Ramulus mori shoot harvester

A technology of cutting machine and mulberry branch, applied in the field of cutting machine for mulberry branches, can solve the problems of unoptimized longitudinal feeding smoothness of mulberry branches, small working range, low working efficiency, etc. Wide range and fast cutting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

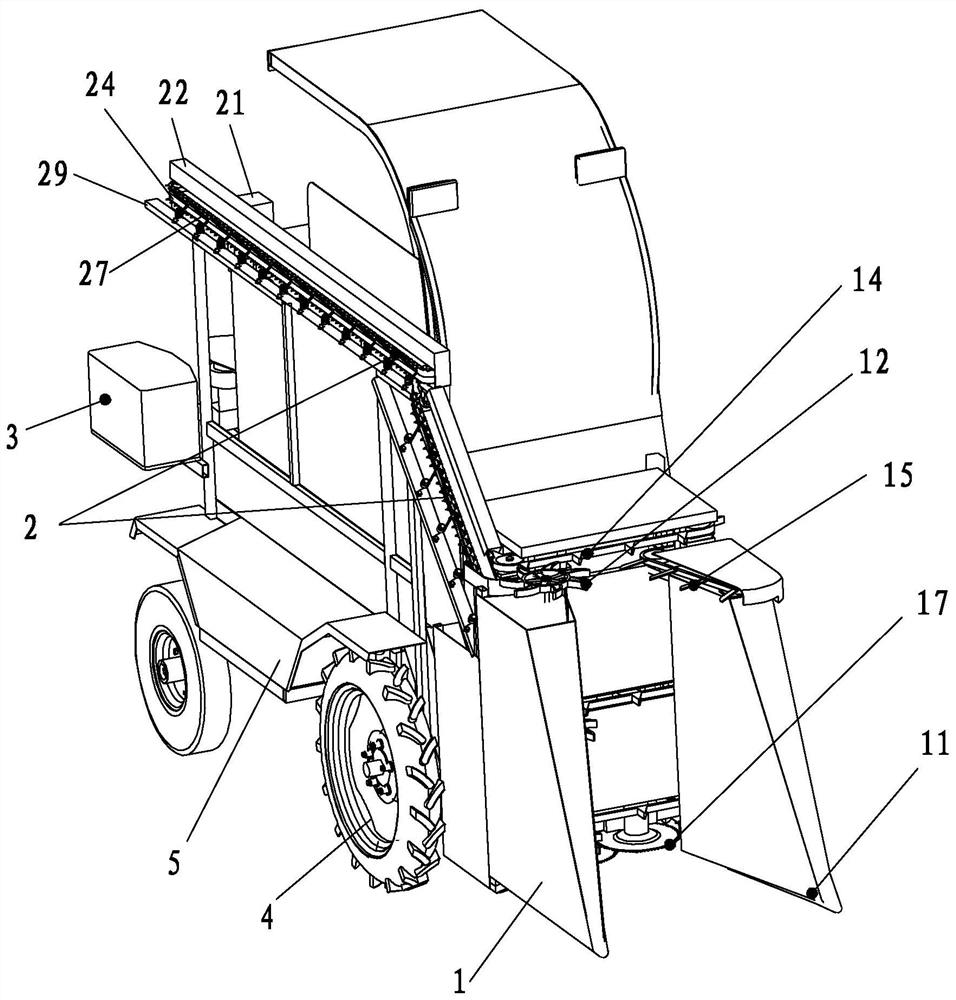

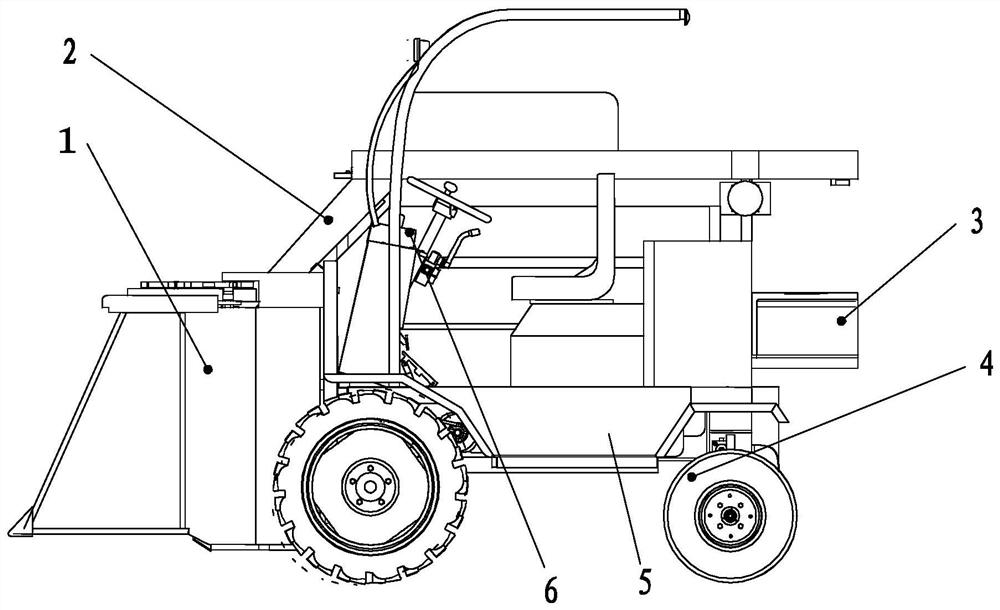

[0040] Embodiment 1: a kind of mulberry branch cutting machine, such as Figure 1-Figure 3 As shown, it includes a cutting and gathering device 1, a conveying device 2, a collection mechanism 3, a running mechanism 4, a vehicle body 5 and a manipulation mechanism 6. The vehicle body is installed on the traveling