Patents

Literature

33results about How to "Required strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

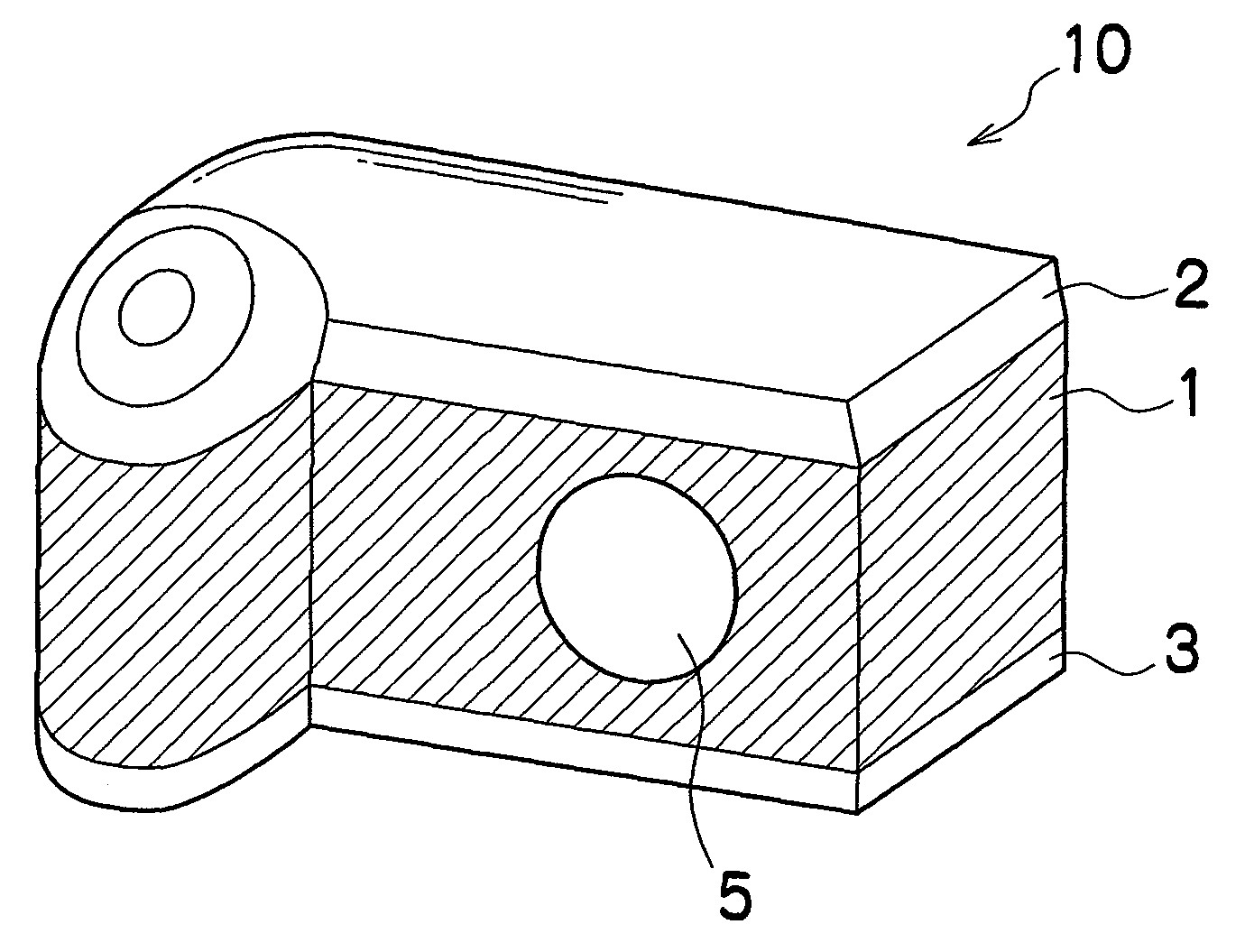

Fusion-bonded product having high-strength part and manufacturing method thereof

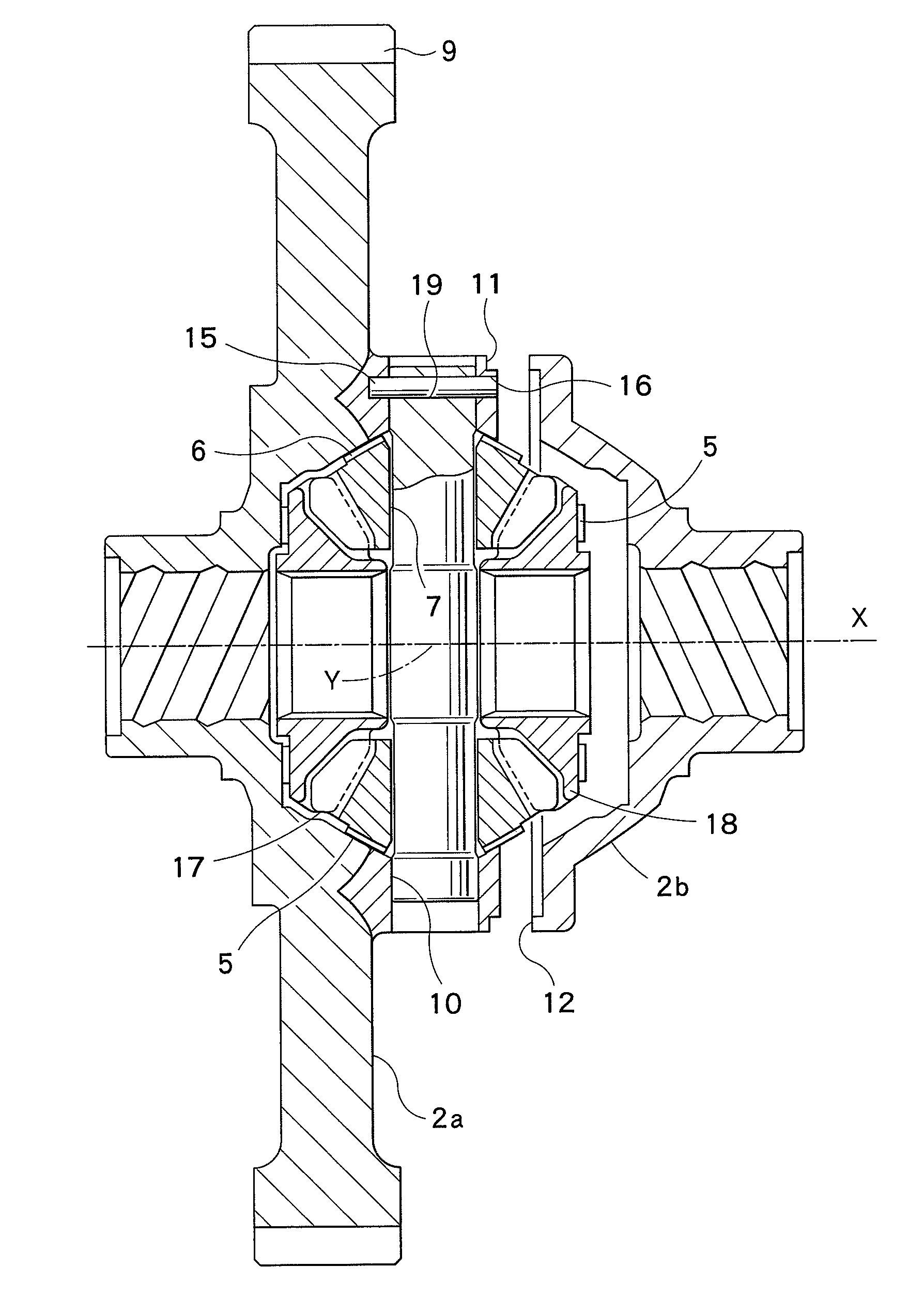

InactiveUS20080138649A1Easily obtainPrevent generation of crackTransmission elementsElectron beam welding apparatusCarbon steelFusion welding

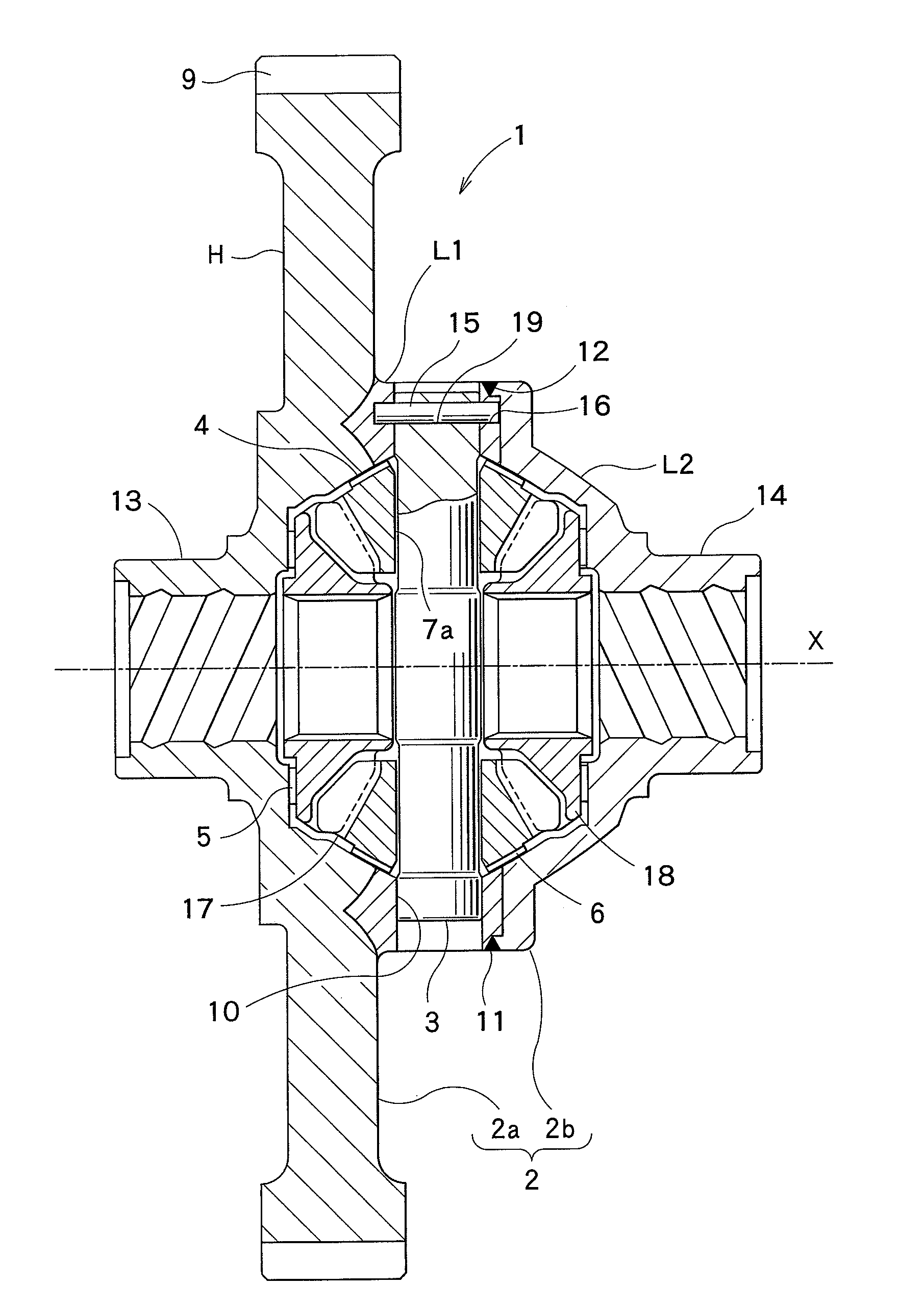

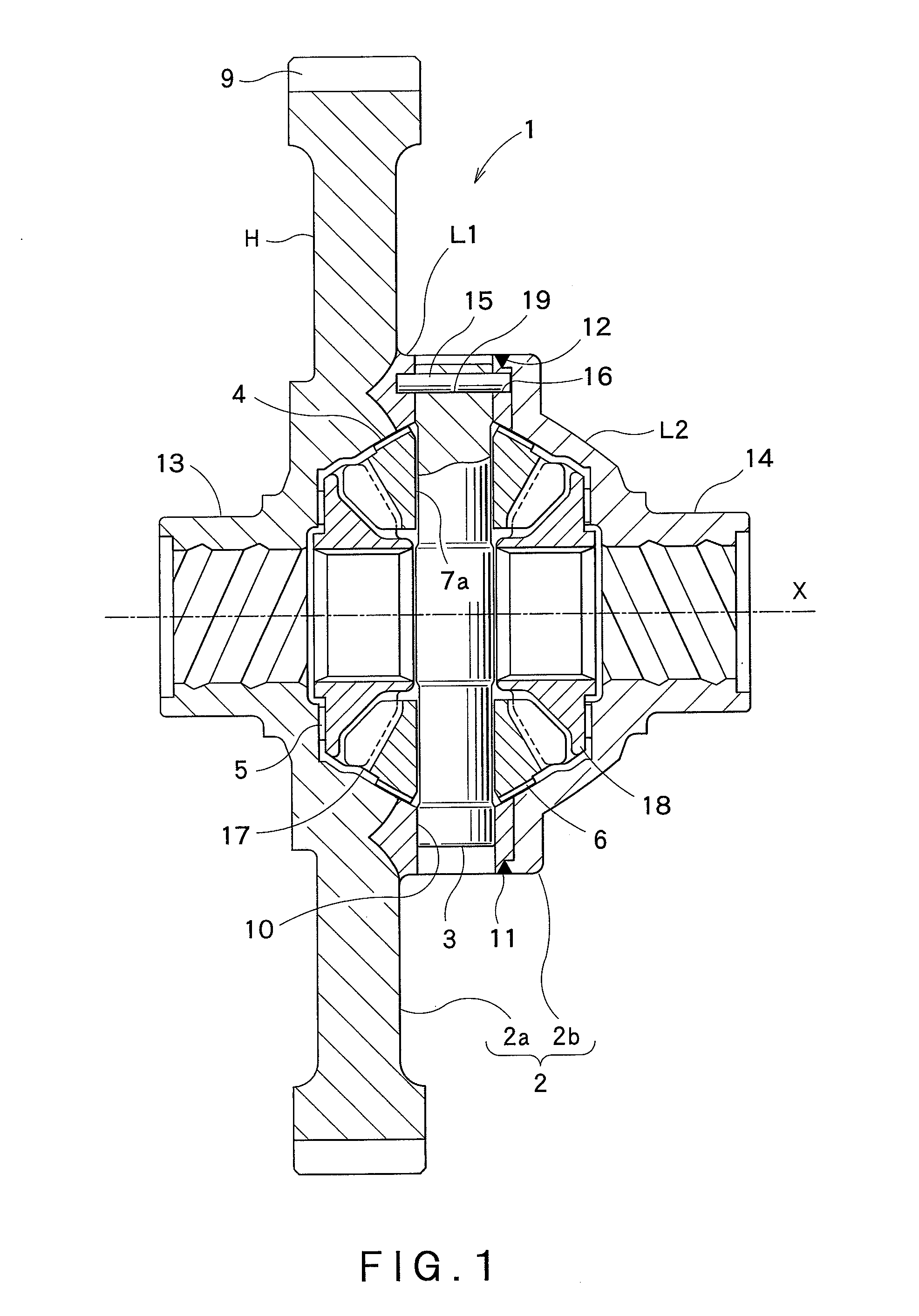

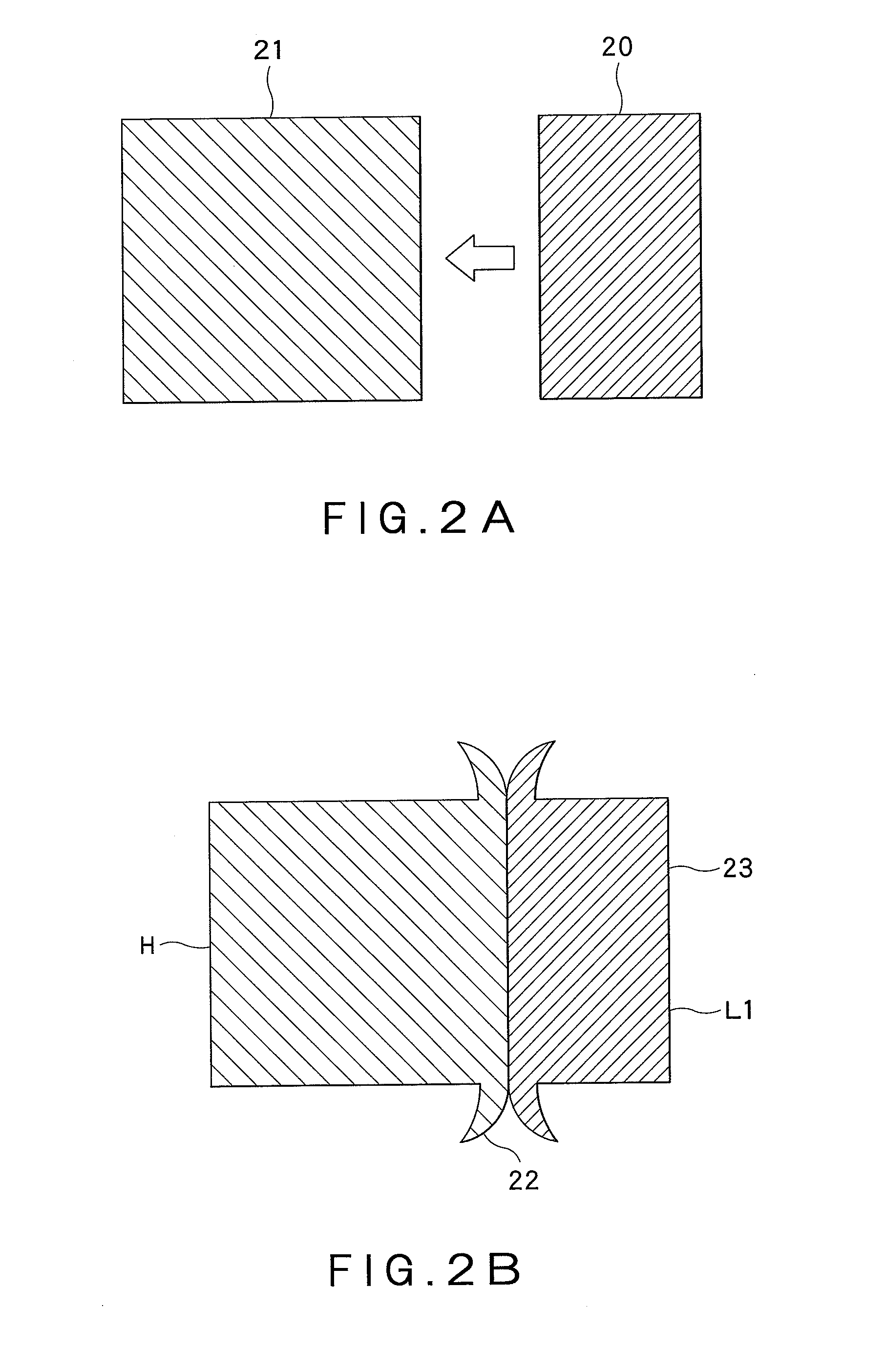

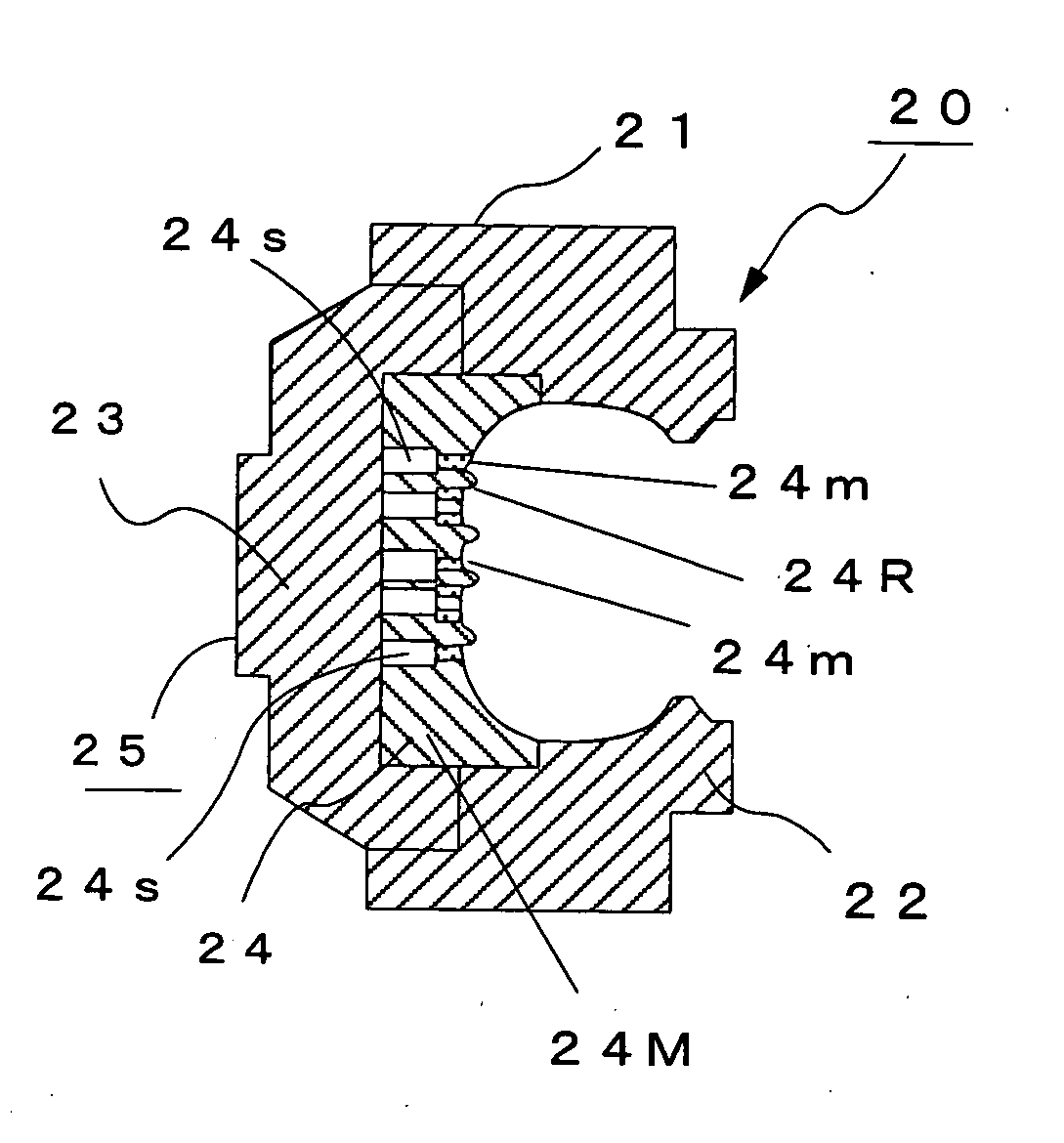

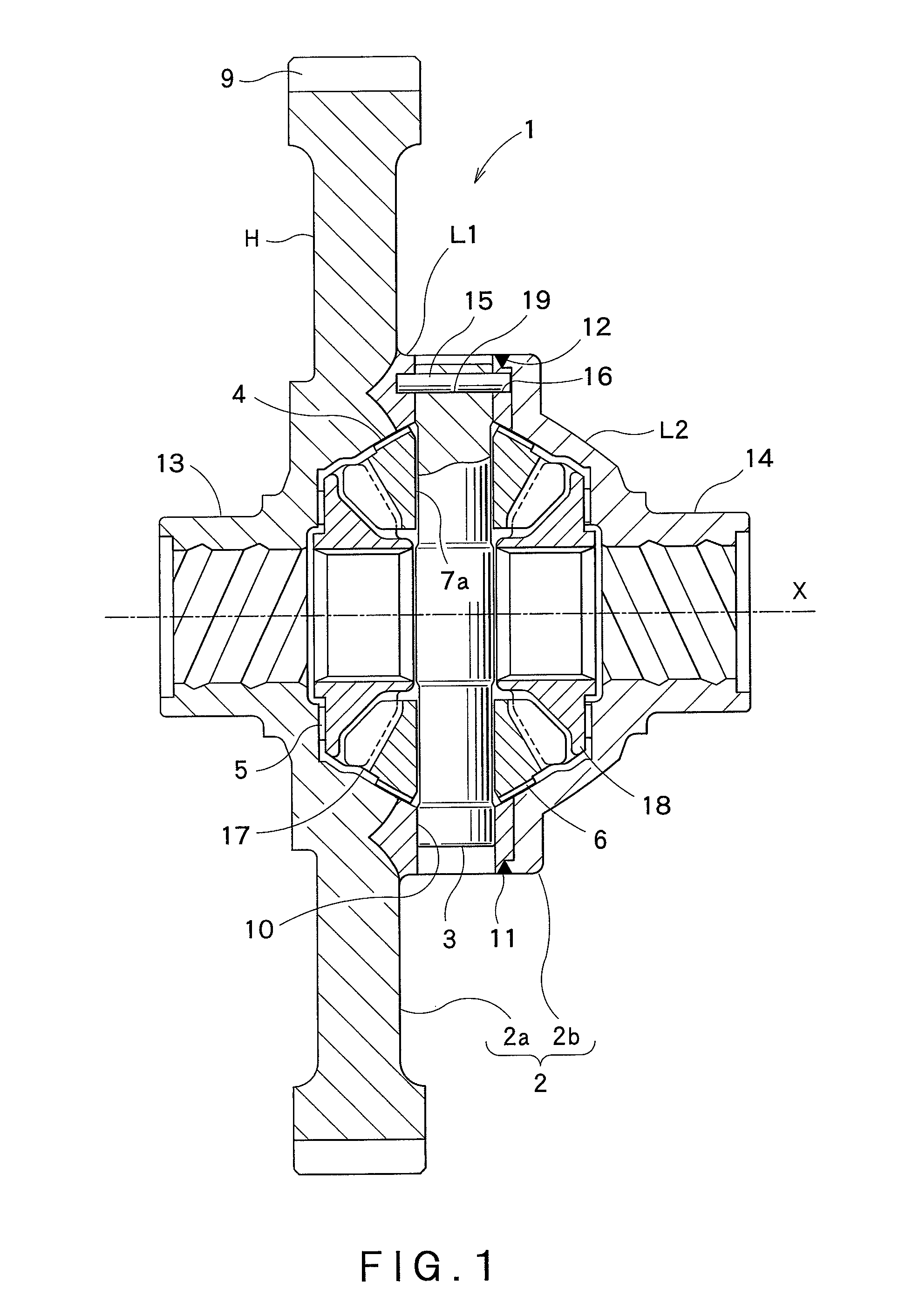

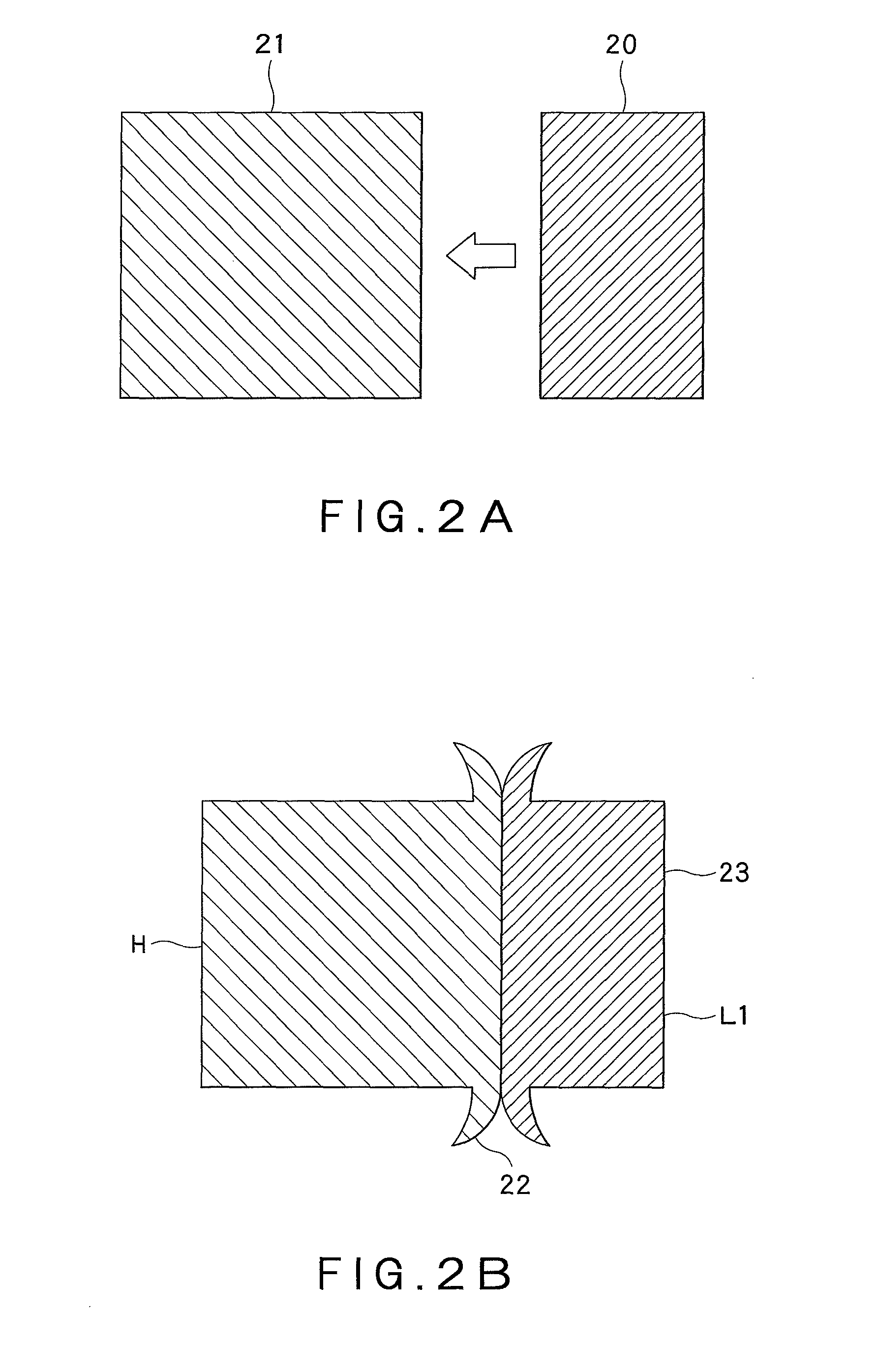

The present invention is a fusion-bonded product having a high-strength part, comprising: a first preform (2a) constituted by integrally, frictionally pressure-welding a first low-carbon steel part (L1) made of low-carbon steel containing less than 0.45% of C and a high-carbon steel part (H) made of high-carbon steel containing not less than 0.45% of C; and a second preform (2b) having a second low-carbon steel part (L2) made of second low-carbon steel containing less than 0.45% of C; wherein the high-carbon steel part (H) of the first preform (2a) is provided with a high-strength part (9) that has been previously formed into a desired shape and quenched, the second low-carbon steel part (L2) of the second preform (2b) has been previously formed into a predetermined shape, and the first low-carbon steel part (L1) of the first preform (2a) and the second low-carbon steel part (L2) of the second preform (2b) are bonded to each other by fusion welding.

Owner:MUSA PRECISION IND

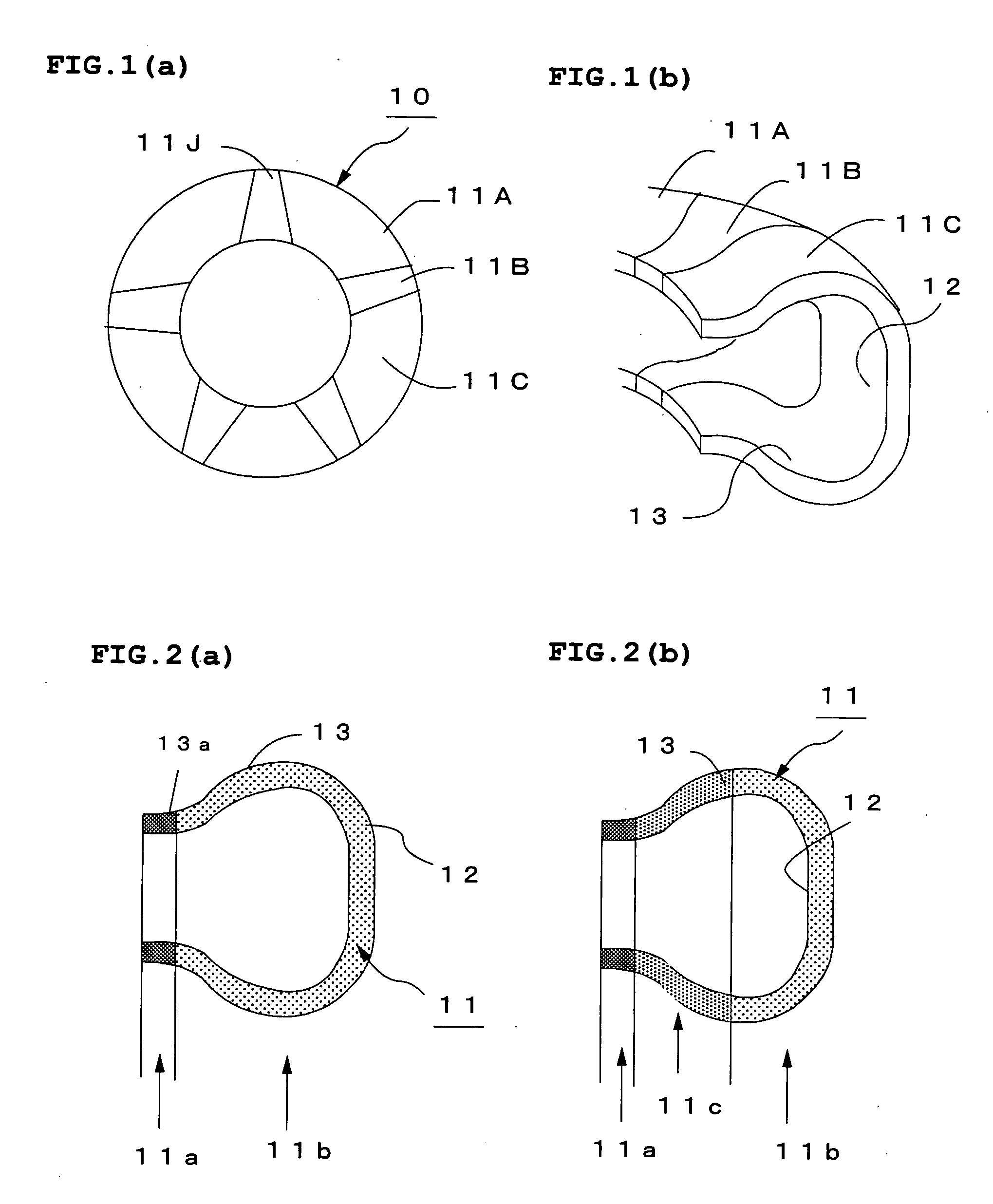

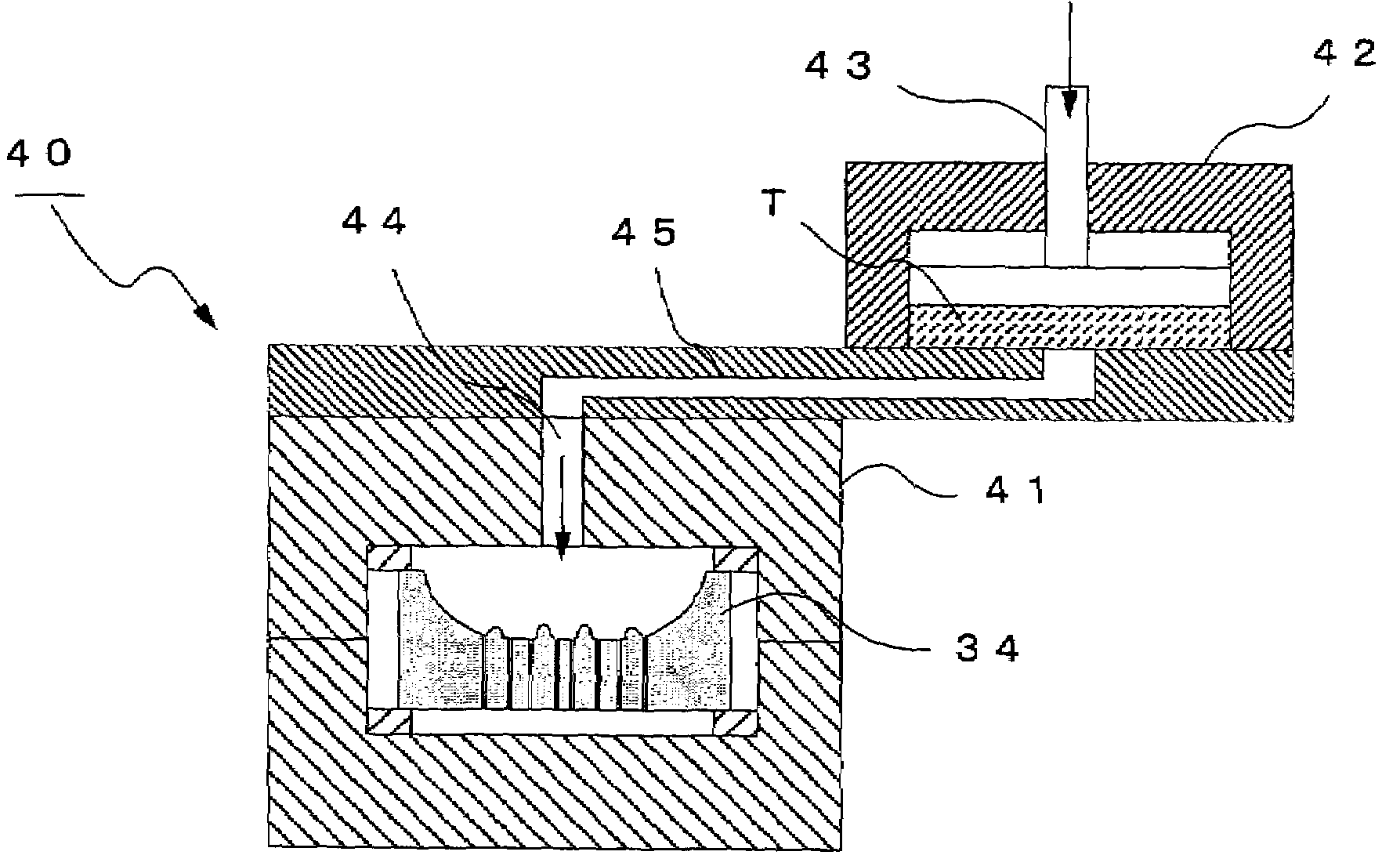

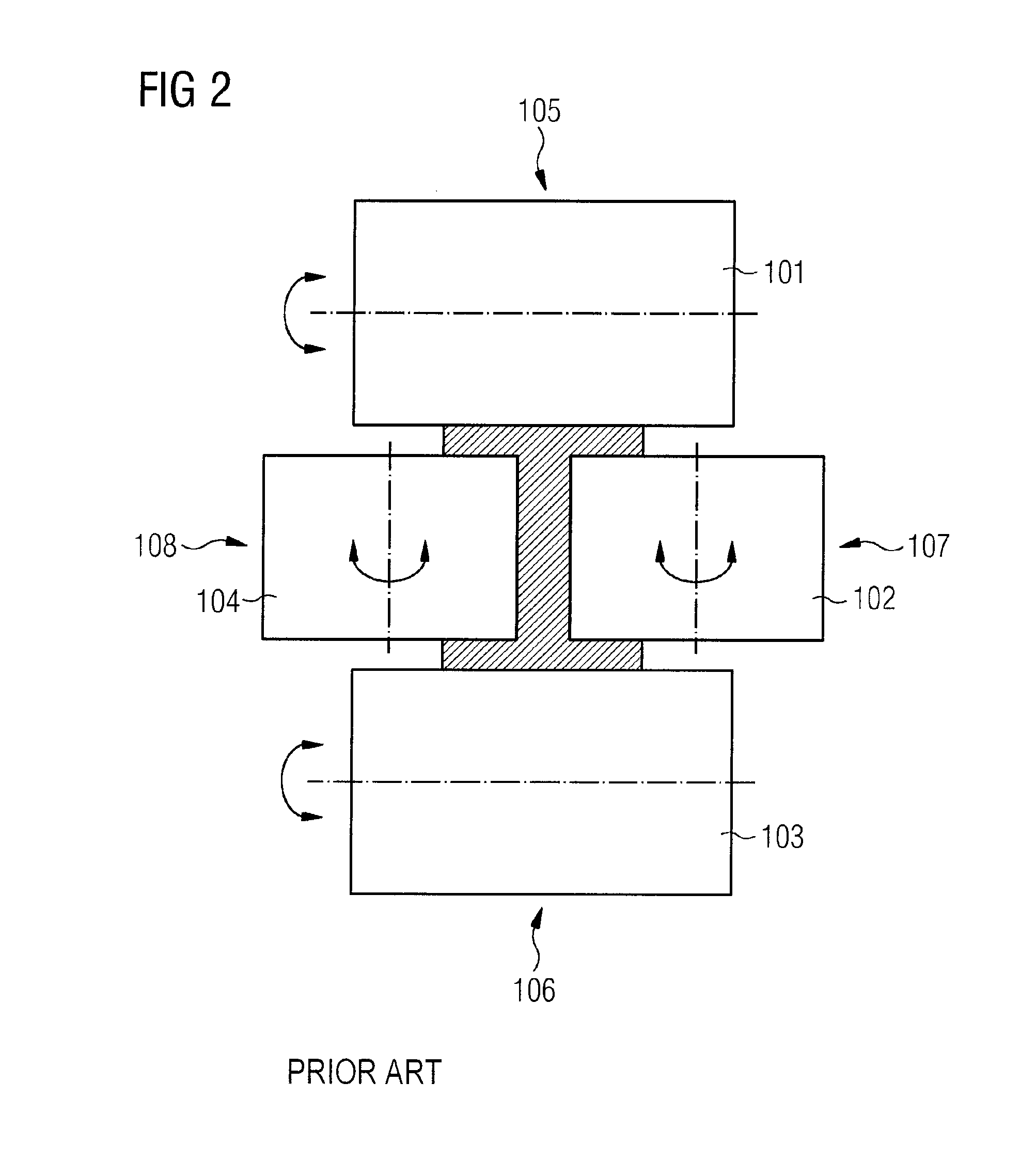

Method for producing tire vulcanizing mold and tire vulcanizing mold

ActiveUS20060257511A1Easily moldedRequired strengthTransportation and packagingTyresDensity distributionMachining time

A 3-D solid model of a tire vulcanizing mold is constructed on CAD, lamination models the optimum value of the pitch of which is determined in consideration of molding accuracy and processing time are created by dividing this model in a predetermined lamination direction, slice data for each layer corresponding to the lamination pitch of each segment are created, a sector mold of the tire vulcanizing mold is manufactured by a powder sintering method based on the slice data, and the density of a sintered body is controlled by adjusting the output of a laser beam or the exposure time of the laser beam applied to the powders to provide a density distribution on the plane and in the depth direction of a mold element for each layer so as to obtain a tire vulcanizing mold having a hybrid structure.

