Patents

Literature

255results about How to "Good bending properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

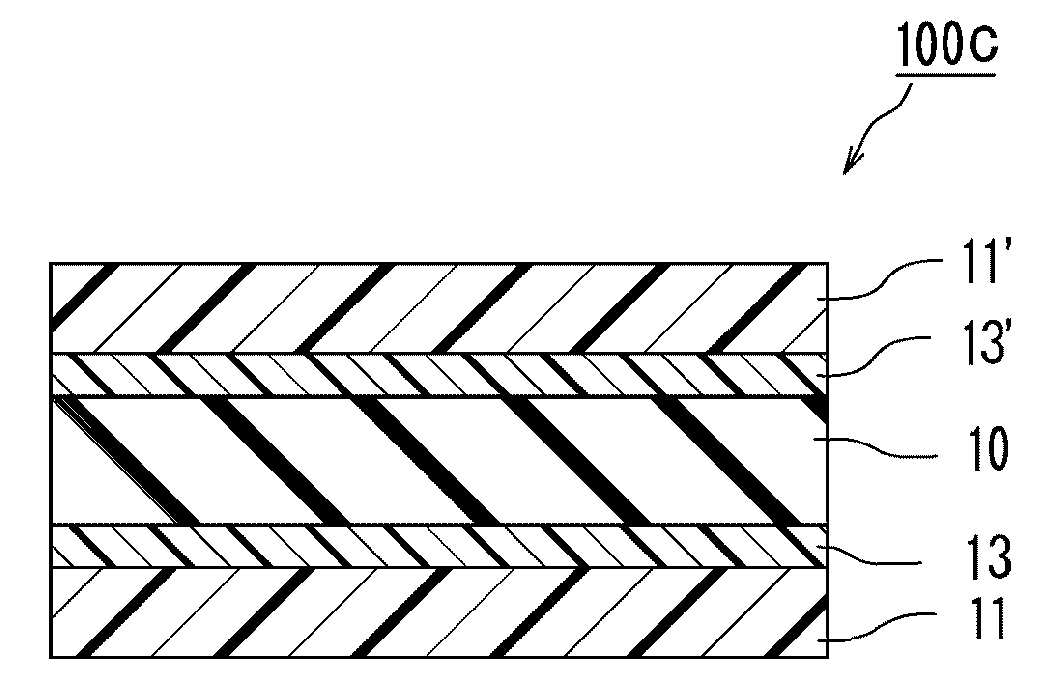

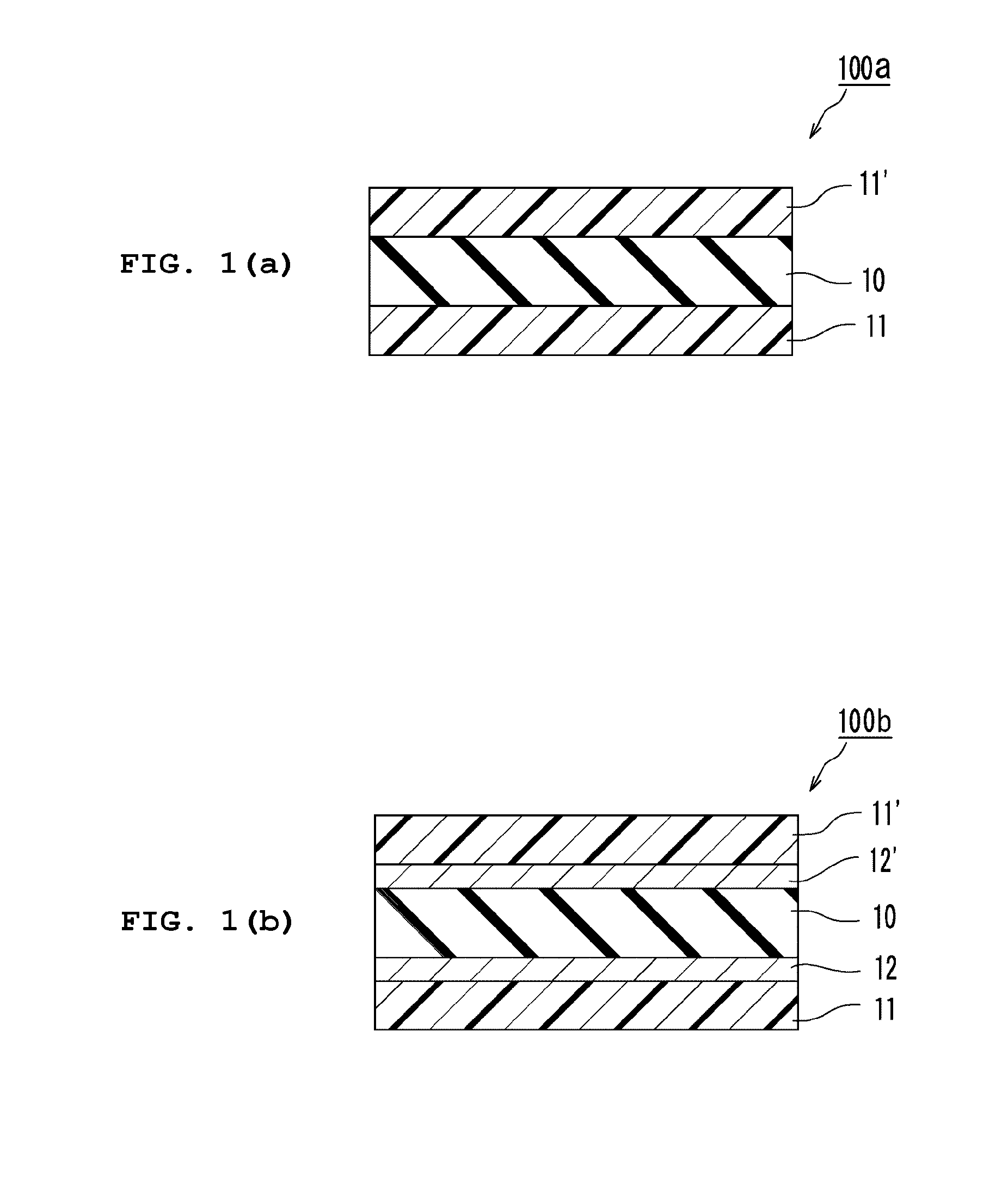

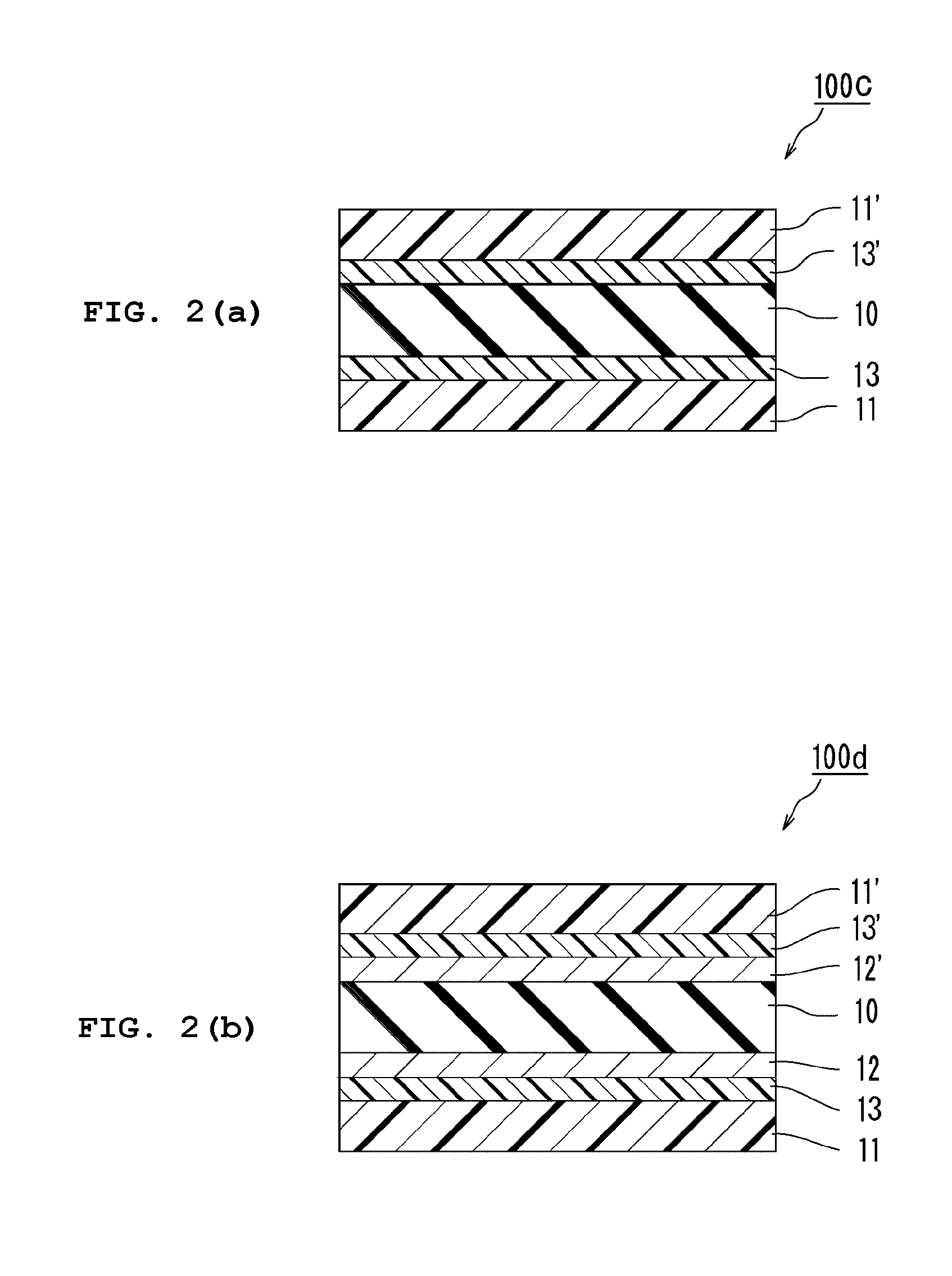

Transparent substrate

ActiveUS20120196103A1Inhibit progressGood bending propertiesBox making operationsPaper-makingMetallurgyPliability

Owner:NITTO DENKO CORP

Flexible display panel and display device

ActiveCN107578707AGood bending propertiesSmall bending radiusIdentification meansDisplay deviceEngineering

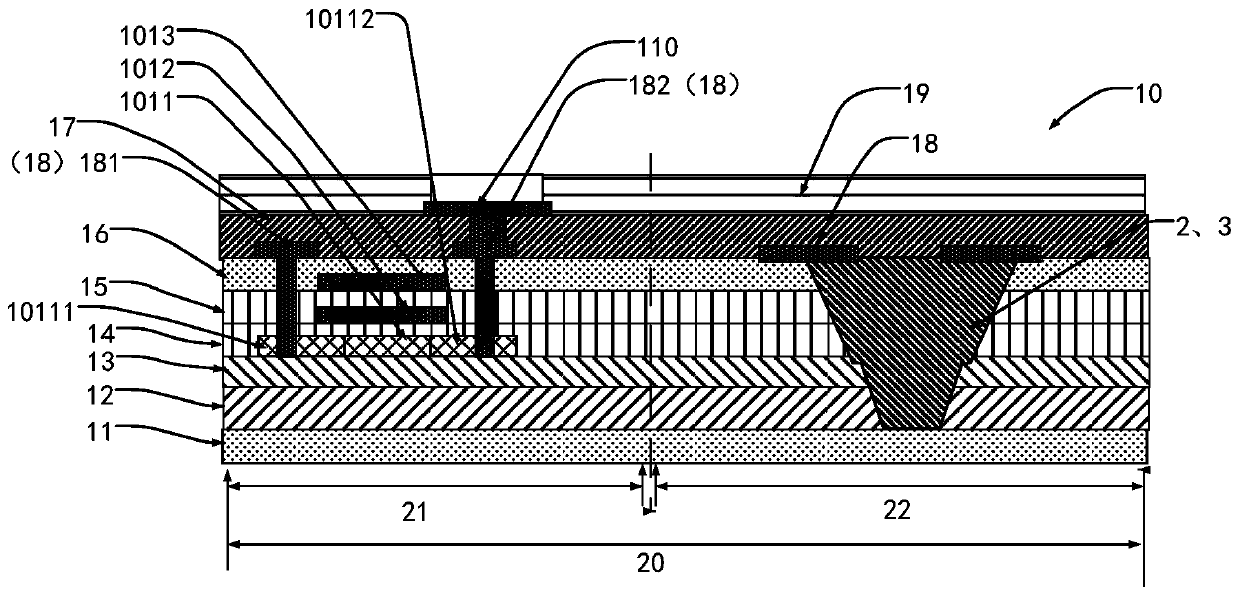

The invention relates to a flexible display panel and a display device. The display panel comprises a first film, a second film, a first area and a second area, the elastic modulus of the first film is larger than that of the second film in the first area, and the elastic modulus of the first film is smaller than that of the second film in the second area. When the flexible display panel is bent,the positions of the first film and the second film in the display panel are different, and the first film and the second film are different in deformation during bending. Therefore, bending stress applied to the first film and the second film with corresponding different elastic modulus is balanced, the bending property of the flexible display panel is improved, and the flexible display panel canbear a smaller bending radius.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

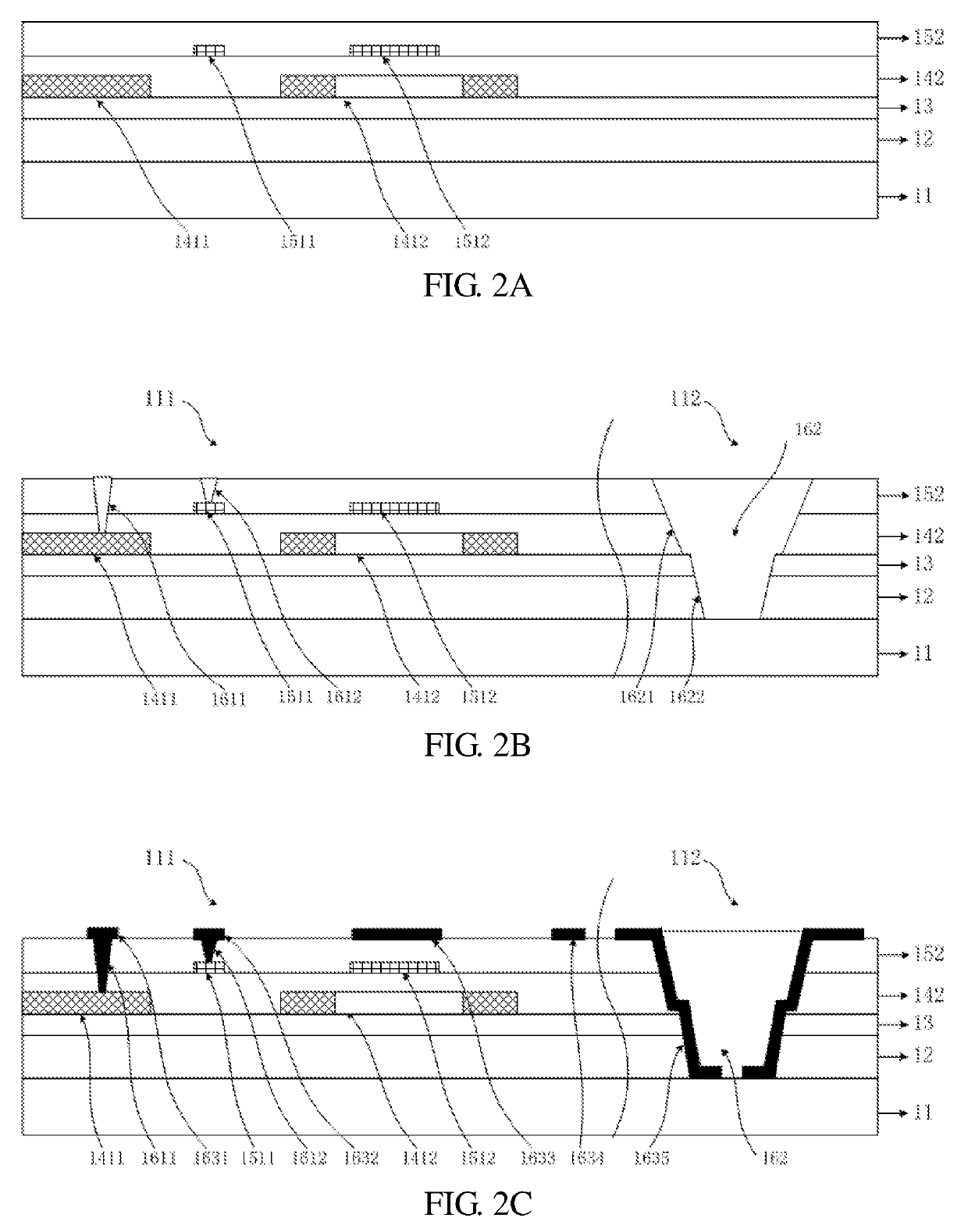

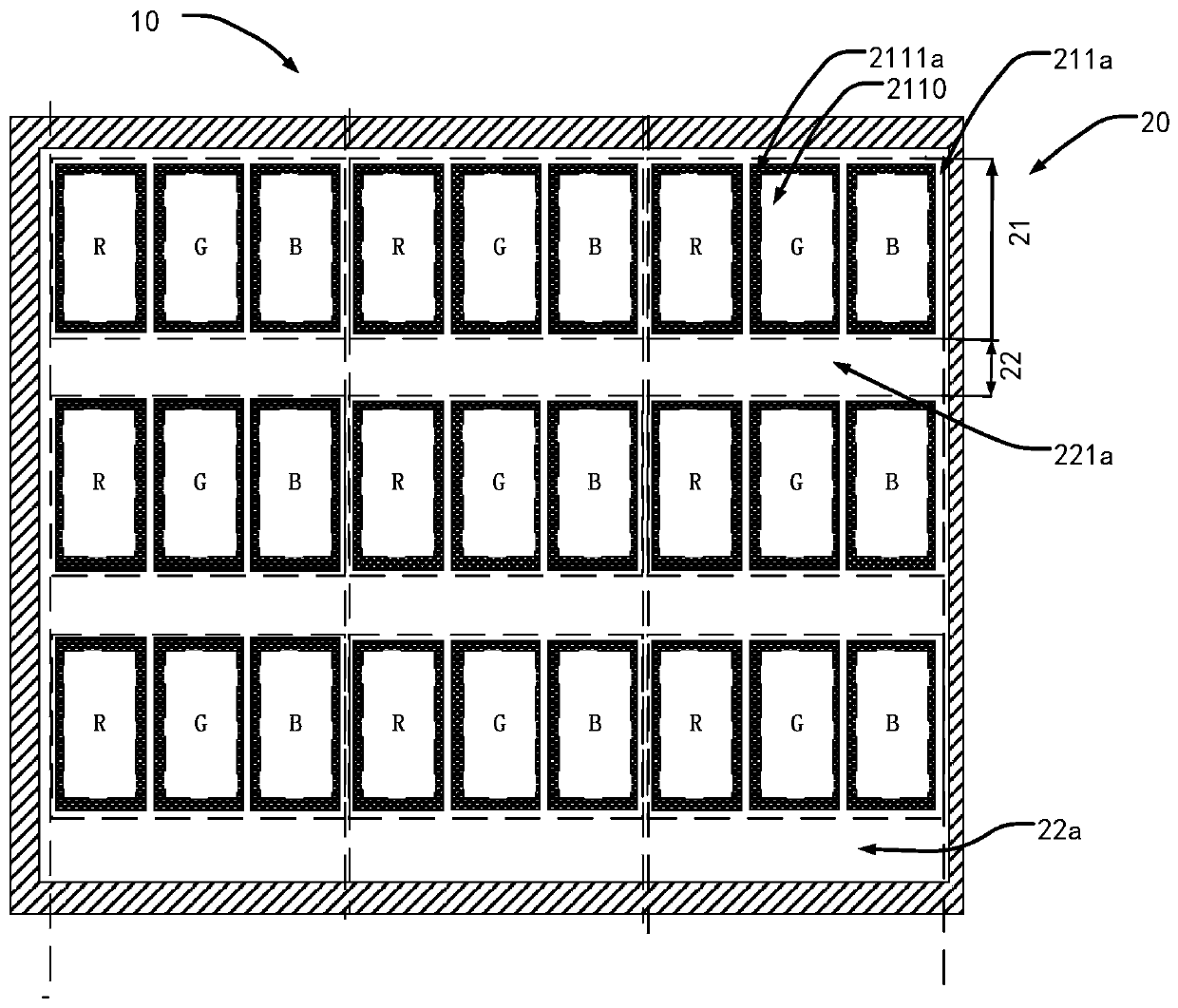

Display substrate, preparation method of display substrate and display device

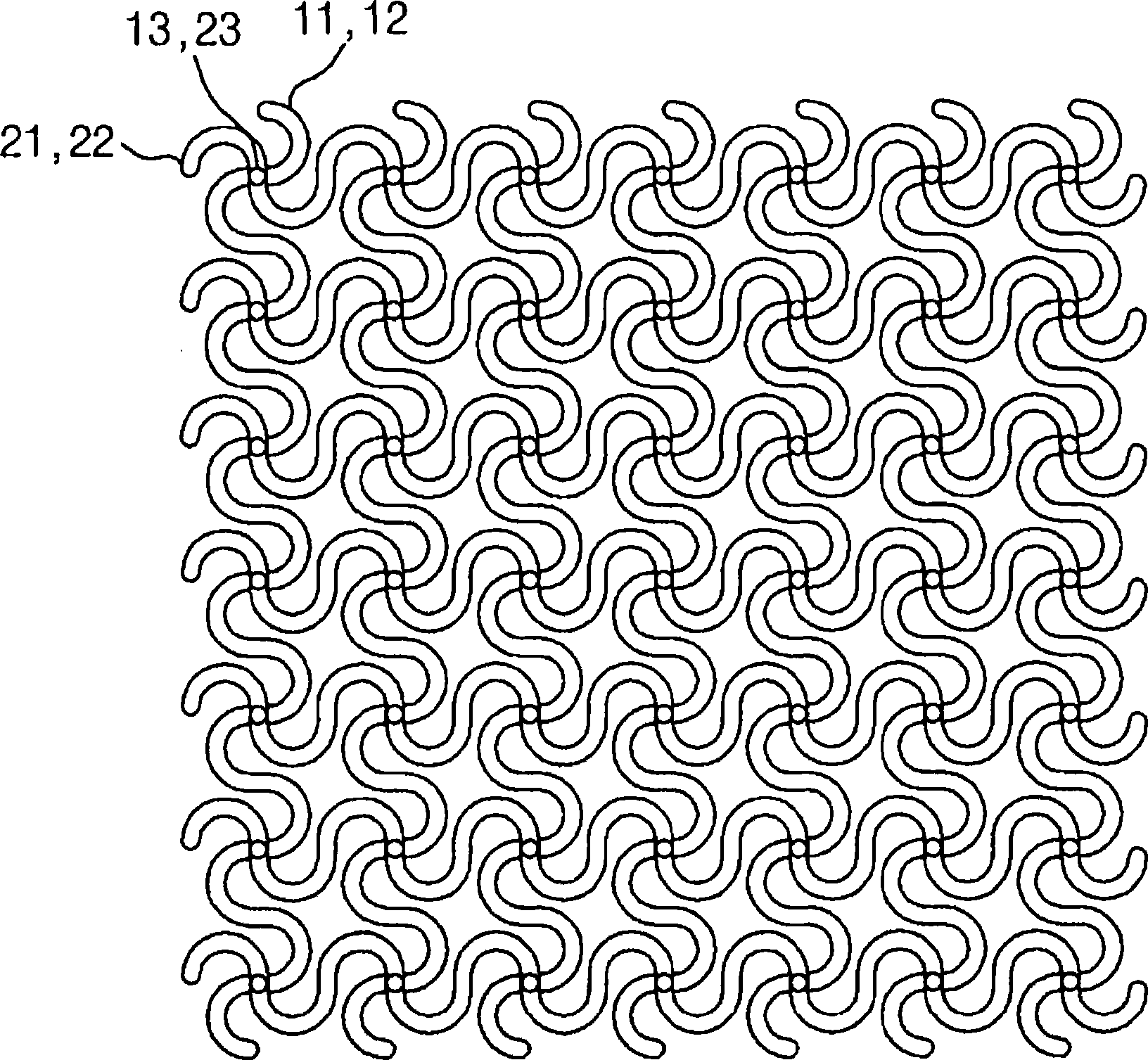

InactiveCN108878486AImprove tensile propertiesGood bending propertiesSolid-state devicesSemiconductor devicesElectricitySignal lines

The invention provides a display substrate, a preparation method of the display substrate and a display device, and relates to the technical field of display. The display substrate comprises a flexible substrate, a plurality of pixel islands located on the flexible substrate, groove holes located between the adjacent pixel islands, and inter-island connecting lines for communicating the adjacent pixel islands; thin film transistors and signal lines electrically connected with the thin film transistors are arranged in the pixel islands; and the inter-island connecting lines are used for enabling the signal lines of the adjacent pixel islands to be electrically connected. According to the invention, the tensile property and the bending property of the OLED display substrate can be improved,so that the OLED display substrate capable of being bent can be realized.

