Patents

Literature

215results about How to "Improve layout flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

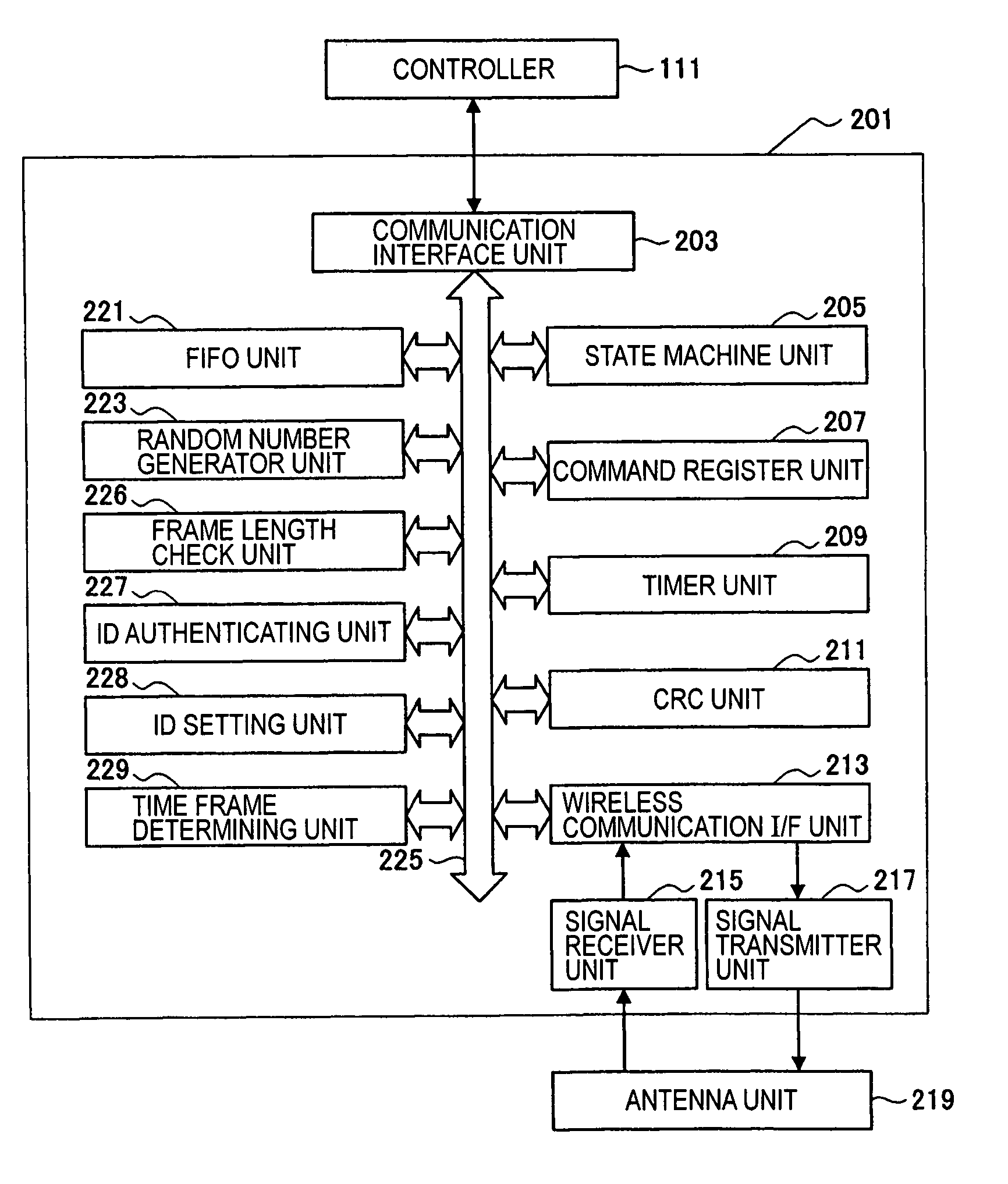

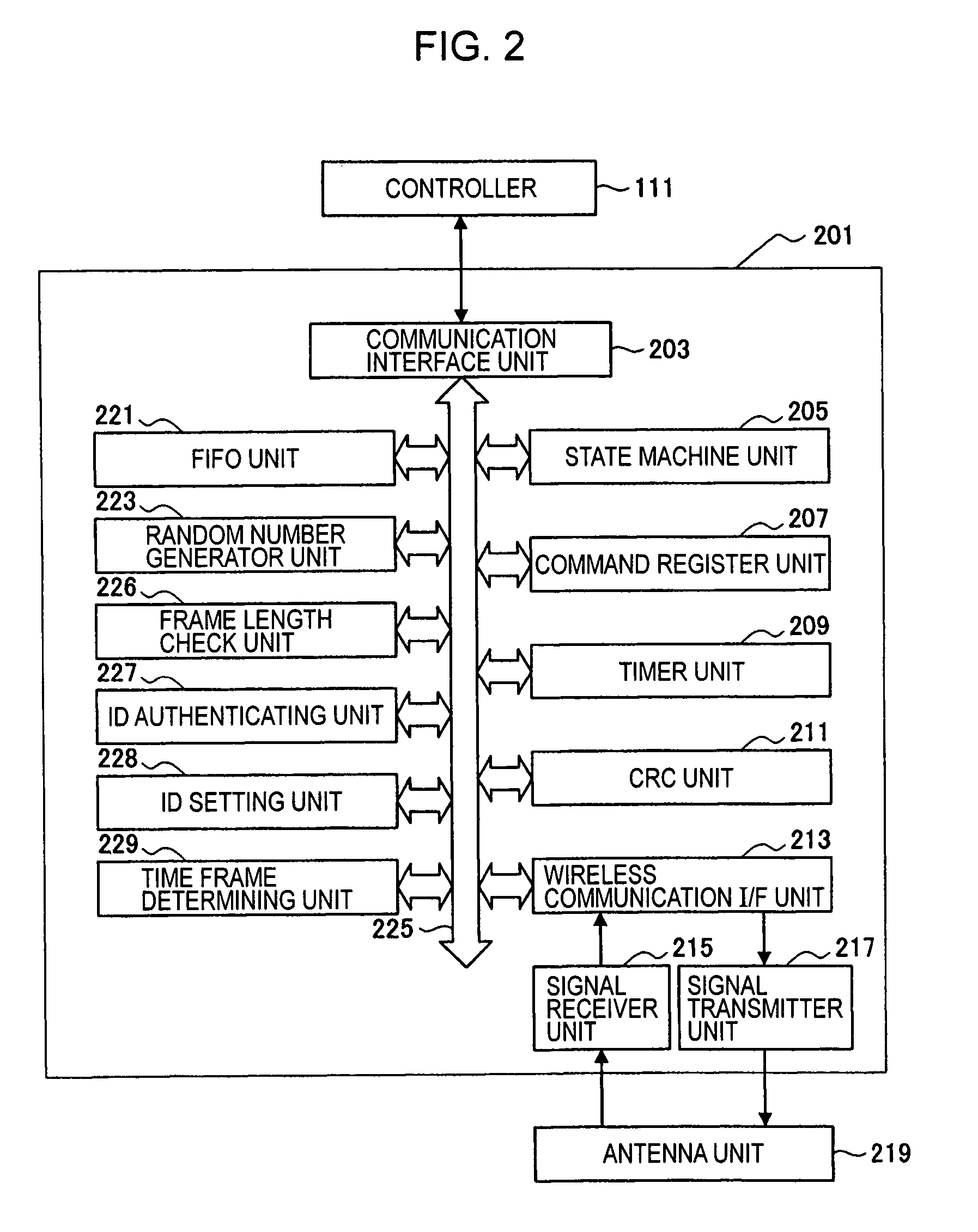

Wireless communication apparatus and response data processing method therefor

InactiveUS20050111420A1Efficient data storageEfficient use ofUnauthorised/fraudulent call preventionDigital data processing detailsCommunication interfaceReal-time computing

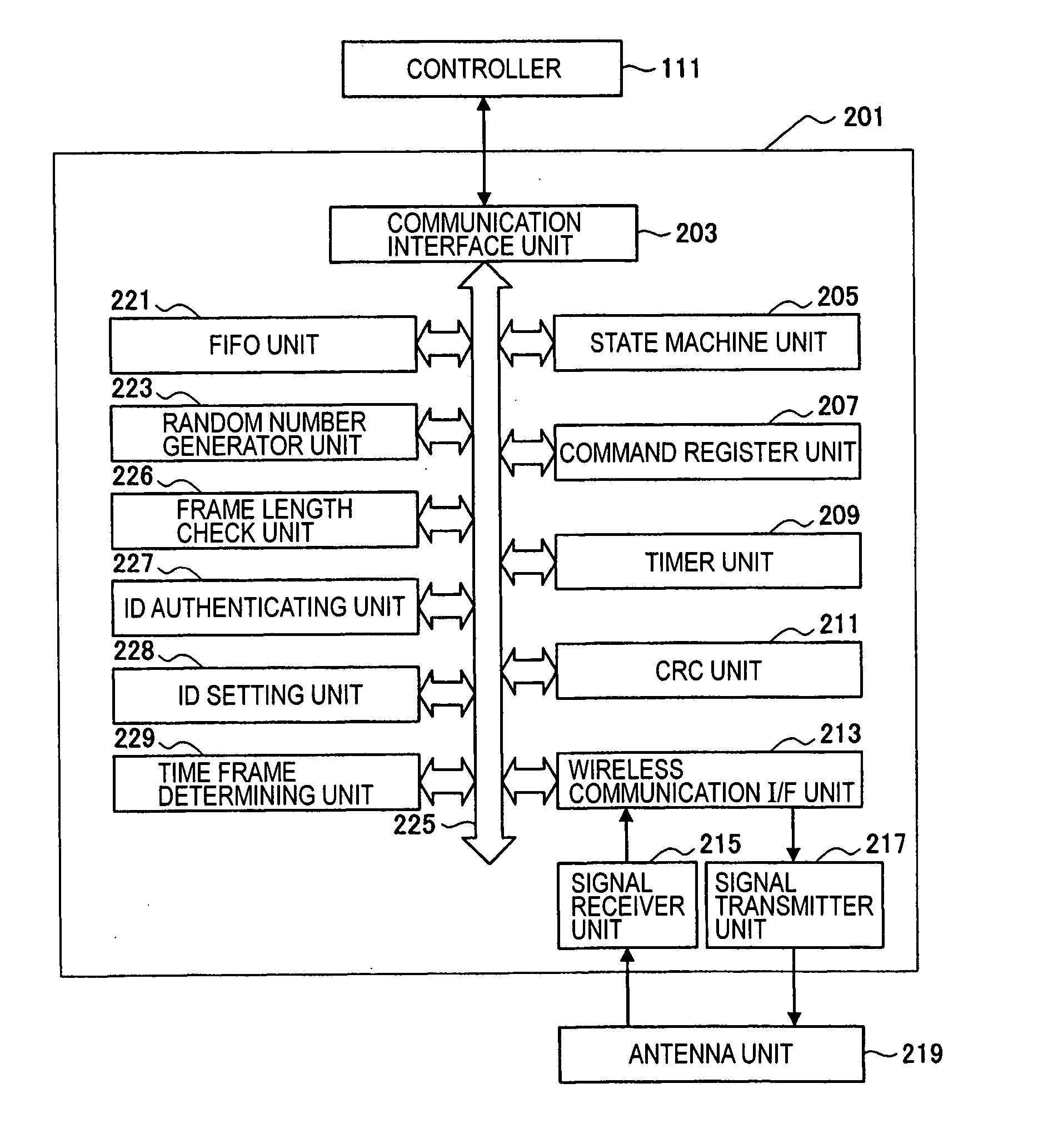

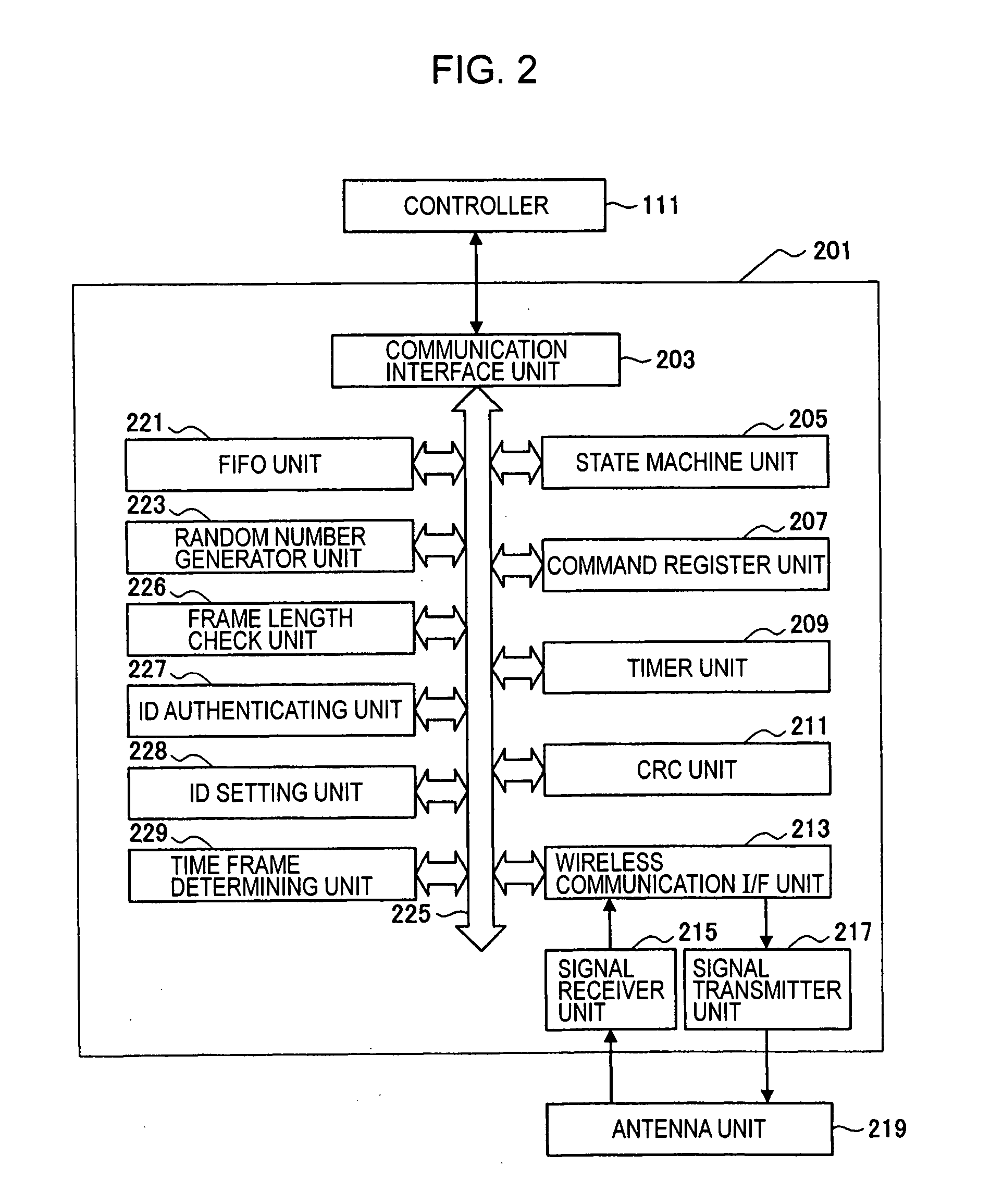

A wireless communication apparatus that communicates data with an external wireless apparatus in a wireless communication range includes a controller and a wireless communication interface device is provided. The wireless communication interface device includes a transmitting unit that transmits response request data to the external wireless apparatus, a counter that counts time for determining whether or not a time limit for waiting for the response data has elapsed, a storage unit that stores the response data, a receiving unit that receives first response data from the external wireless apparatus and that instantaneously receives second response data without an instruction from the controller when the time limit has not elapsed, a frame length checking unit that checks a frame length of the received response data, and an error detector that performs error detection on the response data.

Owner:SONY CORP

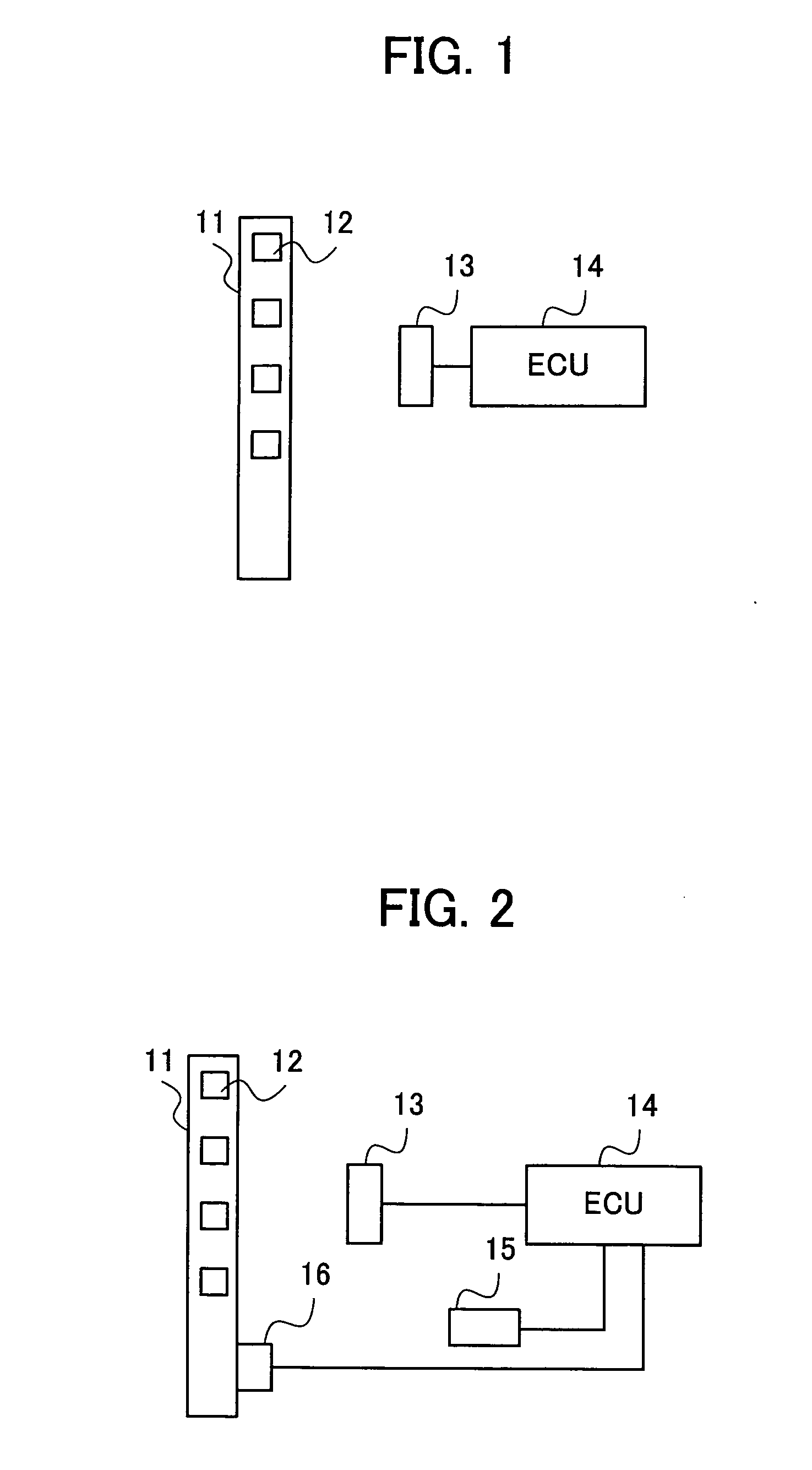

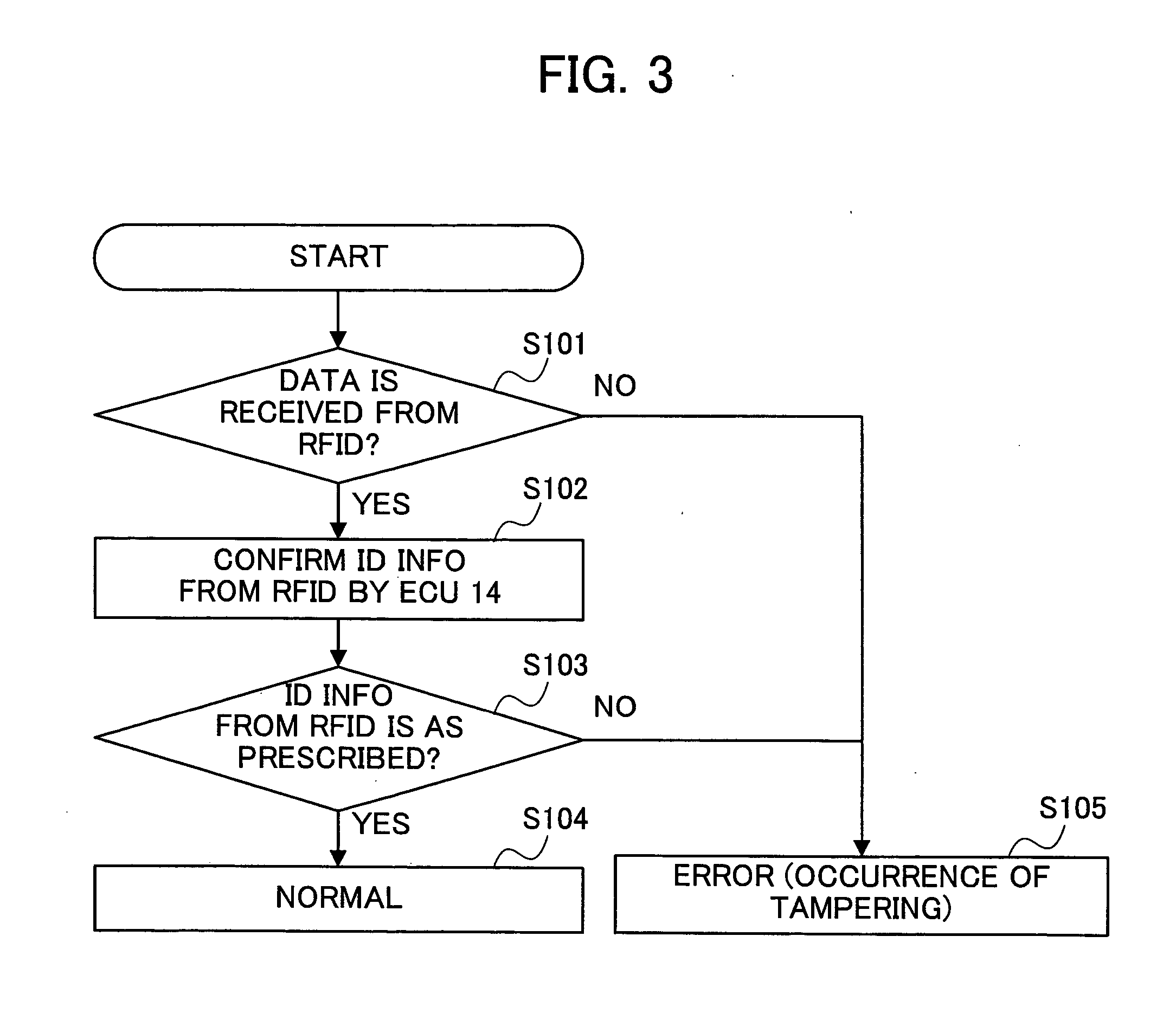

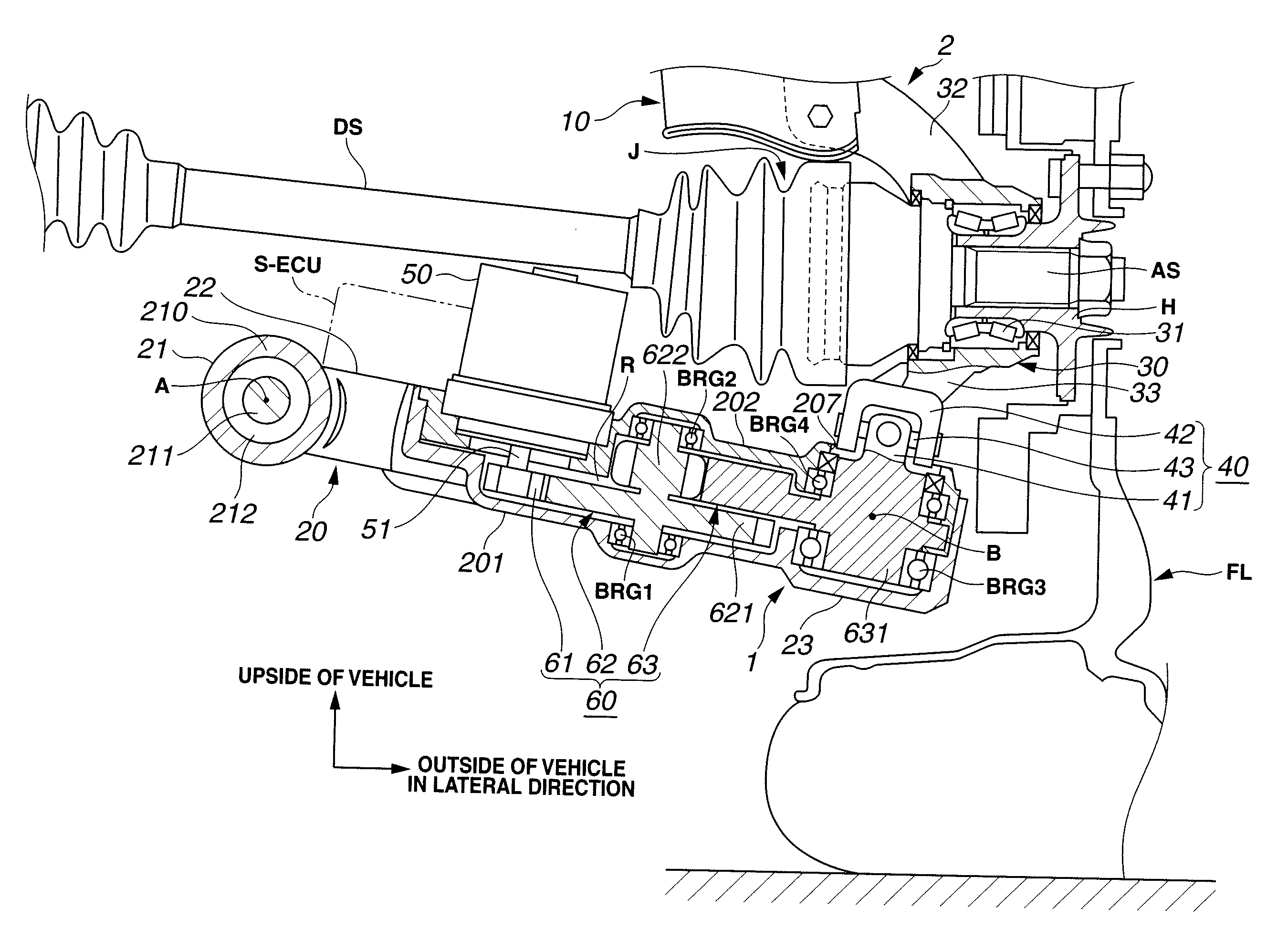

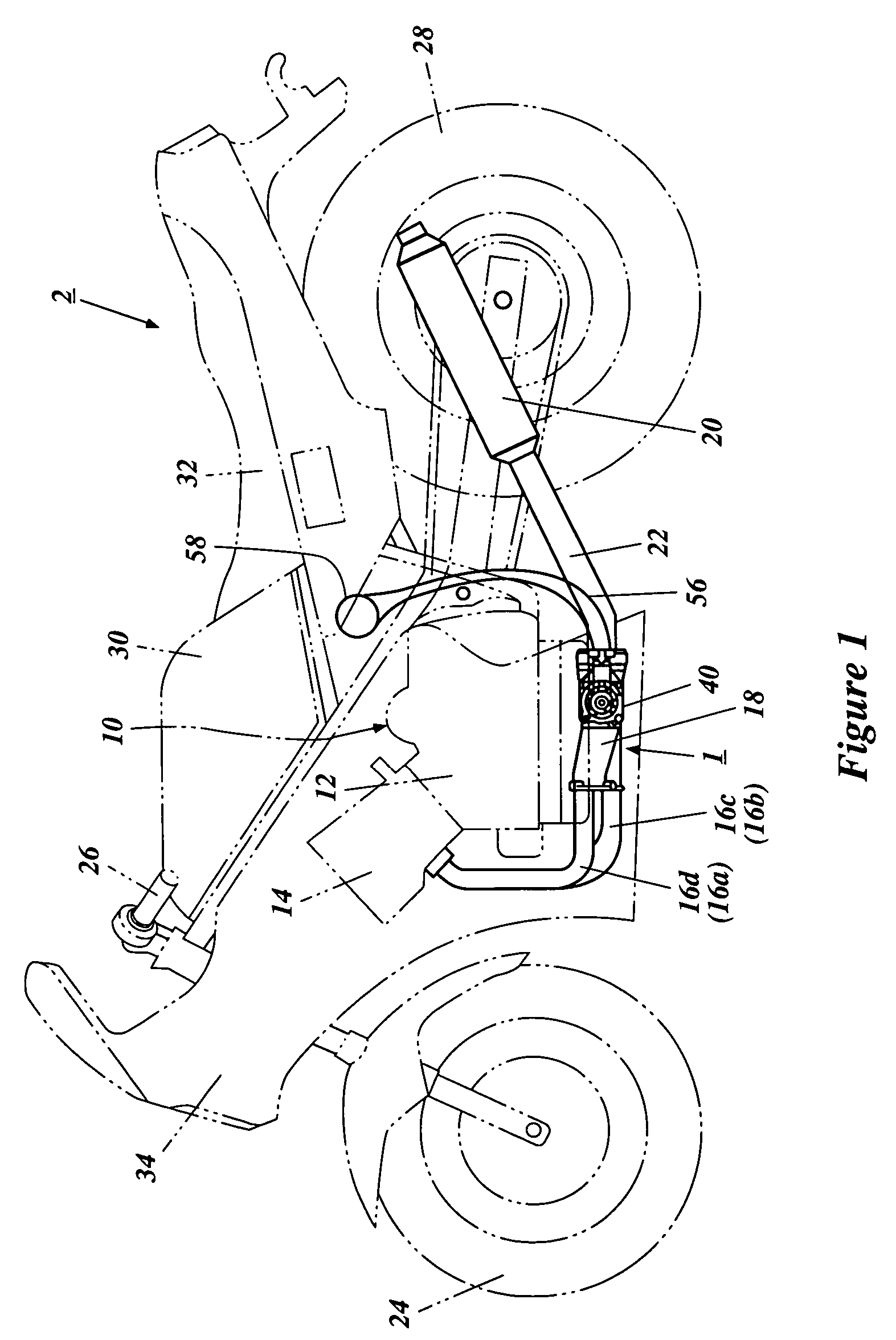

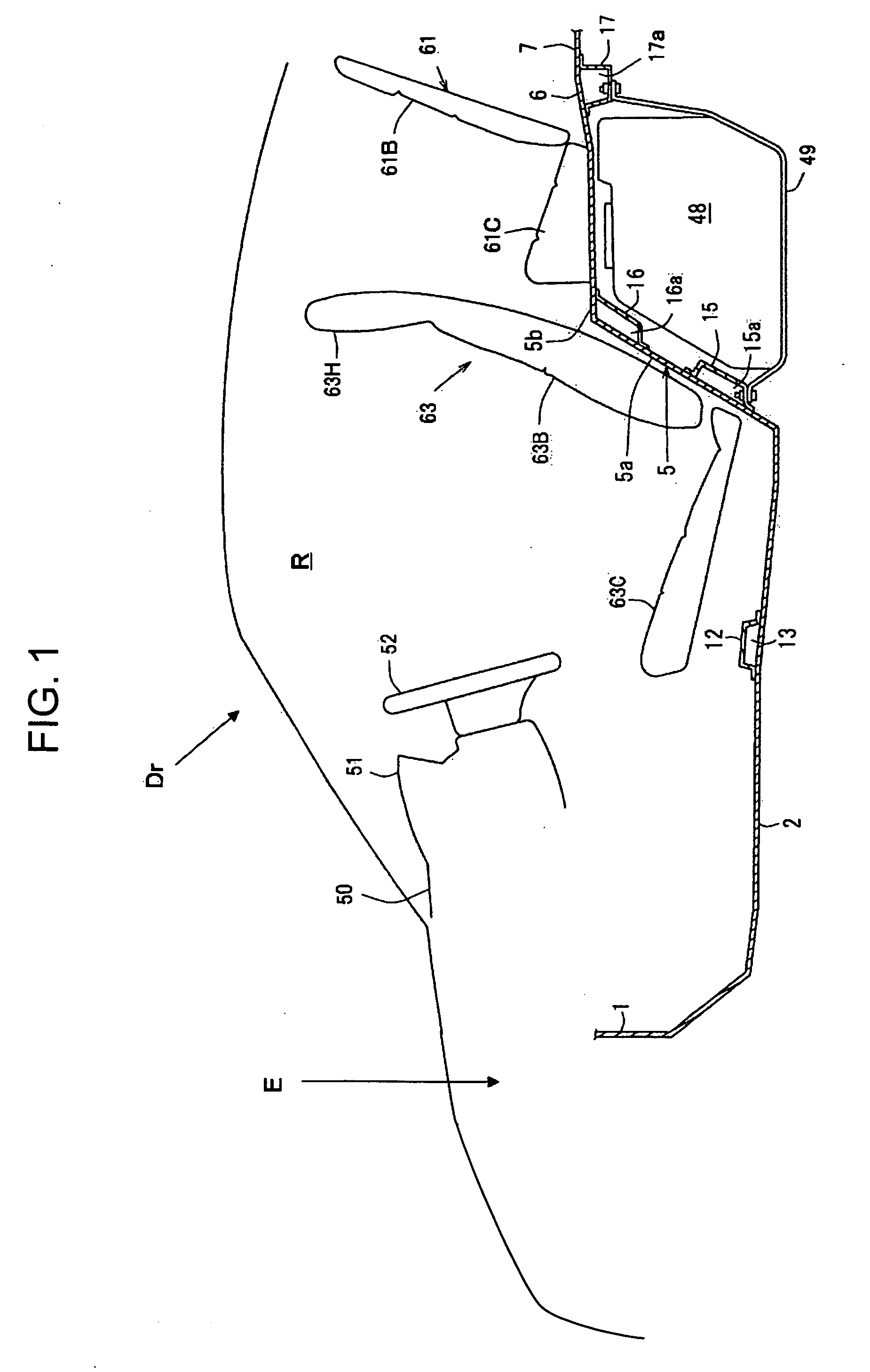

Vehicle component tamper detection system

InactiveUS20070018830A1Remove restrictionsImprove layout flexibilityTicket-issuing apparatusAnti-theft devicesSlurryRadio frequency

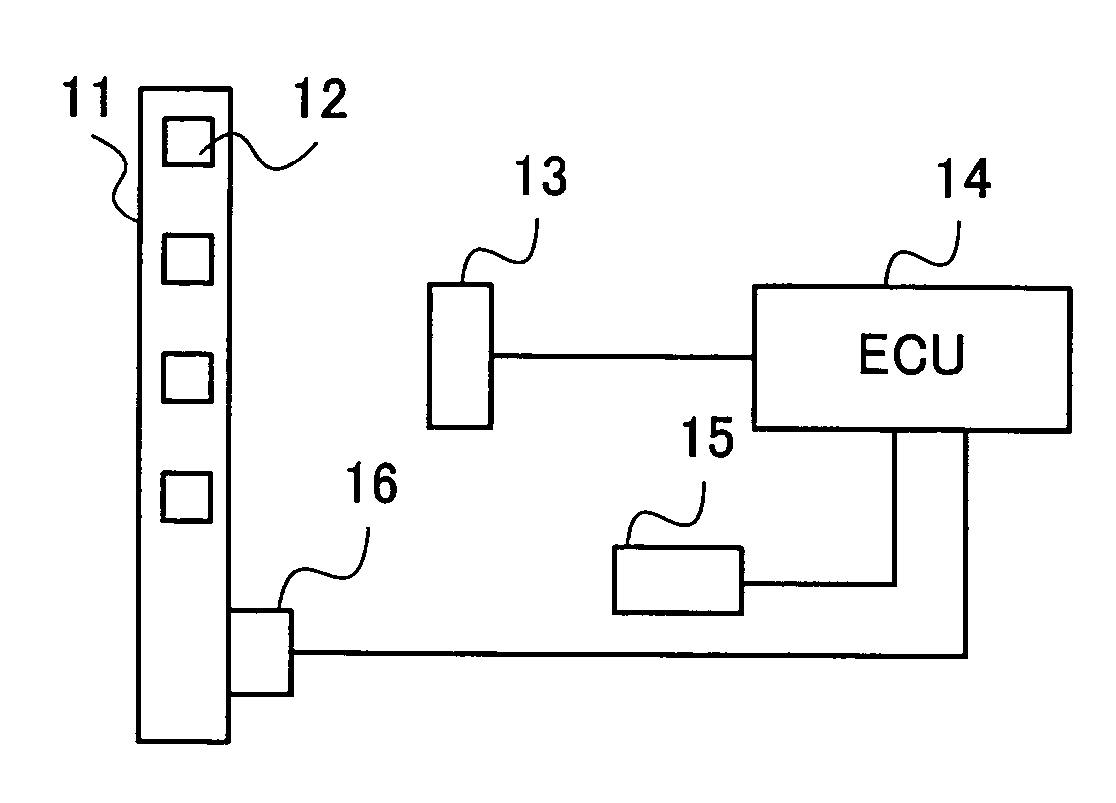

A vehicle component tamper detection system is provided capable of appropriately preventing tampering from occurring, and of facilitating and ensuring detection of such tampering when it occurs, while maintaining flexibility in layout and in manufacturing processes. The present invention omits wiring between an RFID 12 and an ECU 14 by employing a small radio frequency identification integrated circuit (RFID) to wirelessly transmit signals to a receiver 13. With this configuration, the present invention contributes to increased layout flexibility as well as a reduction in assembly steps and manufacturing costs. Furthermore, because the RFID 12 is small, the RFID 12 may be mixed in slurry and disposed at an inconspicuous portion of a detection target component 11. Subsequently, it is possible to hinder visual confirmation of the RFID 12, thereby making the tampering itself difficult.

