Patents

Literature

94results about "Strip/foil conductors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

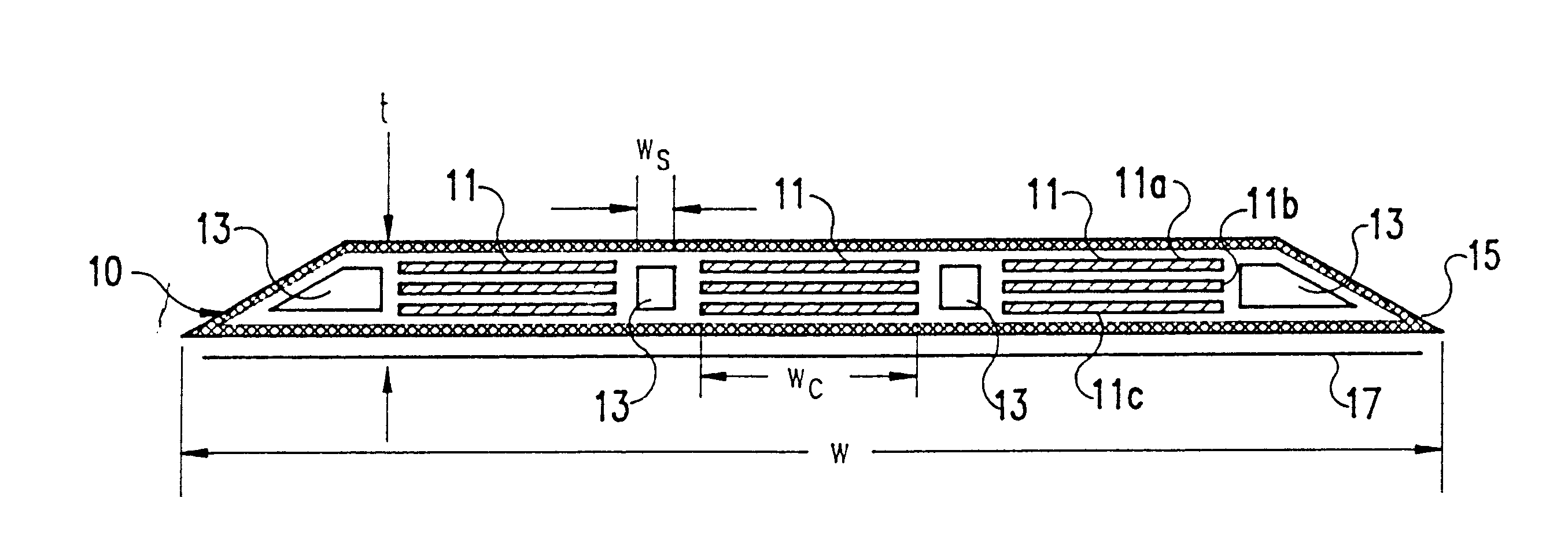

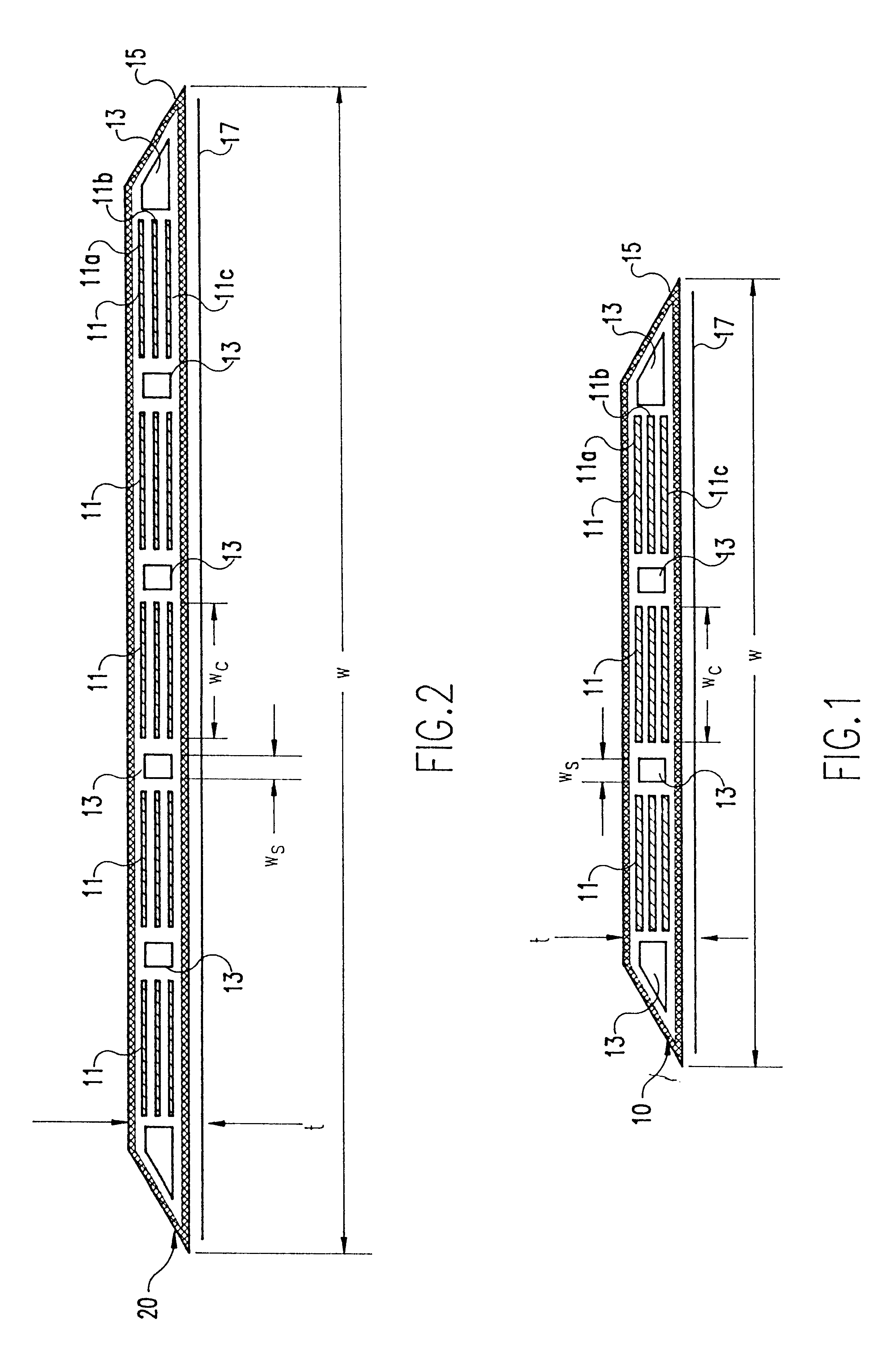

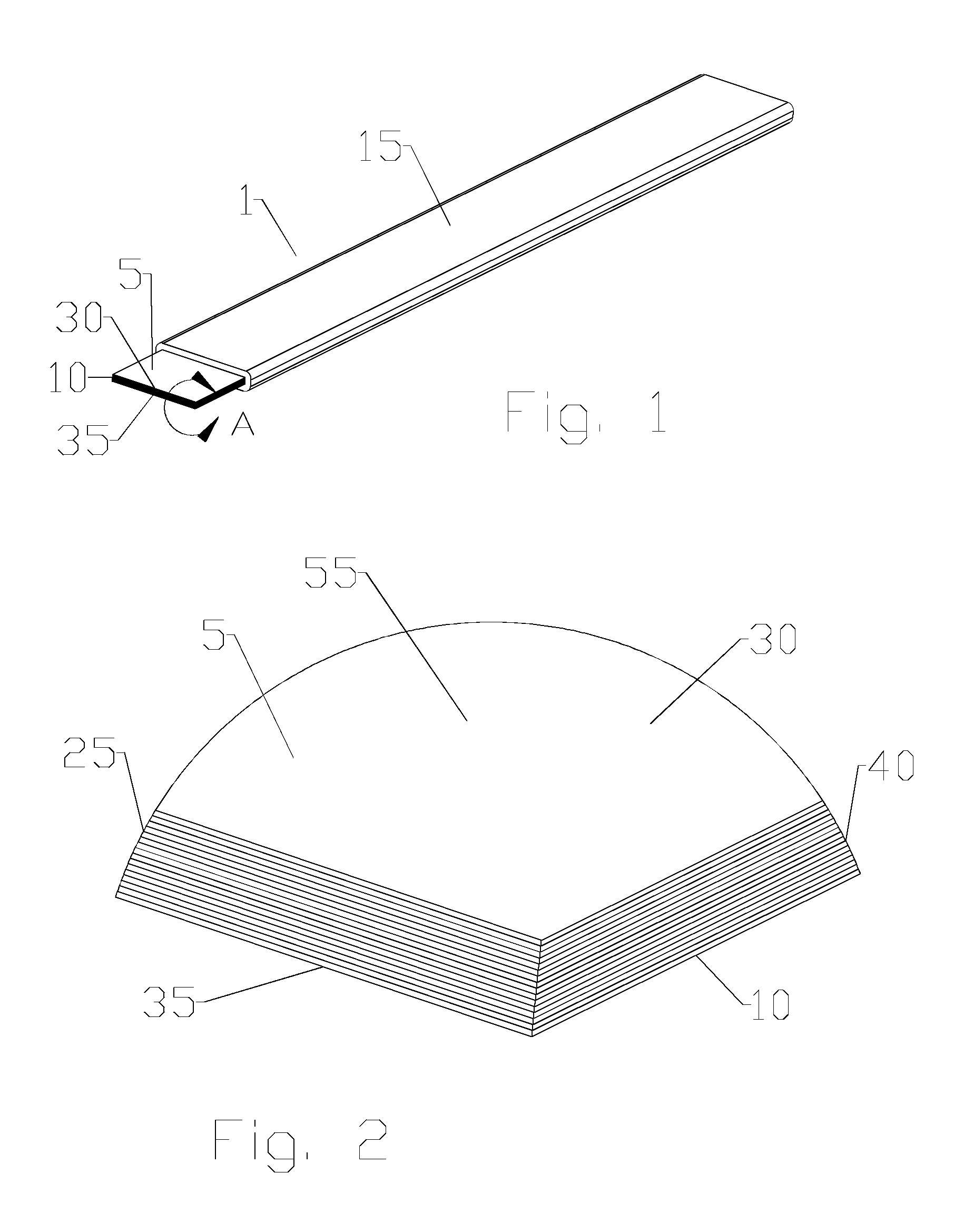

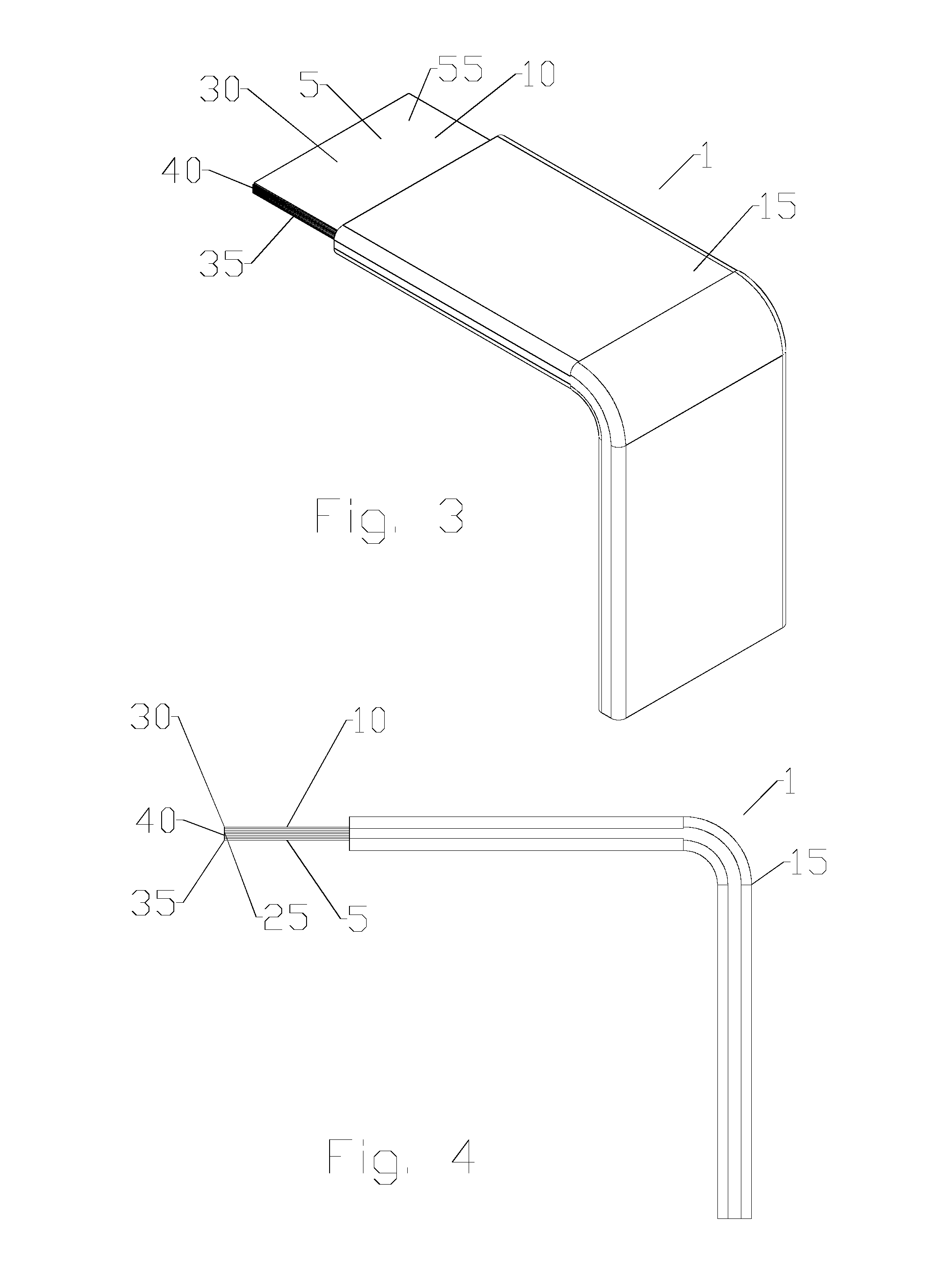

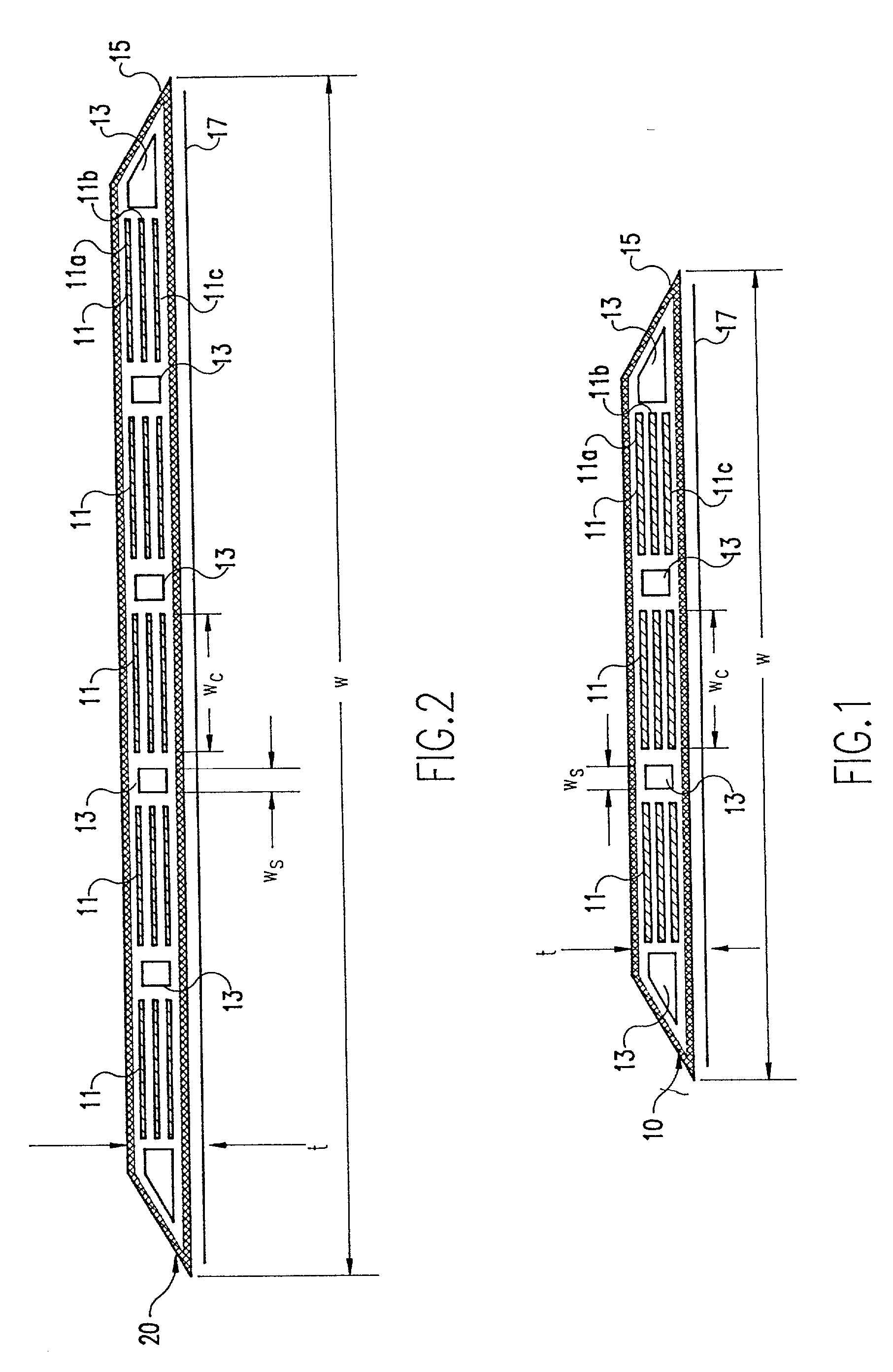

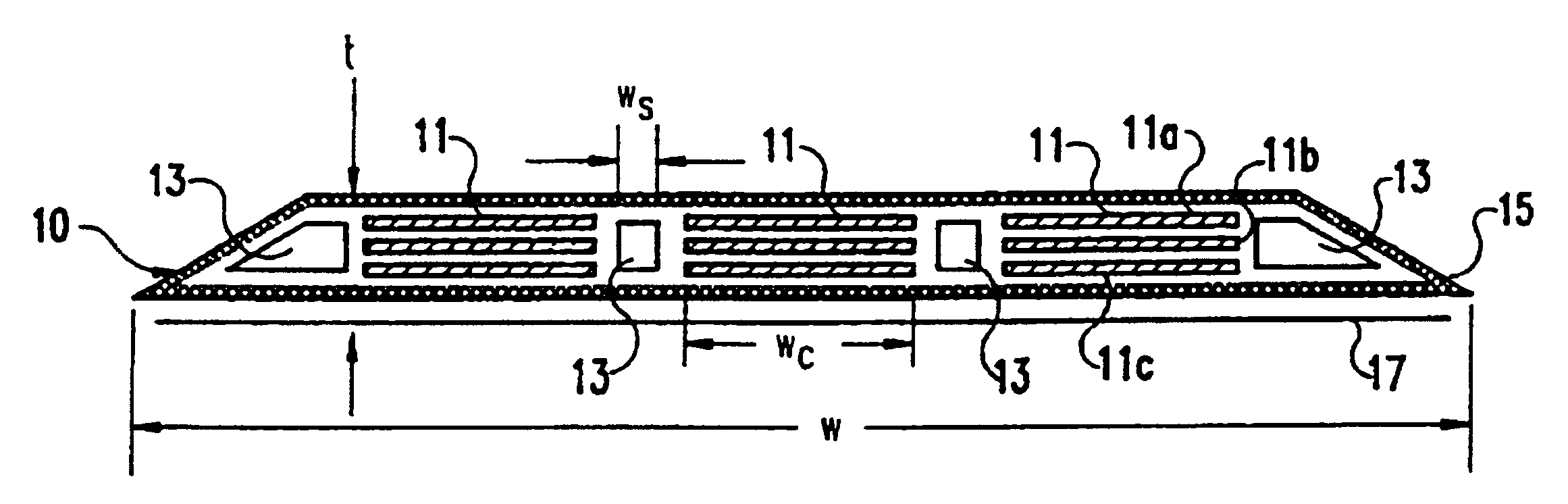

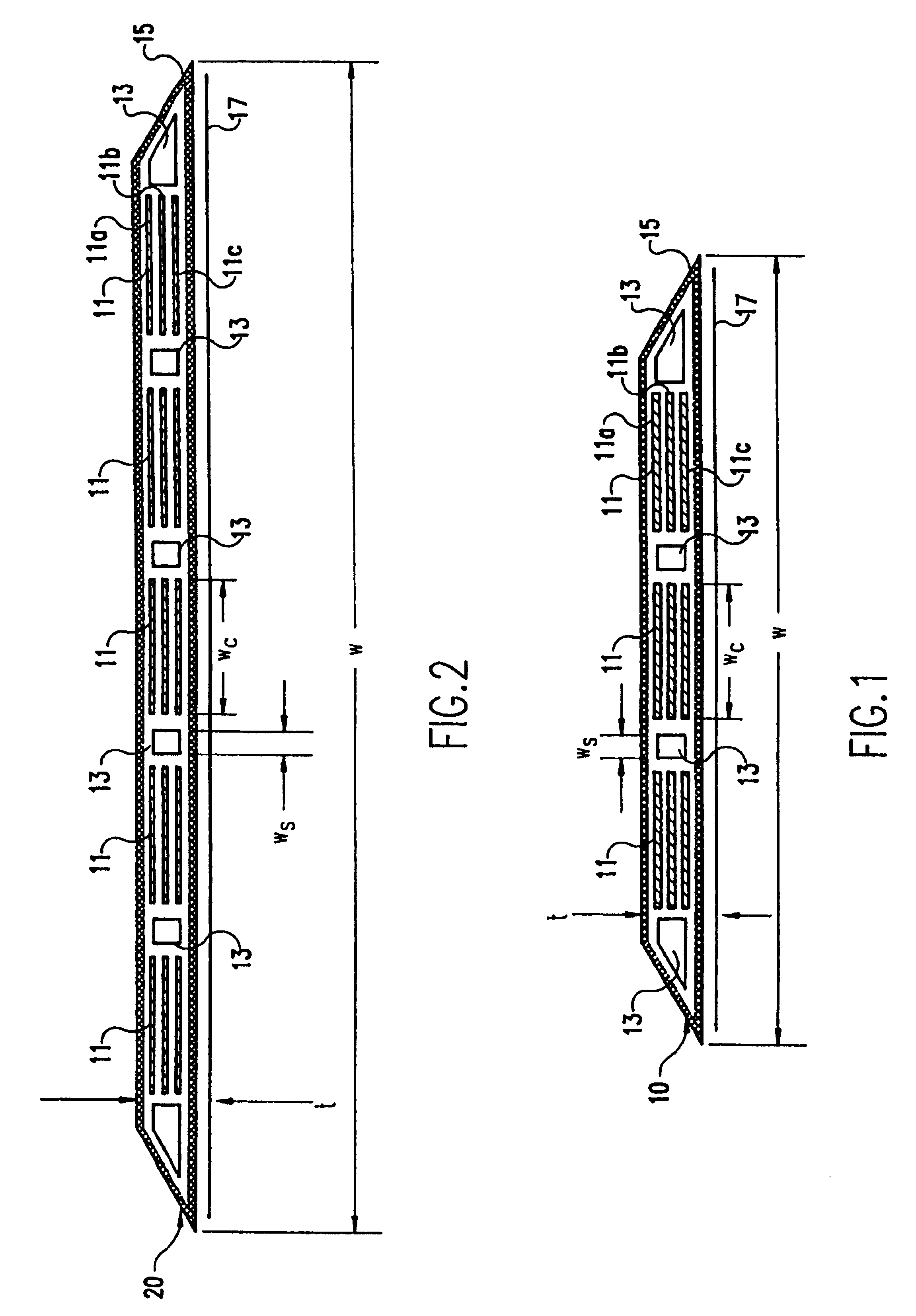

Flat surface-mounted multi-purpose wire

InactiveUS6492595B2Strip/foil conductorsCoupling device connectionsInsulation layerElectrical conductor

A multi-purpose wire includes at least one elongated conductor having a width of at least 0.125 inches. The conductor includes at least one conductive layer having a thickness no greater than about 0.0200 inches. The wire also includes a bonding material between each conductor, and an insulation layer surrounding the conductor and bonding material.

