Patents

Literature

88results about How to "Conveying orderly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

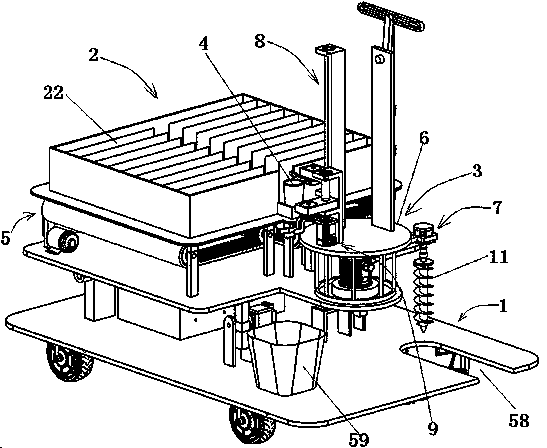

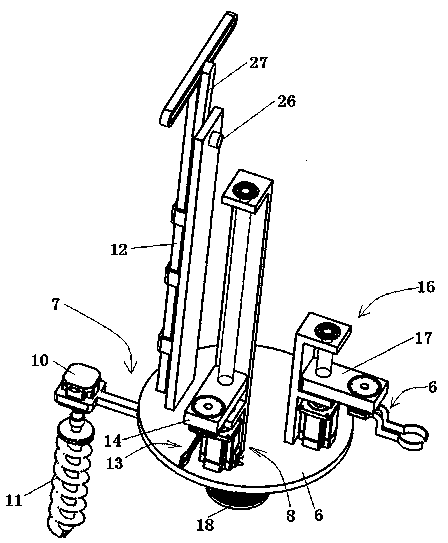

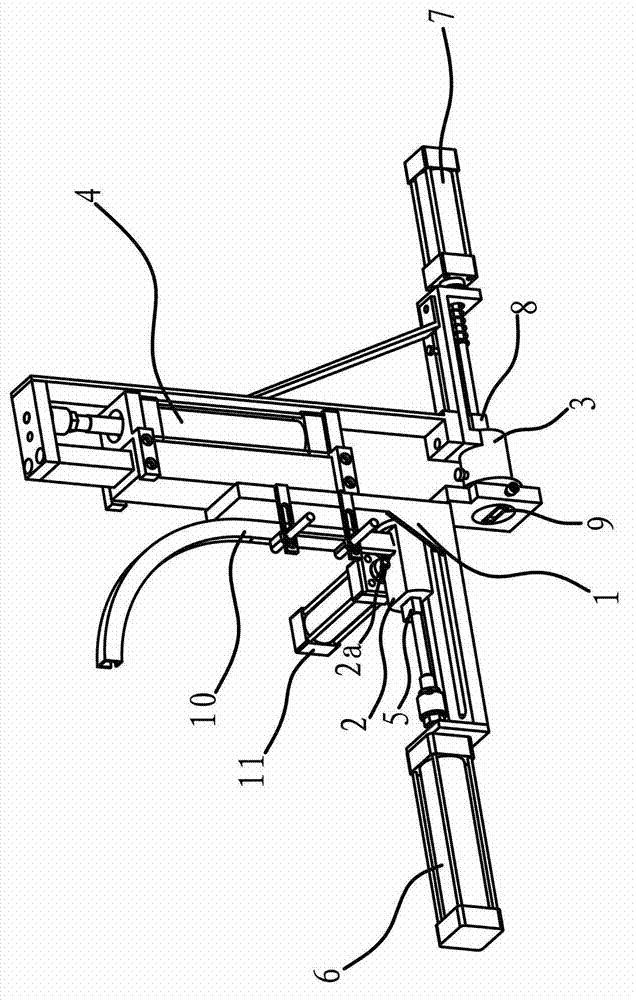

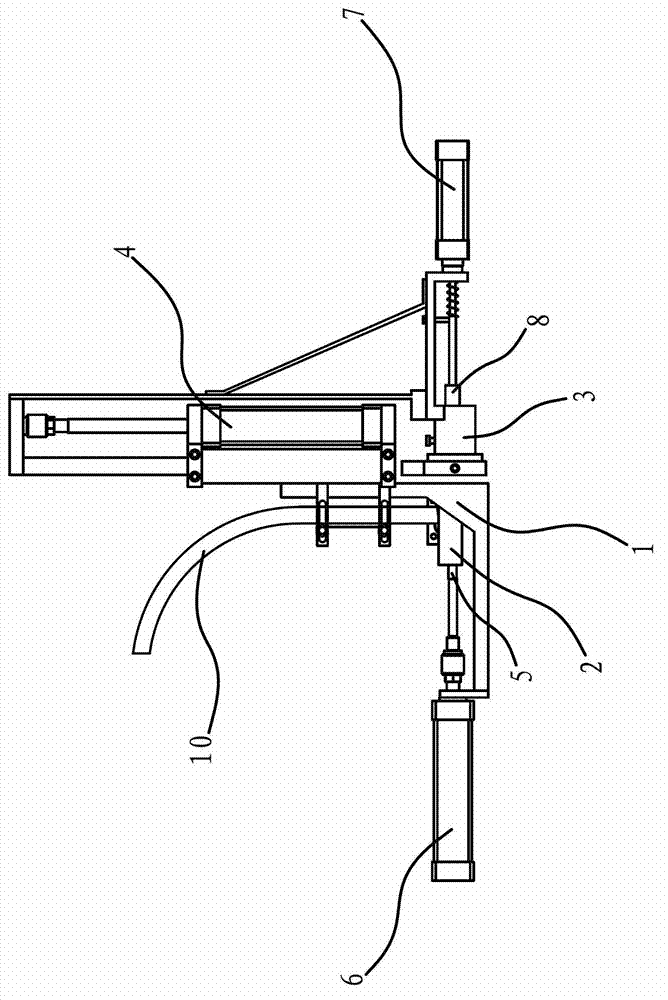

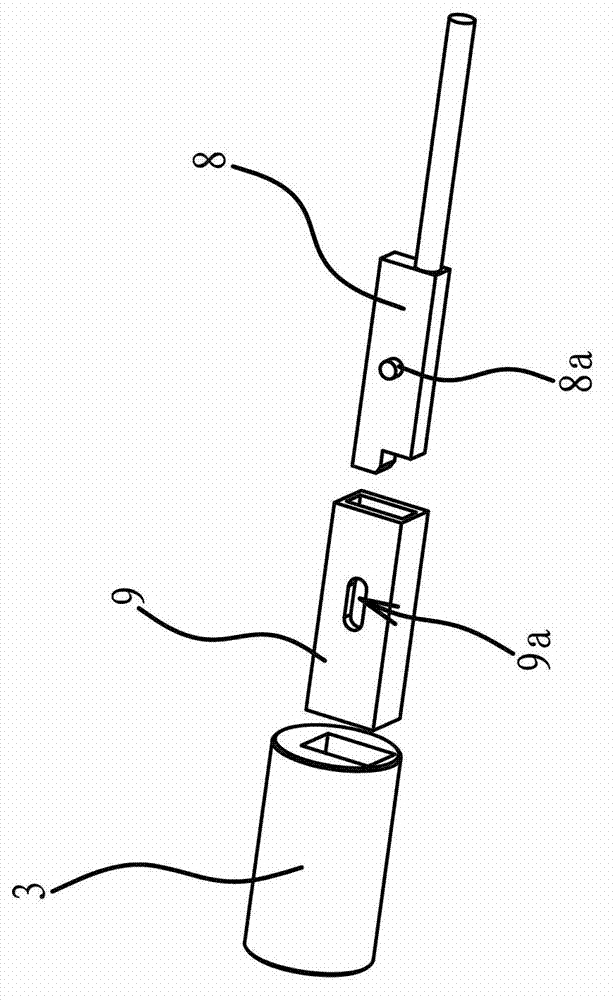

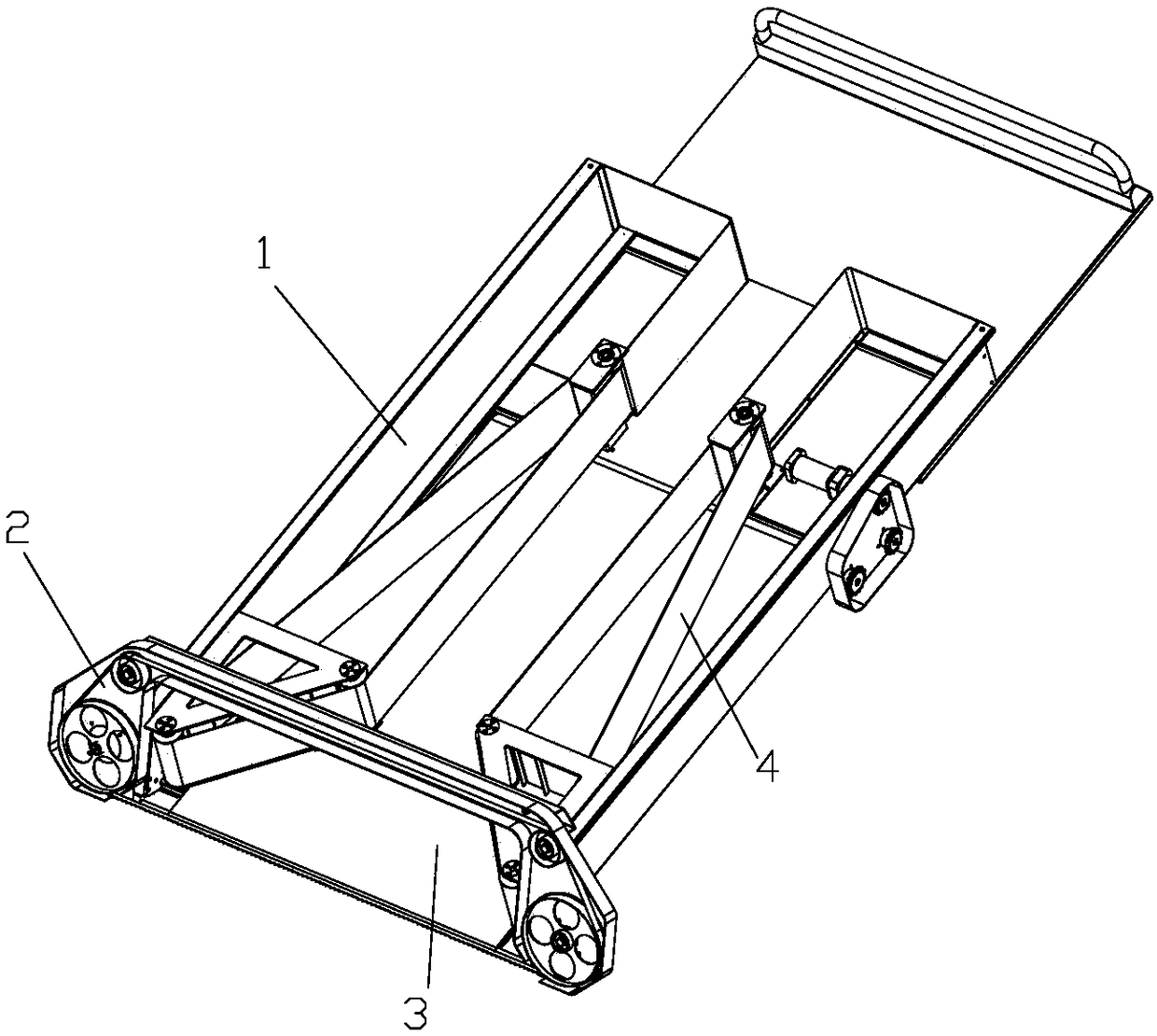

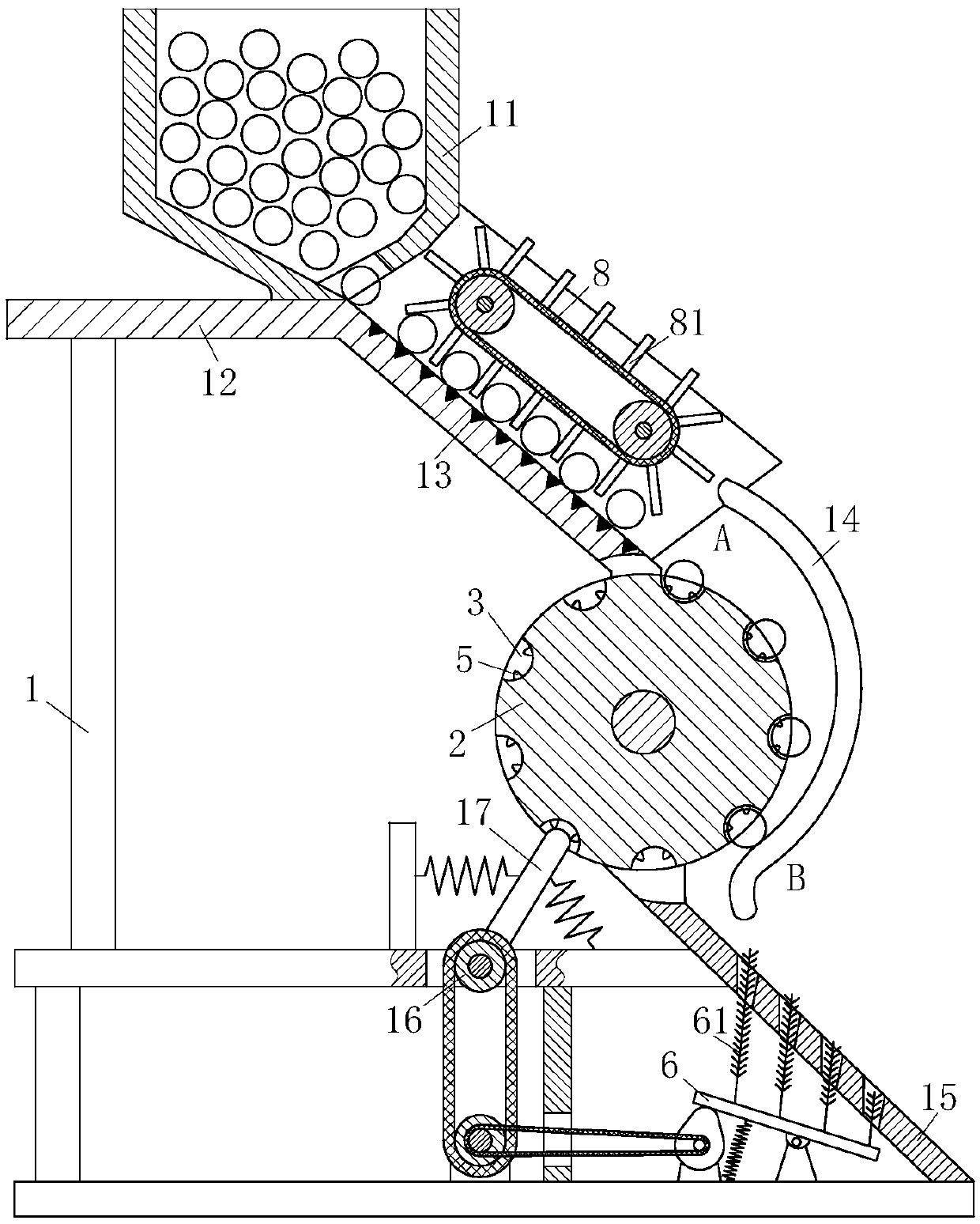

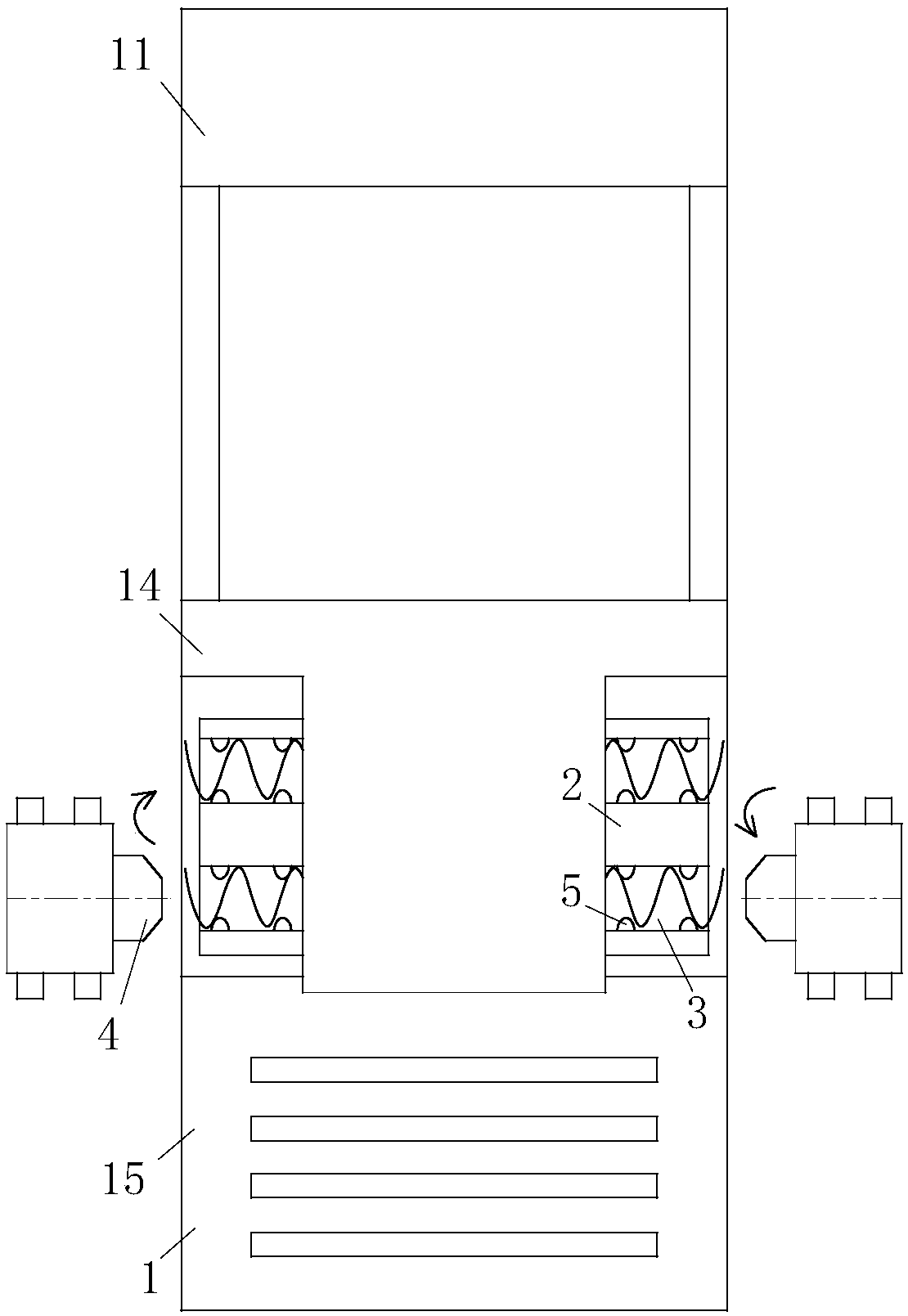

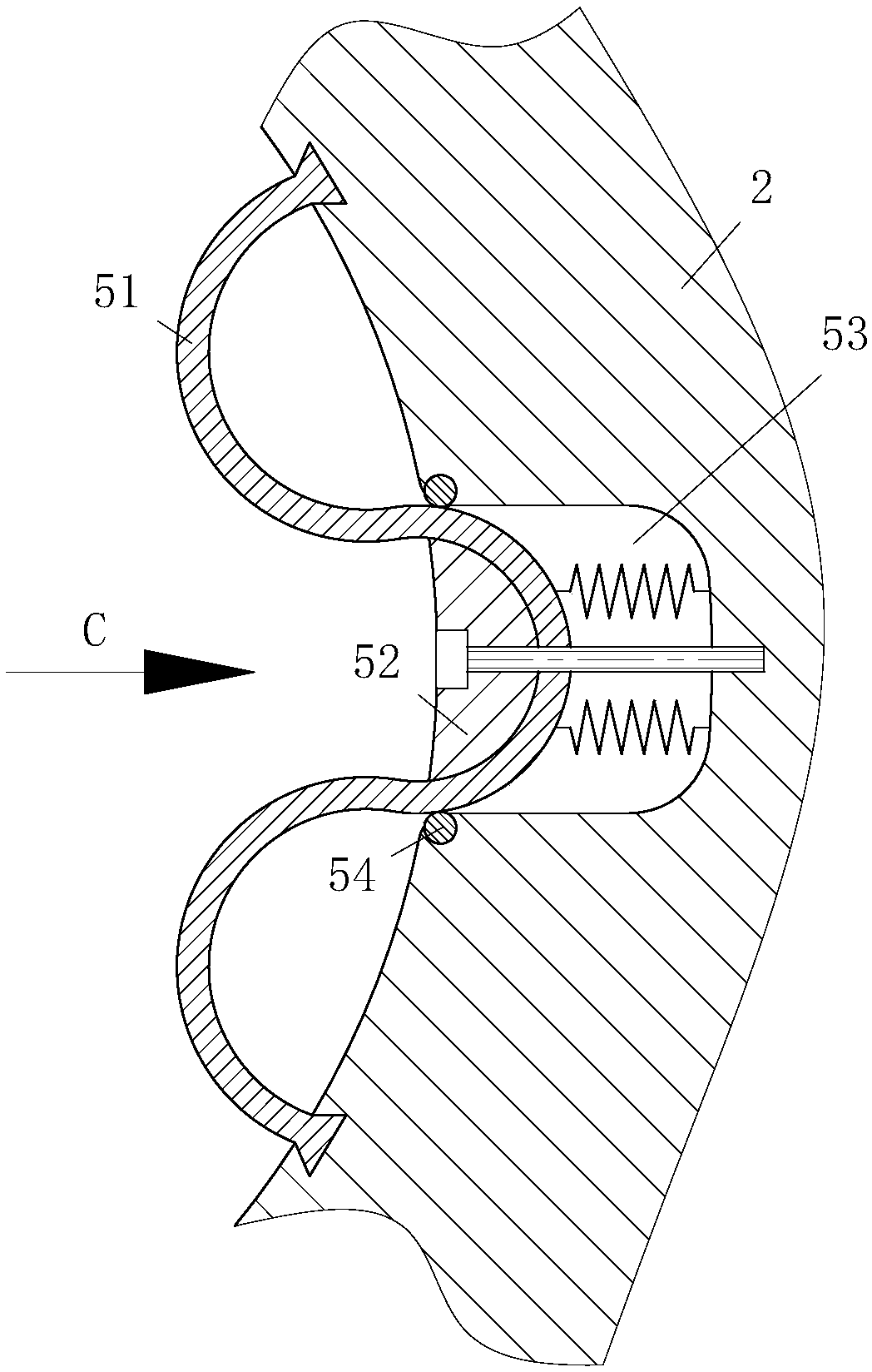

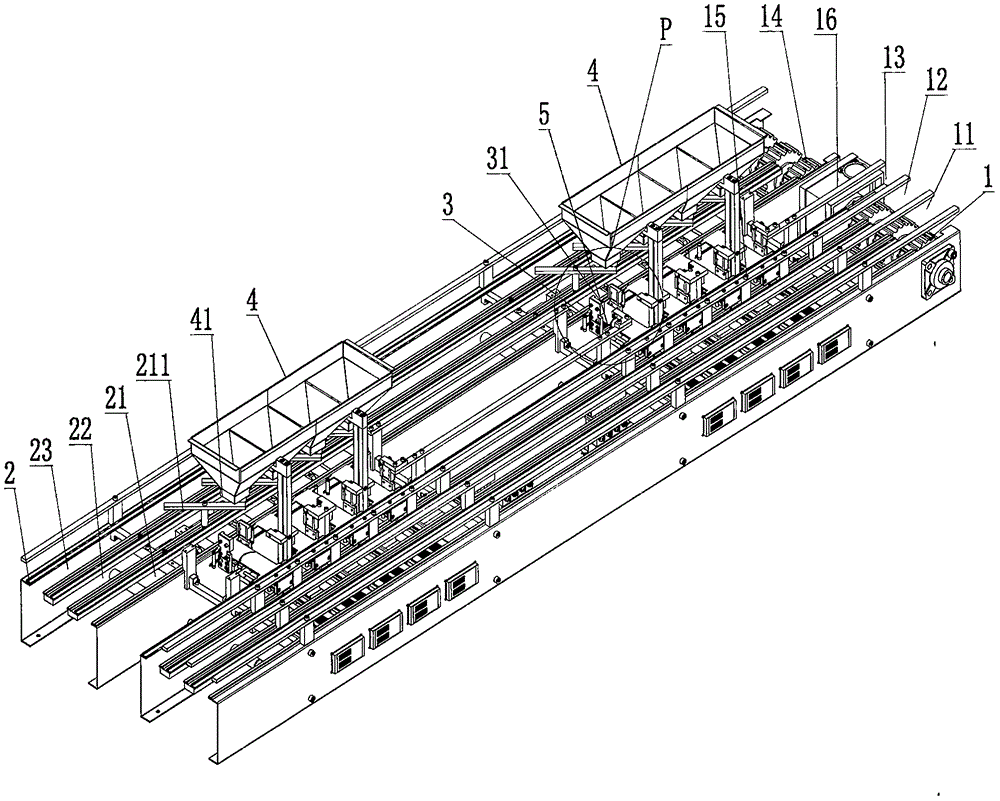

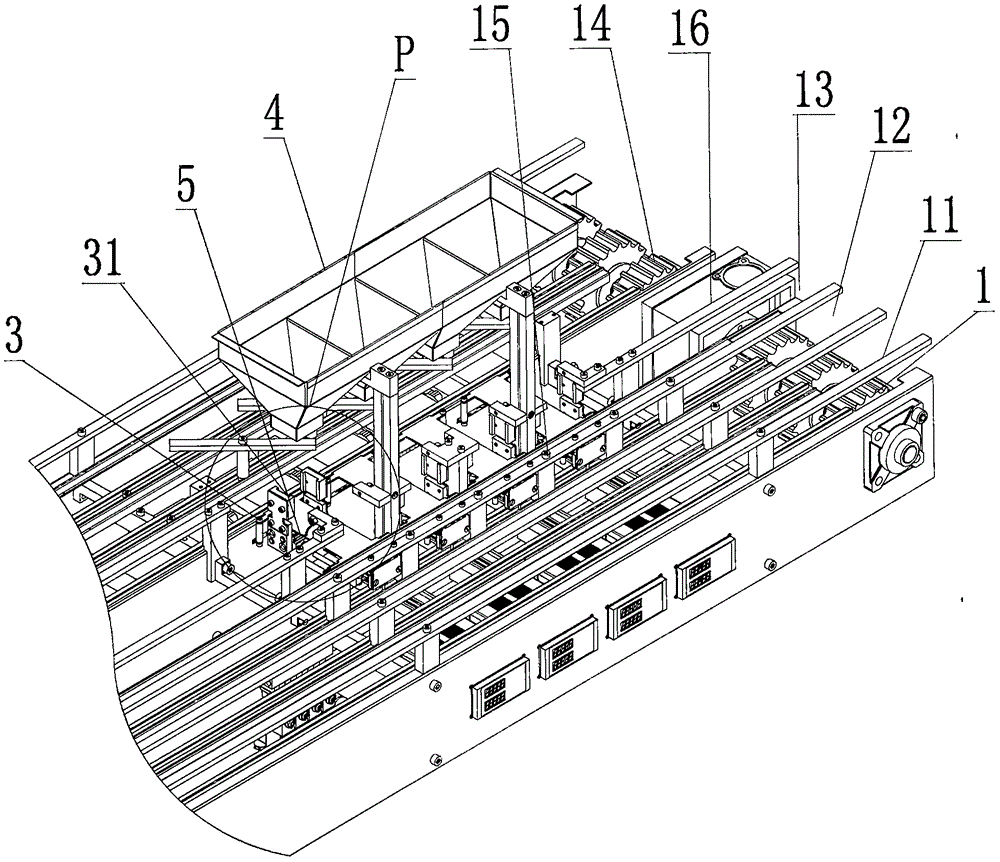

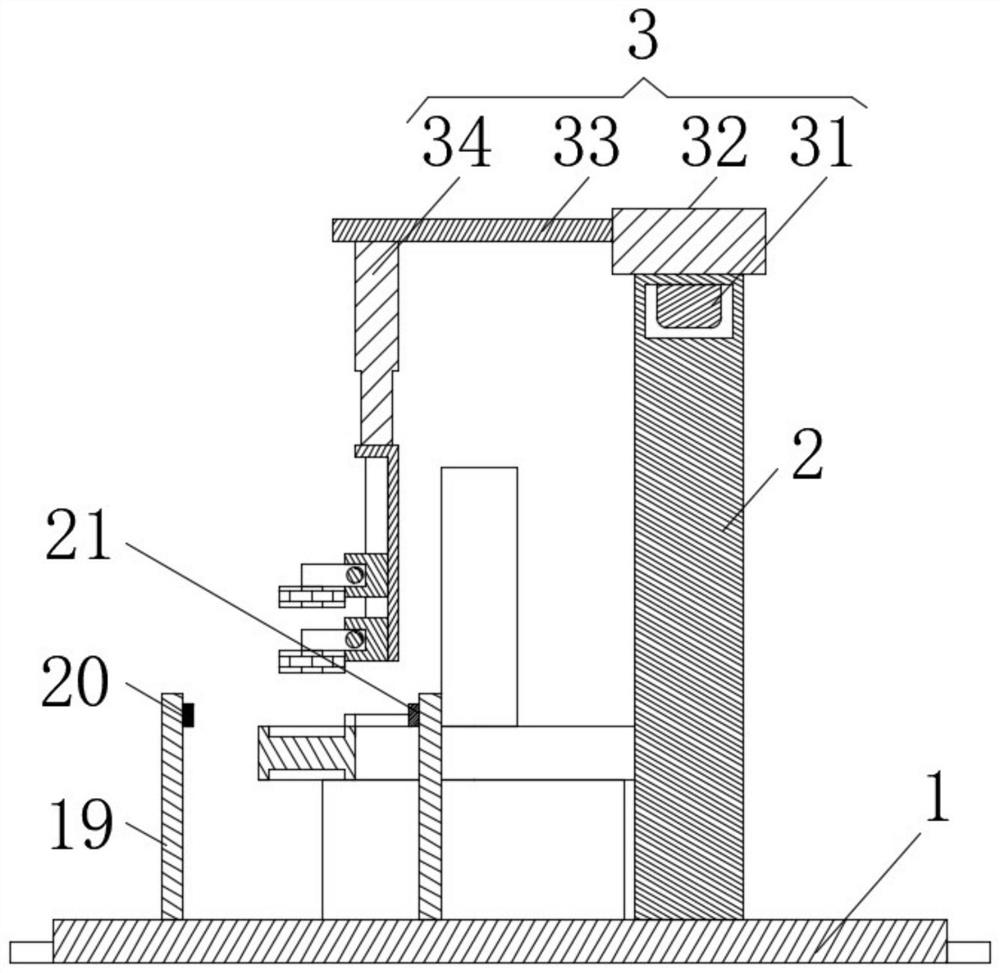

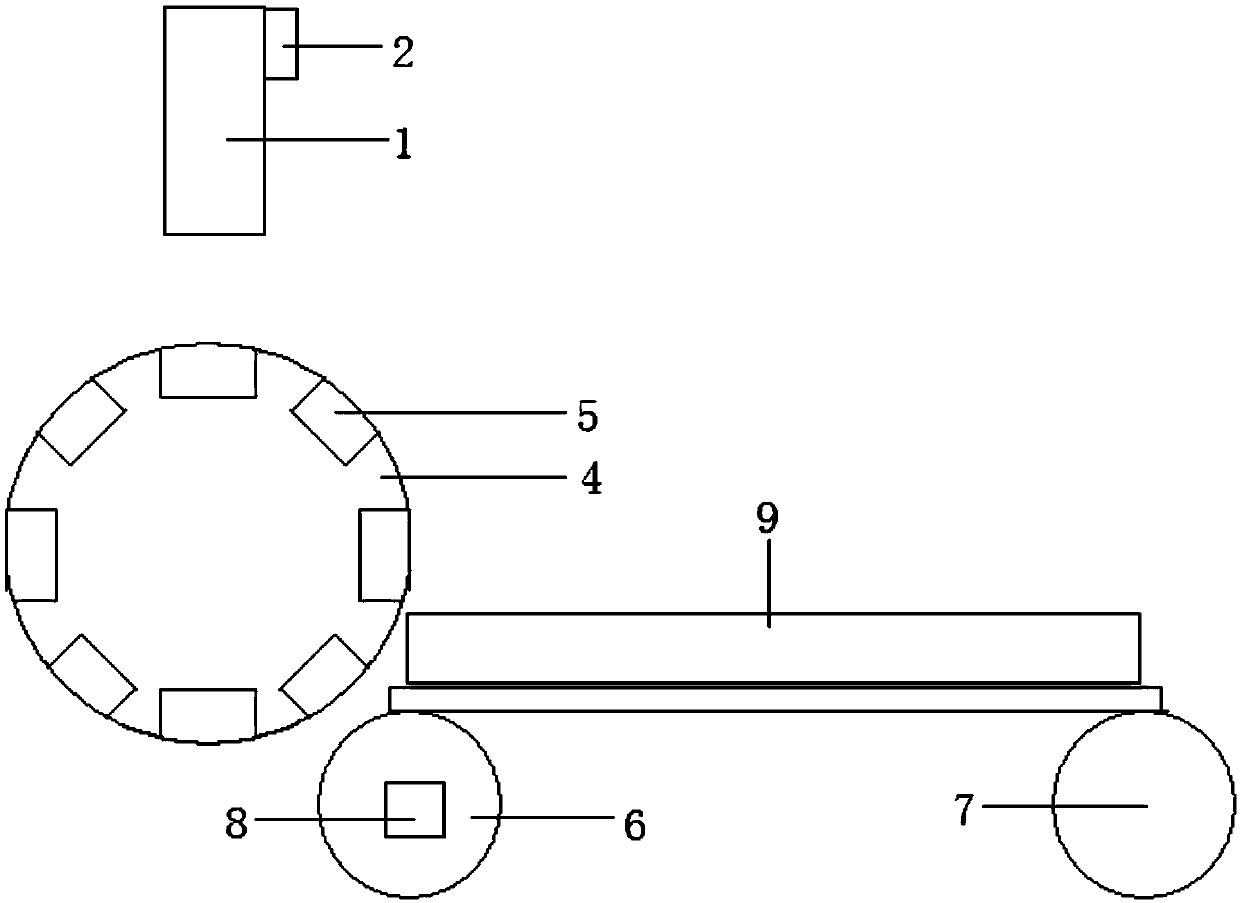

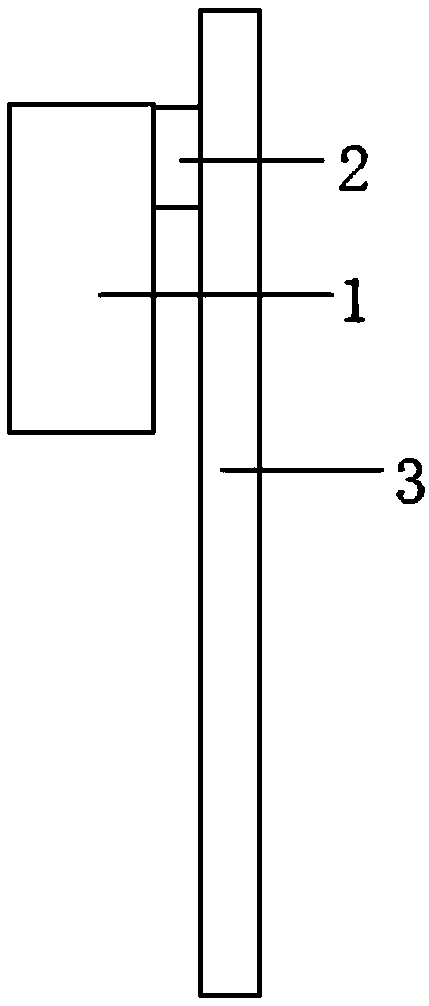

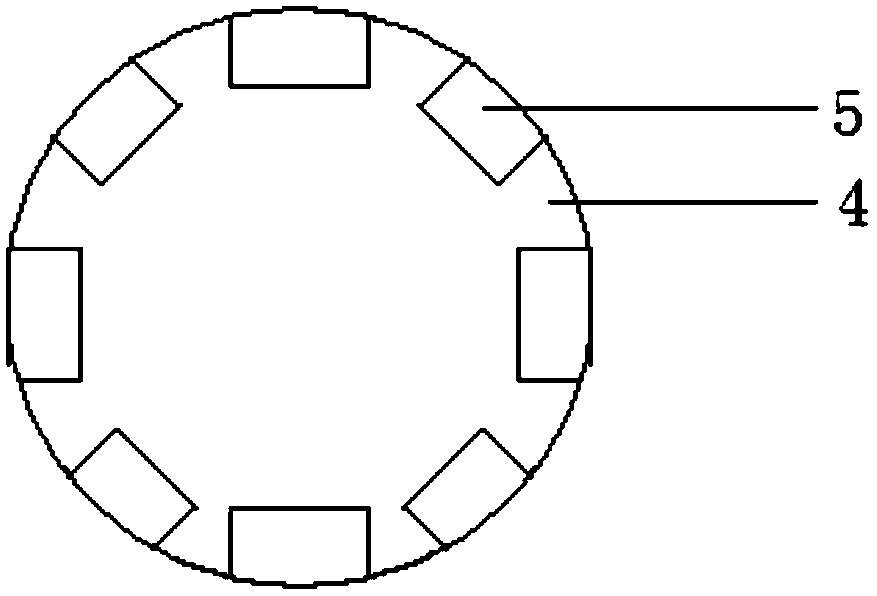

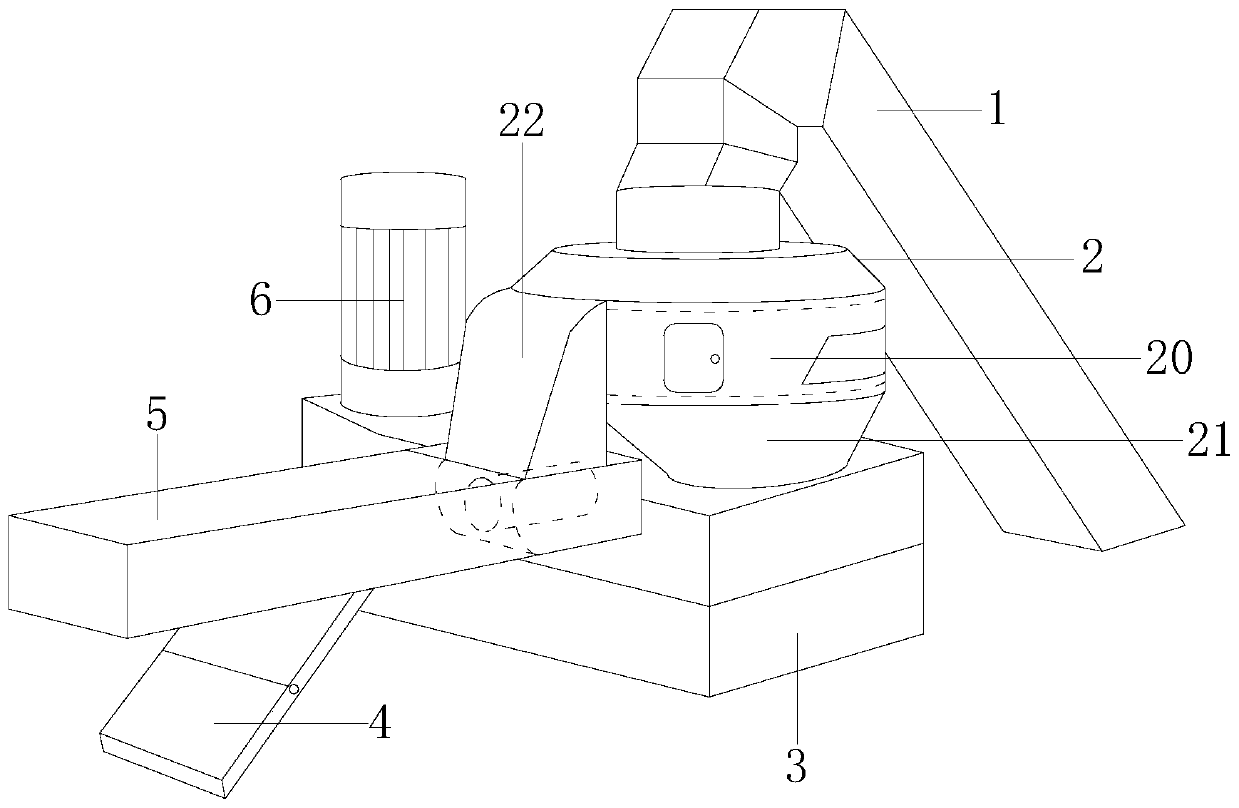

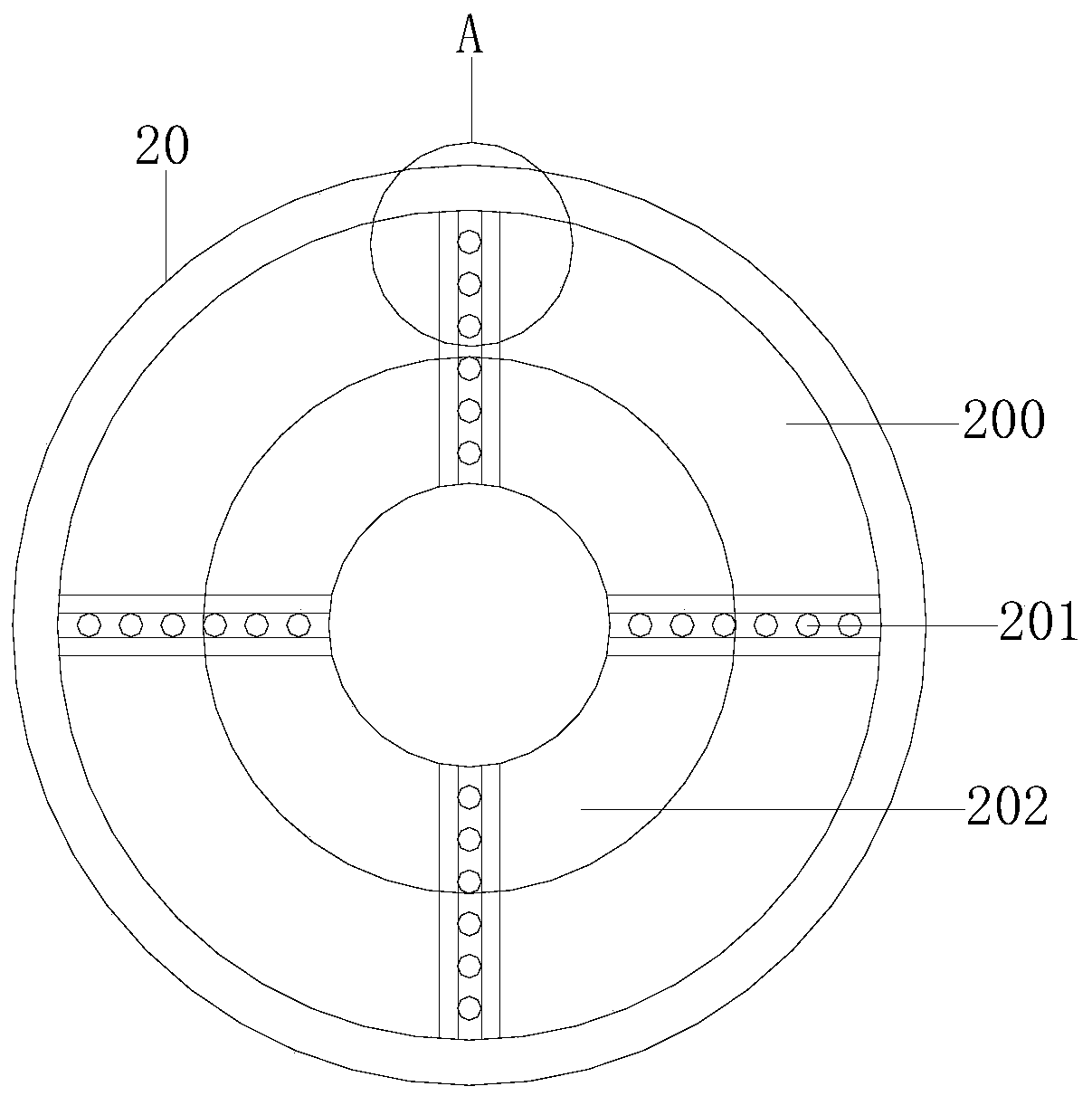

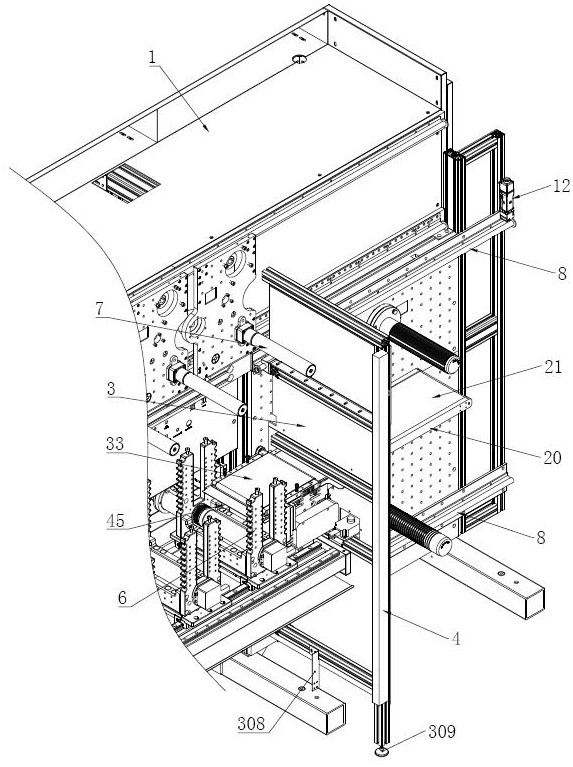

Tree planting machine

ActiveCN108739219AImprove planting efficiencyCompact structurePlantingFurrow making/coveringEngineeringMechanical engineering

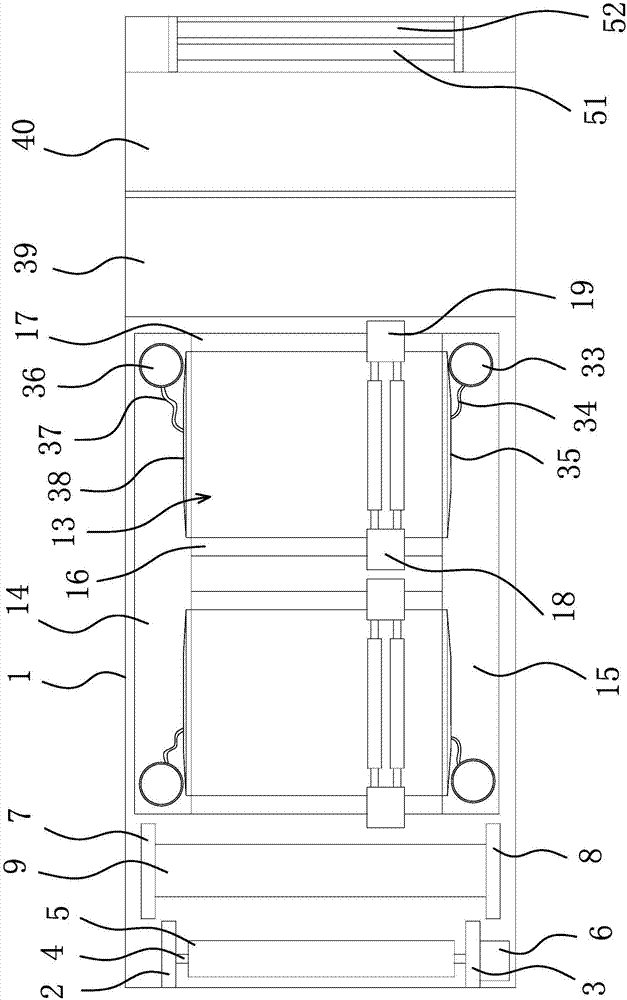

The invention discloses a tree planting machine. The tree planting machine comprises a machine frame, a sapling conveying system and a sapling planting device, wherein the sapling conveying system comprises a conveying belt fixed to the machine frame and used for containing sapling cups, the sapling planting device and the tail end of the conveying belt are adjacently arranged, and the sapling planting device comprises a drilling mechanism, a sapling grabbing mechanism and a sapling cup recycling mechanism which are fixed to the same rotary disc; the drilling mechanism comprises a drill bit driven by a drilling motor, and a sliding rod for driving the drill bit to move up and down; the sapling grabbing mechanism comprises a grabbing claw for grabbing saplings, and a sliding block for driving the grabbing claw to slide up and down; the sapling cup recycling mechanism comprises a mechanical claw for grabbing the sapling cups, and a moving block which drives the mechanical claw to move upand down; the rotating disc is driven by a rotating motor fixed to the machine frame. The tree planting machine is compact in structure and can conveniently complete drilling, sapling transportation,sapling grabbing and planting, soil covering and the like, saplings can be continuously planted in batches, the labor is liberated, the sapling planting efficiency is greatly improved, and time and labor are saved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