Owner:BOE TECH GRP CO LTD

Copper alloy, copper alloy plate, and process for producing the same

This invention provides a copper alloy having excellent stress relaxation resistance, comprising Ni: 0.1 to 3.0% (% by mass; the same shall apply hereinafter), Sn: 0.01 to 3.0%, and P: 0.01 to 0.3% with the balance consisting of copper and unavoidable impurities, characterized in that the content of Ni in an extraction residue after extraction separation on a filter having an opening size of 0.1 [mu]m by an extraction residue method is not more than 40% in terms of the proportion to the content of Ni in the copper alloy. In the extraction residue method, 10 g of the copper alloy is immersed in 300 ml of a methanol solution having an ammonium acetate concentration of 10% by mass. This copper alloy is used as an anode. On the other hand, platinum is used as a cathode. Galvanostatic electrolysis is carried out at a current density of 10 mA / cm<2>. A solution containing this copper alloy dissolved therein is subjected to suction filtration by a polycarbonate membrane filter having an opening size of 0.1 [mu]m, and the insolubles as the residue are separated and extracted on the filter. The content of Ni in the extraction residue is determined by dissolving the insolubles as the residue on the filter in a solution composed of a mixture of aqua regia and water at a ratio of 1 : 1, and then analyzing the solution by ICP emission spectrometry.

Owner:KOBE STEEL LTD

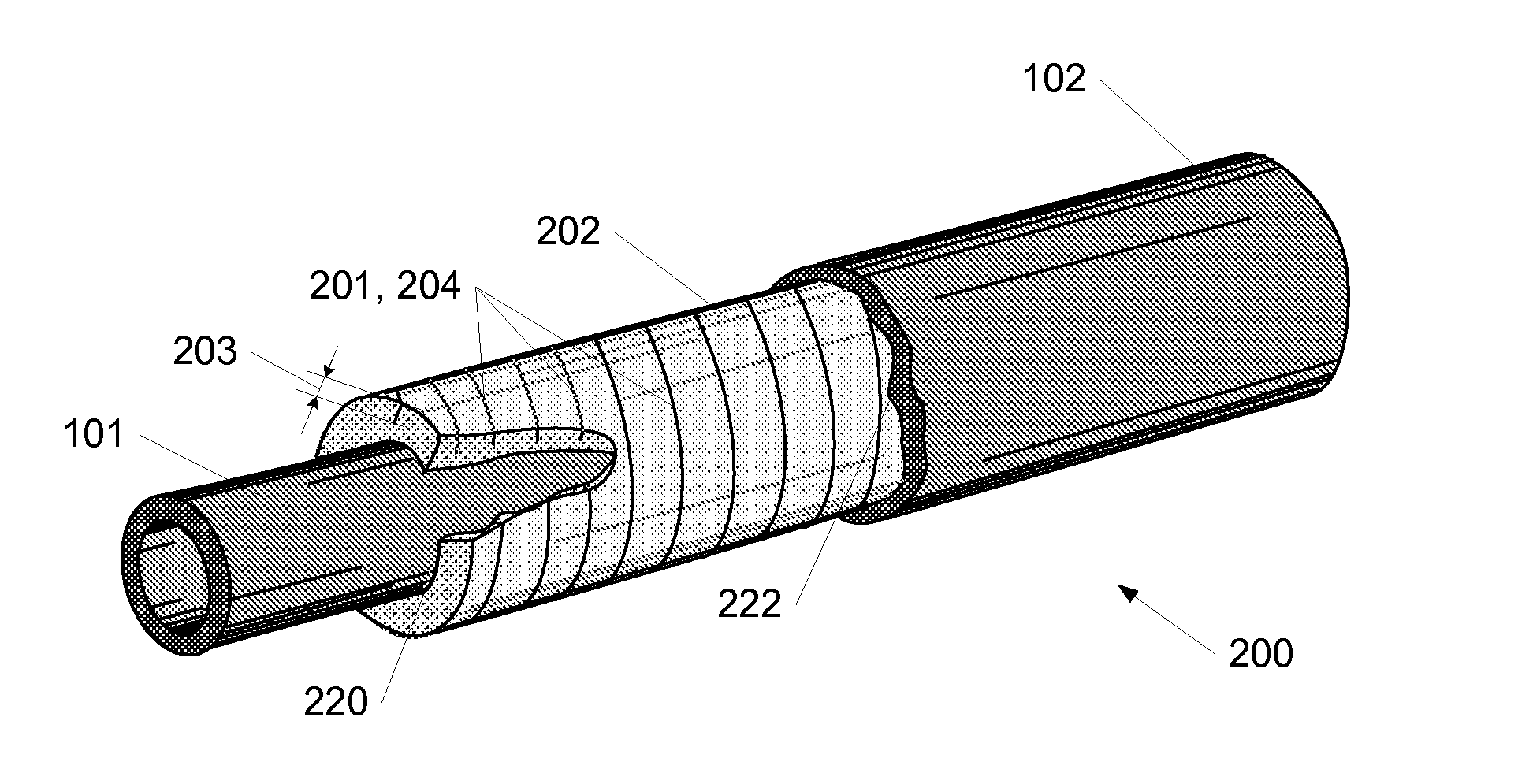

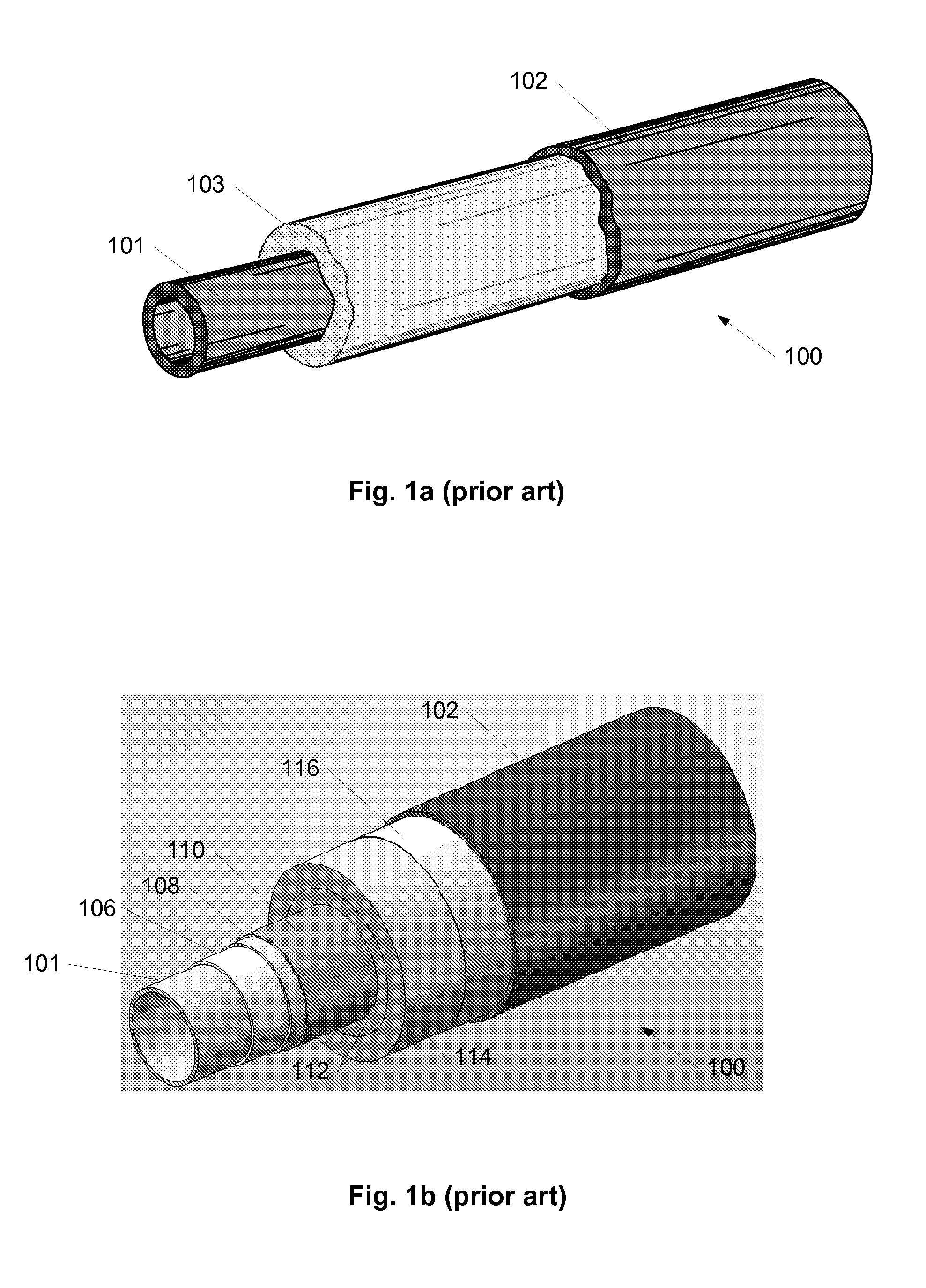

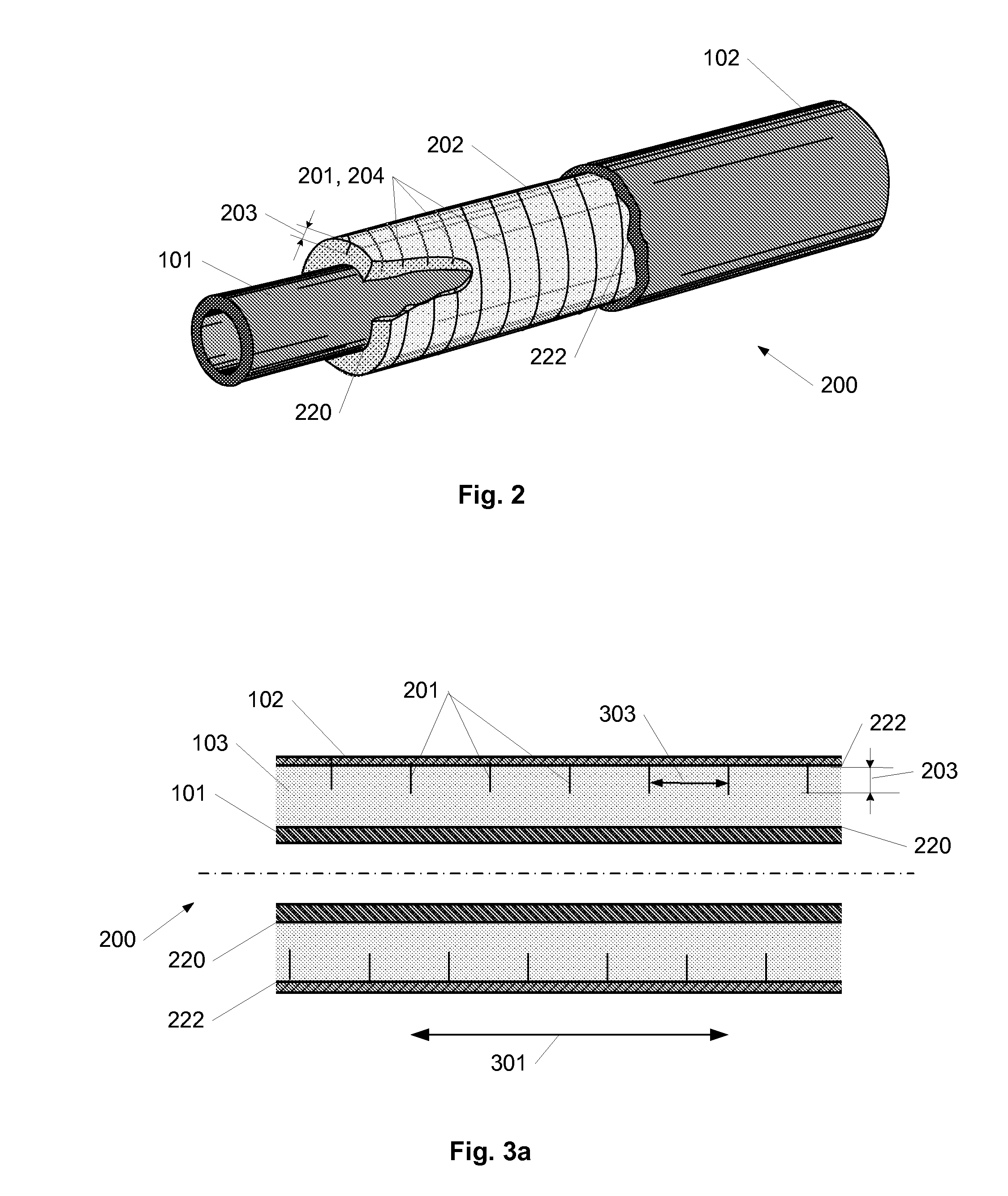

Bendable Pre-Insulated Pipeline Assembly

ActiveUS20100260551A1Improve bending performanceFaster and less involved method of installationPipe laying and repairThermal insulationThermal insulationEngineering

This invention relates to a pipeline assembly especially for offshore installation comprising an inner carrier pipe, a casing and at least one closed-cell and / or solid thermal insulation material layer placed in between the casing and the inner carrier pipe, and the at least one insulation layer being directly or indirectly bonded to at least the casing and the inner carrier pipe. The pipeline assembly has improved bending properties which is achieved as the insulation material layer comprises at least one slit substantially transversely to the longitudinal direction of the pipeline assembly. The slit can be applied as a helical or circumferential cut, enabling the pipeline assembly to be rolled onto a reel or spool which greatly improves the pipeline assembly installation process. Methods of improving the bending properties of such a pipeline assembly are also described.

Owner:LOGSTOR

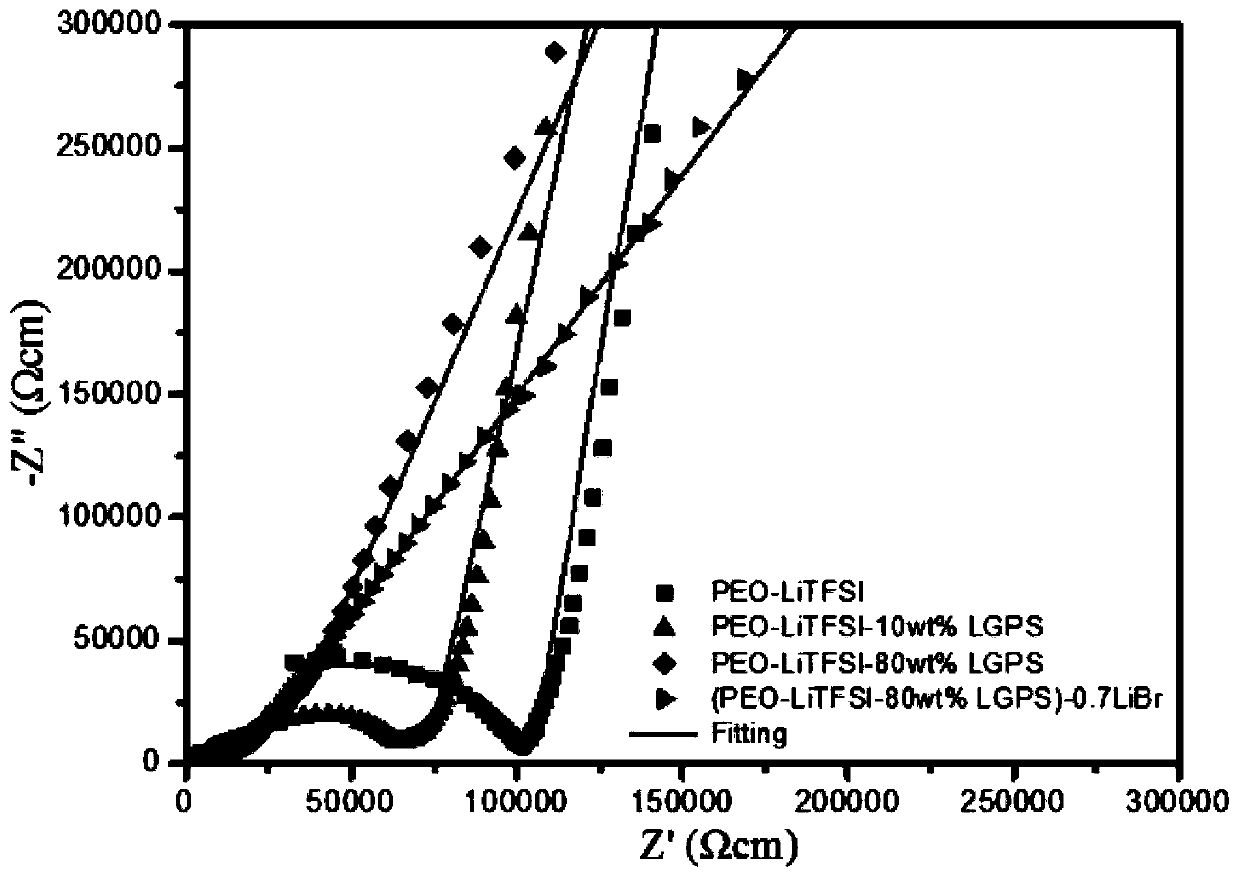

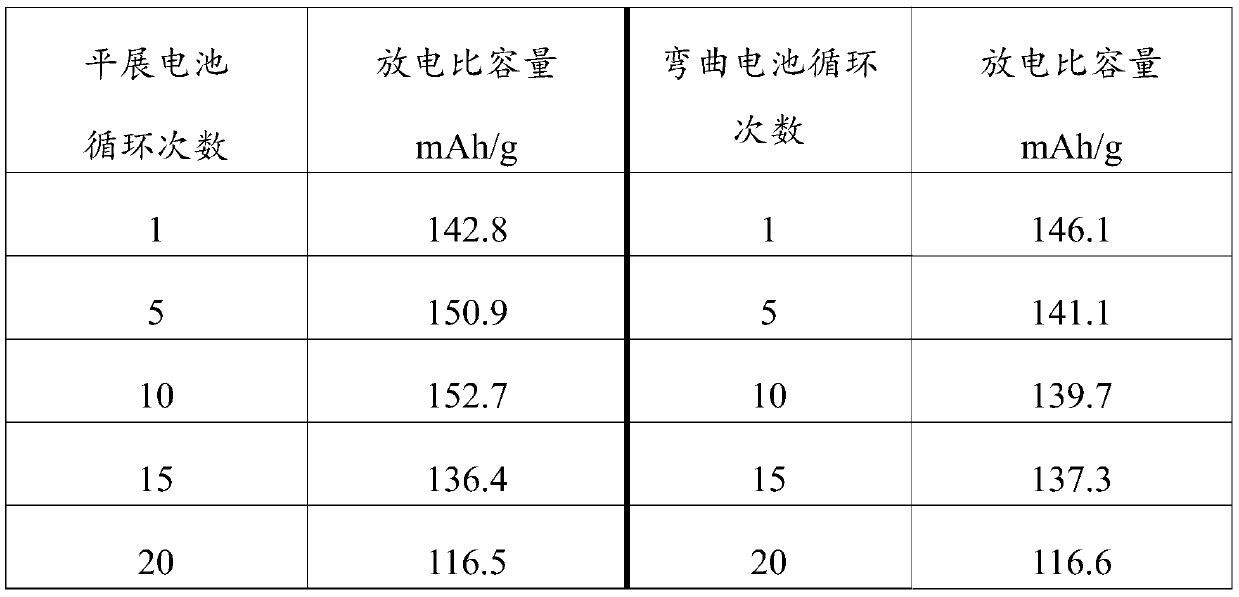

Flexible composite solid-state electrolyte, full-solid-state lithium-ion battery and preparation method thereof

ActiveCN110085904AGood flexibilityImprove dispersion uniformityFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteComposite electrolyte

The invention provides a flexible composite solid-state electrolyte, a full-solid-state lithium-ion battery and a preparation method thereof. The solid-phase mixing of a sulfide solid-state electrolyte or a modifier thereof, a thermoplastic polymer or a modifier thereof and lithium salt enables the composite solid-state electrolyte to have good flexibility while improving the dispersion uniformityand effective contact of each component. A halide, phosphate and / or an oxide are added to the sulfide material especially before the composition of the sulfide solid-state electrolyte and the polymersolid-state electrolyte, thereby providing a multi-dimensional channel for lithium ion transmission, increasing the disordered degree of lithium ion distribution, and being capable of further improving the lithium ion conductivity and electrochemical stability of the composite solid-state electrolyte. The flexible composite electrolyte has the advantages of high lithium conductivity at the room temperature, good electrochemical stability, easy preparation and processing, ability of being bent and cut and the like. The formed flexile full-solid-state battery has good mechanical performance andbending performance, and improves the cycle life and energy density.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