Owner:SOUTHWIRE CO LLC

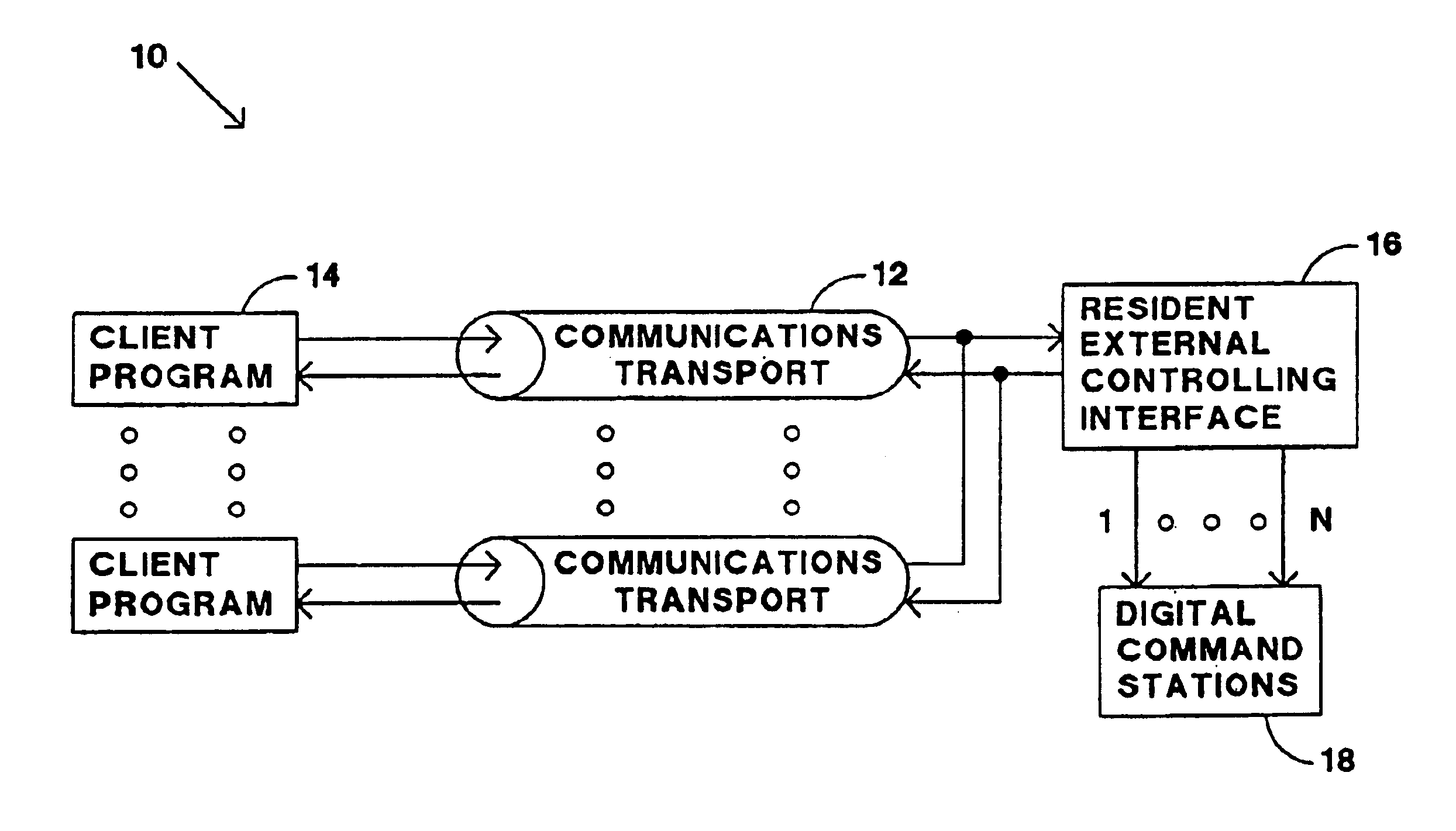

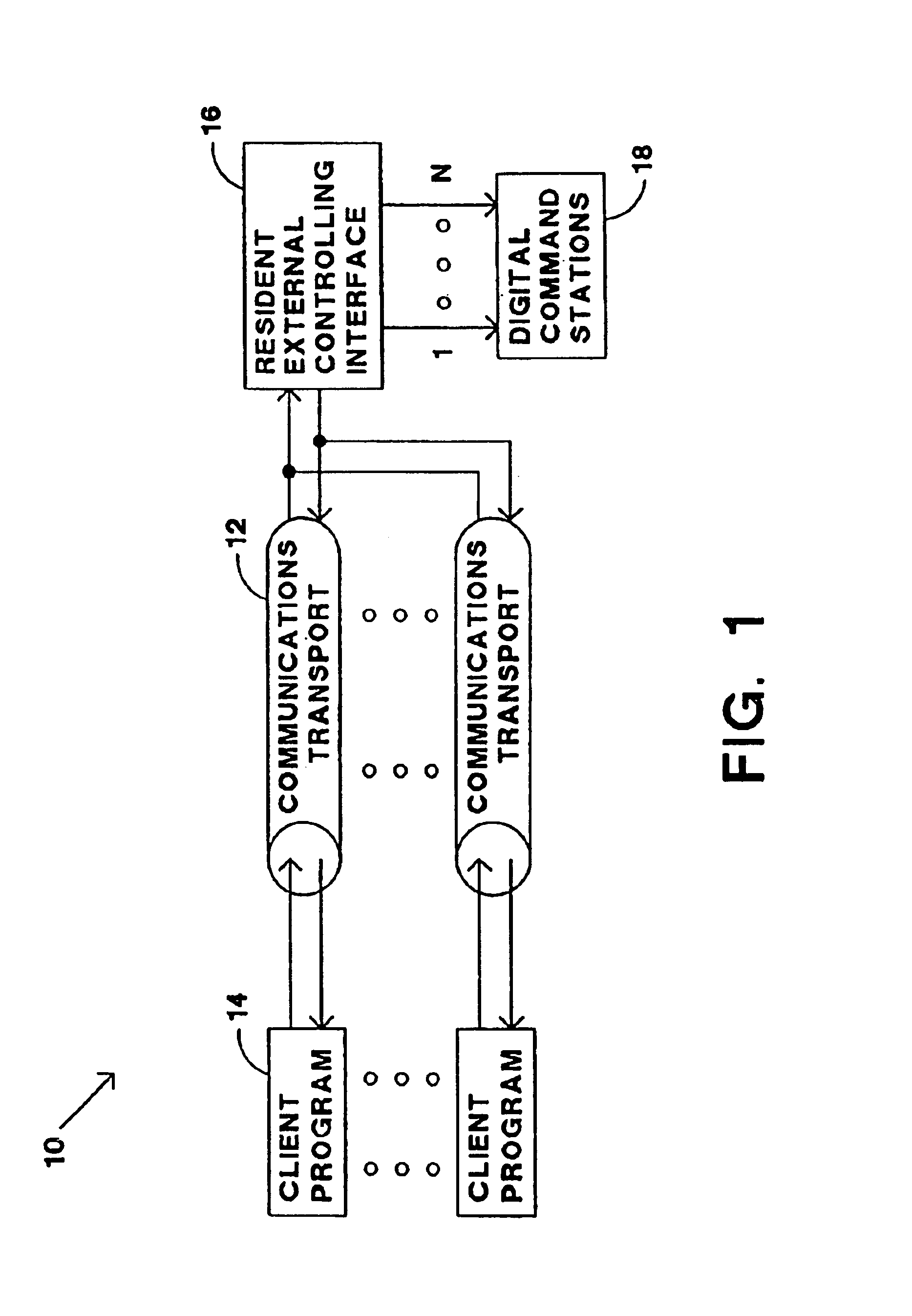

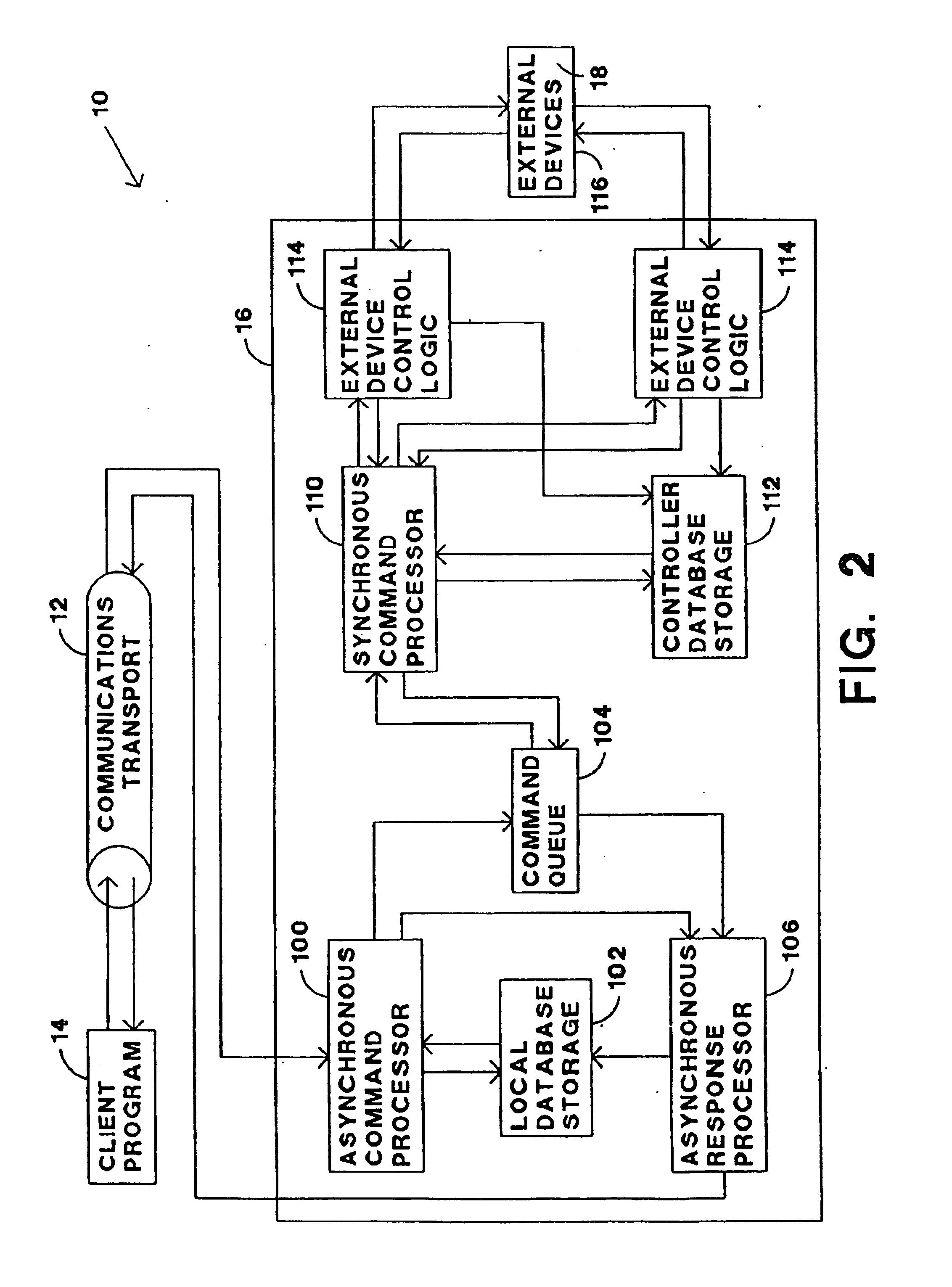

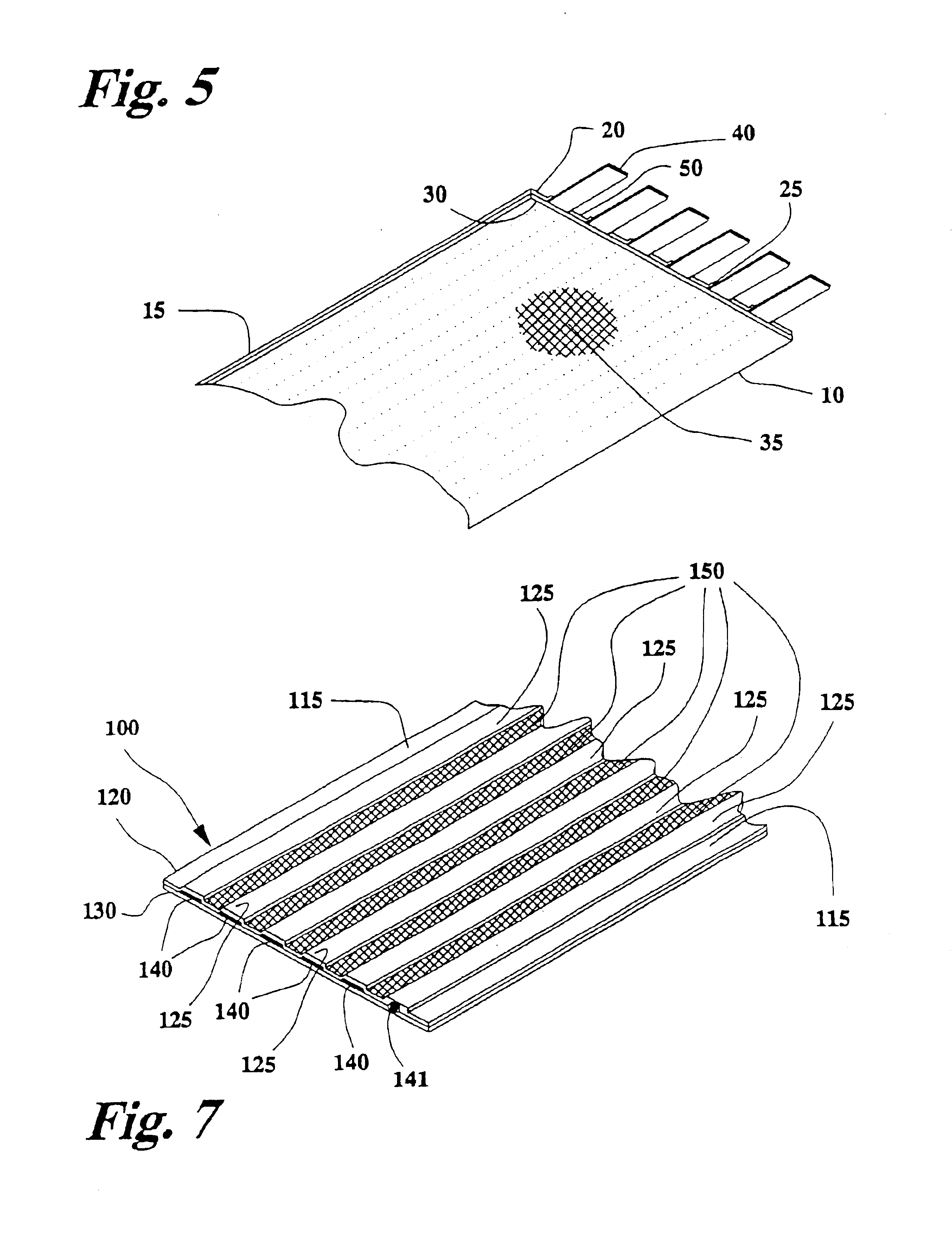

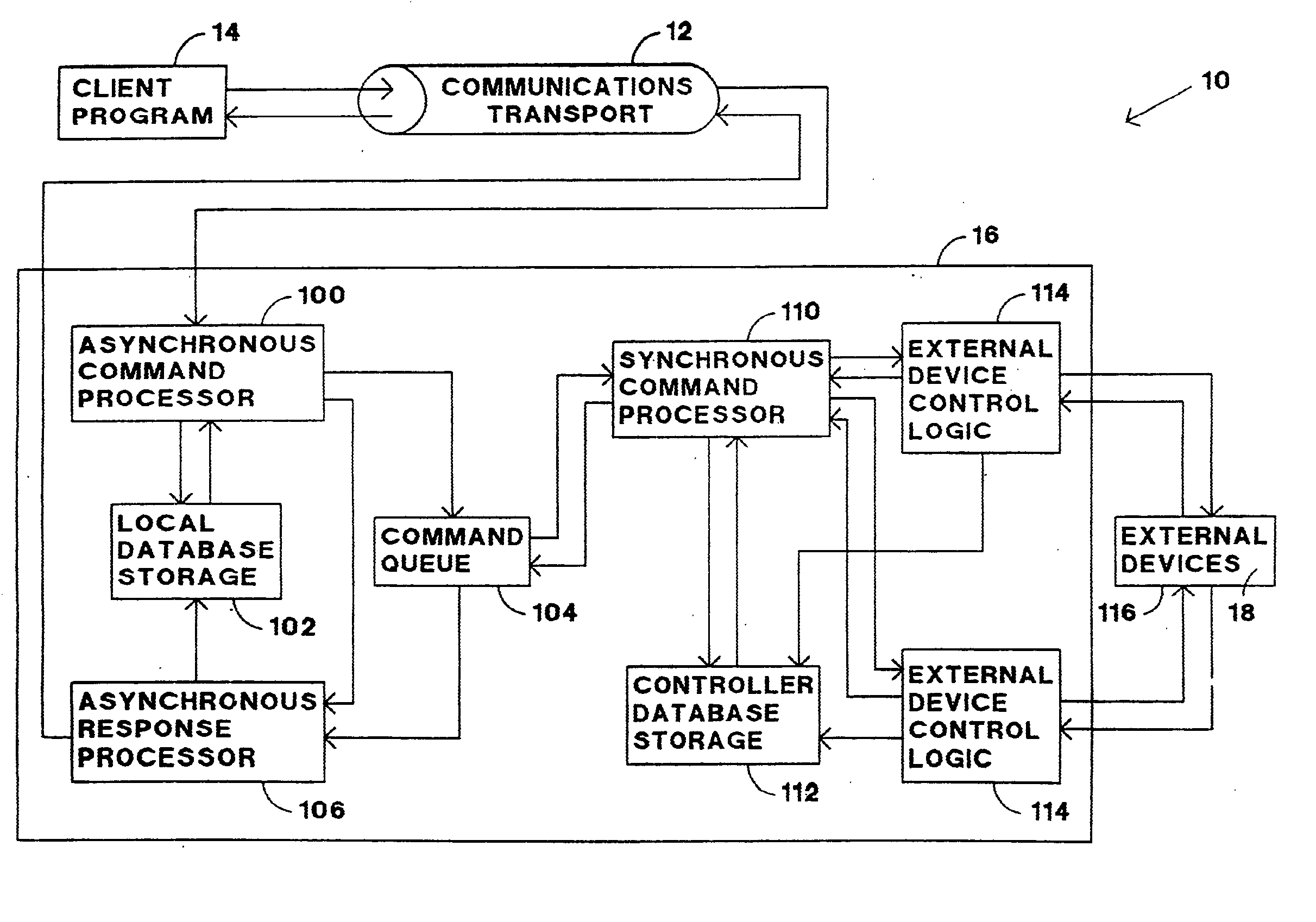

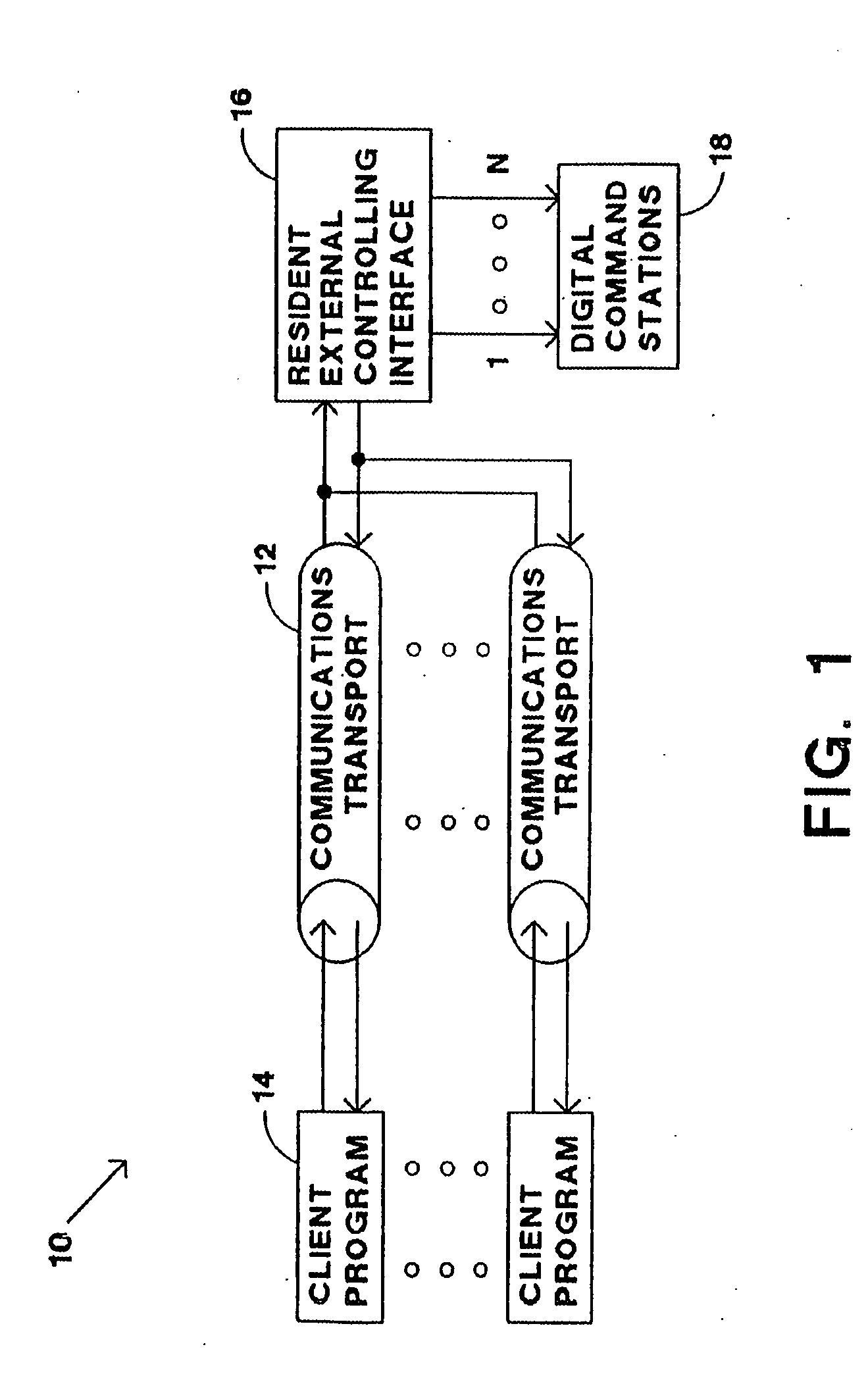

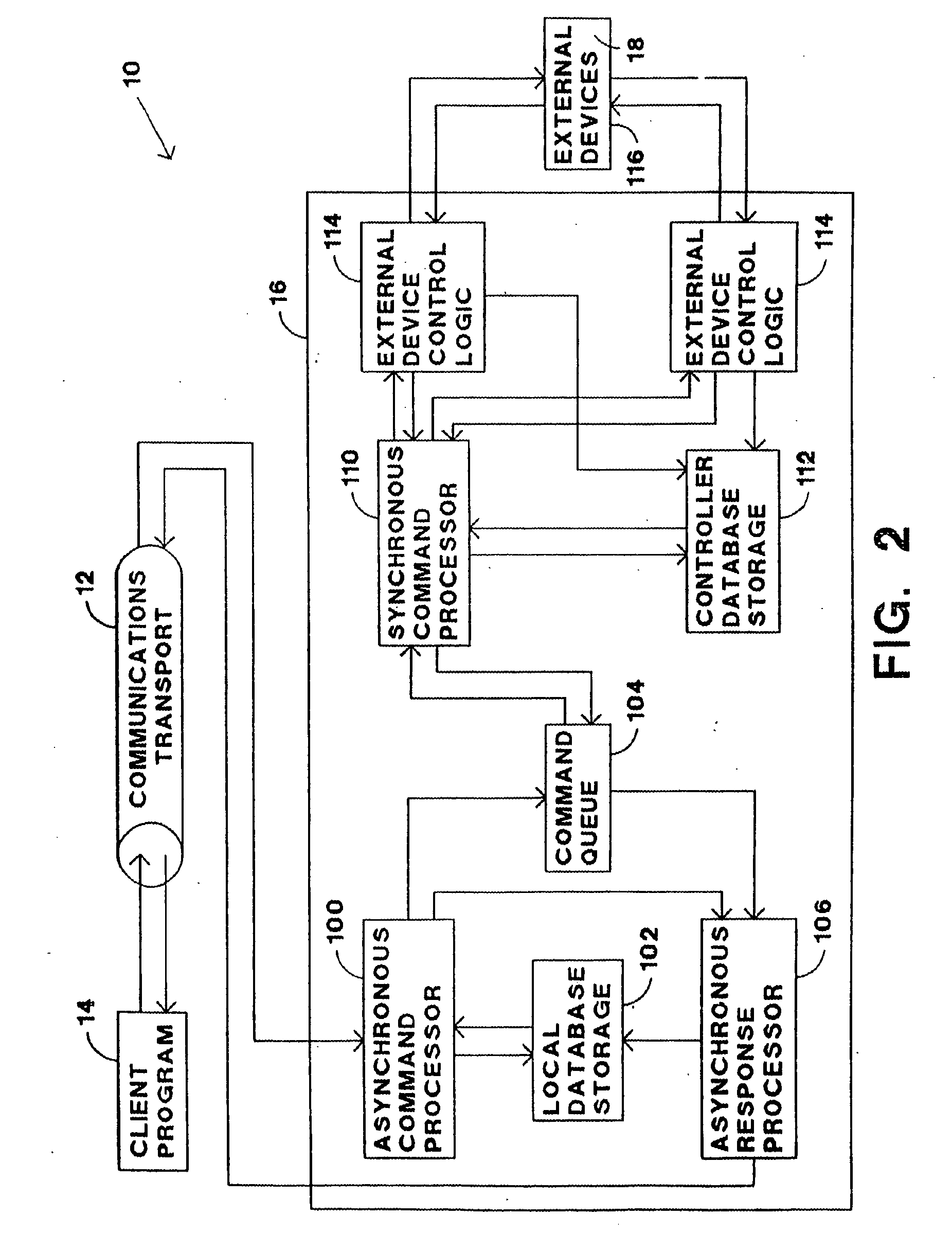

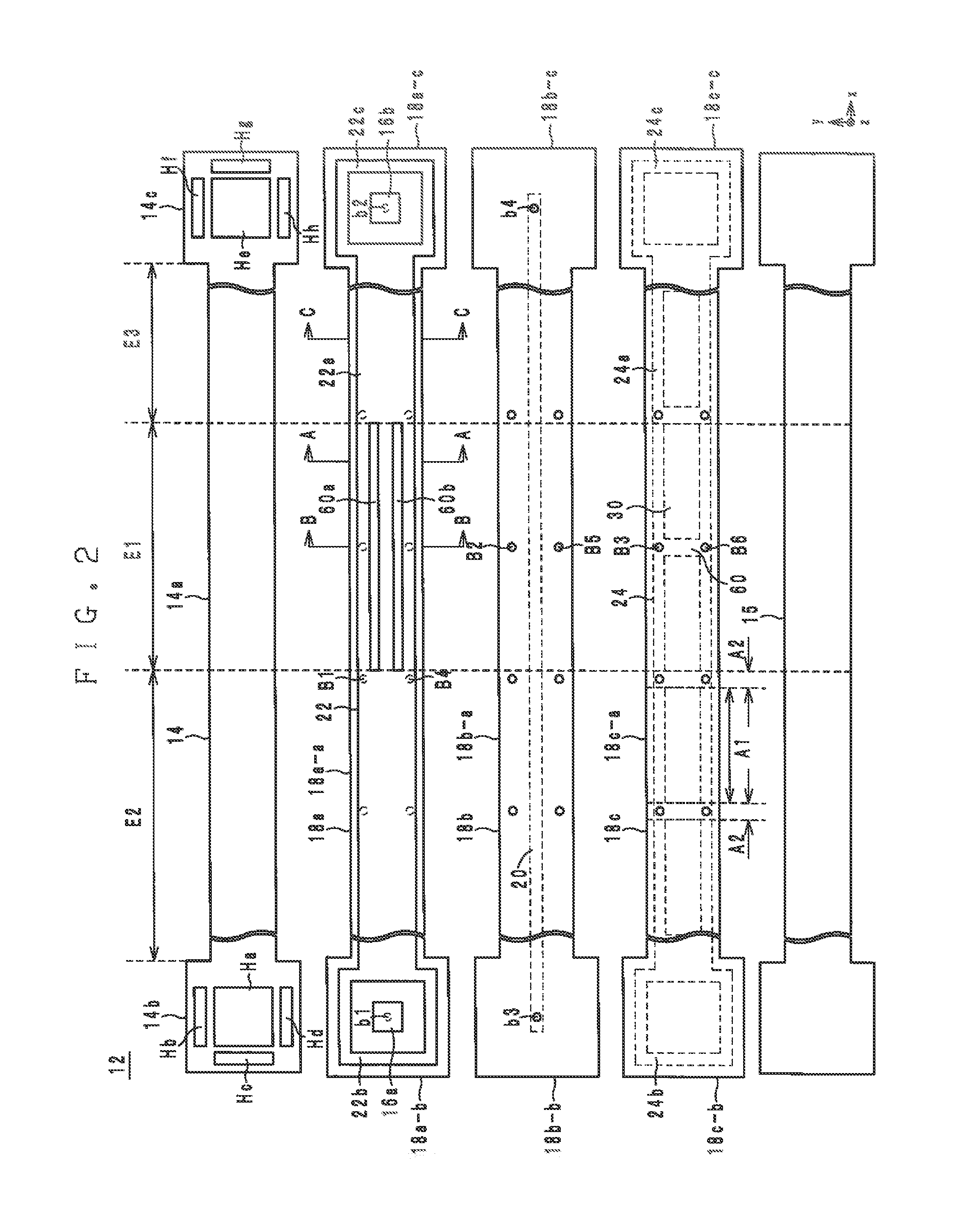

Model train control system

InactiveUS6909945B2Ensure correct executionStrip/foil conductorsElectric devicesComputer hardwareControl system

A system which operates a digitally controlled model railroad transmitting a first command from a first client program to a resident external controlling interface through a first communications transport. A second command is transmitted from a second client program to the resident external controlling interface through a second communications transport. The first command and the second command are received by the resident external controlling interface which queues the first and second commands. The resident external controlling interface sends third and fourth commands representative of the first and second commands, respectively, to a digital command station for execution on the digitally controlled model railroad.

Owner:KATZER MATTHEW A

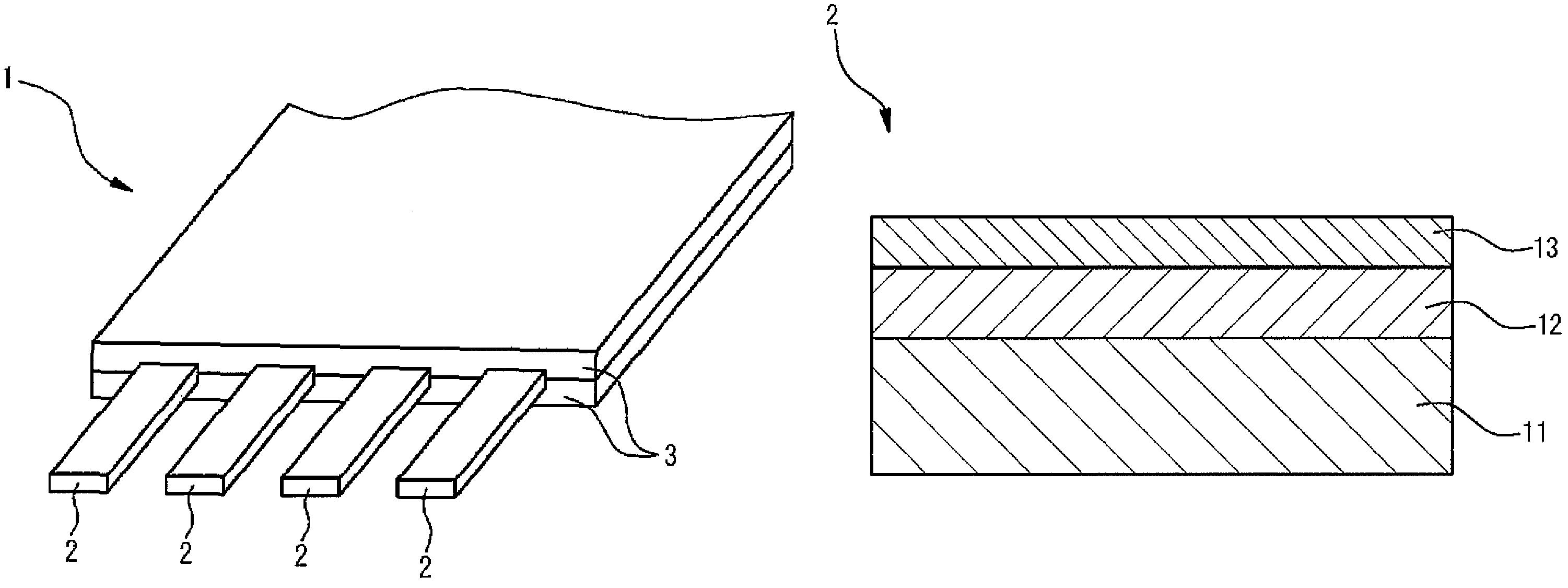

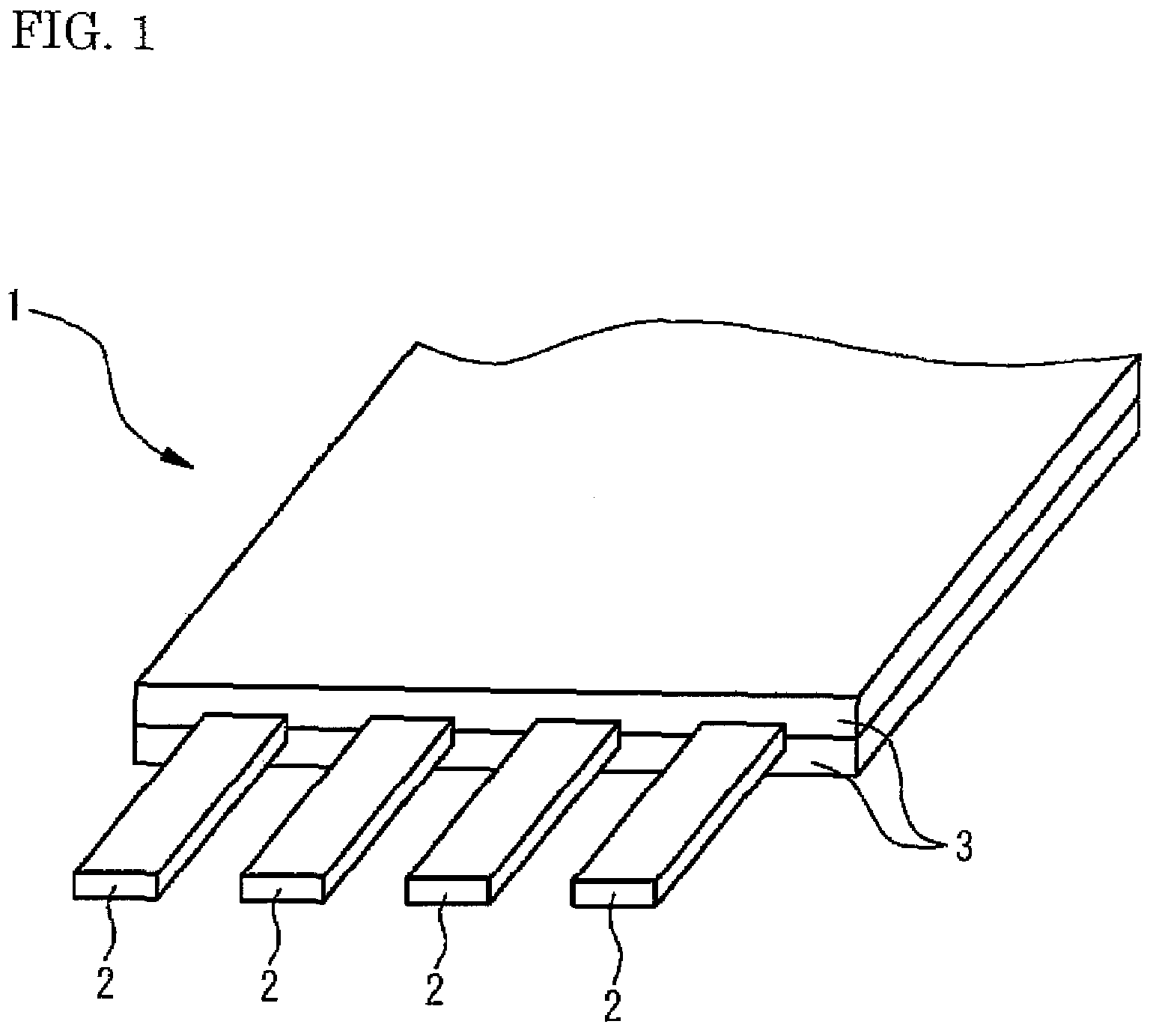

Flat cable

InactiveUS7482540B2AmountReduce formationStrip/foil conductorsFlat/ribbon cablesElectrical conductorTin plating

A flat cable includes a plurality of flat conductors each including a copper substrate, the flat conductors being aligned in a plane, and an insulating resin that covers the flat conductors. At least a terminal part of each of the flat conductors has a tin-copper alloy layer on the copper substrate, and a zinc-containing tin plating layer on the tin-copper alloy layers. The thickness of the tin-copper alloy layer is at least 0.2 μm and not greater than 1.0 μm. The thickness of the zinc-containing tin plating layer is at least 0.2 μm and not greater than 1.5 μm. The total thickness of the tin-copper alloy layer and the zinc-containing tin plating layers is at least 0.4 μm and not greater than 1.7 μm.

Owner:SUMITOMO ELECTRIC IND LTD

Communication cable including a helically-wrapped shielding tape

ActiveUS20160064119A1Good electrical contactStrip/foil conductorsElectrically conductive connectionsElectrical conductorEngineering

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

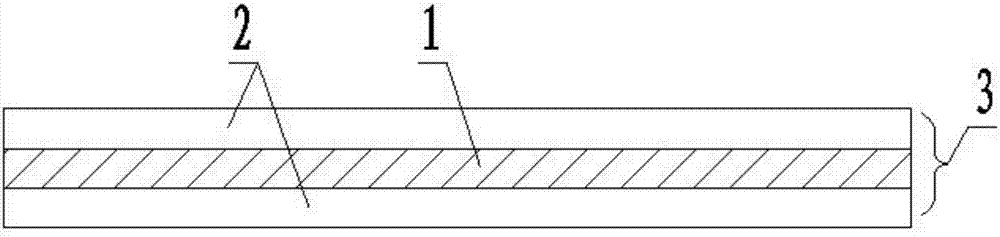

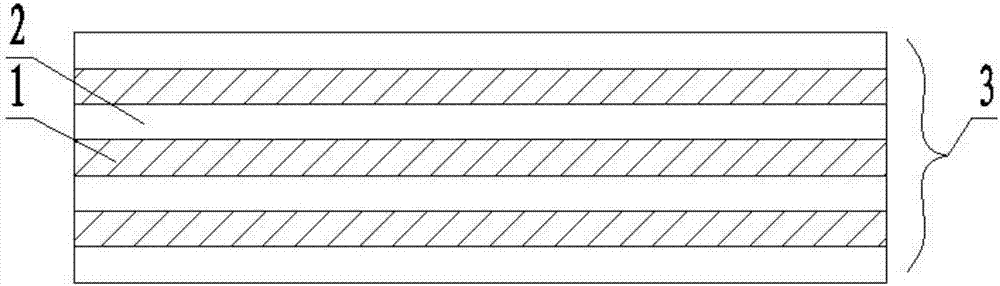

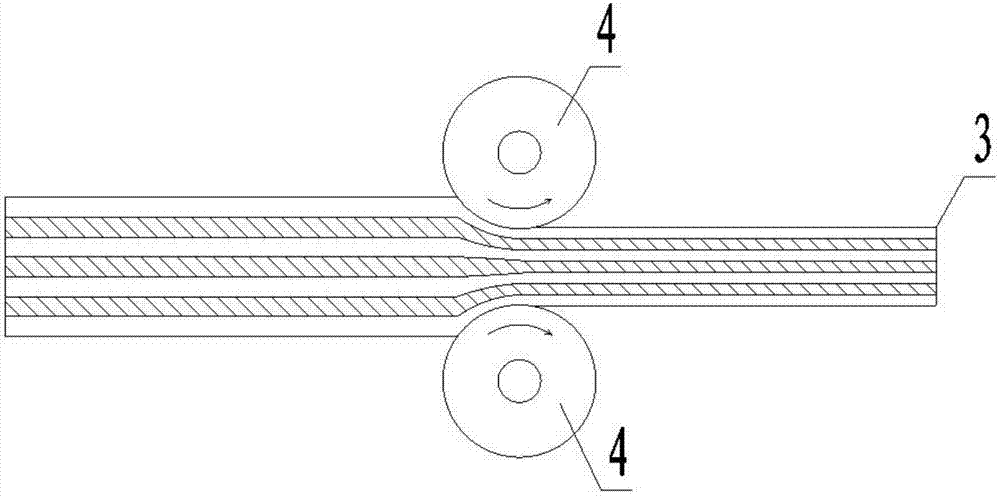

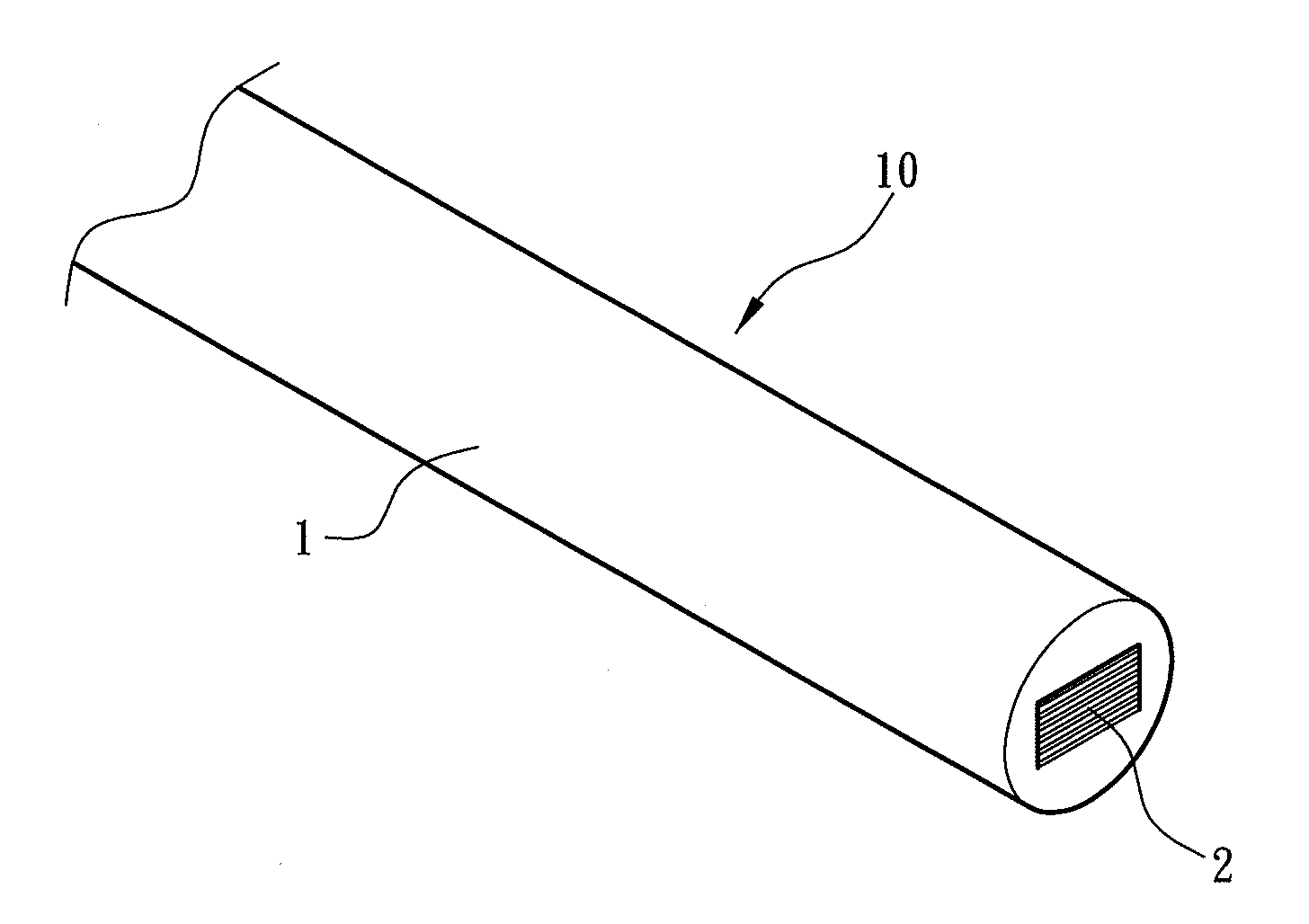

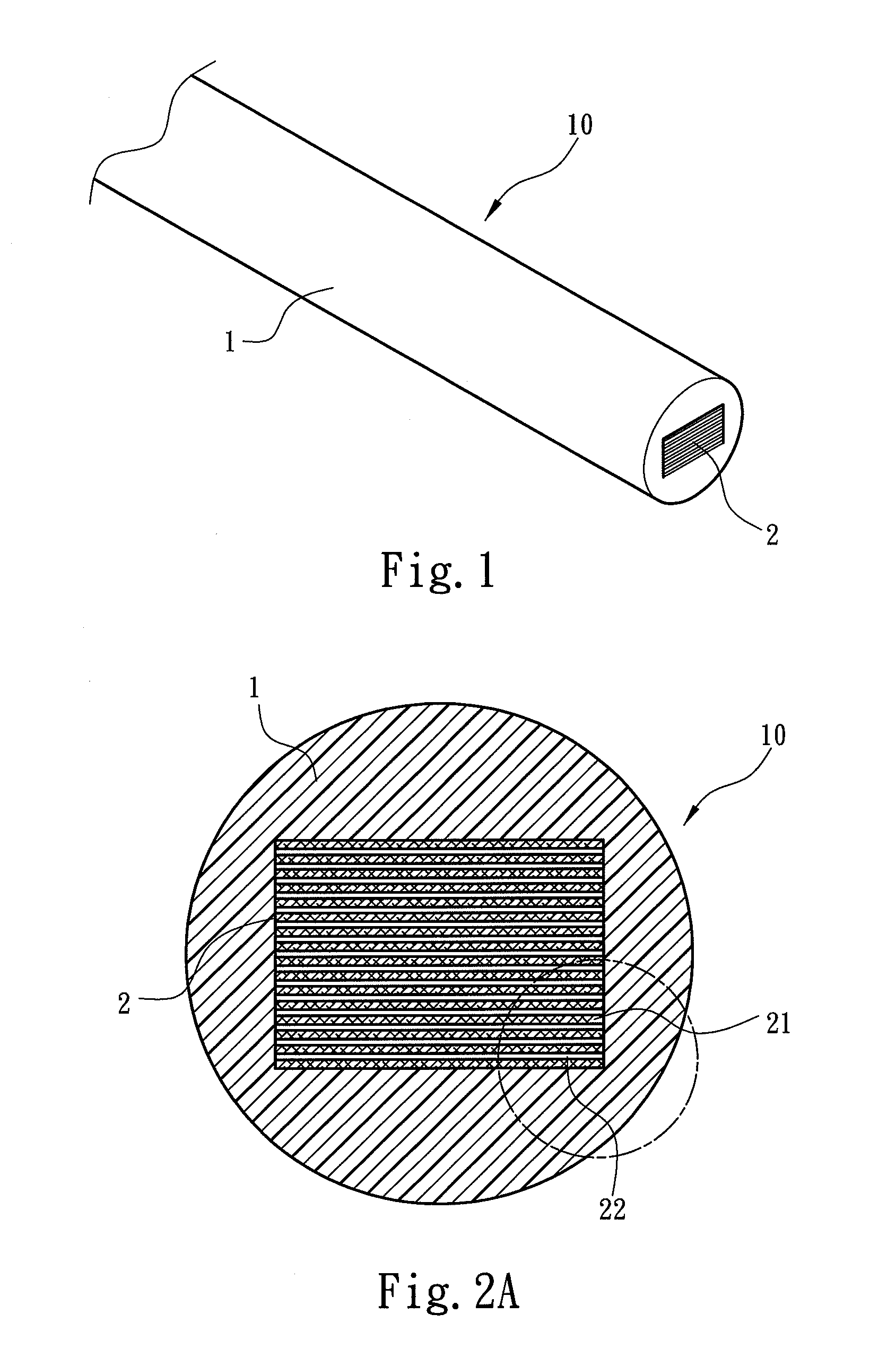

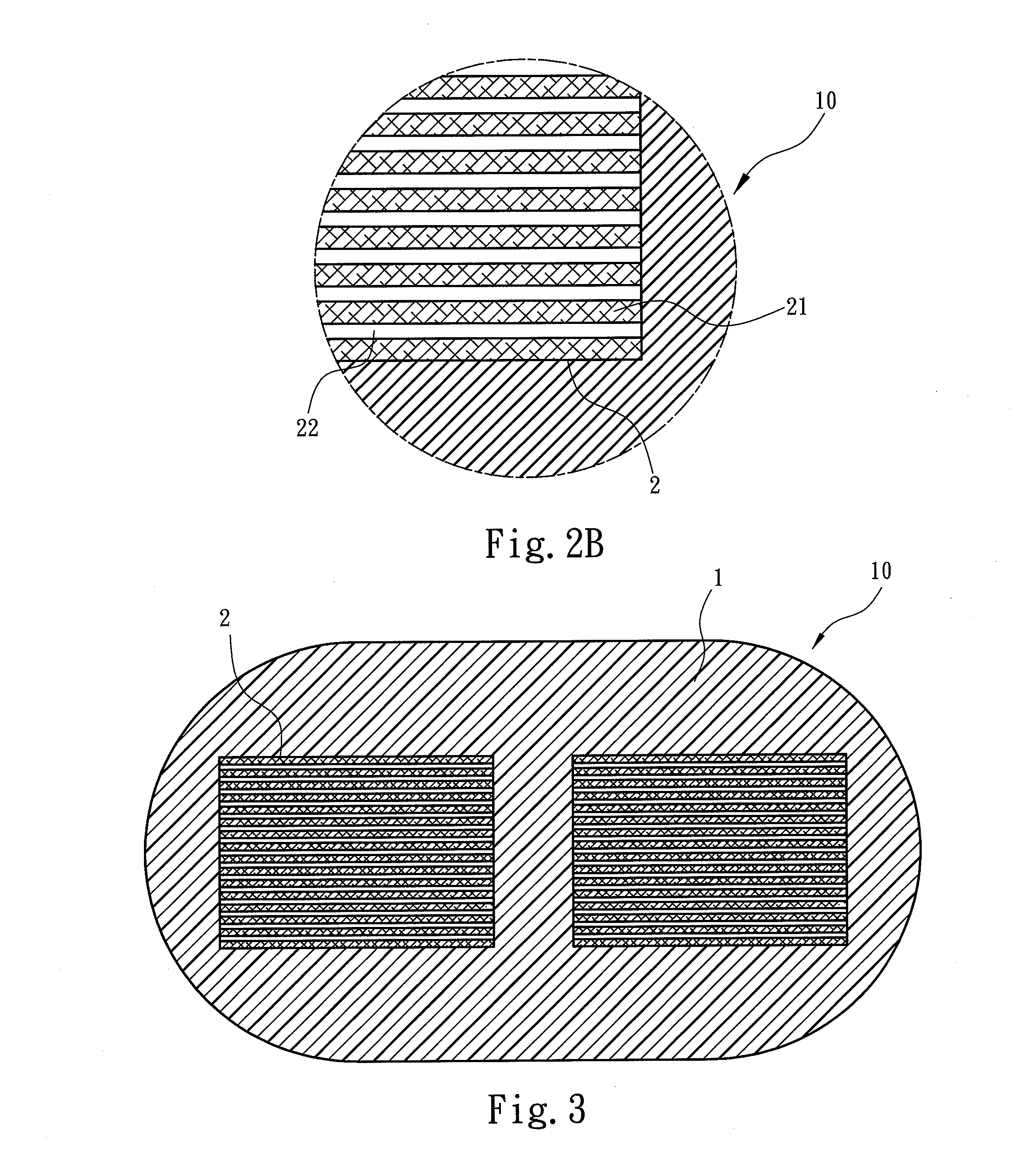

Graphene-based electrical conductor and preparation method thereof

InactiveCN106898408AHigh power transmission efficiencyIncrease contactStrip/foil conductorsConductive layers on insulating-supportsElectric power transmissionElectrical conductor

The invention discloses a graphene-based electric conductor and a preparation method thereof. The graphene-based electric conductor comprises a layered structure; the layered structure comprises graphene layers (1) and substrate layers (2) which are alternately arranged; and each graphene layer (1) is compressed between two adjacent substrate layers (2). The preparation method of the graphene-based electric conductor includes the following steps that: one or more graphene layers are laminated with two or more substrate layers, so that a graphene layer and substrate layer alternately connected sheet can be formed; and the sheet is compressed, so that the graphene layer can be compressed between two adjacent substrate layers, so that a layered structure can be formed, and the graphene-based electrical conductor is obtained. The graphene-based electric conductor of the invention has the advantages of low resistance and small electric power loss. With the graphene-based electric conductor and the preparation method thereof adopted, power transmission efficiency can be improved, the distribution range of a power grid can be expanded, and compression processing can be facilitated.