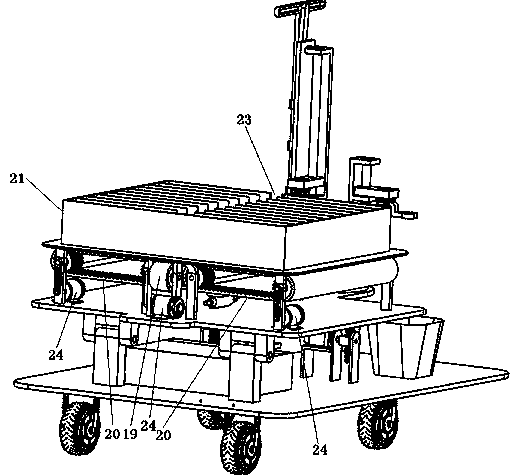

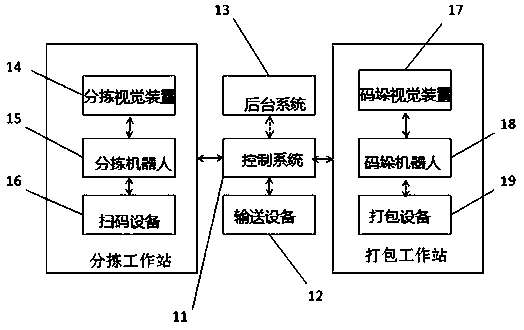

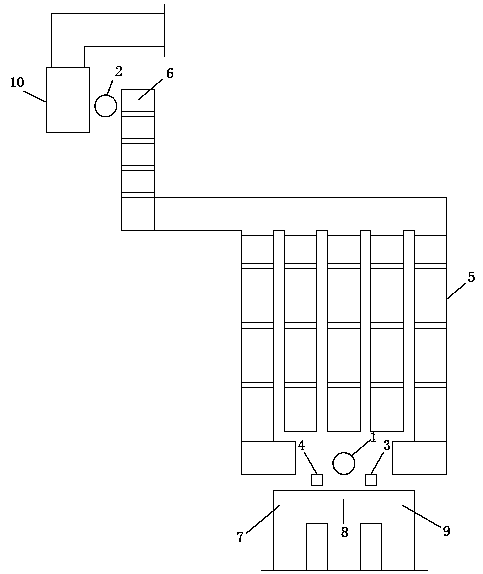

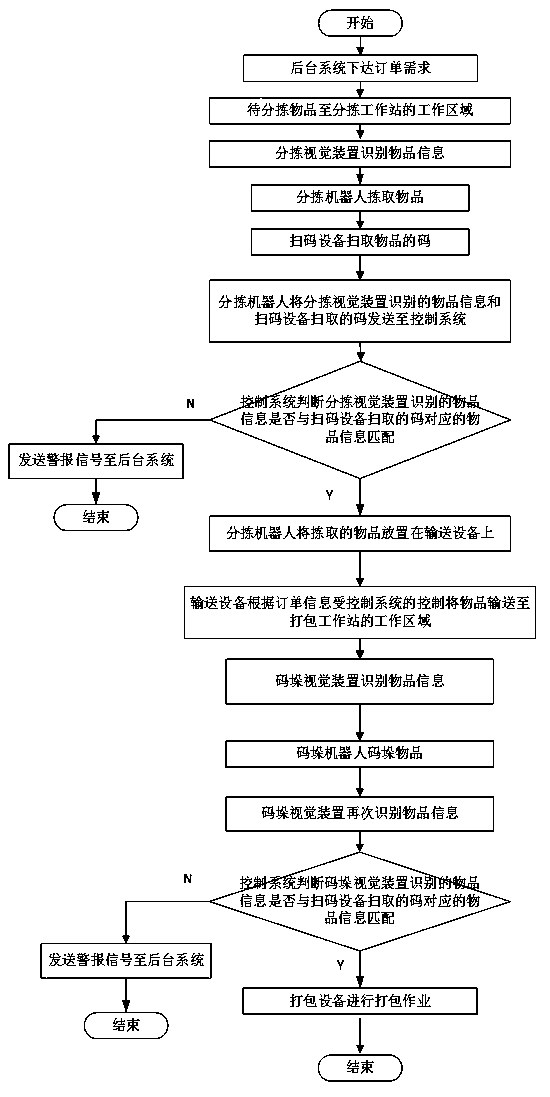

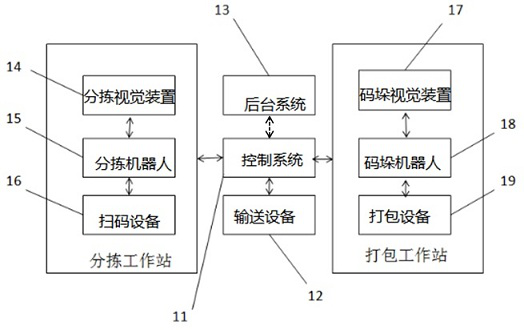

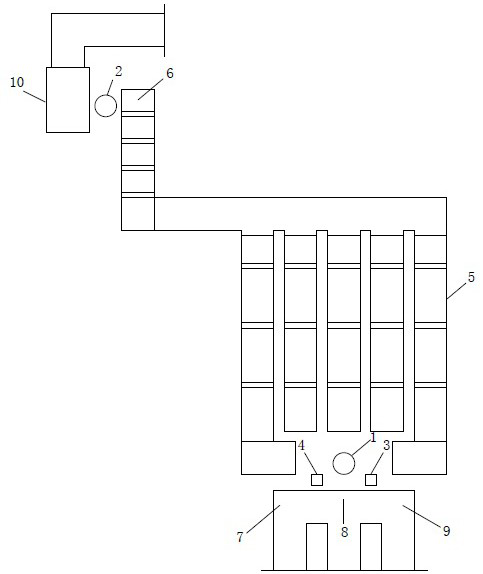

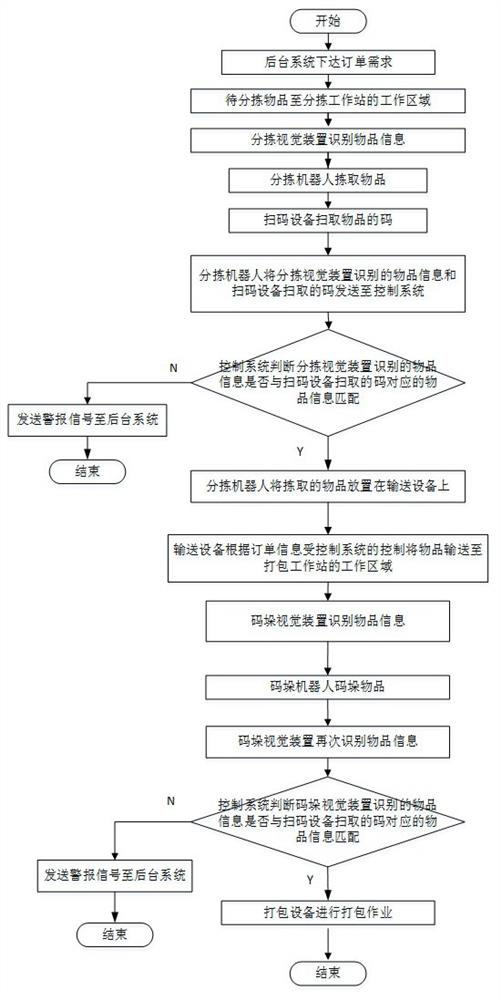

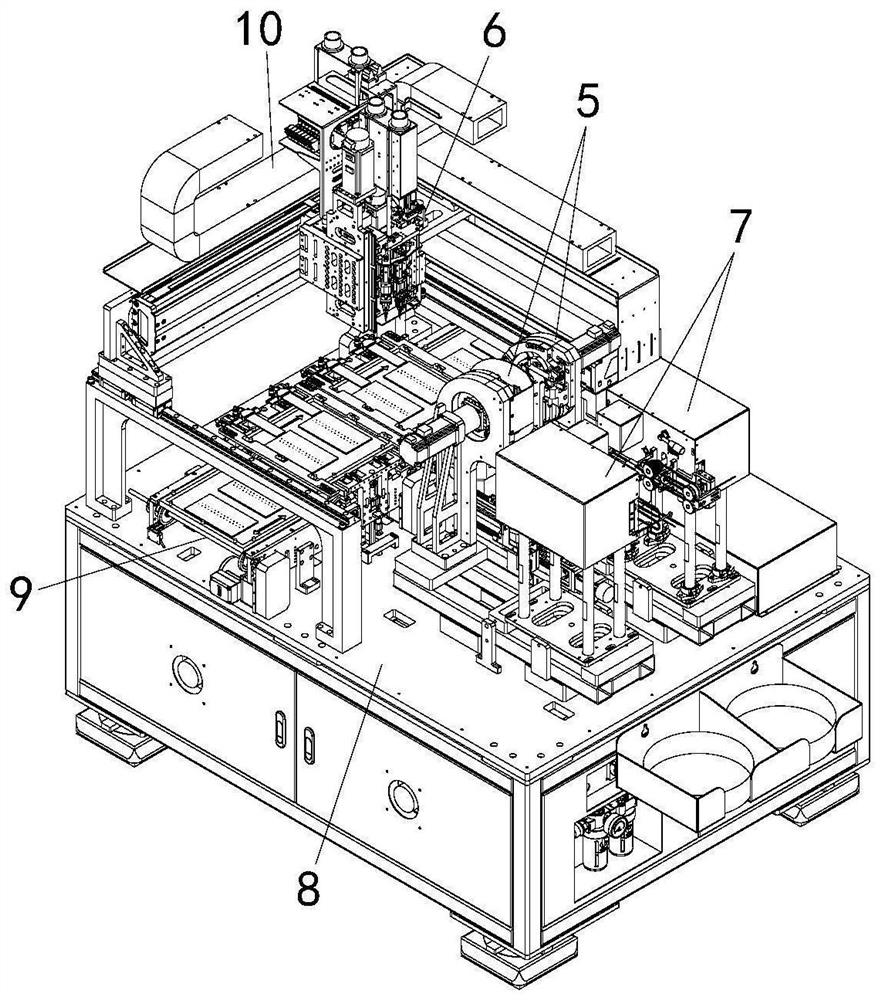

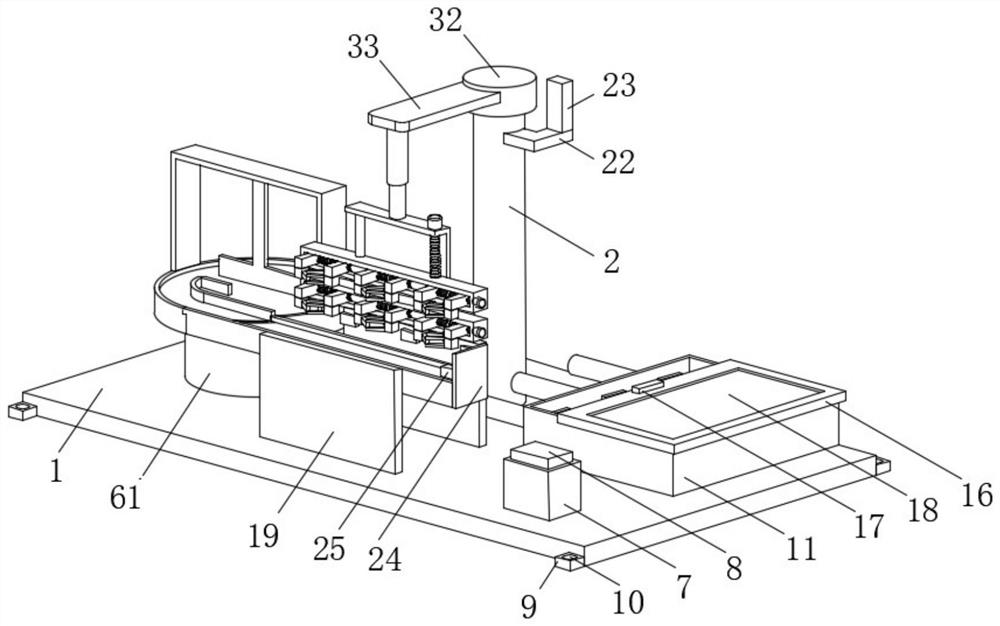

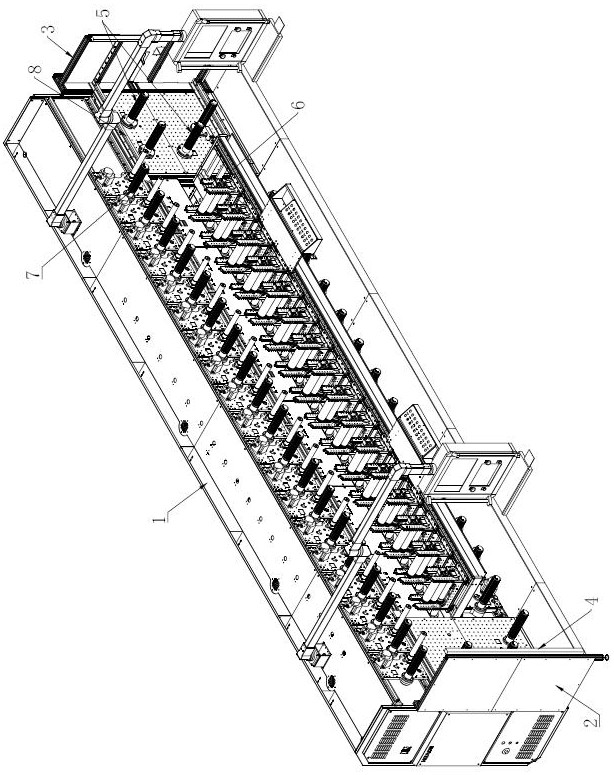

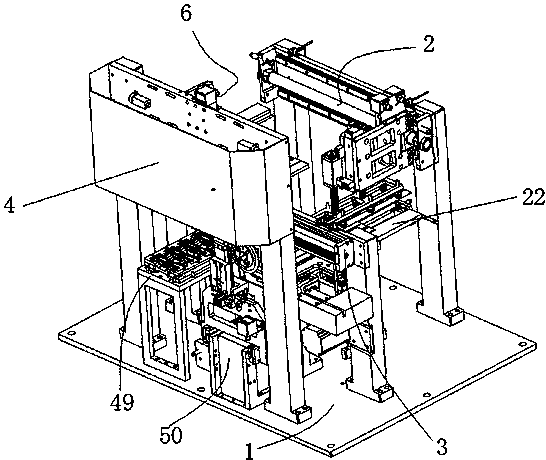

Intelligent sorting and packing system and sorting and packing method thereof

ActiveCN108722882AImprove work efficiencyReduce error rateCo-operative working arrangementsStacking articlesControl systemSimulation

The invention provides an intelligent sorting and packing system. The intelligent sorting and packing system comprises a sorting work station, a packing work station and a control system electricallyconnected with the sorting work station and the packing work station. The sorting work station comprises a sorting visual device, a sorting robot and a code scanning device. The sorting visual deviceand the code scanning device are both electrically connected with the sorting robot. The control system comprises a database module and a controller. The controller is arranged to judge whether objectinformation identified by the sorting visual device is matched with object information corresponding to the code scanned by the code scanning device or not, when the object information identified bythe sorting visual device is matched with the object information corresponding to the code scanned by the code scanning device, the controller sends a sorting signal to the sorting robot, and when theobject information identified by the sorting visual device is not matched with the object information corresponding to the code scanned by the code scanning device, the controller generates an alarmsignal to a background system. The packing work station is arranged to conduct stacking and packing operation. A sorting and packing method of the intelligent sorting and packing system achieve unmanned sorting and packing operation of objects, the operation efficiency is improved, and the error rate and the labor cost are lowered.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

