Patents

Literature

40results about How to "Smooth delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

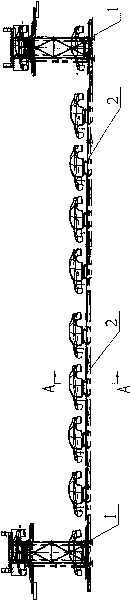

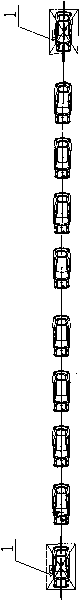

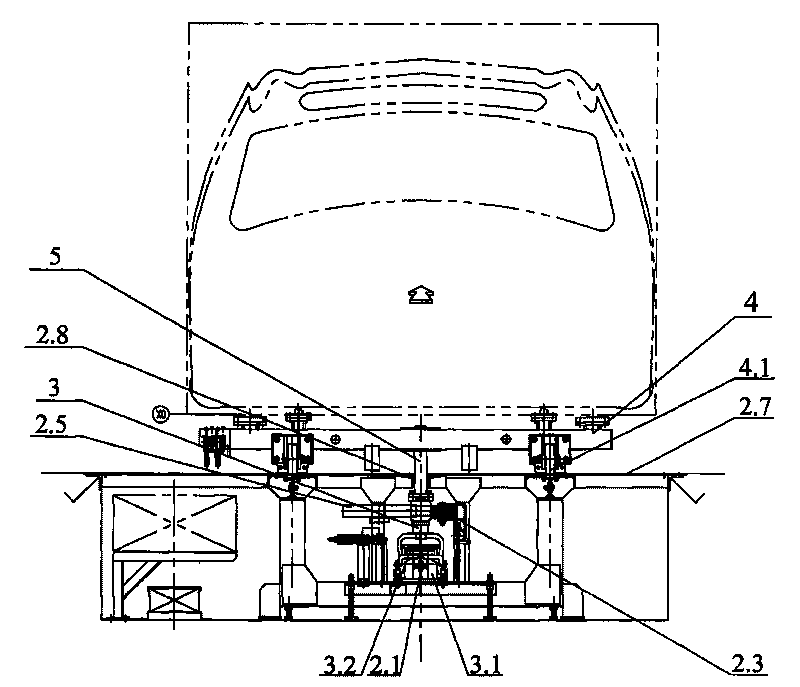

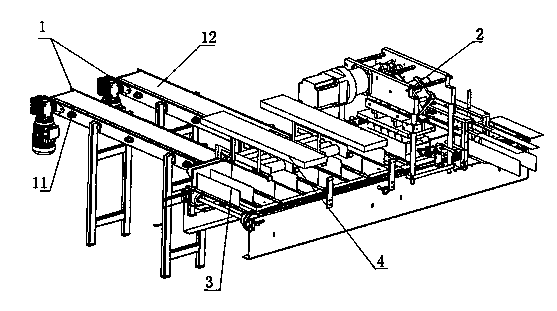

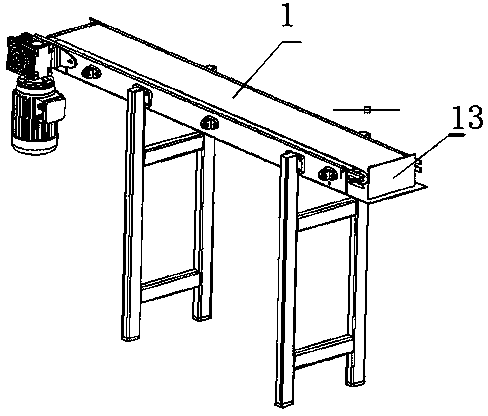

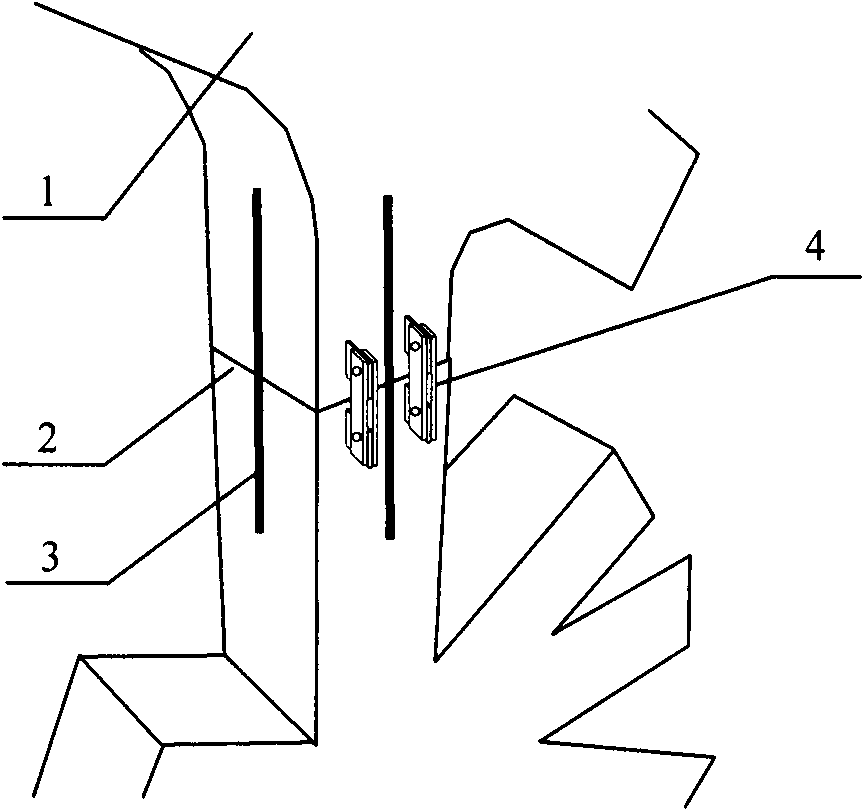

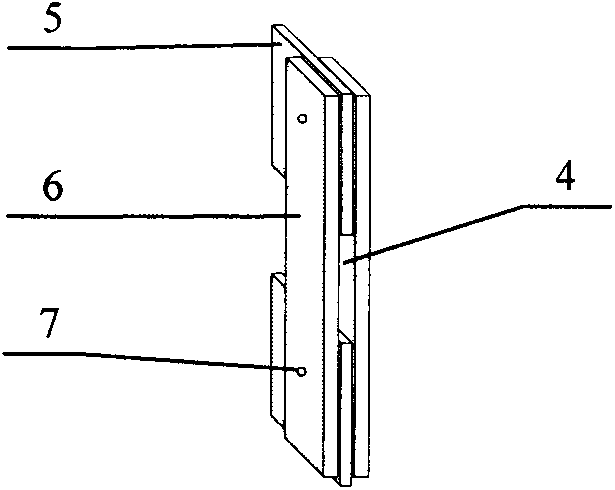

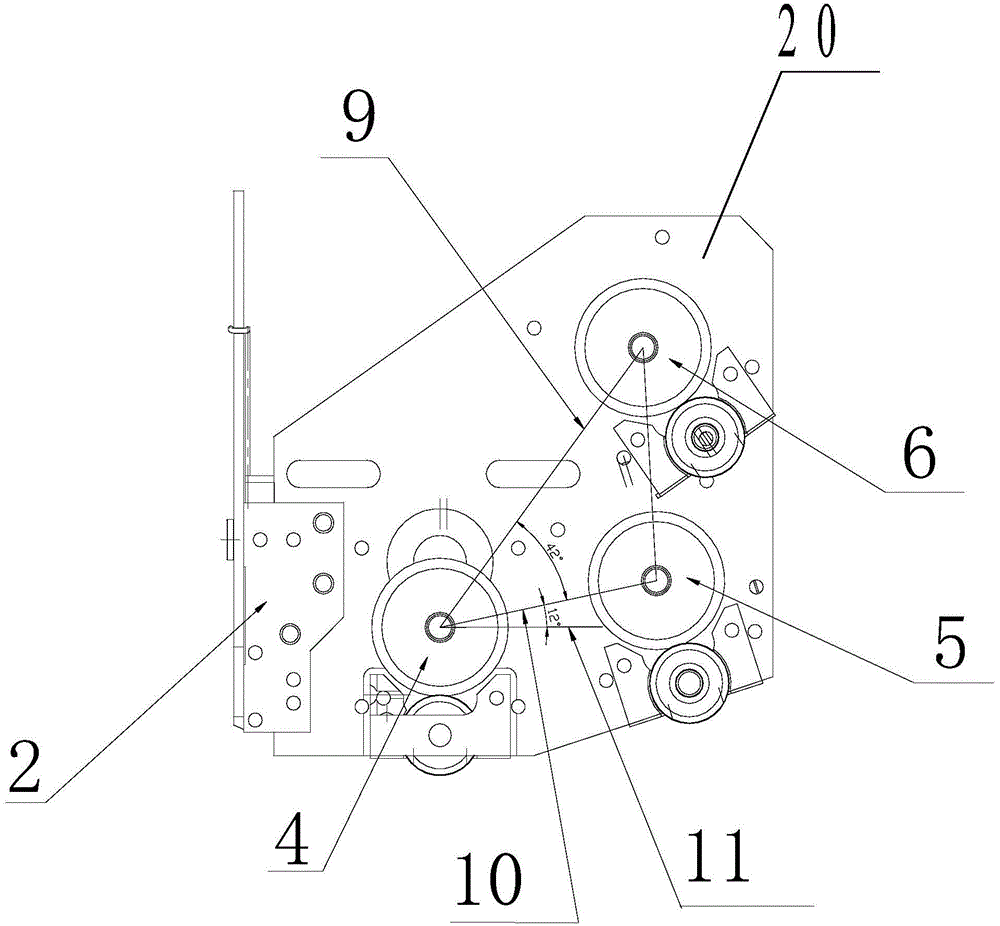

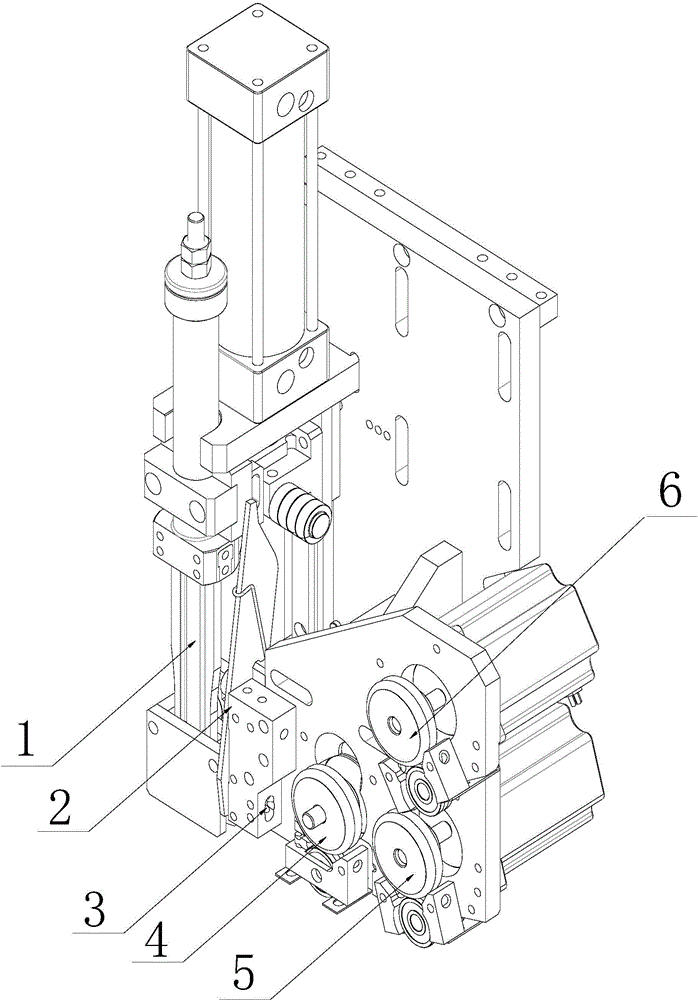

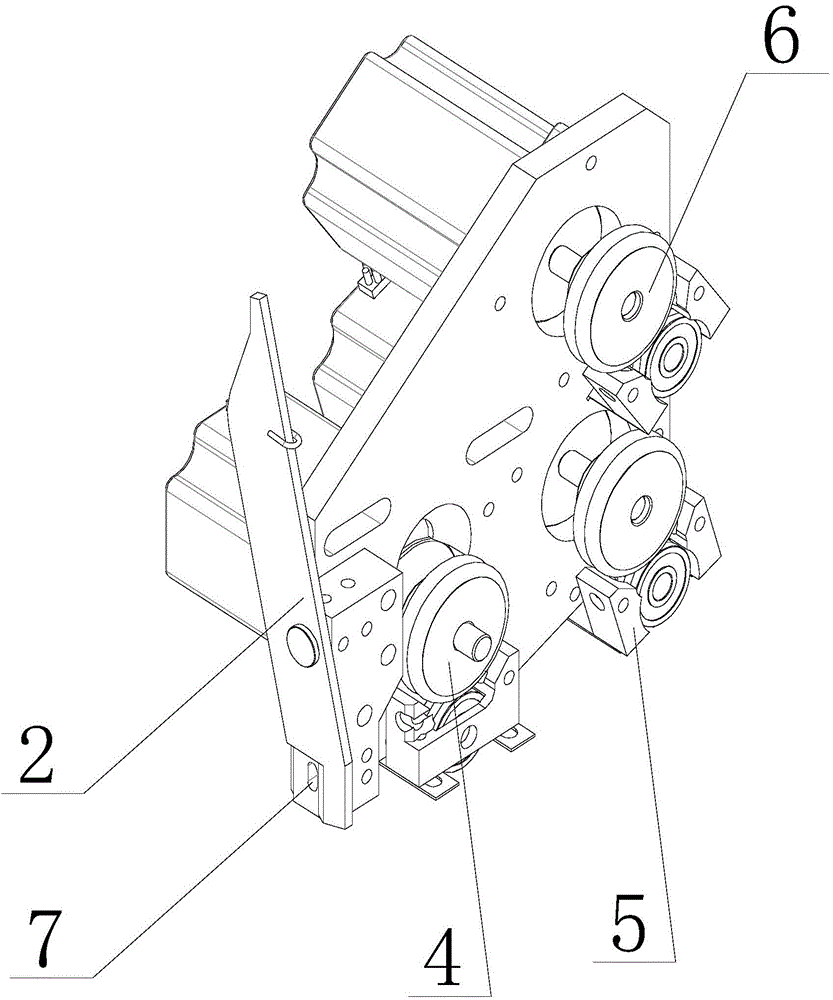

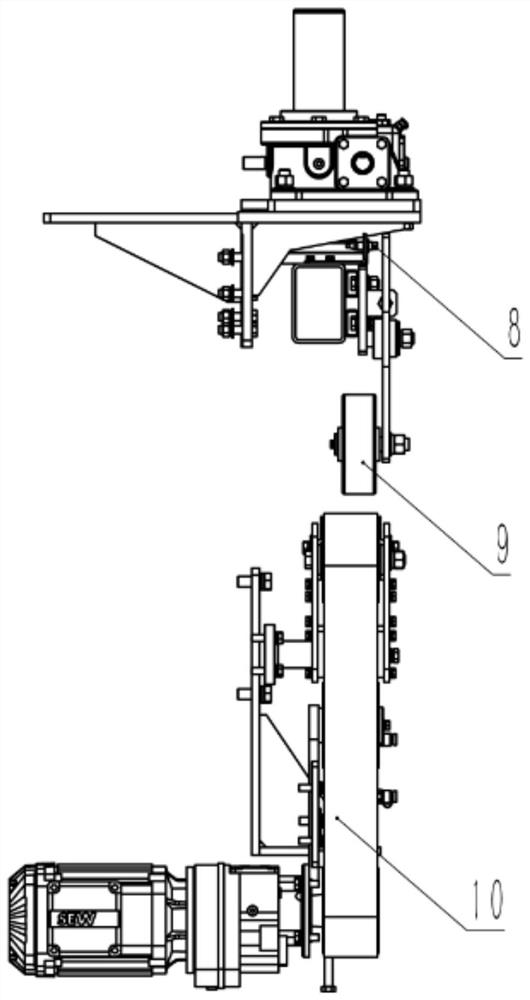

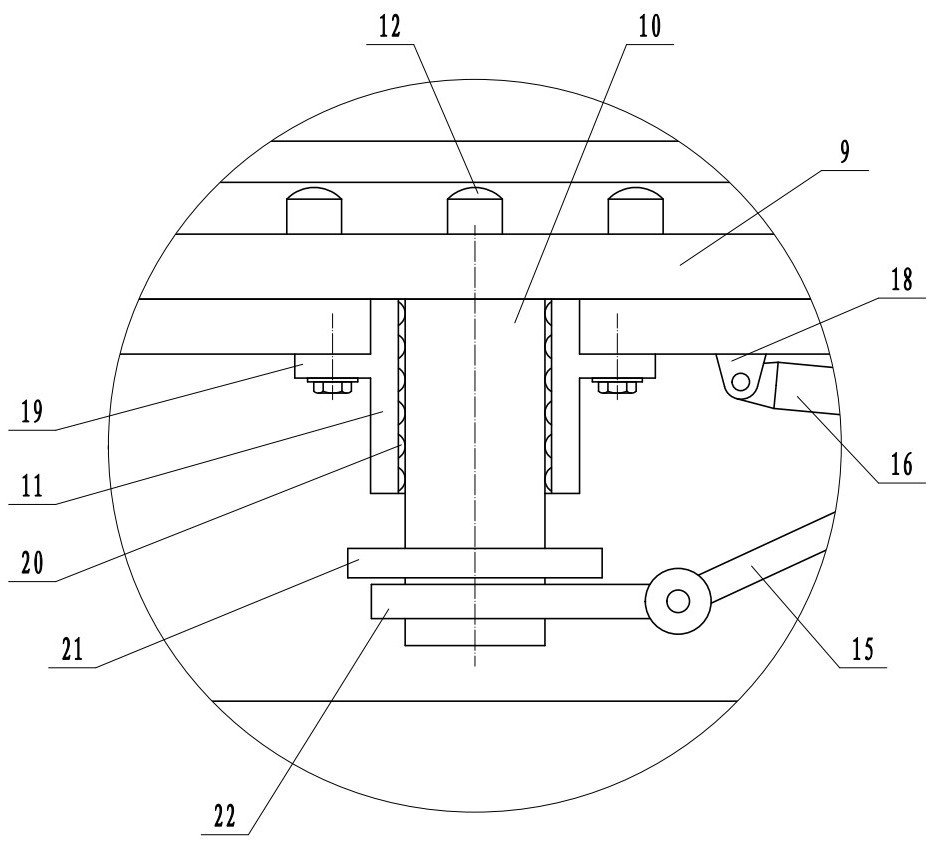

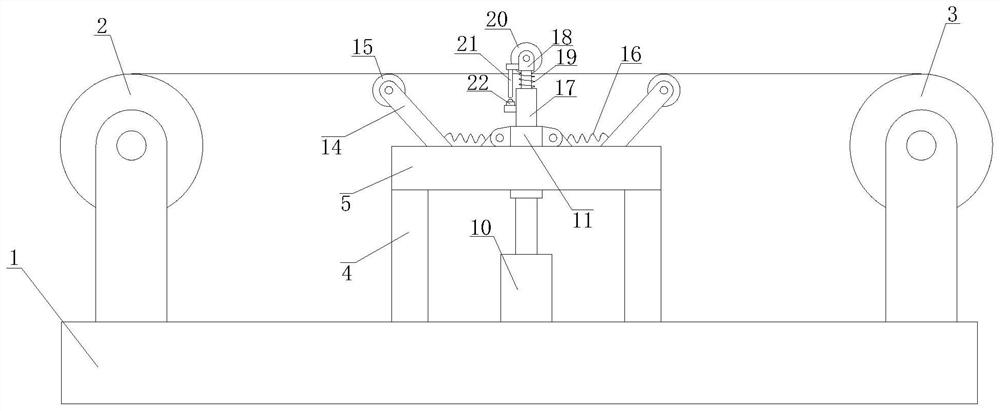

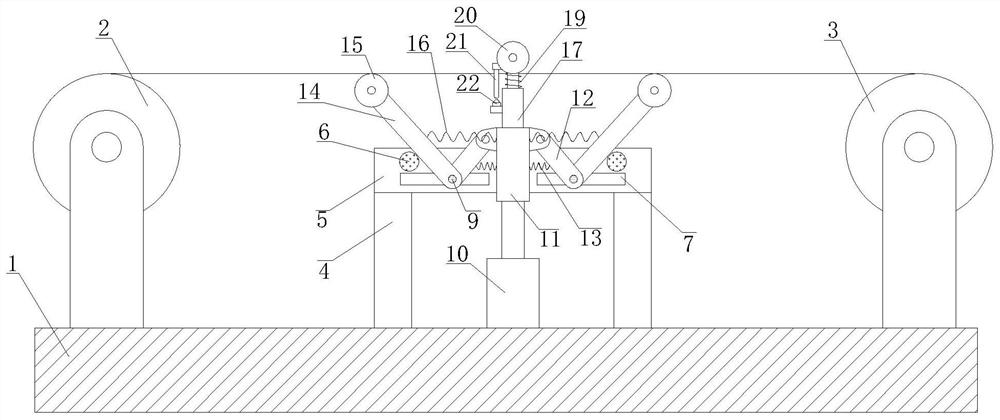

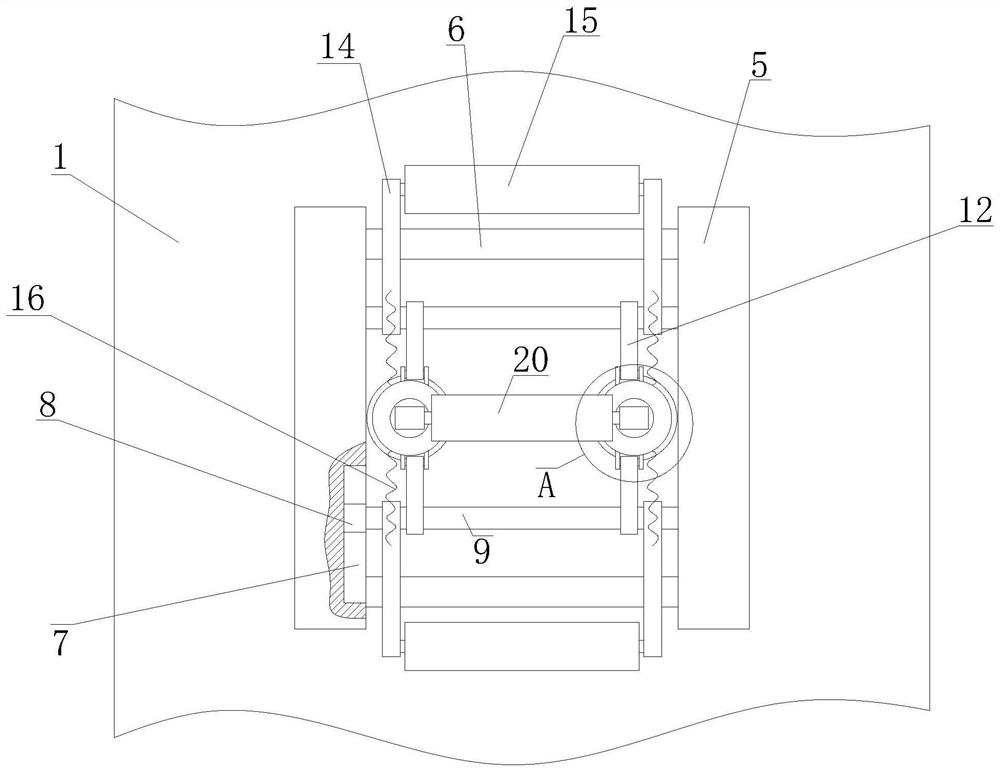

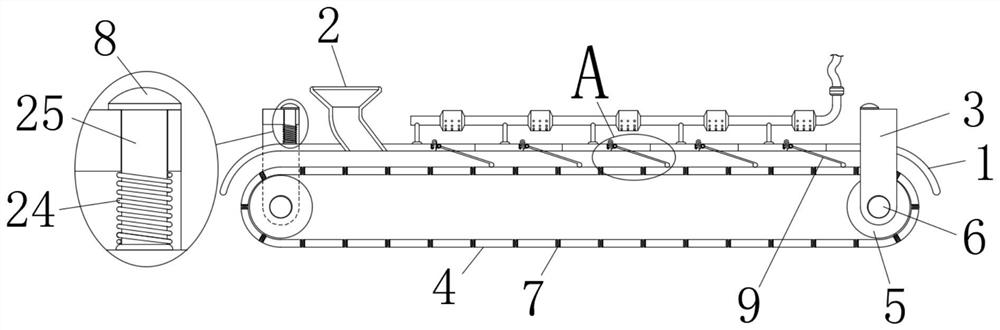

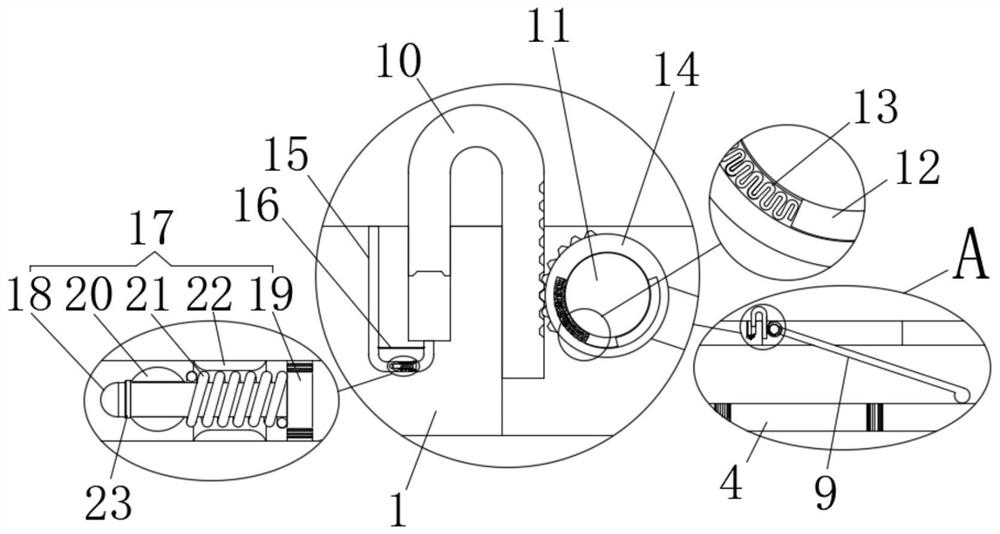

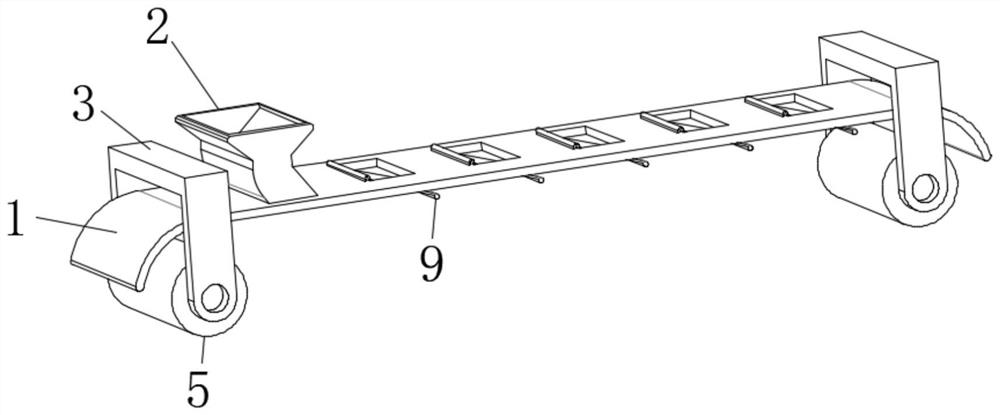

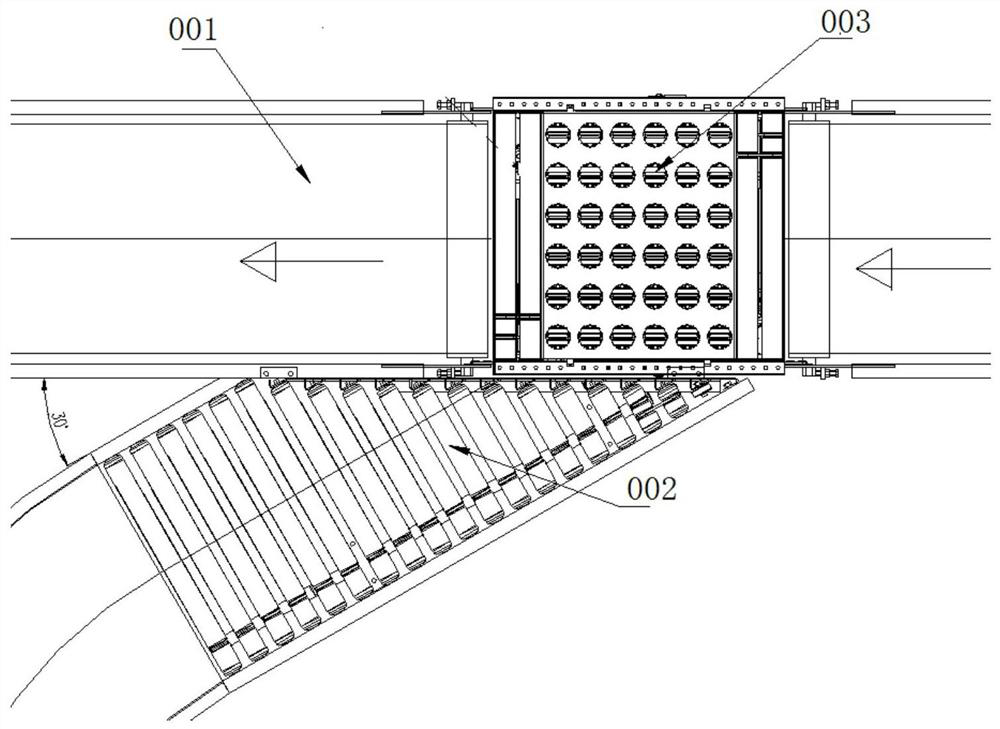

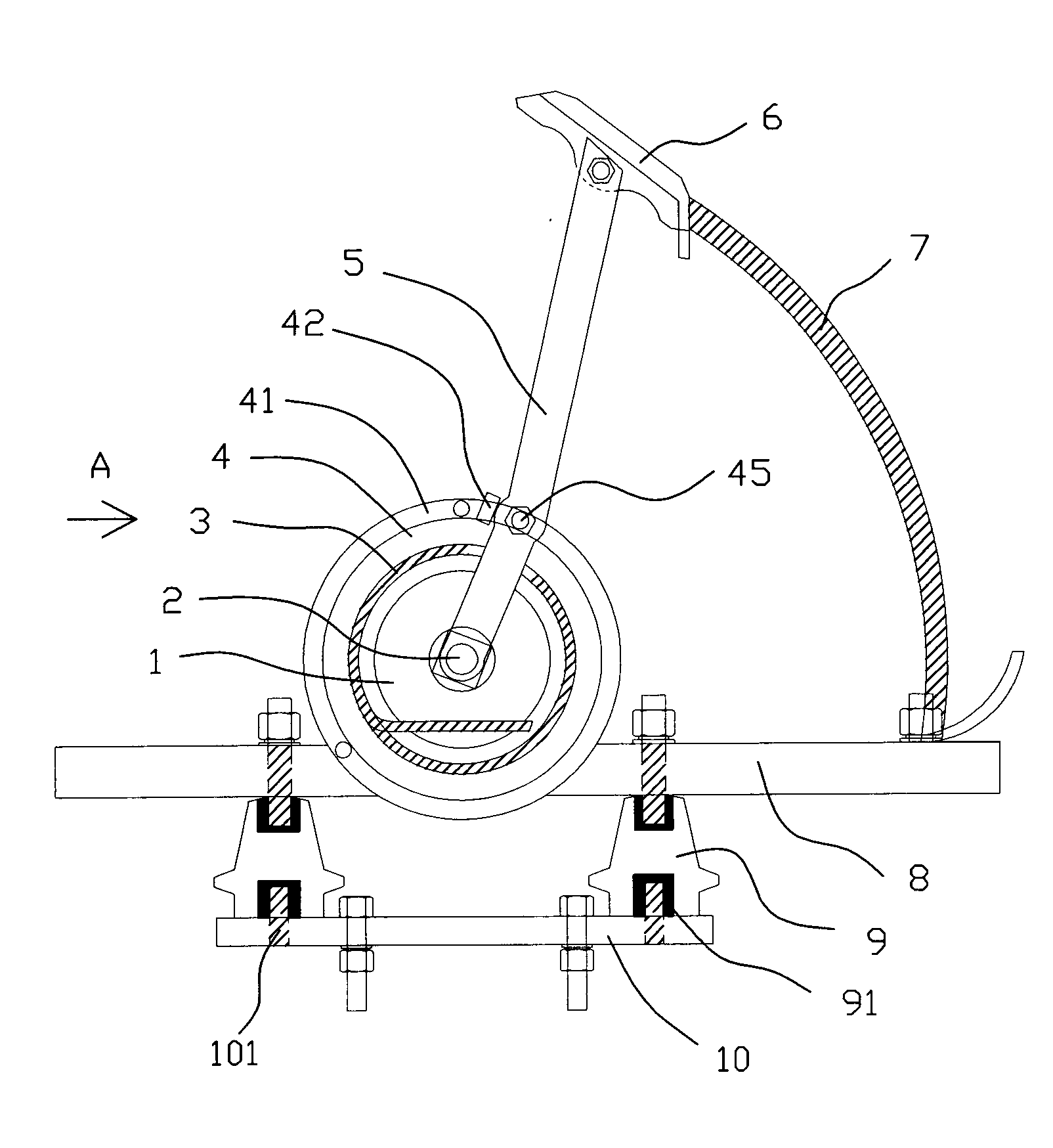

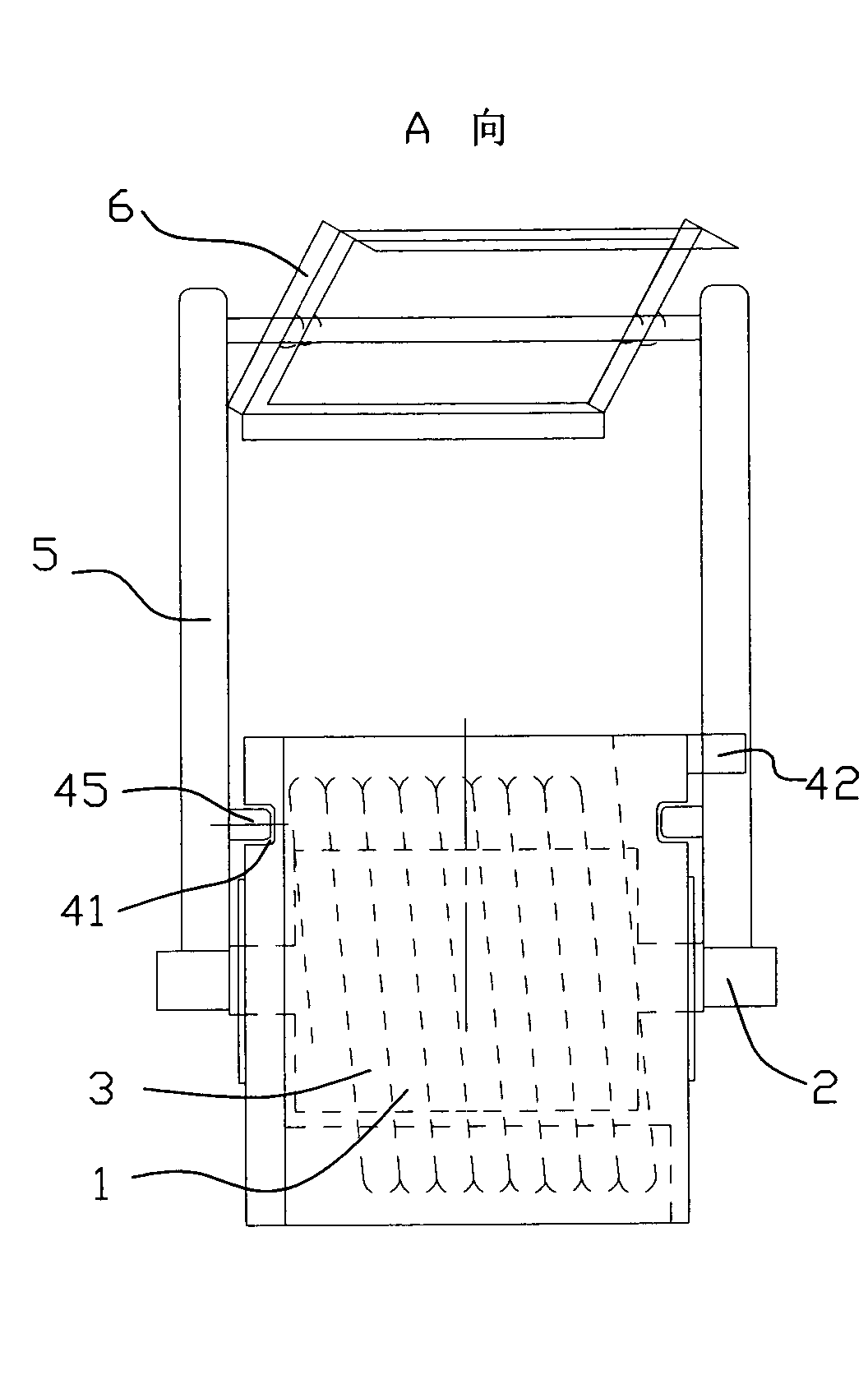

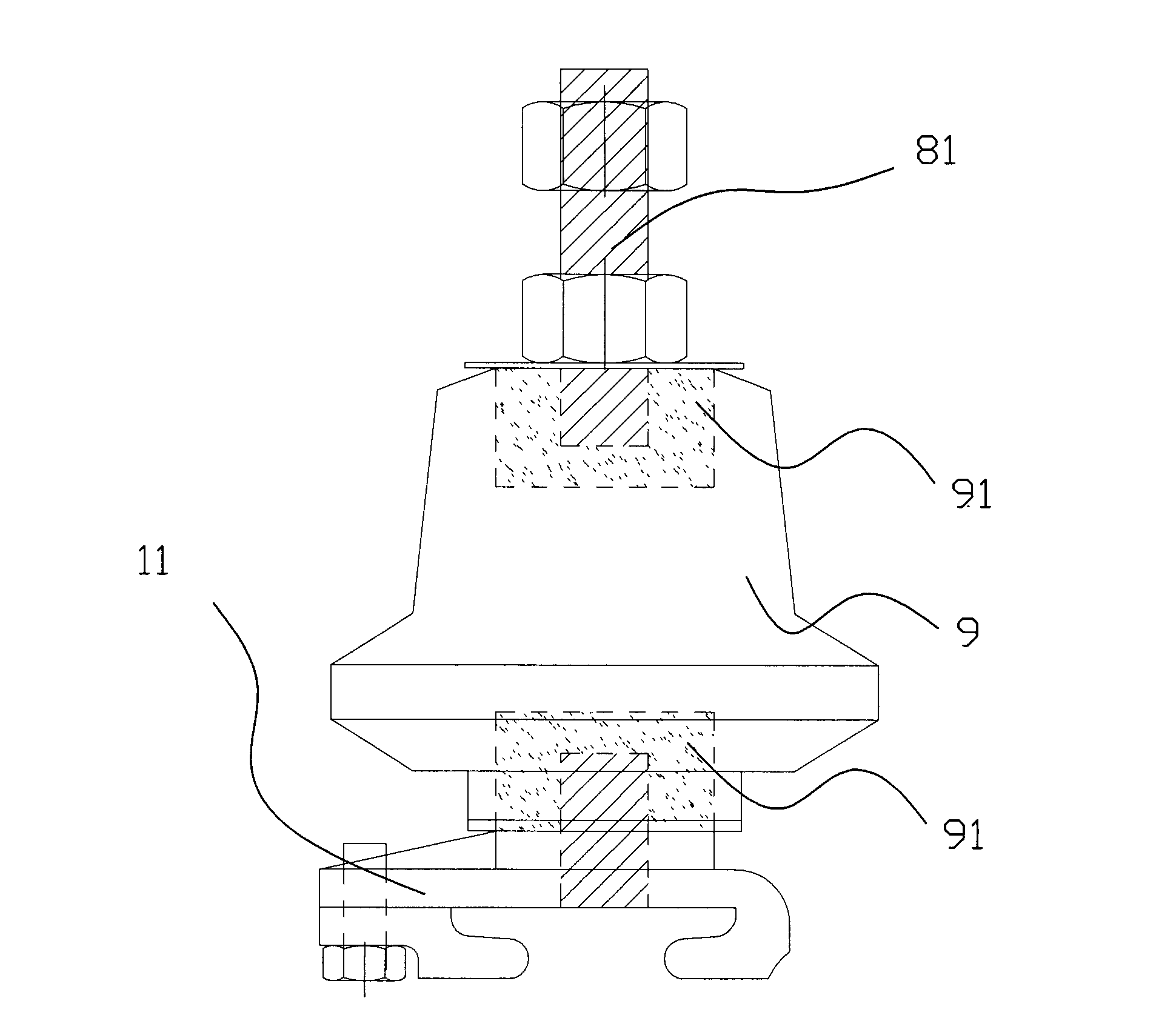

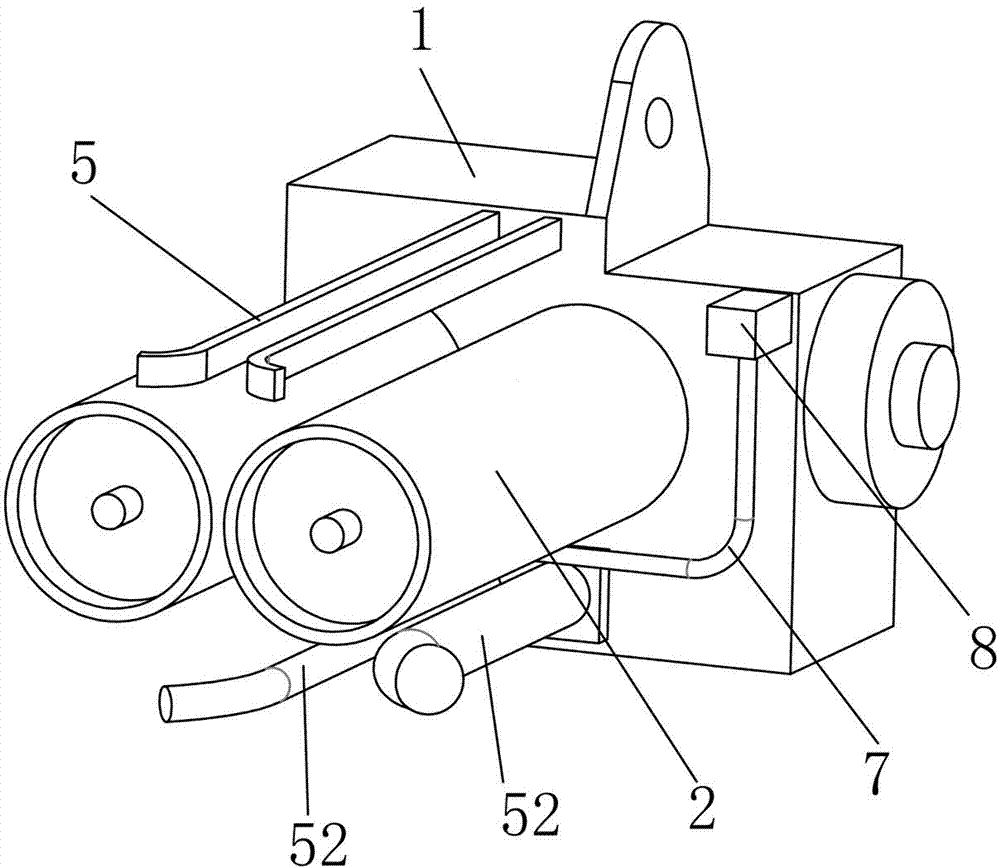

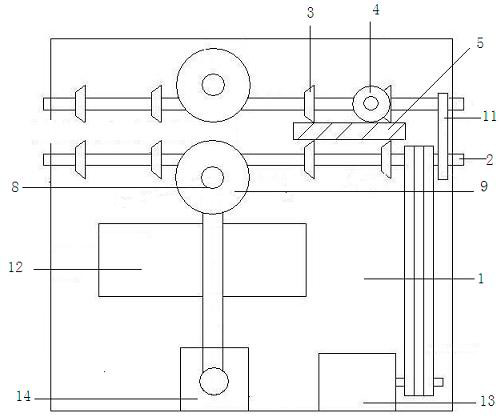

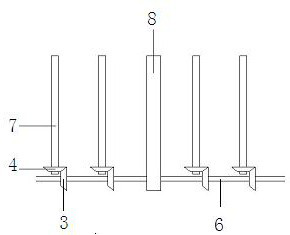

Friction type adjusting line delivery system

ActiveCN101734474ASmooth transmissionReduce noiseConveyor partsVehiclesFriction driveOperational costs

The invention relates to a friction type adjusting line delivery system which comprises rectilinear friction drive devices, an adjusting line upper element hoist, an adjusting line lower element hoist, trolley positioning devices and a trolley stopper, wherein the rectilinear friction drive devices are distributed along a friction track line body at intervals; the adjusting line upper element hoist and the adjusting line lower element hoist are respectively arranged at an outlet and an inlet of the line body and provided with track hoists; the trolley positioning devices are respectively distributed on lifting tracks of the hoists; and the