Patents

Literature

108results about How to "Good conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

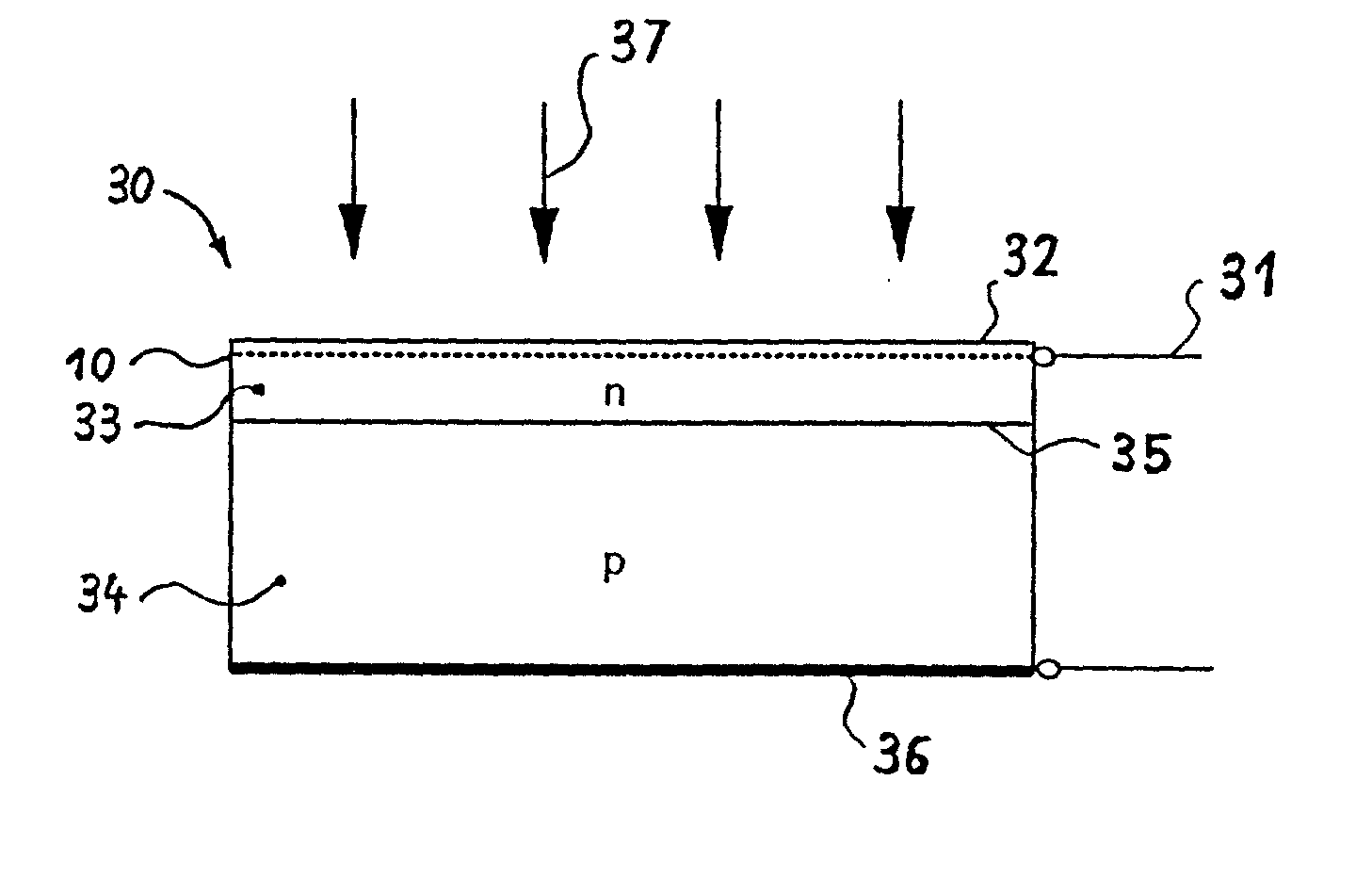

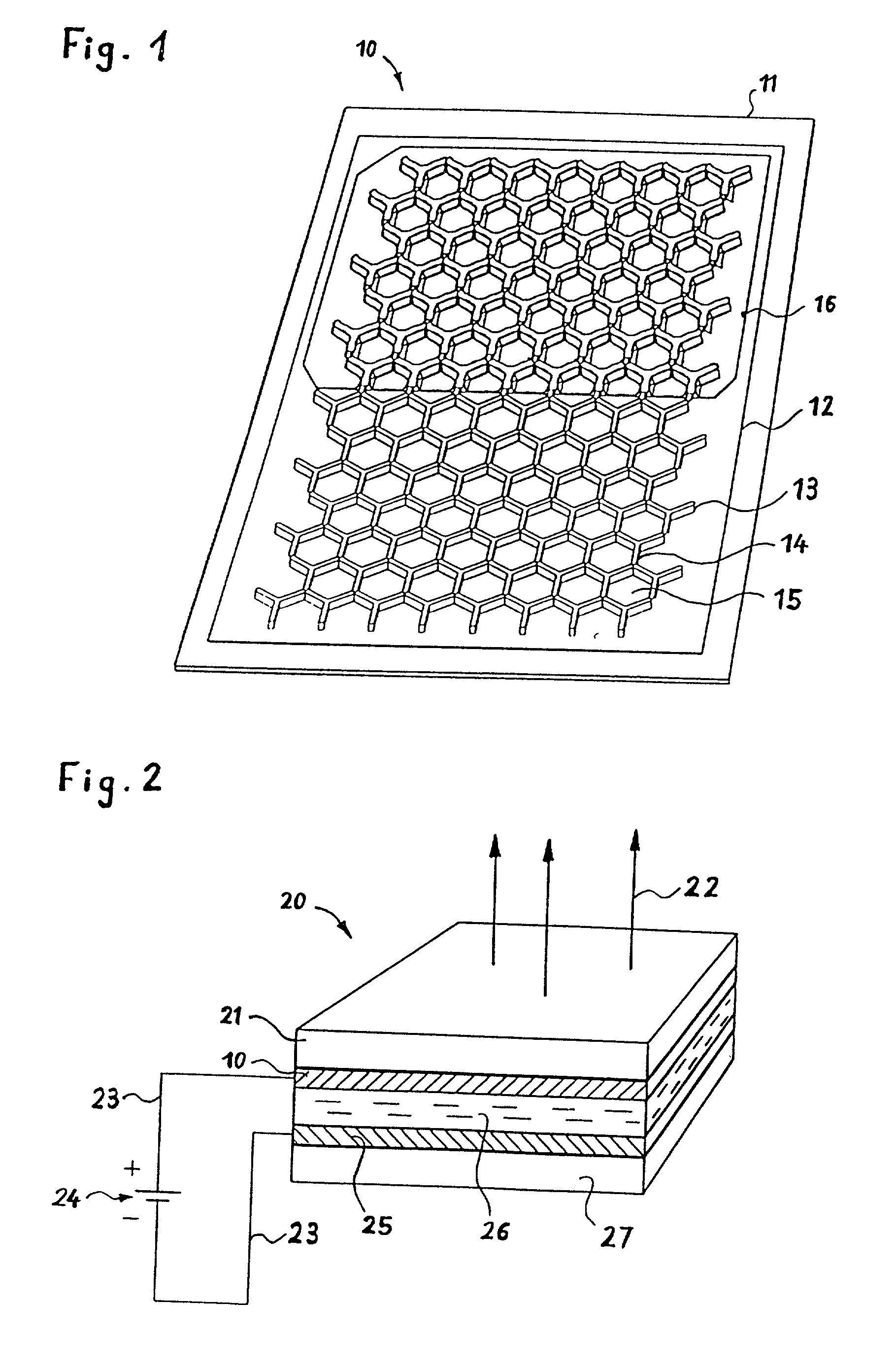

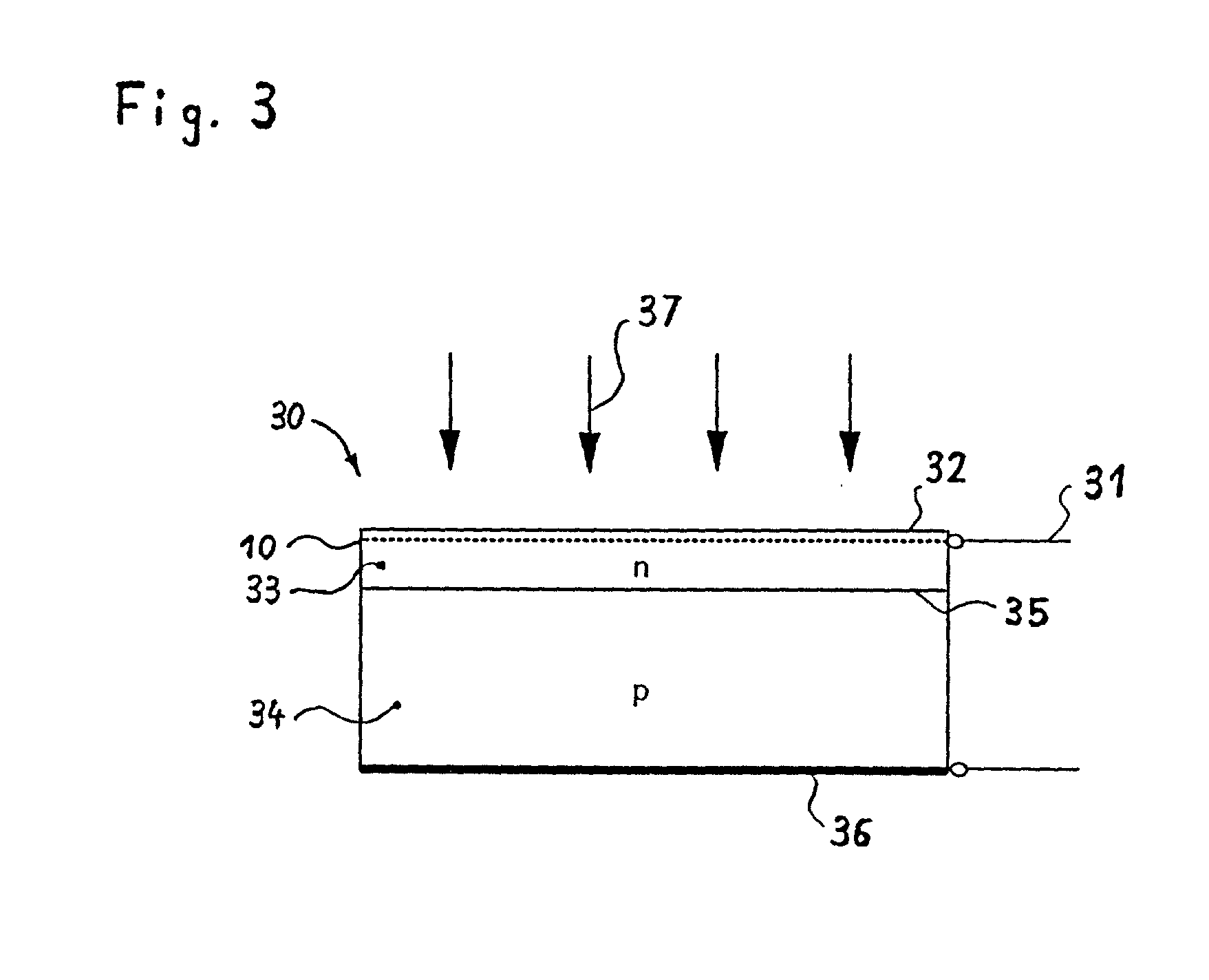

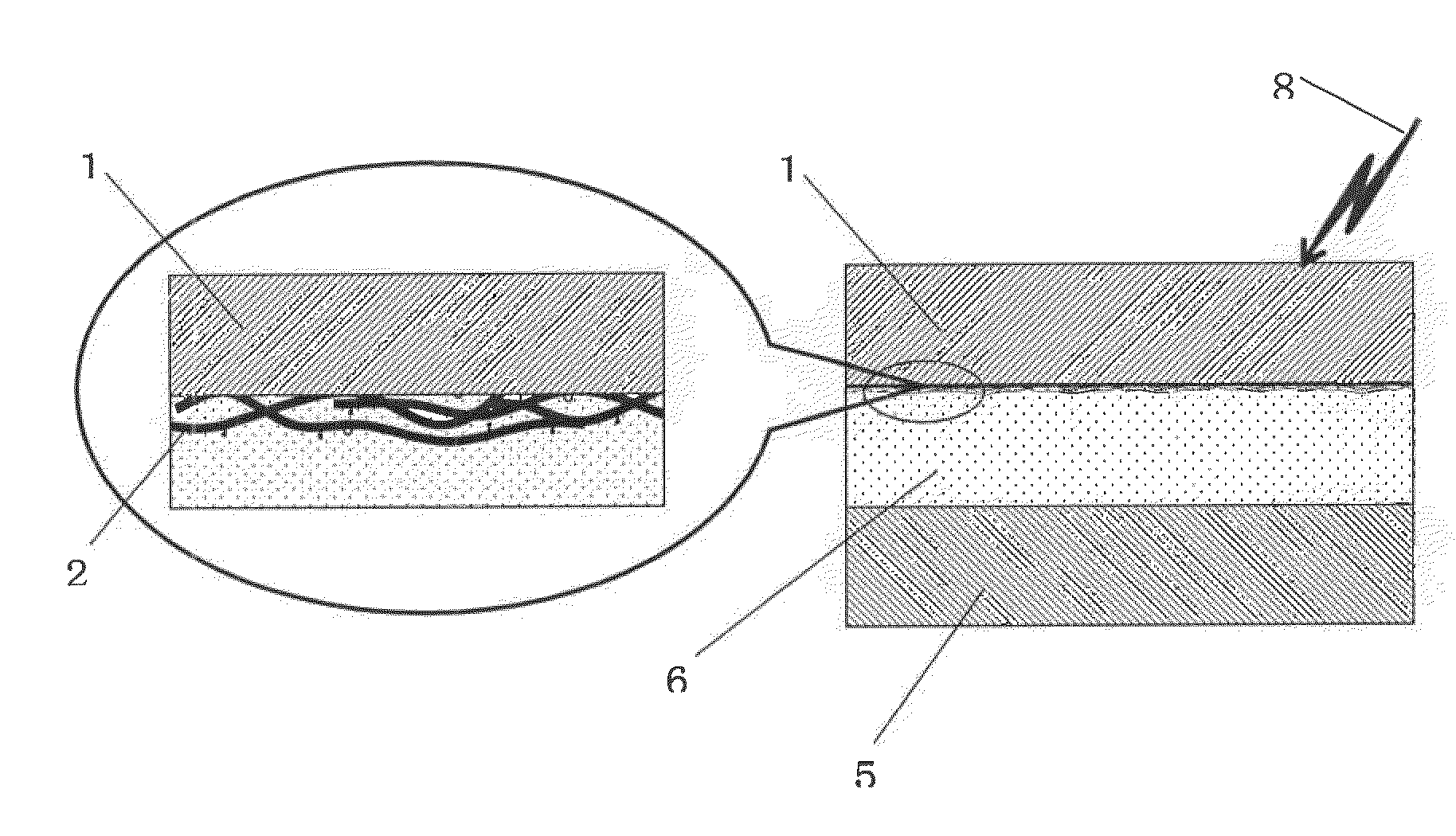

Electrode for use in electro-optical devices

InactiveUS20020130605A1Good conductivityLess energyMaterial nanotechnologyElectric discharge tubesForward scatterElectro-optics

An electrode for an electro-optical device is provided. Light is passing through this electrode which comprises a pattern of conductive elements. The elements have dimensions small compared to the wavelength of light, so that the electrode appear transparent. The light intensity distribution after having penetrated the electrode compared with the light intensity distribution before having penetrated the electrode is influenced by forward scattering.

Owner:AU OPTRONICS CORP

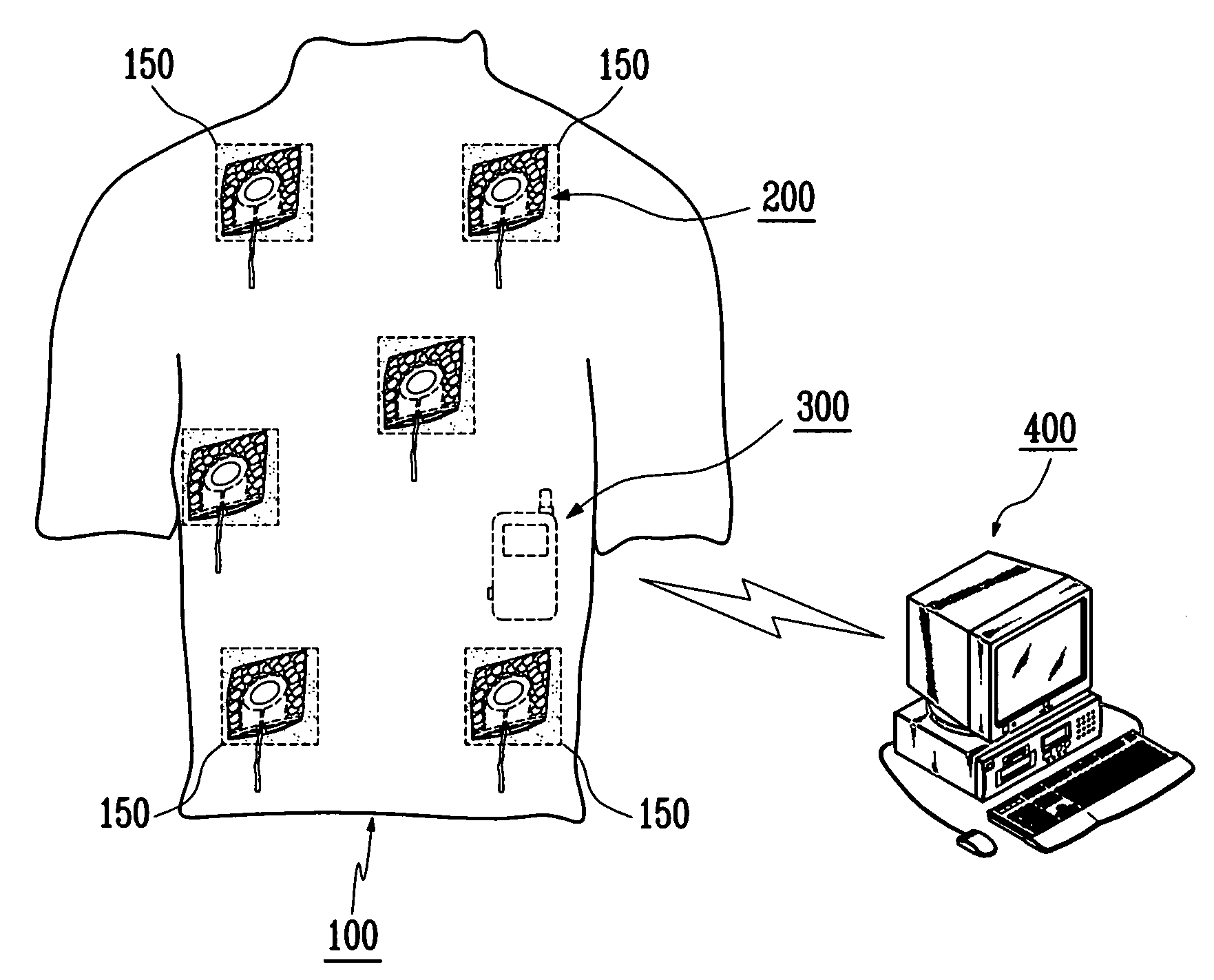

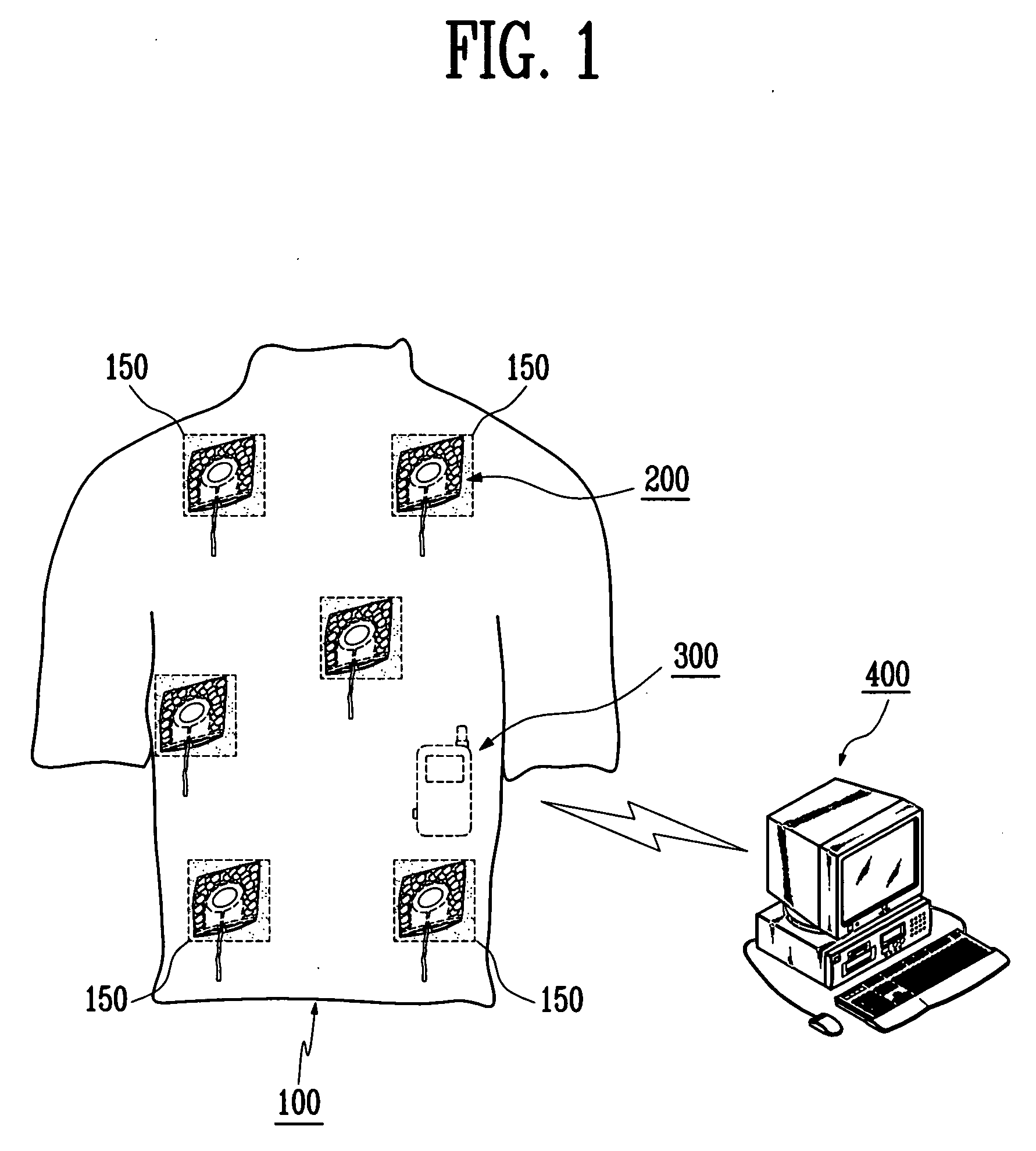

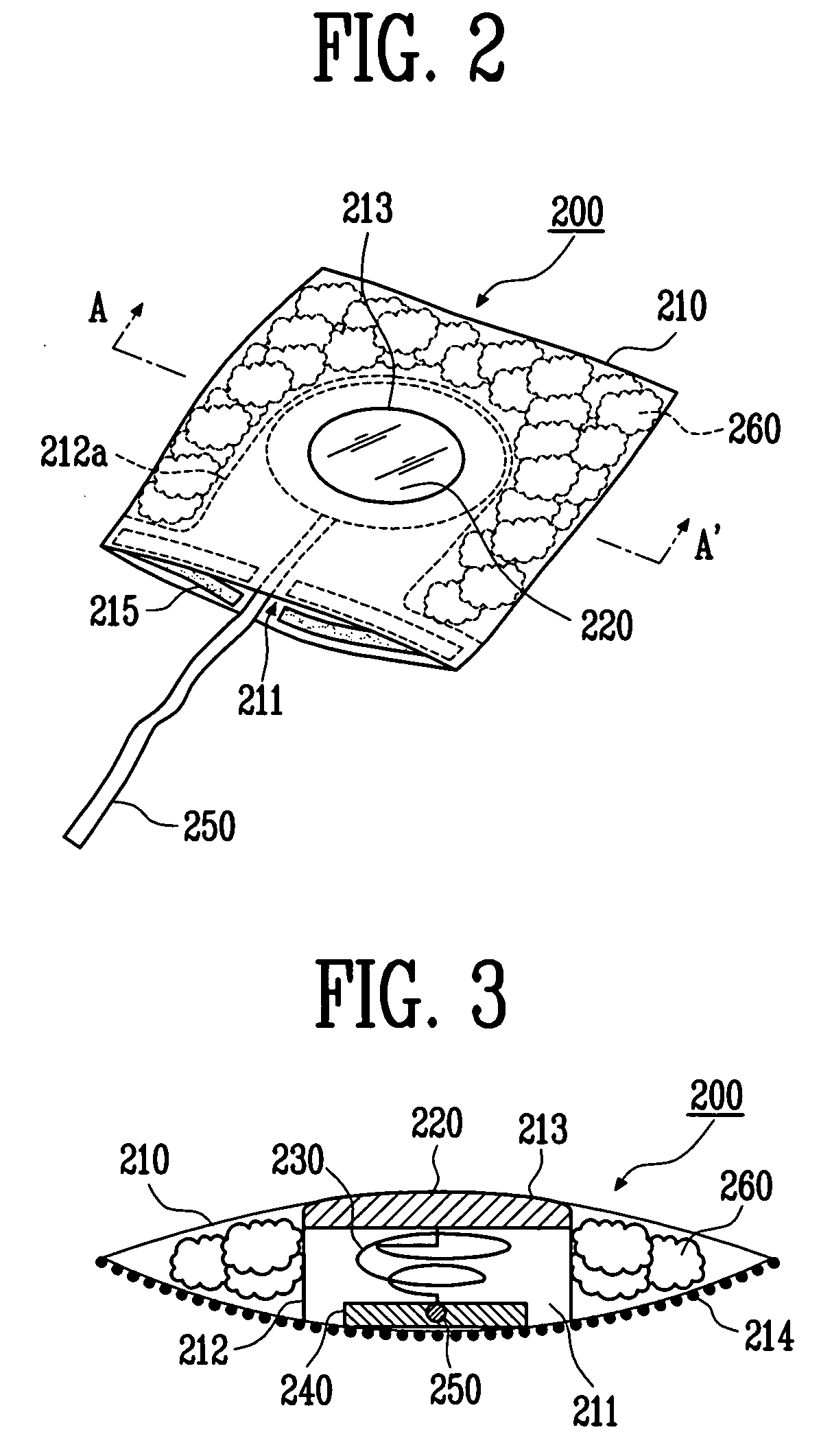

Wearable physiological signal detection module and measurement apparatus having the same

InactiveUS20050261564A1Long wearGood conductivityElectrocardiographyWriting connectorsMeasurement deviceEngineering

Provided are a wearable physiological signal detection module and a measurement apparatus having the same. A physiological signal detection module including a measuring electrode implemented by a dry electrode having good conductivity to detect various physiological signals is detachably disposed inside the clothing closely adhered to user's skin. The measuring electrode can be in stable contact with the user's skin as well as the detection module can be conveniently worn for a long time. The various physiological signals detected by the measuring electrodes are wirelessly transmitted to an external device, thereby conveniently monitoring the physiological signal of the user in real time.