Owner:BRIDGESTONE CORP

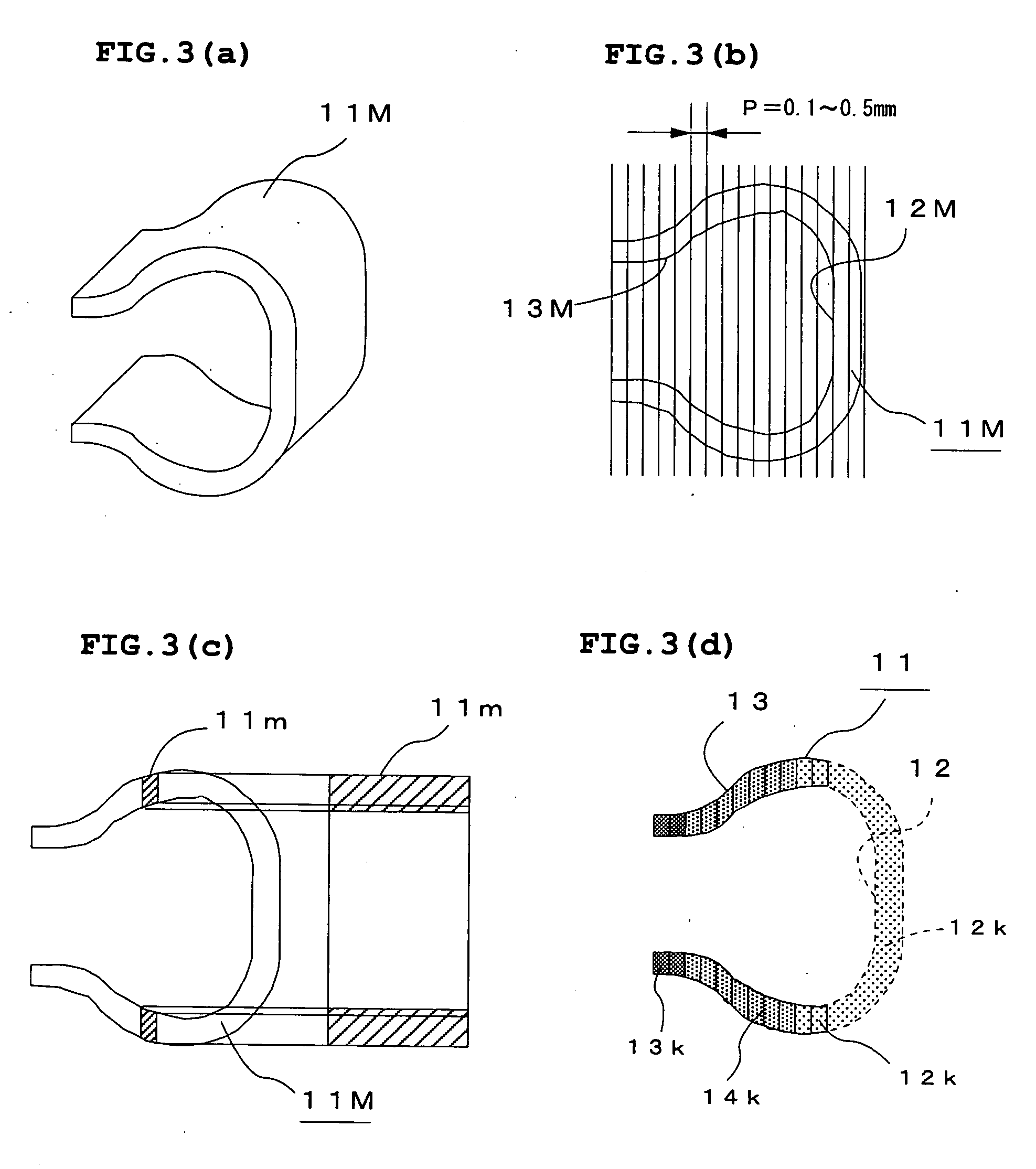

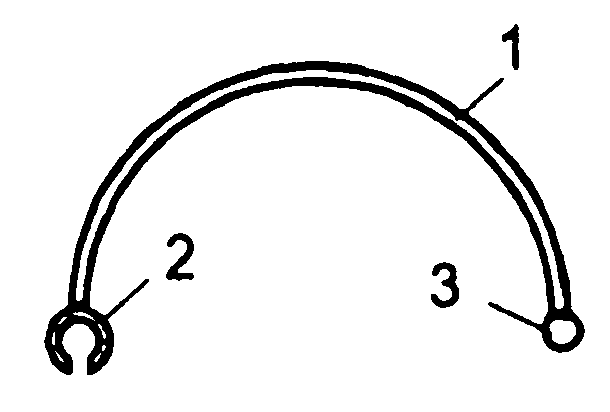

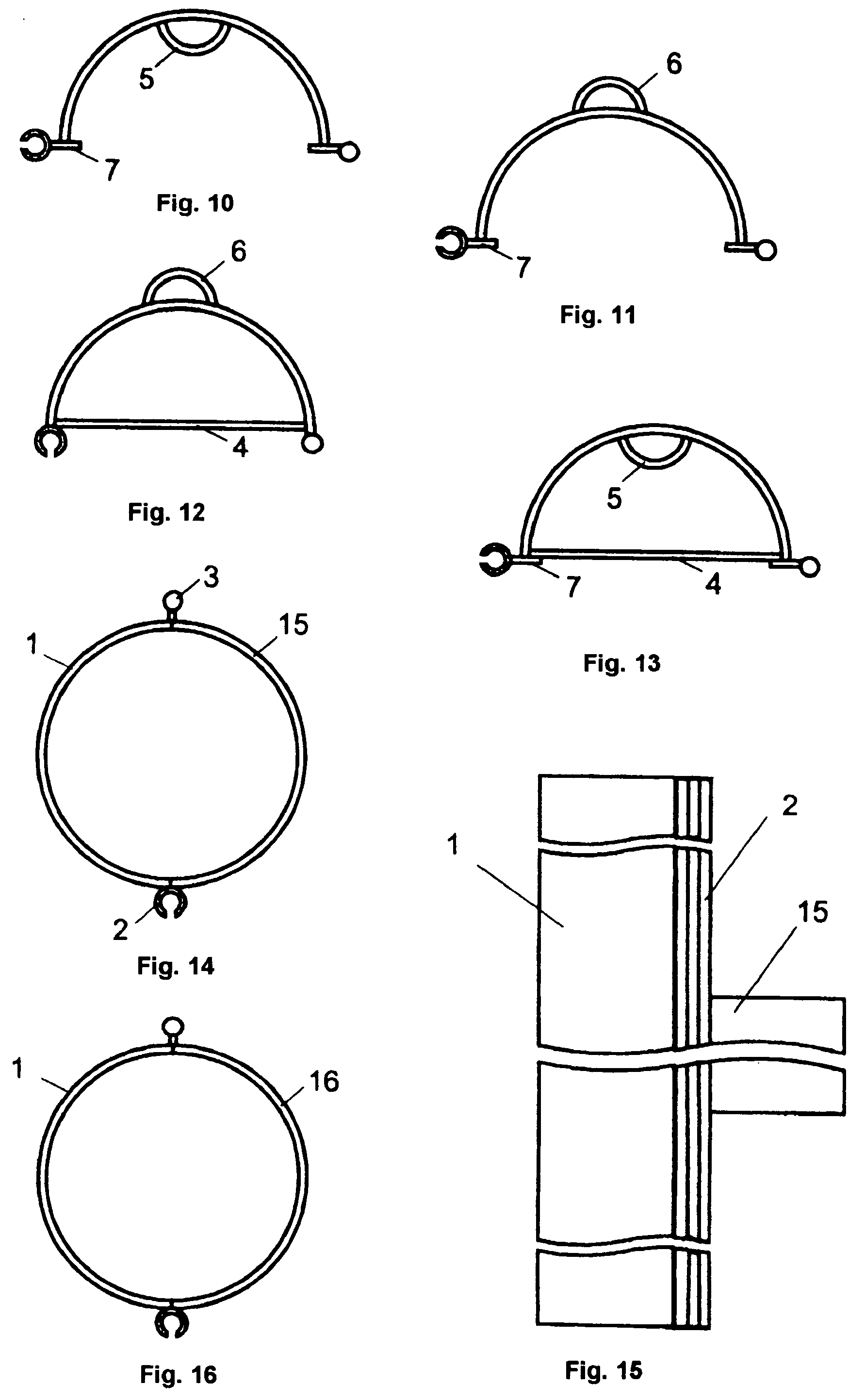

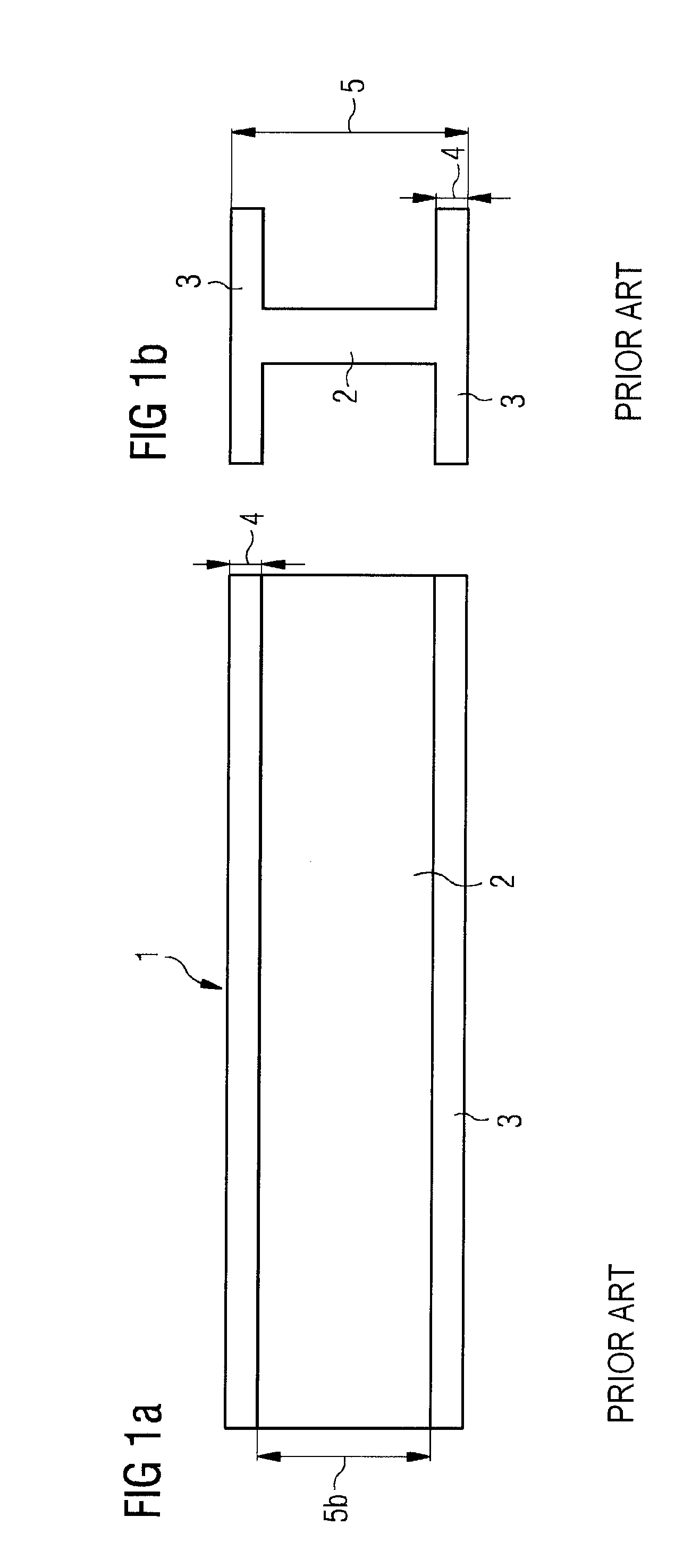

Grooved sheet pile and method for production thereof

InactiveUS20040120775A1Good mechanical resistanceReduce necessityArtificial islandsExcavationsSheet pileCorrosion resistant

The inventive grooved sheet pile having a though-type body is produced by cutting a cylindrical segment (1) from a round tube along the length thereof, and fixing locking elements (2 and 3) to the side edges of said segment. The segment (1) can be cut together with an annular section (15) of a tube (16) and reinforced by fixing elements (4), an internal (5) or external (6) strap, internal (8 and 9) and / or external (10 and 11) faceplates or stiffening ribs fixed thereto. Said segment can be embodied from sections of cylindrical segments welded to each other. At least one section (18) has an increased thickness or is made of a corrosion-resistant material. In order to produce an enlarged grooved pile, two or more cylindrical segments (1) cut from a tube are used. Said segments are disposed in a parallel position with respect to each other and fixed to each other with the aid of reinforcing elements (12, 13, and 14). The locking elements (2 and 3) are fixed to the lateral side of the thus obtained panel. Said invention makes it possible to simplify the production of the grooved piles and to expand the variability of the design thereof. Said production can be carried out without rolling mills.

Owner:SHEET PILE LLC

Method for producing tire vulcanizing mold and tire vulcanizing mold

InactiveUS7384252B2Simple moldingRequired strengthTransportation and packagingTyresDensity distributionLight beam

A 3-D solid model of a tire vulcanizing mold is constructed on CAD, lamination models the optimum value of the pitch of which is determined in consideration of molding accuracy and processing time are created by dividing this model in a predetermined lamination direction, slice data for each layer corresponding to the lamination pitch of each segment are created, a sector mold of the tire vulcanizing mold is manufactured by a powder sintering method based on the slice data, and the density of a sintered body is controlled by adjusting the output of a laser beam or the exposure time of the laser beam applied to the powders to provide a density distribution on the plane and in the depth direction of a mold element for each layer so as to obtain a tire vulcanizing mold having a hybrid structure.