trolley stopper is arranged on a friction track of the inlet of the adjusting line lower element hoist. The invention thoroughly changes a delivering way of a traditional car body adjusting line, has novel structure, high automation degree, simple control, low equipment and operation cost and convenient maintenance and is a delivery equipment system in a type of low noise, low pollution and environmental protection.

Owner:MIRACLE AUTOMATION ENG CO LTD

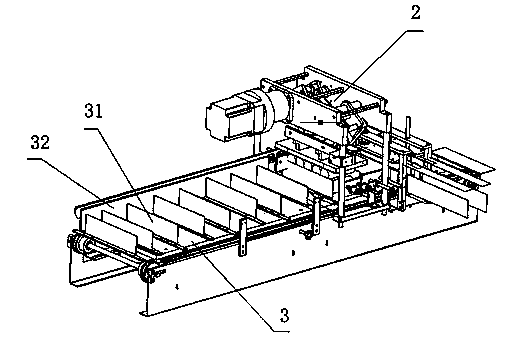

Flattening conveying method suitable for flat rolling packing machine

ActiveCN104290962ASmooth deliveryOmit the flipping processPackagingManufacturing engineeringAutomation

The invention discloses a flattening conveying method suitable for a flat rolling packing machine, and relates to the technical field of package technology of flat rolling tissues. The method includes the first step of material arrangement, the second step of clamping and conveying the arranged material to a material laminated layer, the third step of conveying the two layers of materials to material flattening positions and the fourth step of conveying the flattened material to a next work station, wherein the step of material arrangement refers to that the materials to be conveyed are arrayed in one row, and the number of the materials arrayed in one row is set in advance, the step of clamping and conveying the arrayed material to the material laminated layer refers to that one row of materials are clamped, conveyed and overlapped on the materials to be conveyed which are already arrayed in one row, and then two layers of materials are formed, the step of conveying the two layers of materials to material flattening positions refers to flattening the two layers of laminated materials. The flattening conveying method is used for processing, the technology is simple, the automation degree is high, and production efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

