Building cement brick forming equipment based on raw material reprocessing linkage pressing

A construction cement and reprocessing technology, which is applied to auxiliary molding equipment, ceramic molding machines, cement mixing devices, etc., can solve the problems of unguaranteed processing accuracy, deviation of applied pressure, poor mixing effect, etc., to shorten processing time, The effect of improving material quality and reducing mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

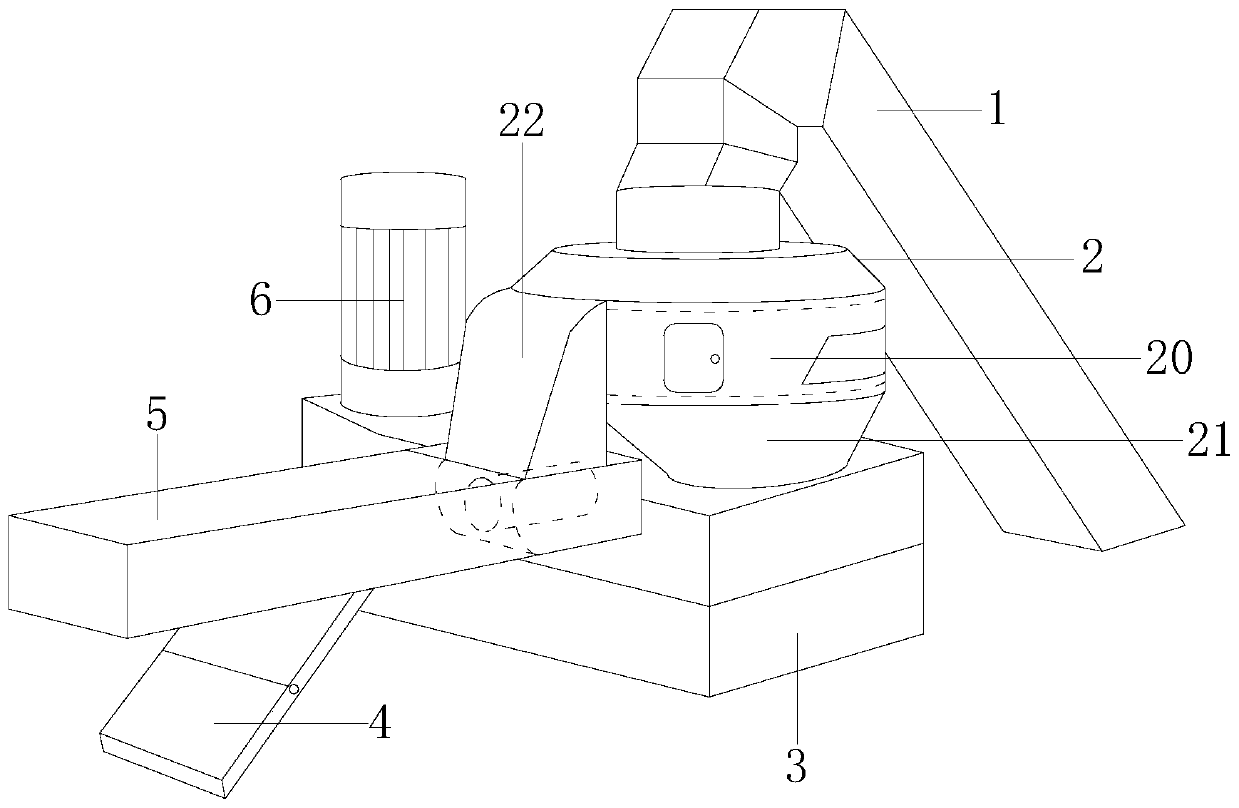

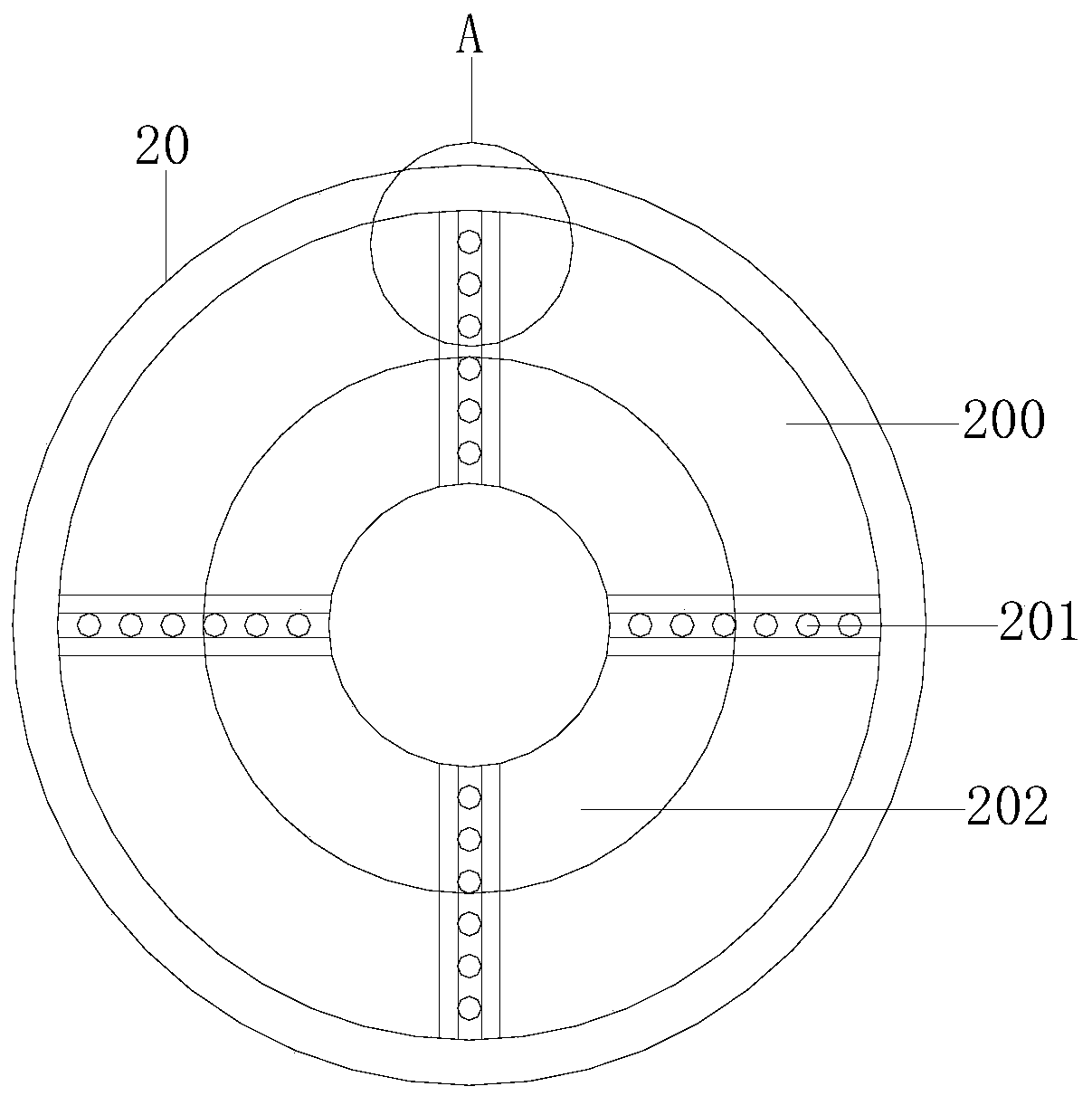

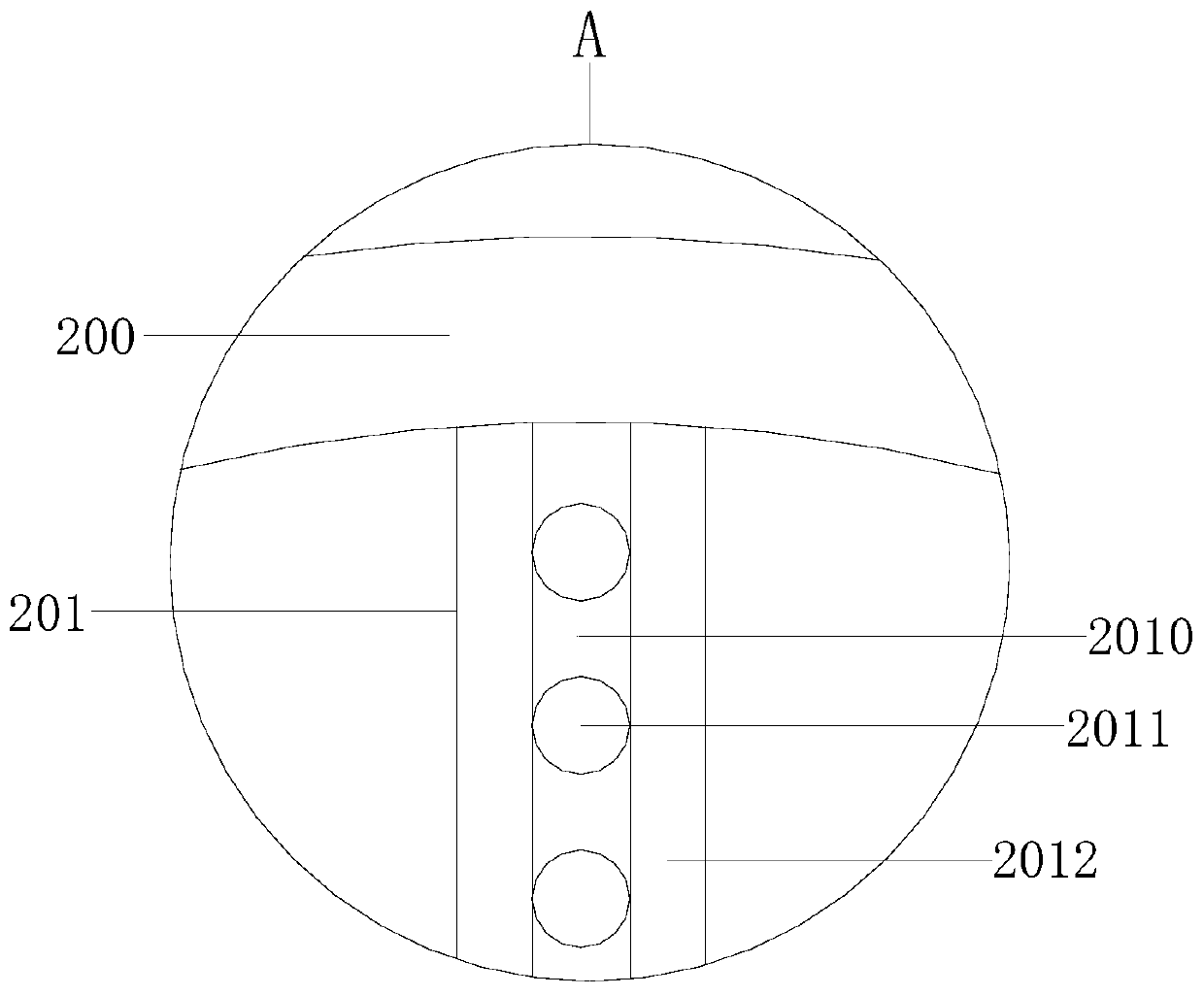

[0030] Example 1 see Figure 1-5 , the present invention provides a technical solution for building cement brick molding equipment based on raw material reprocessing and linkage pressure: its structure includes a feeding frame 1, a molding machine 2, an underframe 