Owner:ELECTRONICS & TELECOMM RES INST

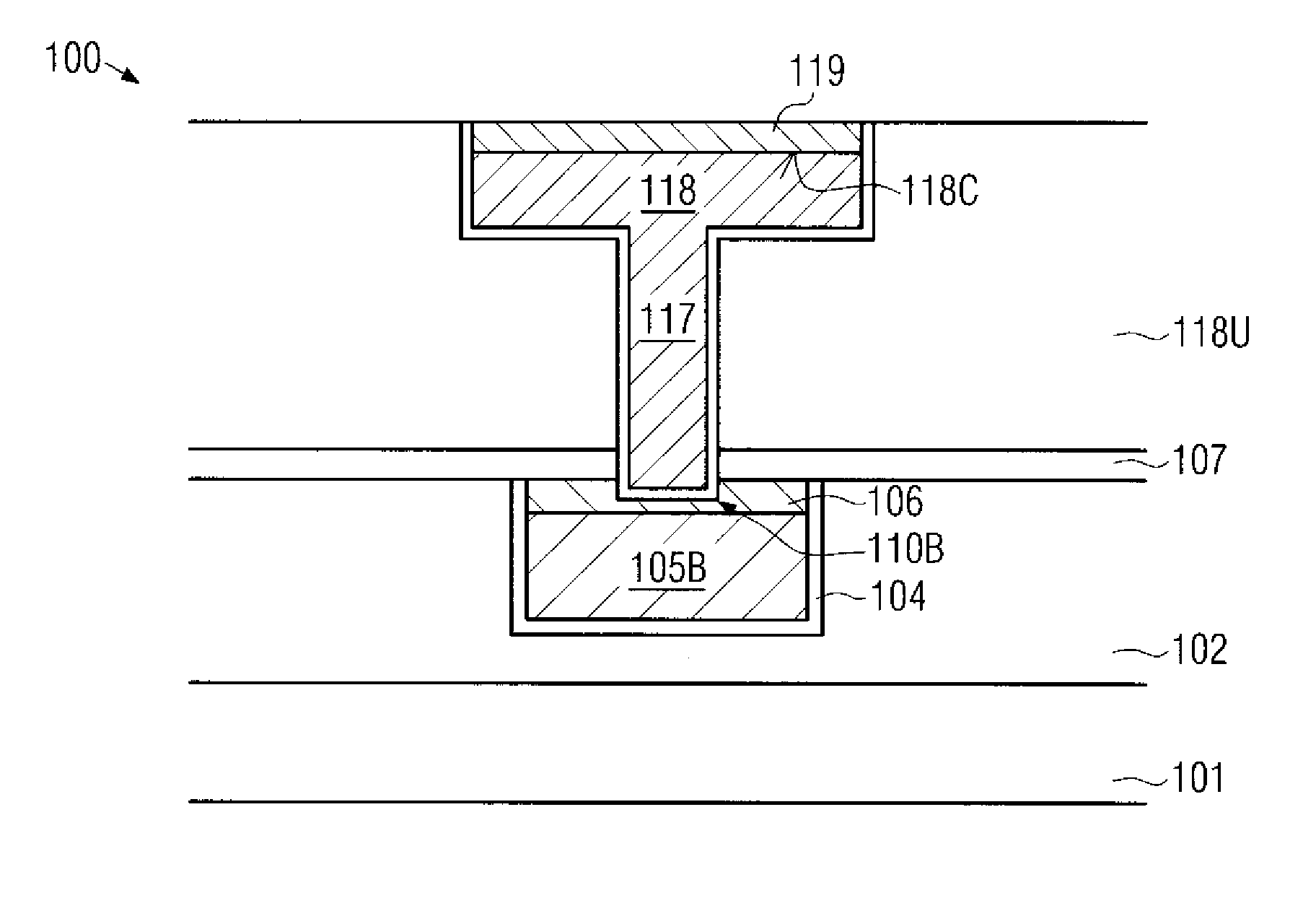

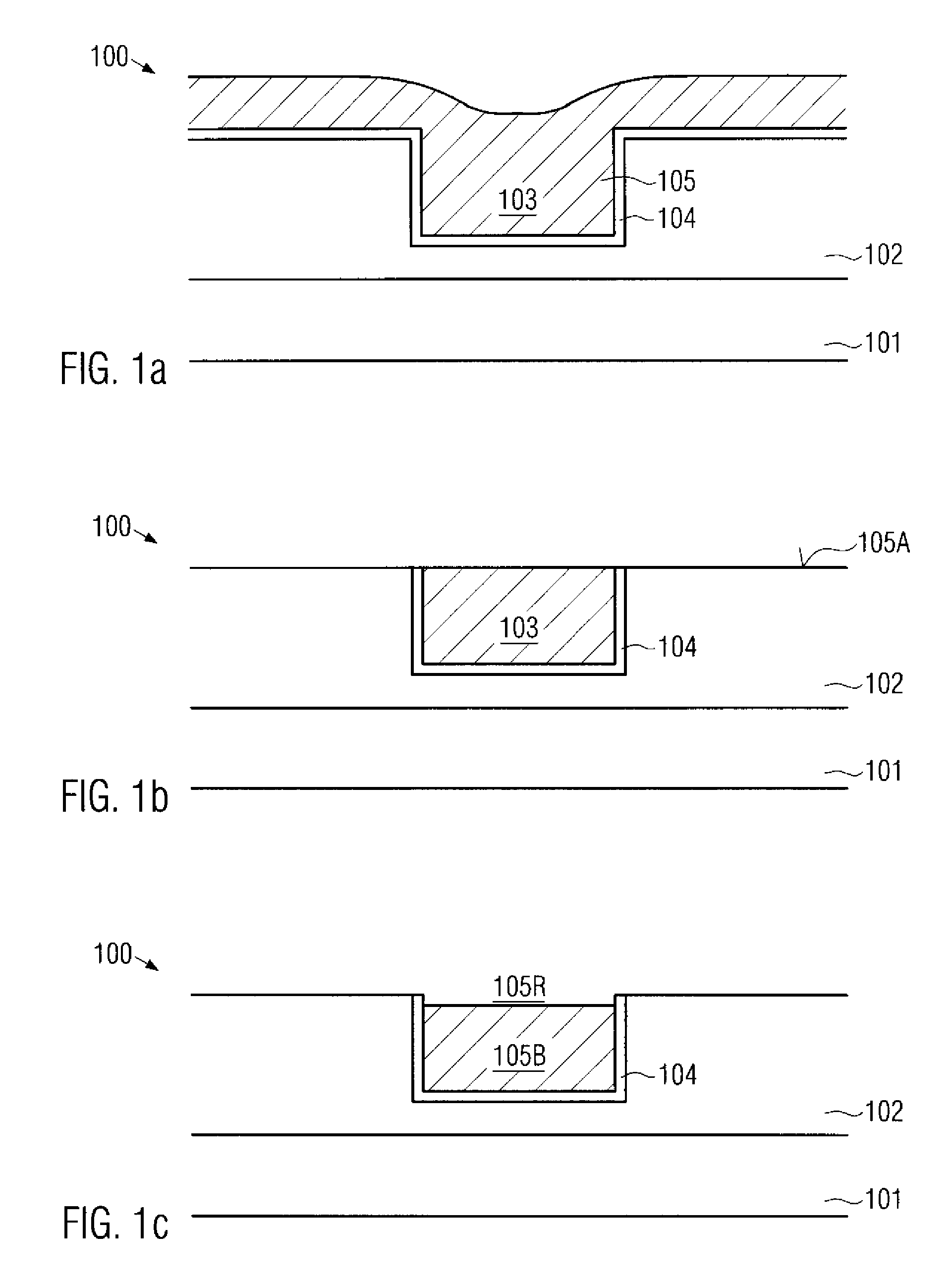

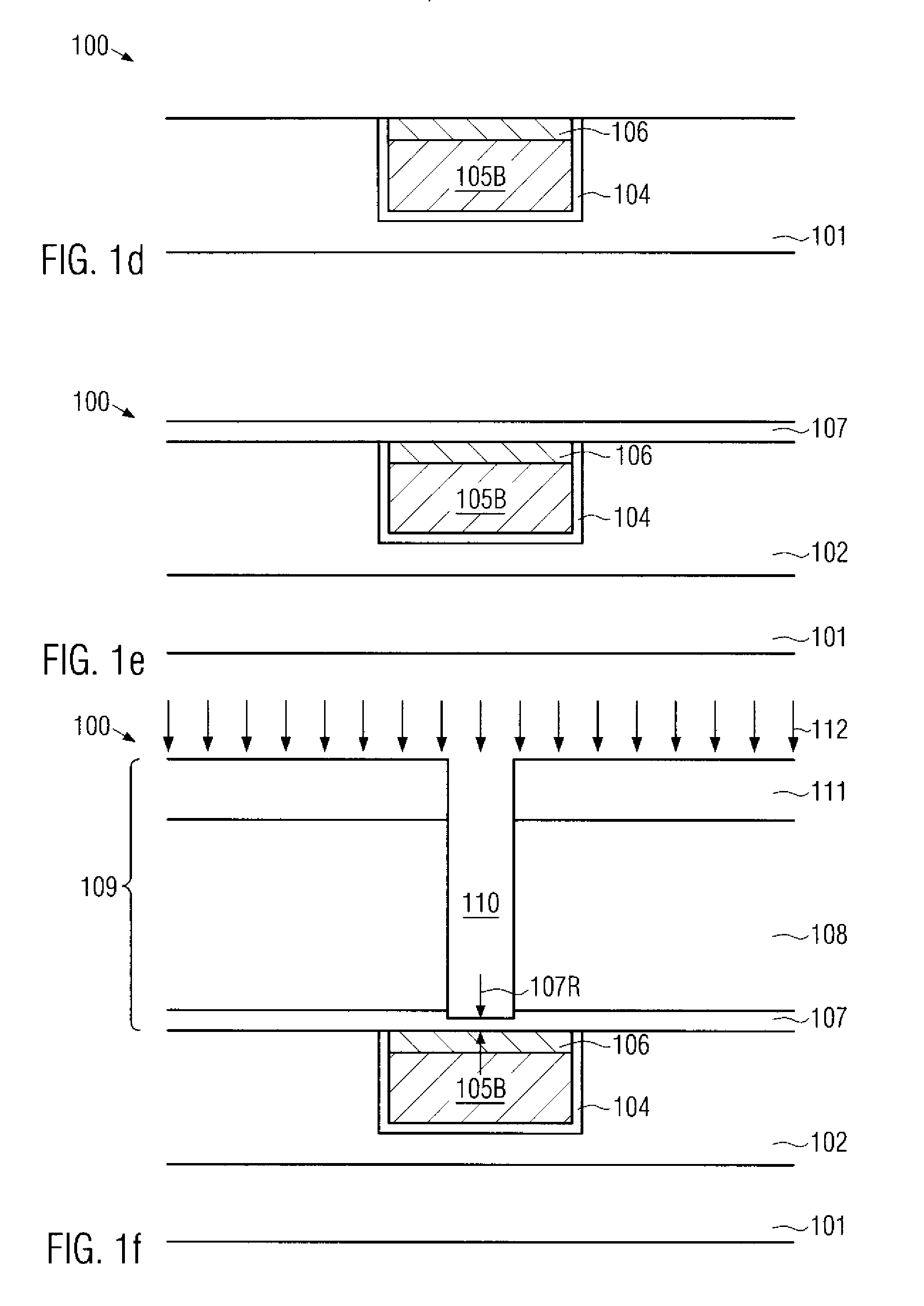

Technique for forming a copper-based metallization layer including a conductive capping layer

InactiveUS20070077761A1Reduce riskSimple materialSemiconductor/solid-state device detailsSolid-state devicesCopperMaterials science

By providing a conductive capping layer for metal-based interconnect lines, an enhanced performance with respect to electromigration may be achieved. Moreover, a corresponding manufacturing technique is provided in which via openings may be reliably etched into the capping layer without exposing the underlying metal, such as copper-based material, thereby also providing enhanced electromigration performance, especially at the transitions between copper lines and vias.

Owner:ADVANCED MICRO DEVICES INC

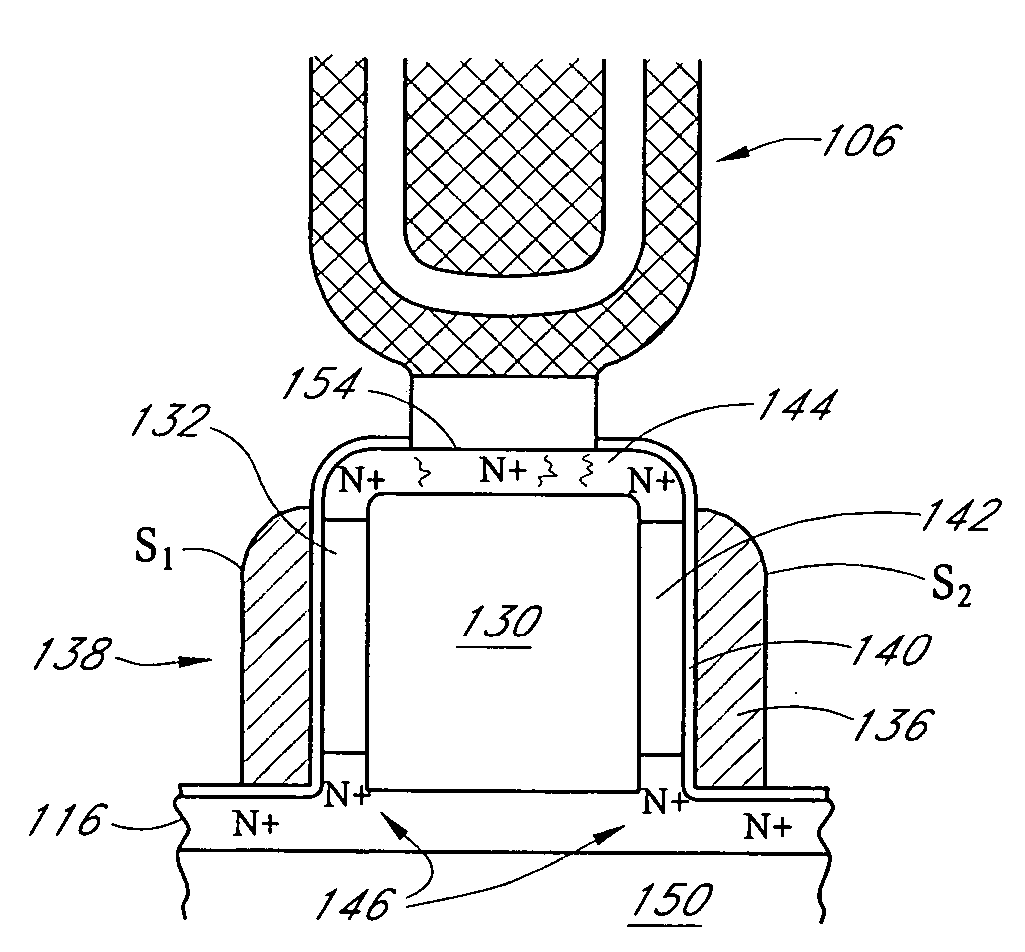

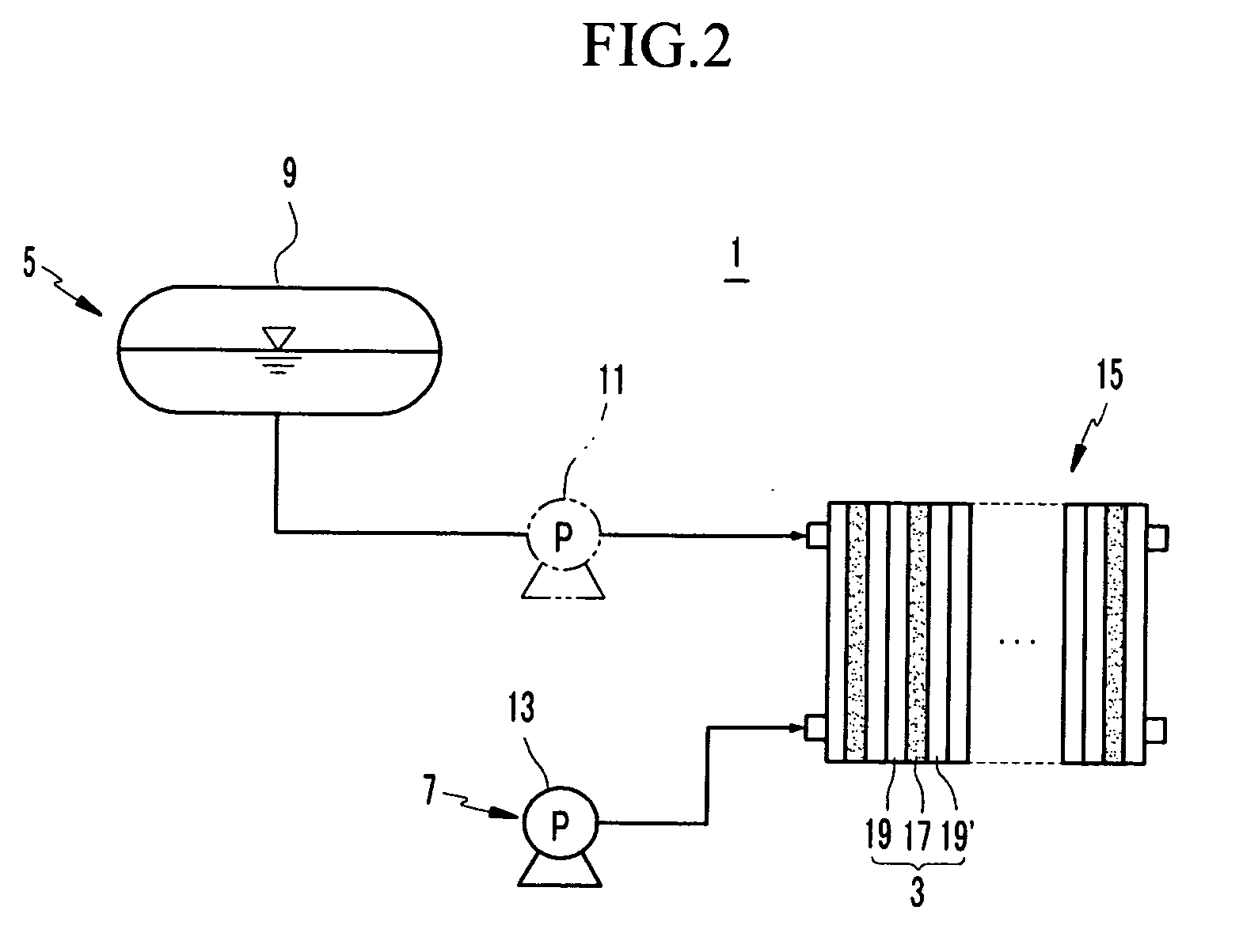

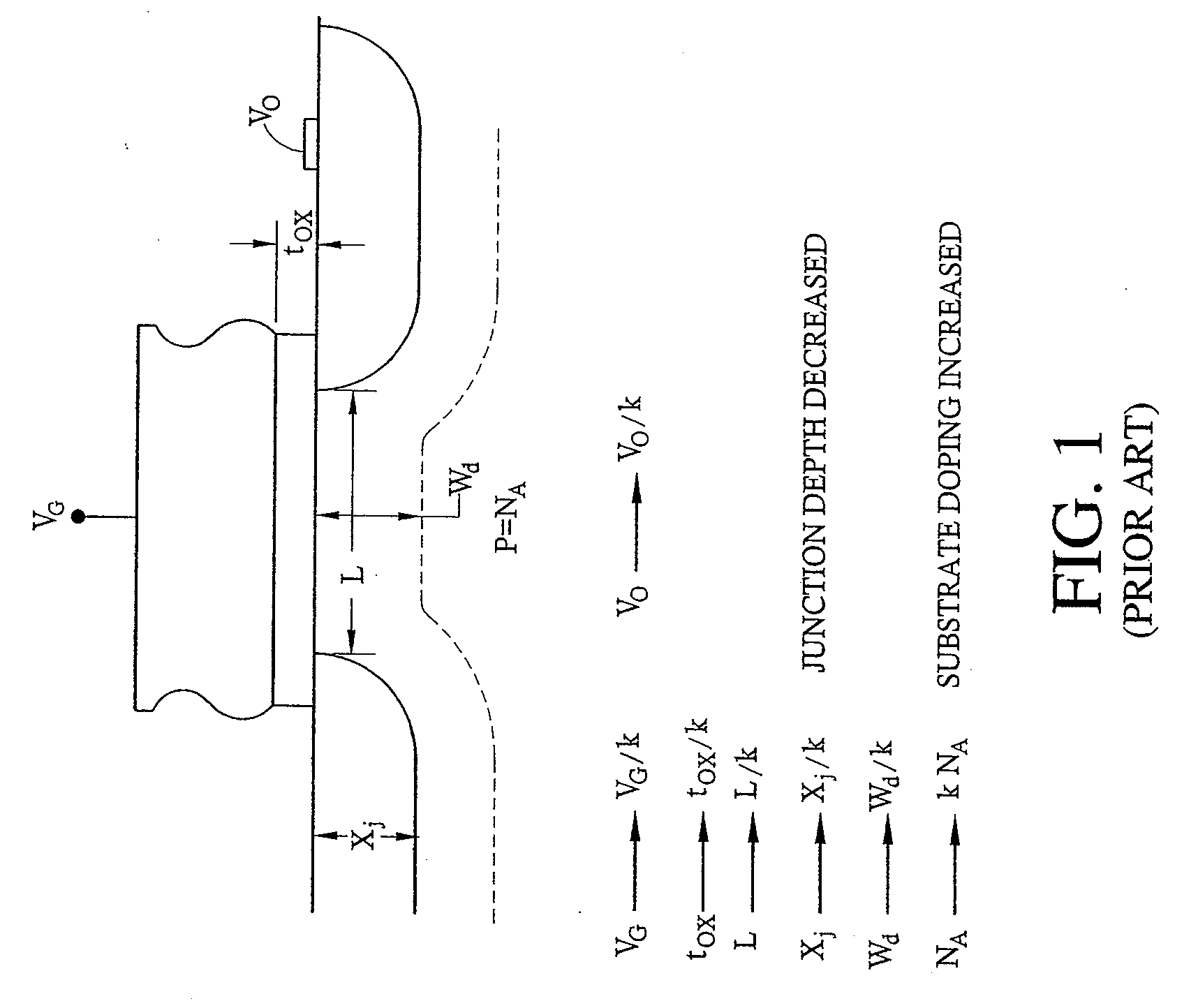

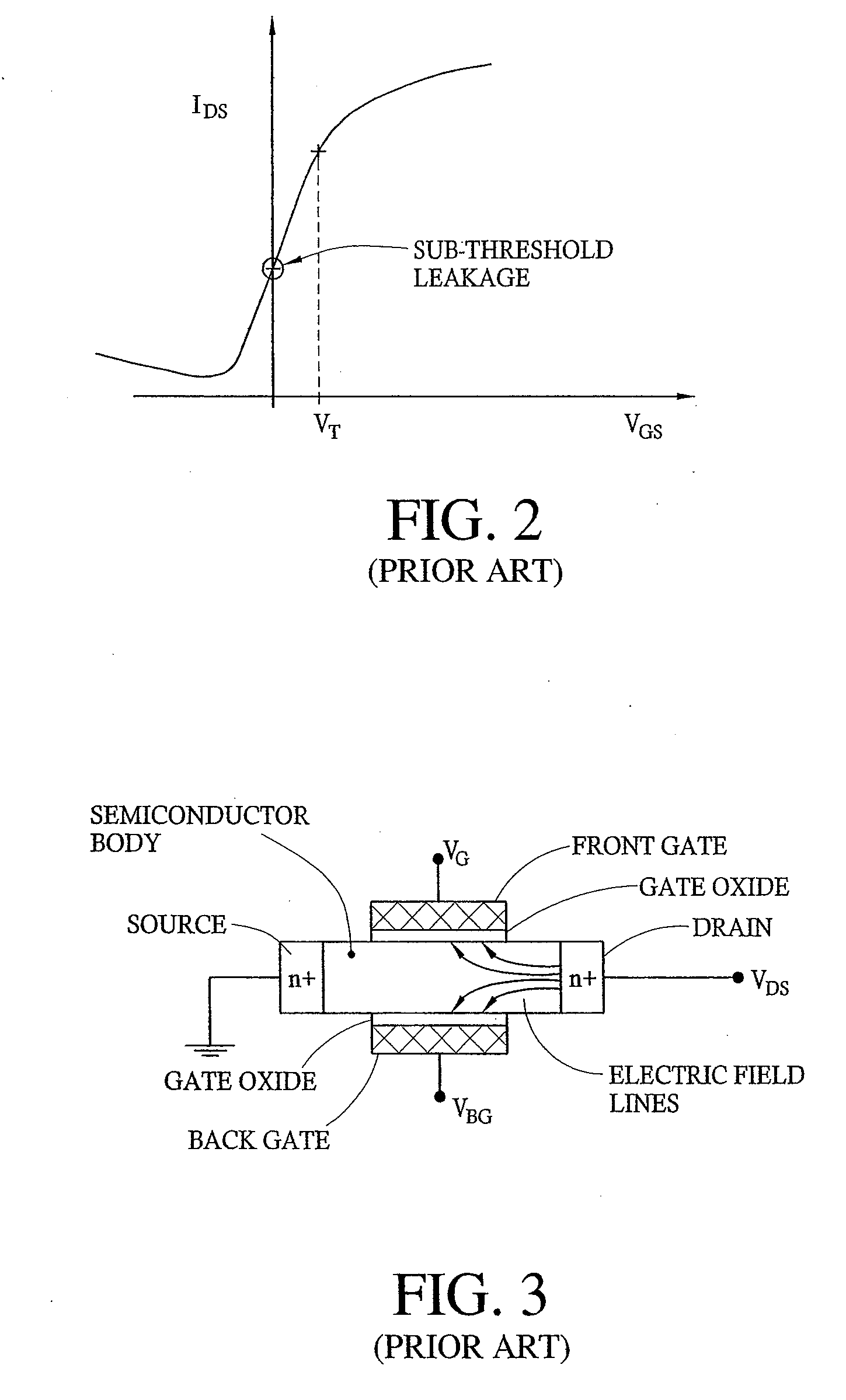

Surround gate access transistors with grown ultra-thin bodies

ActiveUS20070018206A1Satisfies needGood conductivitySolid-state devicesSemiconductor devicesLateral asymmetryBit line

A vertical transistor having an annular transistor body surrounding a vertical pillar, which can be made from oxide. The transistor body can be grown by a solid phase epitaxial growth process to avoid difficulties with forming sub-lithographic structures via etching processes. The body has ultra-thin dimensions and provides controlled short channel effects with reduced need for high doping levels. Buried data / bit lines are formed in an upper surface of a substrate from which the transistors extend. The transistor can be formed asymmetrically or offset with respect to the data / bit lines. The offset provides laterally asymmetric source regions of the transistors. Continuous conductive paths are provided in the data / bit lines which extend adjacent the source regions to provide better conductive characteristics of the data / bit lines, particularly for aggressively scaled processes.

Owner:MICRON TECH INC

Method of manufacturing display device

InactiveUS20080081532A1Efficiently formedAccuracy and efficiency of resolutionPhotomechanical apparatusVessels or leading-in conductors manufactureAlloy elementElectrically conductive

A display device manufacturing method of manufacturing a display device including a direct-contact structure formed on a glass substrate by directly superposing an Al alloy film forming wiring lines of an Al alloy and a transparent conducting film forming pixel electrodes in direct contact, and a deposit of part or all of an alloying element of the Al alloy or a concentrated layer containing part or all of the alloying element of the Al alloy, sandwiched between the Al alloy film and the transparent conducting film includes a developing process using a resist developer containing an organic base in a concentration between 2 and 3.5% by mass and a sugar alcohol having a carbon number between 4 and 6 in a sugar alcohol concentration between 2 and 10% by mass and not containing any other polyhydric alcohols for developing a resist film in a wiring pattern.

Owner:KOBE STEEL LTD

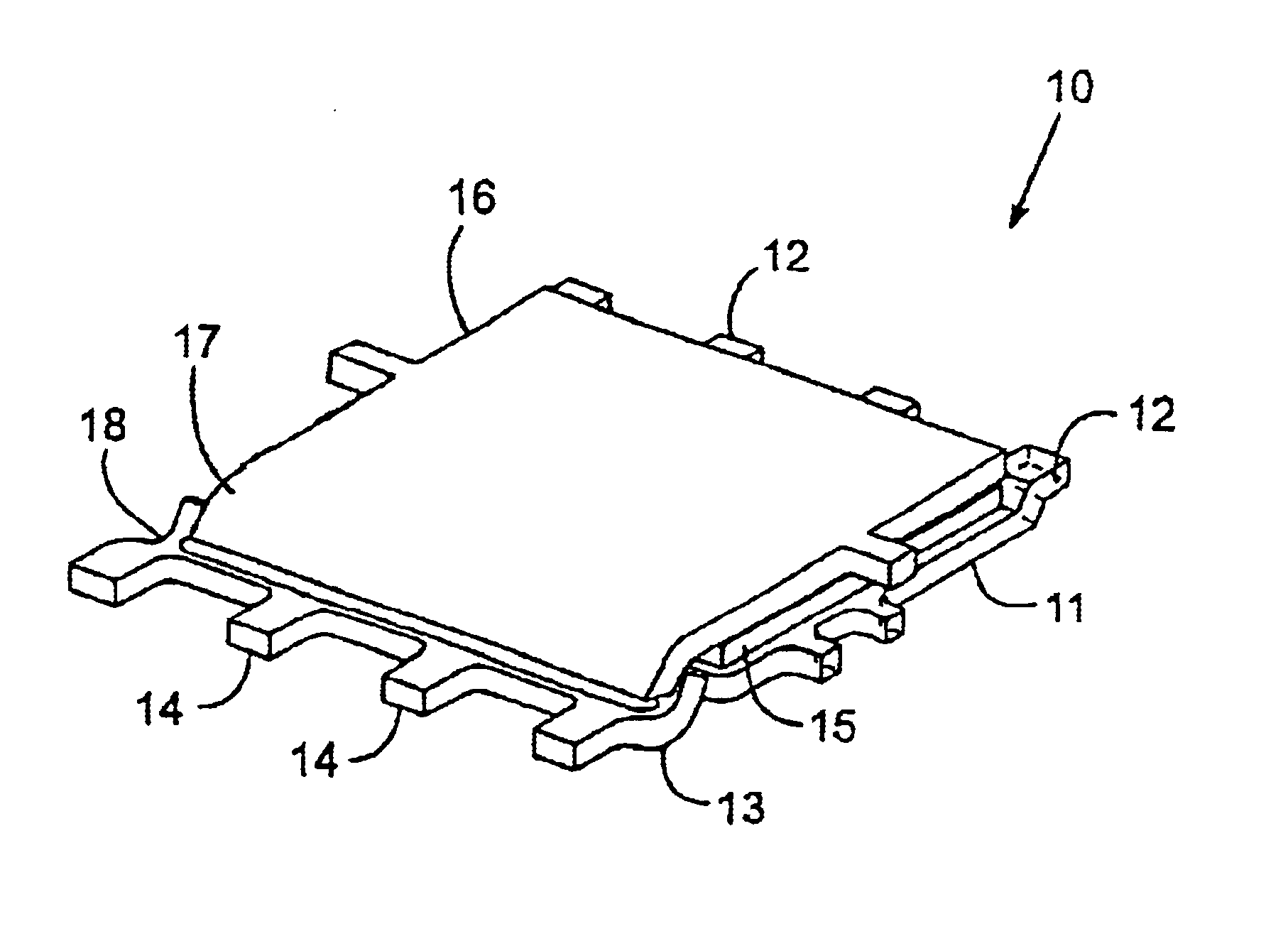

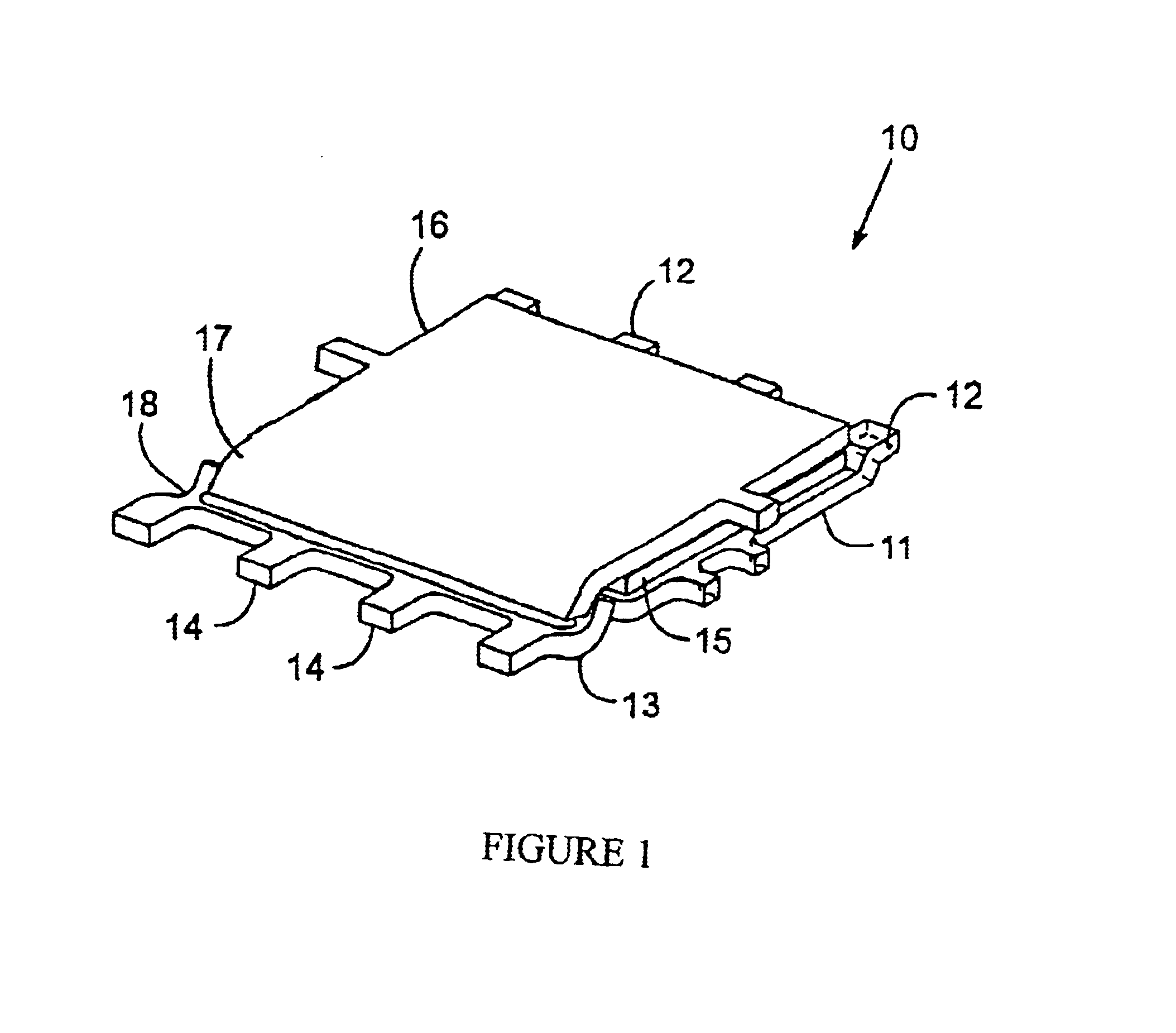

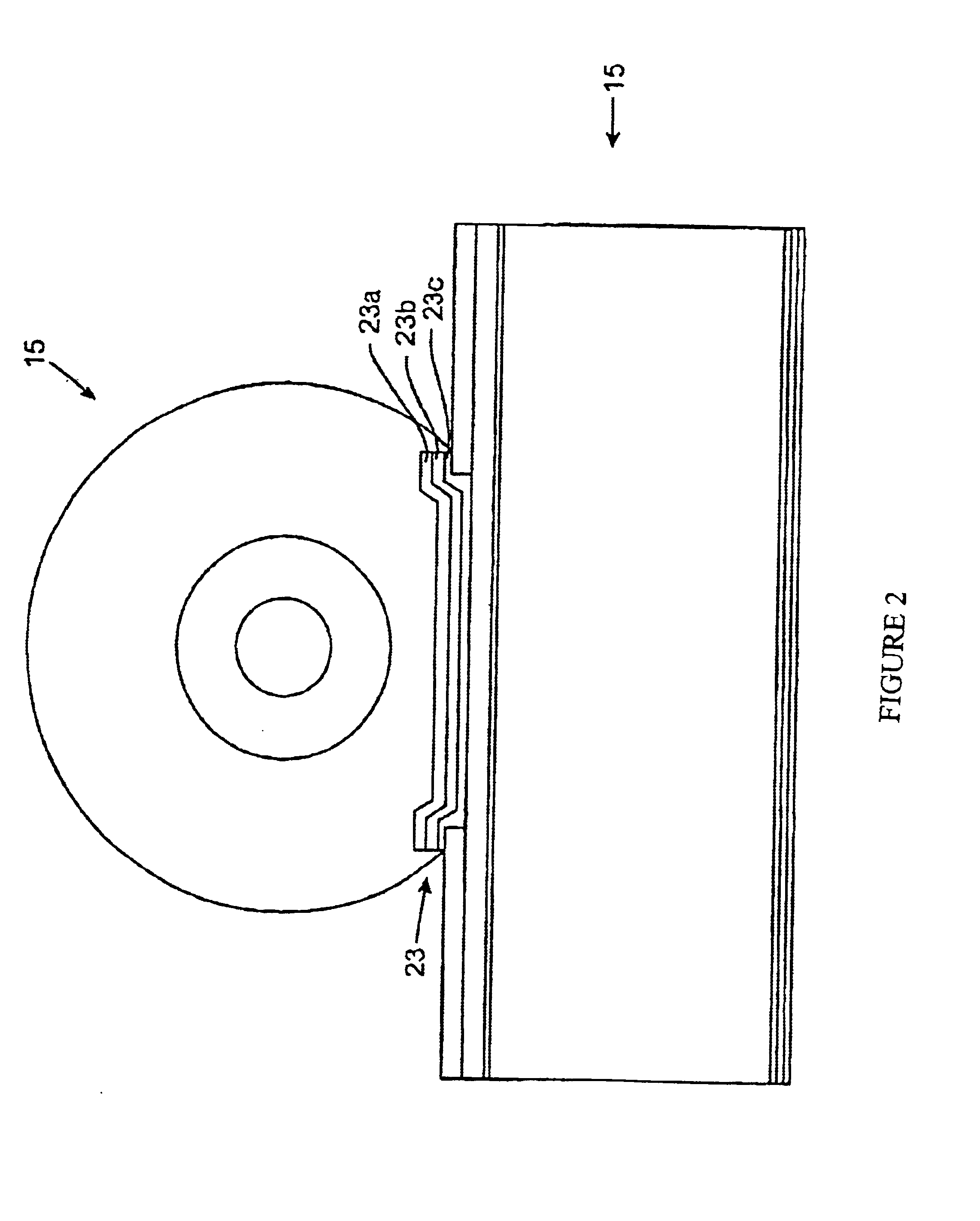

Flip clip attach and copper clip attach on MOSFET device

InactiveUS6870254B1Low rdson performanceGood conductivitySemiconductor/solid-state device detailsSolid-state devicesMOSFETSolder paste

A chip device including a leadframe that includes source and gate connections, a bumped die including solder bumps on a top side that is attached to the leadframe such that the solder bumps contact the source and gate connections, and a copper clip attached to the backside of the bumped die such that the copper clip contacts drain regions of the bumped die and a lead rail. The chip device is manufactured by flip chipping a bumped die onto the leadframe and placing the copper clip on a backside of; the trench die such that the backside of the trench die is coupled to the lead rail. The process involves reflowing the solder bumps on the bumped die and solder paste that is placed between the copper clip and the backside of the bumped die.