Owner:BRIDGESTONE CORP

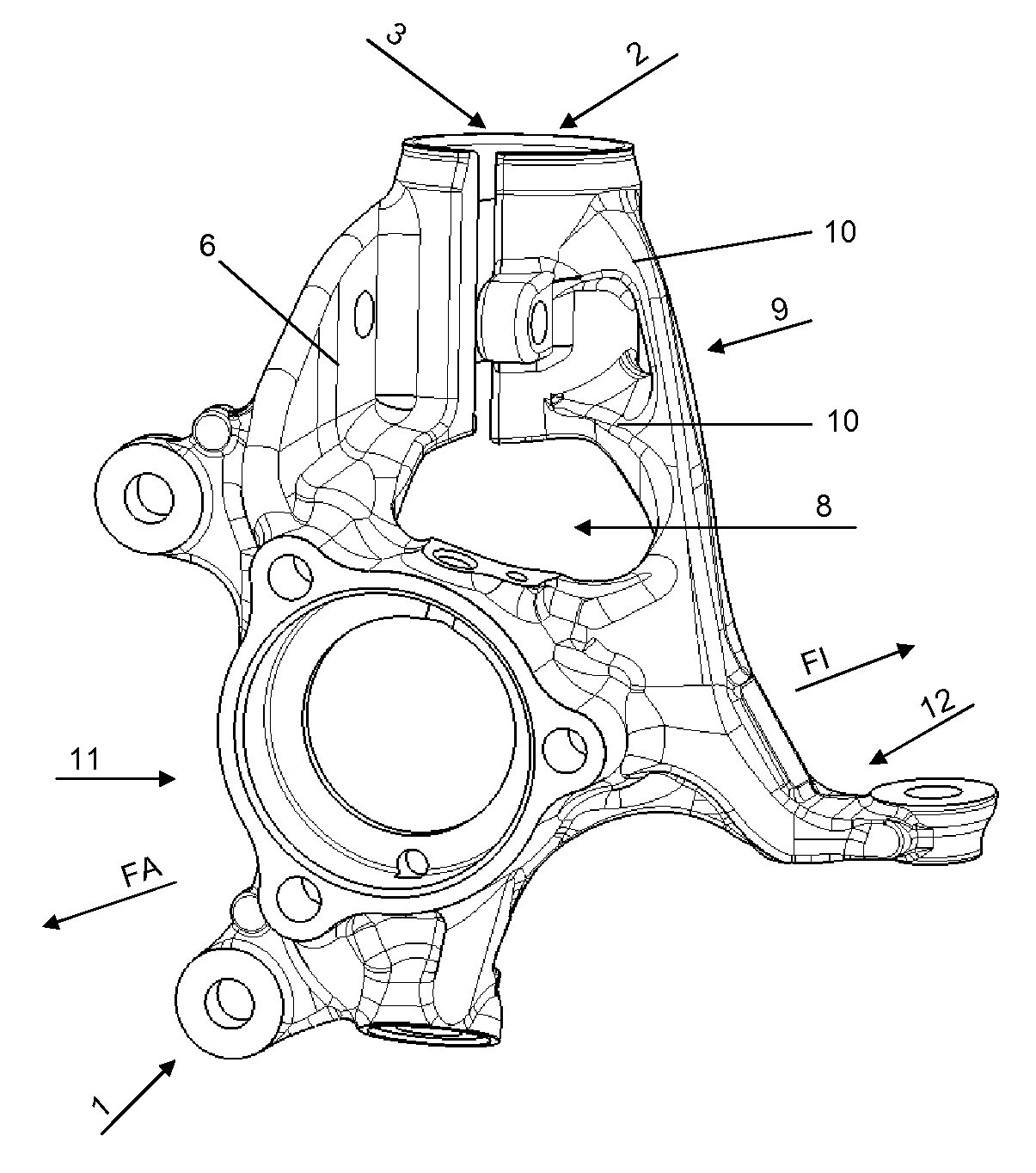

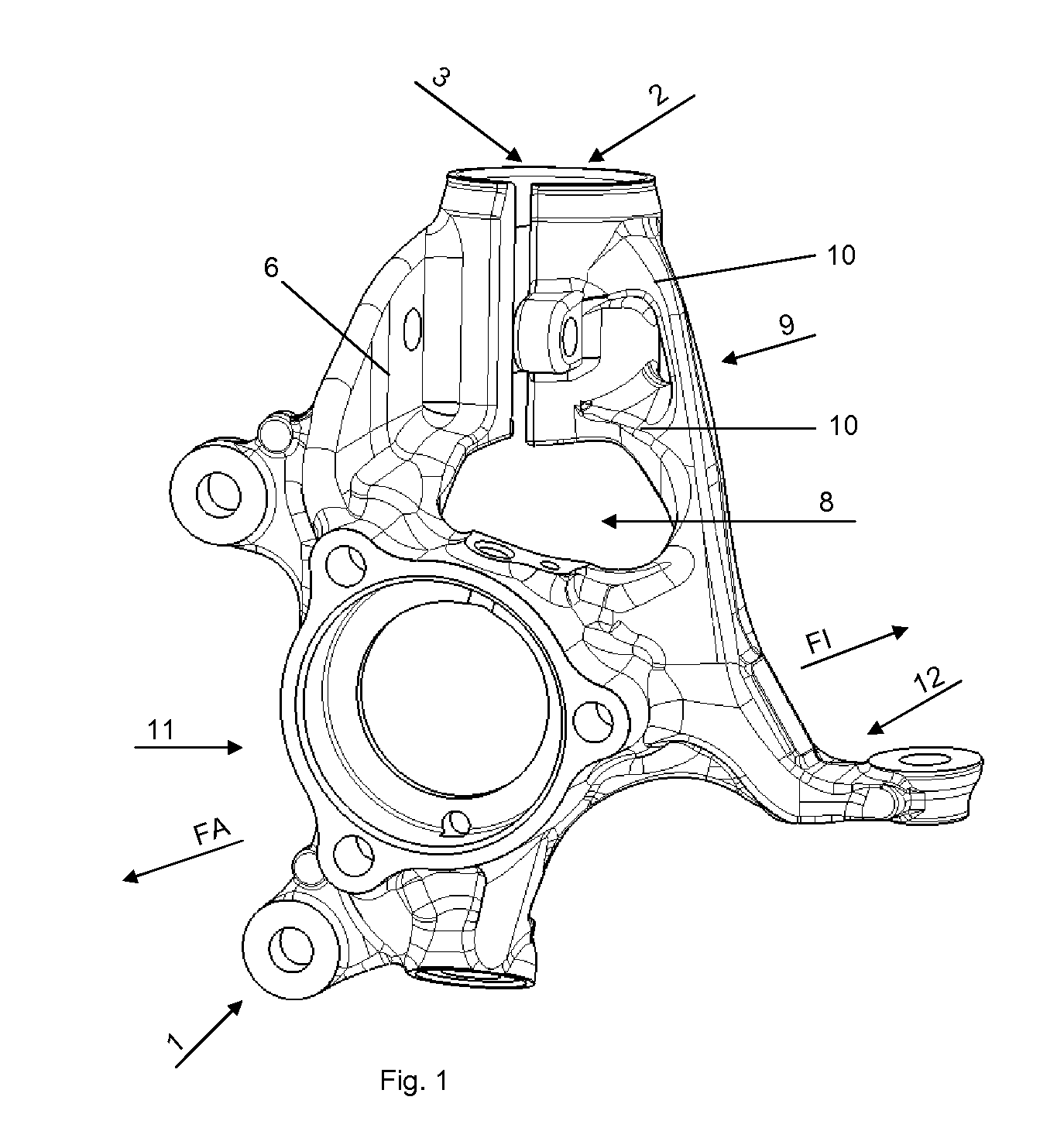

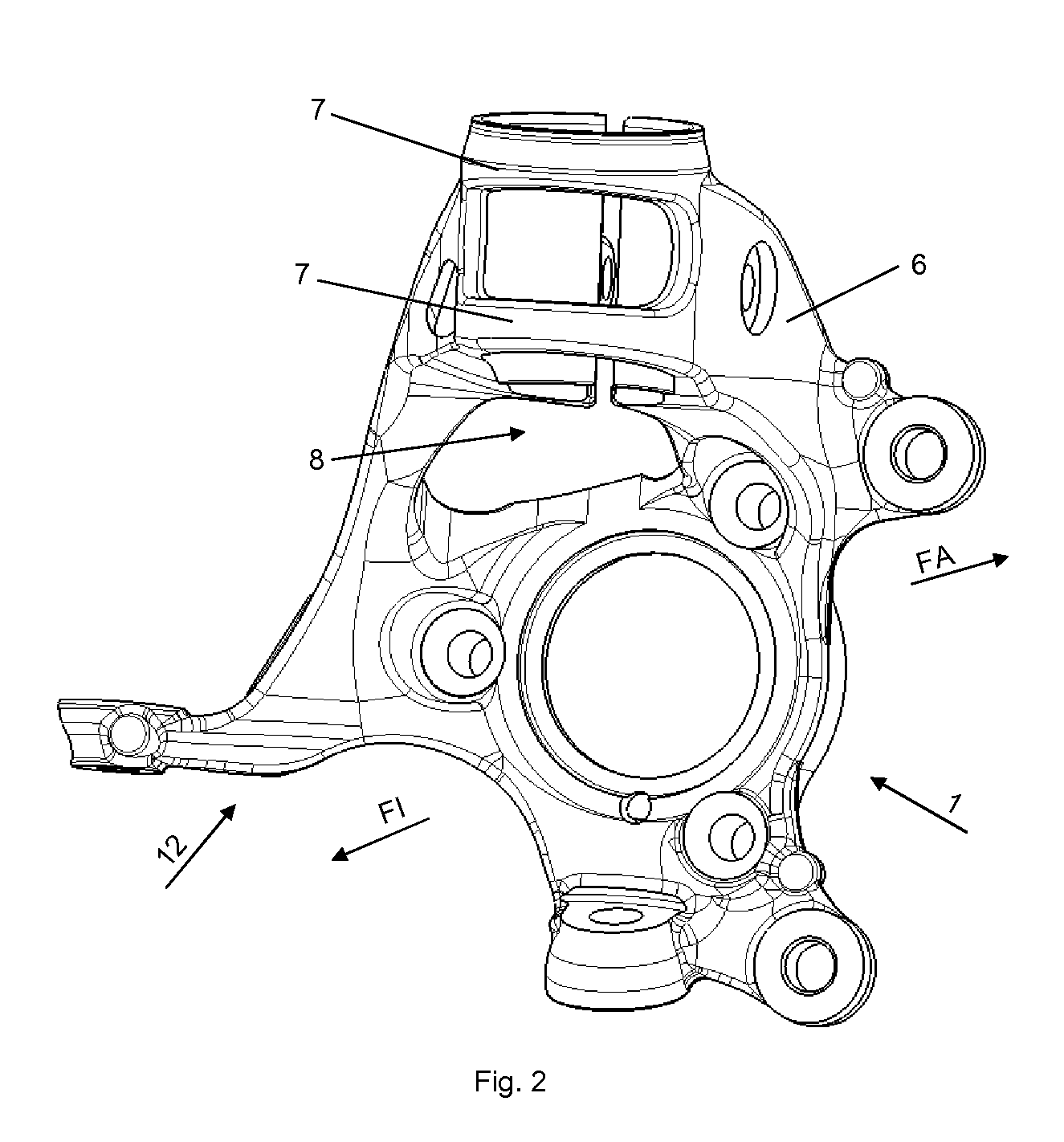

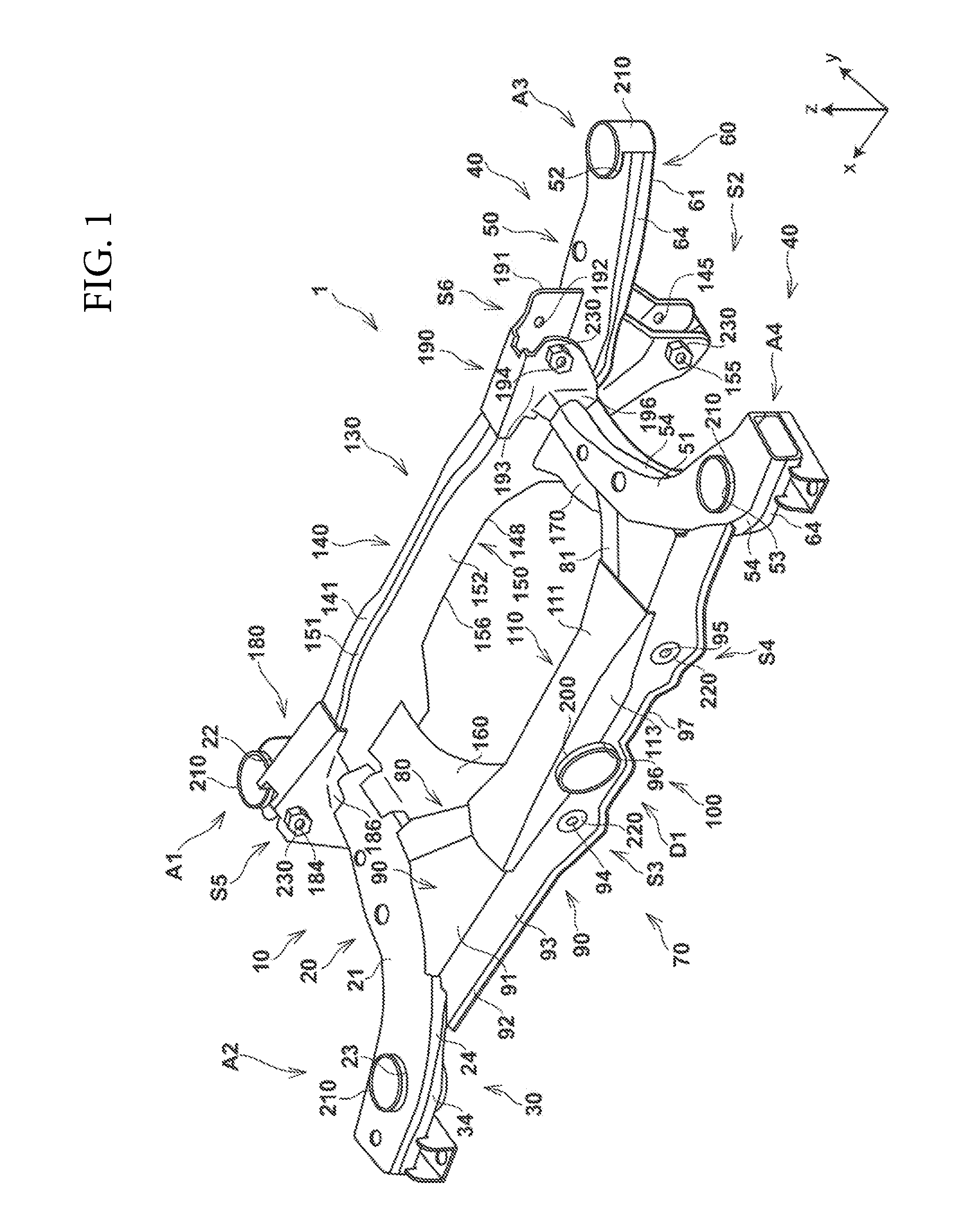

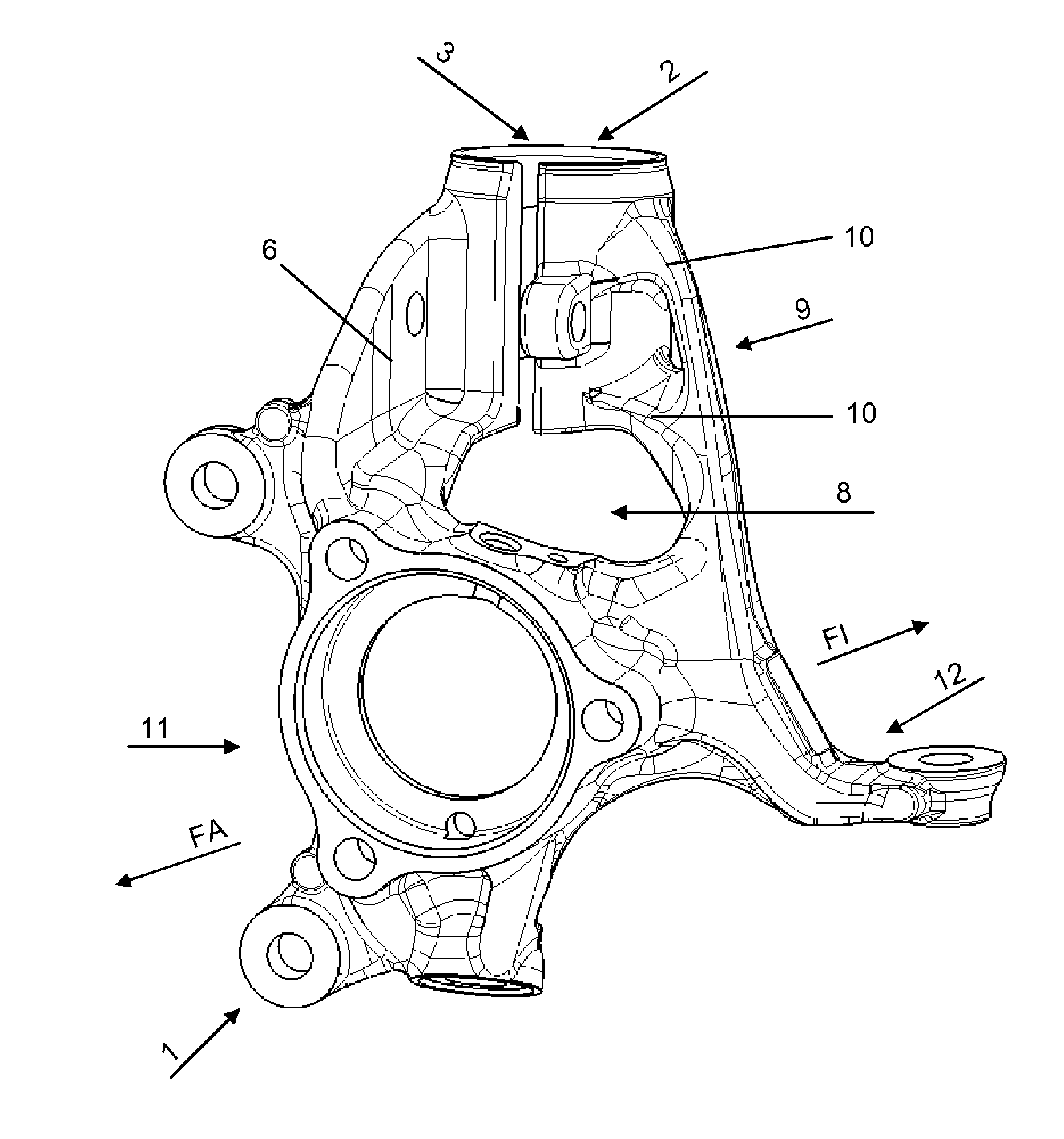

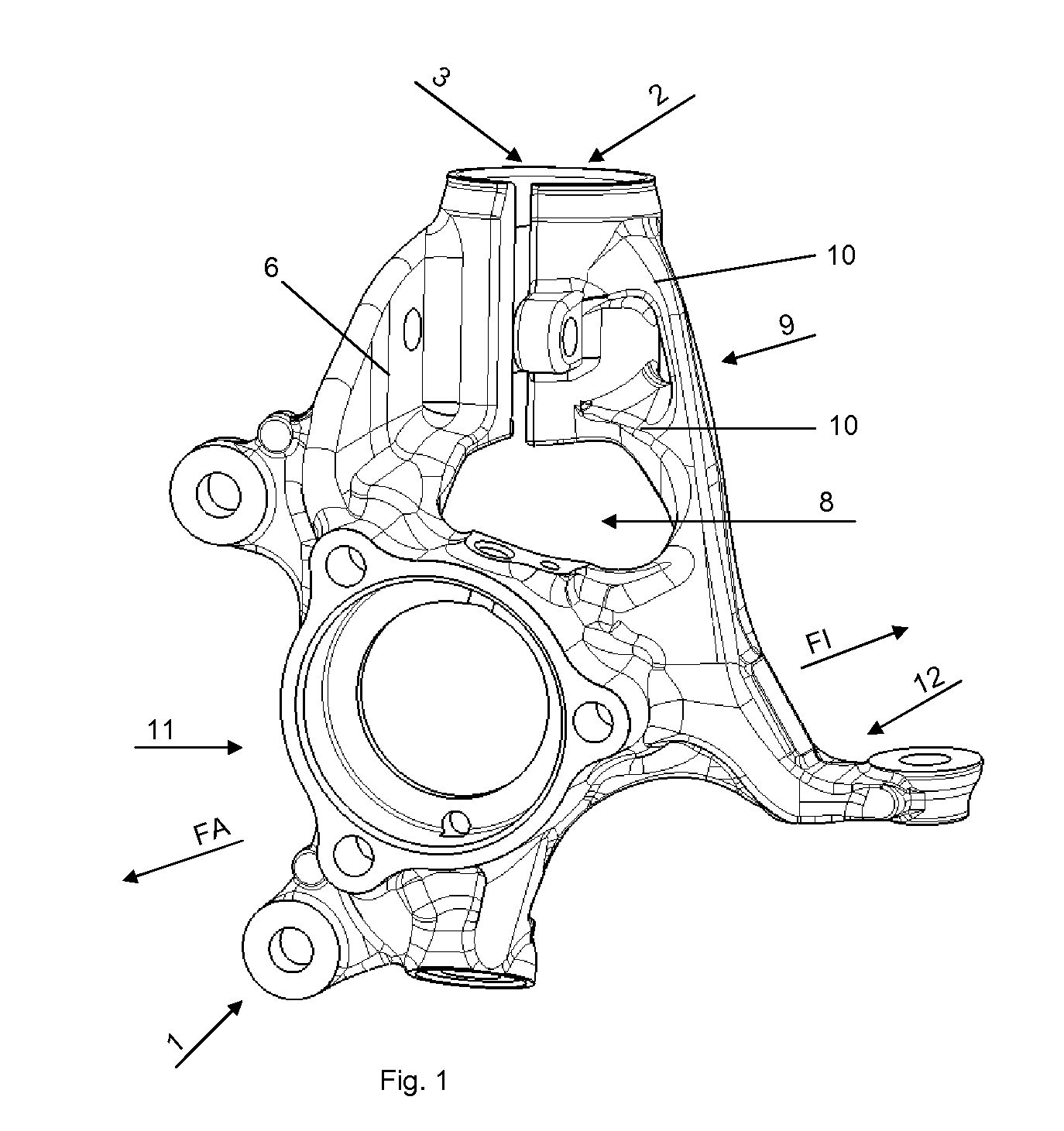

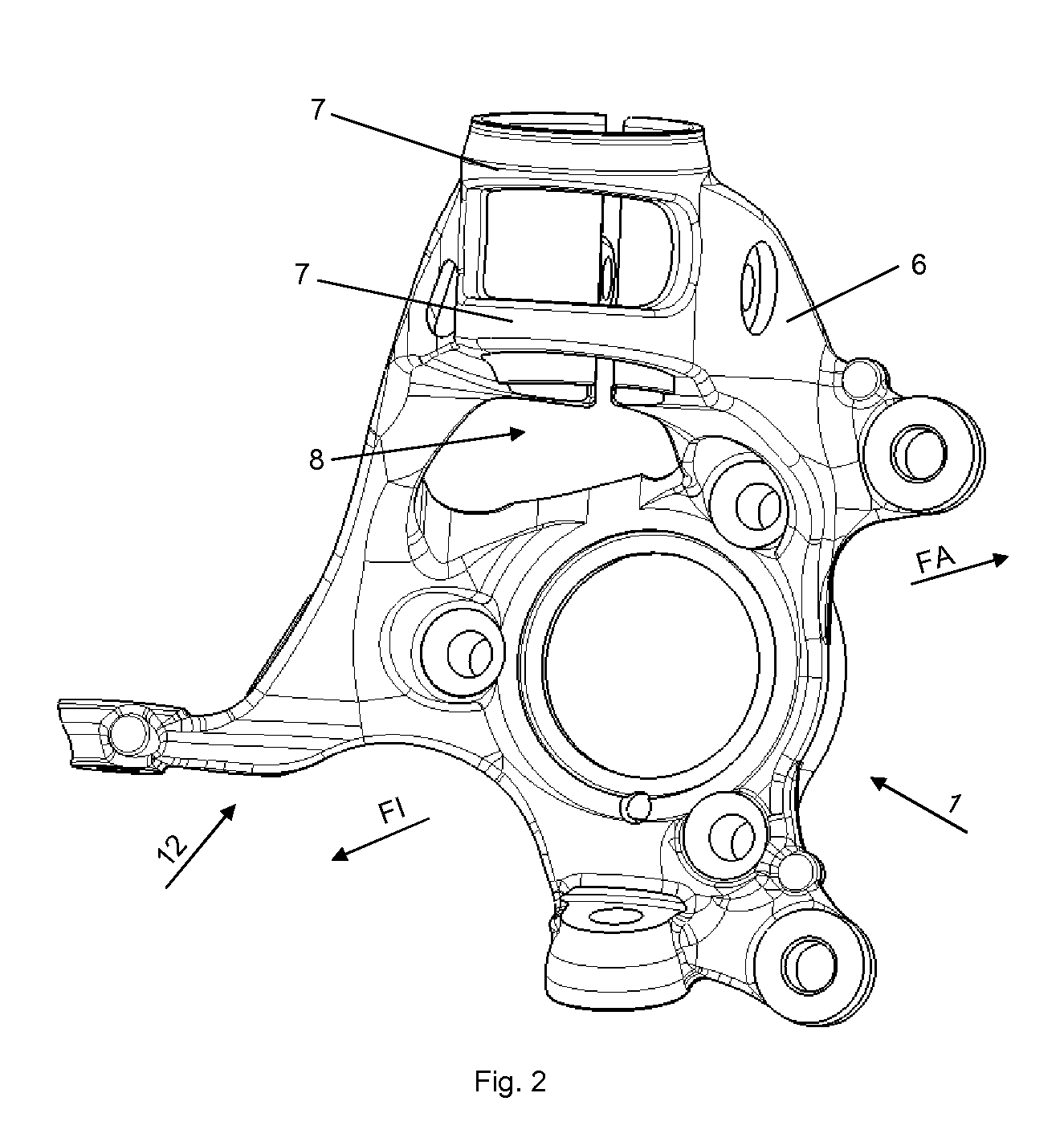

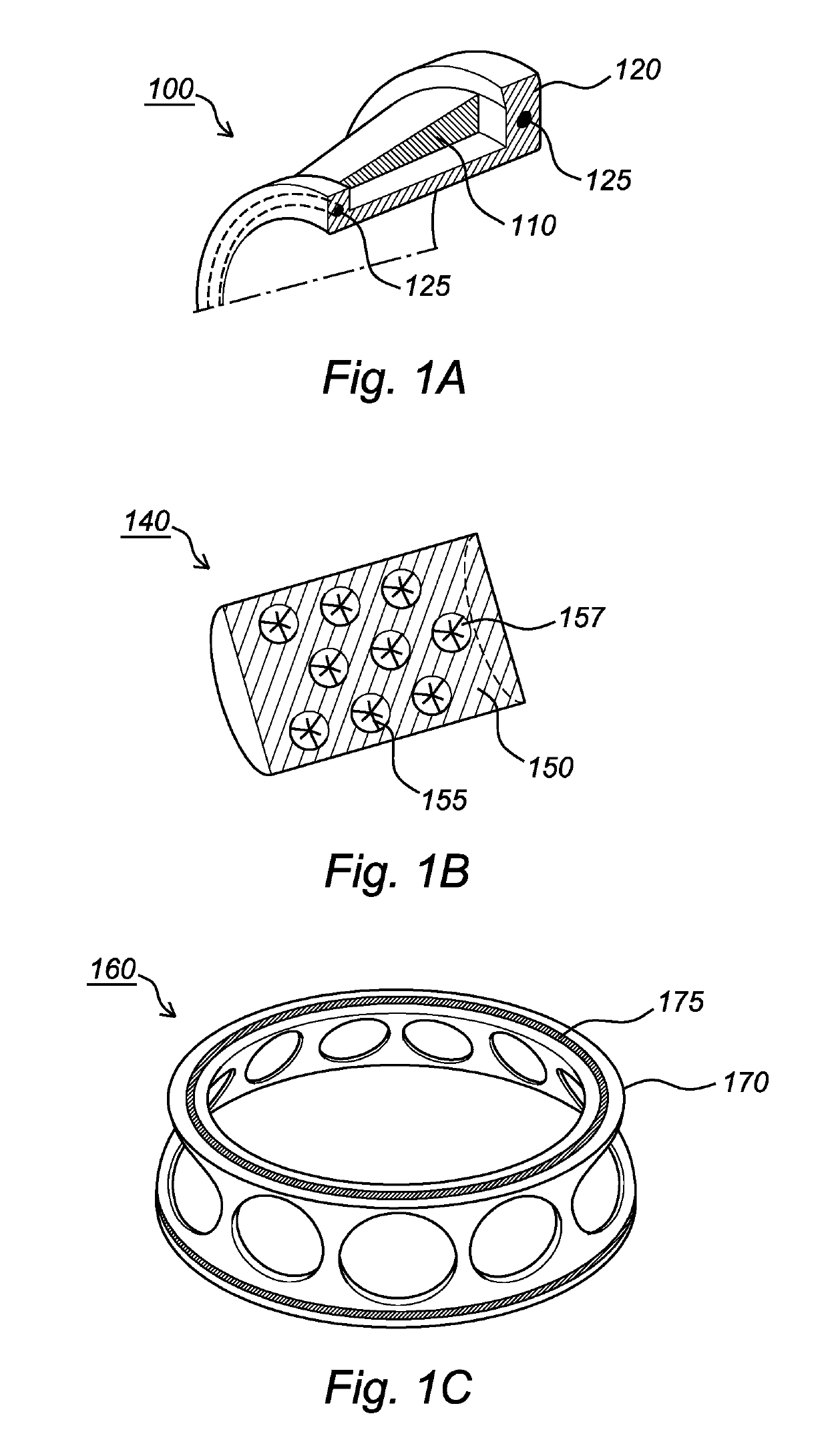

Pivot bearing with turned damper clamping

ActiveUS20130181421A1Fulfils strength requirementMuch materialSteering linkagesMetal-working apparatusMotorized vehicleShock absorber

Pivot bearing for a wheel suspension, in particular for a front axle of a motor vehicle, containing a wheel bearing receiver, a steering arm, a spring strut receiver with a damper clamping and a carrier rib, wherein the damper clamping of the spring strut receiver faces the vehicle outside and the pivot bearing has an opening in the region between the wheel bearing receiver and the damper clamping.

Owner:GEORG FISCHER AG A SCHAFFHAUSEN (SUISSE)

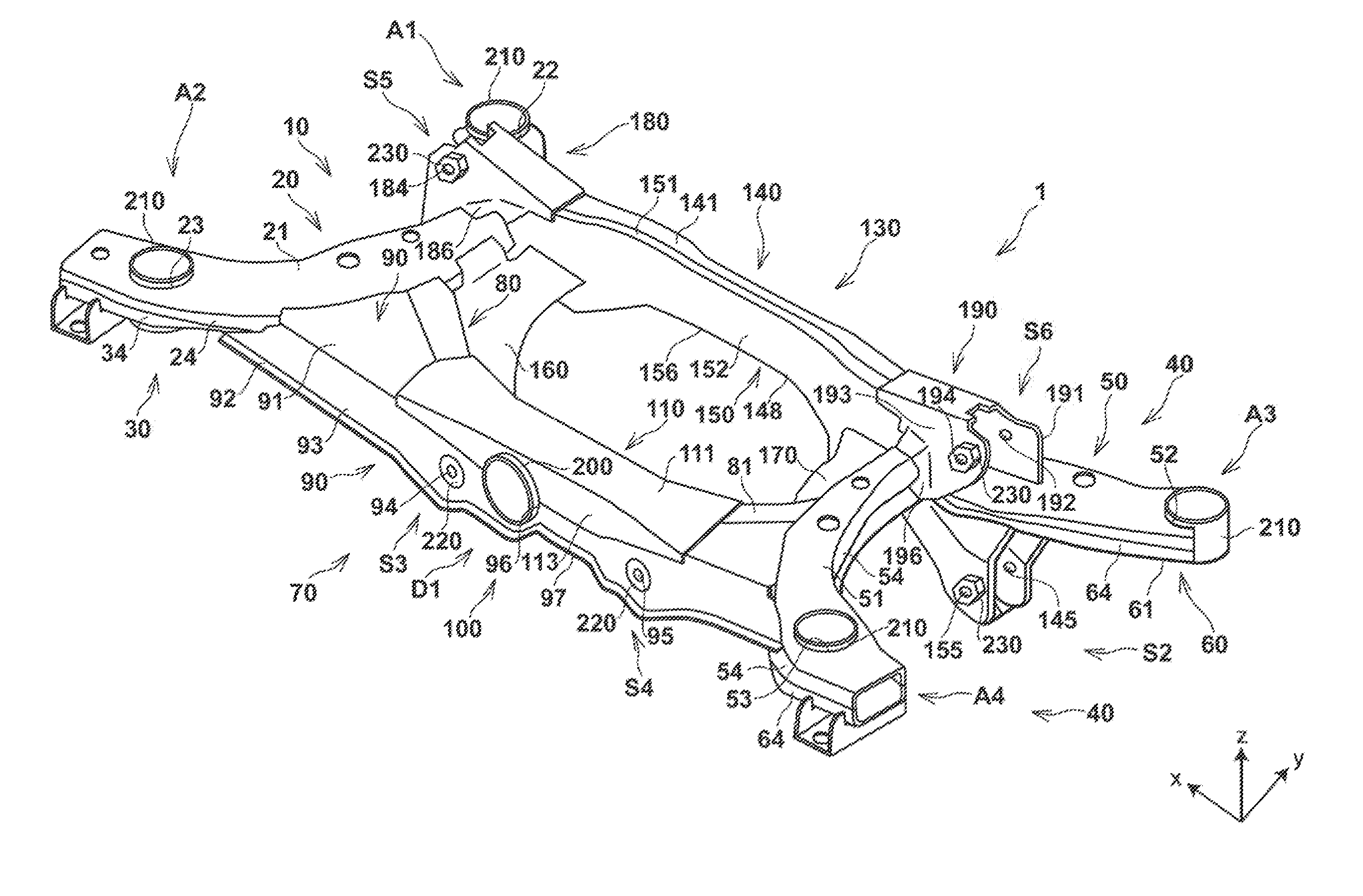

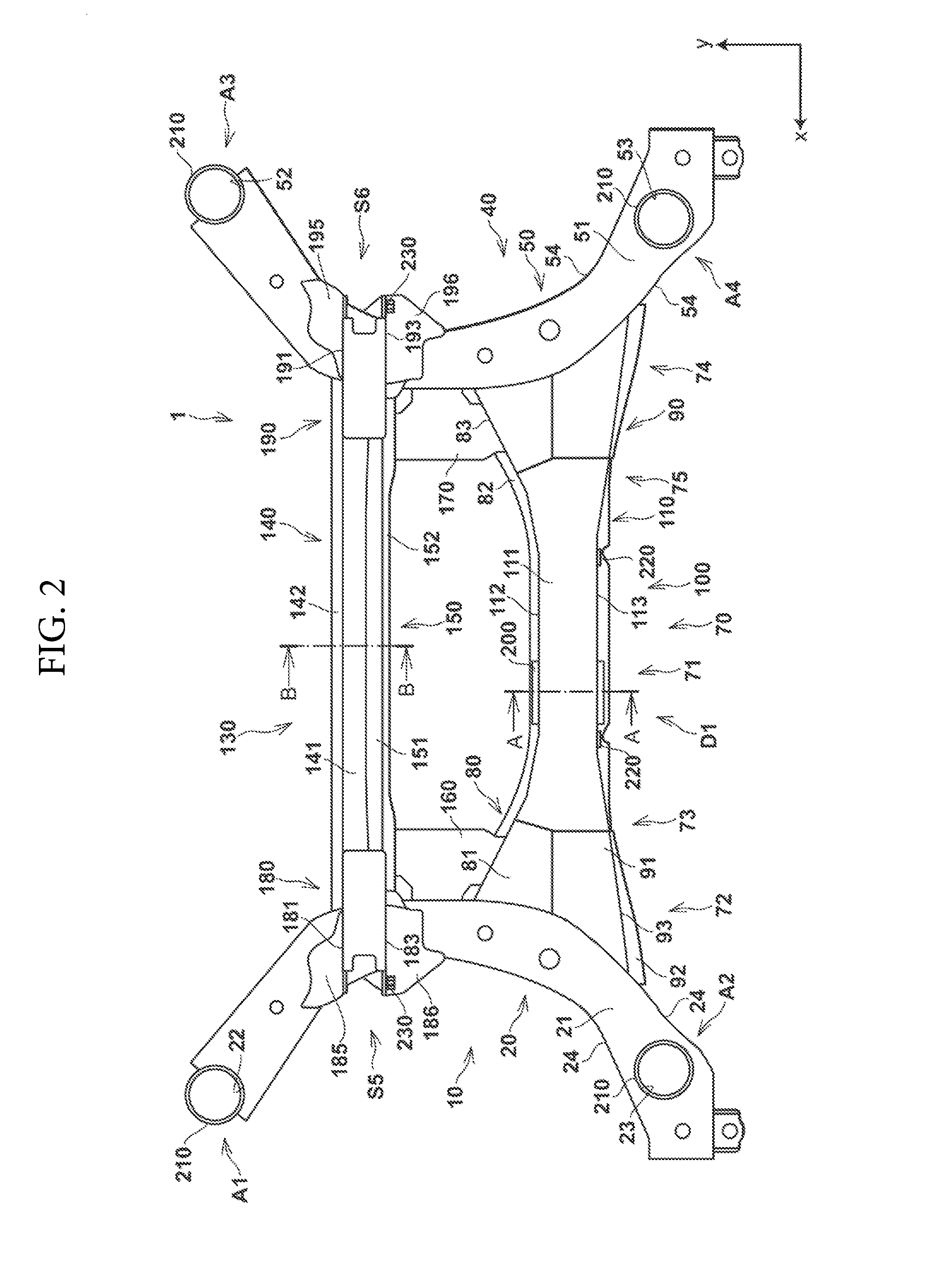

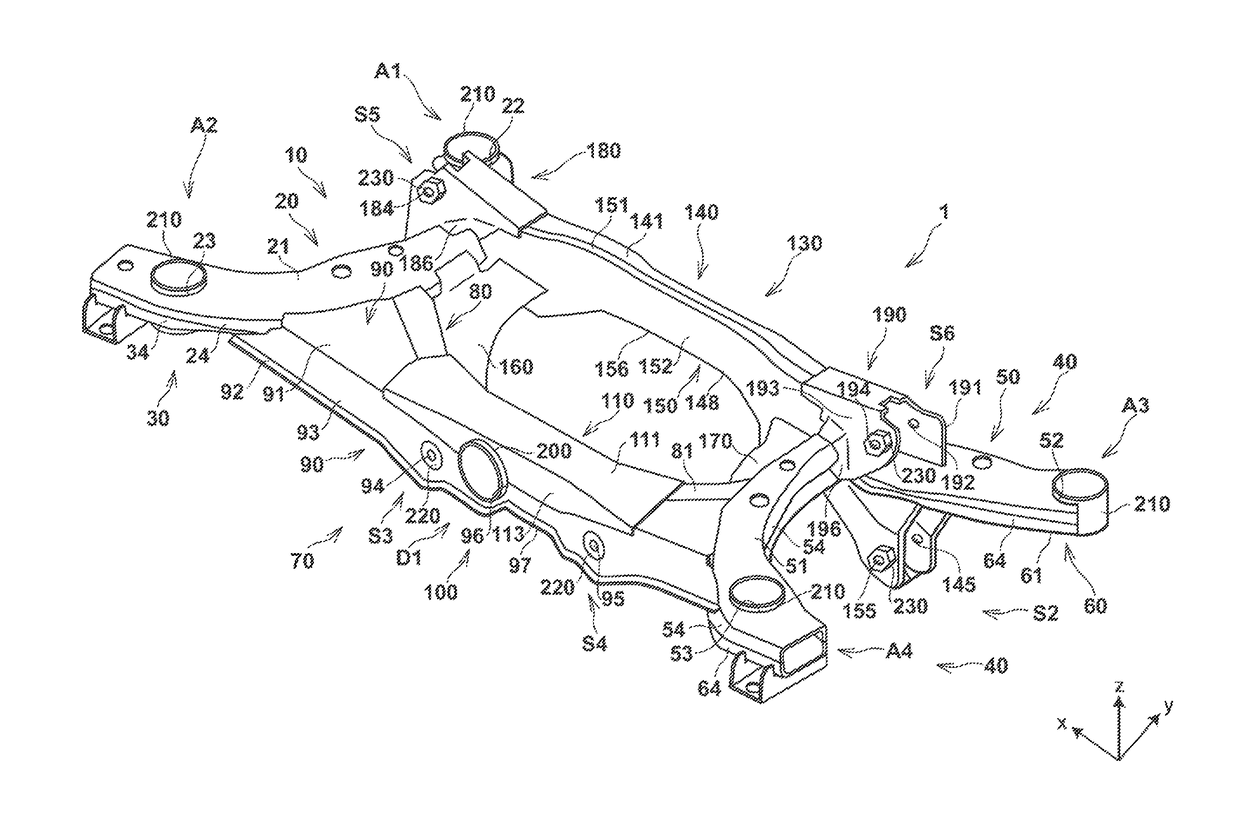

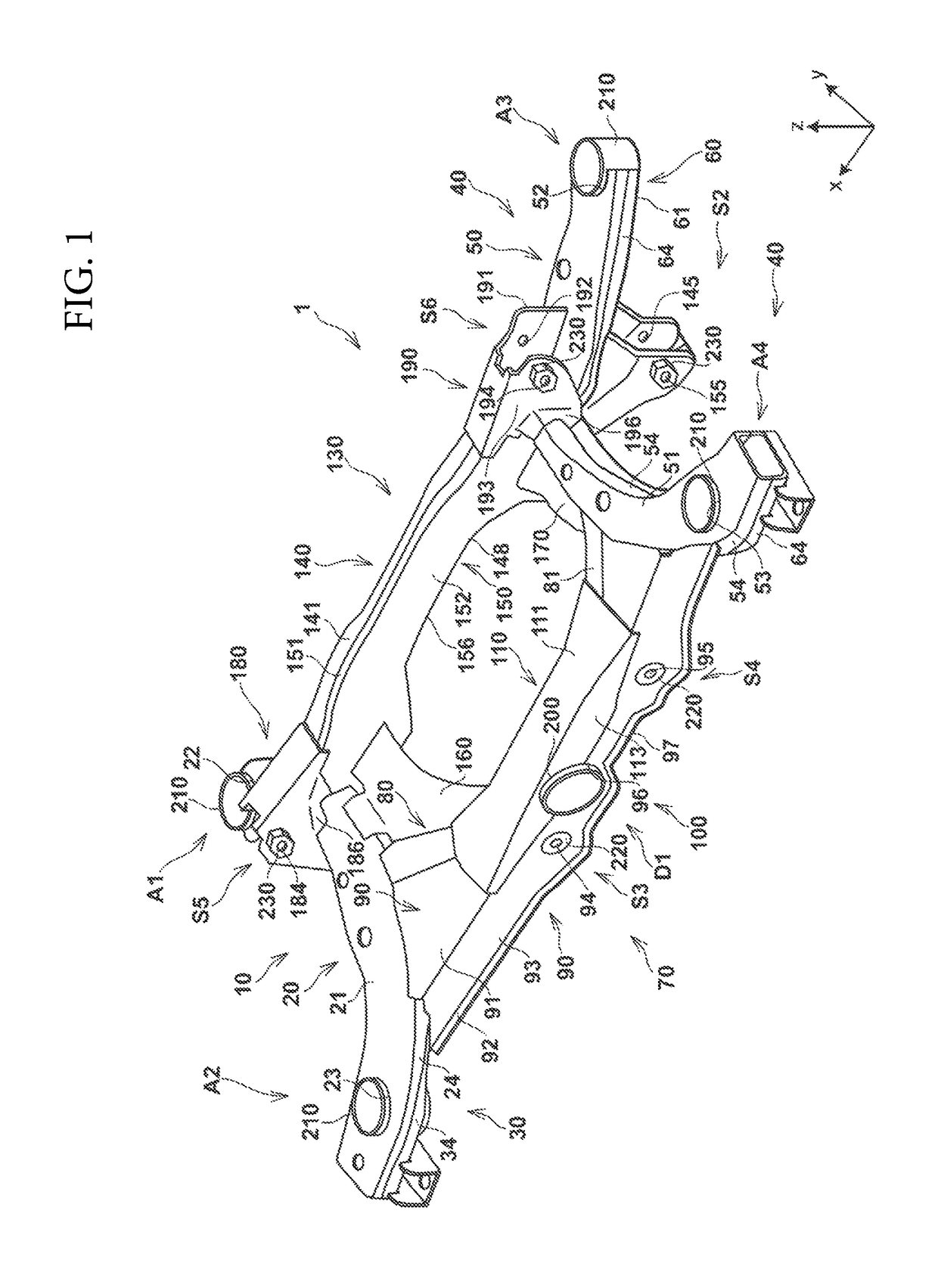

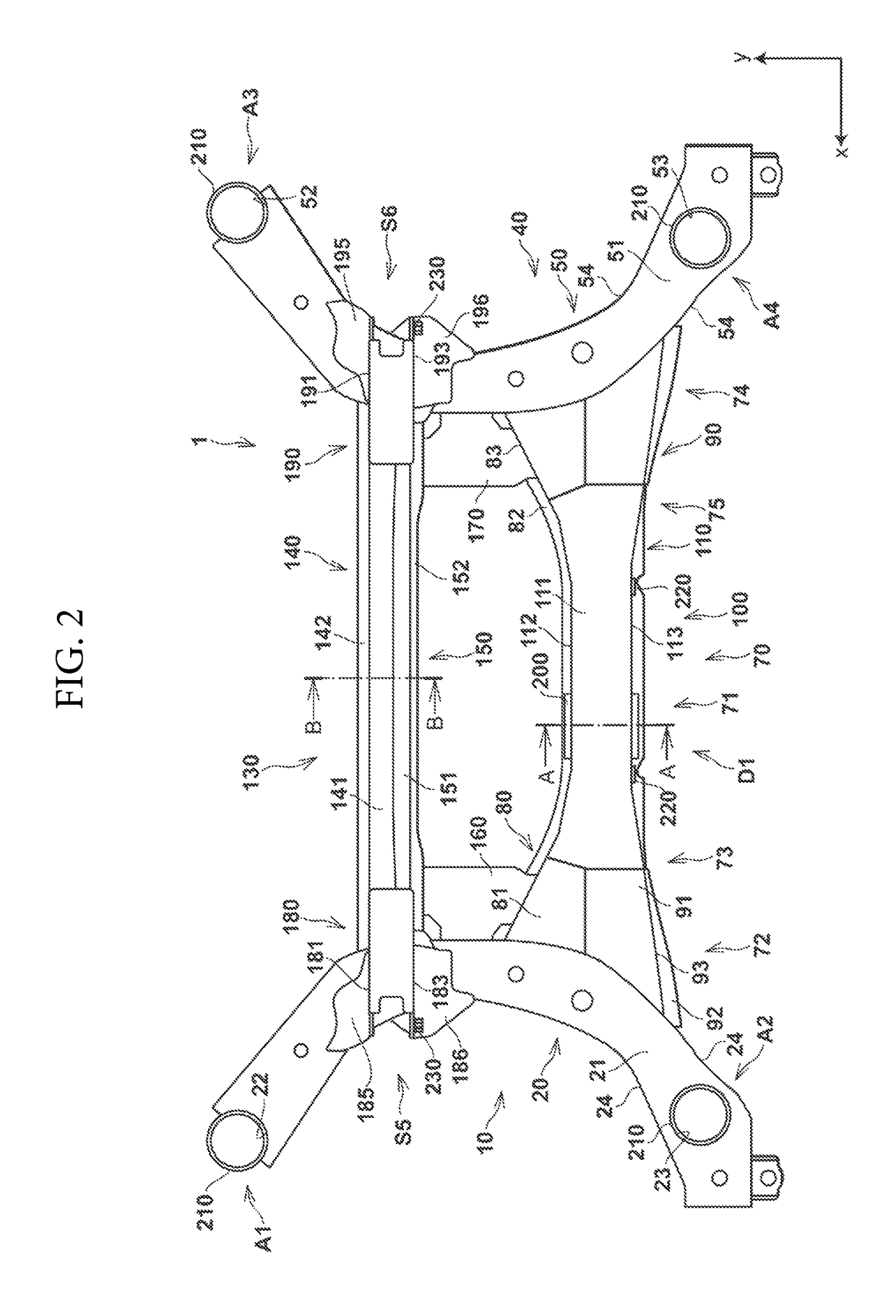

Vehicle subframe

ActiveUS20160347367A1Improve layout flexibilitySimple configurationUnderstructuresInterior spaceVehicle frame

In a vehicle subframe, one of a pair of cross members includes a lower member open to a lower side of a vehicle, with an upper wall thereof having an upper wall recess depressed downward, an upper member arranged so as to cover the upper wall recess from above the vehicle and connected to the lower member, an inside space defined by the lower member and the upper member in cooperation, and a holding member connected to the lower member and the upper member in a mode in which the holding member is sandwiched between the lower member and the upper member, while penetrating the inside space in a longitudinal direction, to hold a component to be mounted.

Owner:F TECH INC

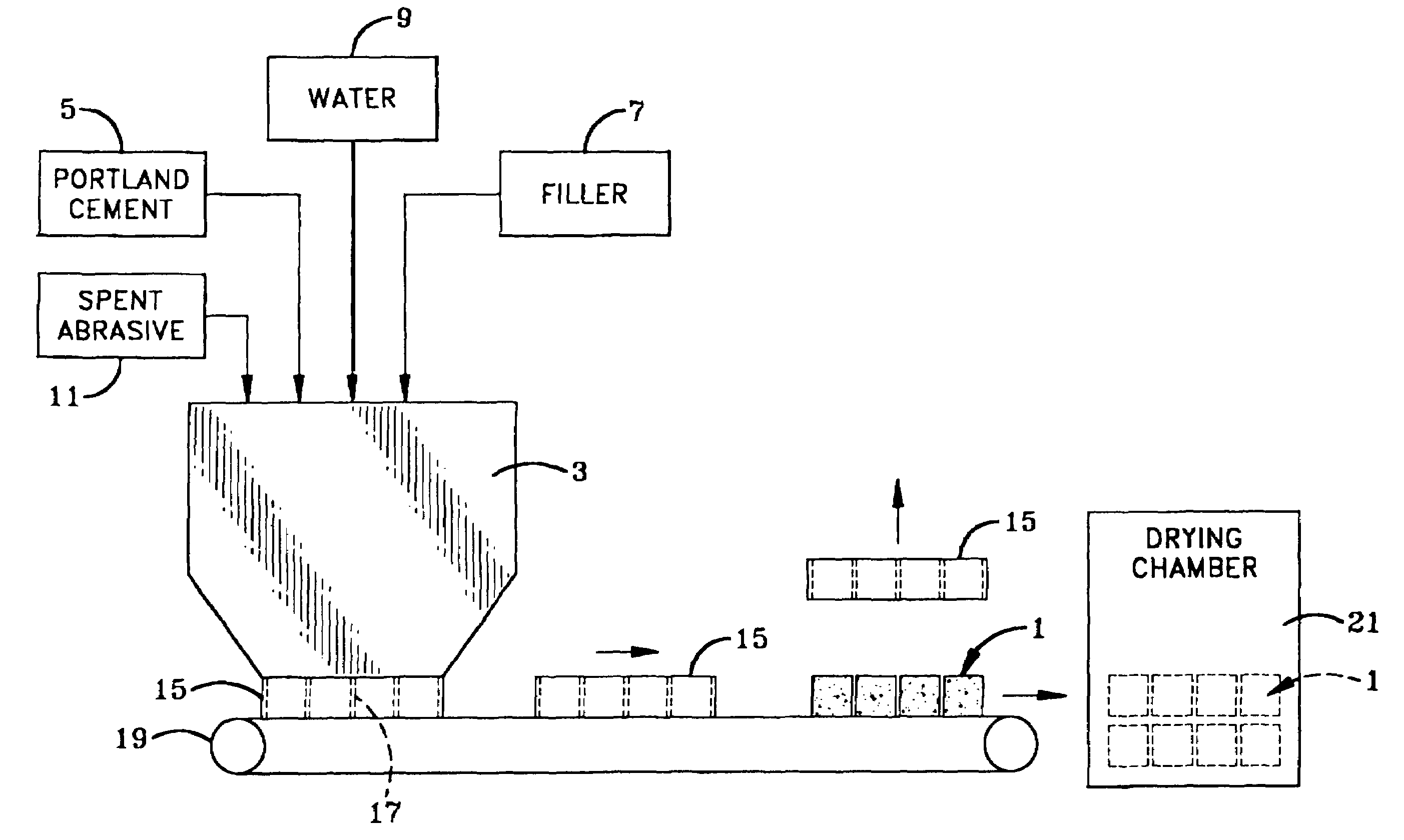

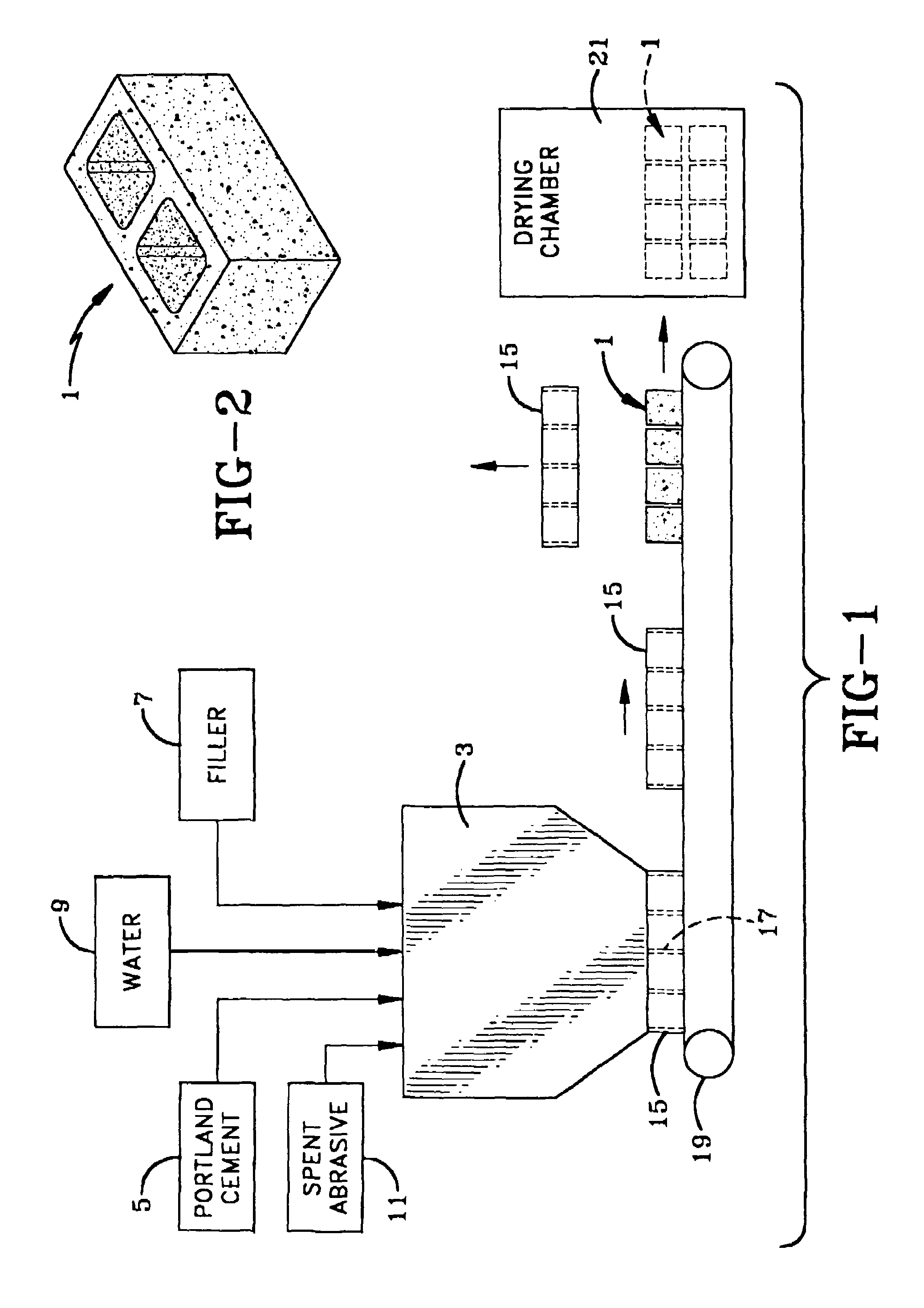

Concrete block and method of making same

ActiveUS7438757B2Improve waterproof performanceRequired strengthConstruction materialOther chemical processesPortland cementWater content

A concrete building block containing Portland cement, a filler, water, and a quantity of particularly sized plastic particles, such as spent abrasive particles of a thermoset plastic. The associated method of producing such blocks eliminates the need of curing the blocks in a heated humidity controlled environment in order for the blocks to attain the required water content for hydration of the cement.