Owner:HANGZHOU CABLE +1

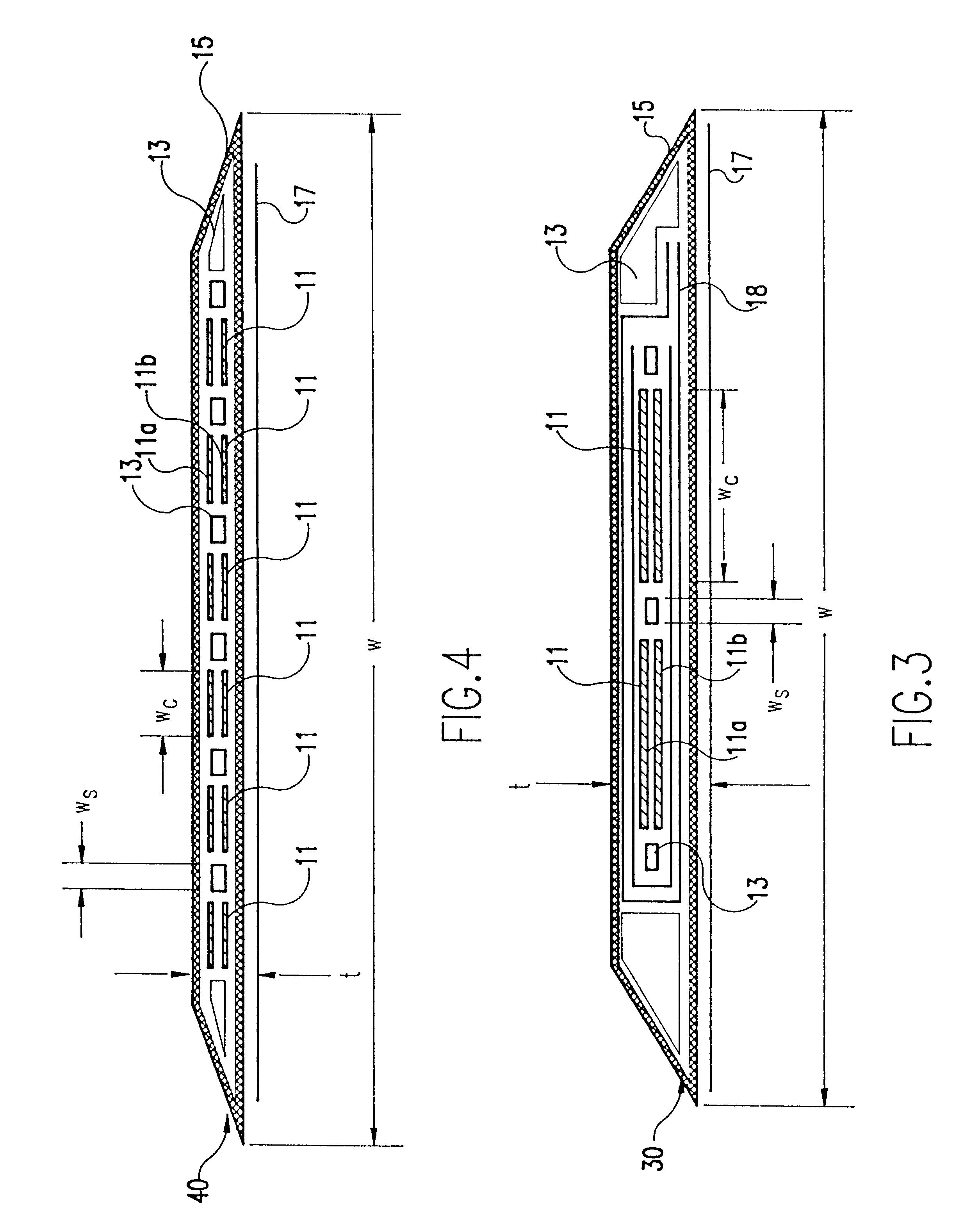

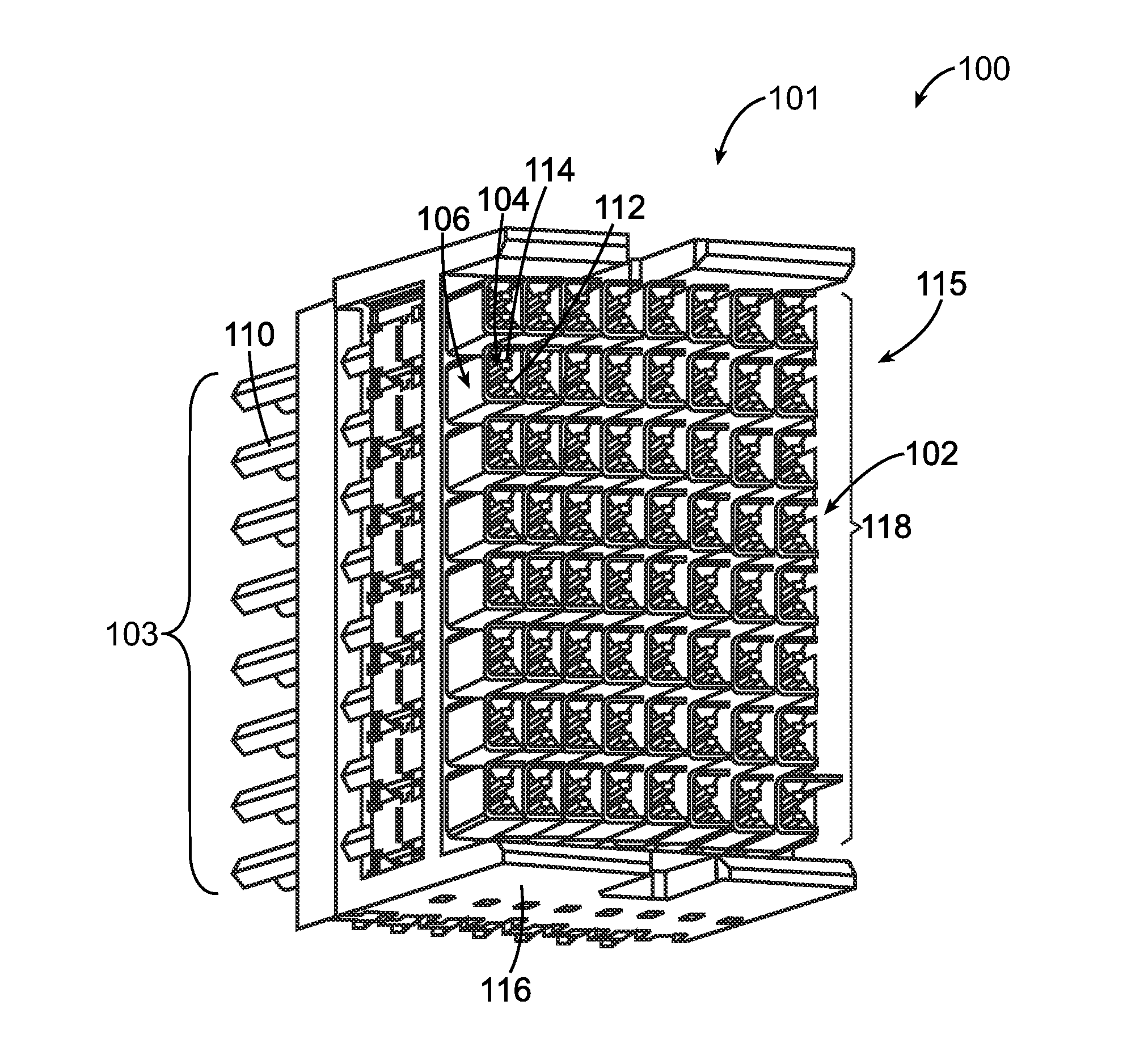

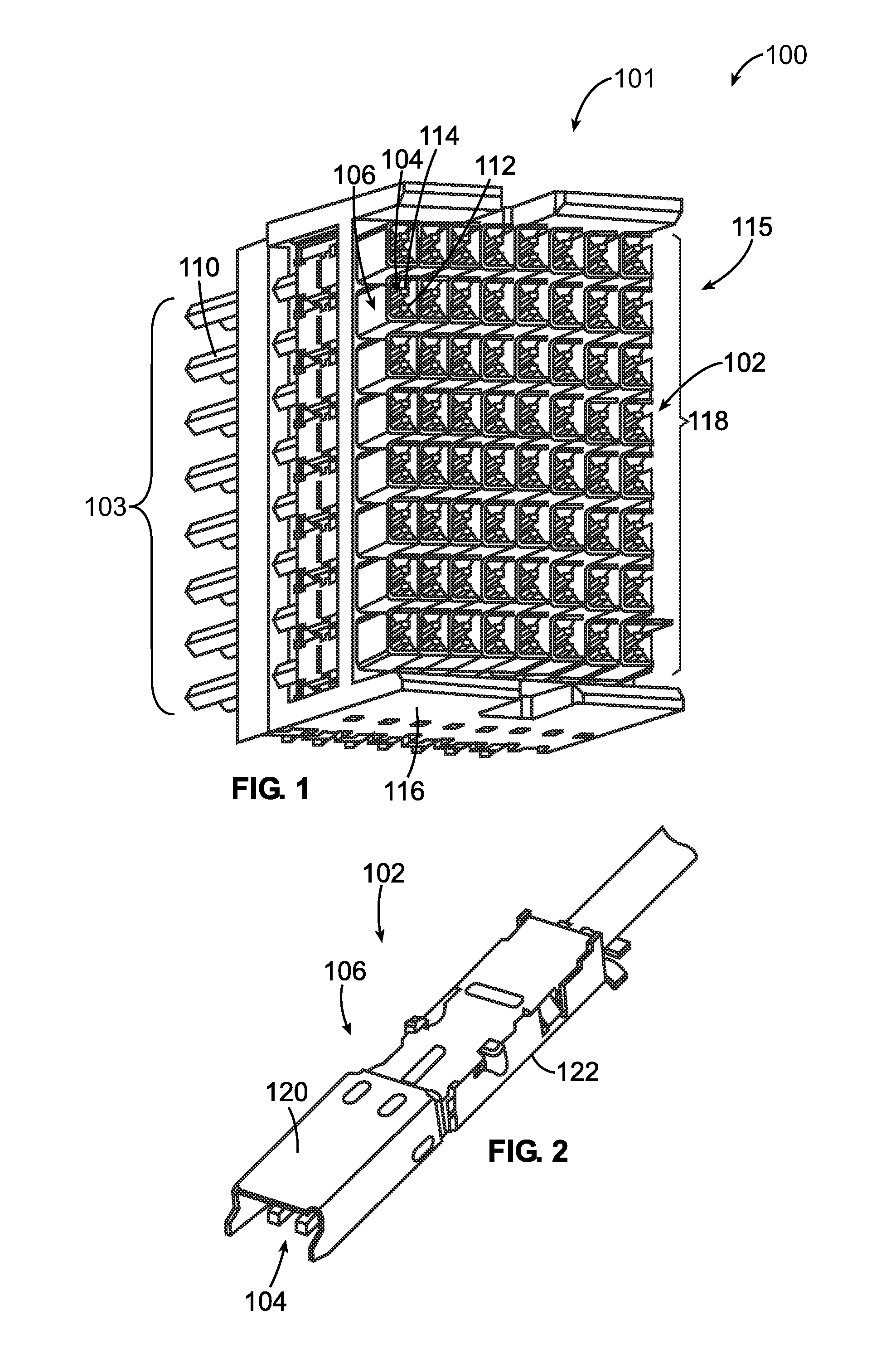

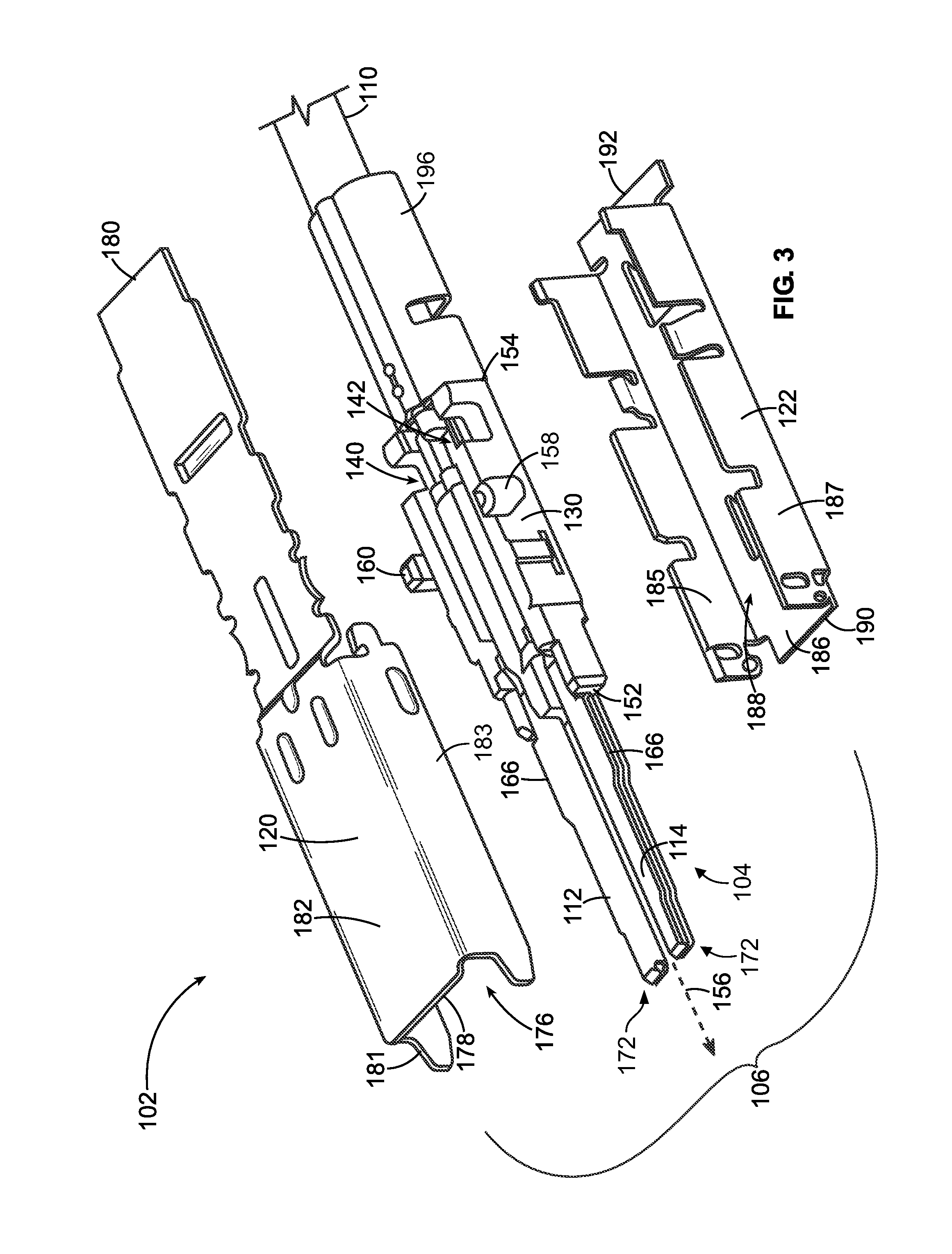

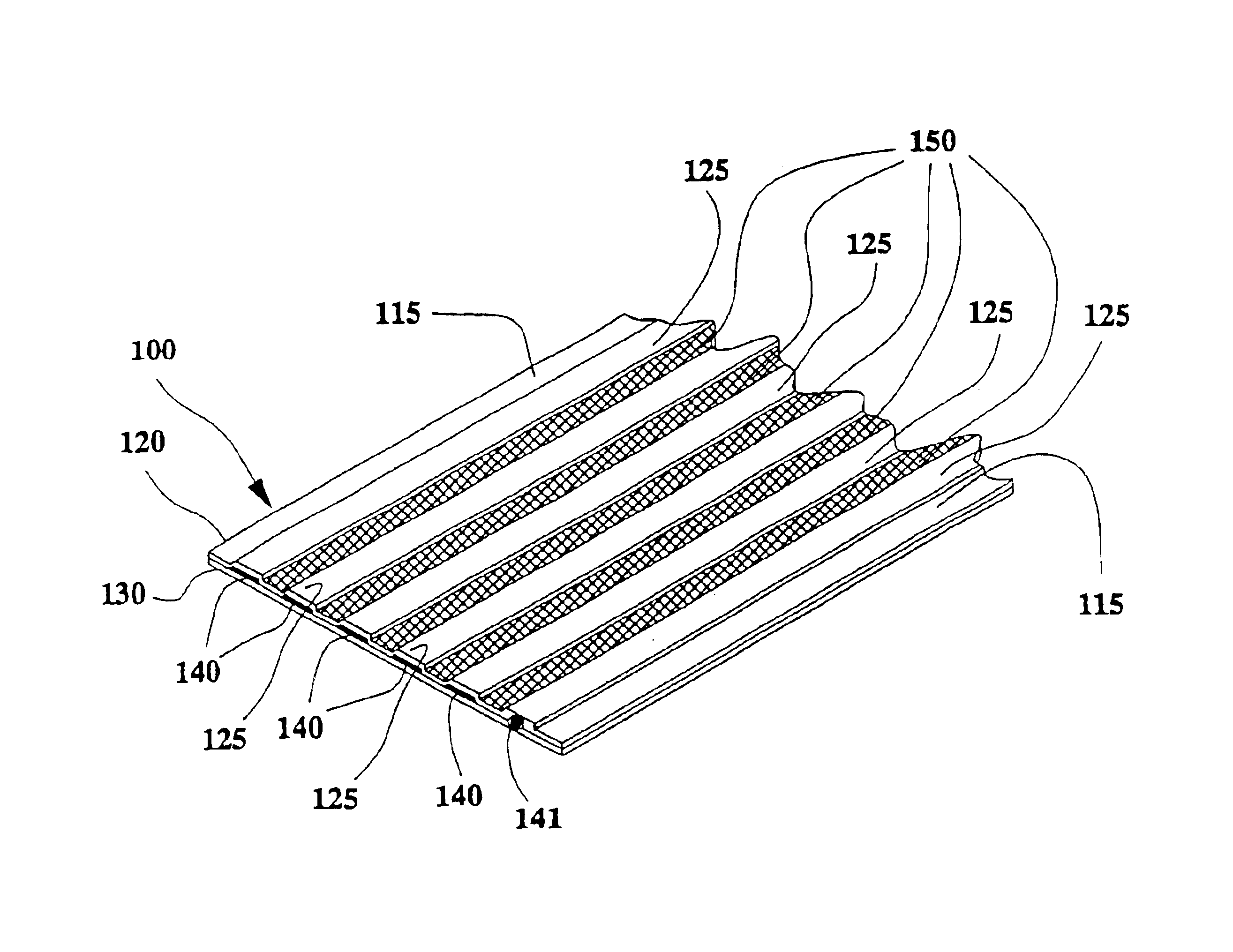

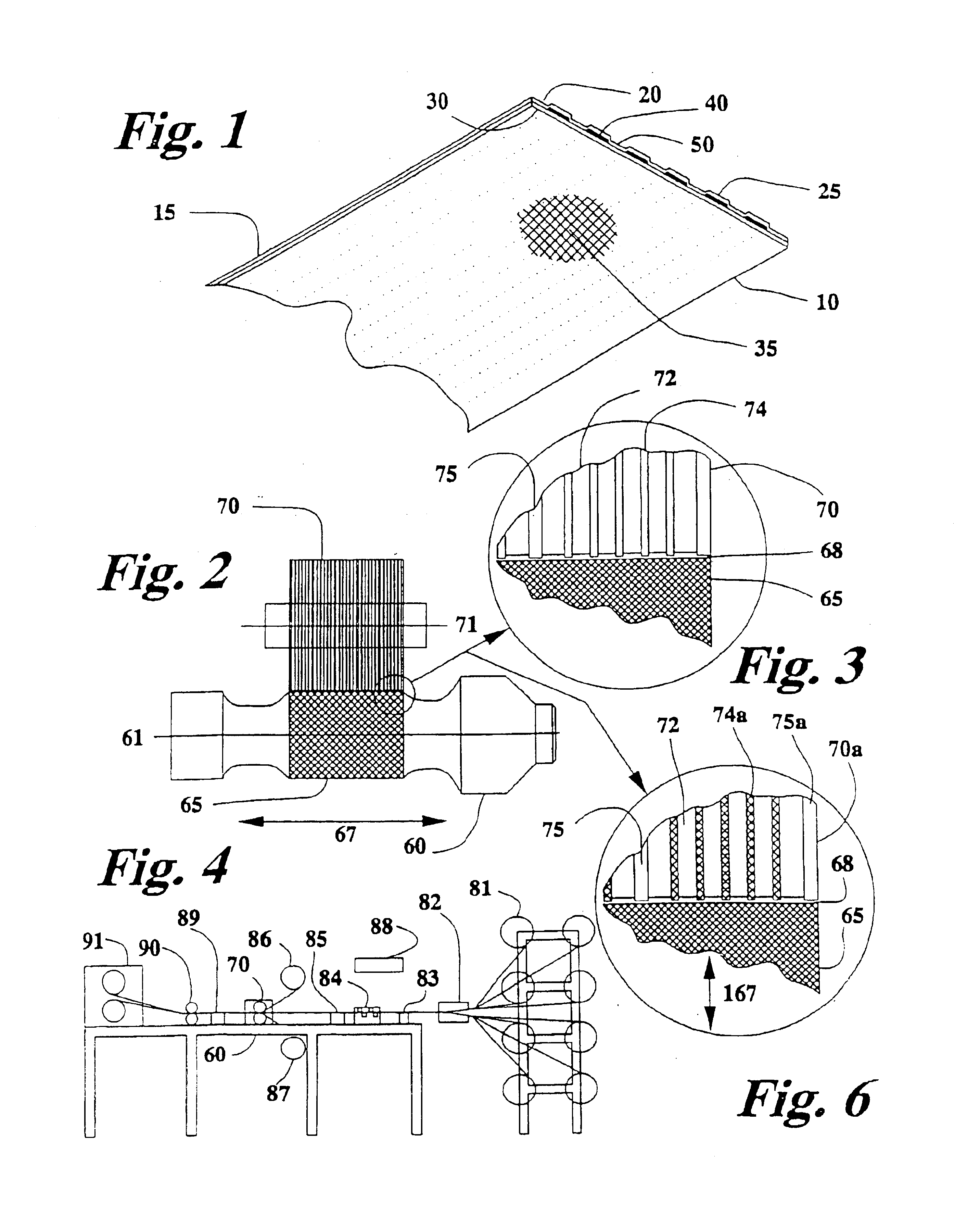

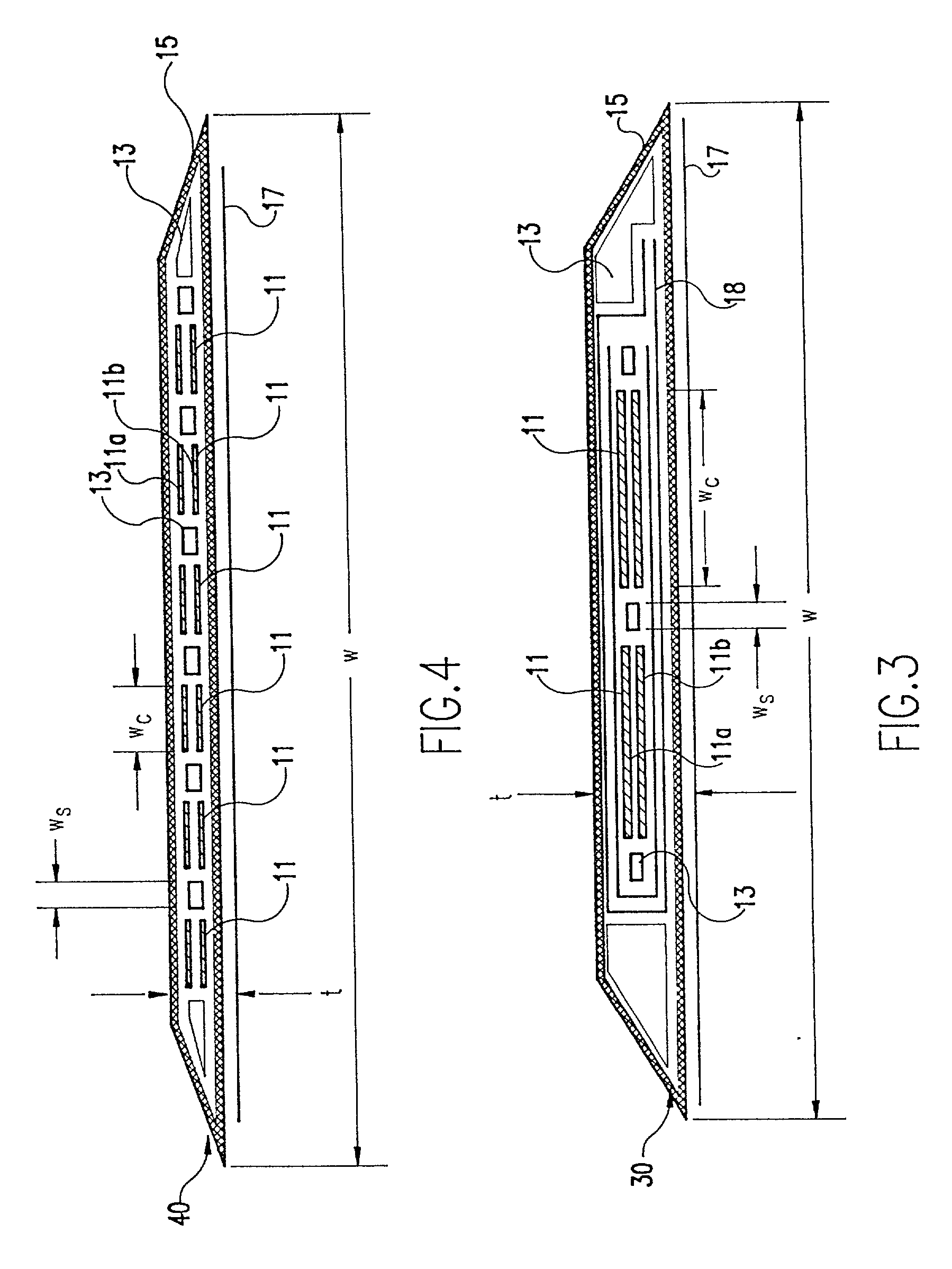

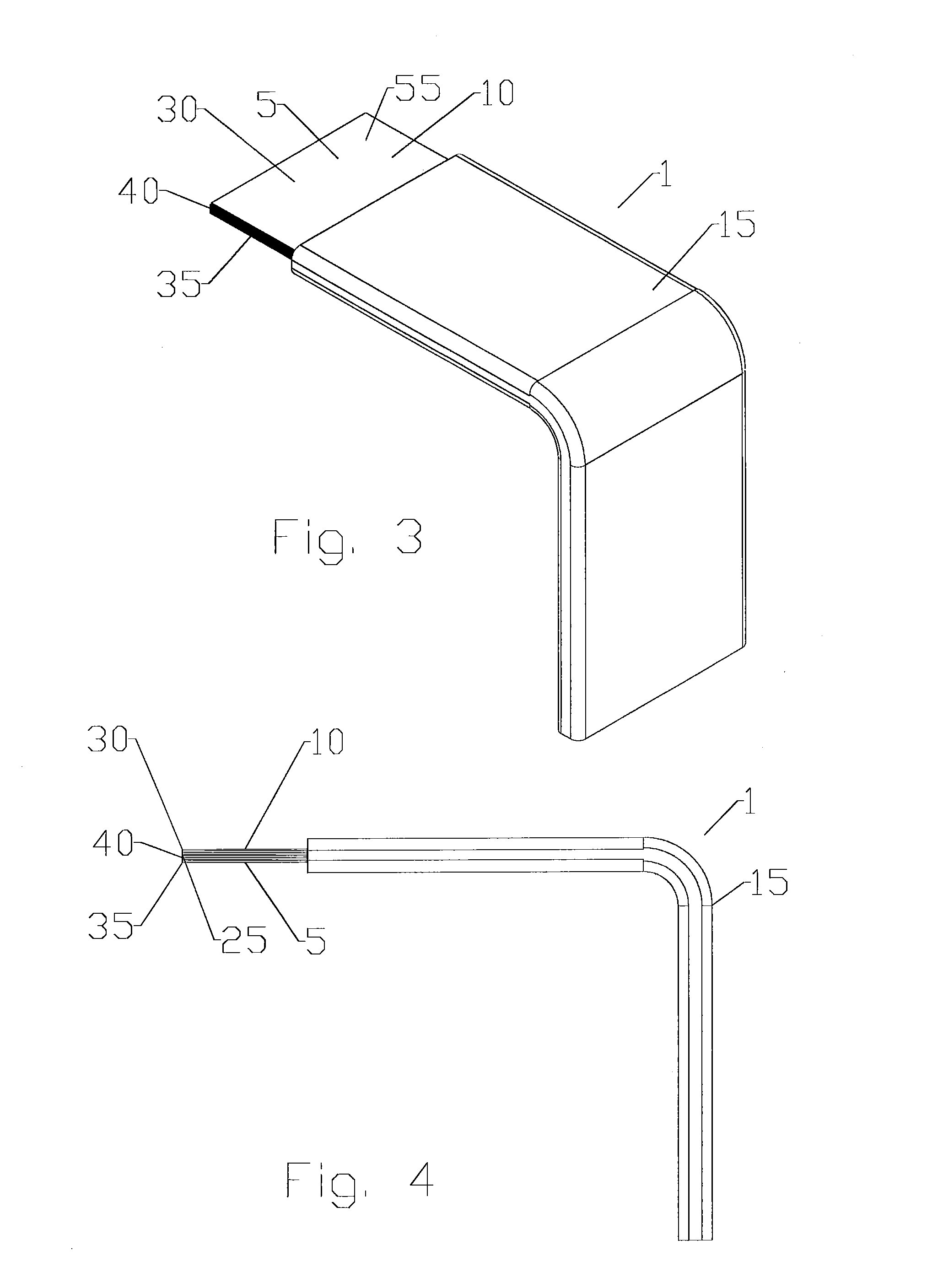

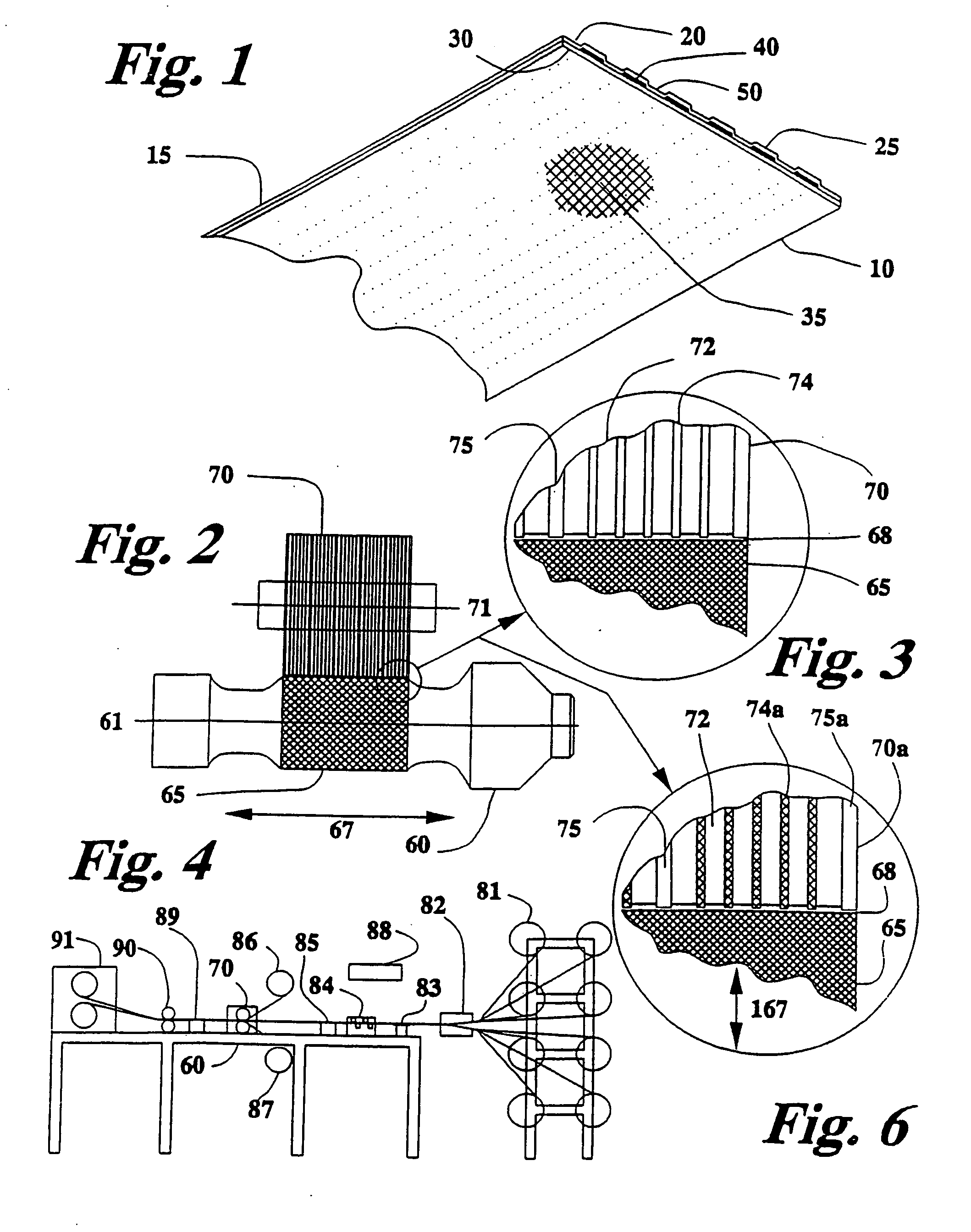

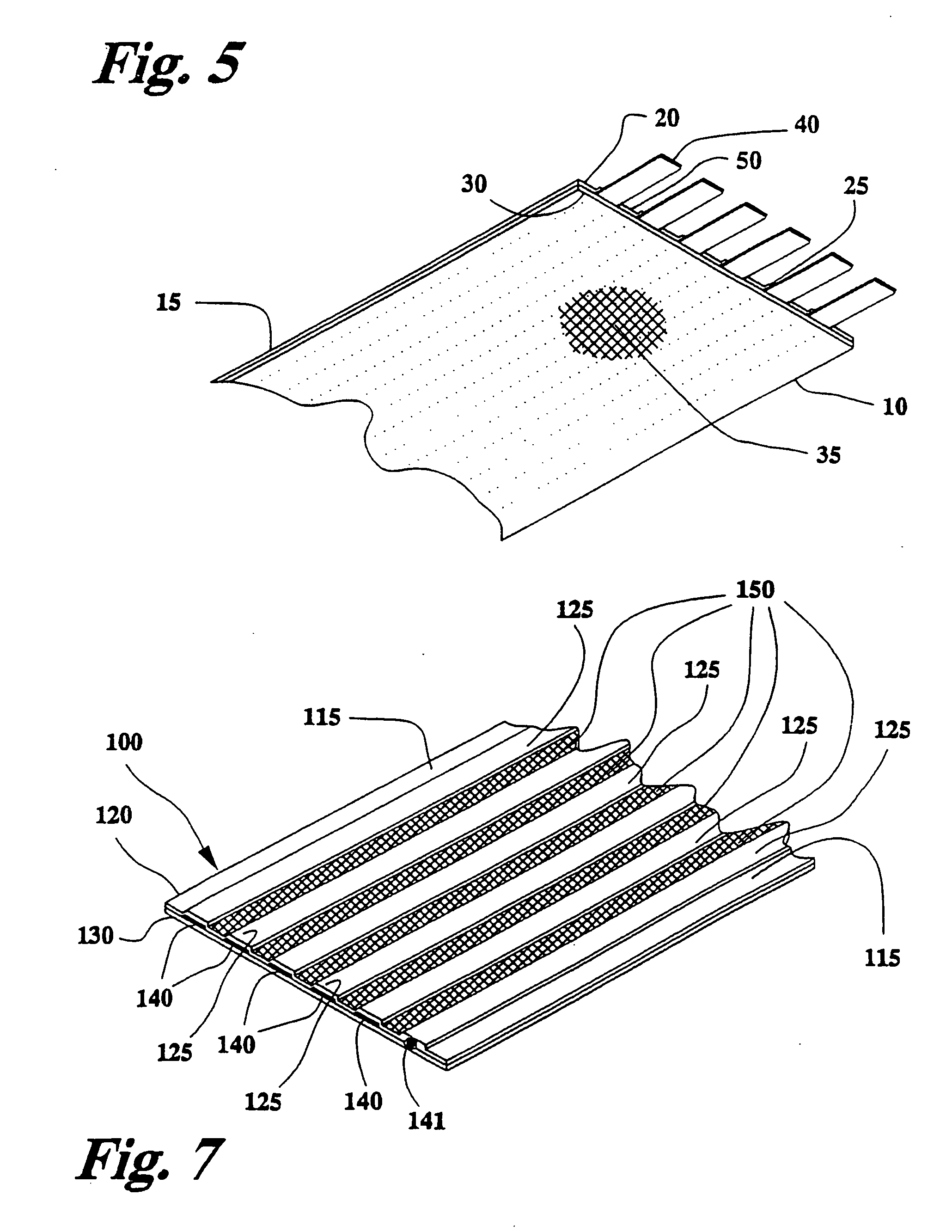

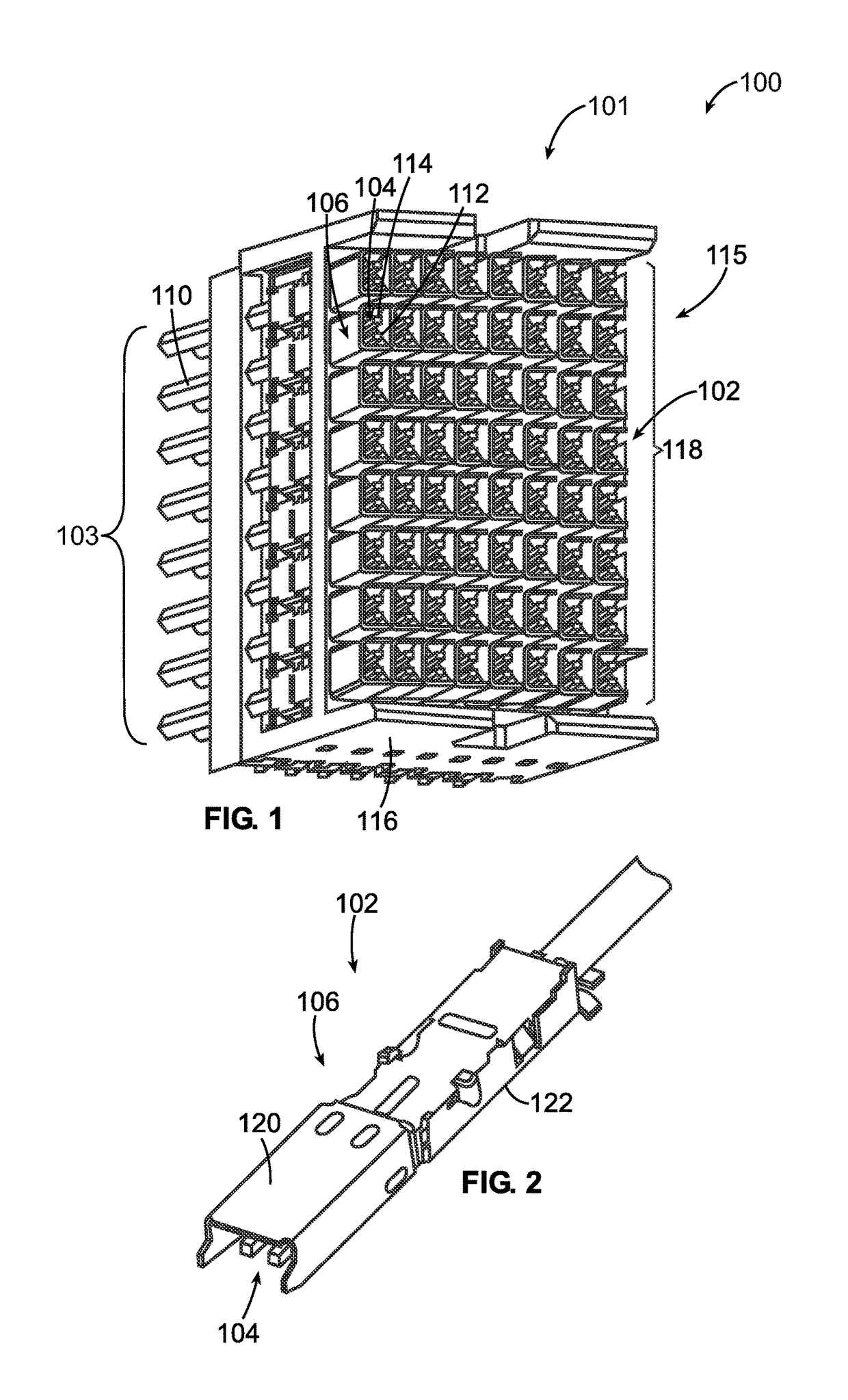

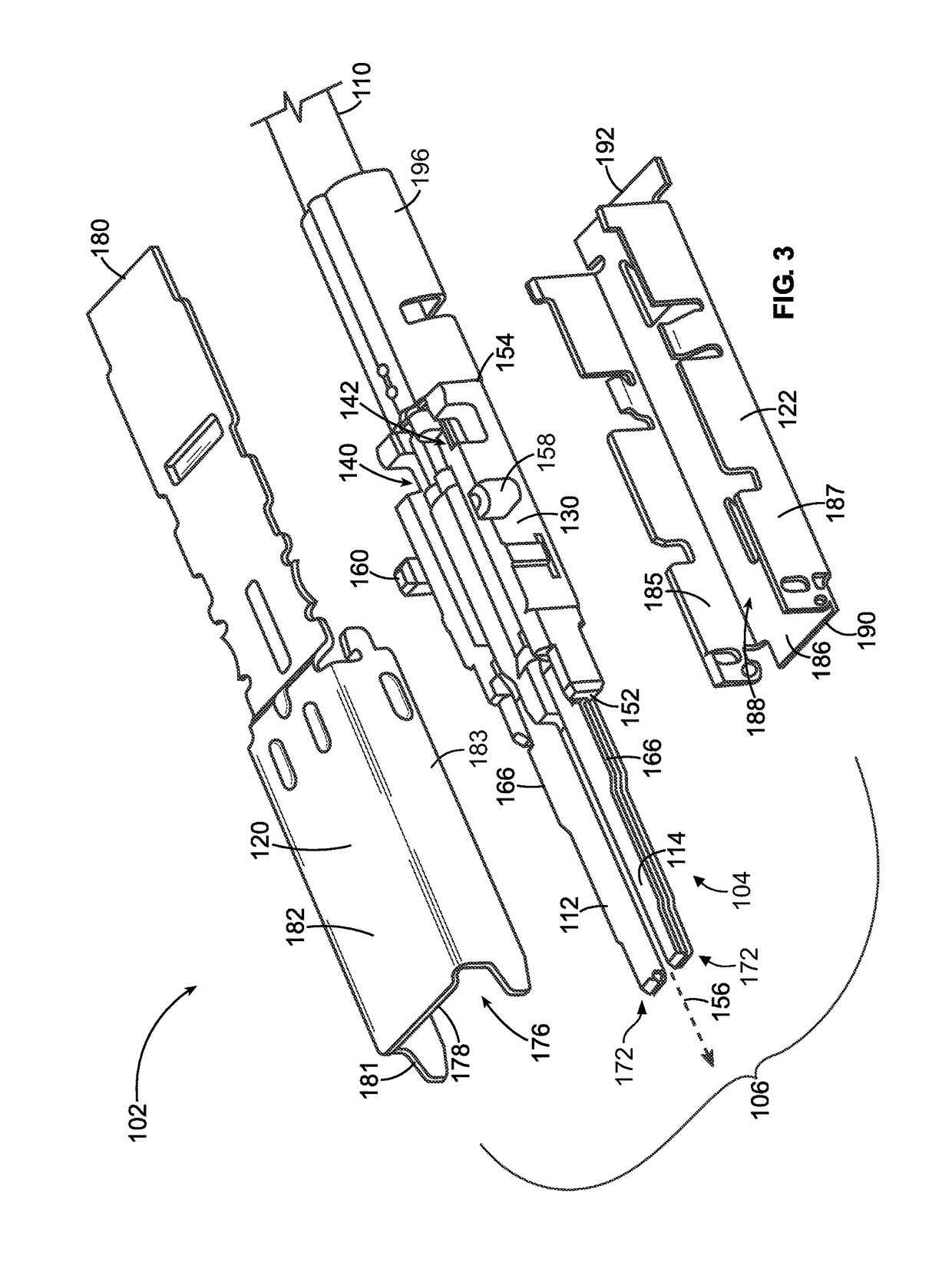

Flat cable and modular rotary anvil to make same

InactiveUS6841735B1Light weightReduce in quantityStrip/foil conductorsRotary current collectorPolyesterSurface pattern

A flat electrical cable and a modular rotary anvil for assembling a flat electrical cable is provided wherein the flat cable includes an upper and lower layer. The upper layer has ribs protruding along its length that are substantially parallel to one another, and continuous substantially parallel and adjacent seams formed therebetween. Conductors are placed between the upper and lower layers adjacent the seams. The present invention may have upper and lower polyester layers having copper conductors therebetween and the seams ultrasonically welded in order to provide a flat electrical cable for various applications such as incorporation in an automobile clockspring. The modular rotary anvil includes multiple removable and interchangeable segments or inserts which provide the ability to impart a smooth or knurled interchangeable segments or inserts which provide the ability to impart a smooth or knurled textured surface pattern to the work-piece. Other inserts include cutting inserts which provide for a seam on the work-piece while a the same time cuts the work-piece along a seam—segments or inserts which provide the ability to impart a smooth or knurled textured surface pattern to the work-piece. Other inserts include cutting inserts which provide for a seam on the work-piece while a the same time cuts the work-piece along a seam.

Owner:METHODE ELETRONICS INC

Model train control system

InactiveUS20060241825A1Ensure correct executionStrip/foil conductorsDigital data processing detailsComputer hardwareControl system

