Patents

Literature

39results about How to "Conveying neatly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

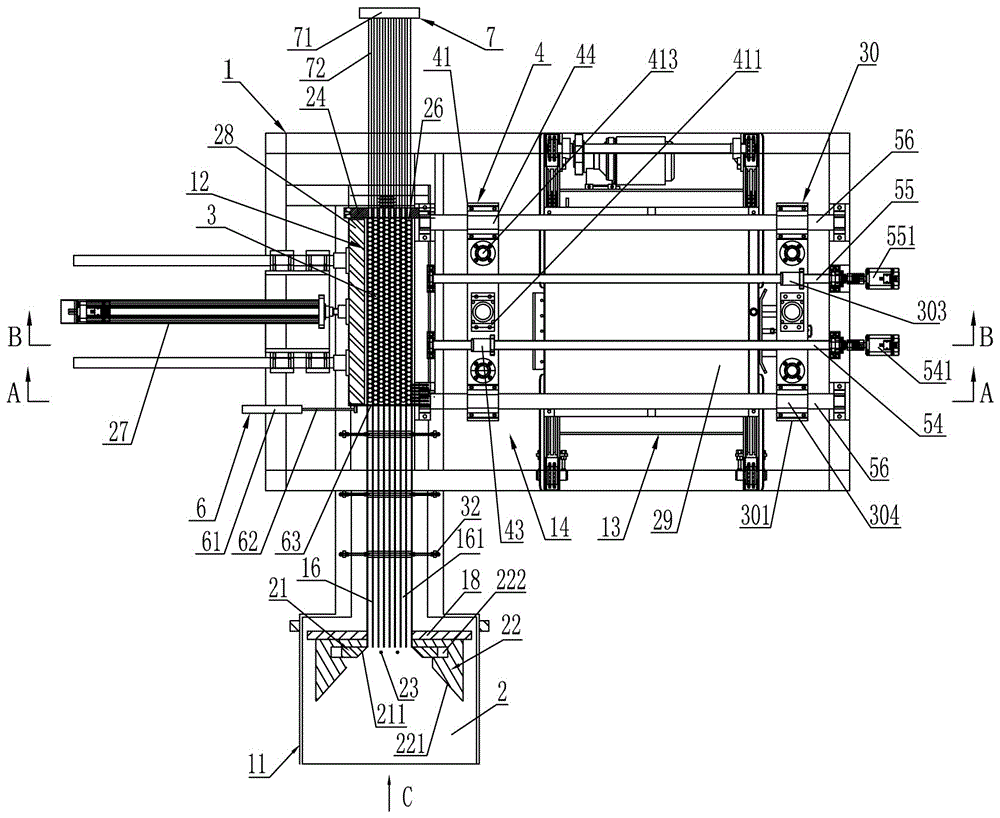

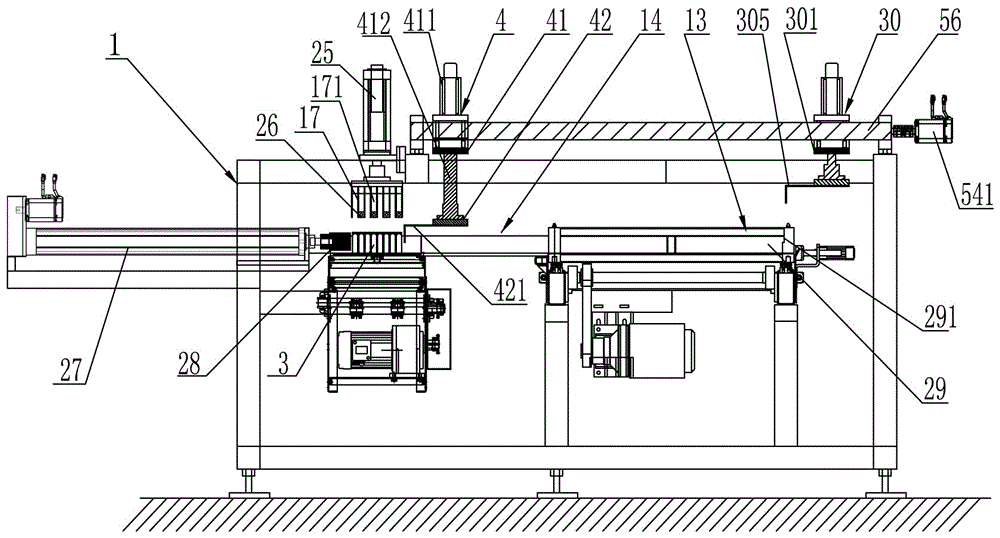

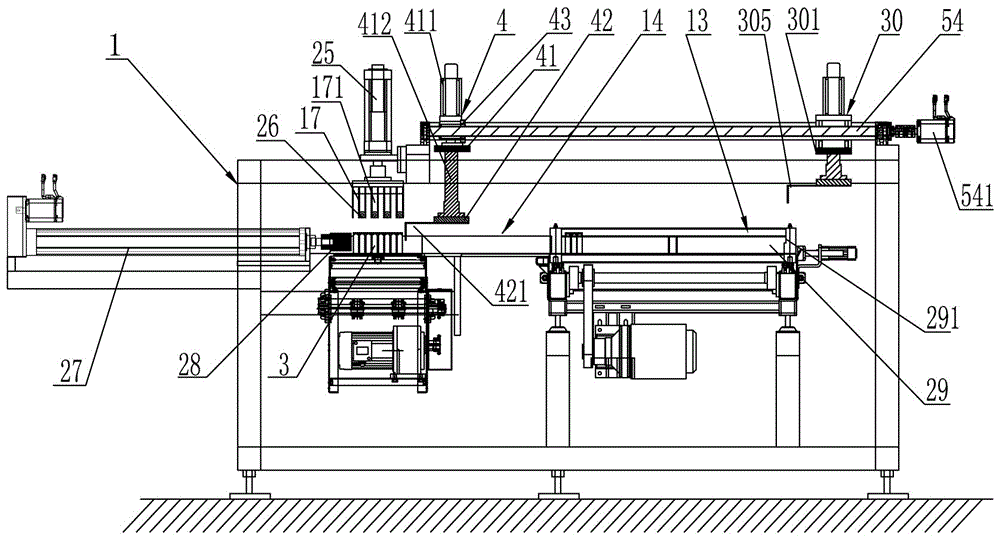

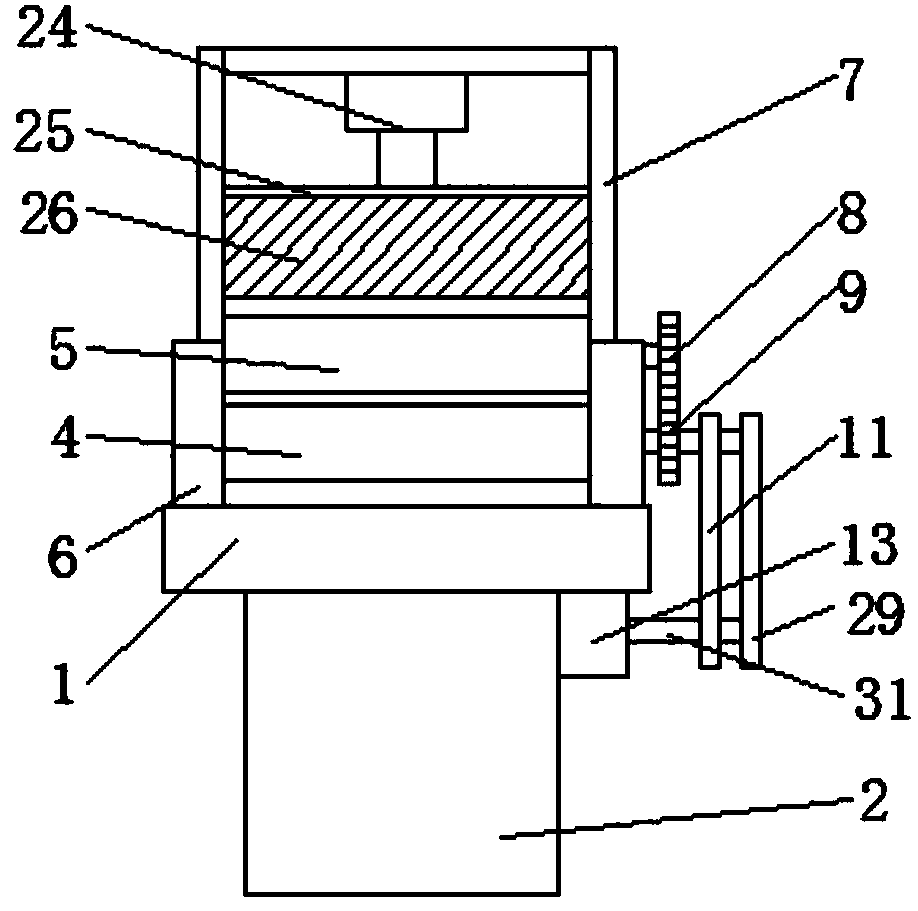

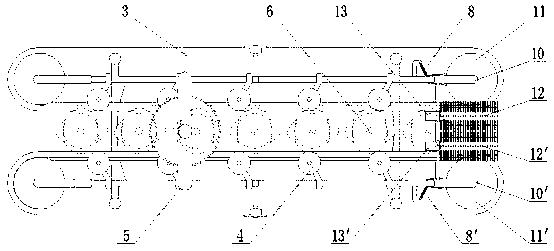

Automatic oral liquid bottle loading machine

ActiveCN106395323AEfficient deliveryConveying neatlyConveyorsLoading/unloadingProtection mechanismBottle

The invention belongs to the field of oral liquid bottle loading equipment and discloses an automatic oral liquid bottle loading machine which comprises a rack, a conveyor belt and a plurality of column conveying channels partitioned by partition plates. A moving block is arranged at an inlet of each column conveying channel and can twist a bottle back and forth; the rack is provided a plurality of column baffles; column channels are partitioned by the column baffles; check blocks are arranged in each column channel at intervals; bottles at the rearmost end of each column abut against the front sides of the baffles or the check blocks; and therefore every two adjacent columns of bottles can be staggered. A to-be-conveyed area is provided with a cylinder and a push plate; the rack is provided with a first bottle protection mechanism, a second bottle protection mechanism and a transition area; and the push plate recedes back after pushing the bottles to the transition area, and the bottles are continuously pushed to a tray by the first bottle protection mechanism and the second bottle protection mechanism. The automatic oral liquid bottle loading machine has the advantages that the bottles can be prevented from blocking the inlets of the column conveying channels, the columns of bottles can be staggered so that the bottles are not prone to scattering in the subsequent pushing process, and the bottle pushing process can be more efficient.

