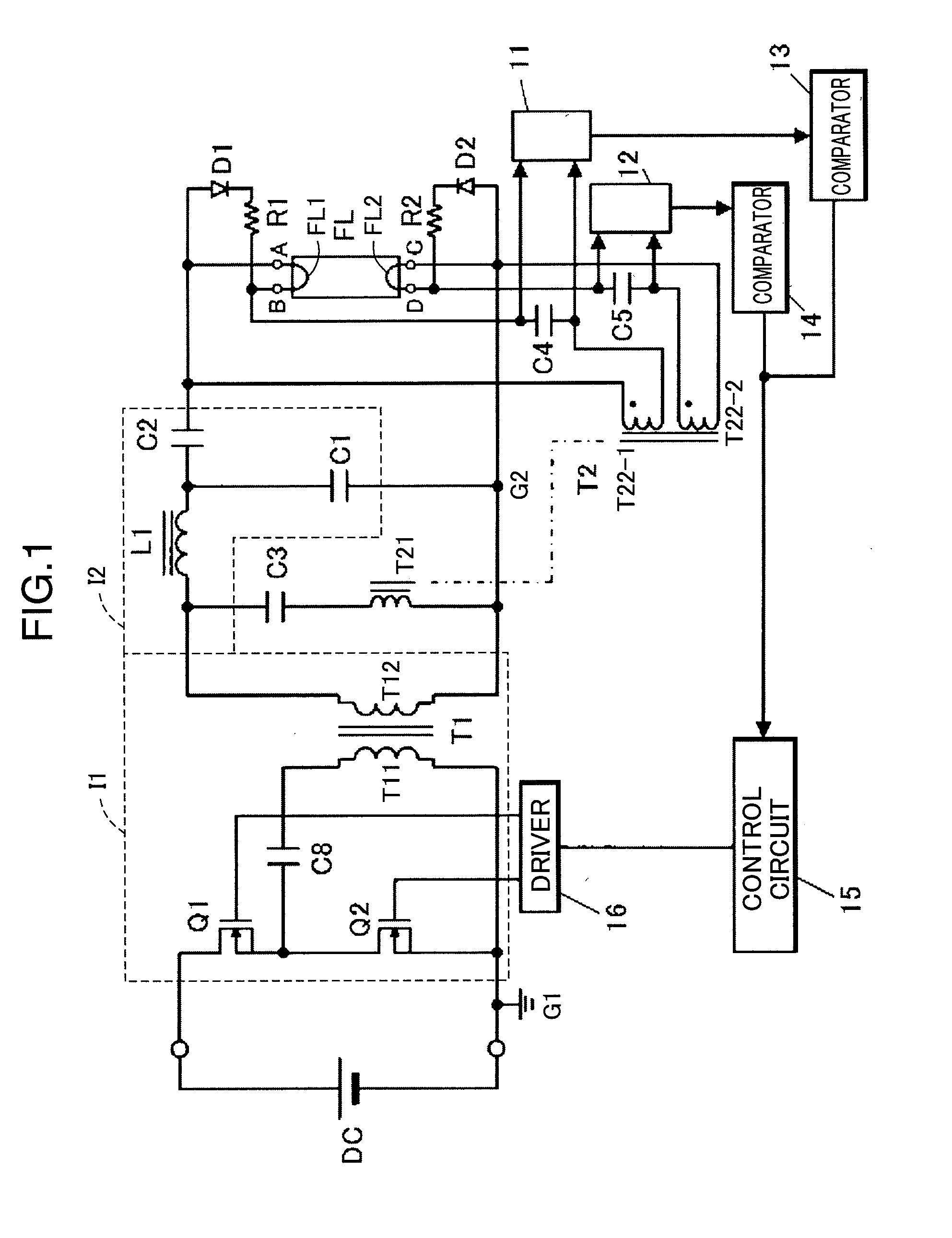

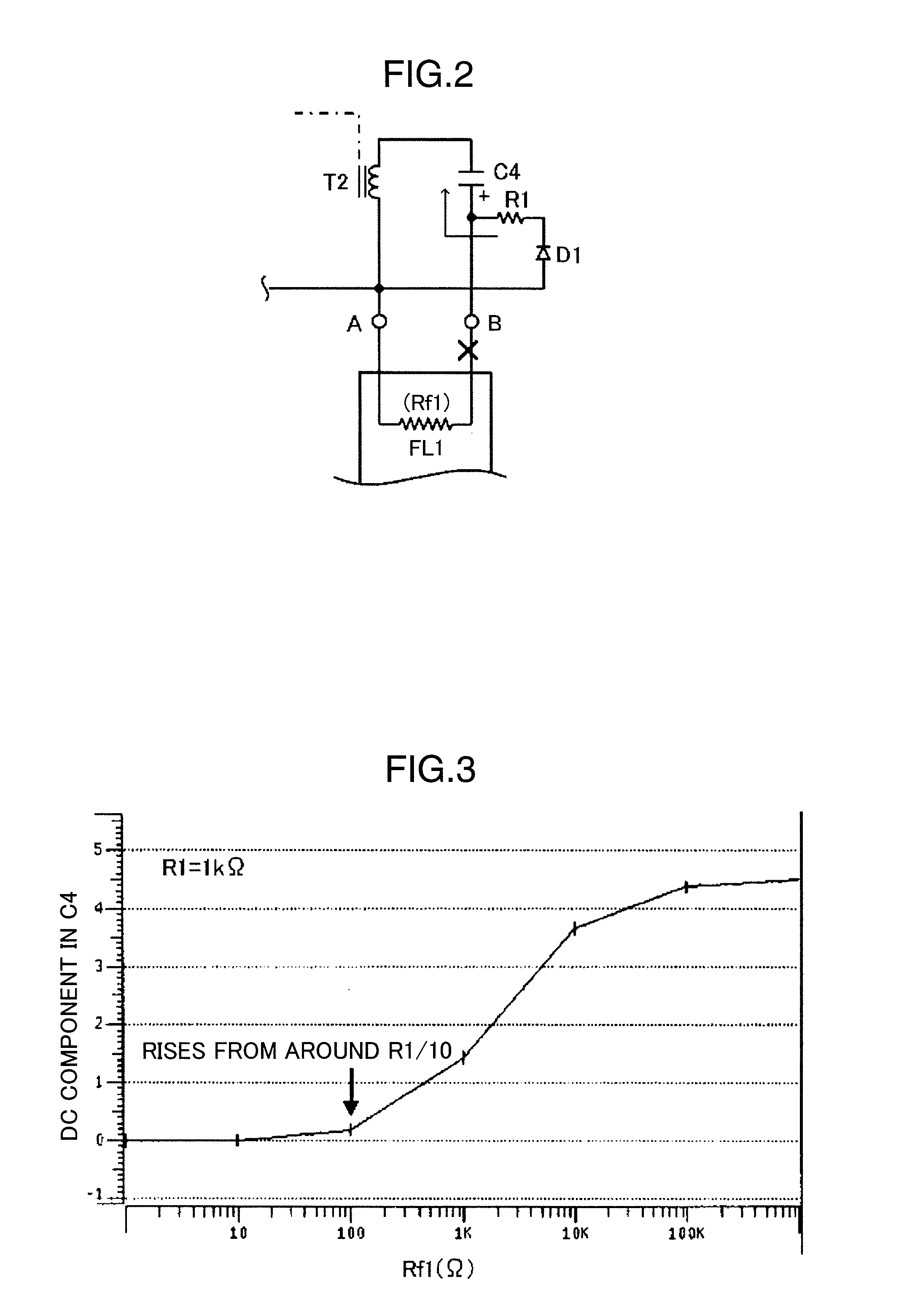

Discharge lamp operating device, illumination device and liquid crystal display device

InactiveUS20100176739A1Without increasing number of componentDetect disconnection of filamentsElectric light circuit arrangementElectric discharge lampsLiquid-crystal displayTransformer

A series circuit comprising a diode and a resistance is connected in parallel to a filament, and a series circuit comprising a diode and a resistance is connected in parallel to a filament. The filaments are preheated by a preheating current supplied from secondary windings of a preheating transformer, via preheating capacitors. Detection circuits detect DC voltage components of the preheating capacitors. Comparators compare the DC voltage components of the preheating capacitors with a reference voltage. The comparators cause a control circuit to protect the inverter circuit if an abnormality of the filaments is detected.

Owner:PANASONIC CORP

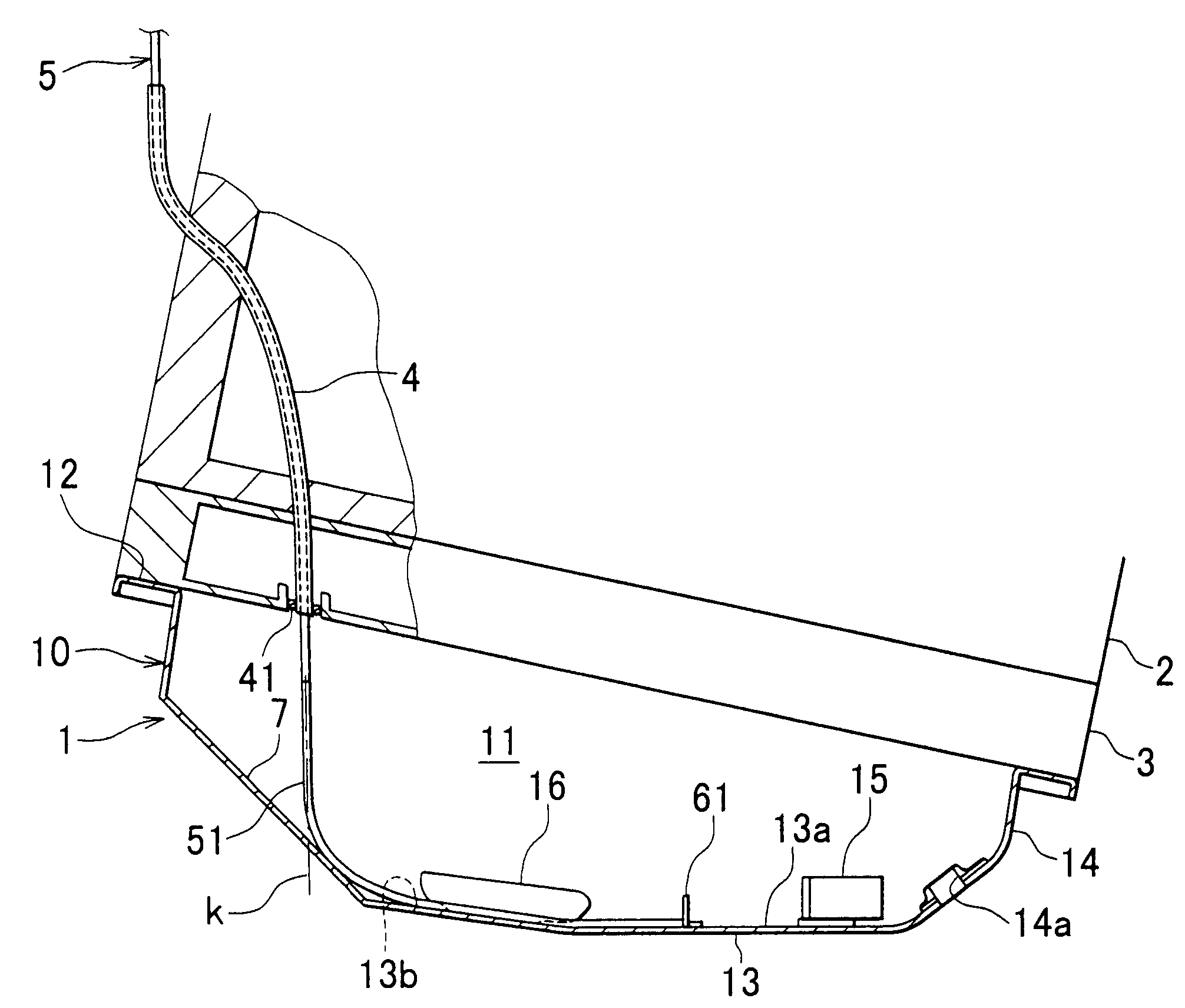

Oil pan structure

InactiveUS20060130801A1Simple processSmooth oil absorptionCrankshaftsCasingsPetroleum engineeringNozzle

An oil pan structure includes a tubular level-gauge guide into which an oil level-gauge that measures the amount of oil stored in the oil pan is inserted. The oil pan structure further includes a nozzle guide that guides the end of a nozzle of an oil changer, which is inserted into the level-gauge-guide when the oil in the oil pan is replaced with new oil, to a position near the deepest portion of the reservoir portion.

Owner:TOYOTA JIDOSHA KK

Battery pack

ActiveUS8163419B2Reliable heatingWithout increasing number of componentCell temperature controlCell component detailsElectricityElectrical battery

A battery pack comprises a plurality of battery modules and a holding spacer which holds the battery module. A plurality of projections are provided on the holding spacer. The projections contact the battery module to hold the battery module and form a flow path for a coolant. A heat generating structure is embedded in the holding spacer or inserted into a hollow section of the holding spacer. In a cold climate, electricity is applied to the heat generating structure, to heat the battery module.