Owner:U S TECH MEDIA INC

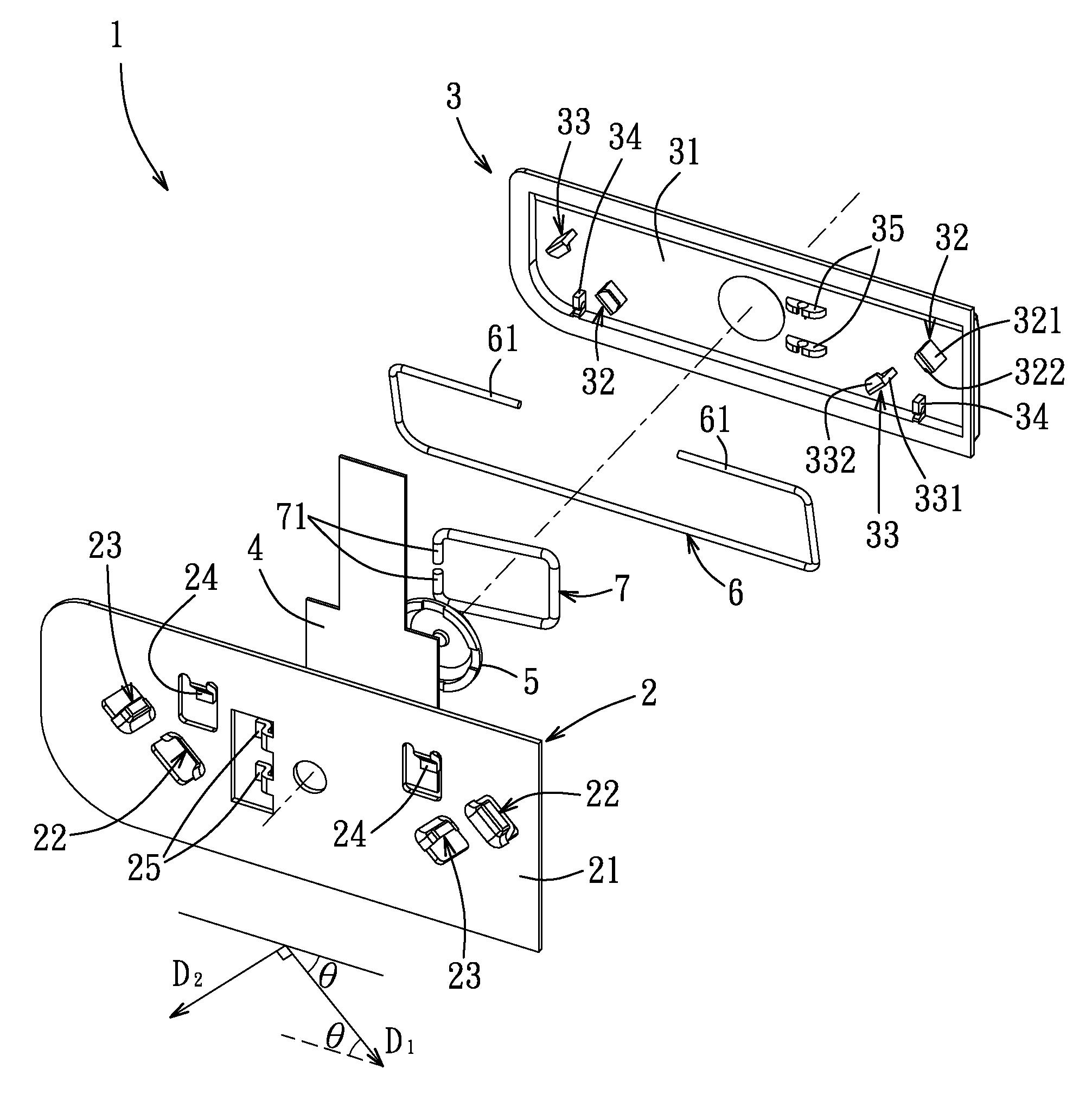

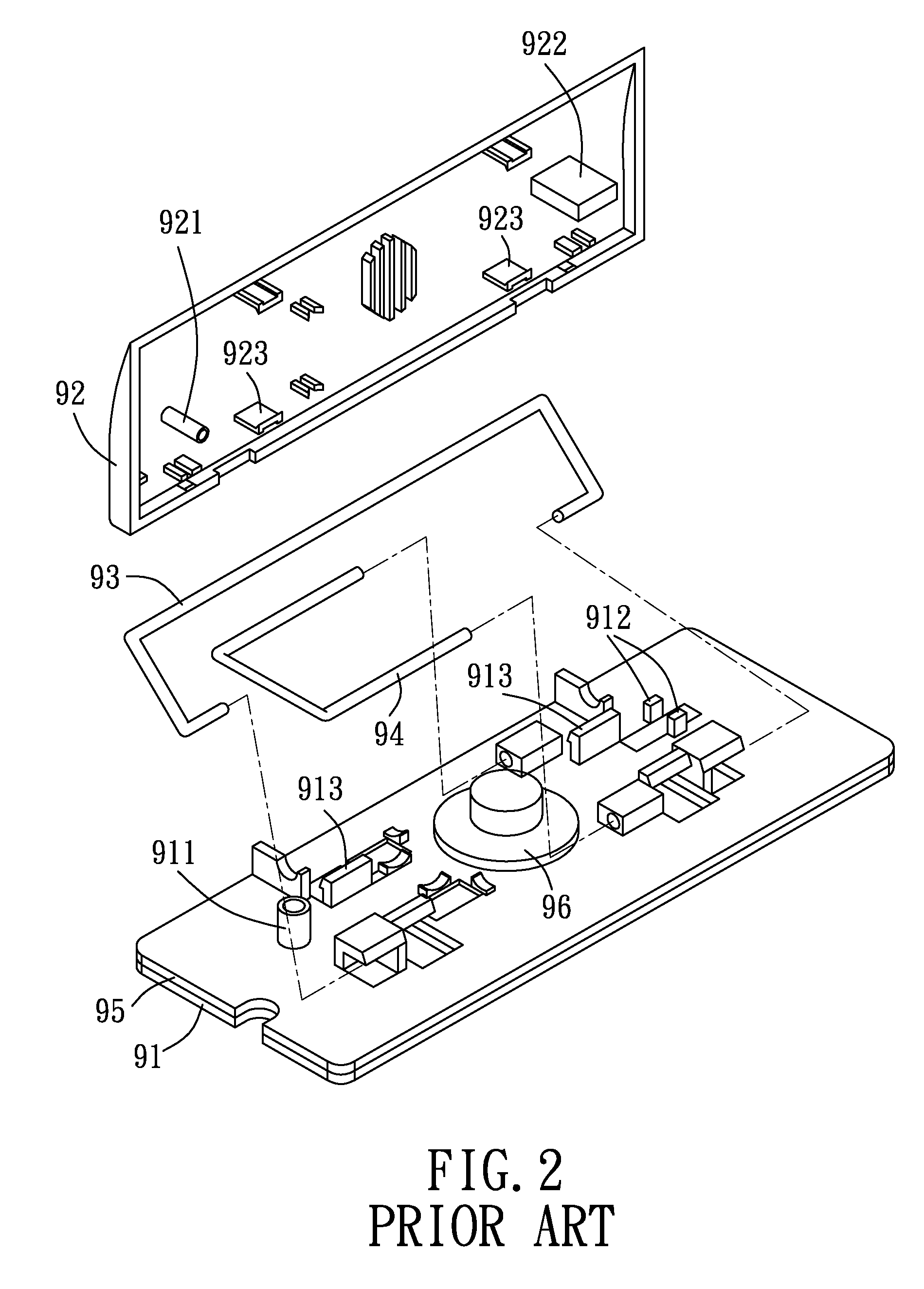

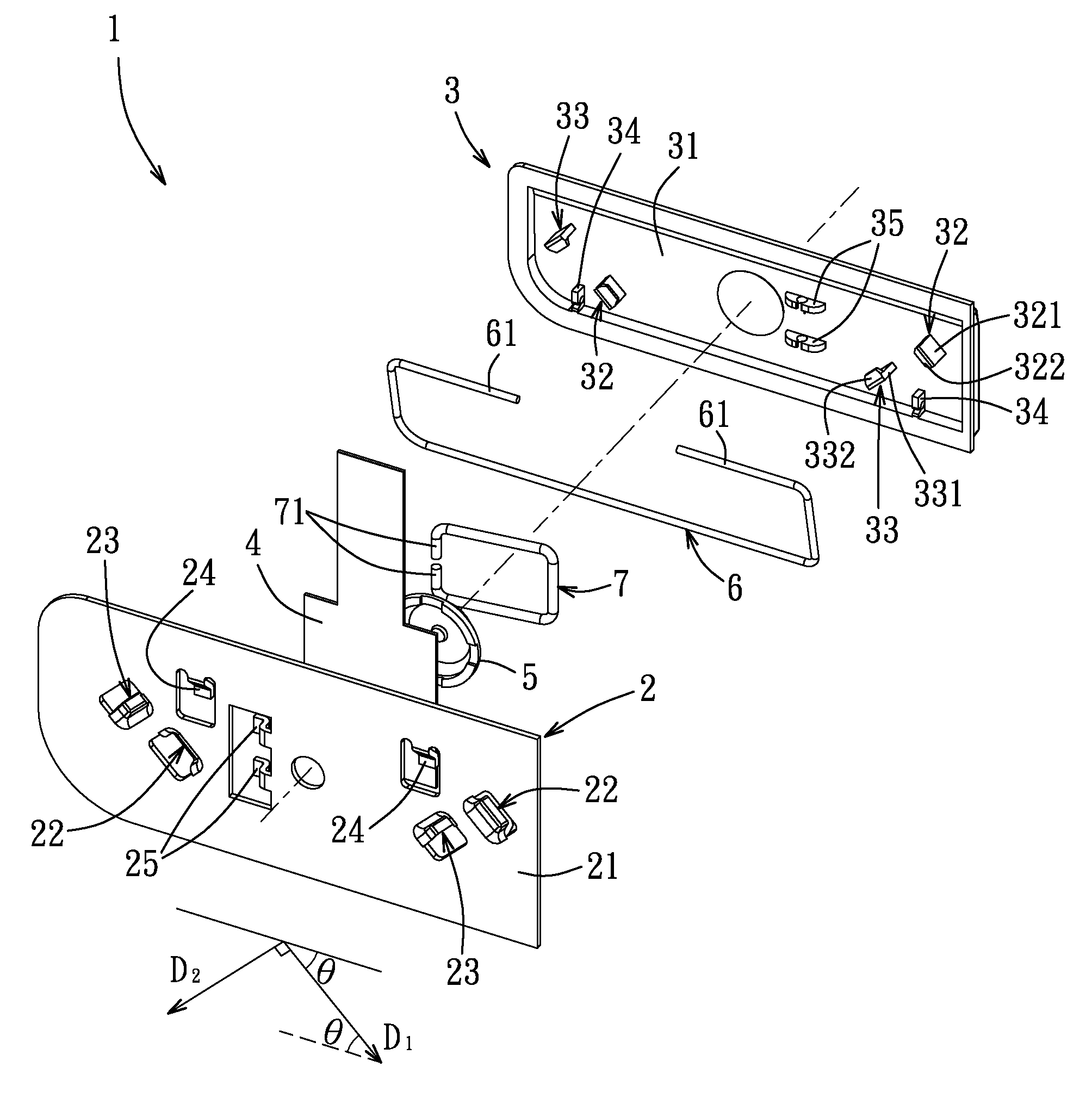

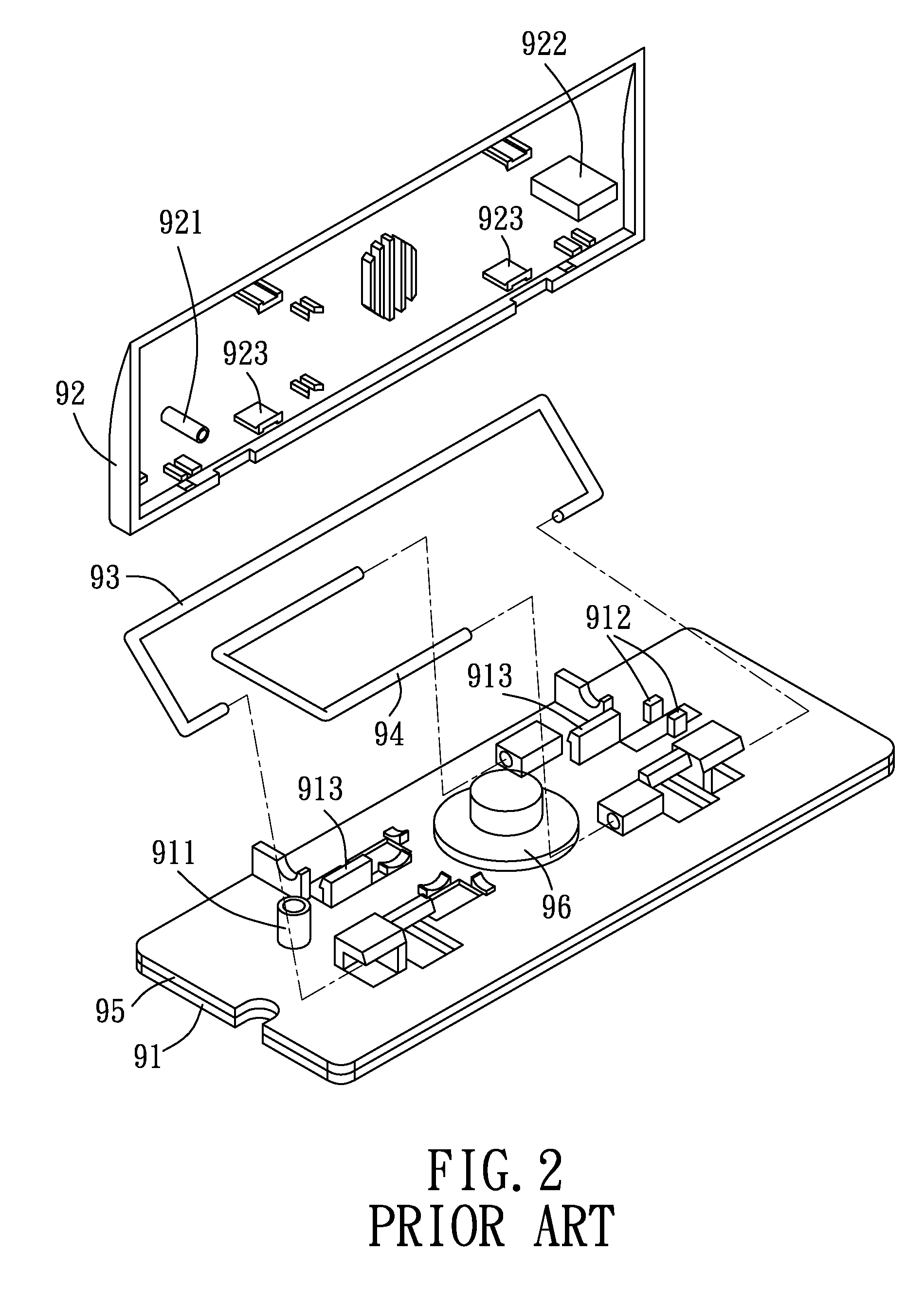

Keyswitch device, supporting seat and key cap thereof

ActiveUS8653389B2Simple structureReduce manufacturing costContact operating partsOther printing apparatusKey pressingEngineering

Owner:WISTRON CORP

Pivot bearing with turned damper clamping

ActiveUS8708356B2Required strengthMuch materialSteering linkagesResilient suspensionsMobile vehicleSnubber

Pivot bearing for a wheel suspension, in particular for a front axle of a motor vehicle, containing a wheel bearing receiver, a steering arm, a spring strut receiver with a damper clamping and a carrier rib, wherein the damper clamping of the spring strut receiver faces the vehicle outside and the pivot bearing has an opening in the region between the wheel bearing receiver and the damper clamping.

Owner:GEORG FISCHER AG A SCHAFFHAUSEN (SUISSE)

Keyswitch device and assembly of supporting seat and key cap thereof

A keyswitch device includes a supporting seat, a key cap, a circuit board disposed on the supporting seat, and an elastic member located between the key cap and the circuit board. The supporting seat includes a base board and two first confining members that are formed on the base board and that are spaced apart from each other. The key cap includes a cap body and two first hooks that engage respectively the first confining members, thereby inhibiting the key cap to move in horizontal directions with respect to the supporting seat, and allowing the key cap to move vertically in a range equal to the height of the first blocking parts of the first confining members. When the key cap is moved downward, the elastic member deforms to press the circuit board so as to generate a corresponding signal.

Owner:WISTRON CORP

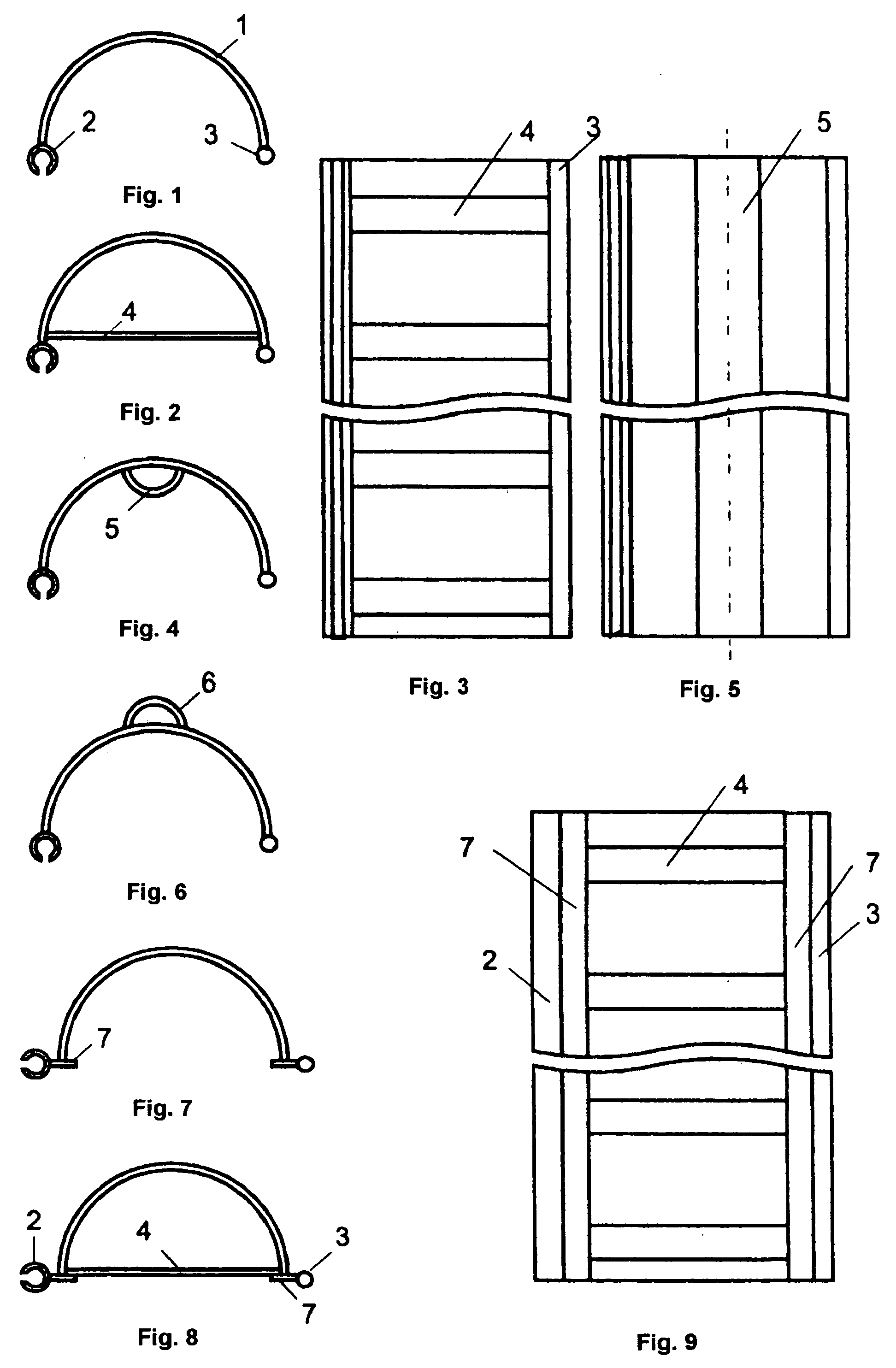

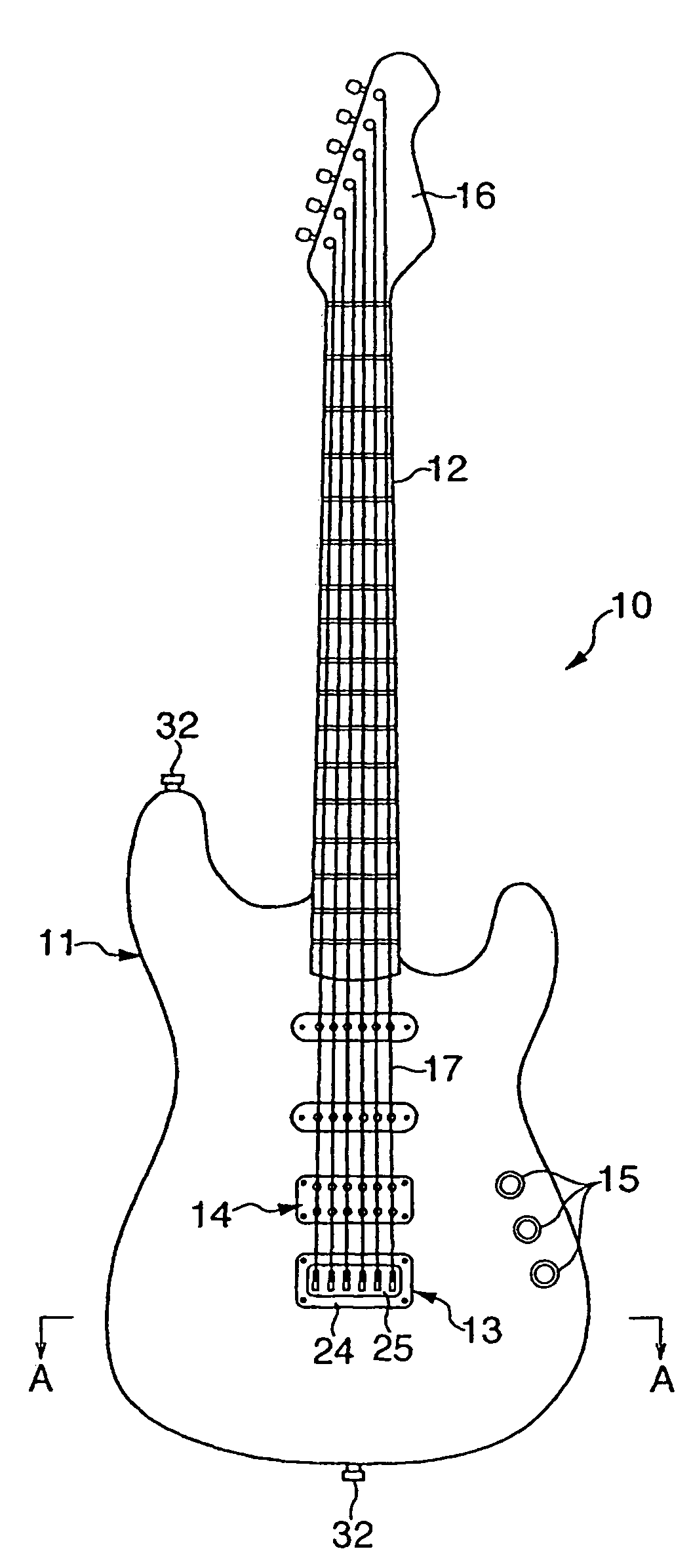

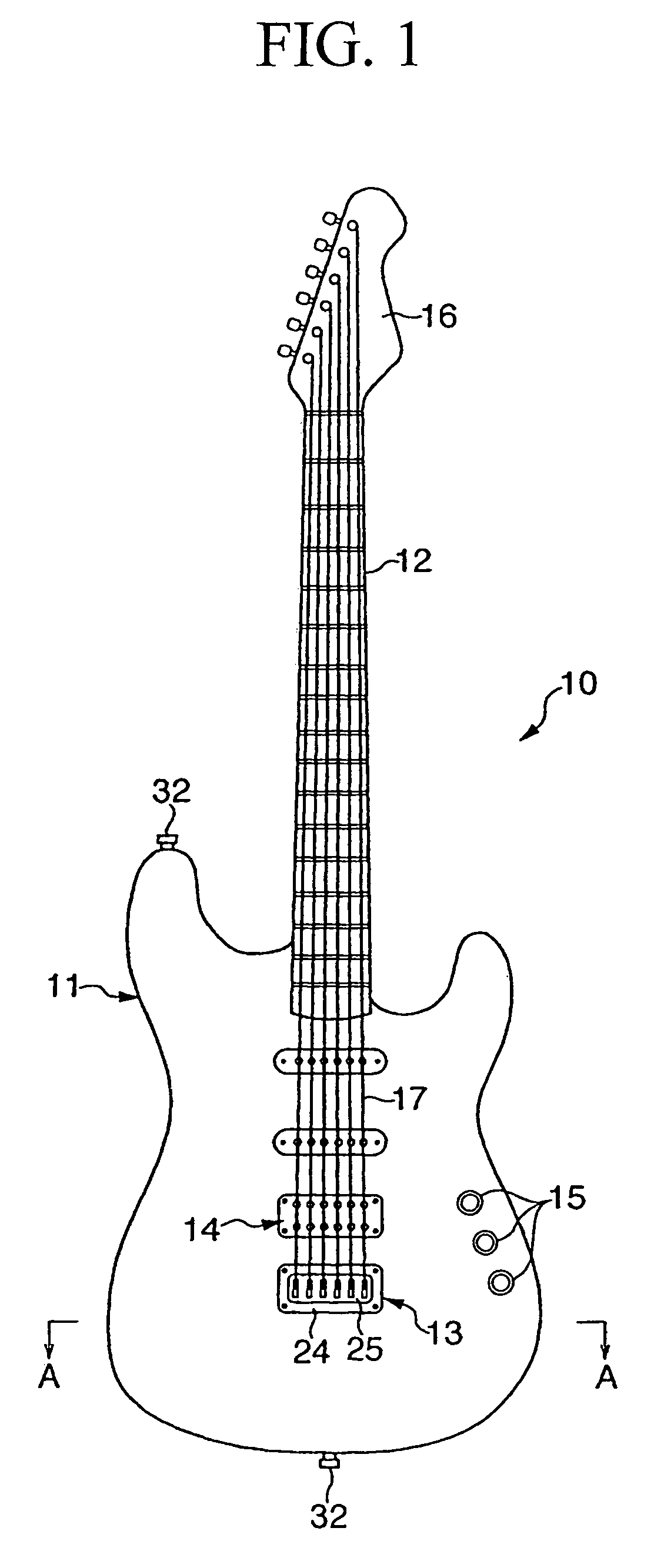

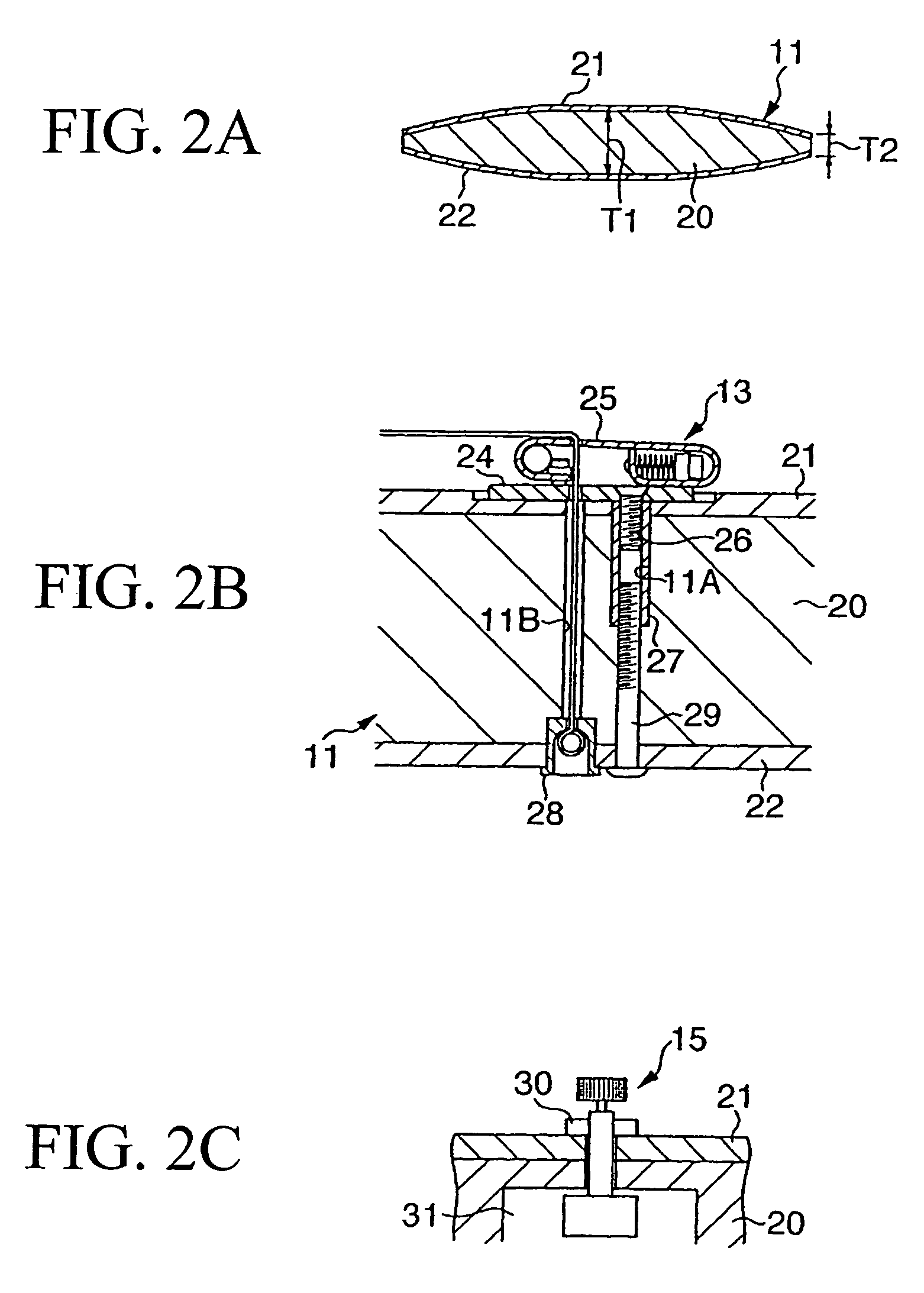

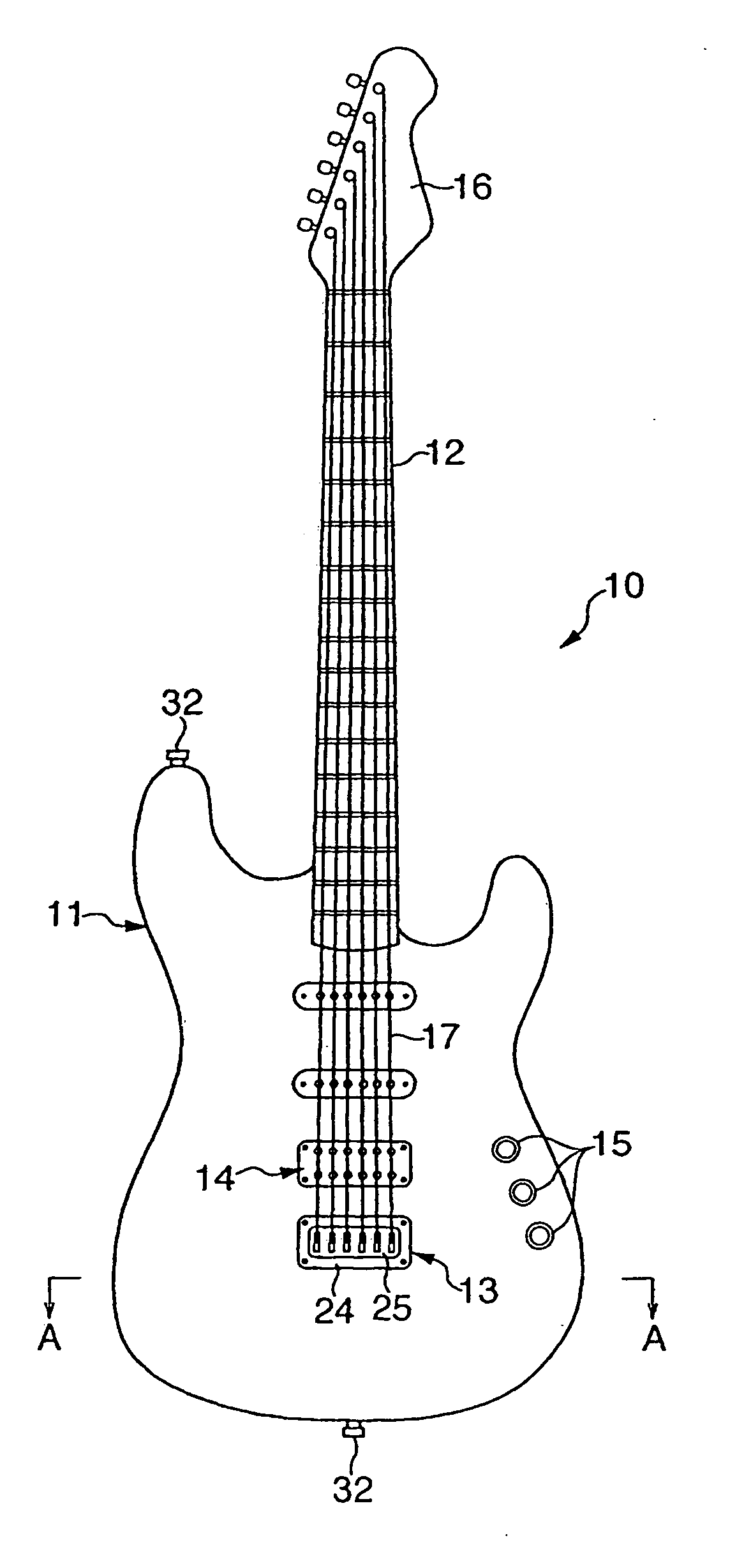

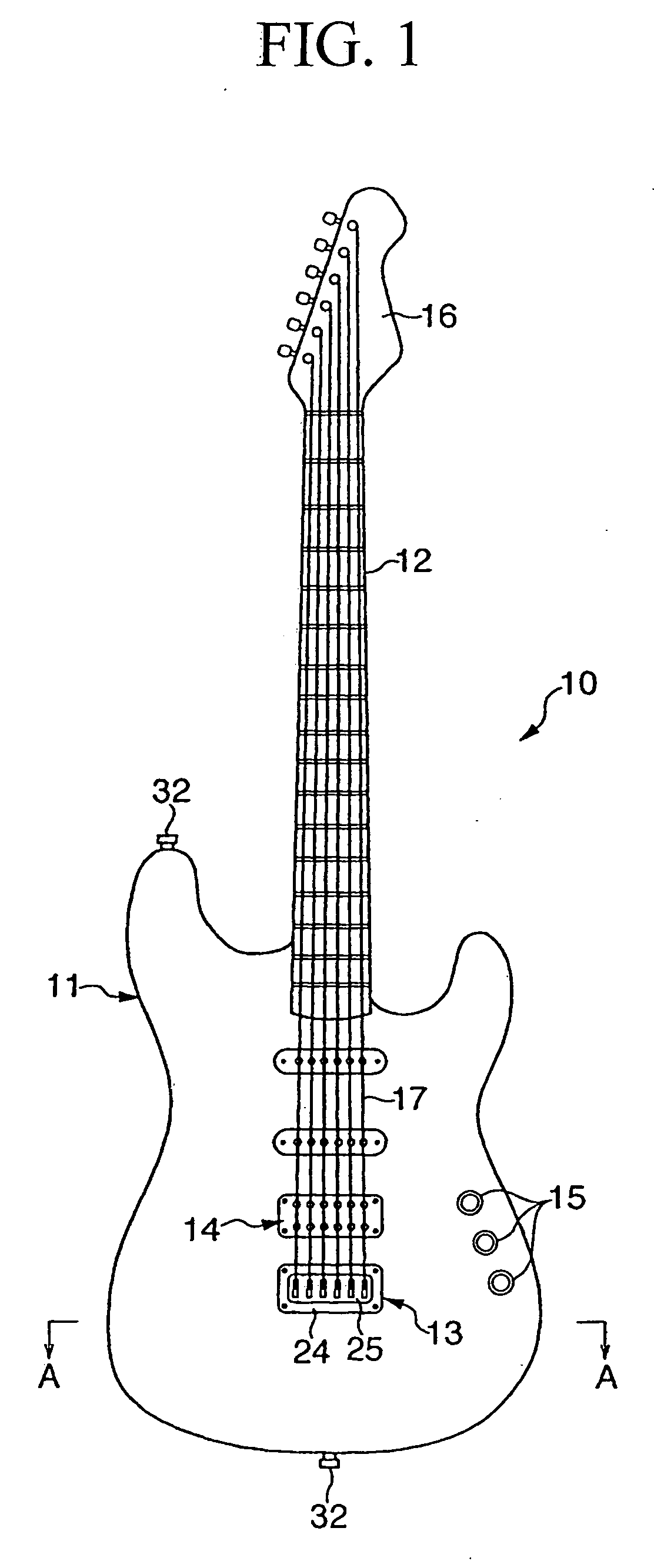

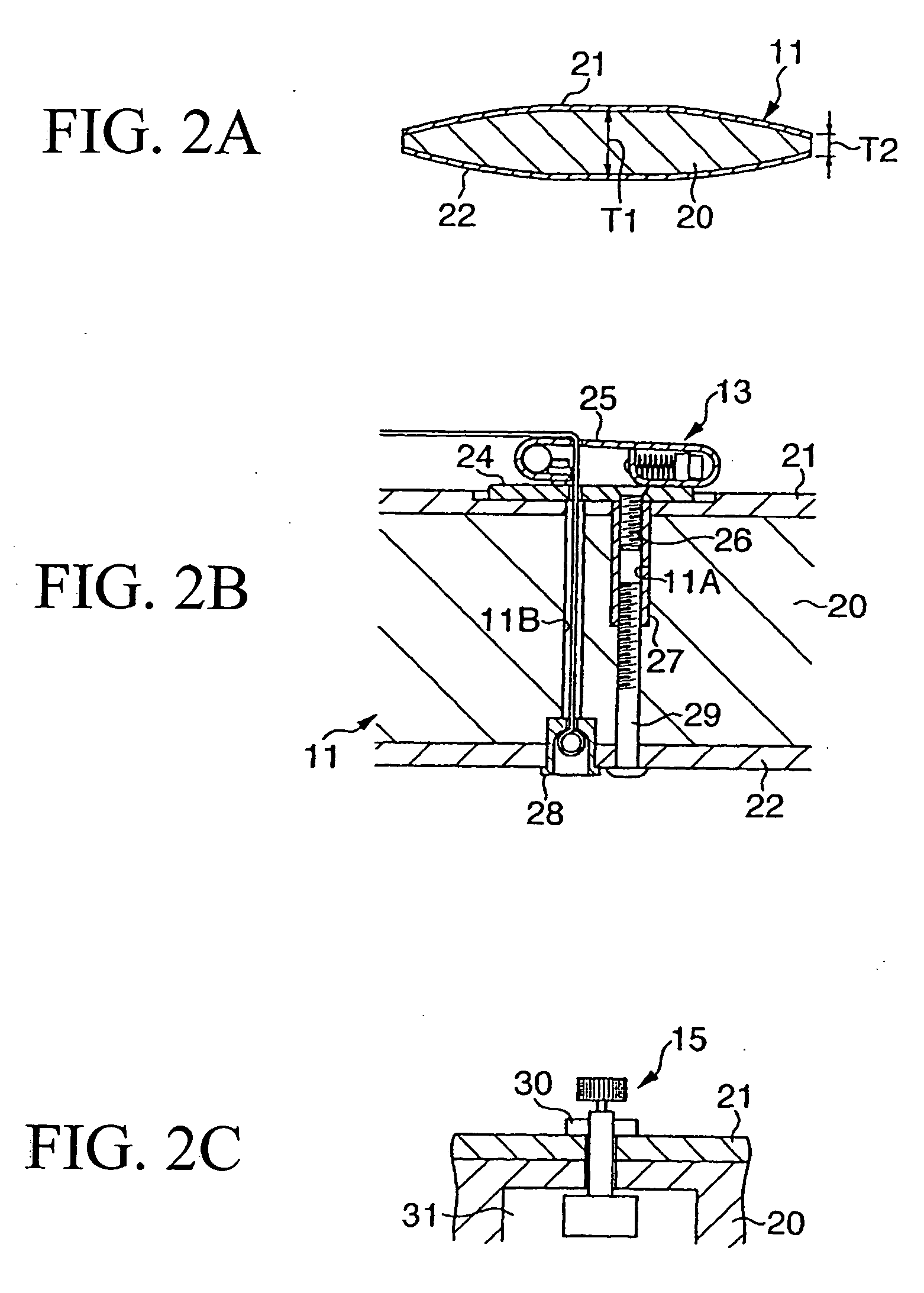

Body structure of stringed instrument

A body structure of a stringed instrument is designed to reduce weight and to improve sound quality with respect to a solid body, which is constituted by a core material and a pair of decorative boards, wherein the core material is composed of a single material having a relatively low specific gravity (e.g., 0.4 or less) such as falcata, bass wood, and balsa, while the decorative boards each have hardness greater than that of the core material. The core material has curved flatness (or curvature) in which both sides lying in the width thereof are reduced in thickness compared with the center portion thereof. The core material having a relatively low specific gravity is sandwiched between the hard decorative boards; hence, it is possible to reduce the overall weight while securing satisfactory strength.

Owner:YAMAHA CORP

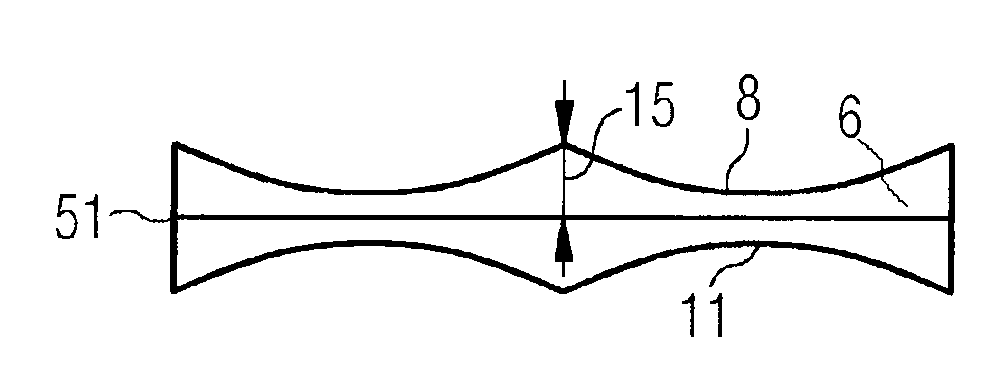

Method of manufacturing a beam

InactiveUS20150375282A1Required strengthKeep it flatSoldering apparatusLoad-supporting pillarsEngineeringFlange

A method of manufacturing a beam comprises rolling, in a longitudinally profiled rolling process, two flange pieces (6,7), such that one surface (8) of each rolled flange piece is profiled according to a predetermined thickness profile; and joining (12,13) the rolled flange pieces together via a web of the beam or by profiled surfaces of the flanges.

