Friction type adjusting line delivery system

A conveying system and line adjustment technology, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as many equipment failure points, easy pulsation and crawling, and oily chains, etc., to achieve convenient expansion, strong flexibility, The effect of smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

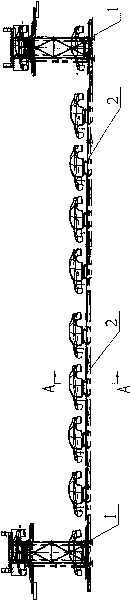

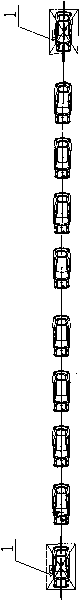

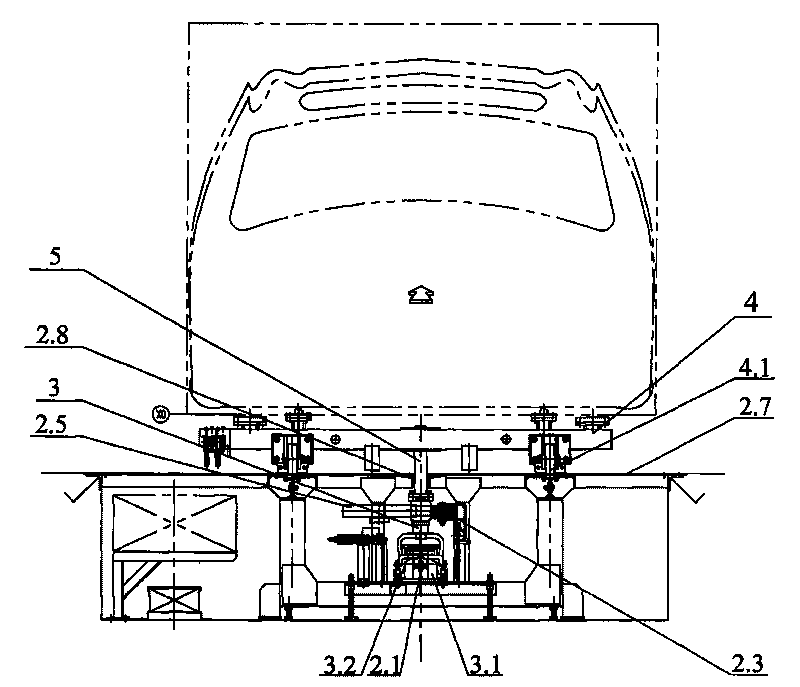

[0026] As shown in the figure: the friction-type adjustment line conveying system includes the adjustment line upper and lower lifts 1 fixed on the left and right sides, and a friction track conveyor 2 is fixed between the two adjustment line upper and lower lifts 1. The type track conveyor 2 has a fixedly arranged conveying walking guide rail 2.1, and the upper and lower parts elevator 1 on the adjustment line has a fixedly arranged transfer traveling guide rail 1.1, and the transfer traveling guide rail 1.1 is intermittently joined with the conveying walking guide rail 2.1, and also There is a conveying trolley 3 running in the transfer walking guide rail 1.1 and the conveying walking guide rail 2.1, the turret on the conveying trolley 3 is provided with a traveling wheel 3.1 and a guide wheel 3.2, and a friction rod 3.3 is fixedly connected to the conveying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com