Owner:ZHANGJIAGANG HUANYU PHARMA EQUIP

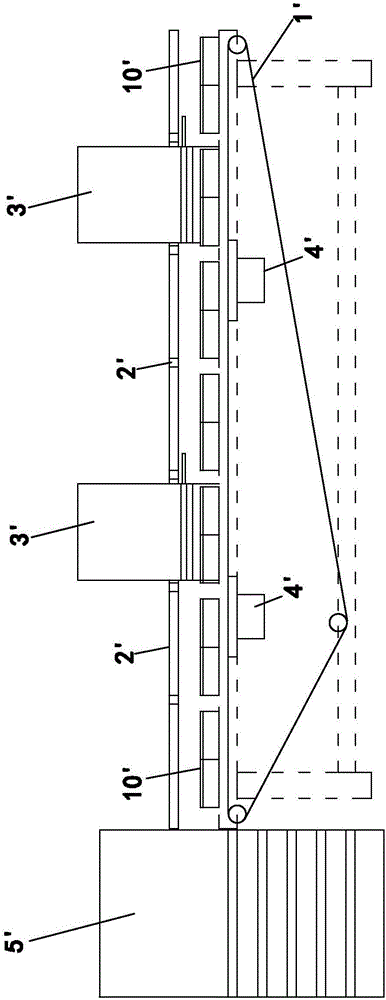

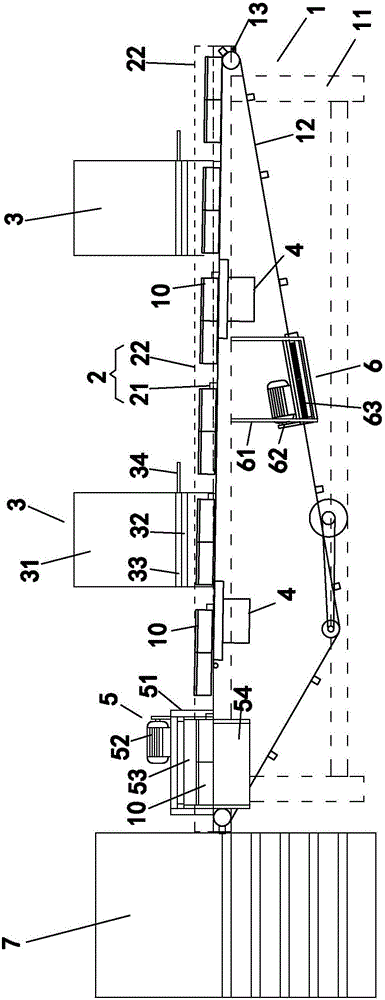

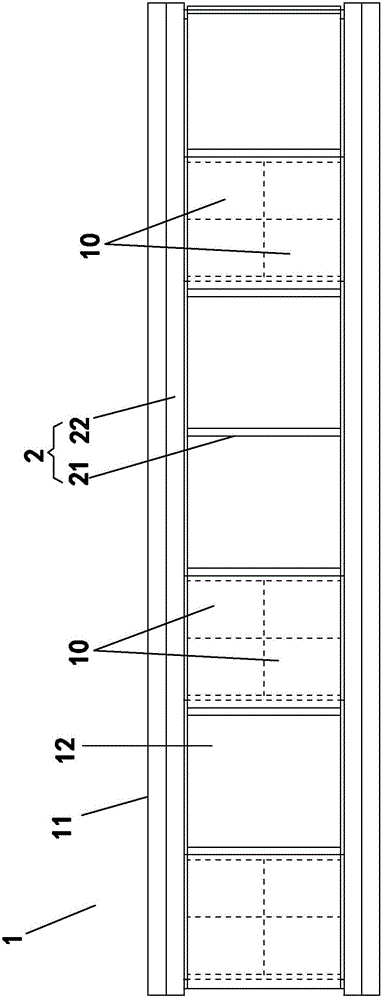

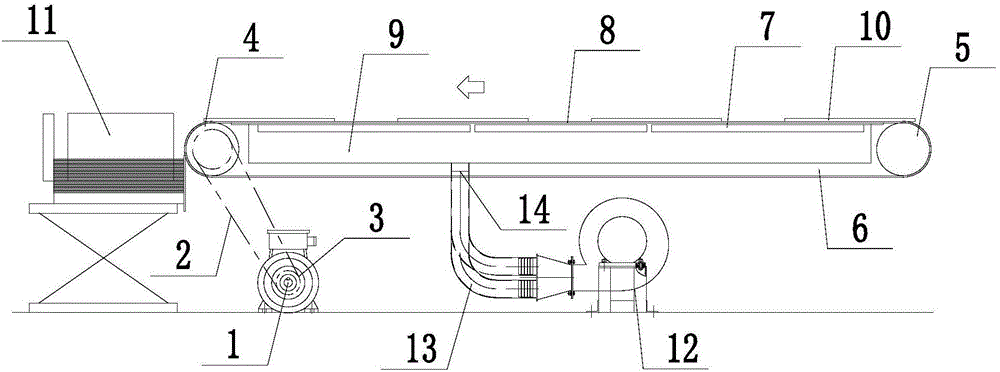

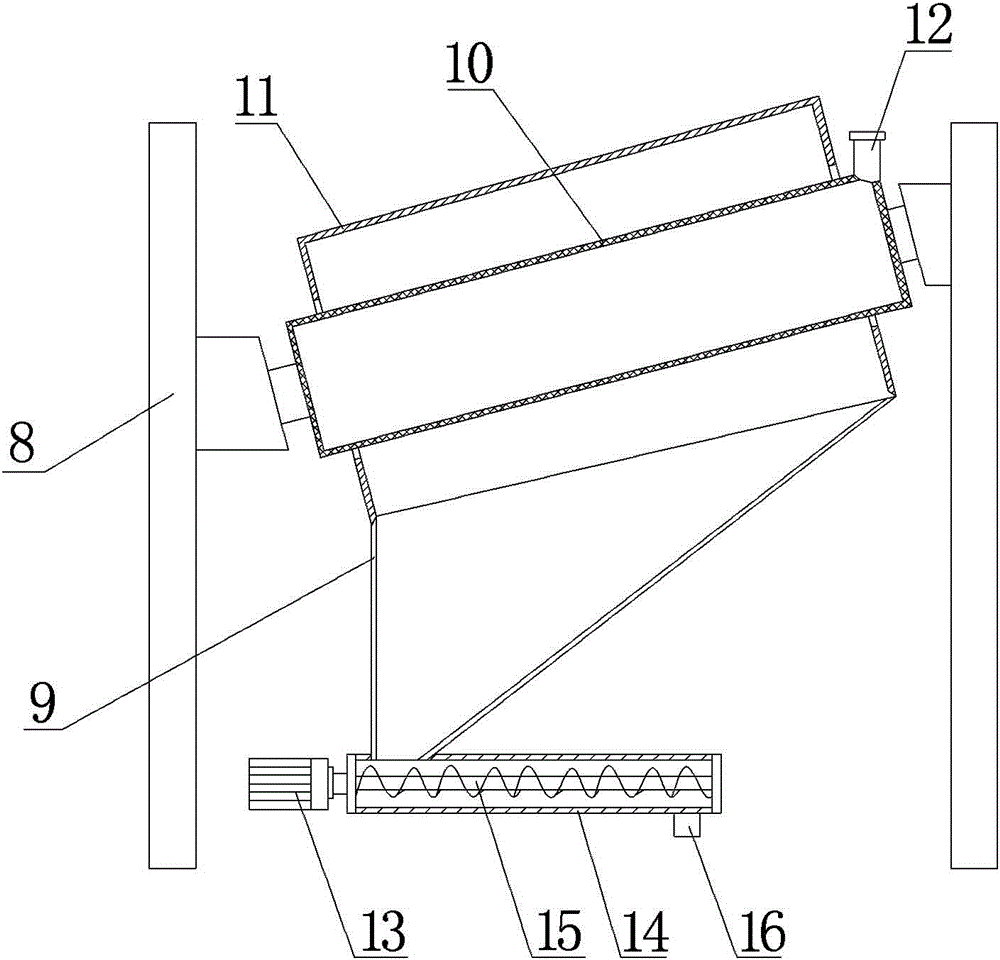

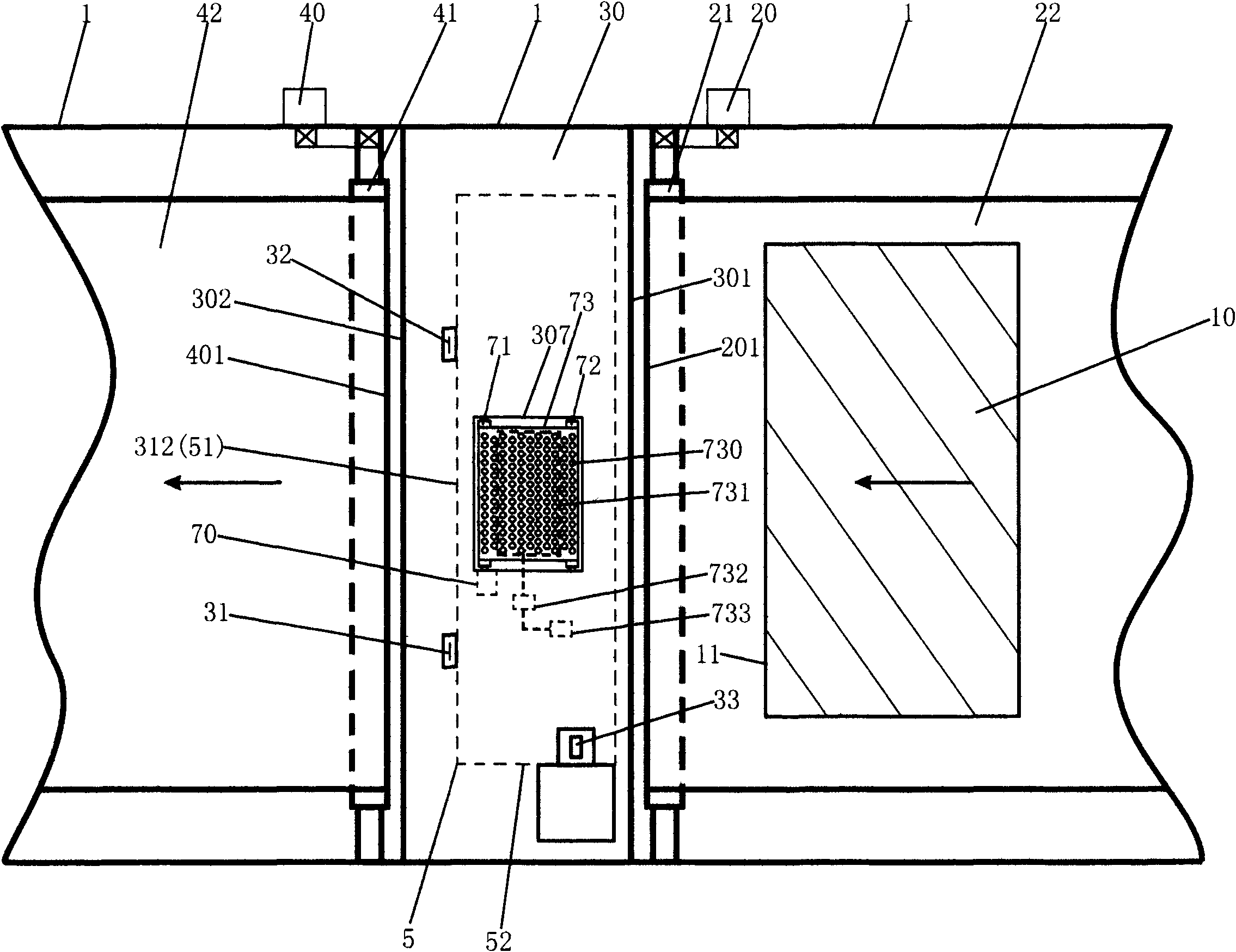

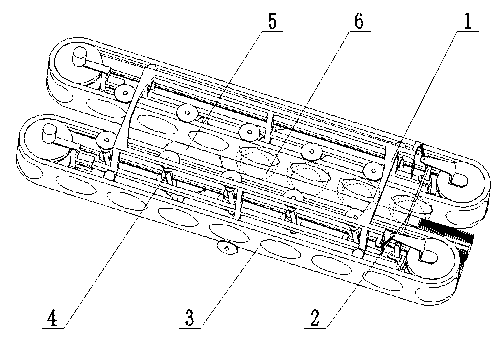

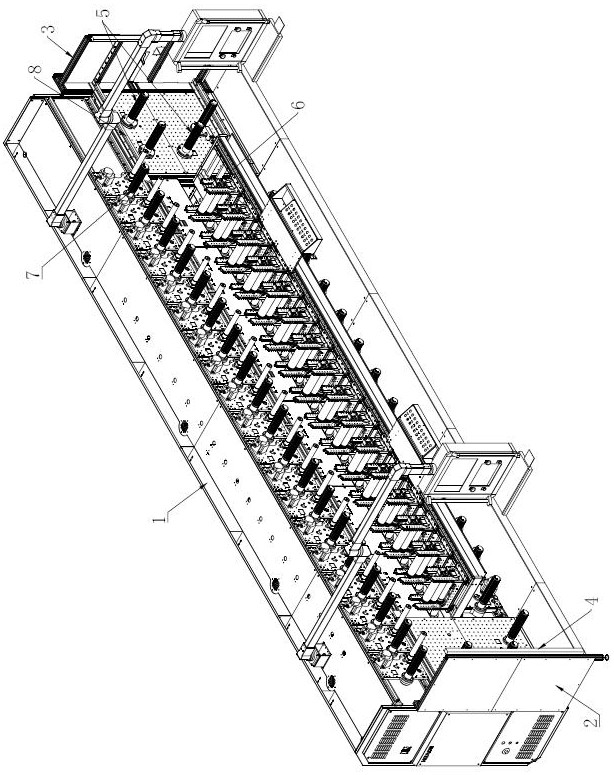

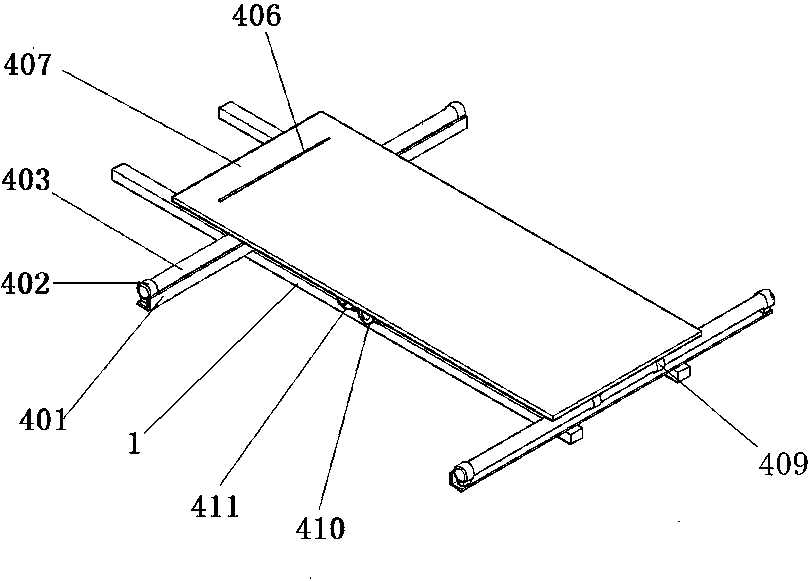

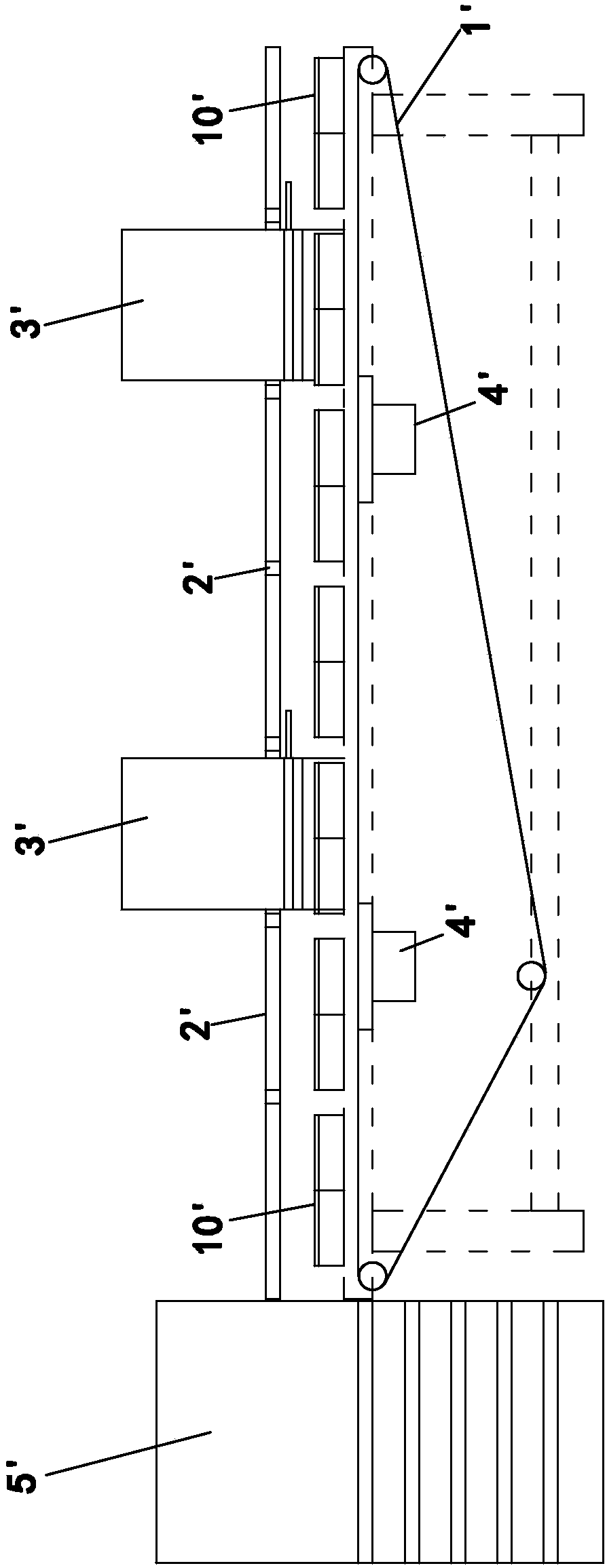

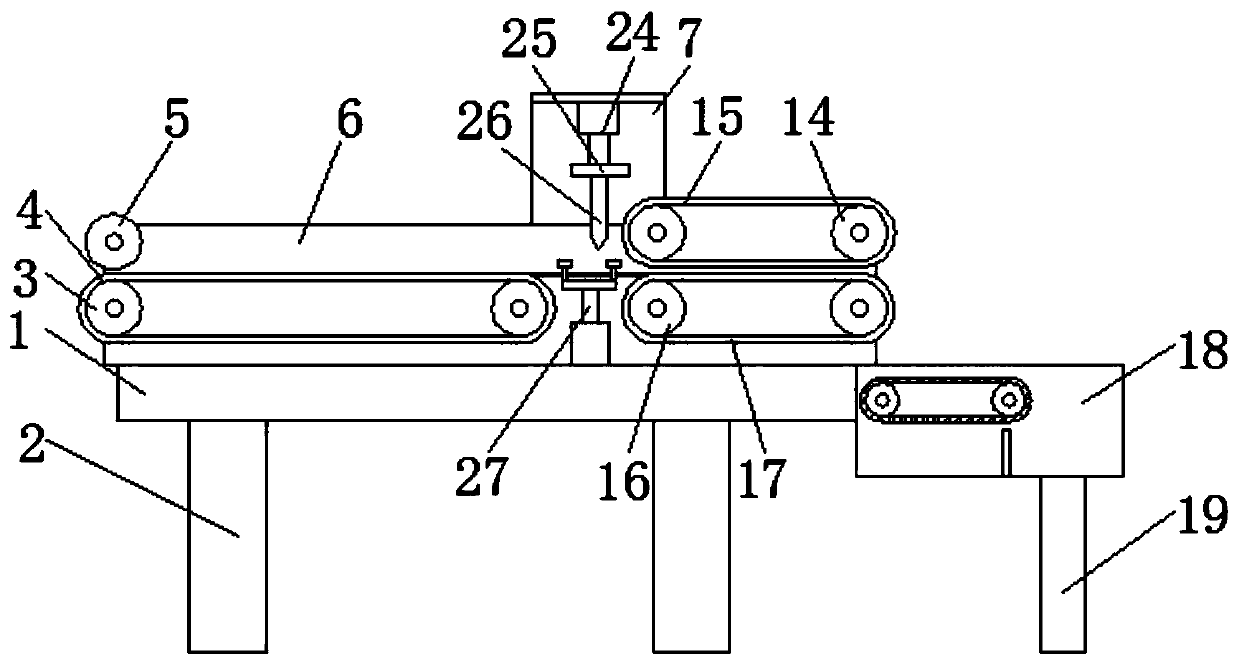

Automatic brick production line

ActiveCN105835213APrecise positioningConveying neatlyFeeding arrangmentsShaping conveyorsProduction lineBrick

The invention discloses an automatic brick production line. By means of the automatic brick production line, stability and reliability of production and operation of the automatic brick production line are improved. The automatic brick production line comprises a conveying device used for conveying brick molds, a positioning device and a discharging device. The conveying device comprises a machine frame, a conveying caterpillar band and a transmission mechanism. The discharging device comprises a material barrel, a discharging baffle and a quantitative discharging gate plate. Material outlet holes are formed in the bottom of the material barrel. Discharging holes are formed in the discharging baffle. Material containing holes are formed in the quantitative discharging gate plate. According to the positioning device, block strips are arranged on the conveying caterpillar band, the conveying caterpillar band inclines so that the brick molds can lean on the block strips, the plurality of block strips are evenly distributed in the length direction of the conveying caterpillar band at fixed intervals, a variable frequency motor is adopted as a power source in the transmission mechanism, and the brick molds during conveying can be accurately and correspondingly arranged below the discharging device by controlling the working frequency of the variable frequency motor.

