Patents

Literature

99results about How to "Precise adsorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

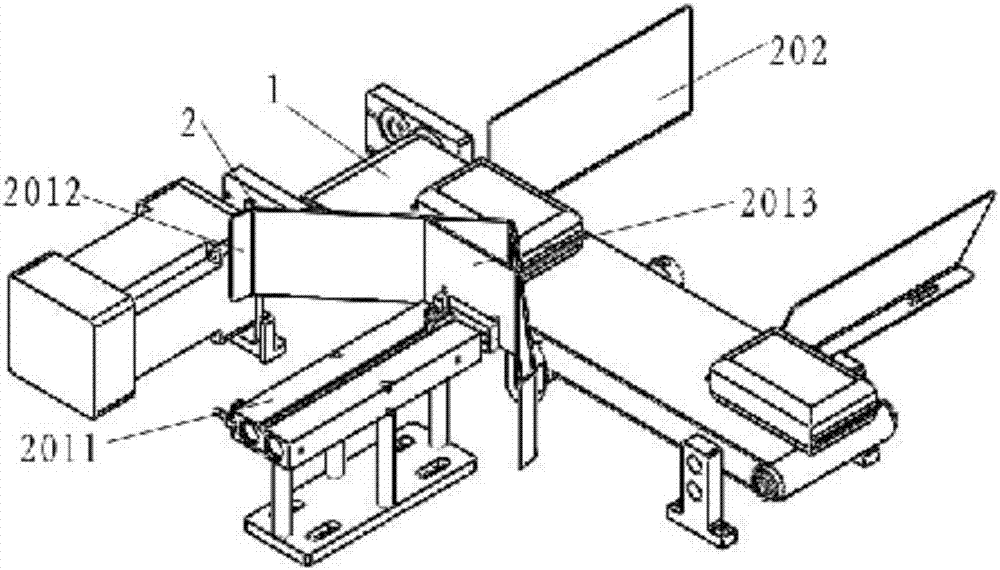

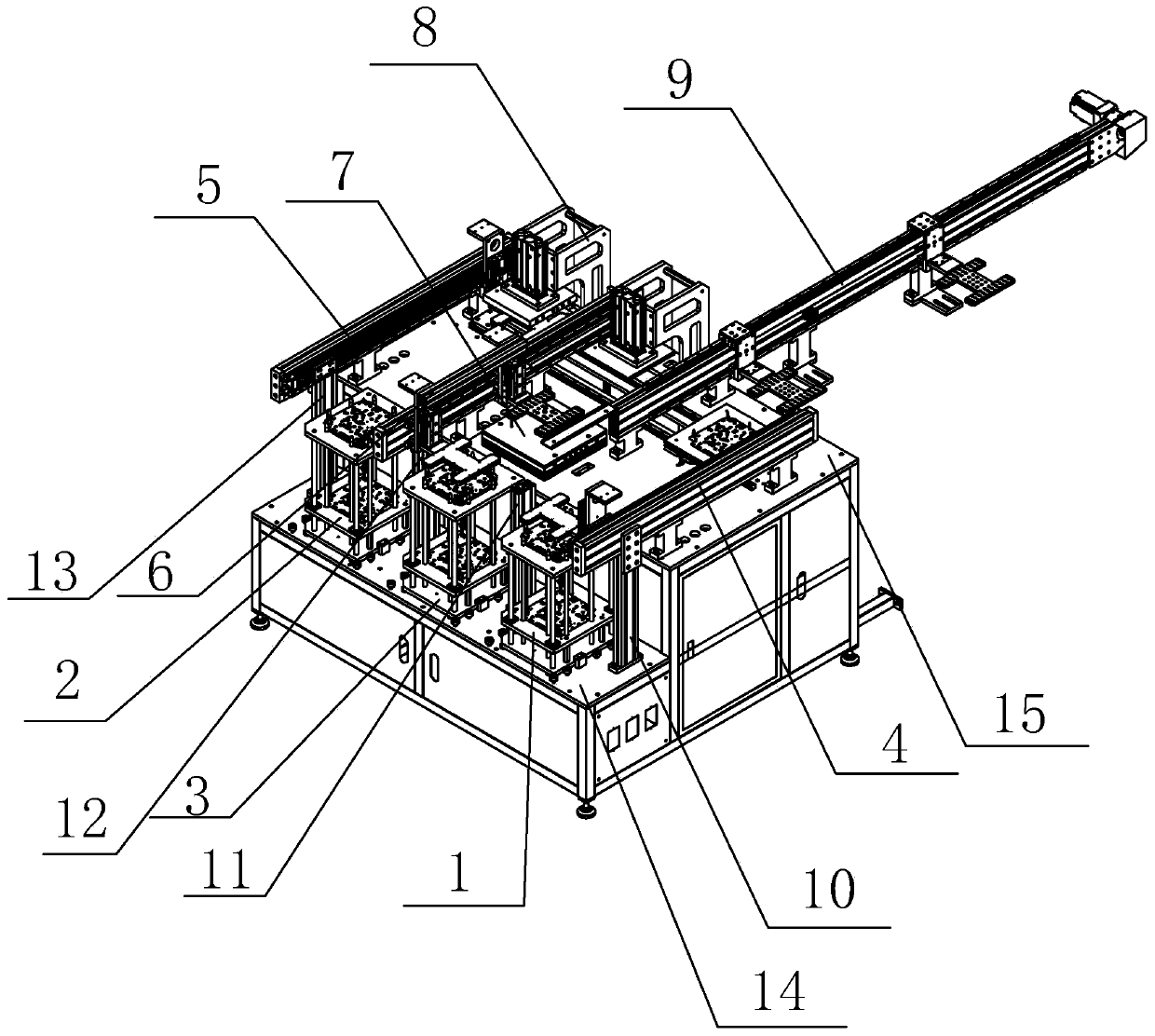

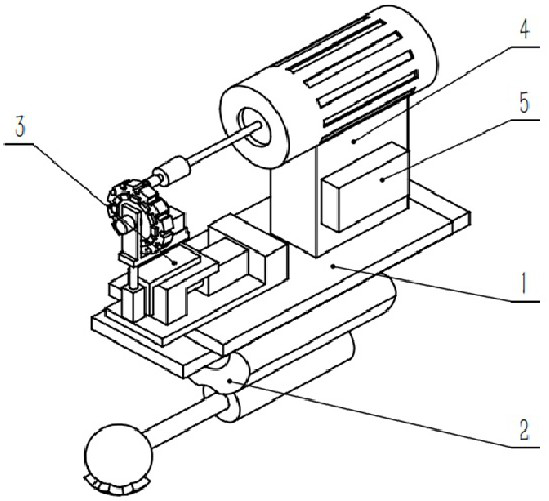

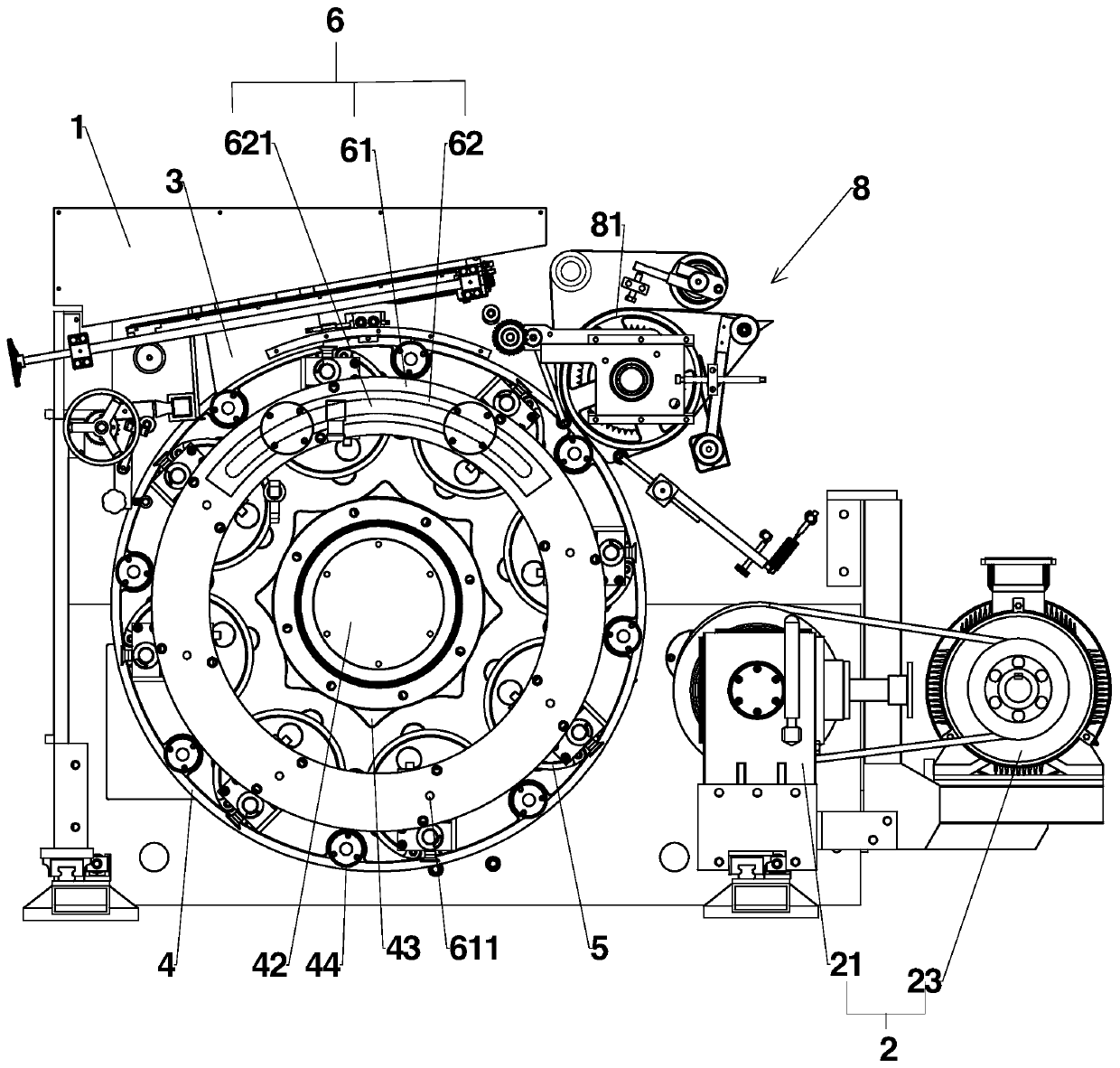

Intelligent adjustable bread packaging equipment

ActiveCN107244446ARealize intelligenceRealize regulationPackaging machinesPackaging bakeryOutput deviceEngineering

The invention discloses intelligent adjustable bread packaging equipment which comprises a conveying device used for conveying bread to be packaged. The conveying device is provided with a horizontally-arranged chain plate conveying belt. The feeding end of the chain plate conveying belt is provided with a fault recycling device. The discharging end of the chain plate conveying belt is provided with a separation groove. One side of the separation groove is provided with a pushing device which pushes bread in the separation groove to a packaging device opened by a bagging device. A packaging bag used for the bagging device is output by an adjustable packaging bag output device and transferred by a taking device. The fault conditions can be intelligently avoided, intelligent seamless connection of the packaging process is achieved, labor is reduced, the production efficiency is greatly improved, the cost is saved, adjustment can be achieved according to different sizes of packaging bags, accordingly, different specifications of products can be packaged, the applicability is high, the structure is simple, and adjustment is convenient.

Owner:福建达峰智能科技股份有限公司

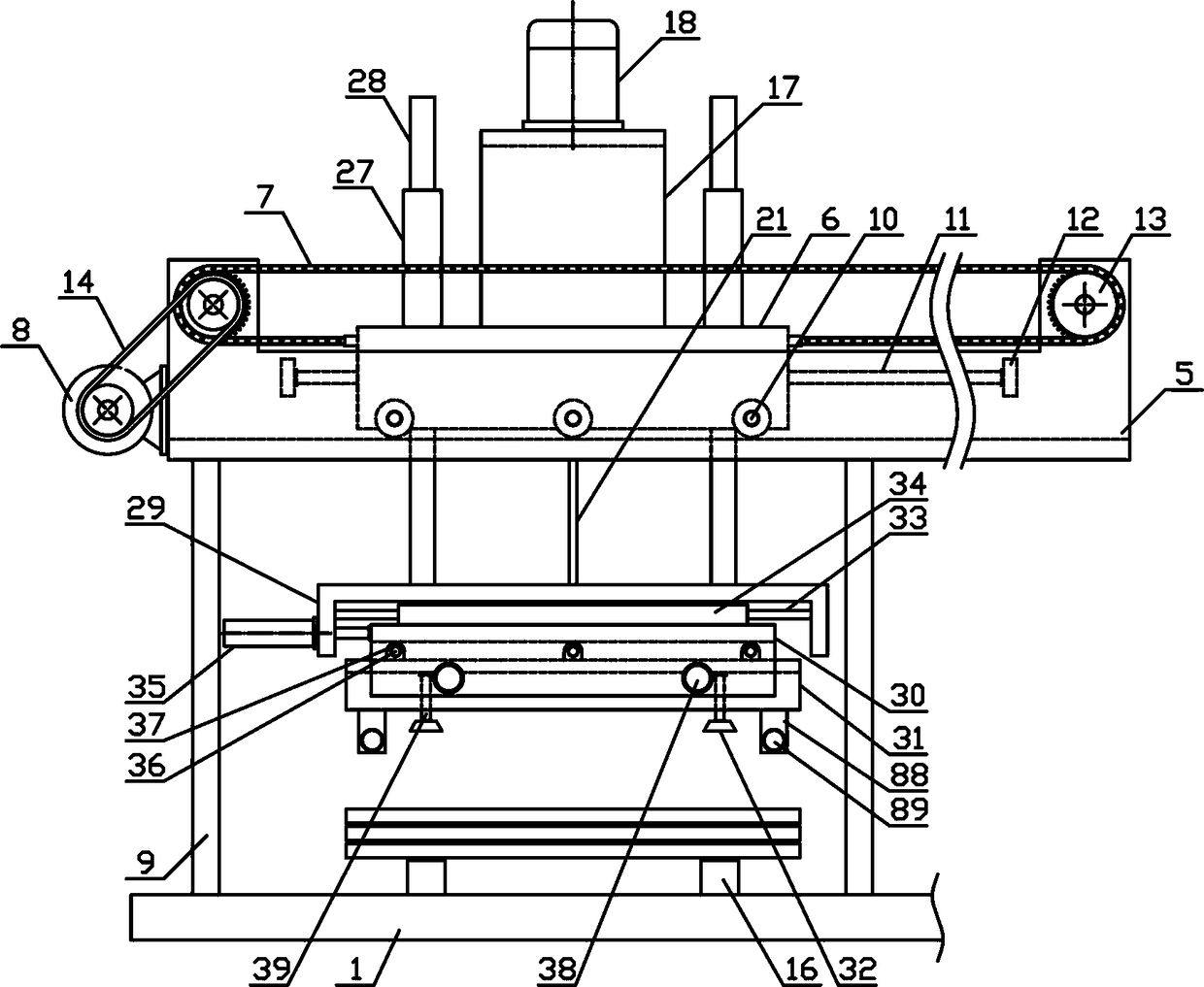

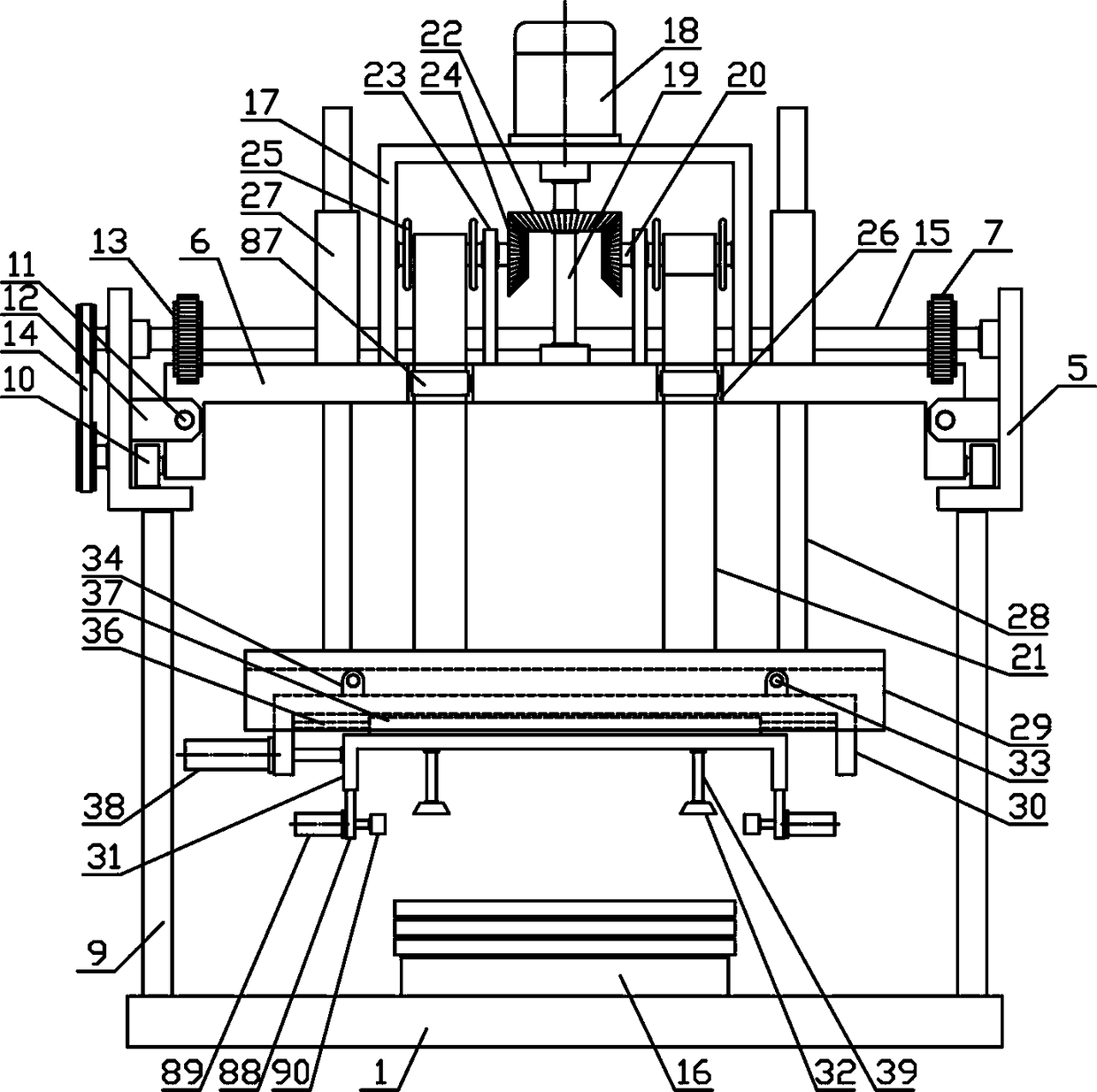

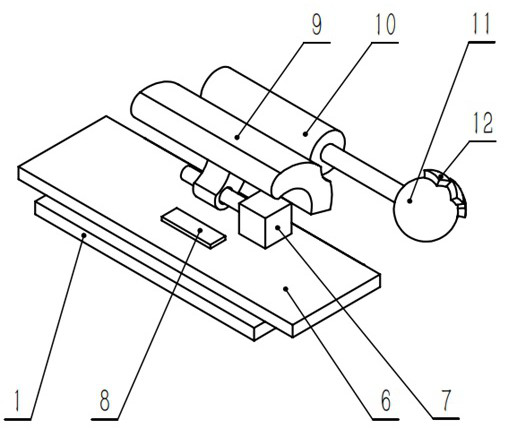

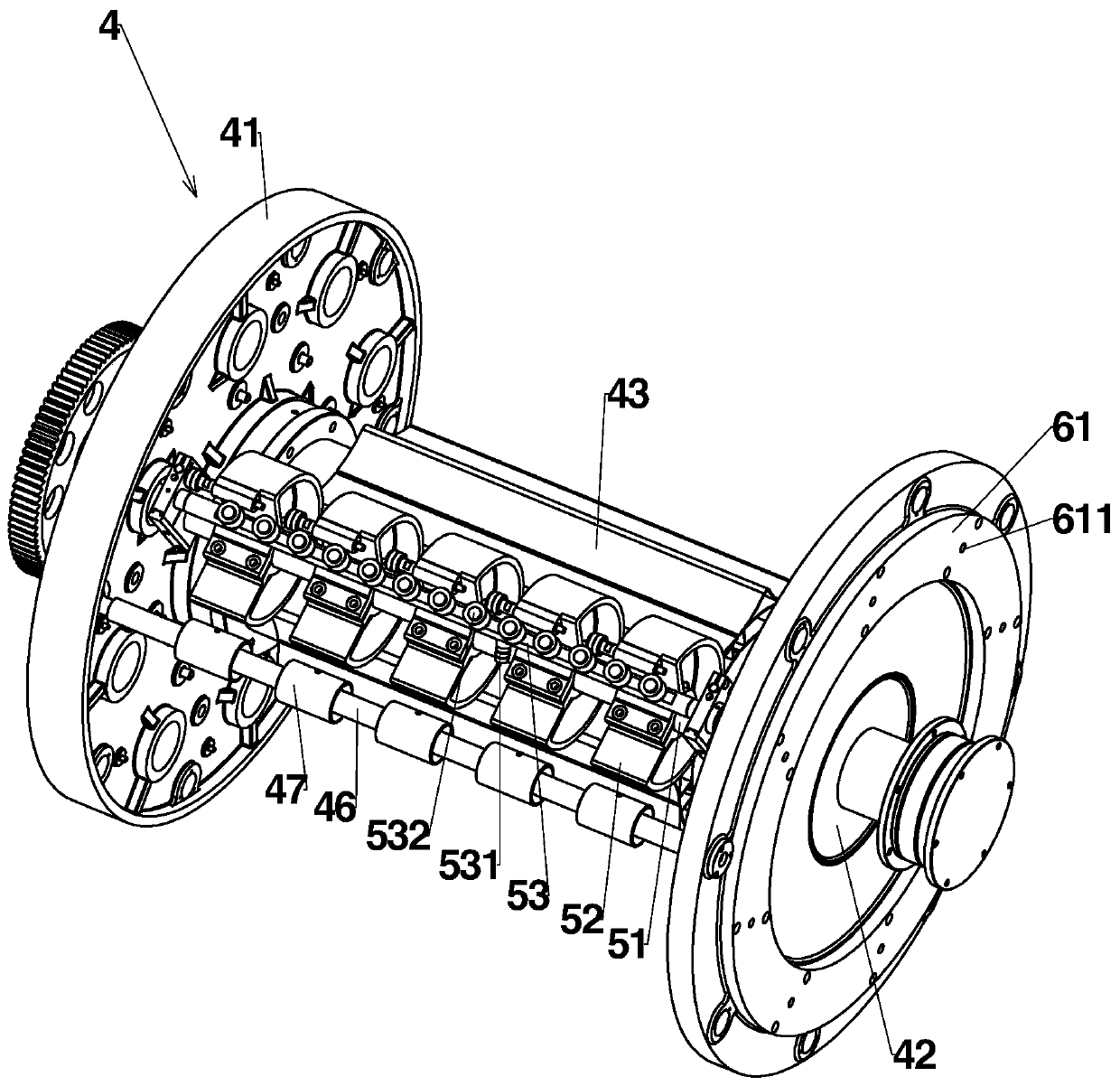

Plate veneering processing device

ActiveCN109015955AReasonable structural designSmooth and accurate adsorption and fixationPlywood pressesVeneer pressesMechanical equipmentHot press

The invention discloses a plate veneering processing device, and belongs to the field of plate processing mechanical equipment. A feeding mechanism, a skin covering mechanism and a surface pressing mechanism are horizontally and fixedly arranged on the upper side of a fixing base in sequence in the horizontal direction. A lifting mechanism is vertically arranged in the middle of the upper side ofa horizontal-moving guide plate, and a plate adsorbing mechanism is horizontally arranged on the lower side of the lifting mechanism. A plurality of plate bearing rotating rollers are horizontally androtationally connected to a plate bearing support sequentially in the horizontal direction. A skin pulling mechanism is horizontally arranged on the positions, on one sides of the multiple plate bearing rotating rollers, on the plate bearing support, and a surface pressing support is vertically arranged on the position, on one side of the skin covering mechanism, on the fixing base. A plate bearing platform is horizontally and fixedly arranged in the middle of the surface pressing support, and a hot pressing support is horizontally located on the upper side of the plate bearing platform. Theplate veneering processing device is reasonable in structural design, plates can be horizontally moved and fed accurately block by block, the plates can be automatically subjected to skin covering processing, efficient and stable veneering processing for the plates is achieved, and thus needs for processing and using are met.

