Preparation method of graphene/nickel-aluminum bi-metal hydroxide composite material and application thereof

A hydroxide and composite material technology, applied in the field of electrochemistry, can solve the problems of poor dispersibility of composite materials, large layers of nickel-aluminum bimetallic hydroxides, serious agglomeration of graphene, etc., and achieve good conductivity and electronic conductivity. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

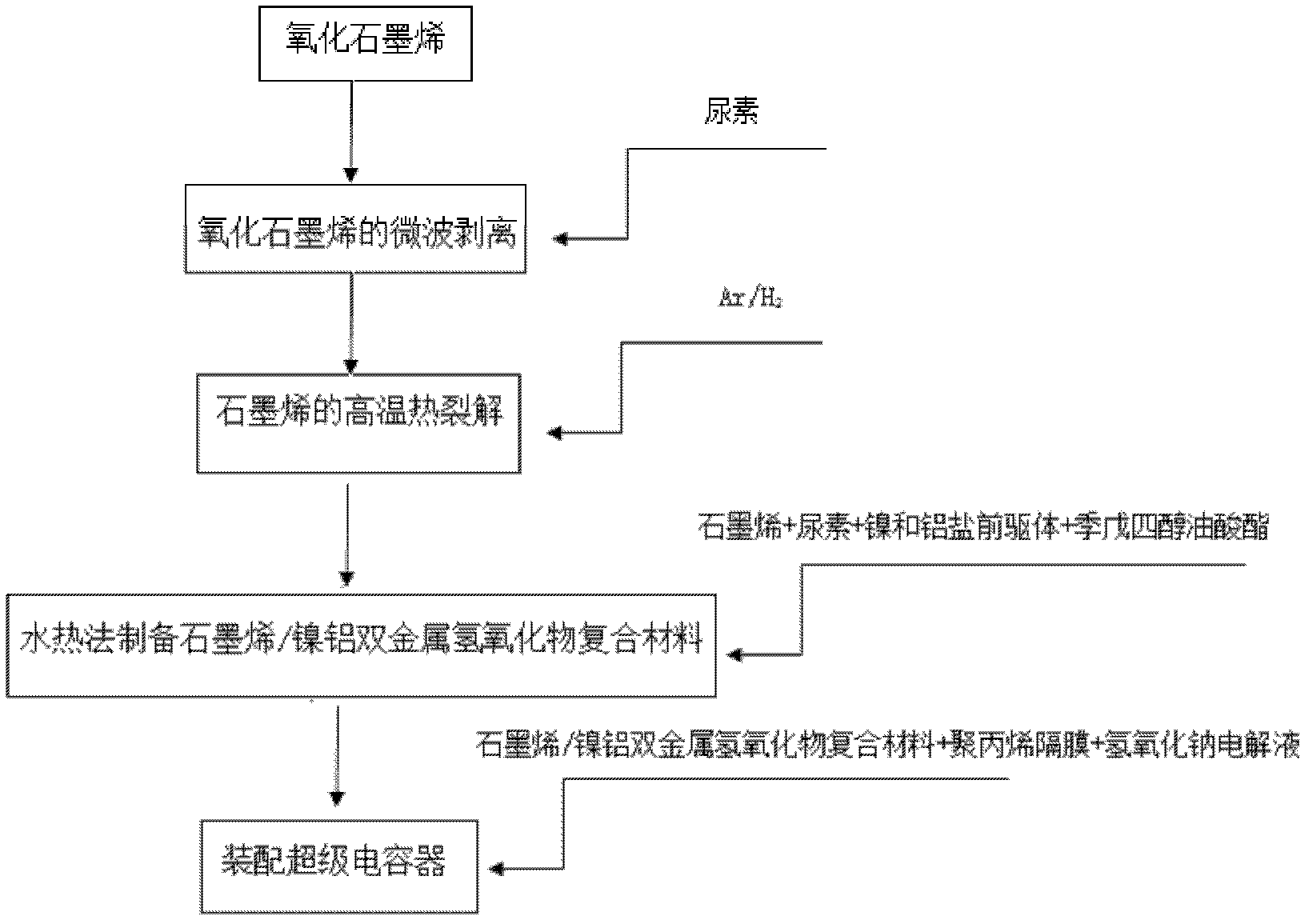

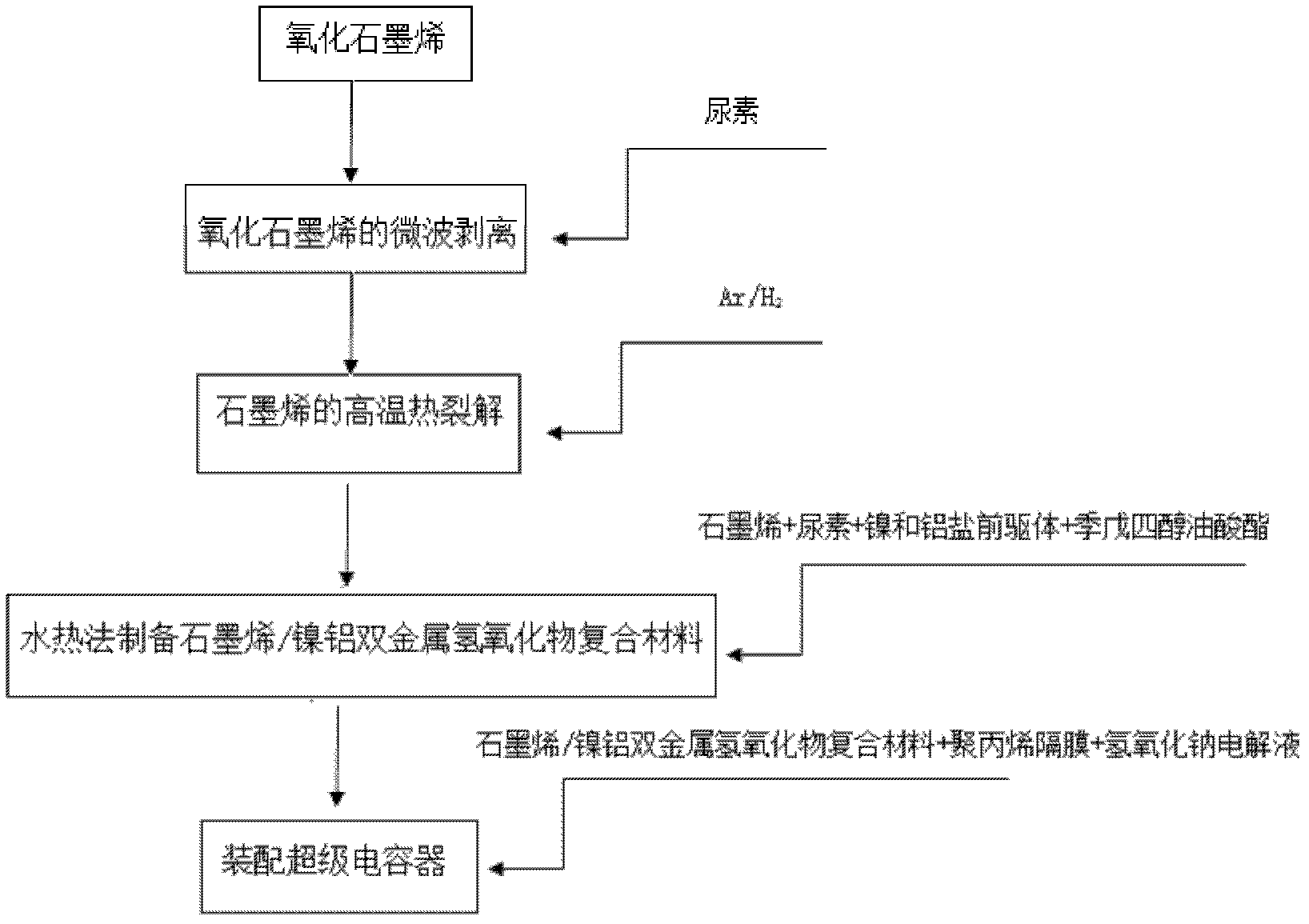

Method used

Image

Examples

Embodiment 1

[0028] Put 1600mg of urea into a 500mL beaker, add 800mg of graphite oxide and 320g of deionized water, place the beaker into an ultrasonic generator and ultrasonically shake for 15 minutes, filter under reduced pressure, collect the filter cake with a water content of 10%, and then place the filter cake Into the microwave oven for 30 seconds to produce 480mg graphene; 480mg graphene is put into the tube furnace, and Ar and H 2 The mixed gas with a volume ratio of 1:1 was heated to 900°C, kept for 20 minutes, and then cooled to room temperature to obtain 460mg of deeply reduced graphene; 100mg of graphene was put into the autoclave, and 500mg of nickel nitrate, 500mg aluminum nitrate, 20000mg deionized water, 20mL pentaerythritol oleate and 800mg urea, tighten the sealing cap of the autoclave, heat up to 130℃, and keep it for 12 hours, take it out, cool to room temperature, filter, and collect 750mg graphene / nickel Aluminum bimetallic hydroxide; 10mg graphene / nickel aluminum bim...

Embodiment 2

