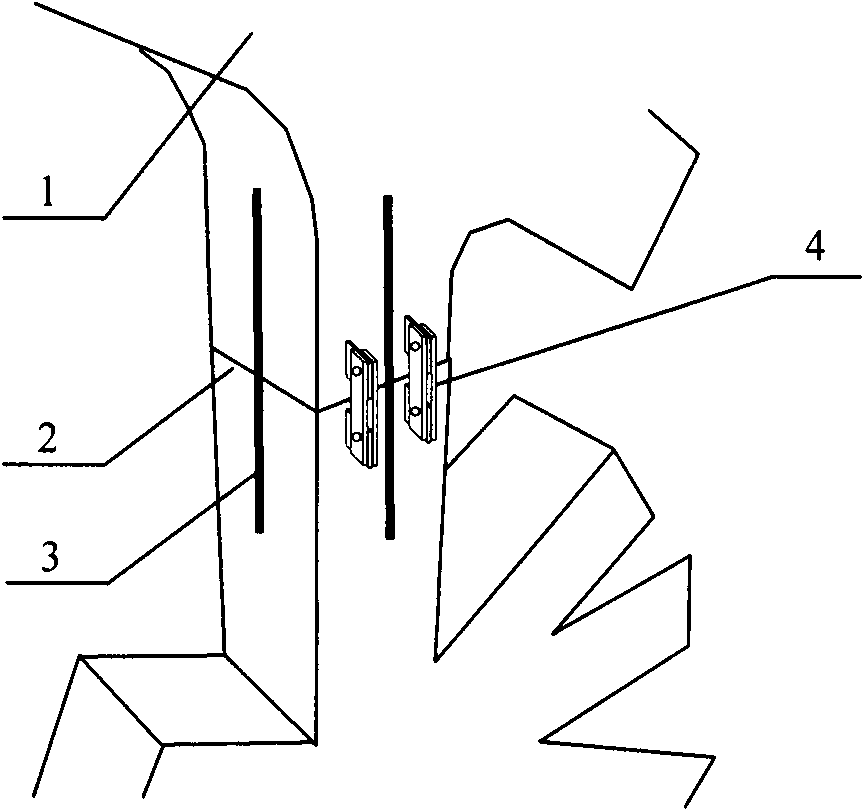

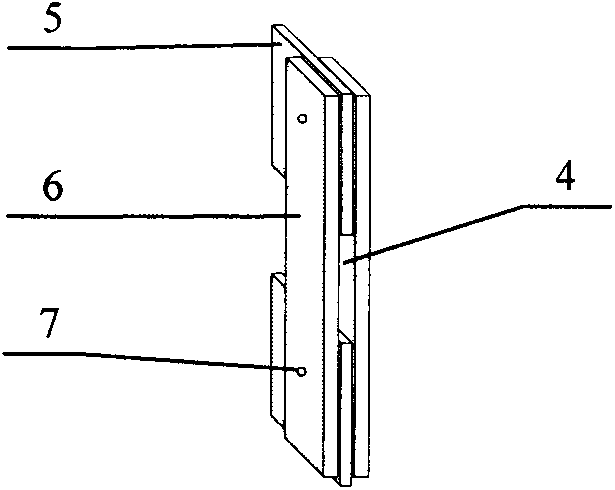

Improved construction method for hoisting and welding large-tonnage cast steel component complex joints

A construction method and technology of cast steel joints, which are applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of rare disclosure of improved technology, and achieve the effects of good integrity, reduced workload, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Example: Using a network control center as a carrier, solve the welding problem of dissimilar materials by drawing up welding process instructions, preparation of test pieces, welding, weld inspection, sampling processing, inspection of patterns, and preparation of welding process evaluation reports. Finally, based on the welding procedure evaluation report, combined with welding construction experience and actual welding conditions, the welding procedure specification or welding operation instruction book and welding procedure card are compiled to guide the welding of cast steel and section steel dissimilar materials. The best welding specification parameters and process of steel castings and profile steel dissimilar materials are obtained through comparative tests of heat and non-preheating, restraint and unrestraint, etc., and the common defects of casting steel and profile steel dissimilar materials are solved through experiments Prevention and Elimination.

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com