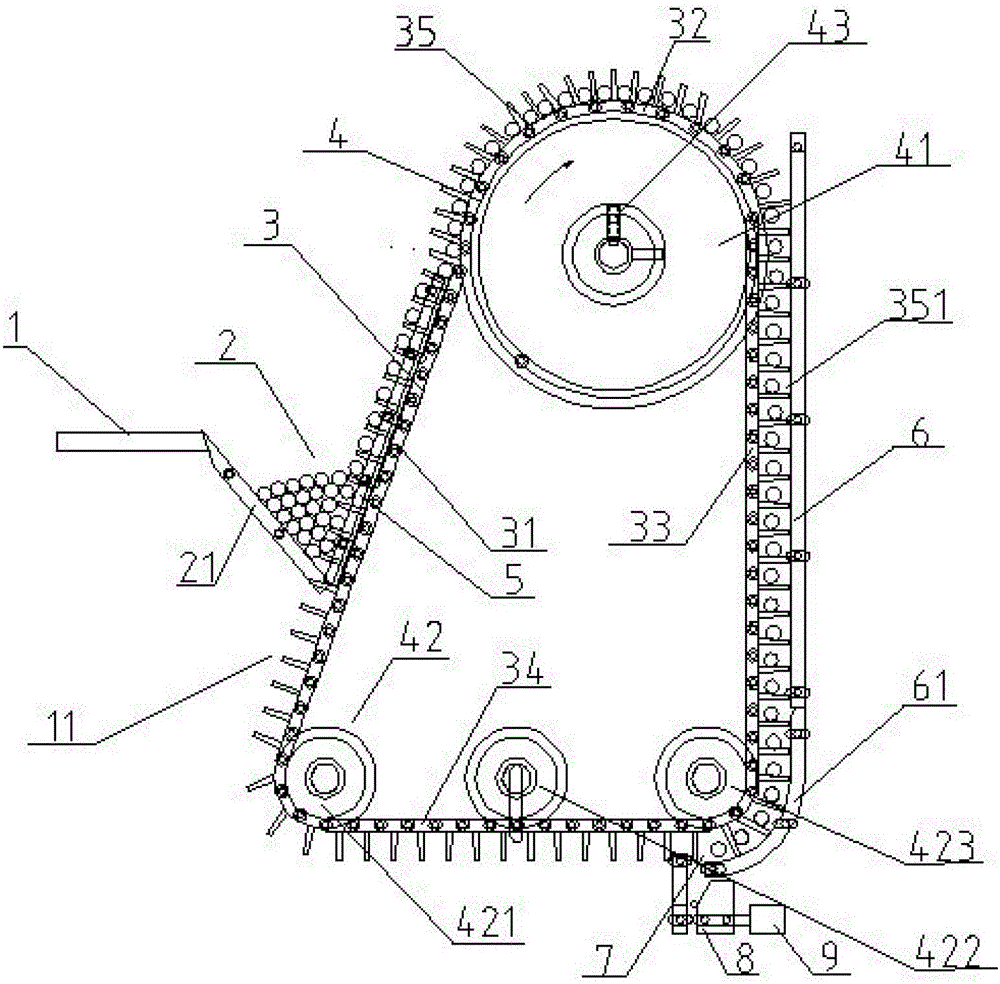

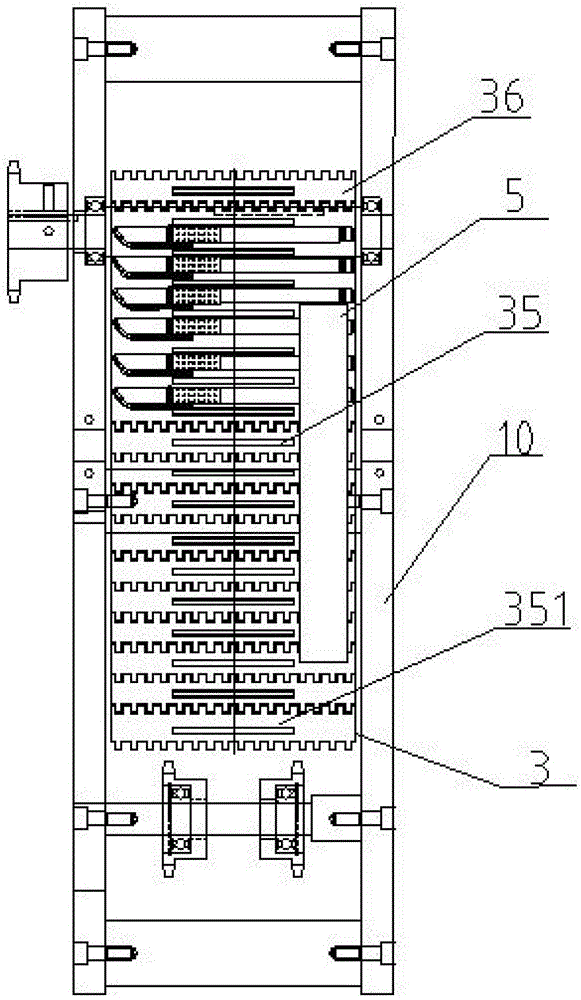

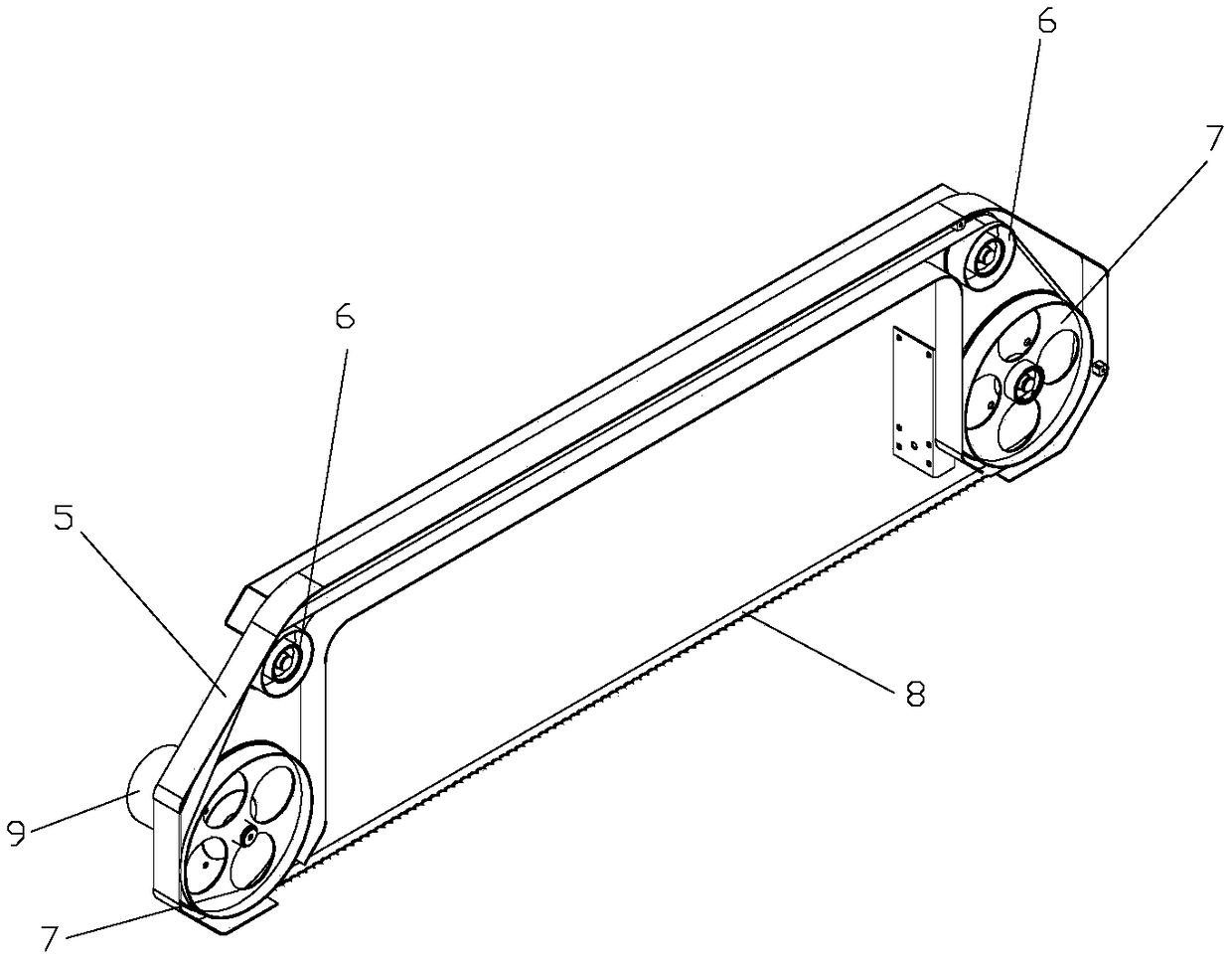

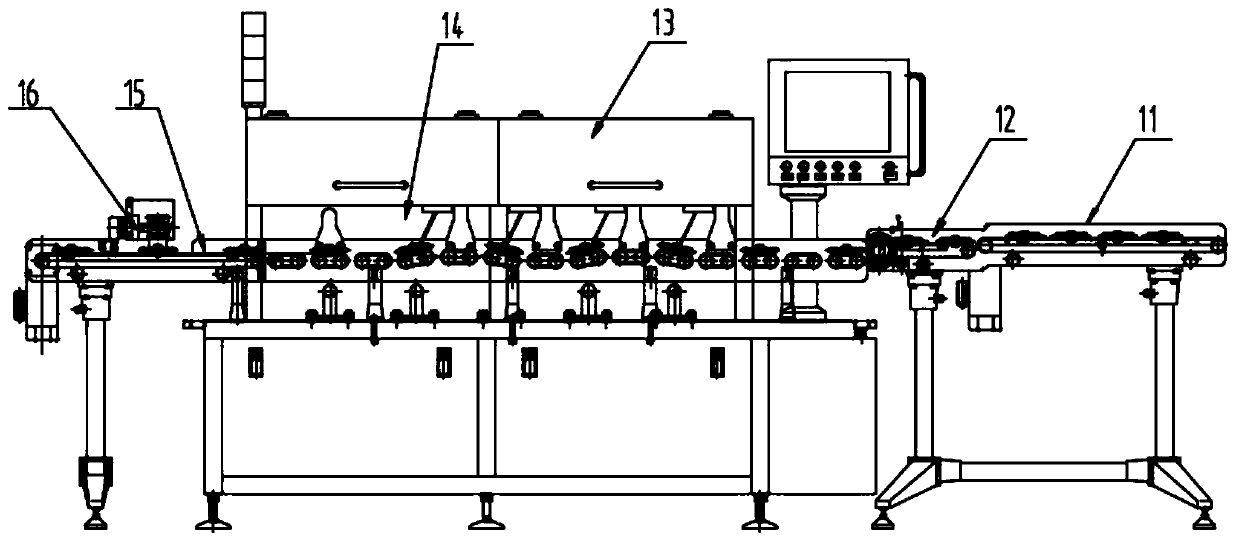

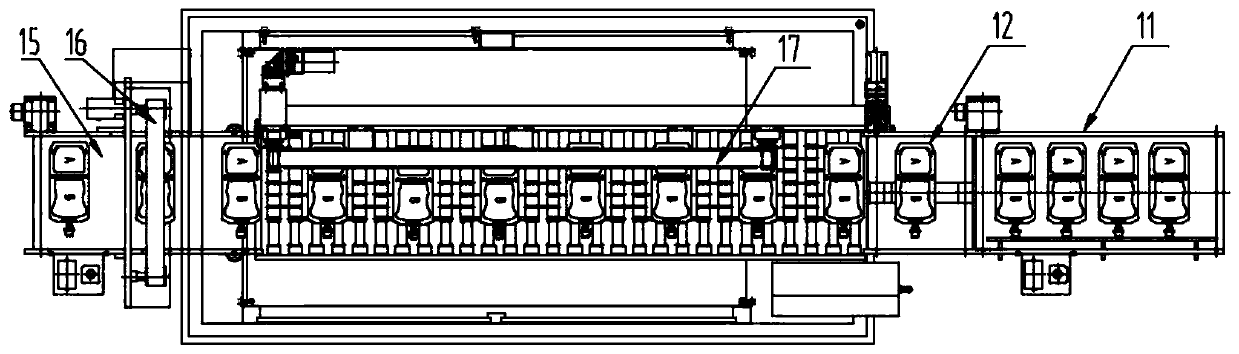

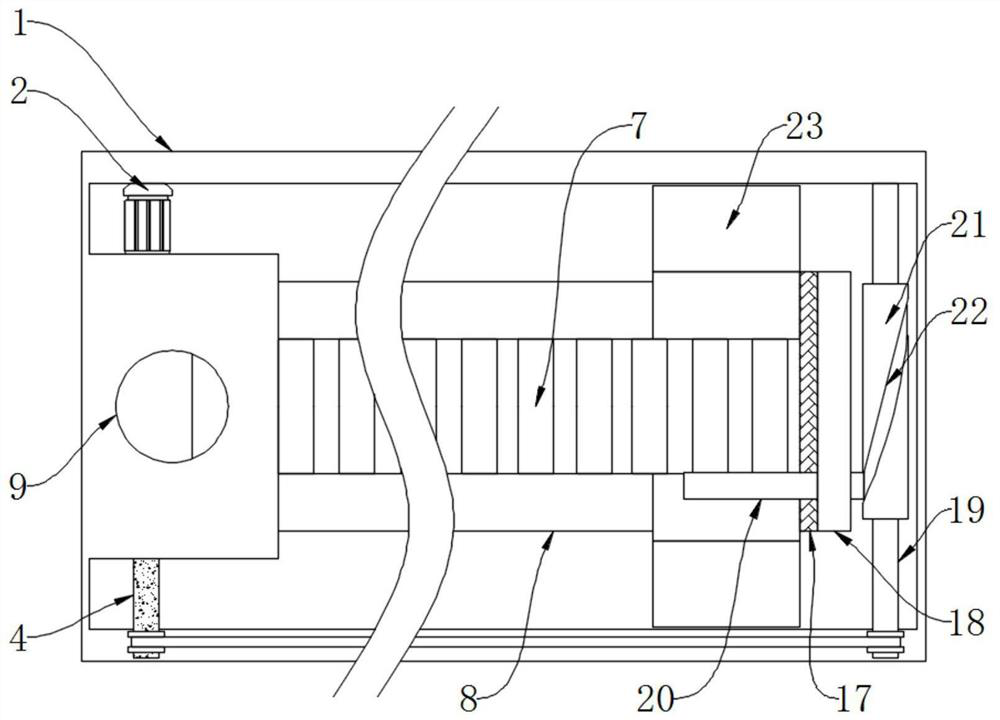

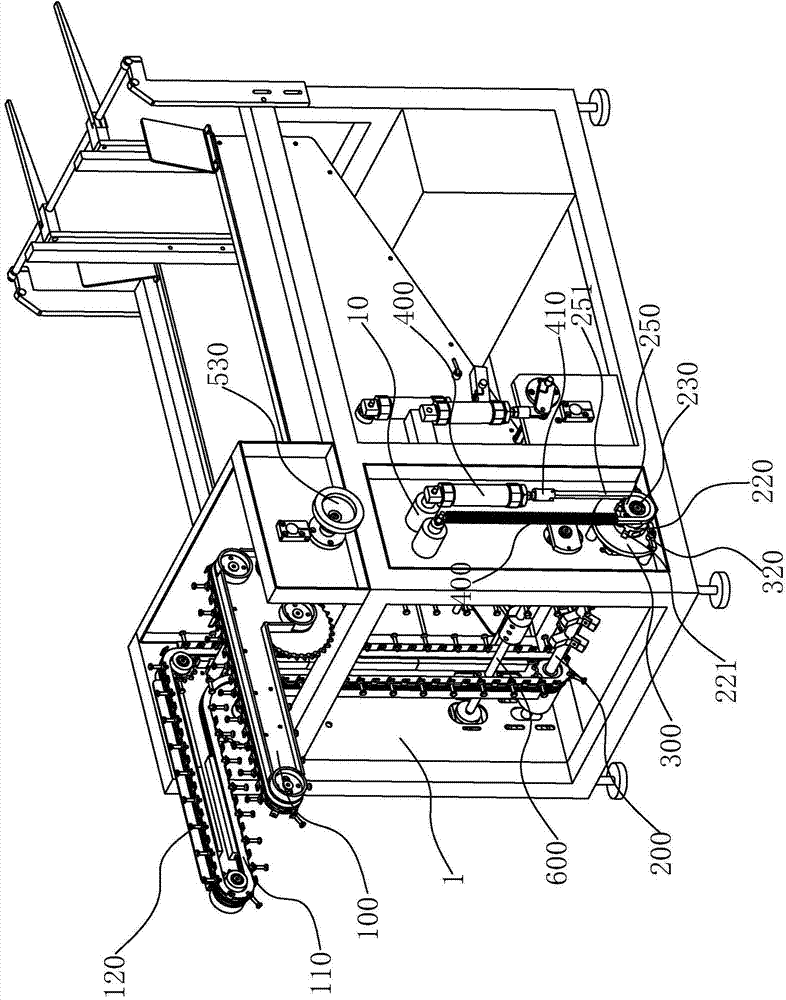

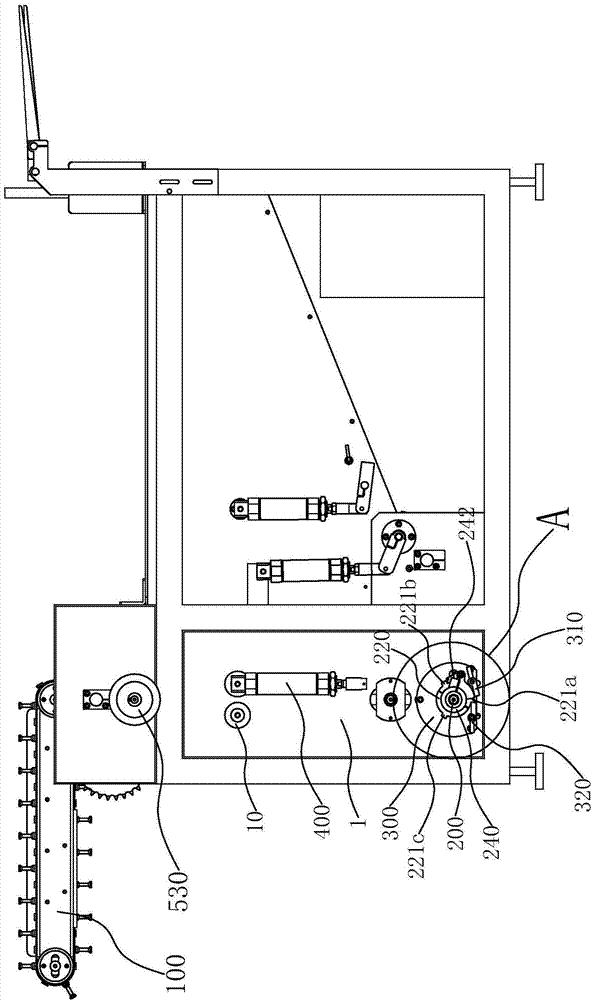

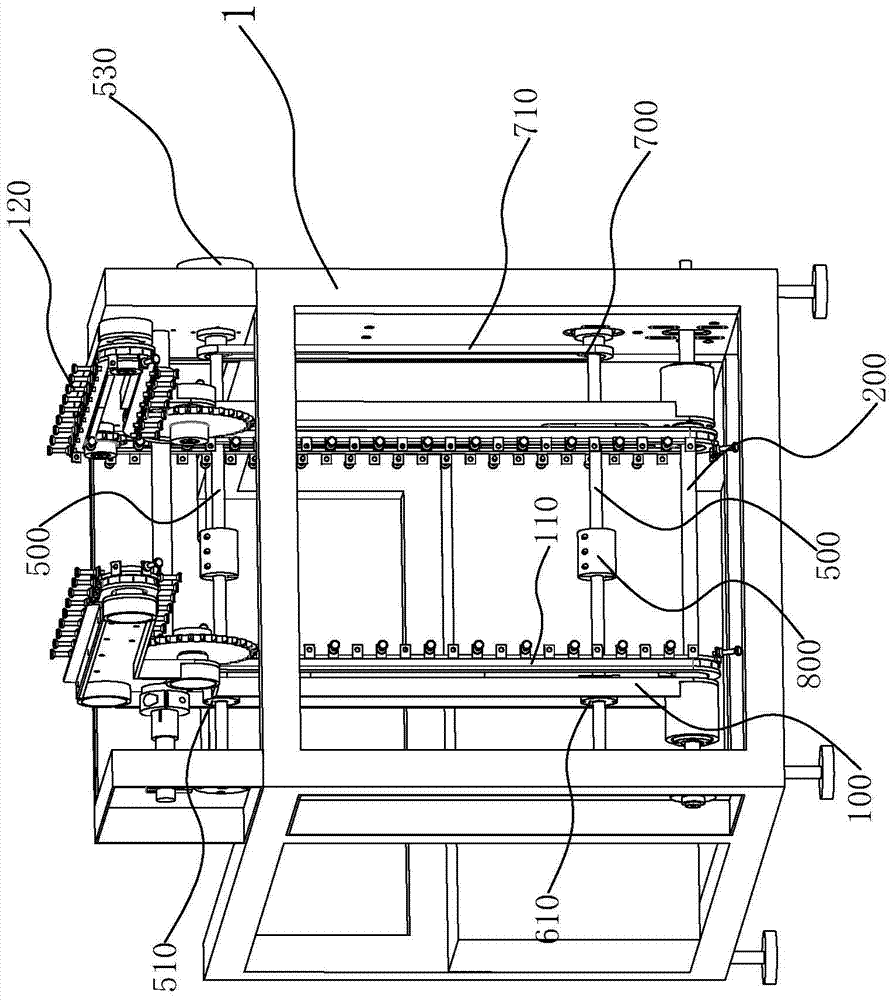

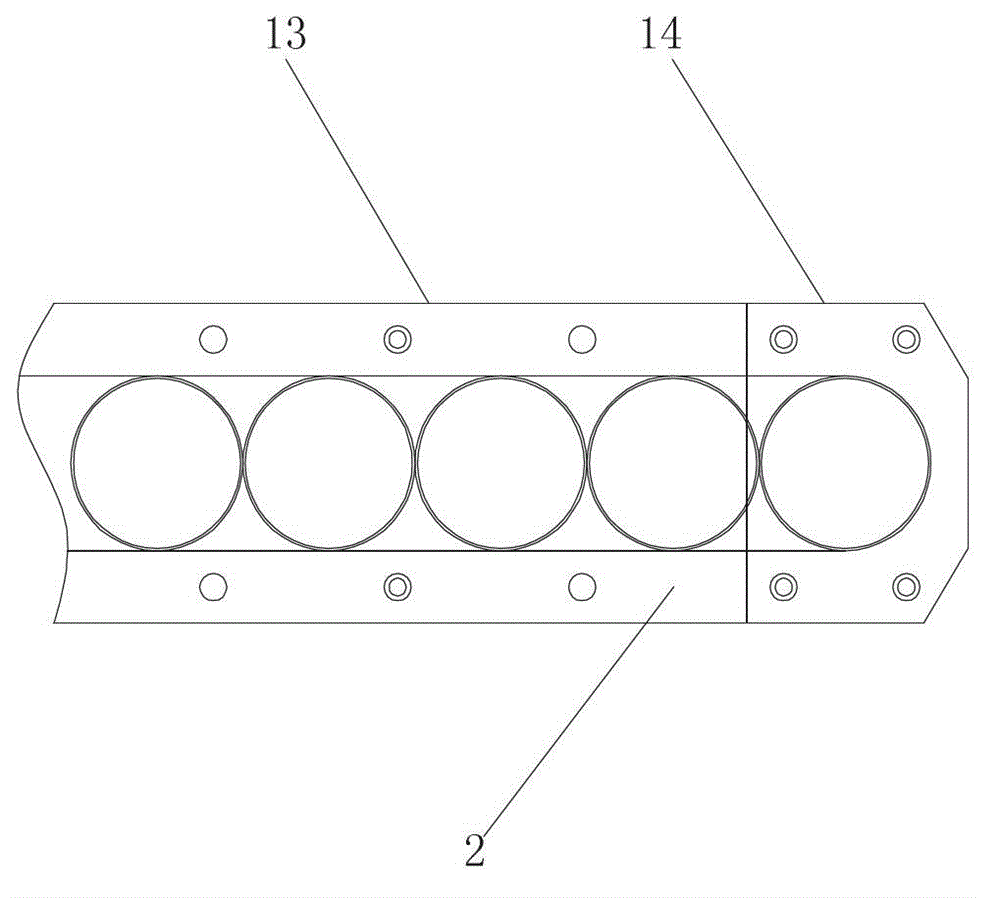

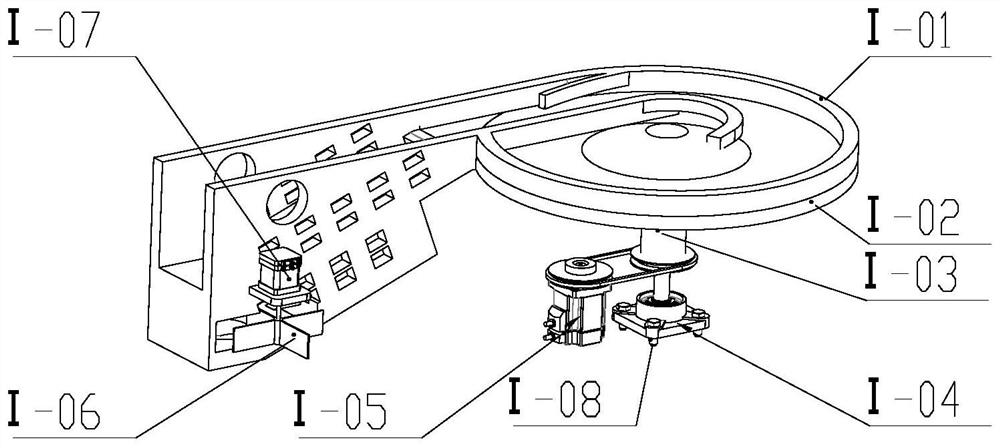

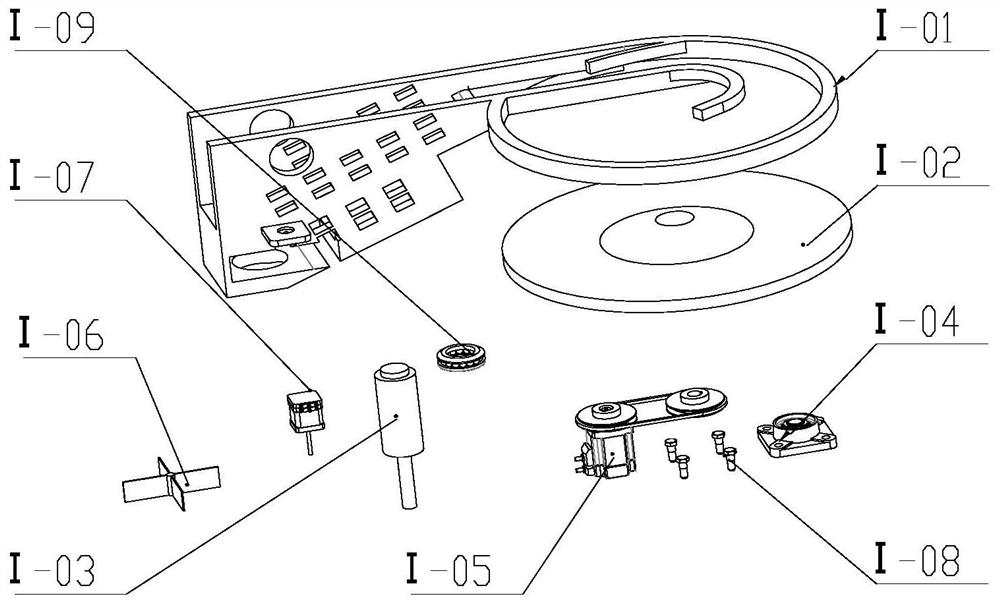

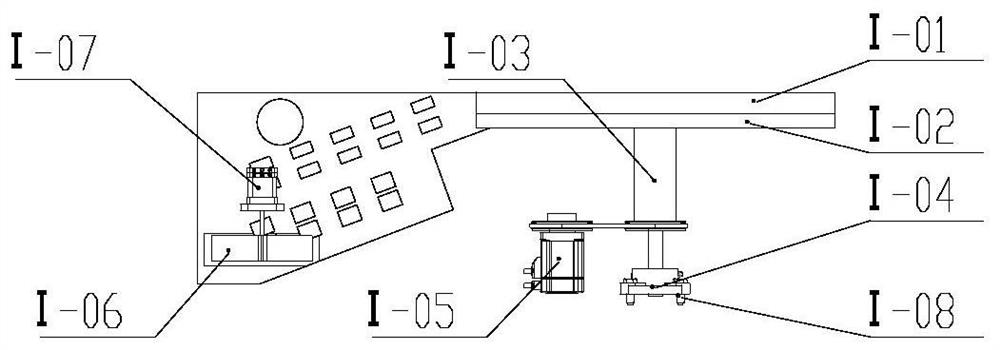

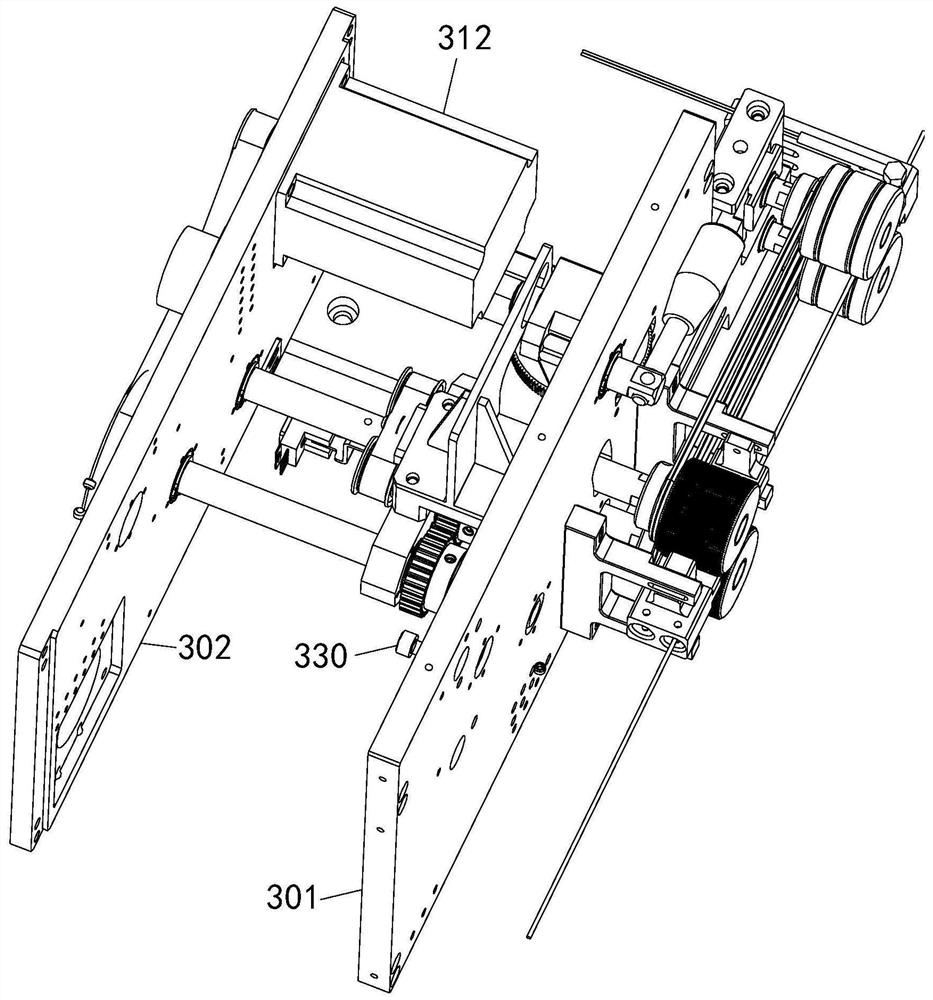

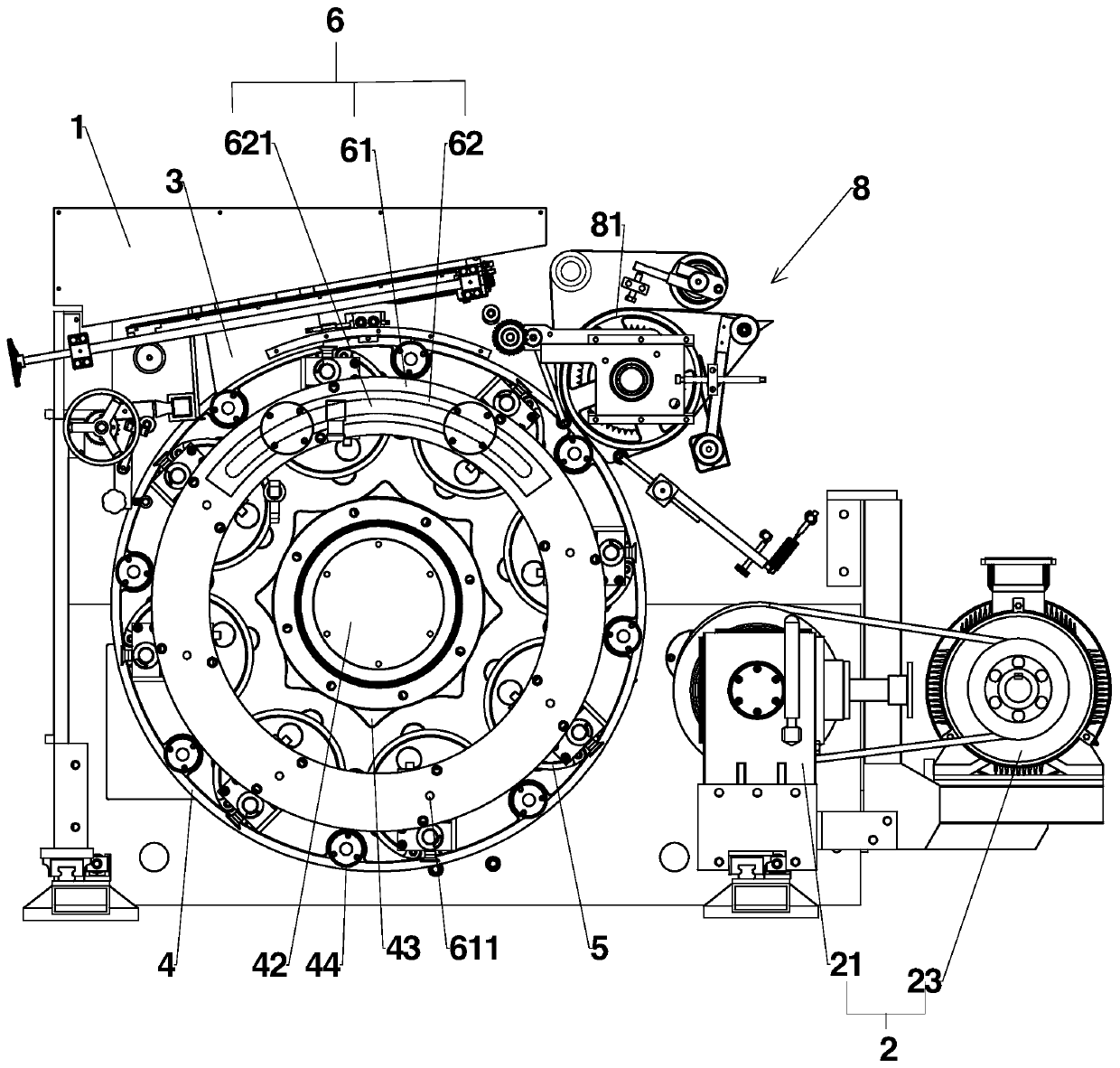

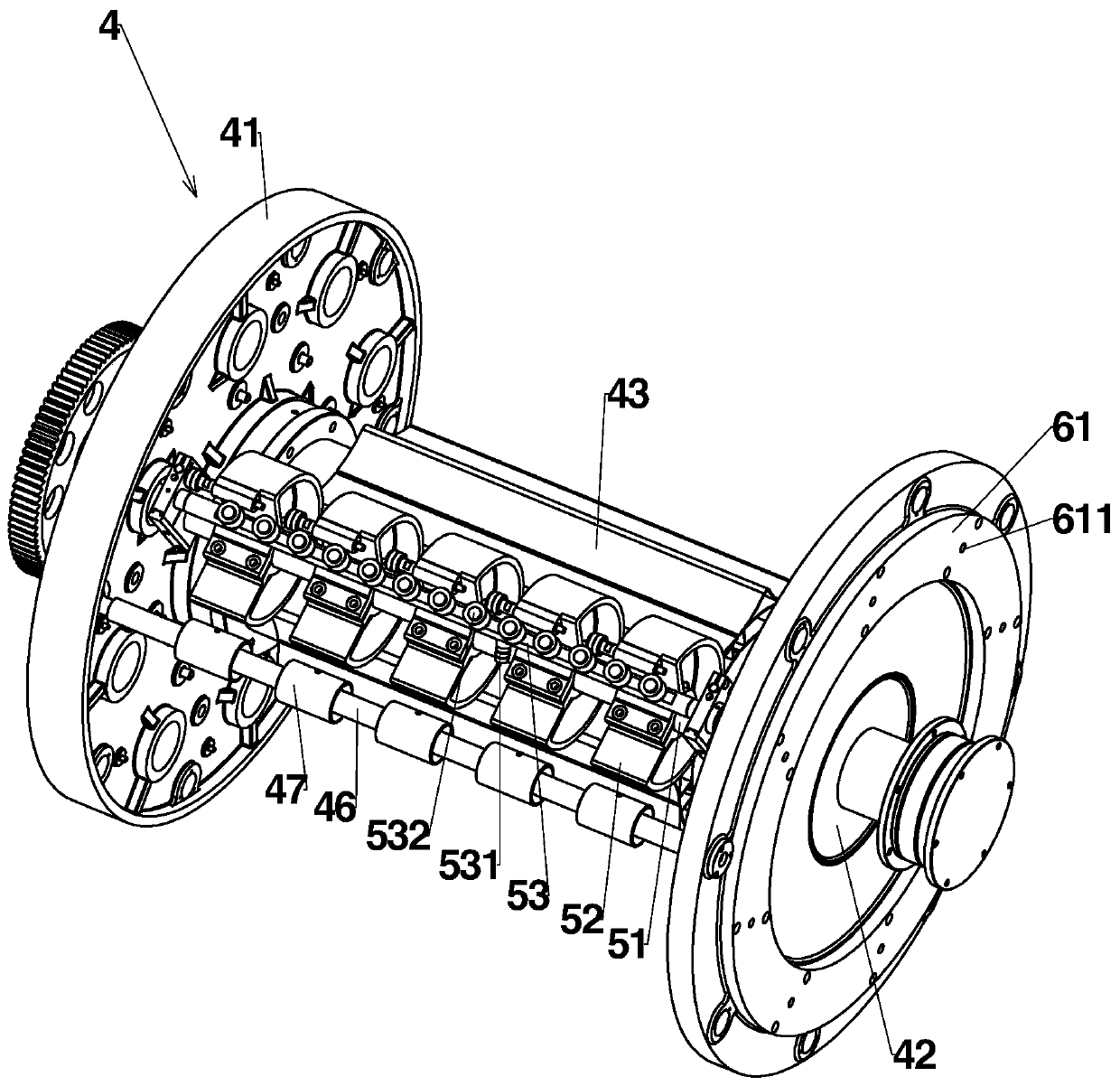

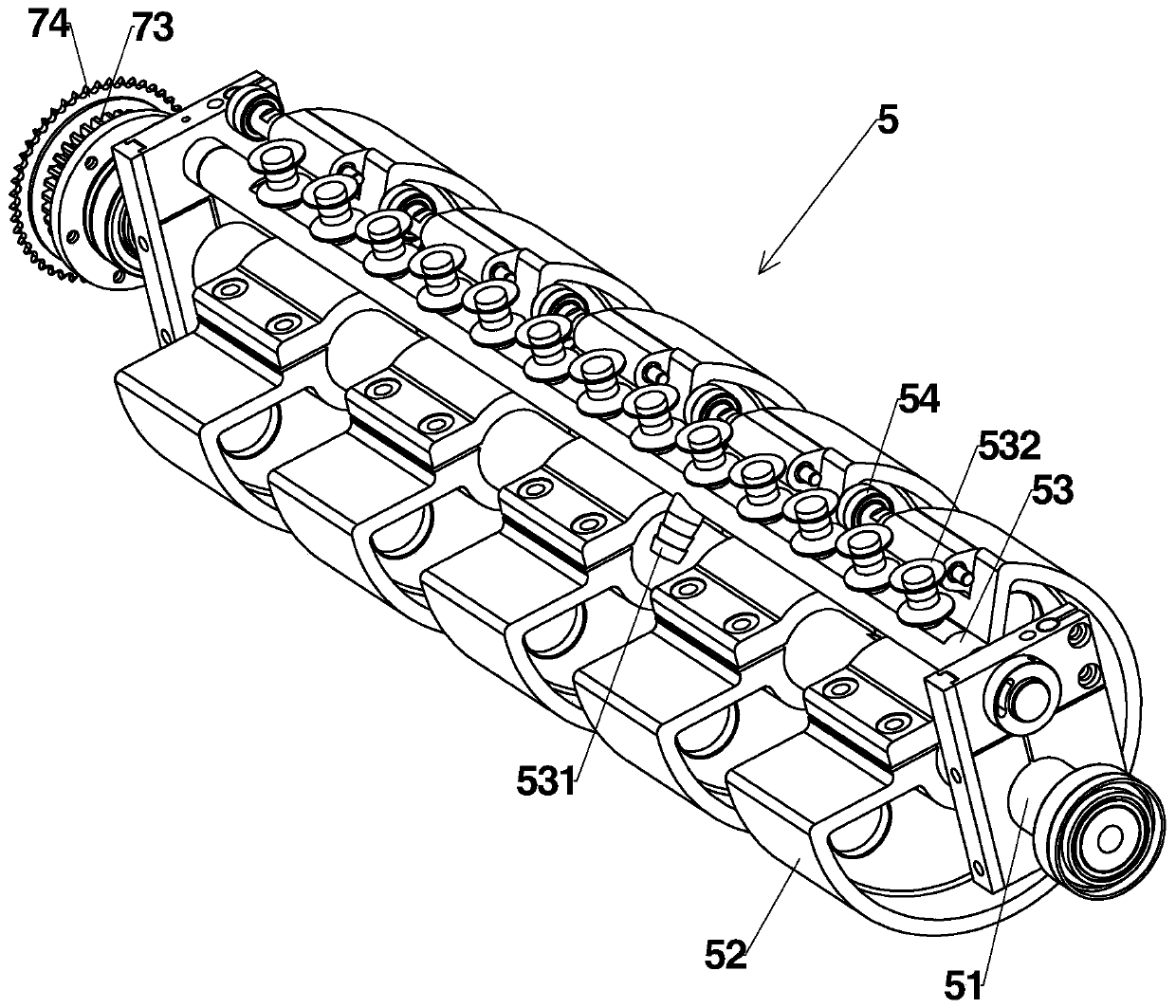

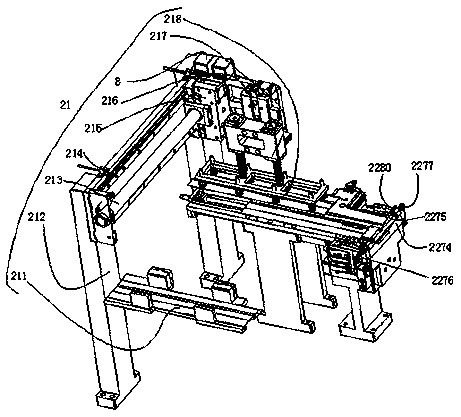

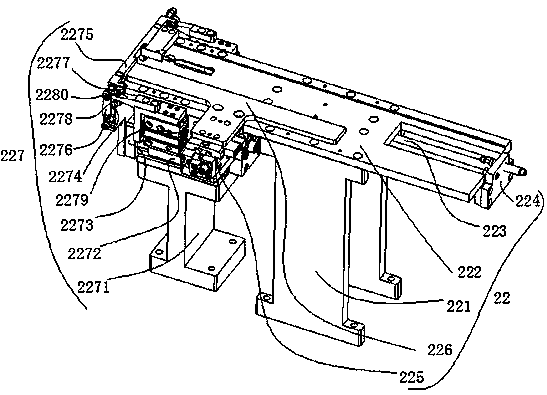

Automatic sorting feeding device for finished product pens

ActiveCN103144970ARealize automatic sorting and feeding, fromRealize the automatic boxing of the penConveyorsLoading/unloadingDrive wheelDrive motor

The invention discloses an automatic sorting feeding device for finished product pens. The automatic sorting feeding device comprises a machine frame, a material cabin, a chain wheel, a sorting mechanism and a conveying mechanism, wherein the material cabin and the chain wheel are arranged in the machine frame, the sorting mechanism is used for sorting the finished product pens stacked in the material cabin, the conveying mechanism is used for conveying the sorted finished product pens, the sorting mechanism is fixedly arranged on the conveying mechanism, the conveying mechanism is annularly surrounded and arranged on the chain wheel, an annular conveying rail is formed, the chain wheel comprises a driving wheel and a driven wheel, the driving wheel is matched with the driven wheel through the driving of a driving motor and drives the conveying of the conveying mechanism and the sorting mechanism, the automatic sorting of the finished product pens is realized, one end of an automatic sorting feeding mechanism is also connected with a counting device and a box filling device, and the counting package of the finished product pens is further realized. The automatic sorting feeding device has the advantages that the sorting feeding of the finished product pens can be realized, so the automatic box filling of the pens is realized, a large amount of labor is saved, and the package efficiency of the finished product pens is improved.