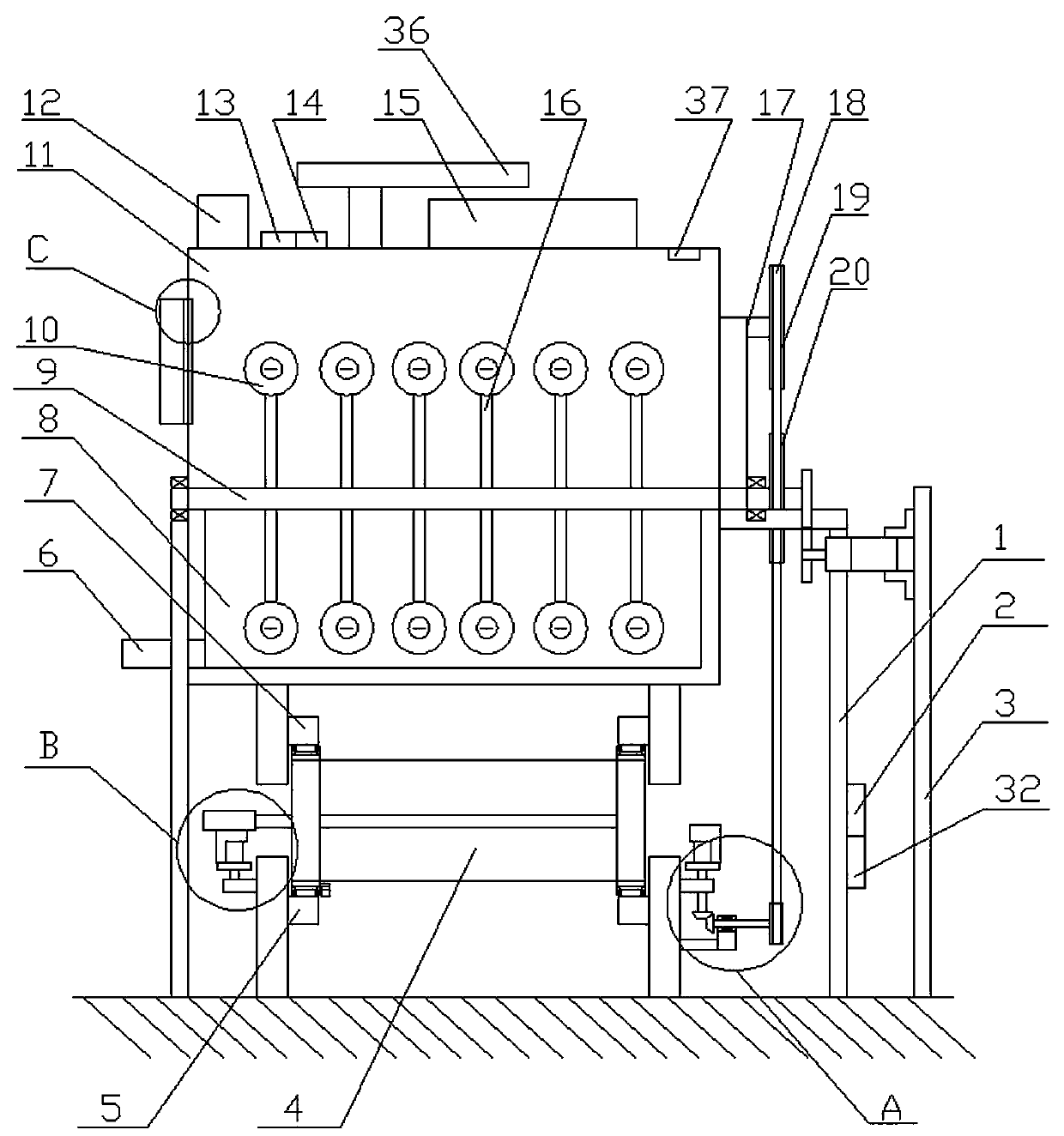

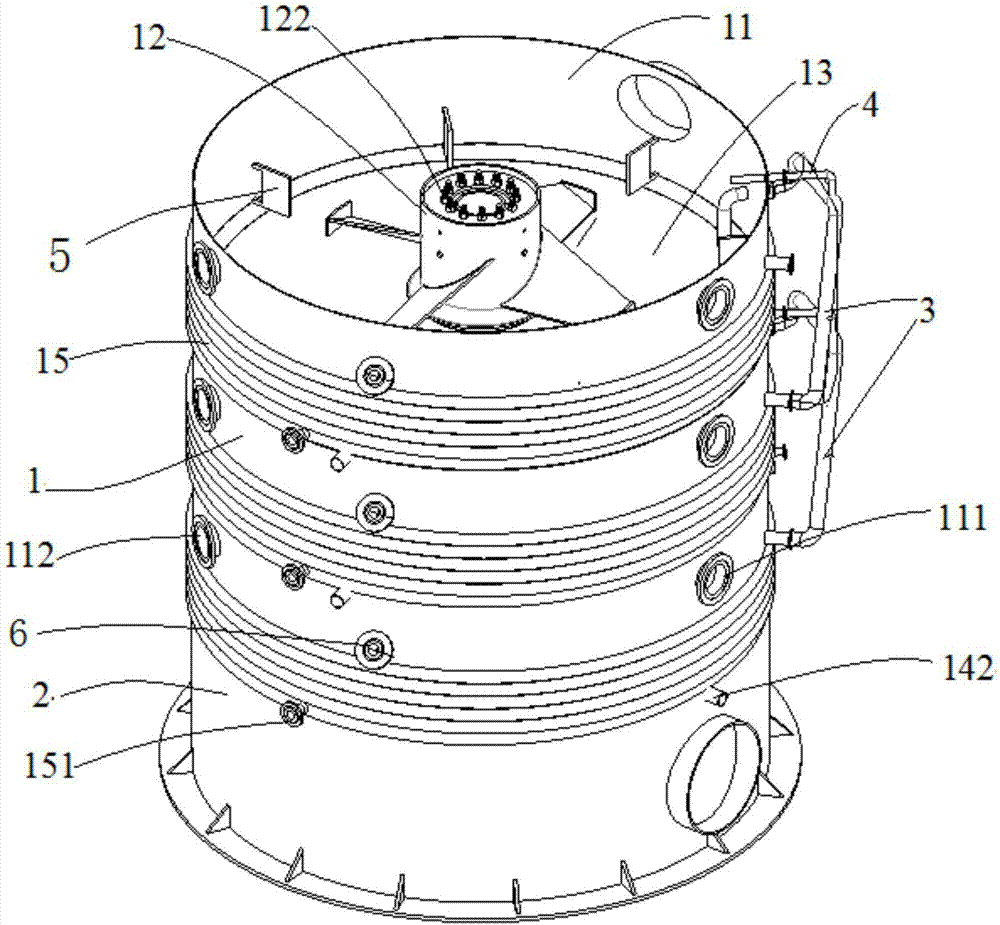

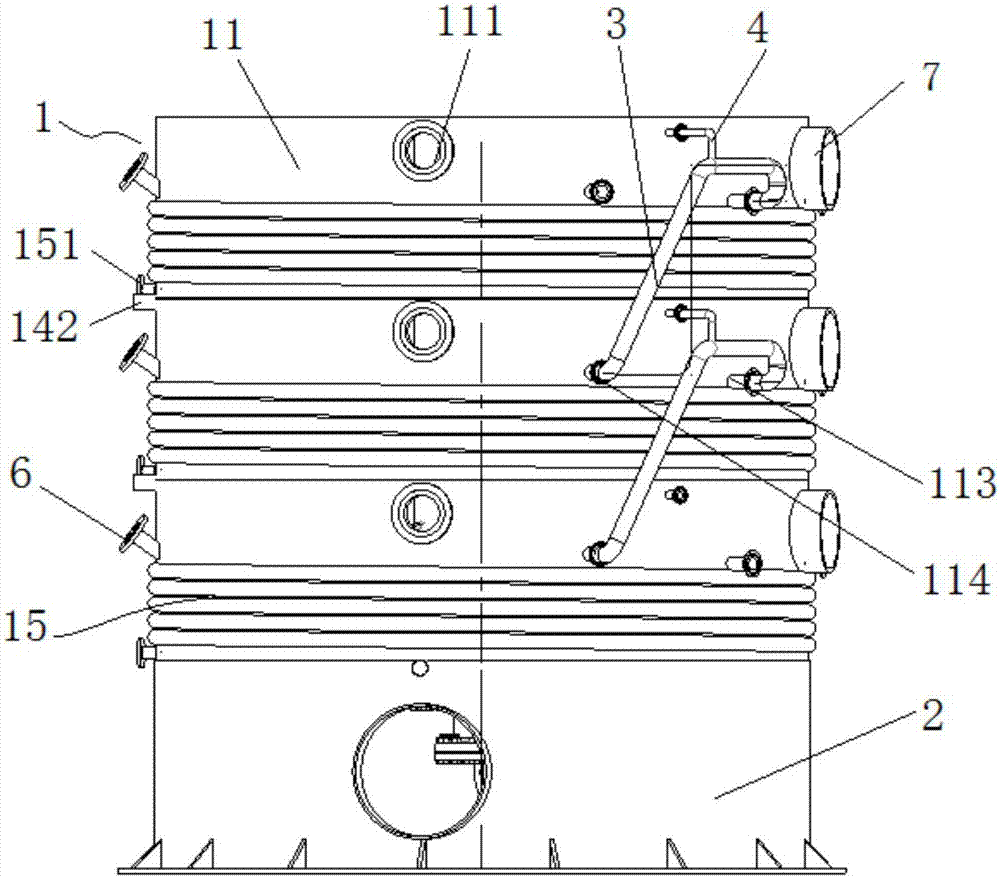

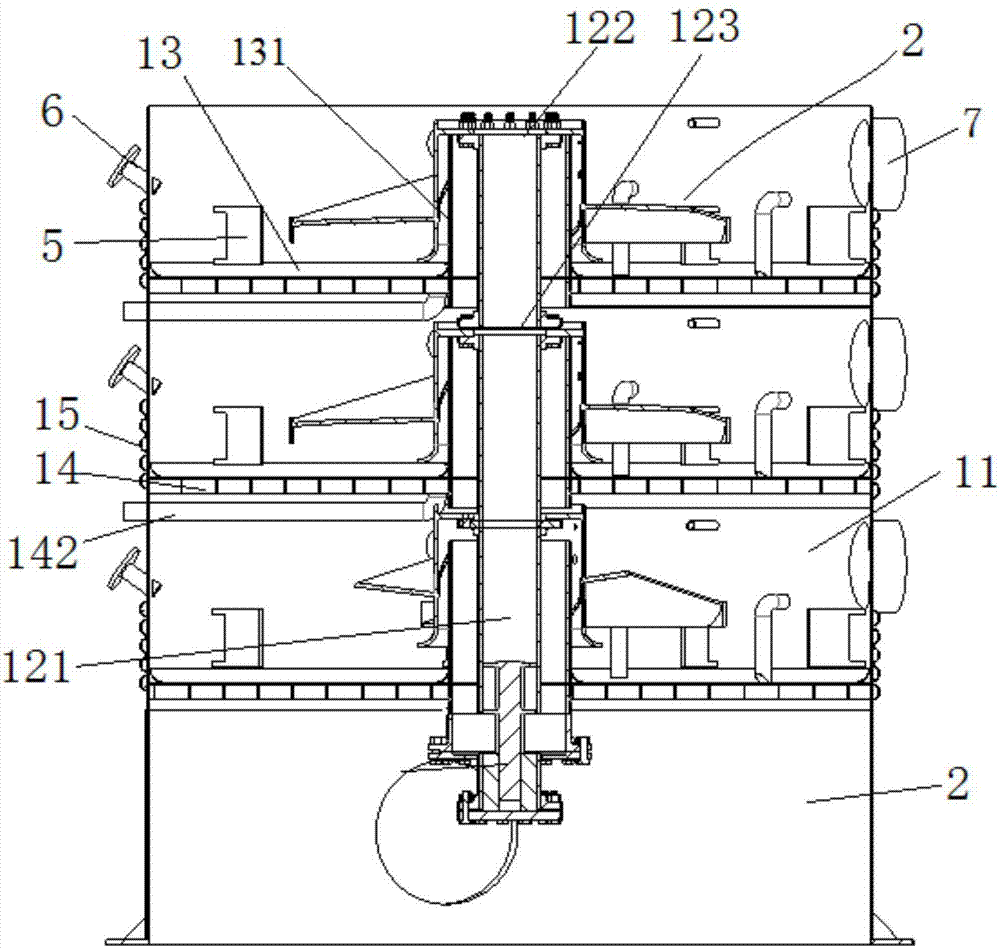

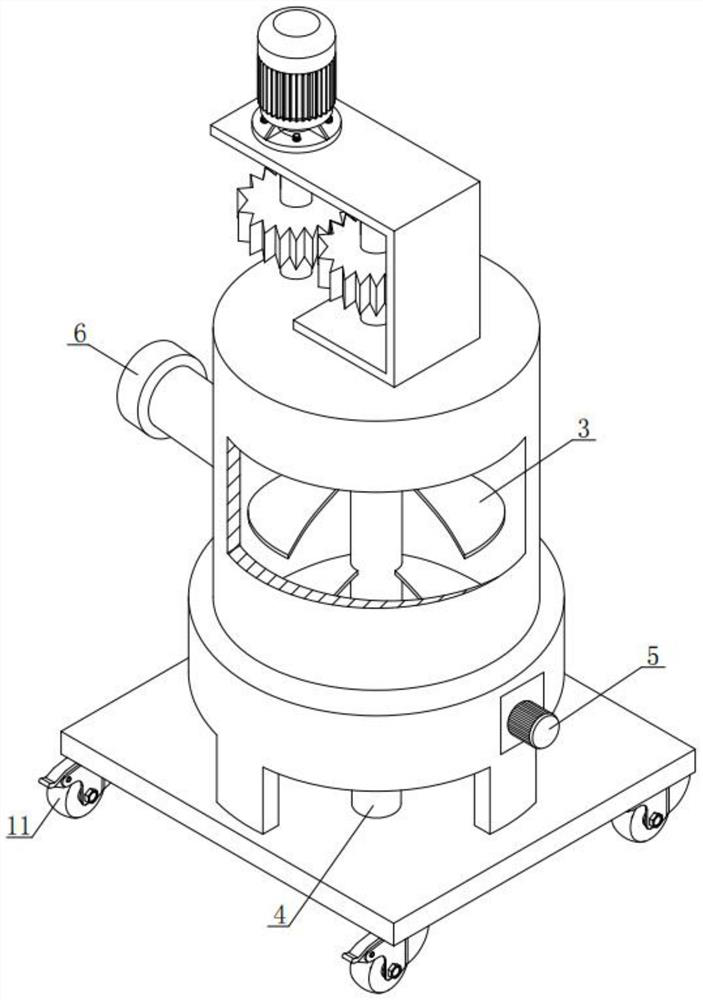

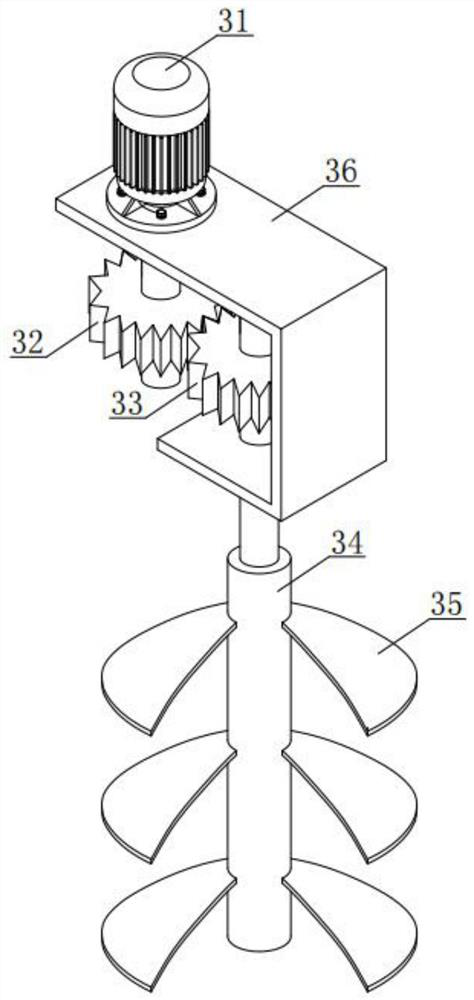

Urban sewage treatment aerating device

ActiveCN107827255ASmooth deliveryIncrease contact areaWater aerationSustainable biological treatmentWind drivenMunicipal sewage

The invention provides an urban sewage treatment aerating device. The urban sewage treatment aerating device comprises a stereo aeration tank, a stirring mechanism, a wind driving mechanism, a power transmission mechanism, an auxiliary driving mechanism and a control mechanism. The stirring mechanism is arranged on the stereo aeration tank which is arranged on multiple supporting columns, the winddriving mechanism is arranged below the supporting columns to match with the stirring mechanism, the power transmission mechanism is arranged on the lateral side of the stereo aeration tank to connect with the stirring mechanism and the wind driving mechanism, the auxiliary driving mechanism is arranged on one side of the supporting columns to match with the power driving mechanism, and the control mechanism is used for controlling the wind driving mechanism , the stirring mechanism, the power transmission mechanism and the auxiliary driving mechanism. By direct wind driving and a unique structure of the aeration tank, energy consumption can be reduced while pollution caused by odor in a fermentation process can be reduced while great processing effects can be obtained, and aeration effects can be improved by adding of aeration components.