Owner:SEMICON COMPONENTS IND LLC

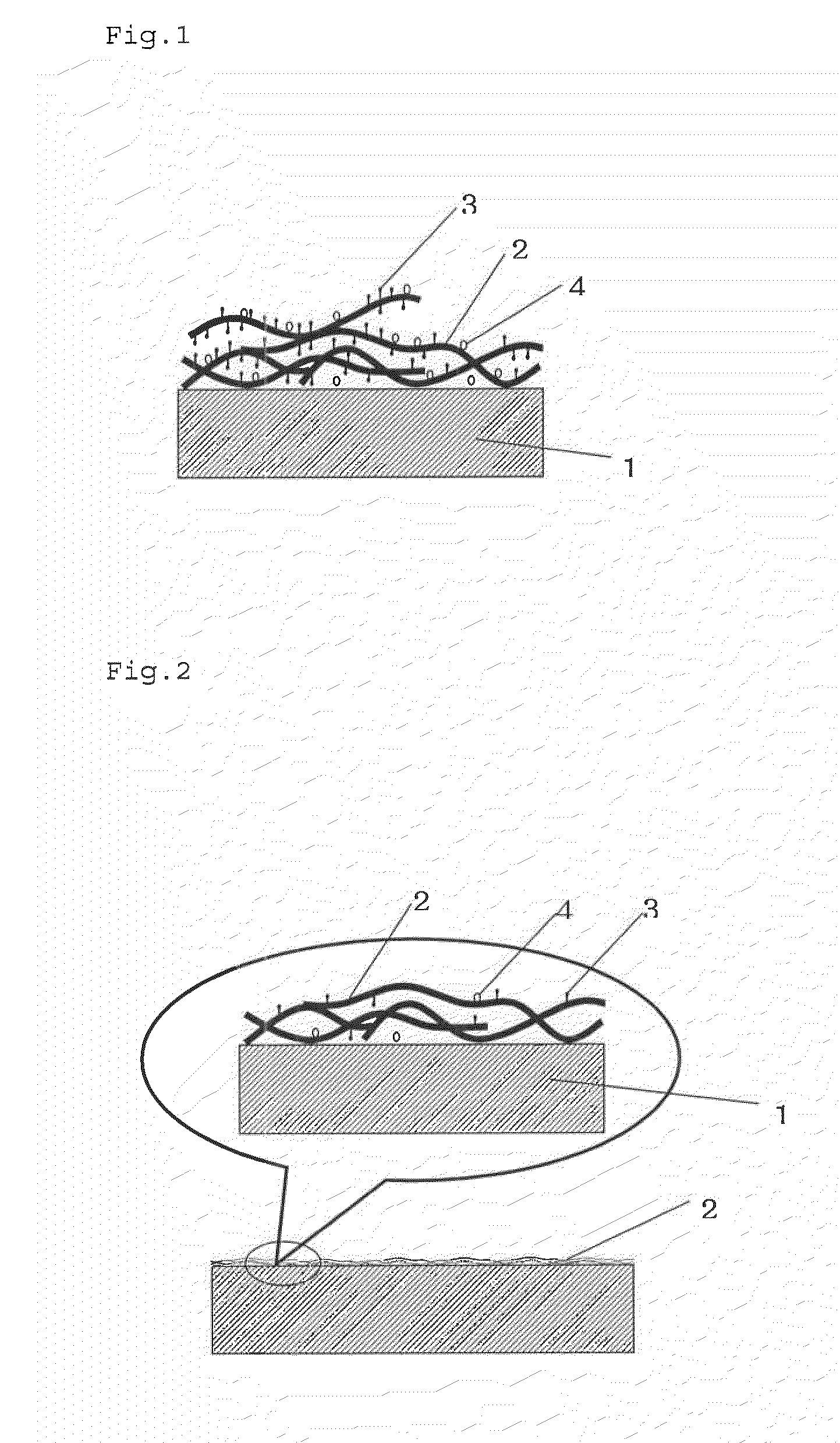

Method for producing carbon nanotube-containing conductor

ActiveUS20100252184A1High conductivityGood conductivityMaterial nanotechnologyDecorative surface effectsCarbon nanotubeLiquid resin

The invention is to provide a method for producing an inexpensive carbon nanotube-containing conductor having high transparency and high conductivity as well as excellent durability. The invention is a method for producing a carbon nanotube-containing conductor having a conductive layer on the surface of an objective substrate, and the method includes the steps of pressing a release substrate having a carbon nanotube network layer, via the carbon nanotube network layer thereon, against a transparent objective substrate coated with an electron beam-curable liquid resin composition to infiltrate the liquid resin composition into the carbon nanotube network layer; irradiating it with electron beams to cure the liquid resin composition; and peeling away the release substrate to obtain an objective substrate having a resin composition layer with carbon nanotubes embedded in the surface thereof. According to the invention, a conductor and a conductive film having high conductivity and transparency as well as excellent strength and durability are obtained.

Owner:MEIJO NANO CARBON

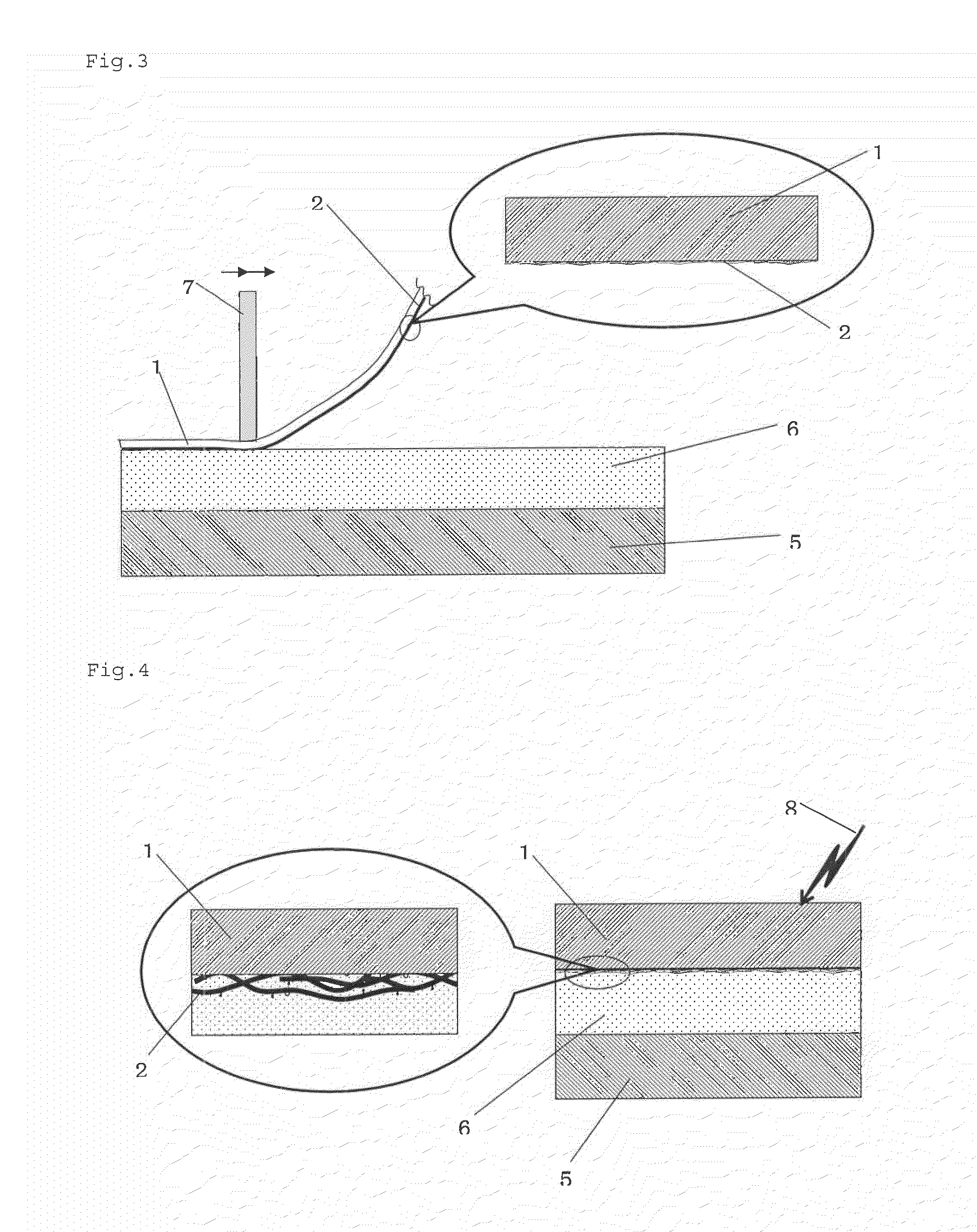

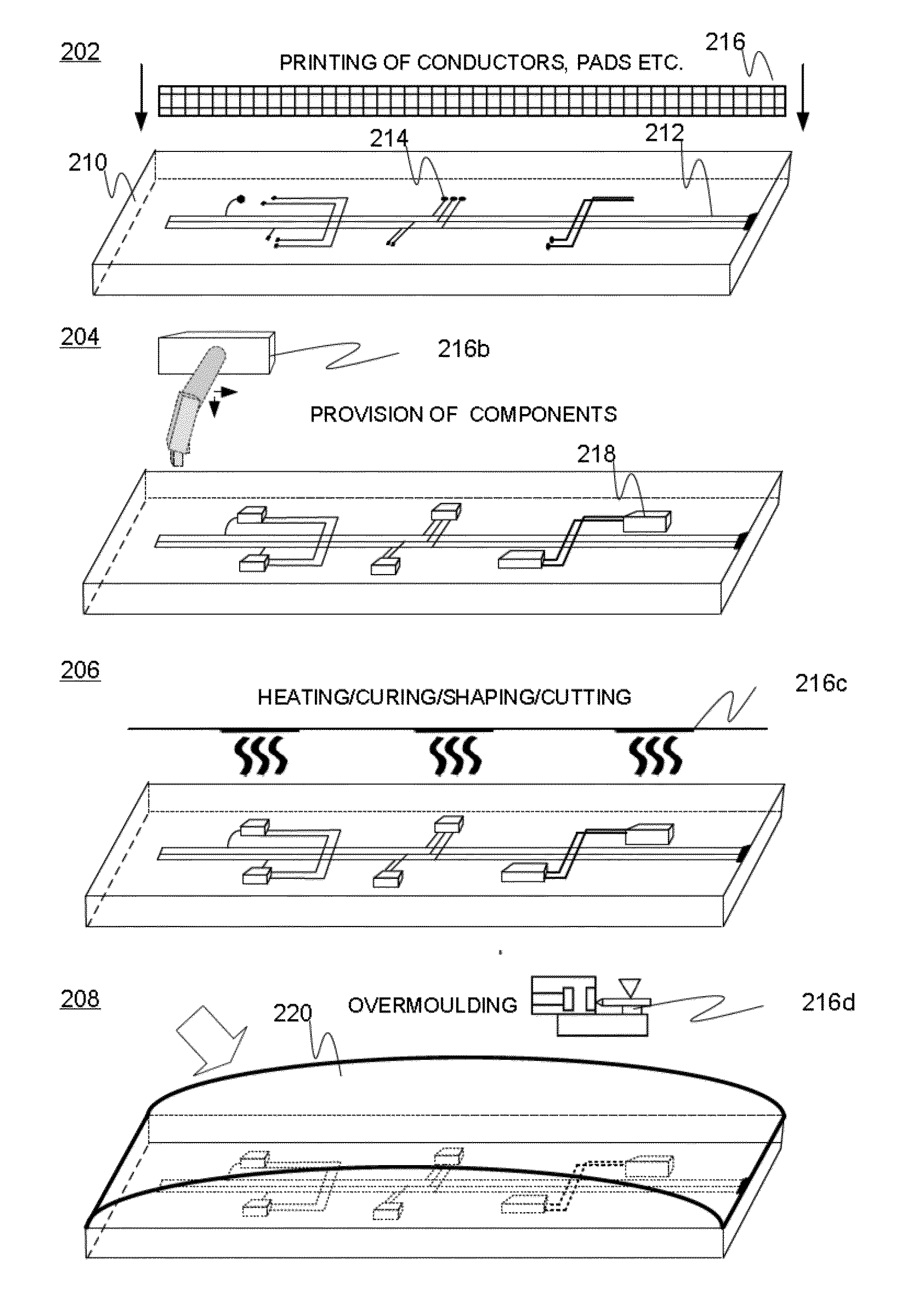

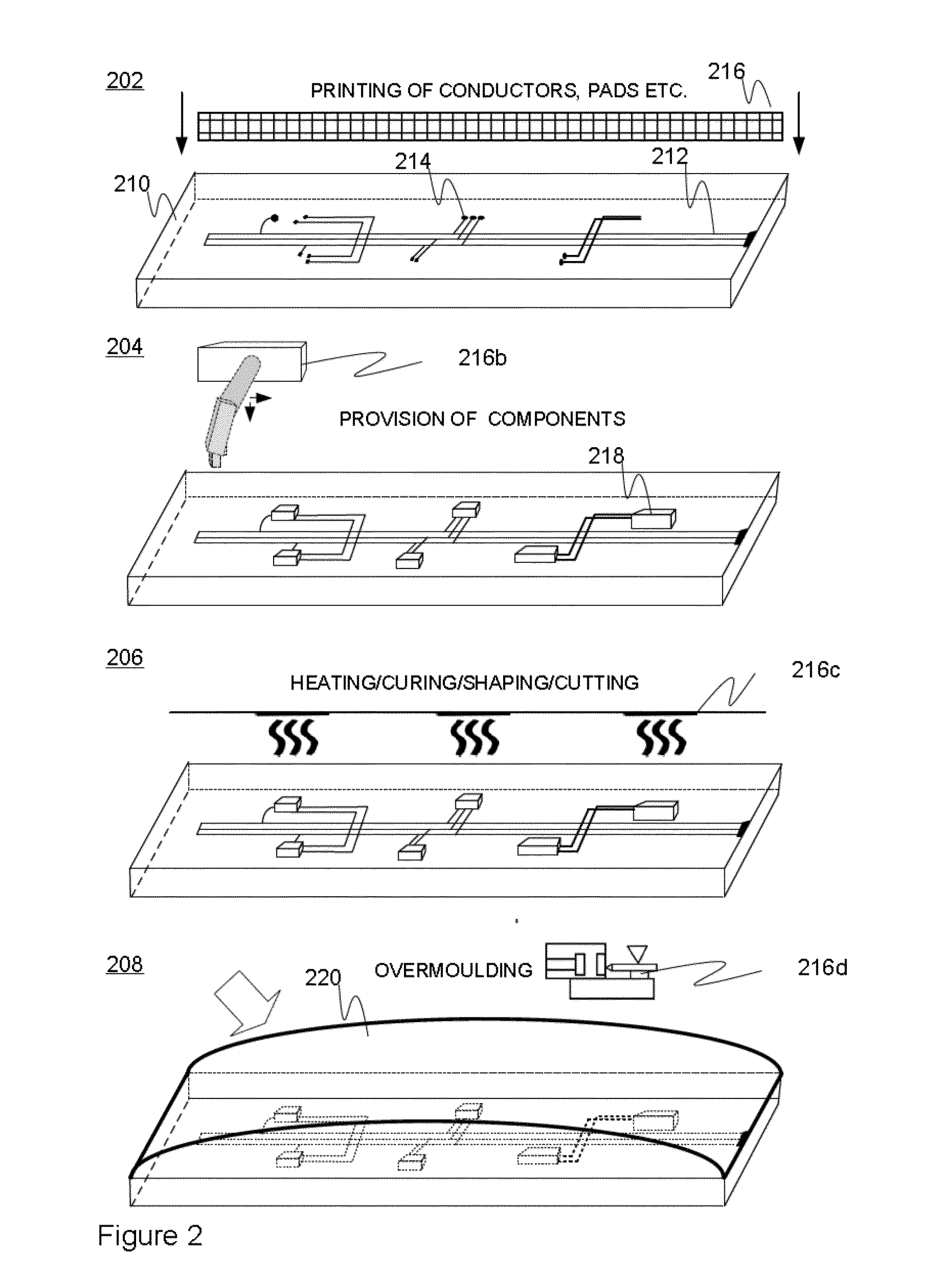

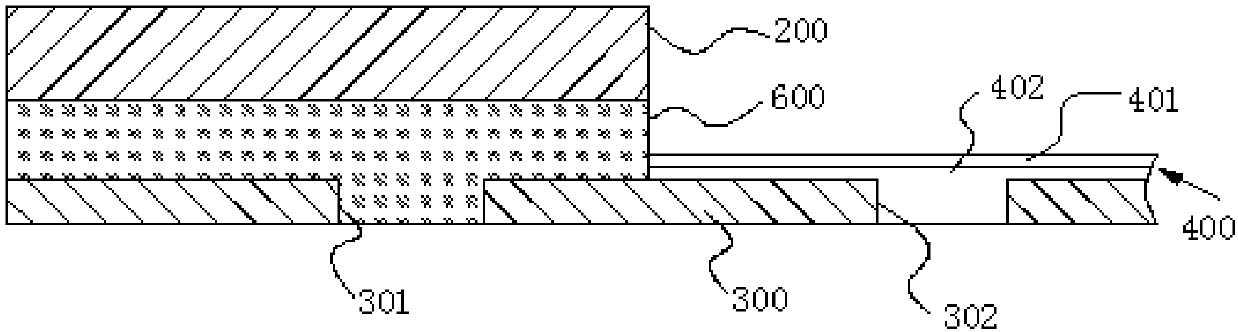

Method for manufacturing electronic products, related arrangement and product

PendingUS20150257278A1Reduced number of manufacture stepGood conductivityTransparent dielectricsElectrical connection printed elementsIntegrated circuitElectrical connection

A method for manufacturing an electronic product, comprising providing a flexible, optionally optically substantially transparent or translucent, substrate film, printing a number of conductive traces of conductive ink on the substrate film, said traces defining a number of conductors and conductive contact areas for the contacts of at least one electronic surface-mountable component, disposing the at least one electronic surface-mountable component, such as an integrated circuit, on the substrate film so that the contacts meet the predefined contact areas when they are still wet to establish the electrical connection therebetween, and further securing, optionally overmoulding, the component. Related arrangement and electronic product are presented.

Owner:TACTOTEK

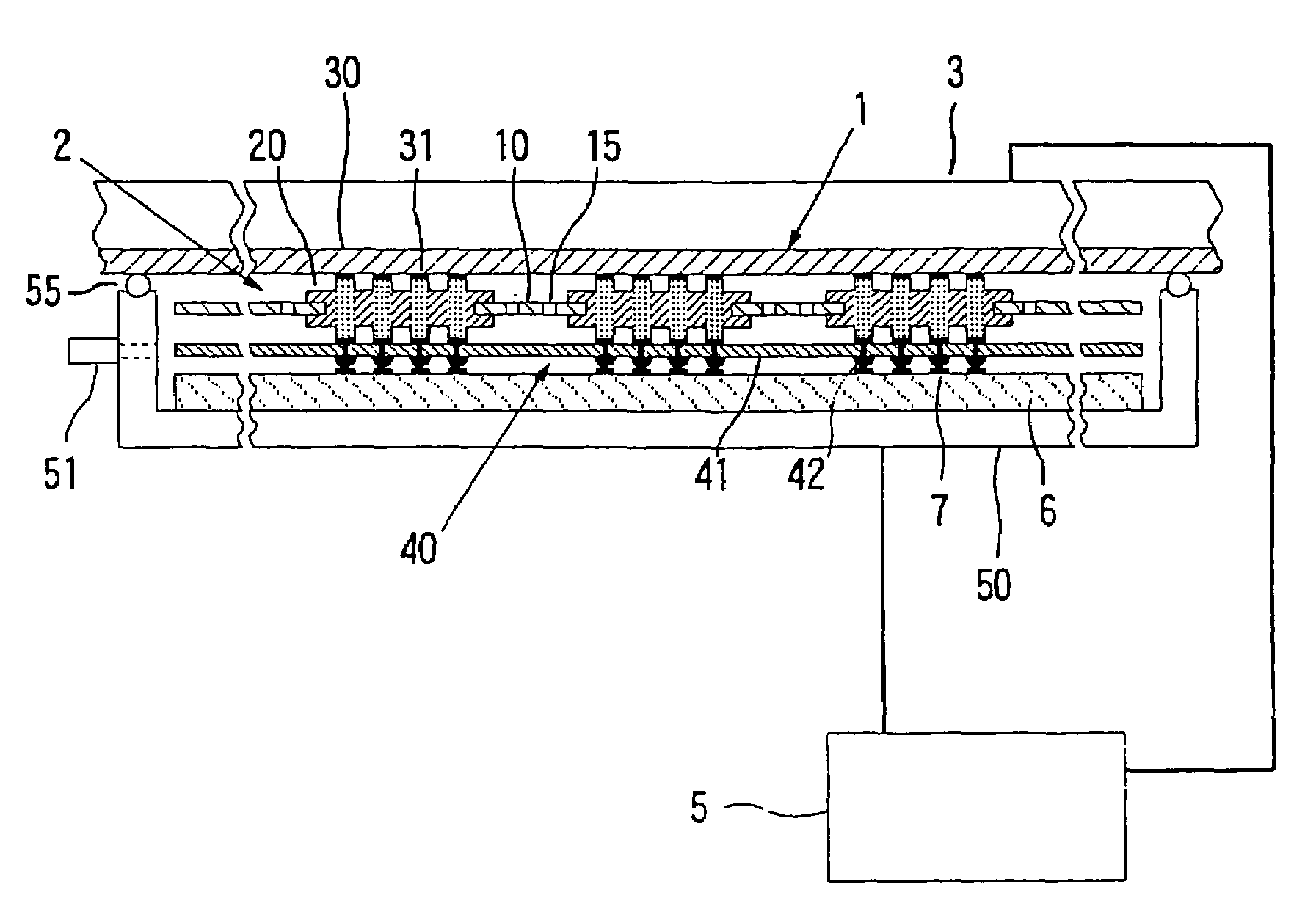

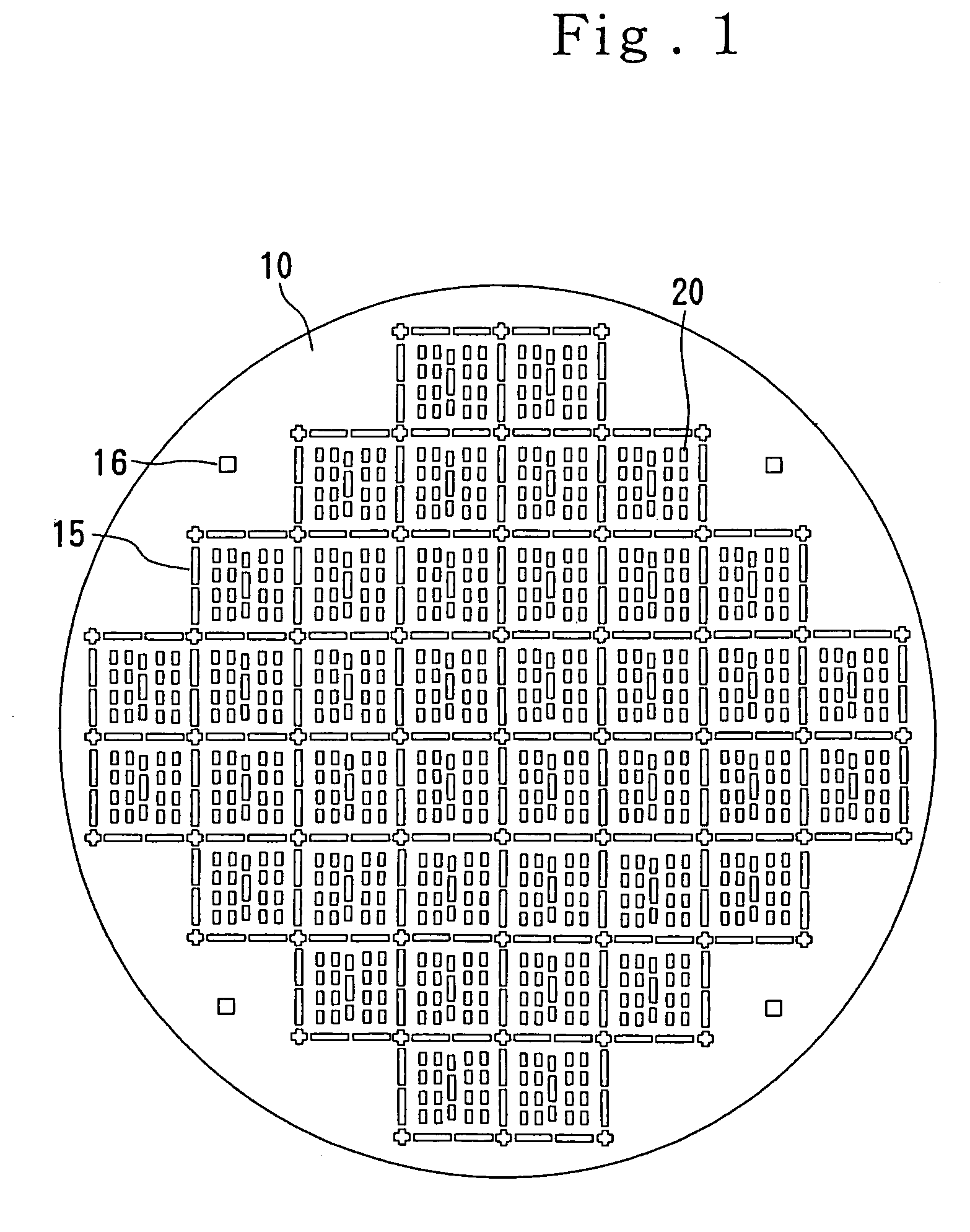

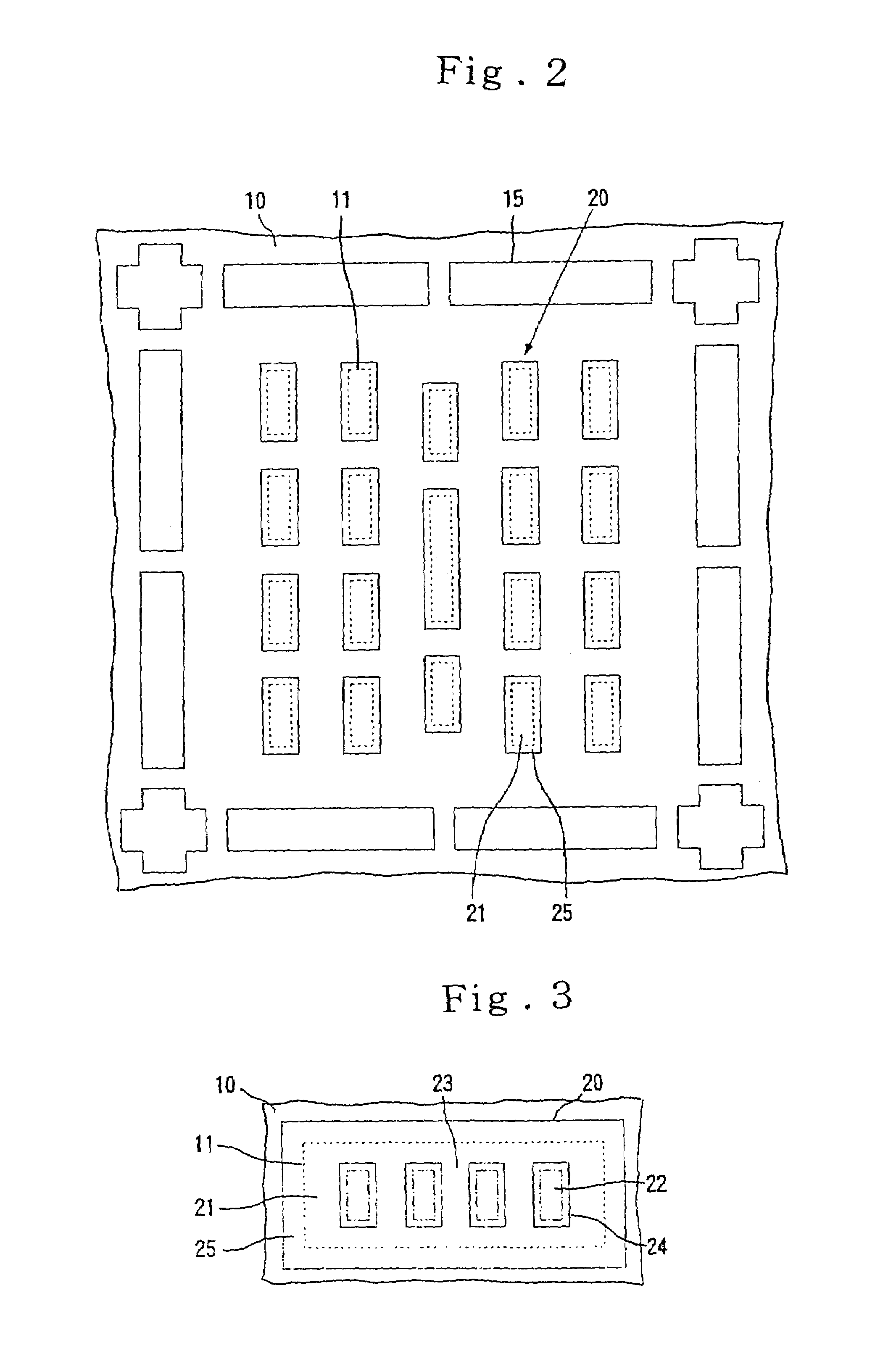

Anisotropically conductive connector, its manufacture method and probe member

InactiveUS6969622B1Conduct with easeGood conductivityNon-insulated conductorsSemiconductor/solid-state device testing/measurementEngineeringElastic anisotropy

An anisotropically conductive connector, by which positioning, and holding and fixing to a wafer to be inspected can be conducted with ease even when the wafer has a large area, contains a frame plate having a plurality of anisotropically conductive film-arranging holes formed corresponding to regions of electrodes to be inspected of a wafer, and a plurality of elastic anisotropically conductive films arranged in the respective anisotropically conductive film-arranging holes and supported by the inner peripheral edge thereabout.