3, a supporting frame 4, a feeding frame 5, and a motor 6. The feeding frame 1 is installed and connected with the forming machine 2, the forming machine 2 is locked with the bottom frame 3, the support frame 4 is connected with the feeding frame 5 shafts, the feeding frame 5 is installed on the bottom frame 3, and the forming The machine 2 is assembled and connected with the feeding frame 5, the motor 6 is locked on the bottom frame 3, the molding machine 2 is composed of a mixing machine 20, a molding frame 21, and a pressing structure 22, and the mixing machine 20 is connected with the molding machine. The frame 21 is embedded and connected, and the pressing structure 22 is installed on the molding frame 21. The m...

Embodiment 2

[0032] Example 2 see Figure 6-10 , the present invention provides a technical scheme of building cement brick molding equipment based on raw material reprocessing and linkage pressure application: the structure of the pressing structure 22 includes a cover frame 220, a bottom frame 221, and a pressing device 222, and the cover frame 220 and The bottom frame 221 is locked, and the pressing device 222 is installed on the bottom frame 221. The pressing device 222 includes a forming square device 2220, a pressing cover 2221, a pusher 2222, a pressure booster 2223, and a connecting column 2224. The pressure booster 2223 acts as a linkage to apply pressure, which shortens the processing time. The forming square device 2220 is provided with a square opening 90 for discharging. The forming square device 2220 and the pusher 2222 are installed and connected through the pressing cover 2221 , the pressure booster 2223 is installed on the pusher 2222, the pusher 2222 is buckled with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com