Owner:SUZHOU KAILEISHENG AUTOMATION TECH CO LTD

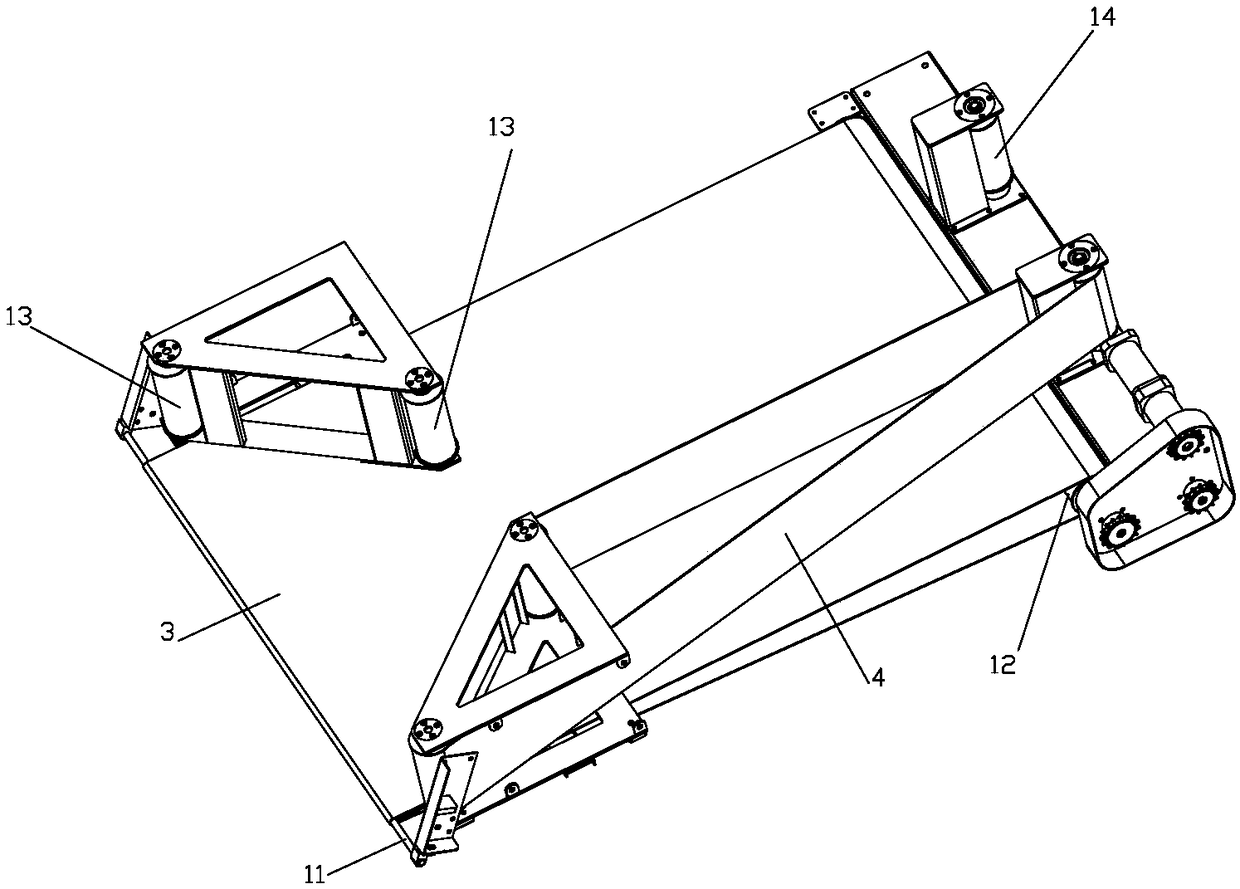

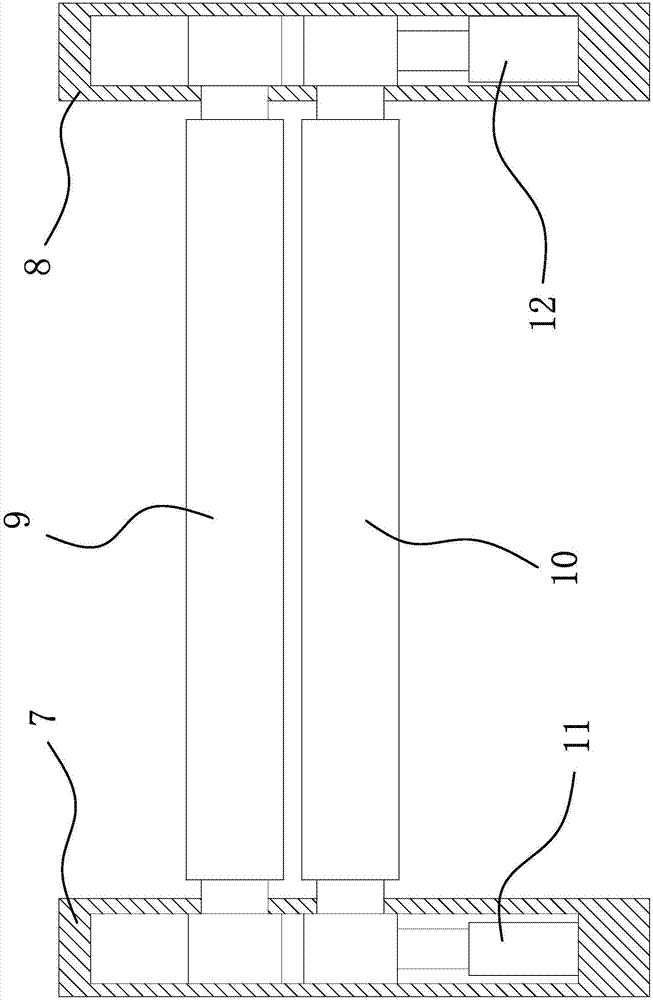

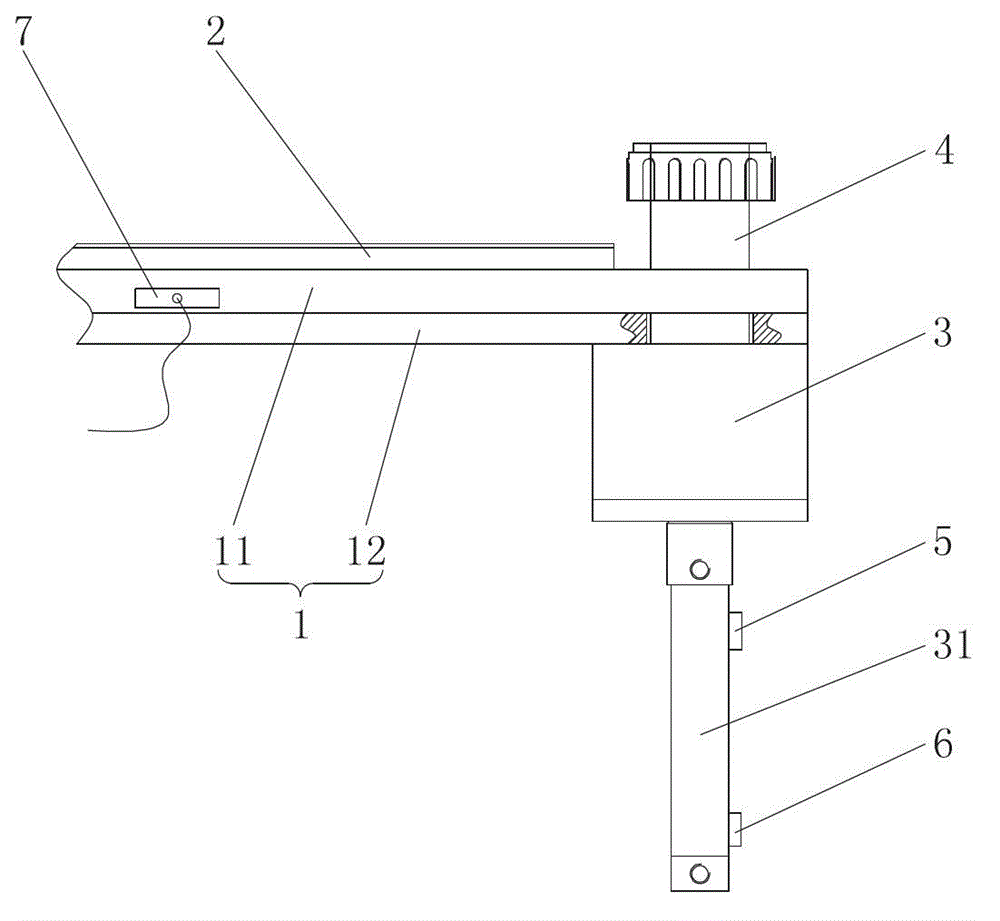

Feeding device of irregular workpiece automatic processing machine tool

The invention provides a feeding device of an irregular workpiece automatic processing machine tool and belongs to the technical field of machine tool components. The feeding device of the irregular workpiece automatic processing machine tool solves the problem that an existing feeding device of the processing machine tool cannot convey irregular workpieces to a clamp of the machine tool smoothly and accurately. The feeding device of the irregular workpiece automatic processing machine tool comprises a support, a barrel-shaped rear material receiving sleeve is fixed on the support, a front material receiving sleeve is arranged on the support, a translation driving mechanism is arranged on the support, a rear material pushing rod is arranged in a cavity of the rear material receiving sleeve, a first driving mechanism is arranged on the support or the rear material receiving sleeve, a front material pushing rod is arranged in the front material receiving sleeve, a second driving mechanism is arranged on the front material receiving sleeve, a front material receiving inner sleeve is further arranged between the front material pushing rod and the front material receiving sleeve, the front material receiving inner sleeve is provided with strip-shaped holes, bosses are arranged on the sides of the front material pushing rod, and the bosses are embedded in the strip-shaped holes. The feeding device of the irregular workpiece automatic processing machine tool has the advantage of being capable of conveying the irregular workpieces to the clamp of the machine tool smoothly and accurately.

