Flexible conductive soft board and its manufacturing method, stimulating electrode and its manufacturing method

A flexible conductive and stimulating electrode technology, which can be used in equipment, electrodes, head electrodes, etc. for the manufacture of conductive/semi-conductive layers. Flexible and rich line layout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

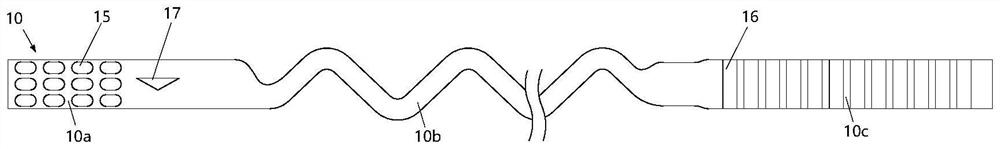

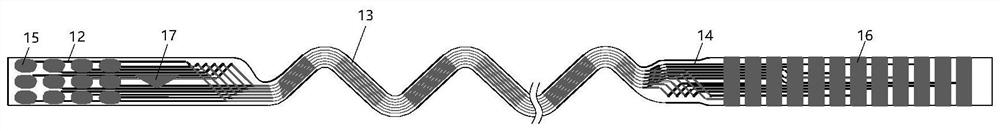

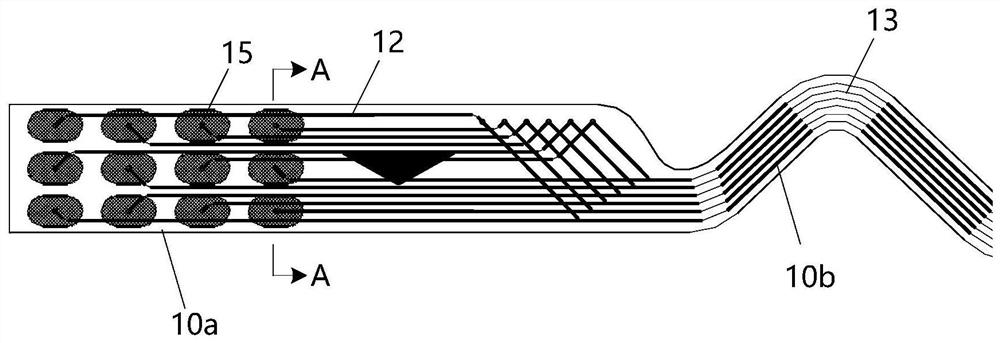

[0072] Referring to FIG. 1 to FIG. 4, an embodiment of the present application provides a flexible conductive soft board 10, the flexible conductive soft board 10

[0074] In some embodiments, the total length of the flexible conductive soft board 10 may be 300mm, 400mm, 500mm or

[0075] The length of the stimulation section 10a can be 10mm, 12.05mm or 20mm, and the length of the middle section 10b can be 300mm,

[0076] In some embodiments, the thickness of the flexible substrate 11 may be 20 μm, 25 μm or 30 μm, wherein the flexible

[0077] In some embodiments, the middle section 10b of the flexible conductive soft board 10 may be a wavy structure. wavy

[0079] In some embodiments, in the thickness direction of the flexible conductive soft board 10, the plurality of conductive layers may be

[0081] In some embodiments, the thickness of the first conductive layer 12 may be the same as the thickness of the second conductive layer 13, the third conductive layer 14

[0082] The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com