Owner:ZHEJIANG MINGTAO IND

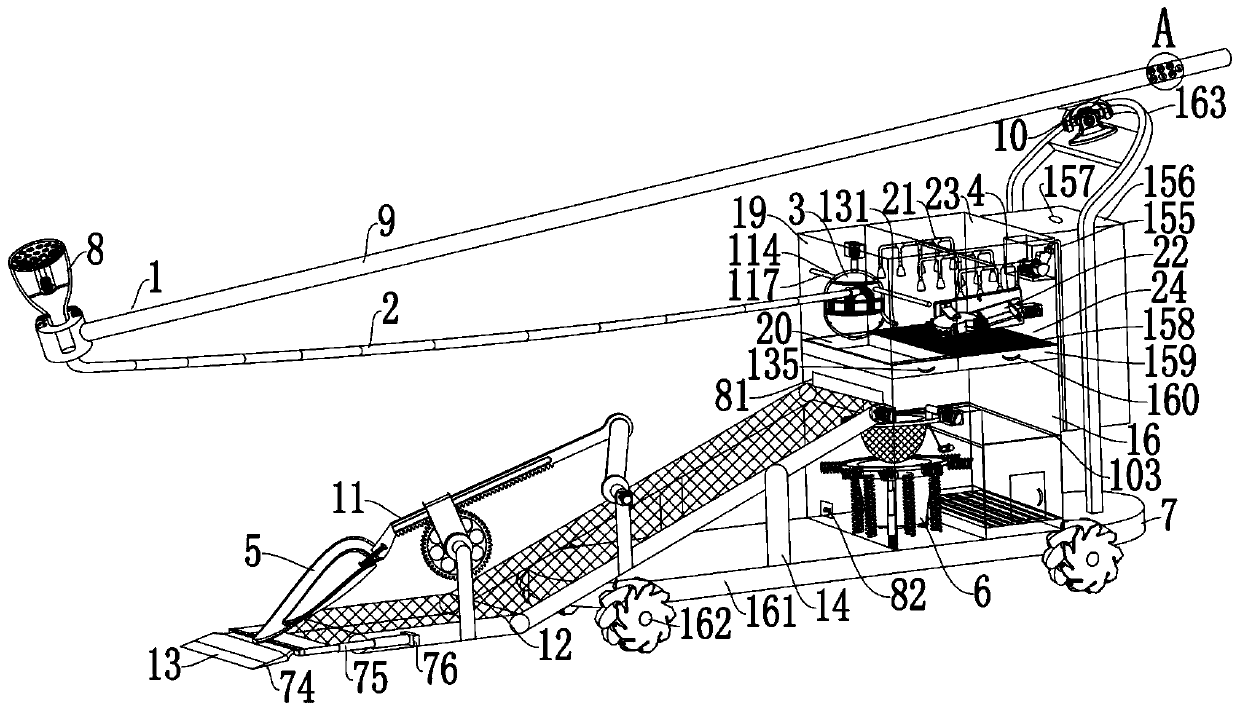

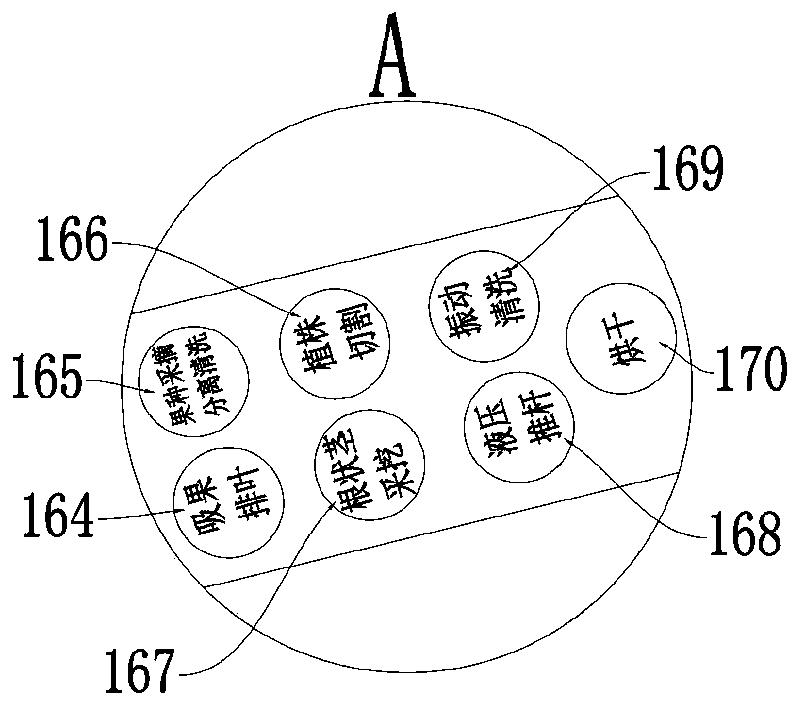

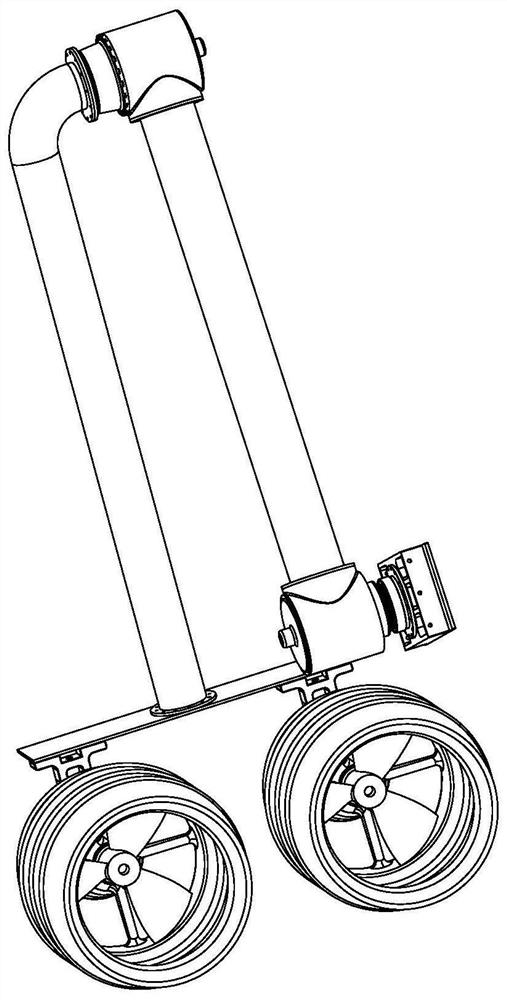

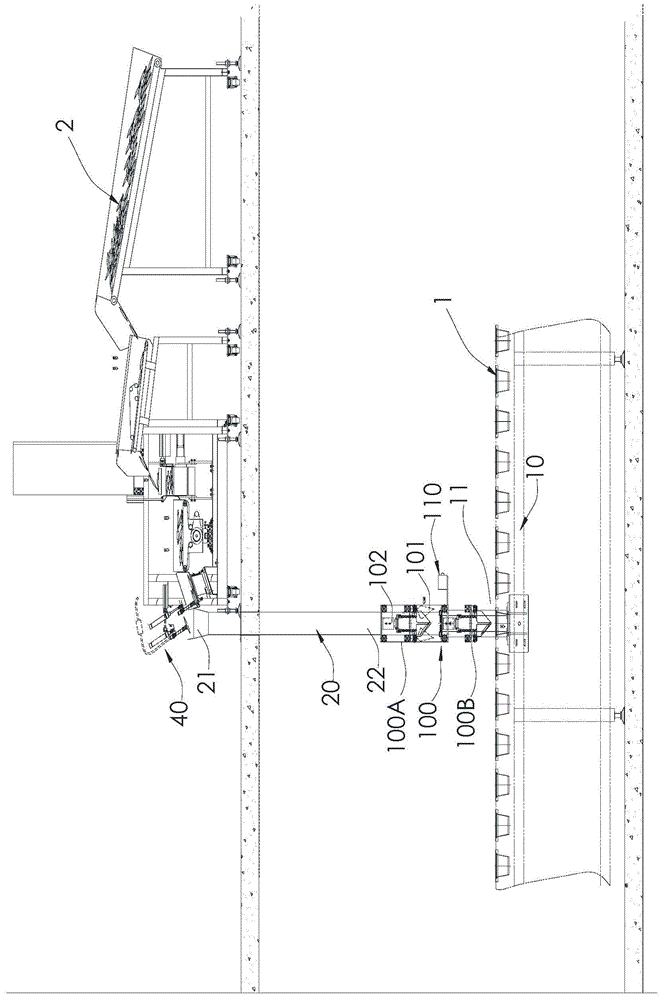

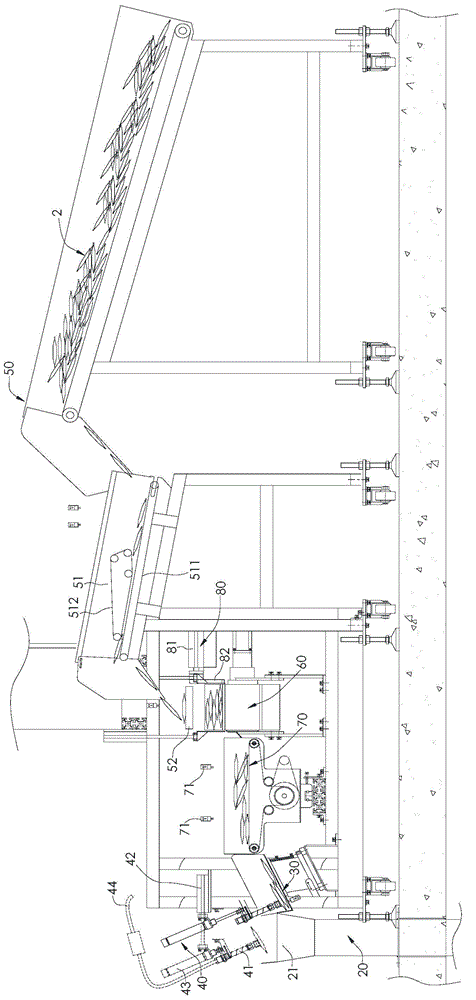

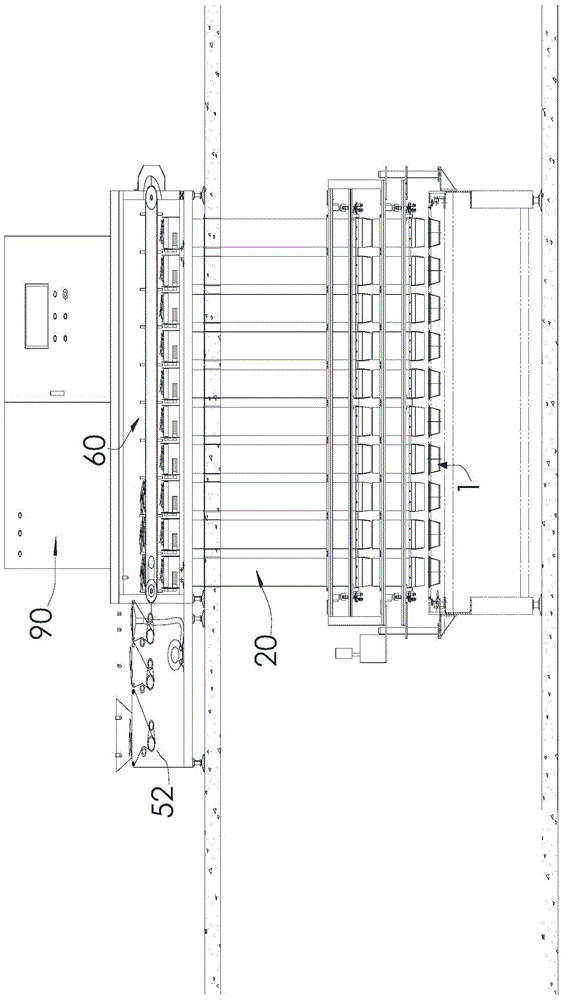

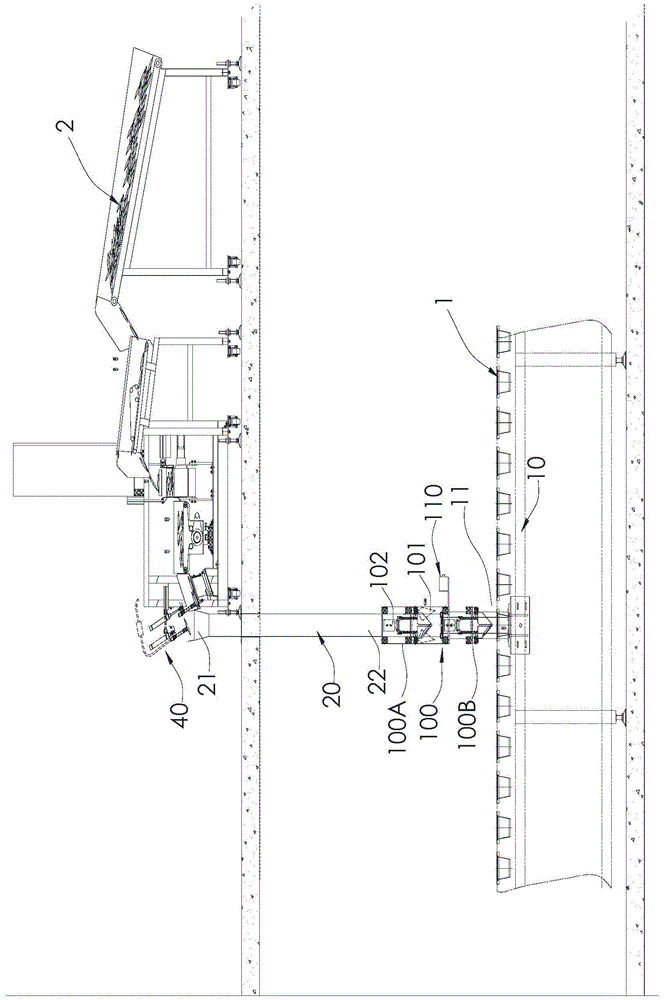

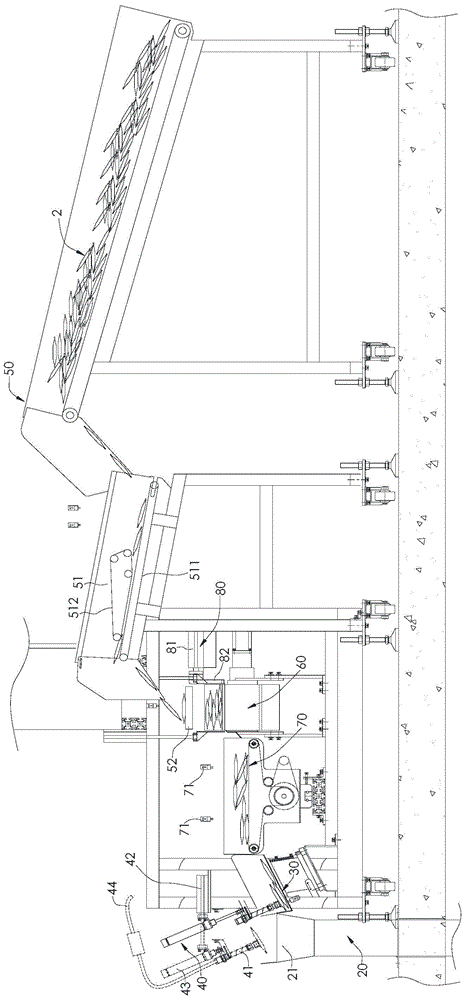

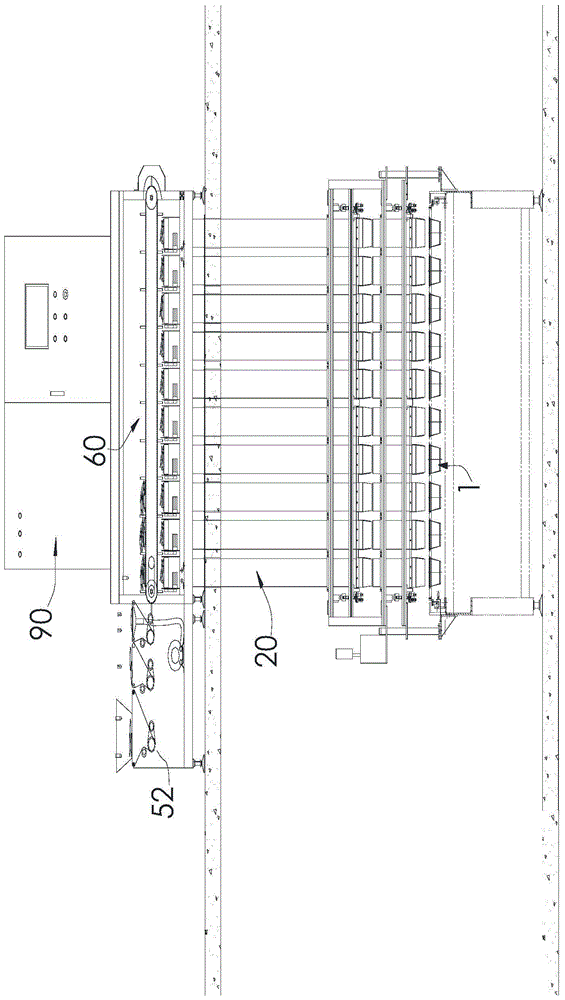

Preset-type fruit harvesting, root digging and reverse weight compensation rapid-washing vehicle for hidden dysosma versipellis

ActiveCN110278771APrecise adsorptionAchieve lossless pickingLiftersTopping machinesDysosma versipellisEngineering

The invention discloses a preset-type fruit harvesting, root digging and reverse weight compensation rapid-washing vehicle for hidden dysosma versipellis, and belongs to the technical field of picking machines for dysosma versipellis. The vehicle comprises a hidden preset-type precise positioning and rotary harvesting mechanism, a 360-degree fruit seed friction flexible lossless separation mechanism, a full-coverage-type reciprocating rotation brushing mechanism, a human-hand-simulation self-restoration shaking-type lossless harvesting and digging conveying mechanism, an all-directional reverse weight compensation-type rhizome rapid-washing and drying mechanism and a portable moving device. Particularly, the preset fruit harvesting, root digging and reverse weight compensation rapid-washing vehicle for hidden dysosma versipellis has the advantages that with the principle of local features, the vehicle achieves preset-type selective precise lossless harvesting of fruits of dwarf-type dysosma versipellis under leaves, the fruits are subjected to 360-degree all-directional friction to flexibly separate out pulp, entire and lossless rhizomes are precisely dug with machines by imitating shapes of artificial digging shovels, the reverse effect and weight compensation principle are combined, and the surfaces and grooves of the rhizomes are subjected to all-directional multiplex vibration-type rapid cleaning and drying.

Owner:XUZHOU YUNCHUANG PROPERTY SERVICE CO LTD

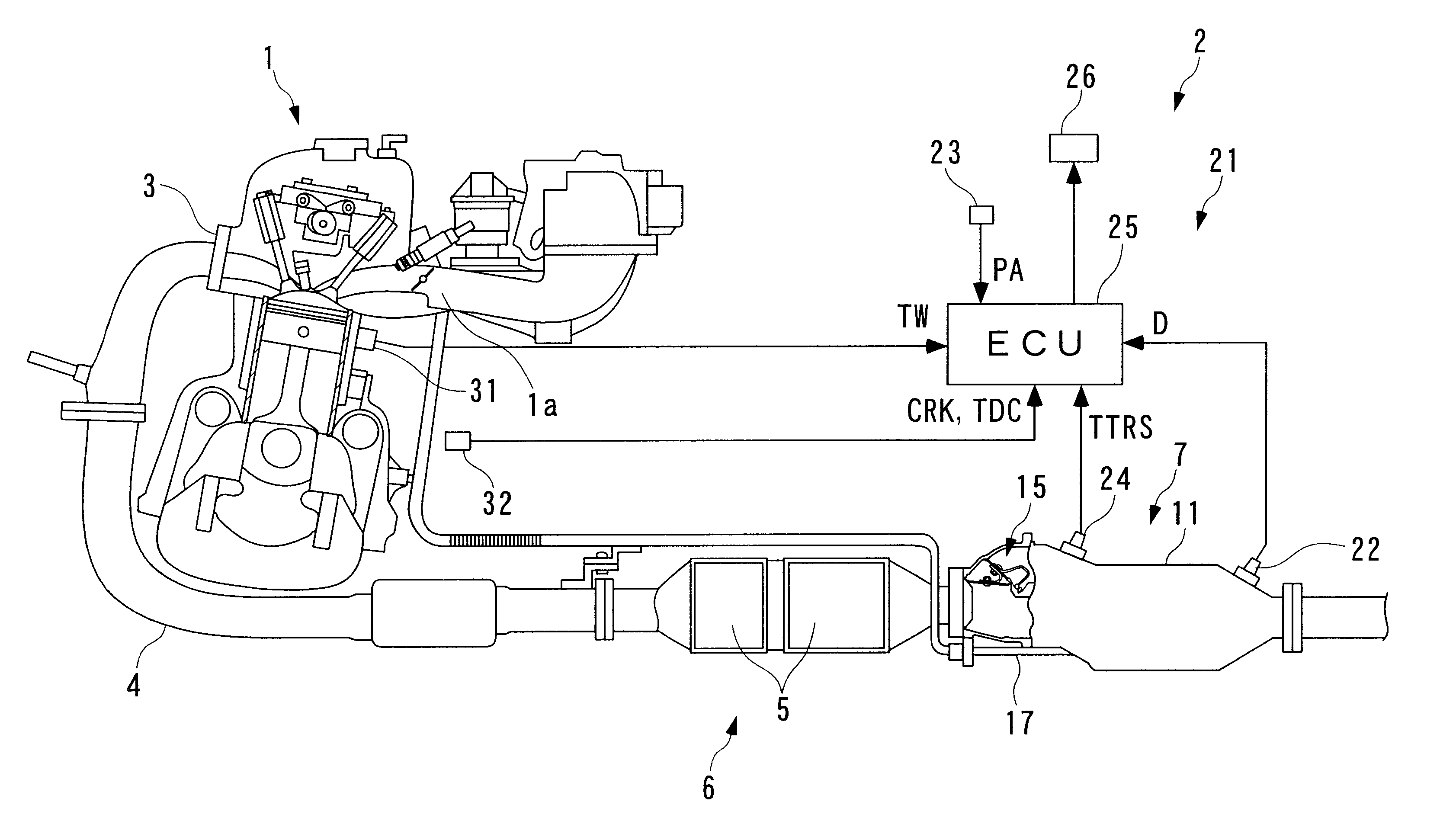

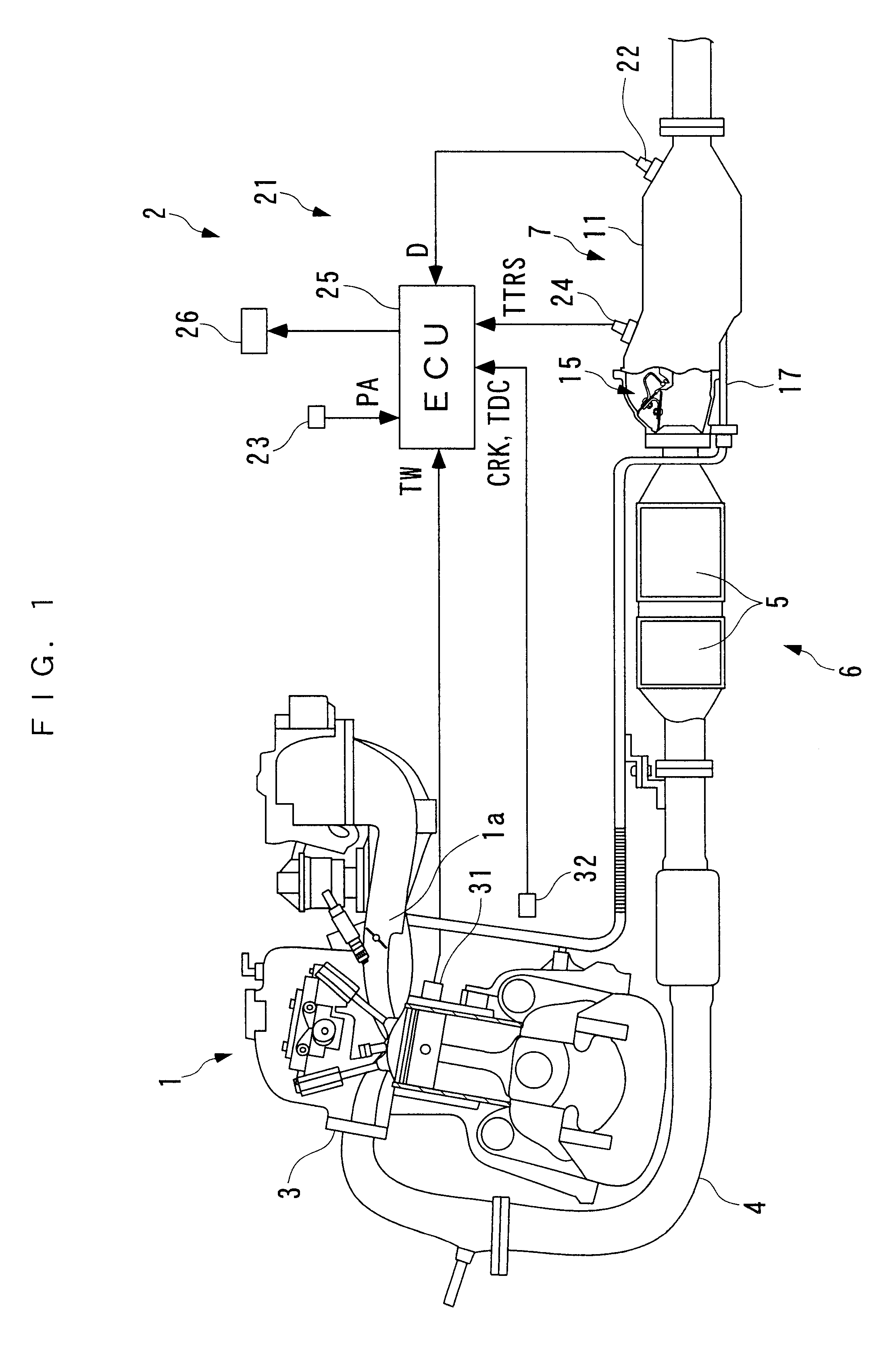

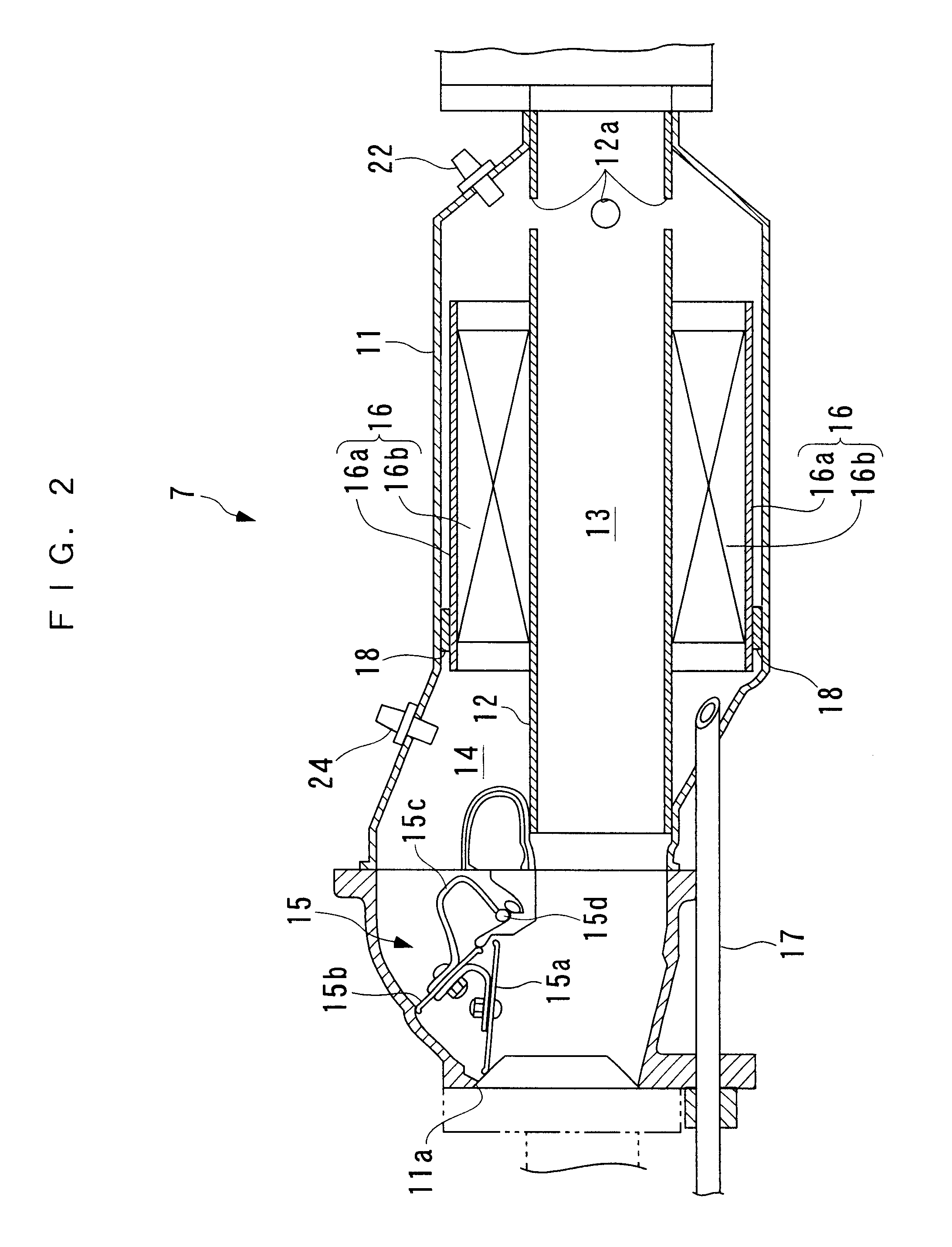

Catalyst state detector for exhaust gas purifying catalyst

InactiveUS6763655B2Accurate detectionLow priceElectrical controlInternal combustion piston enginesSorbentEnvironmental engineering

