Electrical ribbon conductor for motor vehicles

A flat conductor, motor vehicle technology, applied in the direction of conductors, insulated conductors, vehicle parts, etc., can solve the problems of flat conductor insulator damage, long cycle, flat conductor manufacturing cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

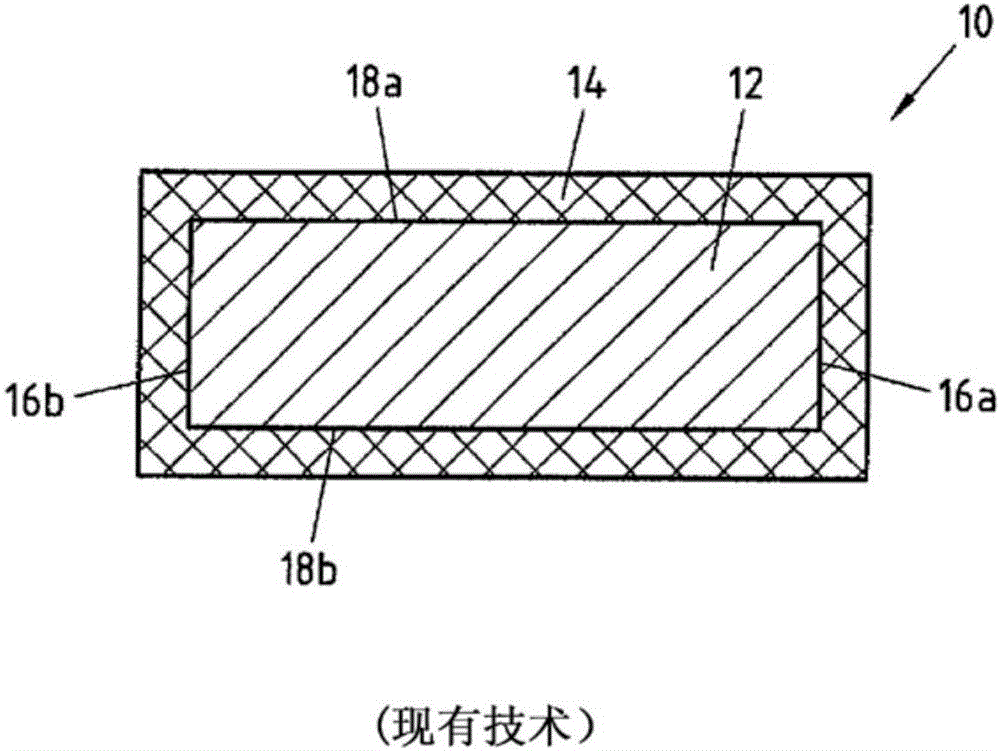

[0054] figure 1 The cross section of the first electrical flat conductor 10 in the prior art is shown. The flat conductor has a flat conductor core 12 made of a conductive flat conductor material (for example, aluminum alloy) and an insulator 14 made of an insulating material (for example, polyvinyl chloride) surrounding the flat conductor core 12.

[0055] The flat conductor core 12 has a rectangular cross-section, which is defined by two narrow sides 16a-b in terms of its own width and two wide sides 18a-b in terms of its height. Therefore, the height of the flat conductor core 12 is smaller than its width. In a rectangular cross-section, the narrow side surfaces 16a-b and the wide side surfaces 18a-b of the flat conductor core 12 intersect each other at right angles, respectively, so that the flat conductor core 12 has very sharp edges. These sharp edges can strongly press the insulator 14, so that damage to the insulator 14 often occurs especially during the bending and form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com