Owner:鲁仕宝

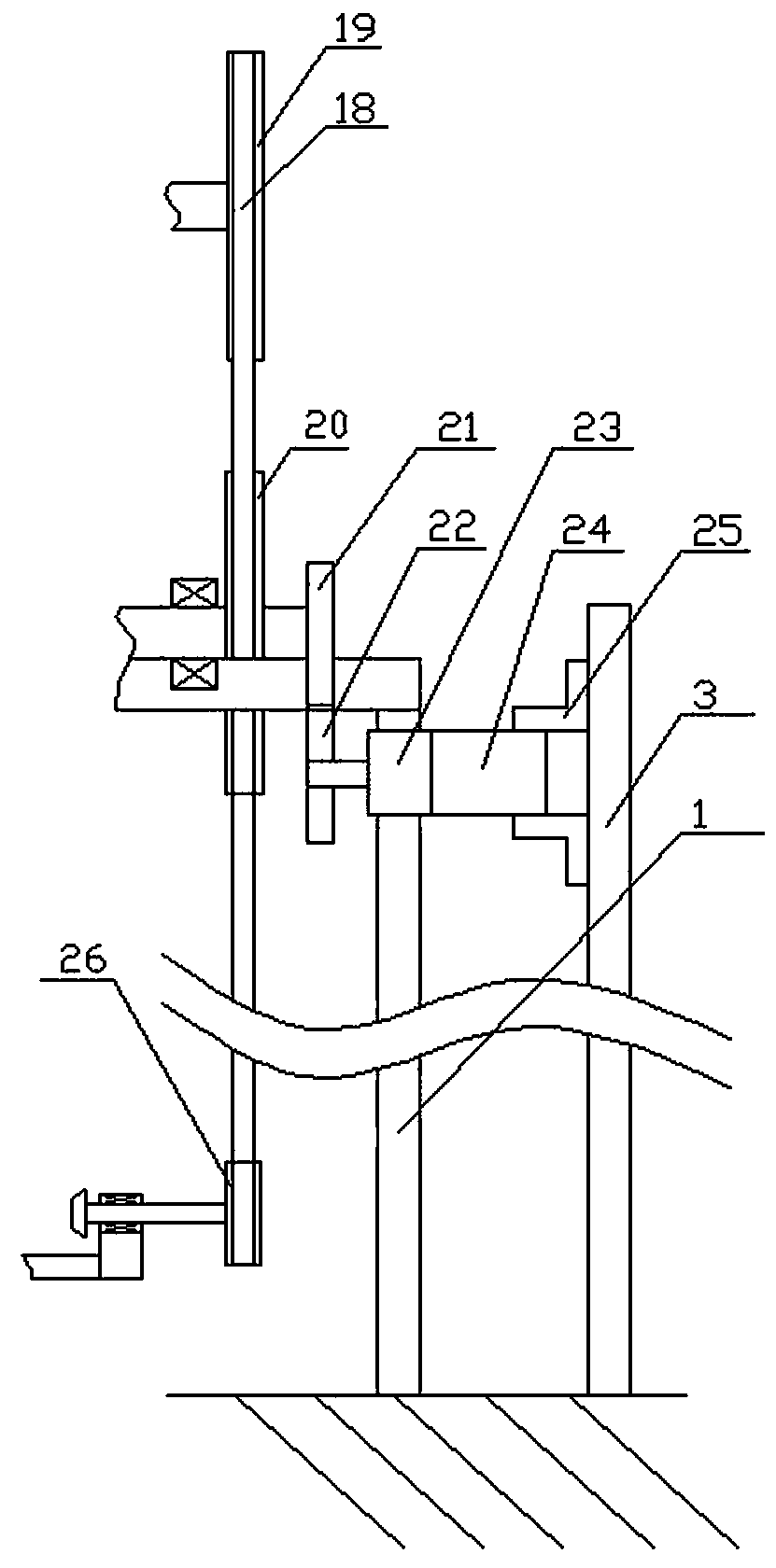

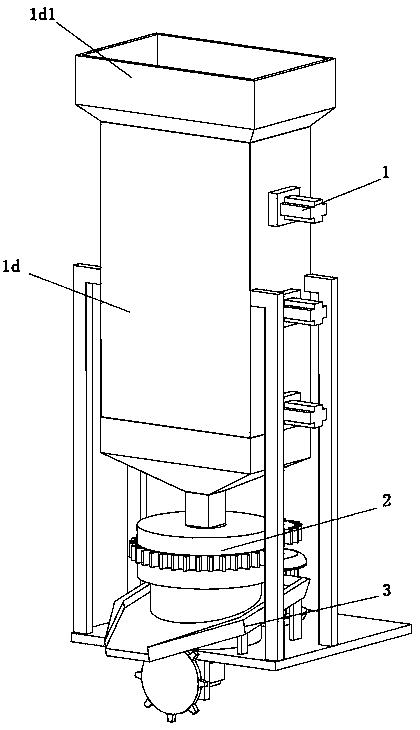

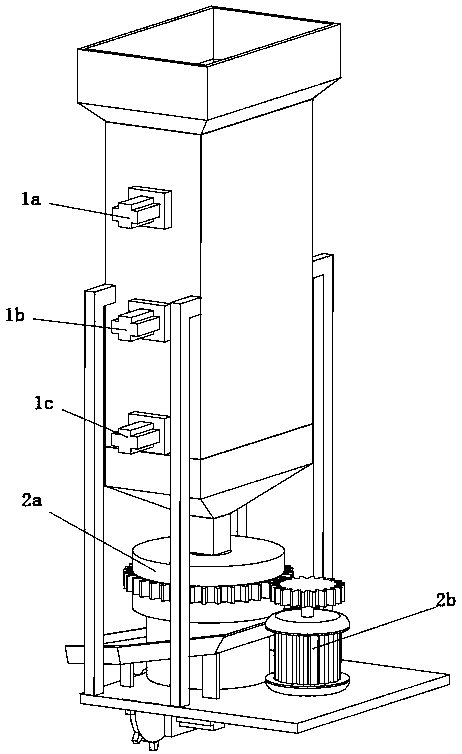

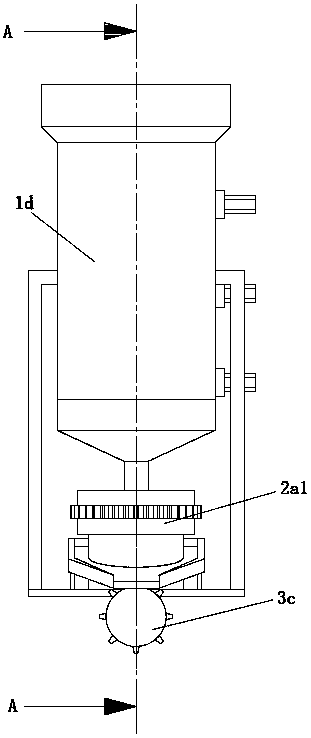

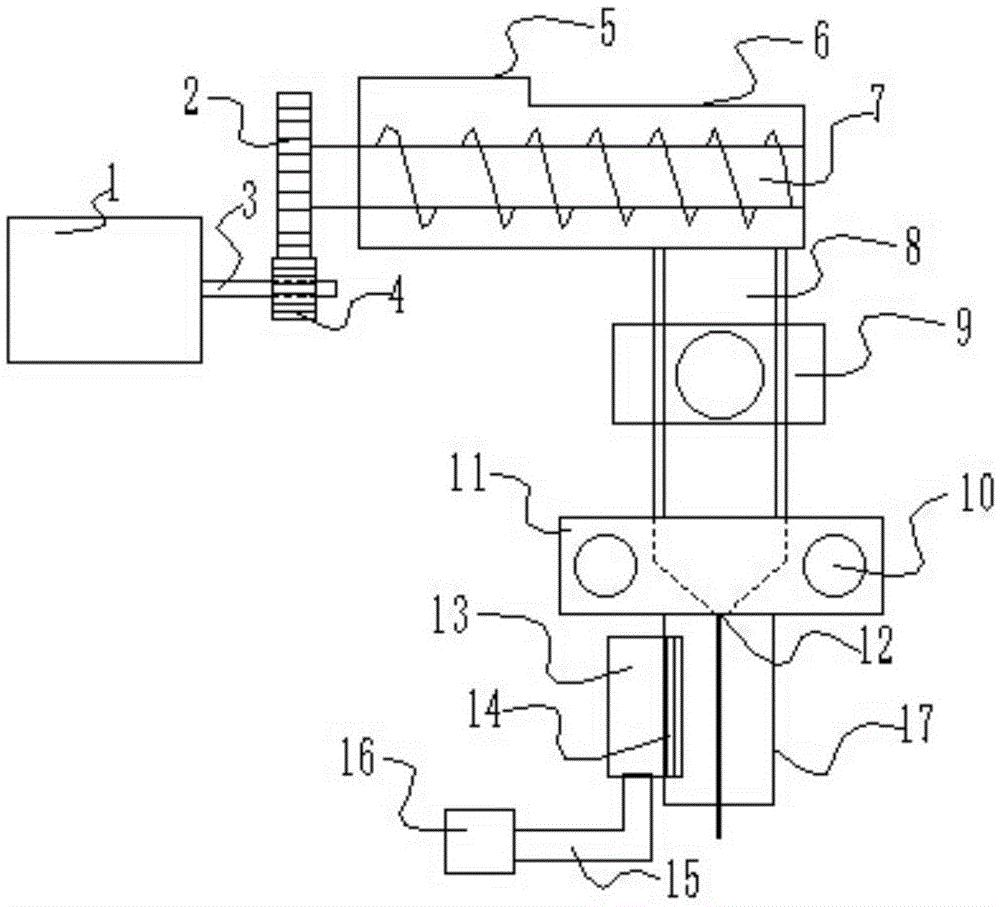

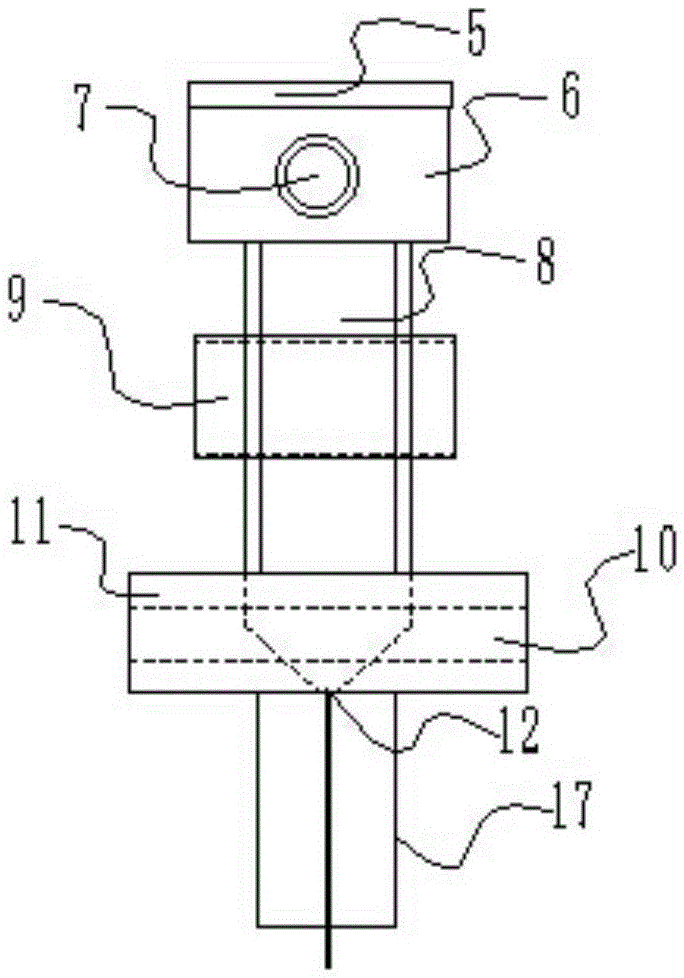

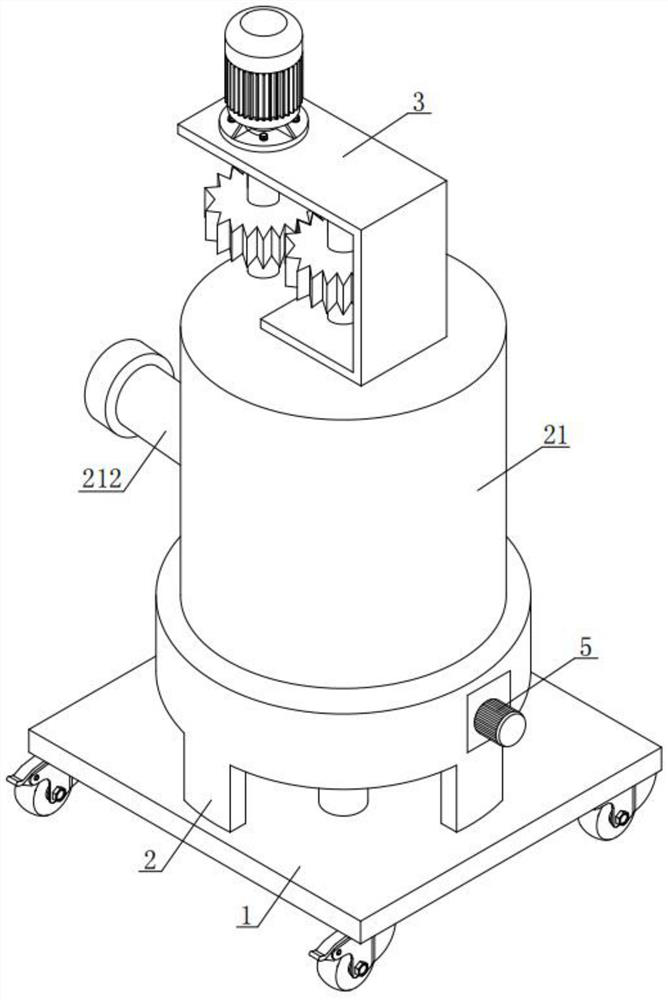

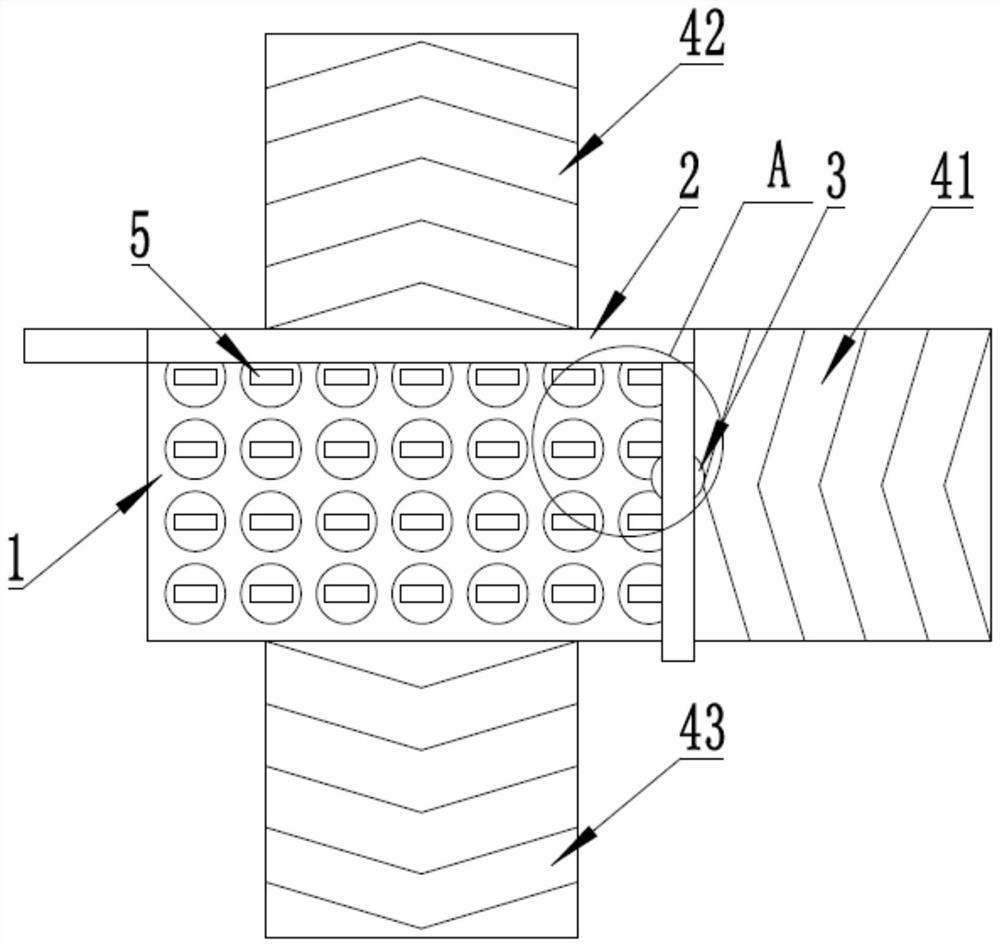

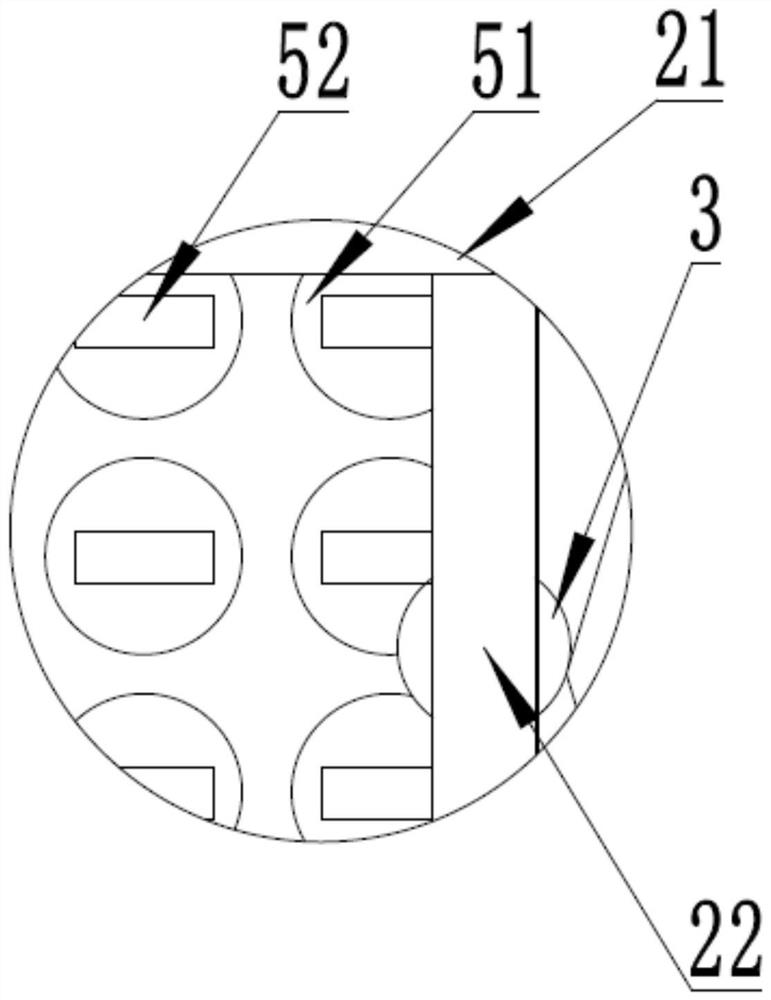

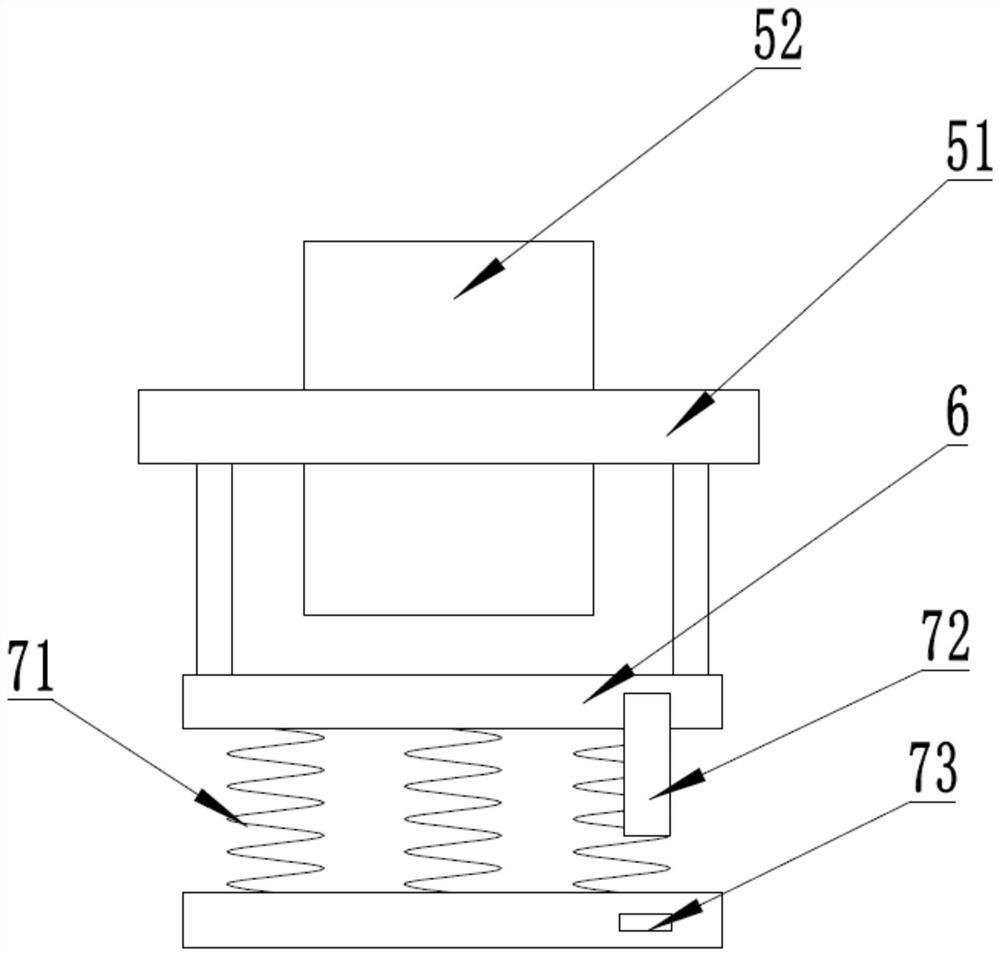

Traditional Chinese medicinal material crushing and grinding equipment

InactiveCN108187860AGuaranteed to crush completelySmooth deliveryCocoaGrain treatmentsEngineeringMaterials processing

The invention relates to the field of medicinal material processing equipment, in particular to traditional Chinese medicinal material crushing and grinding equipment. The traditional Chinese medicinal material crushing and grinding equipment comprises a crushing device, a grinding device and a control device; the crushing device comprises a first crushing component, a second crushing component and a third crushing component, wherein the first crushing component is used for performing low-degree crushing on a traditional Chinese medicinal material; the second crushing component is used for performing intermediate-degree crushing on the traditional Chinese medicinal material; the third crushing component is used for performing high-degree crushing on the traditional Chinese medicinal material; the first crushing component, the second crushing component and the third crushing component are arranged at an equal interval from top to bottom; the grinding device is arranged under the third crushing component and comprises a grinding disc and a driving component, wherein the grinding disc is used for grinding the crushed traditional Chinese medicinal material; the driving component is used for driving the grinding disc to rotate; the control device comprises a controller and a plurality of rotating speed sensors, wherein the rotating speed sensors are electrically connected with the controller. The traditional Chinese medicinal material crushing and grinding equipment provided by the invention adopts a stable material conveying way, can prevent blocking of the material and can guarantee complete crushing of the traditional Chinese medicinal material by virtue of a screening component and a grinding component.

Owner:鲍孟波

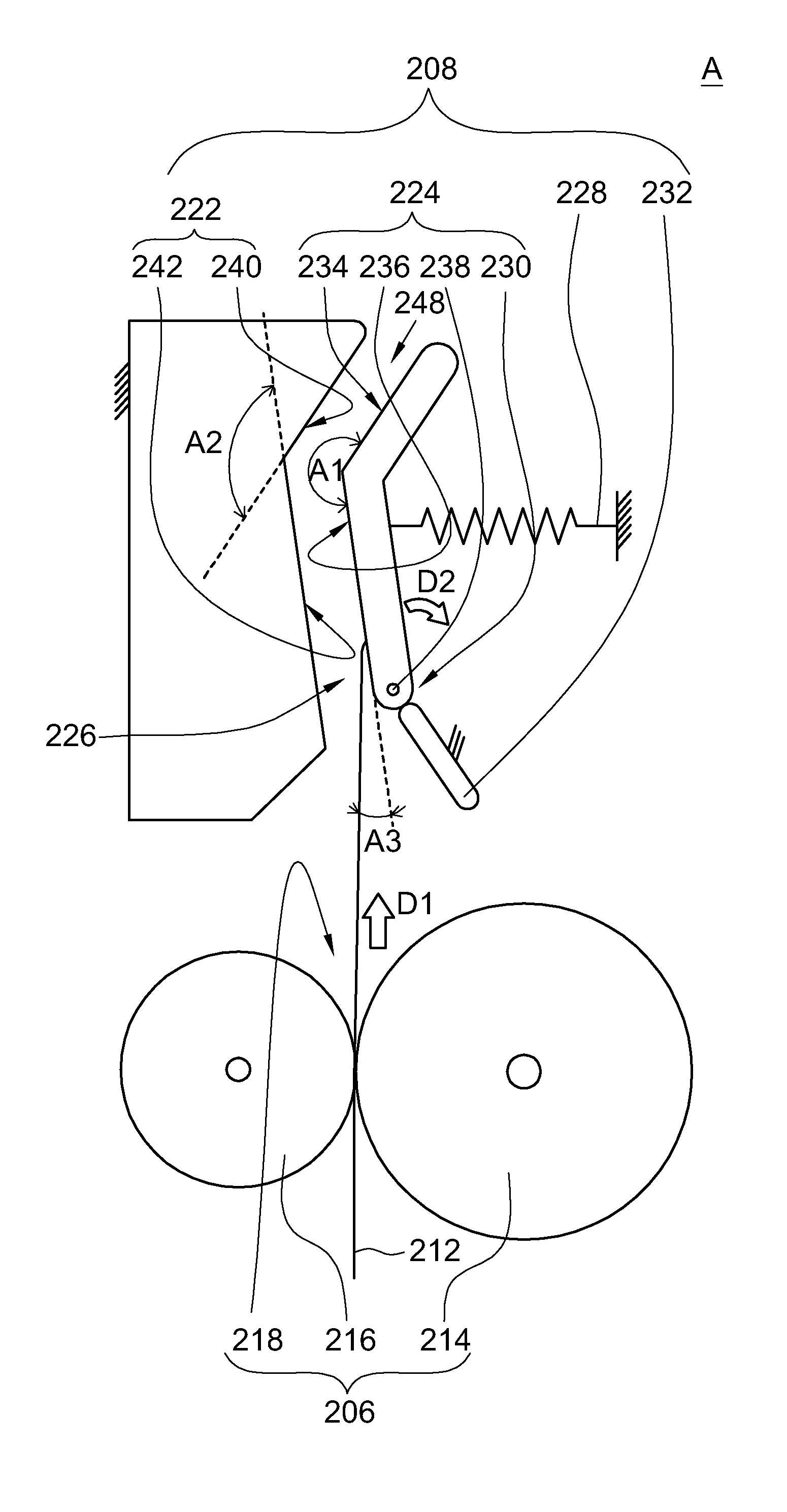

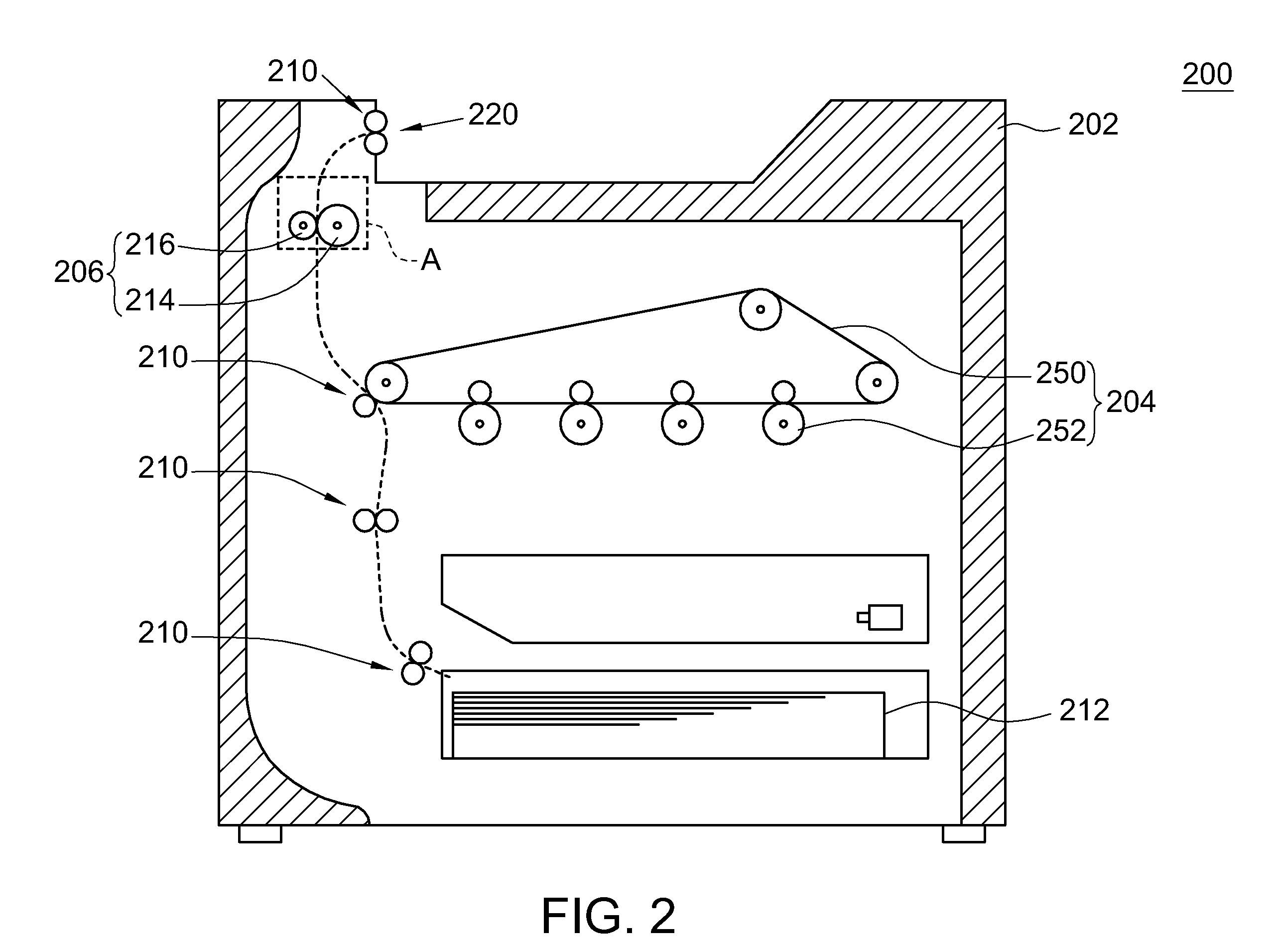

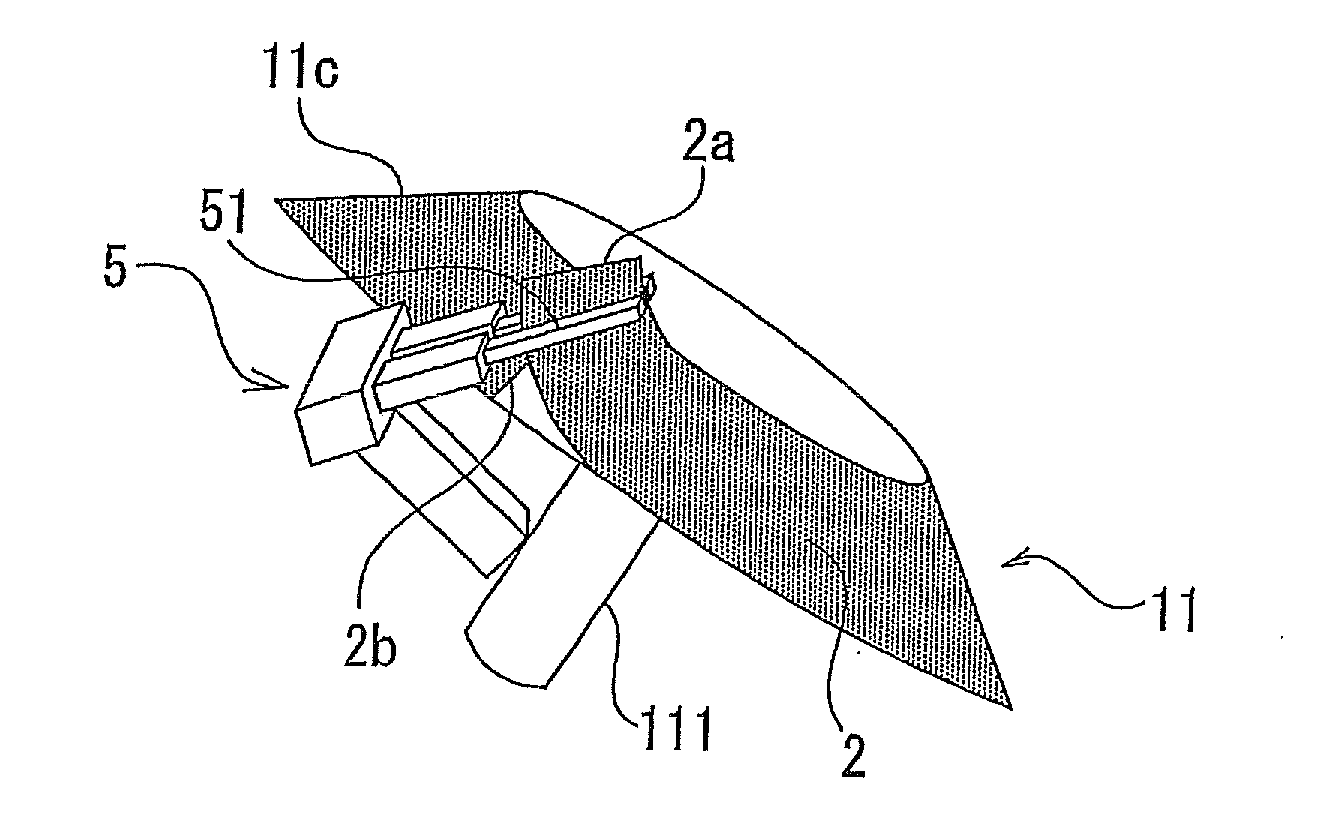

Paper guiding mechanism and printer using the same

InactiveUS20100135705A1Smooth deliveryStable deliveryElectrographic process apparatusComputer printingRecording media

Owner:AVISION

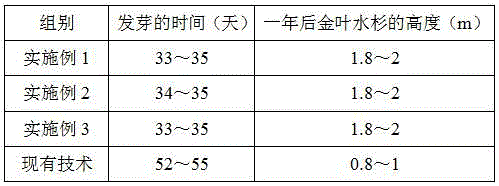

Method for seedling and grafting metasequoia glyptostroboides GoldRush

The invention discloses a method for seedling and grafting metasequoia glyptostroboides GoldRush in the technical field of forestry plant culture. The method comprises the following steps: preparing a nutrient solution which is prepared from the following components in percentage by weight: 1-3 percent of plant hormone, 1-3 percent of cane sugar, 0.5-1.5 percent of acetylacetone and 1.5-2 percent of alpha-methyl tert-butyl ether, mixing for later use; preparing scion and stock; grafting the scion on the grafting surface of the stock from November to December, coating the grafting position with gauze soaked with the nutrient solution, and binding with a belt; and covering the stock and scion with a mulching film after grafting is completed, and tearing an opening in the mulching film corresponding to a bud when the bud grows for 3-4cm to facilitate growth of the bud. The method has the beneficial effects of maintaining the physiological activities of the stock and scion, promoting formation of a dredging tissue and benefiting nutrition and moisture transmission, and overcomes the technical problem in the prior art that the grafting opening cannot be easily healed and the scion grows slowly since the stock does not supply sufficient moisture and nutrition to the scion.

Owner:遵义彩中彩苗木专业合作社

Improved construction method for hoisting and welding large-tonnage cast steel component complex joints

InactiveCN103495793AReduce workloadHarm reductionArc welding apparatusWelding/soldering/cutting articlesCarrying capacityElectroslag welding

The invention provides an improved construction method for hoisting and welding large-tonnage cast steel component complex joints. Through studying the welding technology of cast steel joints and section steel dissimilar steel, cracks are not prone to being generated by welding in a low-temperature state, welding quality is good, and using requirements are satisfied; the welding quality of electroslag welding is guaranteed without weakening carrying capacity, and a theoretical basis is provided for welding of cast steel and section steel dissimilar materials; the improved construction method has important theoretical value and application value and provides a basis for welding of similar structures of engineering or the same industry; integrality is good, force transmission is smooth, anti-fatigue performance is good, force application to a steel structure is more reasonable, the overall structure is more stable, the workload of aerial operation is reduced, the quality of the overall engineering is improved, construction cost is lowered, and hazards of the aerial operation to constructors are lowered; besides, the technological process of the improved construction method is simple, and operating is convenient.