A system which operates a digitally controlled model railroad transmitting a first command from a first client program to a resident external controlling interface through a first communications transport. A second command is transmitted from a second client program to the resident external controlling interface through a second communications transport. The first command and the second command are received by the resident external controlling interface which queues the first and second commands. The resident external controlling interface sends third and fourth commands representative of the first and second commands, respectively, to a digital command station for execution on the digitally controlled model railroad.

Owner:KATZER MATTHEW A

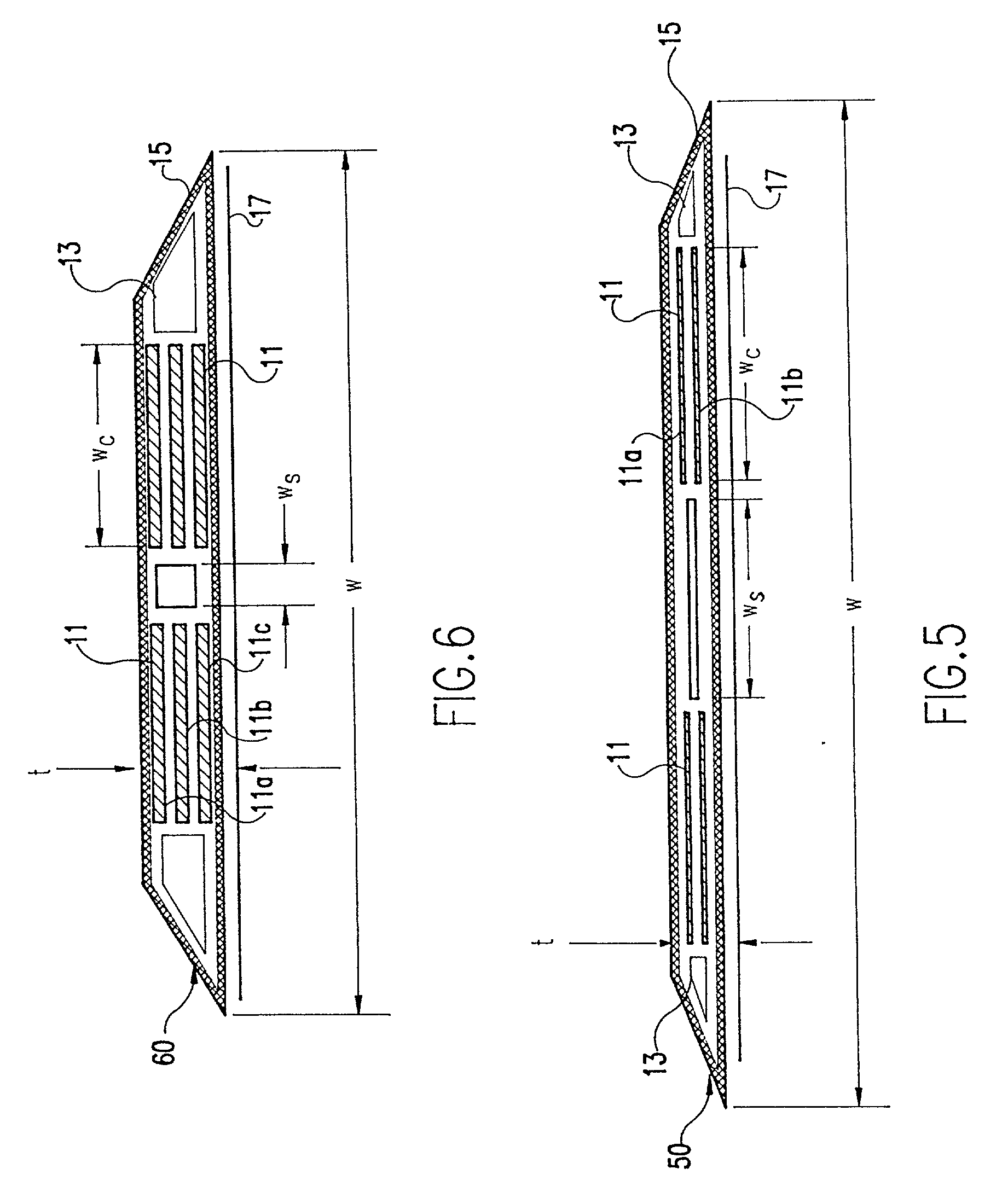

Flexible Electrical Power Cable

InactiveUS20140027153A1Good bending propertiesEasy to installStrip/foil conductorsConductive materialElectrical conductorPower cable

An electrical cable has a plurality of generally rectangular cross-section conductors superposed in a stack, the stack surrounded by a polymer jacket. The stack may be provided with a lubrication layer provided between at least two of the conductors. Conductors of the stack may have a thickness that is greater proximate the middle of the stack than at the top and bottom of the stack and / or a width that is less at the top and the bottom than at the middle. Further stacks may also be provided parallel and coplanar with the first stack, also surrounded by the polymer jacket.

Owner:COMMSCOPE TECH LLC

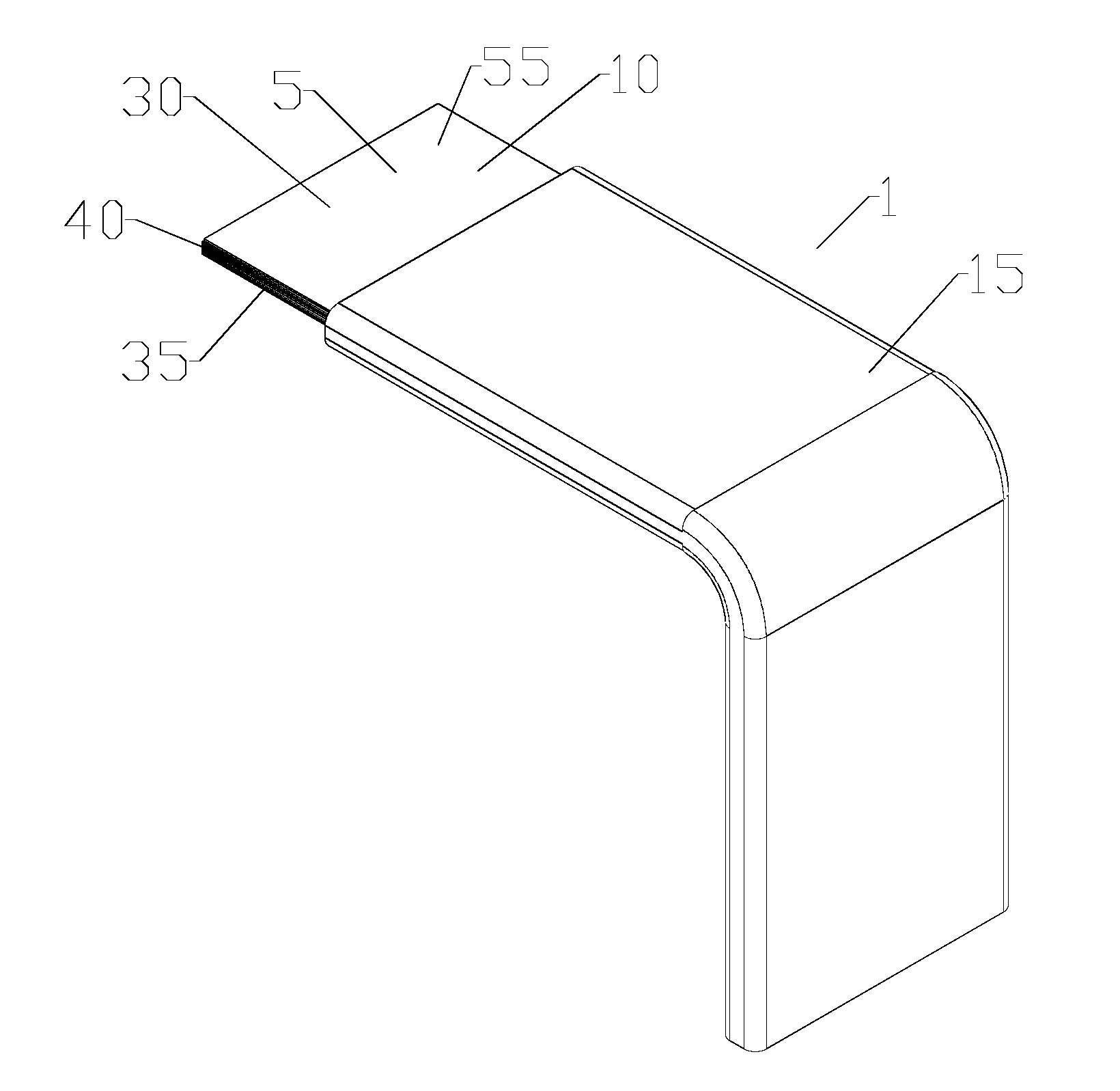

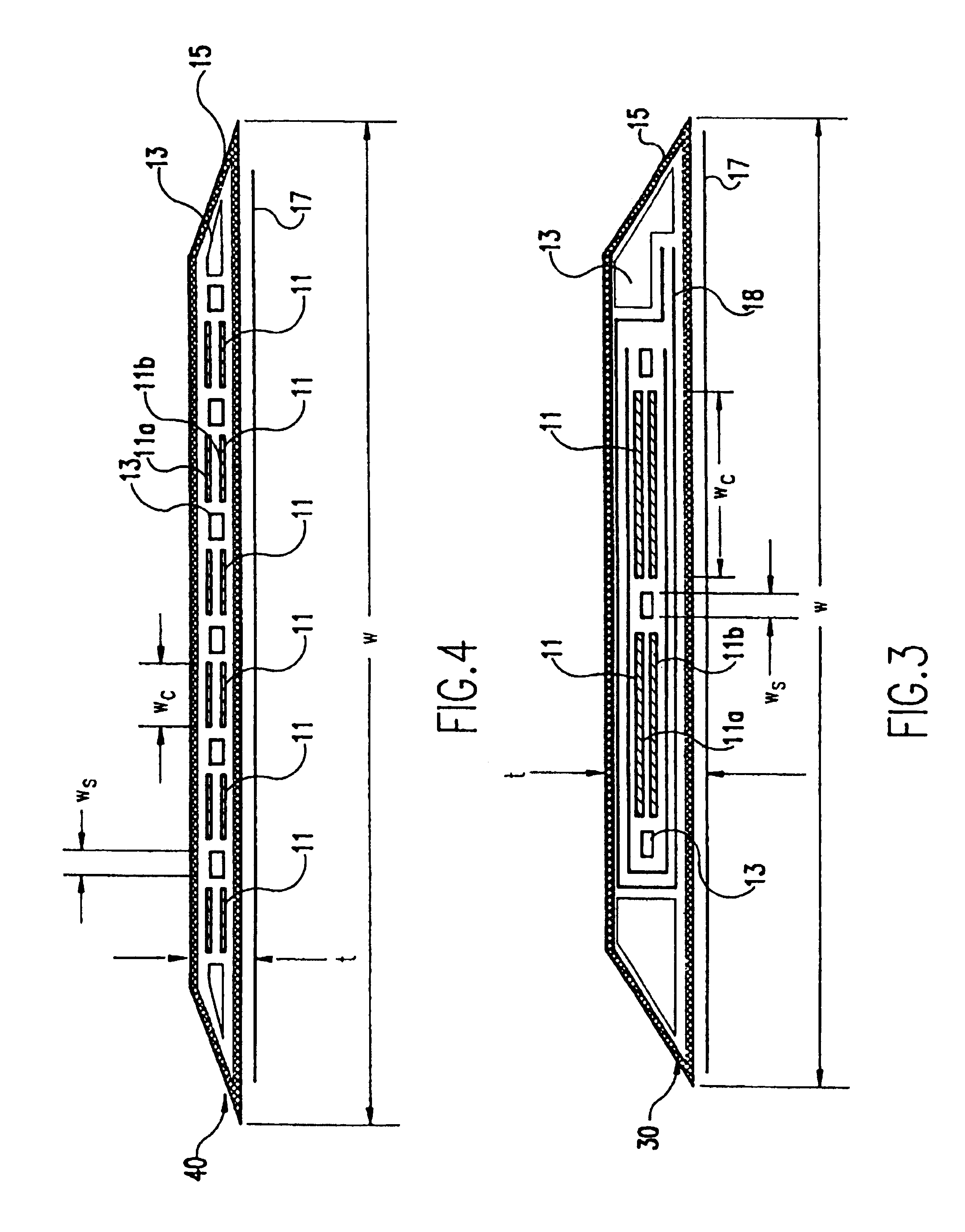

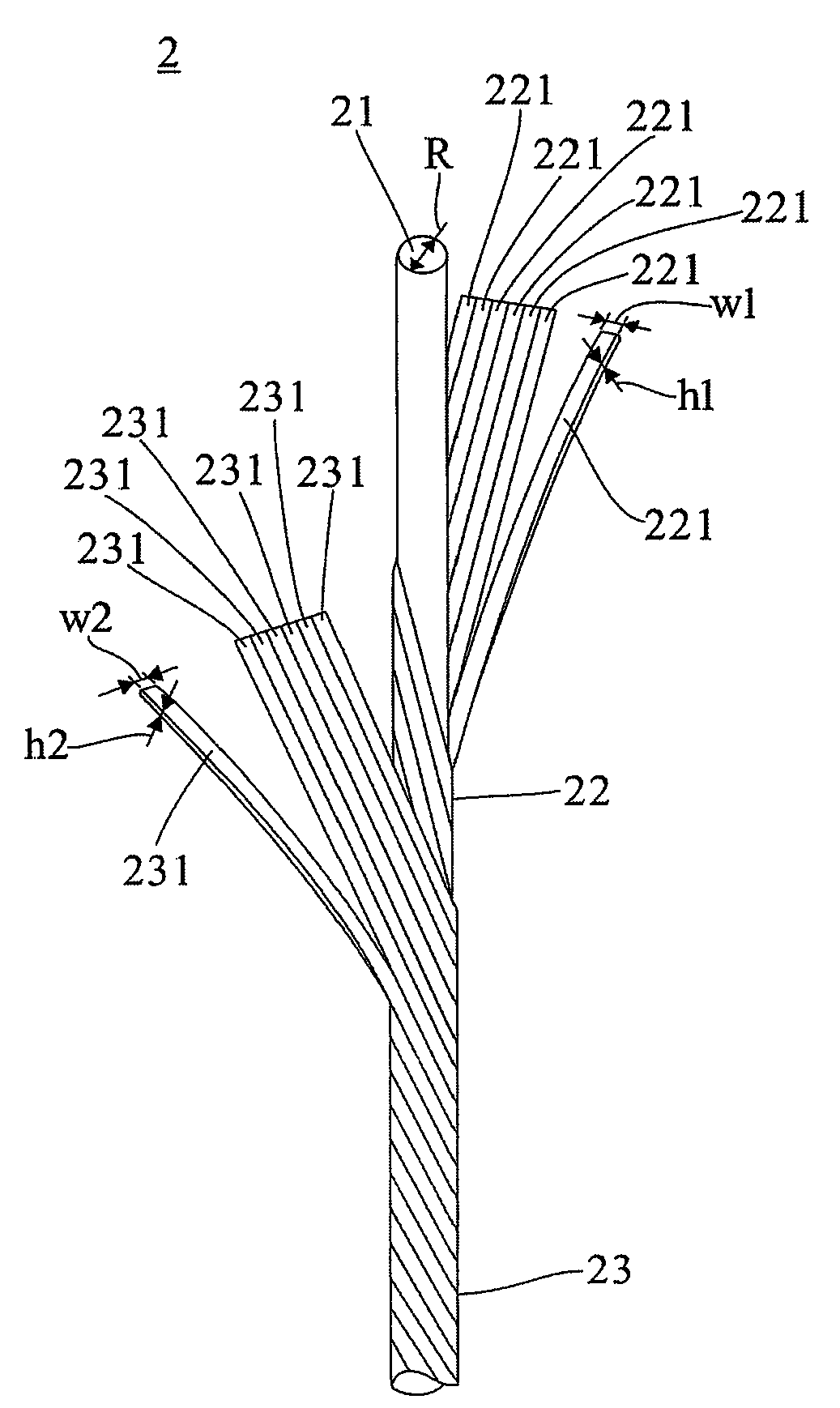

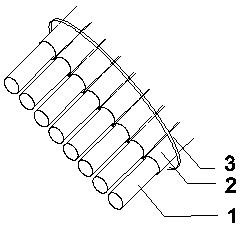

Conducting wire structure and method of manufacturing a conducting wire core

InactiveUS20110155417A1Area maximizationImprove conductivityStrip/foil conductorsFlat/ribbon cablesElectrical conductorInsulation layer

A conducting wire structure and a method of manufacturing a conducting wire core, the conducting wire comprises at least one core and an insulation skin encasing the core. The core is formed by stacking a plurality of flattened conductors with flattened cross sections interposed by an insulation layer. The insulation layer bonds two neighboring flattened conductors to form the core in an integrated manner. The flattened conductors can conduct an identical electric signal. Thus the surface area of the flattened conductors can transmit electric power or signal to maximize conductive area of one core. The method of manufacturing a core includes: providing a plurality of flattened conductors with flattened cross sections through a conductor flattened fabrication means; coating an insulation layer on the surface of the flattened conductors through a coating means; and stacking the flattened conductors coaxially to form a core. Thus conductive surface area can be maximized.

