Automatic bee pollen screening device and screening method

A screening device and screening method technology, applied in the fields of mechanical design, automatic control, and machine vision, can solve the problems of blockage of the suction pipe of the solenoid valve, limitation of the processing mechanism, affecting the color sorting effect, etc., to eliminate inconvenience, improve efficiency and stability. The effect of improving the quality of image acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to further illustrate the technical principle and purpose of the present invention, the system structure, features, functions and specific implementation methods of the present invention are further described below in conjunction with the accompanying drawings and examples, as follows:

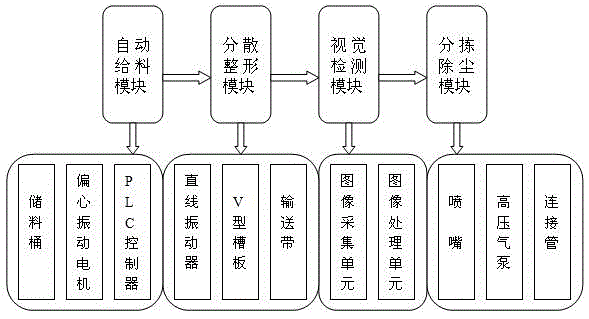

[0056] Such as figure 1 As shown, it is a schematic diagram of the automatic sorting structure framework of bee pollen according to the present invention:

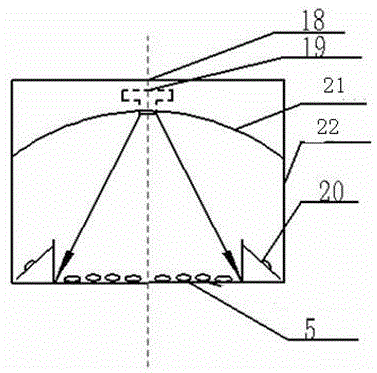

[0057] The automatic feeding module mainly includes a storage tank 1, an eccentric vibrating motor 2 and a PLC controller 14, wherein a group of inclined baffles 1.1 are installed on the bottom of the storage tank 1, and an eccentric vibrating motor is installed under the inclined baffle 1.1. 2; the eccentric vibration motor 2 is connected with the PLC controller 14;

[0058] Pour a certain amount of bee pollen into the storage tank 1 (the water content is 5%-8%, and the particle size after primary screening is between 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com