Owner:HONDA MOTOR CO LTD

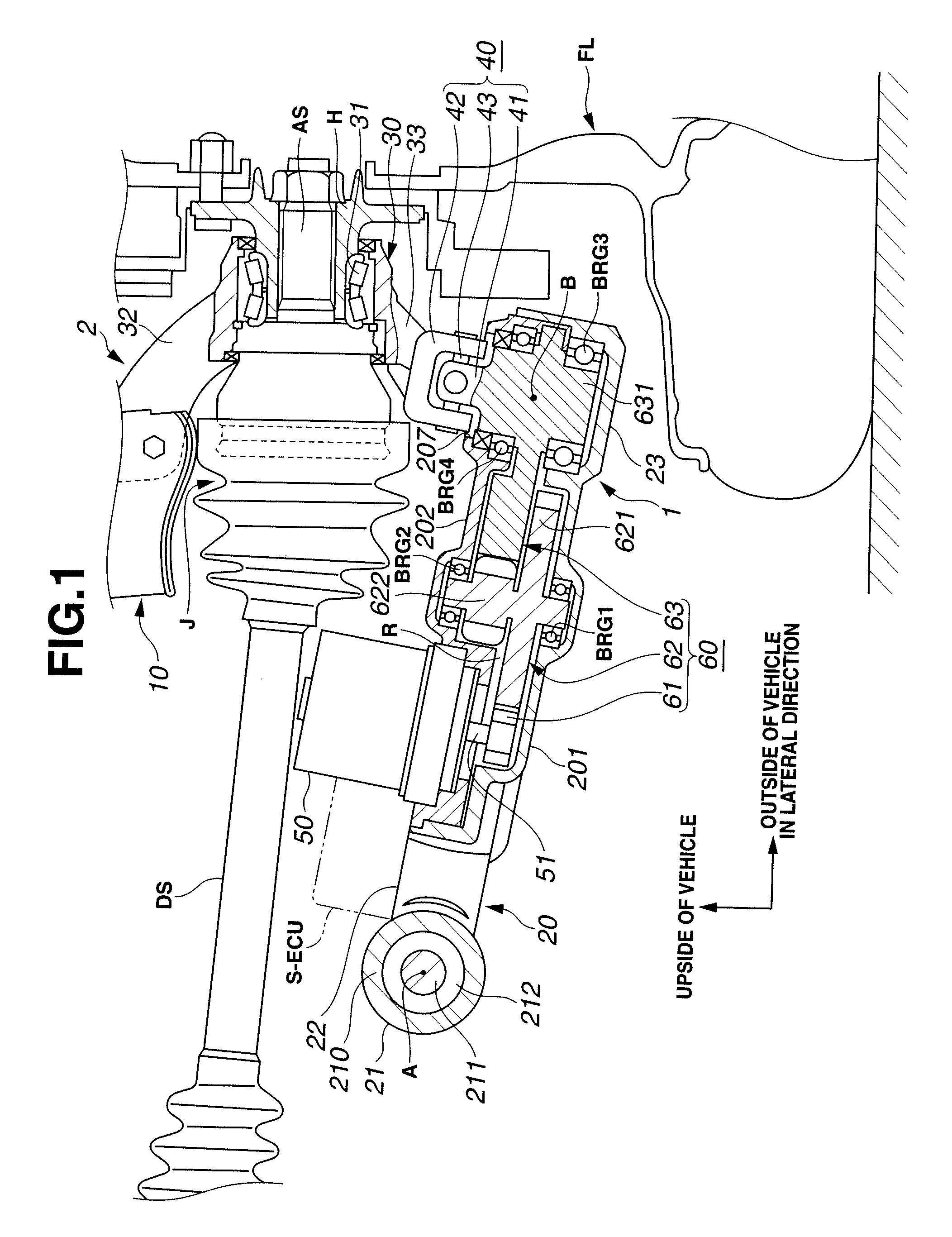

Steering apparatus

ActiveUS20090057050A1Improve layout flexibilityEnhance saleabilitySteering linkagesFluid steeringControl armControl theory

A steering apparatus includes an axle housing rotatably supporting a wheel hub on which a steered road wheel is installed, and a lower suspension-system control arm adapted to be oscillatingly supported at one end on a vehicle body and having a turning portion provided at the other end for pivotably supporting the axle housing by the turning portion. An electric motor is installed on the lower arm for turning the axle housing by a driving force produced by the motor. A rotation axis of the motor and a pivot of the axle housing are arranged to be offset from each other.

Owner:HITACHI ASTEMO LTD

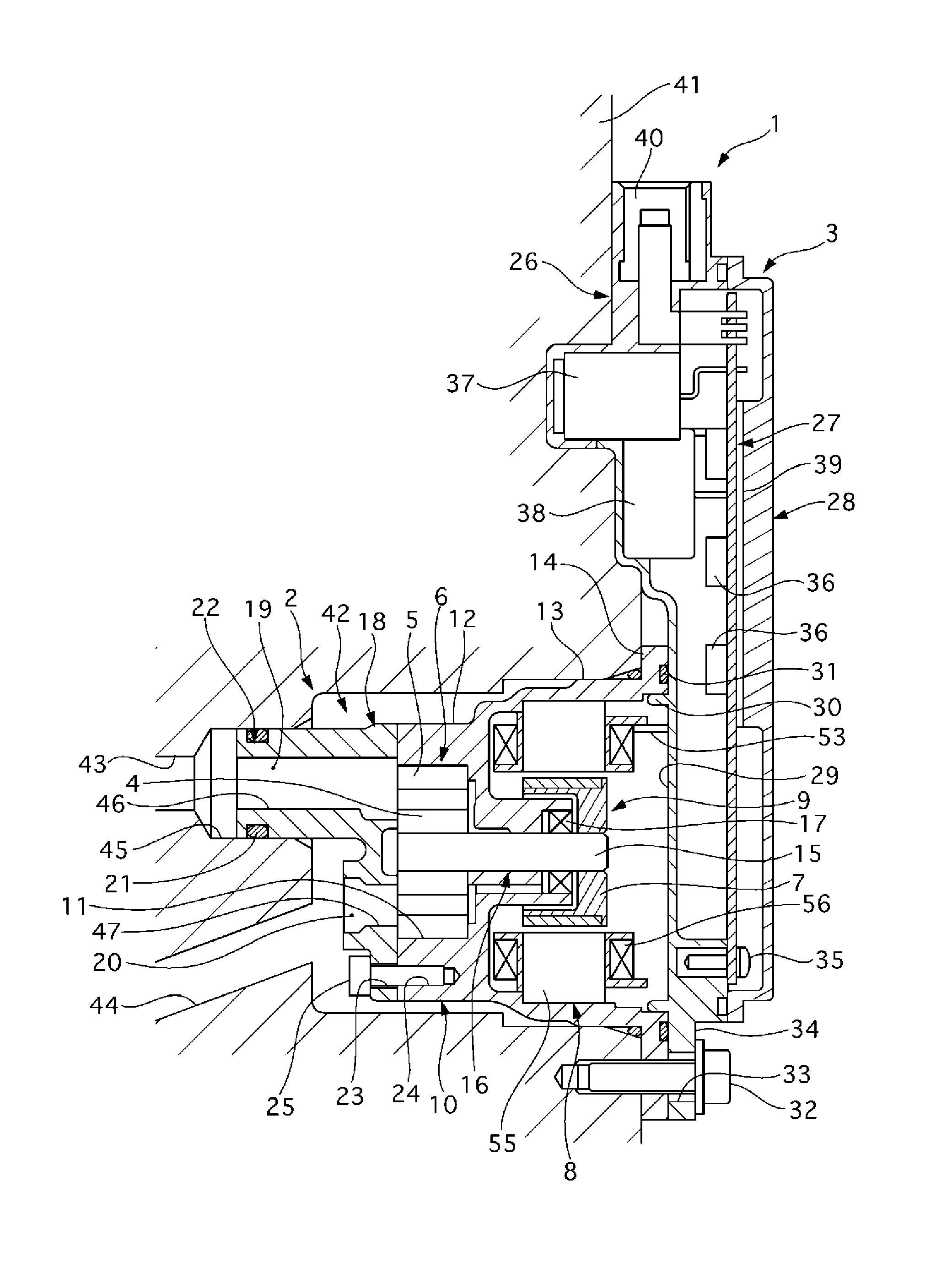

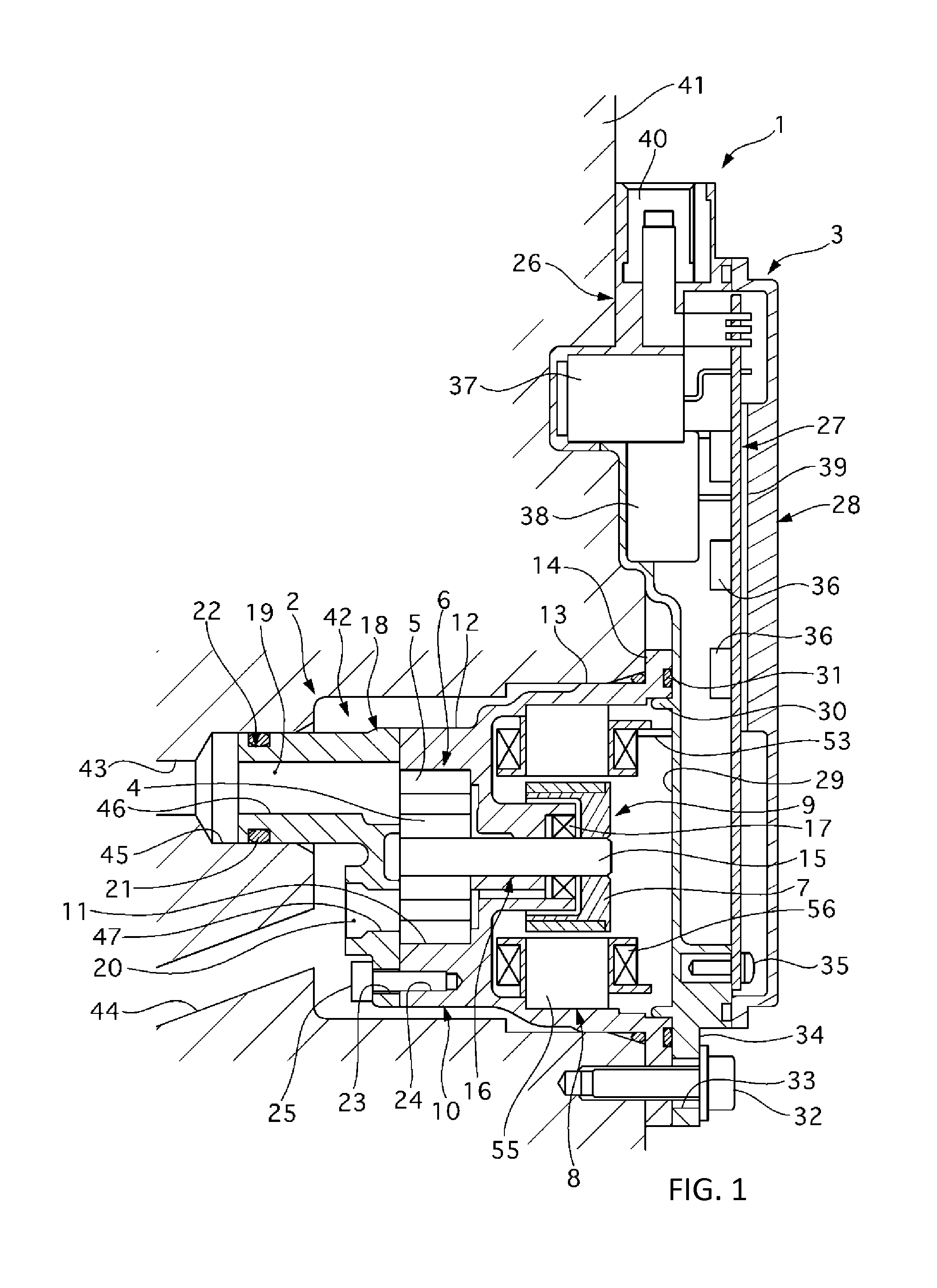

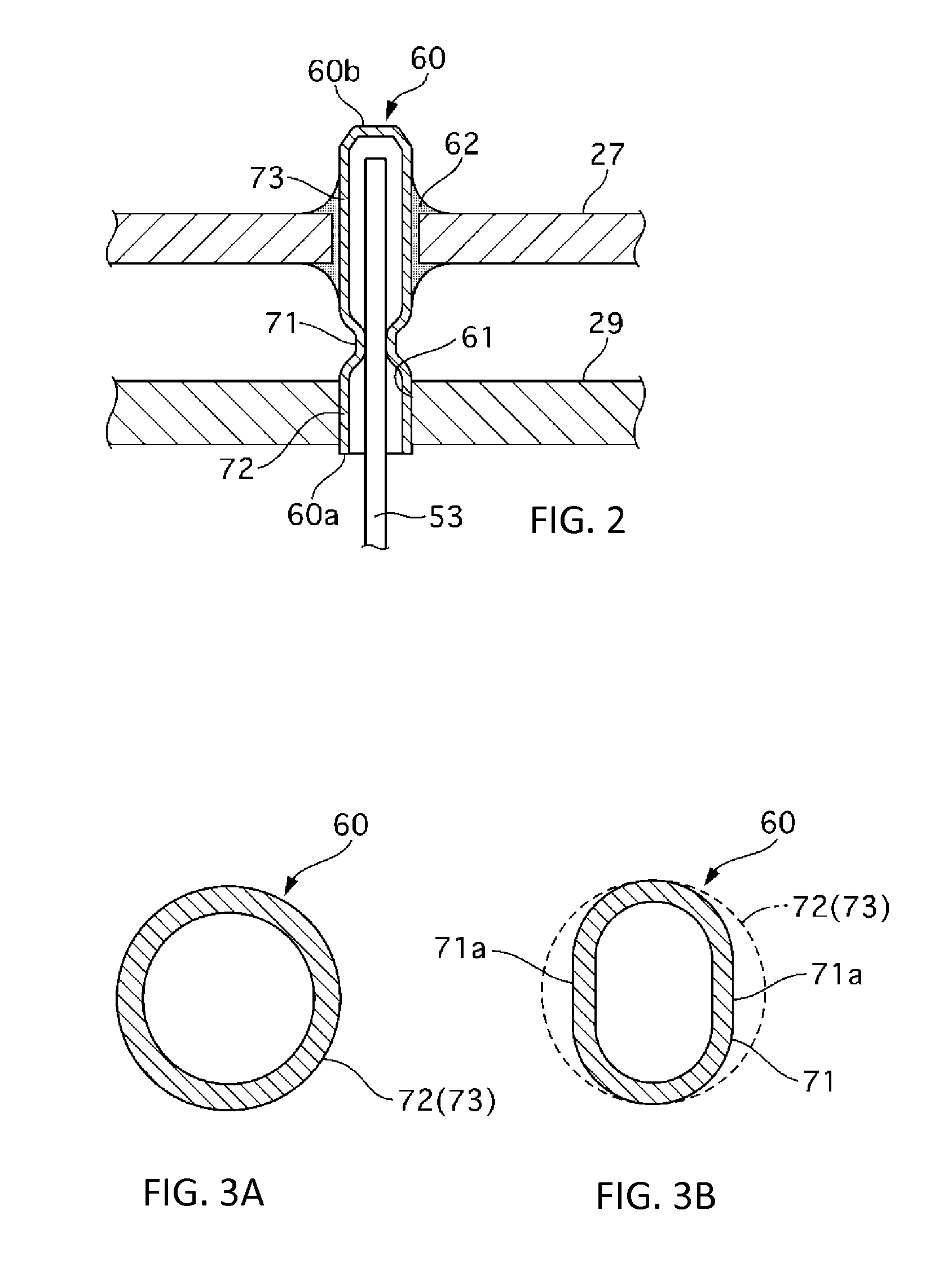

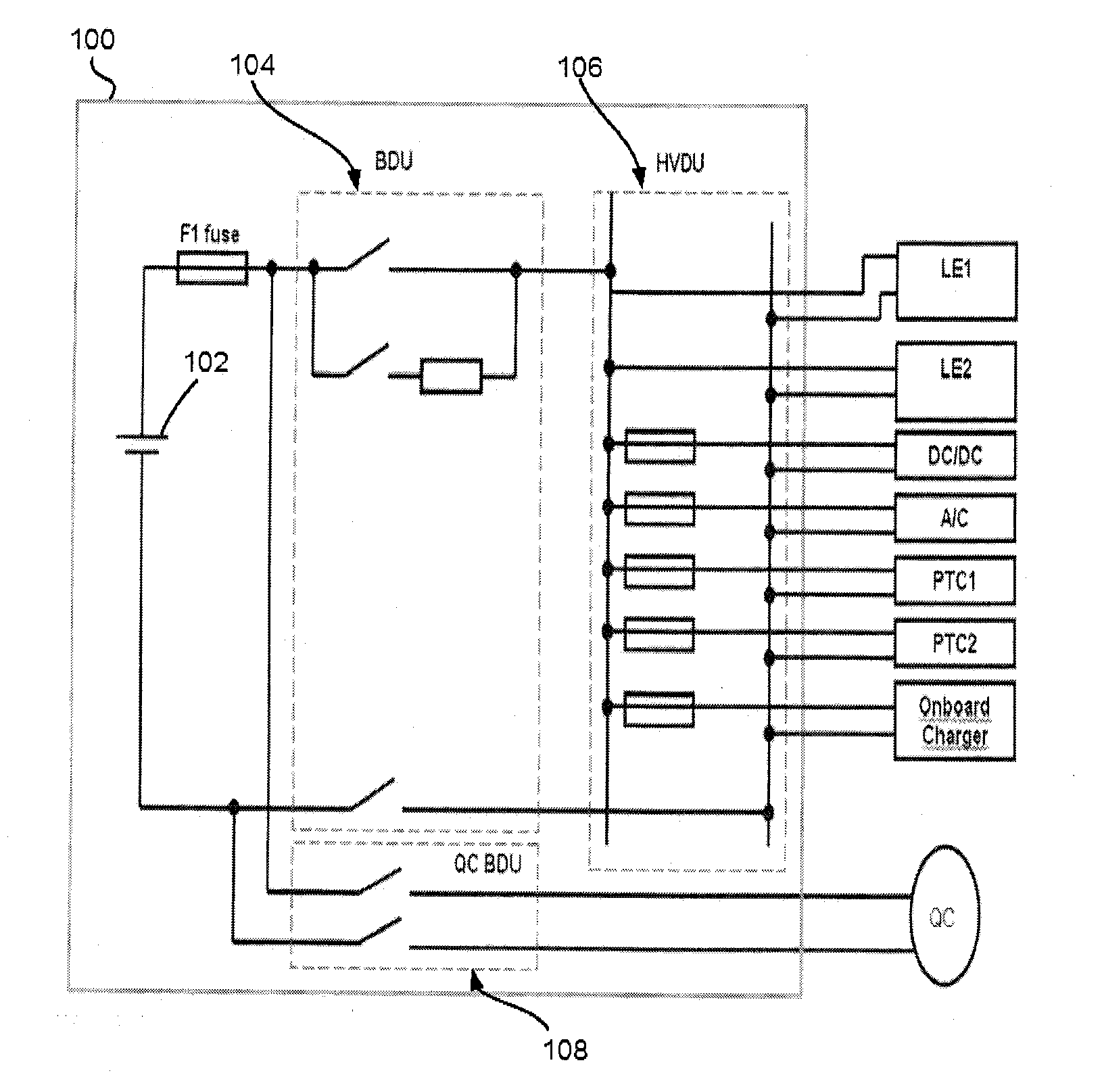

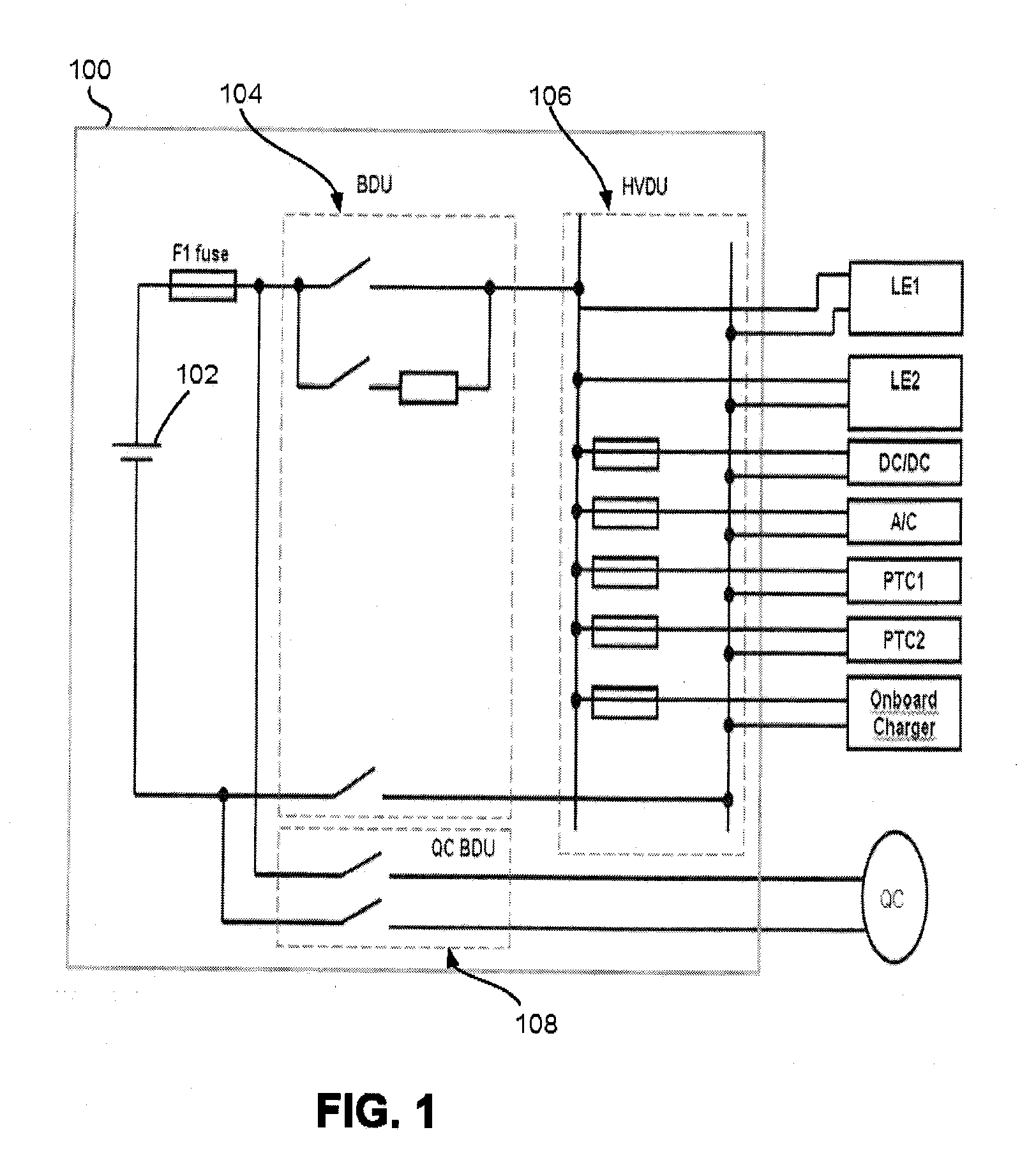

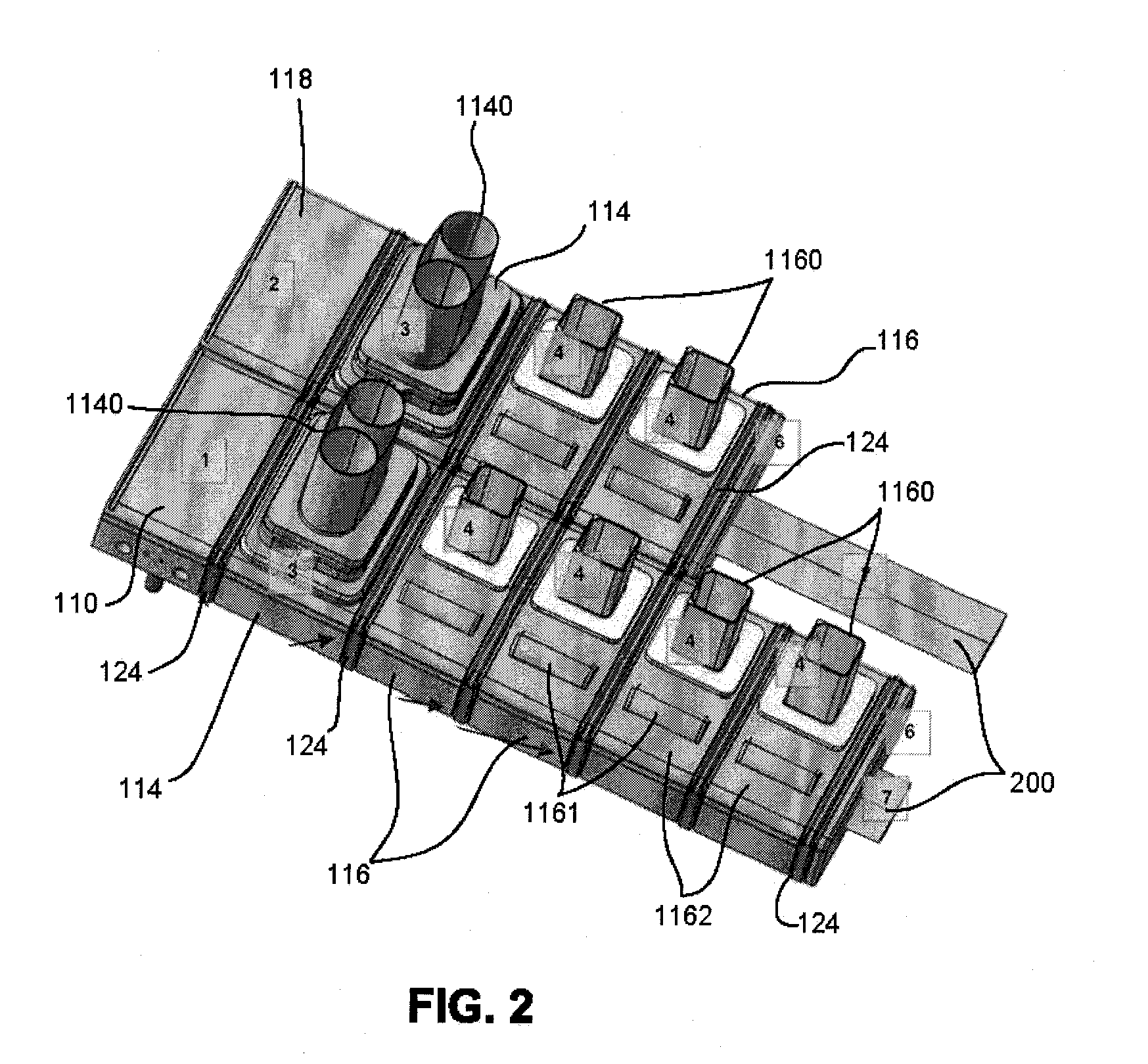

Mechanical and Electrical-Integrated Drive Unit

InactiveUS20140054991A1Improve layout flexibilityMinimize impactAssociation with control/drive circuitsRotary piston pumpsEngineeringElectronic component

A mechanical and electrical-integrated drive unit is provided that is configured to be able to protect a control circuit board from thermal stress, a contaminant, or operating fluid from a motor housing chamber and that can improve the flexibility of layout of electronic components mounted on the control circuit board. The drive unit includes a motor, a control circuit board for controlling energization of the motor, the circuit board installed integrally with the motor, an obstruction portion isolating the motor from the circuit board, and an inverter housing for the circuit board. A coil wire of the motor is covered at its end by a conductive thin-walled narrow tube so as to be joined to the tube. The tube is fixedly inserted into a through-hole formed in the obstruction portion so that at least the leading end portion of the tube is projected into the inverter housing.

