6060 aluminum alloy board for curtain wall and preparation method thereof

An aluminum alloy plate and aluminum alloy technology, applied in the field of aluminum alloy, can solve the problems of inability to meet the corrosion resistance, strength and load requirements, differences in joint corrosion-prone strength, poor welding performance, etc., and achieve small size, good processing performance, and welding performance. good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

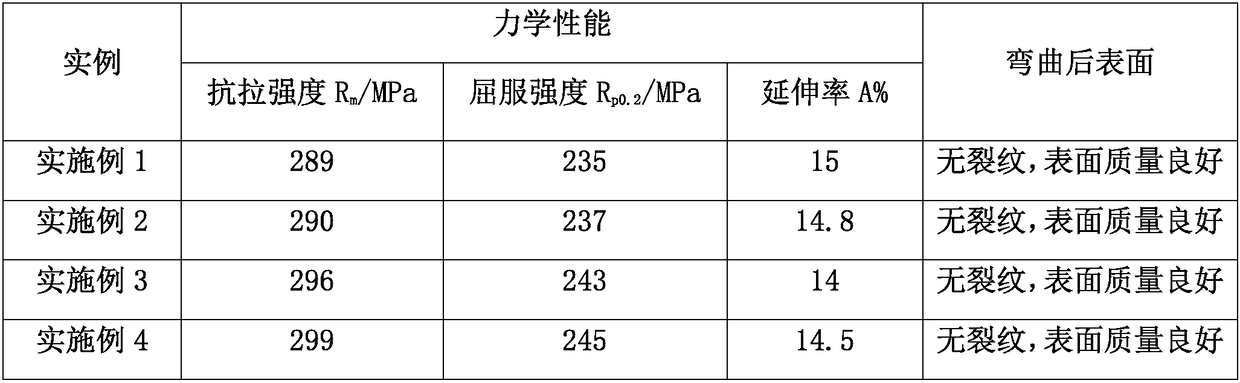

Examples

Embodiment 1

[0028] A kind of 6060 aluminum alloy sheet material for curtain wall, comprises the following steps:

[0029] A. Ingredients: ingredients according to the following mass percentages: Si 0.35%, Fe 0.12%, Cu 0.05%, Mn 0.08%, Mg 0.45%, Cr 0.02%, Zn 0.03%, Ti 0.03%, other individual impurities ≤ 0.05%, The total amount of impurities ≤ 0.15%, the balance is Al;

[0030] B. Smelting: put the prepared aluminum alloy raw materials except Ti in a smelting furnace for smelting, and then place them in a holding furnace for 5-10 hours to keep warm, and cast the warmed aluminum alloy melt into an aluminum alloy ingot through a launder, wherein Add Al-3Ti-B wire grain refiner in launder;

[0031] C. Hot rolling: After sawing and milling the smelted aluminum alloy ingot, heat it to 550°C, heat it for 3 hours, and roll it into an aluminum alloy coil. The hot-rolled deformation of the aluminum alloy coil is 78%. The final rolling temperature of hot-rolled coils is 300°C;

[0032] D, cold ro...

Embodiment 2

[0037] A kind of 6060 aluminum alloy sheet material for curtain wall, comprises the following steps:

[0038] A. Ingredients: ingredients according to the following mass percentages: Si 0.35%, Fe 0.12%, Cu 0.05%, Mn 0.08, Mg 0.45%, Cr 0.02%, Zn 0.03%, Ti 0.03%, other individual impurities ≤ 0.05%, total impurities Amount ≤ 0.15%, the balance is Al;

[0039] B. Smelting: put the prepared aluminum alloy raw materials except Ti in a smelting furnace for smelting, and then place them in a holding furnace for 5-10 hours to keep warm, and cast the warmed aluminum alloy melt into an aluminum alloy ingot through a launder, wherein Add Al-3Ti-B wire grain refiner in launder;

[0040] C. Hot rolling: After sawing and milling the smelted aluminum alloy ingot, heat it to 540°C, heat it for 12 hours, and roll it into aluminum alloy coil. The hot rolling deformation of the aluminum alloy coil is 85%. The final rolling temperature of hot-rolled coils is 300°C;

[0041] D, cold rolling: co...

Embodiment 3

[0046] A kind of 6060 aluminum alloy sheet material for curtain wall, comprises the following steps:

[0047] A. Ingredients: ingredients according to the following mass percentages: Si 0.45%, Fe 0.18%, Cu 0.03%, Mn 0.10%, Mg 0.55%, Cr 0.01%, Zn 0.04%, Ti 0.05%, other single impurities ≤0.05%, The total amount of impurities ≤ 0.15%, the balance is Al;

[0048] B. Smelting: put the prepared aluminum alloy raw materials except Ti in a smelting furnace for smelting, and then place them in a holding furnace for 5-10 hours to keep warm, and cast the warmed aluminum alloy melt into an aluminum alloy ingot through a launder, wherein Add Al-5Ti-0.2B silk grain refiner in launder;

[0049] C. Hot rolling: heat-treat the smelted aluminum alloy ingot inhomogeneously, hold it at 560°C for 8 hours before hot rolling, then lower the temperature to 520°C, roll it into aluminum alloy coils, and the hot-rolled deformation of aluminum alloy coils The content is 98%, and the final rolling temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com