Owner:INNOTRANS TECH

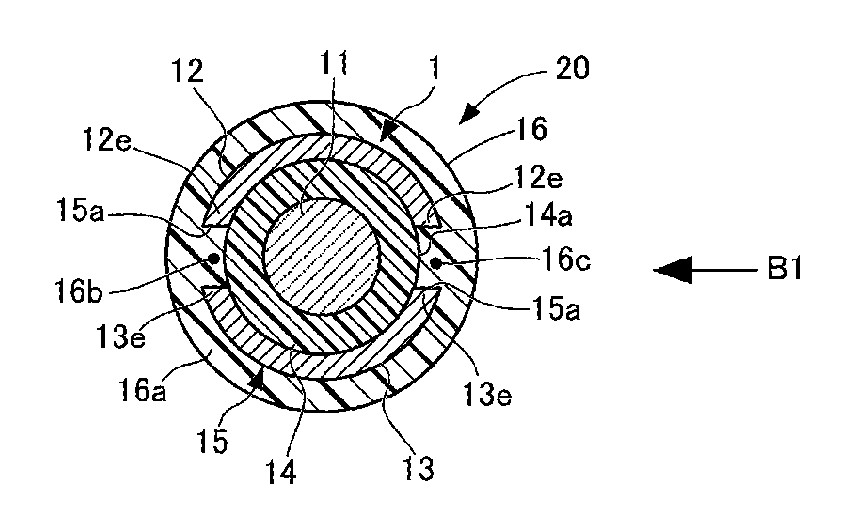

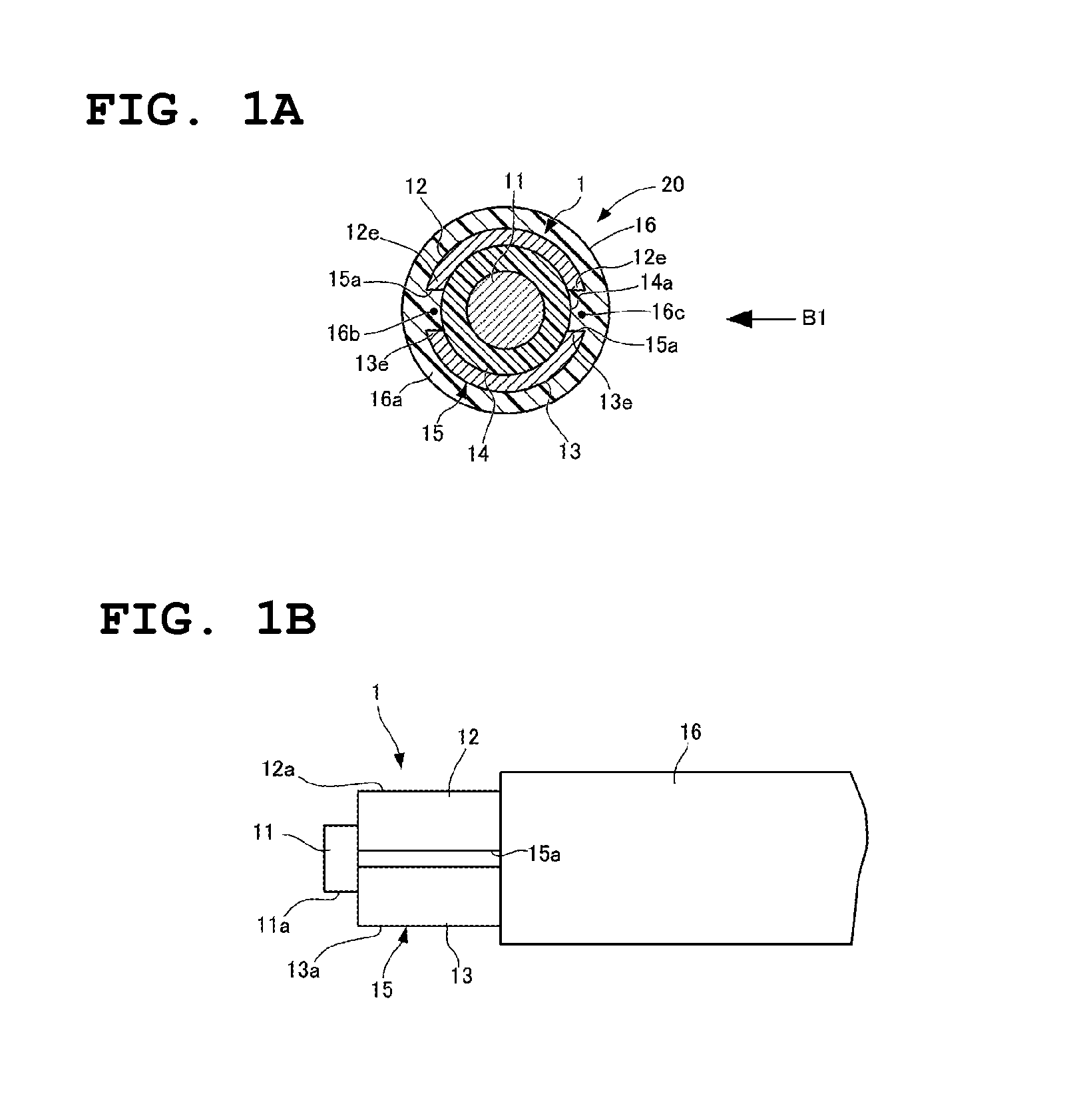

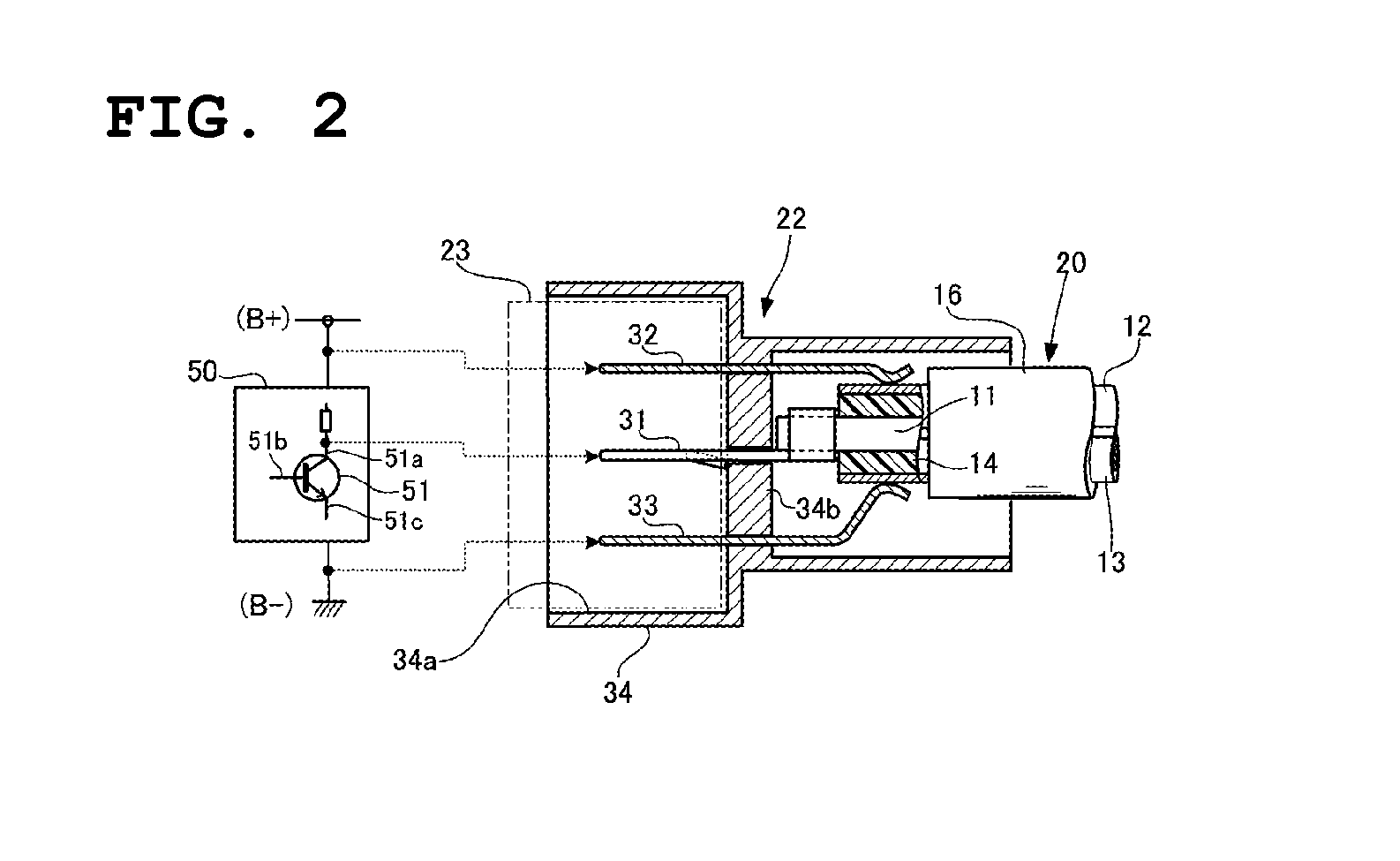

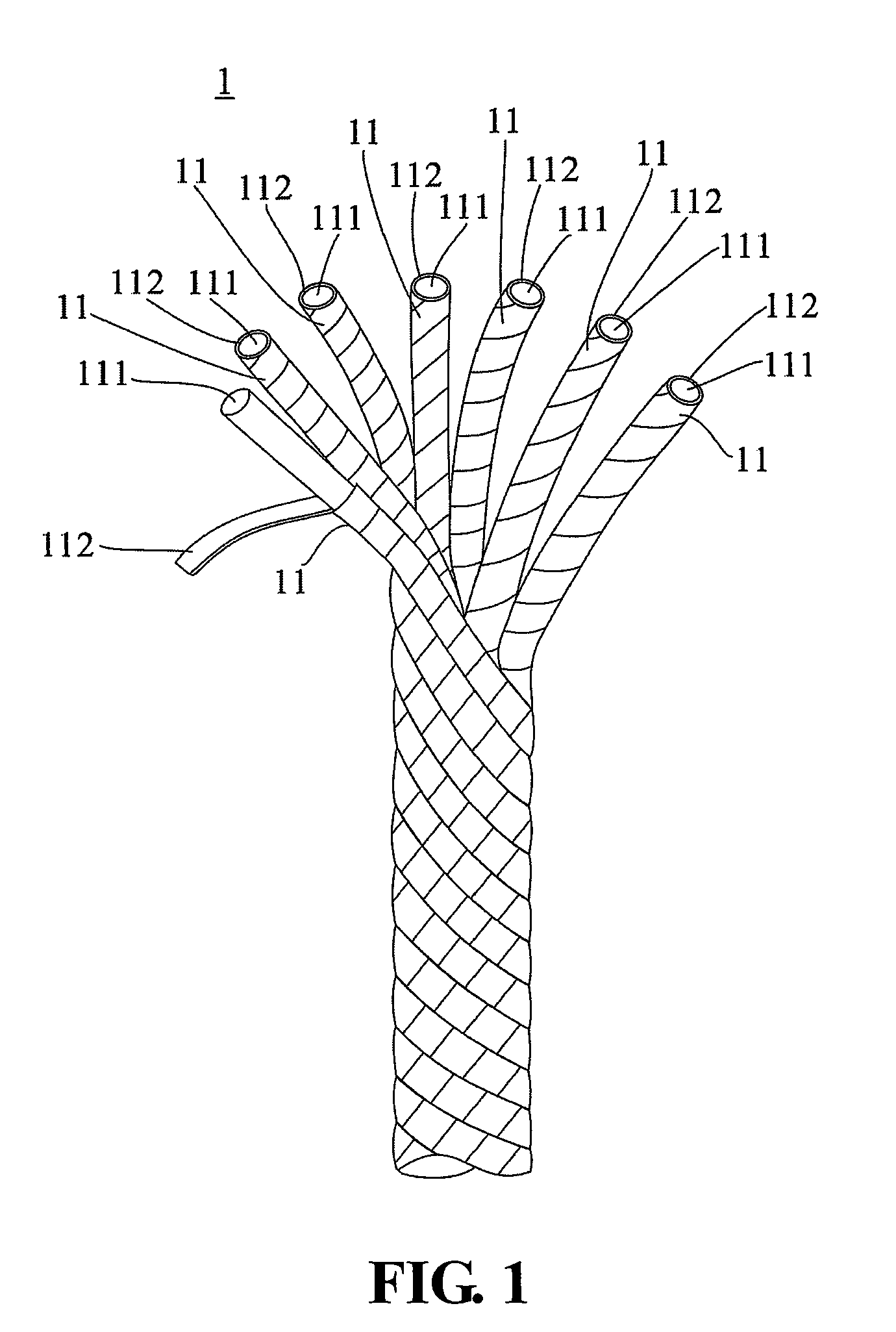

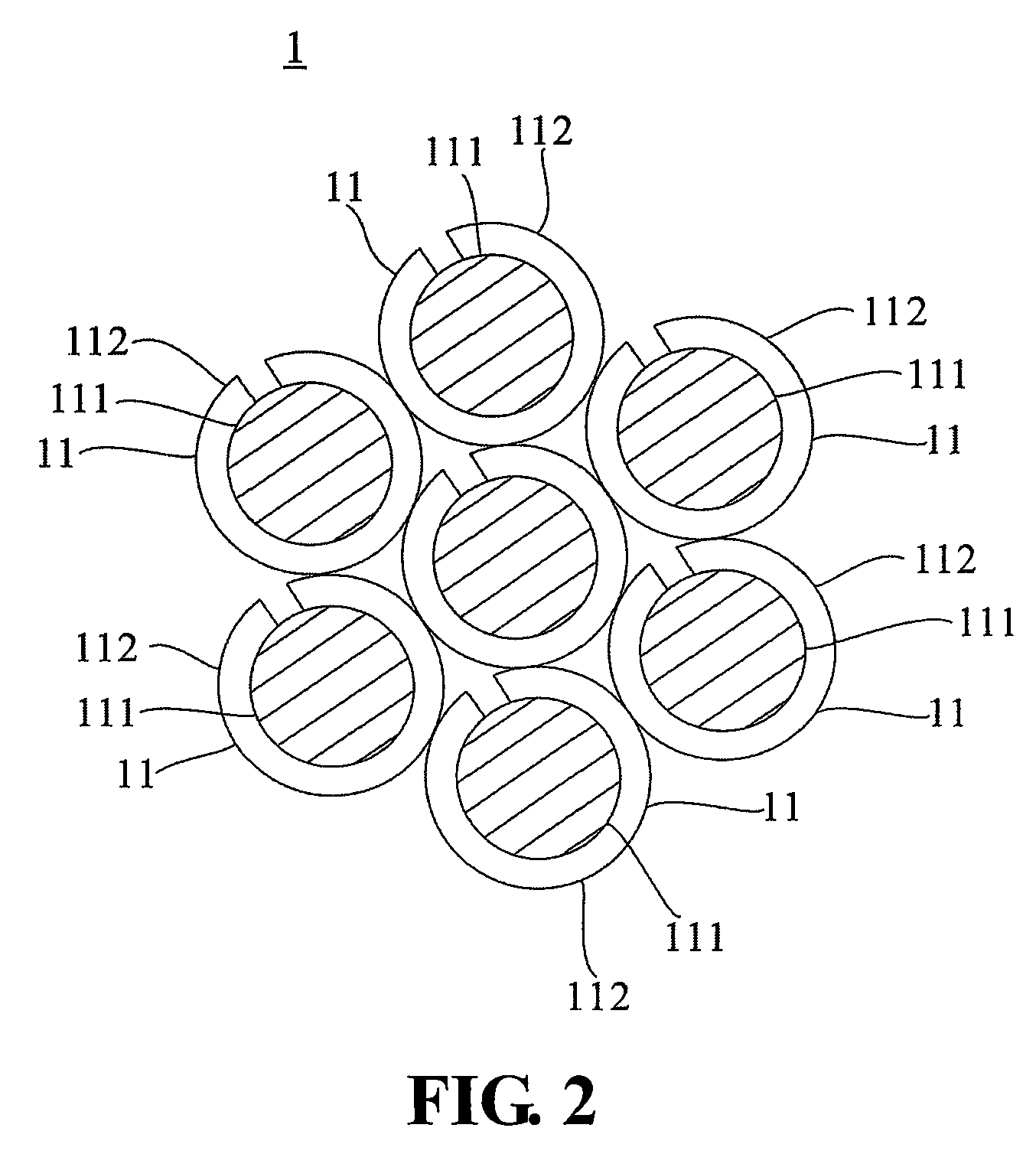

Wire harness

InactiveUS20160064118A1Reduce in quantityEasy to handleStrip/foil conductorsElectrically conductive connectionsElectrical conductorMechanical engineering

Provided is a wire harness having a shielding structure that can achieve a required shielding effect while sufficiently meeting the requirements of weight reduction and cost reduction. The wire harness includes a wire group constituted by a plurality of wires and a retaining member that surrounds the wire group such that the wire group is retained in the form of a bundle, wherein the wire group is configured to include a first wire composed of a linear conductor that is located toward the center of the wire group, a tube-shaped wire sheathing that surrounds the first wire, and a second wire and a third wire that are composed of an opposing pair of split tube-shaped conductors that are insulated from each other with the first wire and the wire sheathing being interposed therebetween.

Owner:SUMITOMO WIRING SYST LTD

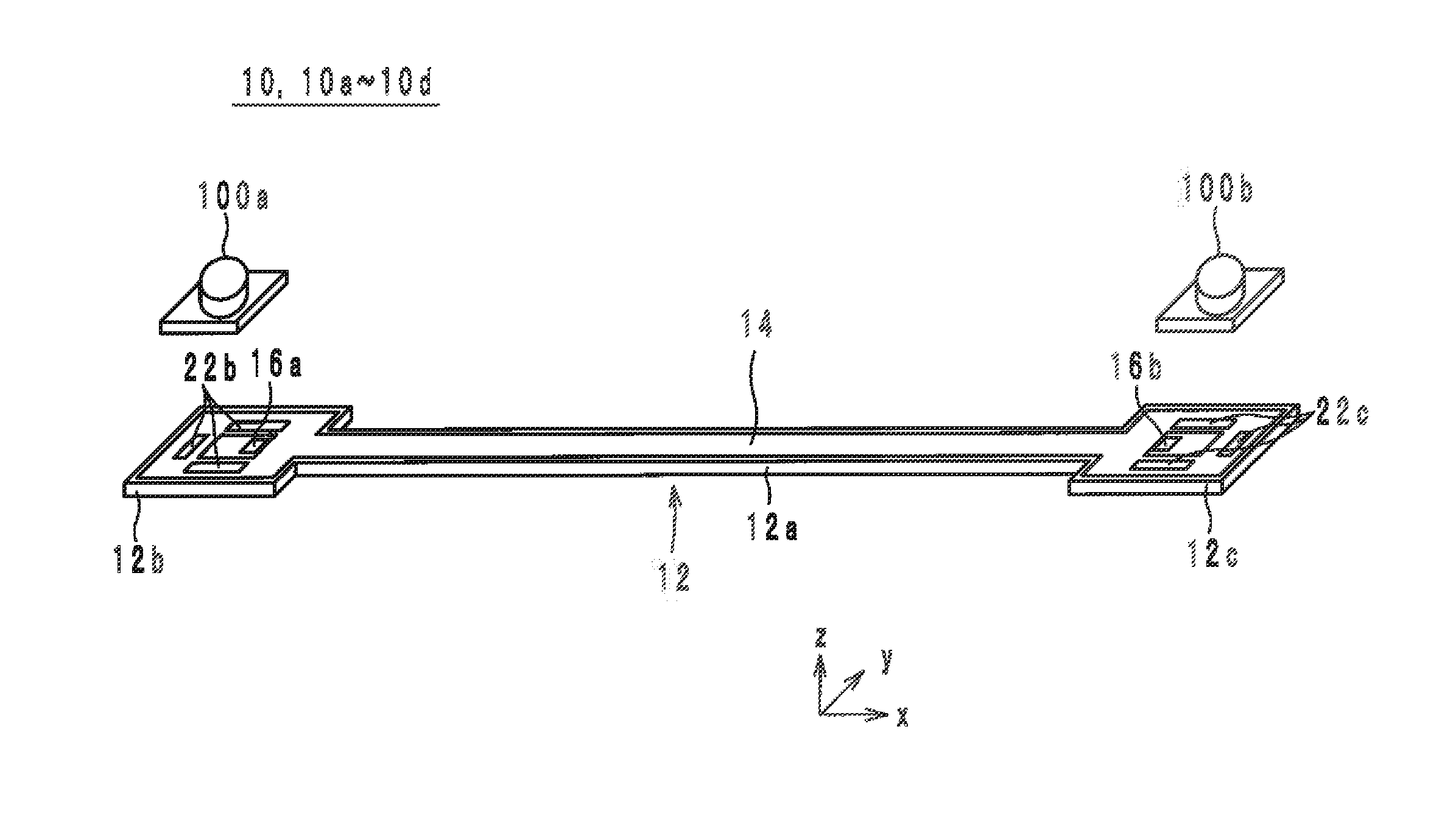

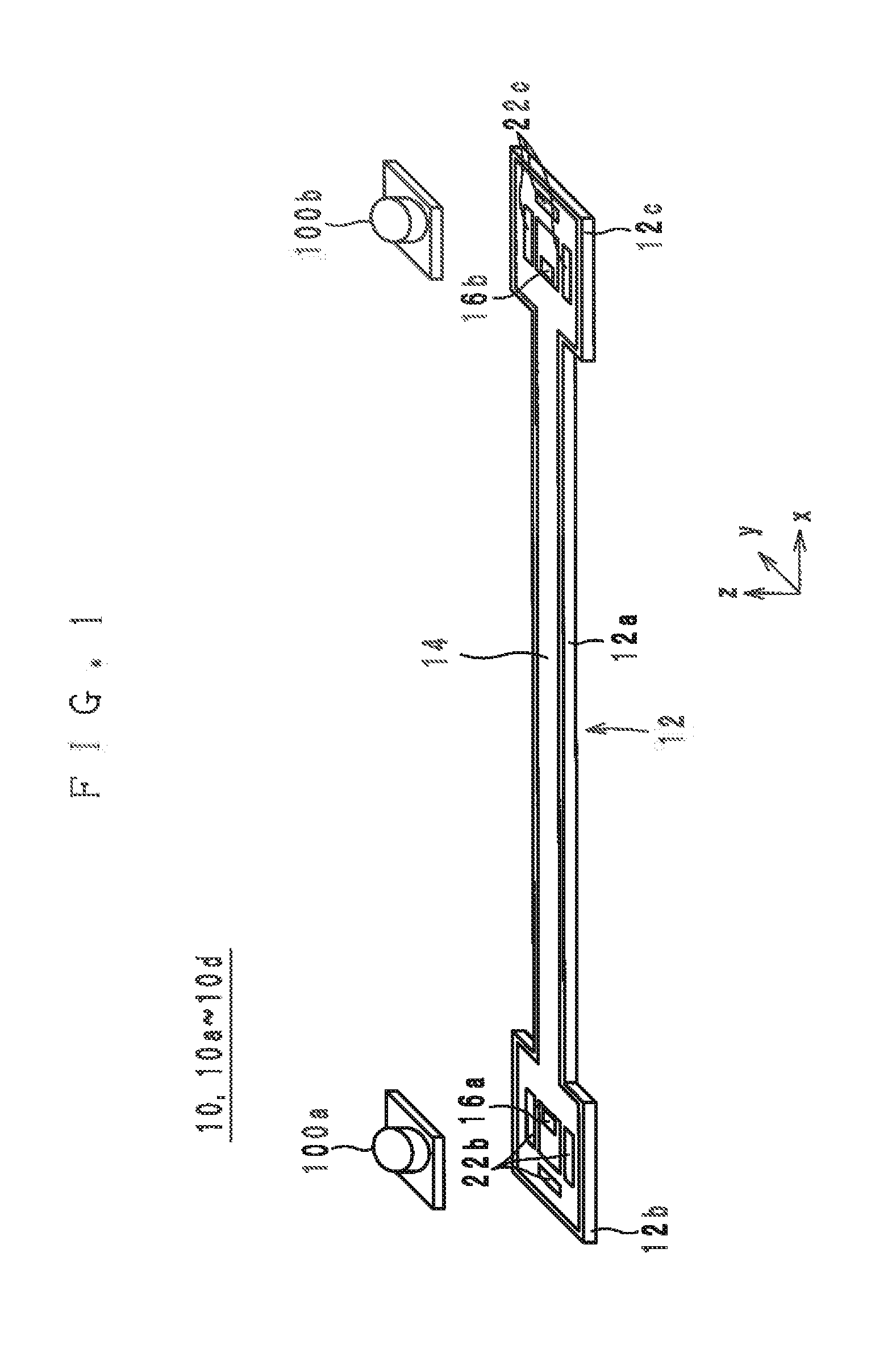

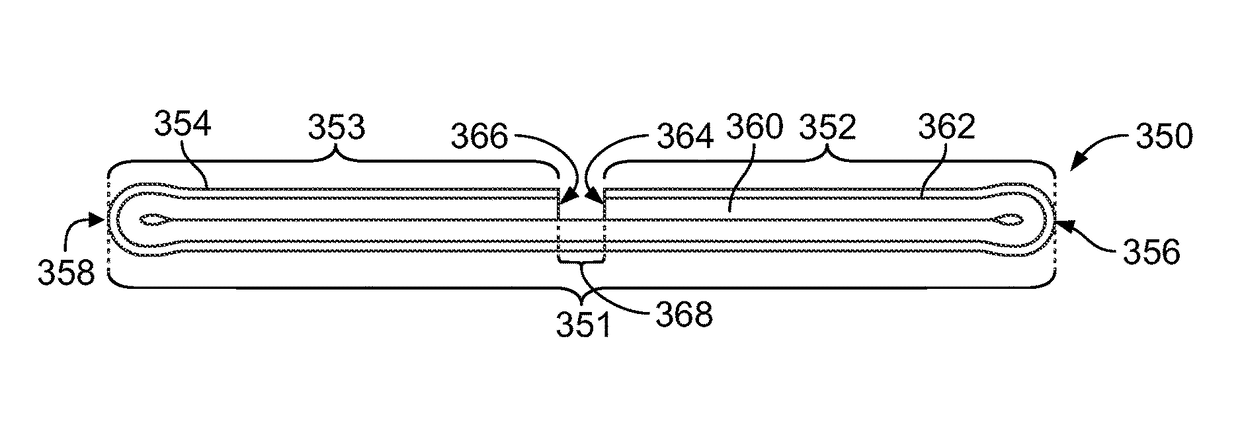

High-frequency signal line and manufacturing method thereof

ActiveUS20150087353A1Diminishing and eliminating risk of shiftRisk of a shift of the characteristic impedance from an intended value is diminished or eliminatedOrnamental structuresSpecial ornamental structuresEngineeringDielectric body

A high-frequency signal line includes a linear signal line and a first ground conductor provided at a dielectric body to extend along the dielectric body. The first ground conductor includes a first main surface and a second main surface opposed to each other in a direction of lamination. A strip-shaped protrusion extending along the signal line is provided on the second main surface of the first ground conductor.

Owner:MURATA MFG CO LTD

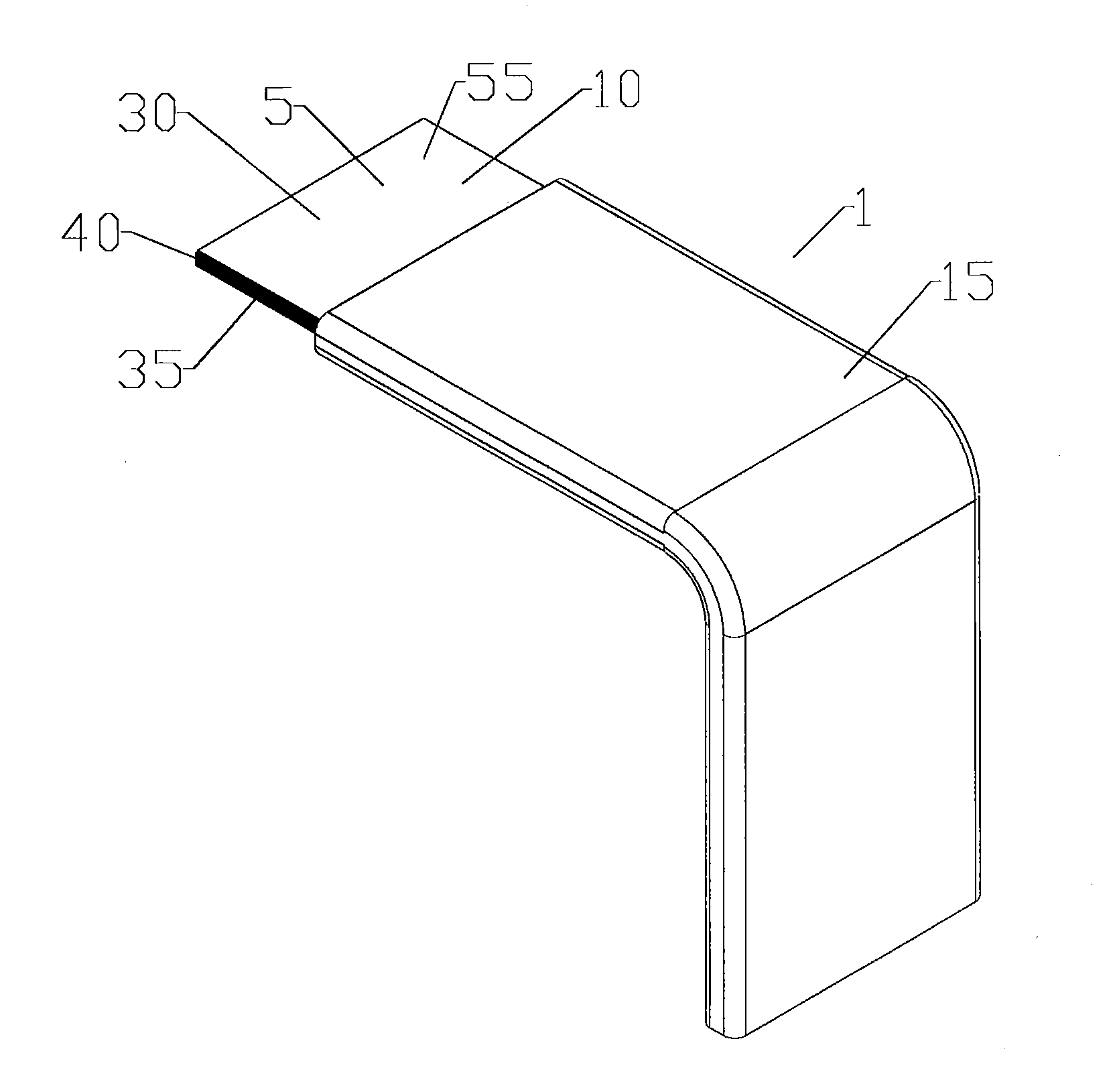

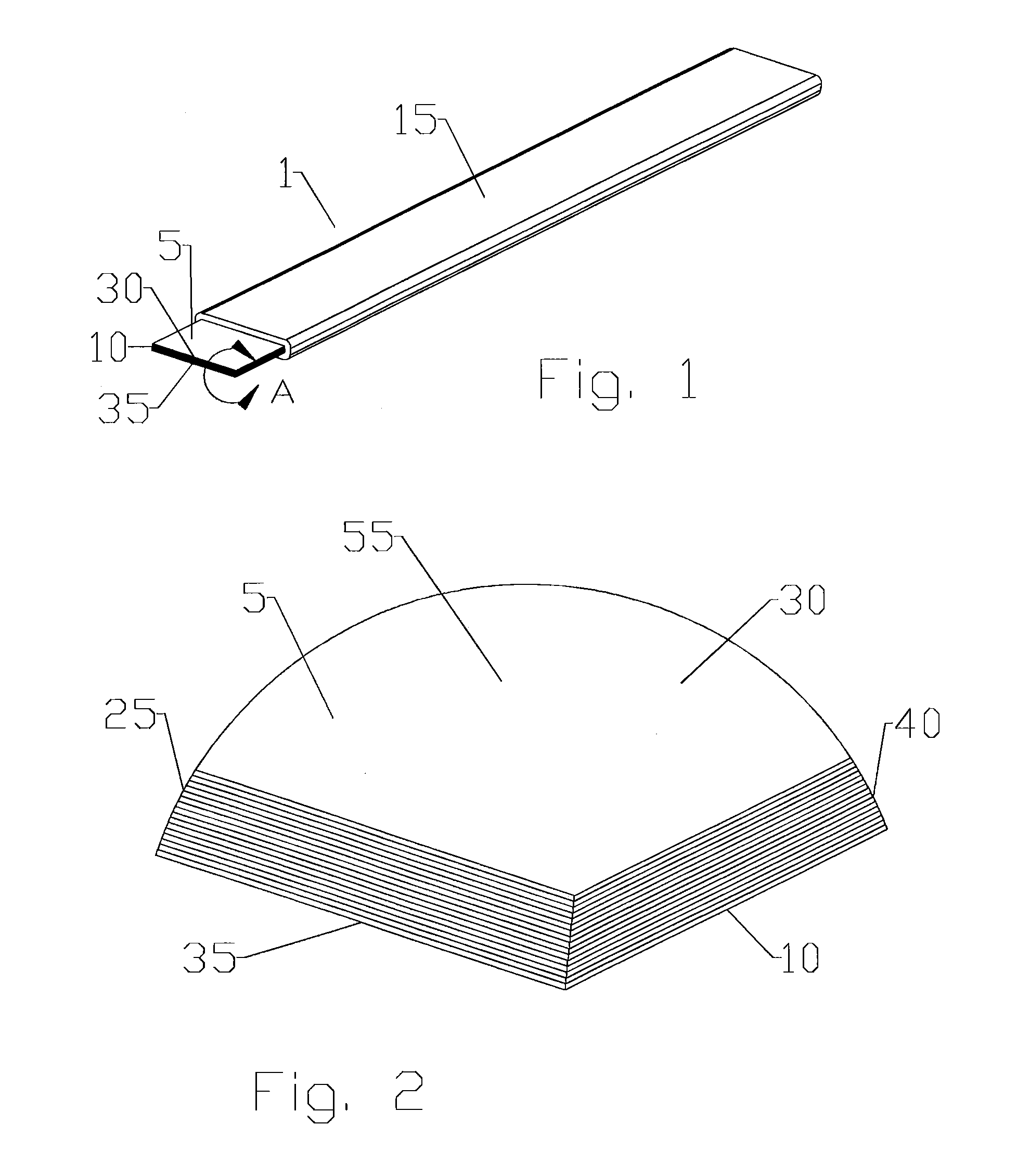

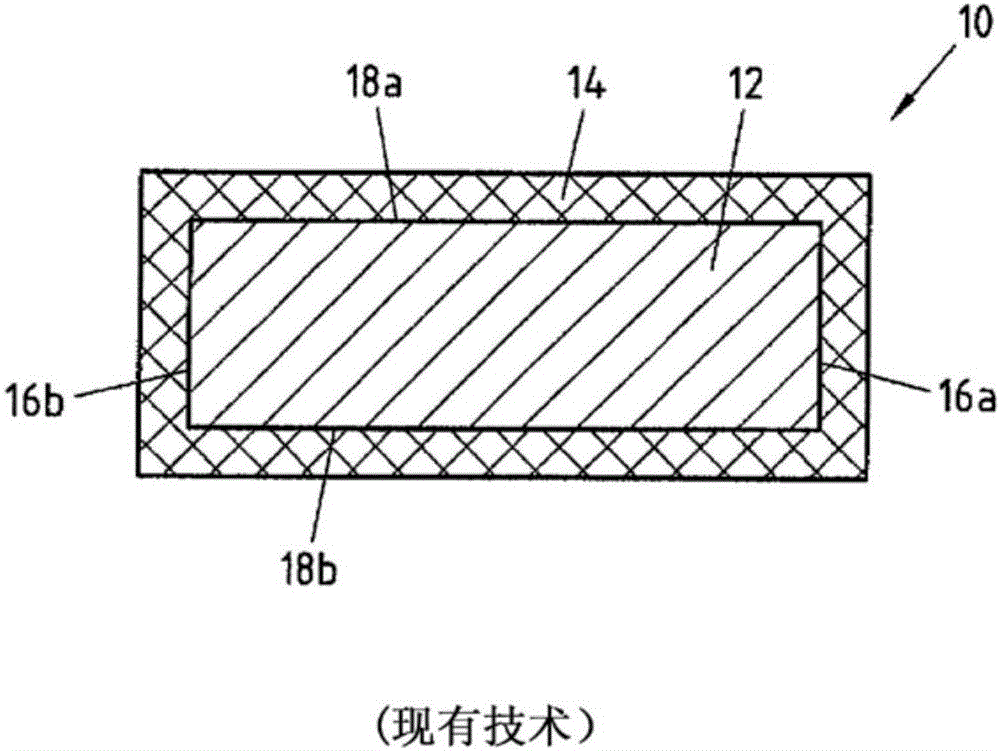

Flat surface-mounted multi-purpose wire

InactiveUS20010015283A1Strip/foil conductorsCoupling device connectionsInsulation layerElectrical conductor

A flat, surface mounted, flexible, multi-purpose wire is disclosed. The flat wire has a plurality of flat elongated conductors spaced apart in a generally parallel relationship. Each of the flat conductors comprises a plurality of copper layers. An adhesive material separates the flat conductors and an insulation layer surrounds the flat conductors and the adhesive material, with the adhesive material bonding to the insulation layer. A cross-sectional height of the flat conductors and insulation layer is such that the multi-purpose wire will blend in with the surface when painted or after wallpaper is applied.