mechanism, and the operating mechanism is used to control the running of the traveling mechanism and start and stop of the cutting and gathering device and the conveying device.

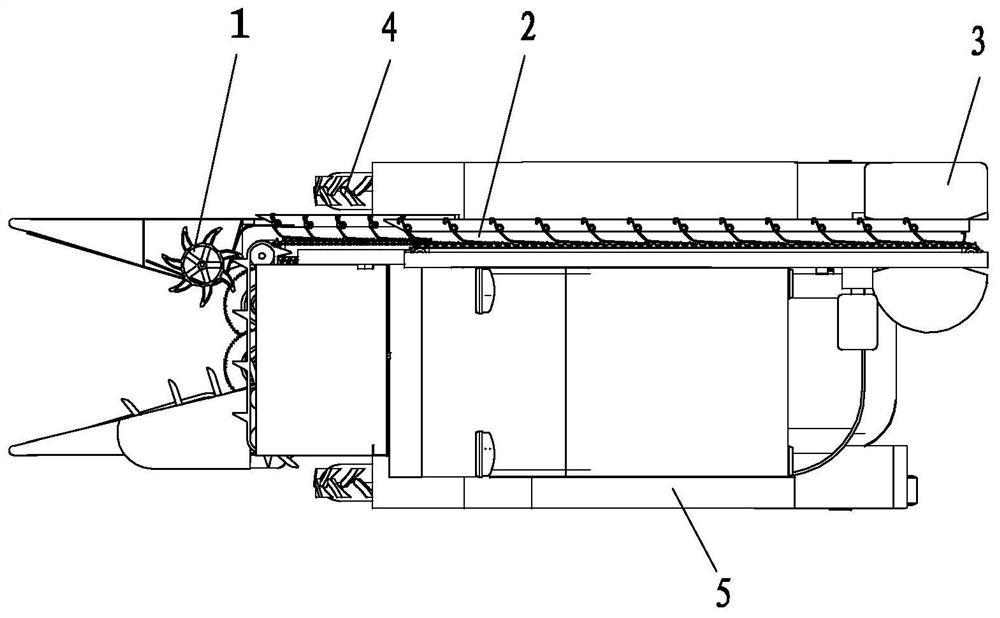

[0041] The cutting and gathering device 1 (such as Figure 4-Figure 6 Shown) comprises cutting device, conveying and gathering device, frame 113 and the front baffle plate 16 that is installed on the frame. The frame is mounted on the front end of the vehicle body.

[0042] The conveying and gathering device comprises a conveying motor 19, a power transmission shaft 110, a longitudinal conveying chain 15, a transverse conveying assembly and two front-end gathering feed baffles 11 installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com