Safe, efficient and convenient cyclic adsorption and desorption process and adsorption and desorption tower

An adsorption-desorption, high-efficiency technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of waste of resources, no mutual restraint feedback, unfavorable disassembly and cleaning, etc., to save maintenance costs, avoid uneven adsorption, and facilitate The effect of cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in combination with specific embodiments.

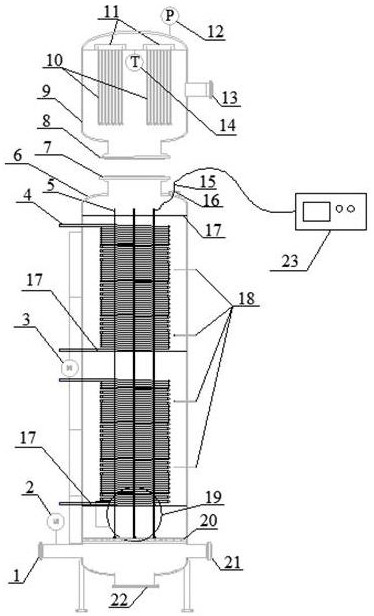

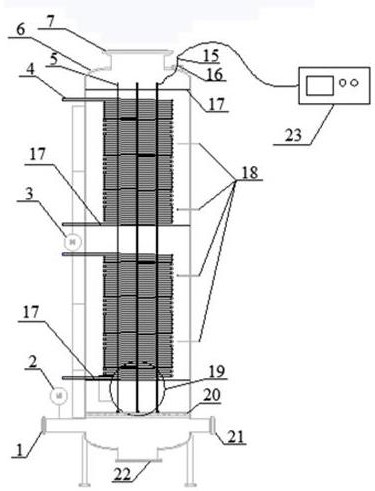

[0049] In this embodiment, when the on-site gas (mainly oil-air-air mixture, the gas flow rate is 500 Nm 3 / h, the gas temperature is normal temperature) is recovered, the temperature of the cold cycle system is 8°C, the temperature of the heat cycle system is 70°C, and the oil gas concentration in the exhaust gas is required to be 3 . Through the technical scheme of the present invention combined with the attached figure 1 And attached figure 2 Describe in detail.

[0050] Such as figure 1 As shown, a safe, efficient and convenient cyclic adsorption-desorption process includes the following steps:

[0051] (1) Position and fix several temperature-measuring thermocouples 15 on several fixed rods 5 with scales, number and record them; Remove the fixing plate 17, wherein the position marked 0 of the fixing rod 5 and the position of the bottom of the adsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com