Owner:HONDA MOTOR CO LTD

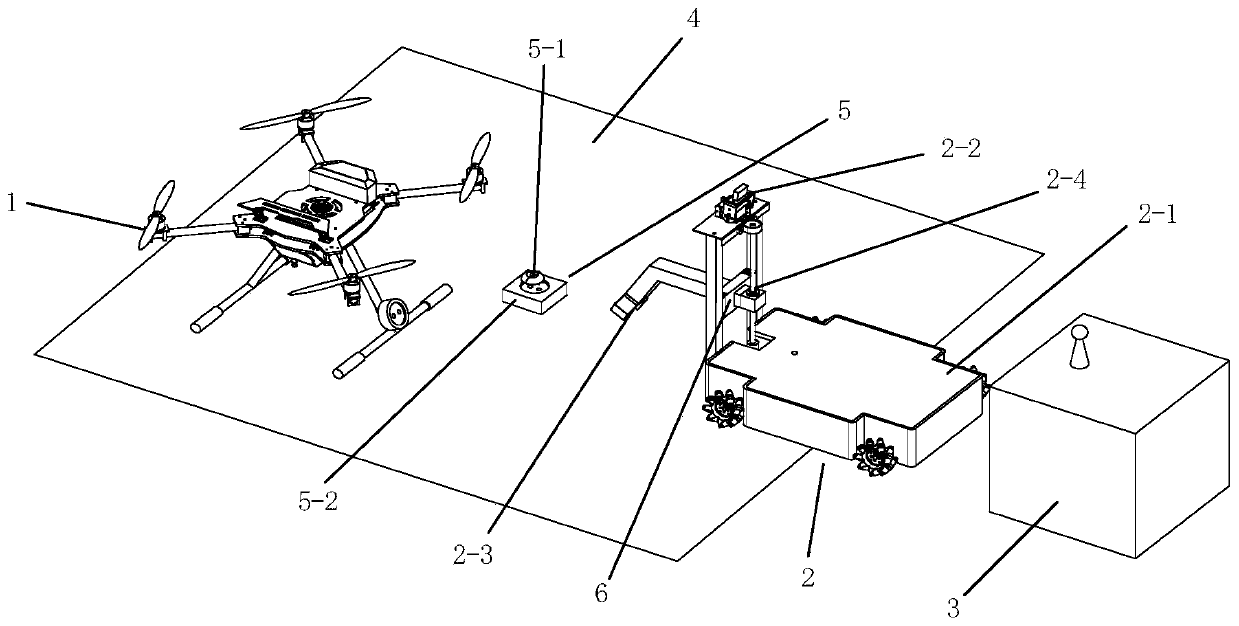

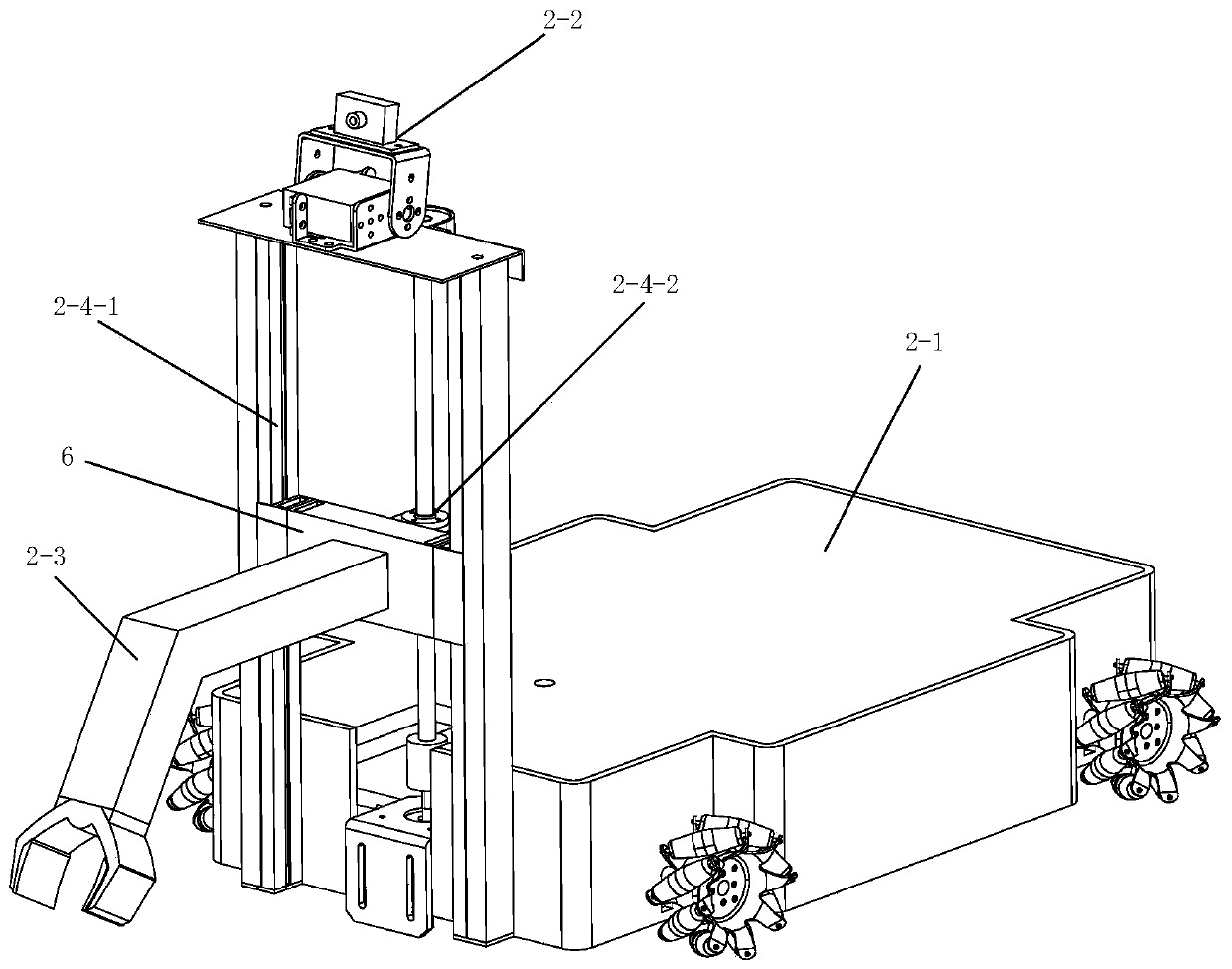

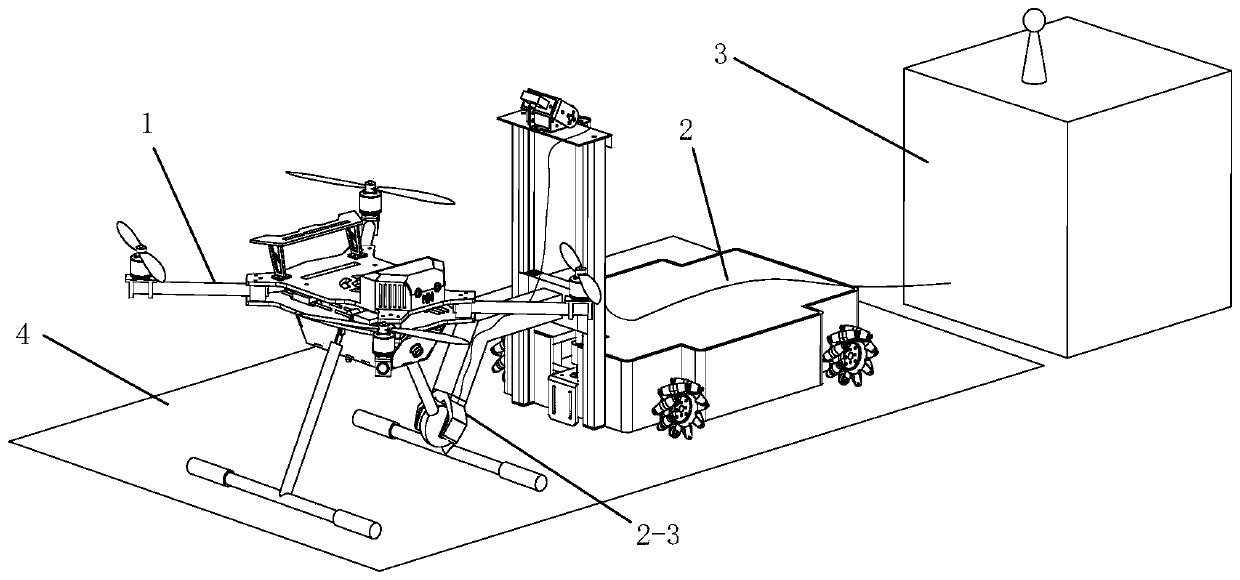

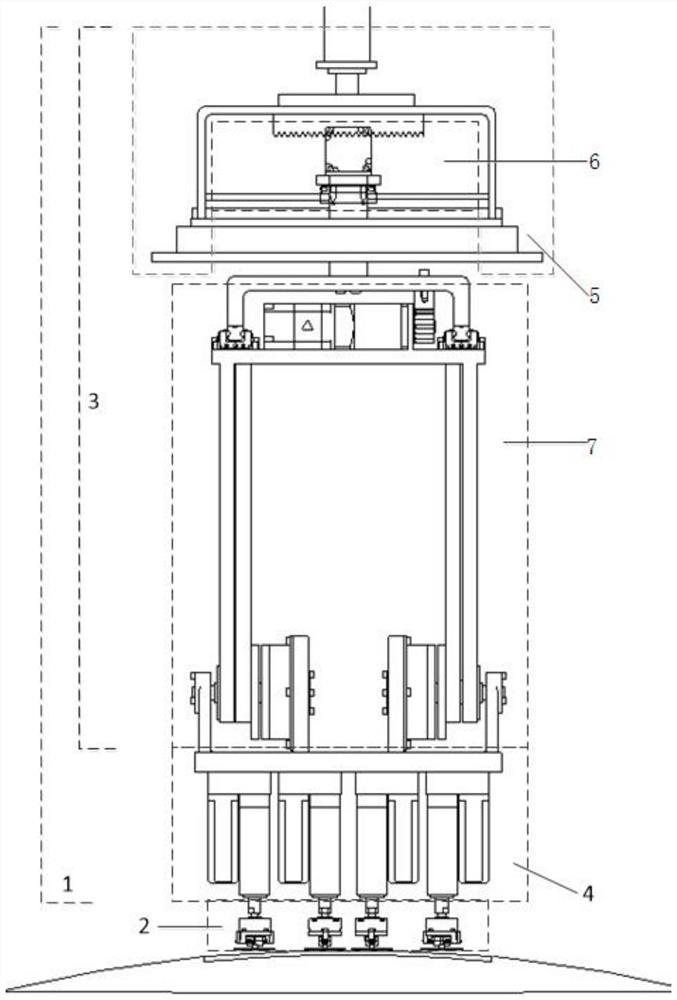

Unmanned aerial vehicle charging system

PendingCN110654259ARealize unmanned managementAvoid Manual WiringCharging stationsElectric vehicle charging technologyRobot handUncrewed vehicle

The invention discloses an unmanned aerial vehicle charging system. The system involves an unmanned aerial vehicle, a movable trolley, an auxiliary base station and a parking apron; the unmanned aerial vehicle is provided with a charging connector; the movable trolley comprises a trolley main body, a camera module, a GPS module, a trolley communication module, a main controller, a manipulator anda vertical lifting mechanism, wherein the vertical lifting mechanism is arranged at the front end of the advancing direction of the trolley main body in an erected mode, the manipulator is slidably fixed with the vertical lifting mechanism through a fixing part, the camera module is arranged at the top of the vertical lifting mechanism, the GPS module, the trolley communication module and the maincontroller are all arranged on the trolley main body, and the main controller is connected with the camera module, the GPS module and the trolley communication module correspondingly; and the auxiliary base station is provided with a base station communication module. The unmanned aerial vehicle charging system has the advantages of being simple and rapid in process, high in efficiency, high in stability, capable of saving manpower resources and the like.

Owner:GUANGDONG UNIV OF TECH

Preparation method of shellfish high F value oligopeptides

ActiveCN110144377APrecise adsorptionRaise the F valueOther chemical processesPeptide preparation methodsDendrimerHydrolysate

The present invention discloses a preparation method of shellfish high F value oligopeptides. The preparation method comprises the following steps: shellfish meat is washed clean, the washed shellfishmeat is homogenized, then enzymatic hydrolysis is conducted to obtain an upper layer enzymatic hydrolysate, a dendrimer is used to prepare a molecular imprinting material, the molecular imprinting material adsorbs aromatic amino acids in the enzymatic hydrolysate to obtain a high F value oligopeptide solution, and high F value oligopeptide powder is prepared by freeze-drying. The raw materials ofthe product are liable to obtain and cheap, the preparation method is simple and convenient for industrial production, has a product yield of 75% or more, and the product has a F value of 50 or moreand can be used as a dietary source component for patients with liver diseases.

Owner:LUDONG UNIVERSITY

Denitration agent and preparation method thereof

InactiveCN105435620AReduce concentrationFast selective adsorptionDispersed particle separationRare-earth elementAlkaline earth metal

The invention provides a denitration agent and a preparation method thereof, and belongs to the technical field of catalytic cracking auxiliaries. The denitration agent is prepared from 60-85 parts of activated aluminum oxide, 1-10 parts of compound of a noble metal element, 1-5 parts of chloride of rear earth elements, 1-15 parts of nitrate of transition metal elements, 1-10 parts of nitrate of alkaline earth metal elements and 20-200 parts of water. The denitration agent can effectively decrease the concentration of NOx in flue gas, and meanwhile carbon monoxide in the flue gas is not consumed in the working process.

Owner:山东骏飞环保科技有限公司 +2

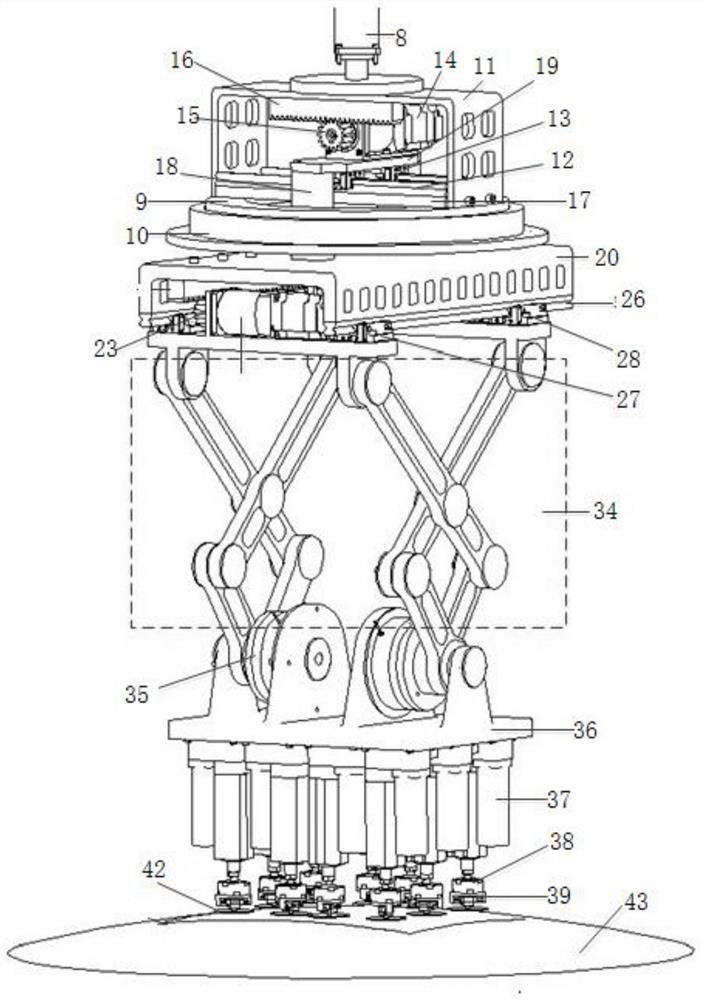

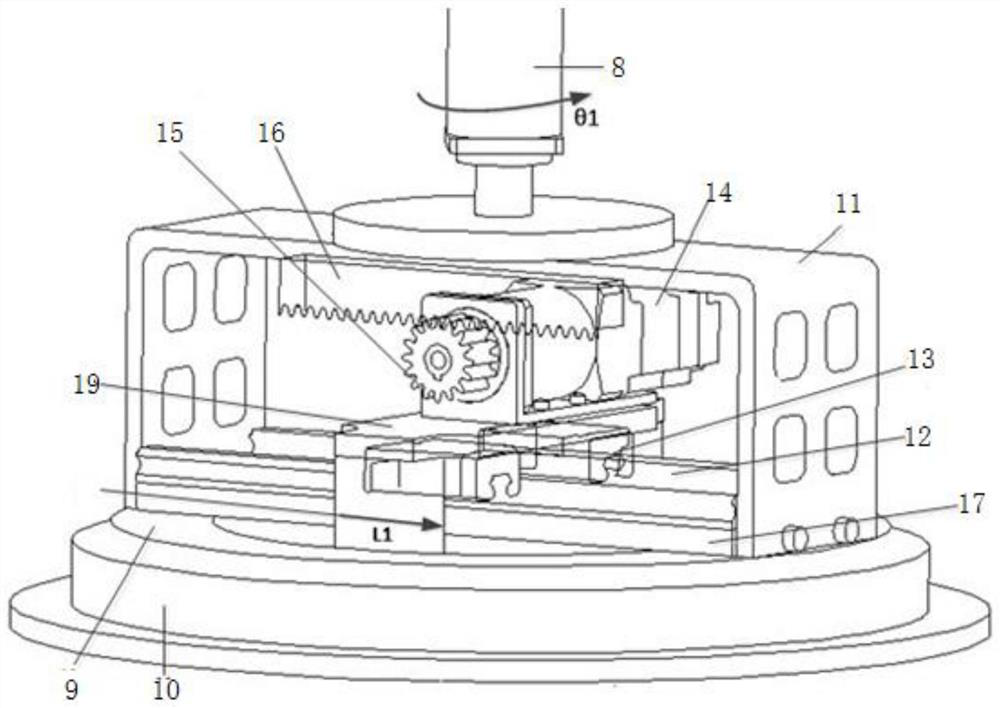

Adsorption loading and unloading device

ActiveCN111634681APrecise loading and unloadingPrecise positioningConveyor partsControl theoryVertical motion

The invention discloses an adsorption loading and unloading device which comprises a three degree-of-freedom feeding mechanism and an adsorption platform, wherein the three degree-of-freedom feeding mechanism comprises a coarse adjustment mechanism and a fine adjustment mechanism; the coarse adjustment mechanism comprises a rotary motion module, a horizontal motion module and a vertical motion module, and the horizontal motion module is arranged on the rotary motion module; the upper end of the vertical motion module is rotationally connected with the horizontal motion module, and the lower end of the vertical motion module is rotationally connected with the fine adjustment mechanism; the rotary motion module, the horizontal motion module and the vertical motion module can respectively drive the fine adjustment mechanism to doe rotary motion, horizontal motion and vertical motion; the adsorption platform is connected with the fine adjustment mechanism; and the lower end of the adsorption platform is used for adsorb an object to be taken. The invention can provide the adsorption loading and unloading device with high-strength adsorption, accurate and rapid positioning, a flexible and adaptive curved adsorption surface and high security, so as to solve the problems of the prior art.

Owner:JILIN UNIV

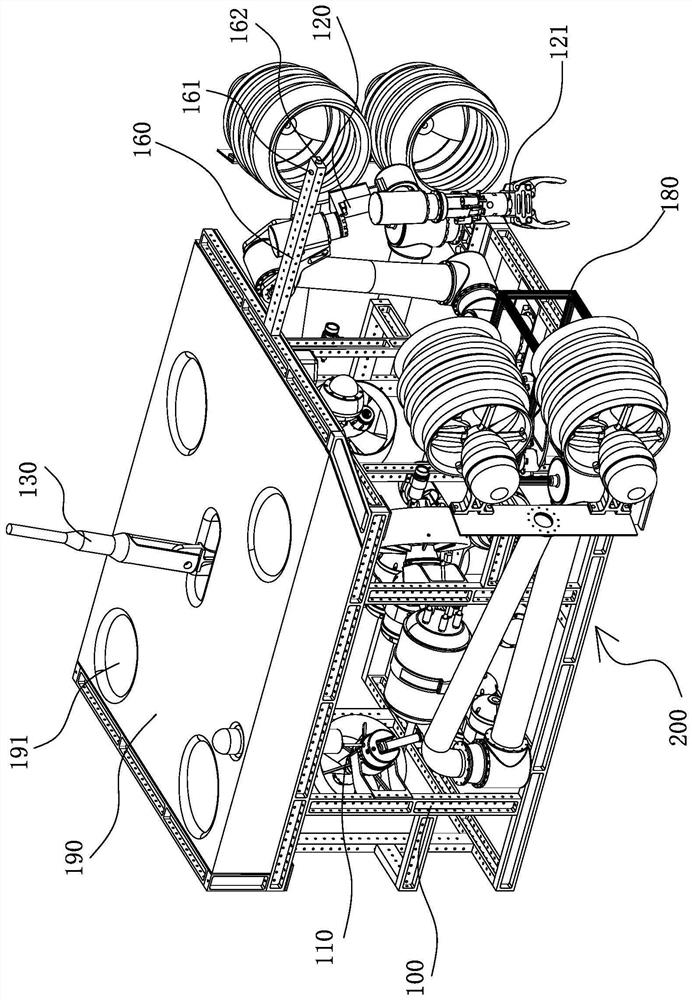

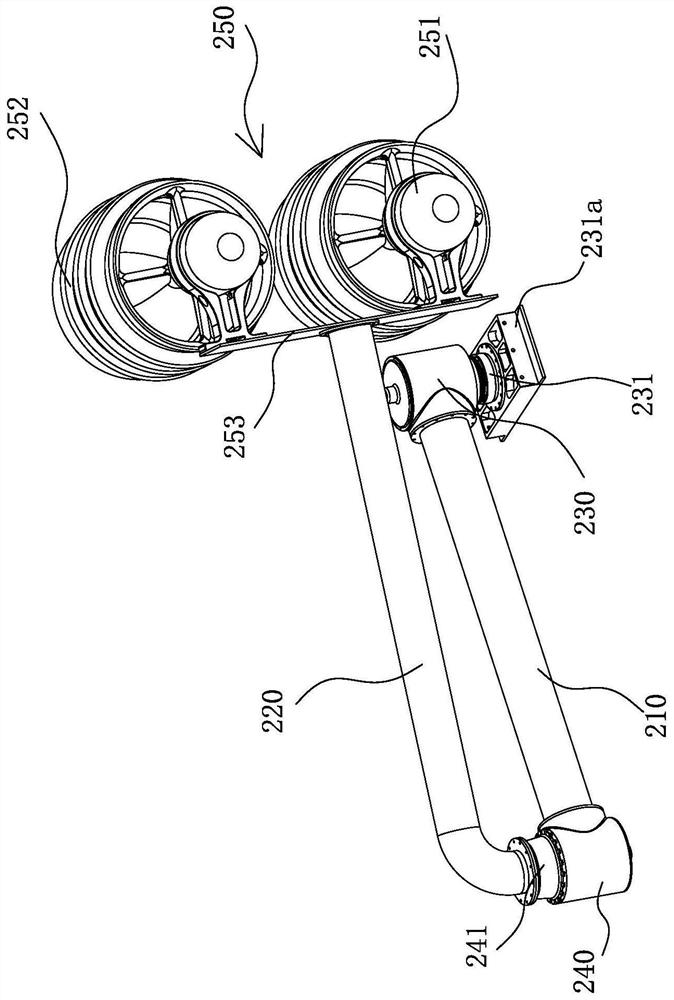

Underwater robot applied to bridge pier maintenance and maintenance method thereof

ActiveCN113386930AAvoid wash away situationsFirmly connectedNavigation by speed/acceleration measurementsBridge structural detailsMarine engineeringControl theory

The invention provides an underwater robot applied to bridge pier maintenance and a maintenance method thereof, and belongs to the technical field of underwater robots. The invention solves the problem that existing underwater robots cannot stably work in a torrent area. According to the underwater robot applied to bridge pier maintenance and the maintenance method thereof, the underwater robot comprises a frame, a wall holding mechanism, a first propeller and a mechanical arm. When the underwater robot moves to the bridge pier needing to be overhauled, the wall holding mechanism is unfolded and adsorbed to the bridge pier needing to be overhauled, and therefore stable connection between the underwater robot and the bridge pier is achieved, so that the situation that the underwater robot is washed away by torrent beside the bridge pier is avoided, and then an operator can control the mechanical arm to maintain the surface of the bridge pier.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

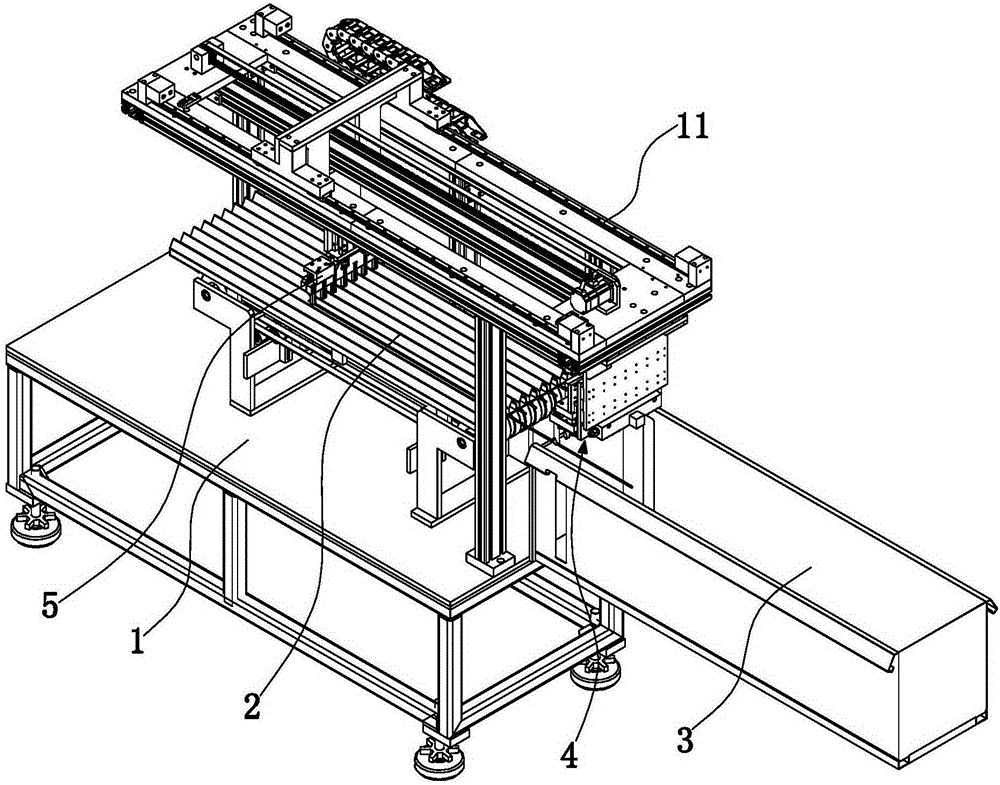

Paper bag automatic feeding device

InactiveCN109911662AConveying orderlyStable deliveryArticle feedersArticle separationPulp and paper industry