Owner:PANASONIC EV ENERGY CO LTD

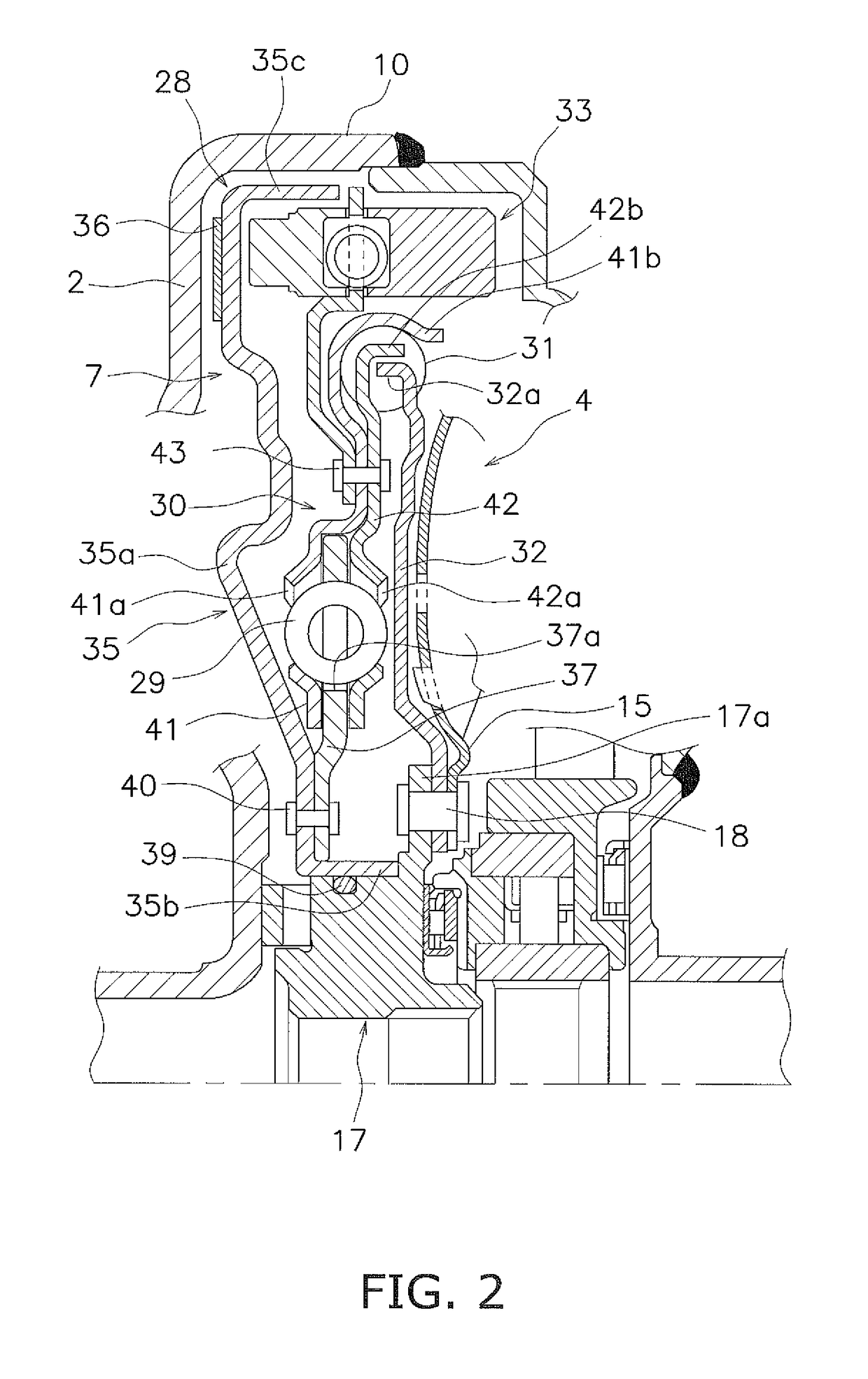

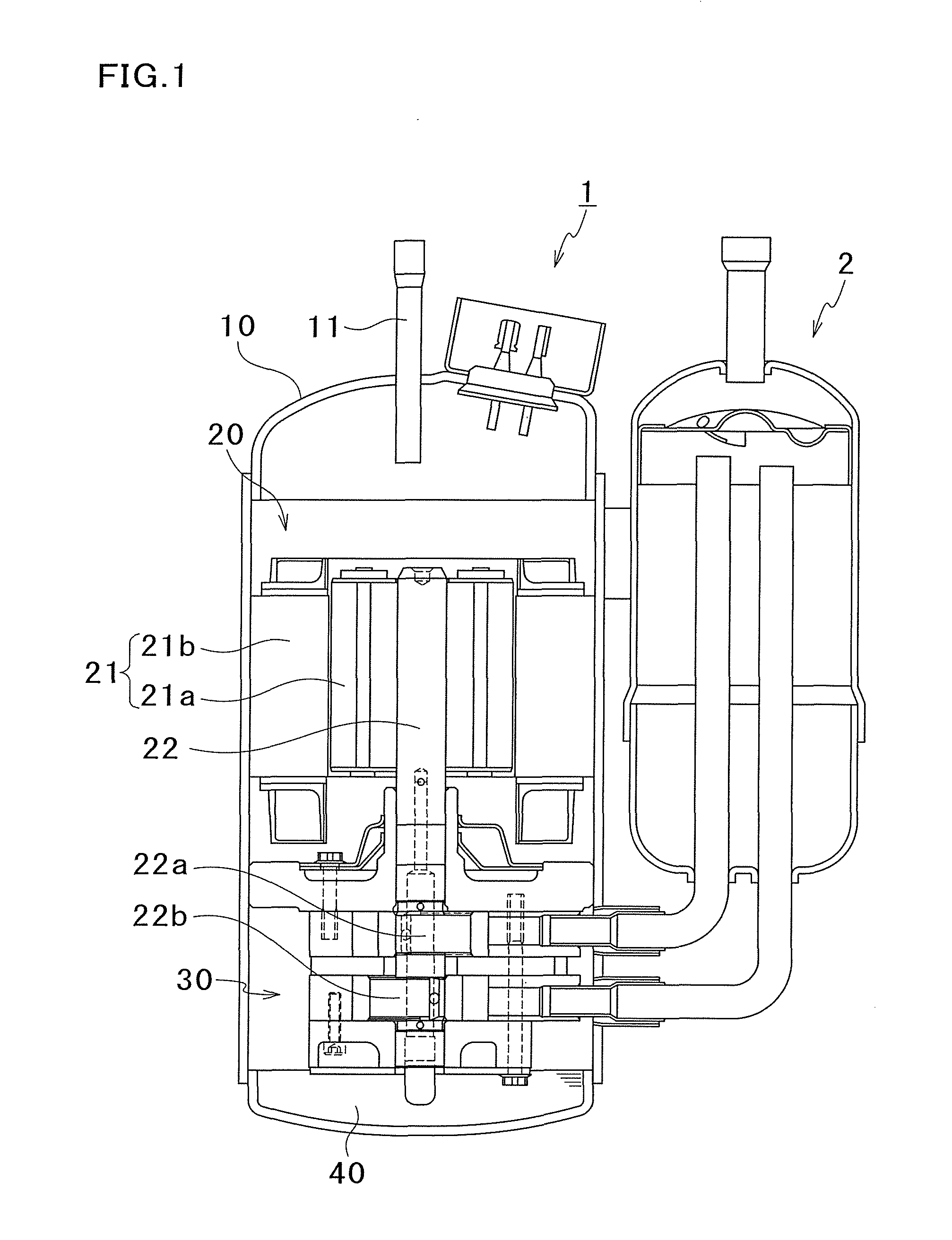

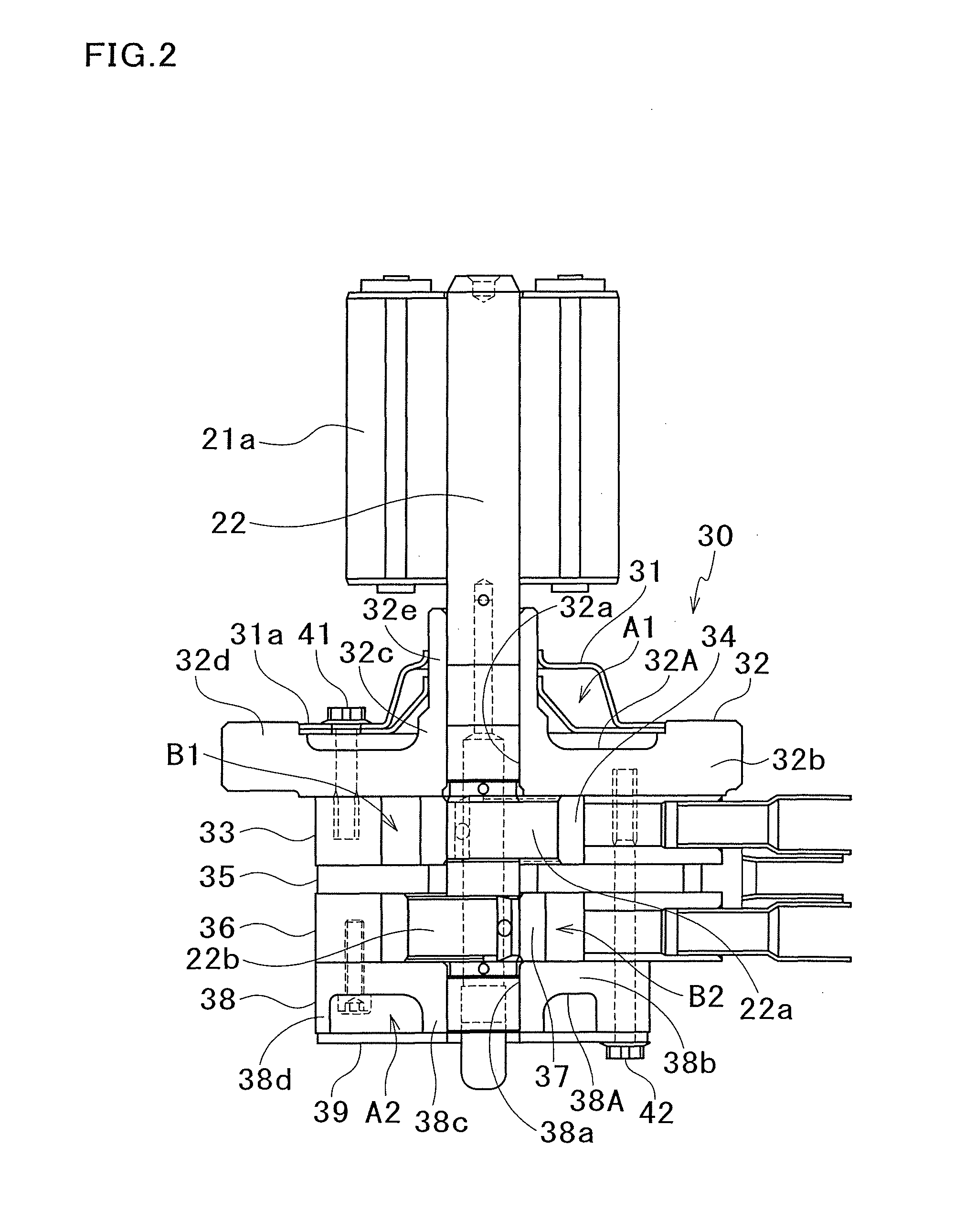

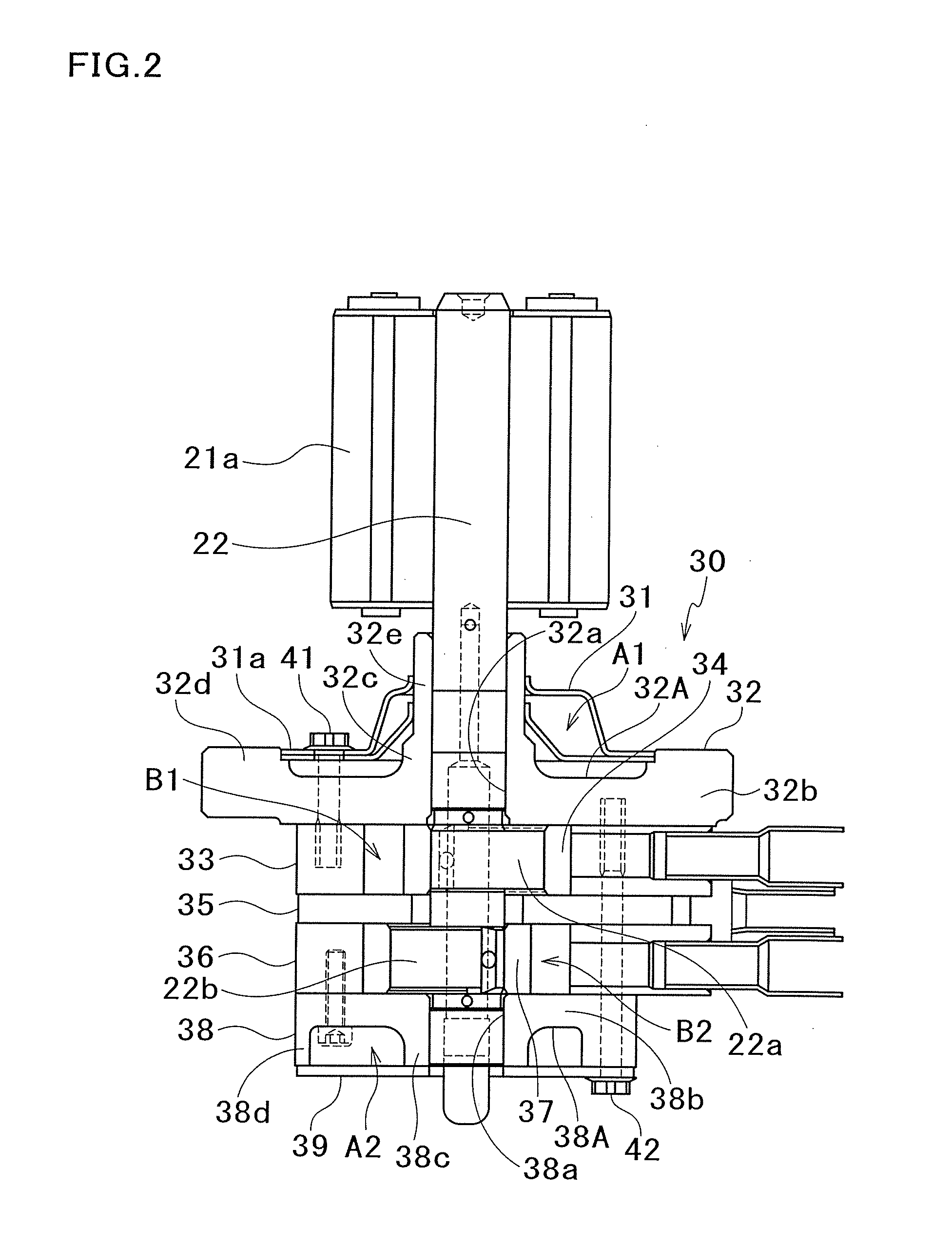

Lock-up device for torque converter

ActiveUS9784352B2Reduce variationWithout increasing number of componentRotating vibration suppressionFluid gearingsHysteresisEngineering

A lock-up device for a torque converter is disposed between a front cover coupled to an engine-side member and a torque converter body and directly transmits a torque from the front cover to a turbine of the torque converter. The lock-up device includes a clutch portion to transmit the torque from the front cover to an output side. The lock-up device includes an intermediate member in a power transmission path between the clutch portion and the turbine. An input-side damper mechanism mounted between the clutch portion and the intermediate member attenuates variation in rotational speed. An output-side damper mechanism mounted between the intermediate member and the turbine generates a hysteresis torque larger than a hysteresis torque of the input-side damper mechanism and attenuates variation in rotational speed. The lock-up device also includes a dynamic damper device coupled to the intermediate member and that attenuates variation in rotational speed.

Owner:EXEDY CORP

Oil pan structure

InactiveUS7322335B2Smooth oil absorptionWithout increasing number of componentCrankshaftsCasingsPetroleum engineeringNozzle

An oil pan structure includes a tubular level-gauge guide into which an oil level-gauge that measures the amount of oil stored in the oil pan is inserted. The oil pan structure further includes a nozzle guide that guides the end of a nozzle of an oil changer, which is inserted into the level-gauge-guide when the oil in the oil pan is replaced with new oil, to a position near the deepest portion of the reservoir portion.

