Alloyed negative electrode, preparation method thereof and lithium ion battery

A lithium-ion battery, alloying technology, applied in the direction of negative electrode, battery electrode, secondary battery, etc., can solve the problems of reducing the safety stability and service life of the battery, increasing the irreversible capacity, pulverizing and breaking the pole piece, etc. Industrial application, improve cycle stability and service life, small volume expansion and deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

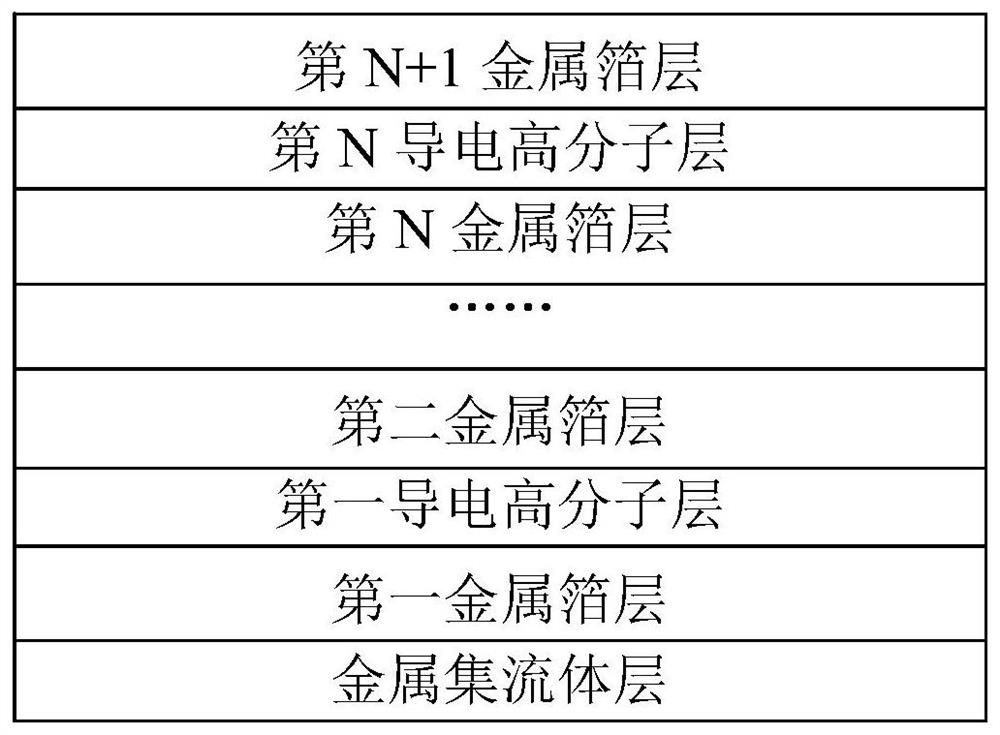

[0033] The second aspect of the embodiment of the present application provides a method for preparing an alloyed negative electrode, comprising the following steps:

[0034] Step (1), preparing a first conductive polymer layer on the surface of the first metal foil layer, and setting a second metal foil layer on the surface of the first conductive polymer layer away from the first metal foil layer;

[0035] In step (2), the conductive polymer layer and the metal foil layer are alternately laminated on the surface of the second metal foil layer away from the first conductive polymer layer to obtain an N-layer conductive polymer layer and an N+1 metal foil layer. Alloyed negative electrodes arranged in alternate layers; wherein, N is a positive integer ranging from 1 to 10.

[0036] The preparation method of the alloyed negative electrode provided in the second aspect of the present application uses the metal foil layer as the base material, and sequentially prepares a conductiv...

Embodiment 1

[0058] A composite aluminum foil negative electrode, comprising the following preparation steps:

[0059] Step (1): Prepare polymer slurry: Weigh conductive polymer polyaniline and add DMF solvent to fully mix and stir to form uniform polymer slurry;

[0060] Step (2): Obtain a clean aluminum foil layer with a thickness of 5 μm;

[0061] Step (3): coating: evenly coat the polyaniline slurry on the first surface of the aluminum foil layer by scraping, and form the first conductive polymer layer after the slurry is completely dried;

[0062] Step (4): Composite rolling: set a second clean aluminum foil layer on the surface of the first conductive polymer coating, and then perform rolling to make the polymer coating evenly embedded in the middle of the aluminum foil;

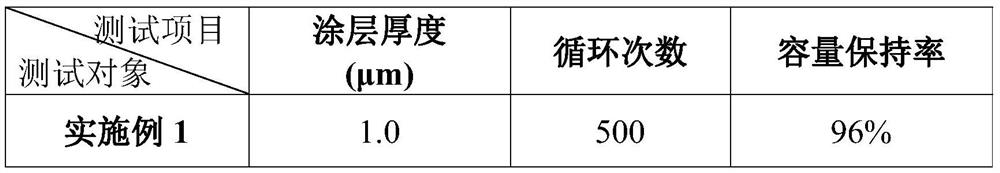

[0063] Step (5): Repeat steps (2) to (4) to obtain a composite aluminum foil structure with 5 layers of conductive polymer intermediate buffer layers, and the average thickness of the intermediate conductive polym...

Embodiment 2~6

[0067] The structures and preparation methods of the composite aluminum foil negative electrodes provided in Examples 2-6 of the present application are the same as those in Example 1, except that the conductive polymer materials are different, as shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com