Owner:玉环市佳颂自动化科技有限公司

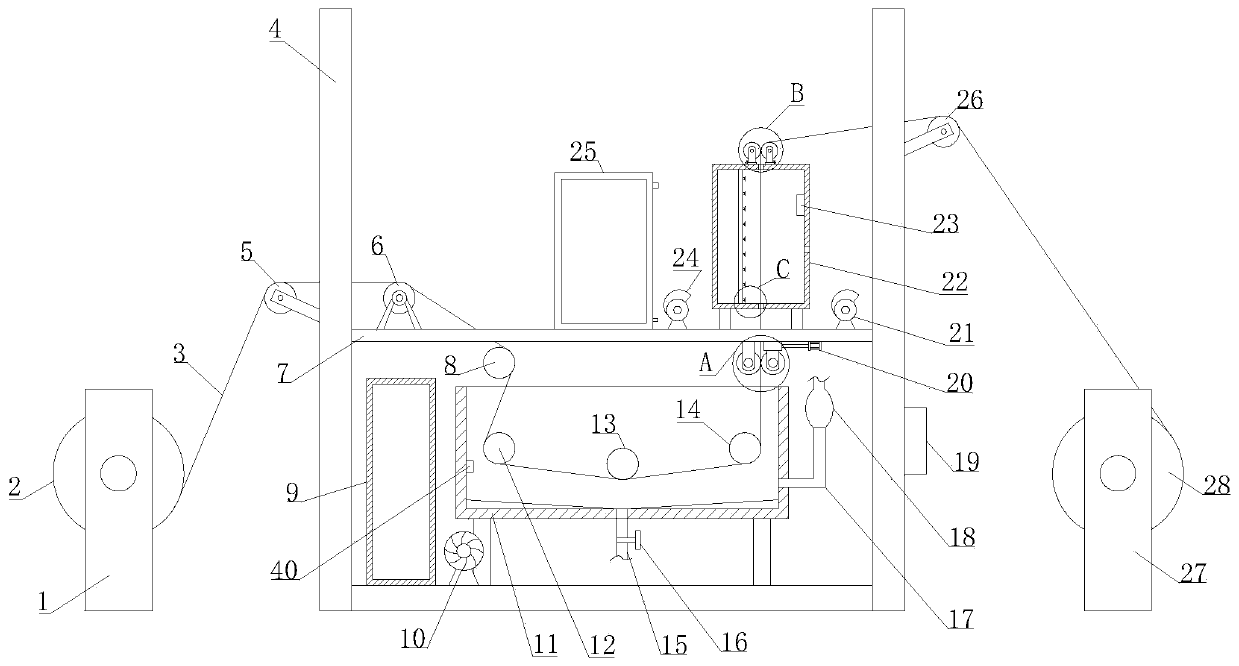

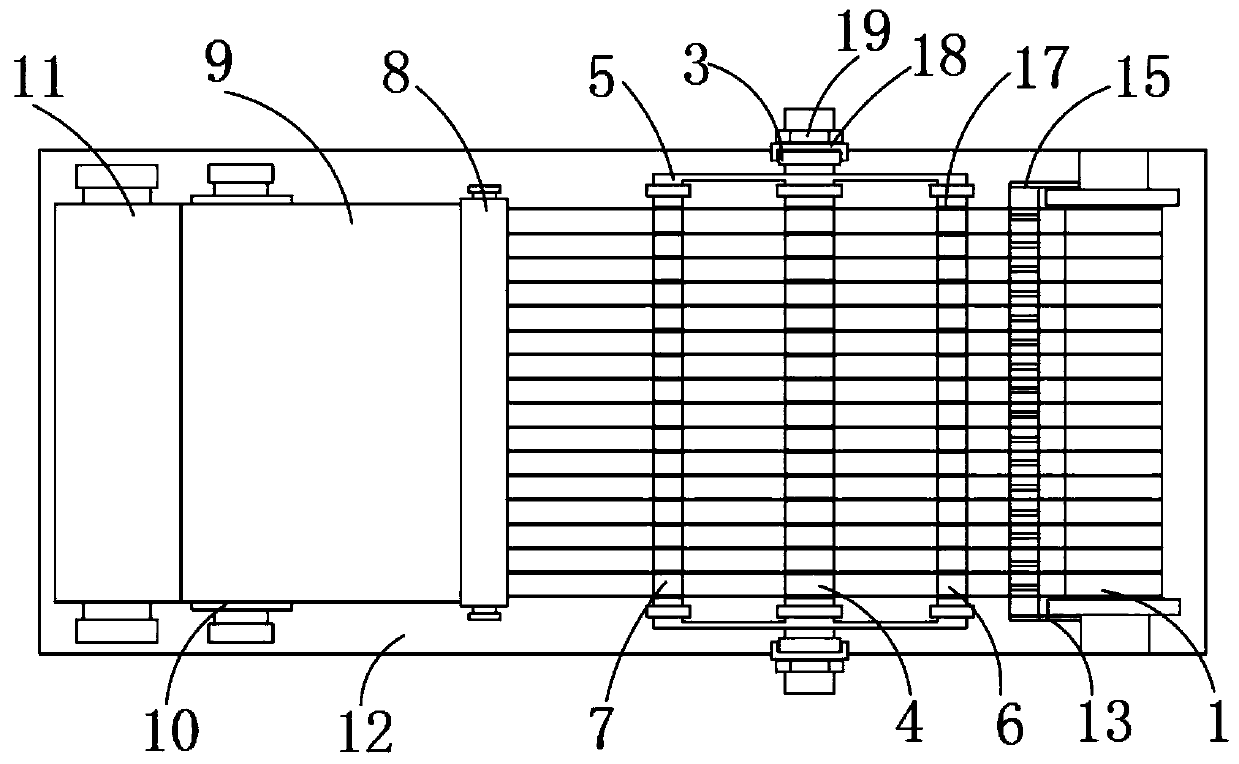

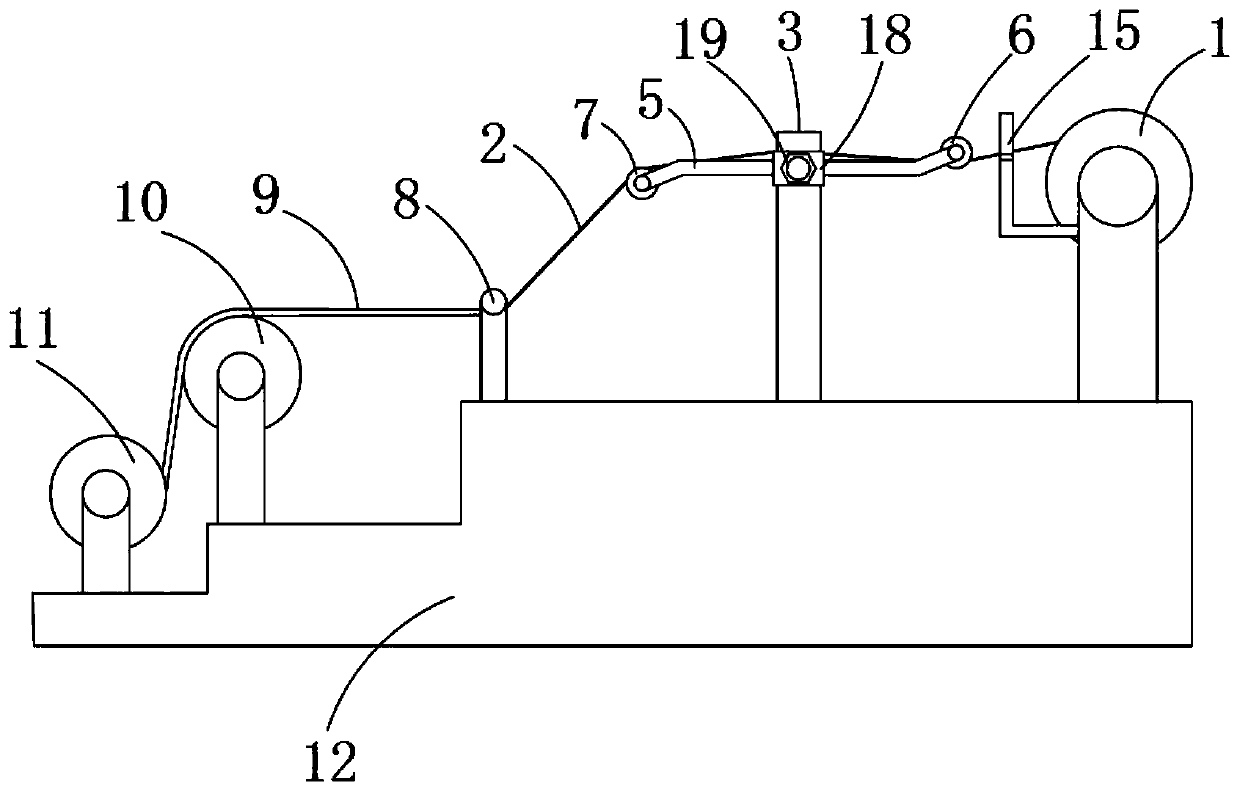

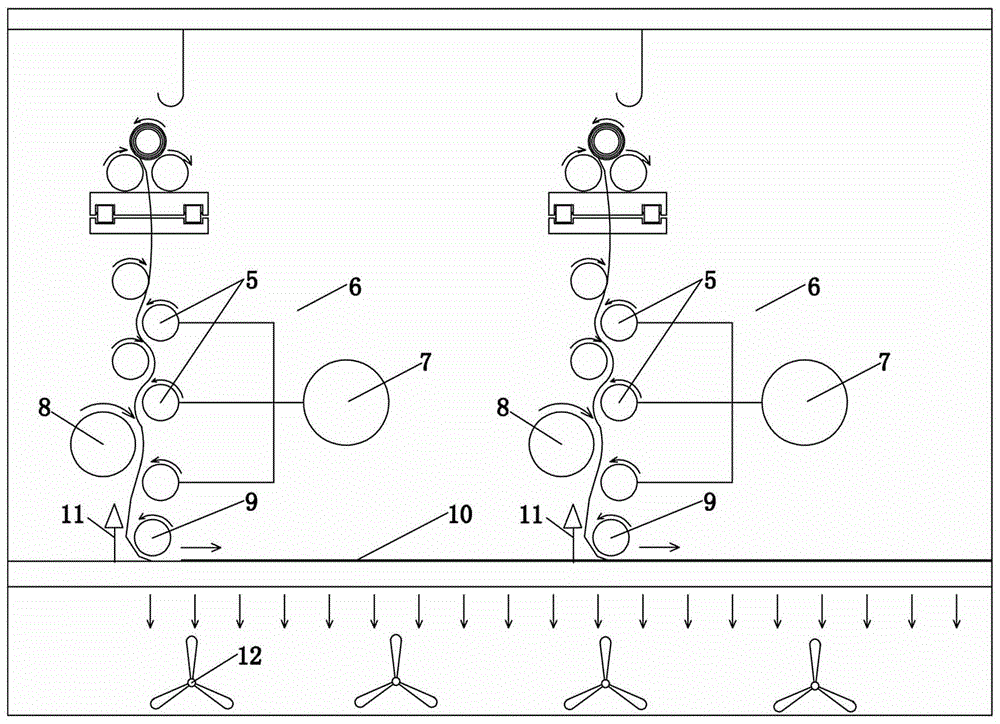

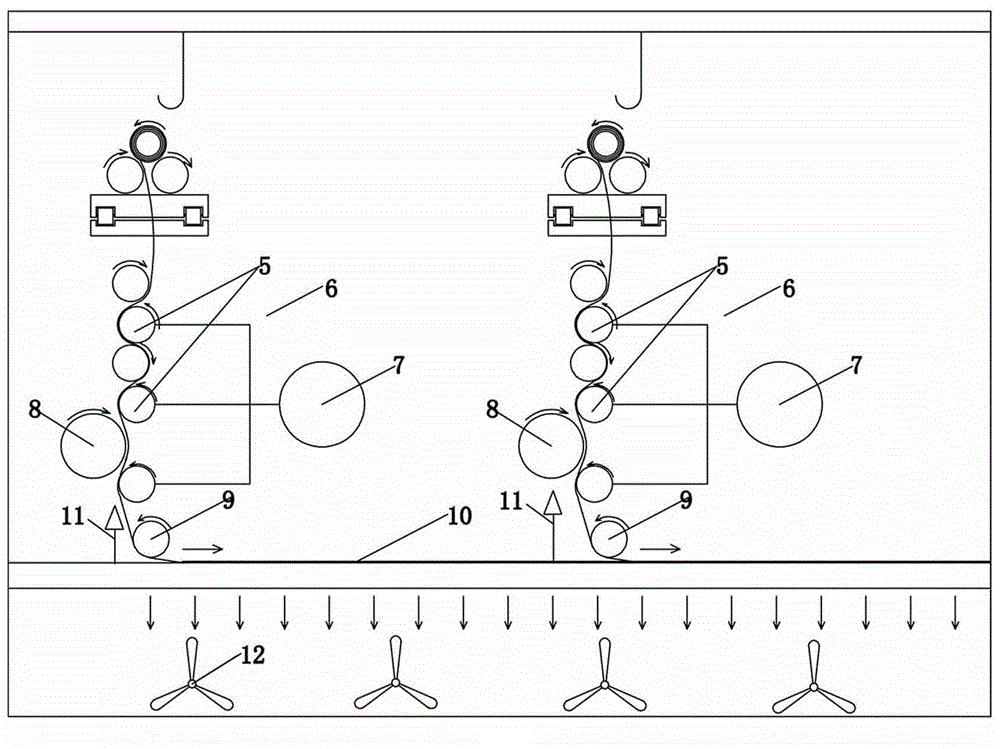

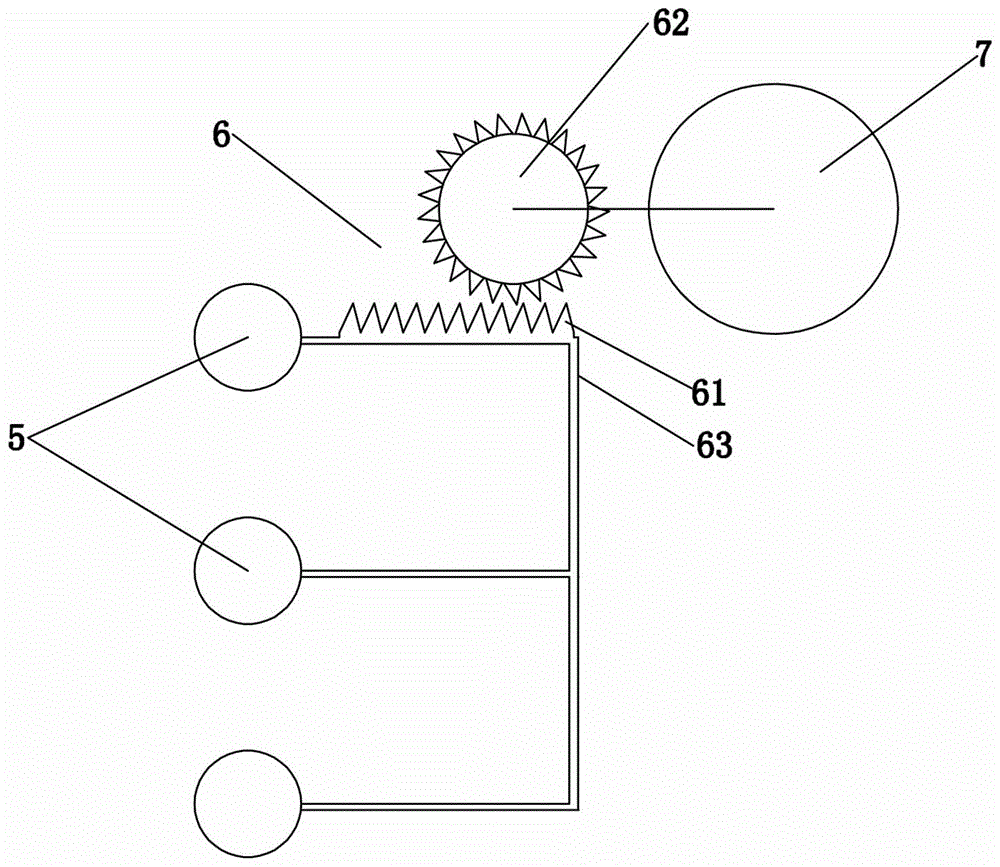

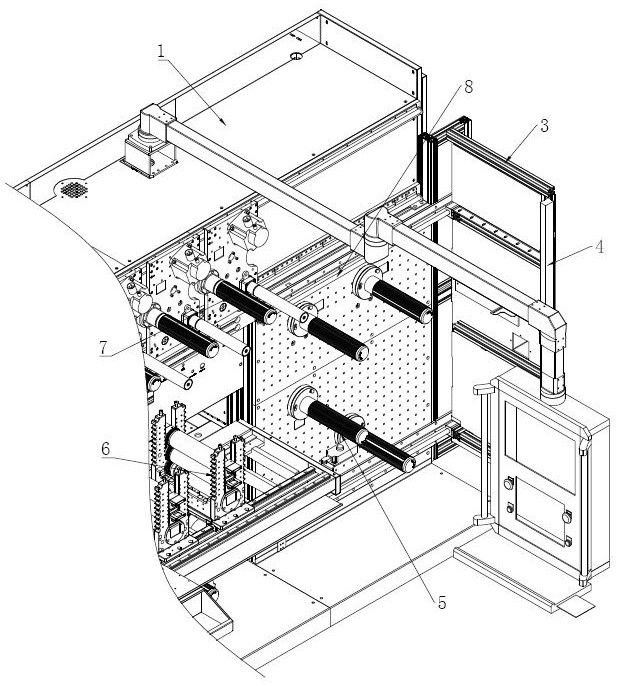

Cotton yarn processing slasher

InactiveCN110344192AConveying orderlyQuick and orderly sizingLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnPulp and paper industry

The invention belongs to the technical field of cotton yarn processing, particularly relates to a cotton yarn processing slasher, and aims to solve the problem of low sizing efficiency of an existingyarn. The technical scheme includes that the slasher comprises a frame, a first guide roller, a second guide roller, a third guide roller, a squeezing roller component and a fourth guide roller, a yarn unwinding device and a yarn winding device are arranged on two sides of the frame, a squeezing device, a drying box and a heating box are arranged on a mounting plate on the frame, the drying box iscommunicated with the heating box through an air supply device, a sizing box storing slurry is arranged on the frame, yarns are outputted by the yarn unwinding device, sequentially pass the first guide roller, the second guide roller, third guide roller and the squeezing roller component and are soaked into the slurry, the yarns are squeezed by the squeezing device, and the squeezed yarns penetrate the drying box, pass the fourth guide roller and are wound on the yarn winding device. According to the slasher, the yarns can be rapidly conveyed, sized, dried and wound, so that the sizing efficiency of the yarns is improved.

Owner:徐州嘉搏纺织股份有限公司

Orderly harvesting and conveying device for stem leaf vegetables

The invention relates to an orderly harvesting and conveying device for stem left vegetables. The device comprises a rack, a cutting device installed on the rack and a rotary bottom conveyor belt, wherein the front end of the bottom conveyor belt is positioned at the back of the cutting device and is inclined towards the rear upper part. The device is characterized in that the device also comprises rotary side conveyor belts installed on the rack; the side conveyor belts are symmetrically arranged above the bottom conveyor belt; a Y-shaped conveying passage with a shrinking inlet is formed bythe side conveyor belts and the bottom conveyor belt; the width of the inlet front end is the same as that of the cutting device; and the side conveyor belts and the bottom conveyor belt operate at equal linear speed. The conveying manner that the vegetables are collected in a vertical state initiatively, adjacent vegetables are clustered together to be conveyed backwards by the bottom conveyor belt and the side conveyor belts, a good and coincident vertical state can be maintained in the conveying process, the stem left vegetables can be harvested and conveyed in good order, and the device has the characteristics of simple structure and high operation efficiency.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

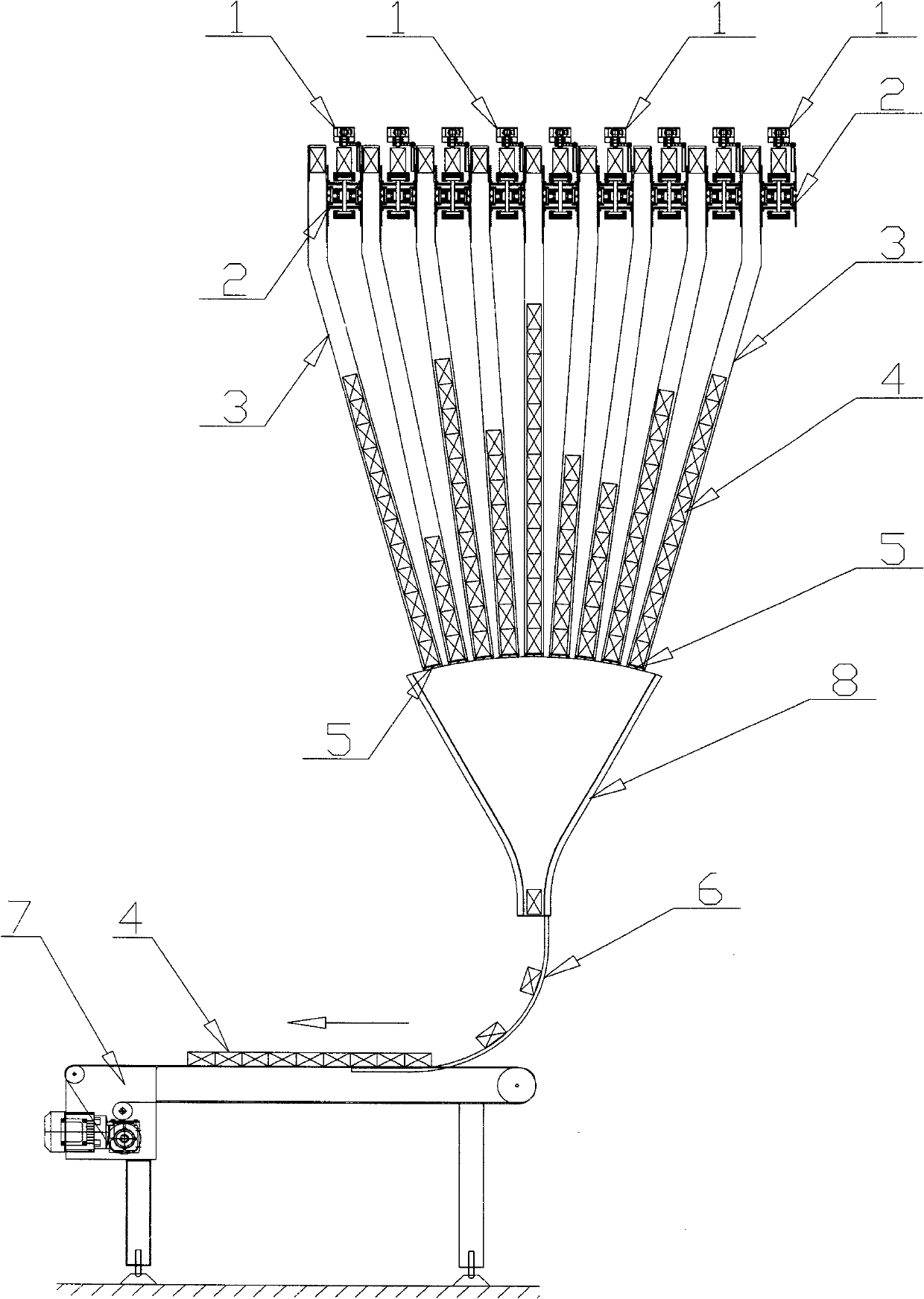

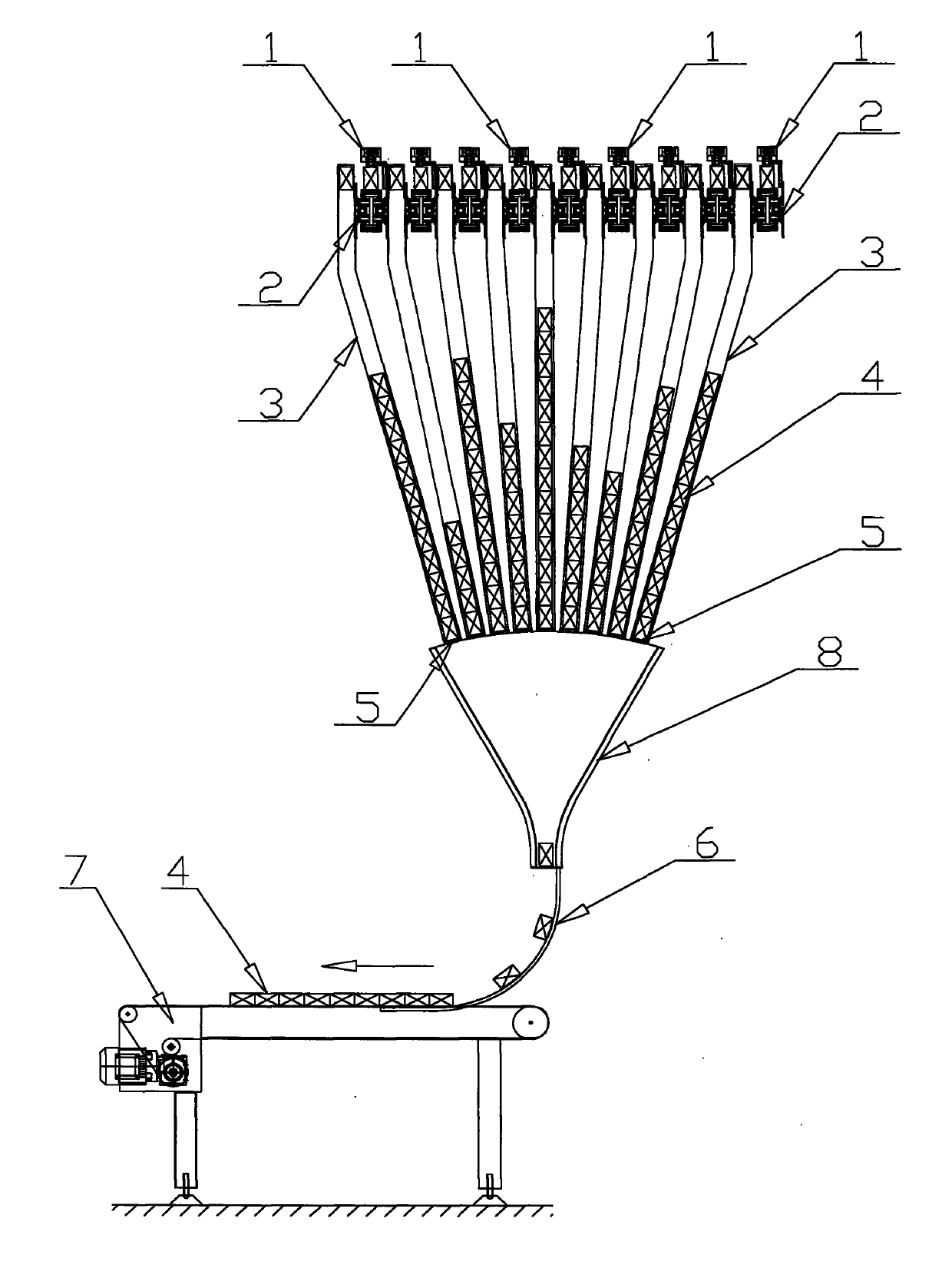

Air-powered air cushion packing machine

InactiveCN101792063AConveying orderlySmooth landingPackagingConveyor partsLow noiseSquare cross section

The invention provides an air-powered air cushion packing machine, which comprises N overhead horizontal cigarette carton conveyors, N groups of horizontal cigarette carton transverse setting mechanisms and a horizontal synchronous gathering conveyor, wherein the N groups of horizontal cigarette carton transverse setting mechanisms correspond to the N overhead horizontal cigarette carton conveyors one by one, and N is a natural number of more than or equal to 1; an air-powered air cushion vertical passage is arranged corresponding to each group of horizontal cigarette carton transverse setting mechanisms; the horizontal synchronous gathering conveyor is arranged under the air-powered air cushion vertical passage; the lower part of the air-powered air cushion vertical passage is provided with an air-tight valve; the air-powered air cushion vertical passage is a vertical passage with square cross section; and the size of the square is 1 to 5 millimeters more than that of a single edge of the bottom surface of a cigarette carton. The air-powered air cushion packing machine has the prominent advantages of high efficiency, no energy consumption, no friction loss, low noise and stable or ordered delivery.