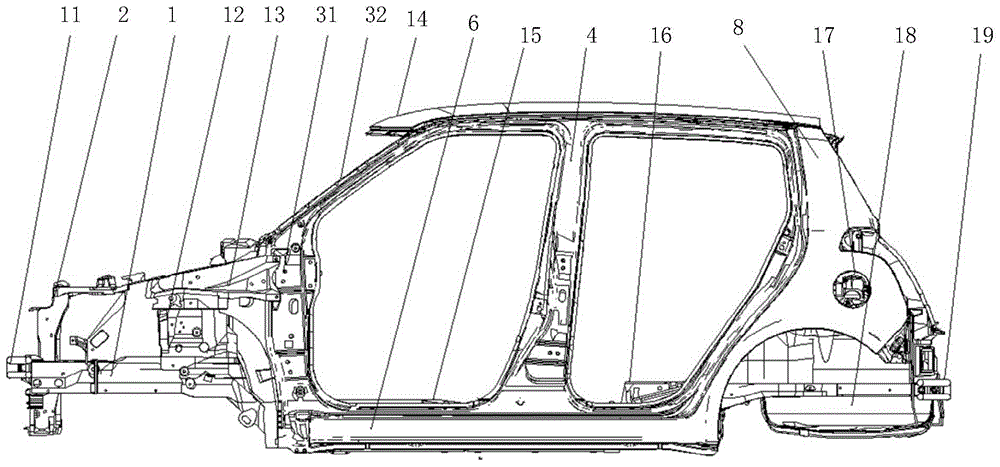

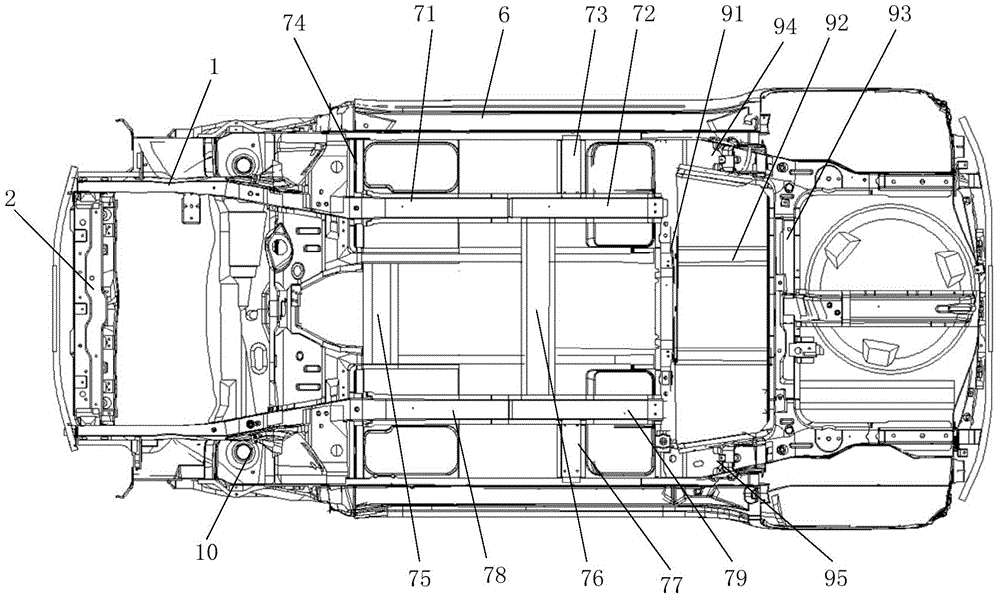

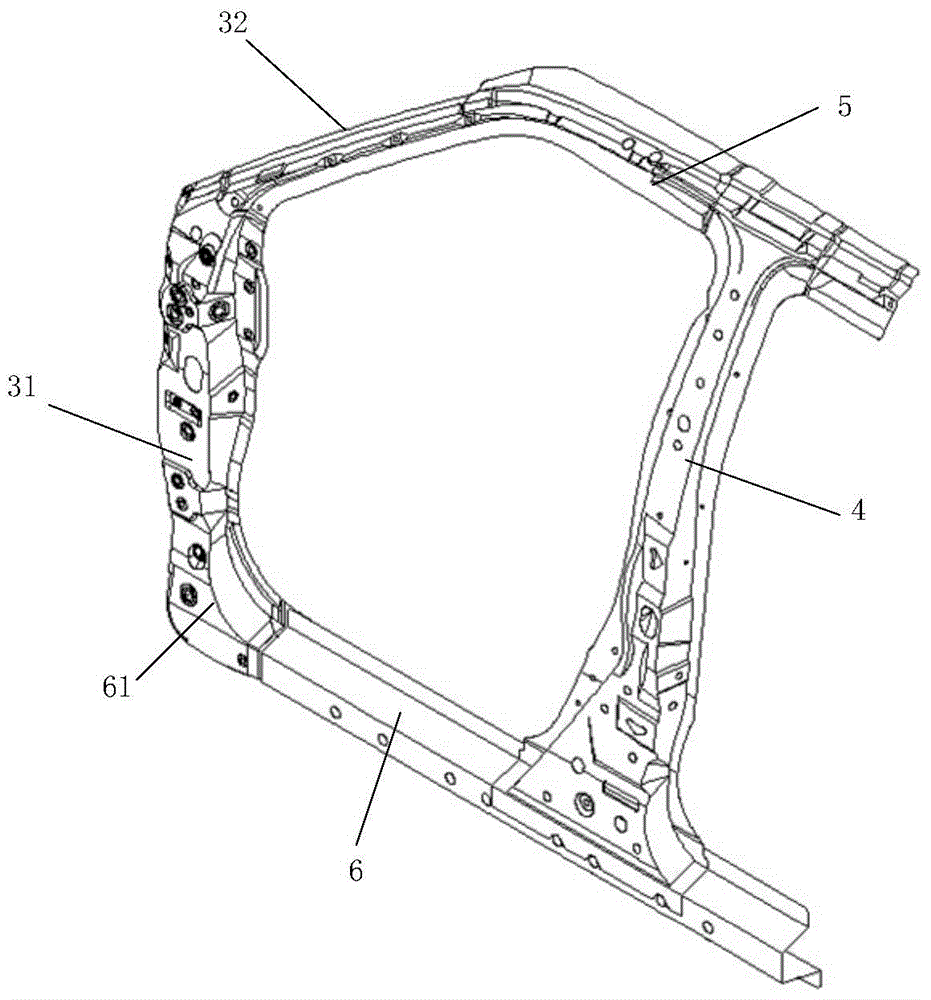

Body in white bend resistance structure and arrangement mode thereof

ActiveCN105015623AIncrease local overlapImprove bending resistanceSuperstructure subunitsMonocoque constructionsStructural engineeringEngineering

The invention provides a body in white bend resistance structure and an arrangement mode thereof. The lower end of a lower vertical plate of a column A is in overlap connection with a sill strip. The upper end of the lower vertical plate of the column A is in overlap connection with an outer plate of the column A. The outer plate of the column A is in overlap connection with an upper beam of a column B. The upper end of an outer plate of the column B is in overlap connection with the upper beam of the column B. The lower end of the outer plate of the column B is in overlap connection with the sill strip. Two to three layers of spot welding connection is formed at each overlap joint to form a closed structure. The bend resistance section of the sill strip, the bend resistance section of the vertical plate of the column A, the bend resistance section of the outer plate of the column A and the bend resistance section of the upper beam of the column B are each in a closed annular shape. Due to the fact that the bend resistance sections form the closed annular shapes and are composed of three or four sheet metal parts, the bend resistance is improved; due to extending sections at the upper and lower ends of the outer plate of the column B, the overlap connection efficiency of the upper beam and the sill strip of the column B and the outer plate of the column B is enhanced, and the bend resistance performance is improved; the transverse and longitudinal staggered closed structure has the effect of enhancing inertia torque, and the bend resistance performance is improved.

Owner:CHINA AUTOMOTIVE ENG RES INST

Flexible display panel and method for manufacturing same

ActiveUS20190259967A1Low hole densityGood bending propertiesStatic indicating devicesDigital data processing detailsEngineeringFlexible display

The present disclosure provides a flexible display panel and a method for manufacturing same. The present disclosure not only ensures improvement of bending characteristics of display panels but also ensures high pixels per inch (PPI) of the display panels. Moreover, IR-drop is lowered and display uniformity of the panels is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

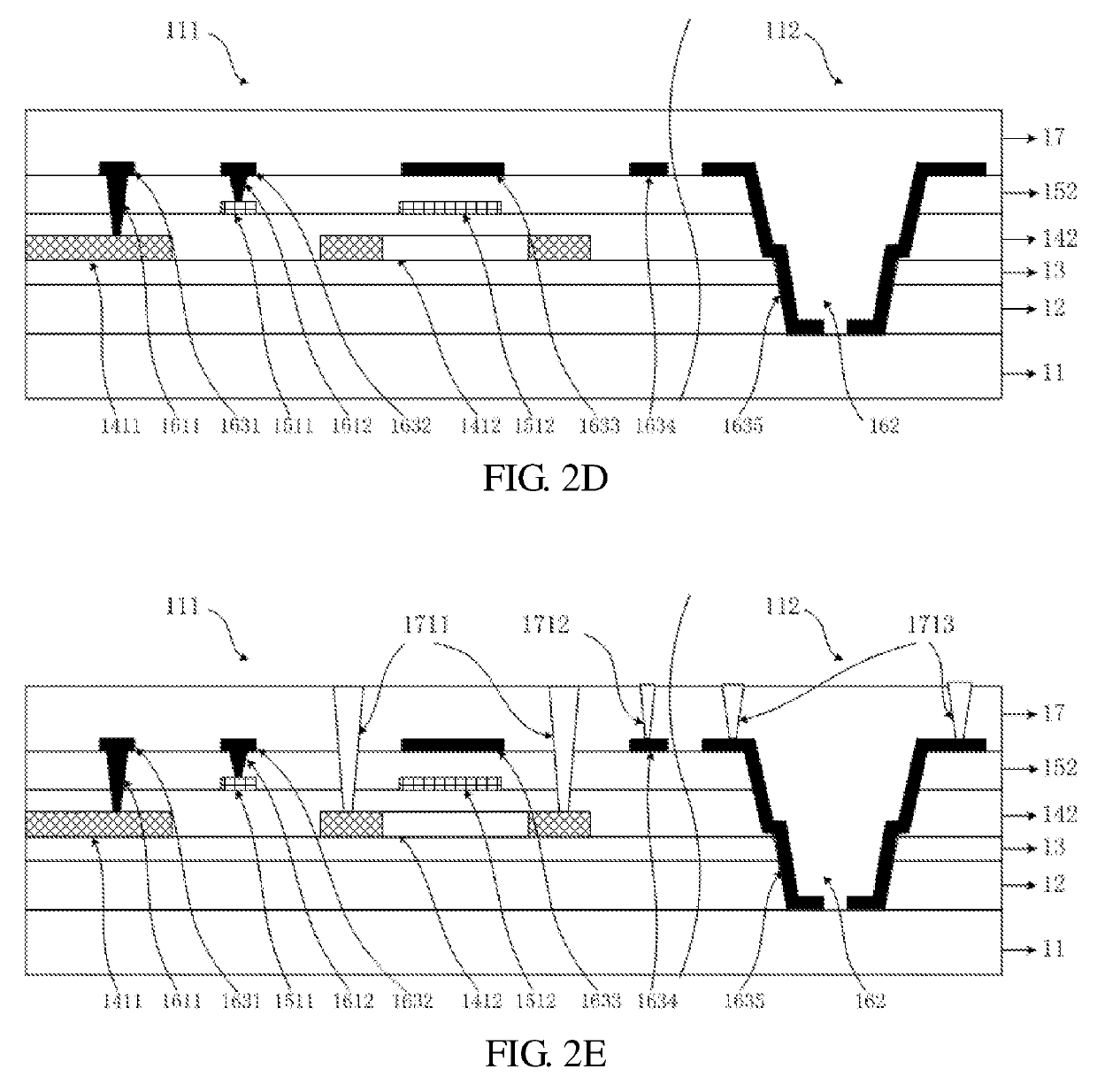

Bending non-sensitive fibre optical with moderate modulus filed diameter

ActiveCN1818728AWiring construction is convenientEasy to curlOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingMode field diameterSingle-mode optical fiber

A monomode optical fiber with suitable mode-field diameters, whcih is not sensitive to bending, is available for double windows of 1310nm and 1550nm wavelengths. It consists of three sub-layered cores and three sub-claddings with different refraction index profiles. The third layer of the sub-claddings is of pure silicon dioxide glass. It is suitable for distribution in rooms.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

Copper alloy material for electric/electronic parts and method of producing the same

InactiveUS20110186192A1High mechanical strengthImprove conductivityConductive materialUltimate tensile strengthImpurity

A copper alloy material for an electric / electronic part, having a composition comprising Co 0.5 to 2.0 mass % and Si 0.1 to 0.5 mass %, with the balance of Cu and inevitable impurities, in which a copper alloy of a matrix has a grain size of 3 to 35 μm, a precipitate composed of Co and Si has a particle size of 5 to 50 nm, the precipitate has a density of 1×108 to 1×1010 number / mm2, and the copper alloy material has a tensile strength of 550 MPa and an electrical conductivity of 50% IACS or more.

Owner:FURUKAWA ELECTRIC CO LTD

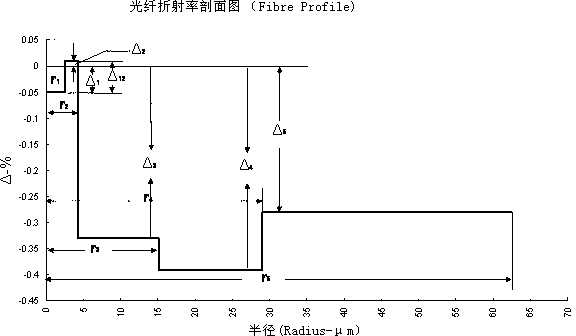

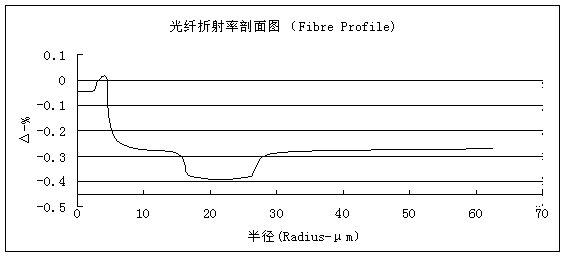

Optical fiber large in effective area

ActiveCN103257393AImprove bending characteristicsGood bending propertiesOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingCommunications systemRelative refractive index

The invention relates to an optical fiber large in effective area. The optical fiber large in the effective area comprises a fiber core layer and a covering layer. The optical fiber large in the effective area is characterized in that the fiber core layer comprises an inner core layer and an outer core layer, the radius r1 of the inner core layer is 1 to 4 microns, a relative refractive index difference delta 12 of the inner core layer to the outer core layer meets the condition that -0.2% <= delta 12 < 0%, the relative refractive index difference of the inner core layer to the outer core layer is invariant or gradually increased along with increasing of the radius, the radius r2 of the outer layer is 4 to 7 microns, and the relative refractive index difference delta 2 of the outer core layer is -0.15 % to 0.05 %; the covering layer comprises an inner covering layer, a sunk concave covering layer and an outer covering layer, the inner covering layer covers the fiber core layer, the radius r3 of the inner covering layer is 7 to 20 microns, the relative refractive index difference delta 3 is within the range of -0.5 % to -0.1 %, the radius r4 of the sunk concave covering layer is 12 to 40 microns, the relative refractive index difference delta 4 is within the range of -1.0 % to -0.3 %, and the relative refractive index difference delta 5 is within the range of -0.2% to -0.4%. The optical fiber large in the effective area has a large effective area, quite low transmission loss and good curve characteristics, and is particularly suitable for application of a long-distance high-speed large-volume communication system.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

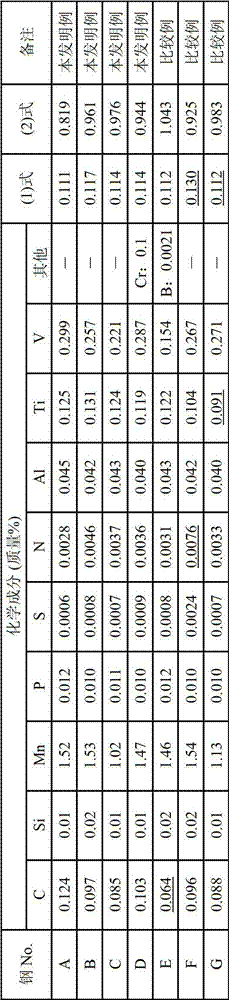

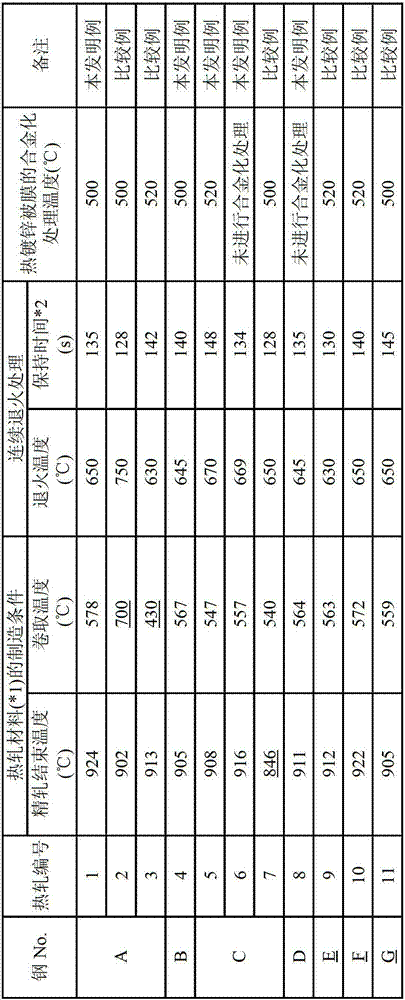

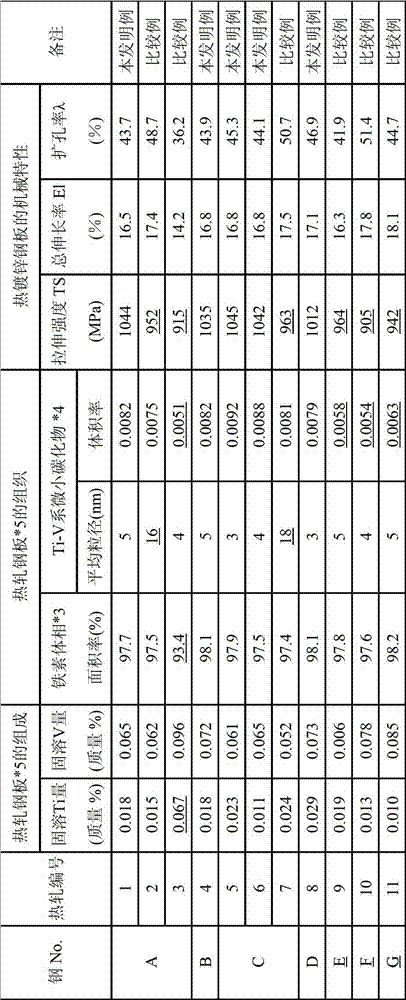

Hot-dip galvanized steel sheet with high tensile strength and superior processability and method for producing same

ActiveCN102906295AEasy to processHigh elongationHot-dipping/immersion processesFurnace typesPhysical chemistryCarbide

Disclosed is a hot-dip galvanized steel sheet with high tensile strength that is provided with both strength and processability (elongation and stretch flangeability) and a method for producing the same. Specifically disclosed is a hot-dip galvanized steel sheet with high tensile strength that has tensile strength of 980 MPa or greater and superior processability. This hot-dip galvanized steel sheet has a composition containing 0.07 - 0.13% C, 0.3% or less Si, 0.5 - 2.0% Mn, 0.025% or less P, 0.005% or less S, 0.0060% or less N, 0.06% or less Al, 0.10 - 0.14% or less Ti, and 0.15 - 0.30% V (% by mass) such that S and N satisfy Ti >= 0.10 + (N / 14*48 + S / 32*48) and 0.8 <= (Ti / 48 + V / 51) / (C / 12) <= 1.2 (wherein C, Ti, V, S and N are the content for each element in % by mass). The composition further contains 0.04 - 0.1% V in solid solution and 0.05% or less Ti in solid solution, and the remainder is Fe and unavoidable impurities. The hot-dip galvanized steel sheet has a matrix that is 97% or more in areal proportion of the overall structure of the ferrite phase and a hot-dip galvanized coating or alloyed hot-dip galvanized coating on the surface of a hot-rolled steel sheet that has fine carbide that has an average particle diameter of less than 10 nm and contains Ti and V dispersed and precipitated, with a structure forming 0.007 or more in areal proportion of the overall structure of that fine carbide.

