Battery anode material pretreatment device

A positive electrode material and battery positive electrode technology, applied in the field of battery positive electrode material pretreatment equipment, can solve the problems of poor adhesion of positive electrode slurry, easy to fall off, etc., and achieve the effects of easy deformation and transmission, smooth transmission, flexible control and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings.

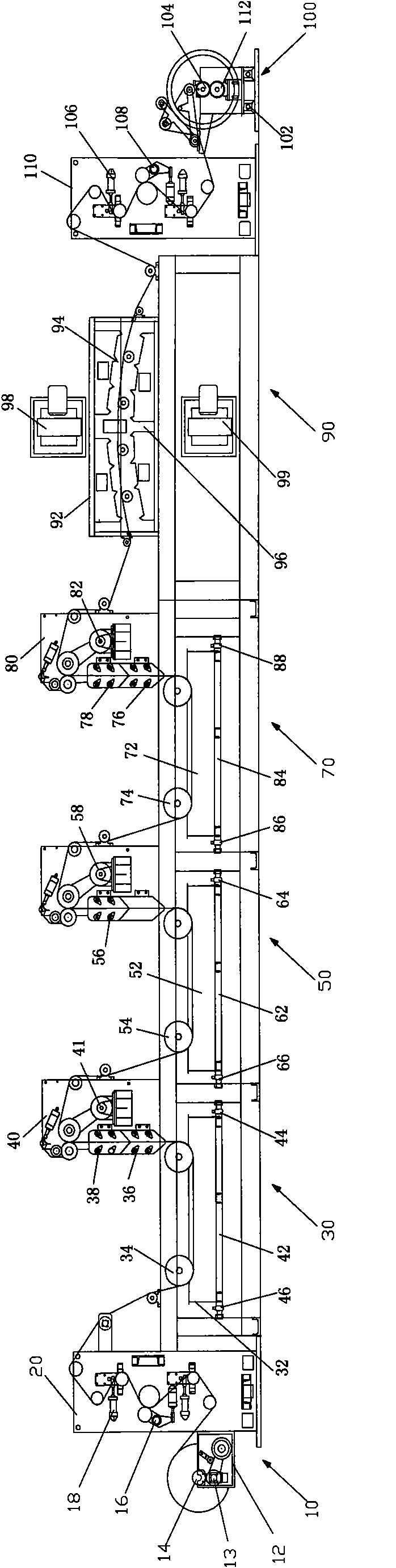

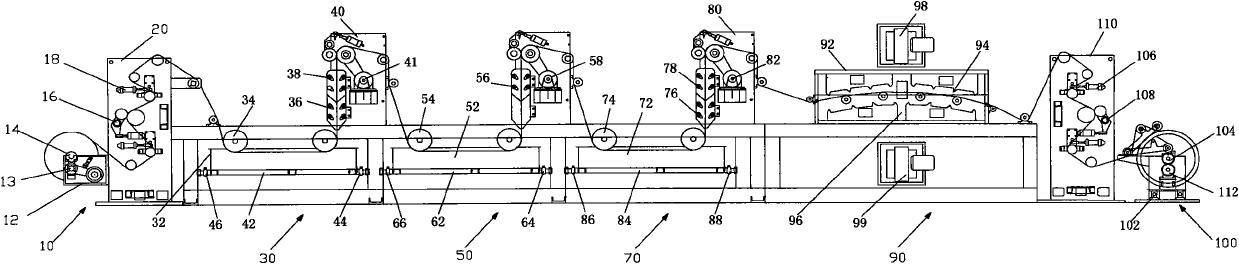

[0014] Please refer to figure 1 , the present invention relates to a battery cathode material pretreatment equipment, the pretreatment equipment is mainly aimed at the treatment of the cathode base material, using ultrasonic heating device heating, alkali erosion spraying method, so that the surface of the battery cathode base material is corroded, pits appear, Then rinse with pure water to remove the lye on the surface of the base material, then immerse and spray with pure water to thoroughly rinse the lye on the surface of the base material, and finally air-dry with a hot air drying device before winding. In this way, the surface of the positive electrode base material is treated to make the surface lose its smoothness and smoothness, so as to facilitate the adhesion of the positive electrode slurry, better avoid falling off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com