Owner:SOUTHWIRE CO LLC

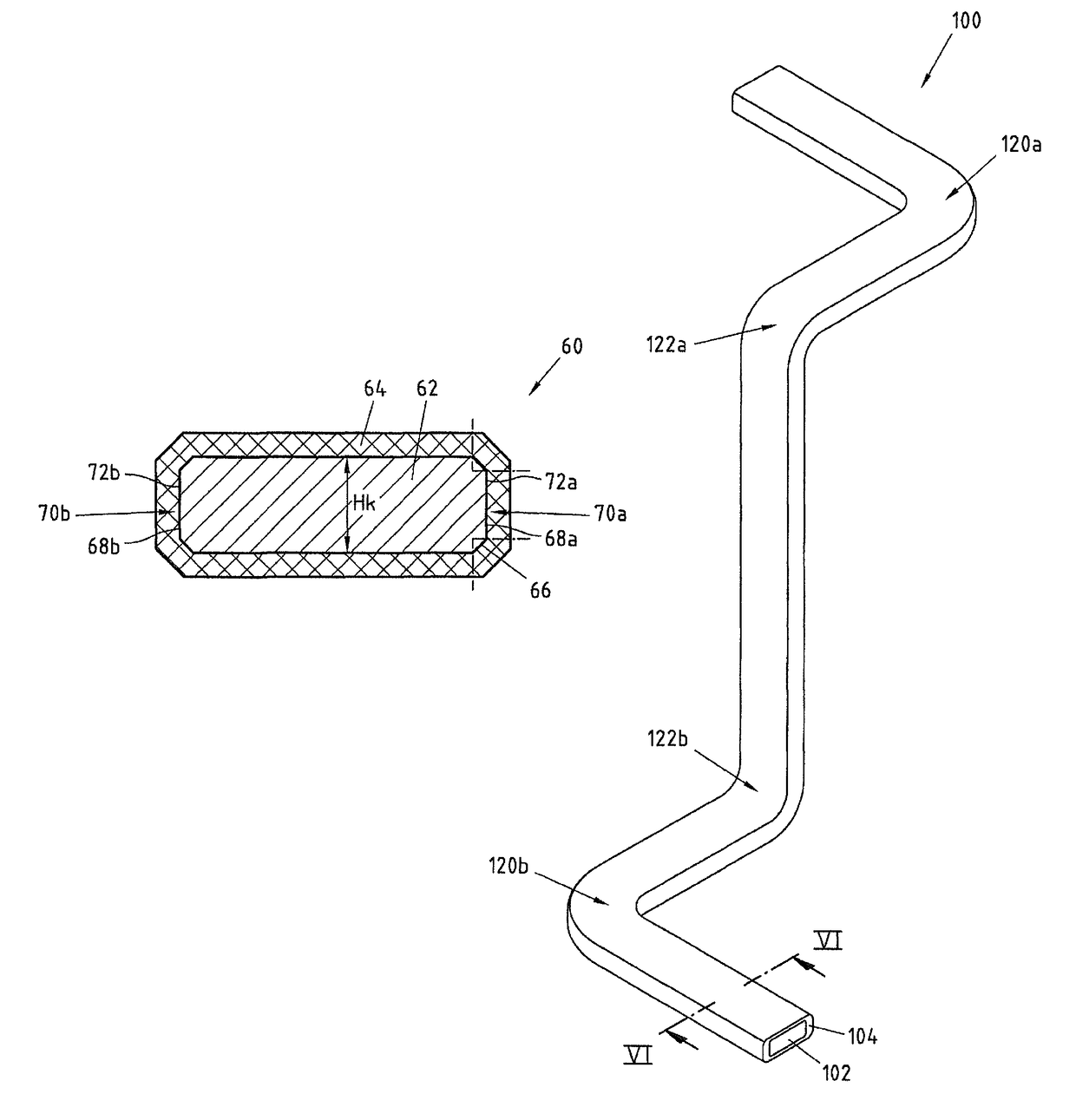

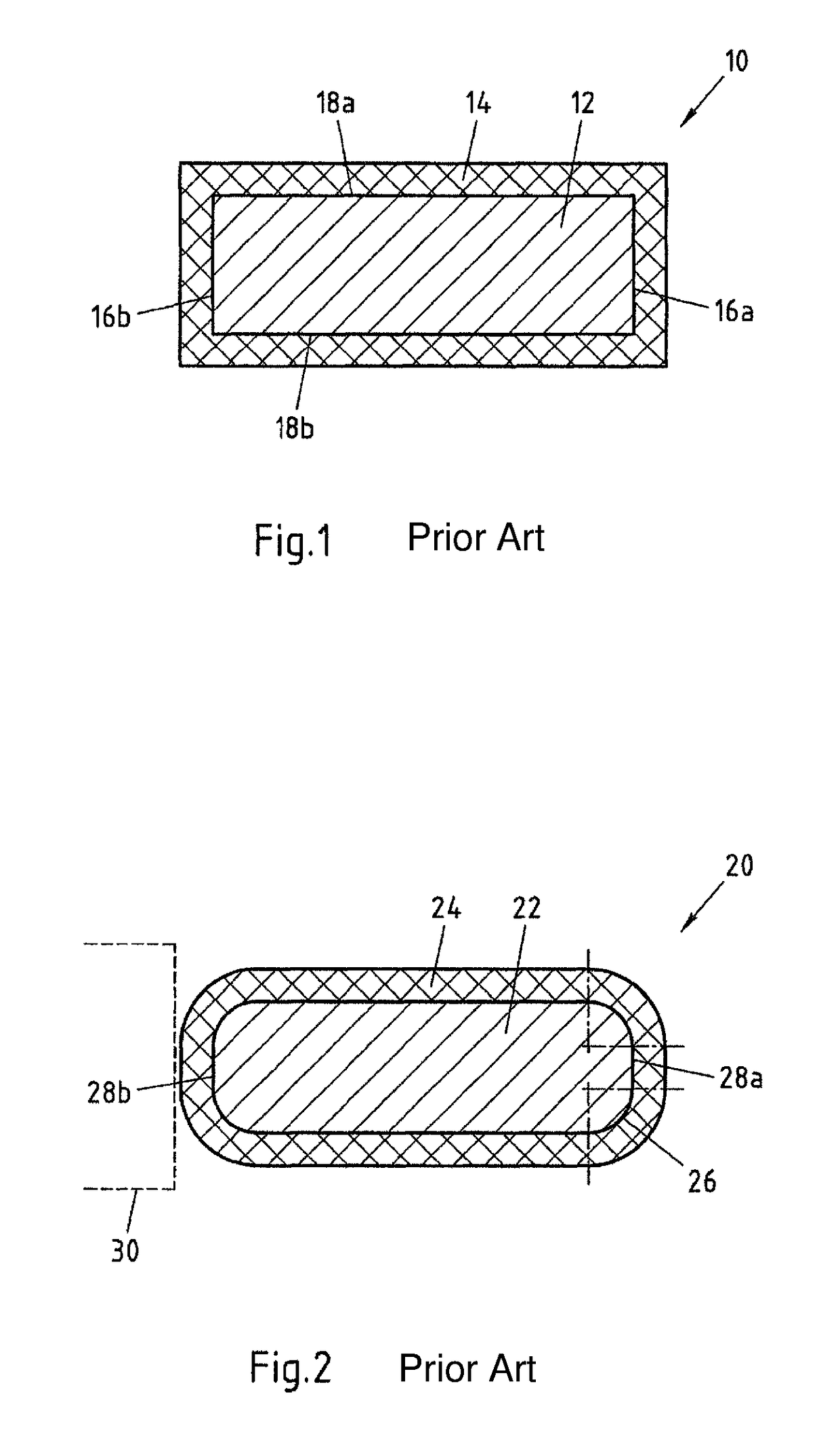

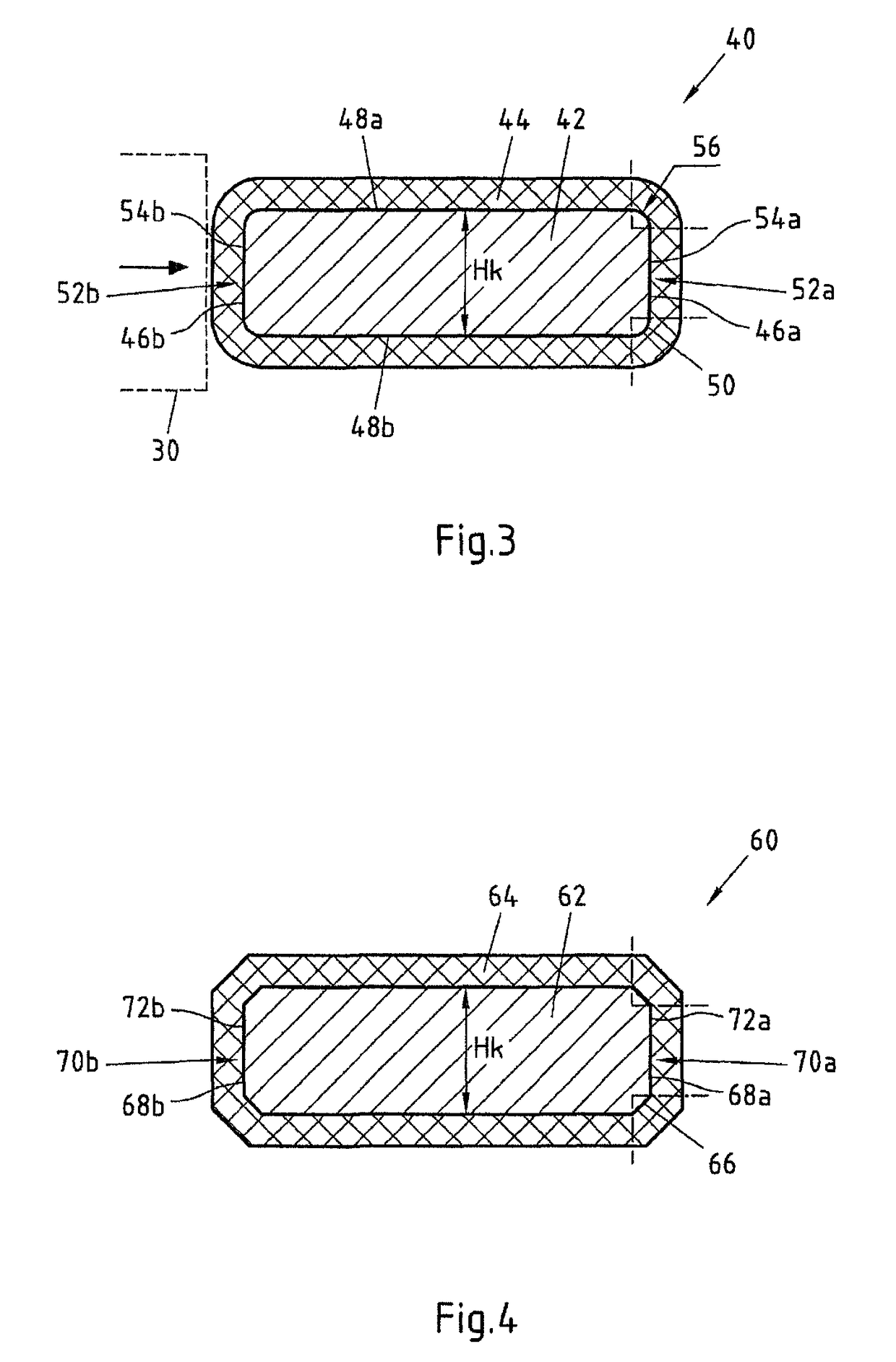

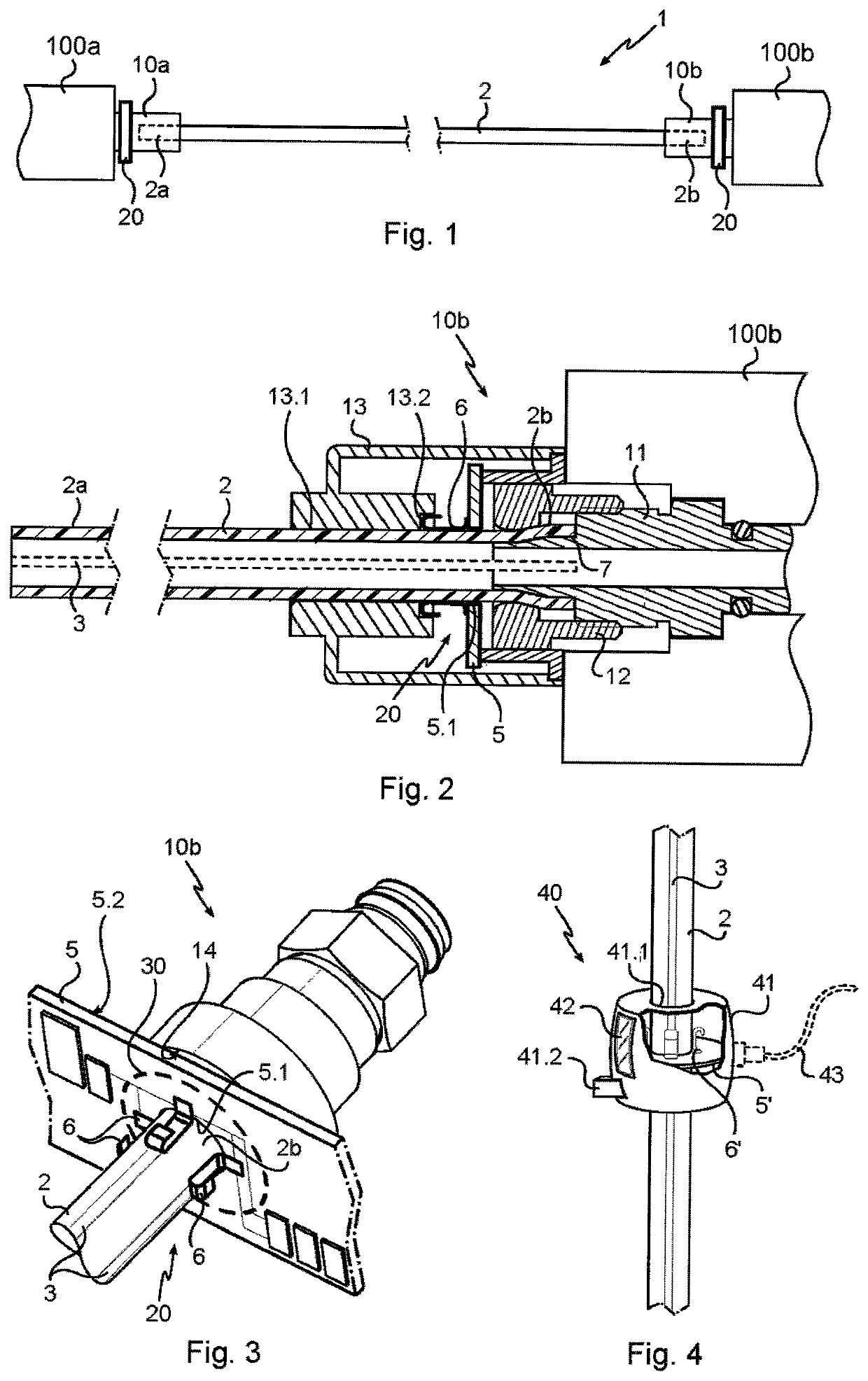

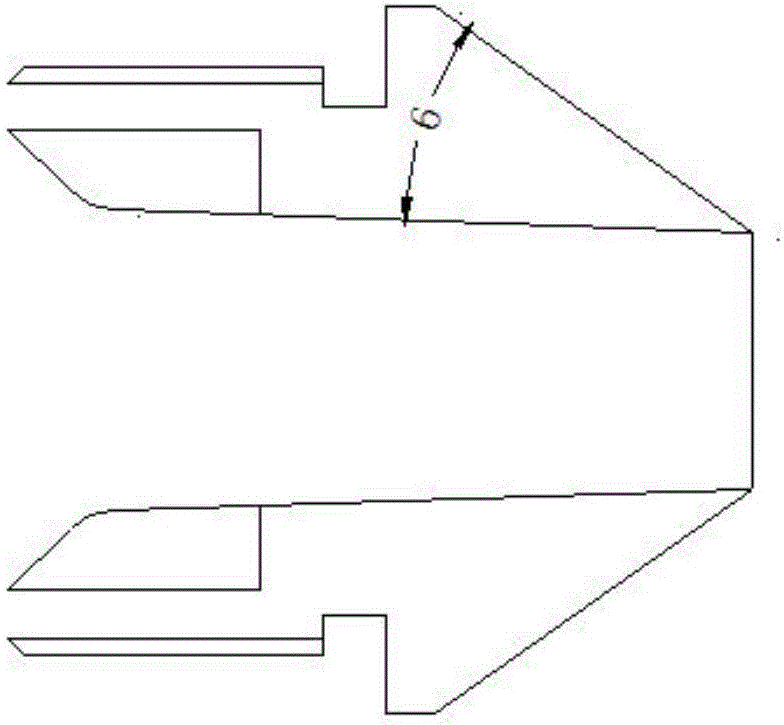

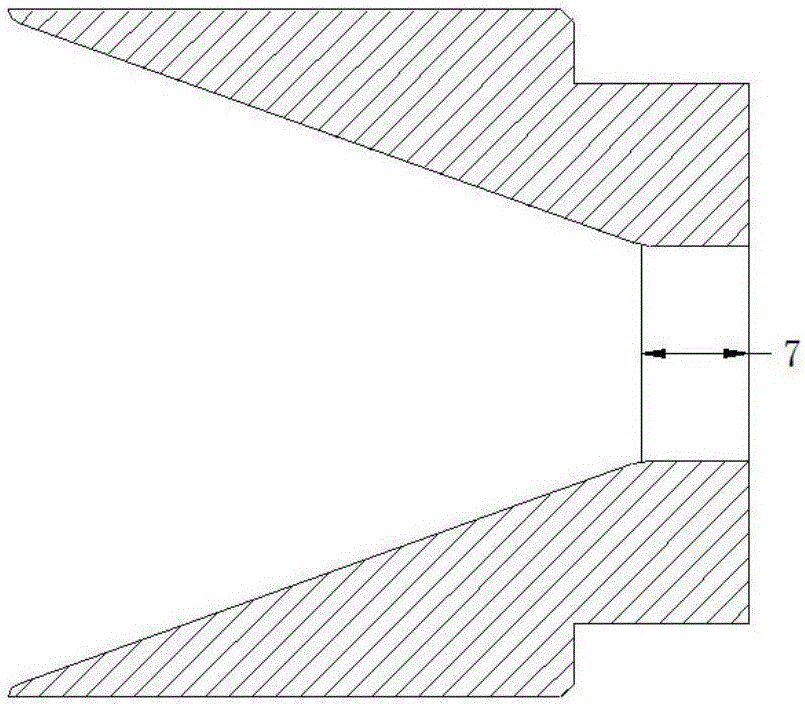

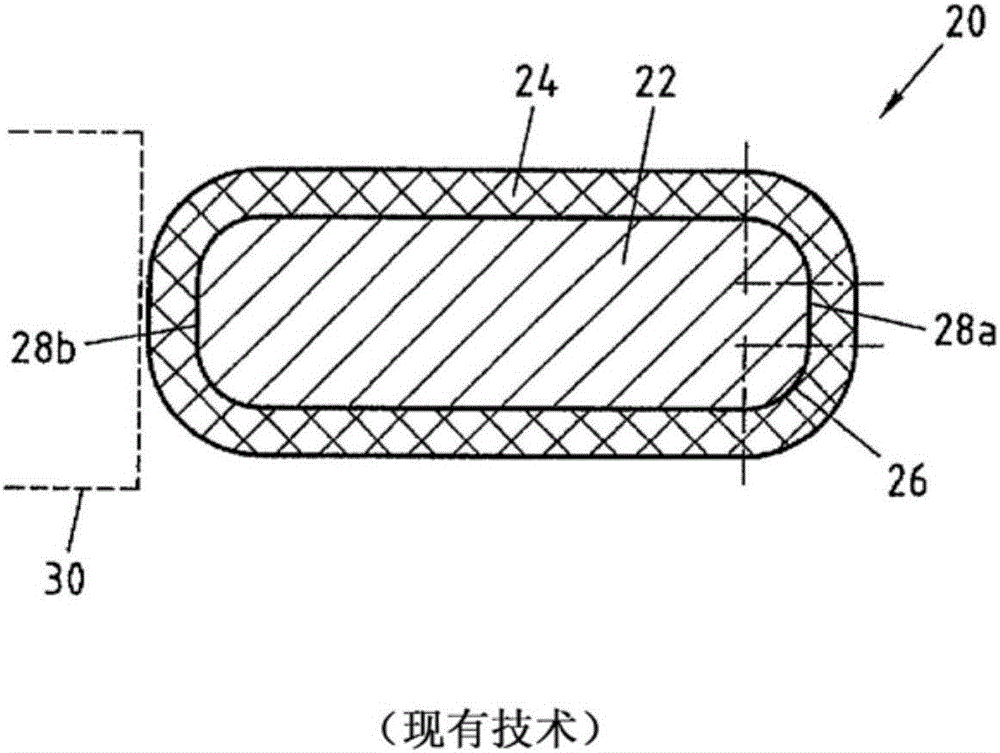

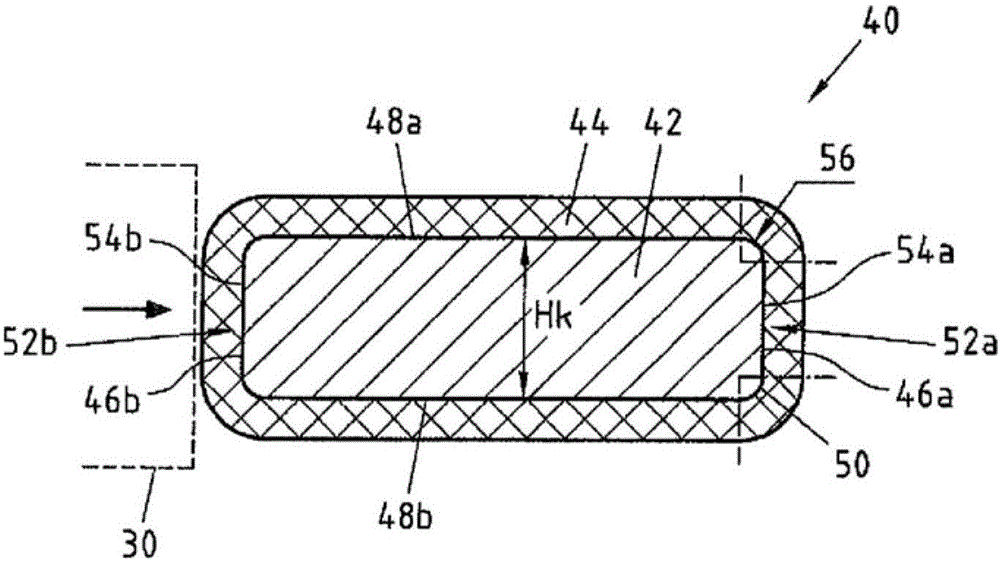

Electrical flat conductor for motor vehicles

ActiveUS10074461B2Improve the immunityIncrease wall thicknessStrip/foil conductorsFlat/ribbon cablesElectrical conductorEngineering

The invention relates to an electrical flat conductor (40, 60, 80, 100) for motor vehicles with a flat conductor core (42, 62, 82, 102) of electrically conductive flat conductor material and with an insulation of an insulating material encasing the flat conductor core (42, 62, 82, 102), wherein the height (Hk) of the flat conductor core (42, 62, 82, 102) is less than the width (Bk) of the flat conductor core, wherein the flat conductor core (42, 62, 82, 102) has at least one narrow side (46a-b, 68a-b, 86a-b, 106a-b), which limits the width of the flat conductor core (42, 62, 82, 102) on one side, wherein the at least one narrow side (46a-b, 68a-b, 86a-b, 106a-b) of the flat conductor core (42, 62, 82, 102) has at least in sections over the length of the flat conductor (40, 60, 80, 100) a partial surface (52a-b, 70a-b, 114a-b), whose contour in the cross-section of the flat conductor core (42, 62, 82, 102) forms a straight section (46a-b, 54a-b, 72a-b, 116a-b), which extends over a part of the height of the flat conductor core (42, 62, 82, 102), wherein the straight section (46a-b, 54a-b, 72a-b, 116a-b) extends over at least 75% of the height of the flat conductor core (42, 62, 82, 102). The invention furthermore relates to an electrical flat conductor (40, 60, 80, 100) for motor vehicles with a flat conductor core (42, 62, 82, 102) of electrically conductive flat conductor material and with an insulation (44, 64, 84, 104) of an insulating material encasing the flat conductor core (42, 62, 82, 102) , wherein the height (Hk) of the flat conductor core (42, 62, 82, 102) is less than the width (Bk) of the flat conductor core (42, 62, 82, 102) and wherein the insulation (44, 64, 84, 104) at least in sections over the length of the flat conductor (40, 60, 80, 100) on at least one side (46a-b, 48a-b, 68a-b, 86a-b, 88a-b, 106a-b, 108a-b) of the flat conductor core (42, 62, 82, 102) has a greater wall thickness than on at least one other side (46a-b, 48a-b, 68a-b, 86a-b, 88a-b, 106a-b, 108a-b) of the flat conductor core (42, 62, 82, 102).

Owner:AUTO KABEL MANAGEMENTGMBH

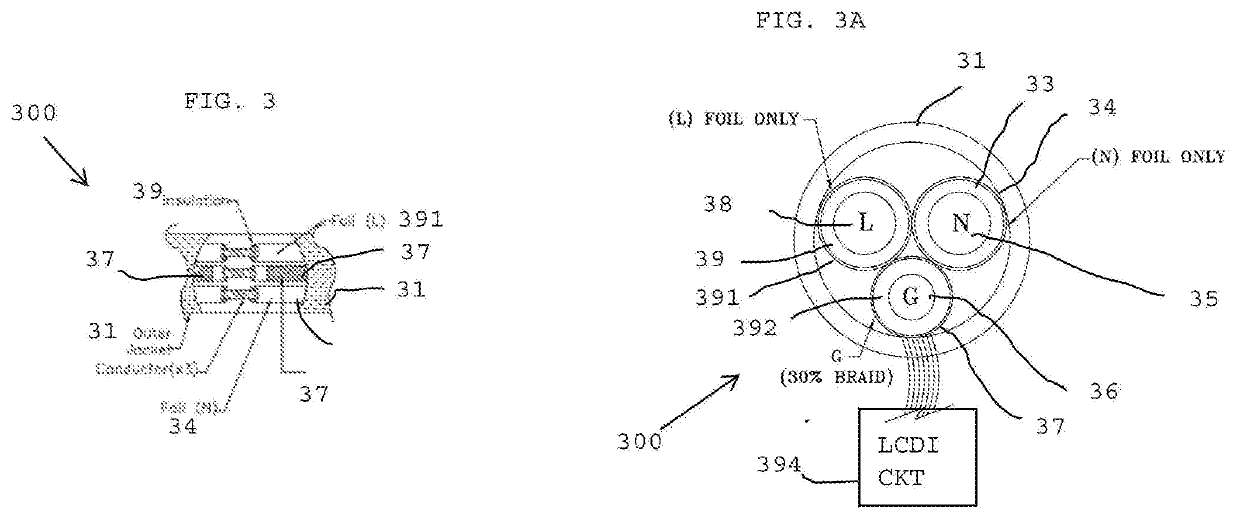

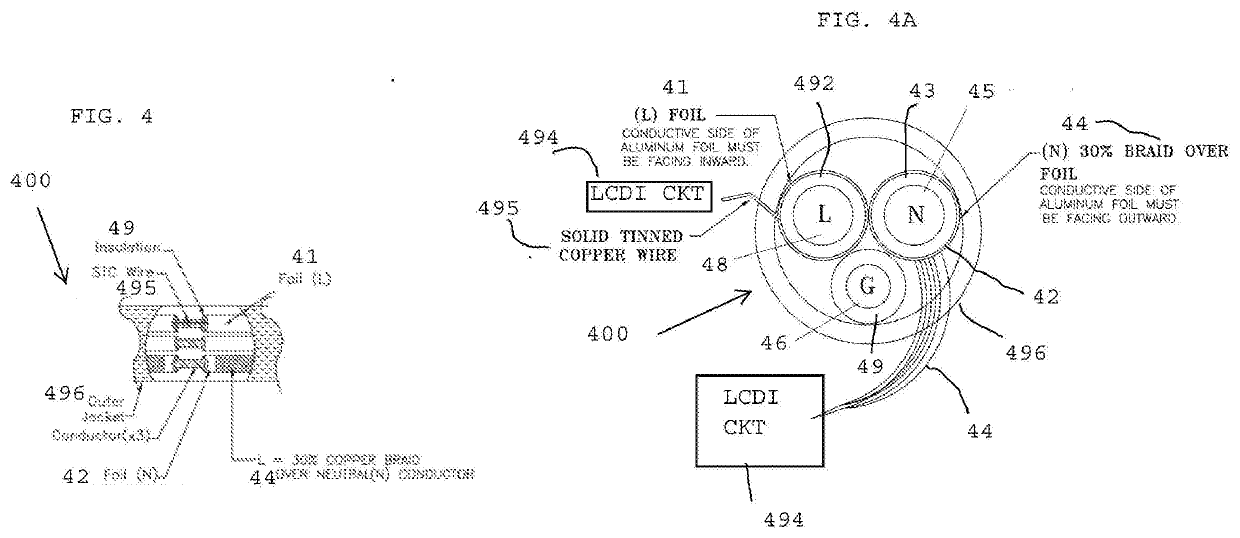

LCDI Power Cord

A power cord with leakage current detection function includes an insulated neutral wire and aluminum foil wrapping or surrounding the neutral wire insulator. The neutral wire aluminum foil has a conductive side and a non-conductive side, wherein the non-conductive side is adjacent to the outside of the neutral wire insulator and the conductive side is facing outwards. The power cord also includes an insulated line wire surrounded by aluminum foil where the conductive side is facing outwards and in contact with the conductive side of the aluminum foil surround the neutral wire. The power cord also includes a copper braid surrounding an insulated ground wire, wherein the copper braid is in simultaneous electrical contact with the conductive sides of the line and neutral aluminum foil wraps.

Owner:TOWER MFG

Flexible electrical power cable

ActiveUS20160217884A1Good bending propertiesEasy to installStrip/foil conductorsPlastic/resin/waxes insulatorsElectrical conductorPower cable

An electrical cable has a plurality of generally rectangular cross-section conductors superposed in a stack, the stack surrounded by a polymer jacket. The stack may be provided with a lubrication layer provided between at least two of the conductors. Conductors of the stack may have a thickness that is greater proximate the middle of the stack than at the top and bottom of the stack and / or a width that is less at the top and the bottom than at the middle. Further stacks may also be provided parallel and coplanar with the first stack, also surrounded by the polymer jacket.

Owner:COMMSCOPE TECH LLC

Flat surface-mounted multi-purpose wire

InactiveUSRE42085E1Strip/foil conductorsCoupling device connectionsInsulation layerElectrical conductor

A multi-purpose wire includes at least one elongated conductor having a width of at least 0.125 inches. The conductor includes at least one conductive layer having a thickness no greater than about 0.0200 inches. The wire also includes a bonding material between each conductor, and an insulation layer surrounding the conductor and bonding material.

Owner:NEWELL CO INC

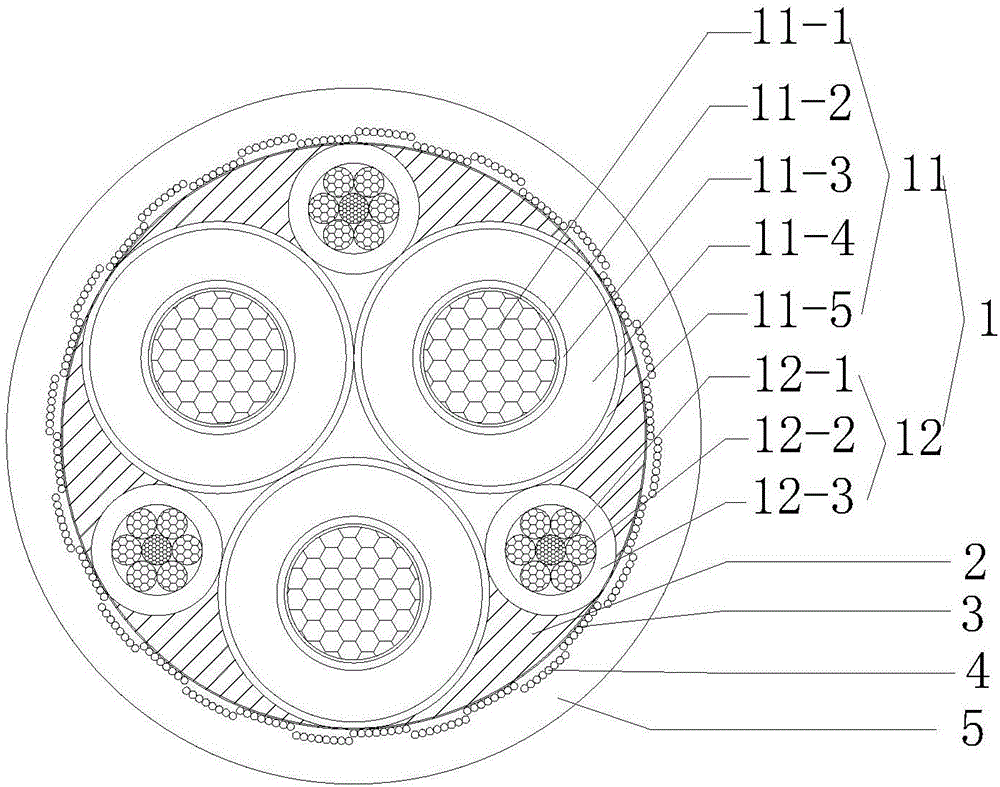

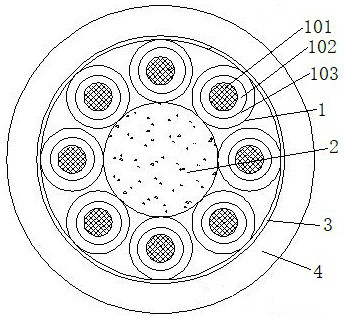

Medium-voltage trailing cable applied to intelligent energy tunneling machine and production process

InactiveCN106653162AHigh tensile strengthHigh strengthStrip/foil conductorsPower cables with screens/conductive layersCopper conductorPower cable

The invention discloses a medium-voltage trailing cable applied to an intelligent energy tunneling machine and a production process. The medium-voltage trailing cable includes a cable core, a side gap filler, a second semiconducting nylon band, a fiber-braided reinforcing layer and a sheath which are distributed sequentially from inside to outside; the cable core comprises three power cable cores and three neutral cable cores; the three neutral cable cores are arranged between every two power core cores and tangent to the power cable cores; gaps among the power cable cores, the neutral cable cores and the second semiconducting nylon band are filled with the side gap filler; and the neutral cable core includes a copper foil wire stranded conductor, neutral cable core copper conductors and a second semiconducting shielding layer which are distributed sequentially from inside to outside. According to the medium-voltage trailing cable applied to the intelligent energy tunneling machine and the production process of the invention, the copper foil wire stranded conductors are added into the neutral cable core copper conductors, KEVLAR fiber lines in the copper foil wires have high strength, high softness, low creep and the like, and therefore, the tensile strength of the neutral cable cores can be effectively improved.