Owner:JFE STEEL CORP

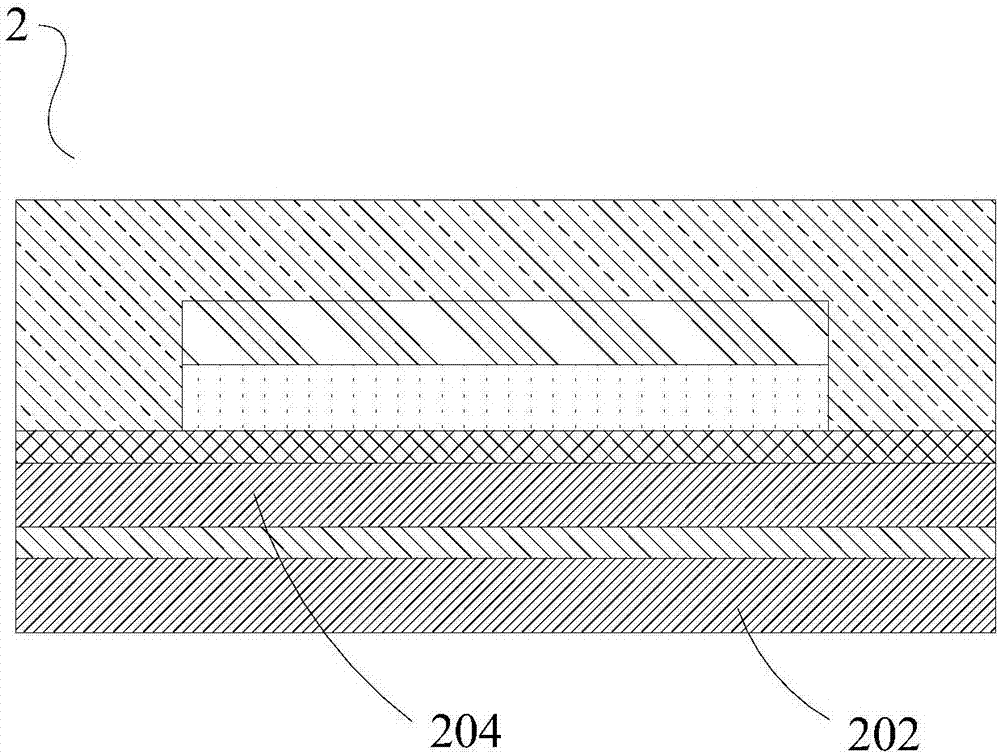

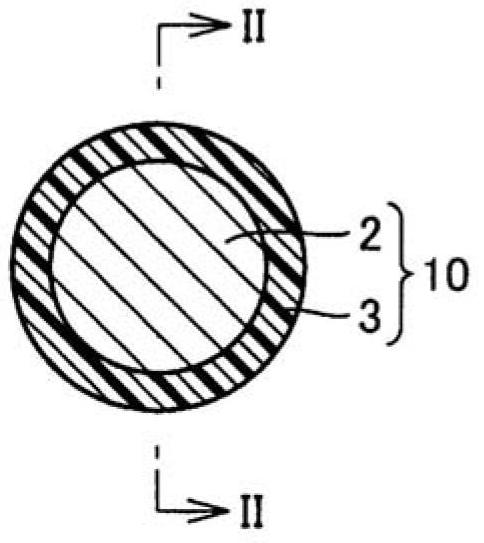

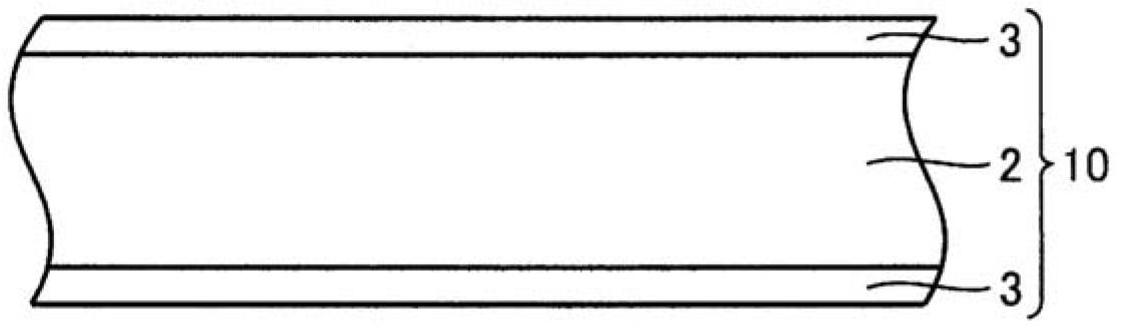

Aluminum alloy wire

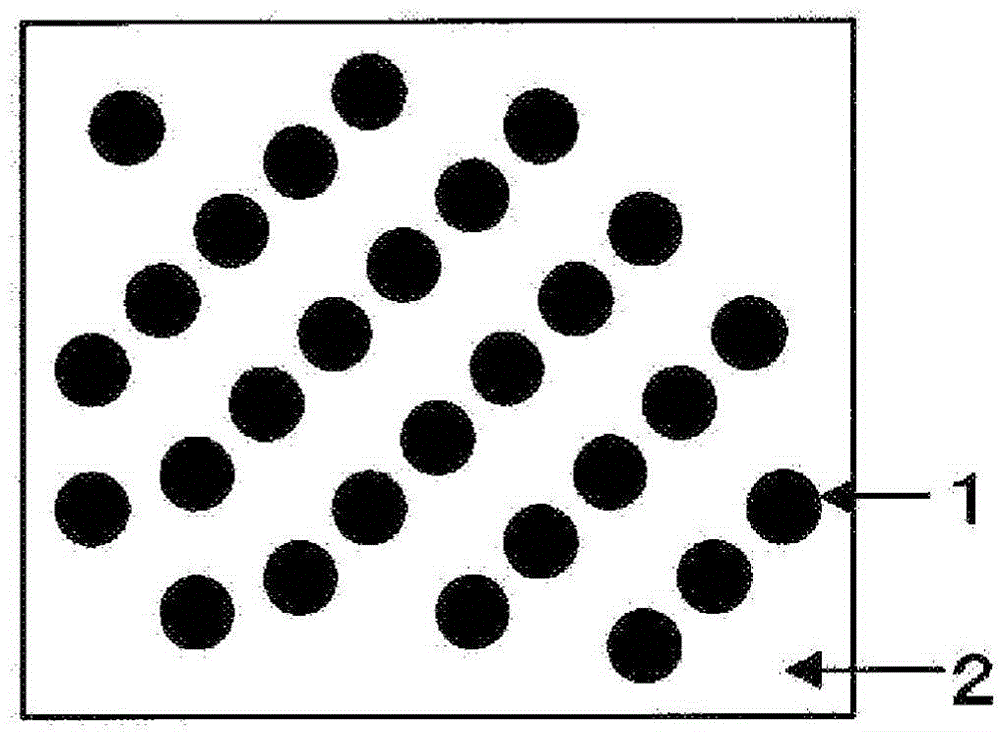

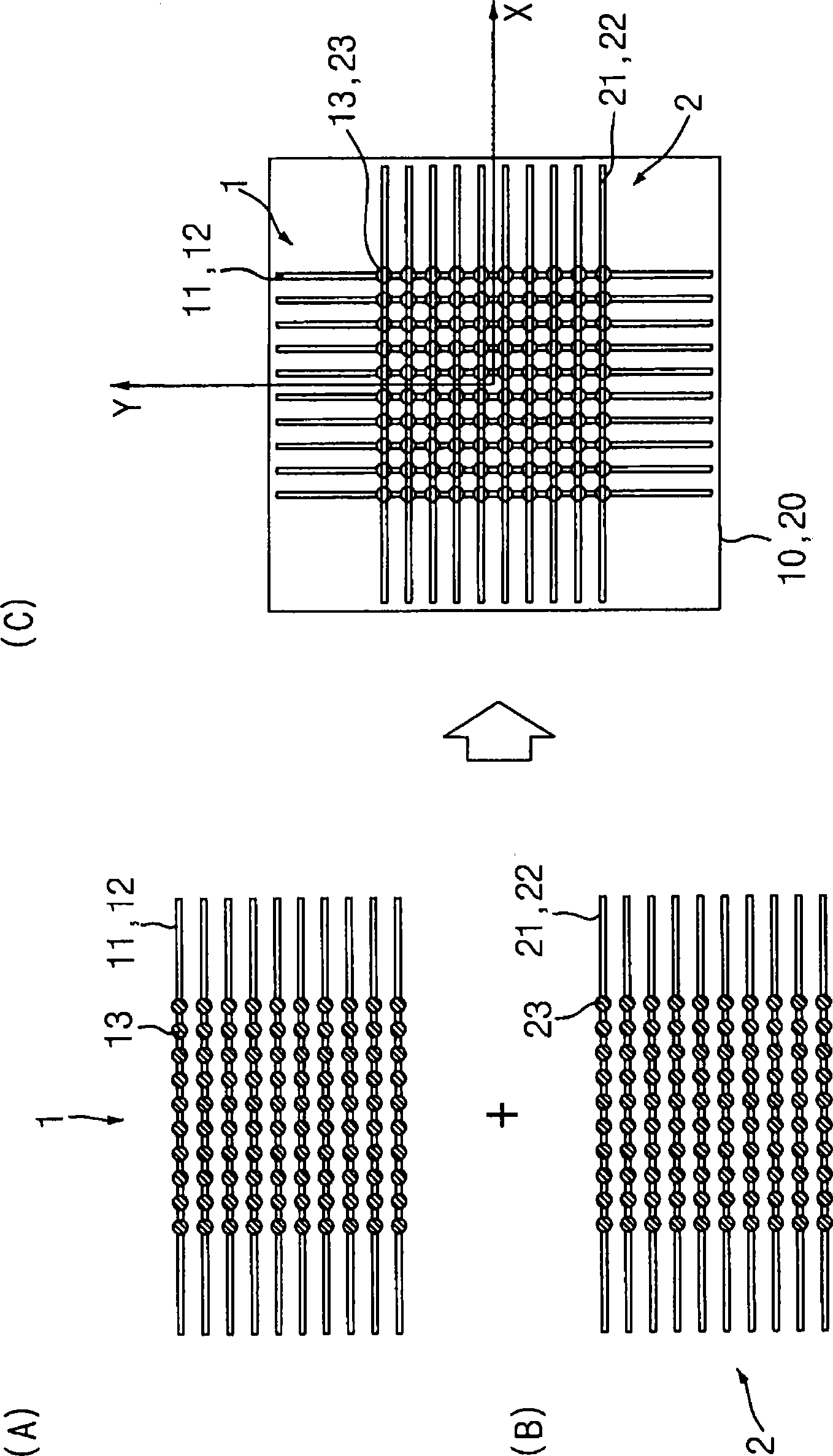

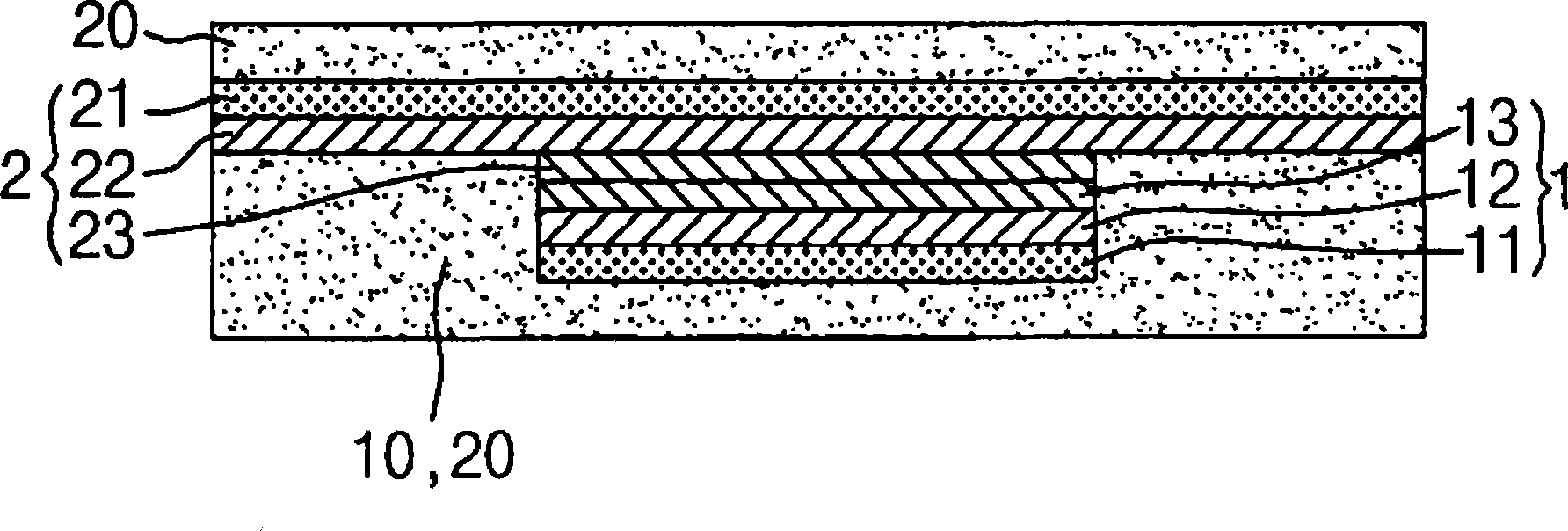

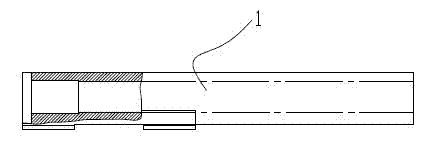

ActiveCN102695813AGood bending propertiesGood strength propertiesSingle bars/rods/wires/strips conductorsApparatus for heat treatmentSolid solutionUltimate tensile strength

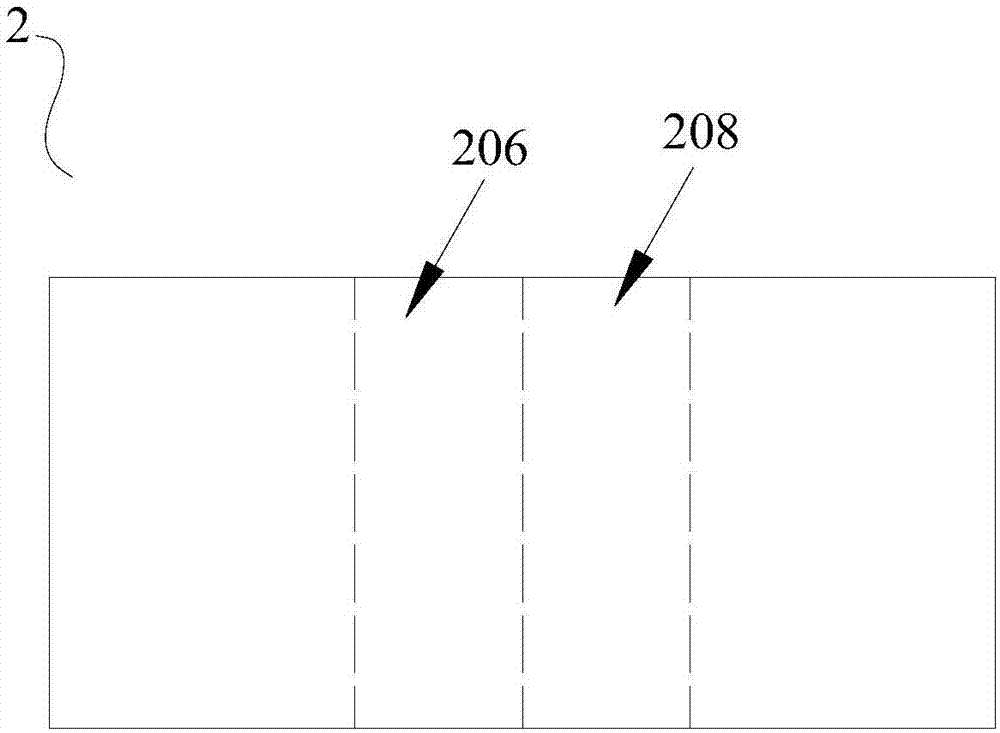

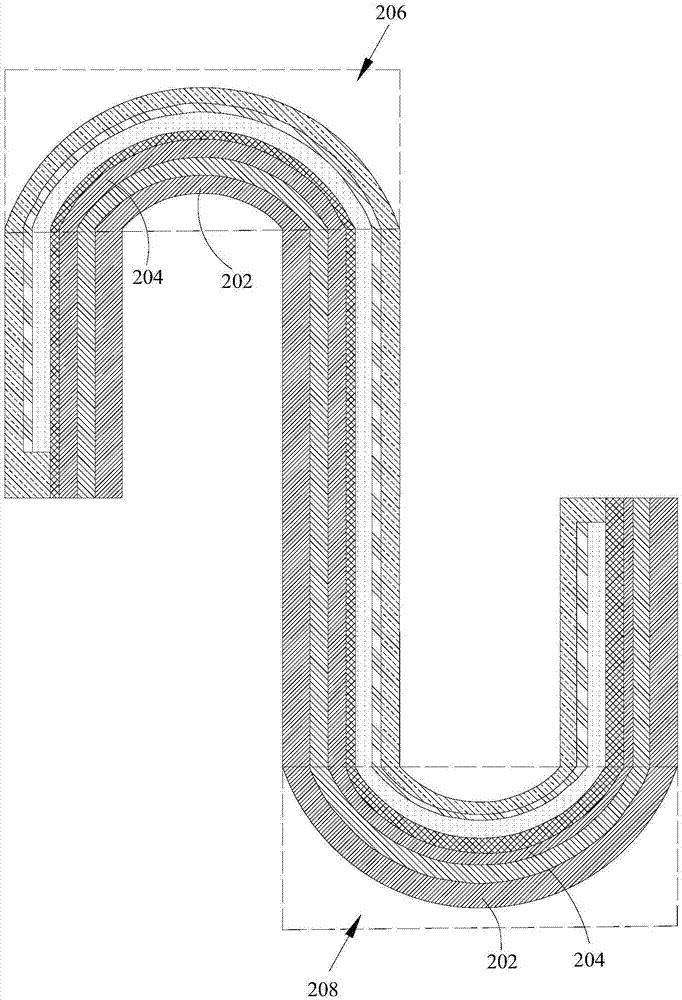

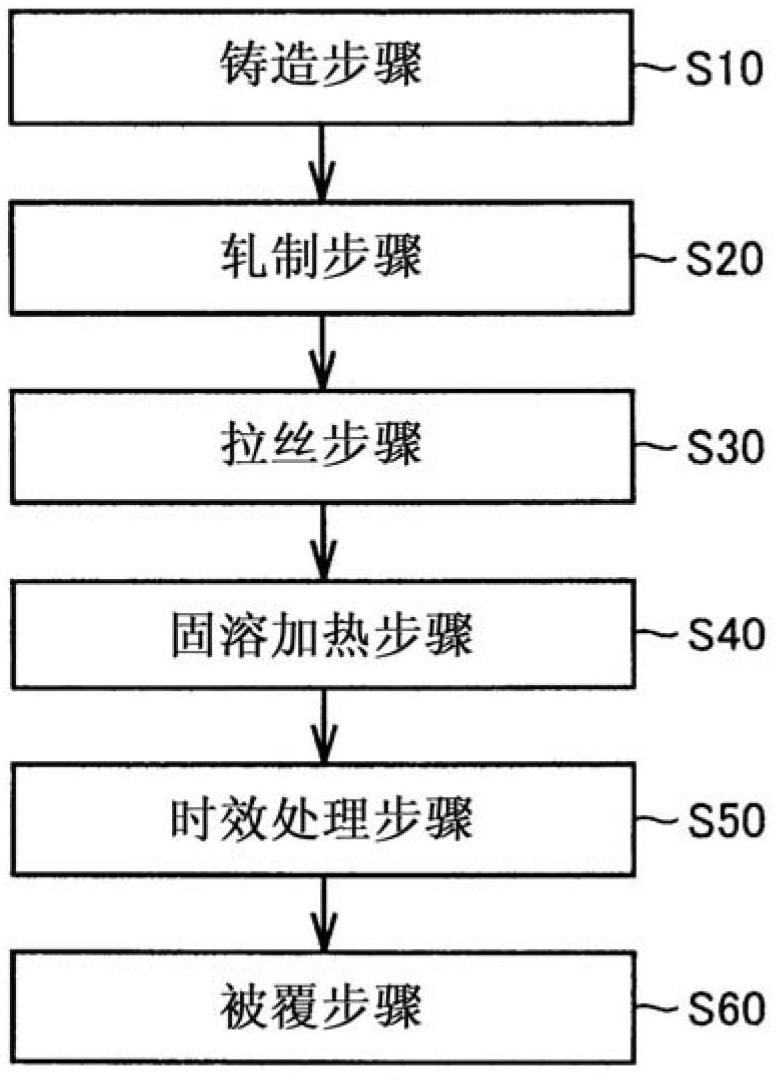

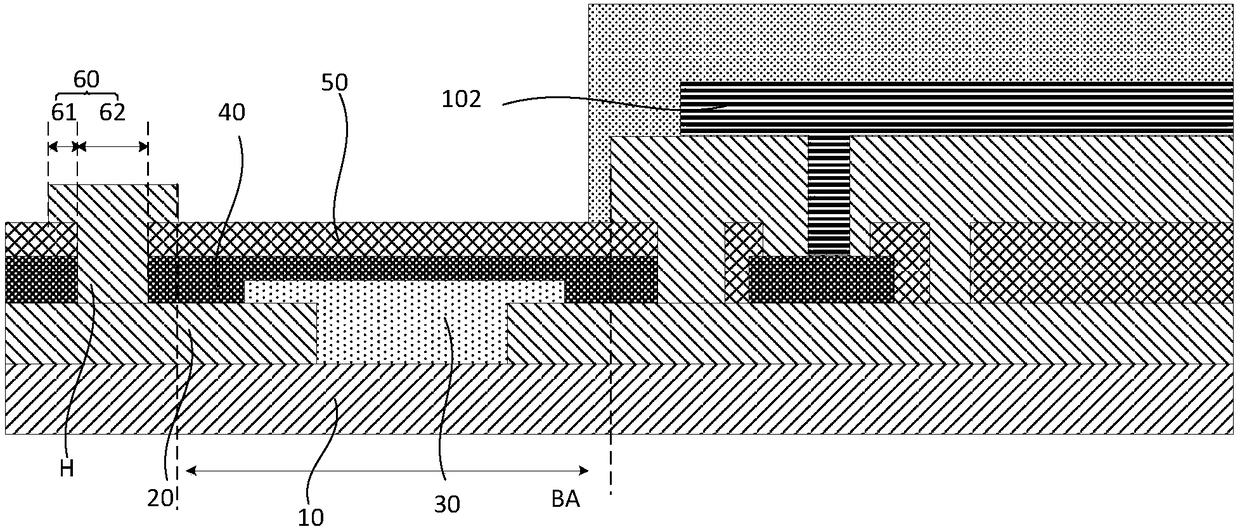

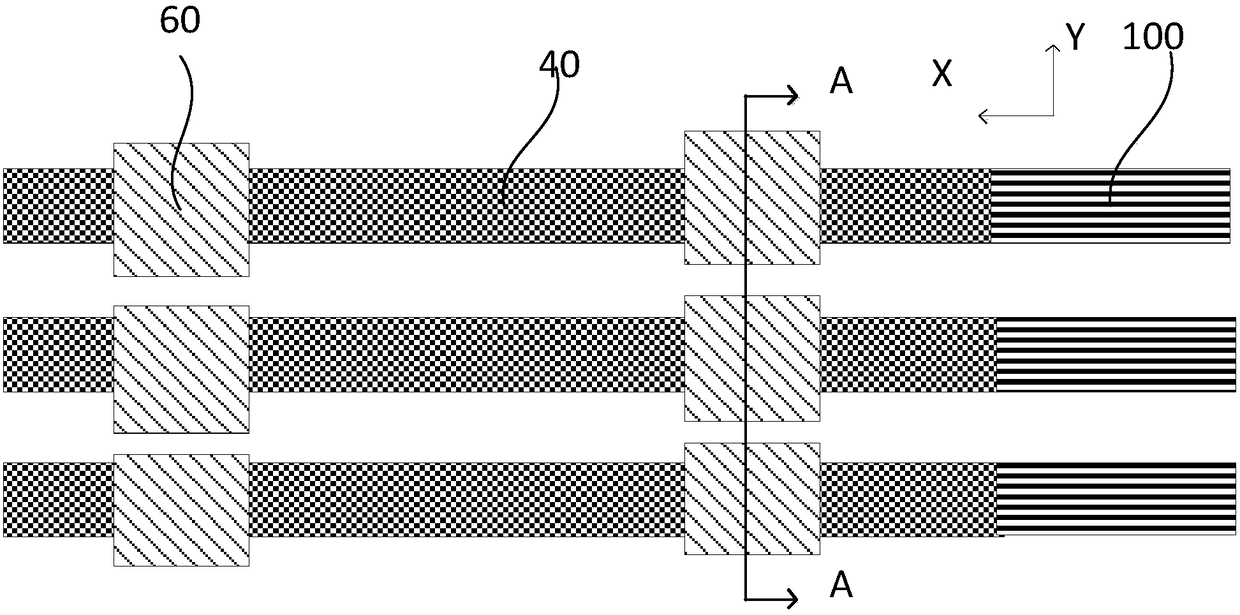

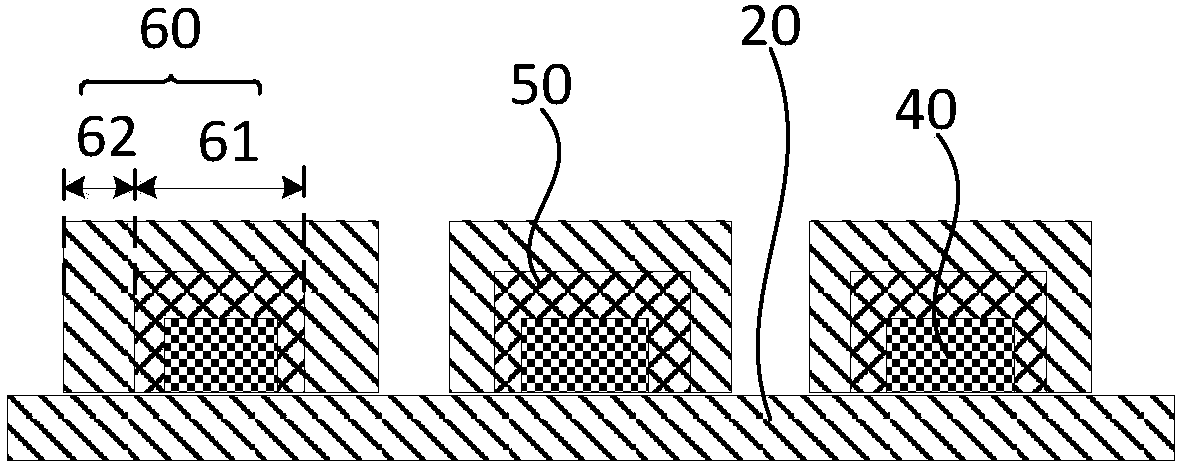

Provided are an aluminum alloy wire (2) having excellent flexing characteristics, strength, and electrical conductivity, a twisted aluminum alloy wire, a covered electric wire (10) including the alloy wire or twisted wire, a wire harness including the covered electric wire (10), a process for producing the aluminum alloy wire, and a process for producing the covered electric wire (10). The aluminum alloy wire (2) contains, in mass%, 0.1-1.5% Mg, 0.03-2.0% Si, and 0.05-0.5% Cu, the remainder comprising Al and impurities. The aluminum alloy wire (2) satisfies the relationship 0.8=Mg / Si (by mass)=3.5, and has a conductivity of 35-58 %IACS, a tensile strength of 150-400 MPa, and an elongation of 2% or more. This aluminum alloy wire (2) is produced through the steps of casting, rolling, wire drawing, and solution heat treatment in this order. By using the specific composition and by conducting a solution heat treatment after wire drawing to sufficiently bring the additional elements into a solid-solution state, the aluminum alloy wire (2) having excellent flexing characteristics can be obtained.

