Preparation of nitrogen rich three dimensional mesoporous carbon nitride and its sensing and photocatalytic properties

a three-dimensional mesoporous carbon nitride and nitrogen rich technology, applied in the field of three-dimensional nitrogen rich mesoporous materials, can solve the problems of limited chemical reactivity, inefficient sensing and/or solar energy conversion of catalysts, and cost-intensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of Three-Dimensional Cubic Mesoporous Silica Template, KIT-6

[0062]Pluronic P-123 (4.0 g) was dissolved in a solution containing distilled water (144 g) and HCl (36 wt. %, 7.9 g) with stirring at 35° C. After complete dissolution, n-butanol (4.0 g) was added immediately. After stirring 1 h, TEOS (8.6 g) was added to the homogeneous clear solution with constant agitation. The mixture was kept under vigorous and constant agitation at 35° C. for 24 hours. Subsequently, the reaction mixture was aged at 150° C. for 24 h under static conditions. The molar gel composition of the synthesis mixture was 0.041TEOS:0.0007P123:0.054C4H9OH:0.076HCl:8.28 H2O. The white solid product was filtered hot without washing, dried in oven at 100° C. for 24 h, and then calcined in air at 540° C.

example 2

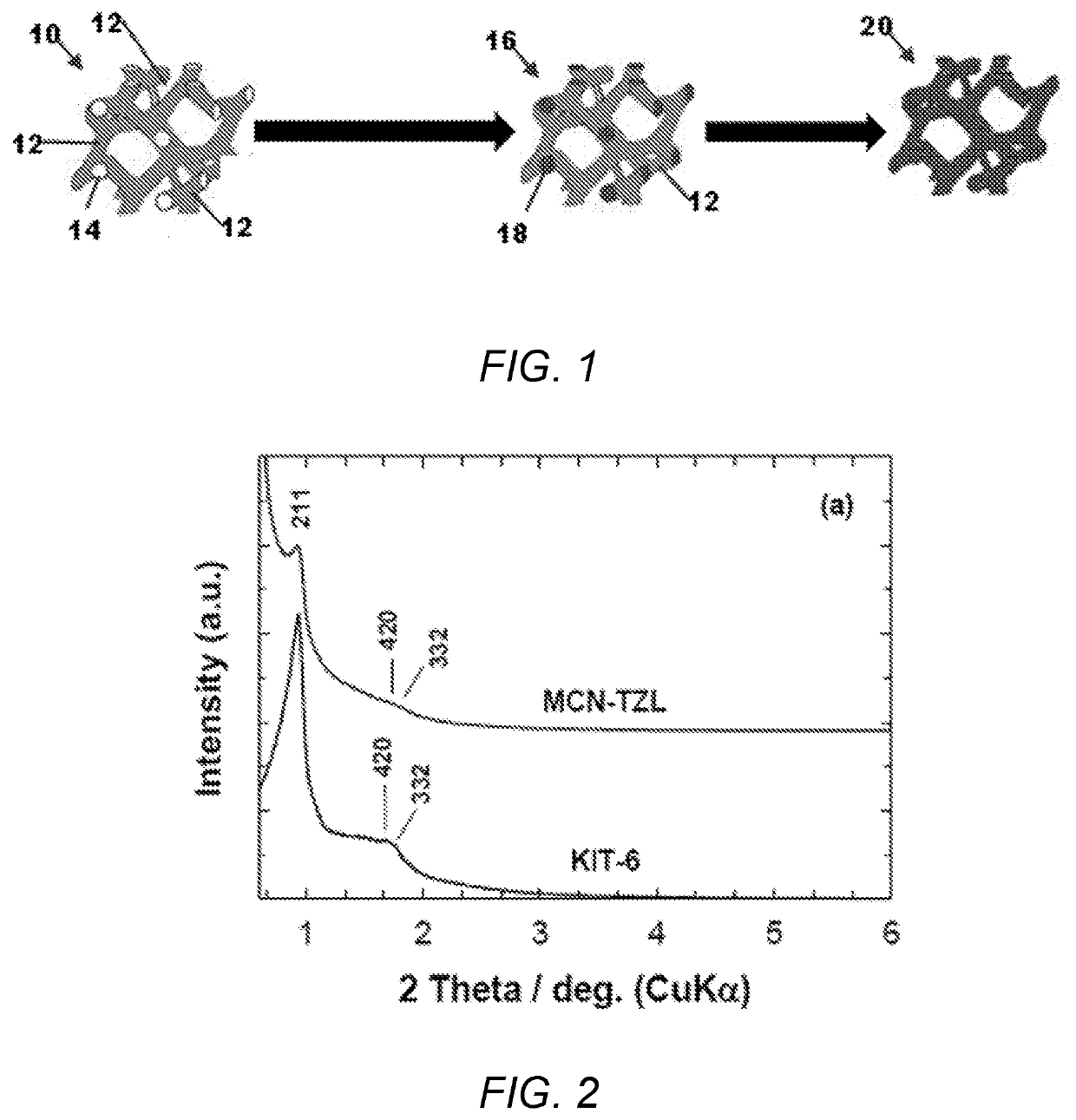

Synthesis of Three-Dimensional Mesoporous Carbon Nitride MCN-TZL from 3-AT

[0063]3-amino-1,2,4-triazole (3.0 g, 3-AT) and KIT-6 (1.0 g) was mixed in acidic DI water (0.16 g HCl in 4-5 g DI water). The mixture agitated for few minutes at a few degrees above room temperature. Upon complete dissolution, the mixture was placed in a drying oven for 6 hours at 100° C. and then 160° C. for another 6 hours. The composite of silica template and partially condensed 3-AT was heat treated at 500° C. in argon atmosphere. The composite obtained after carbonization was treated with HF at room temperature to dissolve the silica template. The template free carbon nitride (MCN-TZL) obtained was filtered, washed several times with ethanol, and dried at 100° C.