Owner:福建省东方水泥制品有限公司

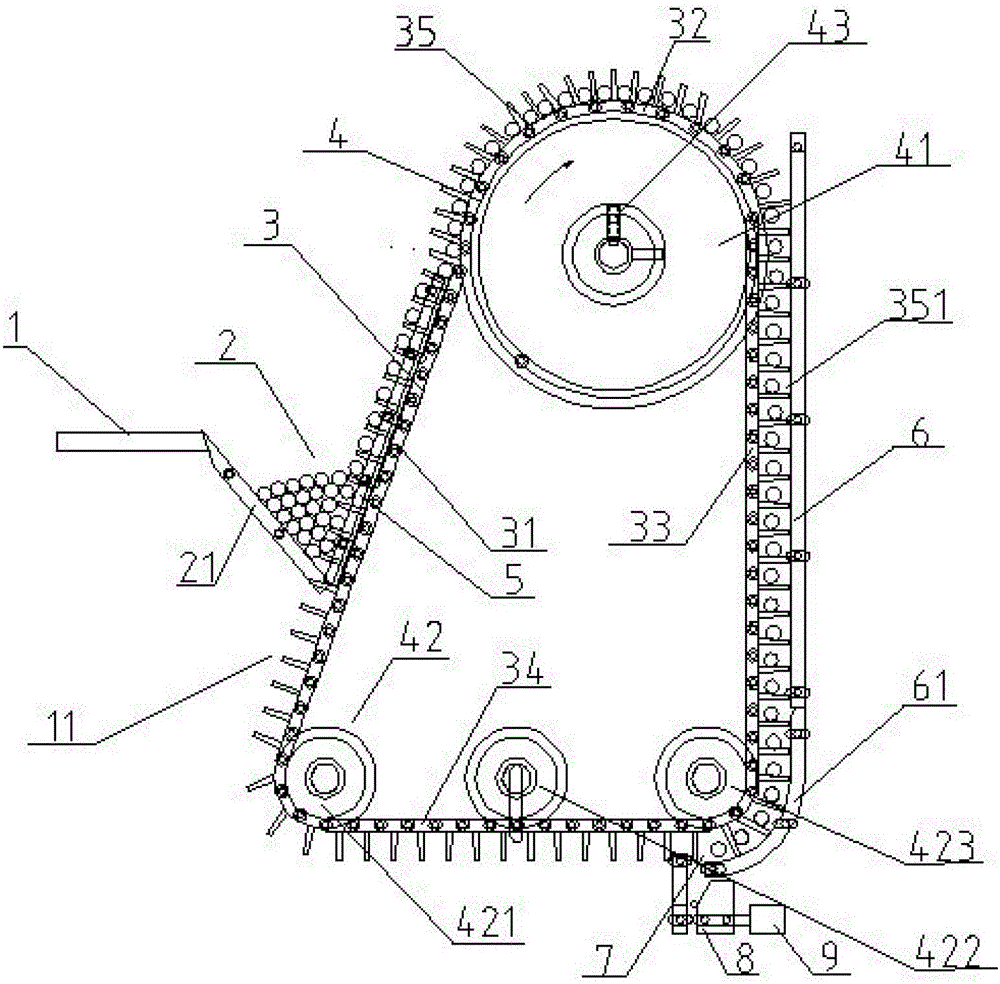

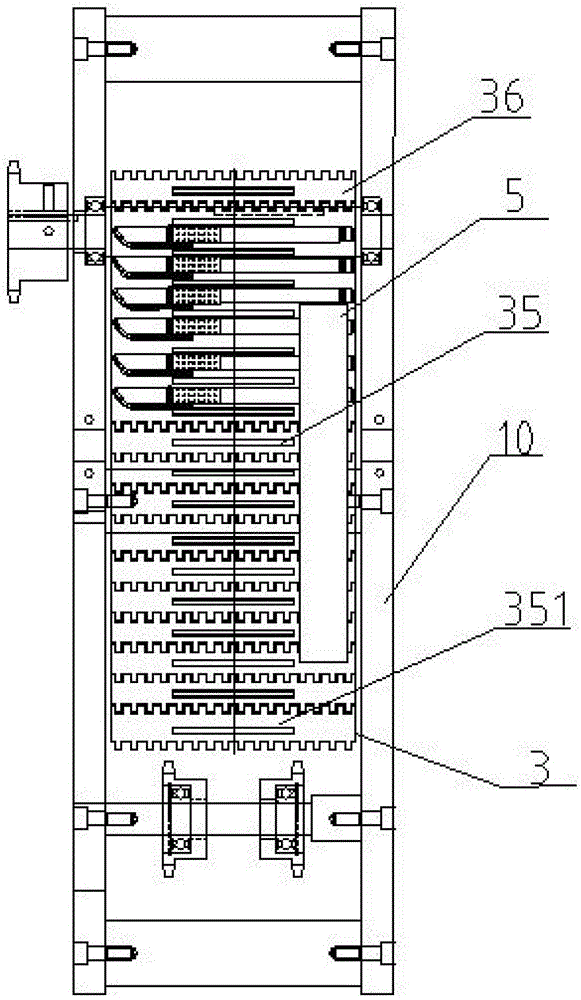

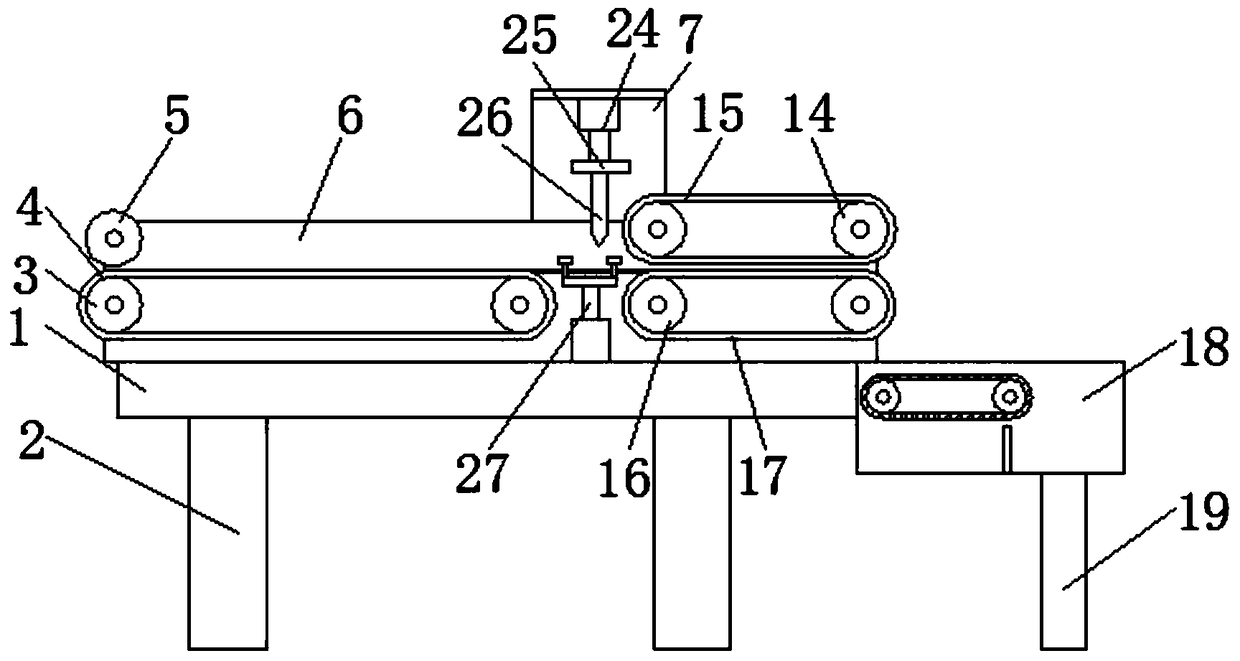

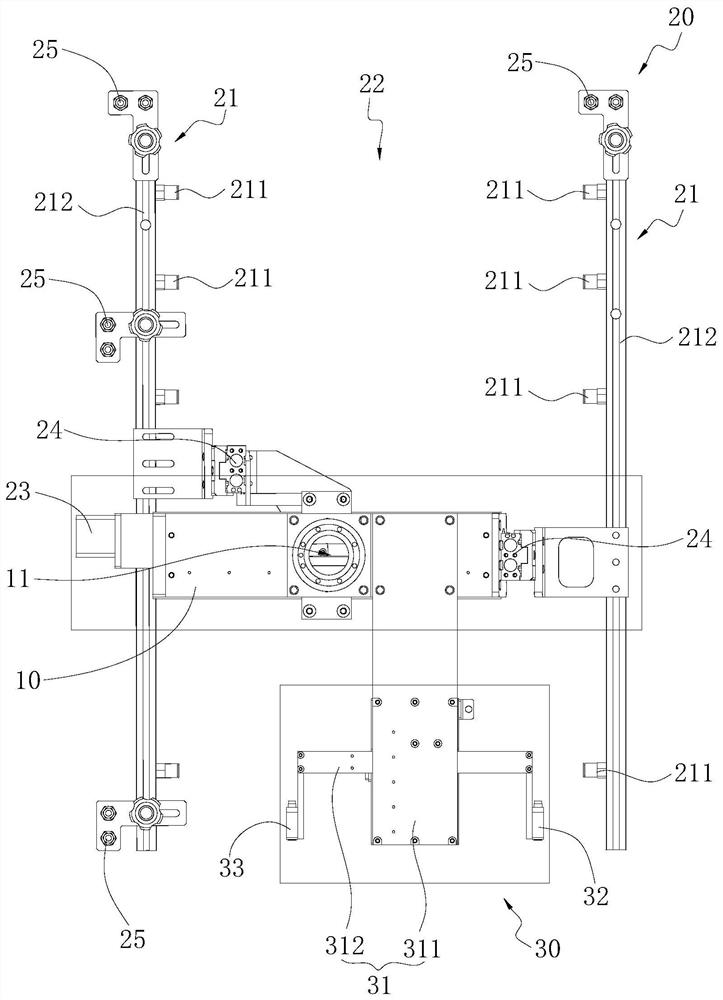

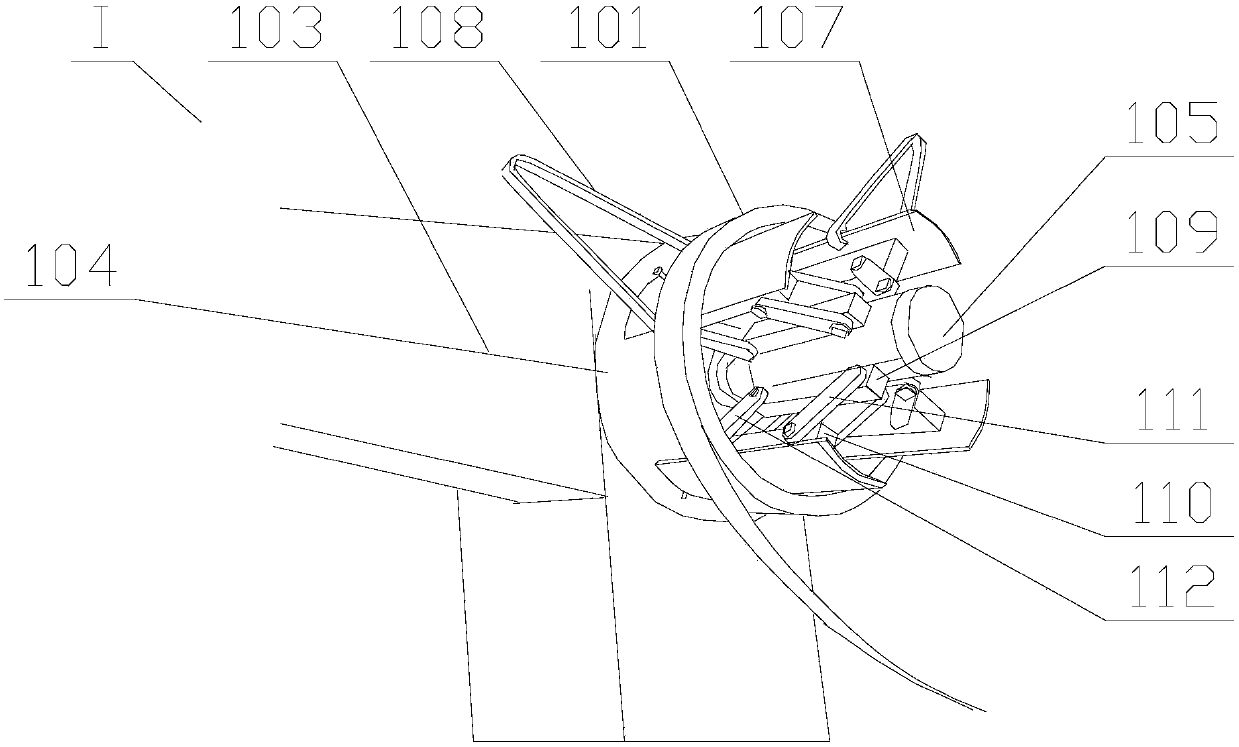

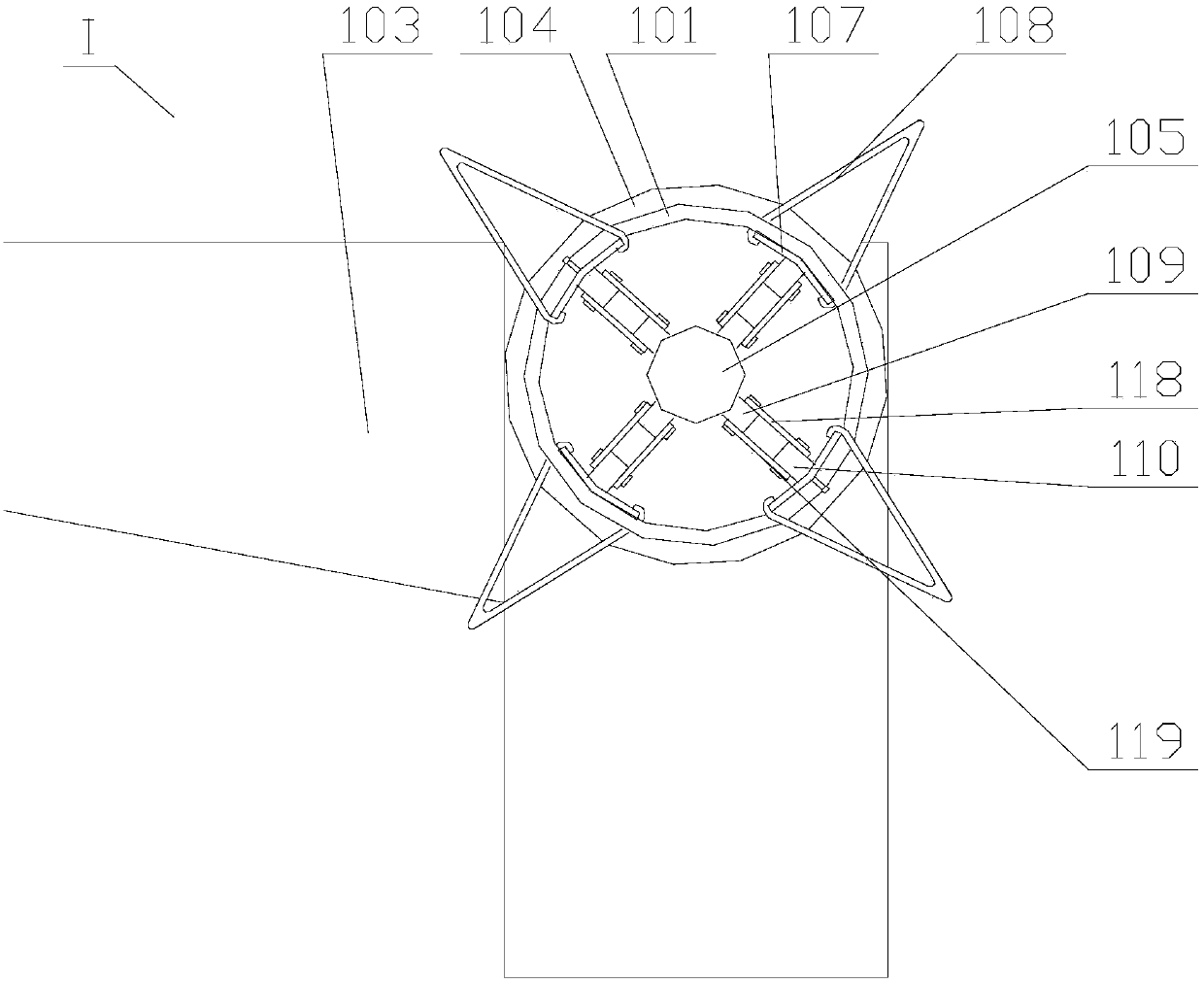

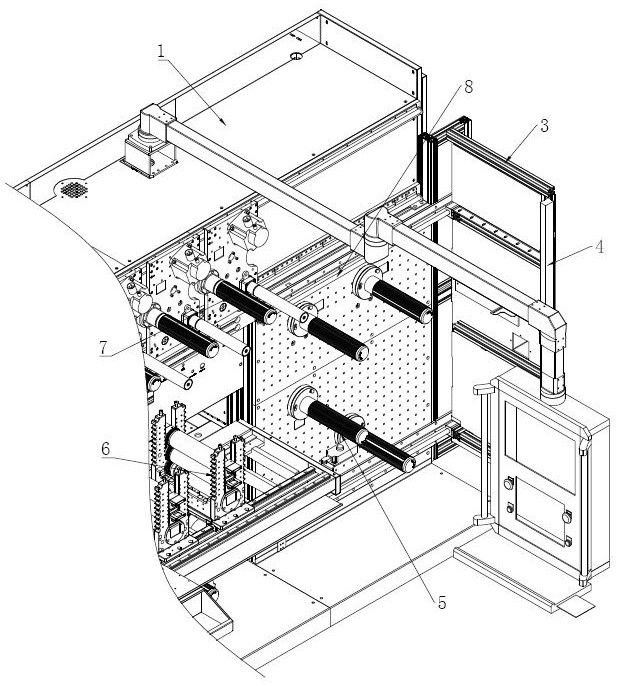

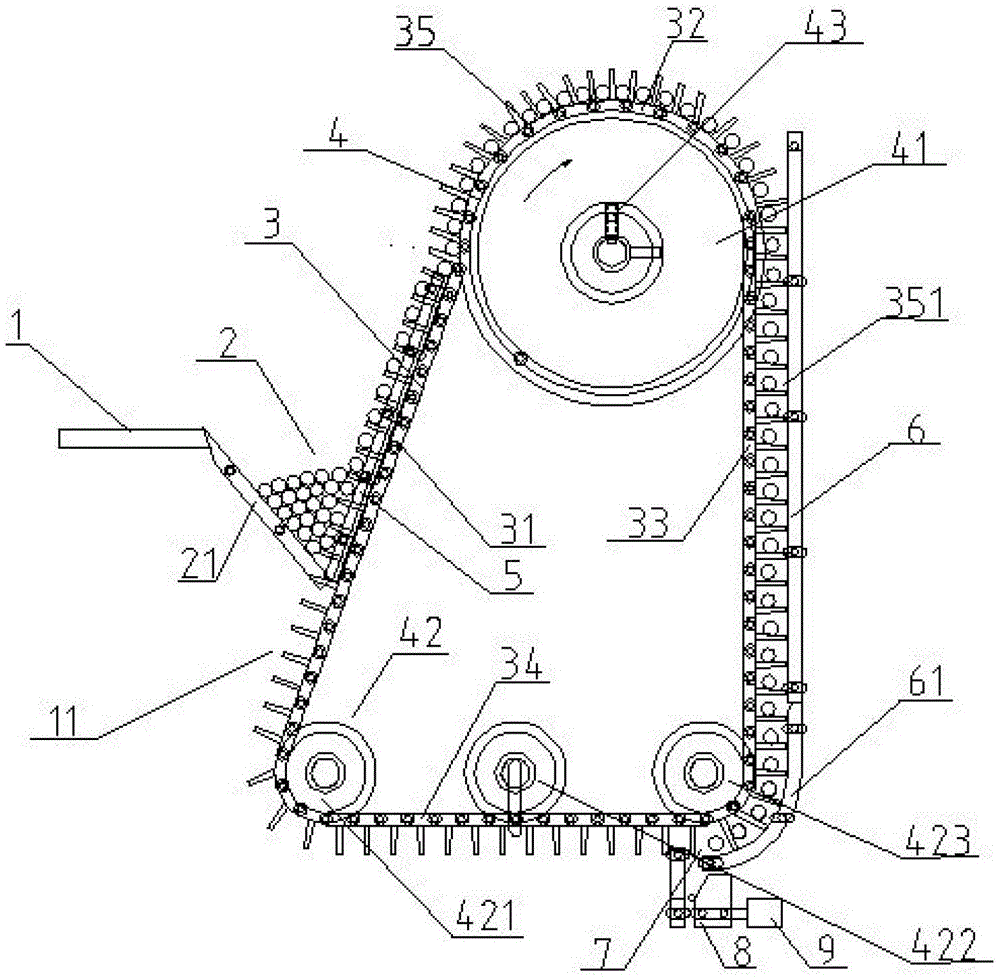

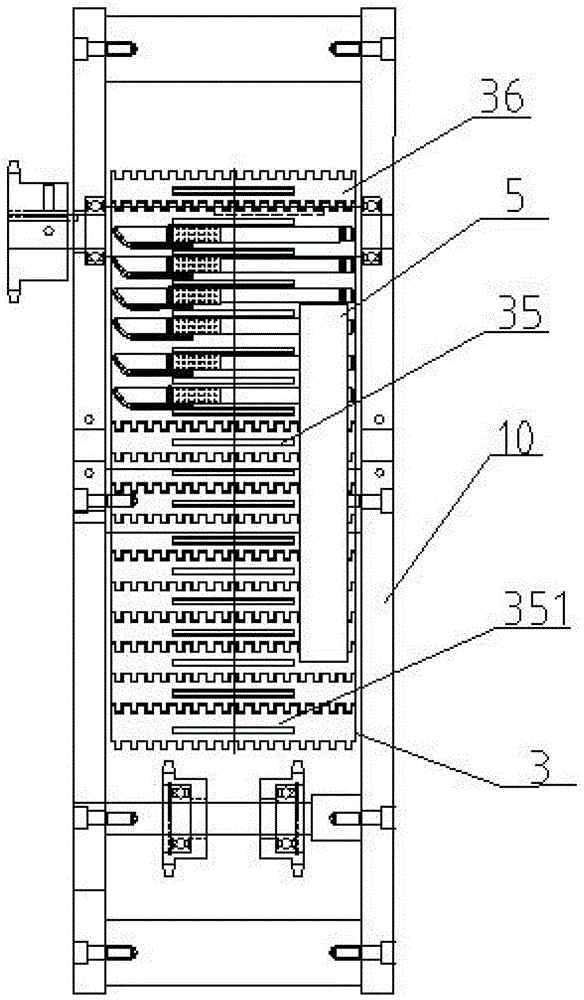

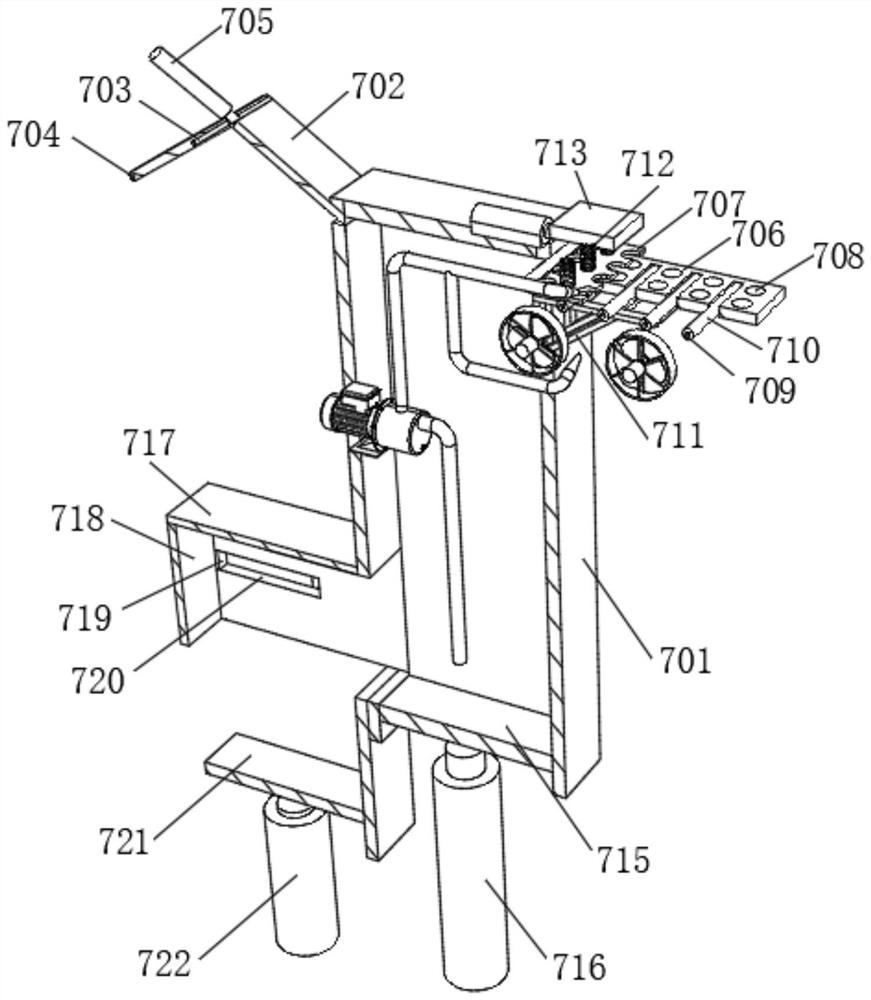

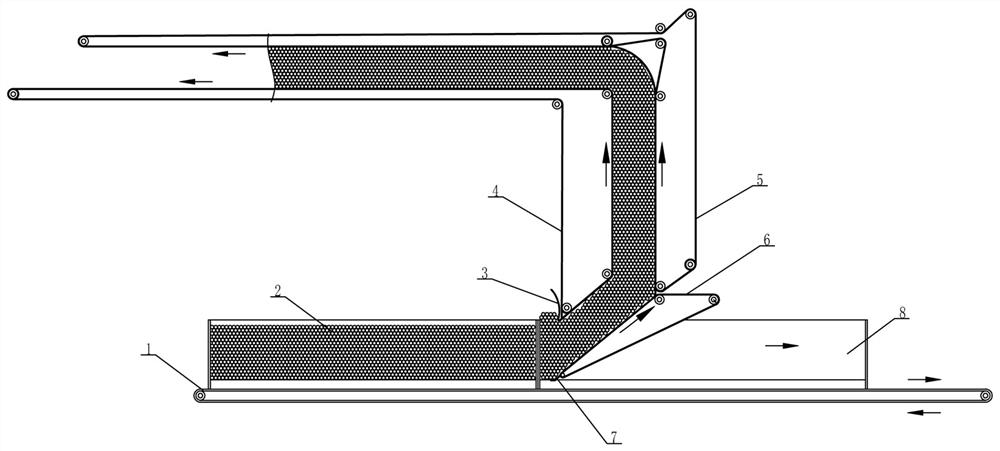

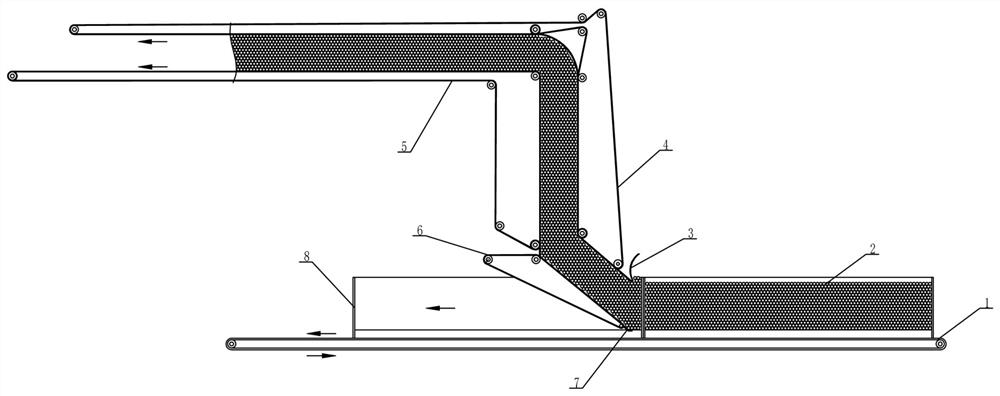

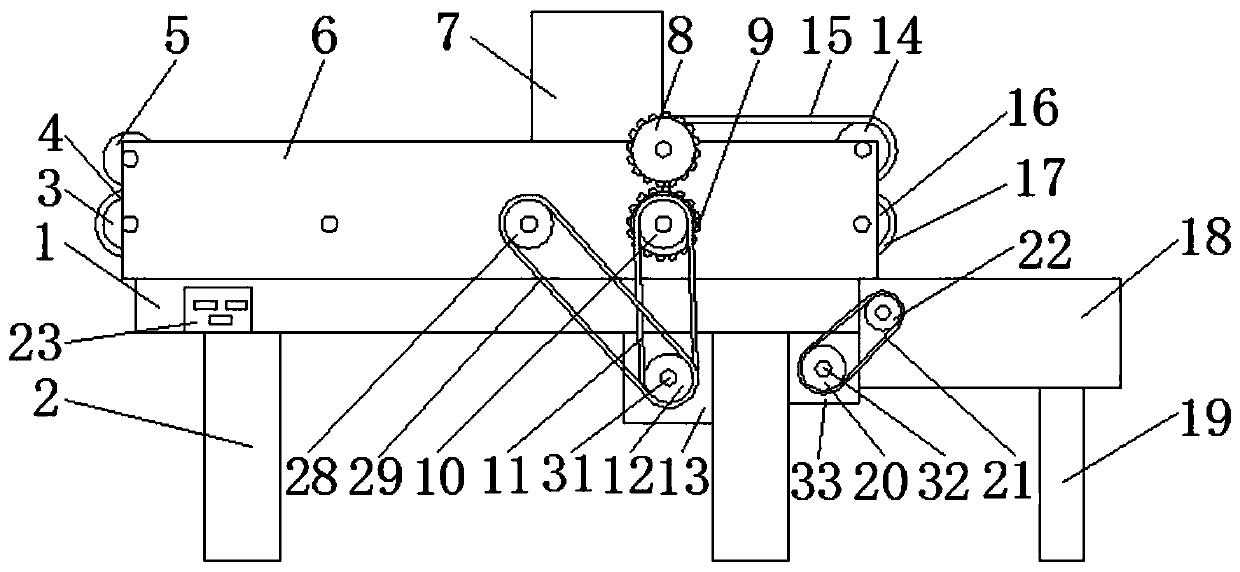

Automatic sorting feeding device for finished product pens

ActiveCN103144970ARealize automatic sorting and feeding, fromRealize the automatic boxing of the penConveyorsLoading/unloadingDrive wheelDrive motor

The invention discloses an automatic sorting feeding device for finished product pens. The automatic sorting feeding device comprises a machine frame, a material cabin, a chain wheel, a sorting mechanism and a conveying mechanism, wherein the material cabin and the chain wheel are arranged in the machine frame, the sorting mechanism is used for sorting the finished product pens stacked in the material cabin, the conveying mechanism is used for conveying the sorted finished product pens, the sorting mechanism is fixedly arranged on the conveying mechanism, the conveying mechanism is annularly surrounded and arranged on the chain wheel, an annular conveying rail is formed, the chain wheel comprises a driving wheel and a driven wheel, the driving wheel is matched with the driven wheel through the driving of a driving motor and drives the conveying of the conveying mechanism and the sorting mechanism, the automatic sorting of the finished product pens is realized, one end of an automatic sorting feeding mechanism is also connected with a counting device and a box filling device, and the counting package of the finished product pens is further realized. The automatic sorting feeding device has the advantages that the sorting feeding of the finished product pens can be realized, so the automatic box filling of the pens is realized, a large amount of labor is saved, and the package efficiency of the finished product pens is improved.

Owner:SUZHOU KAILEISHENG AUTOMATION TECH CO LTD

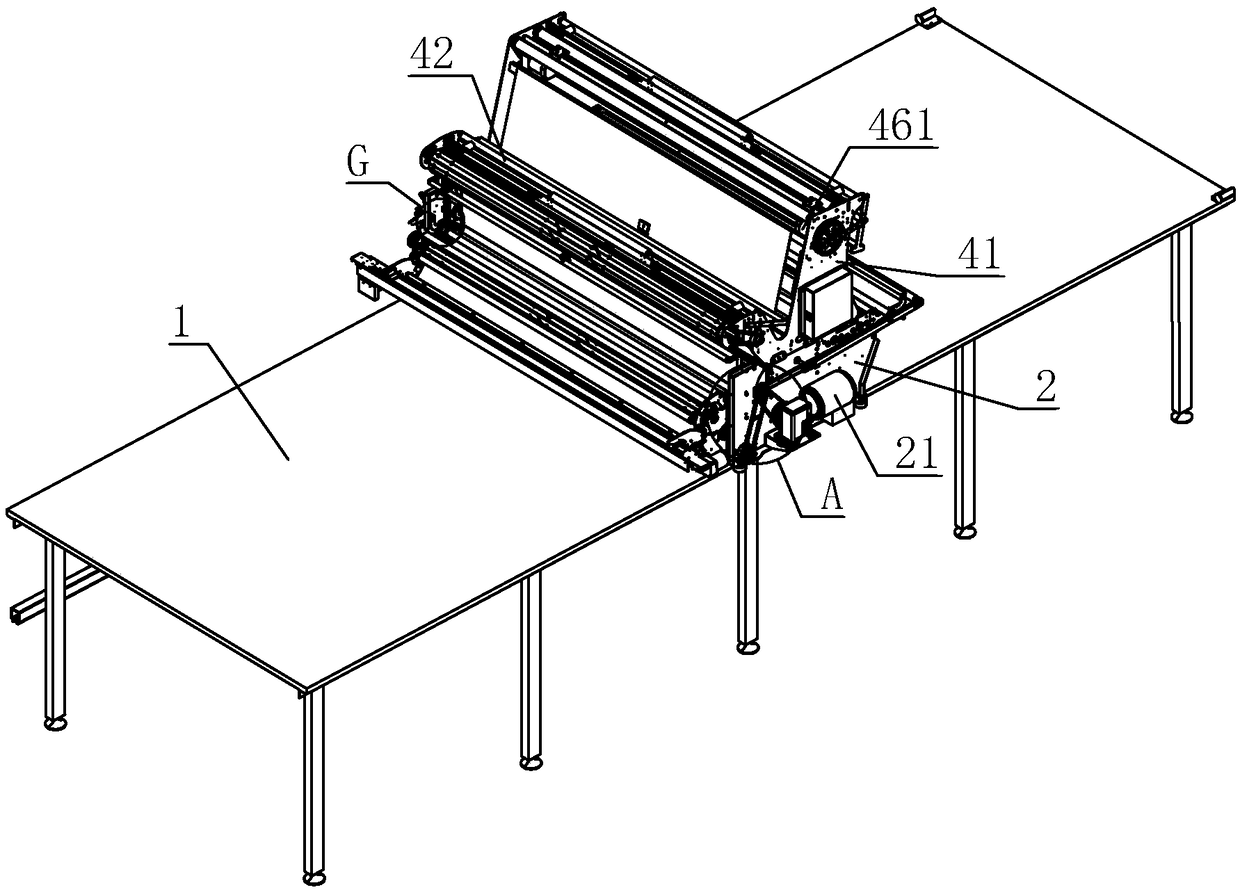

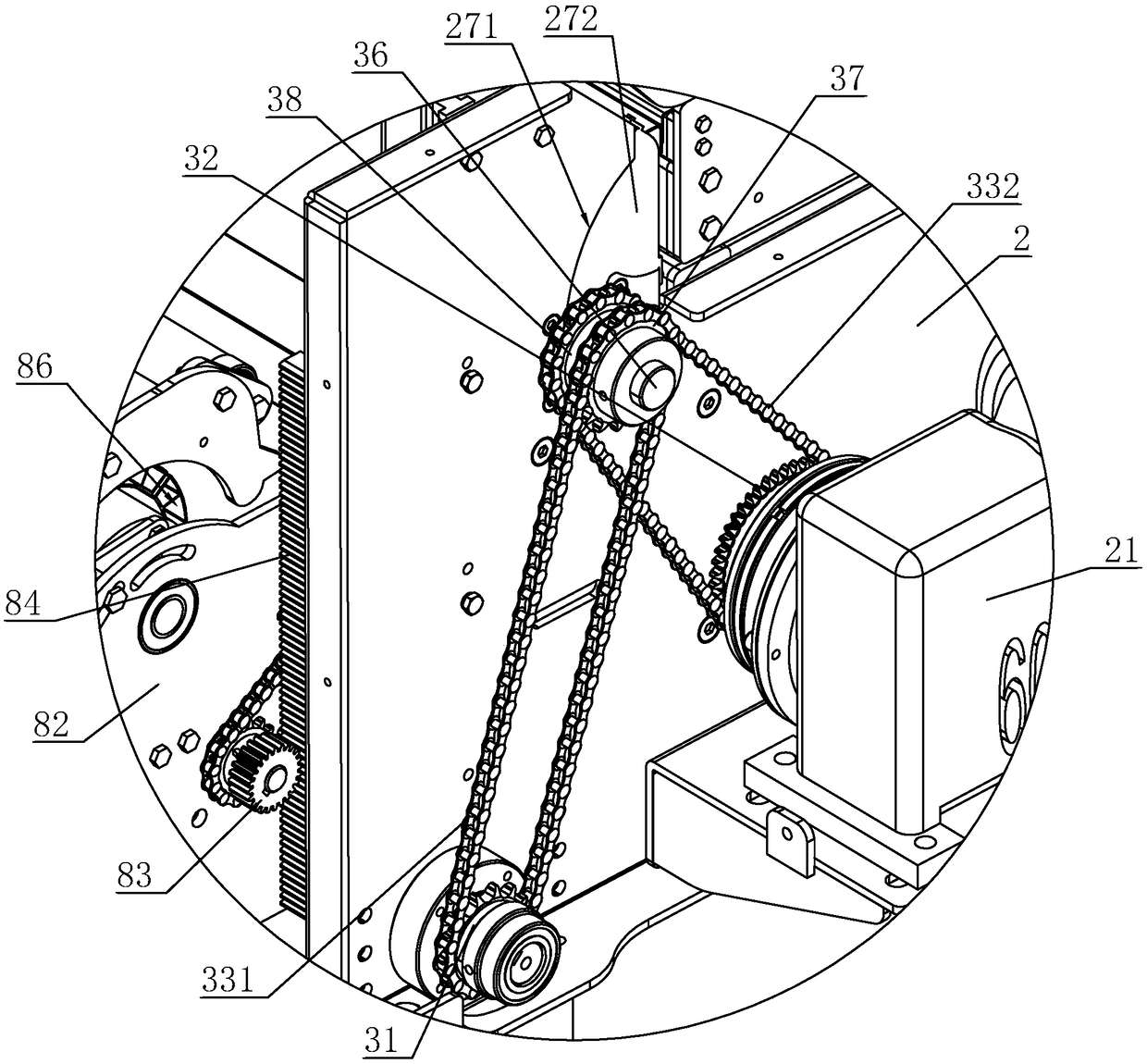

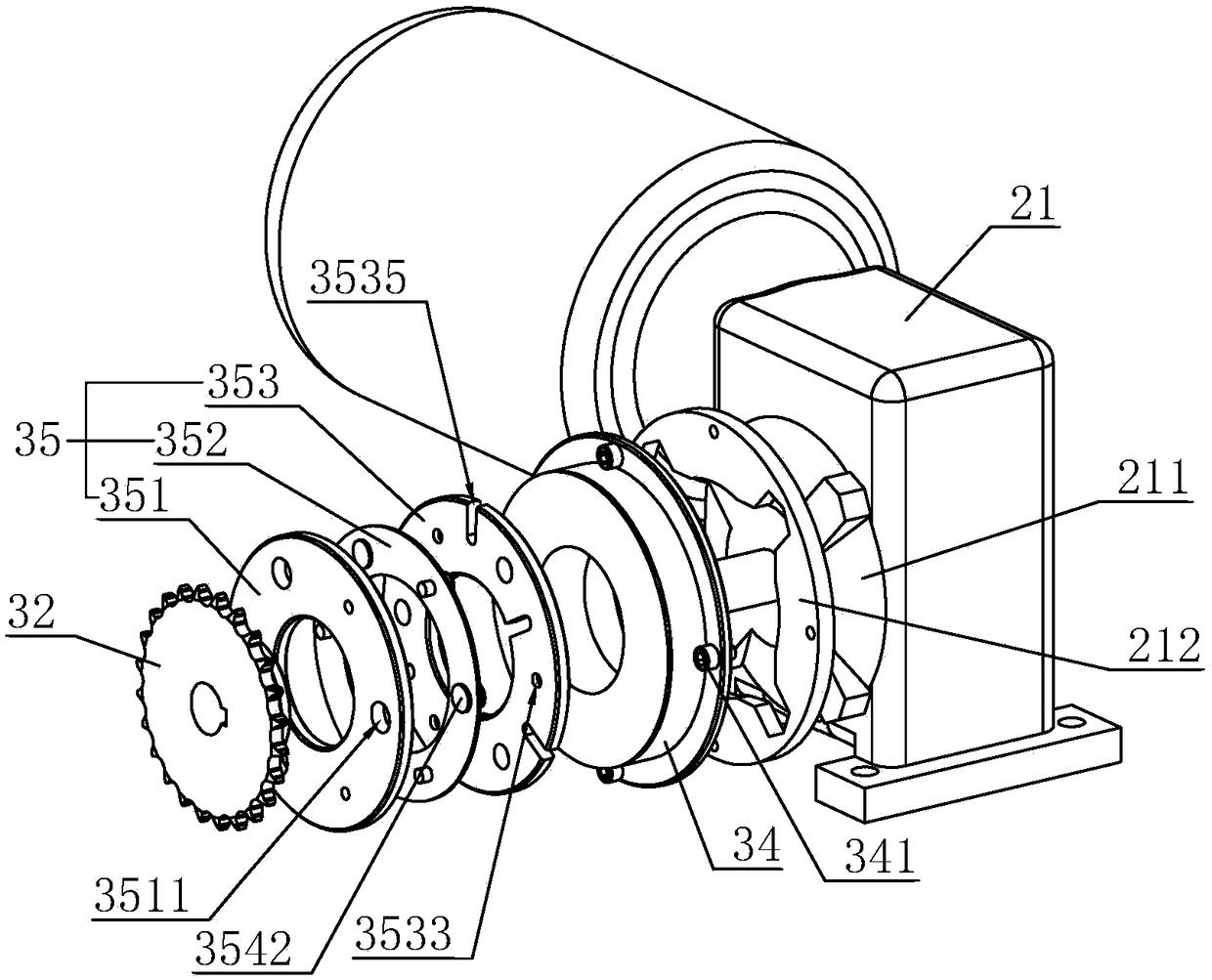

Knitting spreading machine and fabric spreading method thereof

PendingCN109132693AReduce slip distanceSmall length errorUnfolding thin materialsWebs handlingSprocketEngineering

The invention discloses a knitting spreading machine and a fabric spreading method thereof, relating to the technical field of garment processing equipment, comprising a fabric spreading platform, a frame which is rotatably provided with rollers and moves on the fabric spreading platform, and traveling motors which are installed on the frame and connected to the rollers and having brake mechanismsmounted thereon, wherein the brake mechanisms include first sprockets coaxially coupled to the rollers and second sprockets mounted on output shafts of the traveling motors, chain sets mounted on thefirst sprocket and the second sprocket, electromagnets mounted on the traveling motors and connected to a power source, and positioning assemblies mounted on the second sprockets and attracted by theelectromagnets. Through the positioning of the positioning assemblies and the electromagnets, the frame can be stopped rapidly, thereby greatly reducing the sliding distance of the frame, reducing the length error of the fabric spreading, and improving the accuracy of the fabric spreading.