Owner:YONGSHENG CONSTR GRP

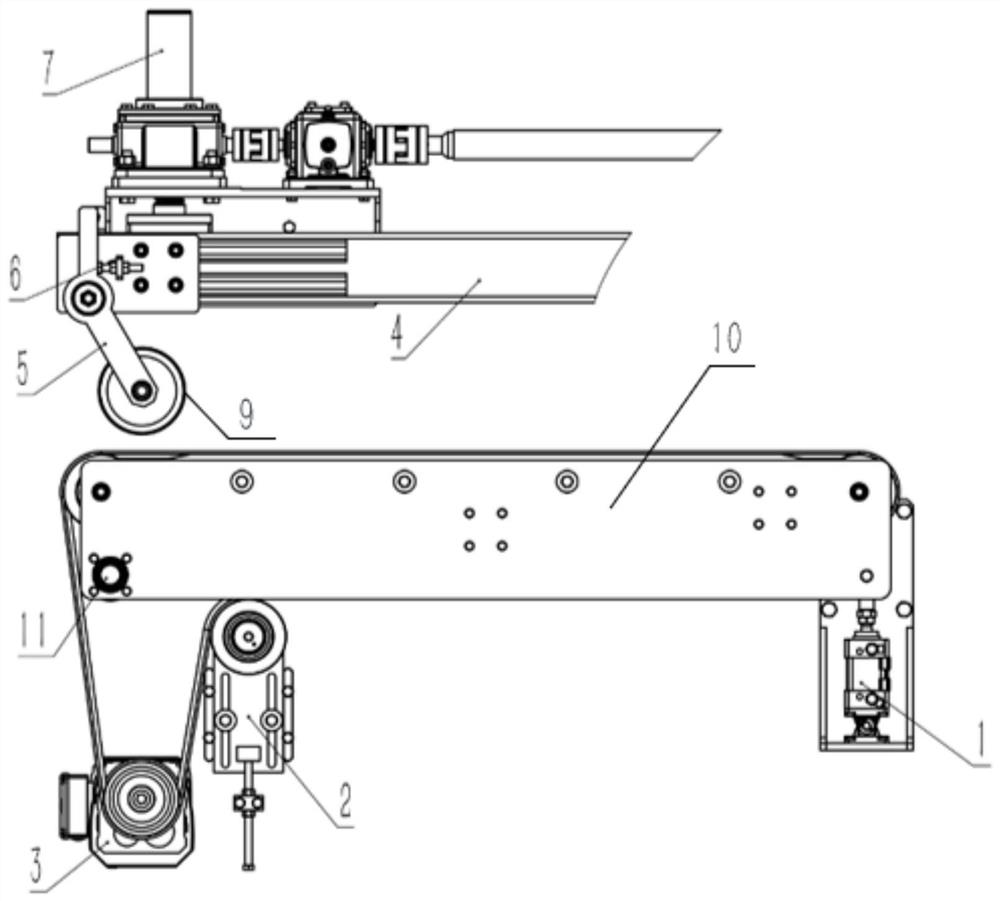

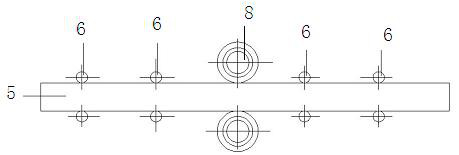

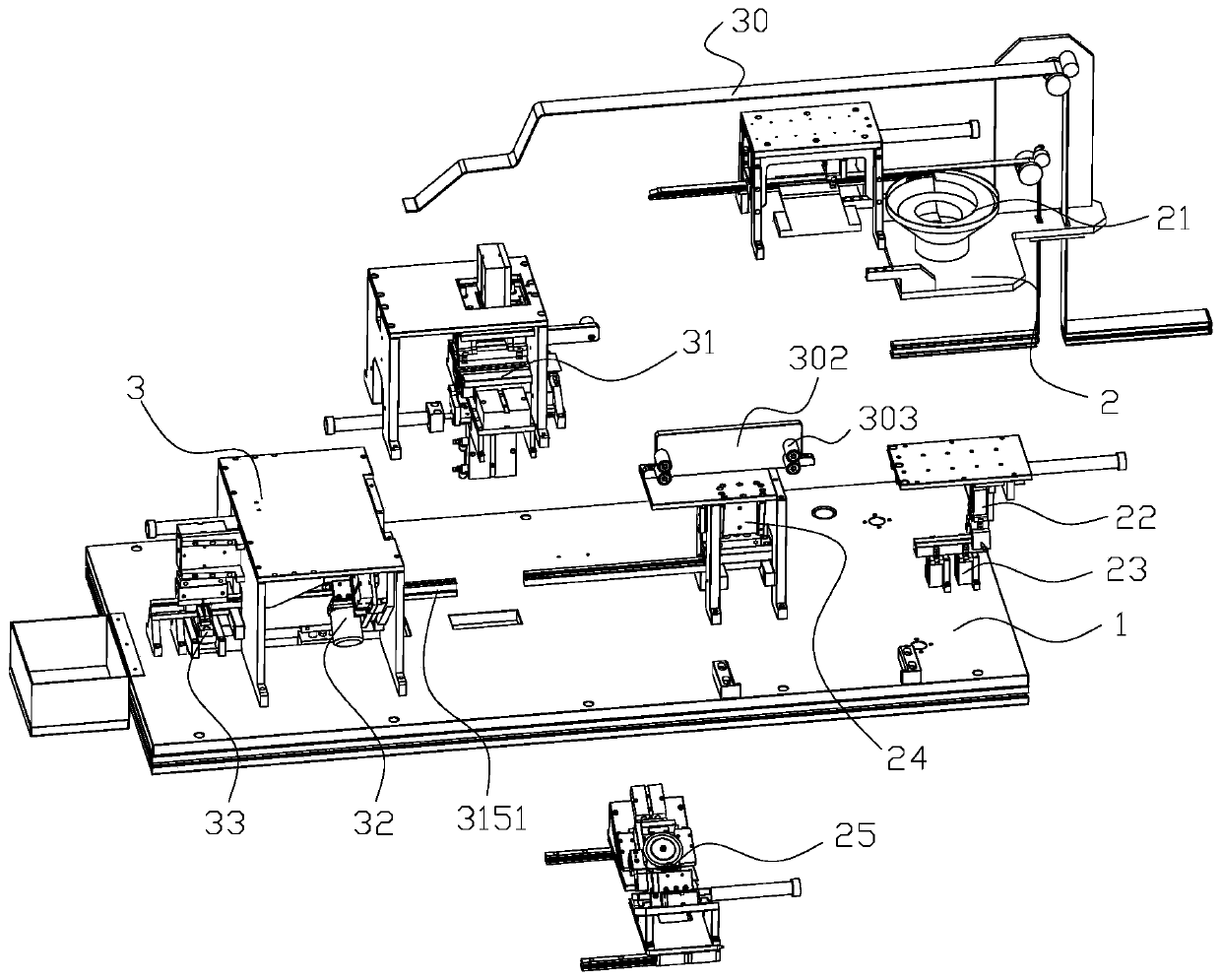

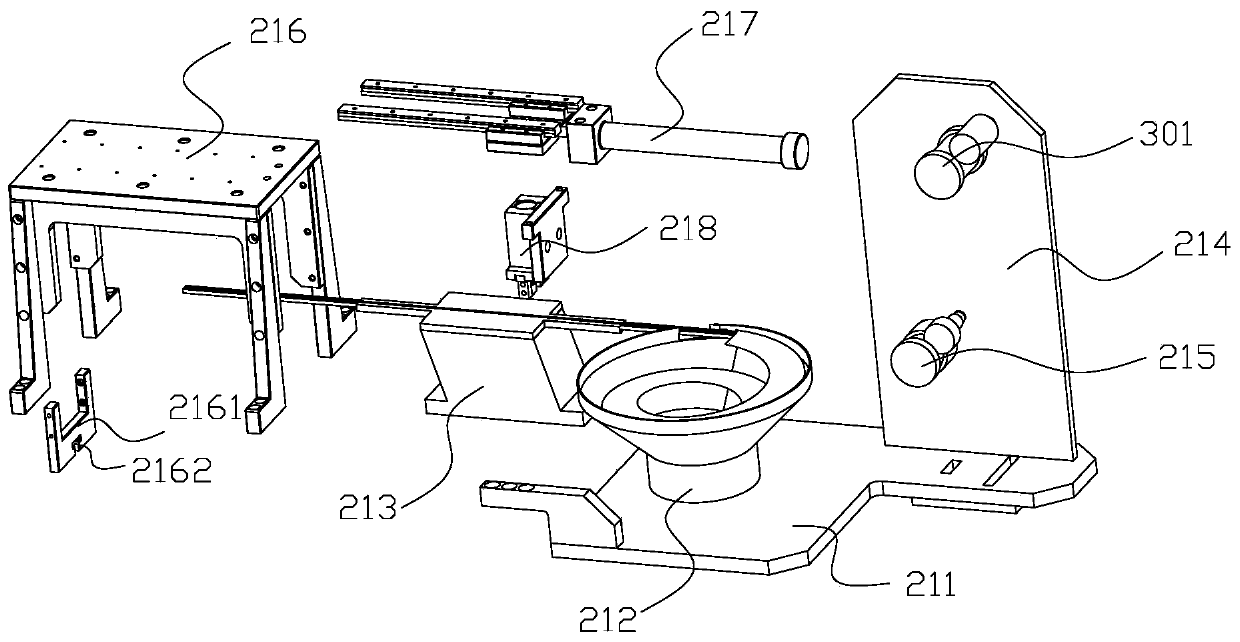

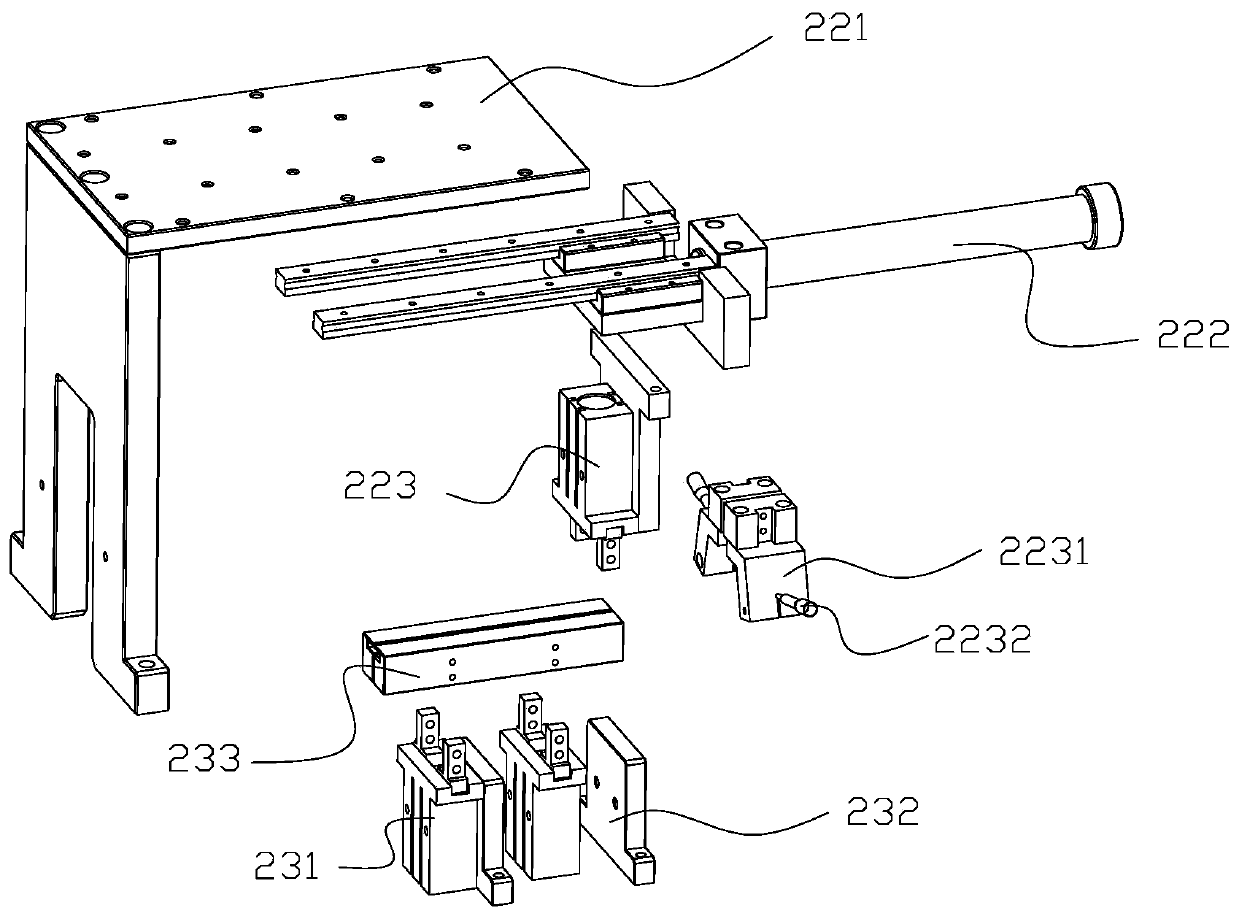

Three-lead feeding mechanism of combined firework pot adhesion device

The invention discloses a three-lead feeding mechanism of a combined firework combination device. A base plate is provided with a first feeding unit and a second feeding unit in a front-rear sequence. Each feeding unit is composed of a feeding wheel set capable of clamping leads vertically and a lead conveying pipe. The base plate is further provided with a third feeding unit. The circle centers of feeding wheels of the three feeding units are distributed to form a triangle on the base plate. The front end openings of the lead conveying pipes of the three feeding units are stacked vertically to form a front end opening row. A rear end opening of a lead fixing channel is connected with the front end opening row and corresponds to each other in height. A front end opening of the lead fixing channel is provided with a lead cutting mechanism. The three-lead feeding mechanism can achieve conveying of the leads of three different specifications on one device for use and is smooth in feeding, low in failure rate and compact, small and exquisite in structure.

Owner:LIUYANG WUYI TECH MACHINERY CO LTD

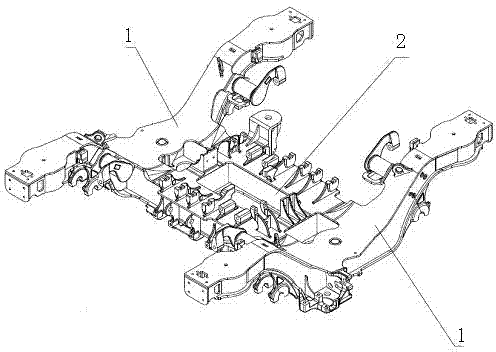

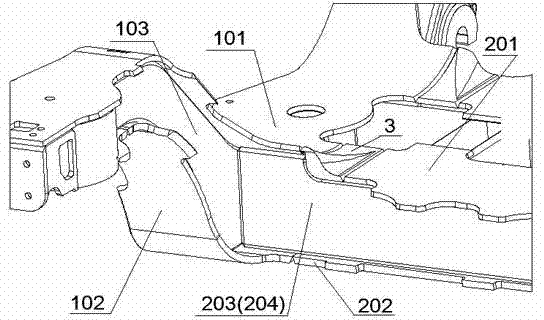

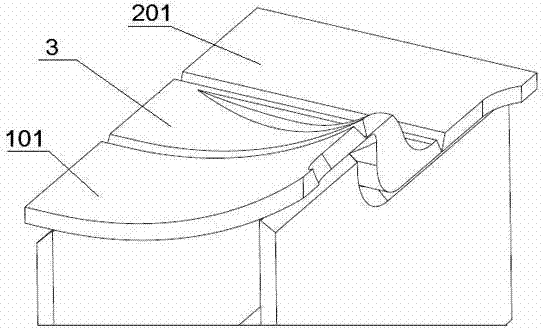

Standard motor train unit power bogie frame

Disclosed is a standard motor train unit power bogie frame. The standard motor train unit power bogie frame is characterized in that side beams and a beam are connected in splicing and variable section mode, an upper cover plate of each side beam extends inwards, and achieves variable section butting against an upper cover plate of the beam through a connection block, the connection block is of a space curved face structure, a lower cover plate of each side beam extends inwards, and butts against a lower cover plate of the beam, and an outer stand plate and an inner stand plate of the beam respectively extend outward, and are inserted into the side beams and directly connected with inner stand plates of the side beams. Section variation of the standard motor train unit power bogie frame can not cause stress concentration and achieves comparable stress level. The connection block is of the space curved face structure, and achieves smooth transition from the upper cover plates of the side beams to the upper cover plate of the beam on geometrical characteristics, and therefore smooth transmission of stress between the upper cover plates of the side beams and the upper cover plate of the beam is achieved. Continuous transition of a box-like structure can be achieved, and rigidity value of the major structure of the standard motor train unit power bogie frame is at the mean value level, and then a rigidity increase on a connection area and stress concentration caused by the rigidity increase are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

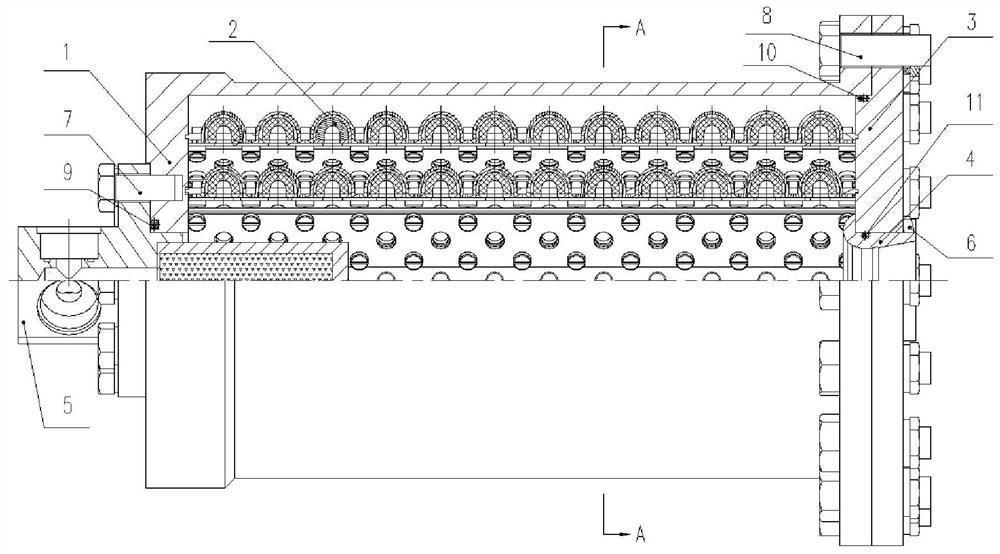

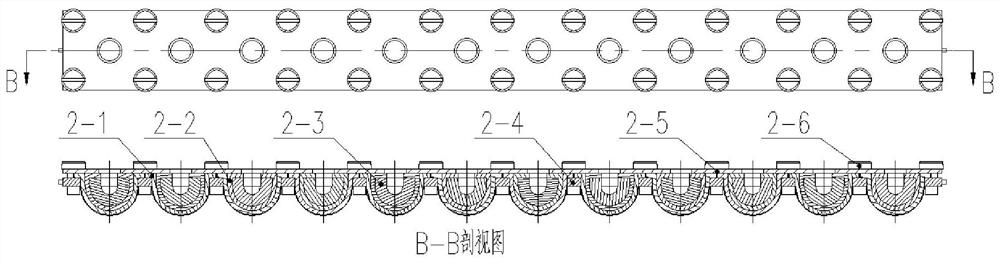

Multistage segmental tower type simulation continuous crystallizer

PendingCN107970639ASmooth deliveryPromote growthEvaporator accessoriesSolution crystallizationSupersaturationEngineering

The invention discloses a multistage segmental tower type simulation continuous crystallizer. The multistage segmental tower type simulation continuous crystallizer comprises a plurality of crystallizer units which are serially connected stage by stage, wherein each crystallizer unit comprises a cylinder and a stirrer which is positioned in an inner cavity of the cylinder and is provided with stirring blades; a column tray which is connected with the edge of the inner side of each cylinder in a sealing manner is arranged in the cylinder; the stirrer in the crystallizer at each stage verticallypenetrates through the middle part of the corresponding column tray; the upper end and the lower end of each stirrer are respectively detachably and fixedly connected with the stirrer in the adjacentcrystallizer unit; a base is arranged at the lower end of the lowermost-stage crystallizer unit; an end enclosure is arranged at the uppermost-stage crystallizer unit; two ends of the serial crystallizers are respectively and fixedly connected with the end enclosure and the base by bearings; a feeding hole and a discharging hole which are communicated with the inner cavity of each cylinder are formed in the outer wall of the cylinder; the feeding holes and the discharging holes of all the crystallizer units are serially connected by a pipeline. The crystallizer unit of each stage in the multistage segmental tower type simulation continuous crystallizer disclosed by the invention can maintain lower crystallizing supersaturation, and excessive fine crystals are prevented from being generated; meanwhile, the phenomenon of backmixing of a mother solution is avoided and the crystallizing efficiency is improved.

Owner:ZHONGYI GLASS FIBER REINFORCED PLASTICS

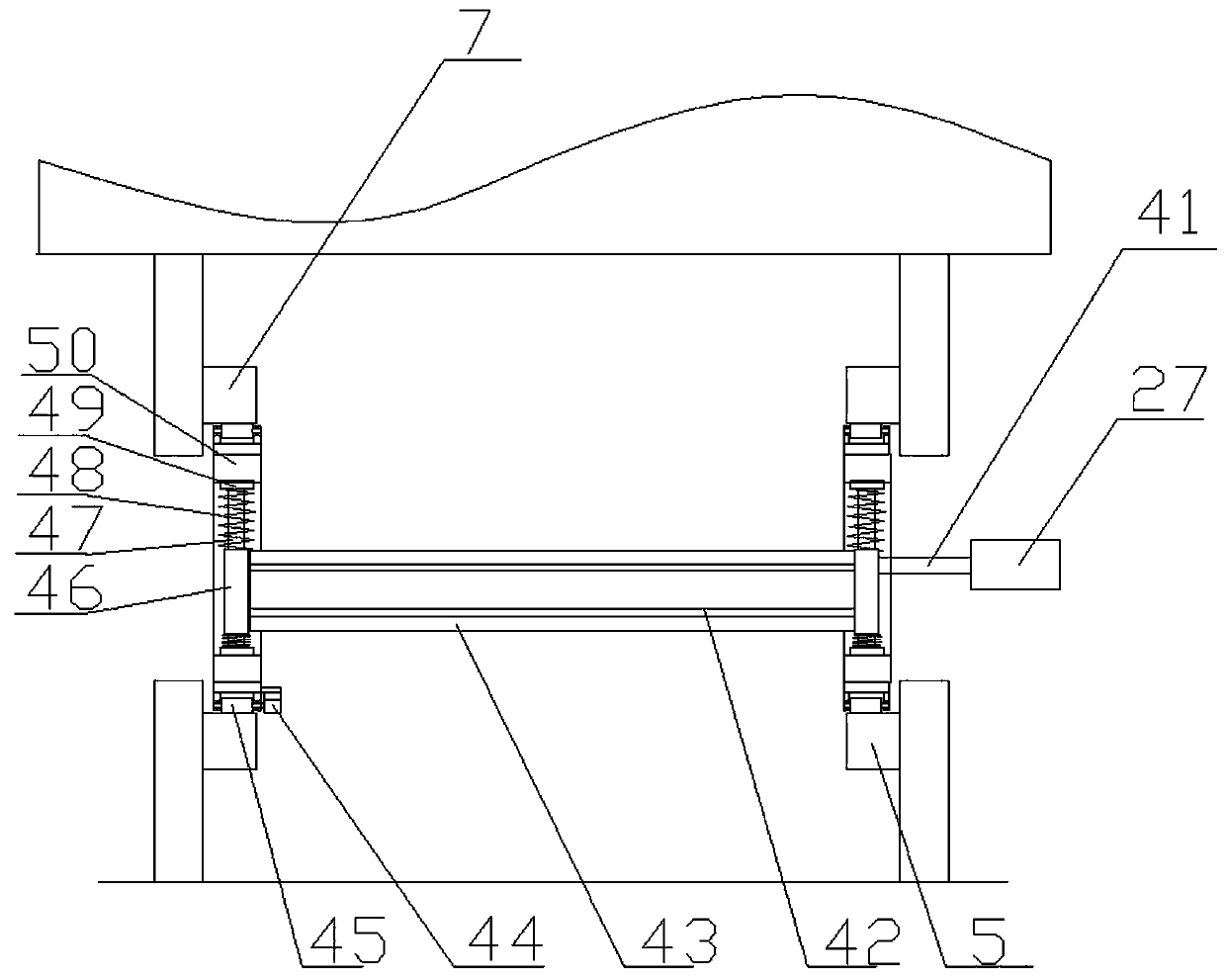

Precise positioning and conveying mechanism and method for gypsum board

PendingCN113772365APrecise positioningThe way of conveying is smoothConveyorsControl devices for conveyorsPhysicsEngineering

The invention relates to the technical field of gypsum board production equipment and discloses a precise positioning and conveying mechanism for a gypsum board. The precise positioning and conveying mechanism for the gypsum board comprises a conveyor belt mechanism, a power mechanism gear motor of the conveyor belt mechanism, a caster and a proximity switch which are mounted above a conveyor belt, a supporting rotating shaft and a lifting cylinder which are arranged at the two end parts of the conveyor belt mechanism respectively, and a PLC control system which is in electric signal connection with a gear motor and the lifting cylinder. The invention further discloses an precise positioning and conveying method for the gypsum board.The time points when the gypsum board enters and leaves are recognized through the caster and the proximity switch, a width of the gypsum board is determined according to a conveying speed, and the conveyor belt mechanism is controlled by the PLC control system to accurately convey the gypsum board to a designated position, so that the gypsum board is positioned very accurately; and after a corresponding procedure is conducted at the designated position, the gypsum board is conveyed to a next procedure through rotation descending of the conveyor belt mechanism, and the conveying mode is more stable, so that the cleaning problem caused by a damage to the gypsum board is solved, and the stability of the equipment is improved.