Owner:HITACHI AUTOMOTIVE SYST LTD

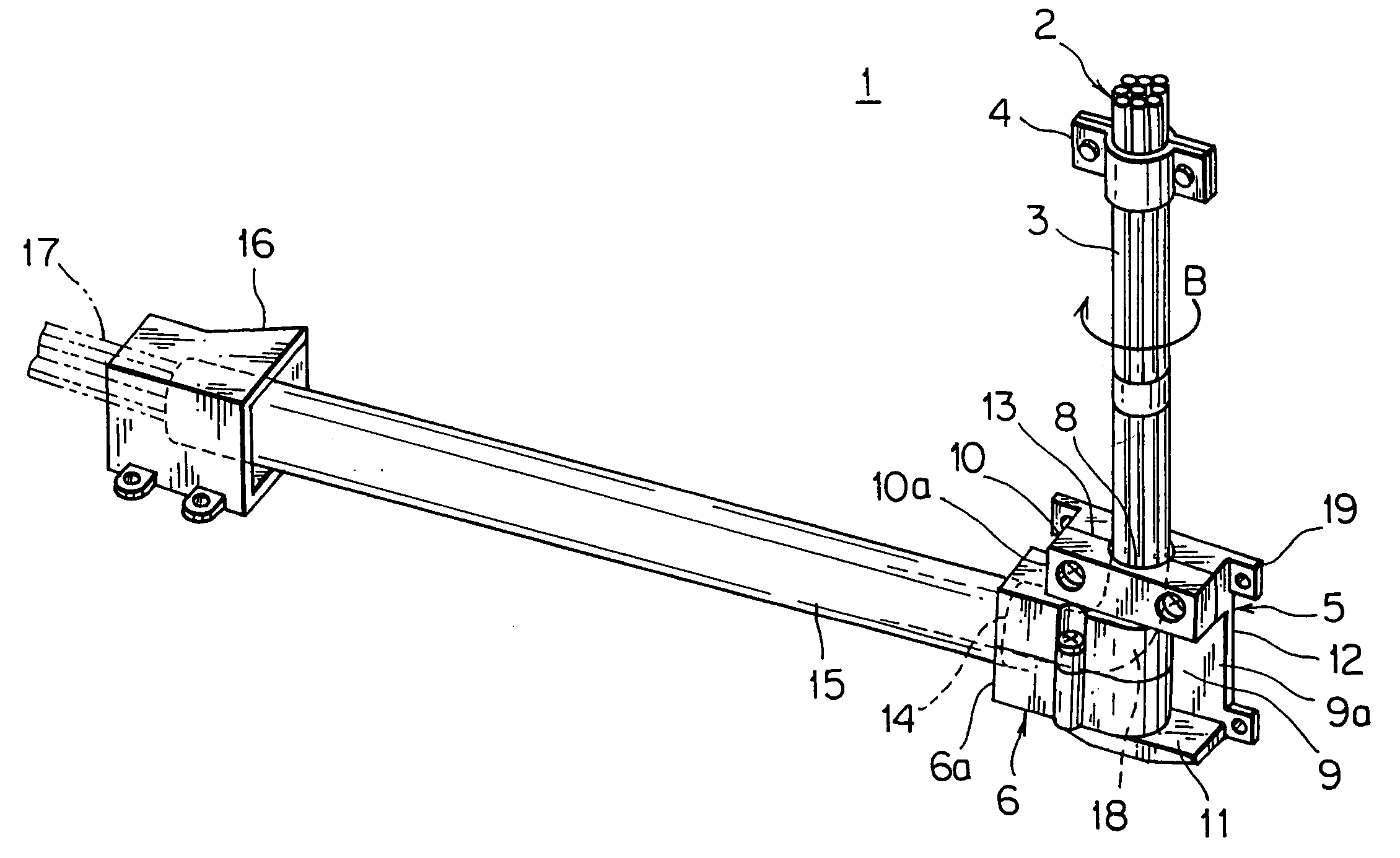

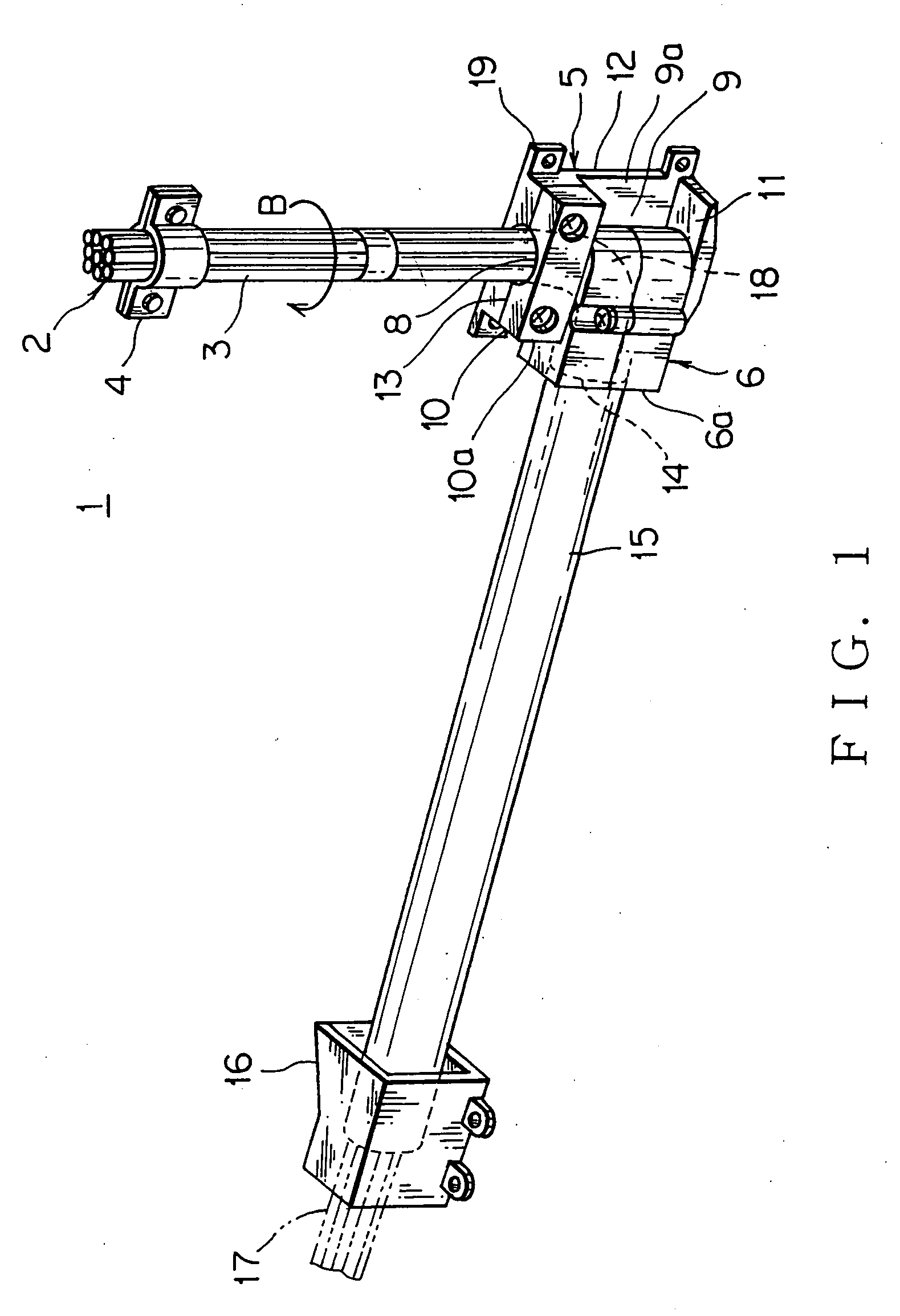

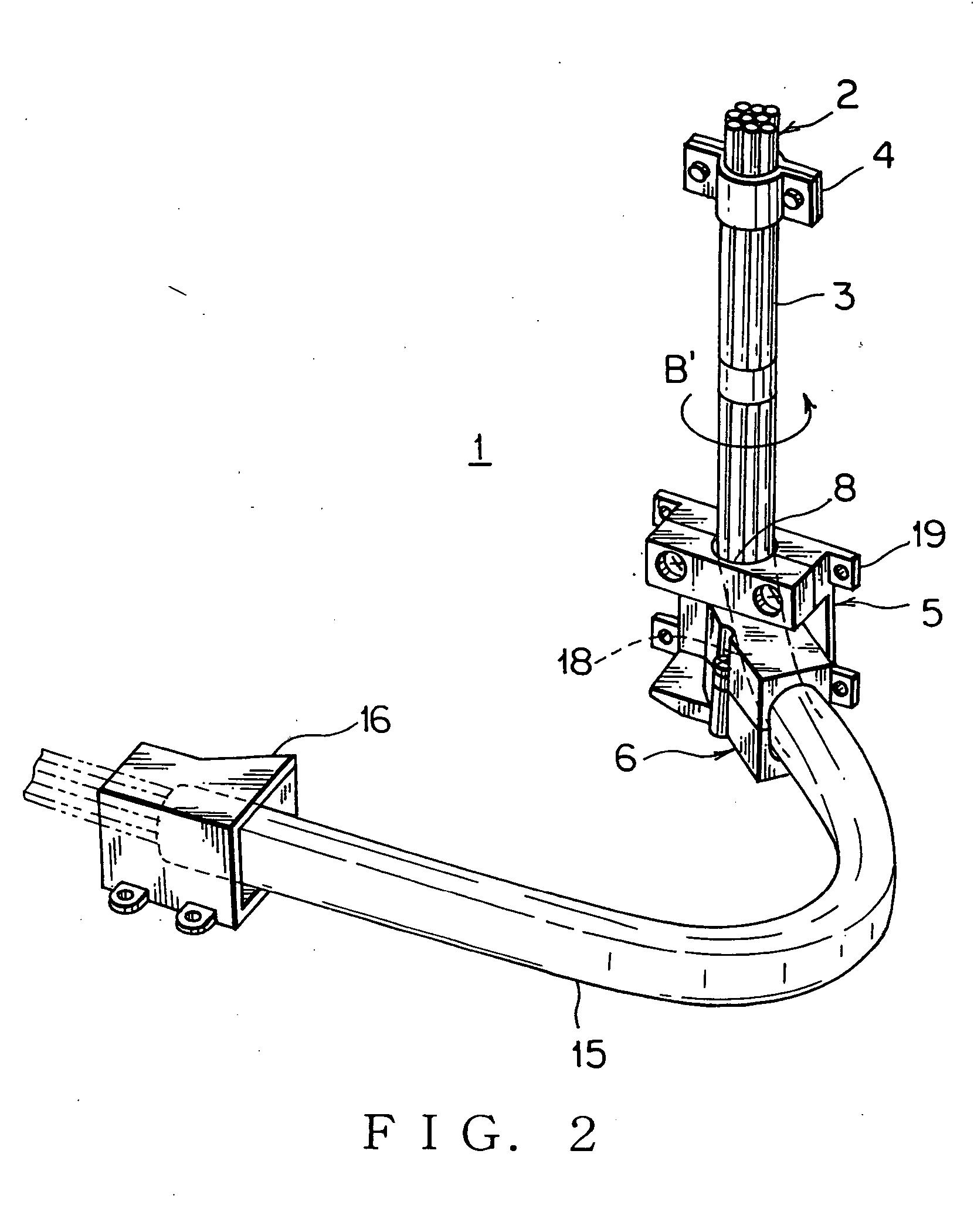

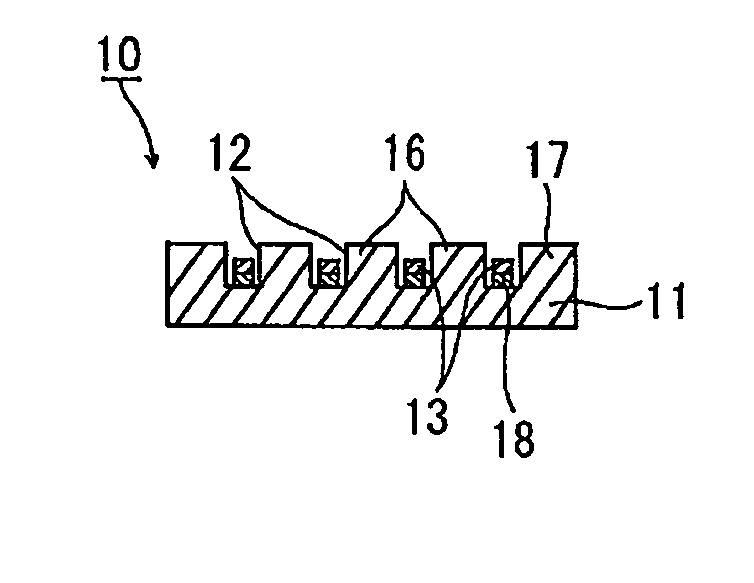

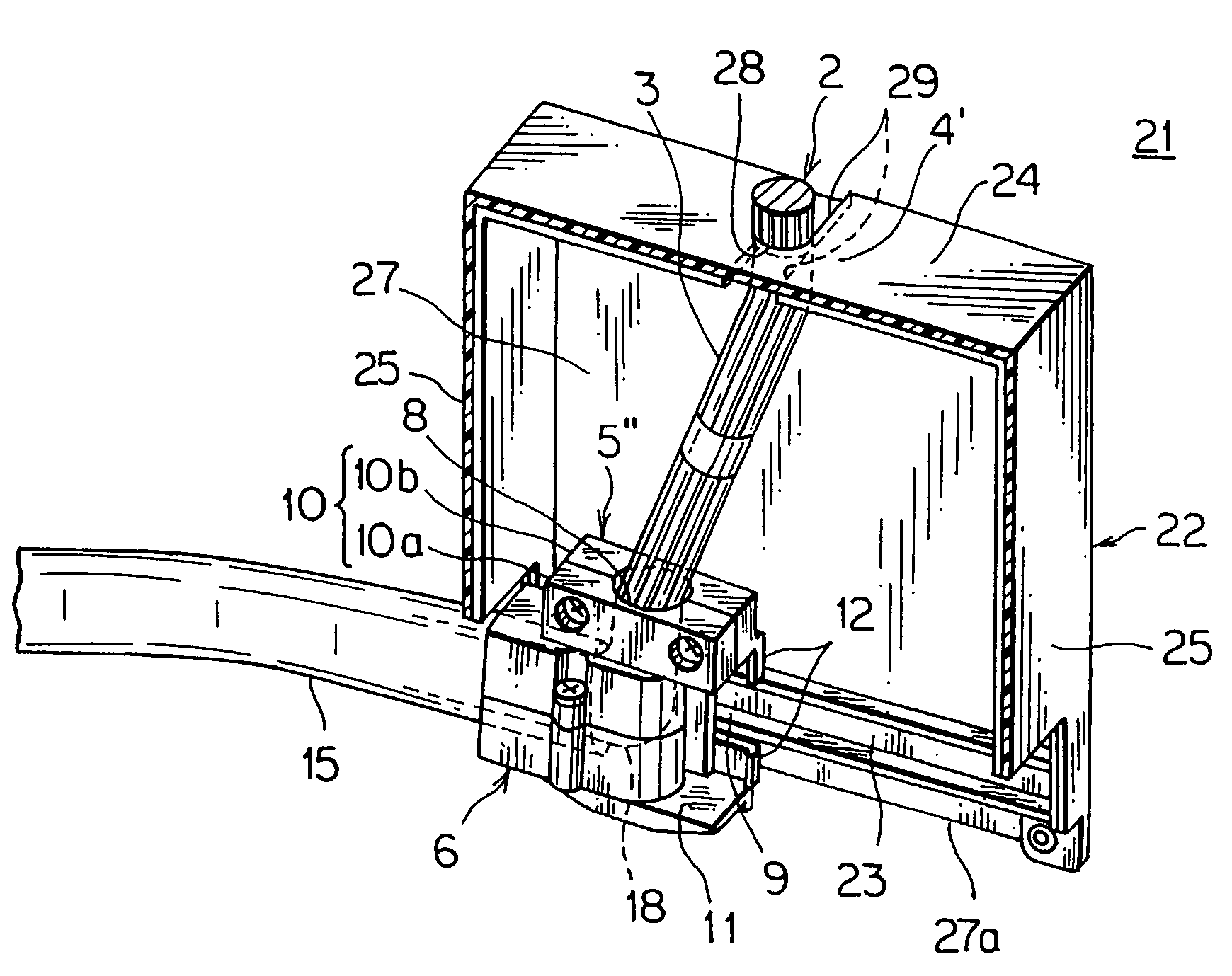

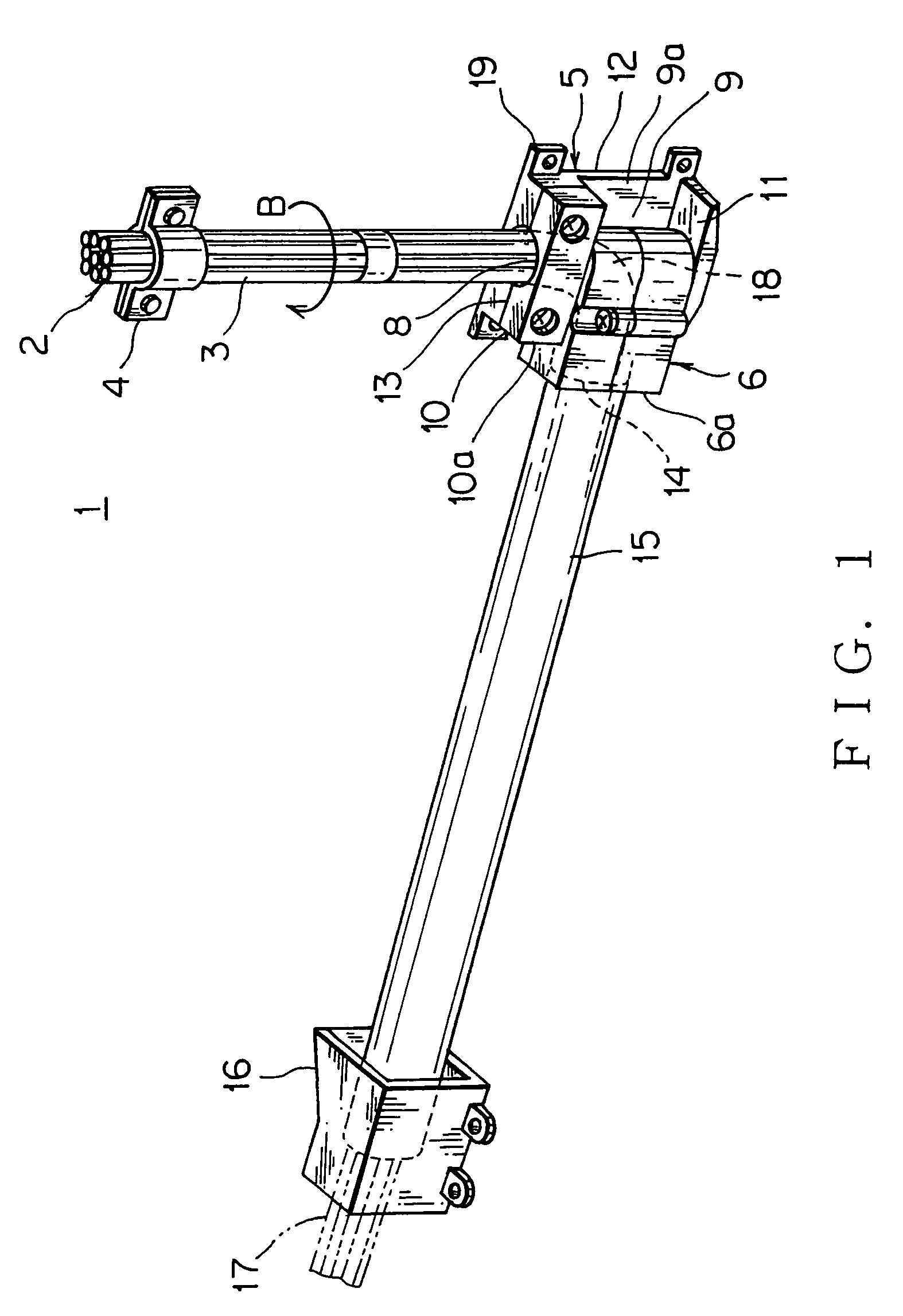

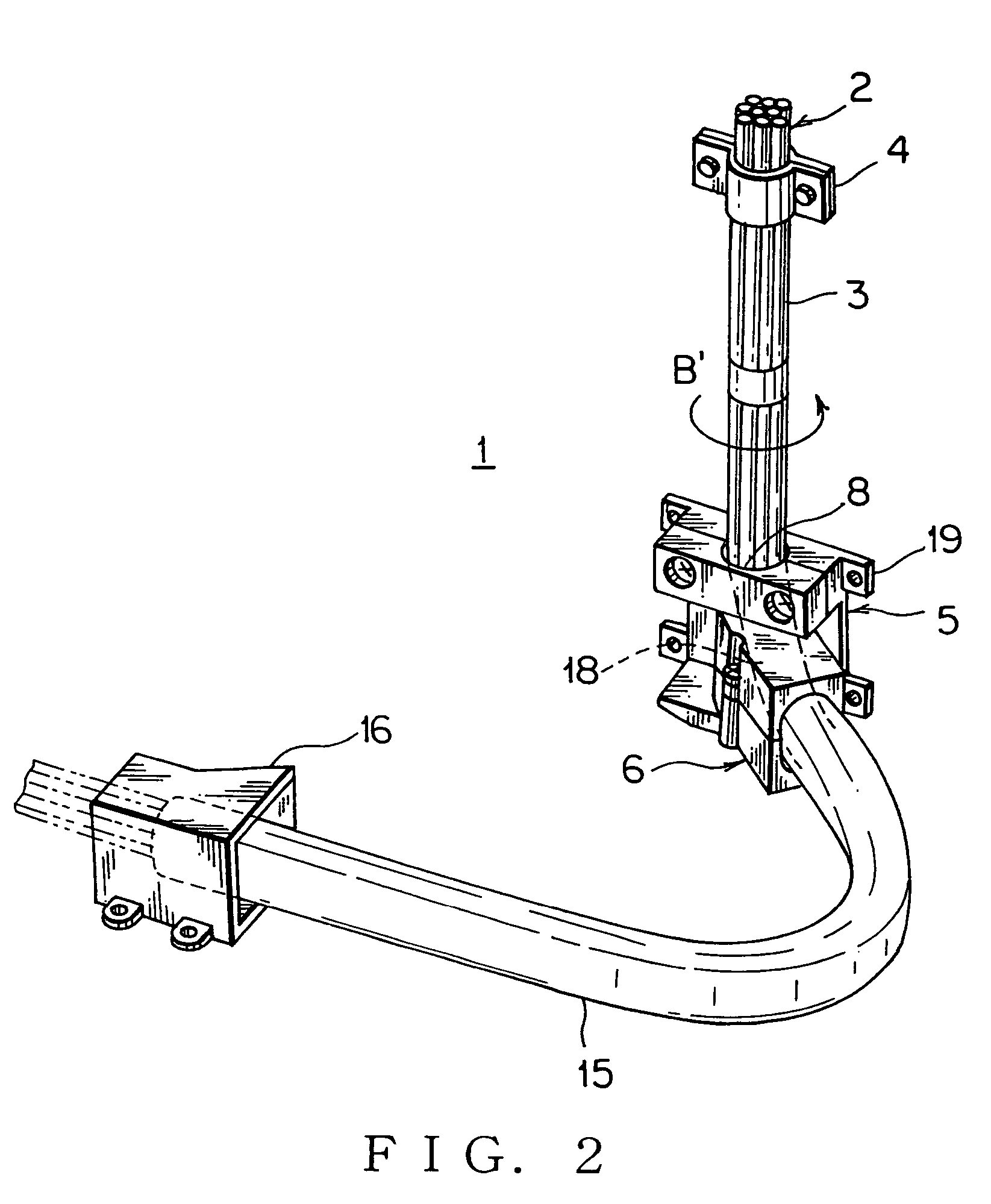

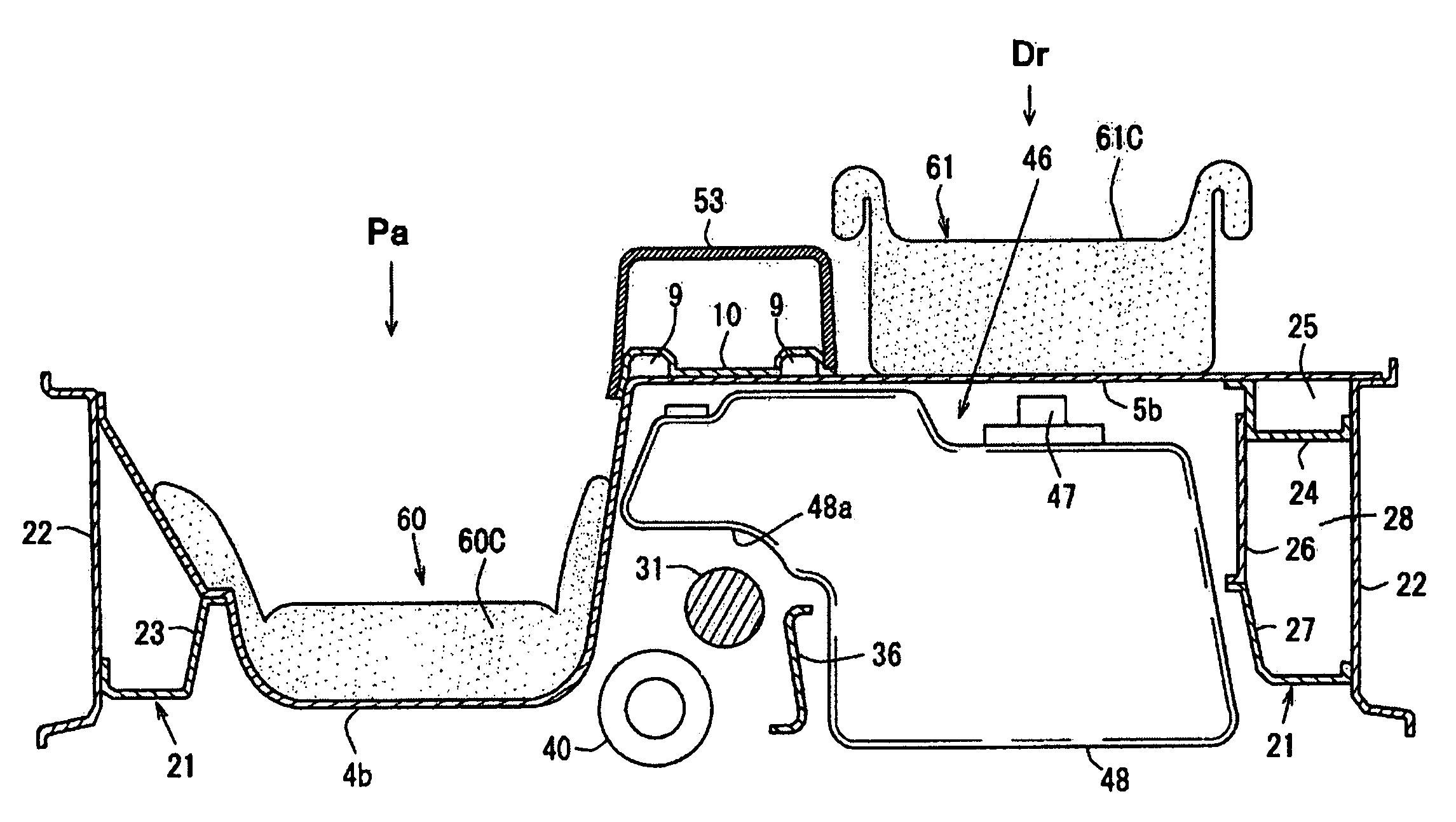

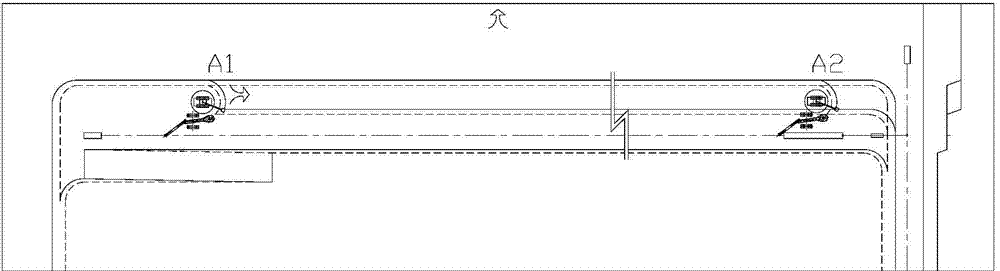

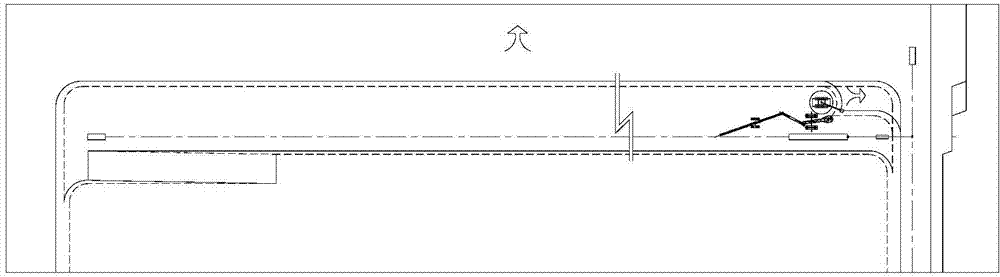

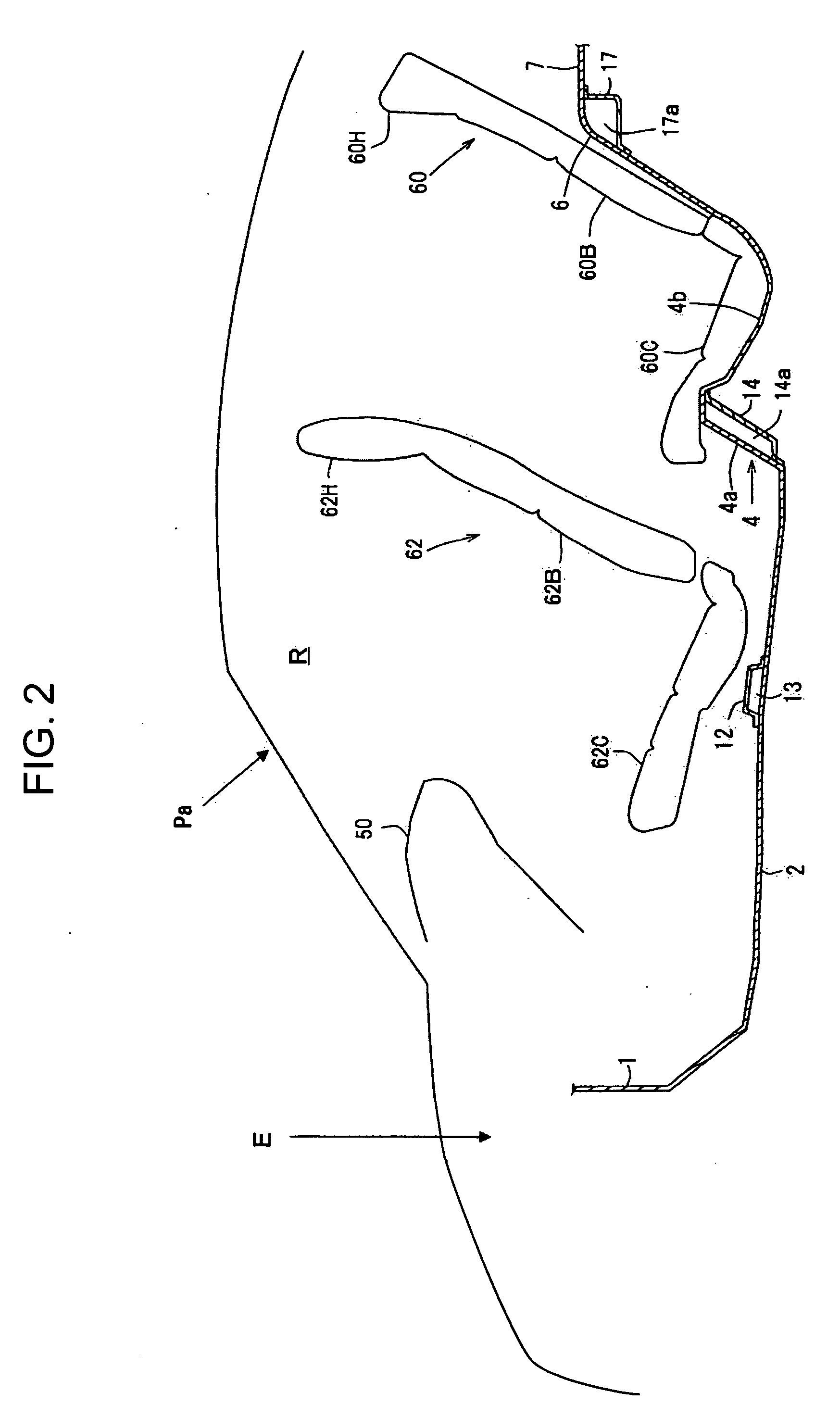

Power supply apparatus for sliding structure

ActiveUS20070084619A1Vertical path portion can be shortenedSmall structure sizeCoupling device connectionsElectric discharge tubesCable harnessElectrical and Electronics engineering

Providing a power supply apparatus for a sliding structure, which can be arranged in a small space in the sliding structure, the power supply apparatus includes a wiring harness having a vertical path portion; a harness fixing member for fixing one end of the vertical path portion of the wiring harness on the sliding structure; a fixed base fixed on the sliding structure for holding the other end of the vertical path portion; and a swing member mounted on the fixed base to swing freely in a horizontal plane for allowing the vertical path portion to be twisted along a circumferential direction of itself and leading a part of the wiring harness continued to the vertical path portion toward a fixed structure. Instead of the fixed base, a movable base 5′, and a guide rail to be engaged with the movable base can be applied.

Owner:YAZAKI CORP +1

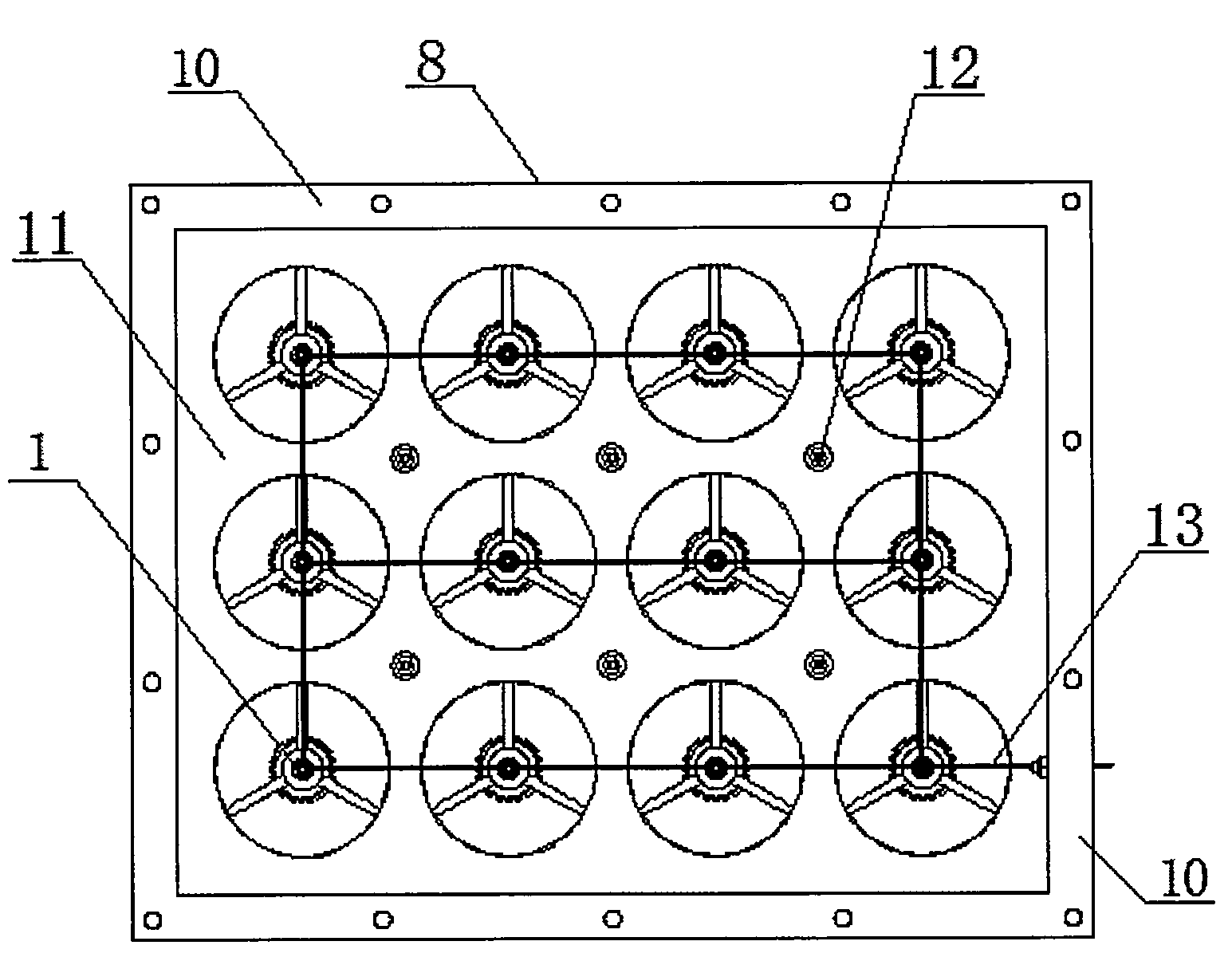

Fuel cell separator, fuel cell device, and electronic applied device

InactiveUS20050266295A1Small sizeImprove layout flexibilityFuel cells groupingFuel cell auxillariesFuel cellsMiniaturization

Fuel cell separation, fuel cell device, and electronic applied device technical field are provided. A fuel cell separator capable of making a fuel cell device compact and reducing variations in air supply amount to generating cells. Oscillating fans as fluid oxidant supplying means are respectively provided at openings of channels. The oscillating fans are individually driven to respectively supply air into the channels. The oscillating fans are included in a separator body of a separator. As compared with the case that the oscillating fans are provided separately from a fuel cell body having the separator as a component, the limitation to layout of the fuel cell body and various units for effecting stable electric power generation in the fuel cell body can be reduced, and the fuel cell device can be reduced in size.

Owner:SONY CORP

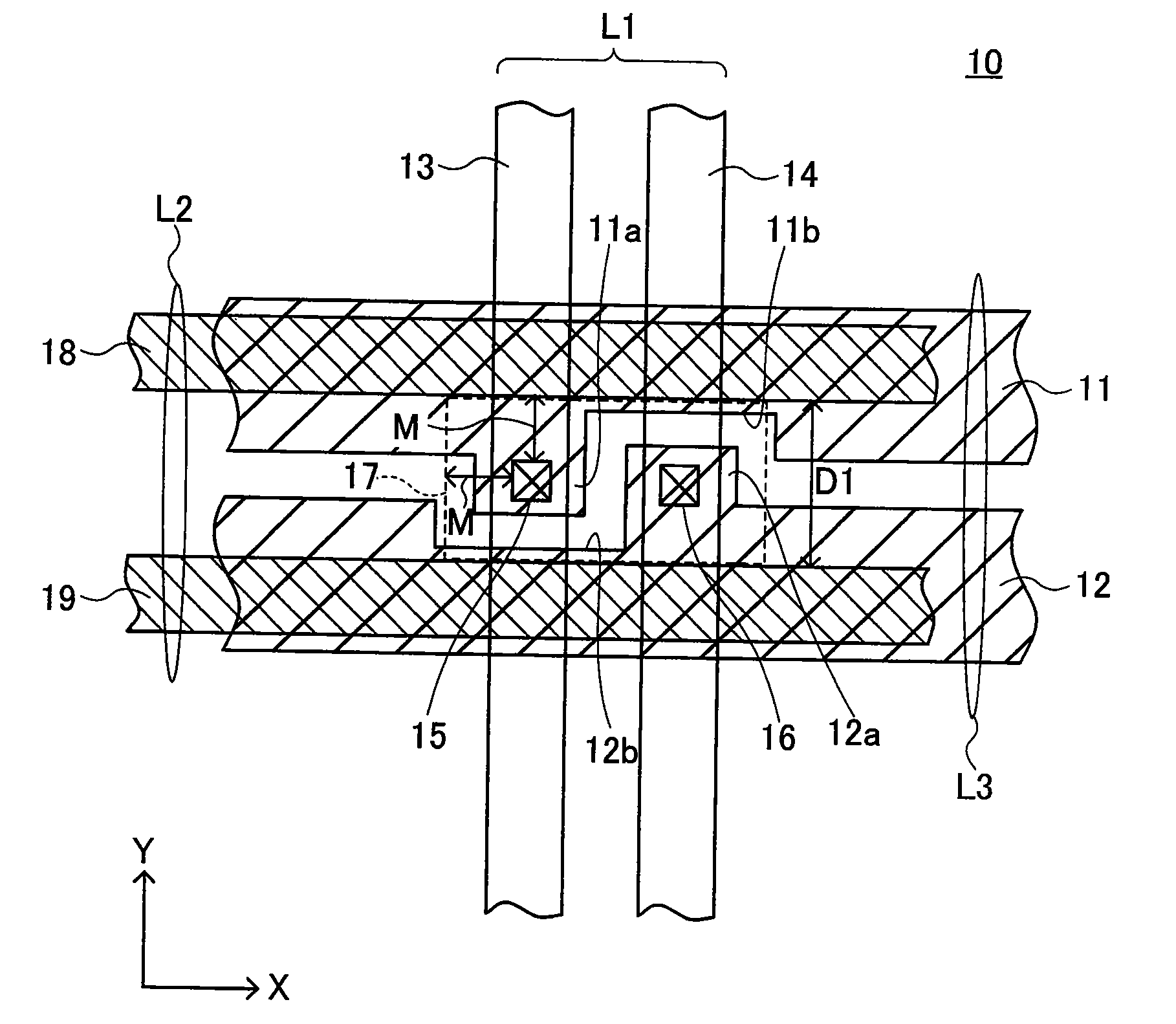

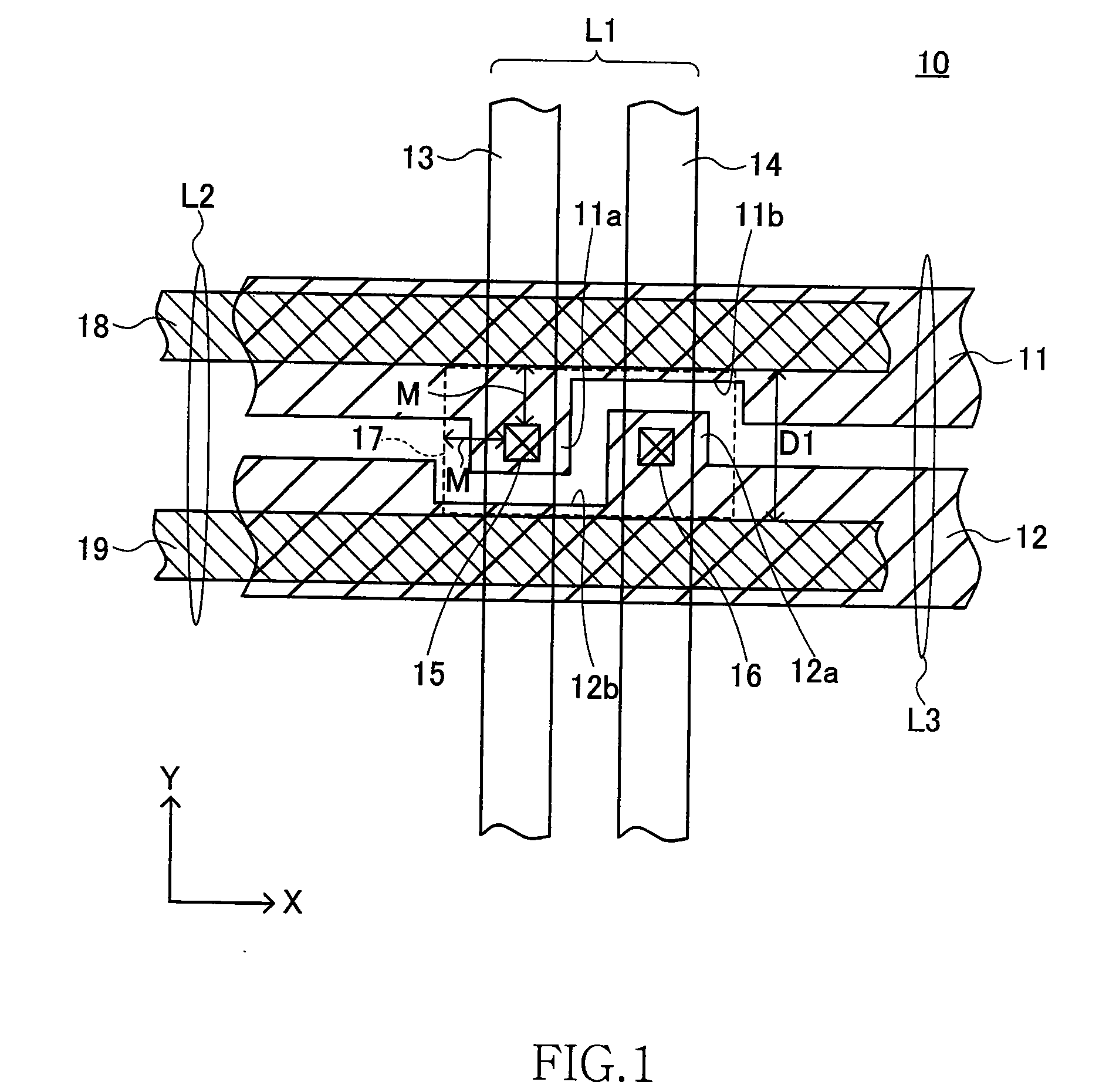

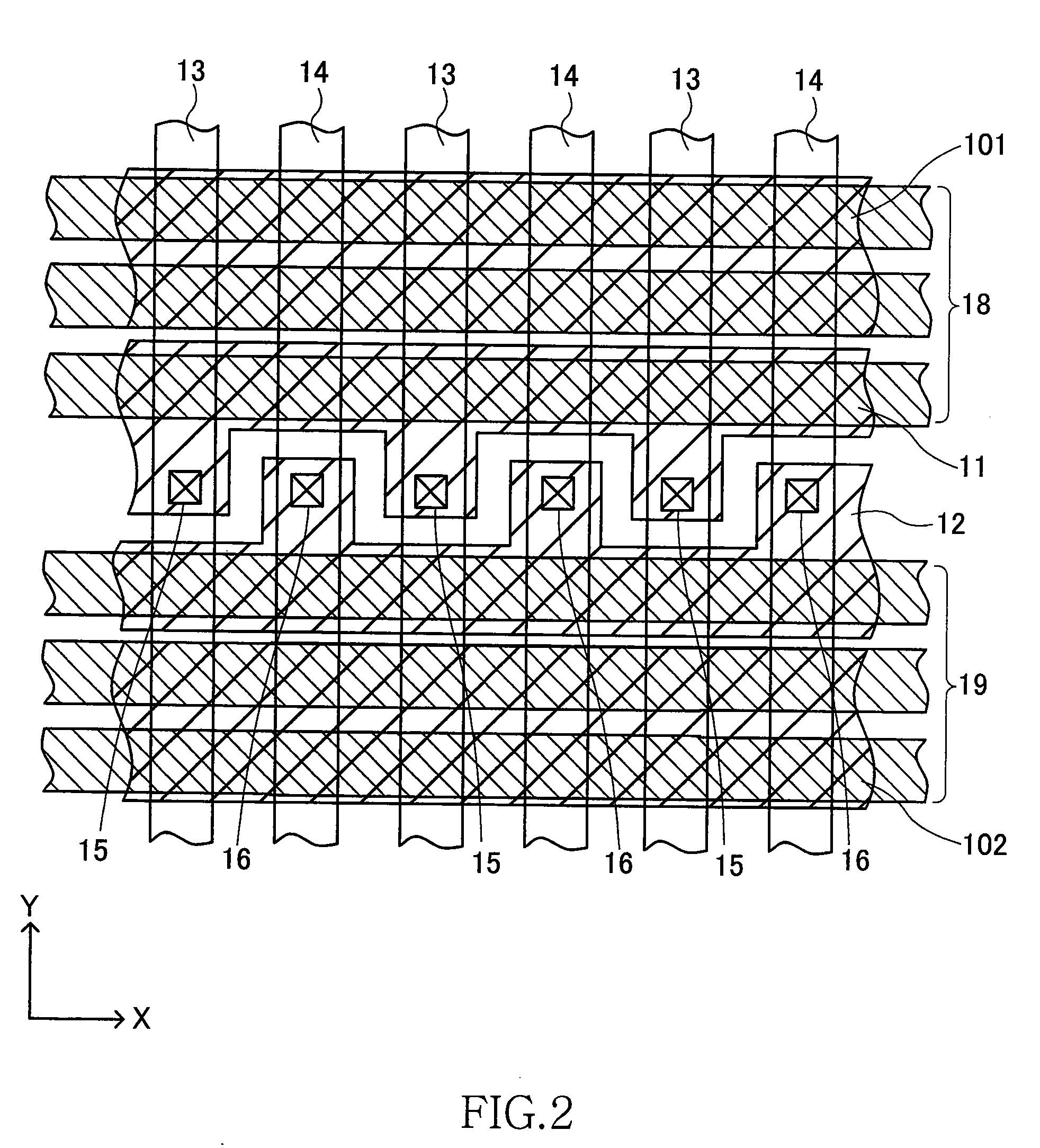

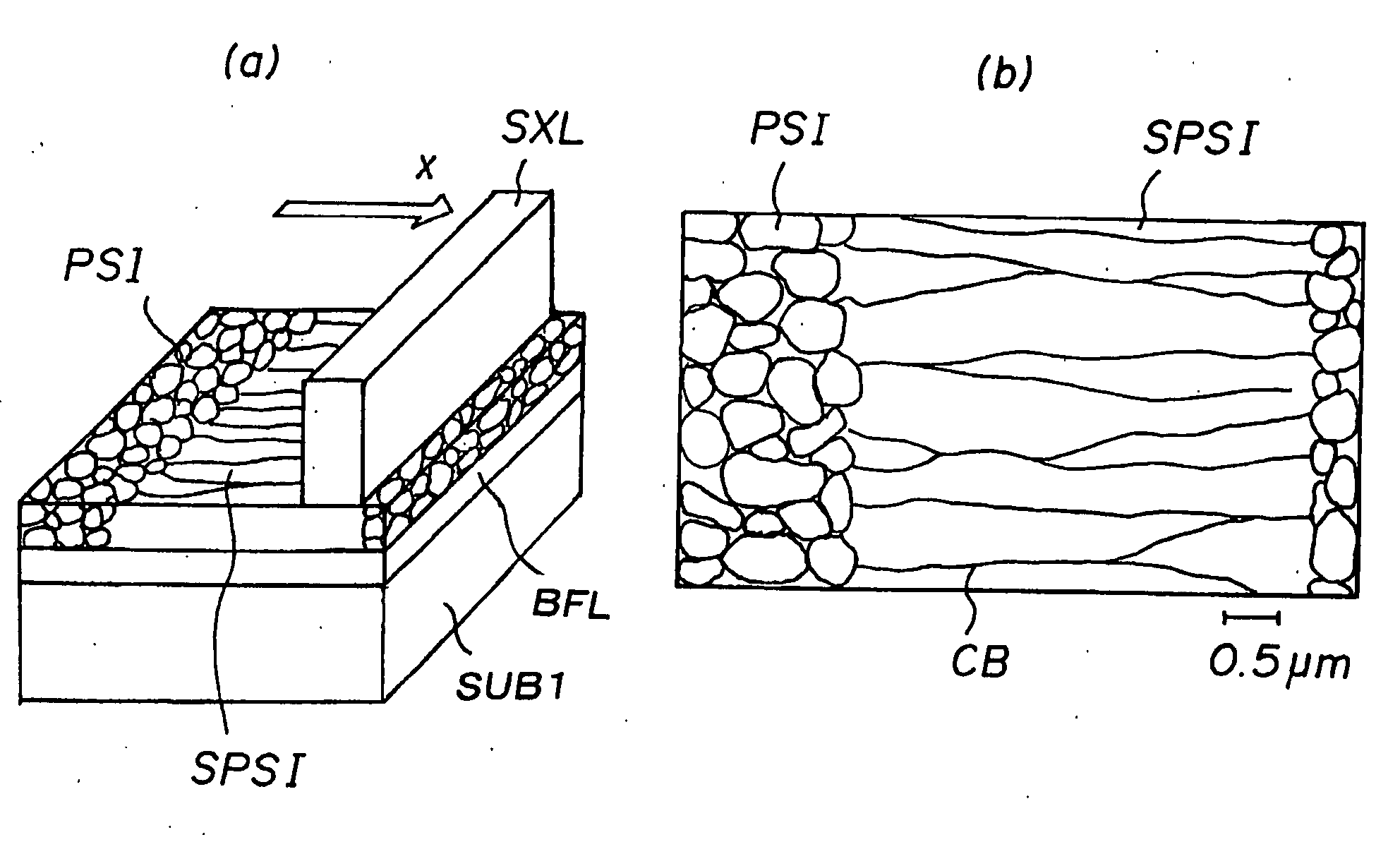

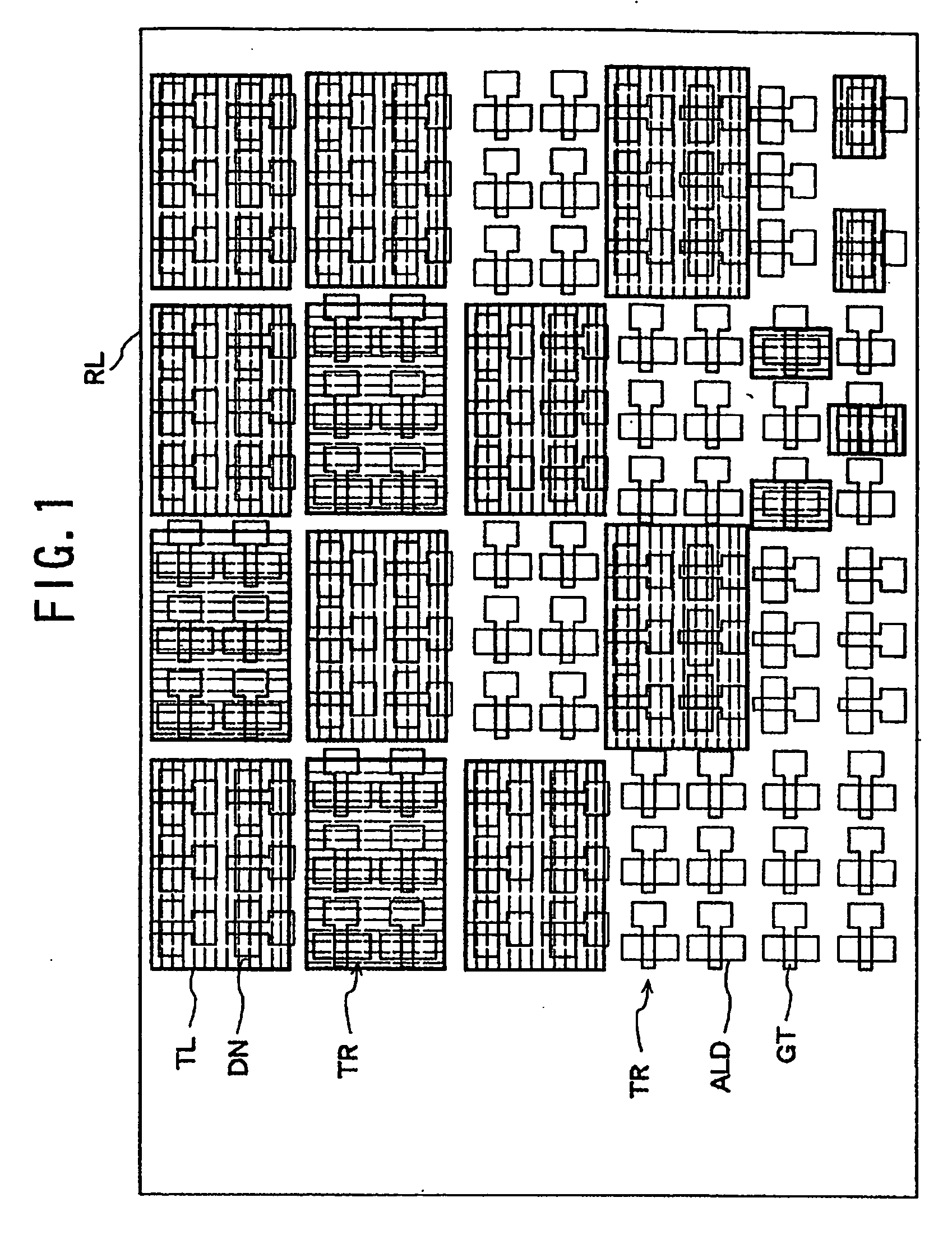

Semiconductor device having plurality of wiring layers and designing method thereof