Owner:SUMITOMO ELECTRIC IND LTD +2

Flexible display panel and flexible display device

ActiveCN108538852AGood bending propertiesImprove contact effectSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerStress relief

The invention relates to a flexible display panel and a flexible display device. The flexible display panel comprises a flexible substrate, a first inorganic layer, a stress relief layer, multiple wires, an insulation layer and a second inorganic layer, wherein the flexible substrate comprises a bent area; the first inorganic layer is arranged on the flexible substrate, and the first inorganic layer in the bent area comprises a groove; the stress relief layer fills the groove; the multiple wires are arranged on the first inorganic layer and the stress relief layer; the insulation layer coversthe multiple wires; the second inorganic layer is arranged at least one end of the bent area and comprises a first part and a second part, the first part is contacted with the insulation layer and thesecond part is contacted with the first inorganic layer. the contact performance between the wire and the first inorganic layer can be effectively improved, the wire is thus pinned by the second inorganic layer, and the phenomenon that film peeling or warping happens to two ends of the bent area in the case of bending and signal transmission is influenced can be prevented.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Rolled copper foil

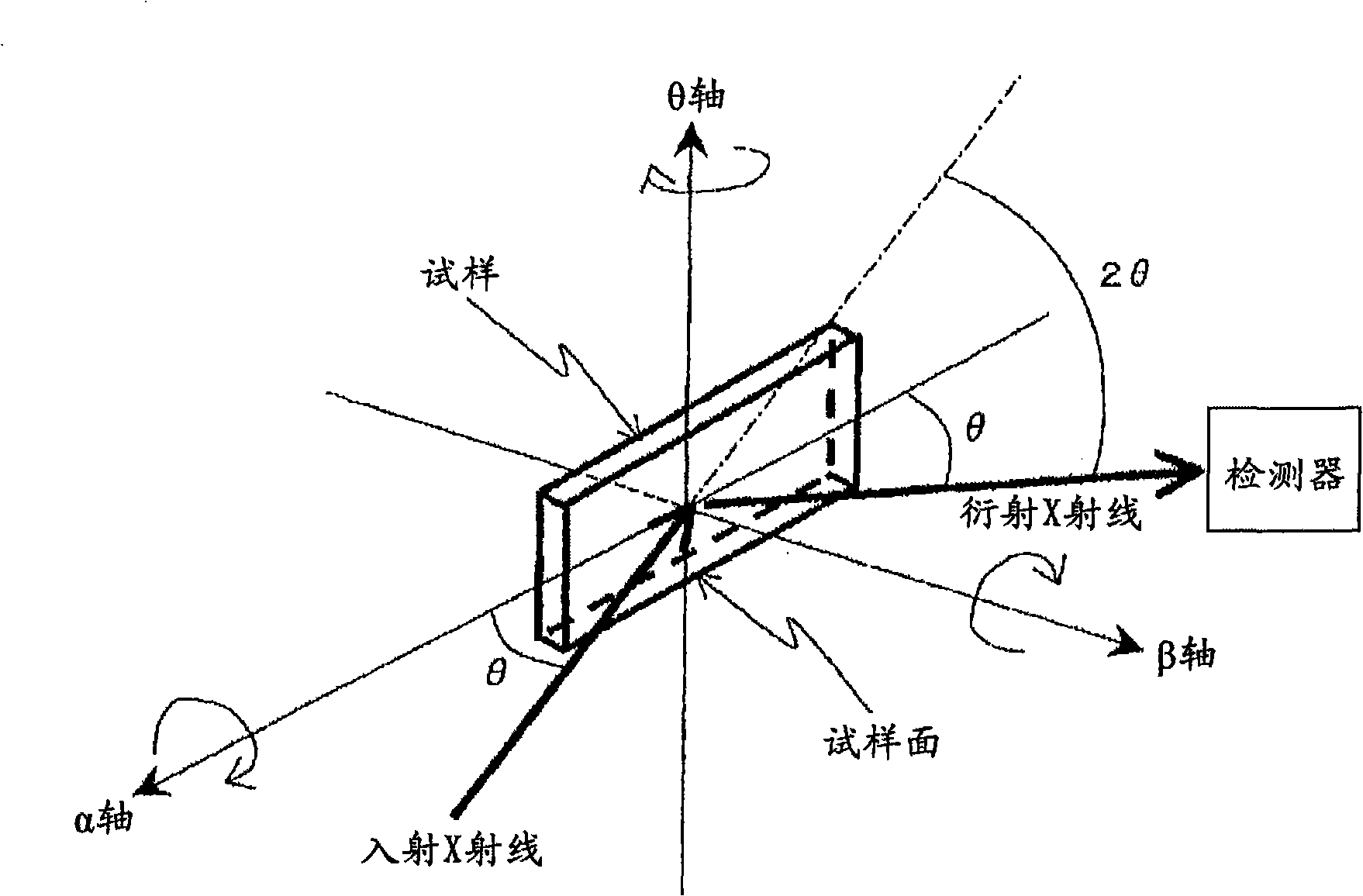

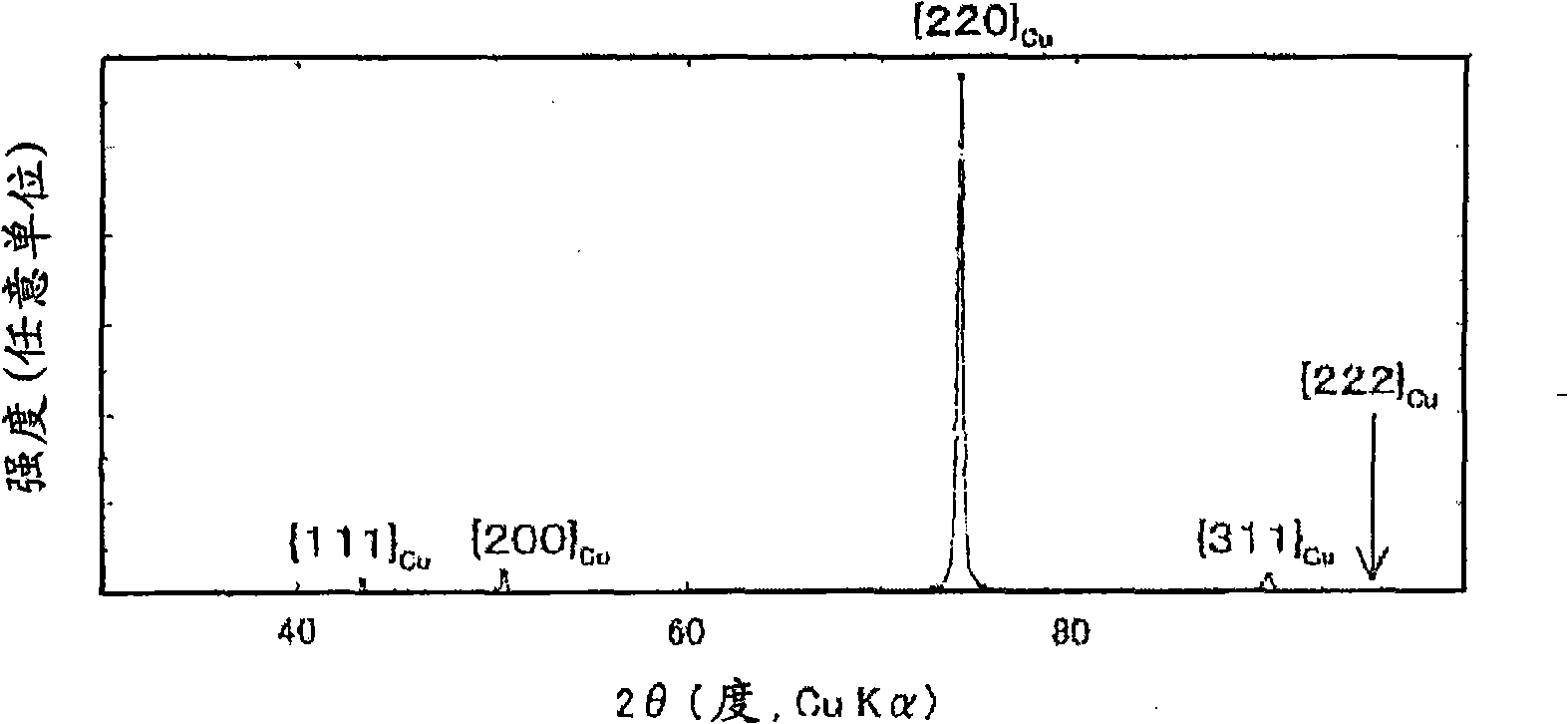

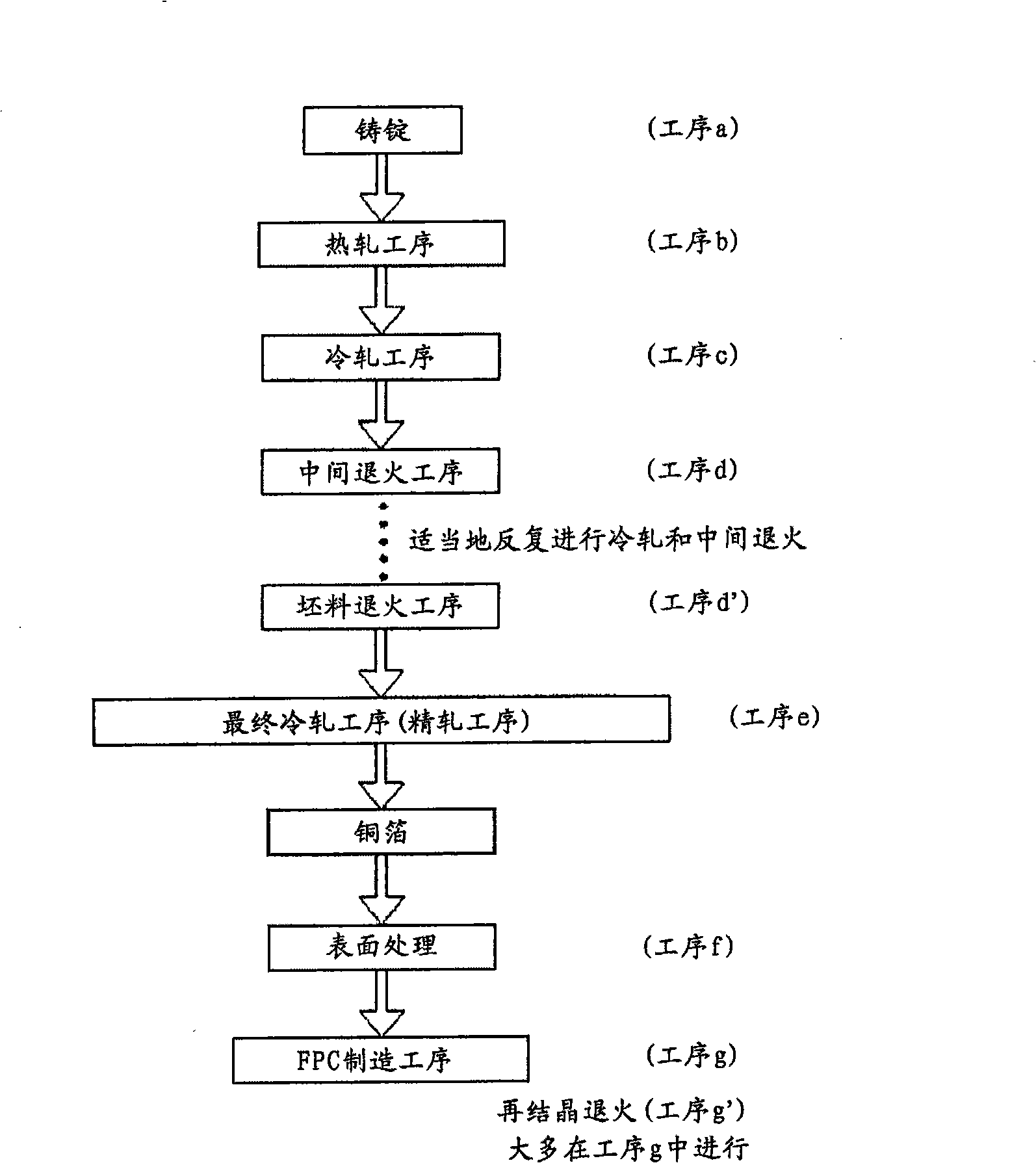

ActiveCN101346042AGood bending propertiesInsulating substrate metal adhesion improvementPrinted circuit aspectsHigh densityX-ray

Along with development in downsizing, increase in the integration degree (higher density mounting) and higher performance of electronic equipment in recent years, further higher requirement for flexible fatigue property has been increased more and more than usual for the flexible printed circuit. The invention provides a rolled copper foil with more excellent flexible fatigue property, characterized in that: the rolled copper foil obtained after a final cold rolling step but before a recrystallization annealing includes a crystal grain alignment wherein: when normalized intensity of {200}Cu plane diffraction of a copper crystal in results obtained by an X-ray diffraction pole figure measurement with respect to a rolled surface is plotted against at different values of angle [alpha], the normalized intensity being obtained during a [beta] scanning in the pole figure measurement, a ratio of a maximum value A of the normalized intensity with angle [alpha] in a range of 40[deg.] to 60[deg.] to a maximum value B of the normalized intensity with angle [alpha] in a range of 80[deg.] to 90[deg.] is equal to or greater than 4 (A / B>=4); and [0018] when the normalized intensity increases with increasing angle [alpha] in a range of 25[deg.] to 45[deg.], there is essentially no area in which the normalized intensity increases stepwise. It is possible to provide a rolled copper foil having more excellent flexible fatigue property than usual by the recrystallization annealing.

Owner:JX NIPPON MINING & METALS CORP

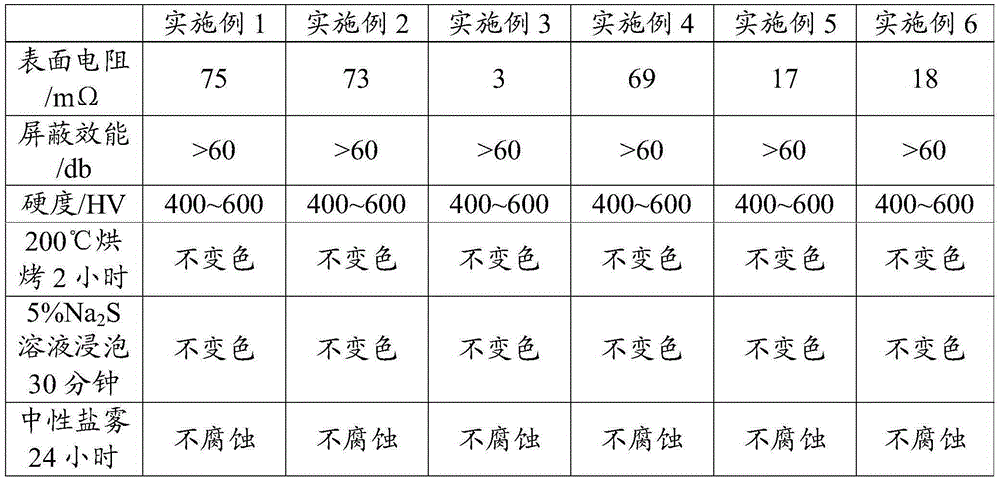

Electromagnetic wave shielding film, printed circuit board including shielding film and preparation method of circuit board

InactiveCN105246313AGood bending propertiesAvoid wear and tearPrinted circuit detailsMagnetic/electric field screeningElectromagnetic electron waveProtection layer

The invention relates to an electromagnetic wave shielding film, and the film includes a shielding improvement layer, a shielding efficiency layer and a shielding protection layer which are sequentially compounded from bottom to top. The invention further provides a printed circuit board including the electromagnetic wave shielding film, and a preparation method of the circuit board. The electromagnetic wave shielding film provided by the invention has the advantages of good shielding efficiency, high abrasion resistance, ageing resistance and anti-deformation capacity and the like. The printed circuit board has good shielding property; the preparation method is easy to operate; and industrial production application is facilitated.