Owner:BOTHCHEERS INTELLIGENT EQUIP (QINGDAO) CO LTD

Battery anode material pretreatment device

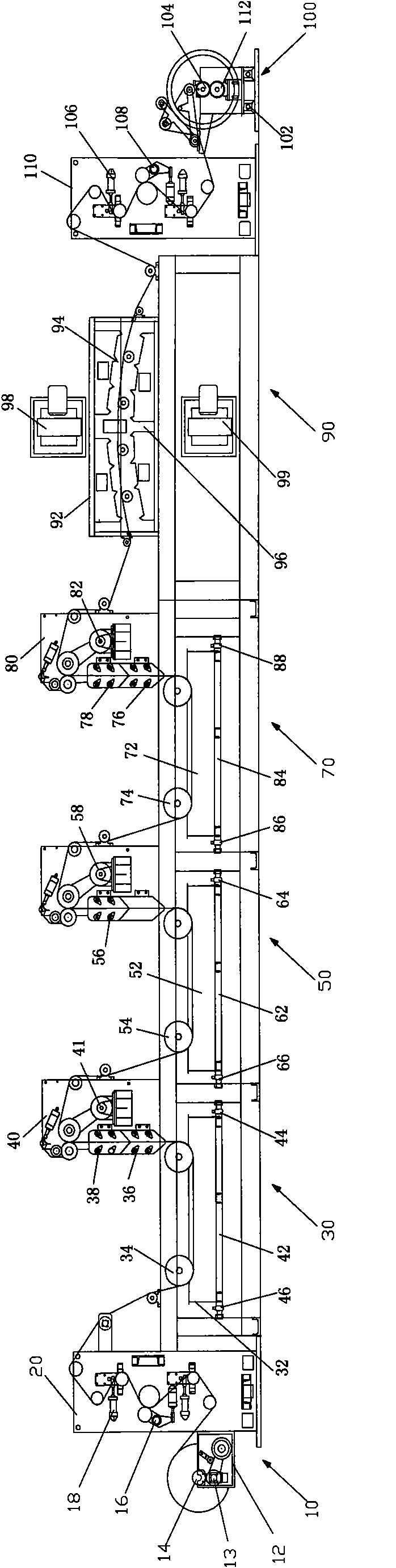

ActiveCN102024935AEasy to shape and transferSmooth deliveryElectrode manufacturing processesElectrode carriers/collectorsElectrical batteryAnode

The invention discloses a battery anode material pretreatment device, comprising a coil handling apparatus and a wrap-up device which are used for coating an anode material, and the anode material is transferred to the wrap-up device from the coil handling apparatus. An etching device for carrying out surface treatment on the anode material and a cleaning device for removing stains and etching liquid of the anode material subject to surface treatment are arranged on the transferring route of the anode material between the coil handling apparatus and the wrap-up device. The etching device of the pretreatment device is used for corroding the surface of the battery anode material to obtain cavities which are more convenient for adhering anode sizing agent; and the cleaning device is used for washing alkaline liquid on the surface of the anode material.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

Polyester spinning device for spinning

InactiveCN105586648ASmooth deliveryGood value for promotionSpinning head liquid feederMelt spinning methodsPolyesterElectric heating

The invention relates to the field of spinning, in particular to a polyester spinning device for spinning. By means of the spinning device, processing of polyester spinning is achieved, and the problem that the polyester yielding efficiency is low is solved. The spinning device comprises a feed box, a feed inlet is formed in the upper end of the feed box, a feed screw is arranged in the feed box, a first gear is arranged at one end of the feed screw, the first gear is meshed with a second gear, and the second gear is connected with an electromotor through a driving rod; the lower end of the feed box is connected with a feed pipe, a metering pump is arranged on the feed pipe, the lower end of the feed pipe is connected with a polyester spray head, a heating aluminum block is arranged outside the polyester spray head, electric heating pipes are arranged in the heating aluminum block, a heat radiating cavity is formed in the lower end of the heating aluminum block, an air intake cavity is formed in the middle of the heat radiating cavity, the lower end of the air intake cavity is connected with an air supply pipe, a blower is arranged at the tail end of the air supply pipe, and a rectifying plate is arranged in the air intake cavity. The polyester spinning device for spinning is simple in structure, convenient to use and suitable for various places.

Owner:宝璐纺织(苏州)有限公司

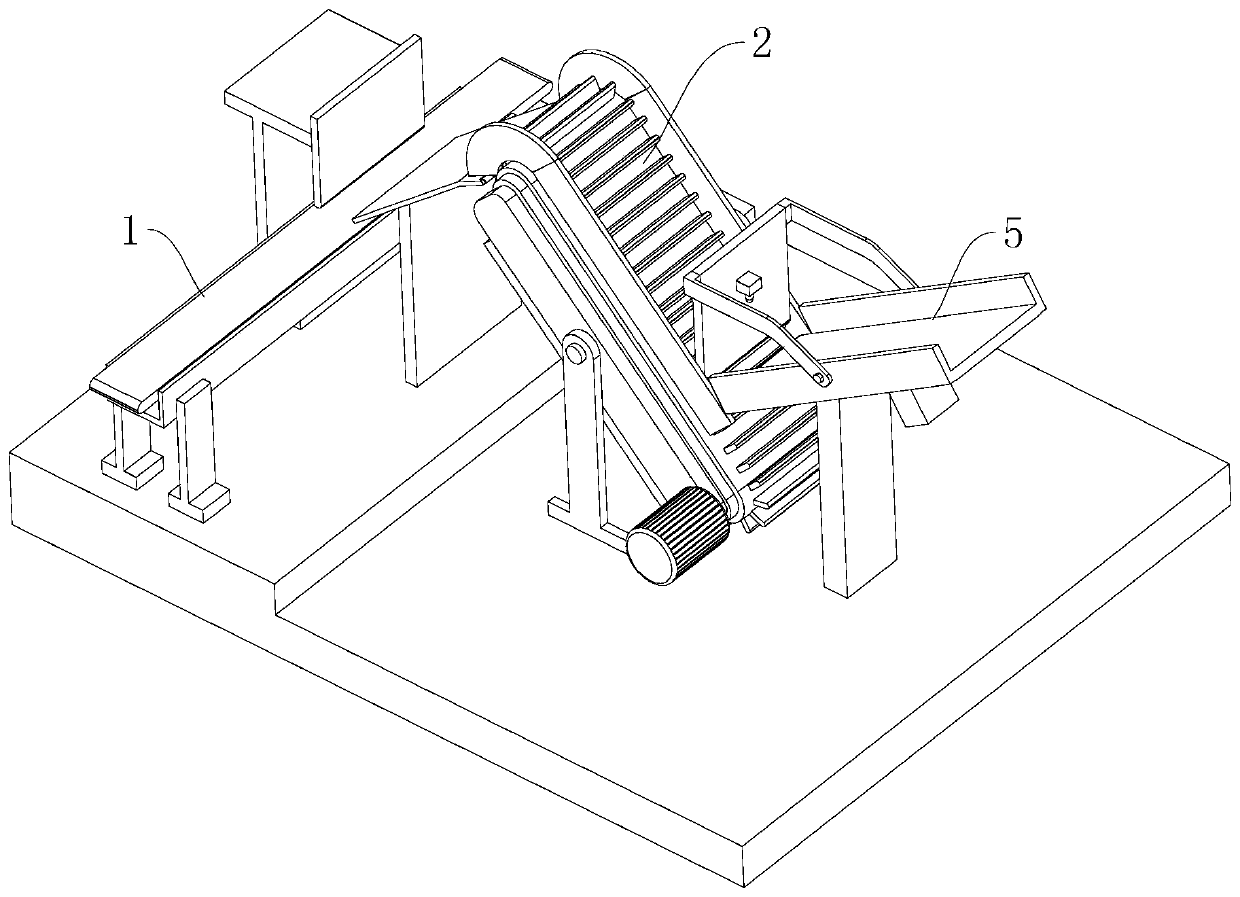

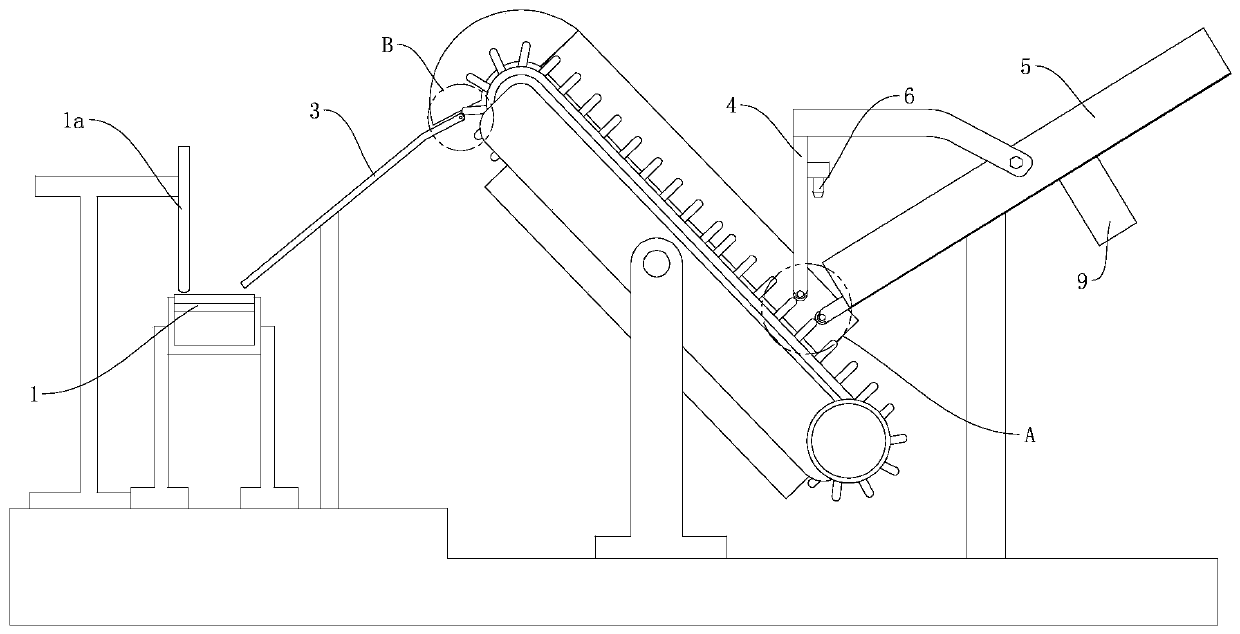

Automatic conveying device for Kandelia candel

InactiveCN110482162ASmooth deliveryWon't breakControl devices for conveyorsMechanical conveyorsKandelia candelMechanical engineering

The invention relates to the field of Kandelia candel processing, and in particular relates to an automatic conveying device for Kandelia candel. The automatic conveying device comprises an unloadingconveying belt, a transportation conveying belt, a guide plate, a blanking sliding way, a distance measuring sensor, a first drainage mechanism and a second drainage mechanism, wherein the transportation conveying belt is arranged obliquely, and the downstream end of the transportation conveying belt is upturned; the blanking sliding way is obliquely arranged on one side of the transportation conveying belt, and the first drainage mechanism and the distance measuring sensor are arranged between the blanking sliding way and the transportation conveying belt; the second drainage mechanism is arranged at the downstream end of the blanking sliding way; a plurality of stirring plates distributed at equal distance in the conveying direction are arranged on the conveying plane of the transportation conveying belt, and a storage space is formed between every two adjacent stirring plates; the guide plate is obliquely arranged at the downstream end of the transportation conveying belt; a first gravity sensor and a second gravity sensor are respectively arranged in the first drainage mechanism and the second drainage mechanism; and a vibration motor is arranged at the bottom of the blanking sliding way. The automatic conveying device can transfer the single Kandelia candel in a set attitude.

Owner:景宁丽恒模具加工厂

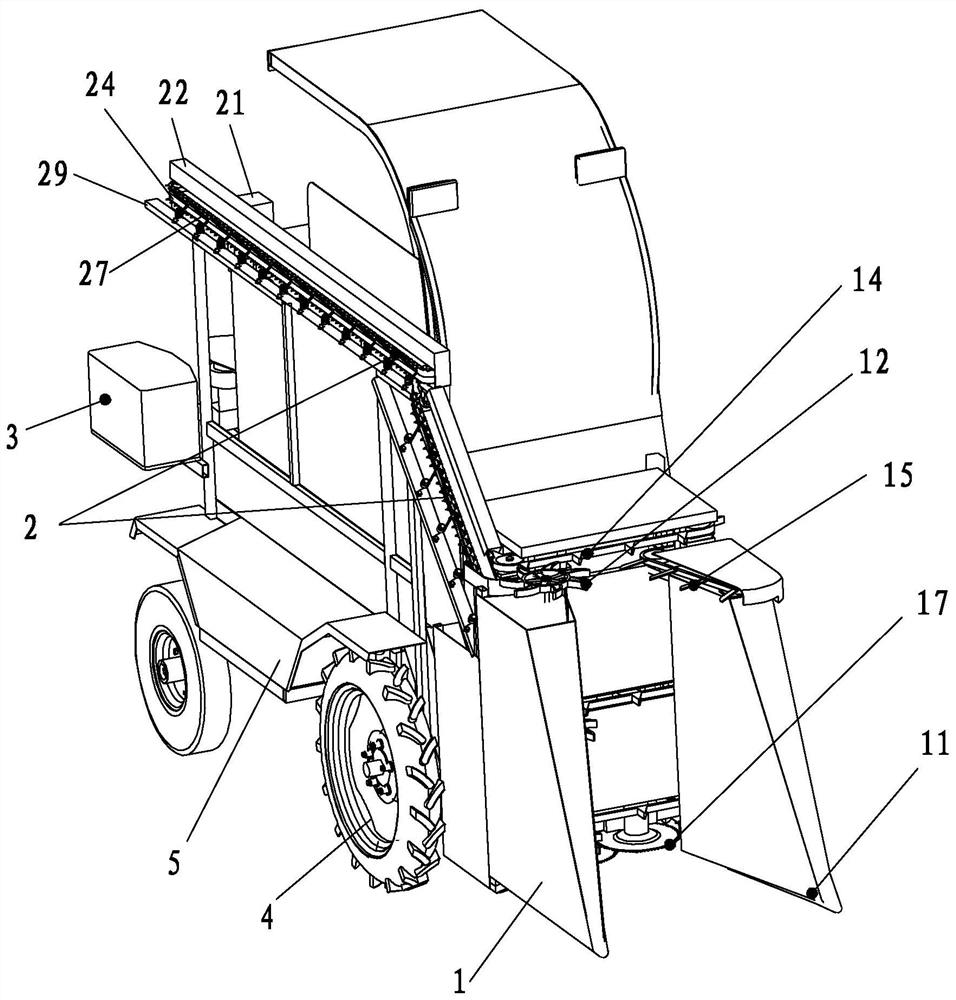

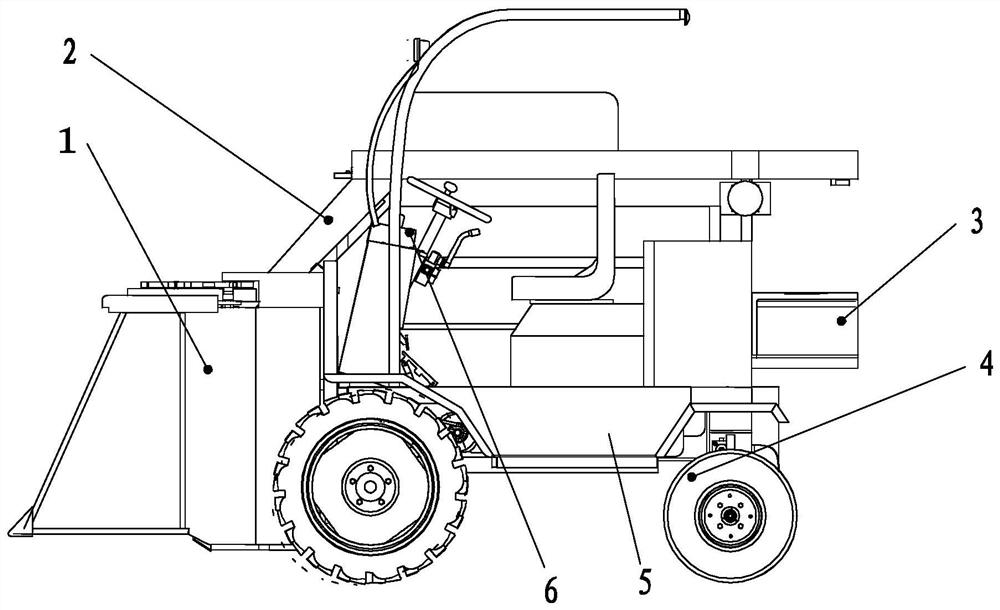

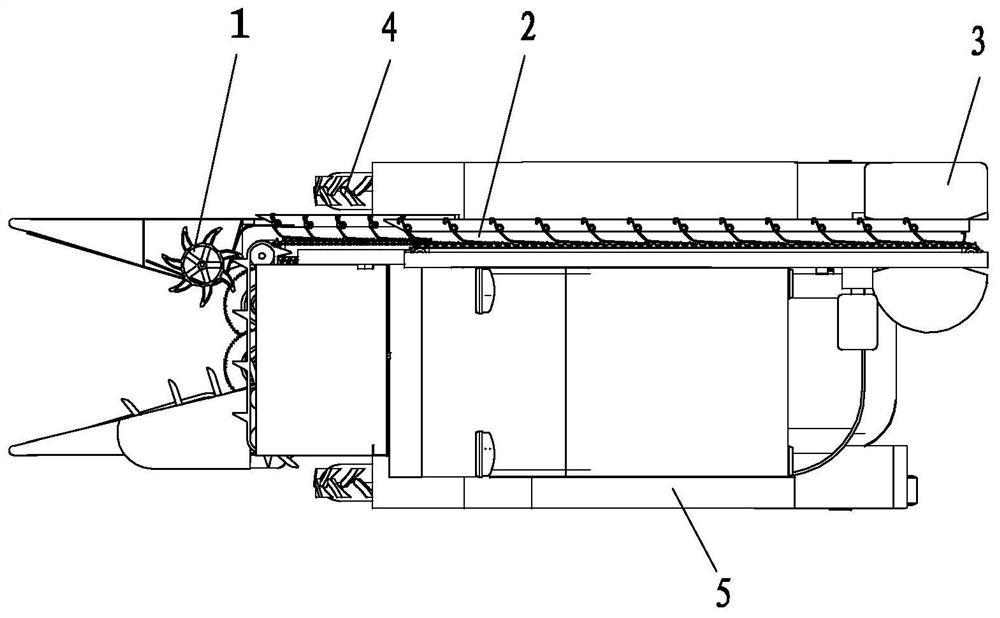

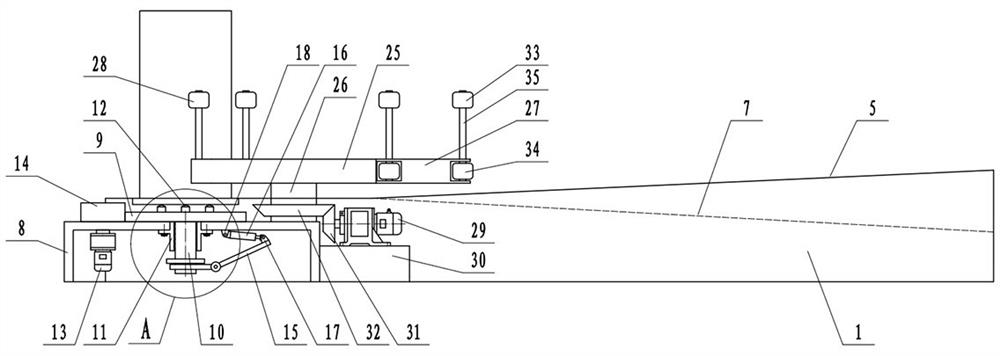

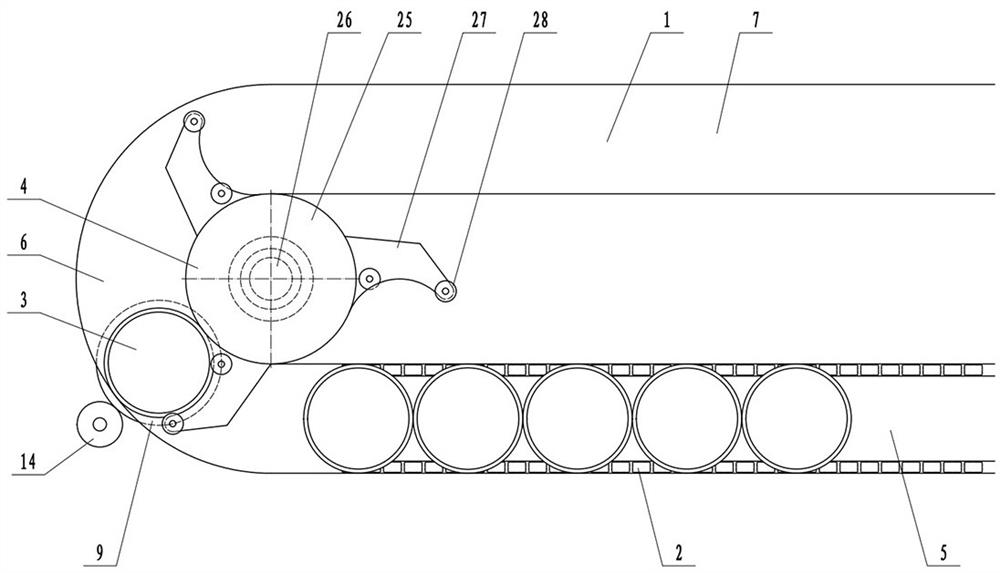

Ramulus mori shoot harvester

PendingCN114190181ARealize mechanical integrationSmooth entryCuttersCutting implementsAgricultural engineeringDrive motor

The invention relates to a mulberry twig reaper which comprises a cutting and gathering device, a conveying device, a collecting mechanism, a walking mechanism, a vehicle body and a control mechanism, the cutting and gathering device comprises a cutting device, a conveying and gathering device, a rack and a front baffle, and the conveying device comprises a driving motor, a supporting frame and a conveying assembly. The conveying assembly comprises a double-side sharp tooth chain, a chain support, a pressing strip installation plate and a plurality of spring pressing strips, an inlet of a conveying channel of the conveying device communicates with an outlet of a material guide plate of the cutting and gathering device, and the collecting mechanism is installed at the outlet of the conveying channel of the conveying device. The mulberry twig reaper can mechanically realize cutting, gathering, long-distance conveying and collecting work of mulberry twigs, the cutting and gathering device is provided with a longitudinal conveying chain, feeding is smoother, and the gathering and conveying effect is good; the conveying device adopts a conveying mode that sharp tooth chains on the two sides are matched with spring pressing strips, the clamping and conveying effects on the mulberry twigs are good, and the conveying device is suitable for long-distance mulberry twig conveying.

Owner:广西金元祥智慧农业科技有限公司

Conveying and pouring equipment for building concrete construction

PendingCN113547638ABlock deliverySmooth deliveryDischarging apparatusCement mixing apparatusArchitectural engineeringStructural engineering

The invention discloses conveying and pouring equipment for building concrete construction, and belongs to the technical field of building concrete construction. The conveying and pouring equipment comprises a conveying base, a supporting base is installed at the top of the conveying base, a concrete mixing bin is installed on the supporting base, an anti-solidification mixing mechanism is arranged on the concrete mixing bin, a discharging opening is formed in the bottom of the concrete mixing bin, a discharging pipe is installed on the discharging opening, and an anti-blocking material shaking mechanism is arranged on the discharging pipe and installed on the supporting base. According to the conveying and pouring equipment for the building concrete construction, concrete can be stirred and mixed through a rotating transmission shaft and anti-solidification mixing blades, concrete solidification is prevented, it is guaranteed that concrete conveying work is smoothly carried out, the discharging pipe can move in a reciprocating mode along with an anti-blocking material shaking assembly through the anti-blocking material shaking assembly which moves in a reciprocating mode, and the concrete in the discharging pipe is shaken, so that the discharging pipe is prevented from being blocked, the concrete can be normally conveyed and discharged, and the pouring efficiency of the concrete is improved to a certain extent.

