Prefabricated slab performance detection device

A detection device and prefabricated board technology, applied in sorting and other directions, can solve problems such as low efficiency, affecting accuracy, and high error, and achieve the effects of improving detection efficiency, improving accuracy, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

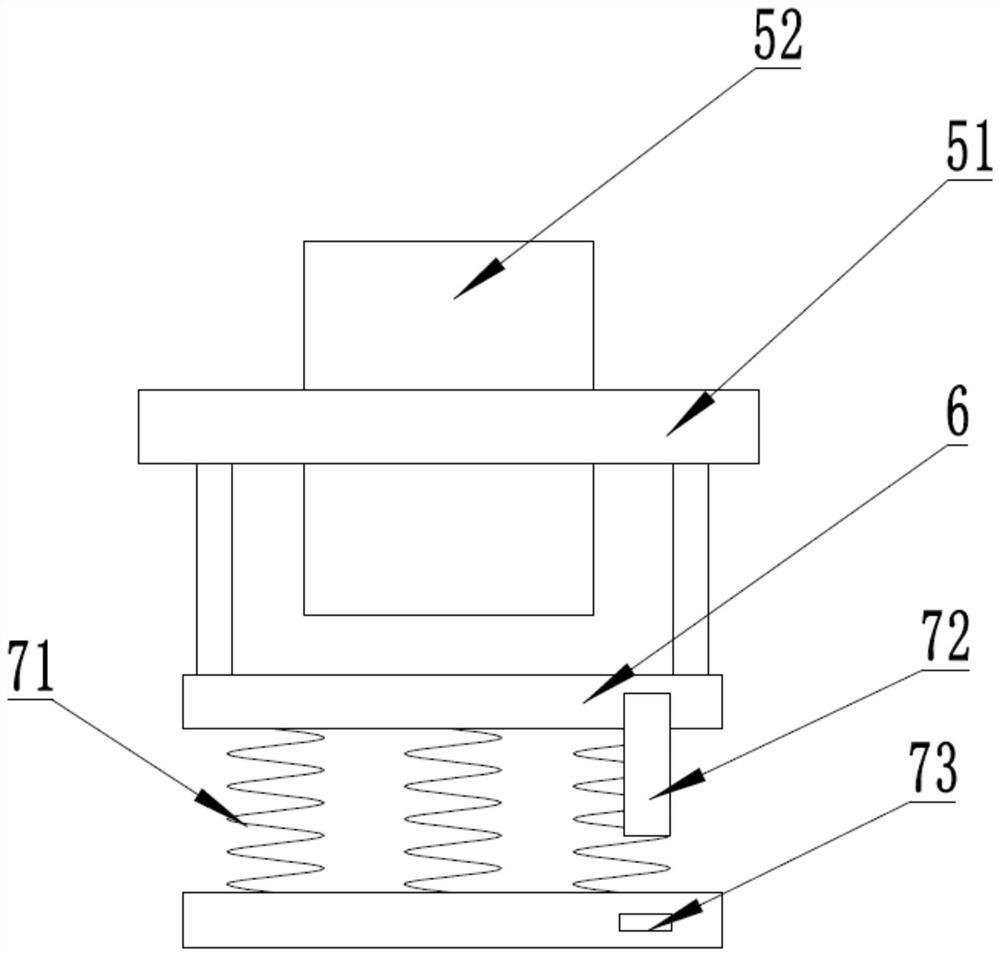

[0038] As an embodiment, the detection part includes an elastic part 71, a trigger part 72 and a detection part 73. The elastic part 71 is connected to the bottom of the steering mechanism 6, and the trigger part 72 is installed on the steering mechanism 6. When the prefabricated board is carried on the transport unit 5, The steering mechanism 6 descends against the elastic force of the elastic member 71 , so that the trigger member 72 contacts the detection member 73 , and the detection unit detects that the prefabricated panel is carried on the transport unit 5 .

[0039] For example, the detection part 73 is a fixed contact arranged under the steering mechanism 6, and the trigger part 72 is a movable contact arranged on the steering mechanism 6. When the steering mechanism 6 descends, the movable contact contacts the fixed contact, and the contact pass detection circuit.

[0040] As an implementation manner, the performance detection component 3 may be an ultrasonic detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com