Owner:朱春芳

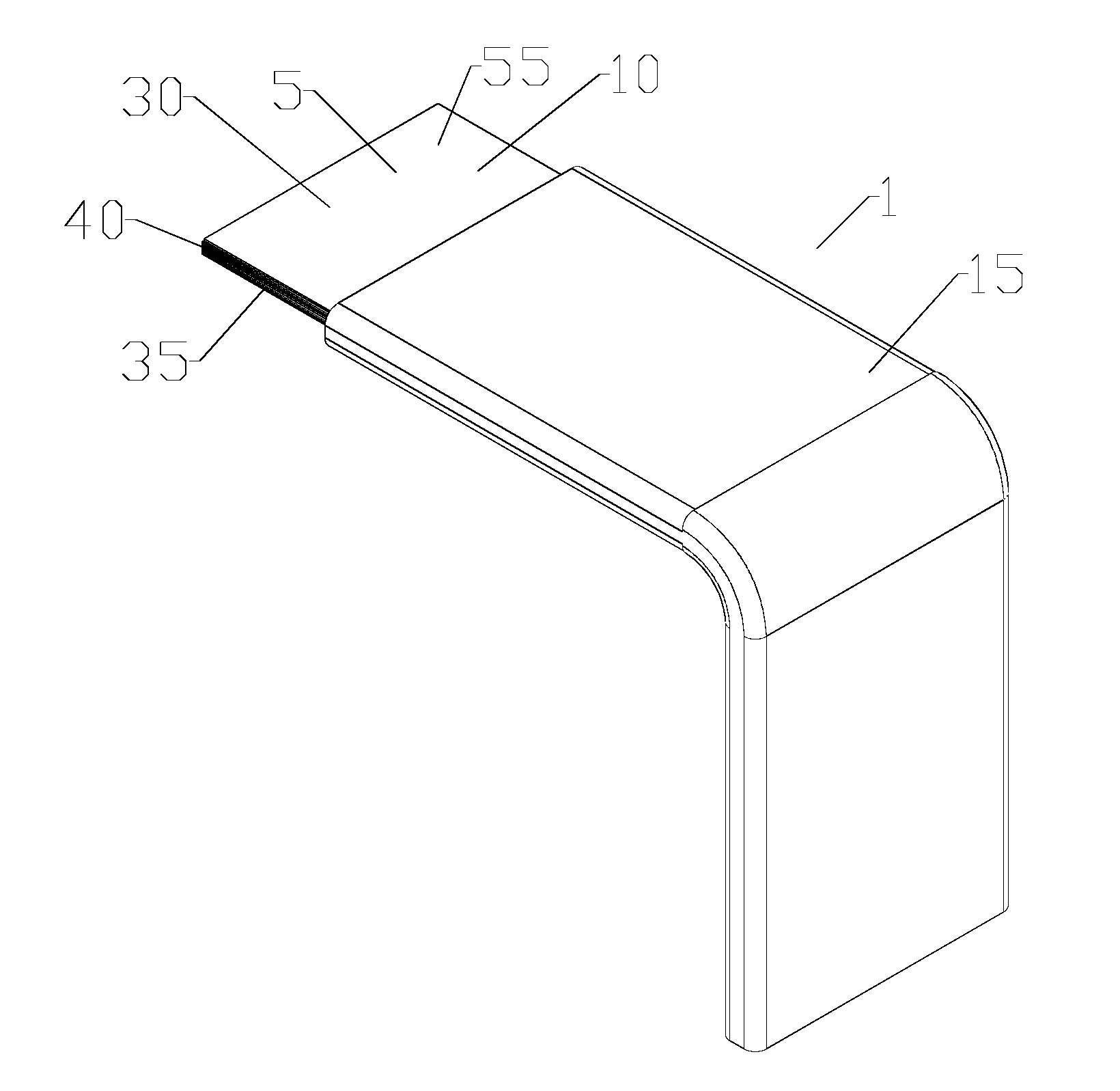

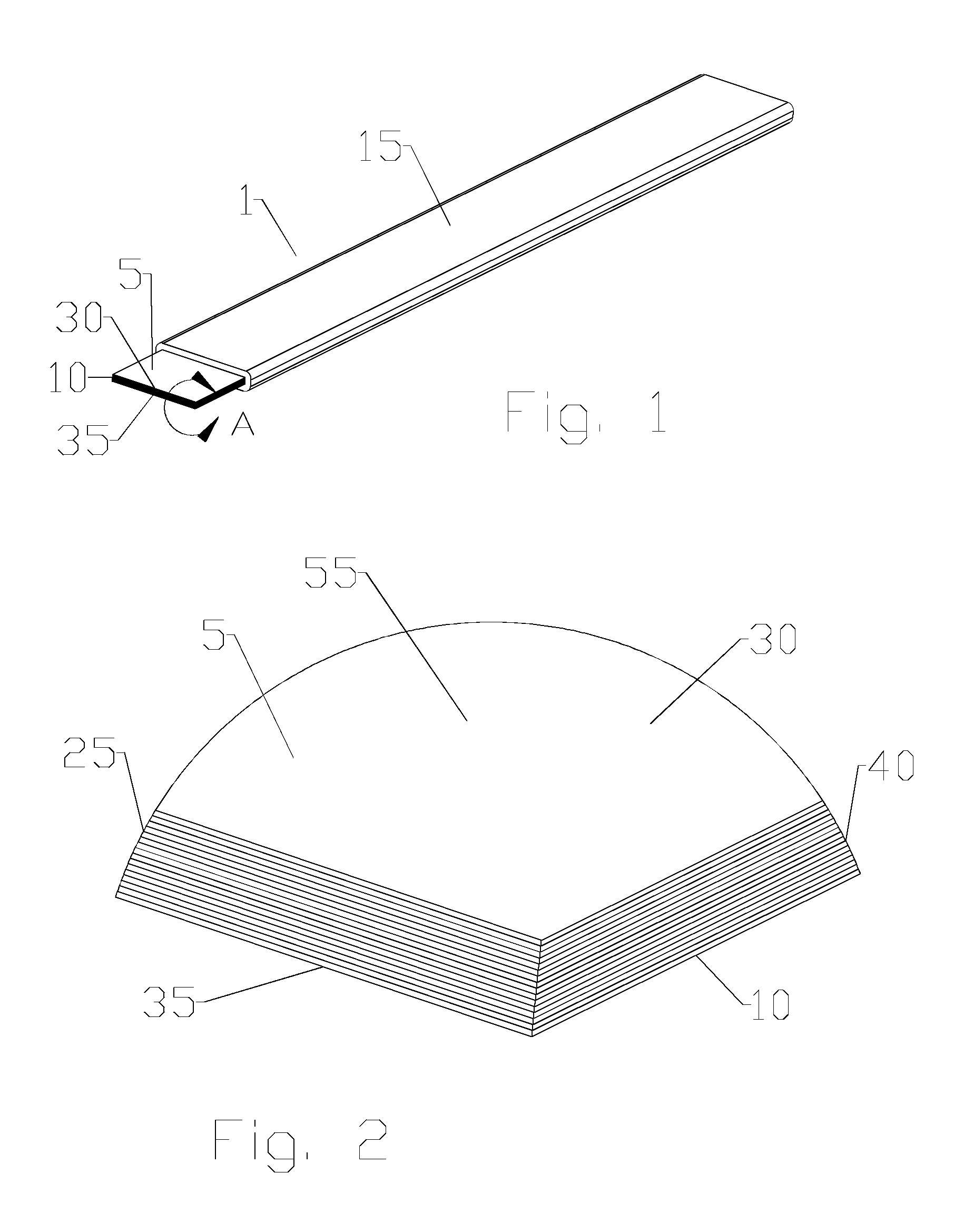

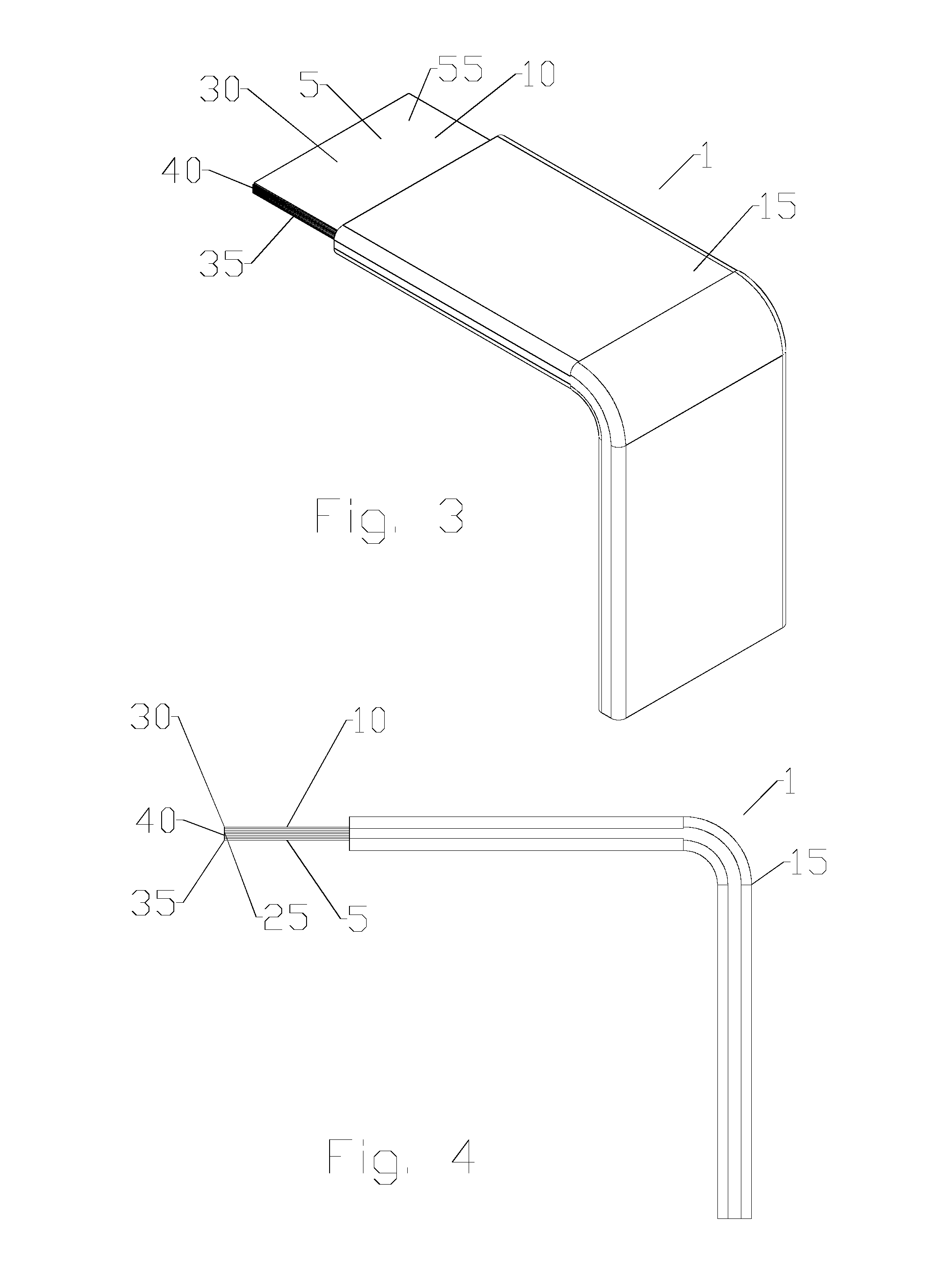

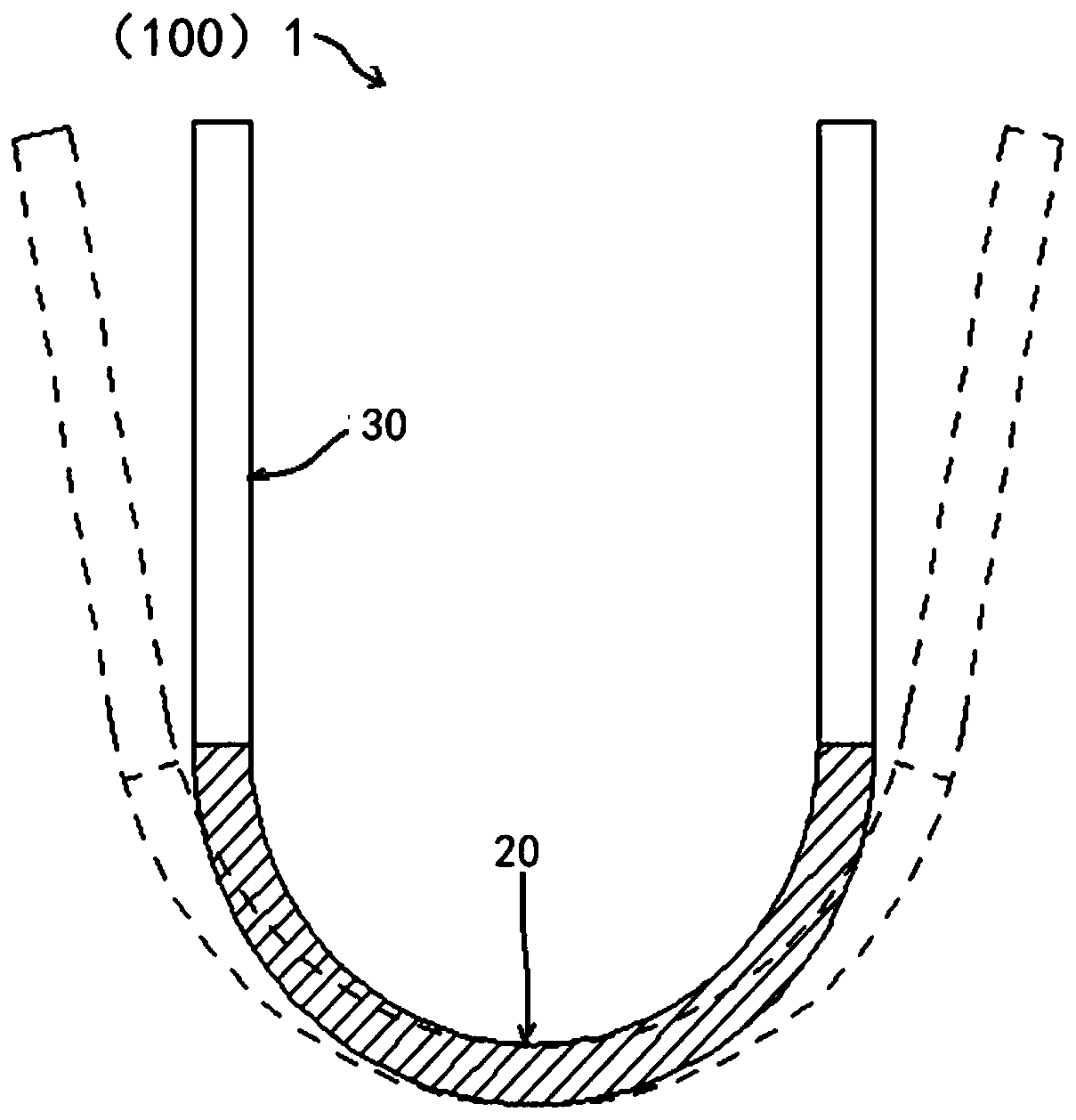

Flexible Electrical Power Cable

InactiveUS20140027153A1Good bending propertiesEasy to installStrip/foil conductorsConductive materialElectrical conductorPower cable

An electrical cable has a plurality of generally rectangular cross-section conductors superposed in a stack, the stack surrounded by a polymer jacket. The stack may be provided with a lubrication layer provided between at least two of the conductors. Conductors of the stack may have a thickness that is greater proximate the middle of the stack than at the top and bottom of the stack and / or a width that is less at the top and the bottom than at the middle. Further stacks may also be provided parallel and coplanar with the first stack, also surrounded by the polymer jacket.

Owner:COMMSCOPE TECH LLC

Display panel and display device

ActiveCN109860252AImprove bending effectRelease stressSolid-state devicesIdentification meansPhotoresistSurface plate

The present invention discloses a display panel. The display panel comprises a bending region and a non-bending region connected with the bending region, and the display panel further comprises an array substrate. The array substrate comprises: a plurality of first pixel regions which are mutually arranged in parallel in multiple lines and arranged in the bending region; a plurality of second pixel regions which are mutually arranged in parallel in multiple lines and arranged in the non-bending region; and a plurality of flexible connection regions configured to connect with adjacent first pixel regions and connect with the first pixel regions and the second pixel regions, wherein each flexible connection region is internally provided with a slot, and each slot is filled with an organic photoresist layer. According to the invention, the slots are arranged in the flexible connection regions of the bending region to form an inorganic layer slot between two adjacent lines of pixel regionsin the bending region to separate from each two lines of pixel regions, and the slots are filled with the organic photoresist layers so as to effectively relieve the stress of each inorganic layer ormetal wiring corresponding in the display panel, especially in the array substrate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

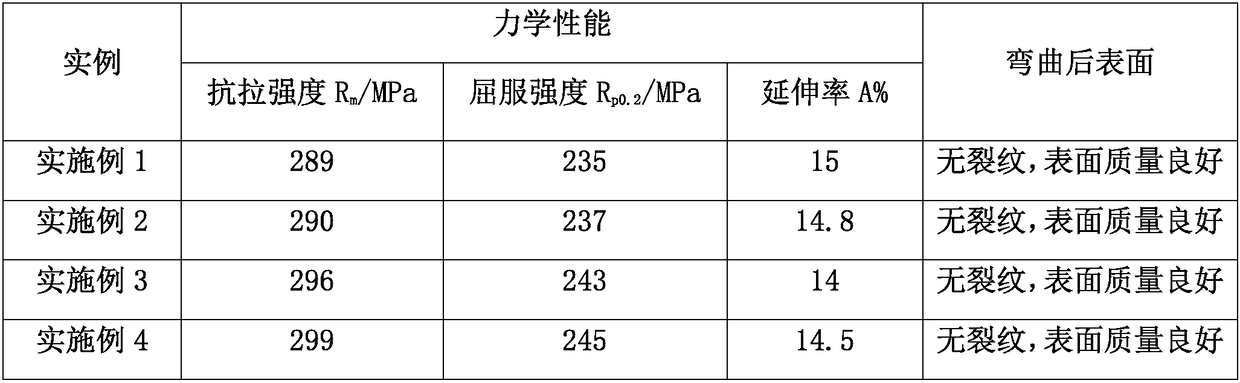

6060 aluminum alloy board for curtain wall and preparation method thereof

The invention belongs to the technical field of aluminum alloys, and relates to a 6060 aluminum alloy board for a curtain wall and a preparation method thereof. The alloy elements such as magnesium, iron and chromium are optimally adjusted, the product is enabled to have the relatively high elongation while having the high strength, the compound is enabled to be uniformly distributed in the thickness direction of the board through the optimized technologies of casting, hot rolling, cold rolling and solid solution and ageing, the size of the compound is thin and small, the aluminum alloy boardwith the high surface and bending performance and flat board shape can be obtained, meanwhile, by combining the specific rolling technology rule and solid solution ageing rule, the technological procedure is simple, and the aluminum alloy board is suitable for factory large-scale production, and has the high yield.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

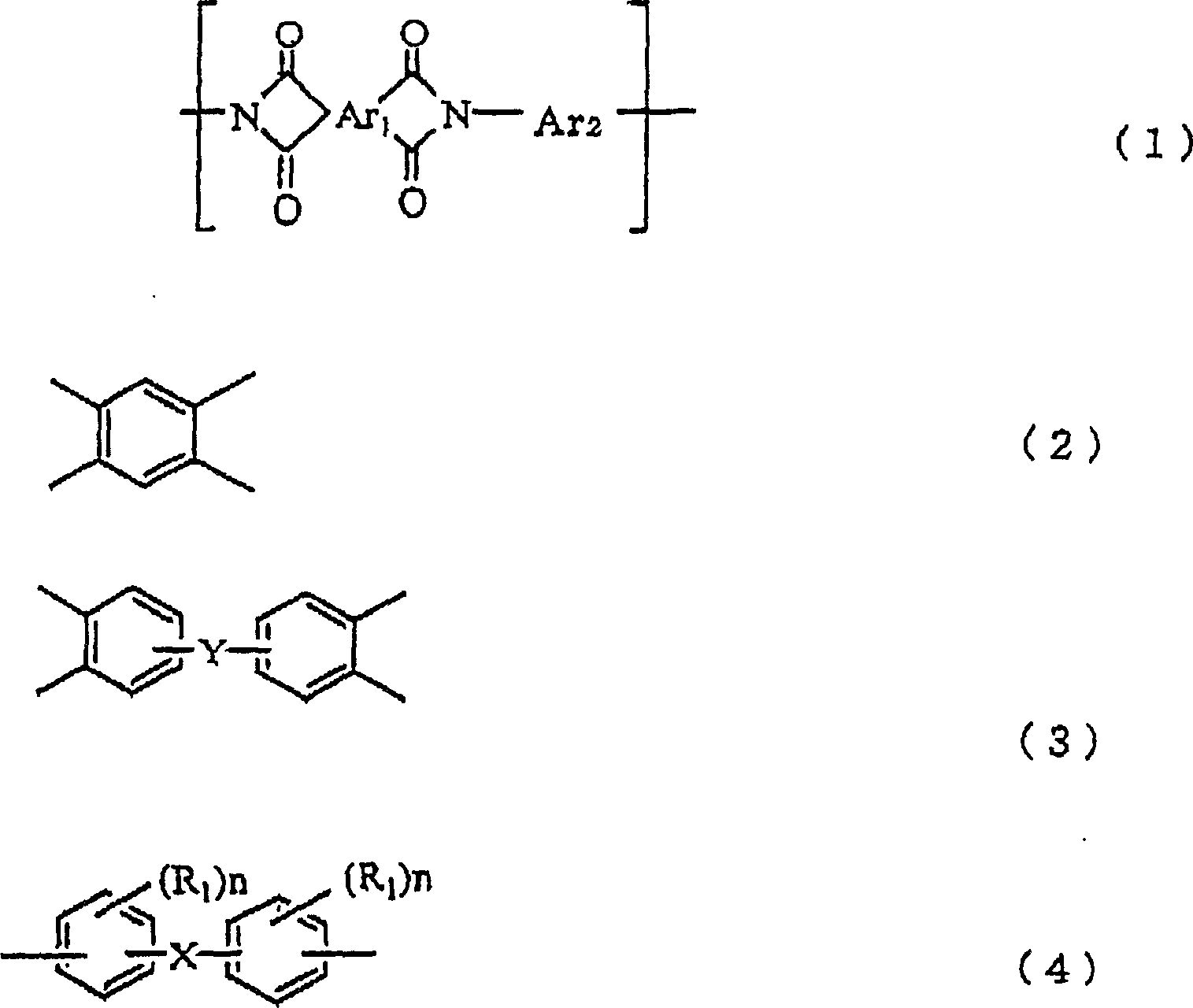

Fiber reinforced polypropylene resin composition, molding material and prepreg

ActiveCN104066783AImprove interfacial adhesionExcellent mechanical propertiesCarbon fibresThin material handlingPolyolefinPolypropylene

An objective of the present invention is to obtain a molded article with excellent mechanical properties and water degradation resistance by using: a fiber reinforced polypropylene resin composition that contains a carbodiimide modified polyolefin (a), a polypropylene resin (b) and reinforced fiber (c), wherein the content of carbodiimide group in the resin component in the fiber reinforced polypropylene resin composition is 0.0005 to 140 mmol with respect to 100 g of a matrix resin component, and the reinforced fiber (c) is sized by a polyfunctional compound (s); and a molding material using the same.

Owner:TORAY IND INC

Tactile sensor for curved surfaces and manufacturing method thereof

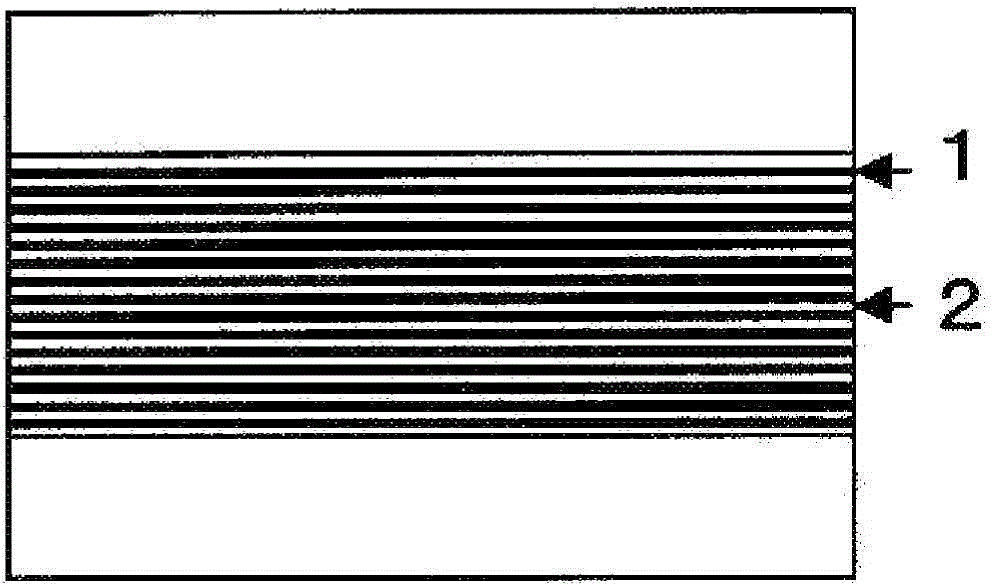

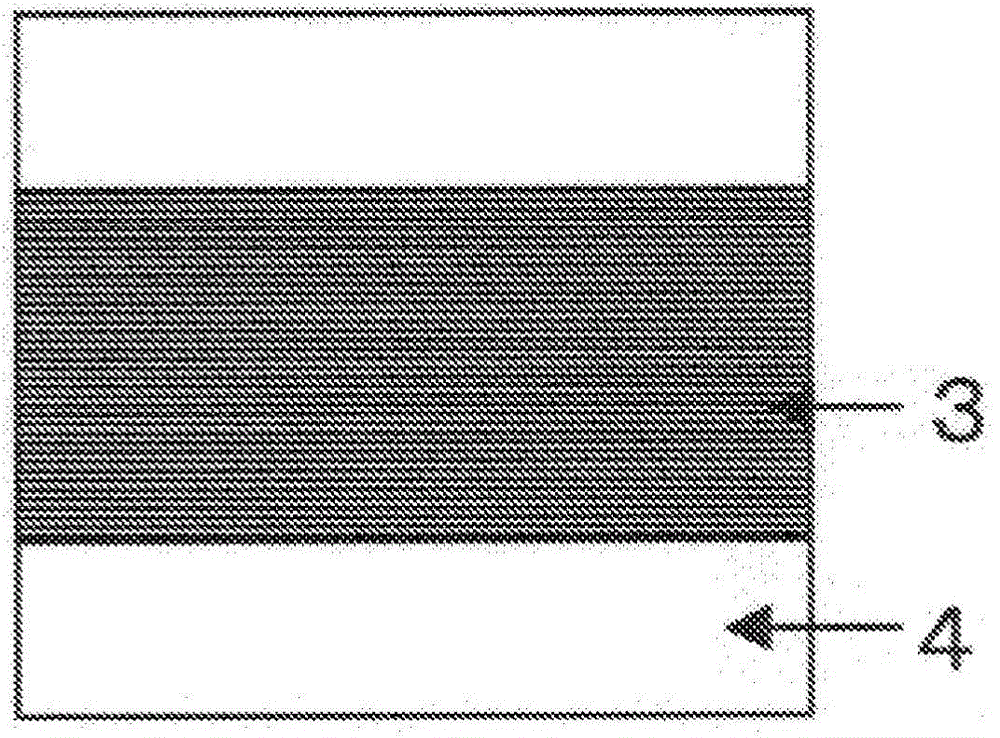

InactiveCN101512311AGood bending propertiesEnhance resilienceFilm/foil adhesivesForce measurement using piezo-resistive materialsEngineeringTactile sensor

A tactile sensor for curved surfaces applicable to objects with multi-dimensional curvature and a small radius of curvature and a manufacturing method thereof are disclosed. The tactile sensor for curved surfaces includes a lower pattern including a plurality of lower polymer film layers spaced at specified intervals in a lower direction, lower metal layers disposed on the lower polymer film layers, and a number of lower resistors disposed on the lower metal layers, an upper pattern including a plurality of upper polymer film layers spaced at specified intervals in a direction perpendicular to che lower direction, upper metal layers disposed on the upper polymer film layers, and a number of upper resistors disposed below the upper metal layers to be electrically connected to the lower resistors, and a lower polymer layer and an upper polymer layer to bond the lower pattern and the upper pattern to each other.