Owner:TOYOTA JIDOSHA KK

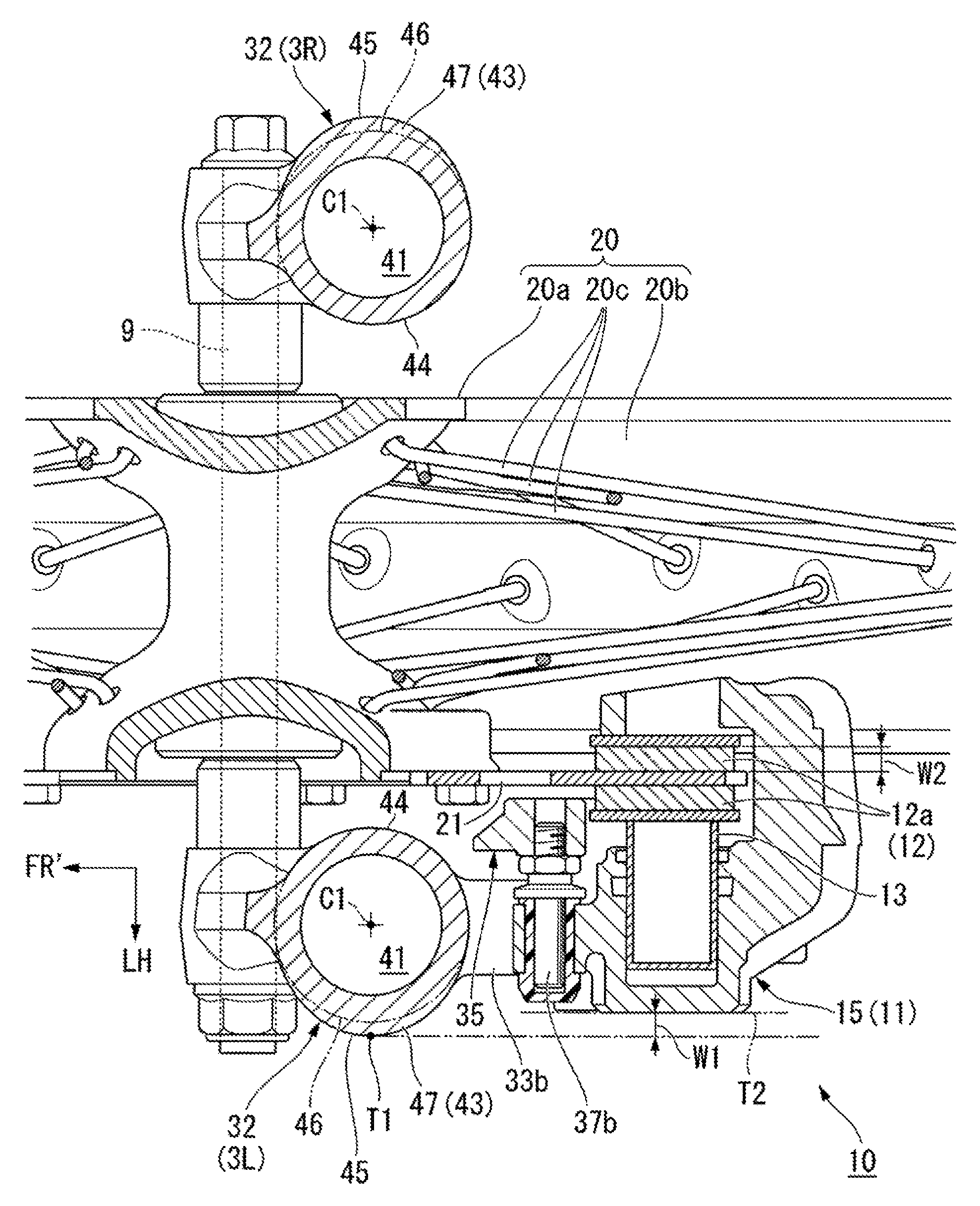

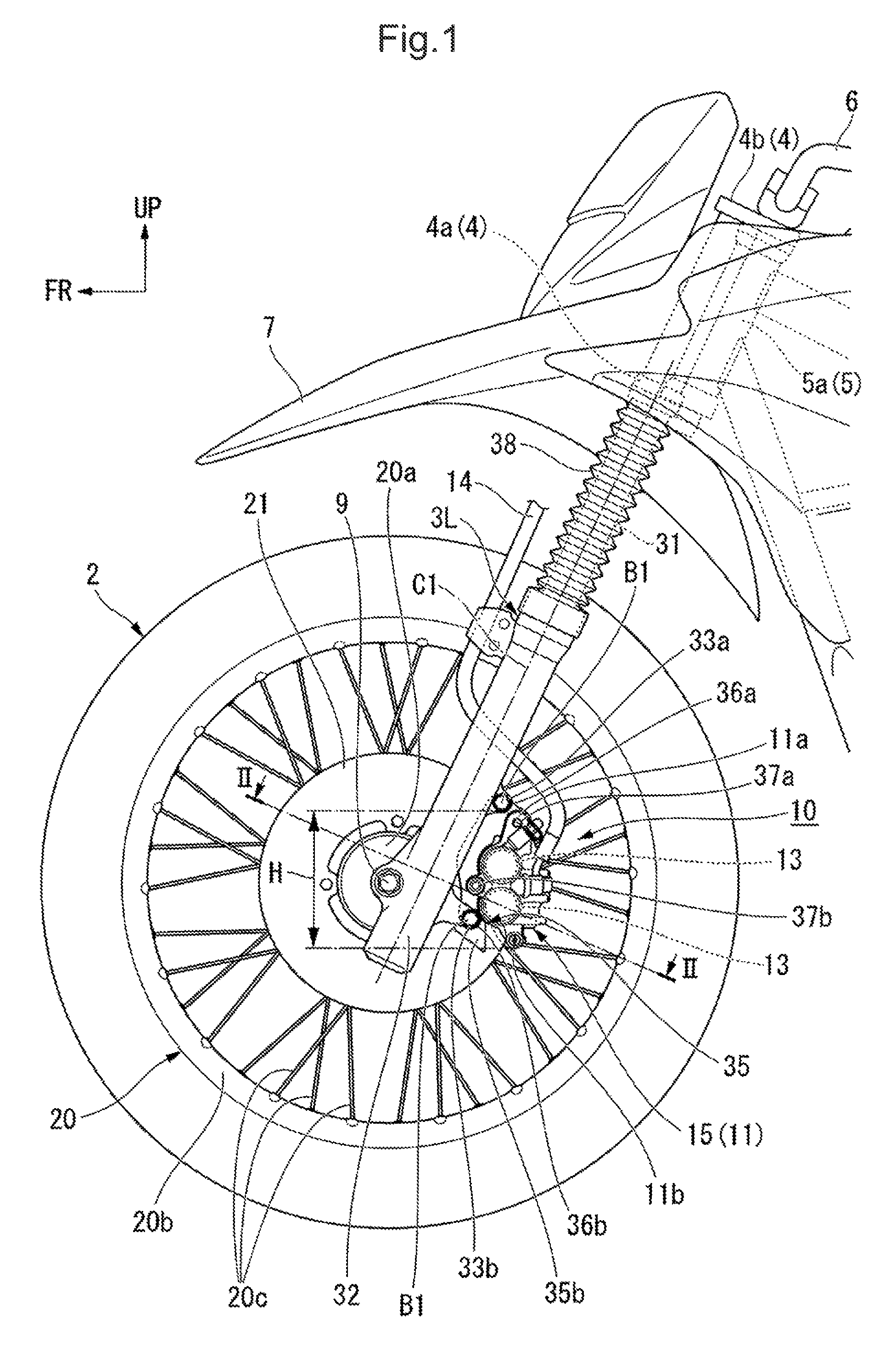

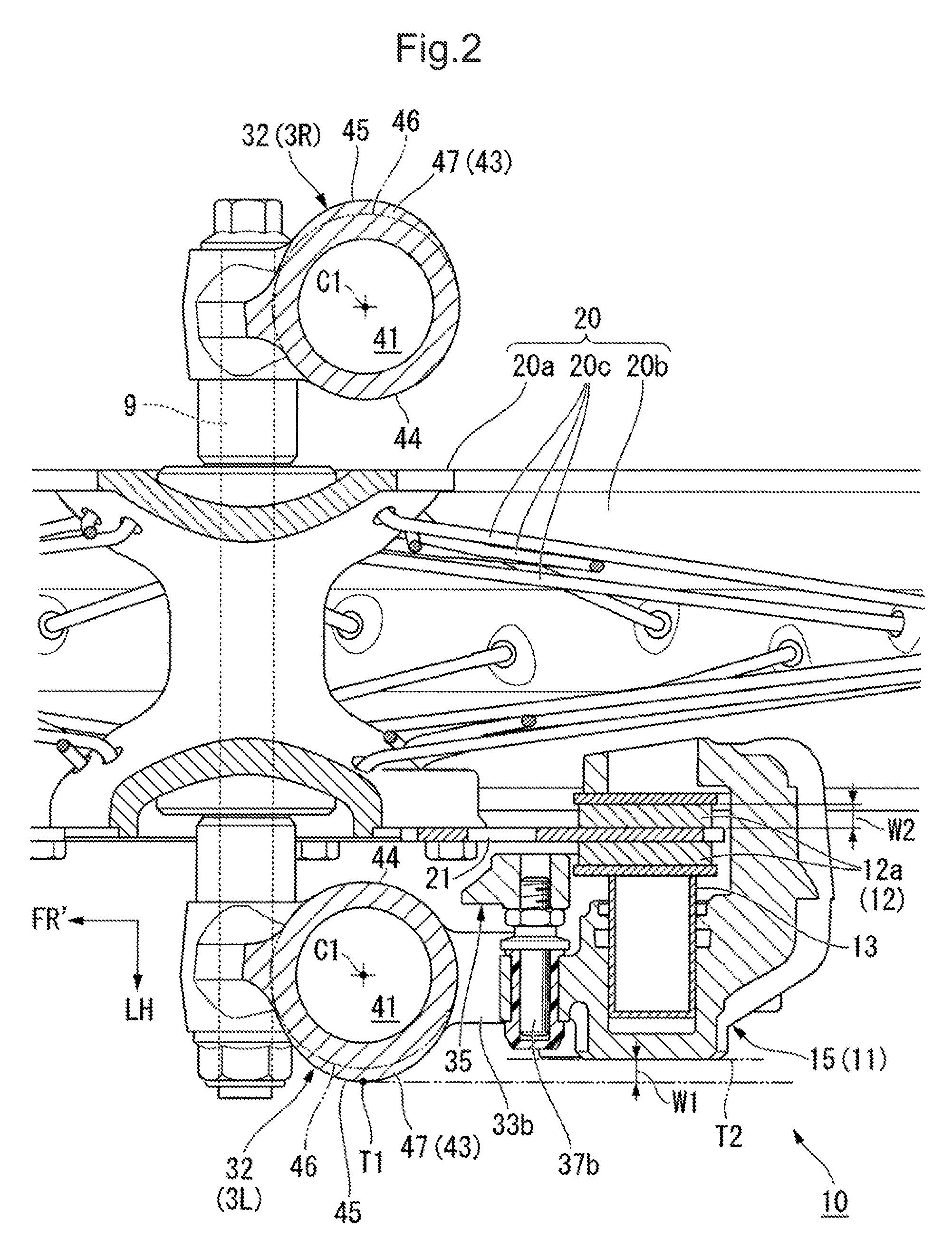

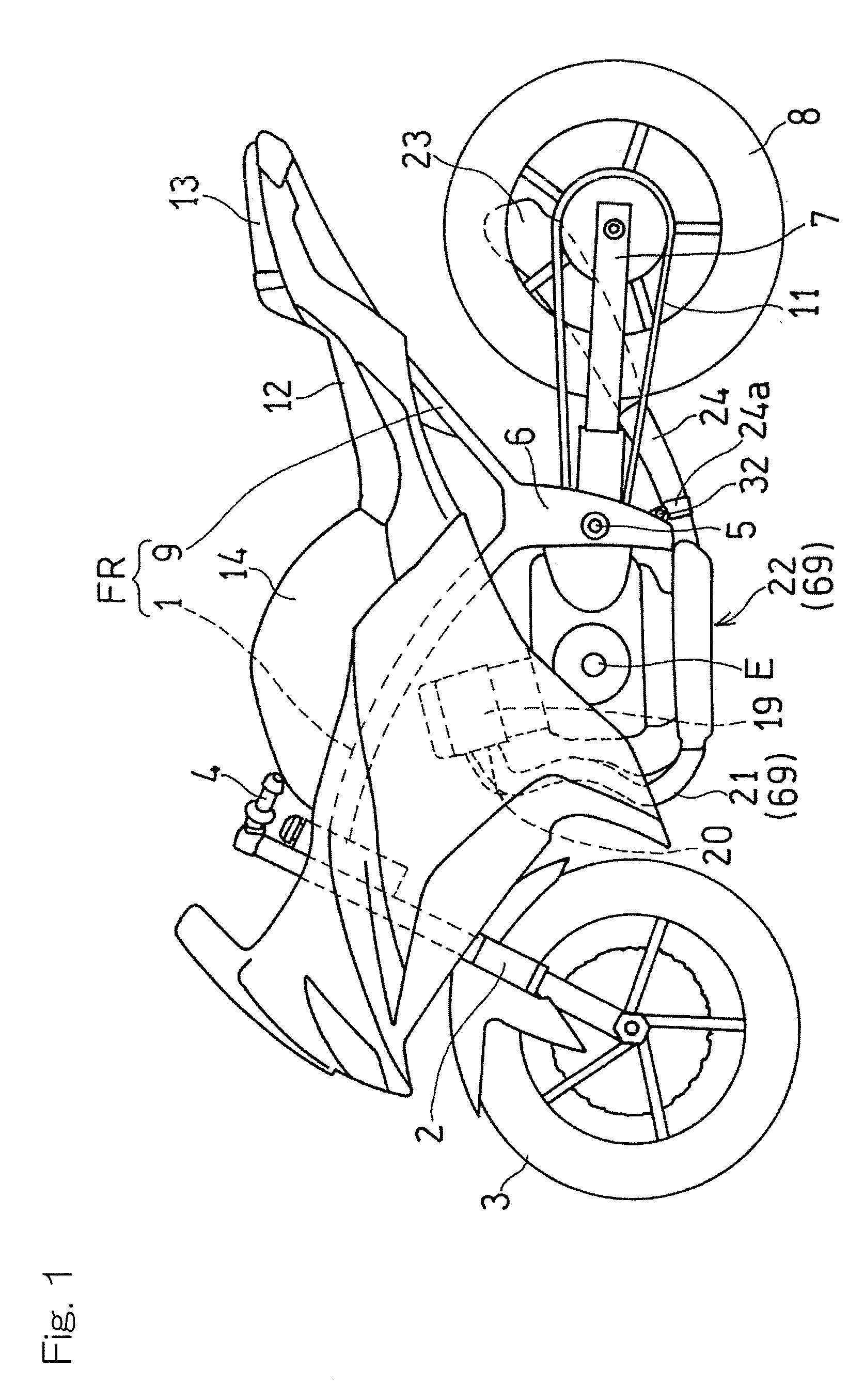

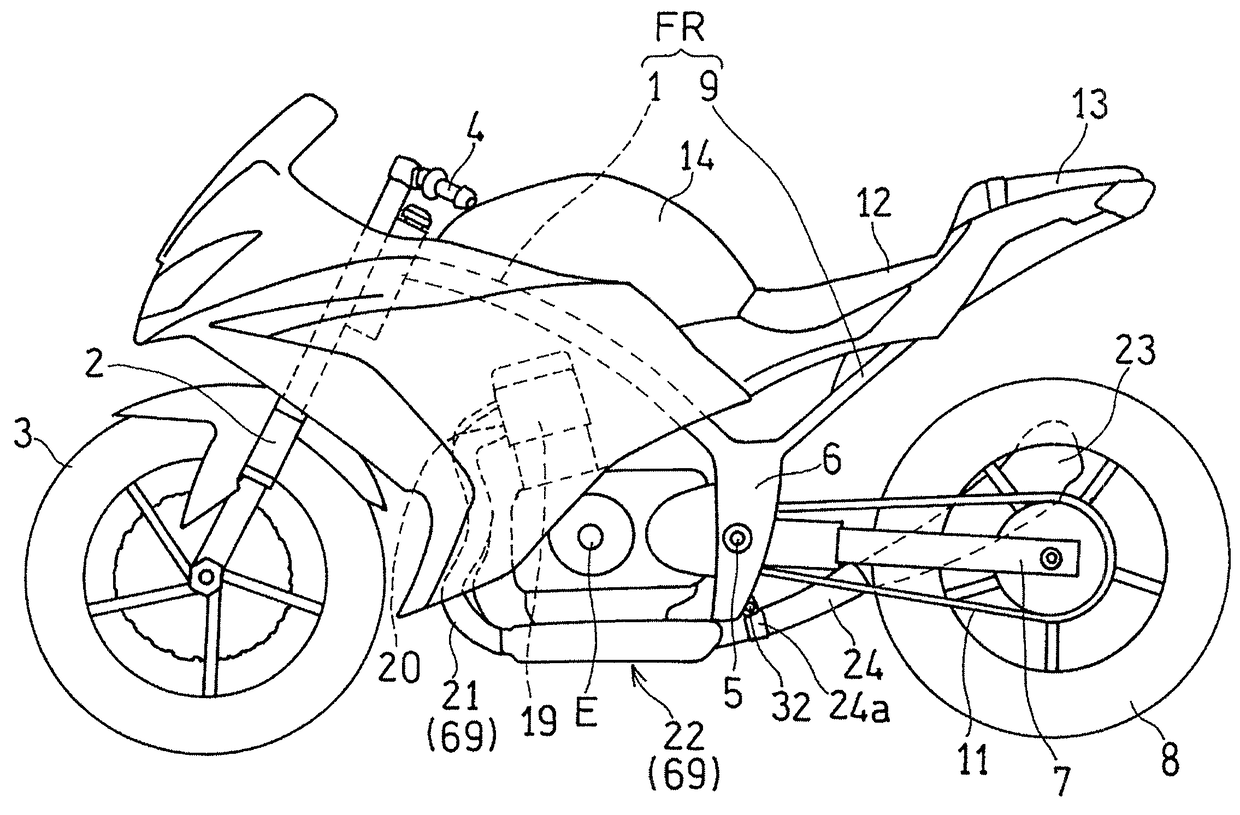

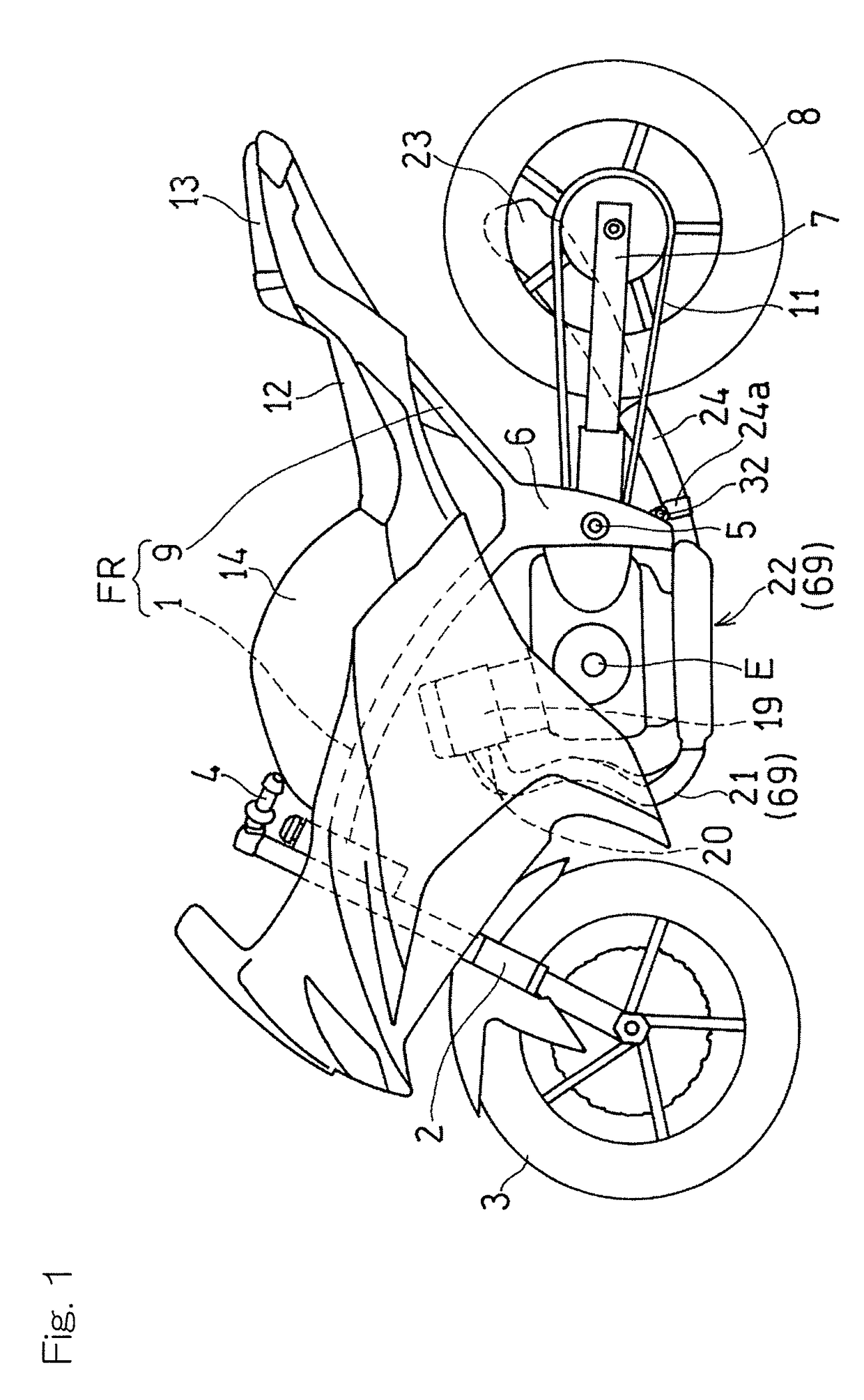

Straddle type vehicle

ActiveUS8991543B2Reduce impactWithout increasing number of componentWheel based transmissionFrictional rollers based transmissionEllipseCalipers

Owner:HONDA MOTOR CO LTD

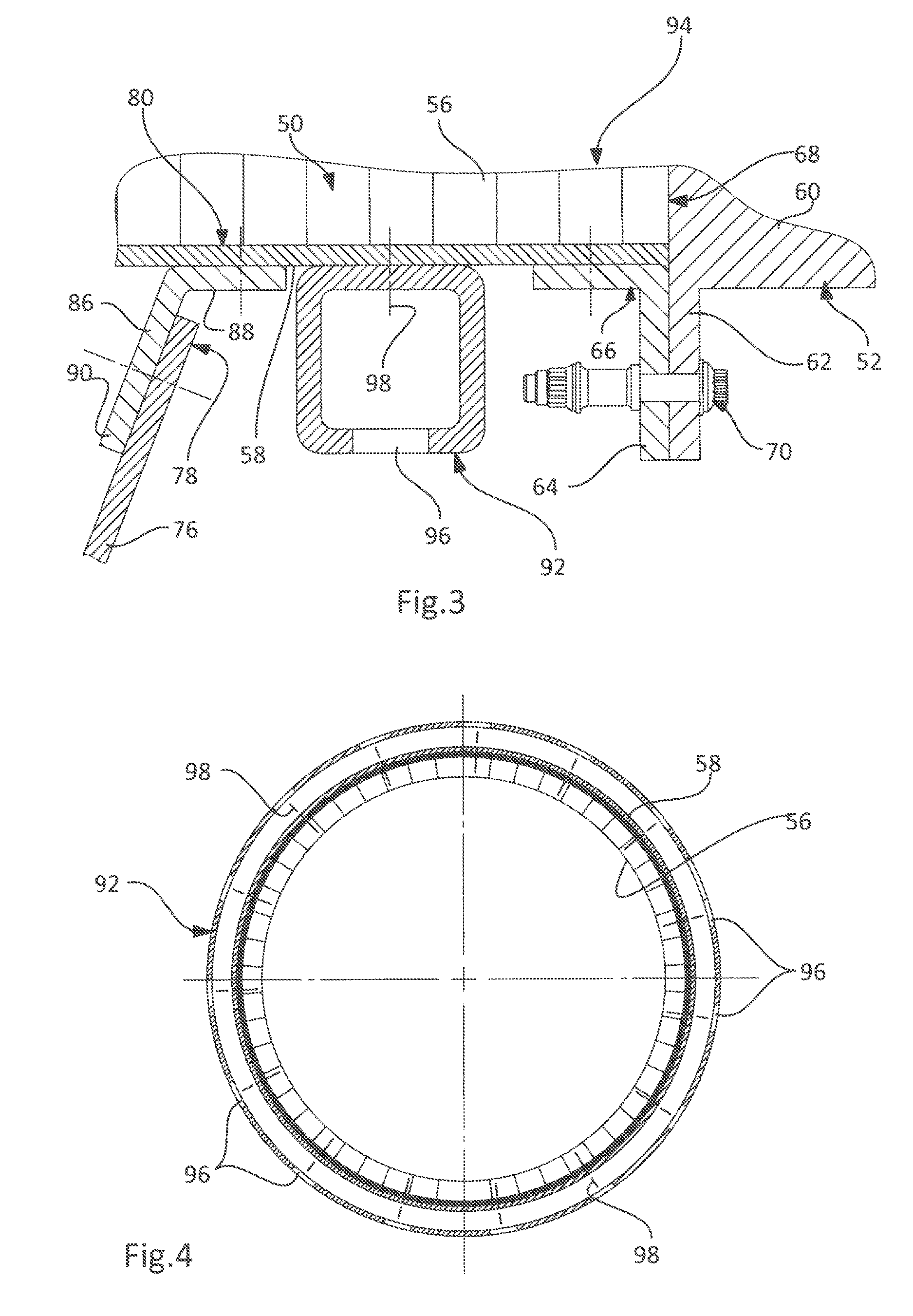

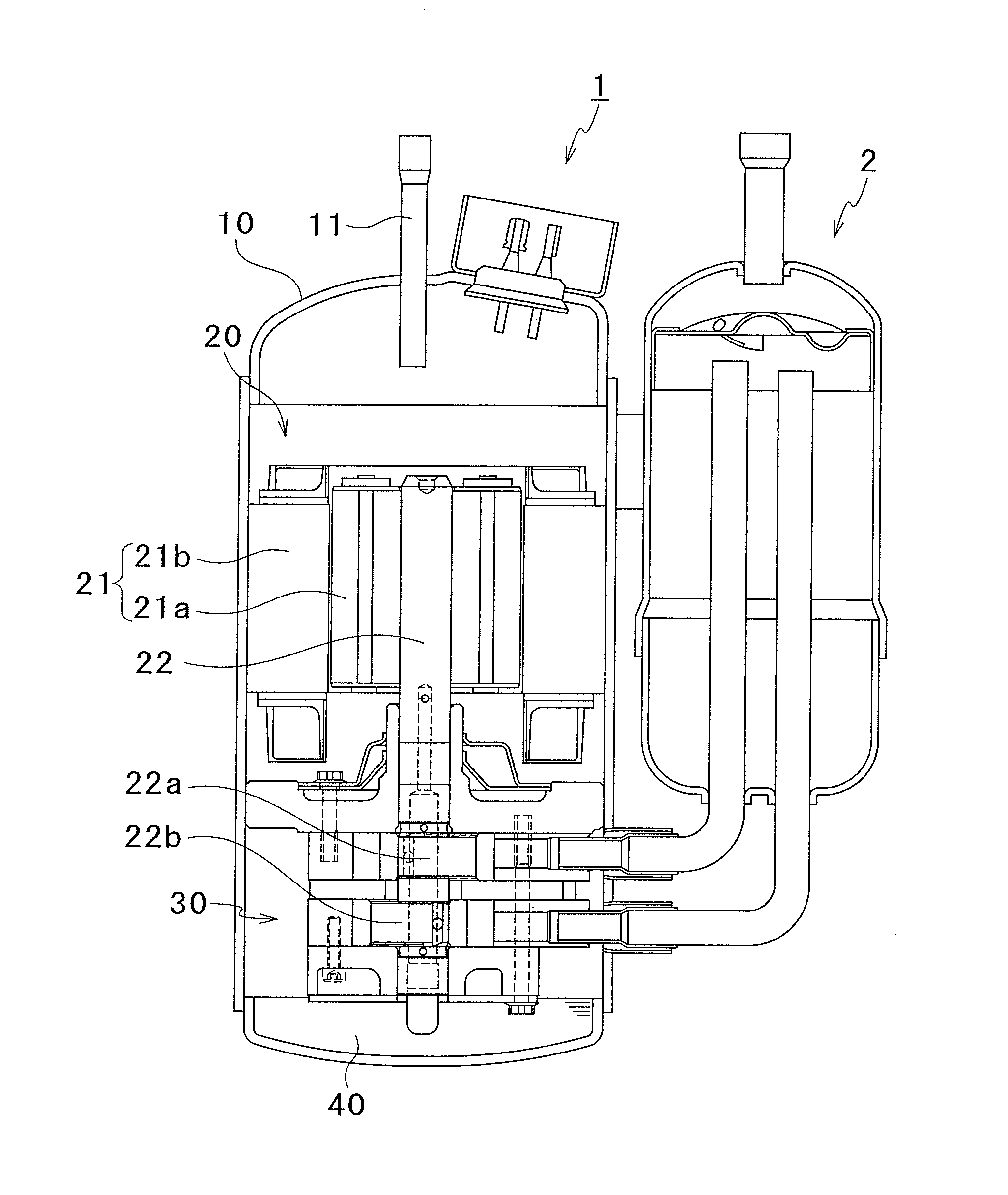

Sealing structure and compressor

ActiveUS8596995B2Improve machining accuracyIncrease the number ofRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringMuffler

A sealing is arranged between a rear head having an ejection port configured and arranged to eject compressed refrigerant and a rear muffler disposed so that a muffler space is formed between the rear muffler and the rear head. The rear head includes a main body having a bearing hole, an annular boss portion protruding from the main body and circumscribing the bearing hole, and an annular side wall protruding from the main body and circumscribing the boss portion. The rear muffler has an opening and is fastened to the end surface of the side wall so that the peripheral portion of the opening contacts the end surface of the boss portion. Preferably, the end surface of the boss portion has a part entirely further from the main body than the end surface of the side wall.