Owner:浙江精力玛智能机械有限公司

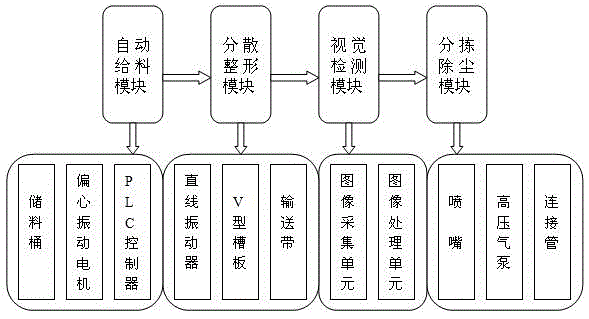

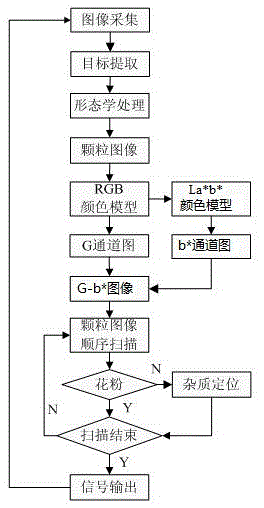

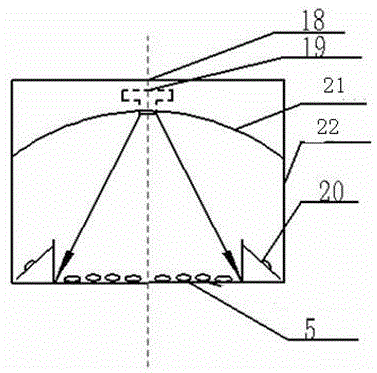

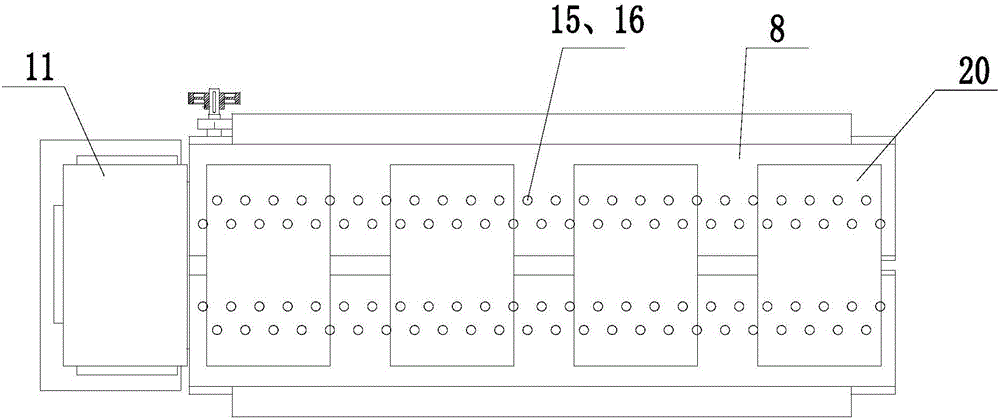

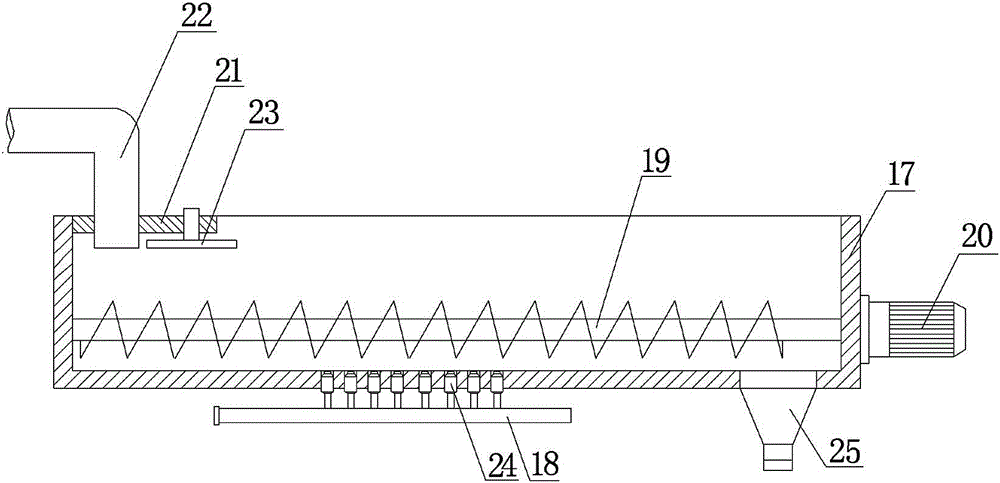

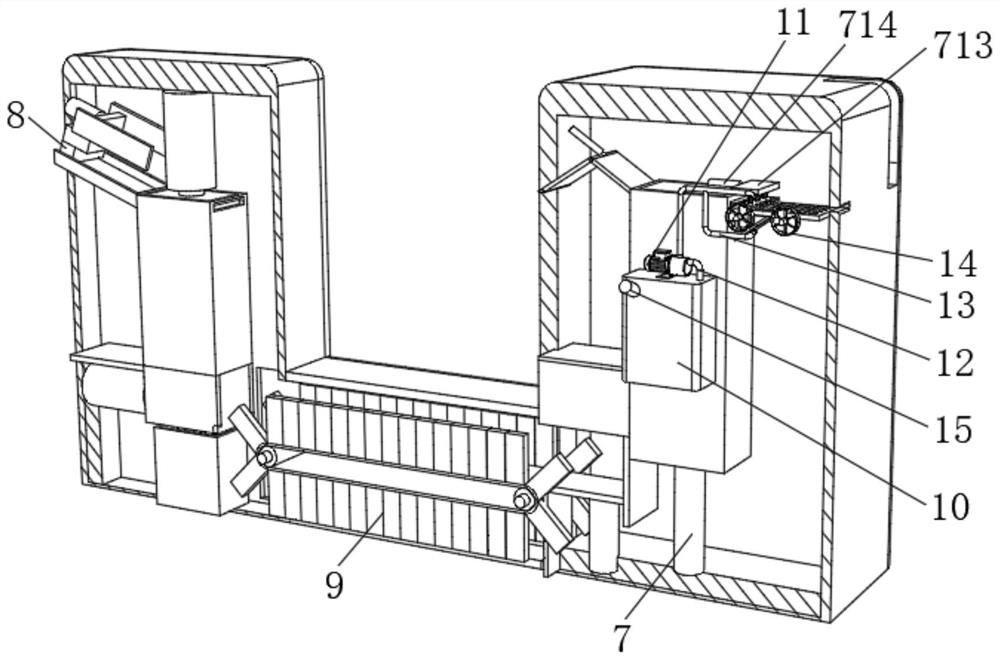

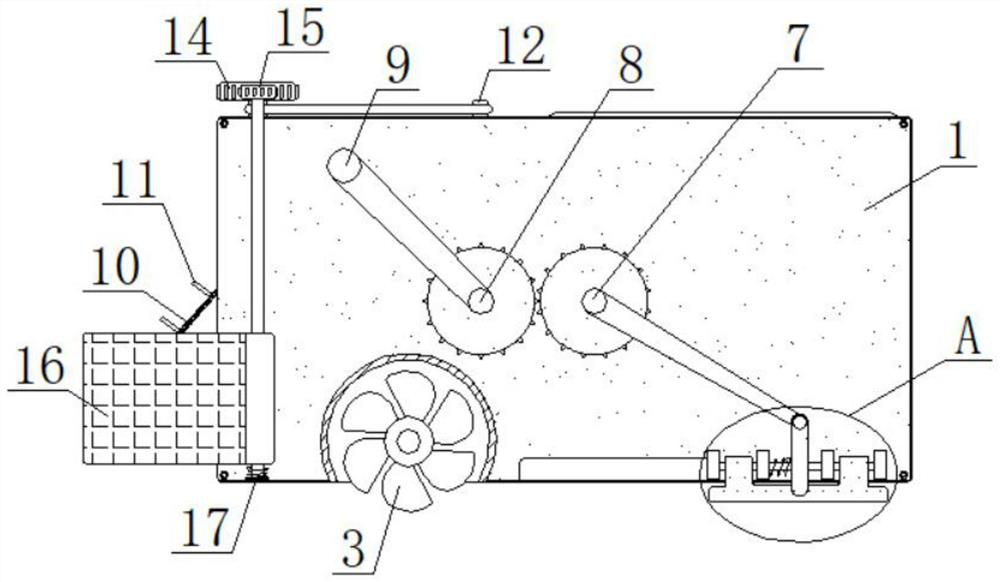

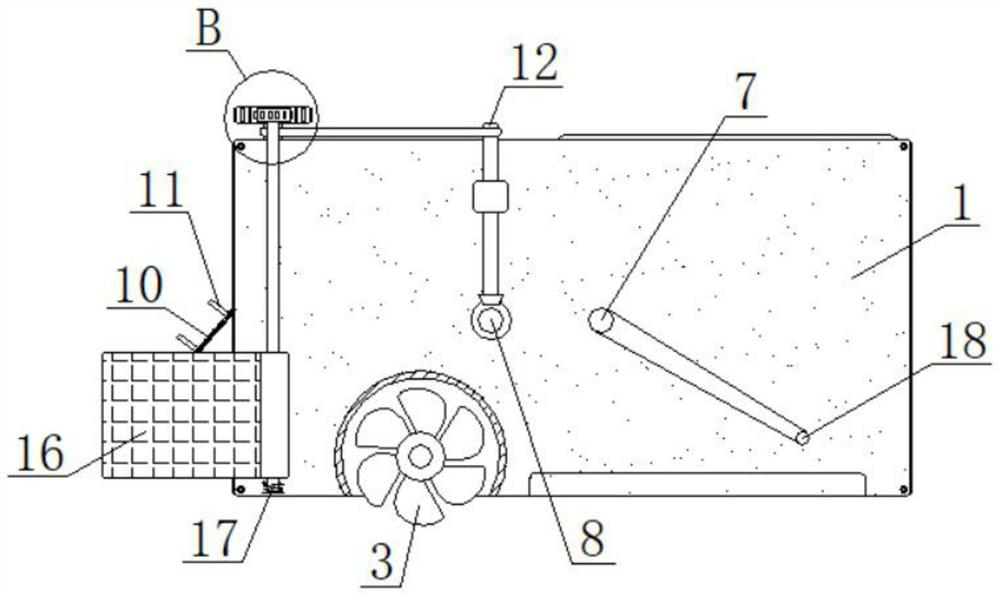

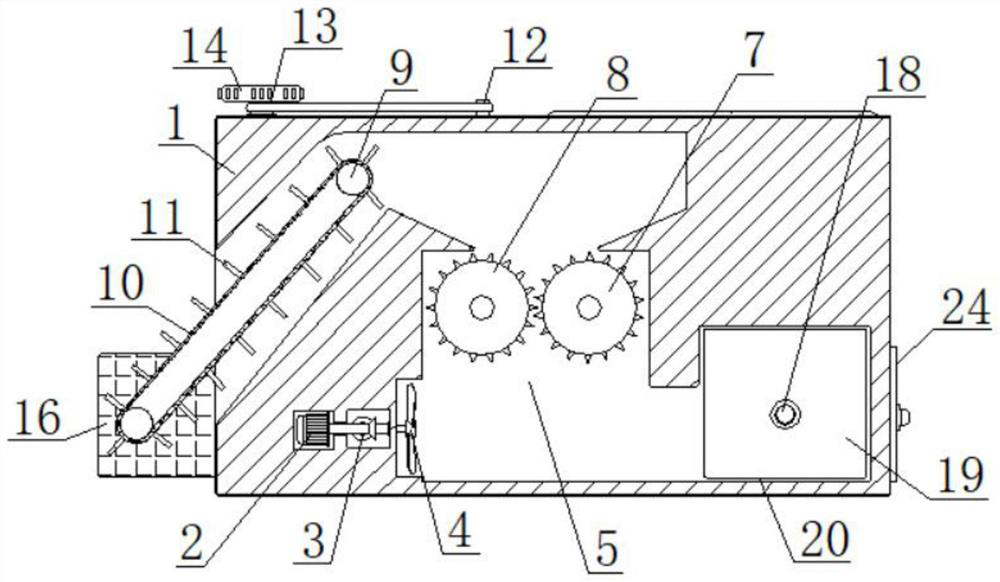

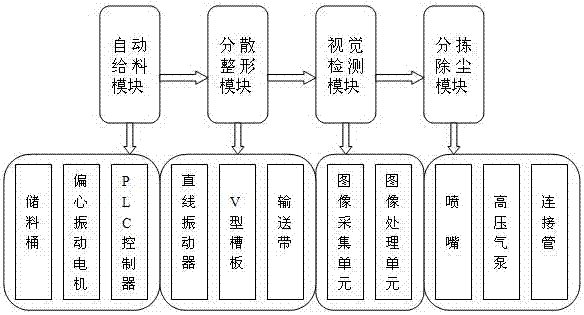

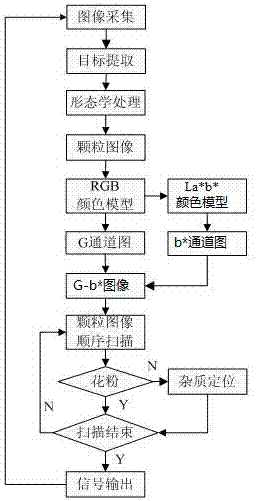

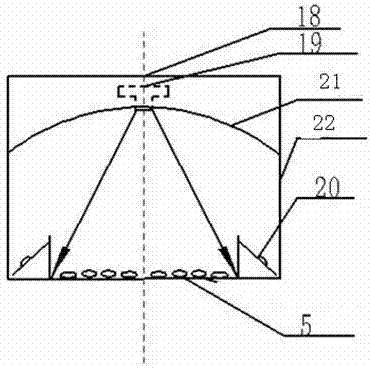

Automatic bee pollen screening device and screening method

The invention belongs to the technical field of machine vision, mechanical design and automatic control and relates to an automatic bee pollen screening device and a screening method. The device comprises an automatic feeding module, a dispersion shaping module, a visual inspection module and a sorting dust removal module. Bee pollen to be sorted is poured into a storage barrel of the automatic feeding module; the bee pollen is supplied to a V-shaped groove plate of the dispersion shaping module through an eccentric vibration motor, performs climbing movement on the V-shaped groove plate, is uniformly dispersed, falls on a conveying belt to be shaped and then moves forwards at a constant speed; image acquisition is performed through an image acquisition unit of the visual inspection module; image information is processed through built-in computer software and then transmitted to a programmable logic controller (PLC) to be controlled so as to control the actions of the eccentric vibration motor and a spray nozzle, and the bee pollen is screened. By means of the automatic bee pollen screening device and the screening method, the problems that small-particle bee pollen is prone to being broken, irregular in shape, difficult to disperse and sort and not obvious in color difference are solved, and the sorting speed is increased under the condition that the sorting accuracy is guaranteed.

Owner:JIANGSU UNIV

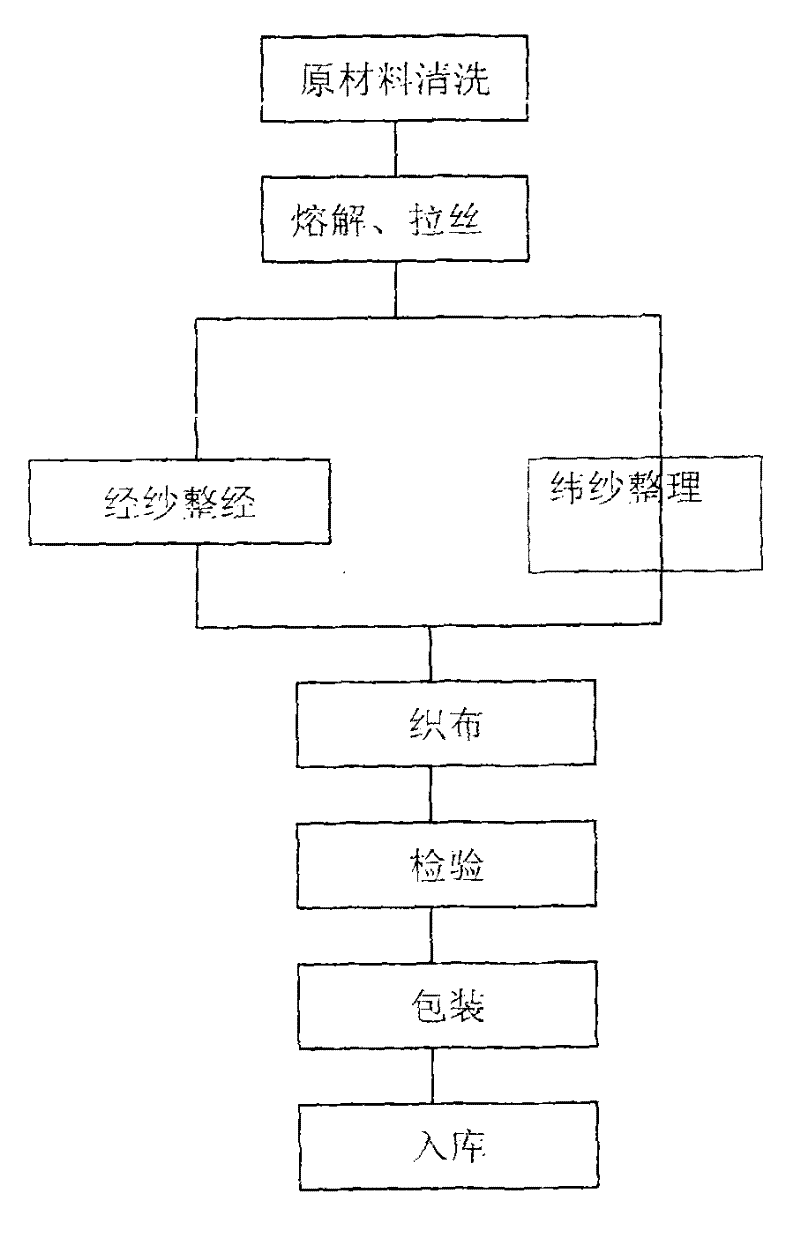

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

Metal sheet conveying device

The invention relates to a metal sheet conveying device, in particular to tinplate (aluminum sheet) coil stock high-speed uncoiling, flattening and sheared sheet conveying used in the metal printing tinmaking industry. The metal sheet conveying device comprises a motor, a synchronous belt, a synchronous pulley, a driving roller, a tensioning roller, a conveyor frame, a belt base plate and a conveying flat belt. The conveyor frame is arranged in a closed space, and the closed space is connected with an air draft device. The belt base plate covers the upper side of the closed space. The belt base plate is provided with a plurality of first small hole belts. The first small hole belts are composed of a plurality of first small holes which are longitudinally arranged and connected with the closed space. The conveying flat belt is arranged above the belt base plate. Second small hole belts are arranged on the conveying flat belt and correspond to the first small hole belts. The second small hole belts are composed of a plurality of second small holes which are longitudinally arranged and connected with first small holes. By means of the metal sheet conveying device, the problems caused in the tinplate high-speed conveying process are solved, the tinplate shearing speed is greatly increased, and thus high-speed shearing is made possible.