ActiveUS20100327459A1Flexibility of layout be enhanceRestriction on be relaxSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical conductor

A semiconductor device includes first and second wirings formed in a first wiring layer and extending parallel to an X direction, third and fourth wirings formed in a third wiring layer and extending parallel to a Y direction; fifth and sixth wirings formed in a second wiring layer positioned between the first and second wiring layers, a first contact conductor that connects the first wiring to the third wiring; and a second contact conductor that connects the second wiring to the fourth wiring. The first and second contact conductors are arranged in the X direction. According to the present invention, because the first and second contact conductors that connect wiring layers that are two or more layers apart are arranged in one direction, a prohibited area that is formed in the second wiring layer can be made narrower. Therefore, the flexibility of the layout of the second wiring layer is enhanced and the restriction on the wiring density can be relaxed.

Owner:LONGITUDE LICENSING LTD

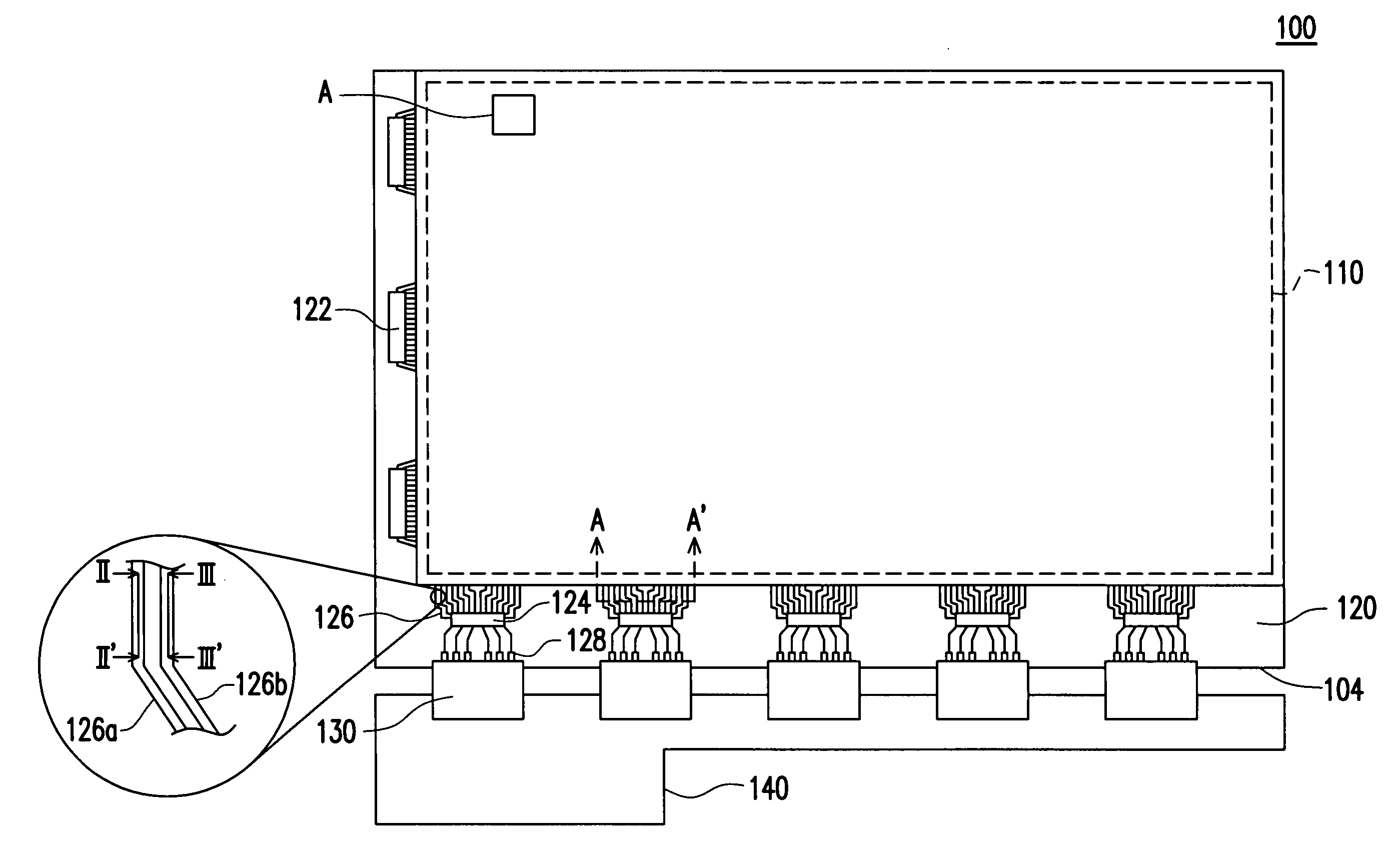

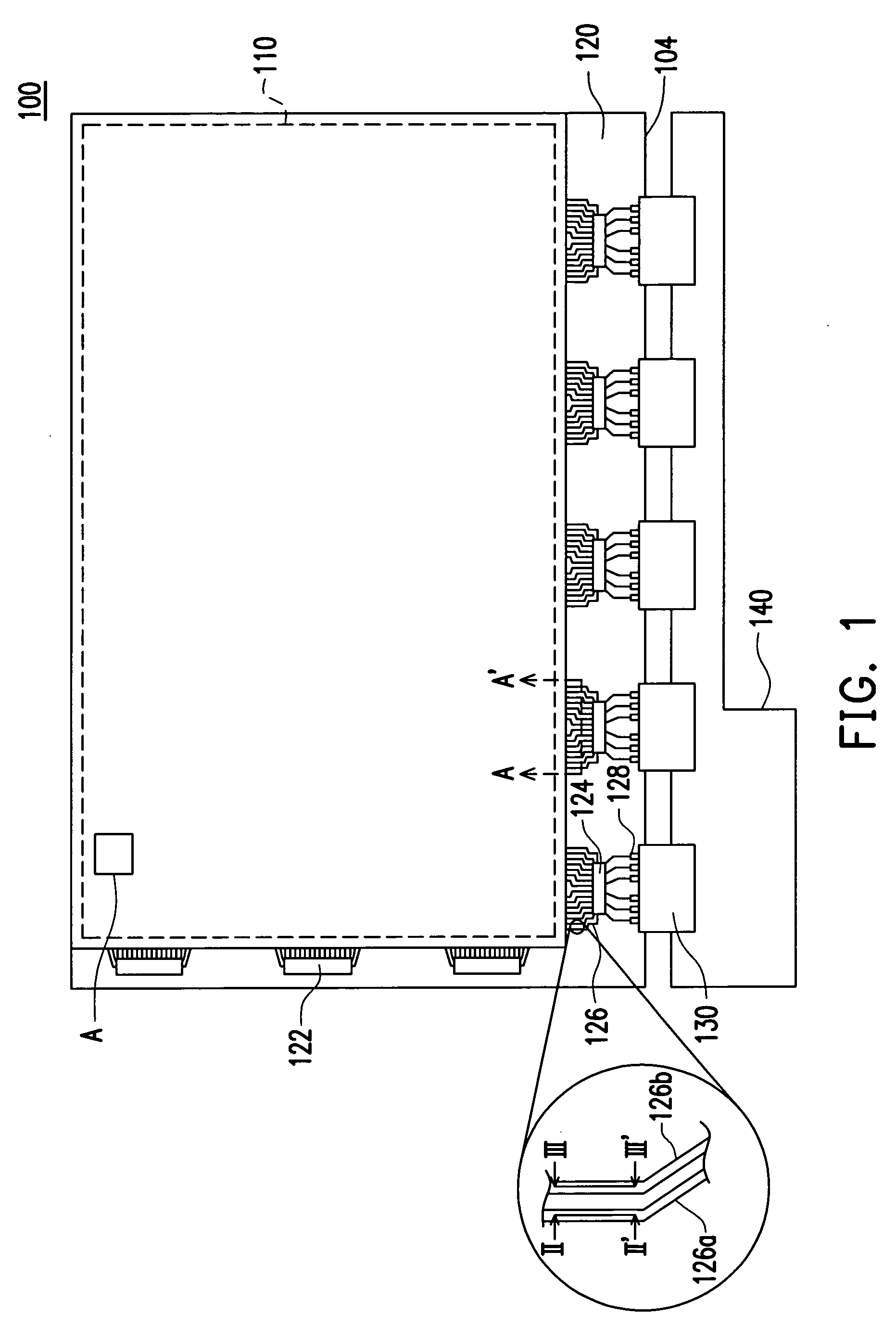

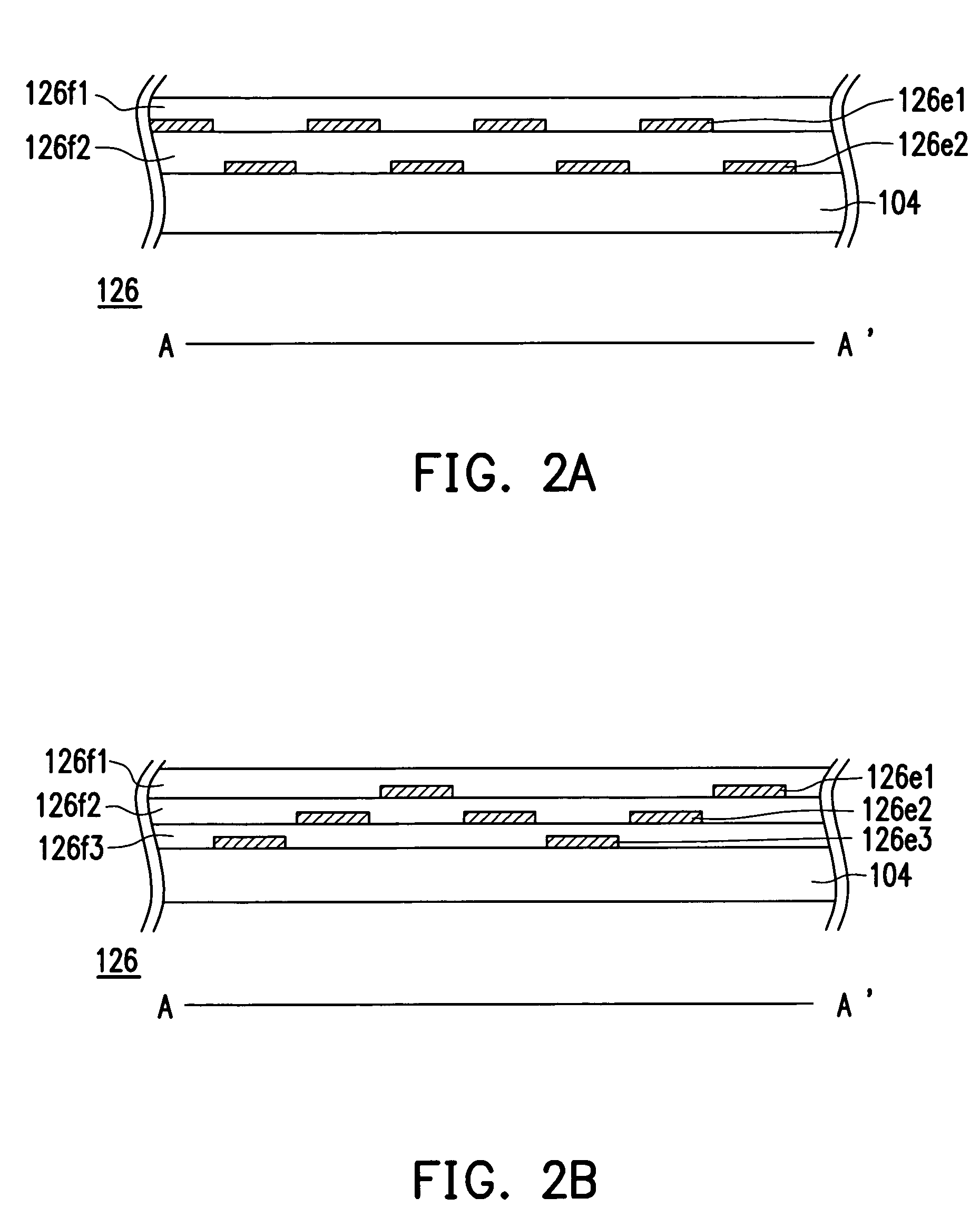

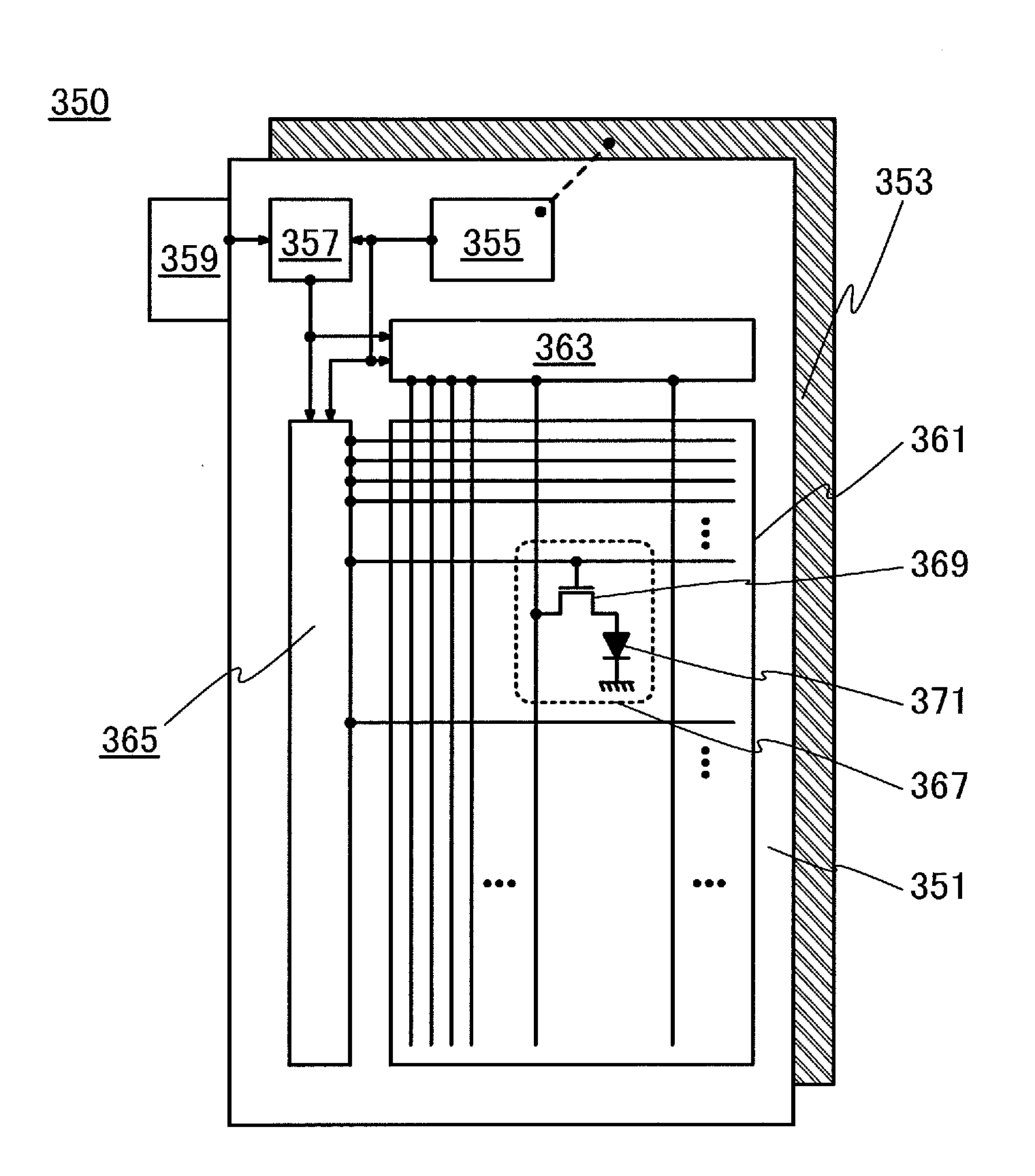

Active-matrix display panel

InactiveUS20060232738A1Improve layout flexibilityReduce in quantityNon-linear opticsActive matrixComputer science

An active-matrix display panel including a display area, a peripheral region and a fanout circuitry is provided. The peripheral region is connected with at least one side of the display area. The fanout circuitry is arranged on the peripheral region and is a multi-layered routing structure. By using the multi-layered routing structure aforementioned, the layout flexibility is improved significantly.

Owner:PRIME VIEW INTRNAT

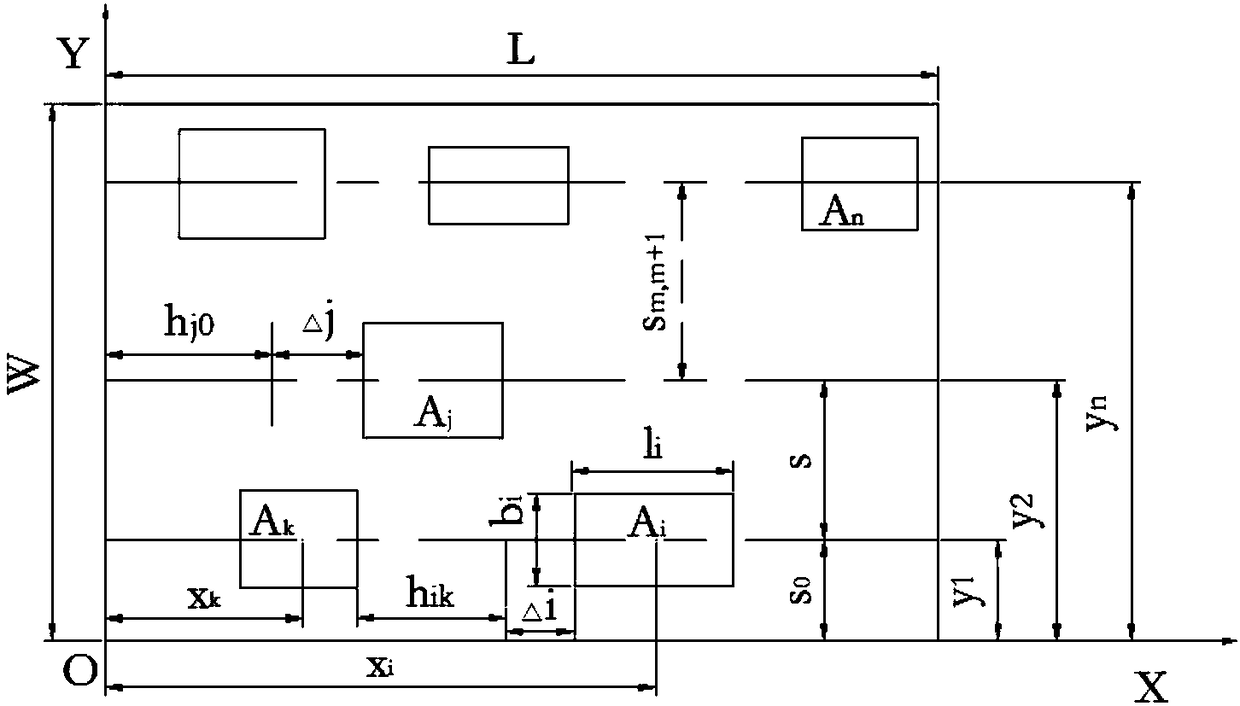

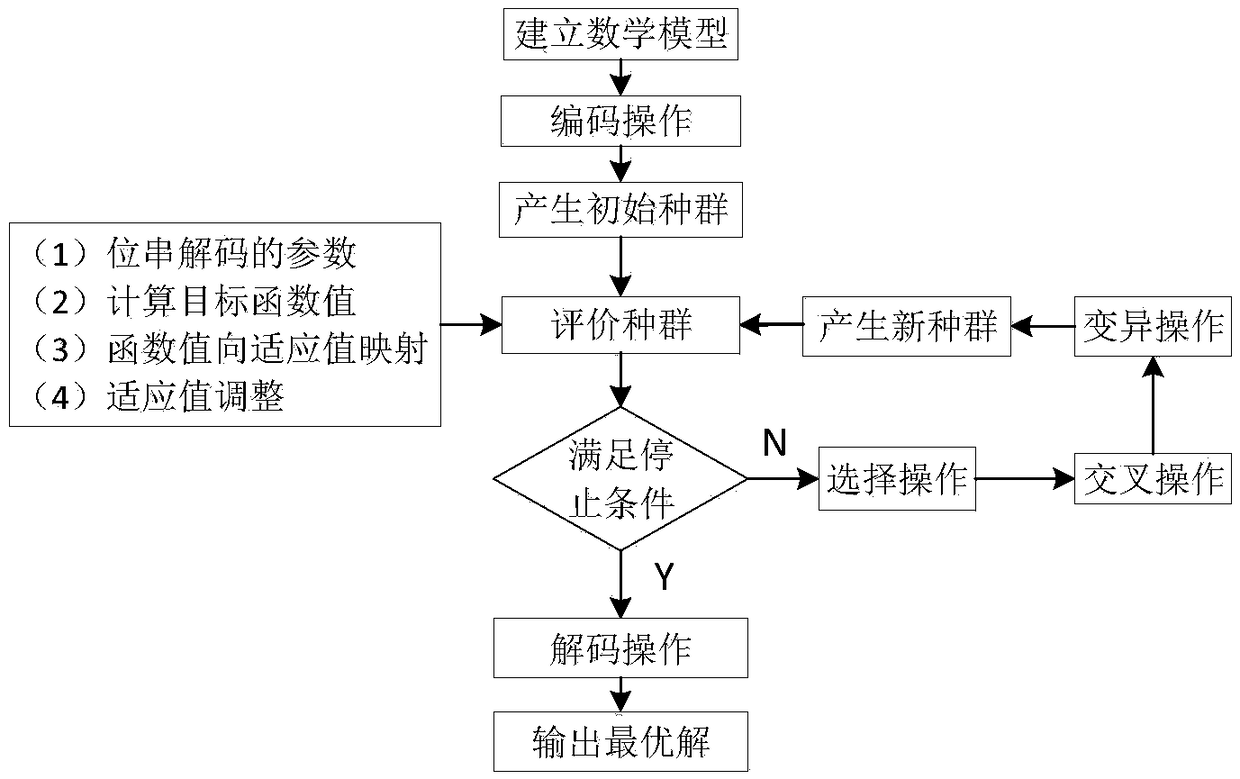

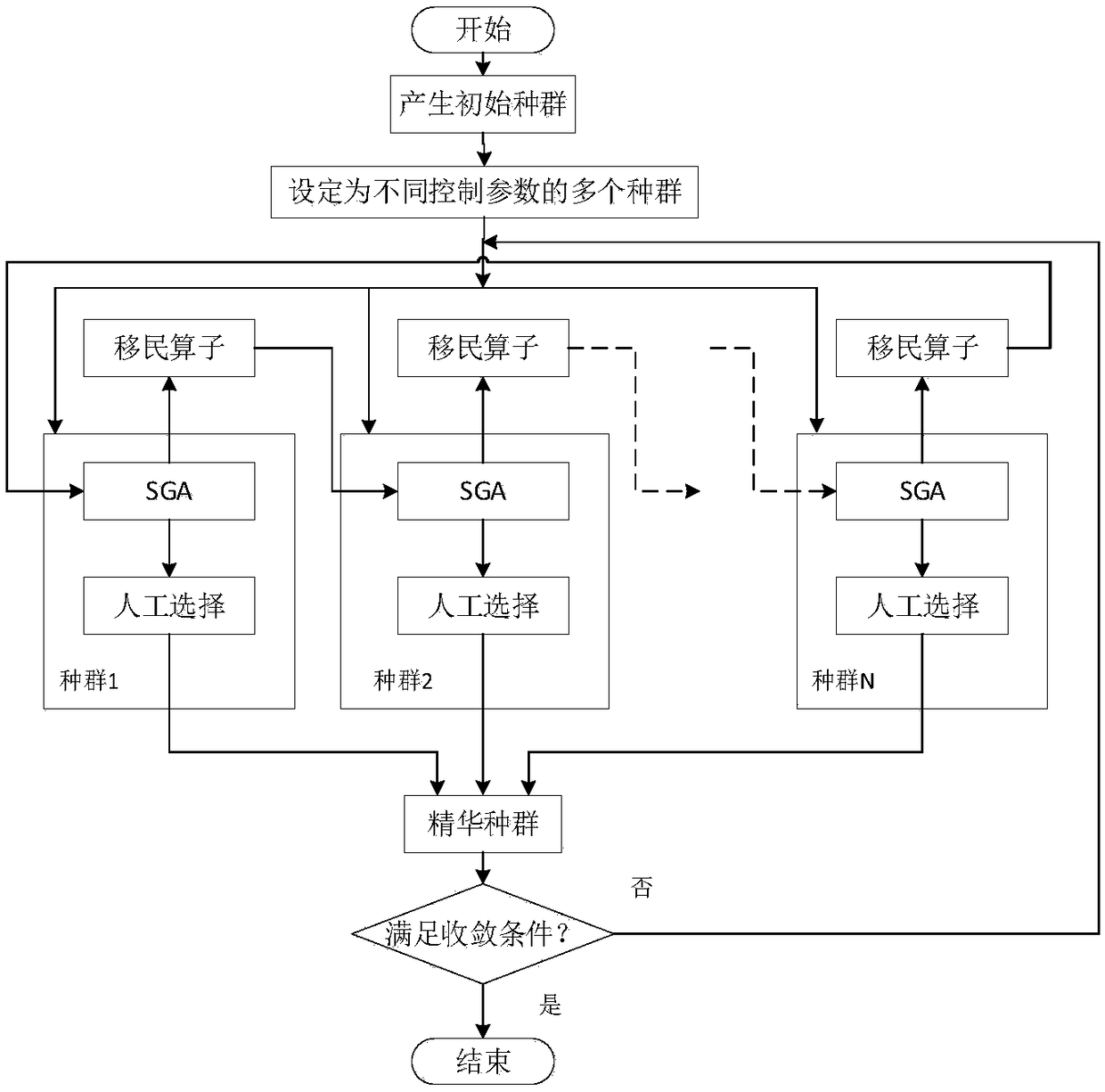

Multi-objective optimized overall workshop layout method based on multi-population genetic algorithm

InactiveCN108573114AOptimal layout schemeImprove layout flexibilityGeometric CADArtificial lifeMathematical modelMulti-objective optimization

The invention discloses a multi-objective optimized overall workshop layout method based on a multi-population genetic algorithm. The method comprises the following steps: firstly, a multi-row linearworkshop layout mathematical model is established, and a functional area layout problem is converted into a combined optimization mathematical model problem; secondly, based on the optimization objective of minimum total material handling cost and maximum area utilization ratio of workshop layout, a precise workshop layout model is established by taking account of constraints including horizontaland vertical placement of main streets and functional areas, adaptive row spacing and the like of the manufacturing workshop, and multiple optimization objectives are converted into a single evaluation function with a weighting method; finally, solving is performed with the multi-population genetic algorithm, immigration operators are linked with populations in the solving process, information exchange and co-evolution of multi-population are achieved, different crossover and mutation probability parameters are set for different populations by crossover and mutation probability control formulae, and different search purposes are guaranteed. The total logistics handling cost of the workshop can be effectively reduced, and the utilization rate of the workshop area is increased.

Owner:SOUTHWEST JIAOTONG UNIV +1

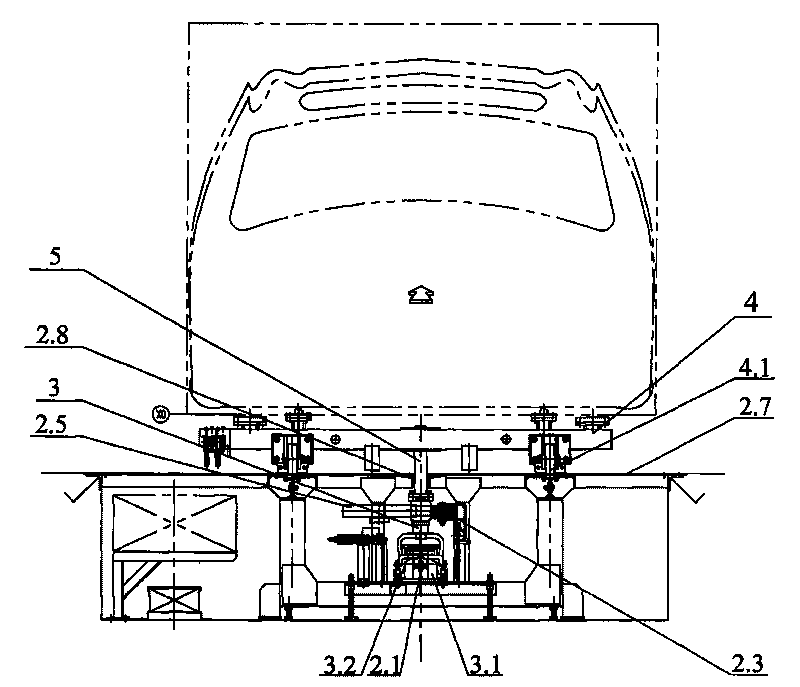

Friction type adjusting line delivery system

ActiveCN101734474ASmooth transmissionReduce noiseConveyor partsVehiclesFriction driveOperational costs

The invention relates to a friction type adjusting line delivery system which comprises rectilinear friction drive devices, an adjusting line upper element hoist, an adjusting line lower element hoist, trolley positioning devices and a trolley stopper, wherein the rectilinear friction drive devices are distributed along a friction track line body at intervals; the adjusting line upper element hoist and the adjusting line lower element hoist are respectively arranged at an outlet and an inlet of the line body and provided with track hoists; the trolley positioning devices are respectively distributed on lifting tracks of the hoists; and the trolley stopper is arranged on a friction track of the inlet of the adjusting line lower element hoist. The invention thoroughly changes a delivering way of a traditional car body adjusting line, has novel structure, high automation degree, simple control, low equipment and operation cost and convenient maintenance and is a delivery equipment system in a type of low noise, low pollution and environmental protection.