Owner:DAIKIN IND LTD

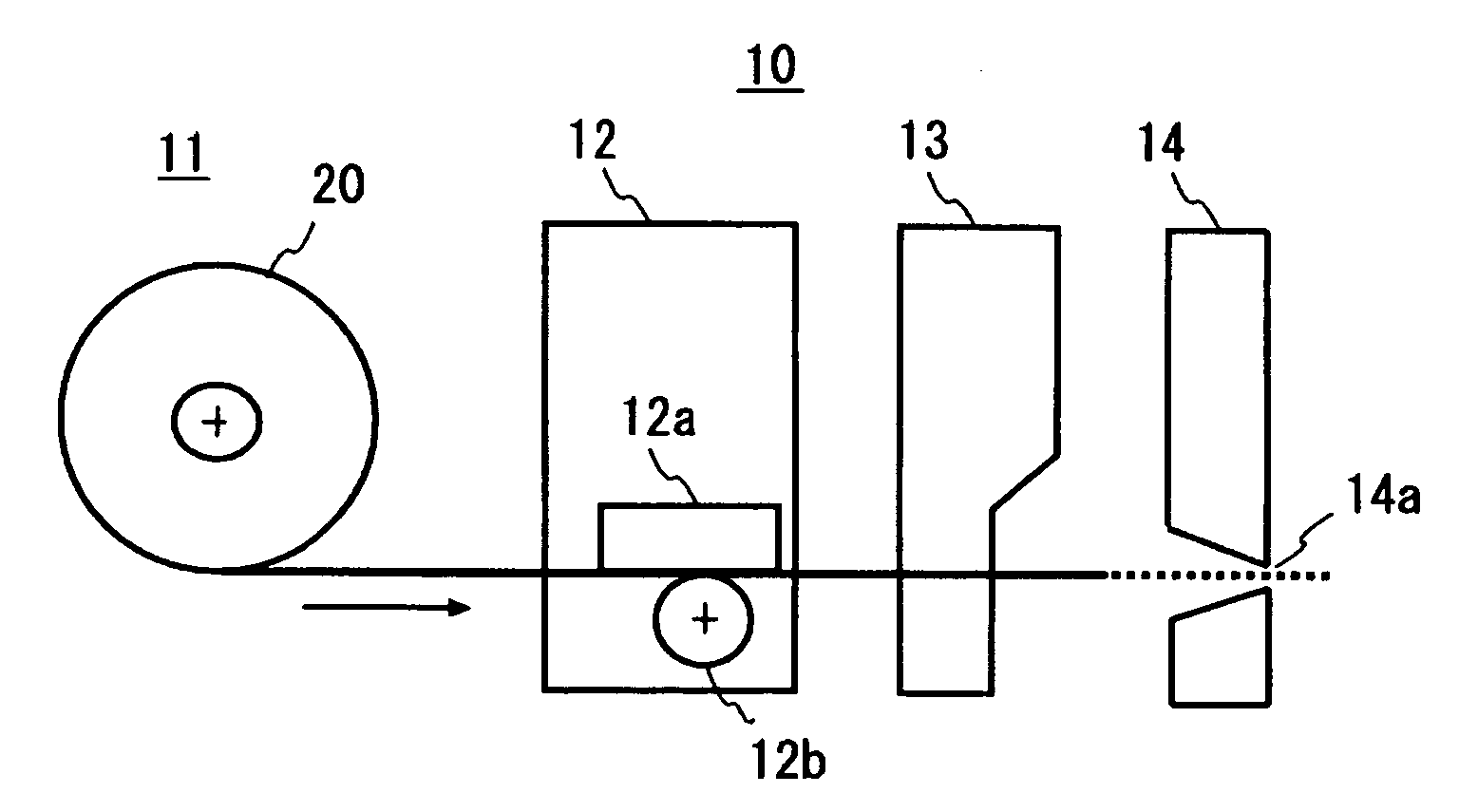

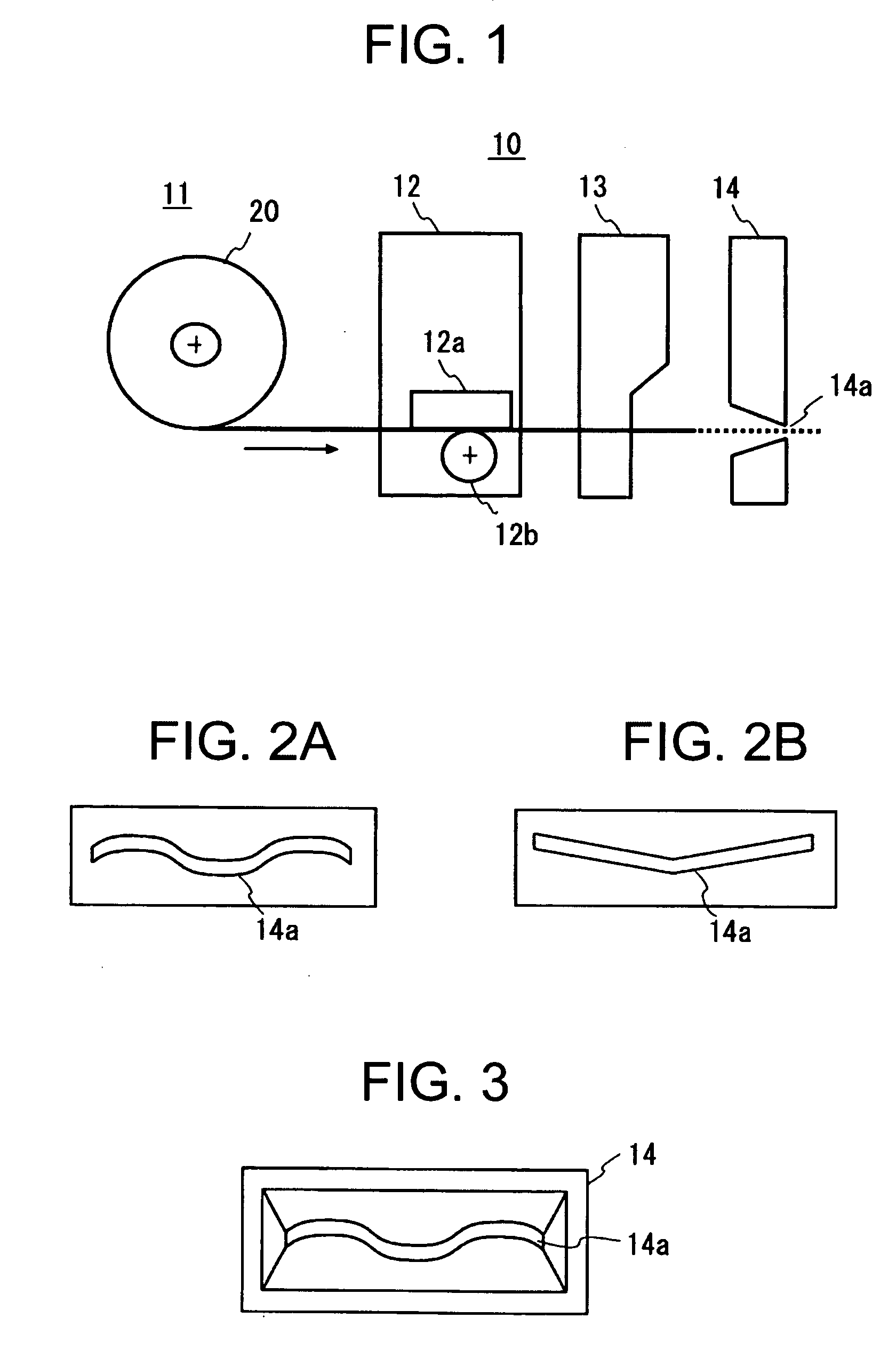

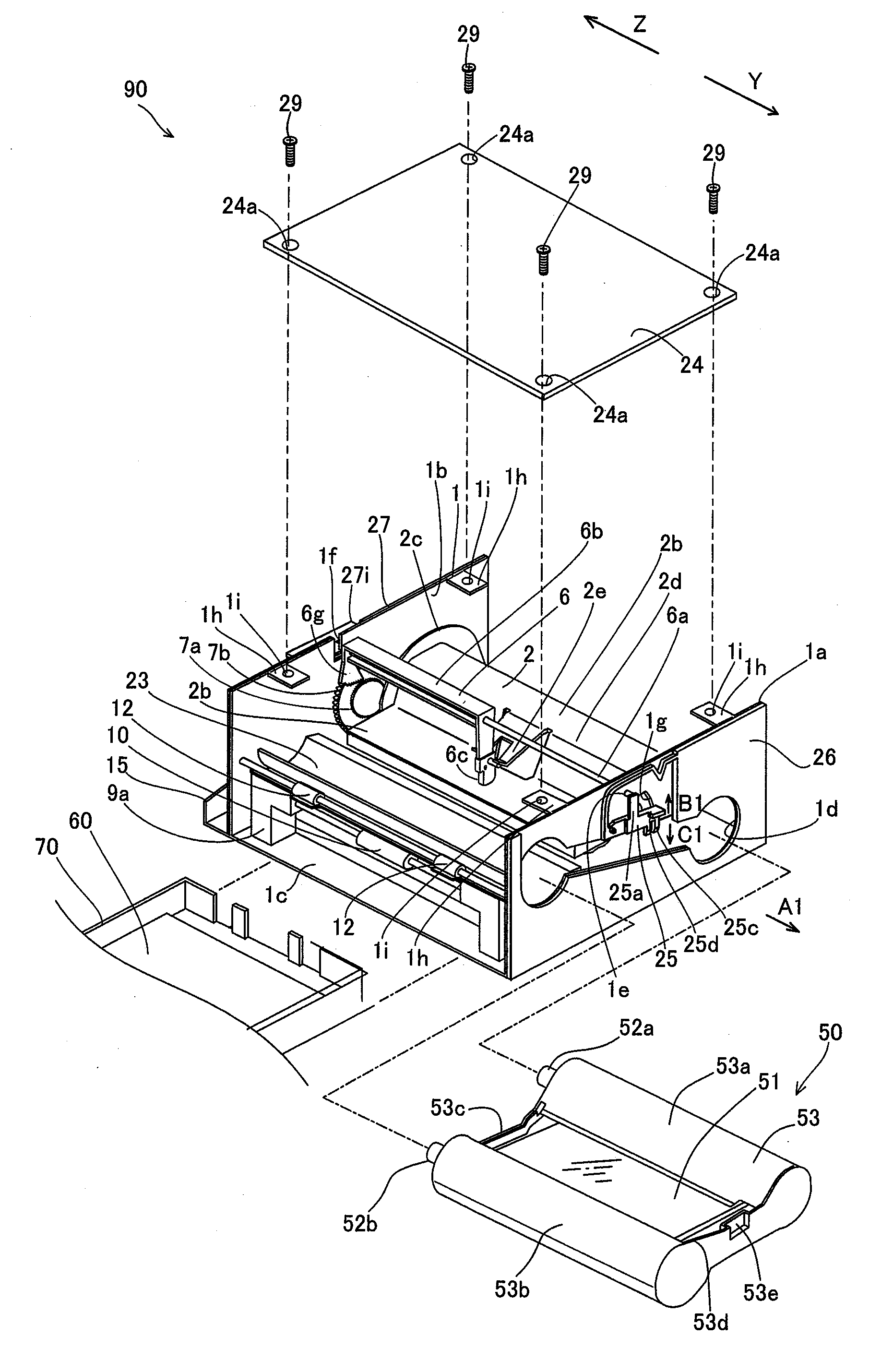

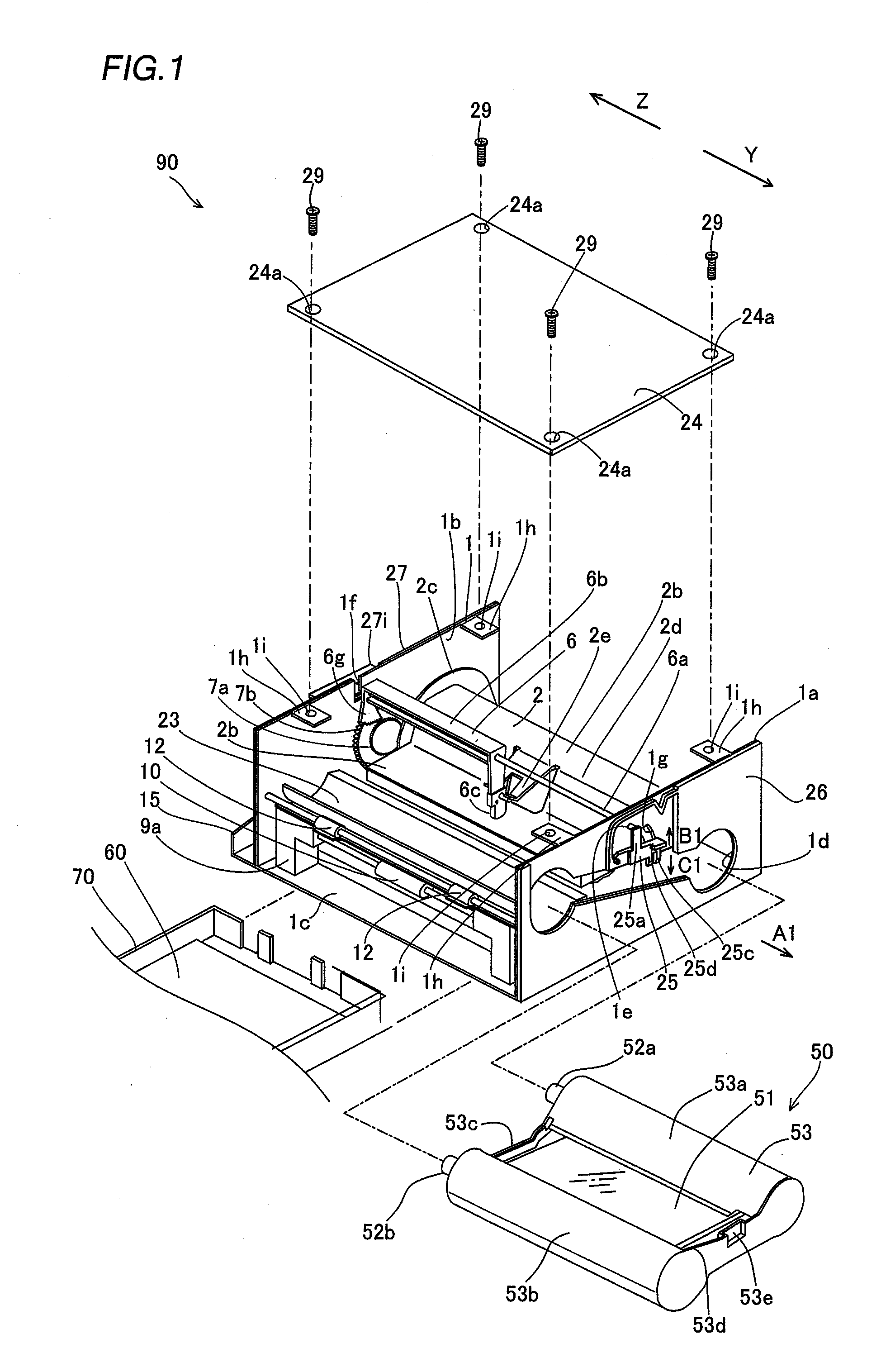

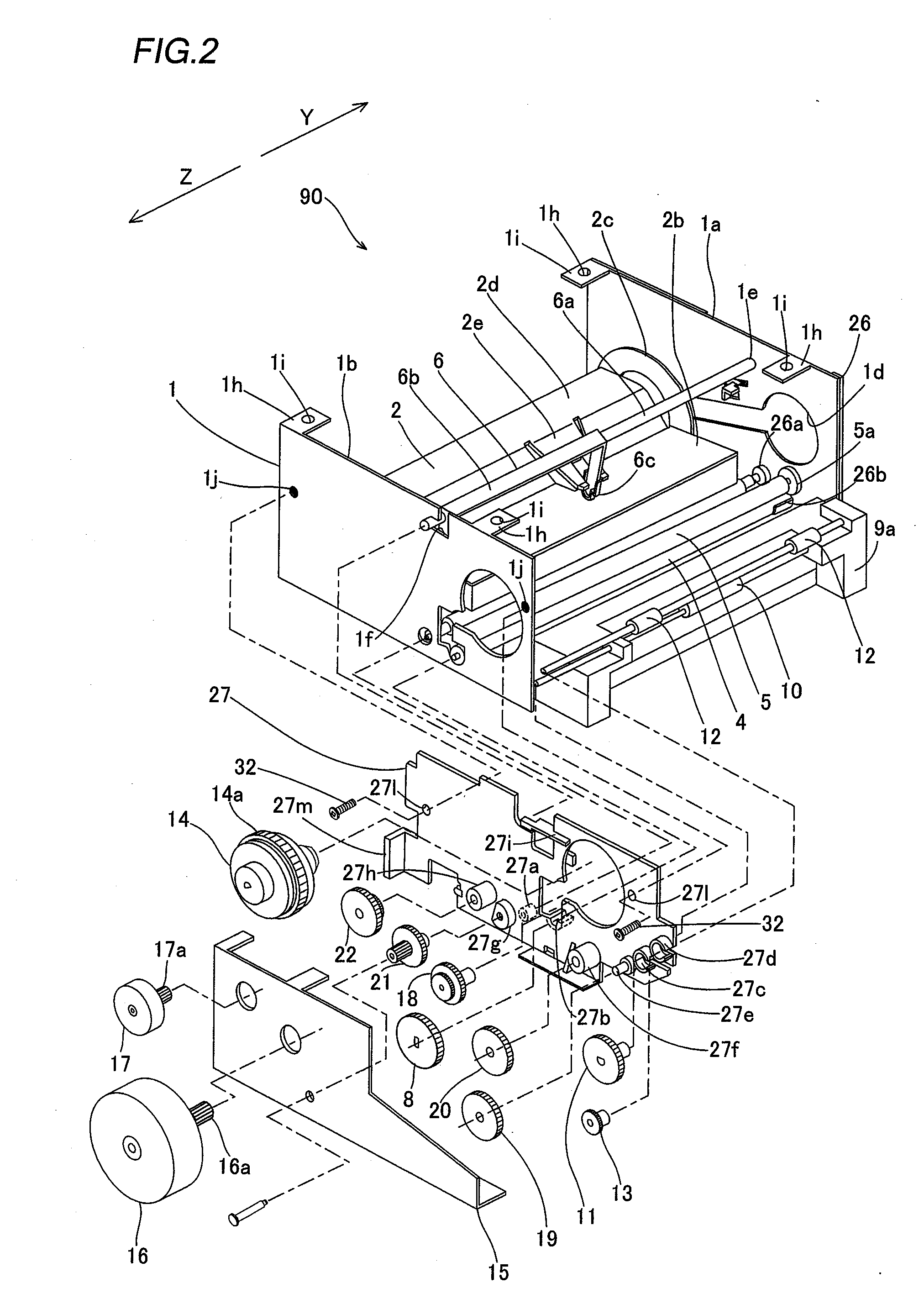

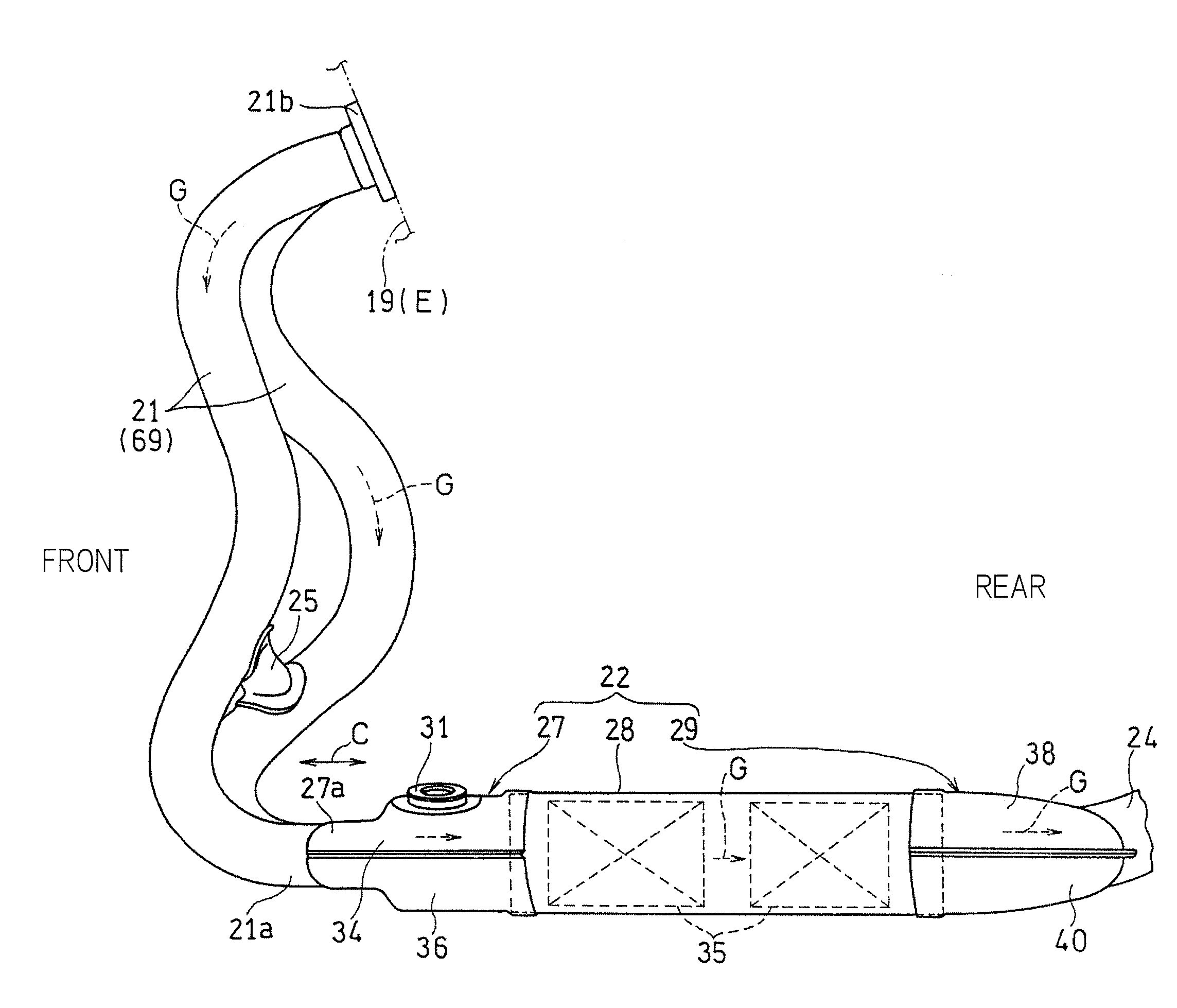

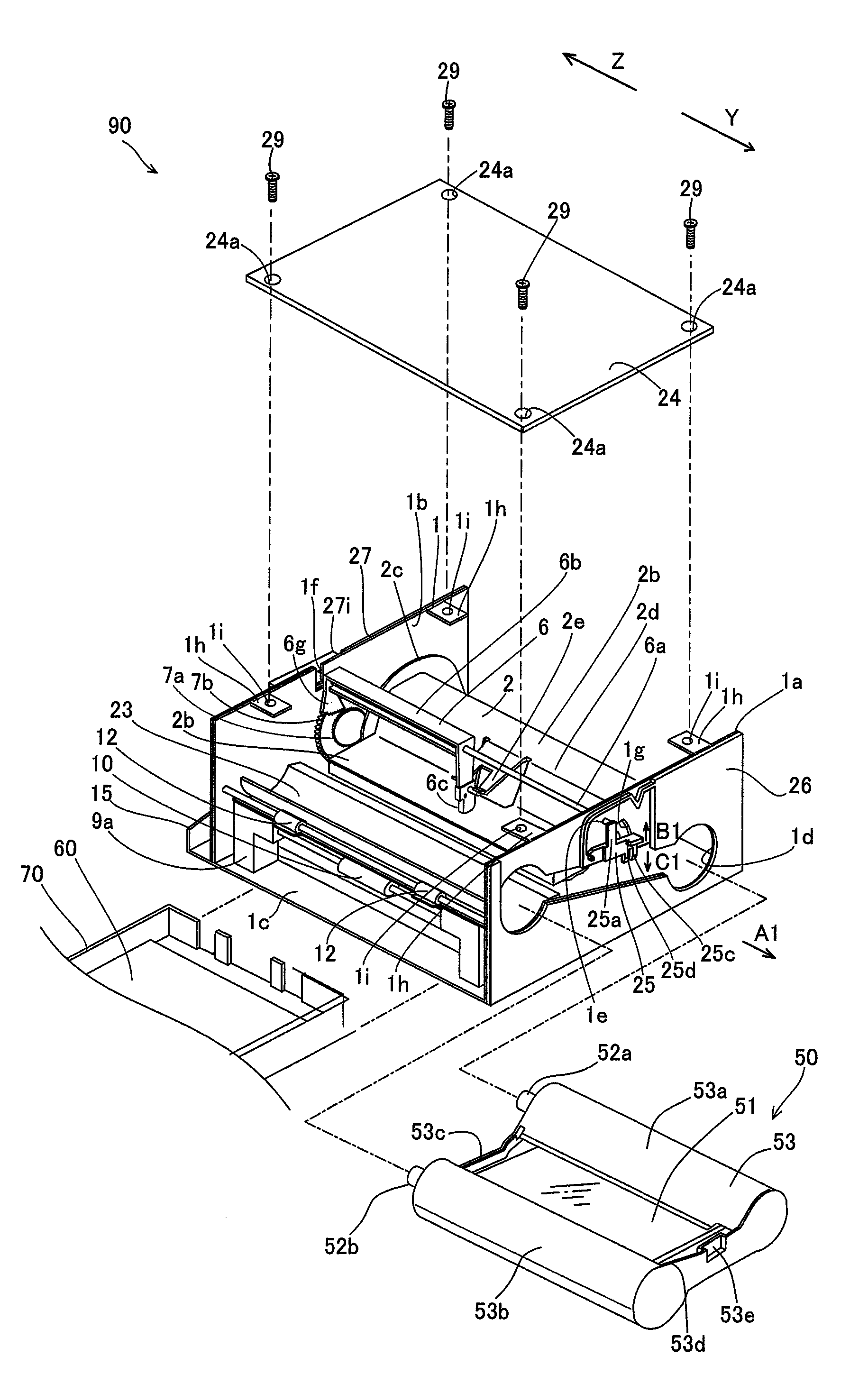

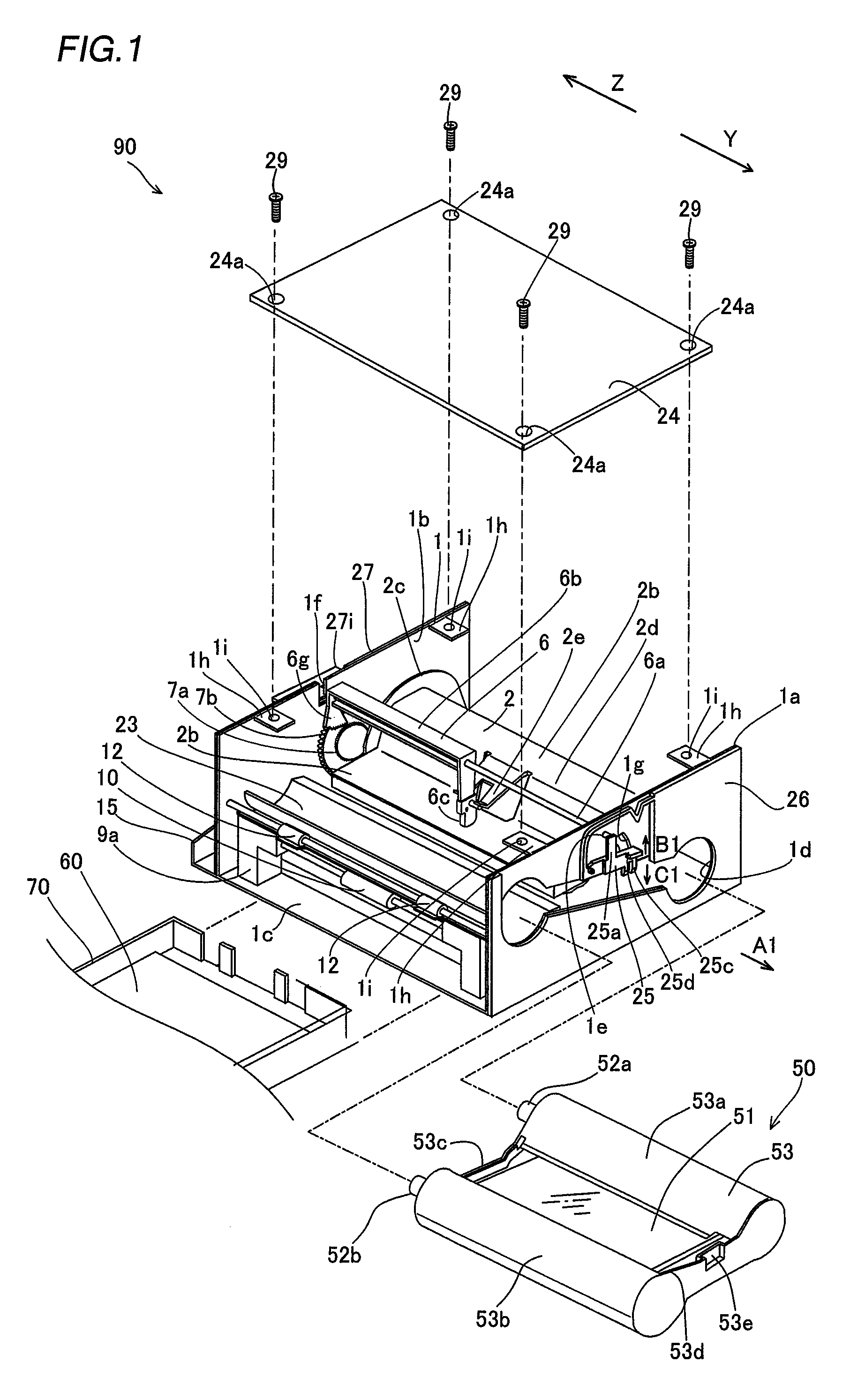

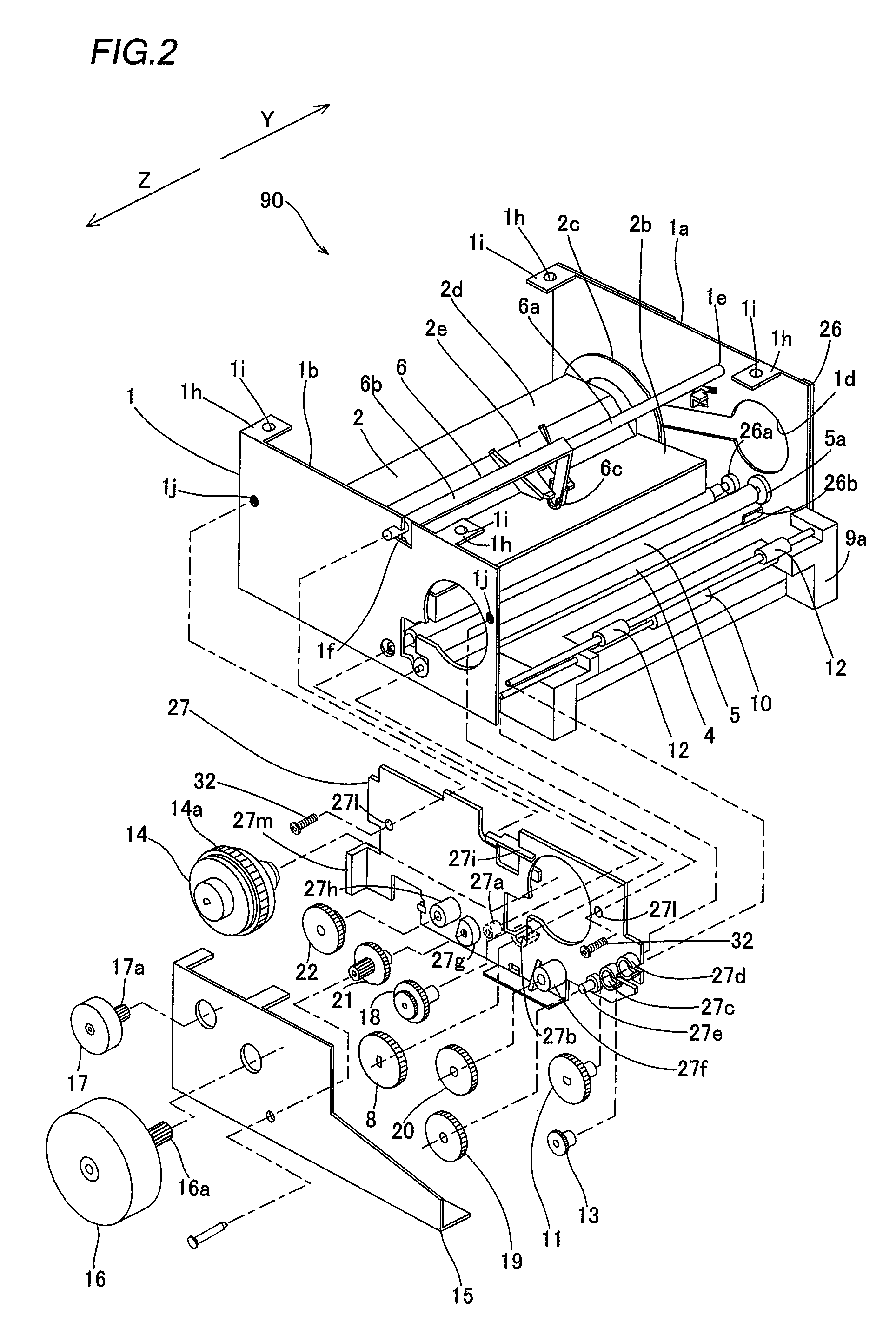

Printer and issuing apparatus

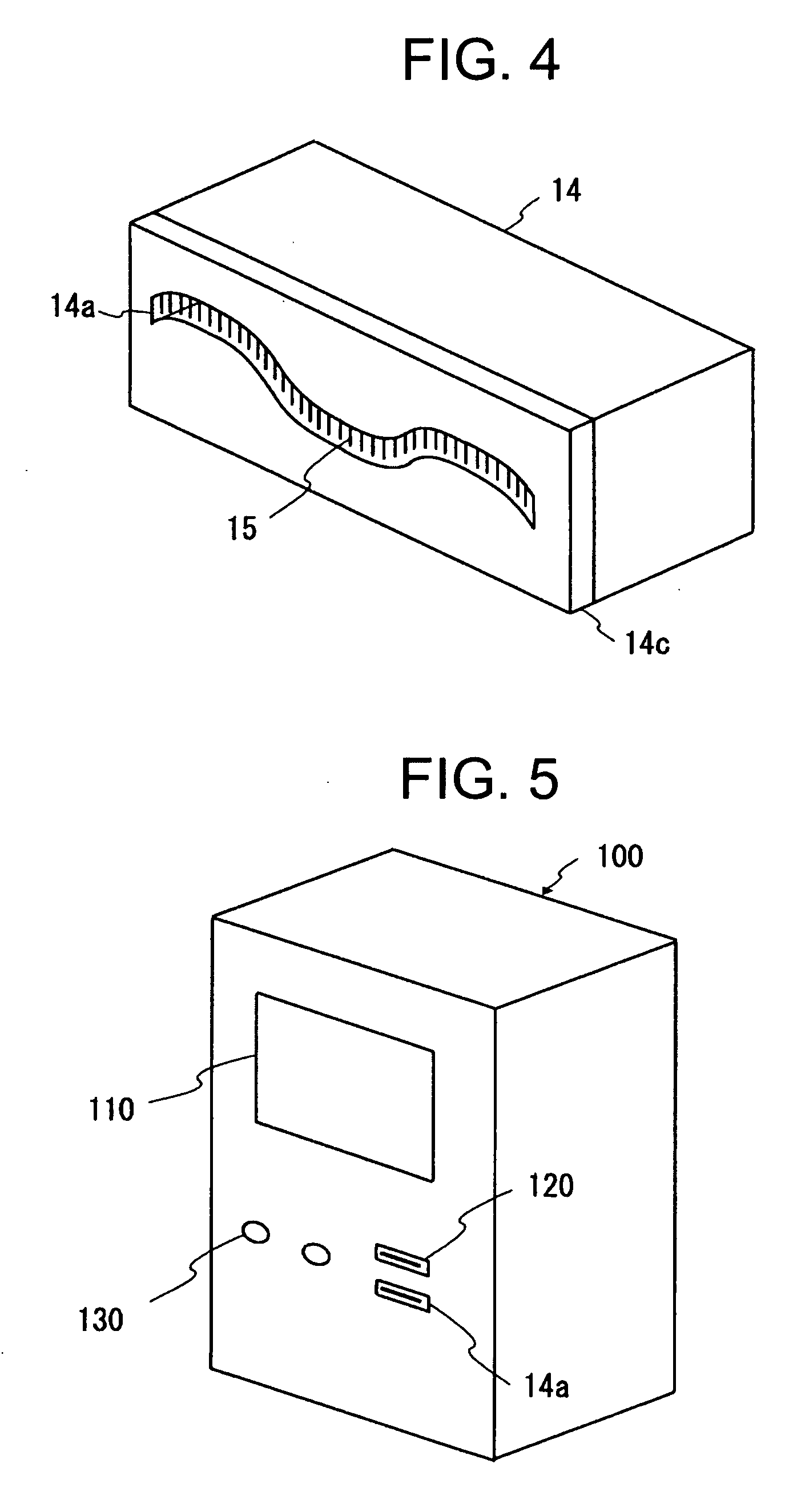

InactiveUS20090090774A1Increase elasticityPrevent insertionVisual presentation using printersOther printing apparatusEngineeringMechanical engineering

In order to provide a printer and an issuing apparatus for effectively preventing a user from mistakenly inserting a card into a discharge port of tickets or the like without increasing the number of components, in the printer or the issuing apparatus having the printer built-in, an outlet of a discharge port (14a) for discharging a printed sheet is formed into a shape other than a linear shape, such as a corrugated shape or a “dogleg” shape when seen from a front thereof. Further, it is desirable that the discharge port be formed to be gradually reduced in opening area from an inlet side thereof to an outlet side thereof.

