Preparation method of CdS/Cu5FeS4 heterojunction semiconductor photocatalyst

A photocatalyst and semiconductor technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as high price and scarcity limitation, and achieve extended life, narrow band gap, and enhanced visible light catalysis. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

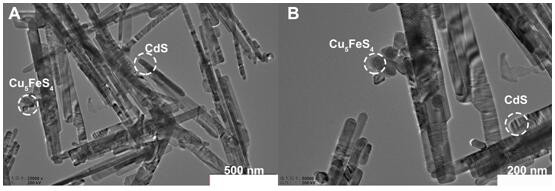

Embodiment 1

[0017] (1) First, to prepare CdS, under ultrasonic treatment, thiourea and CdCl 2 Disperse in 10 mL of ethylenediamine, respectively, and continue sonication. The mixture was transferred to an autoclave, sealed and kept at 160 °C for 48 hours. After natural cooling to room temperature, the solid product was collected manually and thoroughly washed by centrifugation with deionized water for 3-6 times, then dried in an oven for 12 hours, and the CdS sample was obtained and ground for the next step.

[0018] (2) Preparation of Cu 5 FeS 4 First, weigh 0.0990 g CuCl and 0.2730 g FeCl 3 ·6H 2 O was respectively dispersed in 15 mL of ethylenediamine, and the two solutions were mixed after ultrasonication for 15 min, and a 4-fold excess of (NH 4 ) 2 S solution. Then, the solution was transferred to a 50 mL Teflon-lined reactor, and after reacting at 180 °C for 24 hours, the black solid was washed with deionized water and absolute ethanol for 5 to 8 times, and the precipitate wa...

Embodiment 2

[0021] As described in Example 1, the difference is to add Cu in step (2) 5 FeS 4 The amount is adjusted to 0.25 mL, then the final catalyst contains 0.25 wt% Cu 5 FeS 4 0.25 wt% CdS / Cu 5 FeS 4 Plasma composite photocatalyst.

Embodiment 3

[0023] As described in Example 1, the difference is to add Cu in step (2) 5 FeS 4 The amount of is adjusted to 0.75 mL, then the final catalyst contains 0.25 wt% Cu 5 FeS 4 0.25 wt% CdS / Cu 5 FeS 4 Plasma composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com