Owner:PRIMETALS TECH

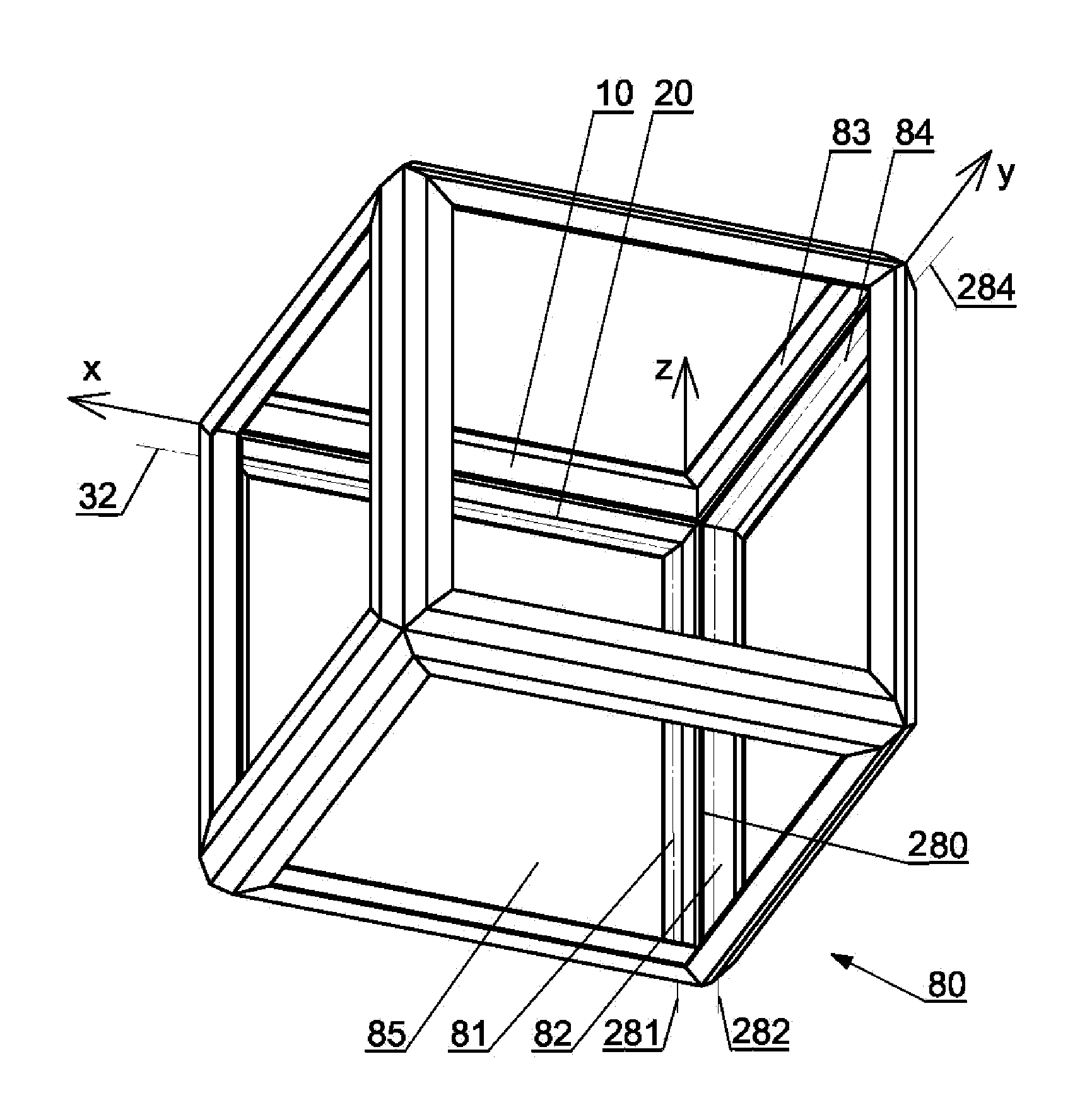

Structural profile system

InactiveUS8998526B2High-precision fitRequired stiffnessStructural elementsDomestic mirrorsEngineering

Owner:AIFO GRP ZAJAC ZIECIK STABRAWA SPOLKA JAWNA

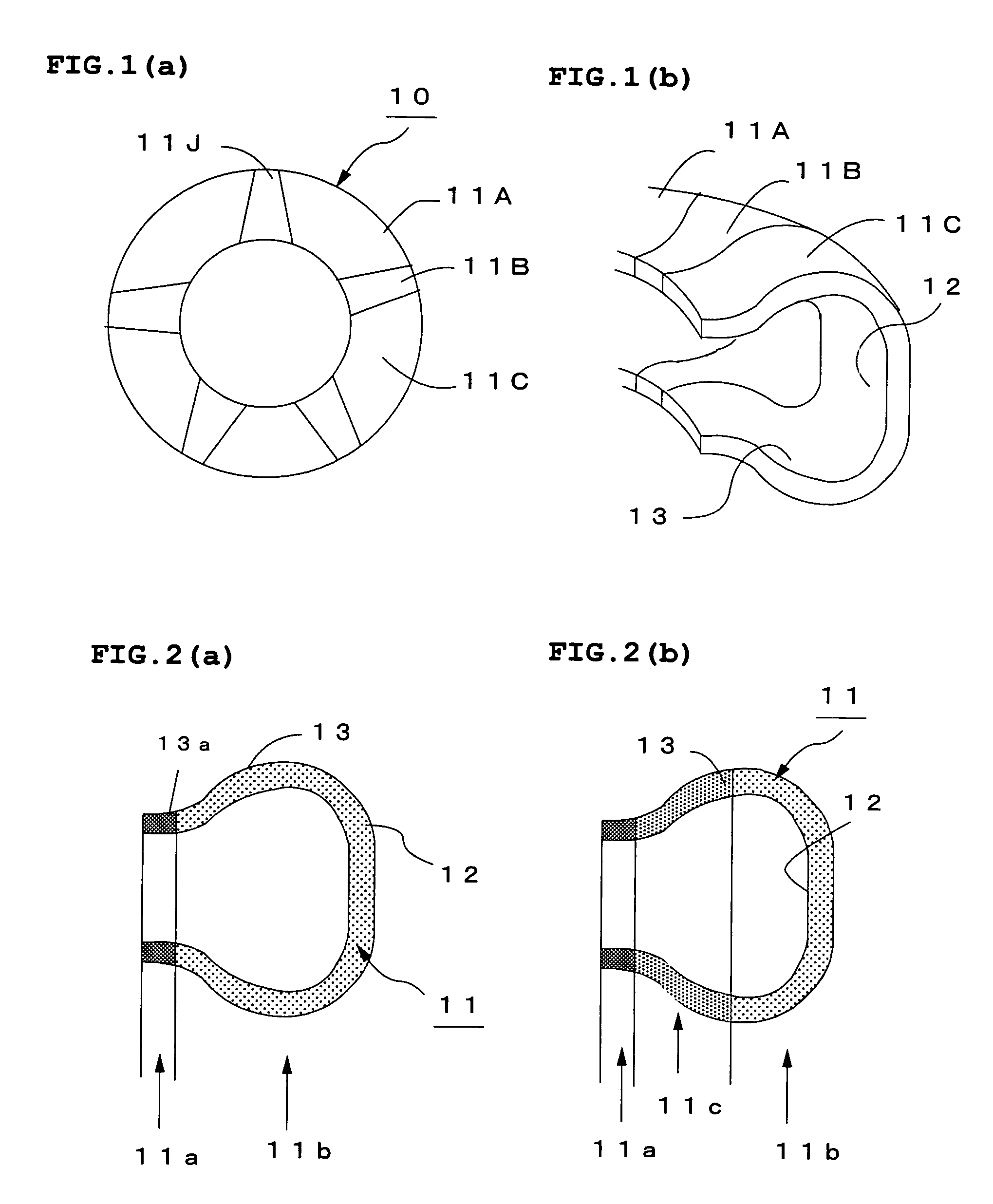

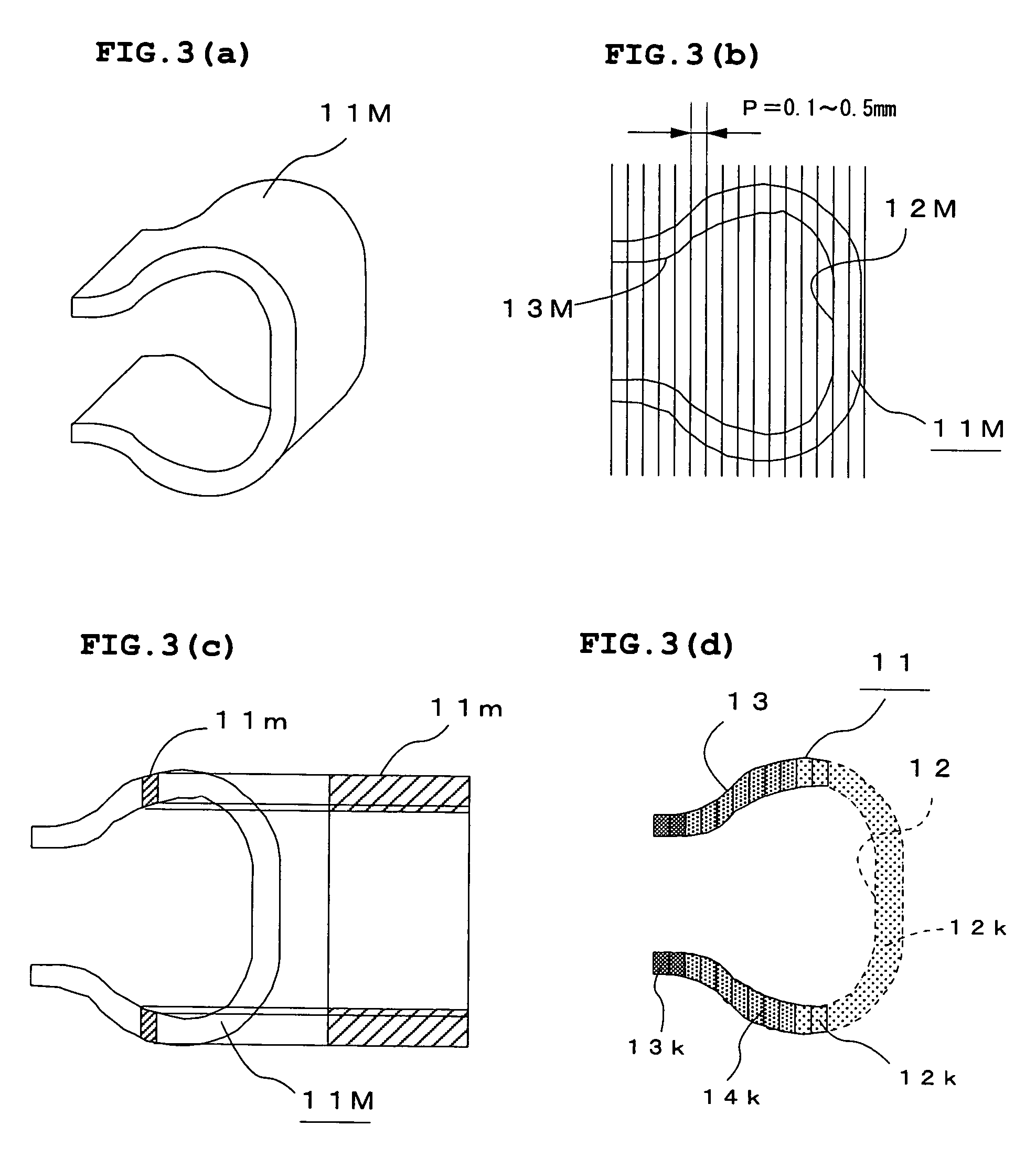

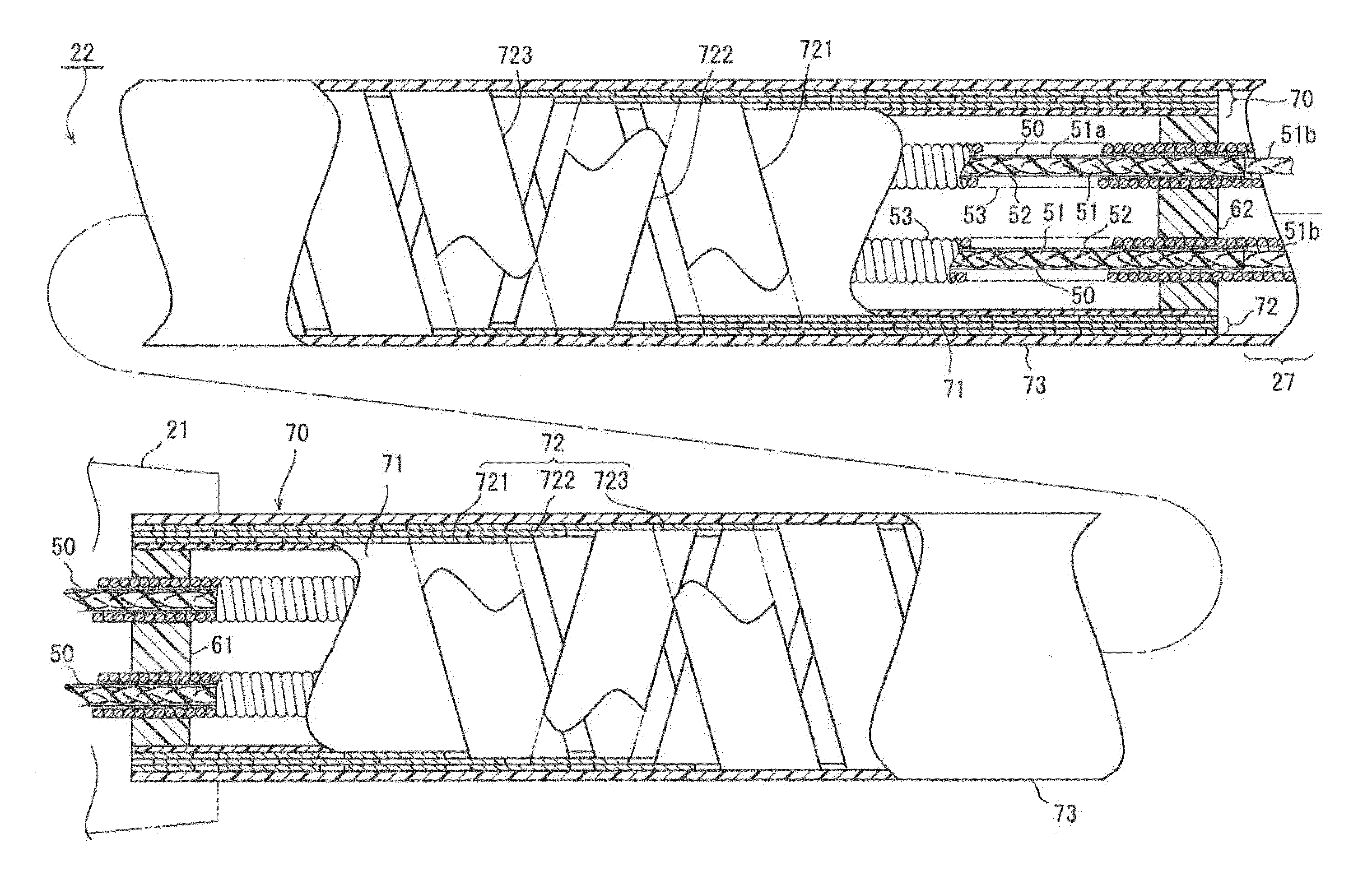

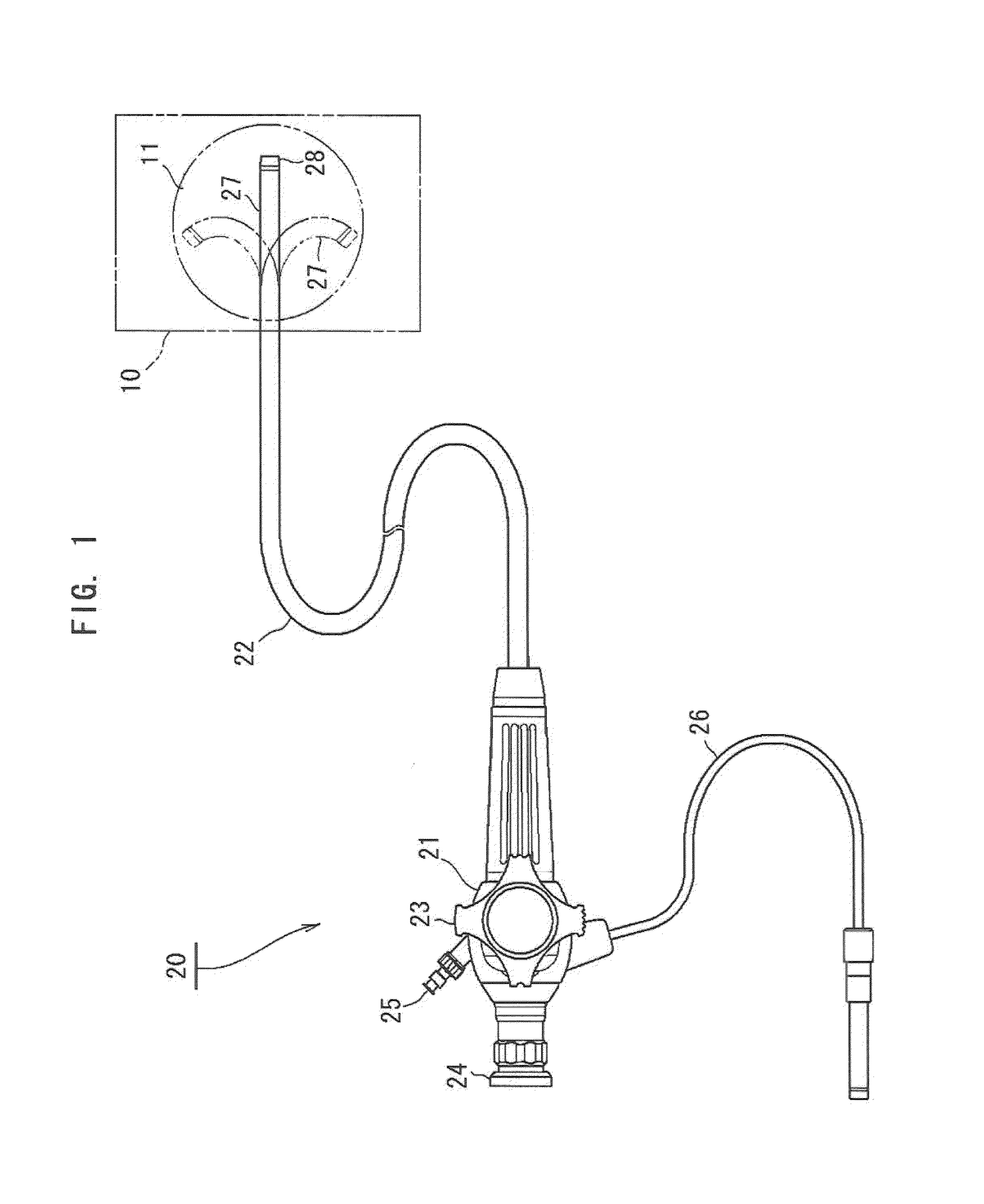

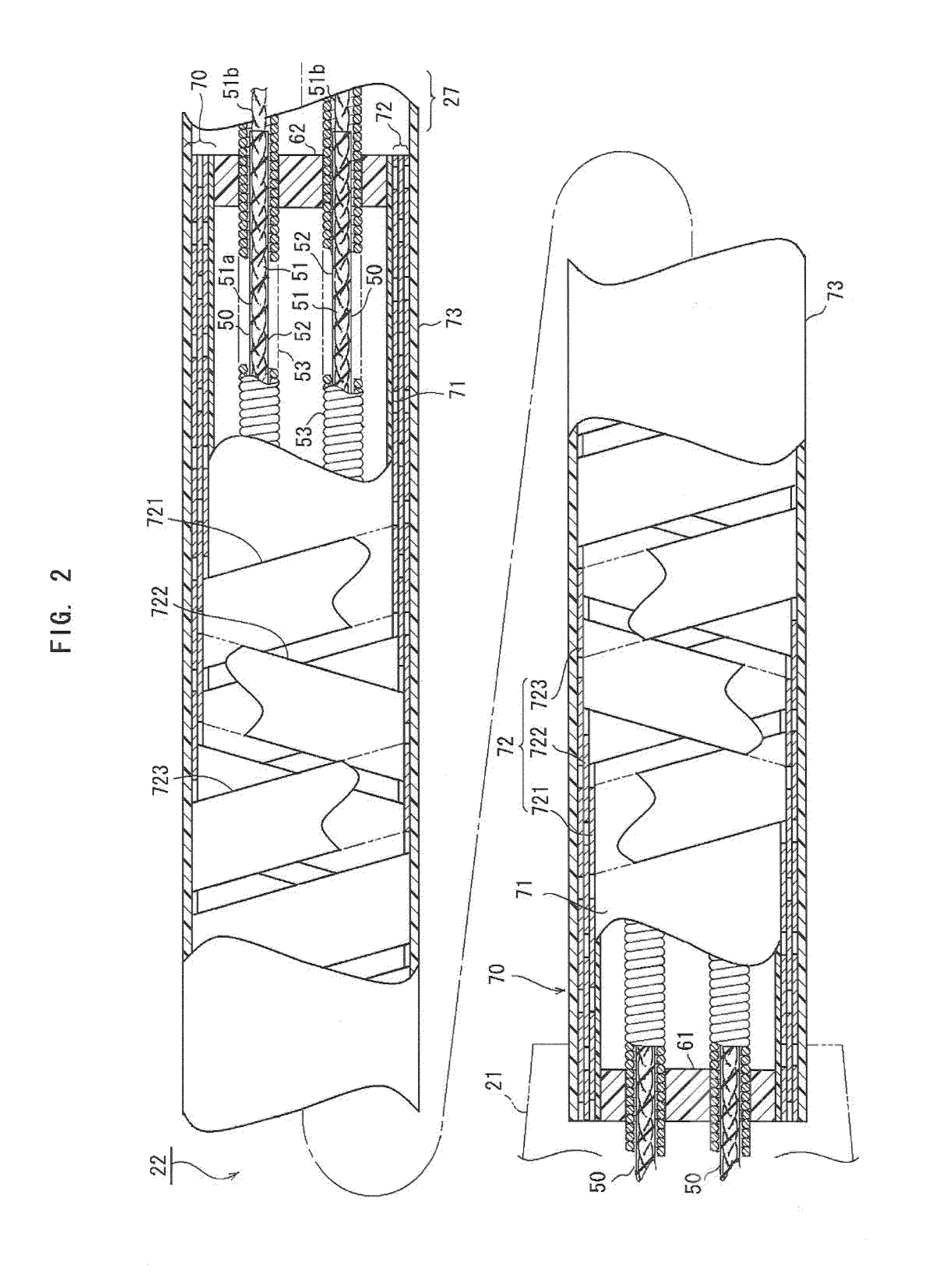

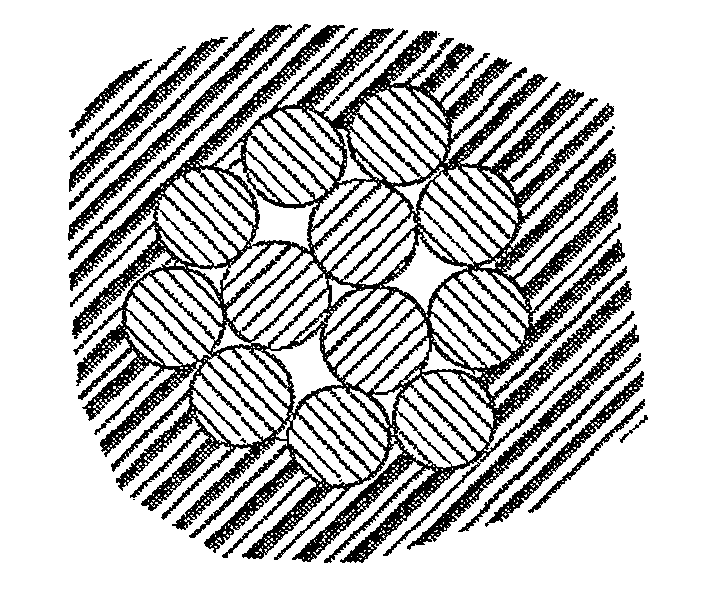

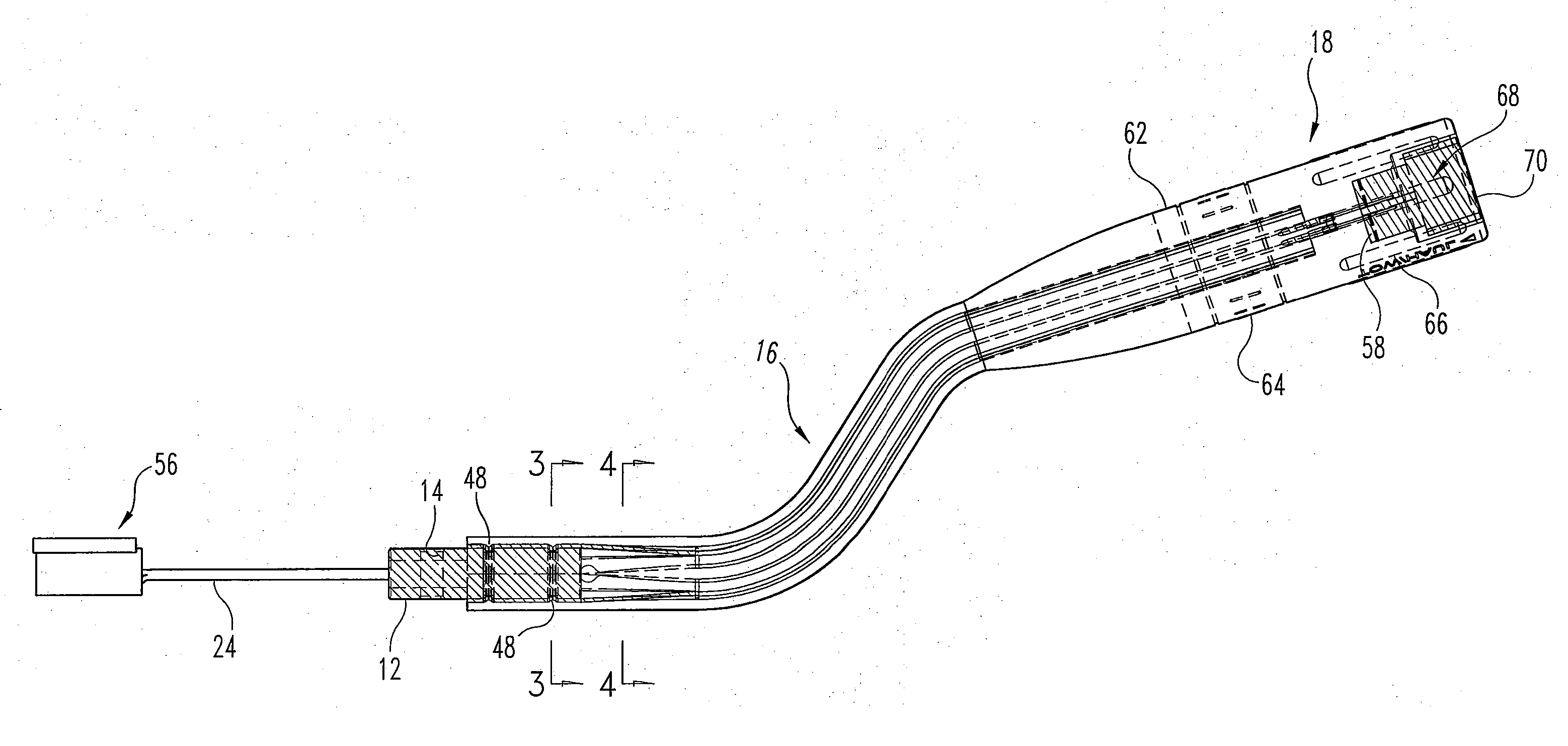

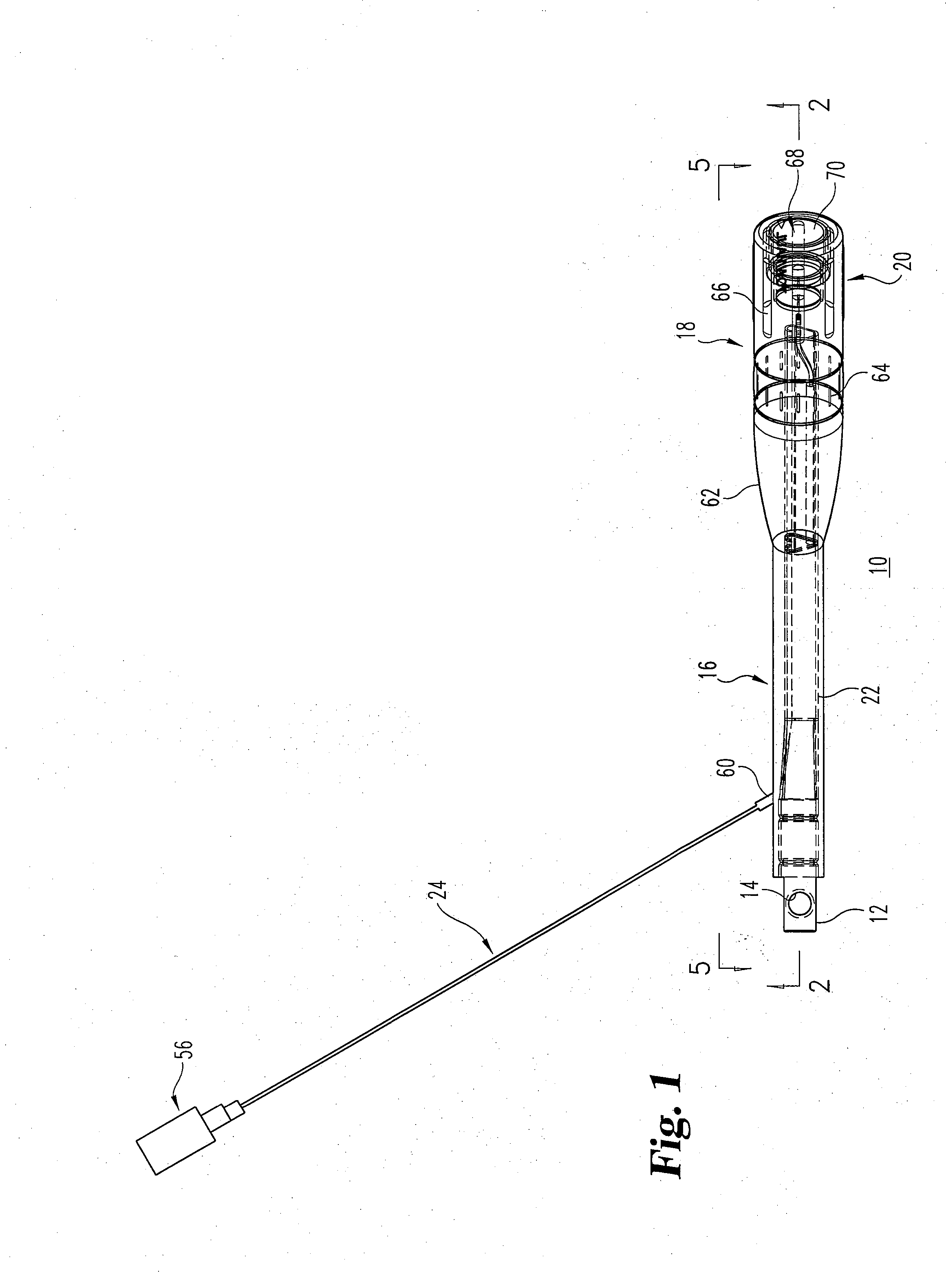

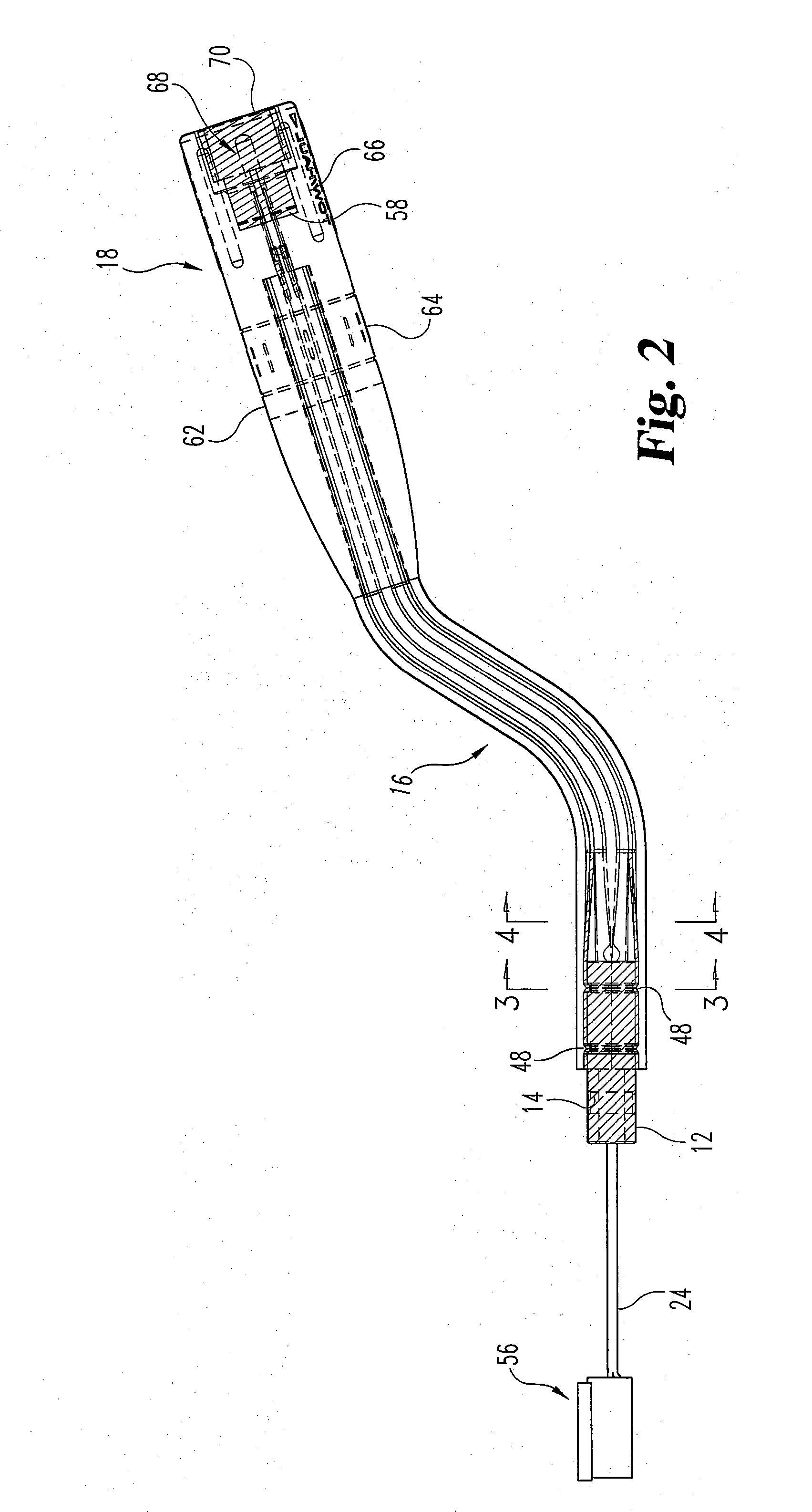

Flexible endoscope suitable for MRI

ActiveUS8696551B2Required strengthRequire flexibilitySurgeryEndoscopesMagnetic susceptibilityFlexible endoscopy

The flexible endoscope 20 has a flexible insertion portion 22 to be inserted in an observation zone 11 of a MRI apparatus 10. The insertion portion 22 has an inner tube 71 made of resin, triple helical tubes 72 covering the inner tube 71 and an outer tube 73 made of resin and covering the triple helical tubes 72. The triple helical tubes 72 include a first helical band 721 helically wound around an outer peripheral surface of the inner tube 71, a second helical band 722 helically wound around an outer periphery of the first helical band 721 in a direction opposite to a winding direction of the first helical band 721 and a third helical band 723 helically wound around an outer periphery of the second helical band 722 in a direction opposite to the winding direction of the second helical band 722. The first to third helical bands 721, 722, 723 are made of phosphor bronze or copper-silver alloy, which are materials having low magnetic susceptibility.