Owner:HANGZHOU HENGLI CUTTING EQUIP

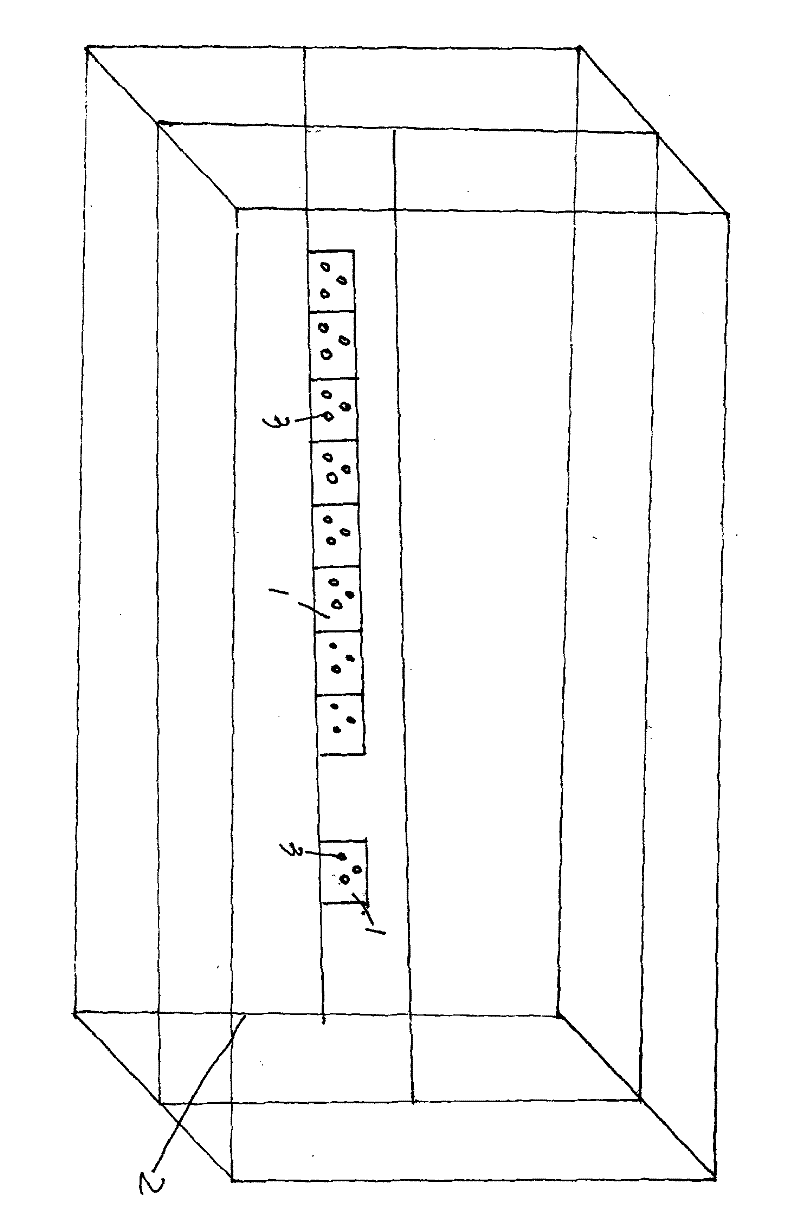

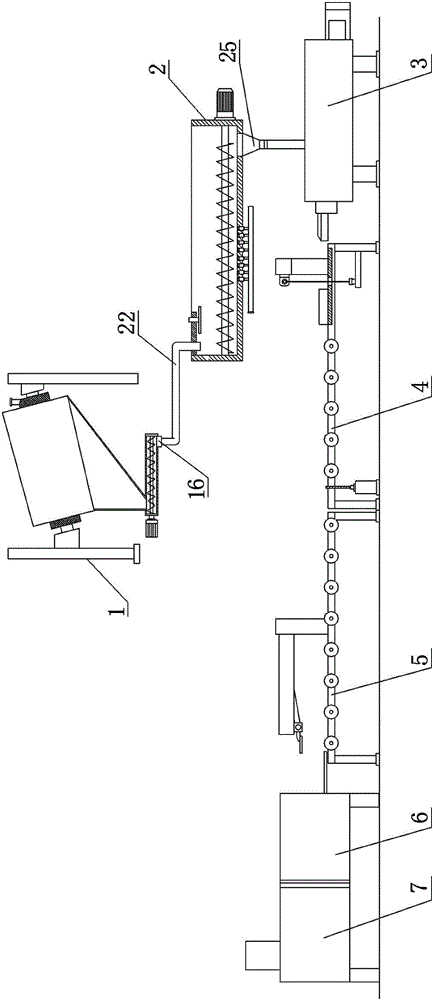

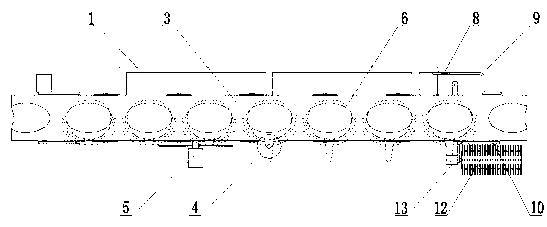

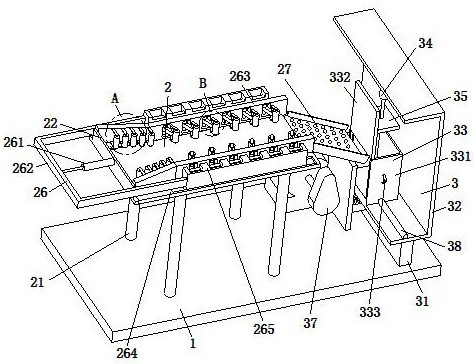

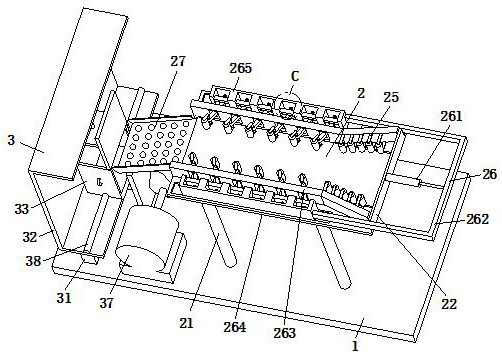

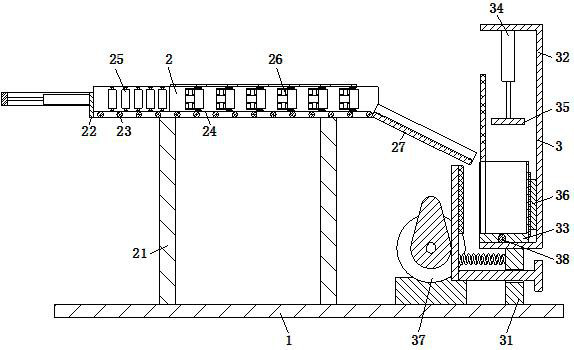

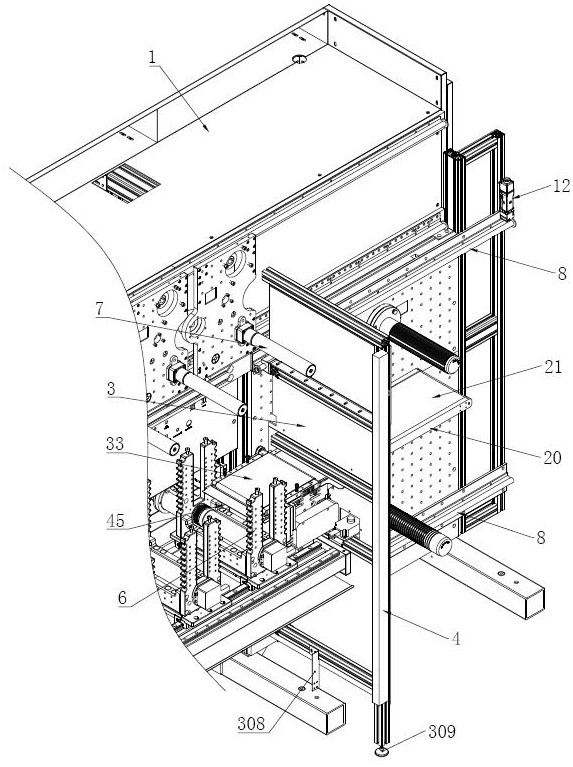

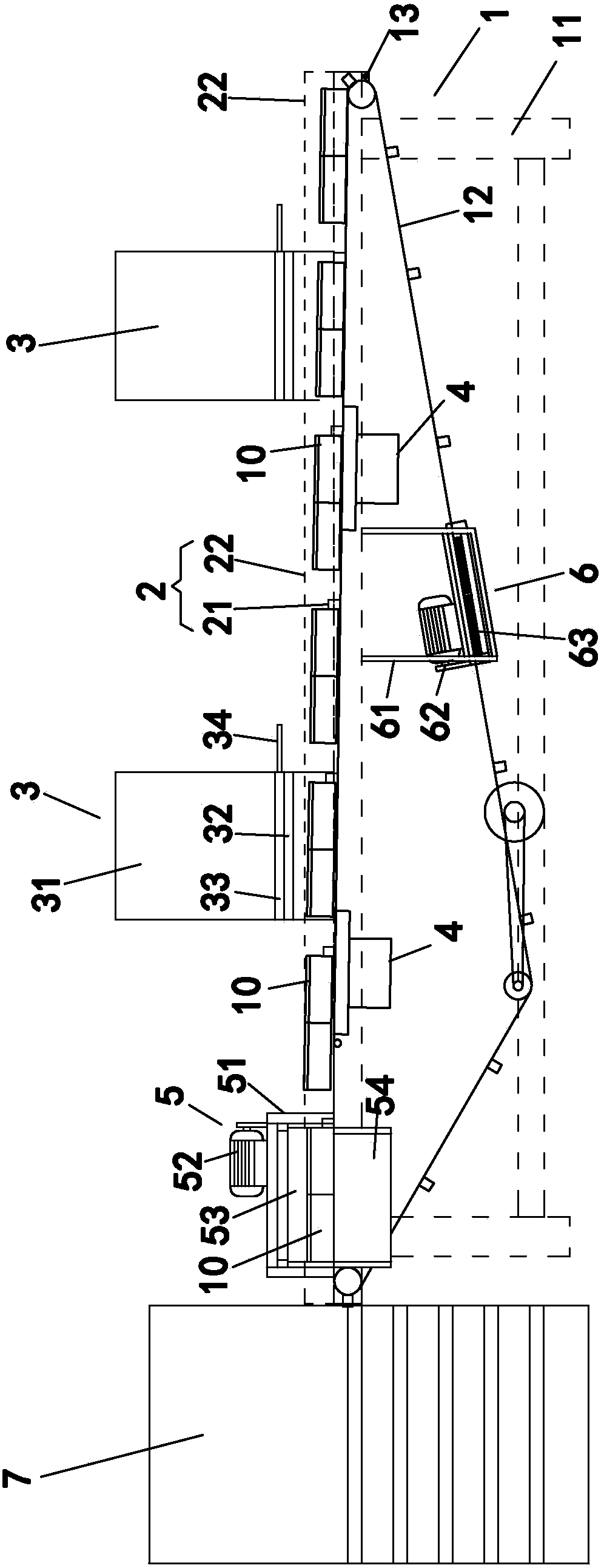

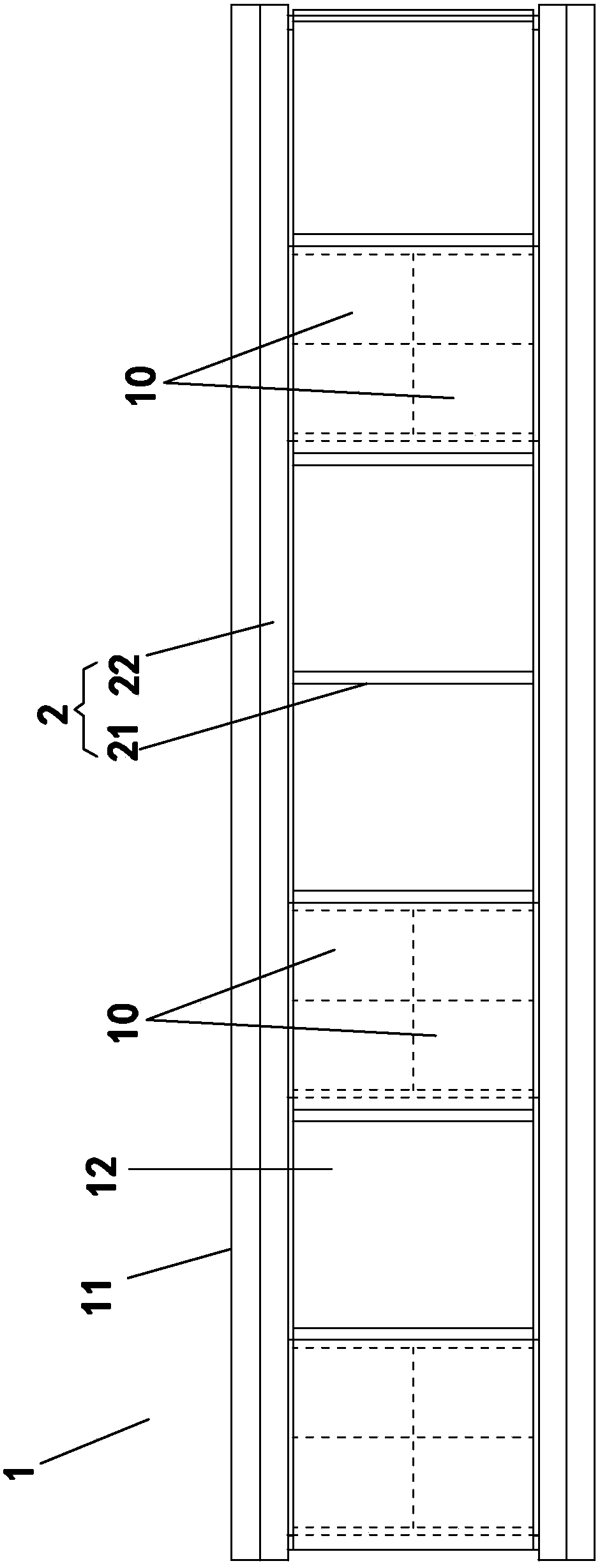

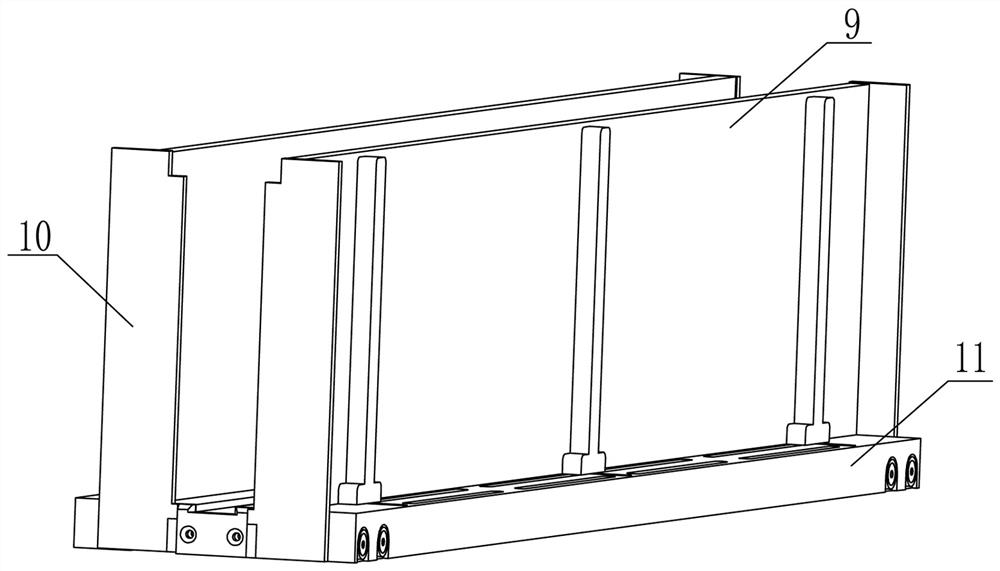

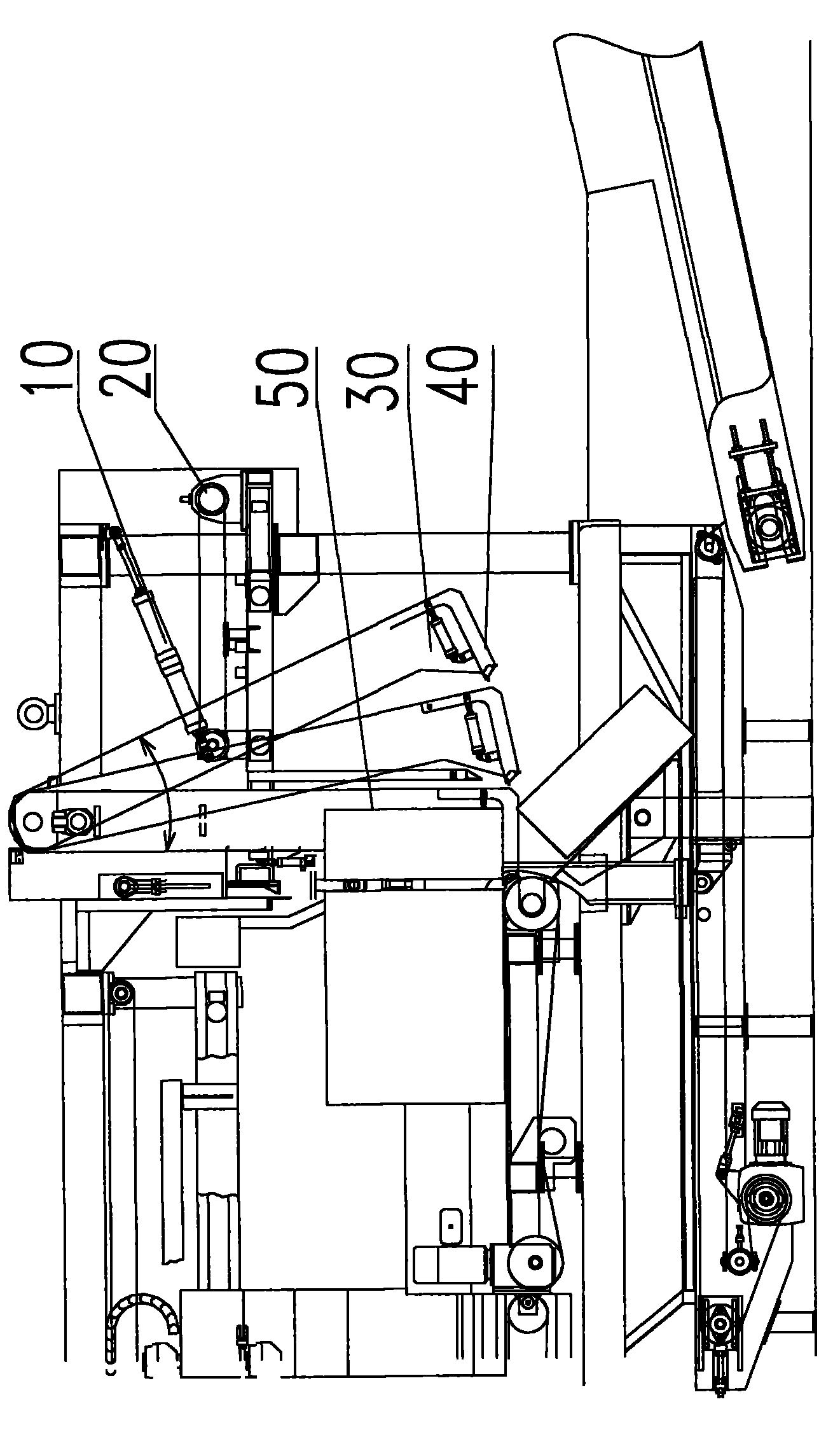

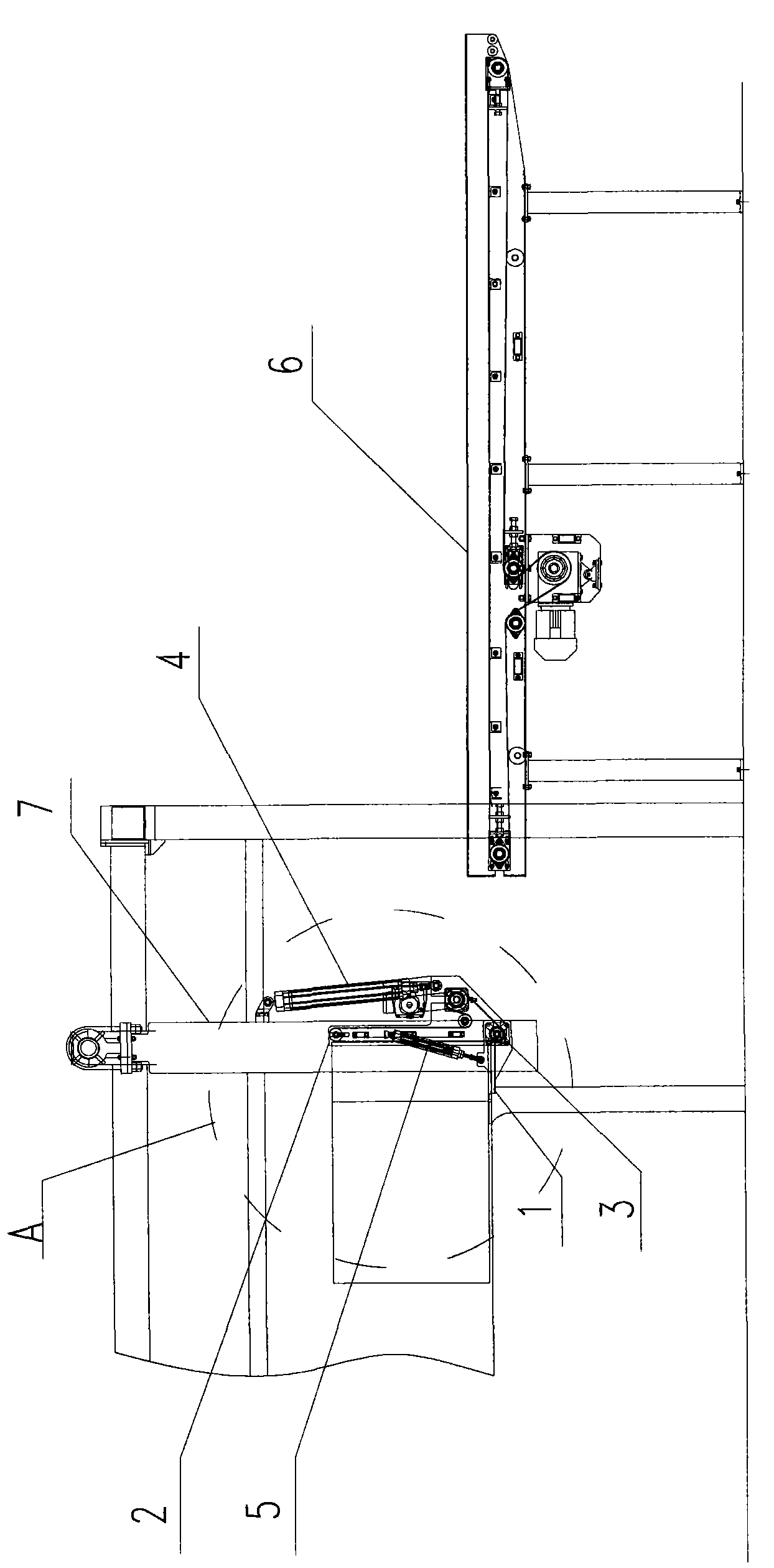

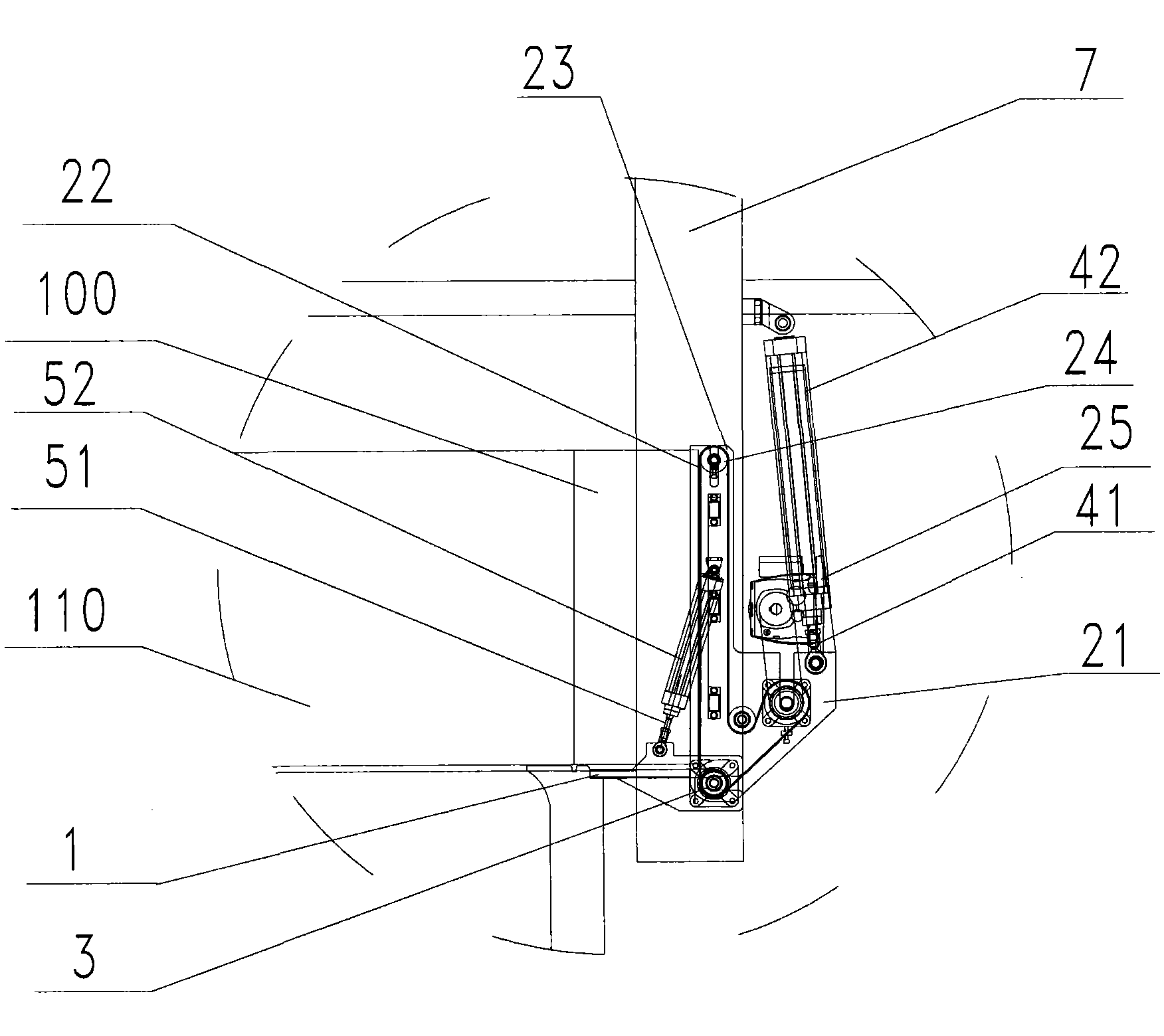

Production line for automatically producing perforated bricks

ActiveCN105196411AWell mixedImproved particle size distributionMixing operation control apparatusCeramic shaping plantsProduction lineBrick

The invention discloses a production line for automatically producing perforated bricks. The production line comprises a shale screening device (1), a stirrer (2), a perforated brick extrusion forming machine (3), a perforated brick cutting machine (4), a machine (5) for arranging the perforated bricks in order, a drying device (6) and a calcination device (7). A feed pipe (22) of the stirrer (2) is connected with a discharge port (16) of the shale screening device (1), a rack A and a rack E are spliced, a rack B and a rack F are spliced, a discharge pipe (25) of the stirrer (2) is connected with the inlet end of the perforated brick extrusion forming machine (3), the outlet end of the perforated brick extrusion forming machine (3) is arranged above a flat plate (30) and located between two vertical plates (33), and the drying device (6) is communicated with the calcination device (7). The production line has the advantages that the screening efficiency is improved, shale and water are fully mixed, notches are flat, the cutting efficiency is high, and the perforated bricks can be conveyed into the drying device in order.

Owner:LANGZHONG JINBORUI NEW WALL MATERIAL

Device for cutting synthetic material bristles for glass grinding

ActiveCN109330177AReduce labor intensityShorten the timeBristleGrinding devicesBristleSynthetic materials

The invention provides a device for cutting synthetic material bristles for glass grinding, which comprises a workbench, wherein both edges of the bottom surface of the workbench are fixedly connectedwith a first supporting leg respectively, and the bottom surface of the workbench is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a first rotatingshaft, and the outer surface of the first rotating shaft is fixedly connected with a second rotating wheel and a sixth rotating wheel. The front end and rear end of the top surface of the workbench are fixedly provided with a blocking plate respectively, a guiding roller, two conveying rollers, two upper rollers and two lower rollers are arranged between the two blocking plates, the guiding roller is arranged on one side of the blocking plates, the conveying rollers are arranged under the guiding roller and the two conveying rollers are placed horizontally. The device overcomes the defects inthe prior art and is reasonably designed to automatically cut the bristles. The time and the effort are saved, the production efficiency is improved, and the useless bristles left by the cutting canbe effectively removed, the quality of the bristles is improved.

Owner:安徽省潜山县潜源鬃刷有限公司

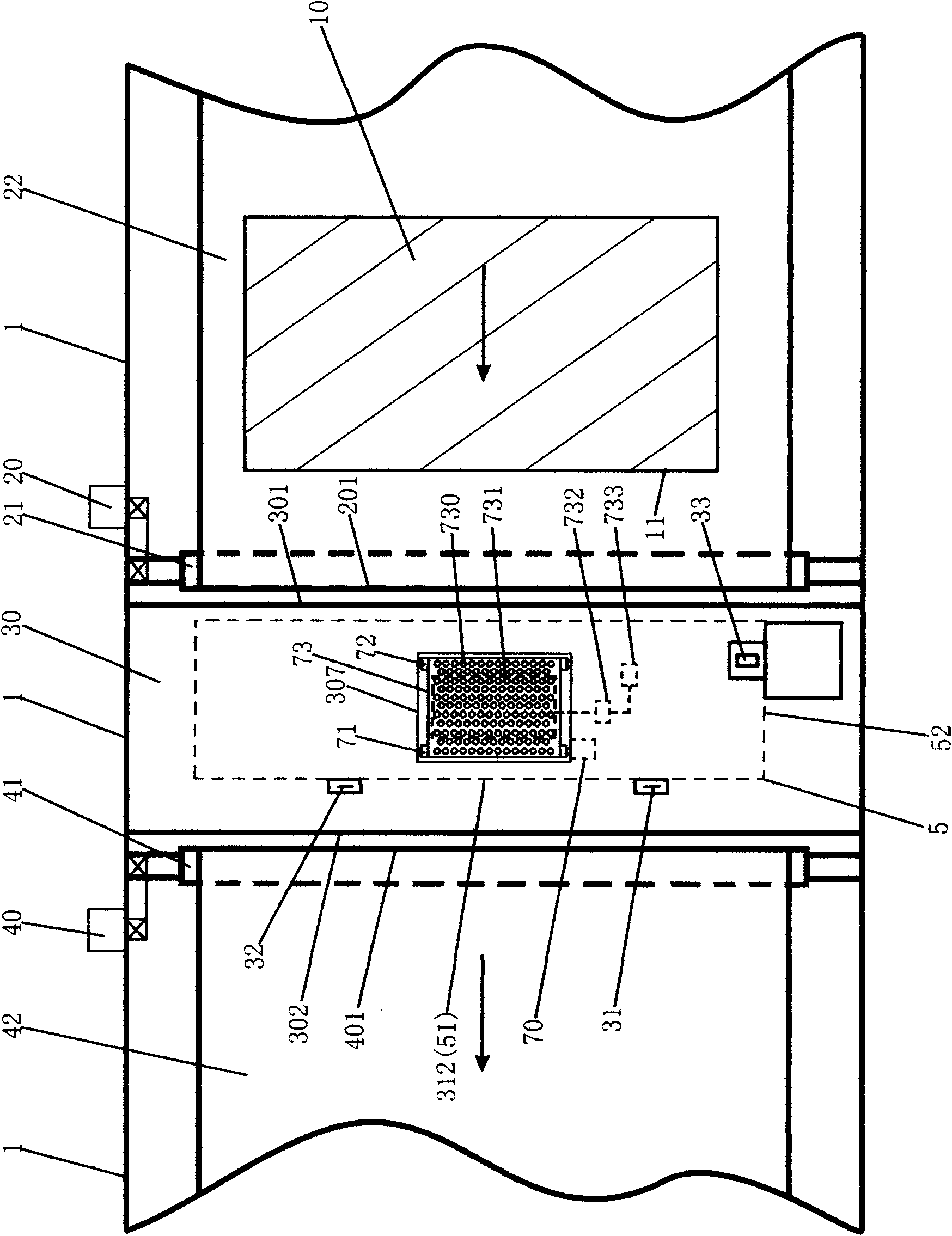

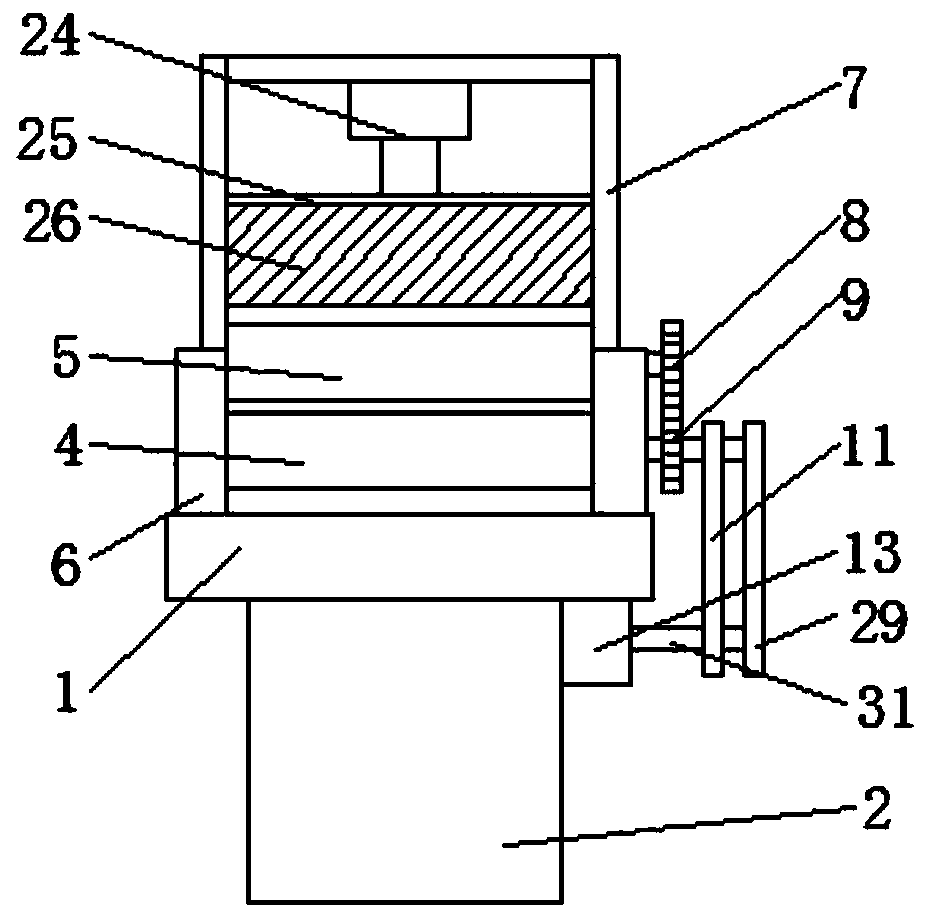

Paper conveying mechanism

InactiveCN102491112AConveying neatlyStable deliveryRegistering devicesArticle feedersPulp and paper industryProcessing accuracy

The invention relates to a paper conveying mechanism, which is characterized by comprising a machine frame, a paper feeding mechanism, a deviation correcting adsorption paper feeding mechanism and a paper discharge mechanism, wherein the paper feeding mechanism, the deviation correcting adsorption paper feeding mechanism and the paper discharge mechanism are sequentially arranged on the machine frame, the paper feeding edge of the deviation correcting adsorption paper feeding mechanism is connected with the paper discharge edge of the paper feeding mechanism, and the paper discharge edge of the deviation correcting adsorption paper feeding mechanism is connected with the paper feeding edge of the paper discharge mechanism. Therefore, the paper conveying mechanism has the advantages that in the paper conveying process, the problem of paper skewing or deviation generated in the conveying process is solved through the deviation correction treatment by the deviation correcting adsorption paper feeding mechanism so that the paper can be orderly forwards conveyed, the paper can be stably and reliably forwards conveyed through the adsorption positioning of the deviation correcting adsorption paper feeding mechanism so that the printing or processing accuracy of paper printing processing equipment is ensured, and the quality detection accuracy of printed products and the detection accuracy of code spraying equipment are ensured. The paper conveying mechanism can be applied to paper processing equipment such as paper printing processing equipment, printed product quality detection equipment and code spraying equipment.

Owner:陈晓滨

Guide soil-brushing device of head vegetable harvesting machine

The invention discloses a guide soil-brushing device of a head vegetable harvesting machine. The guide soil-brushing device of the head vegetable harvesting machine comprises a support, a connecting rod, a guide soil-brushing mechanism, a conveying mechanism, a supporting mechanism and a cutting mechanism, wherein the support is of a bilaterally-symmetrical structure, the guide soil-brushing mechanism is installed on the front portion of the support, the cutting mechanism is installed on the lower side of the middle rear portion of the support, and the conveying mechanism and the supporting mechanism are installed on the left and the right sides of the support. The guide soil-brushing mechanism comprises driven conveying wheels, front upper connecting plates, front lower connecting plates, springs, soil-brushing motors and rotary drum brushes. The guide soil-brushing mechanism will automatically guide a conveying track of head vegetables along with advancing of the vegetable harvesting machine, and cleans redundant soil of the roots of the vegetables. The guide soil-brushing device of the head vegetable harvesting machine achieves automatic guide of the conveying track of the head vegetables, can clean the redundant soil of the roots of the vegetables, ensures subsequent stable and orderly conveyance and effective cutting of the roots, reduces damage to the vegetables in the process of conveyance, and improves the cleaning degree of the vegetables.