Owner:KOREA RES INST OF STANDARDS & SCI

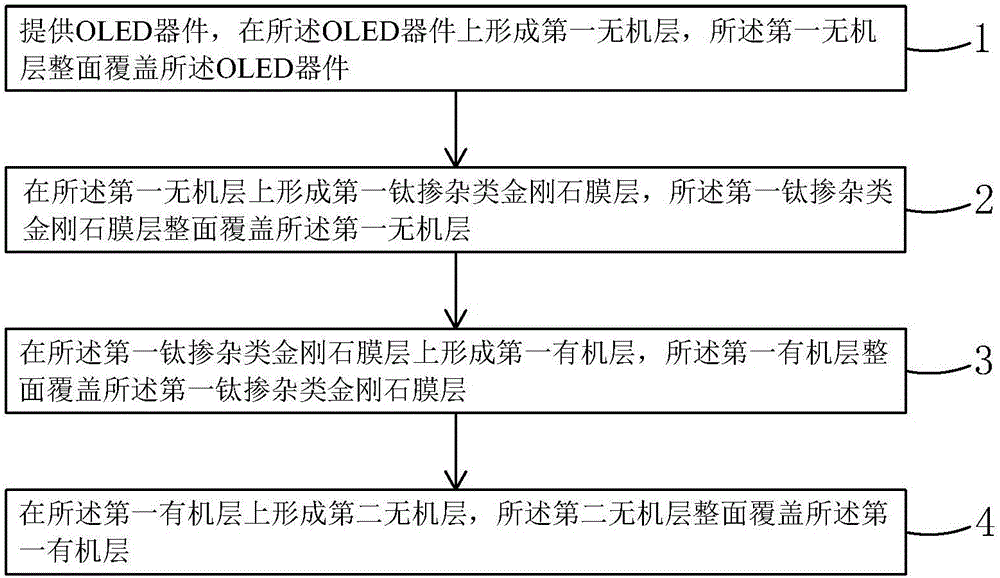

OLED (Organic Light Emitting Diode) encapsulation method and OLED encapsulation structure

ActiveCN106654045AHigh light transmittanceFast heat conductionSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceTitanium

The invention provides an OLED (Organic Light Emitting Diode) encapsulation method and an OLED encapsulation structure. A titanium-doped diamond film layer is introduced into an OLED film encapsulation layer; the light transmittance, bending property, thermal conductivity and water-oxygen blocking capability of the OLED film encapsulation layer are improved by using relatively high light transmittance, relatively good flexibility, high thermal conductivity and relatively low water-oxygen transmittance of the titanium-doped diamond film layer, and then the usability and service life of an OLED display panel are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

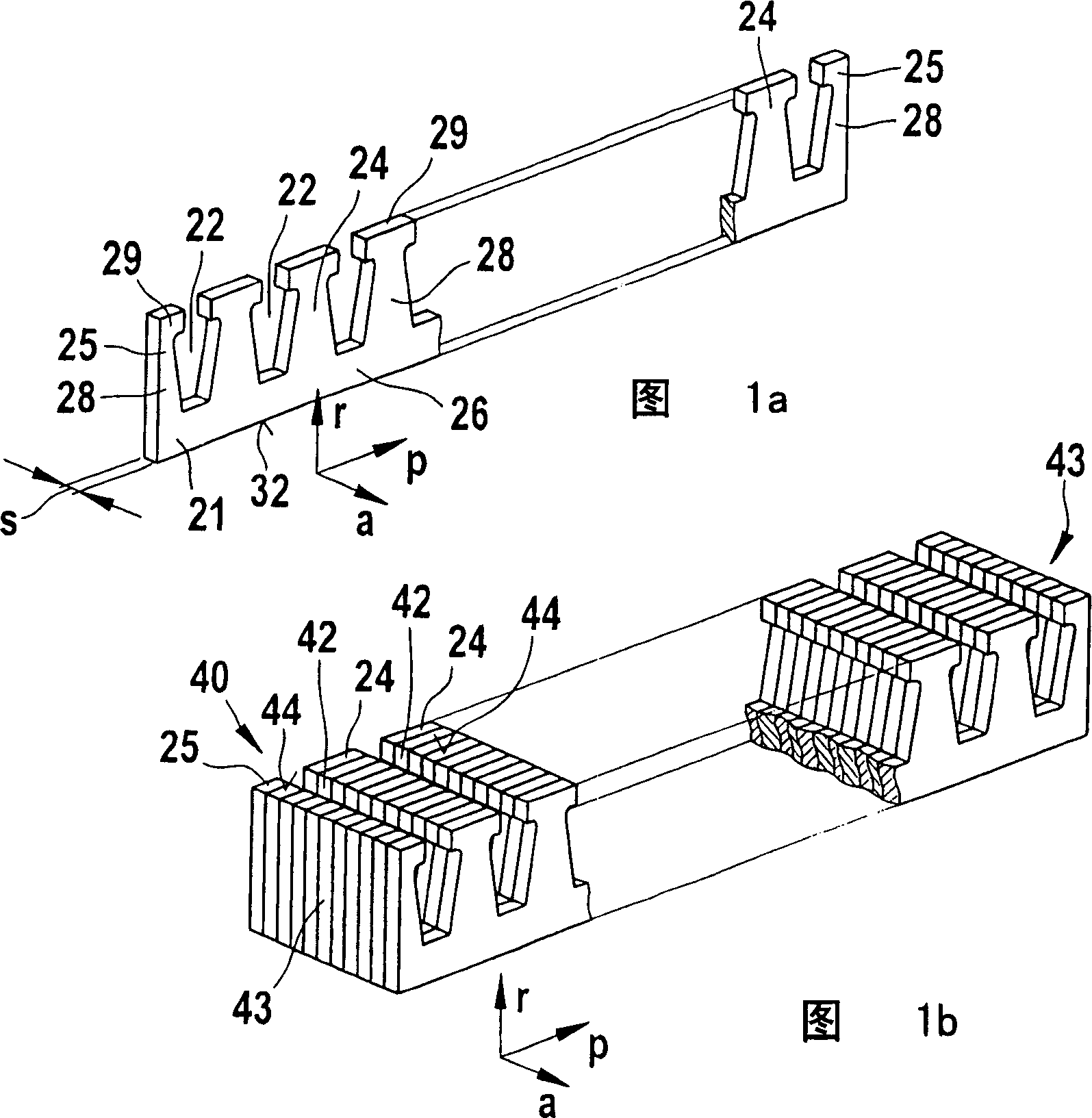

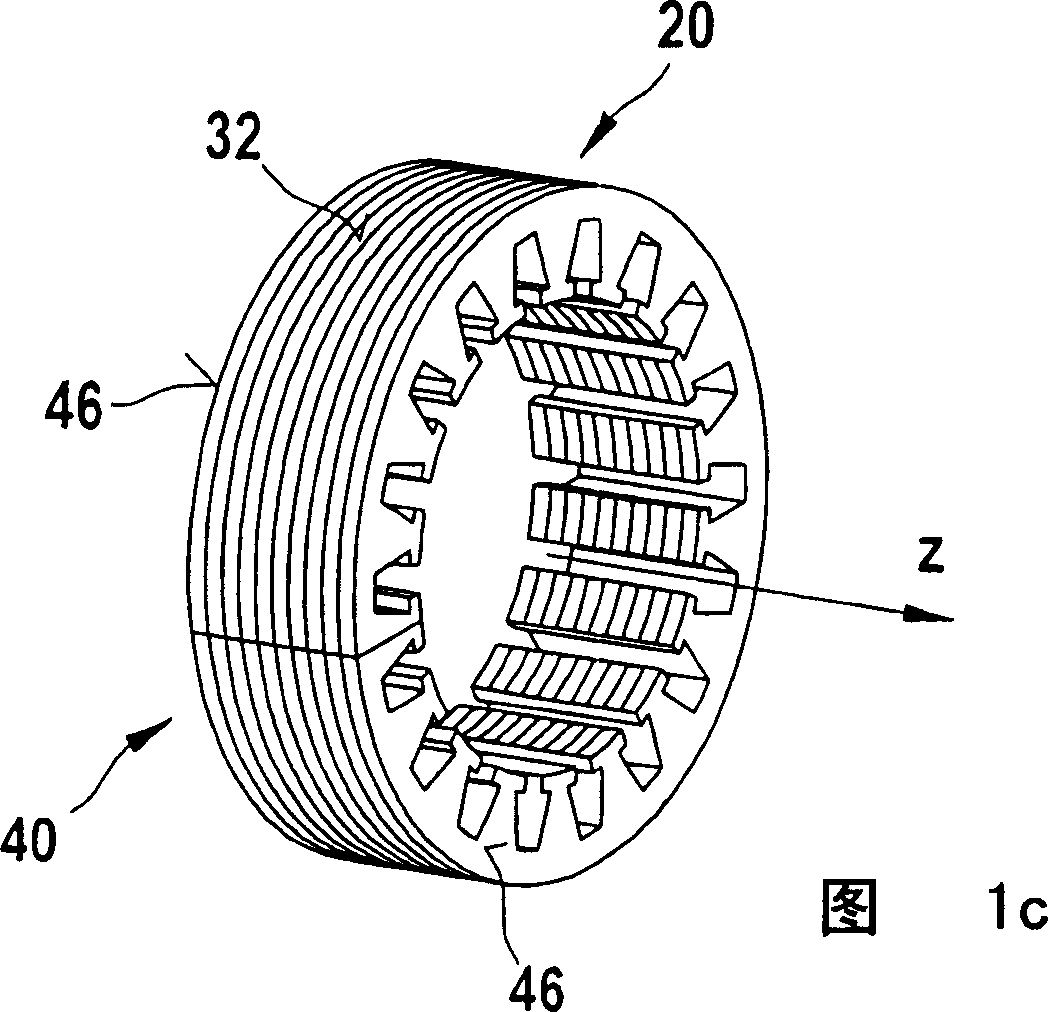

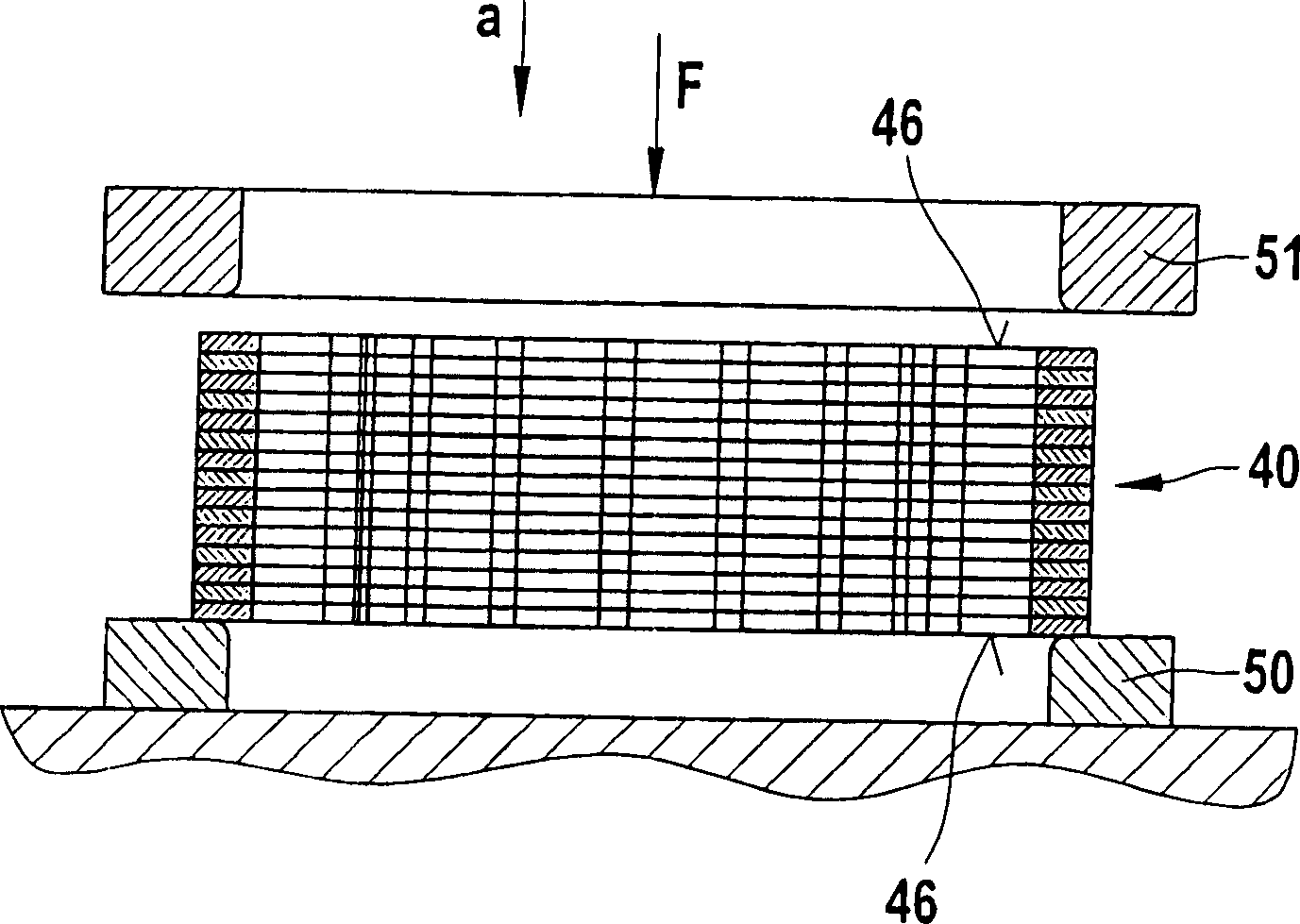

Method for the production of a stator and stator produced according thereto

InactiveCN1902801AReduce the elastic deformation componentReduce the degree of clampingMagnetic circuit stationary partsManufacturing stator/rotor bodiesThin sheetElectrical and Electronics engineering

Owner:SEG AUTOMOTIVE GERMANY GMBH

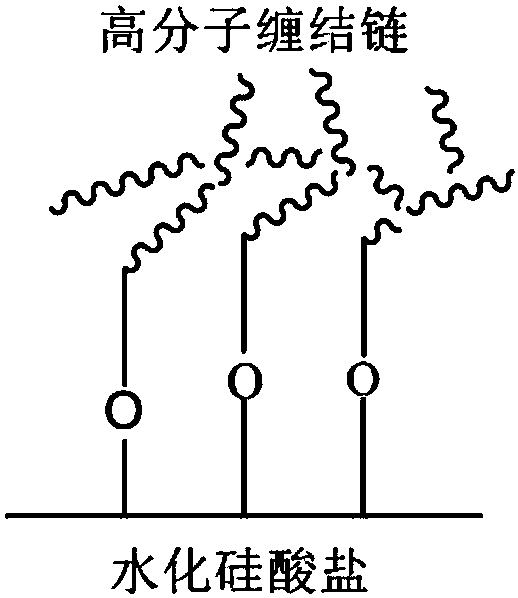

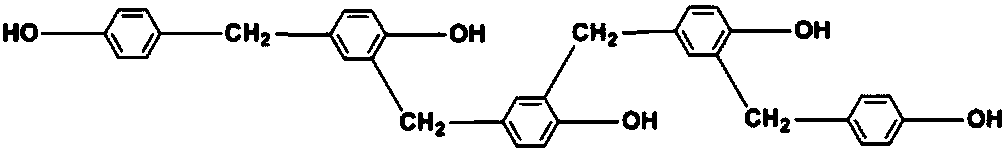

Butyl rubber reactive bonding layer used for pre-paving reactive-bonding waterproofing coiled material, preparation method thereof, and the pre-paving reactive-bonding waterproofing coiled material

ActiveCN107603519AHigh strengthHigh hardnessNon-macromolecular adhesive additivesLayered productsInsulation layerSilicon dioxide

The invention discloses a butyl rubber reactive bonding layer used for a pre-paving reactive-bonding waterproofing coiled material, a preparation method thereof, and the pre-paving reactive-bonding waterproofing coiled material, and relates to the technical field of high-molecular pre-pavement materials. The butyl rubber reactive bonding layer is mainly produced from: 100 parts of raw rubber, 9.5-15.5 parts of a linear tackifying resin containing terminal hydroxyl group structure, and 12.5-19.5 parts of active filler comprising active silicon dioxide and aluminum oxide. The reactive bonding layer solves the defects that a bonding layer of a waterproofing coiled material in the prior art is liable to flow, deform and wrinkle when being heated, is brittle at low temperature, is free of sticking feet only if a single anti-sticking layer or insulation layer exists, and is poor in stripping strength with post-poured concreted. The butyl rubber reactive bonding layer can form permanent chemical bonds with concrete, so that a real skin-type water-proofing structure is formed between the pre-paved high-molecular waterproofing coiled material and the concrete, and the bonding layer is freeof sticking feet and allows people to walk thereon without coverage by sand and coating layers. In addition, the reactive bonding layer has good low temperature resistance and thermal stability.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

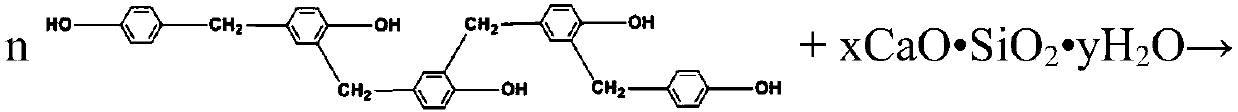

Method for manufacturing laminated core

InactiveCN1906827AGood bending propertiesGood forming precisionMagnetic circuit stationary partsManufacturing stator/rotor bodiesCouplingMagnetic poles

A method for manufacturing a laminated core comprising a step of punching a metal plate to form a stripe yoke core piece having a shape like a linearly developed yoke of a laminated core and having a coupling recess at the peripheral edge corresponding to the inner circumference, a step of winding and laminating the stripe yoke core pieces spirally and caulking them to form a yoke laminate, a step of punching a metal plate to form a pole core piece having a coupling protrusion at the root end, a step of laminating a predetermined number of pole core pieces and caulking them to form a magnetic pole laminate, and a step of winding a wire on the magnetic pole laminate, then fitting the coupling protrusion in the coupling recess, and thus coupling the yoke laminate and the magnetic pole laminate.

Owner:MITSUI HIGH TEC INC

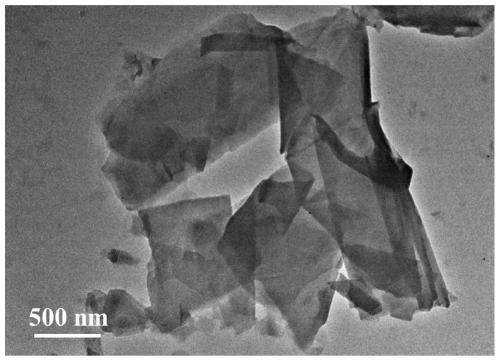

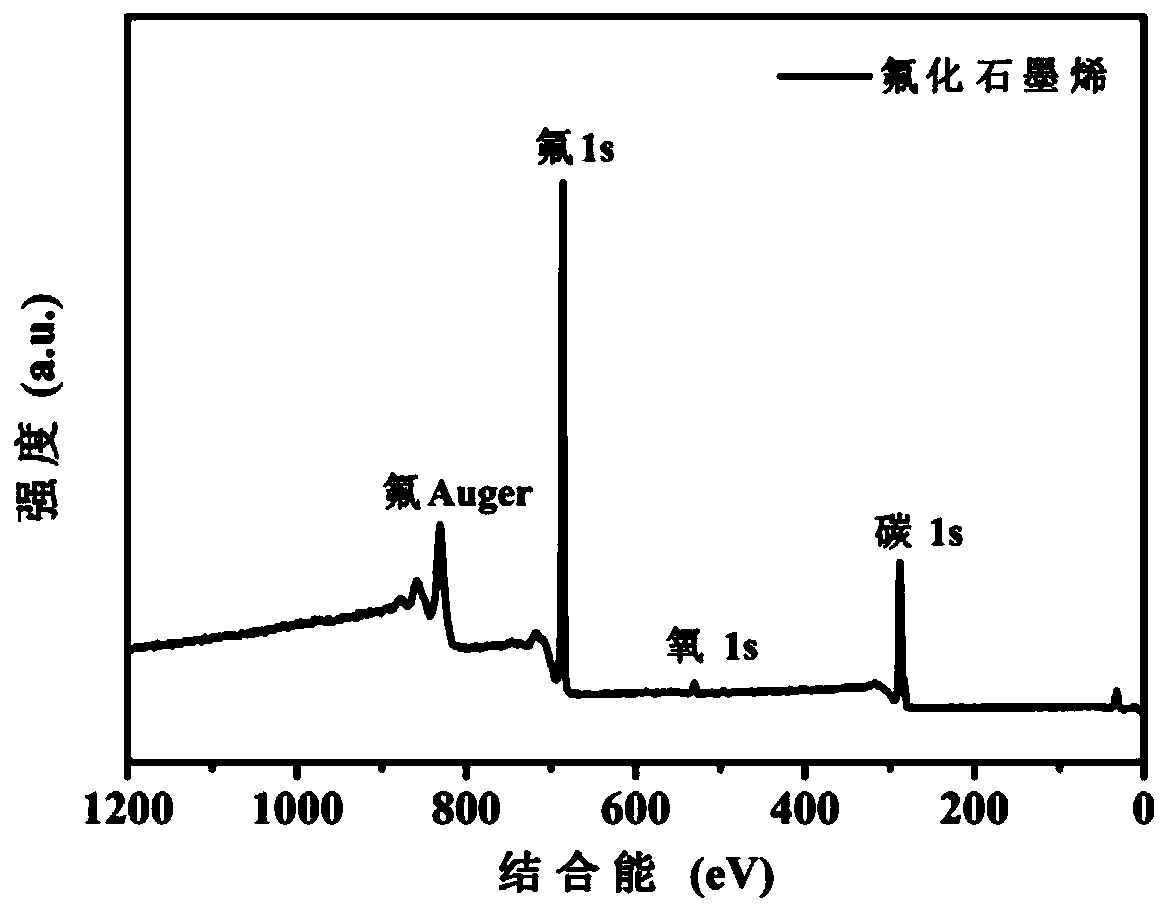

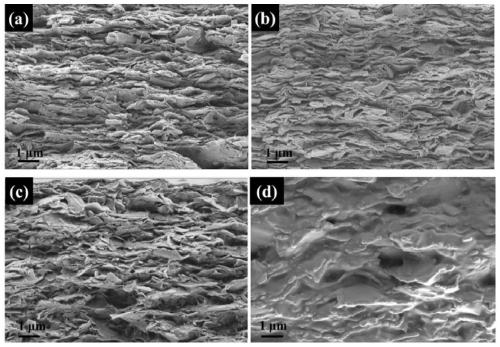

Flexible and electrically insulating fluorinated graphene heat-conducting composite film as well as preparation and application thereof

ActiveCN109912912ASolve insulation problemsImprove thermal conductivityHeat-exchange elementsIn planeComposite film

The invention relates to a flexible and electrically insulating fluorinated graphene heat-conducting composite film as well as preparation and an application thereof. The composite film comprises fluorinated grapheme nanosheets and polyvinyl alcohol. The preparation comprises the following steps: uniform dispersion of polyvinyl alcohol / fluorinated graphene is treated with a decompression-assistedfiltering film forming method to enable the fluorinated graphene nanosheets to be orderly stacked on a base film. The fluorinated graphene composite film obtained with the method not only has high in-plane thermal conductivity, but also maintains good electrical insulation and bendability, thereby having potential application value in future thermal management of flexible electronic devices. The method is convenient to operate, has relatively simple preparation conditions and low production cost, facilitates batch production and large-scale production, and has good industrial production foundation and broad application prospect.