Owner:ISC CO LTD

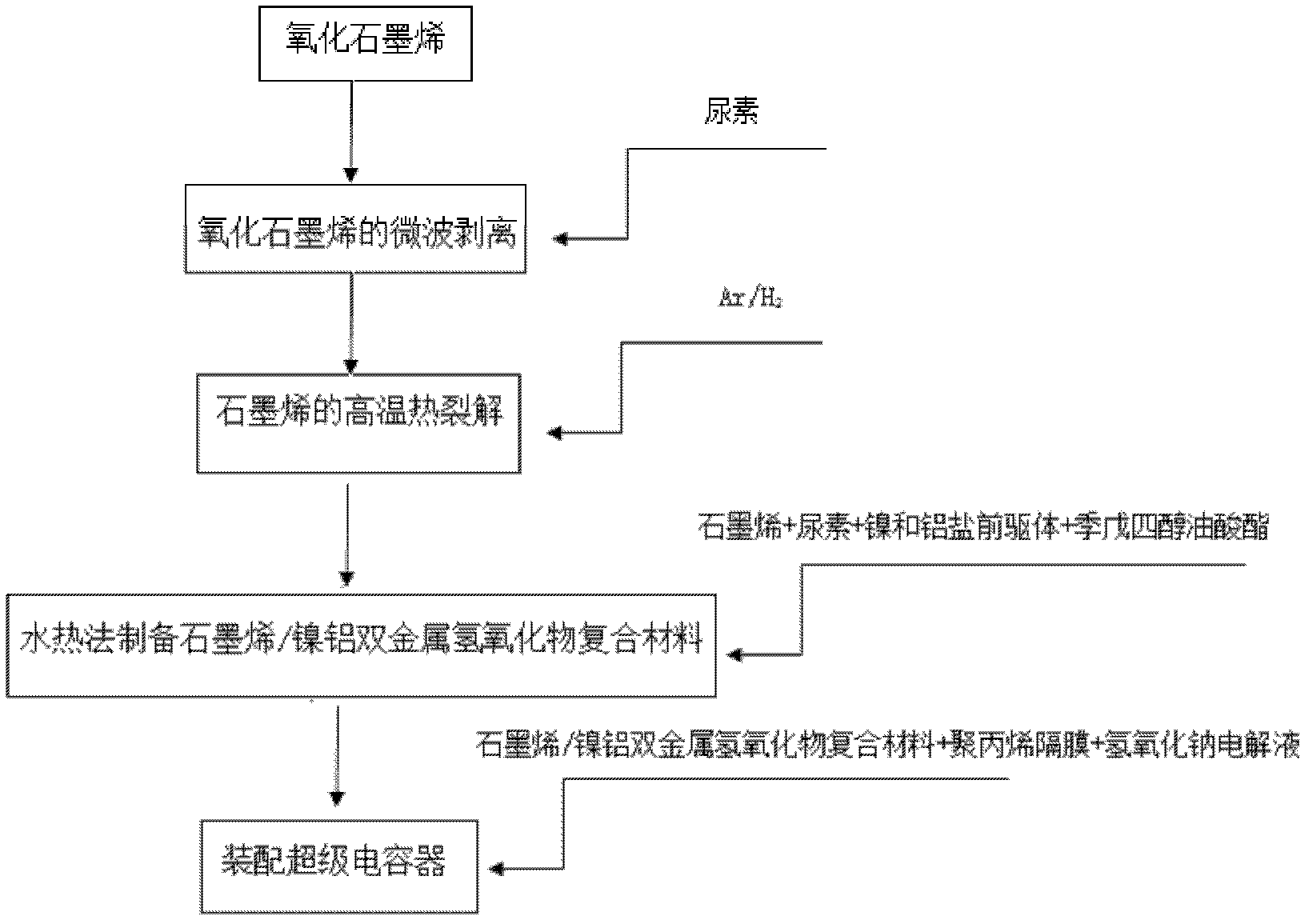

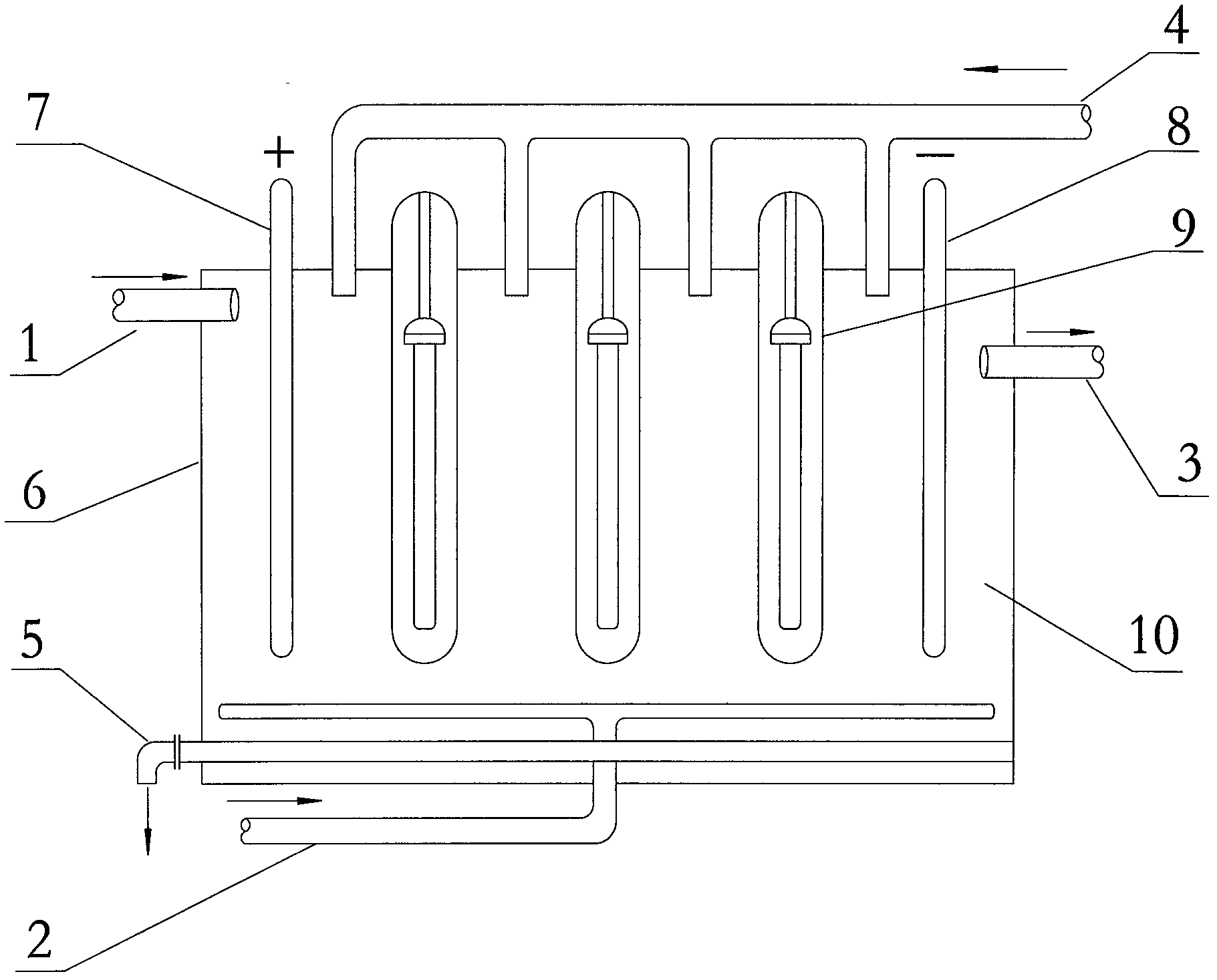

Preparation method of graphene/nickel-aluminum bi-metal hydroxide composite material and application thereof

ActiveCN102496480AGood electronic conductivityGood conductivityElectrolytic capacitorsCvd grapheneEnvironmental chemistry

The invention discloses a preparation method of a graphene / nickel-aluminum bi-metal hydroxide composite material and an application thereof, belonging to the technical field of electrochemistry. The preparation method comprises the following steps of: preparing a mixed solution by a stripping enhancer, oxidized graphene and deionized water, dispersing the mixed solution by ultrasonic wave; decompressing and filtering the mixed solution to obtain a filtering cake, and arranging the filtering cake into a household microwave oven to radiate; placing a graphene filtering cake into a tubular furnace, charging Ar / H2 mixed gas, and executing high-temperature thermal cracking; and adding an alkali source compound, nickel and aluminum salt precursors, a medium regulating agent and the deionized water to prepare a reactant mixing solution, and transferring the reactant mixing solution to a high-pressure reaction kettle to carry out a hydrothermal reaction, and finally obtaining the graphene / nickel-aluminum bi-metal hydroxide composite material. According to the preparation method of the graphene / nickel-aluminum bi-metal hydroxide composite material, disclosed by the invention, toxic chemical agents are not used at two steps of reduction of the graphene, thus damage on the health of a human body and environmental pollution because a large number of harmful chemical agents such as hydrazine hydrate and the like are taken as a strong reducing agent in a chemical reduction method can be eliminated fundamentally.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

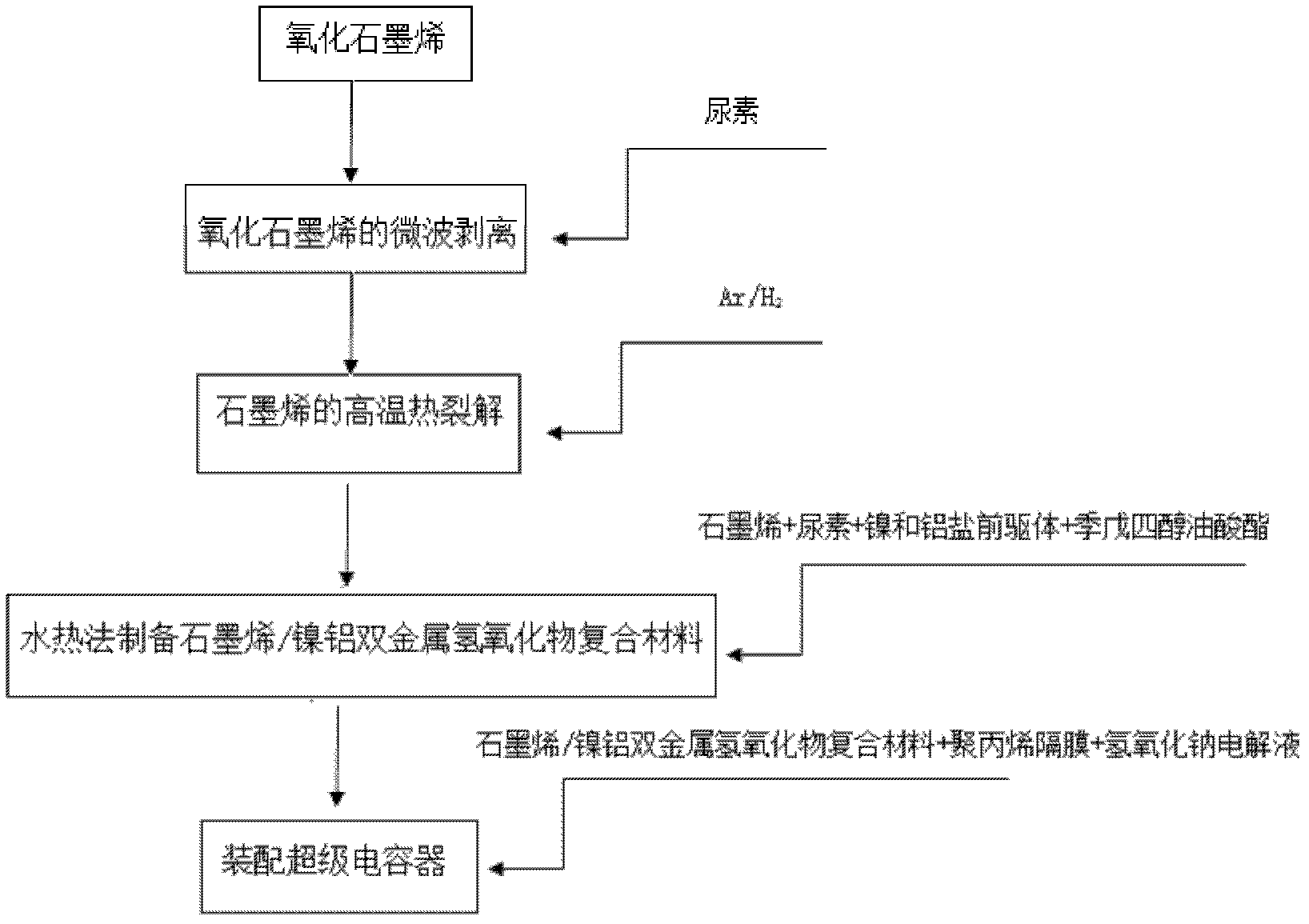

Device and method for treating high-salinity and degradation-resistant organic industrial waste water by performing photoelectrical synchro coupling and catalytic oxidation on three-dimensional particles

InactiveCN102874960AGood conductivityImprove photocatalytic activityMultistage water/sewage treatmentSurface coatingCatalytic oxidation

The invention discloses a device and a method for treating high-salinity and degradation-resistant organic industrial waste water by performing photoelectrical synchro coupling and catalytic oxidation on three-dimensional particles. An anode rod compounded with a titanium-based coating, a stainless steel cathode rod and ultraviolet source condensers are arranged in a reaction device, compressed air is introduced, a nano semiconductor oxide surface coating ceramic medium serving as a carrier is in a suspension state, a hydroxyl radical is formed on an anode under the synchro coupling action of electrolytic oxidation desalination and photo-catalytic oxidation in the alkaline environment, Cl<-> in waste water is oxidized on the anode to generate Cl2, the Cl2 spreads into a solution for hydrolysis to generate ClO<->, and the ClO<-> can oxidize organic matters in the waste water and desalt the waste water; under the action of the ultraviolet source condensers, organic pollutants in the waste water are degraded; and by a side reaction, namely an oxygen evolution reaction during electrolysis, high-density dissolved oxygen is generated, and a hydroxyl radical .[OH] is generated by reacting the dissolved oxygen with nano semiconductor oxide photoinduced electrons, so that the activity of photo-catalytic oxidation reaction is enhanced, the mineralization and removal rates of degradation-resistant organic impurities in the waste water are increased, and the process is easy and convenient to operate.

Owner:HUBEI ZHONGBI ENVIRONMENTAL PROTECTION TECHCO

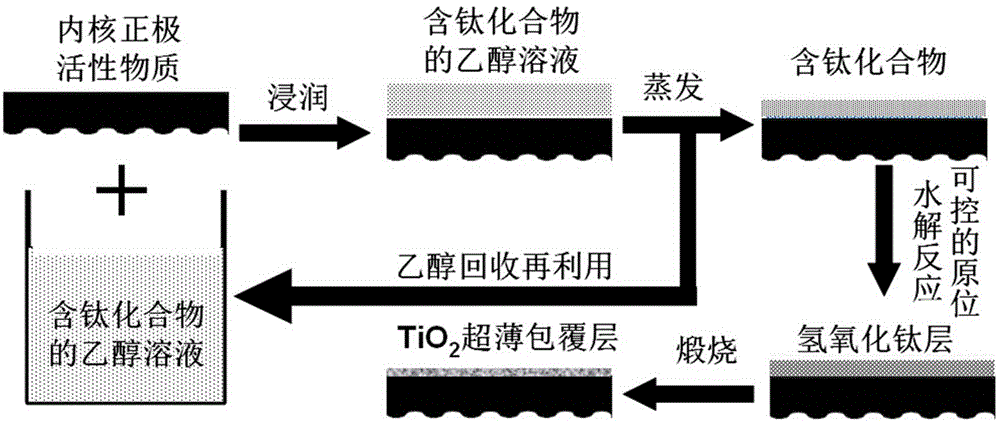

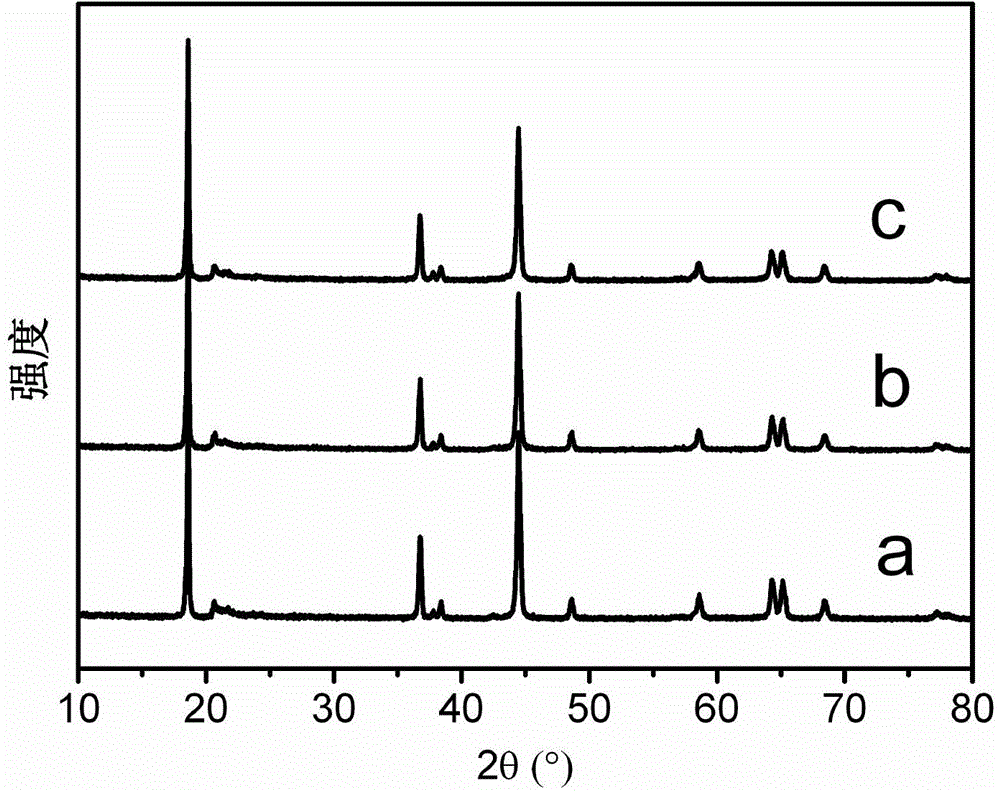

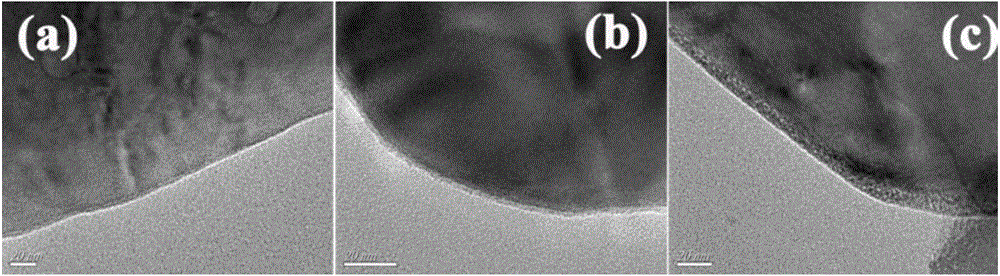

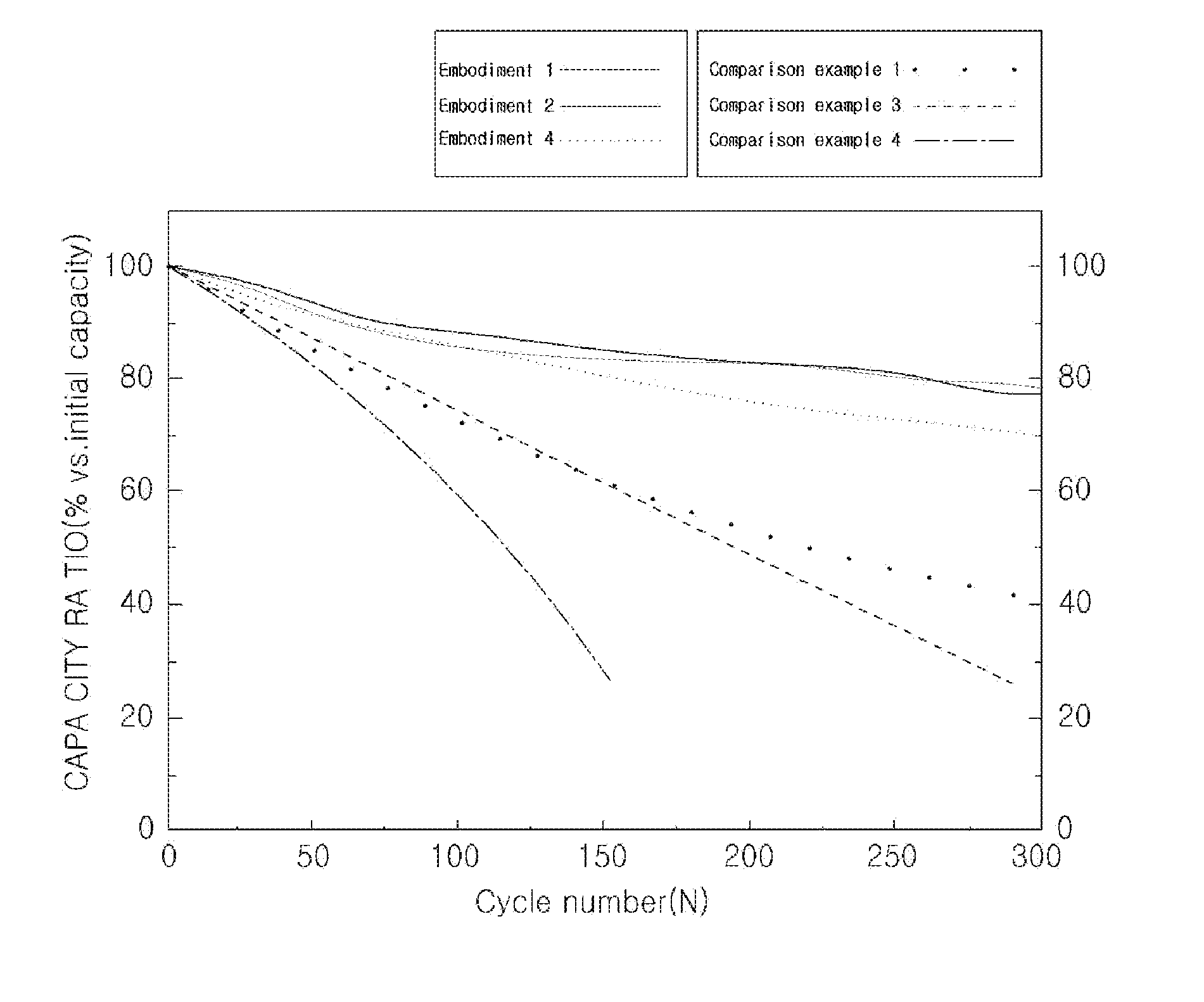

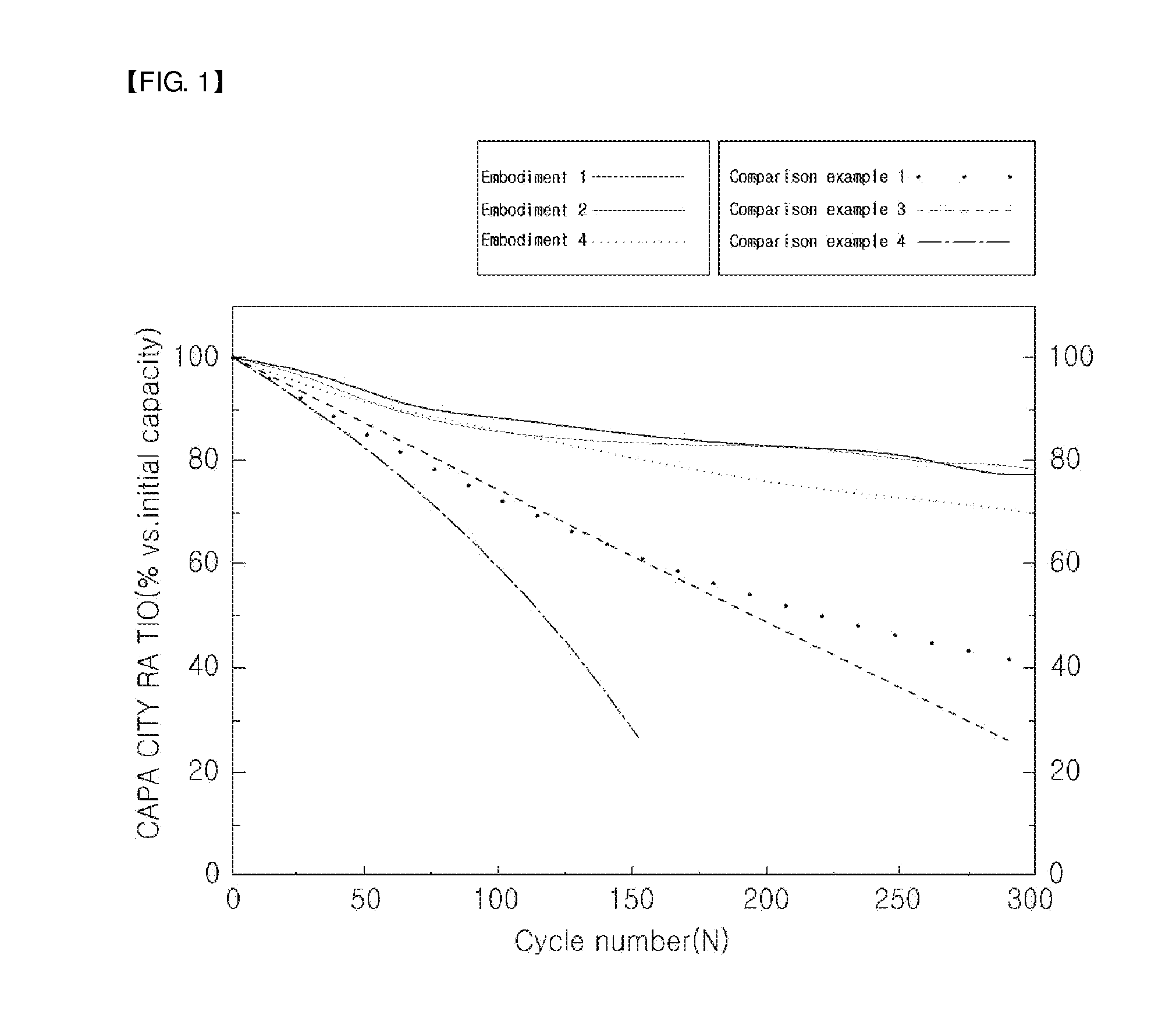

Ultrathin TiO2 coating layer of lithium battery cathode material, lithium battery cathode material and preparation method of lithium battery cathode material

ActiveCN104617267AGood conductivityLower polarization resistanceElectrode manufacturing processesSide reactionCalcination

The invention discloses an ultrathin TiO2 coating layer of a lithium battery cathode material. The coating layer is uniform and compact, and the thickness is only 0.5-20 nm. The lithium battery cathode material with a core-shell type coating structure comprises an inner-core cathode active material and the externally coated ultrathin TiO2 coating layer, wherein a mole ratio of Ti in the coating layer to a transition metal element in the inner-core cathode active material is 0.01%-3%. A preparation method of the lithium battery cathode material comprises steps as follows: a titanium contained compound is dissolved in an organic solvent; the inner-core cathode active material is added to the solution and stirred rapidly, the organic solvent is removed through heating, dry powder is obtained and is placed in dry air for standing to have in-situ hydrolysation with water molecules in air slowly and controllably, and intermediate powder is obtained and placed in an aerobic environment for calcination so as to obtain the lithium battery cathode material. The side reaction between the active material and electrolyte can be effectively inhibited, and the rate capability and the cycle performance of the lithium battery cathode material are improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Lithium secondary battery including water-dispersible binder, conduction agent, and fluoroethylenecarbonate

ActiveUS20110091775A1Improve featuresLarge capacityOrganic electrolyte cellsNegative electrodesWater dispersibleEngineering

The present invention relates to a lithium secondary battery. The present invention provides the lithium secondary battery including a positive electrode, a negative electrode, and a non-aqueous electrolyte solution. The negative electrode includes a water-dispersible binder and a conduction agent. The non-aqueous electrolyte solution includes fluoroethylenecarbonate (FEC). The batteries of the present invention are advantageous in that they have a high efficiency charging lifespan characteristic and enable high capacity charging in a short time.

Owner:LG ENERGY SOLUTION LTD

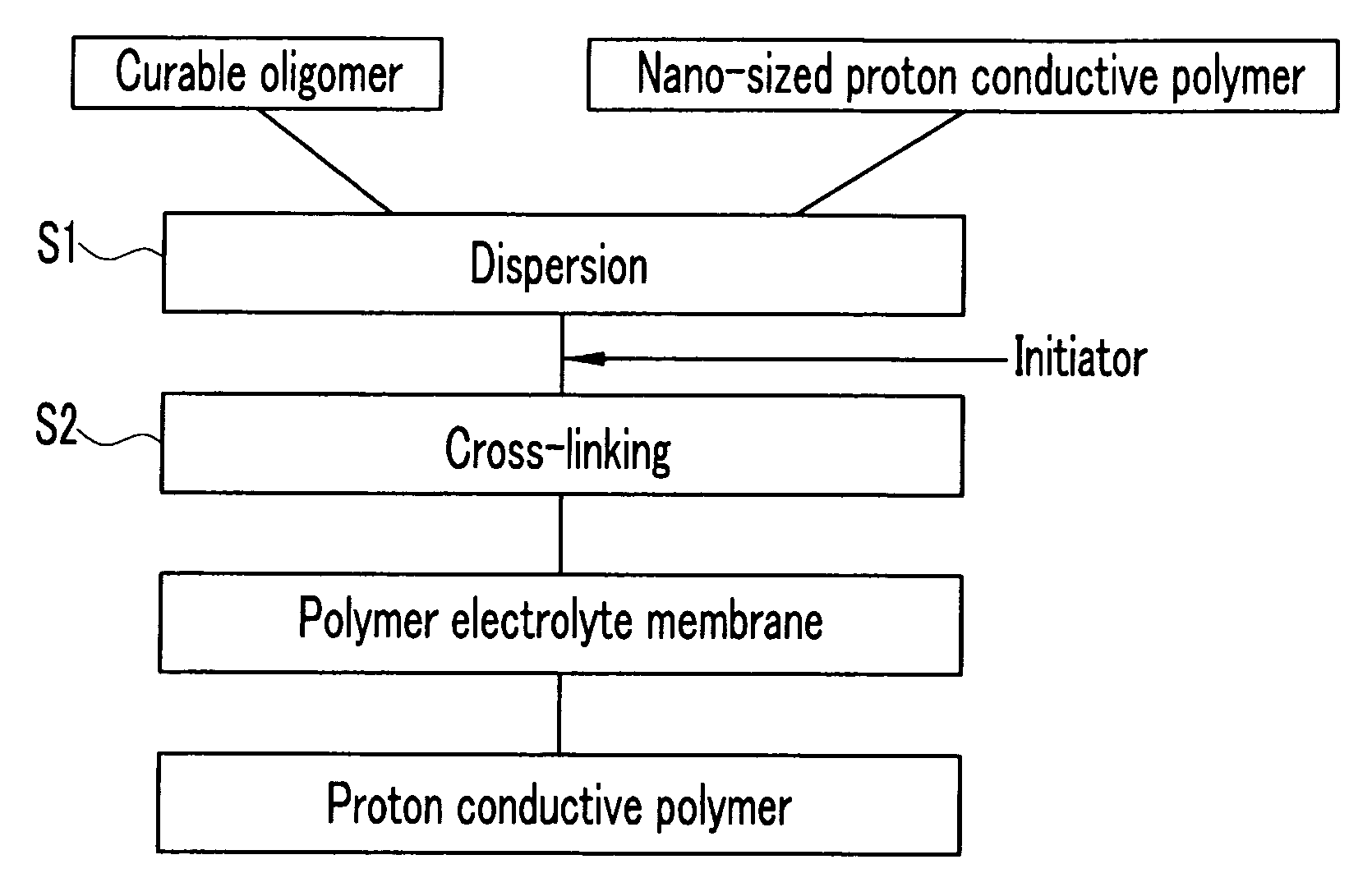

Polymer electrolyte membrane for fuel cell and fuel cell system including the same

InactiveUS20070122676A1Improve strength propertiesGood conductivityMaterial nanotechnologyElectrolyte holding meansHydrocarbonPolymer electrolytes

A polymer electrolyte membrane for a fuel cell includes a polymer matrix comprising a cross-linked curable oligomer with nano-sized proton conductive polymer particles in the polymer matrix. The curable oligomer may include unsaturated functional groups at each end of a chain, and may further include 3 to 14 ethylene oxides. The proton conductive polymer nano particles may include fluorine-based proton conductive polymer nano particles, non-fluorine-based proton conductive polymer nano particles, hydrocarbon-based proton conductive polymer nano particles, and combinations.

Owner:SAMSUNG SDI CO LTD

Surround gate access transistors with grown ultra-thin bodies

ActiveUS20070066019A1Good conductivityAvoid difficultySolid-state devicesSemiconductor/solid-state device manufacturingLateral asymmetryBit line

Owner:MICRON TECH INC

Conductive paste

ActiveUS20140326929A1Good precisionImprove conductivityConductive materialNon-conductive material with dispersed conductive materialConductive pasteSaturated fatty acid

A conductive paste is provided, which includes 3 wt % to 20 wt % of epoxy resin, 10 wt % to 25 wt % of solvent, 0.3 wt % to 5 wt % of latent curing agent, 3.5 wt % to 35 wt % of flaky metal powder surface-treated by saturated fatty acid, and 35 wt % to 75 wt % of flaky metal powder surface-treated by unsaturated fatty acid.