Owner:ZHEJIANG UNIV

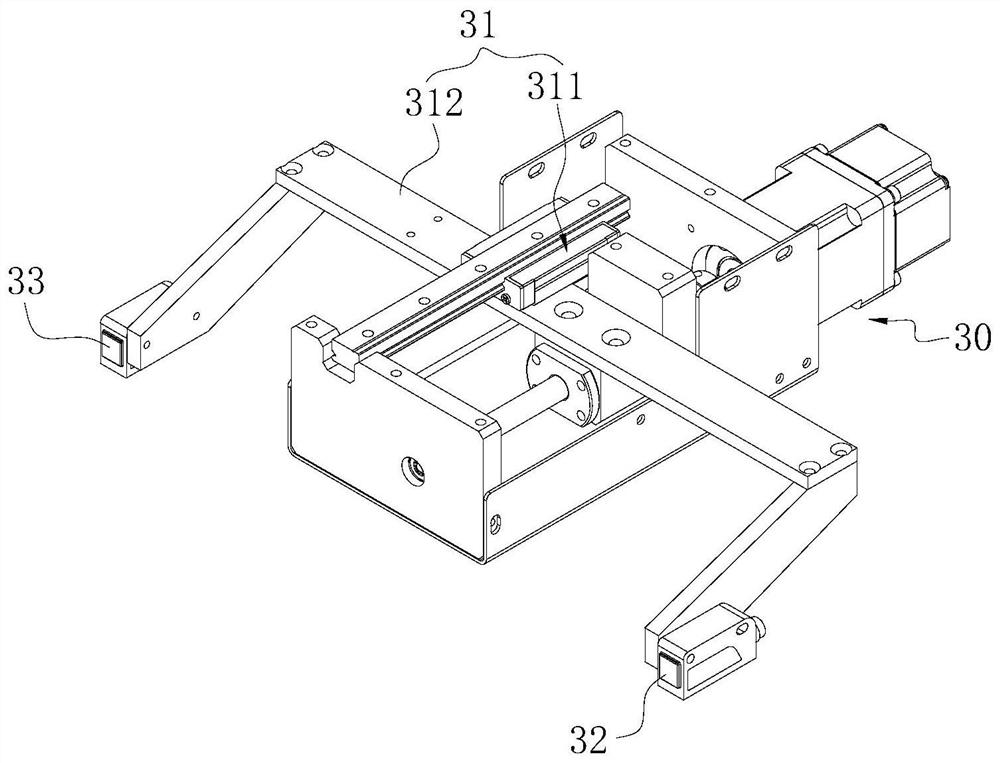

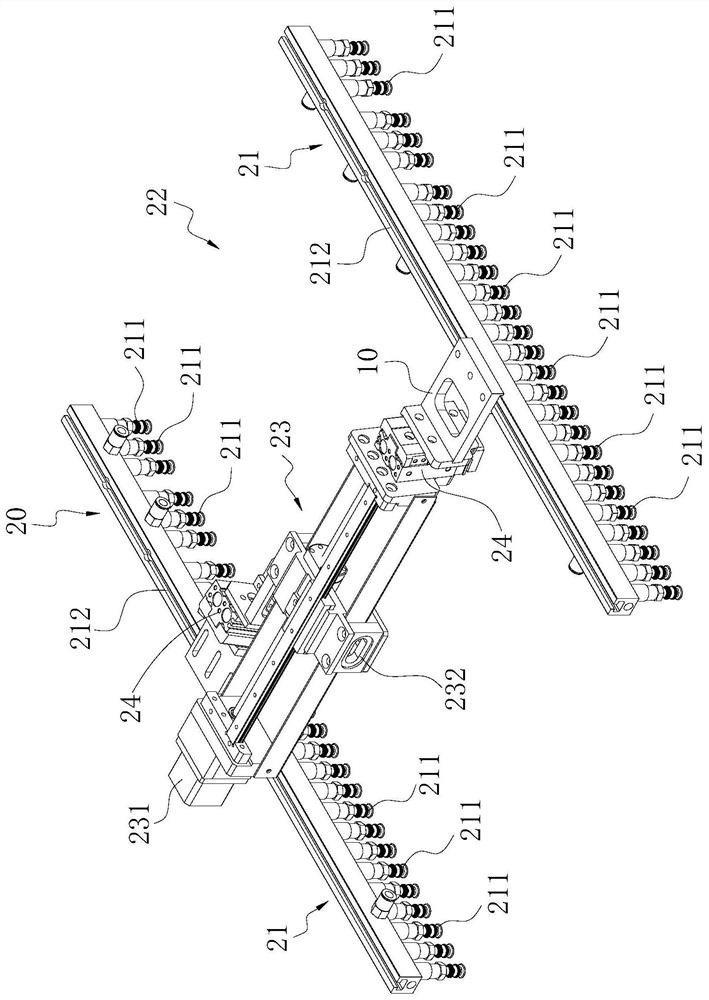

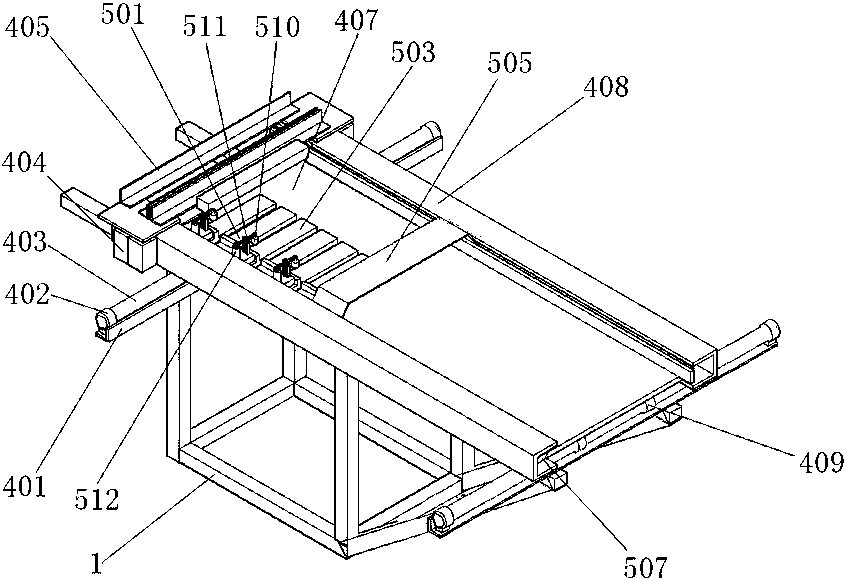

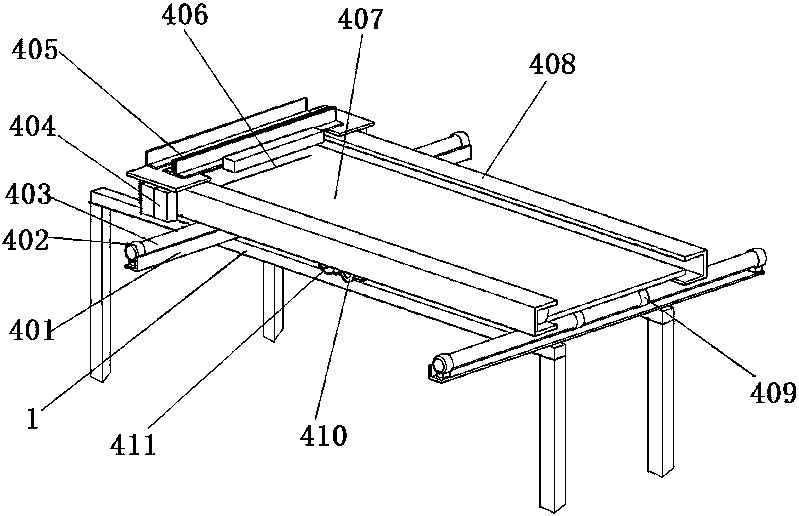

PCB (Printed Circuit Board) picking and placing device and PCB position correcting method

PendingCN113023362AAvoid damageImprove transport efficiencyCharge manipulationConveyor partsRobot handMechanical engineering

The invention belongs to the technical field of circuit board production equipment, and particularly relates to a PCB (Printed Circuit Board) picking and placing device and a PCB position correcting method. The PCB picking and placing device comprises a mounting frame, a picking and placing mechanism and a position recognizing mechanism, wherein the mounting frame is provided with a mounting position for mounting an external mechanical arm; the picking and placing mechanism is mounted on the mounting frame and is provided with a picking and placing area; the picking and placing area is used for sucking or placing a PCB; and the position recognizing mechanism is mounted on the mounting frame and located in the picking and placing area and is used for recognizing the deviation position of the edge of the PCB. If the PCB has a deviation condition, the mechanical arm drives the mounting frame to rotate and / or move at the moment, and the purpose of correcting the position of the PCB and then placing the PCB on another process to achieve transfer is achieved, so that the deviation position of the PCB is corrected in the PCB transfer process, damage to the PCB is avoided in the correcting process, and the transfer efficiency of the PCB is effectively improved. In addition, the mode is also suitable for relatively thin PCBs.

Owner:深圳市创新特科技有限公司

Automatic stacking device for accounting books

PendingCN113460629AConveying neatlyAvoid offsetStacking articlesConveyor partsEngineeringMechanical engineering

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

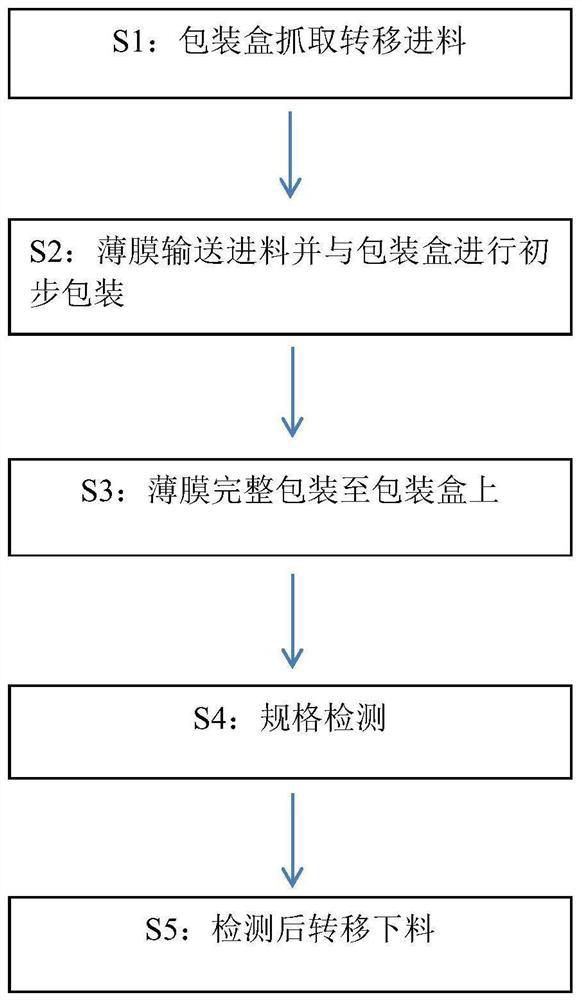

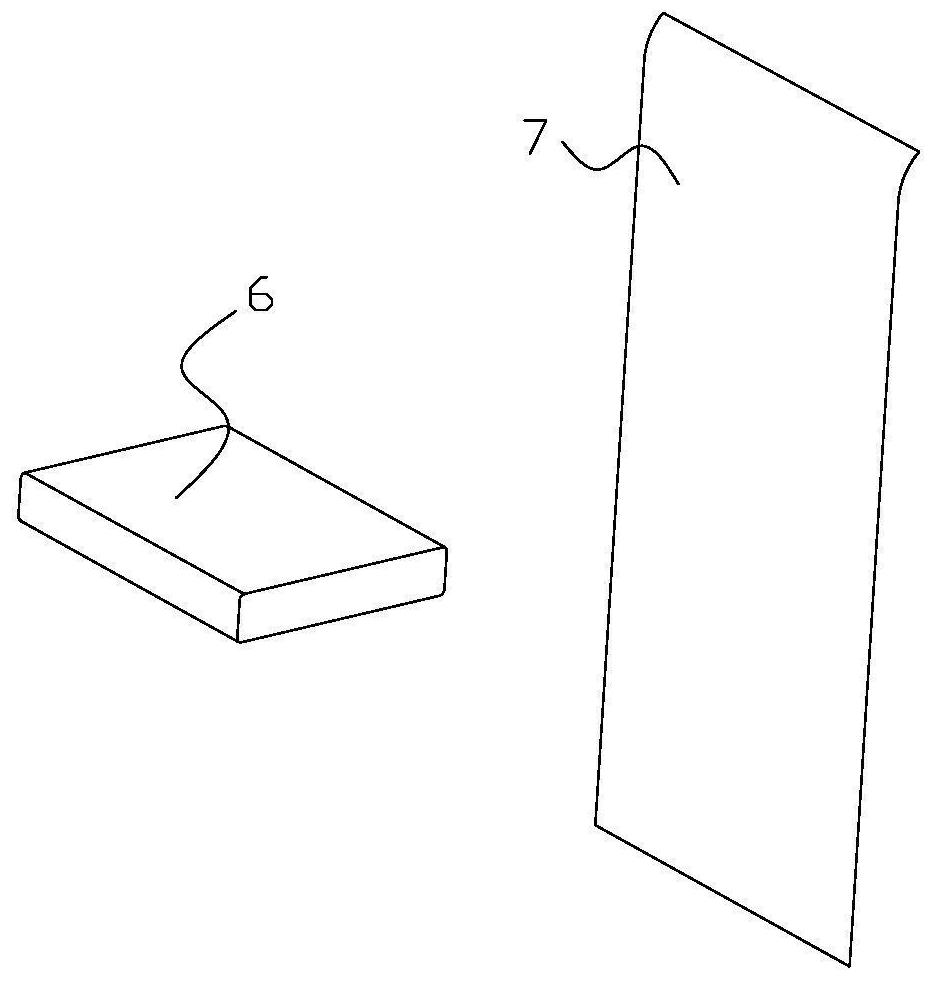

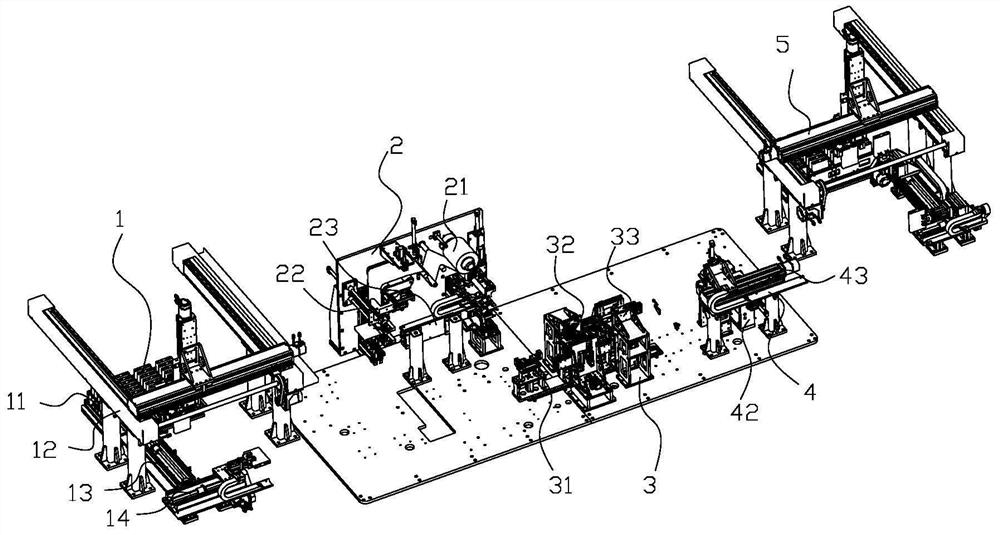

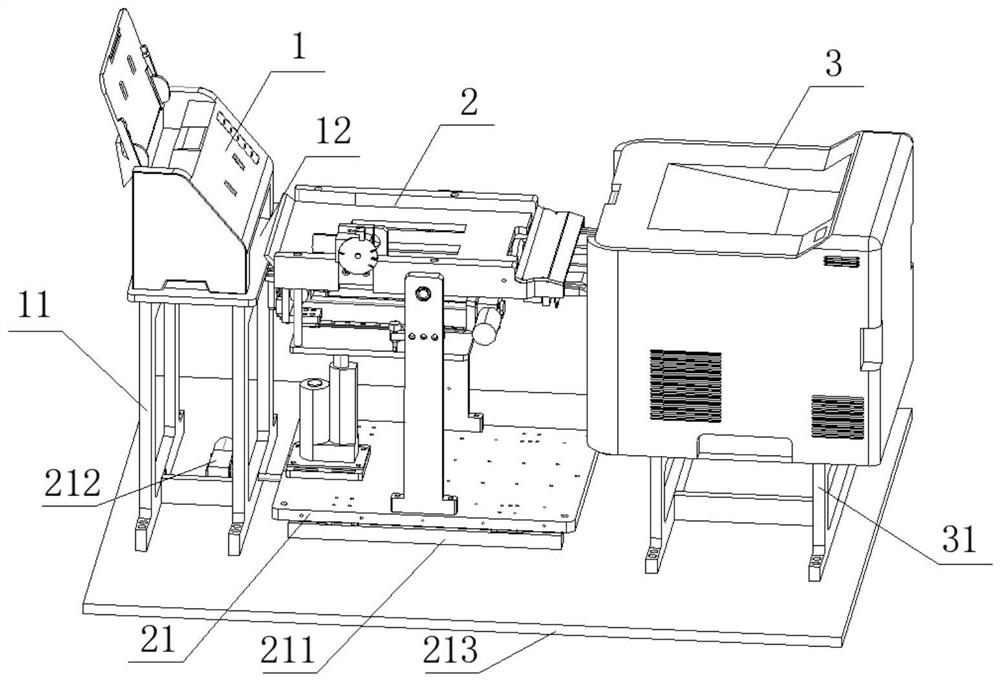

Automatic packaging production equipment for outer film of packaging box and production process thereof

InactiveCN112357186AEasy clampingTension conveyed wellWrapping material feeding apparatusWrapper folding/bending apparatusElectrical and Electronics engineeringManufacturing engineering

The invention belongs to the technical field of package automatic production. Automatic packaging production equipment for an outer film of a packaging box comprises a machine frame, a packaging box feeding device, a film feeding and packaging device, a film corner folding device, a detection device and a discharging device, wherein the packaging box feeding device, the film feeding and packagingdevice, the film corner folding device, the detection device and the discharging device are arranged on the machine frame; the packaging box feeding device is used for transferring packaging boxes tothe film feeding and packaging device, the film feeding and packaging device is used for conveying and feeding films and preliminarily packaging the films to the packaging boxes, and then packaging box film assemblies obtained after preliminary packaging are transferred to the film corner folding device; the film corner folding device is used for completely packaging the films onto the packaging boxes; and the detection device is used for detecting the packaging box specifications of the packaging box film assemblies subjected to packaging, and the packaging box film assemblies are transferredto the discharging device after being detected. The automatic packaging production equipment has the advantages that the automatic packaging efficiency and the automatic packaging quality of the packaging boxes are improved.

Owner:陈由格

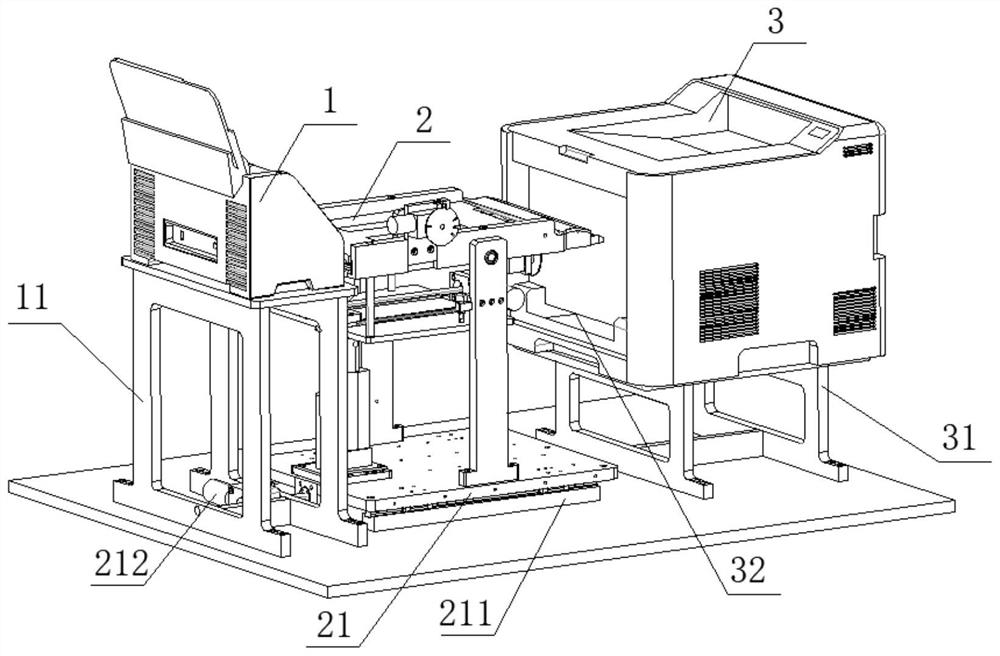

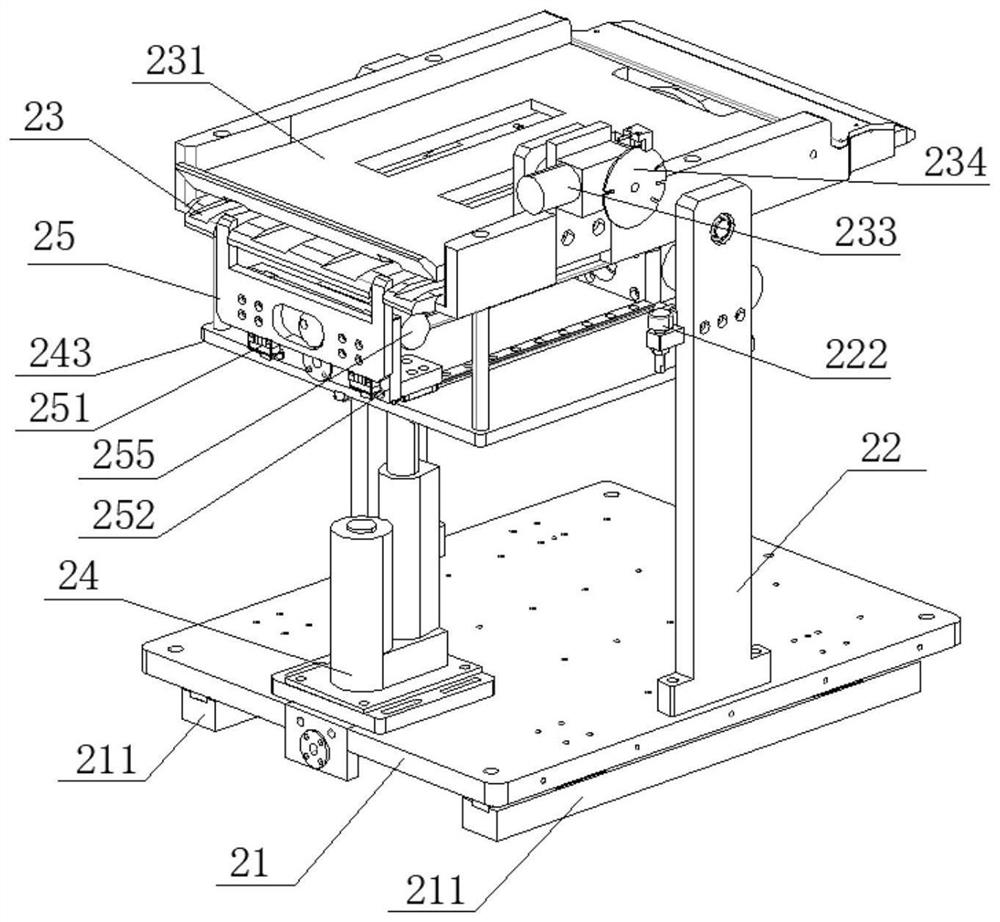

Self-service scanning and printing integrated device

PendingCN111845118ASave time at workConveying neatlyTypewritersOther printing apparatusComputer printingIndustrial engineering

The invention discloses a self-service scanning and printing integrated device. The self-service scanning and printing integrated device comprises a scanner and a printer and further comprises a fileconveying mechanism. The file conveying mechanism comprises a paper storage mechanism, an adjusting device and a pushing device. The storage mechanism comprises a storage plate, a front-end paper inlet and a rear-end paper outlet are formed in the storage plate, and the pushing device pushes paper located on the storage plate. A scanner paper outlet of the scanner is opposite to the front-end paper inlet of the storage plate, and a printer paper inlet of the printer is opposite to the rear-end paper outlet of the storage plate. The paper scanned by the scanner reaches the storage plate throughthe front-end paper inlet from the scanner paper outlet, and the paper on the storage plate is pushed by the pushing device to enter the printer through the printer paper inlet for printing from therear-end paper outlet. By arranging the file conveying mechanism between the scanner and the printer, the scanned paper can be directly fed into the printer to be printed, and manual operation is saved.

Owner:常州荣易升智能设备有限公司

Sheet feeding equipment

PendingCN107900252AConveying neatlyAvoid displacementMetal-working feeding devicesHeat exchange apparatusEngineeringStructural engineering

Owner:ZHEJIANG HOMYOUNG REFRIGERATION EQUIP

Cutting and conveying device for building glass

InactiveCN108145611ASimple structureSimple and fast operationBlast gunsAbrasive blasting machinesArchitectural glassEngineering

The invention discloses a cutting and conveying device for building glass. The cutting and conveying device comprises a supporting table, two sets of connection plates are arranged at one end of the upper surface of the supporting table, a rotary shaft is arranged between the upper ends of each set of connection plates, a conveying belt is arranged between the two rotary shafts, a conveying motoris connected with one side of one of the connection plates through a bolt, a first fixed suction cup can be driven to move through an electric telescopic rod, raw materials in a material box can be grasped and taken through the first fixed suction cup, a cutting spraying head can be driven to move front and back through a third linear motor, and the glass can be cut through a waterjet cutting machine and the cutting spraying head, so that cutting is more convenient, the conveying belt can be driven to rotate through the conveying motor, and the glass can be conveyed through the conveying belt.The cutting and conveying device for the building glass is simple in structure, and easy and convenient to operate, can grasp and take the glass so that cutting can be tidier, provides convenience for people and is more convenient to use.

Owner:阜阳市远大浮法玻璃制品有限公司

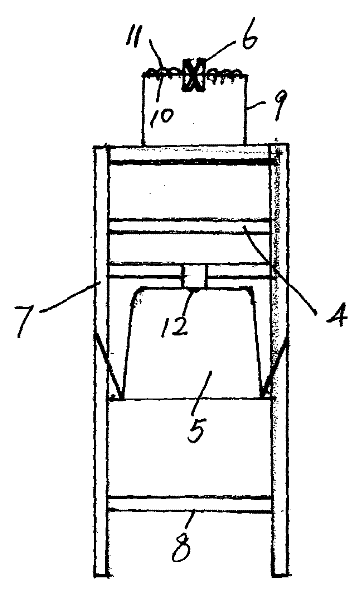

Portable safe material receiving device for circular knife die cutting equipment

The invention belongs to the technical field of circular knife machine equipment, and provides a portable safe material receiving device for circular knife die cutting equipment. The portable safe material receiving device comprises a rack and further comprises a safety grating, a material receiving roller and a conveyor; a second grating mounting frame is slidably mounted at the discharging end of the rack, and the safety grating is mounted on the grating mounting frame; the material receiving roller is detachably installed at the discharging end of the rack, and when strip-shaped products are produced, the material receiving roller is located between the second grating mounting frame and a die-cutting tool holder; and the conveyor comprises a lower conveying frame and an upper conveyingframe, a stripping knife and a hanging frame are further arranged at one end of the lower conveying frame, when sheet-shaped products are produced, the second grating mounting frame is attached to thedie-cutting tool holder, the conveyor is hung on the discharging side of the die-cutting tool holder through the hanging frame, and the other end of the conveyor penetrates through the second gratingmounting frame. According to the portable safe material receiving device, when conversion production of the strip-shaped products and the sheet-shaped products is carried out, tedious disassembly andassembly of the safety grating are not needed, use is safe, convenient and rapid, the sheet-shaped products are conveyed more orderly and tidily, and the material collecting efficiency is greatly improved.