Owner:GANSU CONSTR VOCATIONAL TECHNICAL COLLEGE +1

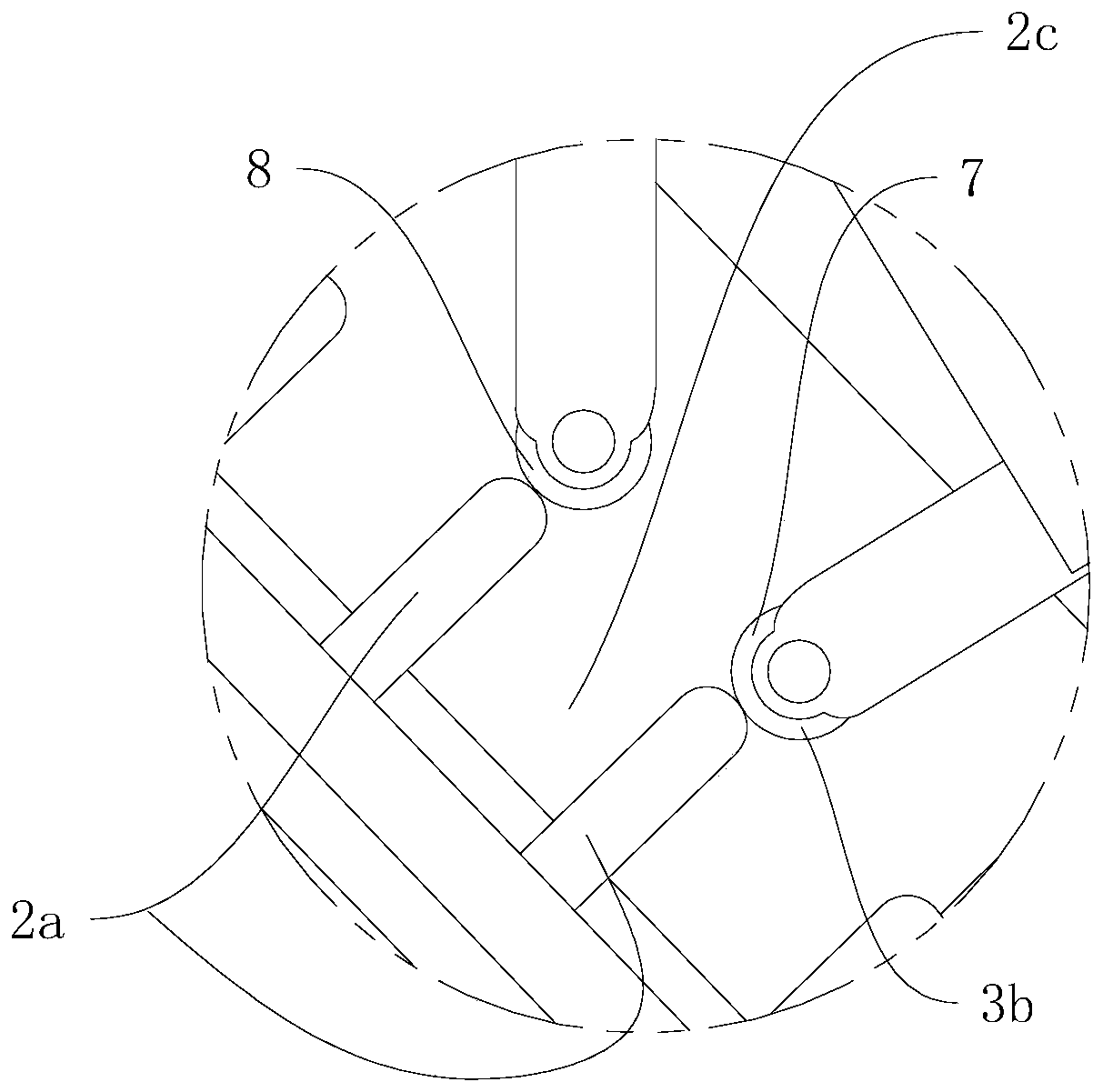

Automatic bobbin replacing device for yarn storage bobbins

The invention provides an automatic bobbin replacing device for yarn storage bobbins, and belongs to the technical field of textile machinery. The automatic bobbin replacing device comprises a U-shaped bobbin replacing table, a bobbin feeding roller, a yarn storage bobbin rotating mechanism and a yarn storage bobbin replacing mechanism; the U-shaped bobbin replacing table comprises a linear bobbin feeding section, a semicircular bobbin replacing section and a linear bobbin discharging section; a yarn storage bobbin rotating fluted disc of the yarn storage bobbin rotating mechanism is arranged on a yarn storage bobbin rotating shaft support in a rotatable and liftable mode through a yarn storage bobbin rotating shaft; a rotating shaft lifting table is arranged at the lower end of the yarn storage bobbin rotating shaft; a yarn storage bobbin rotating driving gear is meshed with the yarn storage bobbin rotating fluted disc; three yarn storage bobbin replacing cambered arms of the yarn storage bobbin replacing mechanism are evenly installed on a yarn storage bobbin replacing rotary disc; and yarn storage bobbin replacement pressing wheel assemblies are installed inside and outside the yarn storage bobbin replacing cambered arms. The yarn storage bobbins can be automatically replaced, the structure is reasonable and ingenious, the automation degree is high, and the reliability is good.

Owner:桐乡市建泰纺织有限公司

Anti-loosening device for cable conveying

ActiveCN111847098AReliable tensionImprove processing efficiencyFilament handlingStructural engineeringElectric cables

The invention relates to the technical field of cable processing, also discloses an anti-loosening device for cable conveying. The device comprises a base, wherein the top of the base is fixedly connected to an unwinding roller and a winding roller, two sets of supporting rods are symmetrically and fixedly connected to the top of the base, the number of supporting rods in each set is two, two fixing plates are symmetrically and fixedly connected between the top ends of the two sets of supporting rods, two limiting rods are symmetrically and fixedly connected between the side surfaces, close toeach other, of the two fixing plates, two sets of sliding grooves are symmetrically formed in the side surfaces, close to each other, of the two fixing plates, and the number of sliding grooves in each set is two. According to the device, the problem that a cable is prone to loosen in a long-distance conveying process, so that the cable may be wound disorderly in the conveying process, and smoothperforming of cable processing is further affected is solved.

Owner:ANHUI ZHONGRUN CABLE GRP SHARES CO LTD

Efficient energy-saving vegetable cleaning machine

ActiveCN112772948AImprove processing efficiencyImprove processing qualityClimate change adaptationFood treatmentMechanical engineeringIndustrial engineering

The invention relates to the technical field of vegetable cleaning, in particular to an efficient energy-saving vegetable cleaning machine. The efficient energy-saving vegetable cleaning machine comprises a guide plate, wherein a feeding opening is fixedly connected to the guide plate, two control frames are respectively arranged at two ends of the guide plate, the guide plate penetrates through the control frames, a rubber conveying belt is arranged at the lower end of the guide plate, and rotating rollers are arranged at the end of the rubber conveying belt. The rubber conveying belt sleeves the rotating rollers, central shafts are arranged at the middle of the rotating rollers in a penetrating manner, and the ends of the central shafts penetrate through plate bodies of the control frames. By means of the structural design, in the conveying process of vegetables, stirring and cleaning work can be performed at the same time, the processing efficiency and quality of the vegetables are improved, parts are exquisite, the function is stable and powerful, and the automatic control and adjustment effect is achieved.

Owner:河北润泽鲜食品加工有限公司

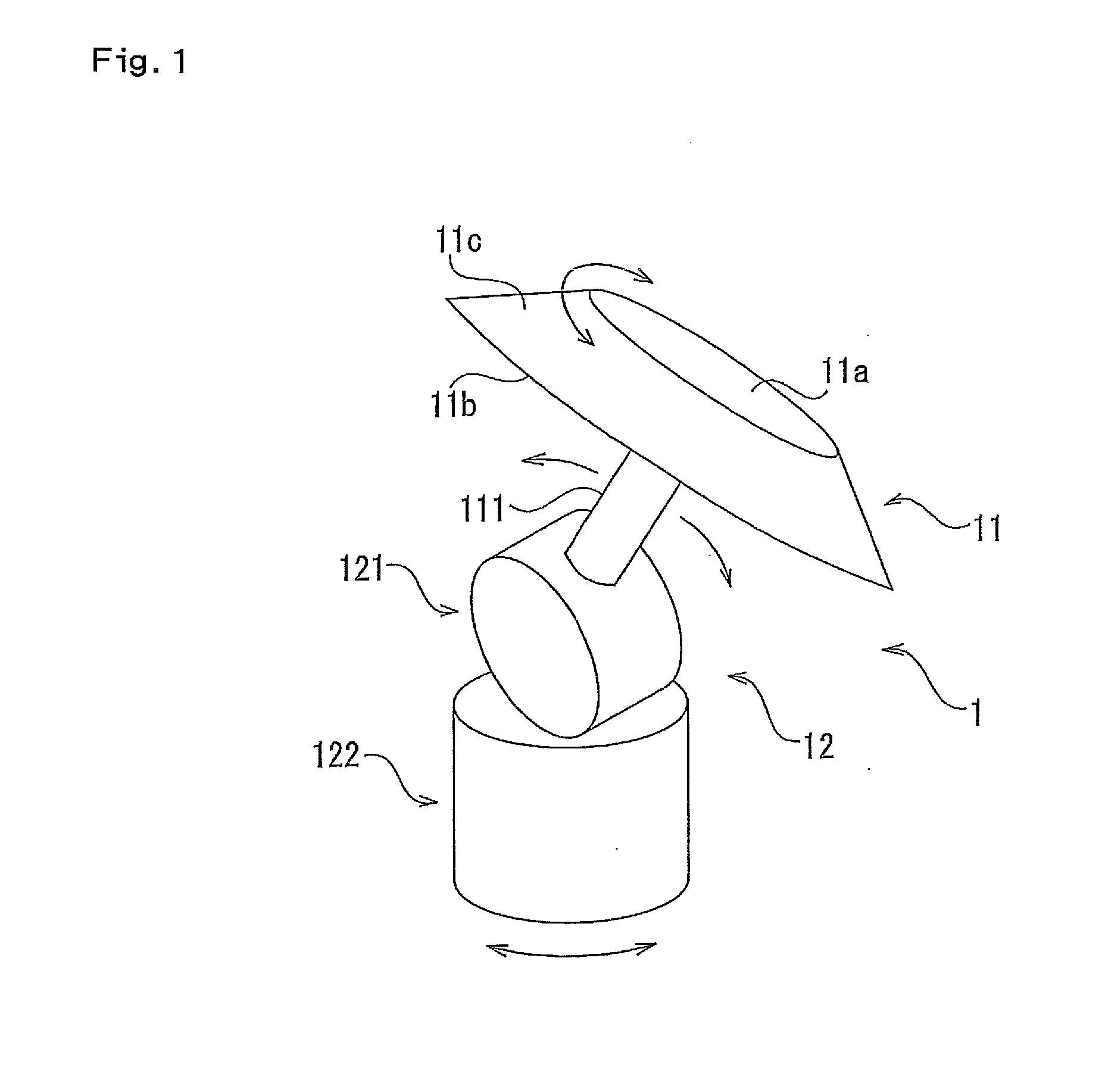

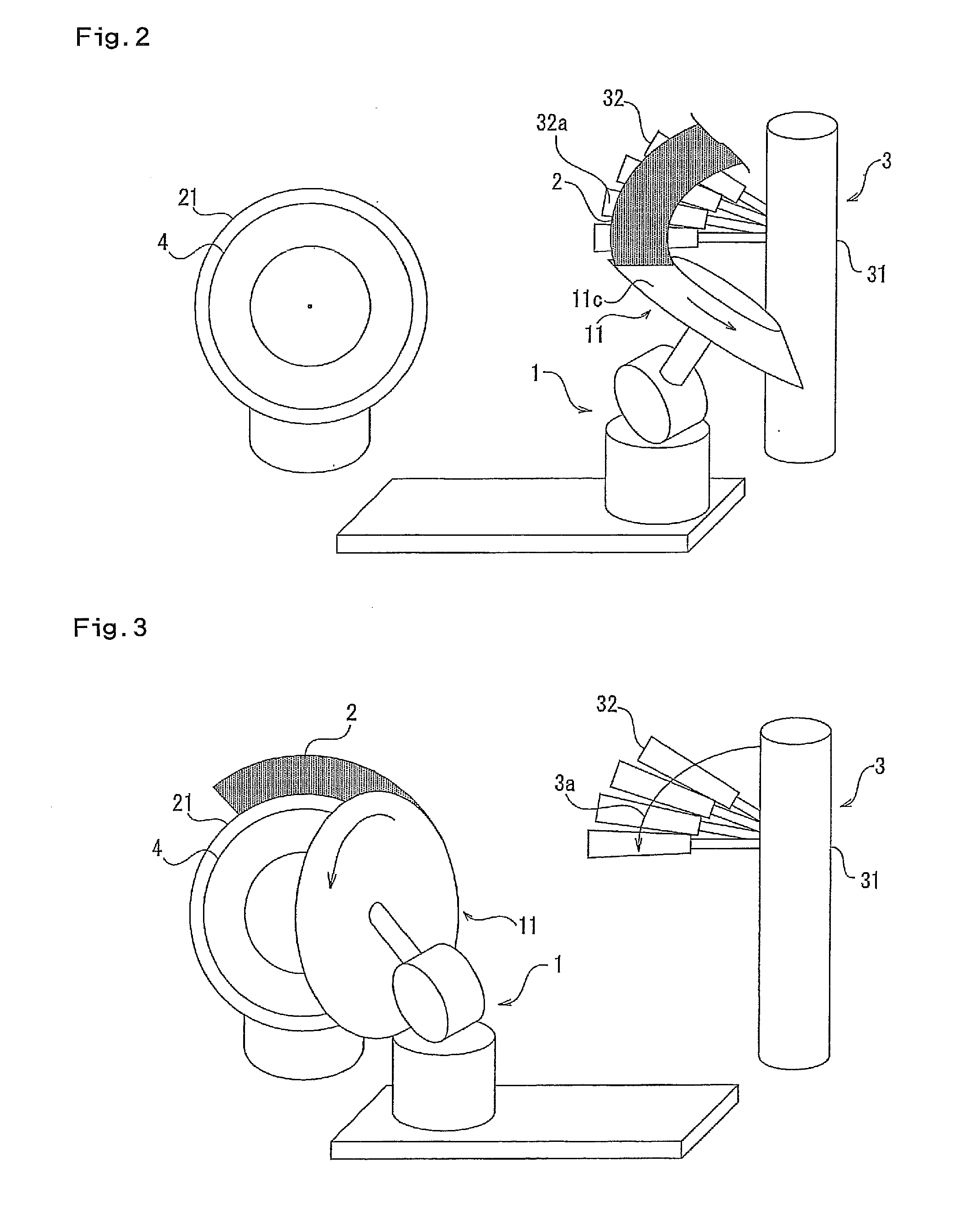

Conveying device

Owner:TOYO TIRE & RUBBER CO LTD

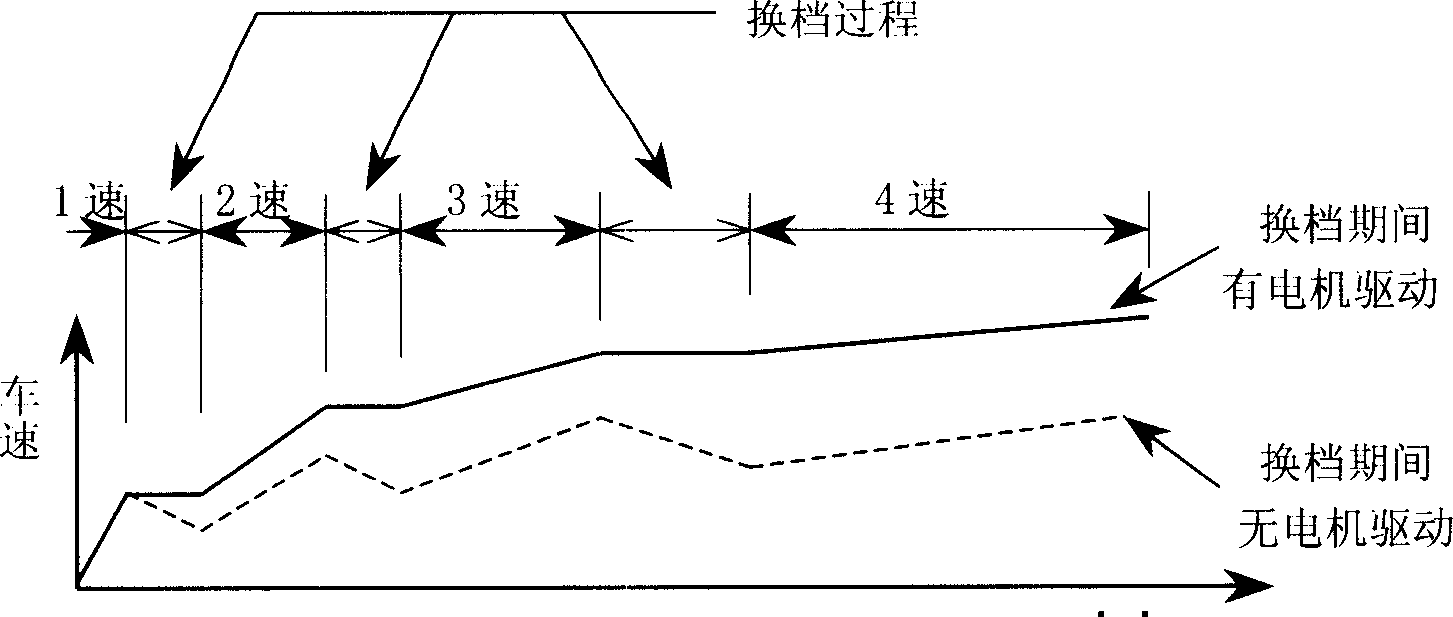

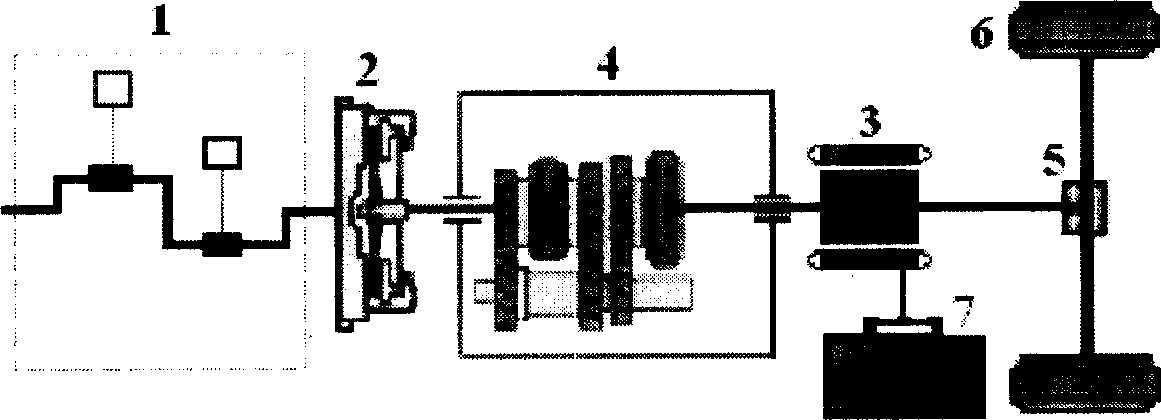

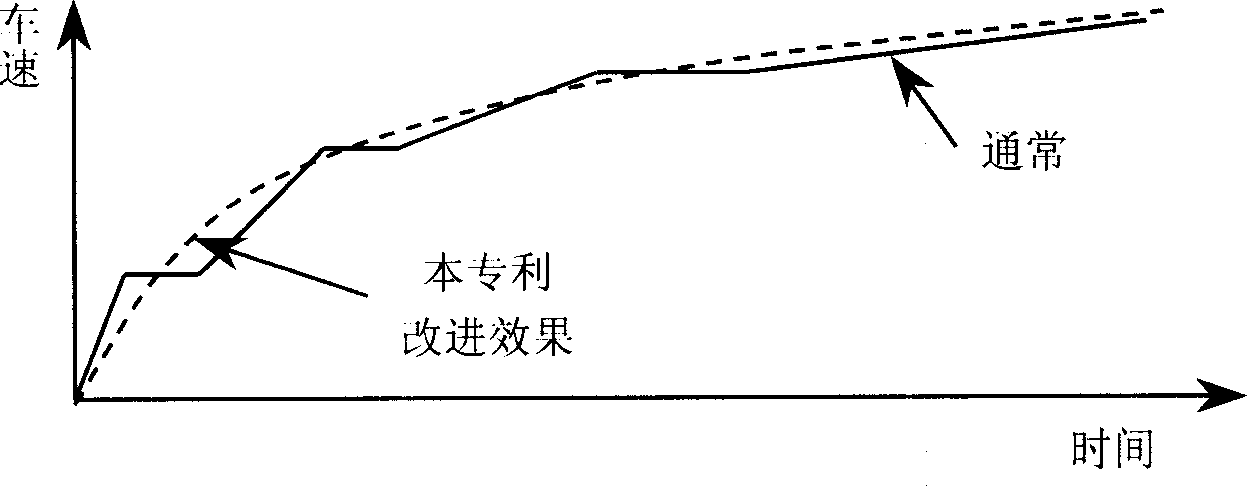

Method for controlling engine torque in hybrid-powered motor speed variator shift process

InactiveCN1908406ASmooth deliveryGood shifting stabilityGearing controlEngine controllersVariatorMotor speed

Owner:FAW GROUP

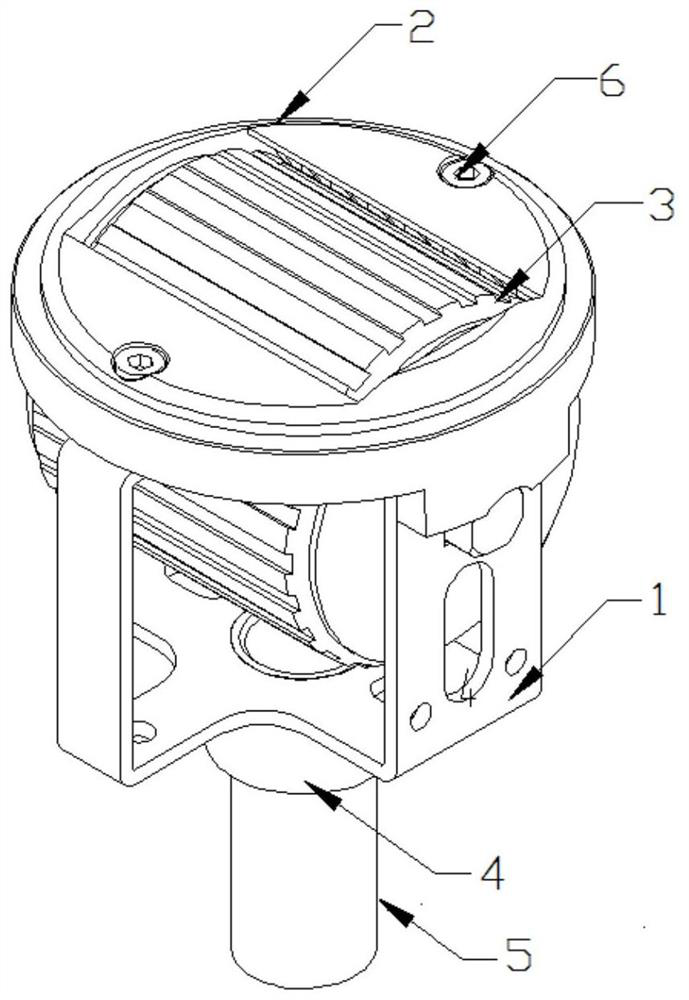

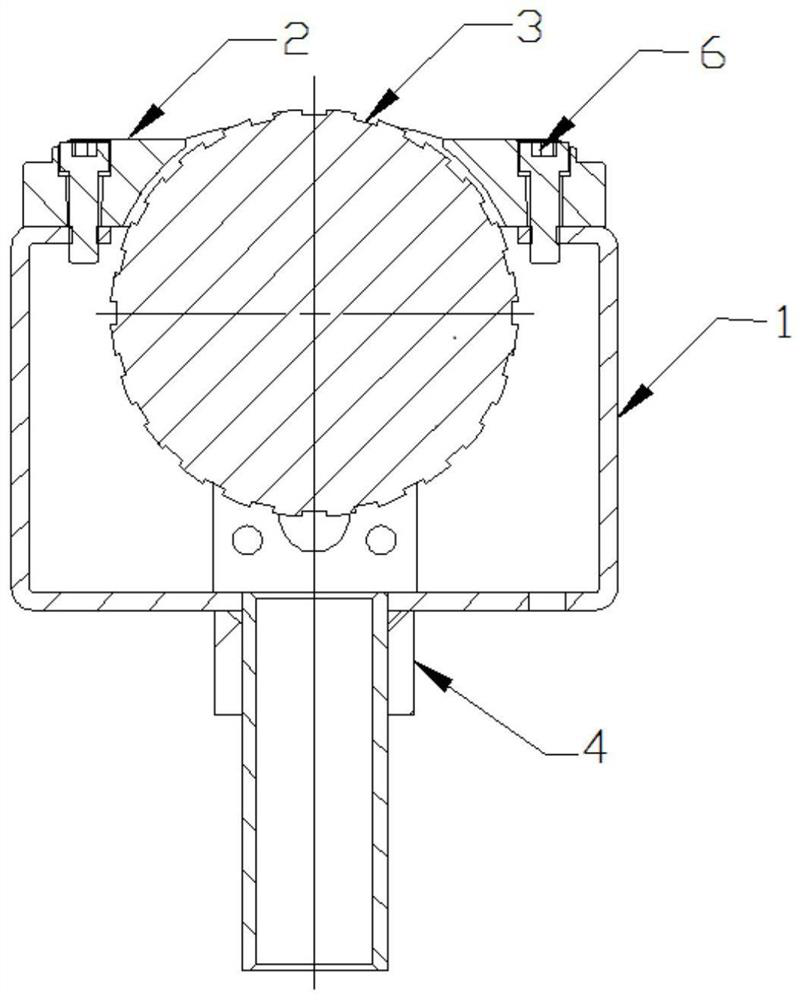

Balance wheel unit of balance wheel type sorting device

The invention relates to a balance wheel unit of a balance wheel type sorting device, the balance wheel unit comprises a support, a conveying roller rotatably mounted on the support and a cover plate fixed on the support, the support is rotatably mounted in the balance wheel type sorting device, the conveying roller is used for conveying articles, the cover plate comprises a circular upper baffle, and the upper baffle is used for supporting the support. The upper baffle is coaxially arranged in the balance wheel mounting through hole, the cover plate is provided with a square slotted hole penetrating downwards in the upper end face of the upper baffle, the conveying roller is located in the square slotted hole, and the upper end part of the conveying roller extends out of the upper end face of the upper baffle; slope guiding parts are arranged on the two end face sides, located on the conveying rollers, of the upper baffle correspondingly, gaps are formed between the inner side faces of the slope guiding parts and the end faces of the conveying rollers, and the upper ends of the slope guiding parts are higher than the upper end face of the upper baffle and lower than the upper ends of the conveying rollers. A conical guide surface is arranged between the upper end of the slope guide part and the edge of the upper baffle, and the guide surface inclines outwards from the side.