Owner:RUYUAN WEI AN PHARM CO LTD

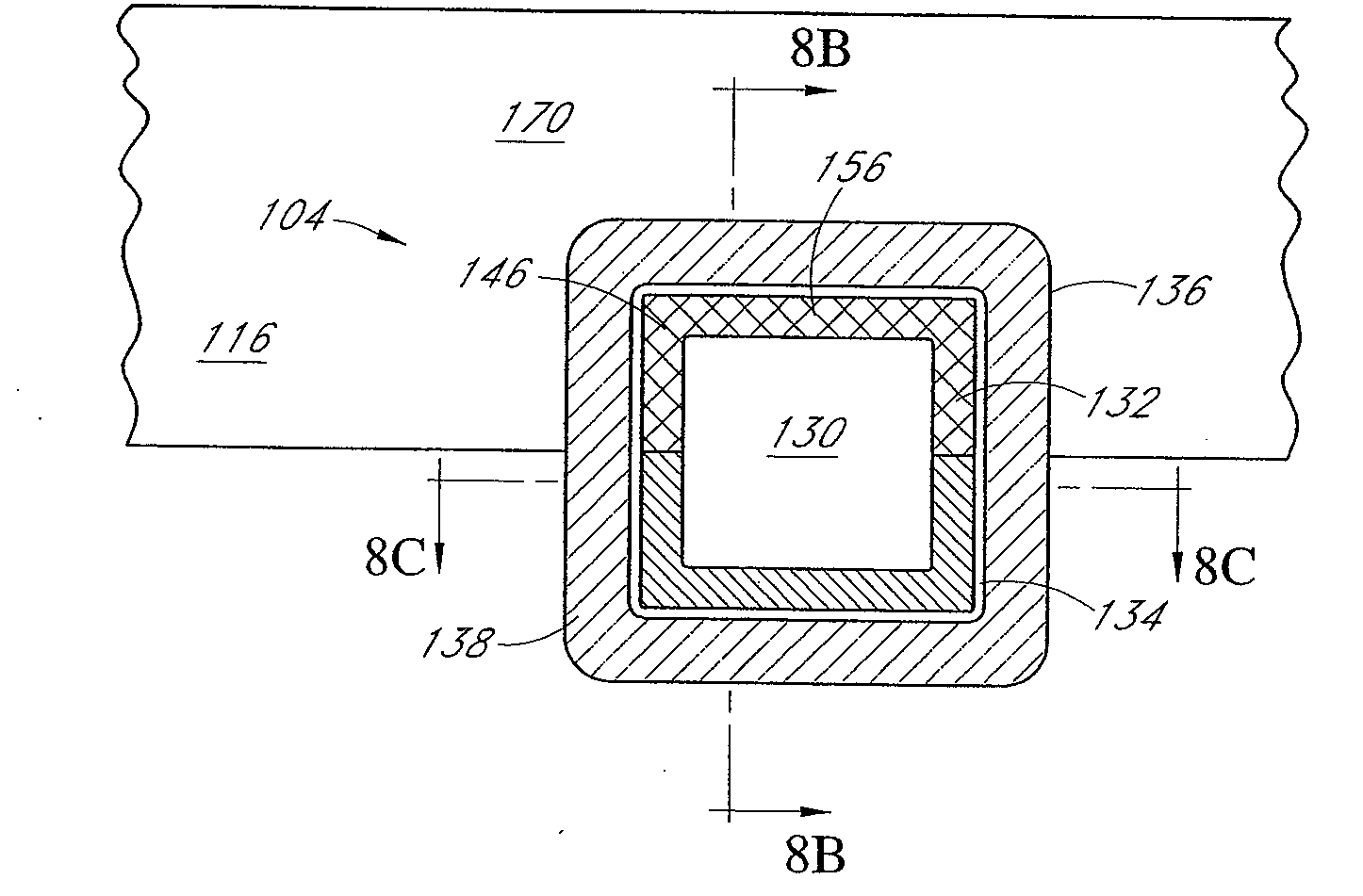

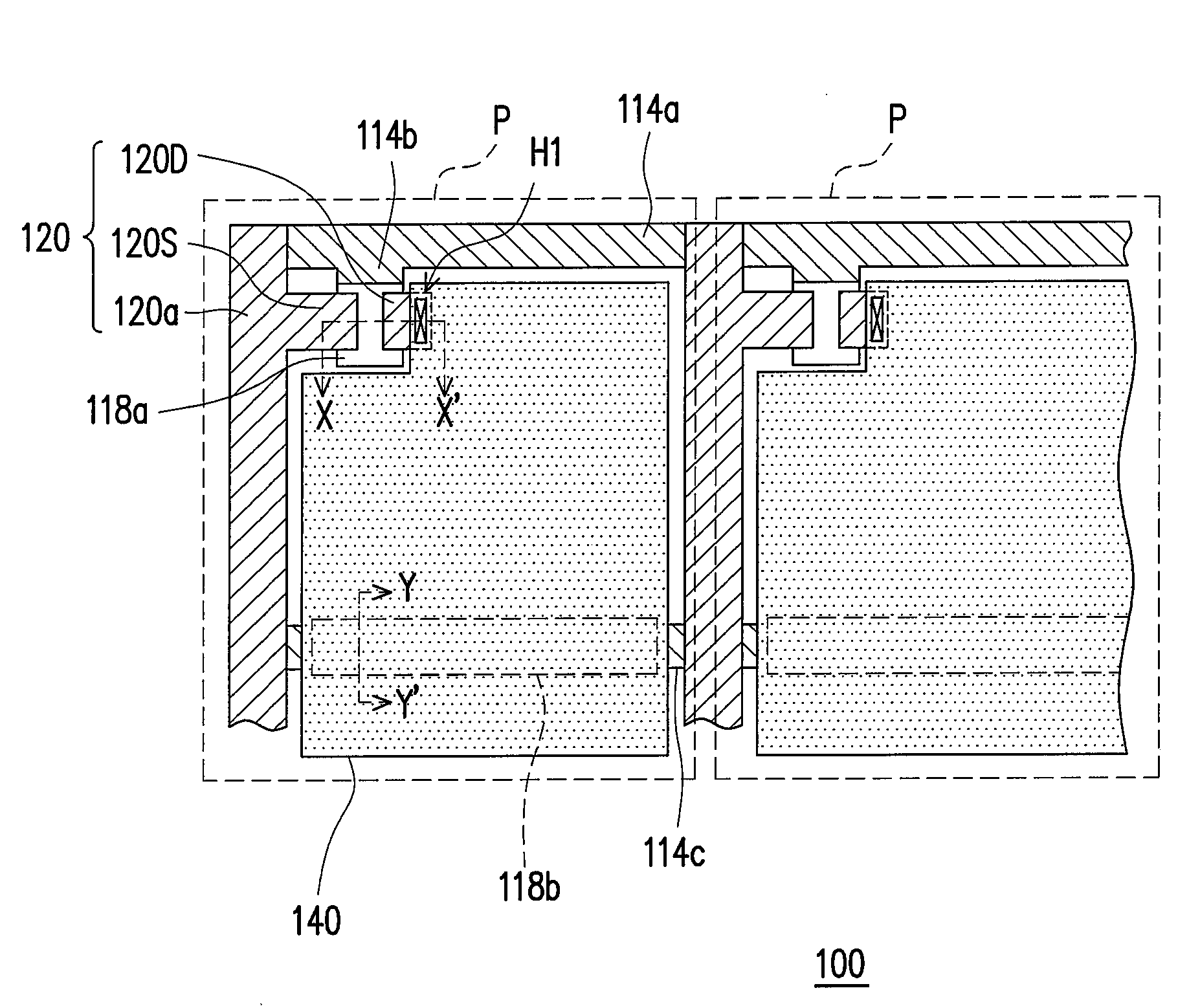

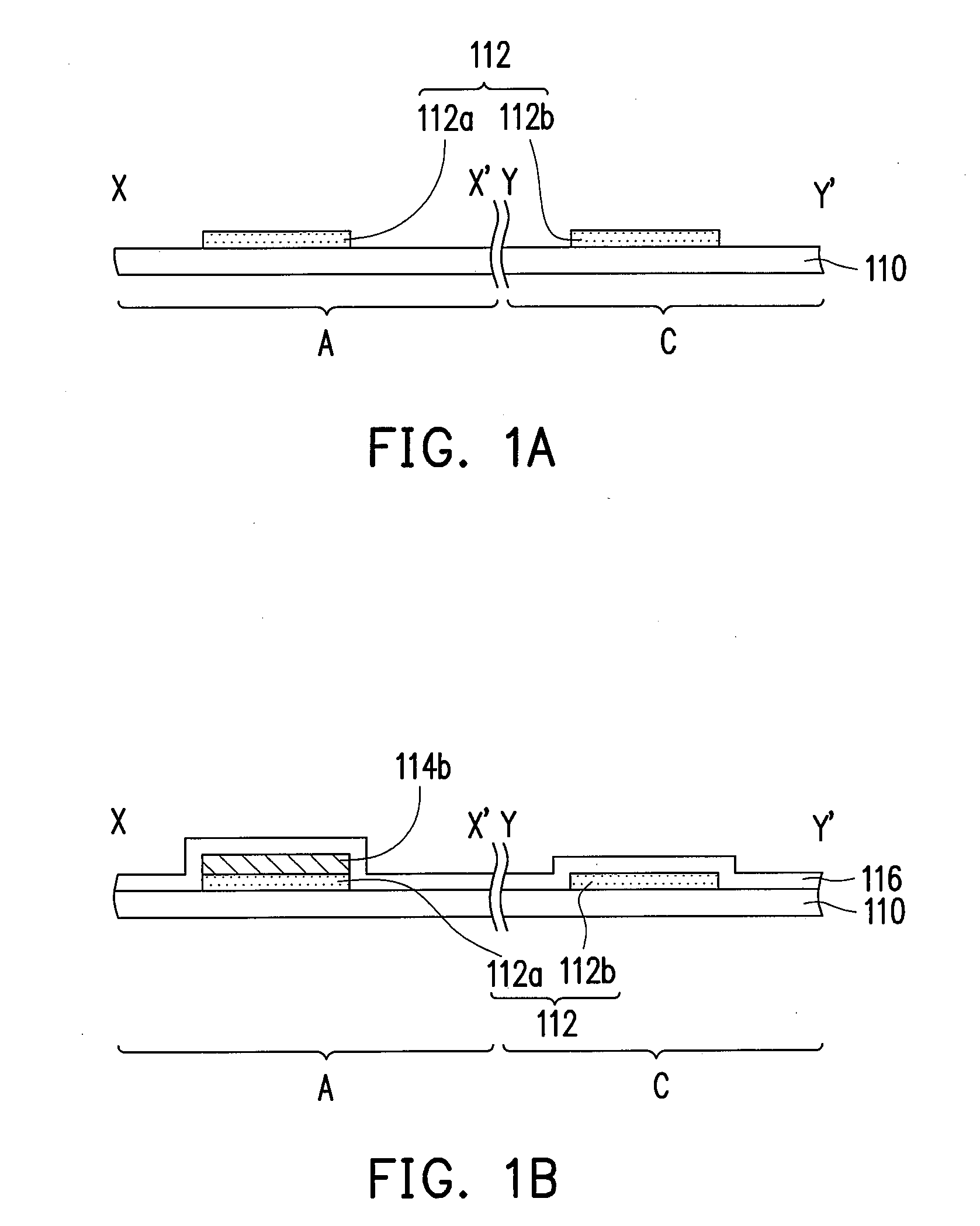

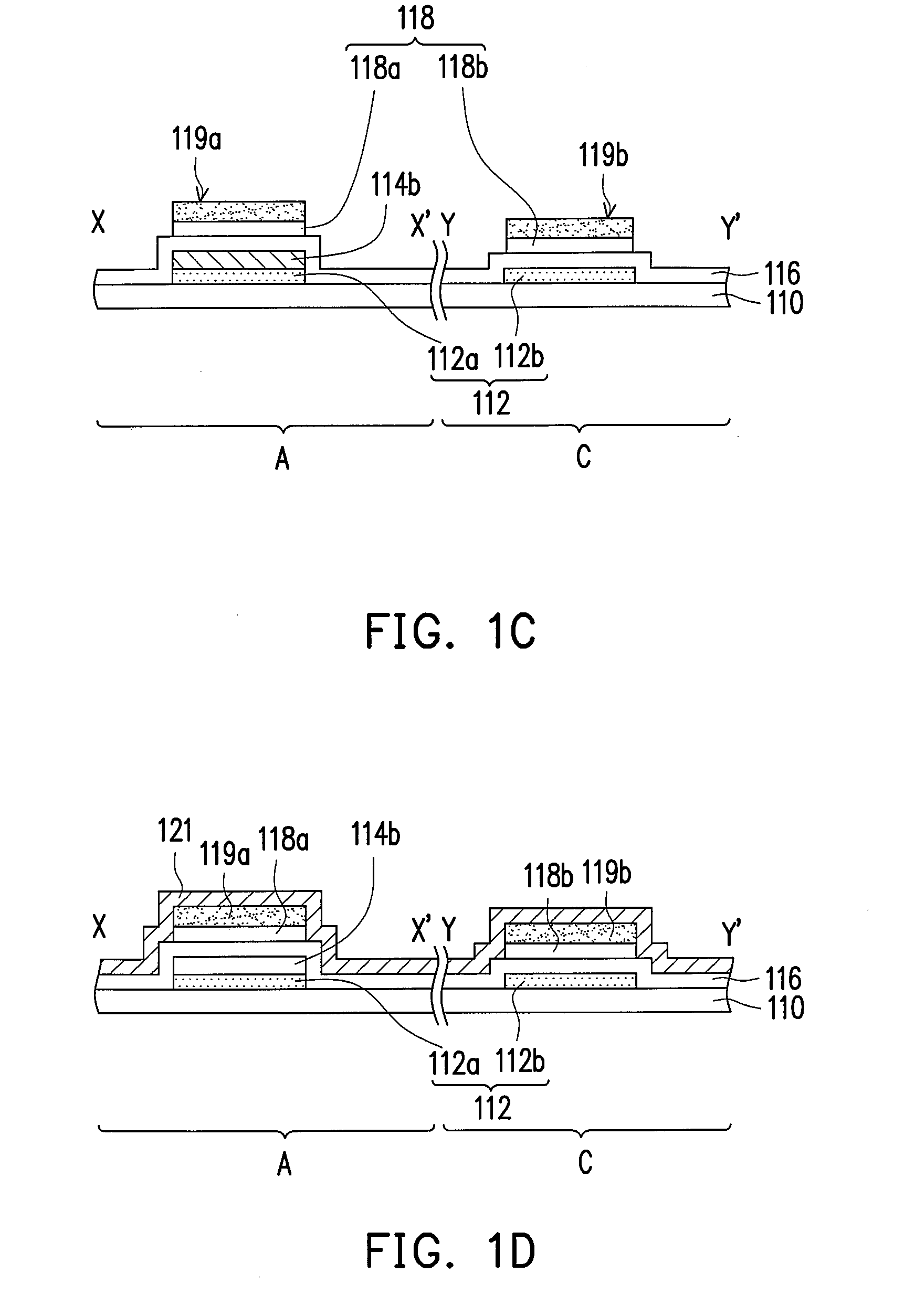

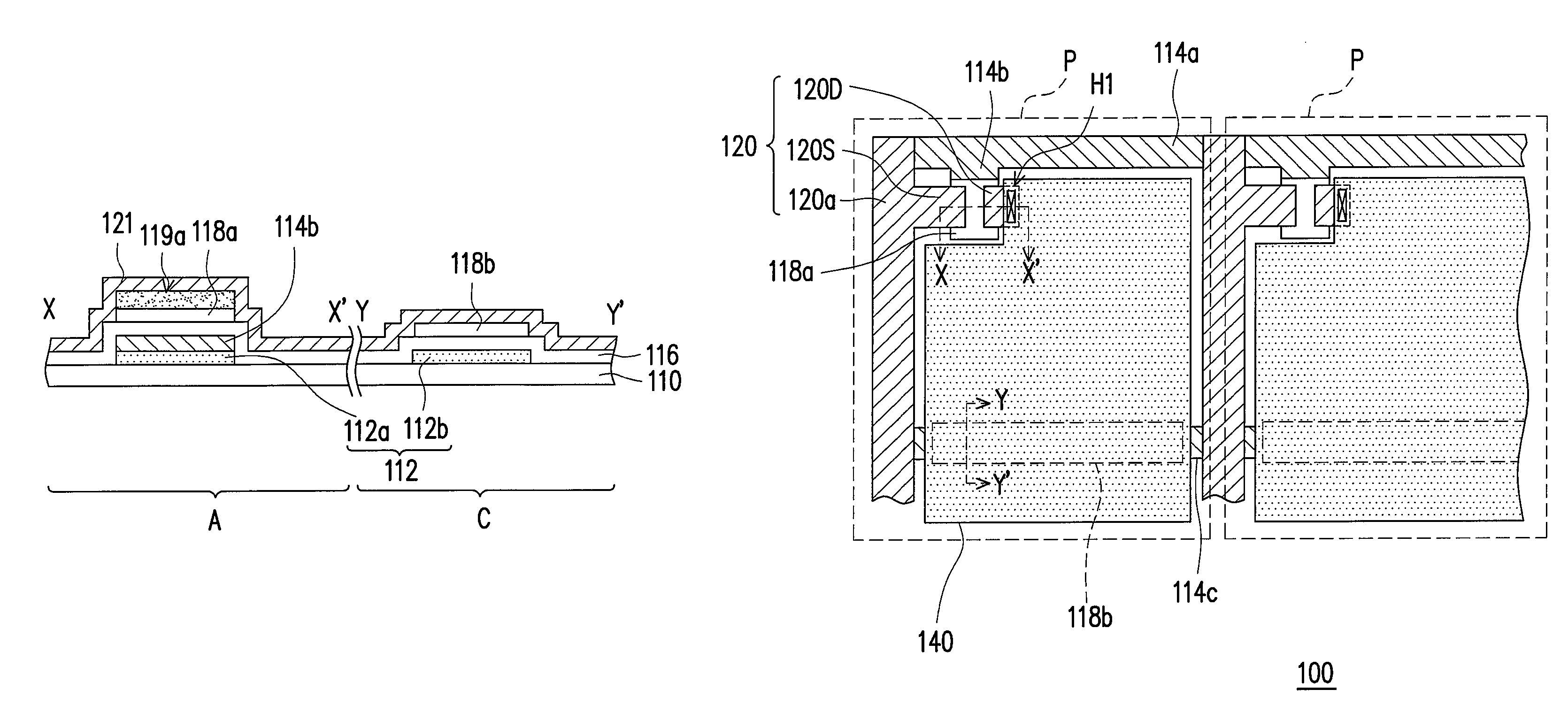

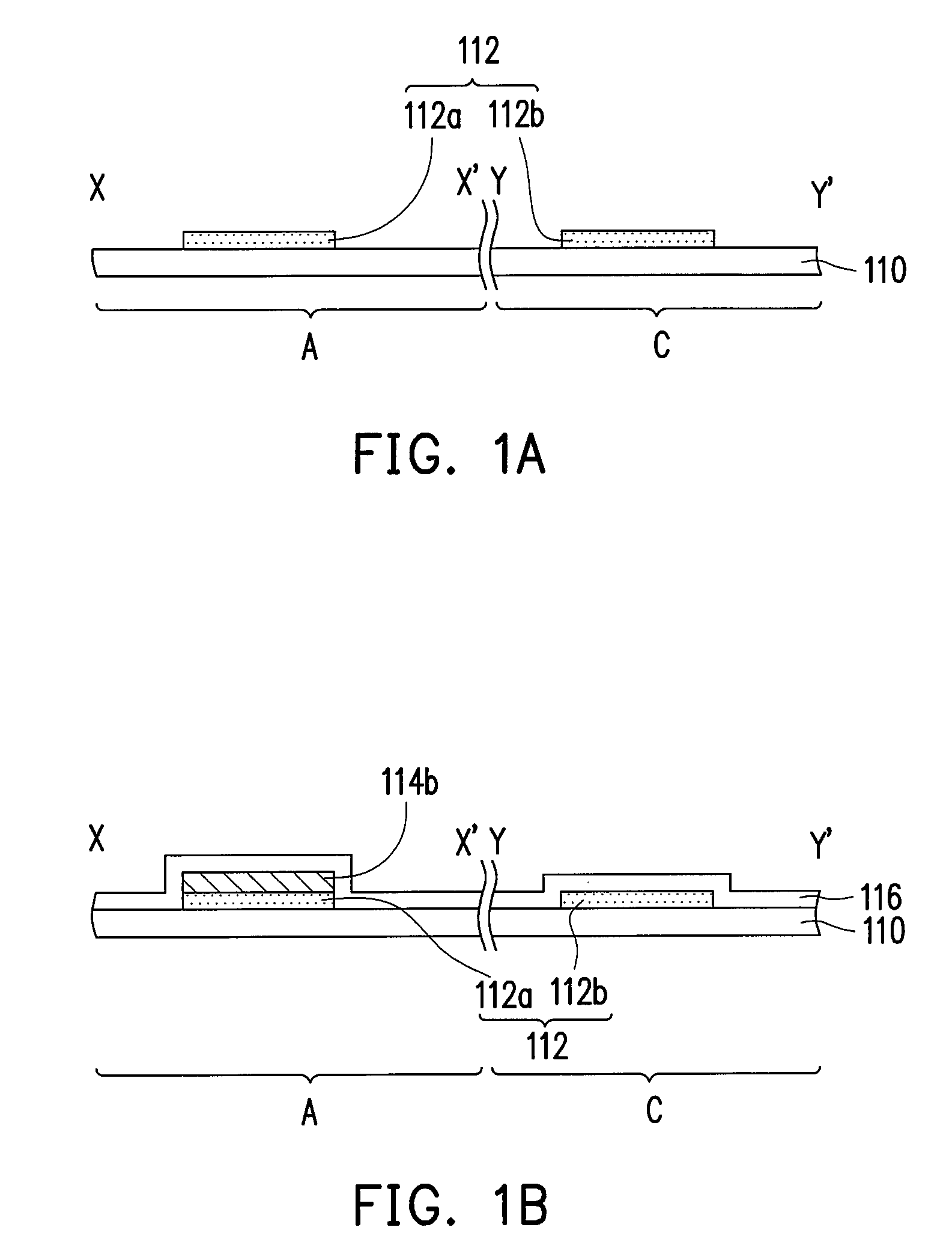

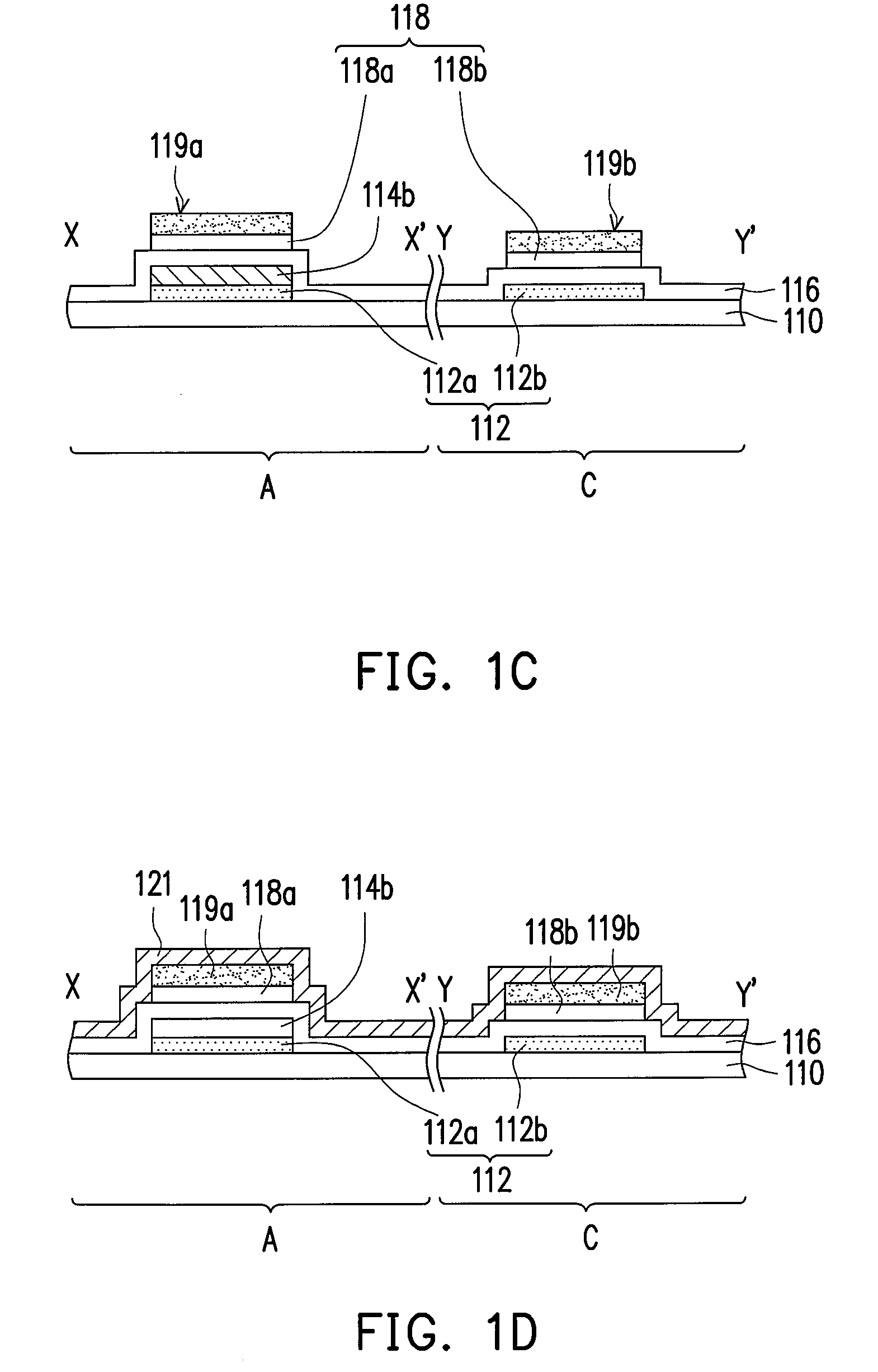

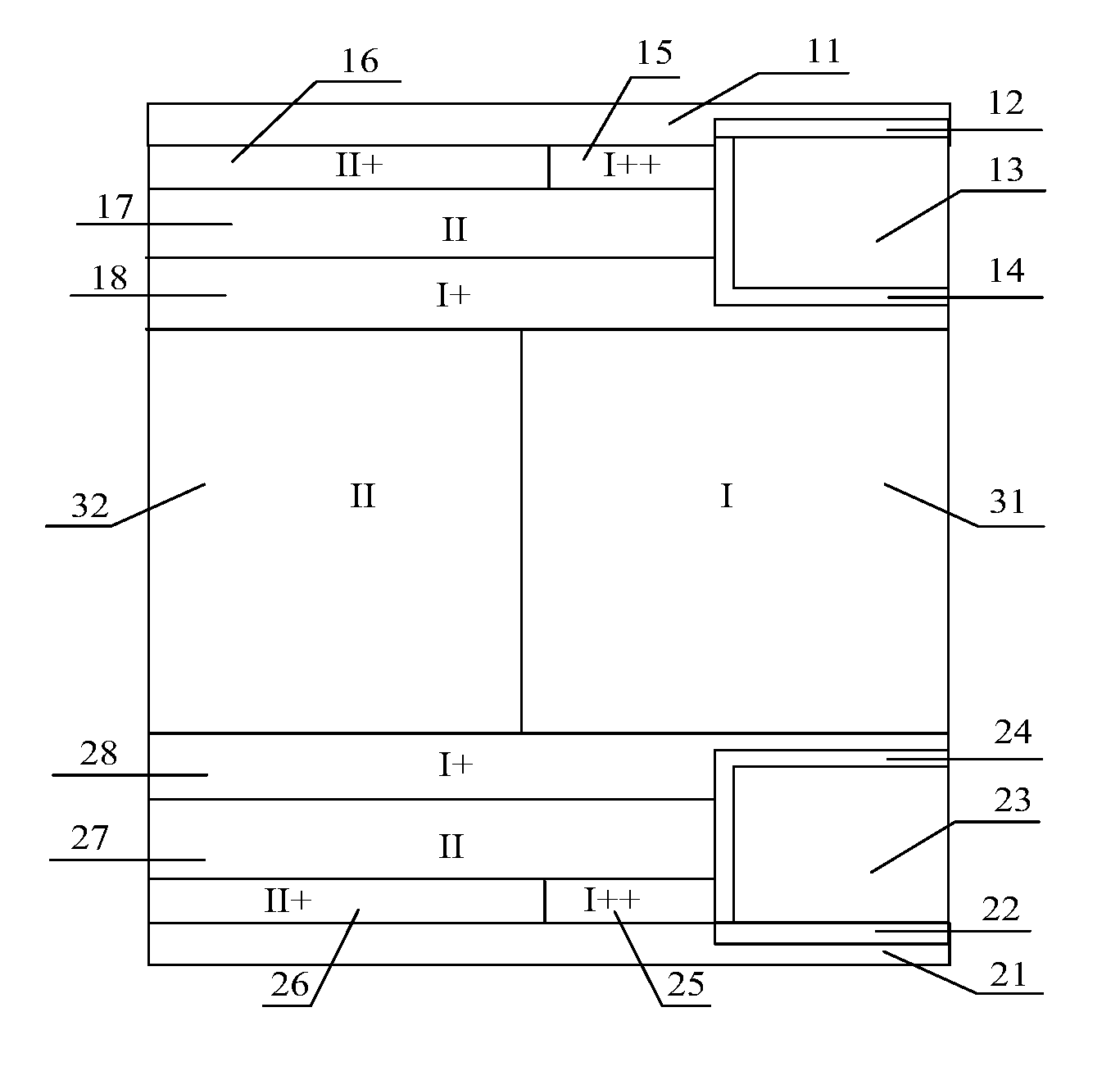

Thin film transistor array substrate and fbricating method thereof

ActiveUS20080111132A1Solve many processesSimplify the manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerScan line

A thin film transistor array substrate and a fabricating method thereof are disclosed. First, a substrate is provided. A patterned transparent conductive layer is then formed on the substrate. Next, a patterned first metal layer is formed to form a plurality of scan lines and a plurality of gates. Thereafter, a gate insulation layer is formed over the substrate. Moreover, a patterned semiconductor layer is formed to form a channel layer above the gates. The semiconductor layer is patterned with the same mask as that for patterning the transparent conductive layer. Additionally, a patterned second metal layer is formed to form a plurality of data lines, a plurality of sources, and a plurality of drains. After that, a dielectric layer is formed over the substrate. Finally, pixel electrodes are formed on the dielectric layer.