Owner:MIRACLE AUTOMATION ENG CO LTD

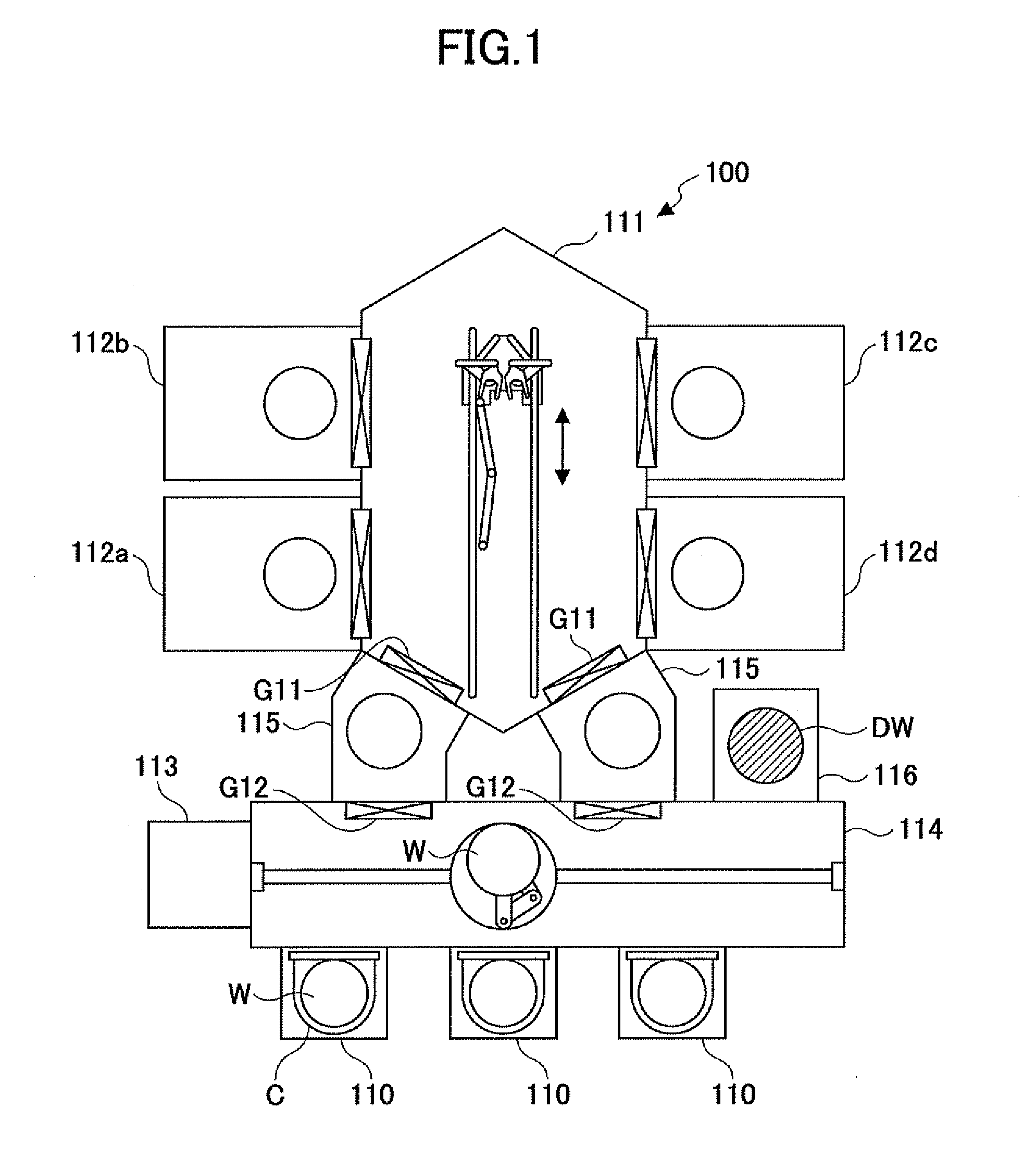

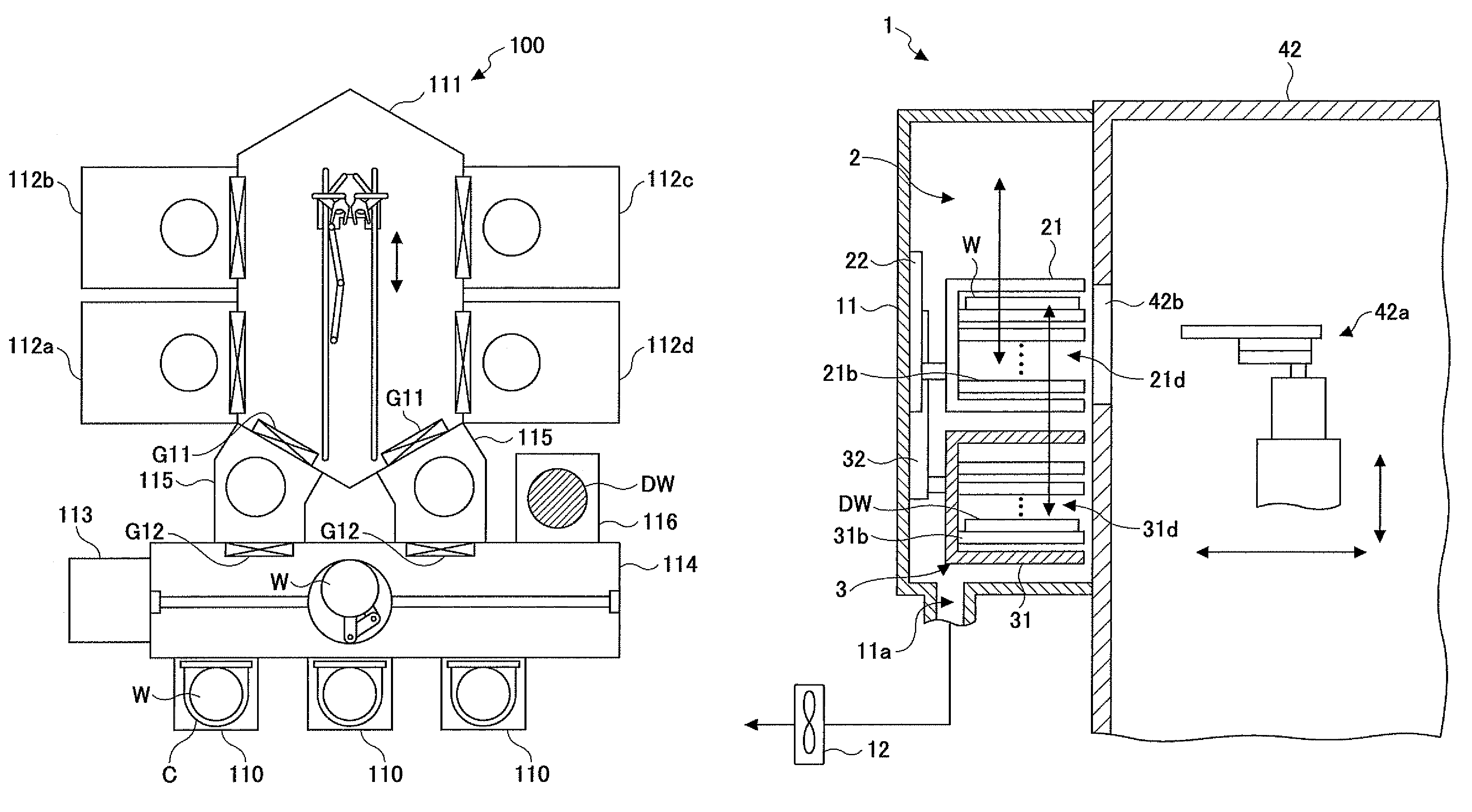

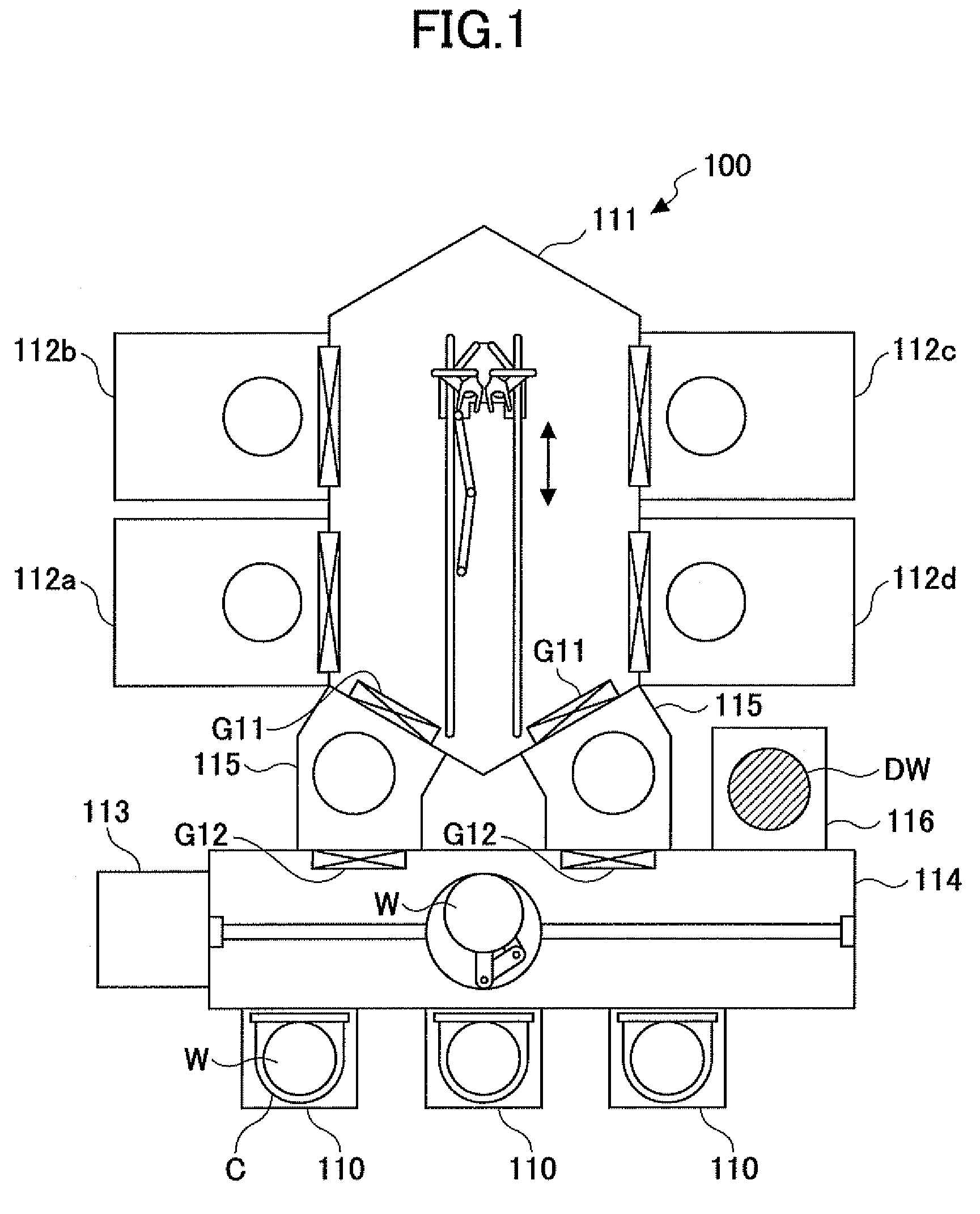

Substrate processing apparatus, substrate processing method, and computer readable storage medium

InactiveUS20100102030A1Improve layout flexibilityImprove design flexibilityDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A substrate processing apparatus is disclosed for bringing a substrate from a carrier, by a substrate transfer portion inside a transfer chamber, into a processing module to perform a process therein. The substrate processing apparatus includes a substrate storing chamber coupled to an exterior of the transfer chamber via a transfer opening to be in communications with the transfer chamber; a first storing shelf in the substrate storing chamber to store substrates for a first storing purpose; a second storing shelf in the substrate storing chamber to store substrates for a second storing purpose different from the first storing purpose; and a shifting mechanism that shifts the first and the second storing shelves to position a substrate storing area of one of the first and the second storing shelves so that substrate transferring is enabled between the substrate storing area and the substrate transfer portion via the transfer opening.

Owner:TOKYO ELECTRON LTD

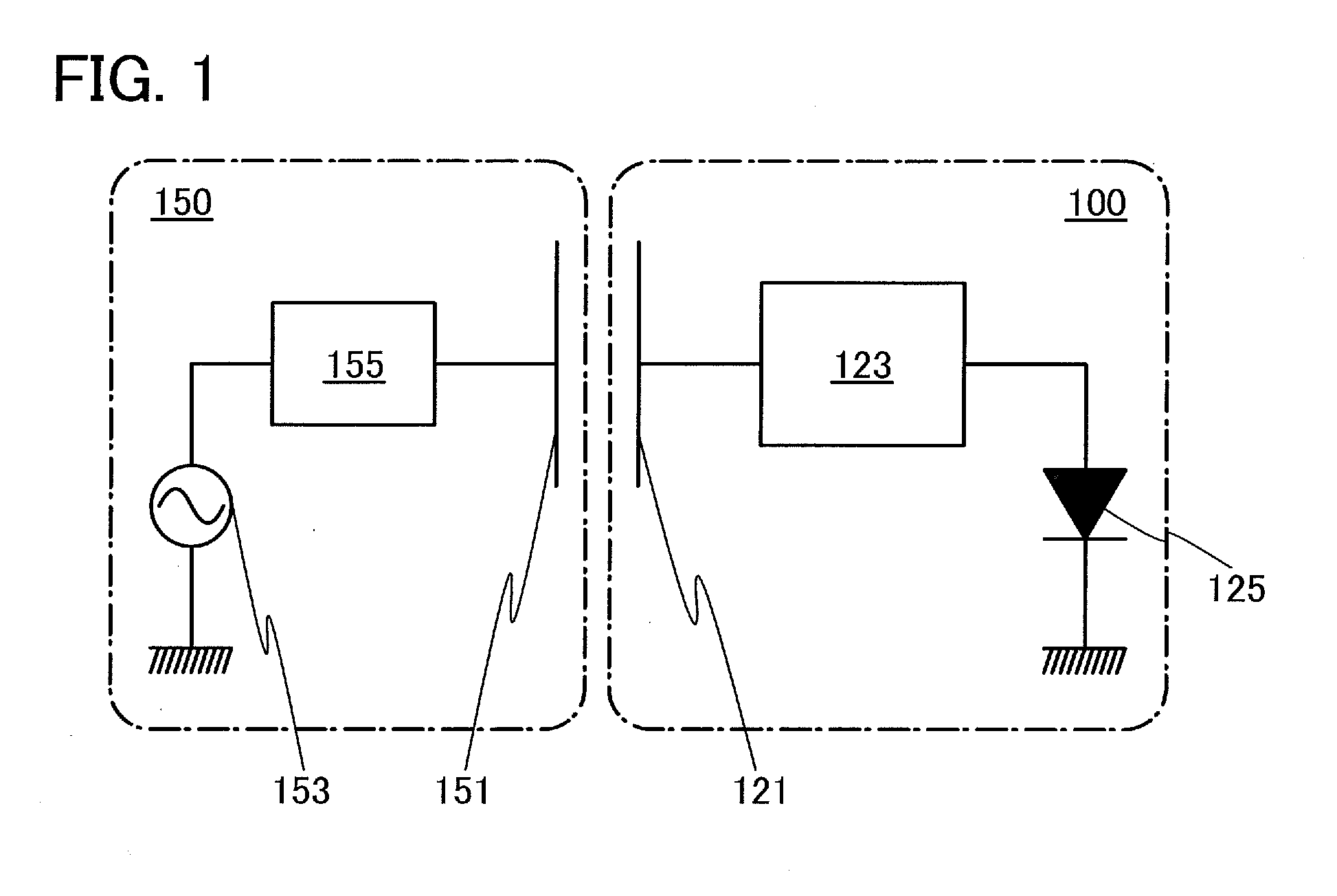

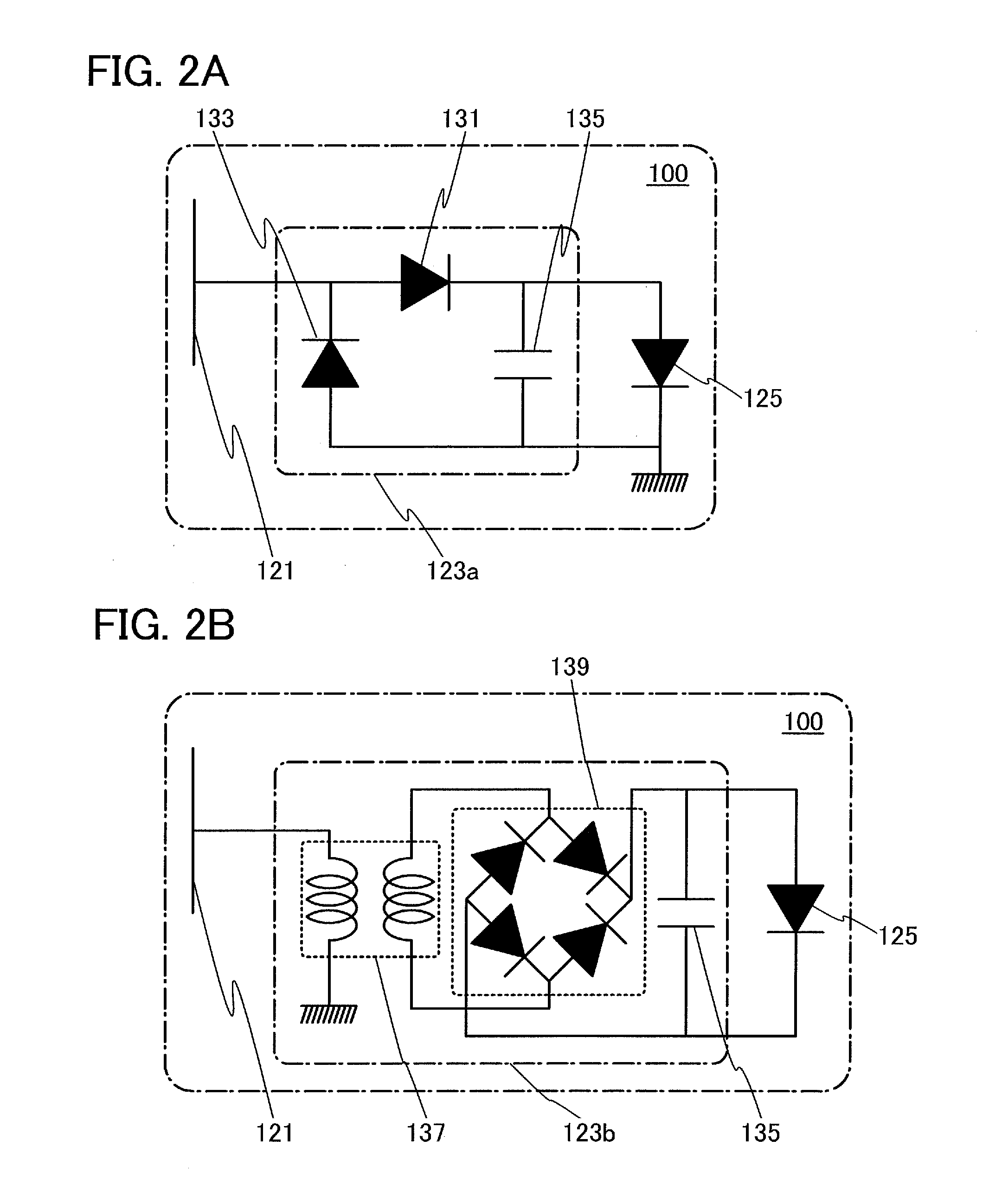

Light-emitting device, display device, light-emitting system, and display system

InactiveUS20120262432A1Improve layout flexibilityGood adhesionElectroluminescent light sourcesSolid-state devicesTransmitted powerDisplay device

A highly reliable light-emitting device is provided. A lighting device or a display device with a high level of safety and without an exposed electrode is provided. A lighting device or a display device with high layout flexibility is provided. A light-emitting system or a display system to which the light-emitting device or the display device can be applied is provided. An electrode for receiving power and a rectifier circuit are provided in a light-emitting device including an organic EL element and arranged so as to face an electrode for transmitting power, whereby alternating-current power is supplied to the light-emitting device. The alternating-current power is rectified by the rectifier circuit to direct-current power so that the organic EL element in the light-emitting device is driven.

Owner:SEMICON ENERGY LAB CO LTD

Power supply apparatus for sliding structure

ActiveUS7482538B2Vertical path portion can be shortenedReduce power levelCoupling device connectionsElectric discharge tubesCable harnessElectrical and Electronics engineering

A power supply apparatus for a sliding structure, which can be arranged in a small space in the sliding structure, the power supply apparatus including a wiring harness having a vertical path portion; a harness fixing member for fixing one end of the vertical path portion of the wiring harness on the sliding structure; a fixed base fixed on the sliding structure for holding the other end of the vertical path portion; and a swing member mounted on the fixed base to swing freely in a horizontal plane for allowing the vertical path portion to be twisted along a circumferential direction of itself and leading a part of the wiring harness continued to the vertical path portion toward a fixed structure. Instead of the fixed base, a movable base 5′, and a guide rail to be engaged with the movable base can be applied.

Owner:YAZAKI CORP +1

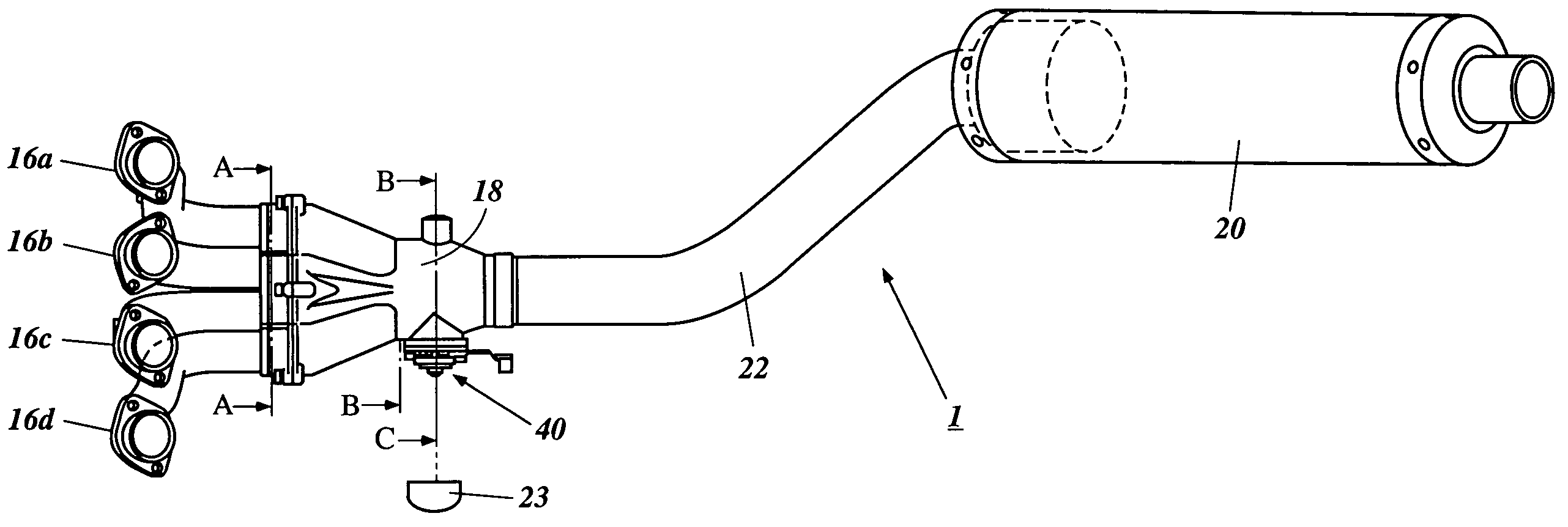

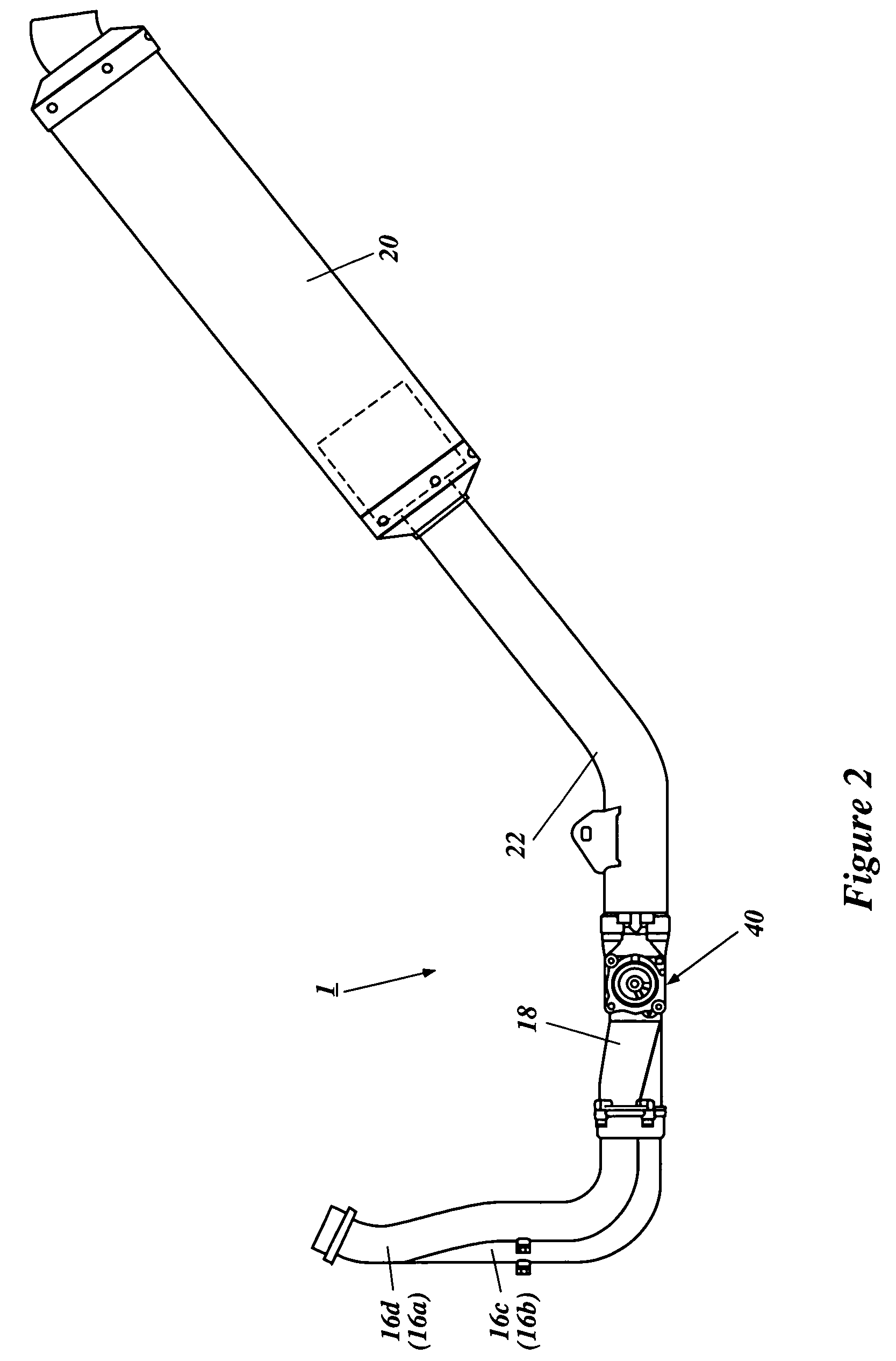

Exhaust system for multi-cylinder engine, and straddle-type vehicle provided with same

InactiveUS7171804B2Increase the number ofImprove layout flexibilityInternal combustion piston enginesExhaust apparatusPulp and paper industryExhaust pipe

An exhaust system for a multi-cylinder engine can include a plurality of exhaust pipes with first upstream ends connected to exhaust openings of a multi-cylinder engine, and a collecting pipe connected to the second downstream ends of the exhaust pipes for collecting exhaust introduced from the exhaust pipes and directing it to a silencer. The collecting pipe has a front-end portion communicated to exhaust passages of the exhaust pipes, a middle portion for collecting the exhaust introduced from the front-end portion, and a rear-end portion for further collecting the exhaust introduced from the middle portion. The middle portion is provided with exhaust control means for controlling the area of the exhaust passages in accordance with engine speed.

Owner:YAMAHA MOTOR CO LTD

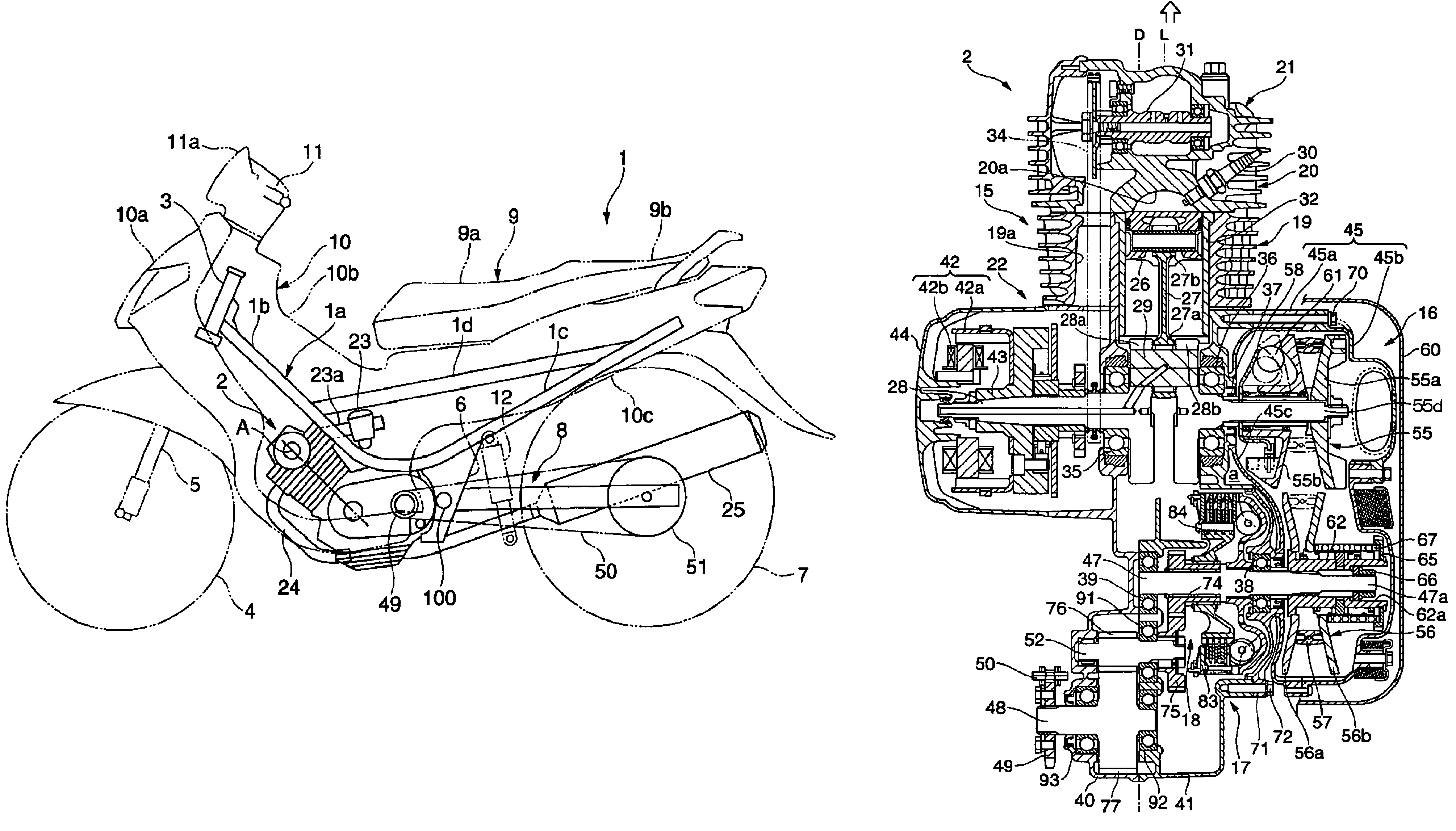

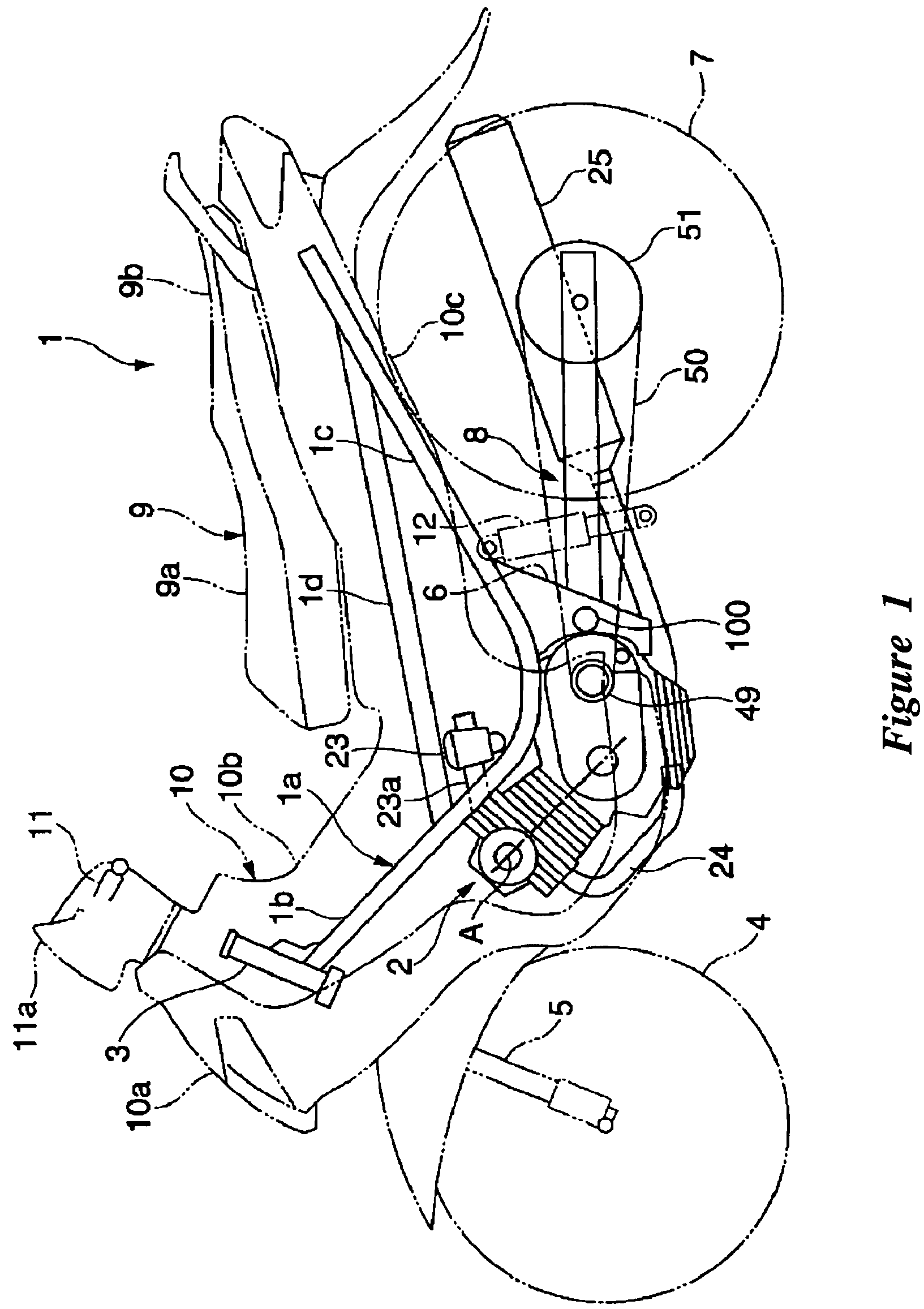

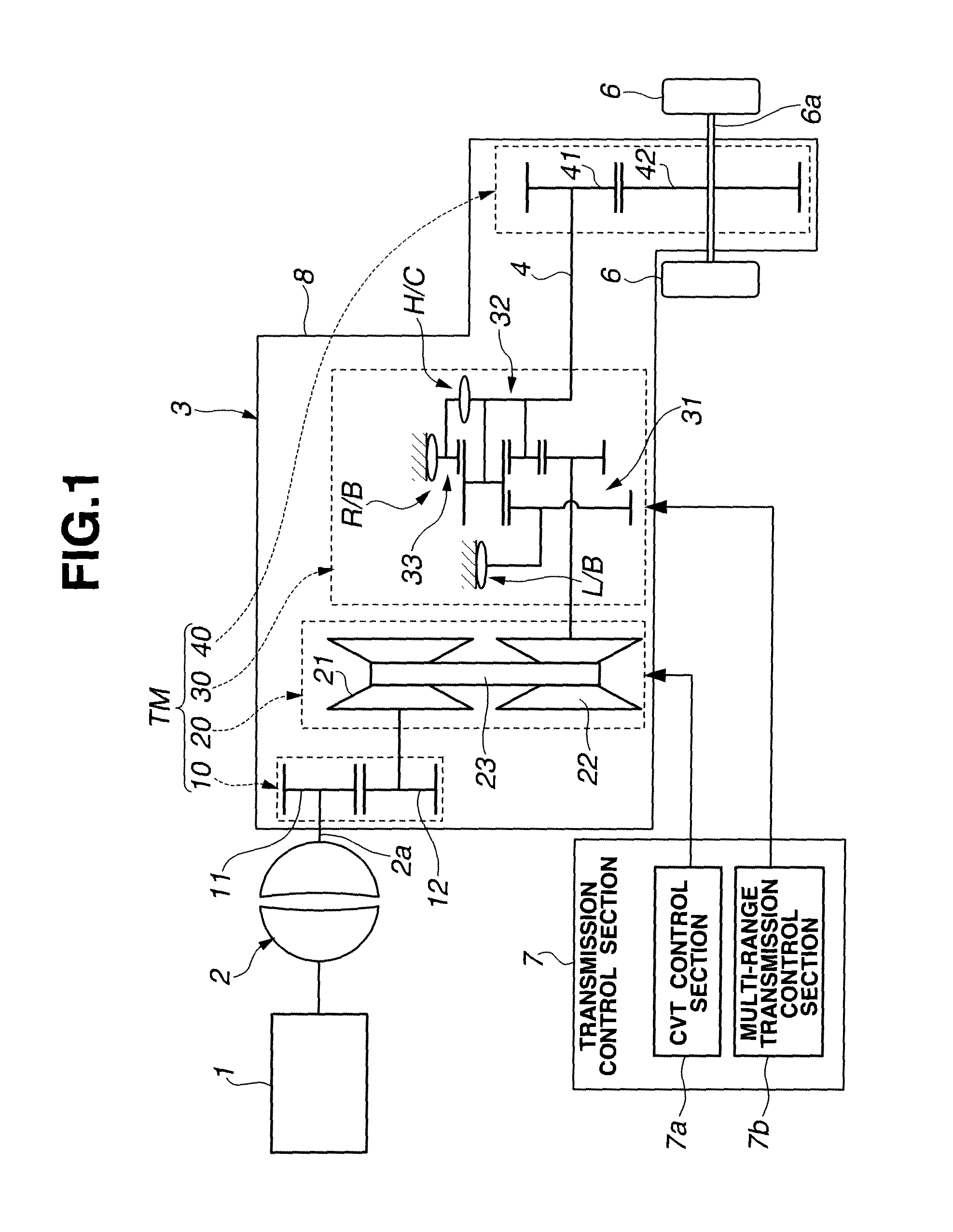

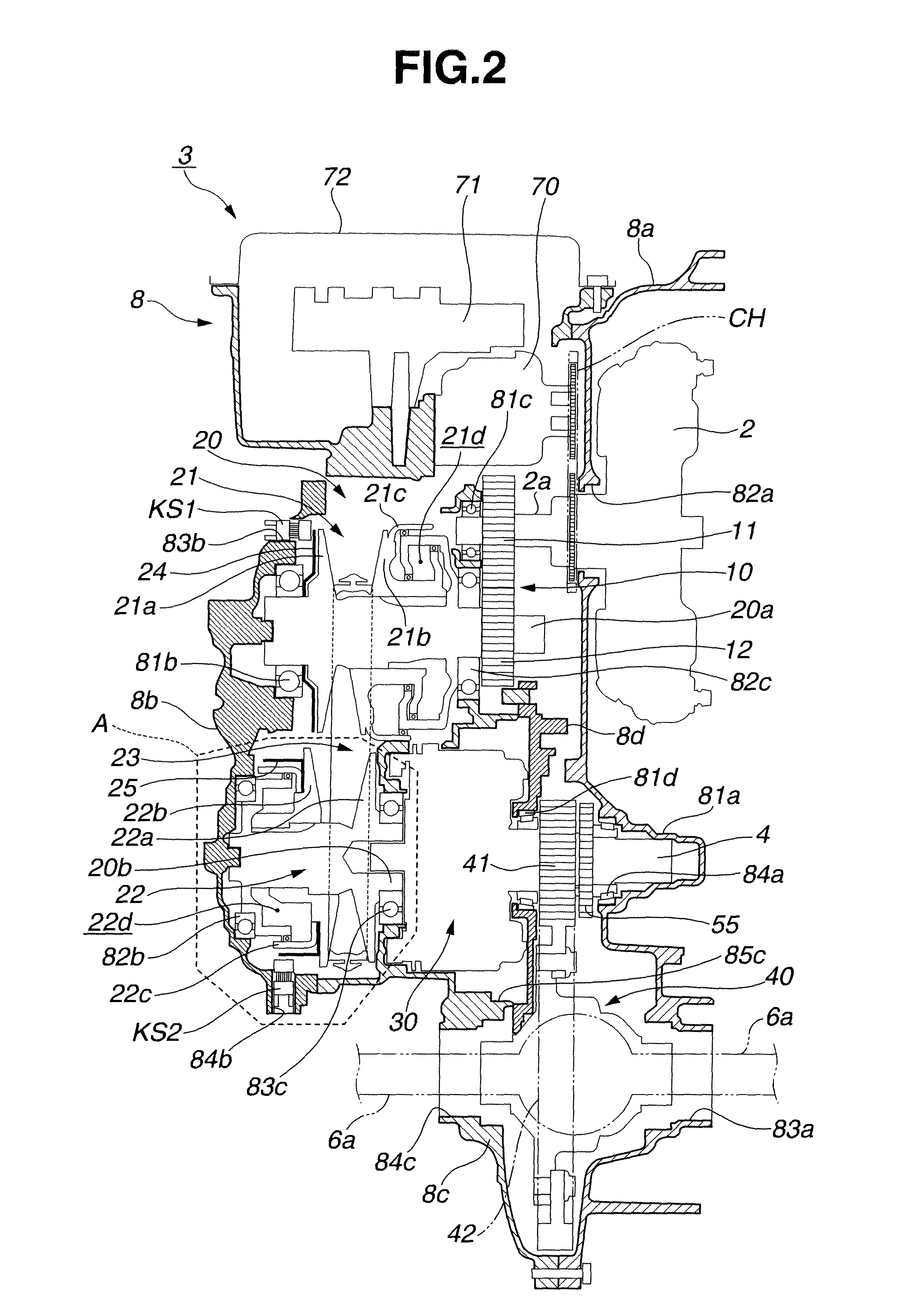

Saddle-type vehicle and engine

InactiveUS7201686B2Improve layout flexibilityWheel based transmissionFrictional rollers based transmissionTransmitterPulley

A saddle-type vehicle has an engine unit with a continuously variable transmission. The transmission has a primary sheave and a secondary sheave that are connected by a flexible transmitter such as a belt. The primary sheave, the secondary sheave and the belt are positioned in a transmission case. A starting kick shaft is positioned on the same side of the engine unit as the transmission case but the starting kick shaft is positioned outside of a profile of the transmission case when the engine unit is viewed from a lateral side.

