V-shaped groove cutting device

A cutting device and cutting mechanism technology, used in metal processing, electrical components, printed circuit manufacturing, etc., can solve the problems of inability to separate small circuit boards, troublesome installation of spare parts, and reduce production efficiency, and achieve stable transportation and improved production efficiency. Work efficiency, stable cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

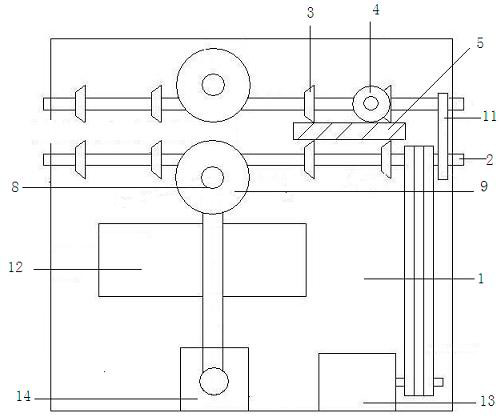

[0020] The implementation of the technical solution will be further described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

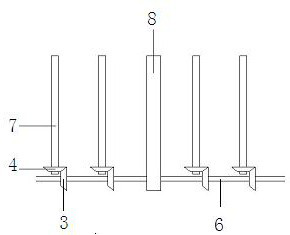

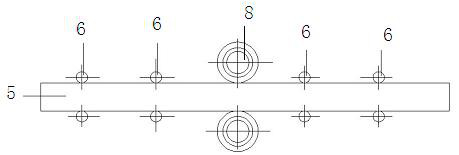

[0021] Such as Figure 1~4 One embodiment shown is a V-shaped groove cutting device, comprising: a box body 1, a transmission mechanism, a cutting mechanism, a first driving mechanism 13 and a second driving mechanism 14, the transmission mechanism, the cutting mechanism and the driving mechanism They are respectively fixed inside the box body 1. The transmission mechanism includes two rotating shafts 2 arranged in parallel up and down. The rotating shafts 2 are connected with the first driving mechanism 13, and a plurality of first cones are evenly arranged coaxially on each of the rotating shafts 2. gear 3, and each first bevel gear 3 meshes with the second be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com