Owner:AU OPTRONICS CORP

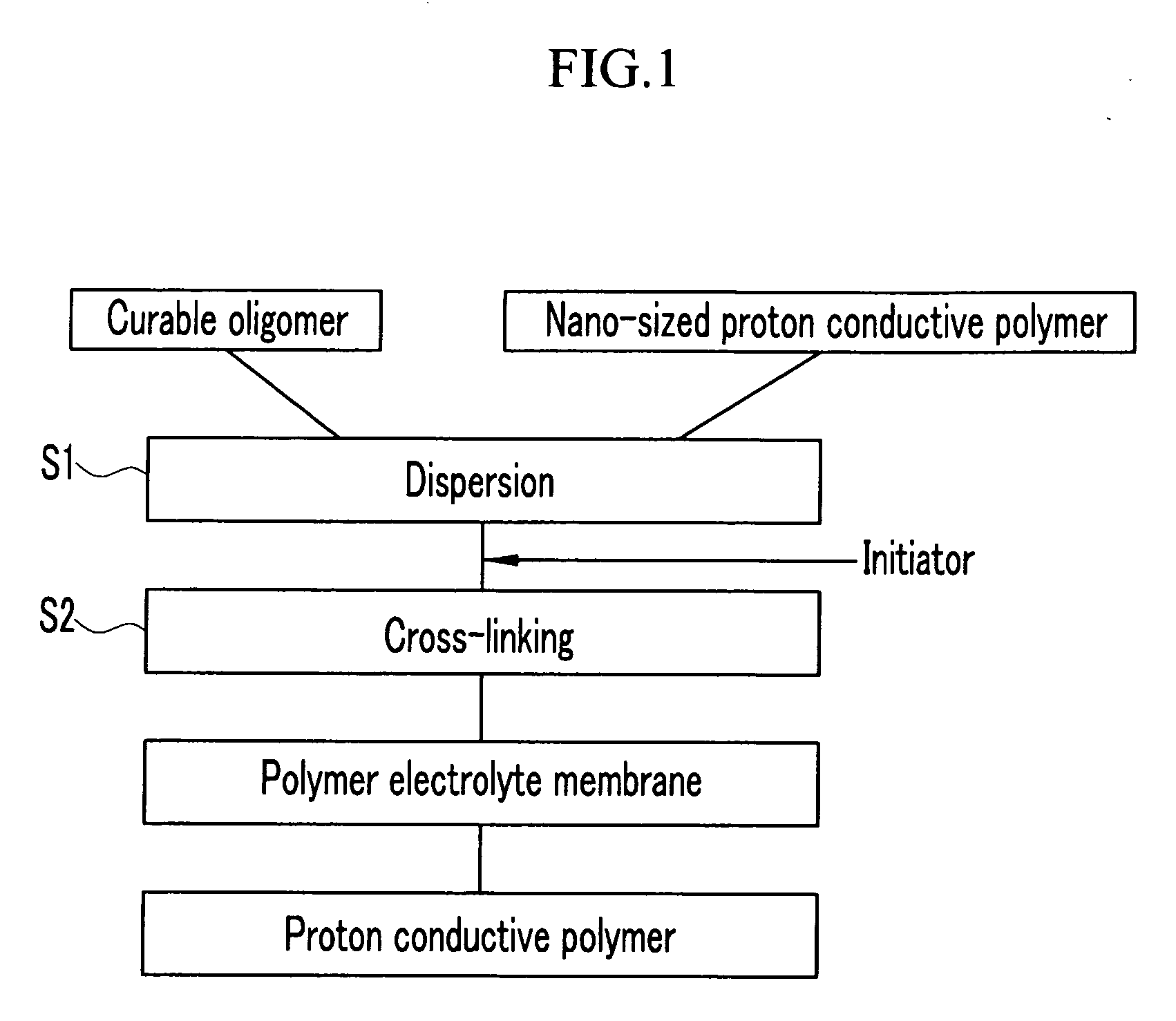

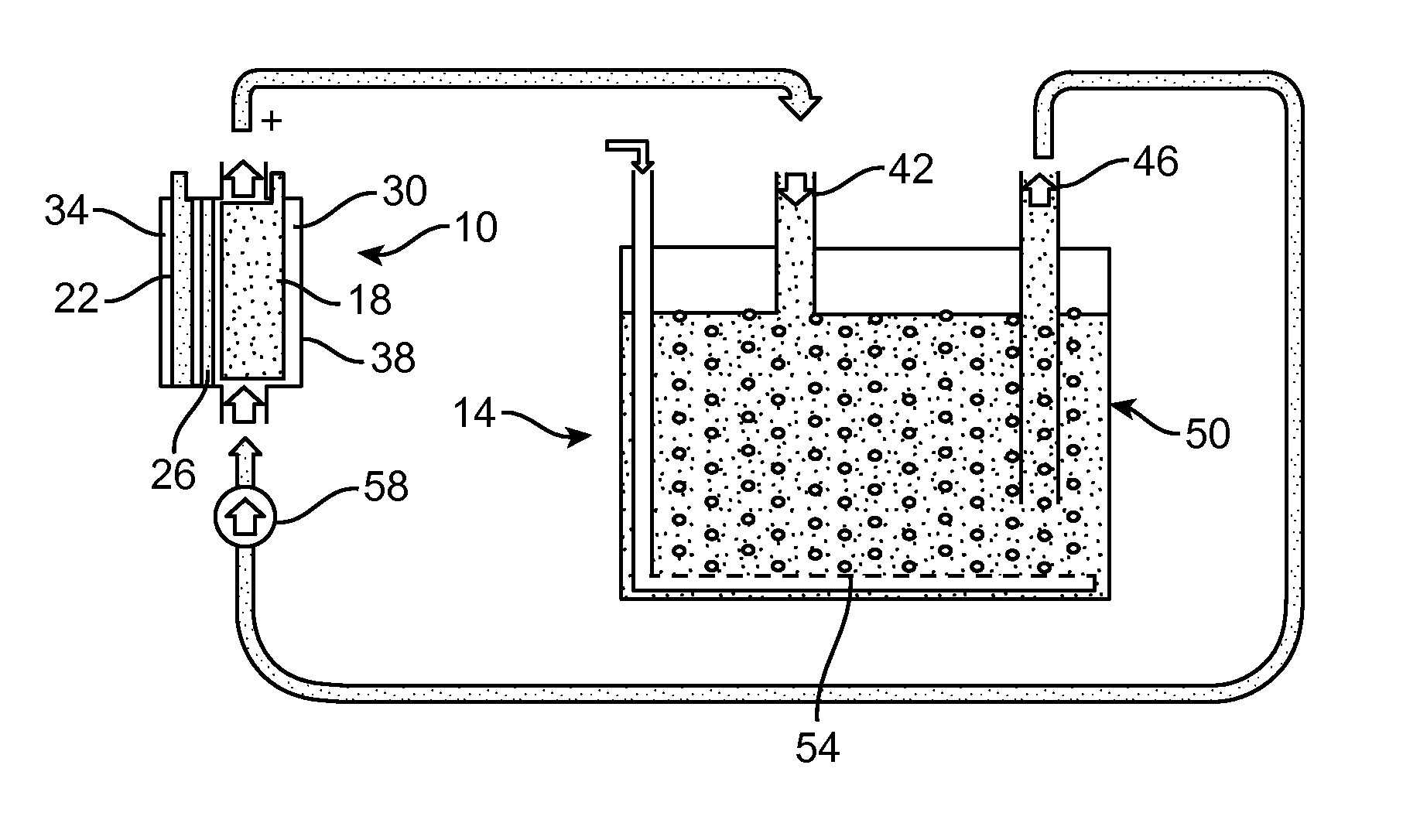

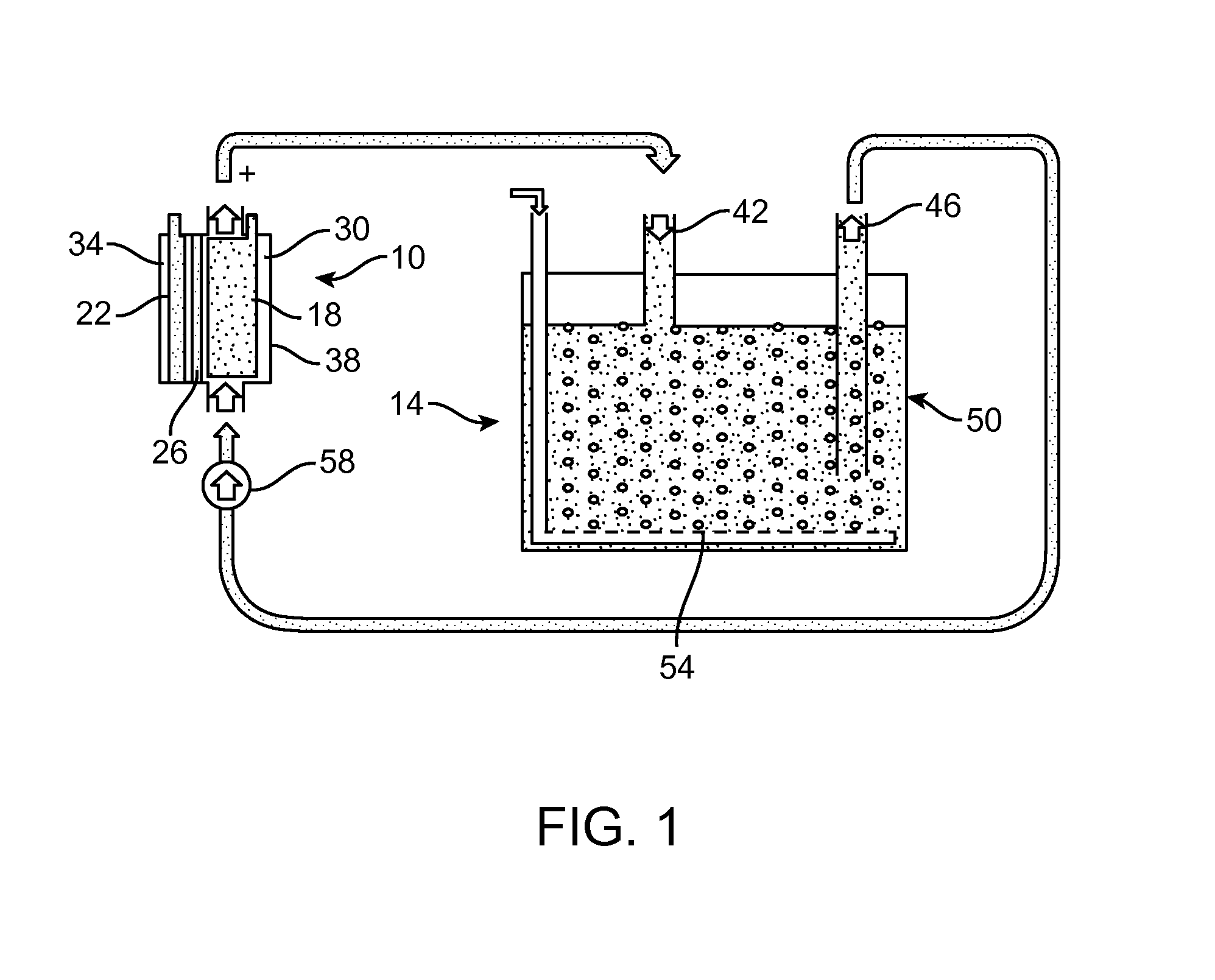

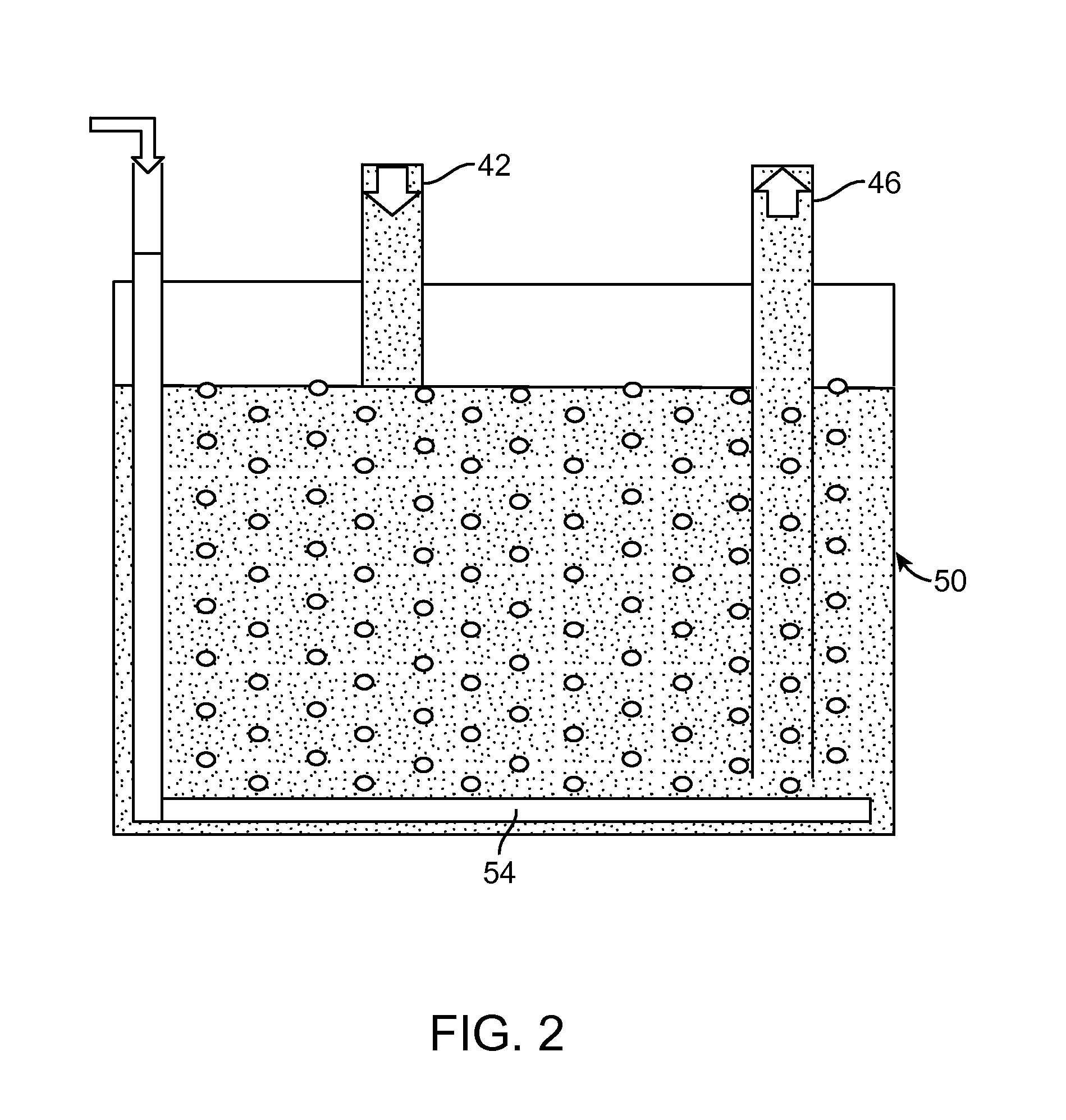

Metal-air flow batteries using oxygen enriched electrolyte

ActiveUS20150125763A1Good conductivityGood chemical stabilityElectrolyte moving arrangementsFuel and secondary cellsElectrochemical responseElectrochemistry

A metal air flow battery includes an electrochemical reaction unit and an oxygen exchange unit. The electrochemical reaction unit includes an anode electrode, a cathode electrode, and an ionic conductive membrane between the anode and the cathode, an anode electrolyte, and a cathode electrolyte. The oxygen exchange unit contacts the cathode electrolyte with oxygen separate from the electrochemical reaction unit. At least one pump is provided for pumping cathode electrolyte between the electrochemical reaction unit and the oxygen exchange unit. A method for producing an electrical current is also disclosed.

Owner:FLORIDA STATE UNIV RES FOUND INC

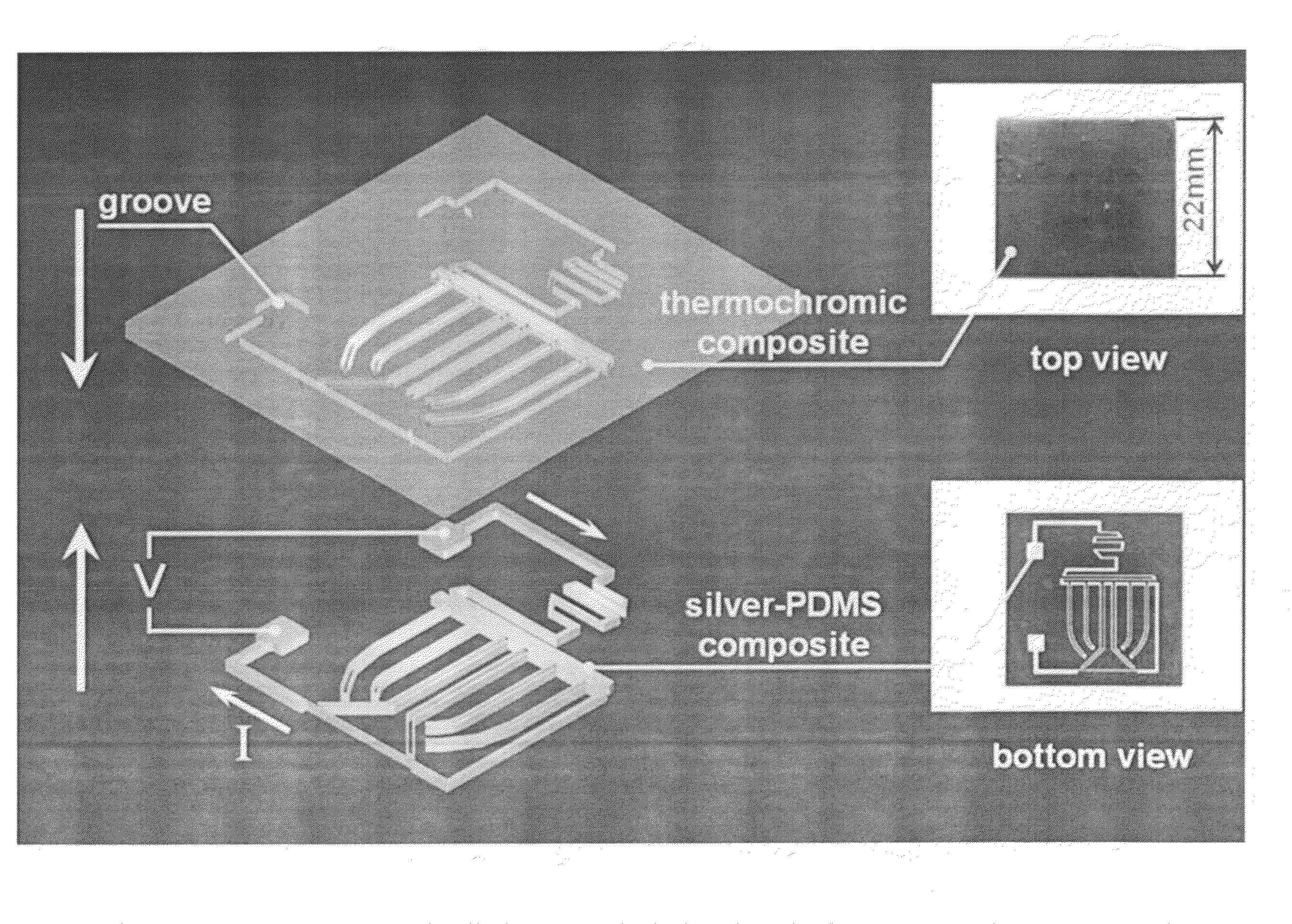

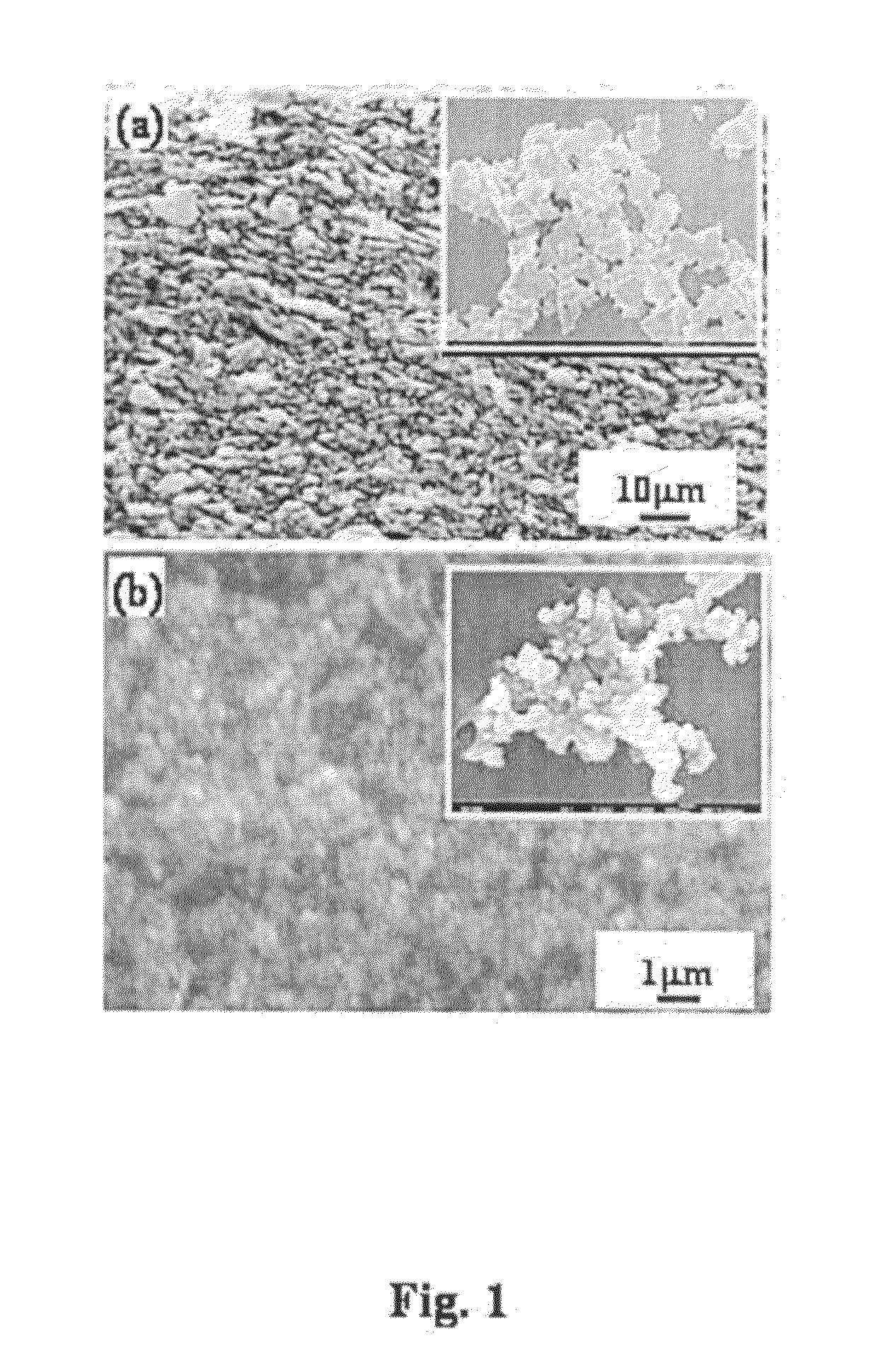

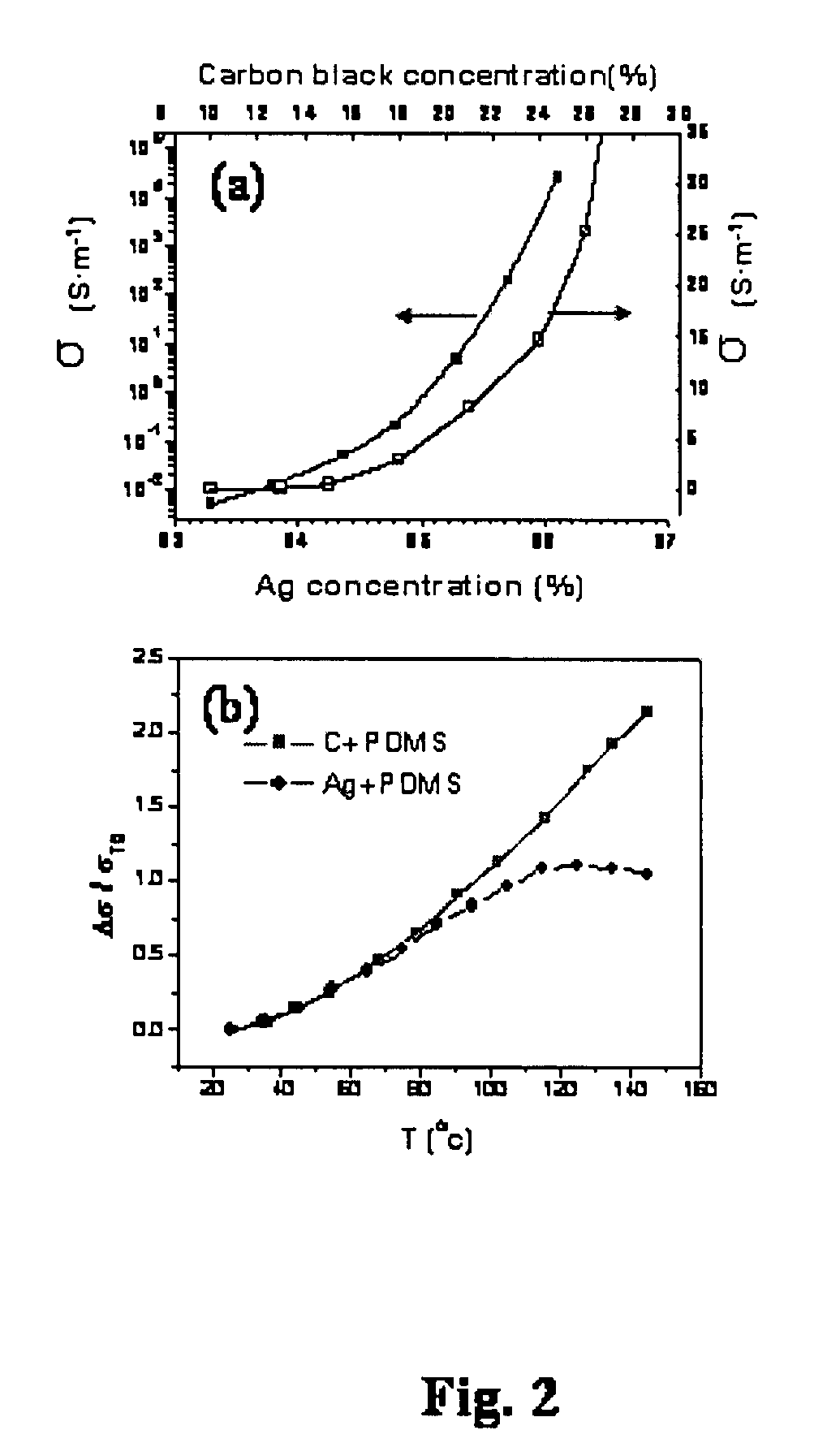

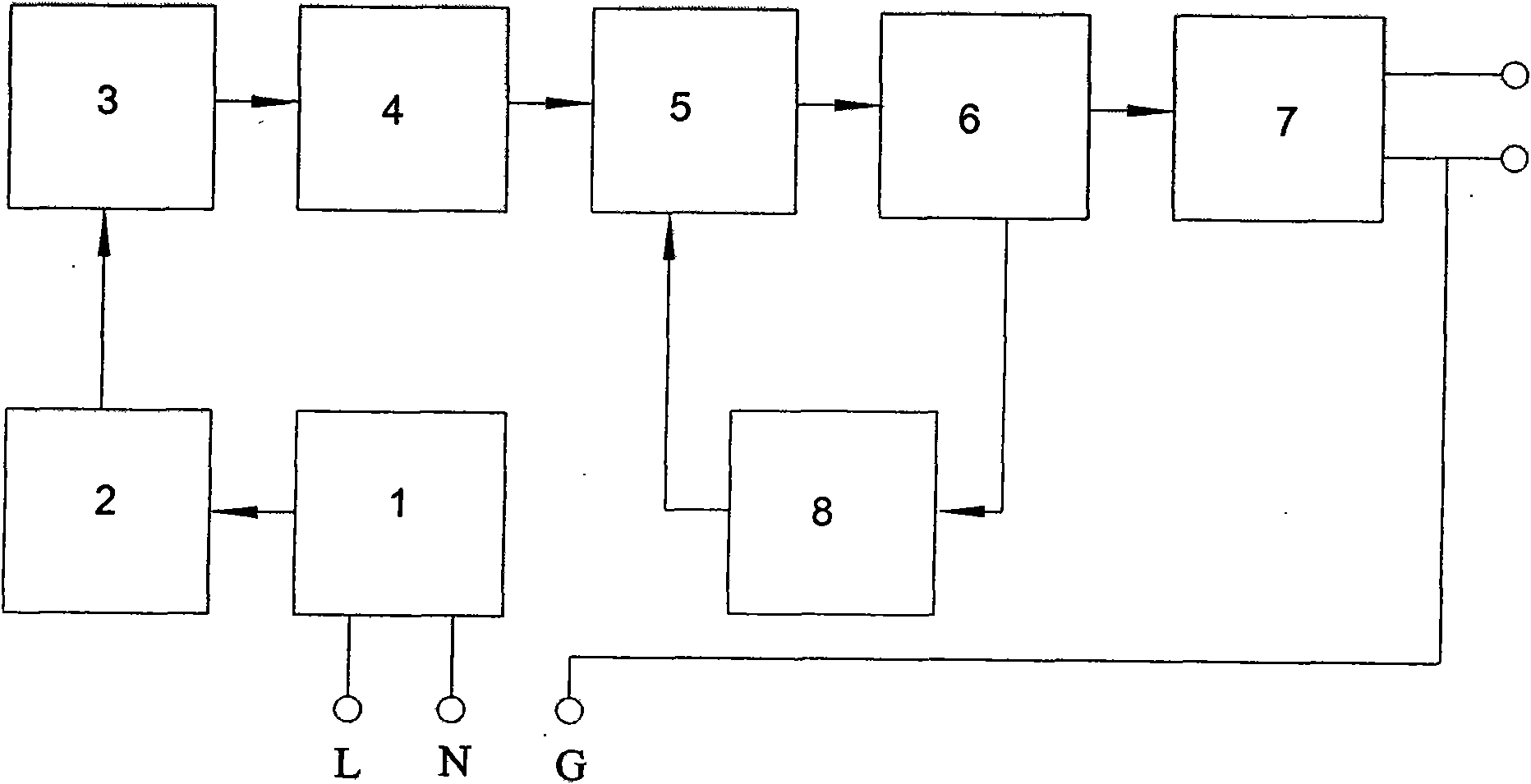

Constructing planar and three-dimensional microstructures with PMDS-based conducting composite

ActiveUS20080123174A1Good conductivityReliable mechanical propertiesLayered productsConductive materialNanometreEngineering

We present an invention on the synthesis of elastic, bio-compatible functional microstructures wherein the designed electrical functionalities are achieved by mixing conducting nano to micro-particles with PDMS gels. The methodology for constructing planar and three-dimensional microstructures by soft-lithographic technique is presented. Applications such as electrodes, conducting strips, two and three-dimensional microstructures for electrical wiring connections, micro heaters, micro heater arrays, flexible thermochromic displays, and applications for microfluidic devices are demonstrated, all with demonstrated elastic flexibility and fall-proof characteristics while maintaining their functionalities. Results obtained are very promising for the utilization of such composites in future micro-fabrications, especially for the bio-chips and microfluidic devices.

Owner:THE HONG KONG UNIV OF SCI & TECH

Conductive paste

InactiveUS20090020733A1Good conductivityExcellent connection reliabilityConductive materialNon-conductive material with dispersed conductive materialOptoelectronicsConductive paste

A conductive paste that includes a binder containing a thermosetting resin and conductive particles, in which the lowest exothermic peak temperature T1 (degrees C.) among at least one exothermic peak obtained by differential scanning calorimetry of the binder and the lowest endothermic peak temperature t1 (degrees C.) among at least one endothermic peak obtained by differential scanning calorimetry of the conductive particles satisfy the relation t1−20<T1 . . . (1), thereby achieving good conductivity and excellent conductive connection reliability.