Owner:MICRON SHIGA INC

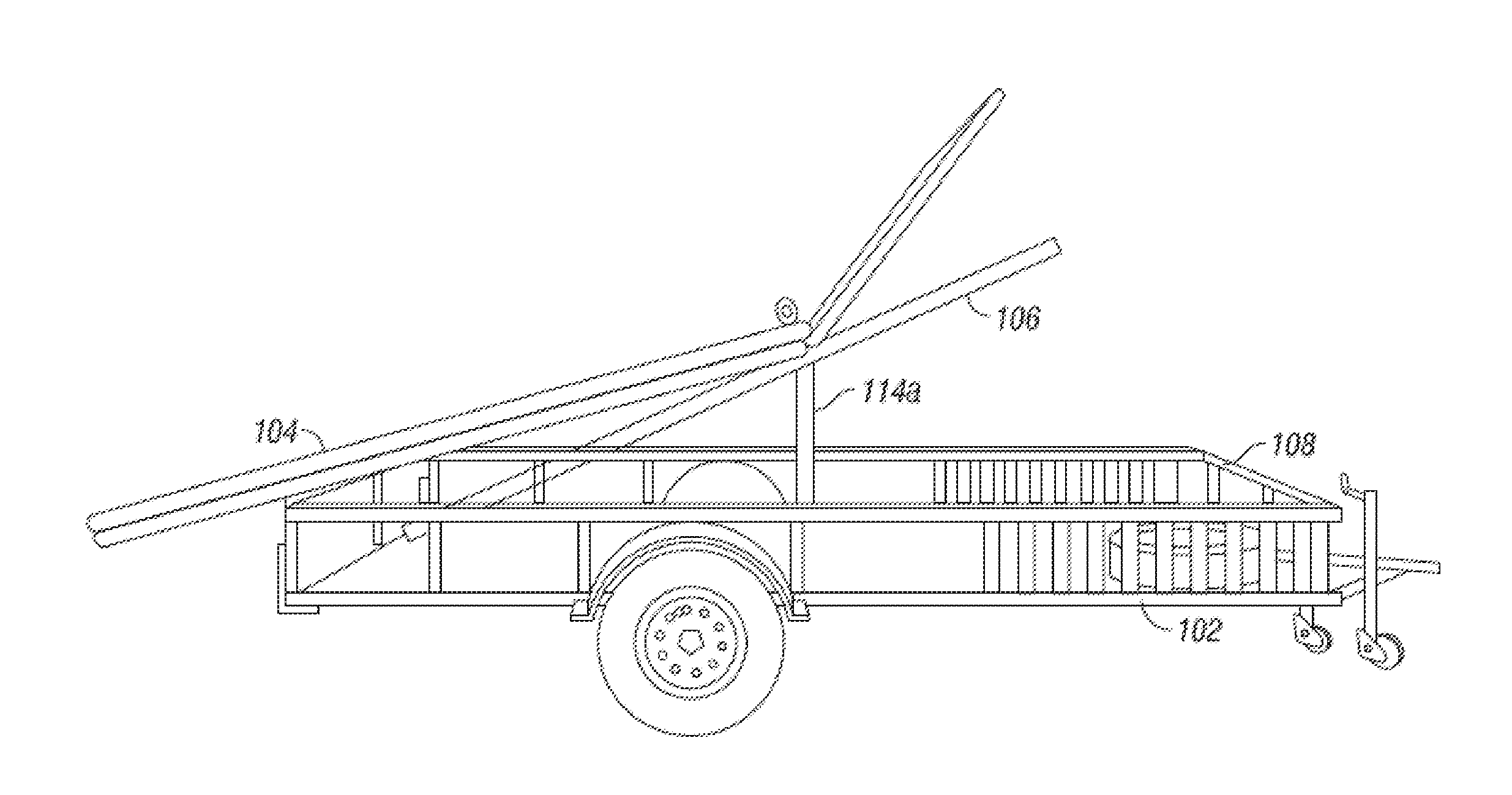

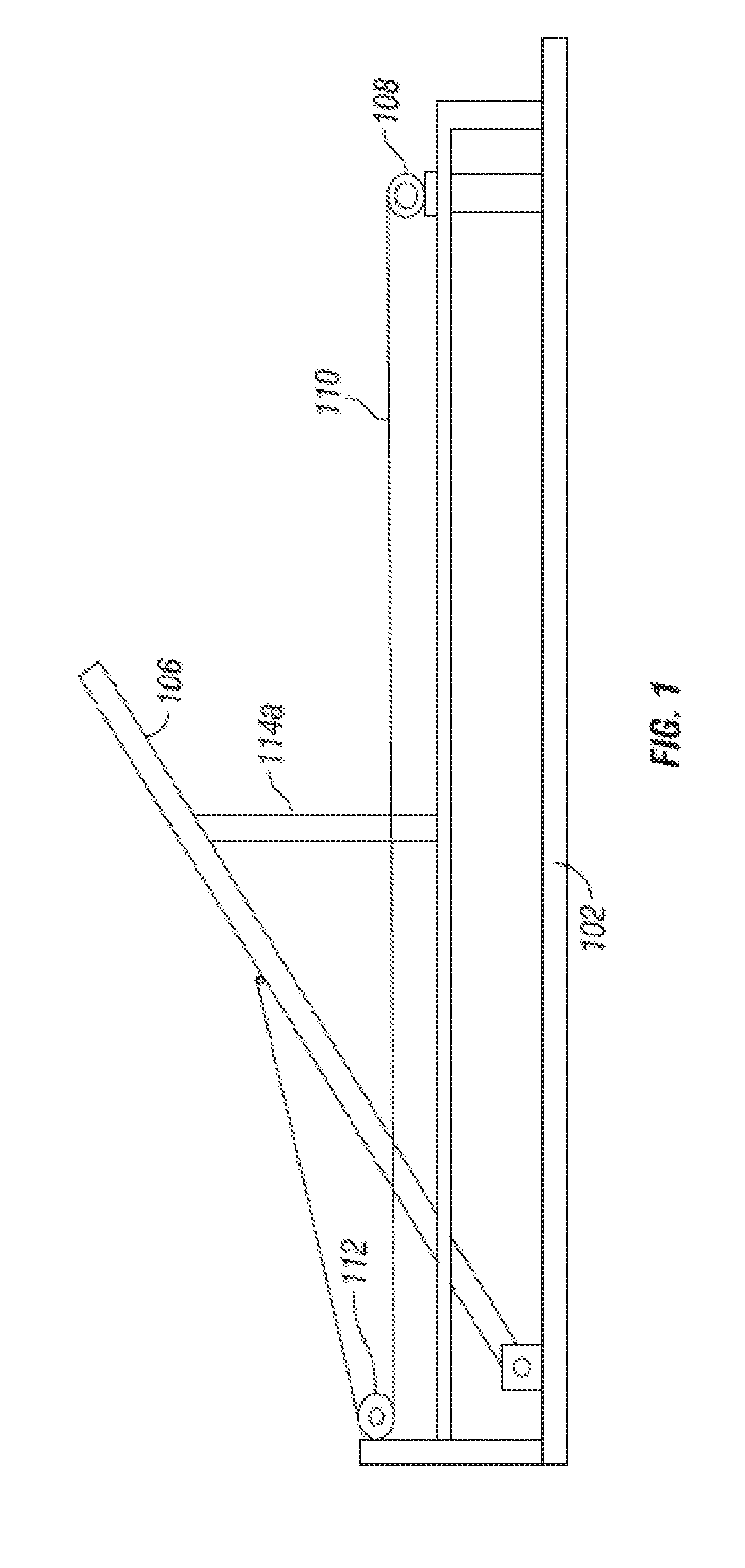

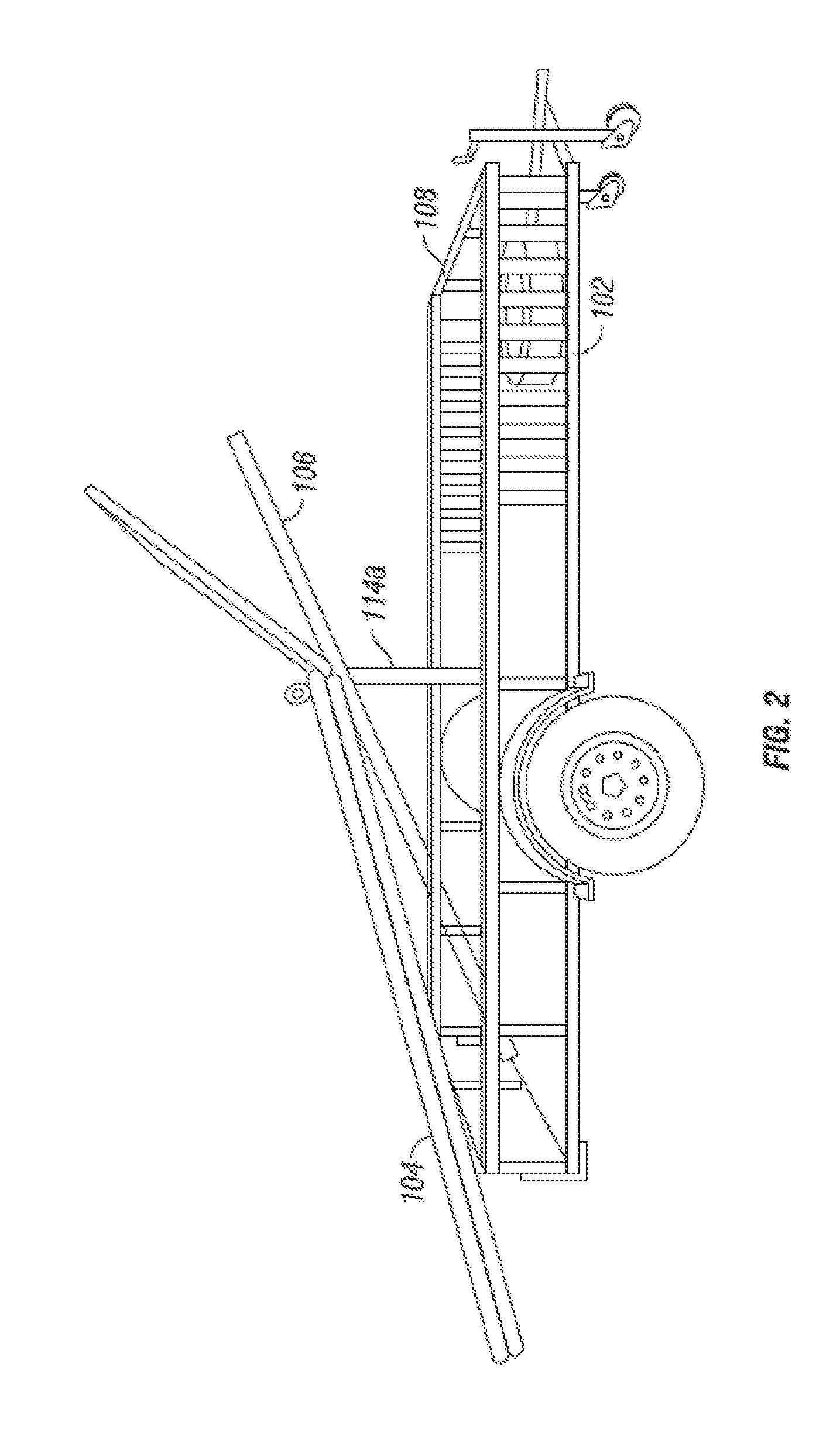

Portable Baseball Backstop

InactiveUS20170056738A1Easy to transportEasy to assembleBall sportsSpace saving gamesSupporting systemWinch

Disclosed herein is a portable baseball backstop mounted on a vehicle trailer and includes a 3 section fencing unit, with optional fourth section placed above the center portion of the 3 section unit. The backstop is permanently attached or mounted to the trailer and easily placed at the desired location for set up and use by players. The backstop is lifted with the help of a winch / pulley system out of the trailer and set up on the ground with the trailer serving as support system for the backstop. Each of the sections of the 3 section unit are secured in the ground for safe use of the backstop and to eliminate any falling of the backstop during play. The backstop is also secured sufficiently to withstand baseball speeds of about 90+ miles per hour.In particular disclosed herein is a first and second planar fence sections. The first planar fence section is attached to a movable shaft. The movable shaft is pivotally connected to a first end of a trailer. The second planar fence section is attached to the first planar fence section, and the second planar fence section is movable with respect to the first planar fence section. A winch is fixed on a second end of the trailer for lifting the movable shaft from a first position to a second position. A pulley system is attached at the first end of the trailer. A cable wound over the winch is secured to the shaft through the pulley system. The portable baseball backstop assembly is easily transported with the trailer, and assembled for use at a variety of locations. The trailer serves to both secure the backstop and transport it to desired locations.

Owner:ESCAMILLA MARK +1

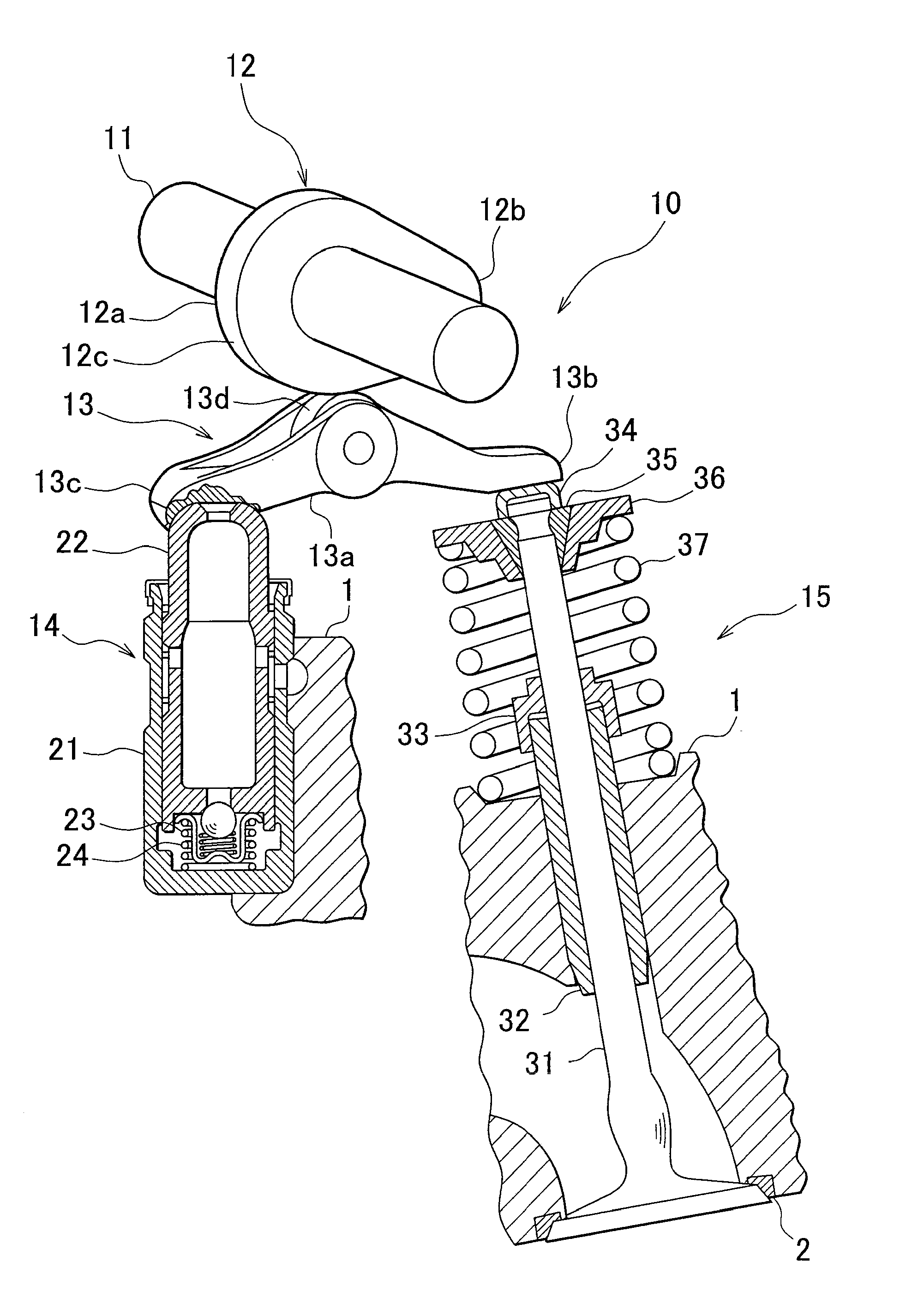

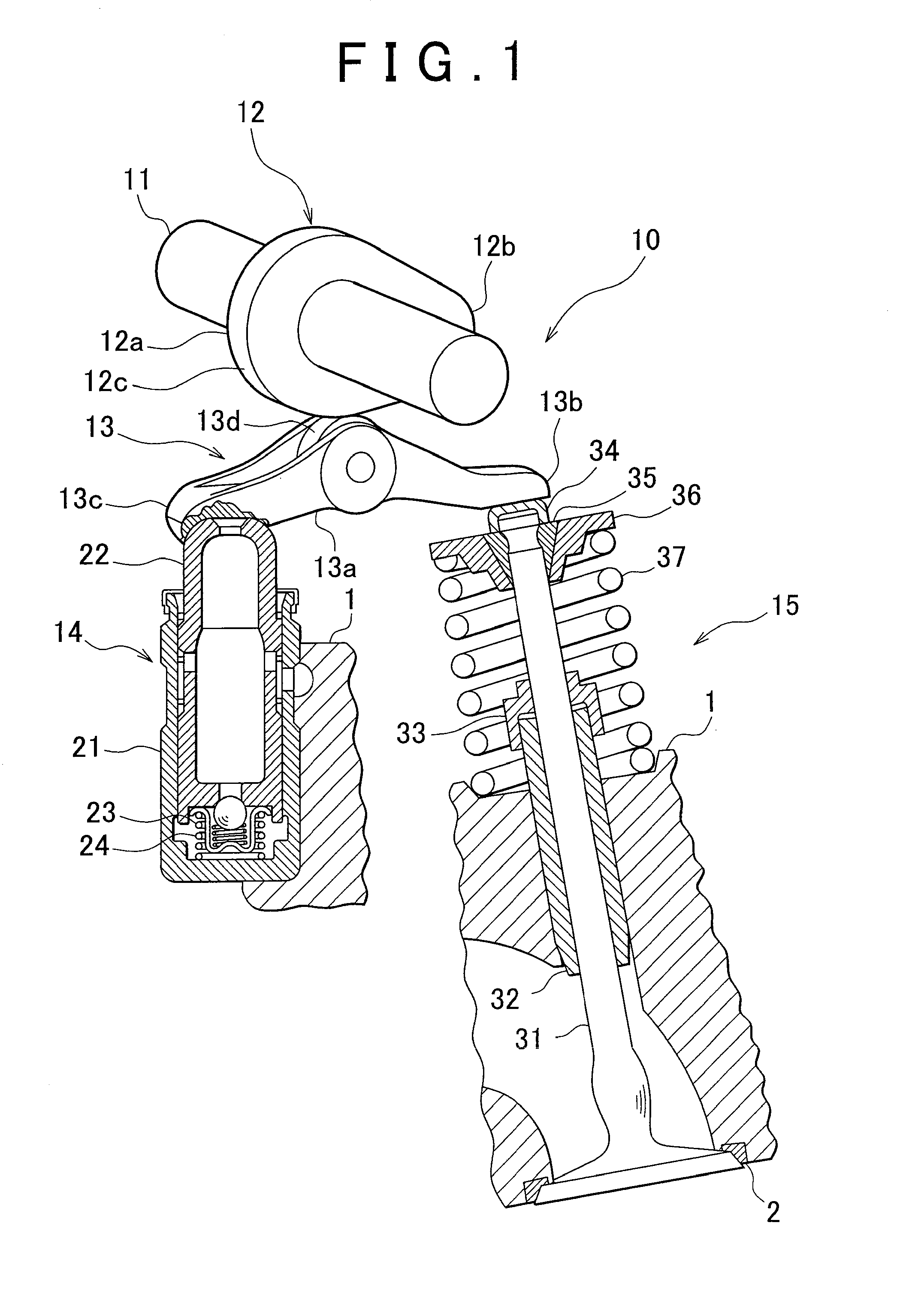

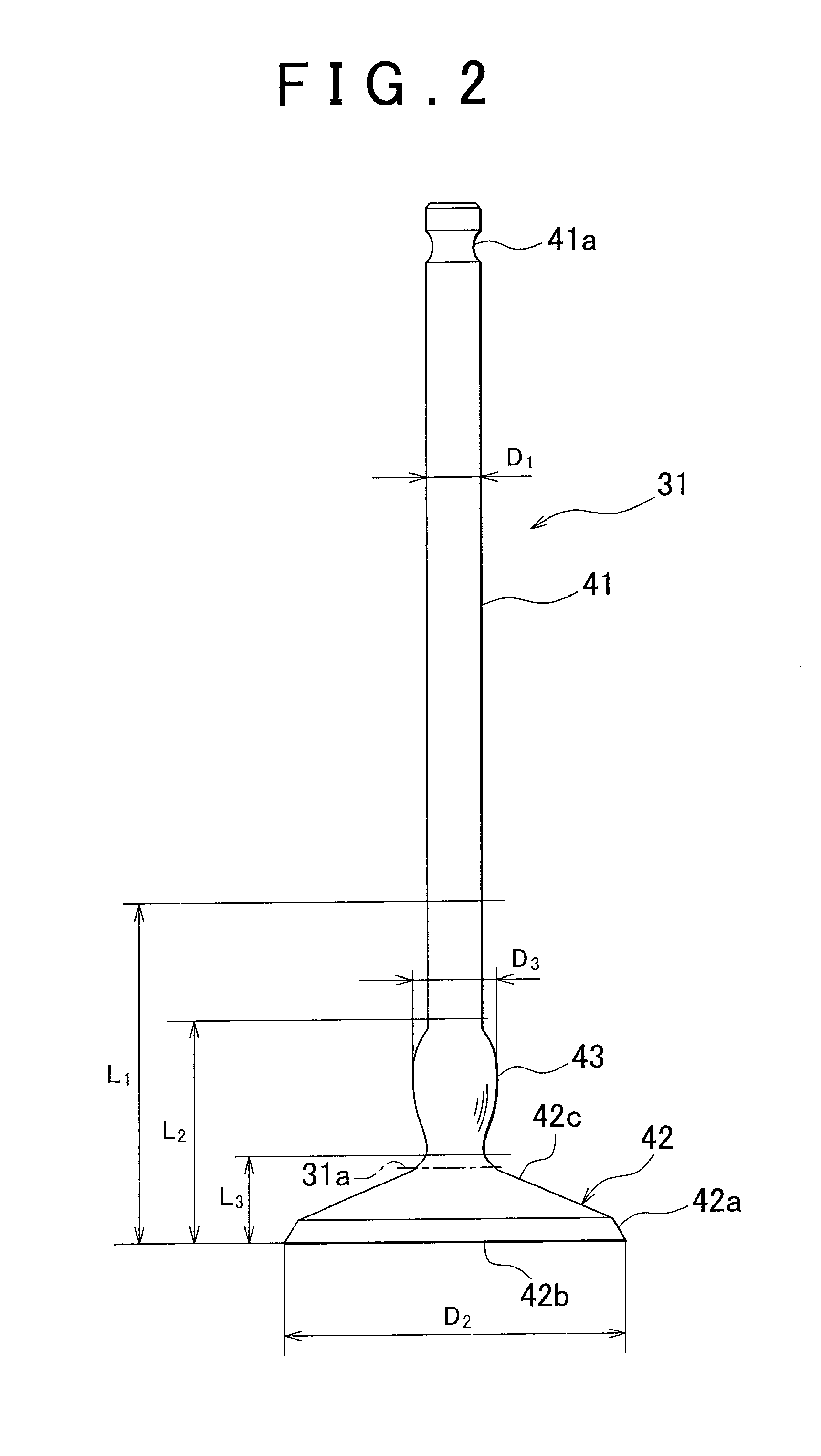

Exhaust valve

InactiveUS20120186553A1Adequate strengthWithout increase of weight and manufacturing costMachines/enginesSlide valveEngineeringExhaust valve

An exhaust valve includes: a shaft section; and a head section that is formed in one end of the shaft section and formed with a valve face that seats on a valve seat disposed in a cylinder head of an internal combustion engine, in which the shaft section has a shaft diameter of a constant diameter; the head section has a head diameter that is larger than the shaft diameter; and a thick shaft section that has a diameter smaller than the head diameter and larger than the shaft diameter is formed within a section between a connecting position that connects the shaft section with the head section and a position that is spaced apart from the head front surface opposite to the valve face in an axial direction by a distance that is approximately the same as the head diameter.

Owner:TOYOTA JIDOSHA KK

Functional air filter

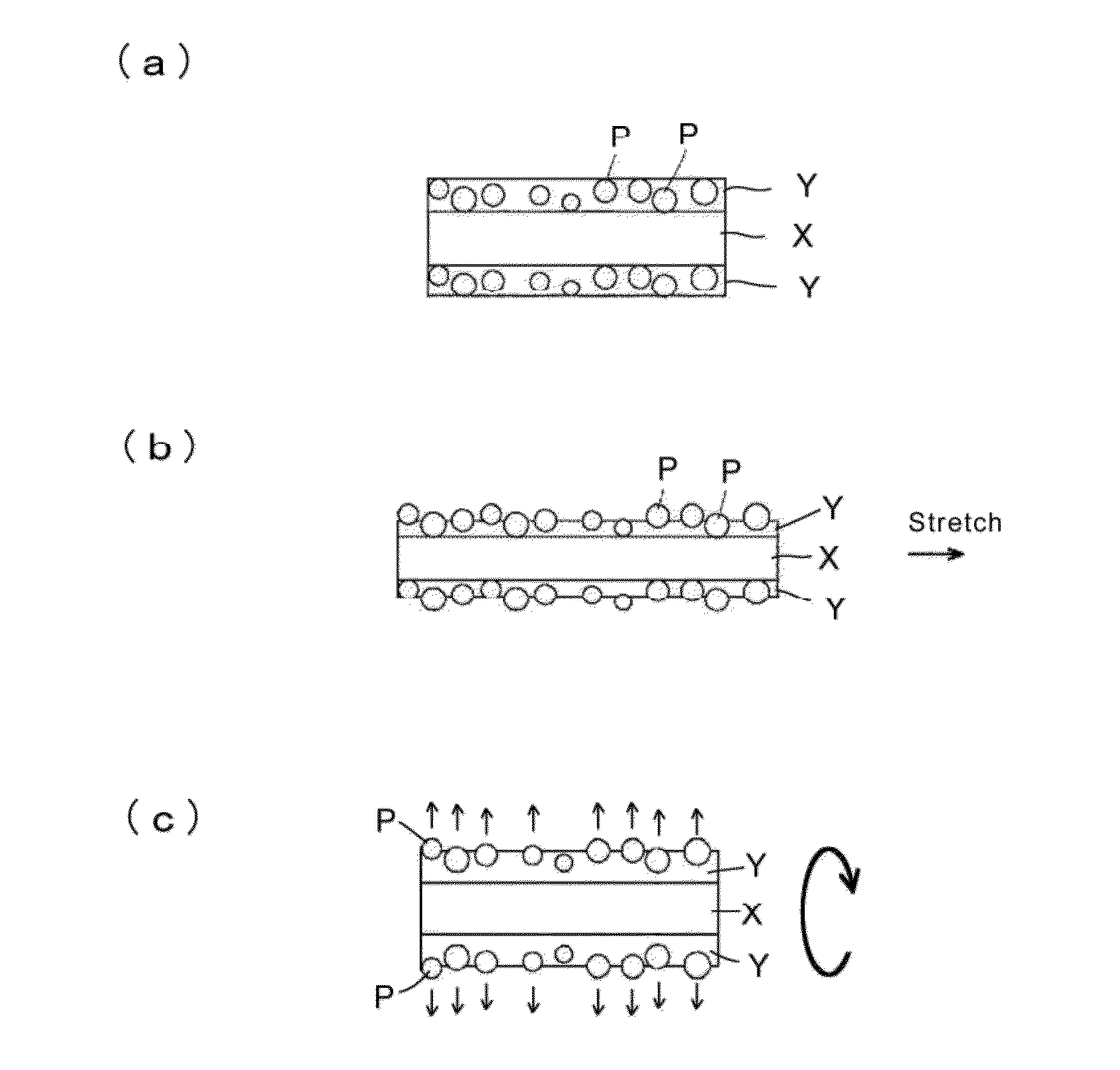

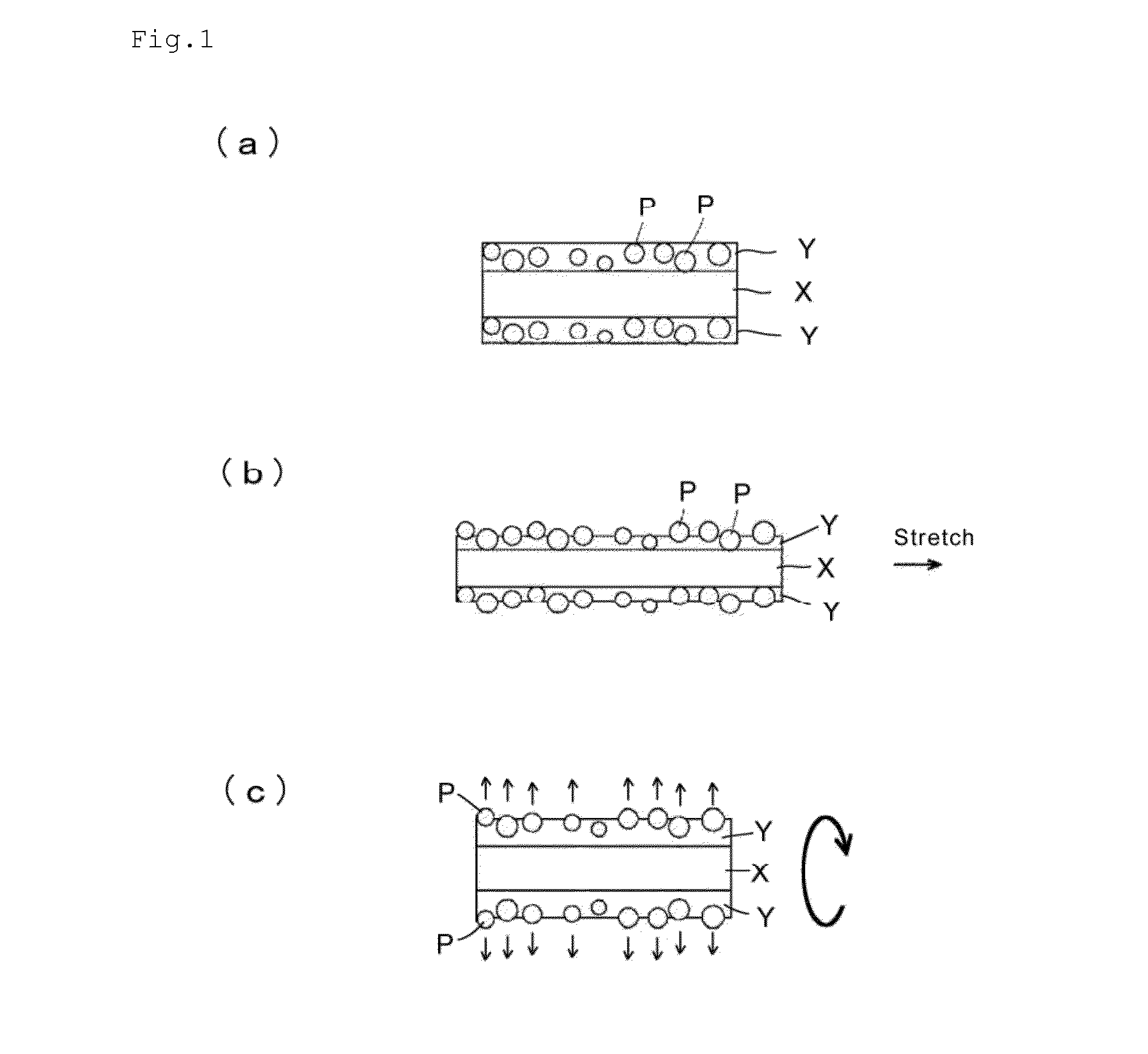

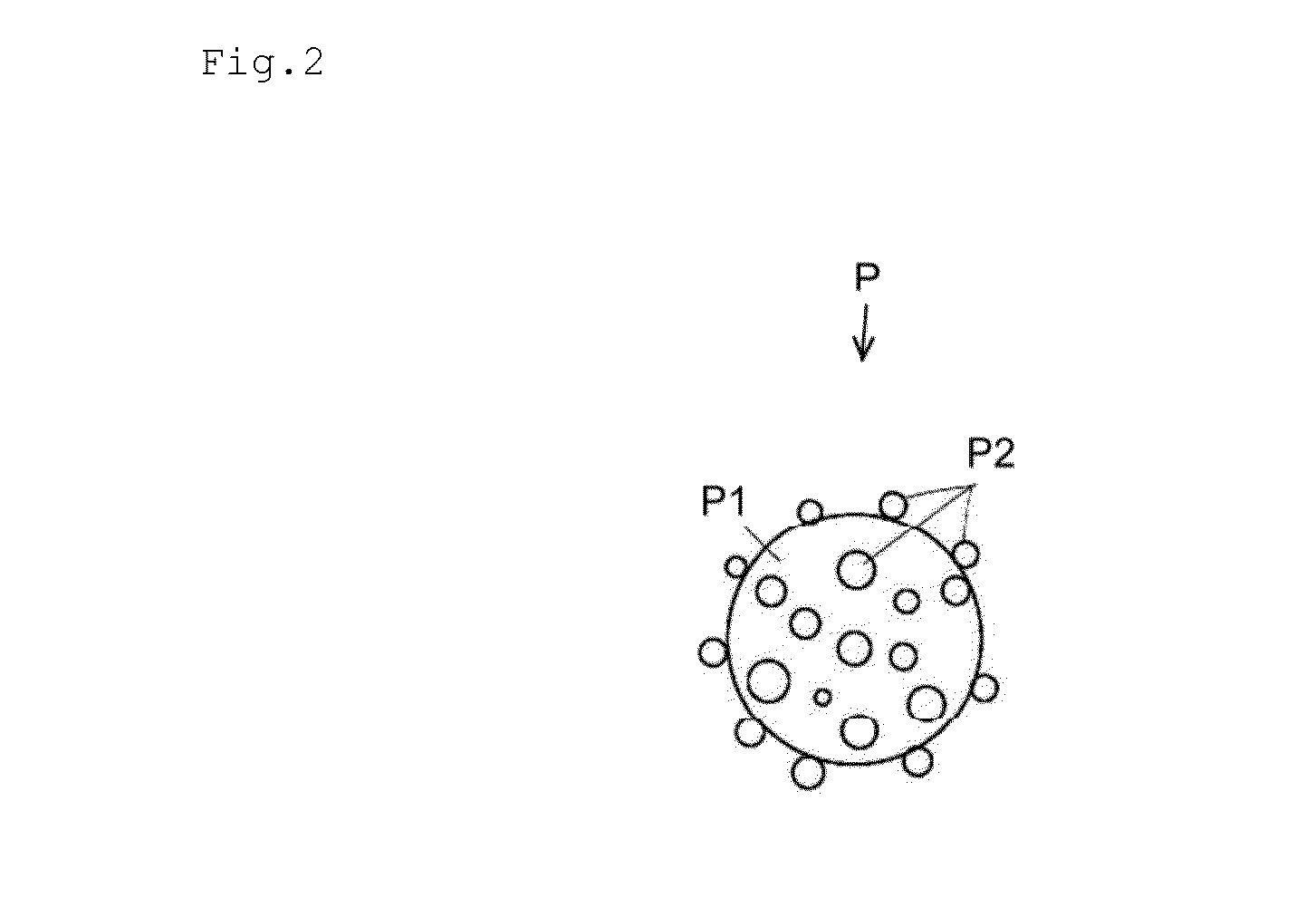

InactiveUS20160271598A1Required strengthGood functionMechanical apparatusDispersed particle filtrationFiberMaterials science

Provided is a functional air filter which can maintain a sufficient function of suppressing breeding of mold and undesired bacteria for a long period thus being hygienic, exhibiting high safety and possessing deodorizing property. In a functional air filter which is manufactured by, at intersections between wefts and warps made of a thermoplastic sheath-core type composite monofilament which is a composite fiber consisting of a core material and a sheath material made of a resin having a lower melting point than the core material, heat-fusing the sheath materials to each other, the composite monofilament is configured such that some particles blended into the sheath material are exposed from a surface of the sheath material. The particle is a mixed particle where fine particles are fixedly adhered to a surface of a coarse particle.

Owner:TAIYO CORP

Body structure of stringed instrument

A body structure of a stringed instrument is designed to reduce weight and to improve sound quality with respect to a solid body, which is constituted by a core material and a pair of decorative boards, wherein the core material is composed of a single material having a relatively low specific gravity (e.g., 0.4 or less) such as falcata, bass wood, and balsa, while the decorative boards each have hardness greater than that of the core material. The core material has curved flatness (or curvature) in which both sides lying in the width thereof are reduced in thickness compared with the center portion thereof. The core material having a relatively low specific gravity is sandwiched between the hard decorative boards; hence, it is possible to reduce the overall weight while securing satisfactory strength.

Owner:YAMAHA CORP

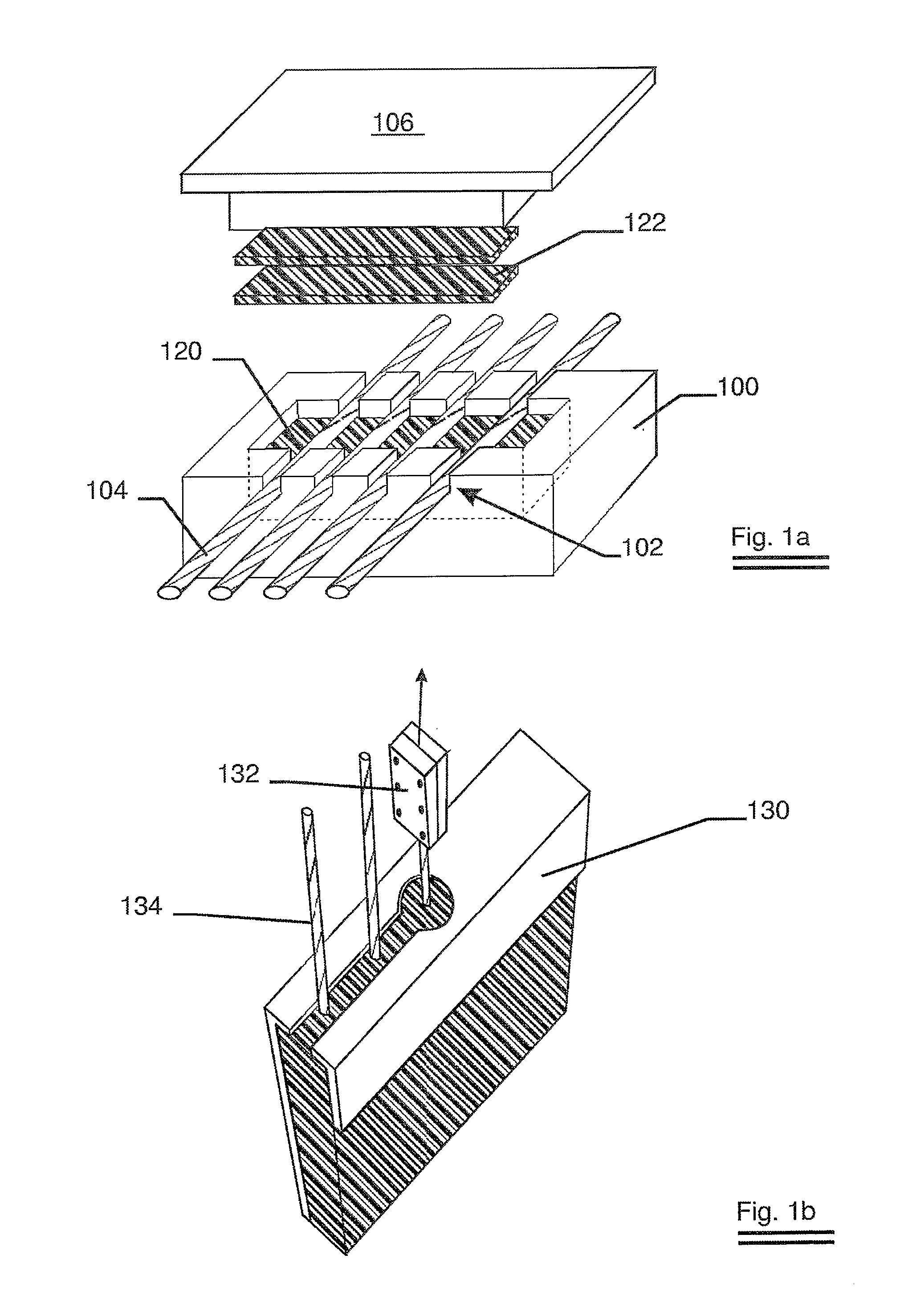

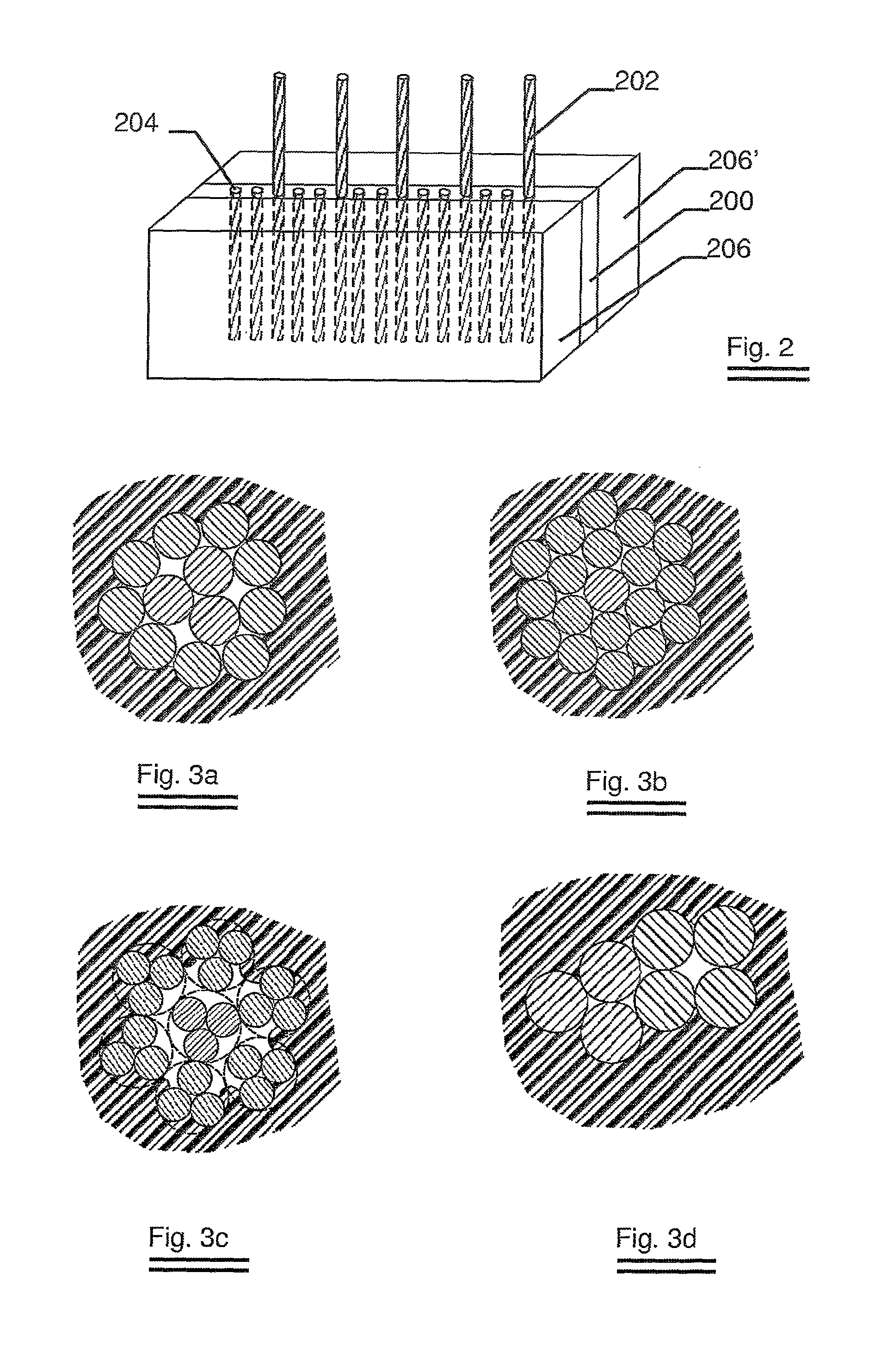

Tube Reinforced With a Polymer and Steel Cord Strip

InactiveUS20070218230A1Maximized ratioReduce in quantityLayered productsPedestrian/occupant safety arrangementEngineeringSteel belt

A strip for the reinforcement of plastic tubes is claimed. The strip is reinforced with steel cords that anchor mechanically very well in the polymer matrix. No chemical adhesion is needed to ensure the force transfer. With such a strip a small connector length from tube to tube or from tube to end-fitting is made possible. The characteristics of such a steel cord are identified.