Owner:FAR EAST CABLE +2

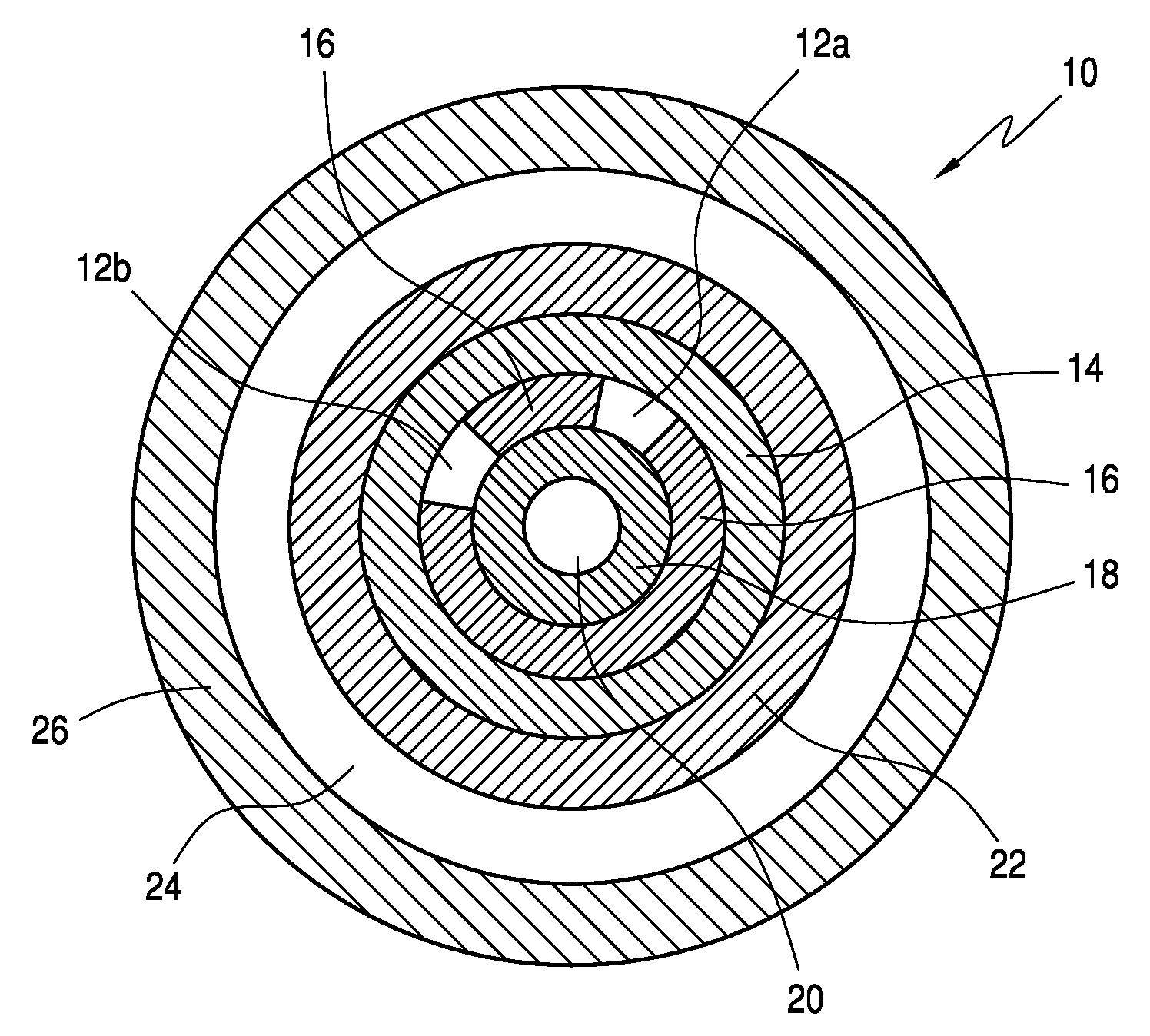

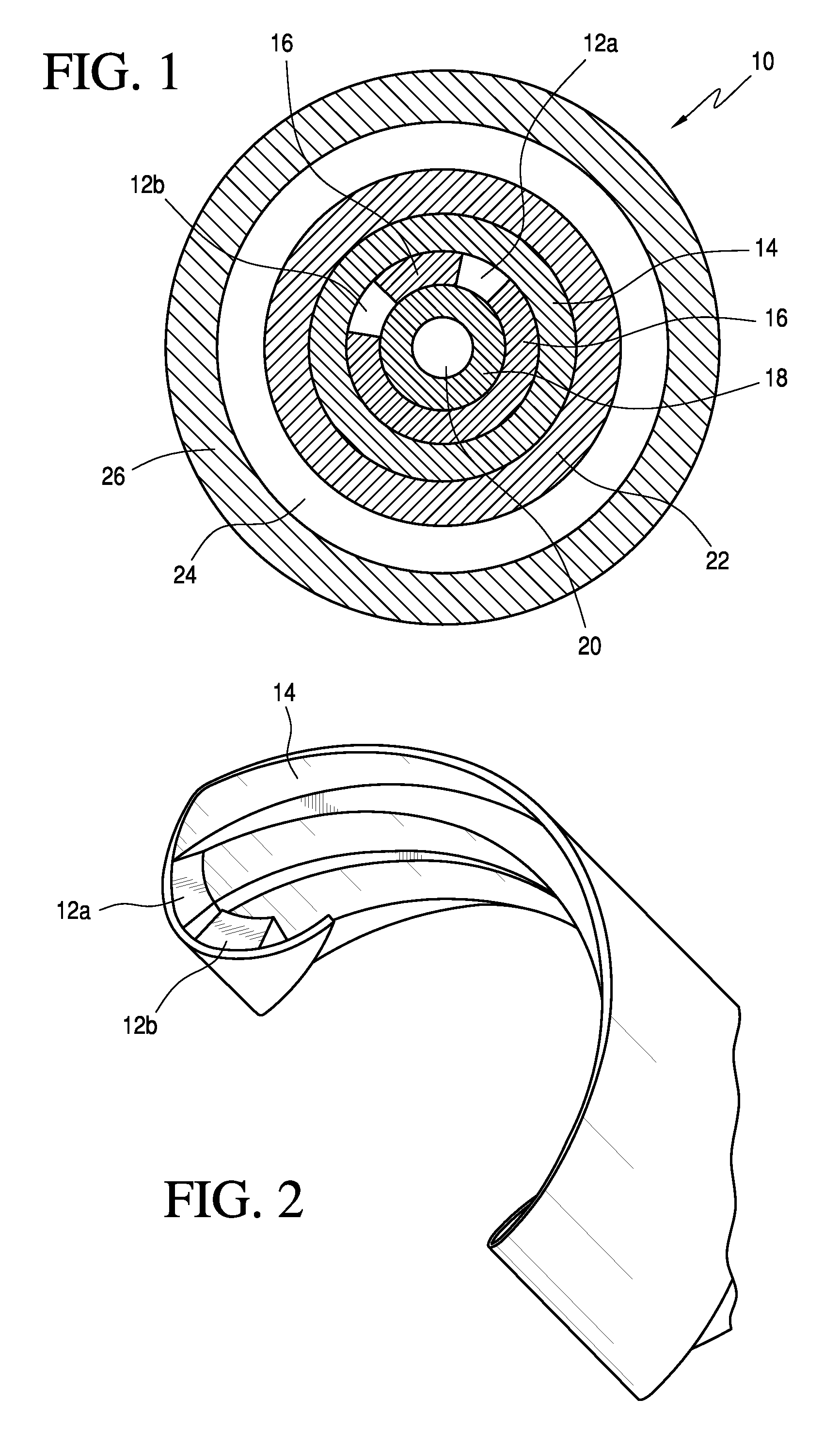

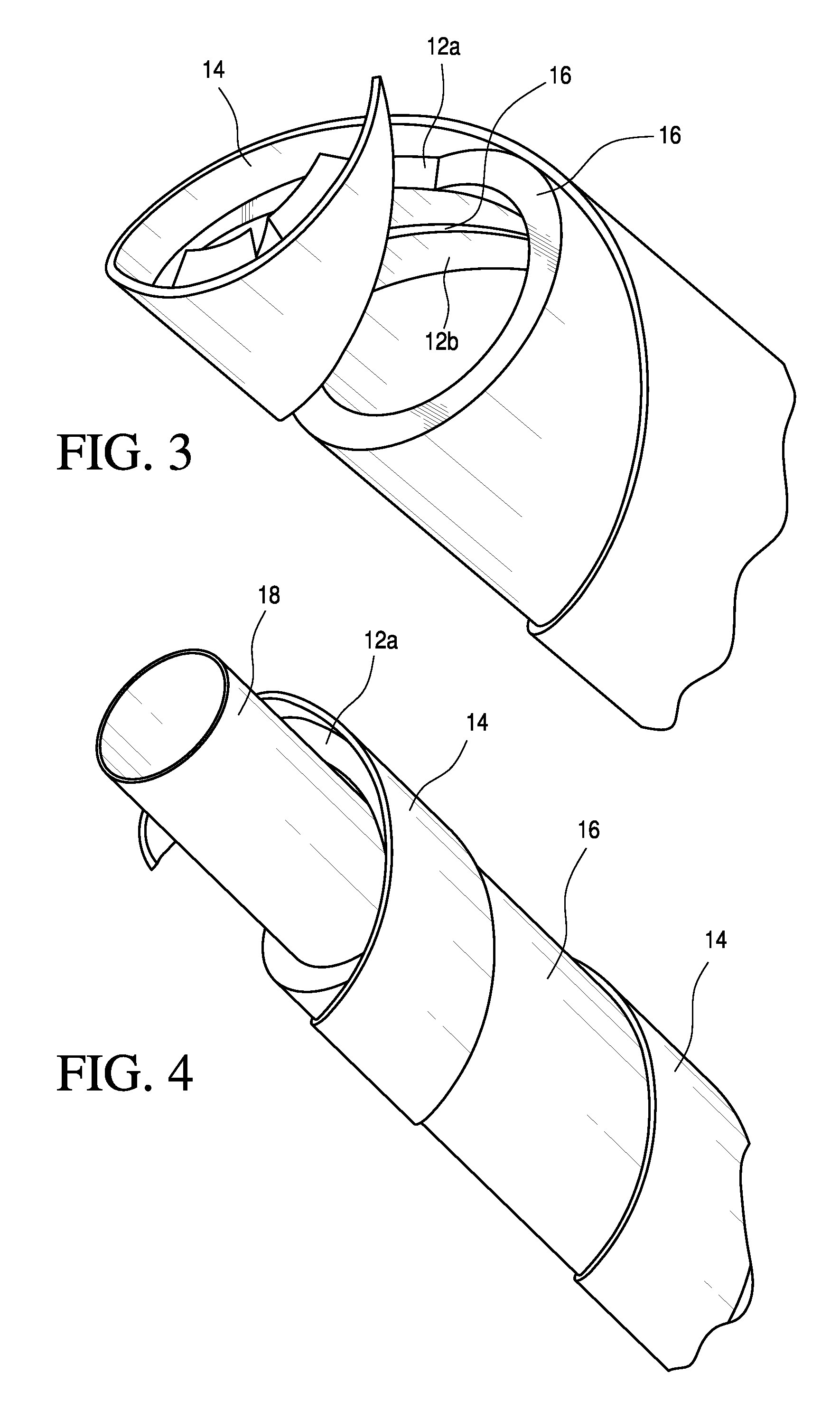

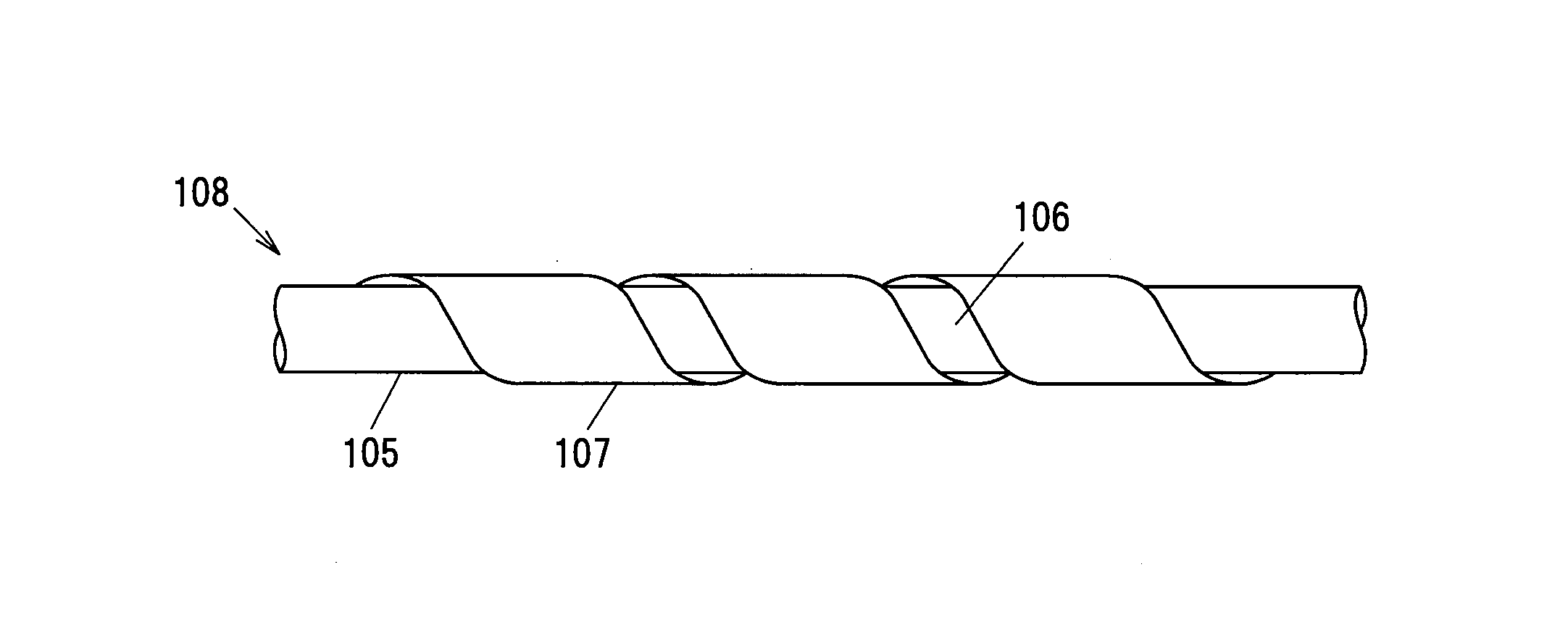

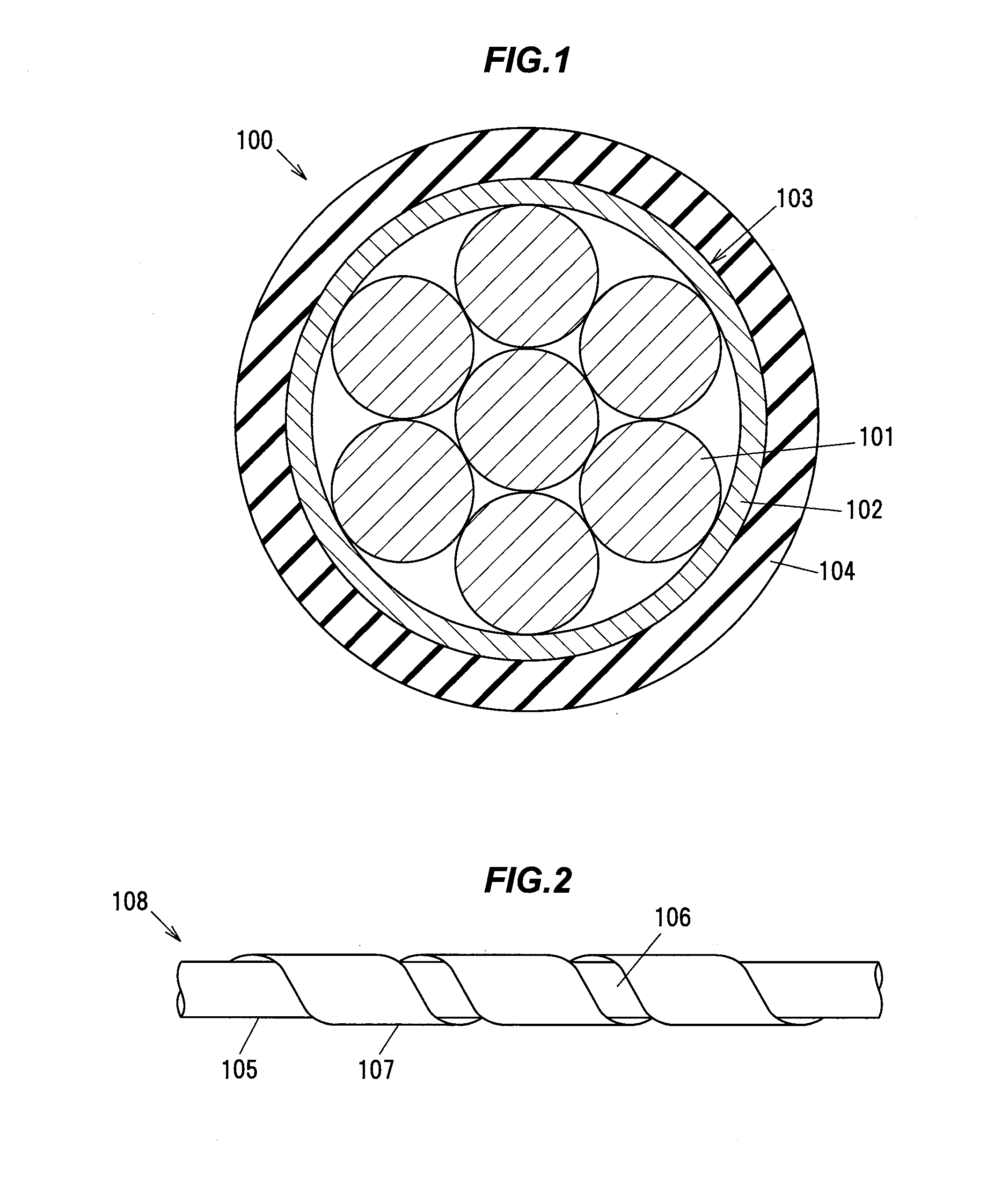

Spirally Wound Electrical Cable for Enhanced Magnetic Field Cancellation and Controlled Impedance

InactiveUS20090223698A1Uniform winding rateStrip/foil conductorsPower cables with screens/conductive layersEngineeringDielectric layer

An electrical cable with enhanced magnetic fields and better controlling of impedances. The electrical cable includes a central ground core, an inner dielectric layer surrounding the central ground core, and a pair of signal conductor wires spirally wound on the inner dielectric layer. The signal conductor wires are separated from the central ground core by a thickness of the inner dielectric layer, and spaced apart from each other and parallel to each other. The cable further includes an intermediate dielectric layer disposed between the signal conductor wires and an outer dielectric layer surrounding the signal conductor wires and the intermediate dielectric layer.

Owner:IBM CORP

Electrical ribbon conductor for motor vehicles

ActiveCN106575548AImprove stabilityIncrease wall thicknessStrip/foil conductorsFlat/ribbon cablesElectrical conductorMotorized vehicle

The invention relates to an electrical ribbon conductor (40, 60, 80, 100) for motor vehicles, comprising a ribbon conductor core (42, 62, 82, 102) which is composed of electrically conductive ribbon conductor material, and comprising an insulation which sheaths the ribbon conductor core (42, 62, 82, 102) and is composed of an insulating material, wherein the height (Hk) of the ribbon conductor core (42, 62, 82, 102) is lower than the width (Bk) of the ribbon conductor core, wherein the ribbon conductor core (42, 62, 82, 102) has at least one narrow side (46a-b, 68a-b, 86a-b, 106a-b) which limits the width of the ribbon conductor core (42, 62, 82, 102) on one side, wherein the at least one narrow side (46a-b, 68a-b, 86a-b, 106a-b) of the ribbon conductor core (42, 62, 82, 102) has a partial surface (52a-b, 70a-b, 114a-b) at least over sections of the length of the ribbon conductor (40, 60, 80, 100), the contour of said partial surface, in cross section of the ribbon conductor core (42, 62, 82, 102), forming a straight section (46a-b, 54a-b, 72a-b, 116a-b) which extends over part of the height of the ribbon conductor core (42, 62, 82, 102), wherein the straight section (46a-b, 54a-b, 72a-b, 116a-b) extends over at least 75% of the height of the ribbon conductor core (42, 62, 82, 102). The invention further relates to an electrical ribbon conductor (40, 60, 80, 100) for motor vehicles, comprising a ribbon conductor core (42, 62, 82, 102) which is composed of electrically conductive ribbon conductor material, and comprising an insulation (44, 64, 84, 104) which sheaths the ribbon conductor core (42, 62, 82, 102) and is composed of an insulating material, wherein the height (Hk) of the ribbon conductor core (42, 62, 82, 102) is lower than the width (Bk) of the ribbon conductor core (42, 62, 82, 102), and wherein the insulation (44, 64, 84, 104) has a greater wall thickness at least over sections of the length of the ribbon conductor (40, 60, 80, 100) on at least one side (46a-b, 48a-b, 68a-b, 86a-b, 88a-b, 106a-b, 108a-b) of the ribbon conductor core (42, 62, 82, 102) than on at least one other side (46a-b, 48a-b, 68a-b, 86a-b, 88a-b, 106a-b, 108a-b) of the ribbon conductor core (42, 62, 82, 102).

Owner:AUTO KABEL MANAGEMENTGMBH

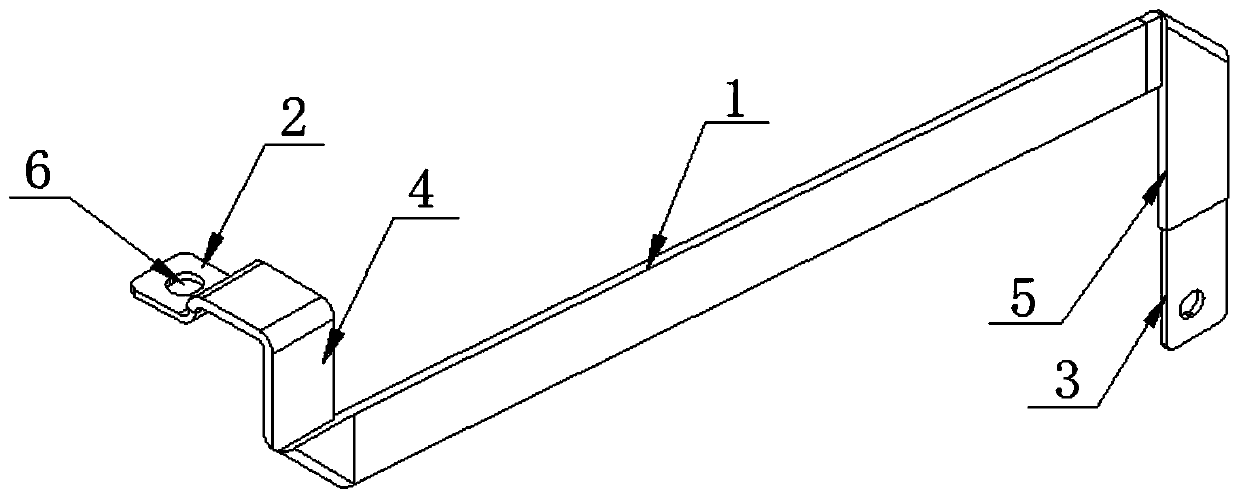

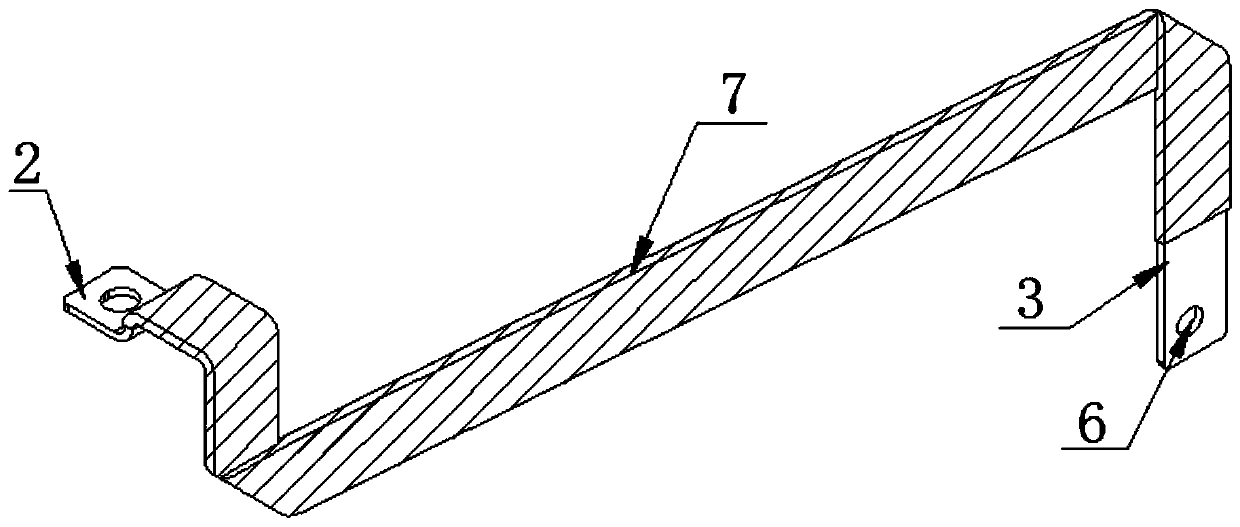

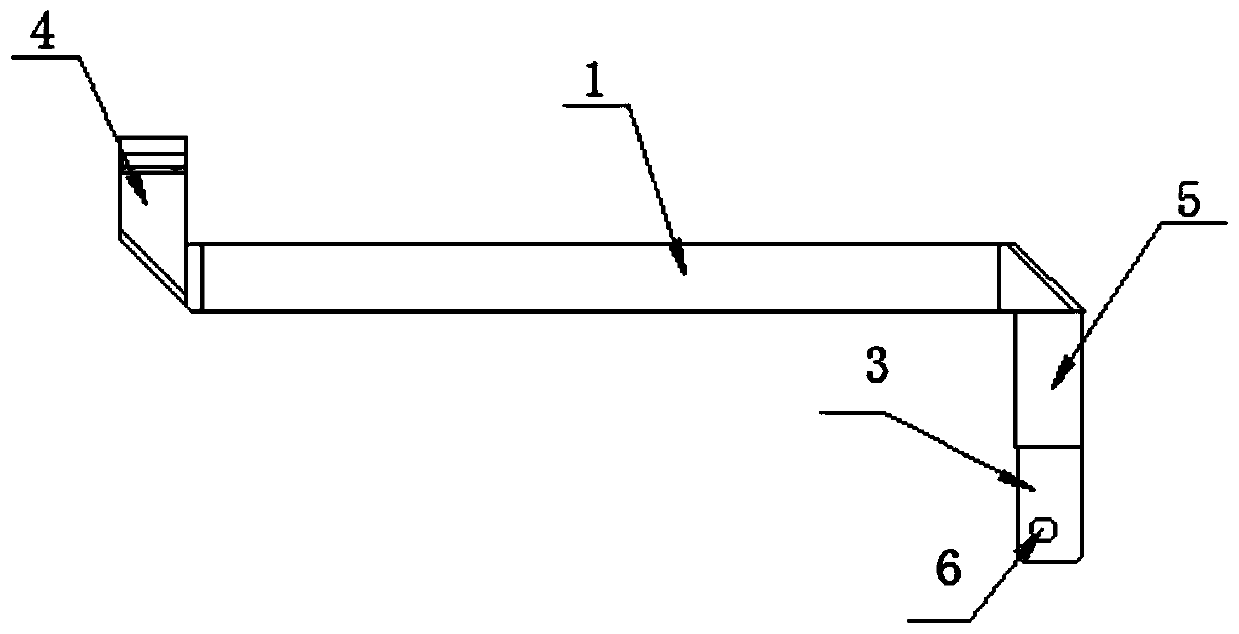

Deformable soft copper bar

PendingCN111145939ASave internal spaceFirmly connectedStrip/foil conductorsFlat/ribbon cablesPower batteryElectrical battery

The invention discloses a deformable soft copper bar. The copper bar comprises a copper bar main body, a first connecting part and a second connecting part, wherein two side ends of the copper bar main body are respectively provided with a first bending part and a second bending part, the side edge of the first connecting part is fixedly connected with the outer side edge of the first bending part, and the top of the second connecting part is fixedly connected with the outer side edge of the second bending part. The invention relates to the technical field of battery module fixing. The deformable soft copper bar can generate deformation within a certain range, the strength requirement can be met, the internal space of the power battery pack can be saved, each electric device in the batterypack can be connected more stably, the advantages of small resistance and strong over-current capability are ensured, the advantage of flexibility is brought, the soft copper bar can eliminate the stress generated during installation and reduce the installation difficulty, and the soft copper bar can be widely applied to new energy automobile power batteries and can be applied to rail transit andpower and electrician industries.