Owner:XUCHANG TOBACCO MACHINERY

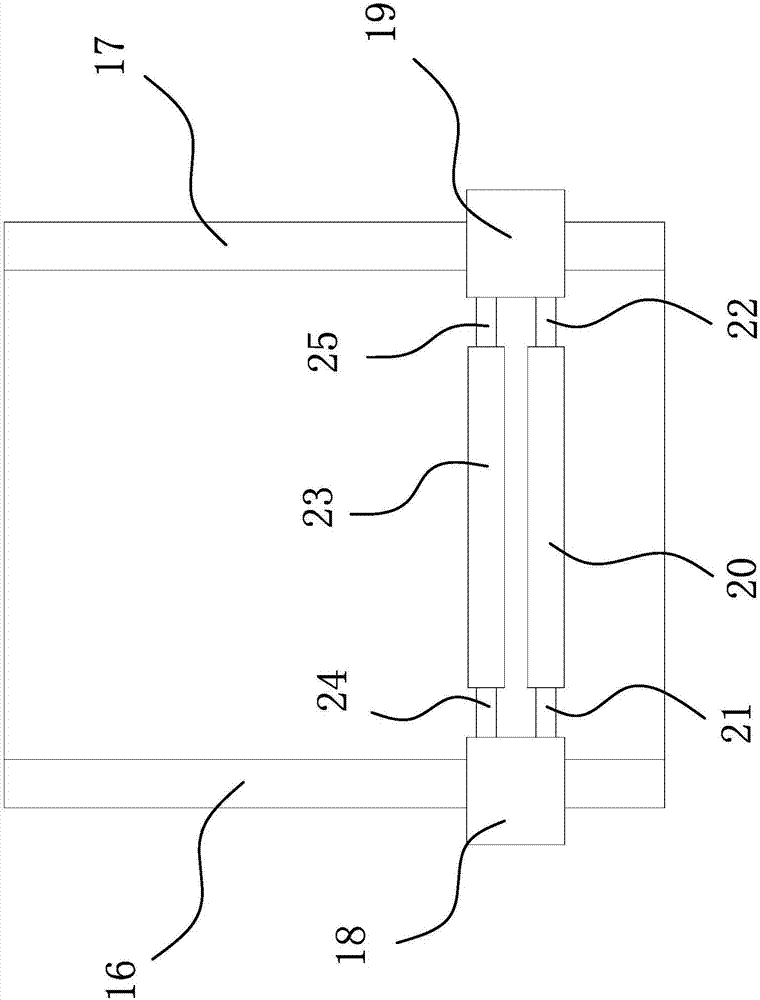

Warp tension adjusting mechanism for weaving functional polyester fabric

The invention discloses a warp tension adjusting mechanism for weaving a functional polyester fabric. The warp tension adjusting mechanism for weaving the functional polyester fabric comprises a fixedbase, wherein a plurality of fixed plates are welded to the top end of the fixed base; rotating rods are embedded on the tops of two supporting frames; clamping plates are arranged at two ends of each rotating rod separately in a sleeving manner; the two ends of each rotating rod are in threaded connection with fixing nuts; connecting rods are welded to two ends of each rotating rod; one ends ofeach two connecting rods are rotatably connected with first rotating rollers through rotating shafts; and the other ends of each two connecting rods are rotatably connected with second rotating rollers through rotating shafts. The warp tension adjusting mechanism for weaving the functional polyester fabric is provided with the connecting rods, the first rotating rollers and the second rotating rollers, because the first rotating rollers and the second rotating rollers are connected together through the connecting rods, the first rotating rollers and the second rotating rollers rotate oppositely when tension is adjusted rotatably, the tension can be adjusted rapidly, an adjustable range is expanded, and an effect of improving the tension adjusting efficiency is achieved.

Owner:长兴钱振纺织有限公司

Double-chamber high-voltage soft bag detector

PendingCN110487486AEasy to captureRealize no dead angle detectionDetection of fluid at leakage pointEngineeringHigh pressure

The invention discloses a double-chamber high-voltage soft bag detector. A detection channel device is arranged on a frame; a feeding mesh belt is arranged at the feeding end of the detection channeldevice, and an output mesh belt is arranged at the discharge end; a waste removing device is arranged above the output mesh belt; the detection channel device comprises a wavy soft bag conveying beltformed by connecting a plurality of power rollers side by side through a connecting belt; a bag head detection device and a bag body detection device are arranged on a detection station of the soft bag conveying belt; the bag body detection device comprises a bag body front side detection device and a bag body back side detection device; the bag body detection device is arranged at the inclined plane position of the soft bag conveying belt, and the inclined plane is formed by connecting at least two power rollers through the connecting belt. and a bag tail clamping device is arranged above thesoft bag conveying belt. The detection stability can be improved, ridge type conveying is adopted, and the detection sensitivity is improved; detection electrodes are arranged in a crossed covering manner to reduce false detection; and the detection electrodes can be automatically adjusted according to the bag body contour, and the leakage point capture sensitivity is improved.

Owner:HUNAN ZHENGZHONG PHARMA MACHINERY

Chain conveying device with self-discharging function

InactiveCN112374087ALabor savingImprove delivery efficiencyConveyorsCleaningElectric machineryDrive motor

The invention discloses a chain conveying device with a self-discharging function, and relates to the technical field of conveying devices. The chain conveying device comprises a device box, wherein adriving motor is fixedly connected to the inner side wall of the device box, a driving rod is fixedly connected to the output end of the driving motor, a first rotating shaft is fixedly connected tothe bottom end of the driving rod, the bottom end of the first rotating shaft is rotationally connected to the device box, the surface of the first rotating shaft is fixedly provided with two drivingsprockets in a sleeve mode, and the surfaces of the driving sprockets are connected to a chain in a meshing mode. According to the chain conveying device, full-automatic feeding is achieved, manual operation is not needed, labor force is saved, the conveying efficiency is improved, products are controlled to enter a conveying belt through a valve, the products are evenly distributed on the conveying belt, the possibility of blockage is reduced, a buffering device is arranged at a discharging port, safety in a conveying process of the products is guaranteed, and when the chain is abnormal due to stains such as dust, a vibration sensor triggers a cleaning device to be started, and the chain is automatically cleaned.

Owner:牛启俊

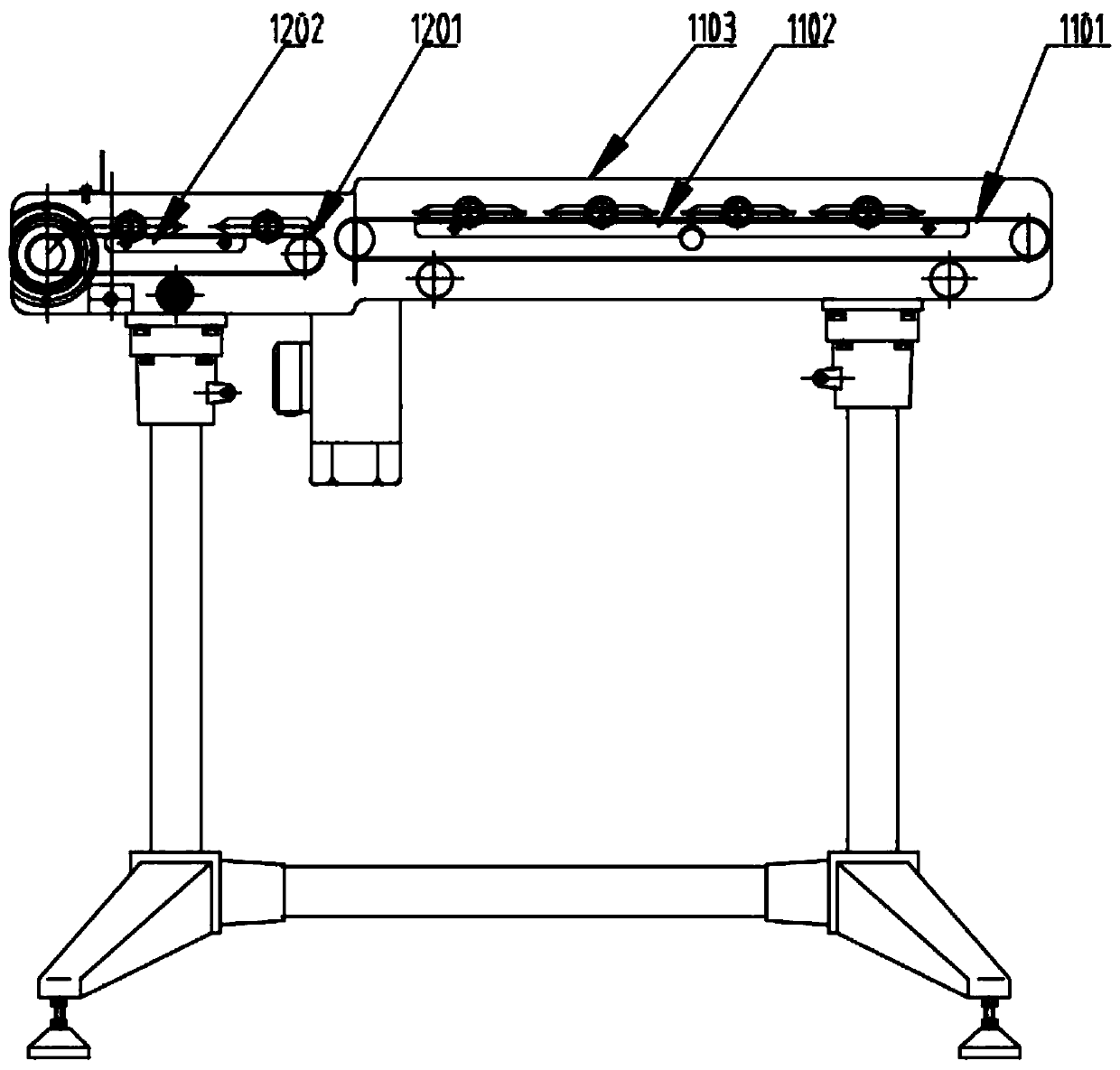

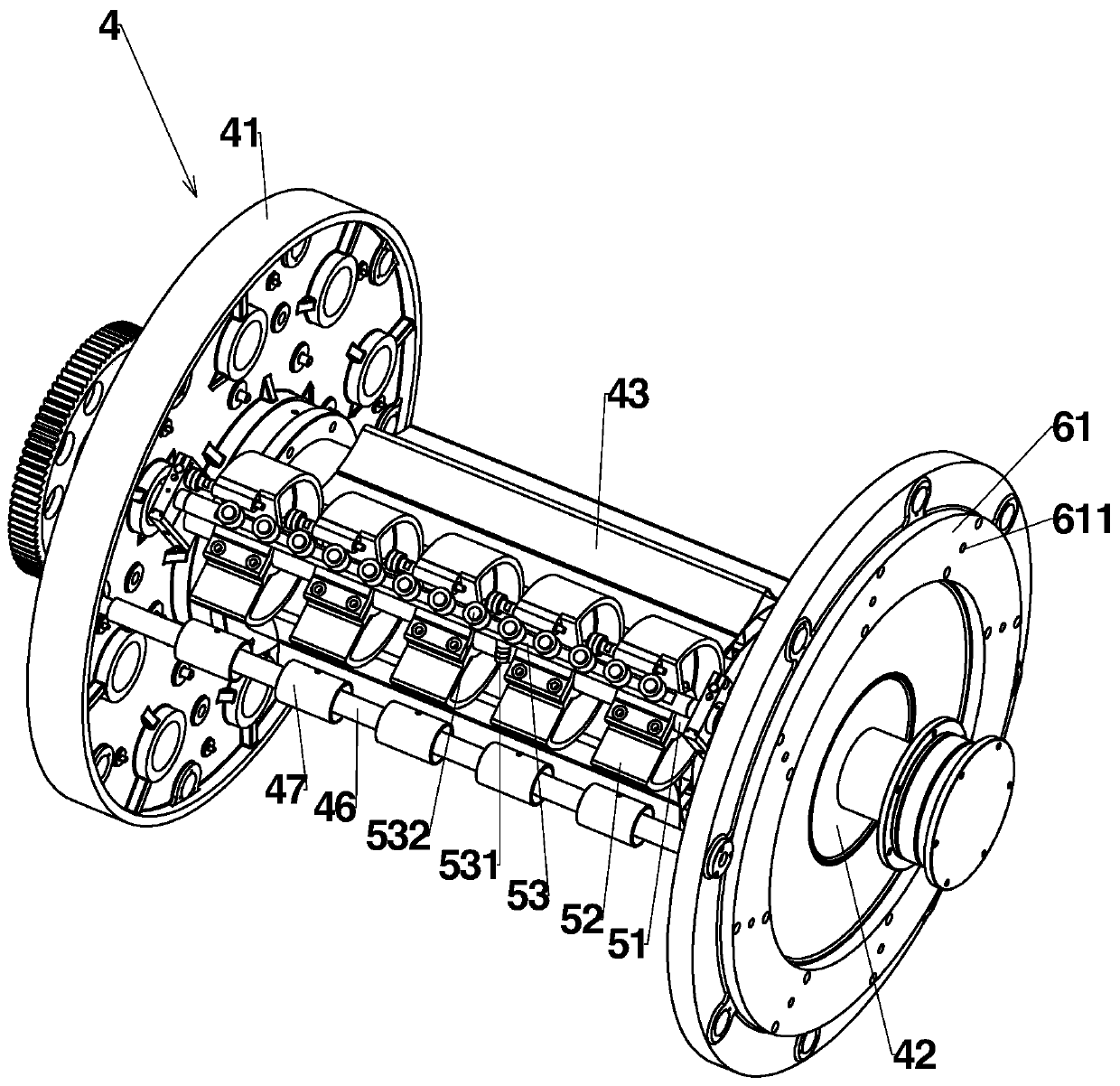

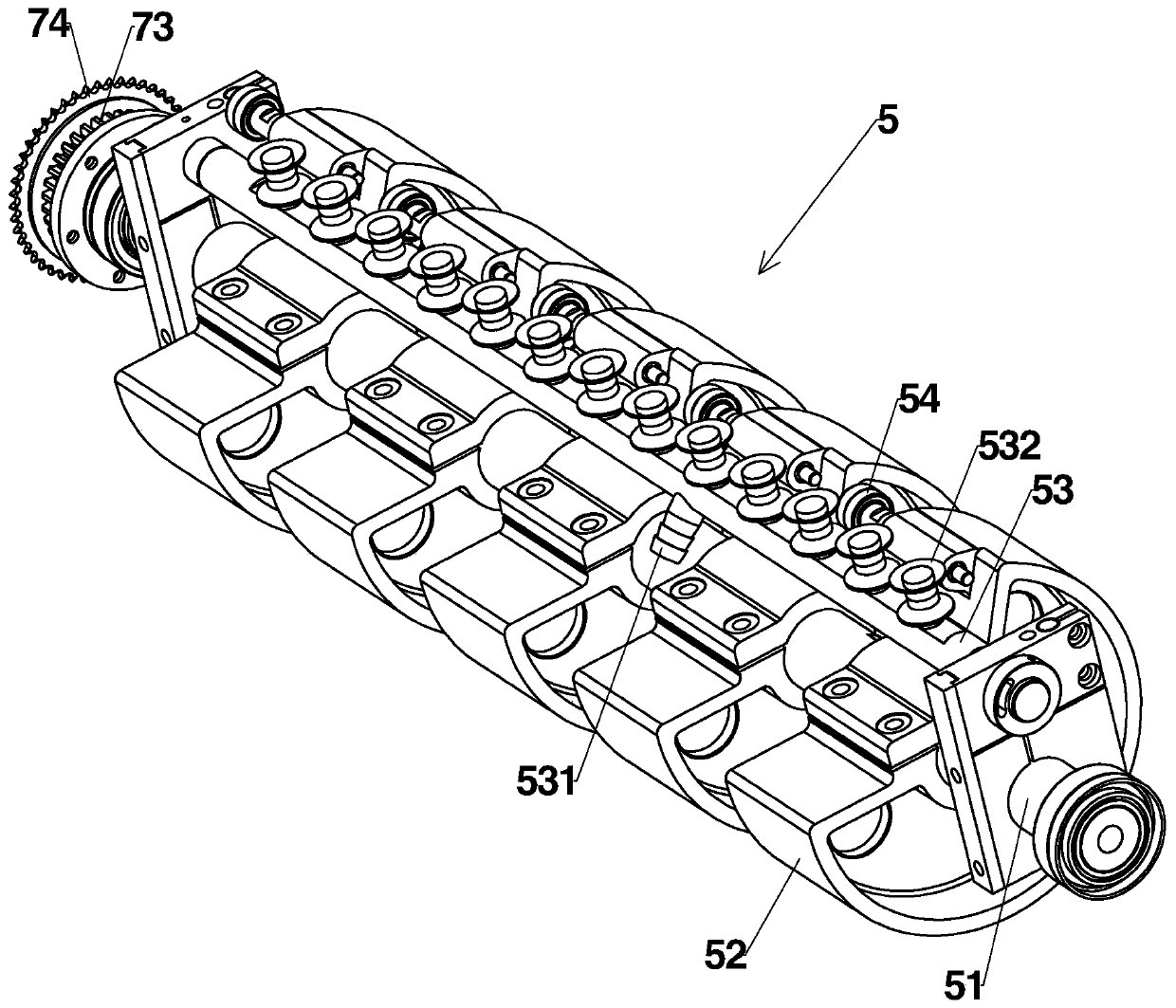

One-way adjustable chain type conveying mechanism

ActiveCN104773444ARealize intermittent movementAvoid delivery disordersConveyorsDrive shaftChain conveyor

The invention provides a one-way adjustable chain type conveying mechanism, belongs to the technical field of automatic machining, and solves the technical problems of disorder and missing during conveying of workpieces with the conventional conveying chain. The one-way adjustable chain type conveying mechanism comprises a link plate frame, a transmission shaft, a transmission device, an arresting device and an adjusting device, wherein a conveying chain is arranged on the link plate frame; a ratchet wheel is arranged on the transmission shaft; the ratchet wheel is provided with a plurality of gear blocks; the transmission device is used for driving the ratchet wheel to rotate and move the conveying chain; when the gear blocks are in contact with the arresting device, the ratchet wheel stops rotating; when the transmission device drives the arresting device to move away from the gear blocks, the ratchet wheel can rotate continually; the adjusting device is connected with the link plate frame, and can drive the link plate frame to move on the transmission shaft. The one-way adjustable chain type conveying mechanism has the beneficial effects that the ratchet wheel is driven to rotate through the transmission device, so that the workpieces can be conveyed orderly. Bidirectional braking of the ratchet wheel is realized in the static state of the ratchet wheel through the arresting device, so that the workpiece conveying accuracy is ensured.

Owner:宁波宫铁智能科技有限公司

Paper bag automatic feeding device

InactiveCN109911662AConveying orderlyStable deliveryArticle feedersArticle separationPulp and paper industry

Owner:江西新明峰包装科技有限公司

Fabric printing production line

InactiveCN107139583AGuaranteed flatnessConveying orderlyRotary pressesPrinting press partsProduction lineDrive motor

The invention provides a fabric printing production line, and belongs to the technical field of machines. The fabric printing production line comprises a rack, a fabric unreeling device for releasing fabric is arranged at one end of the rack, and comprises a first mounting plate and a second mounting plate which are fixed to the rack, an unreeling shaft is arranged between the first mounting plate and the second mounting plate, one end of the unreeling shaft penetrates the first mounting plate, an unreeling roller cylinder is detachably fixed to the unreeling shaft, and a drive motor used for driving the unreeling shaft to rotate is further fixed to the rack; the production line is characterized in that a conveying mechanism for traction conveying of fabric, multiple printing devices for different-dye printing on fabric, a drying device for drying the printed fabric and a neatening device for neatening the dried fabric are arranged on the rack in sequence. The production line has the beneficial effect that the fabric can be subject to assembly printing, and the printing efficiency of the fabric can be improved.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