Owner:NV BEKAERT SA

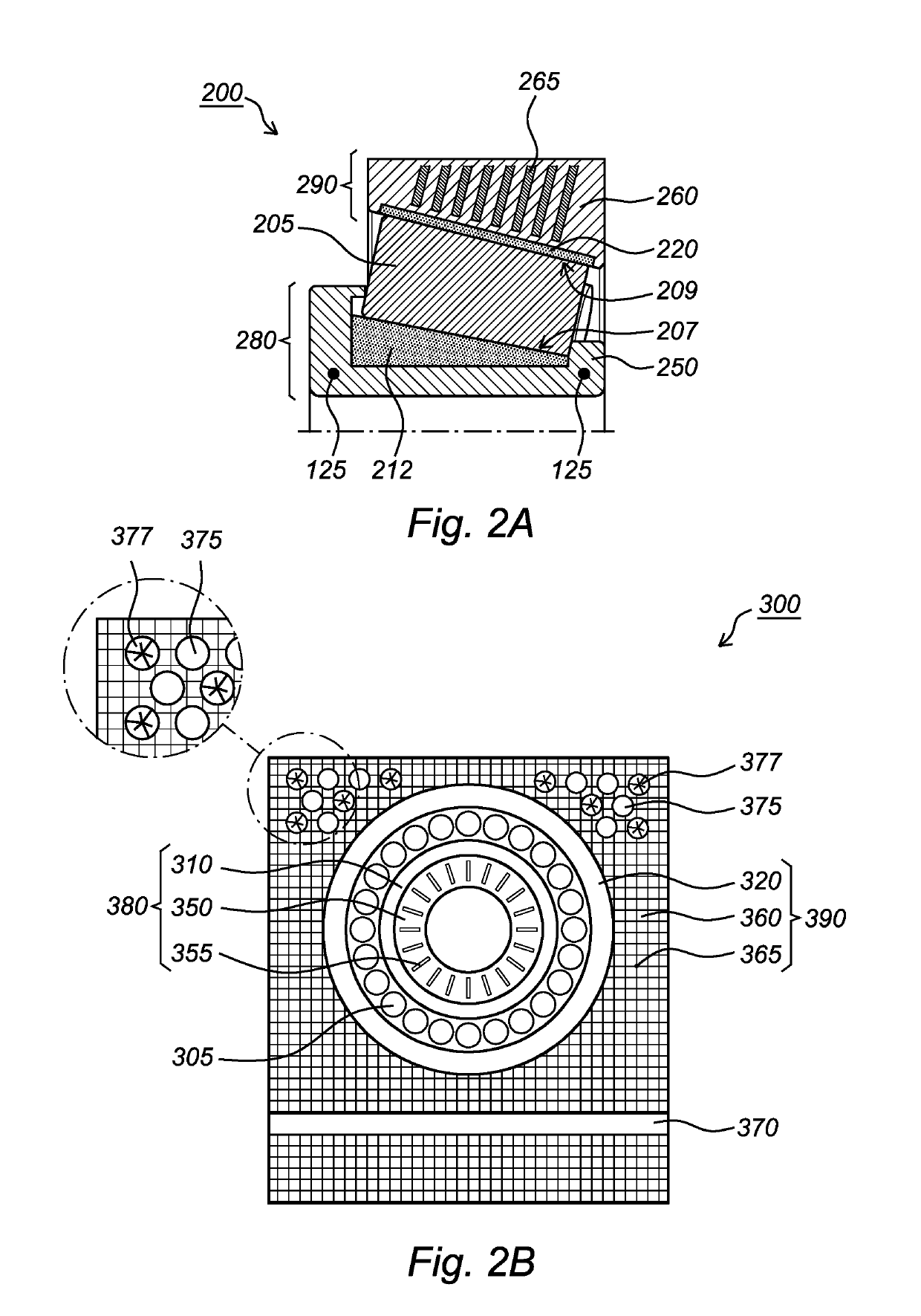

Building block for a mechanical construction

ActiveUS10436252B2Easy constructionReduce weightAdditive manufacturing apparatusShaftsEngineeringActuator

Owner:AB SKF

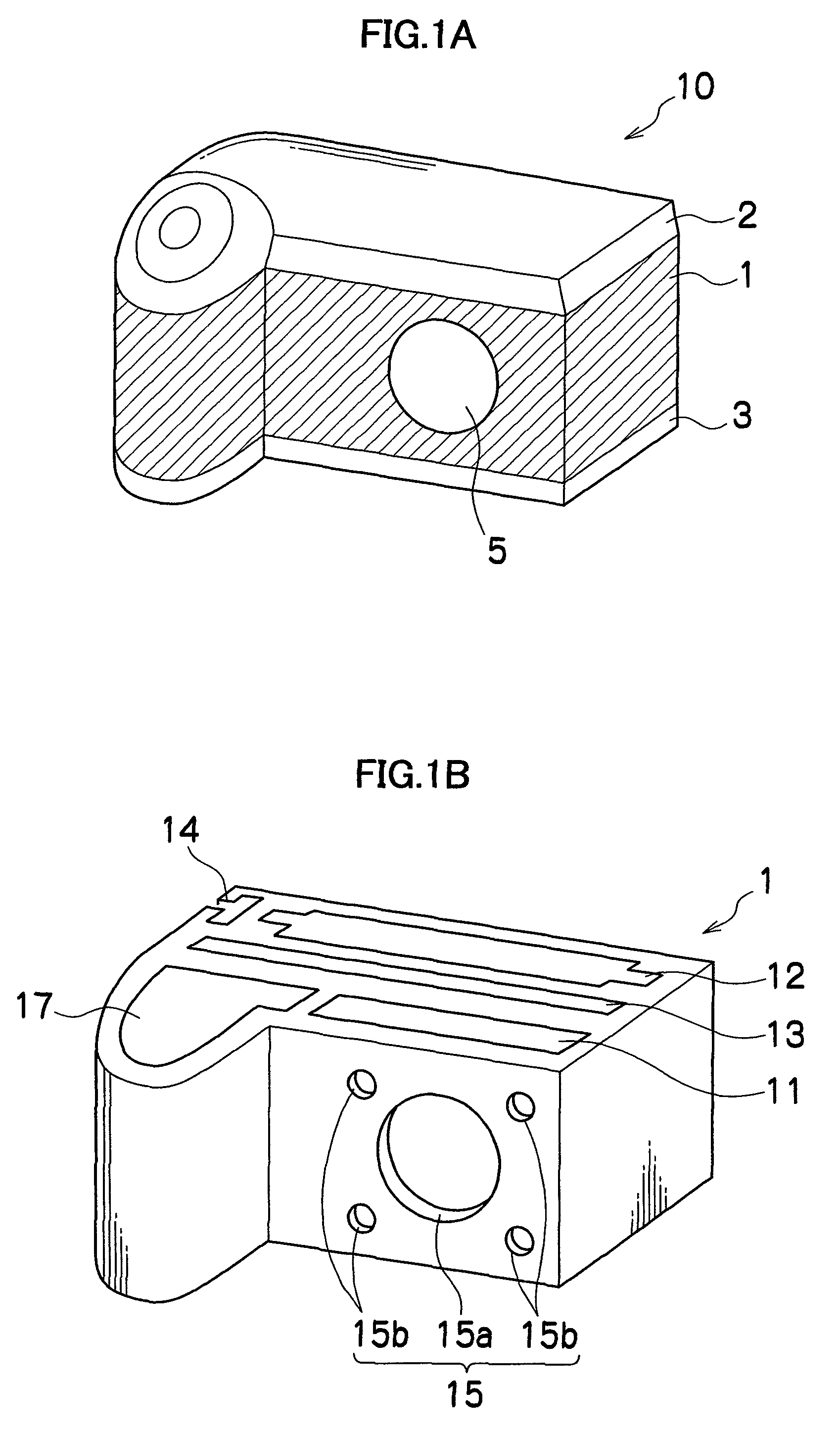

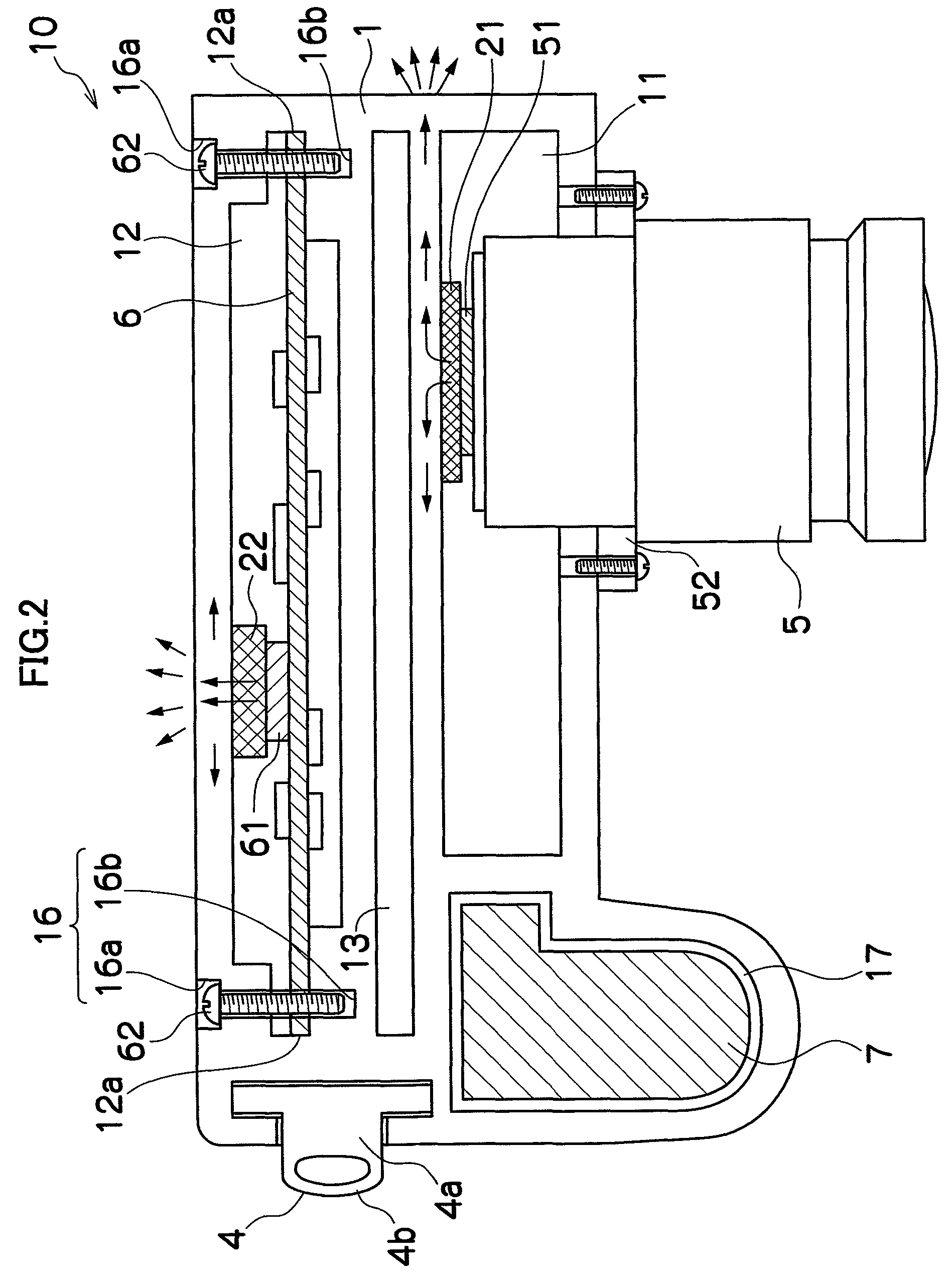

Enclosure for electric equipment and imaging device

InactiveUS7848640B2Excellent in assembling performance and heat transfer propertyReduce the numberTelevision system detailsDigital data processing detailsManufacturing cost reductionElectrical devices

According to an enclosure for electric equipment of an aspect of the present invention, the enclosure having the plurality of accommodation portions accommodating separate contents, respectively, can be formed by one molding without assembling a plurality of components, which can reduce the number of assembling processes. Also, formation by one component eliminates a gap which would be generated by assembling components, which can improve enclosure strength and designability and reduce manufacturing costs.

Owner:FUJIFILM CORP

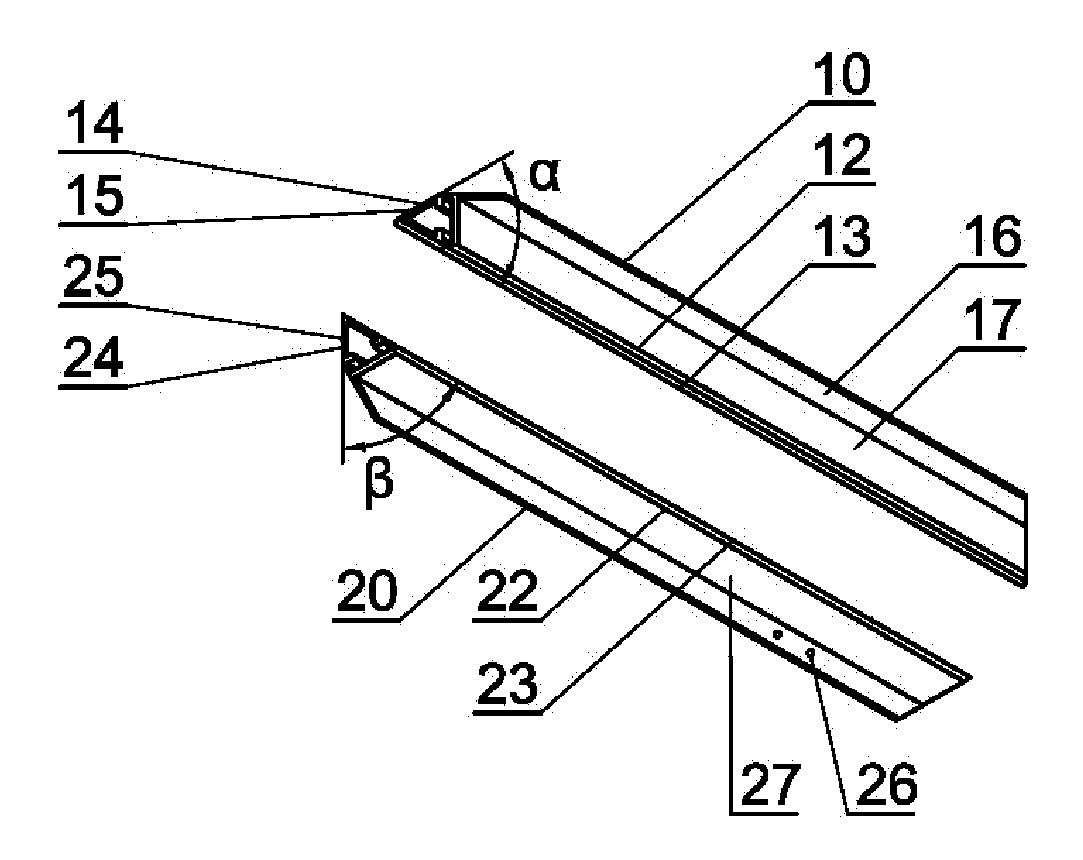

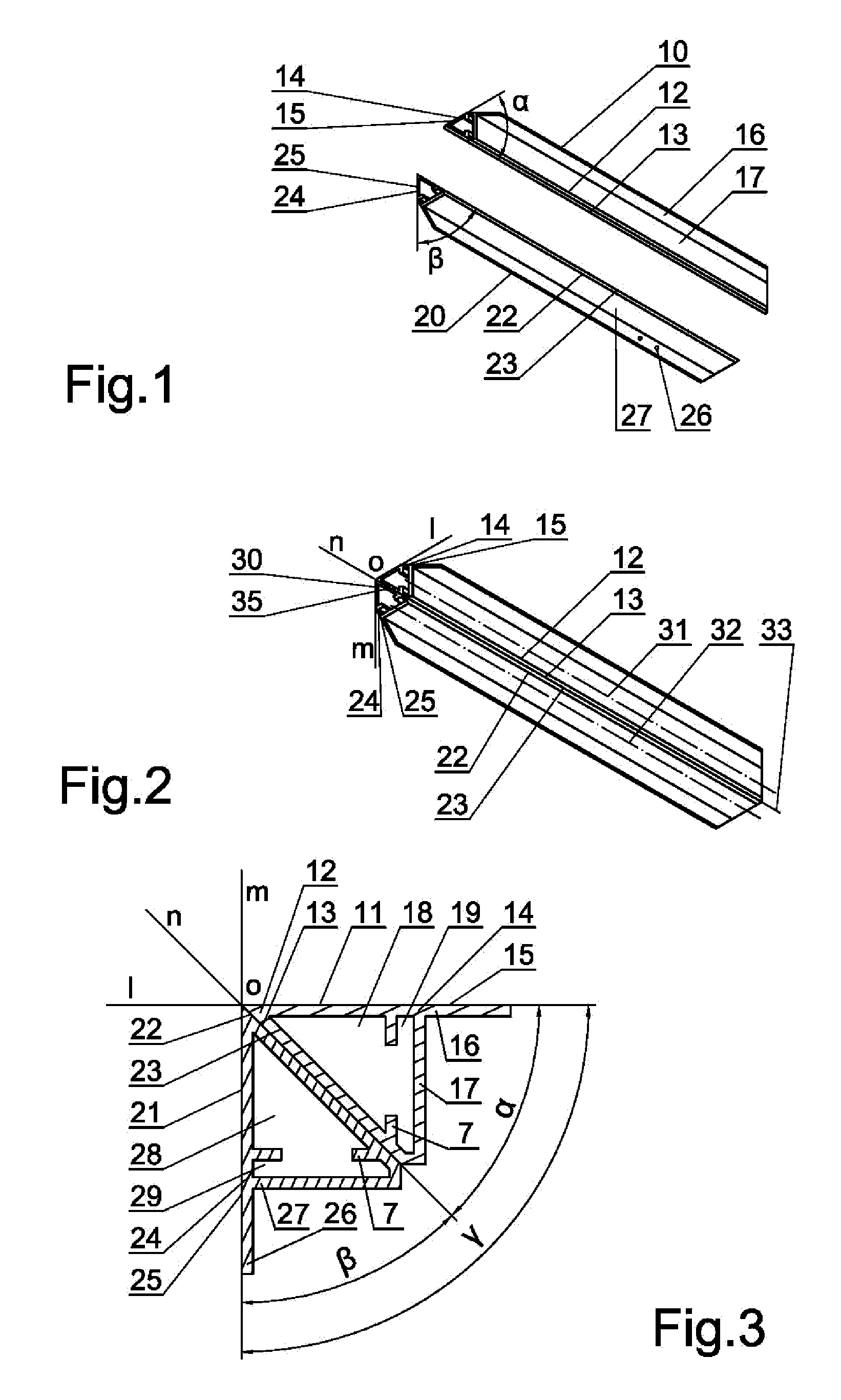

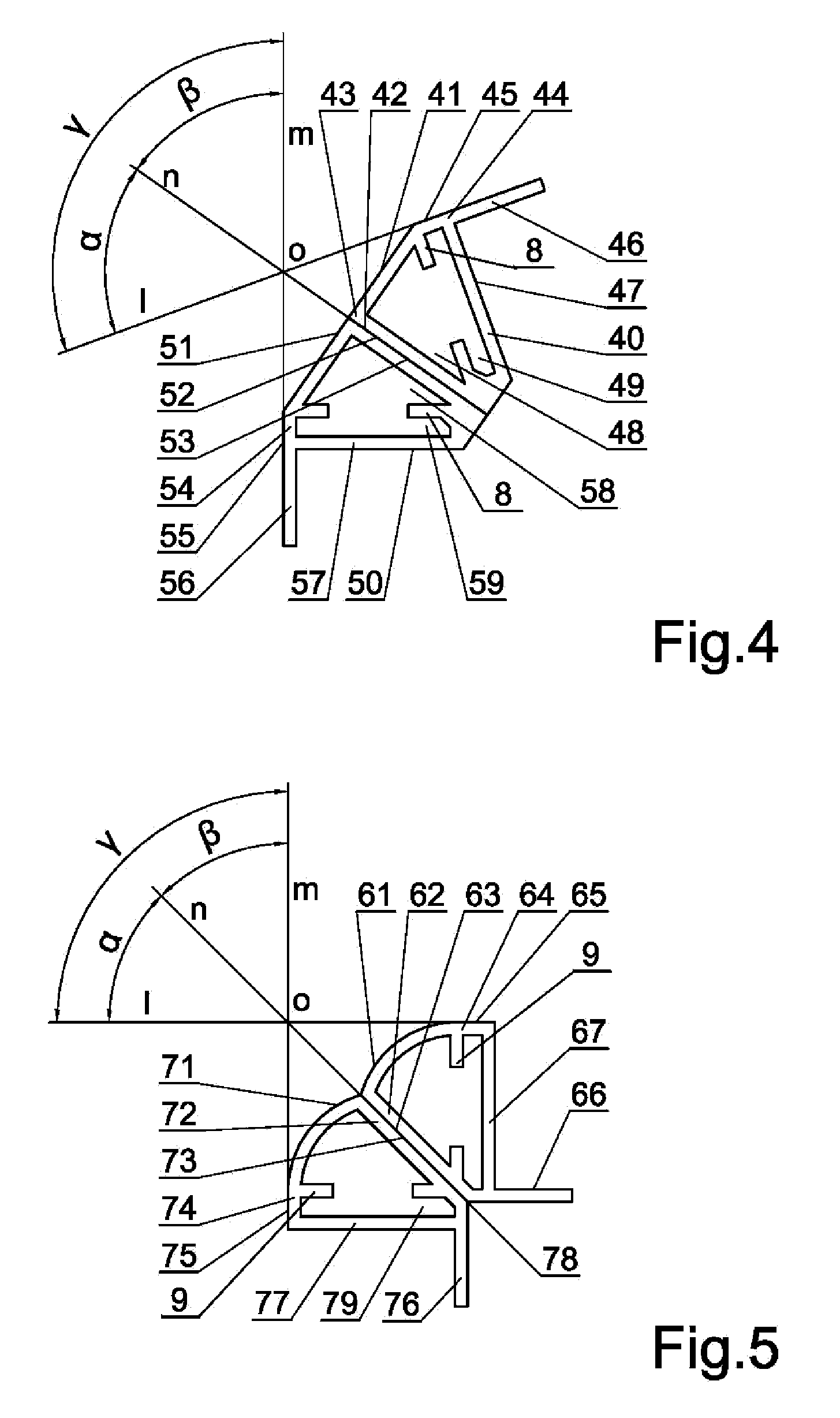

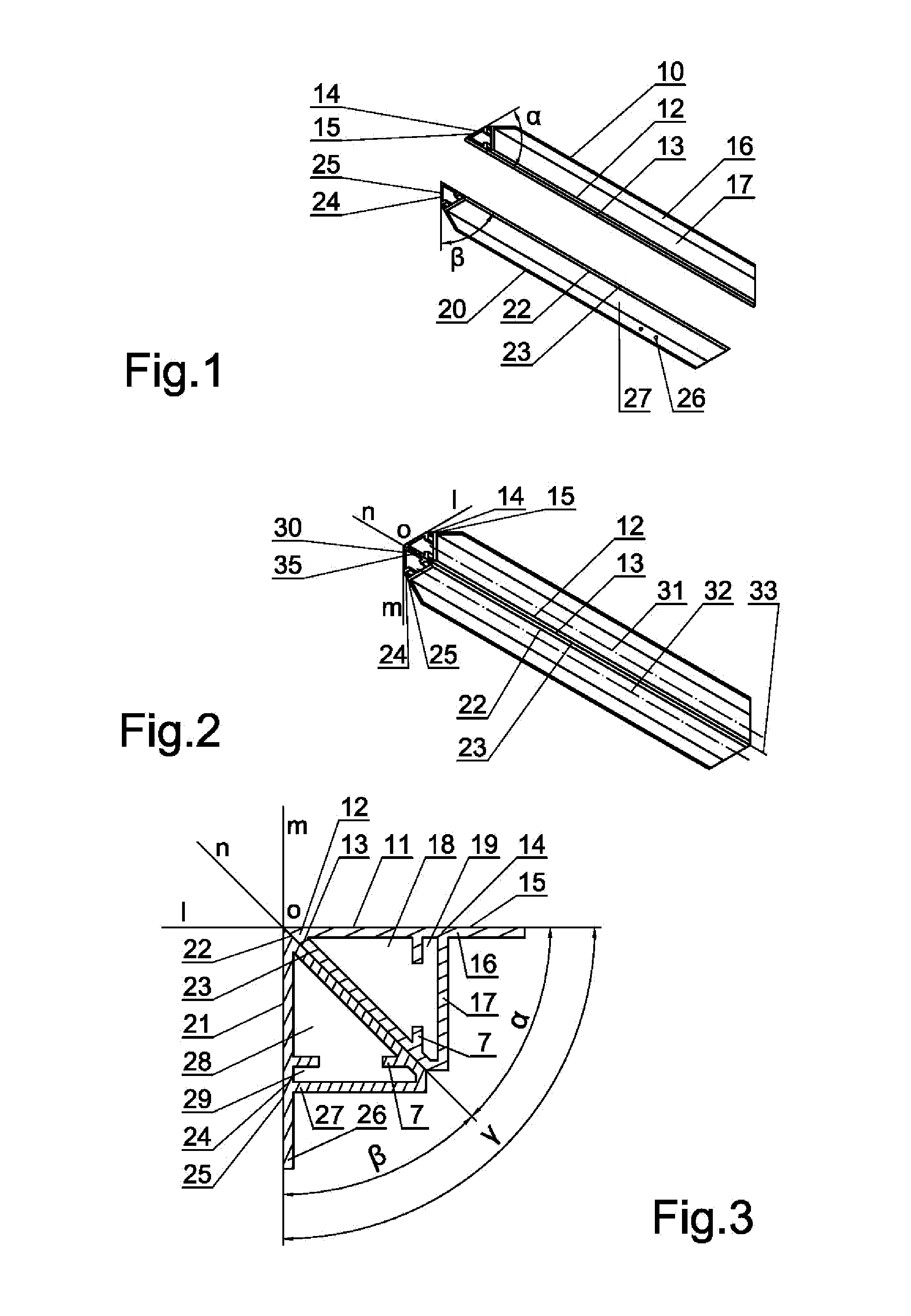

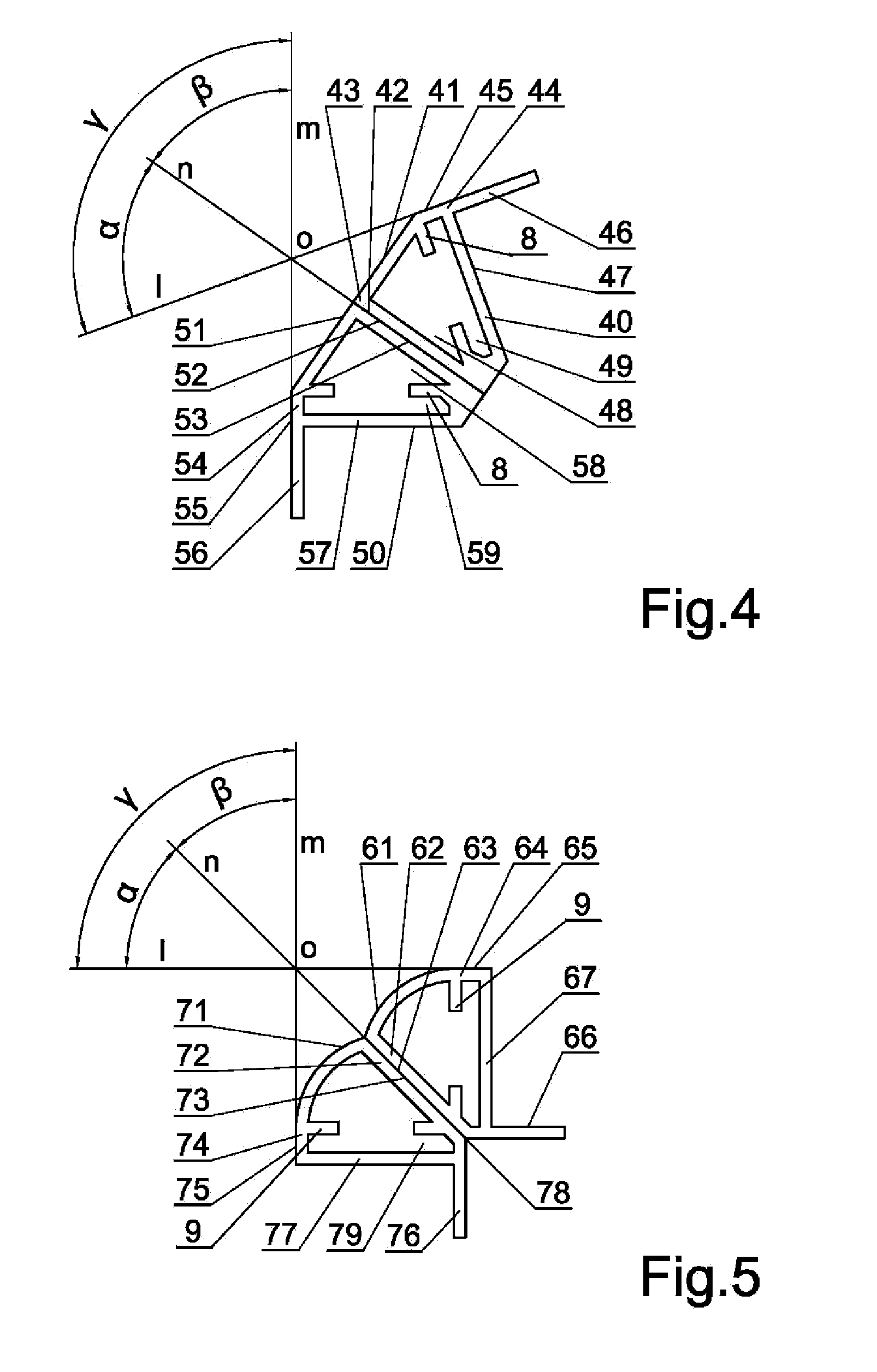

Set of profiles for forming profile structures, complex profile, structure made of profiles and method for making structures using profiles

InactiveUS20140220288A1High-precision fitRequired stiffnessFurniture partsGirdersEngineeringMechanical engineering

A set of profiles for forming complex profiles comprises two profiles, namely a first profile (10) and a second profile (20), adjoining each other and having walls surrounding a main chamber. Each profile (10, 20) of the set has an outer shape which may be inscribed into a triangle, and has an inner wall (12, 22) with a faying face (13, 23) without protruding fragments. The faying faces (13, 23) adjoining each other, after being coated with adhesive enable a joint to be created when the complex profile is discussed, however, in the case of the set of the profiles they are considered to be contact surfaces. After adjoining the first profile (10) and the second profile (20) by attaching the first faying face (13) to the second faying face (23) in order to create a complex profile (30), a first outer surface (15) of first side walls (14) and a second outer surface (25) of second side walls (24) are situated outside of the complex profile and an angle between the first outer surface (15) and the second outer surface (25) equals to a sum of a first angle (α) between the first faying face (13) and the first outer surface (15) of the first side wall (14) of the first profile (10) and a second angle (β) between the second faying face (23) and the second outer surface (25) of the second side wall (24) of the second profile (20).

Owner:AIFO GRP ZAJAC ZIECIK STABRAWA SPOLKA JAWNA

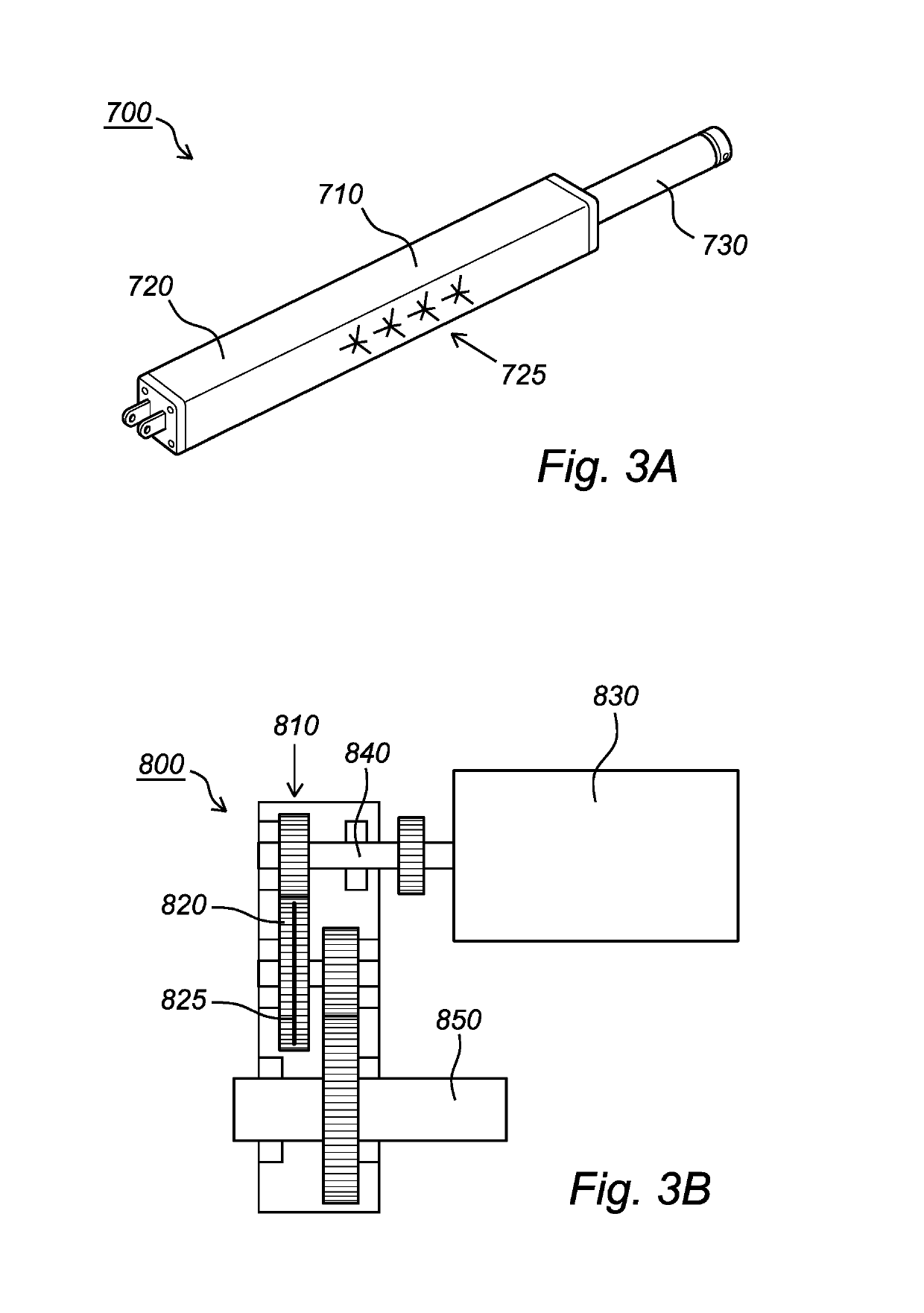

Composite Lever and Method of Making Same

InactiveUS20070295148A1Less-costly to manufactureRequired strengthControlling membersMechanical apparatusElectrically conductivePolyamide

The present invention is a composite transmission selector lever that avoids the multiple manufacturing steps of current levers and in addition gives a significant reduction in cost. The lever comprises an open-sided, elongated stamped, sheet steel element having a triangular cross section shape with the open end of the triangle curved inwardly. The triangular shape is to provide the maximum bending strength to the resultant structure. One end of the mechanism is crimped and / or welded to fasten over the circular section of a base and the other end is formed to extend to an operator handle. A wire for a switch in the handle is laid through the open side of the element and the composite assembly is overmolded with a high strength thermoplastic material, such as polyamide 6, having a surface finish suitable for an as-molded condition. The molding material substantially encloses the interior of the open-sided element, thus securing the electrically conductive wire in place and providing a significant contribution to the overall bending strength of the assembly.

