Catapulting engine

A technology of engines and shells, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as damage to platform equipment, unfavorable platform devices, and launch failures, and achieve high ignition synchronization, mature assembly technology, and launch The effect of small overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

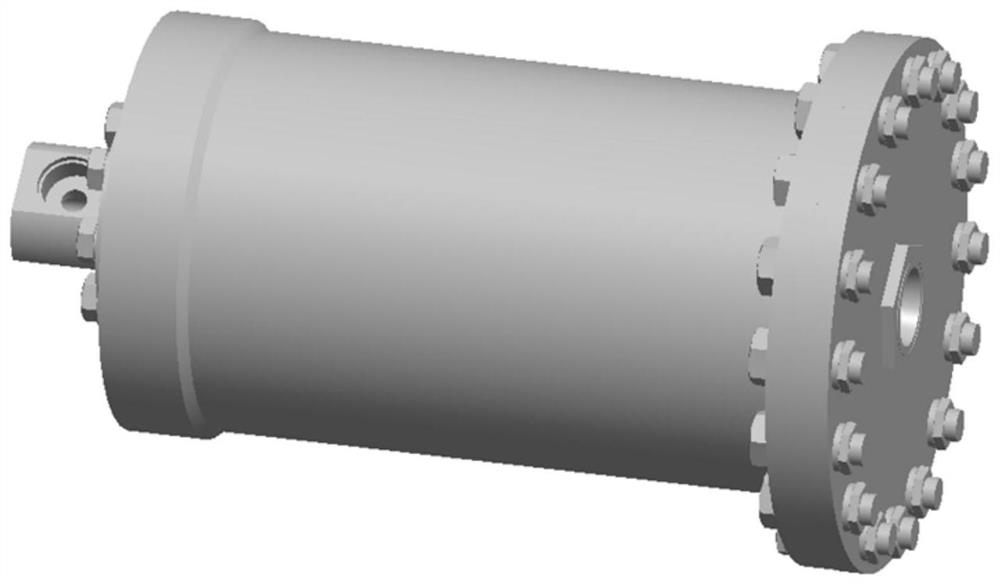

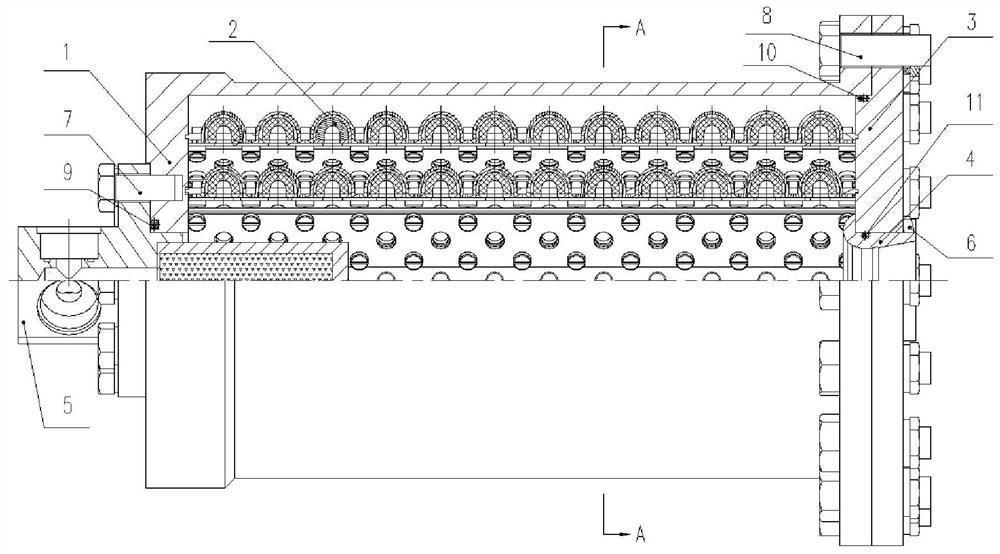

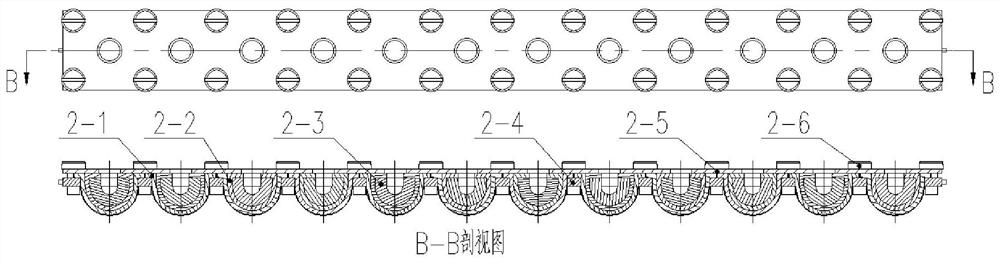

[0016] The catapult engine provided by the present invention comprises a housing, a charge assembly, a rear top cover, a nozzle, an ignition device, a spiral ring, a front bolt, a rear bolt, a front top cover sealing ring, a rear top cover sealing ring, and a nozzle sealing ring . The catapult engine adopts two rows of concentrically arranged spherical charge assemblies to be fixed inside the engine casing, and each row of charge assemblies 2 is arranged in a ring; an ignition device is installed on the head of the casing, and the end face of the O-ring is used for sealing. The rear top cover is connected to the tail of the engine casing, and O-ring seals are used for radial sealing. And the spray pipe is installed in the rear top cover, fixed with a spiral ring, and radially sealed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com