Medium-voltage trailing cable applied to intelligent energy tunneling machine and production process

A technology of smart energy and production technology, applied in power cables, insulated cables, bendable cables, etc., can solve the problems of small outer diameter of neutral core conductors, affecting the bending performance of cables, and large cable hardness, and improving extrusion. The effect of output pressure and setting distance, improve drag performance, improve softness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

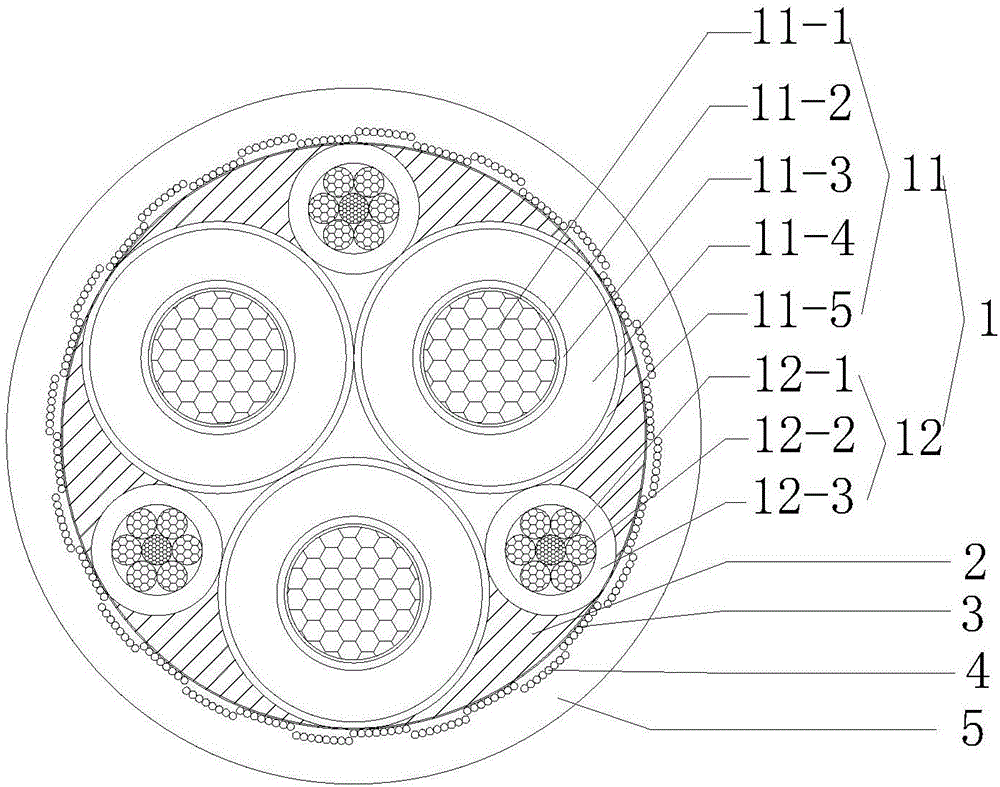

[0034] See figure 1, a medium-voltage towing cable for a smart energy roadheader in this embodiment, from the inside to the outside is the cable core 1, the side gap filling 2, the second semi-conductive nylon belt 3, the fiber braided reinforcement layer 4 and the sheath 5; The cable core 1 includes 3 power cable cores 11 and 3 neutral cable cores 12, and the 3 neutral cable cores 12 are arranged in the side gap of the power cable core 11 and are tangent to the power cable core 11; the material of the side gap filling 2 is rubber Strips, including 6 filling gaps between the power cable core and the neutral cable core; the power cable core 11 includes the power cable core copper conductor 11-1, the first semi-conductive nylon tape 11- 2. The first semiconductive shielding layer 11-3, ethylene propylene rubber insulation 11-4 and insulating shielding 11-5; the insulating shielding 11-5 is made of strippable semiconductive material; the neutral cable core 12 includes copper Foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Strand pitch | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com