Owner:YAMAHA MOTOR CO LTD

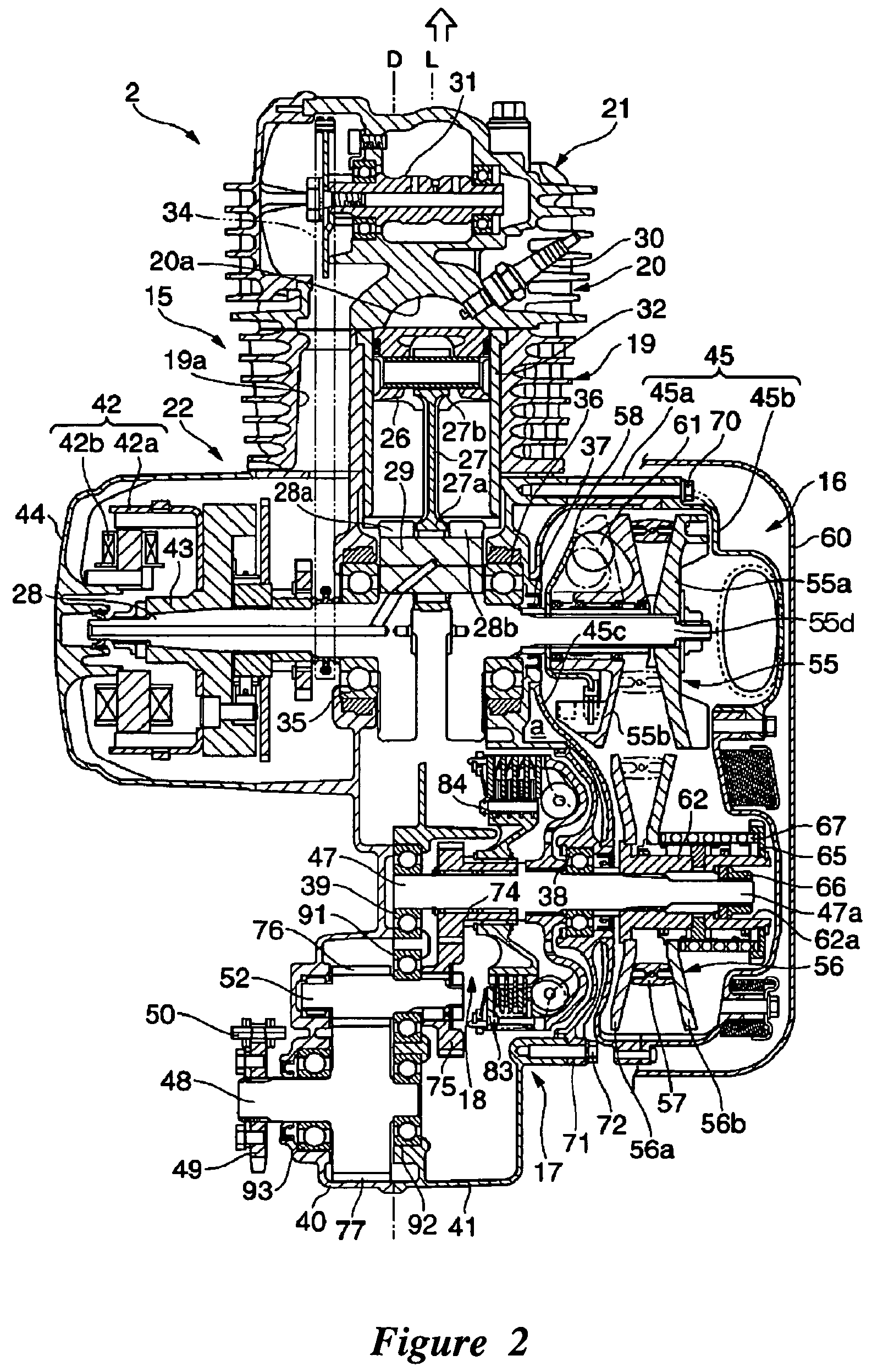

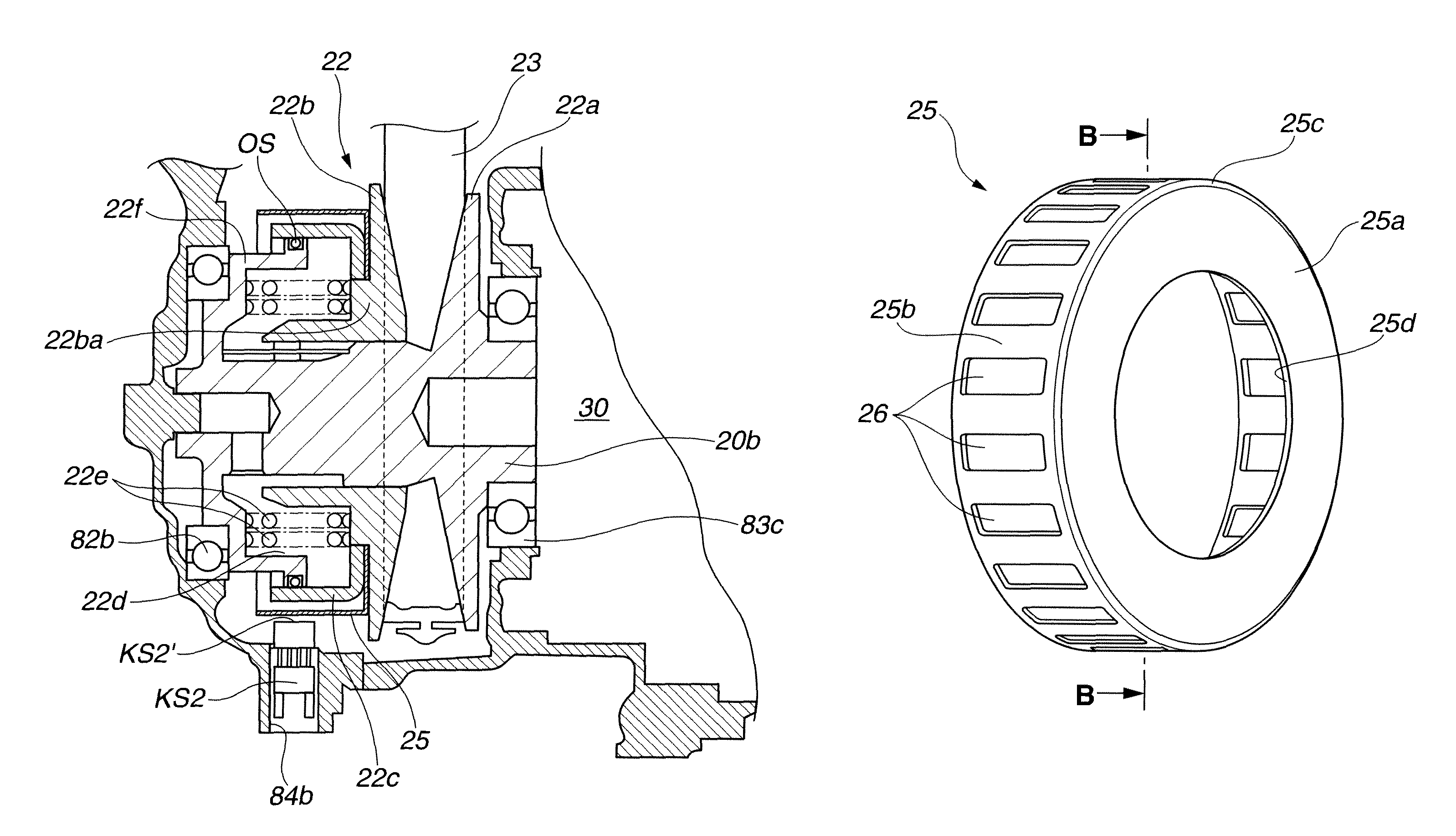

Belt-drive CVT

ActiveUS8460137B2Reduced flexibilityImprove layout flexibilityGearingGearing controlEngineeringPulley

A belt-drive CVT includes a pair of pulleys, each of which has a stationary pulley and a movable pulley that moves toward or away from the stationary pulley in an axial direction of the pulley, a belt that is wound around the pair of pulleys and a rotation state detecting device for detecting rotation of the pulley. The rotation state detecting device has a tone wheel that rotates integrally with the pulley and a sensor that faces the tone wheel. The tone wheel has a cylinder portion that extends along a moving direction of the movable pulley. The cylinder portion is provided with a plurality of detection portions which are arranged at regular intervals in a circumferential direction throughout an entire circumference of the cylinder portion and which extend along the moving direction of the movable pulley.

Owner:JATCO LTD +1

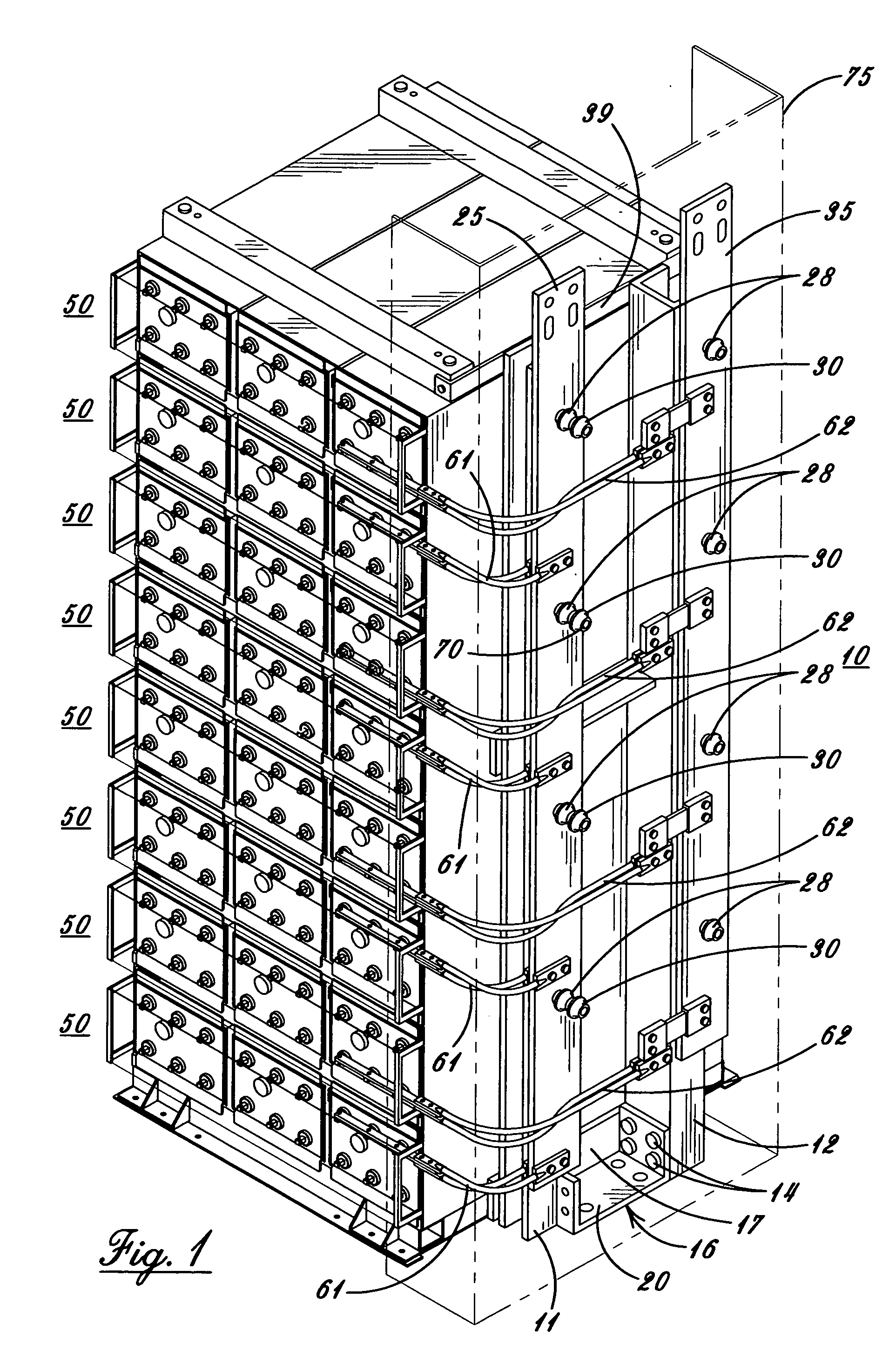

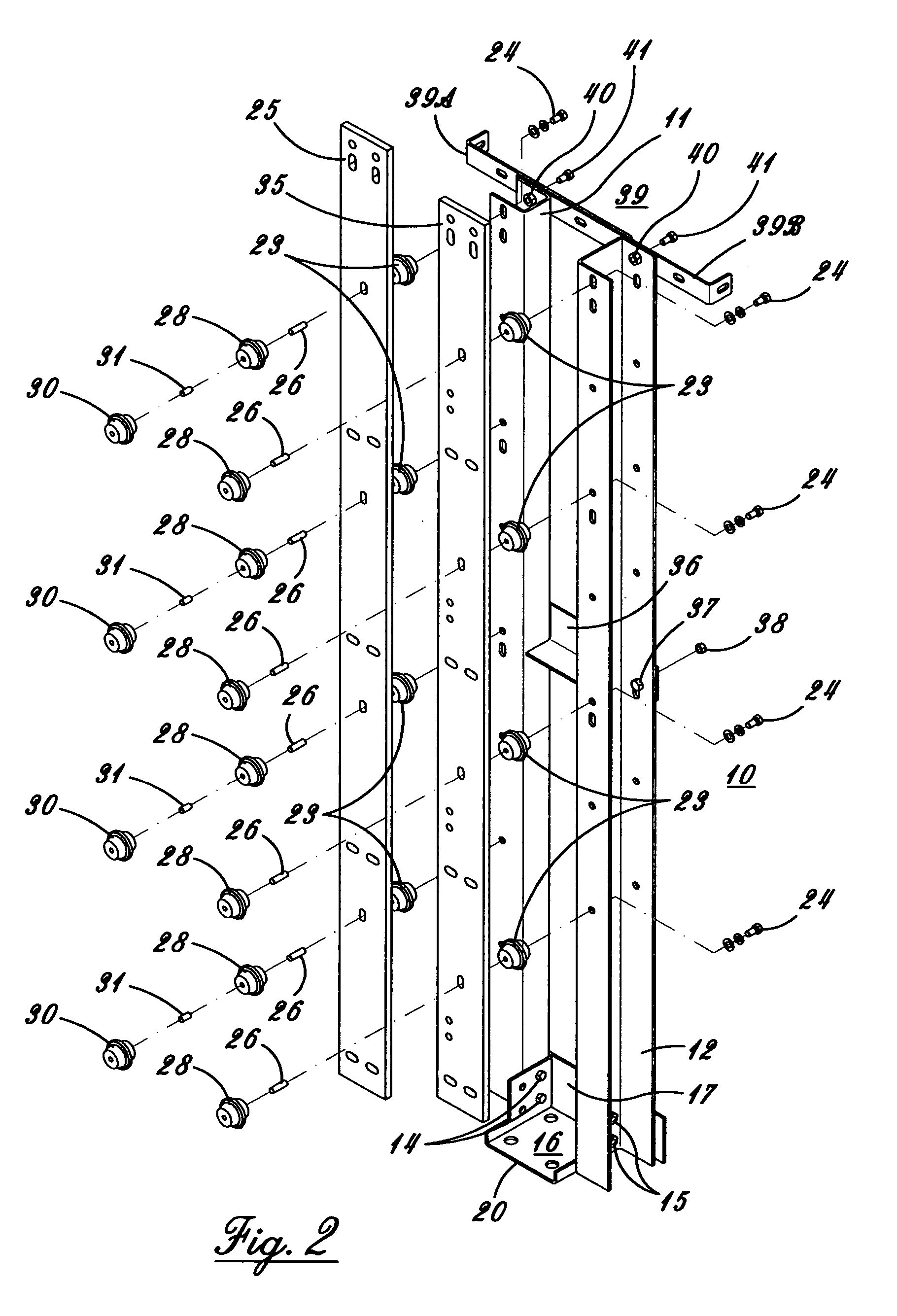

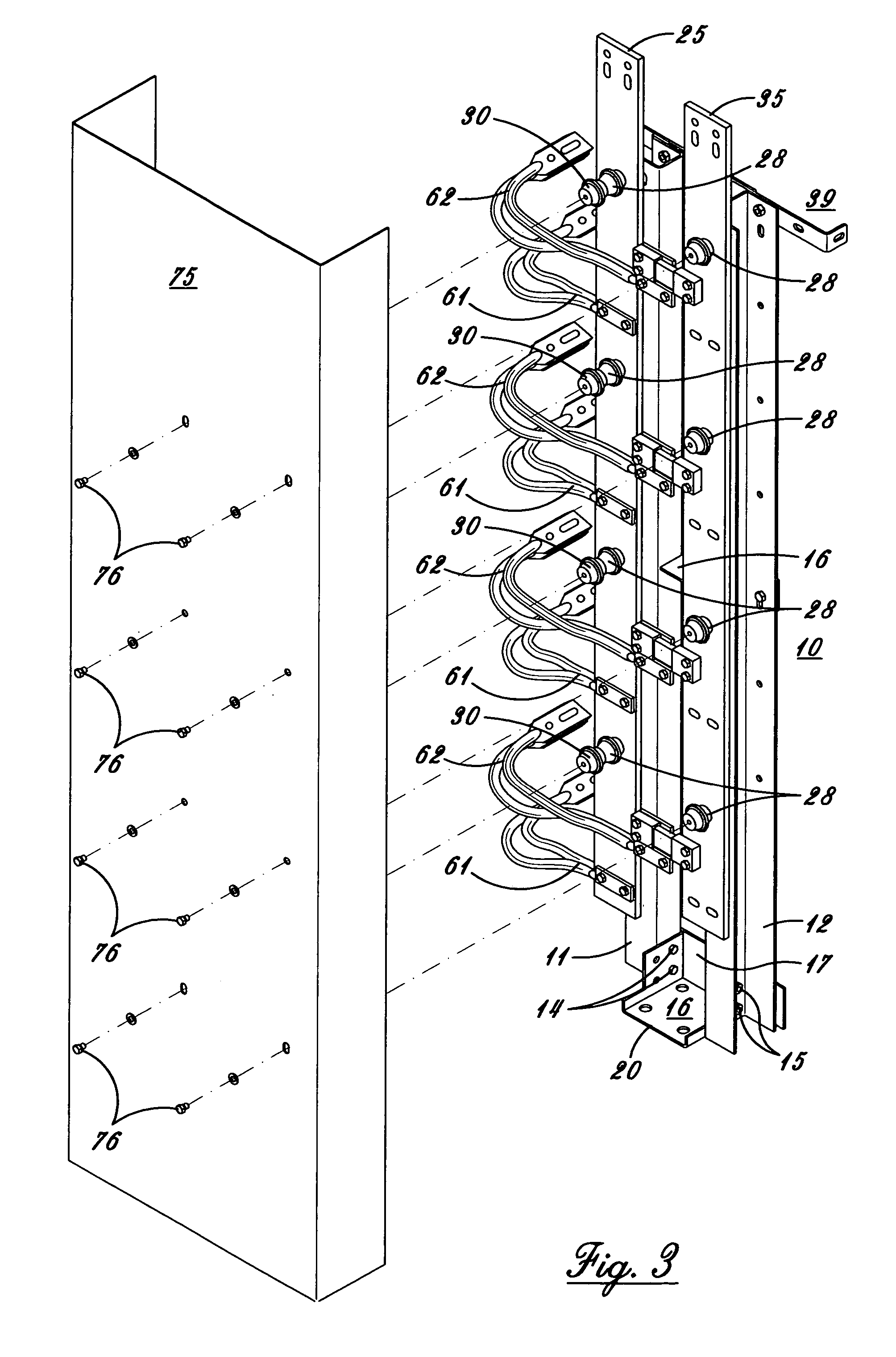

Standalone bus bar kit system

InactiveUS20070018612A1Simple and inexpensive to constructEasy to useBatteries circuit arrangementsLead-acid accumulatorsEmbedded systemProtective shield

Standalone bus bar kit system having two uprights mounted to a floor mounting base, a center mounting bracket connecting the uprights in the middle, upper mounting, brackets connecting the uprights at the top, positive and negative bus bars mounted to insulators carried by the uprights, and which have battery strings connected thereto, and a detachable protective shield carried on insulators on one of the bus bars.

Owner:EAST PENN MFG CO INC

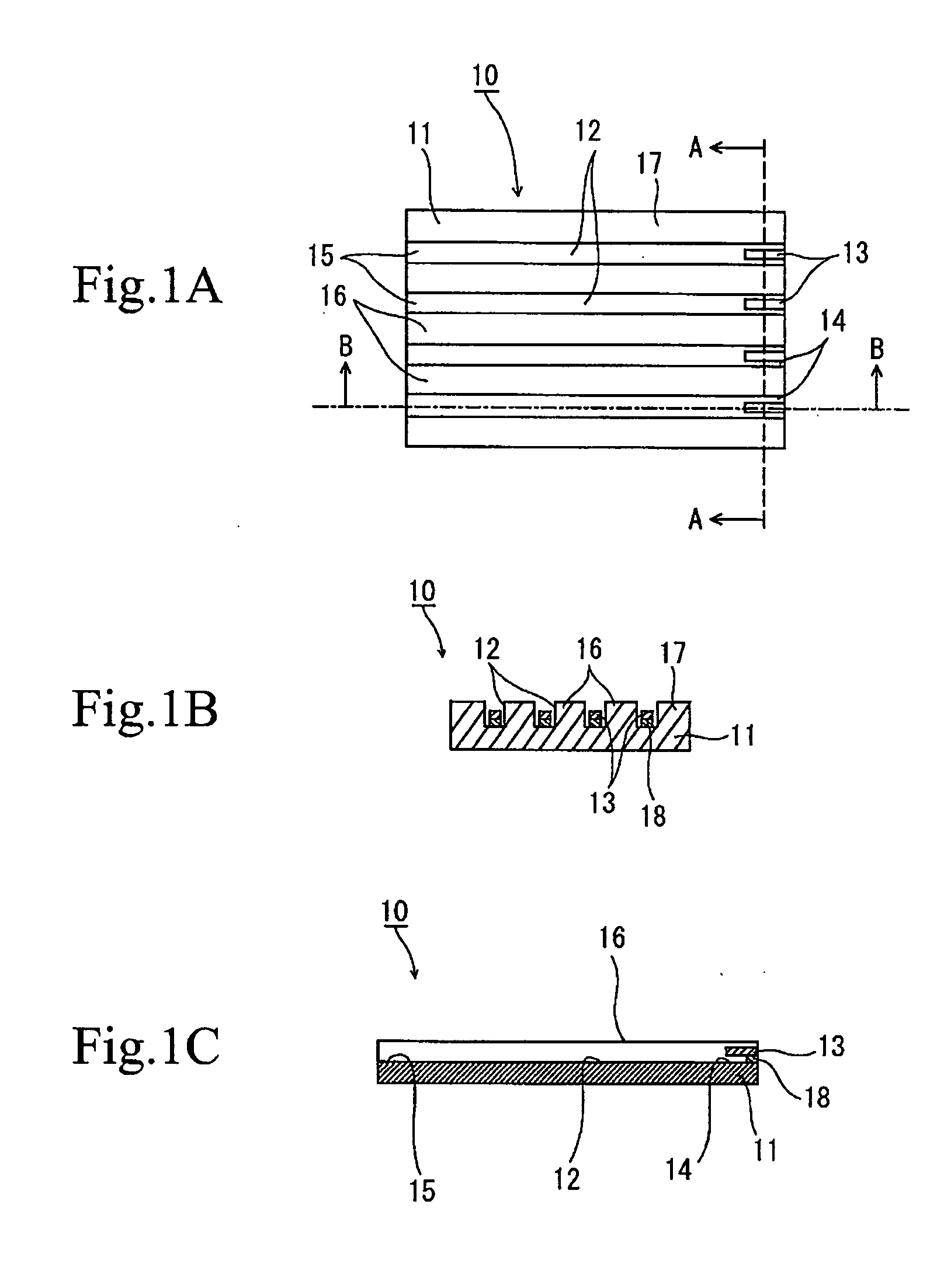

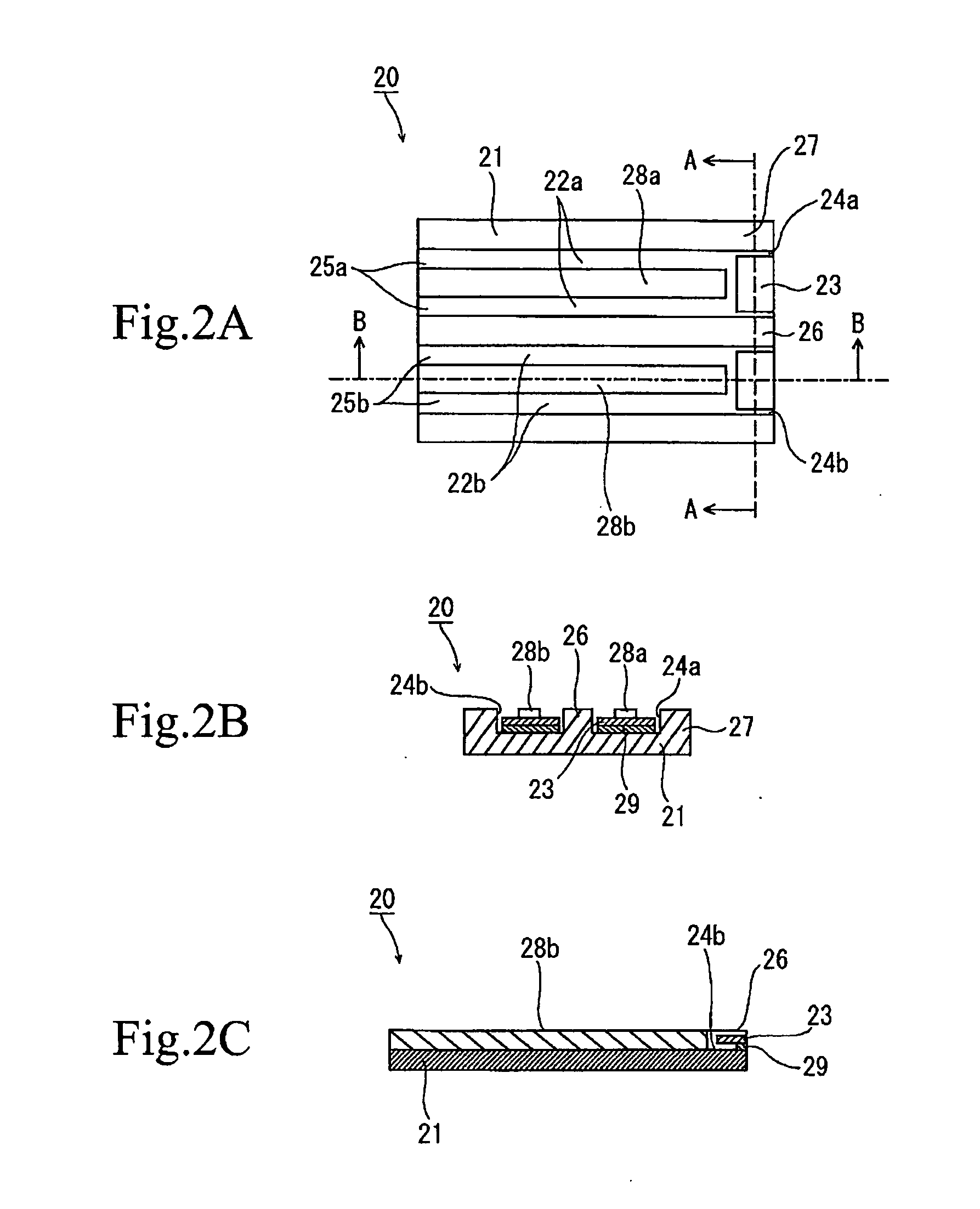

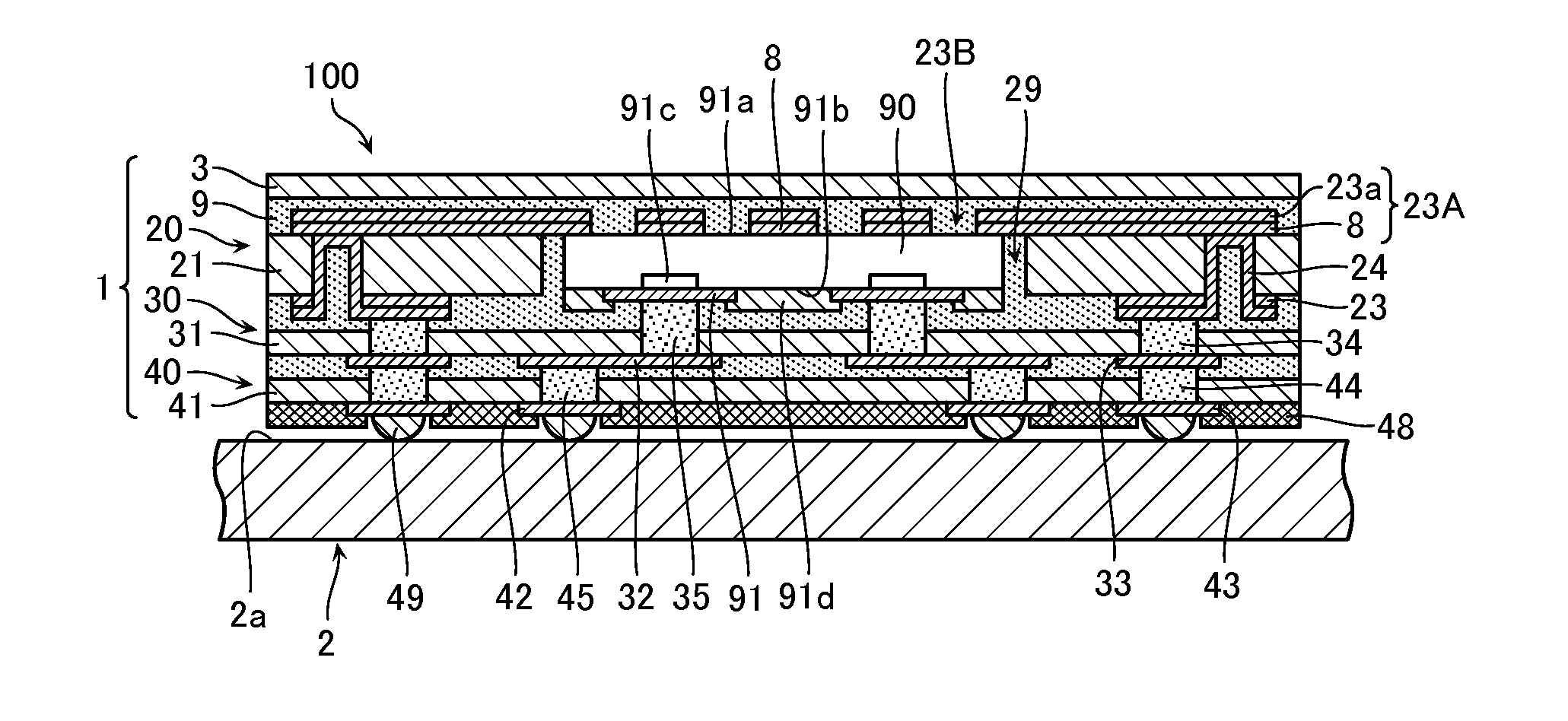

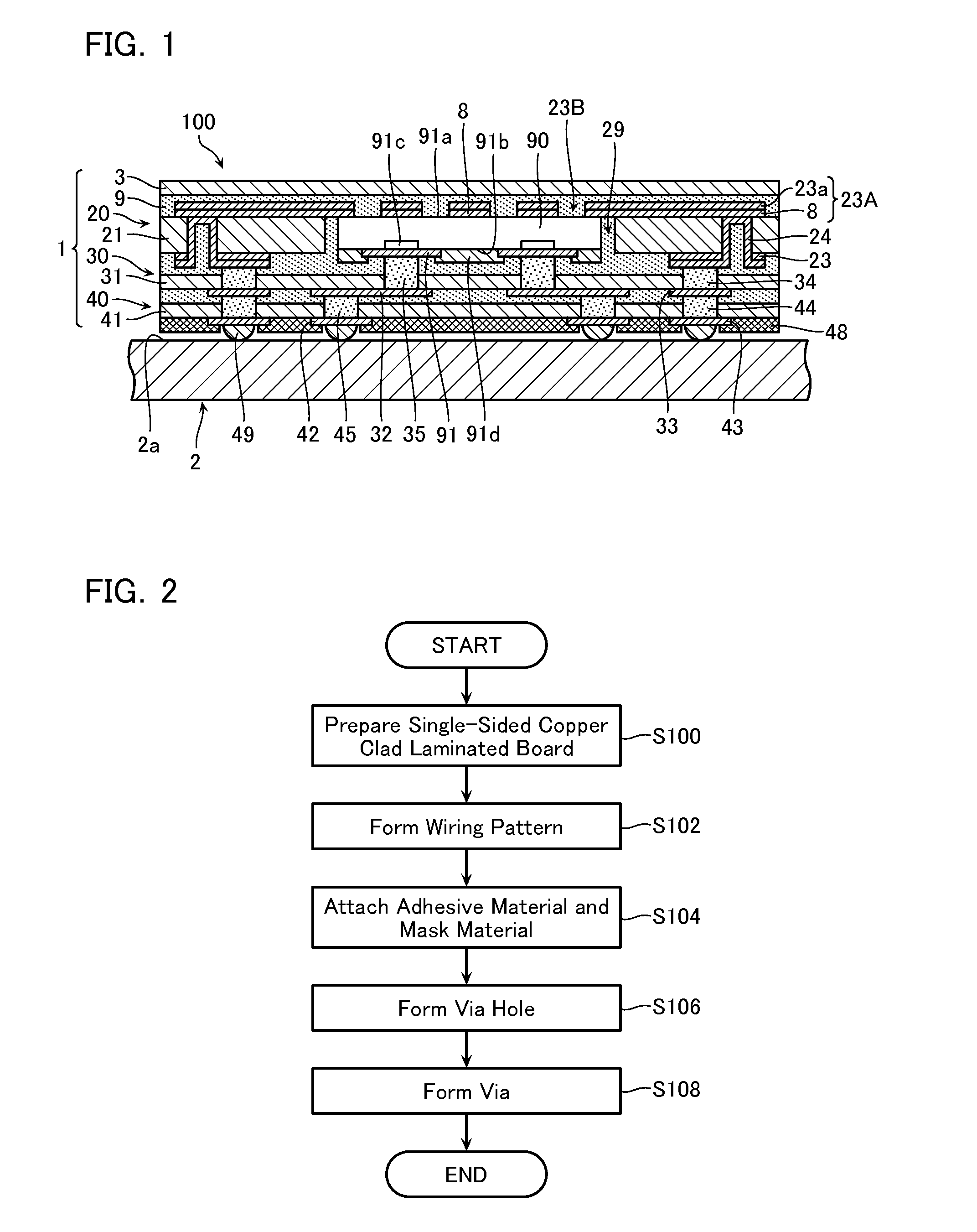

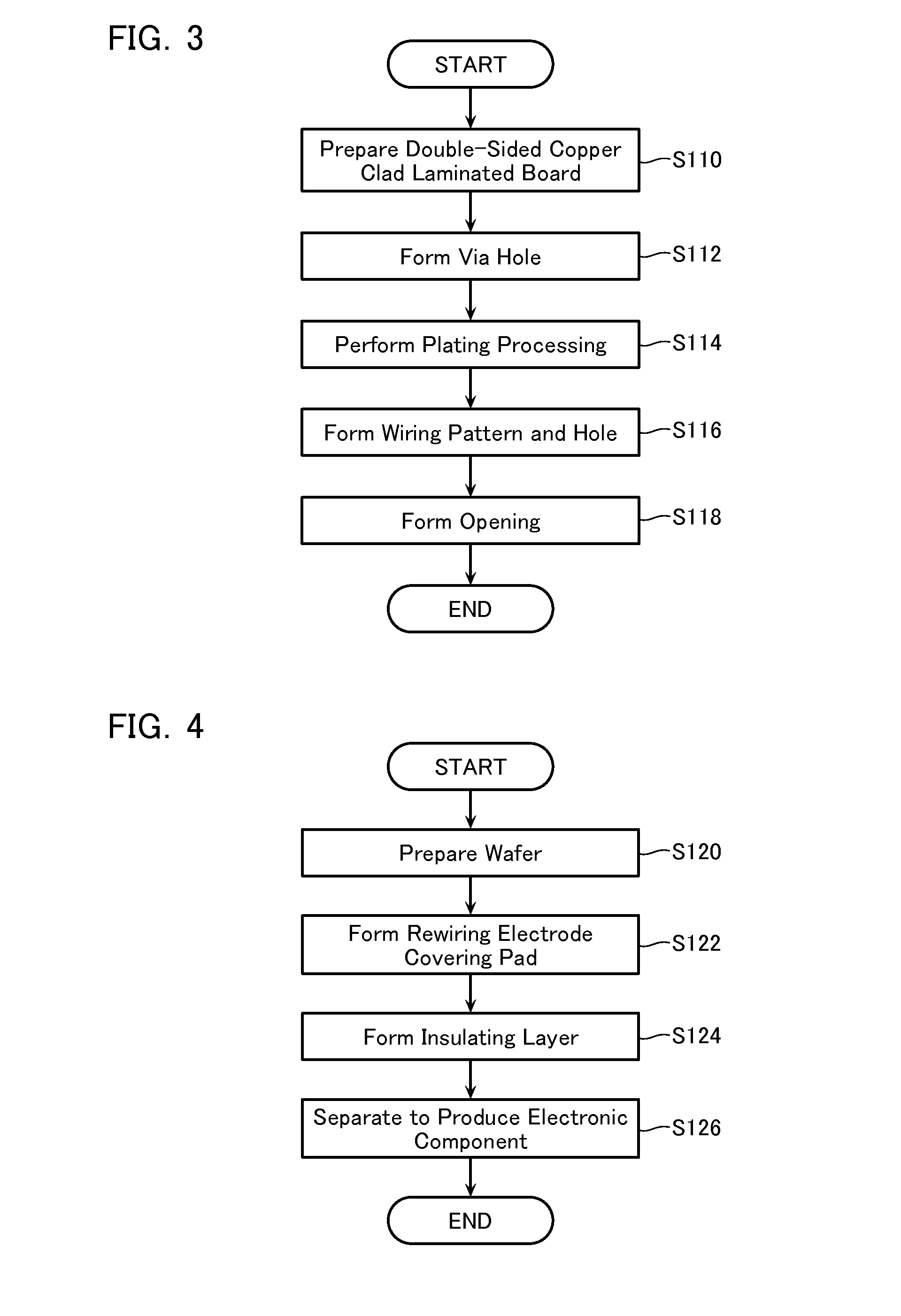

Component built-in board and method of manufacturing the same, and component built-in board mounting body

ActiveUS20140268574A1Improved heat radiation characteristicProne to feverPrinted circuit assemblingSemiconductor/solid-state device detailsHeat conductingEngineering

A component built-in board comprises stacked therein a plurality of printed wiring bases having a wiring pattern and a via formed on / in a resin base thereof, and comprises an electronic component built in thereto, wherein at least a portion of the plurality of printed wiring bases include a thermal wiring in the wiring pattern and include a thermal via in the via, at least one of the plurality of printed wiring bases has formed therein an opening where the electronic component is built, and has formed therein a heat-conducting layer and closely attached to a surface on an opposite side to an electrode formation surface of the electronic component built in to the opening, and the electronic component is fixed in the opening by an adhesive layer stacked on the heat-conducting layer, via a hole formed in a region facing onto the opening of the heat-conducting layer.