example 3

Characterization of MCN-TZL and KIT-6

1. X-Ray Diffraction Analysis

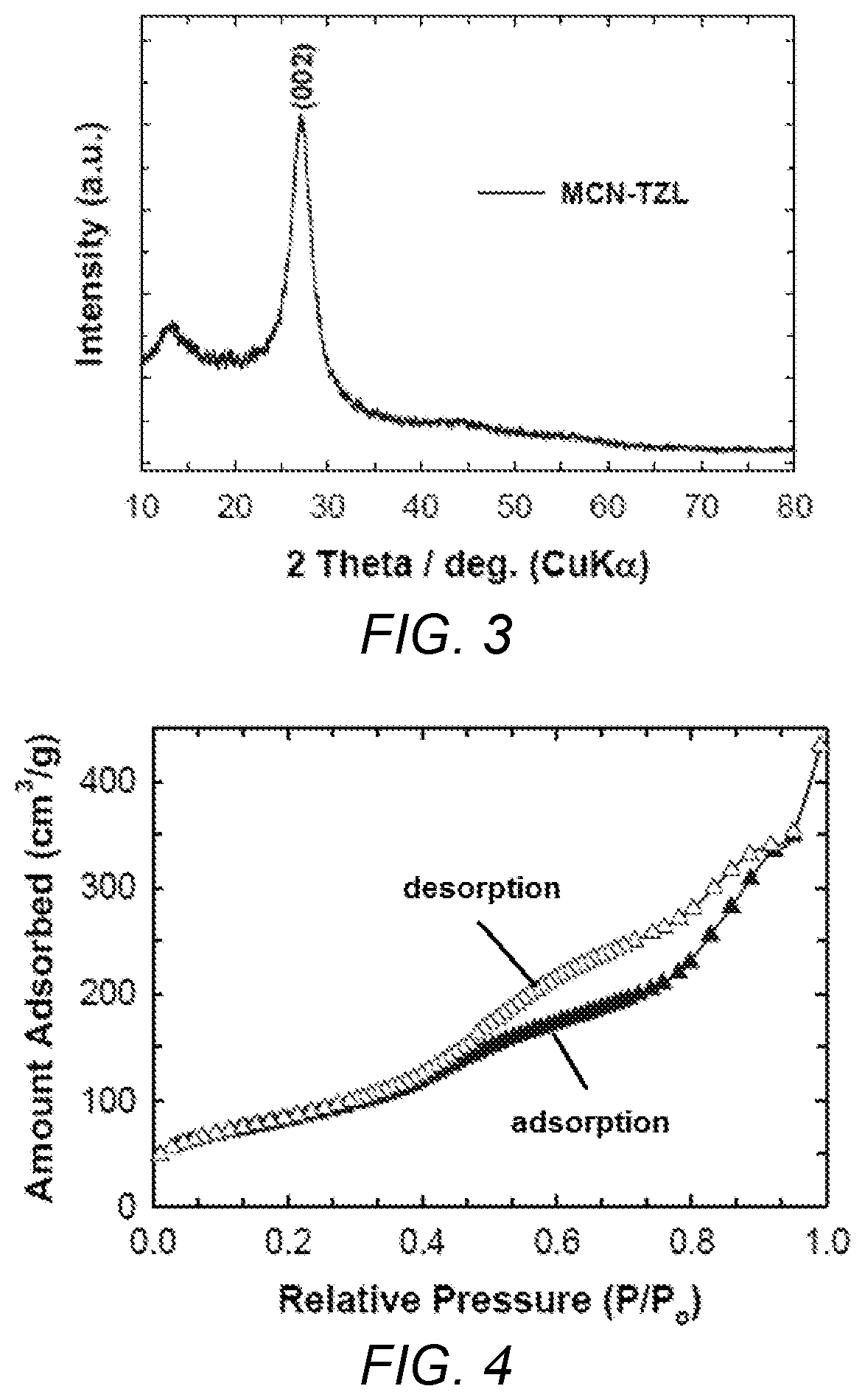

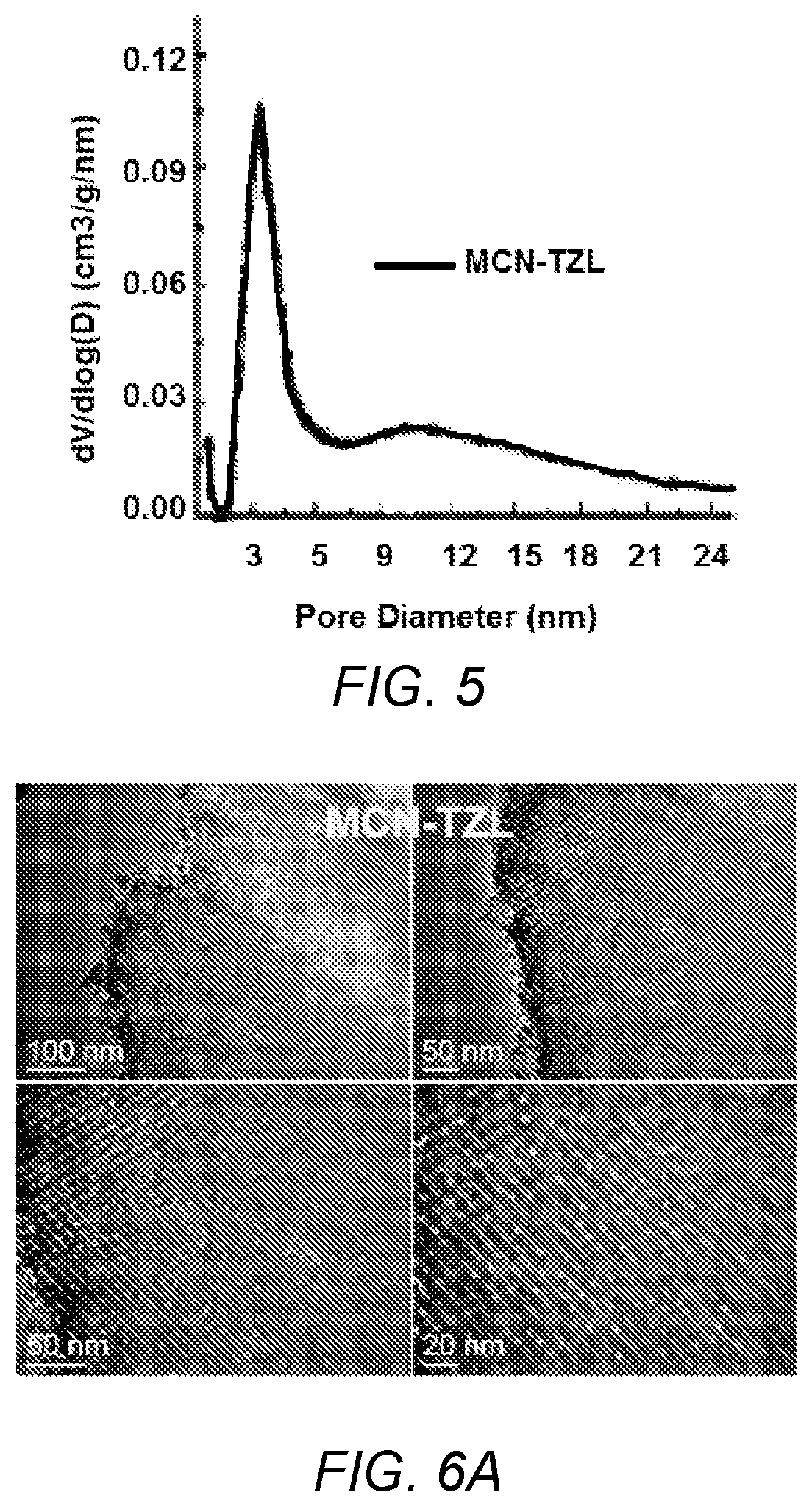

[0064]XRD: Powder XRD patterns were recorded on a Rigaku Ultima+(JAPAN) diffractometer using CuKα (λ=1.5408 Å) radiation. Low angle powder x-ray diffractograms were recorded in the 2θ range of 0.6-6° with a 2θ step size of 0.0017 and a step time of 1 sec. In case of wide-angle X-ray diffraction, the patterns were obtained in the 20 range of 10-80° with a step size of 0.0083 and a step time of 1 sec. FIG. 2 shows the low angle powder XRD patterns of MCN-TZL of the present invention and the 3D mesoporous silica template, KIT-6. FIG. 3 is a wide-angle powder XRD pattern of MCN-TZL of the present invention.

[0065]The XRD pattern of the KIT-6 silica template exhibited a sharp well resolved (211) reflection and several higher order reflections, (420), (332) at 2θ angles below 4°, indicating long range structural ordering with the symmetry of body centered cubic Ia3d space group. The unit cell constant, calculated from the (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com