Air-powered air cushion packing machine

An aerodynamic, chartering machine technology, applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of complex structure, high energy consumption and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

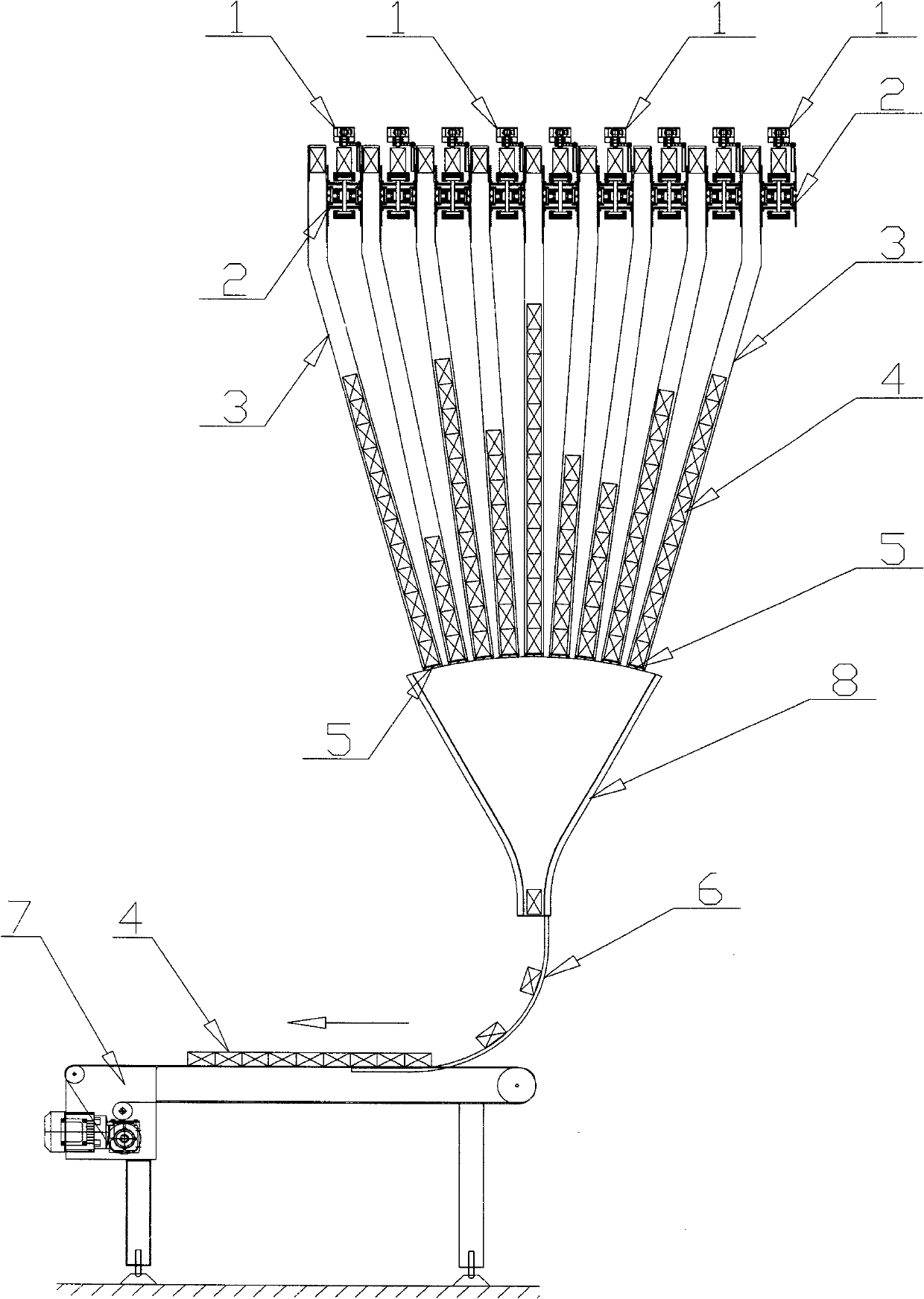

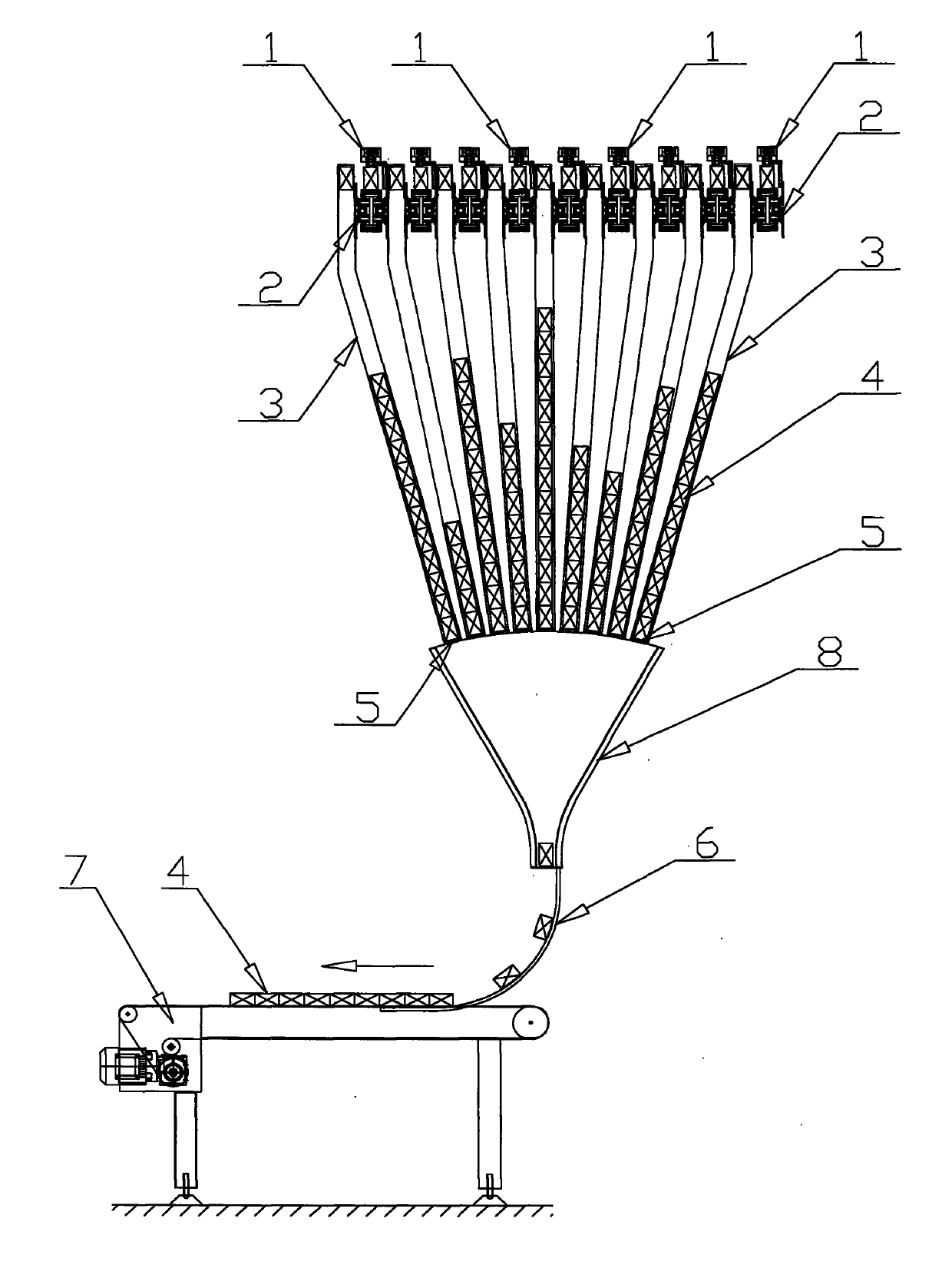

[0011] Such as figure 1 As shown, an aerodynamic air cushion chartering machine includes 9 elevated horizontal rod cigarette conveyors 2, 9 groups of horizontal rod tobacco lateral positioning mechanisms 1 and a horizontal synchronous collection conveyor 7;

[0012] Among them, 9 groups of horizontal cigarette horizontal positioning mechanisms 1 are arranged in one-to-one correspondence with 9 elevated horizontal cigarette conveyors 2, and each group of horizontal cigarette horizontal positioning mechanisms 1 is respectively provided with an aerodynamic air cushion vertical channel 3, so An airtight valve 5 is arranged at the lower part of the vertical channel 3 of the aerodynamic air cushion.

[0013] Based on the above, the aerodynamic air cushion vertical channel 3 is a vertical channel with a square cross section; the size of the squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com