Owner:SHANDONG HOACO AUTOMATION TECH

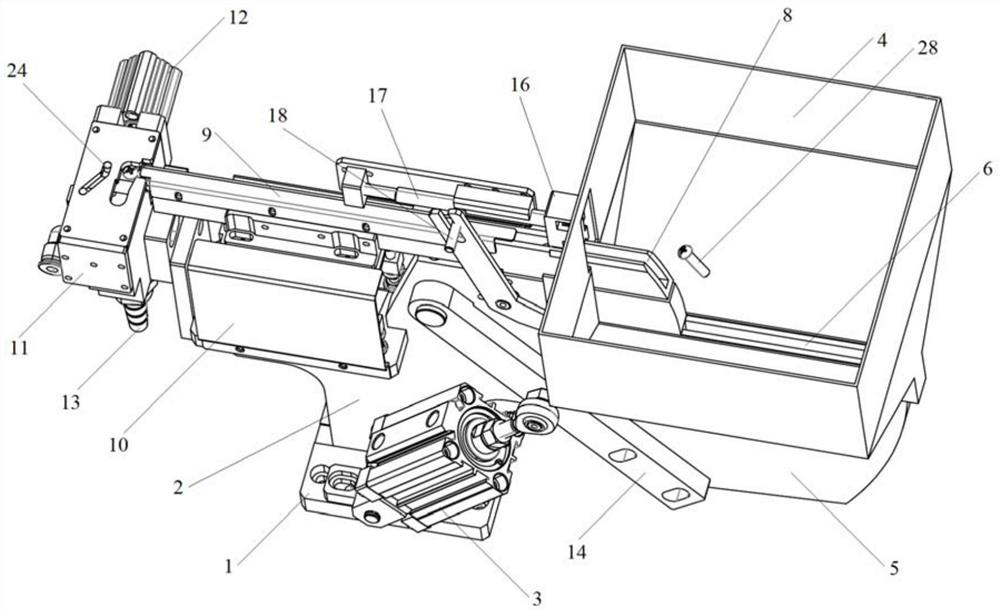

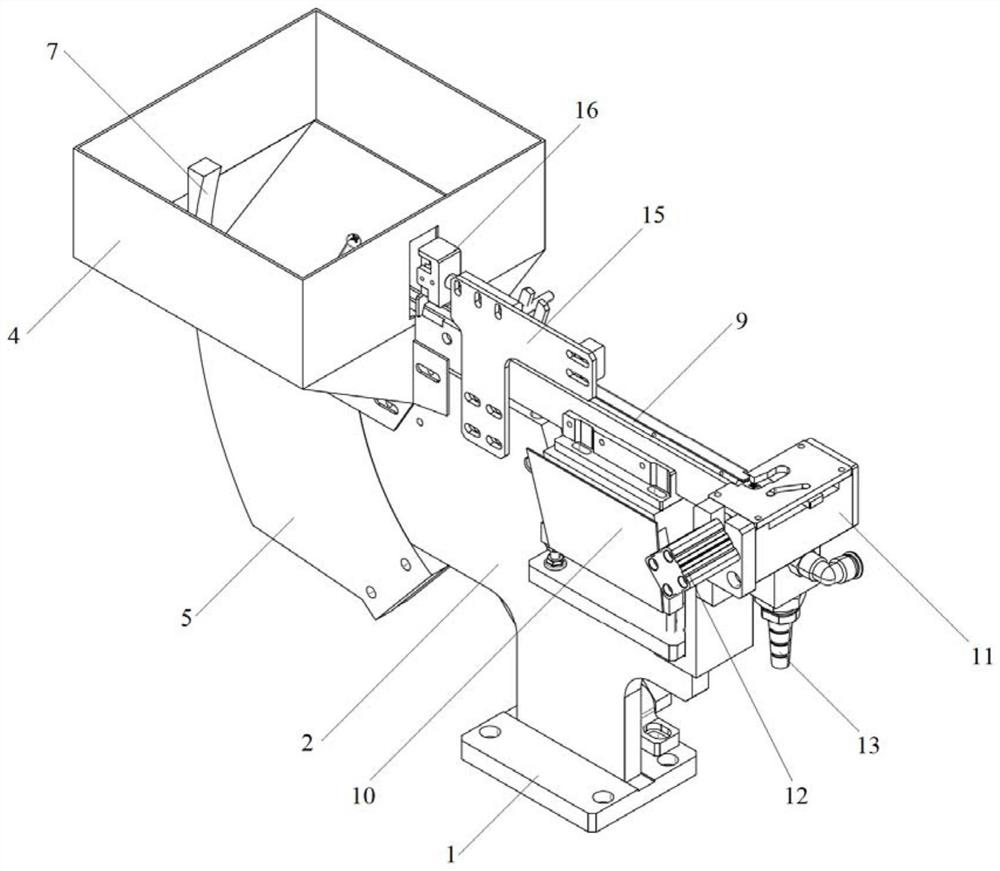

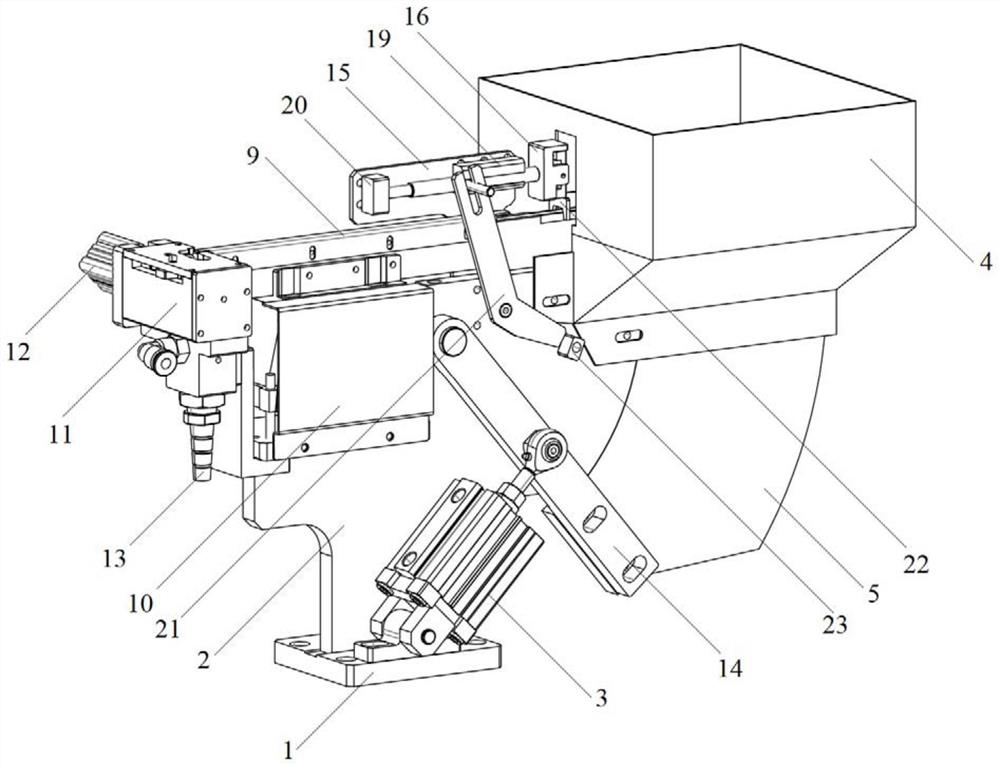

Novel screw feeding mechanism

PendingCN114104701AIncrease productivityReduce labor costsConveyorsControl devices for conveyorsEngineeringMechanical engineering

The novel screw feeding mechanism comprises a feeding unit, a conveying unit, a discharging unit and an auxiliary mechanism, the auxiliary mechanism comprises a base and a supporting plate, the feeding unit comprises a feeding air cylinder, a square hopper, an arc feeding mechanism and a feeding support, and the conveying unit comprises a linear sliding way and a linear feeder. The discharging unit comprises a discharging block and a discharging air cylinder. After entering the square hopper, the screws naturally fall on the hopper groove, the feeding air cylinder is connected with the arc-shaped feeding mechanism through the feeding support, the air cylinder stretches out to drive the arc-shaped feeding mechanism to push the screws into the feeding groove, then the linear feeder provides advancing power for the screws entering the linear sliding way, the screws enter the pushing sliding block, and the screws enter the feeding groove. And the discharging air cylinder pushes the pushing sliding block to convey the screws to the discharging opening, then the screws fall into the discharging opening, and one-time feeding is completed. According to the screw feeding mechanism, manual screw placement can be replaced, the production efficiency is improved, and the labor cost and the time cost are reduced.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

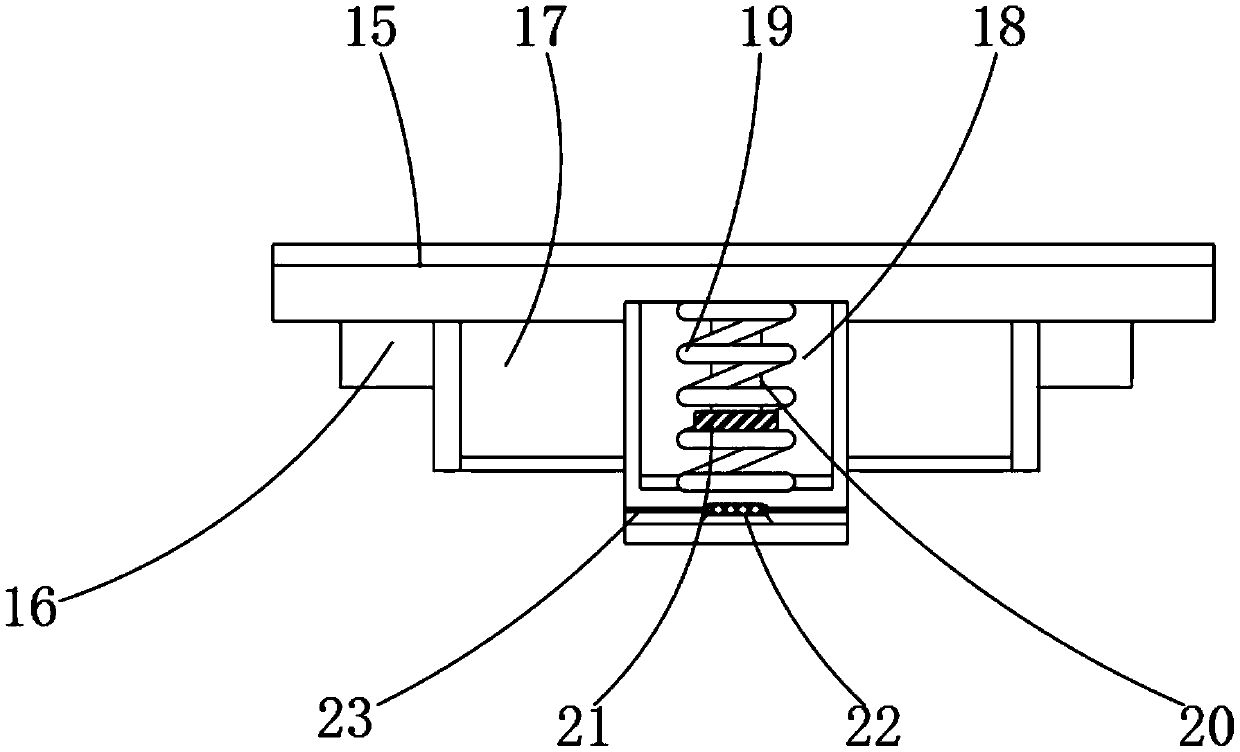

Packaging machine for packaging toilet cleaner

InactiveCN109515873AScientific and reasonable structureEasy to useWrapping material feeding apparatusPackaging automatic controlEngineeringToilet

The invention discloses a packaging machine for packaging toilet cleaner. The packaging machine for packaging the toilet cleaner comprises a packaging table, wherein a packaging machine box is fixedlyarranged at the top of one side of the packaging table; a supporting plate is arranged at the middle end of the bottom of the inner side of a storage chamber; a pressure-bearing plate is fixedly arranged at the bottom of the supporting plate; a pressure-bearing spring is arranged at the middle of the inner side of a telescopic chamber; a fixing column sleeves the middle of the inner side of the pressure bearing spring; an extrusion block is fixedly connected to the bottom end of the fixing column; and a touch switch is fixedly arranged on the lower part of the bottom of the extrusion block. The packaging machine for packaging the toilet cleaner has a scientific and reasonable structure and is safe and convenient to use; after a transfer box which is located above the supporting plate is filled with the toilet cleaner, the audible and visual prompt can be carried out so as to remind workers to pour materials in time through the pressure-bearing plate, the telescopic chamber, the pressure-bearing spring, the fixing column, the extrusion block, the touch switch, a line pipe and an audible and visual alarm, accumulation of the toilet cleaner in the transfer box is avoided, and meanwhile, the labor intensity of manually and frequently checking the quantity of the toilet cleaner in the transfer box is reduced.

Owner:阜阳洁平日化有限公司

A portable safety receiving device for circular knife die-cutting equipment

ActiveCN111873066BEnsure safetyConveying neatlyMetal working apparatusStructural engineeringDie cutting

The invention belongs to the technical field of circular knife machine equipment, and provides a portable safety receiving device for circular knife die-cutting equipment, which includes a frame, and also includes a safety grating, a material receiving roller and a conveyor; the discharge end of the frame is slidably installed There is a second grating mounting frame, and the safety grating is installed on the grating mounting frame; the receiving roller is detachably installed on the discharge end of the frame. Between the tool holders; the conveyor includes a lower conveyor frame and an upper conveyor frame, and one end of the lower conveyor frame is also equipped with a stripping knife and a hanging frame. The machine is hung on the discharge side of the die-cutting knife seat through the hanging frame, and the other end is set through the second grating mounting frame. The present invention does not need to dismantle and disassemble the safety grating when switching between strip products and sheet products.