Owner:THE FUJIKURA CABLE WORKS LTD

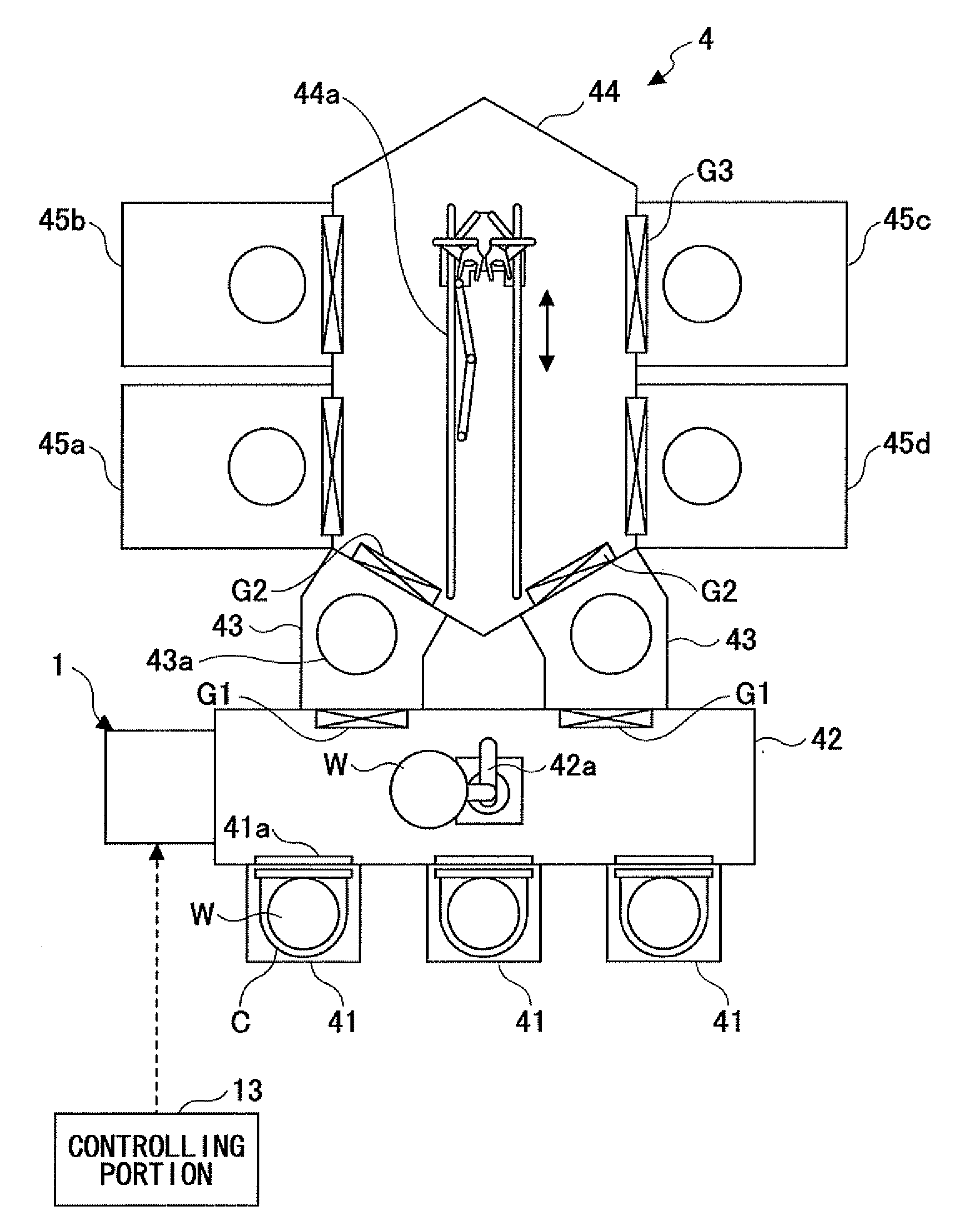

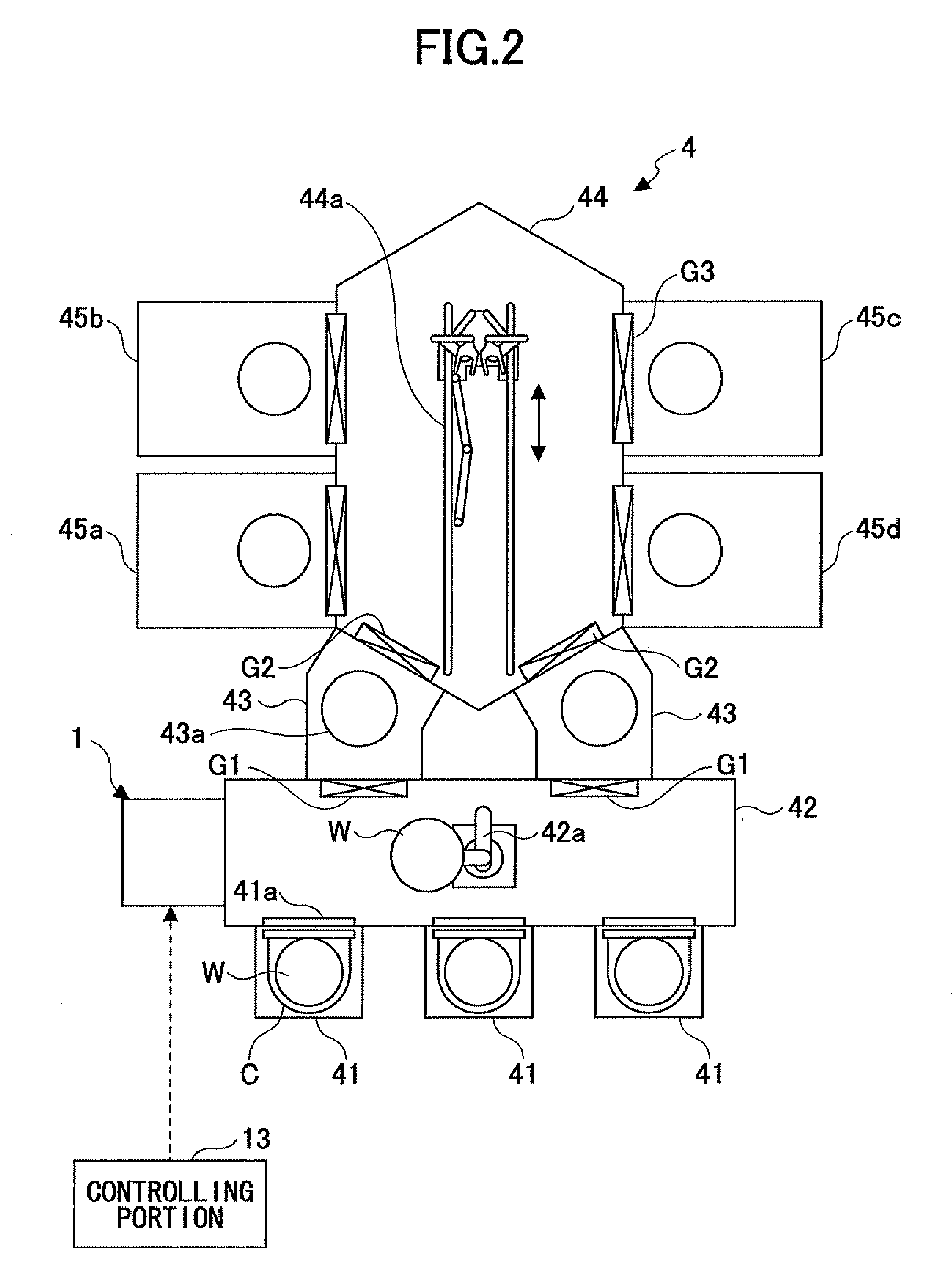

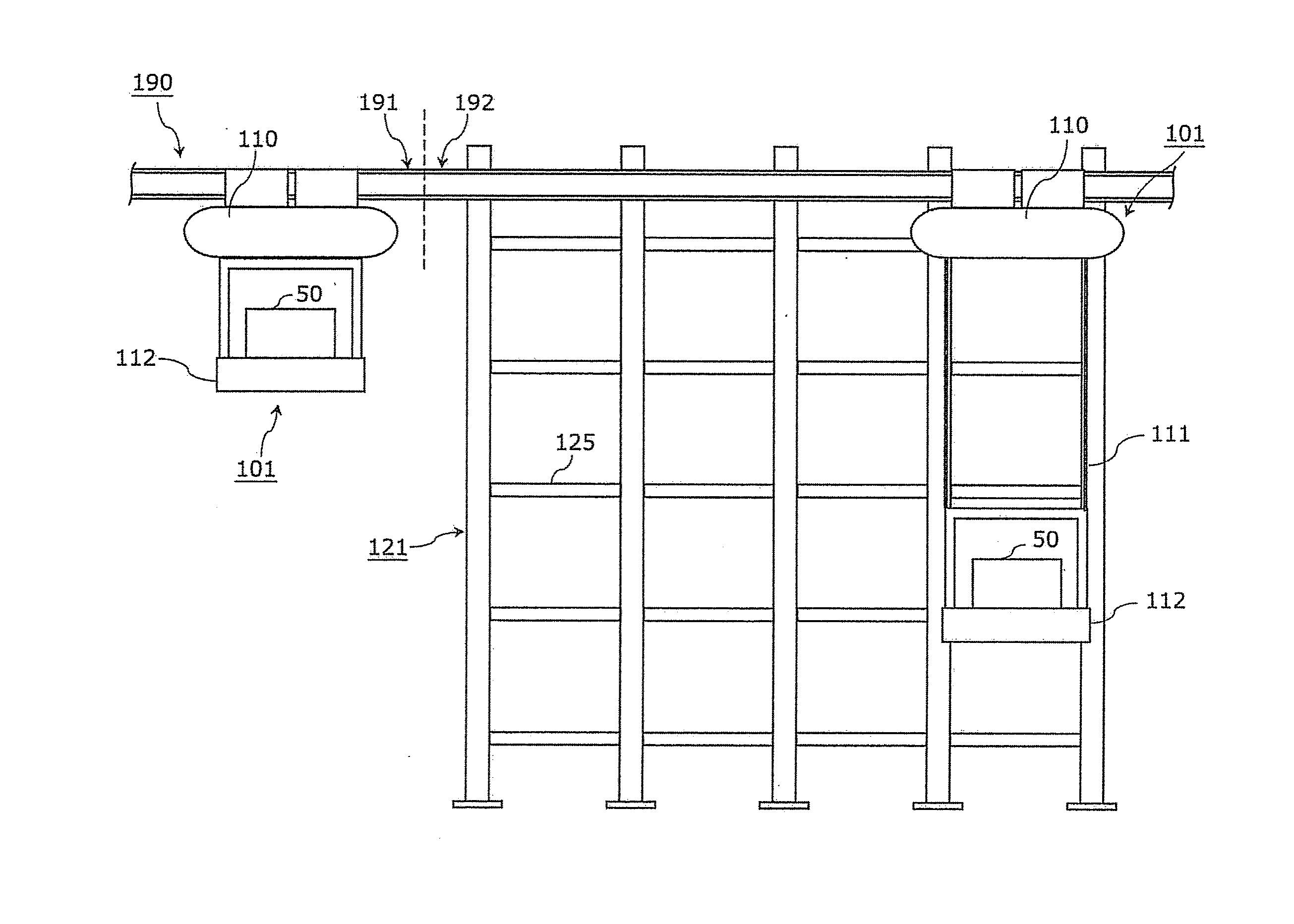

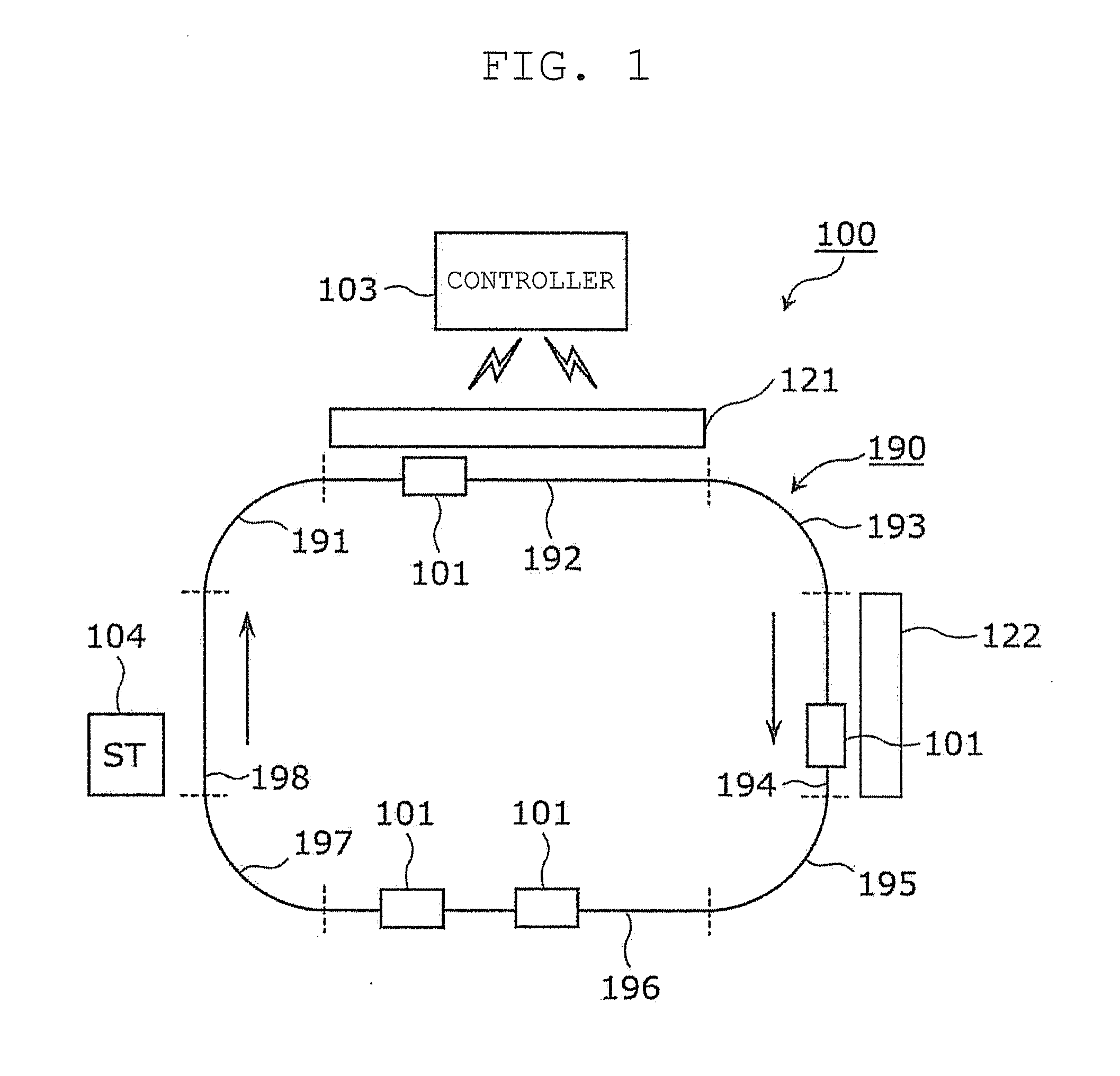

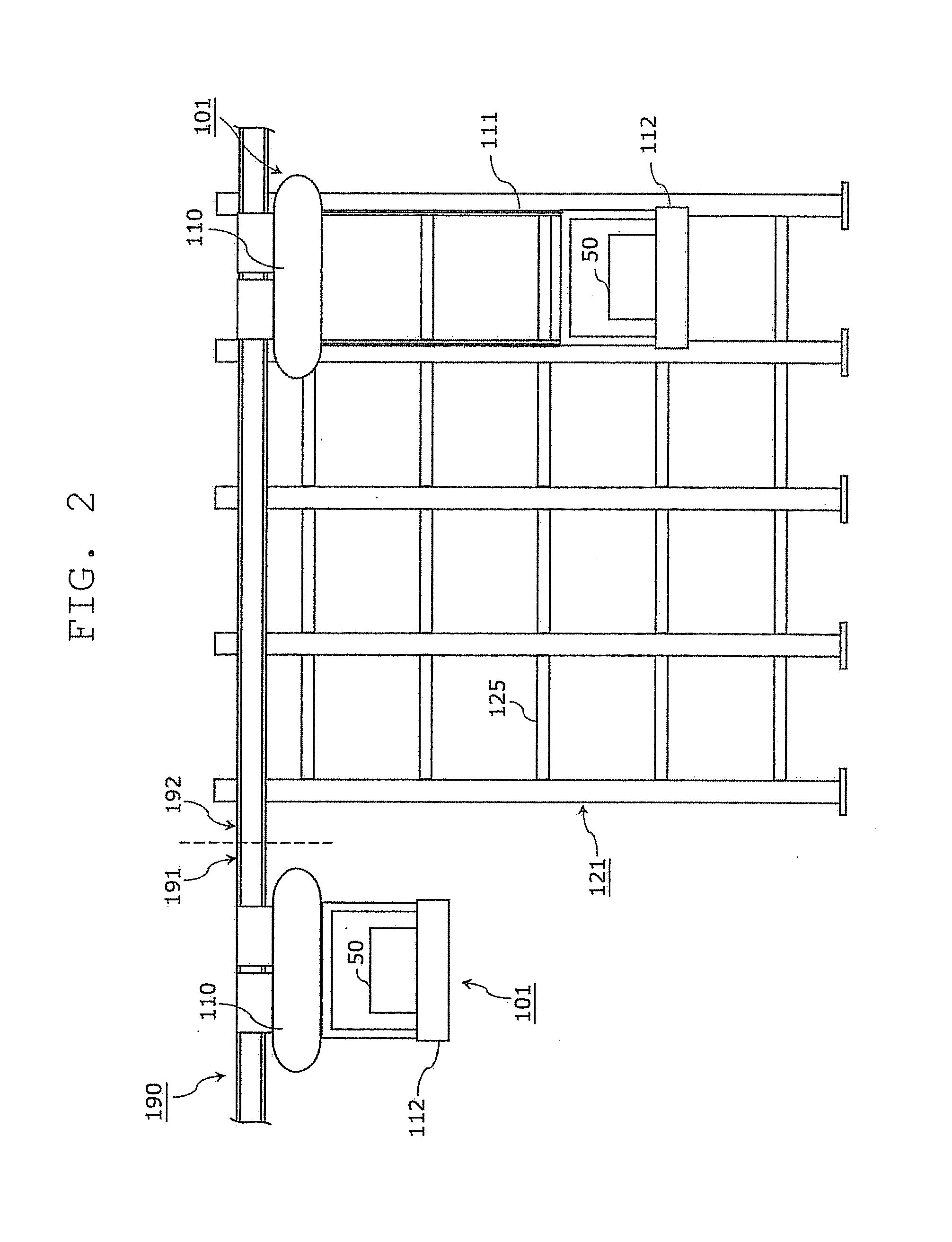

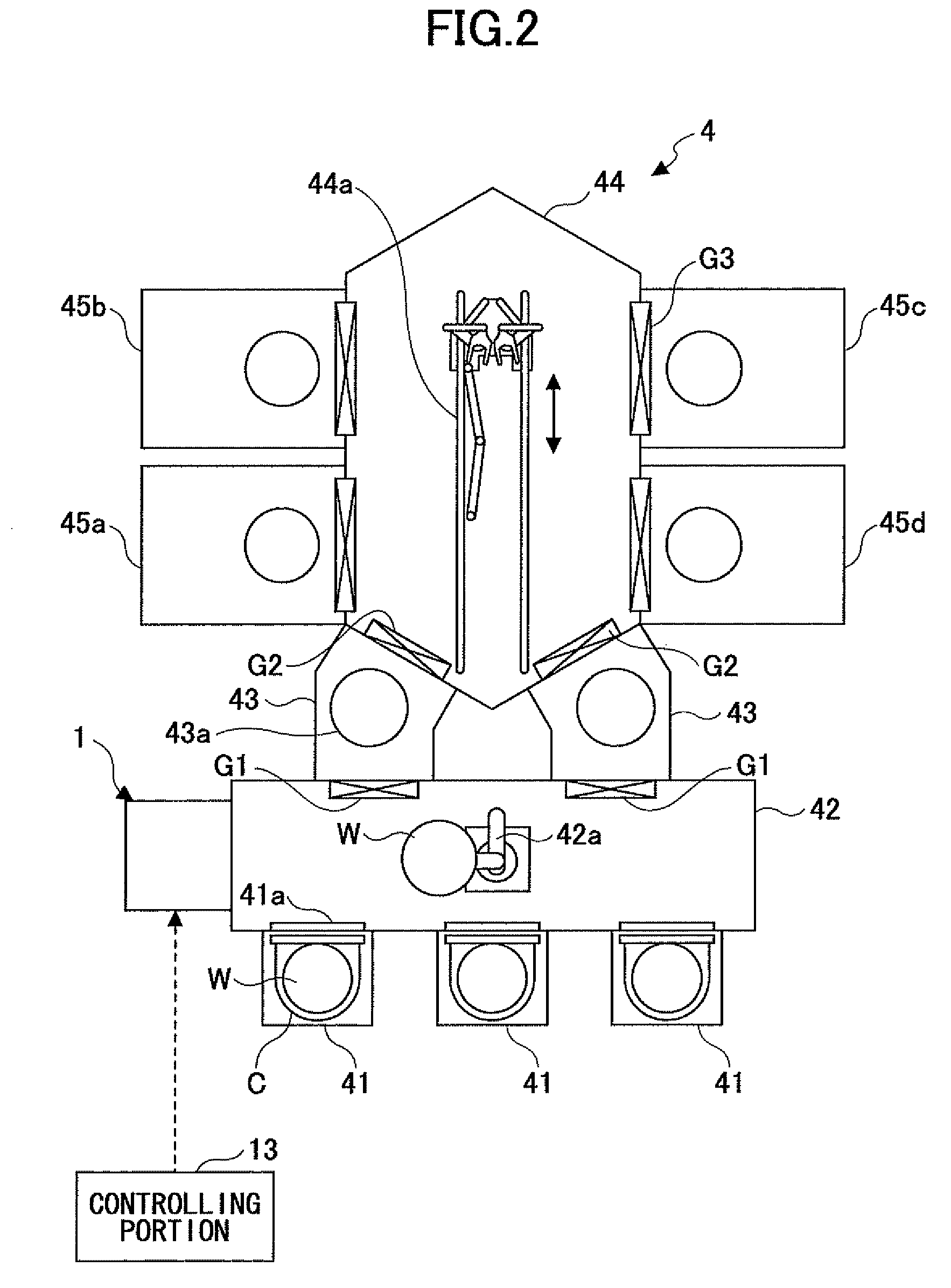

Carrier system and method for controlling carrier system

A carrier system capable of rapidly carrying a cargo includes: a circulation rail which is hung from above and includes a curved part; a plurality of carriers, each of which includes a travelling vehicle that travels along the circulation rail and a lift stage that is liftably hung on the travelling vehicle and serves to hold a cargo, and each of which lifts and lowers the lift stage while traveling along the circulation rail; a plurality of racks which are arranged in parallel along the circulation rail, and each of which includes a plurality of placement parts arranged in parallel in a vertical direction; and a controller which selects any of the plurality of placement parts as a storing position of the cargo and instructs the carrier that holds the cargo out of the plurality of carriers, about the storing position.

Owner:MURATA MASCH LTD

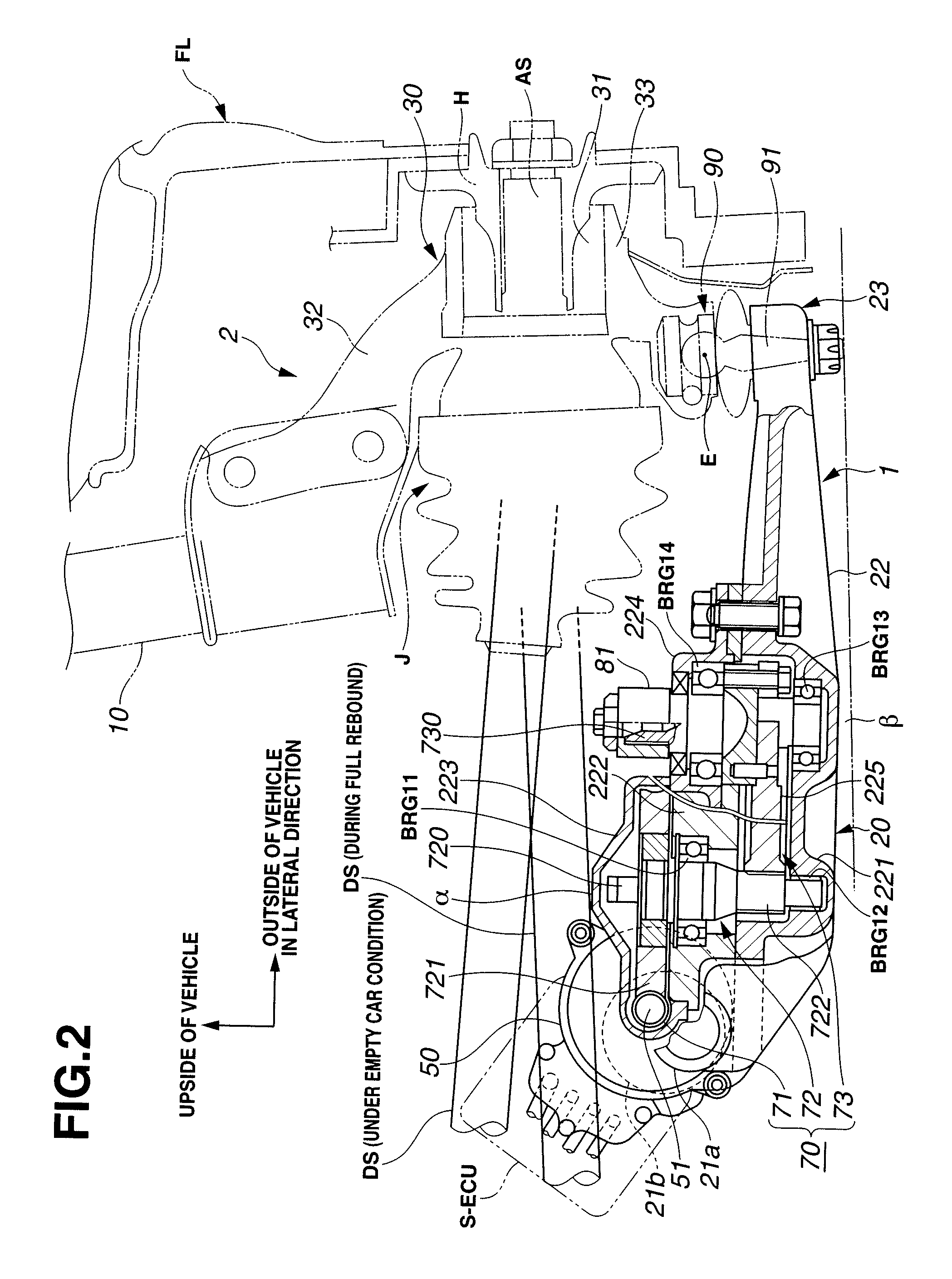

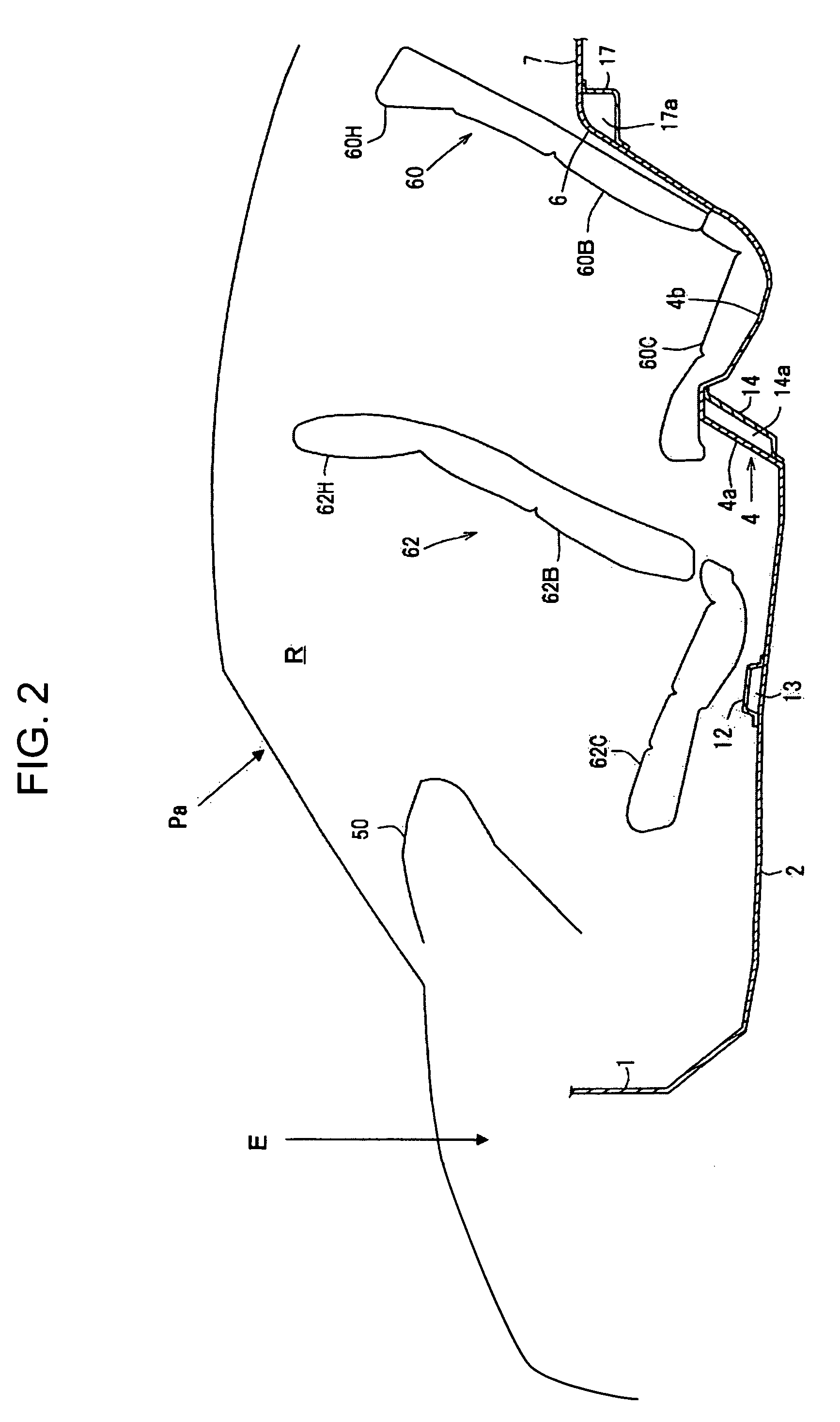

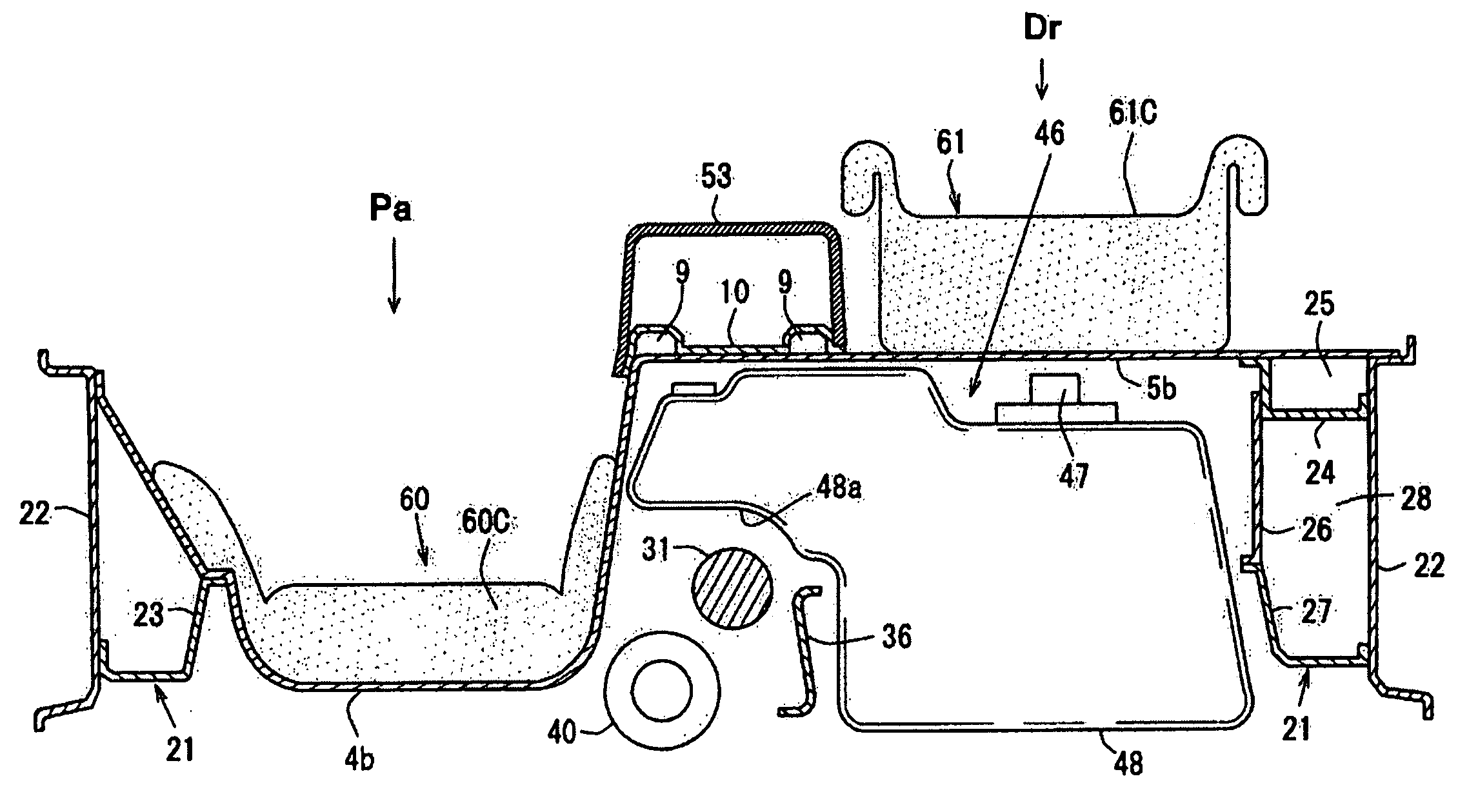

Arrangement structure for auxiliary component of vehicle

InactiveUS7658440B2Improve layout flexibilitySuperstructure subunitsDashboardsEngineeringMechanical engineering

An arrangement structure for an auxiliary component of a vehicle includes a floor panel defining the bottom surface of the passenger compartment. The floor panel includes a first kick-up portion and a second kick-up portion disposed in side-by-side relation to the first kick-up portion in a lateral direction of a vehicle body. The second kick-up portion is formed to have a height greater than that of the first kick-up portion. A first seat is disposed on the first kick-up portion, a second seat is formed to have a smaller size than that of the first seat and disposed on the second kick-up portion, and a cross member is joined along the second kick-up portion in the lateral direction to form a closed section therebetween. The arrangement structure of the present invention allows a vehicle to have a low overall-height compact body while achieving enhanced layout flexibility and assuring a passenger compartment space.

Owner:MAZDA MOTOR CORP

Combined step milling method of strip mine semi-continuous system

InactiveCN104847360AIncrease recoverable volumeImprove layout flexibilityOpen-pit miningEngineeringExcavator

The invention discloses a combined step milling method of a strip mine semi-continuous system. The combined step milling method comprises the following steps that a, a first excavation belt for mining a main mining step is taken as an initial point to mine a first width of the main mining step in the direction of a machine head; b, multiple width mining operations of the main mining step are completed, and a working surface conveying machine is moved; c, movement of the main mining step is completed and excavation of the multiple mining widths is completed, the semi-continuous system is shifted into the first with mining of the next step, and after mining is completed, an excavator continues to carry out notch forming on the next width of the next step, and the next width is excavated; and d, after multiple width mining operations of the next step are completed, the working surface conveying machine is moved. The combined step operation is adopted in the combined step milling method, the exploitable yield of the semi-continuous system within a one-time movement period is effectively increased, the one-time movement service period of the system is prolonged, and therefore the production efficiency of the system is improved.