Owner:DONGHUA UNIV

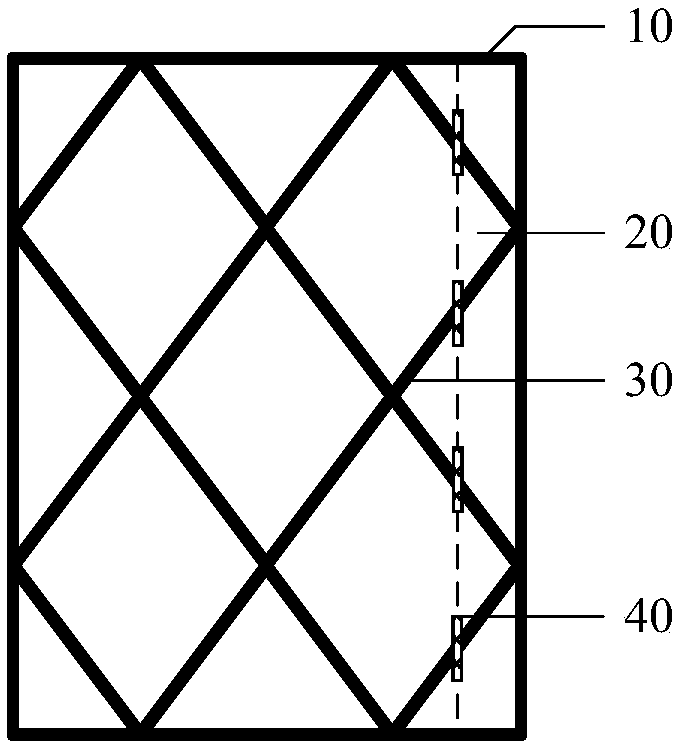

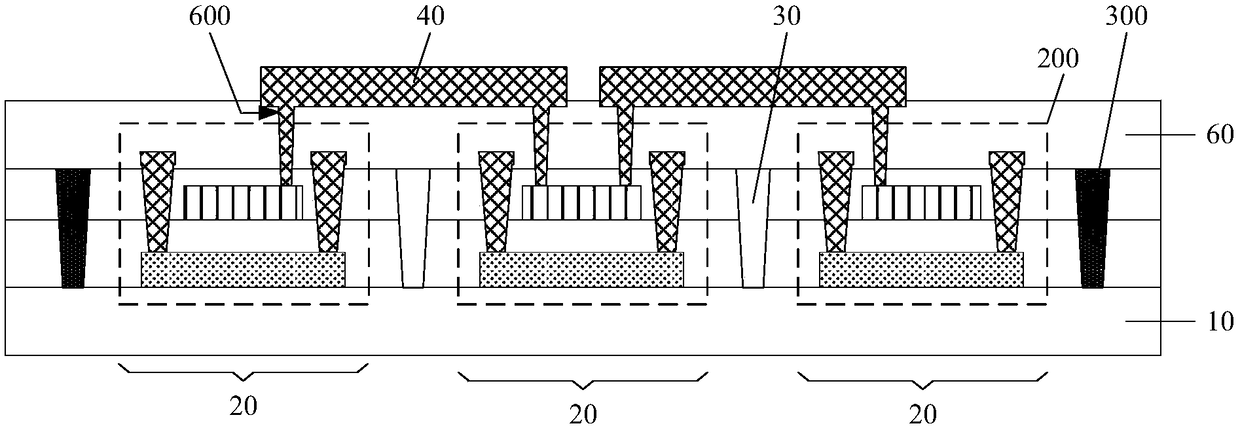

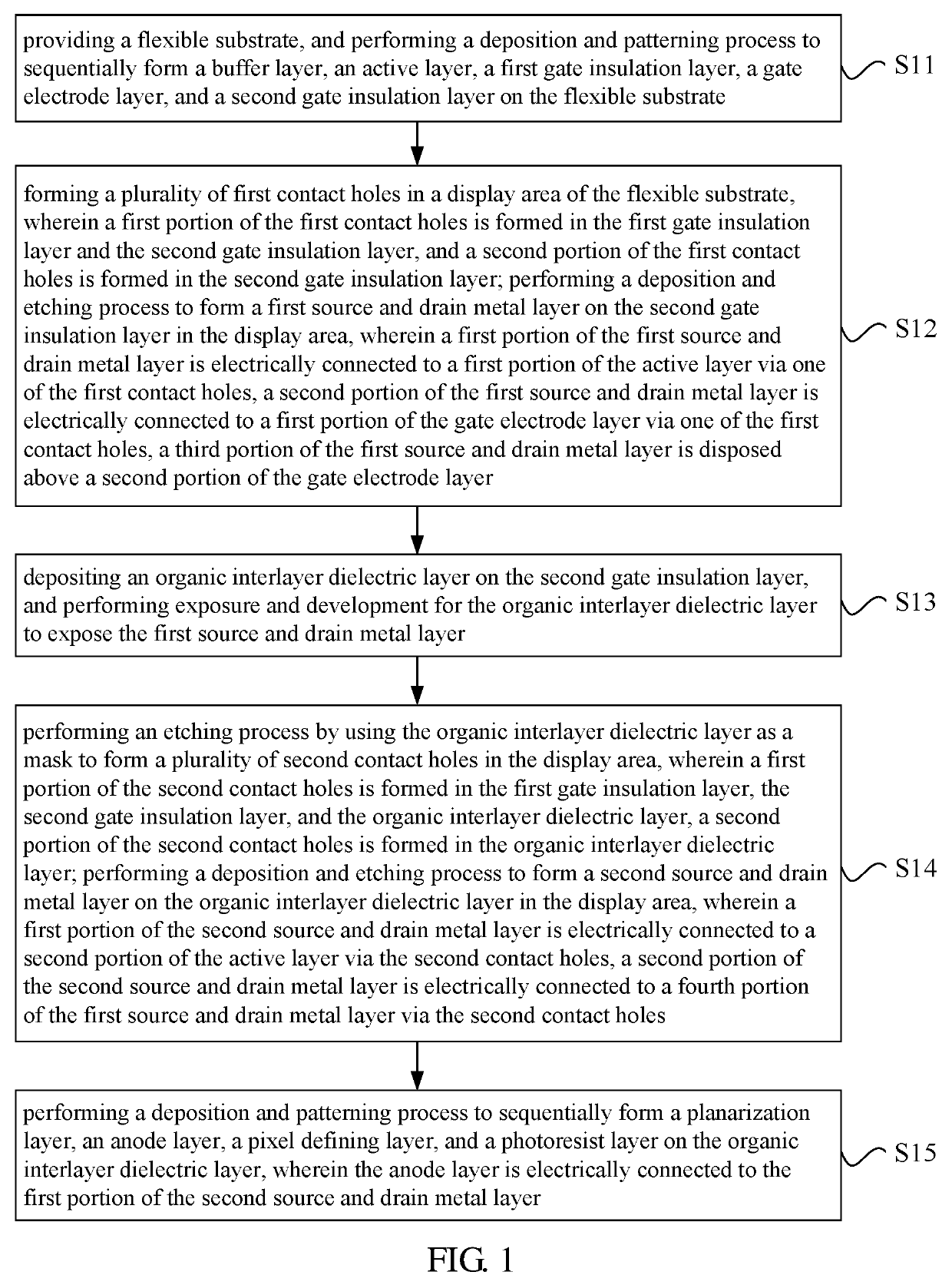

Display panel and preparation method thereof, and display device

ActiveCN110828489AImprove conductivityImprove bending propertiesSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsComposite material

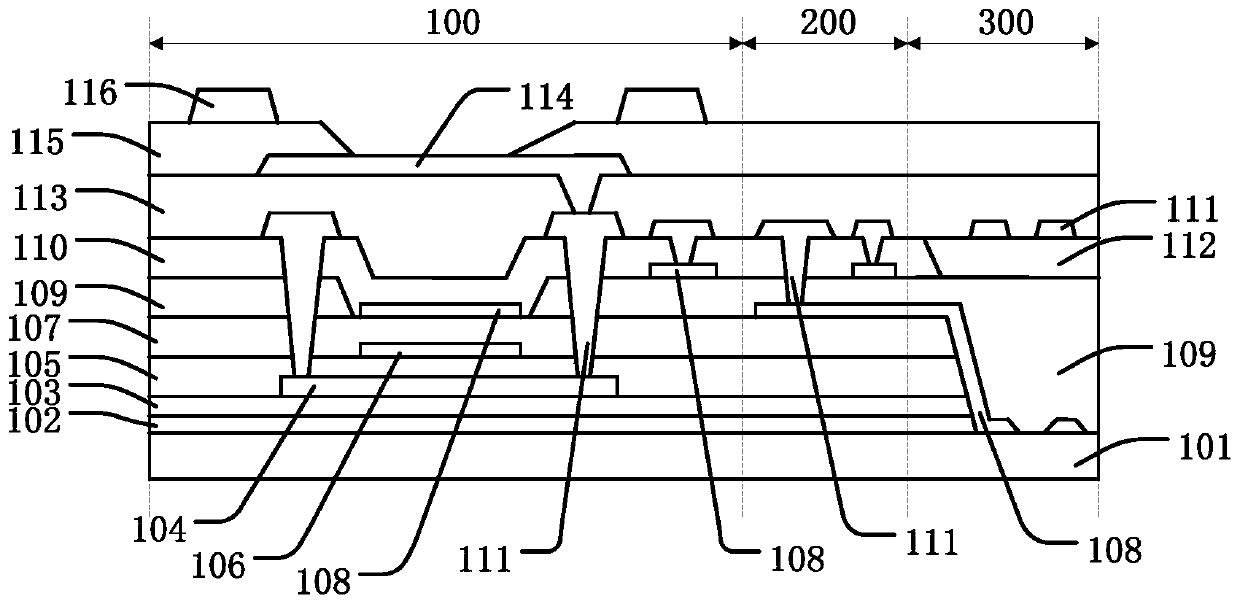

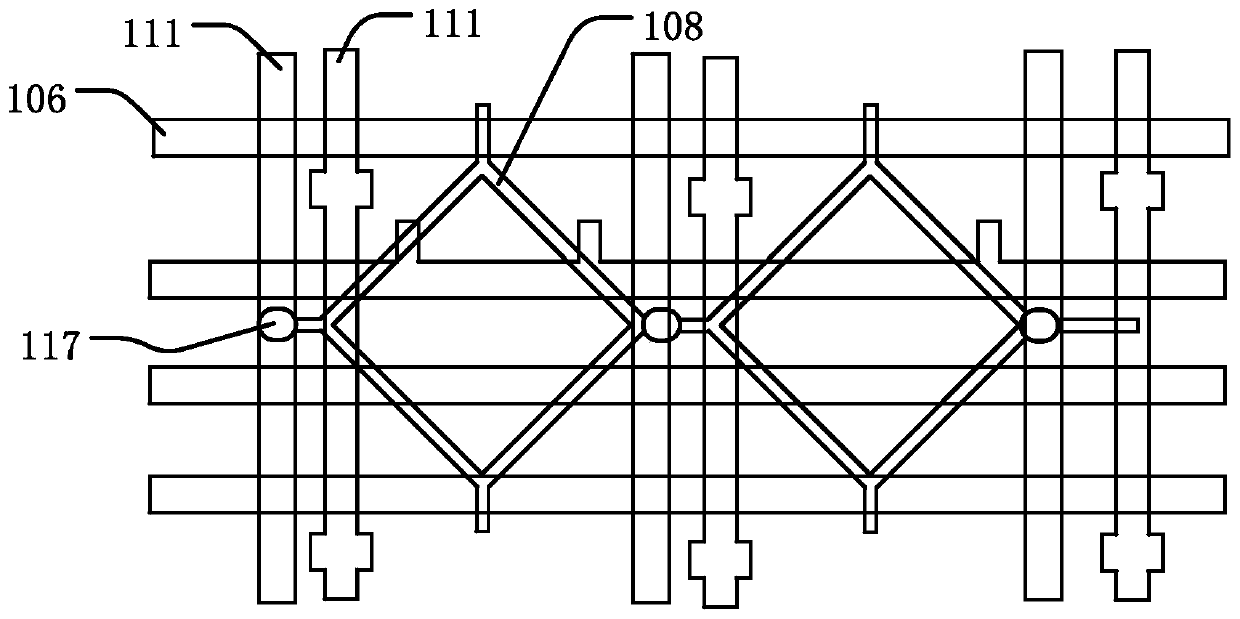

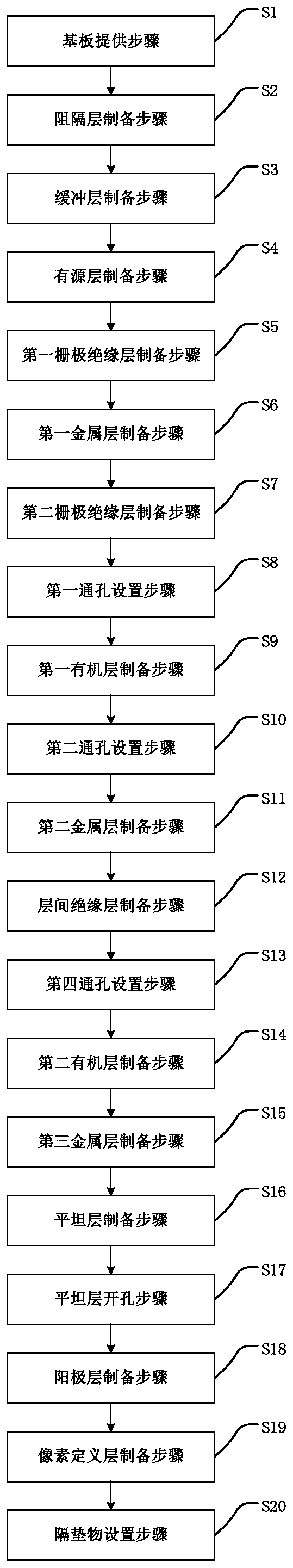

The invention provides a display panel and a preparation method thereof, and a display device. The display panel comprises a display area, a wire changing area and a bending area which are divided inthe horizontal direction; the display panel sequentially comprises a substrate, a barrier layer, a buffer layer, an active layer, a first gate insulation layer, a first metal layer and a second gate insulation layer from bottom to top, and further comprises a first through hole, a second metal layer, a first organic layer, a second metal layer, an interlayer insulation layer and a third metal layer, wherein part of the third metal layer located in the display area penetrates the interlayer insulating layer and is electrically connected to the second metal layer. The display panel has the technical effects that the bending performance of the display panel is improved, the circuit voltage drop is reduced, and the brightness uniformity of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

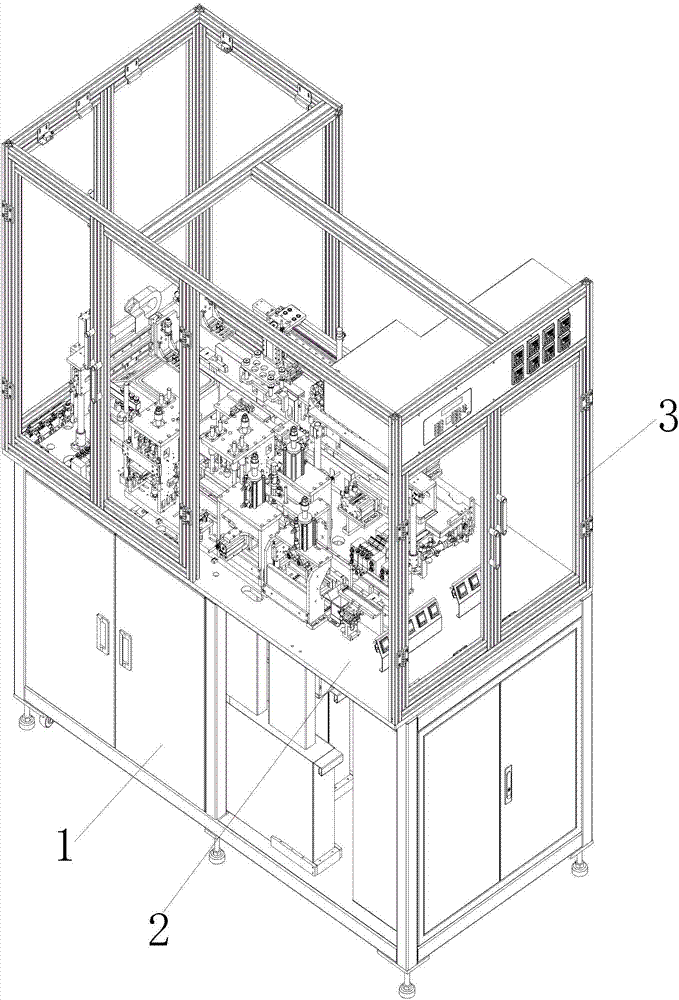

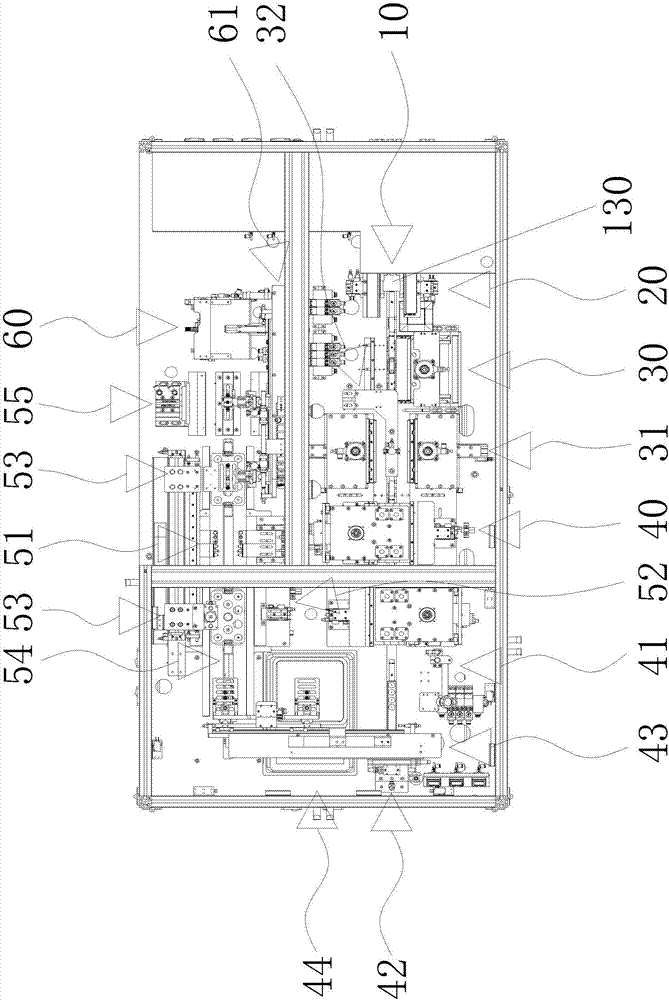

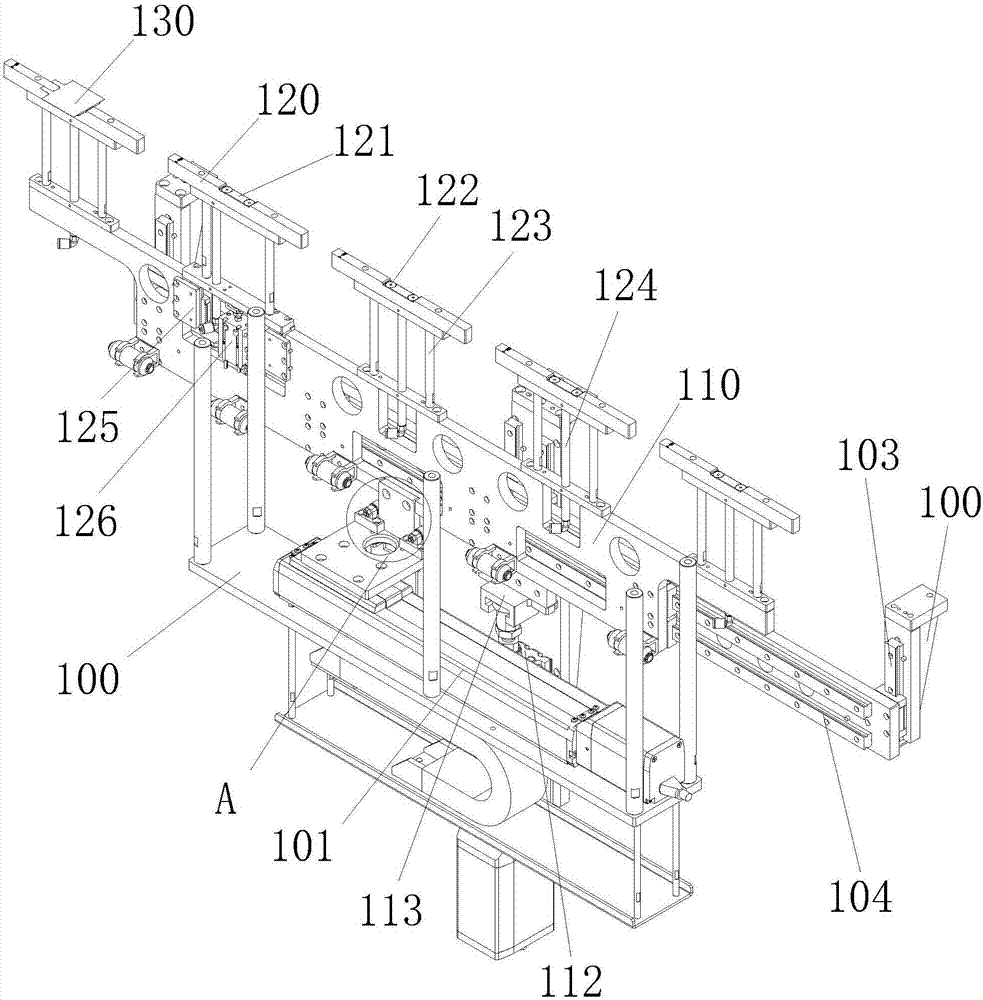

Flanging machine

PendingCN107984733AStrong adsorptionFast deliveryFinal product manufactureElectrolyte accumulators manufactureEngineeringFlanging

The invention discloses a flanging machine. The flanging machine comprises a rack and a base arranged on the rack, wherein a trimming carrying and conveying mechanism, an alignment mechanism, a trimming mechanism and a flanging mechanism are arranged on the base; the trimming carrying and conveying mechanism is used for conveying a battery; the alignment mechanism is positioned on the two sides ofthe trimming carrying and conveying mechanism and is used for seeking the central line of the battery; the trimming mechanism is used for cutting a redundant laminating film; the flanging mechanism is used for bending the residual laminating film; an overturning mechanism used for overturning the battery is arranged in the position, following the flanging mechanism, on the base; a roll folding and carrying mechanism used for carrying the battery, a prepressing locating mechanism which is positioned on the two sides of the roll folding and carrying mechanism and is used for prepressing the laminating film and locating the battery, and a roll folding mechanism used for folding the laminating film through rolling are arranged in the position, following the overturning mechanism, on the base;and a hot pressing shaping mechanism used for leveling the laminating film is arranged in the position, following the roll folding mechanism, on the base. According to the flanging mechanism, trimming, flanging, code scanning, weighing, shaping and overturning can be automatically carried out on the battery, the automation degree is high, product specifications are uniform, the battery is not damaged, manpower is greatly saved, and quality is improved.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

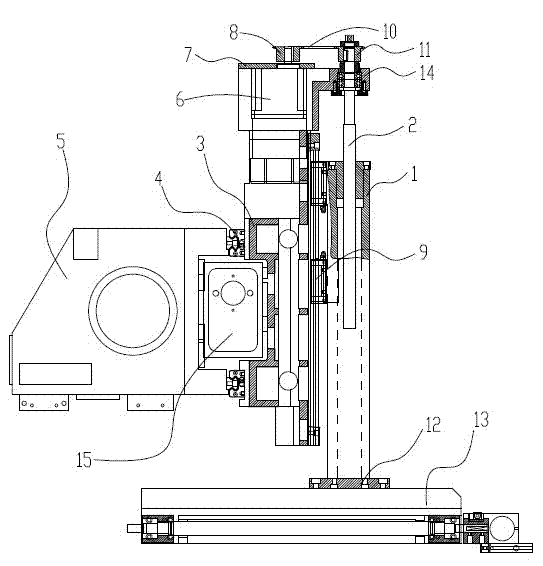

Novel wire-cutting lifting mechanism

The invention discloses a novel wire-cutting lifting mechanism, which comprises a lifting guide rail stable in lifting, high in lifting speed and accurate in positioning. The lifting mechanism is provided with a hollow square lifting guide rail, the hollow part of the lifting guide rail is provided with a lifting screw rod pair, the top ends of the lifting screw rod pair are connected to a lifting screw rod chain wheel, a lifting bearing block is arranged below the lifting screw rod chain wheel, the lifting guide rail is sleeved with an axis-Z linear guide rail pair which is fixedly connected with an axis-X sliding body, the axis-X sliding body is connected with an axis-X linear guide rail pair, an axis-Y sliding body is arranged behind the axis-X sliding body, a lifting motor is arranged above the axis-X sliding body, a motor chain wheel on the upper part of the lifting motor is connected with the lifting screw rod chain wheel through a chain, and the lower end part of the lifting guide rail is connected with a wire feeding rack assembly. The novel wire-cutting lifting mechanism disclosed by the invention has the advantages of high cutting efficiency, improved cutting precision and sliced sheet quality, lightness, high rigidity and reasonableness in stress; and because a gray pig iron casting structure with good stability is adopted, the advantages of light weight and good bending resistance are achieved.

Owner:东莞汉为智能技术有限公司 +1

High flexible copper-clad laminate manufacturing method

ActiveCN1905781AGood bending propertiesSynthetic resin layered productsLaminationElectrolysisCopper foil

This invention provides a method for stably making a flexible copperclad laminate board which exhibits excellent anti-flexion property, the flexible copper clad laminate board being made from a copper foil and a polyimide resin layer. The method for making a copper cladlaminate board composed of a copper foil and a polyimide resin layer comprises the steps of coating a surface of the copper foil with a solution of polyimide precursor resin, performing a drying and hardening process in a subsequent heat treatment process, wherein an electrolytic copper foil is used for the copper foil, and the coated copper foil is held under the temperature of 300 ~ 450 DEG C for 5 to 40 minutes, to grow the copper crystalline particles up to an average crystalline particle diameter of the copper foil two(2)to eight(8) times of that before the heat treatment process.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com