Owner:SHANDONG HOACO AUTOMATION TECH

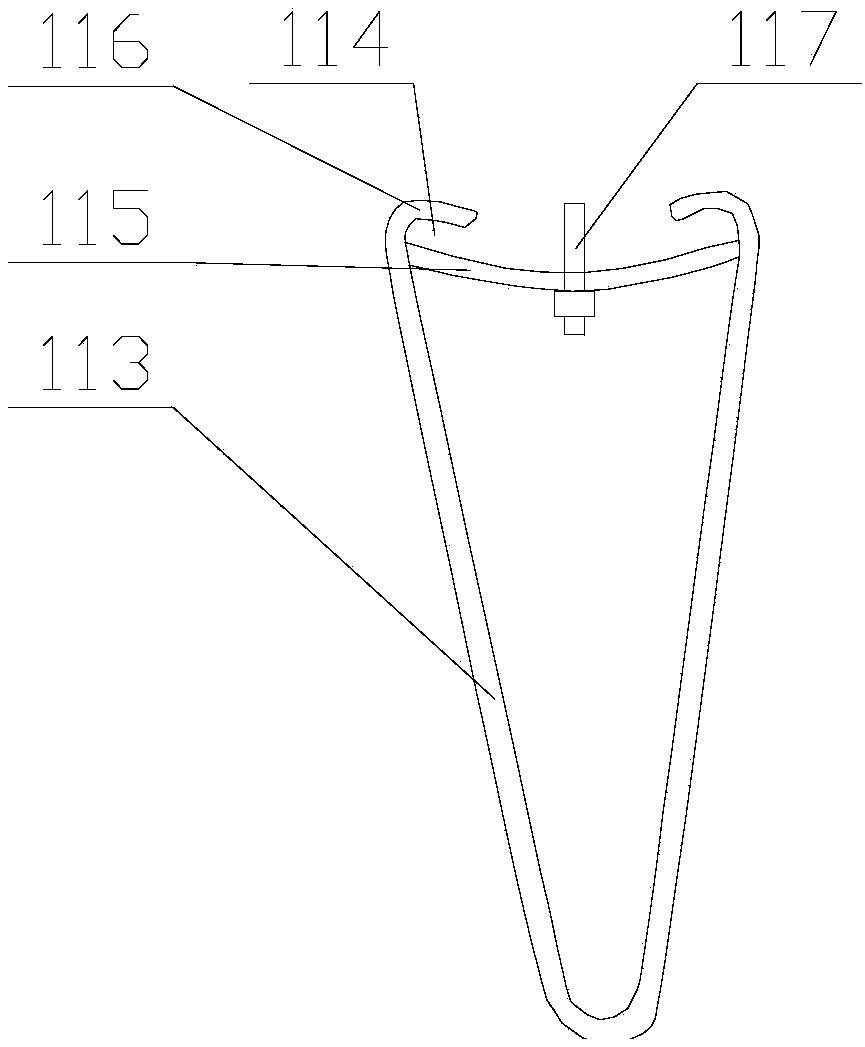

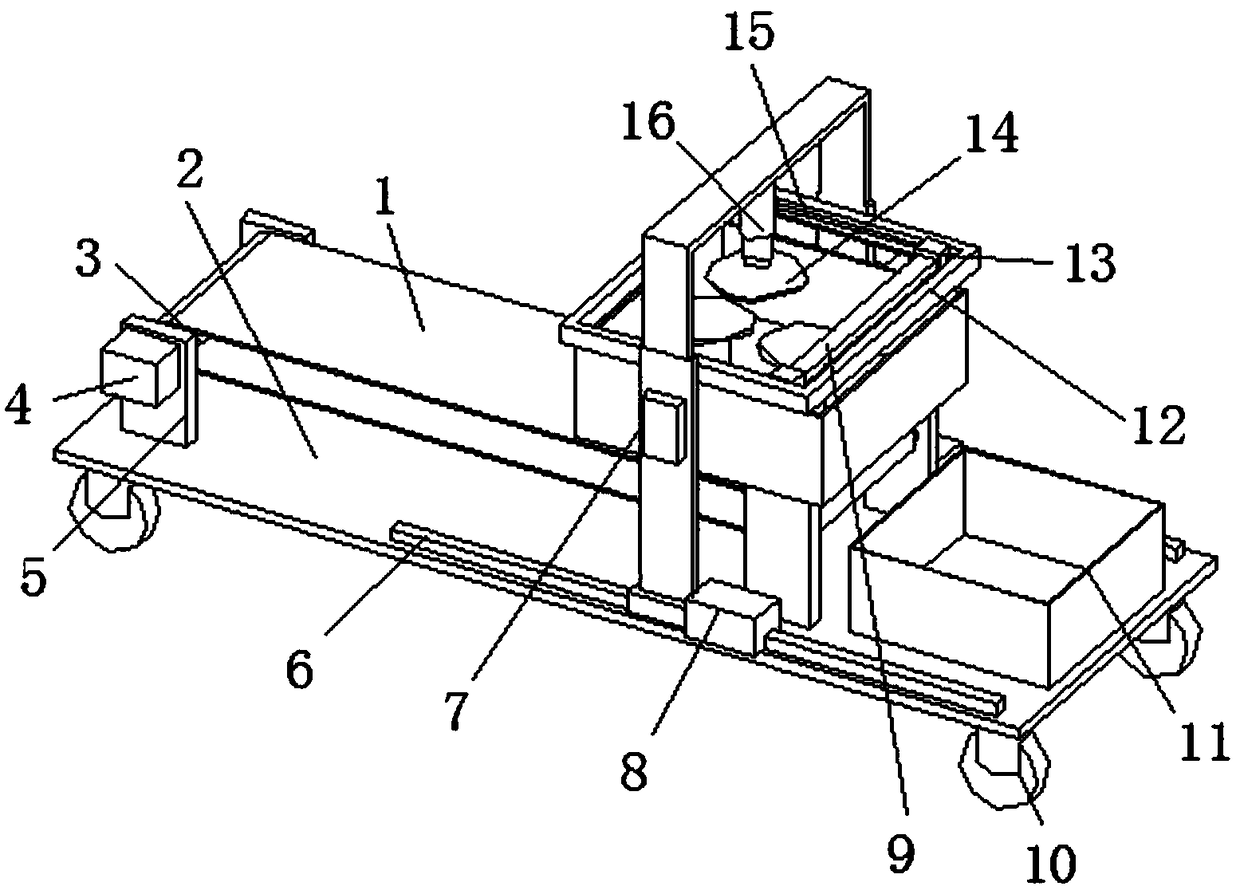

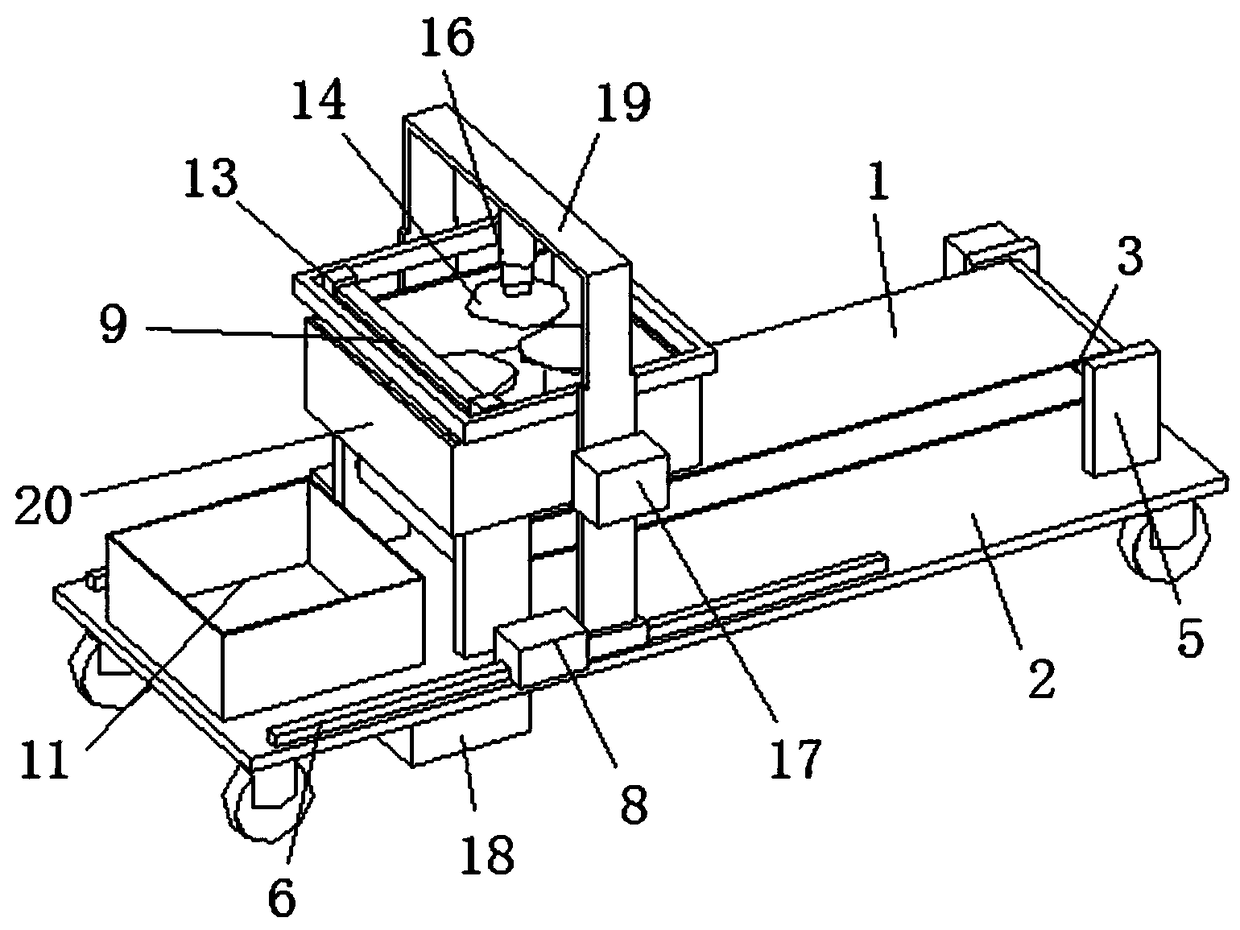

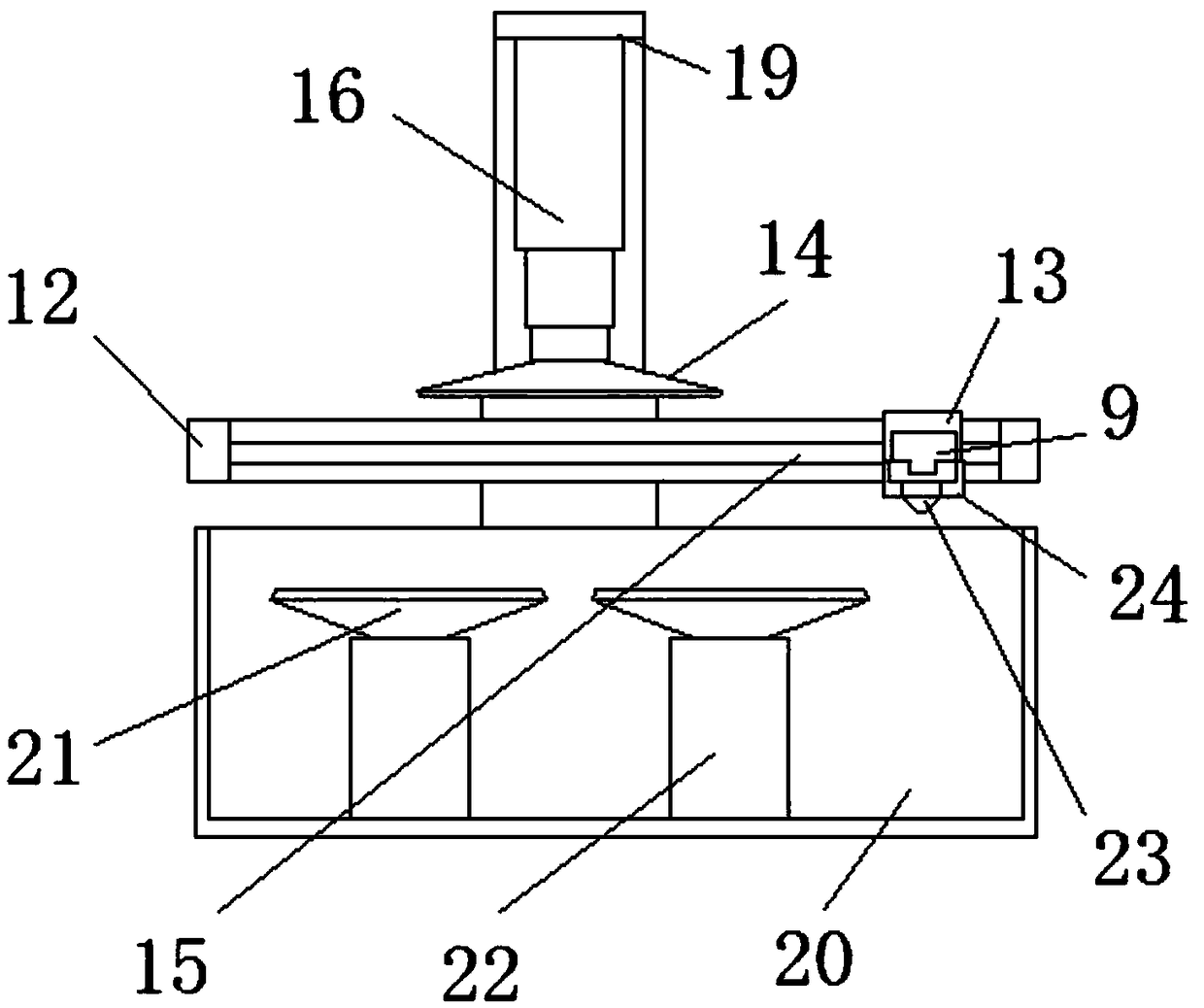

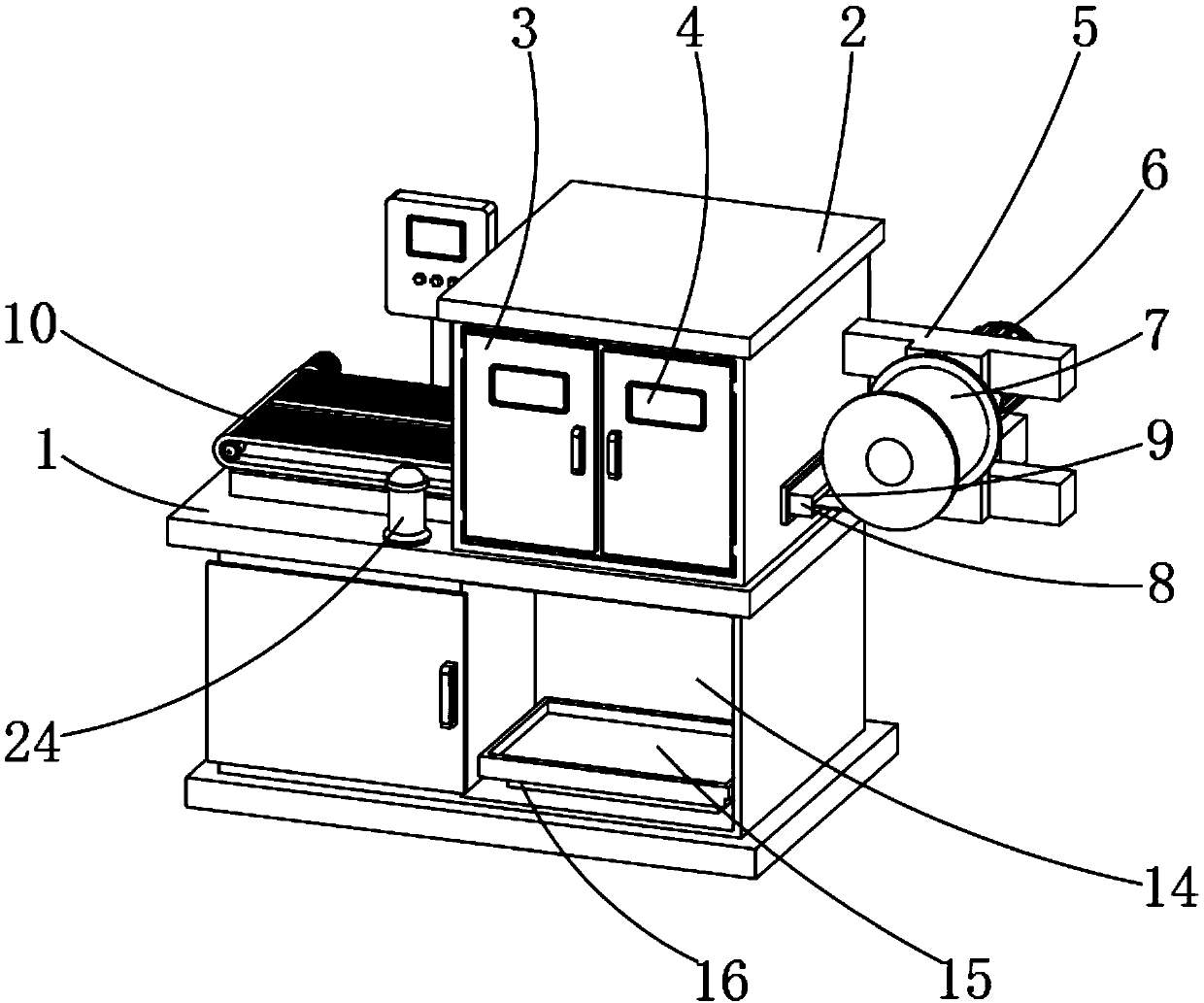

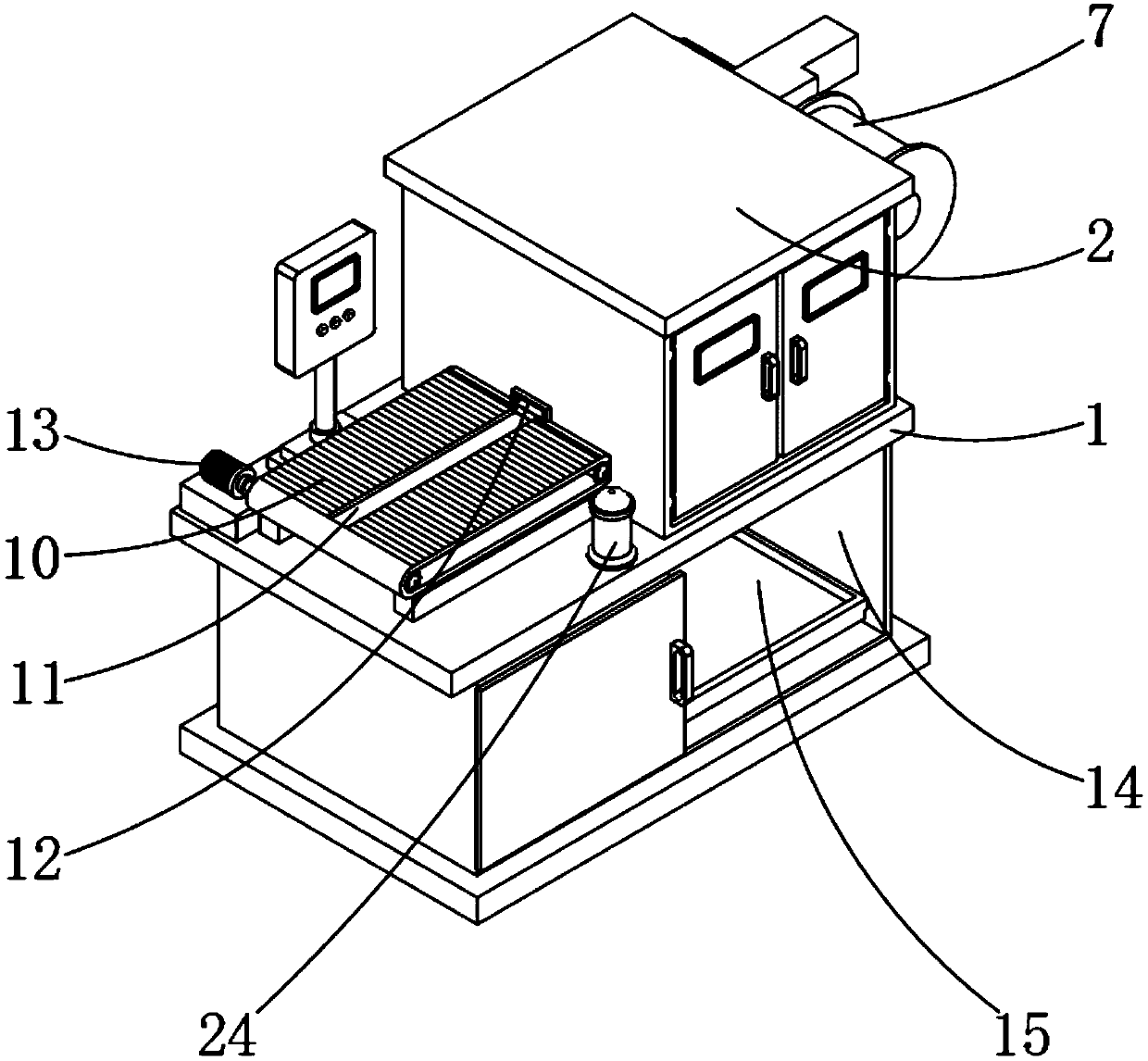

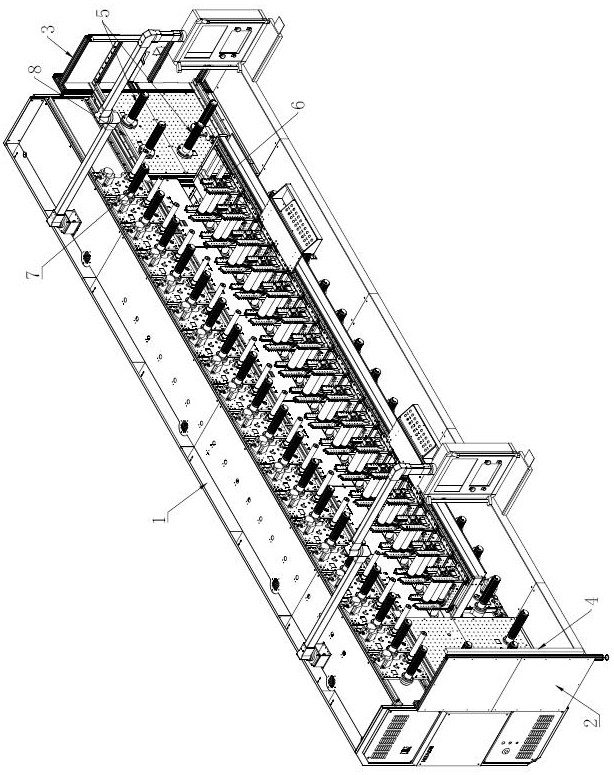

Finished pen automatic sorting and feeding device

ActiveCN103144970BRealize automatic boxingImprove packaging efficiencyConveyorsLoading/unloadingDrive wheelEngineering

The invention discloses an automatic sorting feeding device for finished product pens. The automatic sorting feeding device comprises a machine frame, a material cabin, a chain wheel, a sorting mechanism and a conveying mechanism, wherein the material cabin and the chain wheel are arranged in the machine frame, the sorting mechanism is used for sorting the finished product pens stacked in the material cabin, the conveying mechanism is used for conveying the sorted finished product pens, the sorting mechanism is fixedly arranged on the conveying mechanism, the conveying mechanism is annularly surrounded and arranged on the chain wheel, an annular conveying rail is formed, the chain wheel comprises a driving wheel and a driven wheel, the driving wheel is matched with the driven wheel through the driving of a driving motor and drives the conveying of the conveying mechanism and the sorting mechanism, the automatic sorting of the finished product pens is realized, one end of an automatic sorting feeding mechanism is also connected with a counting device and a box filling device, and the counting package of the finished product pens is further realized. The automatic sorting feeding device has the advantages that the sorting feeding of the finished product pens can be realized, so the automatic box filling of the pens is realized, a large amount of labor is saved, and the package efficiency of the finished product pens is improved.

Owner:SUZHOU KAILEISHENG AUTOMATION TECH CO LTD

Joss paper cutting travelling mechanism

InactiveCN110871465AShort processing timeHigh speedMetal working apparatusPaper cutElectric machinery

The invention discloses a joss paper cutting travelling mechanism. The mechanism comprises a rack, a left-right moving mechanism and a front-rear moving mechanism, and is characterized in that the left-right moving mechanism is composed of a base, a fixing sleeve A, a sliding rail A, contraction pumps A, a pressing plate A, a cutting groove, a face plate, a channel steel, a sliding sleeve A, a screw shaft, a motor B, a sliding sleeve B and bearing seats A, the base is mounted on the rack 1, the fixing sleeve A is mounted on the base, the sliding rail A is mounted in the fixing sleeve A, the sliding sleeve A is mounted on the sliding rail A, the sliding sleeve A is connected with the face plate, the cutting groove is formed in the face plate, the channel steel is mounted on the two sides ofthe face plate, the contraction pumps A are mounted on the channel steel, the pressing plate A is connected with connecting shafts of the contraction pumps A, the sliding sleeve B is mounted on the lower surface of the face plate, the screw shaft is mounted in the sliding sleeve B, the bearing seats A are mounted at the two ends of the screw shaft, and a belt pulley is mounted on the screw shaft.According to the mechanism, the machining time is short, the speed is high, conveying is orderly, and the operation is convenient.

Owner:三穗县创惠科技发展有限公司

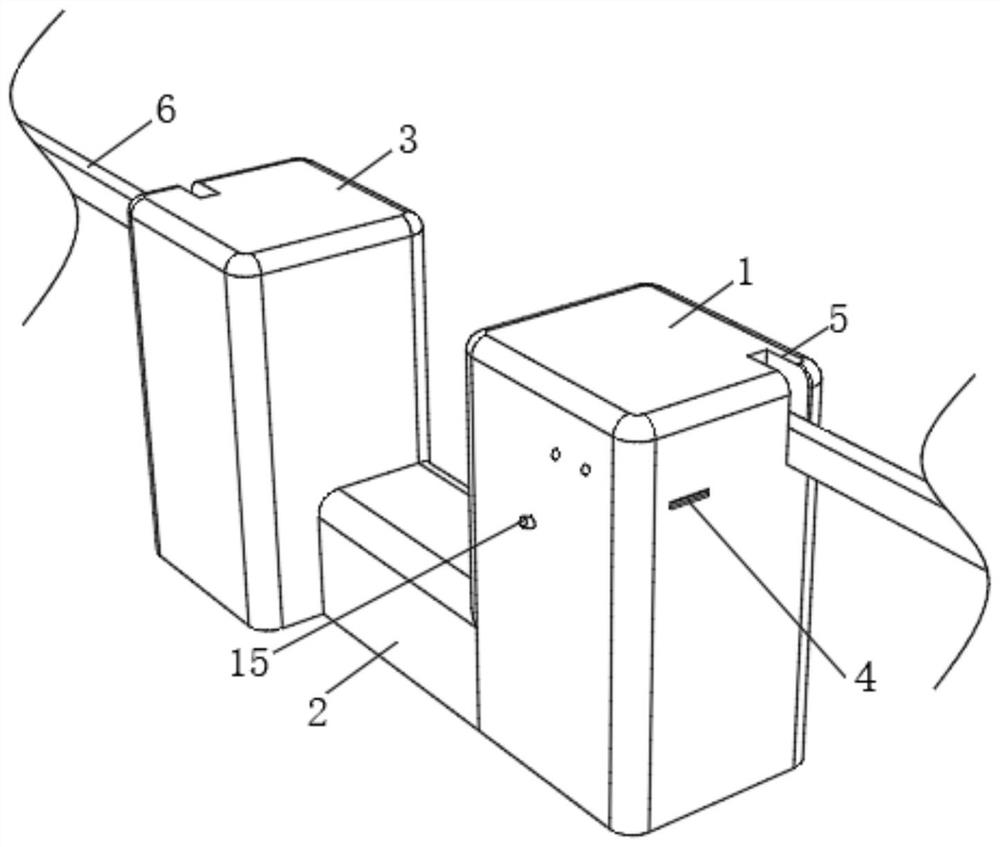

Intelligent card transceiving device for garage

InactiveCN112288051ARealize sending and receivingRealize the use effectConveying record carriersLavatory sanitorySmart cardMechanical engineering

The invention relates to the technical field of smart cards, and discloses a garage smart card receiving and sending device which comprises a first box body, a conveying box is fixedly connected to the bottom of the left side face of the first box body, and a second box body is fixedly connected to the left side face of the conveying box. Clamping grooves are formed in the front side of the rightside face of the first box body and the rear side of the left side face of the second box body correspondingly, and rod grooves are formed in the rear side of the upper surface of the first box body and the front side of the upper surface of the second box body correspondingly. According to the intelligent card receiving and sending device for the garage, through cooperative use of the rod liftingdevice, the card sending device, the card receiving device and the conveying device, receiving, sending and recycling of intelligent cards are achieved, the device is more rapid to use, and through cooperative use of the disinfection bottom plate, the disinfection pressing plate, the disinfection box, the material spraying pipe and the draught fan, disinfection and drying of the cards are achieved; the device is more sanitary and environment-friendly to use, and breeding of a large number of bacteria due to recycling of cards is avoided.

Owner:广州维他科技有限公司

A brick automatic production line

ActiveCN105835213BPrecise positioningConveying neatlyFeeding arrangmentsShaping conveyorsProduction lineBrick

Owner:福建省东方水泥制品有限公司

Self-driven marine environment floating garbage salvage equipment

PendingCN114635401AImprove fishing efficiencySmall footprintWater cleaningElectric machineryDrive motor

The invention discloses self-driven marine environment floating garbage salvage equipment which comprises a machine body sailing on the sea surface, a driving motor is installed in the machine body in an embedded mode, the middle of the output end of the driving motor is connected with water wheels on the two sides through bevel gear connecting pieces, and the output end of the driving motor is connected with a draught fan. The rear side of the machine body is provided with a stepping motor, and the output end of the stepping motor is connected with a main crushing roller; salvage filter plates are connected to the two sides of the left end of the machine body, and the salvage filter plates are arranged on the tooth rollers in a sleeving mode; a compression cavity is formed in the bottom of the inner side of the machine body, and extrusion plates are symmetrically arranged in the compression cavity; and beating plates are symmetrically hinged to the bottom of the outer side of the machine body. According to the self-driven marine environment floating garbage salvage equipment, the salvage mode is rapid and convenient, the salvage range is wider, the salvaged garbage can be crushed and compressed, and meanwhile, marine organisms can be repelled.

Owner:南京辉晴科技有限公司

Bee pollen automatic screening device and screening method

The invention belongs to the technical field of machine vision, mechanical design and automatic control and relates to an automatic bee pollen screening device and a screening method. The device comprises an automatic feeding module, a dispersion shaping module, a visual inspection module and a sorting dust removal module. Bee pollen to be sorted is poured into a storage barrel of the automatic feeding module; the bee pollen is supplied to a V-shaped groove plate of the dispersion shaping module through an eccentric vibration motor, performs climbing movement on the V-shaped groove plate, is uniformly dispersed, falls on a conveying belt to be shaped and then moves forwards at a constant speed; image acquisition is performed through an image acquisition unit of the visual inspection module; image information is processed through built-in computer software and then transmitted to a programmable logic controller (PLC) to be controlled so as to control the actions of the eccentric vibration motor and a spray nozzle, and the bee pollen is screened. By means of the automatic bee pollen screening device and the screening method, the problems that small-particle bee pollen is prone to being broken, irregular in shape, difficult to disperse and sort and not obvious in color difference are solved, and the sorting speed is increased under the condition that the sorting accuracy is guaranteed.

Owner:JIANGSU UNIV

Conveying and emptying method and device for bar-shaped materials

ActiveCN113412961AFull boot transferAvoid damageCigarette manufactureStructural engineeringReclaimer

Owner:XUCHANG TOBACCO MACHINERY

Synthetic material bristle cutting device for glass polishing

ActiveCN109330177BReduce labor intensityShorten the timeBristleGrinding devicesBristleSynthetic materials

The invention provides a device for cutting synthetic material bristles for glass grinding, which comprises a workbench, wherein both edges of the bottom surface of the workbench are fixedly connectedwith a first supporting leg respectively, and the bottom surface of the workbench is fixedly connected with a first motor, the output end of the first motor is fixedly connected with a first rotatingshaft, and the outer surface of the first rotating shaft is fixedly connected with a second rotating wheel and a sixth rotating wheel. The front end and rear end of the top surface of the workbench are fixedly provided with a blocking plate respectively, a guiding roller, two conveying rollers, two upper rollers and two lower rollers are arranged between the two blocking plates, the guiding roller is arranged on one side of the blocking plates, the conveying rollers are arranged under the guiding roller and the two conveying rollers are placed horizontally. The device overcomes the defects inthe prior art and is reasonably designed to automatically cut the bristles. The time and the effort are saved, the production efficiency is improved, and the useless bristles left by the cutting canbe effectively removed, the quality of the bristles is improved.

Owner:安徽省潜山县潜源鬃刷有限公司

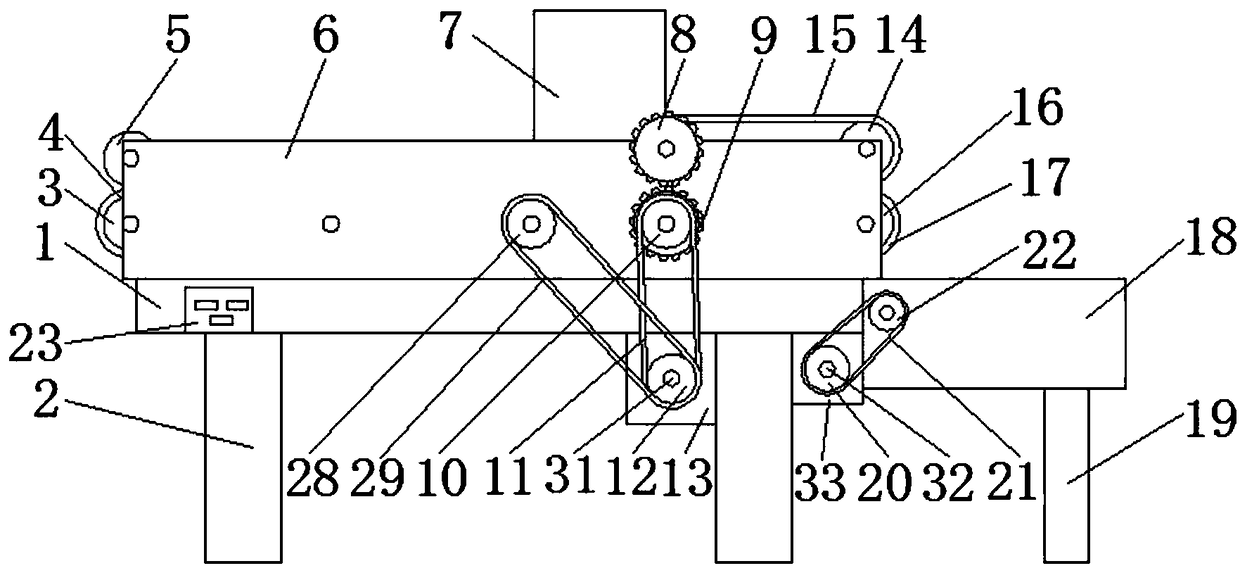

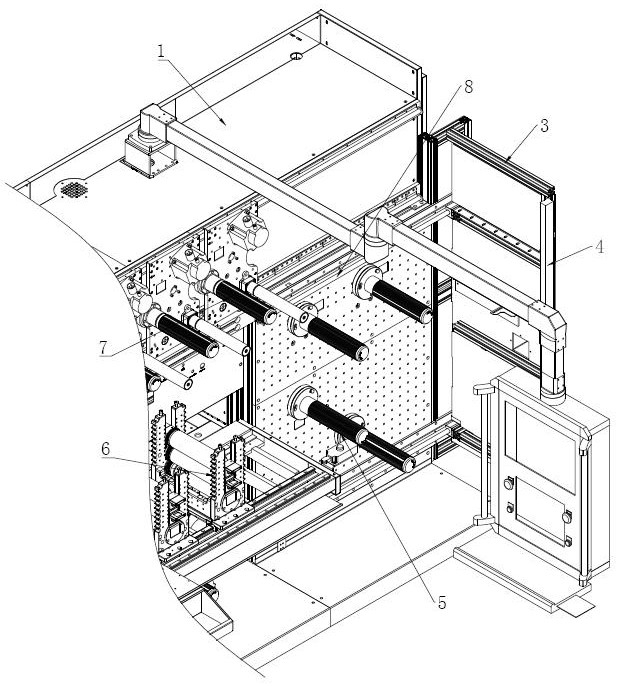

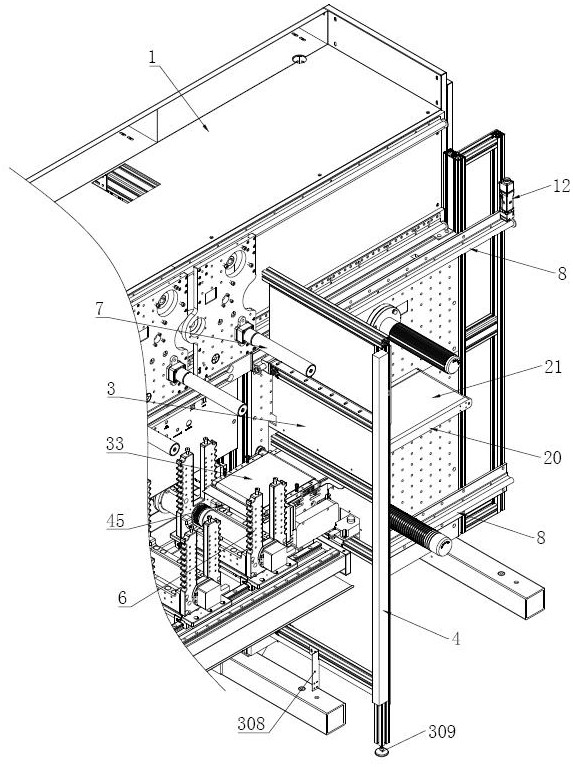

Rotary dumping device and slitter

InactiveCN102524939BReduce breakage rateConveying neatlyTobacco treatmentConveyor partsEngineeringMechanical engineering

The invention provides a rotary dumping device and a slitter. The rotary dumping device comprises a rack, a support plate, a conveying component, a first cylinder and a second cylinder, wherein the rack is provided with a rotating shaft through a bearing, the support plate and the conveying component rotate around the rotating shaft, the support plate is arranged horizontally at an initial state and used for carrying material to be dumped, the conveying component is arranged vertically at the initial state and the conveying surface of the conveying component is opposite to the side of the material to be dumped, the first cylinder is arranged on the rack and drivers the conveying component to rotate around the rotating shaft, and the second cylinder is arranged between the support plate and the conveying component and used for driving the support plate to rotate. Through adoption of the rotary dumping device, the broken rate of the cut material can be reduced, the cut material can be conveyed to the next process step orderly and uniformly, and abnormal sound and dust can be eliminated during the dumping process.

Owner:CHINA TOBACCO SHANDONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com