Owner:HUANENG YIMIN COAL POWER CO LTD

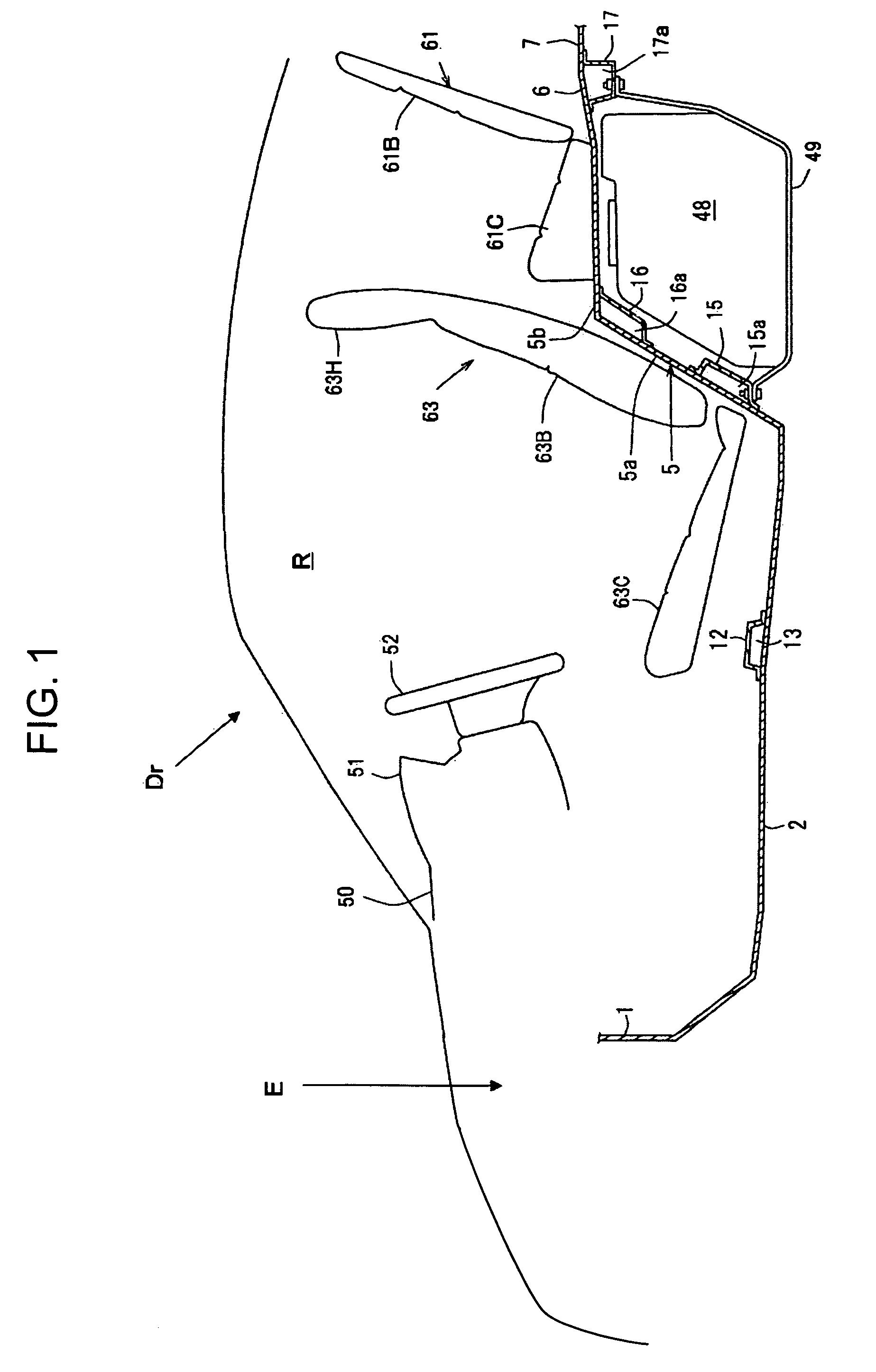

Arrangement structure for auxiliary component of vehicle

InactiveUS20060238000A1Improve layout flexibilitySuperstructure subunitsDashboardsFuel tankEngineering

Disclosed is an arrangement structure for an auxiliary component of a vehicle, which comprises a floor panel defining the bottom surface of the passenger compartment and having a first kick-up portion and a second kick-up portion disposed in side-by-side relation to the first kick-up portion in a lateral direction of a vehicle body and formed to have a height greater than that of the first kick-up portion, a first seat disposed on the first kick-up portion, a second seat formed to have a smaller size than that of the first seat and disposed on the second kick-up portion, and a cross member joined along the second kick-up portion in the lateral direction to form a closed section therebetween. The auxiliary component includes a first fuel tank arranged below the first kick-up portion, and a second fuel tank formed to have a height greater than that of the first fuel tank and arranged below the second kick-up portion. The arrangement structure of the present invention allows a vehicle to have a low overall-height compact body while achieving enhanced layout flexibility and assuring a passenger compartment space.

Owner:MAZDA MOTOR CORP

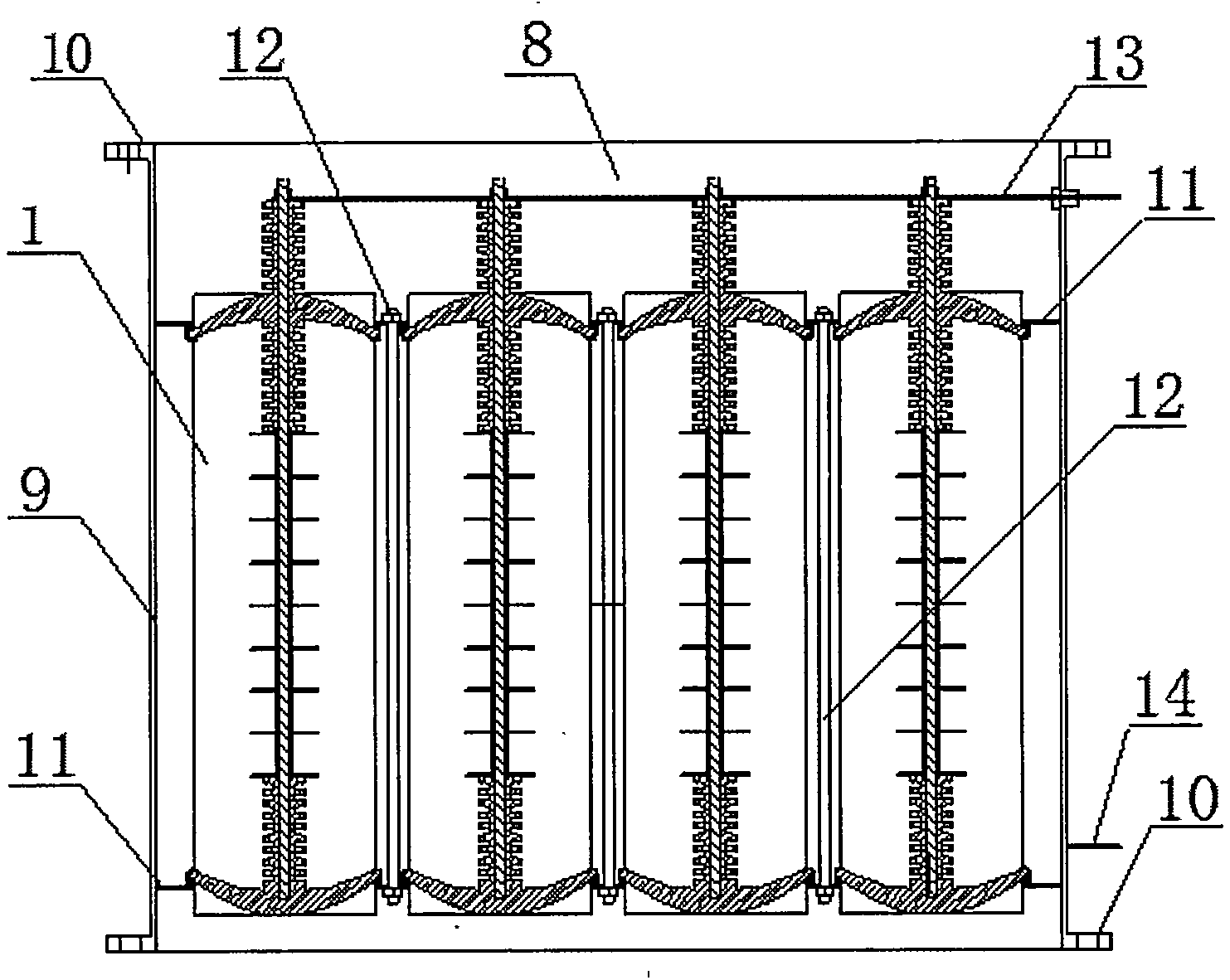

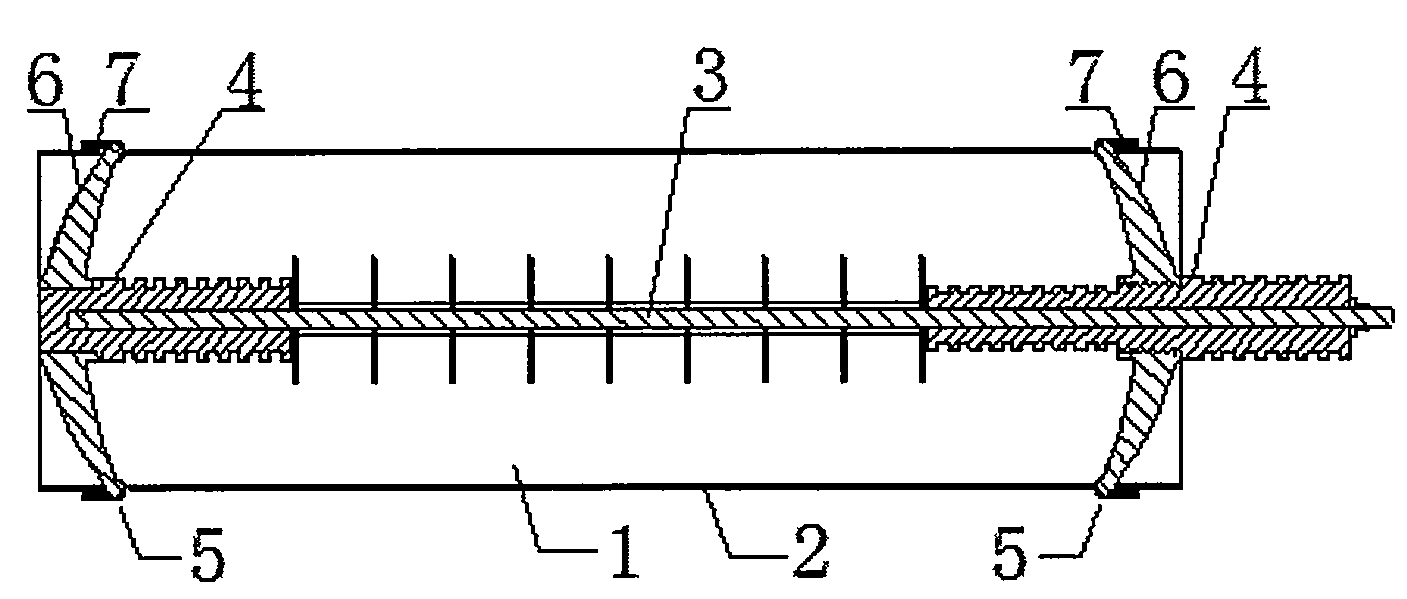

Wire-tubular-type low temperature plasma unit reactor and assembly system thereof

InactiveCN103611395AImprove antioxidant capacityIncrease input voltageDispersed particle separationElectricityHigh humidity

The invention discloses a wire-tubular-type low temperature plasma unit reactor for treating industrial waste gases and an assembly system thereof. The unit reactor is composed of a reactor positive electrode, a circular pipe external electrode and a sealing ring. The reactor positive electrode is formed by central electrodes with different types and insulation components. The insulation supports on the insulation components are stuck into rolled steel grooves of the circular pipe external electrode to form the unit reactor. According to actual requirements of waste gas treating engineering, N unit reactors are employed to be assembled in series and parallel ways and a reactor matrix is formed. The reactor matrix and compression screws are assembled to form a single-box reactor through reactor supporting plates. The single-box reactors are connected in series and electrically connected through box body seal heads and box body flanges and a reactor assembly system is formed. The assembly system is suitable for treatment of various gases with peculiar smell, high-humidity?gases and smoke zones in different quantitative grades. The product is advantaged by safety, energy saving and environmental protection, the flexibility of the system layout is strong, the adaptive condition range is wide and the service life is long.

Owner:SHANGHAI RUIJIN ENVIRONMENT TECH

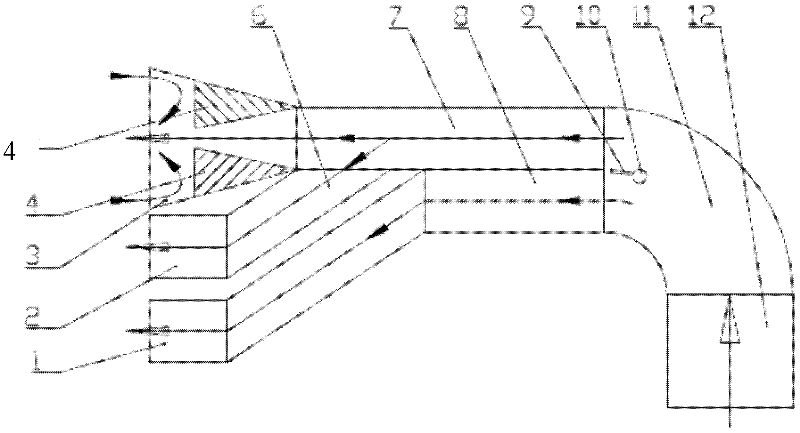

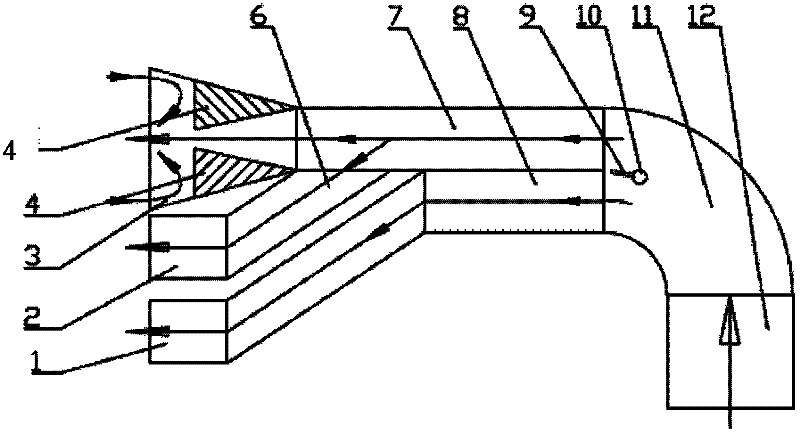

Pulverized coal decoupling combustor and decoupling combustion method thereof

InactiveCN102297425AMeet or exceed concentration efficiencyOver concentration efficiencyPulverulent fuel combustion burnersCombustorGuide tube

The invention relates to a pulverized coal decoupling combustor and a decoupling combustion method thereof. The decoupling combustor comprises a first-stage air duct (12), an inertia separator (11), air current conduits and a spout which are sequentially connected along the air current direction, wherein the air current conduits comprise a dense side air current conduit (7) and a fresh side air current conduit (8); the fresh side air current conduit (8) is communicated with a third-stage spout (1); the dense side air current conduit (7) is connected with a first-stage spout (3); a second-stage spout conduit (6) communicated with the dense side air current conduit (7) is led out of a pipeline between the dense side air current conduit (7) and the first-stage spout (3) on the dense side aircurrent conduit (7); the second-stage spout conduit (6) is communicated with a second-stage spout (2); the first-stage spout (3) is a gradually-increasing spout; a pair of pulverized coal collecting flame stabilizing devices (4) is oppositely arranged at the upper side and the lower side inside the front end of the first-stage spout (3); the cross sections of the pulverized coal collecting flame stabilizing devices (4) along the air current direction is gradually increased; and the area of the cross section of an air current channel is decreased along the air current direction, thus the coupling combustion is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Wireless communication apparatus and response data processing method therefor

InactiveUS7711323B2Efficient use ofLarge installationUnauthorised/fraudulent call preventionEavesdropping prevention circuitsCommunication interfaceTime limit

A wireless communication apparatus that communicates data with an external wireless apparatus in a wireless communication range includes a controller and a wireless communication interface device is provided. The wireless communication interface device includes a transmitting unit that transmits response request data to the external wireless apparatus, a counter that counts time for determining whether or not a time limit for waiting for the response data has elapsed, a storage unit that stores the response data, a receiving unit that receives first response data from the external wireless apparatus and that instantaneously receives second response data without an instruction from the controller when the time limit has not elapsed, a frame length checking unit that checks a frame length of the received response data, and an error detector that performs error detection on the response data.

Owner:SONY CORP

Substrate processing apparatus

InactiveUS8382088B2Improve layout flexibilityImprove design flexibilitySemiconductor/solid-state device manufacturingWork holdersEngineering

A substrate processing apparatus is disclosed for bringing a substrate from a carrier, by a substrate transfer portion inside a transfer chamber, into a processing module to perform a process therein. The substrate processing apparatus includes a substrate storing chamber coupled to an exterior of the transfer chamber via a transfer opening to be in communications with the transfer chamber; a first storing shelf in the substrate storing chamber to store substrates for a first storing purpose; a second storing shelf in the substrate storing chamber to store substrates for a second storing purpose different from the first storing purpose; and a shifting mechanism that shifts the first and the second storing shelves to position a substrate storing area of one of the first and the second storing shelves so that substrate transferring is enabled between the substrate storing area and the substrate transfer portion via the transfer opening.

Owner:TOKYO ELECTRON LTD

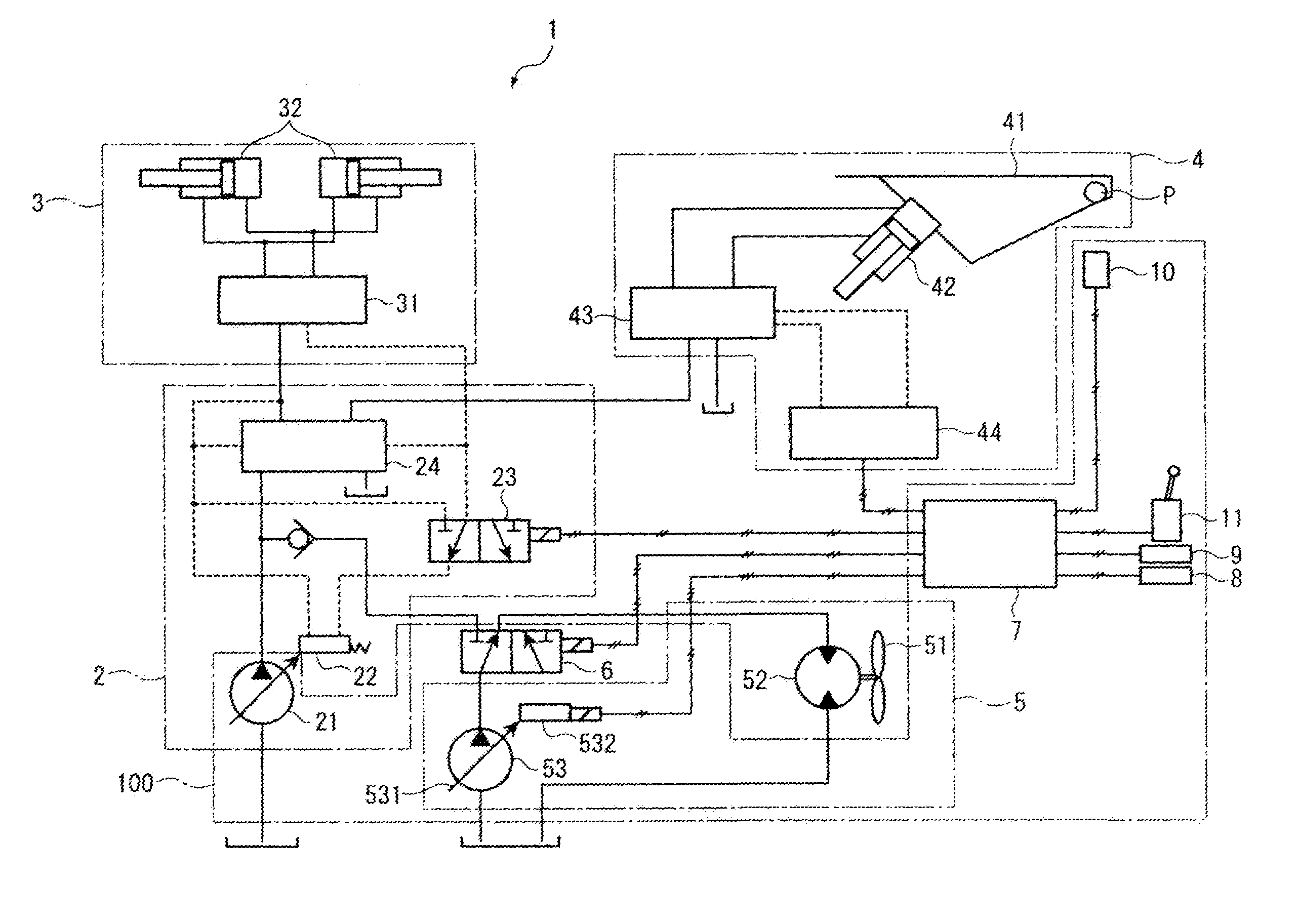

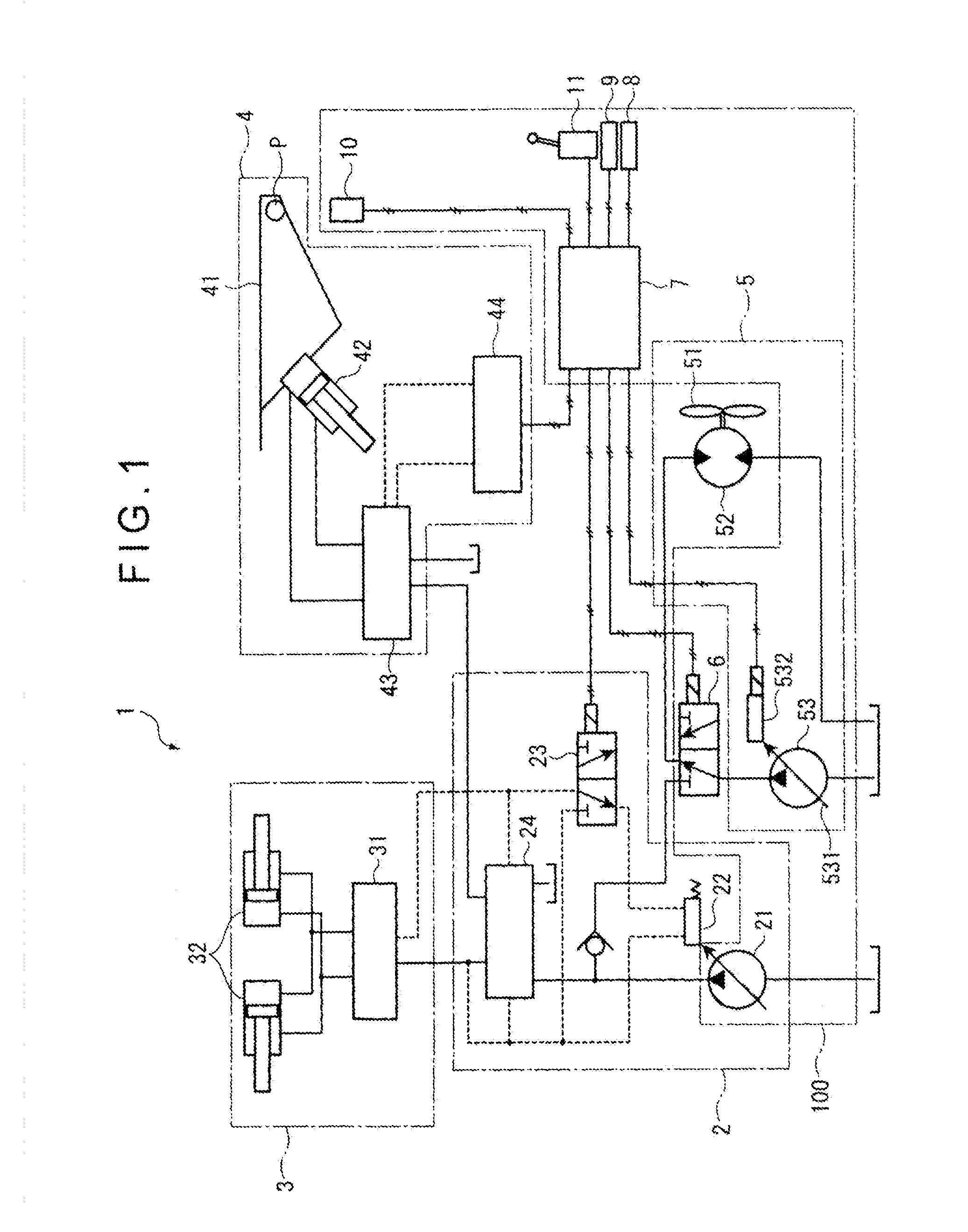

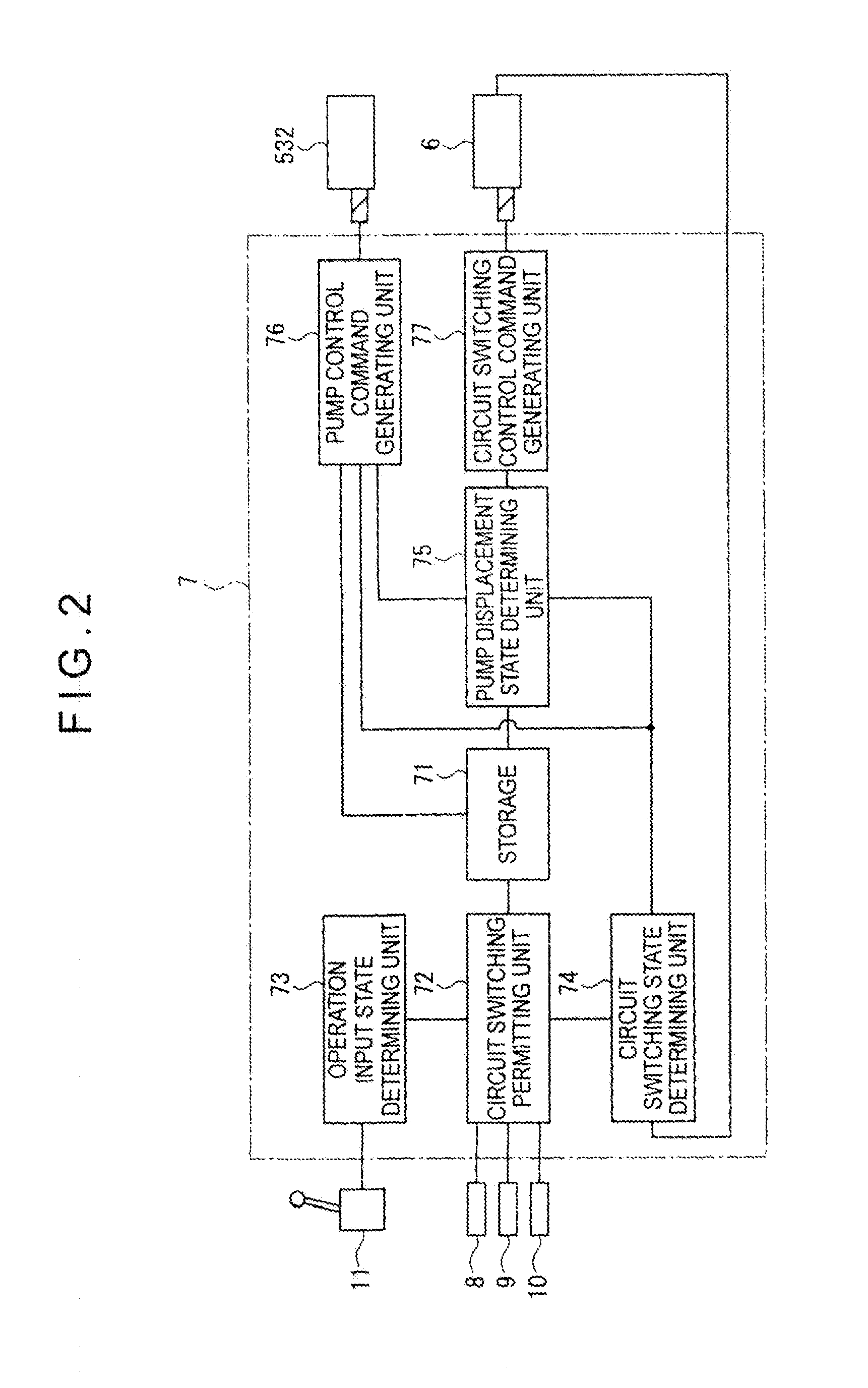

Operating Oil Supplying Device and Construction Machine

InactiveUS20110011076A1Good cleanabilityIncrease costCoolant flow controlFluid couplingsOil supplyActuator

A hydraulic oil supply device includes: a work equipment pump that supplies a hydraulic oil to a hydraulic actuator that drives a work equipment; a fan pump that supplies the hydraulic oil to a hydraulic motor that drives a cooling fan; and a circuit switching valve provided on a hydraulic circuit being branched from a hydraulic circuit connecting the hydraulic actuator with the work equipment pump to be connected to the fan pump, the circuit switching valve selectively connecting a discharge portion of the fan pump to the hydraulic actuator and the hydraulic motor.

Owner:KOMATSU LTD

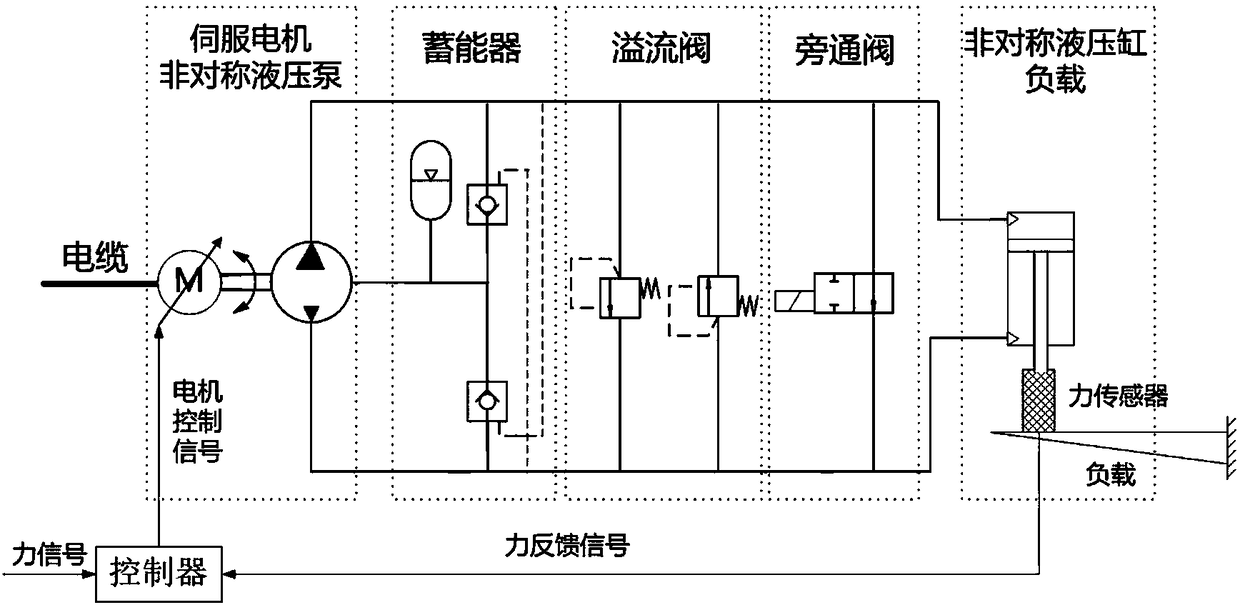

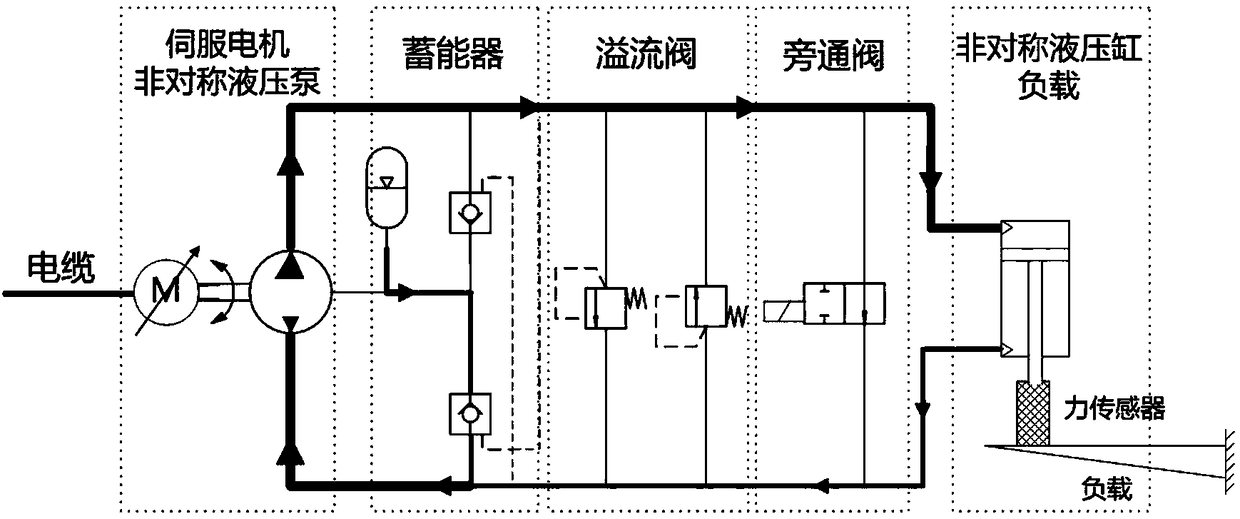

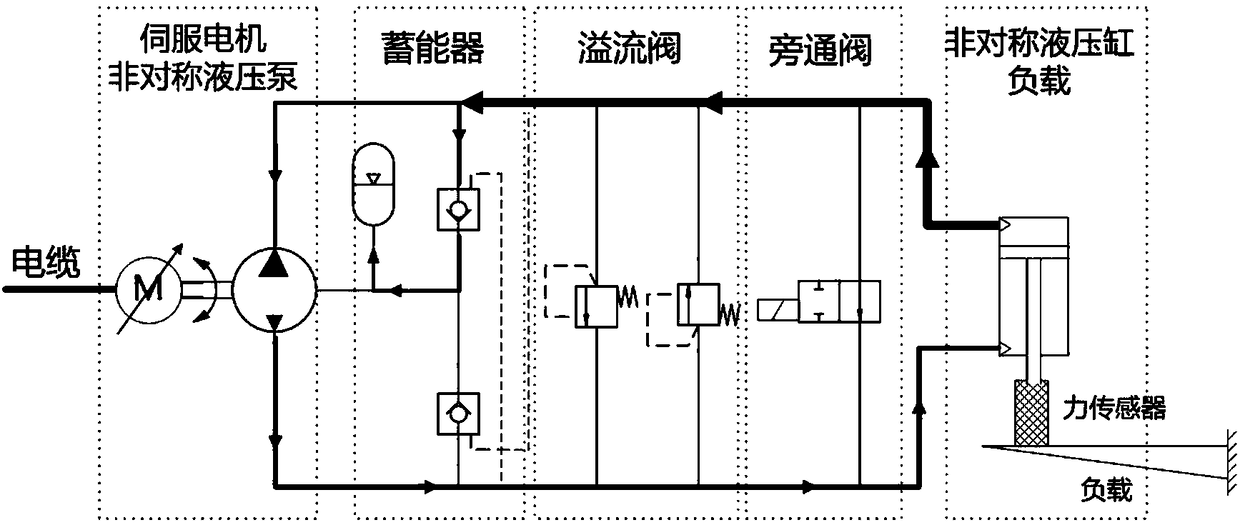

Electro-hydrostatic actuator of asymmetric pump-controlled asymmetric hydraulic cylinder

ActiveCN108506251AIncrease profitImprove layout flexibilityFluid-pressure actuator testingServomotor componentsHydraulic cylinderMotor drive

The invention provides an electro-hydrostatic actuator of an asymmetric pump-controlled asymmetric hydraulic cylinder. The actuator comprises a servo motor, an asymmetric hydraulic pump, the asymmetric hydraulic cylinder, a force sensor and a controller; the servo motor drives the asymmetric hydraulic pump to perform forward rotation and reverse rotation to control the action of the asymmetric hydraulic cylinder; the asymmetric hydraulic cylinder is connected with the force sensor; the force sensor detects the magnitude of the acting force output by the asymmetric hydraulic cylinder, and a force feedback signal is generated according to the magnitude of the acting force, and the force feedback signal is sent to the controller; and the controller generates a motor control signal according to the force feedback signal, and sends the motor control signal to the servo motor.

Owner:BEIHANG UNIV

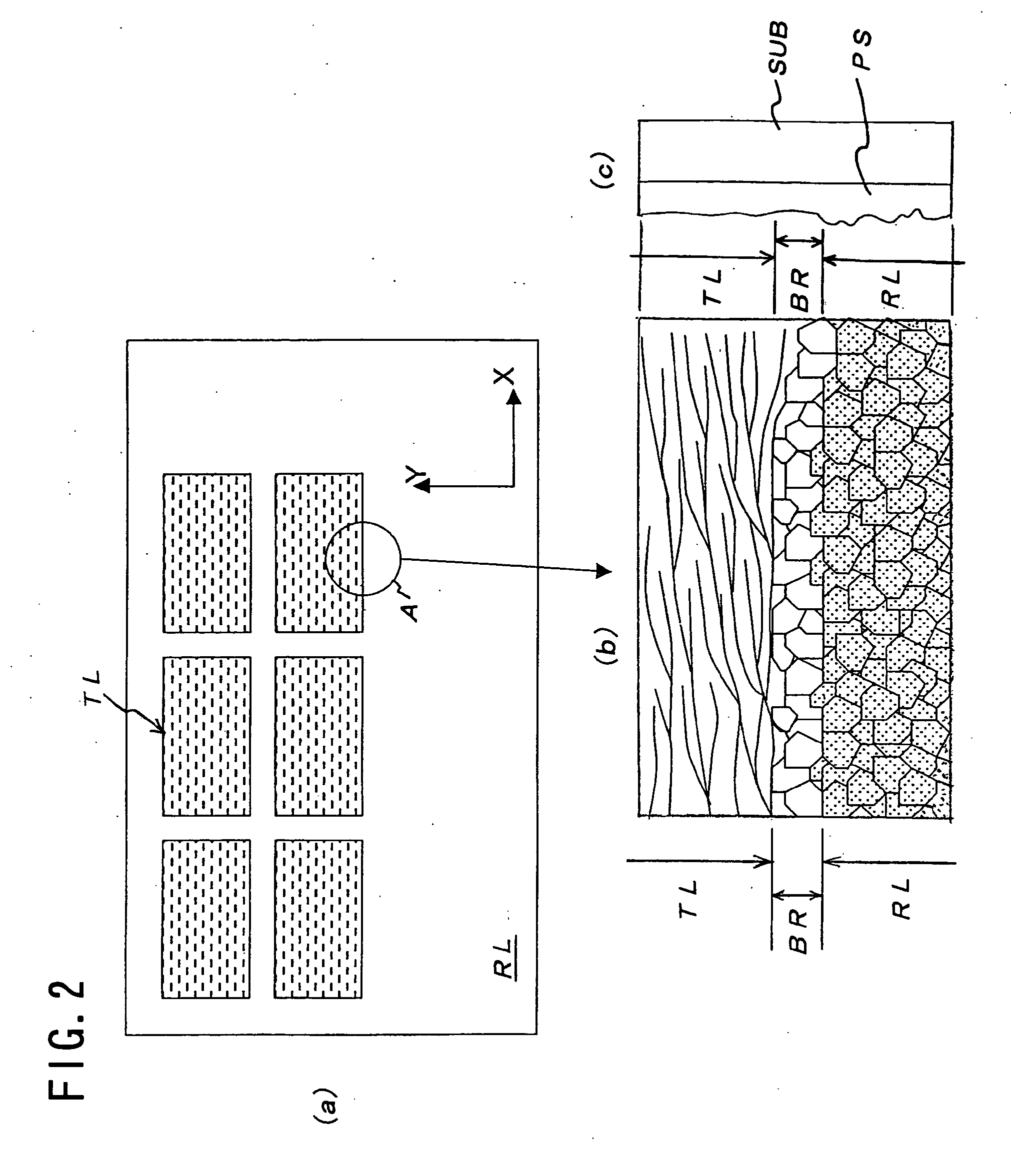

Display Device

ActiveUS20070070283A1Improve space utilizationRaise circuit layout flexibilityTransistorSolid-state devicesEngineeringBand shape

The present invention provides an active matrix display device capable of raising its integration density by reducing the drive circuit area on the active matrix substrate. A semiconductor film presents in the boundary between a quasi-strip crystalline semiconductor film and another semiconductor film is used to form conductive lines, resistors, source / drain electrodes and the like which are respectively connected to thin film transistors formed using the quasi-strip crystalline semiconductor film.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com