Owner:ASAHI KASEI E-MATERIALS CORPORATION +1

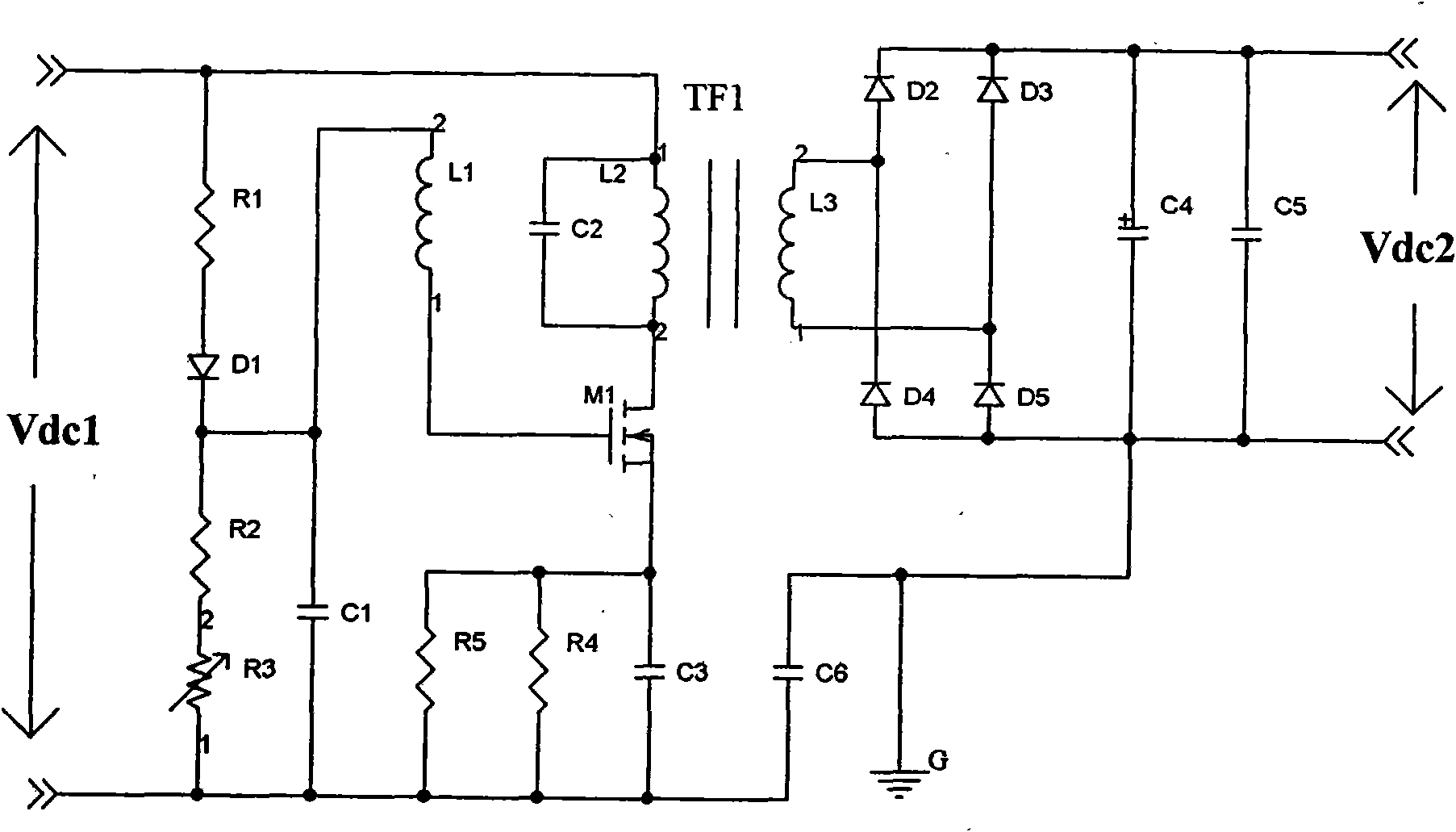

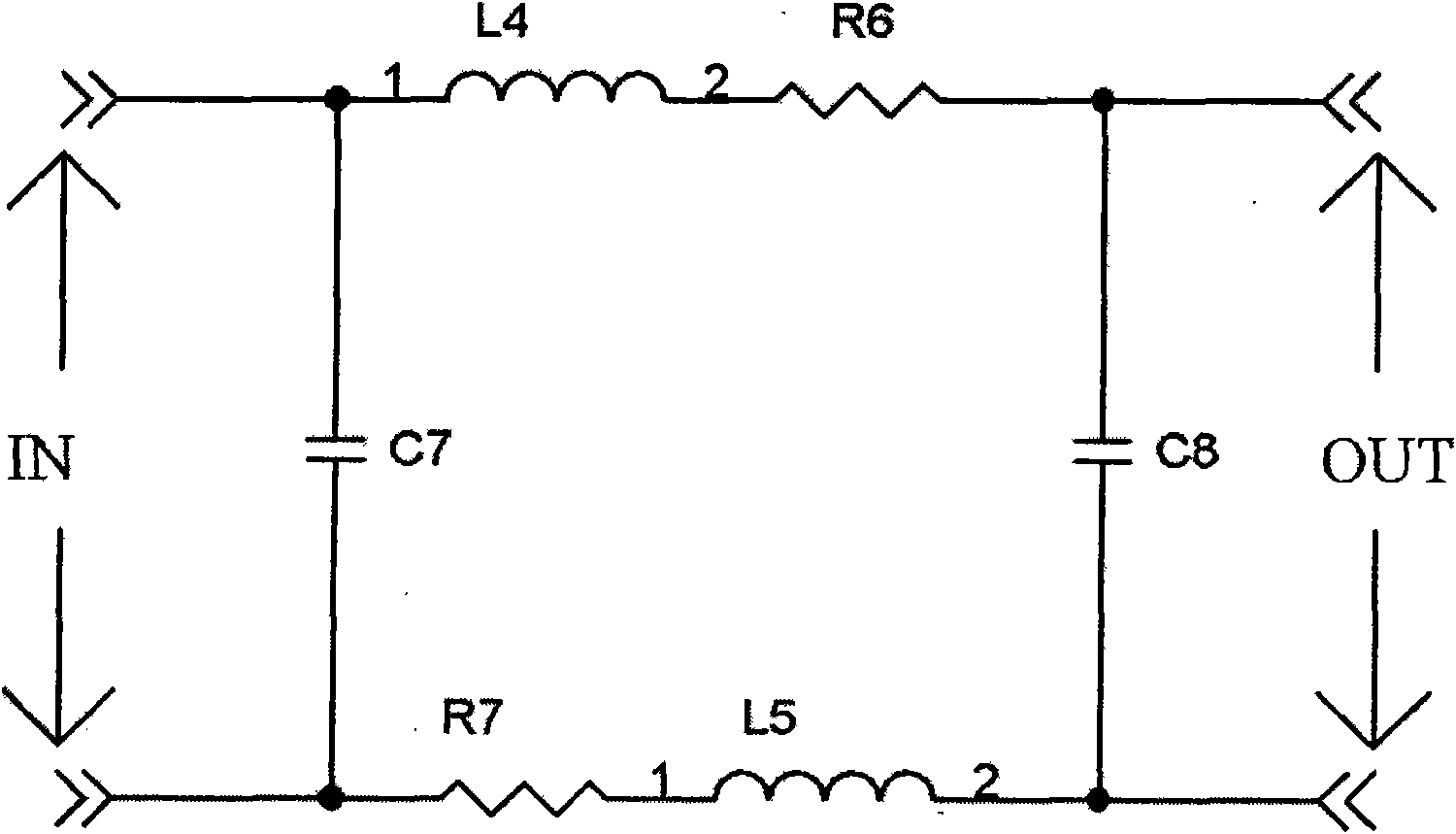

Improved radio-frequency power supply for plasma discharge at atmospheric pressure

InactiveCN101567635AGood conductivityImprove power factorAc-dc conversion without reversalFixed transformersUltrasound attenuationPower factor

The invention discloses an improved radio-frequency power supply for plasma discharge at atmospheric pressure, which solves the problem that the prior self-excitation type radio-frequency oscillating circuit has poor stability and low efficiency. The power supply adopts a switch regulator circuit and achieves the modulating action of a controllable pulse wave to a radio-frequency signal. When applied to the plasma discharge at the atmospheric pressure, the power supply can effectively solve the problems of filamentary discharge and electrode overheating easily generated by the radio-frequency source excitation of the atmospheric plasma which works in a continuous state. Simultaneously, an O-shaped filter (of which the radio-frequency attenuation reaches over 30 dB) consisting of an L-shaped filter and a reversed L-shaped filter is introduced in a circuit, thus a pulse modulation radio-frequency wave has good transmission characteristic. The power supply has the advantages of simple circuit, strong impact resistance, high power factor, small volume, reliable running and the like.

Owner:李庆荣 +4

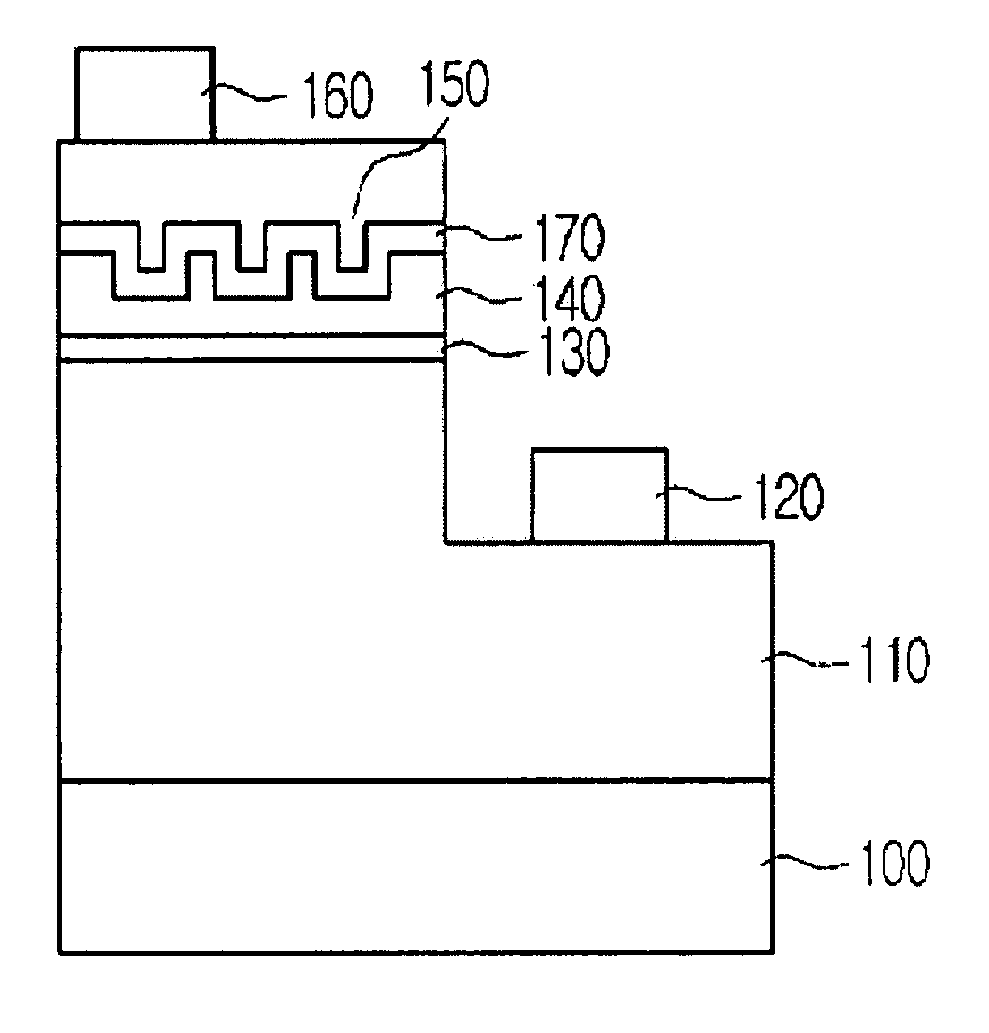

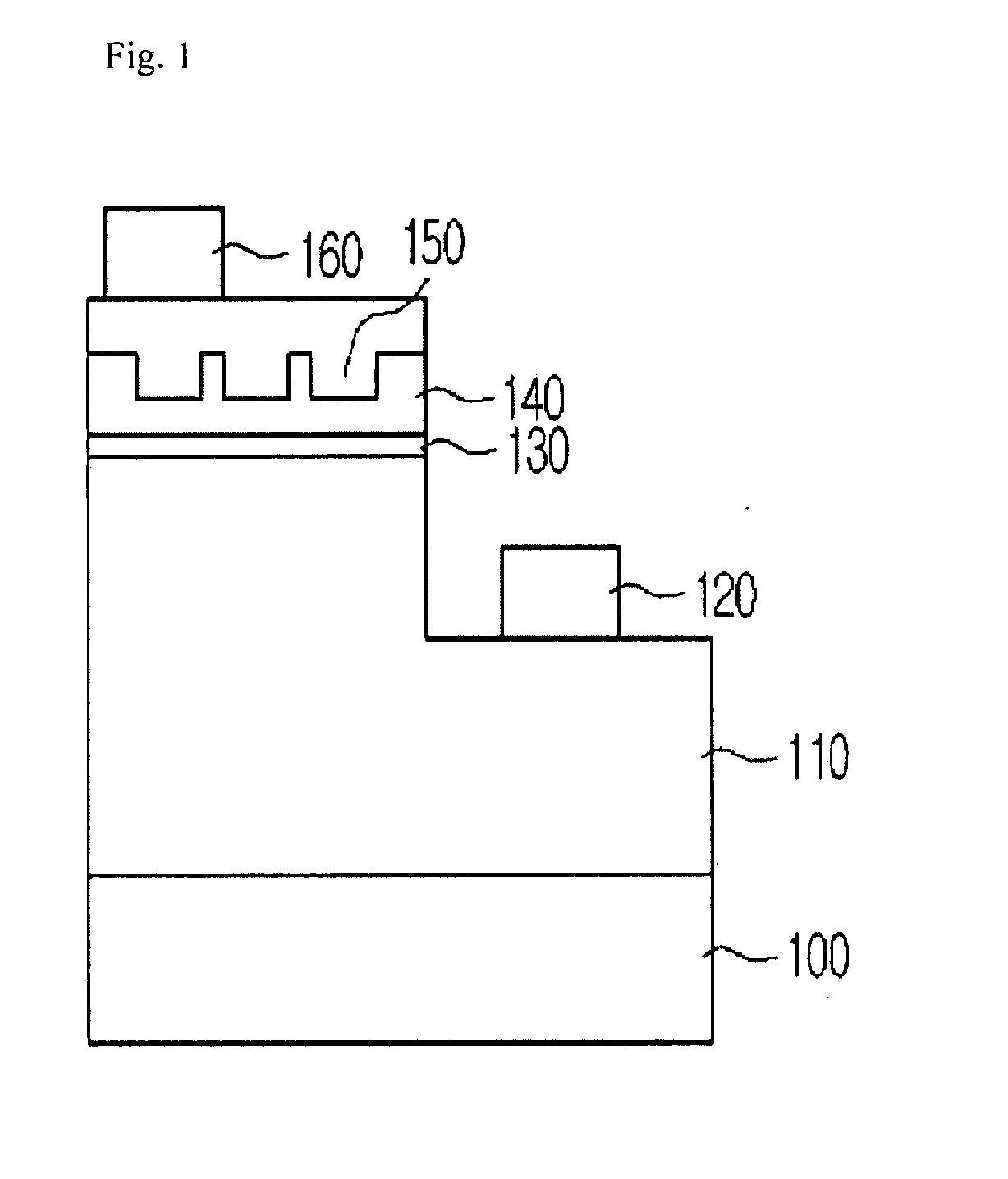

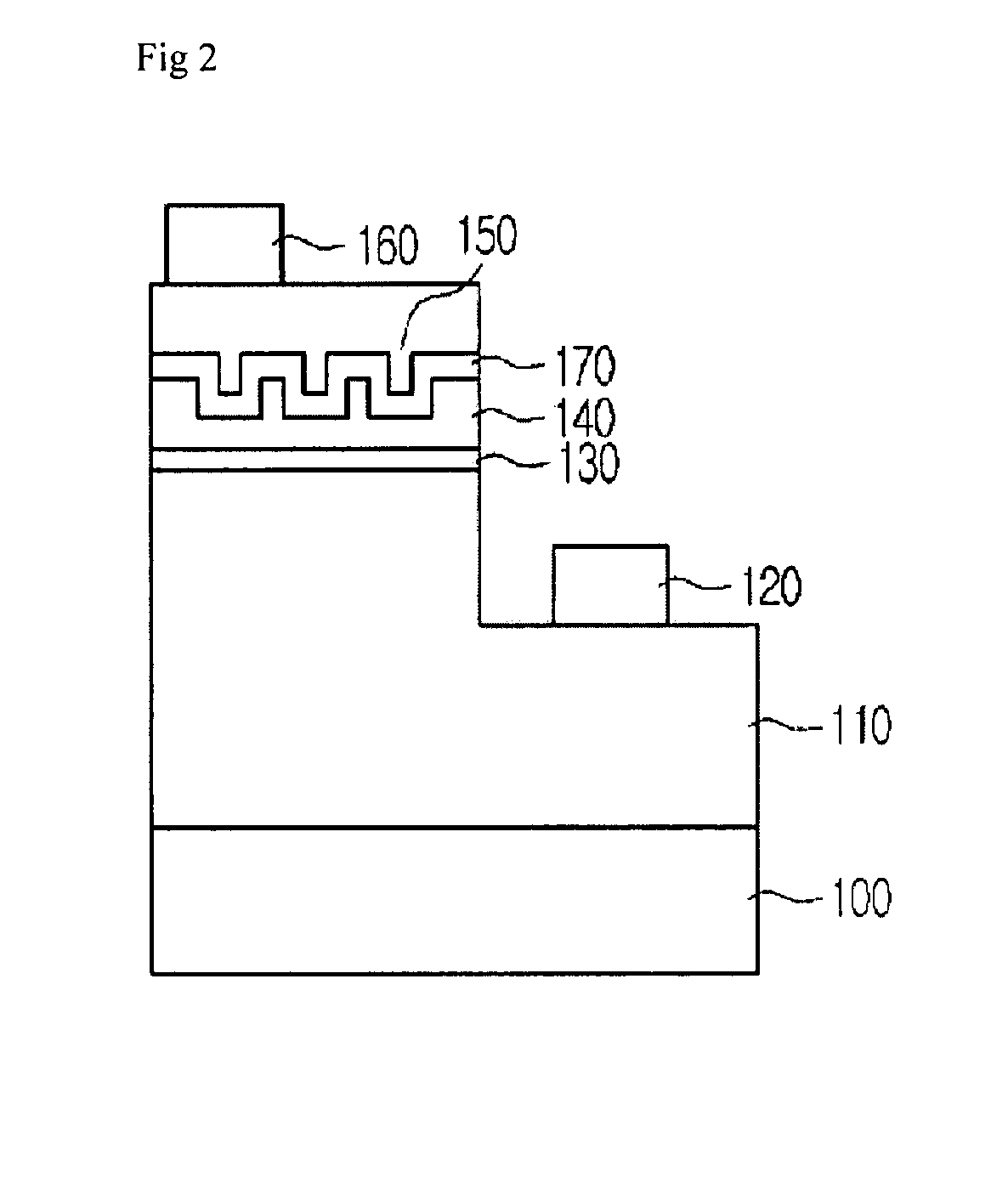

Nitride light emitting device and manufacturing method thereof

ActiveUS20090028202A1Good conductivityReduce light lossLaser detailsSemiconductor/solid-state device manufacturingConduction typeActive layer

A nitride light emitting device includes a first conduction type cladding layer, an active layer, and a second conduction type cladding layer that are stacked on a substrate. The second conduction type cladding layer has an uneven shape including at least one concave and / or convex portion.

Owner:SUZHOU LEKIN SEMICON CO LTD

Thin film transistor array substrate and fabricating method thereof

ActiveUS7799619B2Solve many processesSimplify the manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerScan line

A thin film transistor array substrate and a fabricating method thereof are disclosed. First, a substrate is provided. A patterned transparent conductive layer is then formed on the substrate. Next, a patterned first metal layer is formed to form a plurality of scan lines and a plurality of gates. Thereafter, a gate insulation layer is formed over the substrate. Moreover, a patterned semiconductor layer is formed to form a channel layer above the gates. The semiconductor layer is patterned with the same mask as that for patterning the transparent conductive layer. Additionally, a patterned second metal layer is formed to form a plurality of data lines, a plurality of sources, and a plurality of drains. After that, a dielectric layer is formed over the substrate. Finally, pixel electrodes are formed on the dielectric layer.

Owner:AU OPTRONICS CORP

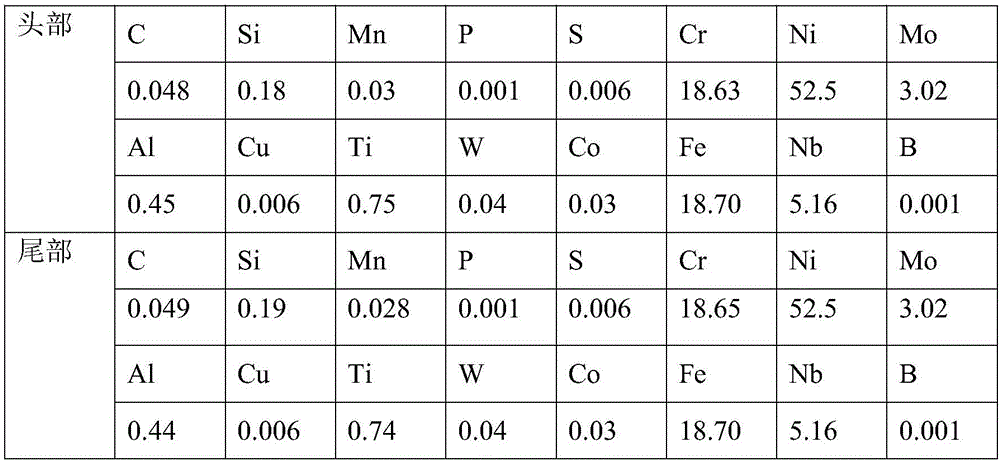

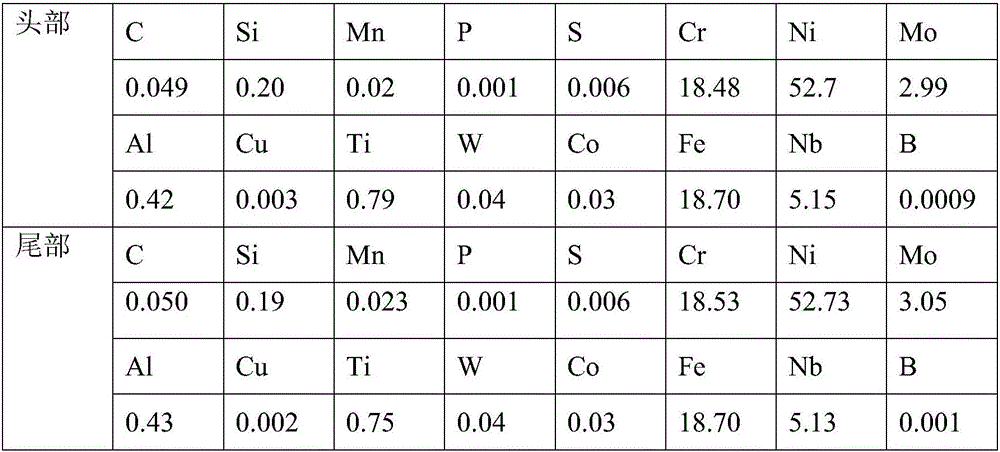

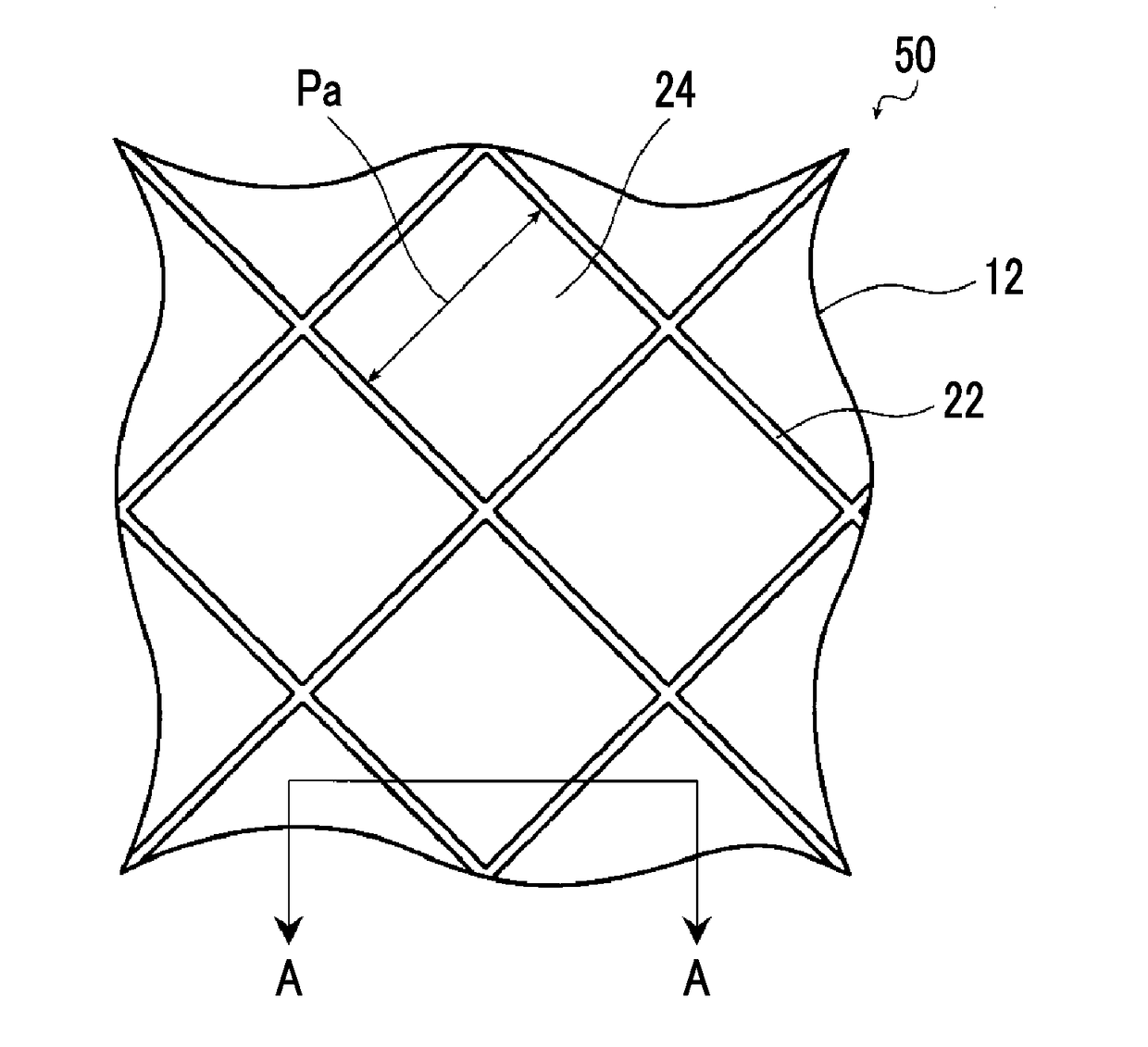

GH4169 alloy steel electroslag remelting refining slag and method for performing electroslag re-melting on GH4169 alloy steel

The invention provides GH4169 alloy steel electroslag remelting refining slag and a method for performing electroslag remelting on GH4169 alloy steel. The GH4169 alloy steel electroslag remelting refining slag comprises the following components in parts by weight: 60-70 parts of CaF2, 15-20 parts of Al2O3, 5-15 parts of CaO, 3-6 parts of MgO and 4-8 parts of TiO2. The method comprises: baking the remelting refining slag, taking the GH4169 alloy steel as a consumable electrode, assembling an electroslag remelting furnace, adding the baked remelting refining slag, aluminum powder and ferrotitanium powder into a crystallizer, turning on power for arc starting so as to establish a slag bath, and then performing remelting smelting on the consumable electrode under the protection of an inert gas. The refining slag provided by the invention has the characteristics of low melting point, low viscosity, high specific resistance, and relatively low air permeability in a high-temperature liquid state, and by adopting the refining slag, less aluminum and titanium elements during remelting of a GH4169 alloy can be over-burnt, so that the obtained steel ingots have bright and clean surfaces and also have qualified and uniform components.

Owner:宝武特冶航研科技有限公司

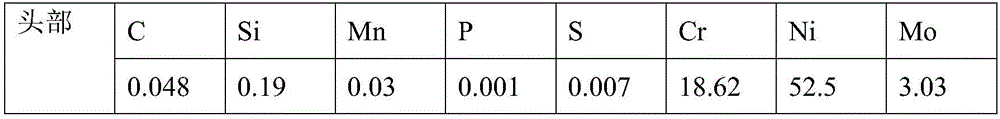

Conductive film, touch panel sensor, and touch panel

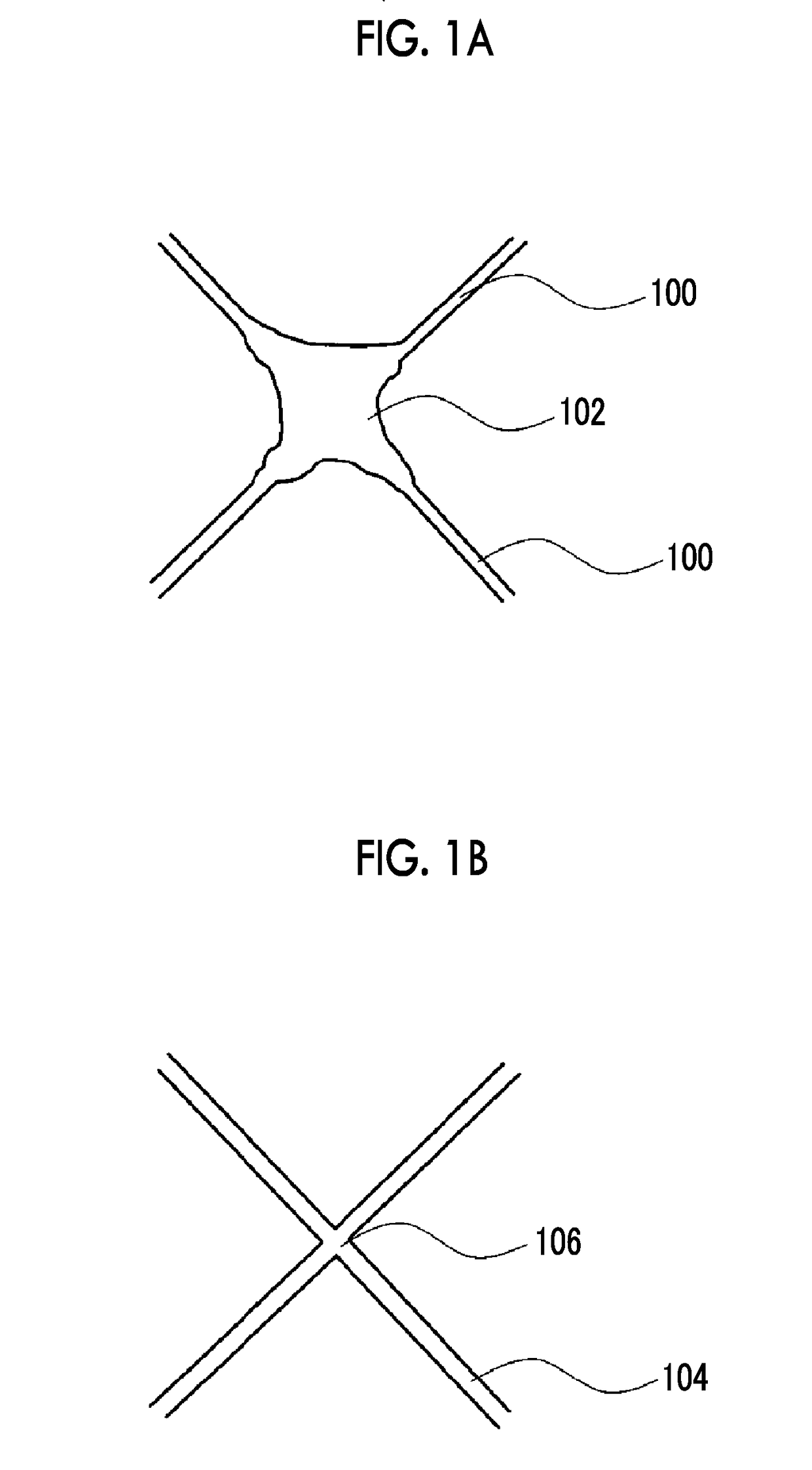

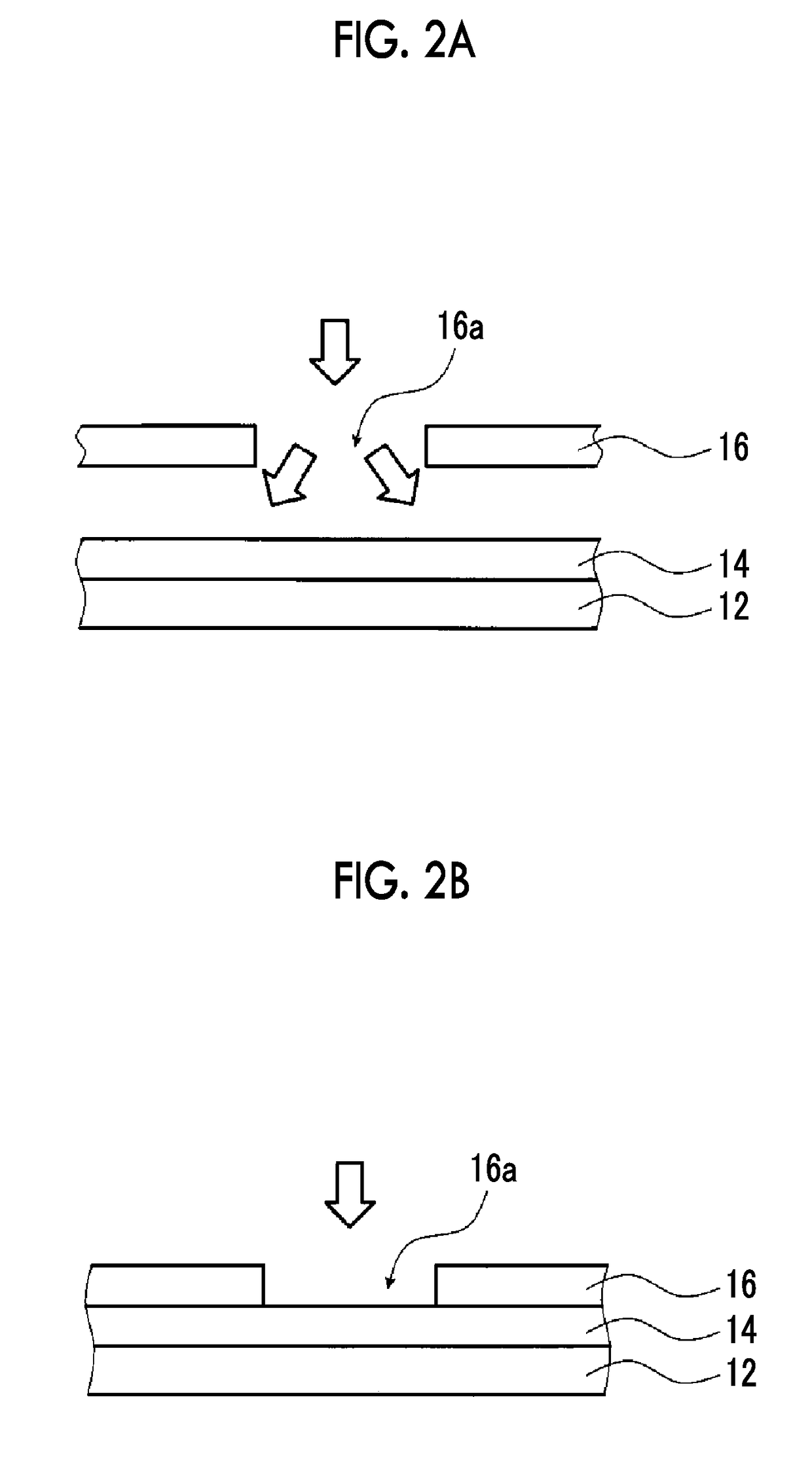

ActiveUS20180046284A1Excellently maintain transparencyGood effectPrinted circuit aspectsLiquid/solution decomposition chemical coatingVisual recognitionTouch panel

According to the invention, there are provided a conductive film which has a mesh-like metal layer composed of metal thin wires and in which visual recognition of the metal thin wires is suppressed and the metal layer has excellent conductive characteristics, a touch panel sensor, and a touch panel. A conductive film according to the invention includes a substrate; a patterned to-be-plated layer which is disposed on the substrate in a mesh pattern and has a functional group interacting with a plating catalyst or a precursor thereof; and a mesh-like metal layer which is disposed on the patterned to-be-plated layer and has a plurality of metal thin wires intersecting each other, an average thickness of the patterned to-be-plated layer is 0.05 to 100 μm, an average thickness of the metal layer is 0.05 to 0.5 μm, and an average intersection growing rate at an intersection of metal thin wires of the mesh of the metal layer is 1.6 or less.