Owner:ZHEJIANG DAMON TECH CO LTD +1

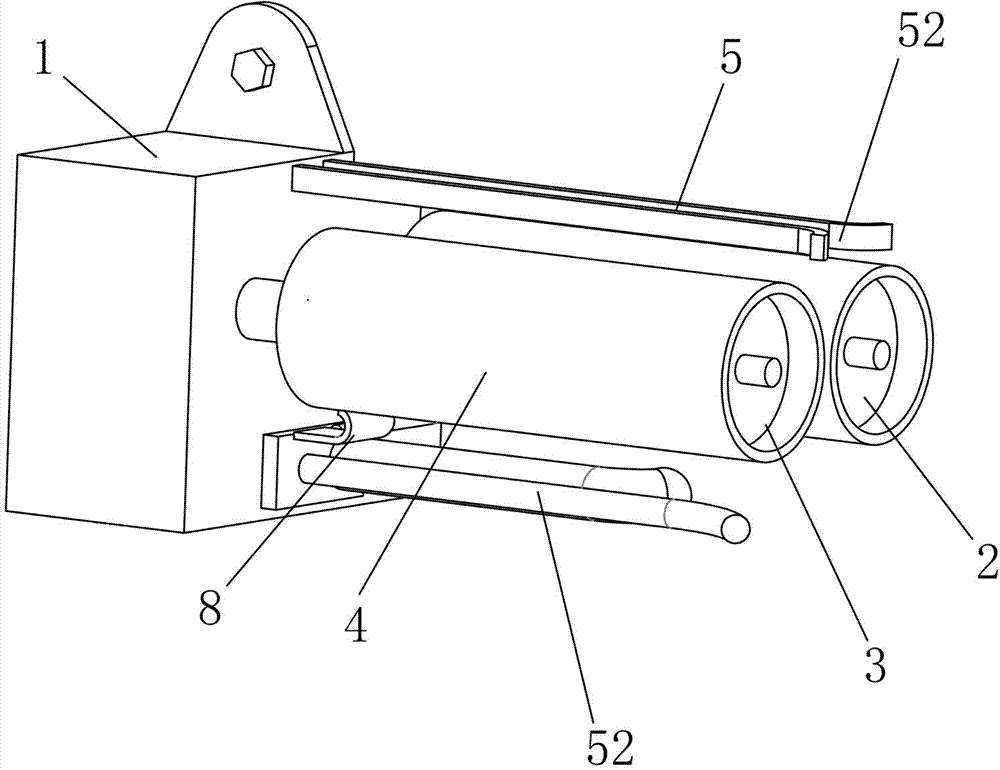

Arm type current collector

InactiveCN102130406ASmooth deliveryEnsure contact tensionRotary current collectorTorsion springCurrent collector

The invention discloses an arm type current collector which relates to improvement on a tension current collector, reduces the probability that an electric brush goes off rails, and avoids complete release of a torsion spring. The arm type current collector comprises an outer cylinder, an inner cylinder, a torsion spring, a rotating arm, an electric brush, a cable connecting column, a soft conductive band, a bottom plate and a seat plate, wherein the torsion spring is arranged between the outer cylinder and the inner cylinder; the soft conductive band is connected with the cable connecting column; the electric brush is movably connected to the head end of the rotating arm; the outer cylinder is fixedly connected with the bottom plate into a whole; the end face of the outer cylinder is provided with a ring of groove; the tail end of the rotating arm is connected to an axial end of the inner cylinder; the arm body of the rotating arm, corresponding to the groove of the outer cylinder, is provided with a guide pin which extends into the groove; and a phase block for limiting the running range of the guide pin is arranged in the groove on the end face of the outer cylinder. The phase block can limit the rotation of the rotating arm within 360 degrees, namely the tensile force of the torsion spring can be restored by only simply pulling the rotating arm back, so that contact tension between the electric brush and a wire / rail of an electrical appliance is guaranteed. In addition, the rotating arm can be turned to adjust the elastic force of the torsion spring.

Owner:江苏江鹤滑线电气有限公司

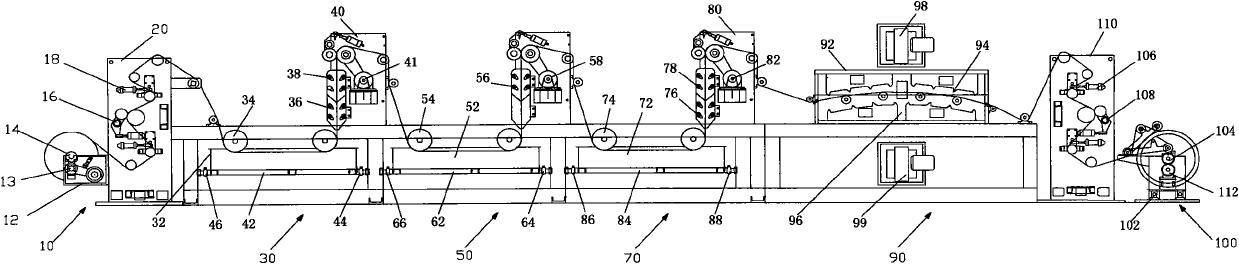

Cloth stretching machine

InactiveCN104495470ASmooth deliveryLess processing failureWebs handlingEngineeringMechanical engineering

The invention relates to the field of cloth production, in particular to a cloth stretching machine for conveying and stretching cloth. The cloth stretching machine comprises a base and a conveying and stretching roller disposed on the base. The conveying and stretching roller includes a conveying roller and a stretching roller. A cloth conveying passage is arranged between the conveying roller and the stretching roller. A stretching assisting layer is disposed on the surface of the stretching roller. A pair of mirrored guide clamp rods is disposed on the base, a guide passage is arranged between the two guide clamp rods, the rear ends of the guide clamp rods are fixedly connected to the base, the front ends of the guide clamp rods are suspended, and the front ends of the two guide clamp rods bend and extend oppositely to form a cloth inlet. A pair of lower guide rods corresponding to the two guide clamp rods is disposed below the conveying and stretching roller. During use, cloth is conveyed downwardly, two cloth stretching machines are oppositely disposed on two sides of the cloth, the front ends of the conveying and stretching rollers incline downwardly, and the two conveying rollers conveys the cloth downwardly while the cloth is stretched towards two sides at the same time during operation.

Owner:ZHEJIANG DAGANG PRINTING & DYEING

PP packing belt based on nano application

The invention discloses a PP packing belt based on nano application. The PP packing belt is composed of an active nano material, PET and auxiliary preparations. The auxiliary preparations include a drying agent, an initiator, a chain extender and a cross-linking agent. The PP packing belt is low in consumption and durable, belt conveyance is smooth, operation interruption is avoided, package damage is avoided, and packaging speed is high; the PP packing belt does not absorb water and is dampproof, tension strength does not change in the presence of water, strength is high, tension resistance is realized, and tenacity is extremely high; under the recovery or combustible condition, sulfur monoxide gas is not generated, and therefore the PP packing belt is good for environment protection and human health.

Owner:东莞市亚兰包装材料制品有限公司

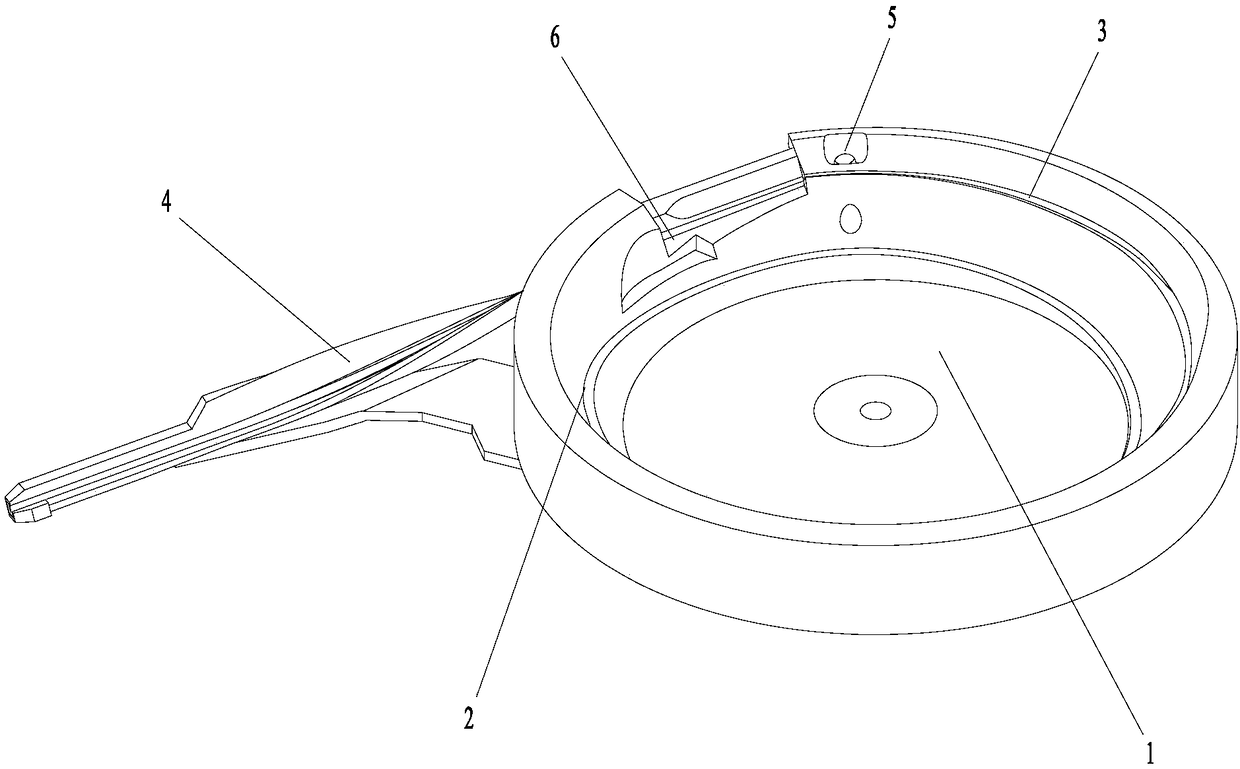

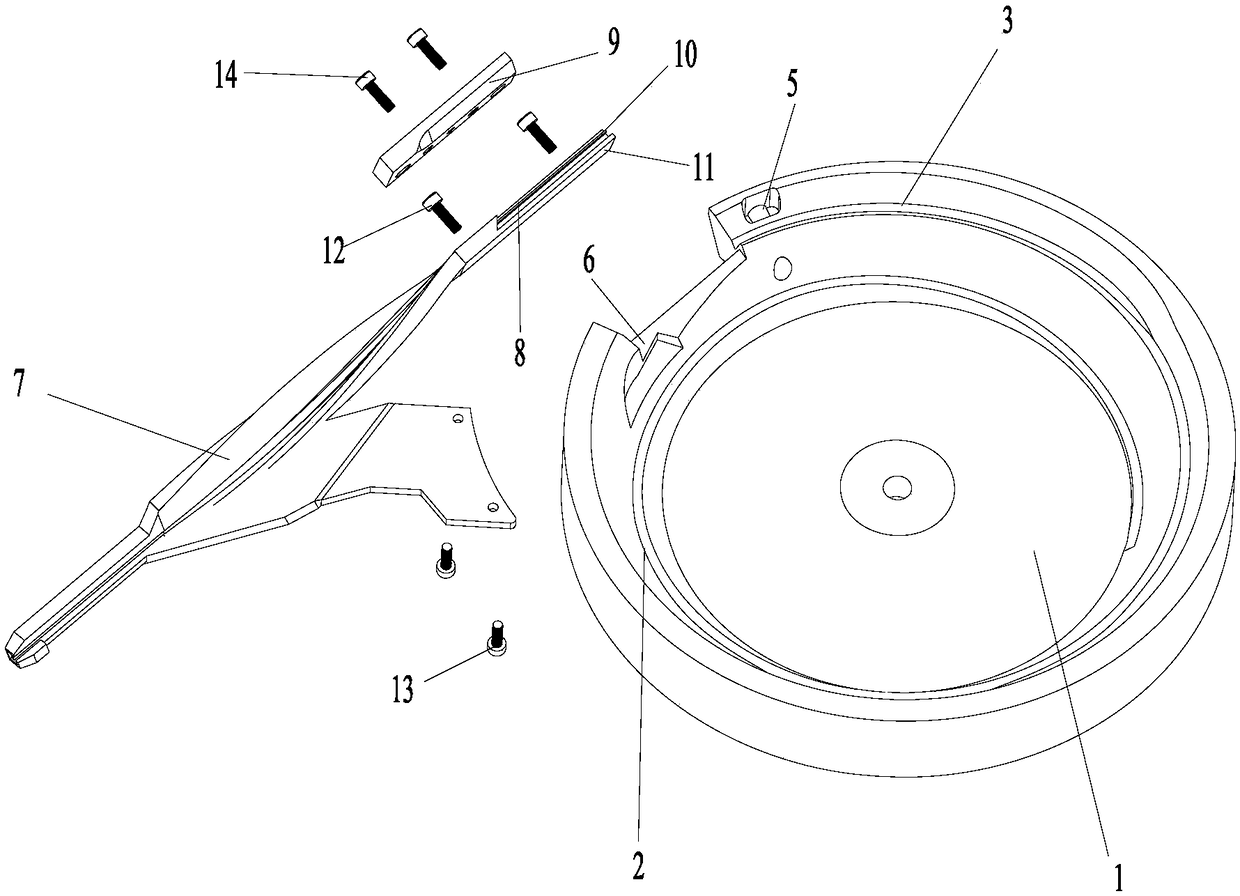

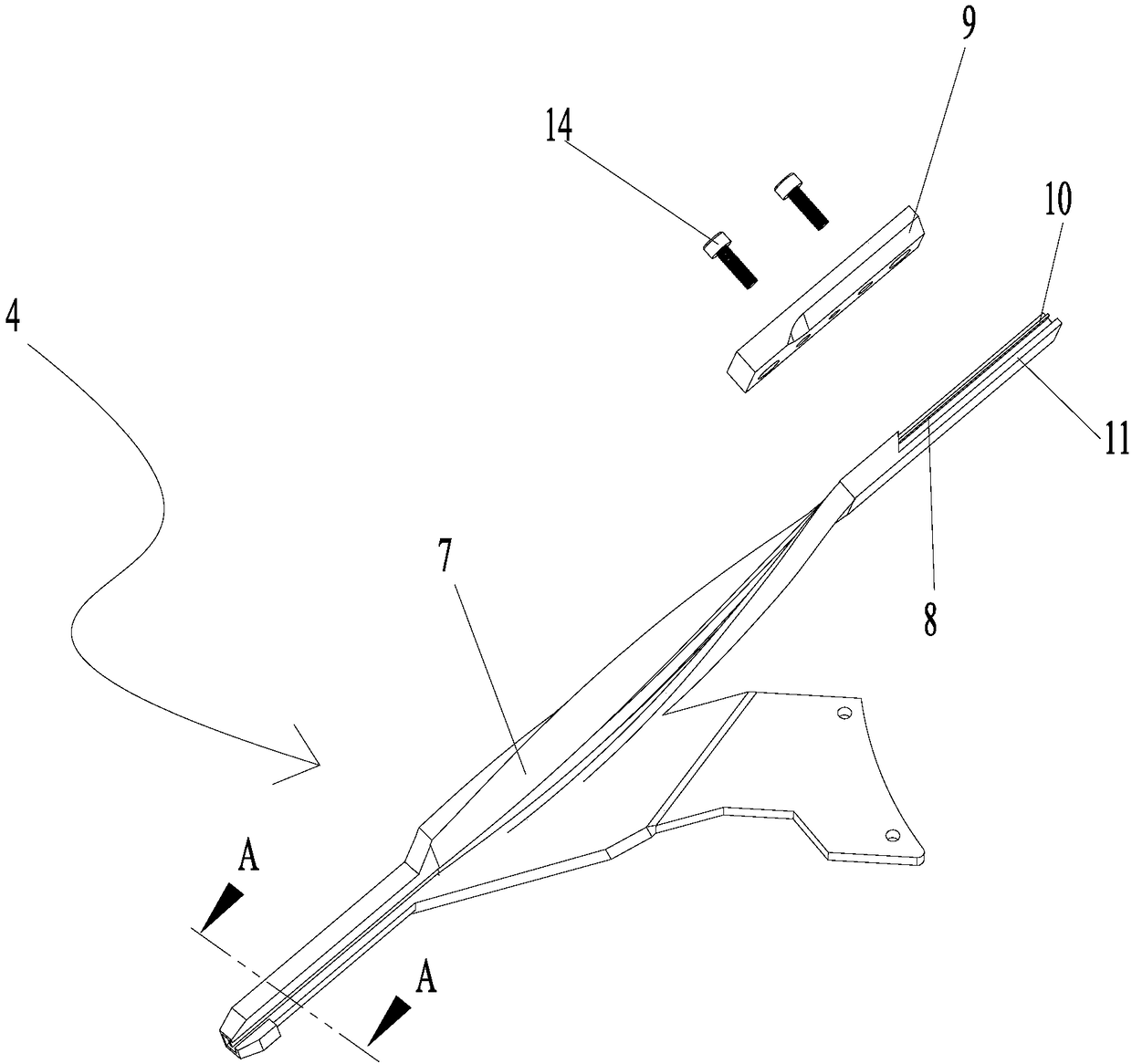

Vibration disc of beading machine

PendingCN108589349ATransmission structure optimizationSmooth deliveryTextile decorationEngineeringMechanical engineering

The invention discloses a vibration disc of a beading machine. Due to optimized design of a transmission structure, a sewing button is subjected to anticlockwise vibration with a main body of the vibration disc and is slowly transmitted to the top of the main body of the vibration disc from the bottom, a groove depth of a groove path at a rear segment is deeper than the groove depth of the groovepath at a front segment, the groove path at the rear segment of the sewing button is orderly inclined, a pawl of the sewing button easily falls on a track of a first-segment sewing button guide rail,adjusting and arrangement can be orderly carried out, ordered adjusting and arrangement of the sewing button can be accelerated at a certain degree, the sewing button can be introduced into a track ofa second-segment sewing button guide rail in a unification mode, the guide rail is buckled at a second segment, and the pawl direction of the sewing button is changed; under effect of the vibration and gravity, the movement of the sewing button is slowly and orderly forward, the conveying of the sewing button is smooth, the fault generation is reduced, and the sewing button conveying efficiency is increased.

Owner:林尧宇

Prefabricated slab performance detection device

PendingCN112718582ASmooth deliverySave human effortSortingStructural engineeringMechanical engineering

One or more embodiments of the invention provides / provide a prefabricated slab performance detection device provided with a detection platform, a moving assembly, a performance detection assembly and a conveying mechanism. Multiple transportation units are arranged on the detection platform, and a steering mechanism for controlling the rotation of the transportation unit is arranged at the bottom of each transportation unit. A detection part used for detecting whether a prefabricated slab is borne on the transportation unit or not is arranged on each transportation unit, when the steering mechanisms drive the transportation units to rotate, the prefabricated slab transportation direction of the transportation units can be changed, and therefore the prefabricated slab is smoothly transported into and out of the detection platform, and manpower consumed when the performance of the prefabricated slab is detected is reduced. The detection efficiency is improved. By means of a control module, the placement position of the prefabricated slab on the detection platform and the size of the prefabricated slab can be obtained according to the detection results of the detection parts, and therefore the starting point, the stopping point and the route of the performance detection assembly driven by the moving assembly can be adjusted, the noise in the detection process is reduced, and the detection accuracy is improved.

Owner:颍上晶宫绿建节能建筑有限责任公司

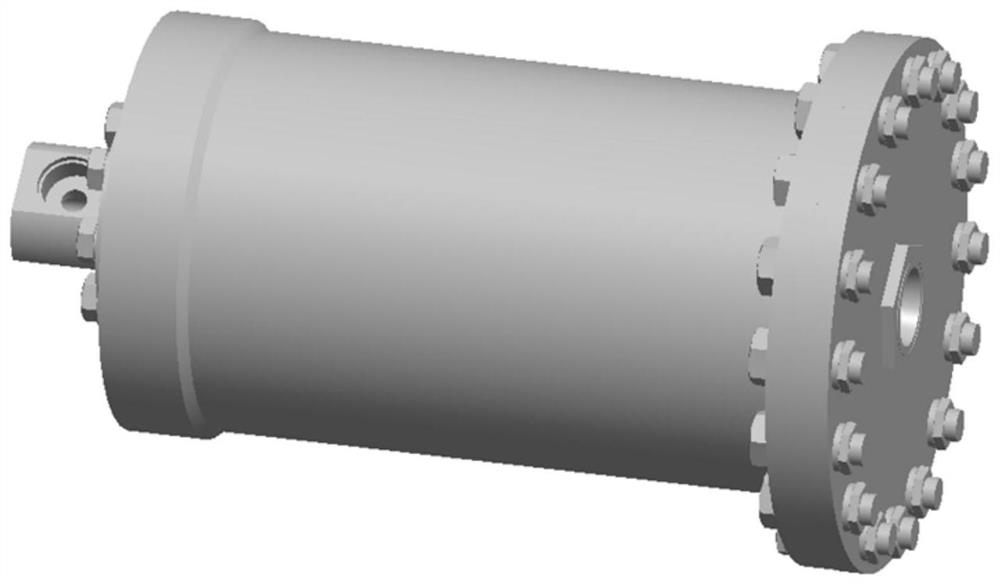

Catapulting engine

ActiveCN111852689AIncrease aspect ratioHigh synchronization of burning surface ignitionRocket engine plantsCombustion chamberRocket

The invention relates to a catapulting engine. The catapulting engine comprises a shell body, charging assemblies, a rear top cover, a spray pipe, an igniting device, a volution, a front bolt, a rearbolt, a from top cover sealing ring, a rear top cover sealing ring, and a spray pipe sealing ring. The catapulting engine has the advantages of large increased area ratio, simple structure, mature process, wide working temperature range, and good trajectory performance. Two rows of charging assemblies are evenly distributed in a combustion chamber shell body, and after ignition of the engine, fuelgas amount of the catapulting engine is gradually increased with time. A two-path ignition tube is installed at the head part, redundancy design is conducted, reliable ignition energy is provided, and spherical propellant is ignited. The volution is used to fix the spray pipe at the tail part, and the process is mature, simple and convenient. The catapulting engine can be applied to of missile orcarrier rocket emission in a wide temperature range, the initial overload is low, and the stability and reliability of missile or carrier rocket emission are improved.

Owner:XIAN MODERN CHEM RES INST

V-shaped groove cutting device

PendingCN112720640AImprove work efficiencySmooth deliveryPrinted circuit manufactureMetal working apparatusStructural engineeringBevel gear

The invention discloses a V-shaped groove cutting device which comprises a box body, a transmission mechanism, a cutting mechanism, a first driving mechanism and a second driving mechanism. The transmission mechanism, the cutting mechanism and the driving mechanisms are fixed to the inner side of the box body; the transmission mechanism comprises two rotating shafts arranged in parallel up and down; each rotating shaft is provided with bevel gears for transmission; second bevel gears are used to drive products to move along the length of the rotating shafts; cutting devices are arranged on the two sides of the upper lines of the rotating shafts respectively and used for cutting the products from the upper side and the lower side; the cutting devices are connected with the second driving mechanism; and a plurality of conveying rollers are arranged on the lower sides of the products and are perpendicular to the rotating shafts. According to the V-shaped groove cutting device provided by the invention, after a large circuit board is machined, a V-shaped cutting mode is adopted, one third of the thickness of the circuit board is cut on the upper surface and the lower surface of the circuit board respectively, so that the circuit board is ensured to be still a whole board; and after spare and accessory parts are well installed and the products are delivered to a product assembling enterprise, the small circuit board can be broken off and detached through slight manual force, so that the work efficiency is improved.

Owner:NANJING COLLEGE OF INFORMATION TECH

Felt bonding and cutting device and method for leather processing equipment

InactiveCN110920220AFacilitate better and smooth transportationSmooth deliveryLamination ancillary operationsLaminationAdhesiveStructural engineering

The invention relates to the field of leather processing. A felt bonding and cutting device for leather processing equipment comprises a drum wheel and felt conveying assembly, a dispensing assembly,a glue leakage preventing assembly, a felt pressing assembly and a felt edge removing assembly. The drum wheel and felt conveying assembly is arranged at the feeding end of a rack. The dispensing assembly is located above the drum wheel and felt conveying assembly, and the glue leakage preventing assembly is arranged below the dispensing assembly. The feeding end of the felt pressing assembly is connected with the discharging end of the drum wheel and felt conveying assembly. The feeding end of the felt edge removing assembly is connected with the discharging end of the felt pressing assembly.The felt bonding and cutting device has the advantages that full-automatic adhesion of leather and felt is achieved, the material conveying efficiency is improved, the adhesive dispensing efficiencyis improved, adhesive dispensing missing is prevented, and the adhesion efficiency is improved.

Owner:王泽凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com