Owner:江西新明峰包装科技有限公司

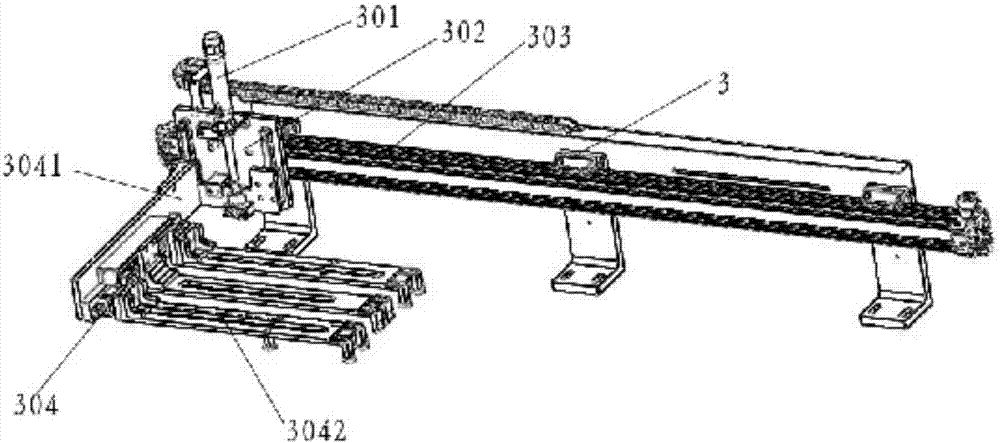

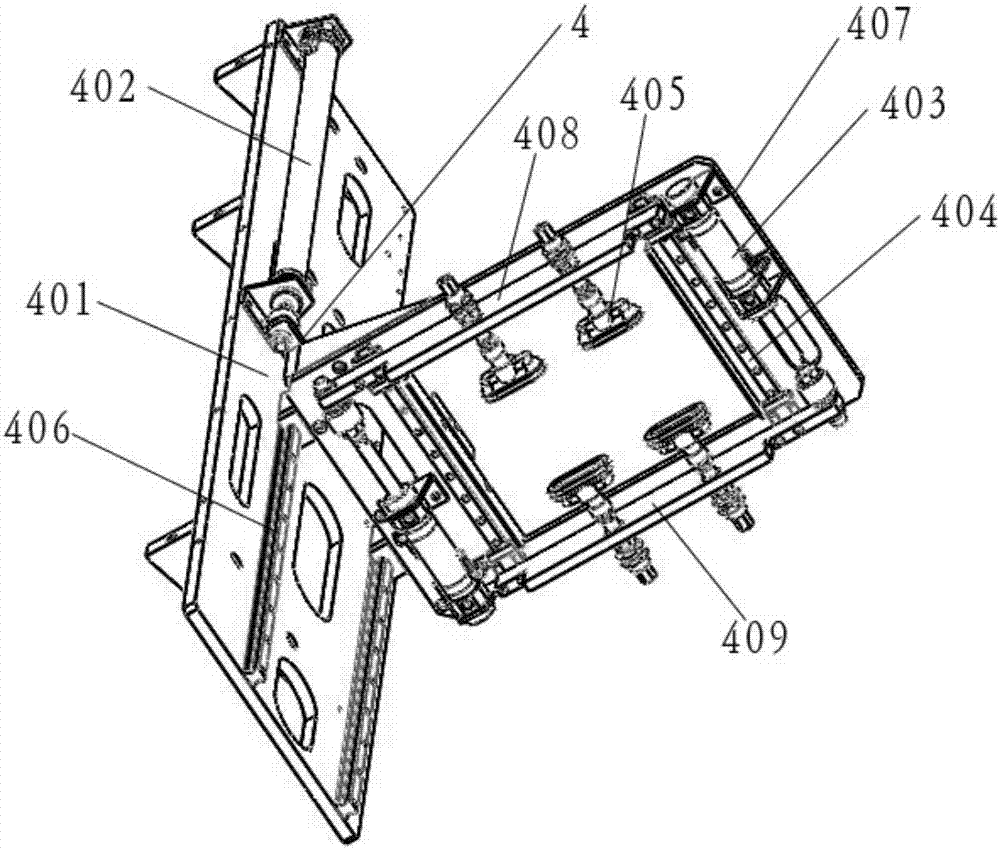

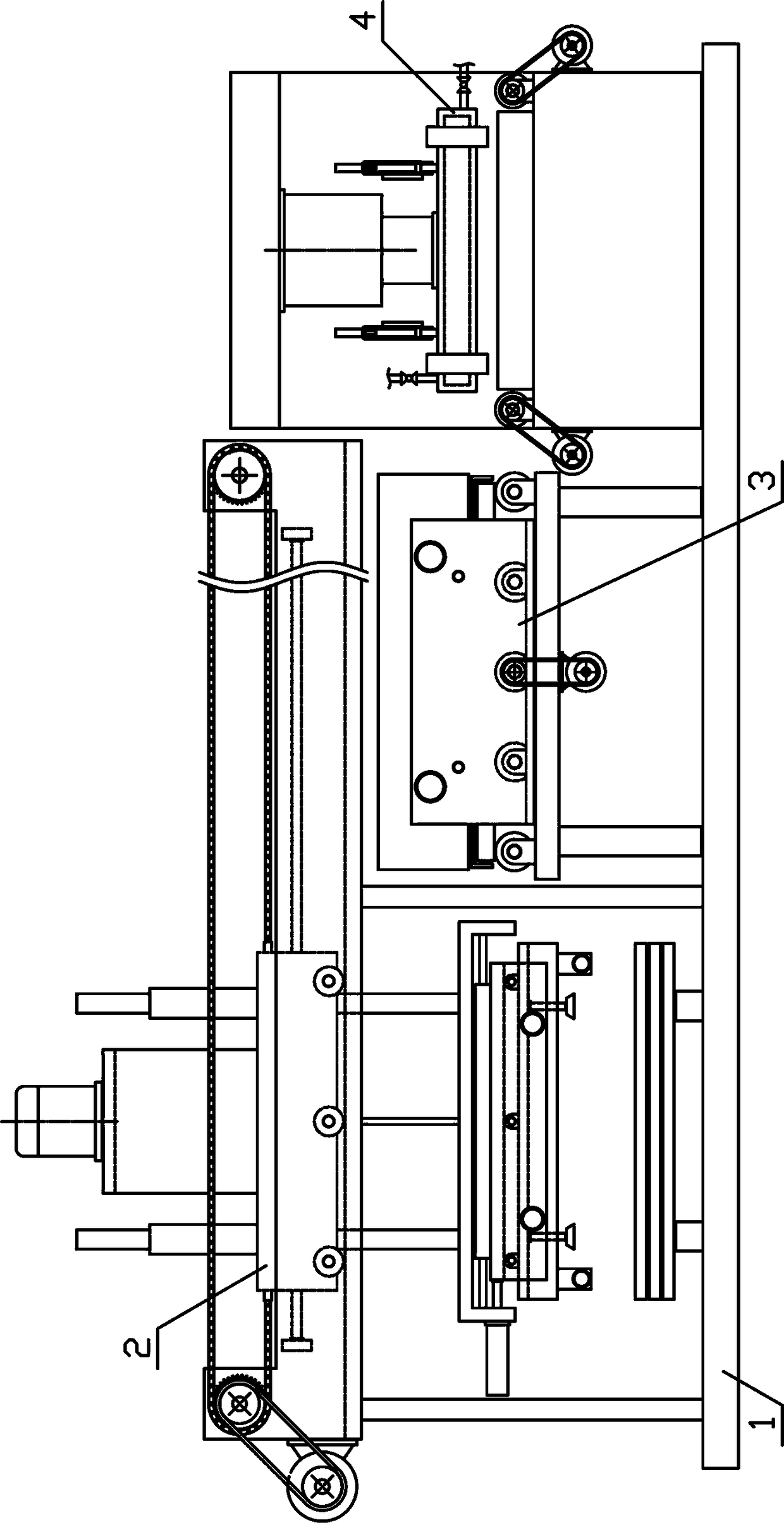

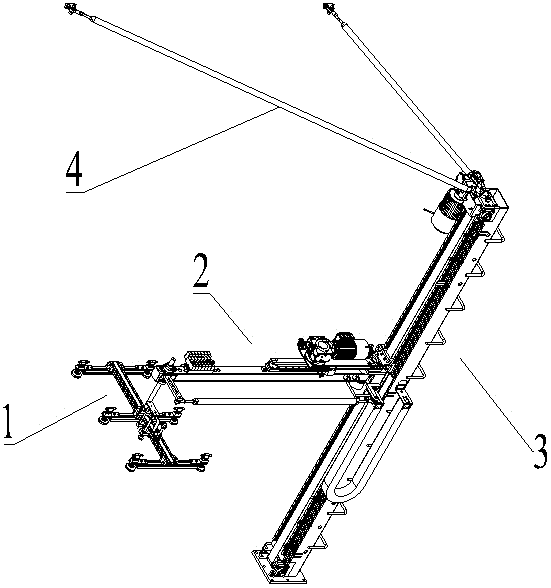

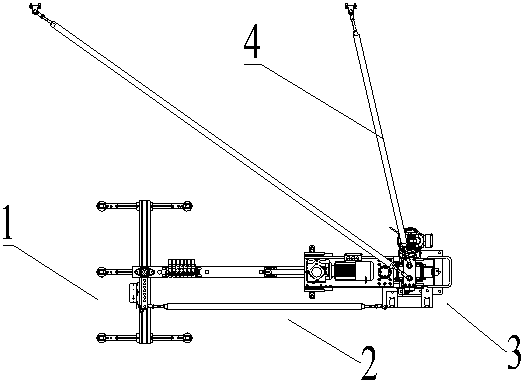

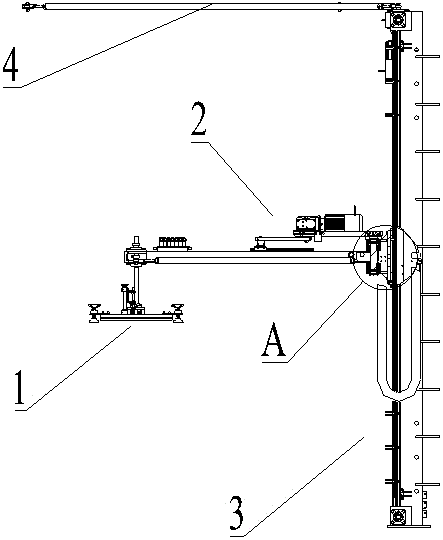

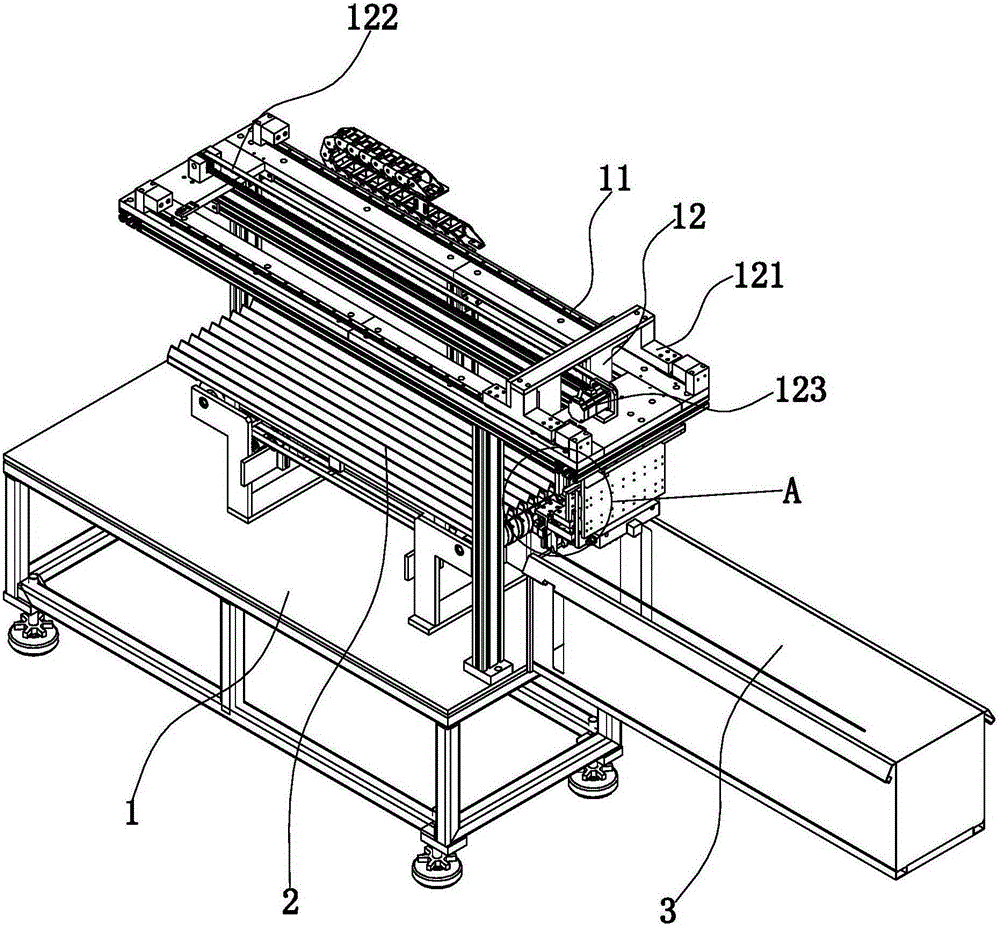

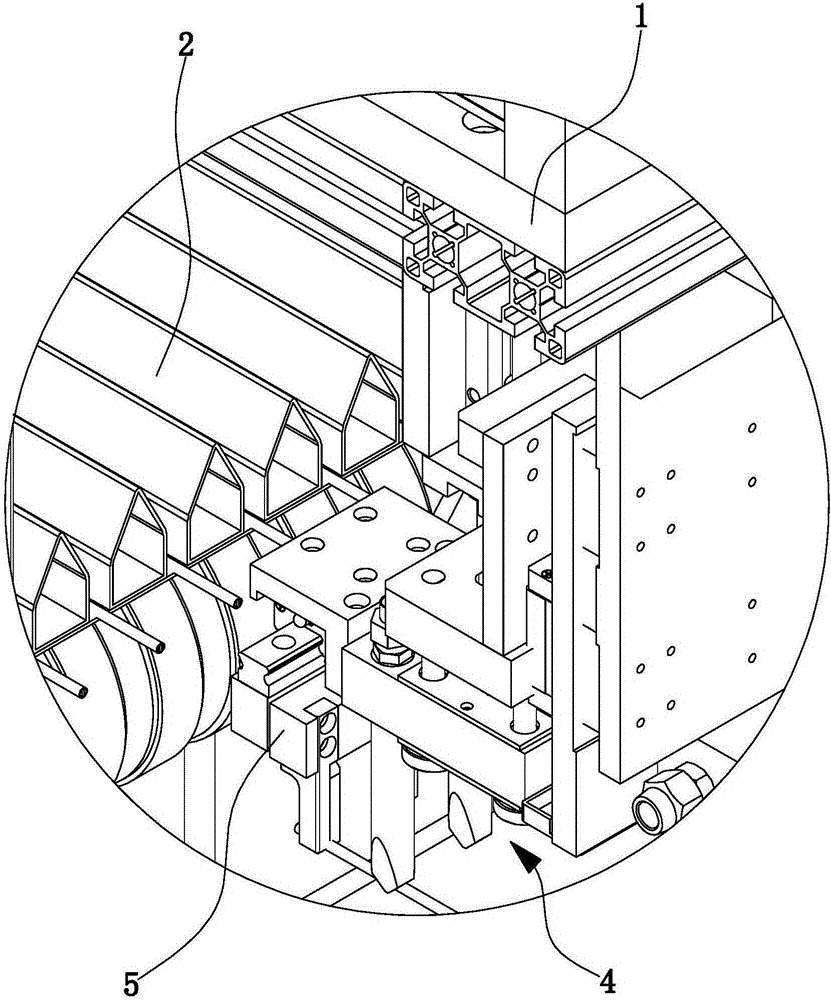

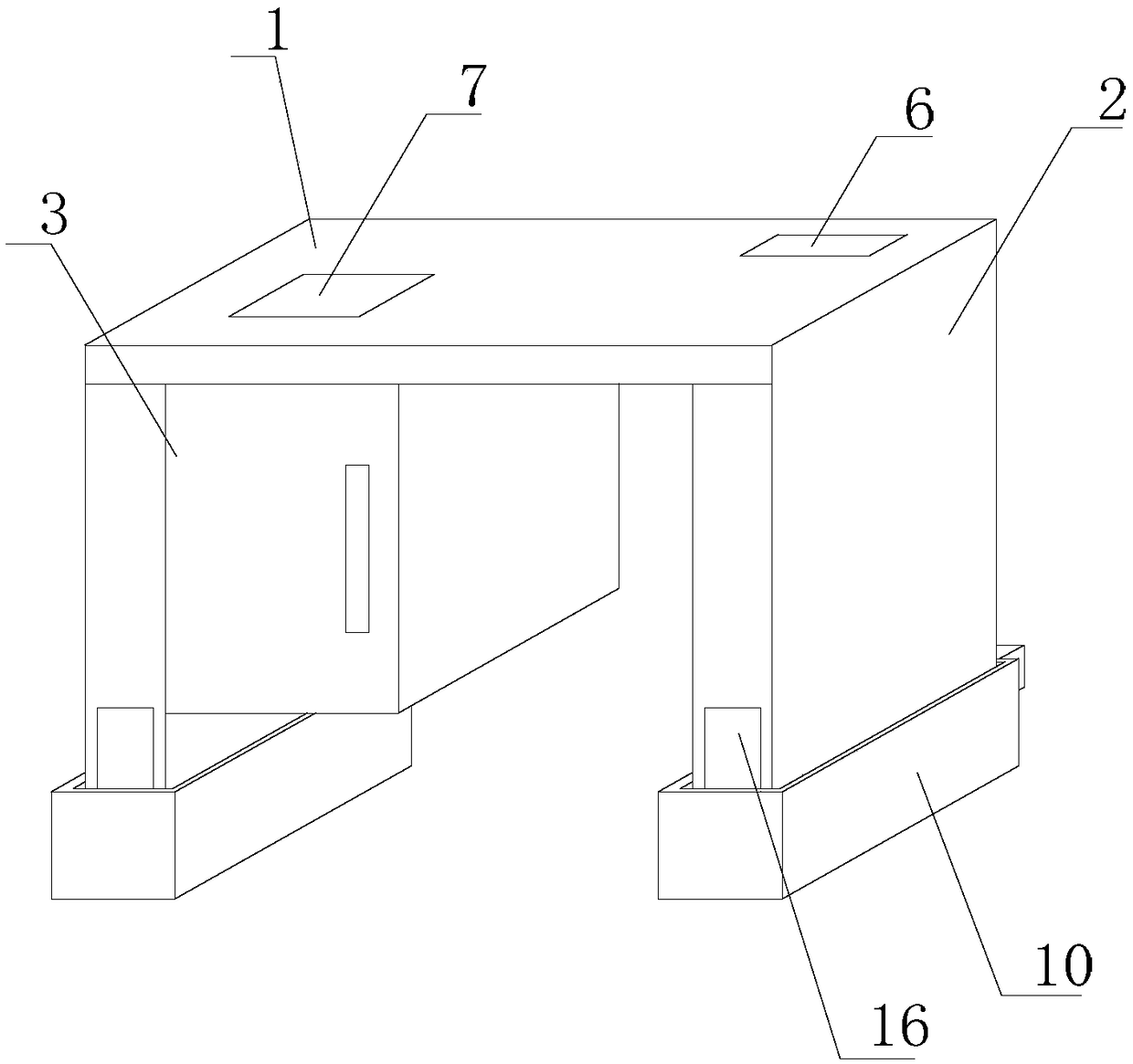

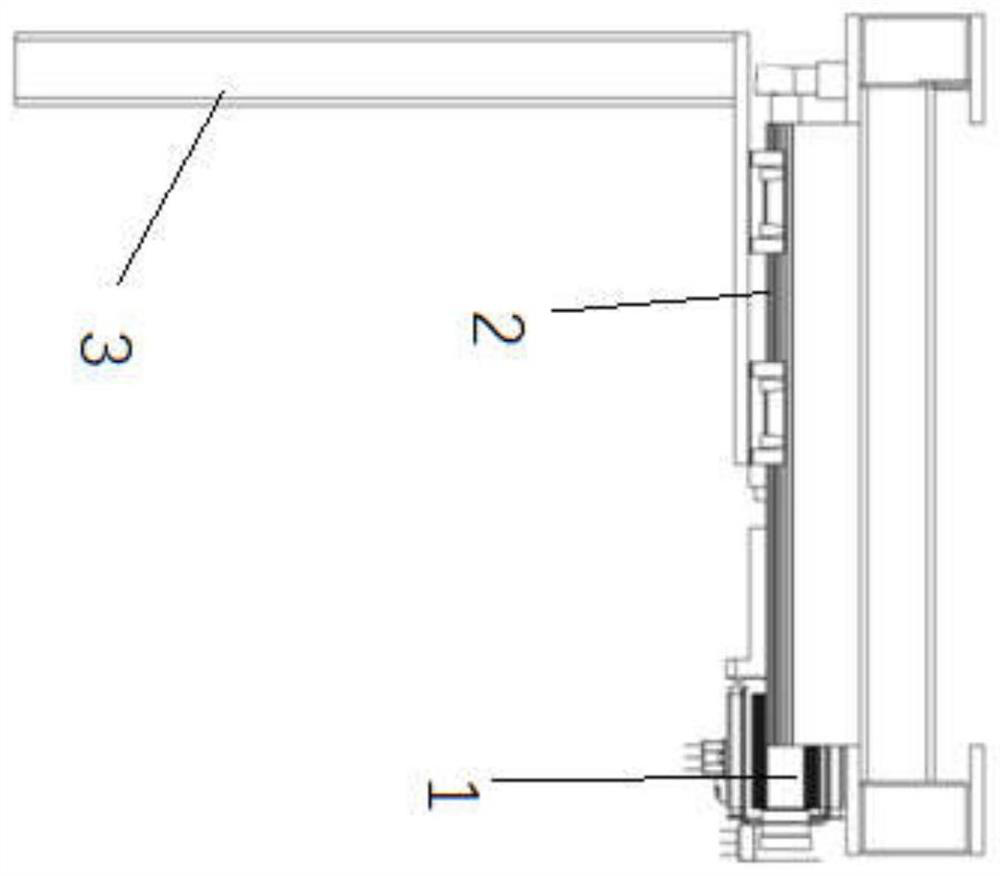

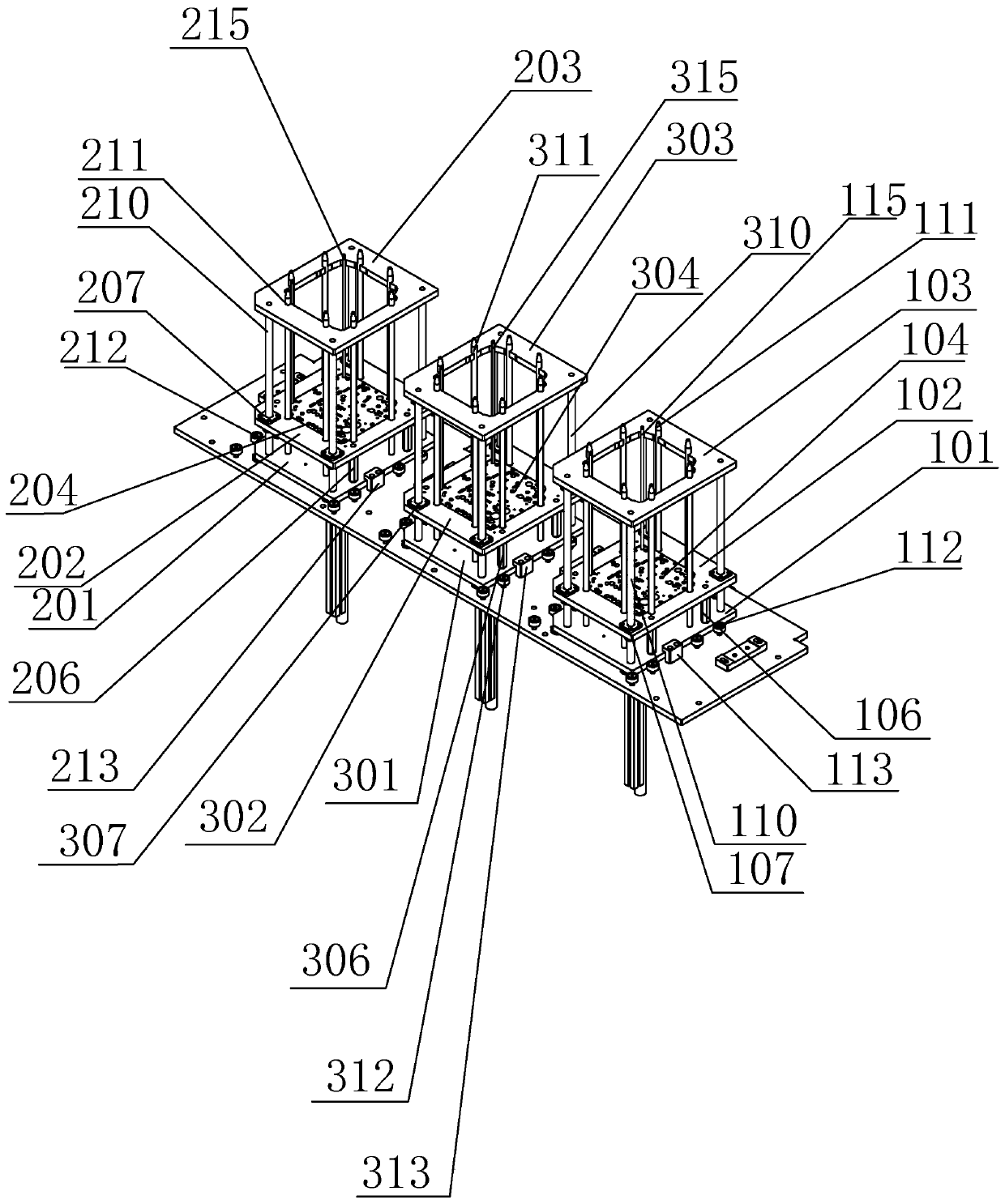

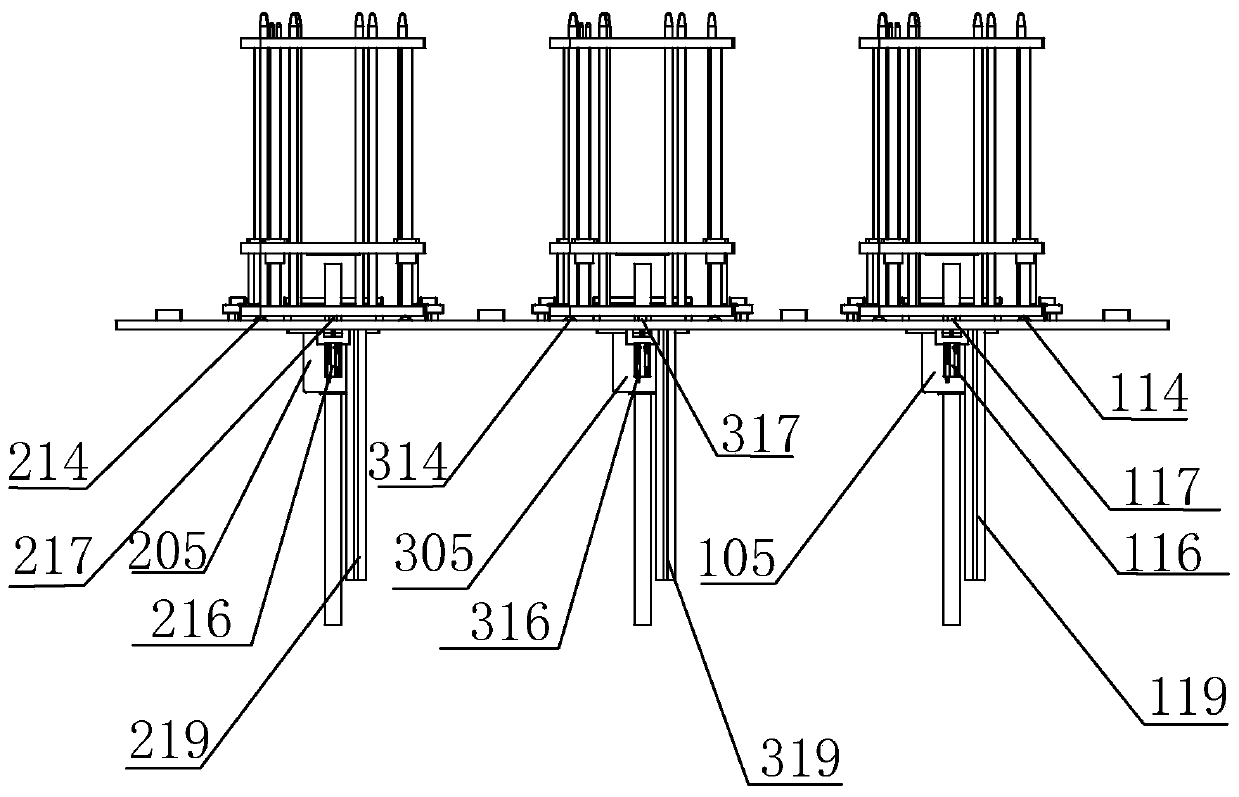

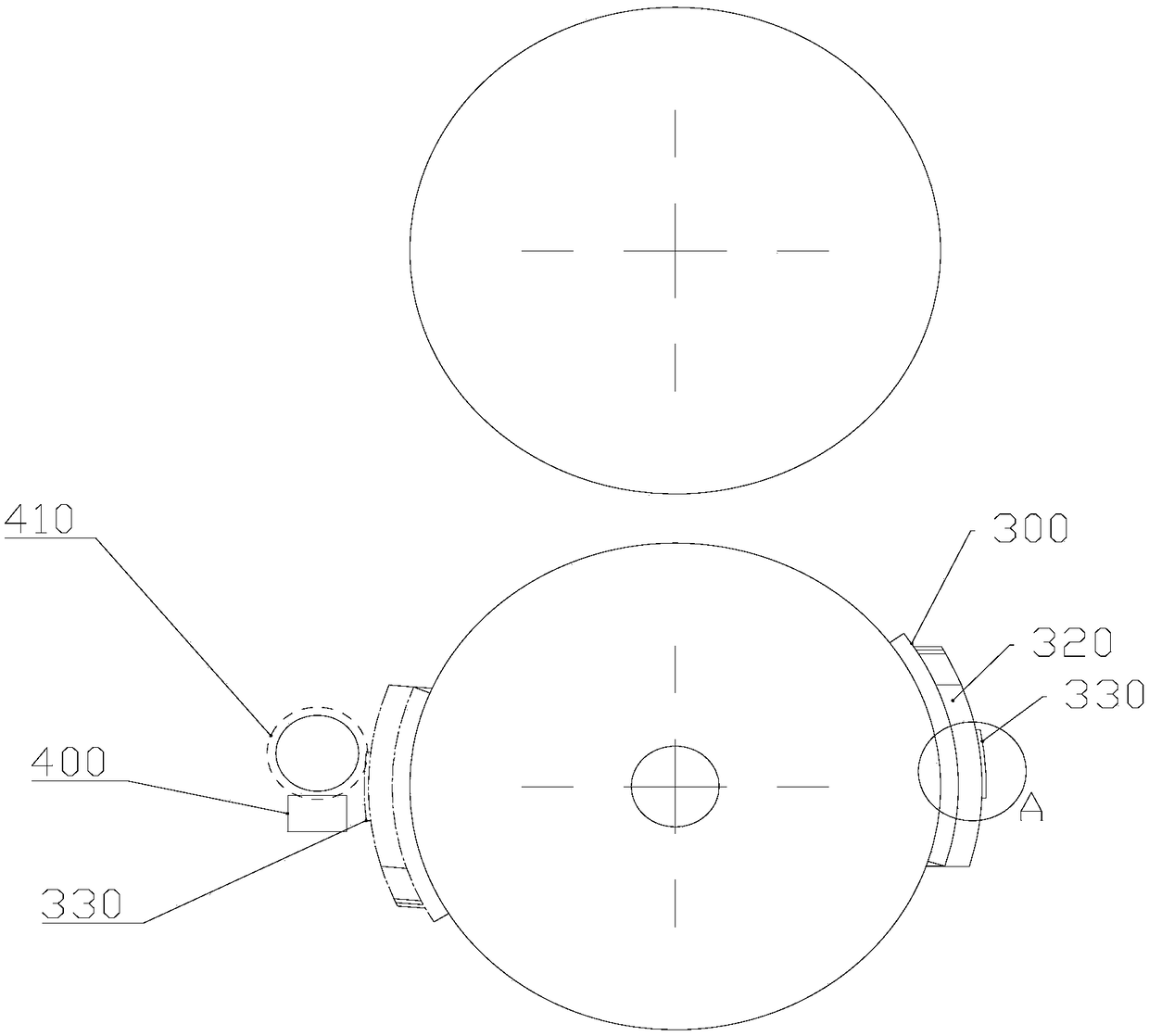

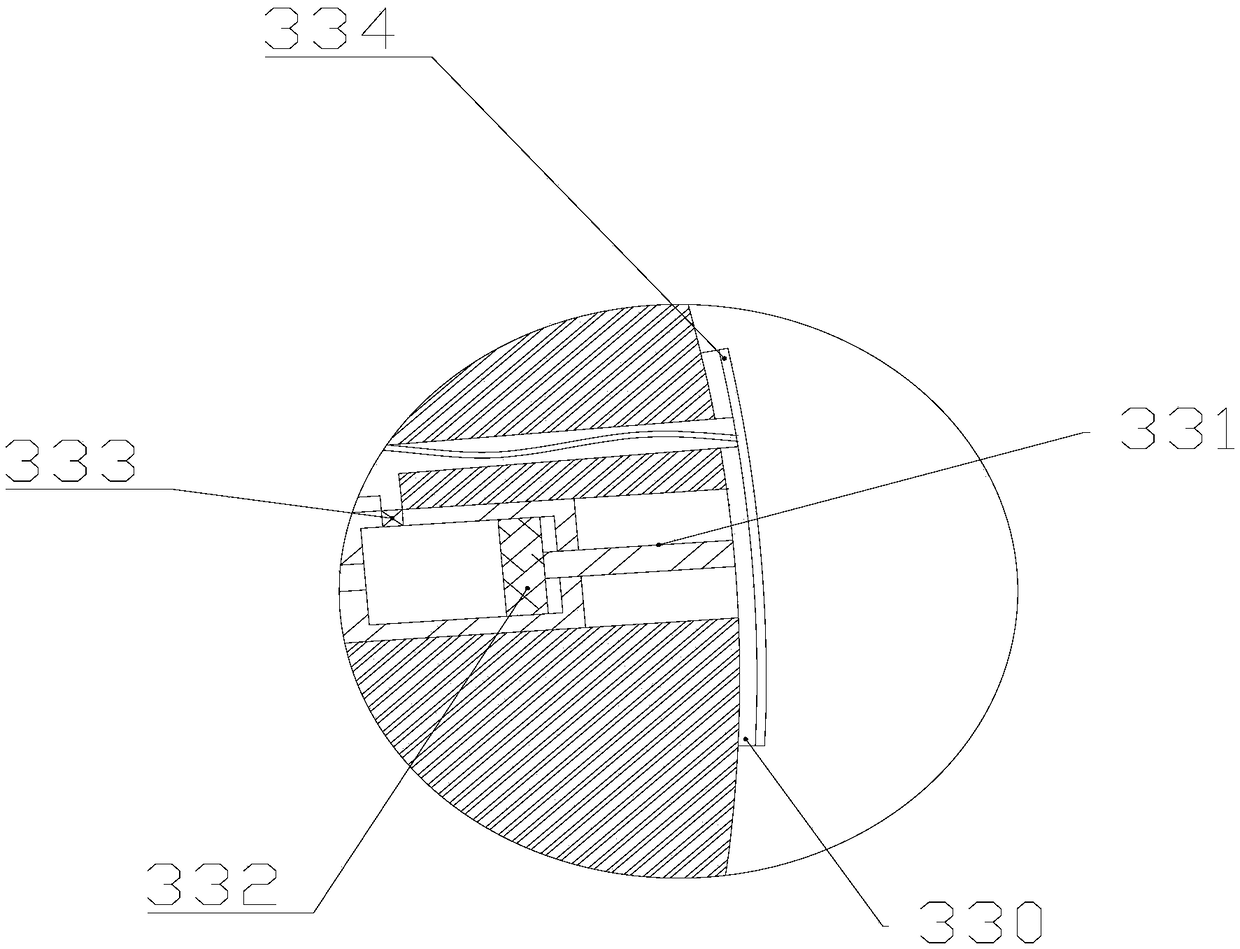

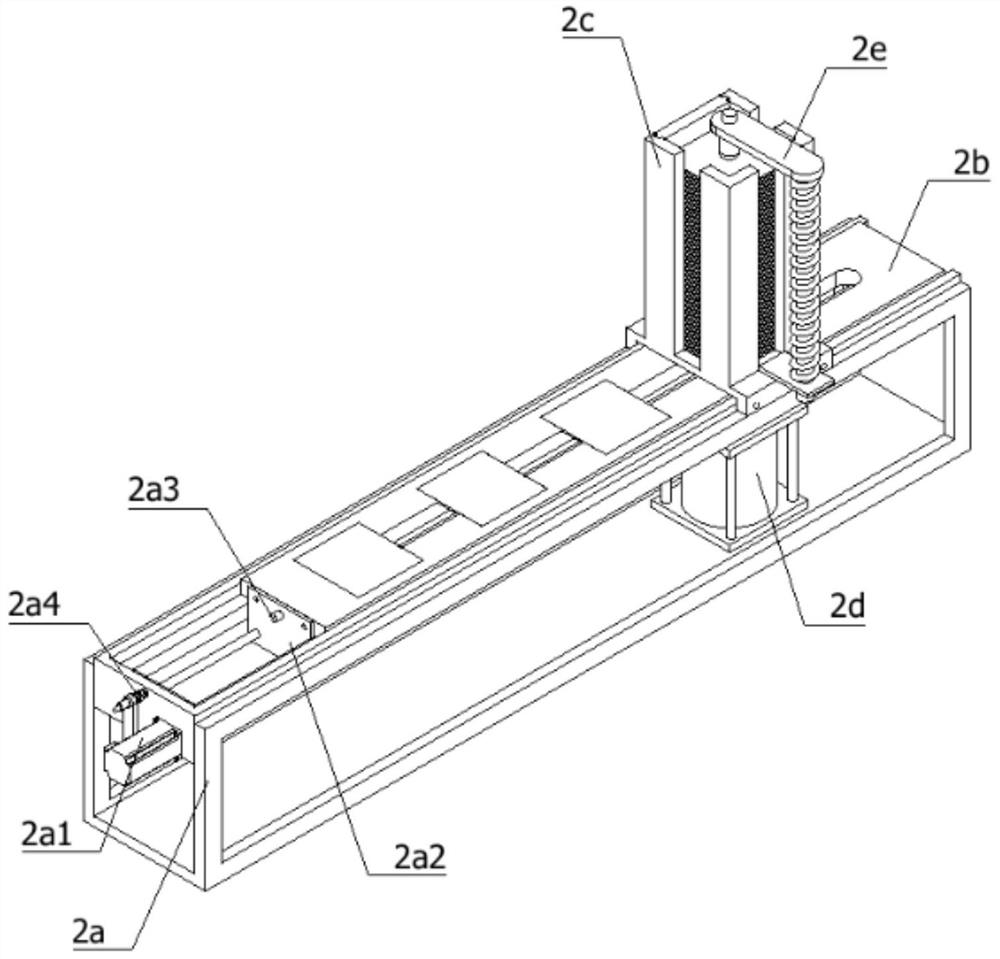

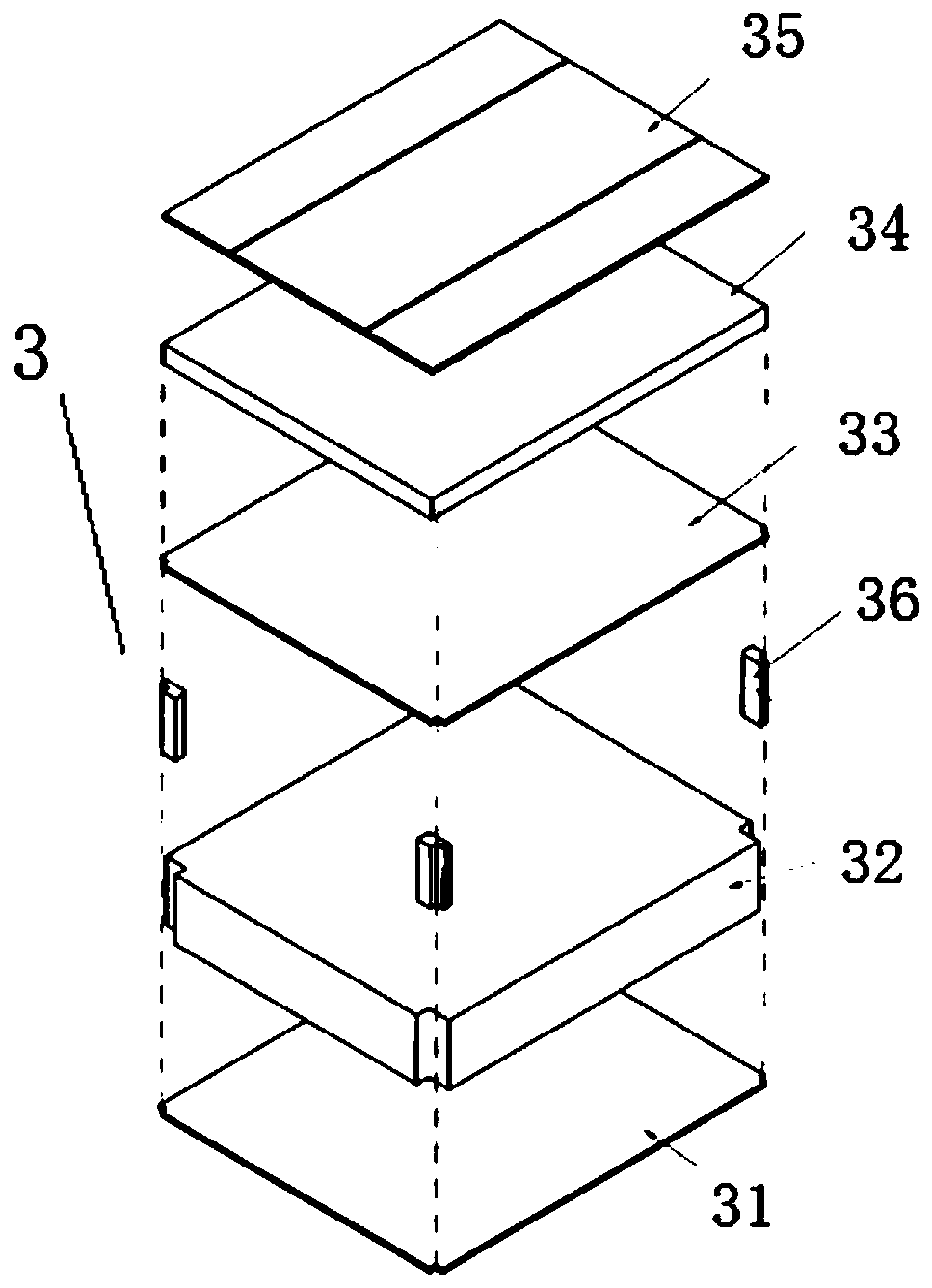

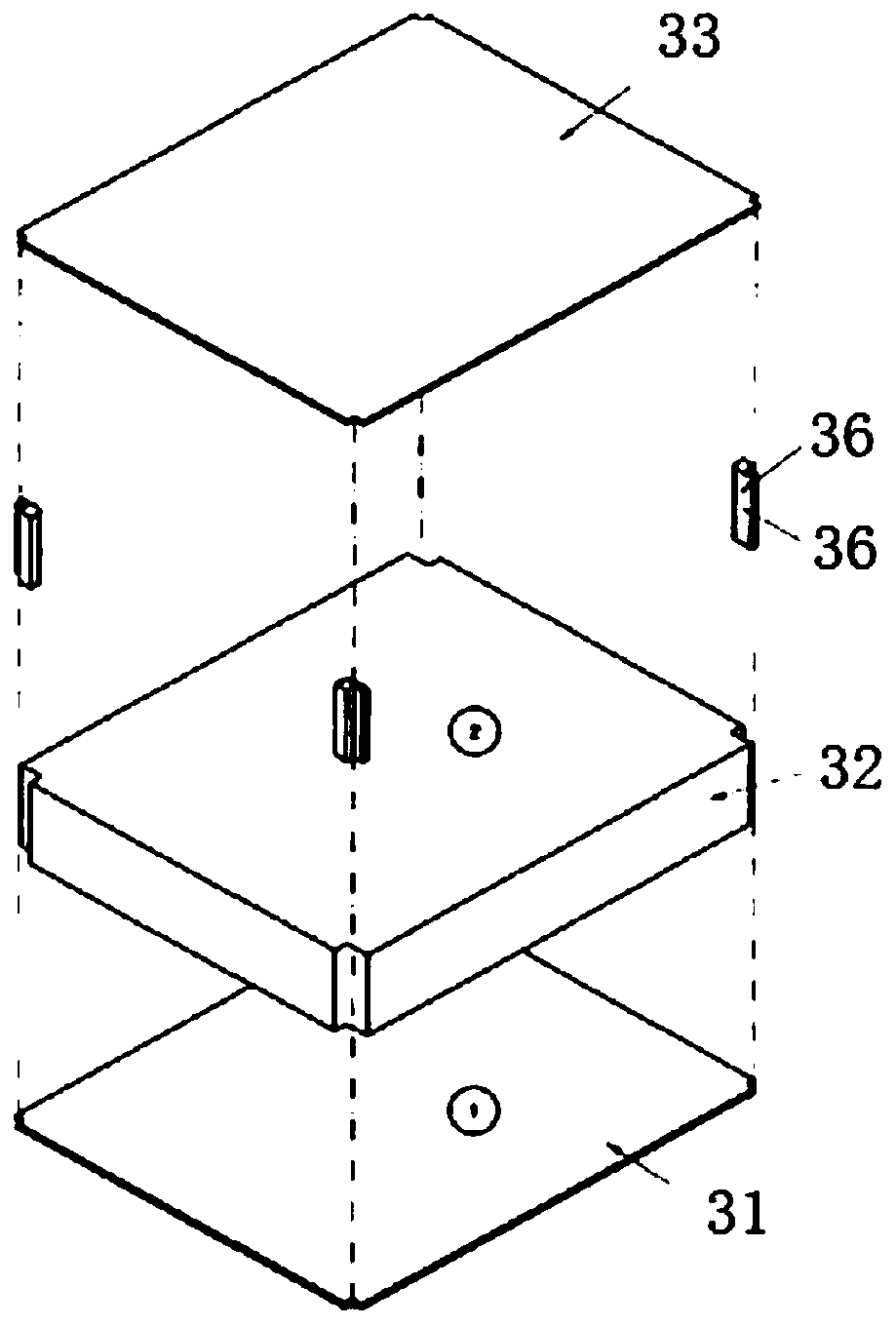

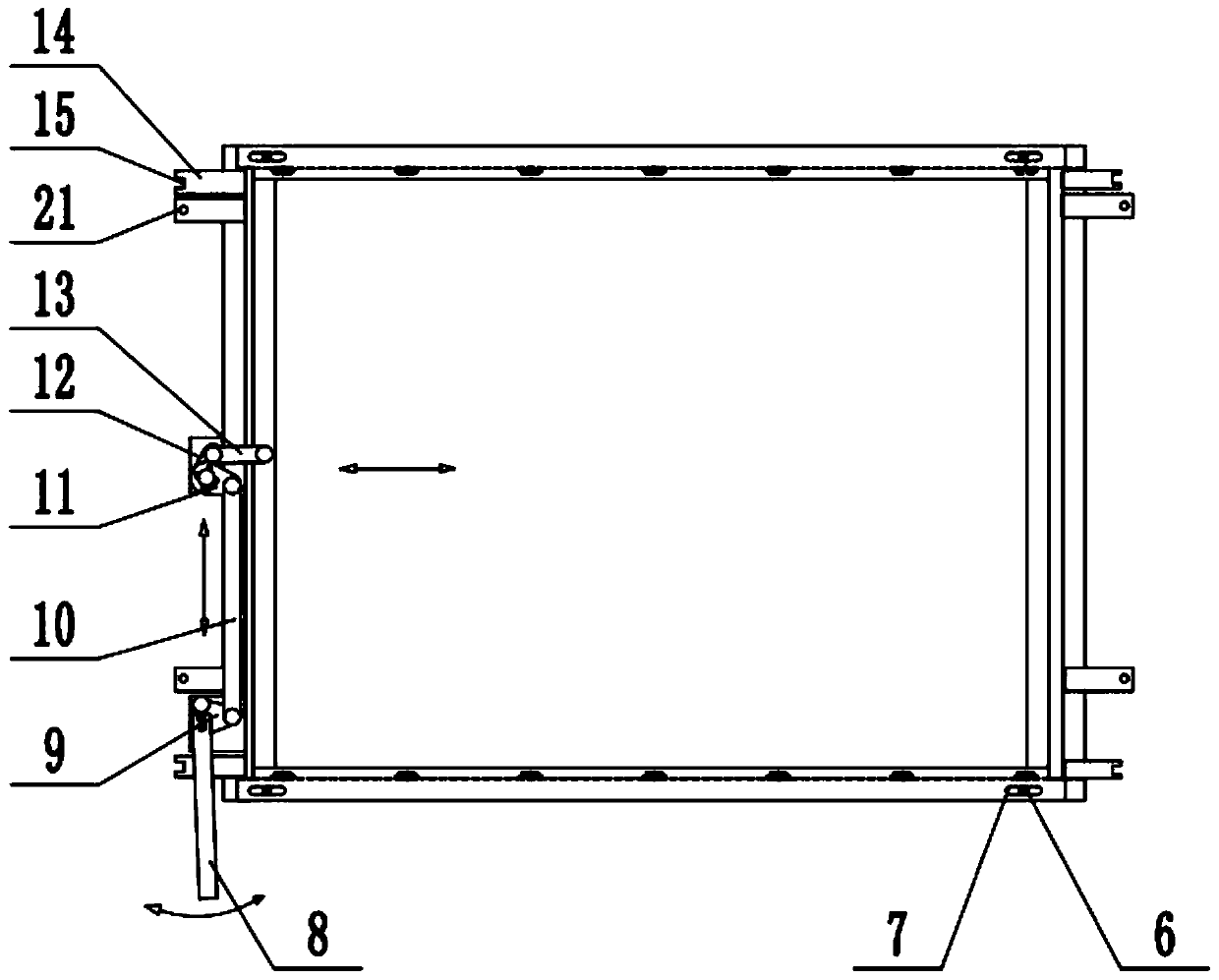

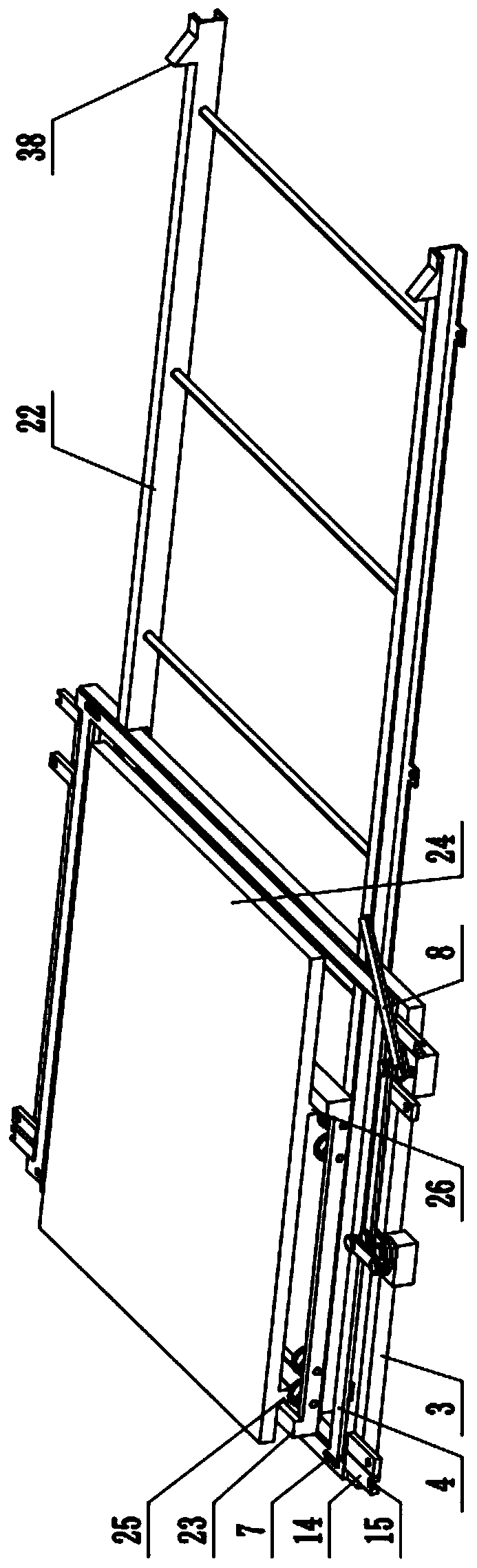

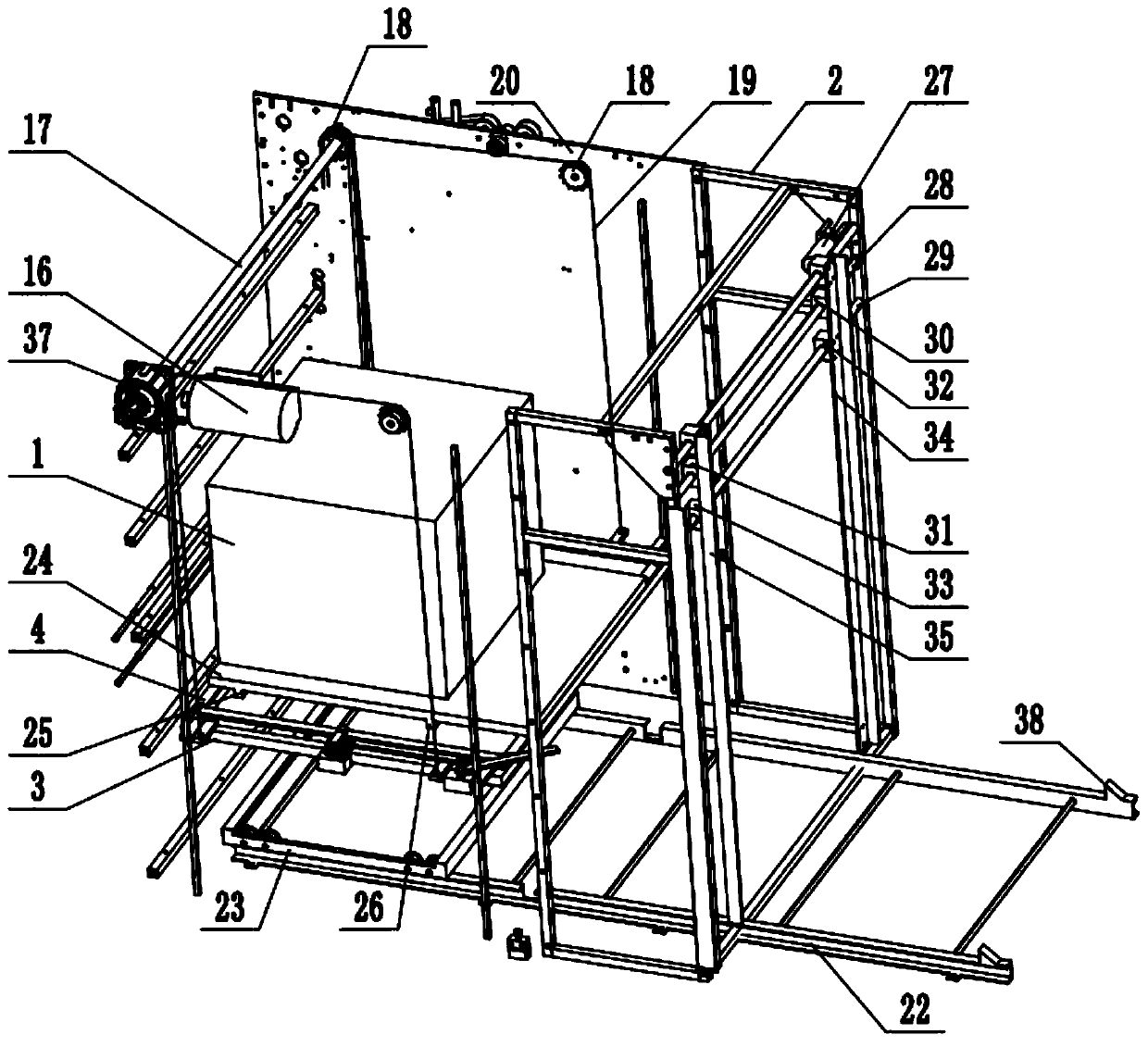

Automatic partition plate arranging device

ActiveCN105416720APrecise adsorptionHigh degree of automationConveyorsPackagingIndustrial engineeringAutomation

The invention discloses an automatic partition plate arranging device which comprises a grabbing plate device (1), a swinging device (2) and a lifting device (3), wherein one end of the swinging device (2) is fixedly connected to the lifting device (3), and the other end of the swinging device (2) is connected to the grabbing plate device (1). The automatic partition plate arranging device has the beneficial effects that: a partition plate can be precisely adsorbed by detecting the position of the partition plate by virtue of an automatic partition plate induction device during partition plate absorption, so that degree of automation is high, and phenomena such as partition plate adsorption, partition plate collision and the like are avoided; the partition plate arranging height is automatically regulated according to the number of stacking layers and height of each layer, so that the degree of automation is high, precision is good and a production process is stable; the automatic partition plate arranging device is small in size, can be used to different packaging machines, can be directly used by regulating parameters according to needs, is wide in range of application, good in universality and suitable for large-scale popularization.