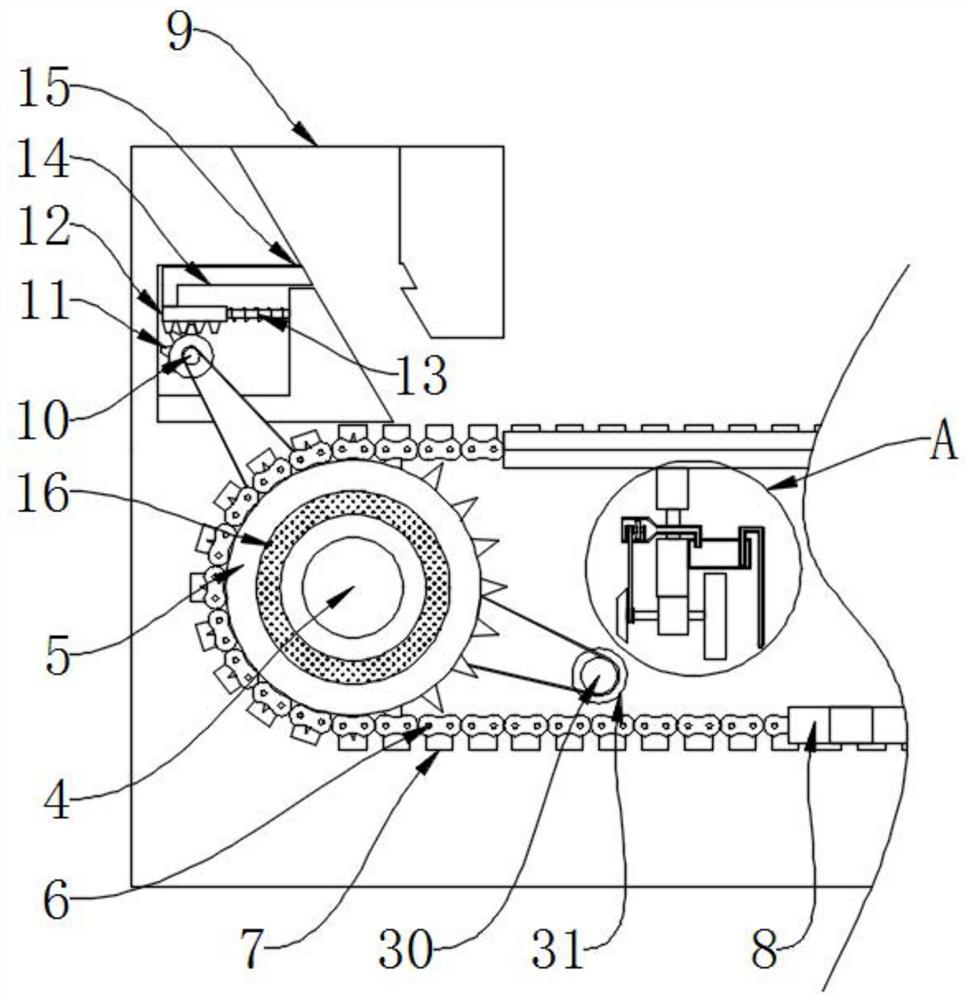

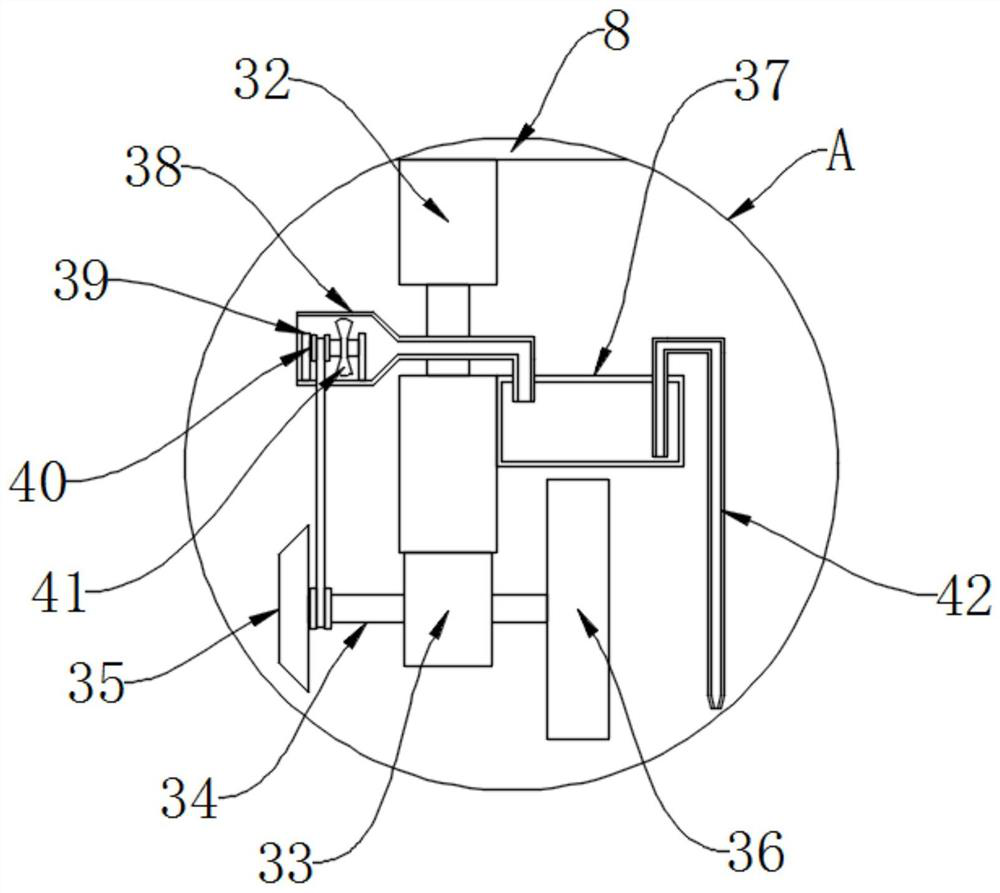

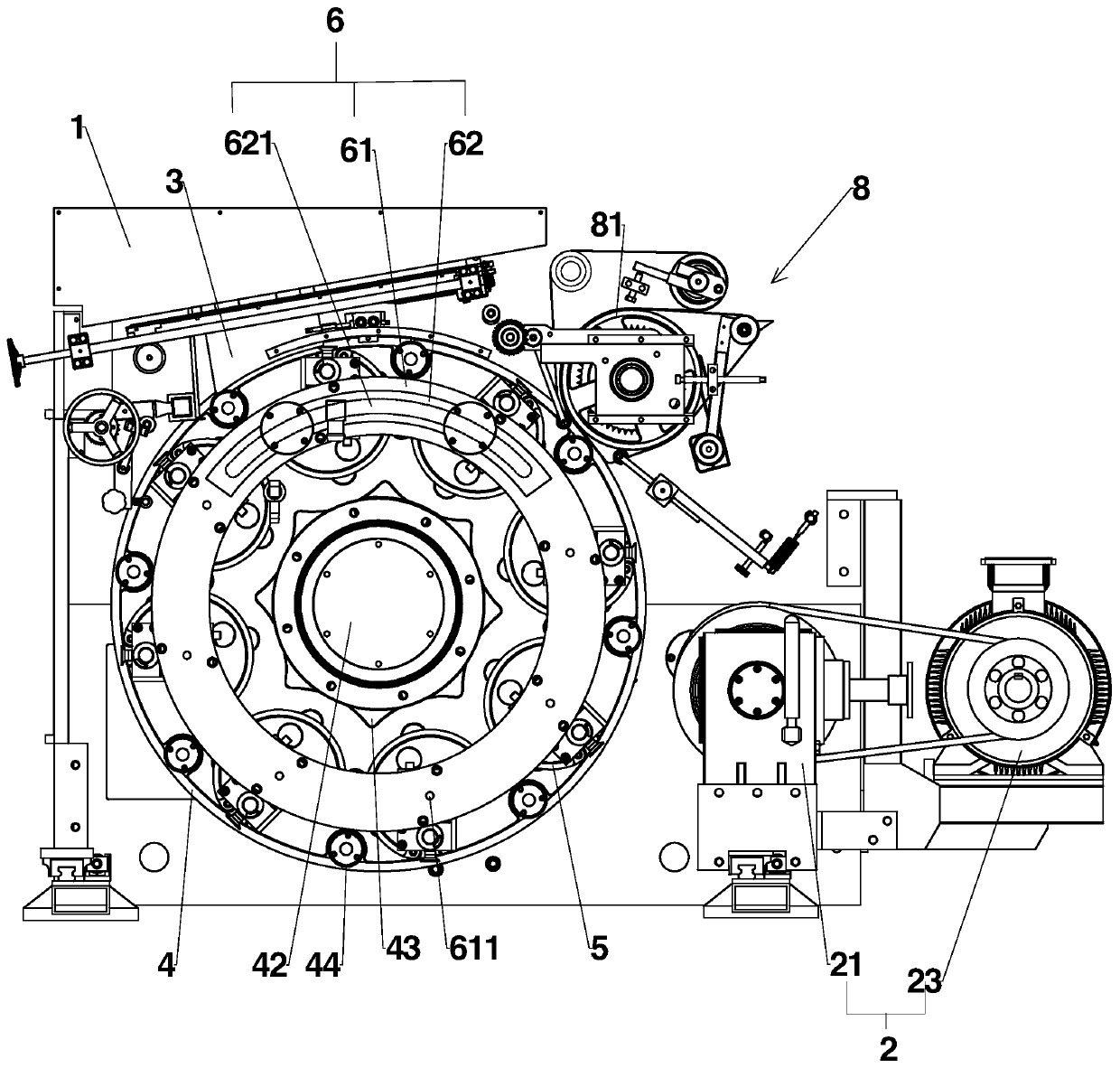

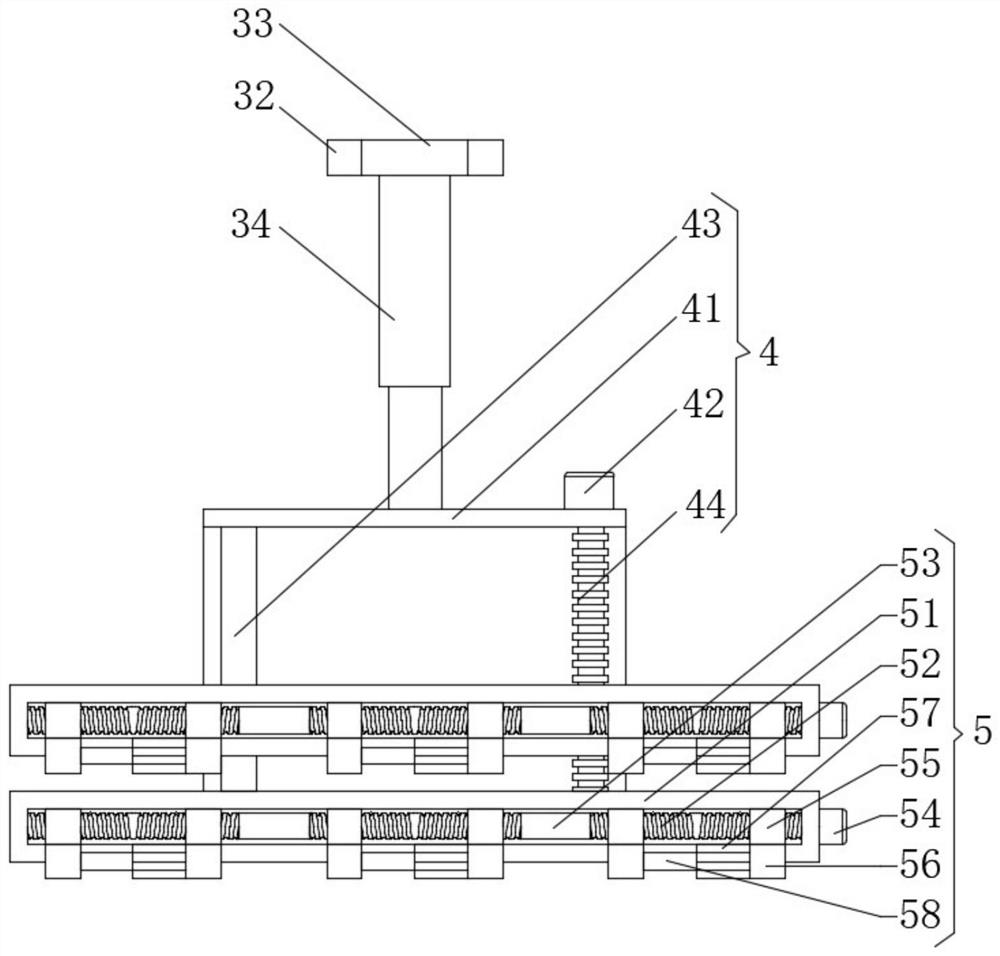

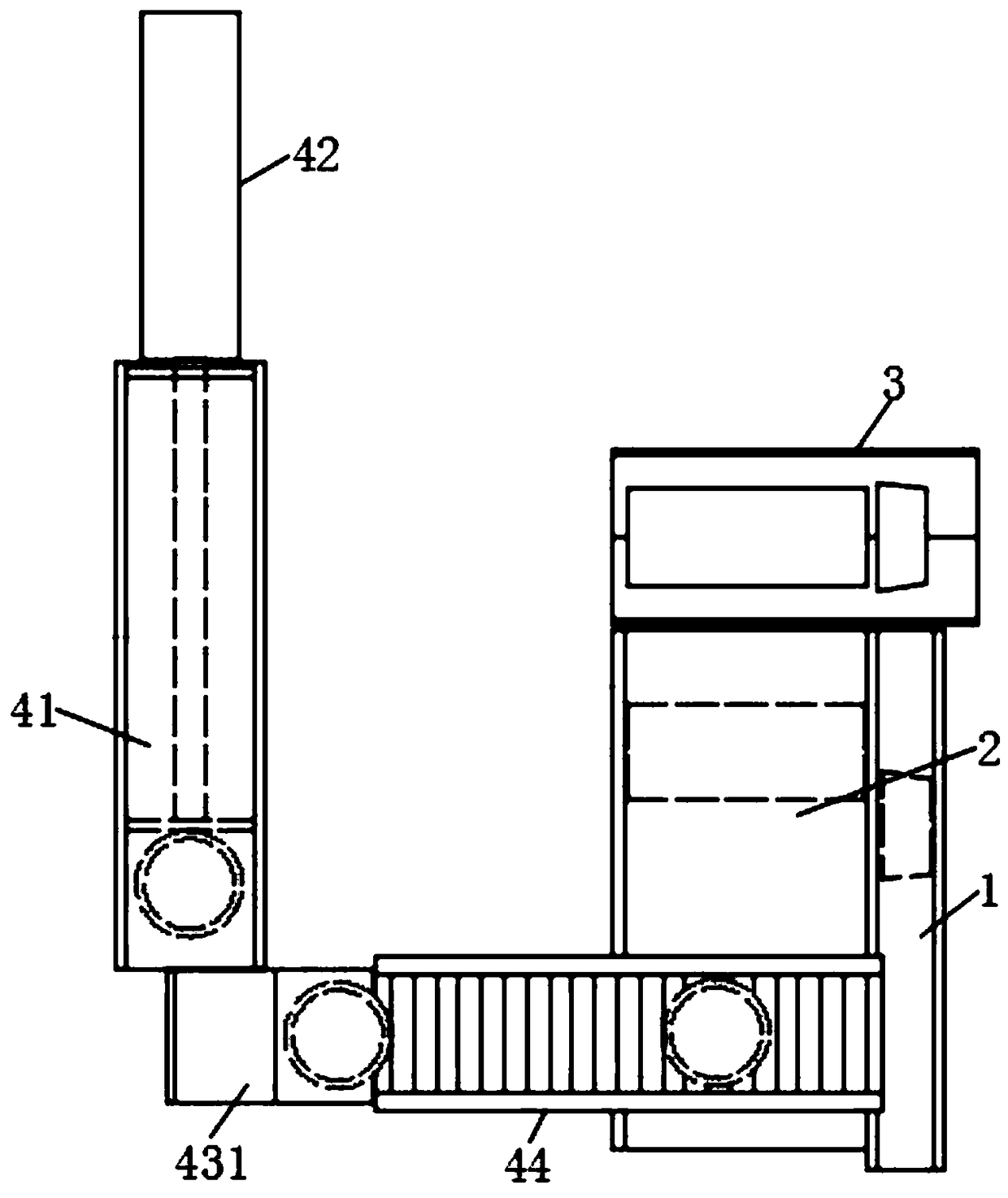

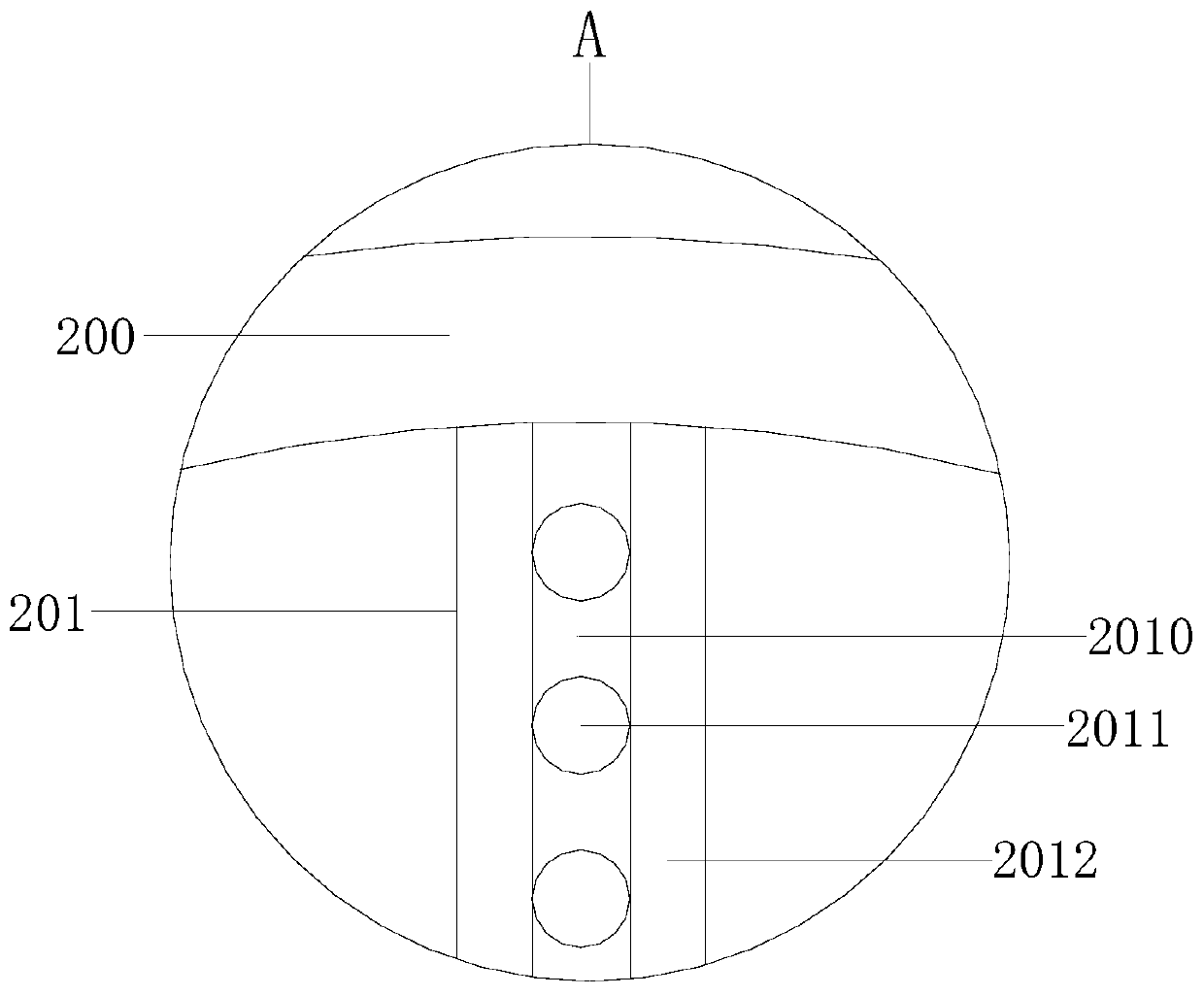

Spring chamfering machine

ActiveCN109551331AEasy to disassembleSimple maintenance and replacementEdge grinding machinesGrinding carriagesElectric machineryEngineering

The invention belongs to the technical field of spring machining equipment, and particularly relates to a spring chamfering machine. The machine comprise a machine frame, wherein a feeding hopper is fixed at the top of the machine frame, a material guide plate connected with the feeding hopper is arranged at the top of the machine frame, the right side of the material guide plate is bent to a slope, and a plurality of magnetic strips are uniformly arranged on the slope of the material guide plate; a clamping roller driven by a first motor is arranged in the machine frame, and a plurality of placing grooves are uniformly formed in the clamping roller in the circumferential direction; an arc-shaped pressing plate is arranged at the lower end of the material guide plate, the pressure plate isarranged on the front-rear face board of the material guide plate, the gap between the pressing plate and the clamping roller is gradually reduced from the position A to the position B, and when a spring moves to the position B, the spring is just clamped through the pressing plate and the clamping roller; two cylindrical chamfering blocks driven by a second motor are arranged in the machine frame, a chamfer is arranged at the front end of each chamfering block, the two chamfering blocks are front-back symmetrically distributed on the two sides of the clamping roller correspondingly, and therotating directions of the two chamfering blocks are opposite; and a discharging plate is arranged at the position, located below the clamping roller, of the machine frame, and four through grooves are uniformly formed in the discharging plate.

Owner:肇庆市肇大体育科技有限公司

Cap delivery device of cap screwing machine

InactiveCN102976084AConveying orderlyNo stackingCapsClosure using capsLower limitBiomedical engineering

The invention relates to a cap delivery device of a cap screwing machine. The cap delivery device comprises a cap guide groove, wherein the cap guide groove consists of two side plates and a bottom plate; the cap guide groove comprises a delivery part and a cap delivery part; a cap pressing plate covers the delivery part; a hole is formed in the bottom plate of the cap delivery part, a cap delivery cylinder is arranged below the bottom plate of the cap delivery part, and a push shaft of the cap delivery cylinder is coaxially and fixedly connected with a cap delivery rod; the cap delivery rod is coaxial with the hole, and the size of the cap delivery rod is matched with that of the hole; an upper limit sensor and a lower limit sensor are arranged on the cap delivery cylinder; and a cap deficiency sensor is arranged on the cap guide groove. The cap delivery device has the advantages of simple structure, excellent cap delivery effect and capability of automatically judging cap deficiency and stopping.

Owner:JIANGSU TOM PACKAGING MACHINERY

Drink bottle transport system

ActiveCN106144428AStreaming is simple and fastAvoid pouring bottlesConveyorsLiquid bottlingTransport systemBottle

Provided is a drink bottle transport system. The drink bottle transport system comprises a bottle-feeding conveyor belt, a bottle-discharge conveyor belt and a plurality of push components for connecting the bottle-feeding conveyor belt with the bottle-discharge conveyor belt. The bottle-feeding conveyor belt comprises a circular conveyor belt, an outer side conveyor belt is additionally arranged on the outer side of the circular conveyor belt, a bottle-discharge opening connected with one of the push components is formed in the inner side of the circular conveyor belt, a horizontal air blowing valve corresponding to the bottle-discharge opening is arranged in the middle of the circular conveyor belt, and a guide rod is arranged at a bottle-feeding opening of the bottle-discharge conveyor belt. A feeding device and a weighing device are further arranged between the bottle-feeding conveyor belt and the bottle-discharge conveyor belt, and a bottle body at the bottle-feeding opening is pushed to a weighing component for feeding and continues to be pushed to the bottle-discharge opening by the push components. The drink bottle transport system is comparatively simple in structure of each part and reasonable in design, prevents a drink bottle from being jammed in front of and behind the feeding device and falling down, guarantees the efficiency and the order of the whole transport process, also is favorable for completing feeding safely and stably, and improves the product qualification ratio.

Owner:邵阳欣源机械有限公司

Multi-stage screening limit feeding device and method

InactiveCN111744807AConveying orderlyImplement screening and classificationSortingStructural engineeringElectrical and Electronics engineering

The invention discloses a multi-stage screening limit feeding device and method. The technical scheme is that the device comprises a limiting rail, a bearing plate, a driving device and a limiting mechanism. A bearing plate is arranged below the head end of the limiting rail. The bearing plate can rotate relative to the limiting rail under the action of the driving device. A multi-layer sorting rail is arranged at the tail end of the limiting rail and provided with a sorting groove. The limiting mechanism is fixed to one side of the limiting rail. The device can screen out materials of different quality levels and can realize the orderly conveying of the materials.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +2

Intelligent sorting and packaging system and sorting and packaging method thereof

ActiveCN108722882BImprove work efficiencyReduce error rateCo-operative working arrangementsStacking articlesComputer hardwareControl system

The invention provides an intelligent sorting and packing system. The intelligent sorting and packing system comprises a sorting work station, a packing work station and a control system electricallyconnected with the sorting work station and the packing work station. The sorting work station comprises a sorting visual device, a sorting robot and a code scanning device. The sorting visual deviceand the code scanning device are both electrically connected with the sorting robot. The control system comprises a database module and a controller. The controller is arranged to judge whether objectinformation identified by the sorting visual device is matched with object information corresponding to the code scanned by the code scanning device or not, when the object information identified bythe sorting visual device is matched with the object information corresponding to the code scanned by the code scanning device, the controller sends a sorting signal to the sorting robot, and when theobject information identified by the sorting visual device is not matched with the object information corresponding to the code scanned by the code scanning device, the controller generates an alarmsignal to a background system. The packing work station is arranged to conduct stacking and packing operation. A sorting and packing method of the intelligent sorting and packing system achieve unmanned sorting and packing operation of objects, the operation efficiency is improved, and the error rate and the labor cost are lowered.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

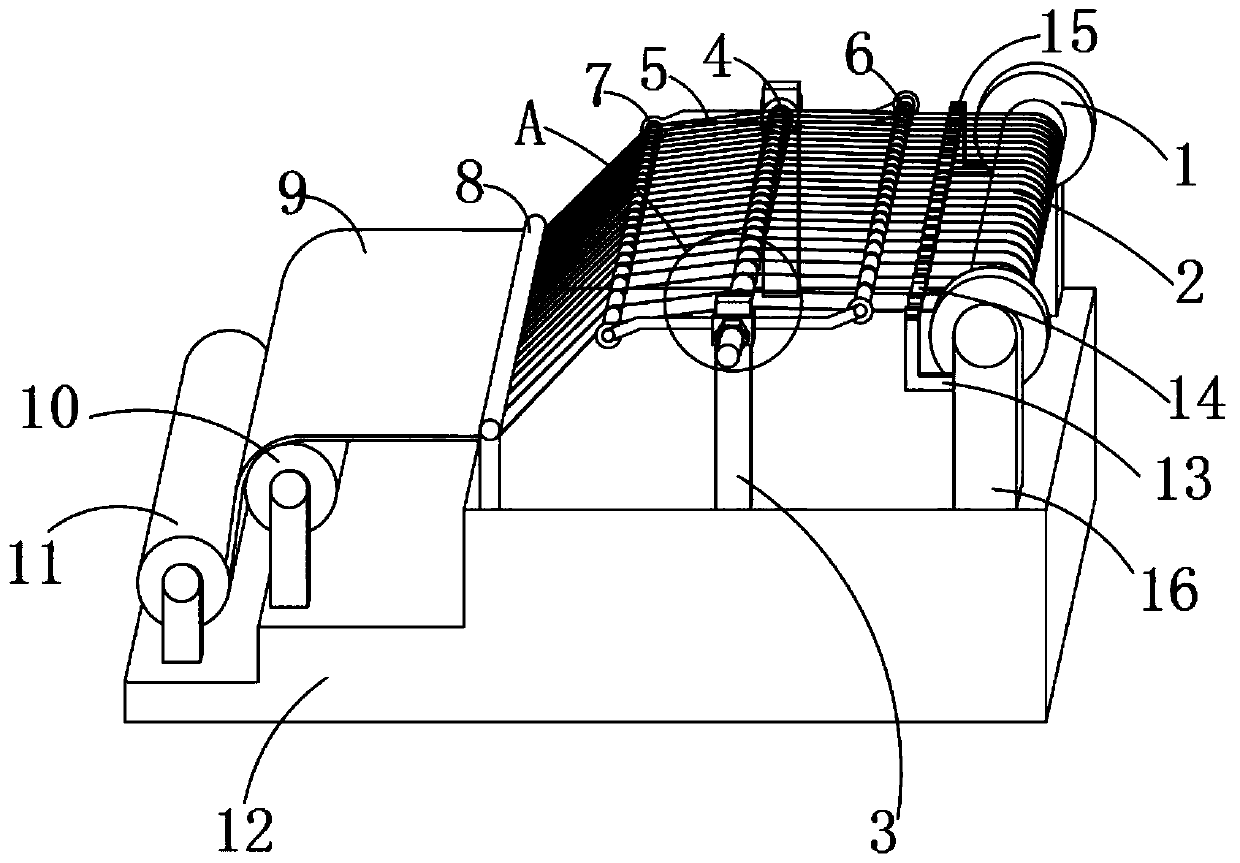

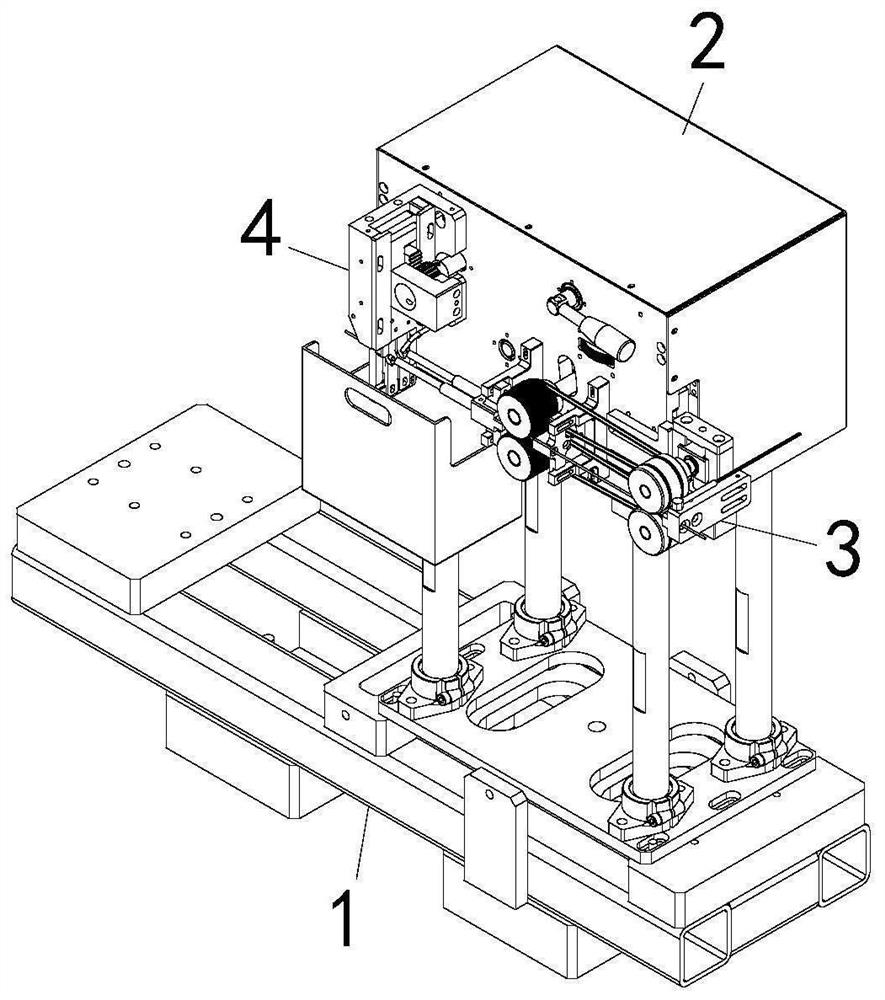

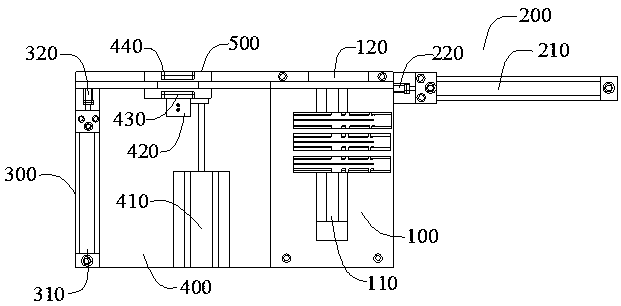

Automatic cable plugging machine

ActiveCN112828571AFast transferGuaranteed no deviation in insertionFinal product manufactureMetal working apparatusStructural engineeringAssembly line

The invention discloses an automatic cable plugging machine. A PCB assembly line, an XYZ three-axis movement mechanism, a cable stripping mechanism, a material receiving transfer mechanism and a cable plugging mechanism are arranged on a workbench. According to the automatic cable plugging machine, orderly feeding and conveying of cables are realized through a cable feeding module, threading is convenient, cable feeding and cable withdrawing are relatively stable, multi-cable conveying can be realized, and the efficiency is high; the cutting and stripping of insulating layers on the surfaces of the cables are realized through the cable stripping module, the cutting of metal wires of the cables can also be realized, and the pluggable cables of which the metal wires are exposed at the two ends are automatically obtained. The stripped cables on the cable stripping module are clamped and received through cable clamping claws of the material receiving module; and then the cables are inserted into all work stations of a transfer module, and the cables are conveyed to the cable plugging mechanism through the transfer module after full plugging, so that circulating and rapid transfer of the cables is realized, and the efficiency is high. The pluggable cables can be quickly and orderly plugged onto a PCB through the cable plugging mechanism, and a guiding structure assists in plugging during plugging, thereby ensuring that the cables are plugged in place without deviation, and ensuring the product quality.

Owner:良忠城精密科技(苏州)有限公司

Bottle clamping mechanism for pharmaceutical equipment

InactiveCN112455815AConveying orderlyEasy to holdPackaging automatic controlElectric machineryThreaded rod

The invention discloses a bottle clamping mechanism for pharmaceutical equipment. The bottle clamping mechanism comprises a bottom plate, a rotating assembly, an adjusting assembly, a clamping assembly and a conveying assembly. A fixed column is fixed on the upper side surface of the bottom plate; the rotating assembly comprises a servo motor, a rotating disc, a connecting plate and a first electric telescopic rod, a mounting cavity is formed in the upper end of the interior of the fixing column, the servo motor is mounted in the mounting cavity, an output shaft of the servo motor is fixed tothe lower end face of the rotating disc, and the connecting plate is fixed to the circumferential face of the rotating disc; the first electric telescopic rod is installed on the lower side face of the connecting plate, and the rotating assembly is arranged to drive the clamping assembly to rotate; the adjusting assembly comprises an L-shaped fixing plate, a first motor, a limiting rod and a threaded rod, the L-shaped fixing plate is fixed to a telescopic arm of the first electric telescopic rod, the good clamping effect is achieved, pharmaceutical bottles with different lengths can be clamped, and multiple bottles can be clamped at the same time.