Owner:FUJIFILM CORP

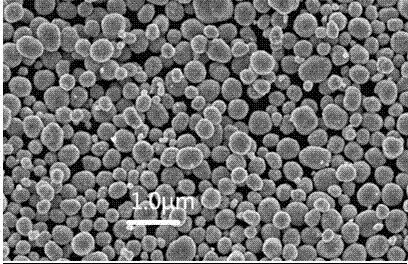

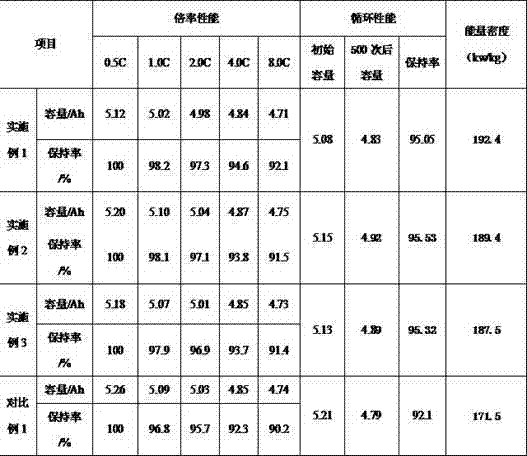

A preparing method of a high-power high-energy density lithium ion battery

InactiveCN104766998ARegular shapeGood conductivityFinal product manufactureCell electrodesCarbon nanotubeLithium electrode

A preparing method of a high-power high-energy density lithium ion battery is provided. According to the lithium ion battery, the cathode material is Li(Ni<0.6>Co<0.2>Mn<0.2>)O2 / carbon nanotube composite ternary material, the inner core is hollow, the outer core is of a double-layer structure, the first layer is Li(Ni<0.6>Co<0.2>Mn<0.2>)O2, and the outer layer is carbon nanotubes. The preparing method includes following steps: 1) preparing the cathode material and 2) preparing an anode material. The ternary material prepared by the preparing method is structured and uniform in morphology, large in particles, irregular in morphology, and high in conductivity. A particle gap is reduced, and compaction density and conductivity of the ternary material are improved. By a chemical vapor deposition method, the carbon nanotubes with high conductivity are deposited on the surface of the ternary material, thus further improving conductivity and rate performance of the lithium ion battery.

Owner:JIANGSU LENENG BATTERY INC

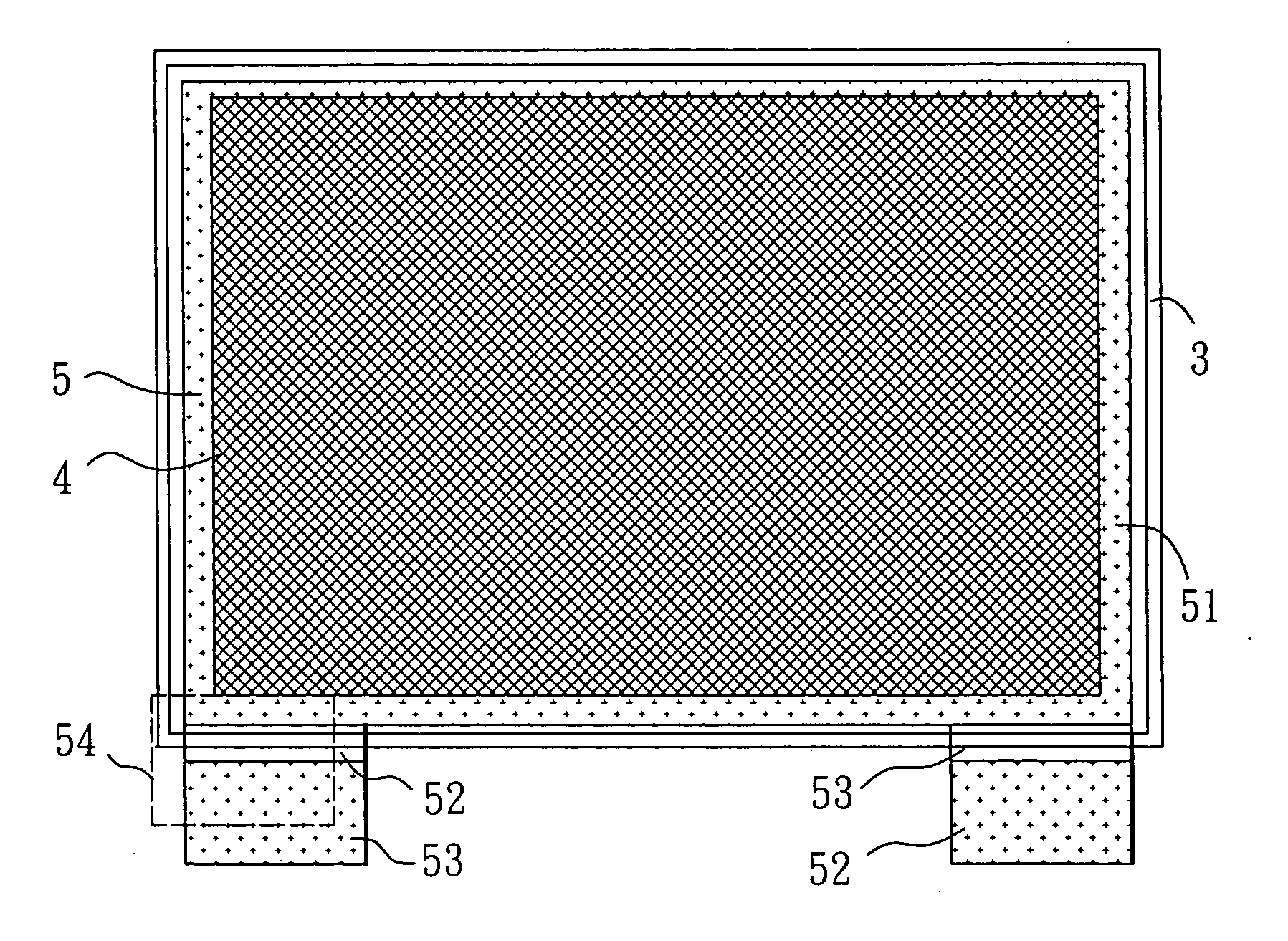

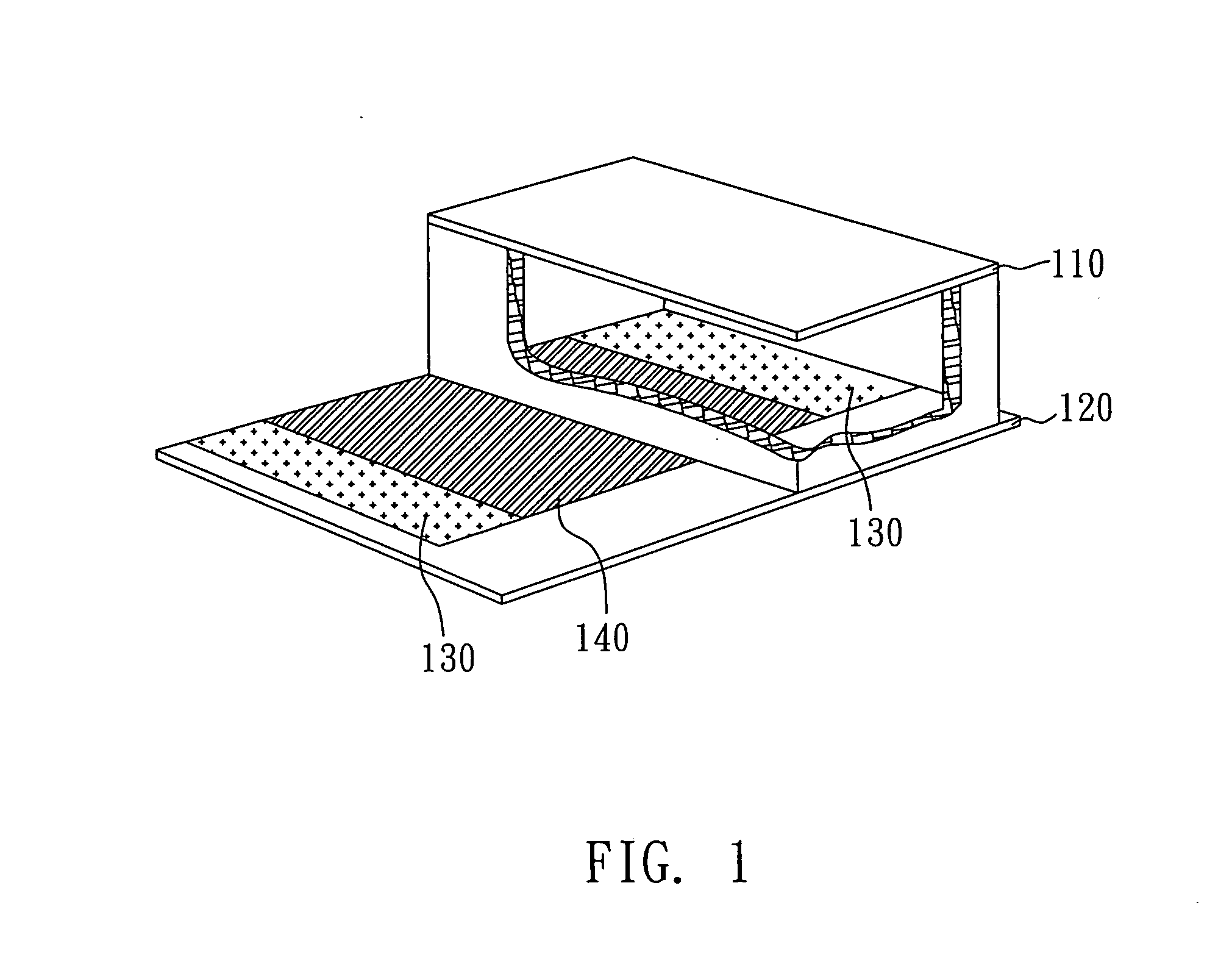

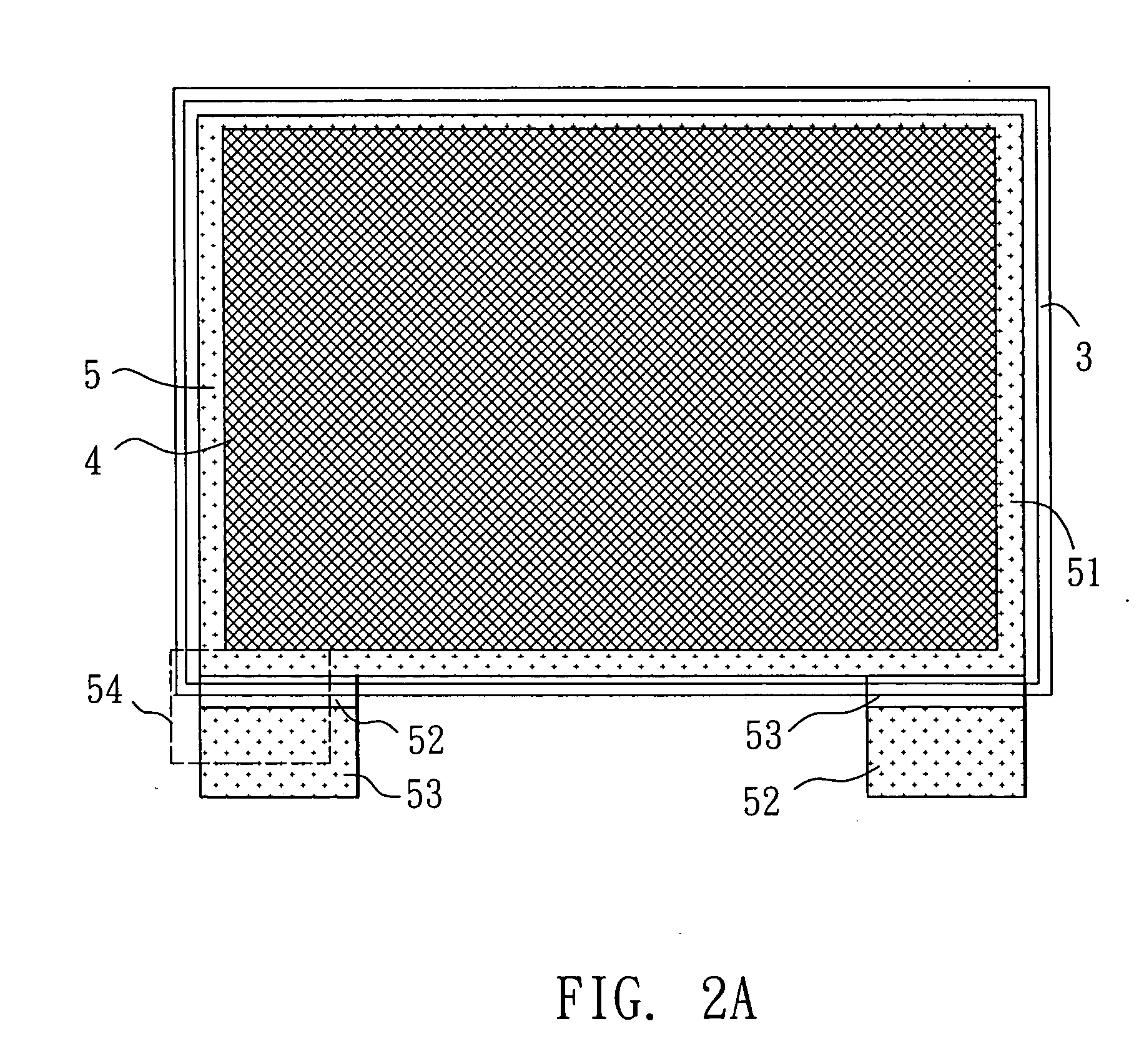

Anode plate for a field emission display device

InactiveUS20050046335A1Sealing strengthSmall sizeCathode-ray/electron-beam tube electrical connectionDischarge tube luminescnet screensField emission displayLuminescence

An anode plate for a field emission display device (FED) is disclosed, which has a substrate; an anode conductive layer formed on the substrate; at least one interspacing conductive band having a plurality of internal gaps for connecting the anode conductive layer and external cable lines, wherein the interspacing conductive band covers a part of the anode conductive layer; and a fluorescent layer located on the anode conductive layer, to serve as a source of luminescence for a field emission display device. The field emission display device includes the anode plate aforesaid as is also disclosed.

Owner:IND TECH RES INST

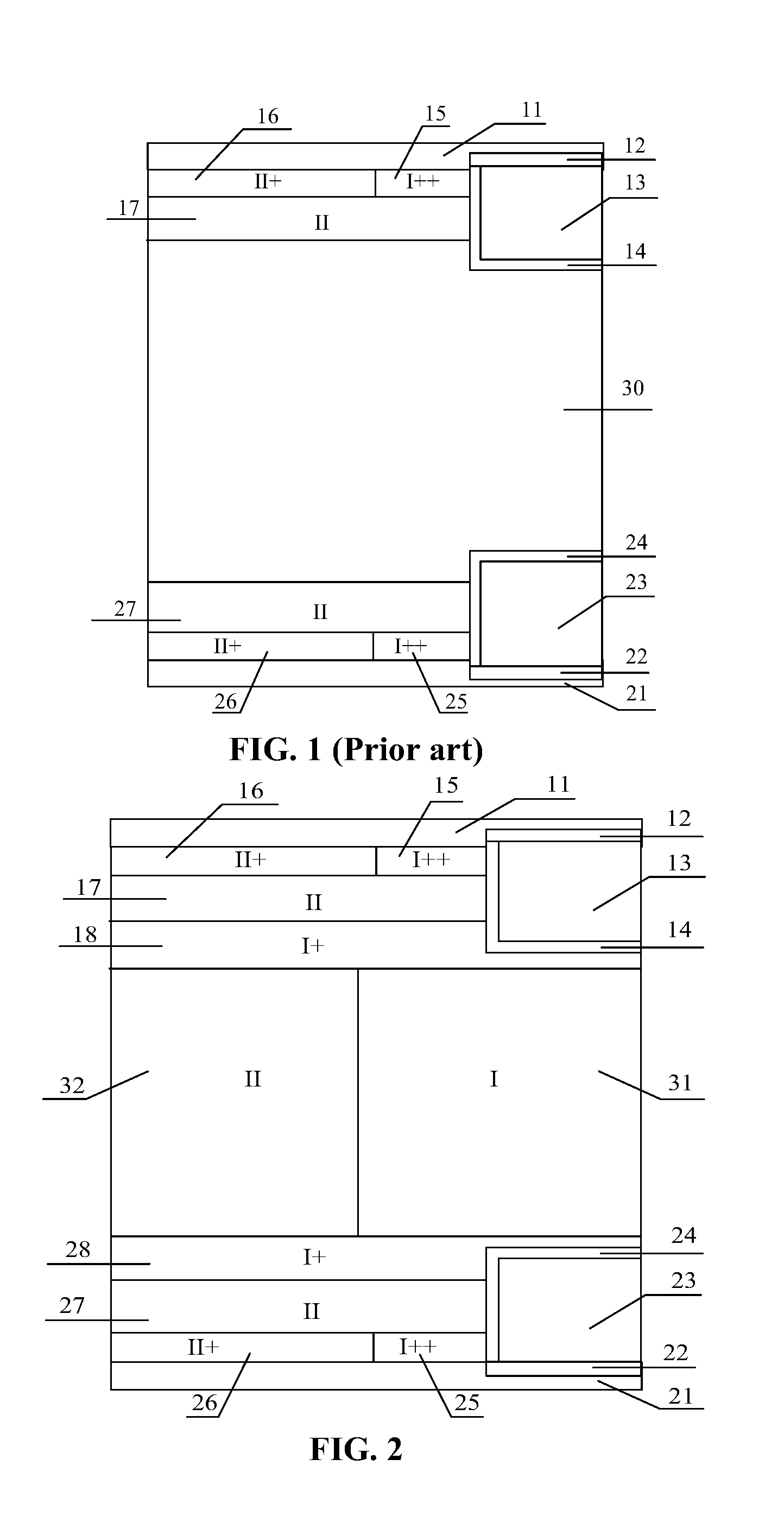

Bidirectional insulated gate bipolar transistor

InactiveUS20160322483A1Good conductivityThin thicknessSemiconductor devicesDielectricGate dielectric

A bidirectional IGBT device, including a cellular structure including: two MOS structures, a substrate drift layer, two highly doped buried layers operating for carrier storage or field stop, two metal electrodes, and isolating dielectrics. Each MOS structure includes: a body region, a heavily doped source region, a body contact region, and a gate structure. Each gate structure includes: a gate dielectric and a gate conductive material. The two MOS structures are symmetrically disposed on the top surface and the back surface of the substrate drift layer. The heavily doped source region and the body contact region are disposed in the body region and independent from each other, and both surfaces of the heavily doped source region and the body contact region are connected to each of the two metal electrodes. The gate dielectric separates the gate conductive material from a channel region of each of the MOS structures.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

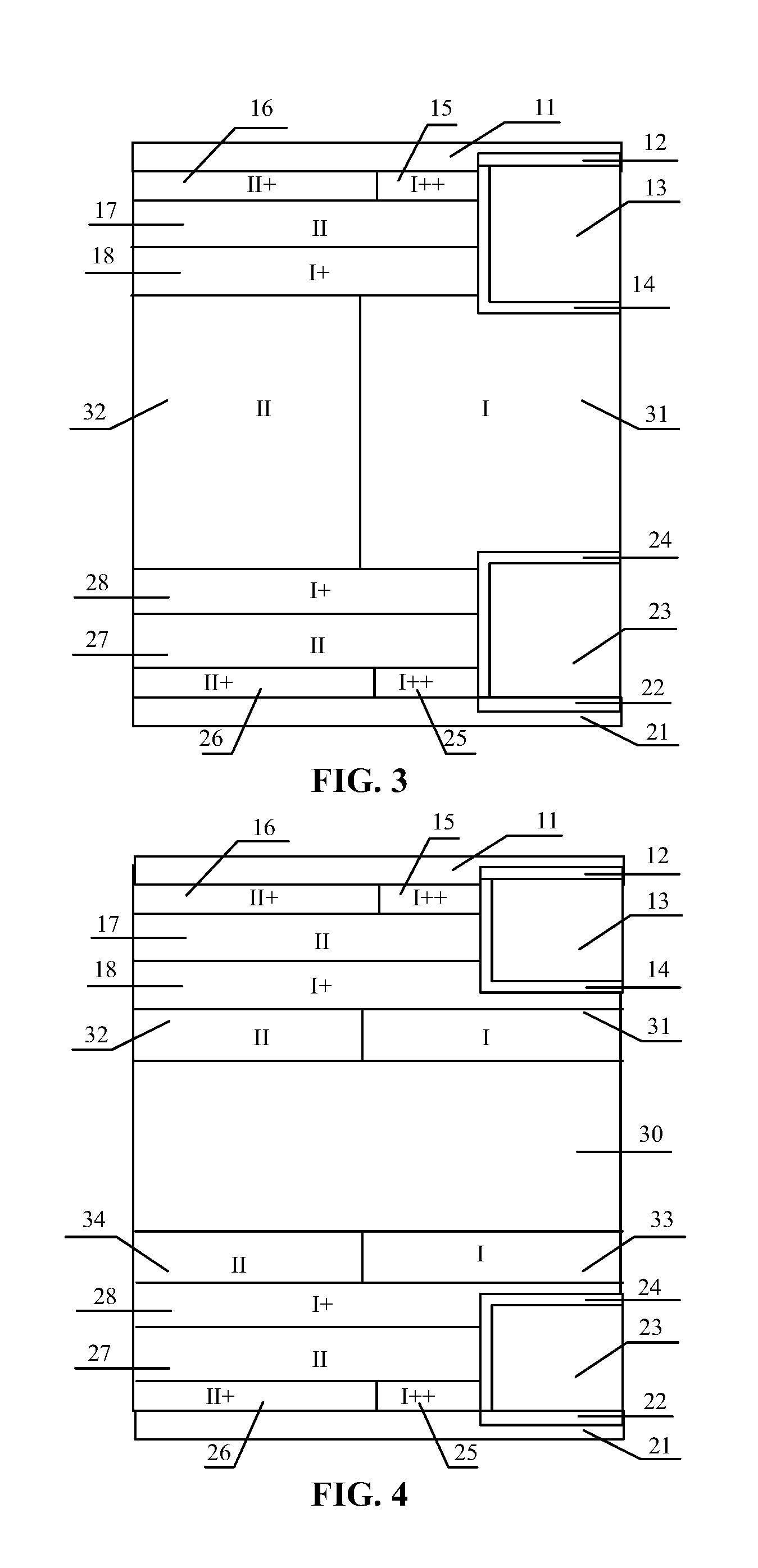

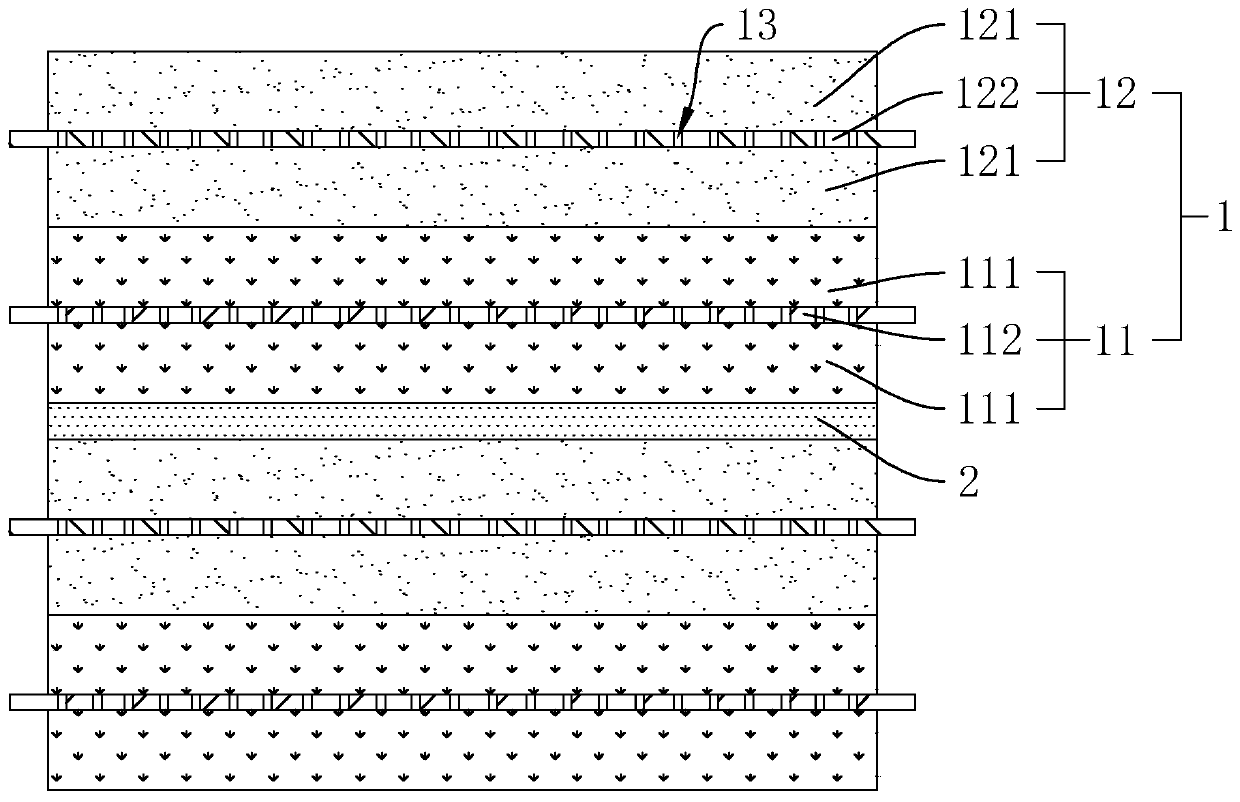

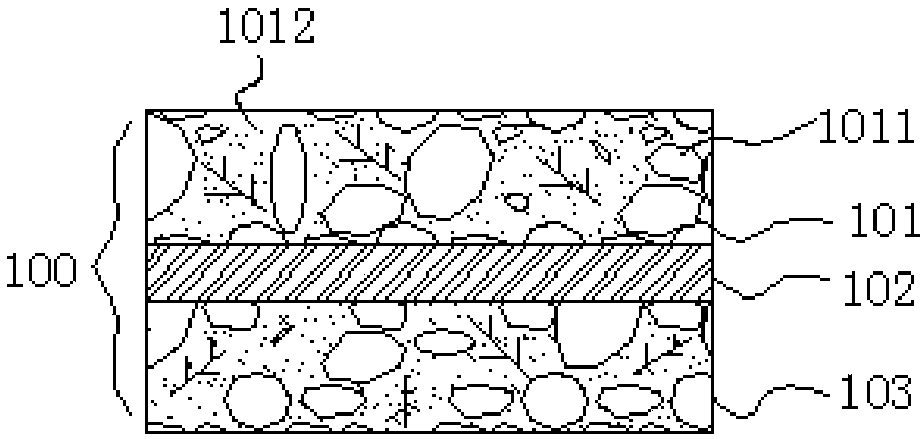

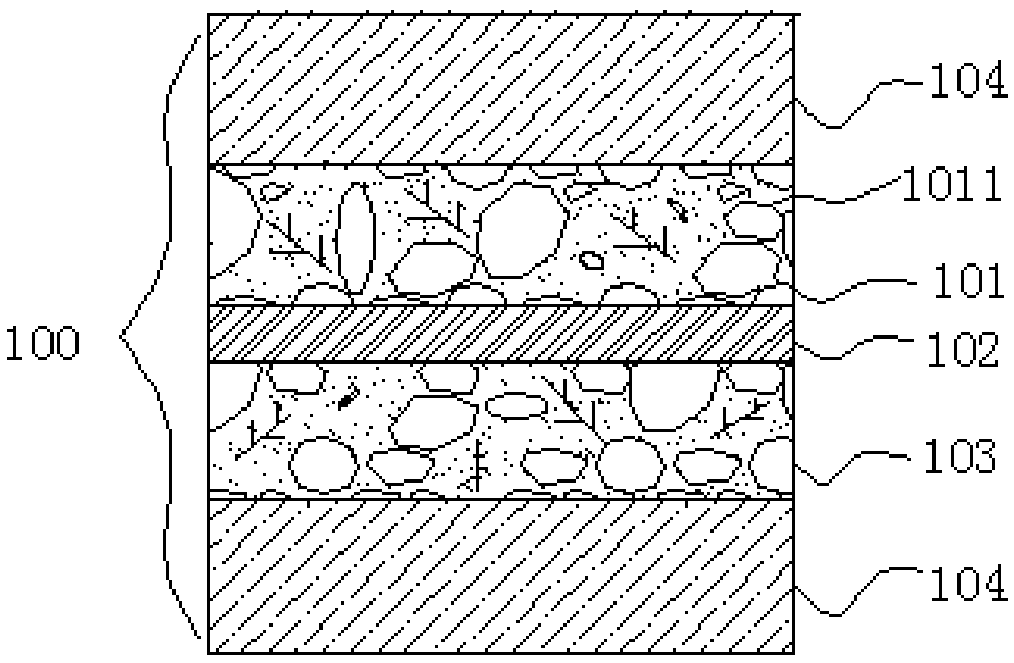

Non-contact mixed solid-liquid electrolyte lithium storage battery and preparation method thereof

ActiveCN110112421AGood conductivityReduce the impactFinal product manufactureElectrode carriers/collectorsCurrent collectorPositive current

The invention relates to the field of lithium storage batteries, and particularly discloses a non-contact mixed solid-liquid electrolyte lithium storage battery and a preparation method thereof. The lithium storage battery comprises a plurality of battery cell units which are sequentially overlapped, and each battery cell unit comprises a positive electrode structure and a negative electrode structure which are overlapped with each other, wherein the positive electrode structure is composed of a positive electrode current collector, and a positive electrode active layer and a positive electrode solid electrolyte layer which are arranged at two sides of the positive electrode current collector in a coated manner; the negative electrode structure consists of a negative electrode current collector, and a negative electrode active layer and a negative electrode solid electrolyte layer which are disposed at two sides of the negative electrode current collector in a coated manner, wherein the positive electrode solid electrolyte layer is attached to the negative electrode active layer, the negative electrode solid electrolyte layer is attached to the positive electrode active layer, anda plurality of through holes are formed in the positive electrode current collector and the negative electrode current collector. The positive current collector and the negative current collector designed by the invention have the functions of the current collector and a diaphragm, and are combined with the positive solid electrolyte layer, the negative solid electrolyte layer and the through holes, so that the safety performance and the battery performance of the lithium storage battery are effectively improved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Multilayer anisotropic puncture type conductive fabric adhesive and FPC reinforcing shielding structure using same

PendingCN109890124ARealize the effect of direct connectionAchieve groundingNon-insulated conductorsPrinted circuit detailsAdhesiveElectromagnetic shielding

The invention discloses a multilayer anisotropic puncture type conductive fabric adhesive and an FPC reinforcing shielding structure using the same, wherein the conductive fabric adhesive comprises anupper conductive adhesive layer, a lower conductive adhesive layer and an ultra-thin conductive fabric layer formed between the upper conductive adhesive layer and the lower conductive adhesive layer; the thickness of the upper conductive adhesive layer is 15-25[mu]m, and the thickness of the lower conductive adhesive layer is 35-45[mu]m; the upper and lower conductive adhesive layers comprise metal conductive particles, wherein the metal conductive particles are at least two kinds of a tree branch shape, a chain shape, a needle shape, a slice shape and a sphere shape, and particle sizes of the metal conductive particles are 40-100[mu]m; and the thickness of the ultra-thin conductive fabric layer is 5-15[mu]m. According to the adhesive, the characteristics of an extremely good grounding effect and an electromagnetic shielding effect, high electrical property, excellent bonding strength, excellent tin soldering property, excellent reliability, excellent flame resistance and the like can be achieved by combining with a reinforcing material and an EMI film under the condition that the FPC does not have a reserved grounding hole, and in addition, the production process can be reduced,and the production cost can be lowered.

Owner:KUSN APLUS TEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com