Owner:SEIKO INSTR INC

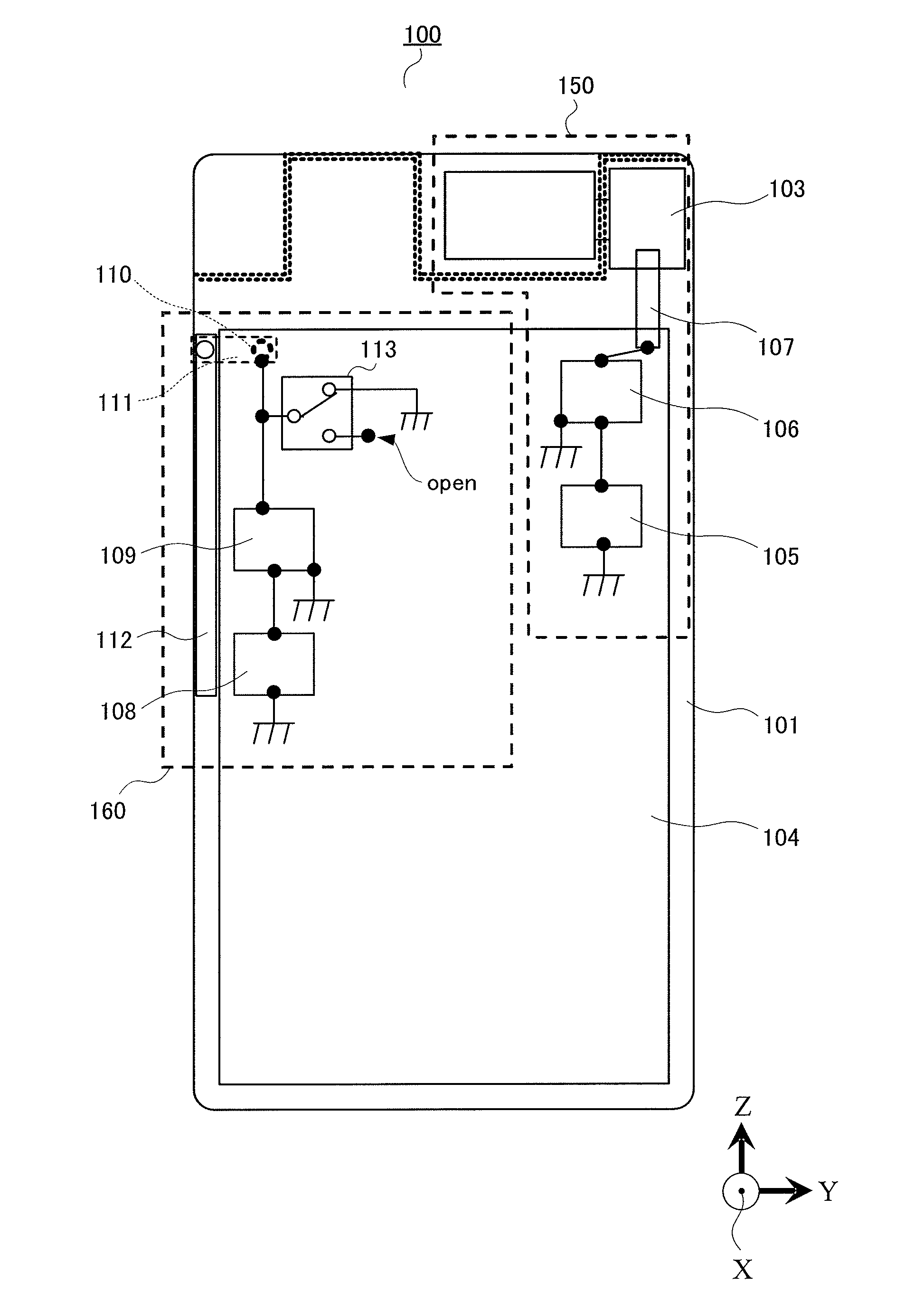

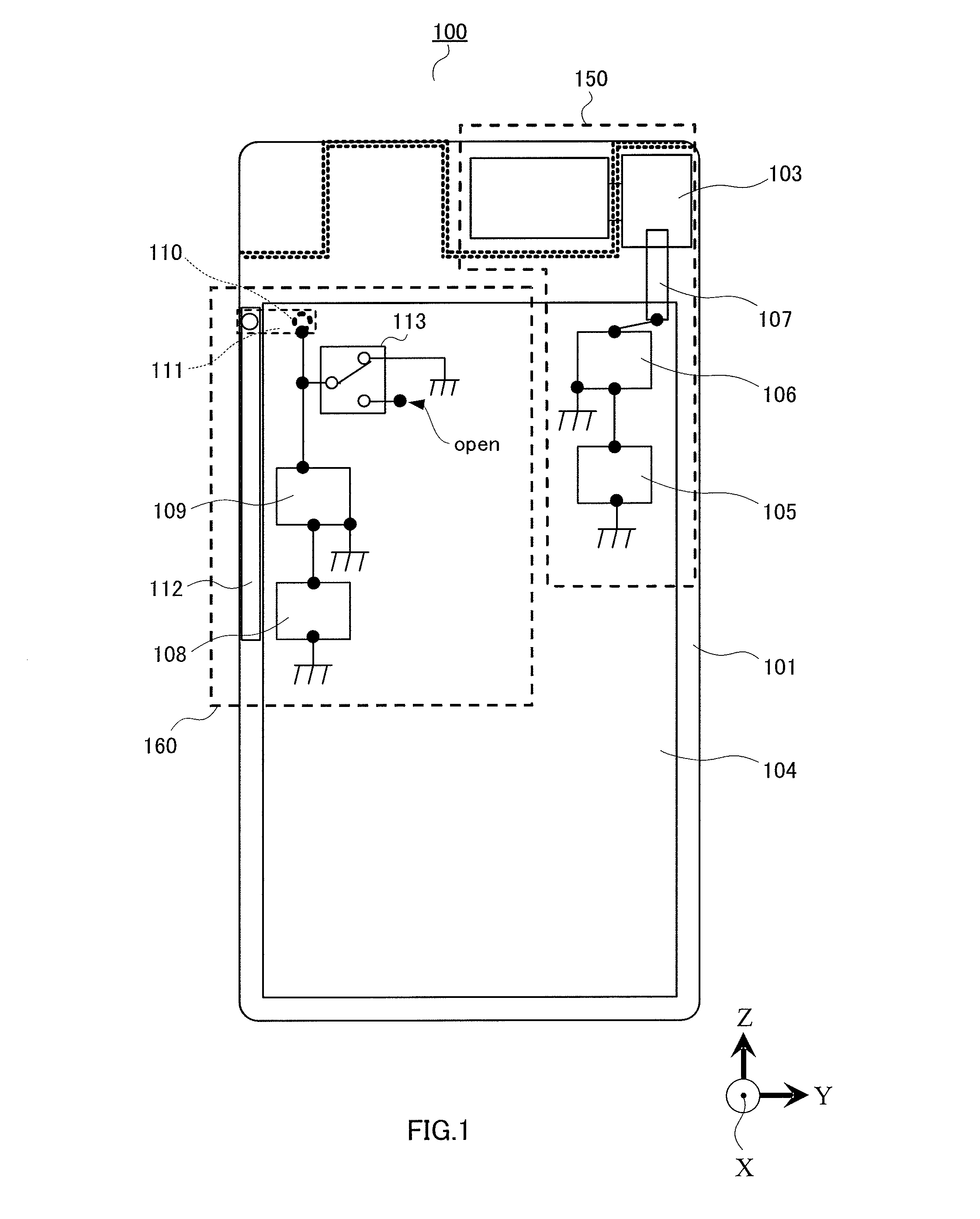

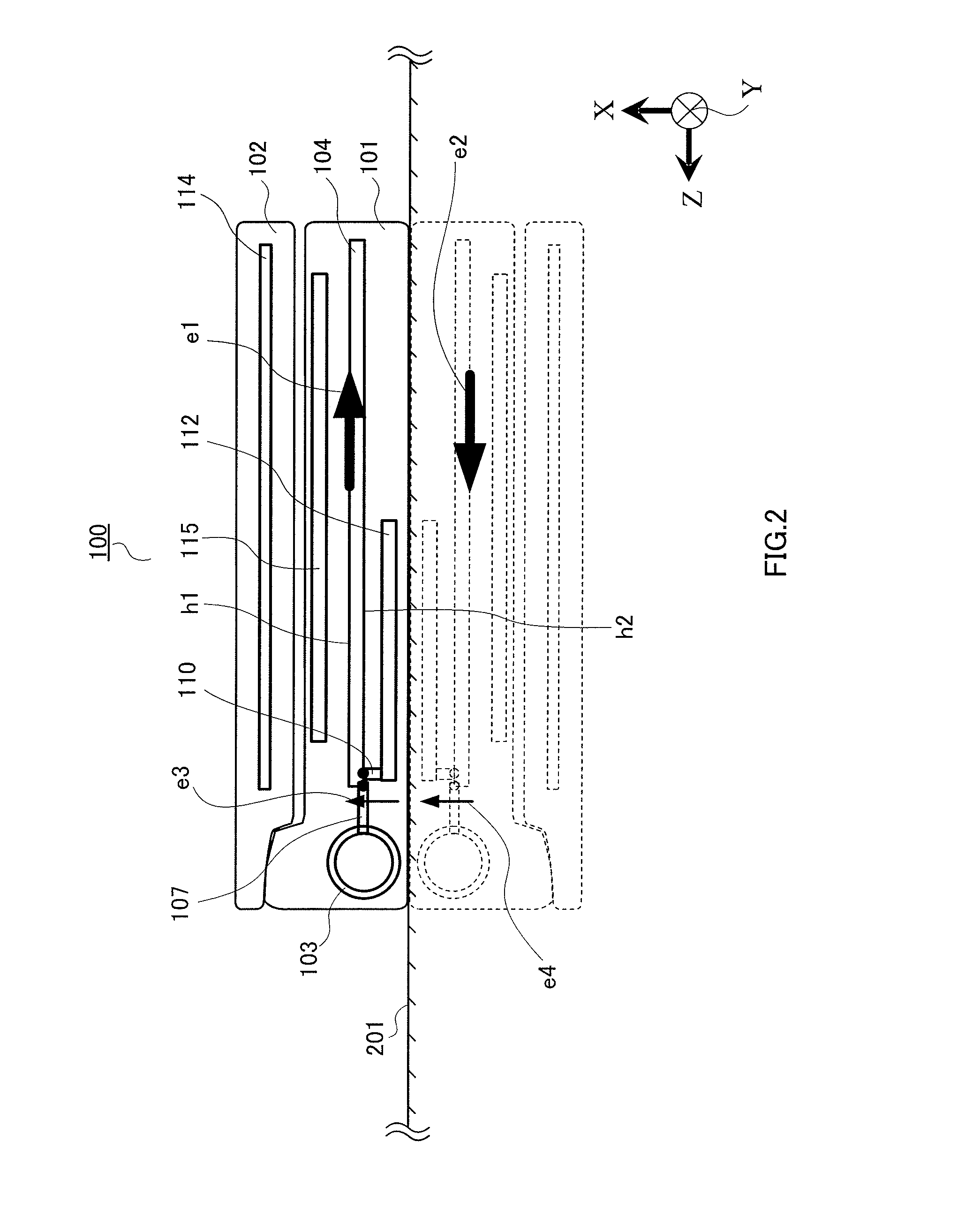

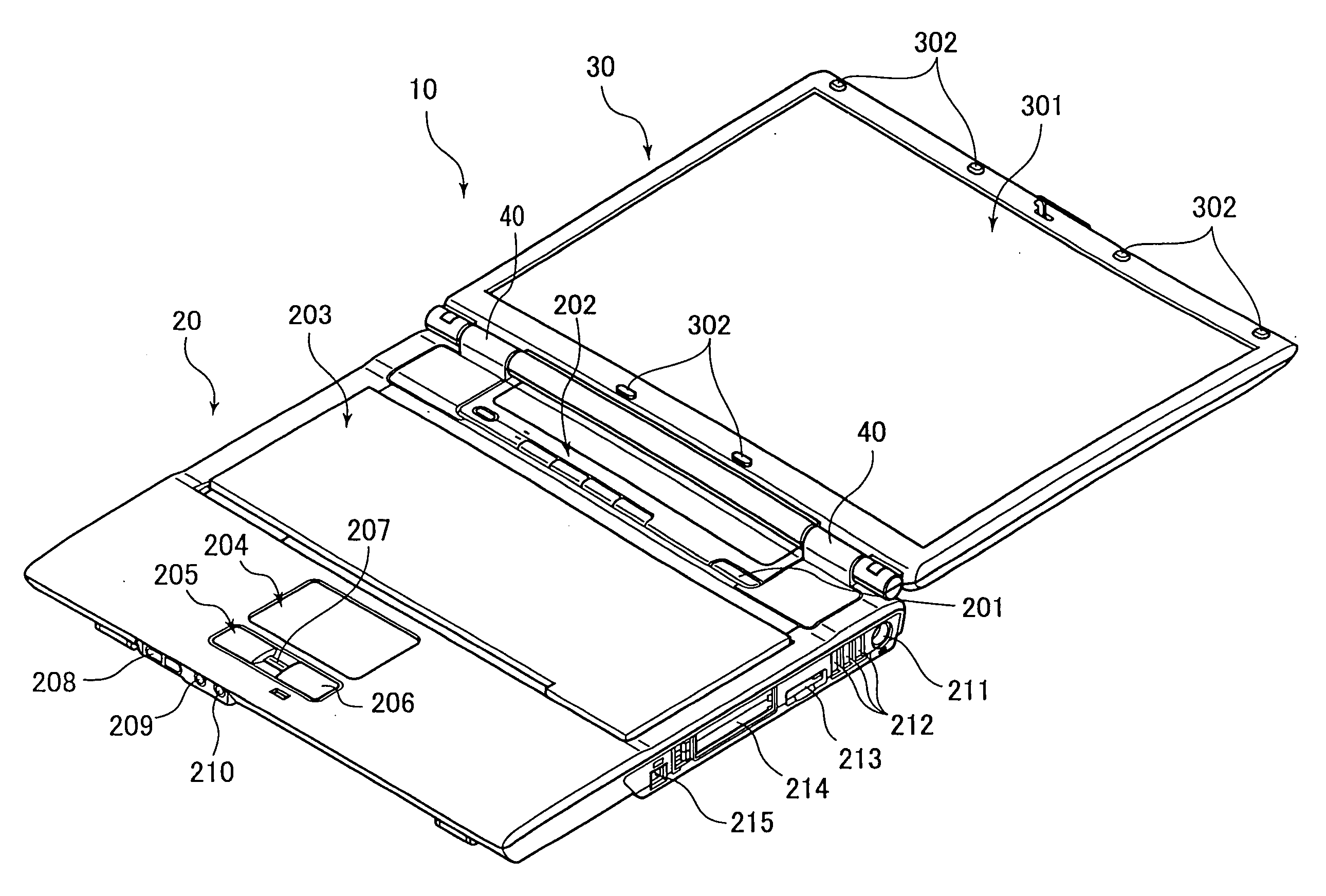

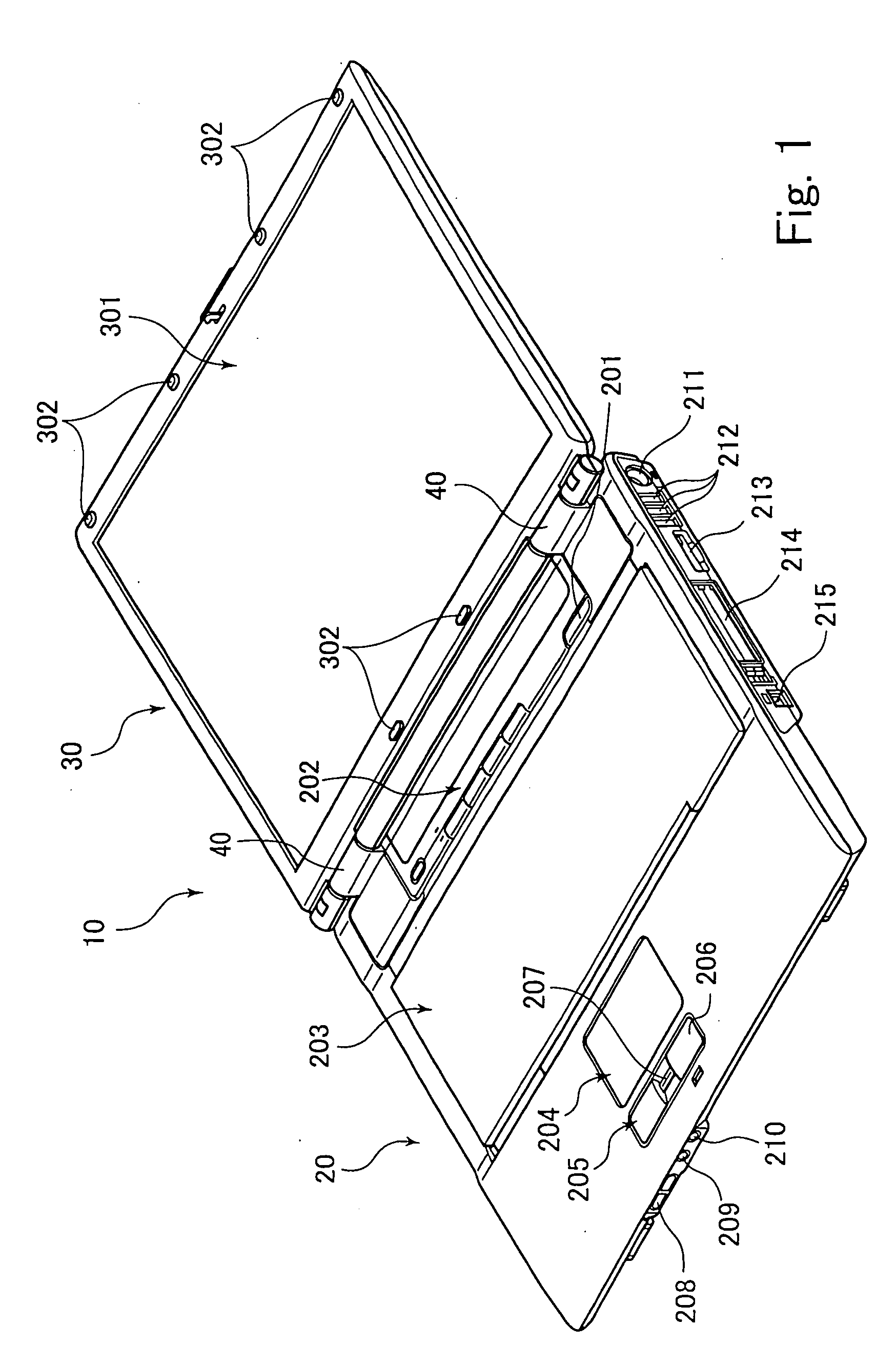

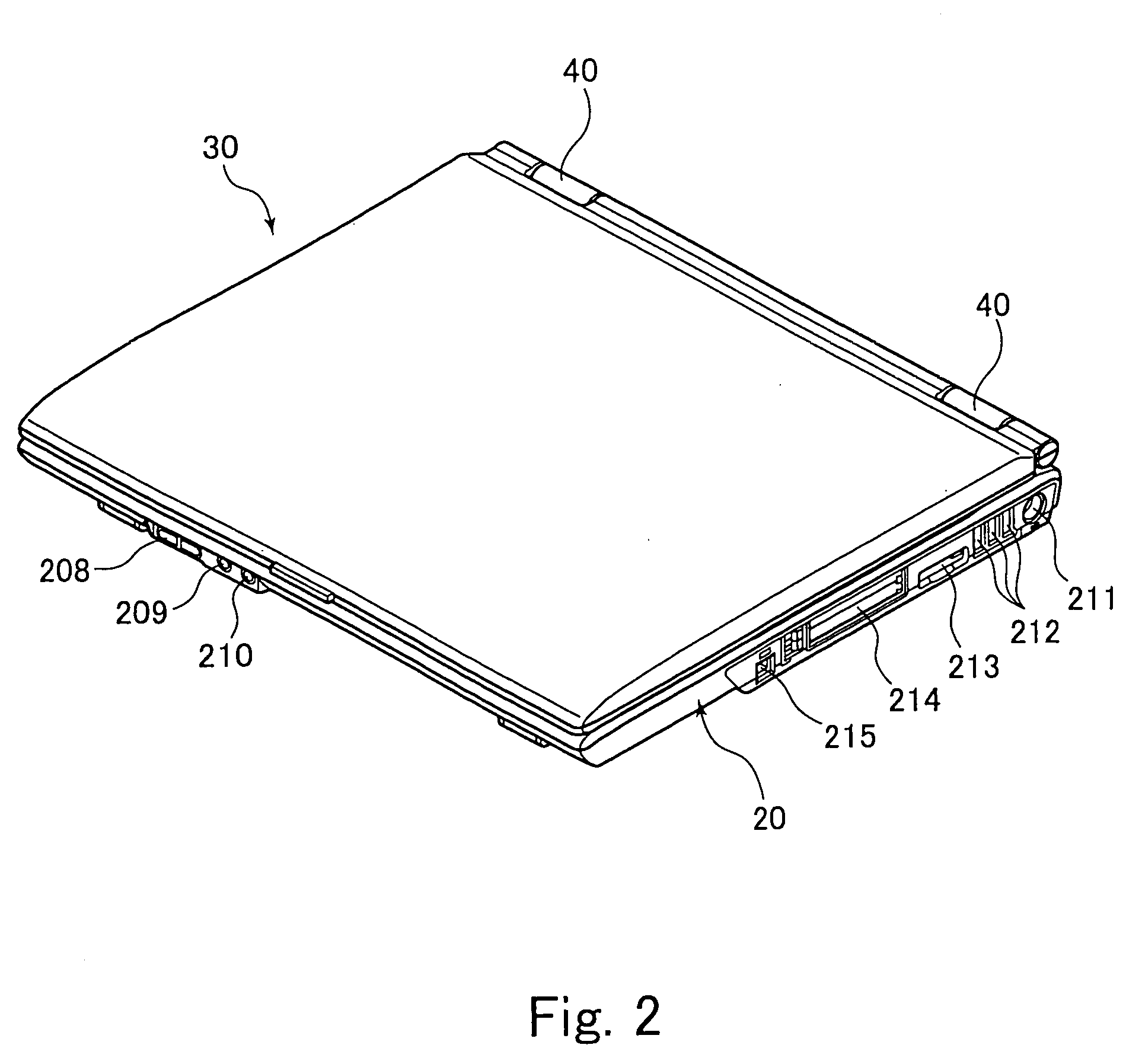

Portable wireless terminal

InactiveUS20120098712A1Without sacrificing designWithout increasing number of componentAntenna supports/mountingsAntenna equipments with additional functionsComputer terminalWhip antenna

Disclosed is a portable wireless terminal wherein deterioration in antenna performance when placed on a metal desk or other structure can be prevented without sacrificing designability and without increasing the number of components. In this terminal, a hinge part (103) functions as an antenna which resonates at a frequency of a first wireless system (150). A whip antenna (112) faces the surface of a first circuit board (104) that is opposite the surface faced by an input device (115), is disposed substantially parallel to the first circuit board (104), and resonates at a frequency of a second wireless system (160). A second contact spring (110) electrically connects a second wireless circuit (108) to the antenna element of a whip antenna (112) and is disposed perpendicularly to the first circuit board (104). A switch (113) grounds the whip antenna (112) and second contact spring (110) to the first circuit board (104) when the second wireless system (160) is not operating.

Owner:PANASONIC CORP

Image Generating Apparatus

InactiveUS20080192106A1Without increasing number of componentRecording apparatusInking apparatusHead pressingImage generation

This image generating apparatus includes a chassis and a side plate, a cartridge stop member provided on a first side surface of the chassis integrally has a first shaft stop portion coming into contact with a first end surface of a shaft of a print head pressing member, and a side plate provided on a second side surface of the chassis integrally has a second shaft stop portion coming into contact with a second end surface of the shaft of the print head pressing member.

Owner:FUNAI ELECTRIC CO LTD

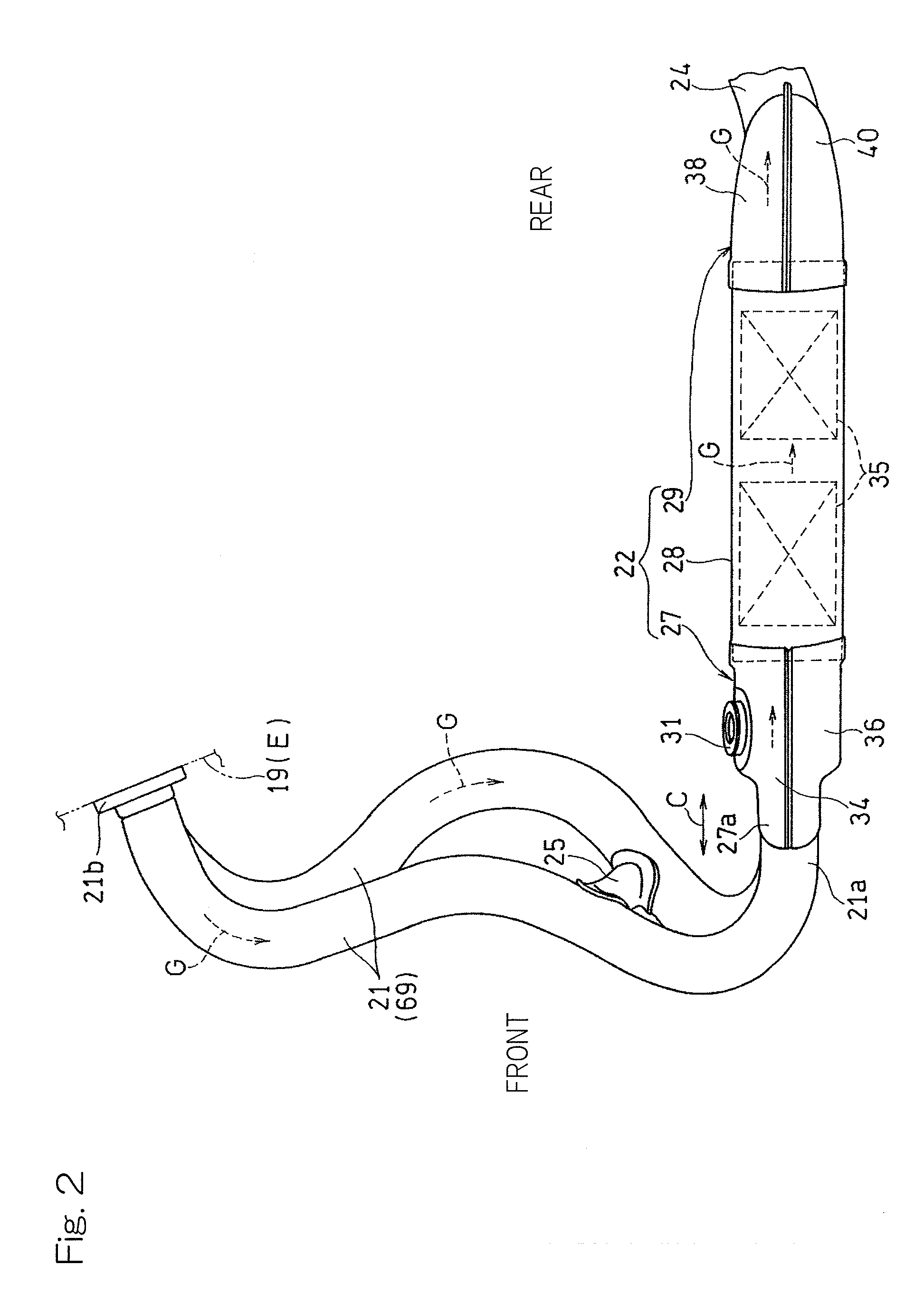

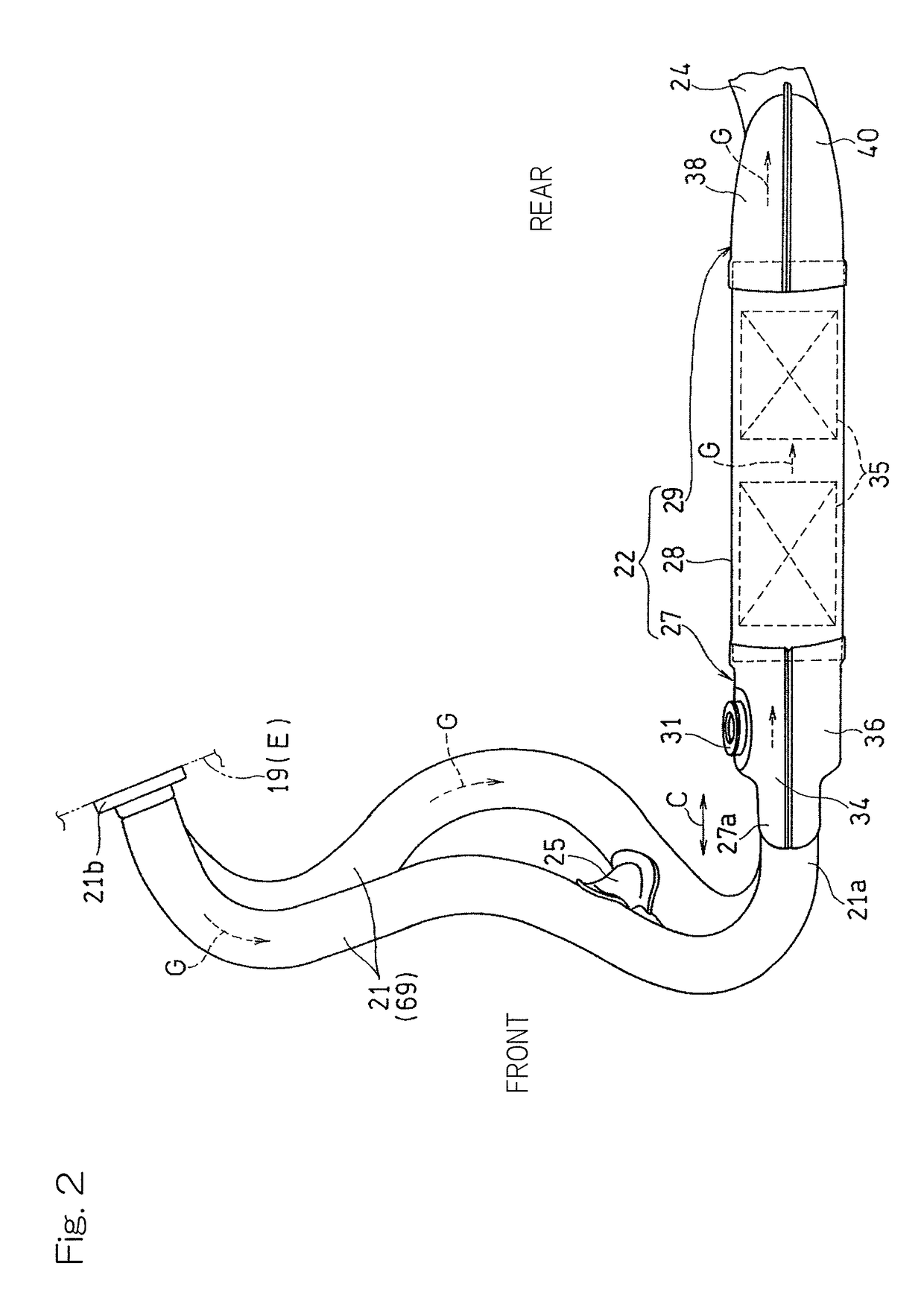

Exhaust device for combustion engine

ActiveUS20160123211A1Reduce stress concentrationReduce concentrationSilencing apparatusMachines/enginesCombustionEngineering

An exhaust device for a combustion engine includes a collecting pipe to which downstream end portions of two exhaust pipes are connected. The downstream end portions of the exhaust pipes are aligned in a lateral direction perpendicular to an axial direction thereof. The downstream end portions of the exhaust pipes have insertion sections that are inserted into an upstream end portion of the collecting pipe. The upstream end portion of the collecting pipe has a cover section that covers the entirety of circumferences of the insertion sections. Outer circumferential surfaces of the insertion sections of the exhaust pipes and an inner circumferential surface of the cover section of the collecting pipe are joined over the entirety of circumferences thereof at a collecting pipe joining region. The collecting pipe joining region has a displacement portion having its position shifted in the axial direction C toward the lateral direction W.