Owner:SACOMA INT

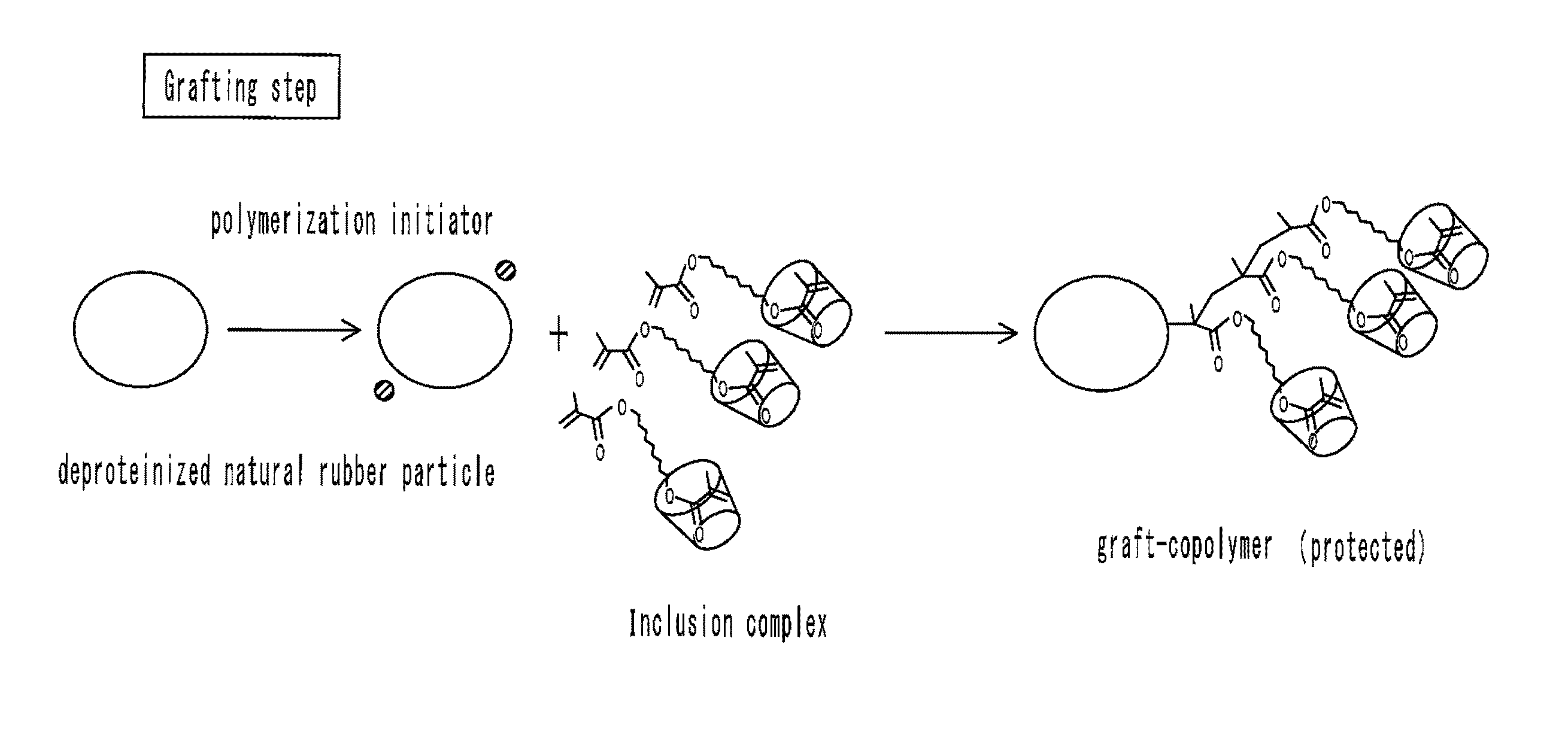

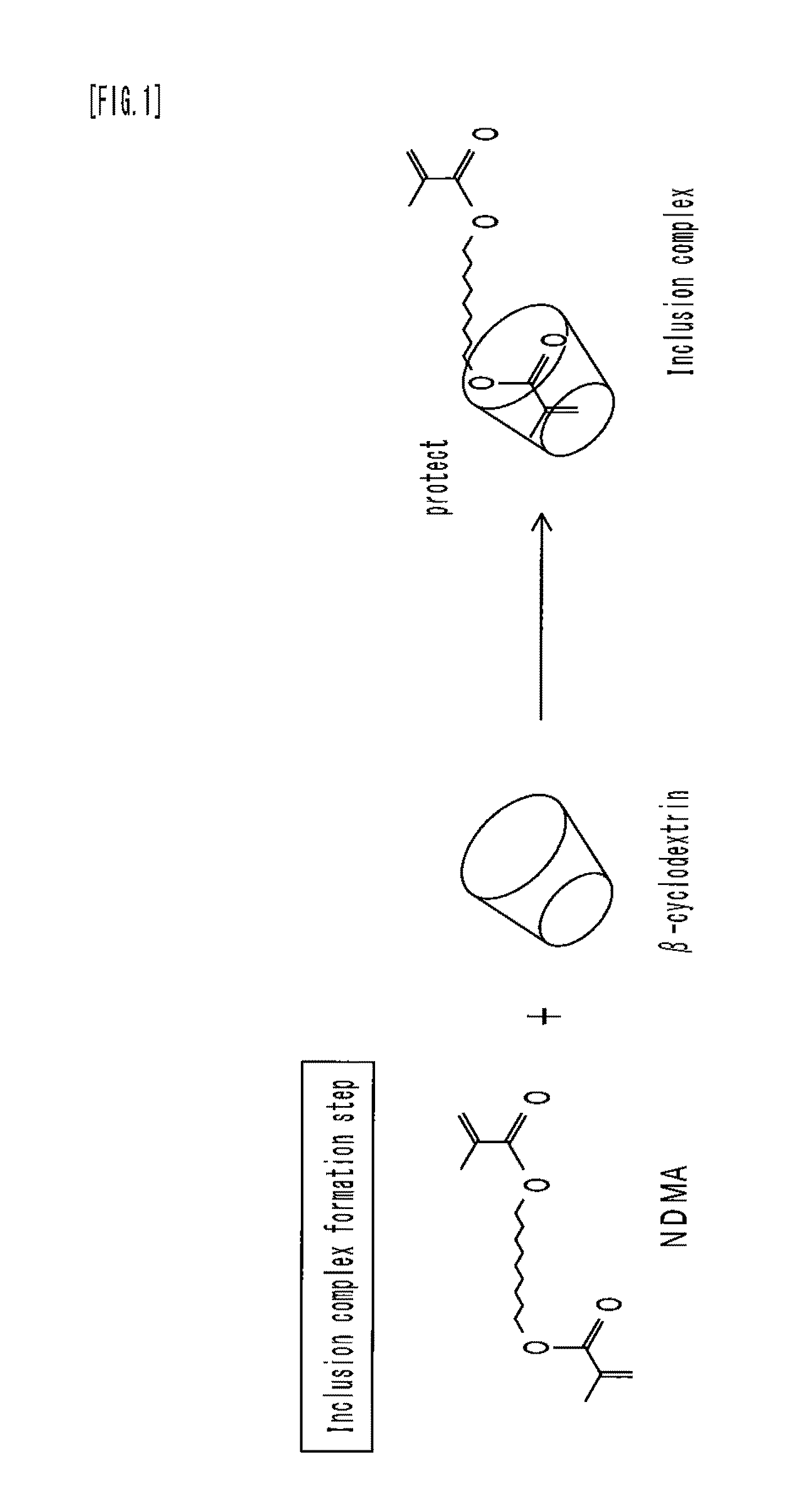

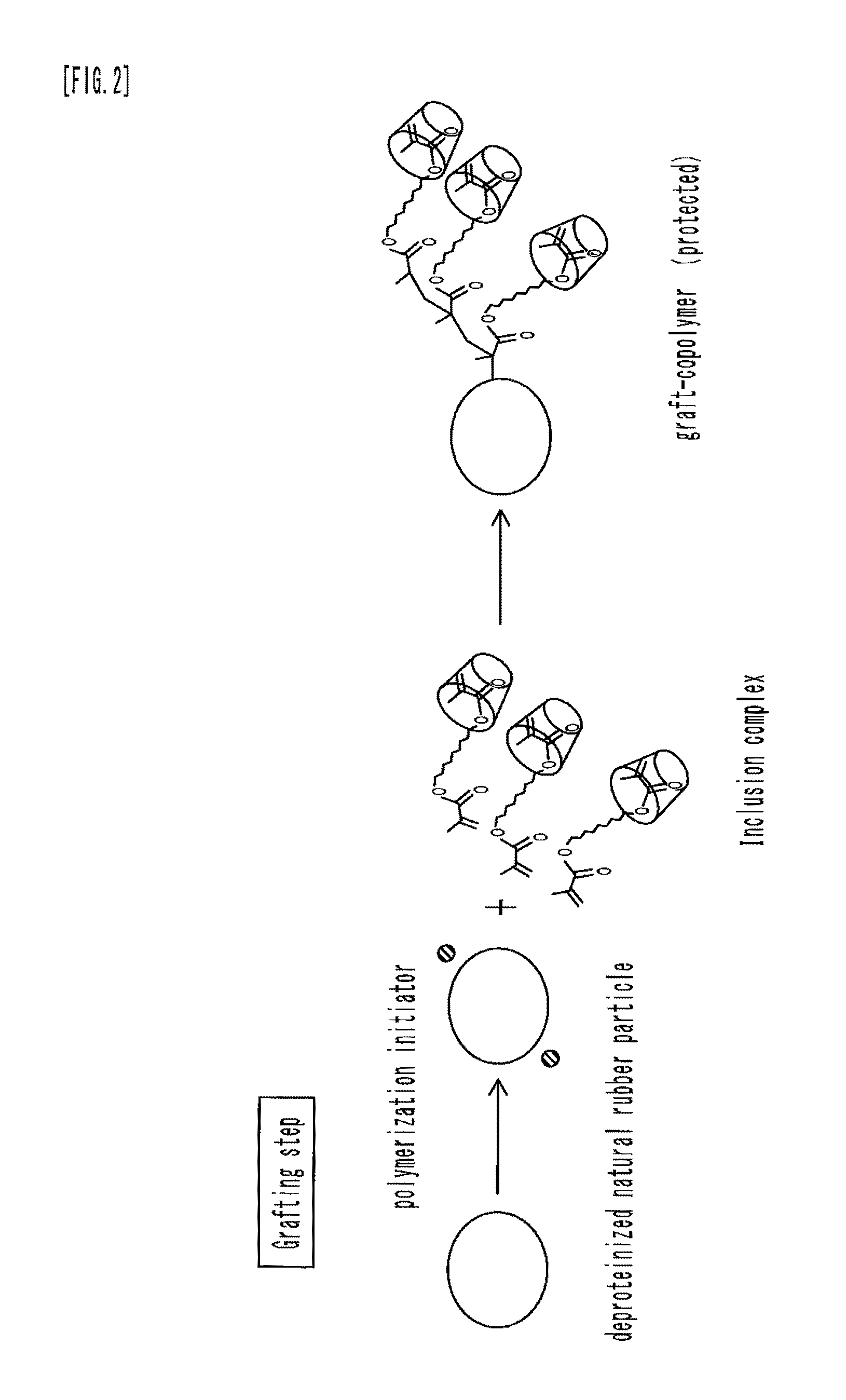

Modified natural rubber particle, production method thereof, and modified natural rubber latex

Owner:NATIONAL UNIVERSITY +1

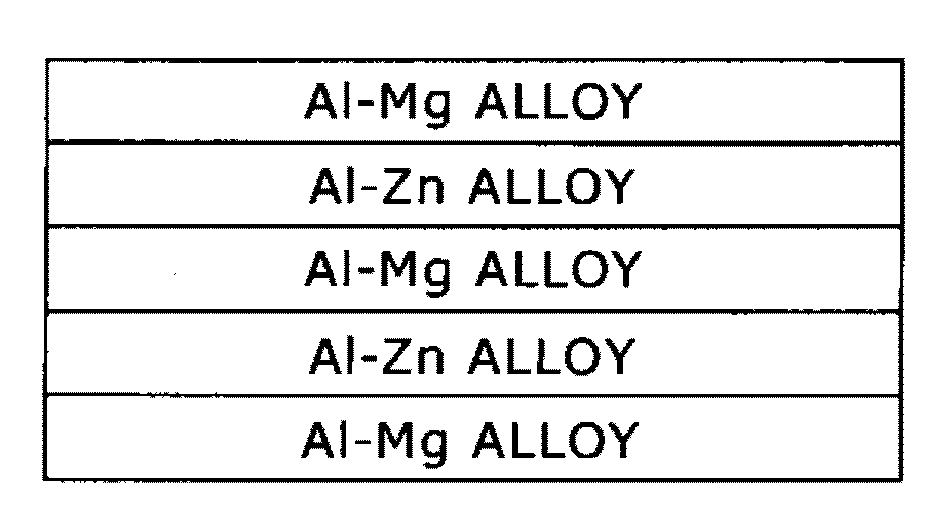

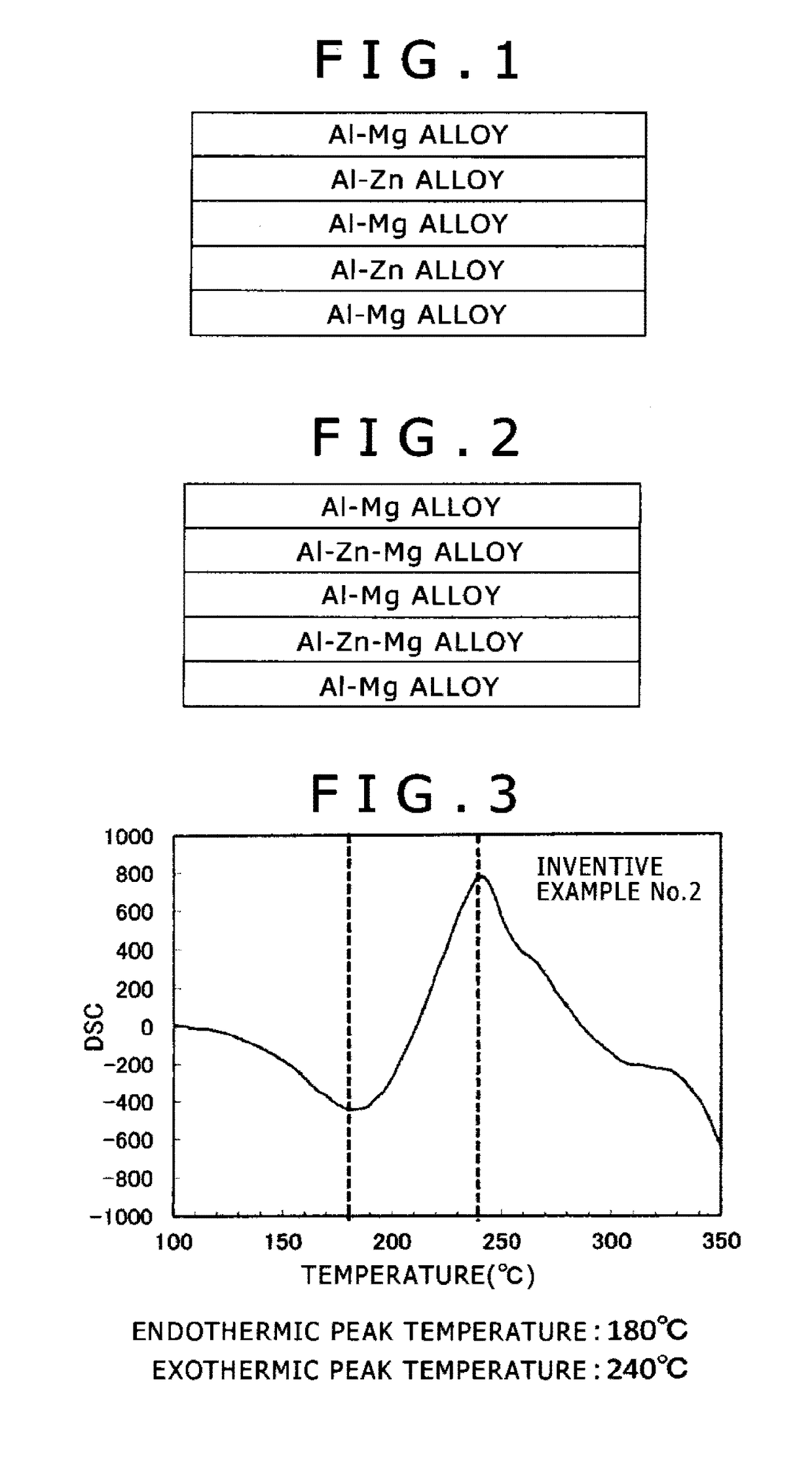

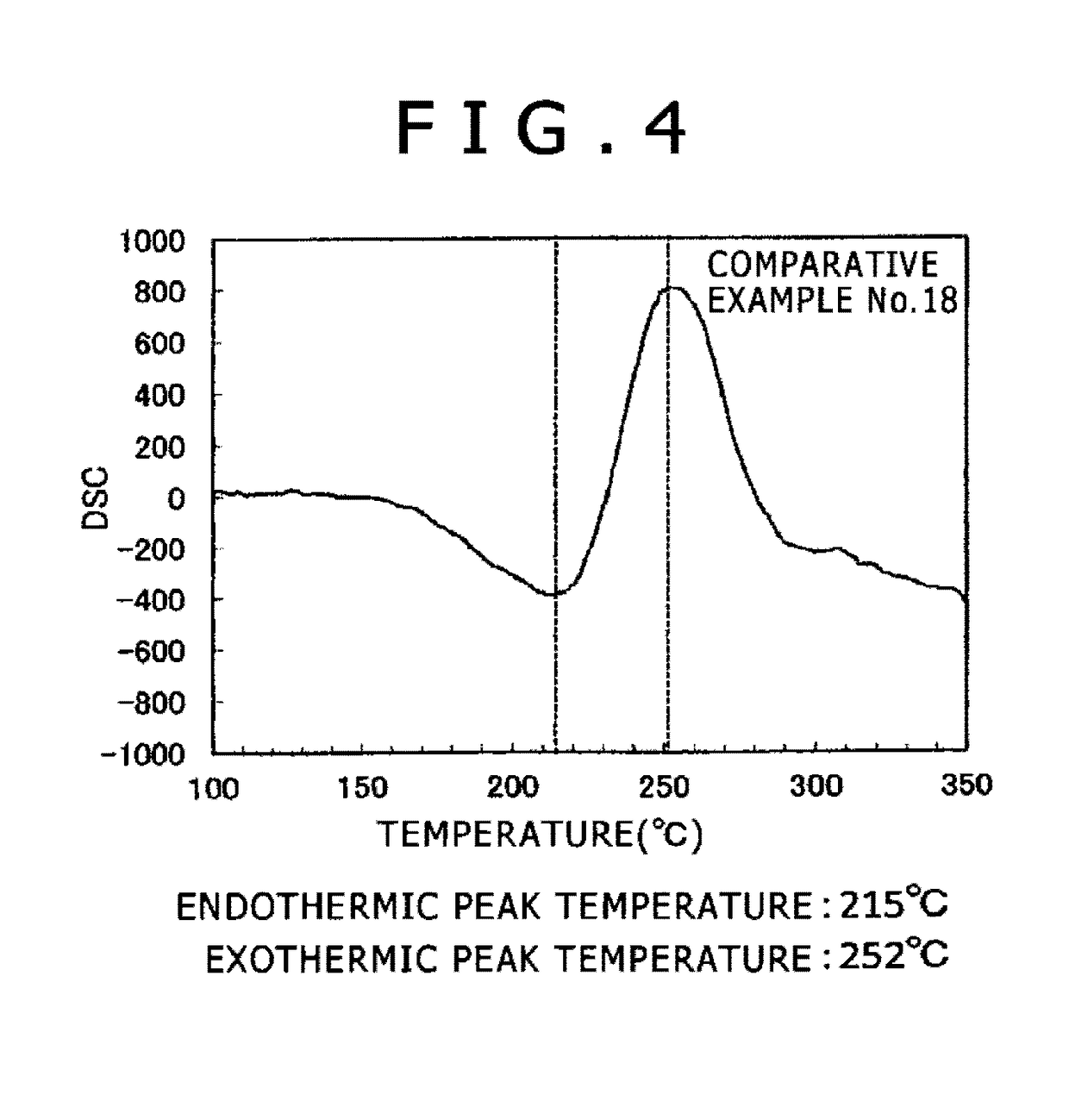

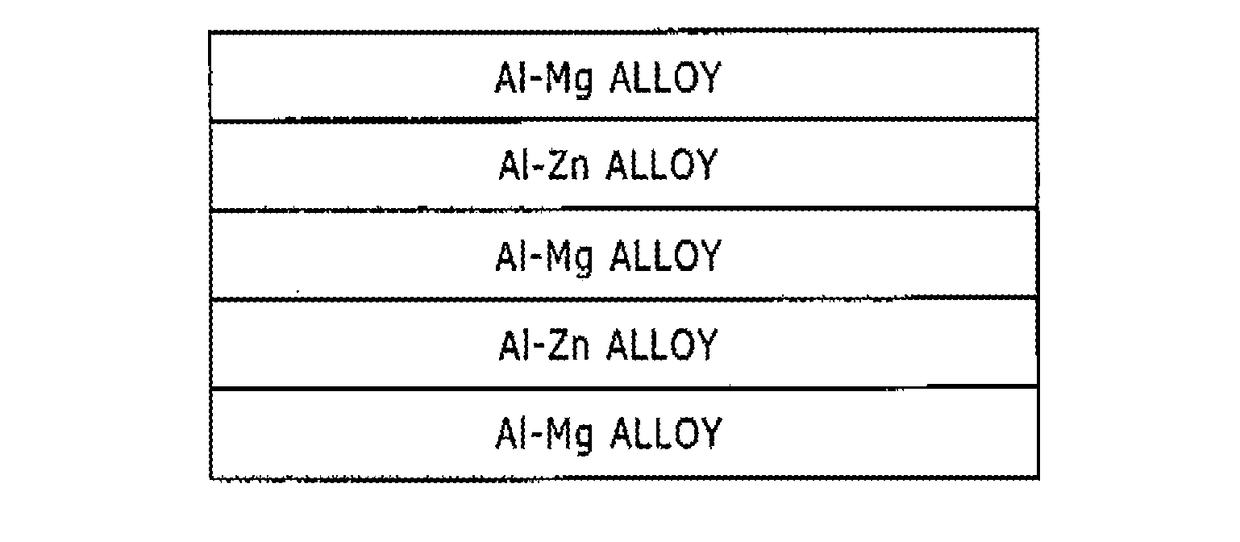

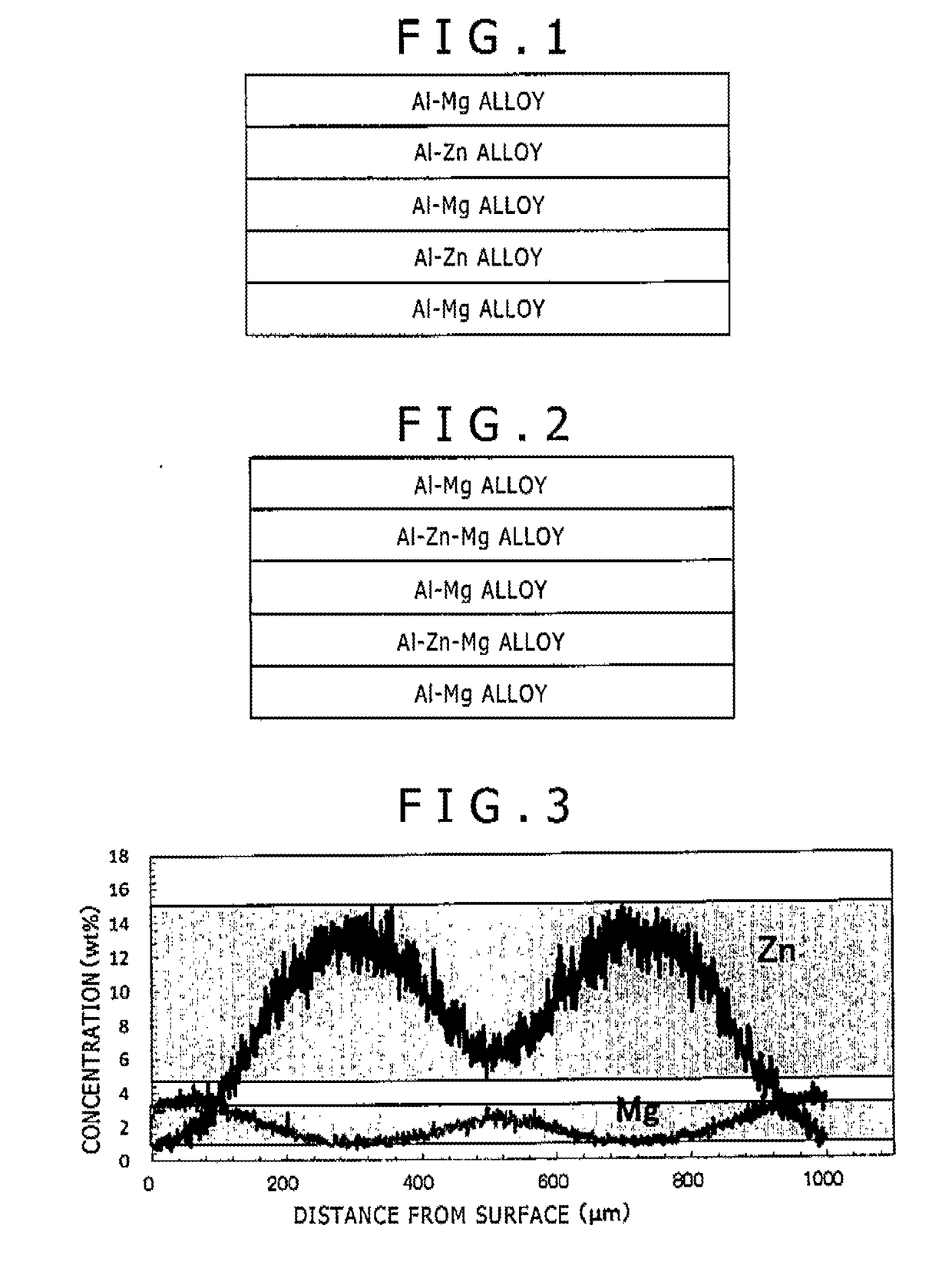

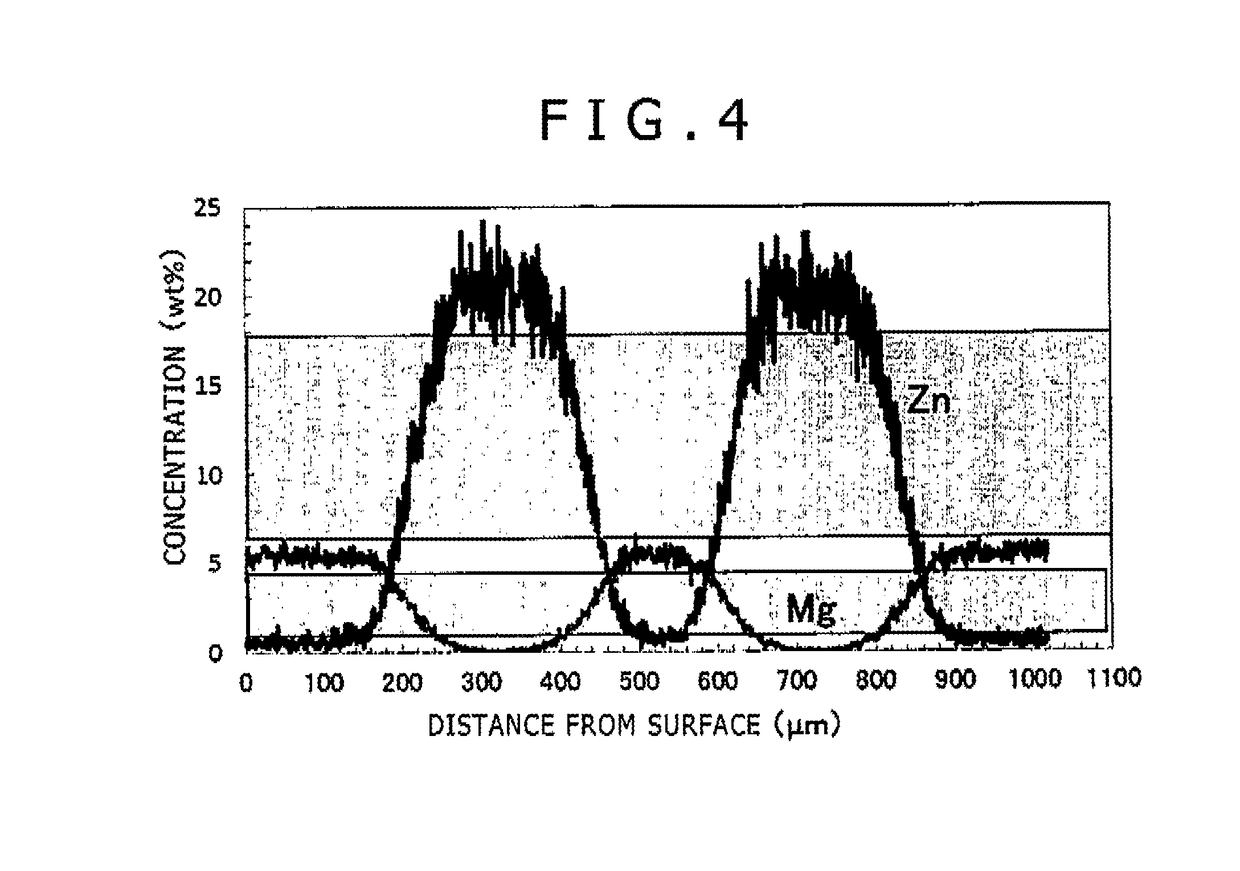

Aluminum-alloy-clad plate and aluminum-alloy-clad structural member

ActiveUS20180022067A1High strengthGood molding effectThin material handlingMetal layered productsUltimate tensile strengthHeat treating

An aluminum-alloy-clad plate which includes a plurality of superposed aluminum alloy layers and which has undergone a diffusion heat treatment. Aluminum alloy layers having specific compositions are superposed so that any adjoining two of these differ in the content of Mg or Zn, and are subjected to a diffusion heat treatment to give a structure which has fine crystal grain diameters and Mg / Zn mutual diffusion regions and which has specific DSC properties. Thus, both higher strength and high formability are imparted.

Owner:KOBE STEEL LTD

Thick steel plate having excellent cryogenic impact toughness and manufacturing method therefor

ActiveUS20190316219A1Improve efficiencyImprove economyFurnace typesHeat treatment furnacesSheet steelImpact toughness

The purpose of one aspect of the present invention is to provide: a thick steel plate capable of removing a conventional normalizing treatment required for ensuring toughness low temperature and cryogenic environments, and having properties equal to or better than those of a conventional steel subjected to the normalizing treatment; and a method for manufacturing the method.

Owner:POHANG IRON & STEEL CO LTD

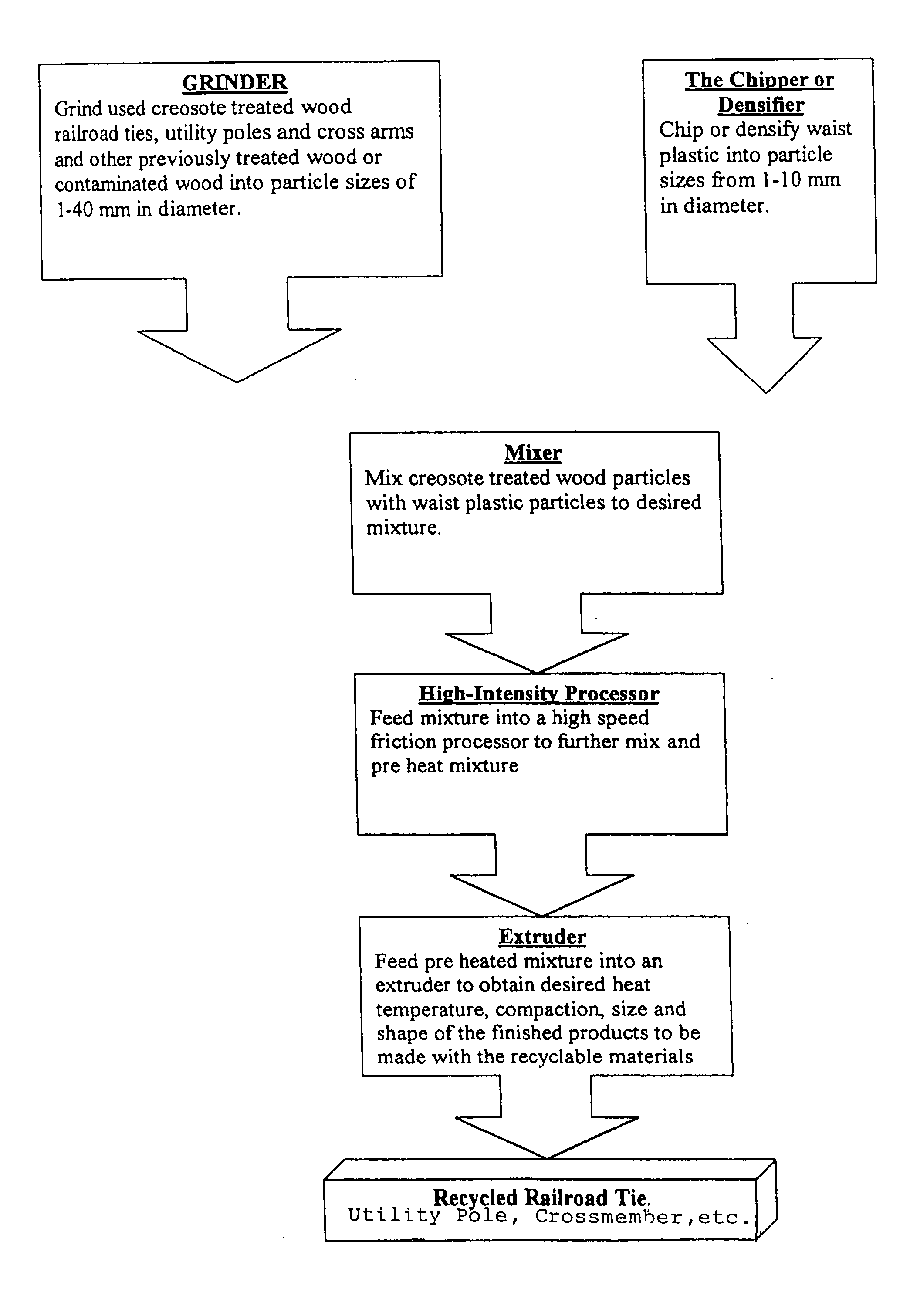

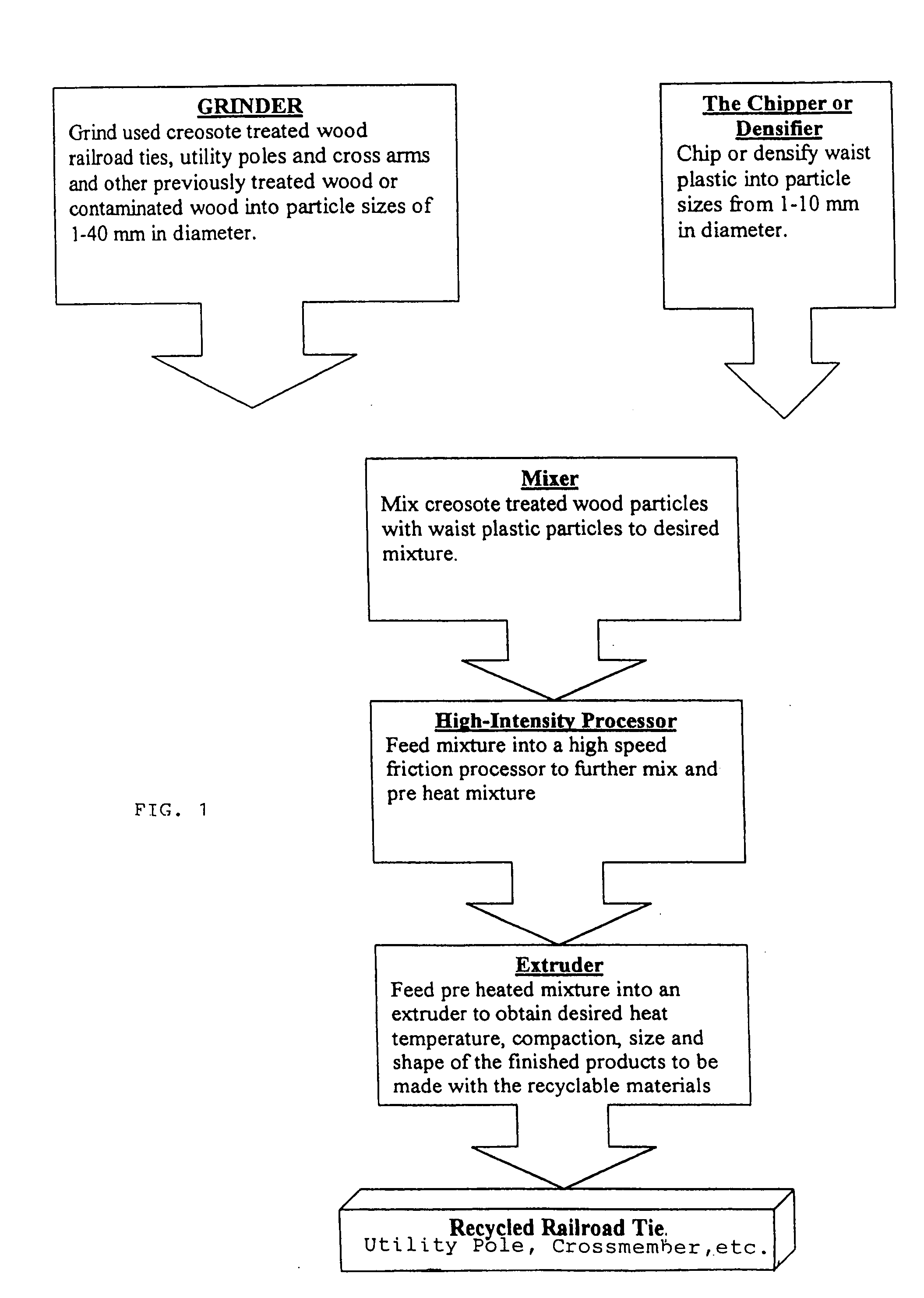

Structural members fabricated from waste materials and method of making the same

ActiveUS20050166535A1Prohibitive expenseRequired strengthBallastwaySolid waste disposalMolten stateThermoplastic

The structural member and fabrication thereof may be formed by mixing wood products chemically treated for durability and thermoplastics products. The fabrication process may included processing the products to a desired particle size; mixing the particles; processing the mixture in a high intensity processor and then processing the mixture in an extruder to obtain a molten state for forming the structural element in a mold. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a search or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:LEON JOSEPH

Vehicle subframe

In a vehicle subframe, one of a pair of cross members includes a lower member open to a lower side of a vehicle, with an upper wall thereof having an upper wall recess depressed downward, an upper member arranged so as to cover the upper wall recess from above the vehicle and connected to the lower member, an inside space defined by the lower member and the upper member in cooperation, and a holding member connected to the lower member and the upper member in a mode in which the holding member is sandwiched between the lower member and the upper member, while penetrating the inside space in a longitudinal direction, to hold a component to be mounted.

Owner:F TECH INC

Fusion-bonded product having high-strength part and manufacturing method thereof

InactiveUS8202628B2Easy to getRequired strengthTransmission elementsDifferential gearingsFusion weldingMechanical engineering

Owner:MUSA PRECISION IND CO LTD

Aluminum-alloy-clad plate and aluminum-alloy-clad structural member

InactiveUS20180001596A1High strengthGood molding effectThin material handlingMetal layered productsComposite plateUltimate tensile strength

An aluminum-alloy-clad plate in which a plurality of aluminum alloy layers are layered and diffusion heat treatment is performed thereon, wherein aluminum alloy layers having a specific composition are layered so as to each have a different content Mg or Zn, the structure of the aluminum alloy clad plate after diffusion heat treatment thereof has a minute crystal grain diameter and a predetermined amount of a specific Mg and Zn inter-diffusion region in which Mg and Zn of layered aluminum alloy layers are diffused with each other, and increased strength and high moldability are obtained at the same time.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com