[0030] Put 1600mg of ammonium bicarbonate into a 500mL beaker, add 800mg of graphite oxide and 220g of deionized water, place the beaker into an ultrasonic generator and ultrasonically shake for 18 minutes, filter under reduced pressure, collect the filter cake with 8% water content, and then filter The cake is placed in a microwave oven under microwave irradiation for 35 seconds to obtain 470 mg of graphene; 470 mg of graphene is placed in a tube furnace, and Ar and H are introduced 2 The mixed gas with a volume ratio of 2:1 was heated to 960°C, kept for 30 minutes, and then cooled to room temperature to obtain 450mg of deeply reduced graphene; 100mg of graphene was put into the autoclave, and 800mg of nickel nitrate, 400mg aluminum nitrate, 30000mg deionized water, 30mL pentaerythritol oleate and 1200mg urea, tighten the sealing cap of the autoclave, heat up to 150℃, and keep for 18 hours, take it out, cool to room temperature, filter, collect 900mg graphene / nickel Aluminum bi...

Embodiment 3

[0032] Put 1000mg of urea into a 500mL beaker, add 800mg of graphite oxide and 250g of deionized water, place the beaker into an ultrasonic generator and ultrasonically shake for 20 minutes, filter under reduced pressure, collect a filter cake with a water content of 10%, and then place the filter cake Into a microwave oven for 40 seconds of microwave radiation, 490mg graphene is prepared; 490mg graphene is placed in a tube furnace, and Ar and H are introduced 2 The mixed gas with a volume ratio of 1:1 was heated to 1000°C, held for 50 minutes, and then cooled to room temperature to obtain 450mg of deeply reduced graphene; 100mg of graphene was put into the autoclave, and 400mg of aluminum nitrate, 600mg nickel nitrate, 36000mg deionized water, 30mL trimethylol pentane oleate and 600mg ammonium chloride, tighten the sealing cap of the autoclave, heat up to 200℃ and keep it for 15 hours, take it out, cool to room temperature, and filter , Collect 800mg graphene / nickel-aluminum do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com