Owner:温州巢语化妆品有限公司

Numerical control feeding and discharging device

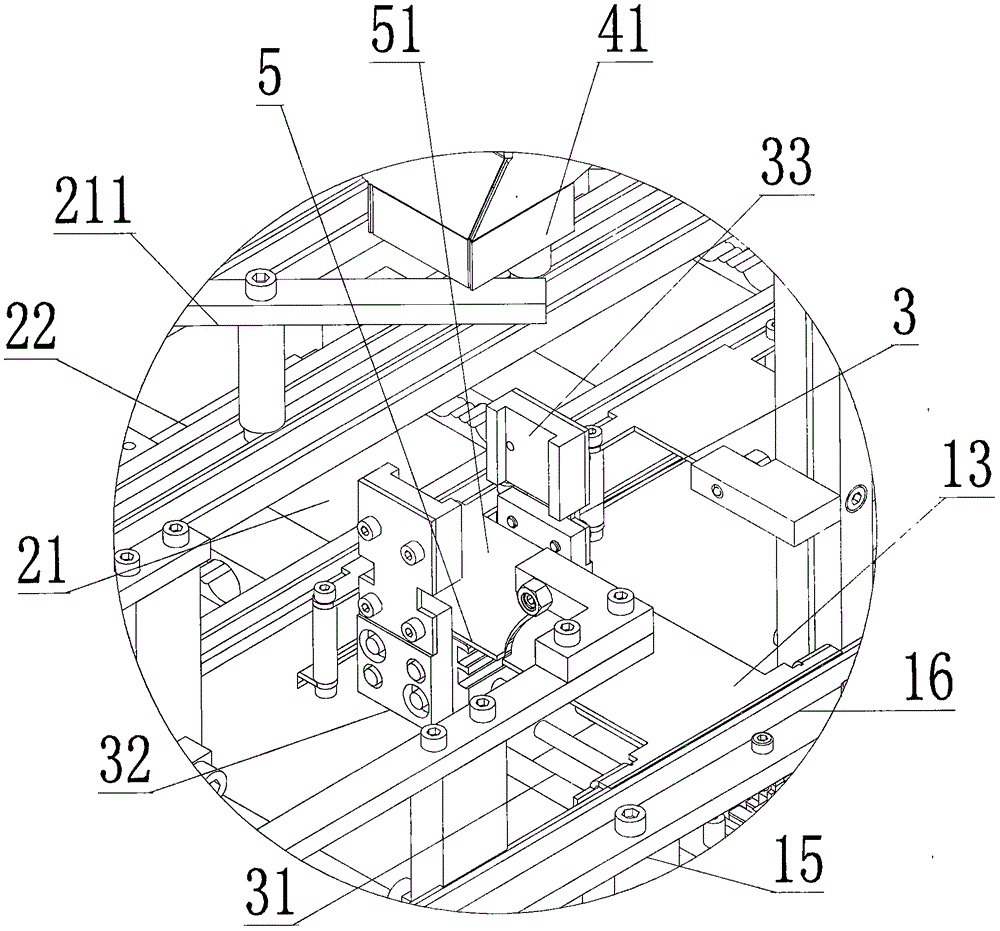

InactiveCN108673221AAvoid unevennessRealize automatic deliveryMetal working apparatusNumerical controlMechanical engineering

The invention relates to a numerical control feeding and discharging device. The numerical control feeding and discharging device comprises a feeding device body, an arranging device and a dischargingdevice body. Workpieces are fed by the feeding device body, conveyed to the arranging device for arrangement and finally conveyed to the discharging device body for conveying. By the adoption of thenumerical control feeding and discharging device, the whole process is automatically operated, the workpiece position is automatically adjusted, and the workpieces are orderly arranged and conveyed tothe discharging position, so that work efficiency is improved.

Owner:SUZHOU XIAOYAN AUTOMATION EQUIP

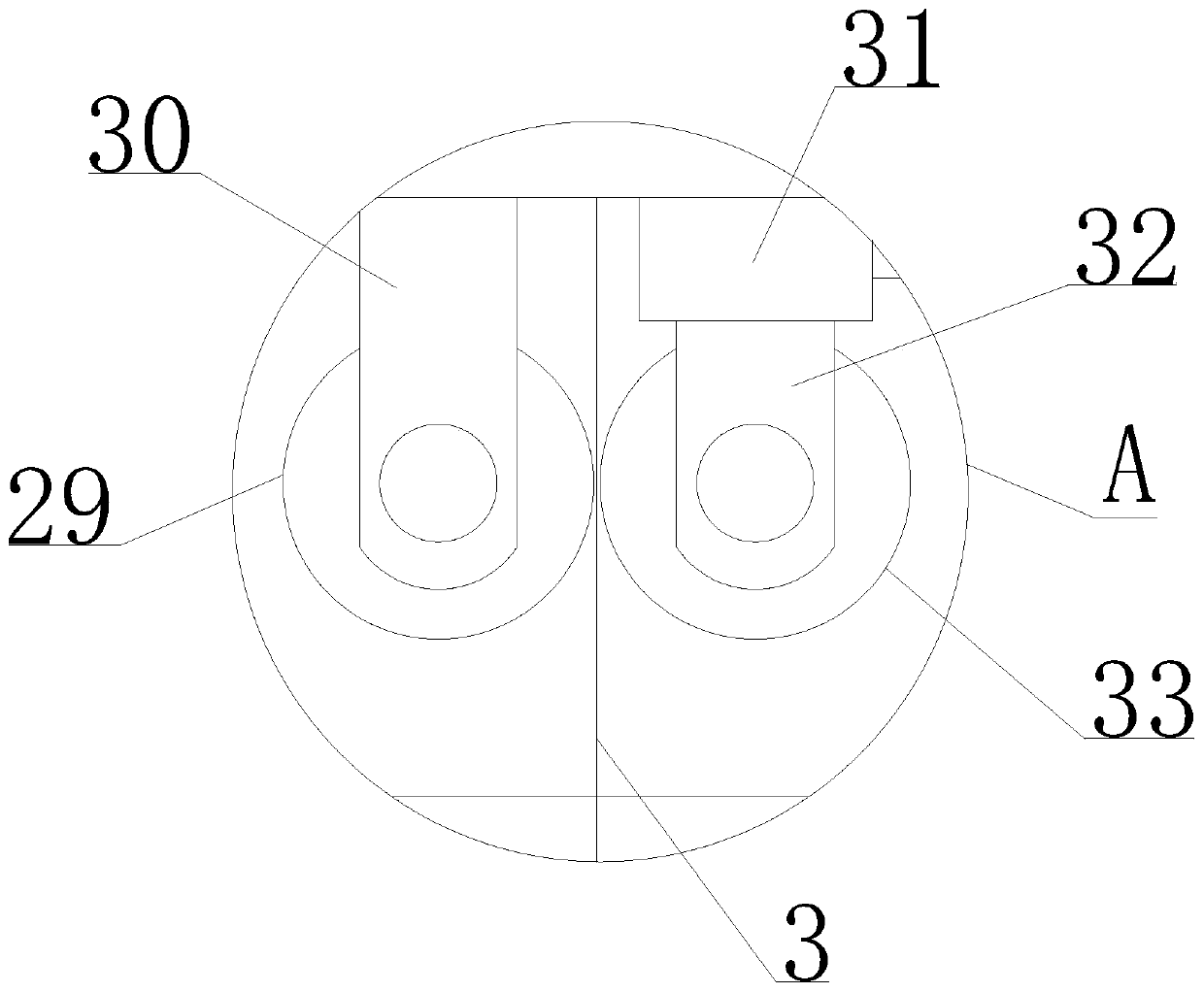

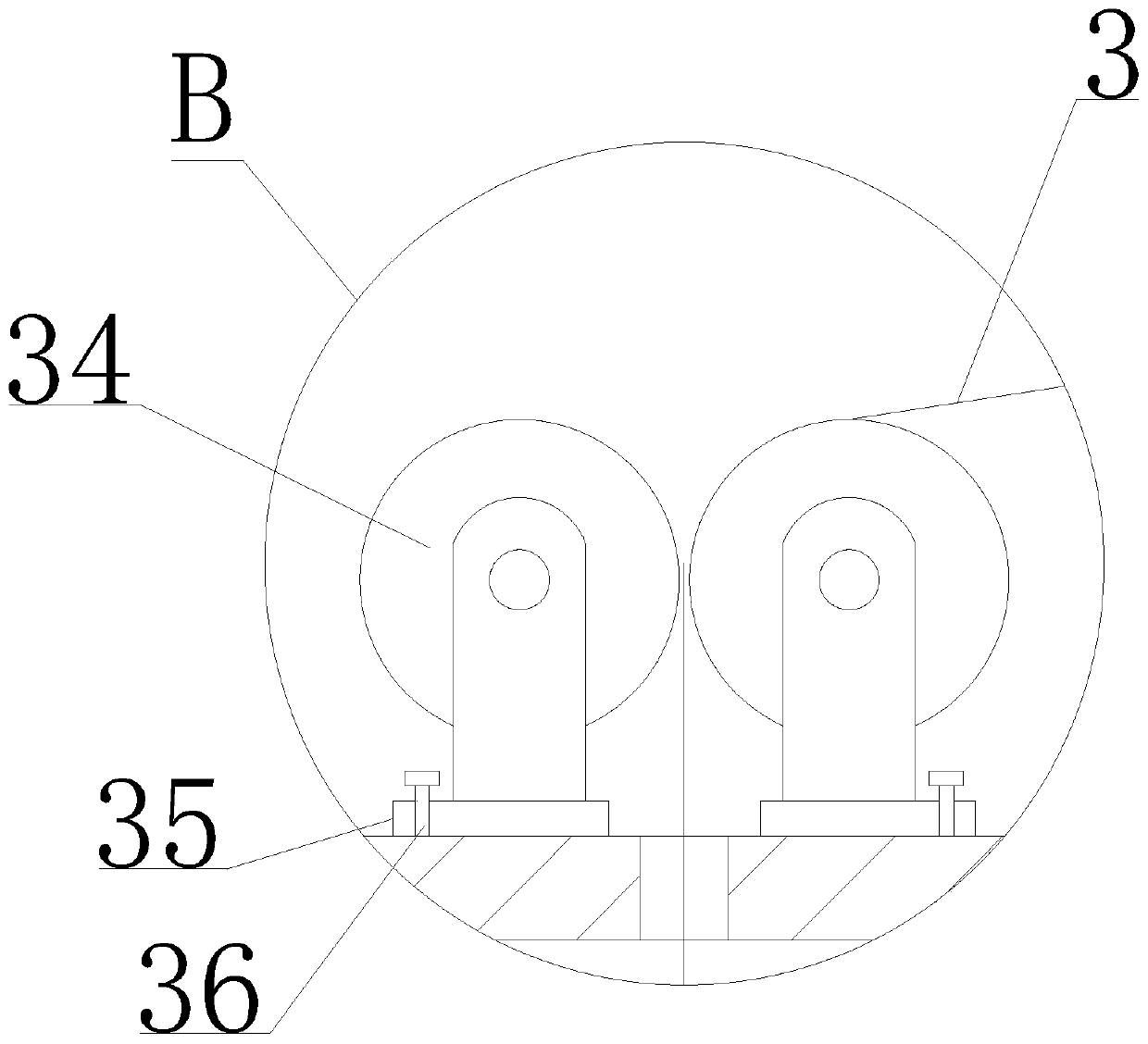

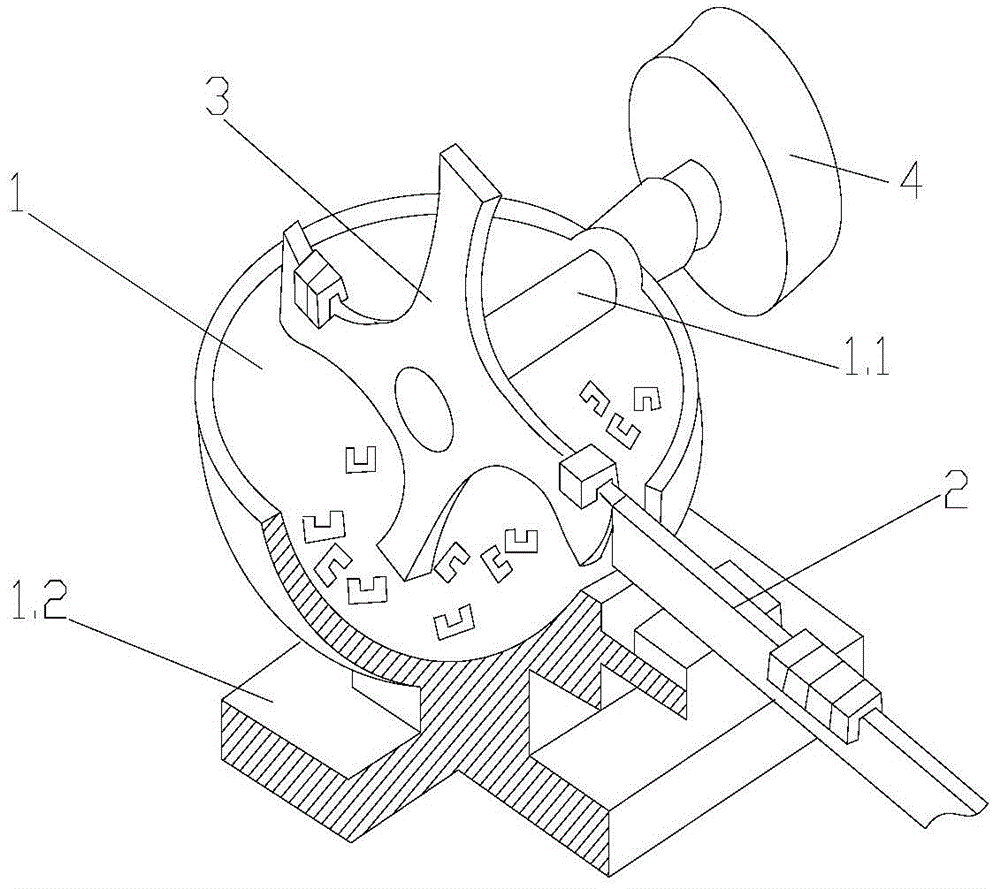

U-shaped workpiece conveying device

InactiveCN104444253AConveying orderlyExquisite structureConveyor partsEngineeringMechanical engineering

The invention relates to the technical field of conveying devices, in particular to a U-shaped workpiece conveying device. The U-shaped workpiece conveying device comprises a hopper, a slideway and a picking paddle, wherein the picking paddle is provided with a plurality of vanes, vertically arranged in the hopper and provided with a rotary shaft extending to the outside of the hopper, the rotary shaft is connected with a driving rotation device, the front end of the slideway extends into the hopper in an upward inclination mode, the rear portion of the slideway extends to the outside of the hopper, the slideway and the picking paddle are on the same straight line, the edge of the picking paddle is tangent with the front end of the slideway, the vanes of the picking paddle are in arc transition, and the end surface of the edge of each vane is also arc. The U-shaped workpiece conveying device is exquisite and simple in structure, not prone to faults and high in efficiency.

Owner:CHANGZHOU GALAXY INNOVATION MAGNETOELECTRICITY

Aluminum tube double-moving extruding machine gasket recycling device and aluminum tube double-moving extruding machine

The invention relates to a gasket recycling device. The gasket recycling device comprises a gasket recycling passage, an aluminum rod conveying passage, an ingot supplying tank and a gasket connectionrecycling mechanism, two ends of the gasket recycling passage and the aluminum rod conveying passage are material inlet ends and material outlet ends, the ingot supplying tank is a tank body with twoends and the upper portion being open and is connected with a mechanical arm, the mechanical arm can drive the ingot supplying tank to move up and down, under an original state, the material outlet ends of the gasket recycling passage and the aluminum rod conveying passage extend to the upper end of one side of the ingot supplying tank correspondingly, the material outlet end of the gasket recycling passage is located on one side of the aluminum rod conveying passage, the end portions of the material outlet ends of the gasket recycling passage and the aluminum rod conveying passage are flushwith each other, the adjacent sides are in fit with each other, the mechanical arm can drive the ingot supplying tank to move upwards or move downwards to return, and the gasket connection recycling mechanism is used for recycling gaskets and putting the gaskets into the gasket recycling passage. The aluminum tube double-moving extruding machine gasket recycling device and an aluminum tube double-moving extruding machine have the advantages that rapid recycling of the gaskets is facilitated, the labor intensity is low, and the production efficiency is high.

Owner:ANLU PHOENIX ALUMINUM LIMITED LIABILITY

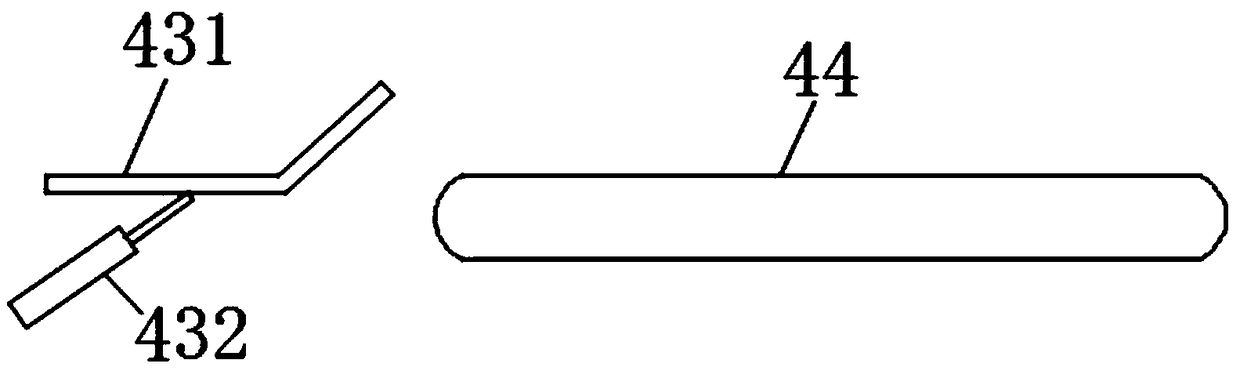

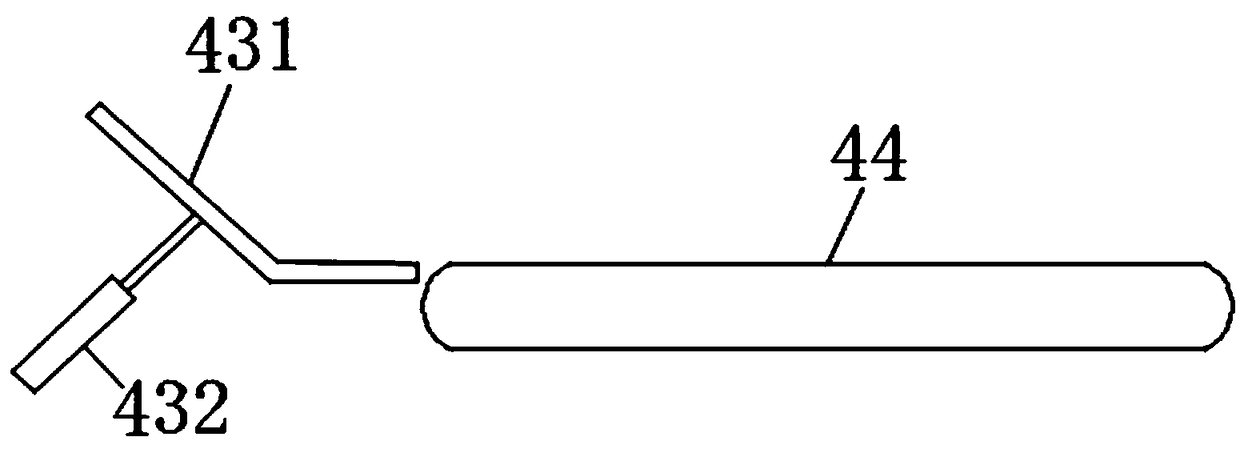

Paper bag transfer mechanism of feeding device

ActiveCN109911663AConveying orderlyStable deliveryArticle feedersArticle separationPulp and paper industryTransfer mechanism

The invention relates to a paper bag transfer mechanism of a feeding device. The paper bag transfer mechanism includes a rotary table and paper adsorption assemblies arranged on the rotary table, therotary table includes disk bodies located at the two ends and a mandrel connecting the two disk bodies, the paper adsorption assemblies are rotatably mounted on the two disk bodies of the rotary table, one of the disk bodies is provided with a transmission mechanism for driving the paper adsorption assemblies to rotate, and the other one of the disk bodies is provided with a distribution mechanismfor distribution of the paper adsorption assemblies; the paper adsorption assemblies include hollow shafts, the hollow shafts are rotatably arranged on the two disk bodies of the rotary table, a plurality of paper adsorption wheels sleeve the hollow shafts, and the paper adsorption wheels is provided with hollow rod bodies; and the hollow rod bodies are provided with suction cups arranged in thelength directions of the hollow rod bodies, the suction cups communicate with the hollow rod bodies, the hollow rod bodies communicate with the hollow shafts, and the hollow shafts are connected witha negative-pressure device through the distribution mechanism, wherein the distribution mechanism and a driving mechanism are arranged on the disk bodies at the two ends of the rotary table correspondingly without interfering with each other. The stability during operation is high.

Owner:江西新明峰包装科技有限公司

A material-pressing guide mechanism for garment cutting equipment

InactiveCN104120602BPrecise deliveryAvoid cropping errorsSevering textilesChain conveyorChain network

The invention relates to the technical field of garment machinery, in particular to a material-pressing guide mechanism for garment cutting equipment. It includes an opening roller, a guide roller, a mesh chain, at least two parallel and horizontal tensioning rollers, and a driving assembly that drives the tensioning roller to move laterally so that the tensioning roller and the opening roller are vertically interlaced. The opening roller and the adjacent tensioning roller are parallel to each other and rotate in opposite directions, and the guide roller is arranged below the opening roller and above the web chain. The present invention effectively prevents the cutting equipment from making mistakes in cutting due to wrinkles in the cloth, resulting in the cut out of the cloth not conforming to the specification, waste of the cloth, and reduction of the production efficiency of the enterprise, which is conducive to improving the cutting precision, simplifying the equipment structure of the cutting bed, and reducing the The production cost and equipment maintenance cost of the enterprise can avoid the mutual influence of each station when conveying the fabric to the network chain, and ensure the normal operation of the garment cutting equipment.

Owner:佛山市顺德区爱斯达科技研发有限公司

Building cement brick forming equipment based on raw material reprocessing linkage pressing

ActiveCN111152335AImprove material qualityWell mixedMixing operation control apparatusPretreatment controlElectric machineryRaw material

The invention discloses building cement brick forming equipment based on raw material reprocessing linkage pressing. The equipment structurally comprises a feeding frame, a forming machine, an underframe, a supporting frame, a conveying frame and a motor, wherein the feeding frame is connected with the forming machine; the forming machine is locked with the underframe; the supporting frame is connected with the conveying frame through a shaft; the conveying frame is installed on the underframe; the forming machine is assembled and connected with the conveying frame; the motor is locked on theunderframe; and the forming machine consists of a mixing machine, a forming machine frame and a pressing structure. Material is screened by distributing and stirring blades, particles with standard specifications fall into a mixing rotating ring from leakage holes to be mixed, the material quality is improved, the mixing is more uniform, and the material mixing time is shortened. Due to the triplelinkage pressing of the pressing device, the processing time consumption is reduced; and a spiral collar spirally drives a plate shaft to rotate and ascend and descend when ascending and descending,the pressing transmission is more stable, and the processing precision is high.

Owner:南通恒达免烧砖机械工程有限公司

Anastomat pin bin tool automatic conveying device

PendingCN110842513AConveying orderlyAccurate delivery accuracyMetal working apparatusAnastomosis couplerProcess engineering

The invention discloses an anastomat pin bin tool automatic conveying device. The device comprises a tool tray for bearing empty pin bin tools; a tool pushing-in mechanism and a tool pushing-out mechanism are arranged in an inlet and an outlet of the tool tray; the tool pushing-in mechanism pushes empty pin bins on the tool trays to a pin pusher preloading position through transverse movement; andthe tool pushing-out mechanism pushes the pin bin tools fully filled with pin pushers onto a finished product tray through longitudinal movement. Through the mode, the anastomat pin bin tool automatic conveying device achieves repeatability in the conveying process, can guarantee stable and quick tool pushing process, meanwhile, achieves higher conveying precision, and guarantees orderly quick conveying of the pin bin tools.

Owner:WUXI BM PRECISION PARTS CO LTD

Portable safe material receiving device for circular knife die cutting equipment

The invention belongs to the technical field of circular knife machine equipment, and provides a portable safe material receiving device for circular knife die cutting equipment. The portable safe material receiving device comprises a rack and further comprises a safety grating, a material receiving roller and a conveyor; a second grating mounting frame is slidably mounted at the discharging end of the rack, and the safety grating is mounted on the grating mounting frame; the material receiving roller is detachably installed at the discharging end of the rack, and when strip-shaped products are produced, the material receiving roller is located between the second grating mounting frame and a die-cutting tool holder; and the conveyor comprises a lower conveying frame and an upper conveyingframe, a stripping knife and a hanging frame are further arranged at one end of the lower conveying frame, when sheet-shaped products are produced, the second grating mounting frame is attached to thedie-cutting tool holder, the conveyor is hung on the discharging side of the die-cutting tool holder through the hanging frame, and the other end of the conveyor penetrates through the second gratingmounting frame. According to the portable safe material receiving device, when conversion production of the strip-shaped products and the sheet-shaped products is carried out, tedious disassembly andassembly of the safety grating are not needed, use is safe, convenient and rapid, the sheet-shaped products are conveyed more orderly and tidily, and the material collecting efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

Test paper slitting and assembling device

PendingCN111283786AReduce labor intensityReduce in quantitySortingMetal working apparatusMechanical engineeringIndustrial engineering

The invention discloses a test paper slitting and assembling device. The test paper slitting and assembling device comprises a base, a feeding device, a discharging device and a cutting device, wherein the feeding device, the discharging device and the cutting device are installed on the base; the discharging device can move back and forth and is arranged in front of the feeding device; and the cutting device is arranged between the feeding device and the discharging device, after the feeding device pushes a full page of test paper forwards by a certain distance, the cutting device is used forcutting off the test paper conveyed by the feeding device, and the discharging device carries the test paper after cutting off outwards. According to the test paper slitting and assembling device, automatic feeding, automatic detecting, automatic assembling, automatic discharging and final assembling of the test paper and a jig assembly to form a finished product of the whole test paper splittingproduction assembling process are achieved, mechanization is achieved in the whole process, the automation degree is high, the manpower cost is reduced, the quality of the finished product is stable,the production efficiency is remarkably improved to be higher than 1600 PCS / h.

Owner:XIAMEN KELIJIE AUTOMATION TECH CO LTD

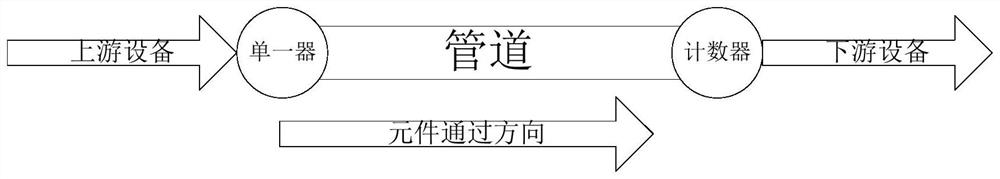

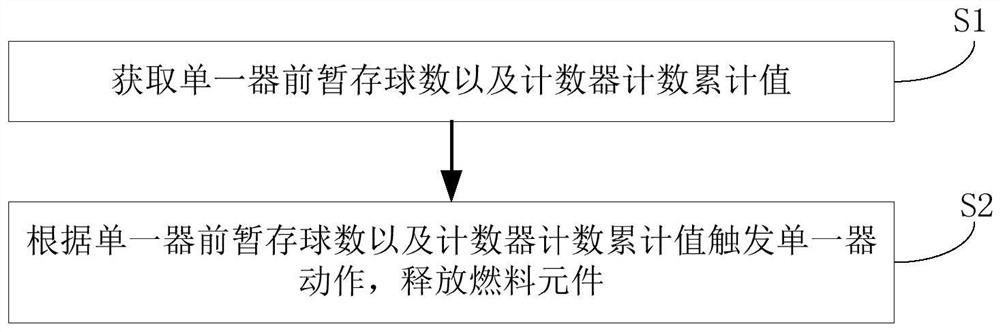

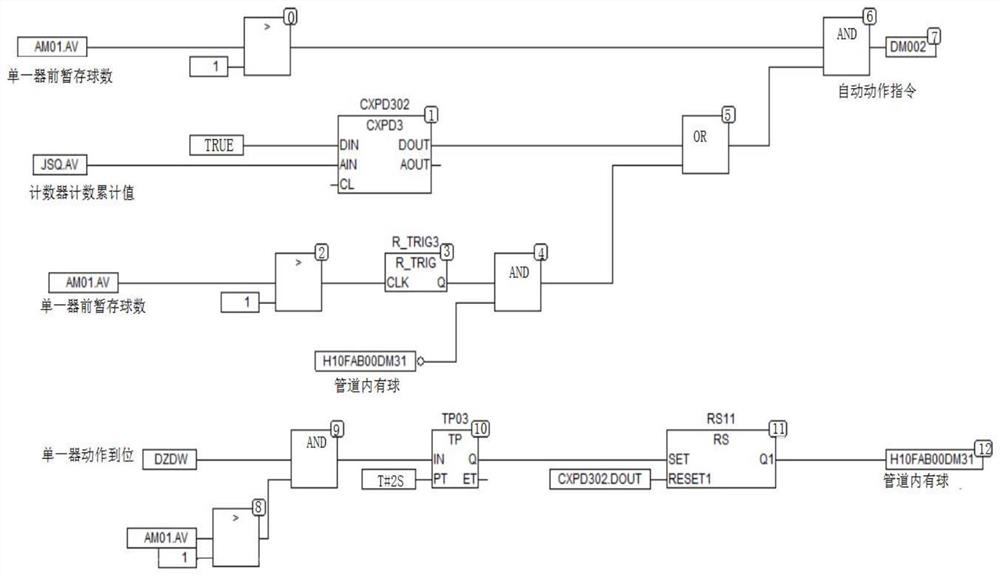

High-temperature gas cooled reactor fuel element conveying control method and system

ActiveCN114005561AConveying orderlyNuclear energy generationReactor fuel elementsThermodynamicsProcess engineering

The invention provides a high-temperature gas cooled reactor fuel element conveying control method and system. The method comprises the steps that the number of temporary storage balls in front of a single device and the counting accumulated value of a counter are obtained; and the single device is triggered to act according to the number of temporarily stored balls in front of the single device and the counting accumulated value of the counter, and the fuel element is released. According to the design of configuration control on the unitary device and the downstream counter, the unitary device acts according to the change of the counter and the number of the upstream balls of the unitary device, so that fuel elements are conveyed to downstream equipment orderly and singly.

Owner:HUANENG SHANDONG SHIDAO BAY NUCLEAR POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com