OLED (Organic Light Emitting Diode) encapsulation method and OLED encapsulation structure

An encapsulation method and encapsulation structure technology, applied in the structure of organic light-emitting devices, gaseous chemical plating, coating, etc., can solve the problems of low light penetration, easy cracks, large film stress, etc., and achieve high thermal conductivity , Improve performance and service life, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

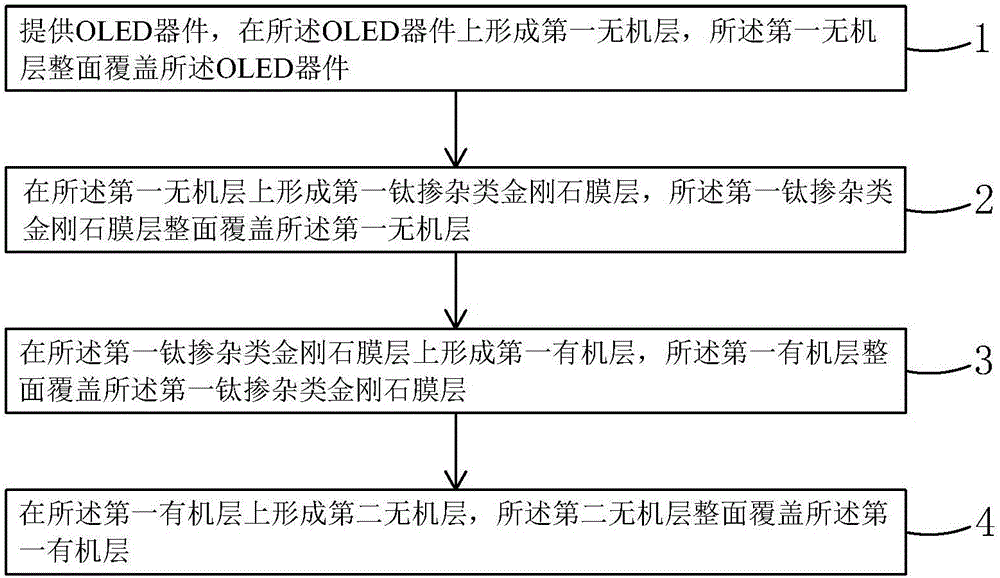

[0044] see figure 1 , is the first embodiment of the OLED packaging method of the present invention, which includes the following steps:

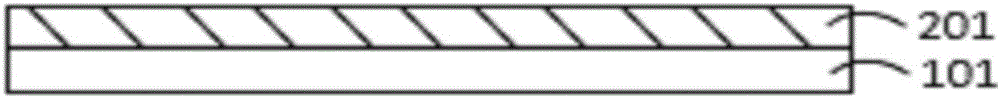

[0045] Step 1, such as figure 2 and image 3 As shown, an OLED device 101 is provided, and a first inorganic layer 201 is formed on the OLED device 101 , and the first inorganic layer 201 covers the entire surface of the OLED device 101 .

[0046] Specifically, in step 1, plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD), atomic layer deposition (Atomic Layer Deposition, ALD), pulsed laser deposition (Pulsed Laser Deposition, PLD), or sputtering (Sputter) method to form the first inorganic layer 201 .

[0047] Specifically, the material of the first inorganic layer 201 includes aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), silicon nitride (SiN x ), silicon carbonitride (SiCN x ), and silicon oxide (SiO x ) in one or more.

[0048] Specifically, the thickness of the first inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com