Owner:广州市裕轻机械制造有限公司

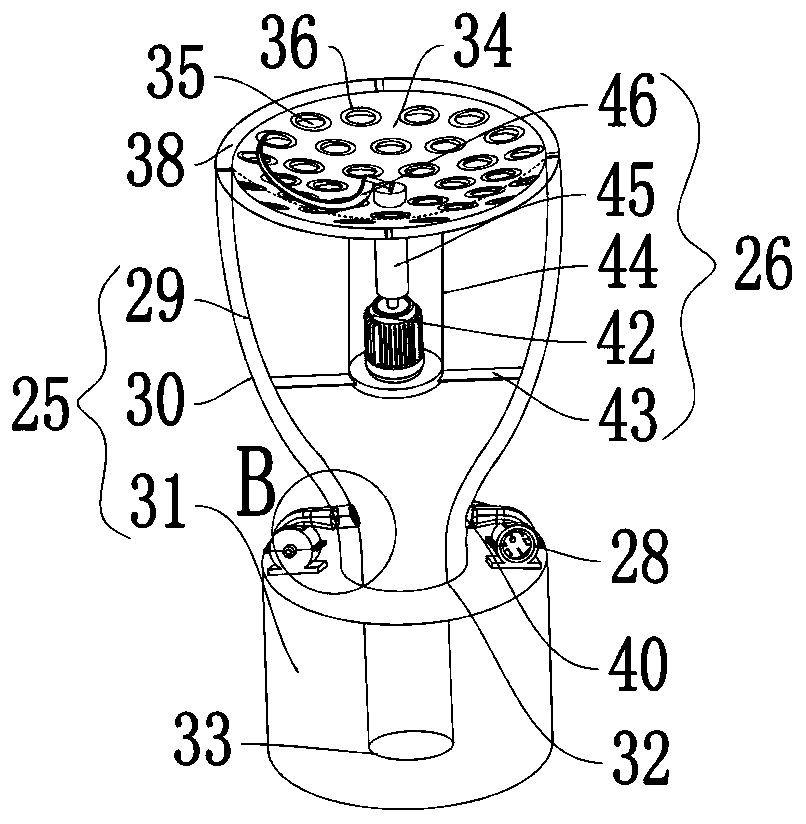

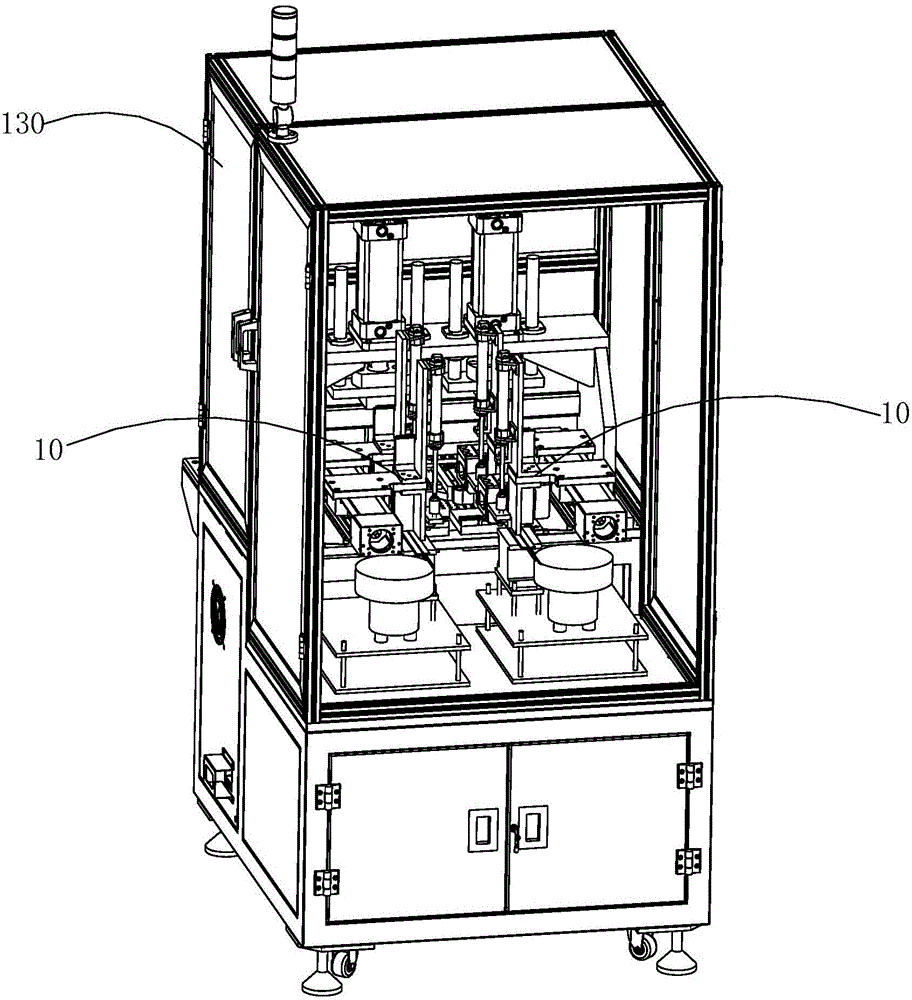

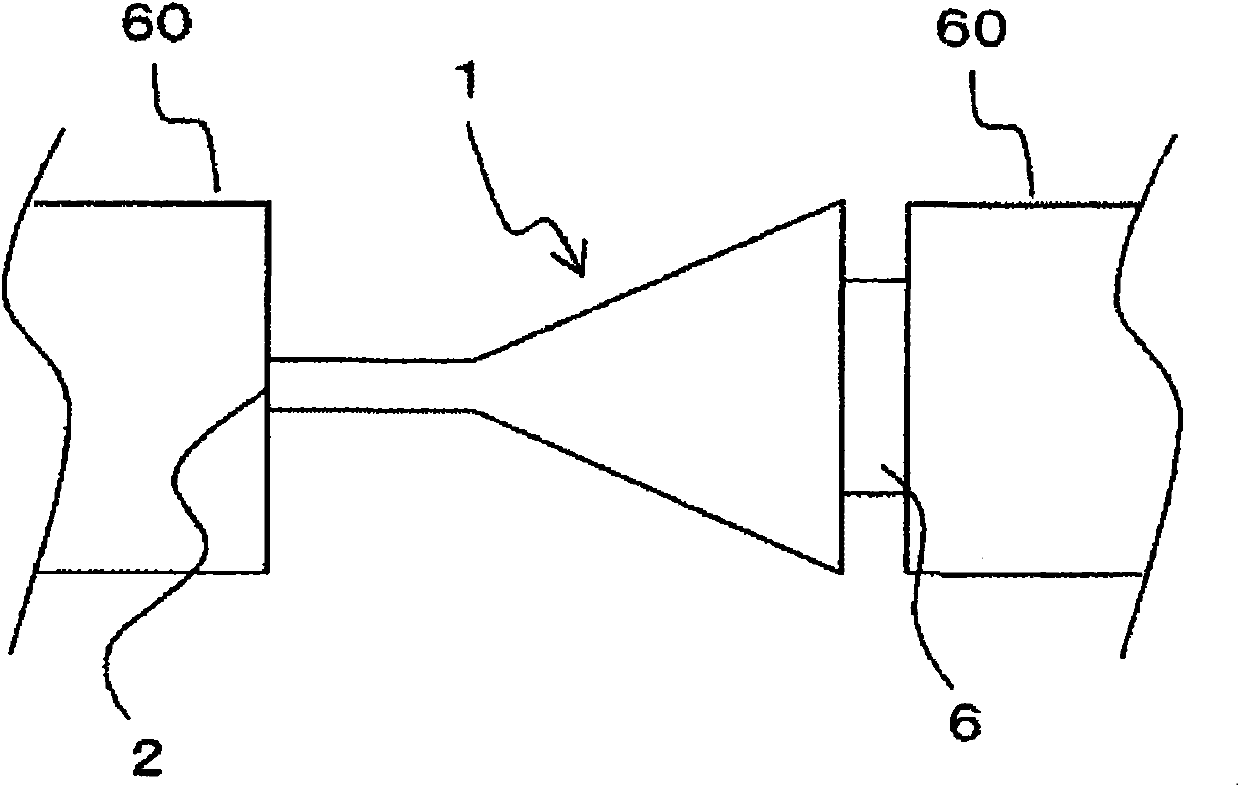

Feeding device of infusion apparatus assembling machine

The invention provides a feeding device of an infusion apparatus assembling machine and belongs to the technical field of medical accessory assembling machines. By means of the feeding device of the infusion apparatus assembling machine, the problem that an existing feeding device is complex in overall structure is solved. The feeding device of the infusion apparatus assembling machine comprises a machine frame and guide rails arranged on the machine frame. A long supporting rack is arranged below the guide rails. A material storage box with a certain length is arranged at one end of the long supporting rack. The length direction of the material storage box is consistent with that of the long supporting rack. The material storage box is close to one end of the long supporting rack and is located below the guide rails. A sucking jaw is connected to the machine frame and located above one end of the material storage box. A clamping jaw which is capable of moving between the upper portion of the long supporting rack and the upper portion of the material storage box in a reciprocating mode is slidably connected to the guide rails. The sucking jaw and the clamping jaw are arrayed on the same line in the direction of the guide rails. When the clamping jaw is located above the material storage box, the clamping jaw is close to the sucking jaw. The feeding device of the infusion apparatus assembling machine can be used for feeding long infusion apparatus catheters.

Owner:MAIDER MEDICAL IND EQUIP

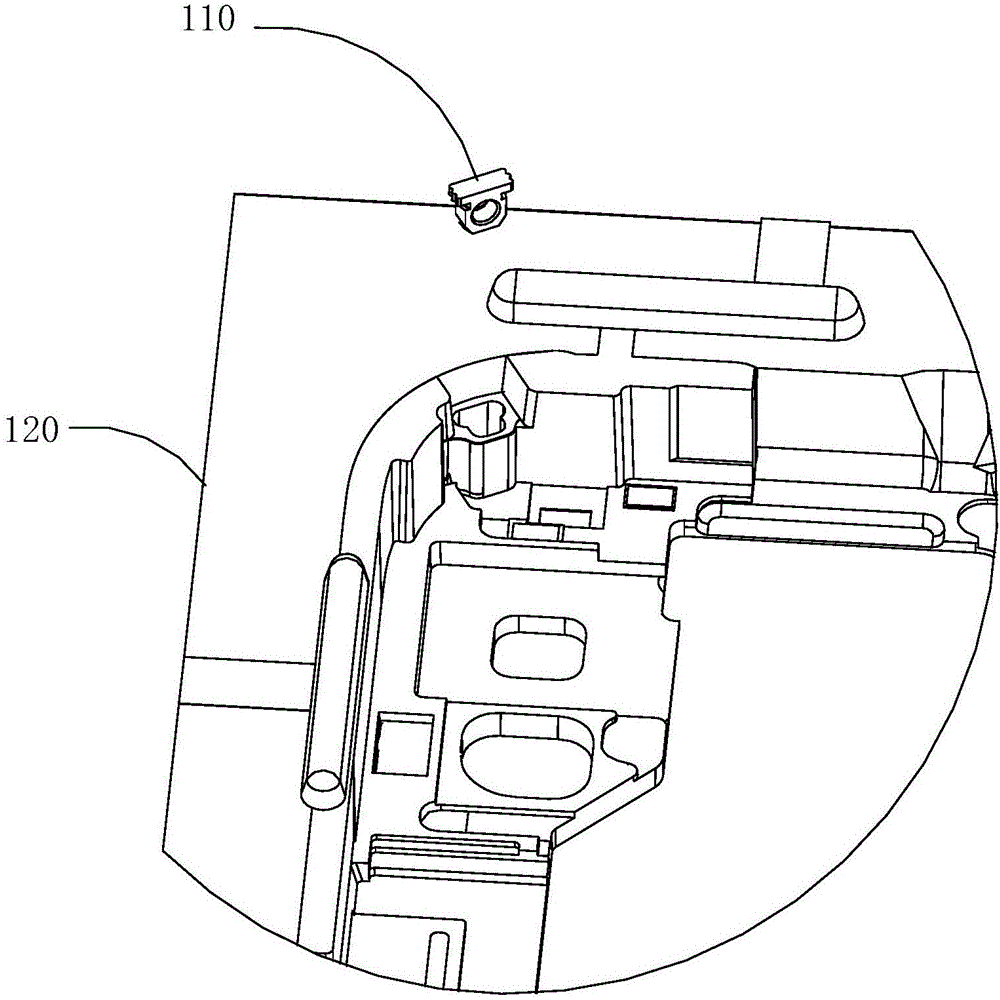

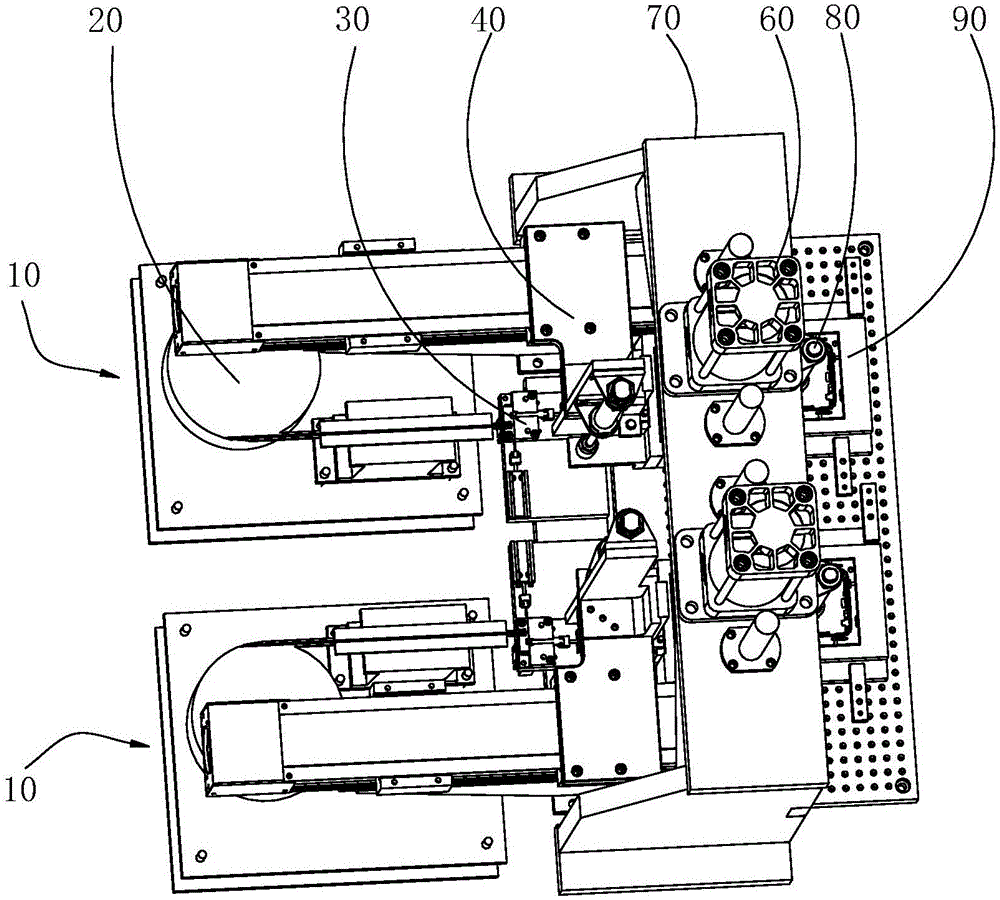

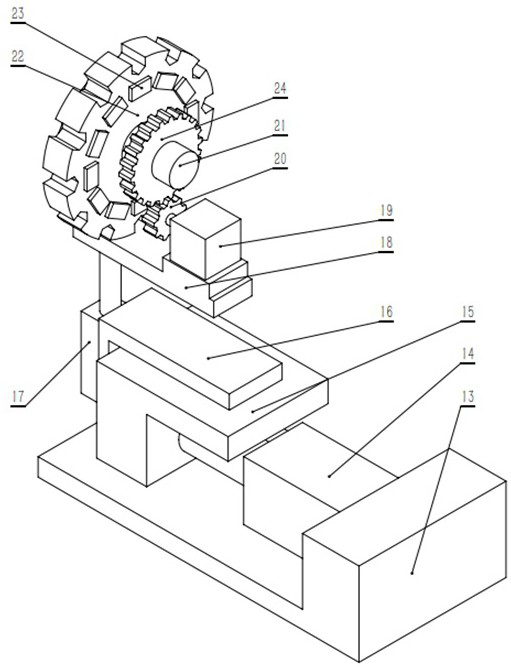

Automatic nut riveting press machine

ActiveCN106736425AImprove riveting efficiencyReduce human inputMetal working apparatusEngineeringMechanical engineering

The invention provides an automatic riveting press machine which is used for riveting and pressing cell phone case nuts into a cell phone case. The automatic nut riveting press machine comprises a cover body and at least one automatic nut riveting press device arranged in the cover body. The automatic nut riveting press device comprises a feeding mechanism, a nut positioning mechanism connected with the feeding mechanism, a cell phone case positioning mechanism which is located at one side, far away from the feeding mechanism, of the nut positioning mechanism, a riveting and pressing mechanism located above the cell phone case positioning mechanism, and a nut transporting mechanism located between the feeding mechanism and the riveting and pressing mechanism; the nut transporting mechanism is located above the nut positioning mechanism. By adopting the automatic nut riveting press machine, the cell phone case nuts are automatically riveted and pressed into the cell phone case, and the riveting and pressing efficiency of the cell phone case nuts is improved; the manpower investment is reduced and the cost is reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD

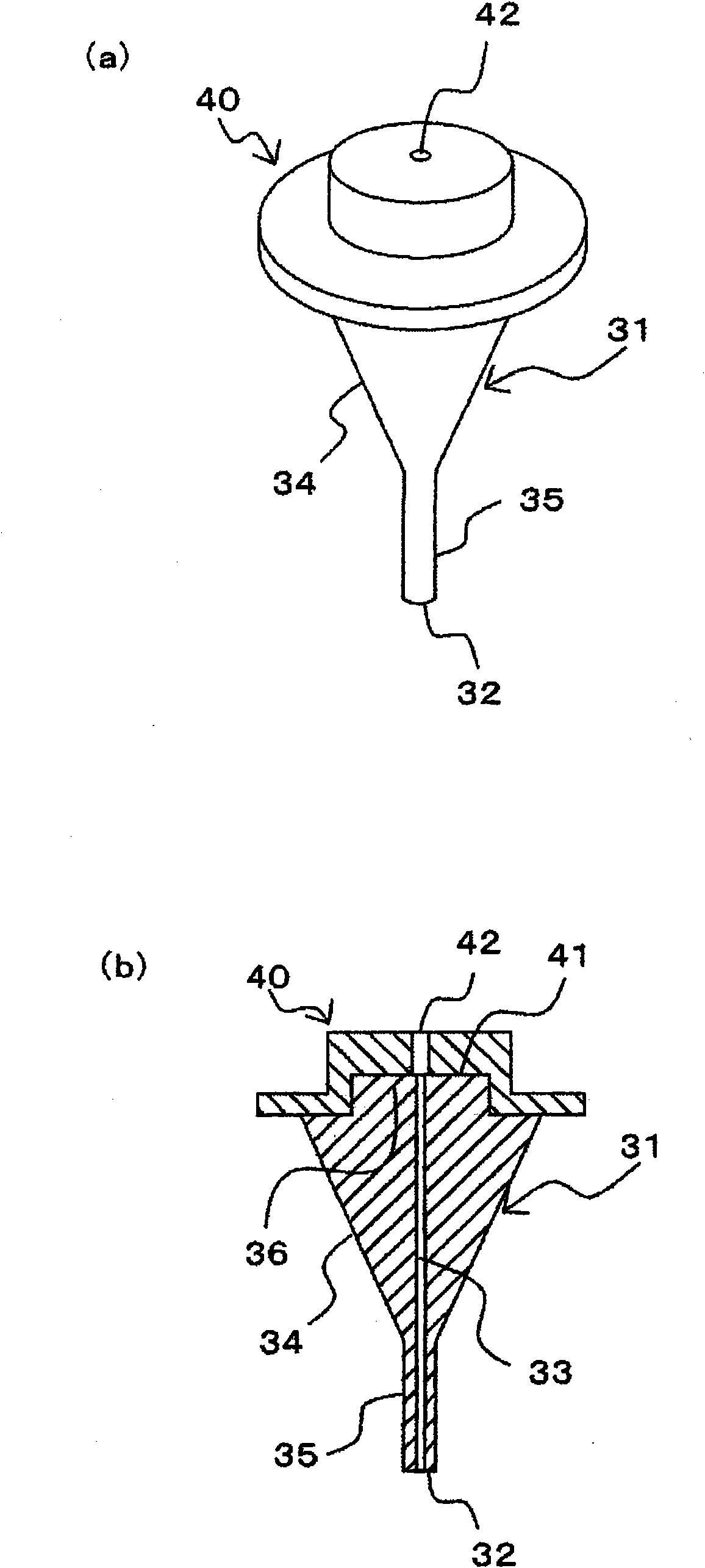

Vacuum holding nozzle

InactiveCN101911860ANo transport installation will take placeWon't pasteGripping headsElectrical componentsHigh densityVolumetric Mass Density

A vacuum holding nozzle is provided which is usable for attaining higher-speed higher-density mounting. The vacuum holding nozzle (1) includes a vacuum holding surface (2) on which a substance to be held is held with suction, and has a suction hole (3) which communicates with the vacuum holding surface (2). The nozzle is characterized in that a tip part thereof including the vacuum holding surface (2) is made of a ceramic, that the ceramic comprises a main ingredient, which constitutes the ceramic, and a second ingredient having an average crystal-grain diameter larger than the average crystal-grain diameter of the main ingredient, and that in the vacuum holding surface (2), crystal grains of the second ingredient are more protrudent than the crystal grains of the main ingredient.

Owner:KYOCERA CORP

Automatic bag throw-in machine for scattered flavoring bags of bowled instant noodles

InactiveCN105059630APrecise deliveryRealize automatic deliveryPackagingConveyor partsEngineeringInstant noodle

An automatic bag throw-in machine for scattered flavoring bags of bowled instant noodles comprises a first conveying mechanism, a charge pipe, a vibratory chute, a vacuum adsorption mechanism, a second conveying mechanism, a third conveying mechanism, a fourth conveying mechanism and a material pushing mechanism, wherein a bag throw-in station is arranged on the first conveying mechanism; the vibratory chute is arranged at one side of the upper end of the charge pipe; the beginning end of the third conveying mechanism is located below the tail end of the second conveying mechanism; a plurality of troughs are arranged on the third conveying mechanism and arranged in the conveying direction of the third conveying mechanism; the fourth conveying mechanism is arranged at one side of the third conveying mechanism; and the material pushing mechanism is arranged at the side, far away from the fourth conveying mechanism, of the third conveying mechanism. The automatic bag throw-in machine realizes automatic throwing of the scattered single flavoring bags, besides, quantitative conveying of the flavoring bags is realized through the third conveying mechanism, and the flavoring bags are vibrated to be in the tiling state through the vibratory chute, so that the flavoring bags cannot be in a randomly stacked state, and accordingly, convenience is brought for the vacuum adsorption mechanism to adsorb the flavoring bags relatively accurately.

Owner:GUANGZHOU FANDOR MECHANICAL & ELECTRICAL EQUIP +1

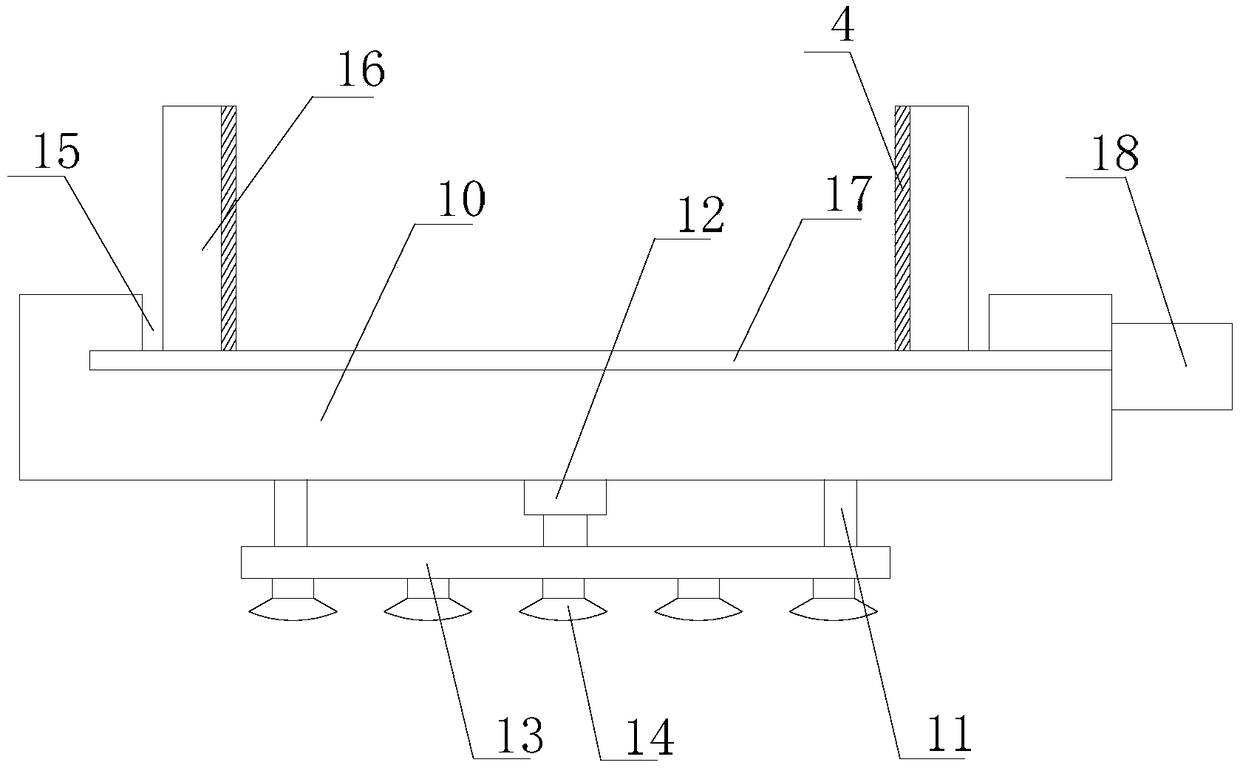

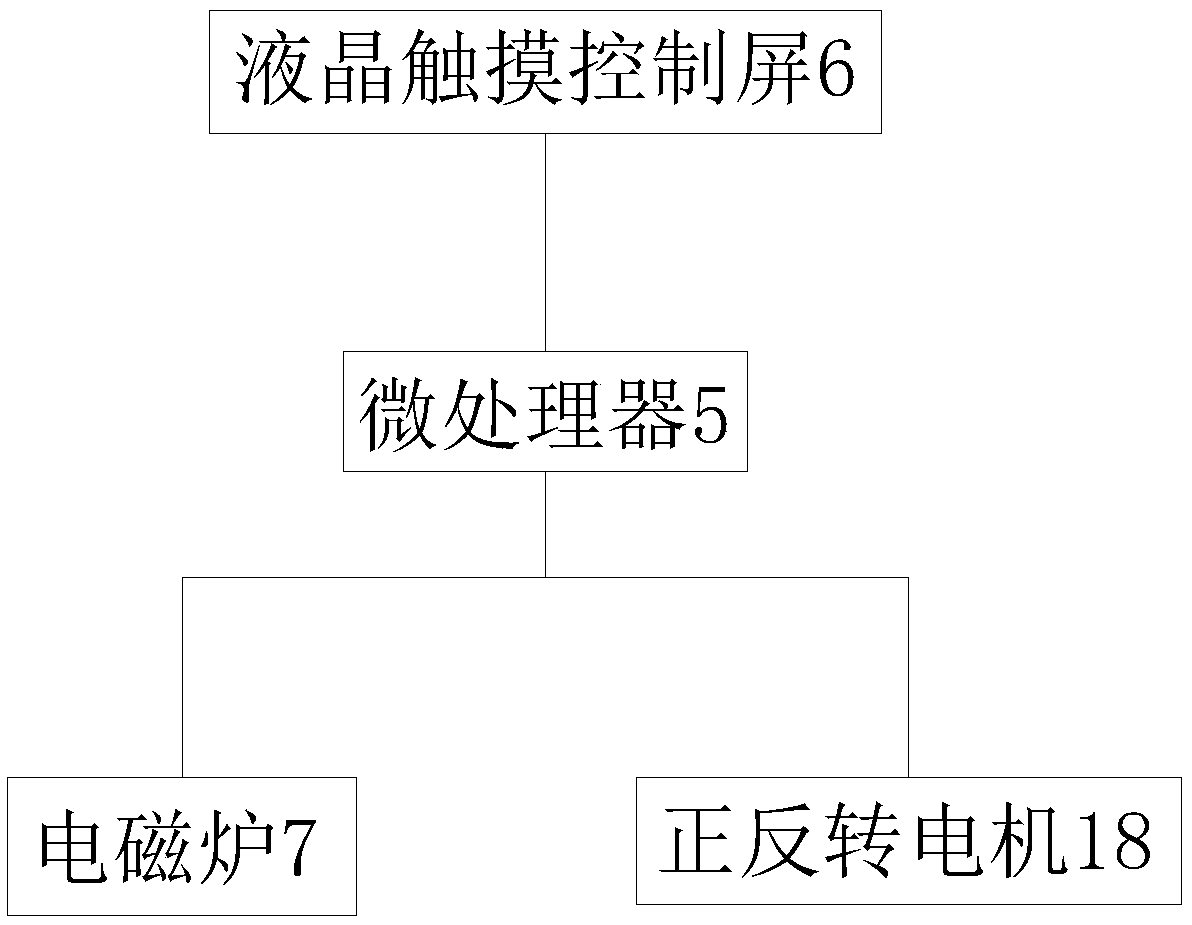

Anti-overturning end table based on negative pressure suckers

InactiveCN108771343ASimple structureScientific and reasonable designServing tablesFeetCookerLiquid crystal

The invention discloses an anti-overturning end table based on negative pressure suckers, and solves the problems that end tables have single function and are inconvenient to use and move and the bottom surface is instable by direct laying. The end table comprises an end table main body, a placing cabinet, a microprocessor, a liquid crystal touch control screen and an induction cooker, wherein a moving device is arranged at the bottom of each pillar and comprises a moving base, a hydraulic jack, a supporting rod, the negative pressure suckers and guide pillars; guide grooves are formed in bottoms of the moving bases; each negative pressure sucker comprises a fixing piece and an adsorption bowl; a mounting groove is formed in the top of each fixing plate, two clamping plates are arranged ineach mounting groove and connected by a lead screw, and forward / reversal rotation motors are arranged at one ends of the fixing plates. The end table can cook tea, and is multifunctional, low in space occupation rate and convenient to move; the end table can be firmly adsorbed on the ground when being fixed on the ground, and potential safety hazard of people near the end table main body can be eliminated while safety of electronic products installed or placed on the end table main body is guaranteed.