Owner:KAWASAKI MOTORS LTD

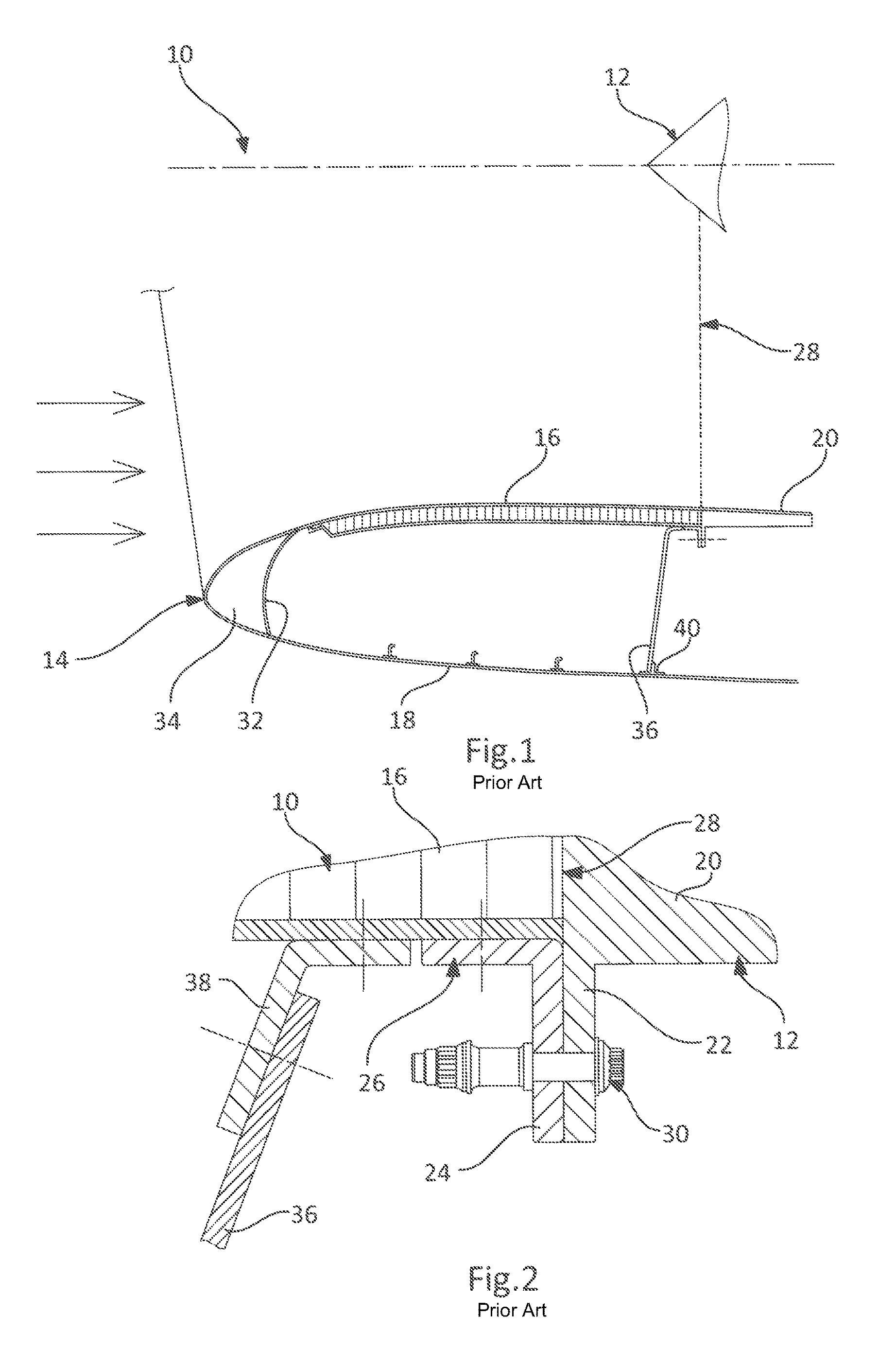

Aircraft nacelle comprising a reinforced connection between an air intake and a powerplant

ActiveUS9567905B2Control deformationImprove rigidityEngine fuctionsEfficient propulsion technologiesEngineeringAirplane

An aircraft nacelle comprising a first duct secured to an air intake and a second duct secured to a powerplant, the first duct comprising an exterior surface and an end portion connected to the second duct. The nacelle includes a hollow section piece in contact with the exterior surface of the first duct which extends over at least part of the circumference of that end portion of the first duct that is connected to the second duct.

Owner:AIRBUS OPERATIONS (SAS)

Image generating apparatus

InactiveUS7593027B2Without increasing number of componentRecording apparatusInking apparatusHead pressingEngineering

This image generating apparatus includes a chassis and a side plate, a cartridge stop member provided on a first side surface of the chassis integrally has a first shaft stop portion coming into contact with a first end surface of a shaft of a print head pressing member, and a side plate provided on a second side surface of the chassis integrally has a second shaft stop portion coming into contact with a second end surface of the shaft of the print head pressing member.

Owner:FUNAI ELECTRIC CO LTD

Electronic apparatus and unit

InactiveUS20070218724A1Without increasing number of componentLow reliabilityEngagement/disengagement of coupling partsRecord information storageMechanical engineeringElectronic equipment

Owner:FUJITSU CLIENT COMPUTING LTD

Sealing structure and comprssor

ActiveUS20100310388A1Improve productivitySecure seal performanceRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringMuffler

A sealing is arranged between a rear head having an ejection port configured and arranged to eject compressed refrigerant and a rear muffler disposed so that a muffler space is formed between the rear muffler and the rear head. The rear head includes a main body having a bearing hole, an annular boss portion protruding from the main body and circumscribing the bearing hole, and an annular side wall protruding from the main body and circumscribing the boss portion. The rear muffler has an opening and is fastened to the end surface of the side wall so that the peripheral portion of the opening contacts the end surface of the boss portion. Preferably, the end surface of the boss portion has a part entirely further from the main body than the end surface of the side wall.

Owner:DAIKIN IND LTD

Fuel injection valve

ActiveUS8128009B2DistanceCurb reboundSpray nozzlesMachines/enginesBiomedical engineeringFuel injection

The objective of the present invention is to realize the structure, of a fuel injection valve, in which bouncing of the needle can be suppressed and the armature position can be fixed while the valve is closed, without increasing the number of components and the number of processes. In a fuel injection valve including an armature that is repelled or attracted by a core, by de-energizing or energizing a coil; a needle that opens or closes a valve seat in accordance with a reciprocal travel of the armature; and a valve-closing spring that biases the needle so as to close the valve, when the coil is de-energized, the needle and the armature are fixed in such a way that the armature can travel in an axis direction by a predetermined amount with respect to the needle, and the coil is preliminarily energized while the fuel injection valve is closed by the needle.

Owner:MITSUBISHI ELECTRIC CORP

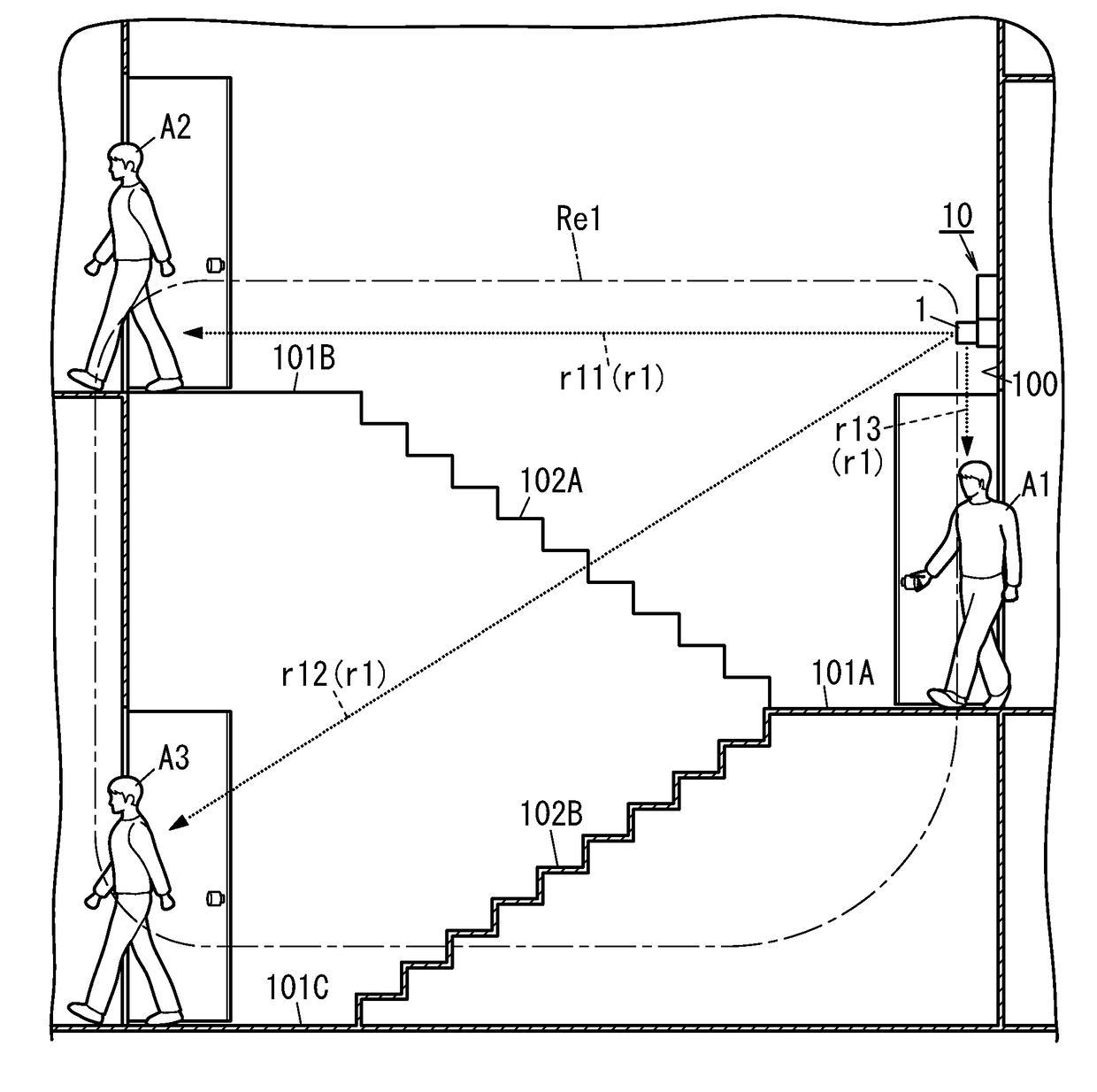

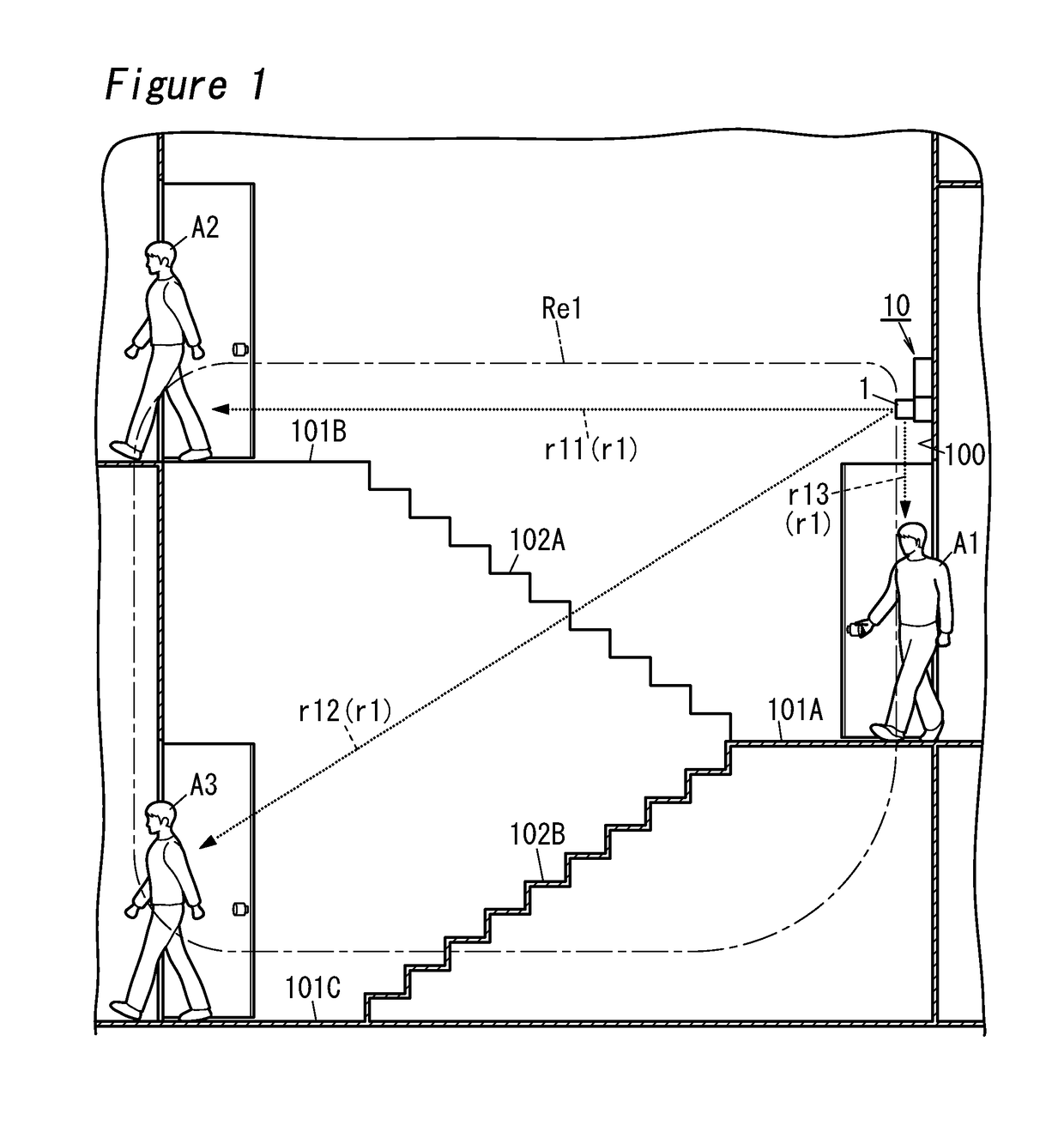

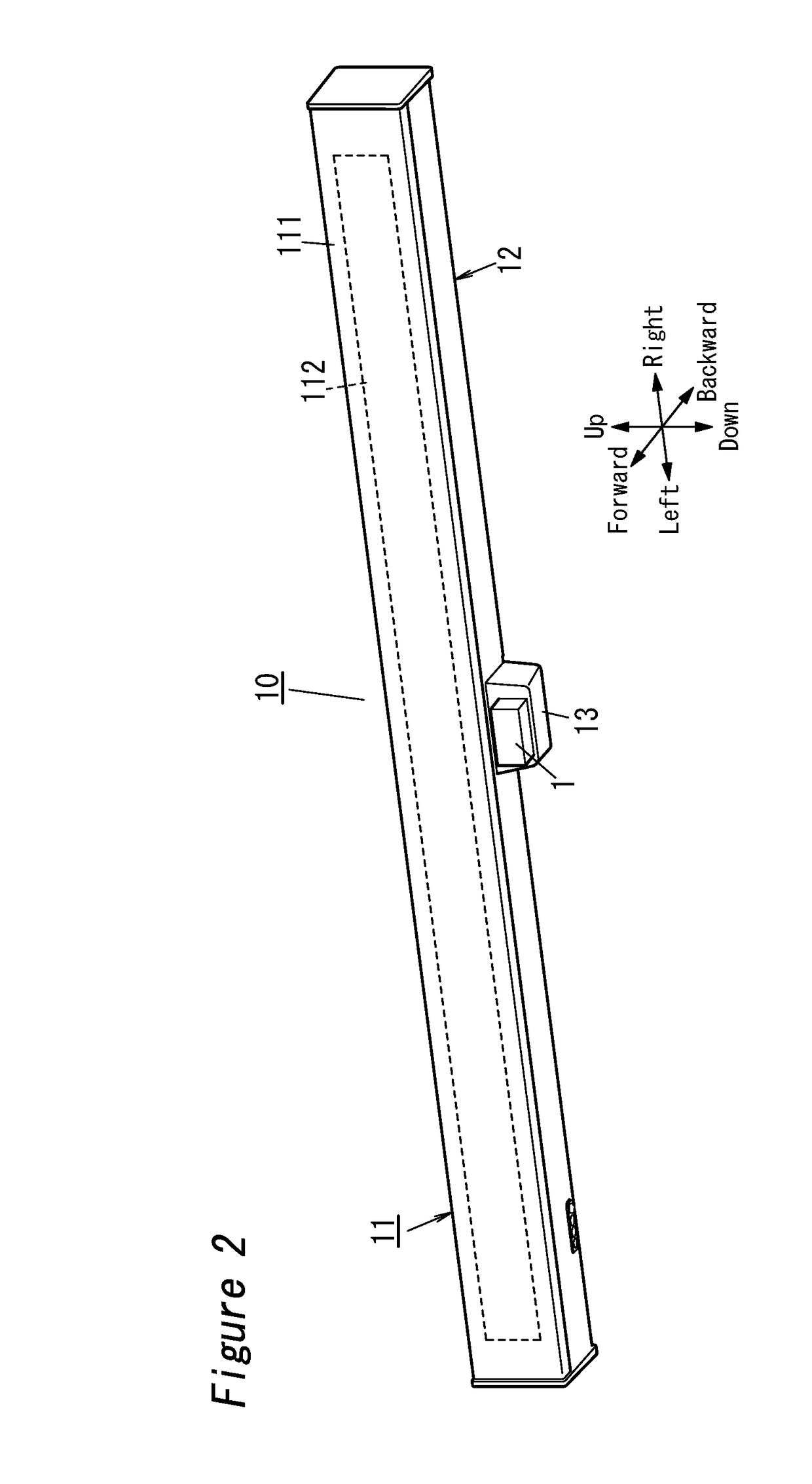

Radio wave sensor and luminaire

InactiveUS20180131090A1Without increasing number of componentReduce directivityAntenna supports/mountingsRadiating element housingsEngineeringRadio wave

A radio wave sensor includes a transmitting antenna configured to radiate radio waves, and a housing that is composed of dielectric material and faces the transmitting antenna. The housing has a first protrusion that protrudes from a region facing the transmitting antenna towards the transmitting antenna. The first protrusion has an entrance surface that allows the radio waves from the transmitting antenna to enter. The entrance surface contains a flat surface parallel to a surface of the transmitting antenna, and an inclined surface that inclines relative to the flat surface in a direction apart from the flat surface.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

