Flexible conductive soft board, manufacturing method thereof, stimulating electrode and manufacturing method thereof

A flexible conductive and stimulating electrode technology, applied in the direction of equipment, electrodes, and head electrodes used to manufacture conductive/semiconductive layers, can solve problems such as the limitation of the number of contacts, and achieve wide application range, line layout and Flexible, rich line layout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] Below, the present application will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, on the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form a new embodiment. .

[0071] The words expressing position and direction described in this application, such as "upper" and "lower", are all described with the accompanying drawings as examples, but changes can also be made according to needs, and all changes are included in this application. within the scope of protection. The accompanying drawings of this application are only used to illustrate the relative positional relationship, and the layer thickness of some parts is drawn in an exaggerated way for easy understanding, and the layer thickness in the drawings does not represent the proportional relationship of the actual layer thickness.

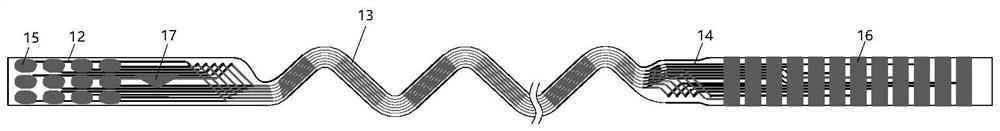

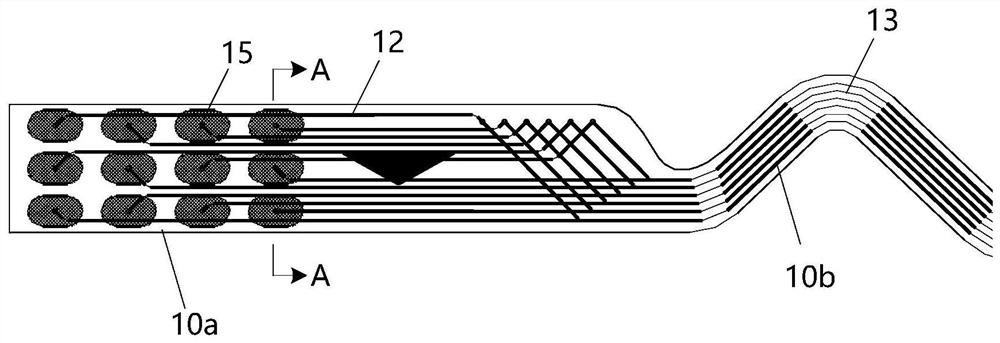

[0072] see Figure 1 to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com