Owner:成都海蒂瑞斯商贸有限公司

Uncoated digital ink jet transfer printing base paper and production method thereof

PendingCN110093806APrecise adsorptionReduce warpageWater-repelling agents additionReinforcing agents additionDigital inkFiber

The invention provides uncoated digital ink jet transfer printing base paper and a production method thereof. The uncoated digital ink jet transfer printing base paper comprises plant fiber and an inorganic filler, wherein an impregnation treatment agent is filled between the plant fiber and the inorganic filler. The invention also discloses the preparation method of the uncoated ink jet transferprinting base paper, and the preparation method comprises the following steps: base paper is prepared by pulping, blending pulp, forming, squeezing and drying; the base paper is further subjected to impregnation treatment; an impregnation liquid penetrates into the base paper and wraps the surfaces of the plant fiber and the inorganic filler on the surface layer of the base paper; and the uncoatedink jet transfer printing base paper can be obtained after subsequent drying and calendering. The uncoated digital ink jet transfer printing base paper has the advantages that the paper surface is flat without warping, ink on the paper surface is easy to dry, the gloss of the ink is not reduced, and the transfer printing is uniform.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

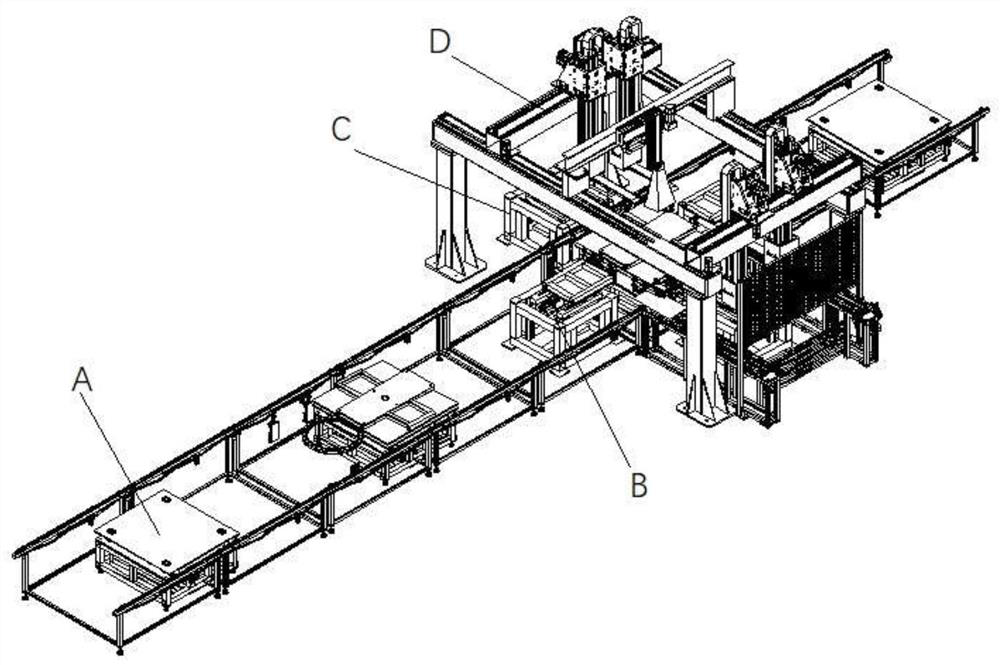

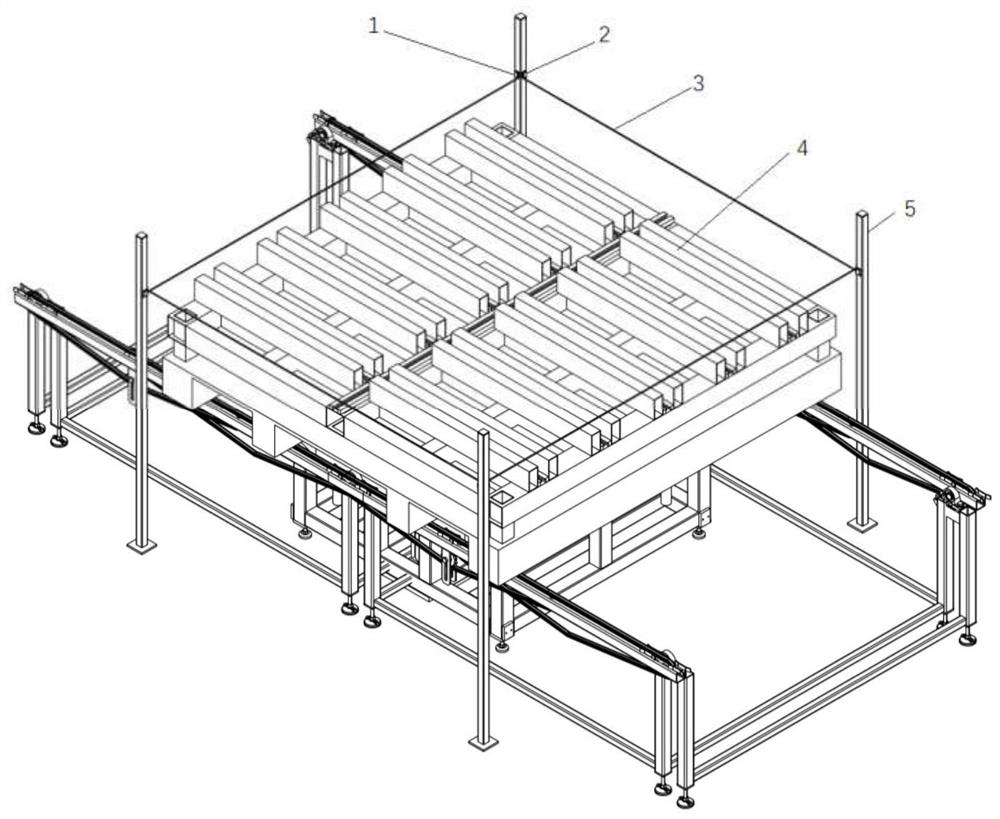

Large plate support replacing system

ActiveCN112320279AHigh degree of automationImprove efficiencyConveyorsControl devices for conveyorsStructural engineeringAdsorption separation

The invention belongs to the field of plate support replacement, and relates to a large plate support replacing system. The large plate support replacing system comprises a weighing platform for weighing plates; an automatic centering mechanism used for carrying out centering treatment on the weighed plates; a lifting and rotating mechanism used for lifting and rotating the plates, wherein a bearing table is arranged on the lifting and rotating mechanism and used for bearing the plates, and the area of the bearing table is smaller than that of the plates; an adsorption separation device arranged around the periphery of the bearing table, located below the table top of the bearing table and used for adsorbing paper at the bottoms of the plates on the bearing table so that the paper on the edges of the plates can be separated from the plates; a lifting device arranged around the bearing table, and a first fork is arranged on the lifting device and used for forking the plates from the paper separation position on the edges of the plates; and a paper extraction device arranged on one side of the bearing table and used for grabbing and moving the edge of the paper separated from the plates after the plates are forked so that the paper can be completely separated from the plates. Automatic plate support replacement is achieved, the labor cost is reduced, and the operation safety is improved.

Owner:百工汇智(上海)工业科技有限公司 +1

Bowl noodle loose bag automatic bag feeding machine

InactiveCN105059630BPrecise deliveryRealize automatic deliveryPackagingConveyor partsInstant noodleMechanical engineering

Owner:GUANGZHOU FANDOR MECHANICAL & ELECTRICAL EQUIP +1

Base body forming device

PendingCN111113032ARealize fully automatic handlingAchieve fitAssembly machinesMetal working apparatusEngineeringWorkbench

Owner:威海山鼎精密机械有限公司

Presswork die cutting device

InactiveCN108705605AAvoidance of twist sticking to cutter rollsEasy to separateMetal working apparatusEngineeringMechanical engineering

The invention relates to a presswork treatment device, in particular to a presswork die cutting device. The presswork die cutting device comprises a frame, a conveying mechanism for conveying presswork, a pressure roller arranged in an outlet of the conveying mechanism, and a cutter roller arranged under the pressure roller; the pressure roller and the cutter roller are mounted on the frame; a diecutting plate is arranged on the cutter roller, and is provided with a positioning block; a closing cutter is arranged on the die cutting plate; the die cutting plate is provided with a closed mounting groove in the range of the closing cutter; a closed mounting block is bonded in the closed mounting groove; a closed elastic block is arranged on the closed mounting block; a negative-pressure airsucking port is formed in the closed mounting block; an open cutter is arranged on the die cutting plate; the die cutting plate is provided with an open mounting groove in the range of the open cutter; and the open elastic block and the closed elastic block both adopt elastic porous materials. The die cutting device totally separates fertilizers from presswork bodies.

Owner:重庆川之舟印务设计有限公司

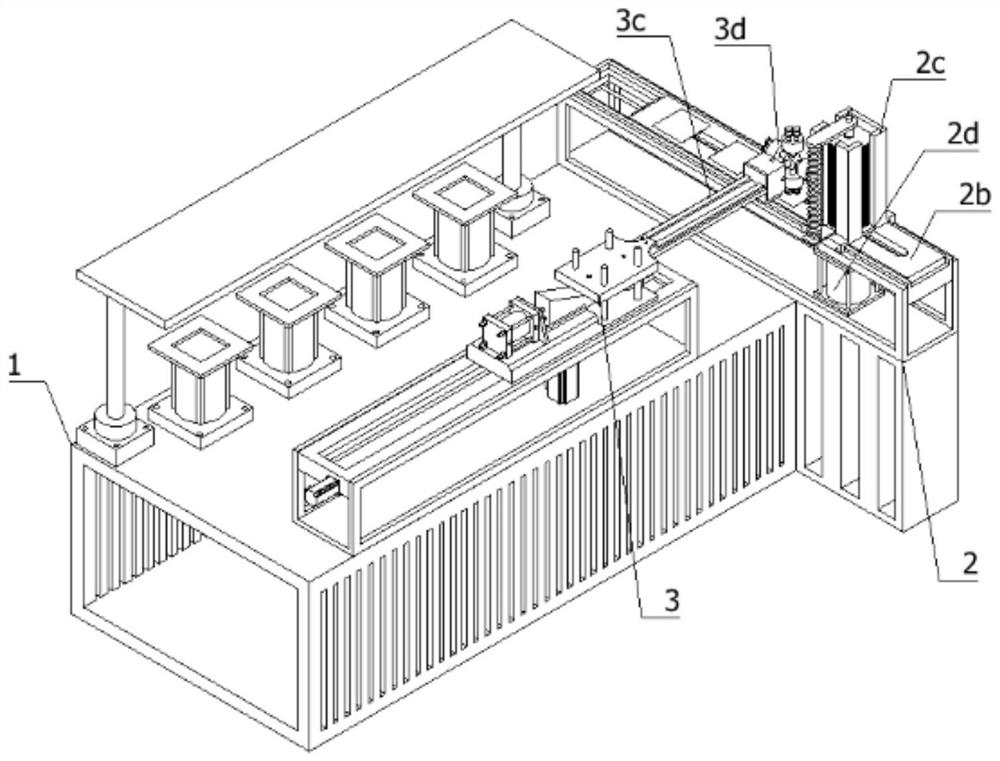

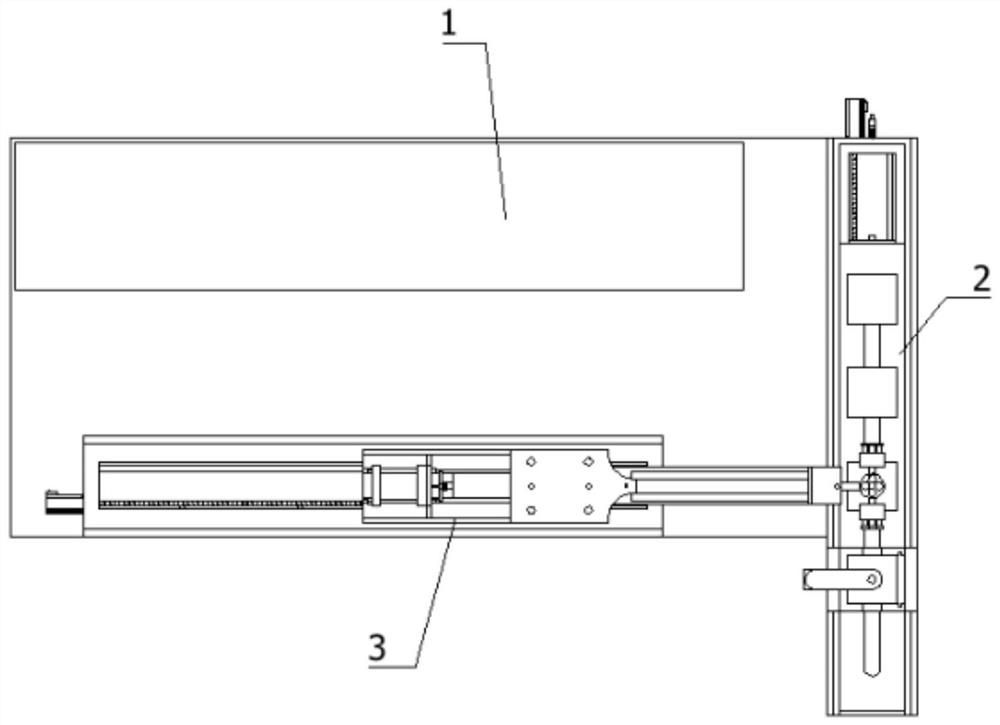

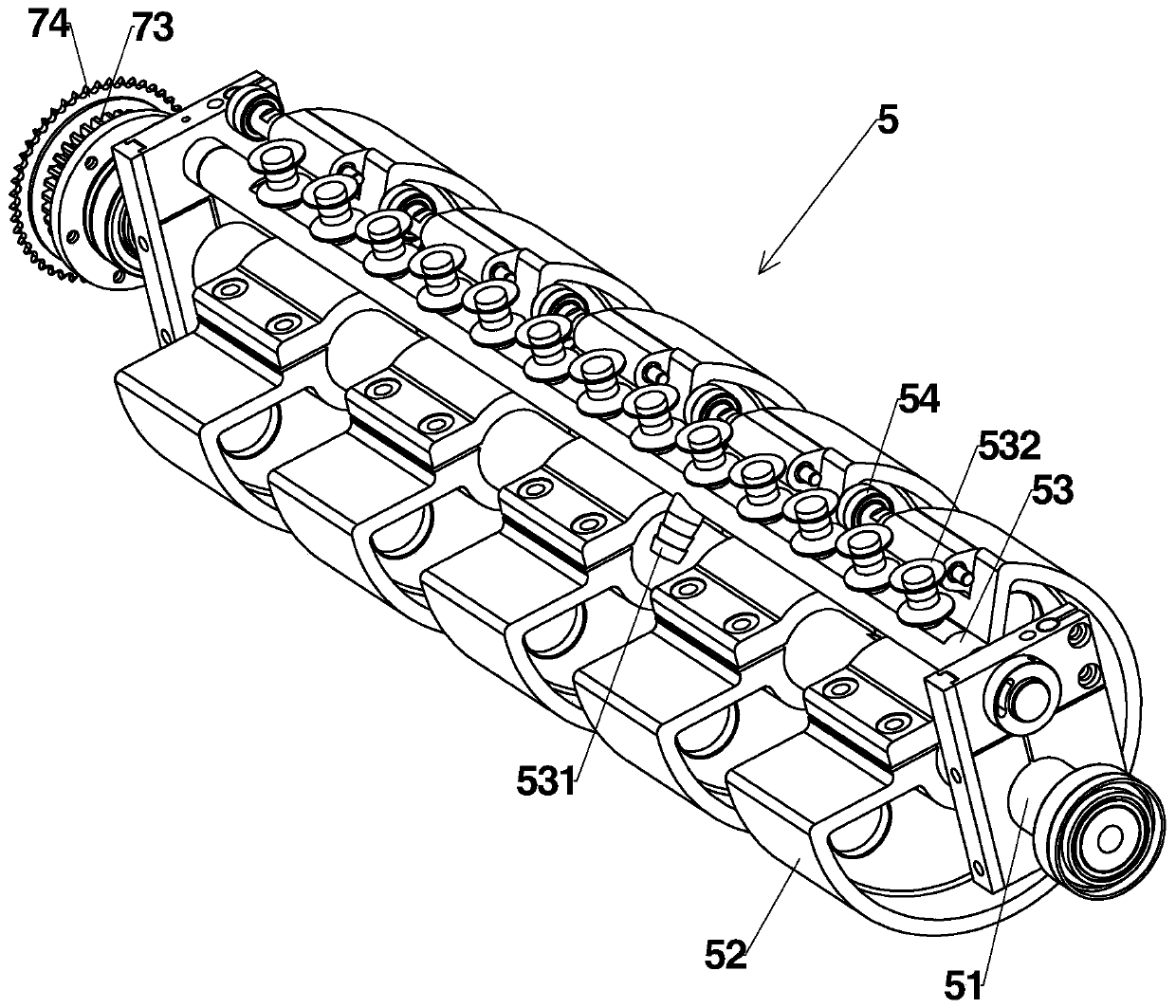

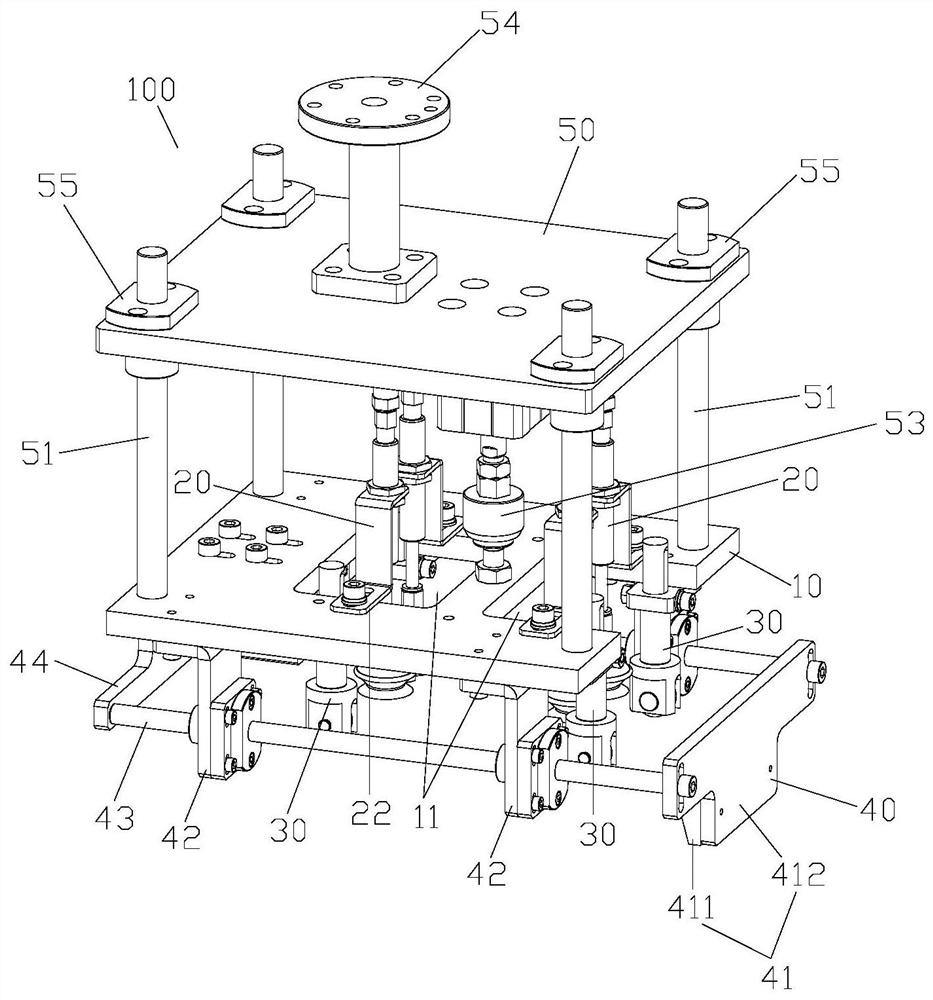

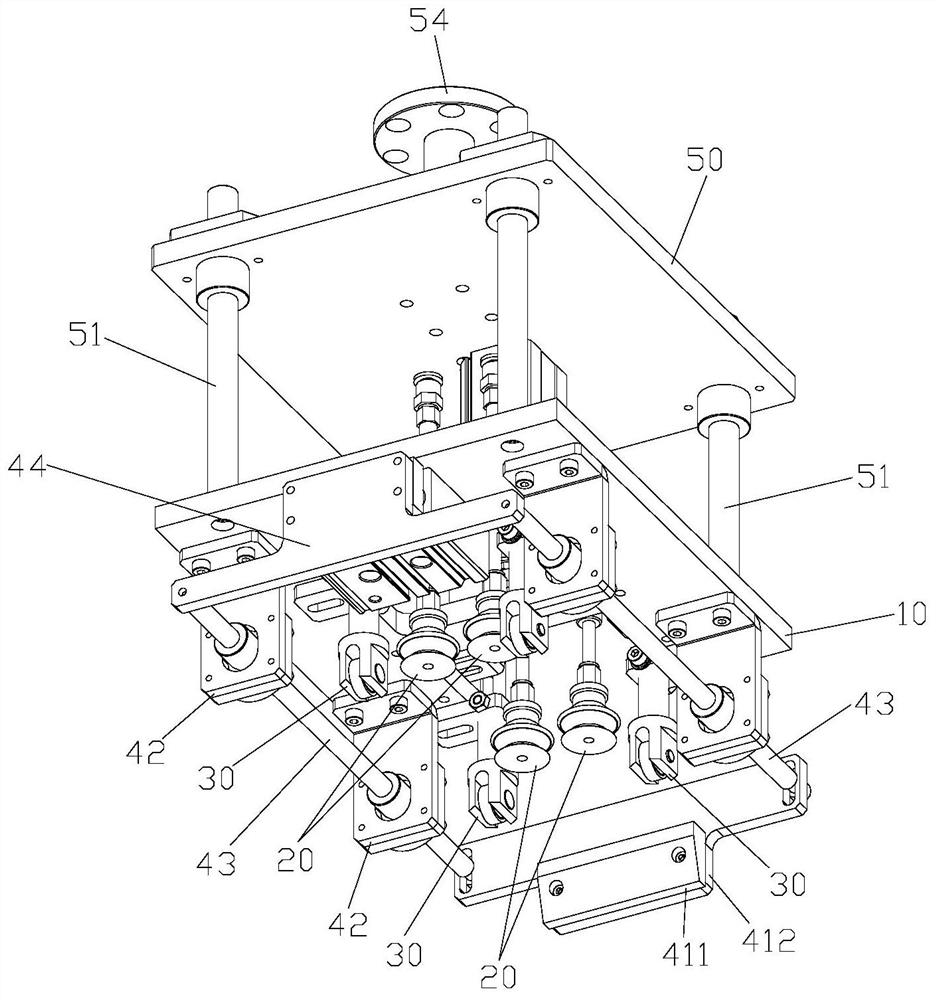

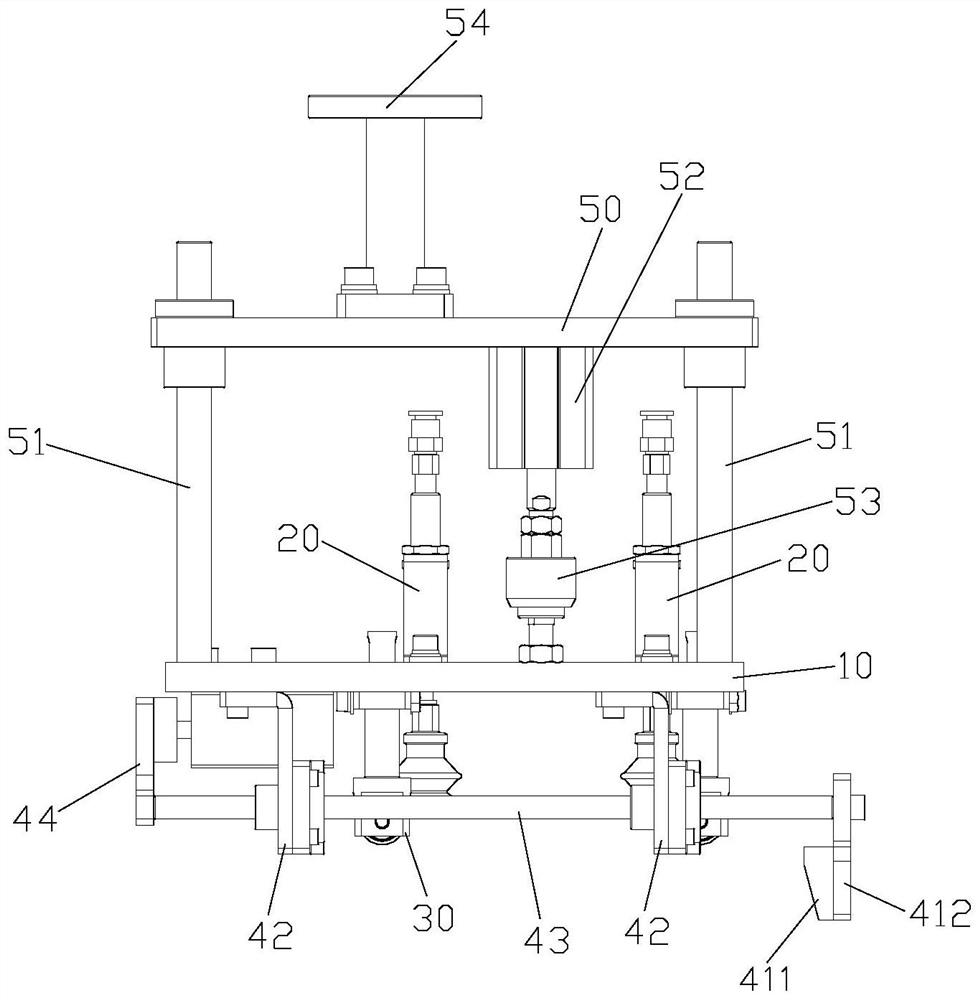

Multi-station high-speed carrying device for press line

ActiveCN113714411AImprove processing efficiencyReduce labor intensityMetal-working feeding devicesPositioning devicesStampingPhysics

The invention relates to the field of multi-station stamping dies, in particular to a multi-station high-speed carrying device for a press line. The multi-station high-speed carrying device comprises a multi-station stamping table, and further comprises a material distributing device and a material sucking device which are arranged on the multi-station stamping table, wherein the material distributing device is used for separating plate-shaped parts to be adsorbed from plate-shaped parts which are not adsorbed according to the number of the plate-shaped parts adsorbed by the material sucking device; and the material distributing device comprises a conveying frame, a material distributing plate arranged at the top of the conveying frame, a material stacking frame and a jacking air cylinder which is arranged on the conveying frame and is positioned under the material stacking frame. According to the multi-station high-speed carrying device, the material distributing device and the material sucking device are matched with each other, thus, the circumstance that numbers of the absorbed plate-shaped parts in different times are different in the process of carrying the plate-shaped parts at the same time is avoided, the processing efficiency of the plate-shaped parts in batches is improved, and the labor intensity of workers is reduced.