Owner:天津恒天新能源汽车研究院有限公司

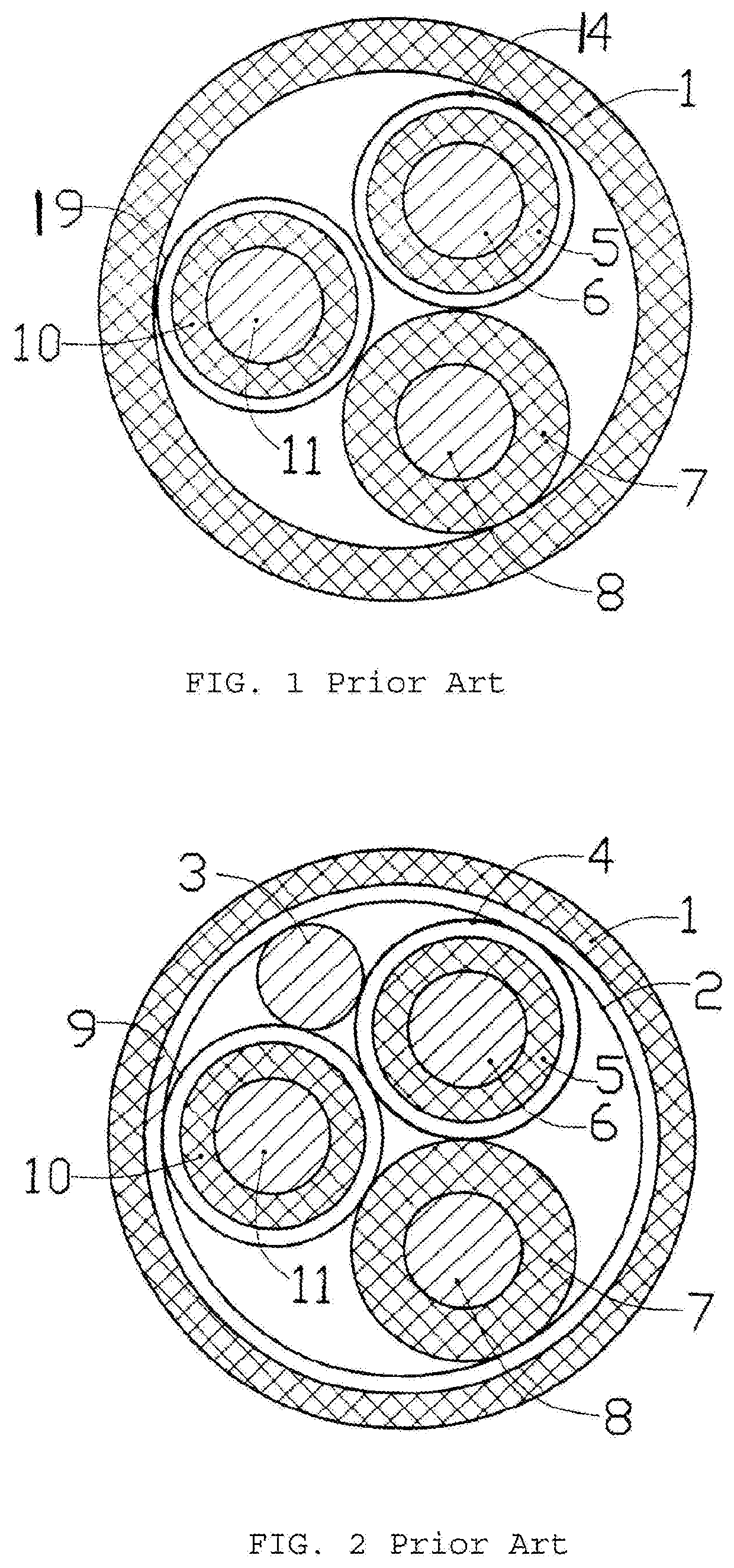

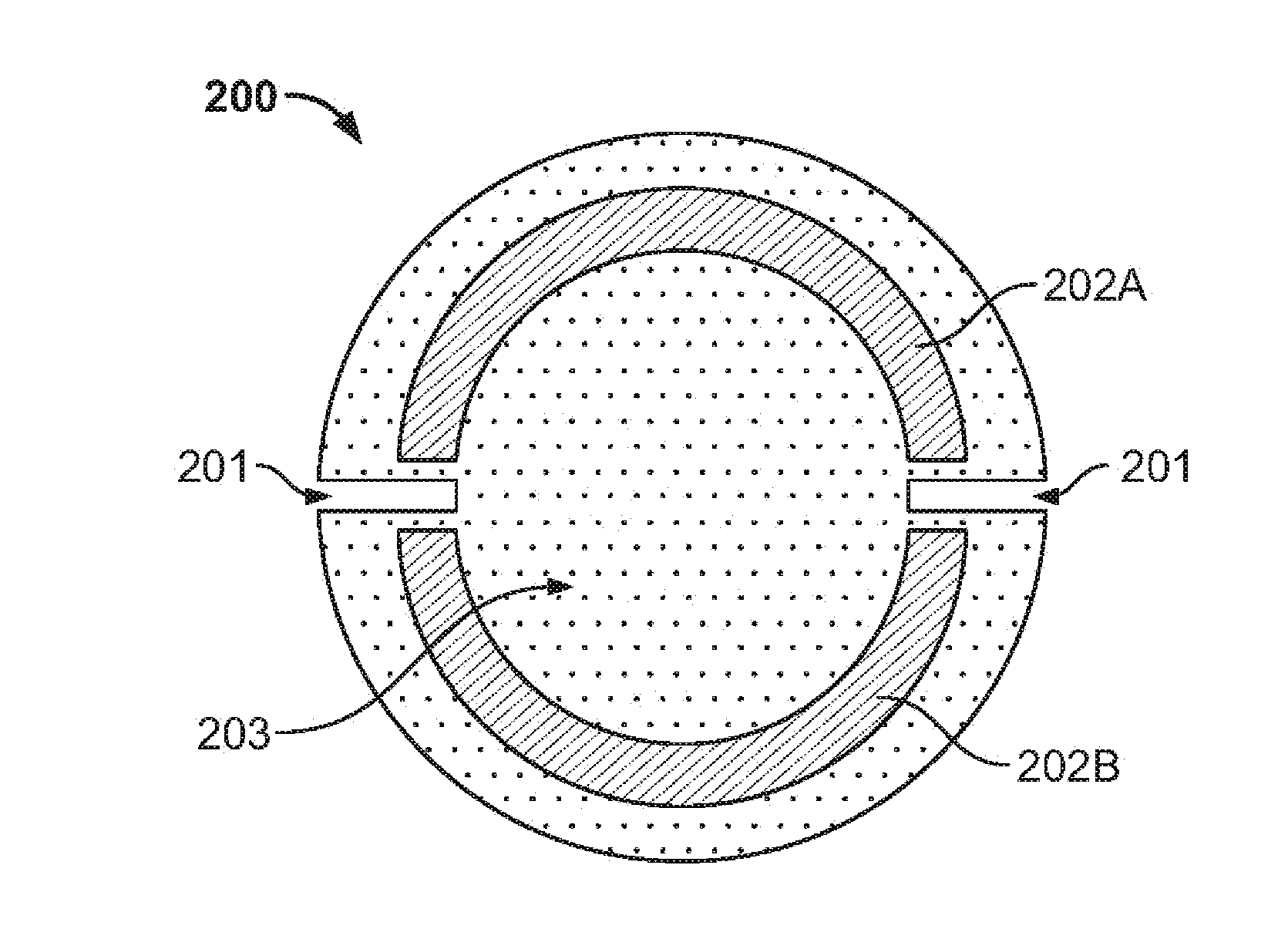

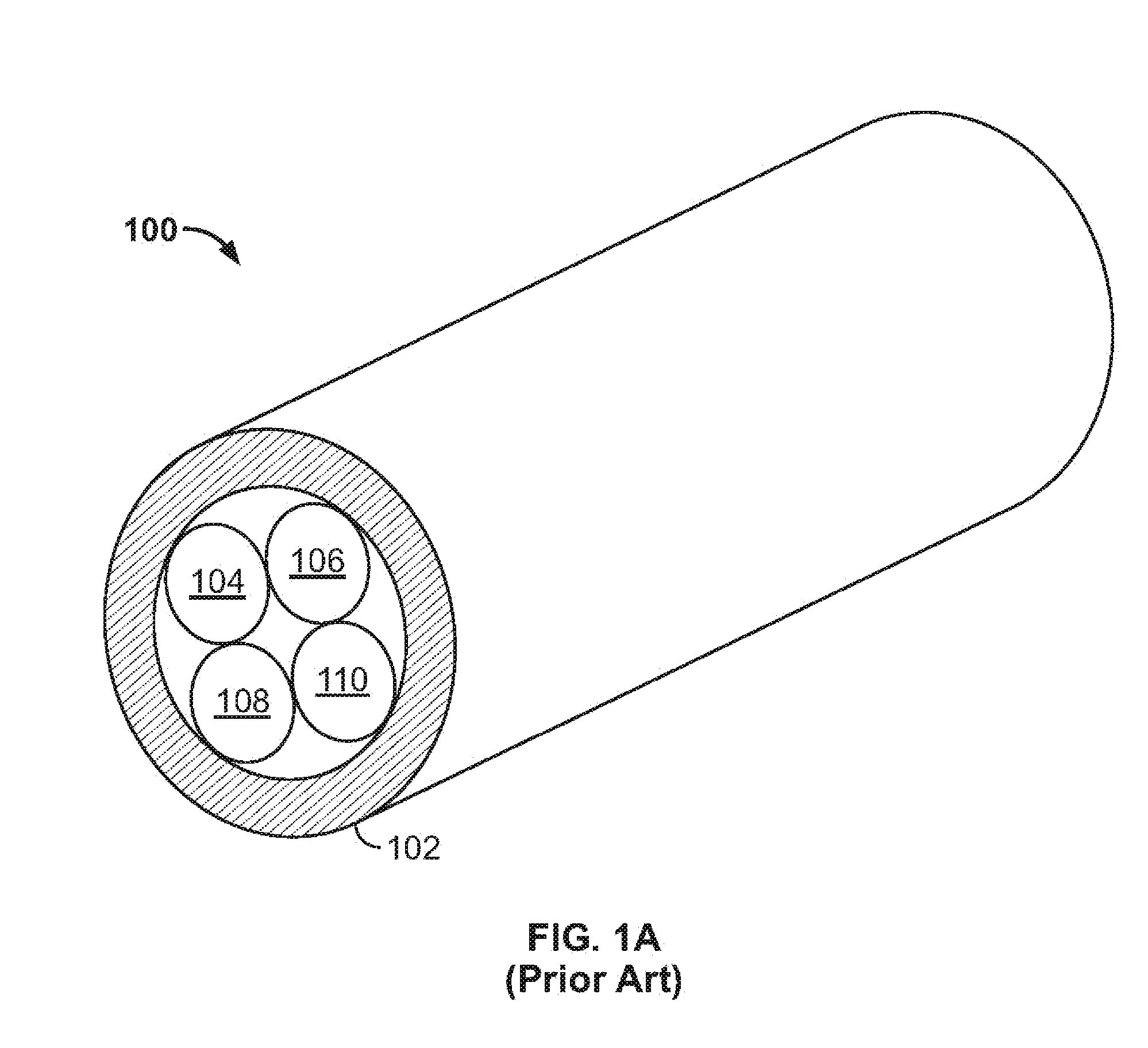

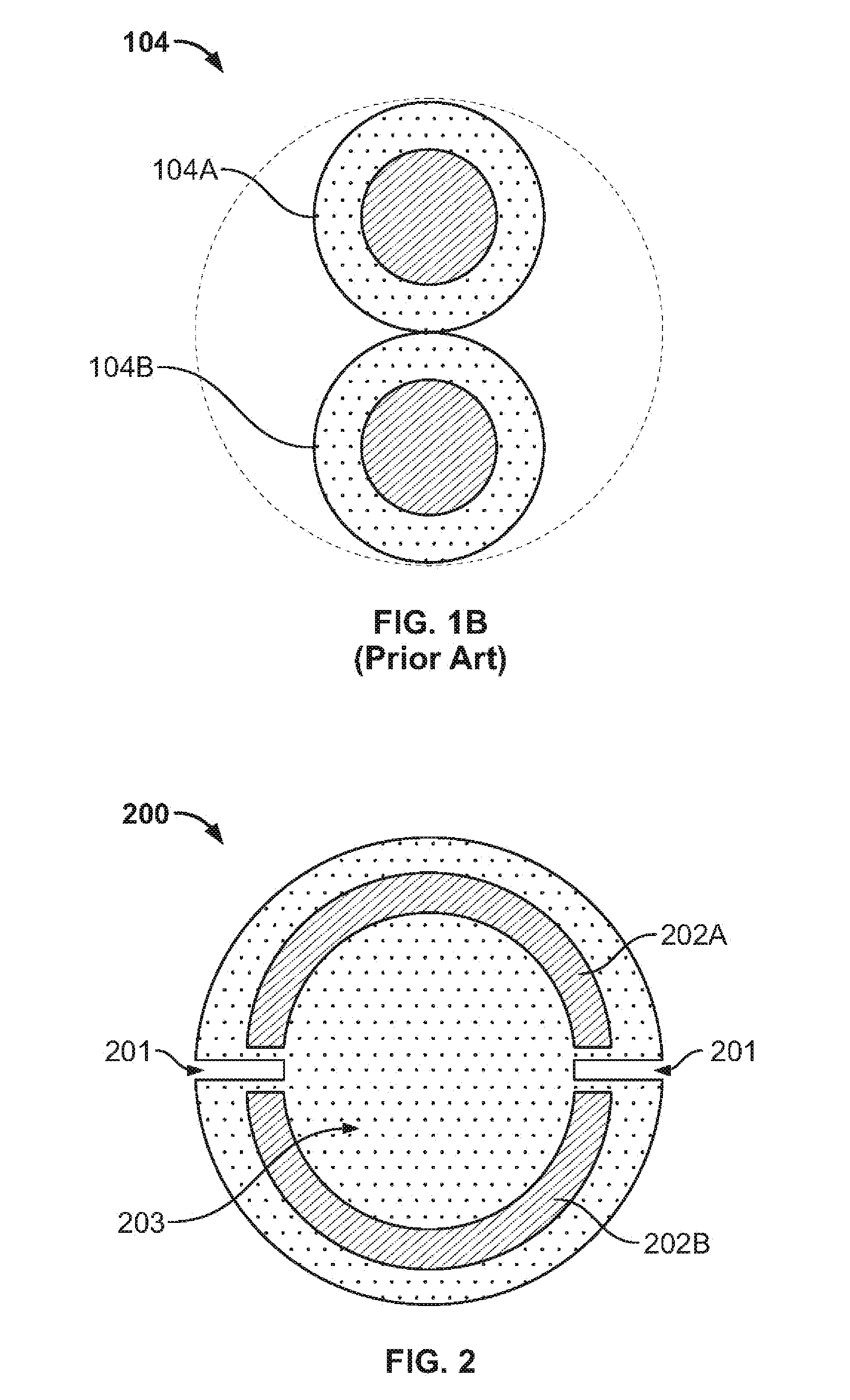

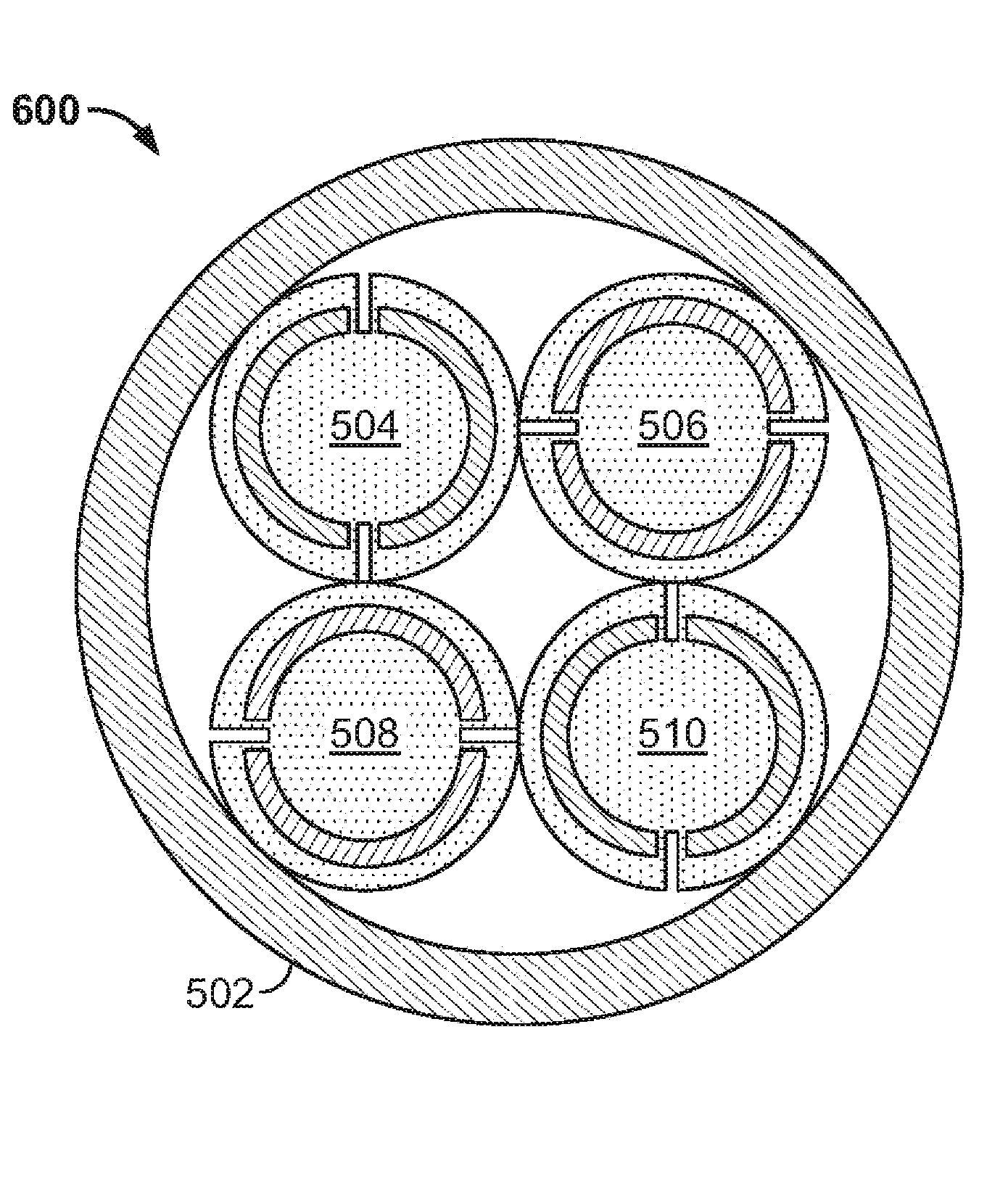

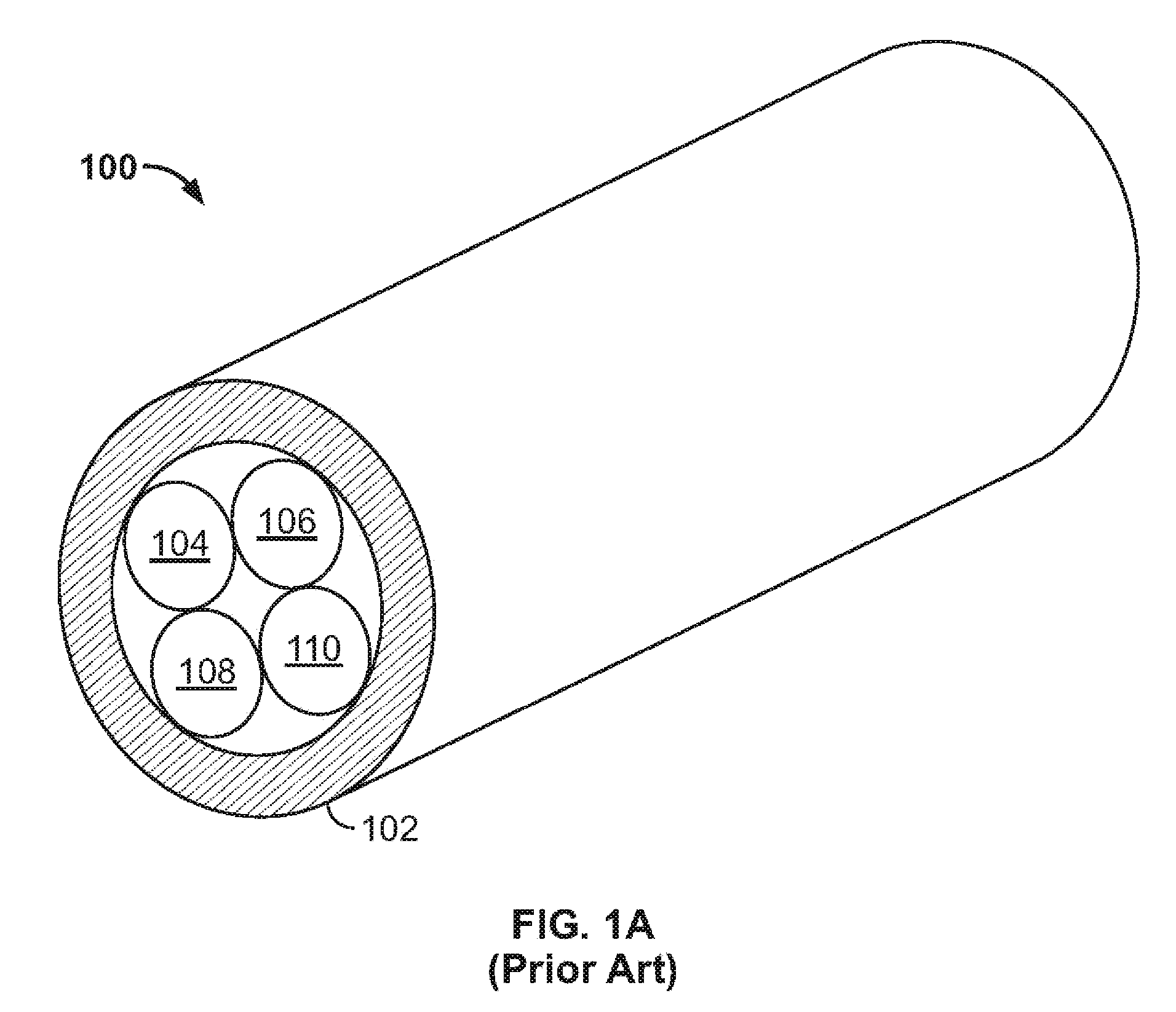

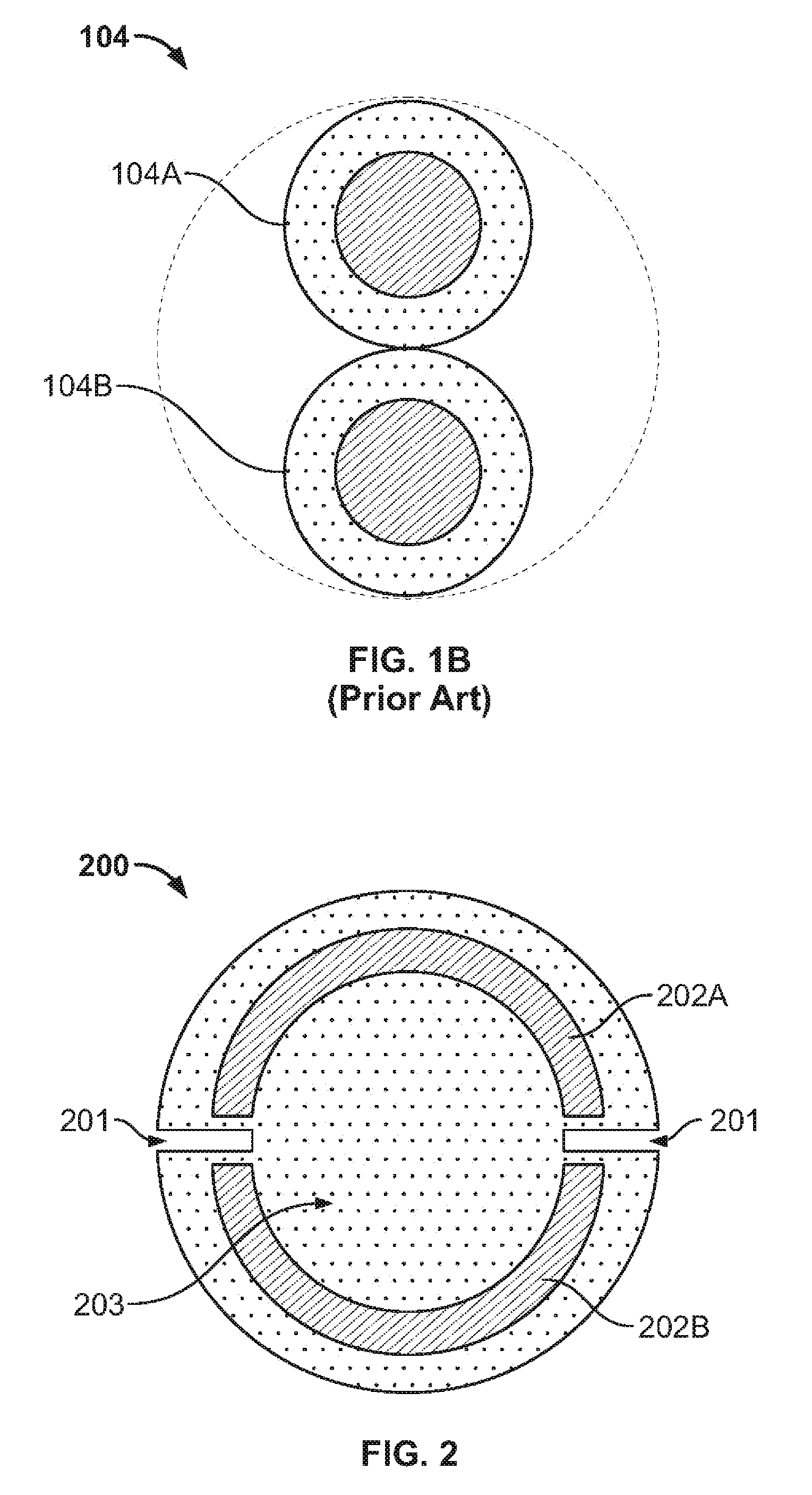

Mirrored arc conducting pair

InactiveUS20070119609A1Create efficientlyStrip/foil conductorsInsulated cablesBare metalElectrical conductor

A mirrored arc geometrical arrangement of two conductors configured to perform similar functions as a traditional twisted pair of wires is presented. The mirrored arc conductor pair occupies the same physical space required by prior art twisted pair cable designs. Each conductor pair includes two inward-facing arc shaped conductors placed within a dielectric material. Each arc shaped conductor may be constructed from thin foil strips of a conducting metal or from a group of separate bare metal conductors which are placed side by side in intimate contact so as to effectively create the same mirrored arc geometry. The conductor pairs may subsequently be bundled to create a data network cable bundle.

Owner:RGB SYST INC

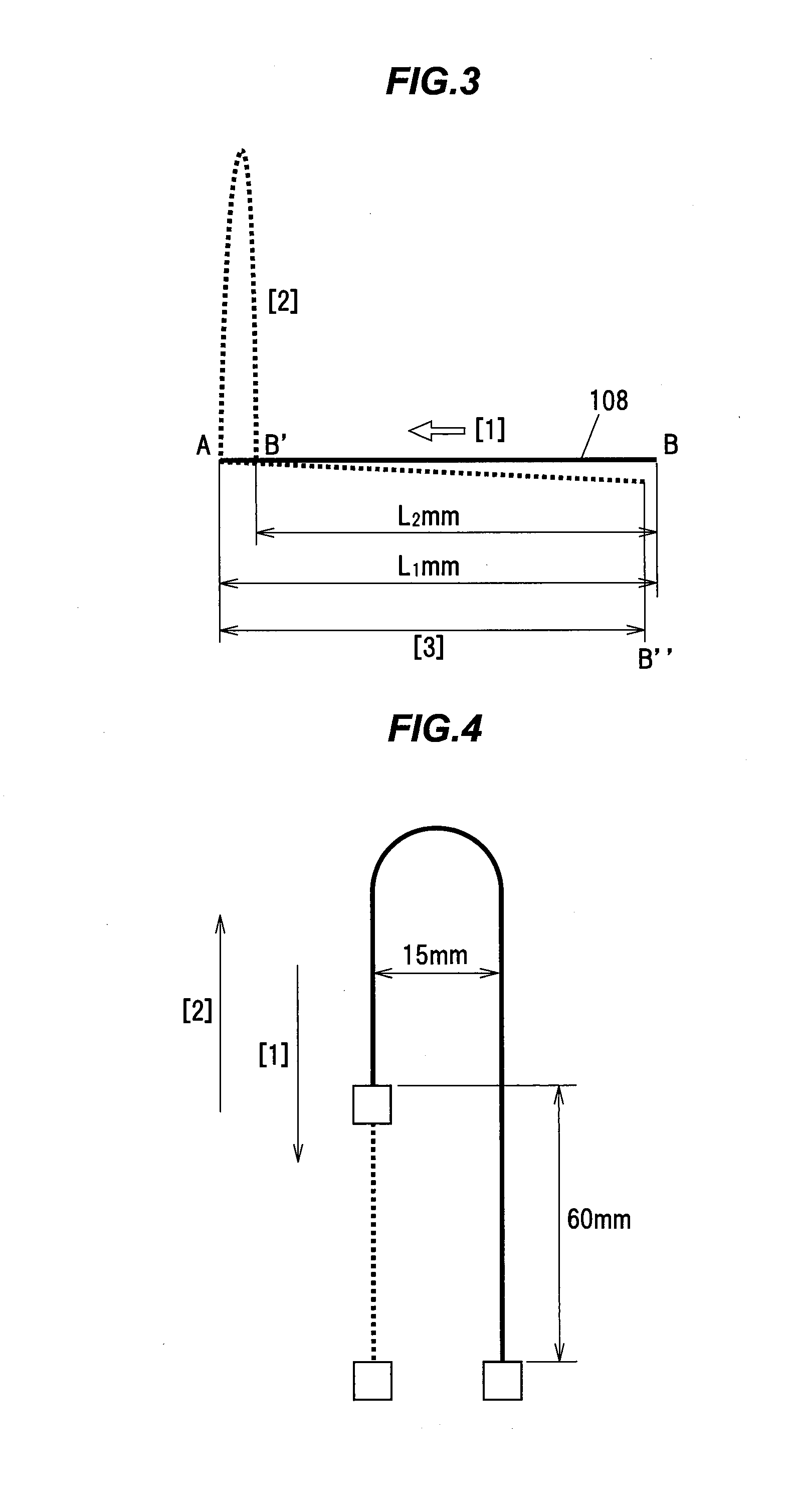

Signal wire

InactiveUS20100170697A1Reduced external diameterLower impedanceStrip/foil conductorsNon-insulated conductorsMetal foilEngineering

A signal wire which at least comprises a flexible core and a metal layer is disclosed. The flexible core has a surface and a longitudinal direction, and the metal layer comprises a plurality of metal foil straps. The metal foil straps are directly and helically wound in parallel on the surface of the core to form a continuously, electrically conductive structure along the longitudinal direction. Thereby, the signal wire has both a decreased external diameter and decreased impedance.

Owner:CHANG ROSA

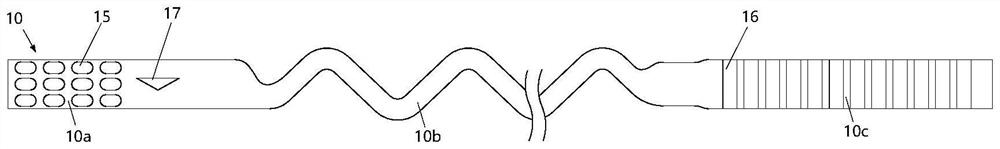

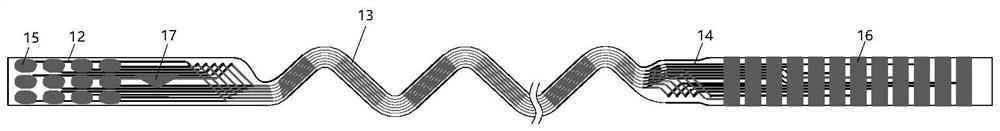

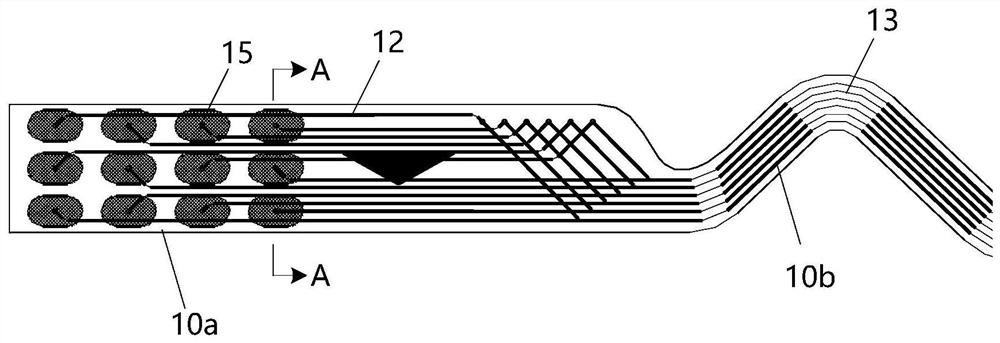

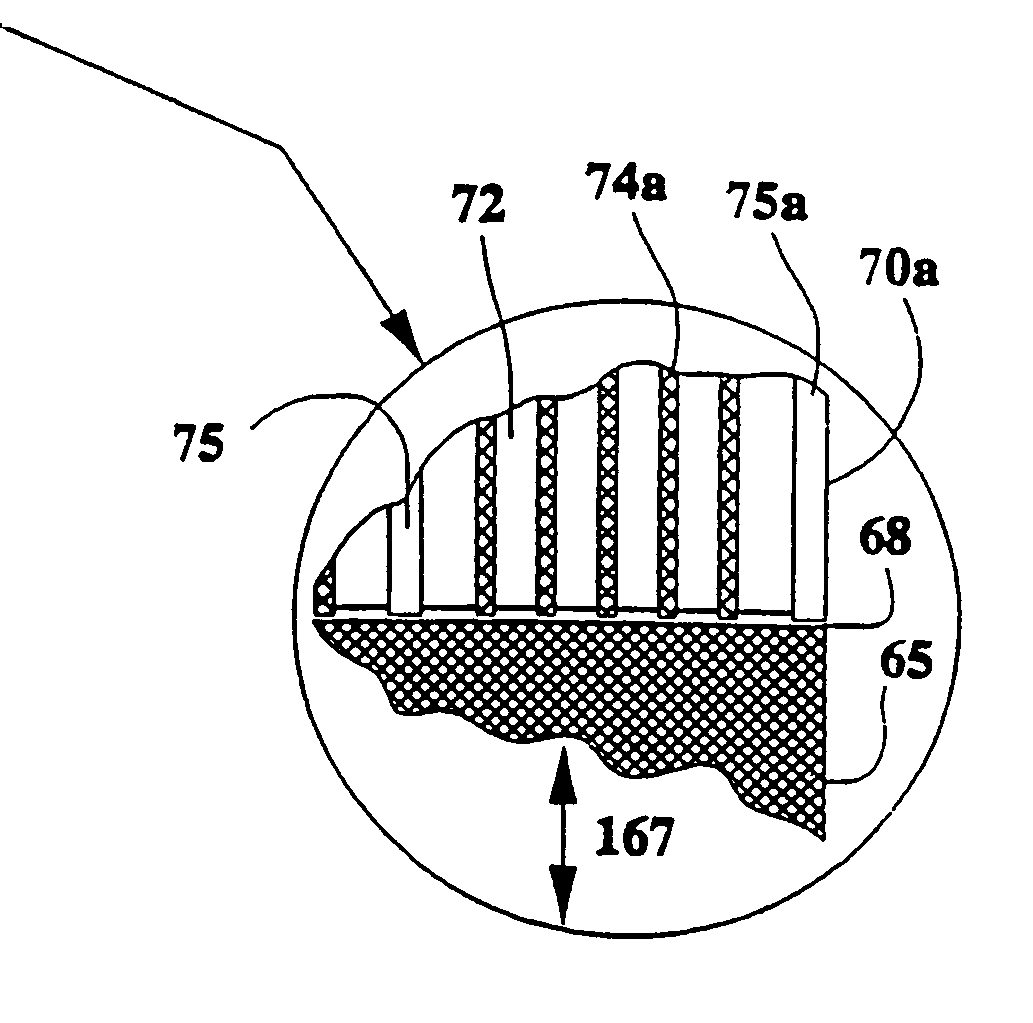

Flexible conductive soft board, manufacturing method thereof, stimulating electrode and manufacturing method thereof

ActiveCN113724920ARich and flexible arrangementStrip/foil conductorsConductive layers on insulating-supportsEngineeringPhysics

The invention provides a flexible conductive soft board and a manufacturing method thereof, and a stimulating electrode and a manufacturing method thereof. The flexible conductive soft board is divided into a stimulating section, a connecting section and a middle section located therebetween along the length direction; the flexible conductive soft board comprises a flexible substrate, a plurality of first conductive layers, a plurality of second conductive layers and a plurality of third conductive layers, the first conductive layers are arranged on the flexible substrate and located in the stimulating section, the second conductive layers are arranged on the flexible substrate and located in the middle section, and the third conductive layers are arranged on the flexible substrate and located in the connecting section; each second conductive layer is electrically connected with at least one first conductive layer and at least one third conductive layer; and an insulating layer is further included and arranged on the flexible substrate and covers the first conductive layers, the second conductive layers and the third conductive layers. The circuit arrangement mode is rich and flexible, and the application range is wide.

Owner:SCENERAY

Clockspring with flat cable

InactiveUS20050090135A1Light weightReduce in quantityStrip/foil conductorsElectrically conductive connectionsSurface patternElectrical conductor

A clockspring for electrically connecting an airbag of a vehicle to crash sensors. The clockspring including a housing that has an inner chamber, and a flat electrical cable with an upper insulator layer, a lower insulator layer connected to the upper layer along substantially continuous parallel spaced-apart seam, and an intermediate layer comprised of individual strands of conductors which lie adjacent and substantially parallel to the seams and the conductors do not have an adhesive residue thereon. The flat electrical cable is mounted in the chamber of the clockspring. Seams positioned between adjacent conductors have a textured surface pattern, and seams positioned along edges of the flat electrical cable have a substantially smooth surface pattern.

Owner:METHODE ELETRONICS INC

Mirrored arc conducting pair

InactiveUS7435907B2Create efficientlyStrip/foil conductorsPlastic/resin/waxes insulatorsBare metalPhysical space

A mirrored arc geometrical arrangement of two conductors configured to perform similar functions as a traditional twisted pair of wires is presented. The mirrored arc conductor pair occupies the same physical space required by prior art twisted pair cable designs. Each conductor pair includes two inward-facing arc shaped conductors placed within a dielectric material. Each arc shaped conductor may be constructed from thin foil strips of a conducting metal or from a group of separate bare metal conductors which are placed side by side in intimate contact so as to effectively create the same mirrored arc geometry. The conductor pairs may subsequently be bundled to create a data network cable bundle.

Owner:RGB SYST INC

Oil-resistant drag chain line and production process

InactiveCN112382431AReduce the risk of premature failureAvoid subsequent use failuresStrip/foil conductorsPlastic/resin/waxes insulatorsElectrical conductorEngineering

The invention discloses an oil-resistant drag chain wire, and the wire comprises a plurality of core wire layers; each core wire layer comprises a Kevlar wire inner layer, a conductor and an insulating layer; the Kevlar wire inner layer is arranged in the center of the conductor, the conductor is tightly coated on the outer surface layer of the Kevlar wire inner layer, and the insulating layer istightly coated on the outer side of the conductor. The plurality of core wire layers are annularly arranged, a Kevlar wire central layer is arranged in the center of the annular arrangement of the plurality of core wire layers, and the outer sides of the plurality of core wire layers are tightly coated with an outer coating layer; according to the drag chain wire, a plurality of machine tool corewires in the prior art are directly compounded into one wire and separated through the insulating layer, only one wire harness needs to be fixed in a machine tool, and the problems that due to the fact that multiple existing machine tool wire harnesses need to be tightly bound together, a cable insulating layer is often damaged to a certain extent due to tight binding, and equipment often operatesin an overload mode, the cable is scrapped in advance due to excessive use or bad use when the cable does not reach the expected service life value is solved.

Owner:乐庭电线工业(常州)有限公司 +2

Communication cable including a helically-wrapped shielding tape

ActiveUS9847154B2Good electrical contactStrip/foil conductorsTwo-part coupling devicesElectrical conductorEngineering

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Medical cable

ActiveUS20160358689A1Enhancing handleability (flexibility)Alleviating a patient discomfortStrip/foil conductorsCoaxial cables/analogue cablesYarnPolyethylene terephthalate

A medical cable includes a plurality of cables, a braided shield covering a circumference of the plurality of cables together and being formed of tubular braided strands, and a jacket covering a circumference of the braided shield. The braided strands includes a copper foil yarn, which includes a highly stretchable polyethylene terephthalate monofilament yarn having a tensile strength of not lower than 700 MPa and an elongation of not lower than 50 percent and not higher than 100 percent, and a copper strip wound helically at a pitch around a surface of the highly stretchable polyethylene terephthalate monofilament yarn. The copper foil yarn has an entire push and recover ratio of not lower than 80 percent.

Owner:HITACHI METALS LTD

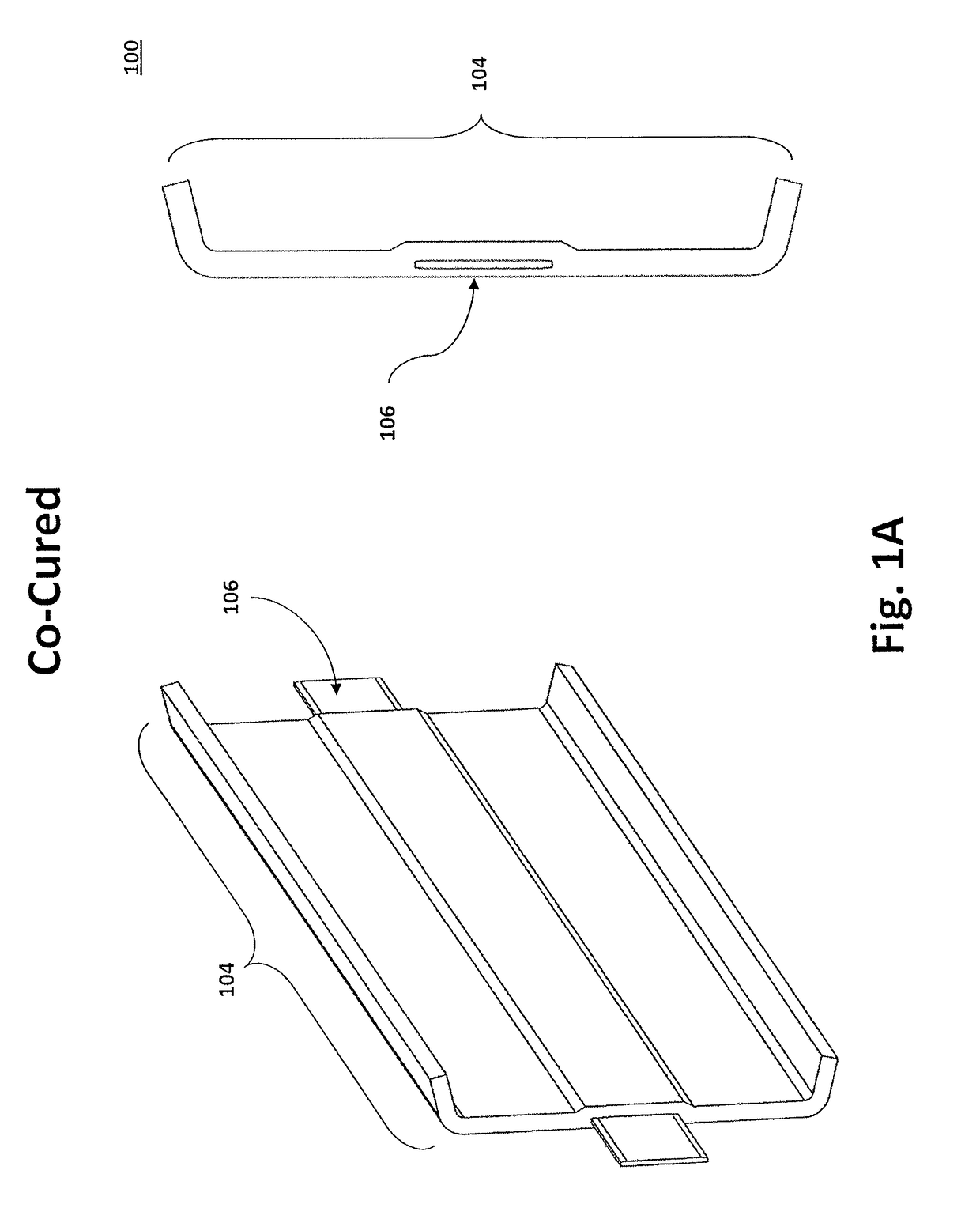

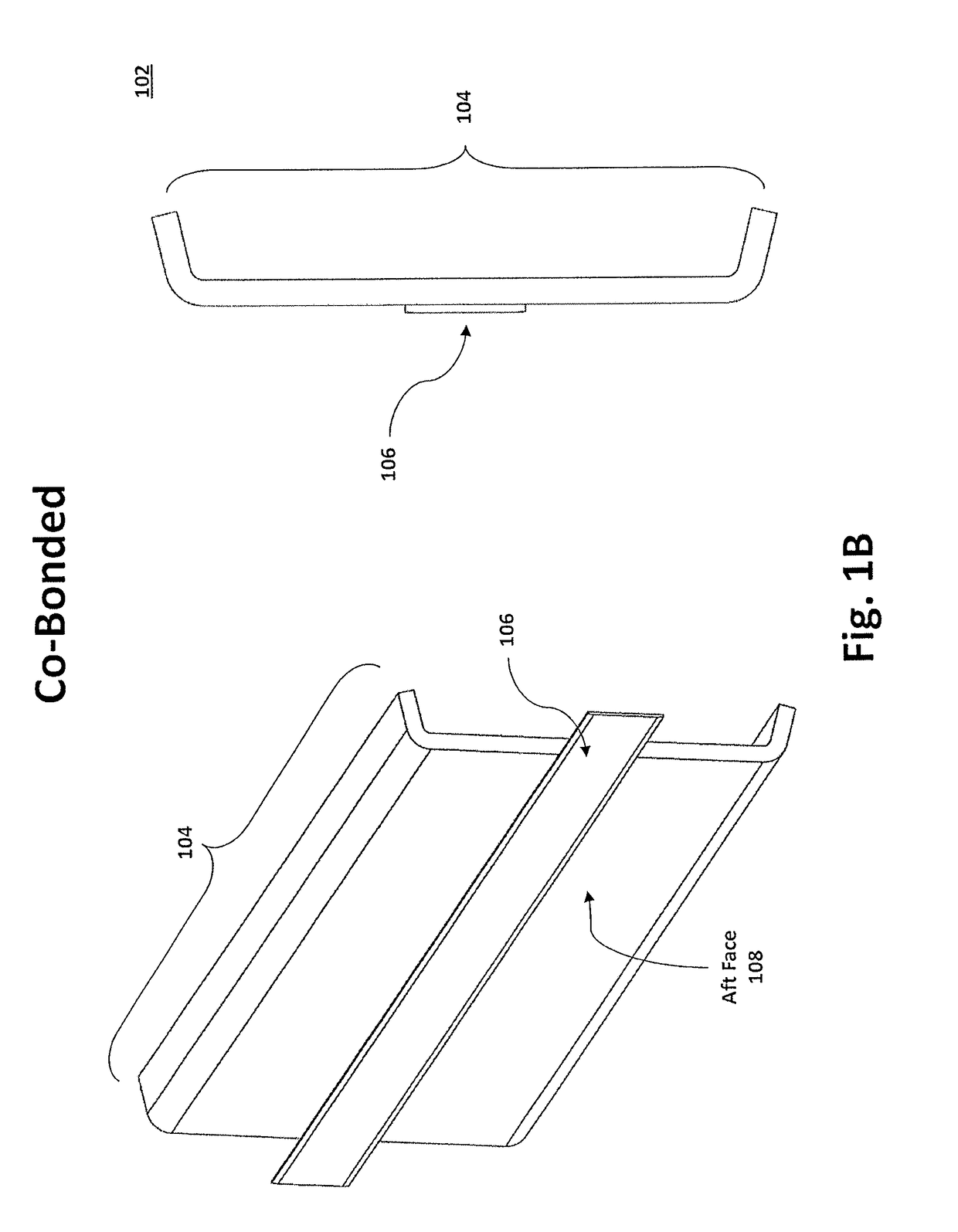

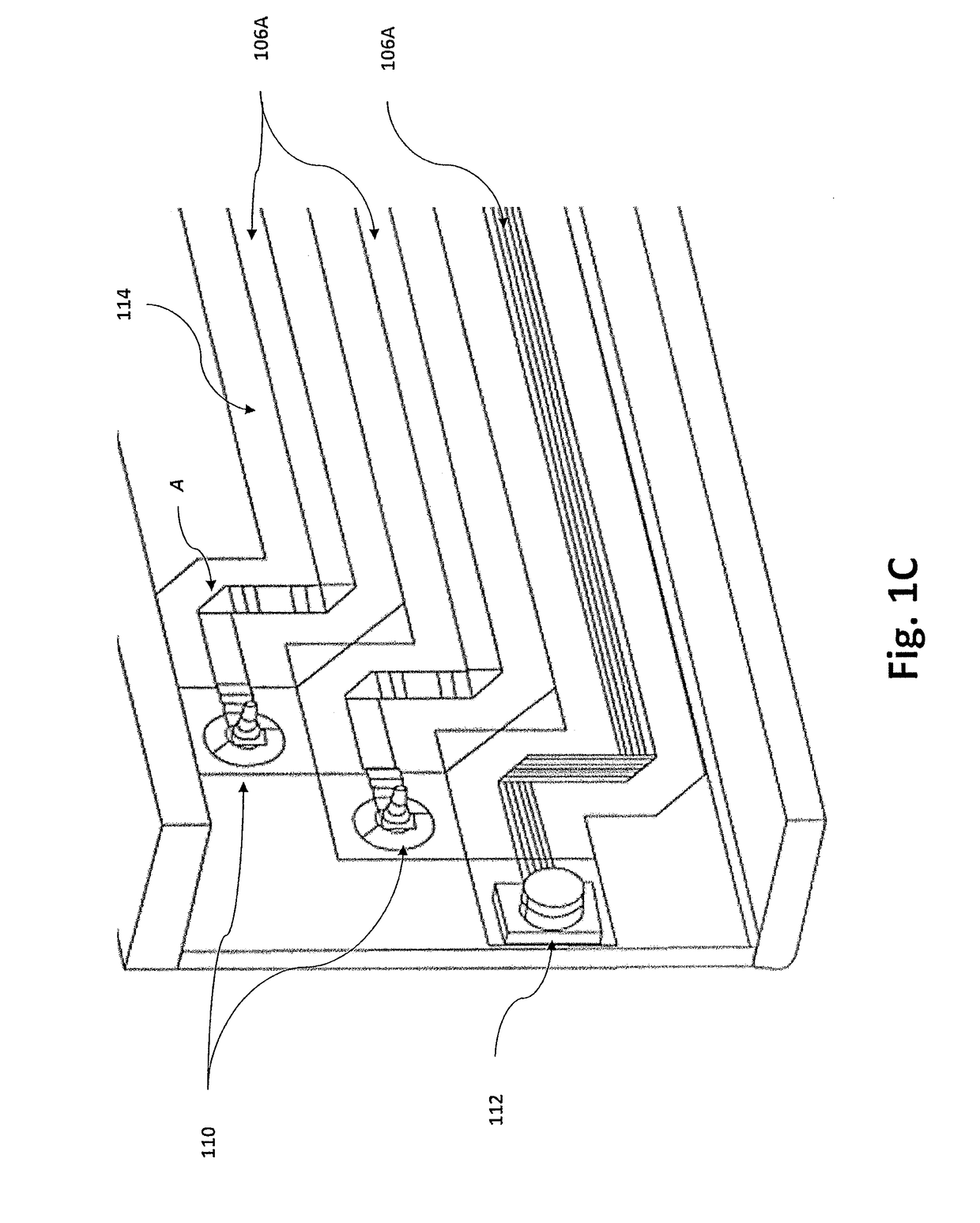

Multi-functional composite structures

A multi-functional composite system generally comprises a core, a plurality of structural composite fiber layers, a matrix material, a connector configured to interface with one or more electrical devices and a composite conductor assembly, the composite conductor assembly having one or more conductors disposed between two or more insulating layers.

Owner:AURORA FLIGHT SCI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com