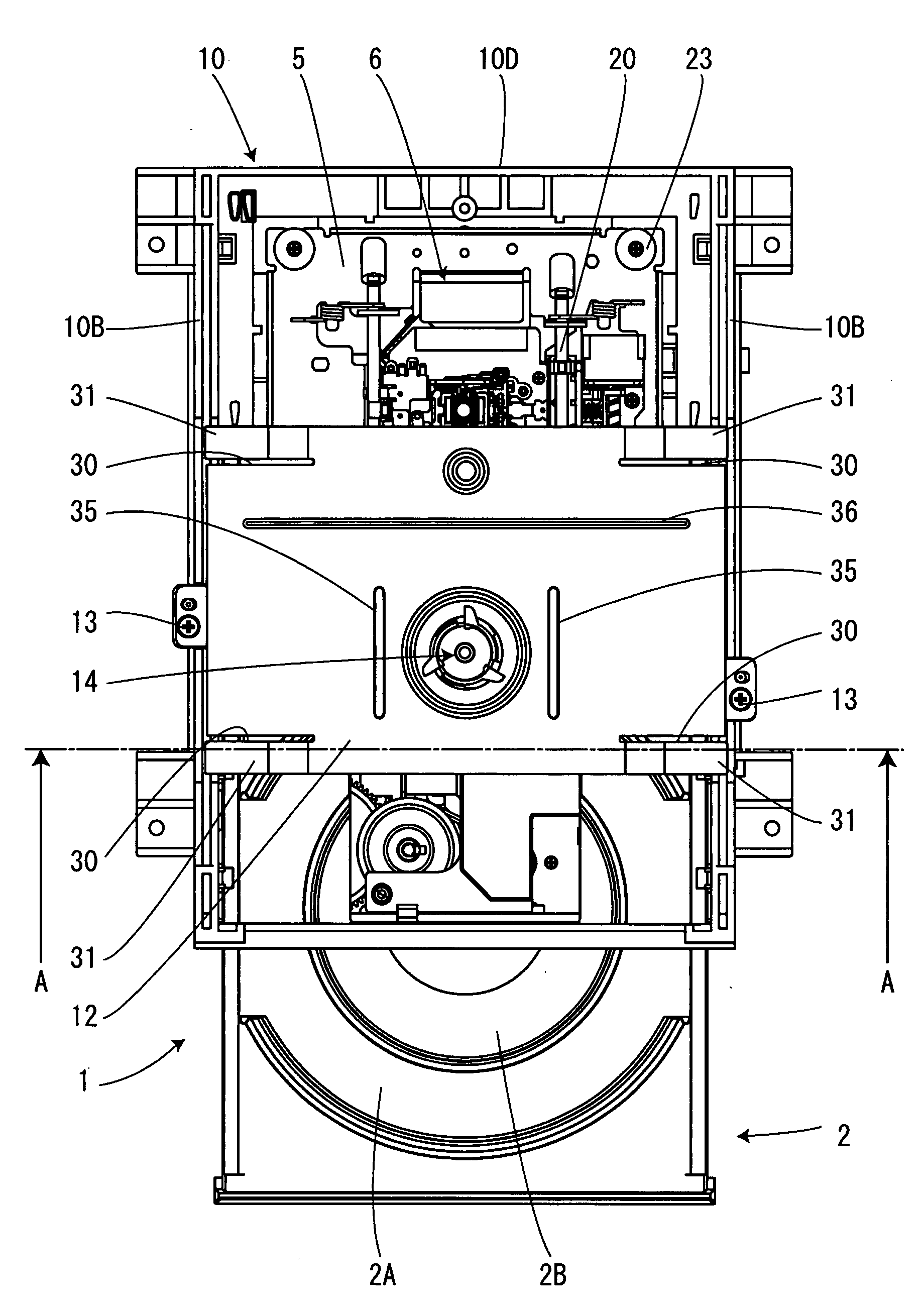

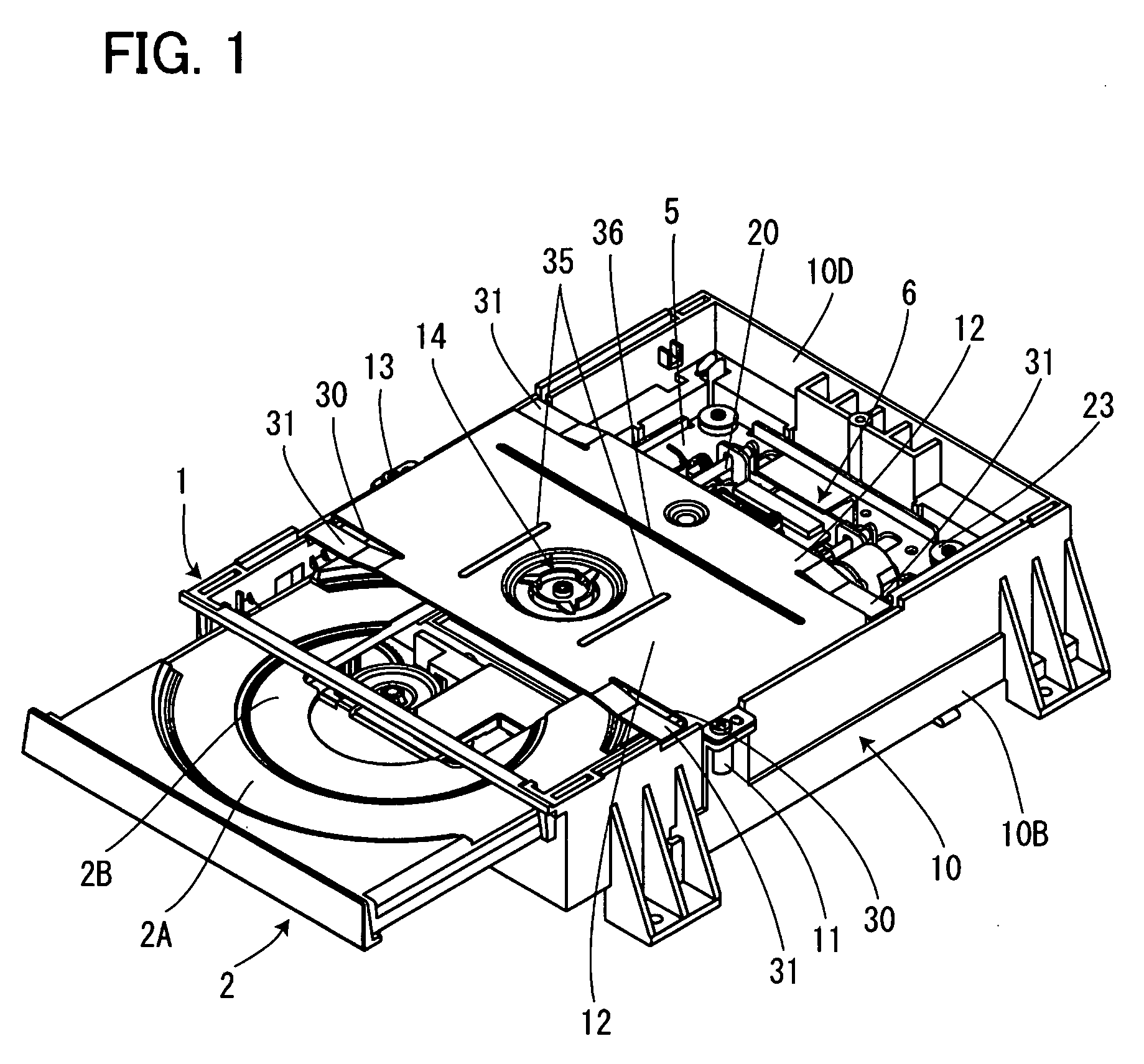

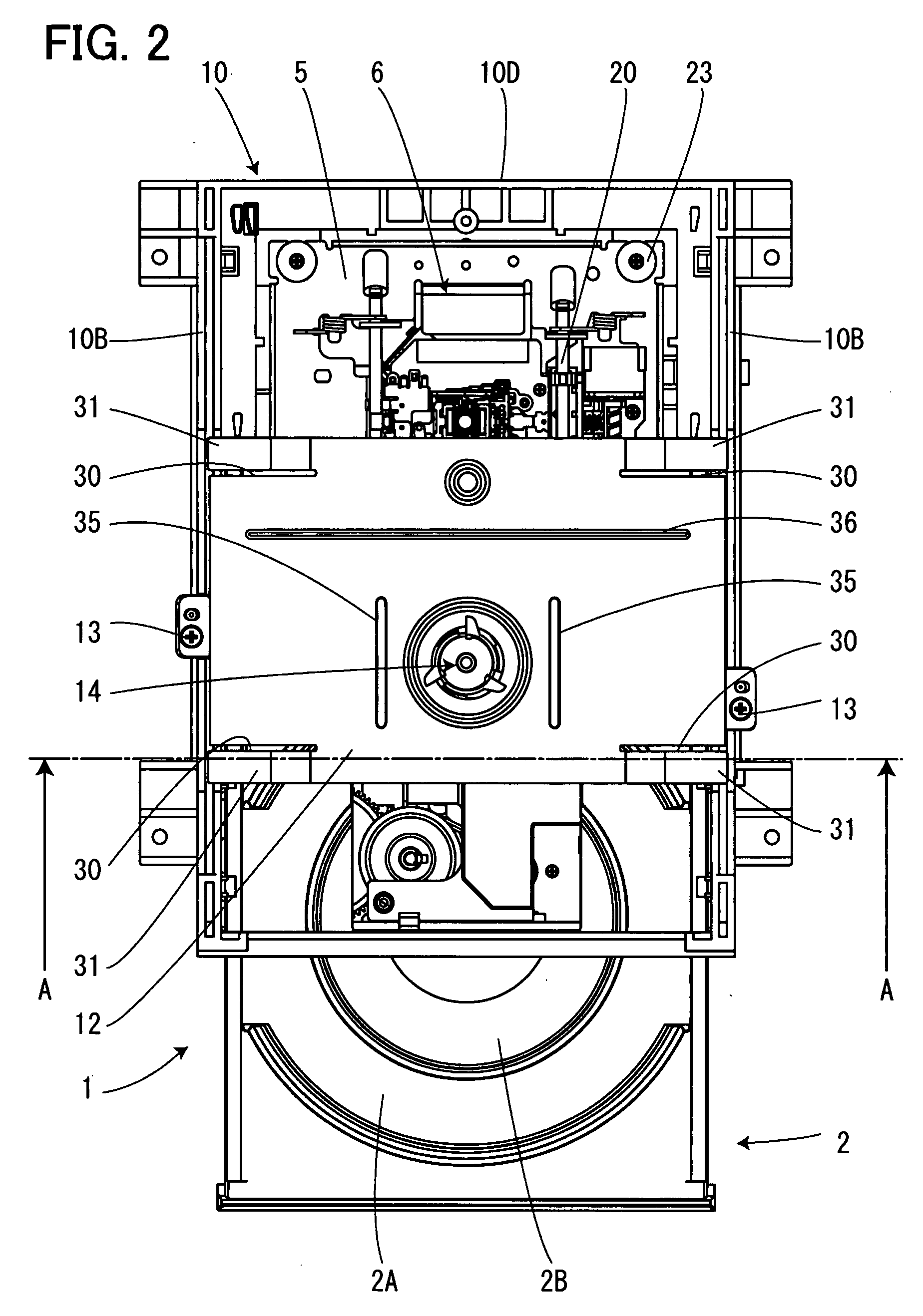

Recording and reproducing device

InactiveUS20070240176A1Suppress collision noiseEliminate grating noiseRecord information storageOptical recording/reproducingEngineering

The present invention reduces contact noise between a turntable and a clamper without increasing the number of components. Spring pieces are formed by forming slit grooves in the corners of a support plate. When the support plate is secured by screws to bosses of a frame, the spring pieces formed in the four corners of the support plate are elastically contacted with the frame, with the support plate slightly floated from the frame. Thereby, vibration transmitted to the support plate from the clamper is absorbed by the spring pieces, thus suppressing noise caused by the vibration transmitted to the support plate.

Owner:ORION ELECTRIC CO LTD

Enclosure for electric equipment and imaging device

InactiveUS7848640B2Excellent in assembling performance and heat transfer propertyReduce the numberTelevision system detailsDigital data processing detailsManufacturing cost reductionElectrical devices

According to an enclosure for electric equipment of an aspect of the present invention, the enclosure having the plurality of accommodation portions accommodating separate contents, respectively, can be formed by one molding without assembling a plurality of components, which can reduce the number of assembling processes. Also, formation by one component eliminates a gap which would be generated by assembling components, which can improve enclosure strength and designability and reduce manufacturing costs.

Owner:FUJIFILM CORP

Exhaust device for combustion engine

ActiveUS9617902B2Easy to joinWithout increasing number of componentSilencing apparatusMachines/enginesCombustionInternal combustion engine

Owner:KAWASAKI MOTORS LTD

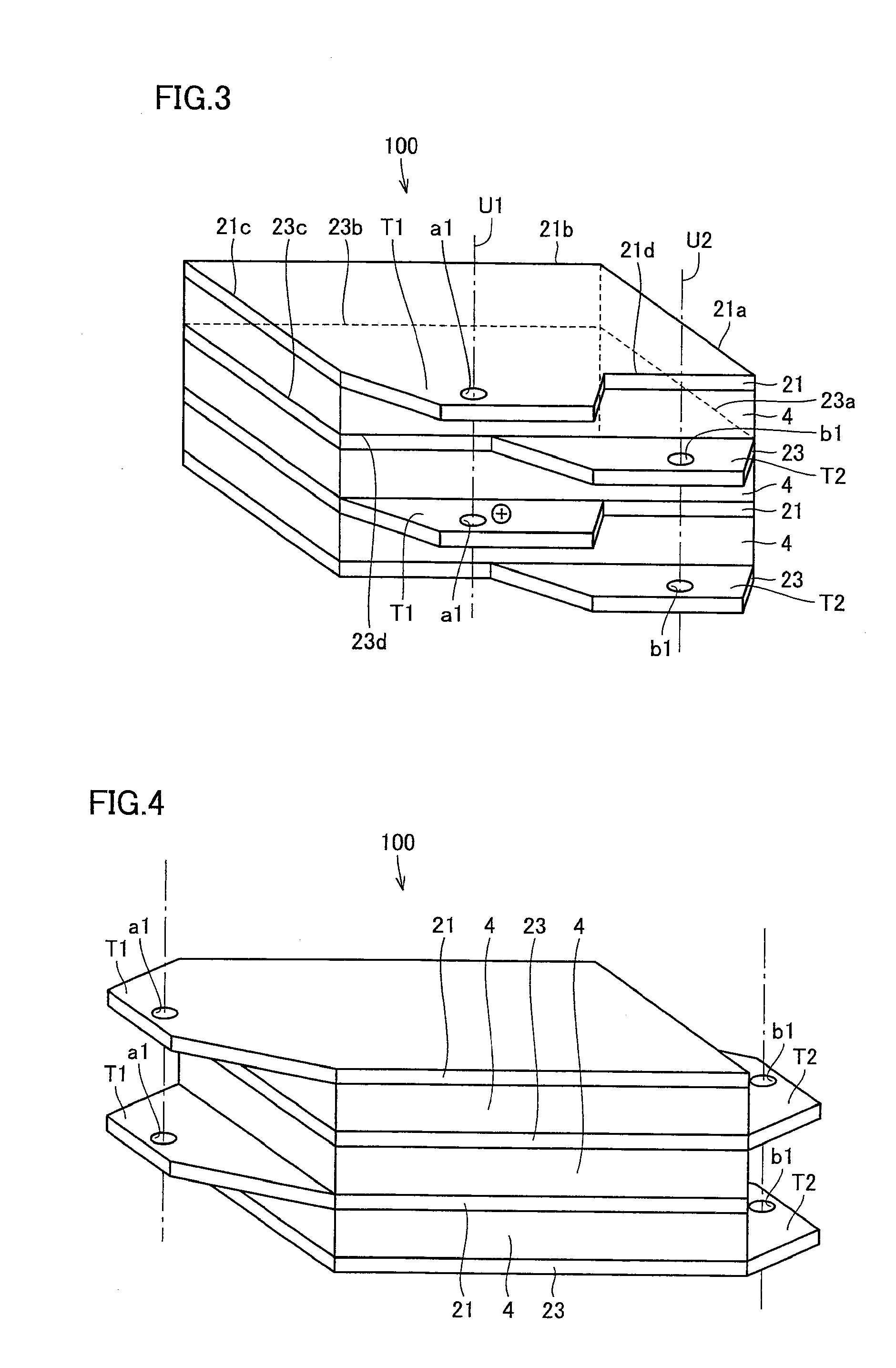

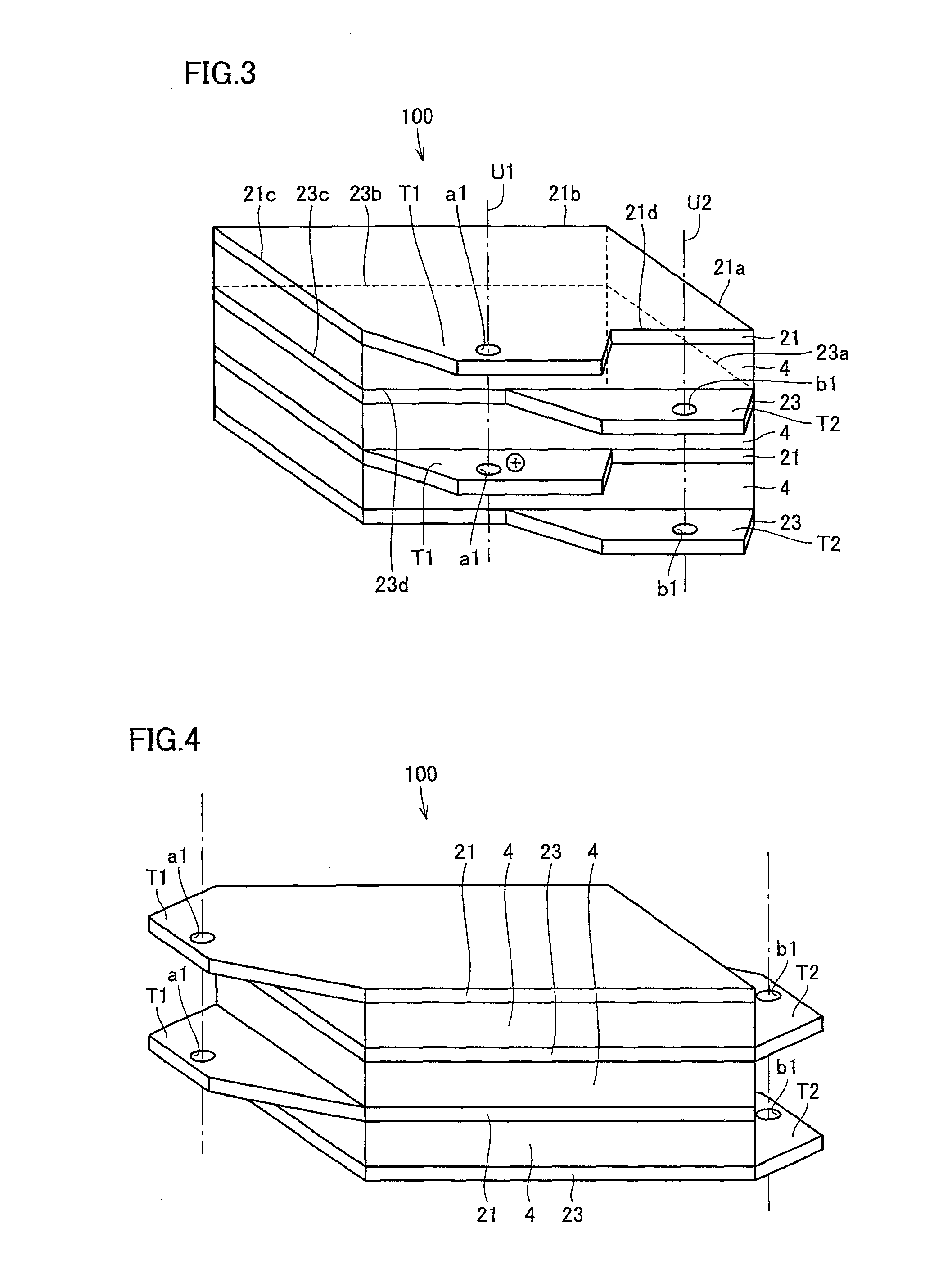

Conductor connection structure of laminated wiring body

ActiveUS20180301831A1Simple structureSimple easePrinted circuit aspectsCoupling device detailsConductive materialsEngineering

Owner:YAZAKI CORP

Display device

InactiveUS20150356931A1Display quality is deterioratedSuppressing intrusion of dustStatic indicating devicesDigital data processing detailsTouch panelEngineering

A display device includes a display, which has a display surface, and a touch panel, which is spaced from and is opposed to the display surface. An opening of a panel frame portion-relative to the touch panel is formed to be larger than an opening of a front case relative to the display unit. An insulator portion extends toward a center of the opening of the front case beyond an inner peripheral part of the front case to mask the front case from eyesight of a user.

Owner:DENSO CORP

Battery assembly

ActiveUS8911894B2Low costWithout increasing number of componentLarge-sized flat cells/batteriesFinal product manufactureBattery cellCharge and discharge

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com