Owner:江苏兴锻智能装备科技有限公司

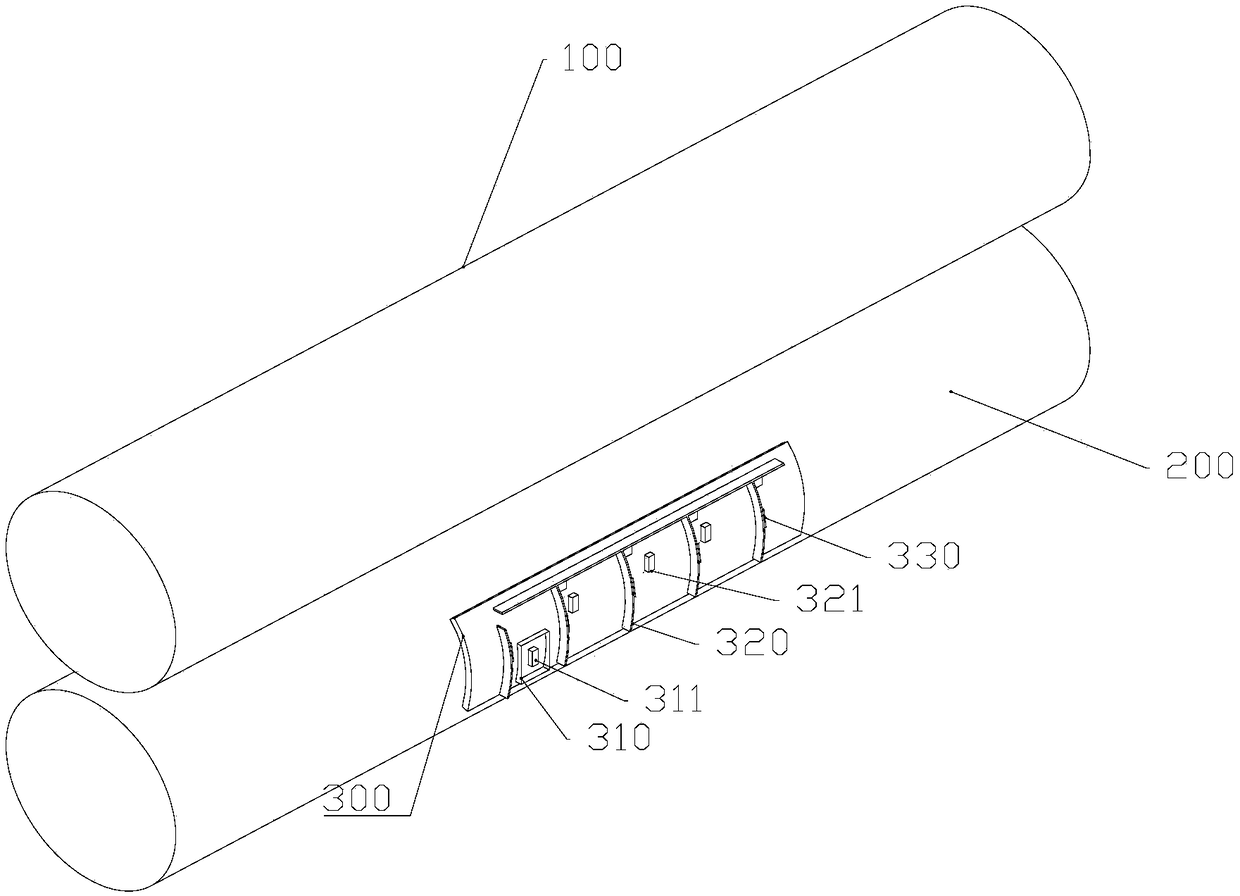

Assembling system for wood right-angle clamping plate of polyurethane insulation box

ActiveCN109940362AAvoid damageImprove feeding efficiencyGripping headsMetal working apparatusUltimate tensile strengthIndustrial engineering

The invention relates to an assembling system of a wood right-angle clamping plate of a polyurethane insulating box. The assembling system comprises a clamping plate feeding device and a clamping plate material taking device; wherein the clamping plate feeding device comprises a clamping plate stock bin, a transverse feeding mechanism, a longitudinal feeding mechanism, a pushing mechanism, a jacking and separating positioning mechanism and the like; and the clamping plate material taking device comprises a material taking grabbing hand for grabbing a right-angle clamping plate on the jacking and separating positioning mechanism, and the industrial robot is connected with the material taking tongs and drives the material taking tongs to move. Compared with the prior art, according to the system, the mechanical automation of the whole process of feeding, grabbing, assembling and positioning the right-angle clamping plate of the insulation box can be realized by matching the right-angle clamping plate of the insulation box, the labor intensity of manual operation in the existing assembling process is improved, the defect that the efficiency is low is overcome, the quality problems such as the connection strength and the assembly precision of the wood right-angle clamping plate due to the error of manual operation are solved, and the like.

Owner:SHANGHAI JIAO TONG UNIV +1

Screwdriver allowing automatic replacement of bit

Owner:建德市远丰工具有限公司

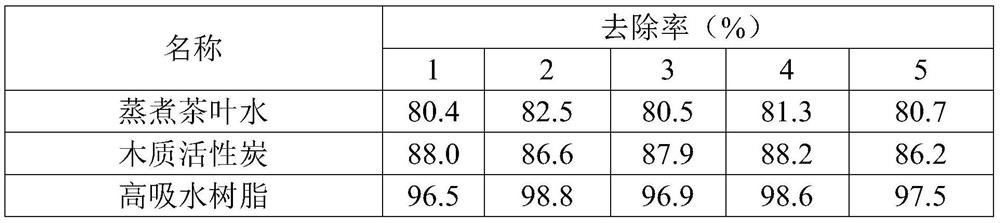

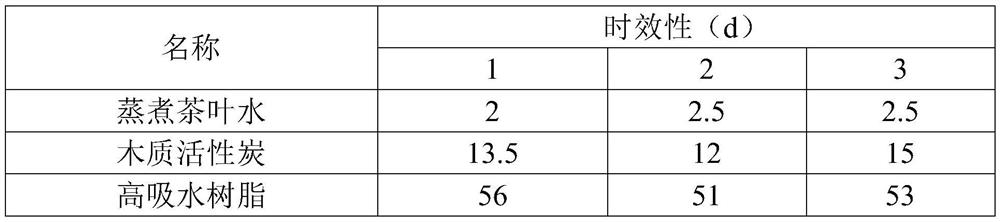

Super absorbent resin carrier adsorption reaction type air purifying agent

InactiveCN112023674ARealize processingPrecise adsorptionGas treatmentDispersed particle separationActive agentSuper absorbent

The invention discloses a super absorbent resin carrier adsorption reaction type air purifying agent, and relates to the technical field of air purification. The air purifying agent comprises a superabsorbent reins, the super absorbent resin is soaked in a functional adsorption solution, and film sealing is conducted for storage after the super absorbent resin is adsorbed to be saturated, whereinthe functional adsorption solution is prepared from the following raw materials in parts by weight: 2-5 parts of a surfactant, 1-2 parts of sodium citrate, 1-2 parts of essence, 10.5-27 parts of a functional adsorbent and 82-96 parts of deionized water. The super absorbent resin is a netty high-molecular non-toxic polymer, has extremely strong water absorption performance, is used as a good reactant carrier after being treated by a surfactant, and reacts with treated harmful substances to realize a function, so that the purpose of simultaneously selective adsorbing and reacting treatment of one or more harmful substances is achieved.

Owner:成都祯鑫科技有限公司

Adhesive-attaching jig

ActiveCN107215523AImprove qualitySimple structureLabelling machinesEngineeringMechanical engineering

The invention relates to an adhesive-attaching jig used for attaching an adhesive ring of a double-faced adhesive tape onto a product. The adhesive-attaching jig comprises an adhesive-attaching element and a location dowel, wherein the adhesive-attaching element is used for adsorbing a protection film of the double-faced adhesive tape; the location dowel is fixedly connected with the adhesive-attaching element; the location dowel can be arranged in a first through hole of the protection film in a penetrating manner to limit a position of the adhesive ring on the adhesive-attaching element; and the location dowel can be arranged in a second through hole in the product in a penetrating manner to align the adhesive ring with an adhesive-attaching position of the product. The adhesive-attaching jig is simple in structure, convenient to use, and capable of accurately attaching the adhesive ring of the double-faced adhesive tape onto the product, so as to improve adhesive-attaching quality.

Owner:GUANGDONG EVERWIN PRECISION TECH

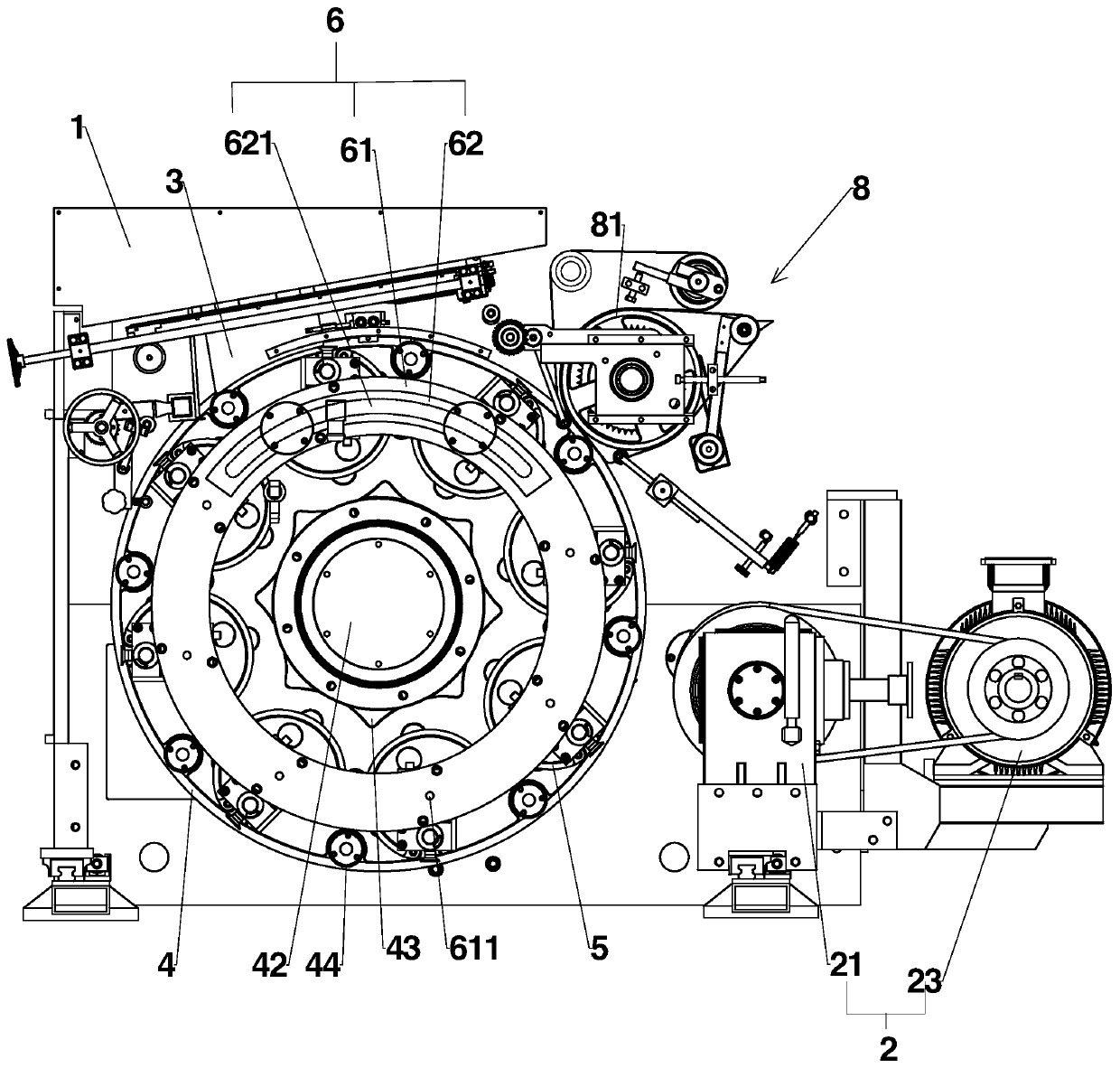

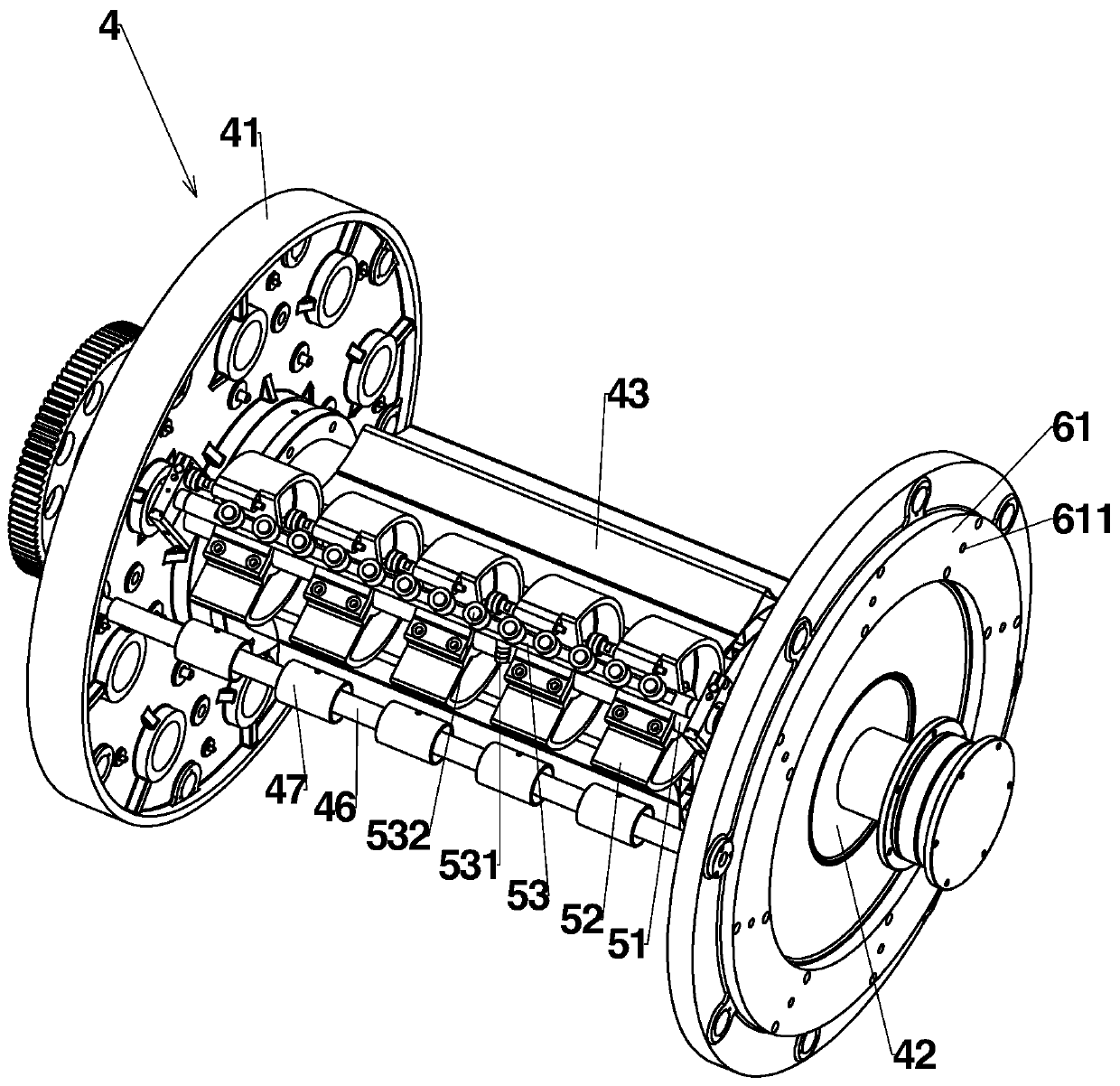

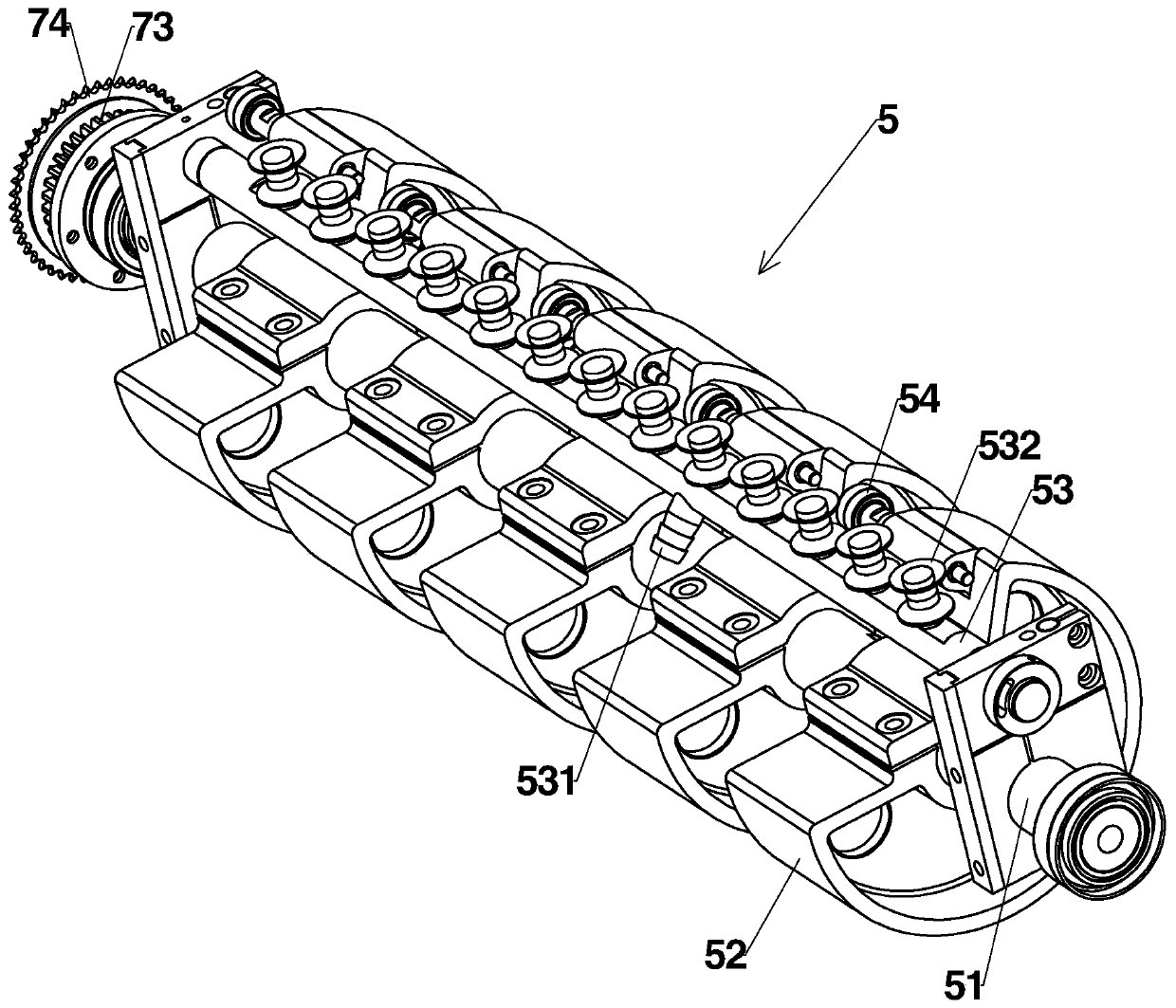

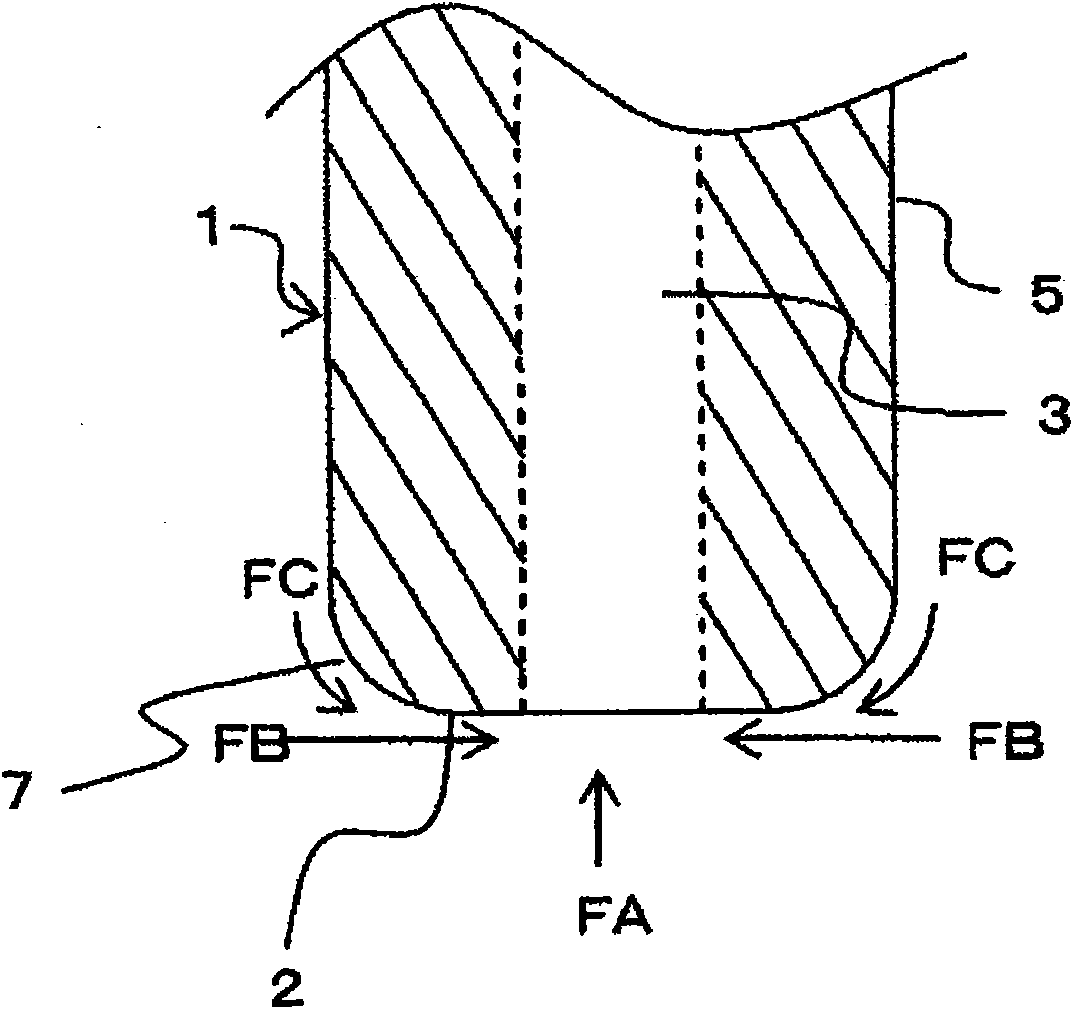

Paper bag transfer mechanism of feeding device

ActiveCN109911663AConveying orderlyStable deliveryArticle feedersArticle separationPulp and paper industryTransfer mechanism

The invention relates to a paper bag transfer mechanism of a feeding device. The paper bag transfer mechanism includes a rotary table and paper adsorption assemblies arranged on the rotary table, therotary table includes disk bodies located at the two ends and a mandrel connecting the two disk bodies, the paper adsorption assemblies are rotatably mounted on the two disk bodies of the rotary table, one of the disk bodies is provided with a transmission mechanism for driving the paper adsorption assemblies to rotate, and the other one of the disk bodies is provided with a distribution mechanismfor distribution of the paper adsorption assemblies; the paper adsorption assemblies include hollow shafts, the hollow shafts are rotatably arranged on the two disk bodies of the rotary table, a plurality of paper adsorption wheels sleeve the hollow shafts, and the paper adsorption wheels is provided with hollow rod bodies; and the hollow rod bodies are provided with suction cups arranged in thelength directions of the hollow rod bodies, the suction cups communicate with the hollow rod bodies, the hollow rod bodies communicate with the hollow shafts, and the hollow shafts are connected witha negative-pressure device through the distribution mechanism, wherein the distribution mechanism and a driving mechanism are arranged on the disk bodies at the two ends of the rotary table correspondingly without interfering with each other. The stability during operation is high.

Owner:江西新明峰包装科技有限公司

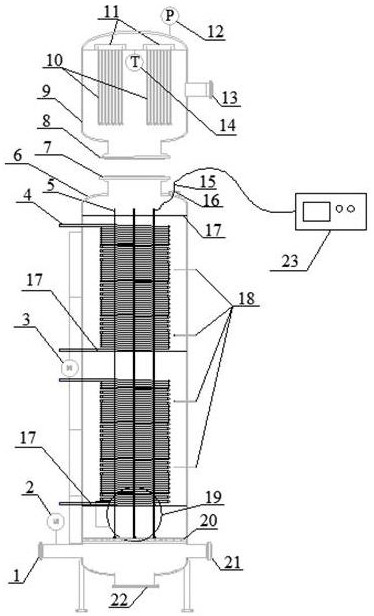

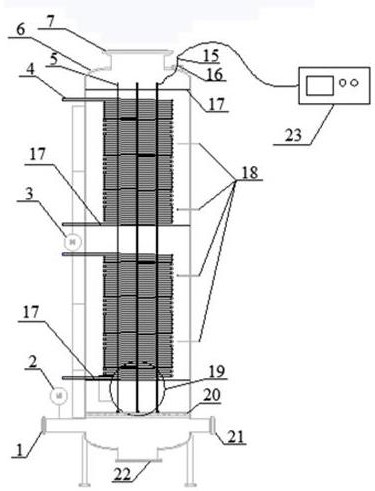

Safe, efficient and convenient cyclic adsorption and desorption process and adsorption and desorption tower

ActiveCN112691503ASimple structureEasy to install and disassembleGas treatmentDispersed particle separationControl systemDifferential pressure

The invention discloses a safe, efficient and convenient cyclic adsorption and desorption process and an adsorption and desorption tower, and belongs to the technical field of oil gas recovery. The cyclic adsorption and desorption tower is simple in structure, a packed tower and an air heating tower can be selectively assembled and disassembled according to actual conditions and are convenient to assemble and disassemble, and a fixing plate and a fixing rod are both of a detachable structure; a coil pipe and a temperature thermocouple can be fixed and accurately positioned while mounting and dismounting are convenient, problems are found in time, the positions of the problems are positioned, and the maintenance cost is saved; the gas inlet flow, the pressure difference and the gas taking result are correlated and fed back to form a safety control system in the adsorption process of the packed tower, whether the flow speed of gas in the tower is normal or not can be judged through a differential pressure gauge, if the pressure difference is too large, whether the gas inlet flow is too large or an adsorbent layer is blocked or not can be judged by combining the gas inlet flow meter and the gas taking result, the blocking position can be determined, and corresponding adjustment is carried out, so that the adsorption process is accurately controlled, and safety accidents are avoided.

Owner:TIANJIN ZHONGDE ENG DESIGN

Surface paper conveying structure of paper laminating machine

The invention discloses a surface paper conveying structure of a paper laminating machine. The surface paper conveying structure of the paper laminating machine comprises a support, a lifting drive mechanism and a lifting seat. The lifting drive mechanism is fixed onto the support and is used for driving the lifting seat to move up and down; the lifting seat comprises an underframe, a bracket, a connecting rod assembly, rollers and screws; the rollers are rotatably connected to the inner sides of a front rod and a back rod of the underframe; the bracket is located on the upper side of the underframe and is in rolling contact with the rollers; through slots extending along the left-and-right direction are formed in a front rod and a back rod of the bracket; the nail body ends of the screwspenetrate through the through slots and are in threaded connection with the underframe; and the connecting rod assembly is used for driving the bracket to horizontally move relative to the underframe.Compared with the prior art, according to the surface paper conveying structure of the paper laminating machine provided by the invention, the lifting seat is divided into the underframe and the bracket, and the horizontal position of the bracket can be adjusted, so that a feeder is accurately adsorbed in the middle of surface paper.

Owner:ANHUI INNOVO BEICHEN MACHINERY MFG CO LTD

Clamping equipment

ActiveCN112621156AAvoid separationReduce the difficulty of assemblyMetal working apparatusEngineeringVALVE PORT

The invention provides clamping equipment. The clamping equipment comprises a movably-arranged mounting plate; an adsorption assembly fixedly arranged on the mounting plate and used for adsorbing a workpiece; a pressing assembly fixedly arranged on the mounting plate and used for abutting against the workpiece; after the adsorption assembly releases the workpiece, the workpiece is kept in contact with the mounting foundation through the pressing assembly; a pushing assembly mounted on the mounting plate; and the pushing assembly comprises a pushing part, and the pushing part is movably arranged so as to abut against the workpiece and push the workpiece to move to a preset position on a mounting foundation. The clamping equipment integrates the adsorption assembly, the pressing assembly and the pushing assembly, the overall structure is compact, the occupied space is small, a valve cover can be flexibly and accurately installed on an air conditioner outdoor unit through the clamping equipment, the assembling difficulty of the valve cover is reduced, and the problem that in the prior art, due to the installation mode of the valve cover, the assembly difficulty of the valve cover is large is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com